Patents

Literature

1661 results about "Perchloric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Perchloric acid is a mineral acid with the formula HClO₄. Usually found as an aqueous solution, this colorless compound is a stronger acid than sulfuric acid and nitric acid. It is a powerful oxidizer when hot, but aqueous solutions up to approximately 70% by weight at room temperature are generally safe, only showing strong acid features and no oxidizing properties. Perchloric acid is useful for preparing perchlorate salts, especially ammonium perchlorate, an important rocket fuel component. Perchloric acid is dangerously corrosive and readily forms potentially explosive mixtures.

Oxide etching method

InactiveUS8168544B2Precise and easy etchingPrecise and highly selective wet etchingDecorative surface effectsFinal product manufactureAcetic acidEtching

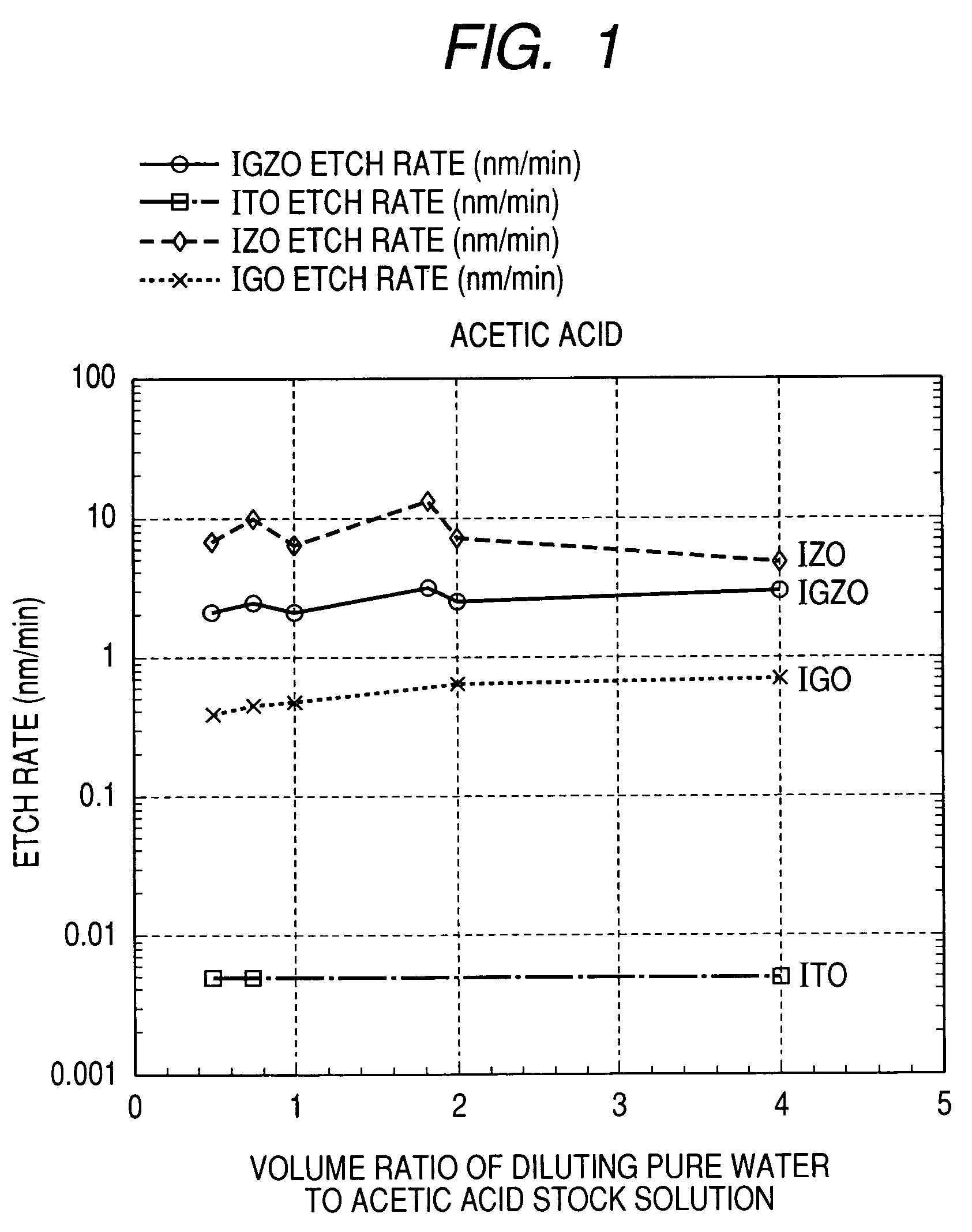

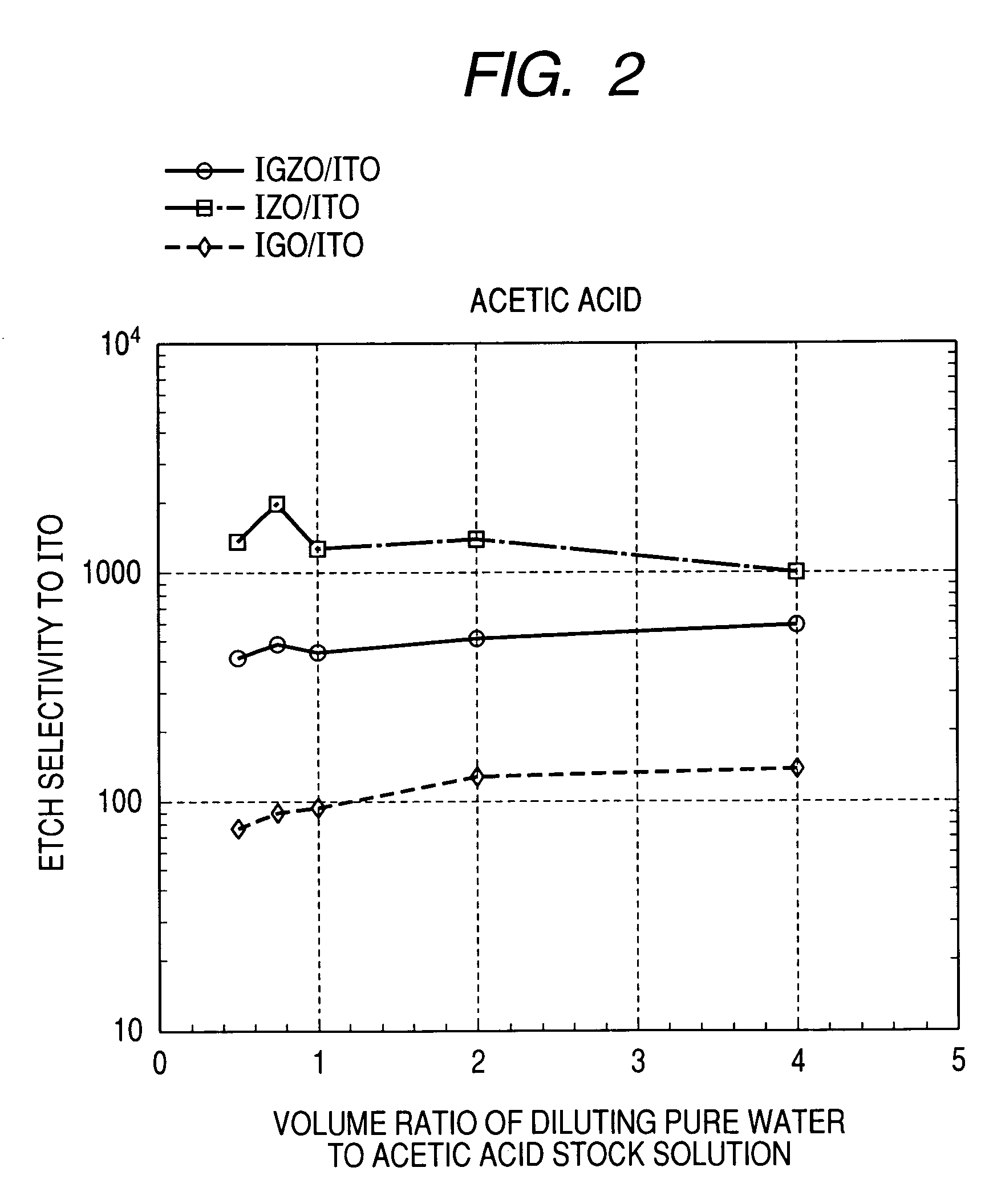

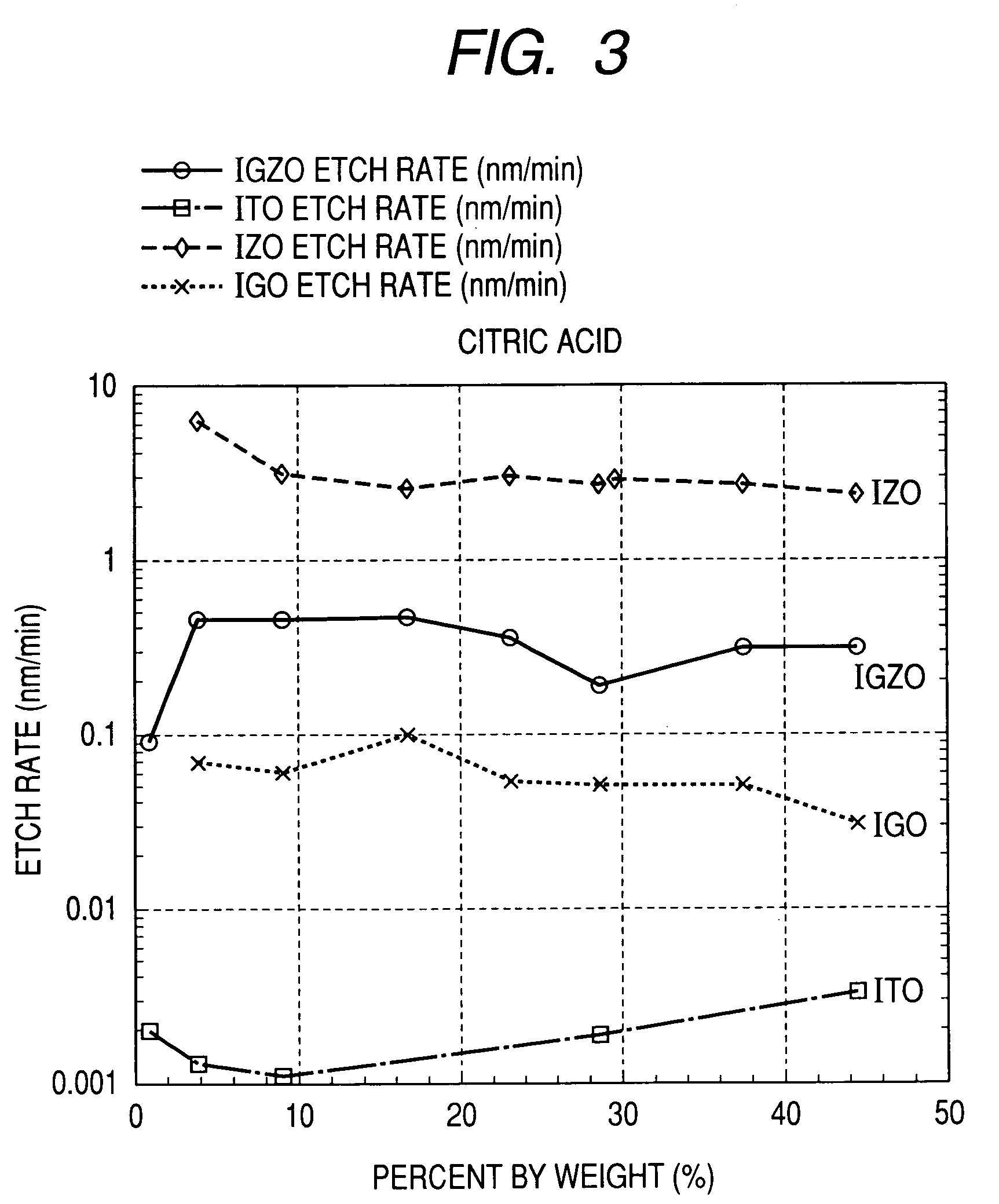

There is provided an etching method of an amorphous oxide layer containing In and at least one of Ga and Zn, which includes etching the amorphous oxide layer using an etchant containing any one of acetic acid, citric acid, hydrochloric acid, and perchloric acid.

Owner:CANON KK

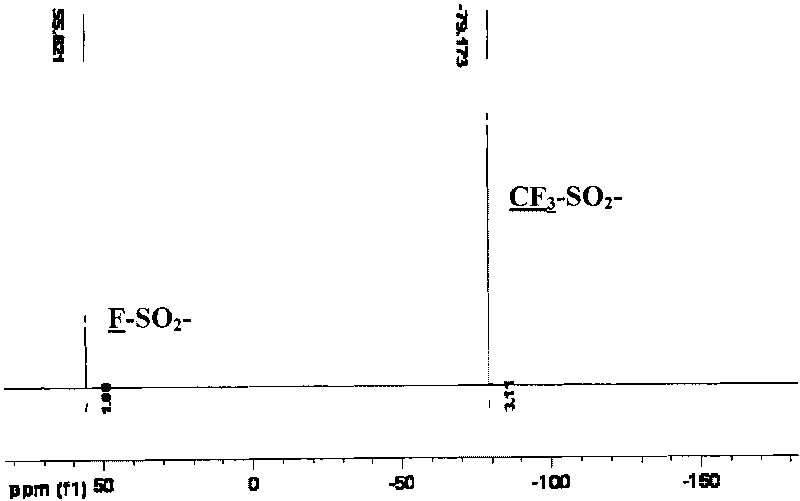

Method for preparing bi-(sulfonyl fluoride) imine and (fluorinated alkyl sulfonyl fluorine sulfonyl) imine alkali metal salt

ActiveCN101747242AAvoid product agglomerationSimple and efficient operationSulfonic acid amide preparationSolventDecomposition

The invention discloses a method for preparing bi-(sulfonyl fluoride) imine and (fluorinated alkyl sulfonyl fluorine sulfonyl) imine alkali metal salt. The method comprises the following steps of: reacting sulfamide and thionyl chloride and chlorosulfonic acid to prepare bi-(sulfonyl chlorine) imine and (fluorinated alkyl sulfonyl chlorine sulfonyl) imine, reacting with antimony trifluoride and potassium carbonate (rubidium or caesium) to obtain corresponding high-purity bi-(sulfonyl fluoride) imine potassium (rubidium or caesium) salt or (fluorinated alkyl sulfonyl fluorine sulfonyl) imine potassium (rubidium or caesium) salt, performing double decomposition exchange reaction using the potassium (rubidium or caesium) salt with the lithium perchlorate (or sodium) or lithium tetrafluoroborate (or sodium) in the aprotic polar solvent to obtain corresponding lithium (or sodium) salt with high purity. The method in the invention has the characteristics of simple operating steps, easy separation and extraction of output, high purity and yield, no environmental pollution, and the like, and is suitable for mass industrial production.

Owner:武汉市瑞华新能源科技有限公司

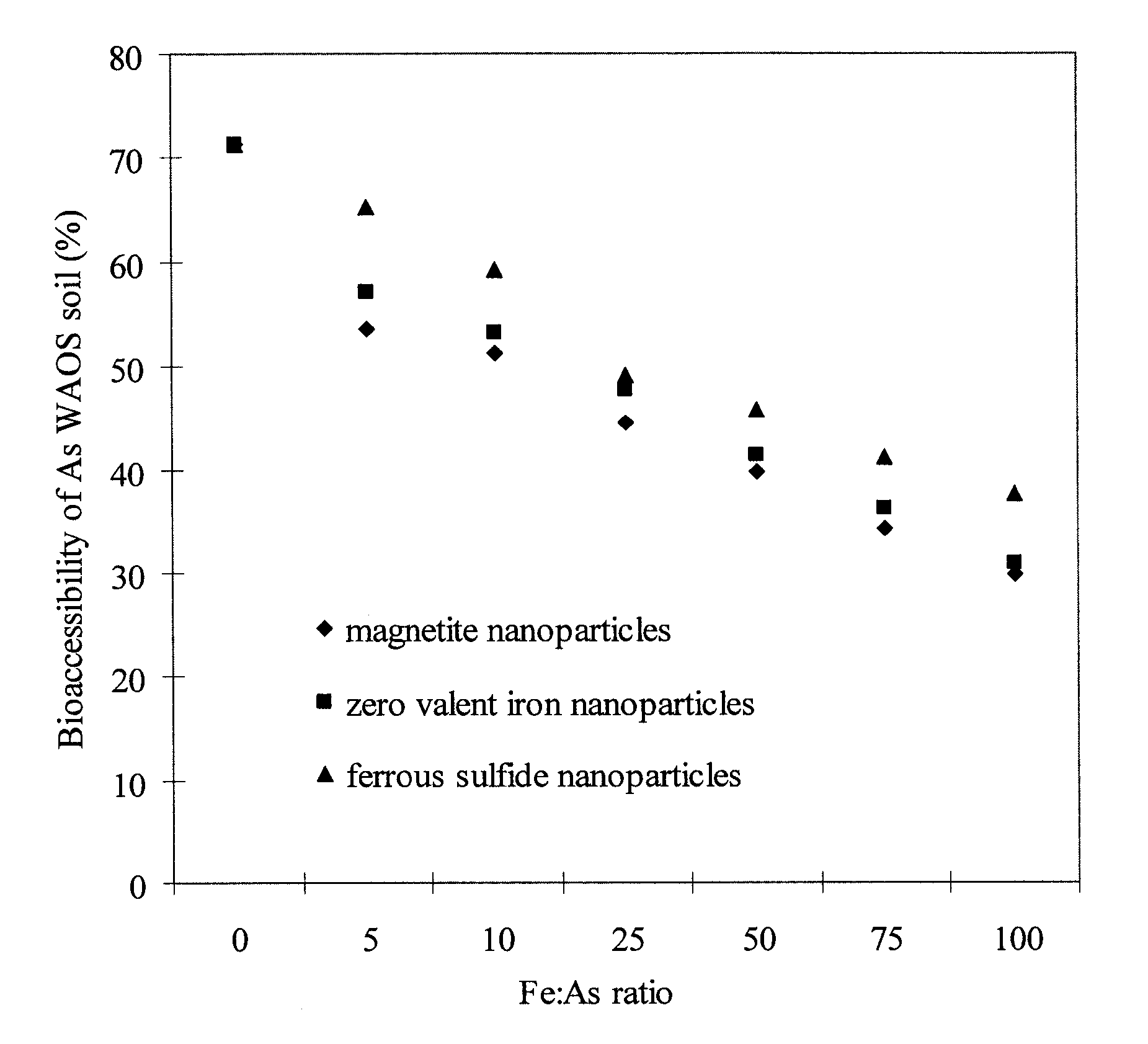

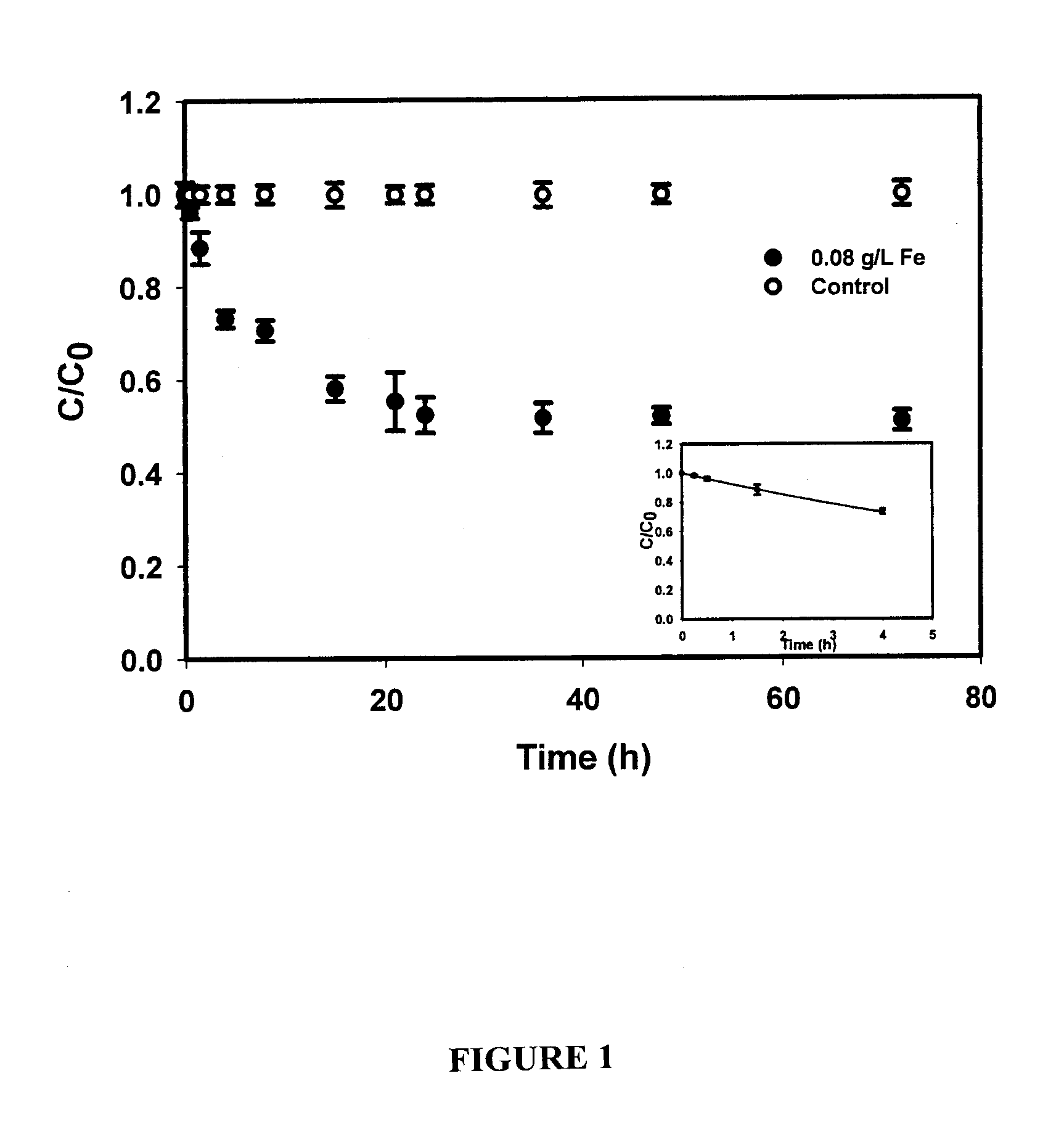

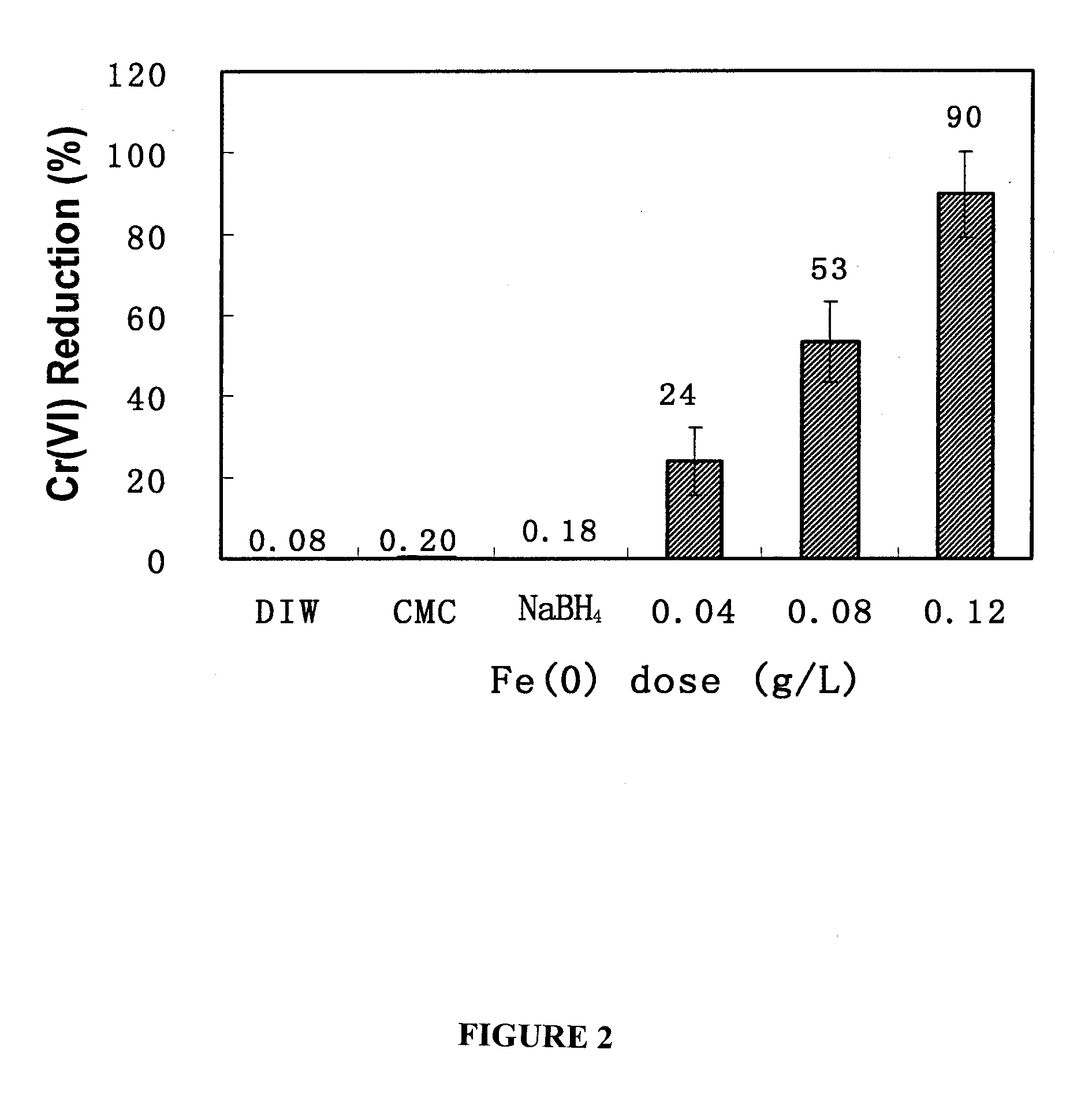

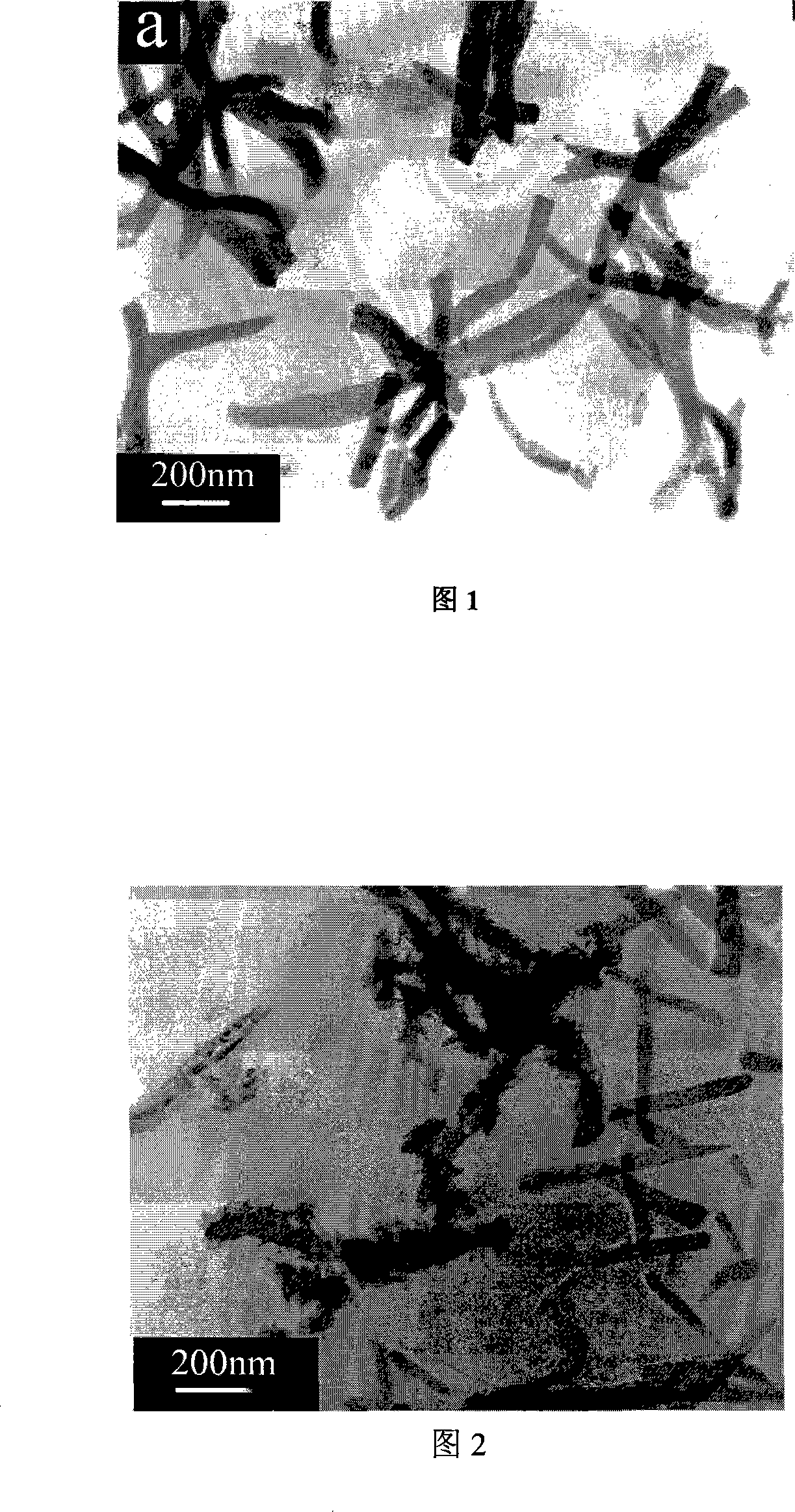

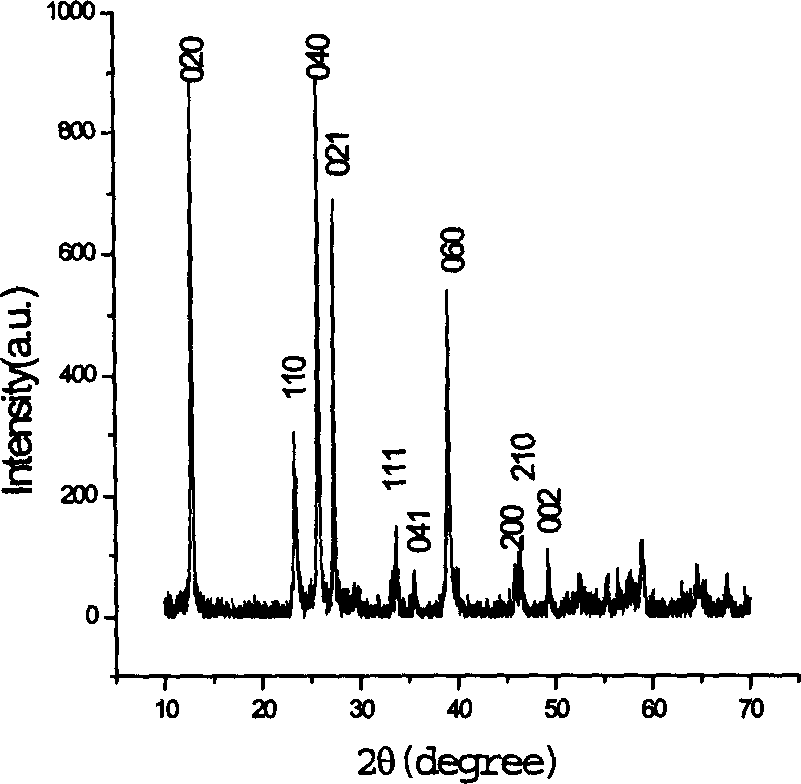

In Situ Remediation of Inorganic Contaminants Using Stabilized Zero-Valent Iron Nanoparticles

InactiveUS20070256985A1Low costProcess environmental protectionMaterial nanotechnologyWater treatment compoundsCelluloseMaterials science

A method for preparing highly stabilized and dispersible zero valent iron nanoparticles and using the nanoparticles as a remediation technology against inorganic chemical toxins in contaminated sites. The method employs a composition containing select polysaccharides (starch or cellulose) as a stabilizer for the iron nanoparticles in a liquid carrier, and results in suspensions of iron nanoparticles of desired size and mobility in water, brine, soils or sediments. The stabilizer facilitates controlling the dispersibility of the iron nanoparticles in the liquid carrier. An effective amount of the composition is delivered to a contaminated site so that the zero valent iron nanoparticles can remediate one or more toxins such as an arsenate, a nitrate, a chromate, or a perchlorate in the contaminated site.

Owner:AUBURN UNIV

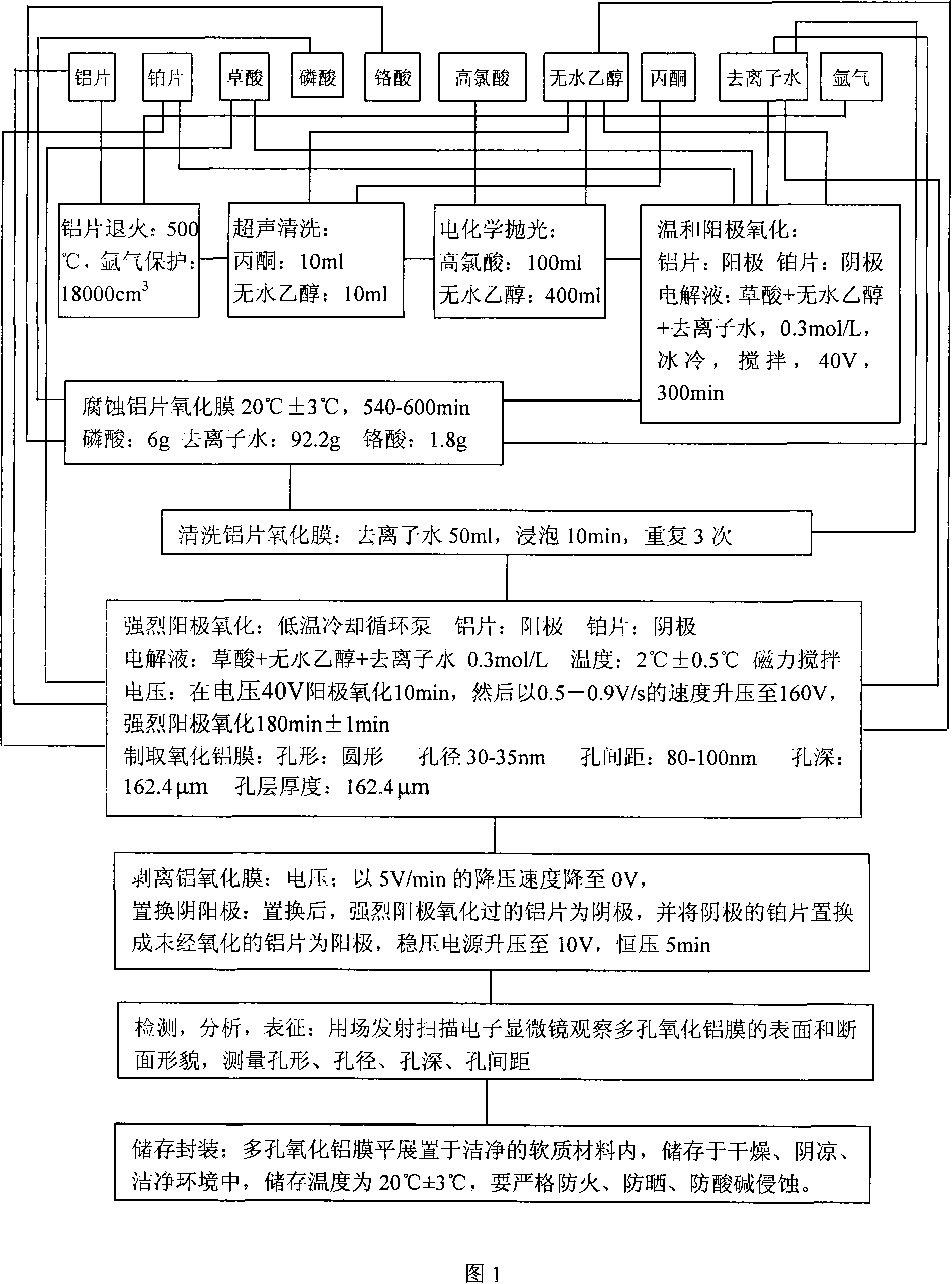

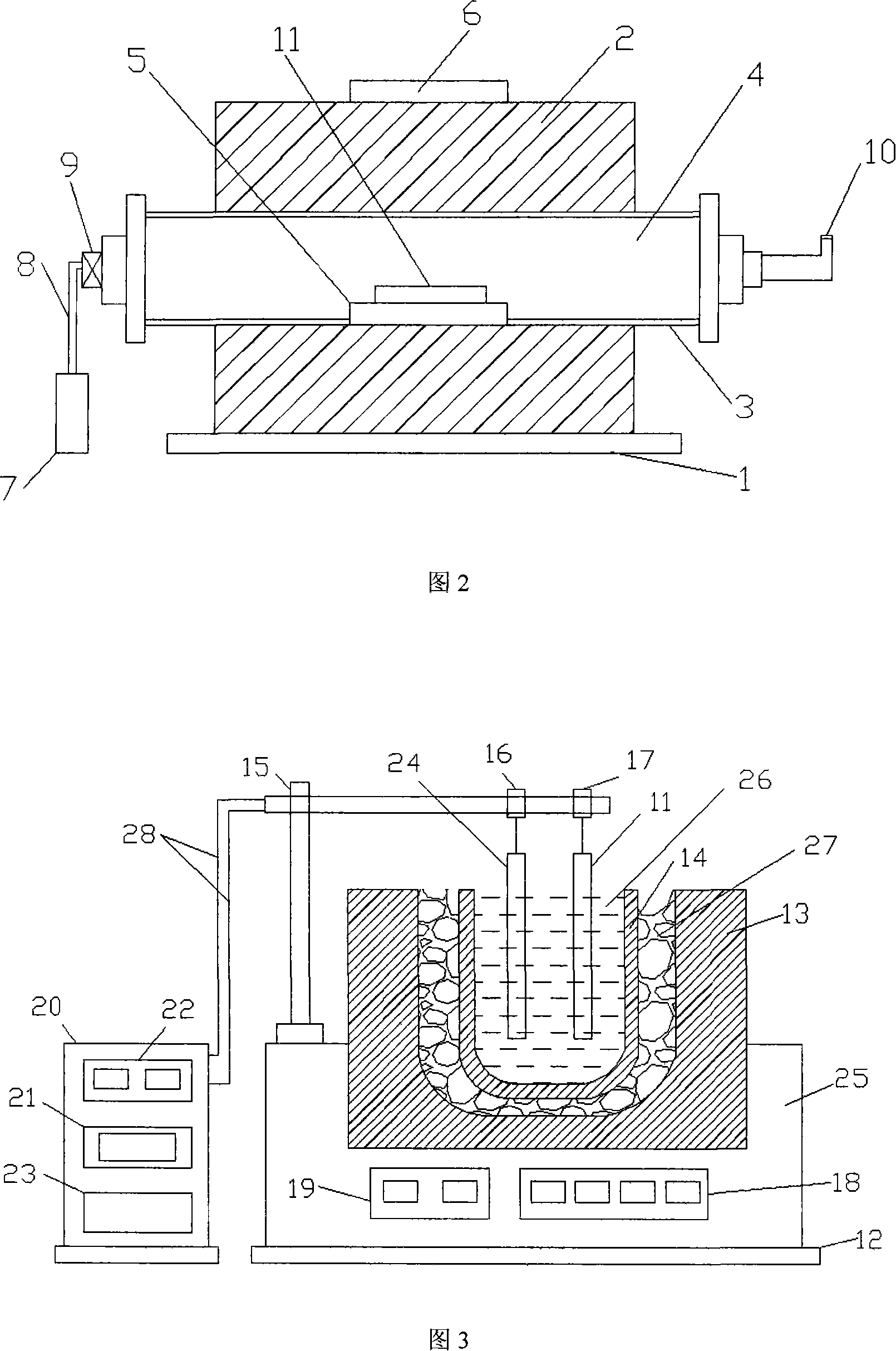

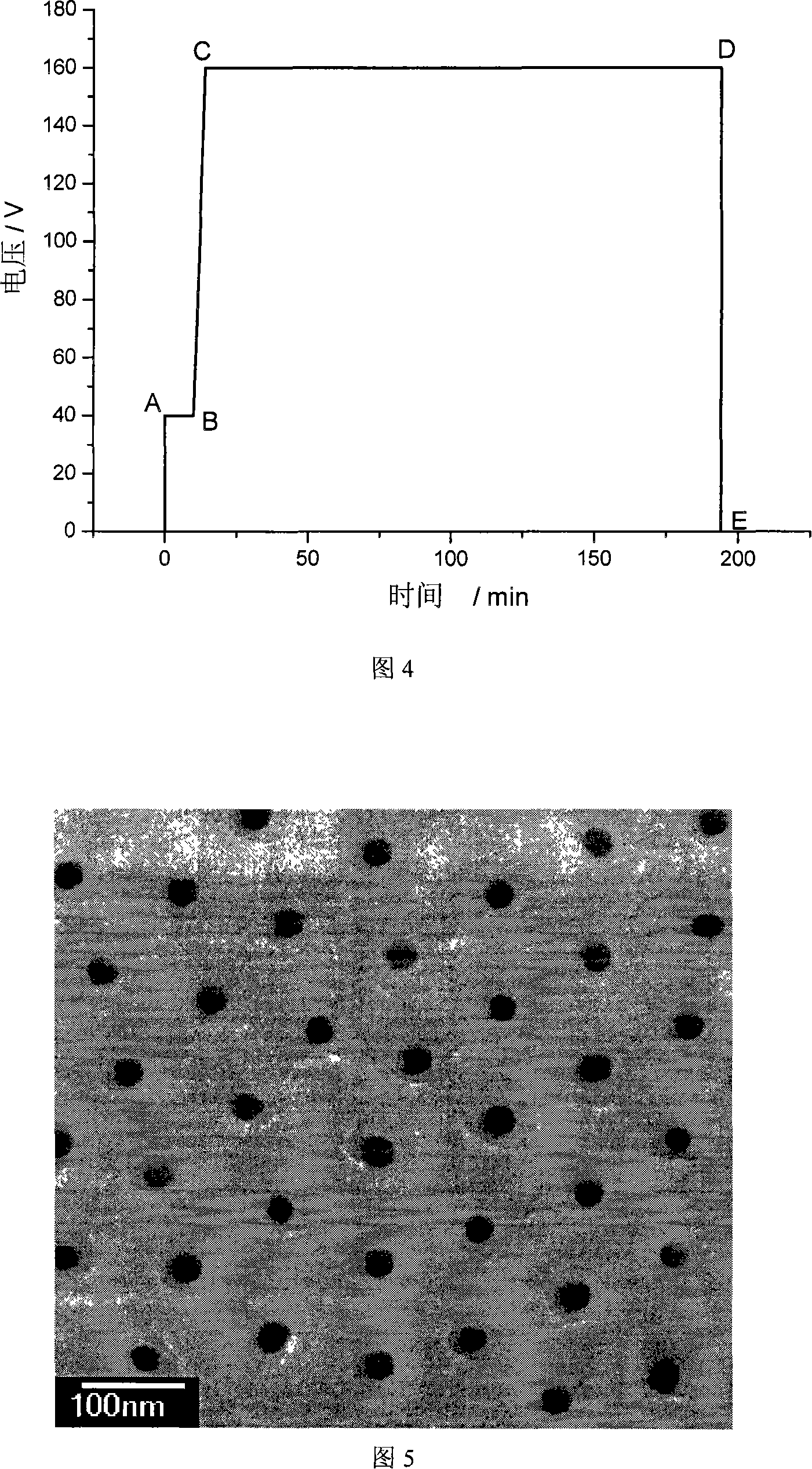

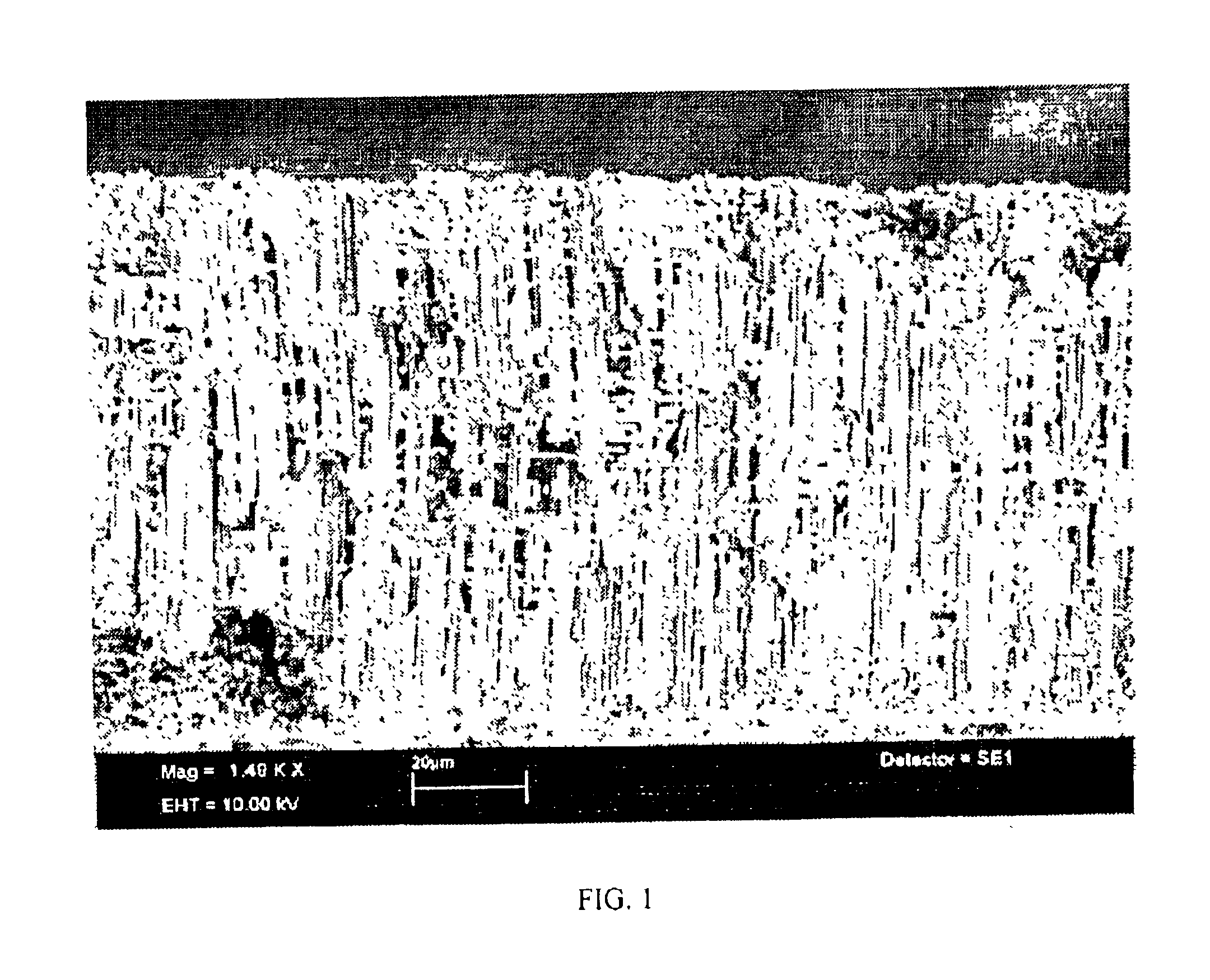

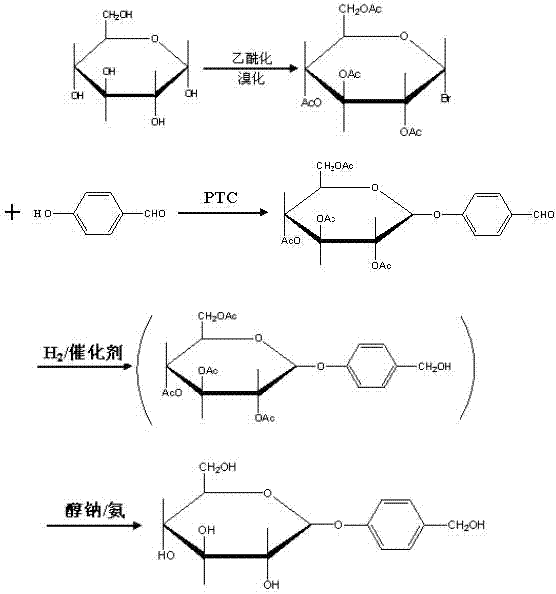

Strong anodic oxidation method for preparing porous pellumina

InactiveCN101139730AReduce pollutionRich sourcesSurface reaction electrolytic coatingShielding gasPhosphoric acid

The invention relates to an intensive anodic oxidation process to prepare porous anodic alumina film. An aluminum sheet is as an anode; a platinum sheet as a cathode; argon as shielded gas; mixed solution of perchloric acid with absolute alcohol as electrochemical polishing compound for the aluminum sheet; mixed solution of oxalic acid, absolute alcohol and deionized water as electrolyte; and mixed solution of phosphoric acid, chromic acid and deionized water as alumina film corrodent. Through aluminum sheet annealing, purging, electrochemical polishing, mild anodic oxidation, corrosion on aluminum sheet oxide film, intensive anodic oxidation and stripping oxide film, and finally, pale yellow, high purity and ordered porous-structured nanometer-leveled alumina film is achieved; The alumina film pore is in circular shape sized in 30 to 35nm, pore distance in 80 to100nm and pore depth in 162.4 micrometers; growth rate of the alumina film is 54 micrometers / h, which is 27 times higher than 2 micrometers / h of growth rate of anodic oxidation aluminum film prepared through mild anodic oxidation process.

Owner:TAIYUAN UNIV OF TECH

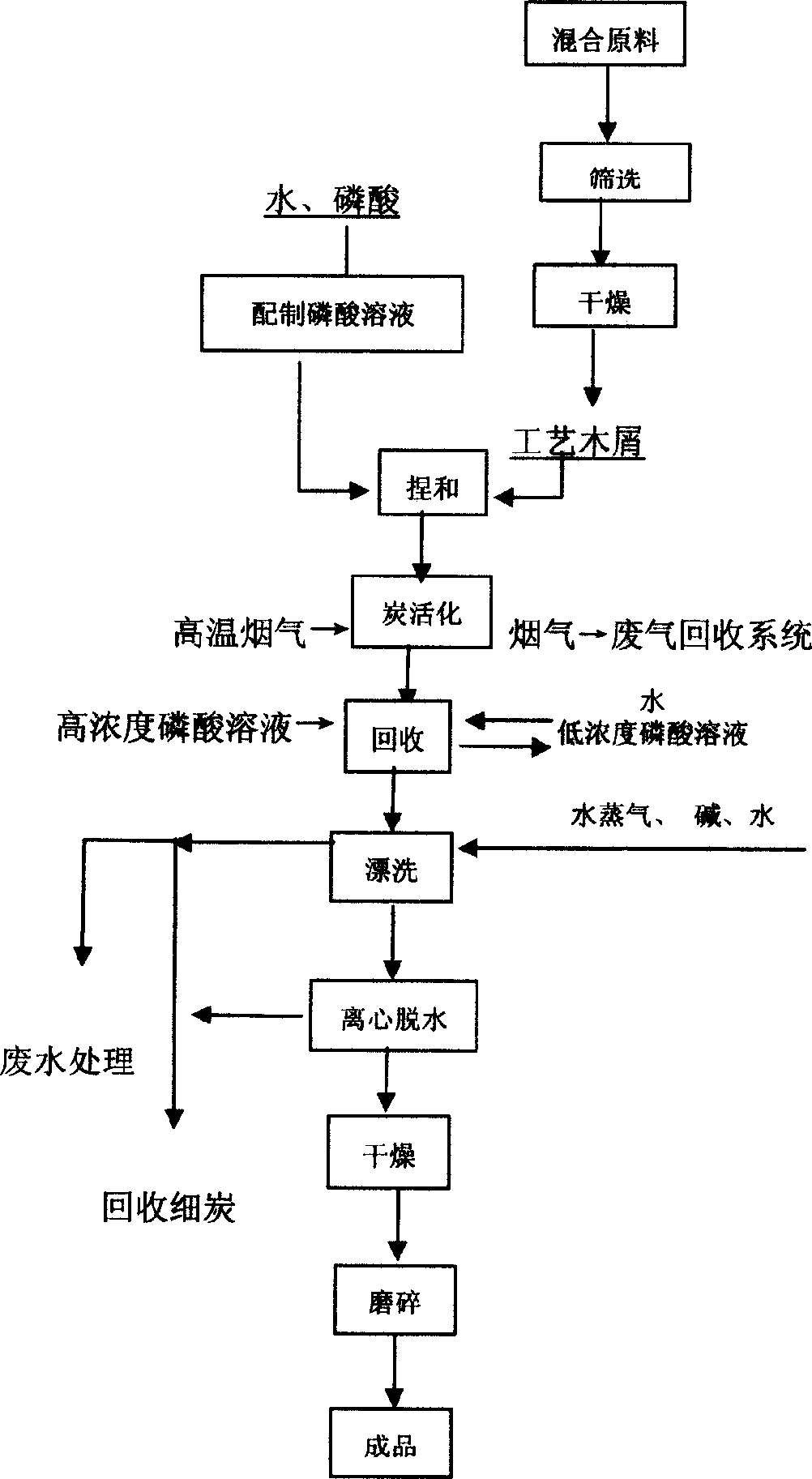

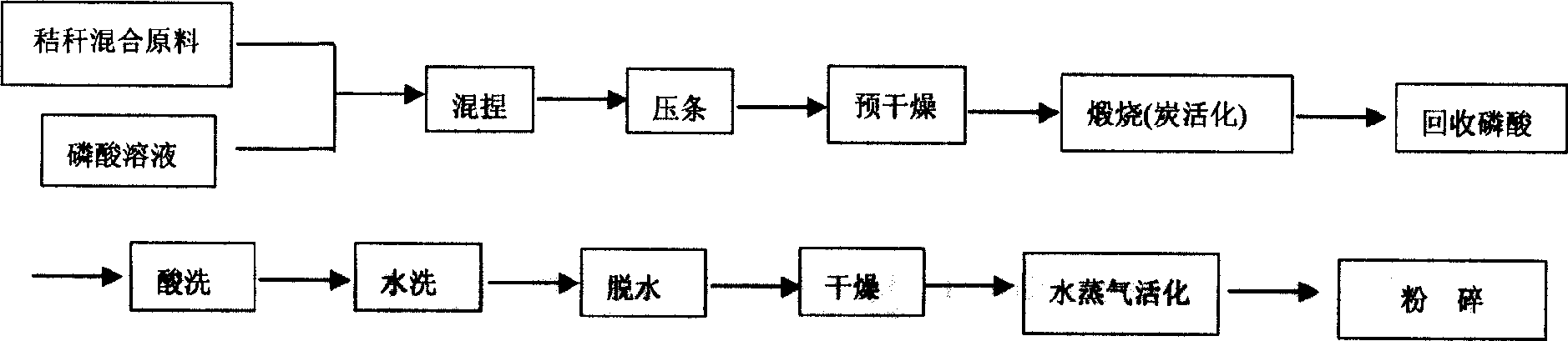

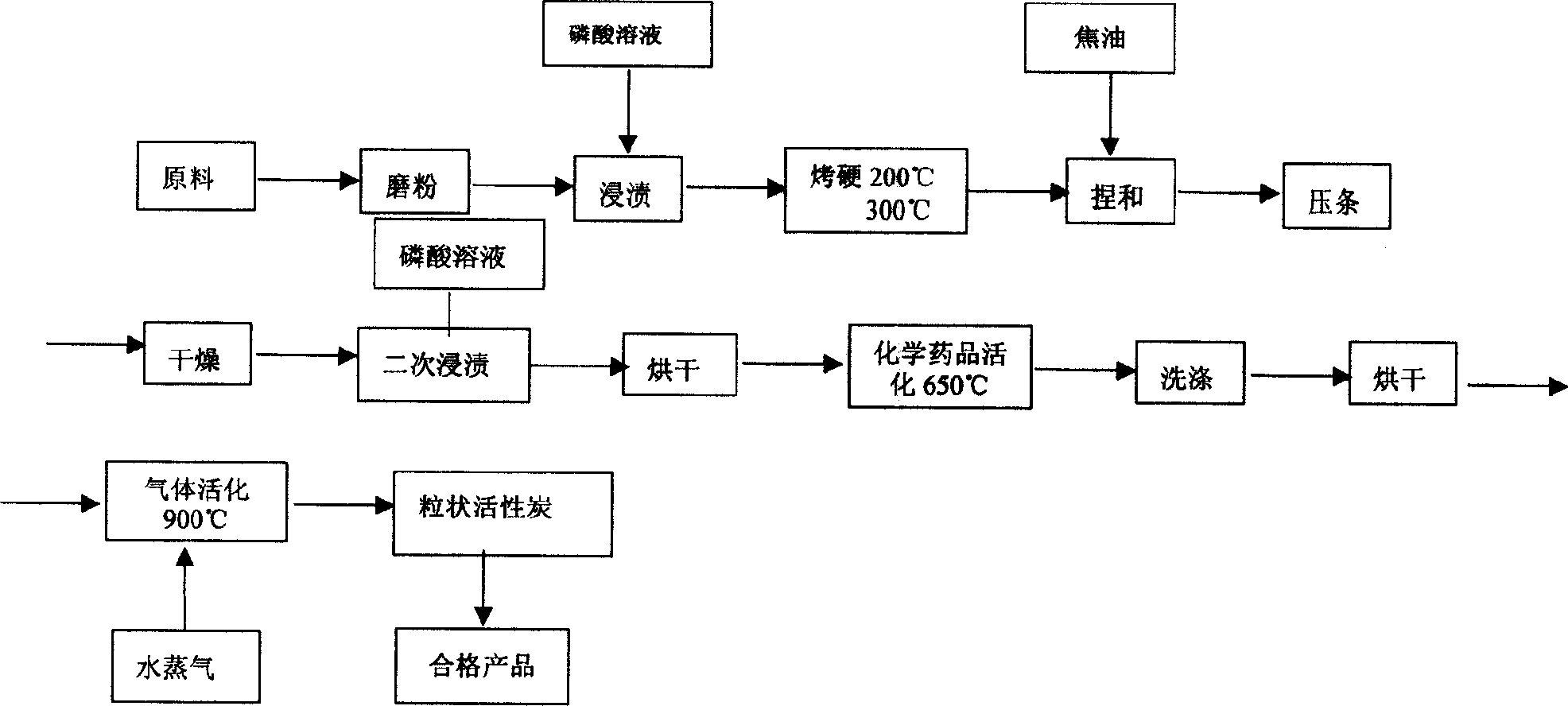

Active carbon producing process with mixed stalk material

The present invention discloses the active carbon producing process with mixed stalk material. The mixed stalk material of crop stalk, waste fruit branch and sawdust is produced into powdered or granular active carbon via phosphoric acid process and combined physical process. Or, the mixed stalk material is produced into powdered or granular active carbon in a chemical physical process with potassium hydroxide as activating agent and perchloric acid for pre-treatment of the material. The present invention has small investment scale, low cost, high utility and simple operation, and the product may be used widely.

Owner:NORTHWEST A & F UNIV

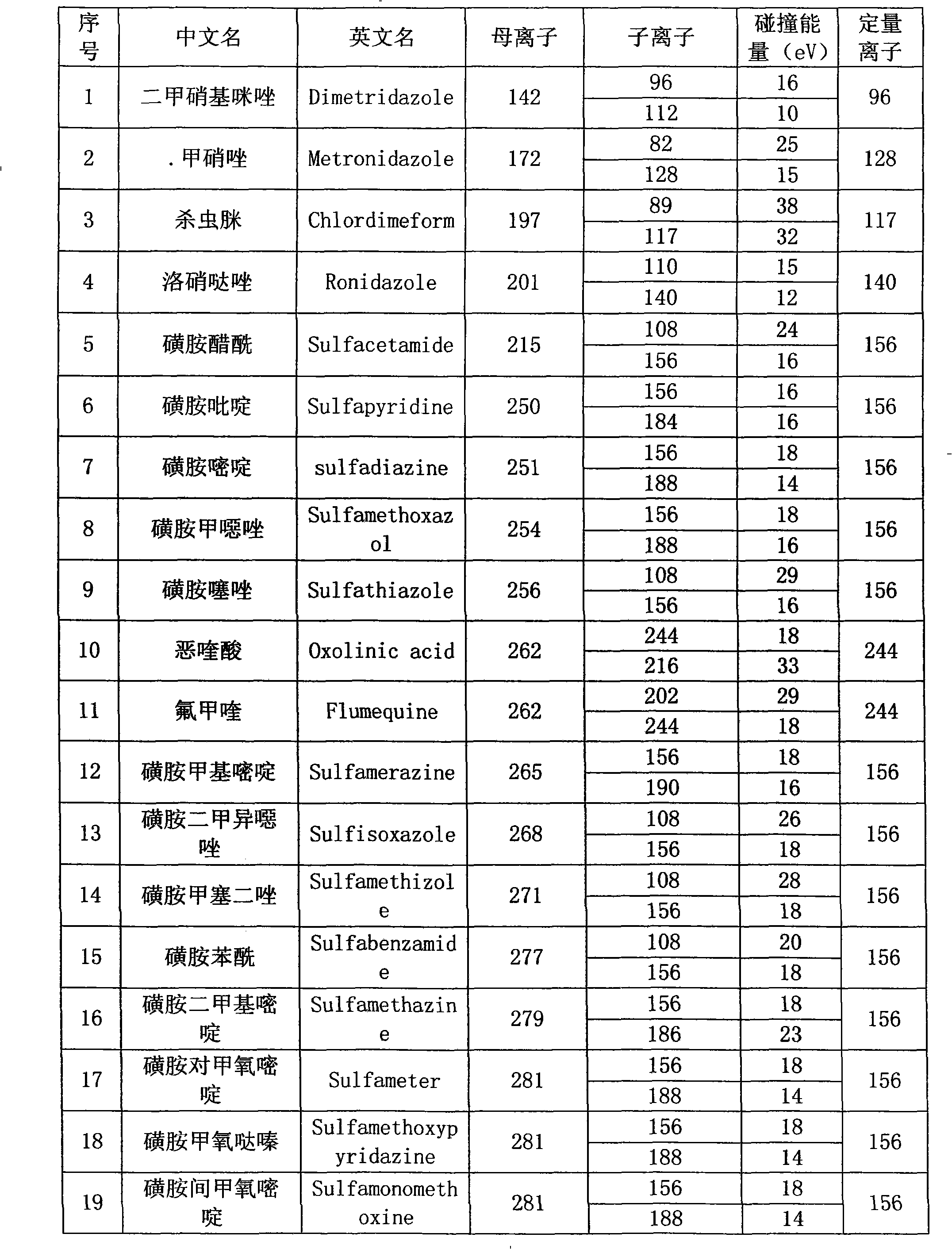

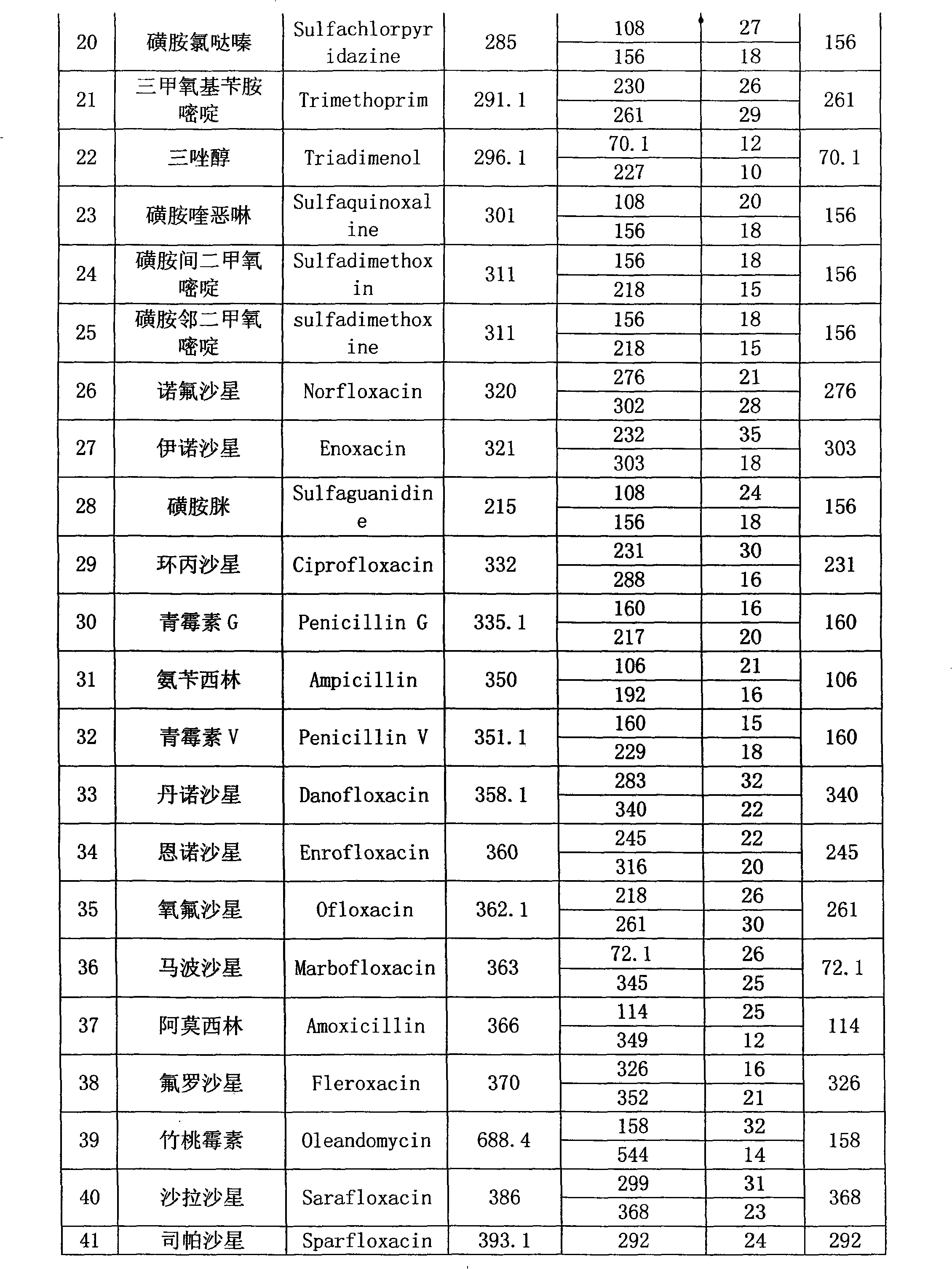

Method for simultaneously detecting multi-kind pesticide residues in bee products

InactiveCN101358953ASolve the problem of matrix effectFast wayComponent separationRetention timePhosphate

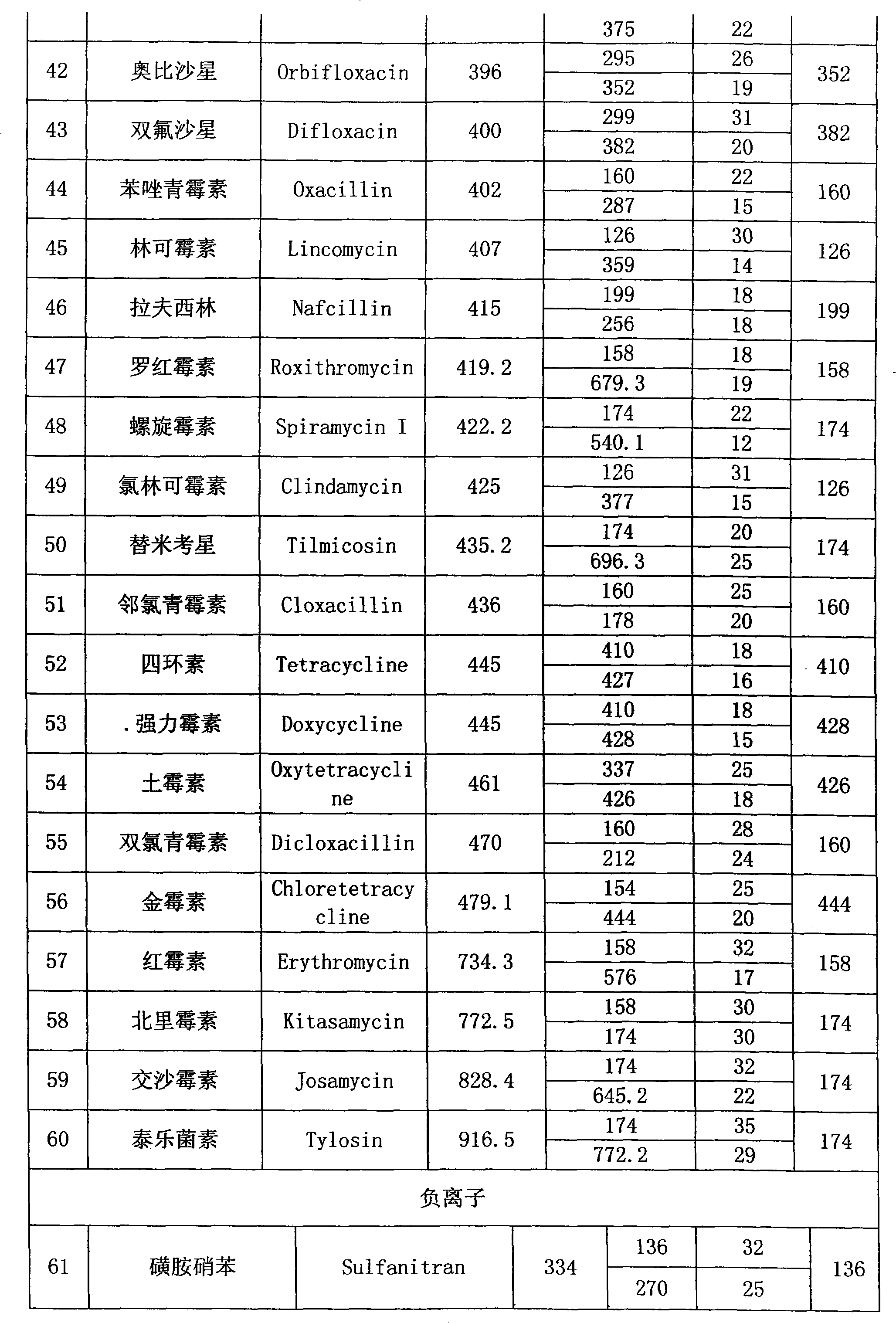

The present invention relates to a method of simultaneously detecting a plurality of agro-veterinary drug residues in bee products. The extracted liquid trichloroacetic acid or perchloric acid and the extracted liquid acetate, phosphate or borate solution are added into a sample; the pH value is controlled between 4.5 and 9.0; the mixed solution is centrifuged, the filtrate is added into a solid phase extraction column to be extracted, the extraction column is eluted and dried, the column is washed by oxalic acid-methanol solution, the volume of the eluent is defined by the aqueous solution of methanol, the eluent is added into liquid chromatography-tandem mass spectrometry to be analyzed and tested, the acquired chromatographic peak is contrasted with the known standard chromatographic peak of the drug, and according to the retention time and the abundance of the mass spectrum ions, the specific name of the detected drug is determined. The method only requires one pre-treatment of the sample, and thus can simultaneously extract 11 classes and more than 60 kinds of veterinary drug residues, such as sulfonamides, quinolones, macrolides, lincomycins, nitroimidazoles, beta-lactams, tetracyclines, chloromycetins, trinethoprims, chlordimeform, triadimenol and the like, the efficiency of analysis is high, and the detection cost is greatly reduced.

Owner:中华人民共和国江苏出入境检验检疫局

High capacitance anode and system and method for making same

InactiveUS6858126B1Lower equivalent series resistanceSacrificing capacitanceAnodisationElectrolysis componentsCapacitancePorosity

A method of producing electrodes for electrolytic capacitors by etching metal foil in a low pH etching electrolyte is disclosed. The low pH electrolyte is an aqueous solution, which comprises hydrochloric acid, glycerol, sodium perchlorate or perchloric acid, sodium persulfate and titanium (111) chloride. Anode foils etched according to the method of the invention maintain high capacitance gains, electrical porosity and strength. The electrical porosity of the etched foils is sufficiently high such that the overall Equivalent Series Resistance (ESR) is not increased in multilayer anodes configurations. Also described is a low pH electrolyte bath composition. Anode foils etched according to the present invention and electrolytic capacitors incorporating the etched anode foils are also disclosed.

Owner:PACESETTER INC

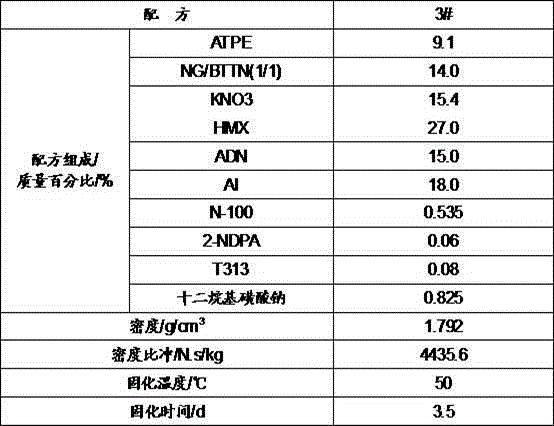

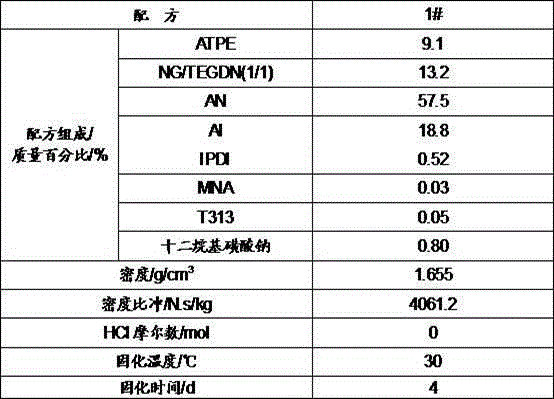

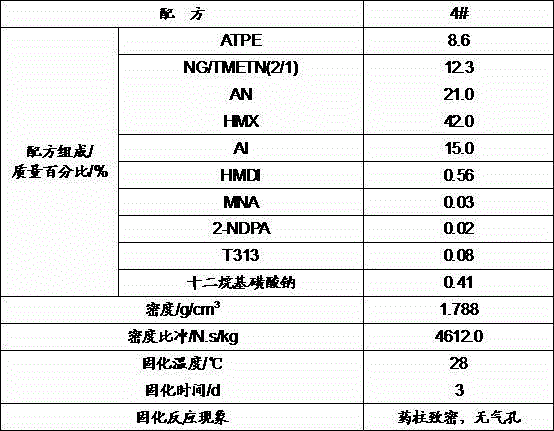

Room-temperature-cured-type clean solid propellant

The invention provides a room-temperature-cured-type clean solid propellant. The room-temperature-cured-type clean solid propellant is prepared from, by mass, 55%-70% of chlorine-free oxidizing agents, 5%-20% of metal fuels, 5%-15% of plasticizers, 5%-10% of amine-terminated polyether adhesives, 0.5%-1.0% of isocyanate curing agents and 0.01%-3% of function auxiliaries. According to the room-temperature-cured-type clean solid propellant, the detect that in the prior art, due to the fact that an oxidizing agent ammonium perchlorate is used in a compound solid propellant, a large amount of HCl gas is contained in a combustion product, and atomospheric pollution is serious is overcome; the amine-terminated polyether adhesives with the high reaction activity are introduced into a compound solid propellant system, and a cross-linking and curing reaction of terminal amino groups and the isocyanate curing agents is utilized, so that room-temperature curing of the amine-terminated polyether propellant is achieved; no HCl gas exists in the combustion product by adding the chlorine-free oxidizing agents.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

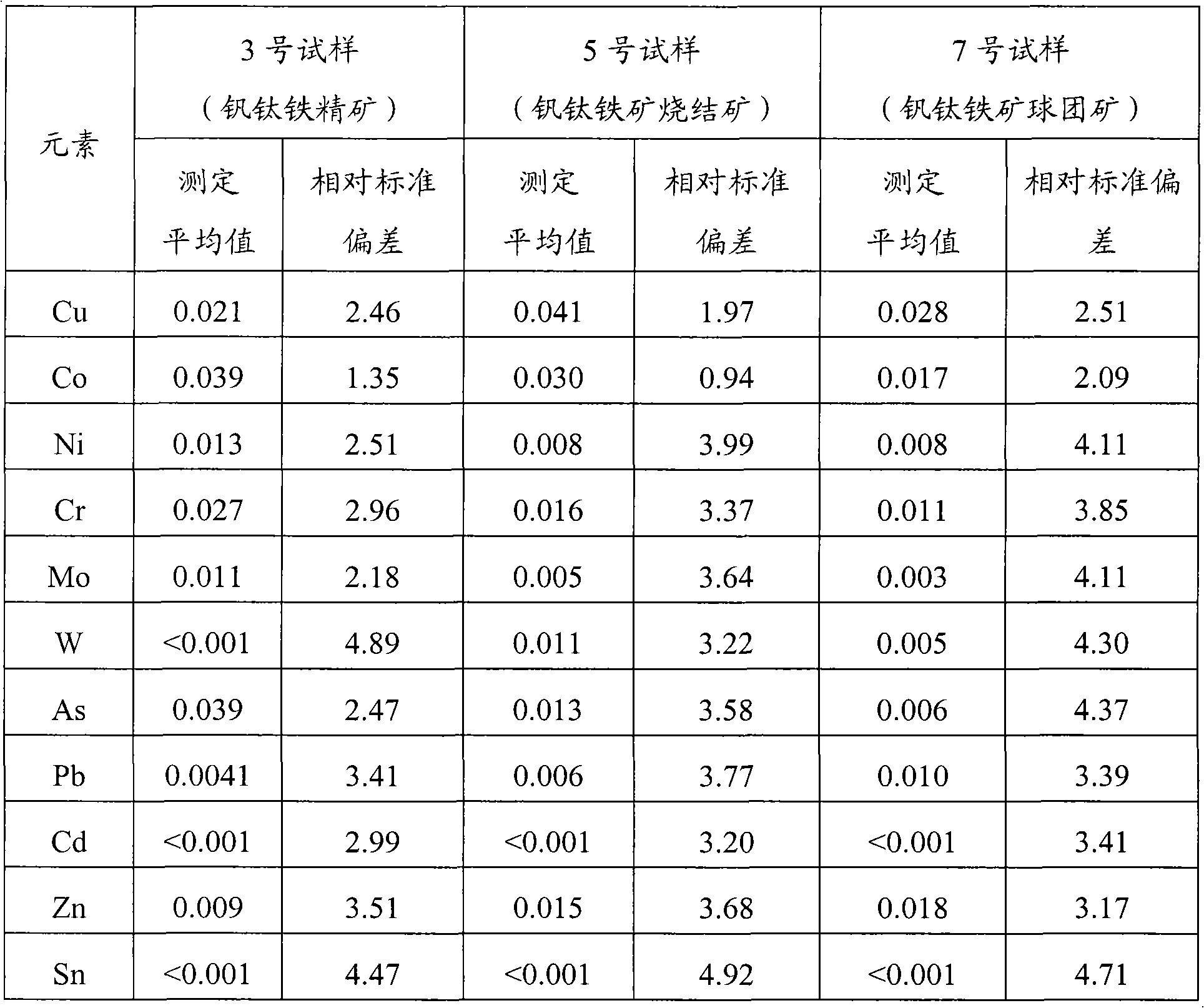

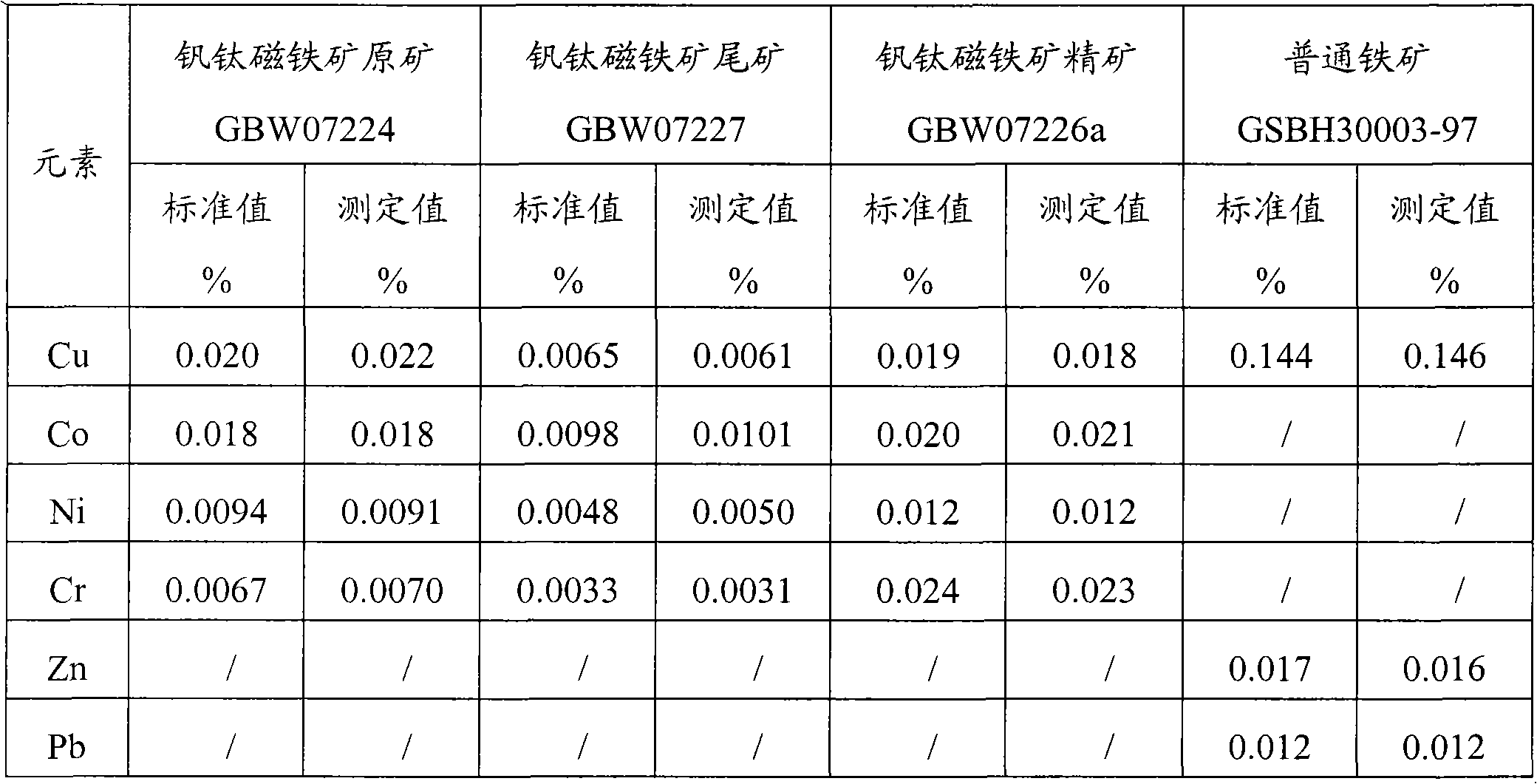

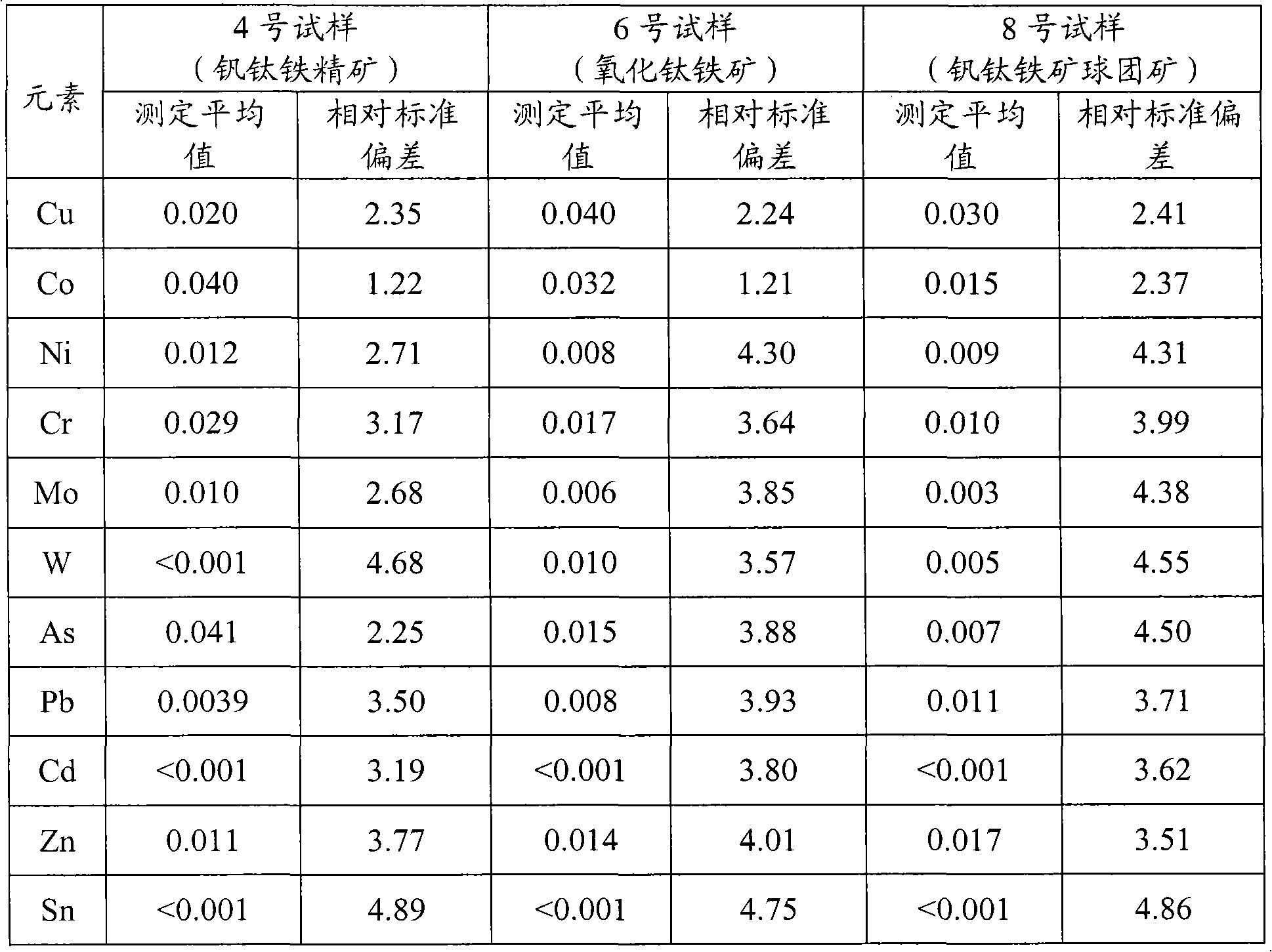

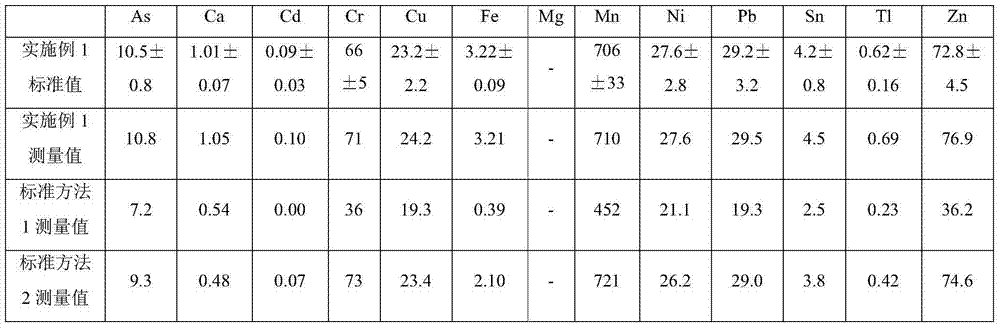

Digestion method and detection method for iron ore

InactiveCN101839828AAvoid influenceImprove detection accuracyPreparing sample for investigationColor/spectral properties measurementsDigestionHigh pressure

The invention provides a digestion method and a detection method for iron ore. The digestion method comprises the following steps: adding an iron ore sample in which hydrofluoric acid and nitric acid (or sulfuric acid) are mixed, then carrying out high-pressure closed microwave digestion to obtain a suspension; and heating the suspension in an unclosed system to secure the second digestion with residual nitric acid (or residual sulfuric acid) and added perchloric acid and hydrogen peroxide, thereby obtaining a solution which is digested fully. The detection method comprises the following steps: preparing a solution with the digested solution, and detecting the prepared solution by inductive coupling plasma atomic emission spectrometry, thereby obtaining content of each element of the iron ore sample. The invention has the advantages of high efficiency, high accuracy, and simple and fast process. Especially, the invention realizes accurate detection of key element content in iron ore, such as As, Pb, Zn, W, Sn, Ca, Mg, Cu, Co, Ni, Cr and Mo which affect product quality of iron and steel smelting and vanadium / titanium extraction.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

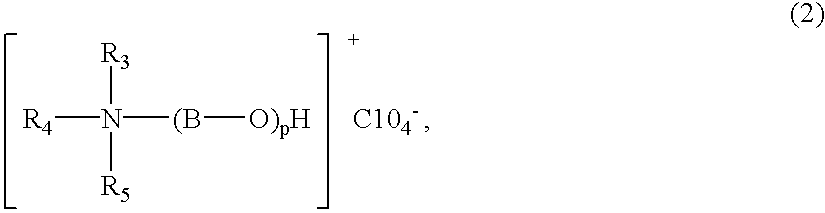

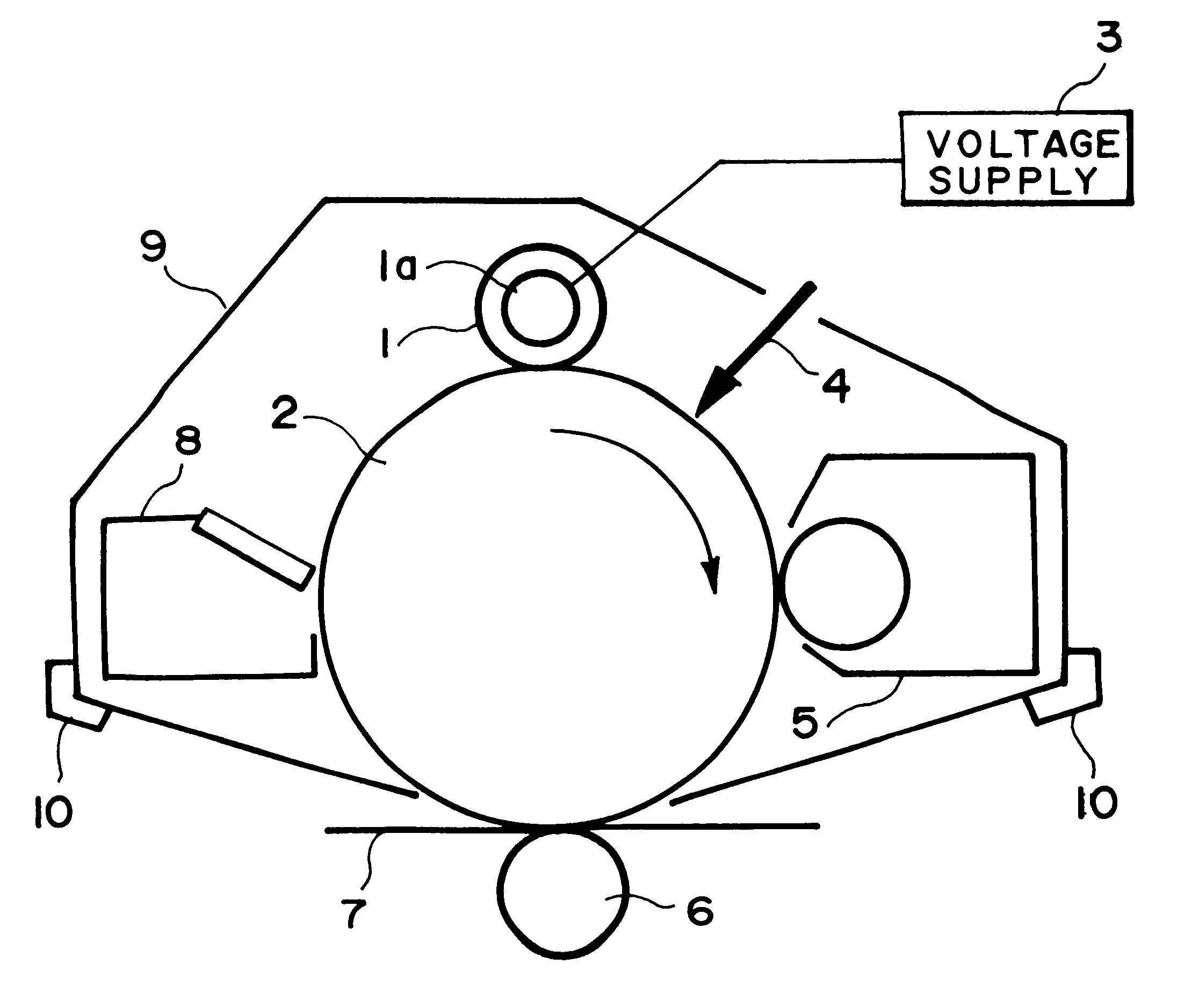

Conductive roller, process cartridge and image forming apparatus

InactiveUS6558781B1Plastic/resin/waxes insulatorsSynthetic resin layered productsPolymer scienceAmmonium compounds

An electroconductive roller is capable of exhibiting stable conductivity regardless of environmental change and is accompanied by small bleed-out of additives. The conductive roller includes an electroconductive support, an electroconductive elastic layer coating the support and a resistance layer coating the elastic layer; wherein the elastic layer comprises at least one species of rubber selected from the group consisting of acrylonitrile-butadiene rubber, epichlorohydrin rubber and chloroprene rubber, an ether oxygen containing alkyl phthalate derivative, a quaternary ammonium perchlorate compound and a fatty oil, and the ether oxygen-containing alkyl phthalate derivative, quaternary ammonium perchlorate compound and fatty oil are contained in a total amount of 0.1-20 wt. parts per 100 wt. parts of the rubber. The conductive roller is suitably used as a contact charging member in an electrophotographic apparatus.

Owner:CANON KK

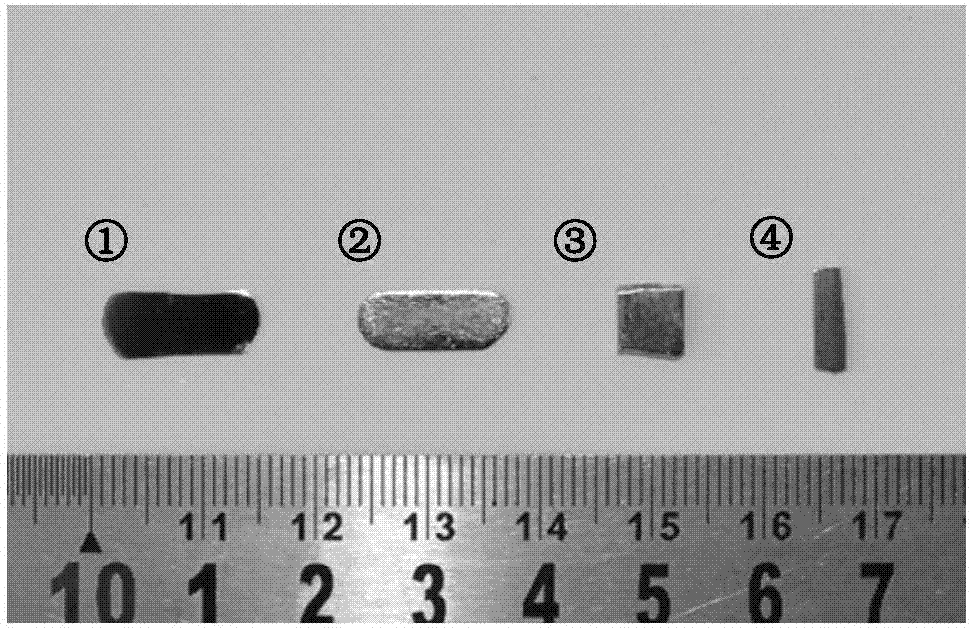

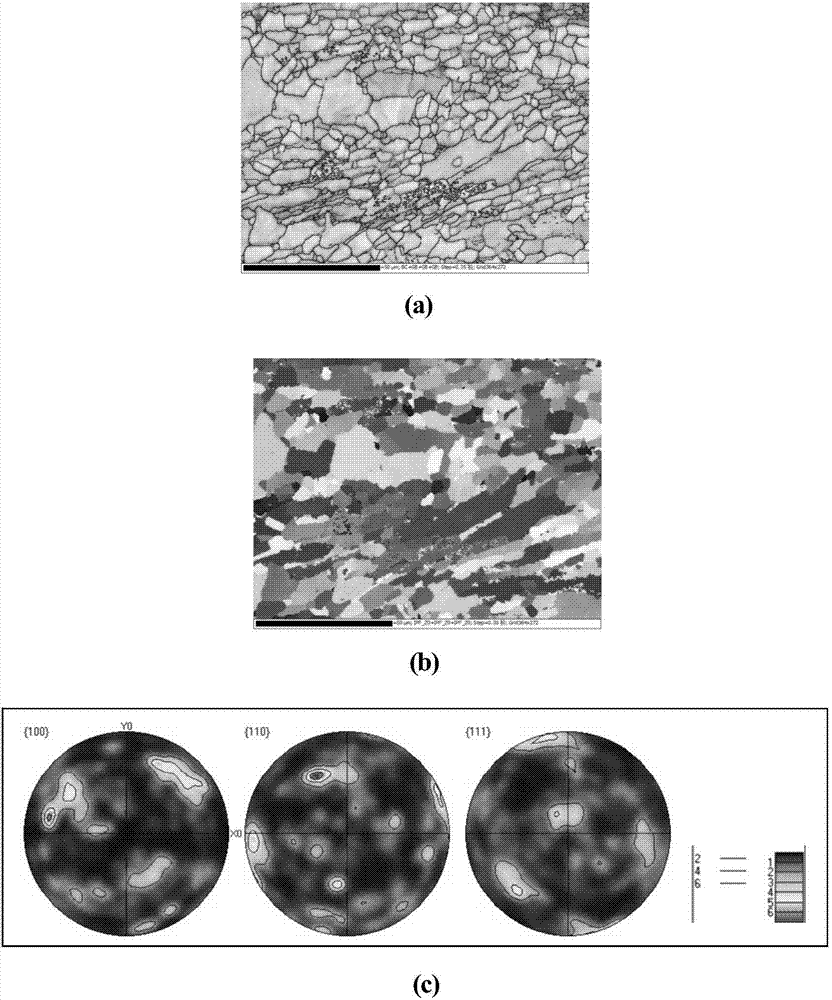

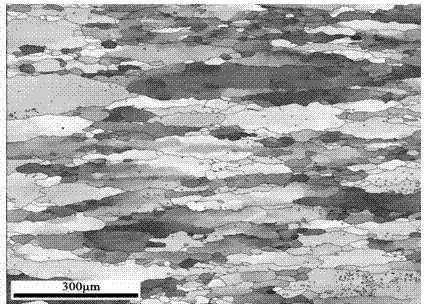

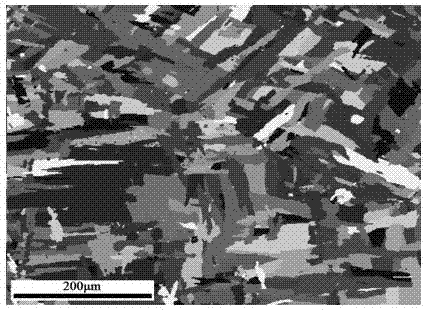

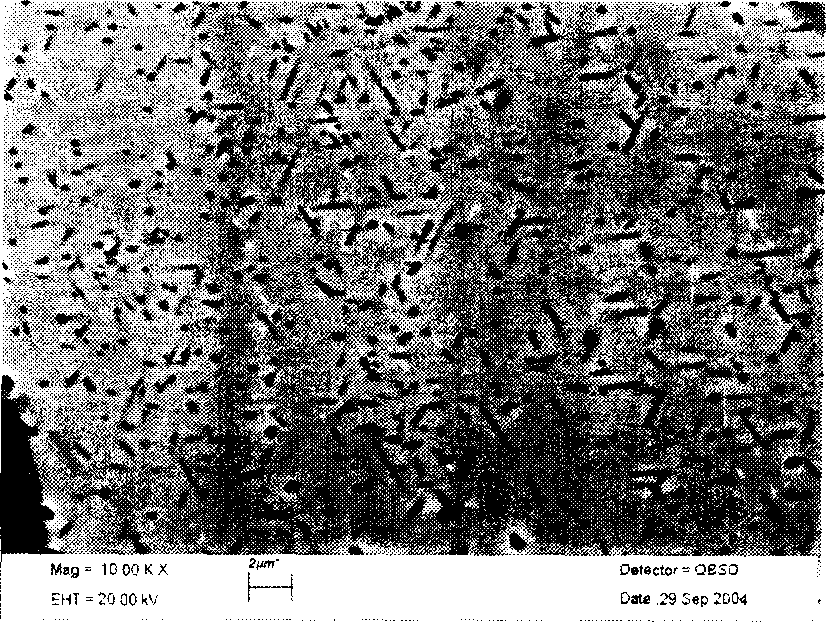

Electropolishing preparation method of sample for EBSD (Electron Back-Scattered Diffraction) analysis of titanium-aluminum alloy

InactiveCN107402150AIncrease the areaEasy and flexible operationPreparing sample for investigationElectrolysisHigh rate

The invention belongs to the technical field of non-ferrous metal analysis and particularly relates to an electropolishing preparation method of a sample for EBSD (Electron Back-Scattered Diffraction) analysis of a titanium-aluminum alloy. The electropolishing preparation method comprises the following steps: firstly, carrying out earlier stage treatment on the sample: determining the size of the sample to be smaller than 7mm*6mm*4mm, and carrying out standard metallographic treatment and mechanical polishing on the testing surface; secondly, setting up a portable device: connecting the sample with a positive pole of a power supply, connecting a stainless steel plate with a negative pole of the power supply and matching the bottom end of electrolyte with a magnetic stirrer; thirdly, preparing the electrolyte: selecting 4 to 12 percent of perchloric acid, 55 to 65 percent of methyl alcohol and the balance of n-butyl alcohol according to the volume ratio, wherein the total amount of the electrolyte is 700ml; putting the electrolyte into a beaker with the volume of 1L; fourthly, carrying out electrolysis treatment, washing and drying: controlling the temperature to be 30 DEG C below zero to 20 DEG C below zero, controlling the voltage to be 25 to 35V and controlling the polishing time to be 40 to 55 seconds. The electropolishing preparation method disclosed by the invention has the advantages of large surface area for treating the sample and suitability for preparing titanium-aluminum alloy samples with various components and various test purposes, which are prepared by different processing method. In addition, the electropolishing preparation method has the advantages of easiness and flexibility in operation, no restriction from site facilities and the like, good polishing effect and high rate of finished products; the device has the characteristics of high mobility, low cost, easiness in promotion and wide application prospect.

Owner:NORTHEASTERN UNIV

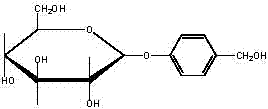

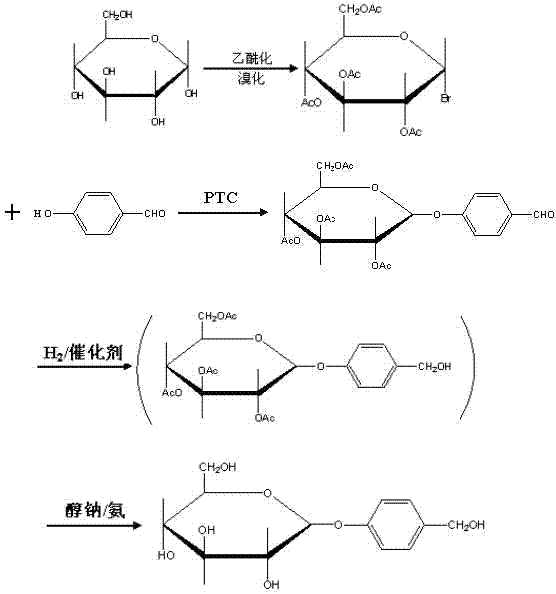

Gastrodin synthesizing method

InactiveCN102516329AReduce pollutionSuitable for industrial productionSugar derivativesSugar derivatives preparationKetone solventsPressure reduction

The invention relates to a gastrodin synthesizing method, which can effectively solve the preparation problem of gastrodin to meet the requirements of the gastrodin in pharmaceuticals. The method comprises the steps of adding catalyst perchloric acid, acetylating anhydrous dextrose by using acetic anhydride to produce per-acetyl dextrose, feeding hydrogen bromide to bromizing hemiacetal hydroxyl of the per-acetyl dextrose to produce bromo-tetraacethyl glucose, further and dropwise adding a bromo-tetraacethyl glucose solution into chloroform and tetrabutyl ammonium bromide, carbonate and para hydroxybenzene in water to obtain 4-formyl benzene-2', 3', 4', 6'- tetraacetyl-beta-D-glucopyranose, performing re-crystallization with ethanol, adding raney nickel or palladium and carbon, feeding hydrogen and pressurizing to hydrogenate, performing filtering, adding sodium alcoholate or ammonia in to filtrate to perform protecting group removal until the reaction is finished completely, performing pressure reduction and concentration to obtain crude gastrodin, and re-crystallizing the crude gastrodin by using alcohol or an alcohol and ester solvent or an alcohol and ketone solvent to obtain the gastrodin. The gastrodin synthesizing method is abundant and cheap in raw materials, simple in process, recycled in solvent, small in pollution and high in quality.

Owner:SHANGHAI MODERN HASEN SHANGQIU PHARMA

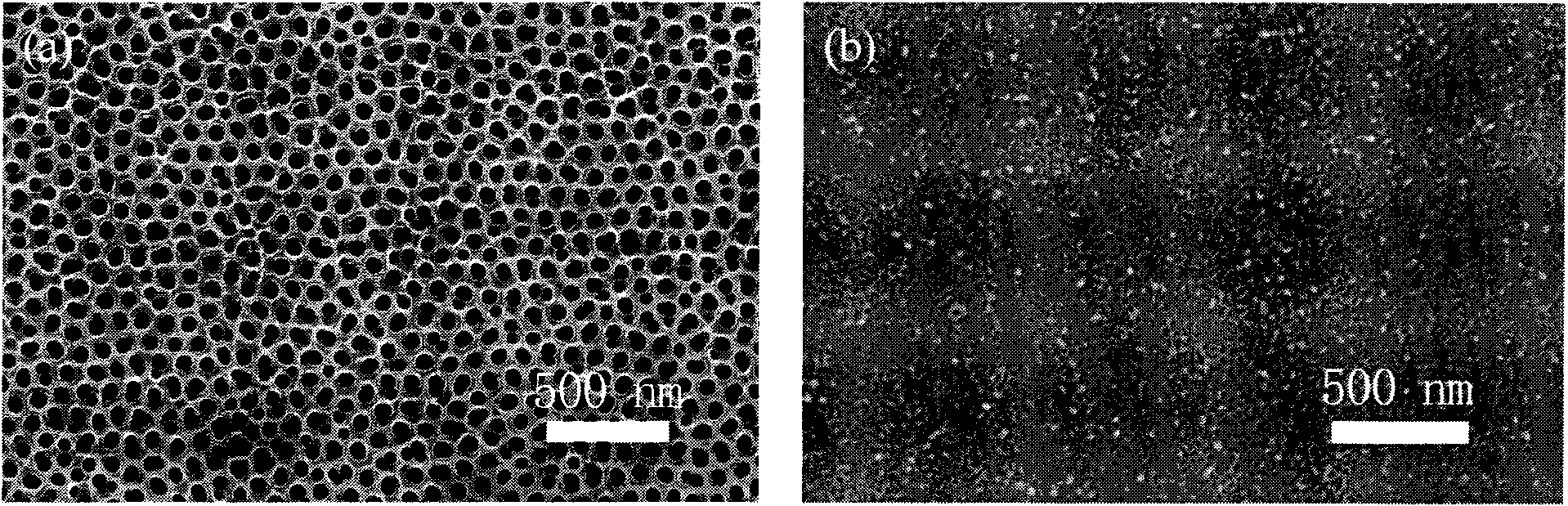

Method for preparing pore diameter controllable through hole anodized aluminum oxide film

The invention relates to technology for preparing an anodized aluminum oxide film, in particular to a method for preparing a pore diameter controllable through hole anodized aluminum oxide film. The method comprises the following steps of: performing anode electrolysis treatment on an anodized aluminum oxide film with an aluminum substrate in mixed solution of perchloric acid and acetone to obtain a pore diameter controllable anodized aluminum oxide film with two open ends in short time (2-300 seconds), wherein the pore diameters at the top end and the bottom end fo the anodized aluminum oxide film are accurately controllable in ranges of between 10 and 100nm and between 5 and 25nm; and putting the aluminum oxide film with the aluminum substrate subjected to stage depressurization-method oxidation into acetone solution of perchloric acid, and applying voltage 5-15V higher than film forming voltage for anode electrolysis treatment to obtain the pore diameter controllable through hole anodized aluminum oxide film. In the method, the pore diameters at the top end and the bottom end of the anodized aluminum oxide film can be respectively controlled, holing and removal of the aluminum substrate are completed by one step, and a plurality of problems of complicated process, time consumption, difficult control of pore diameters and the like in the conventional process for preparing the through hole anodized aluminum oxide film.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Sludge curing agent and sludge curing process employing sludge curing agent

ActiveCN104016626AImprove delivery efficiencyHigh degree of automationSludge treatment by de-watering/drying/thickeningSolid waste managementSludgePolyacrylamide

The invention relates to a sludge curing agent and an application thereof in sludge curing treatment, and belongs to the field of sludge treatment. In order to overcome the technical defect of poor curing effect of the existing sludge curing agent in the prior art, the sludge curing agent which is low in cost and good in curing effect is provided by the invention. The sludge curing agent comprises the following components in parts by weight: 25 to 45 parts of coal ash, 20 to 30 parts of swollen resin, 15 to 20 parts of cement, 7 to 9 parts of water glass, 10 to 12 parts of kieselguhr, 10 to 12 parts of quick lime, 6 to 9 parts of sodium hydroxide, 3 to 8 parts of aluminum sulfate, 8 to 10 parts of polyacrylamide, 6 to 8 parts of magnesium perchlorate and 5 to 15 parts of quartz sand. The sludge curing agent has the advantages of high curing efficiency and large hardness when being applied to the sludge curing treatment. Thus, the sludge curing agent is very suitable for the sludge curing treatment for water conservancy.

Owner:GUANGZHOU WATER CONSERVANCY & HYDROPOWER STATION CONSTR ENG

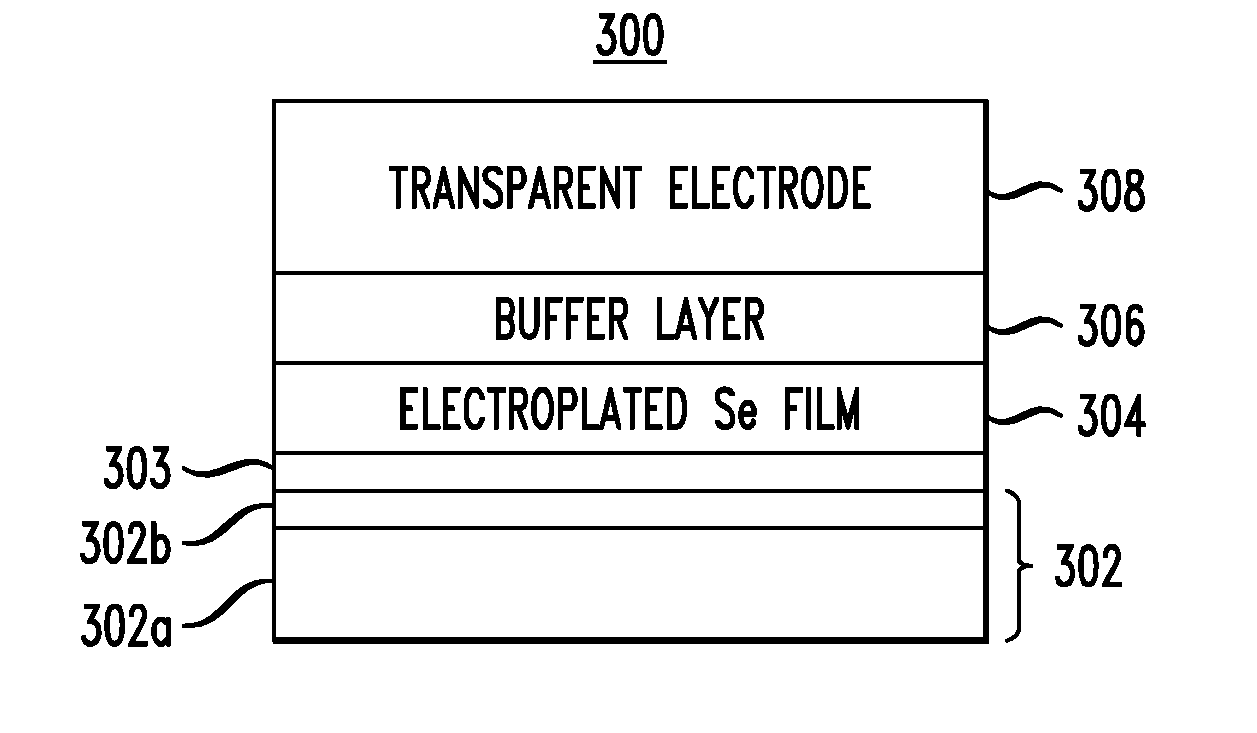

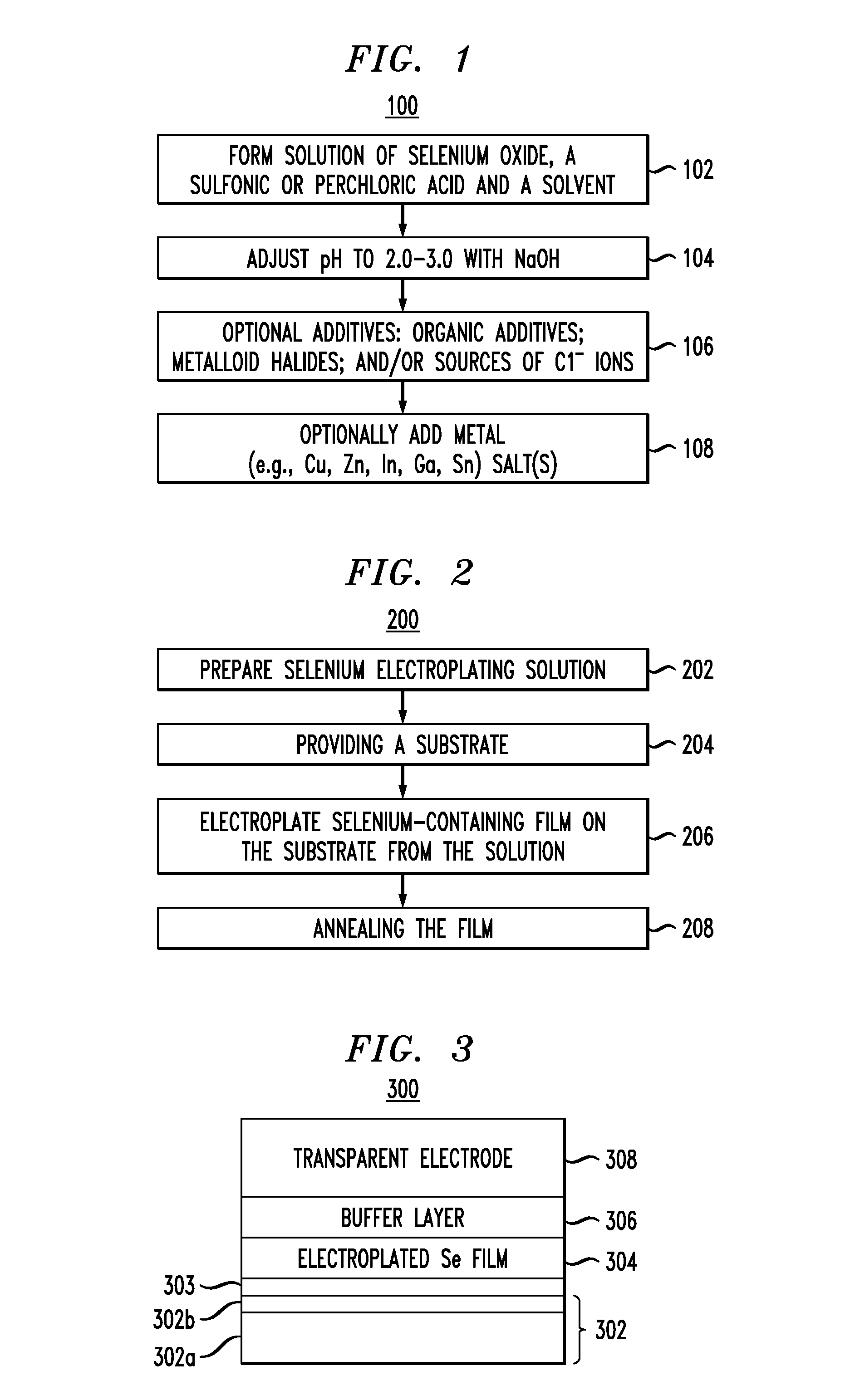

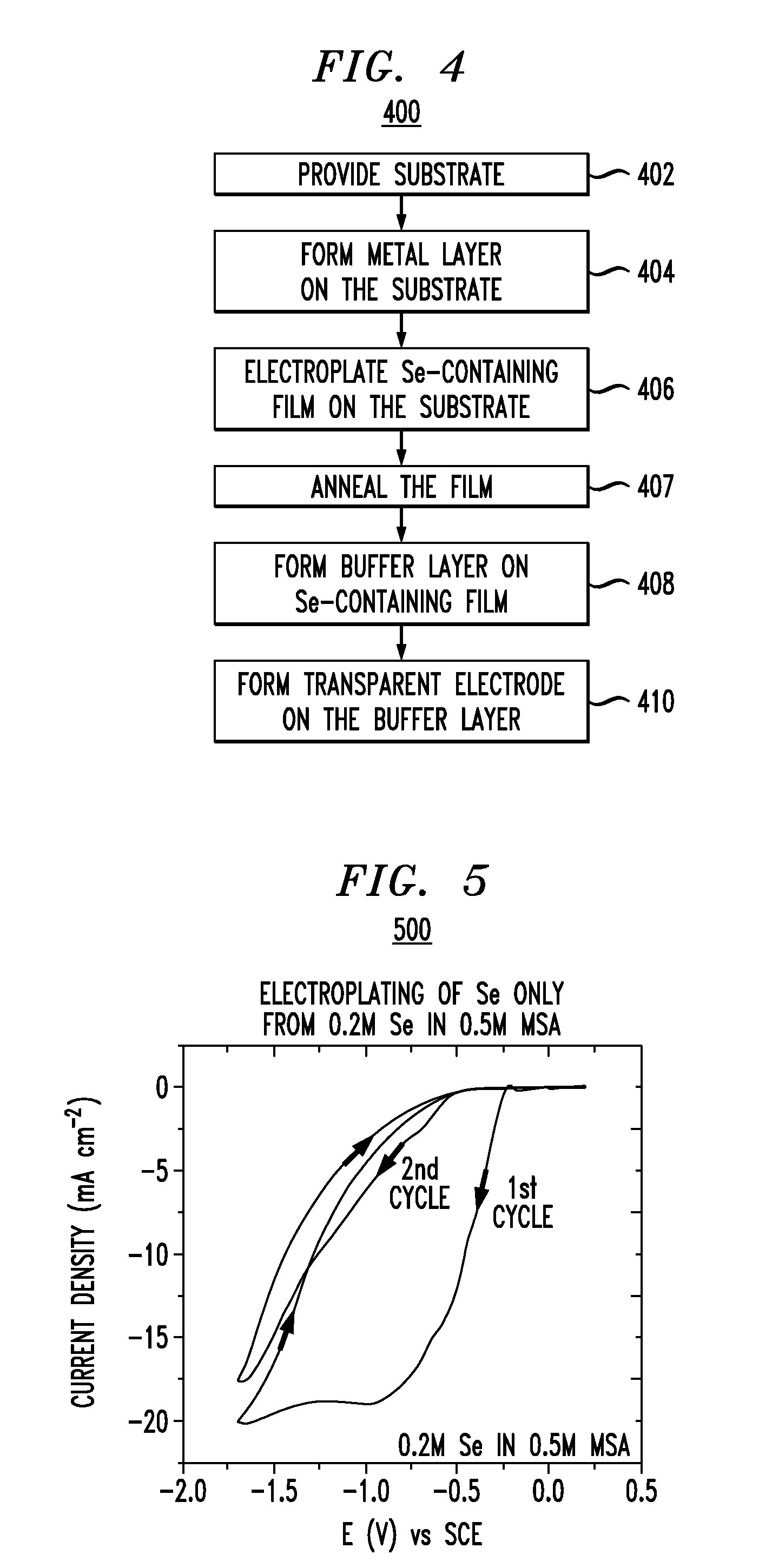

Method and Chemistry for Selenium Electrodeposition

InactiveUS20120061247A1Electrolytic inorganic material coatingSuperimposed coating processAlkaneAryl

Techniques for electrodepositing selenium (Se)-containing films are provided. In one aspect, a method of preparing a Se electroplating solution is provided. The method includes the following steps. The solution is formed from a mixture of selenium oxide; an acid selected from the group consisting of alkane sulfonic acid, alkene sulfonic acid, aryl sulfonic acid, heterocyclic sulfonic acid, aromatic sulfonic acid and perchloric acid; and a solvent. A pH of the solution is then adjusted to from about 2.0 to about 3.0. The pH of the solution can be adjusted to from about 2.0 to about 3.0 by adding a base (e.g., sodium hydroxide) to the solution. A Se electroplating solution, an electroplating method and a method for fabricating a photovoltaic device are also provided.

Owner:IBM CORP

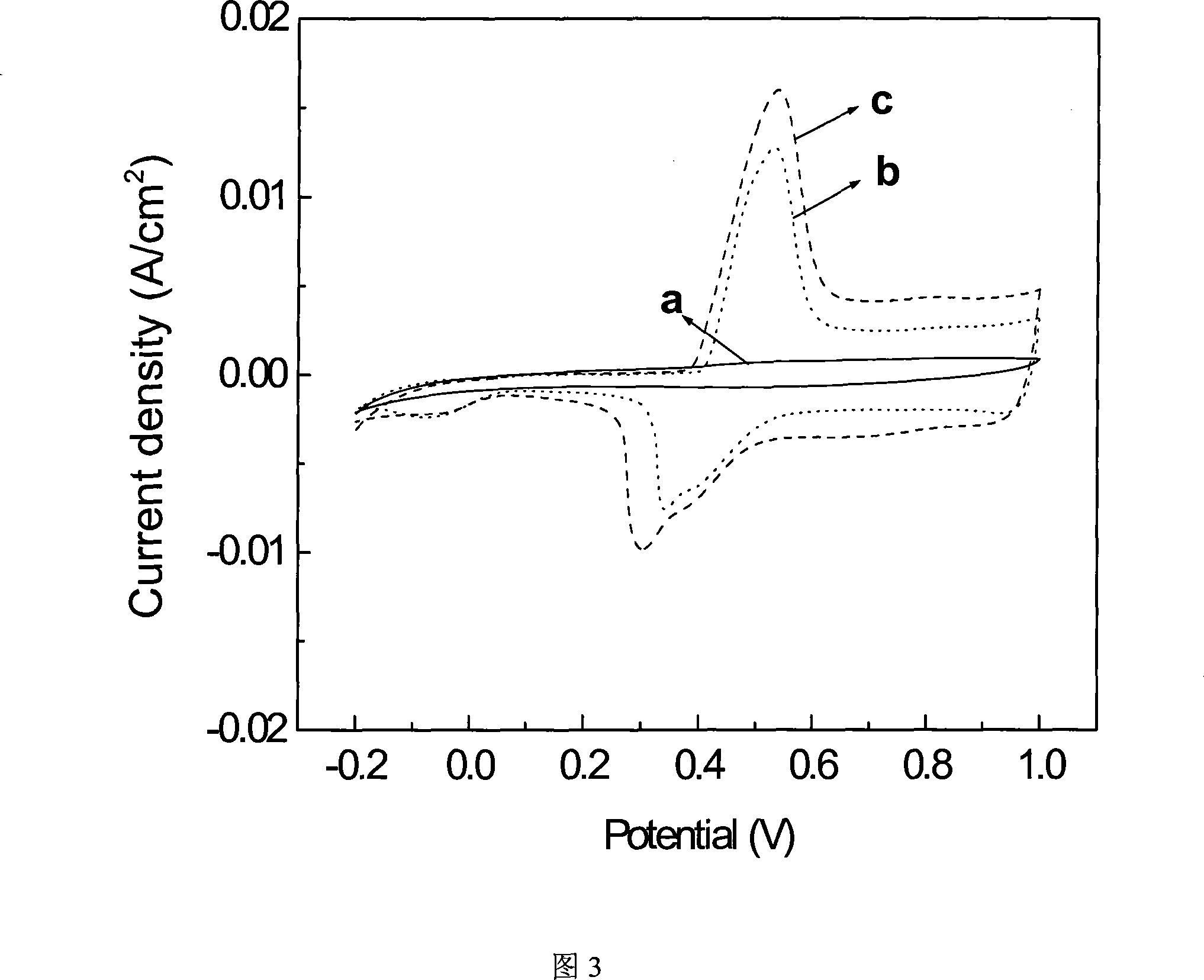

Method for preparing carbon nano-tube modified polyaniline nano fiber composite material

InactiveCN101235199ALarger than surfaceImprove conductivityNon-conductive material with dispersed conductive materialFiberCarbon nanotube

The invention discloses a preparation process of carbon nano-tube modification polyaniline nano fiber conductivity composite material. The characteristics of the invention are that conducting acid treatment for carbon nano-tube with concentrated mixed acid, adding carbon nano-tube which is treated with acid and aniline monomer into perchloric acid water solution according to the weight ratio of 1:6-1-32, and evenly dispersing through ultrasonic processing, using ammonium persulphate as oxidation agent, controlling the molar ratio of ammonium persulphate and aniline monomer within 1:2-1:8, and reacting under the ambient temperature to obtain polyaniline nano fiber / conductivity composite material of polyaniline coating carbon nano-tube coexisting structure. The process has simple art, and is easy to be controlled. The composite material which is prepared has the characteristics of high electricity conductivity ratio and small influence by system pH valve, large specific surface and excellent electrochemistry property and the like, which is expected to be used on electrode material such as second lithium ion cell and super capacitor and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

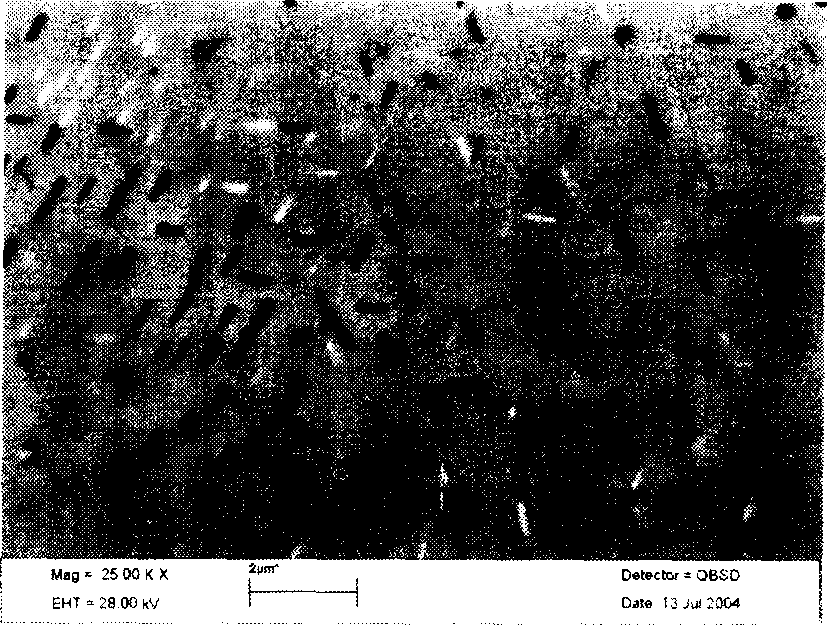

Electrolytic polishing solution for titanium and titanium alloys and electrolytic polishing process

InactiveCN102899711AEasy to get materialsLow costPreparing sample for investigationAcetic acidProcess equipment

The invention discloses electrolytic polishing solution for titanium and titanium alloys and an electrolytic polishing process, wherein the polishing solution is prepared by perchloric acid with volume fraction of 8-15% and acetic acid with volume fraction of 85-92%. The polishing solution is convenient in material selection, easy in preparation and storage, simple in polishing process equipment, easy in operation, smooth in surface, free of obvious scratches and oxide films and high in EBSD (Electron Back-Scattered Diffraction) pattern recognition rate, and has the effects of greatly reducing the superficial stress of the samples and greatly improving the detection precision.

Owner:CHONGQING UNIV

Low vapor pressure solvent for electrochromic devices

The present invention provides an electrolyte for electrochromic devices, the substance comprising γ-butyrolactone (gamma-butyrolactone or GBL). The electrolyte may include polymethylmethacrylate. The electrolyte may further include a salt, such as a salt that includes lithium perchlorate or trifluorosulfonimide. In accordance with further aspects to the invention, the electrolyte may include propylene carbonate.

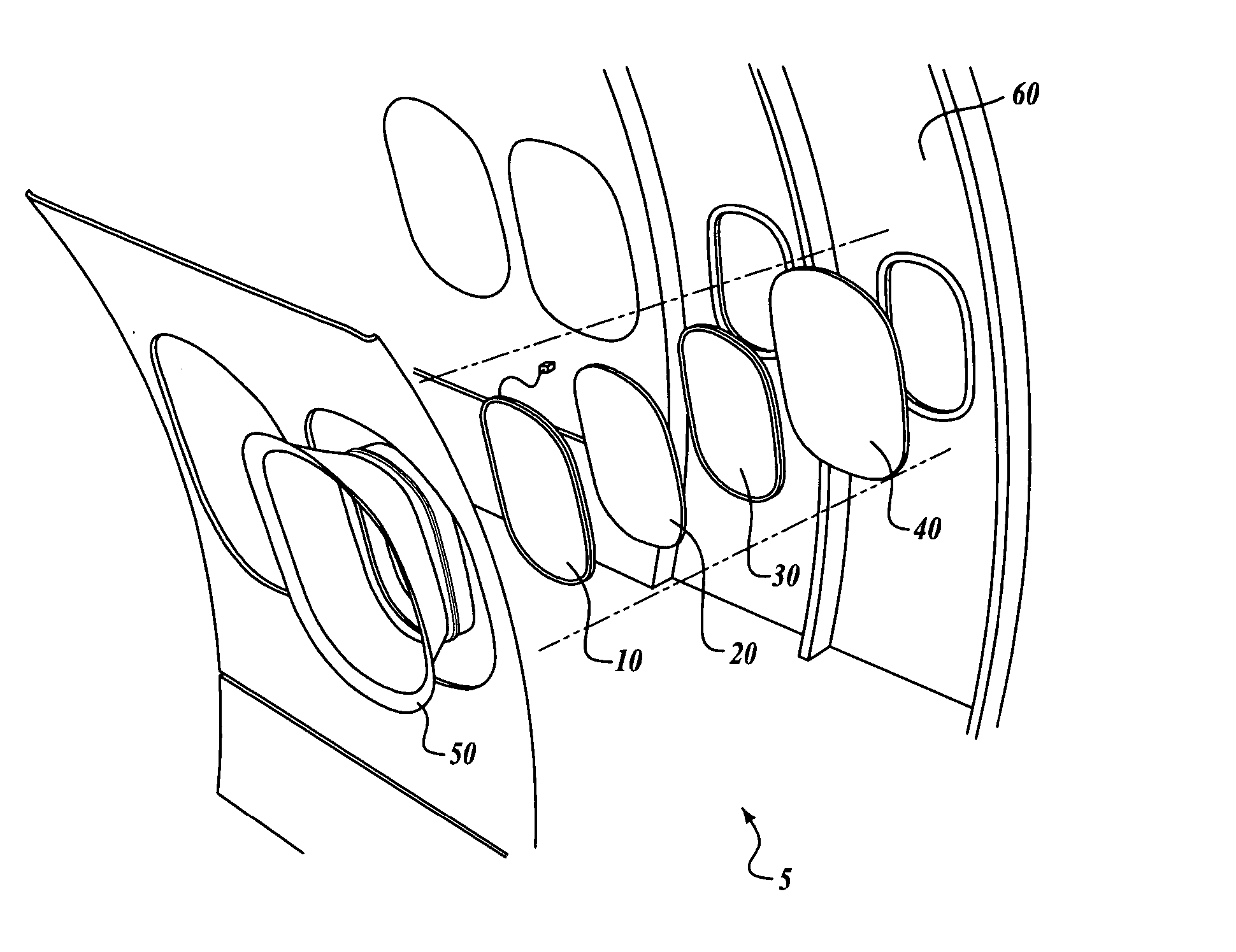

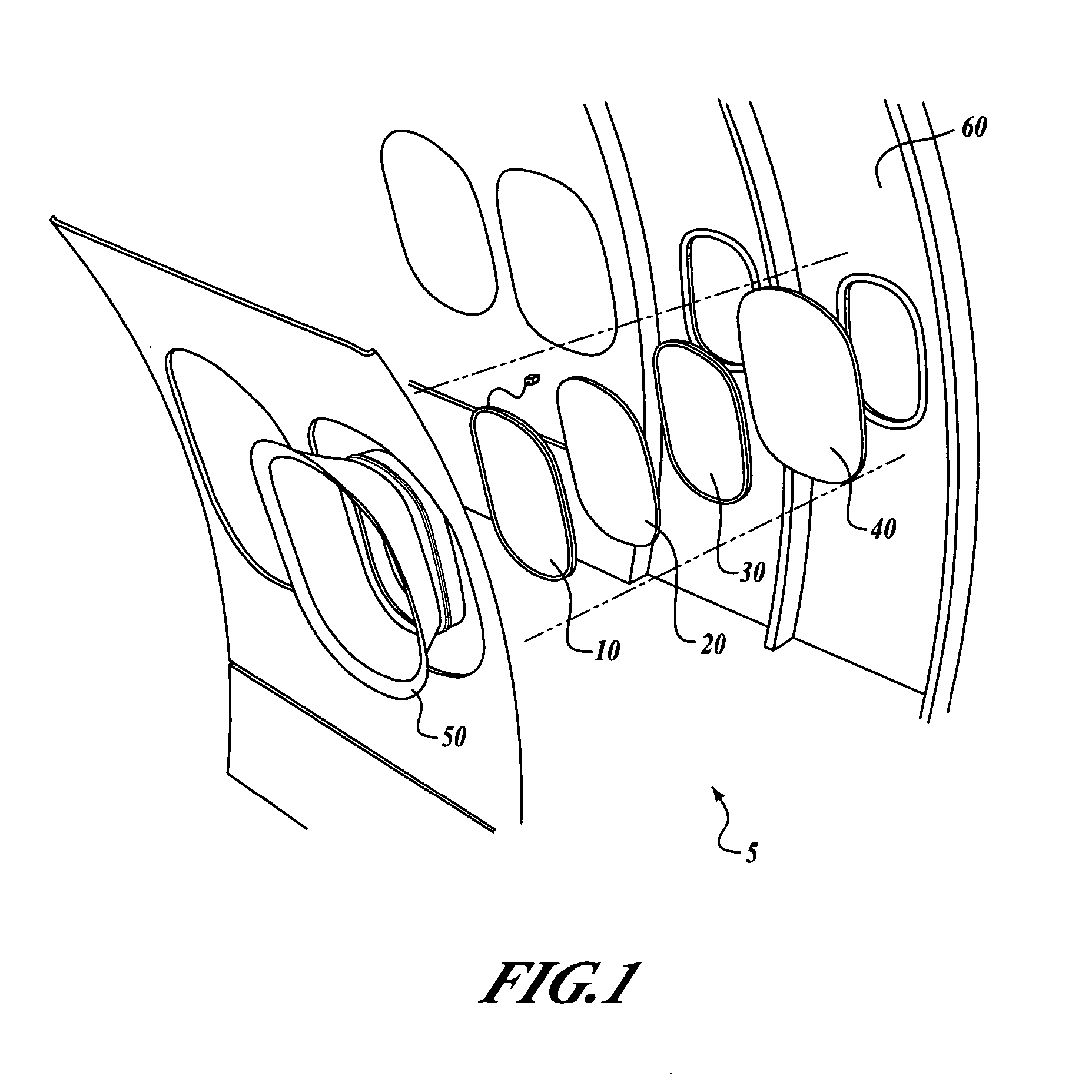

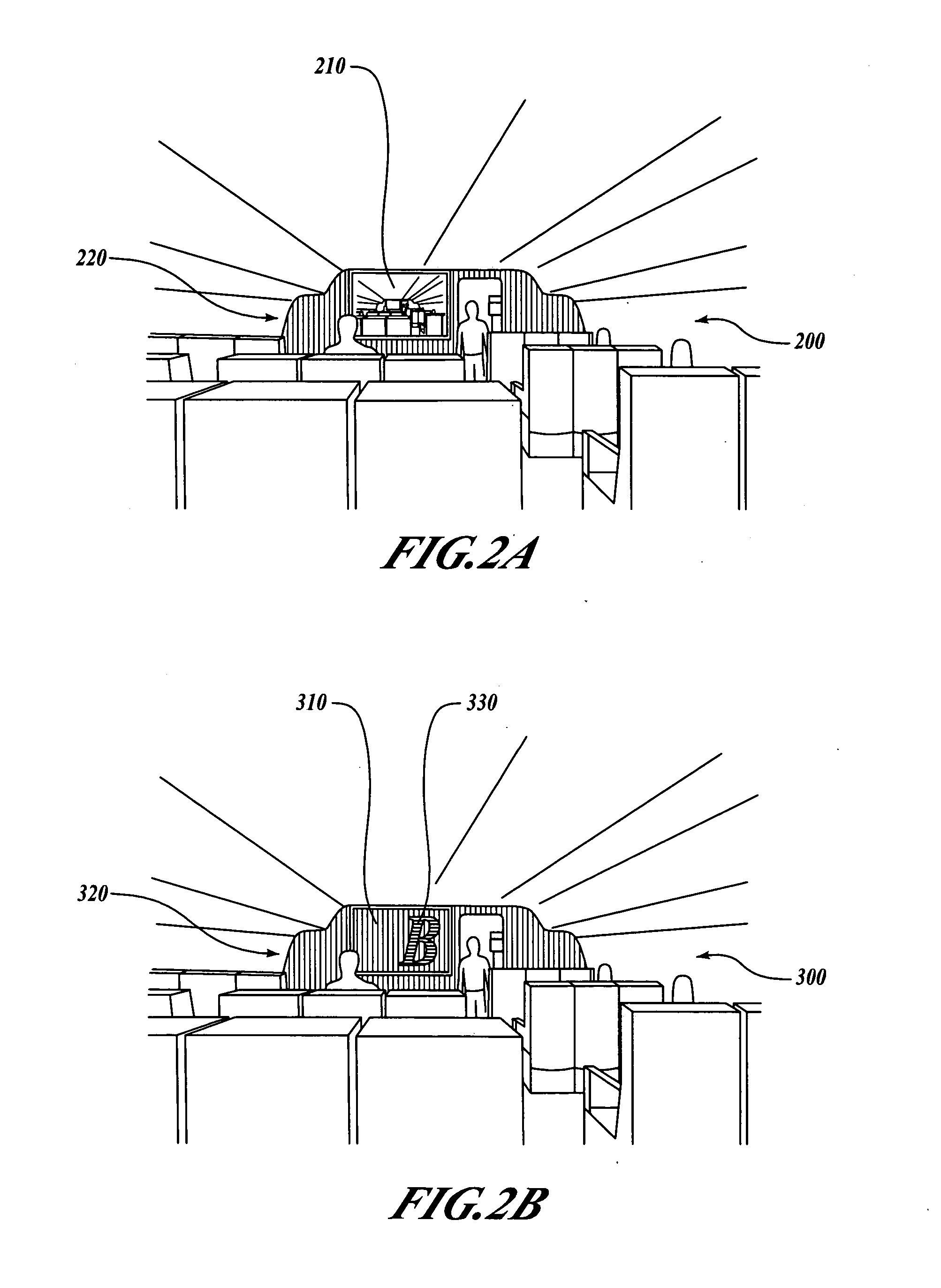

Owner:THE BOEING CO

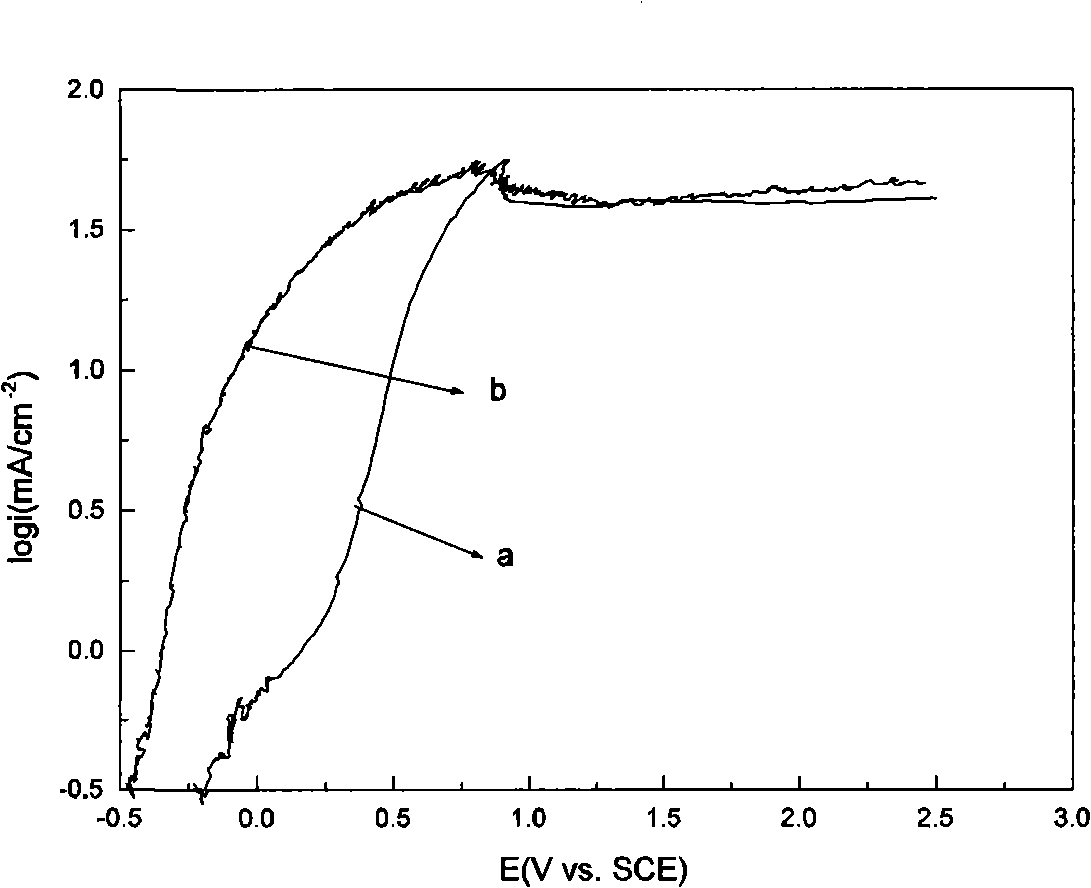

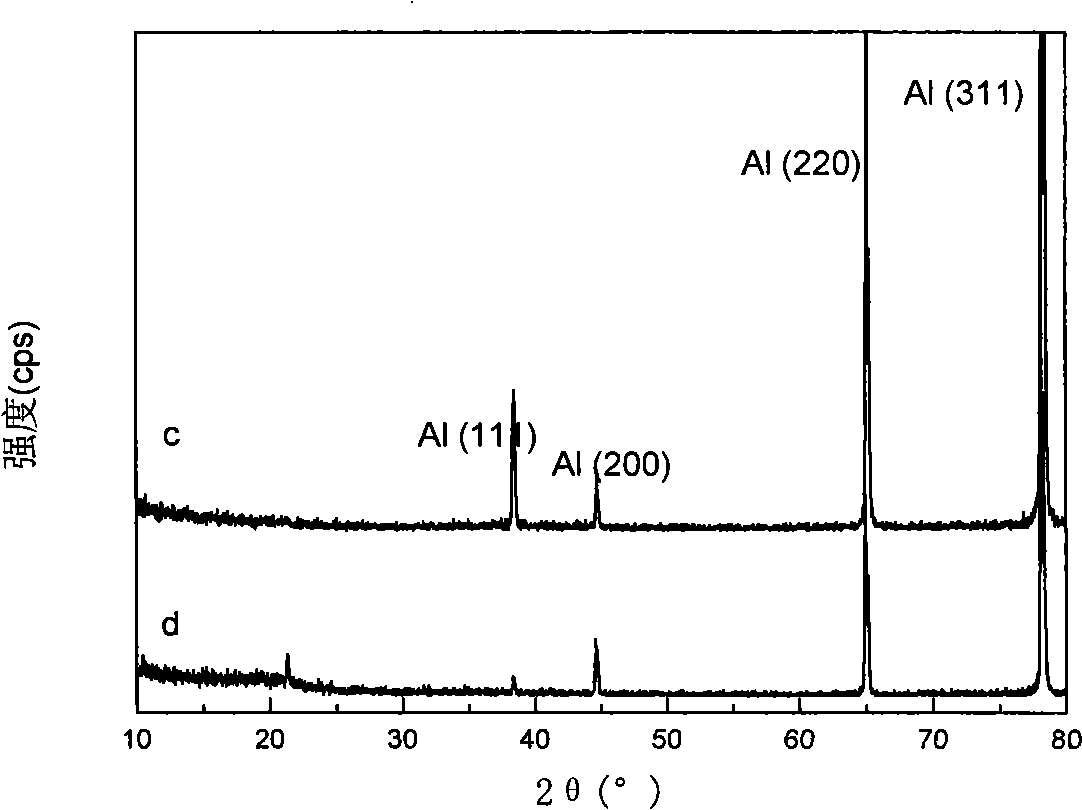

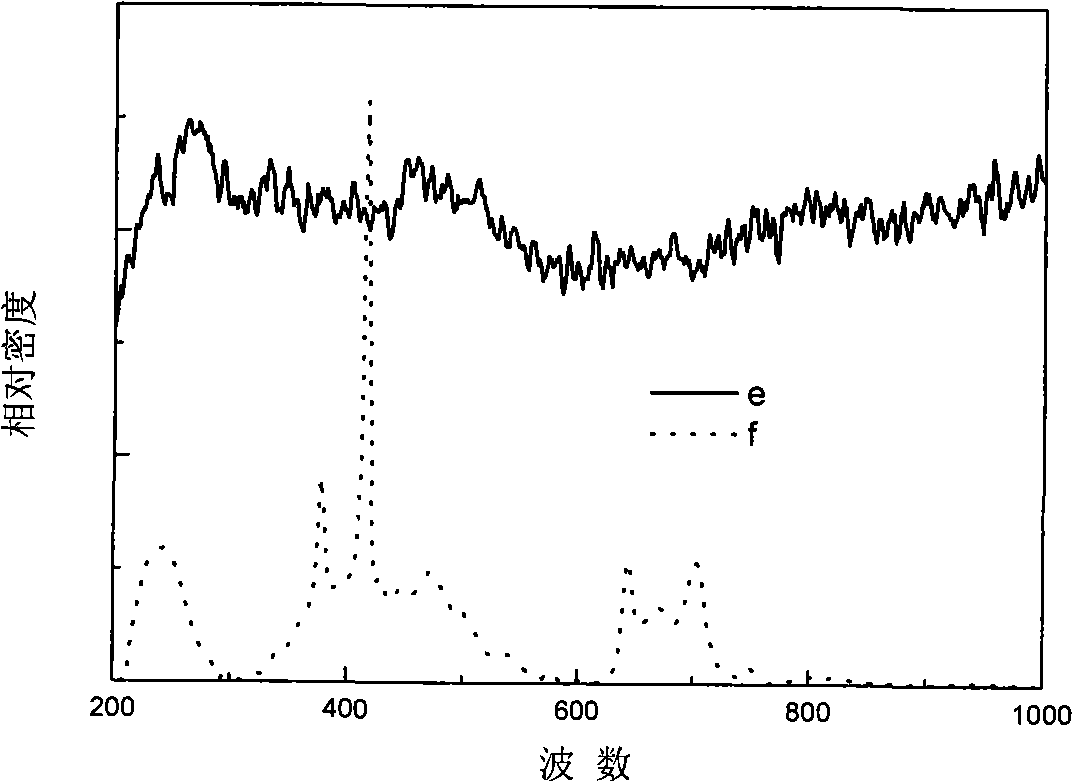

Electrochemical polishing method for high purity aluminum under ultrasonic agitation

The invention relates to an electrochemical polishing method for the high purity aluminium under ultrasonic agitation, which belongs to the fields of the material chemistry and the electrochemistry. The electrochemical polishing method under the ultrasonic agitation comprises the following steps: high purity aluminium foil is added in absolute ethyl alcohol, so as to be cleaned with deionized water and through ultrasonic oscillations, and the natural oxide film in sodium hydroxide is removed; the aluminium foil after being pretreated is used as an anode, the platinum sheet is used as the cathode, the reference electrode is saturated calomel electrode, and the electropolishing solution is the mixed liquor composed of absolute ethyl alcohol and perchloric acid; the electrolysis vessel is positioned in an ultrasonic wave cleaner, and electrochemical polishing is performed on a constant potential rectifier. The self-organizing structure with nanoscale stripe shape is formed on the aluminium surface, the structure is observed by adopting the atomic force microscopy, and the size of the stripe-shaped nanostructure changes under the ultrasonic agitation; the composition of the polishing surface is analyzed through the Raman spectrum and the X-ray diffraction, so as to indicate that the composition of the polishing surface is amorphous aluminum oxide.

Owner:DALIAN UNIV OF TECH

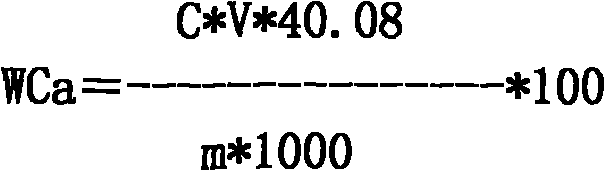

Method for measuring calcium constituent in silicon aluminum calcium barium alloy

InactiveCN101344489AEliminate distractionsReduce the number of operationsMaterial analysis by observing effect on chemical indicatorFiltrationPotassium hydroxide

The invention discloses a method used for measuring the calcium element in a silicon, aluminum, calcium and barium alloy, which comprises the following steps: a test sample is placed in a beaker, and deionized water is added until the test sample is wet; 9.5 to 10.5 millimeter of nitric acid is added; 1 to 2 millimeter of hydrofluoric acid is titrated; the mixture solution is heated until completely dissolved; perchloric acid is added; the mixture solution is heated until the sample volume is reduced to 1 to 2 millimeter; the mixture solution is naturally cooled; the perchloric acid is further added, and the mixture solution is heated until the sample volume is reduced to 1 to 2 millimeter; the hydrochloric acid and the deionized water are further added; the mixture solution is heated until all salts are dissolved, and the mixture solution is naturally cooled until the temperature is lower than 40 DEG C; the test sample is placed into a volumetric flask with scales and diluted with the deionized water; a mother solution is placed into a trigonal cup, the deionized water, trolamine (1 added by 1), lemery, bitter salt and an calcon-carboxylic acid are added, and the mother solution is adjusted to be red with potassium hydroxide; the potassium hydroxide is further added; EDTA is titrated until an end point that the mother solution becomes blue; and an analyzing result is computed. The method does not need precipitation separation and filtration, and has the acute end point without intermediate color and improved measuring accuracy.

Owner:WUHAN IRON & STEEL (GROUP) CORP

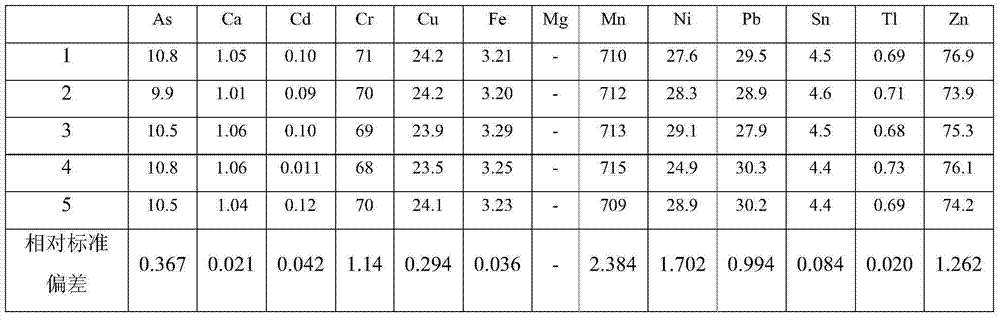

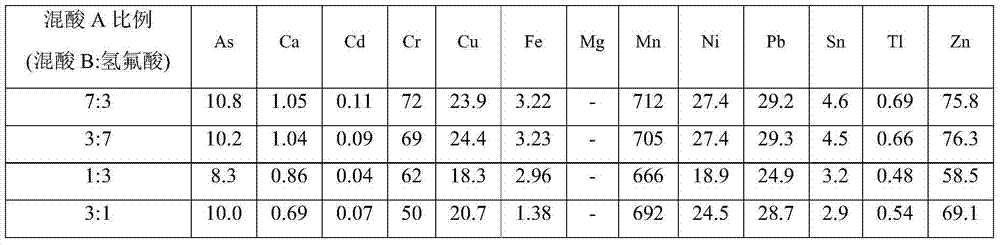

Digestion method of soil metal elements

InactiveCN101634617ADigestion has little practical effectSimple stepsPreparing sample for investigationColor/spectral properties measurementsHydrofluoric acidPerchloric acid

The invention discloses a digestion method of soil metal elements. The method comprises the following steps: (1) weighing a soil sample; (2) preparing a mixed acid A which has a volume ratio of nitric acid to hydrofluoric acid to perchloric acid of 6-10:4-5:2; (3) preparing a mixed acid B which has a volume ratio of the hydrofluoric acid to perchloric acid of 8-10:1; (4) adding the mixed acid A to a digestion cup to decompose soil; (5) adding the mixed acid B to escape silicon; (6) removing acid: washing off acid globules suspending on the cup wall with 0.2-5% diluted hydrochloric acid or diluted nitric acid, controlling temperature of an electric heating plate at 110-130 DEG C and distilling to dryness; and (7) make constant volume: adding the diluted nitric acid to dissolve residue in the digestion cup, and adding the diluted nitric acid of the same concentration to the fixed volume for measurement. The method has high efficiency and improved safety. The method is applicable to measurement of metal elements such as Cu, Zn, Fe, Mn, Ca, Mg, Ni, Pb, Cd and the like in soil and produces accurate and reliable determination results.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

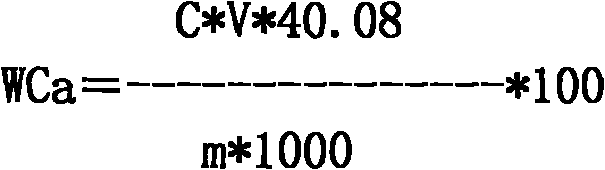

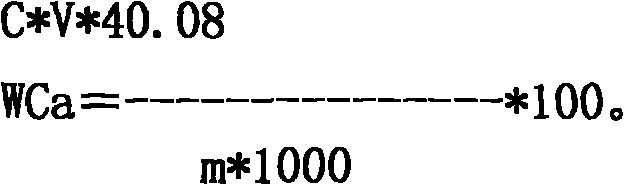

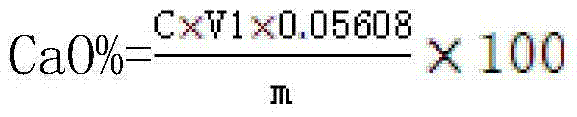

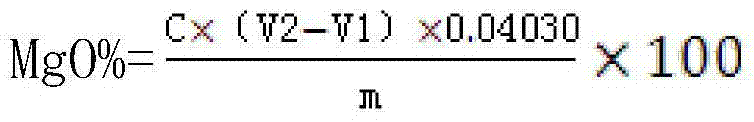

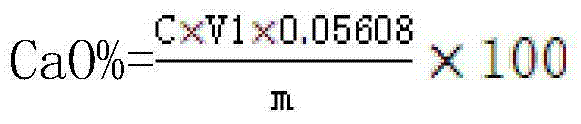

Method for determining calcium oxide and magnesium oxide in iron slag grains

ActiveCN103760158AReduce adsorptionEasy to separateMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationSlagHexamethylenetetramine

The invention provides a method for determining calcium oxide and magnesium oxide in iron slag grains. The determination method comprises the following steps: weighing a sample; heating and dissolving by using acid; adding perchloric acid until the perchloric acid is fumed at a wet salt state; cooling, adding a 20% hexamethylenetetramine solution to adjust the pH (Potential of Hydrogen) value to 7-8, and preserving the temperature; adding a 1% copper reagent, diluting by water and filtering, wherein a filtering solution is a solution to be detected; separately taking the filtering solution, and mixing with the water; adding 1:1 triethanolamine and adjusting the pH to be more than 12 by using 20% potassium hydroxide; adding a calcium carboxylic acid indication agent; titrating by using an EDTA (Ethylene Diamine Tetraacetic Acid) standard solution and calculating the mass percent of the calcium oxide according to a formula shown in the specification; separately taking the filtering solution and mixing with the water in a ratio of 1:1, wherein the amount of the filtering solution is the same as that in the step 4; adding the 1:1 triethanolamine and adding an ammonia buffering solution with the pH of 10; adding a 1% chromium black T indication agent and titrating by using the EDTA standard solution; and calculating the mass percent of the magnesium oxide according to a formula shown in the specification. The method is short in flow and high in speed, and the aims of simplicity, rapidness and accuracy are realized.

Owner:SHENWU TECH GRP CO LTD

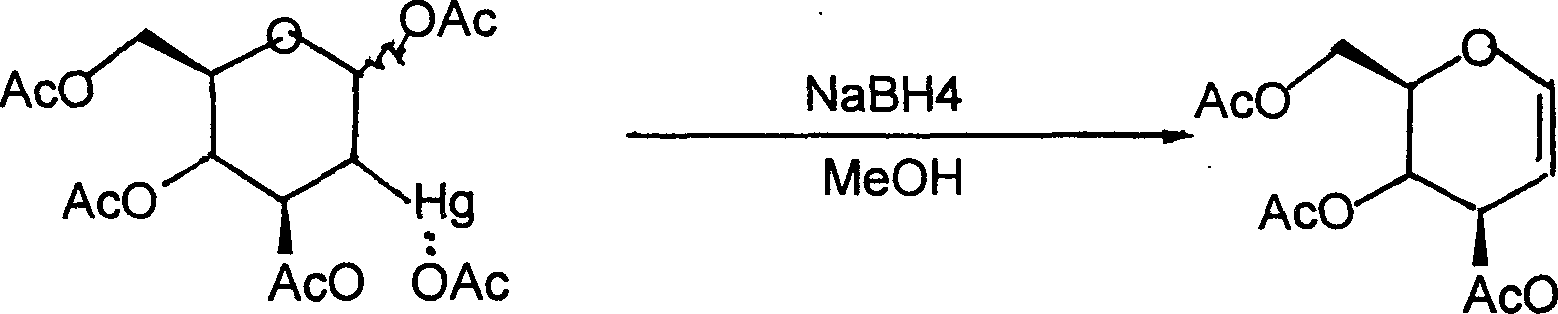

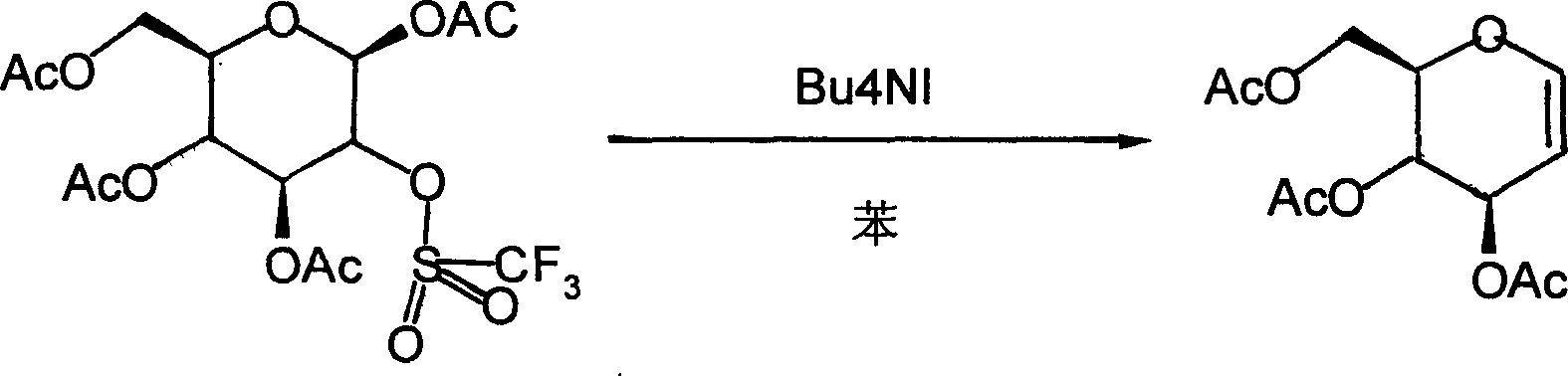

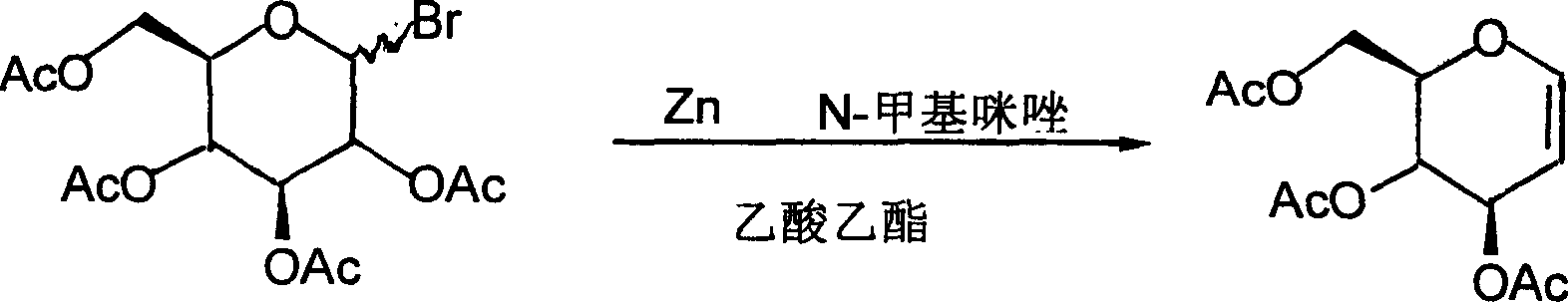

Method for preparing acetylated glucal

InactiveCN1803818ASimple and efficient synthesisWork lessSugar derivativesSugar derivatives preparationP-Toluenesulfonic acidMethanesulfonic acid

The disclosed preparation method for acetylized glucal comprises: preparing the D-acetylized glucose catalyzed by acids (HClO4, H2SO4, ZnCl2, AlCl3, p-toluenesulfonic acid and methanesulfonic acid); without separation or purification, leading directly the product into HBr or equivalent (such as PBr3 and water) to obtain and then recrystallize the coarse 1-bromoacetyl glucose with one of ethyl ether, propyl ether and isopropyl ether; adding Zn, ZnCl2, methanol and Co-ion catalyst to prepare the coarse target; recrystallizing with alcohol for the refined product. This invention saves step and reduces cost.

Owner:朱书汉

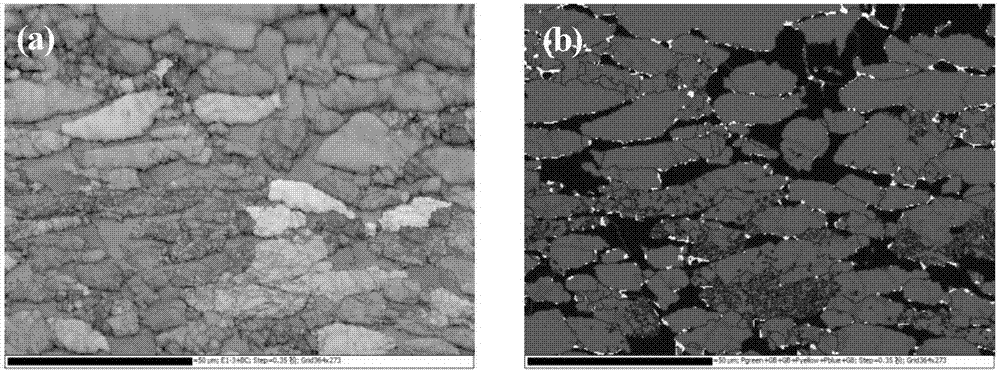

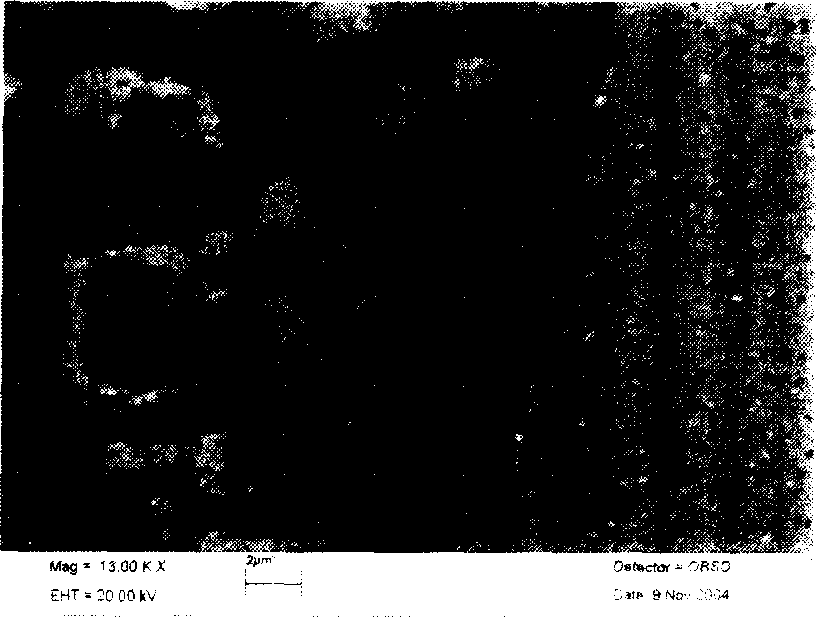

Method for observing microscopic structure of stainless steel

InactiveCN1916597AAvoid formingAvoid corrosion damageSurface/boundary effectPreparing sample for investigationElectrolysisDistilled water

A method for observing microscopic structure of stainless steel includes using alcohol, perchloric acid and so on to prepare electrolytic polishing liquid; polishing prepared test piece; using electrolytic polisher with 23v-40 voltage and 10-30deg.c electrolytic polishing liquid to carry out electrolytic polishing on test piece then washing test piece; placing electrolytic polished test piece into sample chamber of scan electronic microscope and using back scattering electronic detector to observe microstructure of test piece.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

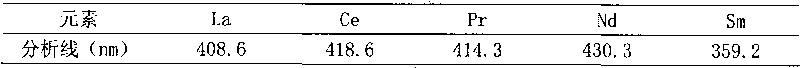

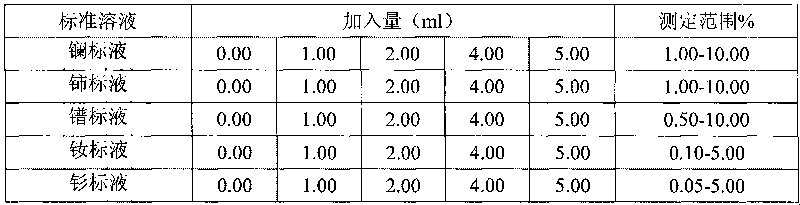

Method for measuring rare earth component in rare earth magnesium alloy

The invention relates to the technical field of ferrous metallurgical analysis, and discloses a method for measuring a rare earth component in a rare earth magnesium alloy. The method comprises the following steps: dissolving a sample through a nitric acid and a hydrofluoric acid; fuming the sample through a perchloric acid; diluting the sample to a certain volume; introducing atomization solution into an inductively coupled plasma atomic emission spectrometer; measuring the intensity of a spectral line to be tested; and calculating the concentration of the corresponding element of the substance to be tested according to the intensity of the spectral line which is measured by the standard substance at known concentration. The method has the advantages of conveniently, quickly and accurately analyzing the rare earth component in the rare earth magnesium alloy and ensuring smooth production.

Owner:ANGANG STEEL CO LTD

Propellant with high energy and low temperature sensitive coefficient of burning

ActiveCN105130720ABoost energy levelsLow burning rate temperature sensitivity coefficientExplosivesAl powderExplosive Agents

A propellant with high energy and low temperature sensitive coefficient of burning comprises 12-15% of an adhesive, 10-13% of a plasticizer, 15-18% of an oxidant, 38-50% of an energetic explosive, 10-18% of a metal fuel and 1.5-2.0% of a small group, wherein the adhesive is glycidyl azide polymer; the plasticizer is triethylene glycol dinitrate or 2,4-dinitro-2,4-diazaalkane; the oxidant is ammonium perchlorate; the energetic explosive is octogen; and the metal fuel is aluminum powder. The propellant has the characteristics of high energy (standard measured specific impulse is greater than 2450N.s / kg) and low temperature sensitive coefficient of burning (not greater than 0.15%K<-1>), and is suitable for tactical missile engines with far required range, strong penetration ability, high reliability and accurate guidance.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

Smokeless polishing treatment solution for high-gloss aluminum profile and method of use

The invention provides a smoke-free polishing treatment solution for a high-gloss aluminum sectional material and a use method thereof. The smoke-free polishing treatment solution is characterized by comprising 85% H3PO4, 98% H2SO4, 30% hydrogen peroxide or potassium permanganate or perchloric acid or sodium molybdate or ammonium persulfate or sodium vanadate, cerium nitrate or sodium silicate, imidazoline or benzotriazole or phytic acid or thiourea, sodium dodecyl benzene sulfonate or sodium benzene sulfonate or sodium toluene sulfonate or sodium xylene sulfonate, and nickel chloride or nickel sulfate or lead acetate. Compared with the prior art, the smoke-free polishing treatment solution provided by the invention has advantage of no generation of high-pollution NOx yellow smoke, and enables the surface of the aluminum sectional material to have excellent gloss and no pitting microscopic defects.

Owner:GUANGDONG XINGFA ALUMINUM

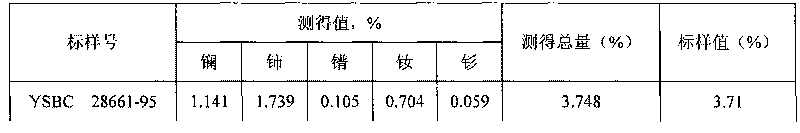

Process for synthesizing nano band of MoO3 monocrystal

A process for synthesizing nanoband of MoO3 monocrystal includes dissolving soluble molybdate and perchloric acid in water, and hydrothermal reaction at 100-200 deg.C while controlling the concentration of H ions (10mol / L[H]>0.01mol / L) and the speed of dropping acid (10mL / min>V7 0.1mL / m). Its advantages are unique ize and shape of product, and high output rate.

Owner:TSINGHUA UNIV

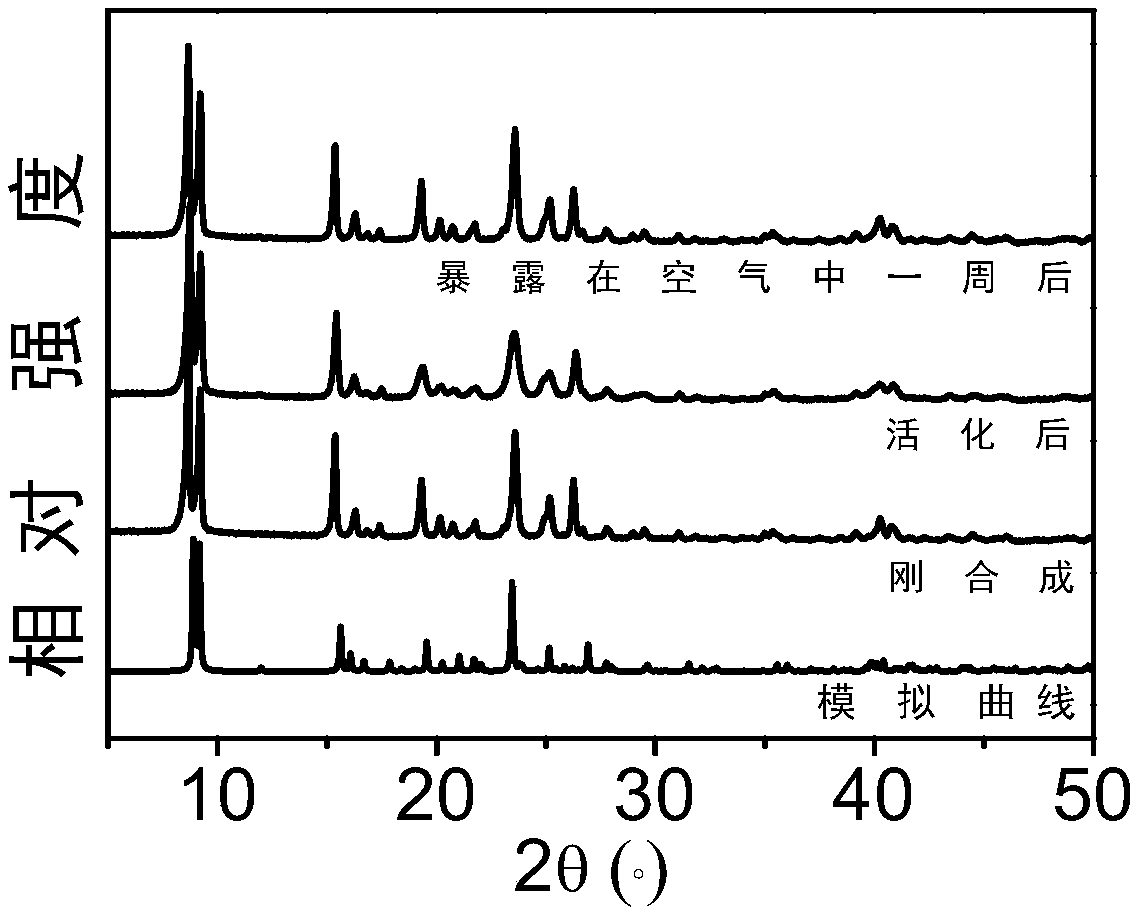

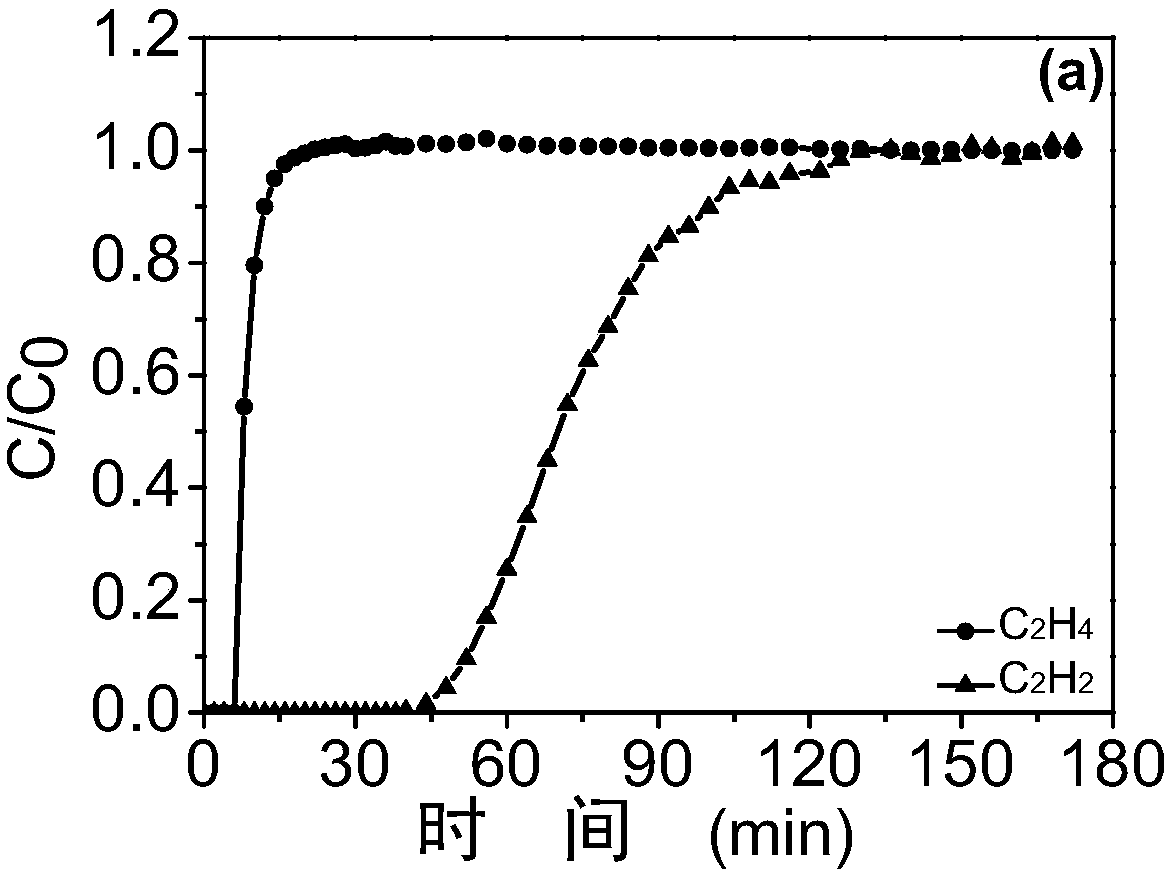

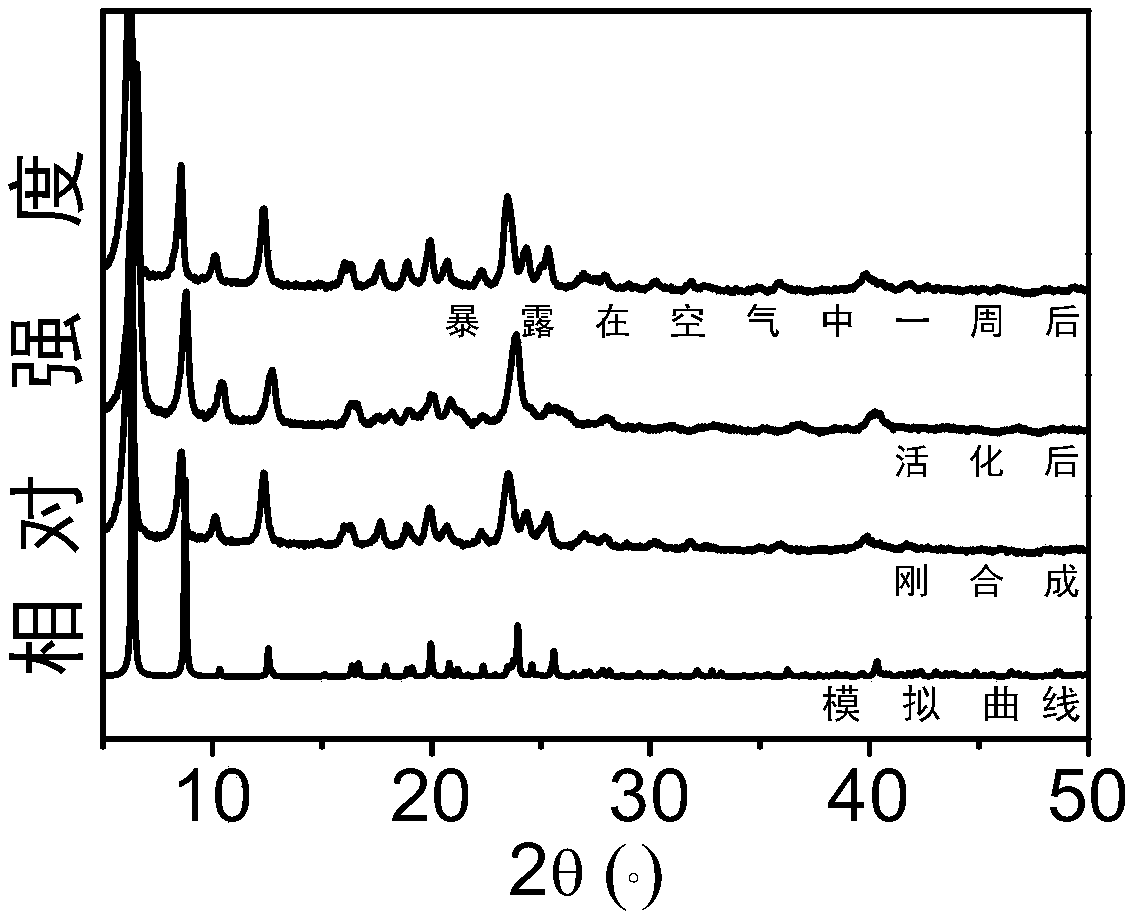

Metal-organic framework material for separating ethylene and acetylene, and method for separating ethylene and acetylene

ActiveCN108671893AImprove stabilityImprove adsorption capacityOther chemical processesDispersed particle separationSorbentPyrazine

The invention provides a metal-organic framework material for separating acetylene and ethylene, and a method for separating ethylene and acetylene. The metal-organic framework material has the advantages of good stability, high adsorption capacity, good adsorption separation selectivity, simple preparation method and low preparation cost. The structural general formula of the metal-organic framework material is Cu2(pzdc)2L.2H2O, pzdc in the formula is pyrazine-2,3-dicarboxylic acid, and the material is a three-dimensional network structure formed by copper ions, the pyrazine-2,3-dicarboxylicacid and an organic ligand A through a coordination bond or an intermolecular action force. The preparation method comprises the following steps: (1) mixing and reacting an inorganic salt, the pyrazine-2,3-dicarboxylic acid, an alkali and the organic ligand in proportion, wherein the inorganic salt is chloride, nitrate, acetate, sulfate or perchlorate of the copper ions; and (2) sequentially washing a product obtained after the reaction is finished with ionized water and anhydrous methanol, and then carrying out vacuum drying to obtain the metal-organic framework material. The metal-organic framework material is used as an adsorbent to adsorb and separate a mixed gas containing ethylene and acetylene.

Owner:ZHEJIANG UNIV

Pretreatment method for heavy metal element detection in solid sample and application of pretreatment method

InactiveCN103543055ARich varietyFully digestedPreparing sample for investigationHydrofluoric acidPretreatment method

The invention discloses a pretreatment method for heavy metal element detection in a solid sample and an application of the pretreatment method. The pretreatment method mainly comprises the five steps: a pre-decomposition stage, a mixed acid decomposition stage, an H2O2 decomposition stage, an acid catching stage and a volume determining stage, wherein the sample is primarily decomposed by using nitric acid in the pre-decomposition stage; the sample is further decomposed by using nitric acid, perchloric acid and hydrofluoric acid in the mixed acid decomposition stage, and the method comprises the main step that the sample is finally decomposed by using H2O2 in the H2O2 decomposition stage. The pretreatment method can be widely applied to the pretreatment for heavy metal element detection in solid samples such as soil, sludge, sediments at the bottom of a lake and the like, and has the advantages of wide application range, high heavy metal recovery rate, simplicity and feasibility in operation and the like.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com