Process for synthesizing nano band of MoO3 monocrystal

A single-crystal nanometer and molybdenum trioxide technology, which is applied in the direction of molybdenum oxide/molybdenum hydroxide, etc., can solve problems such as limiting the application of molybdenum trioxide, and achieve the effects of easy control, high yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

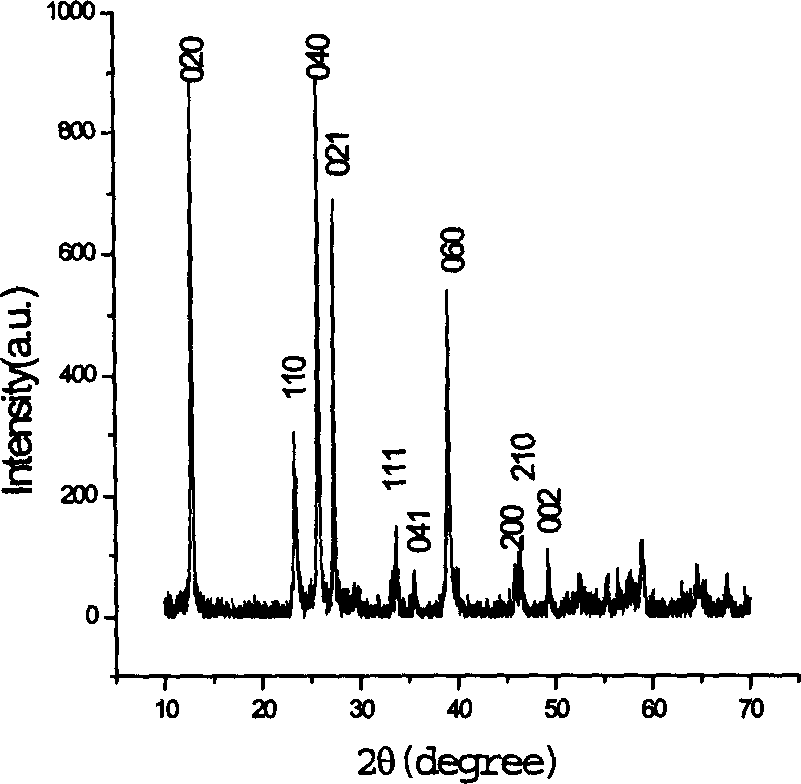

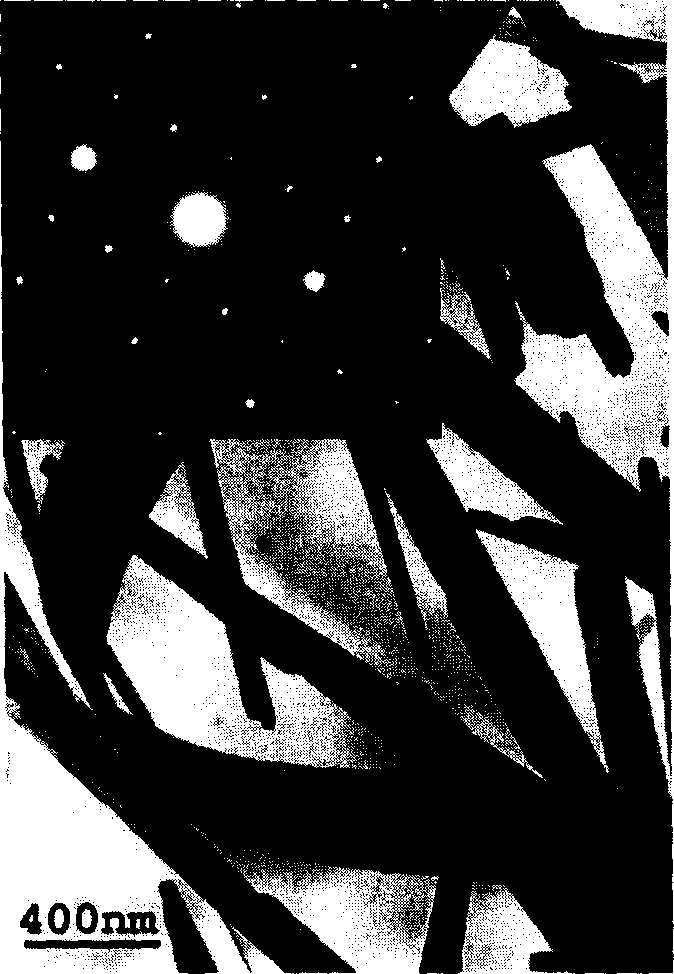

[0018] Weigh 20mmol of analytically pure sodium molybdate, dissolve it in 10ml of deionized water to obtain a 2mol / l clear solution, add 16ml of 4mol / l perchloric acid solution at a rate of 0.5mL / min, stir to keep the solution clear, and place the solution in a 40ml In the reaction kettle, add deionized water, strictly control the solution H + Concentration ([H + ]=1 mol / l). Seal the reactor and react at 100°C for 24h. Then cool to room temperature, open the reaction kettle, filter with a Buchner funnel, wash with deionized water, and obtain a white slightly light green powder. The product is identified as orthorhombic molybdenum trioxide by X-ray powder diffraction; the morphology of the product detected by TEM electron microscope: the diameter is 50-400 nanometers, and the length is 2-15 microns. Electron diffraction of a single nanoribbon proves that the product is a single crystal.

Embodiment 2

[0020] Weigh 10mmol analytically pure potassium molybdate, dissolve it in 10ml deionized water to obtain a 1mol / l clear solution, add 20ml solution of 2mol / l perchloric acid at a rate of 2mL / min per drop, stir to keep the solution clear, and place the solution in 40ml In the reactor, add deionized water, strictly control the solution H + Concentration ([H + ]=0.5mol / l). Seal the reactor and react at 100°C for 24h. Then cool to room temperature, open the reaction kettle, filter with a Buchner funnel, wash with deionized water, and obtain a white slightly light green powder. The product is identified as orthorhombic molybdenum trioxide by X-ray powder diffraction; the morphology of the product detected by TEM electron microscope: the diameter is 100-500 nanometers, and the length is 2-15 microns. Electron diffraction of a single nanoribbon proves that the product is a single crystal.

Embodiment 3

[0022] Weigh 20mmol of analytically pure sodium molybdate, dissolve it in 10ml of deionized water to obtain a 2mol / l clear solution, and dissolve it at a speed of 1mL / min.

[0023] Weigh 20mmol of analytically pure sodium molybdate, dissolve it in 10ml of deionized water to obtain a 2mol / l clear solution, add 16ml of 4mol / l perchloric acid solution at a rate of 1mL / min, stir to keep the solution clear, and place the solution in a 40ml reaction In the kettle, add deionized water, strictly control the solution H + Concentration ([H + ]=1 mol / l). Seal the reactor and react at 140°C for 18h. Then cool to room temperature, open the reaction kettle, filter with a Buchner funnel, wash with deionized water, and obtain a white slightly light green powder. The product is identified as orthorhombic molybdenum trioxide by X-ray powder diffraction; the morphology of the product detected by TEM electron microscope: the diameter is 100-500 nanometers, and the length is 2-15 microns. Elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com