Patents

Literature

955results about How to "Uniform size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for graphene quantum dot film

A disclosed preparation method for a graphene quantum dot film comprises the following concrete steps; employing a modified Hummers process to prepare graphite oxide; dispersing graphite oxide in a dispersant, and using a microwave-assisted solvothermal process to prepare graphene quantum dot; and dropwise adding the graphene quantum dot solution on a liner, and performing spinning coating to obtain the graphene quantum dot film. The method is cheap in raw material, simple in equipment and convenient to operate; the obtained graphene quantum dot is good in solubility and uniform in dimension; and the graphene quantum dot film is uniform in thickness and good in electric conductivity, and has considerable application prospect on the aspect of solar cells.

Owner:CHANGCHUN UNIV OF TECH

Foam of thermoplastic urethane elastomer composition and process for producing the foam

The method of the present invention for producing a urethane-based thermoplastic elastomer composition foam comprises the steps of:adding and mixing 0.1 to 30 parts by weight of carbon dioxide (B) to 100 parts by weight of a urethane-based thermoplastic elastomer composition (A) in a molten state, wherein said urethane-based thermoplastic elastomer composition (A) comprises a urethane-based thermoplastic elastomer (A-1) and other thermoplastic elastomer (A-2) in an (A-1) / (A-2) ratio of 20 / 80 to 99 / 1 by weight, to form a molten urethane-based thermoplastic elastomer composition (C) which is in a state of a mixture of the urethane-based thermoplastic elastomer composition (A) and the carbon dioxide (B) (gas dissolving step); andlowering a temperature of said molten urethane-based thermoplastic elastomer composition (C) (cooling step).The present invention can produce the urethane-based thermoplastic elastomer foam of stable quality over a range from low foamed product to highly foamed product by adding a given quantity of carbon dioxide in the molten urethane-based thermoplastic elastomer quantitatively and stably. It can also produce the foam excellent in flexibility, thermal insulation and surface appearances. It is also excellent in safety, because of use of carbon dioxide in place of the common foaming agent of fluorochlorohydrocarbon or butane, thus causing no air pollution or destruction of the ozone layer.

Owner:MITSUI CHEM INC

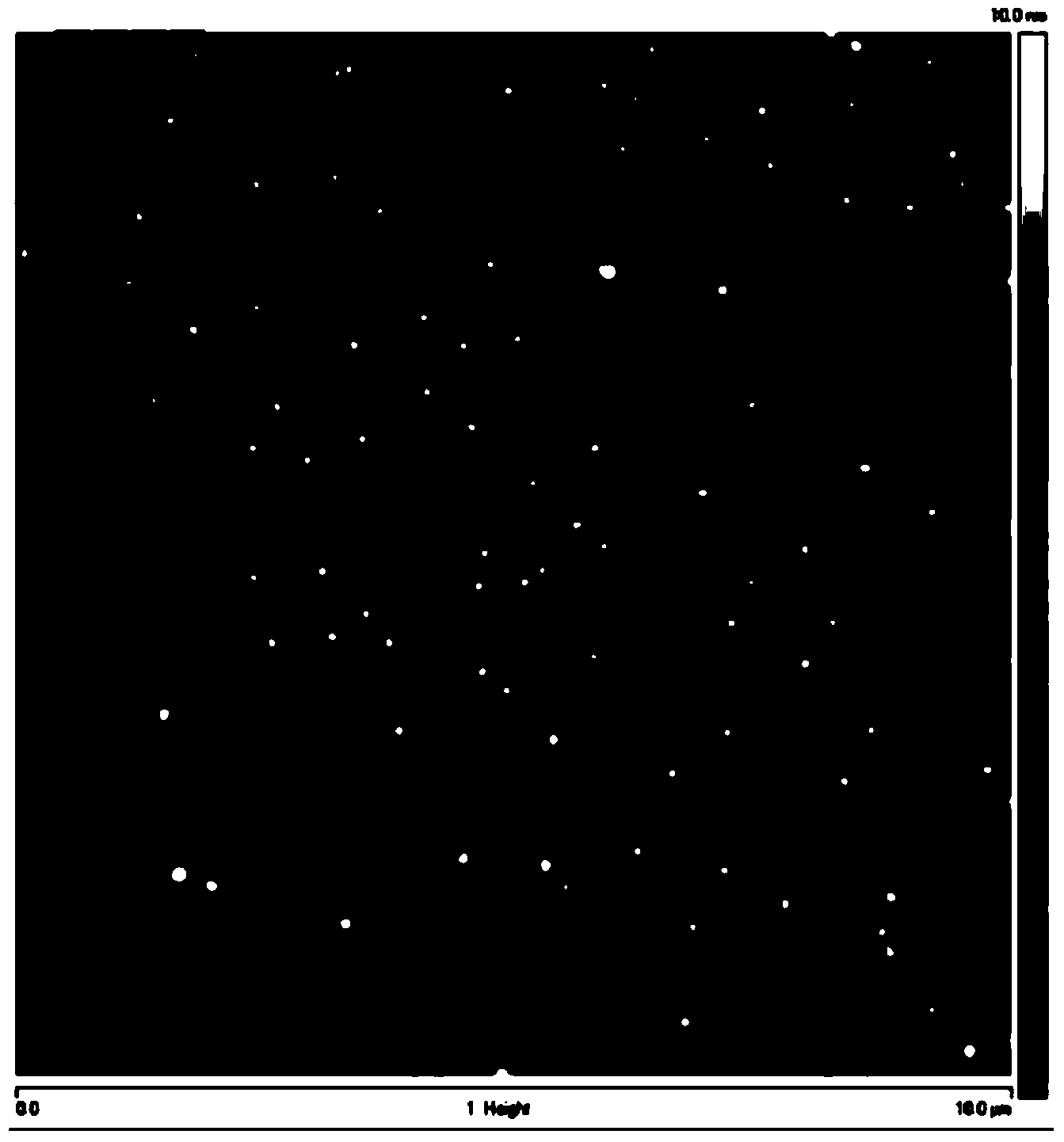

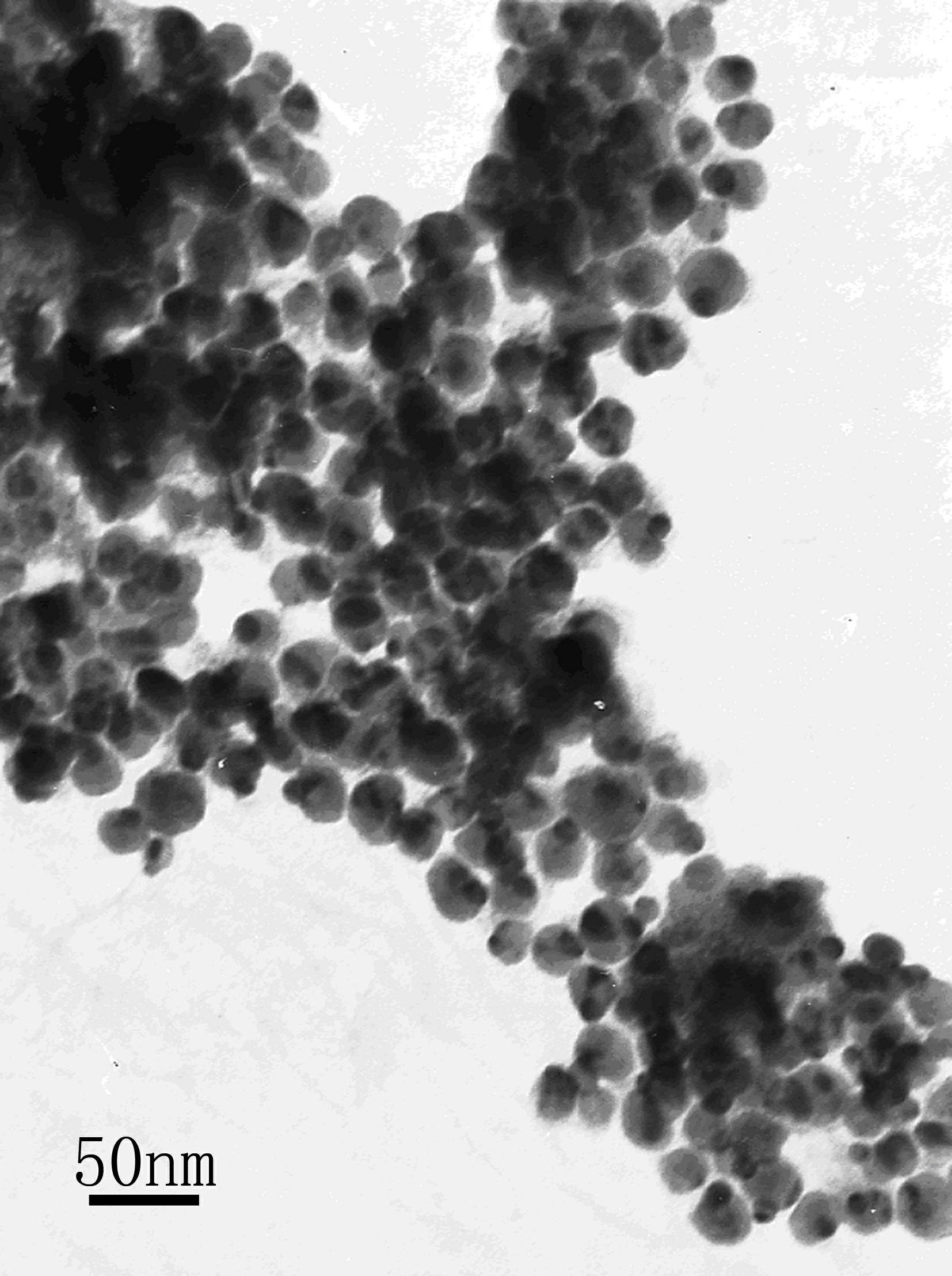

Nitrogen-doped high-luminescent carbon quantum dot and preparation method thereof

ActiveCN103923647ASimple processShort preparation cycleMaterial nanotechnologyLuminescent compositionsUltimate tensile strengthRepeatability

The invention provides a nitrogen-doped high-luminescent carbon quantum dot and a preparation method thereof. The preparation method comprises the following steps: reacting by using a sodium citrate solution as a carbon source and ethanediamine as a source of N under a sealing condition, cooling an obtained product, then separating, and drying a solution obtained after separation so as to obtain the nitrogen-doped high-luminescent carbon quantum dot. The preparation method is simple in process, short in preparation period, low in manufacturing cost and good in repeatability; obtained raw materials are simple and easily available. The nitrogen-doped high-luminescent carbon quantum dot prepared by using the method is uniform in size distribution and high in luminescent density; the luminescent density of the nitrogen-doped high-luminescent carbon quantum dot is about 20 times of that of a general quantum dot, so that the application of the nitrogen-doped high-luminescent carbon quantum dot in the field of cell marking can be expanded. As the improvement of the luminescent density is caused by nitrogen doping, the nitrogen-doped high-luminescent carbon quantum dot prepared by the method has unique application when being used for detecting whether N exists in environments.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

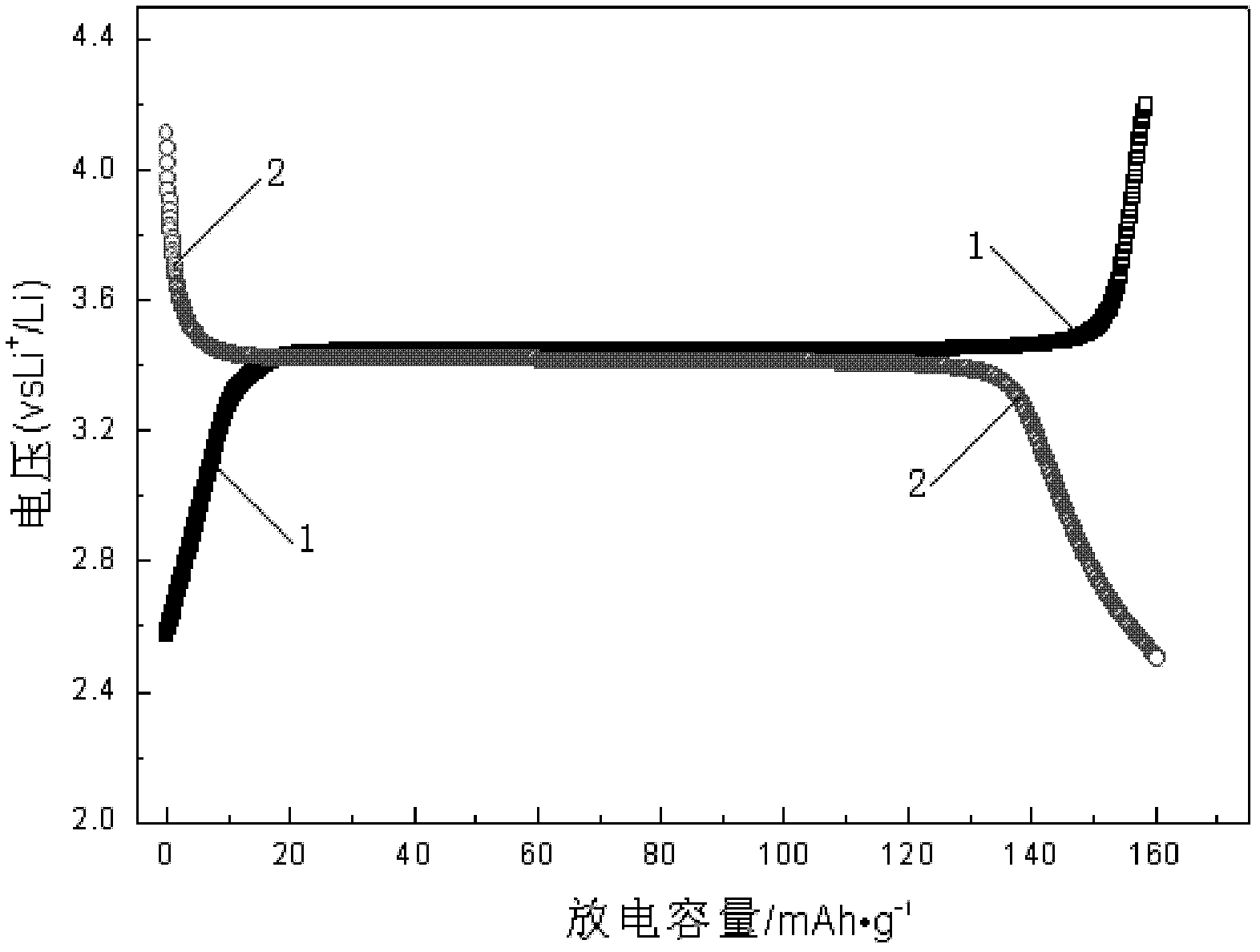

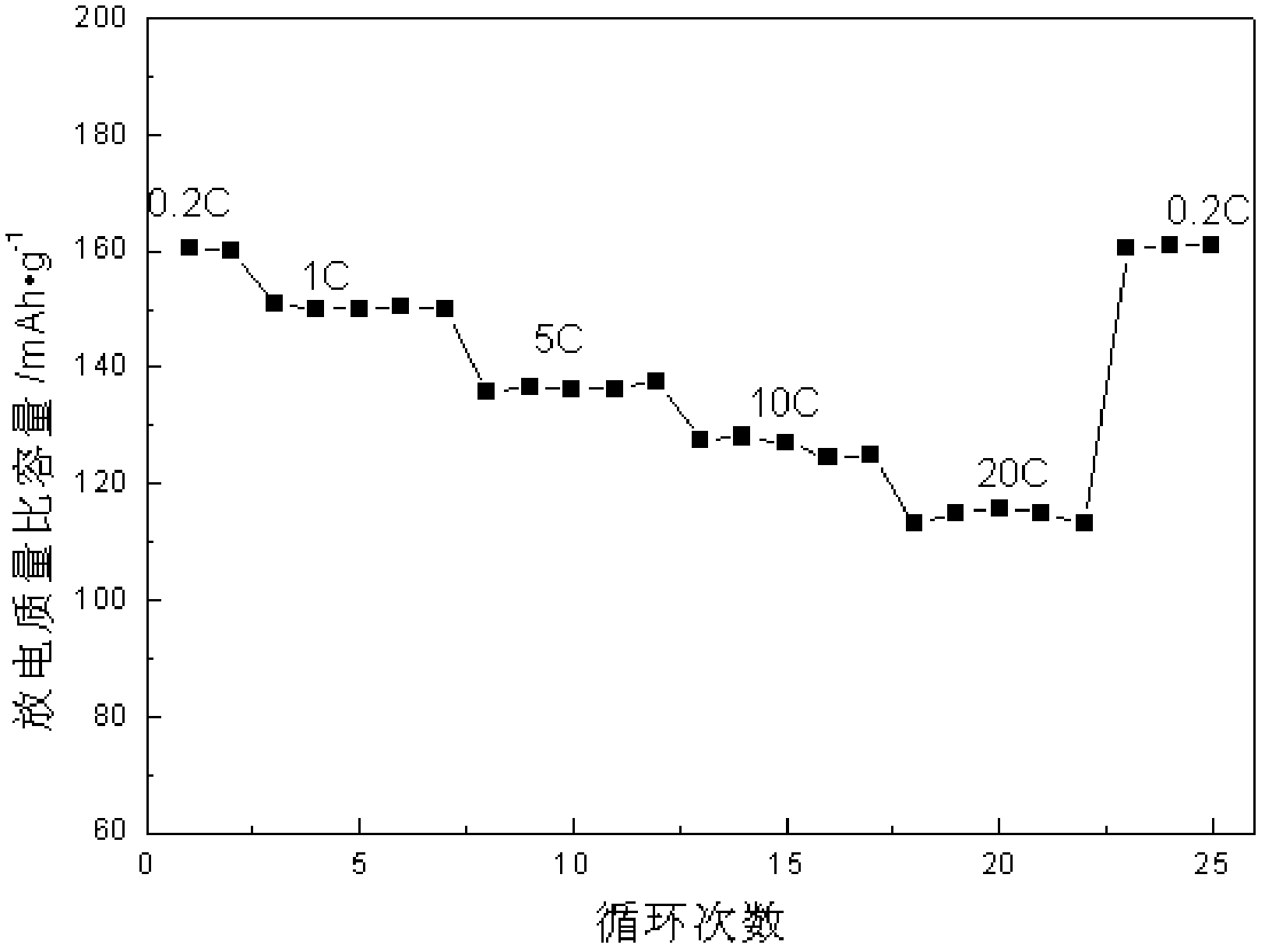

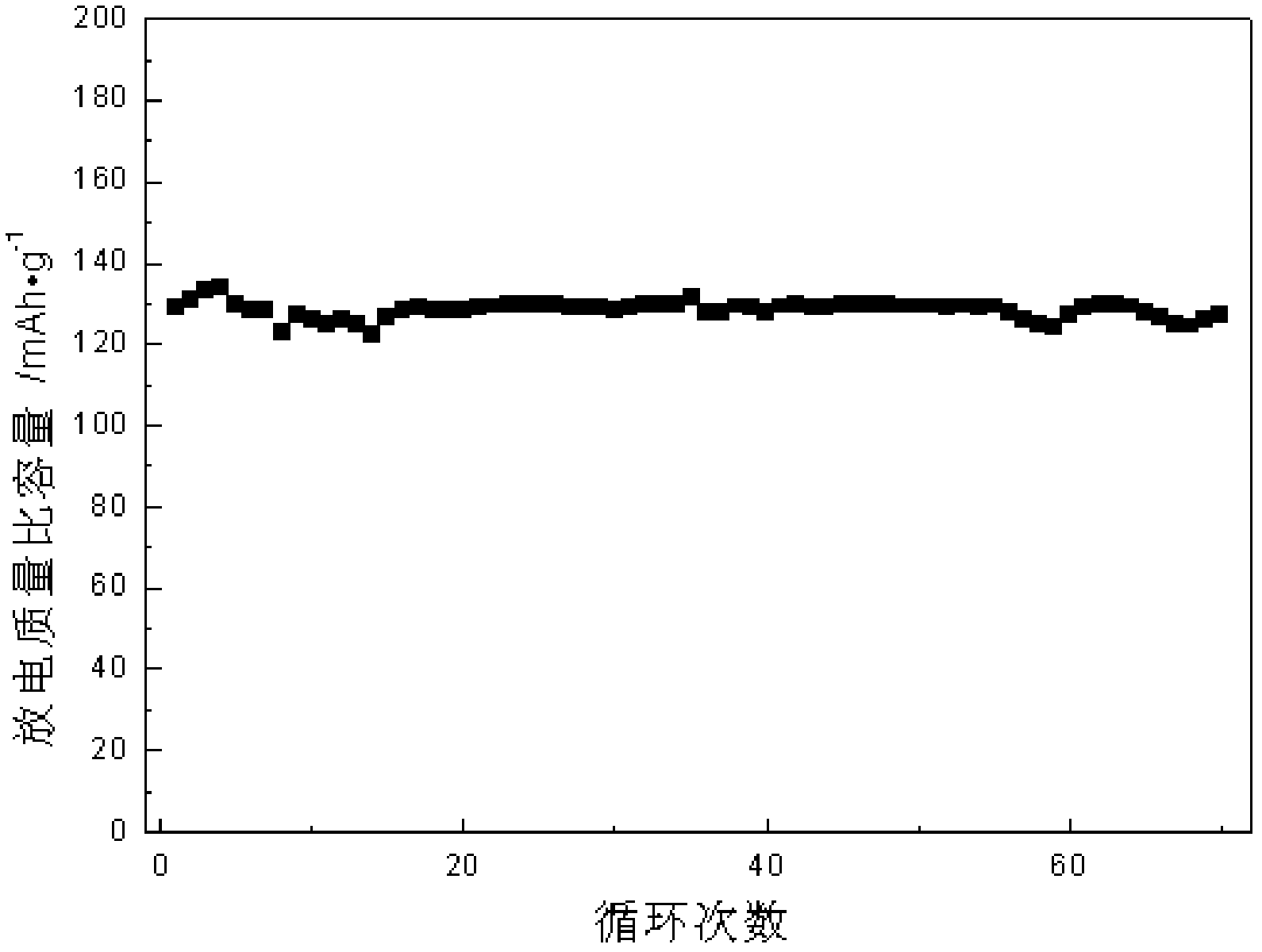

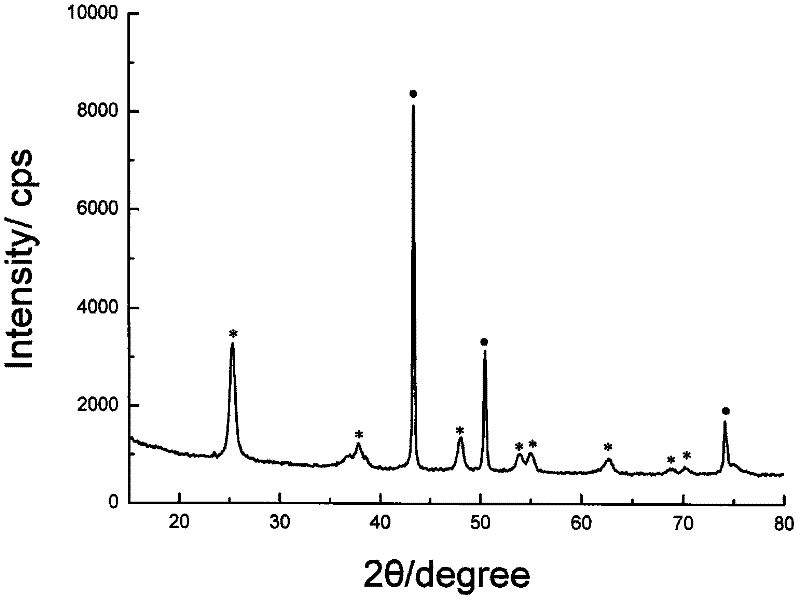

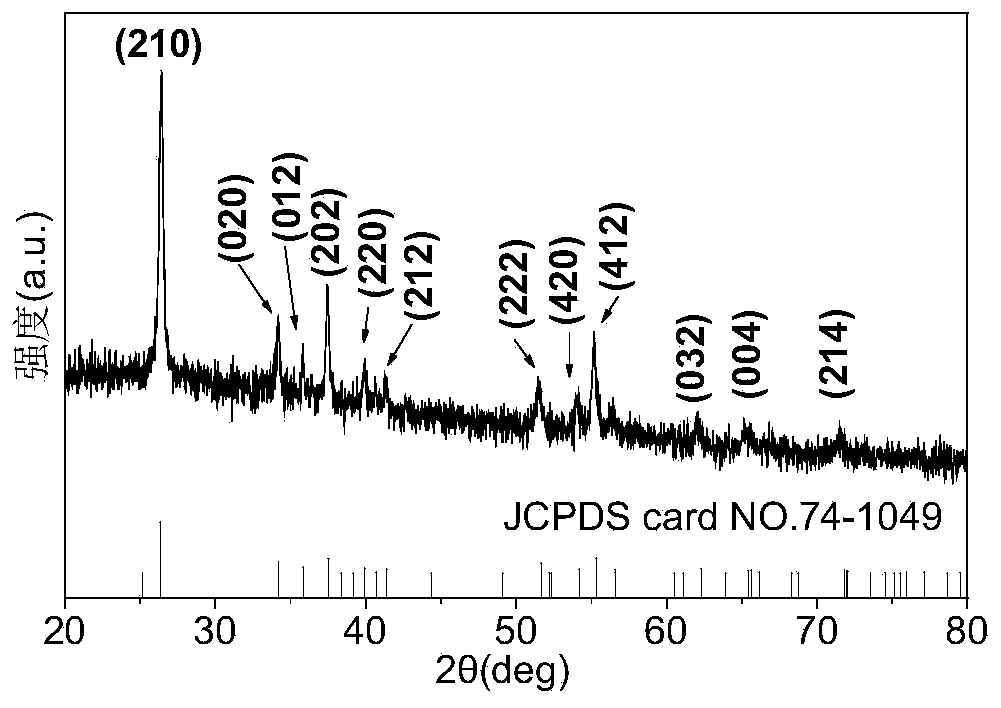

Multi-layer graphene/lithium iron phosphate intercalated composite material, preparation method thereof, and lithium ion battery adopting multi-layer grapheme/lithium iron phosphate intercalated composite material as anode material

InactiveCN102306783AImprove electronic conductivityReduced Diffusion ResistanceCell electrodesSecondary cellsHigh rateSlurry

The invention relates to a lithium iron phosphate intercalated composite material, a preparation method thereof and a lithium ion battery adopting the multi-layer graphene / lithium iron phosphate intercalated composite material as an anode material. In the prior art, the electronic conductivity of the lithium iron phosphate material is poor, high-rate charging / discharging capacity of the lithium ion battery adopting the lithium iron phosphate material as the anode material is poor. The purpose of the present invention is to solve the problems in the prior art, and improve the rapid charging capacity of the power lithium ion battery so as to meet the requirements of the pure electrocar. The composite material is prepared through the following steps that: a rheological phase reaction method is adopted for multi-layer graphene, a trivalent iron salt, a phosphorus compound, a lithium compound and carbon source of small organic molecule to obtain a composite precursor, then the precursor is sintered to obtain the multi-layer graphene / lithium iron phosphate intercalated composite material. The anode slurry of the lithium ion battery anode plate comprises the composite material, a conductive agent and polyvinylidene difluoride. The composite material is an intercalated structure, wherein the lithium iron phosphate particles are intercalated between the multi-layer graphene to form the intercalated structure. The trivalent iron salt is adopted as the raw material, such that the cost is reduced. The lithium ion battery has good charging / discharging cycle performance, wherein the specific capacity is more than 60 mA.h.g<-1> at the rate of 20C.

Owner:HARBIN INST OF TECH

Supported non-noble metal catalyst and preparation and application thereof

ActiveCN105749948AHigh catalytic activityEasy to useOrganic chemistryMolecular sieve catalystsNitro compoundSilicon dioxide

A supported non-noble metal catalyst used for preparation of an azo compound from an aromatic nitro compound by hydrogenation coupling is disclosed, an active component of the supported non-noble metal catalyst is any one or more than two of Co, Mn, Fe, Ni and Cu, a carrier is a nitrogen-doped carbon-inorganic oxide composite, the content of the active component in the catalyst is 0.1-15wt%, and an inorganic oxide is any one of alumina, aluminum hydroxide, magnesium oxide, magnesium hydroxide, silica, SBA-15, magnesium aluminum hydrotalcite, titanium oxide and cerium oxide. A preparation process is as follows: the active component and a nitrogen-containing complex are together impregnated on the inorganic oxide, and then calcined at certain temperature. The catalyst has excellent catalytic performance in the preparation of the azo compound from a nitro compound by selective hydrogenation coupling one-step method. The catalyst is simple in preparation, and has high catalytic activity and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

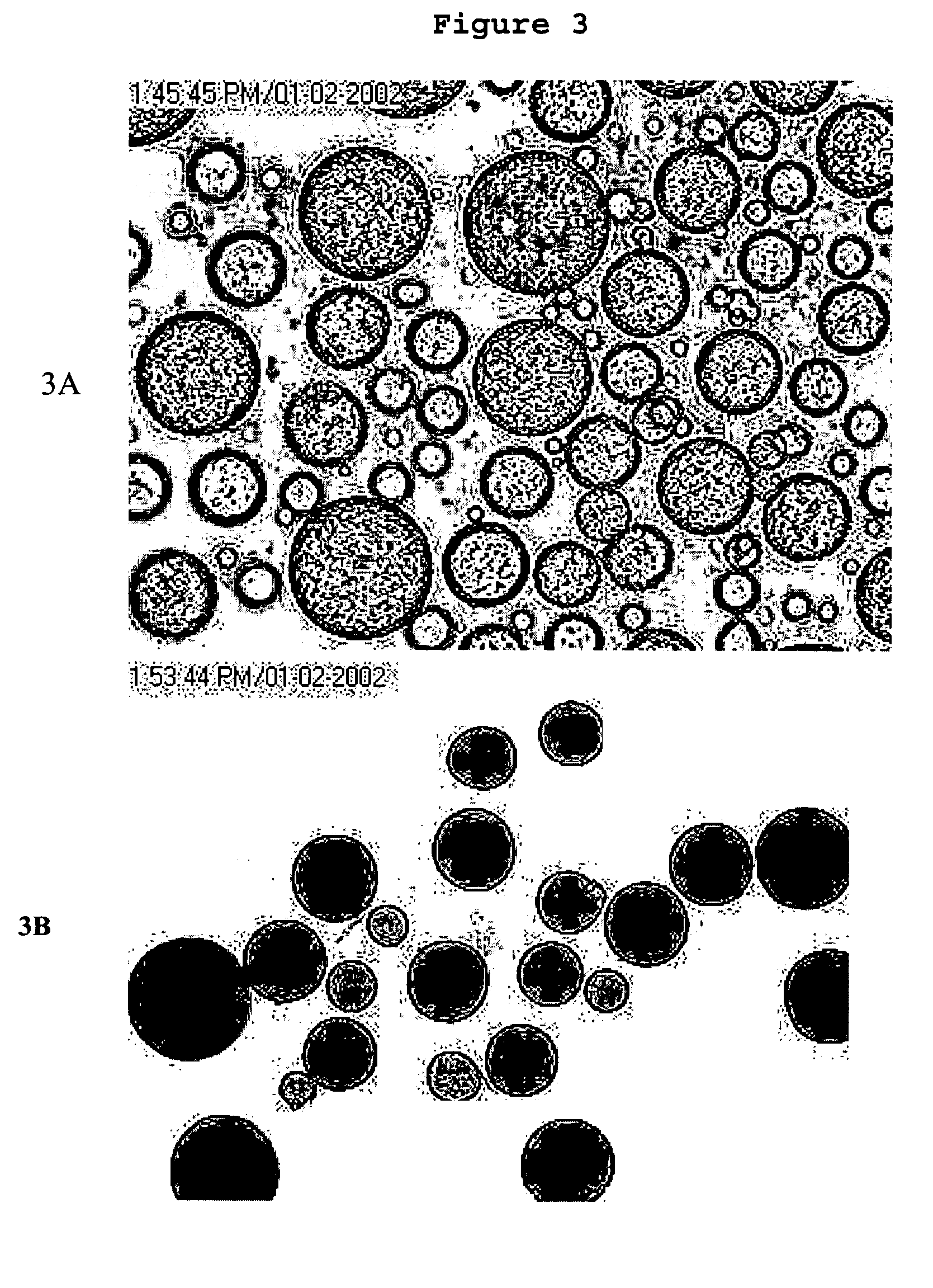

Aquespheres, their preparation and uses thereof

InactiveUS6998393B2Avoid the burst effectCutting portionBiocideOrganic active ingredientsCross-linkEmulsion

This invention provides method for sustained release delivery of structurally delicate agents such as proteins and peptides. Using a unique emulsion system (Stable polymer aqueous-aqueous emulsion), proteins and peptides can be microencapsulated in polysacchride glassy particles under a condition free of any chemical or physical hazard such as organic solvents, strong interfacial tension, strong shears, elevated temperature, large amount of surfactants, and cross-linking agents. Proteins loaded in these glassy particles showed strong resistance to organic solvents, prolonged activity in hydrated state, and an excellent sustained release profile with minimal burst and incomplete release when being further loaded in degradable polymer microspheres. This invention provides a simple yet effective approach to address all the technical challenges raised in sustained release delivery of proteins.

Owner:BIODVERY PHARMATECH LTD

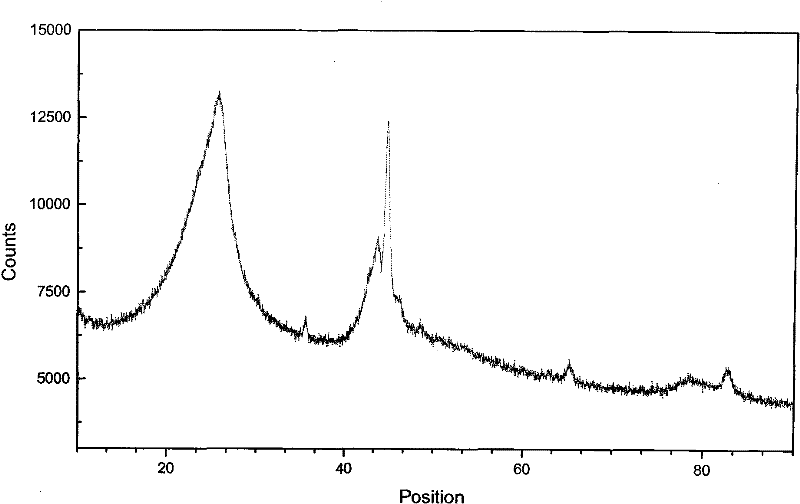

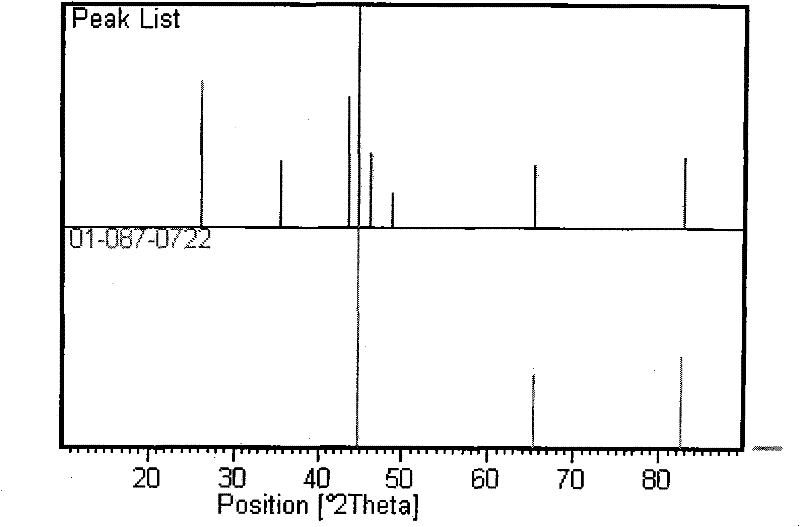

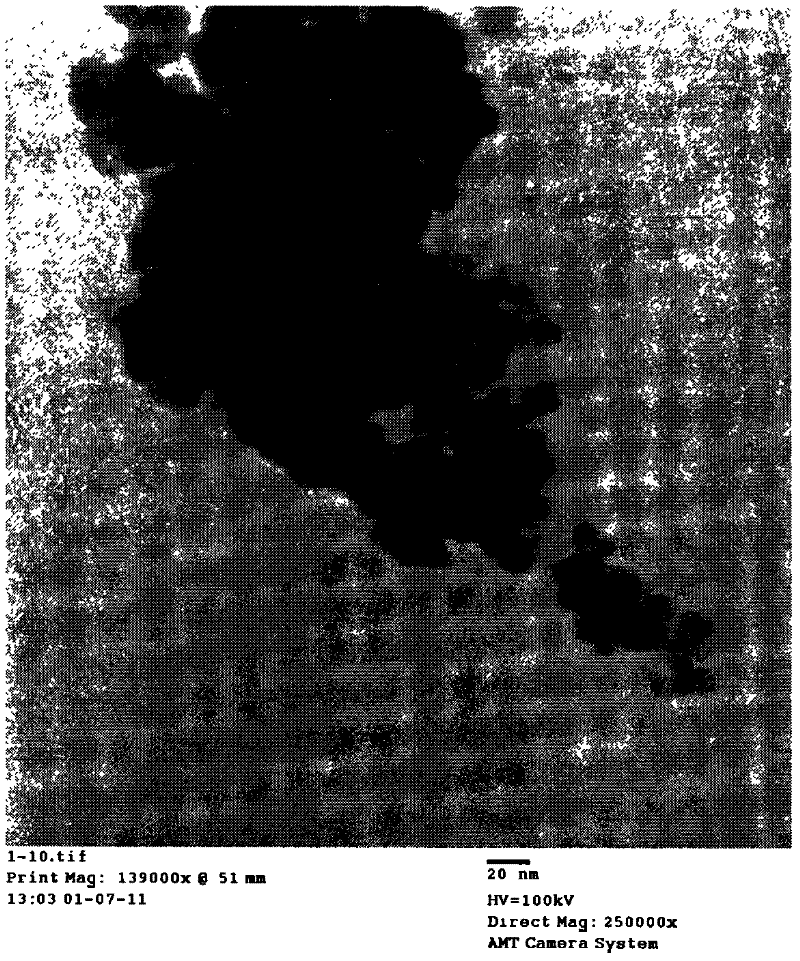

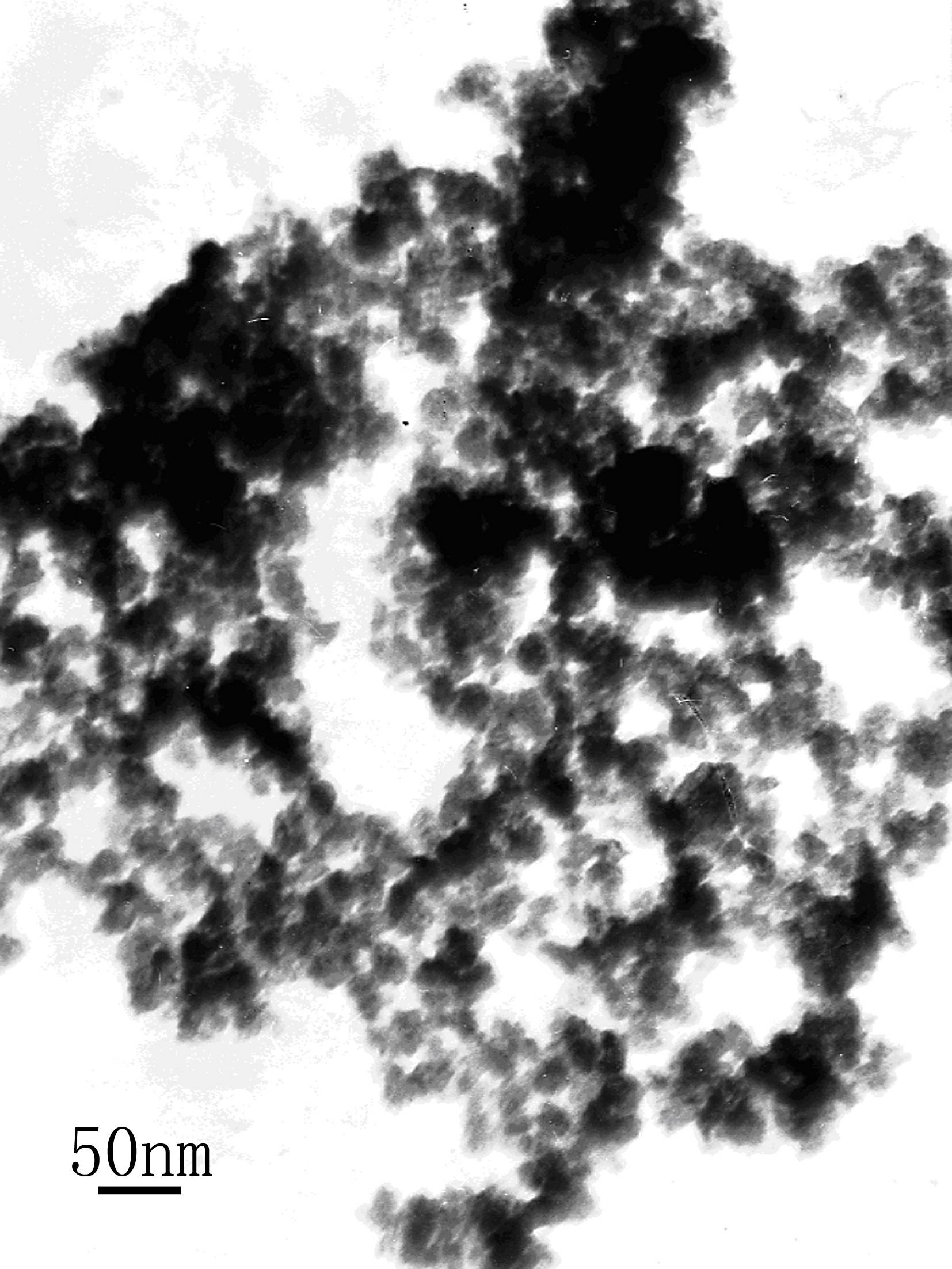

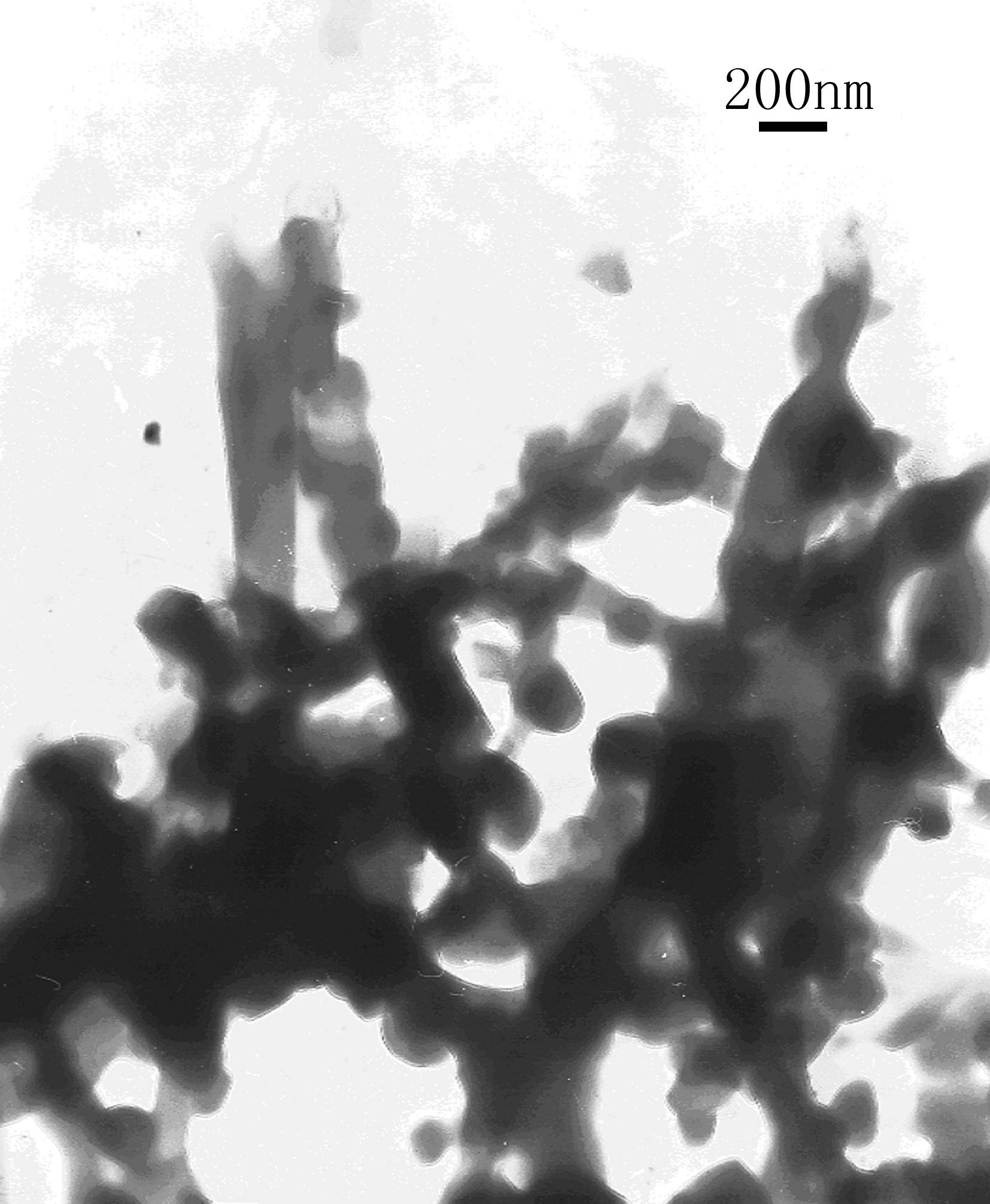

Novel method for preparing load nano zero valent iron

InactiveCN102205419AUniform size distributionPrevent restoreMaterial nanotechnologyCoalReducing agent

The invention discloses a novel method for preparing load nano zero valent iron. The iron source is iron-containing compounds of Fe<2+> and Fe<3+>, such as ferric oleate, ferric hydroxide oxide, ferric chloride, ferric nitrate and the like; and the loads are carbon black, active carbon, kieselguhr, zeolite and other load materials. The method is characterized in that: the iron-containing compounds on the loads are reduced into nano zero valent iron under the atmosphere condition and under the reduction action of reducing agents, such as H2, CO, and reduction carbon (such as coke, reduction coal and the like). The preparation method is environment-friendly, and simple and is low in cost; the expensive reducing agents (such as NaBH4 and the like) are avoided, and organic pollutants (such as halogenated hydrocarbon, pesticide, polychlorinated biphenyls (PCBs) and polycyclic aromatic hydrocarbons (PAHs), inorganic negative ions (such as NO<3->), and heavy metal (such as Cr<6+>, As<3+>, As<5+>, Cu<2+>, Pb<2+>) and the like can be efficiently removed effectively.

Owner:BEIJING NORMAL UNIVERSITY

Multiparticulates of spray-coated drug and polymer on a meltable core

ActiveUS20100068276A1High dissolution rateReduce releasePowder deliveryBiocideMedicineWater soluble drug

A pharmaceutical composition comprises multiparticulates comprising a melt-congeal core and a solid amorphous dispersion layer of a poorly water soluble drug and polymer. The multiparticulates are suitable for improving bioavailability of poorly water soluble drugs. The melt-congeal cores facilitate application of the solid amorphous dispersion layer, and allow incorporation of additional optional components to the core so as to adjust the release of drug from the multiparticulate.

Owner:LONZA BEND INC

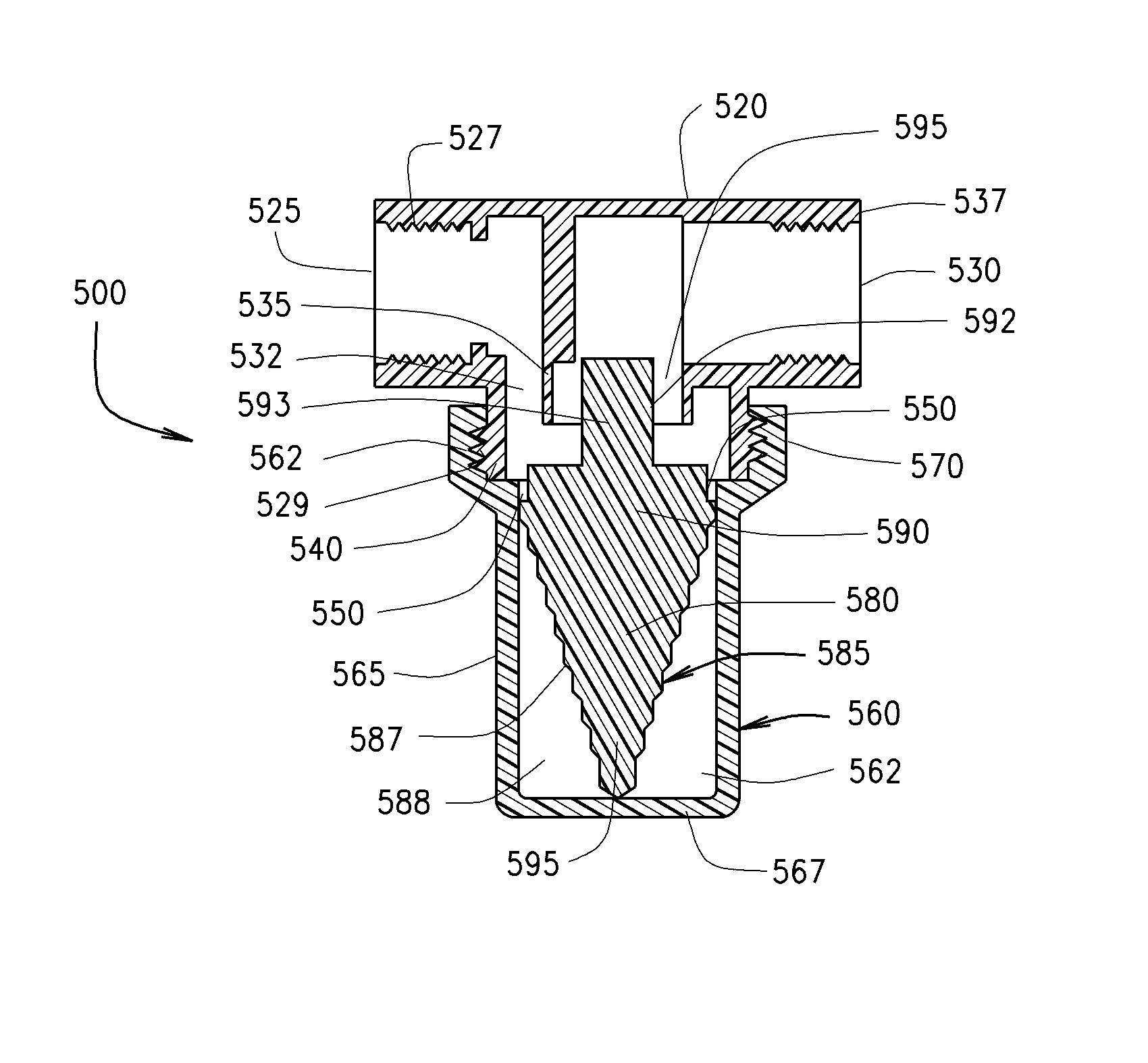

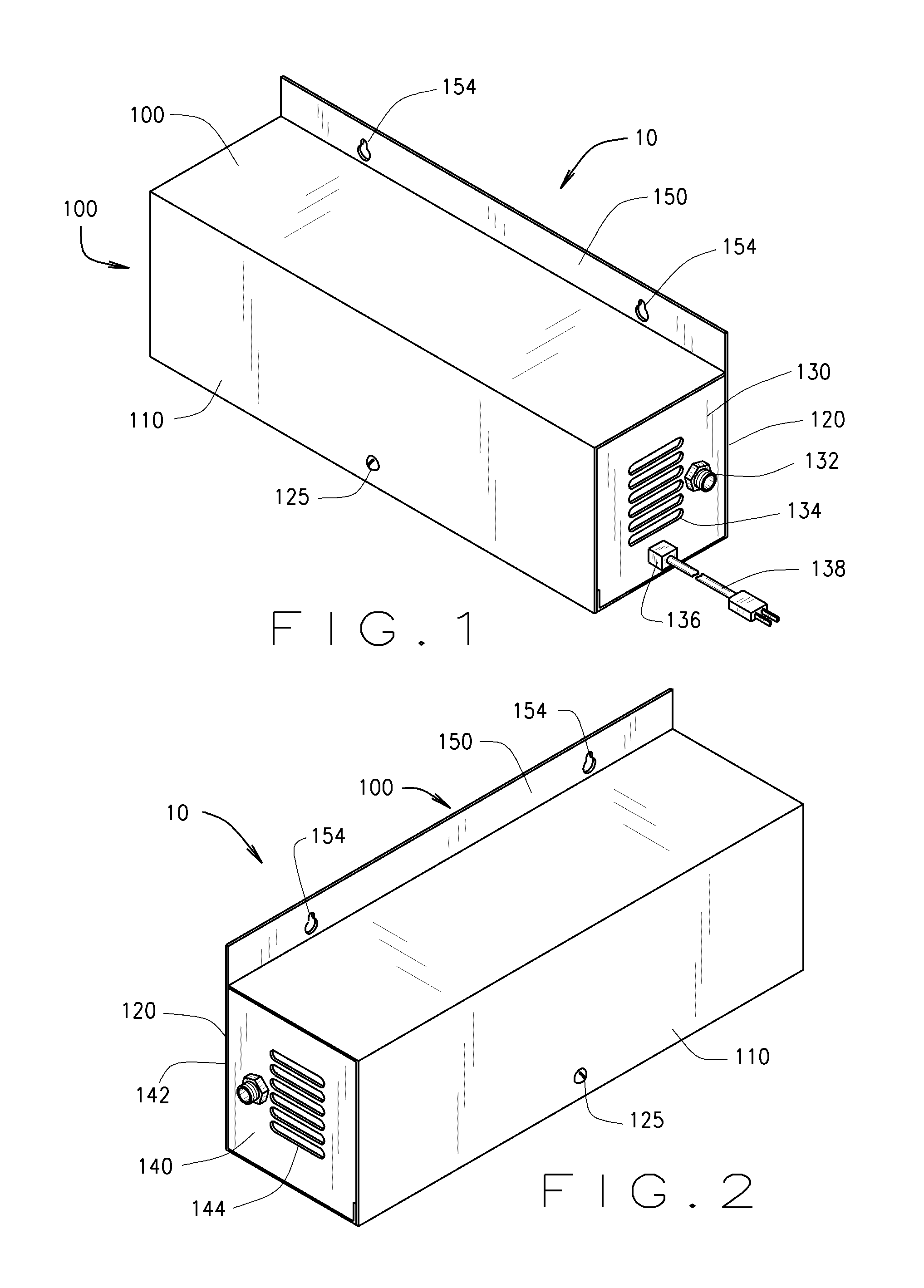

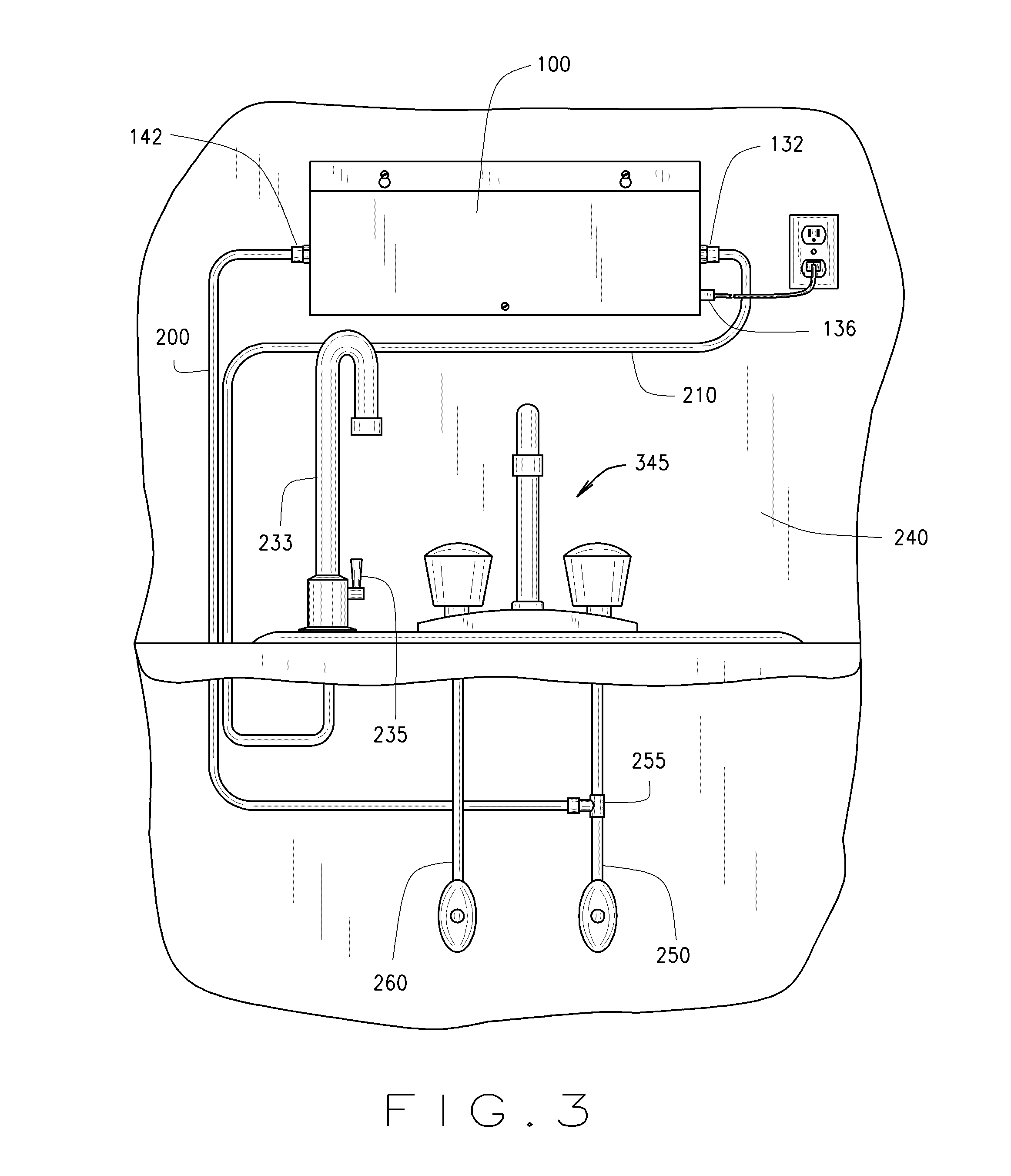

Ozonated liquid dispensing unit

ActiveUS9522348B2Effective and longer lasting cleaning and sanitizing solutionReduce the presence of air bubblesInorganic/elemental detergent compounding agentsFruit and vegetables preservationEngineeringOzone

A reaction vessel and an ozonated liquid dispensing unit are described herein. The unit produces and dispenses an ozonated liquid that may be used to clean and sanitize a variety of articles or used in conjunction with cleaning processes and other apparatus. The reaction vessel is incorporated into the unit to reduce bubbles of ozone gas and to break up bubbles of ozone gas in the ozonated liquid to provide a more effective and longer lasting cleaning and sanitizing solution.

Owner:CLEANCORE SOLUTIONS LLC

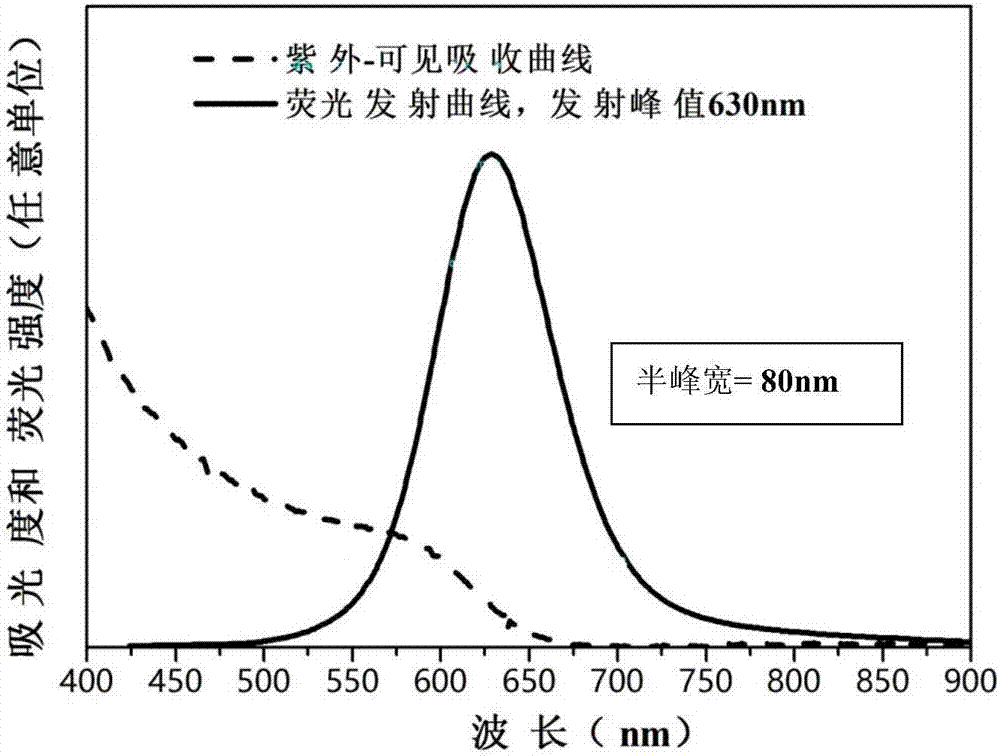

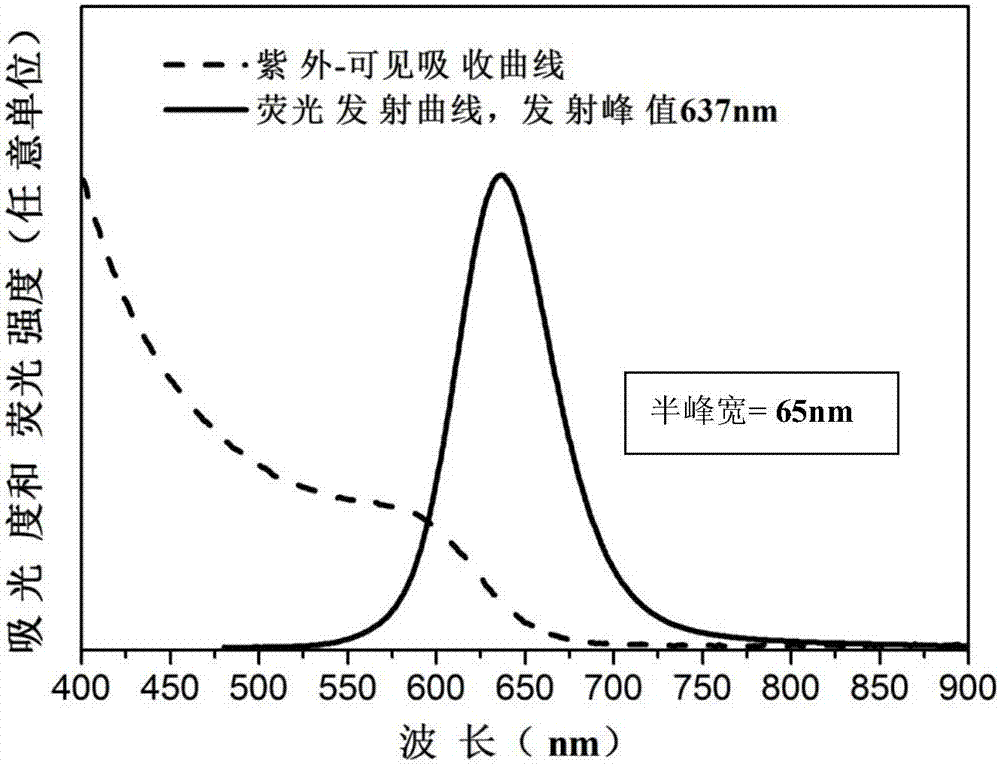

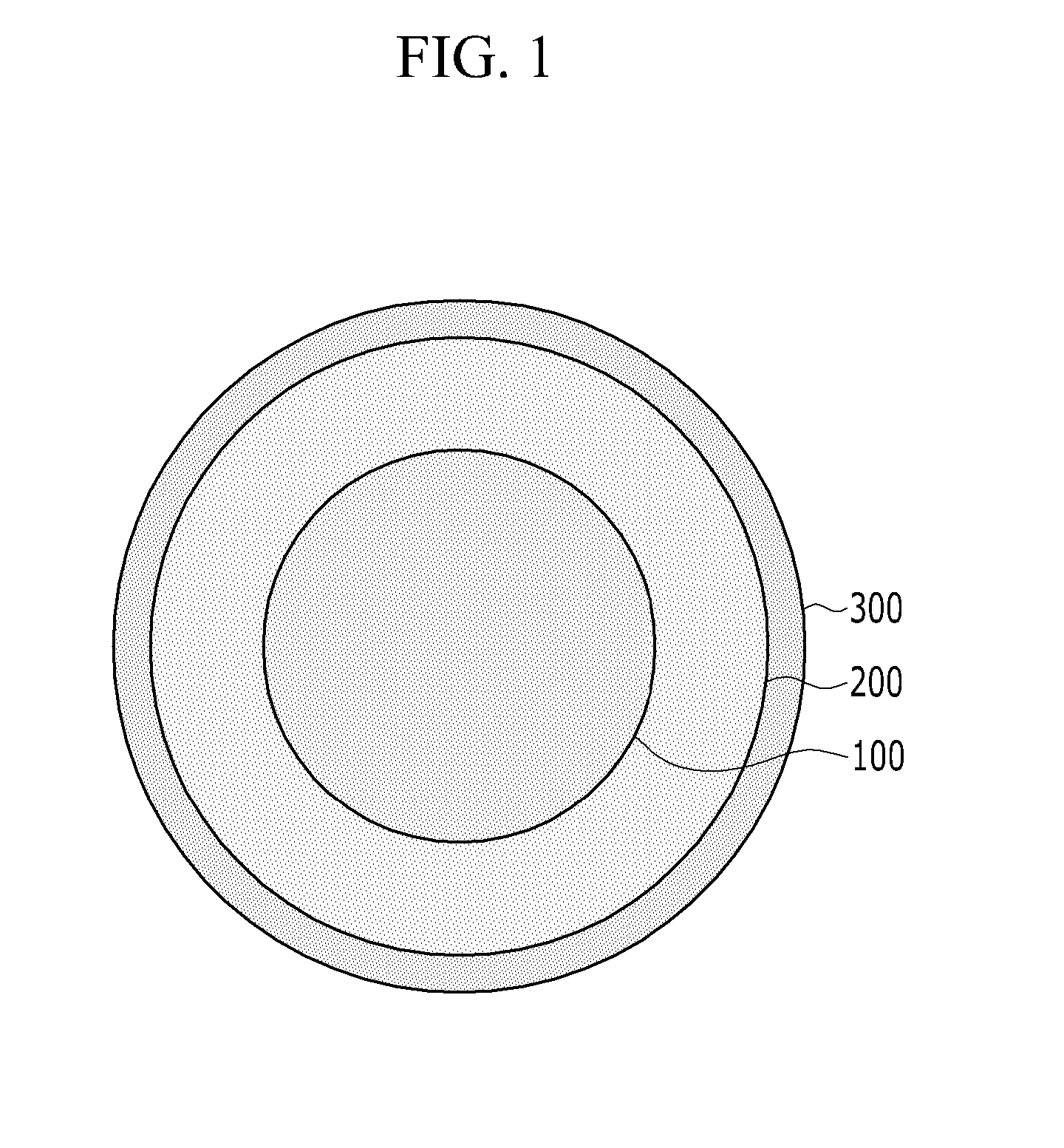

Preparation method of indium phosphide quantum dots

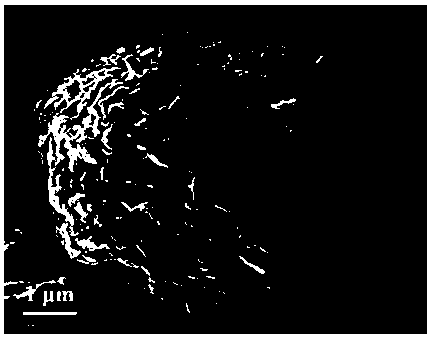

InactiveCN107098324AUniform size distributionGood optical performanceLuminescent compositionsPhosphidesIndiumSurface oxidation

The invention provides a preparation method of indium phosphide quantum dots. The preparation method comprises the following steps: firstly mixing an indium precursor, an acid ligand and a non-coordinating solvent and preparing a uniform indium precursor solution; then adding hydrogen phosphide at a temperature of 100-130 DEG C, raising the temperature to a second temperature and keeping for a period of time; finally regulating the solution to a third temperature and adding a precursor substance required by a synthetic shell to obtain the shell-coated indium phosphide quantum dots. The indium phosphide quantum dots with nuclear shell structures are synthesized by adopting the method of low-temperature nucleating, raised temperature-curing and high-temperature shell-coating; the nucleation and growth processes of indium phosphide nano crystalline nucleuses can be controlled at a low temperature, so that the synthesized quantum dots are uniform in size distribution; meanwhile, the risk of surface oxidation of the indium phosphide nano crystalline nucleuses can also be effectively avoided at a low temperature, so that the optical performance of the indium phosphide quantum dots are improved to a certain degree.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

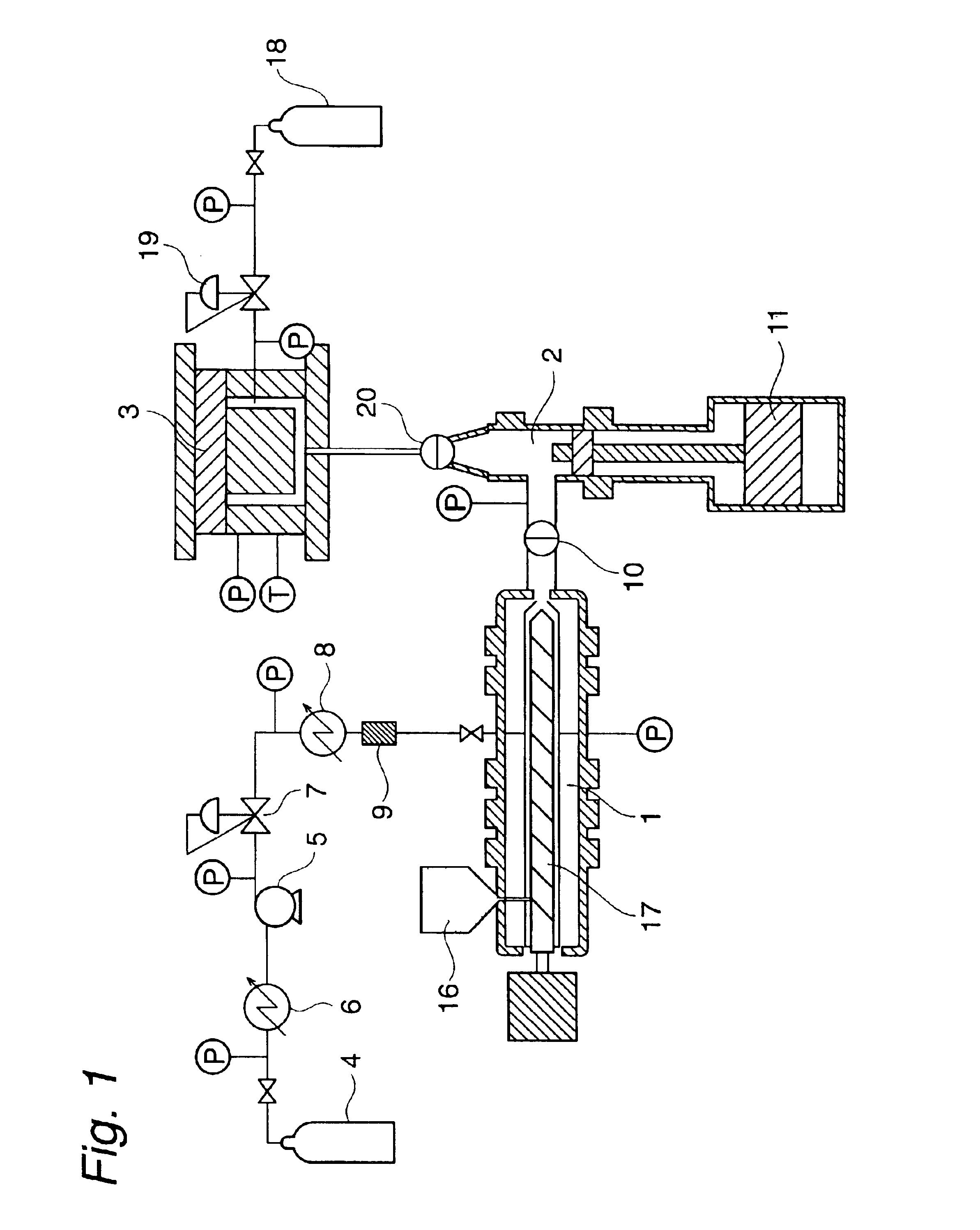

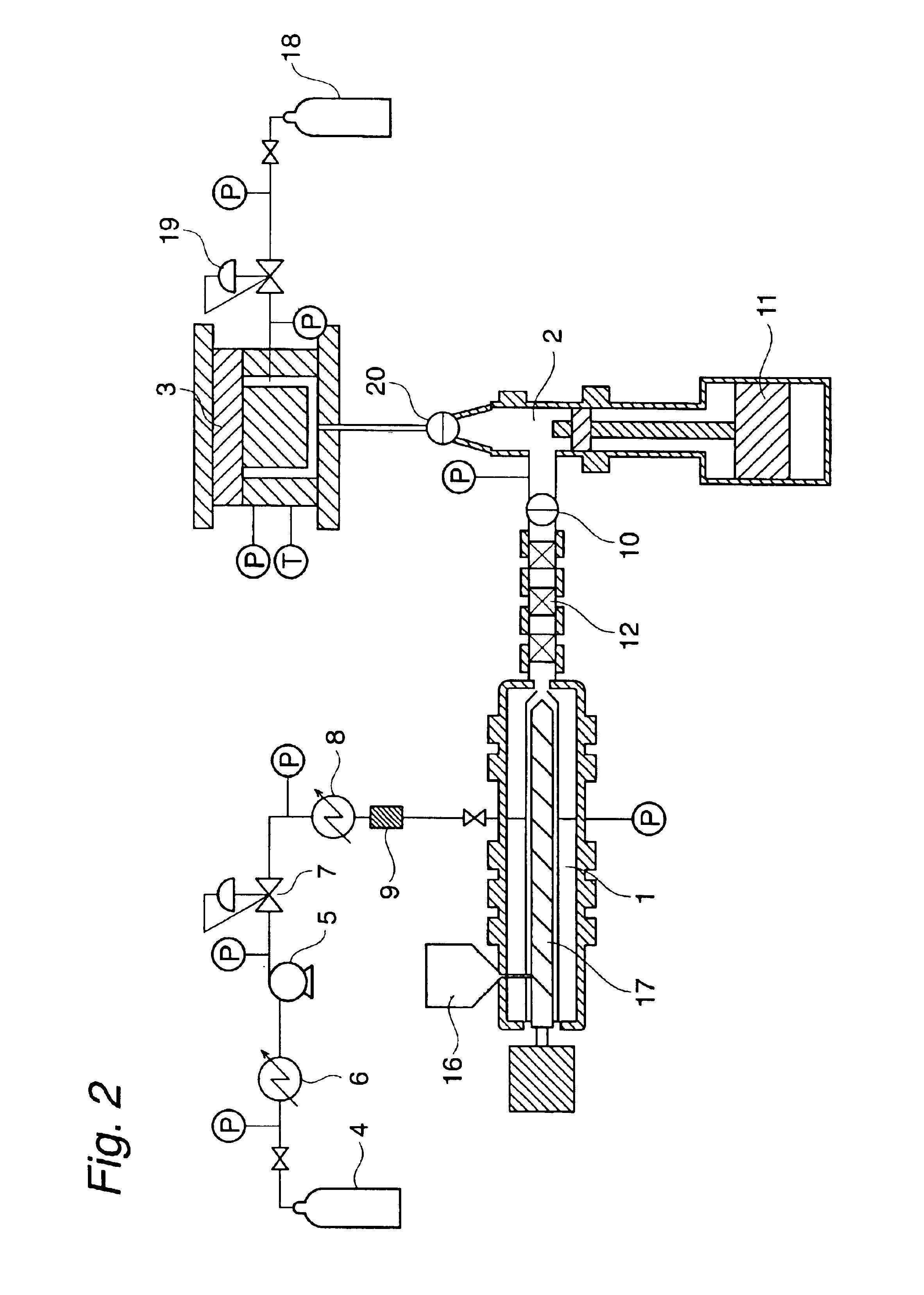

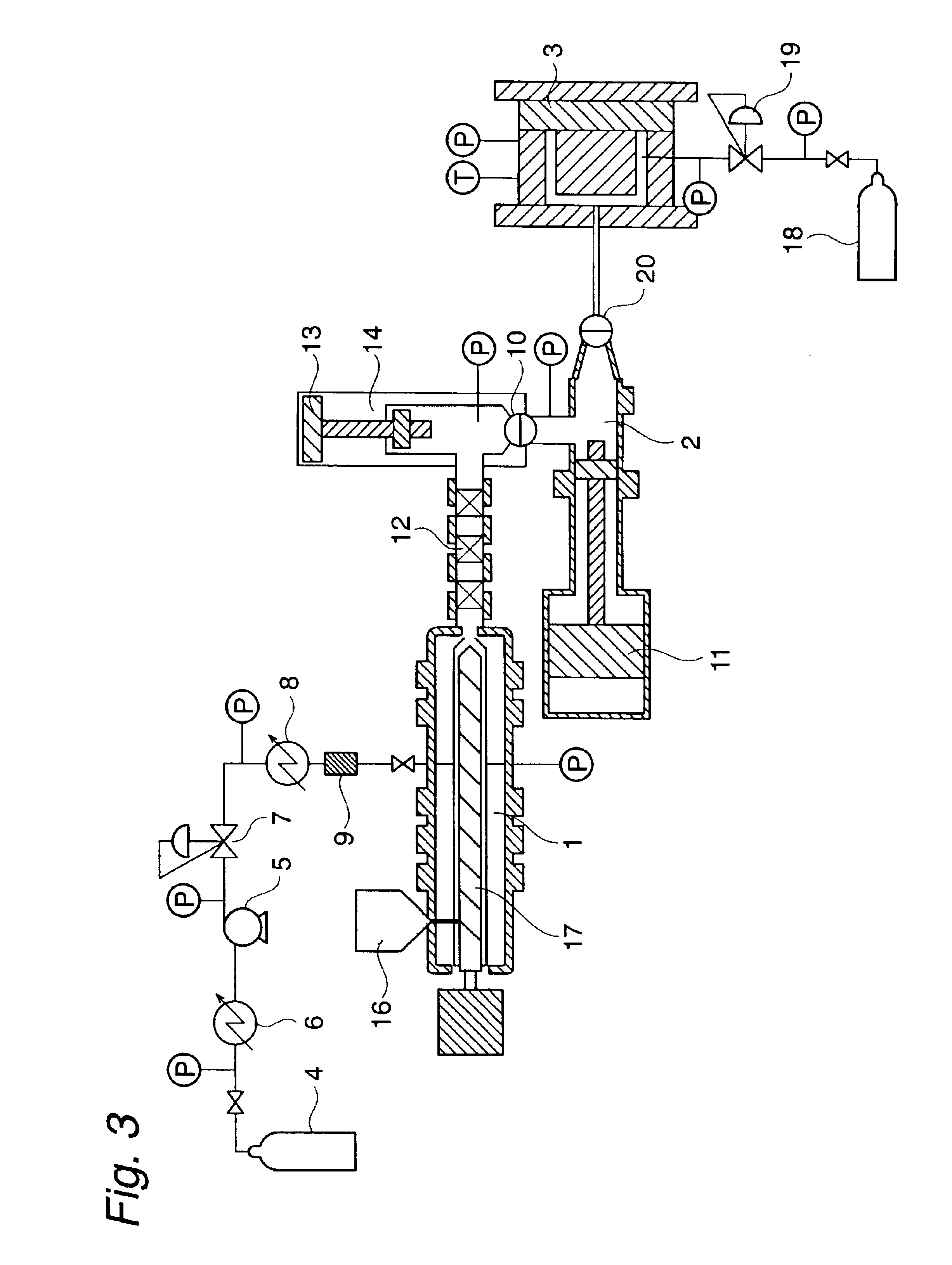

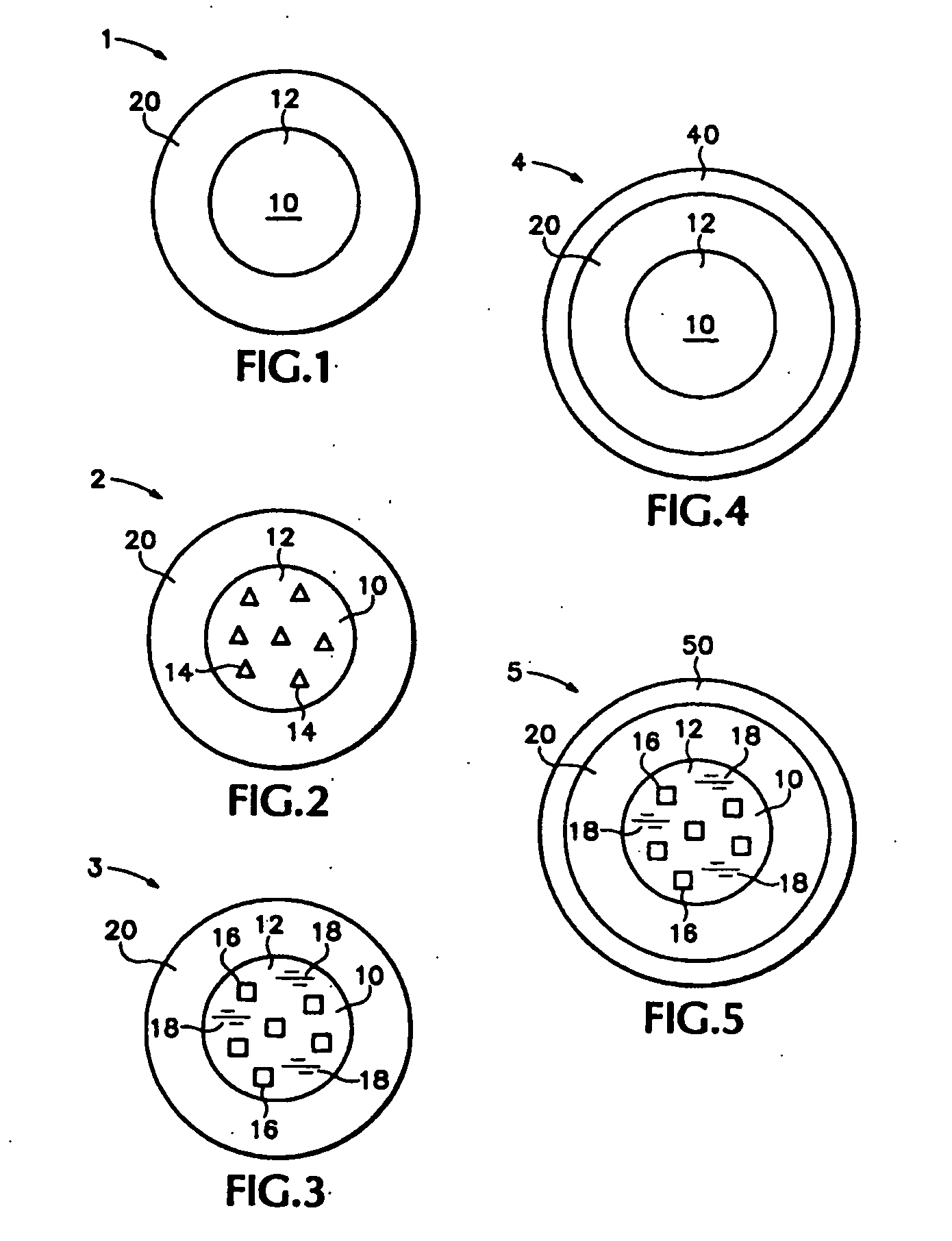

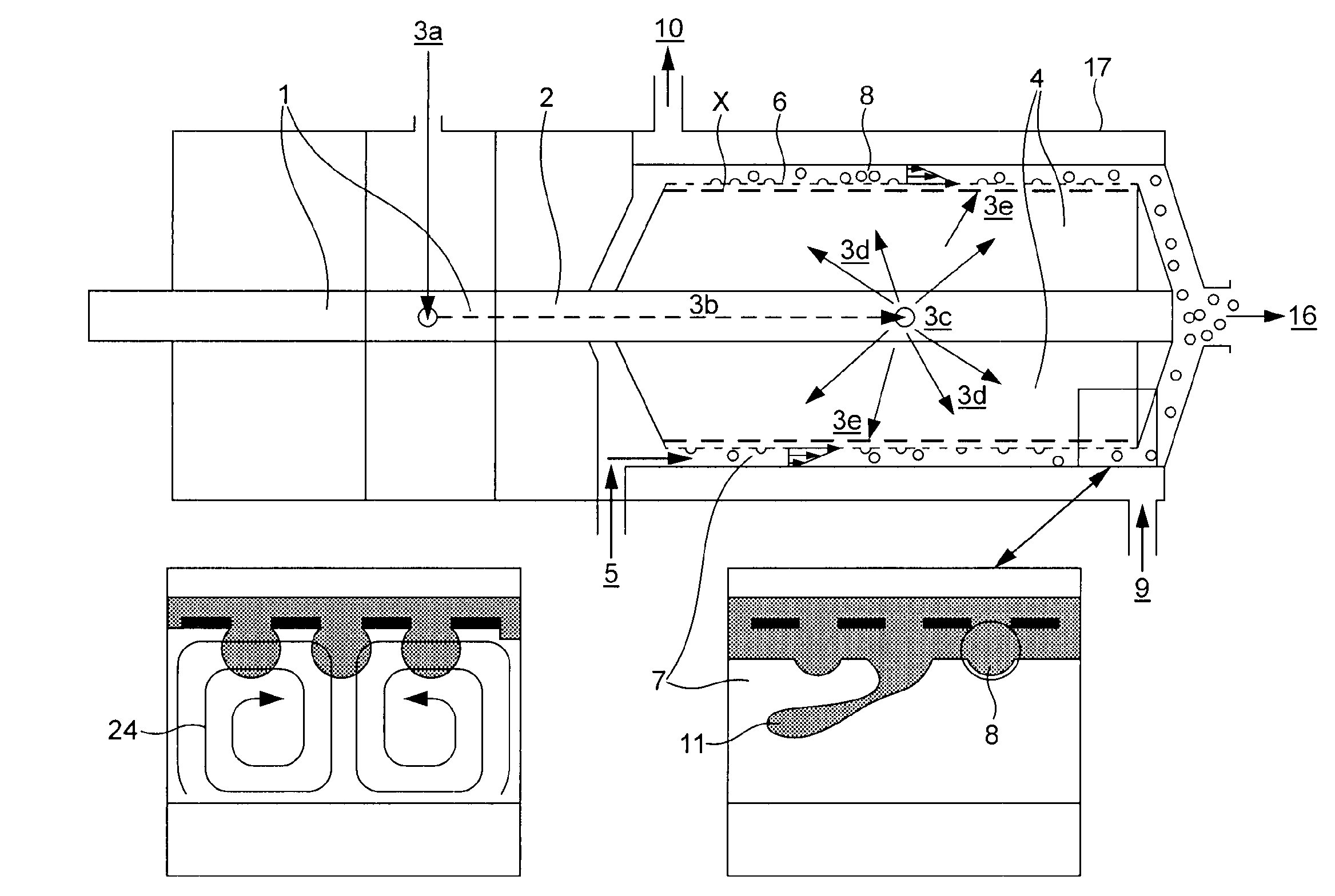

Cylindrical membrane apparatus for forming foam

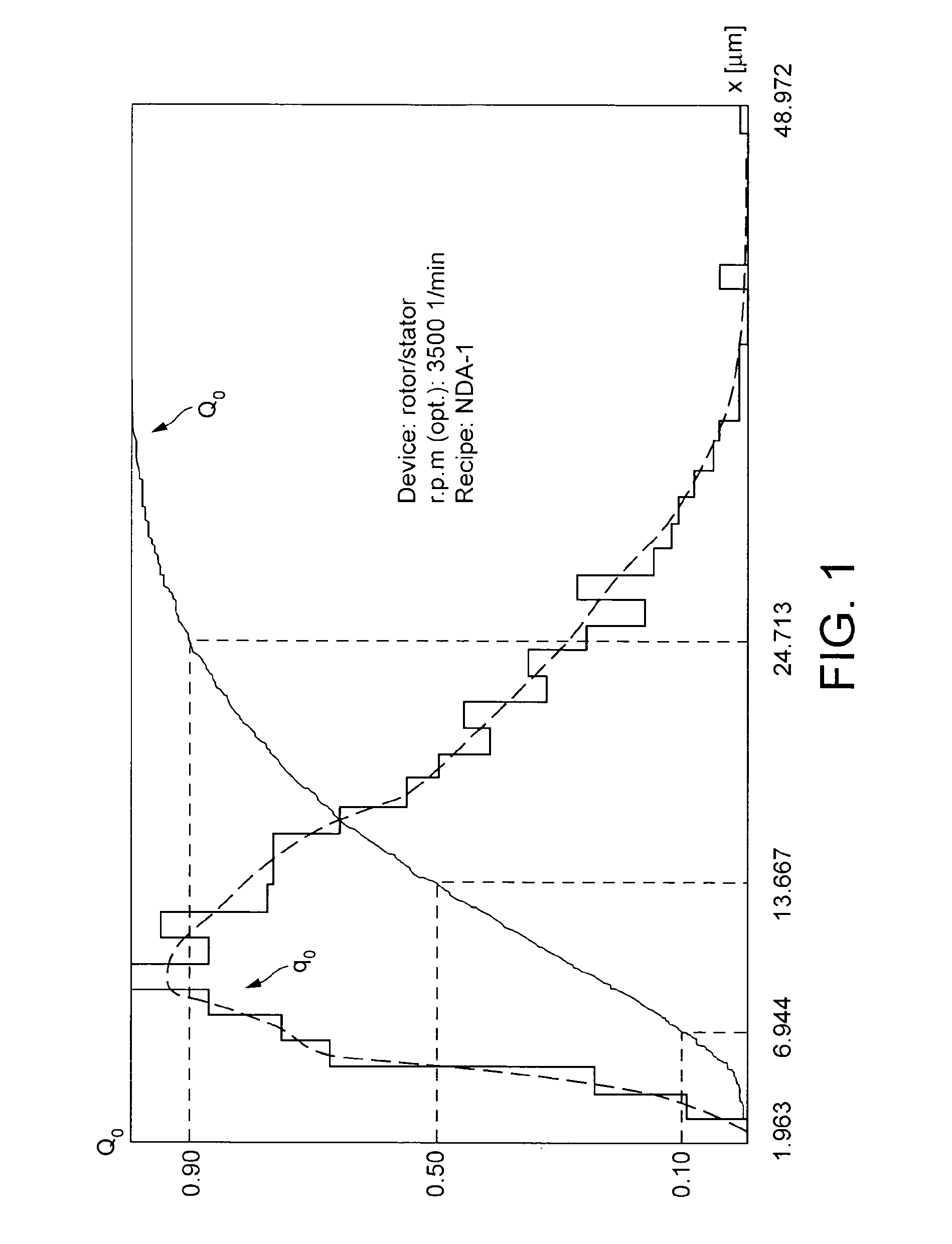

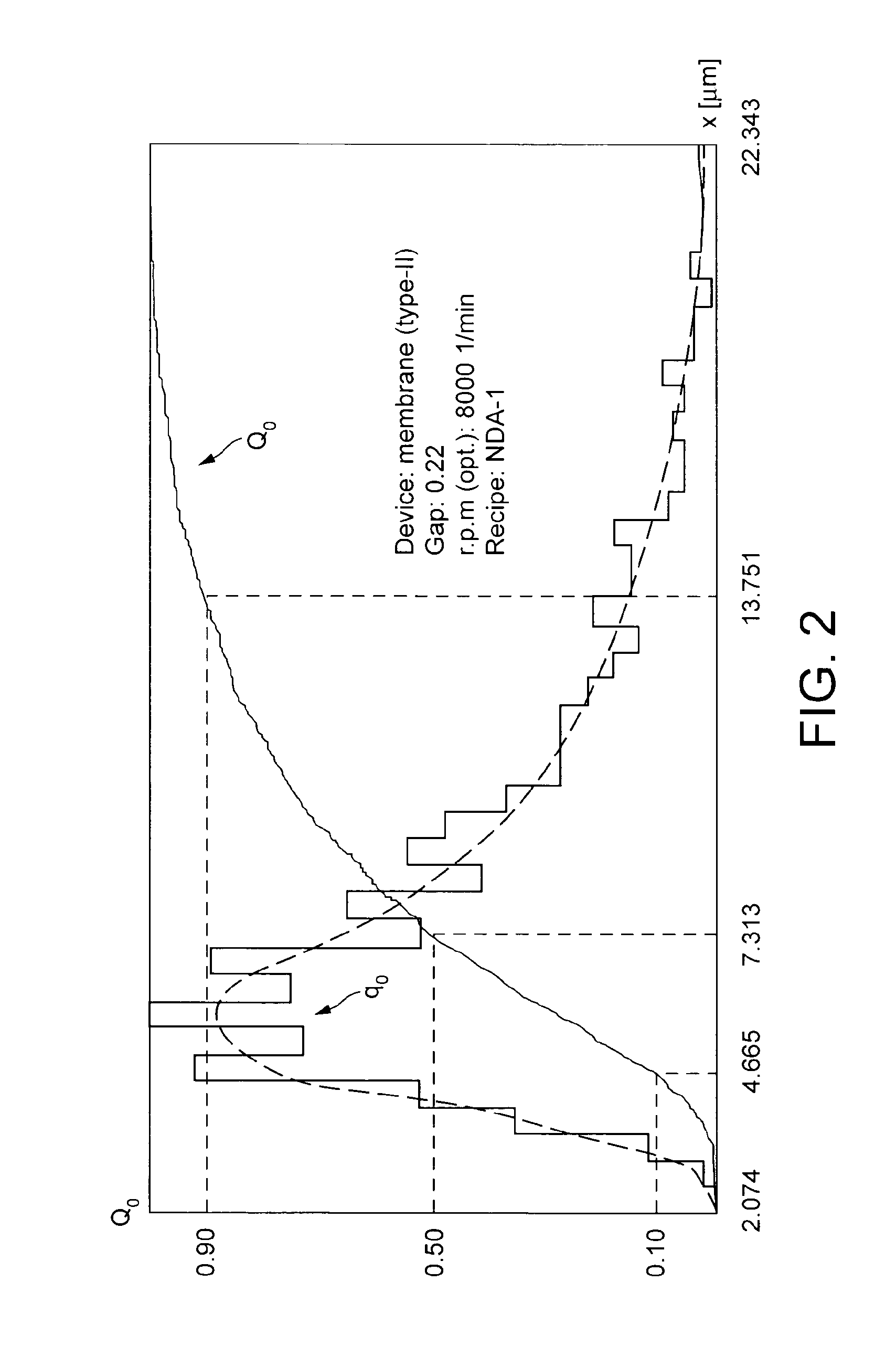

InactiveUS20090323459A1Uniform size distributionFlow mixersTransportation and packagingMean diameterMembrane surface

An apparatus and process for making a foam having a controlled size distribution of gas bubbles in a liquid matrix. The invention utilizes a porous material having a controlled pore size and pore distance to produce a substantially uniform size distribution of gas bubbles; a gas pumping device for directing a flow of gas to and through the porous material to form the gas bubbles; a fluid pumping device for directing a flow of liquid matrix past the porous material and a rotating element moving in the vicinity of the membrane surface causing an additional flow to detach, collect accumulate and entrain the gas bubbles in the liquid matrix to form a foam having gas bubbles of generally uniform size and a substantially uniform gas bubble size distribution. Advantageously, the pore size and pore distance of the porous material, the gas flow from the gas pumping device, the flow field generated by the rotating element and the liquid flow from the fluid pumping device cooperate to provide gas bubbles having a mean diameter X50,0 that is less than 2-2.5 times, preferably less than 1.25-1.5 times the mean pore diameter of the membrane and to provide the foam with a gas bubble diameter distribution ratio X90,0 / X10,0 that is less than 5, preferably less than 3.

Owner:NESTEC SA

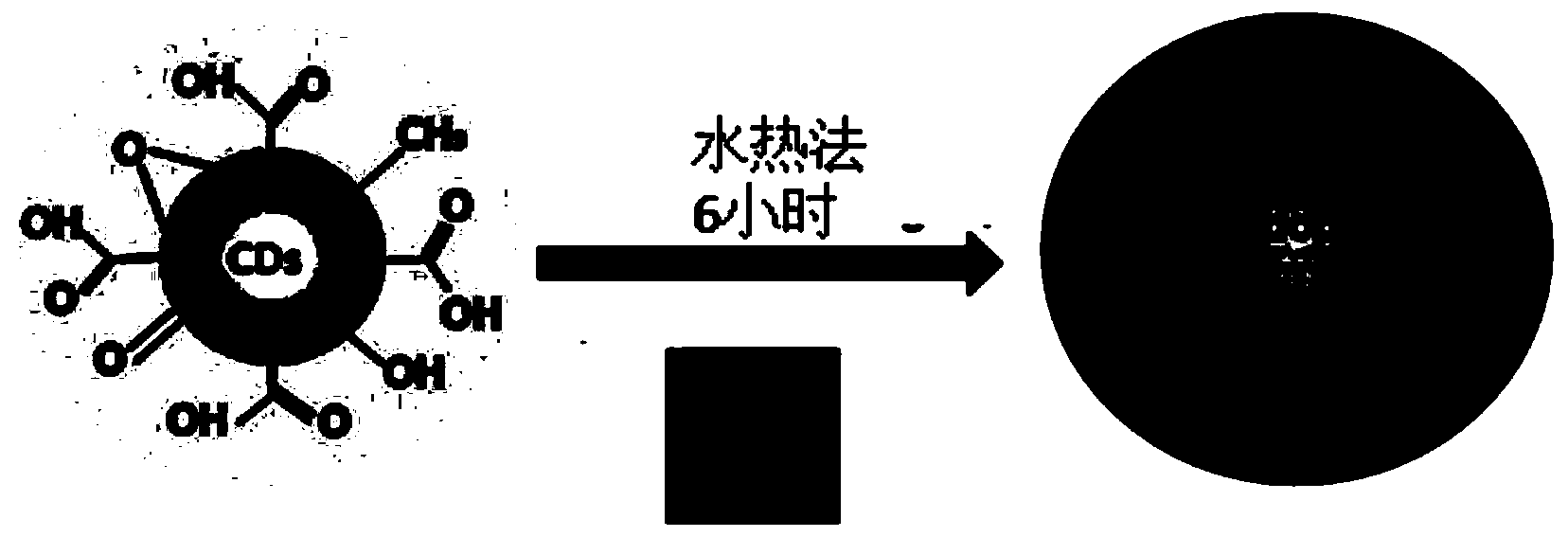

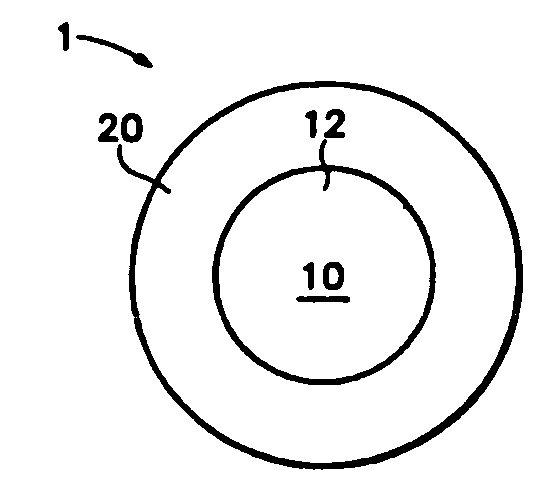

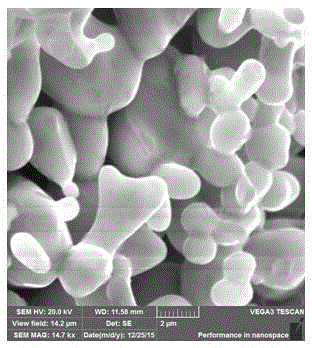

Method for preparing copper-titanium dioxide core-shell nanoparticles

InactiveCN102335605ASmall particle sizeMorphological components are adjustableElectrolytic capacitorsCell electrodesPolyethylene glycolSolvent

The invention relates to a method for preparing copper-titanium dioxide core-shell nanoparticles. In the method, cupric ions provided by cuprous chloride are dissolved into ammonia water; an aqueous solution of polyethylene glycol, an aqueous solution of sodium citrate, an aqueous solution of ascorbic acid, a solution of tetrabutyl titanate (absolute ethyl alcohol) and urea are sequentially addedinto the ammonia water; the ammonia water is put into a teflon-lined stainless steel autoclave after the ammonia water is stirred at room temperature; and the nearly-spherical core-shell nanoparticles are prepared through controlling the temperature and the time for the thermal reaction of the mixed solvents. In the method for preparing the copper-titanium dioxide core-shell nanoparticles, the ascorbic acid serves as a reducing agent and is used for reducing the cuprous ions; and the polyethylene glycol serves as a soft template. The method for preparing the copper-titanium dioxide core-shellnanoparticles has the advantages of simple process, environment-friendliness, low cost and the like; the outer layer of each of the prepared copper-titanium dioxide core-shell nanoparticles is anatase titanium dioxide, and the inner layer of each of the prepared copper-titanium dioxide core-shell nanoparticles is cubic-phase copper elementary substance; and the size distribution is even, and the particle size is controllable, thus the copper-titanium dioxide core-shell nanoparticles can be used as the electrode materials and the photocatalyst materials of dye-sensitized solar cells.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Environment-friendly heat conduction insulating glue used by high-power LEDs and preparation method

ActiveCN101812280AImprove cooling effectImprove work efficiencyNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

The invention relates to an environment-friendly heat conduction insulating glue used by high-power LEDs, which is characterized by being prepared from the following raw materials in percentage by weight: 50-68 percent of micro-grade high-thermal conductive powder, 18-30 percent of epoxy resin, 4-10 percent of curing agent, 7-15 percent of solvent, 0.6-1.5 percent of accelerator and 1-2 percent of additive; and the micro-grade high-thermal conductive powder is selected from a mixture formed by one or more of micro-grade aluminum powder, palladium powder, platinum powder, gold powder, C powder, AlN powder and SiC powder. The invention also relates to a preparation method of the heat conduction insulating glue. The environment-friendly heat conduction insulating glue used by high-power LEDsis obtained by optimizing the matching ratio and the modification of the raw materials and improving and simplifying the preparation process. Besides high resistivity, the heat conduction insulating glue also has high thermal conductivity, higher working temperature, strong viscosity, high cutting strength and fine performance index.

Owner:连云港市昭华光电科技有限公司

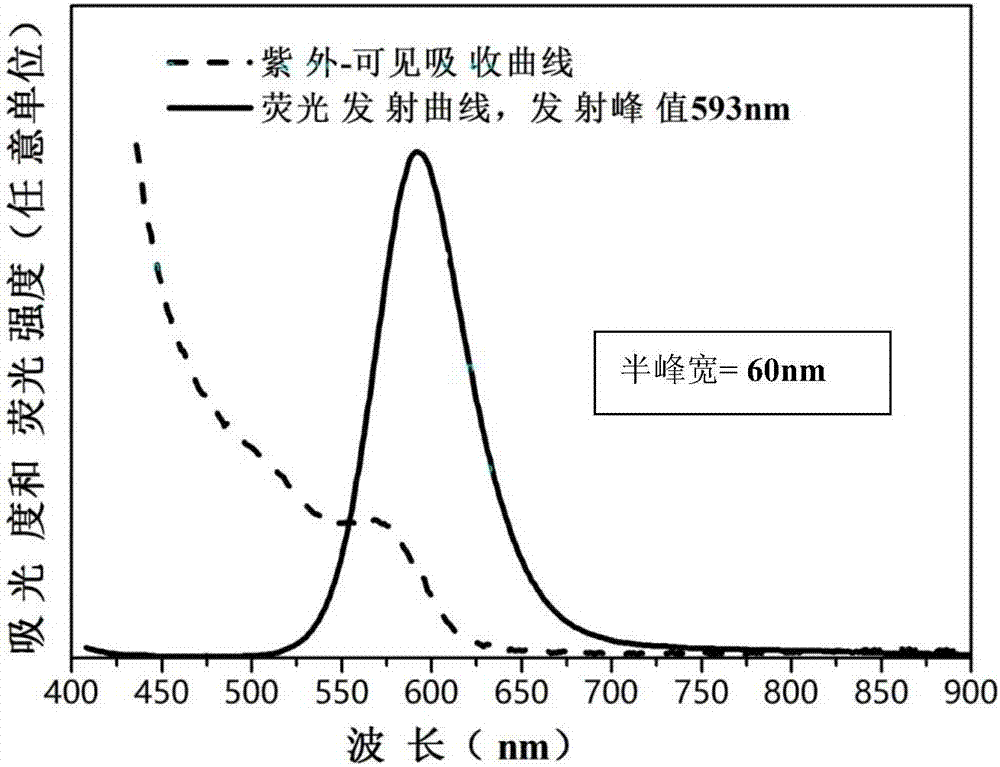

Semiconductor nanocrystal, method of manufacture thereof and articles including the same

ActiveUS20110315954A1Improve stabilitySmall sizeMaterial nanotechnologyLight-sensitive devicesSemiconductor nanocrystalsSemiconductor

A semiconductor nanocrystal including a core including ZnSe, ZnTe, ZnS, ZnO, or a combination comprising at least one of the foregoing, wherein the core has a diameter of about 2 nanometers to about 5 nanometers and an emitted light wavelength of about 405 nanometers to about 530 nanometers; and a first layer disposed on the core, the first layer including a Group III-V semiconductor, wherein the semiconductor nanocrystal has a full width at half maximum of an emitted light wavelength of less than or equal to about 60 nanometers.

Owner:SAMSUNG ELECTRONICS CO LTD

High-performance conductive silver paste and preparation method thereof

ActiveCN101805575AEvenly dispersedUniform size distributionNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

The invention relates to a high-performance conductive silver paste, which is characterized by comprising the following raw materials in percentage by weight: 65-80% of micron-sized metal silver powder, 10-20% of epoxy resin, 1.4-3.5% of curing agent, 6-9% of solvent, 0.5-1.2% of accelerator, 0.05-0.1% of flexibilizer and 1-2% of additive. The invention also discloses a preparation method of the high-performance conductive silver paste. The conductive silver paste of the invention has high conductivity, very high thermal conductivity, high working temperature, strong viscosity and very high shear strength, and the performance indexes are apparently higher than the working performance of the conductive silver paste in the prior art, thereby solving the technical problems of poor shear performance, low working temperature, poorer thermal conductivity, long curing time, high curing temperature, poor viscosity, easy pollution of environment and the like in the field of the conductive silver paste in the prior art.

Owner:连云港市昭华光电科技有限公司

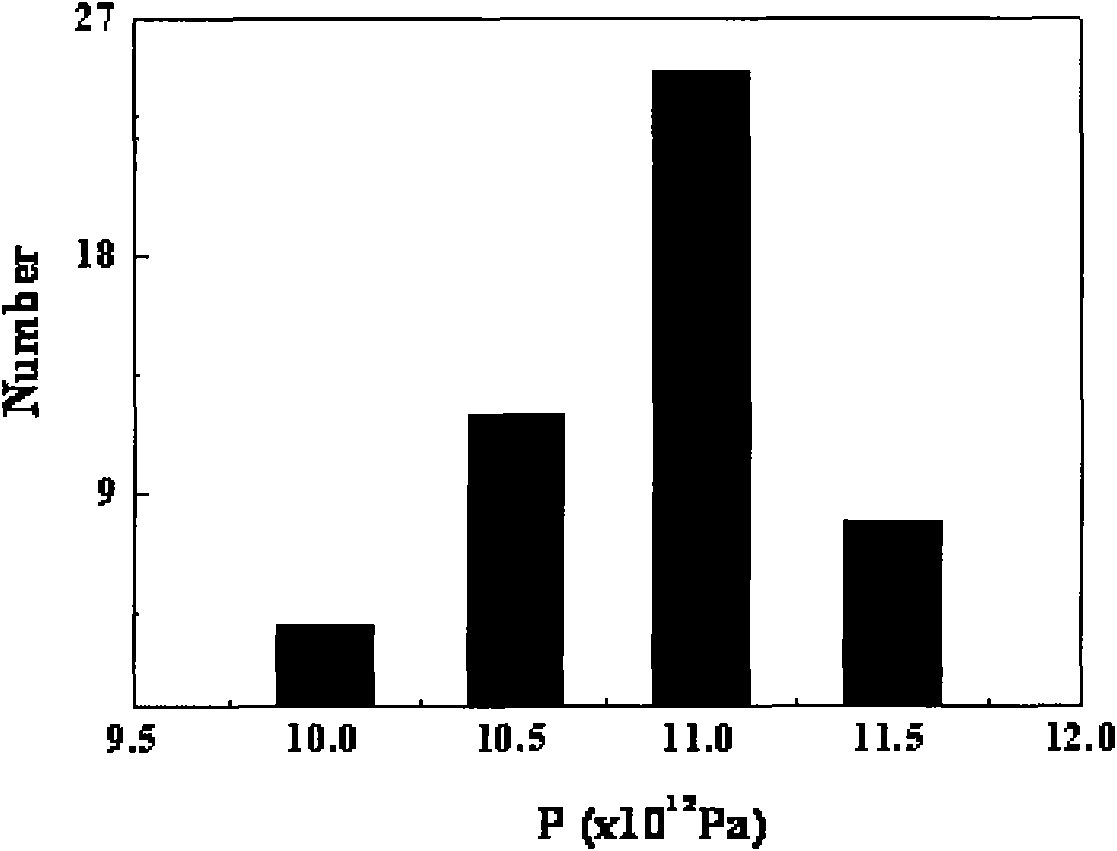

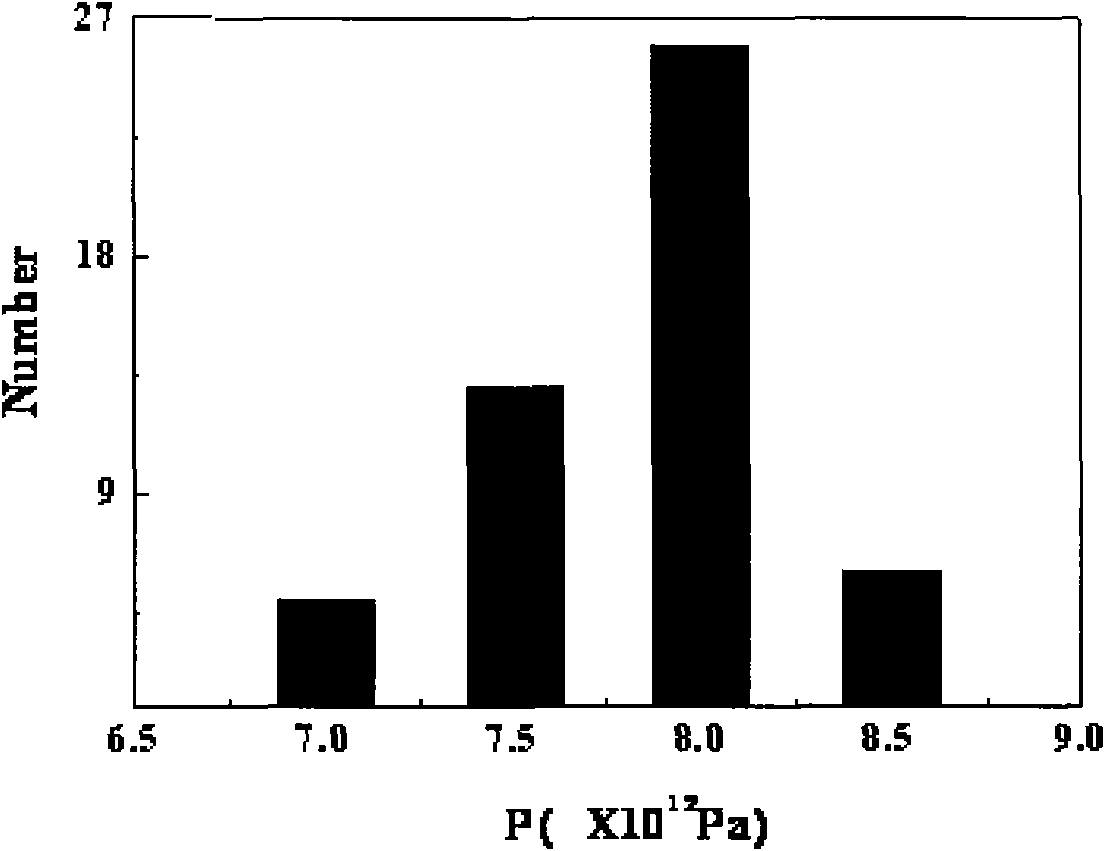

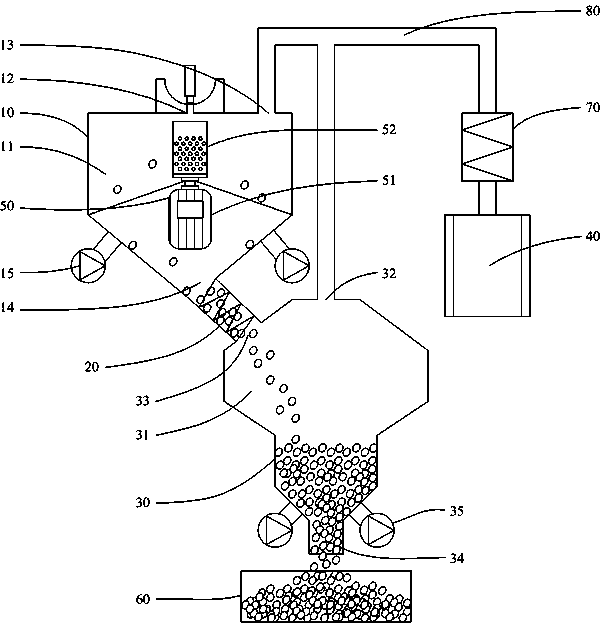

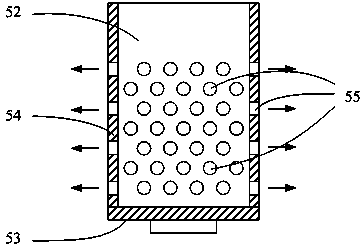

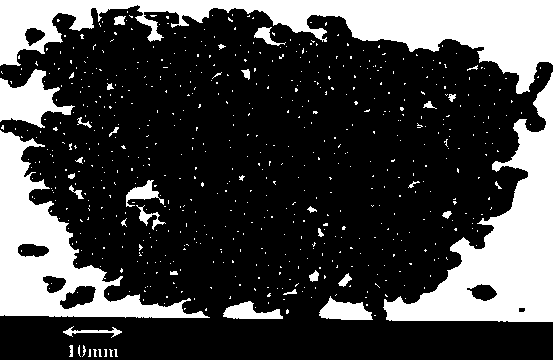

Device and method for recovering residual heat by dry-process granulation of metallurgical slag

ActiveCN103924012AUniform size distributionHigh degree of vitrificationMetallurgical slagMolten slag

The invention provides a device and a method for recovering residual heat by dry-process granulation of metallurgical slag. According to the device, a granulation system and a heat exchange system are systematically transformed, so that blocky slag and slag wool are greatly reduced and cooled slag particles obtained by granulation is relatively uniform in size distribution, relatively high in vitrification degree and good in sphericity and can be directly used as raw materials for producing subsequent products such as cement; the limitation on the slag feeding flow caused by a revolving cup is reduced, so that the rotary energy of the porous revolving cup in a rotary granulation process can be fully utilized, the porous revolving cup can run at a relatively high rotary speed and the granulation efficiency is improved; meanwhile, a two-stage residual heat recovery system is adopted, relatively high heat exchange efficiency and residual heat recovery rate are taken into account, and the problems of low granulation efficiency, relatively poor granulation effect, low heat exchange efficiency, influence on residual heat recovery and utilization and the like during a process for recovering residual heat by dry-process granulation of metallurgical slag in the prior art are solved.

Owner:CHONGQING UNIV

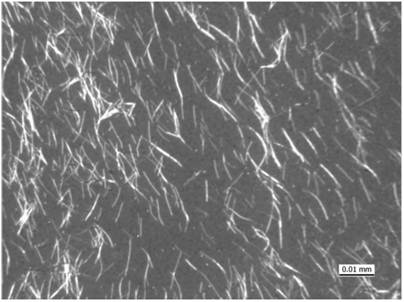

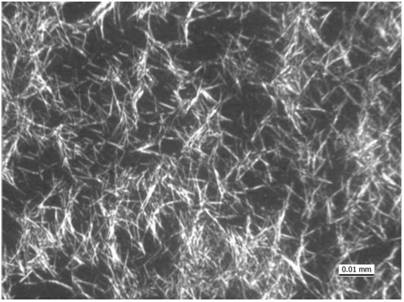

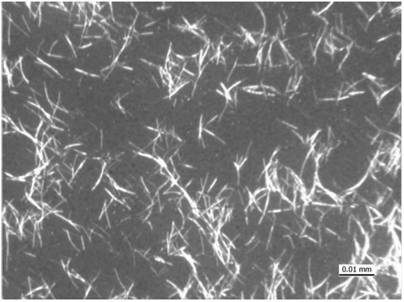

Preparation method of phenolic resin matrix nano activated carbon fiber material

InactiveCN102677193AIncrease flexibilityGood fiber diameterCarbon fibresHeating/cooling textile fabricsFiberCarbon fibers

The invention provides a preparation method of a phenolic resin matrix nano activated carbon fiber material. The preparation method is characterized in that the method specifically comprises the steps of: dissolving benzoxazine monomers and curing catalysts in solvent, adding blending polymers for electrostatic spinning, putting the obtained benzoxazine composite nano fiber membrane in a drying oven for curing, placing the cured benzoxazine composite nano fiber membrane in potassium hydroxide solution for soaking, taking out the benzoxazine composite nano fiber membrane and drying the benzoxazine composite nano fiber membrane in a drying oven to obtain the pretreated benzoxazine composite nano fiber membrane; and placing the pretreated benzoxazine composite nano fiber membrane in a vacuum tube furnace, heating for carbonization under the protection of nitrogen, cooling to room temperature after the carbonization process is ended, acidizing and drying to obtain the phenolic resin matrix nano activated carbon fiber material. The preparation method has a wide application prospect in fields such as activated adsorption, high-temperature catalysis, energy storage and hydrogen storage.

Owner:DONGHUA UNIV

Production method of nanometer silver wire material

The invention discloses a production method of a nanometer silver wire material. The production method comprises the following steps:(1) mixing glycerol, water, polyvinyl alcohol pyrrolidone, silver nitrate and chlorine salt and heating to 180-240 DEG C, and stirring for 30-50 minutes so as to obtain a nanometer silver wire stock solution; (2) cooling the nanometer silver wire stock solution to below 80 DEG C, and diluting with water so as to obtain a diluted nanometer silver wire solution; (3) carrying out desalting and surface active agent removing treatment on the diluted nanometer silver wire solution, and concentrating to obtain a finely purified nanometer silver wire solution; and (4) carrying out spray drying on the finely purified nanometer silver wire solution obtained in step (3) so as to obtain nanometer silver wire powder, and cooling so as to obtain a finished production of nanometer silver wire powder. The production method provided by the invention has the advantages that the process is simple and reliable, the nanometer silver wire is single in shape, the production efficiency is high and the production cost is low; and the produced products have the characteristics of high purity, good quality, uniform size distribution and the like.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

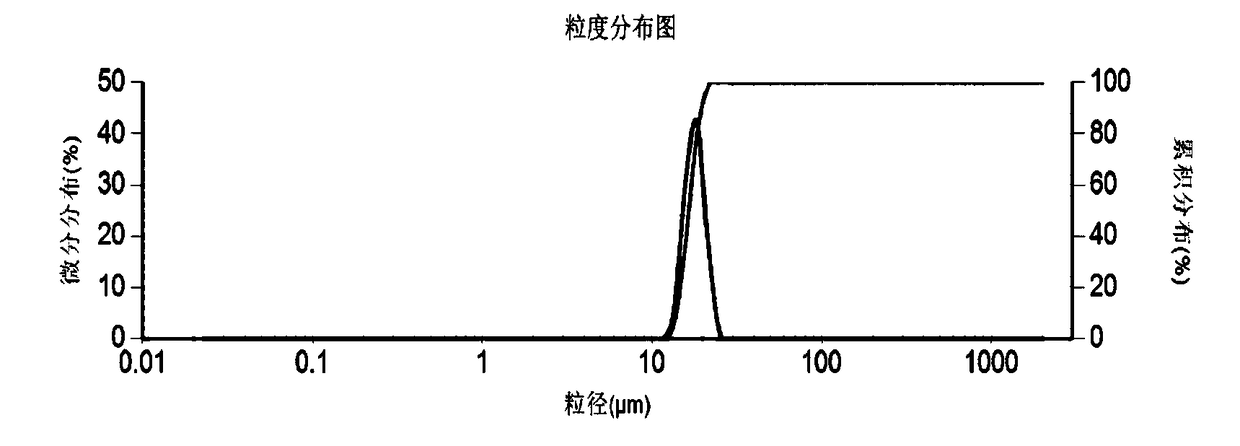

Preparation method of large-particle-size aluminum-doped cobalt trioxide

ActiveCN108649219AIncrease productivityReduce generation costCell electrodesLi-accumulatorsCobalt oxideChemistry

The invention provides a preparation method of large-particle-size aluminum-doped cobalt trioxide, which adopts a continuous production method, and simultaneously removes supernatant containing no material while performing a neutralization precipitation reaction to obtain aluminum-contained cobalt carbonate seed crystal having a particle diameter D50 of 10 to 14.5 [mu]m; further, an aluminum cobalt solution and an ammonium hydrogen carbonate solution are added to the seed crystal for neutralization precipitation reaction until large particle diameter aluminum-doped cobalt carbonate having a particle diameter D50 of 18 to 21 [mu]m is obtained; the obtained aluminum-doped cobalt carbonate is subjected to iron removal, dehydration, washing and drying, and sectional thermal decomposition to obtain a black powdery aluminum-doped cobalt oxide product having a particle size D50 of 17.5-19 [mu]m. The cobalt trioxide doped aluminum obtained by the method of the invention is more uniform, the final product stably obtained by the stable reaction system is relatively stable, and the cobalt carbonate does not appear in the form of small particles or blocks; continuous production can be realized; and the production efficiency is higher.

Owner:JINGMEN GEM NEW MATERIAL

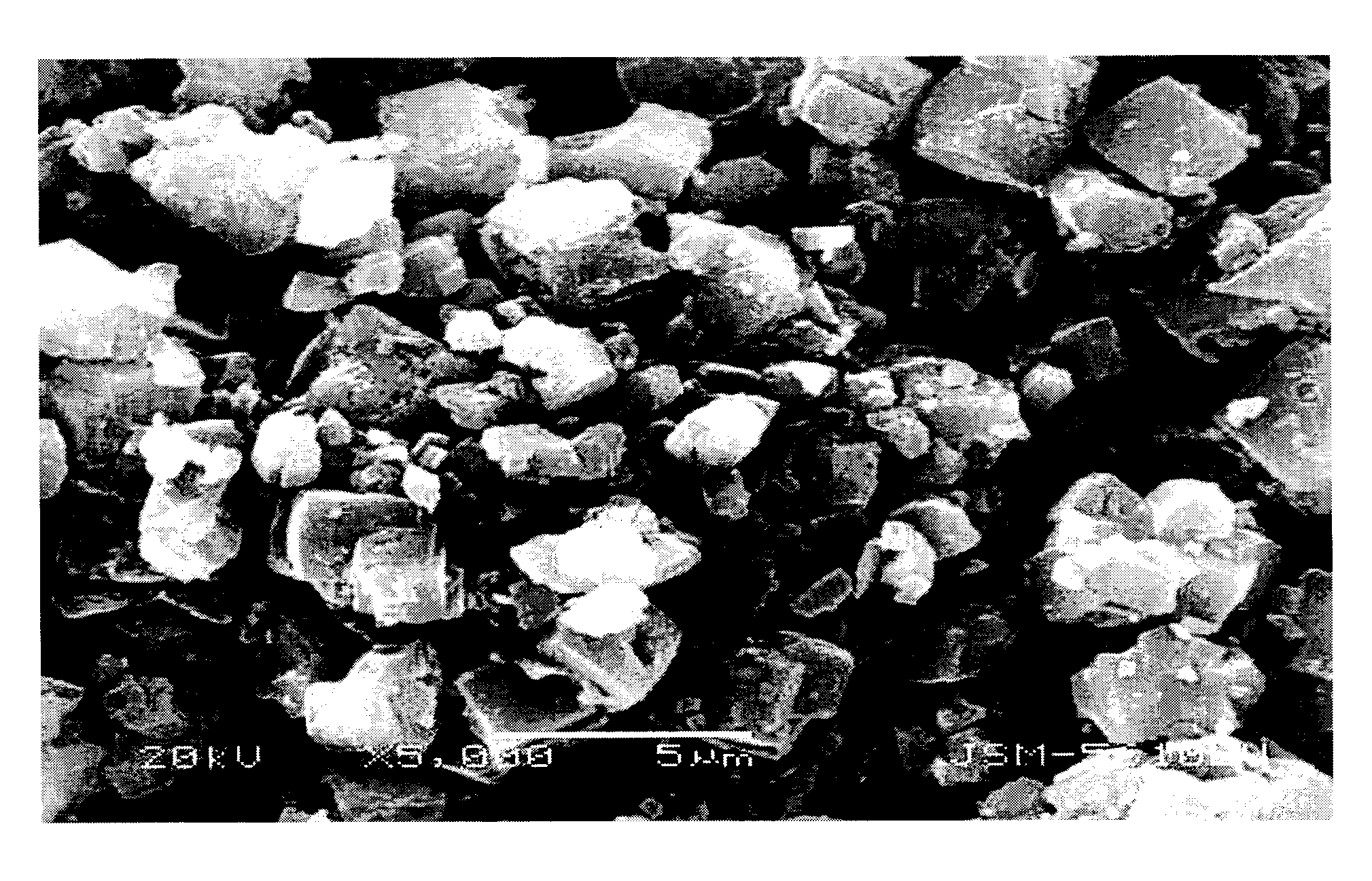

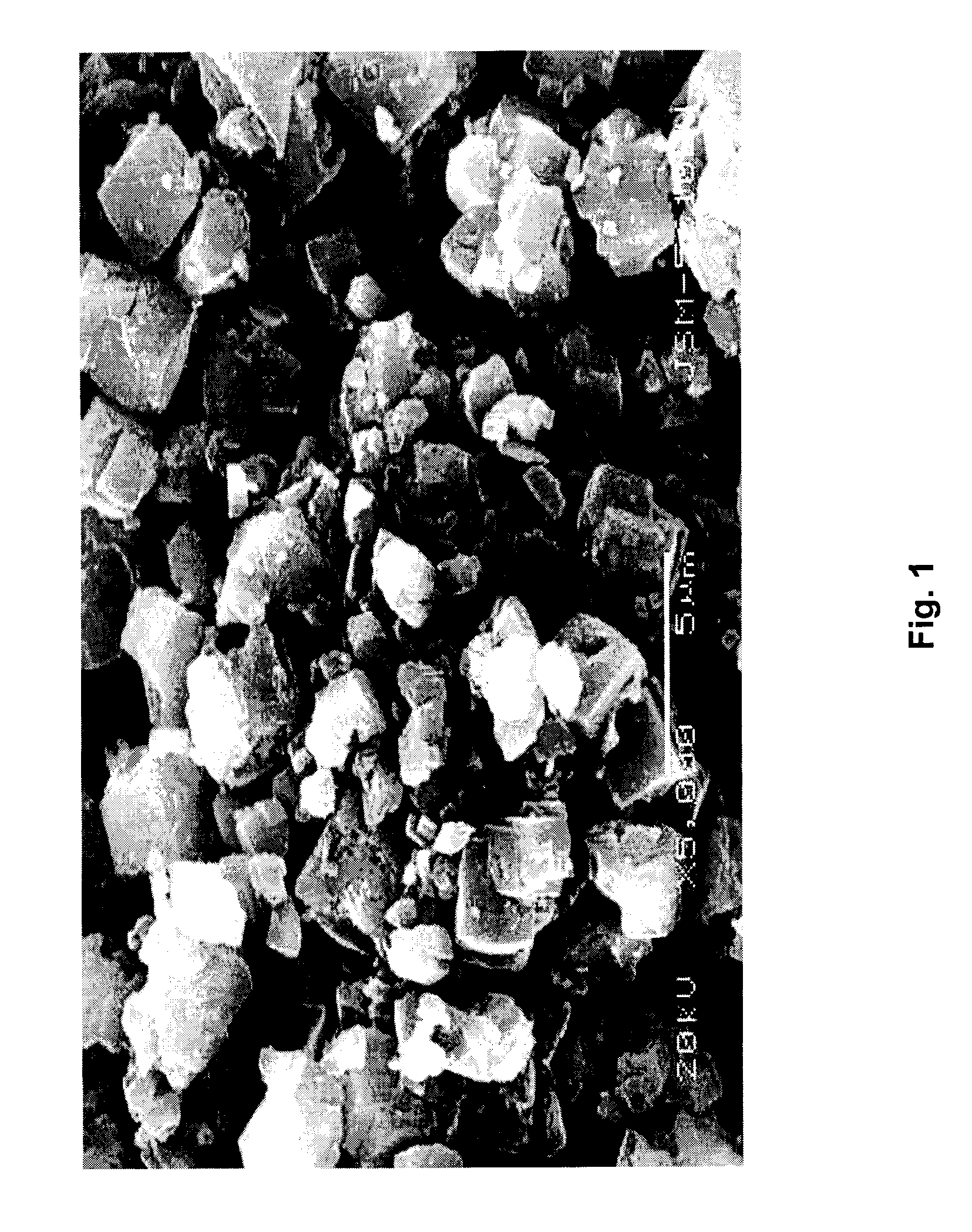

Methods For Preparing Iron Source Material And Ferrous Oxalate for Lithium Ferrous Phosphate

InactiveUS20090252668A1Evenly distributed sizeRegular shapePhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesOxalateLithium

Methods for preparing iron source material and ferrous oxalate for lithium ferrous phosphate are disclosed. One method comprises bringing solution containing ferrite and soluble non-ferrous metal salts in contact with oxalate solution; wherein said method of contact is to allow a flow of the ferrite solution containing ferrite and soluble non-ferrous metal salts to come in contact with a flow of oxalate solution. Another method comprises brings a stream of ferrite solution in contact with a stream of oxalate solution, wherein the flow rates of the ferrite solution and oxalate solution give the resulting slurry a pH of 2-6. The ferrous oxalate particles produces by the methods of the present invention are regularly shaped and have small and evenly distributed diameters. Lithium ferrous phosphate made from iron source material and ferrous oxalate prepared using the methods of the present invention has small particle diameter, homogeneous particle size, good electrical conductivity, and superior electrochemical properties.

Owner:BYD CO LTD

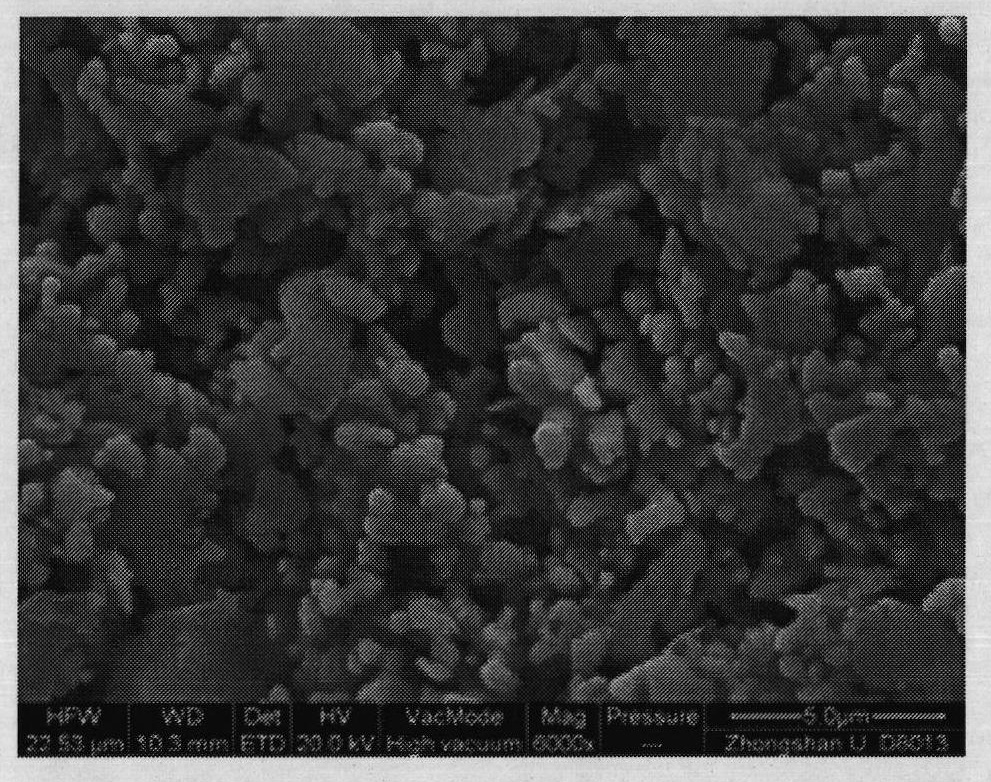

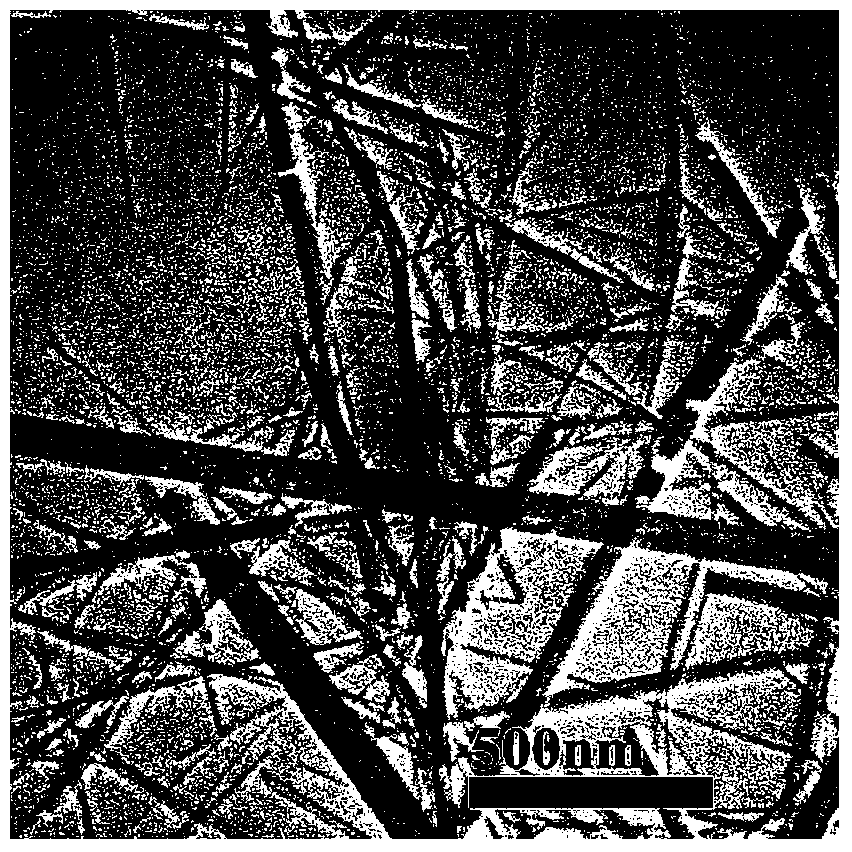

Preparation method for manganese oxide nano rods

InactiveCN104211123ASmall diameterUniform size distributionMaterial nanotechnologyManganese oxides/hydroxidesSesquioxideReaction temperature

The invention relates to a preparation method for manganese oxide nano rods, belonging to the field of nano function materials. According to the preparation method, rod-shaped alkaline manganese oxide can be prepared by using hypermanganate and ethylene glycol under a hydrothermal condition, wherein the longest length of the alkaline manganese oxide can be up to six microns and the diameter size is 10nm-130nm; alkaline manganese oxide precursors are calcined under different calcining conditions to obtain the manganese oxide nano rods with different valence states and different sizes, namely manganese dioxide nano rods, manganese sesquioxide nano rods and trimanganese tetraoxide nano rods. By adopting the preparation method, the problems of an existing solvothermal method that the reaction time is long and the reaction temperature is high when the alkaline manganese oxide nano rods are synthesized and the diameters of the products are great and the products are not uniformly distributed are solved; and the preparation method has the advantages of simplicity in operation and many product varieties.

Owner:JILIN UNIV

Solid base catalyst and method for preparing biodiesel by use of solid base catalyst

InactiveCN103894170AHigh catalytic activitySmall particle sizeFatty acid esterificationBiofuelsProduction rateBiodiesel

The invention relates to a preparation method of a solid base catalyst. The preparation method comprises the following steps: weighing appropriate amount of CH3COONa solid powder and dissolving into distilled water to obtain 200g / L of a CH3COONa solution; weighing certain amount of Al2O3, and performing supersaturated impregnation on Al2O3 for 24h with the prepared CH3COONa solution; and drying the Al2O3 after supersaturated impregnation at 105 DEG C for 4h, calcining for 3h at 500 DEG C and naturally cooling to obtain Na2O / Al2O3 supported solid base catalyst. The invention also discloses a method for preparing the biodiesel with adoption of the Na2O / Al2O3 supported solid base catalyst. The supported catalyst Na2O / Al2O3 prepared by an impregnation method has good catalytic activity in a biodiesel catalytic synthesis process. The optimal process conditions for preparing the biodiesel by use of the supported catalyst are as follows: the reaction temperature is 65 DEG C, the molar ratio of methanol to oil is 9:1, the reaction time is 4h, the using amount of the catalyst is 2%, and the production rate of the biodiesel under the conditions is 85.4%.

Owner:QINGDAO UNITED INNOVATION TECHN SERVICES PLATFORM

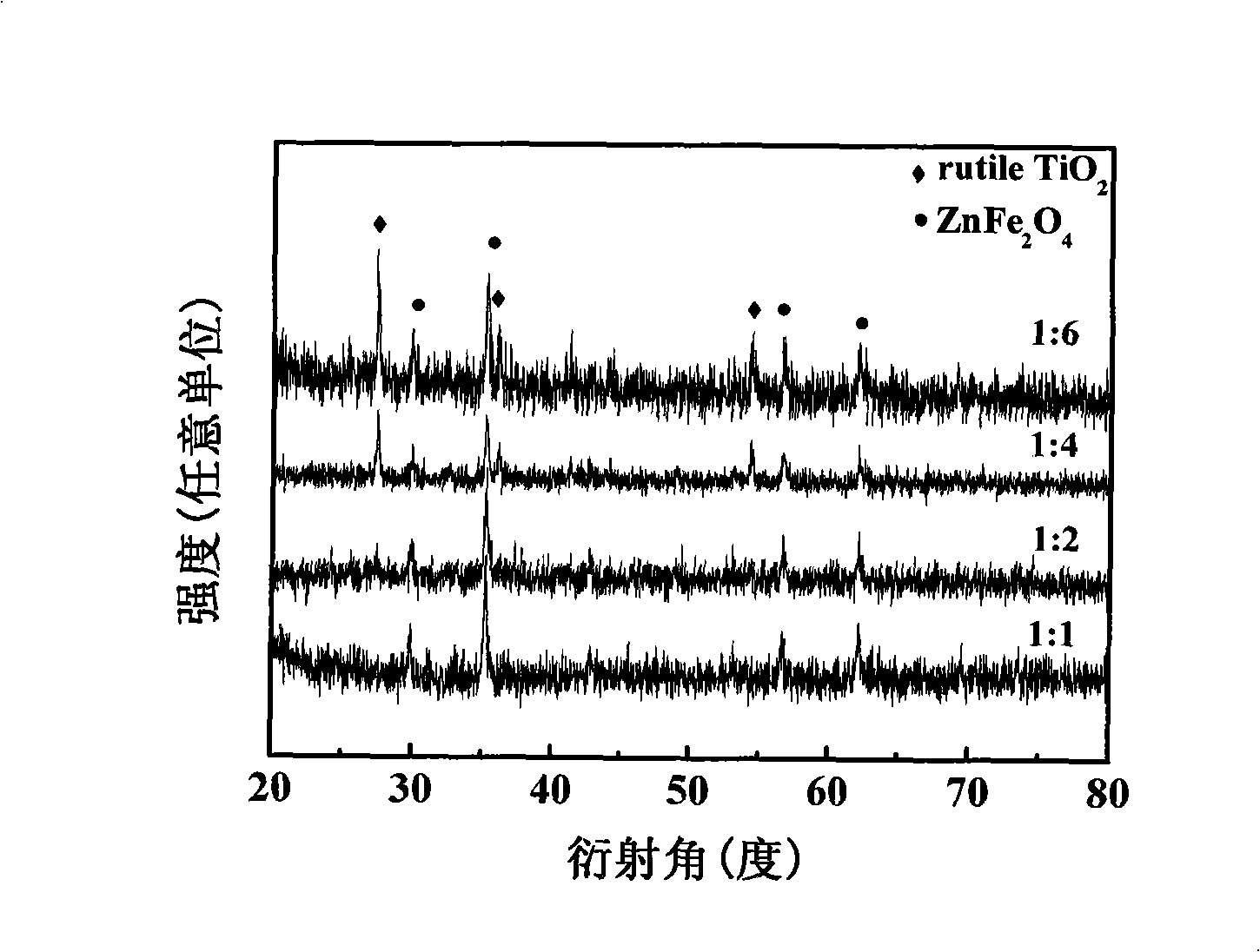

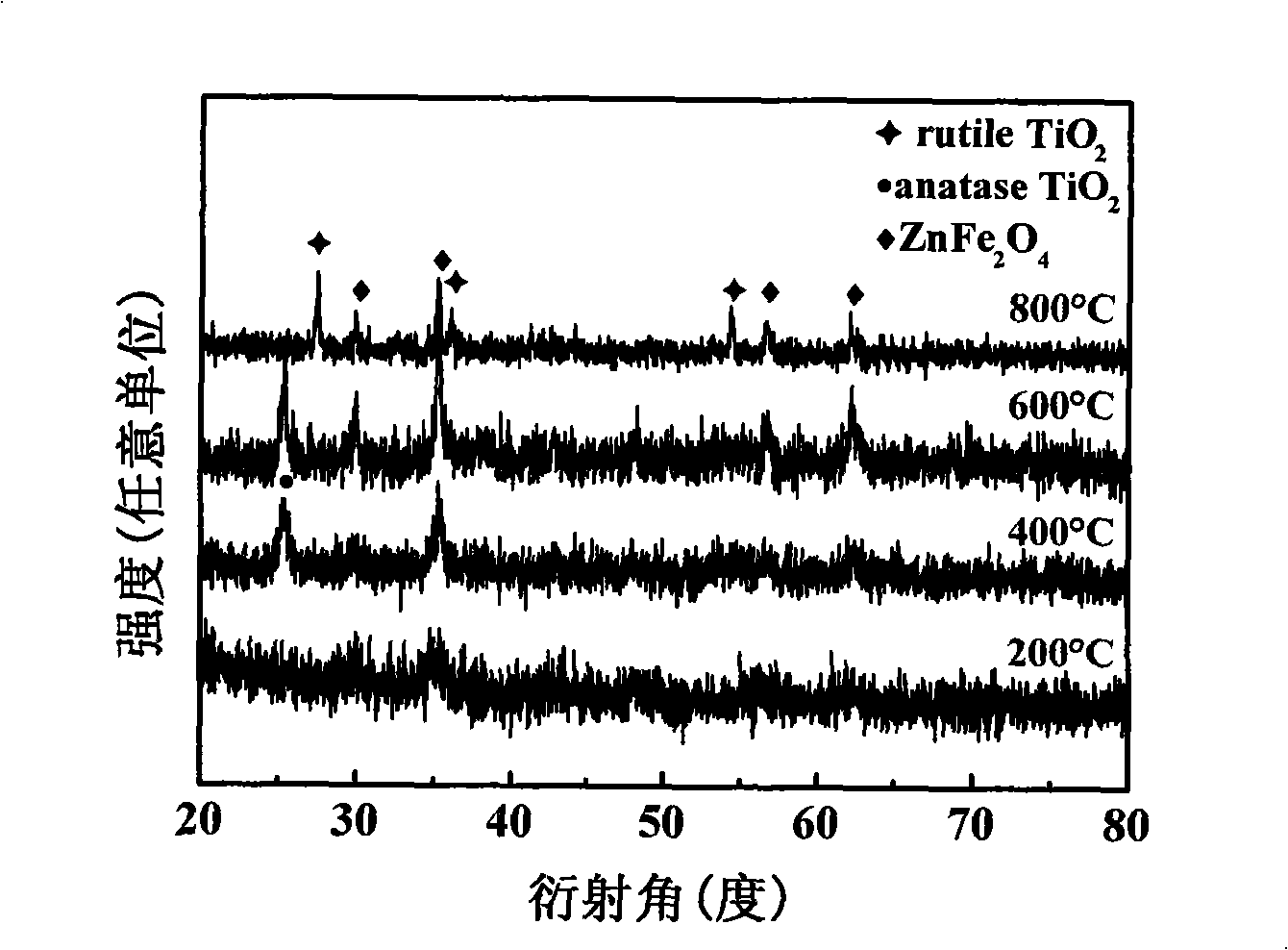

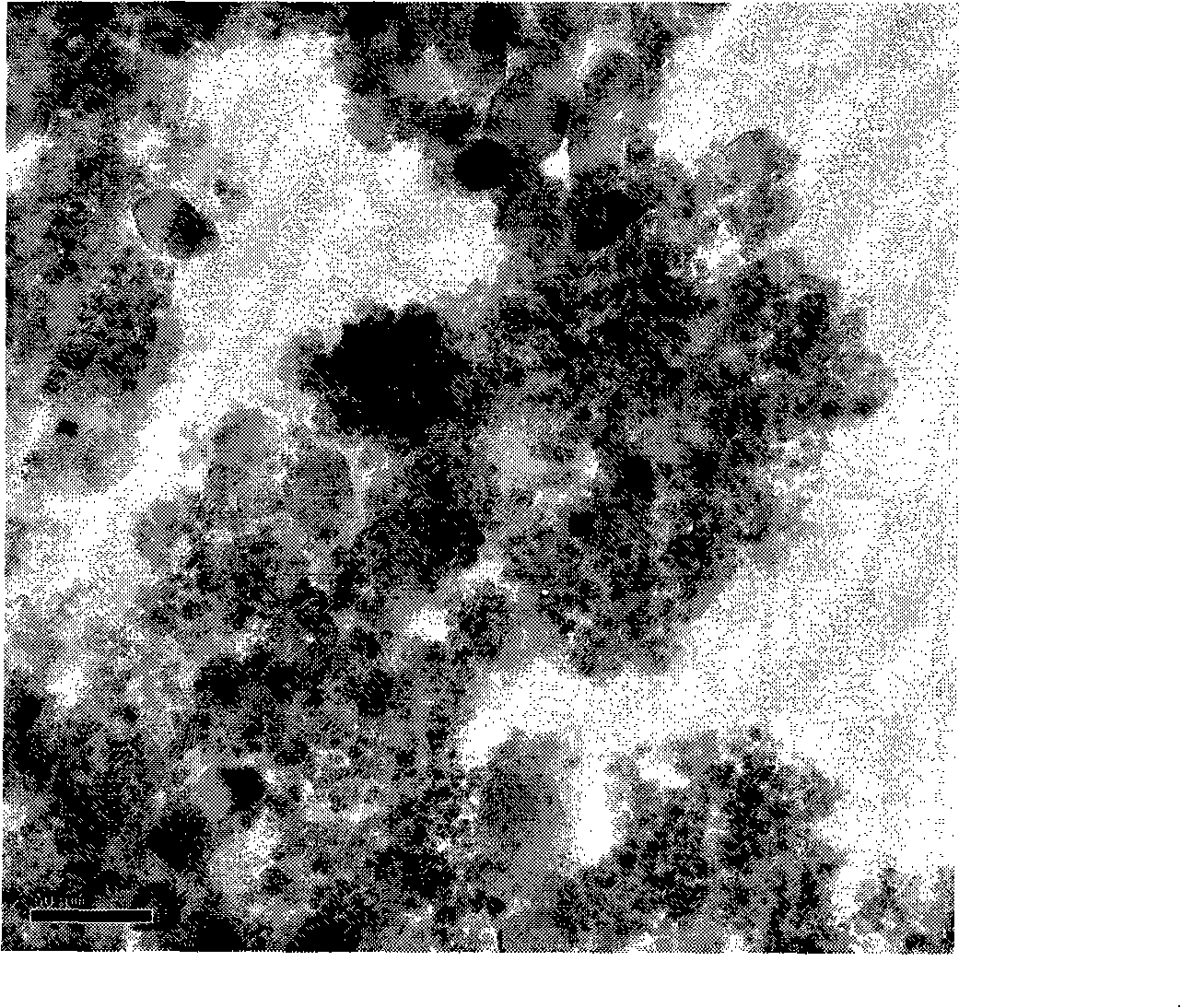

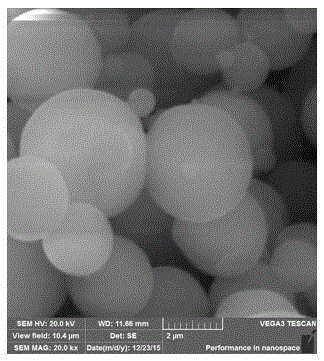

Preparation of TiO2/ZnFe2O4 magnetic composite photocatalyst

InactiveCN101264449AEasy to recycleQuality improvementMetal/metal-oxides/metal-hydroxide catalystsMaterials preparationSeparation technology

The invention relates to a preparation method for TiO2 / ZnFe2O4 magnetic complex photocatalysis, belonging to the technical field of nanometer photocatalysis material preparation, which adopts magnetic material ZnFe2O4 as carrier, requiring no organic compounds or middle-tier; the magnetic material ZnFe2O4 is assembled into magnetic photocatalysis of complexs nanometer grain through the method of sol-gel. The preparation method has the advantages of not only ability to preserve perfect suspension property, and high photocatalysis activity, but also ability to conveniently and rapidly recover magnetic photocatalysis utilizing magnetism separation technology, to reach the purpose of repeated recycle and utilization.

Owner:BEIJING UNIV OF TECH

Method for preparing composite photocatalyst containing activated carbon coating

InactiveCN101757902ALarge specific surface areaGood dispersionDispersed particle separationCatalyst activation/preparationActivated carbonActive component

The invention discloses a method for preparing composite photocatalyst containing activated carbon coating. In the method, activated carbon as coating is attached on foam material matrix, so that activated carbon coating material is formed, the activated carbon coating material is used as carrier to carry titanium dioxide, wherein the titanium dioxide as an active component is 1 percent to 10 percent by weight, the activated carbon coating is 4 percent to 15 percent by weight, and the balance is the foam material matrix. Since the method uses the activated carbon coating as photocatalyst carrier, the dispersibility of the titanium dioxide as an active component can be effectively enhanced, the defects of the traditional activated carbon material, including loose structure and low strength, are overcome, the transmission of light in a system is improved, the process of transferring pollutant to the catalyst surface is improved, and moreover, the service life of activated carbon can be greatly prolonged.

Owner:海盐华强树脂有限公司

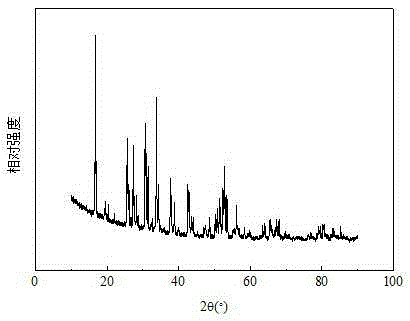

Ceramic solid electrolyte and preparation method thereof

InactiveCN105406118AEnable mass manufacturingUniform size distributionSecondary cellsElectrolytesPerovskite (structure)Spray dried

The invention discloses a ceramic solid electrolyte and a preparation method thereof. The ceramic solid electrolyte comprises at least one of NASICON structure type (LiM<2>(PO<4>)<3>, M=Zr, Ge, Mg, Al), oxide (Li<3x>La<2 / 3-x>TiO<3>) of perovskite structure and oxide (Li<5>La<3>M<2>O<12>) of garnet structure. The preparation method of the ceramic solid electrolyte comprises the following steps of: a) weighing raw materials according to molar ratio of elements in chemical formula of the ceramic solid electrolyte, dissolving the raw materials in solvent, and obtaining mixed solution; b) preparing ceramic solid electrolyte precursor powder from the mixed solution through a spray drying process; c) sintering the precursor powder obtained by spray drying in the air, and finally obtaining the ceramic solid electrolyte with relatively high ionic conductivity and relatively low electronic conductivity. In the method provided by the invention, the spray drying process is used for preparing the ceramic solid electrolyte, spray drying has the advantages that the drying procedure is fast, the mixed solution is directly dried into powder and particle size distribution of the powder is uniform, and thus, large-scale preparation of the ceramic solid electrolyte is expected to be realized, and the method has practical value.

Owner:HARBIN INST OF TECH

Preparation method of spherical nano calcium carbonate

InactiveCN102557100AUniform size distributionSuitable for industrial productionCalcium/strontium/barium carbonatesNanotechnologyPentaerythritolSodium stearate

The invention provides a preparation method of spherical nano calcium carbonate, which is characterized by enabling pentaerythritol to be added in 0.05-0.10 mol / L of sodium carbonate solution to completely dissolve, and slowly adding 1.0-2.0mol / L of calcium chloride solution under blending for reaction to obtain the spherical nano calcium carbonate, wherein the dosage of the pentaerythritol is 0.1-2% of the quality of the product calcium carbonate. Grain size of the btained spherical nano calcium carbonate is about 25nm, size and distribution are even, the whole preparation process is simple,a used crystal form control agent is slow in cost, simultaneously serous fluid obtained by reaction is added in sodium stearate according to 1-5% of the quality of the calcium carbonate, the nano calcium carbonate coated with the sodium stearate is obtained, and the method is applicable to industrialization production of the spherical nano calcium carbonate.

Owner:LANZHOU JIAOTONG UNIV

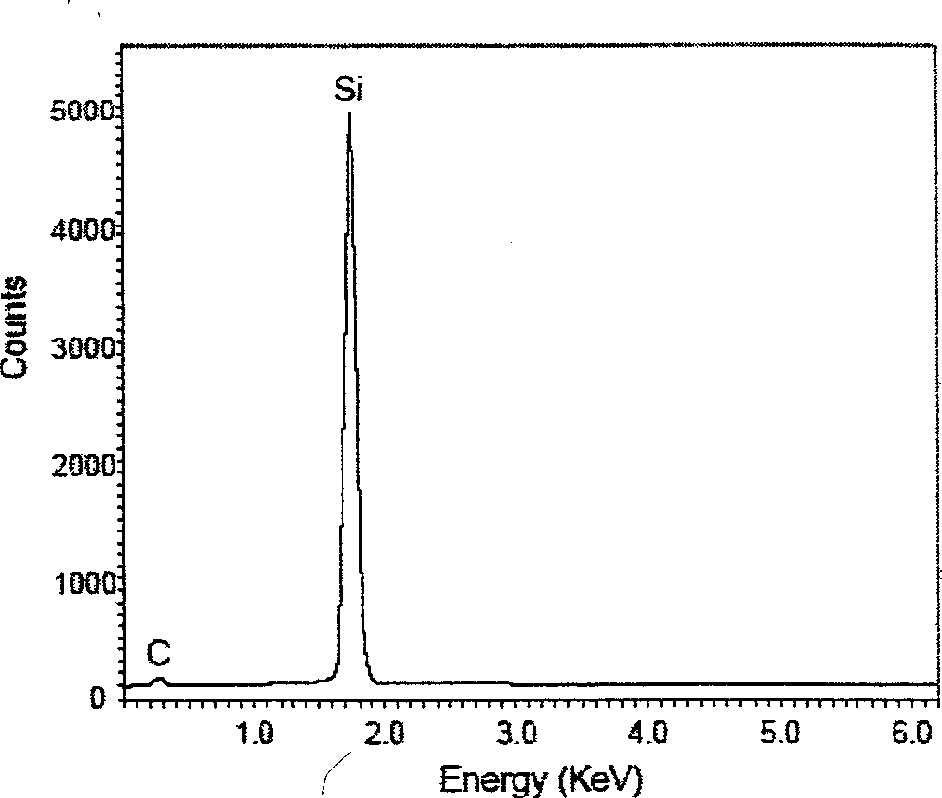

Chemical vapor deposition process of preparing Sic nanotube

The preparation process of SiC nanotube includes the following steps: 1. cleaning and drying graphite sheet as substrate; 2. soaking the substrate in catalyst solution including catalyst comprising organic compound of Fe, Co, Ni and other metals and co-catalyst comprising organic compound of S; 3. chemically vapor depositing gas source compound comprising organic compound capable of being gasified and containing Si-C bond in the carrier gas comprising N2, H2, NH3 or their mixture and with the molar ratio to the gas source compound of 4.5-7.0 at the temperature of 800-1100 deg.c for 0.8-1.5 hr; and 4. purifying treatment. The present invention has the advantages of: low preparation temperature, easily controlled reaction process, simple technological apparatus, low cost, high yield, high product purity, homogeneous product size distribution and easy use in large scale production.

Owner:NAT UNIV OF DEFENSE TECH

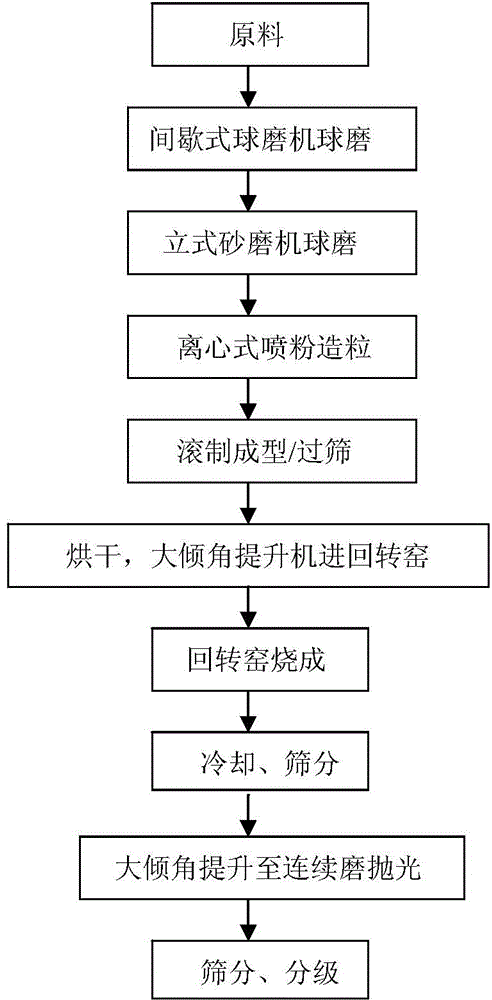

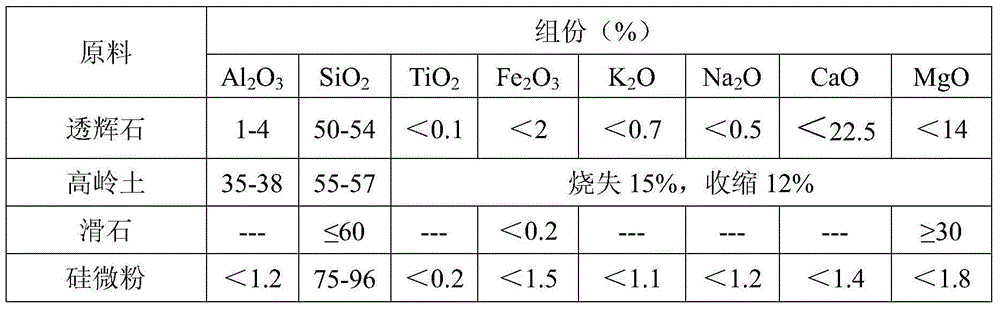

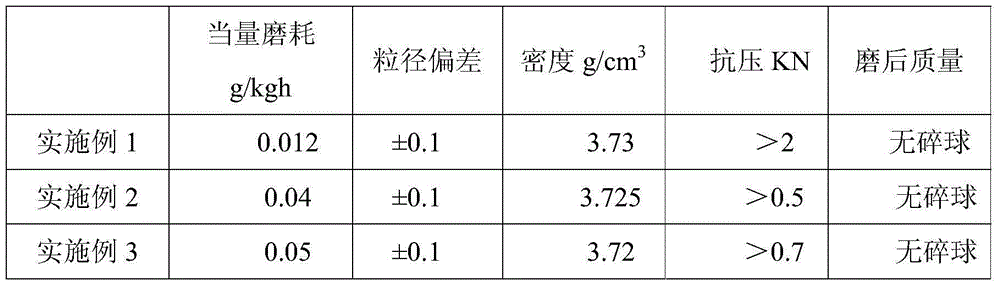

Preparation method of aluminum oxide microbeads

ActiveCN104150882ALower firing temperatureAvoid stickingOther chemical processesPhase conversionBall mill

The invention discloses a preparation method of aluminum oxide microbeads. The preparation method comprises the following steps: by adopting aluminum oxide powder with lower alpha phase conversion rate (80-90%) as a main raw material, adding a composite sintering additive, ball-milling through an intermittent ball mill and a vertical sand mill, and then performing centrifugal type spray pelletization, rolling to forming, drying, sintering in a rotary kiln, and continuous grinding and polishing, to obtain the aluminum oxide microbeads. According to the preparation method, the aluminum oxide powder with relatively low alpha phase conversion rate is adopted, activity of the remaining gamma-aluminum oxide phase in the aluminum oxide powder promotes the sintering of the aluminum oxide, the addition amount of the sintering additive is decreased, and meanwhile the problem that the aluminum oxide microbeads during the sintering of the rotary kiln are caked and collided to be deformed due to excessive glass phase can be solved. Rotary kiln sintering equipment is introduced, the microbeads are under a moving status during the sintering of the rotary kiln, and are evenly heated during sintering, thus being uniform in the structure and performances. The prepared aluminum oxide microbeads have the characteristics of being low in abrasion, high in strength and density, uniform in particle size, free from breakage of beads, and the like.

Owner:JINGANG NEW MATERIALS

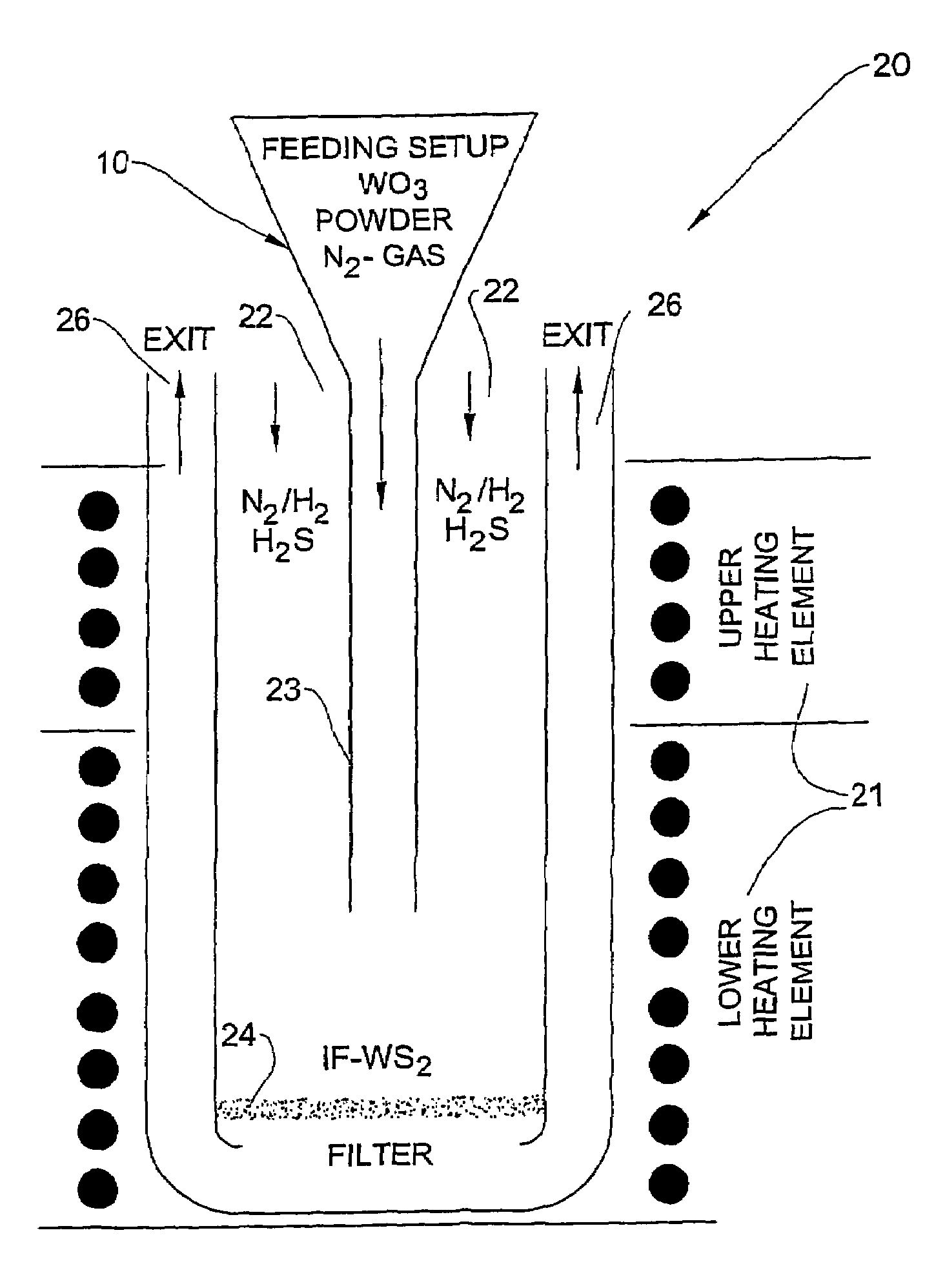

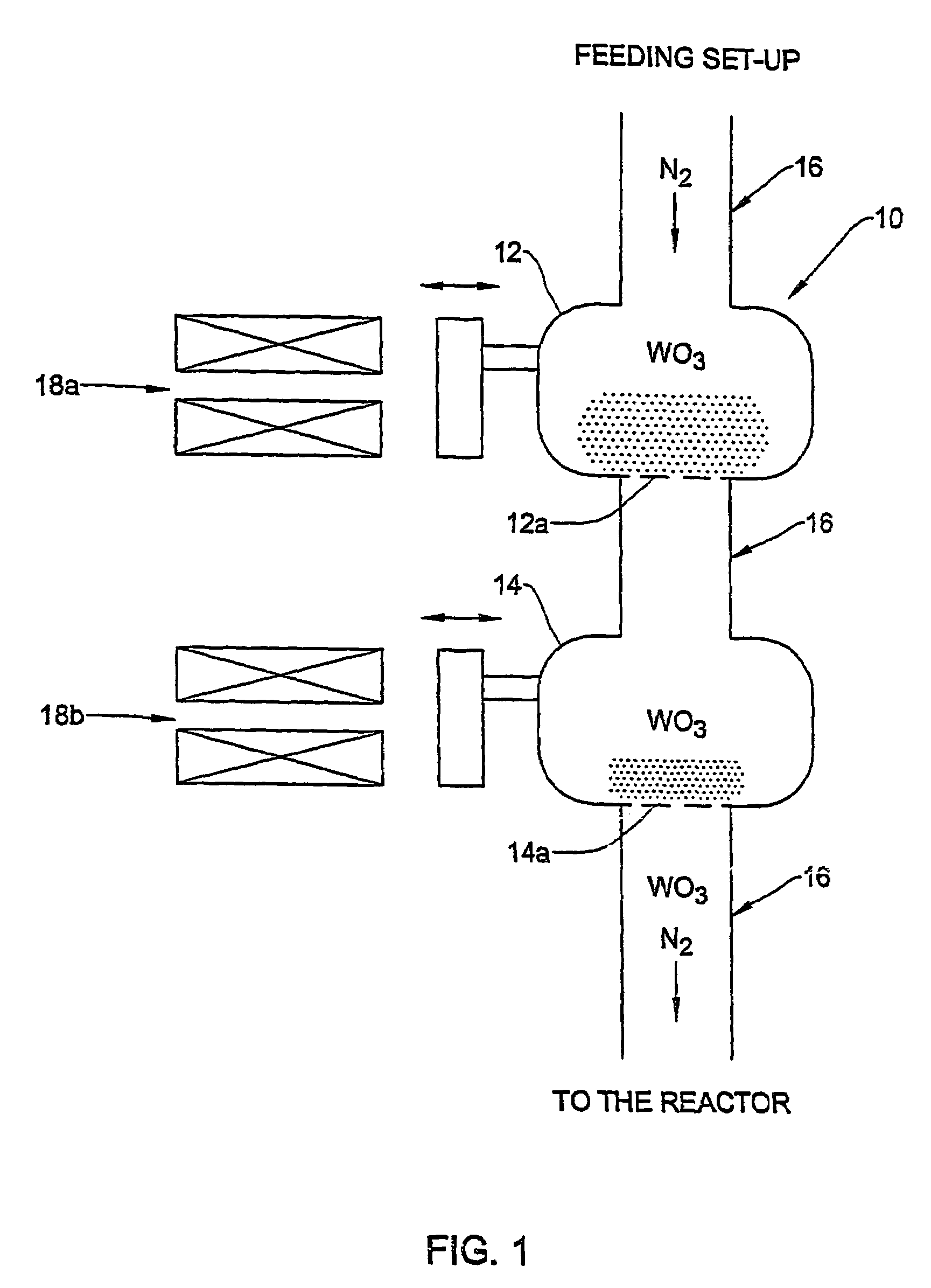

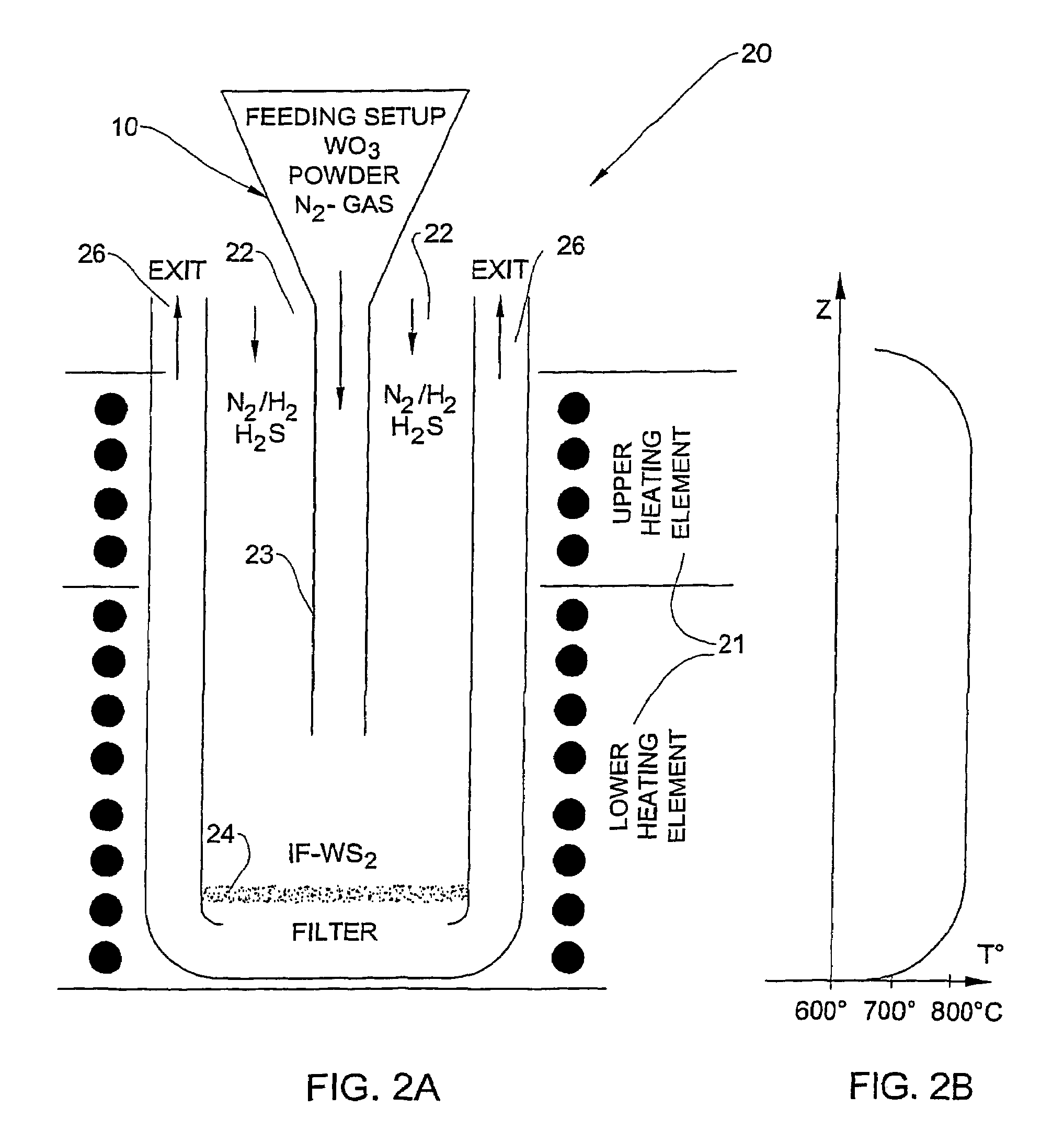

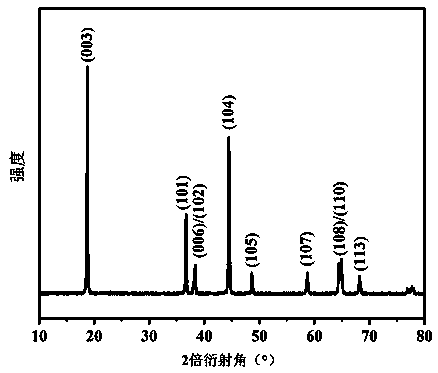

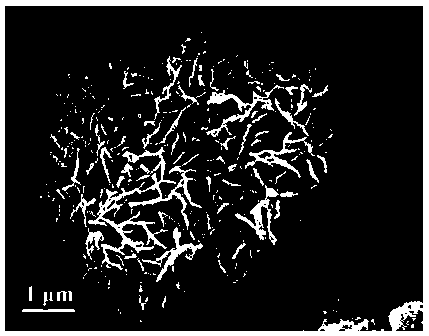

Reactors for producing inorganic fullerene-like tungsten disulfide hollow nanoparticles and nanotubes

InactiveUS7524481B2Uniform spherical shapeUniform size distributionMaterial nanotechnologyNanostructure manufactureTemperature controlNanoparticle

The present invention is related to an apparatus for the production of inorganic fullerene-like (IF) nanoparticles and nanotubes. The apparatus comprises a chemical reactor, and is further associated with a feeding set up and with a temperature control means for controlling the temperature along the reaction path inside the reactor so as to maintain the temperature to be substantially constant. The invention is further directed to a method for the synthesis of IF-WO3 nanoparticles having spherical shape and having a size up to 0.5 mu m and nanotubes having a length of up to several hundred mu m and a cross-sectional dimension of up to 200 nanometer.

Owner:YEDA RES & DEV CO LTD

Core-shell structure high nickel gradient nickel cobalt manganese aluminum quaternary positive electrode material and preparation method thereof

ActiveCN110518219AUniform size distributionStable charging and discharging performancePositive electrodesLi-accumulatorsManganeseCharge discharge

The invention provides a core-shell structure high nickel gradient nickel cobalt manganese aluminum quaternary positive electrode material and a preparation method thereof. The quaternary positive electrode material is spherical particles with an average particle size of 8-10 microns, the diameter of the inner core is 4-6 microns, the thickness of the shell layer is 2-3 microns and the surface ofthe shell layer is sheet-shaped. The nickel content gradually decreases from the center of the core to the surface of the shell structure, the manganese content gradually increases from the center ofthe core to the surface of the shell structure, the cobalt content is uniformly distributed and the aluminum content is uniformly or gradient distributed. The preparation method comprises the follow steps: a low nickel solution I is continuously added into a high nickel solution so that the nickel content in the high nickel solution is continuously reduced, and then the low nickel solution I is continuously pumped into an ammonia aqueous solution to form a continuous reaction system with reduced nickel content, and further hydroxide and carbonate are successively used as precipitants and ammonia water is used as a complexing agent to successively coprecipitate to generate a precursor with a core-shell structure; and then the precursor is sintered with lithium so as to prepare the core-shell structure high nickel gradient nickel cobalt manganese aluminum quaternary positive electrode material. The battery assembled by the positive electrode prepared by the core-shell structure high nickel gradient nickel cobalt manganese aluminum quaternary positive electrode material has high capacity, excellent cycle and rate performance and highly reversible charge-discharge reaction.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com