Preparation of TiO2/ZnFe2O4 magnetic composite photocatalyst

A technology of znfe2o4 and composite light, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., and can solve problems such as increased cost, complex synthesis process, and environmental hazards of organic matter , to achieve the effects of simplified production process, good dispersion, low reaction temperature and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Add zinc acetate and ferric nitrate at a molar ratio of 1:2 into an aqueous NaOH solution with a pH of 10, stir well to dissolve them, and react at 180°C for 24 hours to obtain ZnFe 2 o 4 precipitation.

[0021] (2) ZnFe obtained in step 1 2 o 4 Precipitate 2.41 g dispersed in 200 ml of V 水 :V 乙醇 =1:8 ethanol aqueous solution, ultrasonic for 30 minutes and then stirred for 2 hours, the pH of the solution was adjusted to 5 with glacial acetic acid to obtain solution A.

[0022] (3) Add 3.4 ml of tetrabutyl titanate into 20 ml of ethanol, and stir for 30 minutes to obtain solution B.

[0023] (4) All the solution B obtained in step 3 was dropped into the solution A obtained in step 2 dropwise, and after stirring for 10 hours, the red precipitate C was obtained by centrifugal separation and deionized water washing.

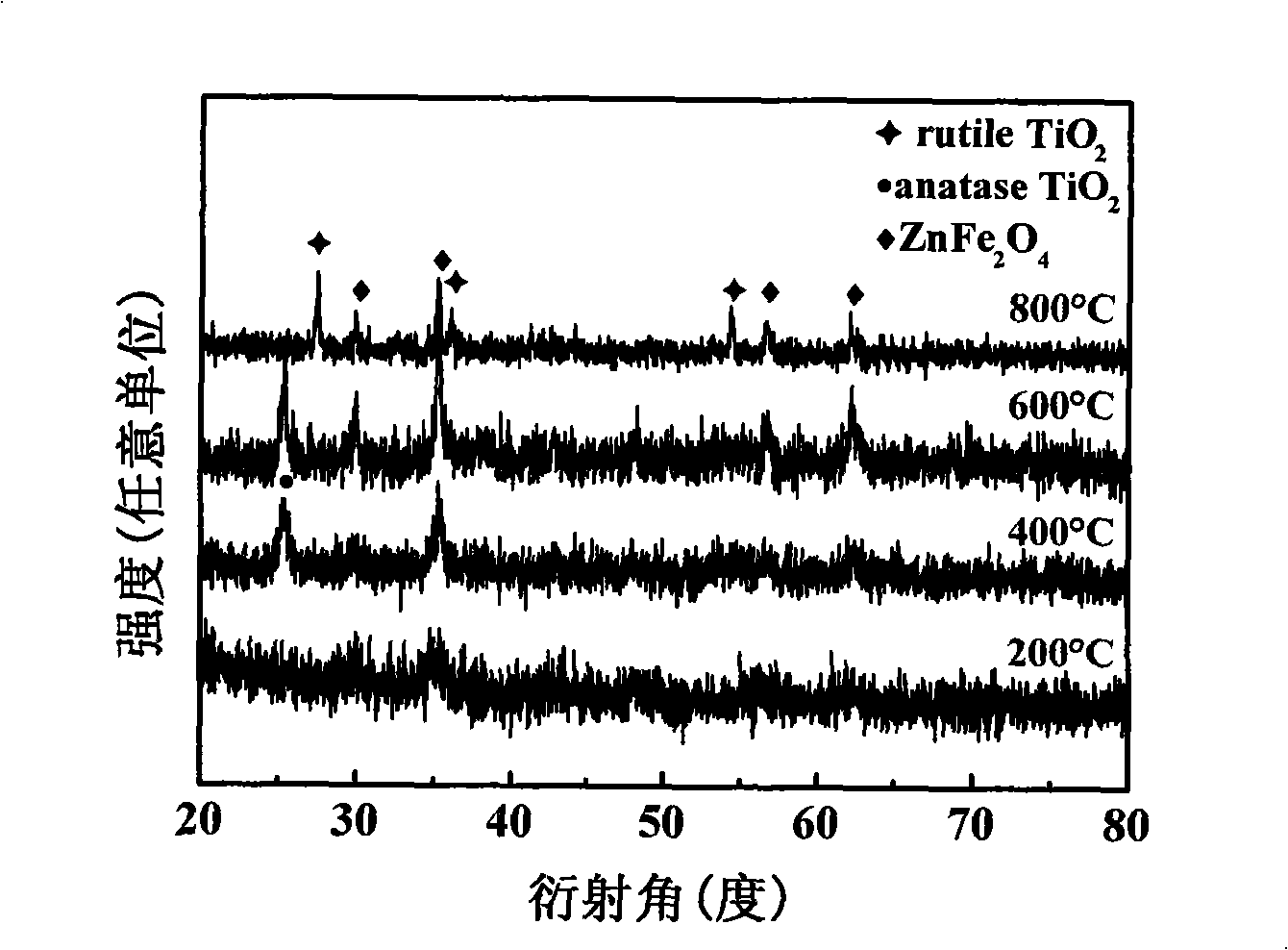

[0024] (5) Calcining the red precipitate C obtained in step 4 at 800° C. for 4 hours to obtain the desired product. The powder X-ray diffraction pa...

Embodiment 2

[0026] (1) Add zinc acetate and ferric nitrate at a molar ratio of 1:2 into an aqueous NaOH solution with a pH of 10, stir well to dissolve them, and react at 180°C for 24 hours to obtain ZnFe 2 o 4 precipitation.

[0027] (2) ZnFe obtained in step 1 2 o 4 Precipitate 2.41 g dispersed in 200 ml of V 水 :V 乙醇 =1:8 ethanol aqueous solution, ultrasonic for 30 minutes and then stirred for 2 hours, the pH of the solution was adjusted to 5 with glacial acetic acid to obtain solution A.

[0028] (3) Add 6.8 ml of tetrabutyl titanate into 20 ml of ethanol, and stir for 30 minutes to obtain solution B.

[0029] (4) All the solution B obtained in step 3 was dropped into the solution A obtained in step 2 dropwise, and after stirring for 10 hours, the red precipitate C was obtained by centrifugal separation and deionized water washing.

[0030] (5) Calcining the red precipitate C obtained in step 4 at 800° C. for 4 hours to obtain the desired product.

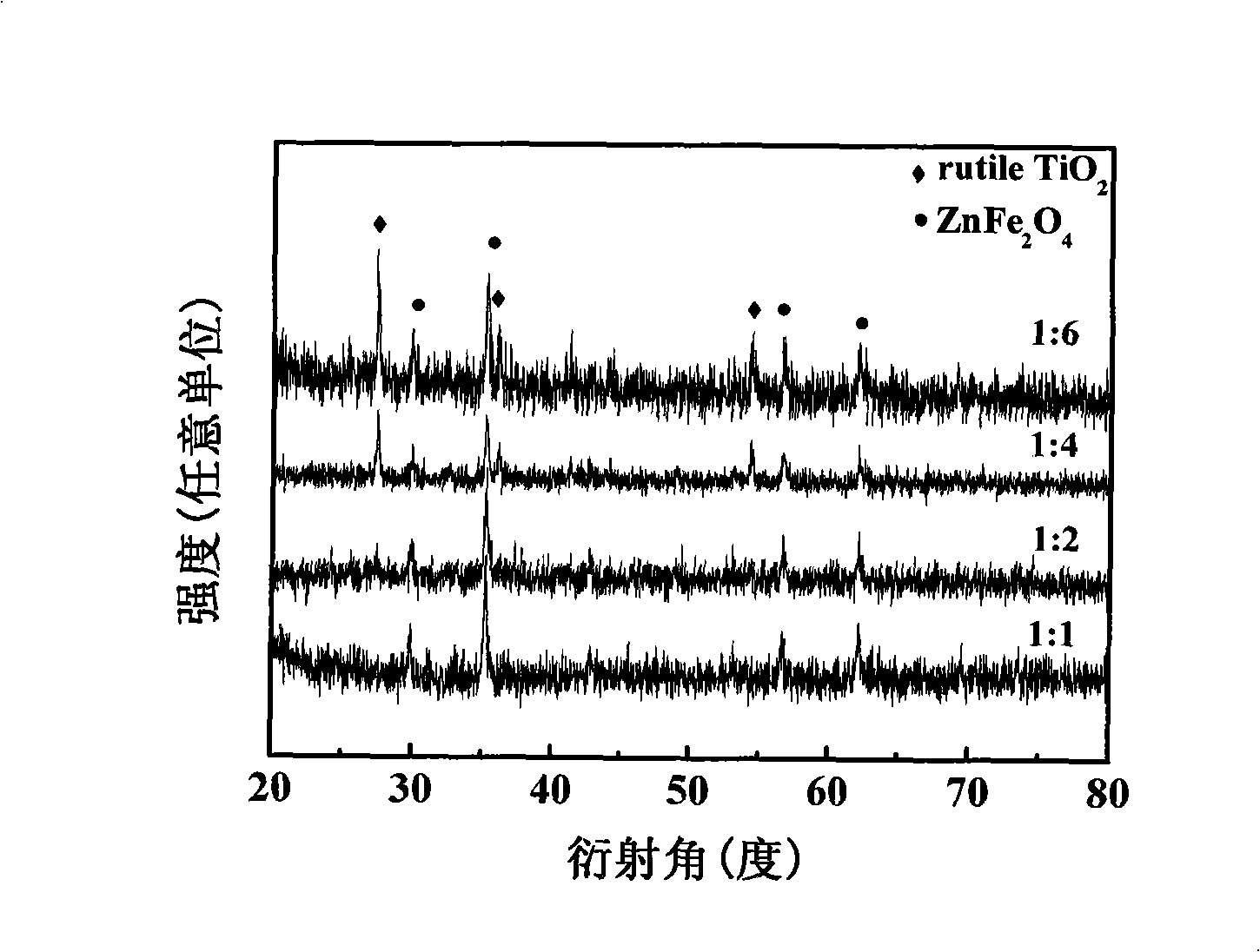

[0031] Such as figure 1 , ...

Embodiment 3

[0033](1) Add zinc acetate and ferric nitrate at a molar ratio of 1:2 into an aqueous NaOH solution with a pH of 10, stir well to dissolve them, and react at 180°C for 24 hours to obtain ZnFe 2 o 4 precipitation.

[0034] (2) ZnFe obtained in step 1 2 o 4 Precipitate 2.41 g dispersed in 200 ml of V 水 :V 乙醇 =1:8 ethanol aqueous solution, ultrasonic for 30 minutes and then stirred for 2 hours, the pH of the solution was adjusted to 5 with glacial acetic acid to obtain solution A.

[0035] (3) Add 12.6 ml of tetrabutyl titanate into 20 ml of ethanol, and stir for 30 minutes to obtain solution B.

[0036] (4) All the solution B obtained in step 3 was dropped into the solution A obtained in step 2 dropwise, and after stirring for 10 hours, the red precipitate C was obtained by centrifugal separation and deionized water washing.

[0037] (5) Calcining the red precipitate C obtained in step 4 at 800° C. for 4 hours to obtain the desired product.

[0038] Such as figure 1 , 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com