Patents

Literature

527results about How to "Ease of industrial scale production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing SAPO-34 molecular sieve by liquid phase crystallization method

ActiveCN101125665AEasy to prepareGood crystallinityMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveAluminium

The invention discloses a method to prepare SAPO-34 molecule sieve through liquid phase crystallization: the precursor compounds of aluminum, silicon and phosphorous are prepared into dry gel, then the dry gel powder and a water solution of organic amine template are placed in a stainless steel high pressure vessel, and the SAPO-34 molecule sieve is synthesized through liquid crystallization. The molecule sieve after being treated can be used for a catalyst for transferring methanol into low carbon olefins. The method solves the wall sticking trouble of hydrothermal synthesis, and has the advantages of simple preparation process, good crystallization degree, simple equipments, and a normal high pressure stainless steel reaction boil can be adopted in the crystallization process, which is beneficial to industrialized mass production, and the organic amine template can be recycled.

Owner:HUALU ENG & TECH +1

Method for preparing absorbing layer of thin film solar cell

InactiveCN101728461AReduce the temperatureReduce softeningFinal product manufactureSemiconductor devicesIndiumNew energy

The invention relates to a method for preparing an absorbing layer of a thin film solar cell, belonging to the technical fields of photoelectric functional material and new energy. The method is characterized in that a Cu-In-Se absorbing layer, a Cu-In-Ga-Se absorbing layer or a Cu-In-Al-Se absorbing layer is prepared by a vacuum magnetron sputtering method; a Cu-In-Se alloy target, a Cu-In-Ga-Se alloy target or a Cu-In-Al-Se alloy target is directly used, and the components of the absorbing layer are controlled by the components of the target; and the film formation quality is controlled by the sputtering technology. The absorbing layer prepared by the magnetron sputtering method can be subsequently treated by annealing in the protection atmosphere, so that the crystallization quality is further improved. The absorbing layer prepared by the method is formed by uniform Cu-In-Se phase, Cu-In-Ga-Se phase or Cu-In-Al-Se phase, so that the component distribution is even, and the components of the absorbing layer are consistent with the components of the target. The method is simple and convenient in technique, easy to control and lower in matrix temperature when in deposition, can select multiple substrates, and ids suitable for industrialized production.

Owner:TSINGHUA UNIV +1

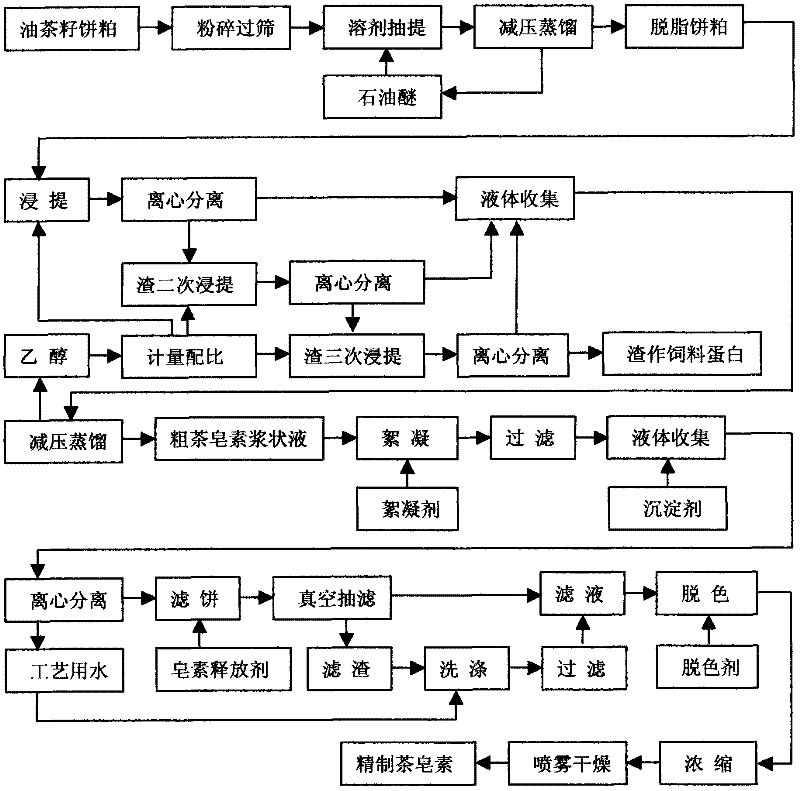

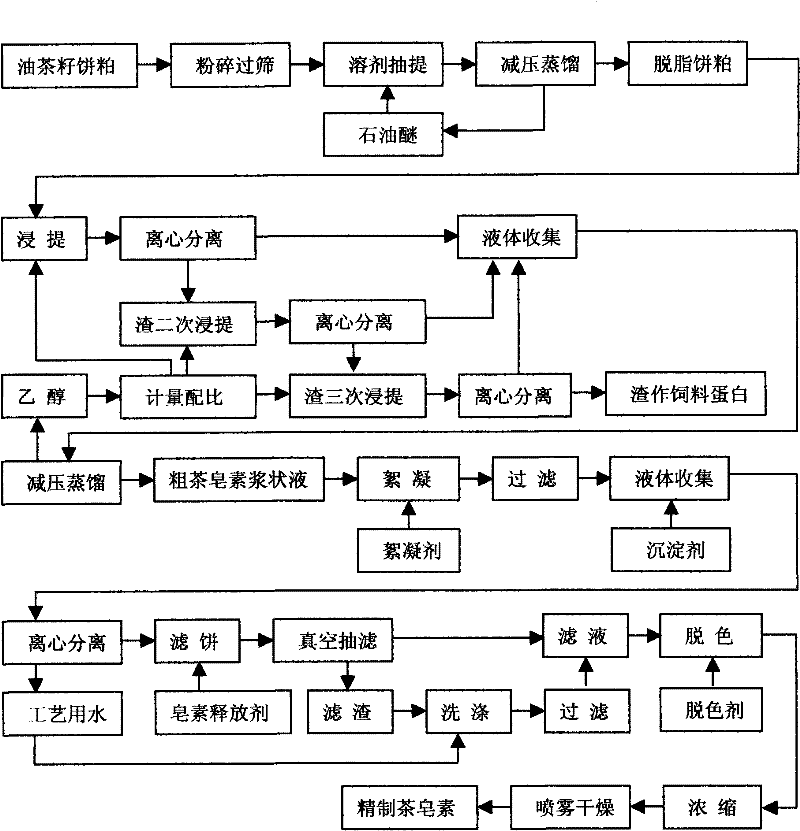

Method for purifying tea saponin in camellia oleifera seed cake

InactiveCN102260316AHigh purityQuality improvementSugar derivativesFood processingMeal powderFiltration

The invention discloses a method for purifying tea saponin from camellia oleifera seed cake, comprising the following process steps: degreasing the pulverized and sieved camellia seed cake with petroleum ether; degreasing the degreased camellia seed cake powder with 85 %~95% ethanol solution is extracted three times to obtain crude tea saponin slurry; the crude tea saponin is purified by flocculation-precipitation release method: in the first step, alum solution is used as a flocculant, and some impurities are removed by filtration; In the first step, the lime emulsion is used as a precipitating agent, so that tea saponin is converted into calcium tea saponin, which is precipitated and separated from water-soluble impurities; in the third step, acetic acid solution is used as a saponin releasing agent, so that calcium tea saponin is converted into tea saponin Dissolved in water, filtered to further remove impurities; the purified tea saponin solution was decolorized, concentrated and spray-dried to obtain refined tea saponin. The process of the invention is simple, the industrial scale production is convenient, and the obtained product has high purity.

Owner:JINGGANGSHAN TEA OIL

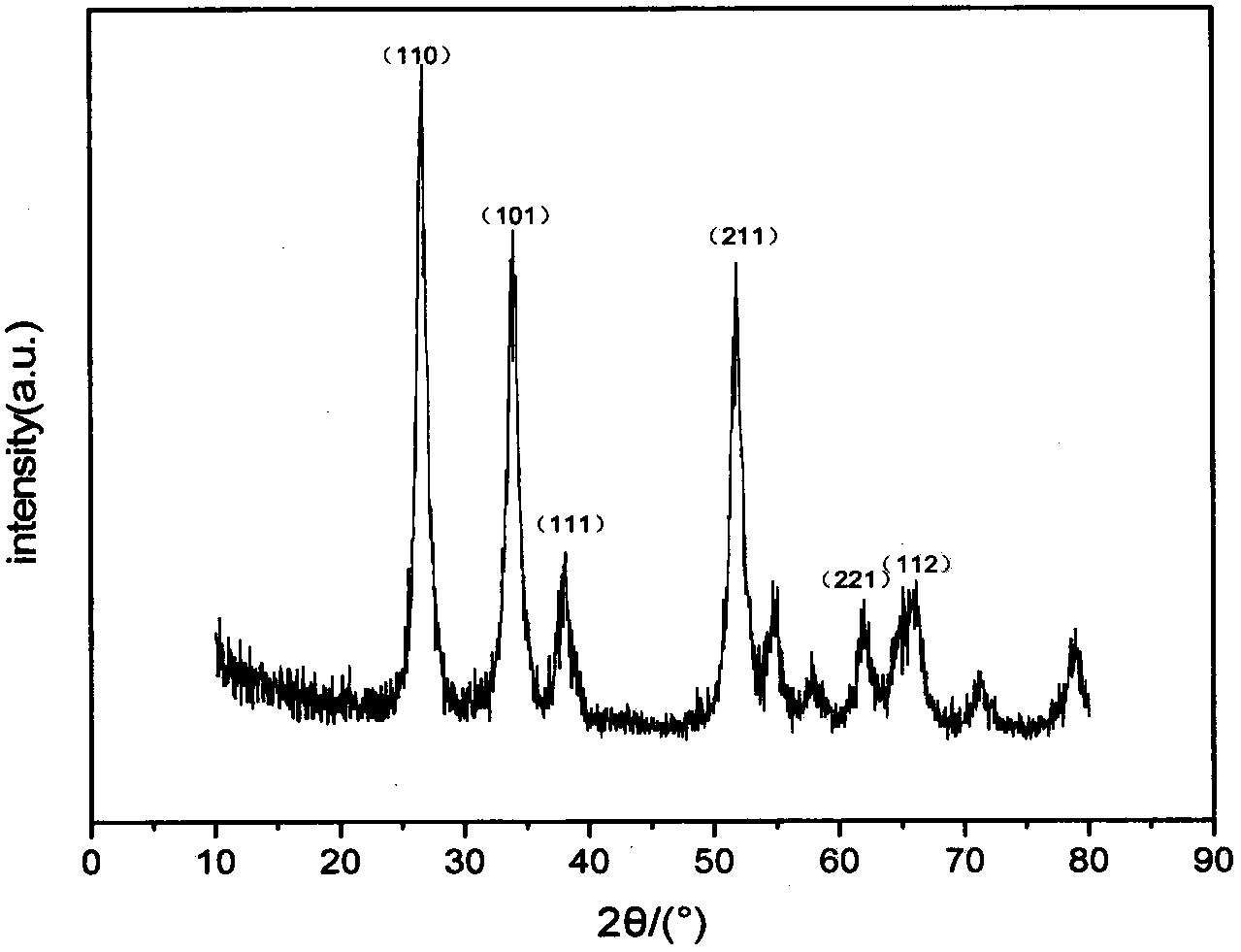

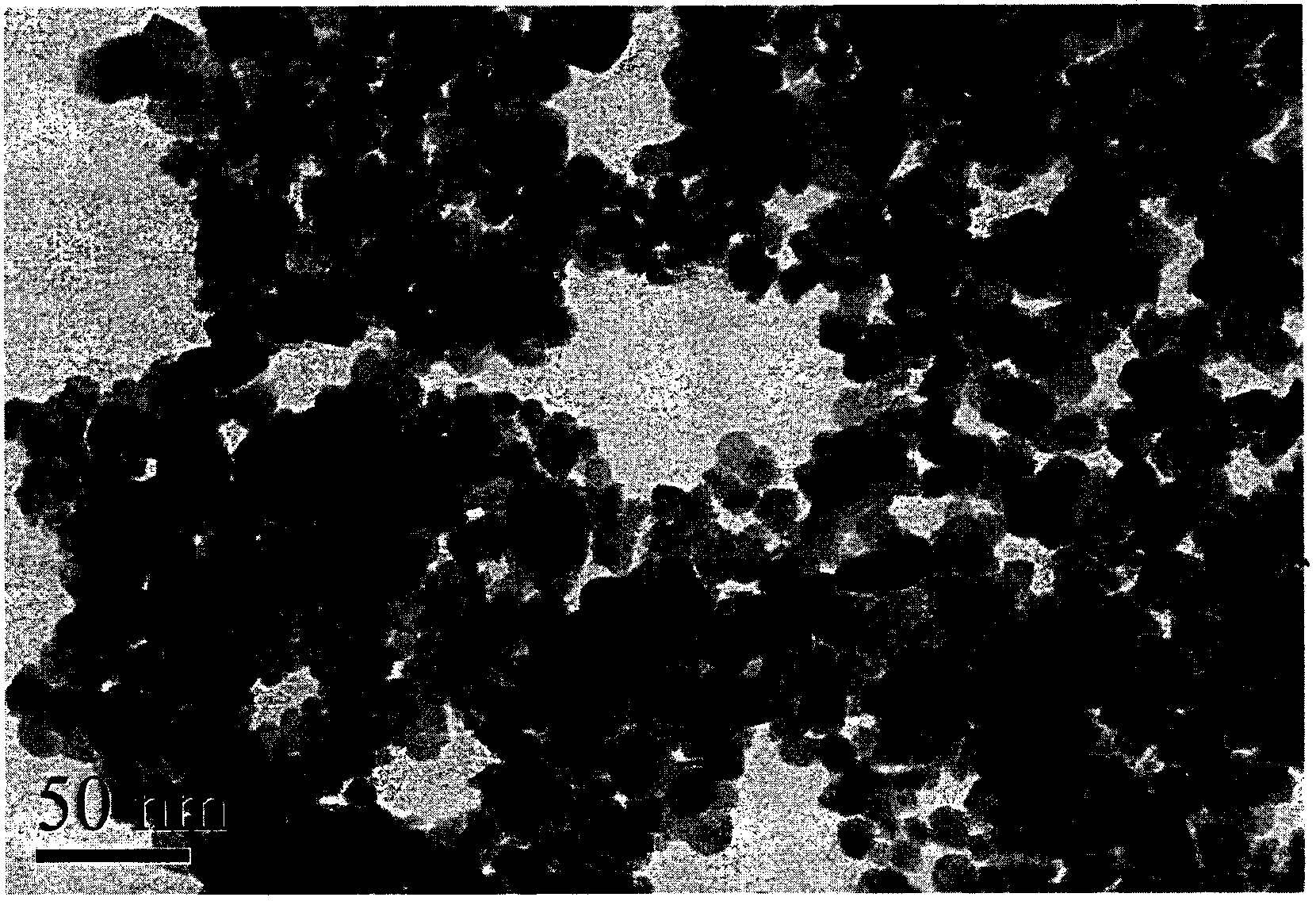

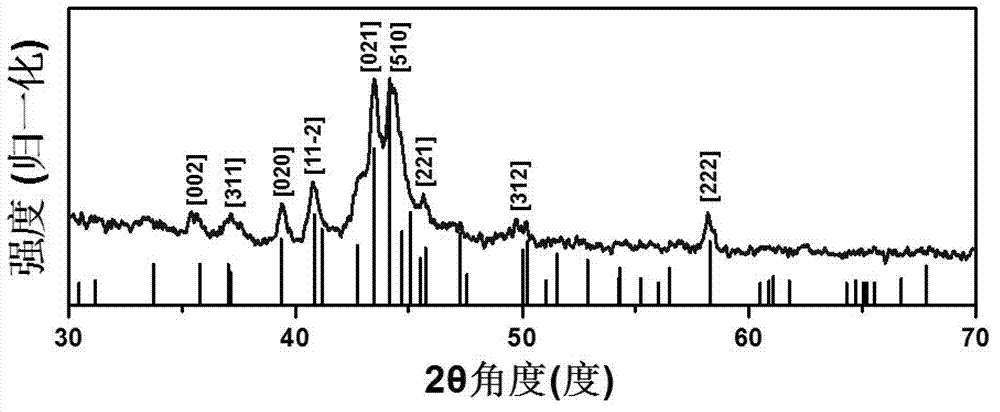

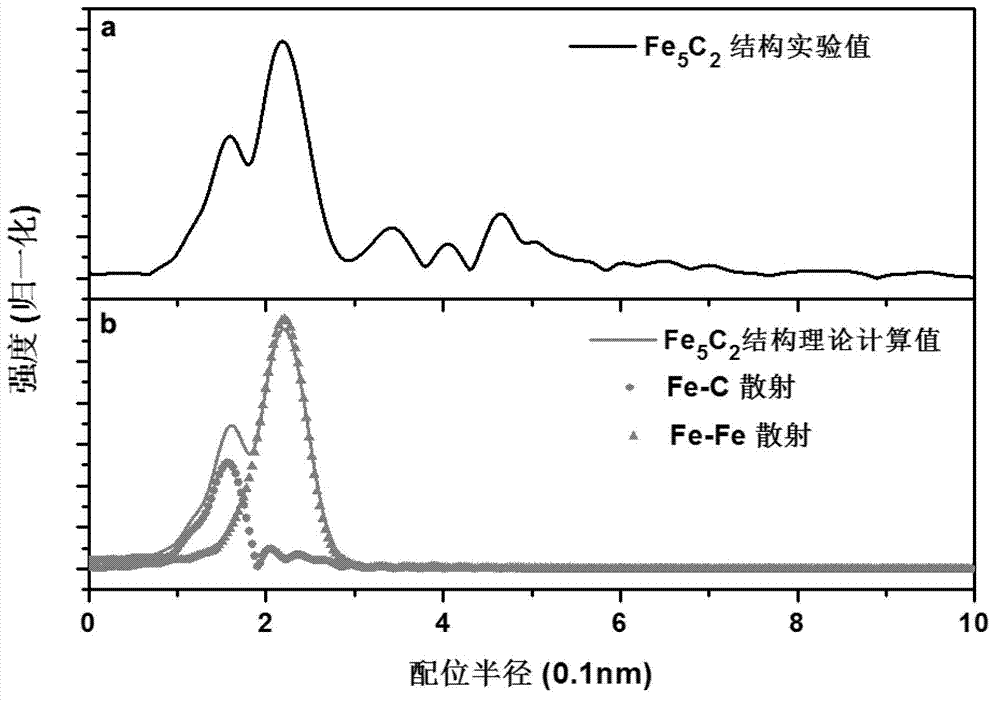

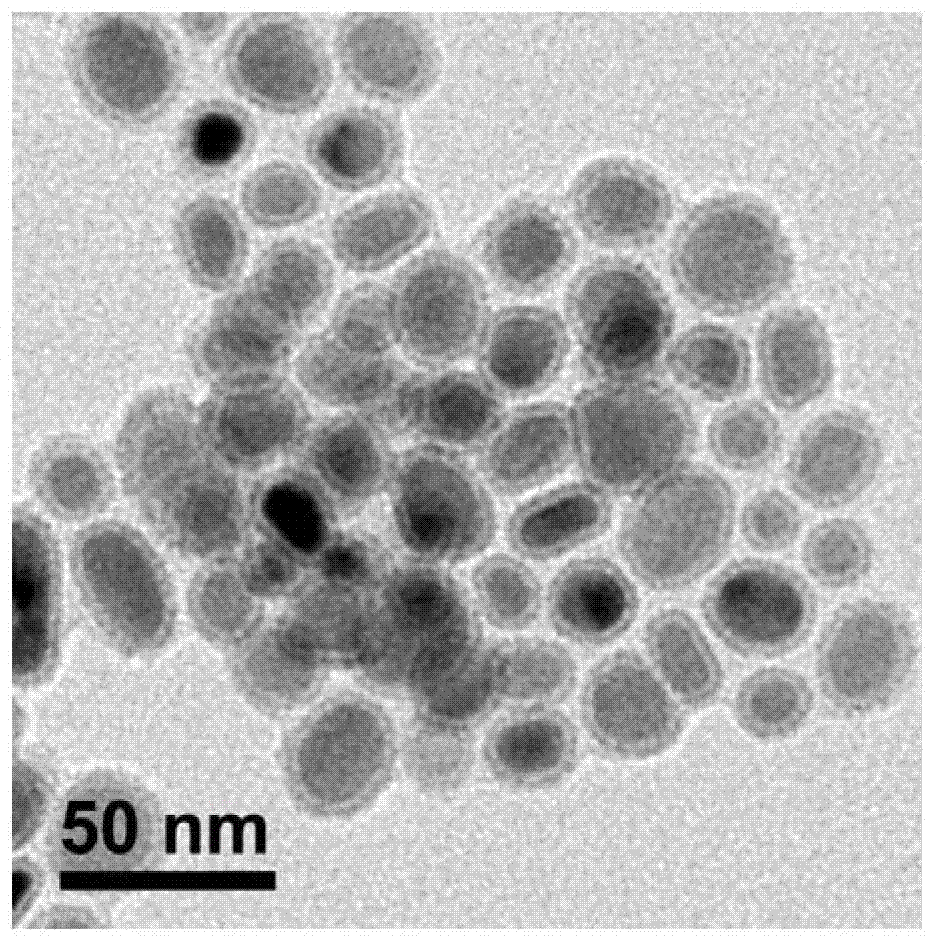

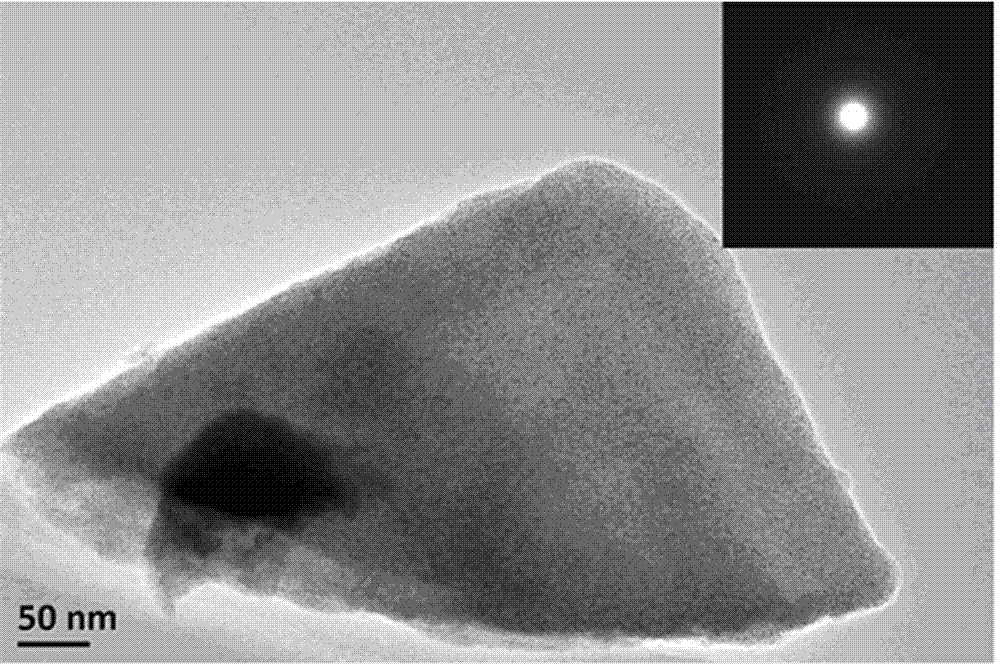

Iron carbide particle, and fabrication method and application thereof

ActiveCN103030143ABig comparisonHigh catalytic activityMaterial nanotechnologyCarbon compoundsCarbonizationMaterials science

The invention provides an iron carbide particle, and a fabrication method and an application thereof. Iron carbide is a nanoparticle taking Fe5C2 as a main component, and a particle size is 1-100nm. The fabrication method of the iron carbide particle comprises the following steps that a carbonization inductive agent and a solvent are mixed to form a mixed solution, a mole ratio of the carbonization inductive agent to the solvent is 1:(100-600), the carbonization inductive agent is halogenated ammonium salt, and the solvent is a long-chain amine solvent with a boiling point greater than 250 DEG C; a zero-valent iron organic compound is added to the mixed solution which is heated to 180-200 DEG C in a protective atmosphere; a reaction system is controlled at 250-380 DEG C for 10-120min; solid-liquid separation is performed after the reaction system is cooled; and the iron carbide particle product is collected. The iron carbide particle takes Fe5C2 as a major phase, is in a nanoparticle shape, can show higher catalytic activity, and is particularly applicable to catalysis of fischer-tropsch synthesis.

Owner:PEKING UNIV

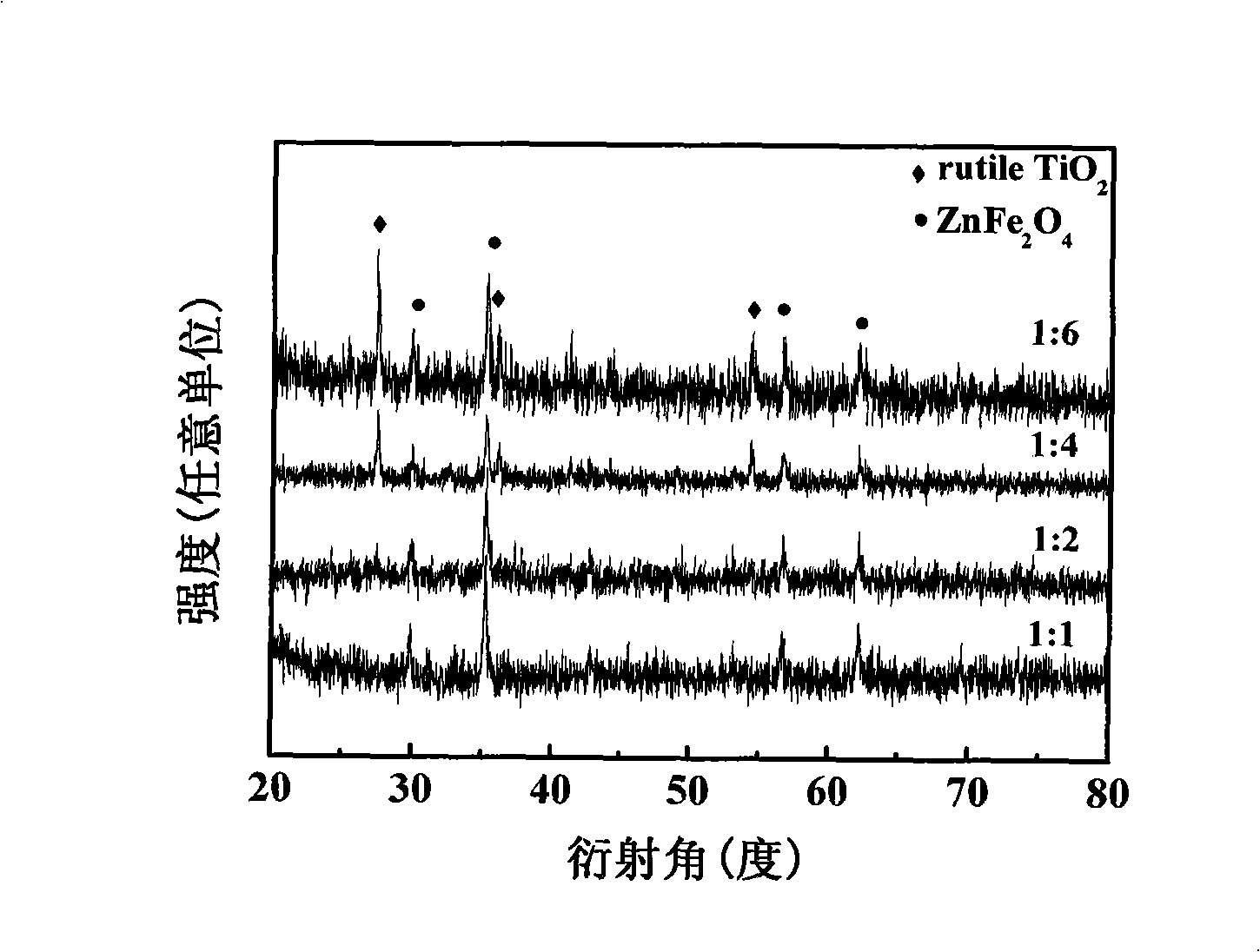

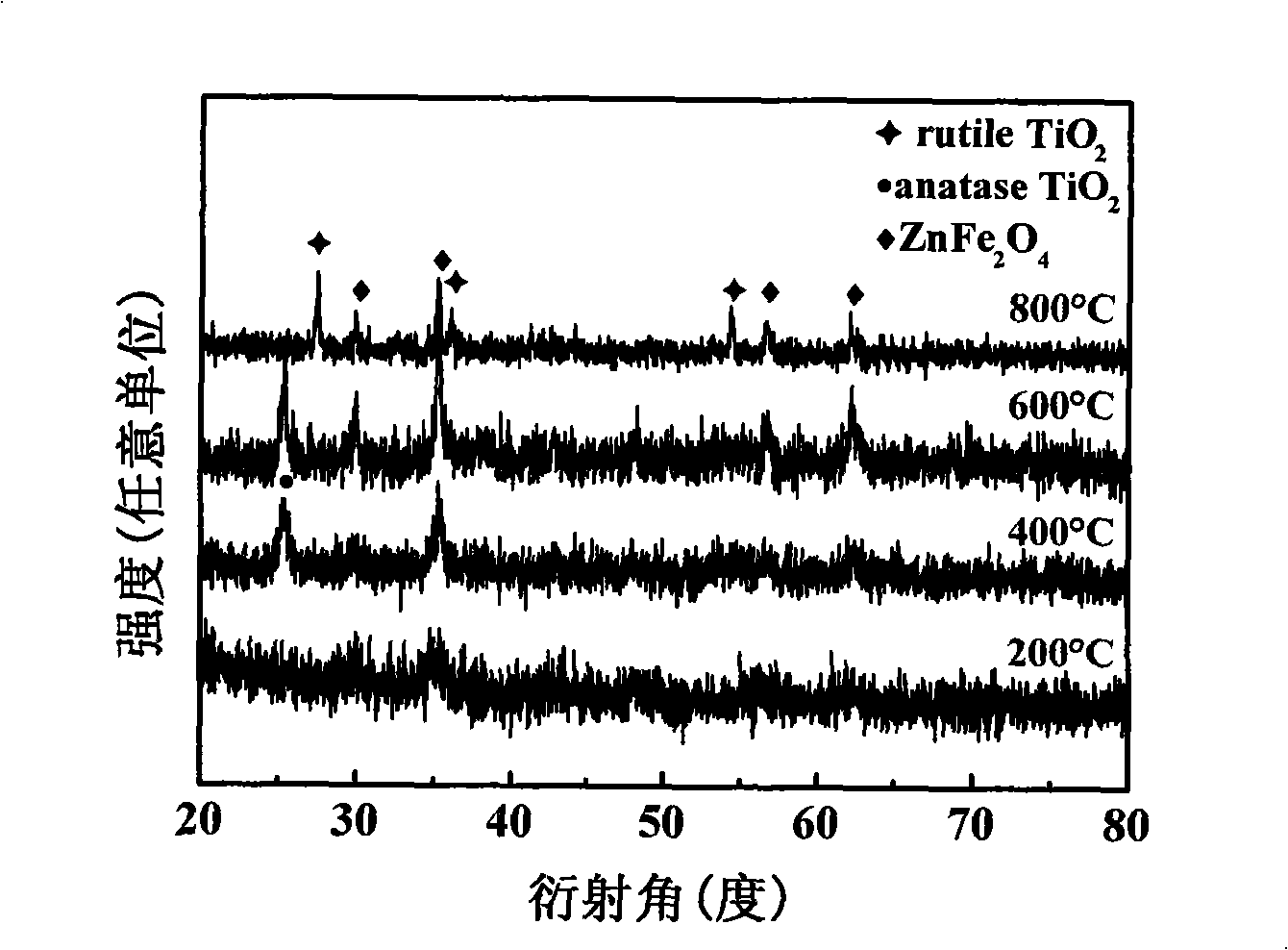

Preparation of TiO2/ZnFe2O4 magnetic composite photocatalyst

InactiveCN101264449AEasy to recycleQuality improvementMetal/metal-oxides/metal-hydroxide catalystsMaterials preparationSeparation technology

The invention relates to a preparation method for TiO2 / ZnFe2O4 magnetic complex photocatalysis, belonging to the technical field of nanometer photocatalysis material preparation, which adopts magnetic material ZnFe2O4 as carrier, requiring no organic compounds or middle-tier; the magnetic material ZnFe2O4 is assembled into magnetic photocatalysis of complexs nanometer grain through the method of sol-gel. The preparation method has the advantages of not only ability to preserve perfect suspension property, and high photocatalysis activity, but also ability to conveniently and rapidly recover magnetic photocatalysis utilizing magnetism separation technology, to reach the purpose of repeated recycle and utilization.

Owner:BEIJING UNIV OF TECH

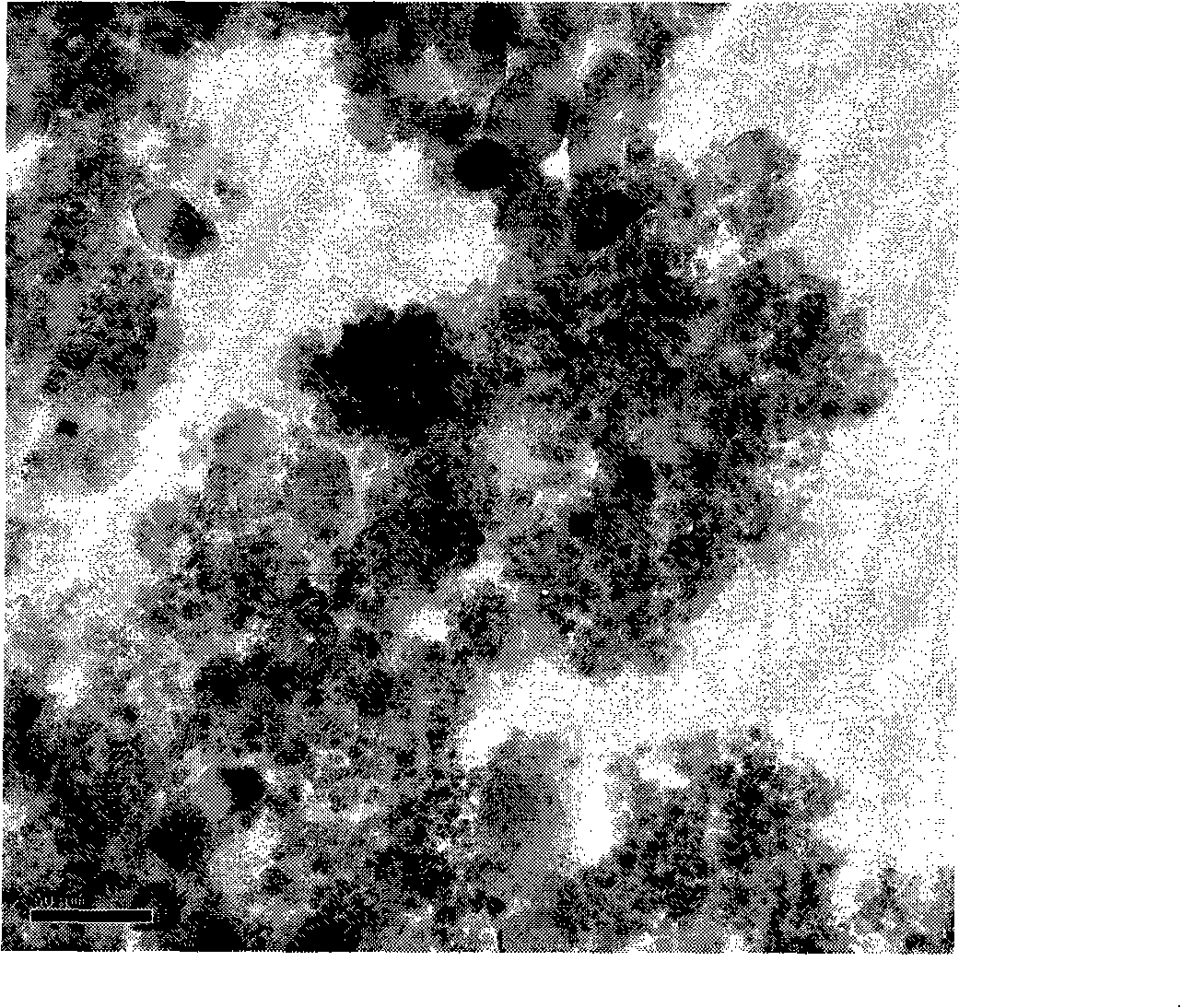

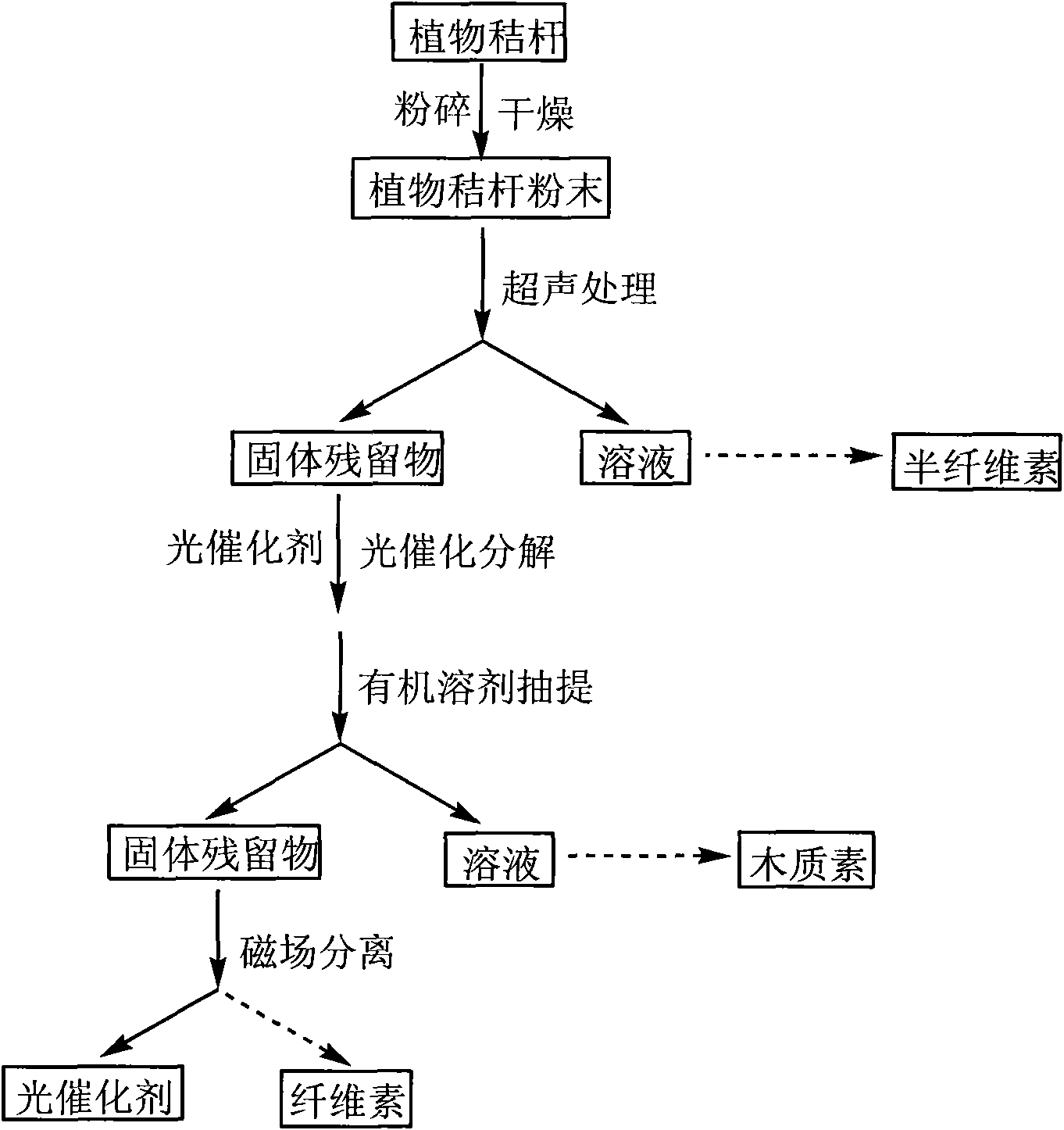

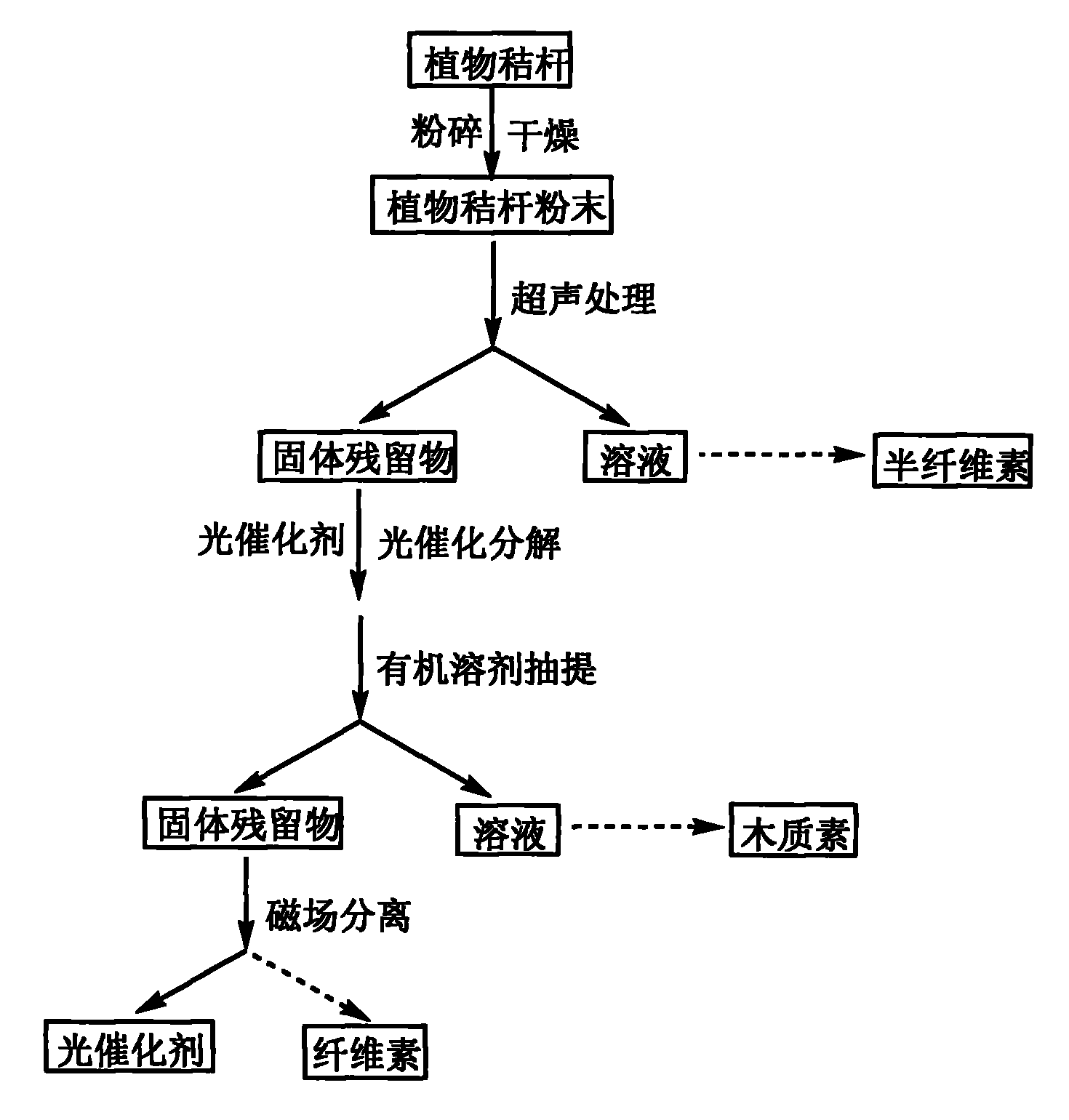

Method for ultrasonically catalyzing and extracting hemicellulose, cellulose and lignin from plant straws

InactiveCN101792495AIncrease profitTake advantage ofLignin derivativesPaper material treatmentOrganic solventRenewable resource

The invention discloses a method for ultrasonically catalyzing and extracting hemicellulose, cellulose and lignin from plant straws. The method comprises the following steps of: (1) airing plant straws and then mechanically crushing, collecting plant straw powder, fully drying and removing moisture; (2) dispersing the dried plant straw powder into a water solution and then carrying out ultrasonic treatment, dissolving the hemicellulose into the water solution, then separating the water solution, and carrying out photocatalytic decomposition on the separated plant straw residuals by taking nano Fe3O4-TiO2 as a photocatalyst with a core-shell structure; (3) separating and extracting lignin from the residuals subjected to the photocatalytic decomposition by using an organic solvent in an extraction way, wherein the extracted residuals are a mixture of the cellulose and the photocatalyst; and (4) putting the extracted residuals under a magnetic field to separate the cellulose from the photocatalyst to obtain the cellulose. The invention successfully realizes the separation and the full utilization of the hemicellulose, the cellulose and the lignin in the plant straws and improves the utilization ratio of renewable resources.

Owner:ZHEJIANG SCI-TECH UNIV

Corundum-mullite honeycomb ceramic heat accumulator

The invention belongs to the inorganic nonmetal field, and relates to a corundum-mullite honeycomb ceramic heat accumulator for waste heat recovery of high-temperature kiln tail gas. The honeycomb ceramic heat accumulator is prepared by the following steps of: forming ceramic powder from corundum, mullite, alumina, clay and the like; adding cellulose, glycerol, glue and water to prepare plastic mud; and mixing, mixing mud, performing vacuum pug, forming, drying and performing high-temperature sintering. The honeycomb ceramic heat accumulator prepared by the method has the characteristics of superior high temperature strength, high heat accumulation capacity, high heat exchange speed, high thermal shock stability, low cost, easiness in operation and adaptation to industrial production.

Owner:晋城市富基新材料股份有限公司

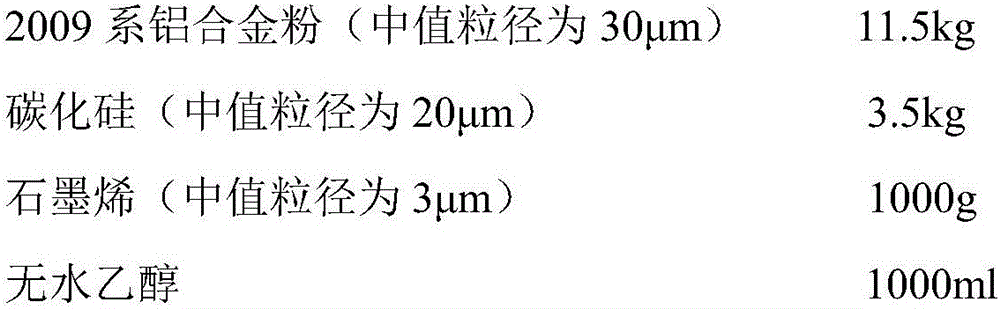

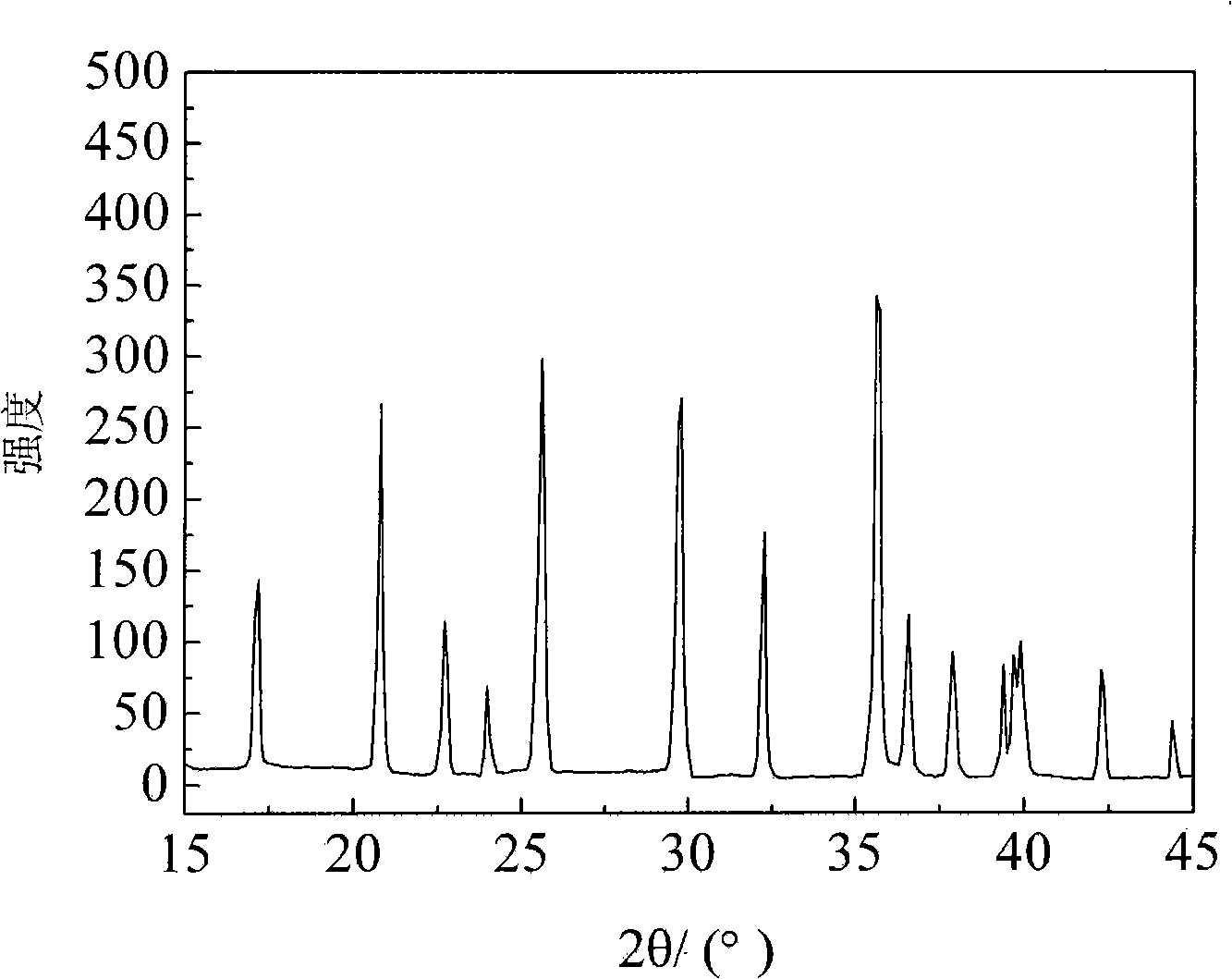

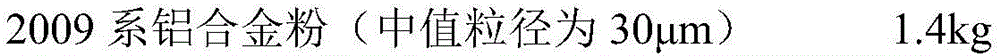

Graphene enhanced aluminium-based silicon carbide composite, preparation method and application thereof

ActiveCN106591666AImprove reliabilityImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesThermal diffusivityElectronic packaging

The invention relates to a graphene enhanced aluminium-based silicon carbide composite and a preparation method thereof. The composite comprises the following substances by volume percent: 40% to 70% of silicon carbide and 0.5% to 5% of graphene, and the balance being aluminium alloy. The composite is prepared through the powder metallurgy method and is obtained through the steps of blending, powder mixing, bagging, vacuum degassing and hot iso-hydrostatic forming treatment. The composite has the advantages of high thermal conductivity, high strength, high plasticity, light weight, good thermal diffusivity, isotropy, and the like, and becomes a second-generation electronic packaging material with wide application.

Owner:BEIJING BAOHANG ADVANCED MATERIALS CO LTD

Biochemical ceramic as well as preparation method and application thereof

InactiveCN101475362AAvoid washing awayNo manual fixation requiredTreatment using aerobic processesSustainable biological treatmentEutrophicationFiltration

The invention relates to biochemical ceramic and a preparation method and application thereof. The biochemical ceramic adopts wastewater sludge as a main raw material and is prepared through the supplementary materials of calcium carbonate or gypsum, clay, dehydrate calcium hydroxide, liquid wax, iron dust or brown iron oxide via anoxic burning. The biochemical ceramic can be used as a biological medium of a granular sludge bed in a biological filter or a trickling filter or during the anaerobic treatment, and can also be used for reducing the water body eutrophication or build a filtration dam to reduce the pollution caused by the wastewater. The retractable biochemical ceramic can automatically fix bacteria so as to prevent the biomass from being flushed away without artificial fixation, and can immobilize the heavy metal elements in the sludge and release no heavy metal elements in the application process. The biochemical ceramic can be used for preparing cogs with different shapes and sizes; therefore, the biochemical ceramic has a wider application prospect.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

Magnesium oxide foam ceramic filter

InactiveCN101164656AImprove protectionEasy to operateFiltration separationCeramicwareBoron carbideMethyl cellulose

The present invention relates to an aluminium oxide foamed ceramic filter with special high-temperature chemical stability. Said aluminium oxide foamed ceramic filter is made up by adopting the following steps: using magnesium oxide, boron carbide and boron trioxide to form ceramic powder, then adding methyl cellulose and water to prepare slurry, using soft polyurethane foamed plastics as carrier, impregnating said carrier with said slurry, extruding to make blank material, drying and sintering so as to obtain the invented magnesium oxide foamed ceramic filter. The invented foamed ceramic filter has good high-temperature stability in the molten magnesium alloy, does not contaminate alloy and possesses good filtering and adsorption efficiency for removing oxide impurity and flux impurity form molten magnesium alloy, so that its filtering purification effect is good.

Owner:晋城市富基新材料股份有限公司

Molybdenum oxide/nitrogen-doped carbon composite electrode material and preparation method thereof

InactiveCN104733716AImprove conductivityHigh specific capacityMaterial nanotechnologyCell electrodesCarbon compositesSynthesis methods

The invention relates to a molybdenum oxide / nitrogen-doped carbon composite electrode material and a preparation method thereof, and belongs to the technical field of preparation of lithium ion battery electrode materials. The molybdenum oxide / nitrogen-doped carbon composite electrode material of a lithium ion battery is prepared from pyrolytic organic amine and an intercalation compound of molybdenum trioxide. The molybdenum oxide / nitrogen-doped carbon composite electrode material has the advantages that homogeneous in-situ composition of nitrogen-doped carbon and molybdenum oxide is realized; the electrical conductivity of the electrode material is improved, and the embedding / stripping capacity of lithium ions is enhanced, so that high specific capacity and good cycle performance are obtained. The molybdenum oxide / nitrogen-doped carbon composite electrode material prepared by the method is a lithium ion battery negative material with excellent performance; the synthesis method is simple in process and low in preparation cost; and large-scale industrial production is easy to realize.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Method for preparing colored foam glass ceramic material from lithium tailings

InactiveCN108191230ASimple preparation processWide firing rangeGlass shaping apparatusPore distributionSlag

The invention provides a method for preparing a colored foam glass ceramic material from lithium tailings. According to the method, the material is prepared from a main material, an auxiliary material, fluxing agents, pore forming agents and colorants by blending and one-time high-temperature sintering, wherein the lithium tailings serve as the main material; cullet serves as the auxiliary material; the fluxing agents comprise sodium fluoride, potassium carbonate, sodium silicate, mirabilite and borax; the pore forming agents comprise calcium carbonate and silicon carbide; the colorants comprise copper oxide, iron oxide, cobalt oxide, chromium oxide, manganese oxide and zinc oxide. The problems of industrial slag accumulation and secondary pollution can be solved effectively with the method, and recycling of resources is realized; the preparation process is simple, the cost is low, and prepared foam glass ceramic is small in bulk density, uniform in pore distribution, adjustable in color, high in compressive strength and high in added value and has good industrial prospect.

Owner:WUHAN UNIV OF TECH

Pineapple bran pressed and packaged fermented feed and processing method thereof

InactiveCN101884364AIncrease production capacityExcellent anaerobic fermentation environmentFeeding-stuffFood processingWater contentNutrient

The invention provides pineapple bran pressed and packaged fermented feed and a production method thereof. Because the pineapple bran has higher feeding value and pineapple proteinase has medicinal effect on animals, the pineapple bran is used as a main raw material; the pineapple bran is added with a leaven, a nutrient additive and a moisture absorbent to prepare the pressed and packaged fermented feed by using scale production equipment through squeezing, drying, pressing and packaging, seal packaging and other processing techniques, wherein the water content of the product is between 50 and 70 percent; and the fermented pineapple bran feed is a special feed additive for beef cattle, dairy cattle, mutton sheep, deer and pig. The method has the advantages of simple process, less equipment investment and low cost, changes waste into treasure, and opens up a novel way for utilizing pineapple processing waste resources; the fermented feed has the advantages of good palatability, rich smell and certain medicinal value, is a green feed, can be processed either on a large scale or by farmers, and can be processed by flexible and variable methods; and the finished feed product has small volume and high density, can be preserved and stored for a long time and transported for long distance, reduces transportation cost, and has remarkable social and economic benefit.

Owner:薛晓宁

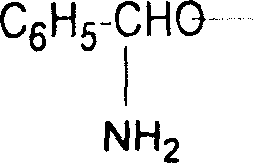

Synthetic method of [1-methyl-2-(8'-octyl hydroxamic acid group)-5-N,N-bi(2'-chloroethyl)]-1H-benzimidazole

ActiveCN102993102AEasy to operateHigh yieldOrganic compound preparationCarboxylic acid amides preparationAcetic acidEthylene oxide

The invention discloses a synthetic method of [1-methyl-2-(8'-octyl hydroxamic acid group)-5-N,N-bi(2'-chloroethyl)]-1H-benzimidazole. NL-101, namely [1-methyl-2-(8'-octyl hydroxamic acid group)-5-N,N-bi(2'-chloroethyl)]-1H-benzimidazole is prepared from chloroacetic acid replacing hypertoxic low-boiling ethylene oxide as a raw material by multi-reactions in one pot. The separating and purifying step is cancelled, the synthetic route is short, and the reaction environment in particular including temperature, pressure and the like can be safely controlled and the method is green and environment-friendly. The invention also discloses a series of intermediate compounds obtained in the reaction of synthesizing NL-101. The purity of NL-101 prepared by the synthetic route through analysis and characterization reaches 95%, and the purity after recrystallization and refining is greater than 99%. The method is high in product yield, easy to operate, and beneficial for industrialized production in a large scale.

Owner:HANGZHOU TINO PHARMA CO LTD

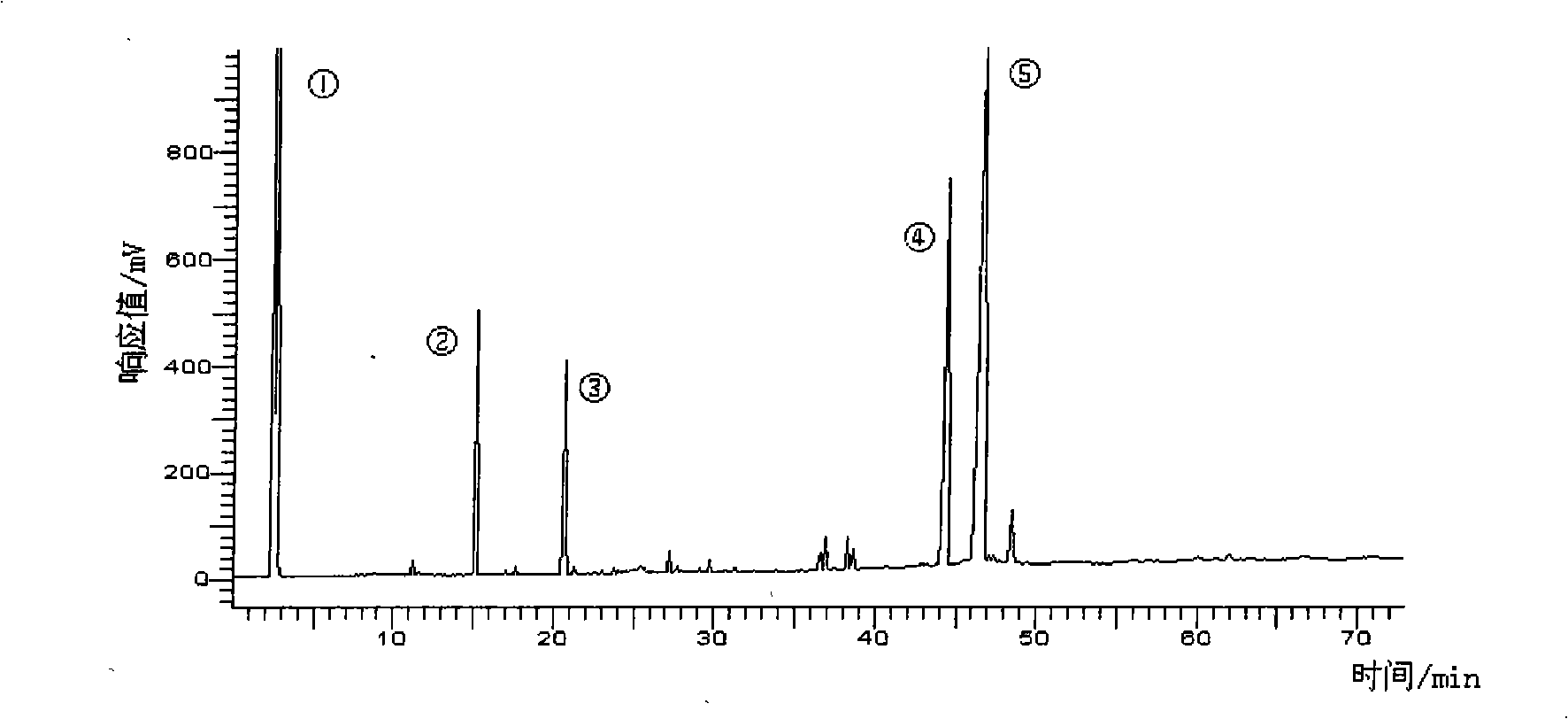

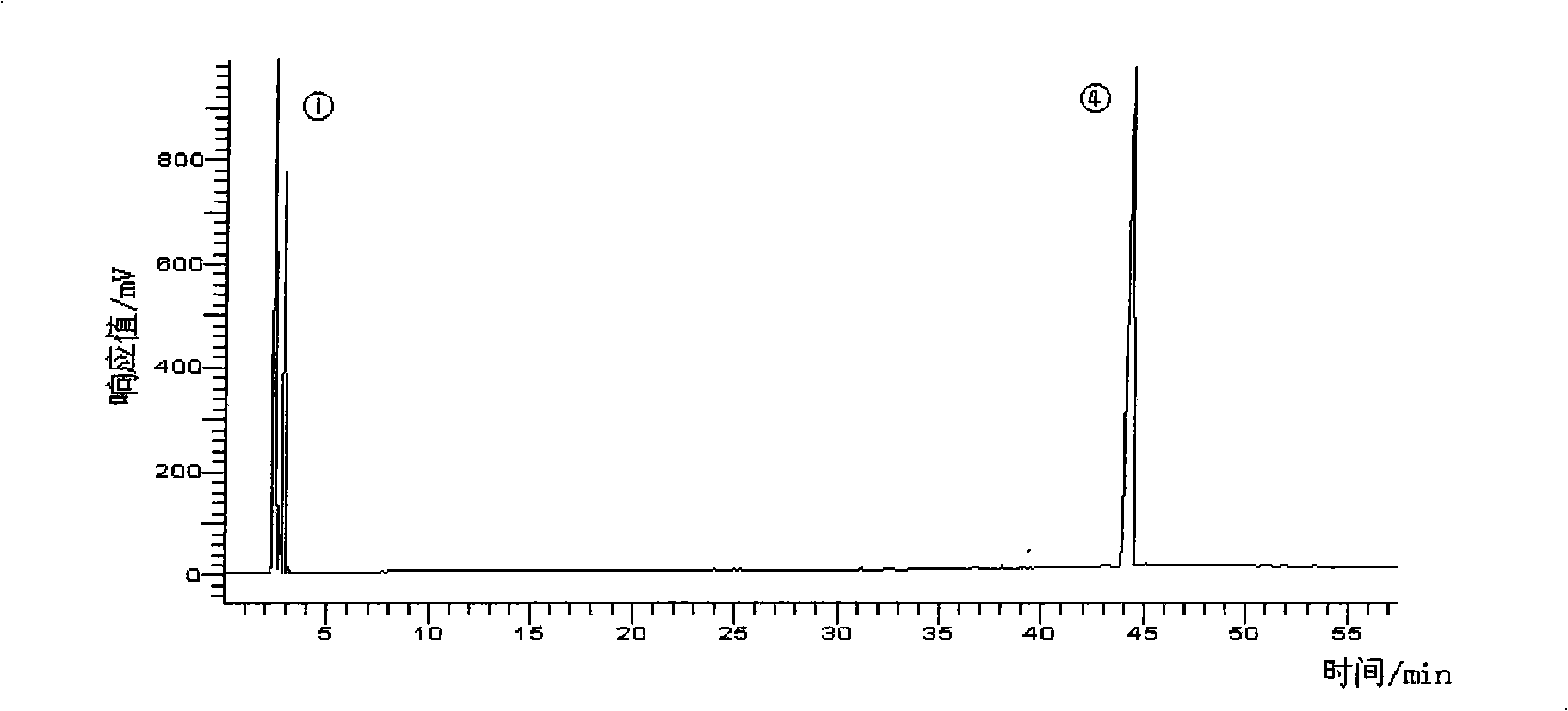

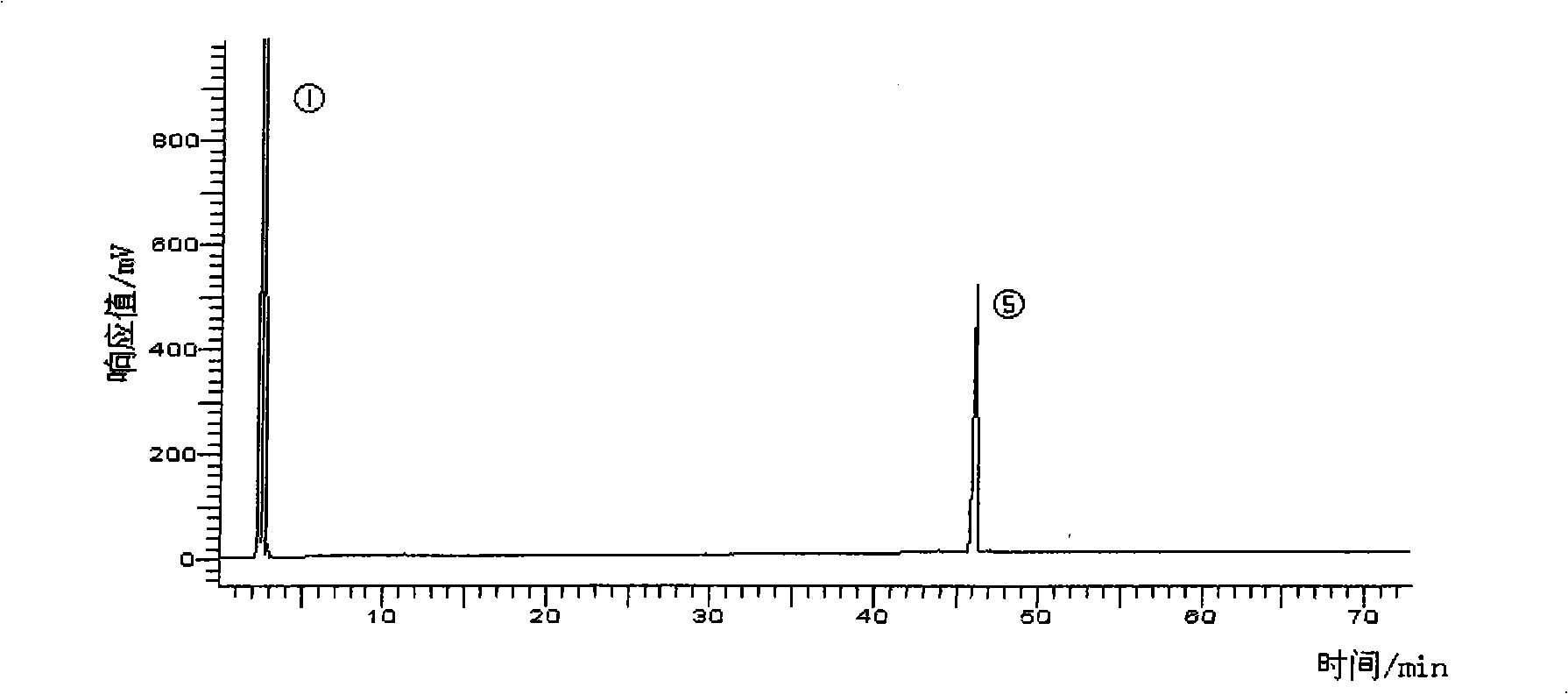

Process for preparing and separating methyl docosapentaenoate and methyl docosahexenoate

ActiveCN101265185AHigh purityHigh yieldOrganic compound preparationCarboxylic acid esters preparationChemistryDocosapentaenoate

The invention relates to a preparation and separation method of docosapentaenoic acid methyl ester and docosahexaenoic acid methyl ester. Microalgae oil is used as raw material to prepare docosapentaenoic acid and docosahexaenoic acid which are mixed with fatty acid to prepare the docosapentaenoic acid methyl ester and the docosahexaenoic acid methyl ester. The separation method of the the docosapentaenoic acid methyl ester and the docosahexaenoic acid methyl ester provided by the method adopts a silver nitrate column method of separating. In the silver nitrate column method, the quality of the methyl ester sample introduction of the mixed fatty acid is 0.5 percent to 10 percent of the quality of filled silver nitrate blangel; elution gradient is n-hexane solution containing acetone the content of which is 0.5 percent to 15 percent; the elution speed is 0.5 to 5ml / min. The preparation and separation method utilizes the silver nitrate column method to obtain the high purity docosapentaenoic acid methyl ester and the high purity docosahexaenoic acid methyl ester, wherein, the content of DPA is raised from 20.32 percent in raw oil to 99.61 percent, the content of DHA is raised from 44.83 percent to 99.02 percent, and the yield rate by using the silver nitrate column method can reach more than 90 percent.

Owner:NANGTONG HAODI ANTICORROSION EQUIP

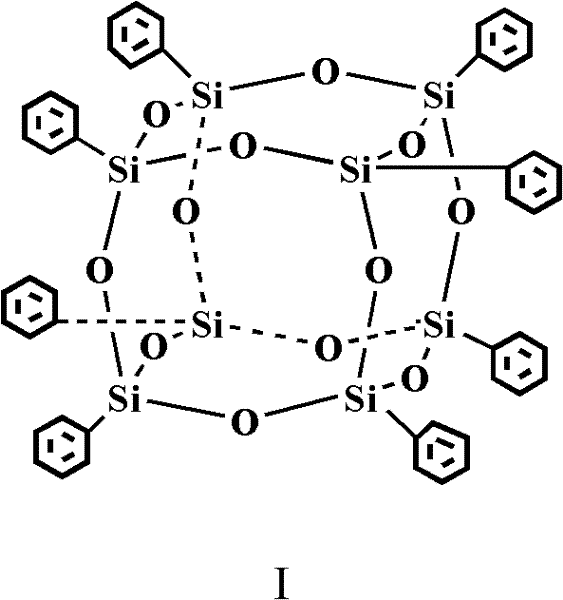

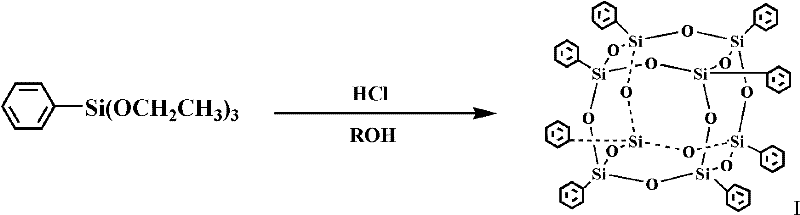

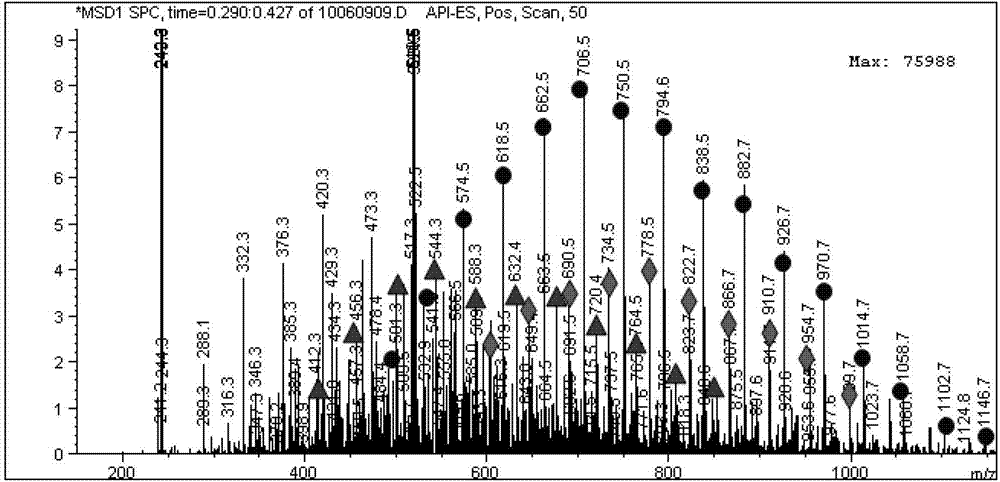

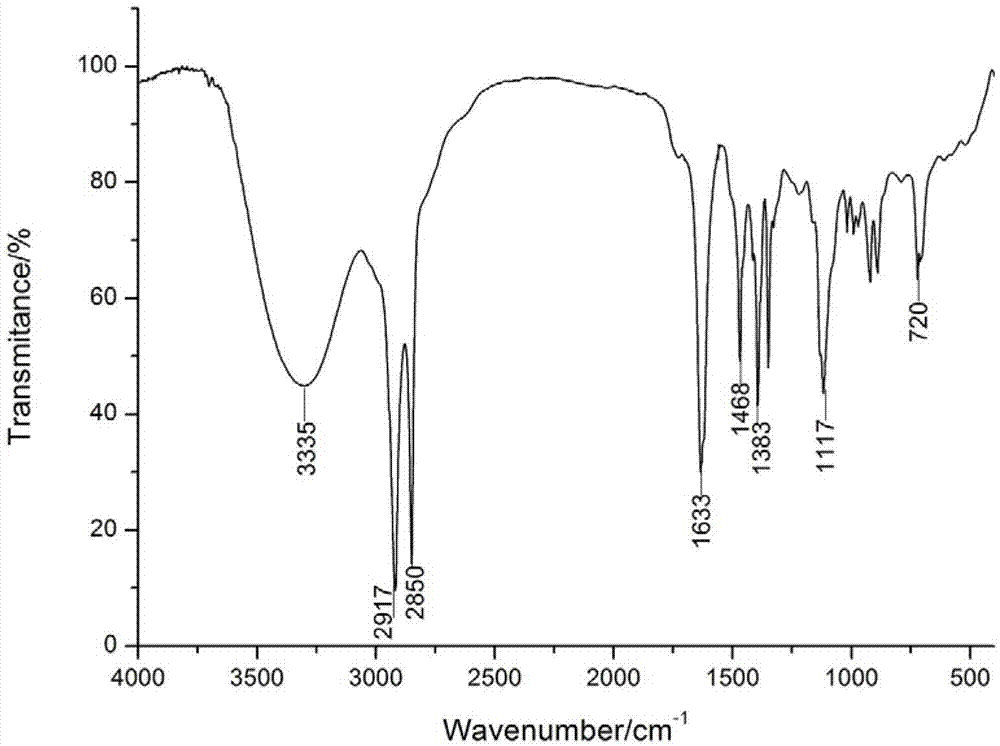

Preparation method of cage poly (phenylsilsequioxane)

ActiveCN102643304ARaw materials are easy to getMild hydrolysis and polycondensation reaction conditionsSilicon organic compoundsAlcoholSynthesis methods

The invention relates to a preparation method of cage poly (octaphenylsilsequioxane). The method is characterized in that phenyltriethoxysilane or phenyltrimethoxysilane is used as a monomer raw material, organic alcohol is used as solvent and the cage poly (phenylsilsequioxane) is prepared through one-step hydrolytic polycondensation under the catalytic effect of hydrochloric acid. The method provided by the invention has the advantages that the raw material is easy to obtain, the reaction conditions are moderate, the operation is simple and convenient to conduct, the reaction period is short, the yield is high, the cost is low, the method is an environmental-friendly poly (octaphenylsilsequioxane) synthesis method and the industrial production is easy to realize.

Owner:SHANDONG UNIV

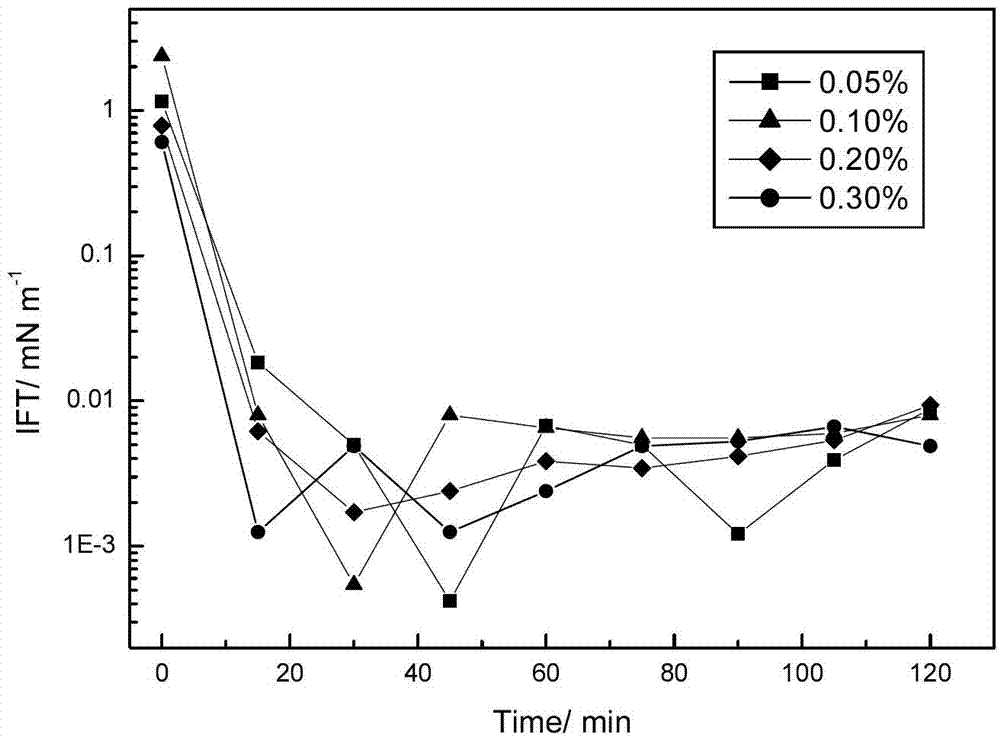

Non-alkali composite flooding compound based on straight-chain fatty alcohol ether carboxylic betaine

ActiveCN102775976AIncrease critical micelle concentrationLower Krafft pointsDrilling compositionBetaineEther

The invention provides a non-alkali composite flooding compound, comprising the following components in percentage by weight: 0.005-0.30% of straight-chain fatty alcohol ether carboxylic betaine amphoteric surfactant, 0.05-0.25% of polymer, and the balance of oilfield injected clear water or return water. According to the invention, the straight-chain fatty alcohol ether carboxylic betaine amphoteric surfactant is used as the essential component of the non-alkali composite flooding compound, to form surfactant / polymer binary system which can reach ultra interfacial tension range with middle-low-temperature middle-low-salt oil deposit and high-temperature high-salt oil deposit, in this way, the requirements on non-alkali composite oil flooding are satisfied.

Owner:PETROCHINA CO LTD

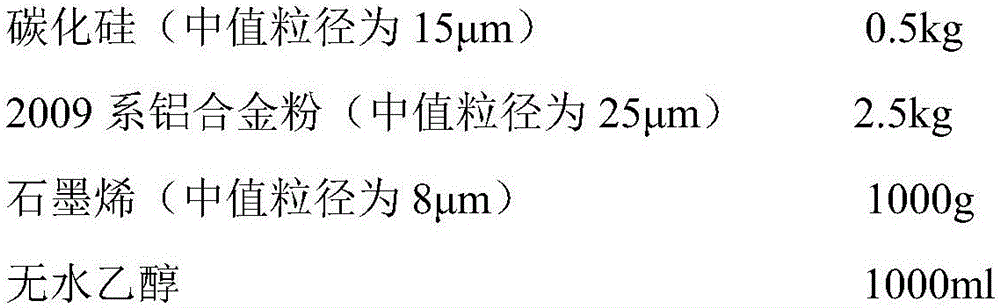

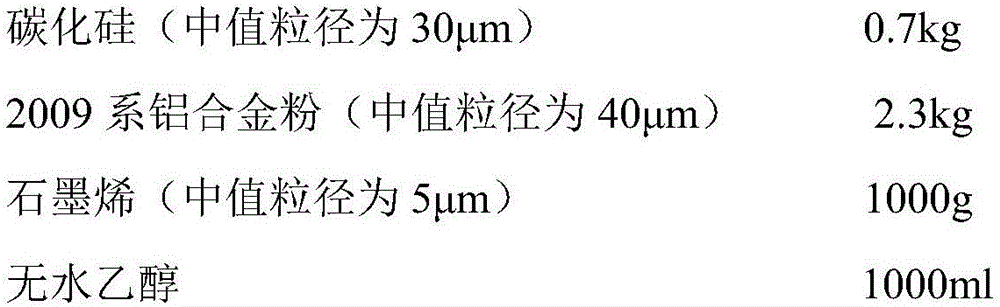

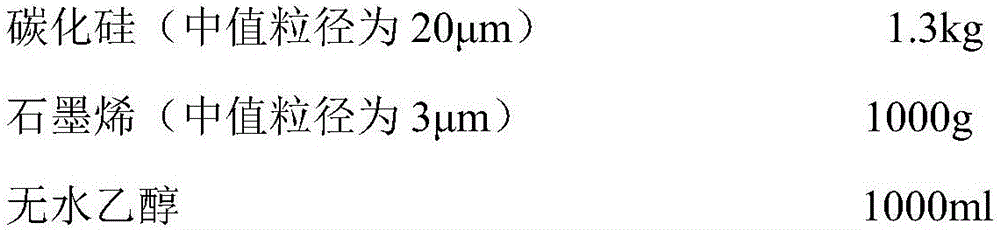

Graphene, aluminum and silicon carbide composite material and preparation method and application thereof

The invention relates to a graphene, aluminum and silicon carbide composite material and a preparation method thereof. The composite material is prepared from of constituents of 10-40 vol% of silicon carbide, 0.5-2 wt% of graphene, and the balance aluminum alloy. The composite material is prepared through a powder metallurgic method and can be obtained through proportioning, powder mixing, packaging, vacuum degassing and hot isostatic forming. The composite material has the advantages of low density, low weight, high hardness, high tensile strength and the like, the strength, fatigue resistance and toughness of the material are remarkably improved through addition of a proper amount of graphene, and thus the composite material has broader application prospects in the field of structural pieces.

Owner:BEIJING BAOHANG ADVANCED MATERIALS CO LTD

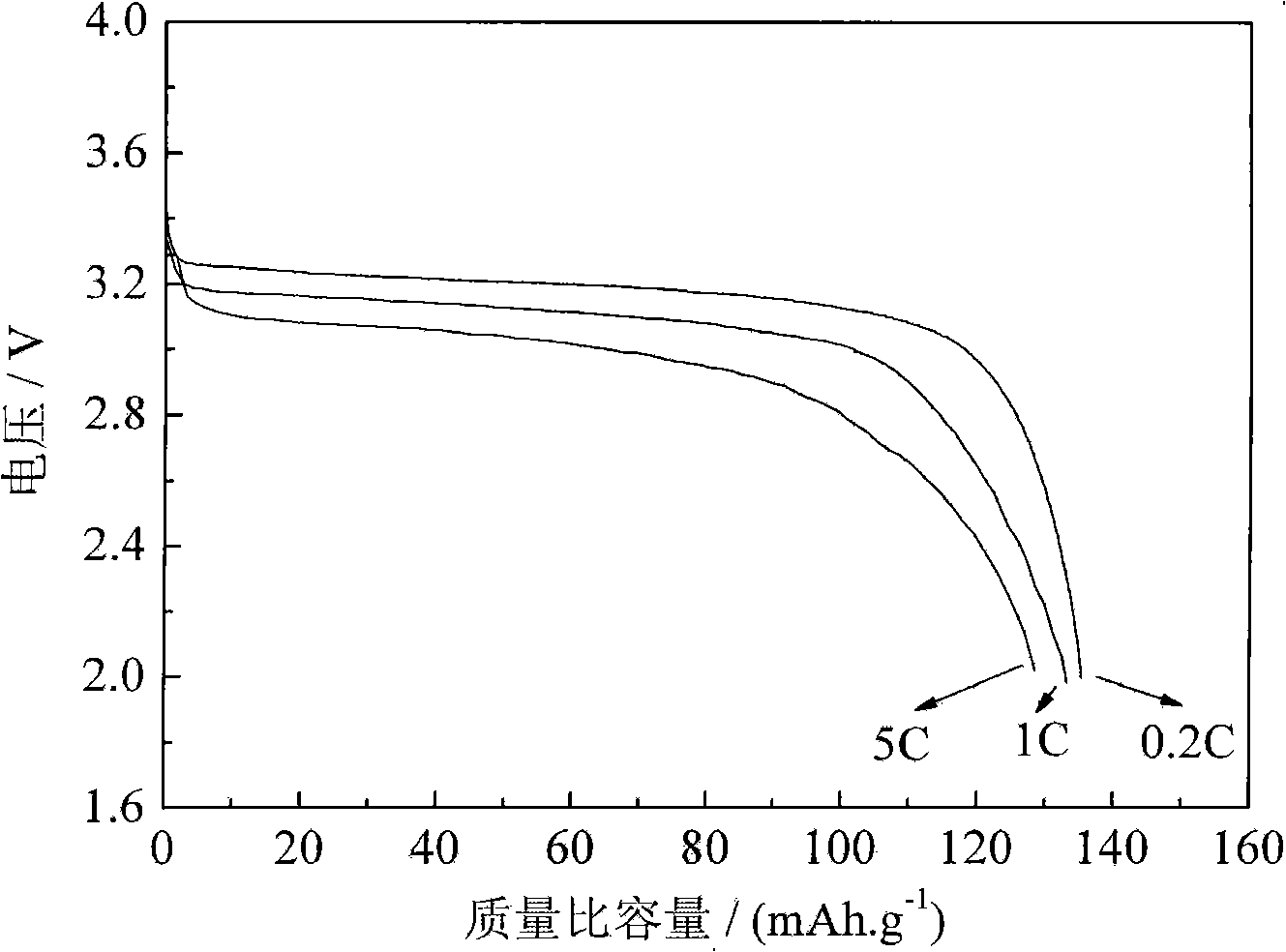

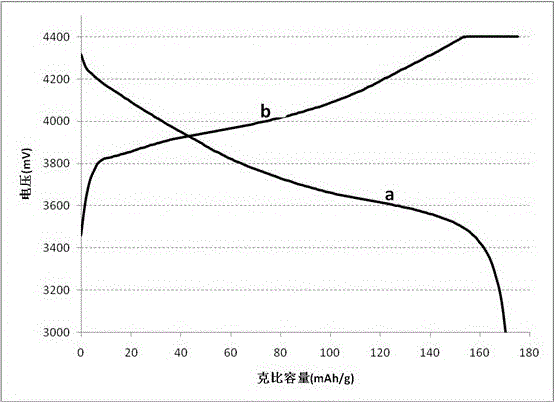

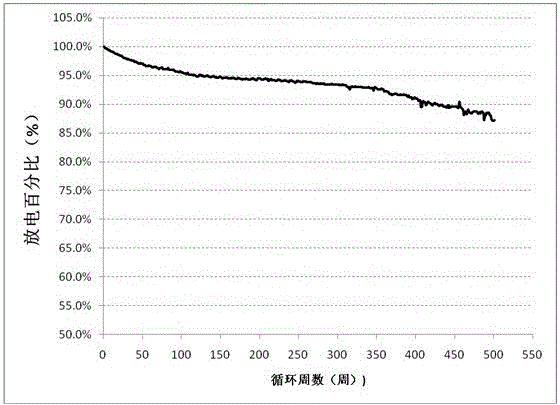

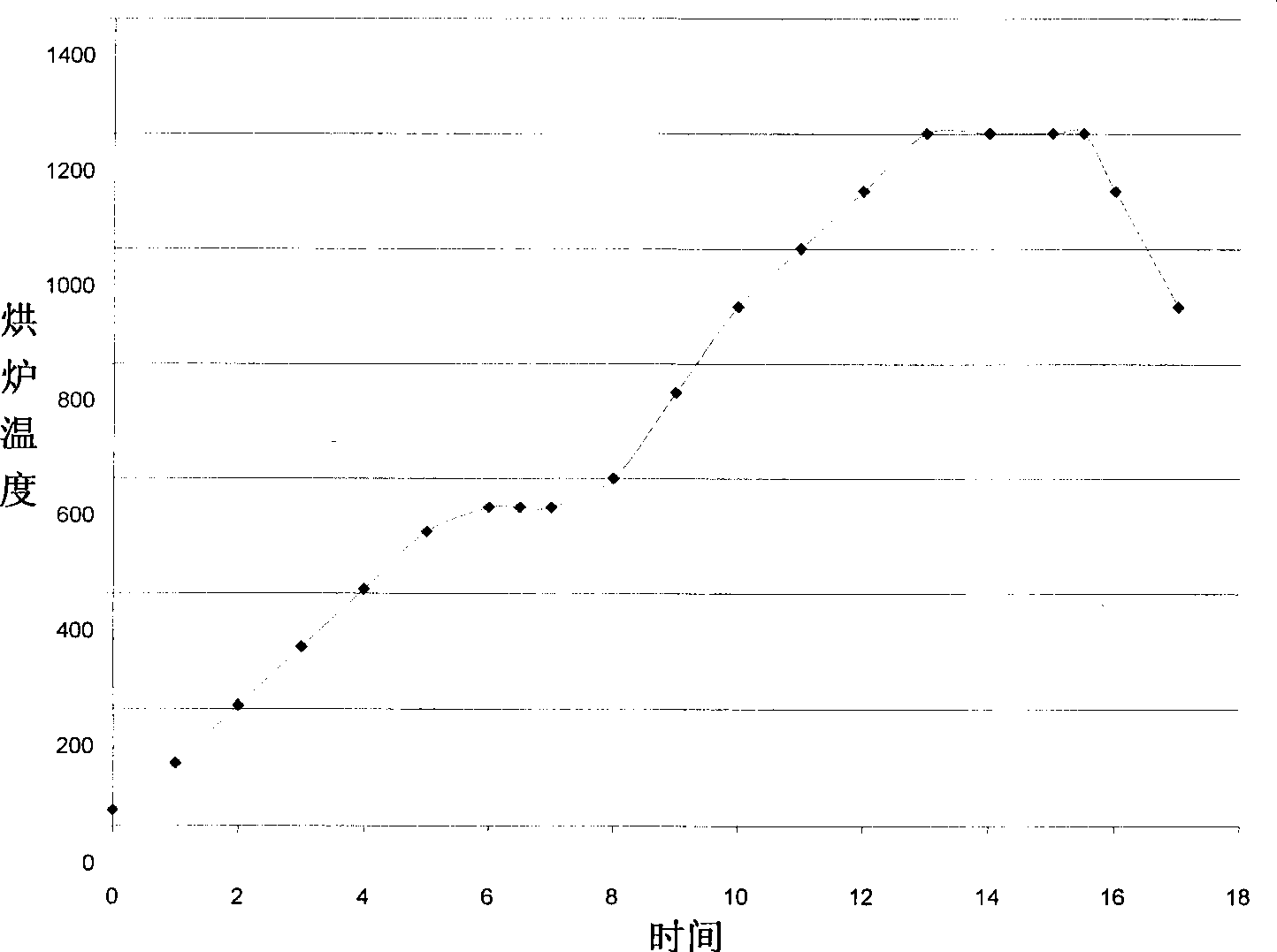

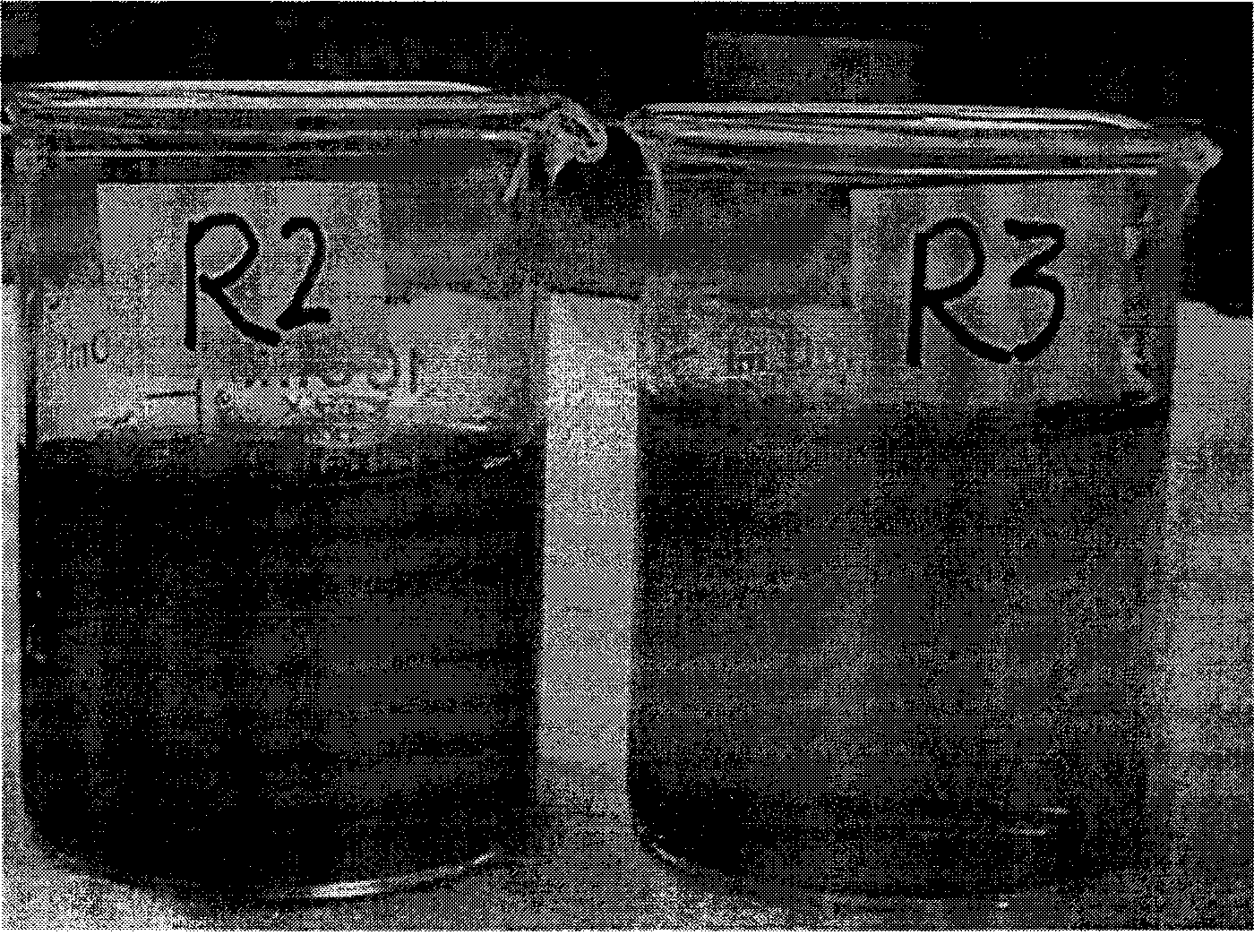

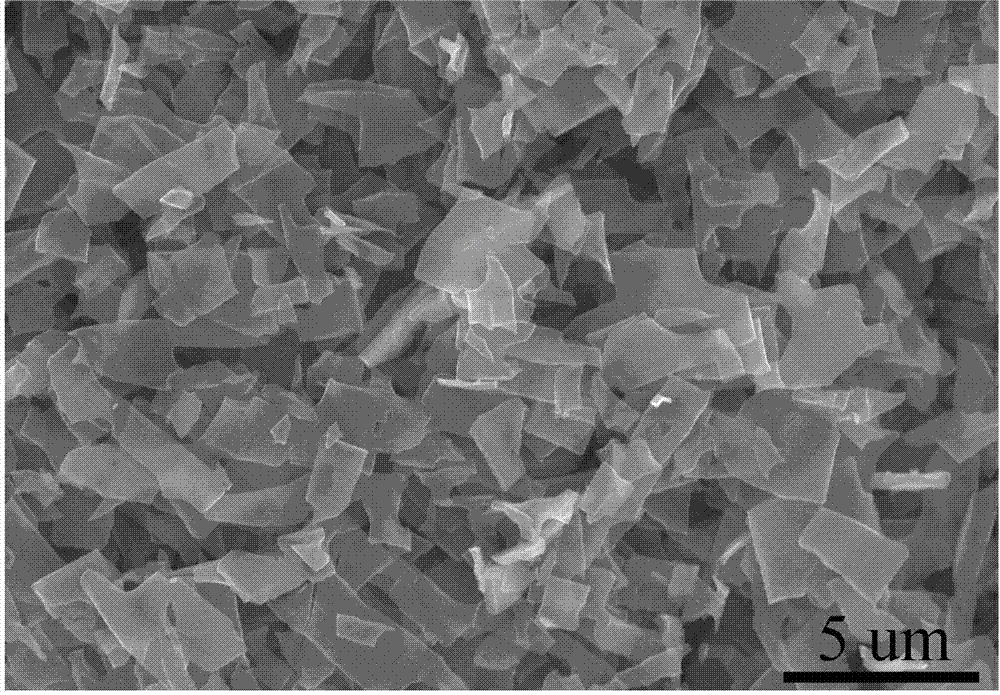

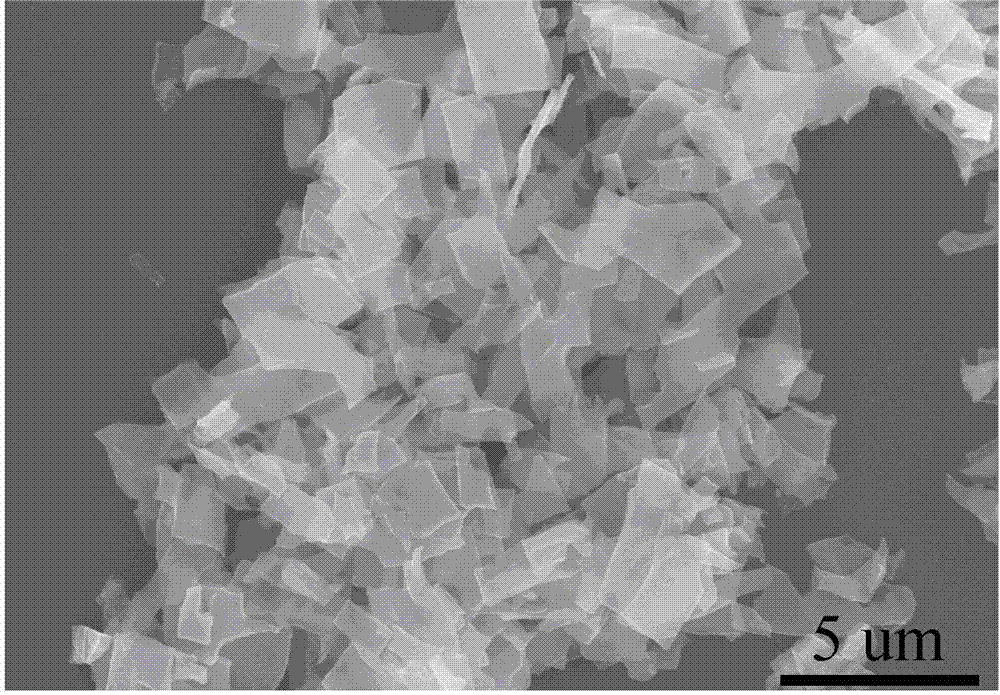

Method for preparing lithium iron phosphate cathode material by three-stage high-temperature solid phase calcination

InactiveCN101279728AWide variety of sourcesLow priceCell electrodesPhosphorus compoundsFurnace temperaturePhosphate

The invention discloses a method for preparing lithium iron phosphate anode material by three-step high temperature solid state sintering and pertains to the technique of chemical power source anode material. The process of the preparation method is that lithium salt, Fe<2+> compound, phosphate and carbon source are mixed according to certain ratio, ground and granulated; particles obtained are transferred in a rotary sintering furnace and carried out predecomposition for 3-10 hours when the temperature is increased to 300-500 DEG C under the protection of nitrogen; the temperature raises to 650-850 DEG C and the heat is preserved for 6-15 hours and then the temperature is dropped to room temperature with furnace temperature; the material obtained is added with carbon source in different amount and is carried out ball milling, the temperature raises to 650-850 DEG C and the heat is preserved for 6-15 hours and then the temperature is dropped to room temperature with furnace temperature, and the lithium iron phosphate anode material is obtained after ball milling. The method of the invention is characterized by simple process, being easy to realize industrial scale production, wide sources of raw materials, low cost, complete crystal form of anode material, regular product pattern, excellent electrochemical performance and high tap density which reaches 1.36g cm<-3>.

Owner:TIANJIN UNIV

Multi-layer carbinol resistance compound film for decomposition-resisting fuel battery and its making method

InactiveCN101034750AImprove resistance to degradationImprove mechanical propertiesCell electrodesFinal product manufactureDistillationDecomposition

The invention relates to the proton exchange membrane which is used for the fuel cell; put concretely it is an multi layered anti-alcohol compound membrane for anti- degenerating the fuel cell; is compound a layer Nafion proton exchange membrane which includes H2O2 decomposition catalyst on the altogether amixing hydrocarbon compound proton exchange membrane side or two sides. Its preparation method is, Nafion alcohol solution with the same volume high boiling point solvent, sets in the flask to reduce pressure distillation, removes alcohol, prepares the Nafion-high boiling point solvent solution, joins the H2O2 decomposition catalyst, the super-sonic surges 30 minutes, match the solution with H2O2 decomposition catalyst / (H2O2 decomposition catalyst +Nafion) load ratio is 1-10%, the solution compound altogether mixing hydrocarbon compound proton exchange membrane side or two sides, after treats solvent volatility, puts in the vacuum drying oven, under 120-160 degree centigrade, handing 2-8 hours, namely obtains the multilayered anti- mellow compound membrane which is used for anti- degeneration fuel cell. The multi layered anti-alcohol compound membrane for anti- degenerating the fuel cell in the invention has good anti-alcohol performance, high conductivity, the high anti-degeneration ability, good mechanics machine capability,the low cost and so on characteristic.

Owner:BEIJING JIAOTONG UNIV

Water-soluble polyvinyl alcohol chopped fiber as well as preparation method and application thereof

ActiveCN102433599ALow water dissolution temperatureEmission reductionSpinnerette packsArtificial filament heat treatmentPolymer scienceSpinning

The invention discloses a water-soluble polyvinyl alcohol chopped fiber of which the water dissolving temperature is 65-75 DEG C. The water-soluble polyvinyl alcohol chopped fiber is prepared by performing spinning and spinning after-treatment on polyvinyl alcohol and water serving as raw materials, wherein the polymerization degree of the polyvinyl alcohol is 1,400+ / -200, the alcoholysis degree is 98.3-99.9 percent, and the mass percentage concentration is 21.0-23.0 percent. The water-soluble polyvinyl alcohol chopped fiber has low water dissolving temperature, and has particularly prominent application effects in the fields of soluble embroidery base cloth, water-soluble paper and the like in the industries of spinning and non-woven fabrics; the water-soluble polyvinyl alcohol chopped fiber is free from salt, so that fiber adhesion is prevented during drying after desalination in the production process; and meanwhile, the strength of the water-soluble polyvinyl alcohol chopped fiber is more than or equal to 3.2 cN / dtex, and the crispation number is more than or equal to 4 / 25 millimeters. The preparation method contributes to industrial mass production, the dissolving temperature of the prepared water-soluble polyvinyl alcohol chopped fiber is 65-75 DEG C, and grading, packaging and transportation are easy.

Owner:CHINA PETROCHEMICAL CORP +1

Dried beancurd with egg filling and production method thereof

InactiveCN101803642ASimple processing methodEasy to eatCheese manufactureAnimal proteinDirect heating

The invention discloses a dried beancurd with an egg filling and a production method thereof, and changes the traditional processing method which adopts the pressure molding of soybean milk with a coagulator and marinating in brine. In the method of the invention, a concentrated soup is added to soybean protein powder to directly season the product without marinating, and then eggs are added according to a certain ratio, mixed and directly heated to be molded without adding any coagulator, thereby making the processing method more convenient. By using the eggs and the soybean protein as the main raw materials, the method comprises the following steps of: adding the concentrated soup for boiling meat, salt, sugar and gourmet powder to the raw materials, mixing, stewing, cooling, slicing, packaging and sterilizing. The product combines the animal protein and the vegetable protein, thereby being more abundant in nutrient components and more elastic. Besides, the product is easy to realize the large-scale industrial production, and can be produced into different tastes, such as spiced taste, spicy taste, spicy and hot taste, barbecue taste and chilli taste.

Owner:师向东

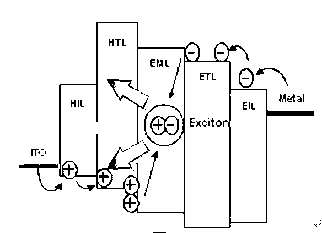

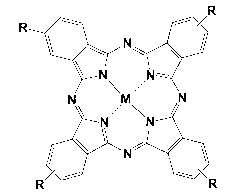

Hole injection material for organic light-emitting device, as well as preparation method and application thereof

InactiveCN103319490AImprove organic solubilityIncrease migration rateOrganic chemistrySolid-state devicesAlkaneElectron hole

The invention relates to a hole injection material for an organic light-emitting device. During a material synthesis process, a straight-chain paraffin group is introduced in the alpha-site of the traditional phthalocyanine ring structure, and different metal substituted ions are used at the centre of the phthalocyanine ring. The hole injection material disclosed by the invention is obtained by performing alkyl substitution on the alpha-site of metal phthalocyanine, simple and convenient to synthesize and purify, and easy to industrially produce in a large scale. Moreover, the pi-conjugated system accumulation of material molecules after film-forming is enhanced, and the carrier migration rate of the material is increased by modifying the interaction force among alkyl groups; a part of isomers can be formed during a synthesis process of alpha-tetra-alkyl substituted phthalocyanine, so that the defect of too high film roughness caused by excessive crystallization during the traditional phthalocyanine molecule film-forming process can be prevented.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Prepn process of nano silver iodide powder

InactiveCN1673093AHigh purityLow costNanostructure manufactureIodide preparationSilver iodideGranularity

The present invention relates to the preparation process of nanometer silver iodide powder. Clear silver sulfate water solution containing silver nitrate in 0.1-0.4 M / L and complexing agent in 0.034-0.2 M / L is dropped slowly into clear potassium iodide water solution containing potassium iodide in 0.1-0.4 M / L, complexing agent in 0.034-0.2 M / L and dispersant in 0.01-0.04 M / L at normal temperature and normal pressure via stirring, and the product is let stand to deposit to obtain nanometer silver iodide deposit. The nanometer silver iodide deposit is filtered, washed and dried at 80-100 deg.c for 1-2.5 hr to obtain nanometer silver iodide powder with granularity below 100 nm. The process is easy to control, pollution-free and suitable for industrial production, and the product has high quality and low cost.

Owner:JILIN UNIV

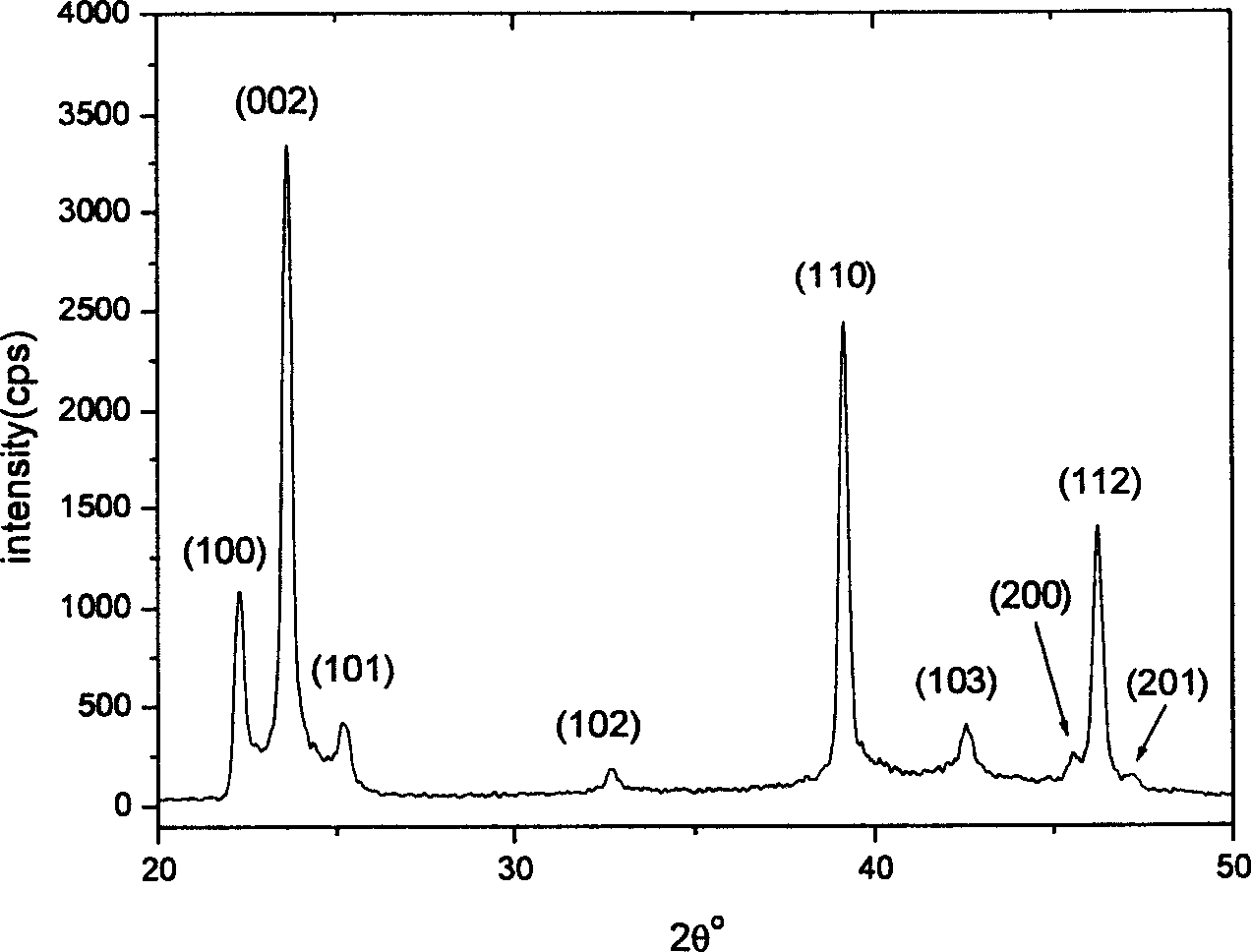

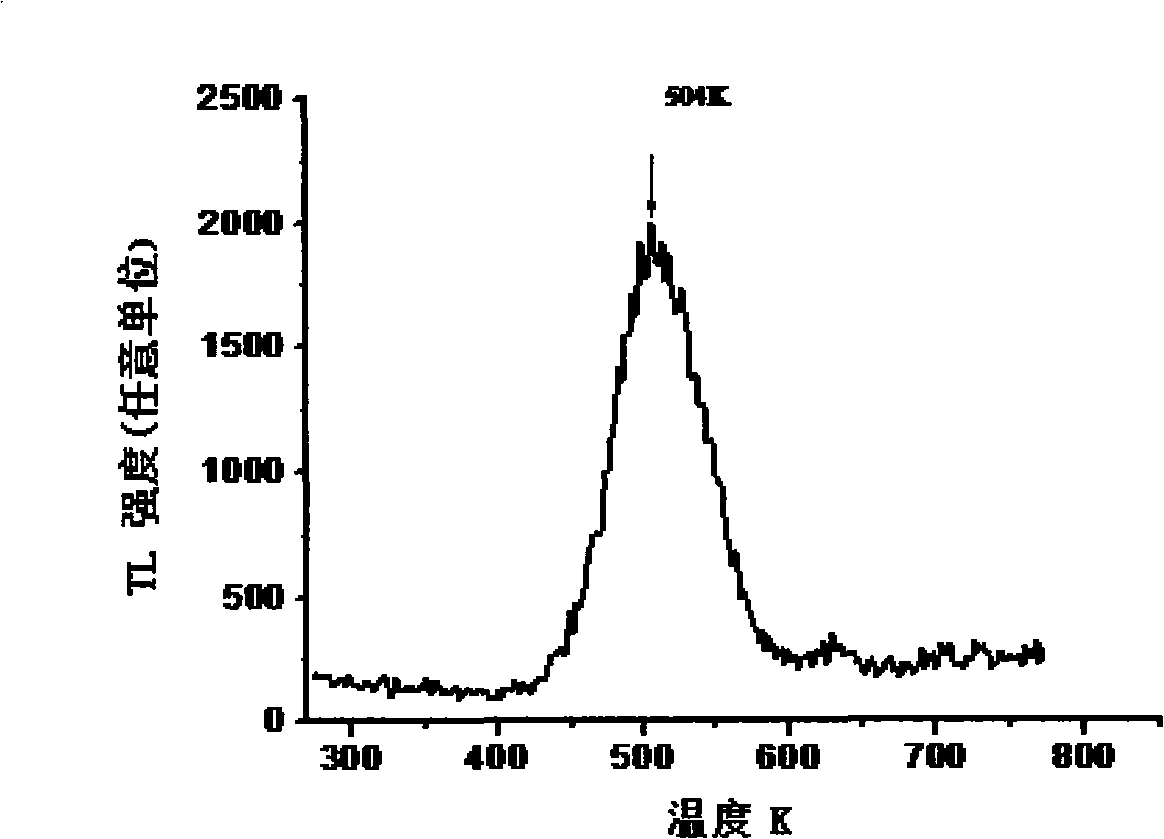

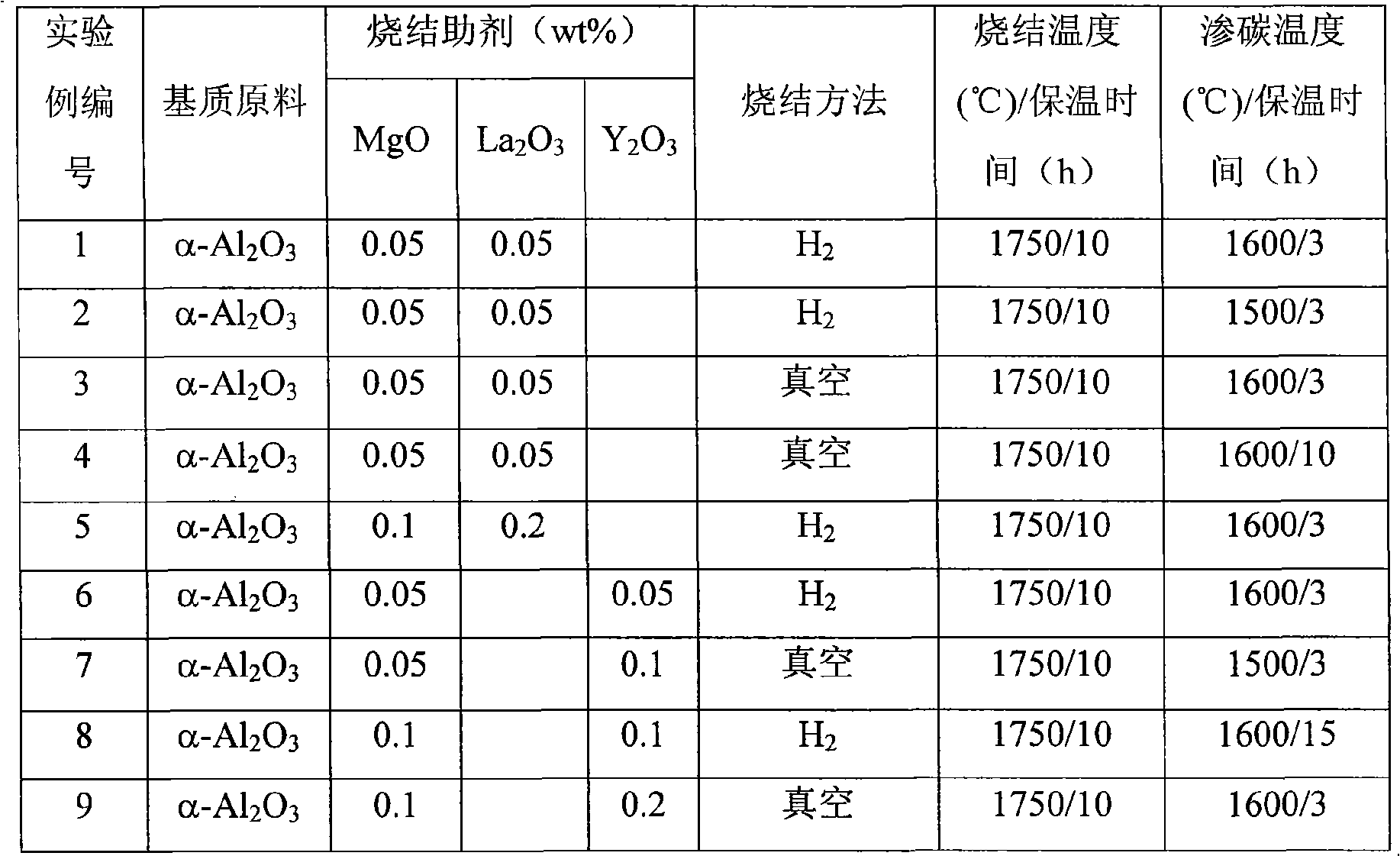

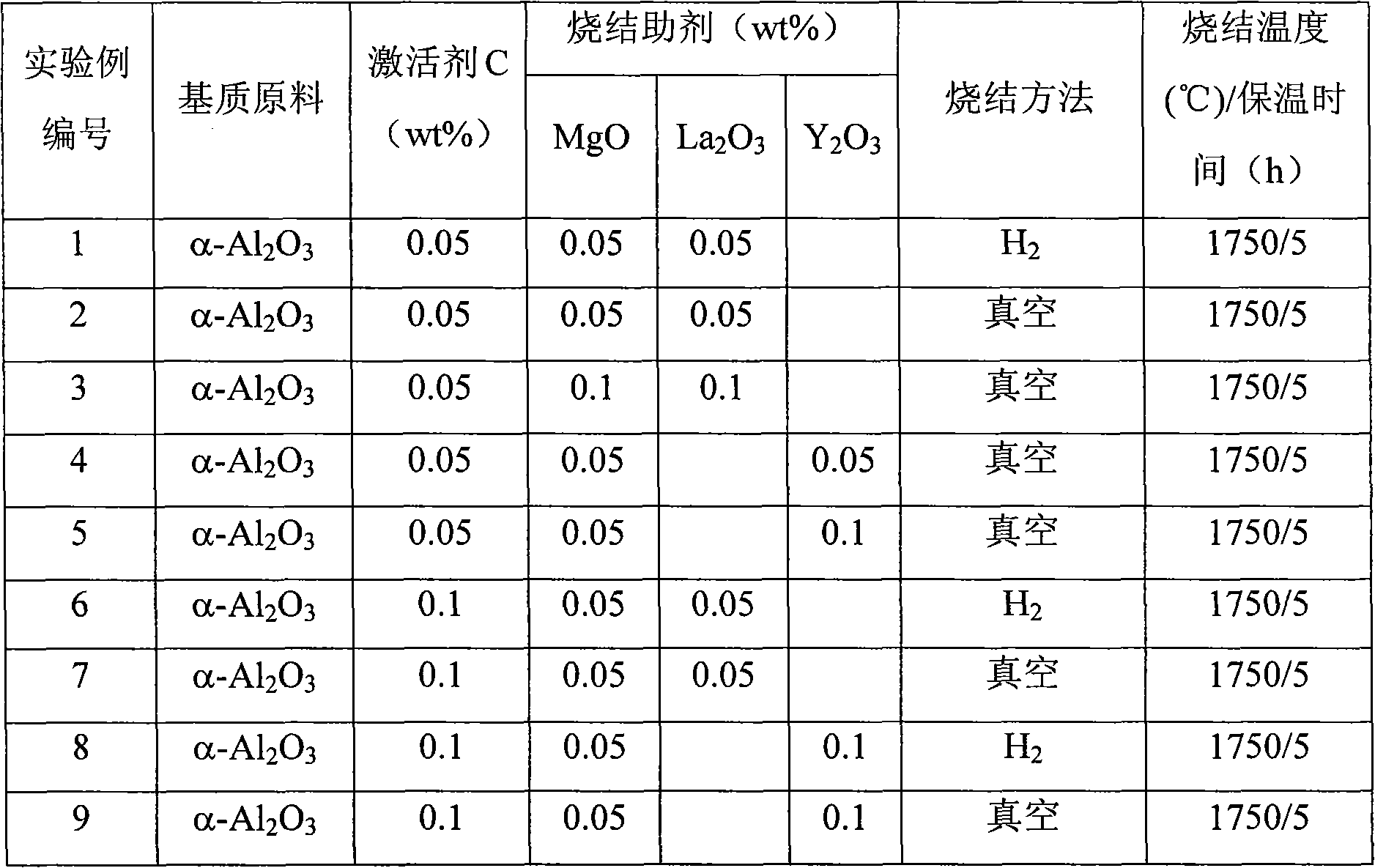

Method for preparing C-doped alpha-Al2O3 transparent ceramic thermoluminescent and photoluminescent material

InactiveCN101560102AReduce manufacturing costEasy to achieve high dopingLuminescent compositionsGraphiteLanthanum compounds

The invention relates to a C-doped alpha-Al2O3 transparent ceramic thermoluminescent and photoluminescent material and a preparation method thereof and belongs to the technical field of ceramic material manufacturing techniques. The method adopts high-purity alpha-Al2O3 and carbon powder or graphite as raw materials and adopts MgO and La2O3 or Y2O3 as sintering aids and a solidoid sintering method to prepare the alpha-Al2O3:C transparent ceramic thermoluminescent and photoluminescent material under a condition of a lower temperature. Detection experiments show that the alpha-Al2O3:C transparent ceramic material prepared by the method has an excellent thermoluminescent property and can be used as a measurement material for radiation dose.

Owner:苏州巍迩光电科技有限公司

Method for preparing halogen-free high-efficiency flame retardant aryloxy cyclotriphosphazene compound

ActiveCN102180908APromote low-carbon and high-efficiencyEase of industrial scale productionGroup 5/15 element organic compoundsPolymer scienceHalogen

The invention discloses a method for preparing a halogen-free high-efficiency flame retardant aryloxy cyclotriphosphazene compound. The flame retardant is a pure white crystal product prepared by reacting sodium phenate and hexachlorocyclotriphosphazene serving as raw materials with dioxane serving as a solvent under heating and stirring, filtering and purifying. The preparation method of the flame retardant overcomes the defects of long reaction time, a yellow product color and high production cost existing in the conventional synthesis method commonly. The prepared flame retardant has the characteristics of high efficiency, no halogen, flame retardance, no toxicity, low smoke and the like, has high compatibility with most of organic polymer materials, and has processing stability and using stability.

Owner:JINAN TAIXING FINE CHEM

Process for synthesizing 3- (or-4)-nitro o-phenylenedinitrile

InactiveCN1369480ASimple processEasy to operatePreparation from N-formylated amino compoundsOrganic solventPolymer science

A process for preparing 3 (or 4)-nitro o-phenylenedinitrile features that a solvent method instead of solid-phase roast method is used to prepare 3 (or 4)-nitro phthaloyimine and the amidation process of 3 (or 4)-nitro phthaloymidine is improved. Its advantages are gentle reaction condition, high purity of product, high safety and less pollution.

Owner:EAST CHINA UNIV OF SCI & TECH +1

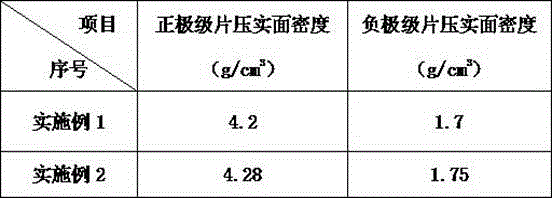

Preparation method for high-capacity lithium ion battery positive electrode tab

InactiveCN105932228AIncrease energy densityEasy to processElectrode manufacturing processesElectrolyte accumulators manufactureElectrical batterySlurry

Owner:QUANZHOU JINTION ELECTRONICS

Method for preparing monodisperse antimony-doped tin oxide nano-powder

InactiveCN103523819AAvoid hydrolysisAchieve true dopingNanotechnologyTin oxidesDispersityParticle-size distribution

The invention relates to method for preparing monodisperse antimony-doped tin oxide nano-powder. The method comprises the following main steps: preparing a precursor under a certain reaction condition; stewing the precursor, washing, filtering and drying a filter cake; grinding and calcining, thereby finally obtaining the nano-powder. The method has the characteristics that a mixed solution of antimonic salt, tin salt, a compounding agent and a dispersing agent is adopted to react; a precipitator is finally added. Thus, the prepared powder is good in dispersity, less in agglomeration, complete in crystallization, and small in particle size distribution; the particle size of the powder is 12-17nm; meanwhile, the preparation method is simple and convenient to prepare, simple in technology, low in cost, short in reaction period, and easy for realization industrial production.

Owner:NANJING UNIV OF TECH

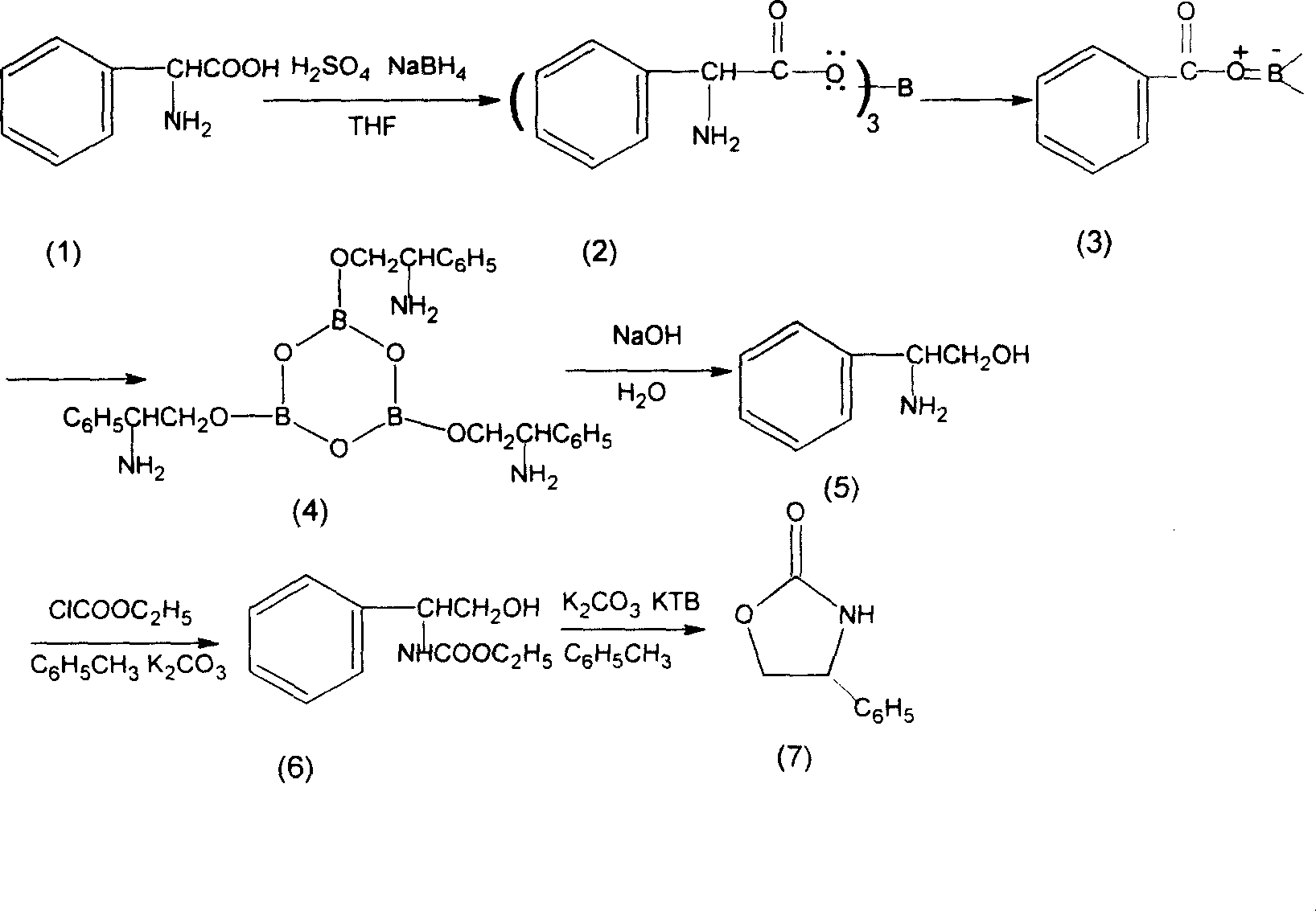

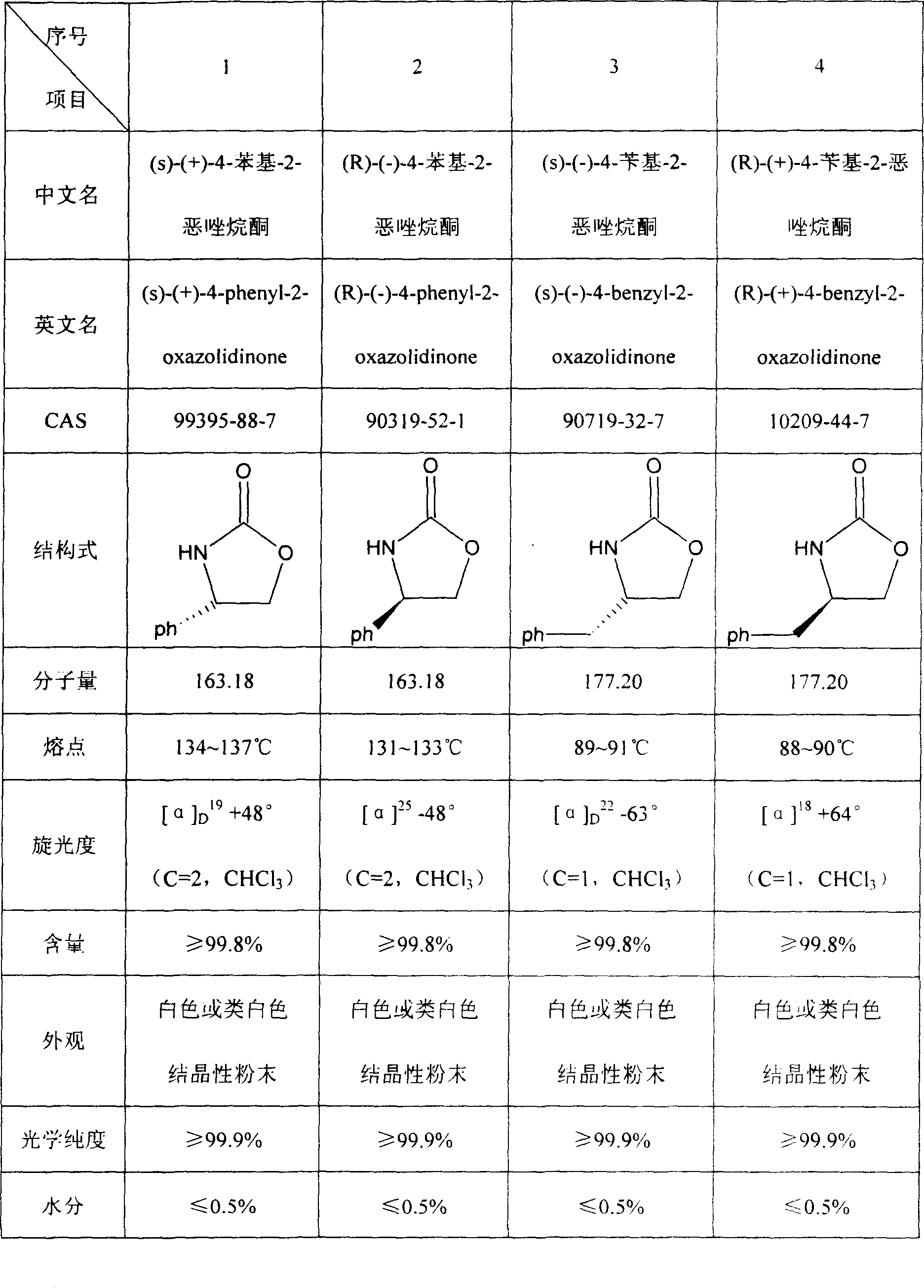

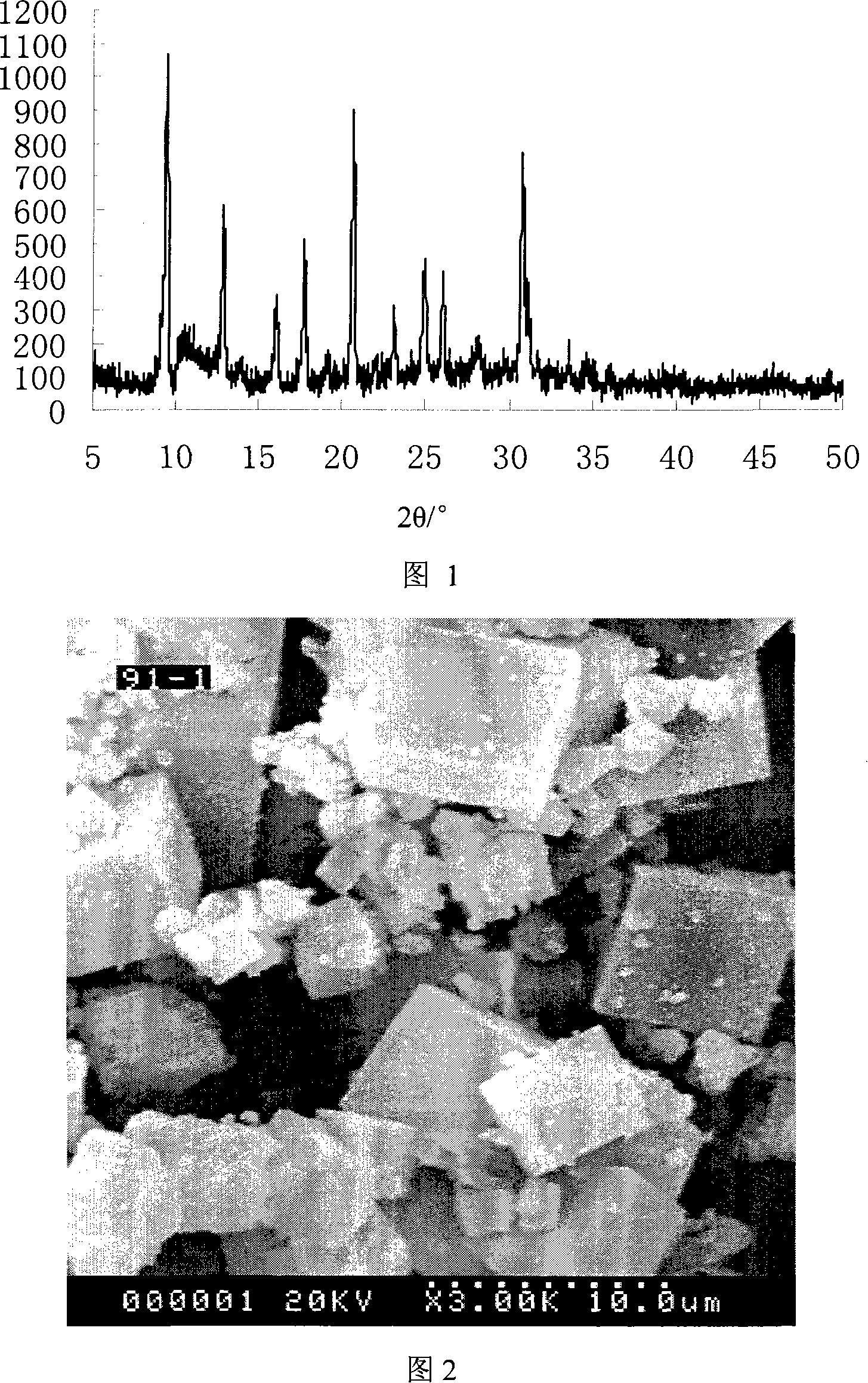

Prepn process of chiral 4-substituent-2-oxazolidone

InactiveCN1931847AMild reaction conditionsCommon reaction conditionsOrganic chemistryAlcoholMetallole

The present invention discloses the preparation process of one kind of chiral 4-substituent-2-oxazolidone. The preparation process includes the first reducing chiral amino acid into alcohol in the presence of Lewis acid and catalyst metal boron compound, the subsequent acylation with acyl chloride compound and no phosgene, and cyclization in buffering solution with strong alkali catalyst. The present invention has low cost, less reaction steps, less wastes produced, high product quality and high total yield, and is suitable for industrial production.

Owner:上海五洲药业股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthetic method of [1-methyl-2-(8'-octyl hydroxamic acid group)-5-N,N-bi(2'-chloroethyl)]-1H-benzimidazole Synthetic method of [1-methyl-2-(8'-octyl hydroxamic acid group)-5-N,N-bi(2'-chloroethyl)]-1H-benzimidazole](https://images-eureka.patsnap.com/patent_img/699fb17d-fcea-43e3-9b32-2956095f09ea/BDA0000091868740000021.PNG)

![Synthetic method of [1-methyl-2-(8'-octyl hydroxamic acid group)-5-N,N-bi(2'-chloroethyl)]-1H-benzimidazole Synthetic method of [1-methyl-2-(8'-octyl hydroxamic acid group)-5-N,N-bi(2'-chloroethyl)]-1H-benzimidazole](https://images-eureka.patsnap.com/patent_img/699fb17d-fcea-43e3-9b32-2956095f09ea/BDA0000091868740000022.PNG)

![Synthetic method of [1-methyl-2-(8'-octyl hydroxamic acid group)-5-N,N-bi(2'-chloroethyl)]-1H-benzimidazole Synthetic method of [1-methyl-2-(8'-octyl hydroxamic acid group)-5-N,N-bi(2'-chloroethyl)]-1H-benzimidazole](https://images-eureka.patsnap.com/patent_img/699fb17d-fcea-43e3-9b32-2956095f09ea/BDA0000091868740000041.PNG)