Patents

Literature

144 results about "Product pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radiation-curable composition and method for manufacturing cured-product patterns therefrom

InactiveUS6096483AHighly radiation curabilityHigh sensitivityImpression capsOrganic chemistrySilicon oxygenUltraviolet lights

The present invention provides a curable composition which comprises (A) a base-generating substance which generates a base when exposed to the action of ultraviolet light, (B) a siloxane polymer which has silicon-hydrogen bonds (Si-H) capable of reacting with hydroxy groups under the effect of the base to form silicon-oxygen bonds (Si-O) and hydrogen molecules (H2), and (C) an acid substance. This composition is cured by irradiation with ultraviolet light. During this ultraviolet irradiation, a mask is placed between a coating film of the composition and the radiation source, and the uncured portions of the composition are dissolved and removed so that a pattern is formed. The residual portions are then heated to produce a pattern-cured product.

Owner:DOW CORNING ASIA

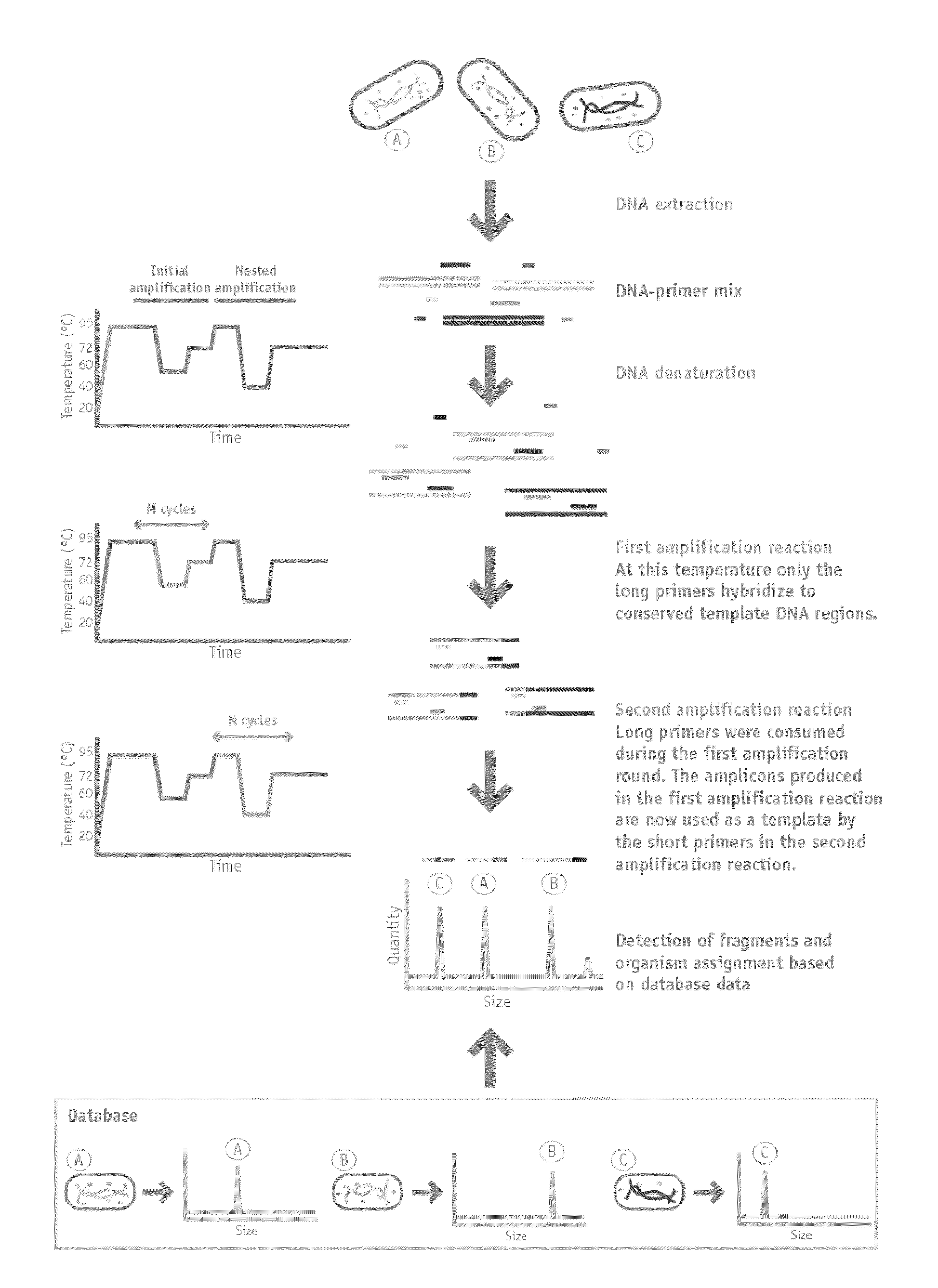

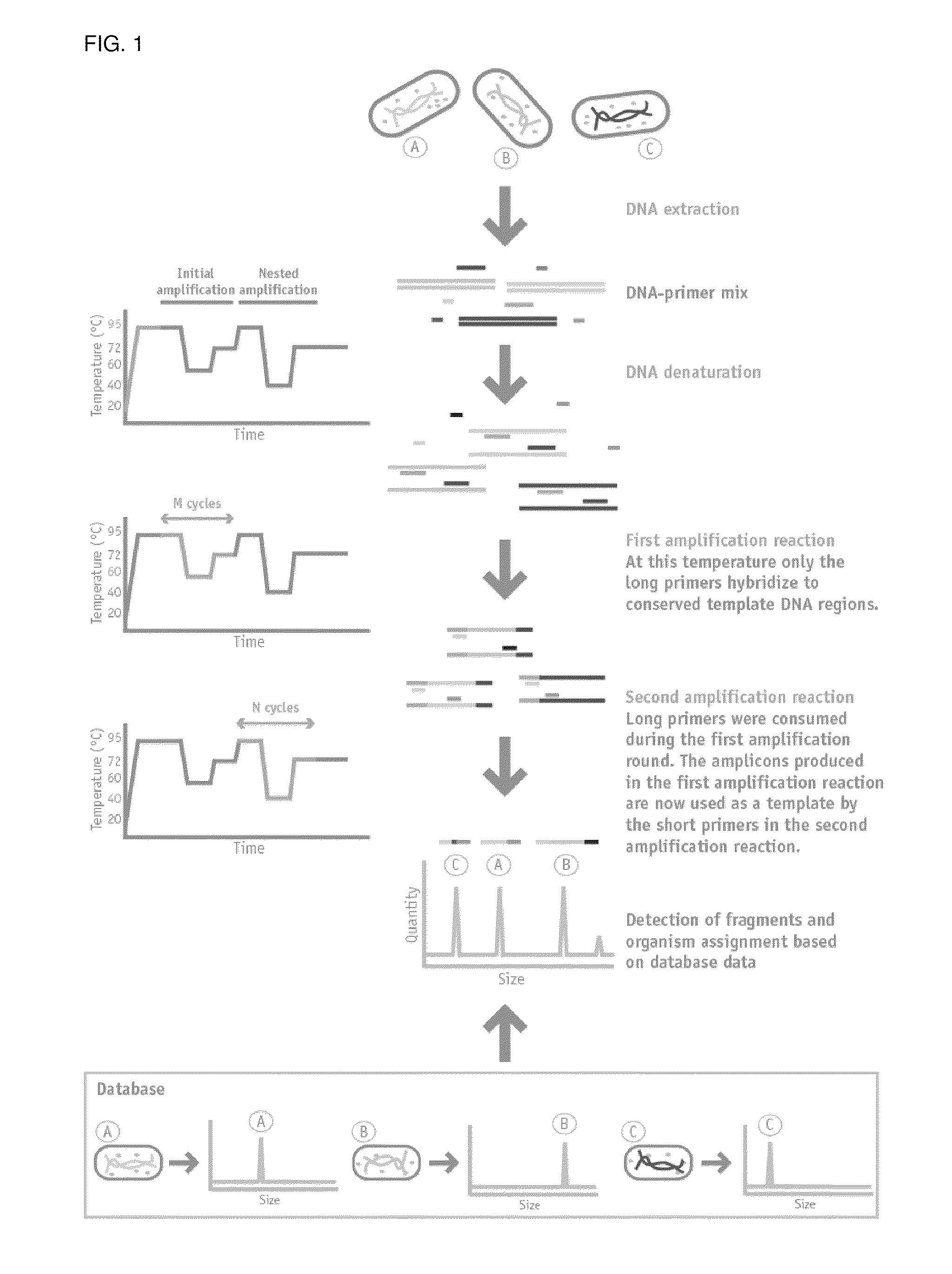

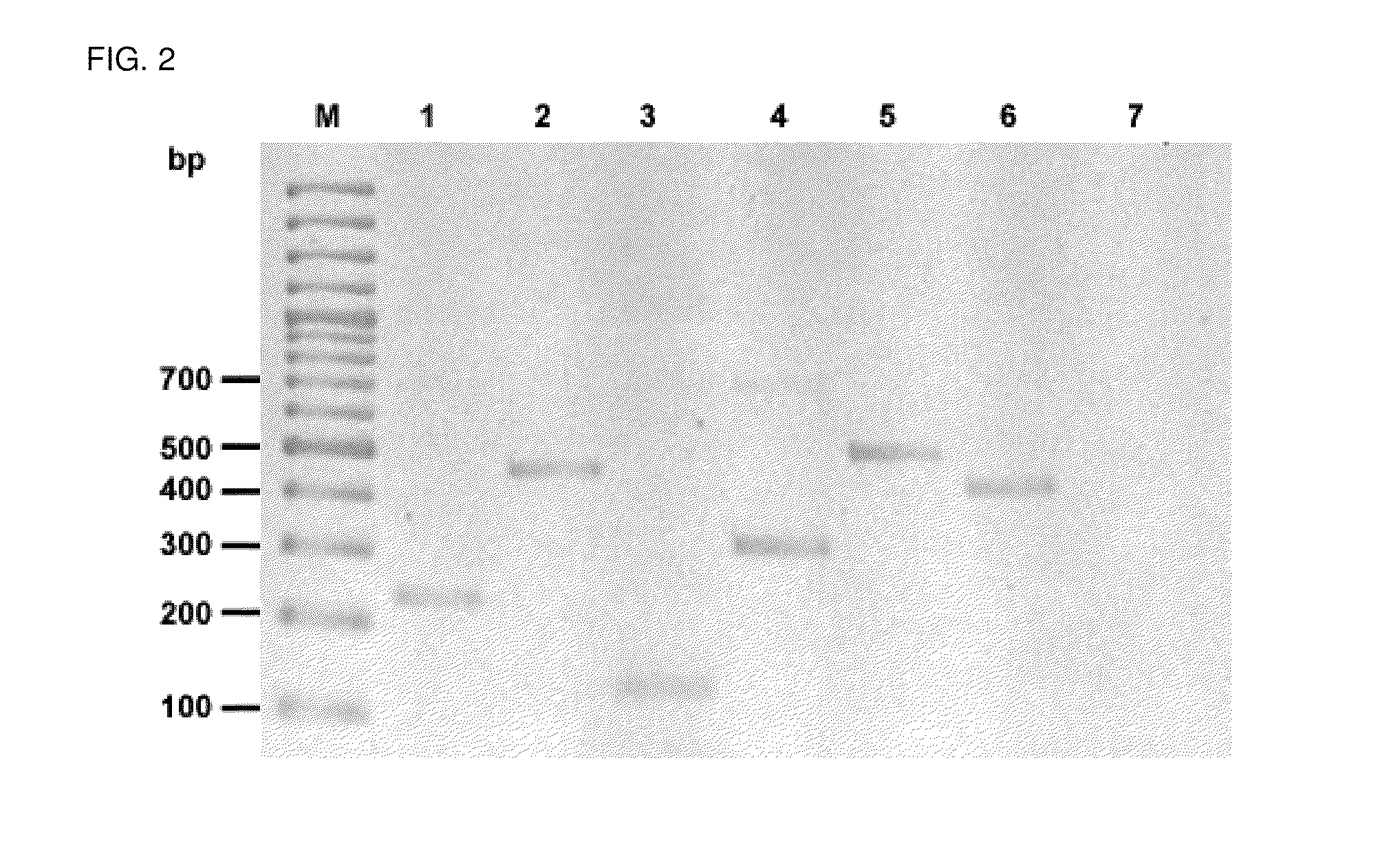

Nested Multiplex Amplification Method for Identification of Multiple Biological Entities

InactiveUS20100273159A1Good discernmentImprove reusabilityElectrolysis componentsMicrobiological testing/measurementOligonucleotide primersNucleotide

The present invention provides a novel molecular method for the simultaneous identification and semi-quantification of multiple targeted biological entities from amongst a plurality. This invention discloses a method based on a multiplex nested amplification reaction in a single closed tube. The first amplification reaction relies on a set of large oligonucleotides for the amplification of common loci in all the targeted biological entities. The second nested amplification reaction relies on a set of short oligonucleotide primers that amplifies specific nucleotide sequences from all the amplicons previously produced in the first amplification reaction and generates an amplified product pattern capable of identifying each targeted biological entity. This method offers fast and accurate simultaneous identification of many targeted biological entities in any sample.

Owner:TAAG GENETICS

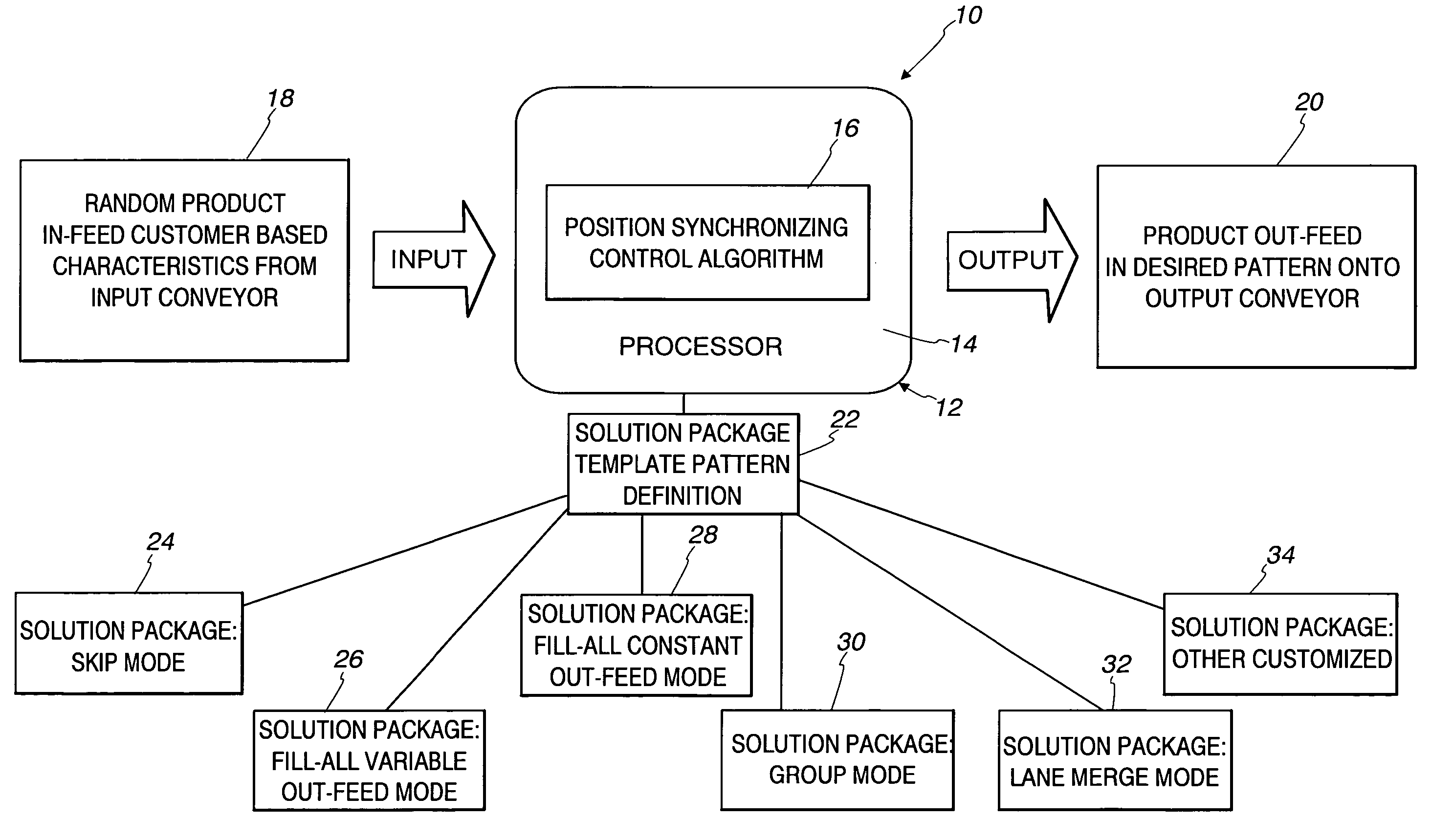

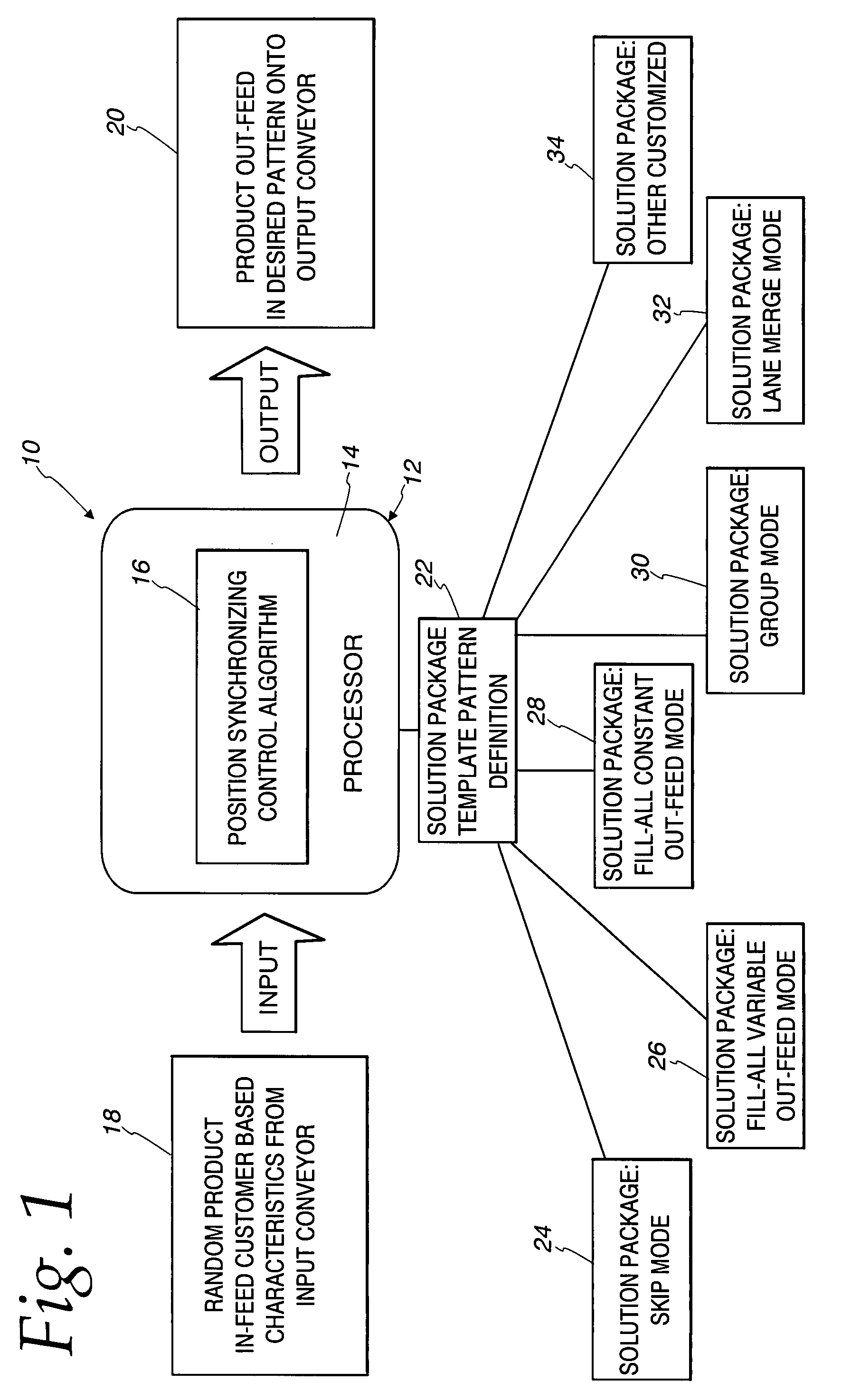

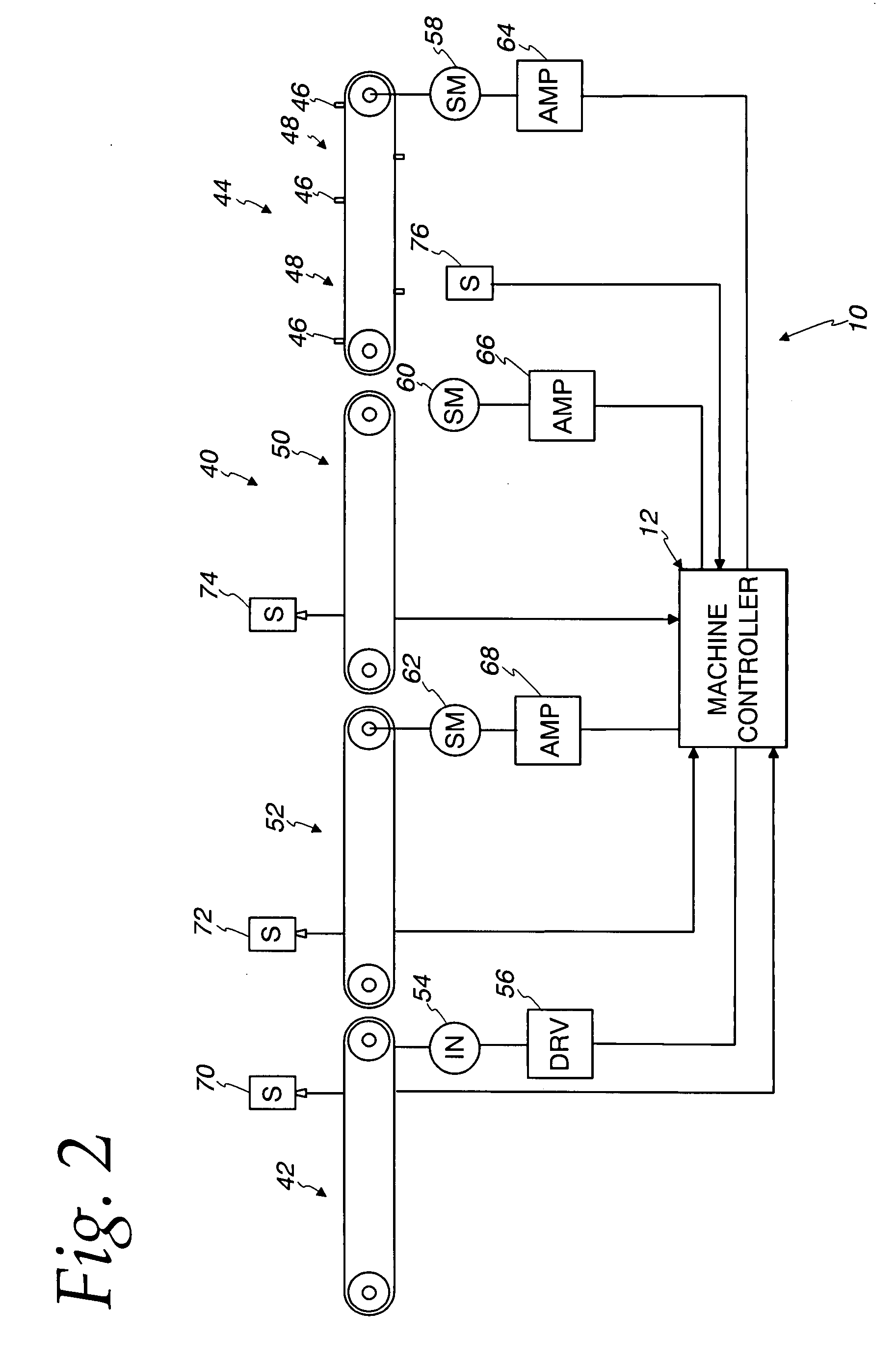

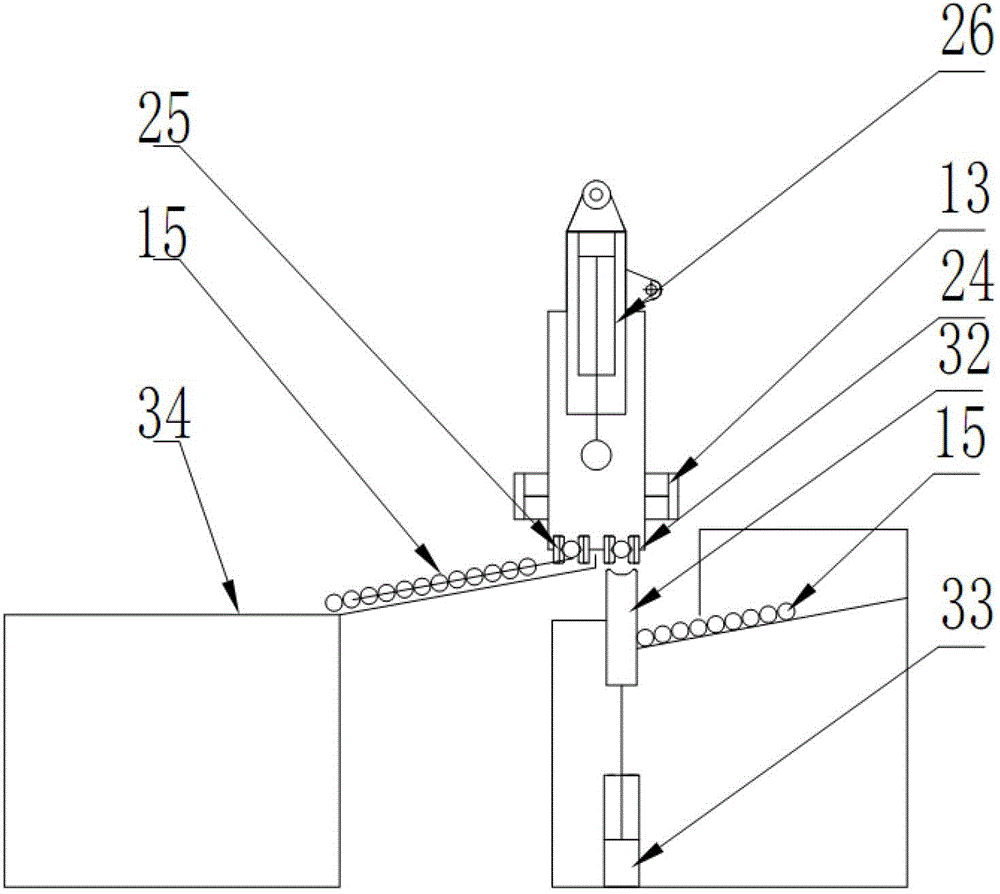

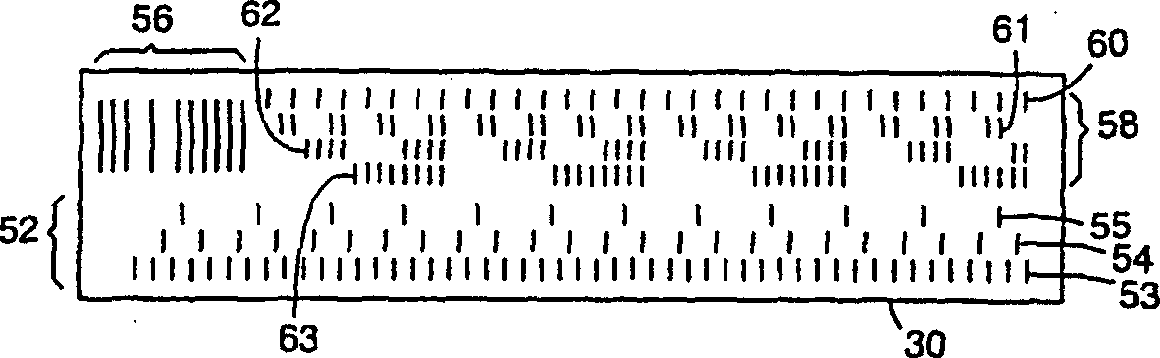

Automated conveying system

InactiveUS20080082206A1Prevent slippingAvoid lossDigital data processing detailsControl devices for conveyorsControl systemProduct pattern

An automated control system is described for a conveying system including an input conveyor supplying a product, a segmented output conveyor delivering a product in a pattern, and one or more synchronizing conveyors disposed between the input conveyor and the output conveyor. The control system comprises a plurality of product position sensors for sensing position of product on each synchronizing conveyor. A conveyor sensor senses segment position of the output conveyor. A plurality of drives, one for each respective conveyor, control the respective conveyors. A database stores a plurality of template pattern algorithms each defining a control algorithm for a distinct product pattern to be delivered from the segmented output conveyor. A controller is operatively connected to the product position sensors, the conveyor sensor and the drives for controlling the conveyors responsive to sensed product position and segment position. The controller includes a programmable processor operable to download a select one of the template pattern algorithms. The controller selectively advances or retards product position relative to the segment position of the output conveyor to release the products onto the output conveyor according to the distinct product pattern defined by the downloaded template pattern algorithm.

Owner:YASKAWA ELECTRIC AMERICA

Wear-resistant and non-slip ceramic tile and preparation method thereof

The invention discloses a wear-resistant and non-slip ceramic tile. A mixed glaze layer of wear-resistant and non-slip particles and engobe is applied to the surface of a moulded ceramic tile base clay blank, wherein the mixed glaze layer of the wear-resistant and non-slip particles and the engobe is prepared from a mixed glaze slurry consisting of an engobe glaze slurry and high-temperature wear-resistant and non-slip particles. The invention further discloses a preparation method of the wear-resistant and non-slip ceramic tile. In the wear-resistant and non-slip ceramic tile, the wear-resistant and non-slip dry particles are inlaid into the engobe glaze layer and are positioned below a ceramic tile pattern decoration layer, so that the particle components and the transparency of the wear-resistant and non-slip dry particles do not affect the color effect of a product pattern, and the wear-resistant and non-slip dry particles are unlikely to be worn or scraped off during actual use; the particle size of the wear-resistant and non-slip dry particles is relatively large, so that the surface of a product achieves a better non-slip and anti-fouling effect.

Owner:JIANGXI HEMEI CERAMICS +1

Multi-system glaze-material stereo comprehensive decorative ceramic tile and preparation method thereof

ActiveCN107311699ADoes not affect the color effectAffect color effectsCeramic shaping apparatusFlooringColor effectBrick

The invention discloses a multi-system glaze-material stereo comprehensive decorative ceramic tile. An abrasion-resistant anti-slip particle layer, an engobe glaze layer, a pattern decoration layer and an abrasion-resistant, matte and transparent glaze decoration layer are sequentially applied to the surface of the ceramic tile from inside to outside. The invention also discloses a preparation method of the multi-system glaze-material stereo comprehensive decorative ceramic tile. In the disclosed multi-system glaze-material stereo comprehensive decorative ceramic tile, the abrasion-resistant anti-slip particle layer is located under the engobe glaze layer and the pattern decoration layer, a product pattern color effect is not affected by its particle components and transparency, and meanwhile the anti-slip particle layer is not easily abraded or scraped off in actual life. In addition, due to relative larger particle size of the particles, better anti-slip and anti-fouling effects can be produced to the surface of the product.

Owner:JIANGXI HEMEI CERAMICS

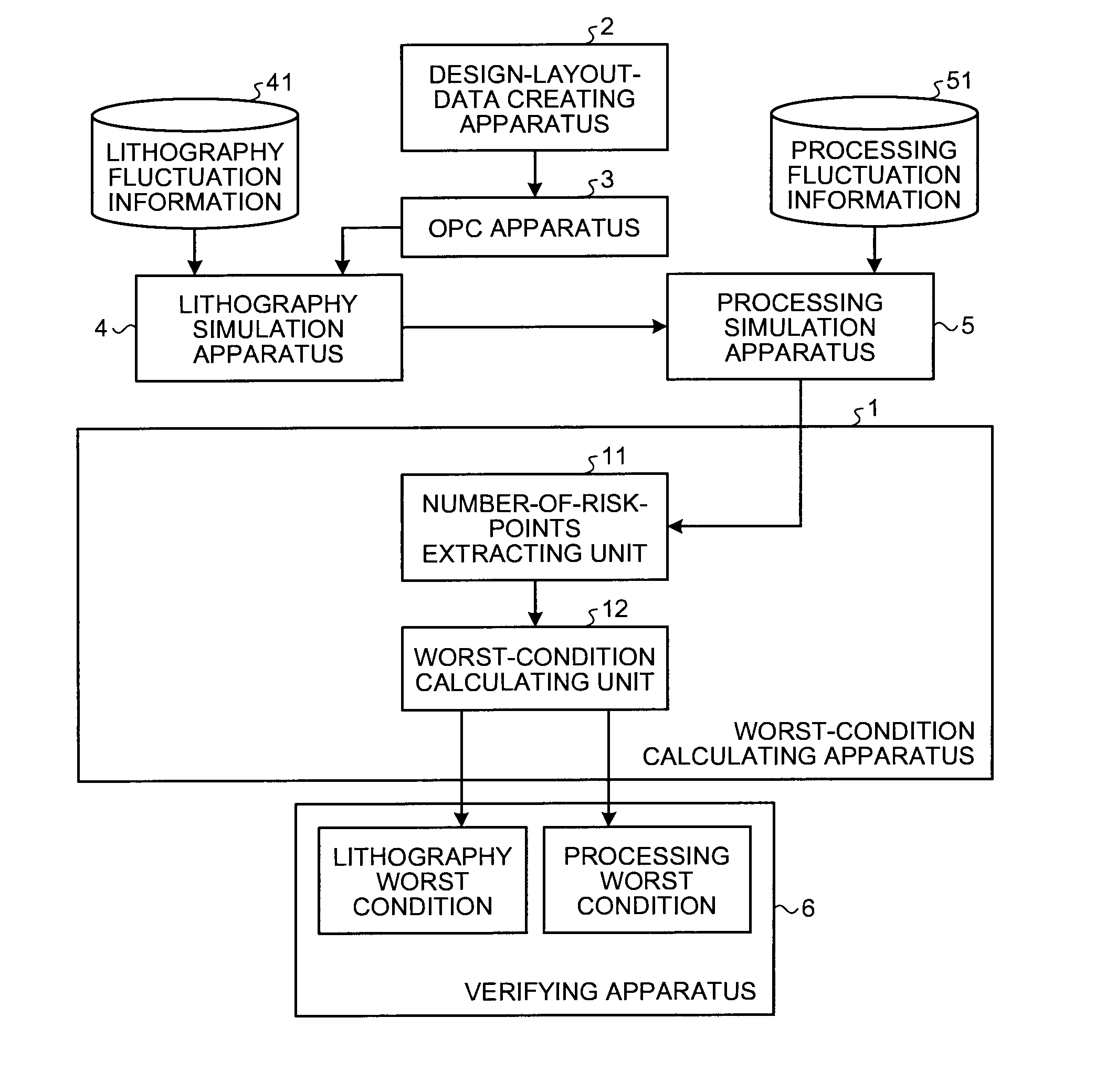

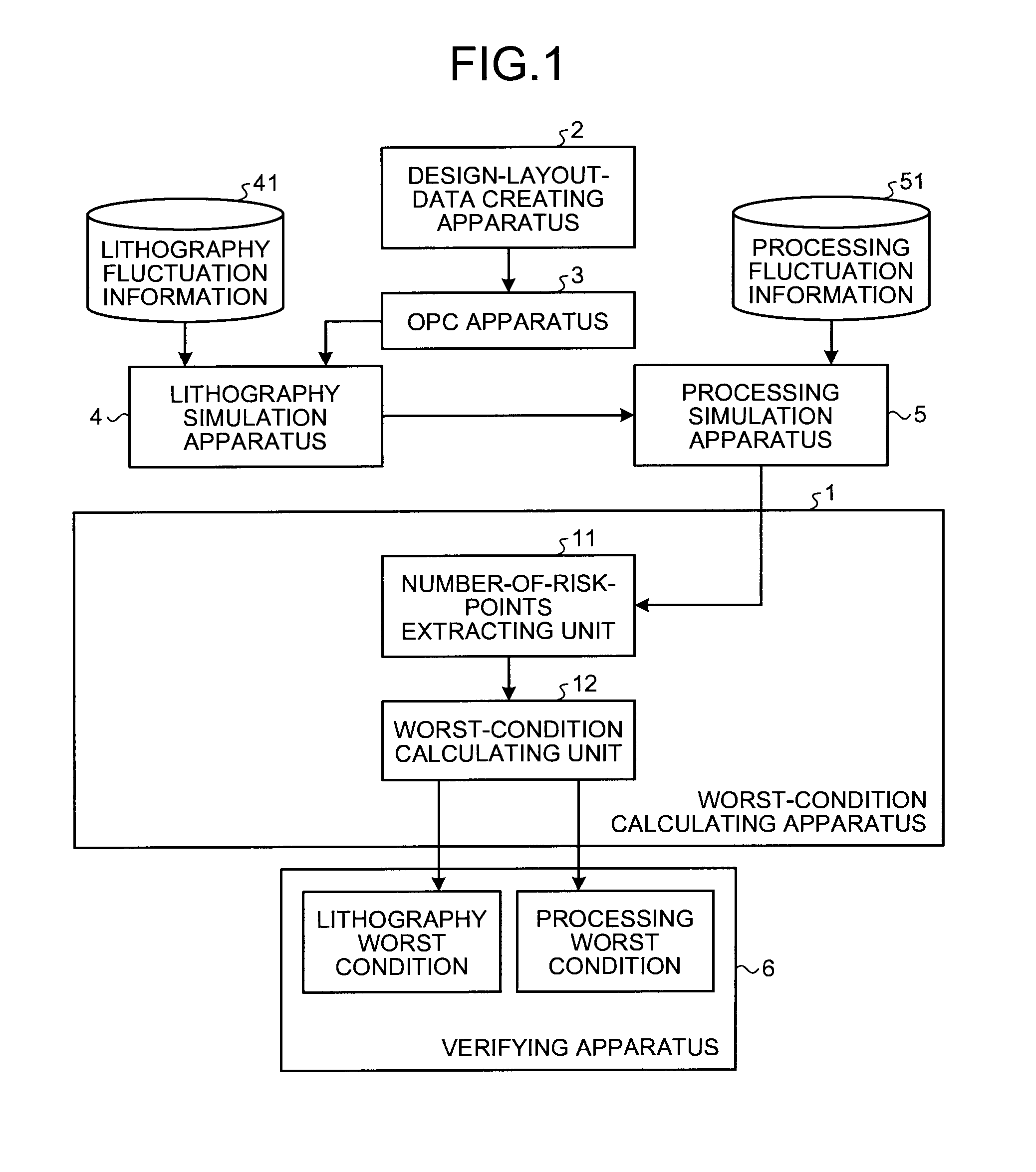

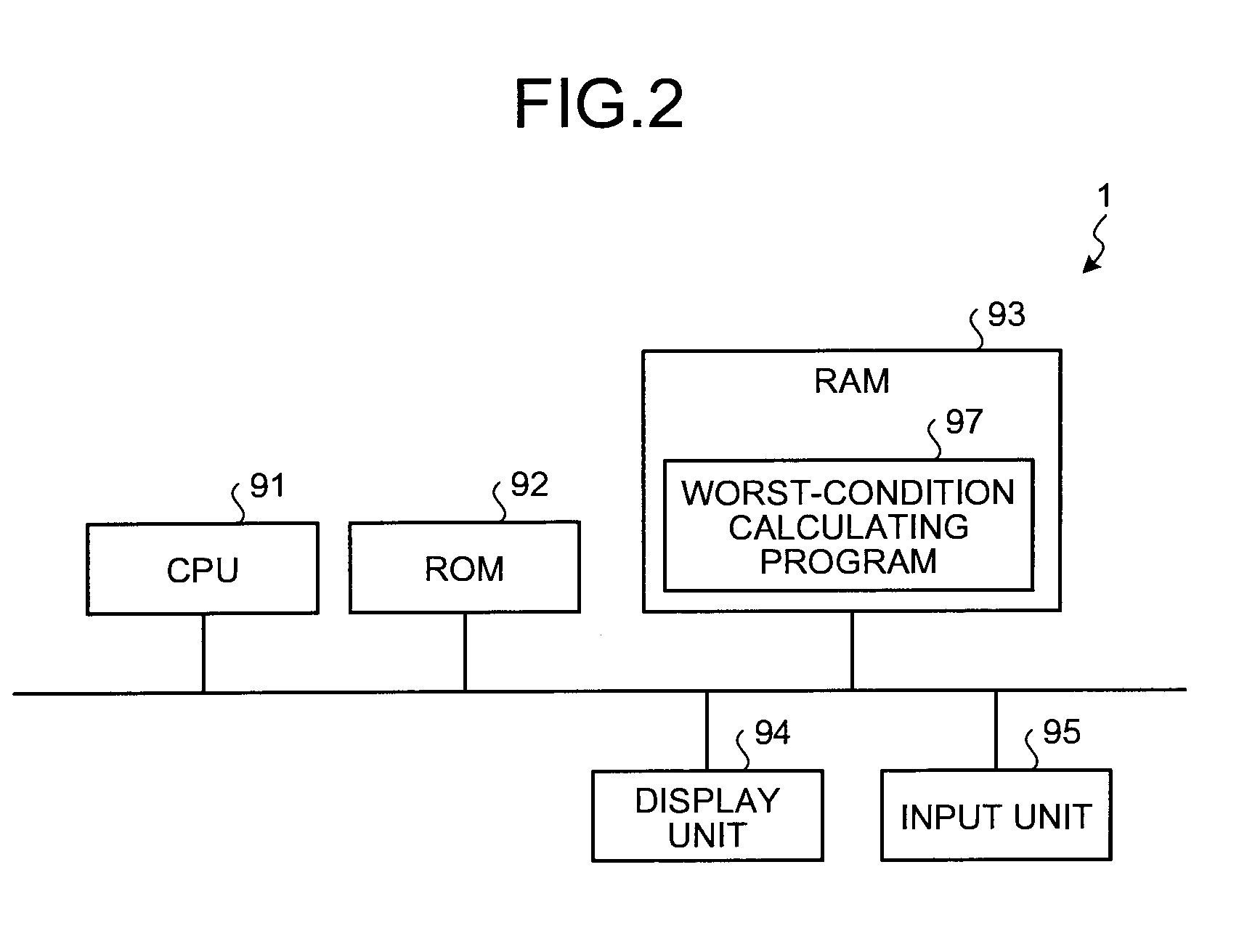

Pattern generating method, method of manufacturing semiconductor device, and computer program product

InactiveUS20100241261A1Raise the possibilitySemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentParallel computingComputation process

Pattern formation simulations are performed based on design layout data subjected to OPC processing with a plurality of process parameters set in process conditions. A worst condition of the process conditions is calculated based on risk points extracted from simulation results. The design layout data or the OPC processing is changed such that when a pattern is formed under the worst condition based on the changed design layout data or the changed OPC processing a number of the risk points or a risk degree of the risk points of the pattern is smaller than the simulation result.

Owner:KK TOSHIBA

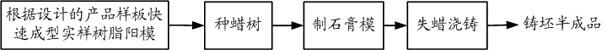

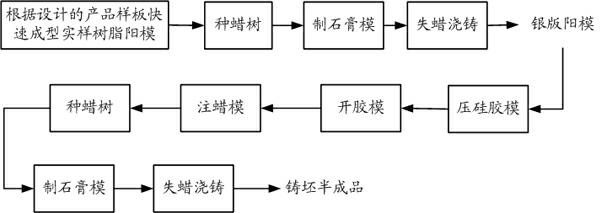

Simplified process method of lost wax casting

InactiveCN102248125ASimple processing methodSimple methodFoundry mouldsFoundry coresParaffin oilsProduct pattern

The invention discloses a simplified process method of lost wax casting, which comprises the following steps in sequence: wax tree planting, plaster mold preparation, and lost wax casting; before the wax tree planting step, the following steps are included: (1) directly molding a resin female mold by a rapid molding device, wherein the resin female mold comprises a mold cavity which has the same shape as the product to be prepared by the simplified process method of lost wax casting; (2) injecting a wax mold: melting paraffin and performing heat insulation, filling the resin female mold with the paraffin in a wax injector, cooling, and finishing to obtain a wax mold. The method of the invention omits a plurality of procedures for mold turnover, saves the cost, and prevents the problem that dimensions and styles deviates the initial design due to multiple male mould-female mold conversion; and the resin female mold is directly molded by the rapid molding device, and thus product pattern replacement is very flexible and rapid.

Owner:SHENZHEN INST OF TECH

Anti-glare hardened film for in-mold decoration

ActiveCN101825729AHigh transparencyHigh haze performancePolyurea/polyurethane coatingsOptical elementsSolventAcrylic monomers

The invention relates to an anti-glare hardened film for in-mold decoration, in the technical scheme, an anti-glare hard coating is coated on a substrate film; the components for preparing the anti-glare hard coating and the weight parts thereof are as follows: 10 to 30 parts of polyurethane acrylate prepolymer, 15 to 40 parts of grafted modified acrylic monomer, 5 to 15 parts of anti-glare particles, 0.5 to 7 parts of photoinitiator, 0.05 to 2 parts of flatting agent, and 30 to 70 parts of solvent. The anti-glare hardened film for in-mold decoration has high transparency and high haze, can effectively prevent the surface reflection from achieving the anti-glare purpose while ensure high clarity of an IMD product pattern, simultaneously has above 2H hardness and excellent anti-corrosion performance, can meet the performance requirements on most 2D and 3D product forming and processing, does not crack when the stretching and forming height reaches above 6mm, and can be widely applied in the fields of anti-glare treatment requirements and matt panel decoration.

Owner:CHINA LUCKY FILM CORP

Method for preparing lithium iron phosphate cathode material by three-stage high-temperature solid phase calcination

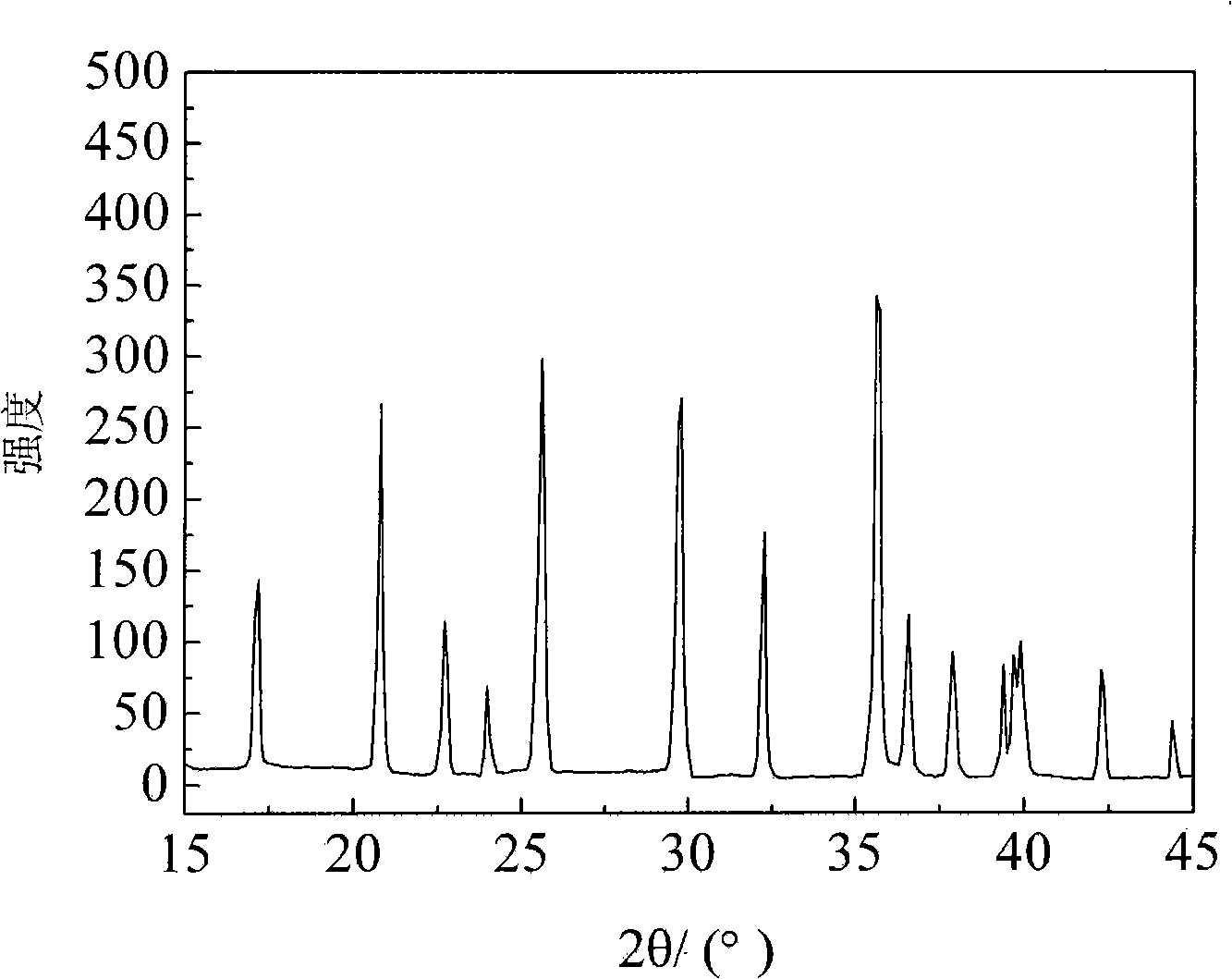

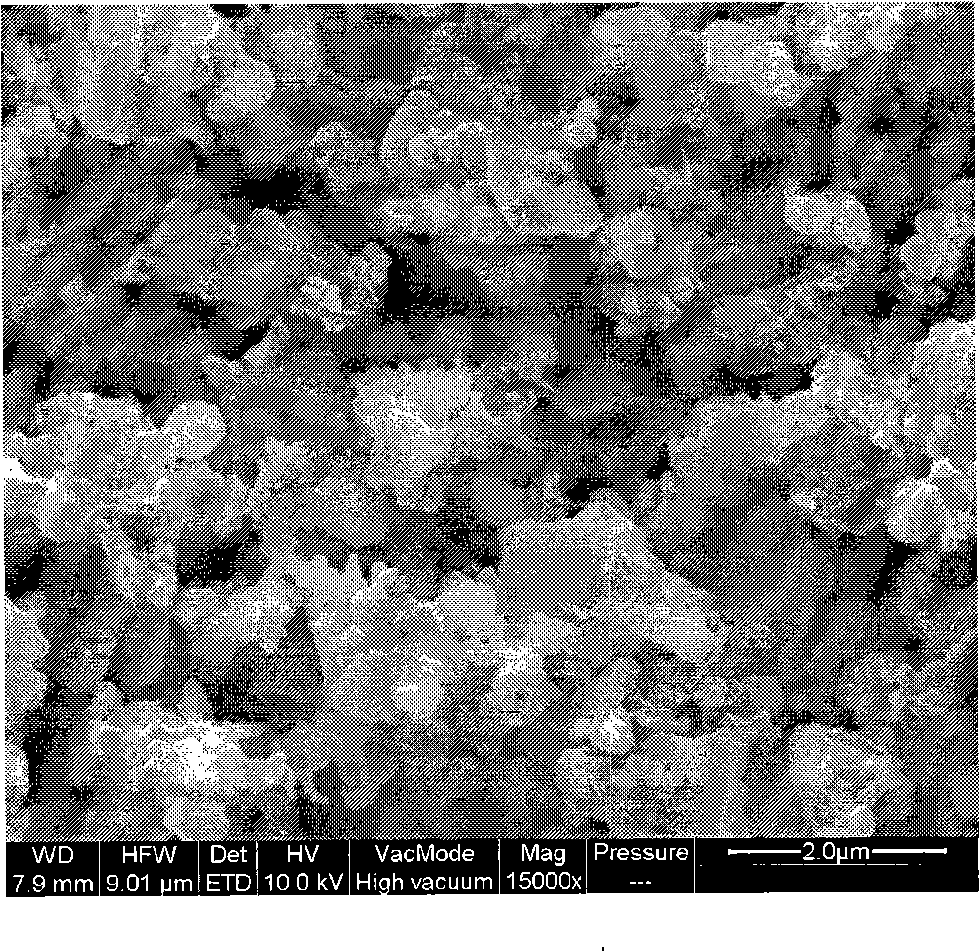

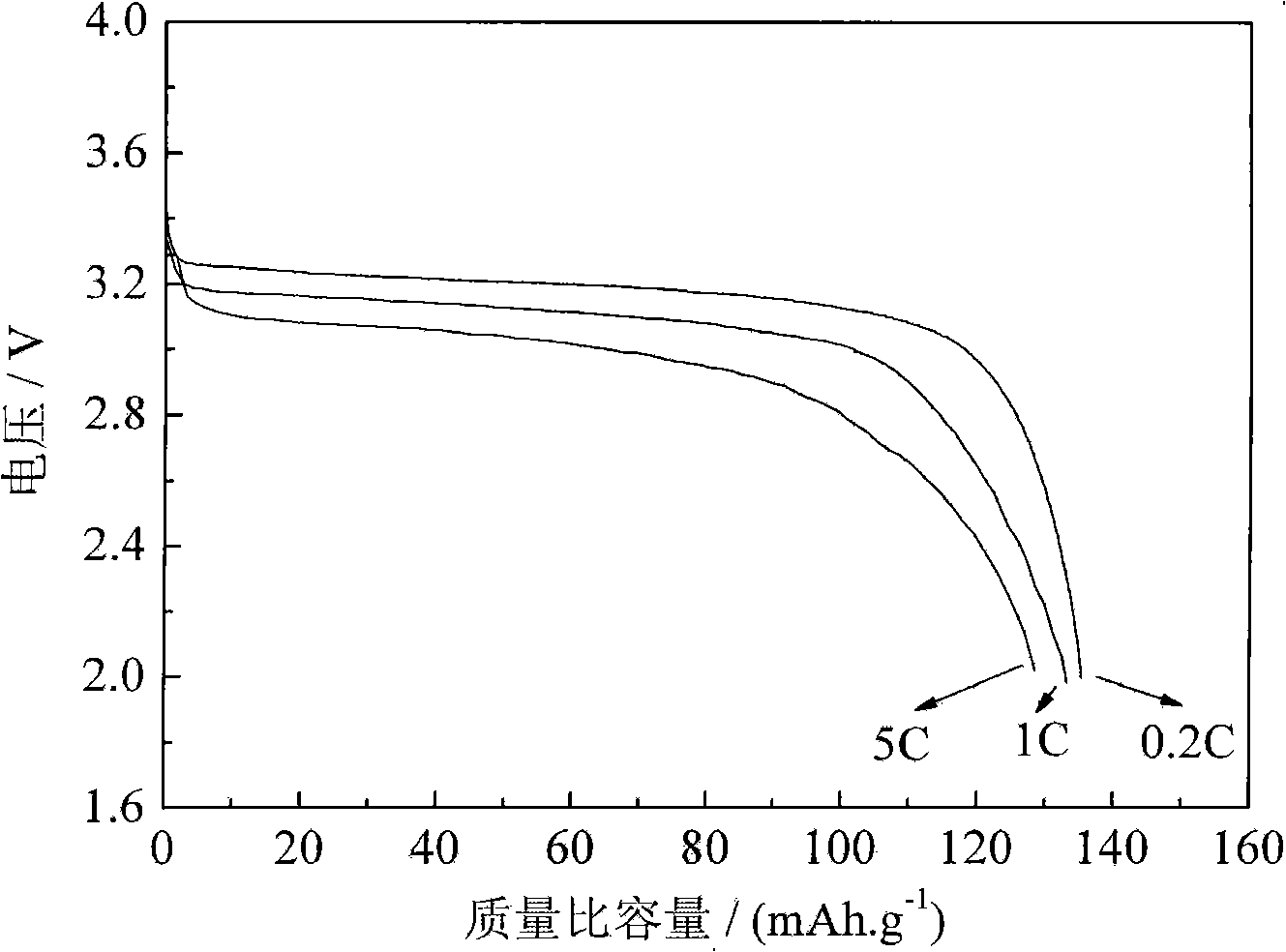

InactiveCN101279728AWide variety of sourcesLow priceCell electrodesPhosphorus compoundsFurnace temperaturePhosphate

The invention discloses a method for preparing lithium iron phosphate anode material by three-step high temperature solid state sintering and pertains to the technique of chemical power source anode material. The process of the preparation method is that lithium salt, Fe<2+> compound, phosphate and carbon source are mixed according to certain ratio, ground and granulated; particles obtained are transferred in a rotary sintering furnace and carried out predecomposition for 3-10 hours when the temperature is increased to 300-500 DEG C under the protection of nitrogen; the temperature raises to 650-850 DEG C and the heat is preserved for 6-15 hours and then the temperature is dropped to room temperature with furnace temperature; the material obtained is added with carbon source in different amount and is carried out ball milling, the temperature raises to 650-850 DEG C and the heat is preserved for 6-15 hours and then the temperature is dropped to room temperature with furnace temperature, and the lithium iron phosphate anode material is obtained after ball milling. The method of the invention is characterized by simple process, being easy to realize industrial scale production, wide sources of raw materials, low cost, complete crystal form of anode material, regular product pattern, excellent electrochemical performance and high tap density which reaches 1.36g cm<-3>.

Owner:TIANJIN UNIV

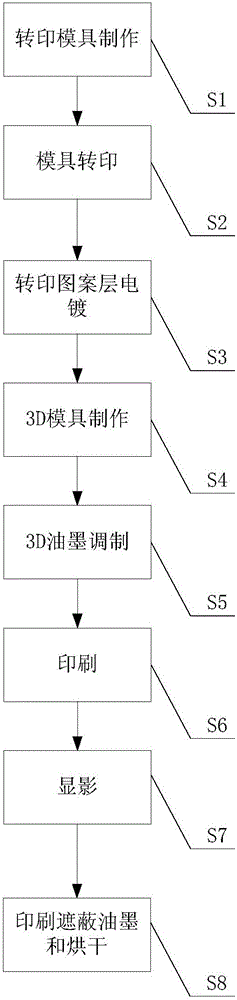

Producing a Marker Pattern and Measurement of an Exposure-Related Property of an Exposure Apparatus

InactiveUS20100328636A1Increase responsivityHigh sensitivityScattering properties measurementsPhotomechanical apparatusSide lobeProduct pattern

Owner:ASML NETHERLANDS BV

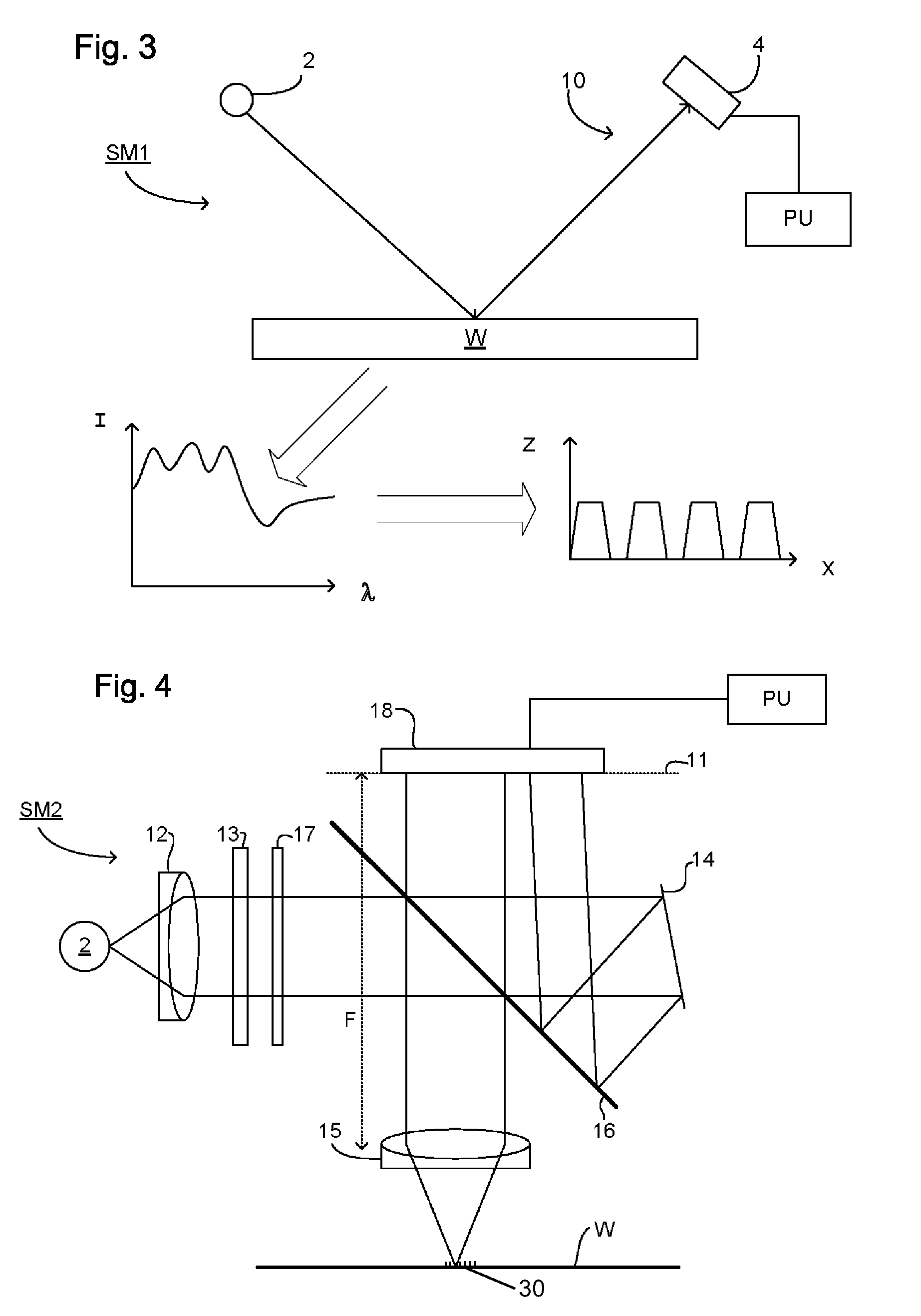

Printing production method

InactiveCN105966101AHigh resolutionPattern changing beautyDuplicating/marking methodsOther printing apparatusCooking & bakingScreen printing

The invention discloses a printing production method. The method includes the steps of manufacturing a transfer printing mold; carrying out mold transfer printing on printing materials through a transfer printing machine; electroplating a transfer-printed pattern layer of a printed product; manufacturing a 3D mold and preparing 3D ink; mounting a screen printing plate on a printing press screen printing plate frame, placing the electroplated printed product on the 3D mold, and carrying out printing by pouring the 3D ink on the screen printing plate; placing the printed product on the 3D mold to carry out developing and molding; and conducting baking after patterns appear. According to the printing production method, the transfer printing technology and the 3D technology are combined, and the product patterns can be finer and higher in resolution ratio and can have the sense of depth.

Owner:广东中裕德电子科技有限公司

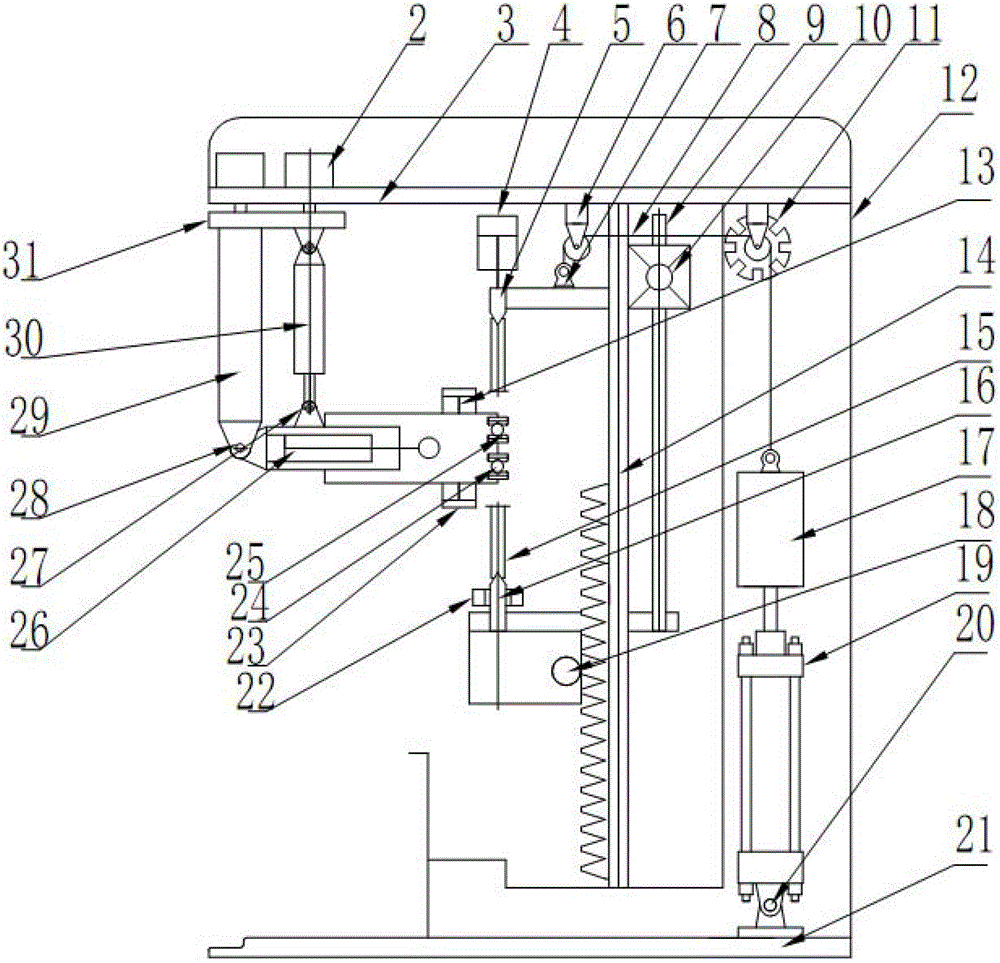

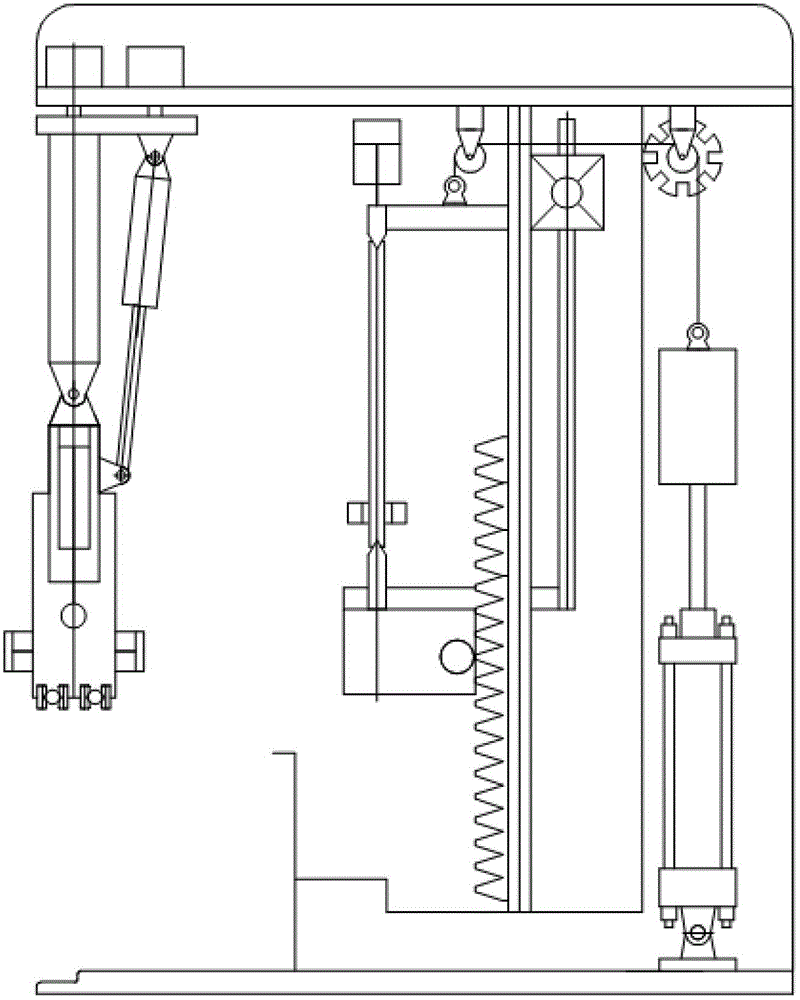

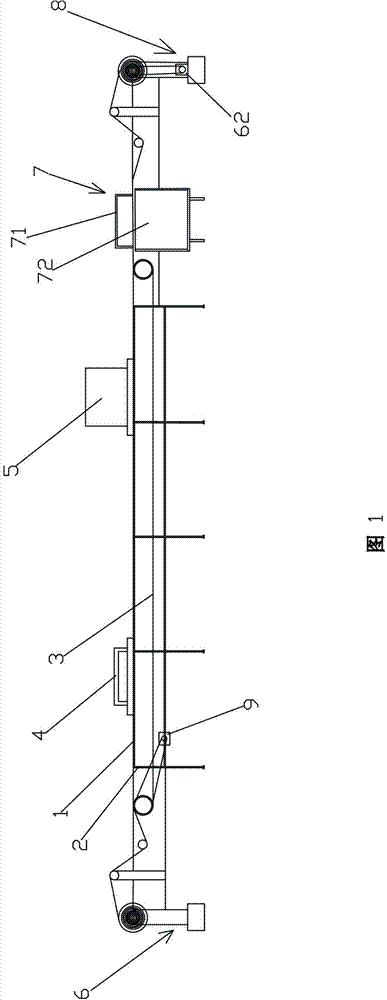

Double-finger automatic workpiece clamping vertical type quenching machine tool

InactiveCN102719632AImprove efficacyImprove work efficiencyQuenching devicesEconomic benefitsProduct pattern

The invention discloses a double-finger automatic workpiece clamping vertical type quenching machine tool which comprises a clamping device, a double-finger workpiece handling device, a heating quenching device and a charging and discharging device; the clamping device clamps the workpiece between an upper centre and a lower center which have adjustable spaces; the double-finger workpiece handling device is arranged on a cross arm of a quenching machine tool body and consists of a clamping manipulator with two manipulator fingers, and an overturning cylinder, the overturning cylinder drives the clamping manipulator to do 90-degree overturning and automatically clamp or disassemble the workpiece from the clamping device; the heating quenching device consists of an induction coil and a water jacket and conducts heating and cooling quenching to the workpiece which penetrates through the induction coil and the water jacket to vertically move; and the charging and discharging device consists of a finished product patterning rack and a charging mechanism which are used for patterning finished products and conveying the workpiece to be machined to the clamping manipulator respectively. The double-finger automatic workpiece clamping vertical type quenching machine tool realizes immediate clamping and quenching of new workpieces after the workpiece is automatically unloaded, saves the loading and unloading time, improves the working efficiency and increases the economic benefits of a user.

Owner:WUXI LIANGXI ELECTRIC FURNACE

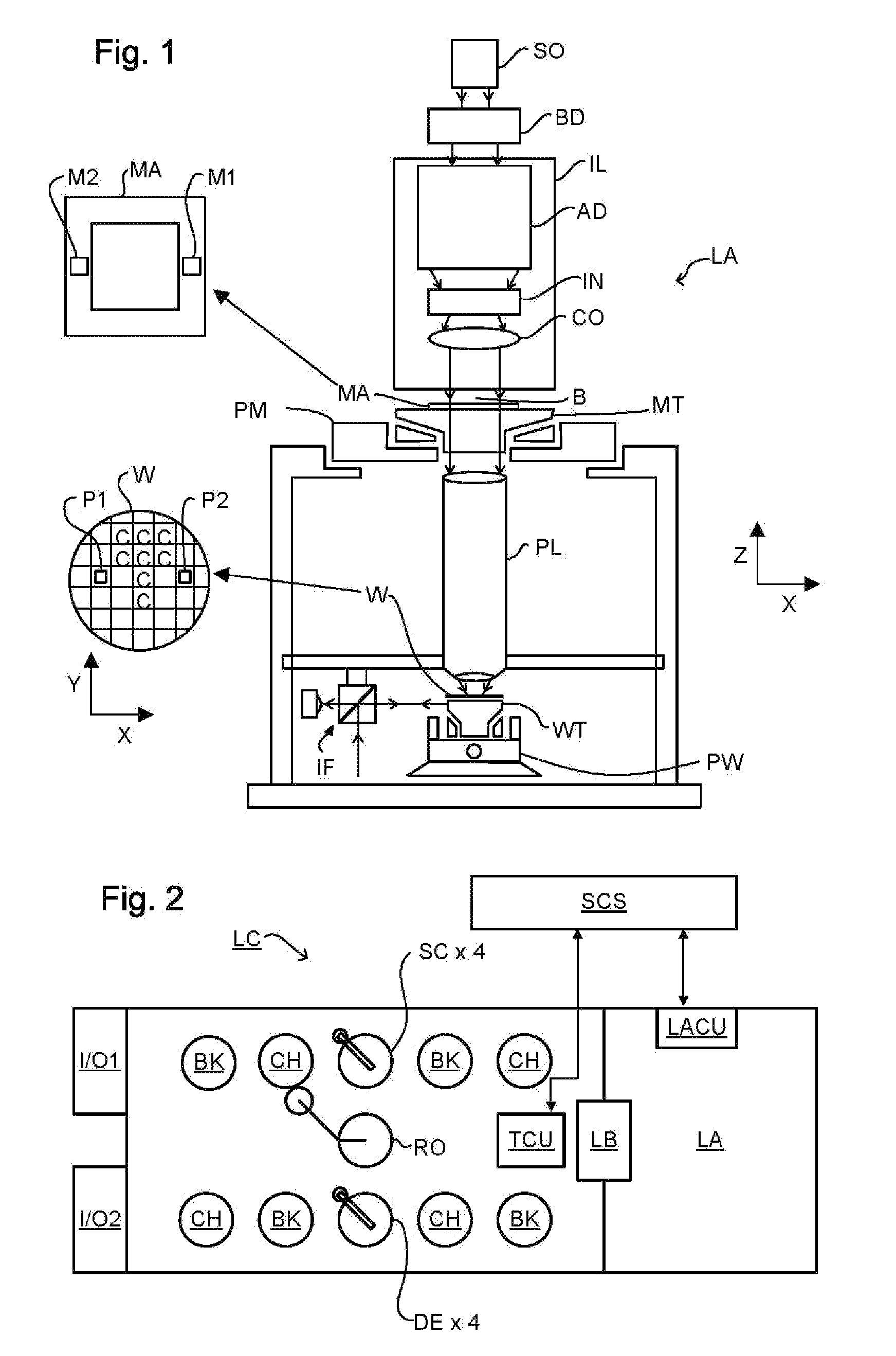

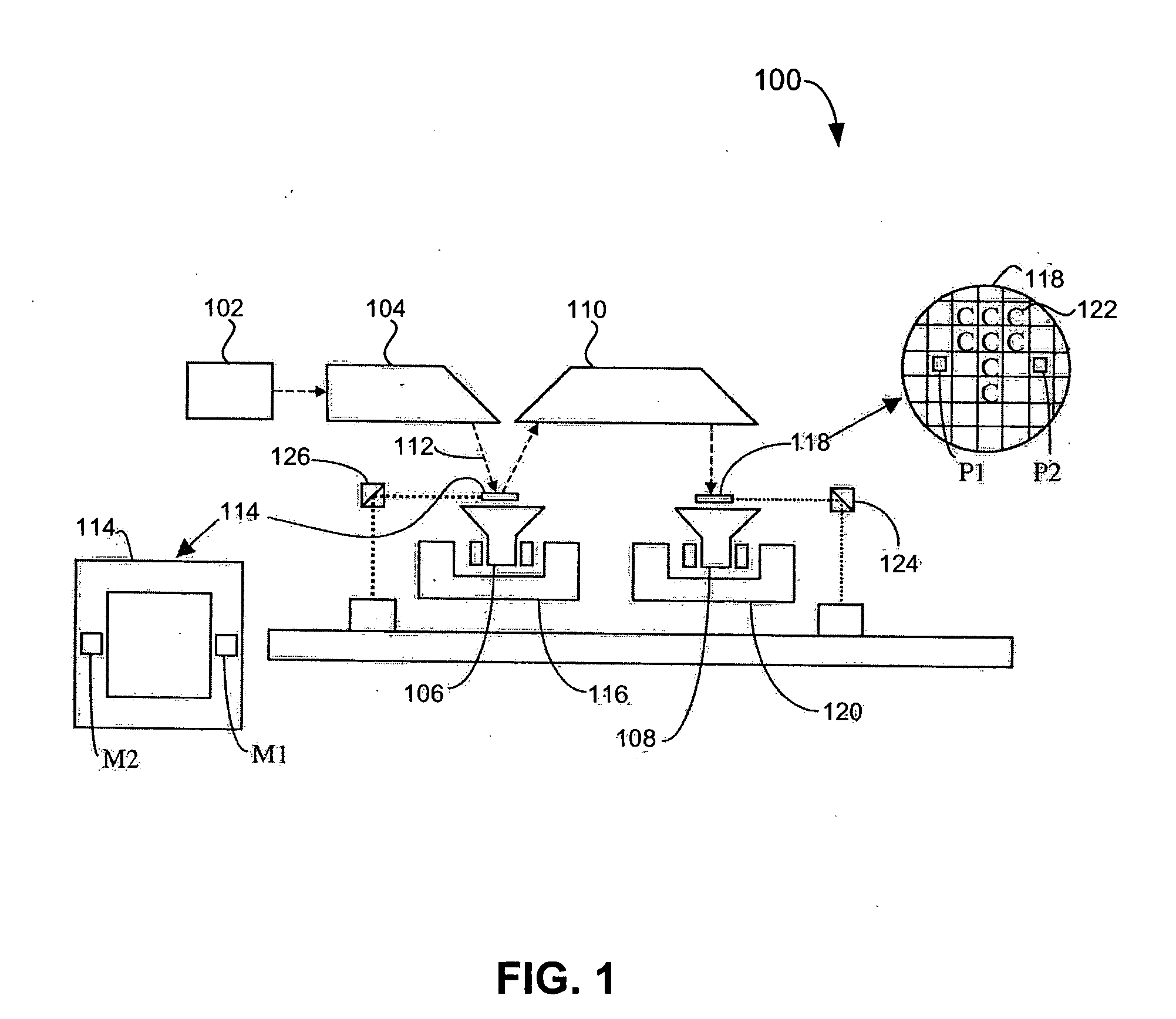

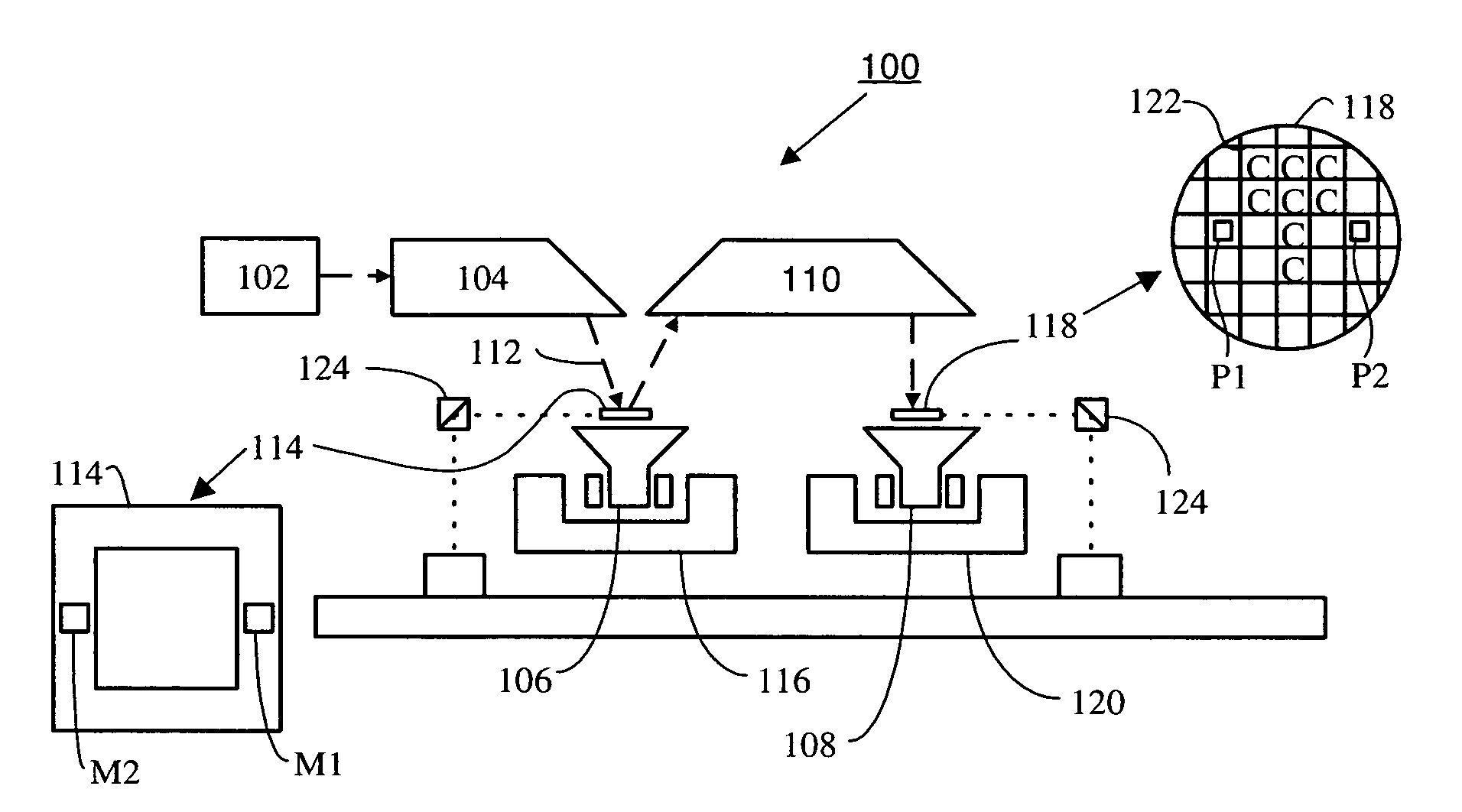

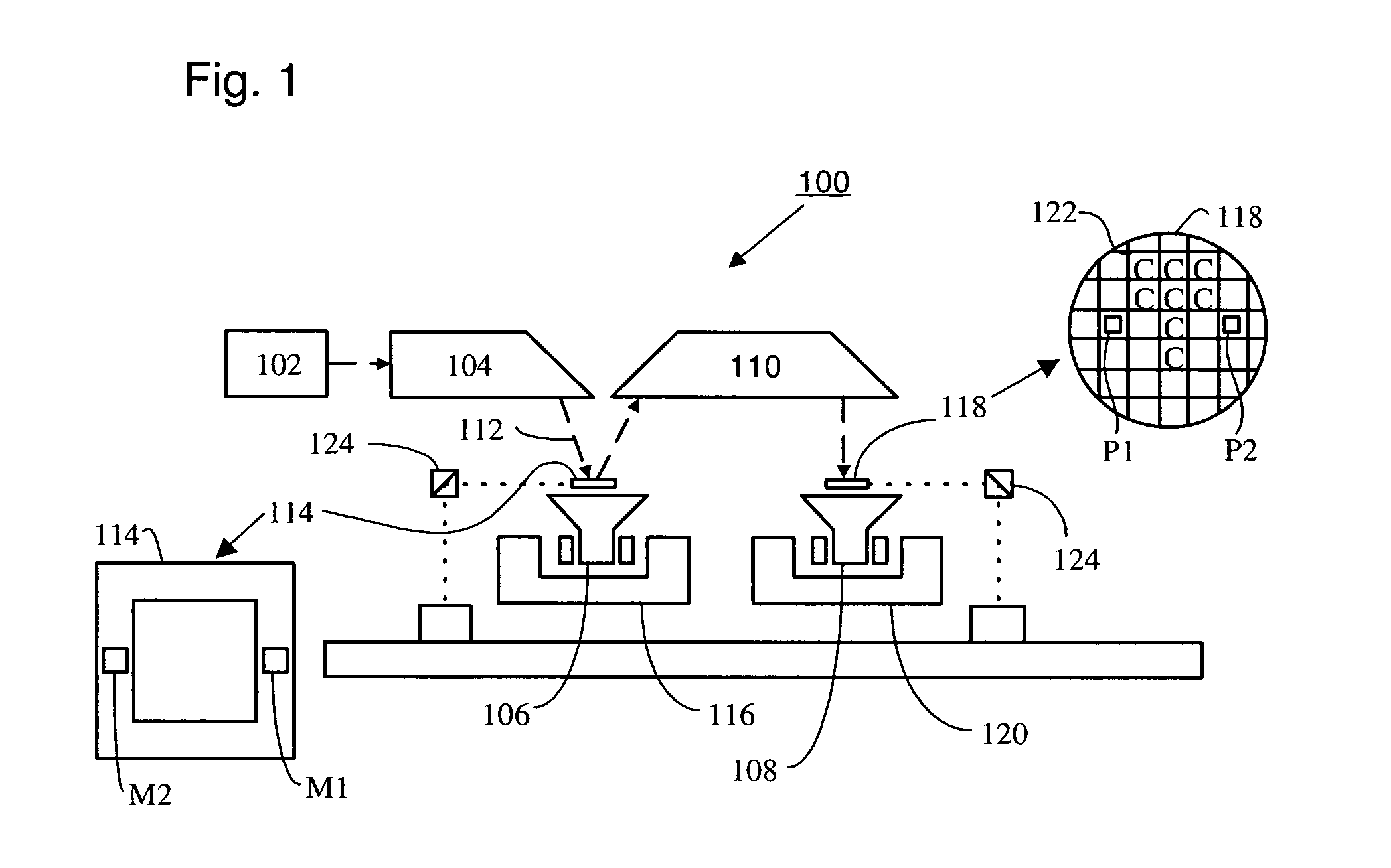

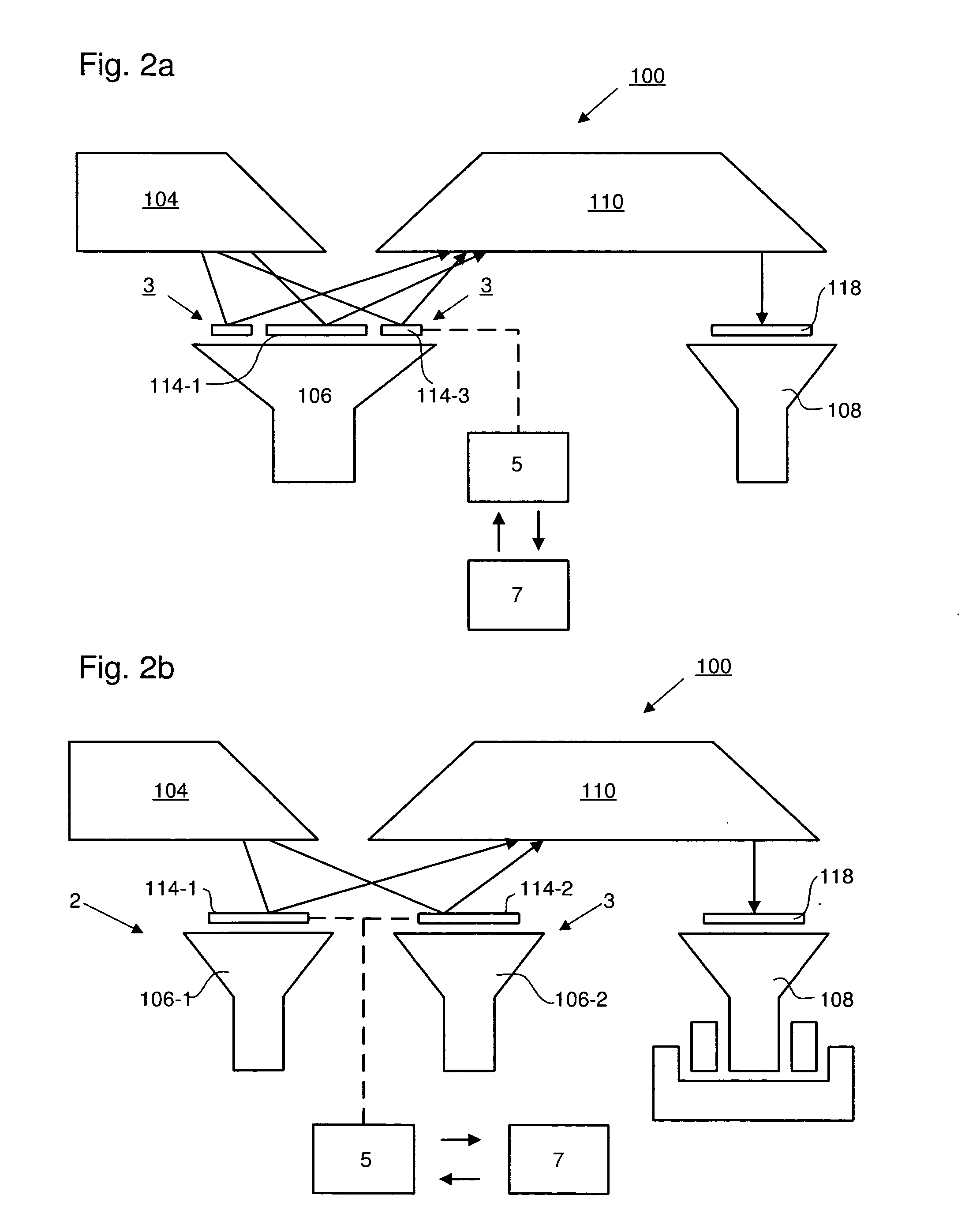

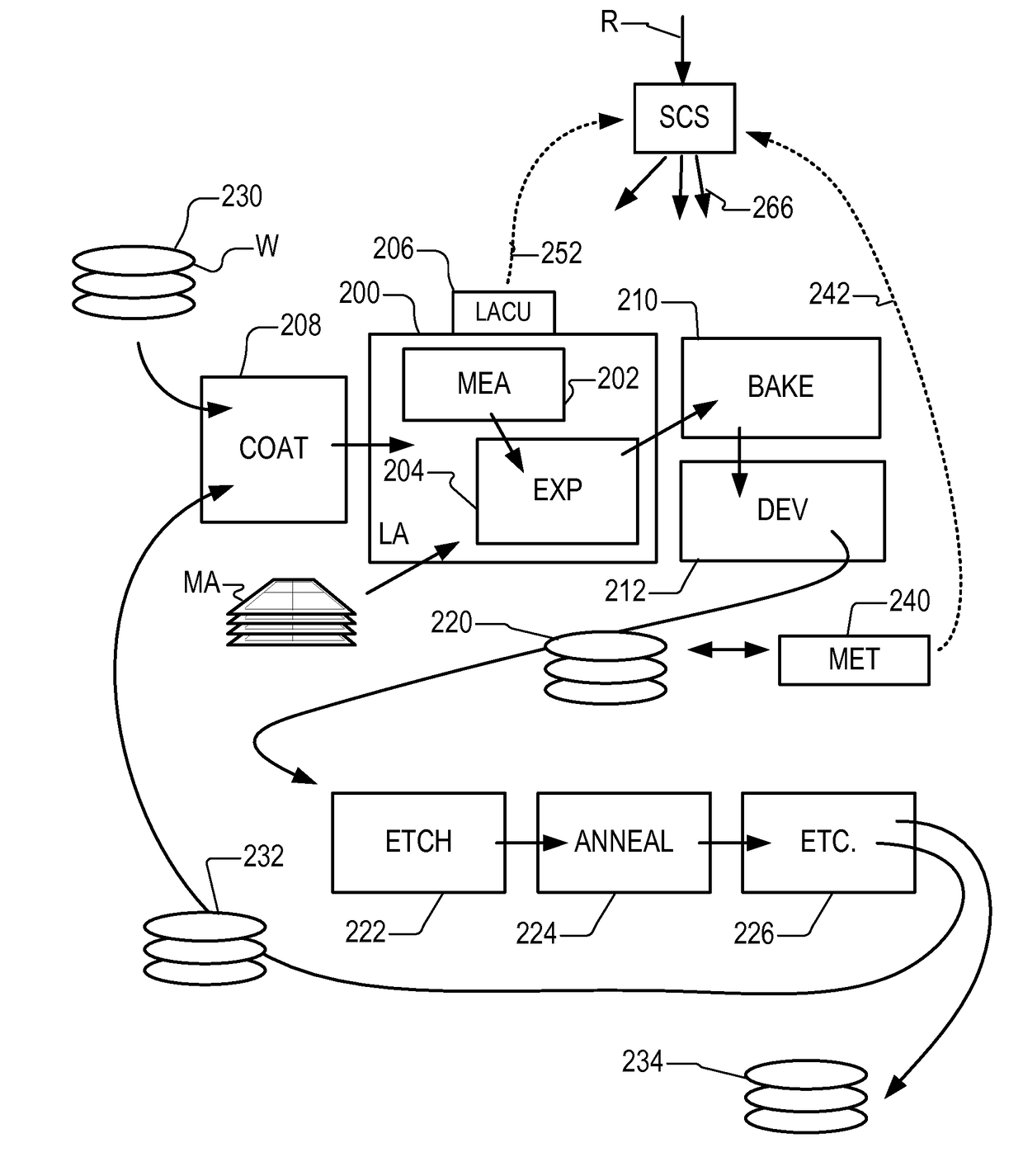

Lithographic apparatus and device manufacturing method

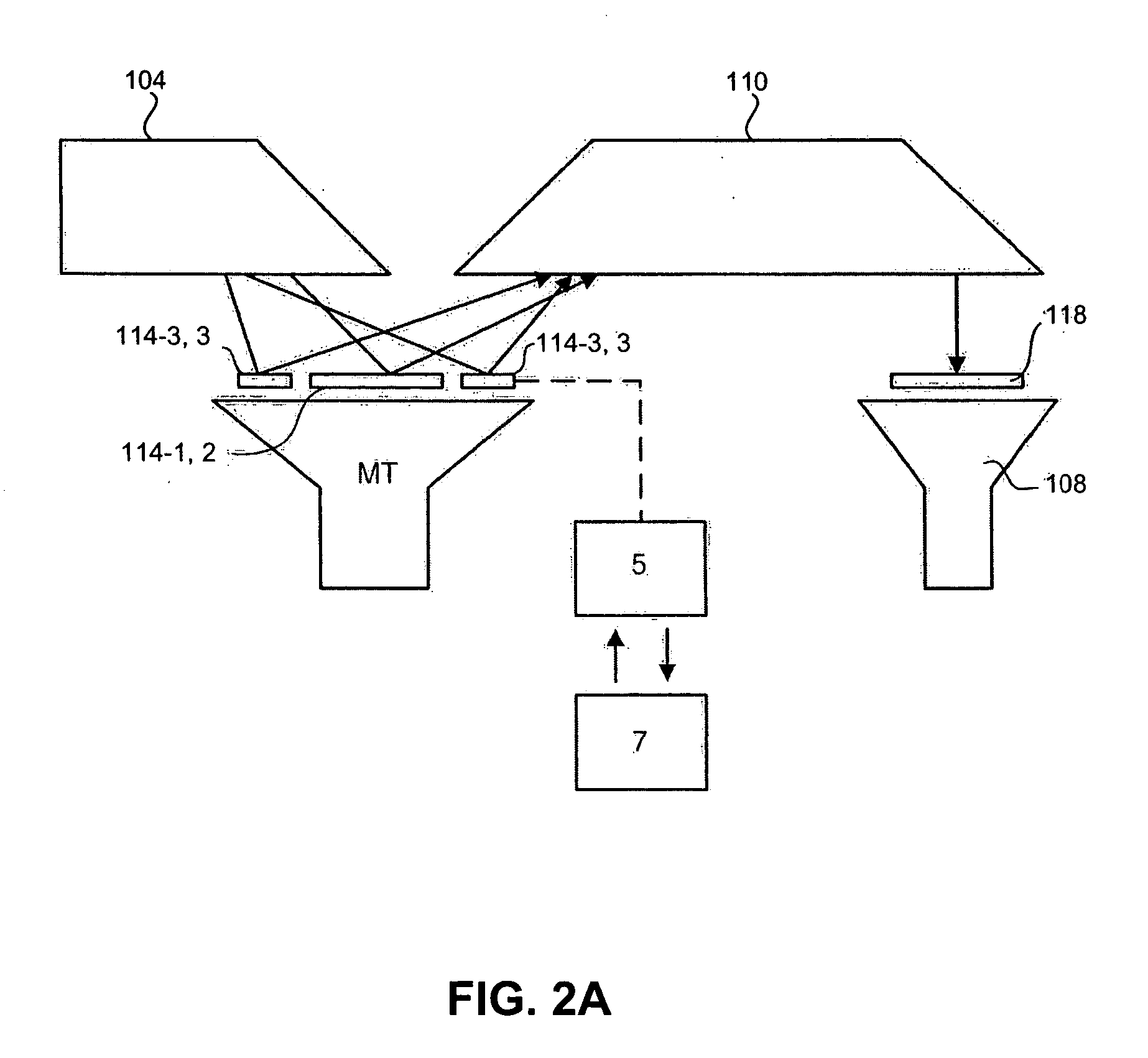

ActiveUS20060012763A1Increase flexibility and choicePhotomechanical apparatusUsing optical meansMetrologyEngineering

A lithographic apparatus and method comprise an illumination system arranged to provide a radiation beam, a support structure configured to support a product patterning device and a metrology target patterning device. The product patterning device imparts a radiation beam derived from the illumination system with a product pattern in its cross-section representing features of a product device to be formed. The metrology target patterning device imparts the radiation beam with a metrology target pattern in its cross-section representing at least one metrology target. The product patterning device is separate from the metrology target patterning device. A substrate table holds a substrate. A projection system project the radiation patterned by the product patterning device and the metrology target patterning device onto a target portion of the substrate. A metrology target patterning device controller adjusts the metrology target pattern independently of the product pattern.

Owner:ASML NETHERLANDS BV

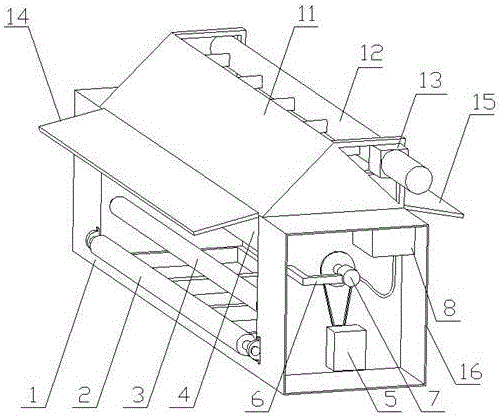

Constant-temperature hot sublimation color development machine

The invention discloses a constant-temperature hot sublimation color development machine. The machine comprises a frame (1), a scutching cloth release roller (2), a cloth collection conveying roller (3), an oil electric heating roller (4), a speed reducing motor (5), a bracket (6), a rotating joint (7), an oil tank (8), an electric heater (9), an electric brush device (10), a smoke collecting cover (11), a smoke discharge pipe (12), a fan (13), a front cover plate (14) and a back cover plate (15). The constant-temperature hot sublimation color development machine has the following advantages: heat conducting oil is used for heating, so that cloth is uniformly heated, the color development and color fixation performances are improved, and product patterns are beautiful in colors and not liable to fade; and dye lampblack generated in the heating process is timely discharged to simulate secondary pollution of the lampblack to the cloth so as to improve the color development effect.

Owner:JINGMEN QIAN NIAN JIAN HEALTH CARE TECH

Automatic printing and cutting integrated machine

ActiveCN102825909ARealize automated productionLabor savingOther printing apparatusNumerical controlProduct pattern

The invention discloses an automatic printing and cutting integrated machine which comprises a combined rack, an annular conveyor belt and a driving device of the annular conveyor belt, wherein the upper part of the combined rack is provided with a working platform; the annular conveyor belt and the driving device of the annular conveyor belt are arranged on the combined rack; an ink jet printing device used for product printing and a numerical control vibration cutter cutting device used for cutting a product pattern are sequentially arranged along the conveying direction above the working platform; the ink jet printing device and the numerical control vibration cutter cutting device are both controlled by the same numerical control device; the driving device of the annular conveyor belt is connected with the numerical control device; the starting point of the conveyor belt is provided with a feeding mechanism; and the finishing point of the conveyor belt is provided with a product collection device and a material collection device. According to the automatic printing and cutting integrated machine, the fully-automatic numerical control production of each technological process of printing and cutting can be realized, a great quantity of manpower is saved in the production process, and the printing quality and the printing precision are improved.

Owner:BLACK GOLD STEEL AUTOMATION TECH FUJIAN

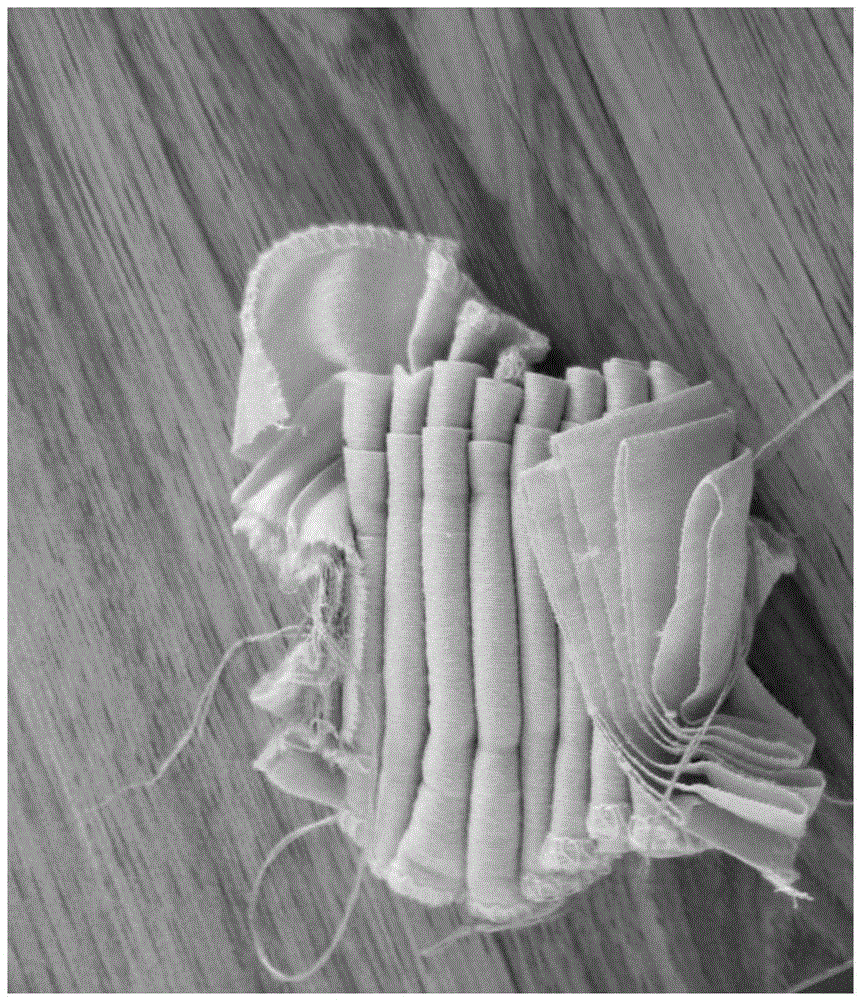

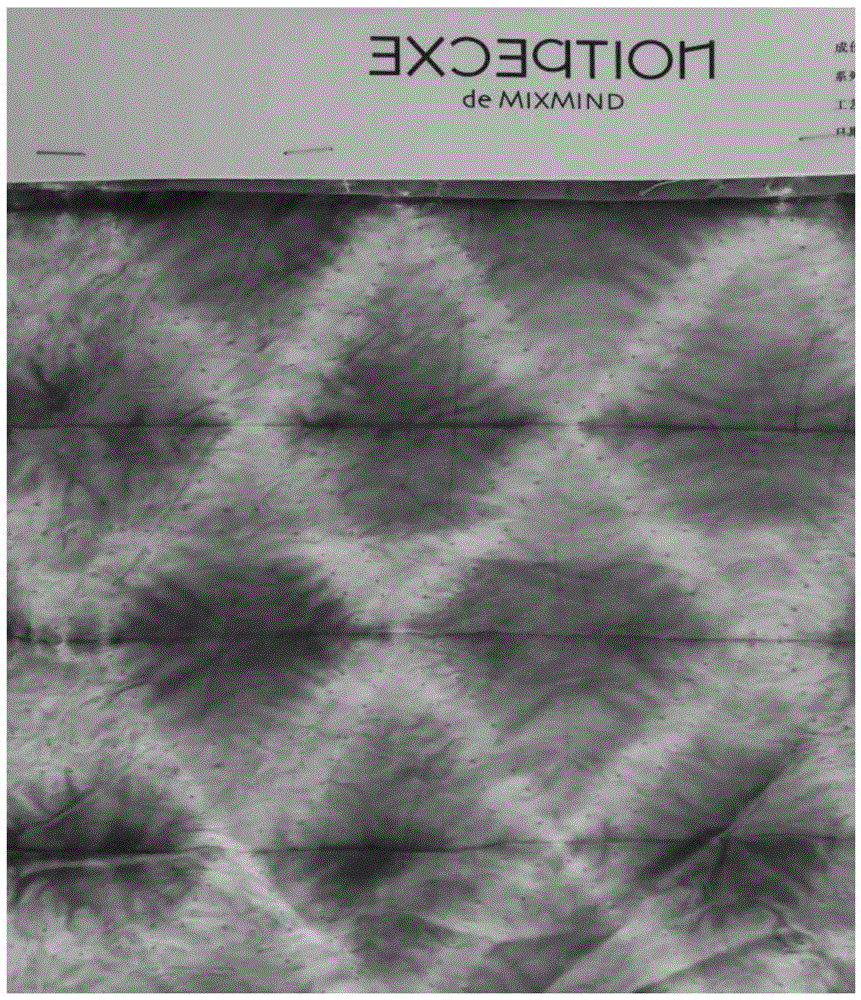

Tie-dyeing method

The invention discloses a tie-dyeing method. The tie-dyeing method comprises the following steps: (1) folding a fabric to be dyed according to the requirements of a production pattern; (2) manufacturing a dyeing part according to the requirements of the production pattern and tying up the dyeing part on the fabric to be dyed, which is folded in the step (1), and positioning to obtain a fabric 1; (3) carrying out active dyeing on the fabric 1, and addling an alkali to carry out color fixation; washing for one time with normal-temperature water to obtain a fabric 2; and (4) removing the dyeing part on the fabric 2 and soaping for two times, washing with water, adding an acid to neutralize and drying to obtain the product. In order to overcome the defects in the prior art that tie-dyeing sewing is complicated, and many needle holes are formed to influence the appearance, the dyeing part is rapidly tied up after the fabric is folded according to the production requirements, and optimal tie-dyeing process steps and parameters are matched; and finally, the obtained product pattern is vivid and natural and a cloth cover is complete and beautiful.

Owner:ZHUHAI JIAN XUAN CLOTHING LTD

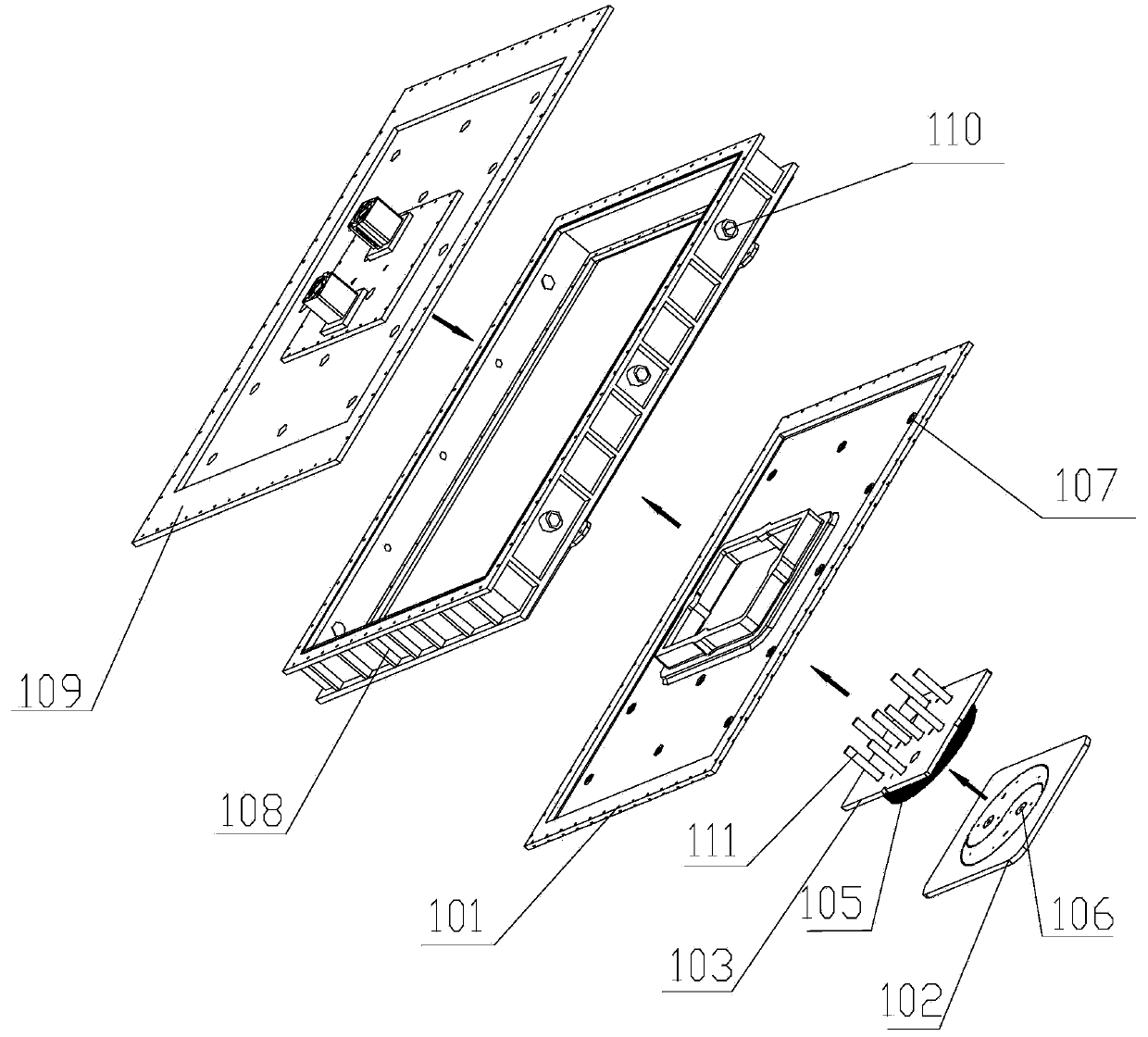

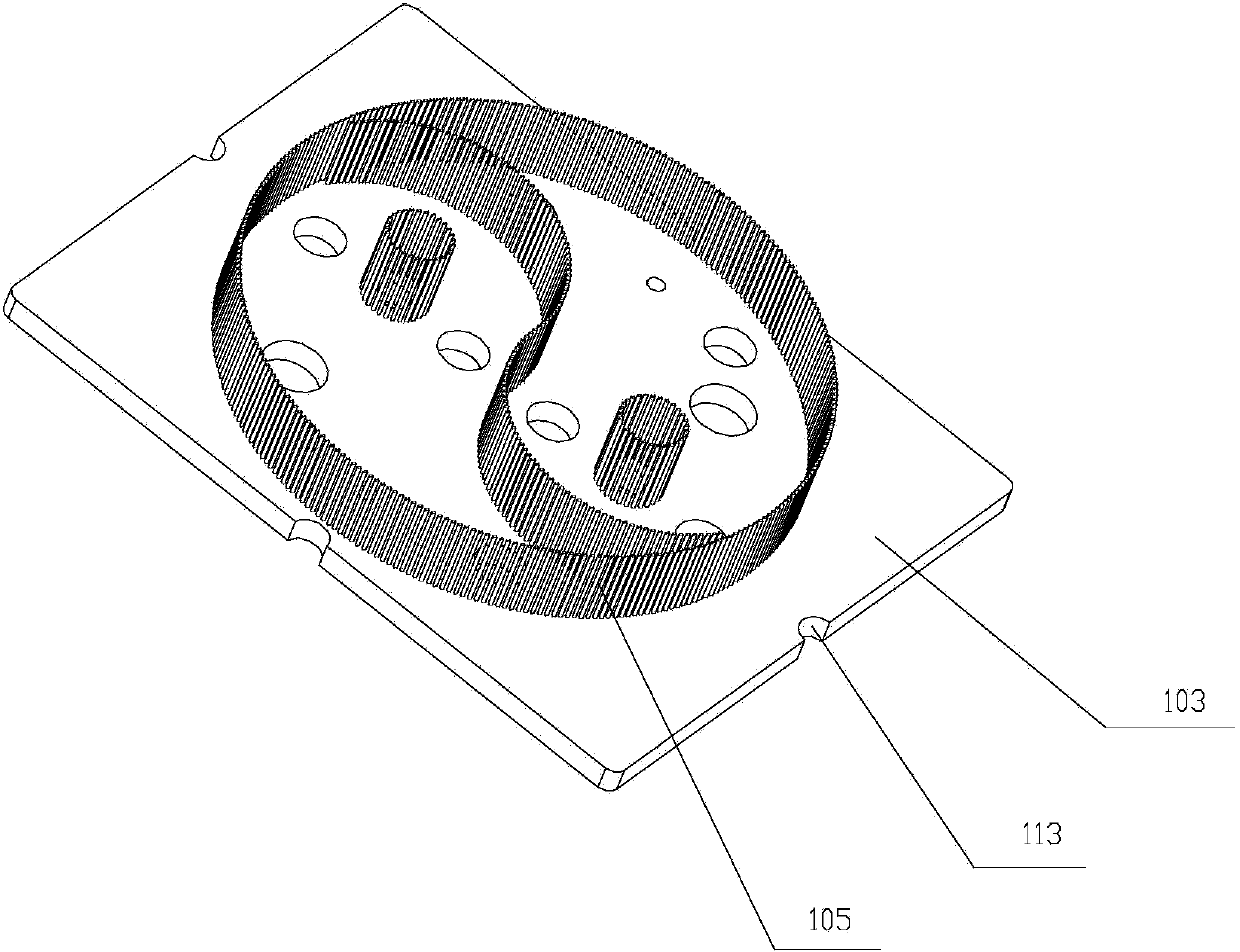

Foaming mold and composite foam forming method

The invention discloses a foaming mold and a composite foam forming method. The mold comprises an upper mold and a lower mold, wherein the upper mold comprises an upper template, a movable plate, a cylinder and a filling hole; a plurality of pins are arranged on the movable plate; the pins are distributed on the surface of the movable plate according to product patterns, and every two pins are spaced in a set distance; jacks which are in one-to-one correspondence with the pins and are inserted into each other are formed in the upper template; the lower mold is opposite to the upper mold and is provided with a lower template; a molding cavity used for molding the product is formed in the upper template and / or the lower template; after die assembly, the outline of the molding cavity is consistent with the appearance of the product; the movable plate makes the pins move along the jacks under drive of the cylinder; when the upper template is tightly attached to the movable plate, the pins stretch into the molding cavity of the molded product. According to the foaming mold and the composite foam forming method, foamed products with different colors and patterns can be molded at a time, the production efficiency is relatively high, the mold number is reduced, and the production cost is saved.

Owner:苏州市佳腾精密模具有限公司

Printed mobile phone case and processing technology thereof

InactiveCN105196471ANot easy to wear offProduction process scienceTelephone set constructionsLithographic artistThin membrane

The invention relates to the technical field of plastic raw material integration and formation, in particular to a printed mobile phone case and a processing technology thereof. The processing technology comprises the steps that ink is overprinted on a processed sheet material, after all colors are superposed, patterns appear, then high pressure formation is conducted on the sheet material according to the stretching proportion of the sheet material, and then the sheet material is placed in an injection mold for injection molding. By means of the processing technology, a product is good in stereo effect, the patterns are vivid, plastic raw materials which are used for bearing the sheet material printing and are subjected to injection molding clamp the ink therein, a rigid shielding layer is formed on the surface, the hardness of the shielding layer reaches 3 H, various decorative patterns can be printed, the surface of a thin membrane can exhibit different textures, therefore a number of different surface textures can be imitated, the stereo-lithography height of three-dimensional patterns can reach 40 mm, the ink is silkscreened on an intermediate layer, the total membrane is arranged on resin, so that letters are not prone to being worn off, the product patterns are difficult to wear, scrape off or discolor, and the stability and durability are achieved.

Owner:洪江基

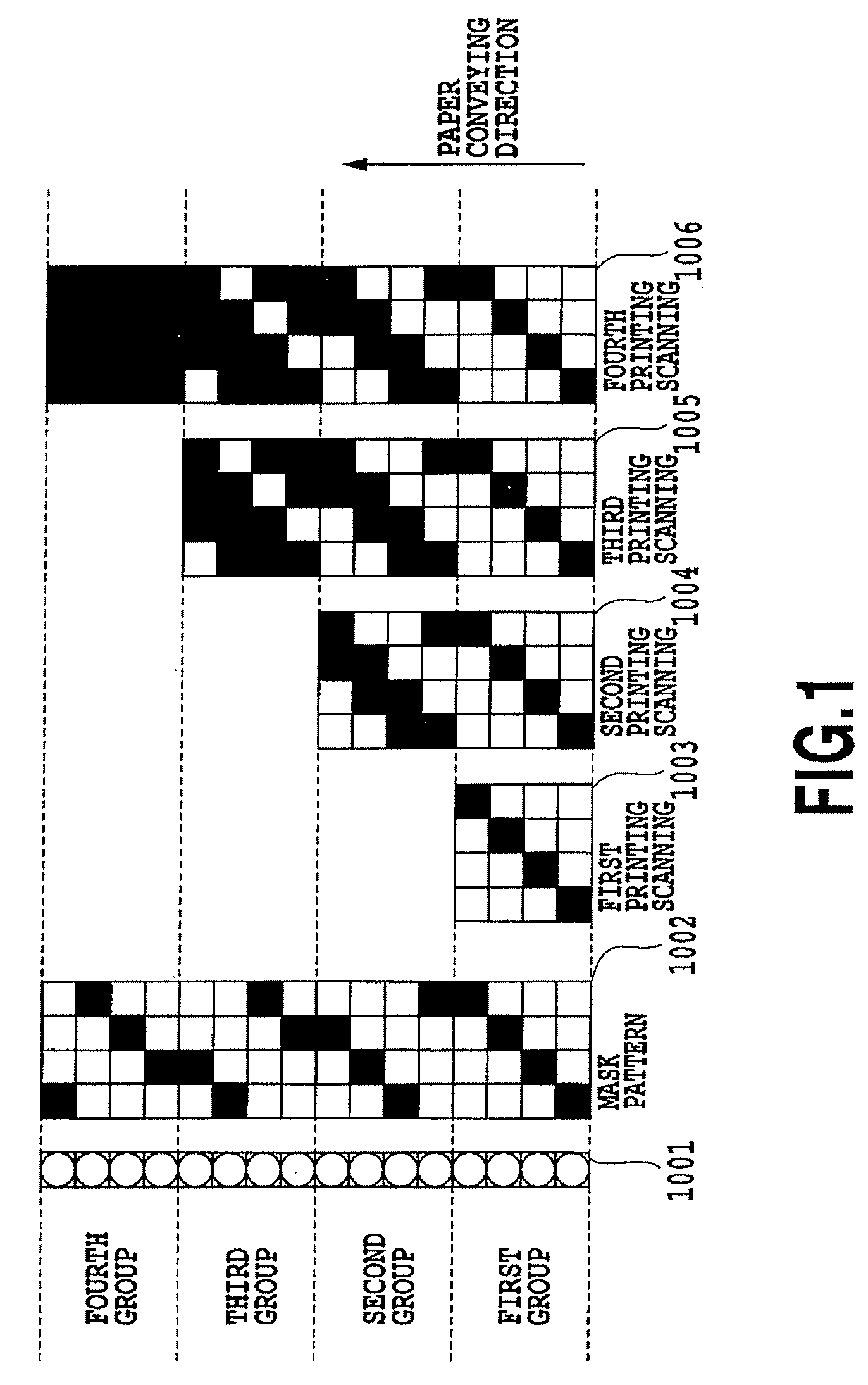

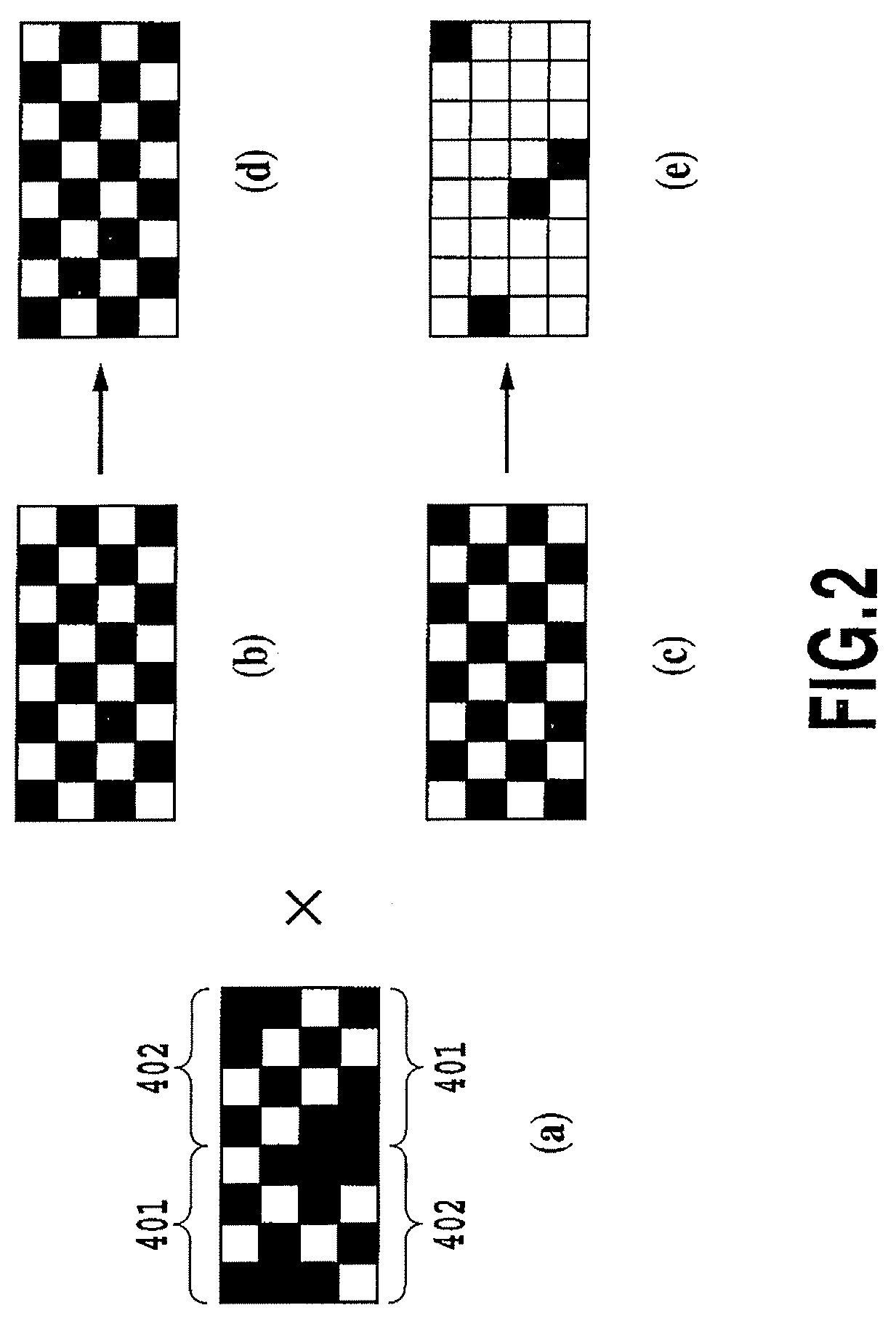

Data processing apparatus, printing apparatus and method of creating mask pattern

ActiveUS7506950B2Reduce distractionsDispersibilityDigitally marking record carriersVisual presentation using printersProduct patternComputer science

A data processing apparatus includes a mask processor for performing a mask process for binary data, which is obtained by a binarization process using a dot arrangement pattern, by using mask patterns having print permitting pixels to generate binary data used for each of a plurality of scans of a print head to a same area of a print medium. A logical product pattern obtained by a logical product operation of an arrangement pattern of the print permitting pixels in at least one of the mask patterns and the dot arrangement pattern satisfies the characteristics of (a) frequency components of a low frequency region are fewer than that of a high frequency region, and (b) peaks of the frequency components do not exist in a region lower side of half of the low frequency region.

Owner:CANON KK

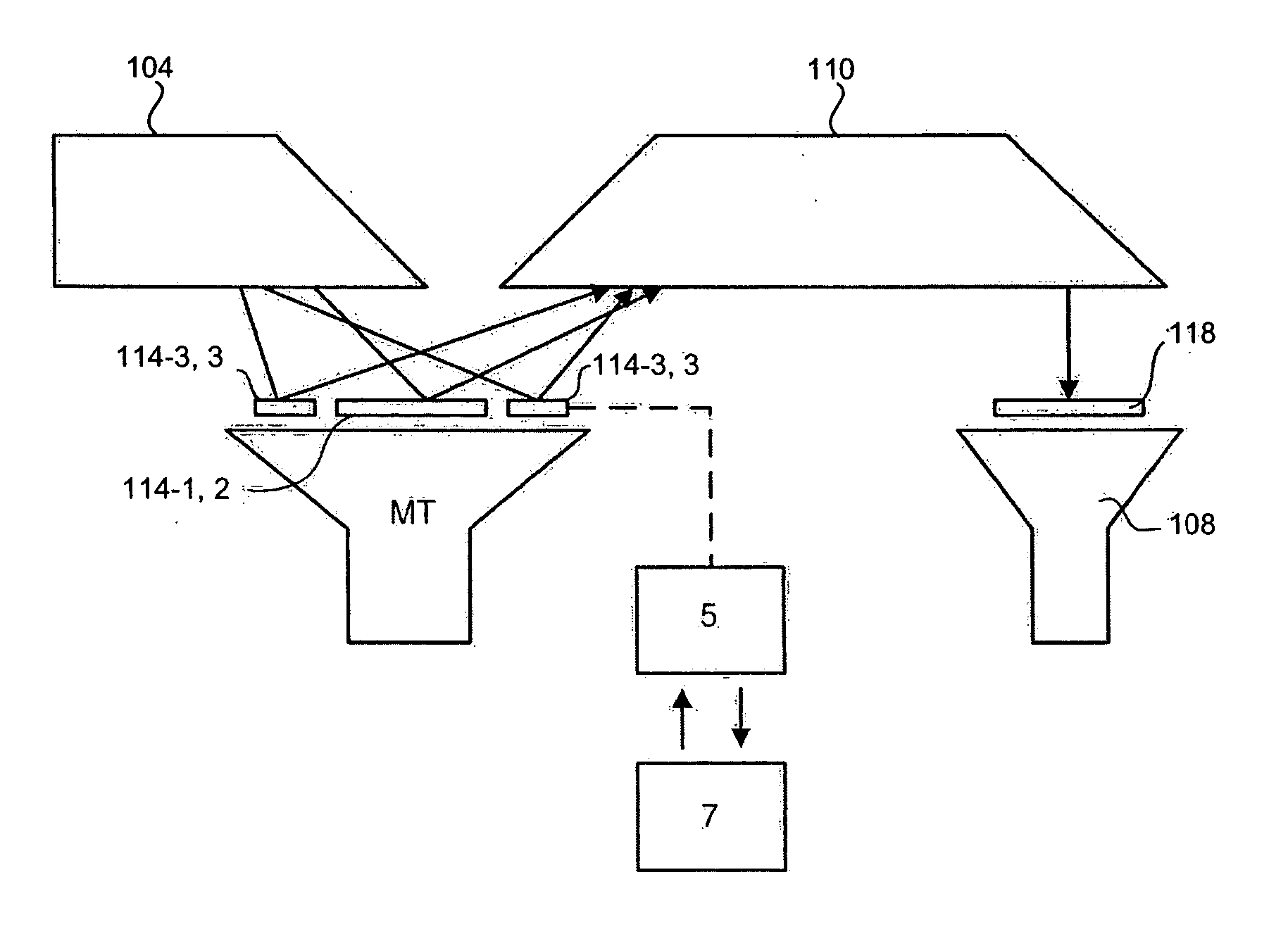

Lithographic apparatus and device manufacturing method

InactiveUS20060012779A1Improved set of exposure settingPhotomechanical apparatusMaterial analysis by optical meansPhysicsProduct pattern

A lithographic apparatus and method comprise an illumination system arranged to provide a radiation beam, a support structure configured to support a product patterning device and a metrology target patterning device. The product patterning device imparts a radiation beam derived from the illumination system with a product pattern in its cross-section representing features of a product device to be formed. The metrology target patterning device imparts the radiation beam with a metrology target pattern in its cross-section representing at least one metrology target. The product patterning device is separate from the metrology target patterning device. A substrate table holds a substrate. A projection system project the radiation patterned by the product patterning device and the metrology target patterning device onto a target portion of the substrate. A metrology target patterning device controller adjusts the metrology target pattern independently of the product pattern.

Owner:ASML NETHERLANDS BV

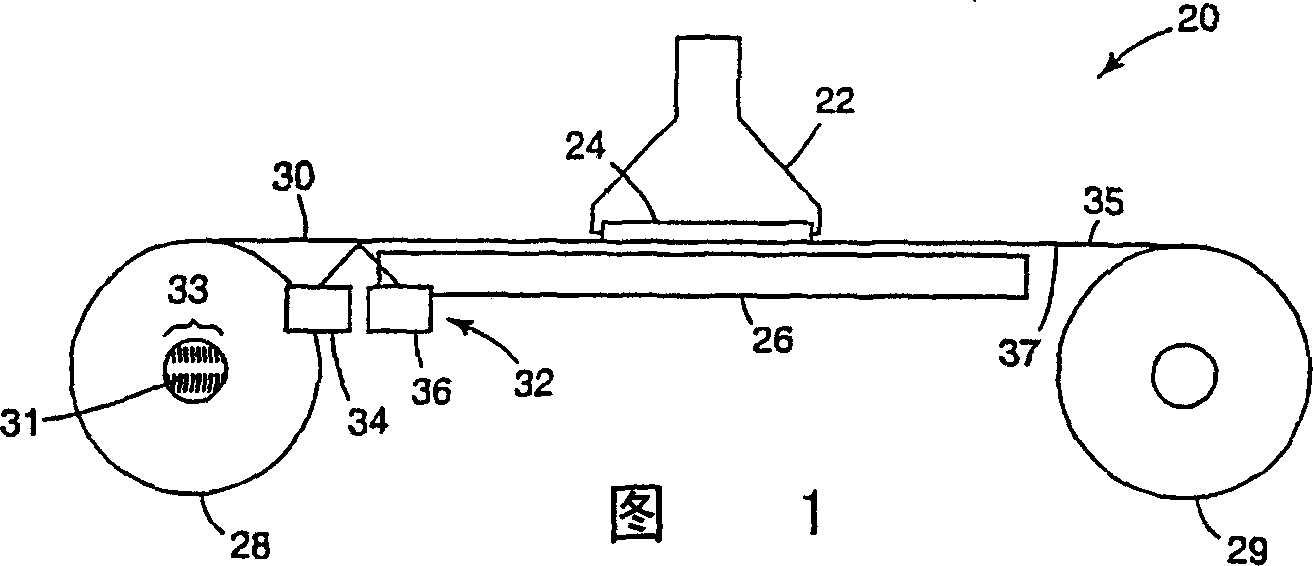

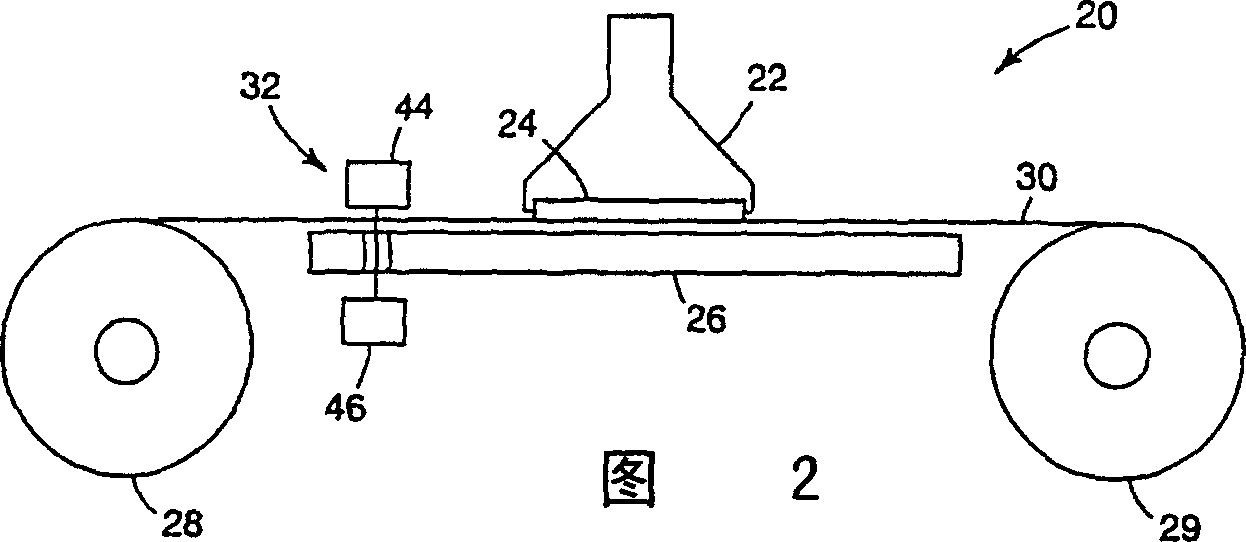

Abrasive processing apparatu sand method for employing encoded abrasive product

An apparatus (20) and method for abrasively processing an article(24) involves the use of an abrasive product (30) provided with a machine discernable pattern representative of information of varying types. The pattern is read while the abrasive product moves relative to the article, and is used to control the movement of the abrasive product (30) relative to the article (24). The pattern may include one or more of the machine discernable electrical characteristic, optical characteristic, topographic characteristic or magnetic characteristic. Reading the pattern may involve one or more of electrically, optically, mechanically or magnetically reading the machine discernable pattern provided on the abrasive product. The pattern may include one or more of indicia, protrusions, depressions, holes, voids, color or pigment variations, bar codes, magnetic transitions or periodic markings. The pattern may include one or more of indexing information, servo information, alignment information or abrasive product identification information. Closed-loop servocontrol of abrasive product movement may be effected using the servo / indexing pattern information. The abrasive product may constitute a movable pad and an abrasive slurry. The pad (30) may be moved in a controlled manner relative to the article (24) such that the pad (30) and the abrasive slurry abrasively contact the article (24). The pattern provided on the pad may be read subsequent to a cleaning operation. An information system may be used to store various types of data derived, in part, from use of the abrasive product pattern information. The stored data may be used for a variety of identification, tracking, accounting, inventory, handling, and statistical purposes.

Owner:3M INNOVATIVE PROPERTIES CO

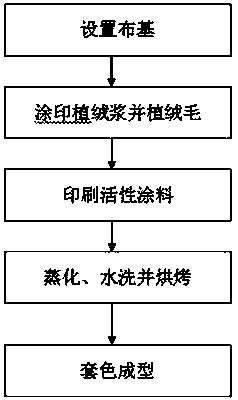

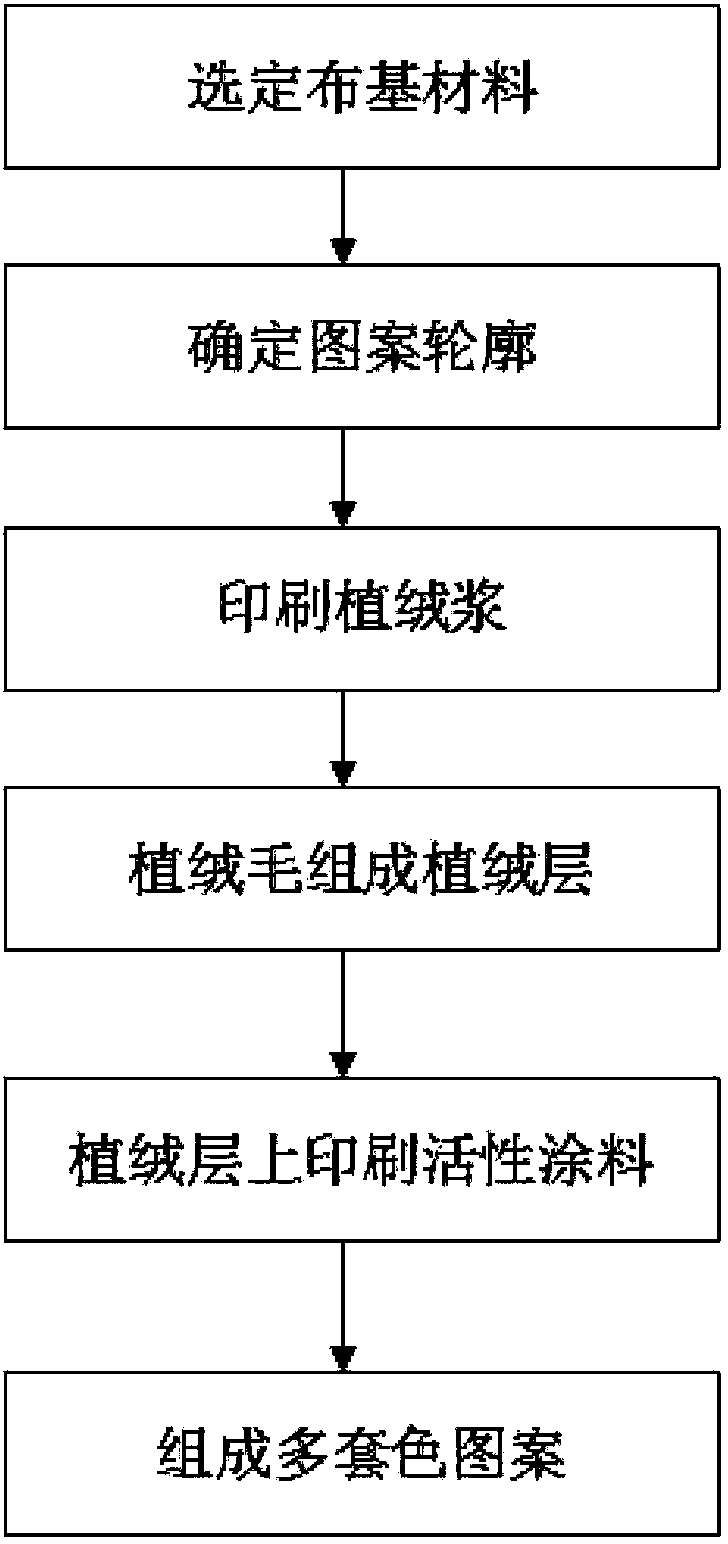

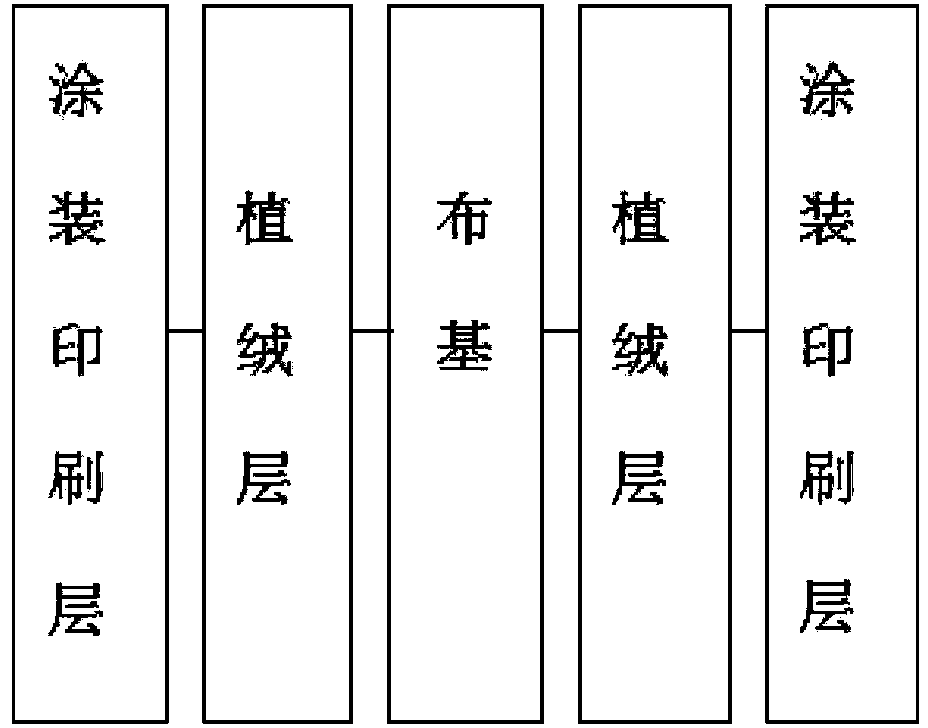

Dye printing process after flocking and flocked cloth

InactiveCN103407277AStrong three-dimensional senseReasonable combination layer designLamination ancillary operationsLaminationPulp and paper industryProduct pattern

The invention discloses a dye printing process after flocking. Flocked cloth comprises a cloth base, wherein the cloth base comprises a dye coat printing layer; flocking pulp is printed on the dye coat printing layer; fluff is flocked on the flocking pulp to form a flocking layer; the printing effect of the dye coat printing layer is combined with the whole pattern of the flocking layer to form a regular setting pattern, After the processing technology including drying and the like are implemented, the flocking pulp for the whole pattern is printed, and fluff with different colors is flocked respectively, so that the regular setting pattern formed by combination of the printing effect and the flocked pattern is obtained, the added value of the original product is improved, the stereoscopic sensation of the product pattern is strong, the pattern structure is reasonable, and integral attractiveness is realized; the product combination layer is reasonable in design, the cloth surface is smooth and soft, different colors and patterns can be matched reasonably as per different requirements, the pattern design is flexible, and needs of different people are met.

Owner:李吉建

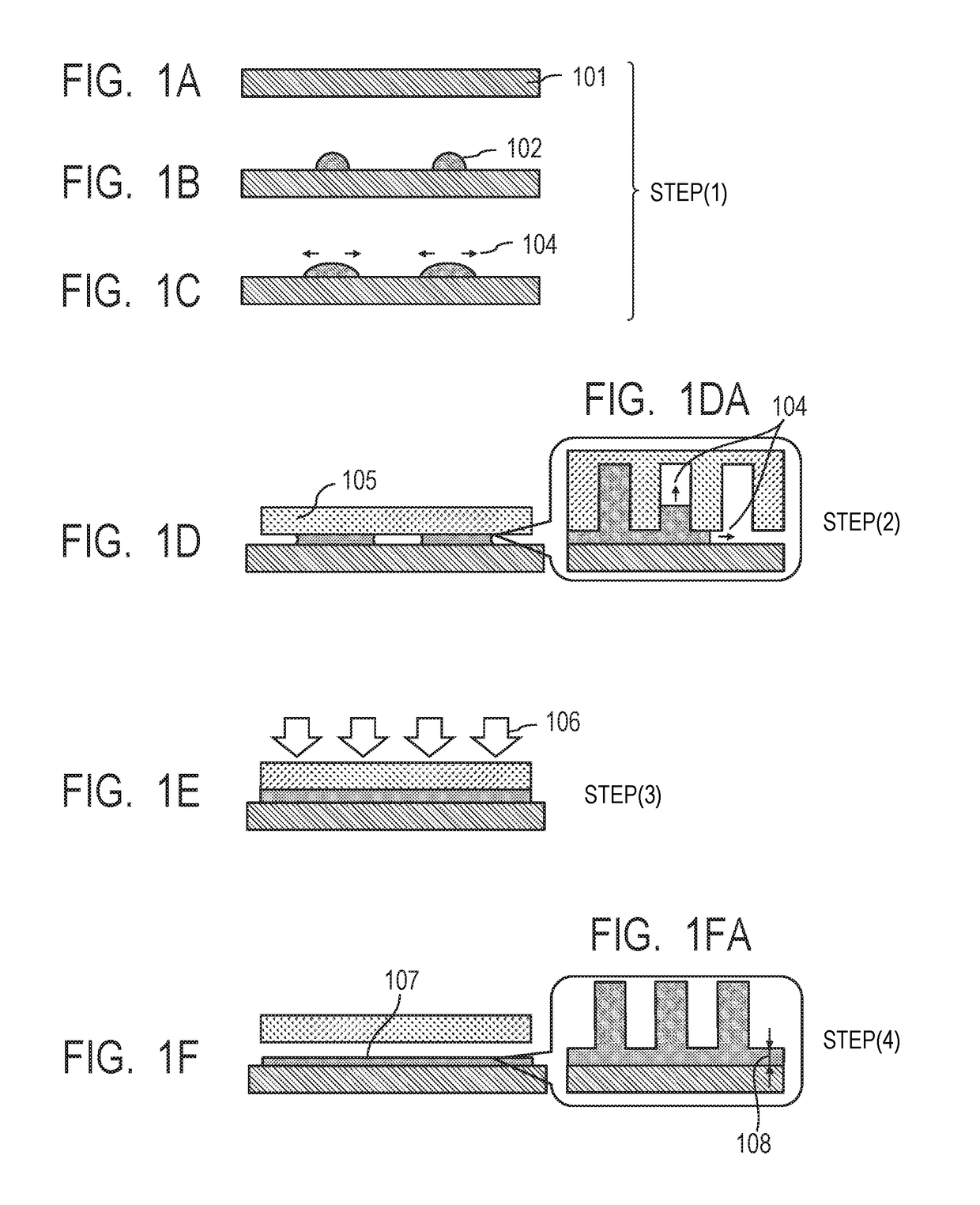

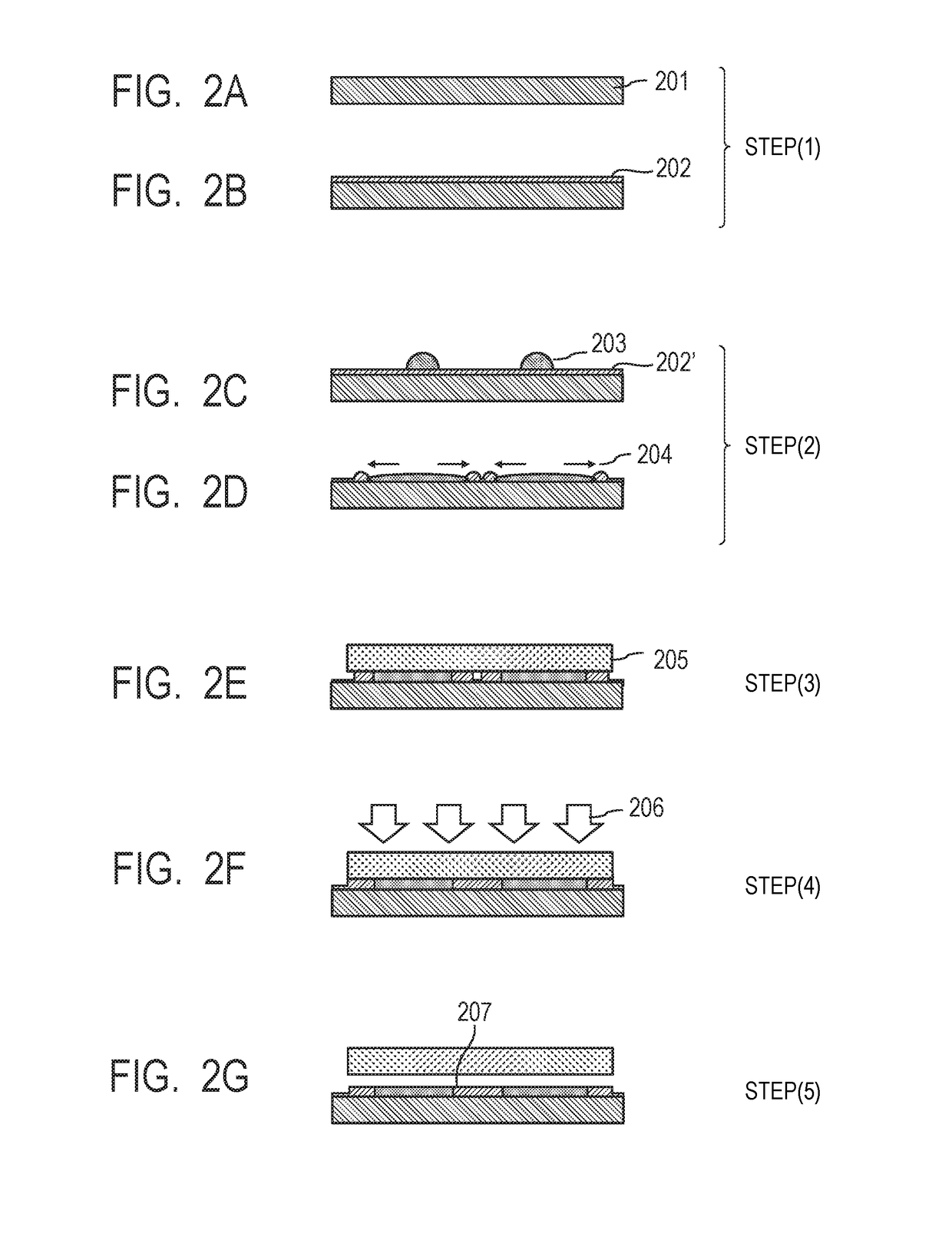

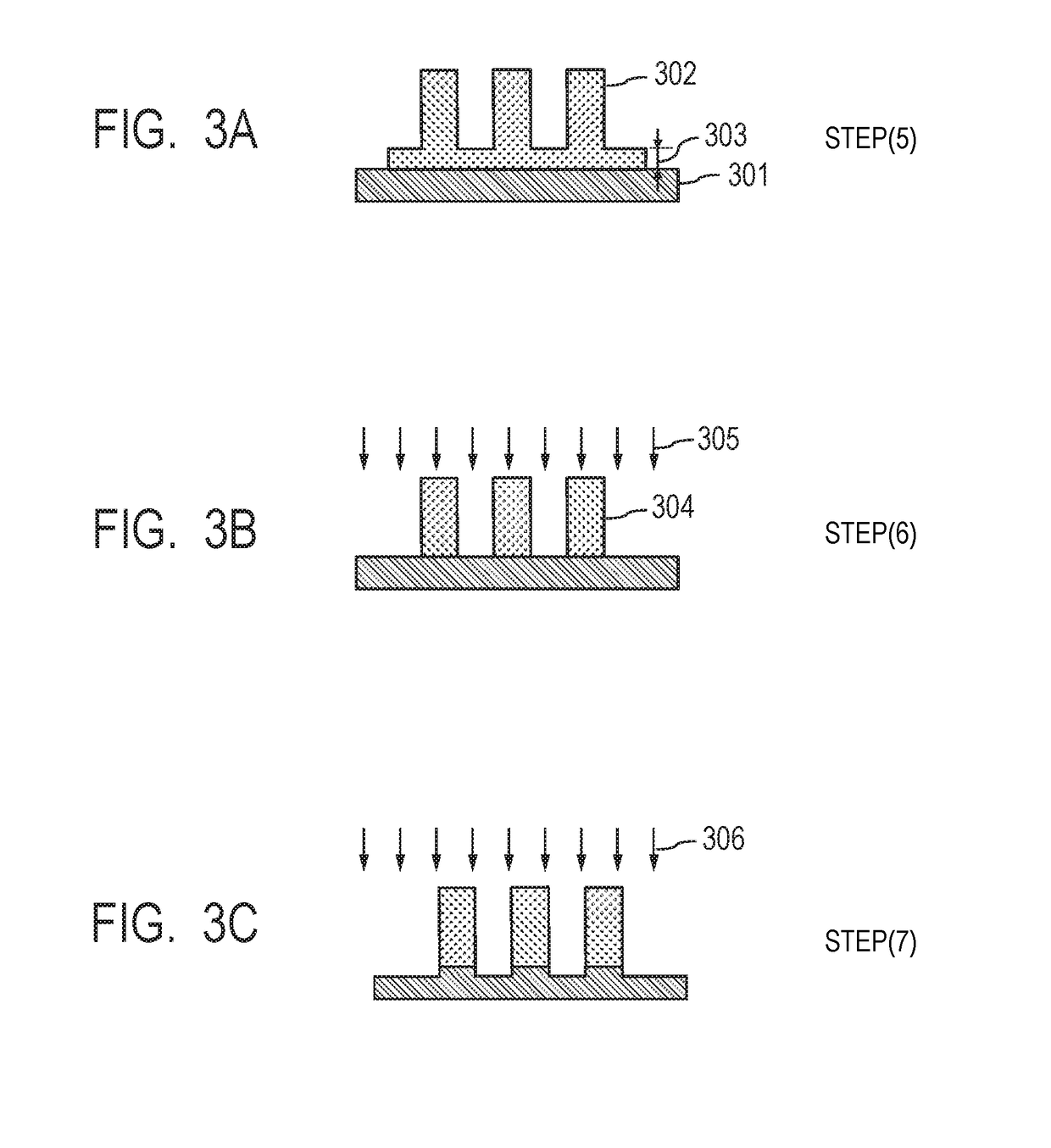

Method of forming pattern of cured product as well as production methods for processed substrate, optical component, circuit board, electronic component, imprint mold and imprint pretreatment coating material

ActiveUS20190030785A1Reduce yieldImprove yield (throughput) of SST-NILNanoinformaticsSemiconductor/solid-state device manufacturingProduct patternSolvent

Provided is a method of producing a cured product pattern, including: a first step (arranging step) of arranging a layer formed of a curable composition (α1′) that is the components of the curable composition (α1) except the component (D) serving as a solvent on a substrate; and a second step (applying step) of applying droplets of a curable composition (α2) discretely onto the layer formed of the curable composition (α1), the curable composition (α1) having a number concentration of particles each having a particle diameter of 0.07 μm or more of less than 2,021 particles / mL, and the curable composition (α1′) having a surface tension larger than that of the curable composition (α2).

Owner:CANON KK

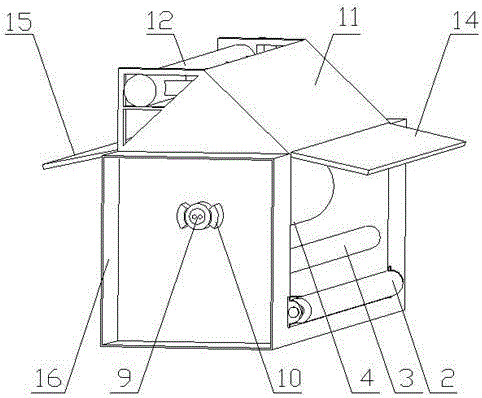

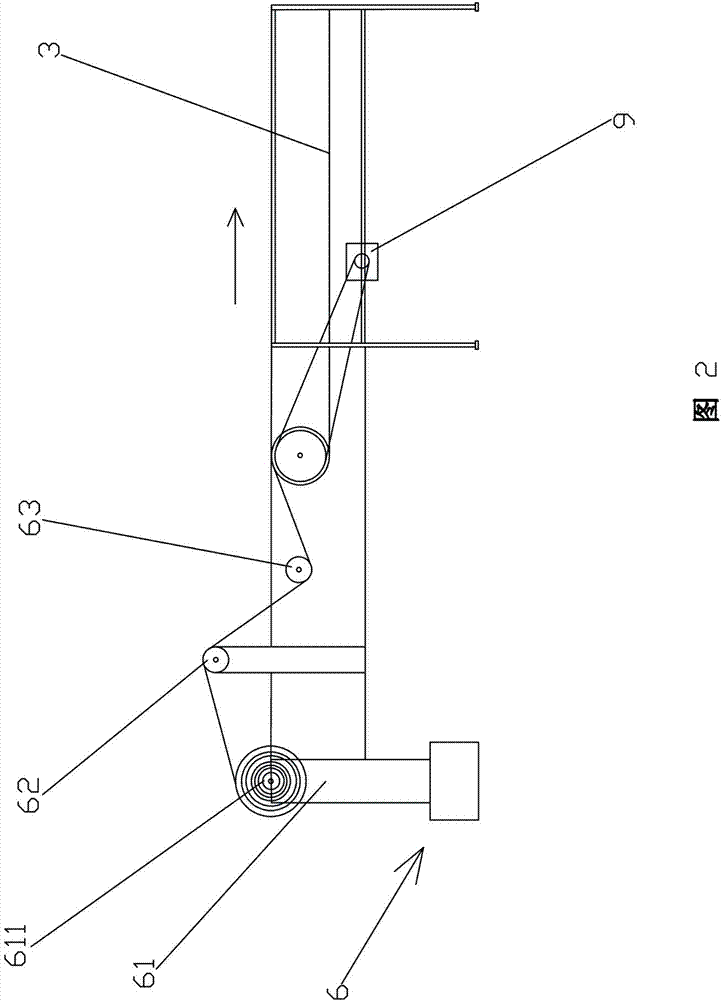

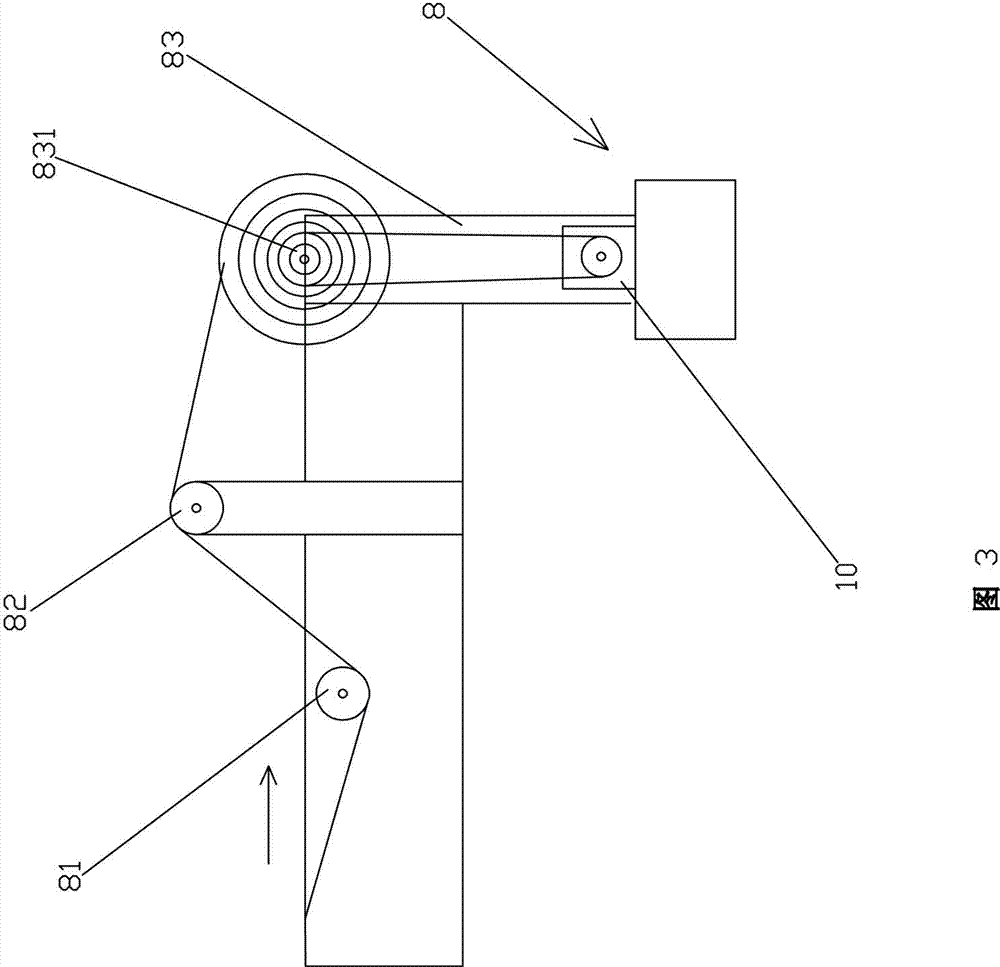

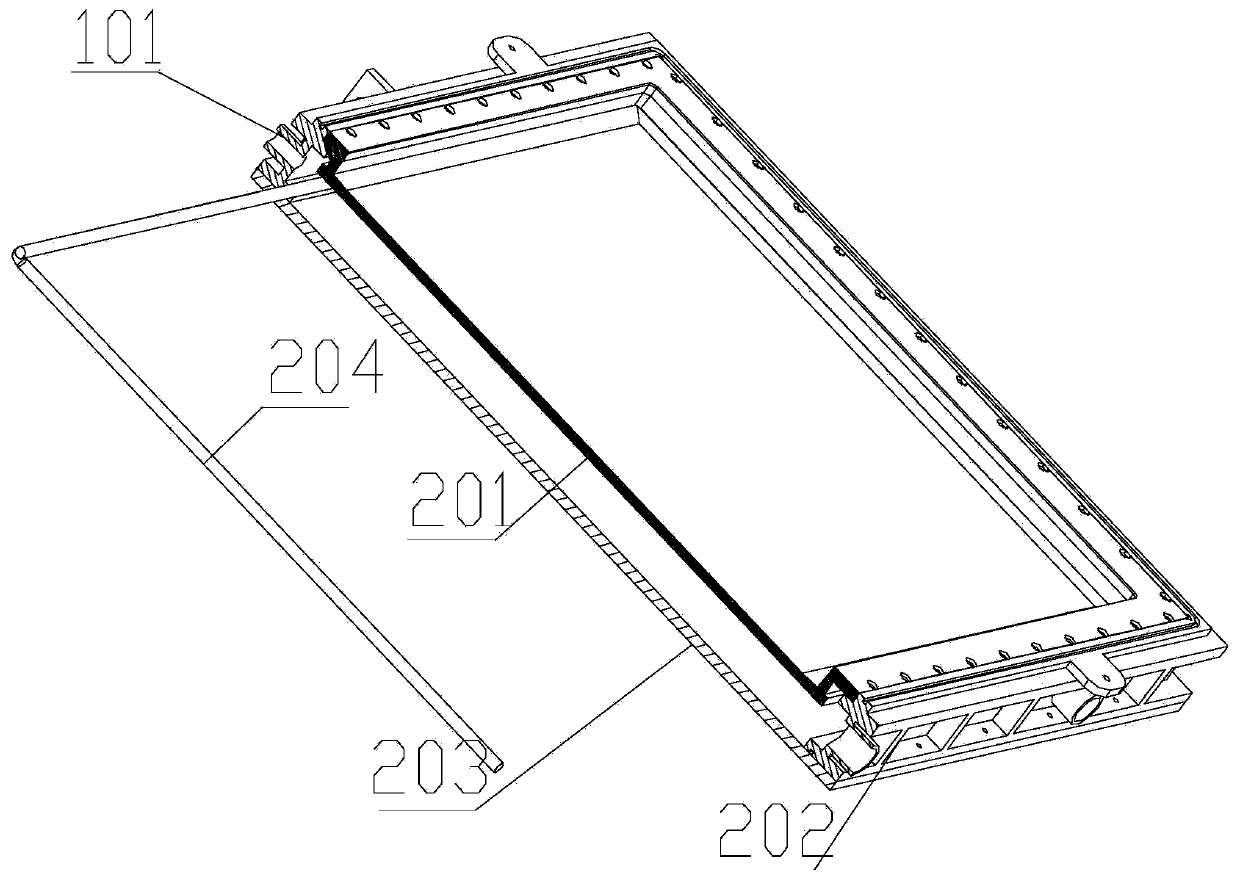

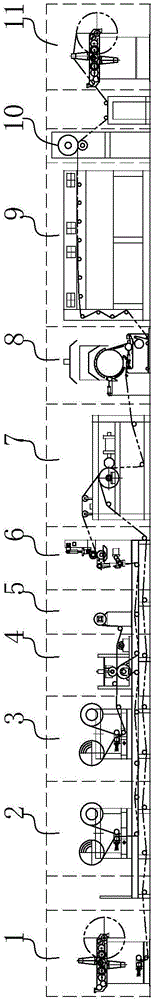

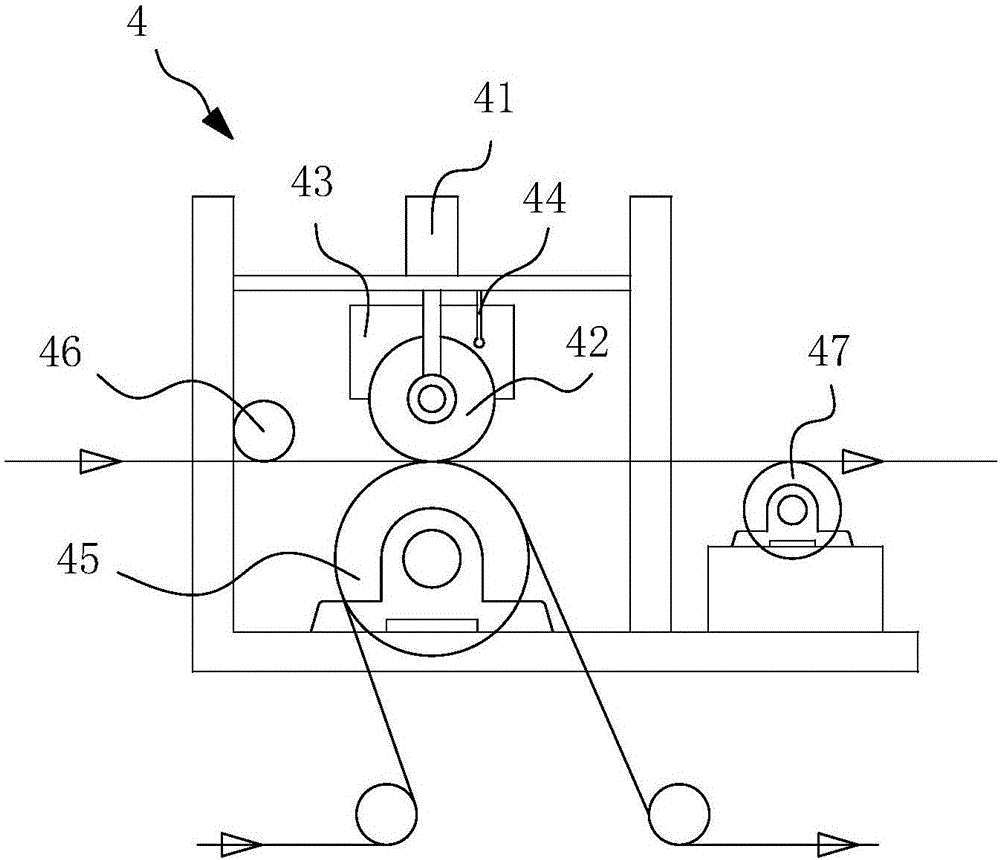

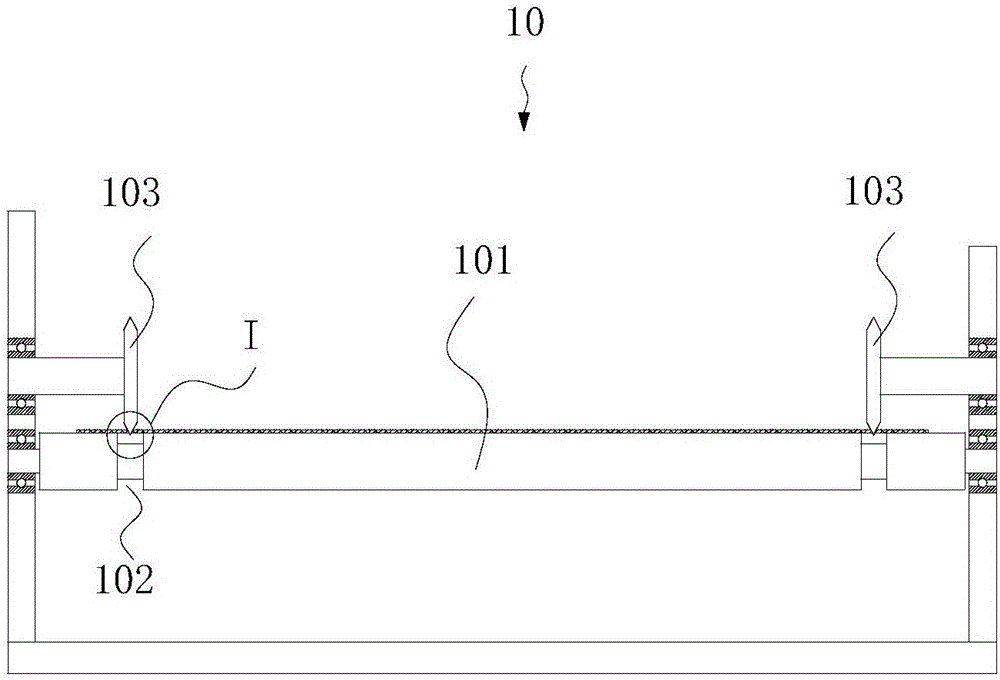

Wall cloth transfer-printing and embossing processing system

ActiveCN106739452AStable winding and unwindingRewinding and unwinding are smoothTransfer printingLamination ancillary operationsProduct patternEngineering

The invention relates to the field of wall cloth production and provides a wall cloth transfer-printing and embossing processing system. The wall cloth transfer-printing and embossing processing system aims at achieving the effects that the automation degree is high, and product quality is good. According to the technical scheme, the wall cloth transfer-printing and embossing processing system comprises a gauze unrolling device, a thin film unrolling device, a transfer-printing film unrolling device, a transfer-printing device, a transfer-printing film withdrawing device, an adhesive application device, an attachment device, a heating and embossing device, a drying device, an edge cutting device and a rolling device, wherein the gauze unrolling device, the thin film unrolling device, the transfer-printing film unrolling device, the transfer-printing device, the transfer-printing film withdrawing device, the adhesive application device, the attachment device, the heating and embossing device, the drying device, the edge cutting device and the rolling device are sequentially arranged in a linear manner. According to the wall cloth transfer-printing and embossing processing system, the transfer-printing film printing technology is adopted; processed wall cloth product patterns are formed integrally; the process is simple; no color difference is generated; and efficiency is high. Compared with the traditional mode that multiple printing machines are adopted for conducting pattern printing, on one hand, equipment cost is lowered, and energy is saved; and on the other hand, the production cycle is shortened, and wall cloth production efficiency is improved.

Owner:ANHUI BAUHINIA WALLPAPER

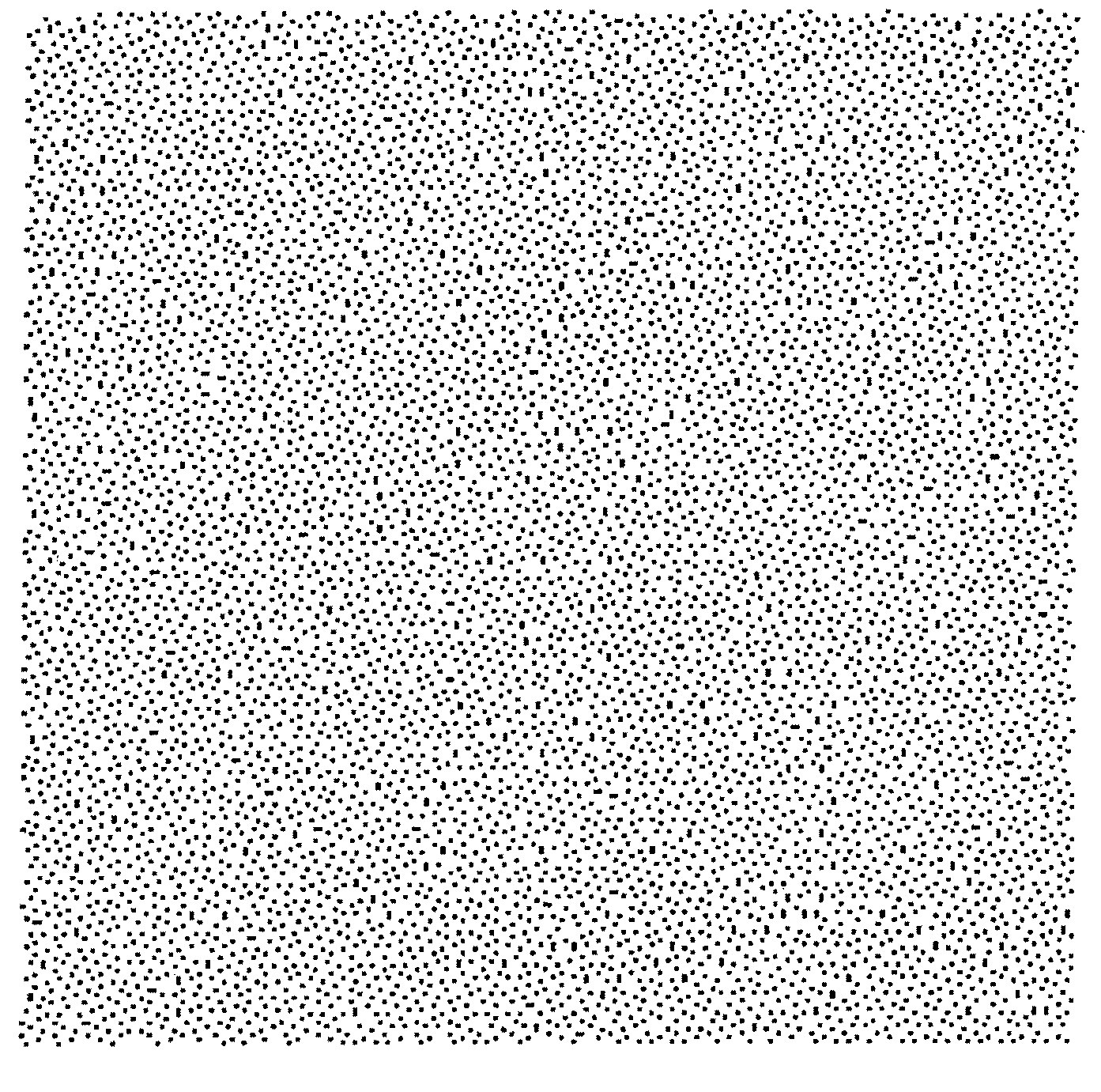

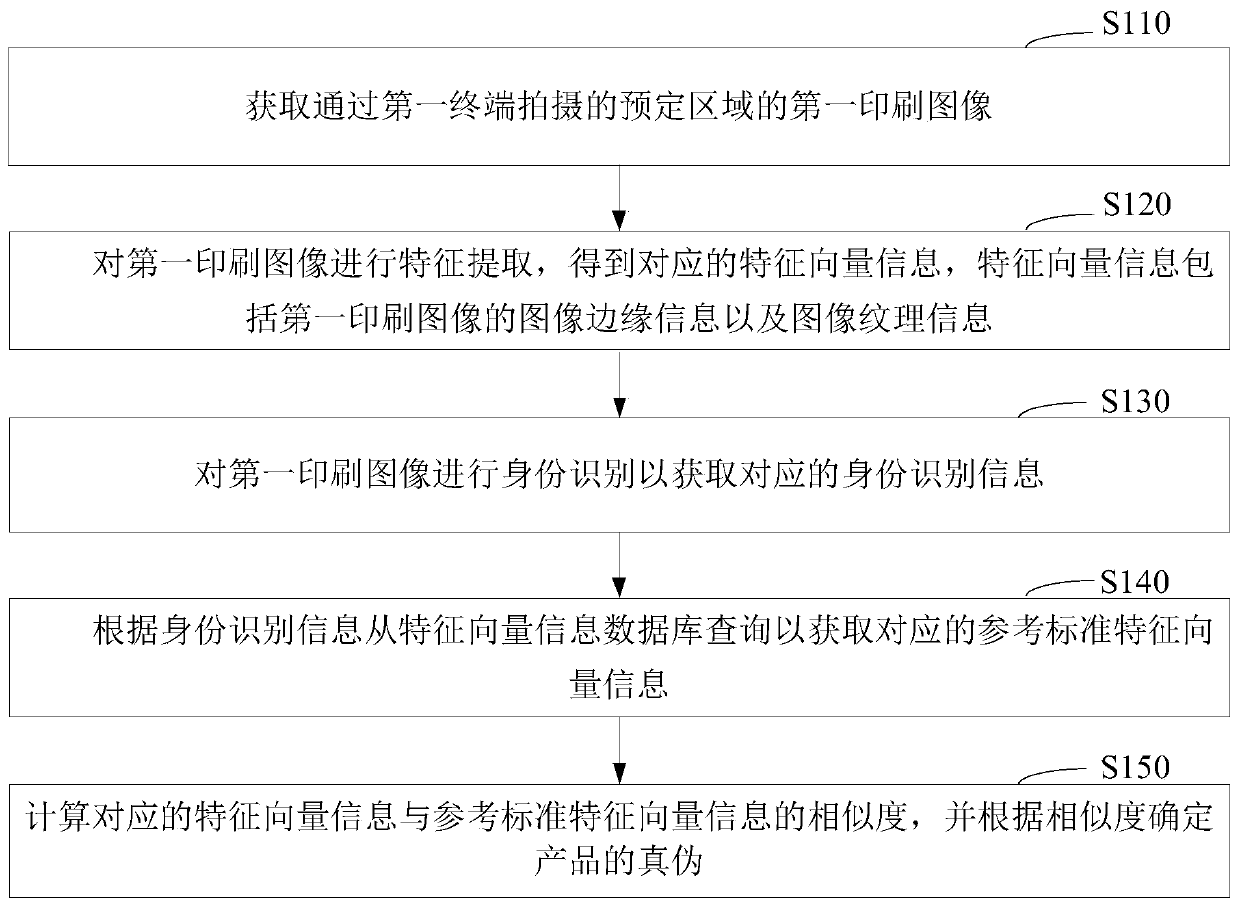

Anti-counterfeiting identification method and system, equipment terminal and computer readable storage medium

PendingCN110222602ALow costImprove anti-counterfeiting performanceCharacter and pattern recognitionFeature vectorGeneration process

The invention relates to an anti-counterfeiting identification method and system, an equipment terminal and a computer readable storage medium. The above anti-counterfeiting identification method comprises the following steps of obtaining a first printing image of a predetermined area shot by a first terminal, performing feature extraction on the first printing image, and obtaining the corresponding feature vector information, wherein the feature vector information comprises the image edge information and the image texture information of the first printing image; performing identity recognition on the first printing image to obtain the corresponding identity recognition information, and according to the identity recognition information, querying from a feature vector information database to obtain the corresponding reference standard feature vector information, calculating the similarity between the corresponding feature vector information and the reference standard feature vector information, and determining the authenticity of the product according to the similarity. According to the anti-counterfeiting identification method, the authenticity of the product can be distinguished by utilizing the non-replicability and randomness during the product pattern printing generation process, so that the anti-counterfeiting capability of the product is greatly improved.

Owner:艾科芯(深圳)智能科技有限公司

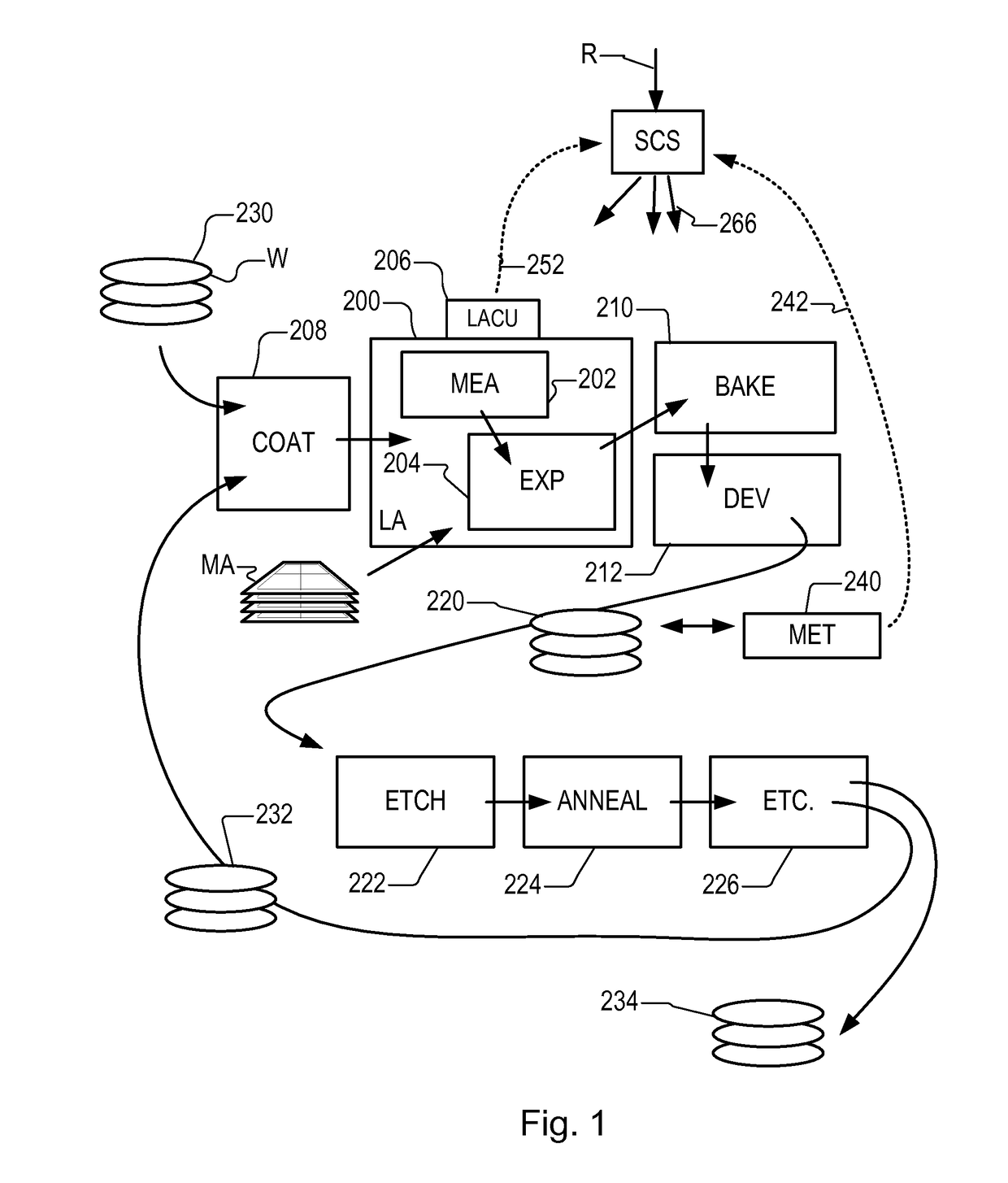

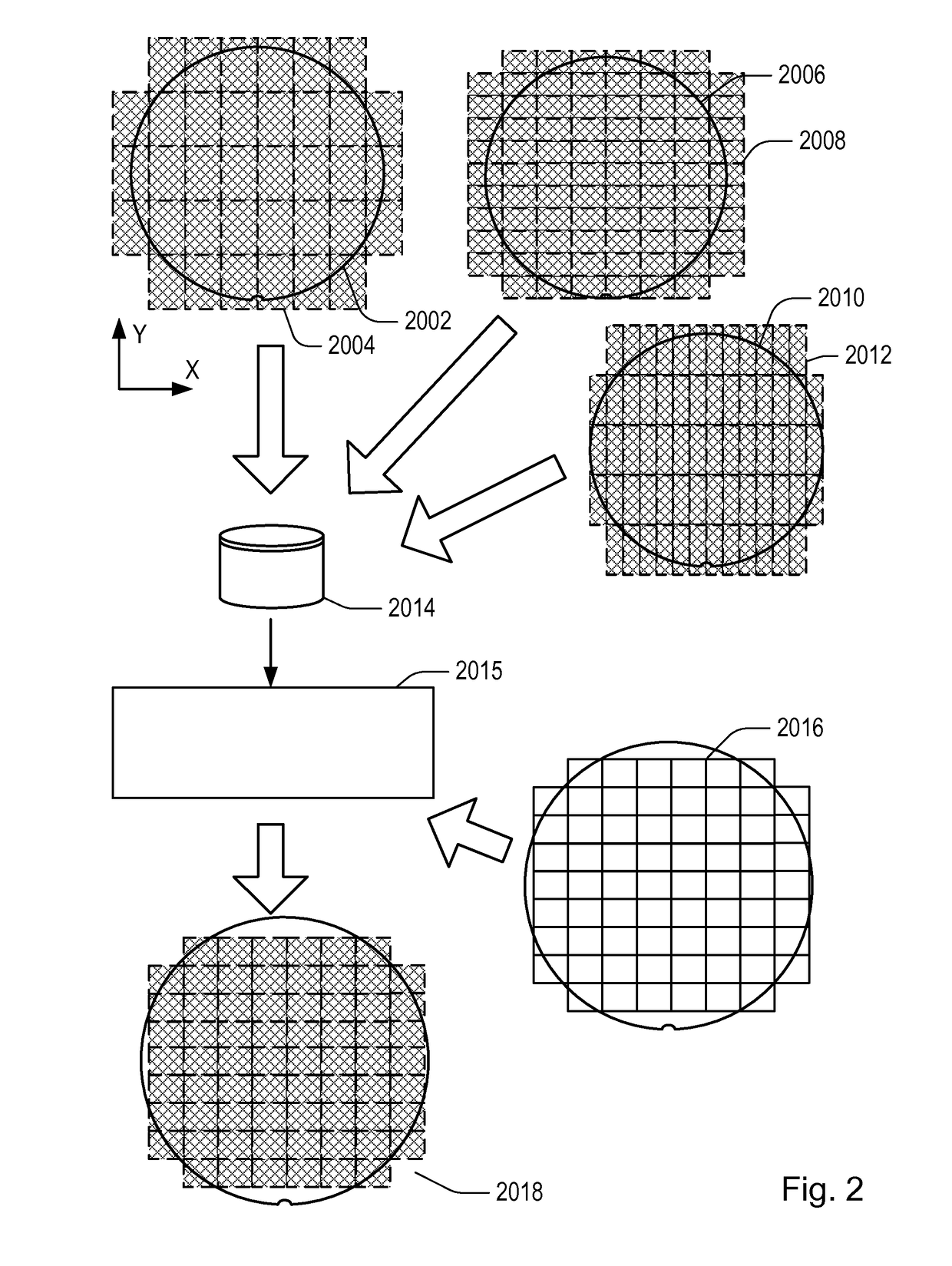

Calibration Method for a Lithographic Apparatus

ActiveUS20180173118A1Shorten the timeImprove accuracyProgramme controlComputer controlProduct patternEngineering

A first substrate (2002) has a calibration pattern applied to a first plurality of fields (2004) by a lithographic apparatus. Further substrates (2006, 2010) have calibration patterns applied to further pluralities of fields (2008, 2012). The different pluralities of fields have different sizes and / or shapes and / or positions. Calibration measurements are performed on the patterned substrates (2002, 2006, 2010) and used to obtain corrections for use in controlling the apparatus when applying product patterns to subsequent substrates. Measurement data representing the performance of the apparatus on fields of two or more different dimensions (2004, 2008, 2012) is gathered together in a database (2013) and used to synthesize the information needed to calibrate the apparatus for a new size. Calibration data is also obtained for different scan and step directions.

Owner:ASML NETHERLANDS BV

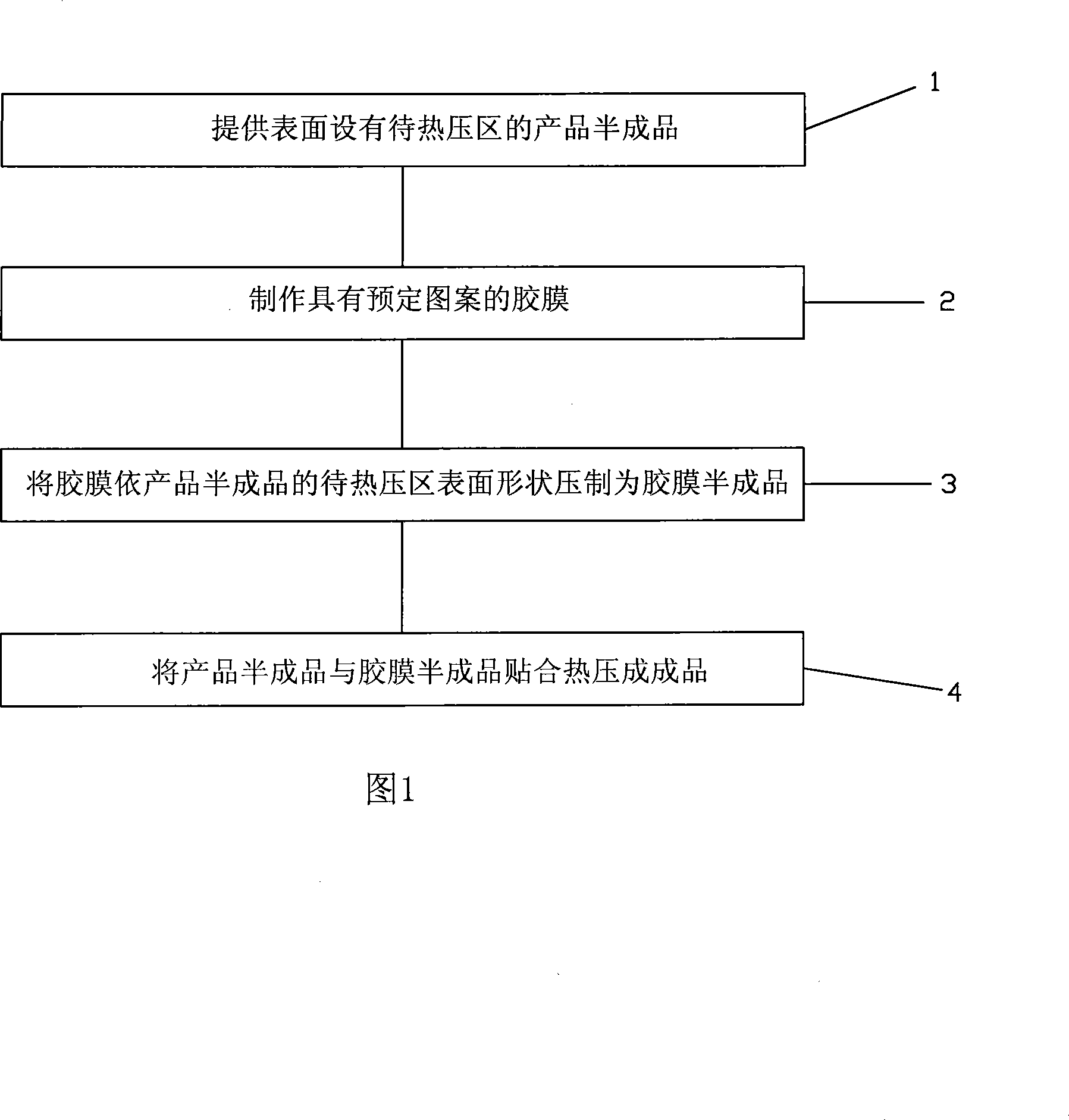

Method for making productí»s pattern

InactiveCN101112846ASimplify the manufacturing processLamination ancillary operationsDecorative surface effectsPulp and paper industryProduct pattern

A making method of a product pattern comprises the steps of step 1: the half finished product with the surface provided with a pressing area to be heated is provided; step 2: the glue film with prearranged pattern js prepared; step 3: the glue film is pressed into the glue film half finished product according to the surface shape of the pressing area to be heated of the half finished product; step 4: the finished product is formed by hot pressing the half finished product and the glue film half finished product. The invention carries out the hot pressing of the glue film half finished product and half finished product with prearranged pattern into a die to produce the finished product, the pre-disposal is not required for the surface of the half finished product and the post disposal is not required for the finished product surface after forming, the making working procedure is simplified, and the pattern after forming is arranged in the interior of the product, thus ensuring the pattern to be exquisite, lifelike, durable and anti-wear.

Owner:林其武

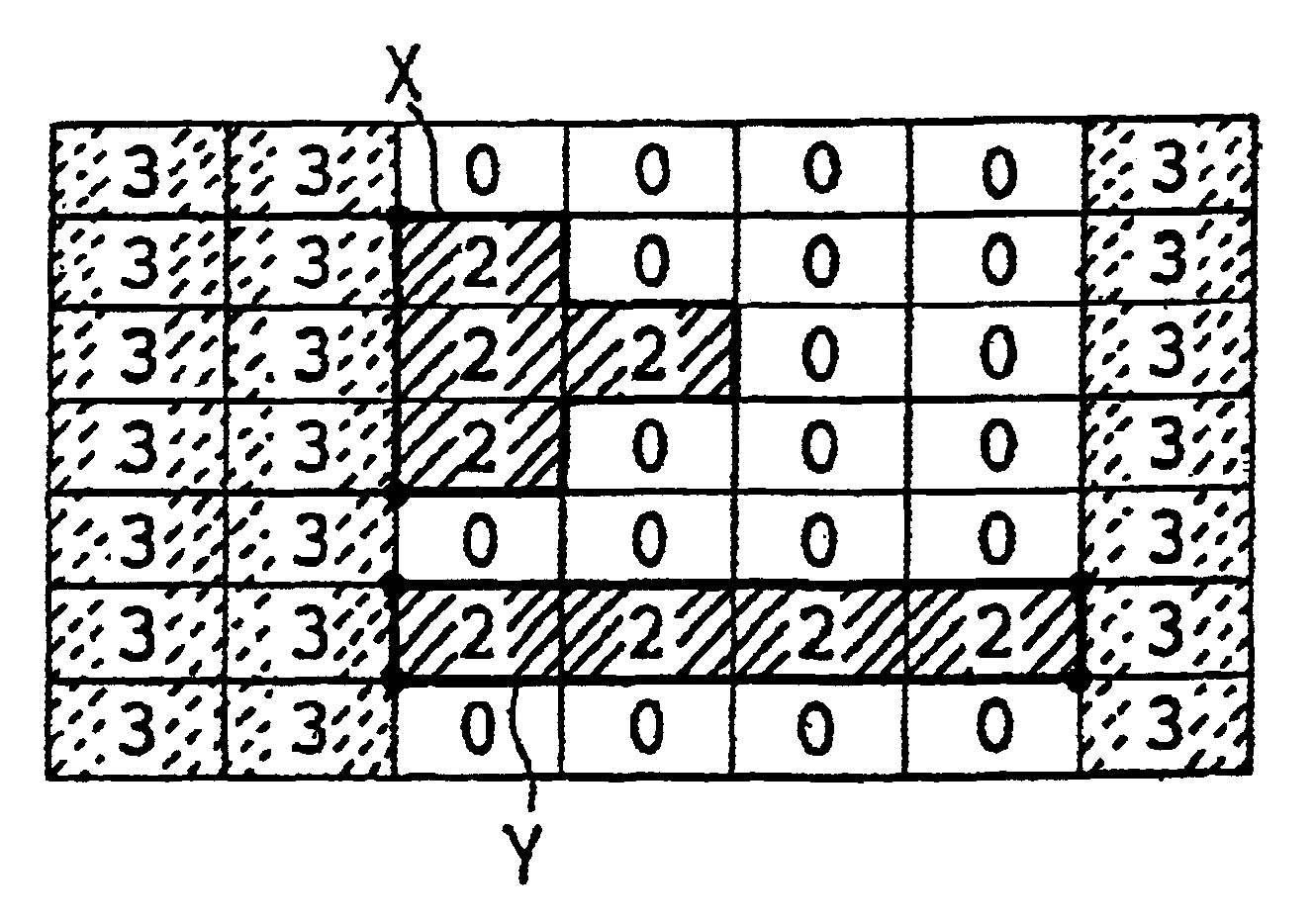

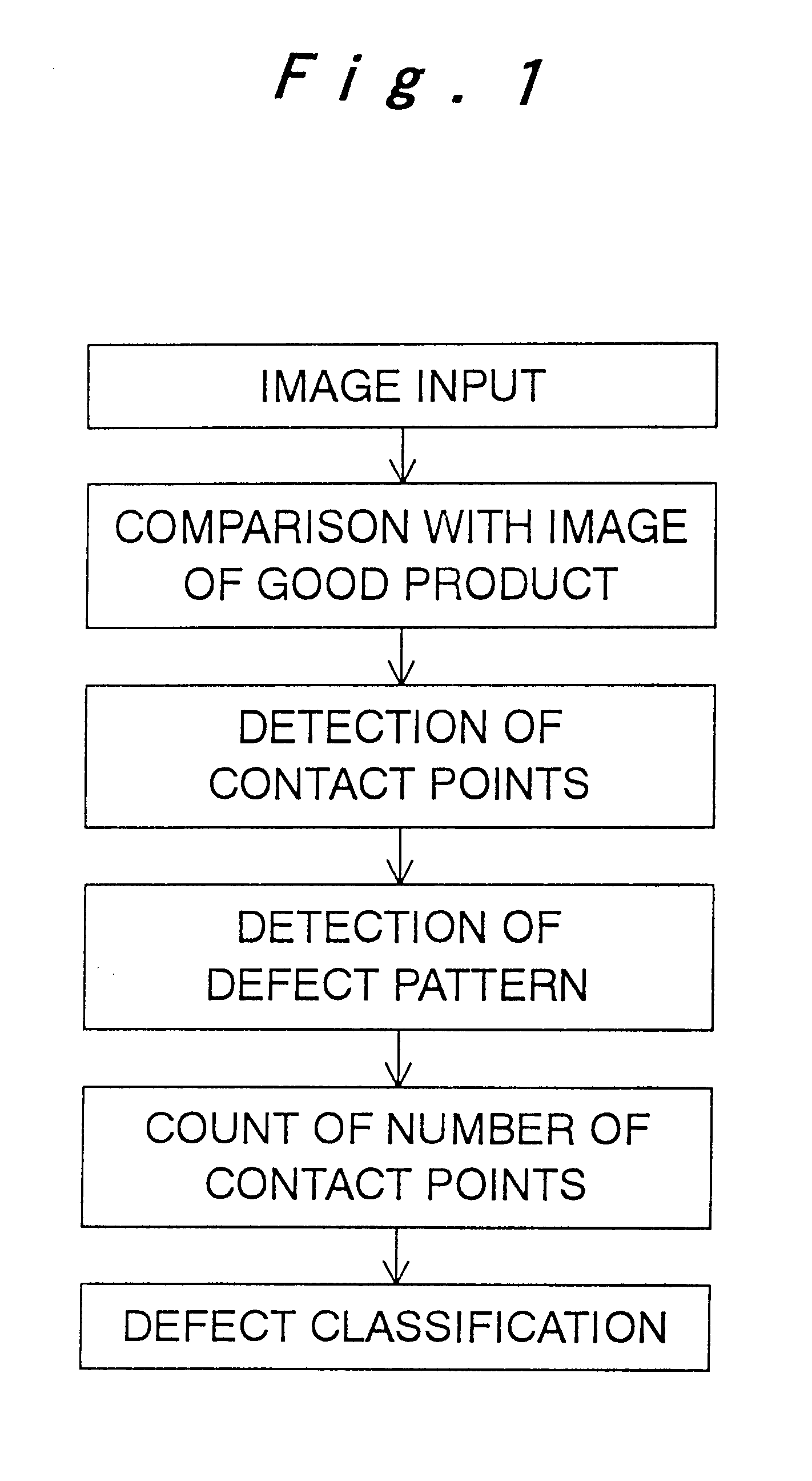

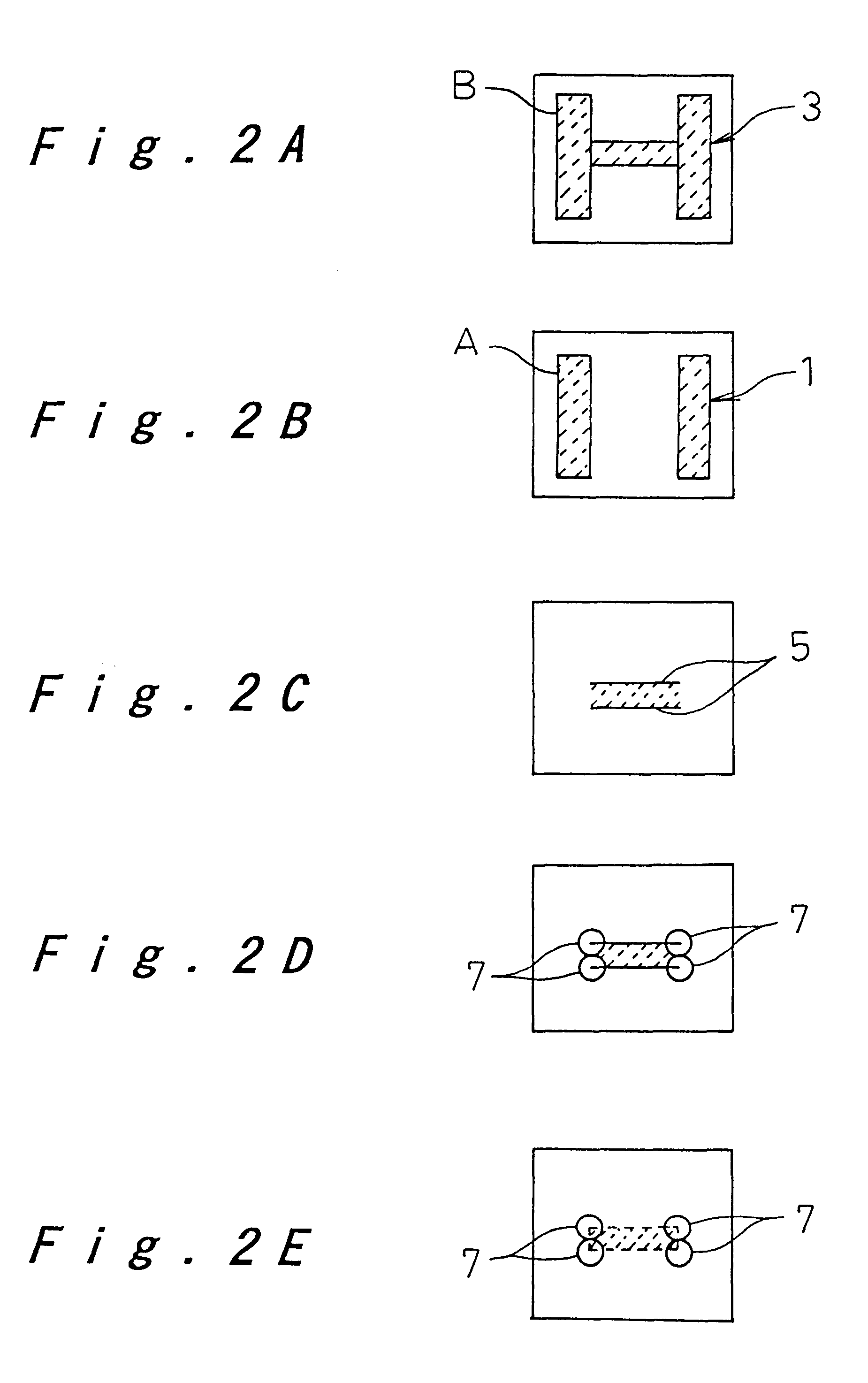

Method of detecting pattern defects

An input subject pattern is compared with a good product pattern that is registered beforehand, and a different portion of these is detected as a defect pattern. The detected defect pattern is classified in accordance with the features of the contour of the defect pattern.

Owner:PANASONIC CORP

Method for producing applique cloth picture

InactiveCN101143542AEasy to processDelicate imageDecorative surface effectsSpecial ornamental structuresGraphicsProduct pattern

A method of manufacturing applique cloth painting is characterized by: (1) product pattern determination; (2) painting; (3) plate making; (4) material selecting; (5) color matching; (6)fabric sizing; (7)pattern making; (8) sewing; (9)deployment; (10) form complementation; (11) thread matching; (12) applique; (13)base making; (14)ironing; (15) width adjustment and (16) packaging. The present invention is discovered, researched and developed and innovated based on the traditional applique and applique cloth paintings; the gold floss or the color fabric is adopted as the painting surface materials, and the satin brocade, the silk or the cherquemolle fabric is adopted as the base cloth material; the product made by the method has bright color, as well as natural, powerful and vivid image; the sewing method without bossy edges is adopted in the making process, and the hot burning processing method is adopted for modeling of the patterns, so that each part of the applique is more vivid with lifelike effect, which improves the process of combining the applique modeling and embroidering and thus the painting surface is more ornamental.

Owner:金映雪

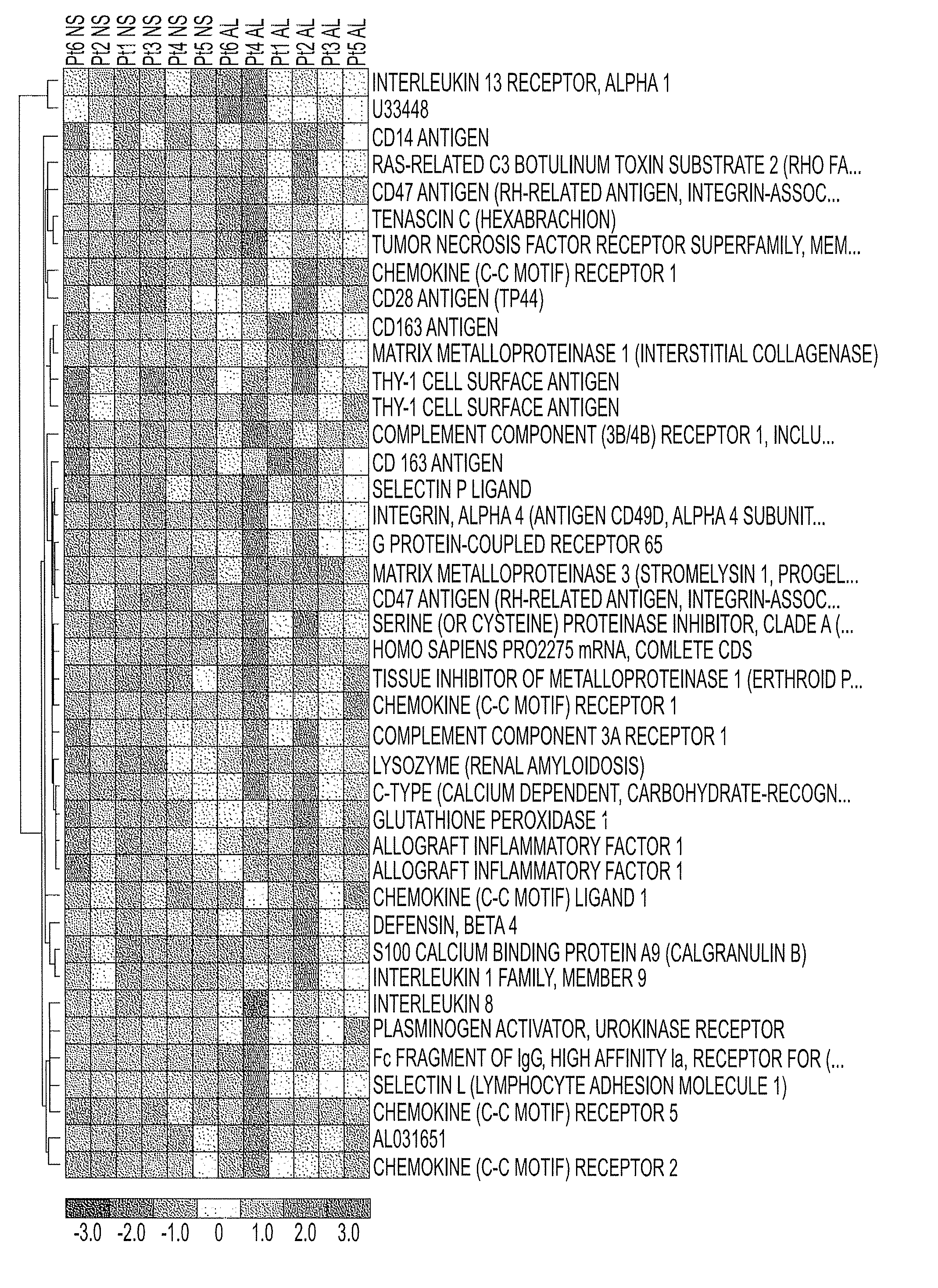

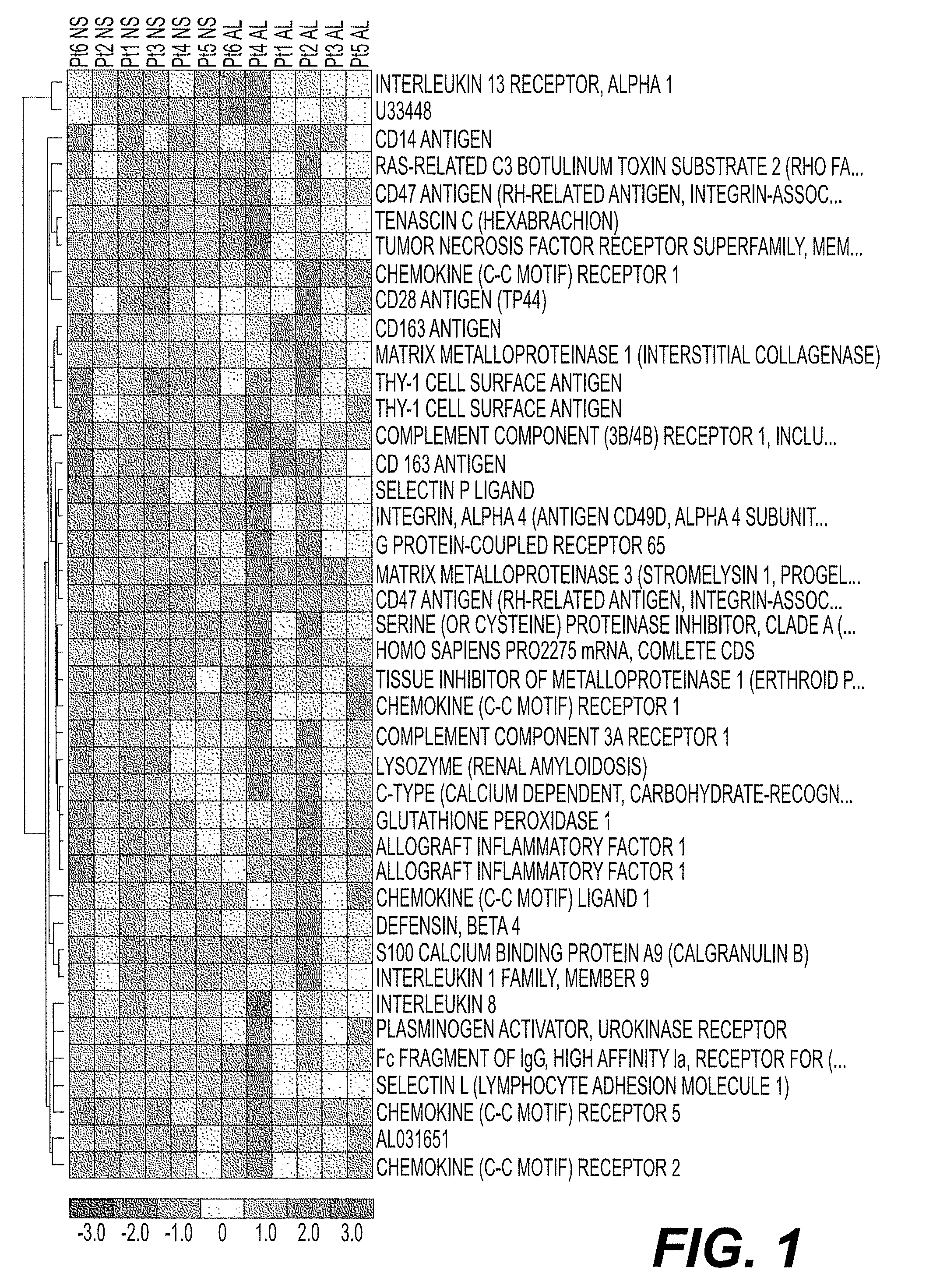

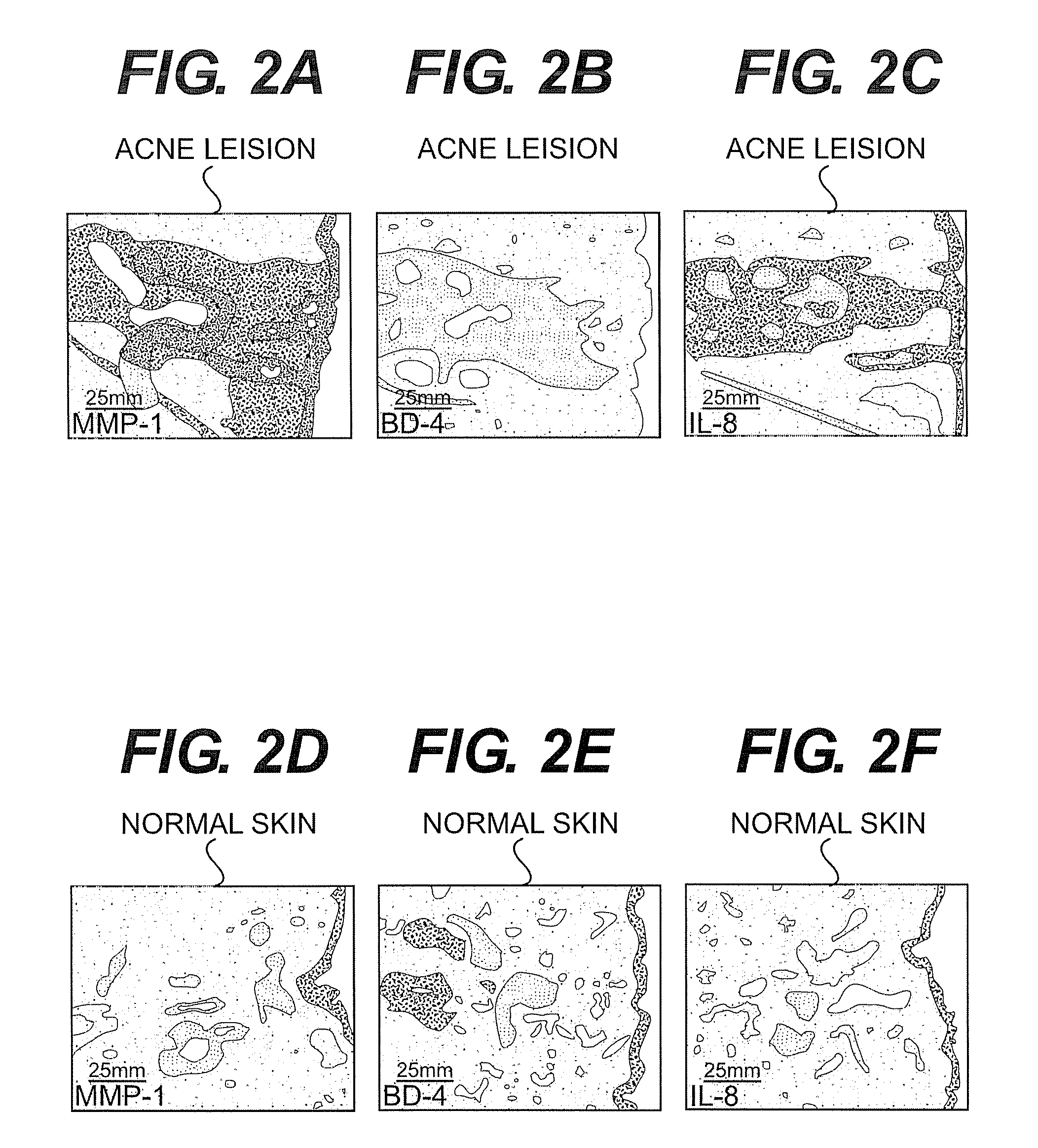

Acne lesion biomarkers and modulators thereof

InactiveUS20090042204A1Microbiological testing/measurementDisease diagnosisTreatment acneProduct pattern

The present invention relates to acne lesions biomarkers / genes expression products pattern and particularly inflammatory acne lesions biomarkers and their uses, modulators thereof and the use of modulators for acne treatment or associated disorders. Invention also concerns in vitro diagnostic methods.

Owner:GALDERMA RES & DEV SNC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com