Double-finger automatic workpiece clamping vertical type quenching machine tool

A quenching machine tool, double-finger technology, applied in quenching devices, manufacturing tools, heat treatment equipment, etc., to increase economic benefits, improve work efficiency, and save time for loading and unloading materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

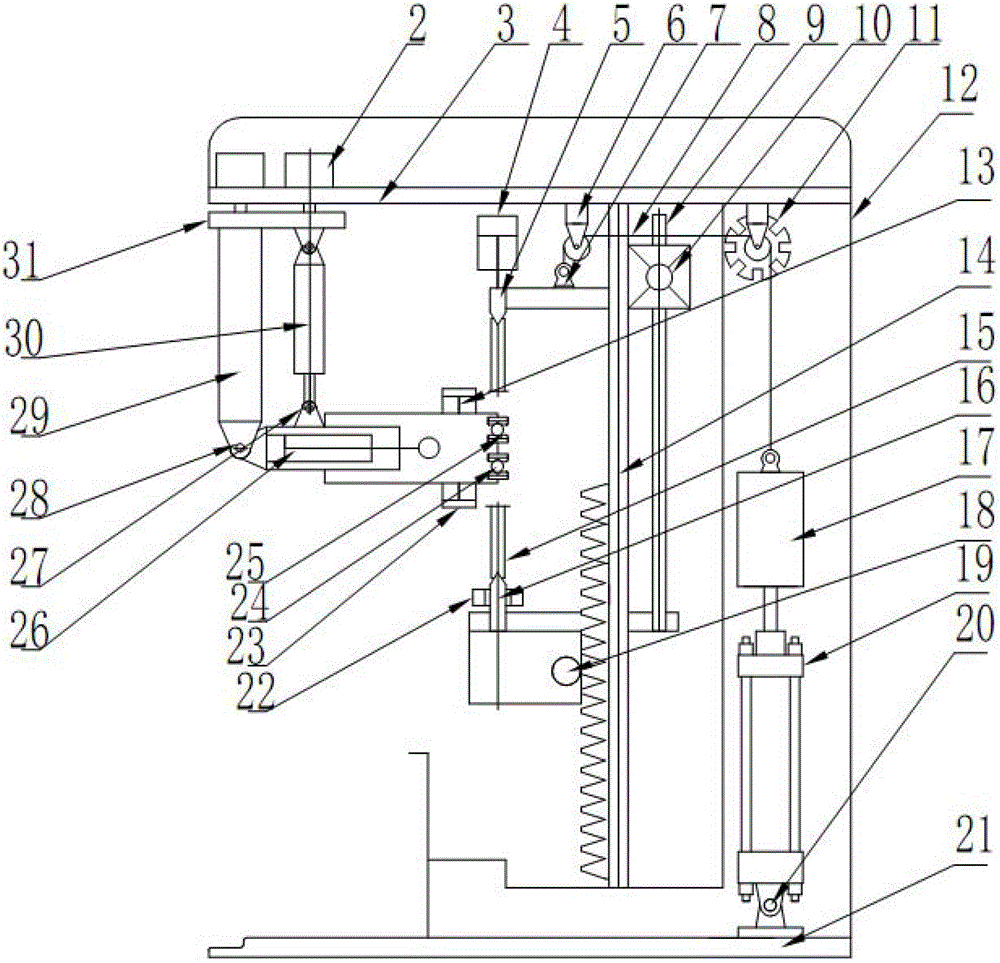

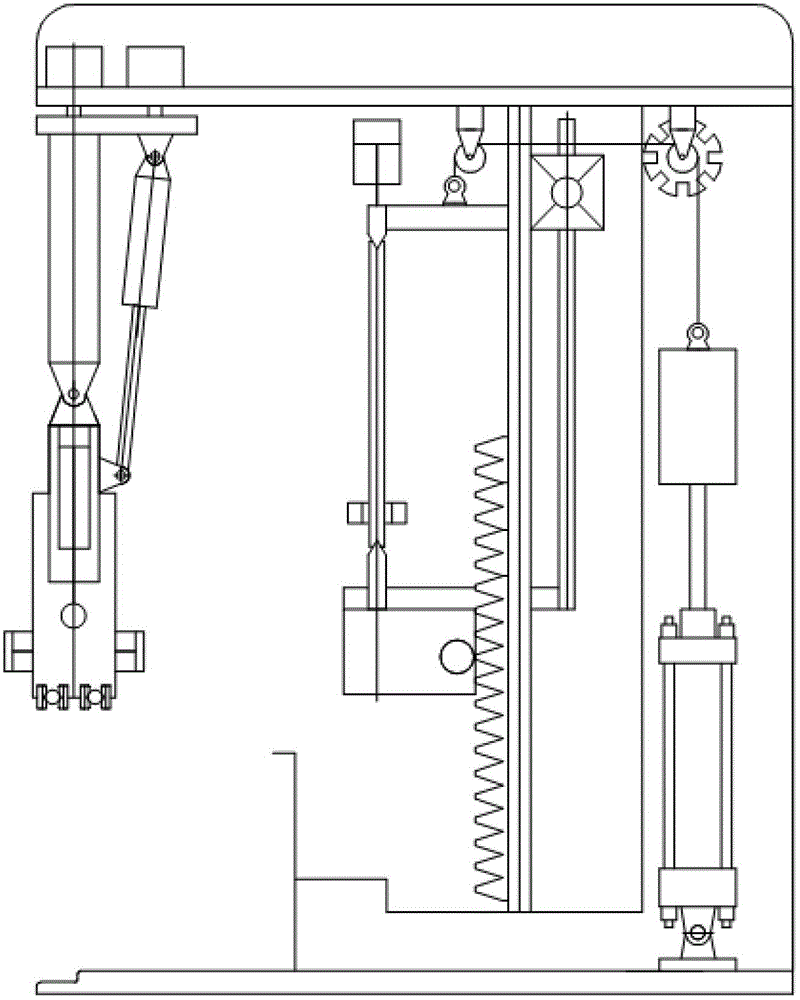

[0019] Such as figure 1 , 2 Shown is a two-finger automatic workpiece clamping vertical quenching machine tool, which includes a clamping device, a two-finger workpiece loading and unloading device, a heating and quenching device, and a loading and unloading device;

[0020] The clamping device includes two tops with adjustable spacing up and down to clamp the workpiece between the two tops 5, 16;

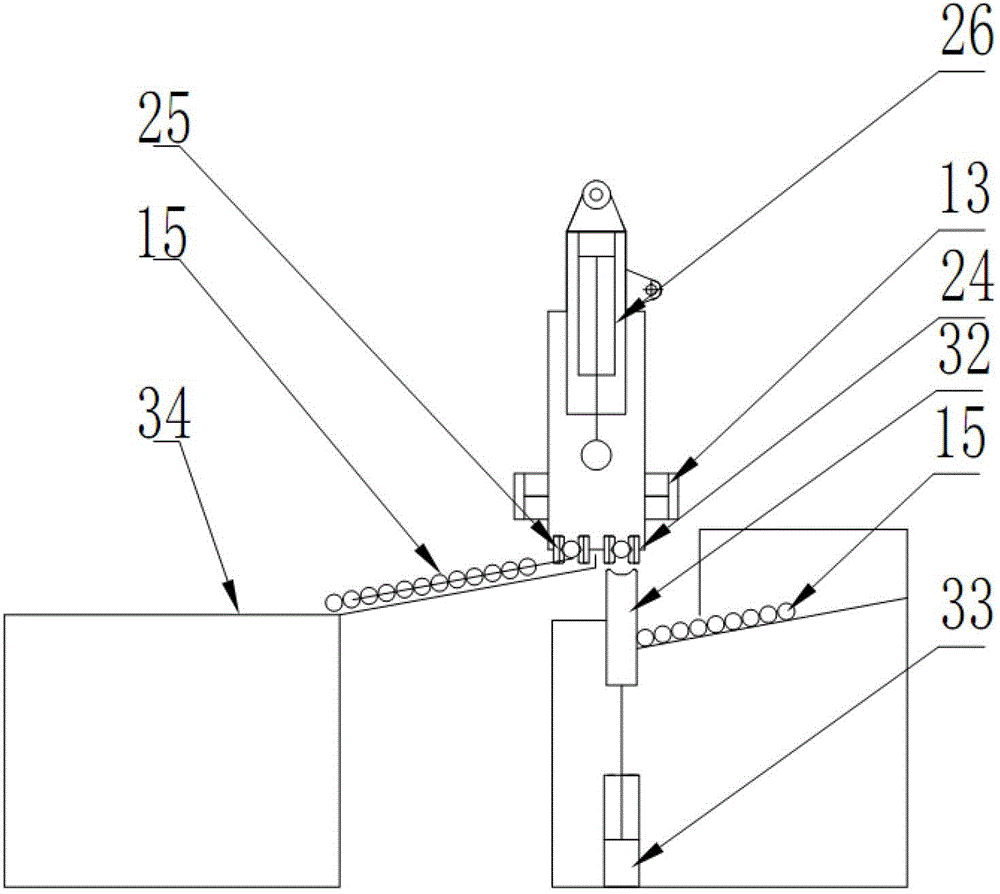

[0021] The two-finger workpiece loading and unloading device is arranged on the cross arm 3 of the quenching machine tool body, and includes a clamping manipulator with two mechanical fingers 24, 25 and a turning cylinder 30. The turning cylinder 30 drives the clamping manipulator to turn over 90 degrees, and The workpiece 15 is automatically clamped or unloaded from the clamping device;

[0022] The heating and quenching device is an induction coil and a water jacket 22, which heats and cools and quenches the workpiece 15 that moves up and down through the induction coil and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com