Wall cloth transfer-printing and embossing processing system

A processing system and wall covering technology, applied in transfer printing, rotary printing machines, printing, etc., can solve the problems of harming health, simple decoration, easy generation of formaldehyde in wall paint, and complicated wallpaper construction process, so as to improve the transfer rate. Improve printing efficiency, shorten production cycle, and avoid missing printing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Attached below Figure 1~5 The present invention is further described.

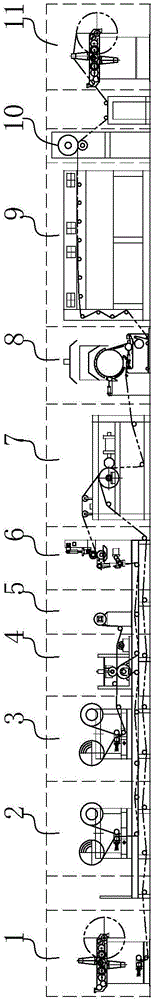

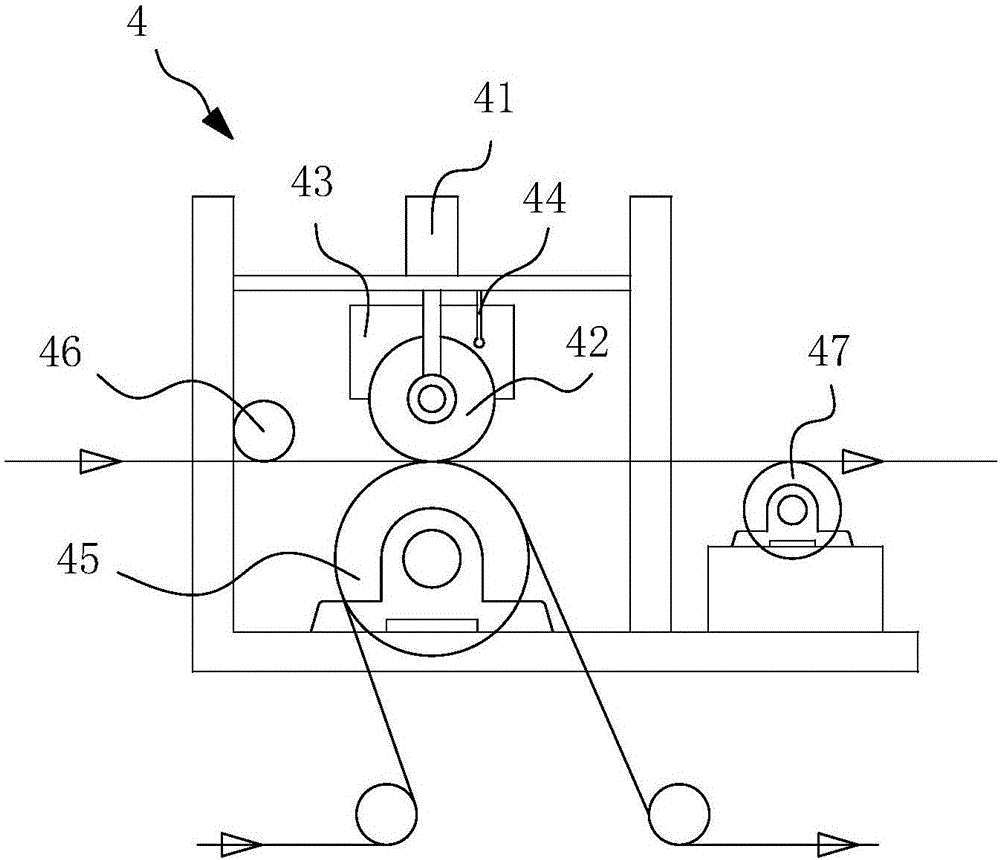

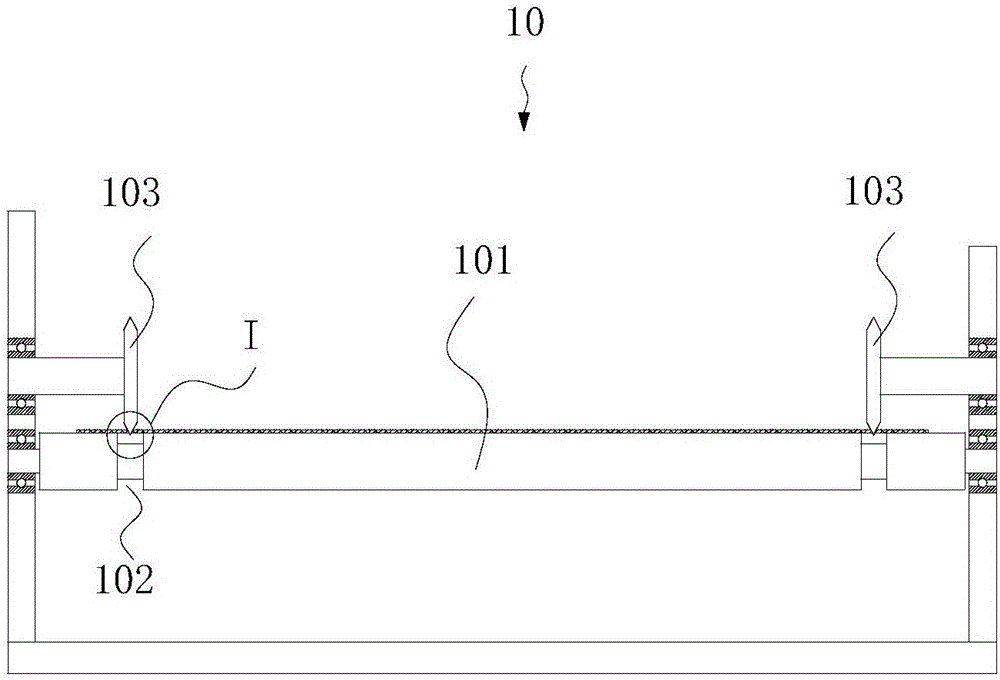

[0025] A wall cloth transfer printing and embossing processing system, including a gauze unwinding device 1, a film unwinding device 2, and a transfer film unwinding device 3 arranged sequentially in a line, which are used to unwind patterns on the transfer film The transfer device 4 for transferring to the film, the transfer film winding device 5 for winding the transferred transfer film, the gluing device 6 for gluing the film with the pattern transferred, and the gluing device 6 for gluing the transferred film Laminating device 7 for bonding the finished film and gauze, heating embossing device 8 for heating and embossing the wall covering after bonding, drying device 9 for drying the embossed wall covering, cutting An edge device 10 and a winding device 11 for collecting wall coverings in separate rolls.

[0026] The gauze on the gauze unwinding device 1 enters the pasting device 7 after bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com