Patents

Literature

129results about How to "Realize lifting movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

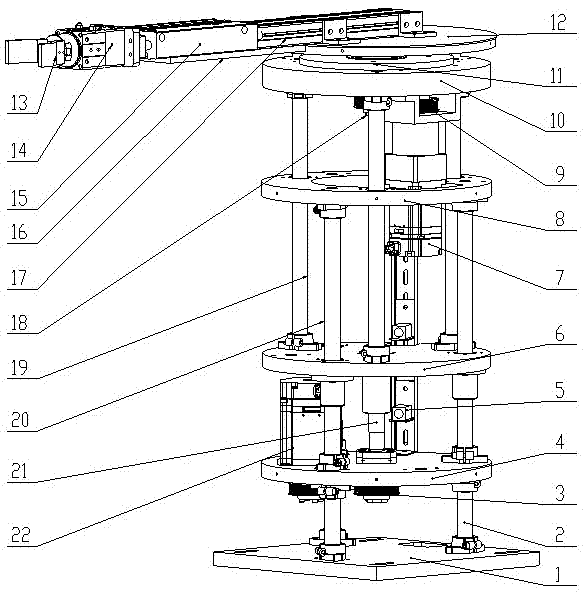

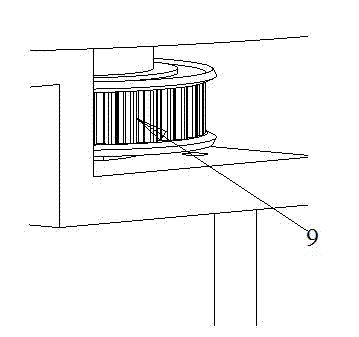

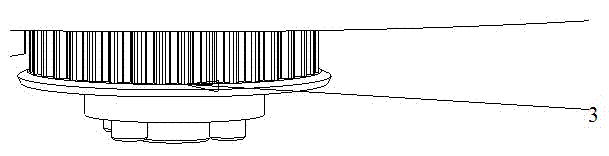

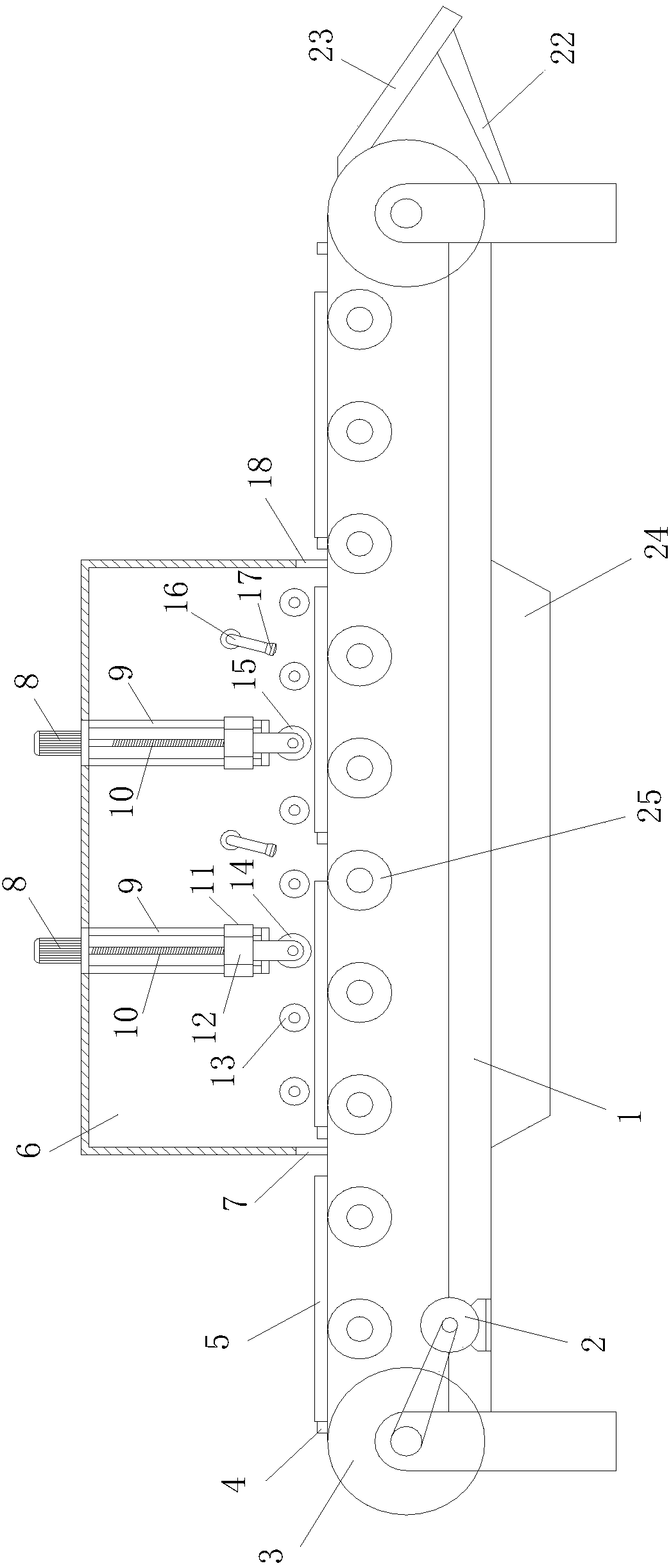

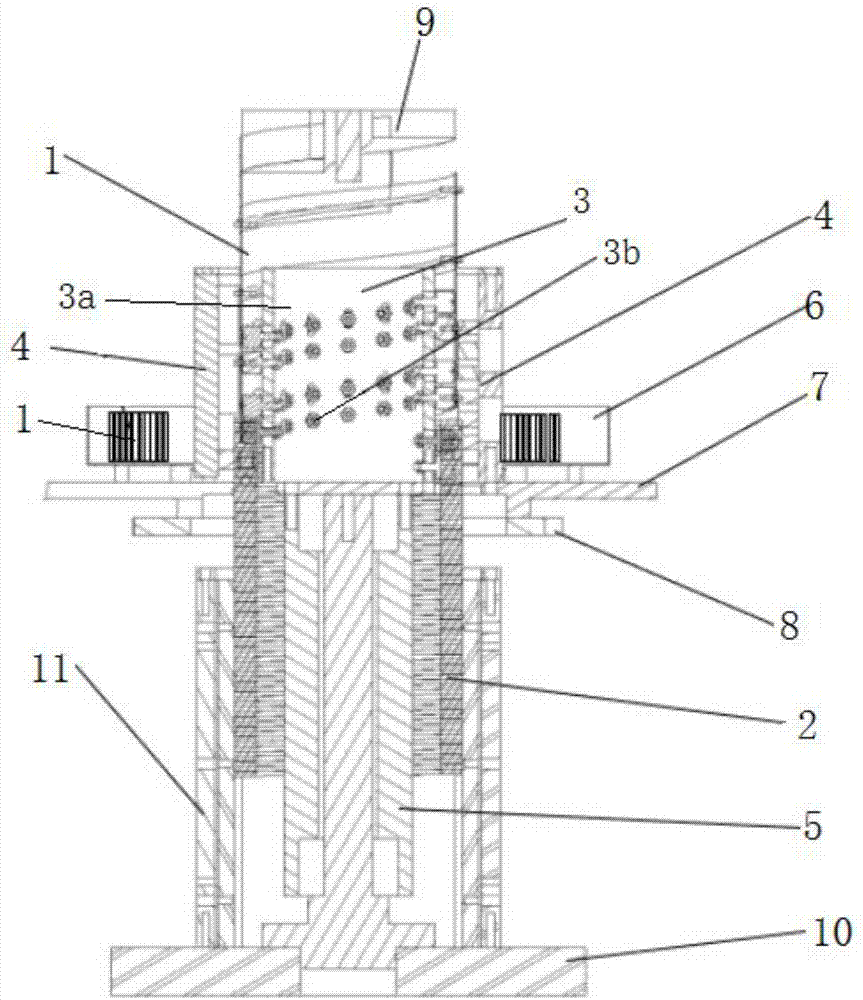

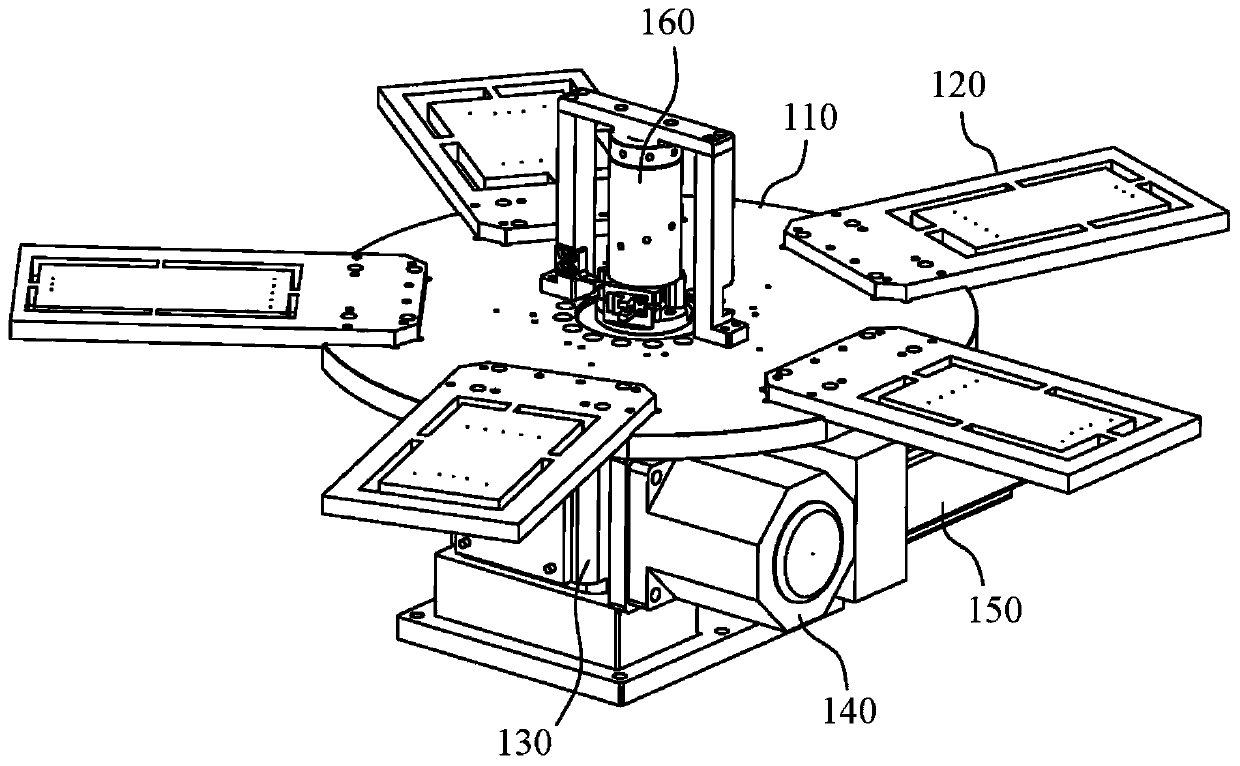

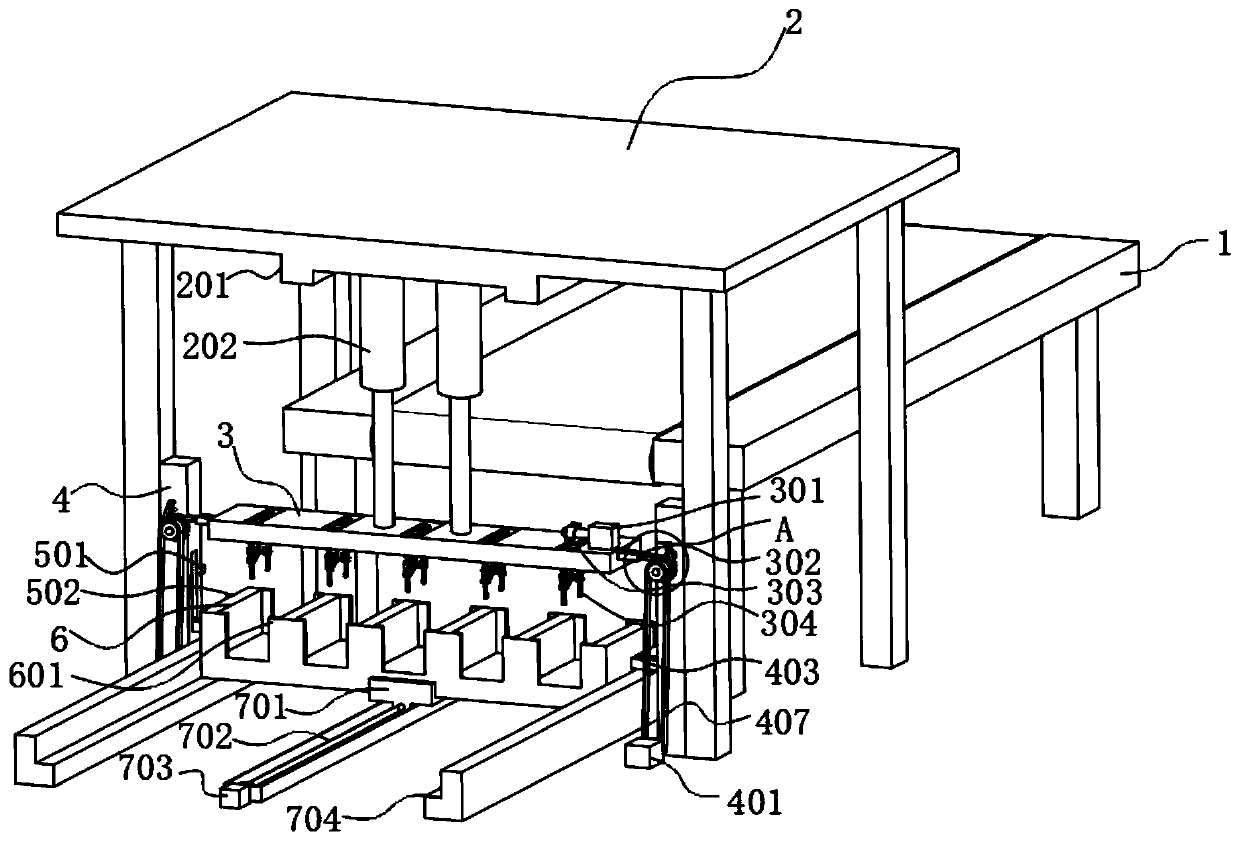

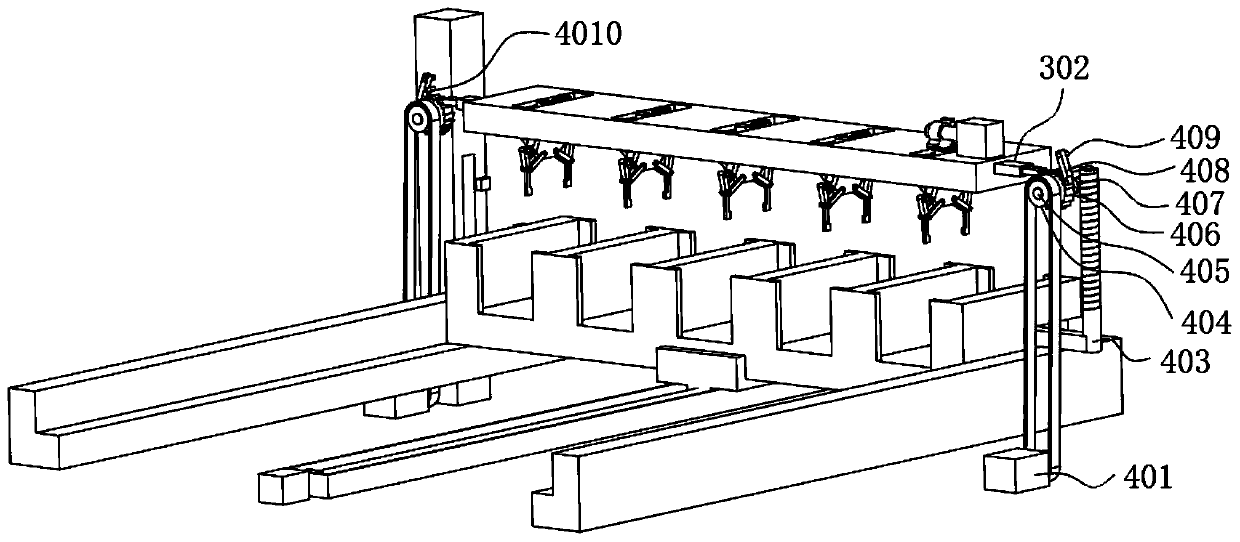

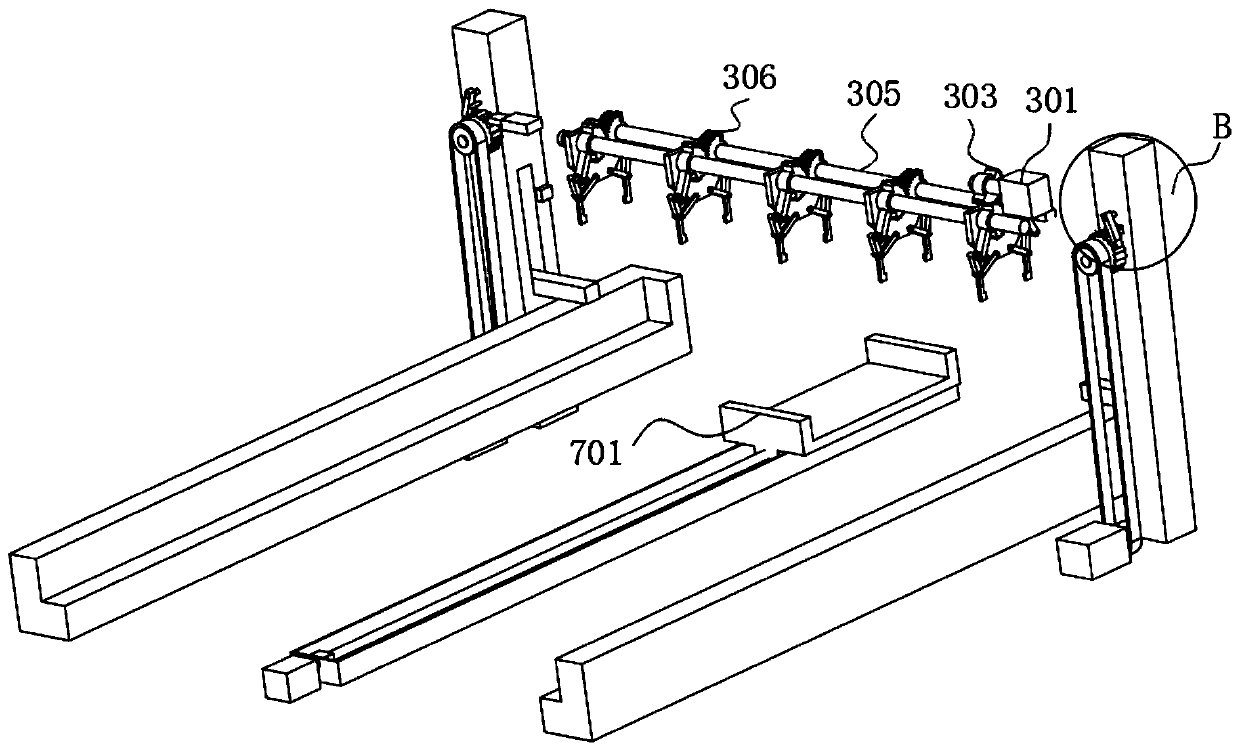

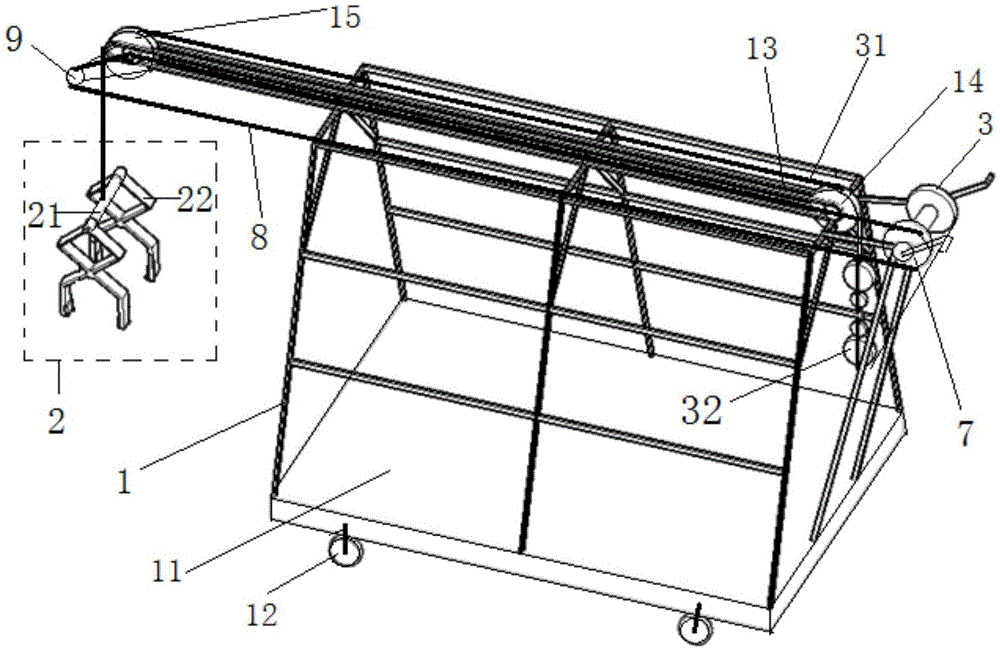

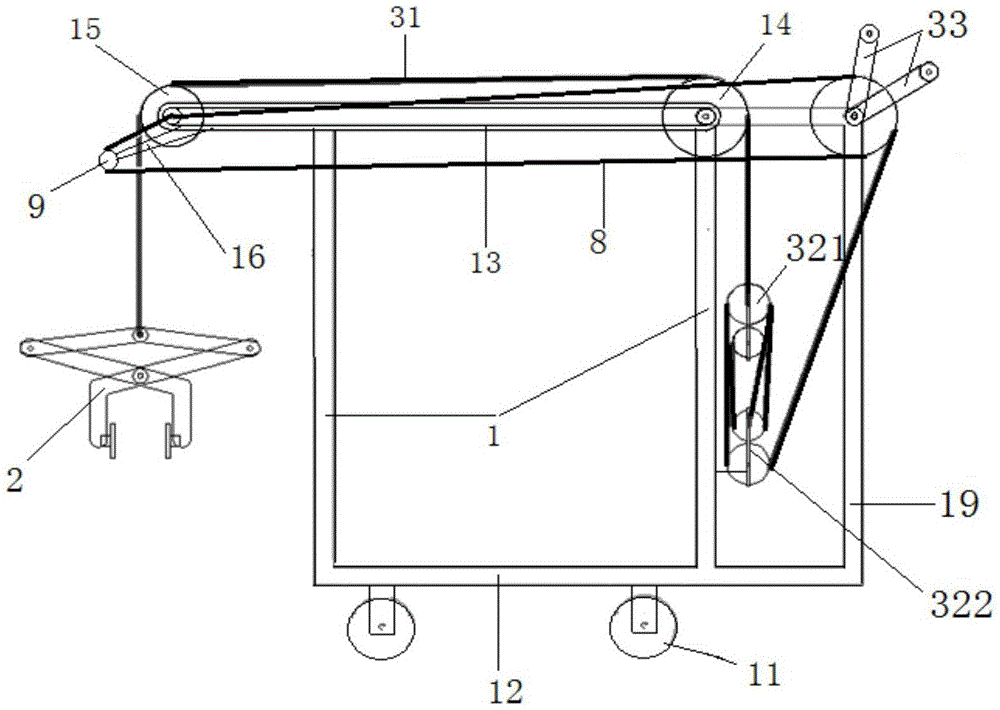

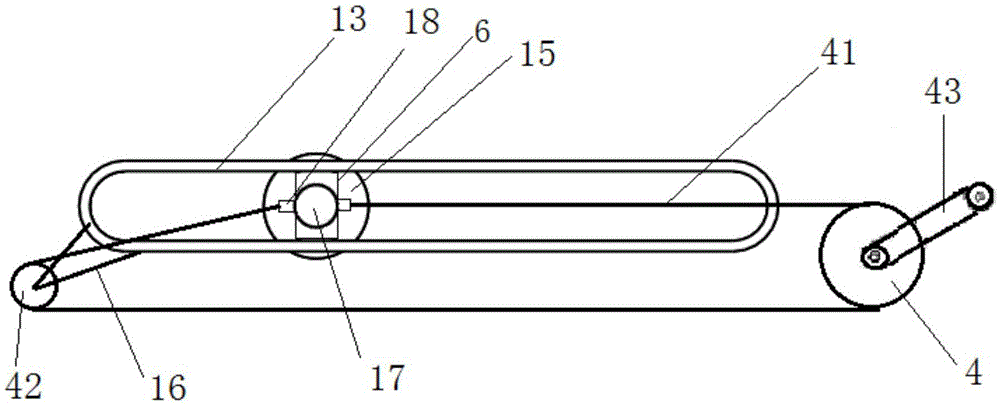

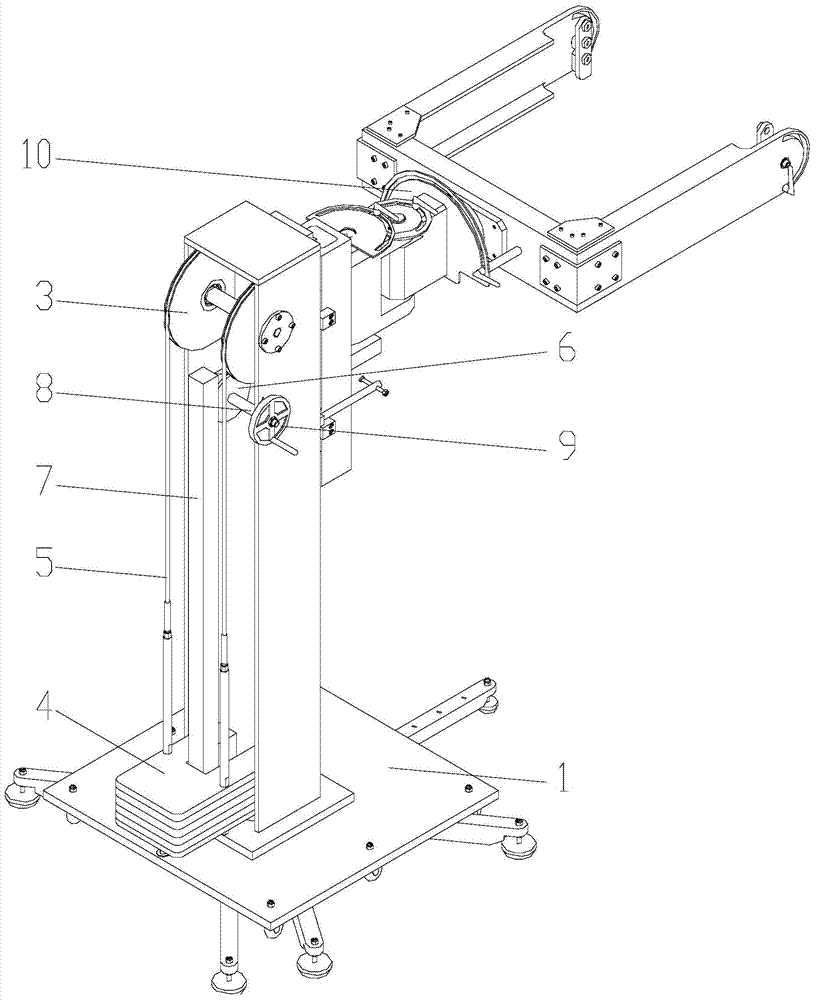

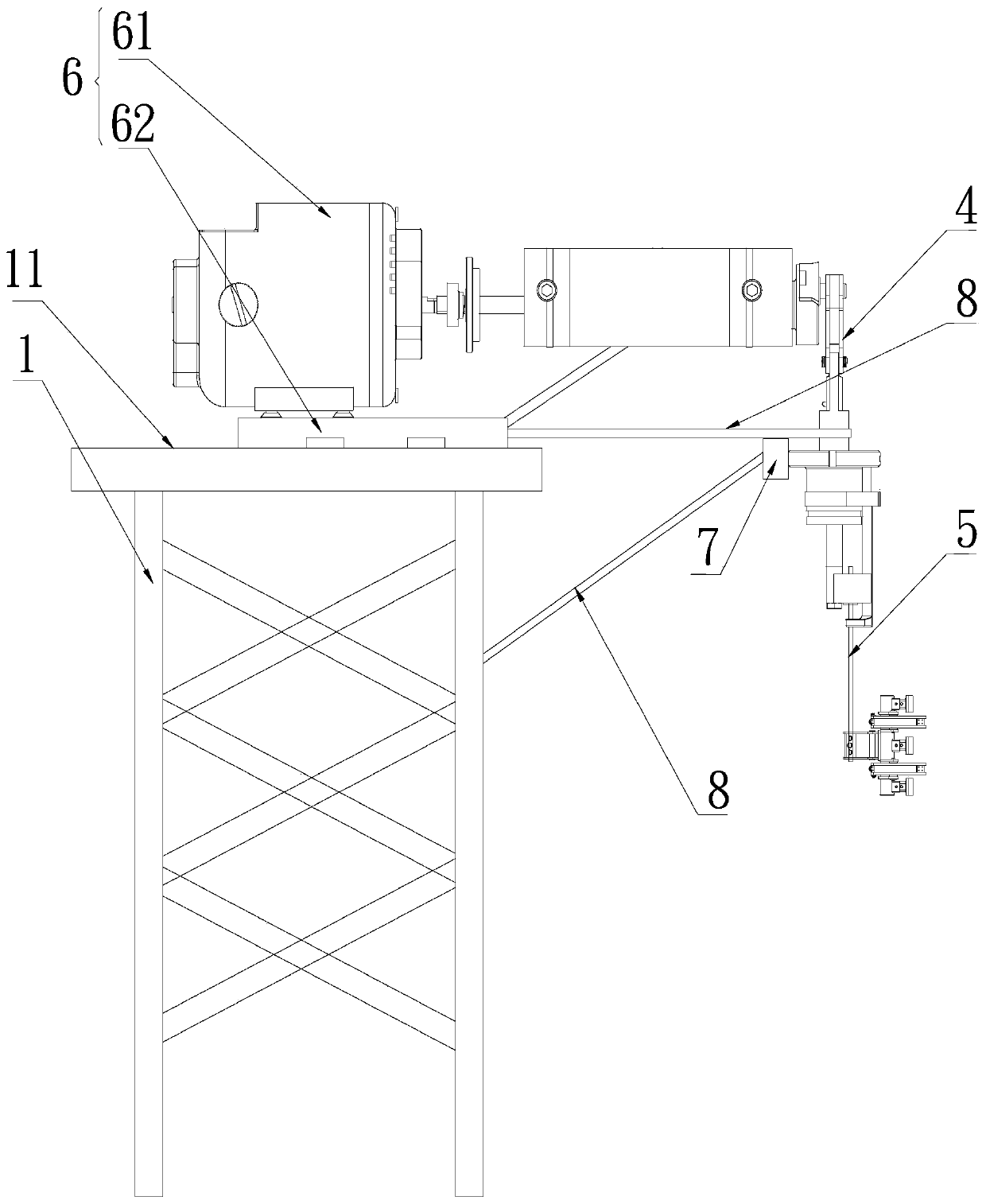

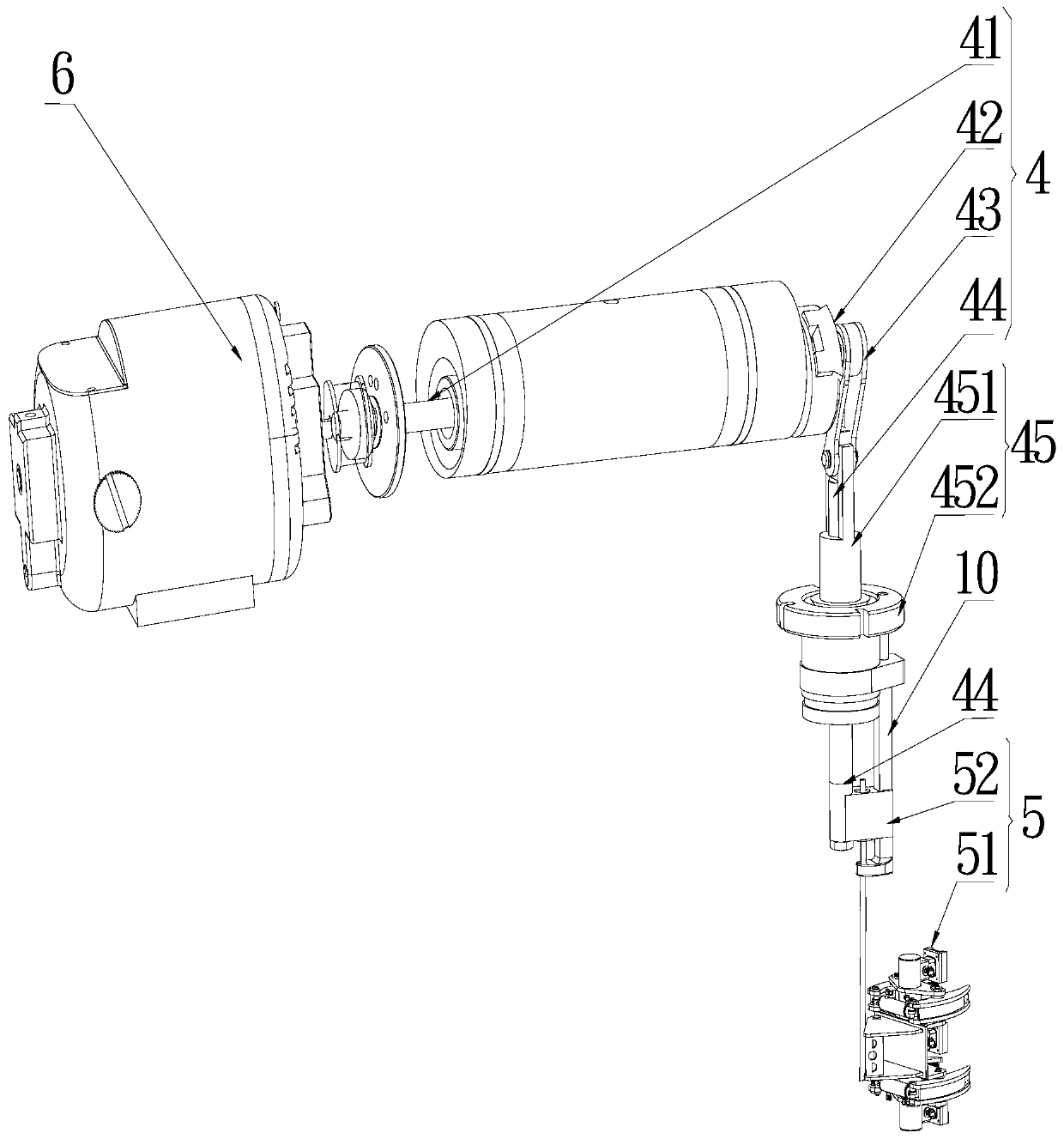

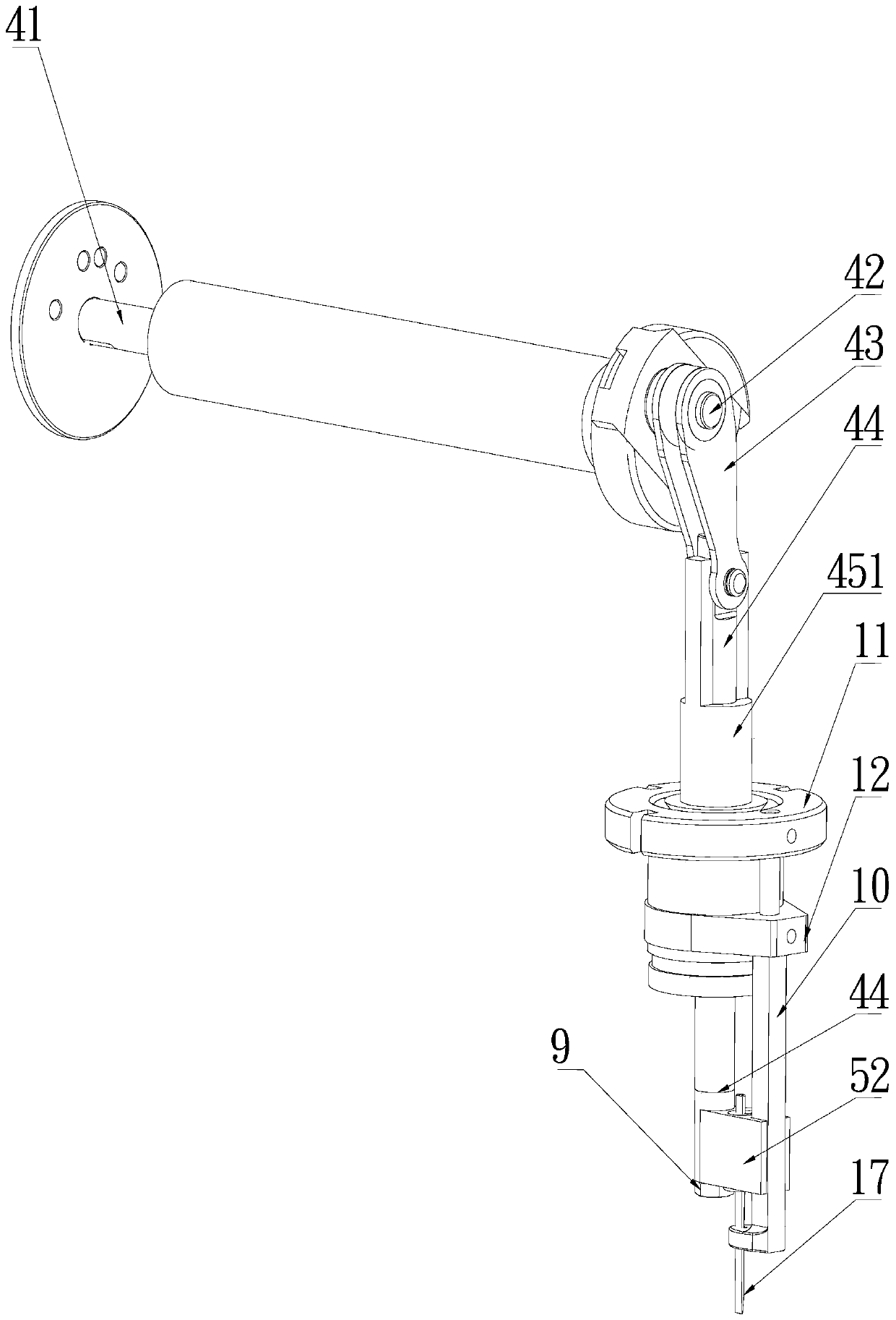

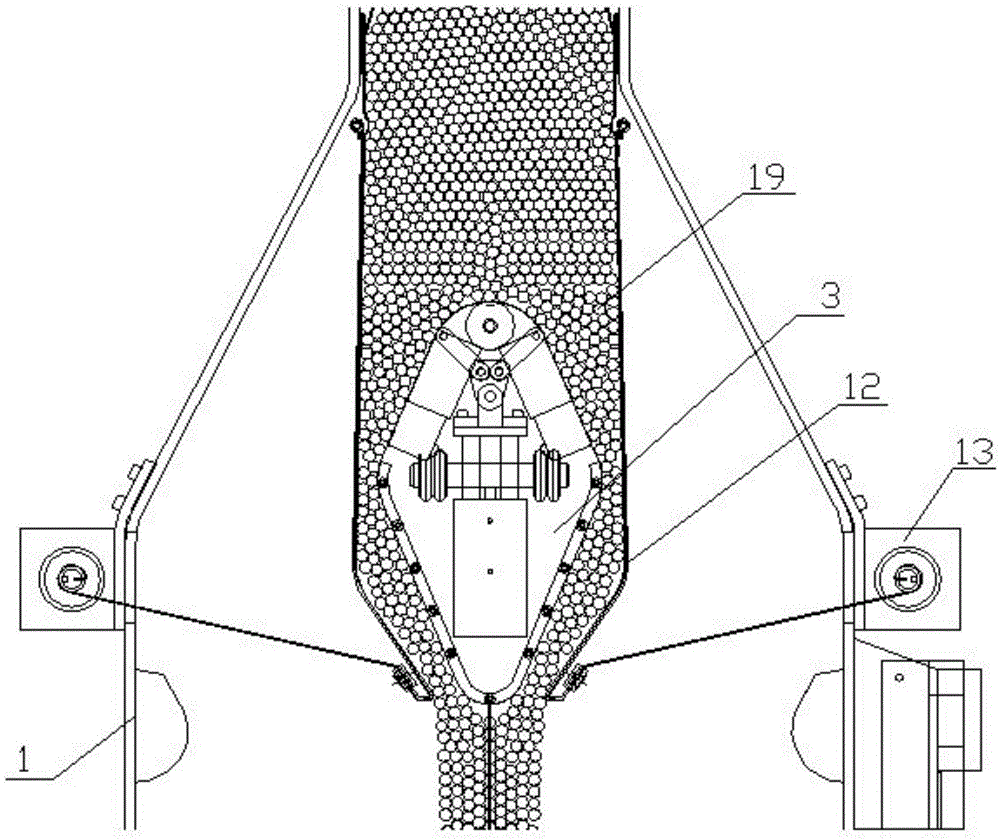

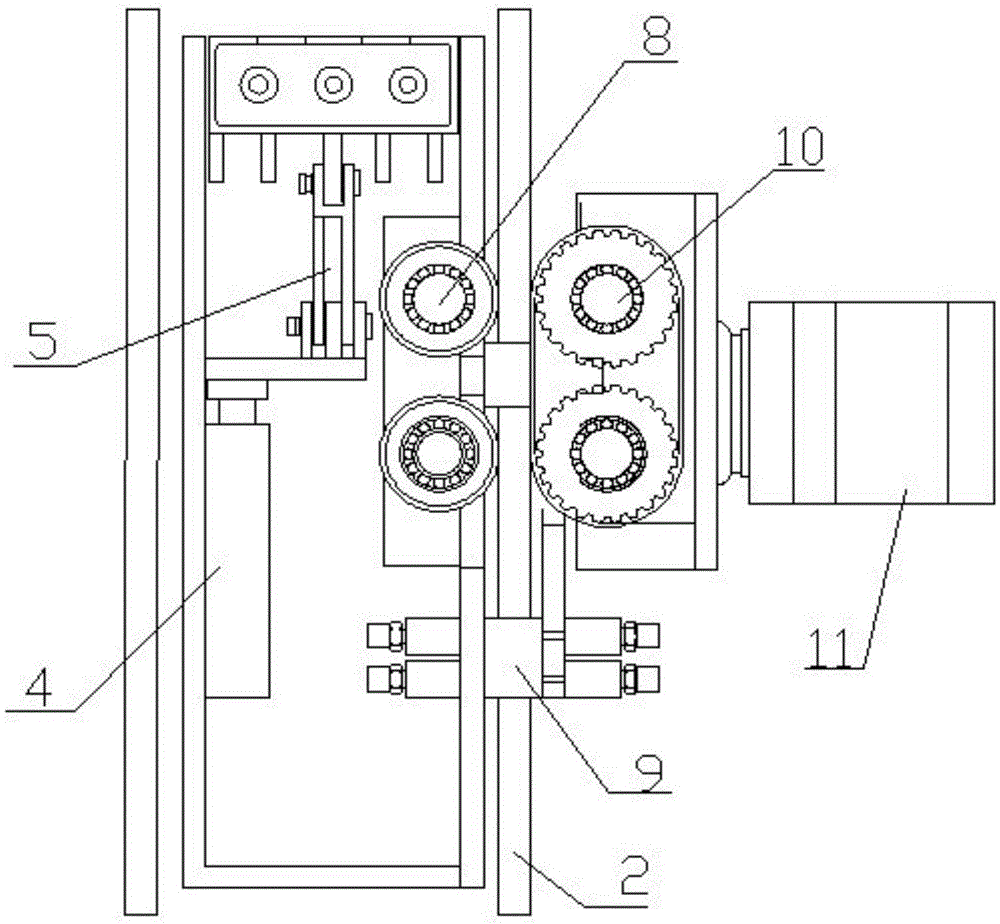

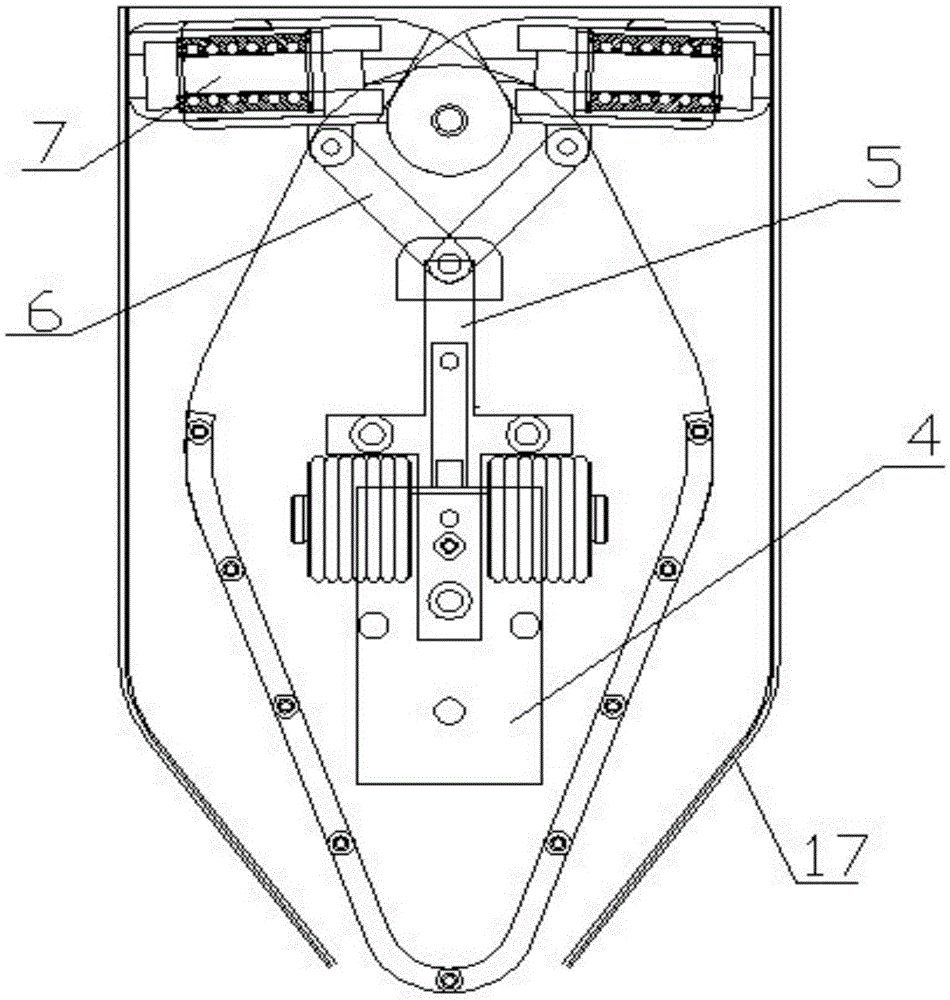

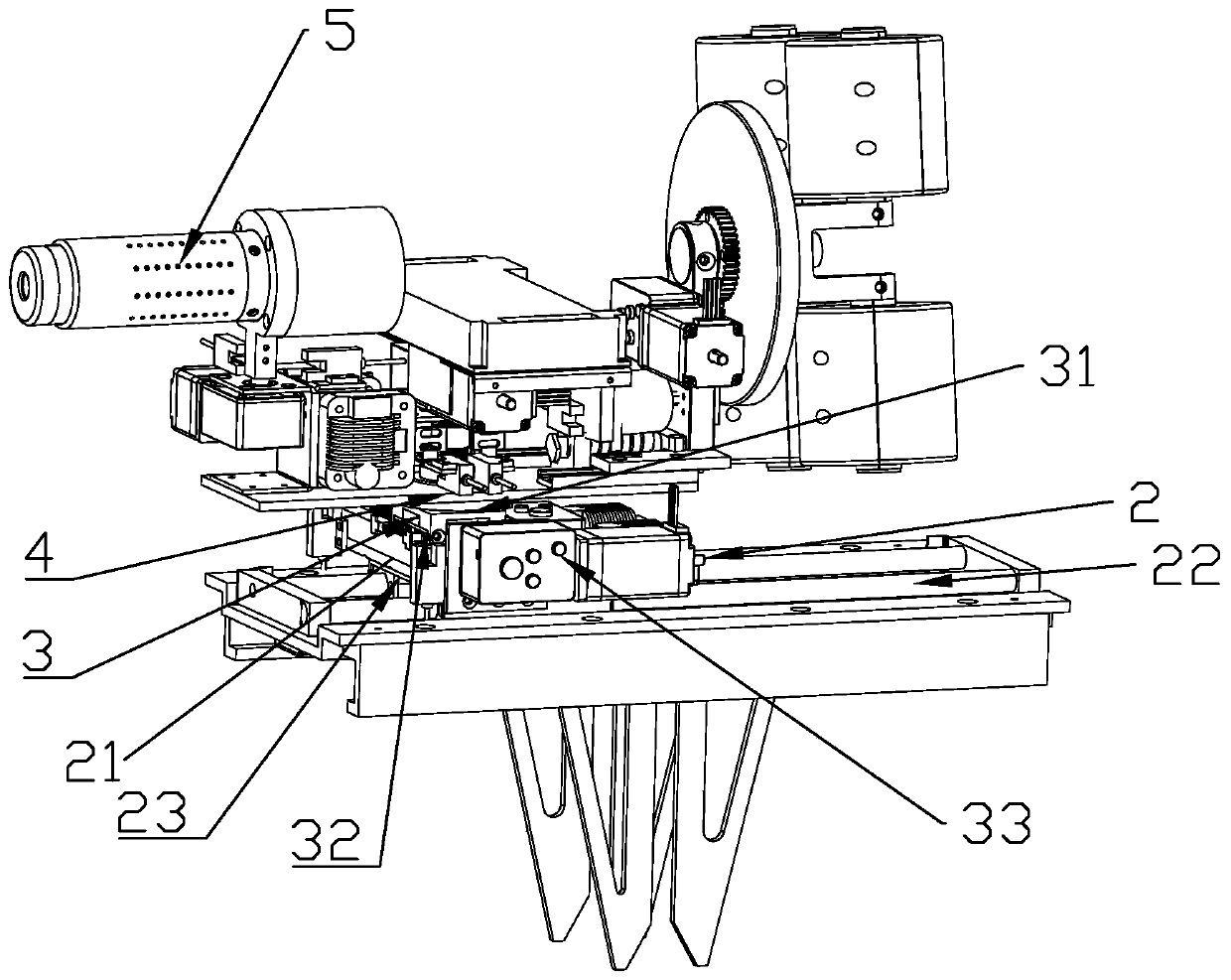

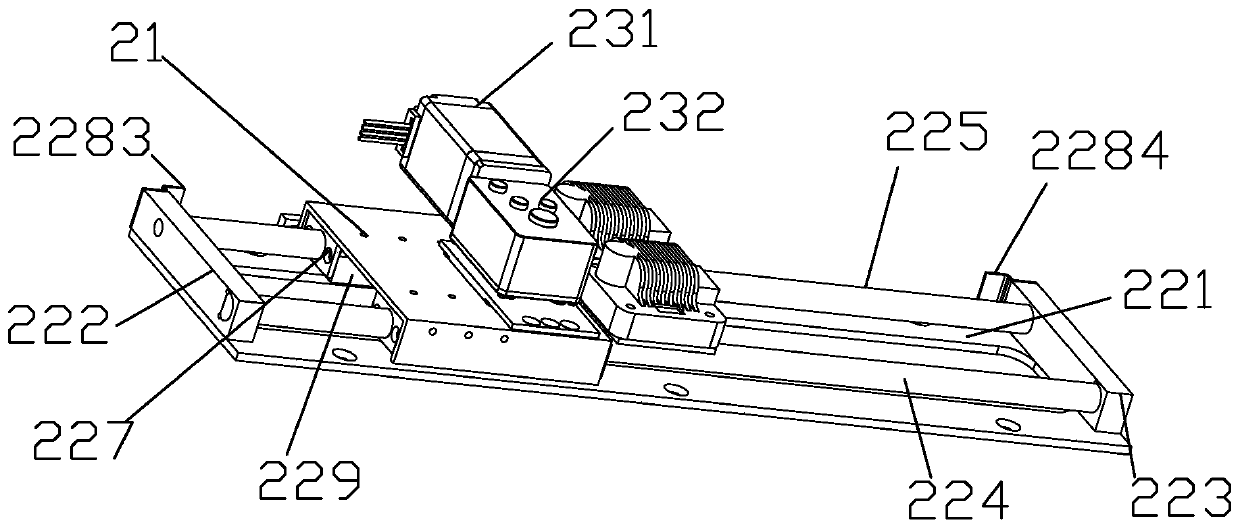

Automatic manipulator of caster support press line

InactiveCN102848379ARealize lifting movementRealize pickup and deliveryProgramme-controlled manipulatorMetal-working feeding devicesRotary stagePunch press

The invention relates to an automatic manipulator of a caster support press line. The automatic manipulator comprises a shell, a structural support, an electric manipulator, a driving device and a control device. The structural frame comprises a fixing plate, guide columns, an upper base, a lower base, an upper lifting table, a lower lifting table and a rotating table, and the upper base, the lower base, the upper lifting table and the lower lifting table are supported by the guide columns in a crossing manner; the electric manipulator is mounted on the rotating table; the driving device comprises two stepper motors, one stepper motor is mounted on the upper lifting table, is connected with a rotary shaft of the rotating table by a synchronous belt pulley and drives the manipulator to rotate, and the other stepper motor is mounted on the lower base, is connected with the lifting tables by a synchronous belt pulley and a lead screw and enables the manipulator to ascend and descend; and the control device comprises sensors and a programmable controller. The automatic manipulator is low in cost and easy to operate, is simple, convenient and stable, can move in various manners, has dust and chip prevention functions, can accurately extend onto a cavity of a punch press according to different characteristics of dies at different stations of the press line, picks up and delivers workpieces and replaces workers to carry out tasks such as carrying, feeding and discharging.

Owner:SOUTH CHINA UNIV OF TECH

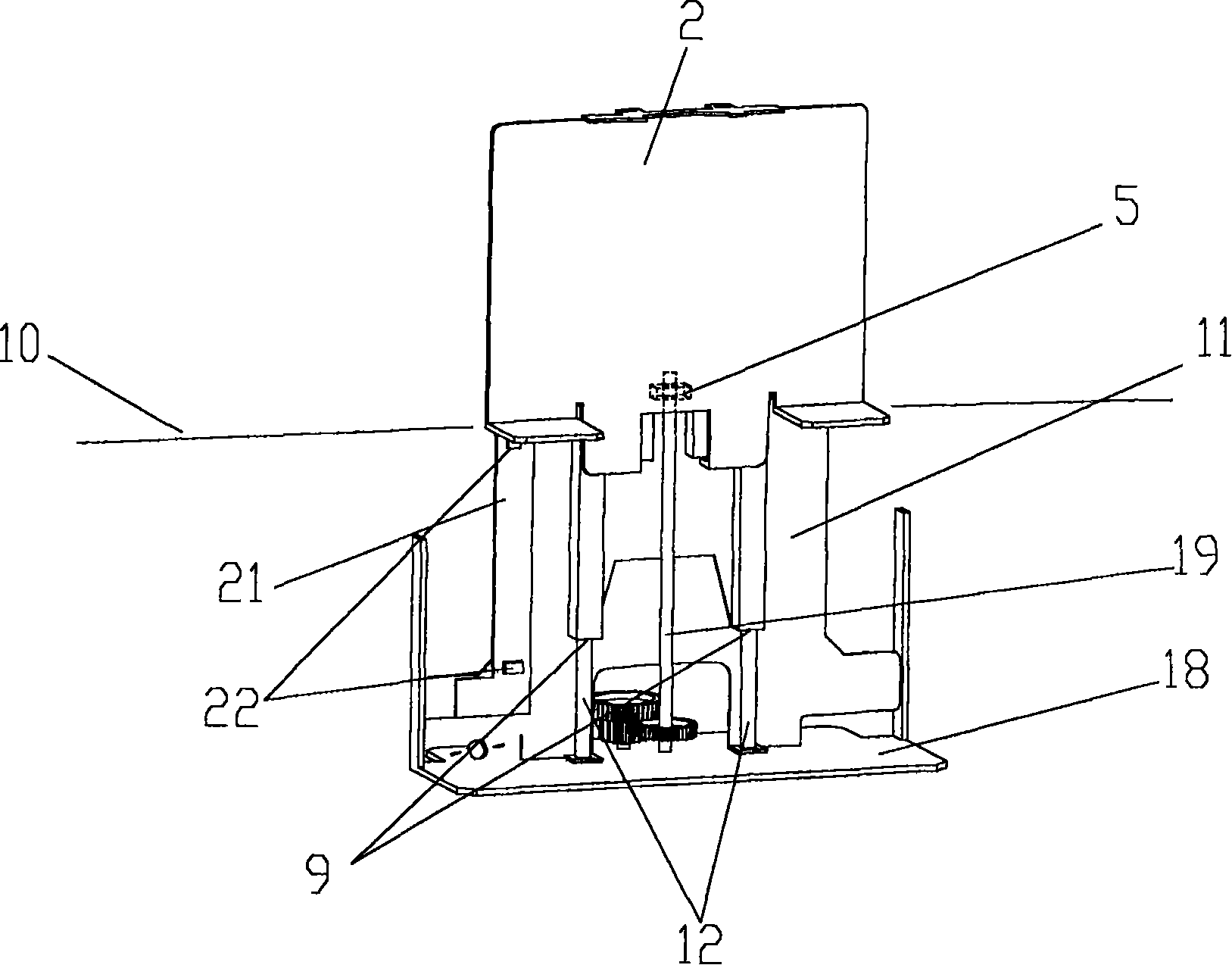

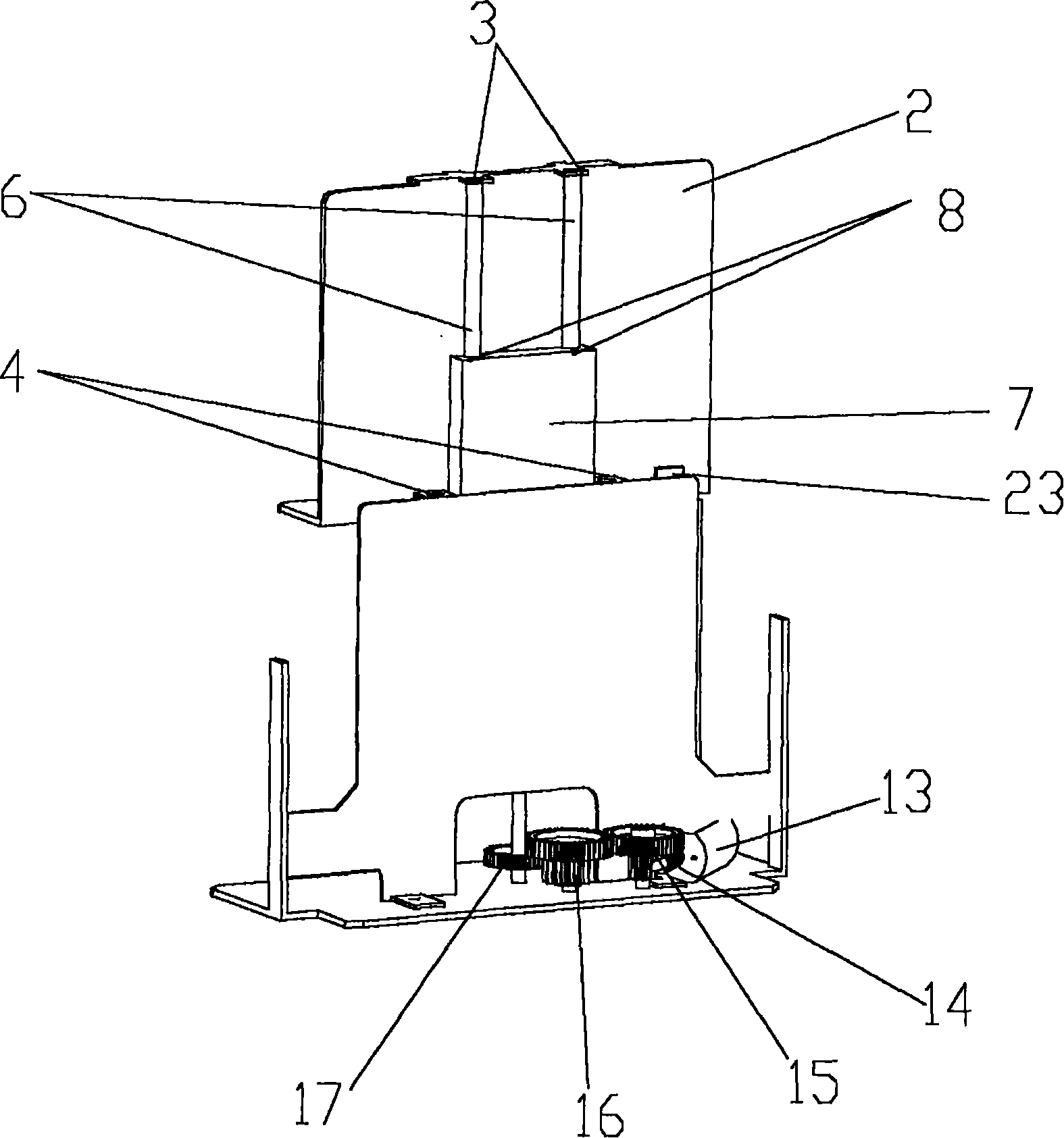

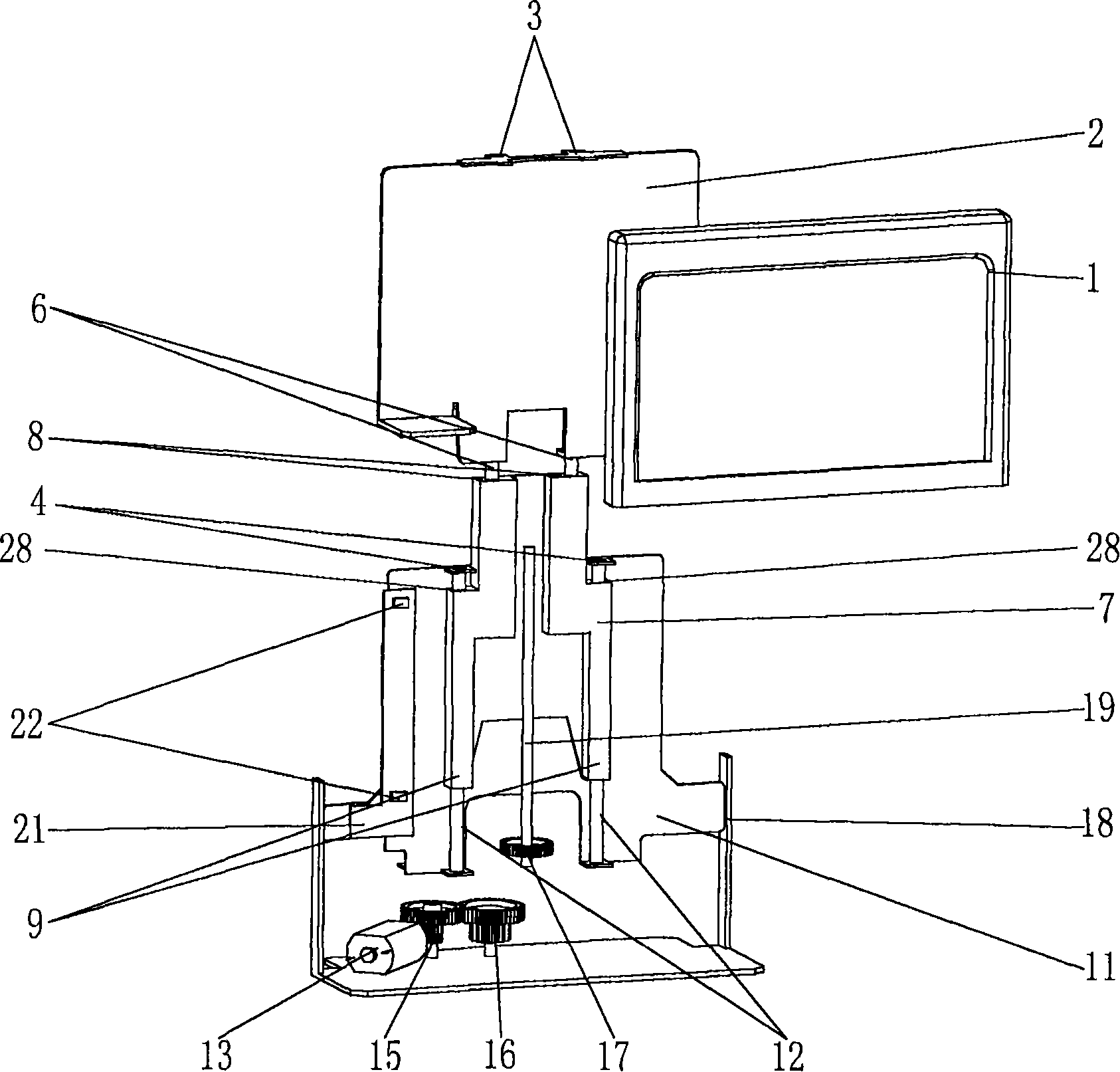

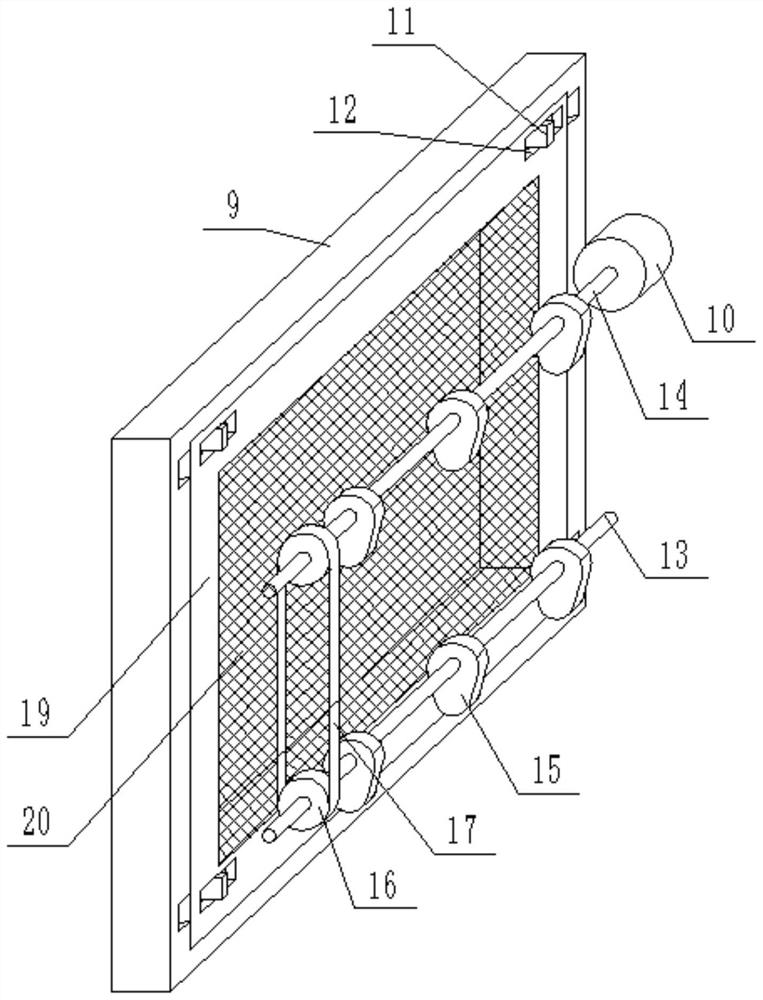

Vehicle-carrying display screen lifting gear

InactiveCN101191579ARealize lifting movementSimple structureInstrument housingStands/trestlesGear driveSelf protection

The invention discloses a vehicular display screen elevating device. The elevating device comprises: a display screen rack which is used for assembling the display screen and is provided with a thread structure; a screw which has one end assembled in a bearing on a base support and meshes with the thread structure on the display screen rack; a gear drive pair which is used for connecting a motor output shaft and the screw; a guide bar holding frame which has one end connected with the base support and is provided with a lower guide bar; an upper guide bar which is arranged on the display screen rack; and a stopper which is provided with a lower guide hole and an upper guide hole respectively matching with the lower guide bar and the upper guide bar, and is also provided with a stopping part for limiting the elevating position of the display screen rack in cooperation with a lower guide bar fixing lug on the guide bar holding frame. The vehicular display screen elevating device of the invention which has anti-clamping and self protective functions can be fixed inside a switch board; the casing face of the display screen matches perfectly with the whole vehicular switch board face, thereby reducing the possibility of damage caused by long-time exposure of the display screen.

Owner:SHENZHEN QICHUANG INVESTMENT

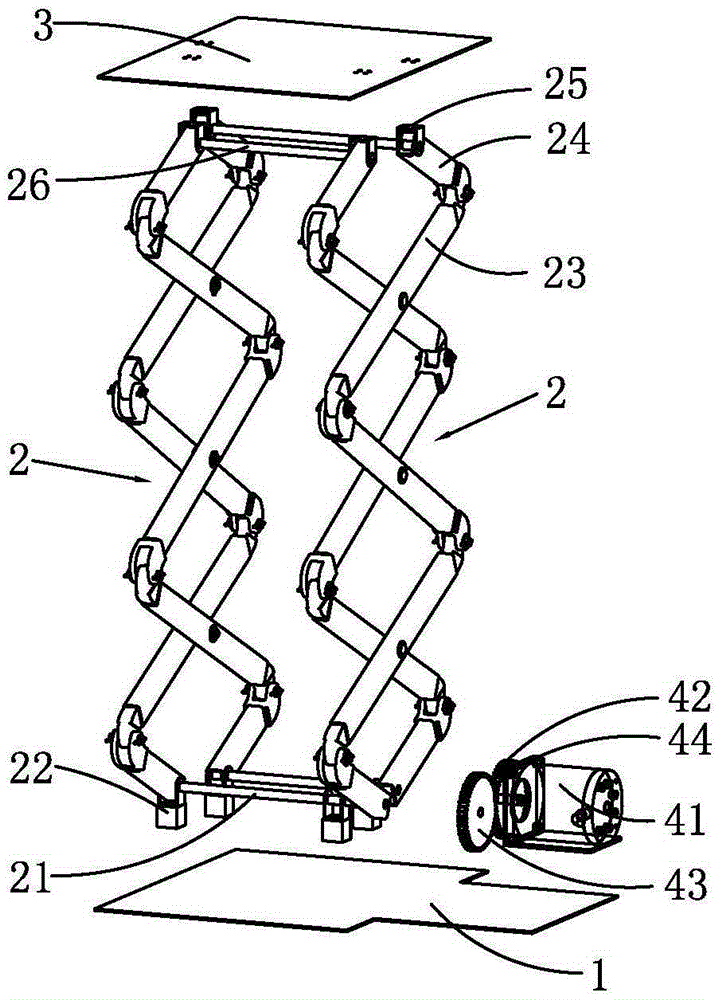

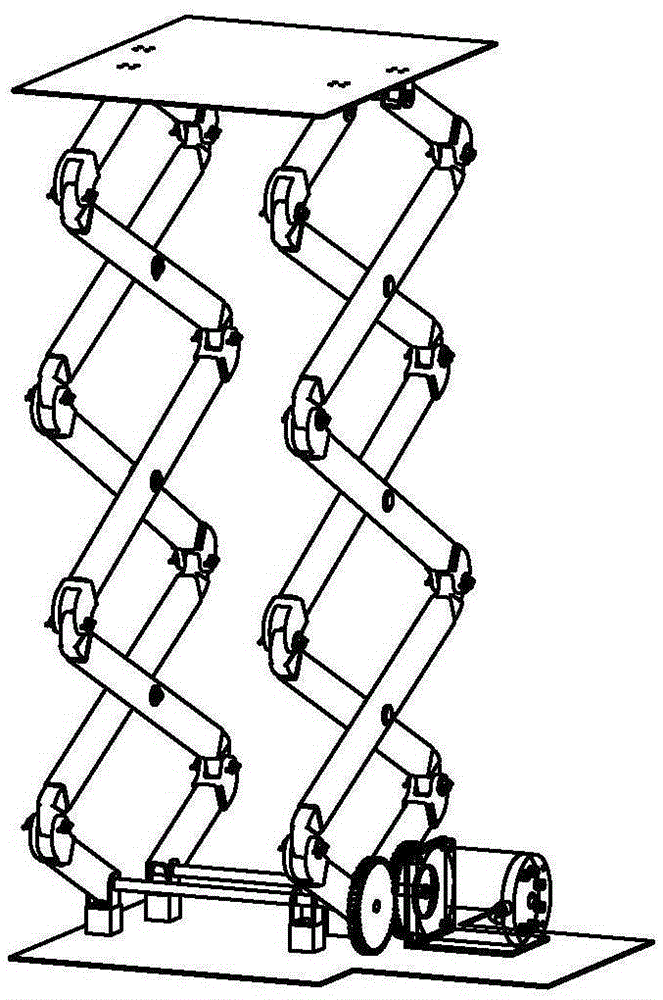

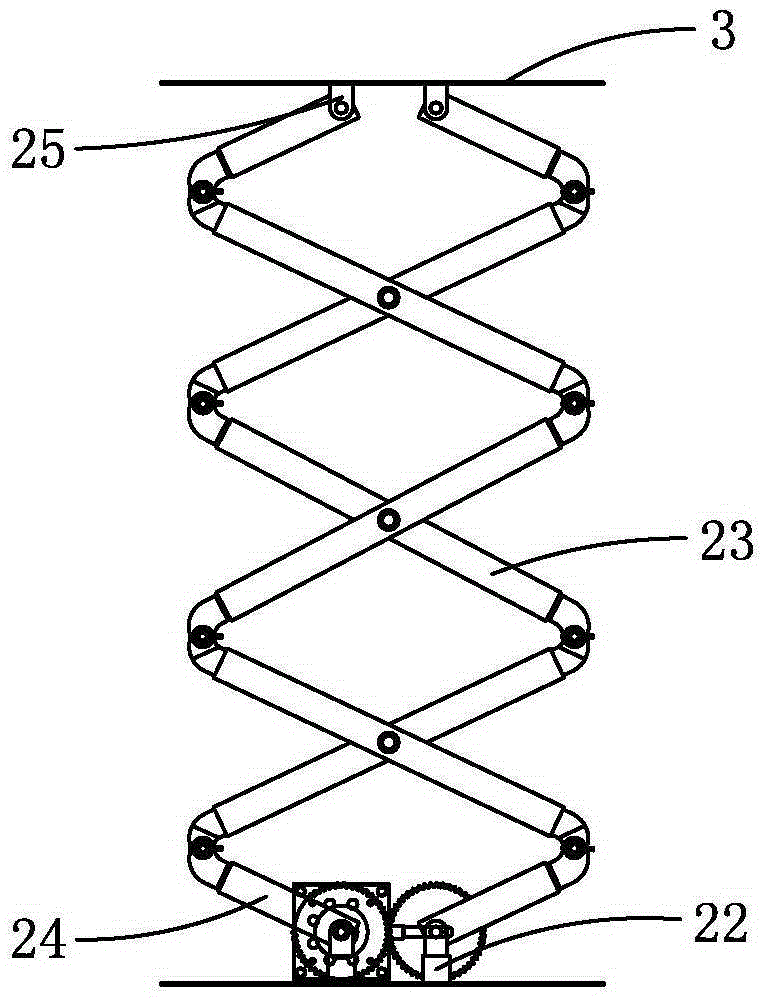

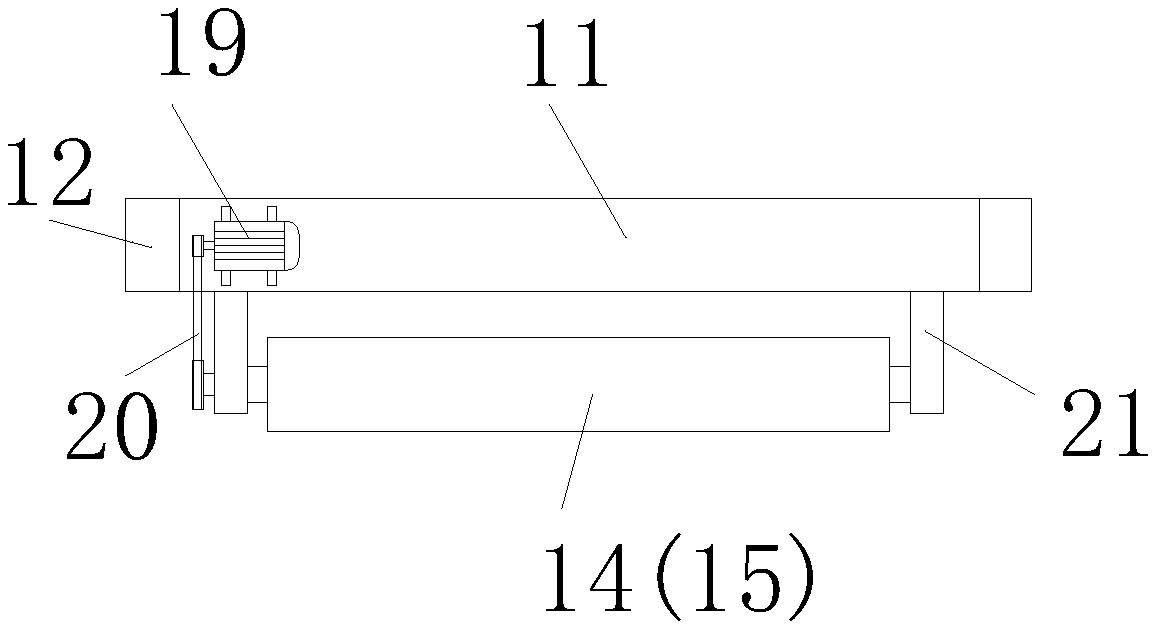

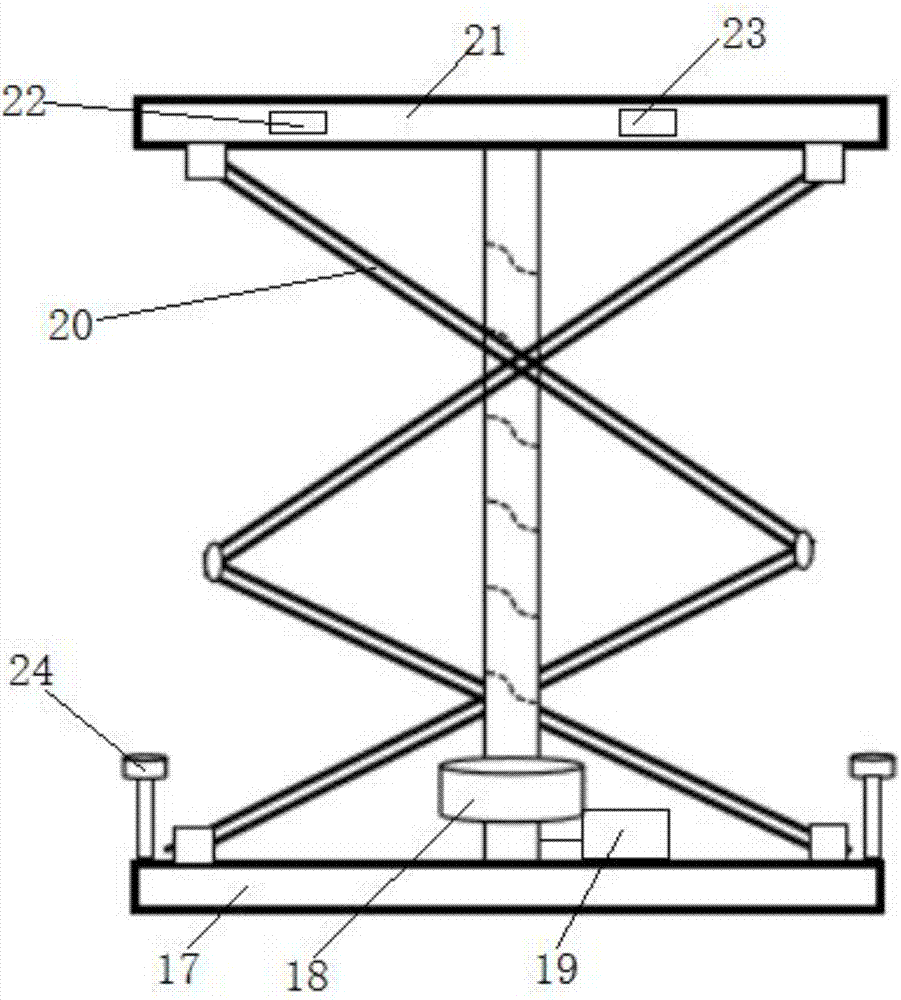

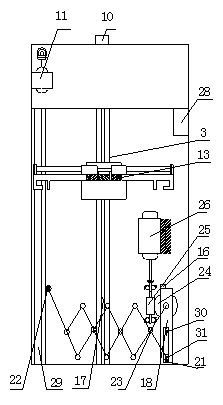

Shear-fork type lifting platform with wheel train transmission

The invention discloses a shear-fork type lifting platform with wheel train transmission. The shear-fork type lifting platform comprises a base, wherein a driving unit and two parallel shear-fork type units are arranged on the base, and the lower ends of the two shear-fork type units are fixedly connected with two parallel driving rods; the driving rods are rotationally connected with a lower connecting piece fixed on the base, and the upper ends of the shear-fork type units are rotationally connected with the lower surface of a working platform; the driving unit is connected with the two driving rods and used for driving the driving rods to synchronously relatively rotate. According to the shear-fork type lifting platform, under the driving of a driving motor, a driving wheel and a driven wheel keep synchronous relative rotation, the driving rods are driven to rotate, the lifting motion of the shear-fork type unit is realized, and therefore the lifting motion of the working platform is realized. The working stroke is greatly increased, and the unnecessary space is reduced. Meanwhile, the torque is increased, and the working load of the working platform is improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

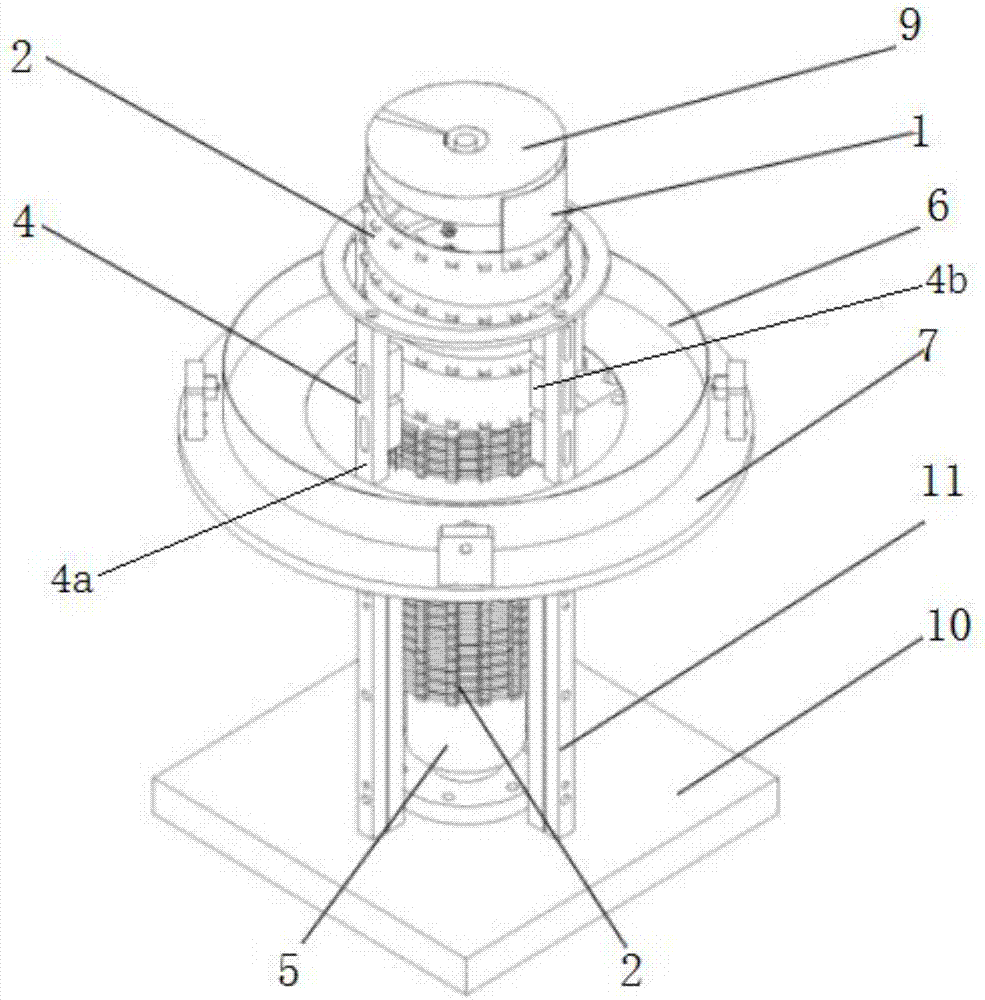

High-speed low-inclusion electroslag remelting device and remelting method thereof

The invention discloses a high-speed low-inclusion electroslag remelting device and a remelting method thereof and belongs to the field of remelting of electroslag. The electroslag remelting device comprises a consumable electrode, a crystallizer, an ultrasonic wave generator and an electrode driving mechanism, wherein one end of a dummy electrode of the electrode driving mechanism is fixedly connected to the consumable electrode; the other end of the dummy electrode is connected to a bearing of a fixing device; an adjustable-speed motor controls the dummy electrode to rotate; one end of a transformer is electrically connected to the dummy electrode through an electric brush, so that the consumable electrode rotates continuously and is affected by ultrasonic wave from the bottom at the same time in the remelting process. Through the remelting method based on the remelting device, the melting of the consumable electrode is accelerated; the energy consumption is reduced; the prepared electroslag ingots are uniform in structures, few in inclusions and high in quality.

Owner:ANHUI FUKAI STAINLESS STEEL

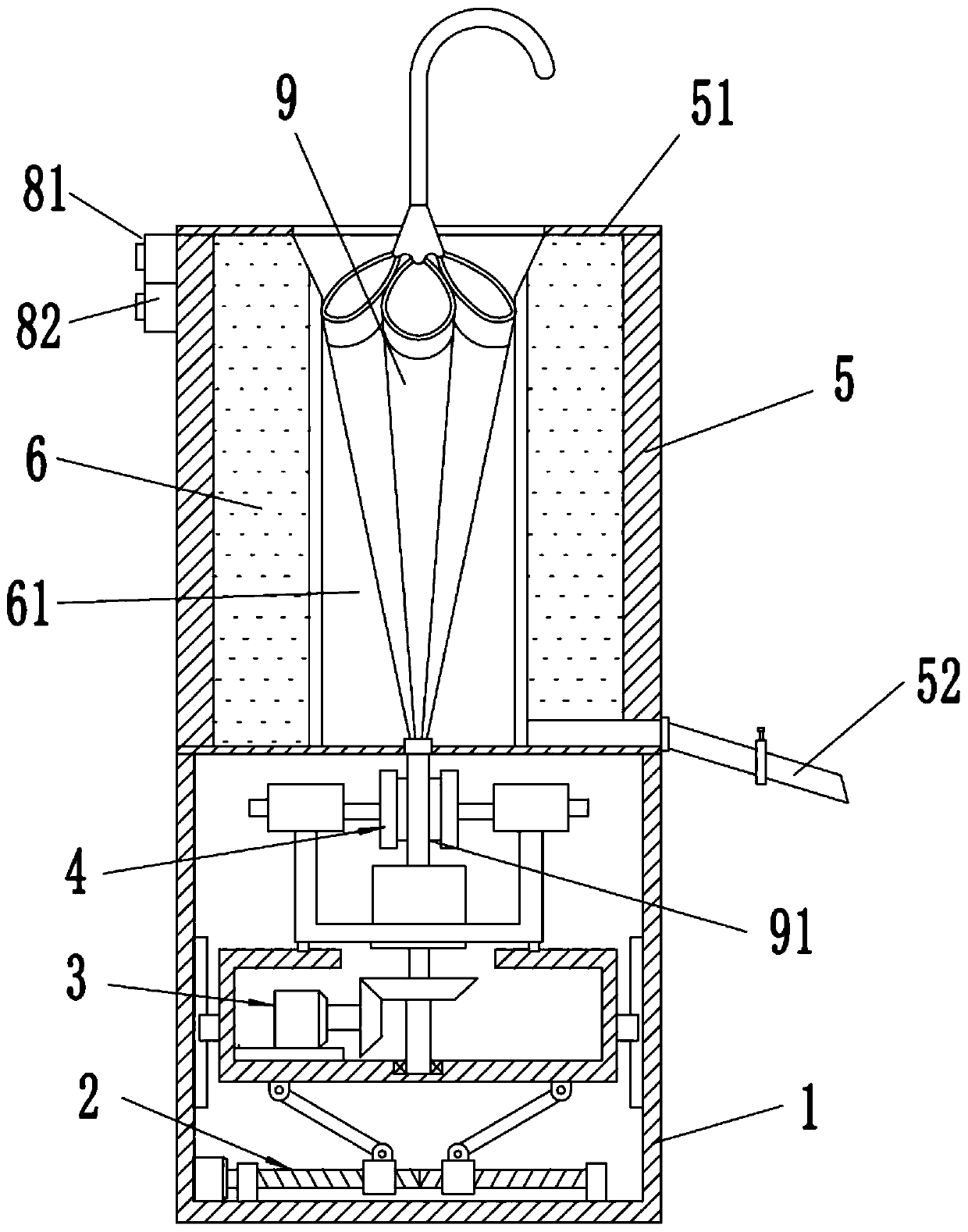

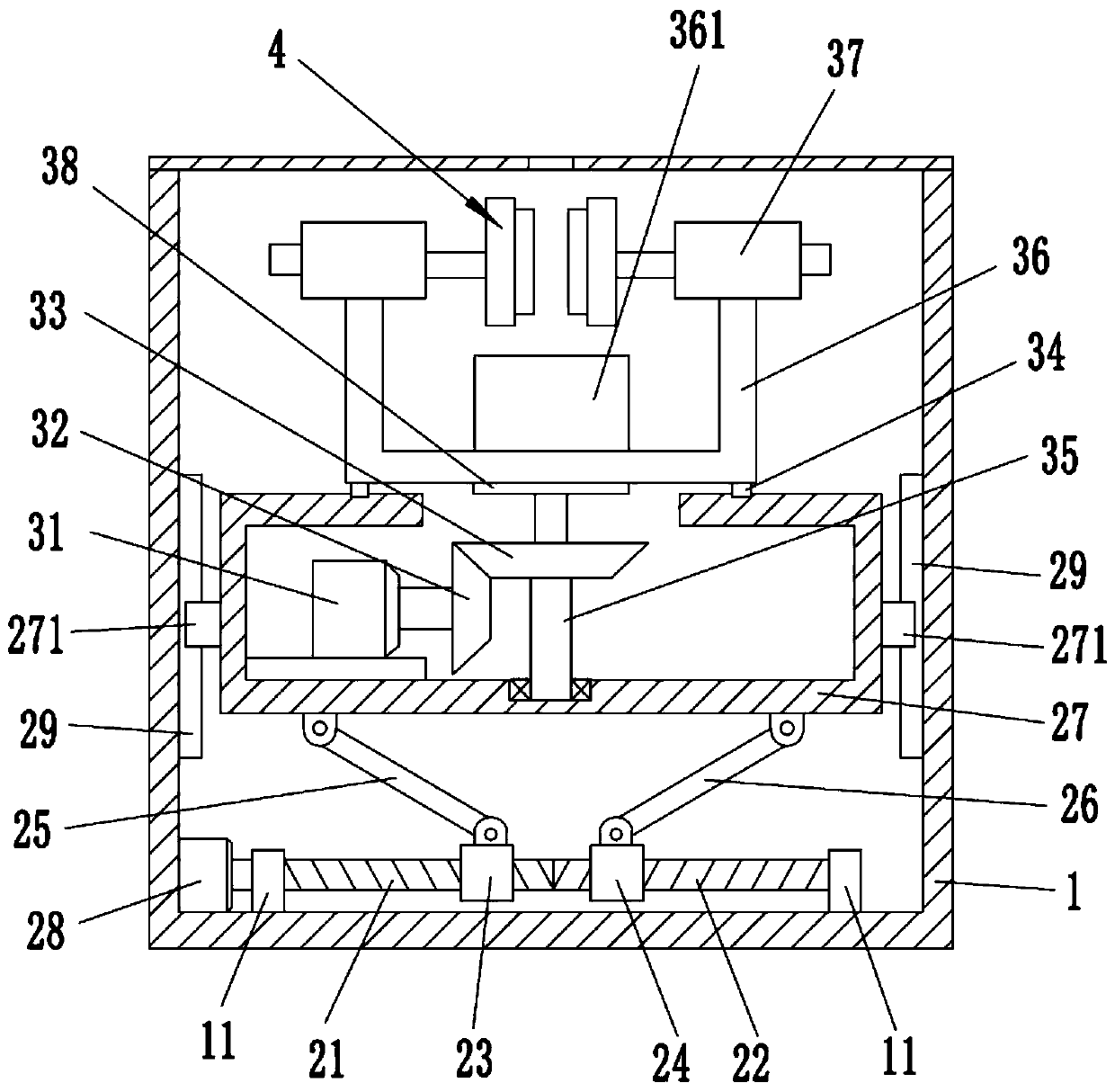

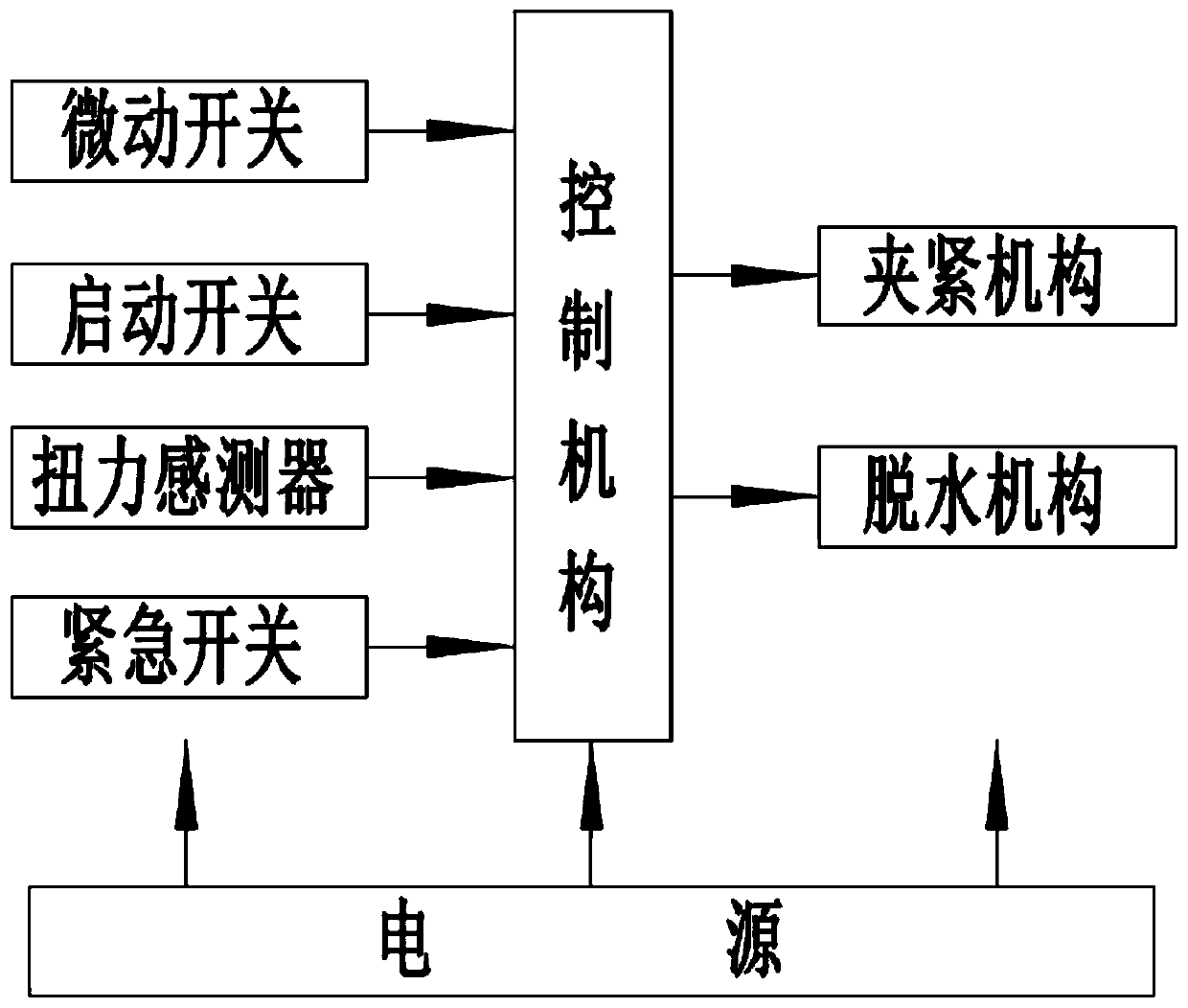

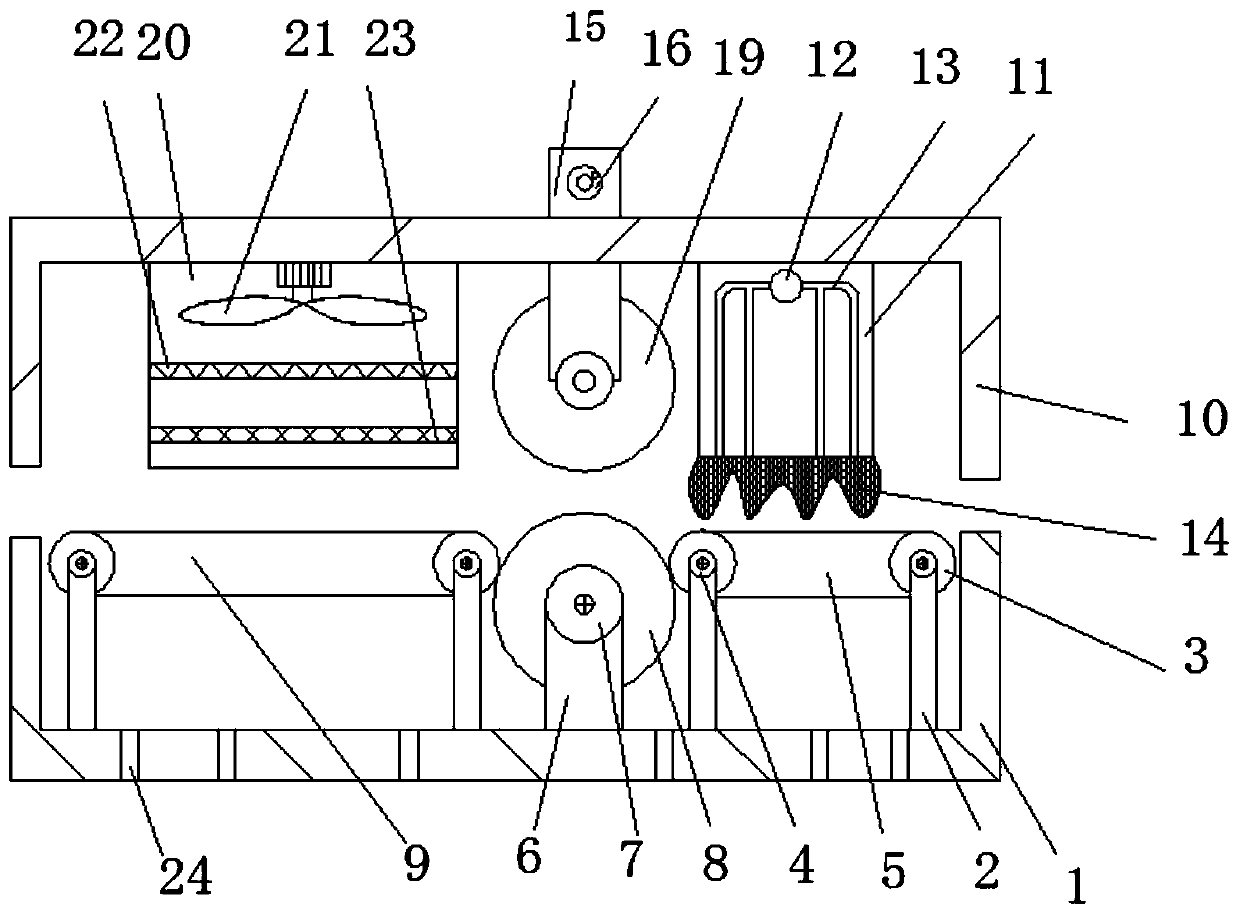

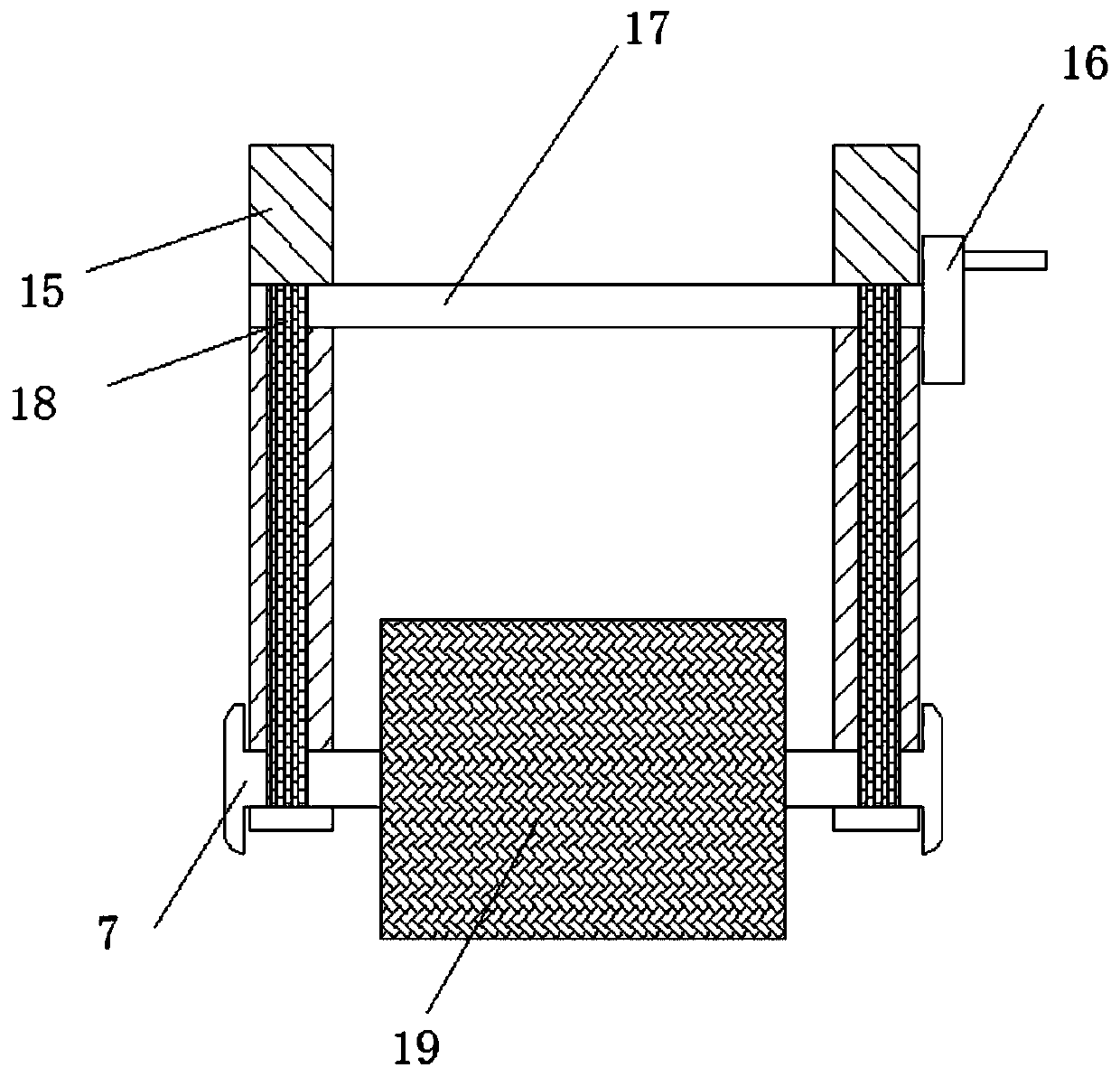

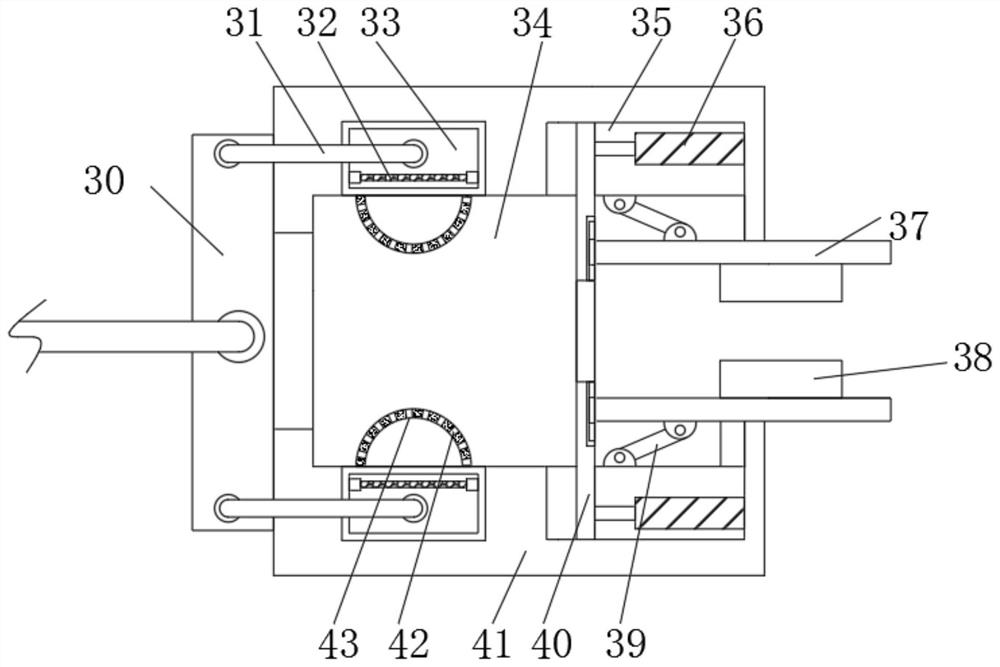

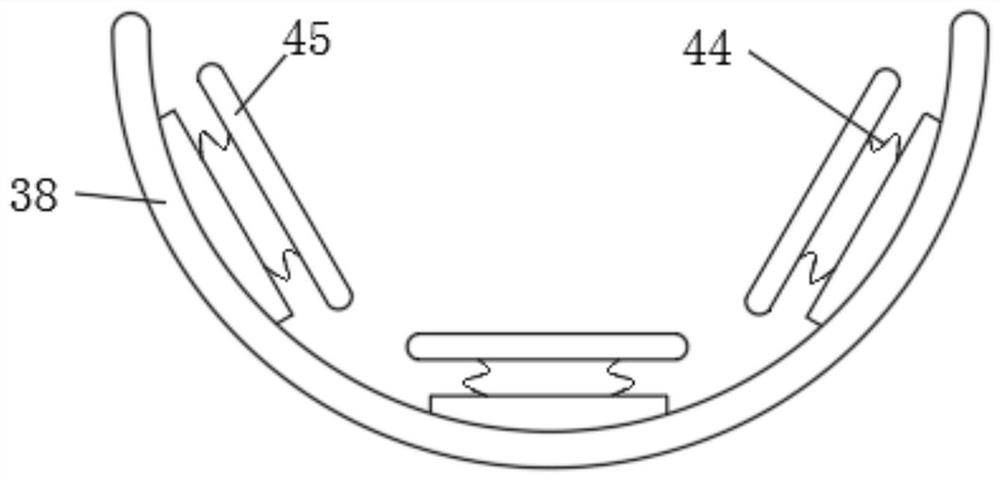

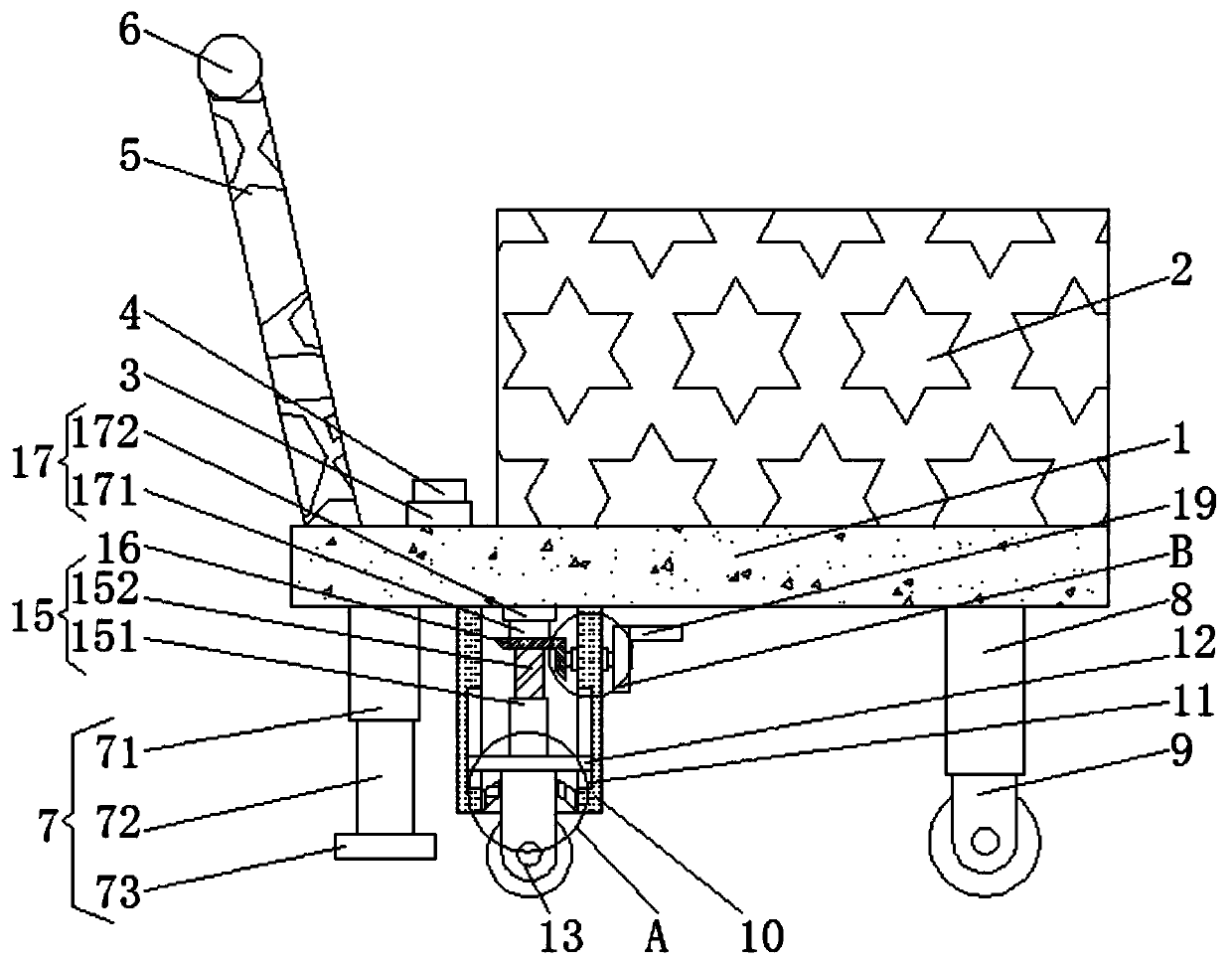

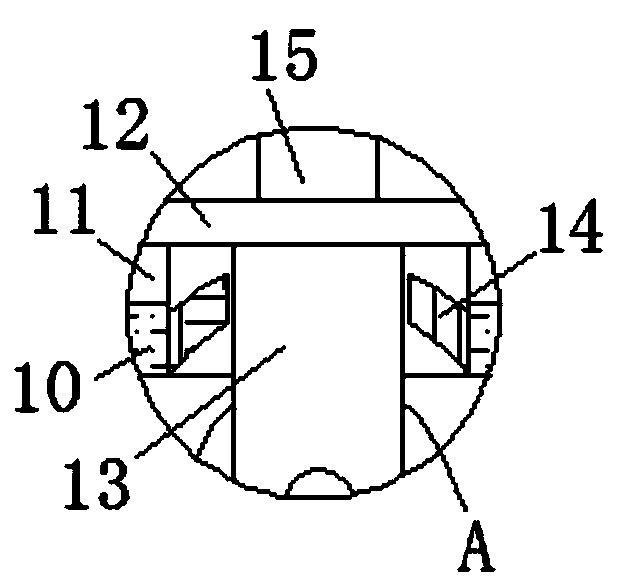

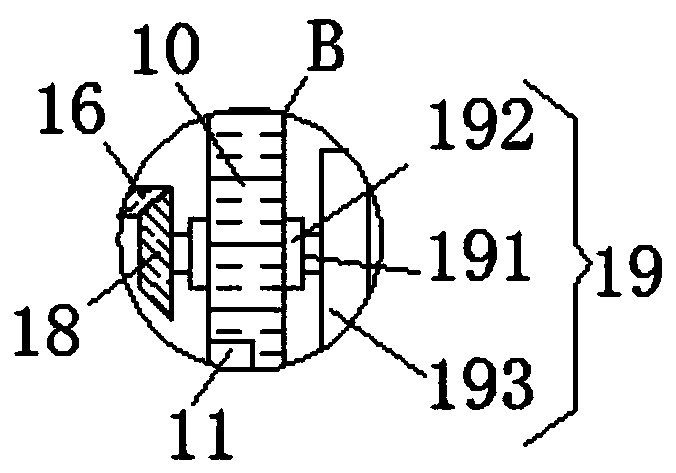

Umbrella water removal machine and control method thereof

InactiveCN109827387ADehydration fastImprove dehydration efficiencyDrying solid materials without heatEngineering

The invention provides an umbrella water removal machine and a control method thereof. A base, a lifting mechanism, a water removal mechanism, a clamping mechanism and a control mechanism are included. The lifting mechanism is arranged in the base. The water removal mechanism comprises a rotation mechanism and an upper barrel. The rotation mechanism is arranged on the lifting mechanism. The upperbarrel is fixed to the upper side of the base. Sponge is arranged in the upper barrel. The rotation mechanism drives an umbrella to rotate for water removal in a sponge containing cavity. The clampingmechanism is arranged on the rotation mechanism, an emergency switch and a start switch are arranged on the outer side of the upper barrel, a rotation shaft of the rotation mechanism is provided witha torsion sensor, and the control mechanism controls the clamping mechanism and the rotation mechanism to work. According to the provided umbrella water removal machine and the control method thereof, efficient umbrella water removal can be achieved, and the water removal effect is good.

Owner:QUANZHOU INST OF INFORMATION ENG

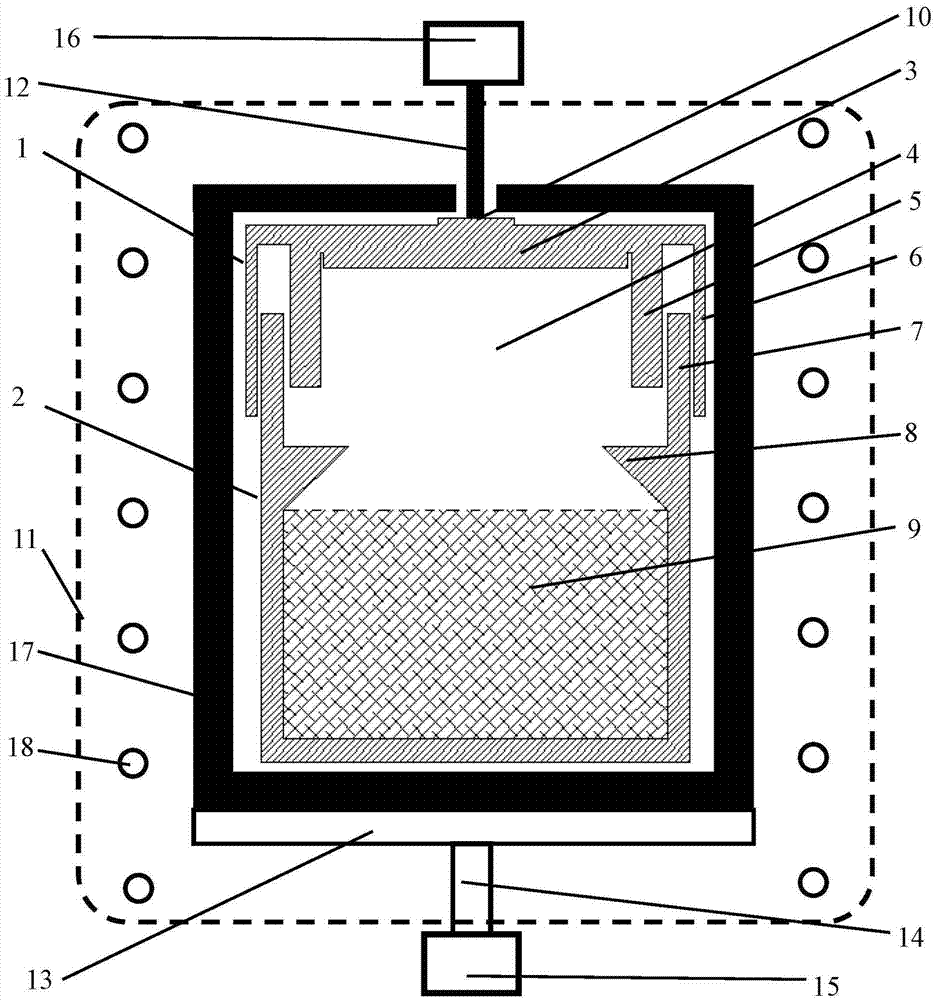

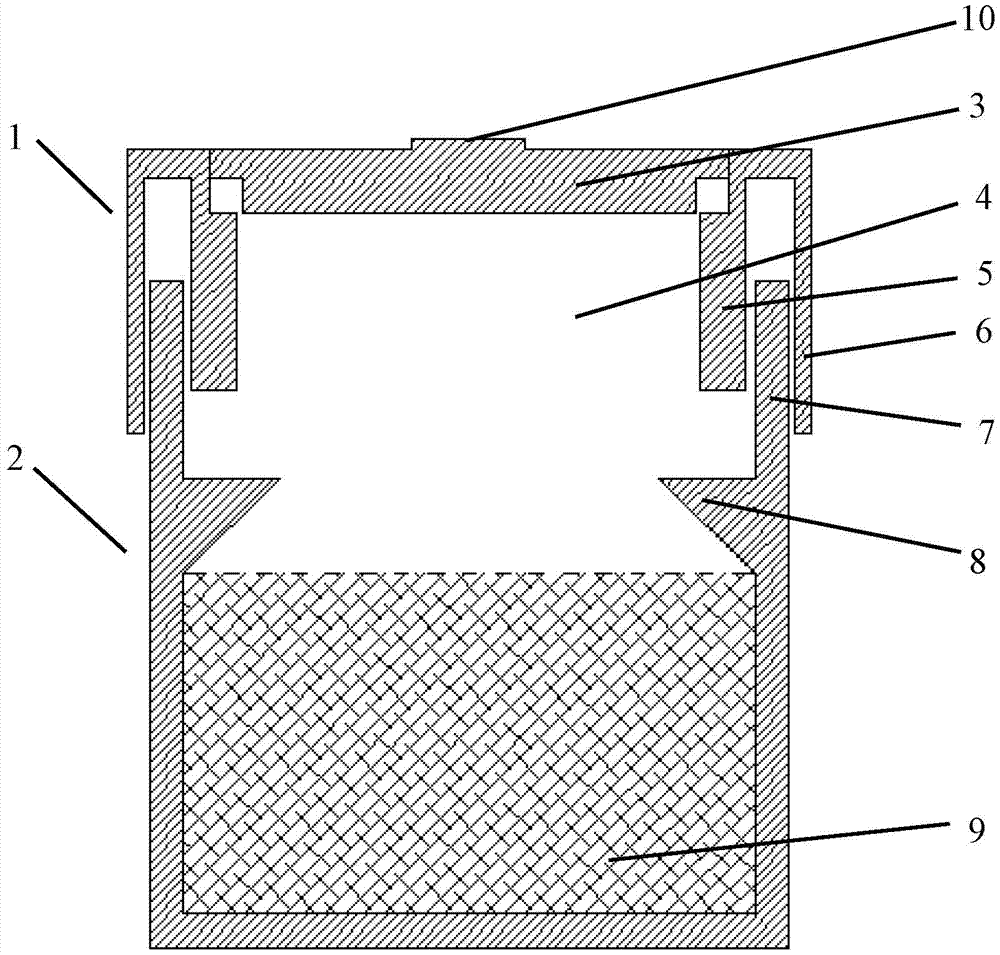

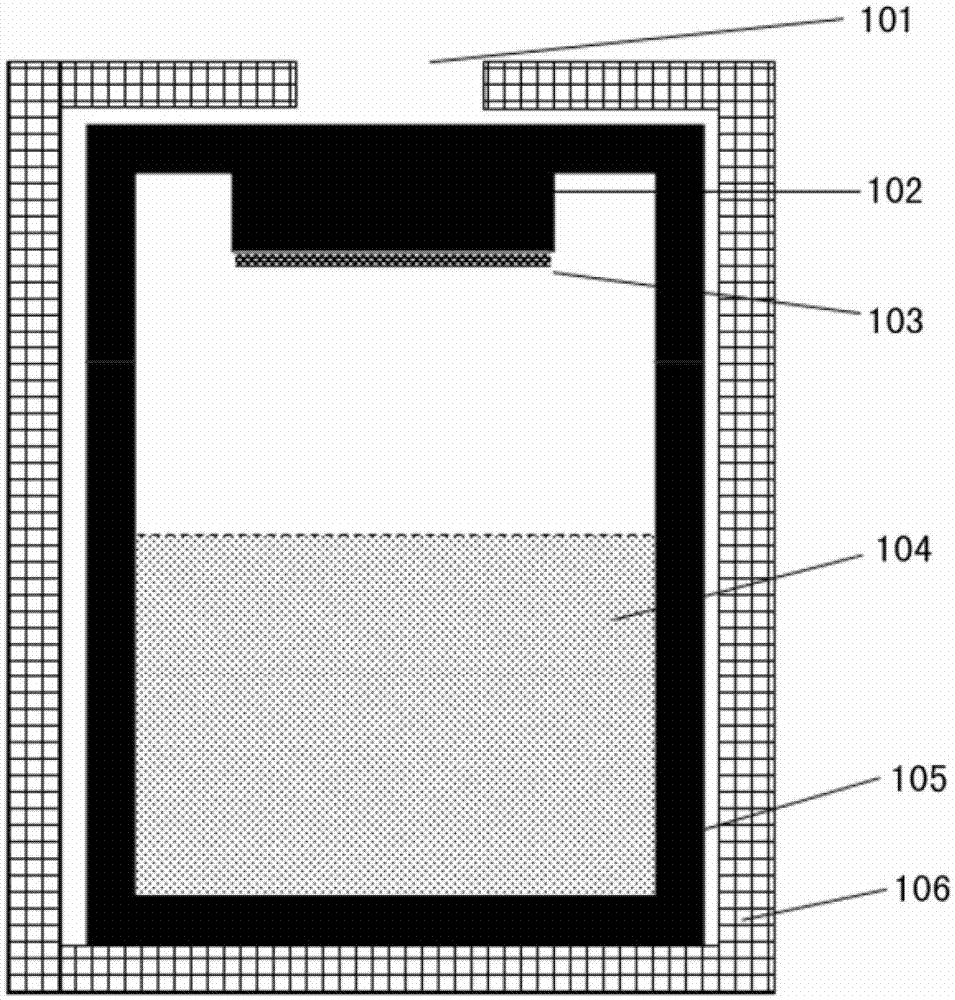

Split type crucible for crystal growth of silicon carbide

InactiveCN106929913AQuality improvementAvoid destructionPolycrystalline material growthFrom condensed vaporsCrucibleEngineering

The invention provides a split type crucible for crystal growth of silicon carbide. The crucible comprises the following components: a raw material chamber for containing raw materials for crystal growth of SiC; a growth chamber which is nested on the upper part of the raw material chamber in relative movement mode in order to form a crystallization area of crystal, wherein the growth chamber comprises a growth chamber, and a seed crystal holder which is arranged on a upper wall of the growth chamber; and a double layer structure which is formed by sidewalls of the growth chamber and comprises an inner cylinder and an outer cylinder. The crucible can be used for adjusting distance between the crystal surface and the raw material surface in a process of growth, and the stability of a temperature field is kept.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

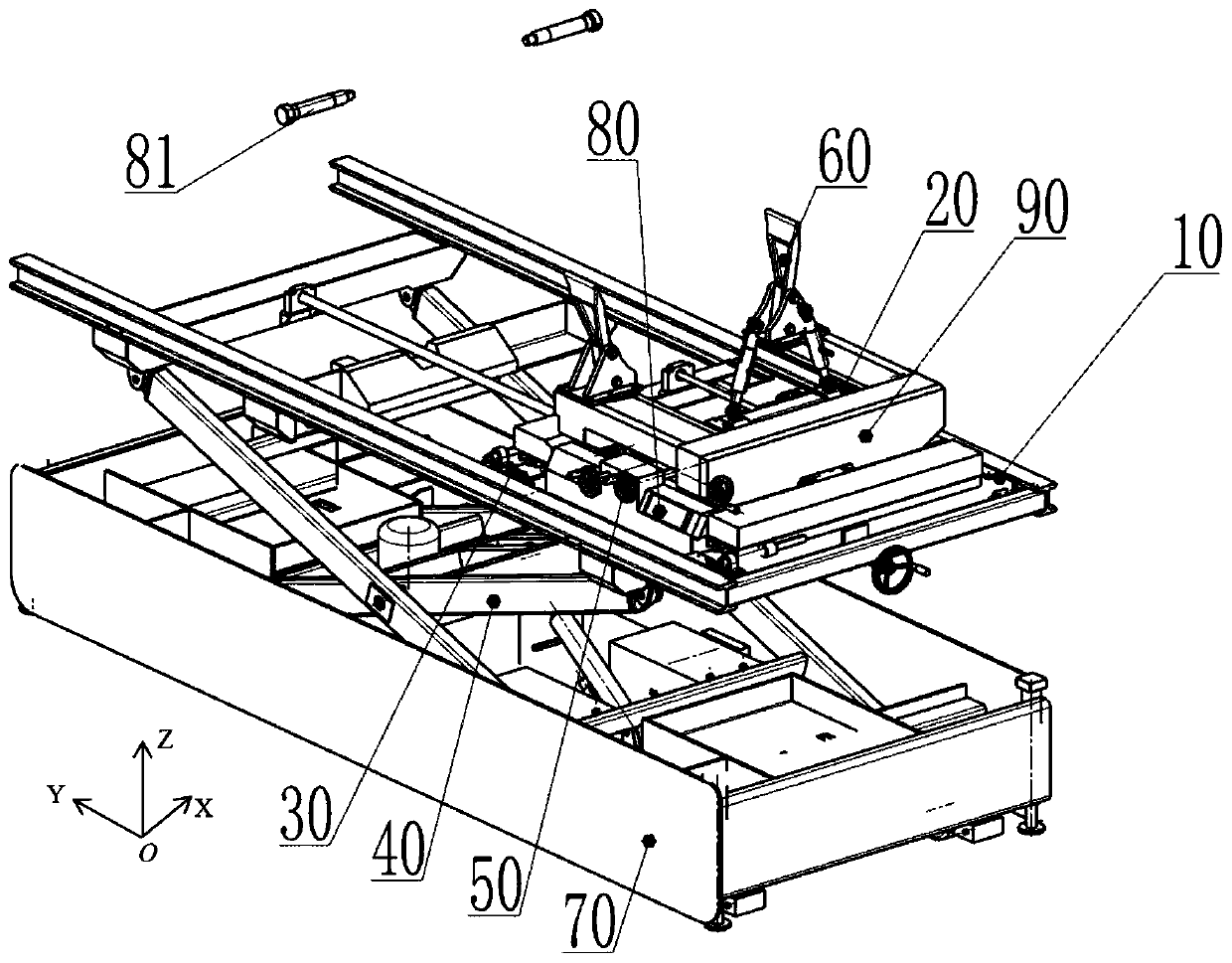

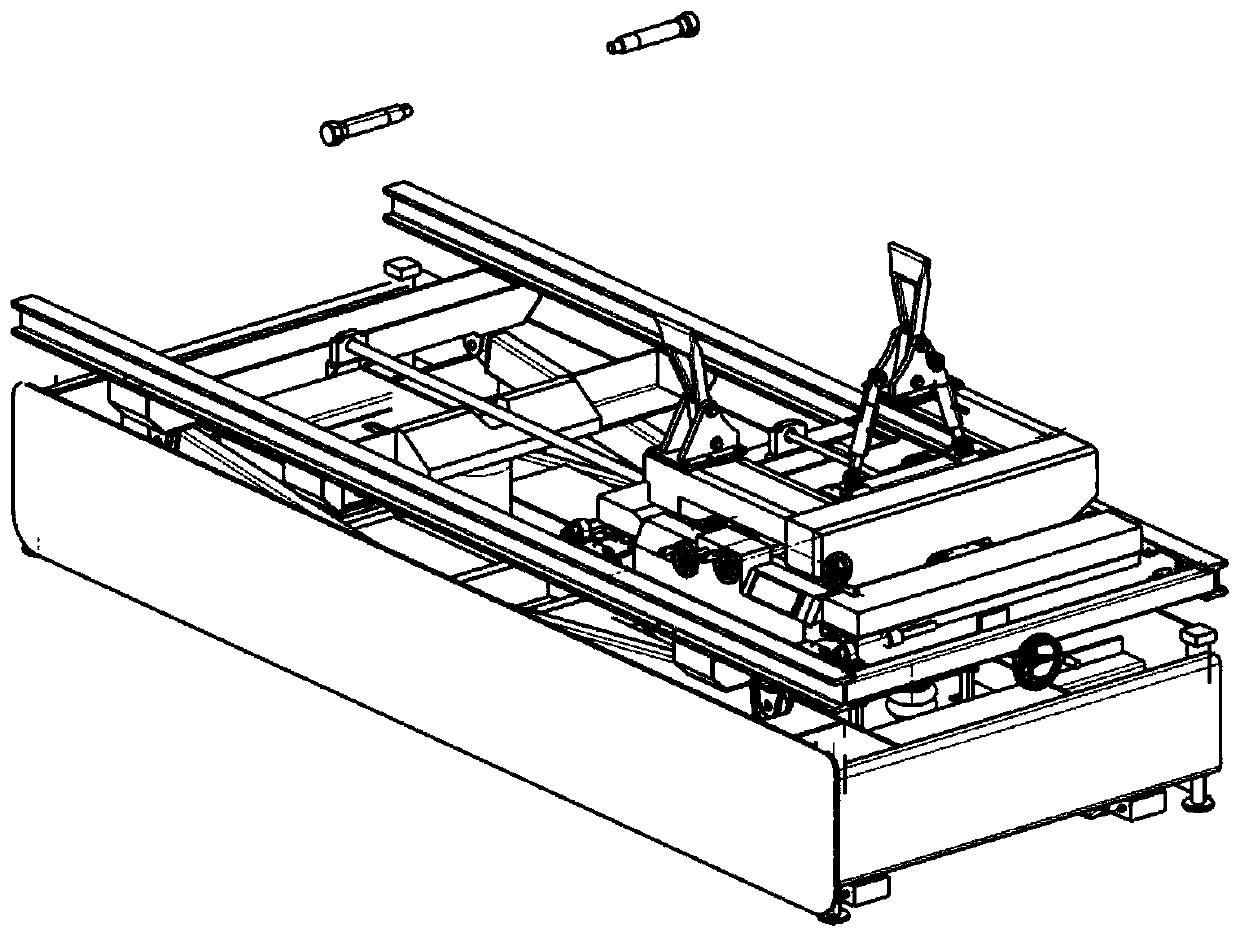

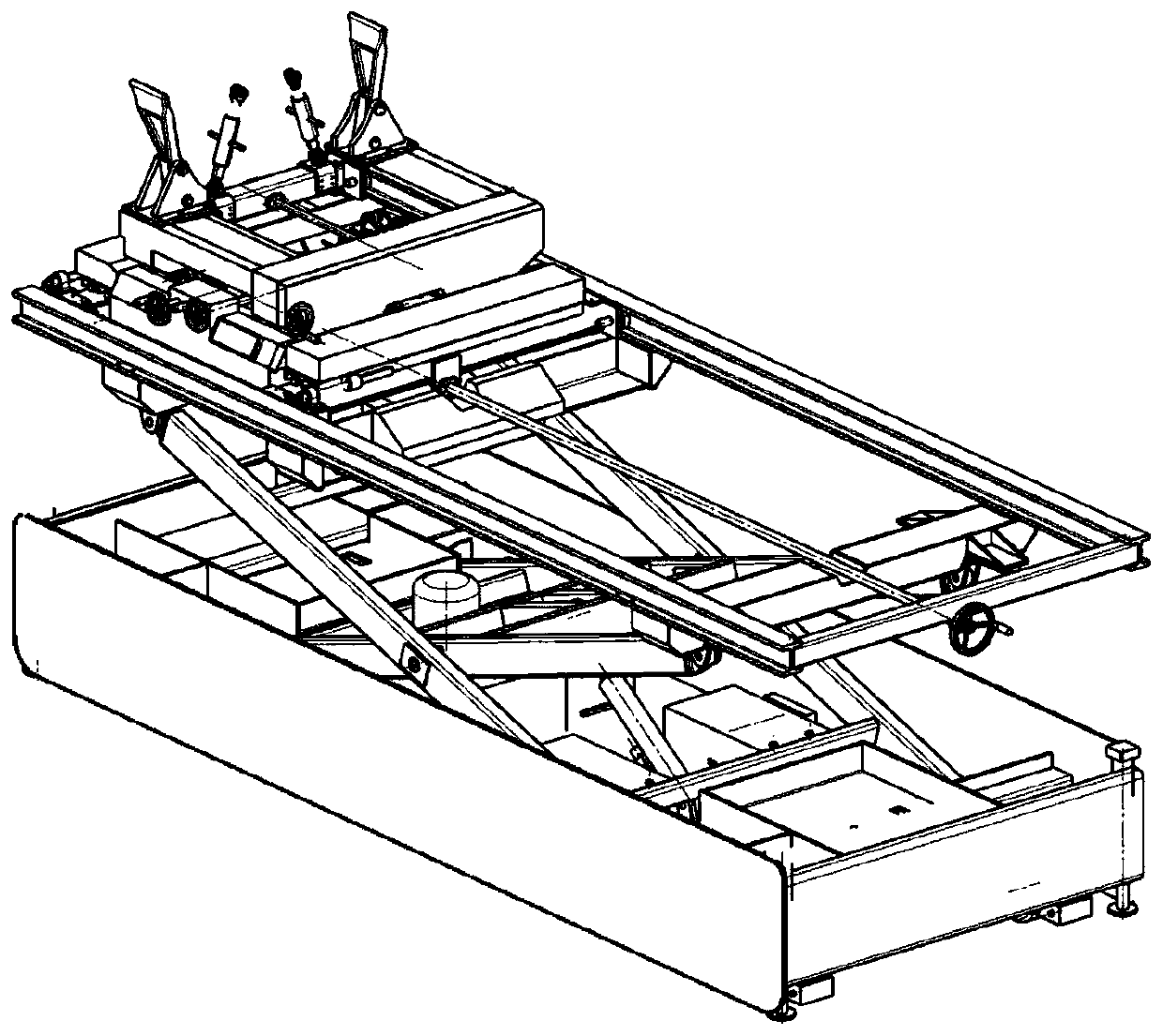

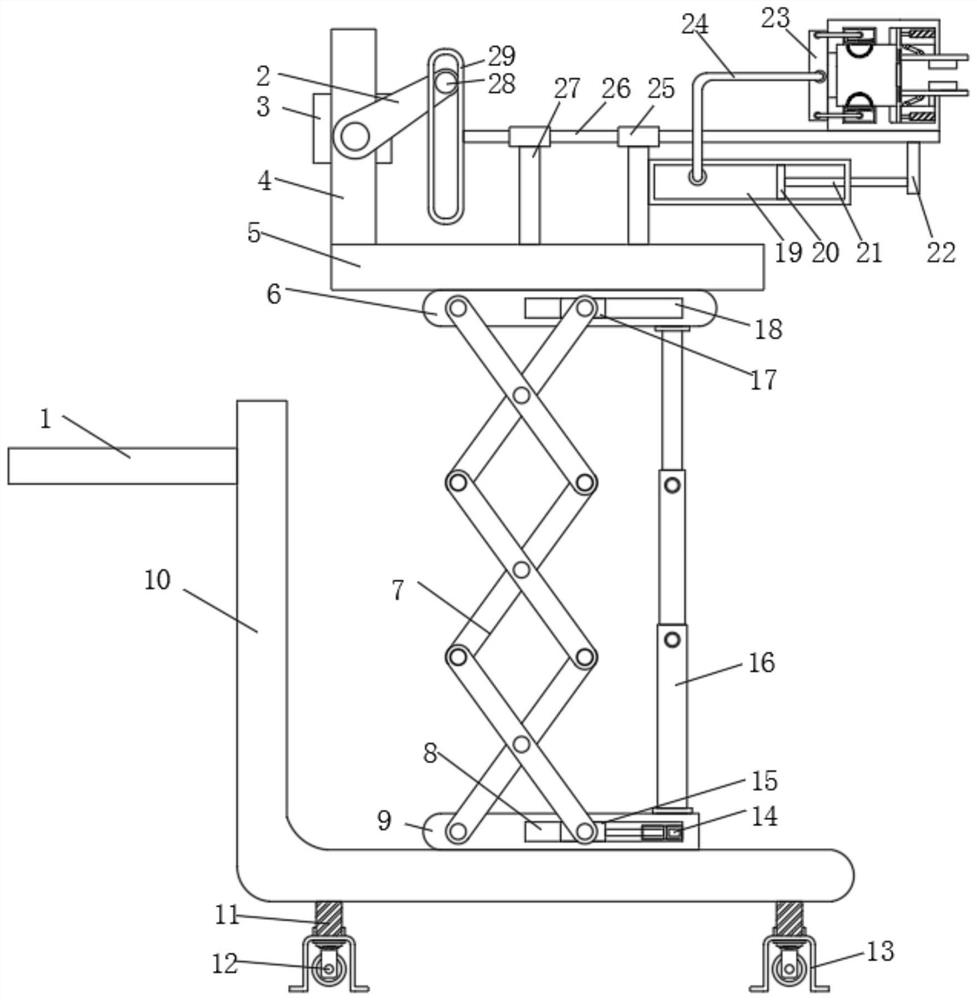

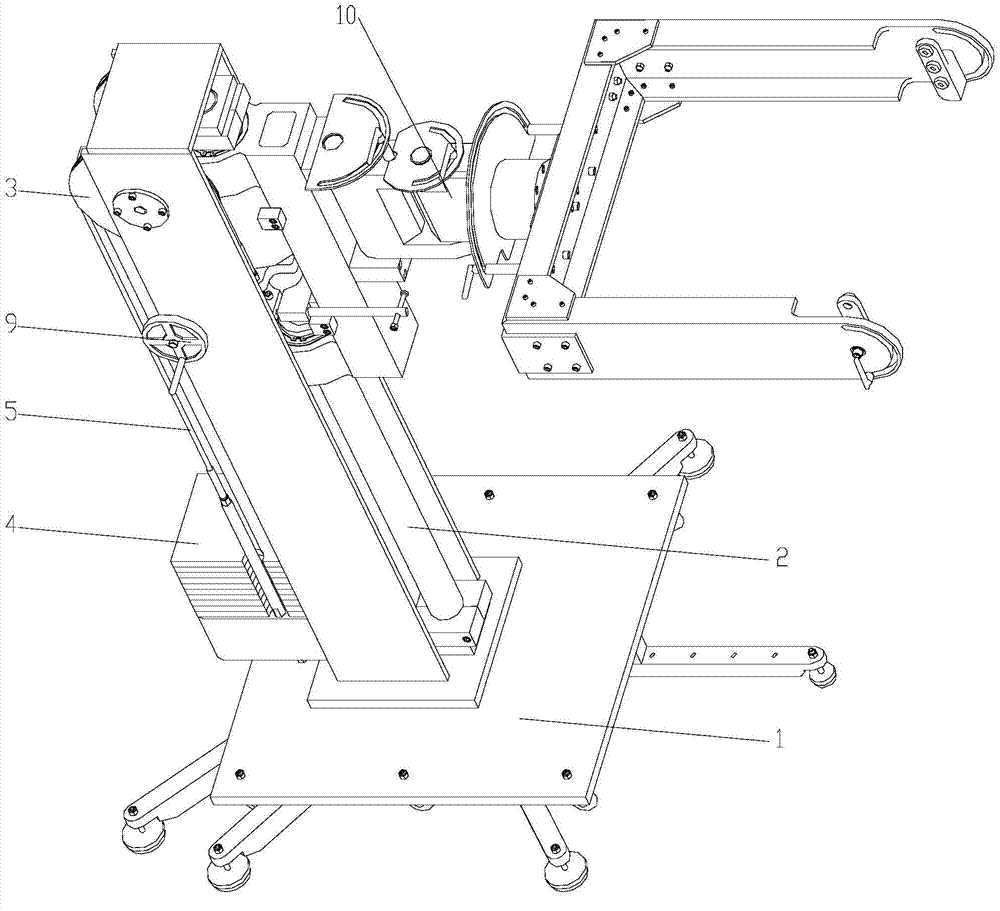

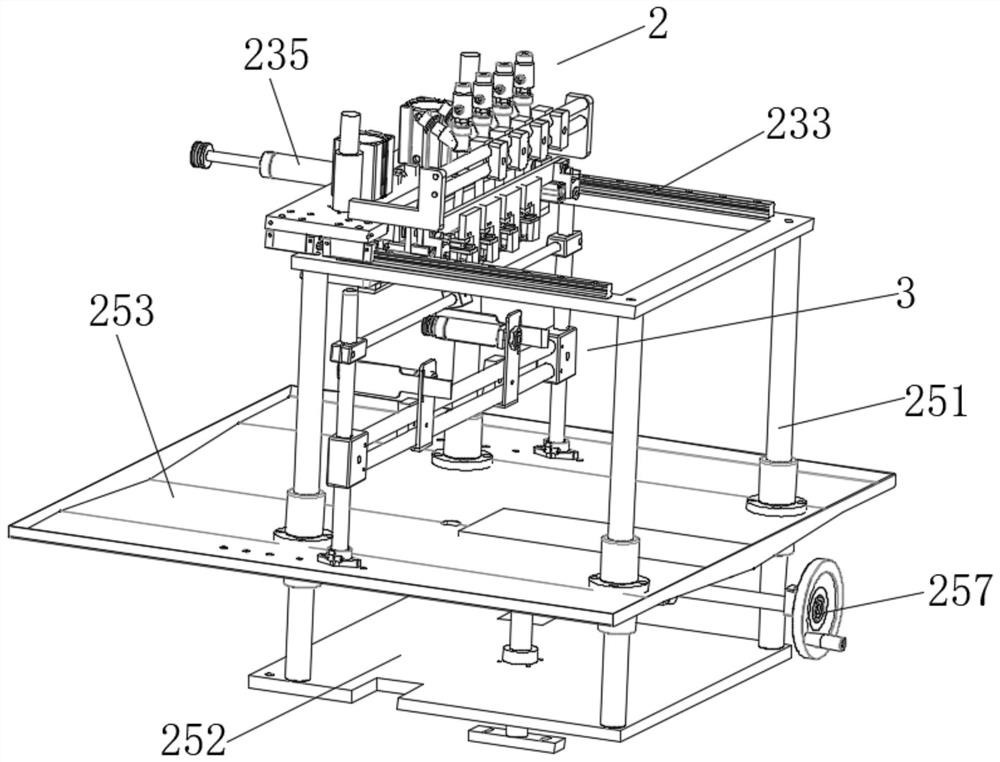

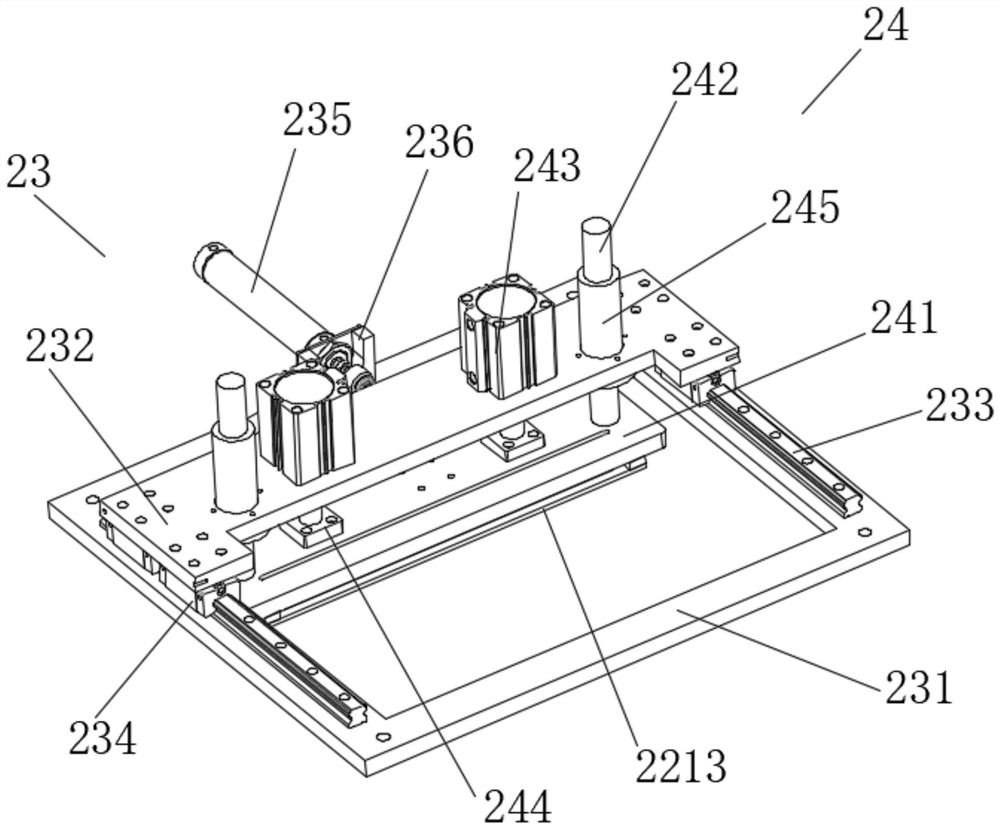

Multi-dimensional posture adjusting platform for airplane ground loading maintenance

ActiveCN110901947AShrink volume is smallCompact structureAircraft maintainanceControl theorySupport point

The invention discloses a multi-dimensional posture adjusting platform for airplane ground loading maintenance, and aims to provide a posture adjusting platform which is convenient to operate, high inworking efficiency and capable of guiding mounting parts to be fed accurately. The method is realized through the following technical scheme: the front fixed supporting point and the rear movable supporting point of the multi-dimensional adjusting platform are hinged through a fork frame rear supporting point and a fork frame front supporting point; the cross lifting adjusting mechanism translates along the Z direction; y-direction translation of first-stage longitudinal movement adjustment is achieved along a first-stage sliding rail of a first-stage longitudinal adjustment mechanism througha screw rod connected with a wide-side first-stage adjustment hand wheel, and Y-direction translation of second-stage longitudinal movement adjustment is achieved by a pulley assembly along a second-stage longitudinal adjustment mechanism installation guide rail; the transverse adjusting mechanism moves along the assembled inner slide rail to realize X-direction translation of transverse and heading adjustment; the direction fine adjustment mechanism changes the heights of the front bearing fulcrum and the rear bearing fulcrum of the second-stage bearing frame through the proportional connecting rod supporting mechanism to achieve pitching adjustment, transverse rolling adjustment and Z-direction height fine adjustment.

Owner:CHENGDU KAITIAN ELECTRONICS

Bamboo slip grinding machine

InactiveCN108274360AStable supportRealize lifting movementEdge grinding machinesGrinding carriagesEngineeringConveyor belt

The invention discloses a bamboo slip grinding machine. The bamboo slip grinding machine comprises a rack, a conveyor belt assembly and a grinding shell, wherein the conveyor belt assembly of which the left end and right end separately penetrate through a feeding opening and a discharging opening of the grinding shell is mounted on the rack; the conveyor belt assembly comprises a driving roller mounted on the rack in a rotating manner, a driven roller, a conveyor belt and a plurality of belt carrier rollers used for supporting the upper conveyer belt; the conveyor belt is arranged on the driving roller and the driven roller in a sleeving manner; the shaft end of the driving roller is in driving connection with a conveying motor on the rack through a transmission component; and a pluralityof bamboo slip storage trays used for placing bamboo slips are placed on the upper surface of the conveyor belt, and a plurality of limiting stop bars used for pushing the bamboo slip storage trays are fixedly distributed on the outer surface of the conveyer belt. The structural arrangement is reasonable, the regulation of grinding or polishing thickness can be realized, the control is accurate, the grinding efficiency is greatly increased, and chips can be effectively collected.

Owner:赵耀祥

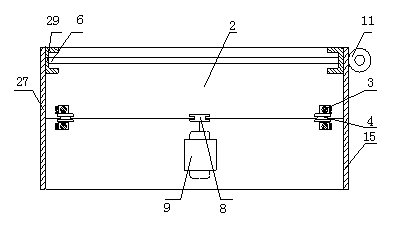

Shears-fork type spiral lifting platform

InactiveCN107445102ASolve the technical problems of occupying a large space sizeIngenious structural designLifting framesSpatial structureIndustrial engineering

The invention relates to a shears-fork type spiral lifting platform. The shears-fork type spiral lifting platform comprises an objective table, a spiral lifting machine, a driving device and a controller, wherein the spiral lifting machine is installed on the ground and is used for supporting the objective table, the driving device is used for driving the spiral lifting machine to move, the controller is used for controlling the driving device to operate, and a shears-fork type telescopic bracket which is fixed to the ground and is used for assisting to support the objective table is installed on the objective table. The shears-fork type spiral lifting platform has the advantage of clever structural design, a spiral lifting cylinder is formed in a way that a spring flat belt is engaged with a toothed spring bar, so that the objective table is driven to lift up and down, and auxiliary support to the objective table is realized by utilizing the shears-fork type telescopic bracket during lifting, so that the overall stability and safety are increased; the stage lifting motion is realized in a spiral lifting mode, the space structure is compact, the technical problem of large space size of a traditional lifting mechanism is solved, and the lifting force cannot be suddenly reduced along with the increase of the lifting height, so that the stability and the safety are high.

Owner:WUHU C&K AUTOMATION TECH CO LTD

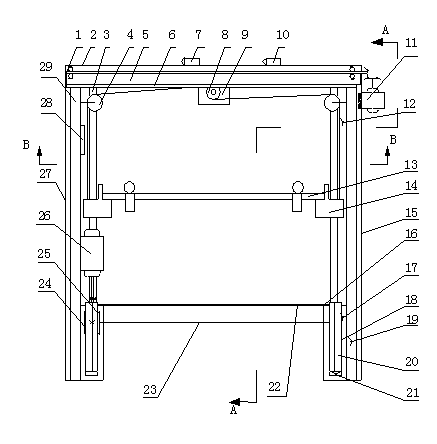

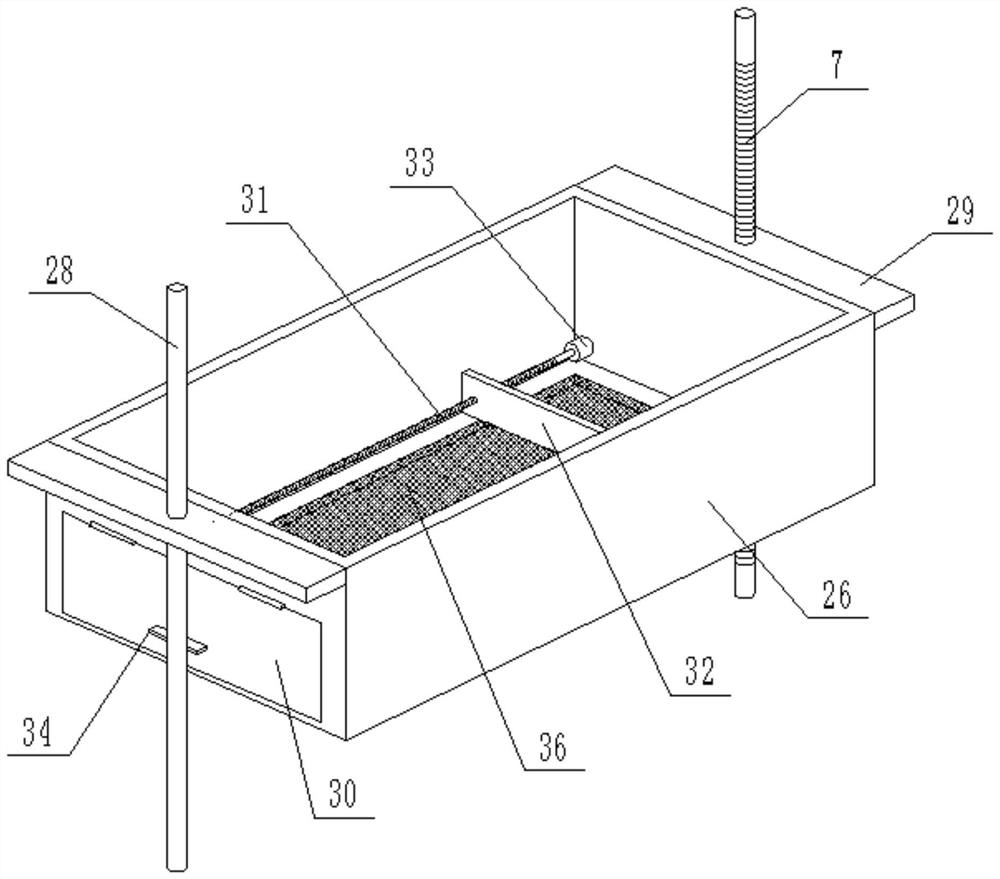

Fully-automatic clothes airing and collecting device

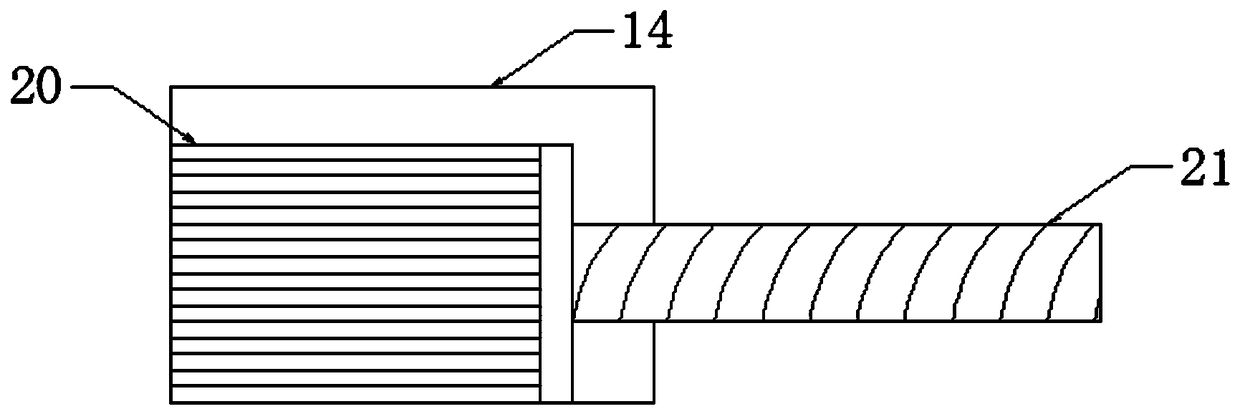

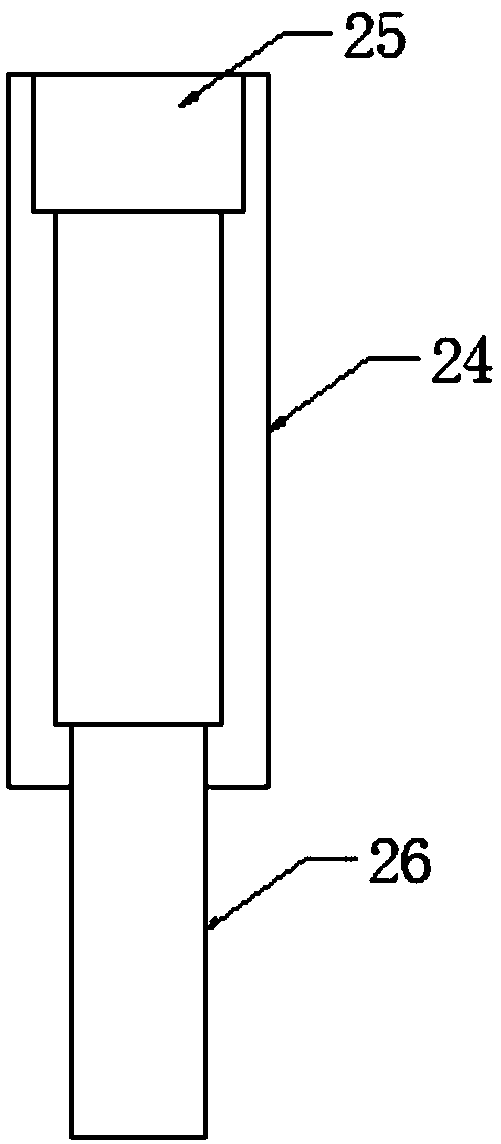

InactiveCN103266457AAutomatic retractionRegular dryingOther drying apparatusTextiles and paperElectric machineryEngineering

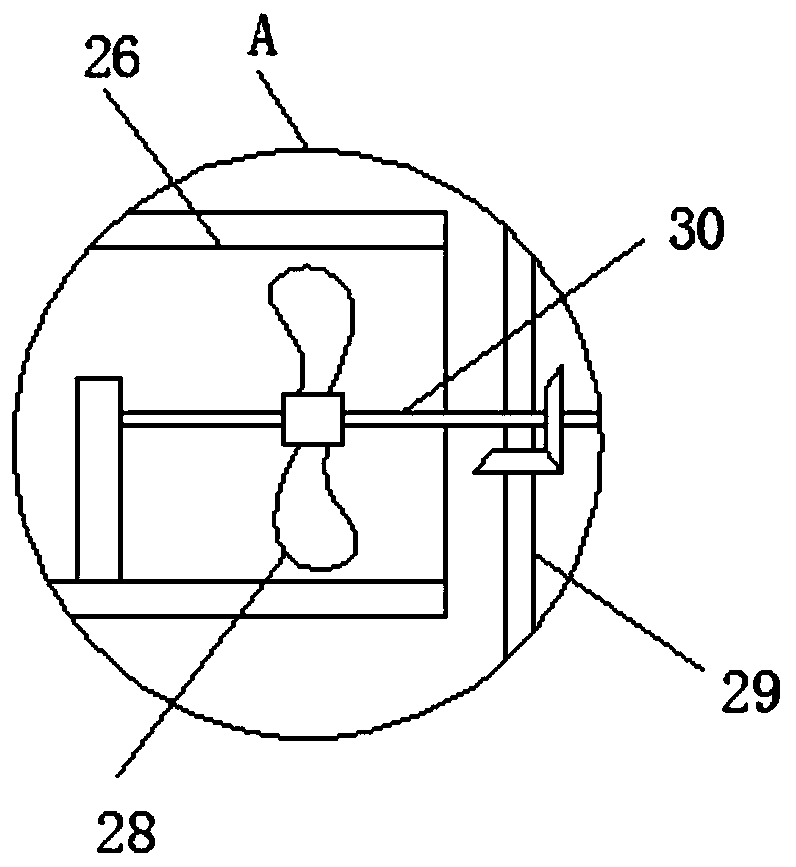

The invention belongs to the technical field of a fully-automatic clothes airing and collecting device. According to the technical scheme, a second motor (26) fixed on a left side plate (27) is in shaft connection with a worm (25) which is meshed with a worm gear (24), outer telescopic rods (20) on an outer telescopic rod shaft (23) are hinged to second sliding blocks (31) in guide grooves, and a third travel switch (30) and a fourth travel switch (21) are correspondingly installed on the upper portion and the lower portion of the right guide groove. A steel wire rope is wound on a wining drum (8) on a shaft of a first motor (9) and is connected with corresponding first sliding blocks (14) through two fixed pulleys (4), and an inner telescopic rod (13) are movably installed on the upper portions of the first sliding blocks (14). A shaft of a third motor (11) is connected with a roller shutter shaft (1) by means of bevel gear transmission, the upper end and the lower end of a roller shutter (5) are respectively connected with the roller shutter shaft (1) and a sliding rod (6) installed in sliding grooves (29), and fully-automatic clothes airing and collecting software is installed in a single chip microcomputer (28). The fully-automatic clothes airing and collecting device has the advantages of being high in safety, convenient to use, and capable of airing and collecting clothes in a timed mode.

Owner:WUHAN UNIV OF SCI & TECH

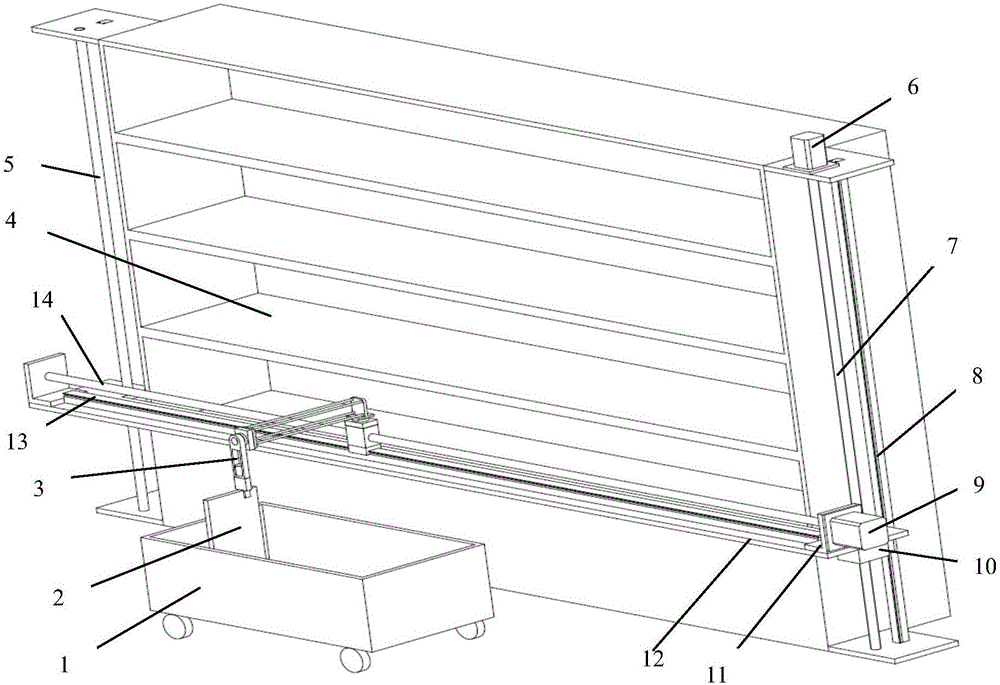

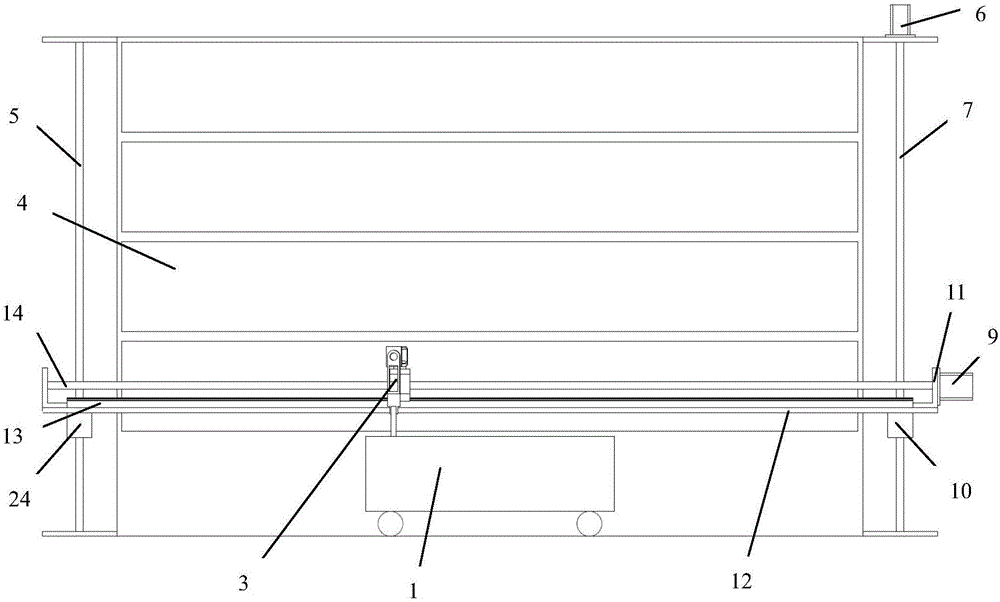

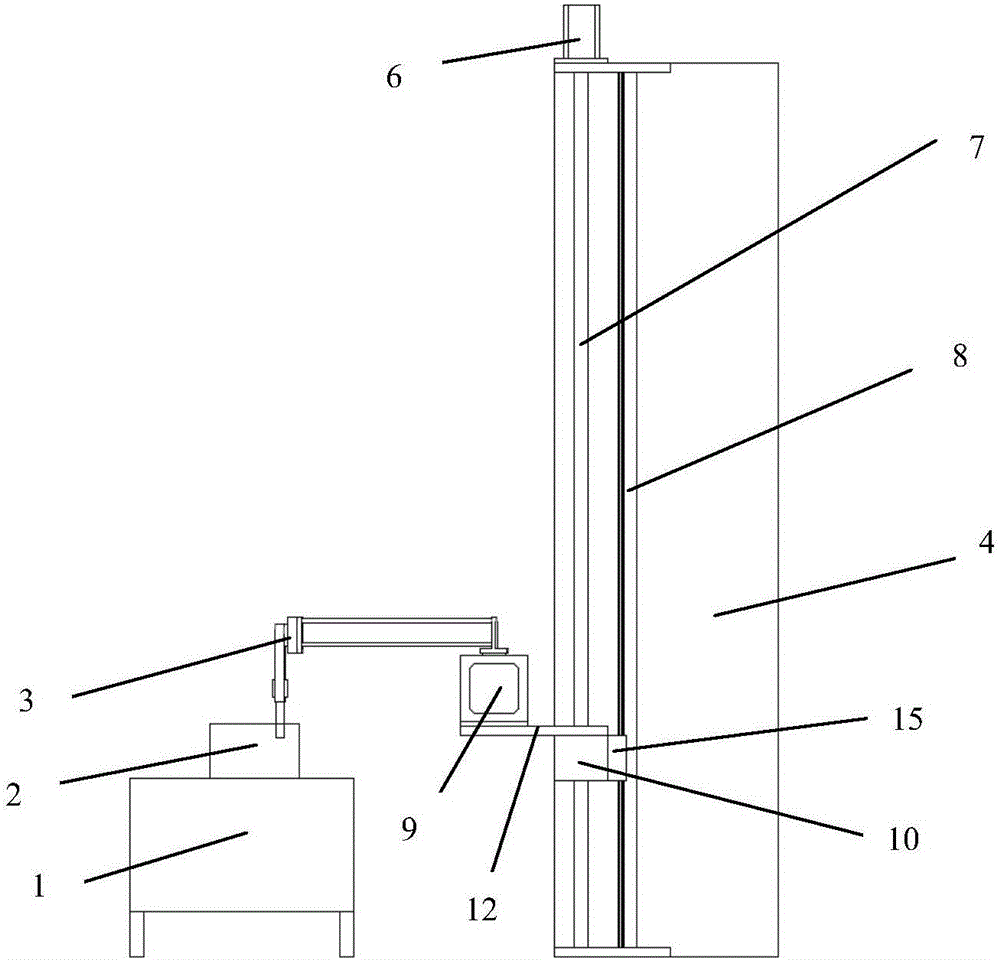

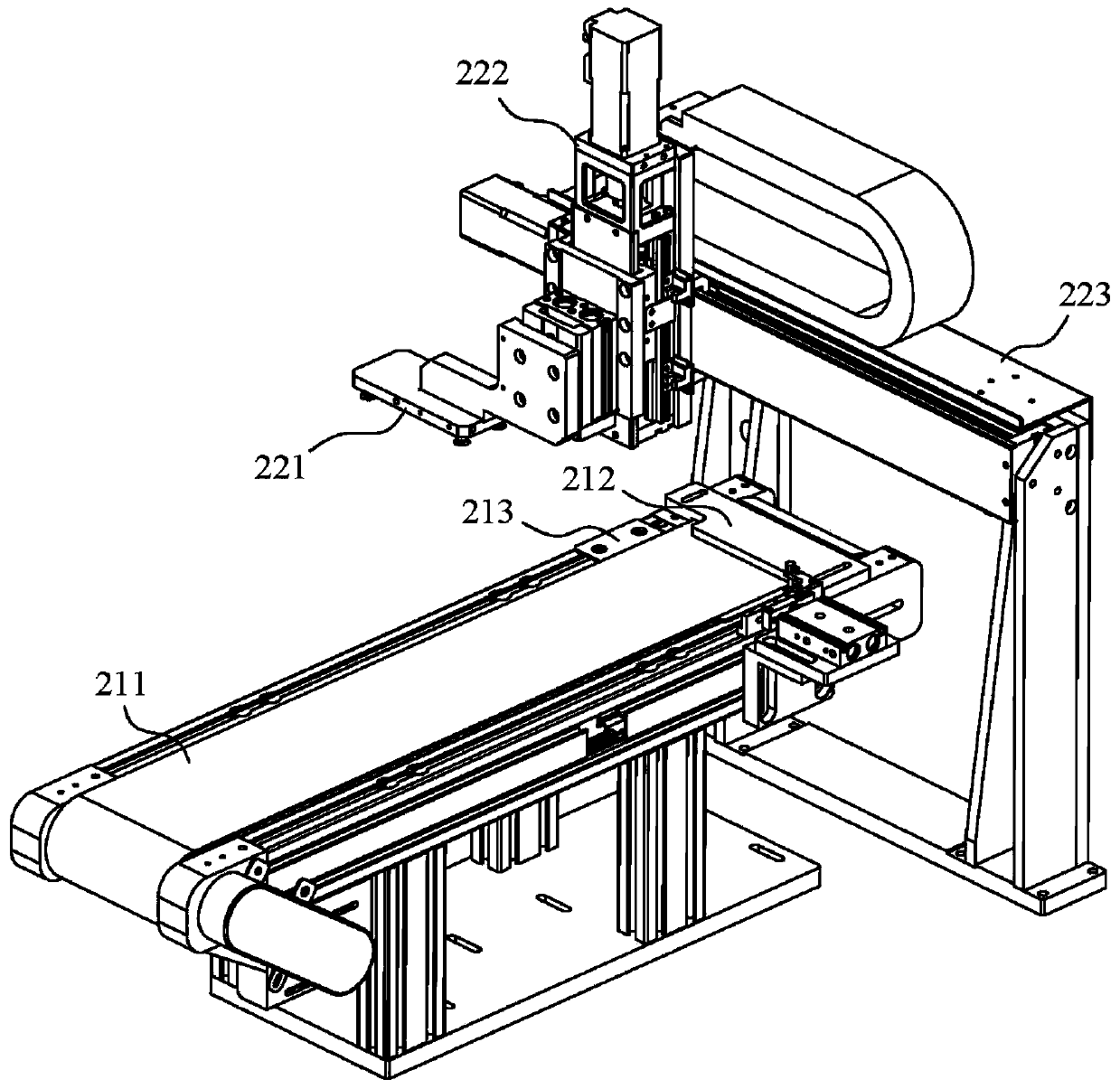

Automatic file pocket shelving device

The invention discloses an automatic file pocket shelving device. The device comprises a feeding trolley, a file cabinet, a grabbing manipulator, a horizontal moving mechanism and a vertical lifting mechanism, wherein the grabbing manipulator comprises a pneumatic finger, a third motor, a connecting rod, a first rotating cylinder, a connecting rod support, a second rotating cylinder and a second lead screw support; the vertical lifting mechanism comprises a first motor, a first ball screw, a first guide track, a first sliding block, a first lead screw support, a guide shaft and a linear bearing; and the horizontal moving mechanism comprises a second motor, motor supports, a lifting supporting plate, second ball screws and a second guide track. File pockets on the feeding trolley are shelved by the grabbing manipulator of the automatic file pocket shelving device. Compared with a traditional artificial file pocket storage mode, the automatic file pocket shelving device is more convenient, workload in a file arrangement process is greatly reduced, file neatening quality is improved, automation of management of files can be realized, and file management efficiency is improved effectively.

Owner:指南者品牌管理(苏州)有限公司

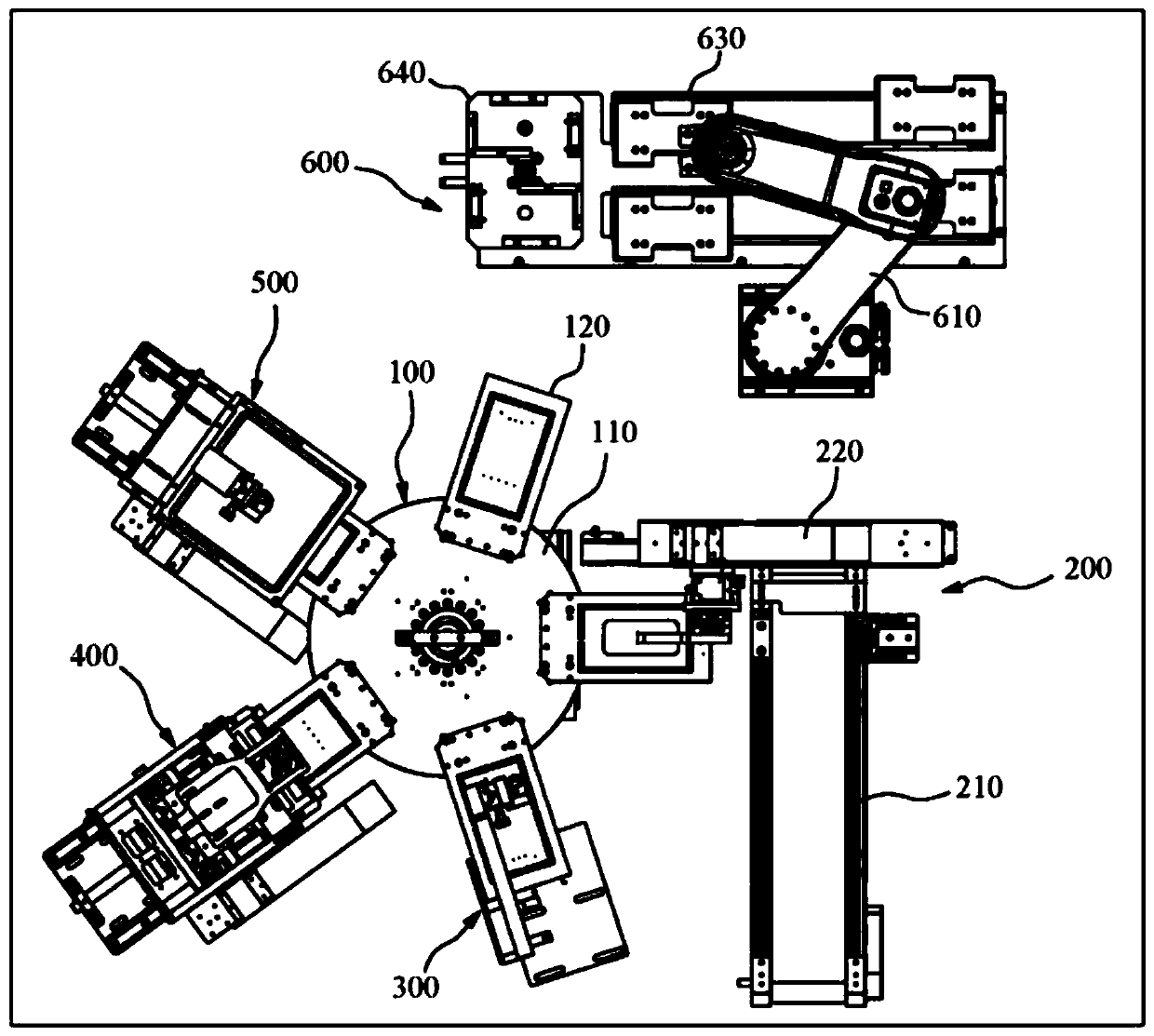

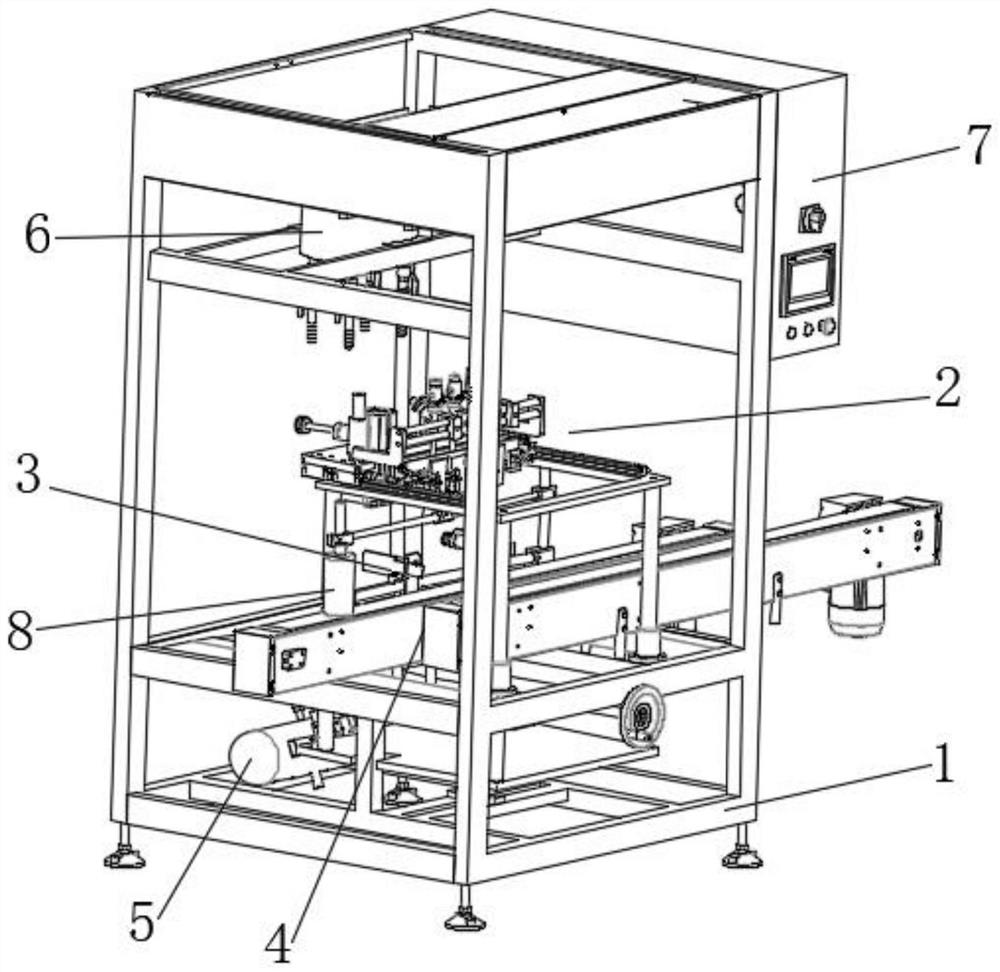

OCA detection device

PendingCN110624856AShort transmission distanceImprove detection efficiencyMaterial analysis by optical meansSortingCoaxial lineEngineering

The invention provides an OCA detection device. The OCA detection device comprises a rotary table, five stations are arranged along the periphery of the rotary table, and the five stations are correspondingly provided with a feeding unit, a first detection unit, a second detection unit, a third detection unit and a discharging unit; the rotary table comprises a rotating disc and a carrier uniformly distributed on the periphery of the disc, the carrier extends along the radial direction of the disk from the edge of the disk to the direction away from the center of the disk; the first detectionunit comprises a first camera and a first surface light source, the first camera is located above the rotary table, the first surface light source is located below the rotary table; the second detection unit comprises a second camera capable of scanning along the radial line of the rotary table and a coaxial light source, the coaxial light source is arranged above the rotary table, and the secondcamera is arranged above the coaxial light source; and the third detection unit comprises a third camera and a second surface light source, the second surface light source is arranged above the rotarytable, and the third camera is arranged above the second light source. The testing device is used for detecting the defects of glue shortage, bubble, concave point and convex point, deformation and being crushed of OCA products.

Owner:DONGGUAN LINGYI PRECISION MFG TECH CO LTD

Large-batch natural emulsion mattress cleaning equipment

InactiveCN110479661AHas a cleaning effectRealize the cleaning functionDrying gas arrangementsCleaning using toolsEmulsionAssembly line

The invention relates to the field of mattress correlation techniques, and discloses assembly line type natural emulsion mattress cleaning equipment. The assembly line type natural emulsion mattress cleaning equipment comprises a lower base, and a supporting seat is fixedly connected in the lower base. The top end of the supporting seat is movably connected with rolling wheels. According to the assembly line type natural emulsion mattress cleaning equipment, a mattress enters the equipment from a first conveying belt, cleaning cloth is arranged above the first conveying belt, and the cleaningcloth can be kept wet all the time through a water dividing pipe in a water pipe cavity and has a cleaning effect. After the mattress is cleaned by the cleaning cloth, water in the mattress can be squeezed out through the cooperation of an upper squeezing wheel and a lower squeezing wheel, then the mattress enters a second conveying belt, and a drying chamber is arranged above the second conveyingbelt. Under pushing of an exhaust fan, air is heated by two heating screens and reaches the mattress to dry the mattress. After drying is completed, the mattress is discharged out of the equipment accordingly, the equipment successfully achieves an assembly line type cleaning function, and the natural emulsion mattress can be efficiently cleaned in large batch.

Owner:杭州盟韵科技有限公司

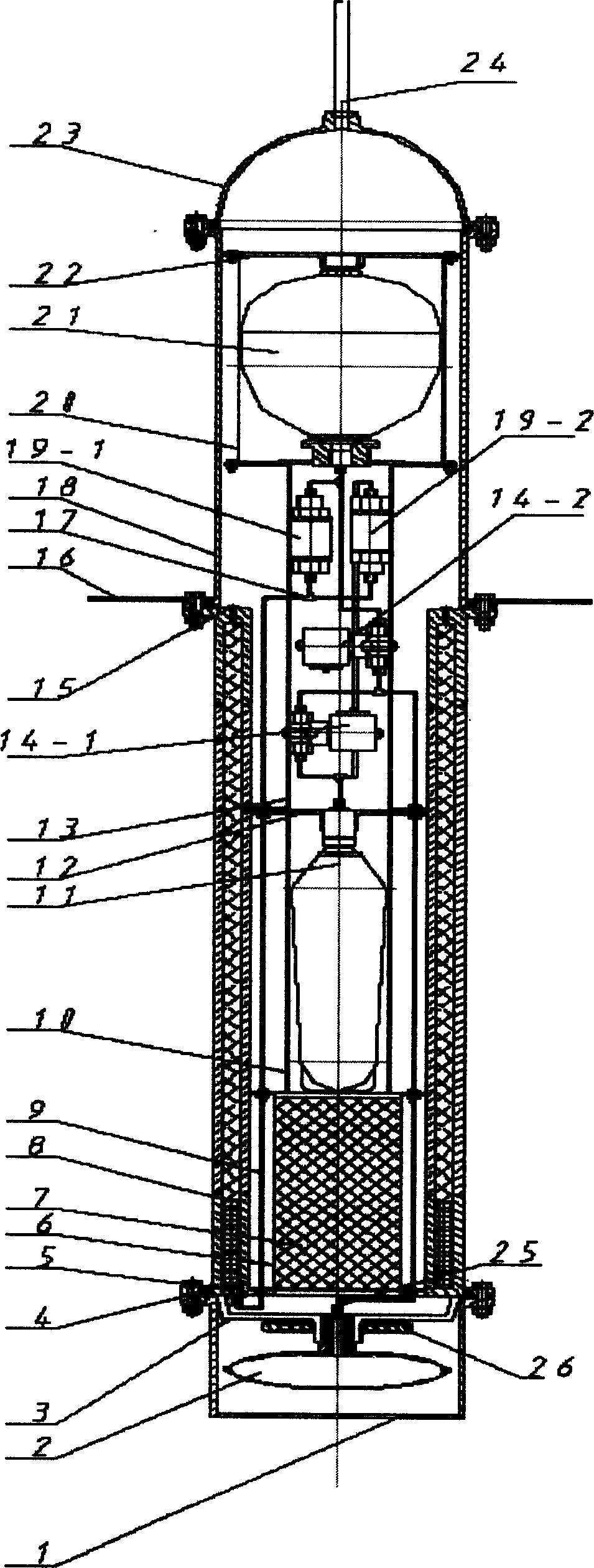

Horizontal lifted underwater robot driven by temperature differential energy

ActiveCN1644452ARealize monitoringRealize lifting movementPropulsive elementsUnderwater vesselsMarine engineeringControl system

A temp difference energy driven underwater robot able to vertically float up or sink down is composed of external and internal leather bags, protecting casing consisting of sealed bottom, sealed cylinder, sealed spherical front end and working chamber of heat machine, electromagnetic valves, check valves and energy accumulator. Said working chamber is respectively connected via forward and backward check valves to energy accumulator and internal leather bag. Two check valves are also communicated to external leather bag.

Owner:TIANJIN UNIV

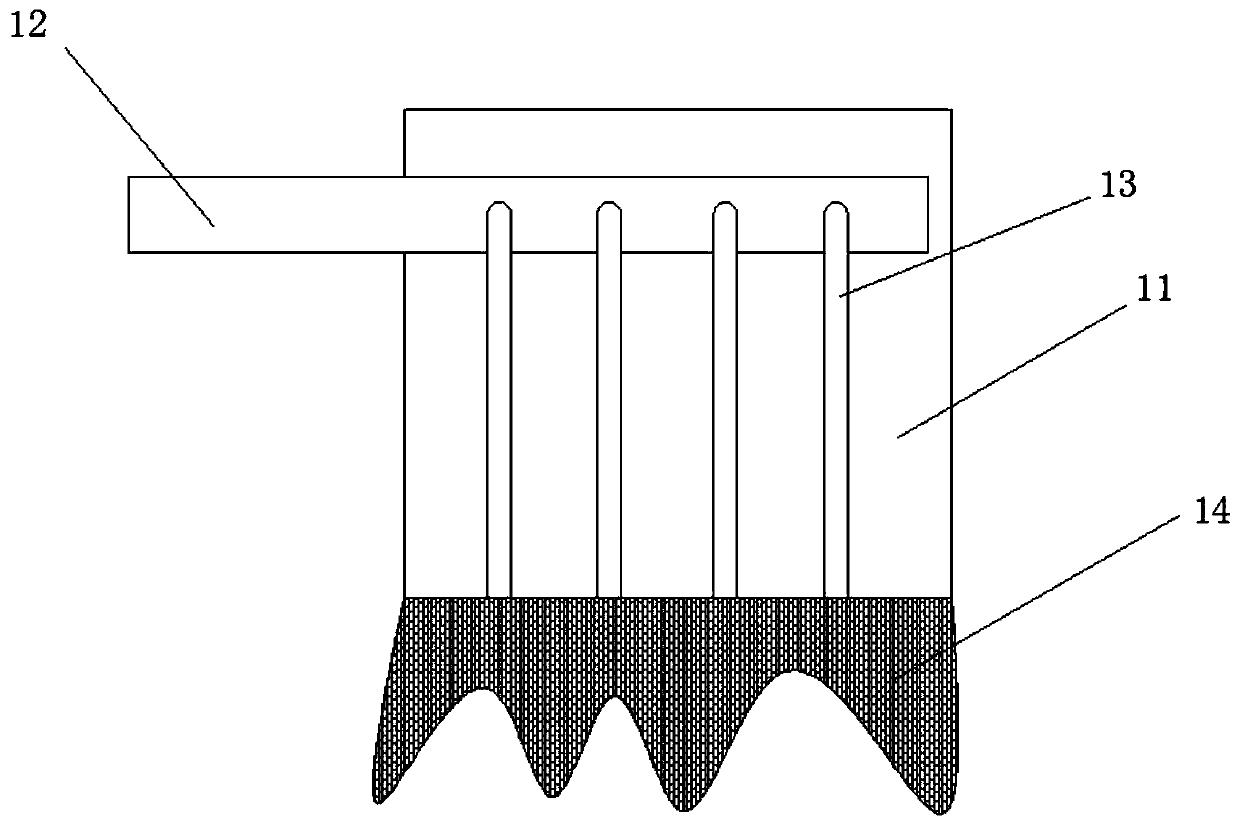

Dust removal device for paper core tube production and processing

PendingCN111589751AAchieve fixationEasy to fixDispersed particle filtrationTransportation and packagingDust controlProcess engineering

The invention discloses a dust removal device for paper core tube production and processing, and belongs to the technical field of paper core tube production. The device comprises a workbench, a support column is arranged at the top of the workbench, a top plate is installed at the top of the support column, a lifting plate is arranged above the workbench, and an adjustment mechanism for adjustingthe height of the lifting plate is installed at the top of the workbench; a transverse plate is slidably installed on the lifting plate, a dust removal brush is installed at one end of the transverseplate, and a horizontal plate is arranged above the top plate; a driving mechanism for adjusting the height of the horizontal plate is arranged on the top plate, a positioning rod is rotatably installed at the bottom of the horizontal plate, a servo motor is installed at the top of the horizontal plate, and an output shaft of the servo motor is connected with the positioning rod in a transmissionmode. According to the device, the fixation of a paper core tube is realized, the dust removal is convenient to carry out, the fixation is convenient, omni-directional dust removal of the paper coretube is realized, the operation is motorized, the labor is saved, dust removal efficiency is improved, dust collection is achieved, the pollution is avoided, the operation is convenient, and the cleaning is convenient.

Owner:响水明恒包装有限公司

Soundbox spraying equipment capable of automatically feeding

ActiveCN111375511AEnsure consistencyRealize automatic loadingSpraying apparatusEngineeringPersonnel safety

The invention discloses soundbox spraying equipment capable of automatically feeding and belongs to the technical field of soundbox spraying. The soundbox spraying equipment capable of automatically feeding comprises a conveying device, a translation platform, a clamping device, a lifting column and a material placing basket; the translation platform is arranged above the front end of the conveying device; a sliding device is arranged on a lower surface of the translation platform; a lower surface of the sliding device is fixedly connected with a telescopic cylinder; and a clamping device is fixedly connected below the telescopic cylinder. Automatic feeding is realized by a transmission device, a clamping jaw device, the translation platform and the conveying device, so that manual work isreduced and personnel safety is guaranteed; manual feeding is not adopted, many workpieces can be placed in the material placing basket at one time and five workpieces can be clamped by the clampingdevice at each time, so that working efficiency is improved; the workpiece grabbing and placing positions are unchanged at each time, so the influence on the spraying effect caused by position changeof the workpieces is reduced; and a conveying mechanism is arranged below the material placing basket and the material placing basket can move back and forth, so that injury caused by that people approaches the spraying position is reduced.

Owner:西安启界海图信息科技有限责任公司

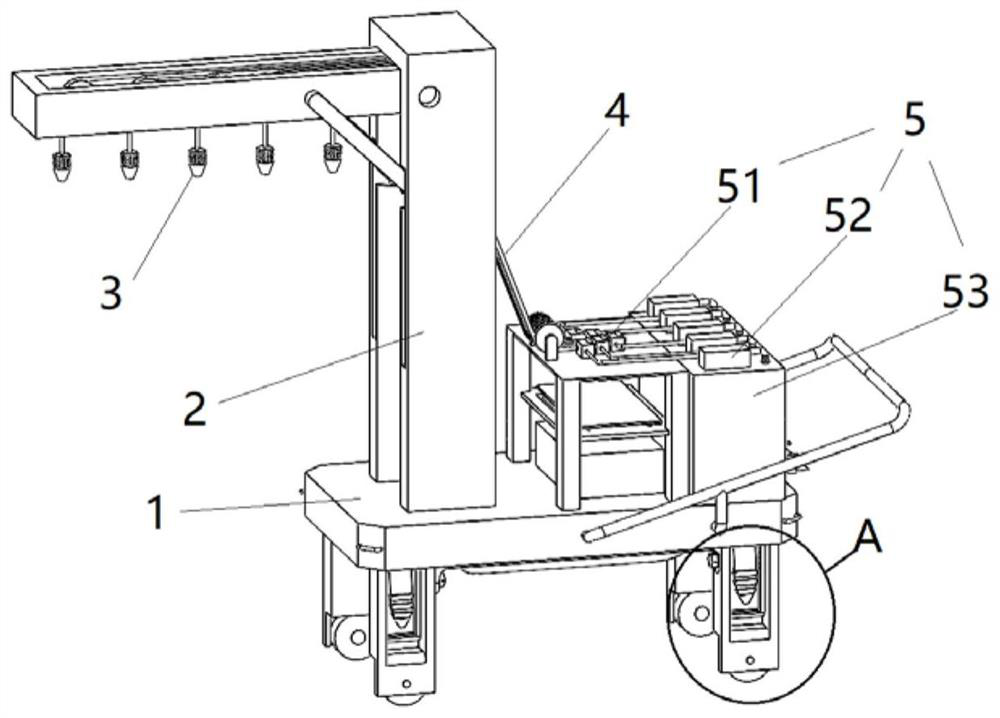

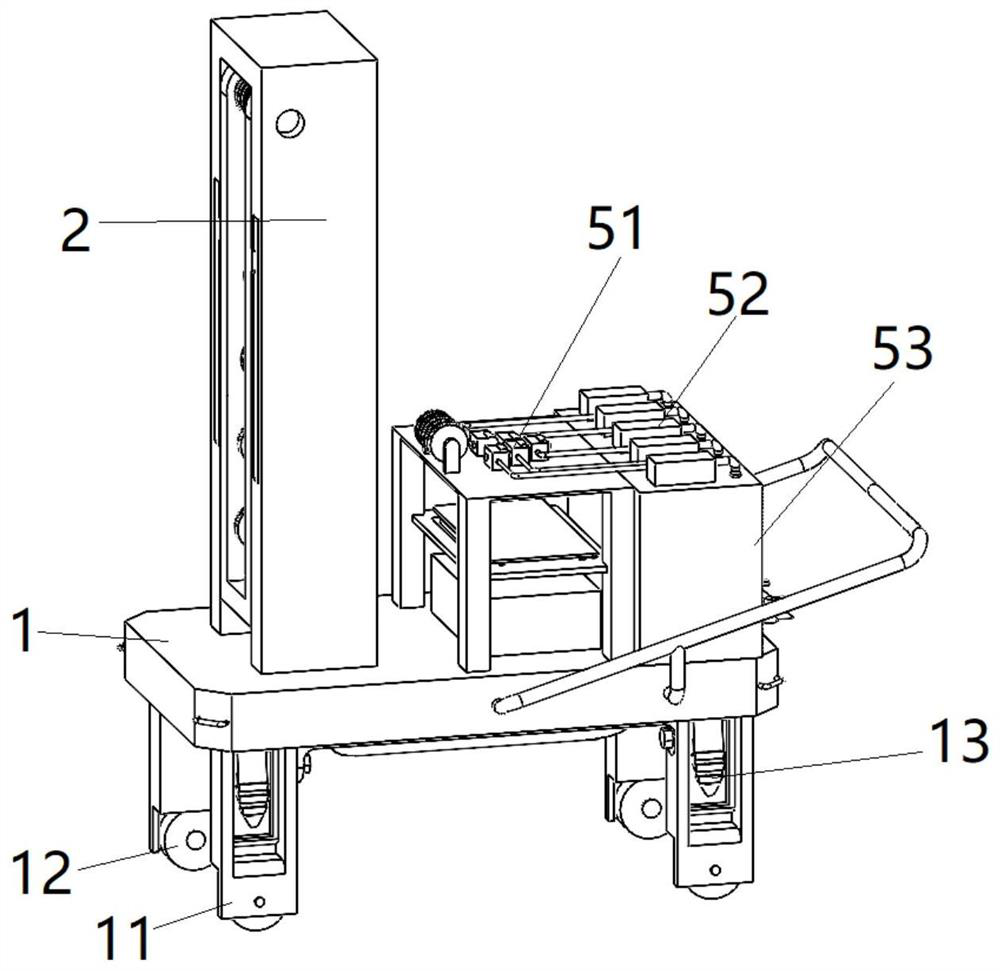

Curbstone construction assisting crane and using method thereof

ActiveCN105544360AEasy and stable clampingRealize lifting movementRoads maintainenceVehicle frameDrive wheel

The invention discloses a curbstone construction assisting crane and a using method thereof. The curbstone construction assisting crane comprises a car frame, wherein a railway is mounted on the car frame, a movable pulley is mounted on the railways, a fixed pulley is mounted at one end of the railway, and is connected with the movable pulley through ropes; a clamp is connected to one ends of the ropes, the other ends of the ropes are connected with a lifting driving wheel through pulley blocks, the lifting driving wheel is mounted on the car frame, a chain wheel is mounted at the tail end of the railway, the chain wheel is connected with a traversing driving chain wheel through a chain, the traversing driving chain wheel is mounted on the car frame, and the movable pulley is fixedly connected to the chain. According to design of the railway, the lifting driving wheel, the fixed pulley, the movable pulley and the clamp, the lifting driving wheel is controlled to rotate and reverse, so that the lifting of the clamp can be realized; according to design of the chain wheel, the traversing driving chain wheel and the chain, the traversing driving chain wheel is controlled to rotate and reverse, so that the horizontal movement of the clamp can be realized; according to design of the special curbstone clamp, curbstones can be more convenient and firm to clamp.

Owner:SHANDONG UNIV

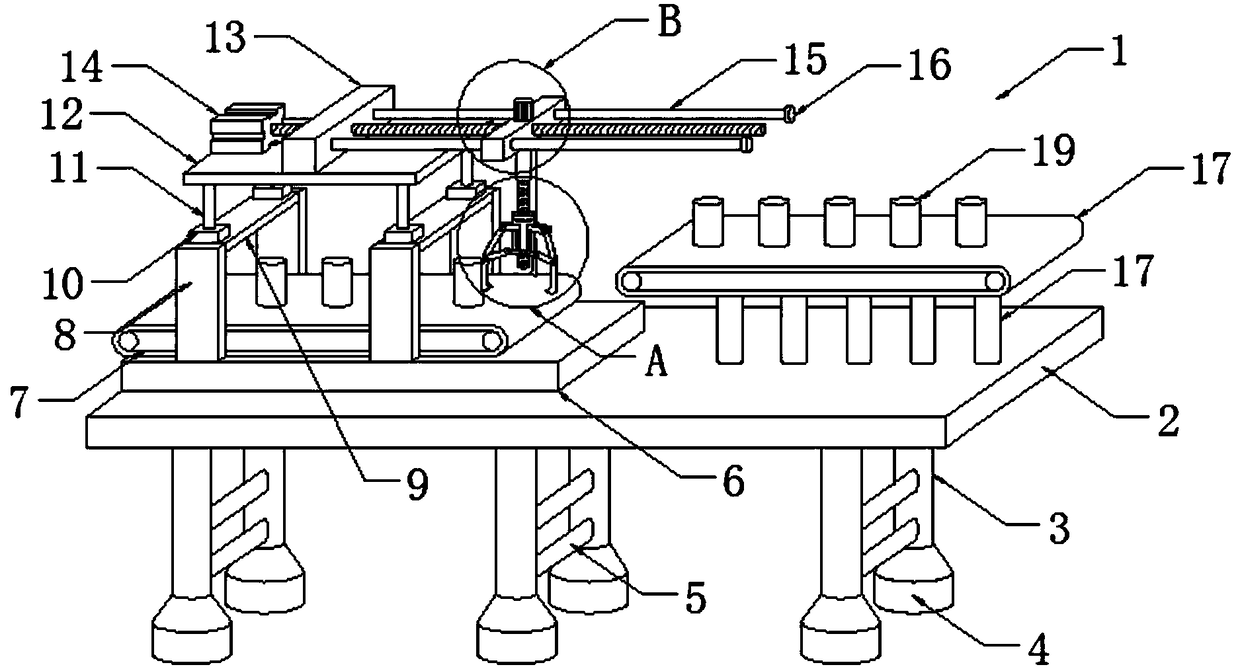

Automatic clamping and feeding mechanical gripper

The invention discloses an automatic clamping and feeding mechanical gripper. The automatic clamping and feeding mechanical gripper comprises a device body which comprises a table, wherein table legsare fixedly arranged at the four corners of the bottom and two ends of the middle part of the table; supporting non-slip mats are arranged at the bottoms of the table legs; two connecting rods are fixedly connected between the two closest supporting legs; a first bearing plate is fixedly arranged at one end of the top of the table; and a first conveyor belt is arranged on the top of the first bearing plate. The automatic clamping and feeding mechanical gripper has the beneficial effects that the device is provided with a first conveyor belt, a second conveyor belt, a second air cylinder, a second piston rod, a clamp seat, a clamp side plate, a first movable plate and a clamping jaw, so that the clamping function of workpieces can be realized, and workpieces of different sizes can also be clamped; after clamping, the workpiece on the first conveyor belt is put on the second conveyor belt through the movement of the air cylinder and a piston, and thus, the clamping and feeding functionsof the device are realized; and the applicability of the device is improved.

Owner:广东嗨学云教育科技有限公司

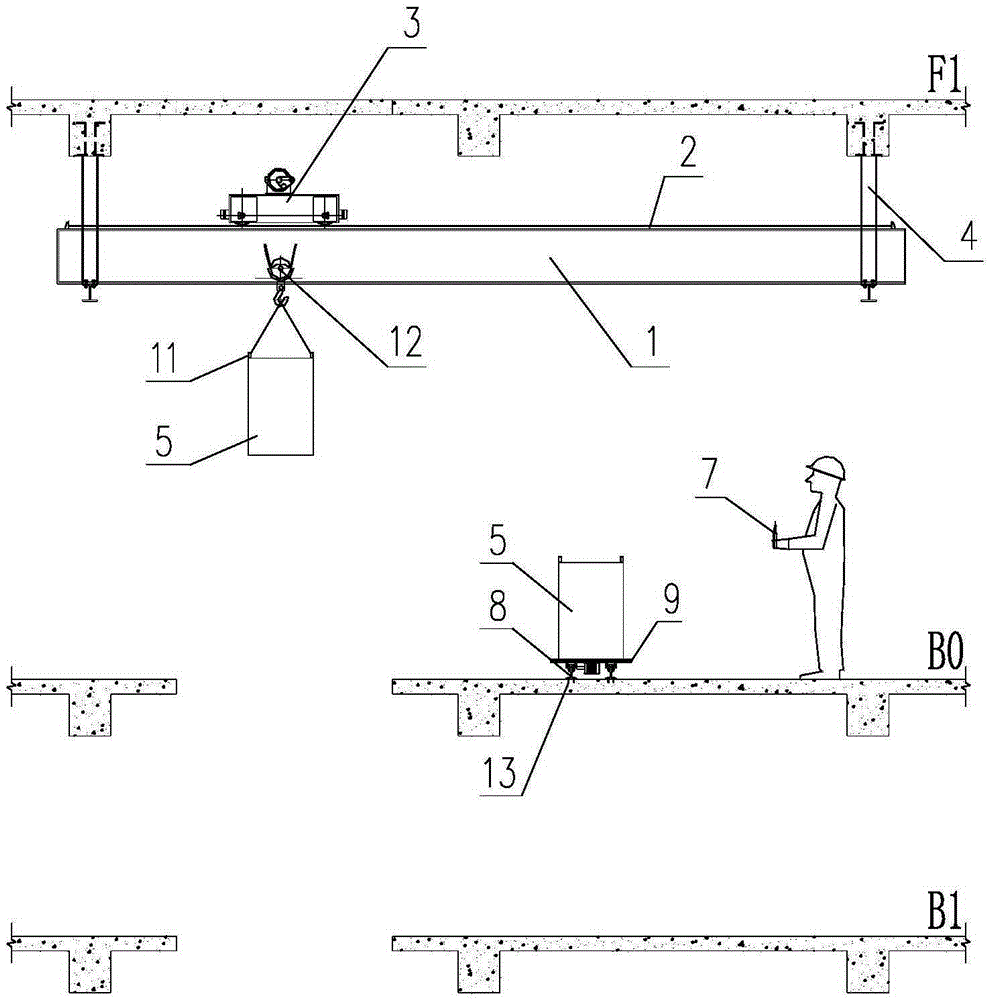

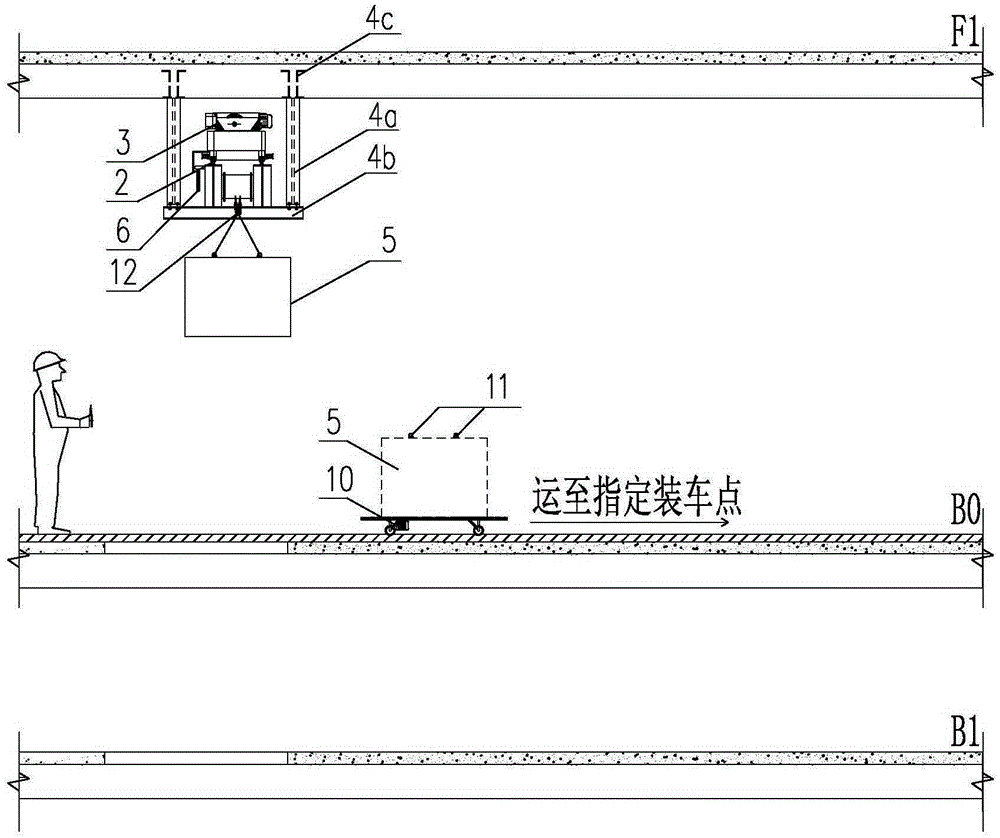

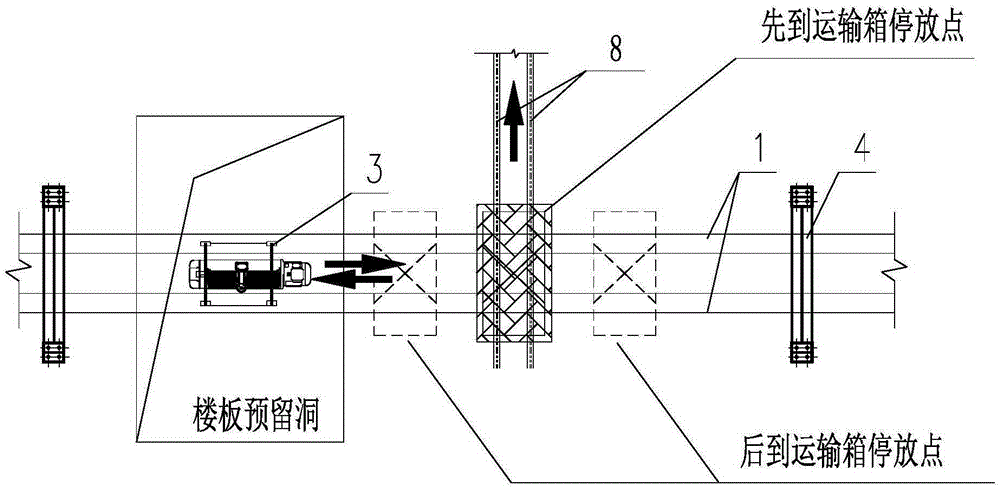

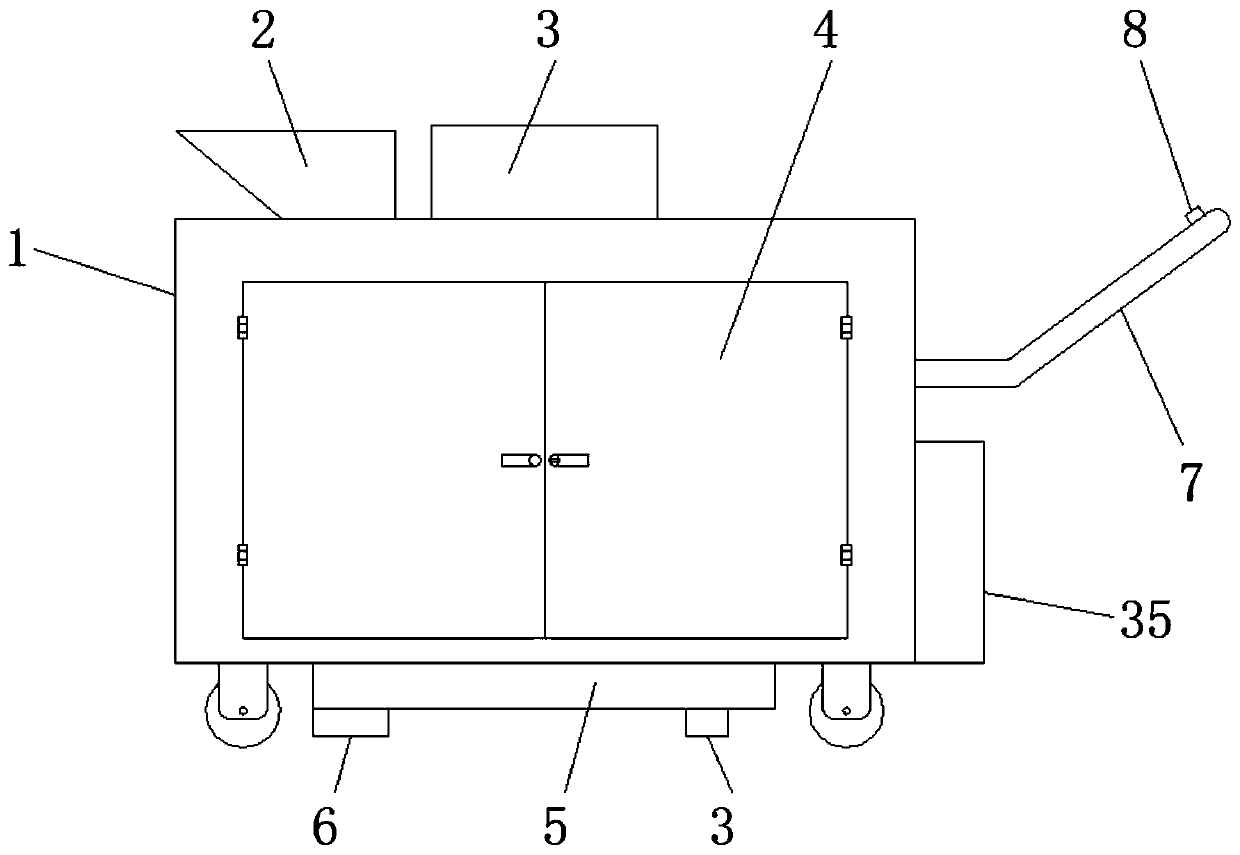

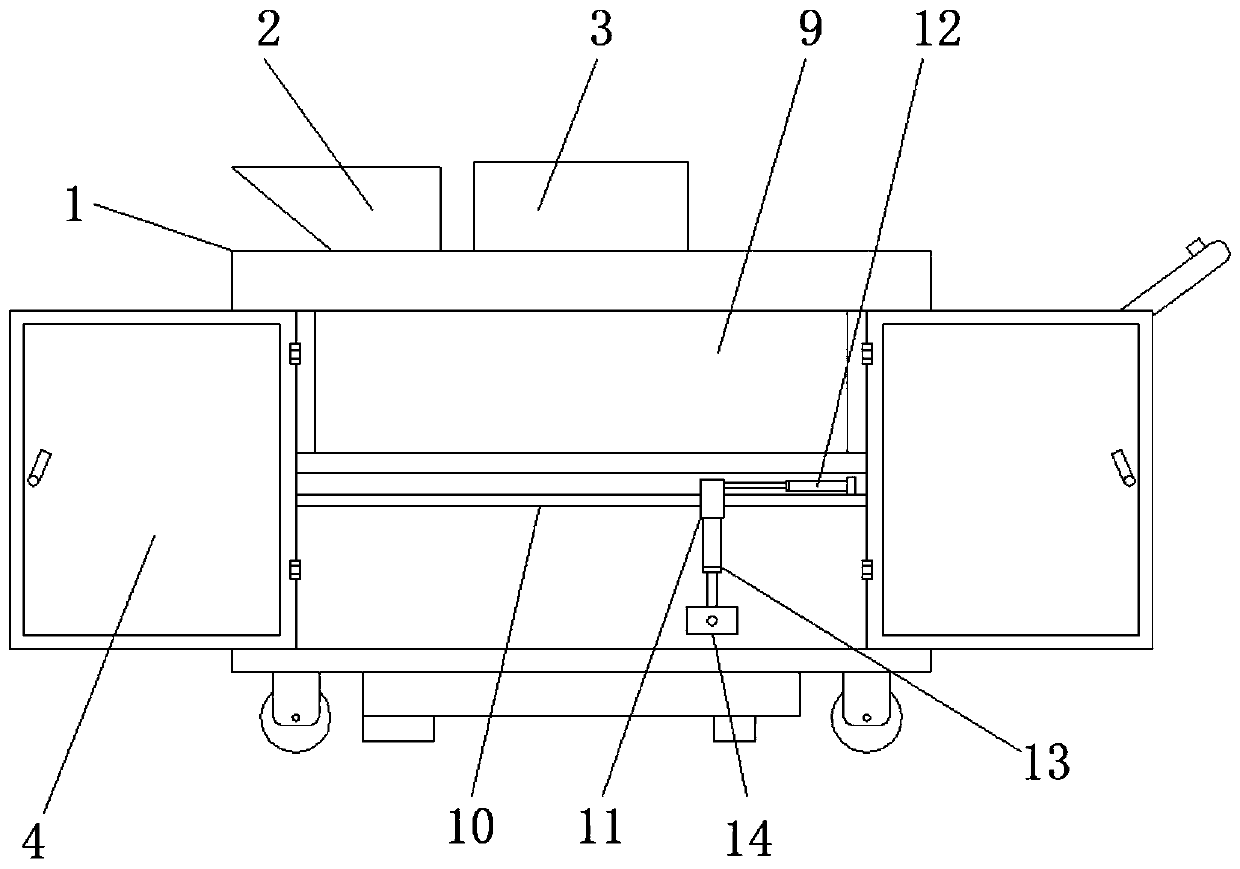

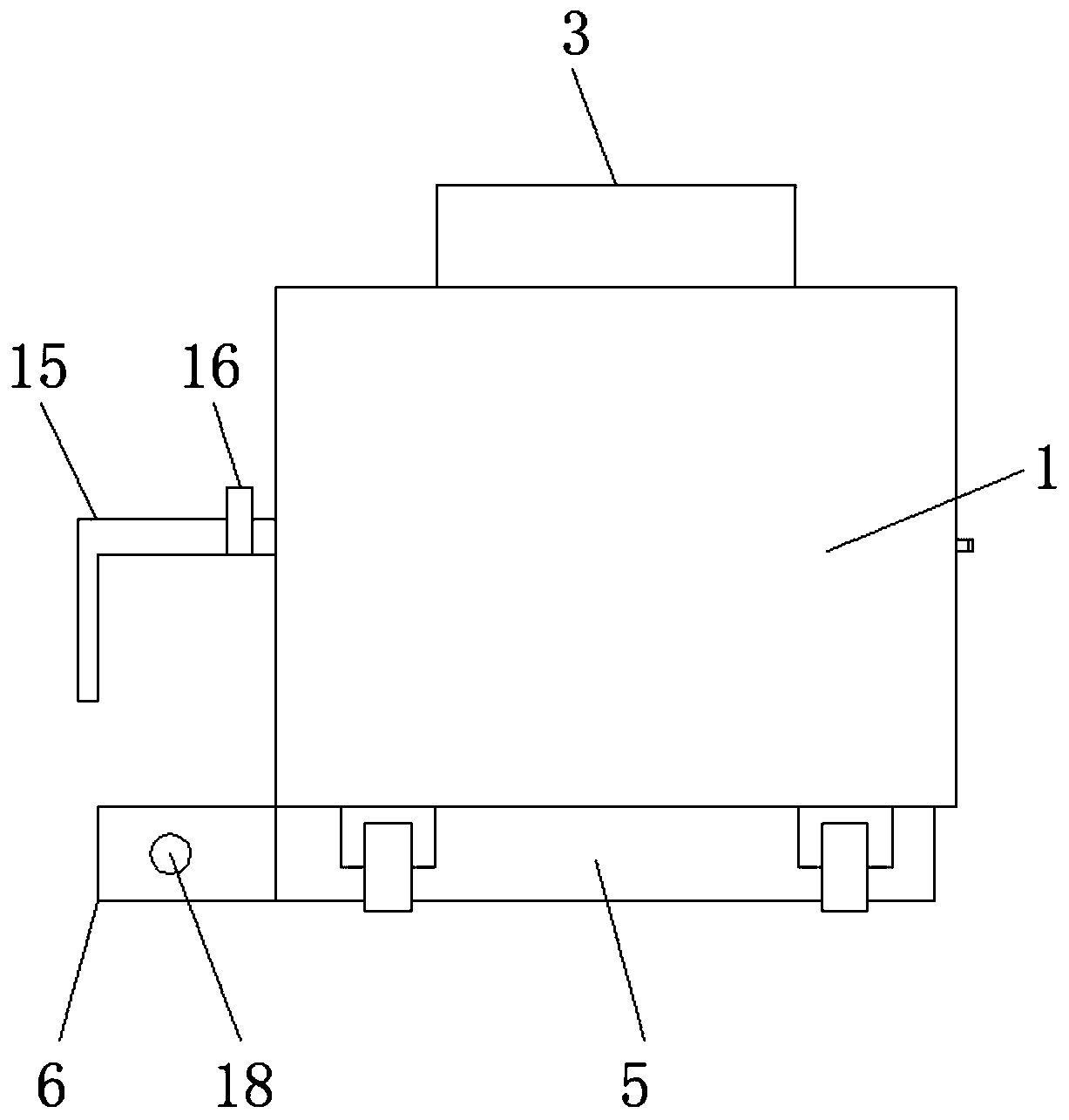

Hanging type unearthing device for bidirectional synchronous reversed construction and construction method

ActiveCN105401582AReduce investmentReduce construction costsArtificial islandsExcavationsBasementArchitectural engineering

The invention provides a hanging type unearthing device for bidirectional synchronous reversed construction and a construction method. A conveying box, filled with wastes produced by basement construction, is lifted out of the ground and transferred onto a long-distance horizontal conveying device through a hanging type crane and then is conveyed to an appointed loading position by utilizing the long-distance horizontal conveying device, the wastes in the conveying box are unloaded into a conveying vehicle by utilizing other cranes, and the empty conveying box is put onto the long-distance horizontal conveying device again, then conveyed back through the long-distance horizontal conveying device and finally conveyed to a basement through the hanging type crane for repeated use. With the adoption of the hanging type unearthing device and the construction method, the cleaning and conveying efficiencies of underground engineering wastes can be effectively improved, the investment of large machines near an unearthing reserved hole in an underground structure is effectively reduced, the construction cost is lowered, and the influence of underground waste cleaning and conveying construction on upper part structure construction can also be greatly lowered.

Owner:SHANGHAI CONSTR NO 1 GRP

Building pavement kerb accurate laying device capable of avoiding dislocation

ActiveCN111287051AAvoid Precise LayingAchieve forward and backward movementRoads maintainenceArchitectural engineeringRoad surface

The invention discloses a building pavement kerb accurate laying device capable of avoiding dislocation. The laying device comprises a laying device body, a feeding port, a protective cover, a door plate, a handrail, a control box, a contact and a control cabinet. A feeding opening is formed in the top of the laying device body; a protective cover is arranged on one side of the feeding opening; adoor plate is arranged on the front side of the laying device body; a kerb containing cover is welded to the bottom of the laying device body, a guide hopper is welded to the lower end of one side ofthe kerb containing cover, a conveying belt is arranged on the front side of the pushing mechanism, a discharging mechanism is arranged in the side, away from the interior of the pushing mechanism, ofthe conveying belt, and a discharging plate is arranged at the output end of the discharging mechanism. According to the building pavement kerb accurate laying device capable of avoiding dislocation,kerbs can be hoisted into the laying device body, the kerbs can be accurately aligned with kerbs laid at road shoulders, the labor intensity of construction workers is relieved, and the laying efficiency is improved.

Owner:吴龙翔

Novel power transmission line deicing equipment for mechanical field

InactiveCN112260201ARealize lifting movementEasy to adjustOverhead installationElectric machineFixed frame

The invention discloses novel power transmission line deicing equipment for the mechanical field, and the equipment comprises a fixed frame, the upper surface of the fixed frame is fixedly connected with a bottom plate, the upper surface, close to the left side, of the bottom plate is connected with a supporting rod, the top end of the supporting rod is connected with a supporting plate, and a lifting frame is arranged between the bottom plate and the supporting plate. A vertical plate is fixedly connected to the upper surface of the left side of the supporting plate, a driving motor is fixedly mounted on the back face of the vertical plate, an output shaft of the driving motor extends to the front side of the vertical plate and is connected with a connecting rod, two supporting columns are fixedly connected to the upper surface of a mounting plate, and limiting blocks are fixedly connected to the tops of the supporting columns. And a mounting strip is movably connected between the twolimiting blocks, and a deicing mechanism is fixedly connected to the upper surface of the end, away from the limiting frame, of the mounting strip. Through the ingenious design of the structure, operation is easy, the working efficiency is greatly improved, and meanwhile the equipment is suitable for power transmission lines with different thicknesses and good in practicability.

Owner:杨友明

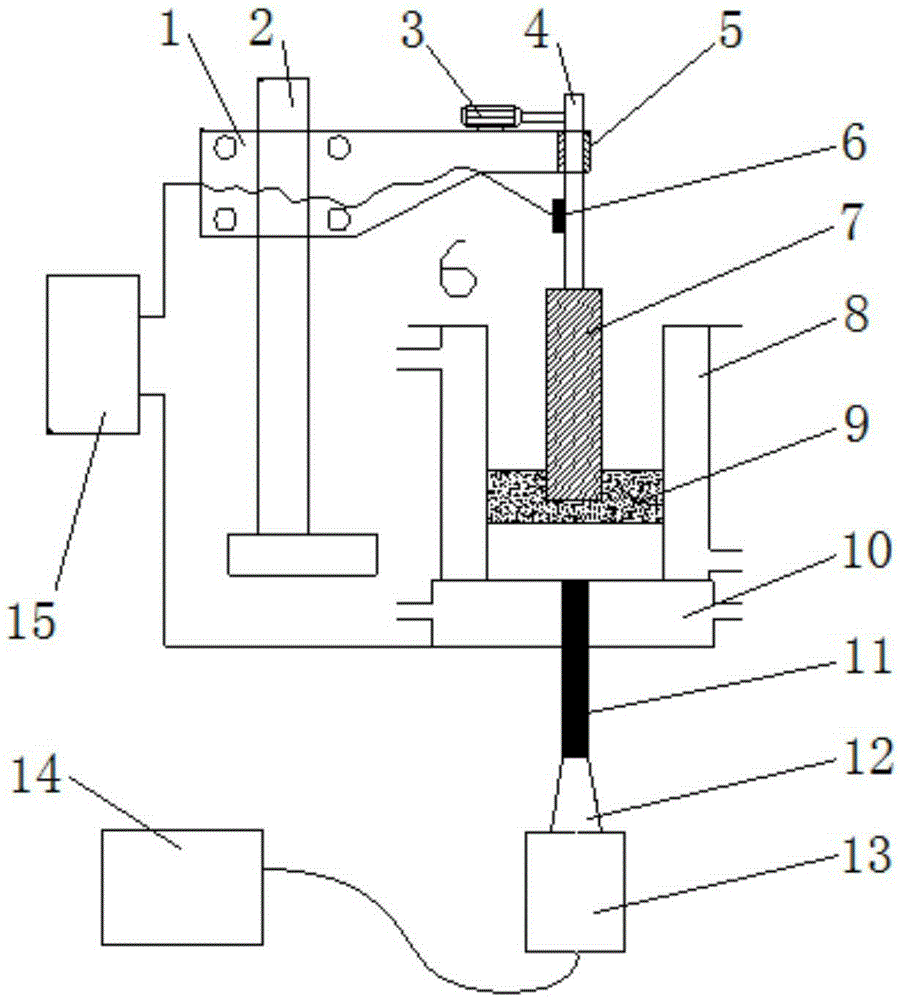

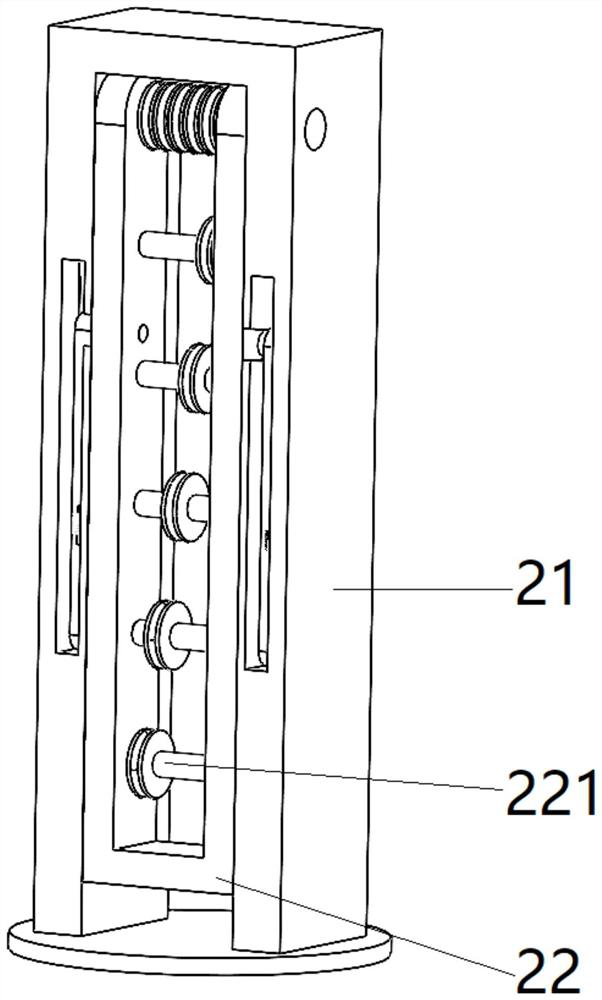

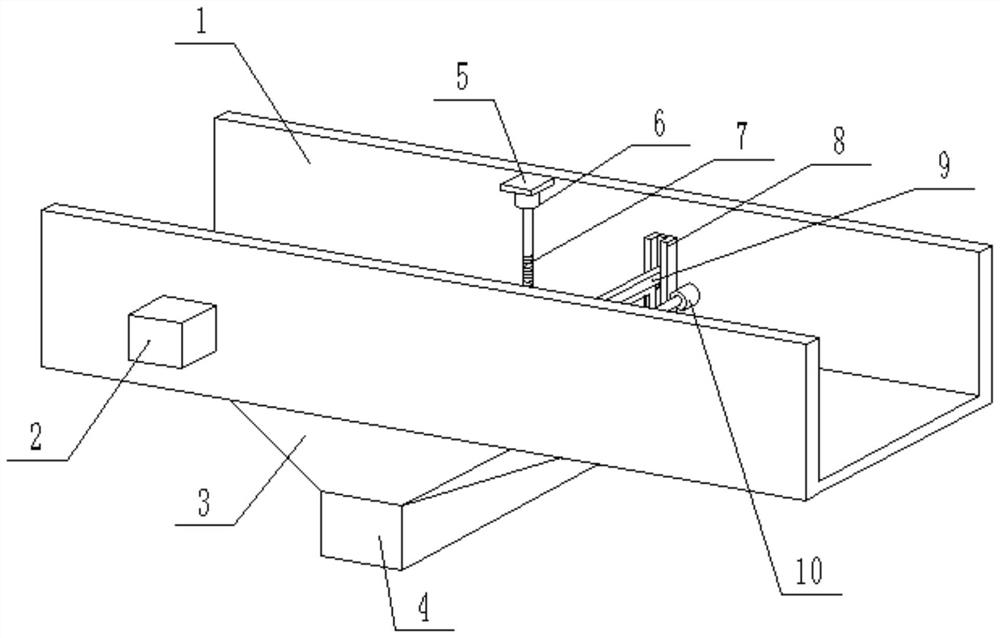

Lifting device controlling measuring head to move and be positioned on Z axis

InactiveCN103672328ARealize lifting movementAchieve positioningElectrical measurement instrument detailsElectrical testingRobotic armEngineering

The invention discloses a lifting device controlling a measuring head to move and be positioned on the Z axis. The lifting device comprises a base, a guide rail, a fixed pulley, a balancing weight and a steel wire tope. The guide rail is perpendicularly installed on the base along the Z axis, the fixed pulley is installed at the top end of the guide rail, the steel wire rope winds around the fixed pulley, one end of the steel wire rope is connected with the balancing weight, the other end of the steel wire rope is connected with a mechanical arm, and the mechanical arm is connected to the guide rail and moves along the guide rail. The lifting device further comprises an accurate adjustment mechanism composed of a gear, a rack, a gear shaft and a turning wheel handle. The lifting device controlling the measuring head to move and be positioned on the Z axis has the advantages that lifting motion and positioning of the measuring head on the Z axis are achieved, the moving position accuracy is accurately controlled, and the handle is easy and convenient to operate and control.

Owner:ACETEC SEMICON

Movable base for electromechanical equipment

The invention discloses a movable base for electromechanical equipment, and relates to the electromechanical technical field. The movable base comprises a bottom plate. The lower surface of the bottomplate is fixedly connected with the upper surfaces of two shells, and the two shells are located on the front side and the rear side of the lower surface of the bottom plate correspondingly. The lower surface of the bottom plate is fixedly connected with two rotating devices. The rotating devices are located in the shells. The bottom ends of the rotating devices are fixedly connected with the upper surface of a first bevel gear. The first bevel gear is engaged with a second bevel gear. The right side face of the second bevel gear is fixedly connected with the left end of an adjusting device.The adjusting device is connected to the right side faces of the shells in a clamped manner. According to the movable base for the electromechanical equipment, through the combined action of a handle,the shells, a second rotating shaft, a second bearing, the second bevel gear, the firs bevel gear, a threaded column, a threaded barrel and a second universal wheel, an electromechanical equipment body does not move any more, and therefore the movable base is more stable when used.

Owner:诸暨市谦谦公子建材经营部

Aluminum profile spraying production line

ActiveCN111013877ASolve efficiency problemsSolve problems that require human assistanceSpray boothsRotational axisManufacturing line

The invention discloses an aluminum profile spraying production line which comprises a conveying device, a spraying device and a plurality of clamping devices. The conveying device comprises a rack, arotary disc arranged above the rack and a rotary block. The clamping device is positioned on the rotary disc; each clamping device comprises a transmission block, a clamping block and a driving block; the transmission block comprises a rotating shaft, an eccentric wheel, a connecting arm, a vertically-arranged connecting shaft and a rotating sleeve set; the rotary sleeve set comprises a fixed sleeve and a rotary sleeve; and threads are arranged on the outer wall of the rotary sleeve around the peripheral side of the rotary sleeve. A rack block is arranged on the rack along the guiding direction of a guide rail; the rack block is in engaged connection with the threads of the rotary sleeve; the end, away from the connecting arm, of the connecting shaft extends outwards in the circumferential direction to form an abutting block. The clamping block comprises a clamping mechanism and a mounting block. The problems that a clamping device is single in function and cannot adapt to aluminum profiles of various sizes, the efficiency is low in the spraying process, and manual assistance is needed are effectively solved. The spraying device further has the advantages of being high in automation level, good in spraying effect and high in practicability.

Owner:佛山市三水凤铝铝业有限公司 +1

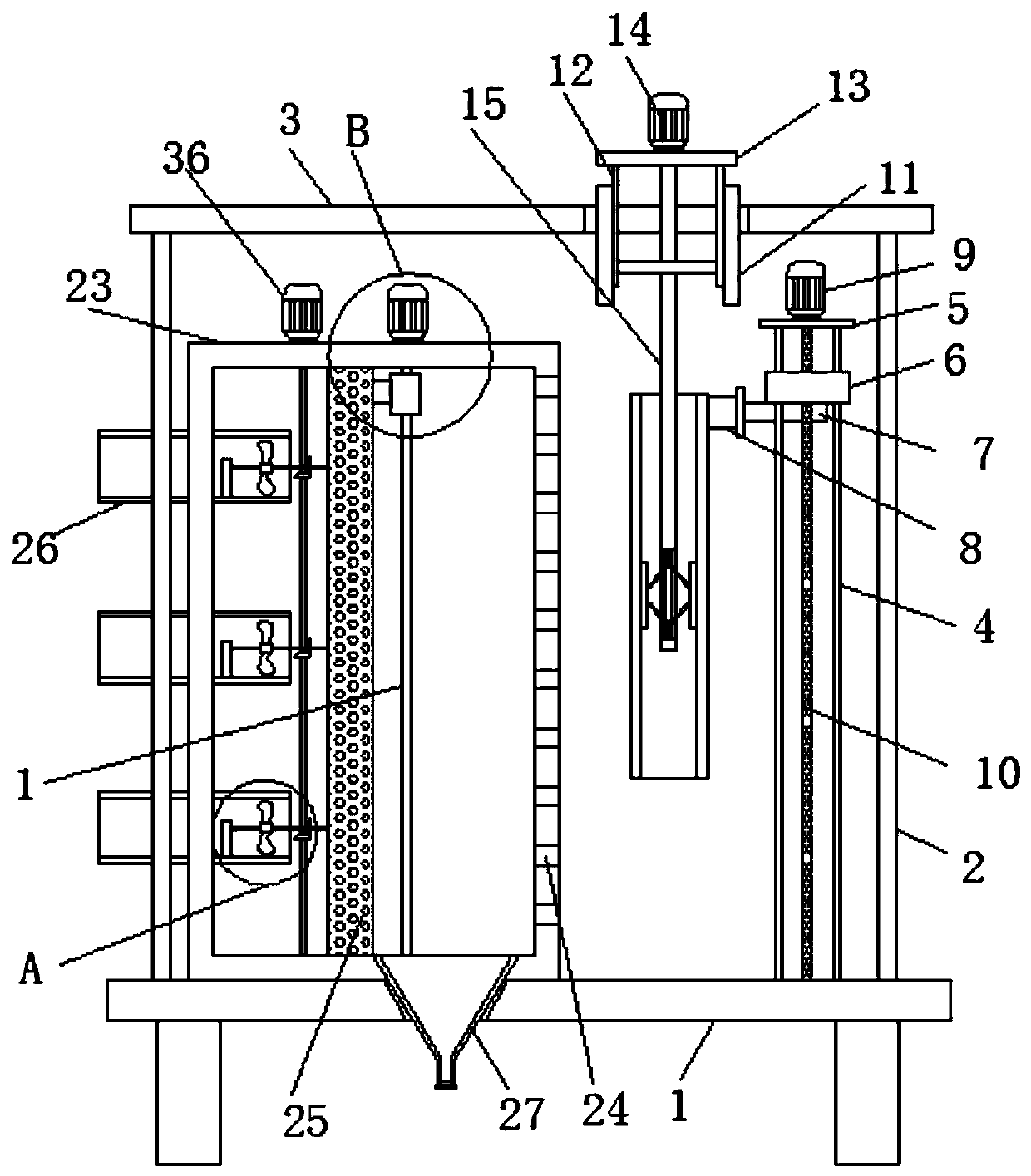

Novel filling machine and filling method thereof

PendingCN111620287ARealize automatic fillingRealize lifting movementLiquid bottlingEconomic benefitsProcess engineering

The invention discloses a novel filling machine and a filling method thereof. The filling machine comprises a rack, wherein a filling device, an intercepting and positioning device and a conveying device are mounted on the rack; the filling device is erected above the conveying device; the intercepting and positioning device is arranged between the filling device and the conveying device; the conveying device is used for conveying filling bottles; the intercepting and positioning device is used for intercepting and positioning the filling bottles conveyed by the conveying device; and the filling device is used for synchronously filling, transferring and weighing the filling bottles. According to the novel filling machine and the filling method thereof, the filling bottles are filled in thetransferring process of a translation assembly, a filling nozzle adopts a filling mode that first-stage filling is matched with second-stage filling, so that the filling efficiency is further improved, then the filling bottles which are filled simultaneously are transferred to a second conveying belt through the translation assembly, the production time difference is fully utilized, the filling efficiency is greatly improved, the production cost is reduced, and the economic benefit is good.

Owner:广州市冠浩机械设备有限公司

Water environment sampling device

PendingCN111811886ARealize lifting movementWithdrawing sample devicesWater environmentMechanical engineering

The invention provides a water environment sampling device. The device comprises a device body, an extension assembly, sampling parts, a sampling pipe and a treatment assembly, wherein the extension assembly is mounted on the device body; the plurality of sampling parts can be arranged at different positions on the extension assembly and are used for collecting different water samples; the treatment assembly is arranged on the device body, the treatment assembly is connected with the sampling parts through the sampling pipe, and the treatment assembly can wind or stretch the sampling pipe, sothat the sampling parts can ascend and descend on the extension assembly, and then the water samples with different depths are collected. Generally speaking, the water environment sampling device canrealize simultaneous collection of multiple water samples at one time.

Owner:吕品 +2

Automatic cigarette catching device of cigarette storage device

ActiveCN105639721AAvoid Work InjuryRealize lifting movementCigarette manufactureDrive wheelEngineering

The invention discloses an automatic cigarette catching device of a cigarette storage device. The automatic cigarette catching device comprises two side plate machine frames oppositely arranged. Two organic glass panels are oppositely arranged in the direction perpendicular to the side plate machine frames. A guide rail groove is formed in the middle of each organic glass panel from bottom to top. A movable splitter is arranged between the two organic glass panels and comprises a mini-type cylinder. One end of a cylinder connection rod arranged on the mini-type cylinder is connected with two connection supporting rods in a rotating mode. The two connection supporting rods are connected with two supporting plate assemblies rotating around the same axis respectively. A set of driven wheels are arranged on the movable splitter and supported by the inner sides of the organic glass panels. Driven wheels are connected with driving wheels supported by the outer sides of the organic glass panels through a connection frame. The automatic cigarette catching device is simple in structure, the automatic cigarette catching action can be achieved, it is avoided that cigarettes are prone to falling when caught manually through supporting plates or occupational injuries possibly happen in the manual cigarette catching process.

Owner:ANHUI YITONG MACHINERY

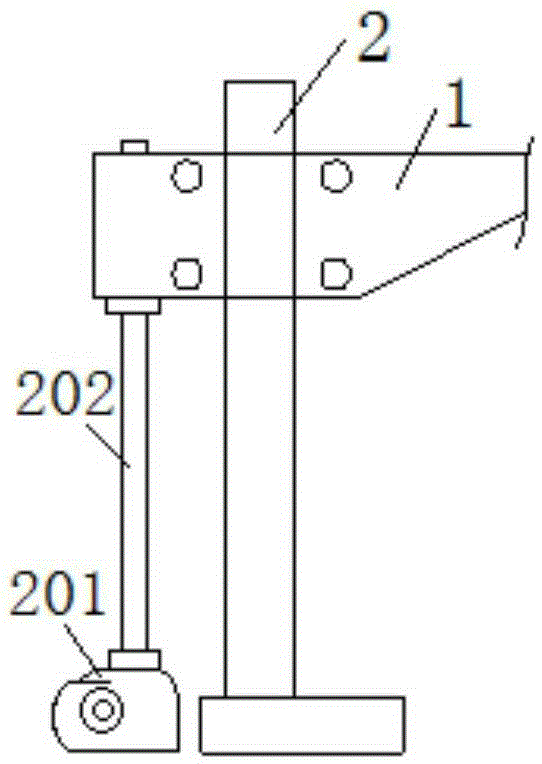

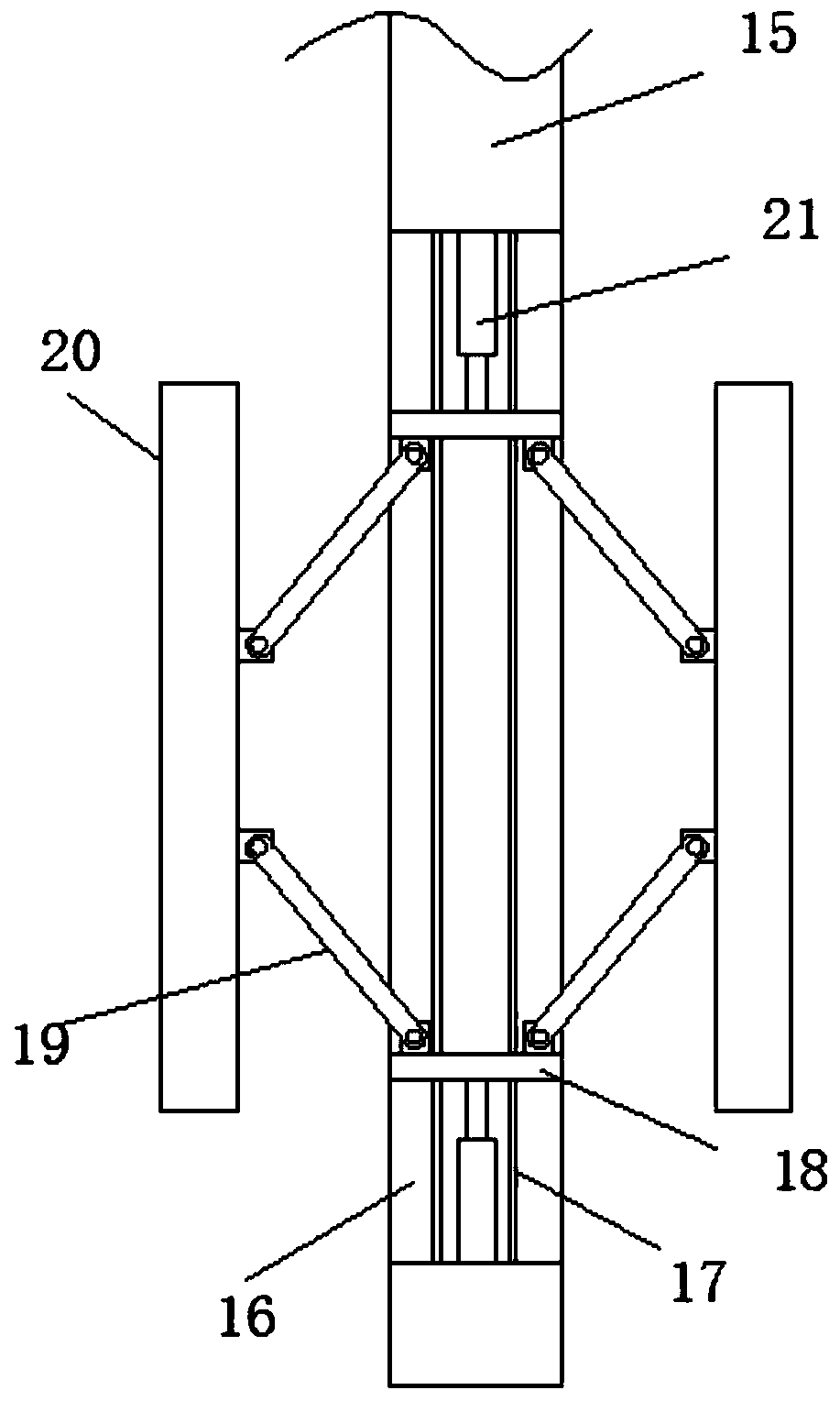

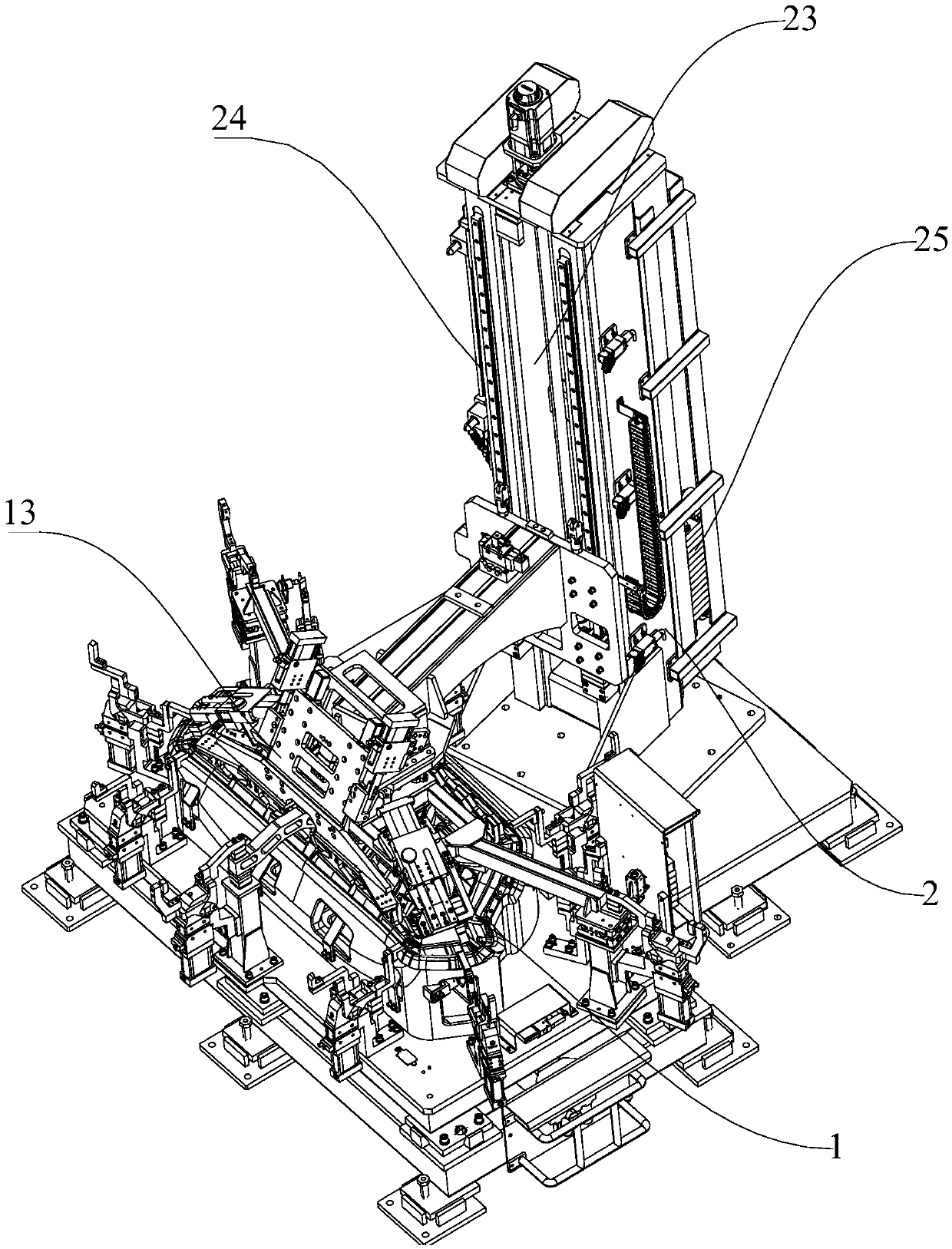

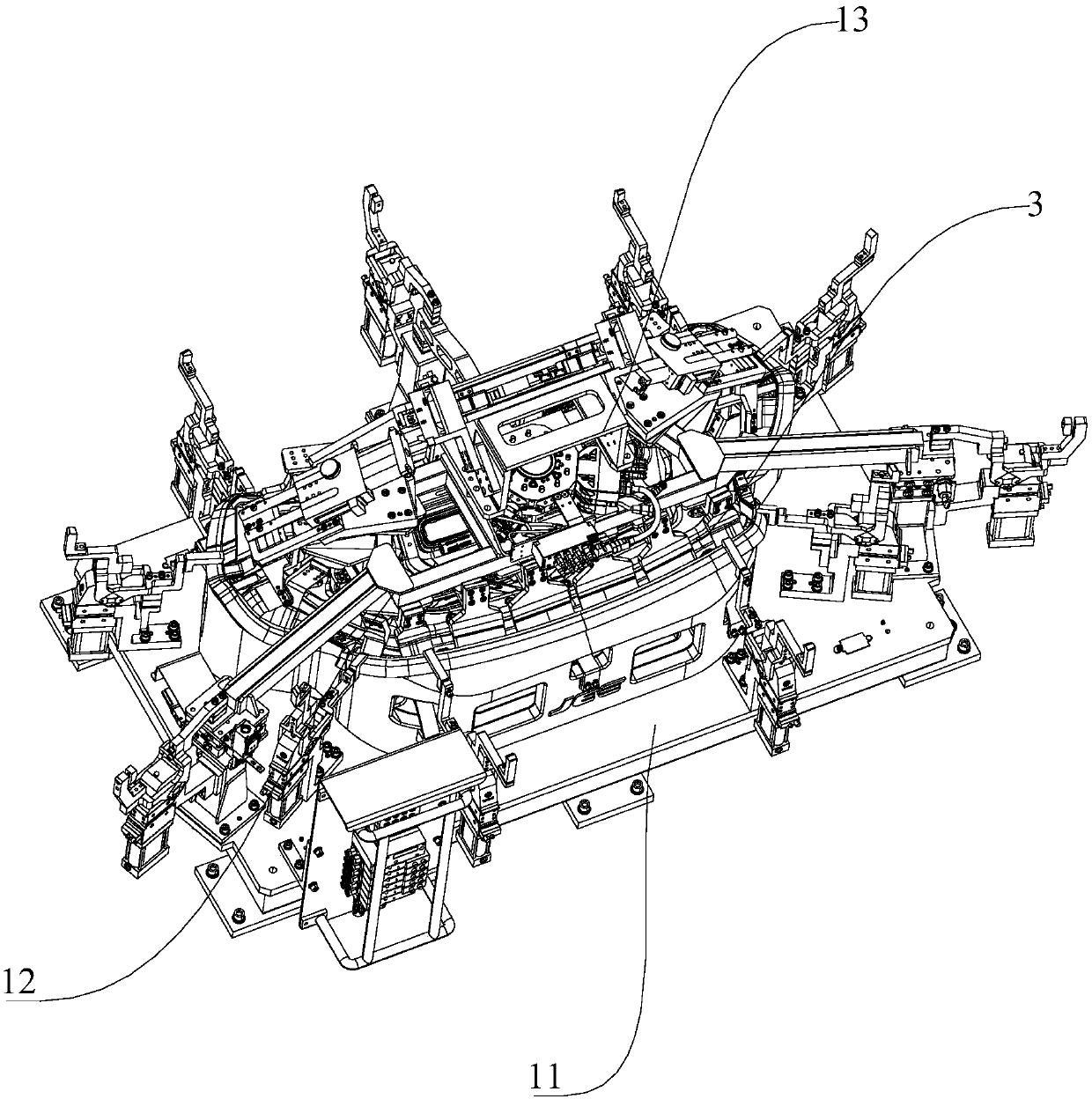

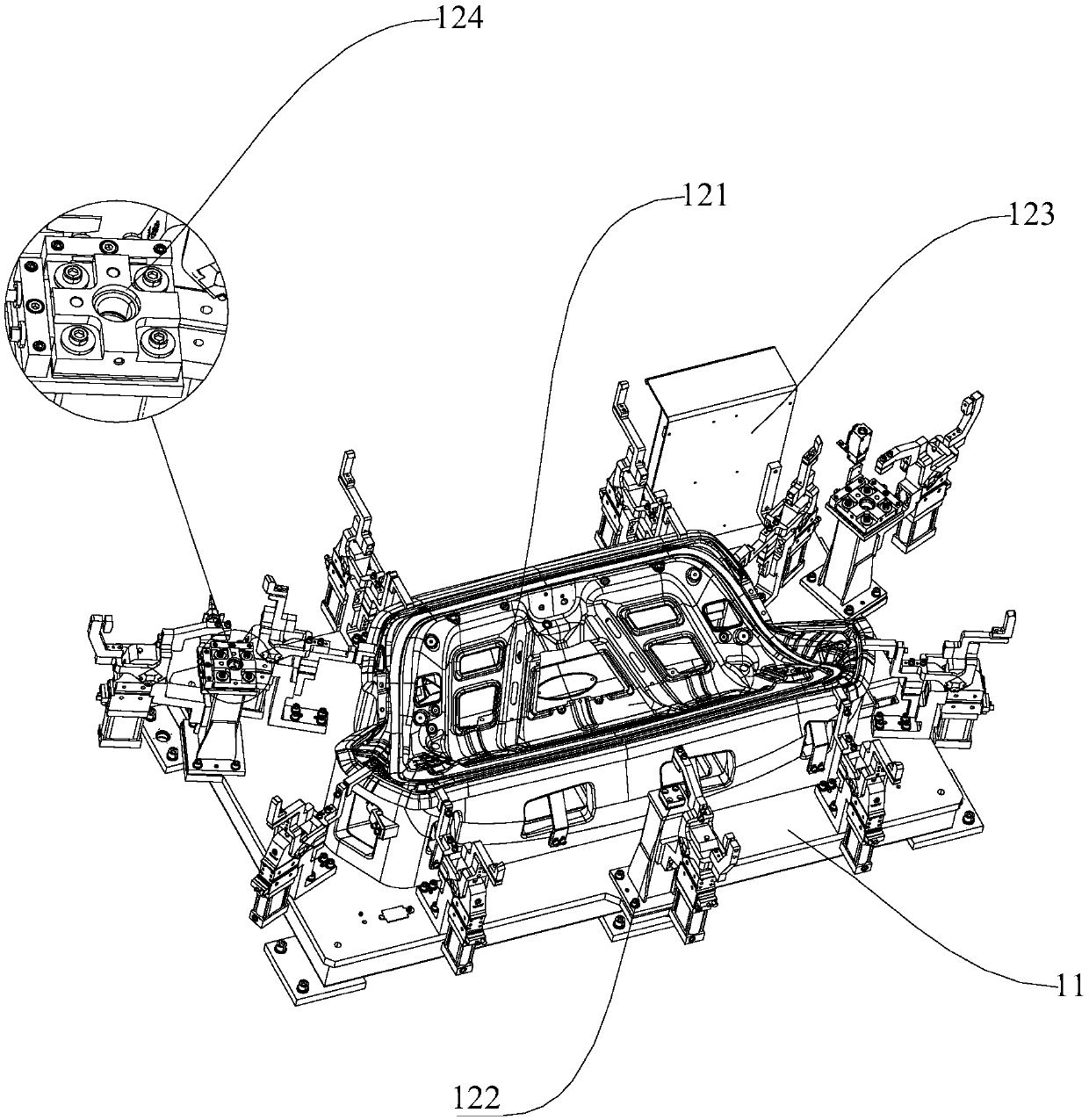

Robot roller hemming bed fixture with lifting mechanism

PendingCN109513838ARealize lifting movementSimple structureMetal-working feeding devicesPositioning devicesWeldingRobot

The invention relates to the field of automobile welding fixtures and provides a robot roller hemming bed fixture with a lifting mechanism. The robot roller hemming bed fixture comprises a roller hemming fixture and the lifting mechanism, wherein the roller hemming fixture comprises a BASE framework, a clamping hemming bed component and a positioning gripper; the clamping hemming bed component ismatched with a workpiece outer plate and used for compressing the workpiece outer plate; the positioning gripper is matched with a workpiece inner plate and used for fixing the workpiece inner plate onto the workpiece outer plate; the lifting mechanism comprises a mounting base, a lifting framework, a lifting device, a positioning device, a counterweight and a connecting framework which is connected with the positioning gripper; the lifting framework is vertically arranged on the mounting base; the positioning device and the lifting device are arranged at the front end of the lifting framework; and the counterweight is mounted at the lateral lower end of the lifting framework. The robot roller hemming bed fixture provided by the invention has the advantages that the structure is simple; the use is convenient; and the positioning gripper is driven by the lifting mechanism to rise and fall, so that the transportation of the positioning gripper can be achieved.

Owner:安徽双骏智能科技有限公司

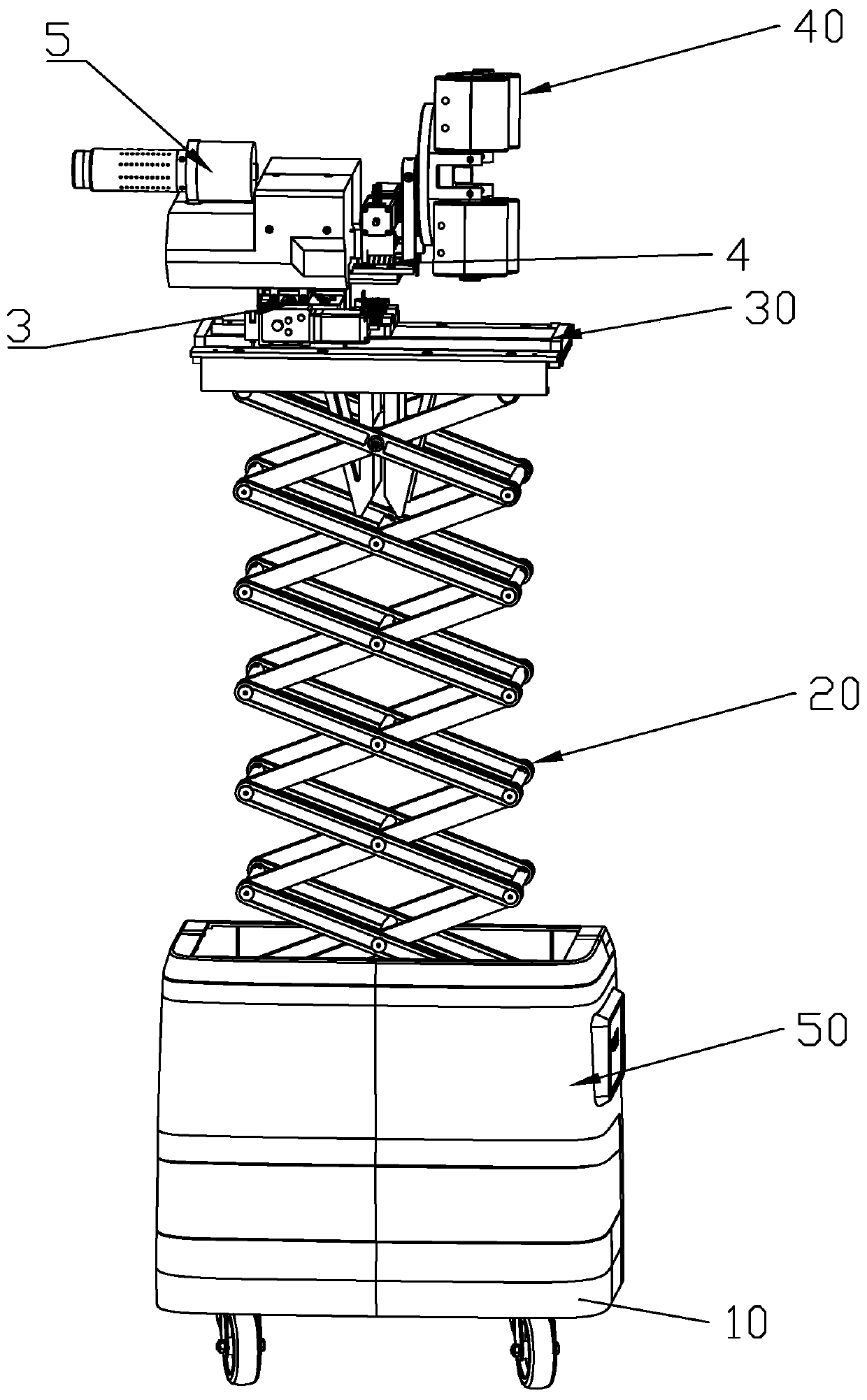

Slave machine detection structure of inspection robot

ActiveCN110411511ASimple structureEasy to operateTesting dielectric strengthRegistering/indicating working of machinesAgricultural engineeringEddy-current sensor

The invention discloses a slave machine detection structure of an inspection robot. The slave machine detection structure comprises a slave machine bottom shell, a shear type adjusting structure of apartial discharge detector, a detection and adjustment structure of the partial discharge detector and an adjusting structure of an eddy current sensor; the partial discharge detector is arranged on the slave machine bottom shell; the shear type adjusting structure is connected with the detection and adjustment structure of the partial discharge detector; the detection and adjustment structure ofthe partial discharge detector is provided with the adjusting structure of the eddy current sensor; the slave machine bottom shell is provided with a controller; the controller is fixed on the side wall of the slave machine bottom shell; the controller is electrically connected with a plurality of sensors, a power source and a motor; and the controller controls corresponding motors to drive the corresponding scissor type adjusting structure, the detection and adjustment structure of the partial discharge detector and the adjusting structure of the eddy current sensor to work according to sensing signals transmitted by the sensors. The slave machine detection structure has the advantages of simple structure, scientificity, convenience, high pertinency, convenience in use, low cost, simplicity in operation and easiness in popularization.

Owner:HANGZHOU SHENHAO TECH

Water diversion structure of water conservancy and hydropower engineering

InactiveCN113373872ARealize lifting movementEasy to operateArtificial water canalsMoving filtering element filtersWater diversionElectric control

The invention discloses a water diversion structure of water conservancy and hydropower engineering. The water diversion structure comprises a water diversion channel, an electric control box is arranged on the outer side wall of the water diversion channel, the lower end of the water diversion channel is connected with a connecting channel, the connecting channel is of a big-end-up funnel-shaped structure, the lower end of the connecting channel is connected with a storage box, and a filter box is arranged in the storage box; the front and rear sides of the filter box are fixedly connected with connecting plates, and a lifting mechanism is arranged outside the filter box; and a baffle net is arranged on the bottom surface of the filter box, a movable door is arranged on one side surface of the filter box, one side of the movable door is movably connected with the inner wall of the filter box, and a scraping device is arranged at the upper end of the baffle net. According to the water diversion structure of the water conservancy and hydropower engineering, dirt can be effectively filtered, meanwhile, the dirt existing in the water diversion structure is convenient to clear, in addition, a filter net and a stop net adopted for filtering in the device are convenient to replace and install, and convenience is brought to operation.

Owner:李树山

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com