Horizontal lifted underwater robot driven by temperature differential energy

An underwater robot and vertical lifting technology, applied to underwater ships, underwater operating equipment, motor vehicles, etc., can solve problems such as limited operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

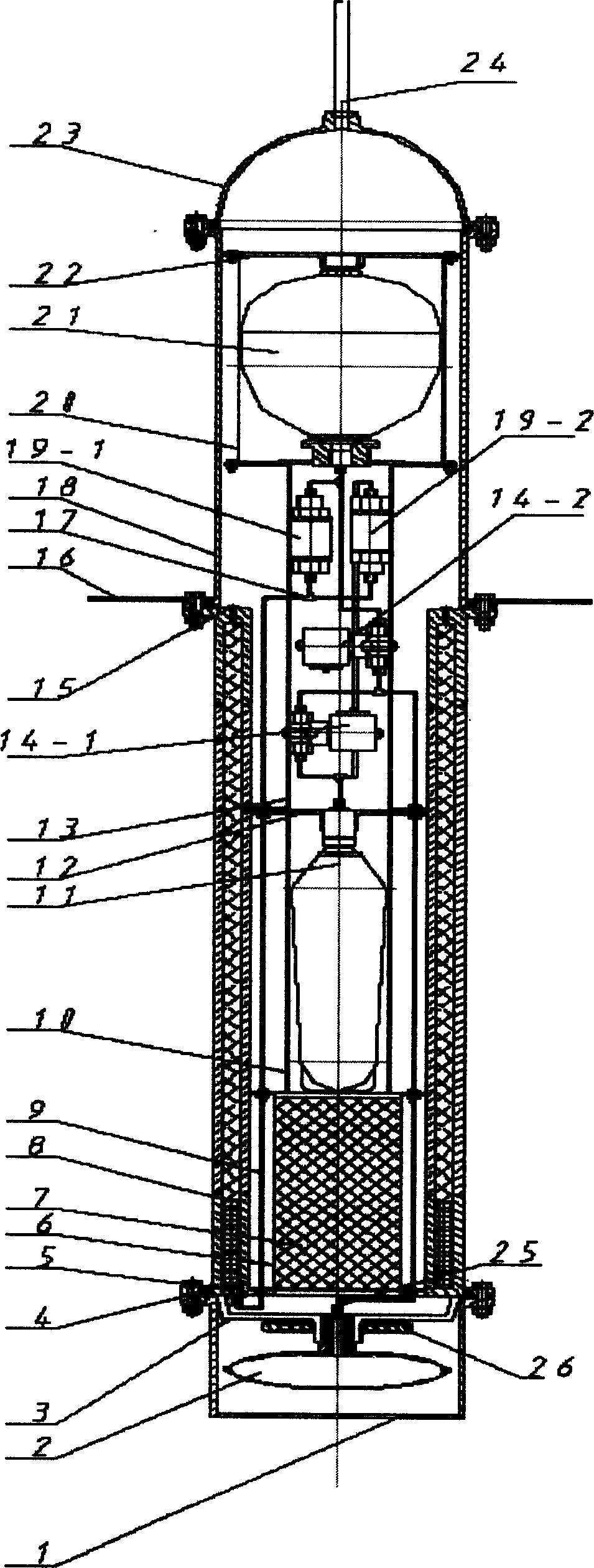

[0008] The structural principles of the present invention will be further described below through embodiments and with reference to the accompanying drawings. The pressure-resistant and sealed part of the underwater robot is composed of an outer skin bag protection shell 1, a sealed chassis 3, a heat engine working chamber 8, and a sealed cylindrical shell 18, and the parts are sealed by O-ring seals. For this embodiment, the accumulator 21 is a diaphragm accumulator with a working volume of 2L and a working pressure of 10Mpa. The working pressure of solenoid valve 14 and check valve 19 is 1.5Mpa. The thermal engine working chamber 8 of the underwater robot mainly plays a sealing role as a part of the pressure-resistant shell. In this embodiment, the temperature difference driven vertical lift underwater robot is designed to work in a water depth of 100 meters, with a water surface temperature of 20°C and a water depth of 100 meters with a temperature of about 10°C. The work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com