Patents

Literature

2437 results about "Heat engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In thermodynamics and engineering, a heat engine is a system that converts heat or thermal energy—and chemical energy—to mechanical energy, which can then be used to do mechanical work. It does this by bringing a working substance from a higher state temperature to a lower state temperature. A heat source generates thermal energy that brings the working substance to the high temperature state. The working substance generates work in the working body of the engine while transferring heat to the colder sink until it reaches a low temperature state. During this process some of the thermal energy is converted into work by exploiting the properties of the working substance. The working substance can be any system with a non-zero heat capacity, but it usually is a gas or liquid. During this process, a lot of heat is lost to the surroundings and so cannot be converted to work.

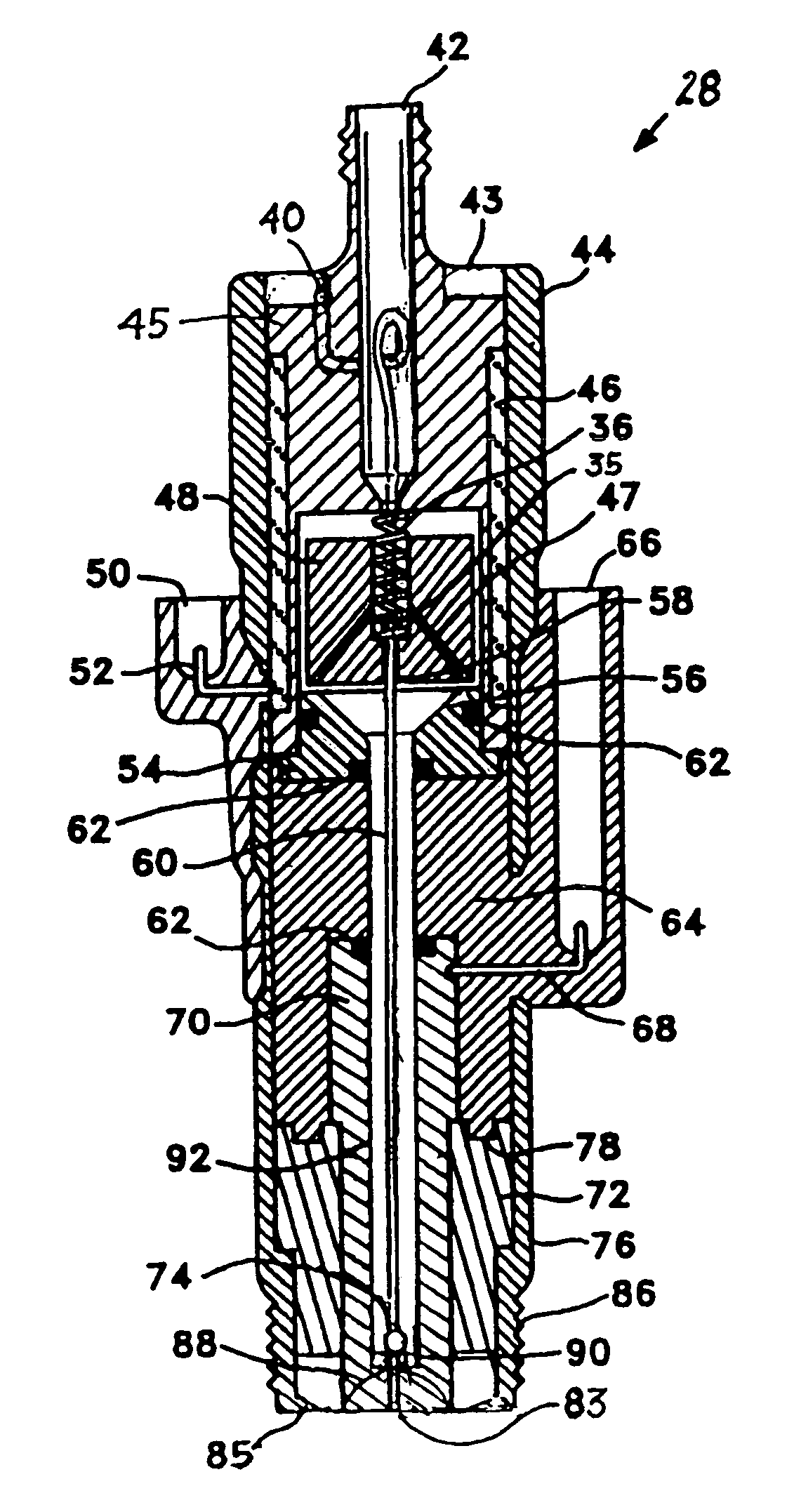

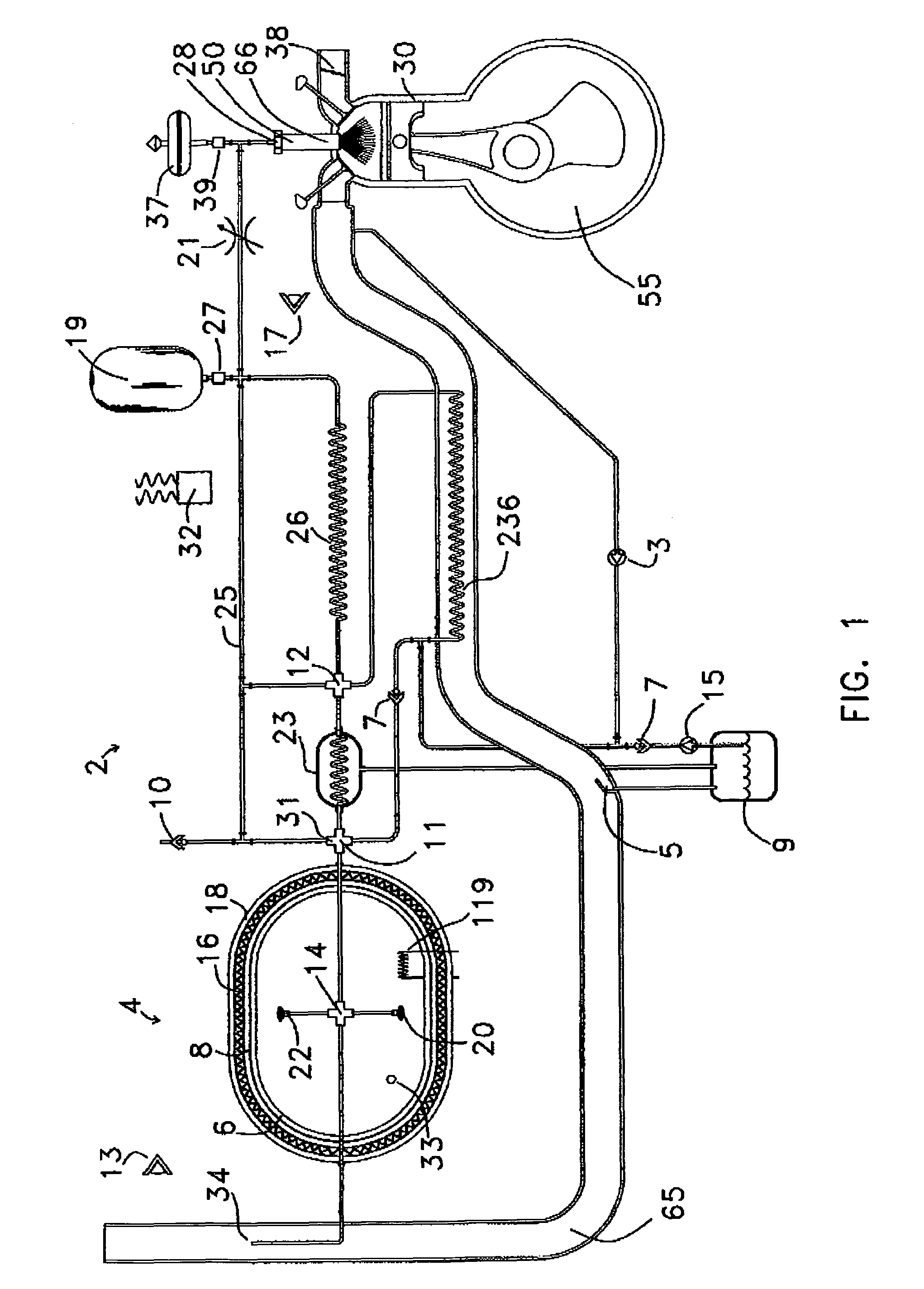

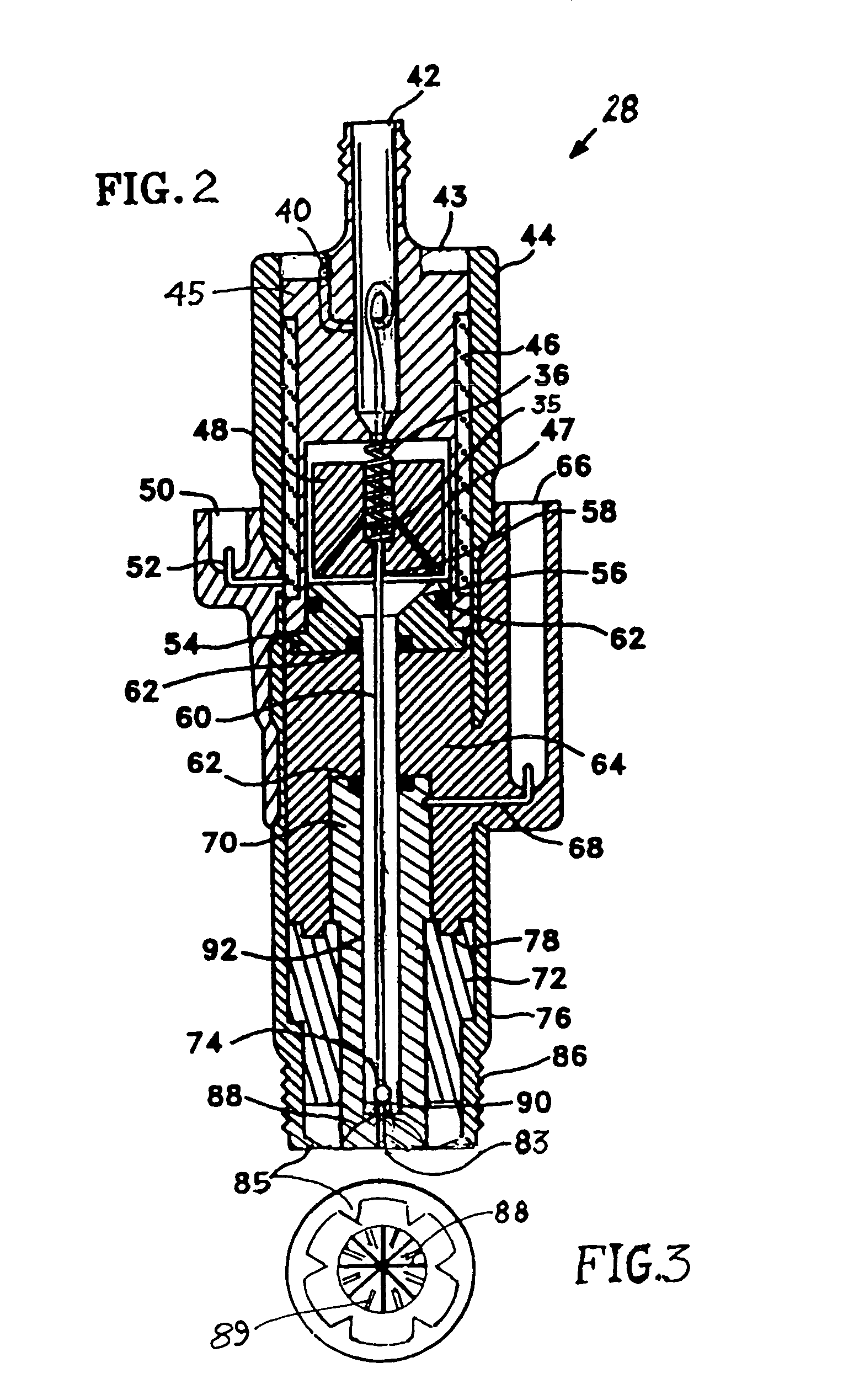

Multifuel storage, metering and ignition system

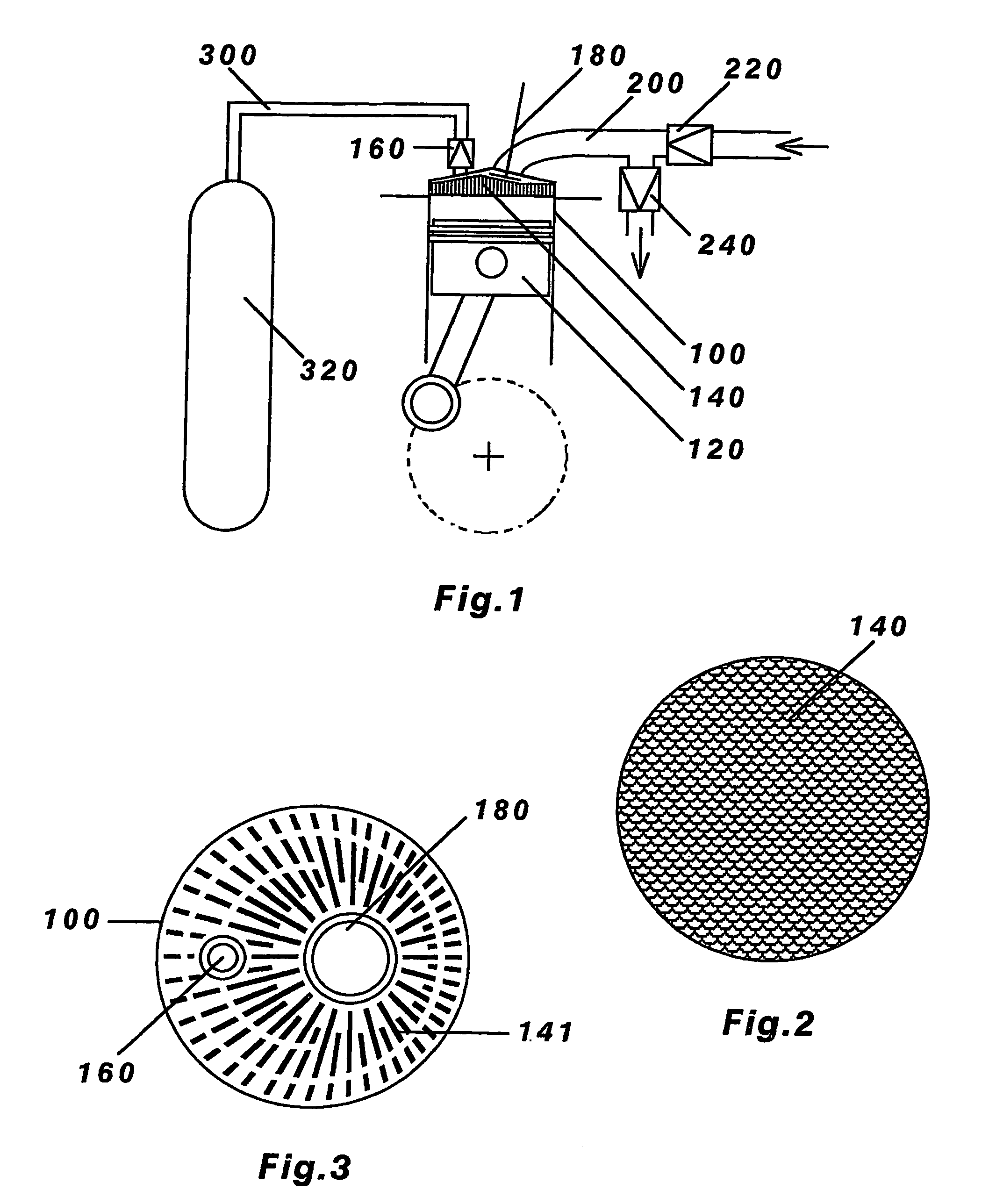

A system for safe storage and efficient utilization of a variety of fuel selections that range in composition and phase from cryogenic mixtures of solids and liquids to elevated temperature gases is provided for unique applications with various types of heat engines and fuel cells including hybridized combinations.

Owner:ADVANCED GREEN INNOVATIONS LLC +1

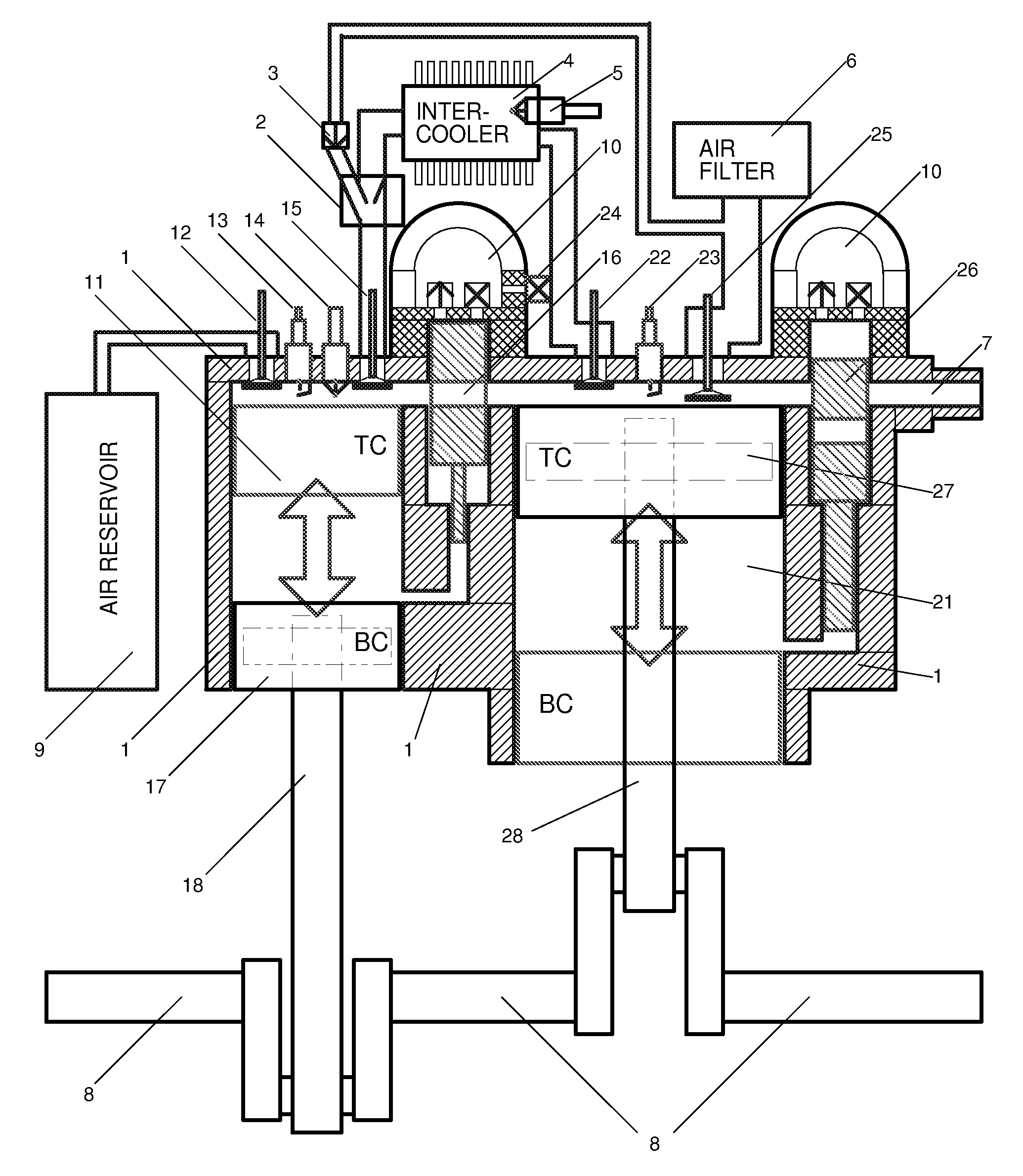

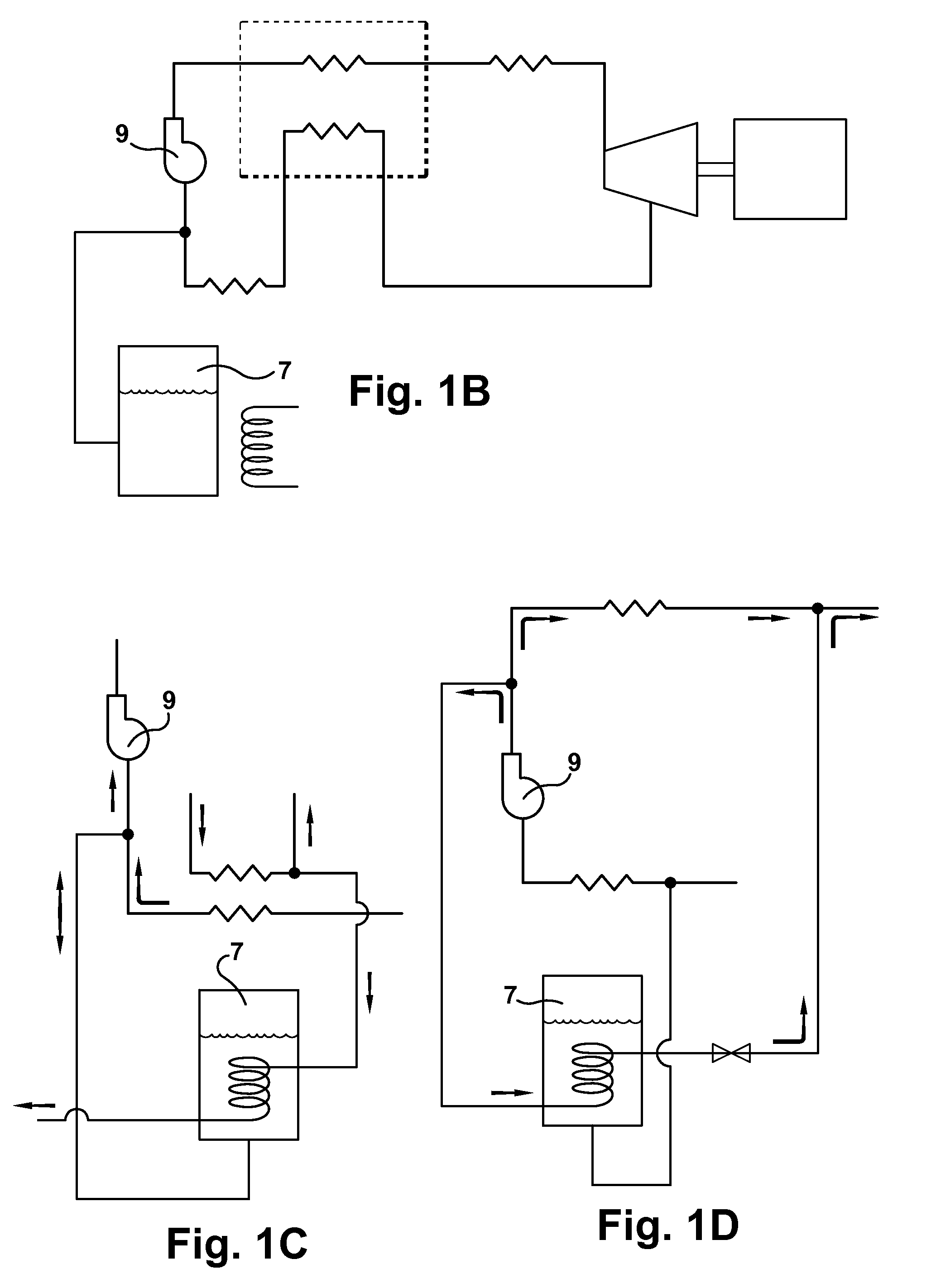

Isothermal reciprocating machines

InactiveUS20060248886A1High materialIncrease heating capacityPositive displacement pump componentsMulti-stage pumpsWorking fluidGas compressor

A reciprocating gas compressor is described operating according to an extended cycle of 4,6 or more strokes, wherein the first two strokes are sequential induction and compression strokes using a low pressure gas as working fluid and compressing it to a high pressure gas, and the remaining strokes are pairs of sequential filling and emptying strokes using more of the low pressure gas as heat transfer fluid for transferring heat from inside the gas compressor to outside the gas compressor. The gas compressor also contains an in-cylinder heat regenerator for absorbing heat from the compressed gas and releasing heat to the heat transfer fluid thus achieving near-isothermal compression. Using parallel principles, a reciprocating gas expander is also described for achieving near-isothermal expansion. Also described are reciprocating machines using the near-isothermal gas compressor and near-isothermal gas expander in combination according to the Ericsson heat engine cycle, the Stirling heat engine cycle and the Stirling refrigeration cycle.

Owner:MA THOMAS TSOI HEI

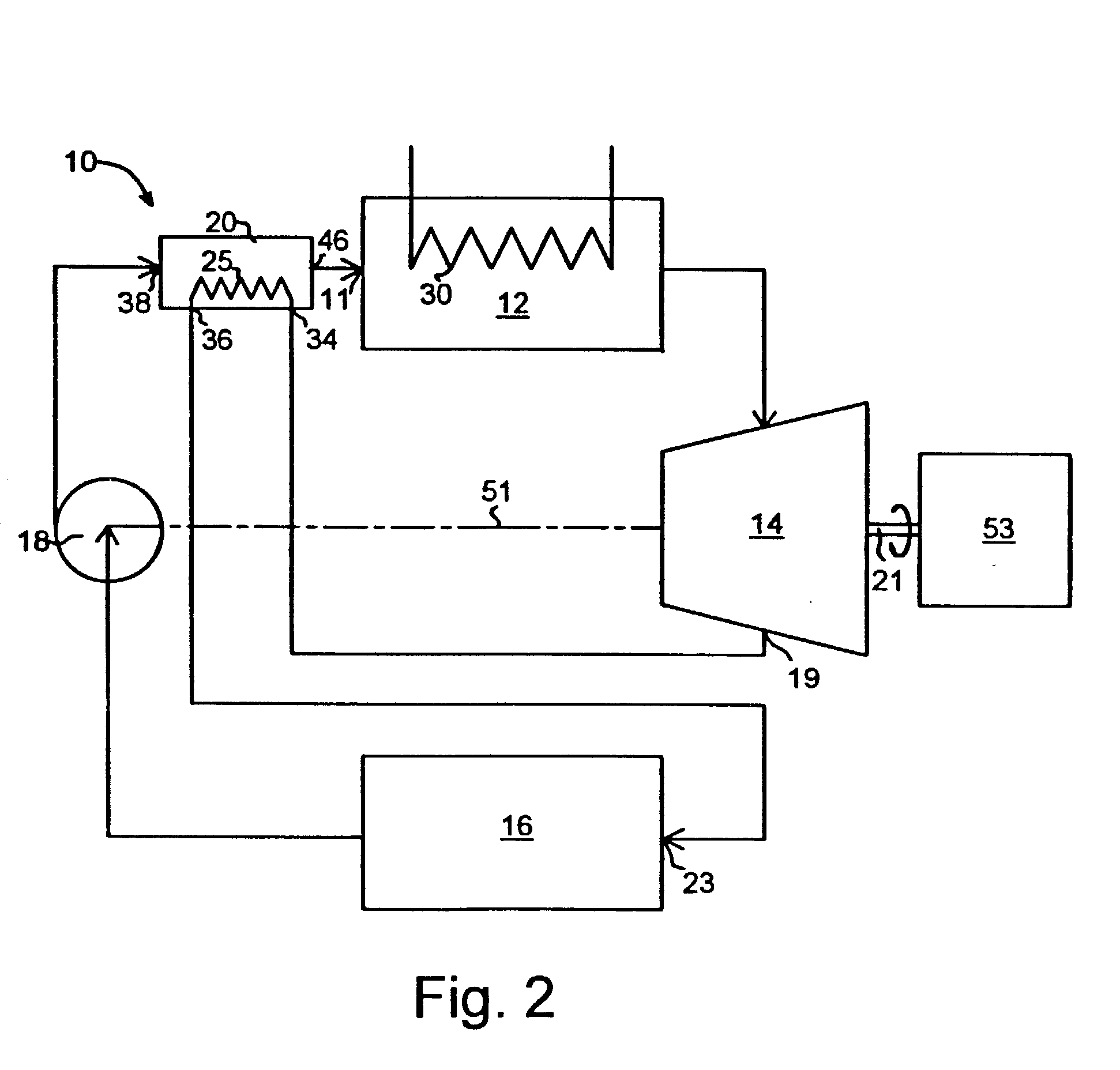

Heat engine

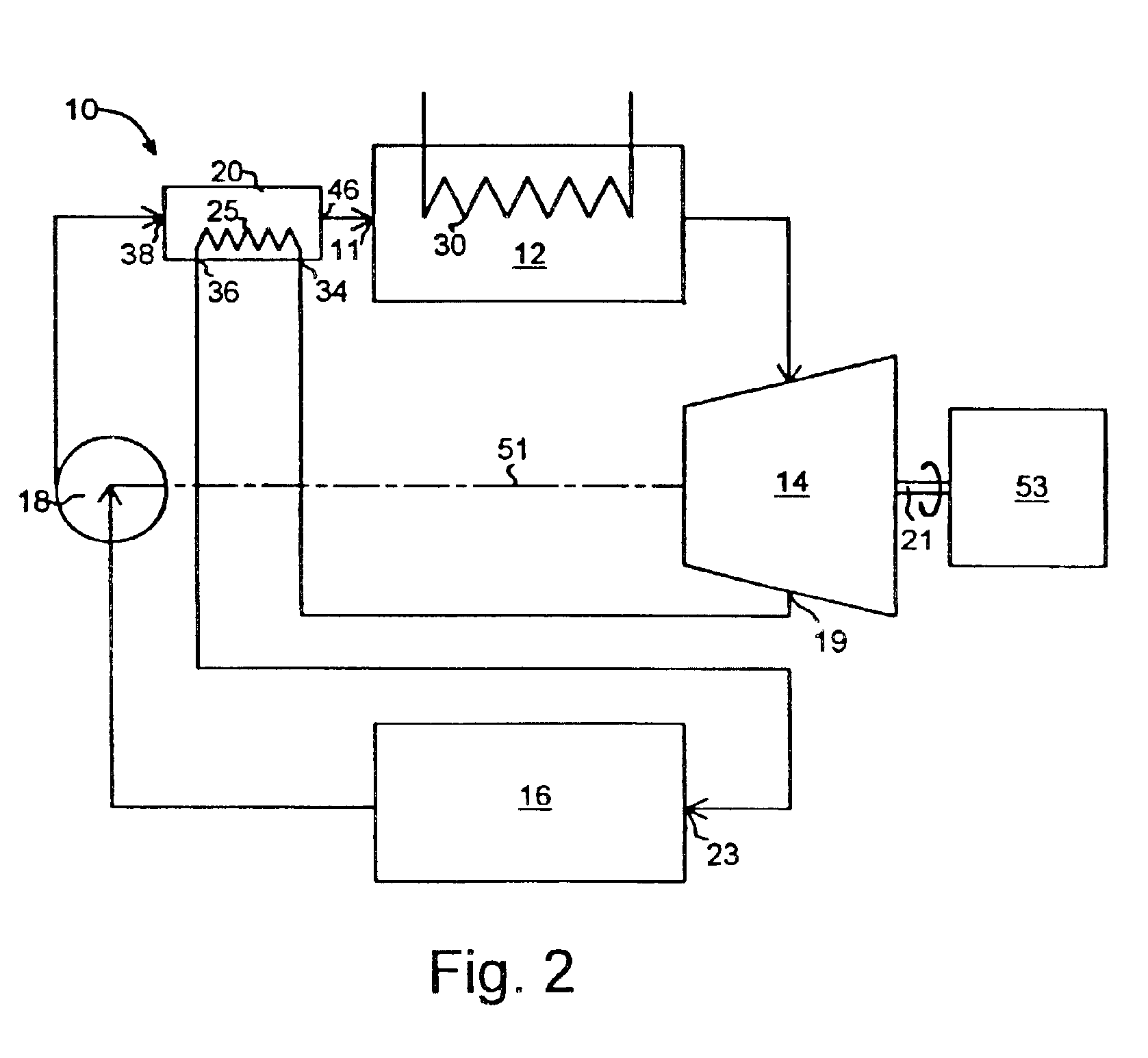

InactiveUS20030000213A1Easy to operateBoilers/analysersClimate change adaptationWorking fluidEngineering

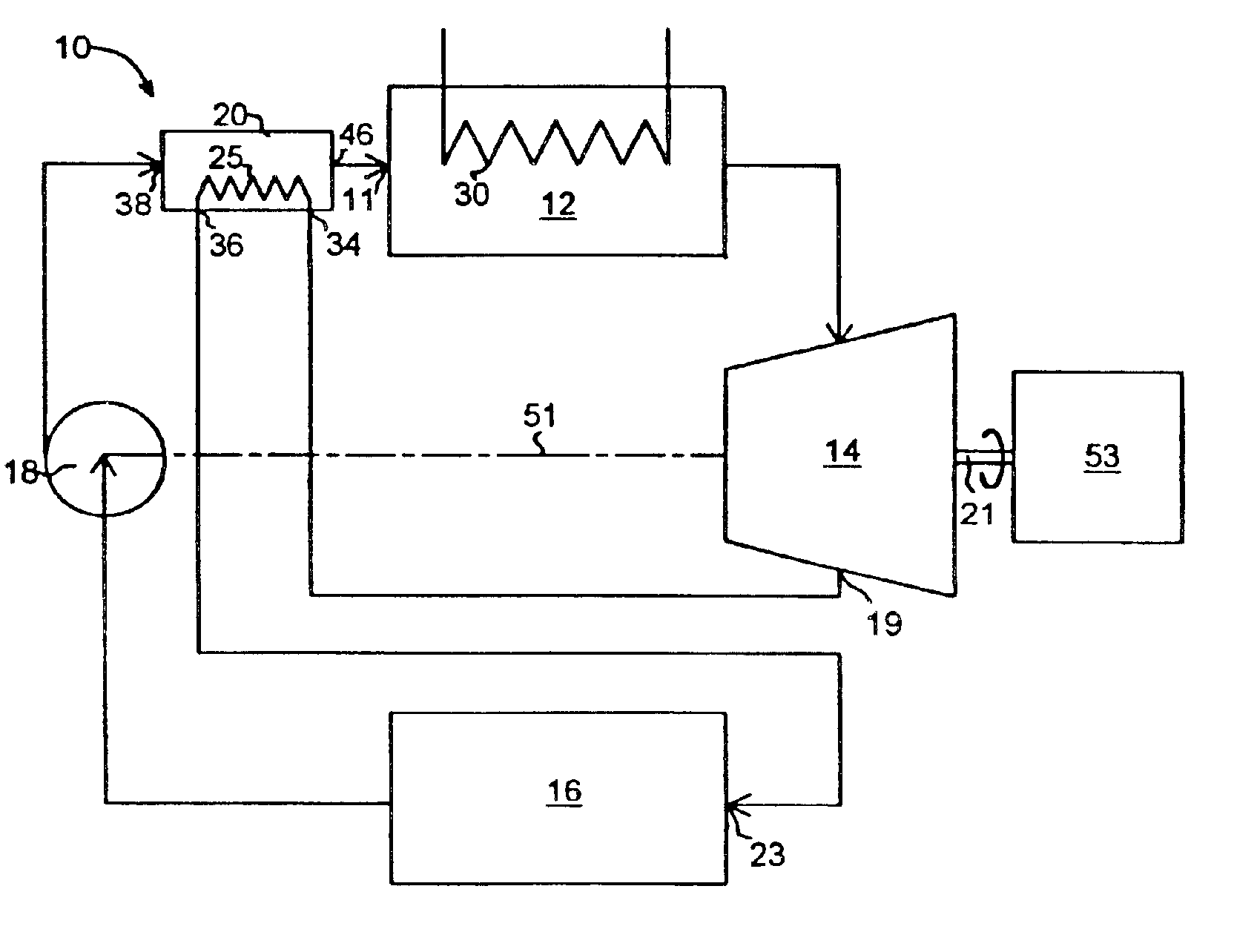

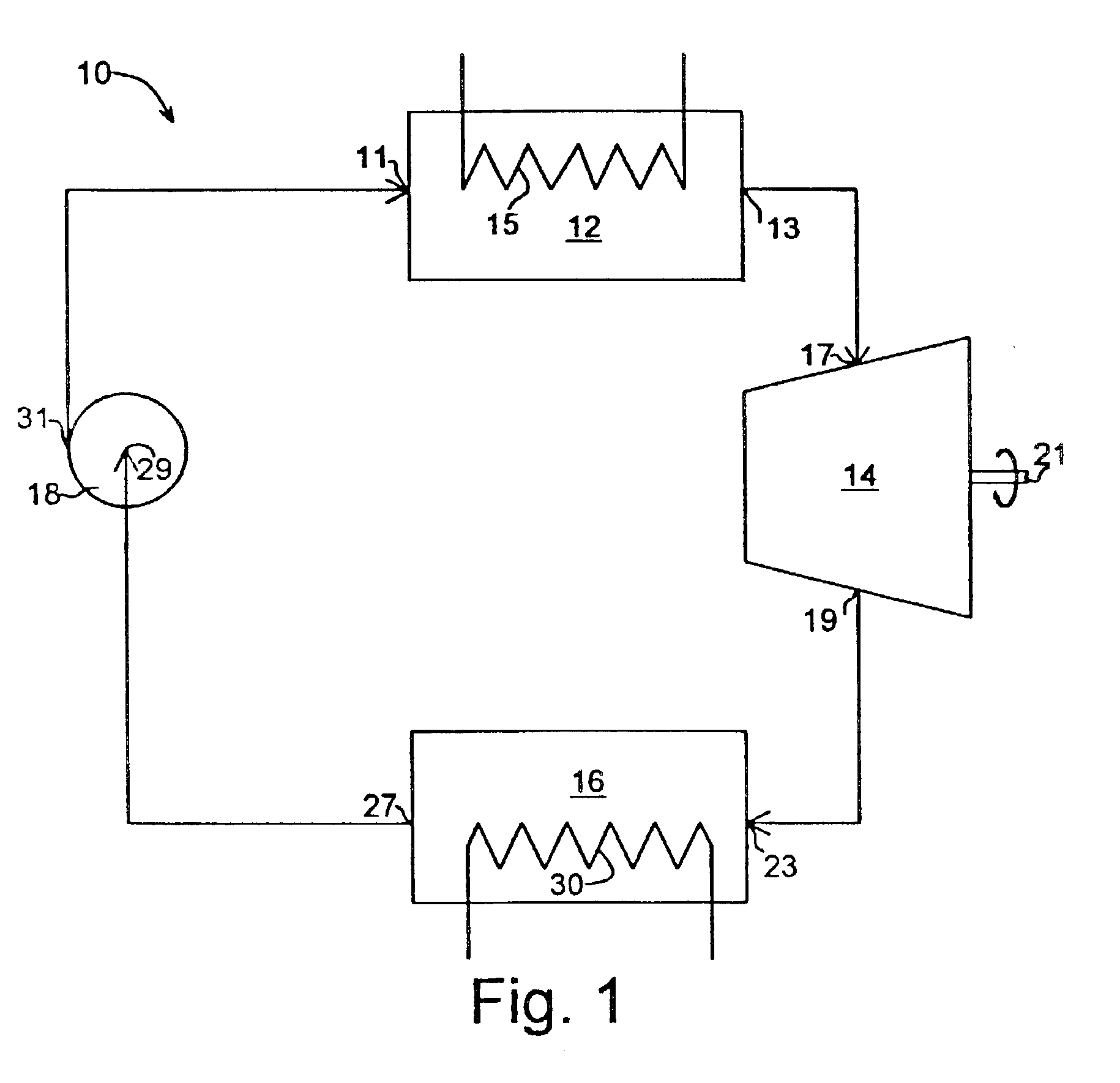

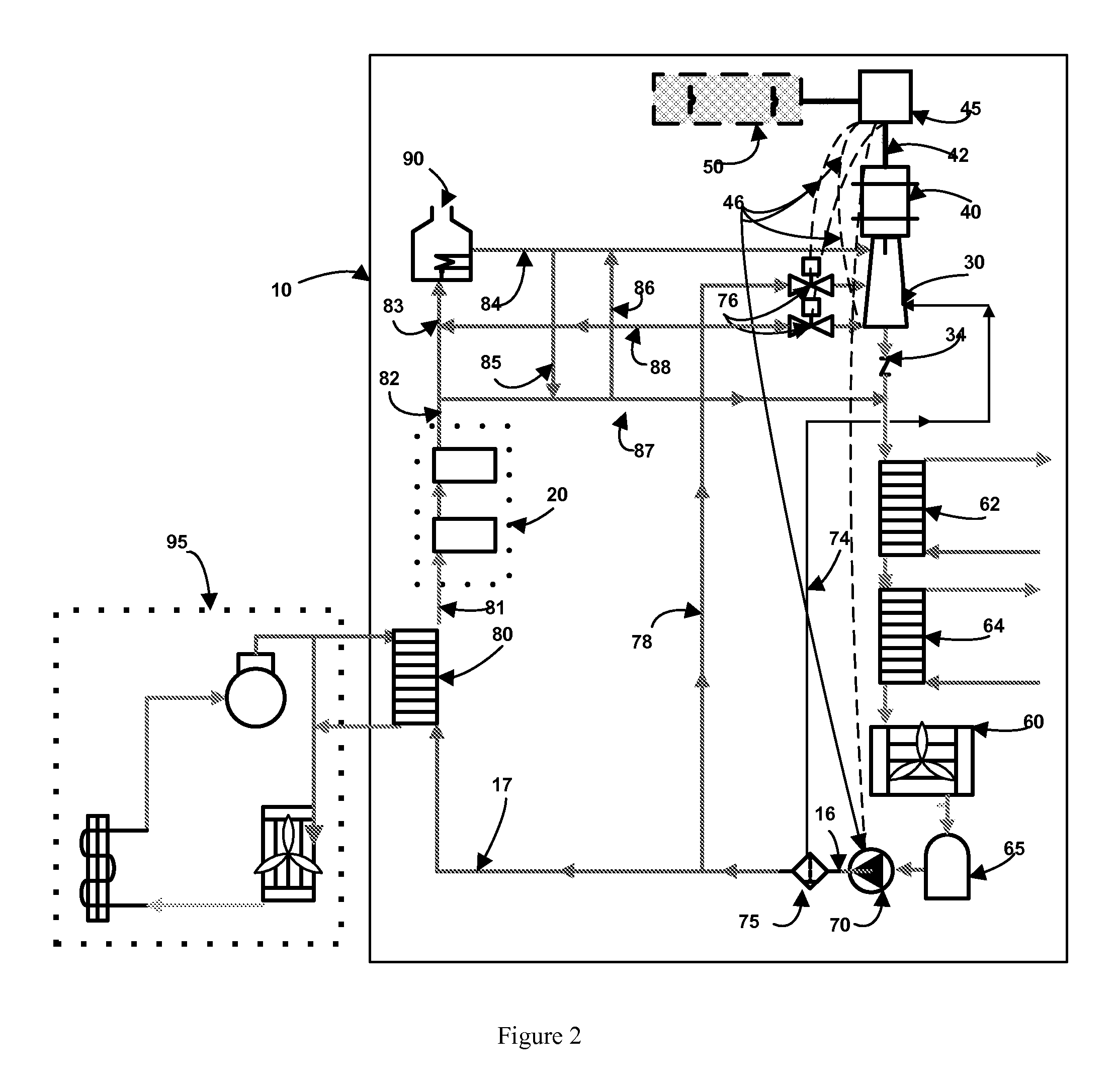

A heat engine (10) achieves operational efficiencies by: 1) recovering waste heat from heat engine expander (14) to preheat heat-engine working fluid, 2) using super-heated working fluid from compressor (402) to pre-heat heat-engine working fluid, and 3) using reject heat from condenser (93) and absorber (95) to heat the heat-engine boiler (12). A dual heat-exchange generator (72) affords continuous operation by using gas-fired heat exchanger (212) to heat generator (72) when intermittent heat source (40), e.g., solar, is incapable of heating generator (72). The combination of heat engine (10) and absorption and compression heat transfer devices (60, 410) allows use of low-temperature heat sources such as solar, bio-mass, and waste heat to provide refrigeration, heating, work output including pumping and heating of subterranean water and electrical generation.

Owner:OHIO STATE INNOVATION FOUND

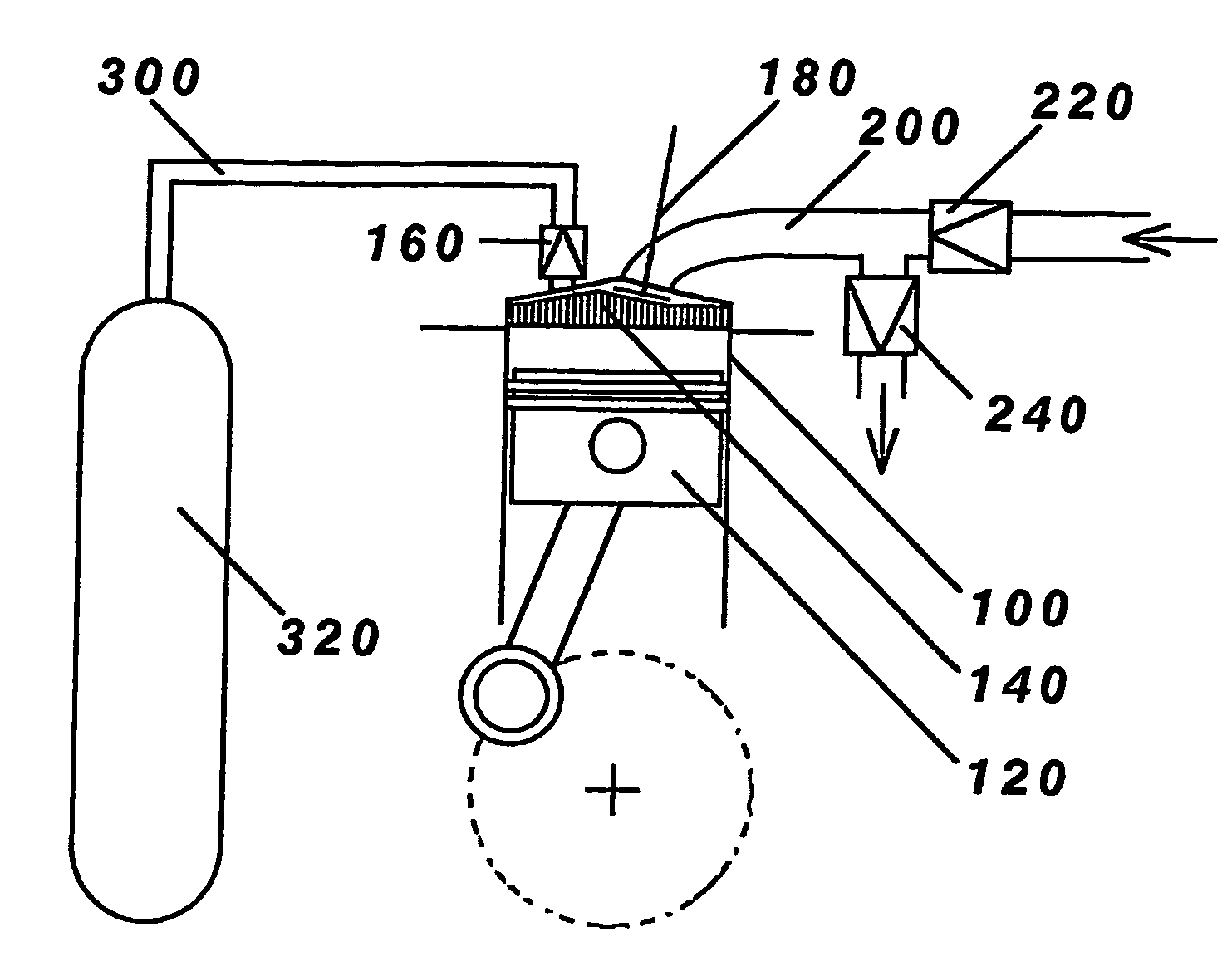

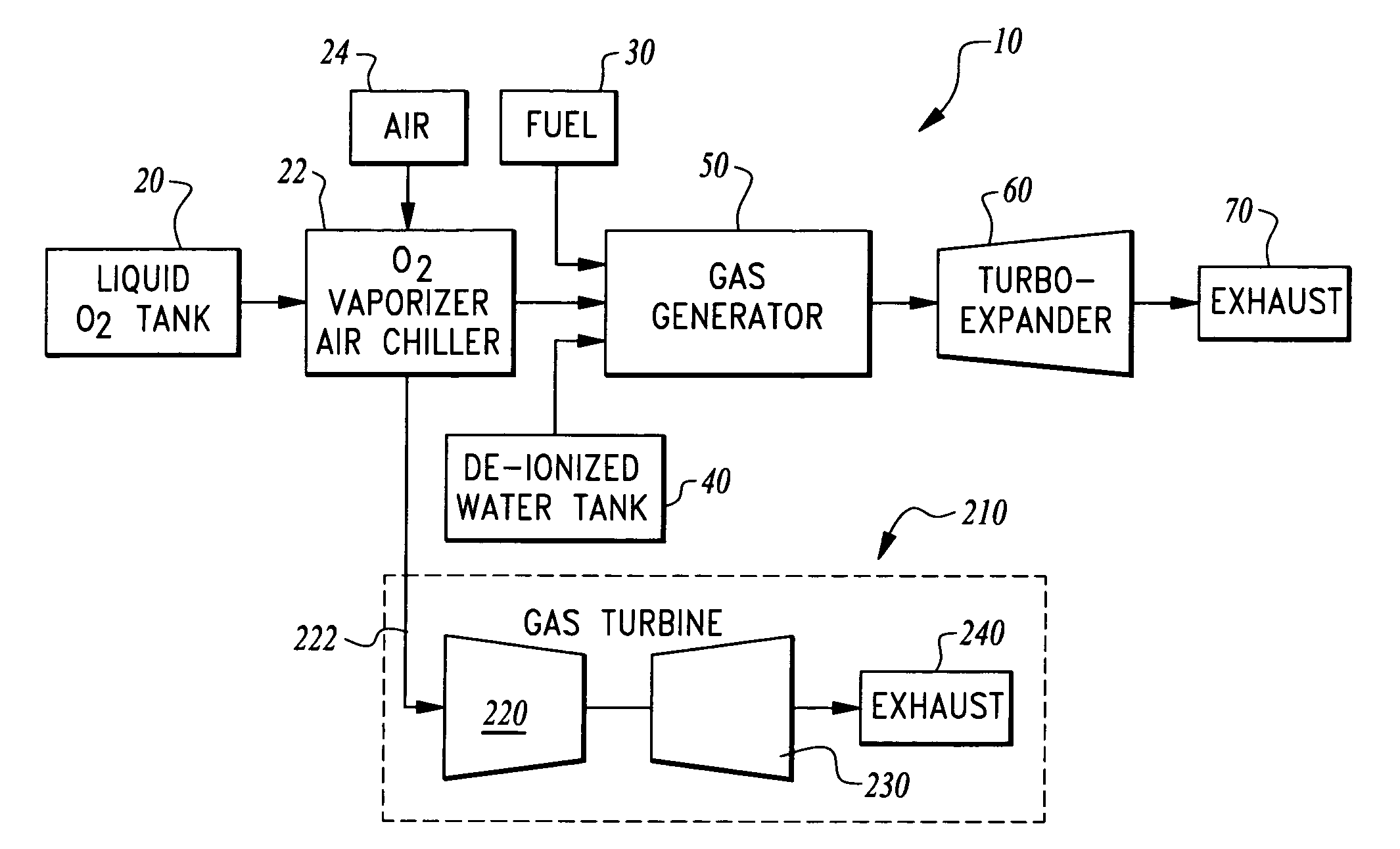

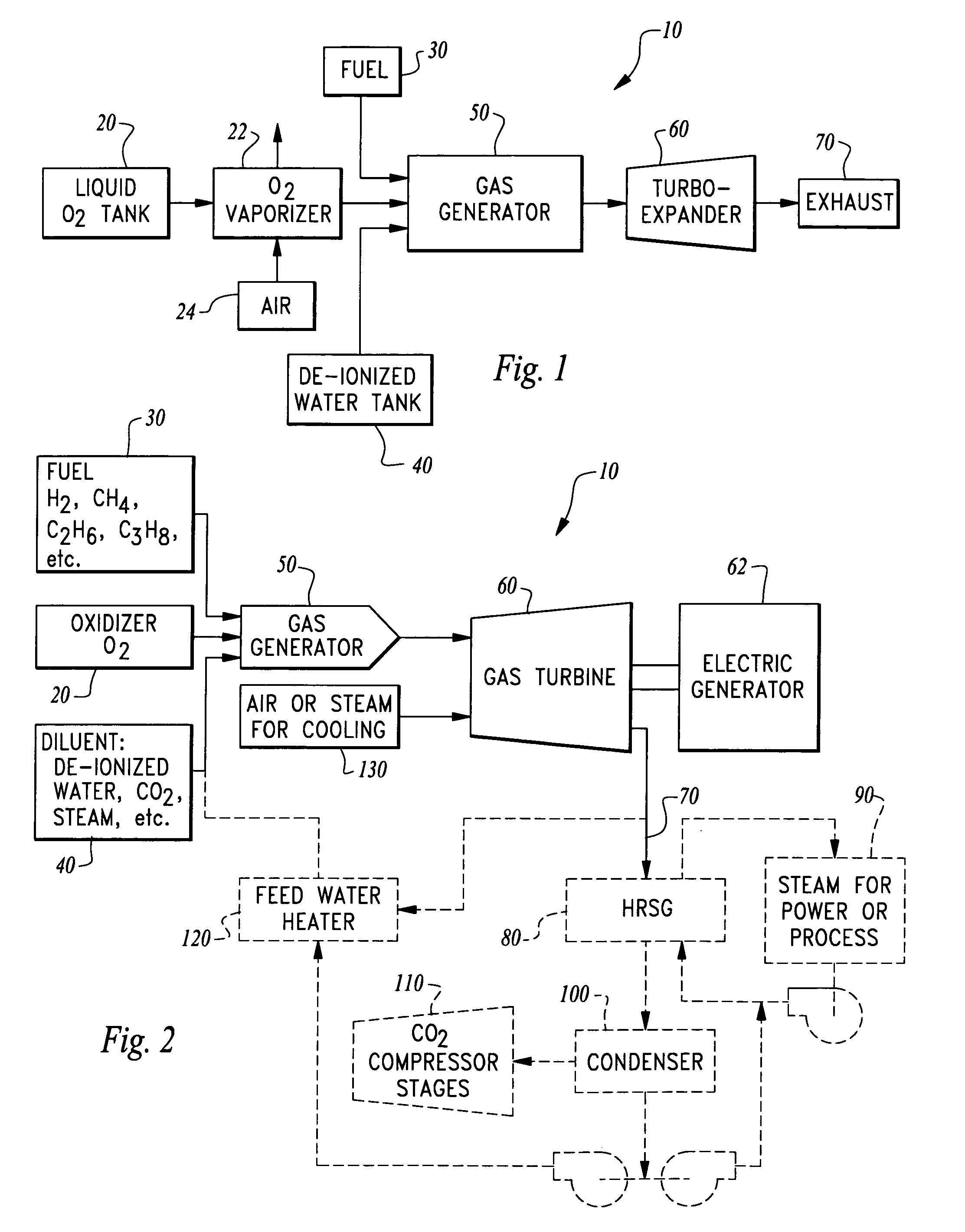

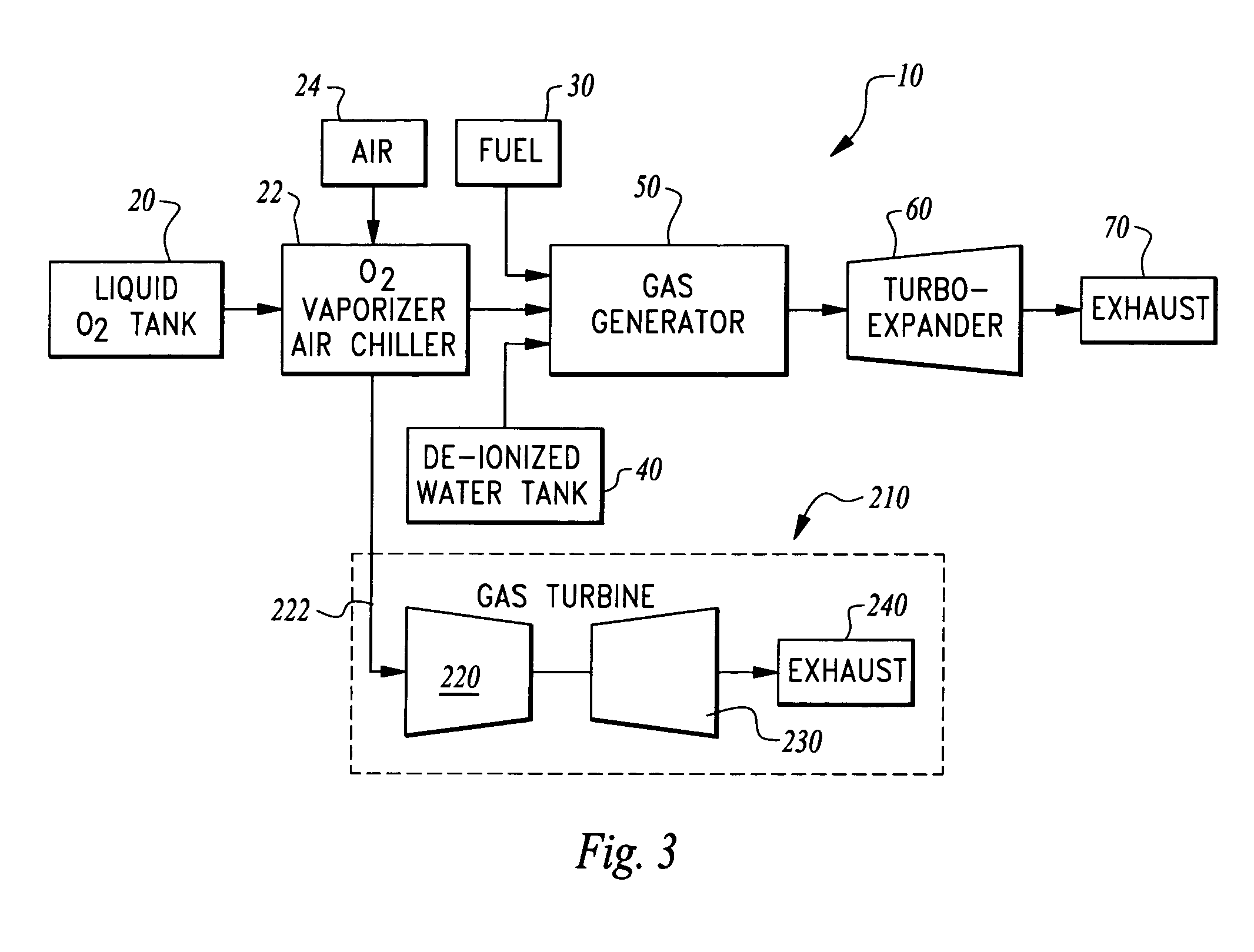

Ultra low emissions fast starting power plant

InactiveUS7827794B1Fast starting low emissionMinimal capital expenseTurbine/propulsion engine coolingGas turbine plantsNuclear engineeringLiquid fuel

The power plant combusts a hydrocarbon fuel with oxygen to produce high temperature high pressure products of combustion. These products of combustion are routed through an expander to generate power. The products of combustion are substantially free of oxides of nitrogen because the oxidizer is oxygen rather than air. To achieve fast starting, oxygen, fuel and water diluent are preferably stored in quantities sufficient to allow the power plant to operate from these stored consumables. The fuel can be a gaseous or liquid fuel. The oxygen is preferably stored as liquid and routed through a vaporizer before combustion in a gas generator along with the hydrocarbon fuel. In one embodiment, the vaporizer gasifies the oxygen by absorption of heat from air before the air is routed into a separate heat engine, such as a gas turbine. The gas turbine thus operates on cooled air and has its power output increased.

Owner:CLEAN ENERGY SYST

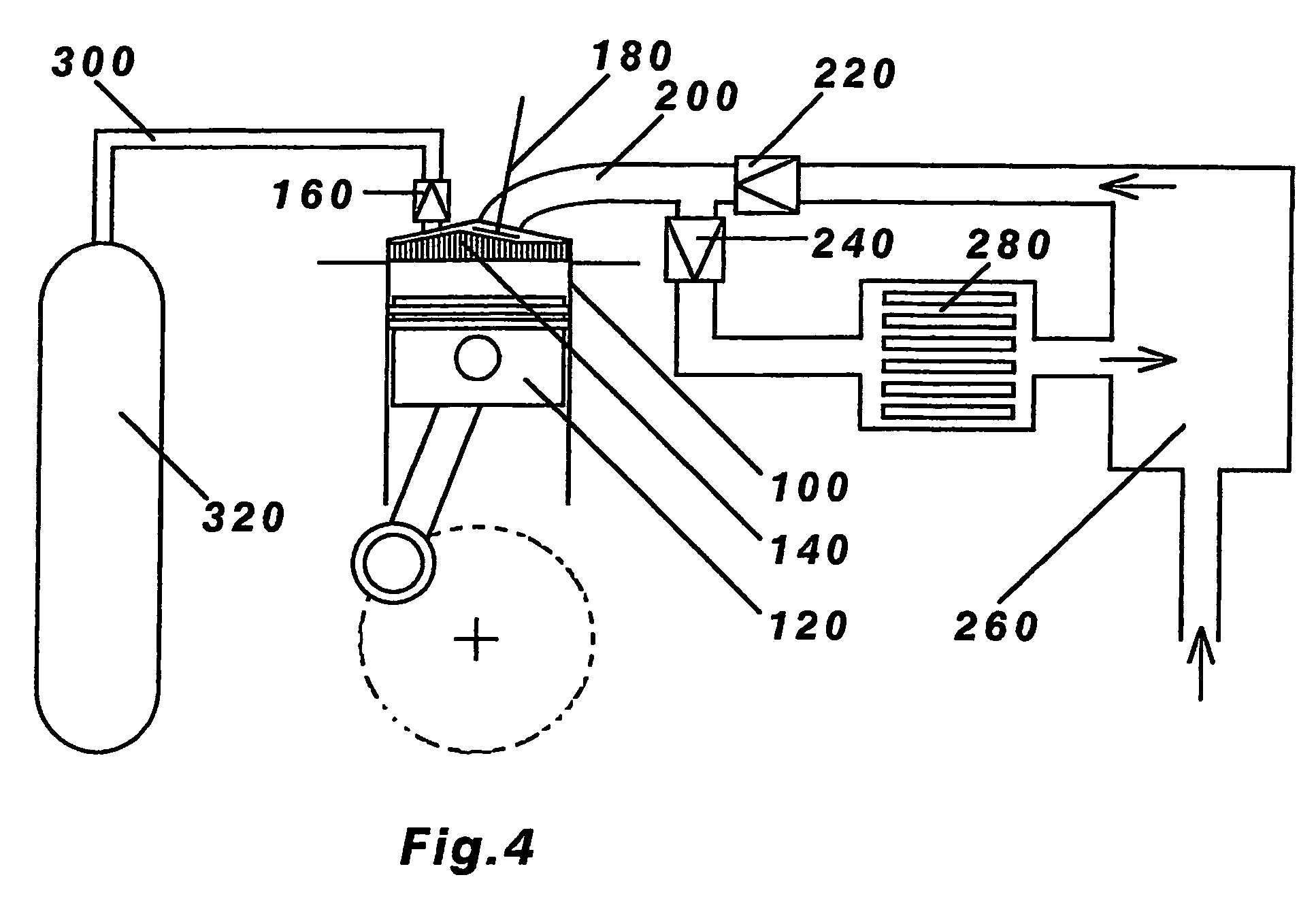

Method and apparatus for converting thermal energy to mechanical energy

InactiveUS20060090467A1Improve efficiencyEfficient regenerationEricsson type enginesSteam engine plantsThermal energyWorking fluid

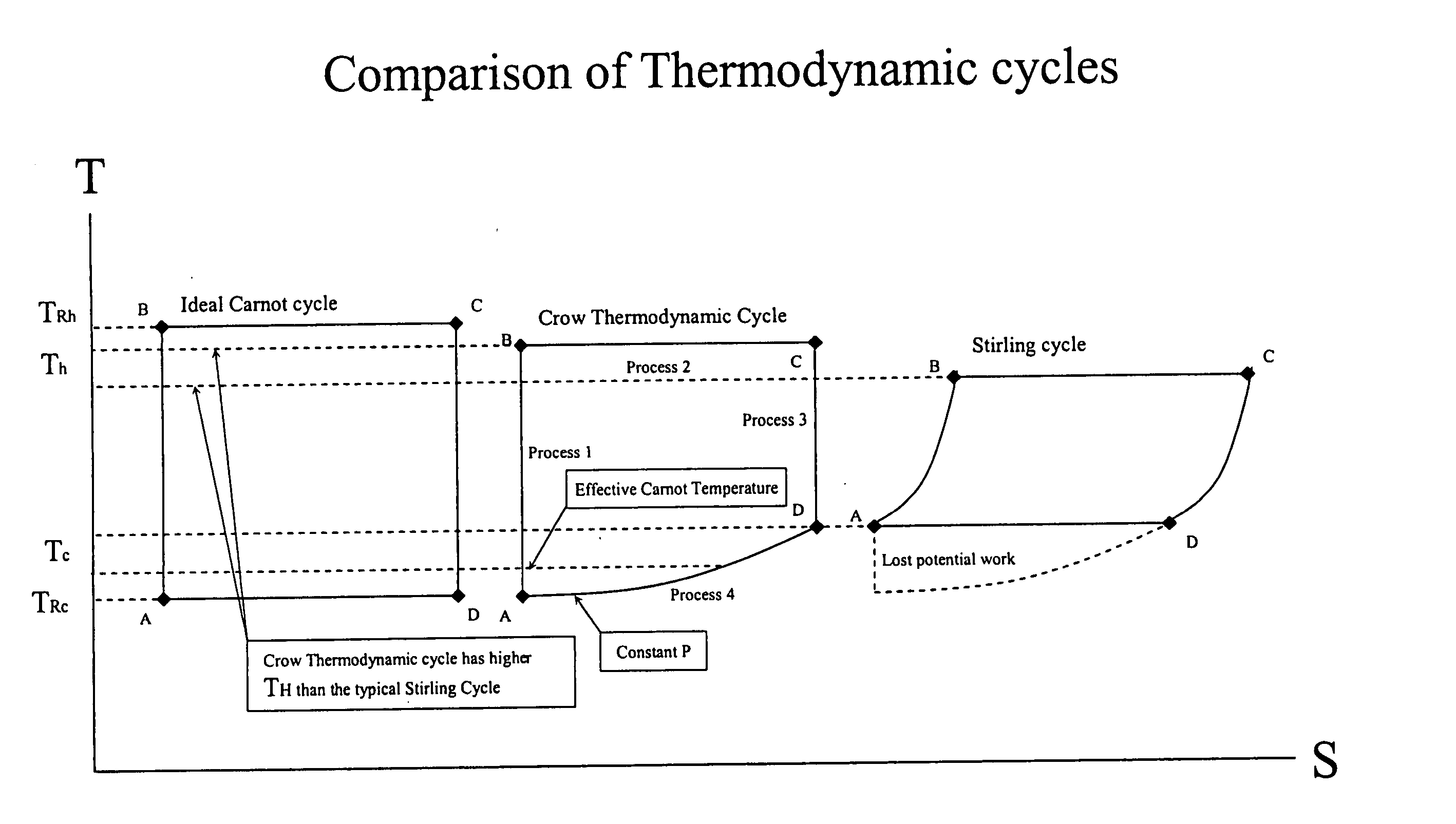

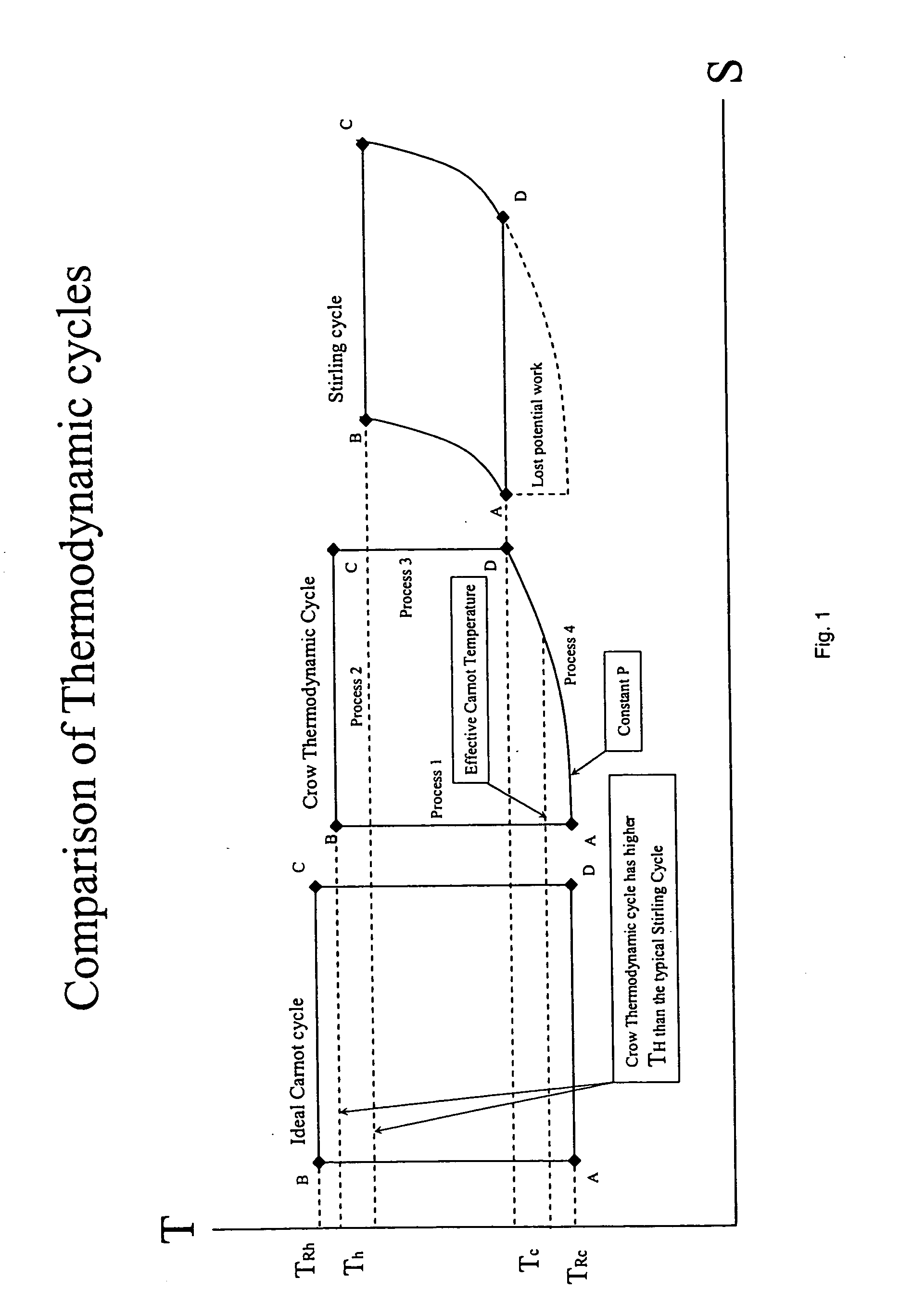

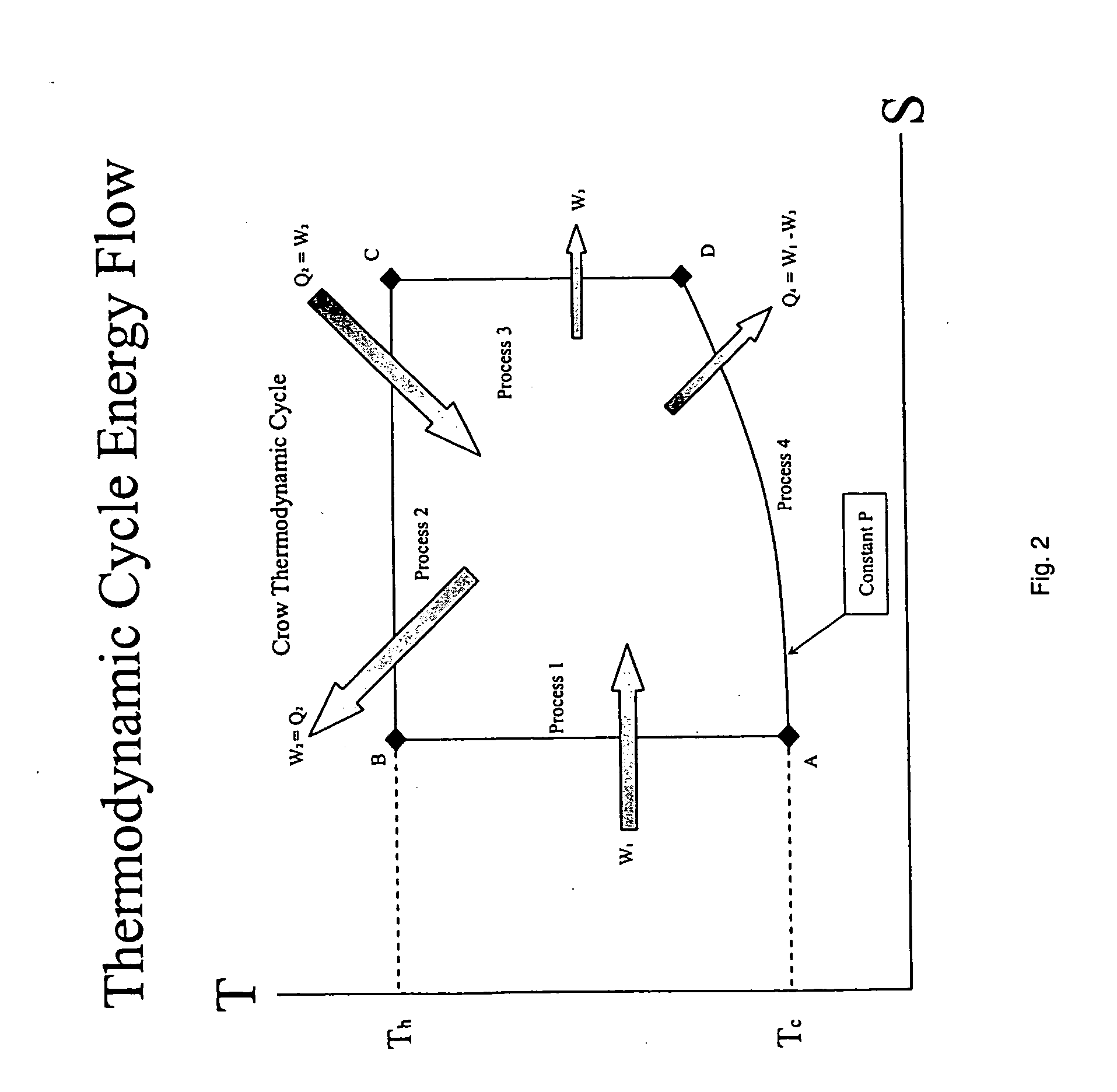

A method and apparatus for converting thermal energy to mechanical energy which can use a wide range of fuels and perform with a high efficiency. Operating on a little utilized thermodynamic cycle of isentropic compression, isothermal expansion, isentropic expansion and finally constant pressure cooling and contraction. The external heat engine utilizes a heat exchanger carrying heat from the external energy source to the working parts of the engine. Pistons and cylinders are activated by appropriate means to adiabatically compress the working fluid, for example ambient air, to transfer the entire mass of the air through the heat exchanger to accomplish isothermal expansion followed by adiabatic expansion and, finally, exhaust the air to ambient to allow for constant pressure cooling and contraction. Valve pistons in conjunction with the cylinders form valves that allow for the exchange of working fluid with ambient. Energy is added to the engine during isothermal expansion, whereby the energy of compression is added by a flywheel or other appropriate energy storage means, said flywheel stores energy recovered during adiabatic expansion. The thermodynamic cycle described and the engine embodiments disclosed, when run in reverse, perform as a heat pump or refrigeration device.

Owner:CROW DARBY

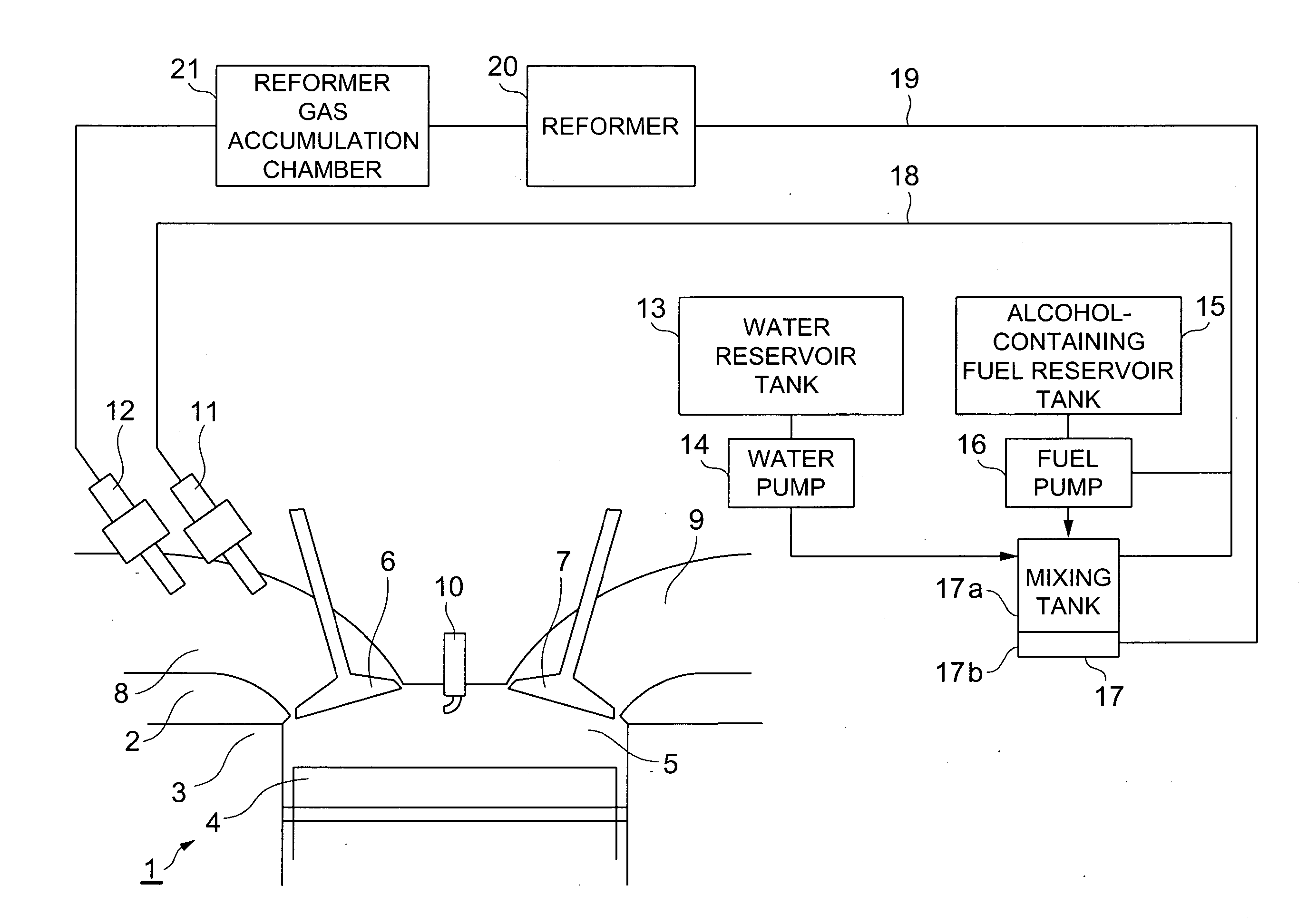

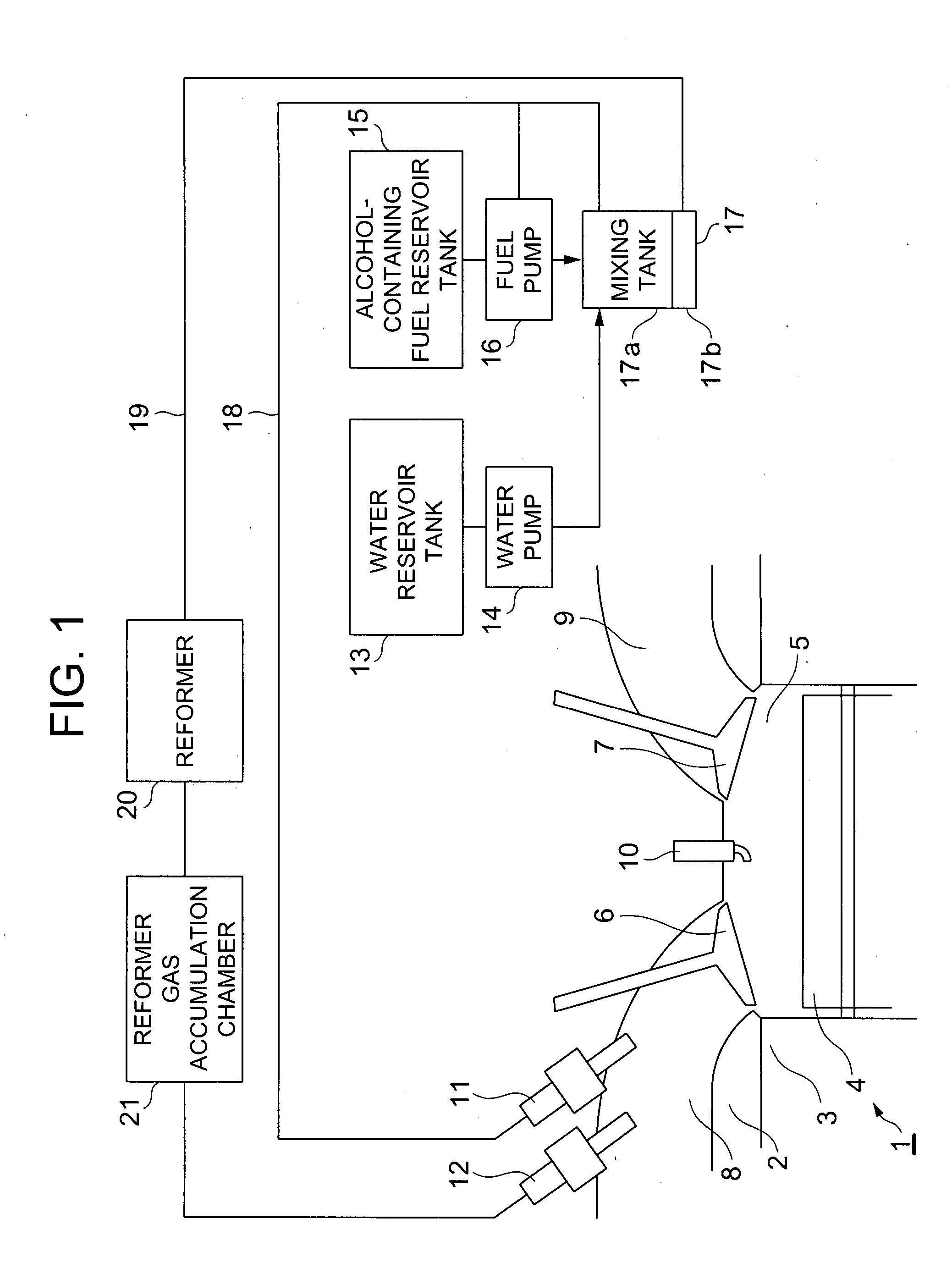

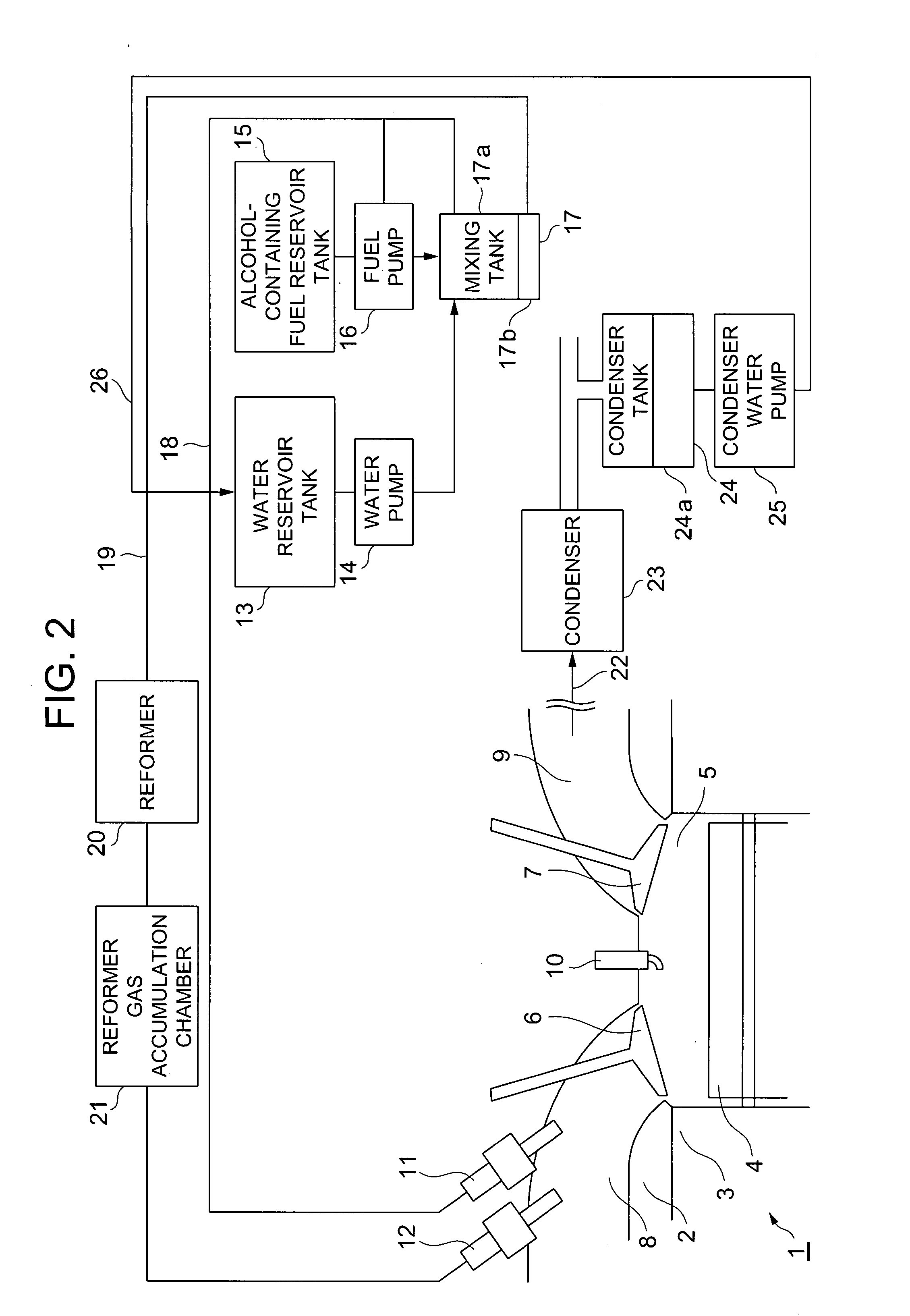

Reforming apparatus, internal combustion engine with reforming apparatus, and fuel cell system with reforming apparatus

InactiveUS20070204813A1Improve fuel consumption rateSimple and compactInternal combustion piston enginesNon-fuel substance addition to fuelElectricityFuel cells

A heat engine system includes a fuel reforming system for supplying a reformed gas to be combusted in an internal combustion engine or used to generate electricity in a fuel cell. An alcohol-containing fuel and water are mixed in a tank and separated into a hydrocarbon based fuel and the fluid mixture of alcohol and water. A reformer uses an endothermic reaction, such as a water vapor reforming process, to obtain the reformed gas from the fluid mixture.

Owner:NISSAN MOTOR CO LTD

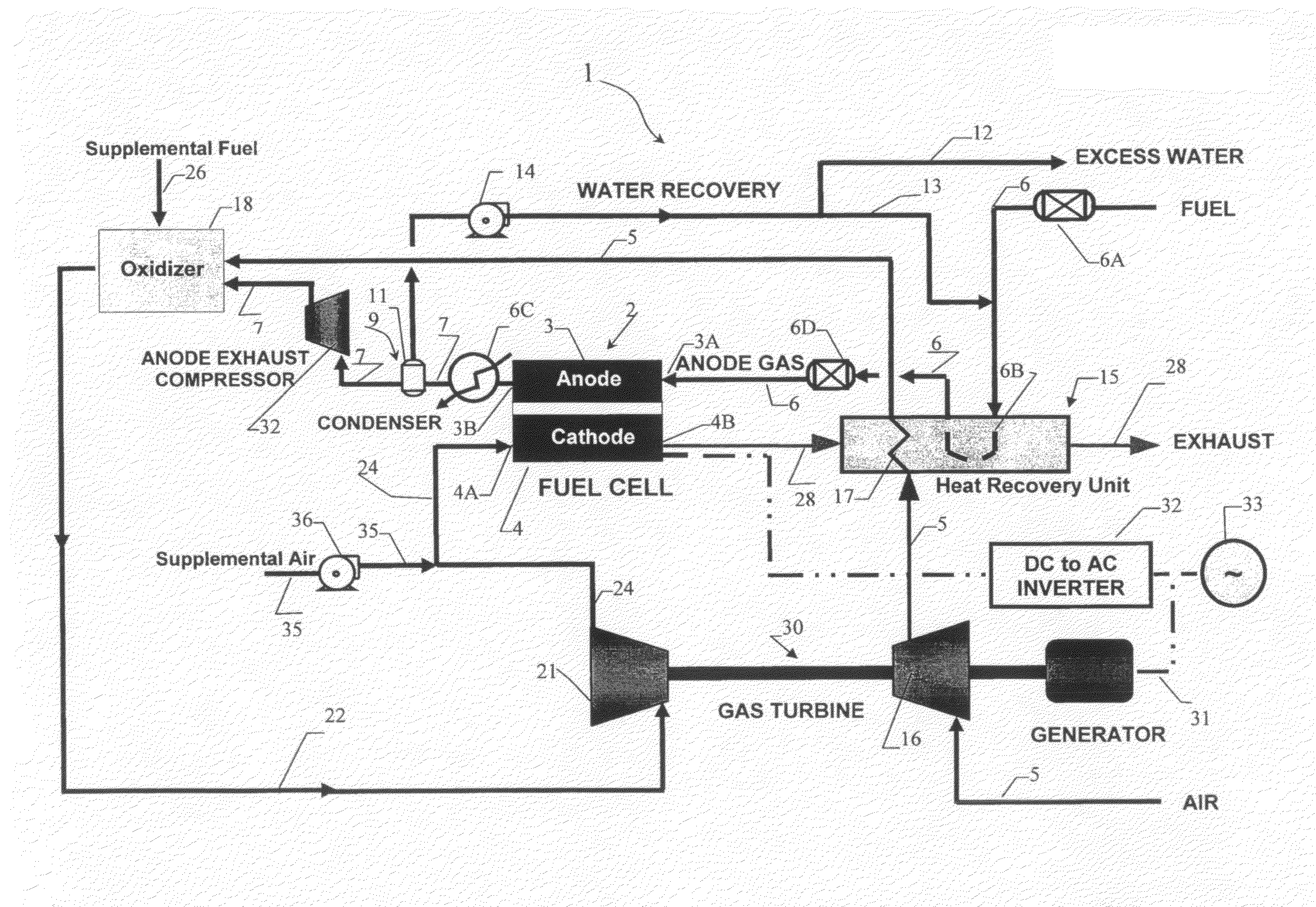

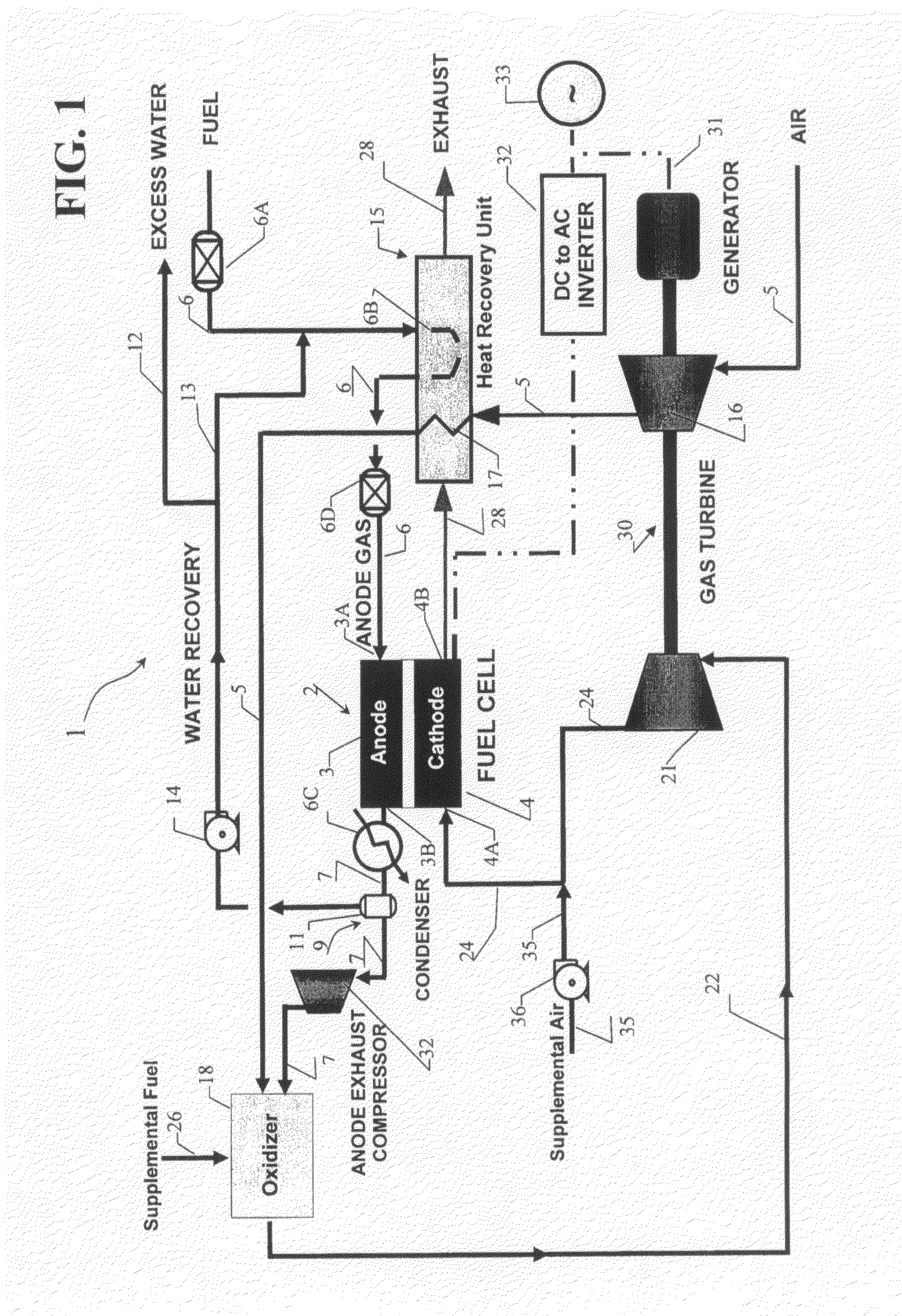

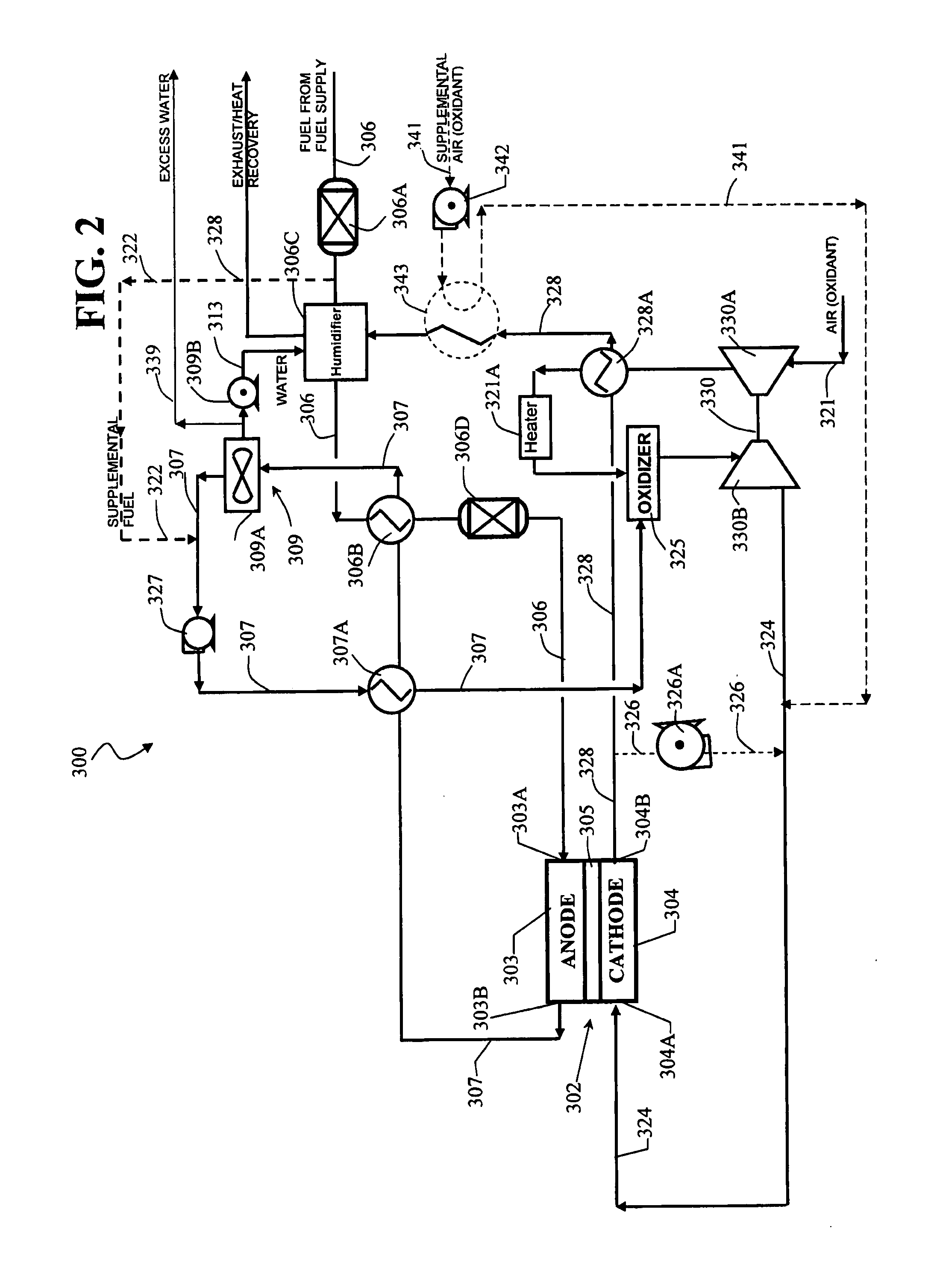

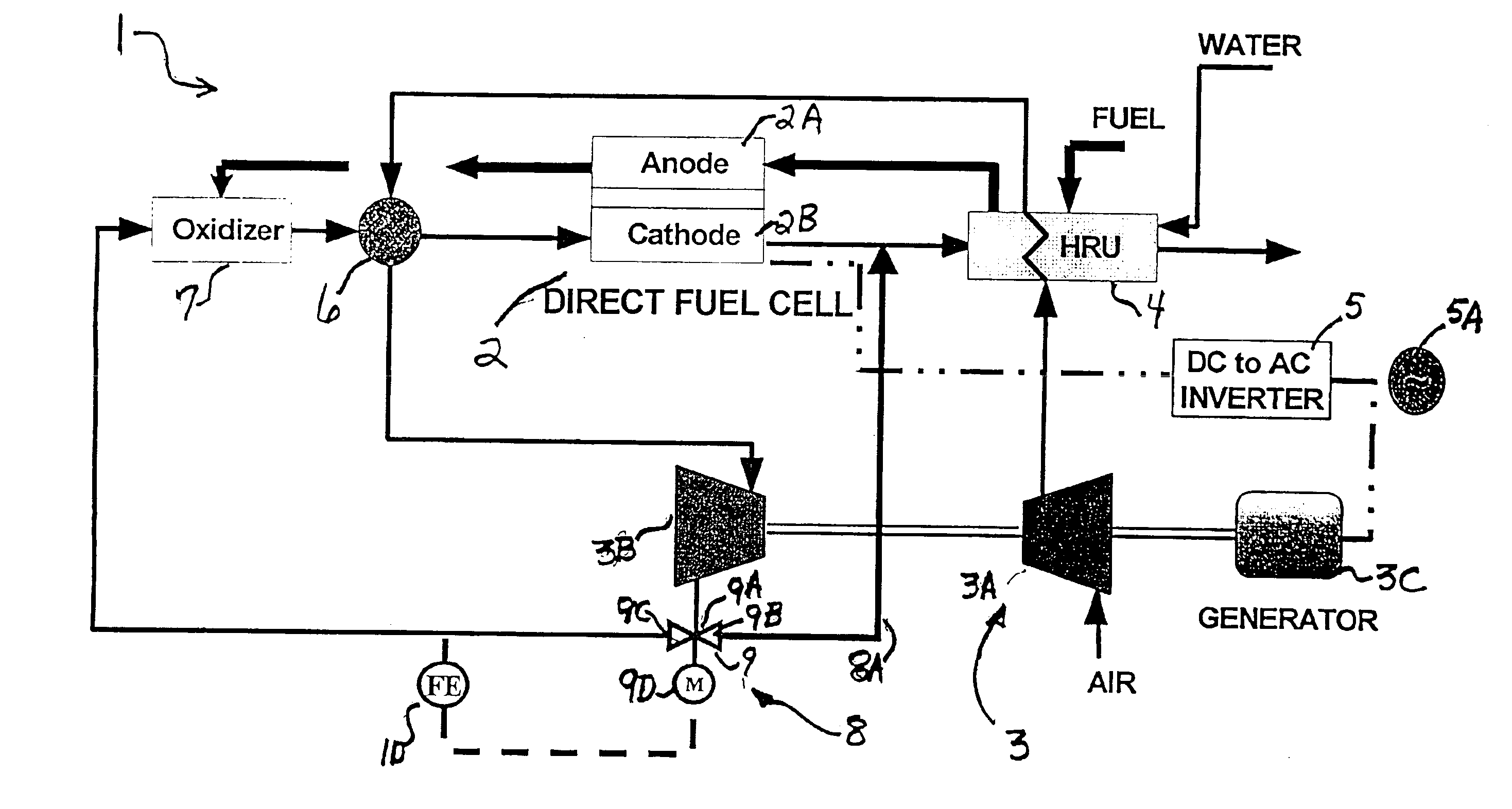

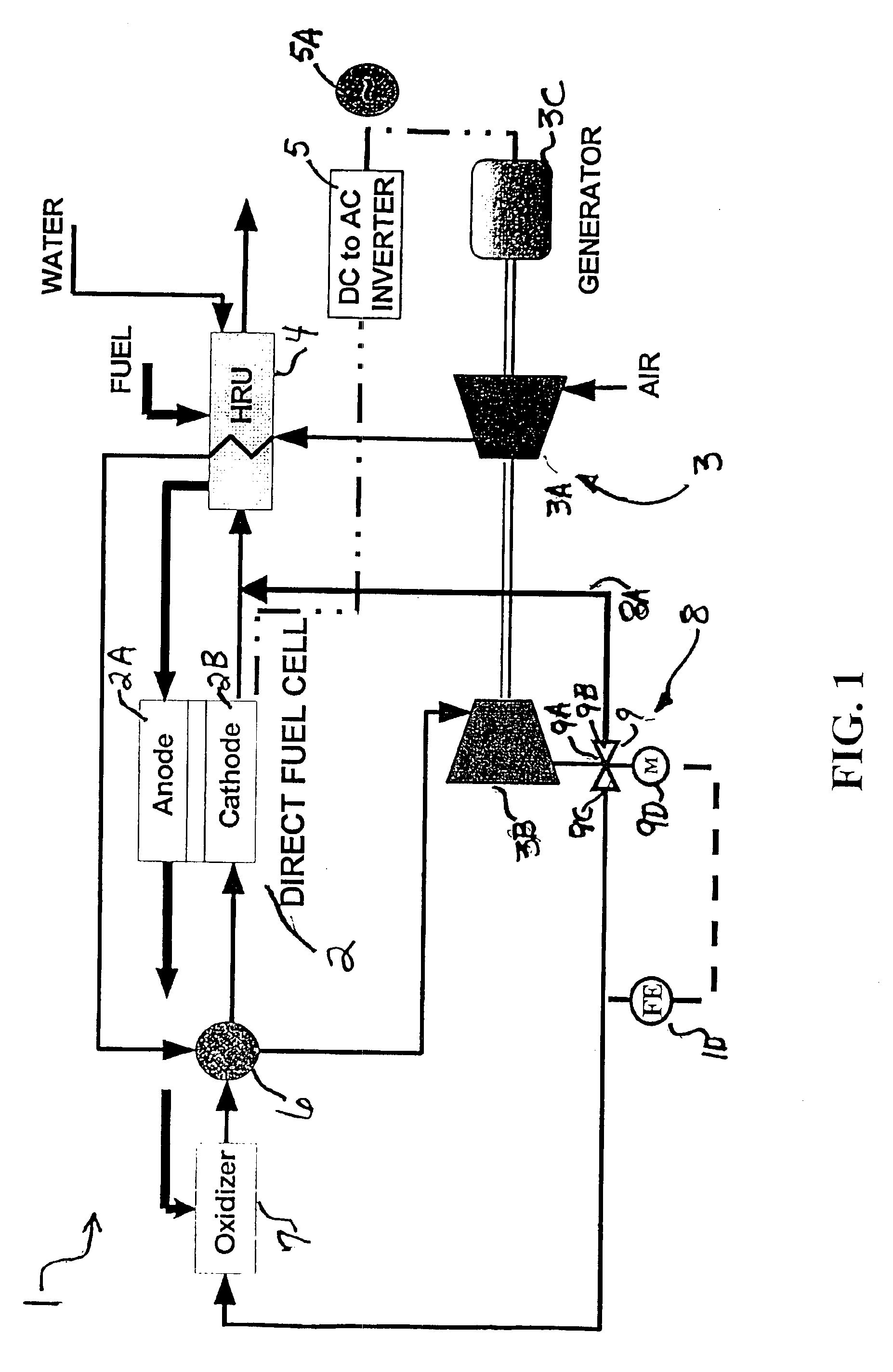

Integrated fuel cell and heat engine hybrid system for high efficiency power generation

ActiveUS20080187789A1Improve system efficiencyImprove efficiencyFuel cell heat exchangeElectricity cogenerationFuel cellsHybrid system

A fuel cell and heat engine hybrid system using a high-temperature fuel cell having an anode compartment adapted to receive fuel from a fuel supply path and to output anode exhaust gas and a cathode compartment adapted to receive oxidant gas and to output cathode exhaust gas. A heat engine assembly is adapted to receive oxidant gas and a further gas comprising one of the anode exhaust gas and a gas derived from the anode exhaust gas and to cause oxidation of the further gas and generate output power, the heat engine also generating heat engine exhaust including oxidant gas. The heat engine exhaust is then used to provide oxidant gas to the cathode compartment of the fuel cell.

Owner:FUELCELL ENERGY INC

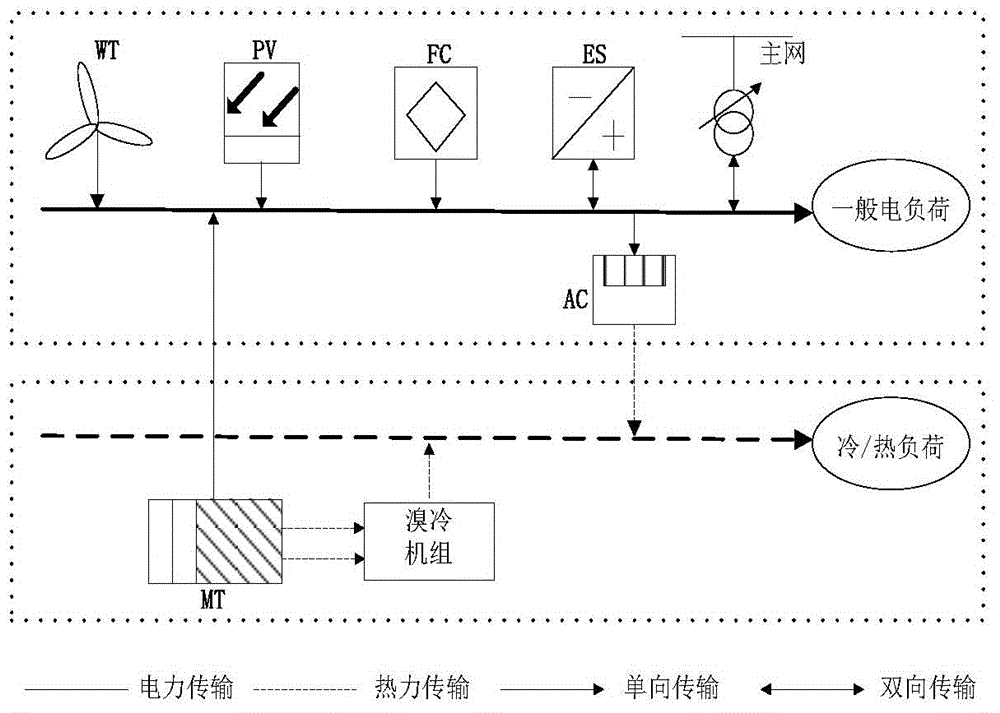

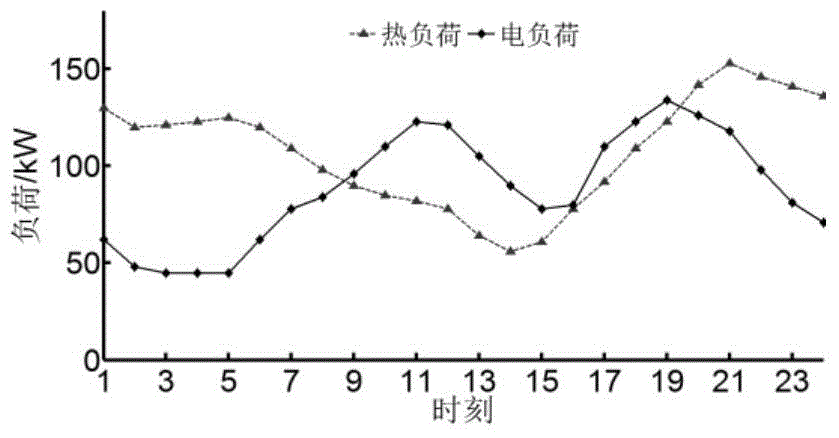

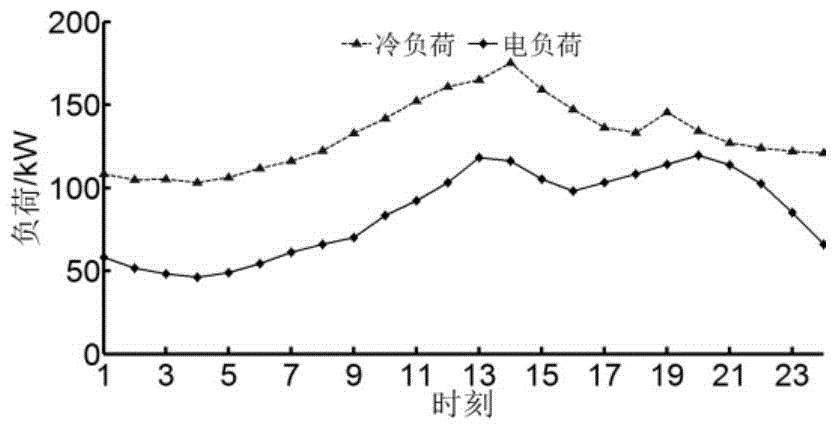

Microgrid operation optimizing method by considering combined supply of cooling, heating and power with stored energy operation strategy

InactiveCN104392286AIncrease revenue from electricity salesLow running costForecastingEnergy gradientMicrogrid

The invention discloses a microgrid operation optimizing method by considering combined supply of cooling, heating and power with a stored energy operation strategy.The microgrid operation optimizing method comprises the following steps of: establishing a CCHP (combined cooling heating and power) microgrid optimizing model; constructing a target optimizing function with a target of lowest generating cost under a microgrid grid-connected operation state; according to the established target optimizing function, comprehensively considering load level of front and time periods with an output trend of each micro power supply, and determining the operation principle of an energy storage unit and a fuel battery to determine the best operation mode of the whole CCHP system in a scheduling period. The microgrid operation optimizing method disclosed by the invention has the beneficial effects that the microgrid electricity selling profits can be effectively increased for energy storage optimization, obvious advantages are provided in lowering the operation cost of the microgrid; the energy resource utilization rate of the stem can be improved and the energy gradient utilization can be realized in comparison with the conventional heat-engine plant and thermal power plant, so that reference is provided for energy saving of the power system; moreover, the energy is saved and the emission is reduced, pollution of air pollutants is greatly reduced, and significance is achieved in improving environmental benefits.

Owner:SHANDONG UNIV

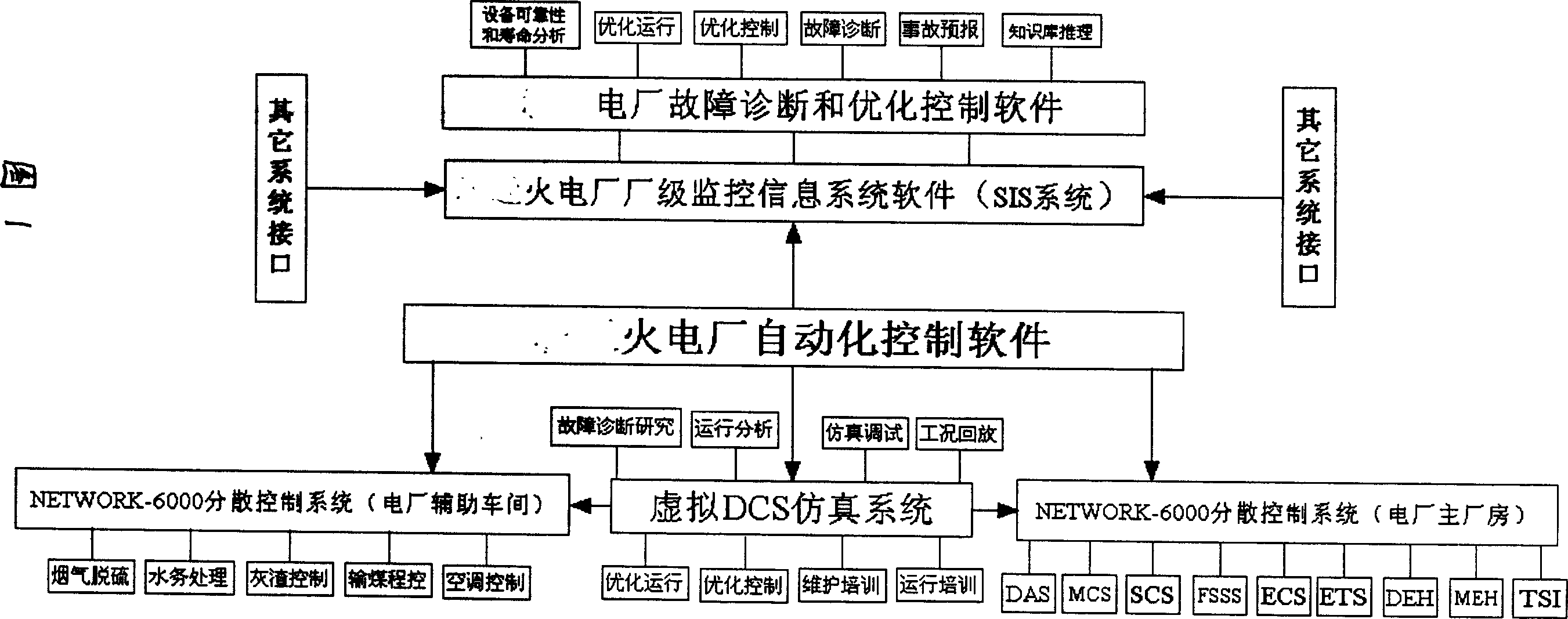

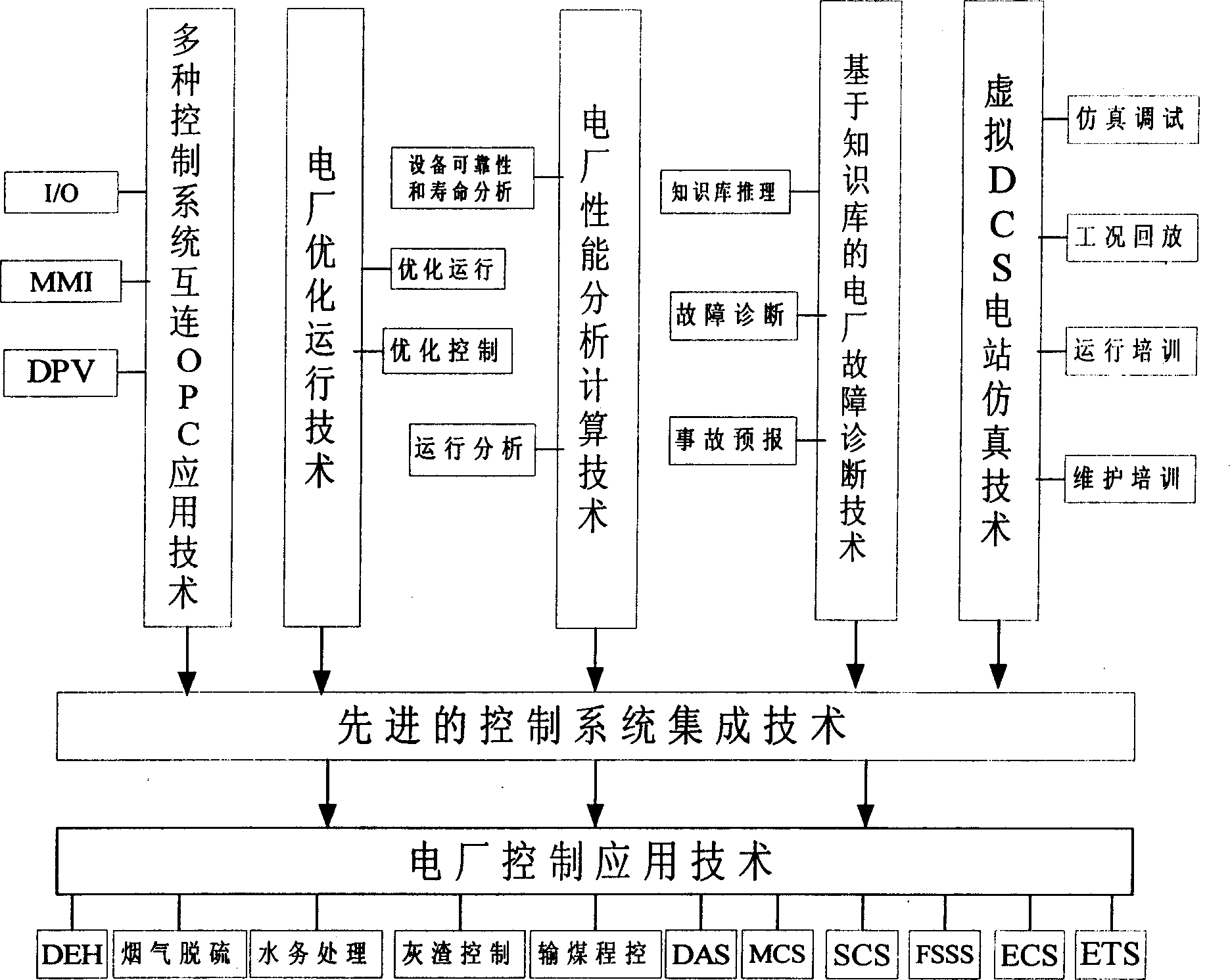

Automatic control system based on artificial intelligence for heat-engine plant

ActiveCN1694025ATake into account maturityGuaranteed growthComputer controlEnergy industryAutomatic controlPower station

The invention discloses a thermoelectric power station automatic control system based on artificial intelligence. It includes dispersible control system, virtual DCS simulation system, program controlling system, monitoring information system and malfunction diagnosing and optimizing controlling system; the dispersible control system is connected with the virtual DCS simulation system and program controlling system; the program controlling system process the operating parameters of every machine group transmitted by dispersible control system, and at the same time transmits data to monitoring information system to display, then transmits malfunction diagnosing and optimizing controlling system to have equipment state monitoring, malfunction diagnosing and forewarns. The invention gathers automatic control, optimizing operation, security monitoring and malfunction diagnosing and forecast. It can improves the automated management level of the thermoelectric power station operation, and enhances enterprises' benefit. It has great economic and applied value in the producing process automatic control of the thermoelectric power station.

Owner:南京科远智慧能源投资有限公司

Heat engine

InactiveUS7062913B2Improve efficiencyBoilers/analysersClimate change adaptationWorking fluidEngineering

Owner:OHIO STATE INNOVATION FOUND

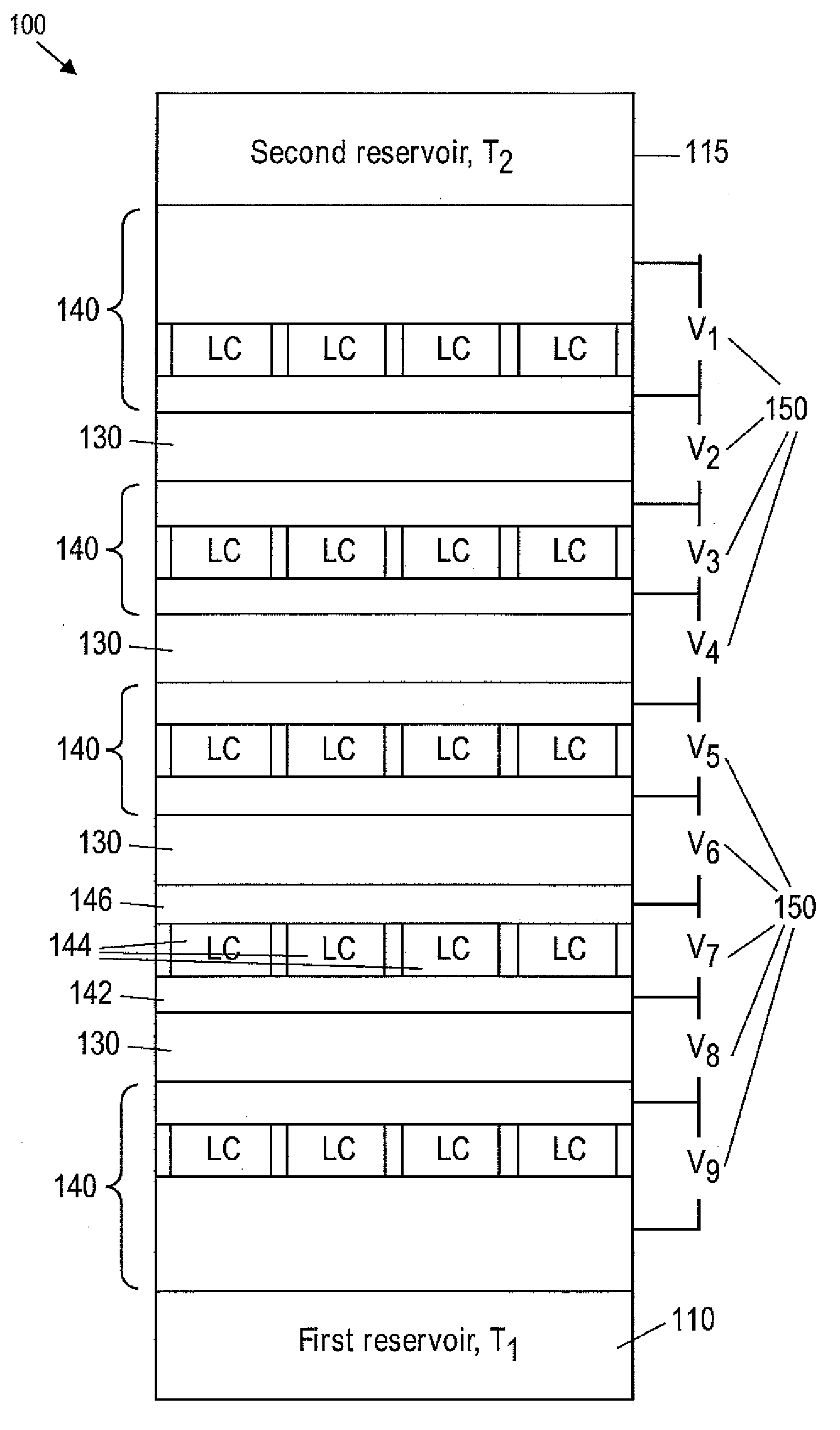

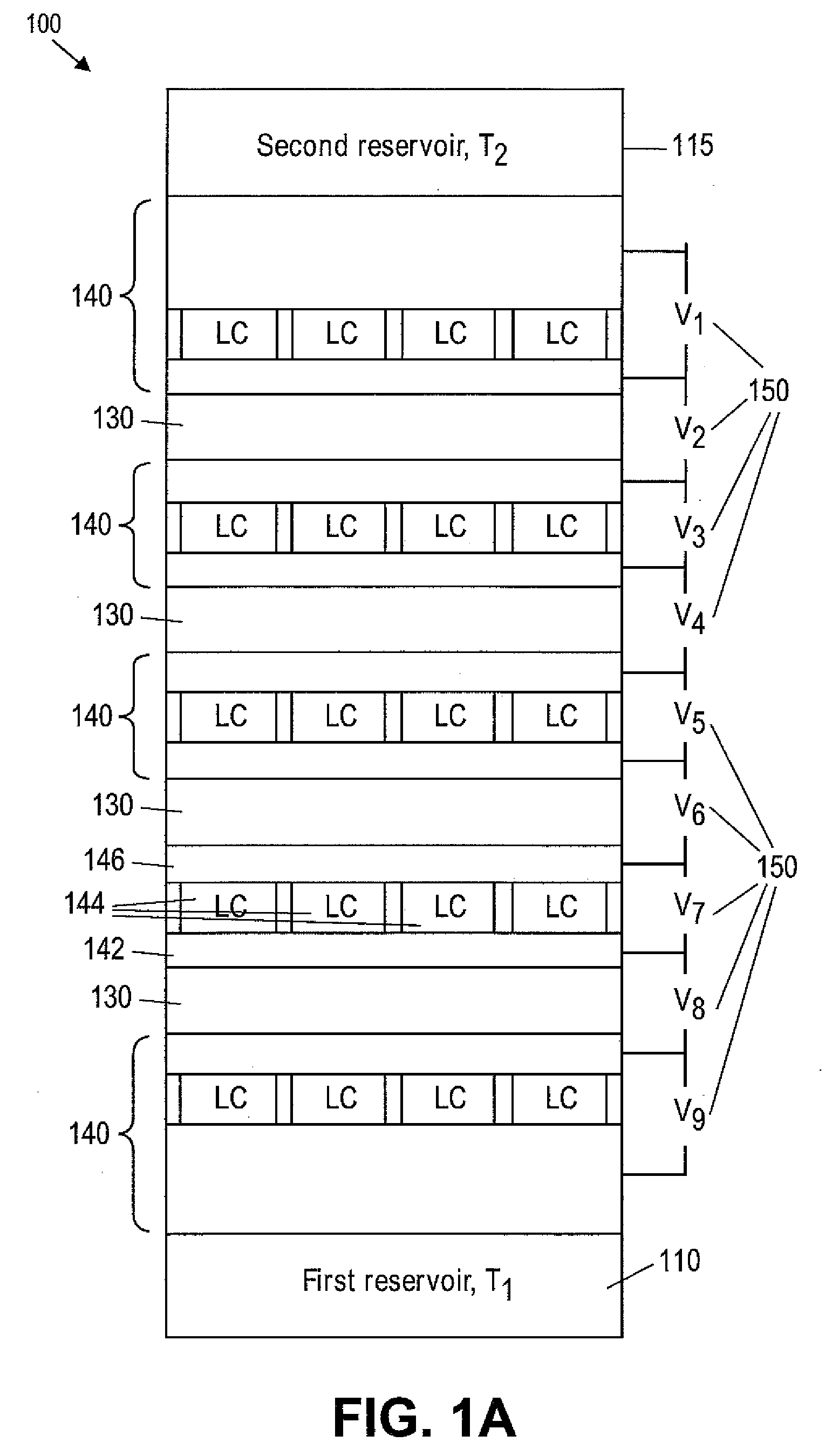

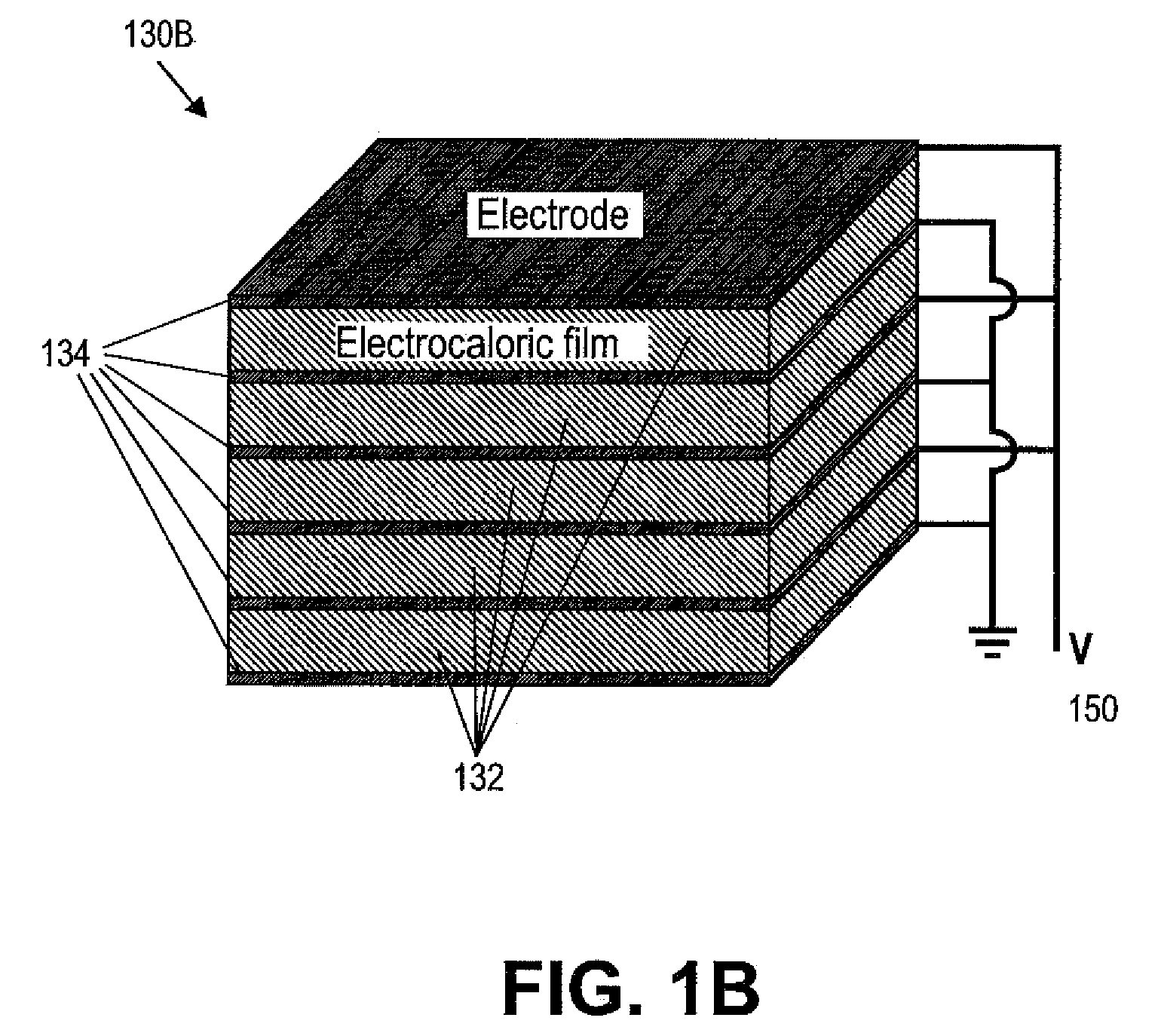

Electrocaloric refrigerator and multilayer pyroelectric energy generator

InactiveUS20100175392A1Thermoelectric device with dielectric constant thermal changeEnergy efficient heating/coolingEngineeringRefrigerated temperature

Provided are electrocaloric devices, pyroelectric devices and methods of forming them. A device which can be a pyroelectric energy generator or an electrocaloric cooling device, can include a first single-layer heat engine having a first side configured to be in contact with a first reservoir and a second side configured to be in contact with a second reservoir, wherein the first reservoir comprises a fluid. The device can also include a second single-layer heat engine having a first side in contact with the first reservoir and a second side in contact with a third reservoir and a channel disposed between the first single-layer heat engine and the second single-layer heat engine, the channel configured to transport the fluid from a first end to a second end. The device can further include one or more power supplies configured to apply voltages to the first and the second single-layer heat engine.

Owner:STC UNM

Heat Engine System

InactiveUS20100287934A1Increase temperatureImprove heat transfer performanceHeat storage plantsSteam useEnergy transferWorking fluid

A heat engine system for producing work by expanding a working fluid comprising first and second components, the system comprising, an apparatus for combining the second component of the working fluid as a liquid with the first component, the first component being a gas throughout the system, a compressor for compressing the first component, a pump for compressing at least most of the second component, a heater for heating the first and second components, an expander for expanding the first and second components to produce the work, and a recuperator for transferring at least some of the energy of the working fluid from the outlet of the expander, to the working fluid from the outlet of the apparatus, wherein a substantial portion of the energy transferred in the recuperator is at least a portion of the latent heat of the second component from the outlet of the expander.

Owner:COMMONWEALTH SCI & IND RES ORG +1

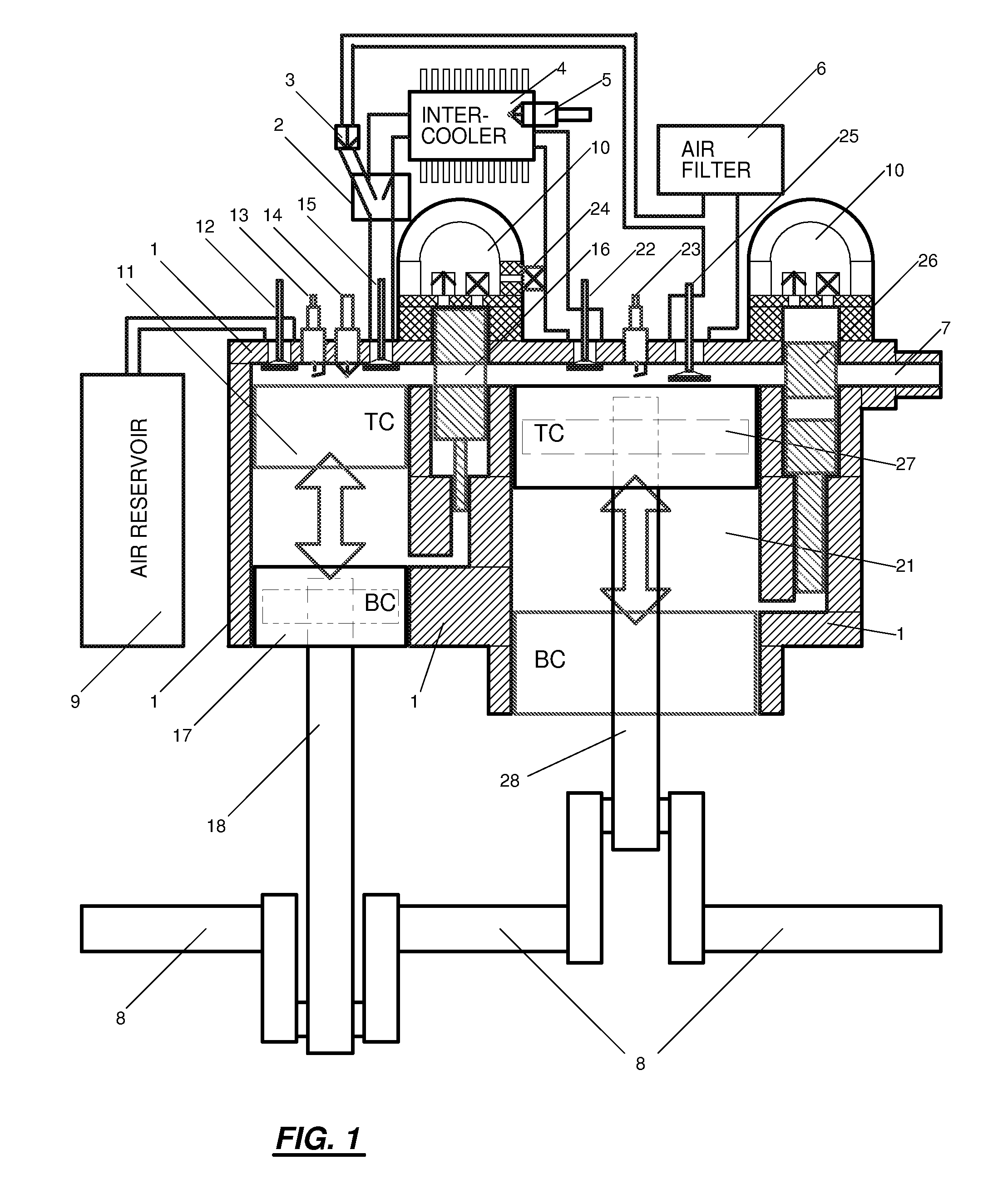

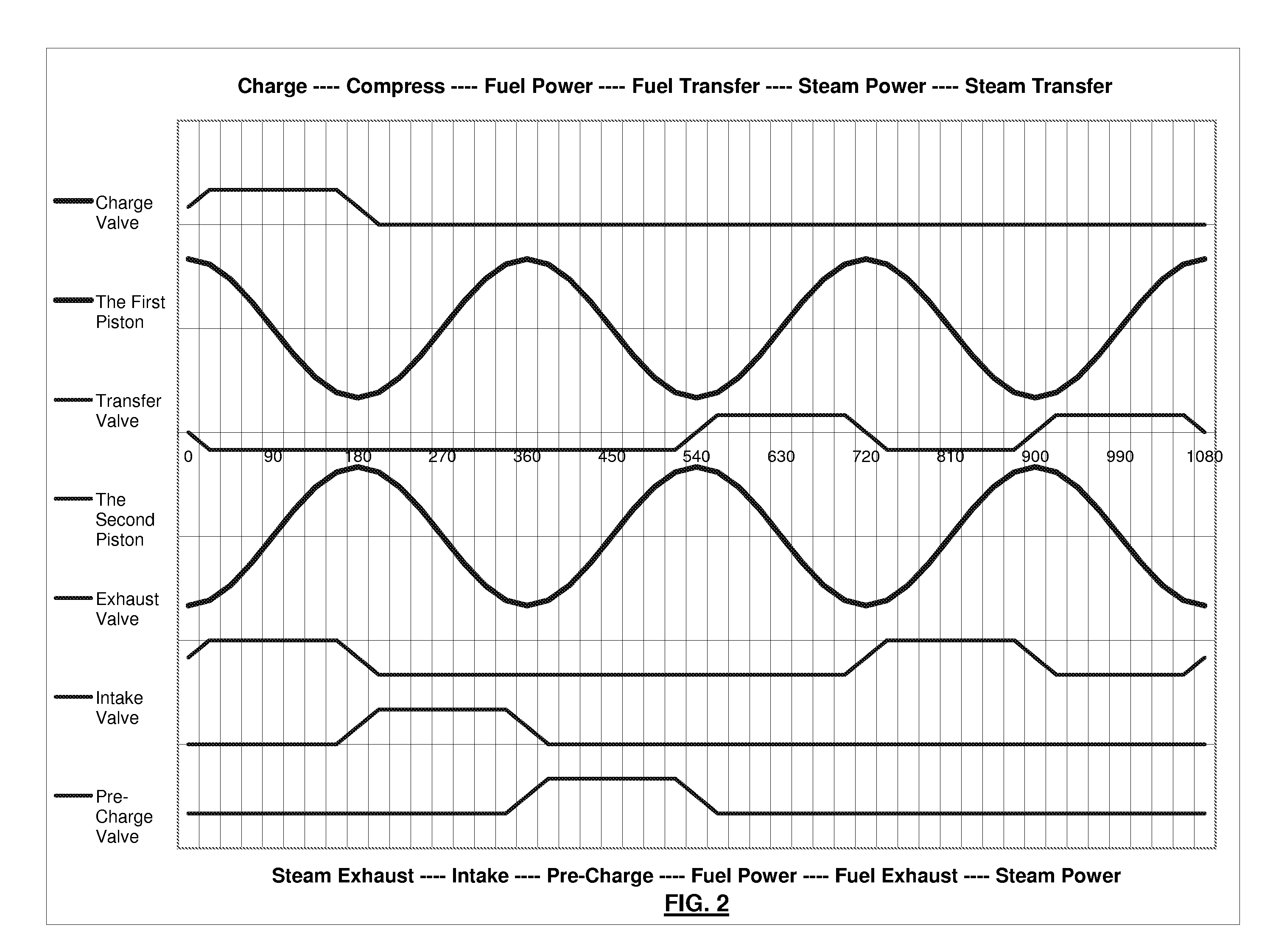

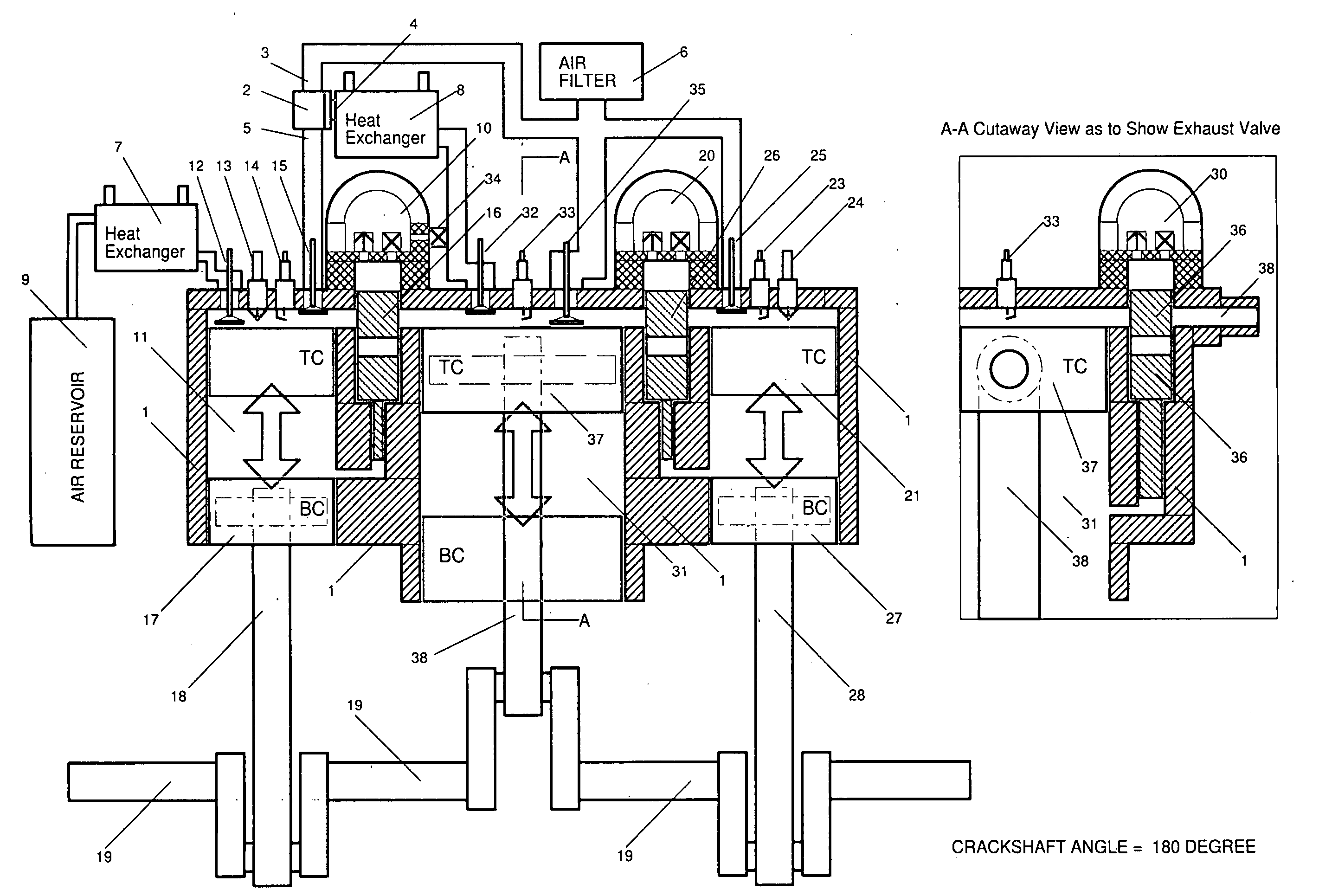

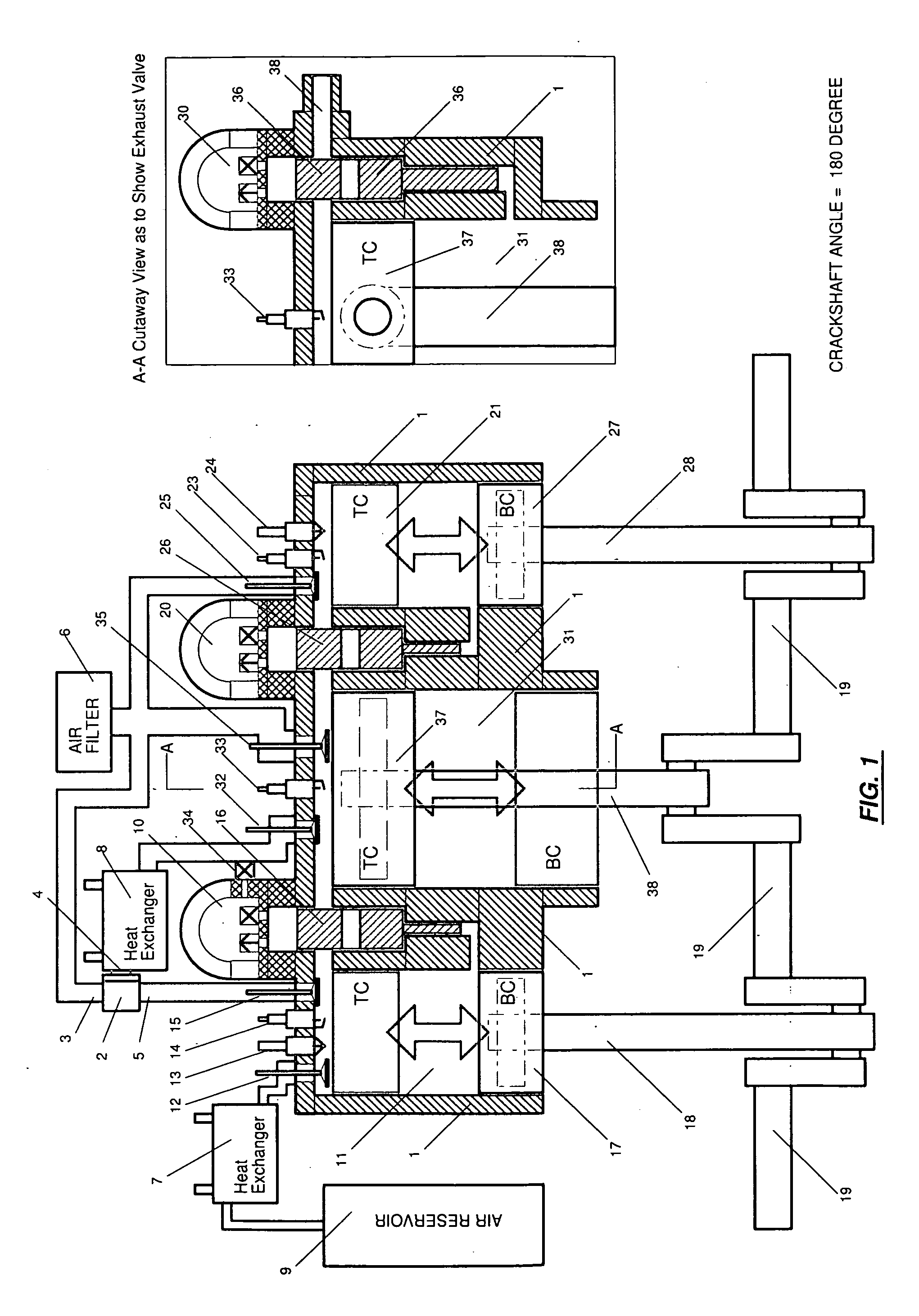

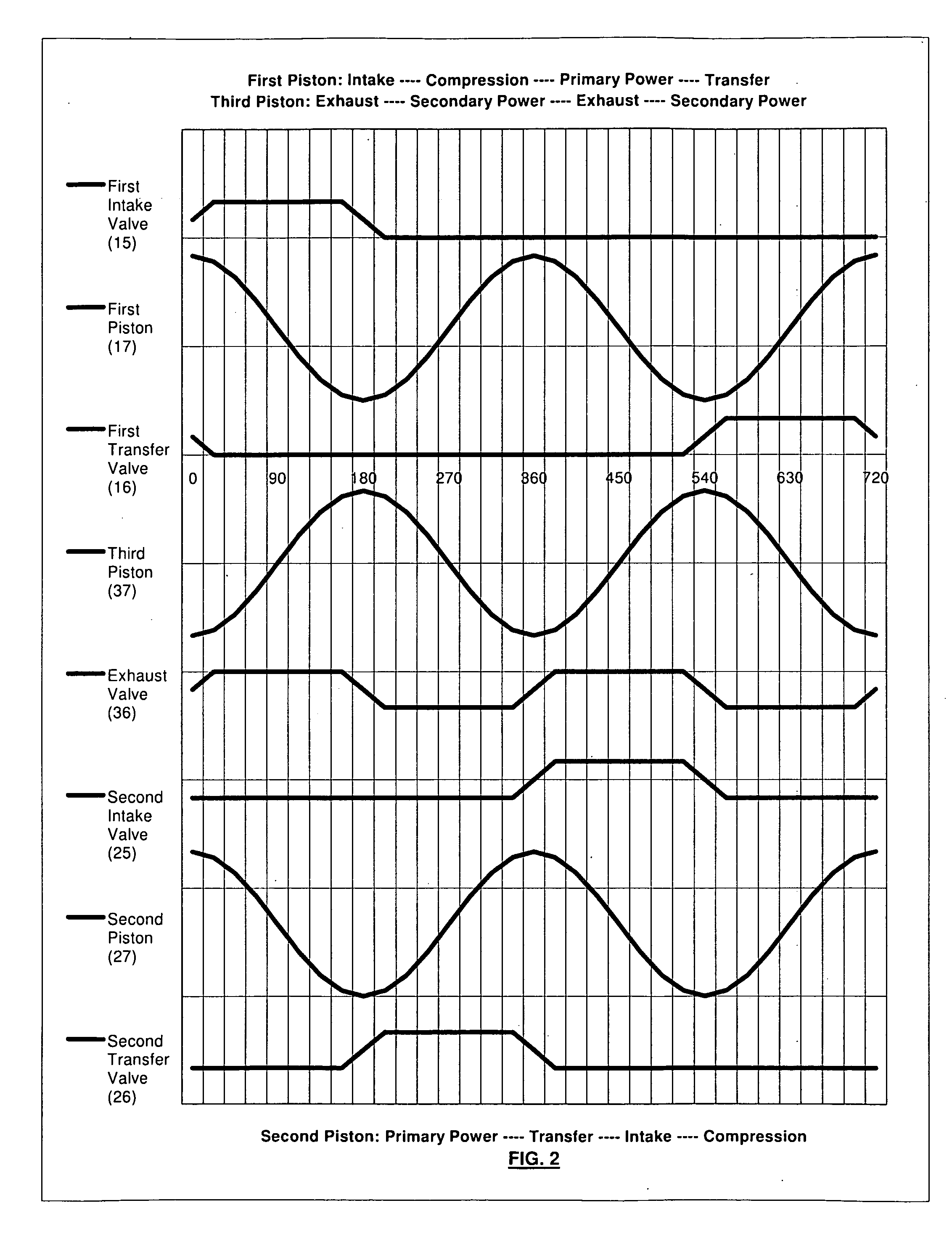

High efficiency integrated heat engine (HEIHE)

InactiveUS20090056331A1Reduce heat lossEfficient heatingInternal combustion piston enginesSteam engine plantsWork periodWorking fluid

The present invention is a High Efficient Integrated Heat Engine, or HEIHE for short. HEIHE is a reciprocal combustion engine integrated with both compound cycle and combined cycle. HEIHE comprises twin compound cylinder structure, with the first cylinder being the primary combustion and / or expansion cylinder; the second cylinder being the secondary combustion and / or expansion cylinder. Power strokes driven by expansions of different working fluids such as air-fuel combustion products, steam and compressed air, are integrated into one engine block. Twin cylinder structure provides compound expansions of three (3) different fluids as to recover the energies that would be lost with the exhaust fluids or during braking. All of these make HEIHE work around six (6) periods with twelve (12) operation strokes. Among six (6) working periods involved, four (4) periods contain four (4) different power strokes but only one of the power strokes consumes the fuel. Thus the fuel conversion efficiency could be greatly increased, or even be doubled comparing with the conventional internal combustion engine (ICE).

Owner:ZHAO YUANPING +1

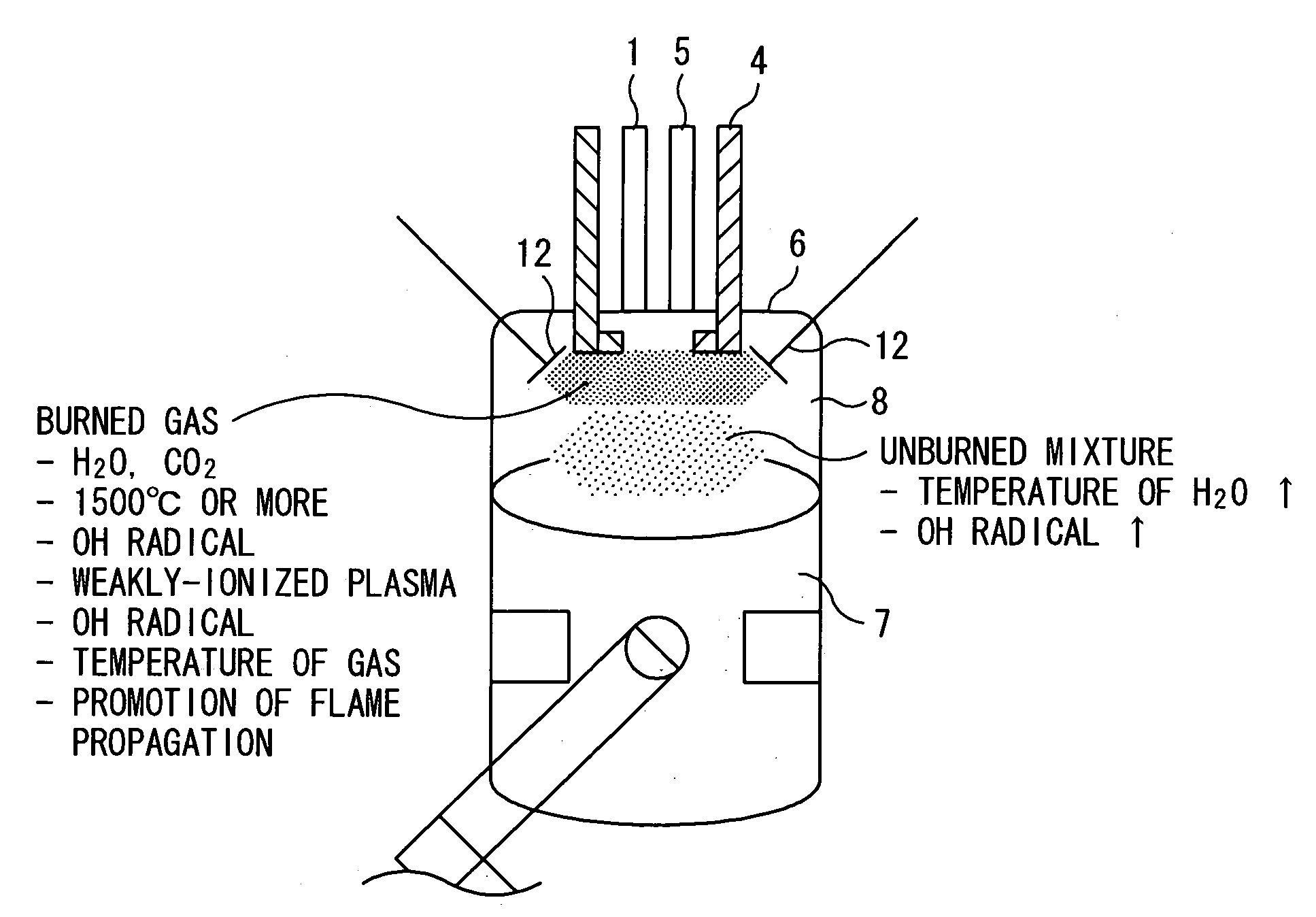

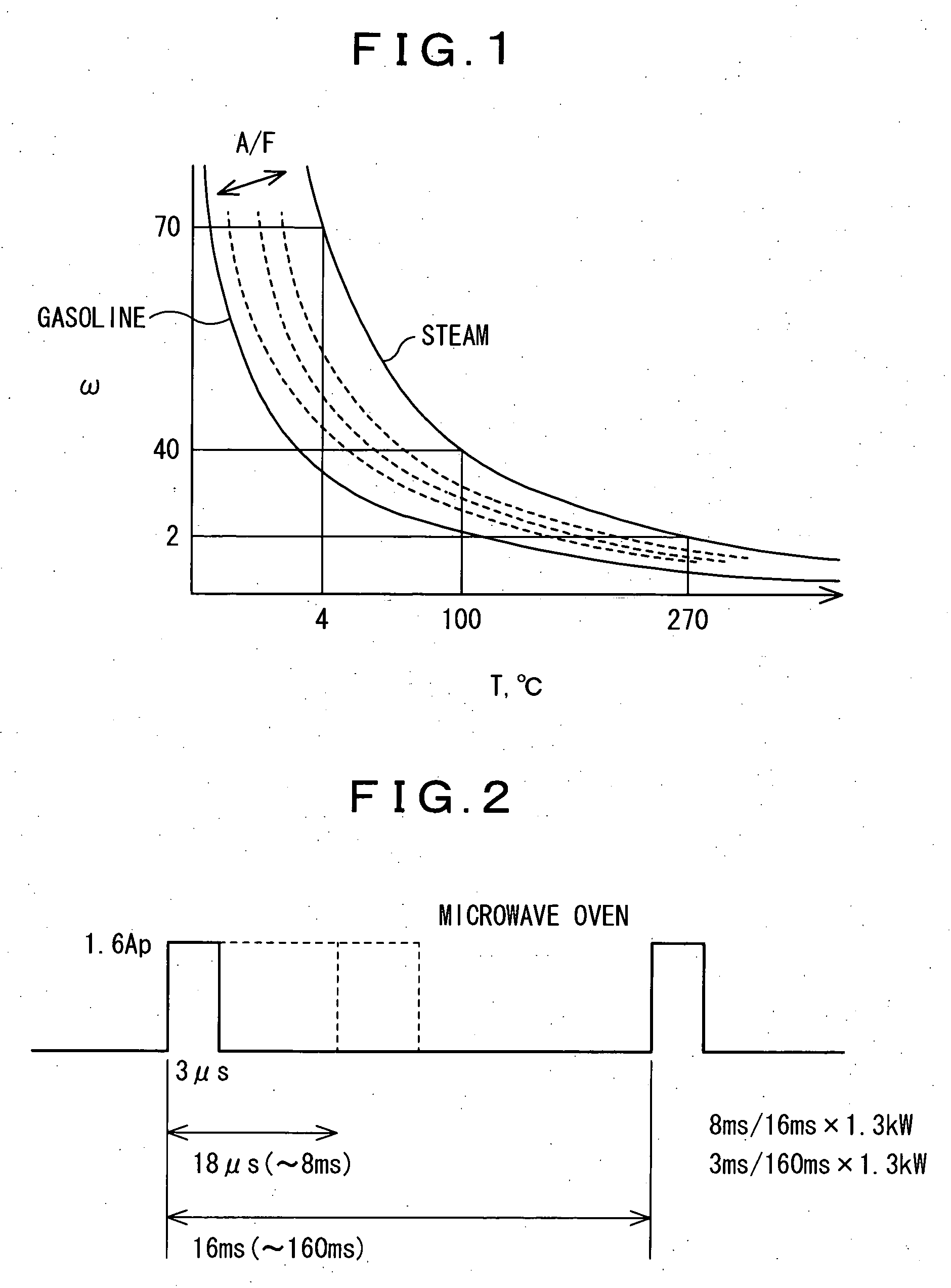

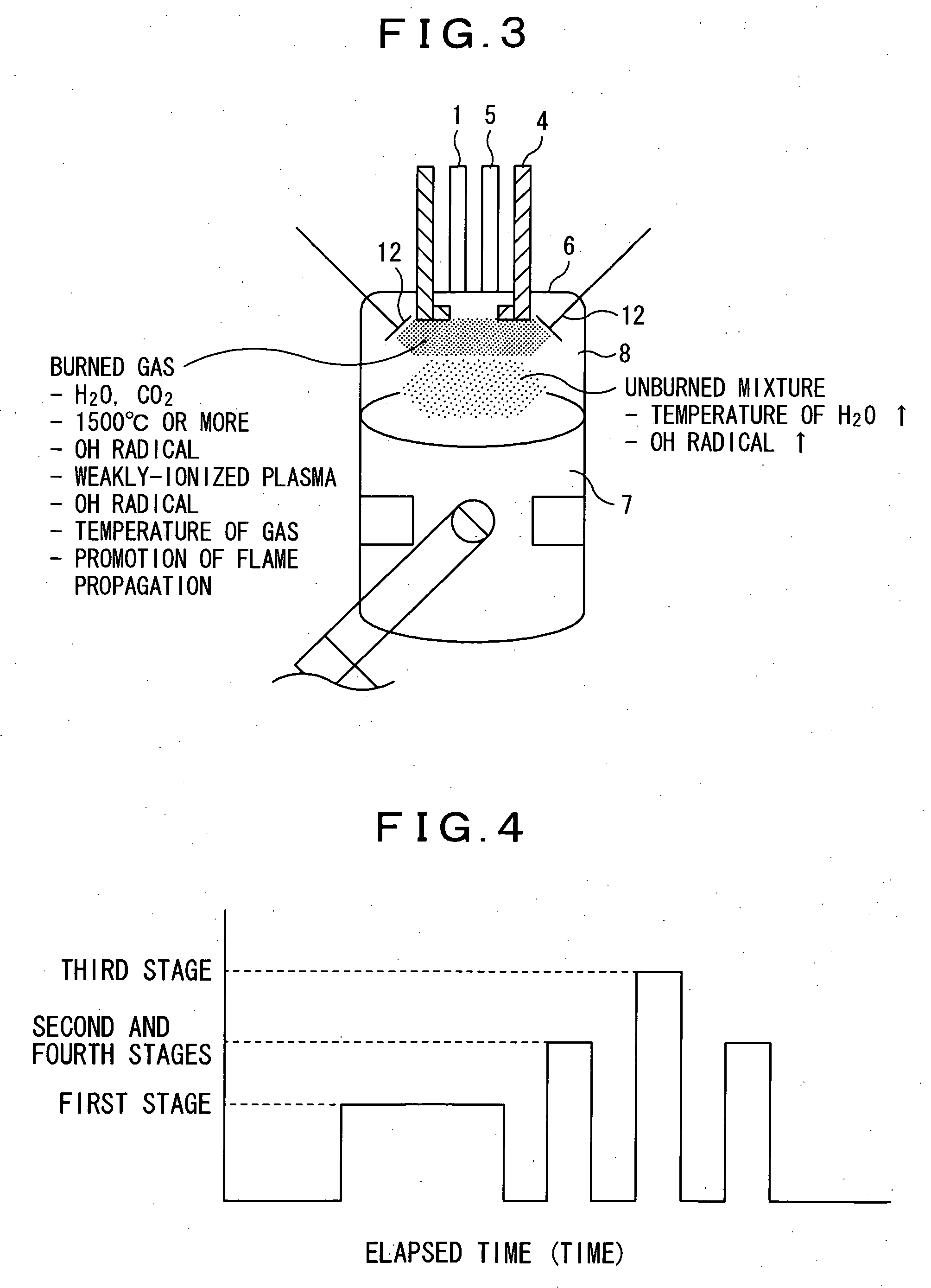

Ignition Apparatus, Internal-Combustion Engine, Ingnition Plug, Plasma Equipment, Exhaust Gas Degradation Apparatus, Ozone Generating/Sterilizing/Disinfecting Apparatus, and Odor Eliminating Apparatus

ActiveUS20090229581A1Eliminate the effects ofStable ignitionInternal combustion piston enginesEngine operationsDielectricEngineering

Stable and highly efficient combustion / reaction is provided, even when fuel ratio of mixture is decreased and combustion / reaction of the lean mixture is performed in a heat engine such as a reciprocating engine, by controlling dielectric constant of mixture in a combustion / reaction chamber by introducing water and / or exhaust gas into the combustion / reaction chamber. A microwave radiation antenna for irradiation of the combustion / reaction chamber, and a discharge unit for igniting the mixture in the combustion / reaction chamber are provided. The dielectric constant of the mixture before the combustion / reaction of the mixture is controlled so that the resonance frequency of the mixture corresponds to the frequency of the microwave.

Owner:I LAB INC

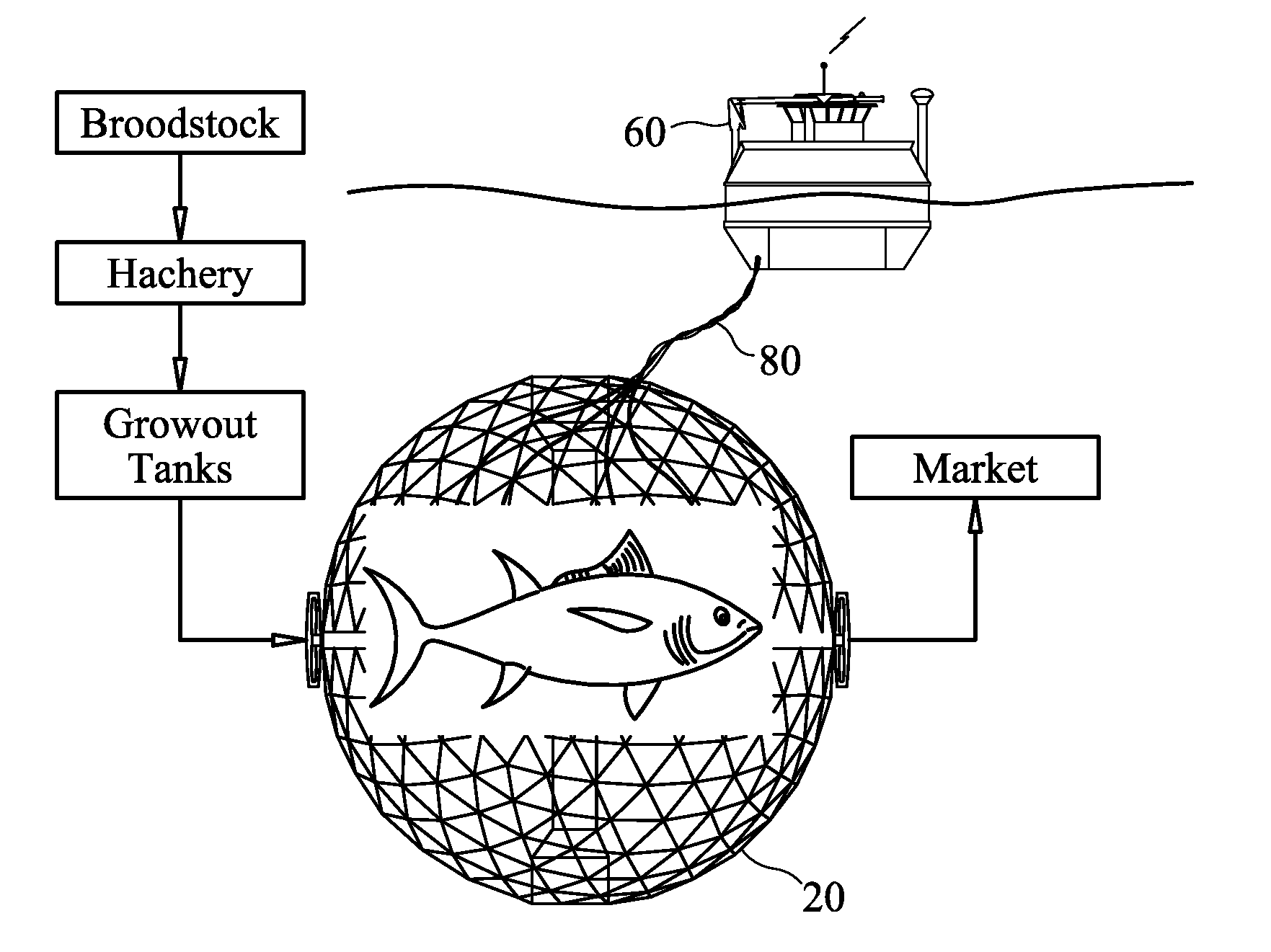

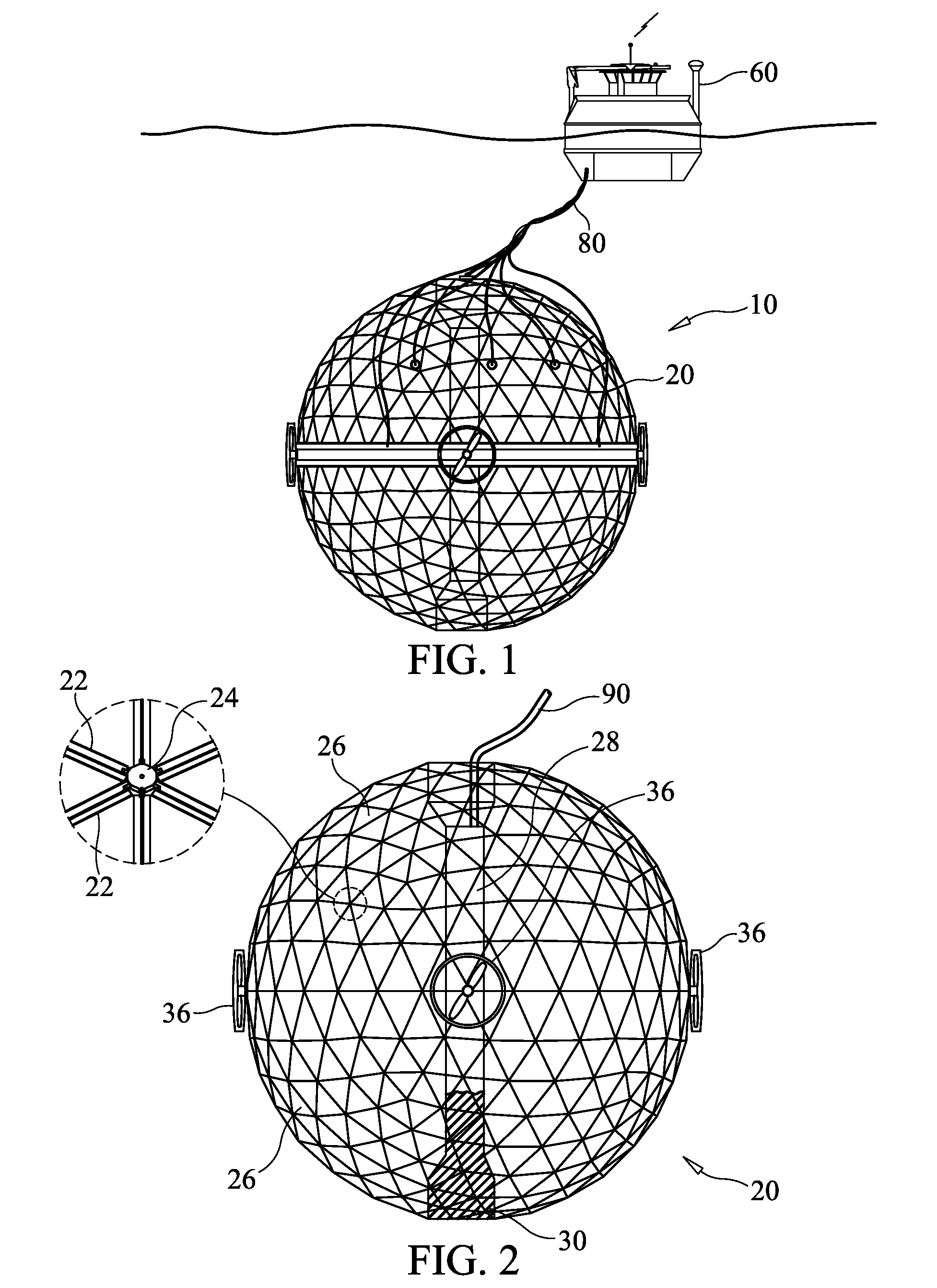

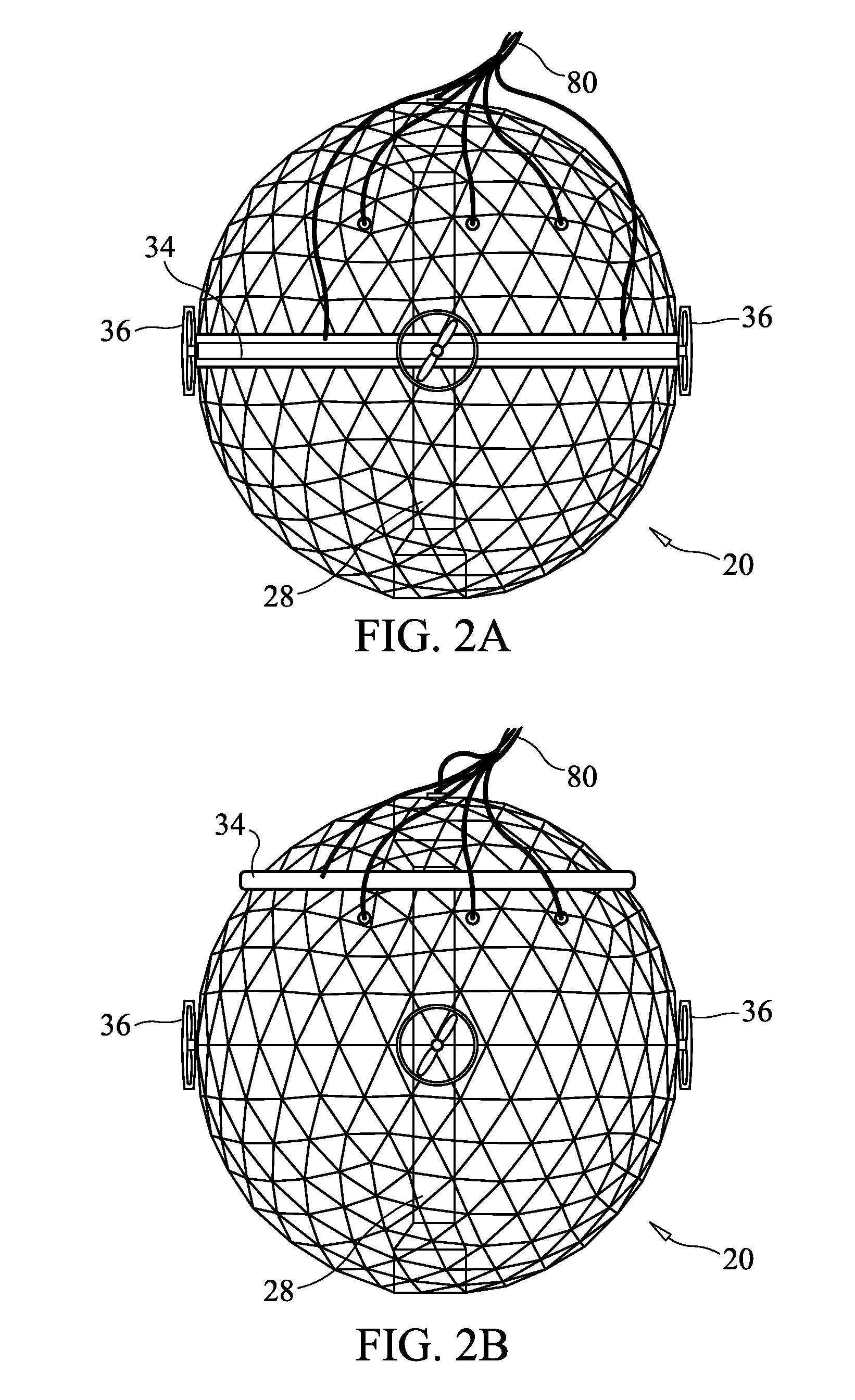

Automated open ocean fish farm structures and systems for open ocean fish farming

ActiveUS20120006277A1Minimize surface waveMinimize tidal forceClimate change adaptationPisciculture and aquariaOcean seaBuoy

An autonomous open-ocean fish-farming structure has a submersible cage enclosure tethered to a topside buoy. The topside buoy stores feed, is equipped with radio telemetry to communicate positioning signals transmitted from external sources, and generates electrical power using, for example, a hybrid solar OTEC heat engine. The structure is navigated and maintained in a geostationary position within the ocean environment by means of position-correction technology and is propelled by thrusters attached to the cage enclosure and, optionally, to the underside of the topside buoy. The self-positioning, self-powered fish-farming structure enables unmanned, extended marine deployment in deeper ocean waters without the need for tethering or anchoring to the ocean floor. Multiple structures can be maintained in a spaced apart configuration to comprise a flotilla of fish farming structures attended by a tender ship that is autonomous, easily serviced and conveniently relocated.

Owner:SPENCER JR TRUSTEE WILLIAM A SPENCER JR LTD TRUST DTD 11 02 2007 WILLIAM A

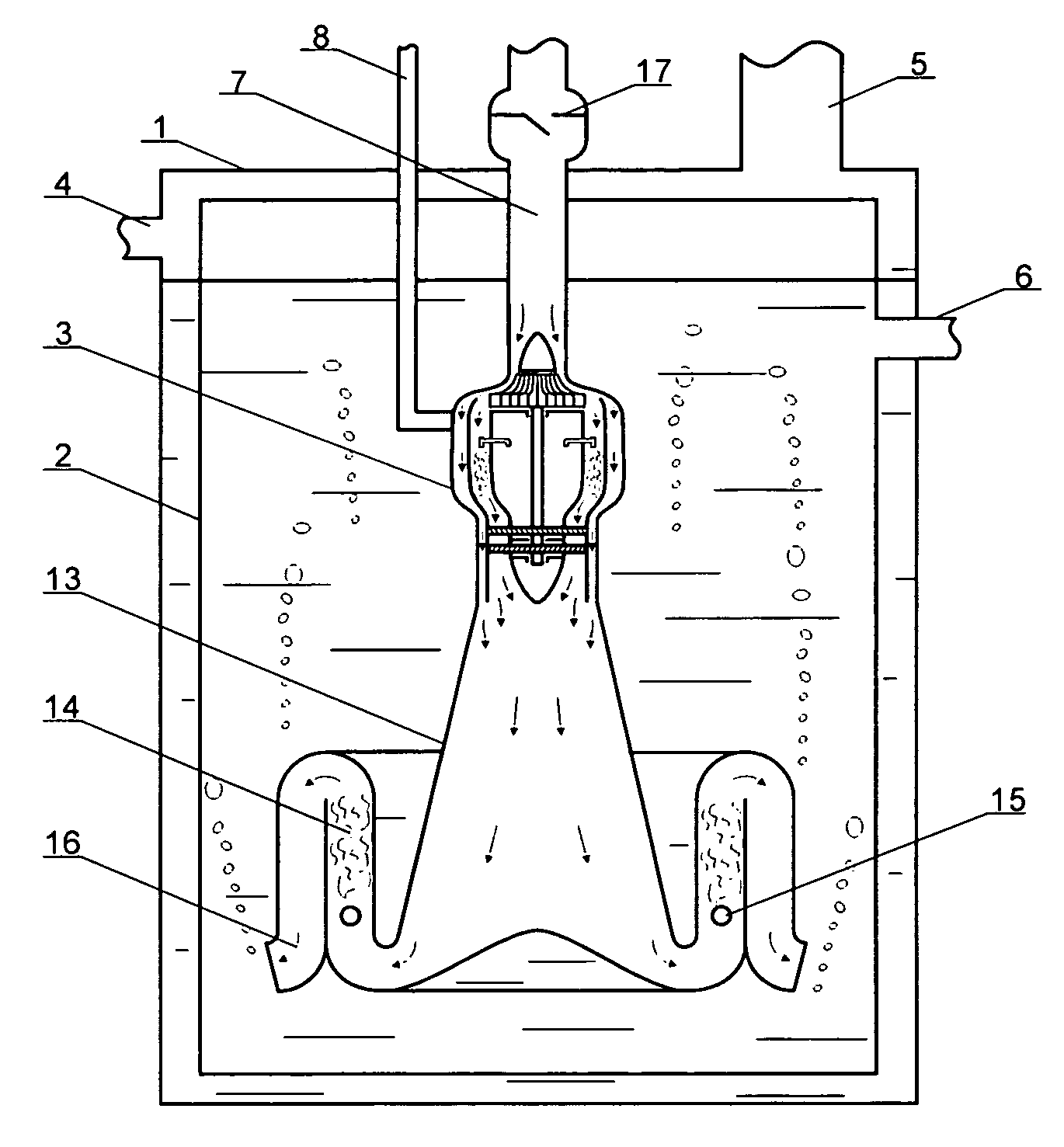

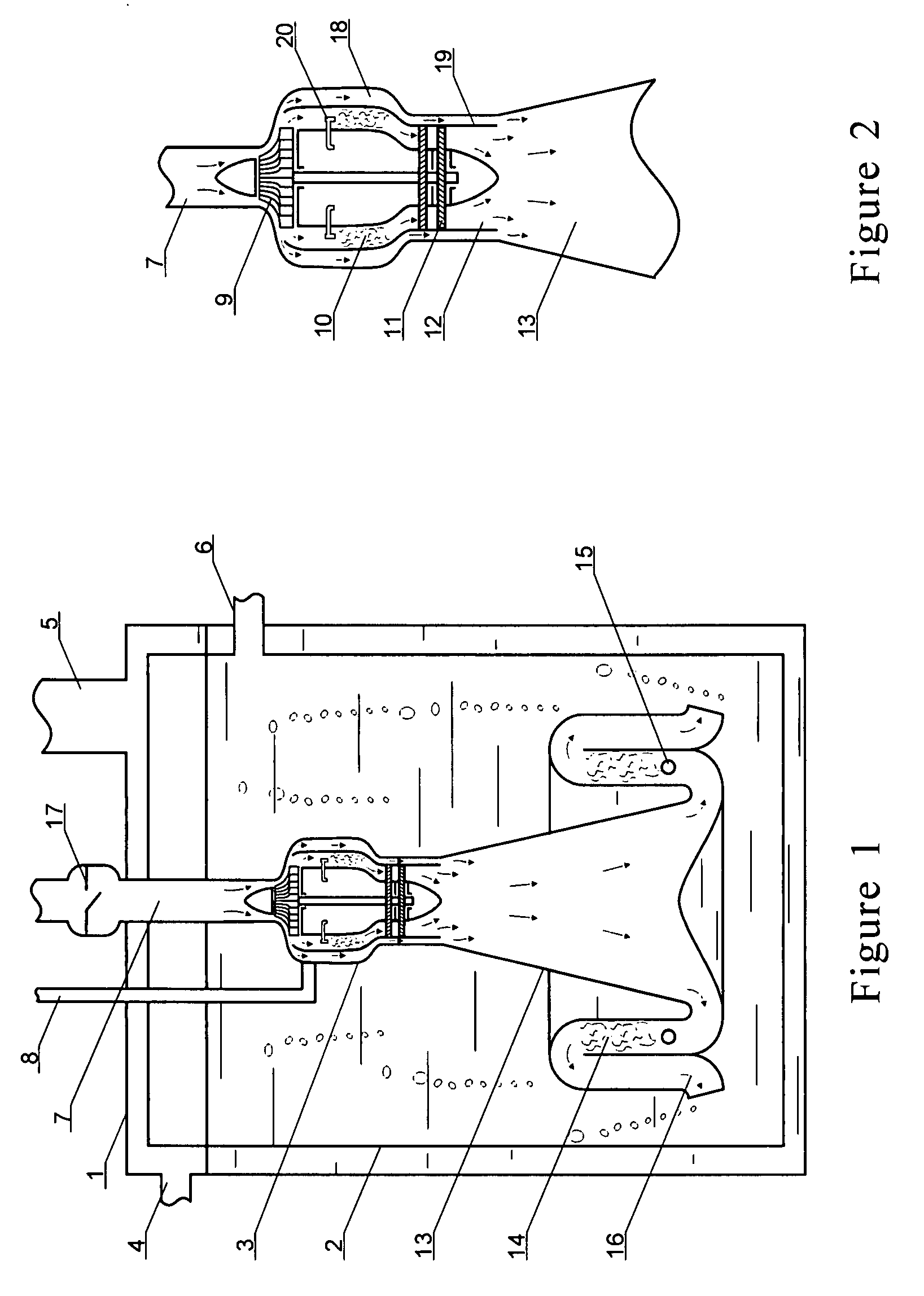

Method and device of turbine submerged combustion boiler

InactiveUS20080035078A1Improve energy efficiencySteam generation using pressureGas turbine plantsComing outHigh energy

The invention is about a submerged combustion method and the device; in details, it is a submerged combustion method and the device utilizing turbine heat engine principle. In the invention, turbine power combustion means is used and substituted conventional submerged combustion system that must equip air blowing means. The high temperature gases generated from the combustion within the turbine power combustion means will do works on turbine, which will drive the air compressor means of the turbine power combustion means to induce air for combustion, and will drive the second-time complete combustion of high temperature gases and the complement fuel, and then the gases will come out from water bottom against tank water pressure and carry out heat interchange with tank water. The turbine submerged combustion boiler device of the invention need not equip air blowing means additionally which would consume energy. So it has high energy efficiency and a simple system structure. And it has features of high heat interchange rate, stable long term heat efficiency, environmental protection, etc.

Owner:LI WEICHENG

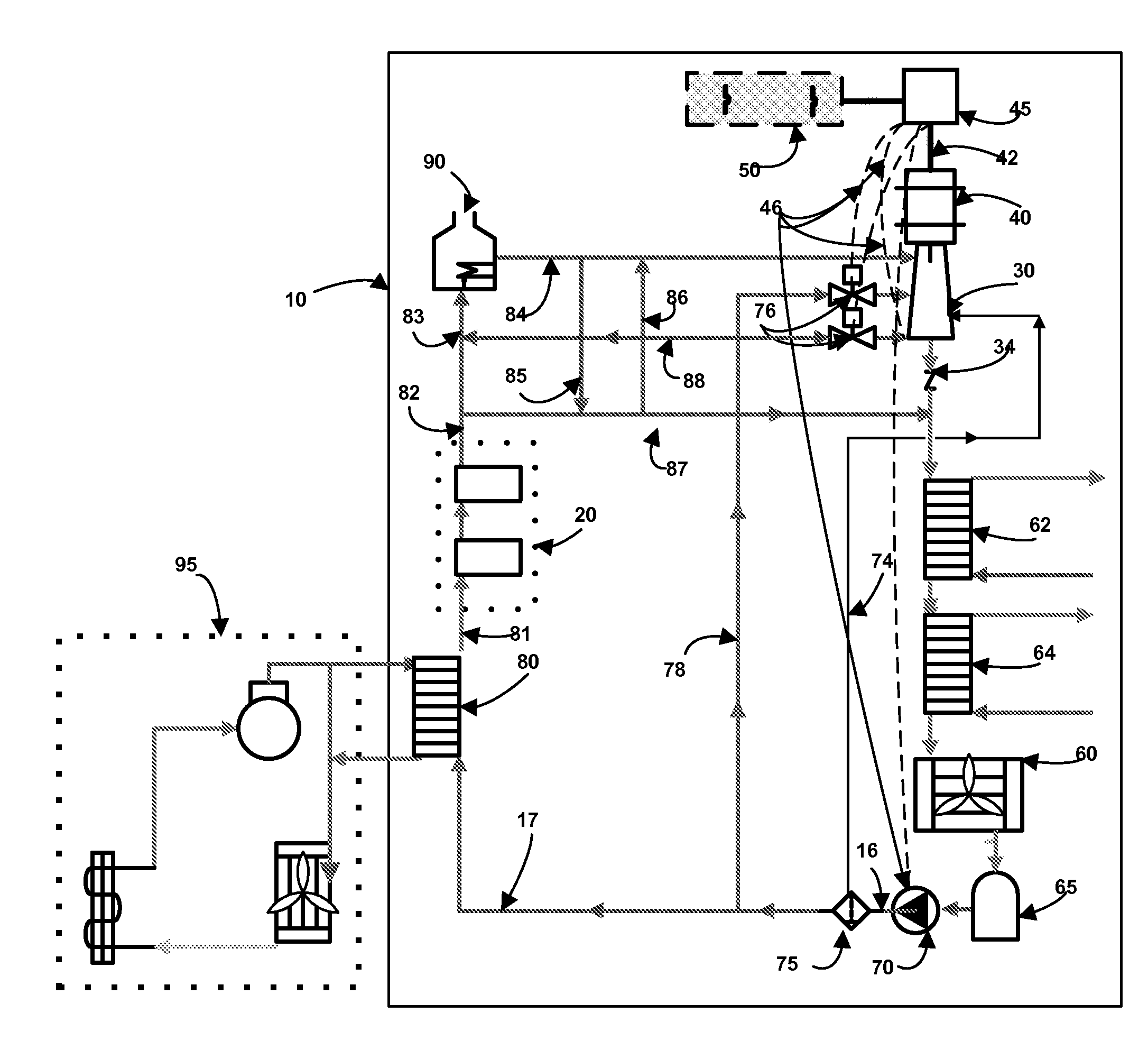

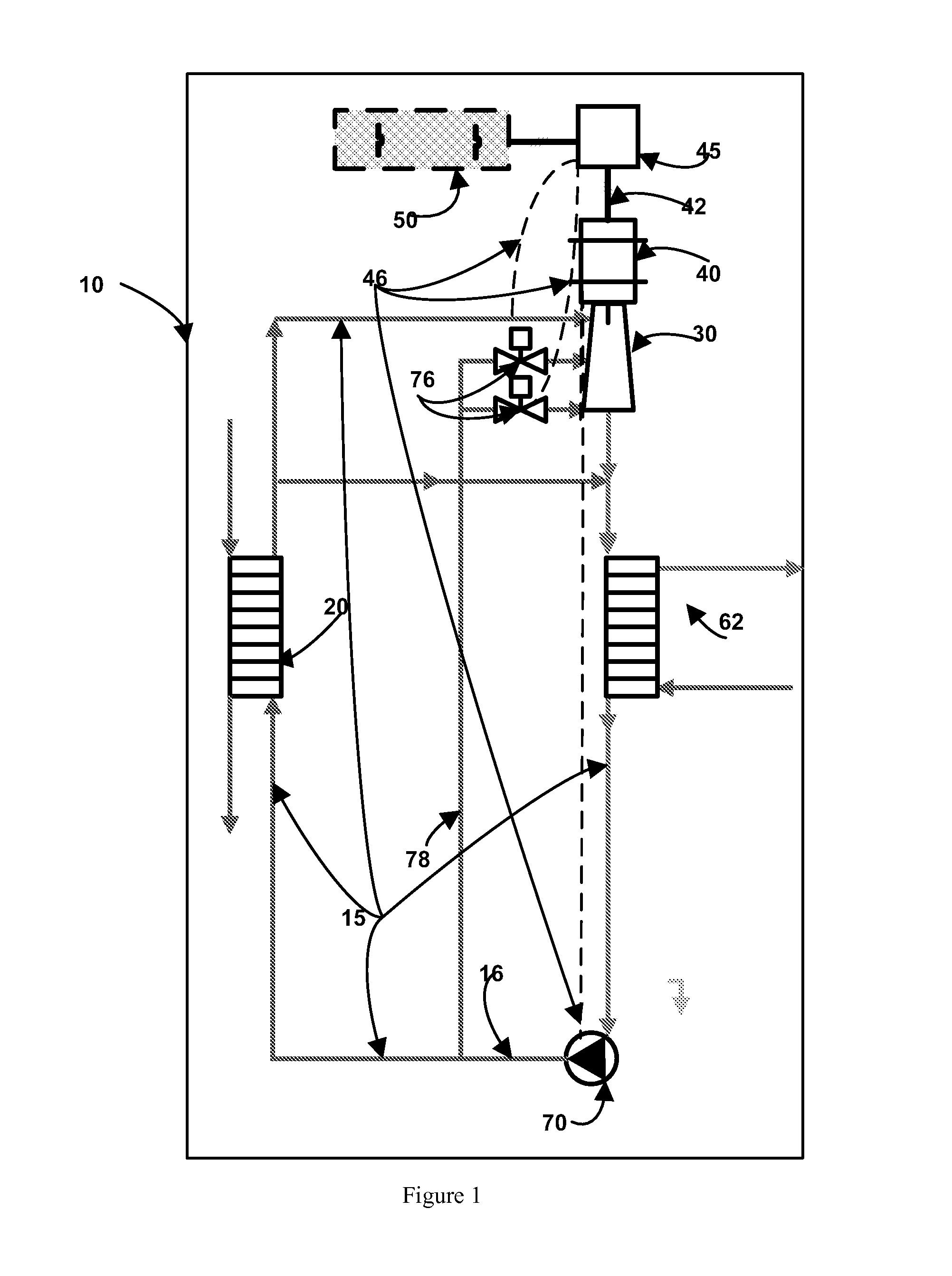

Apparatus and method for producing sustainable power and heat

InactiveUS20080163625A1Maximize energy efficiencyEasy to convertSteam useCombined combustion mitigationWorking fluidWater production

An integrated system provides electricity and heat from solar, waste heat, biomass and fossil fuel energy. The system operates with a volatile organic working fluid that circulates in a variable speed heat engine type cycle, that is heated either to its boiling point, to a saturated state or above its boiling point, or to a superheated gas state, expanded through an expander, with working fluid injected therein such that the fluid exiting the expander is cooled in a condenser in thermal communication with a facility's domestic hot water, space heating or process heating systems, and circulated by a pump. Heat exchange loops define hot water production capability for use in a facility while a generator is coupled to the expander to produce electricity and is connected to the utility grid at fixed frequency and voltage in either a paralleling or island mode.

Owner:OBRIEN KEVIN M

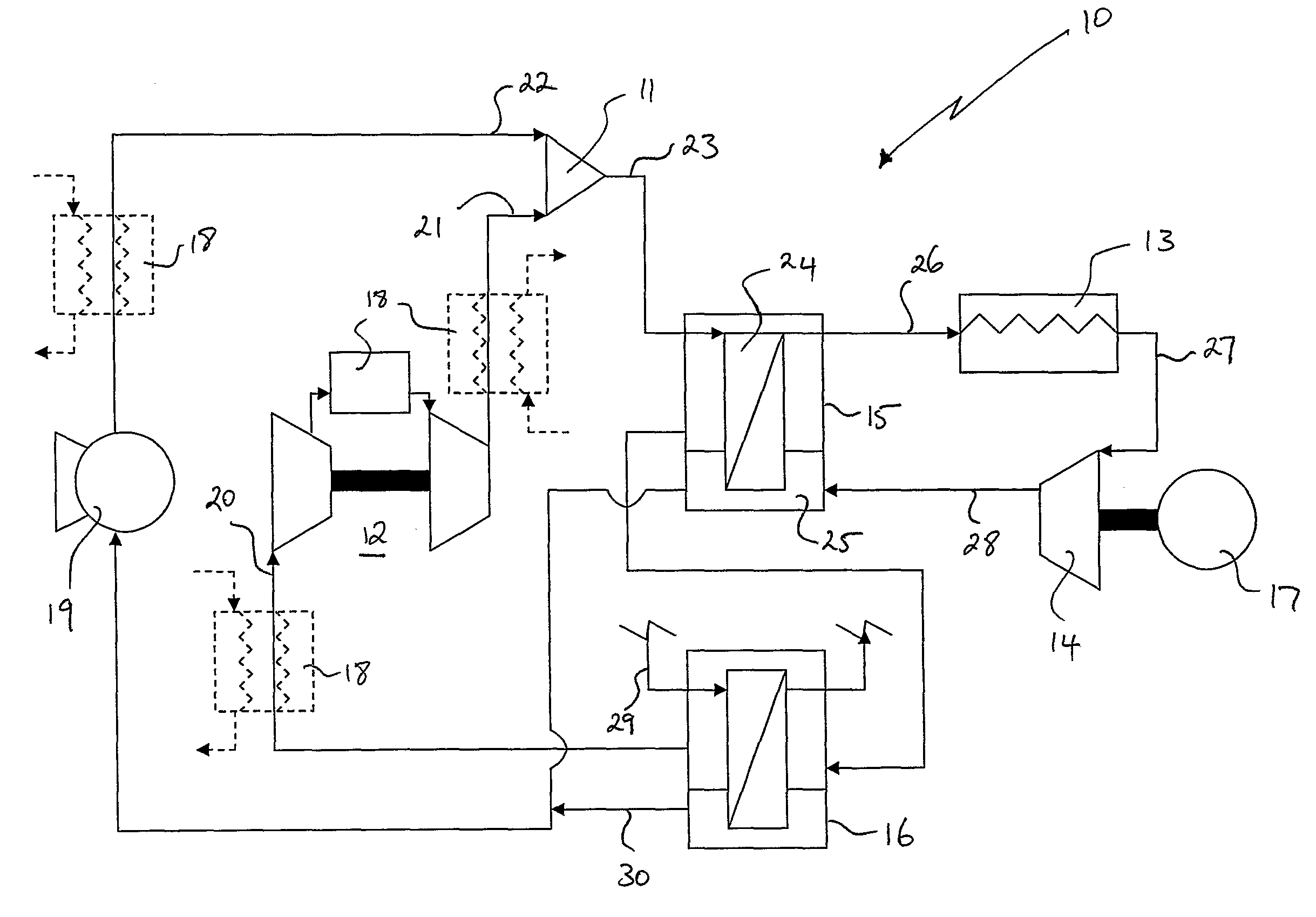

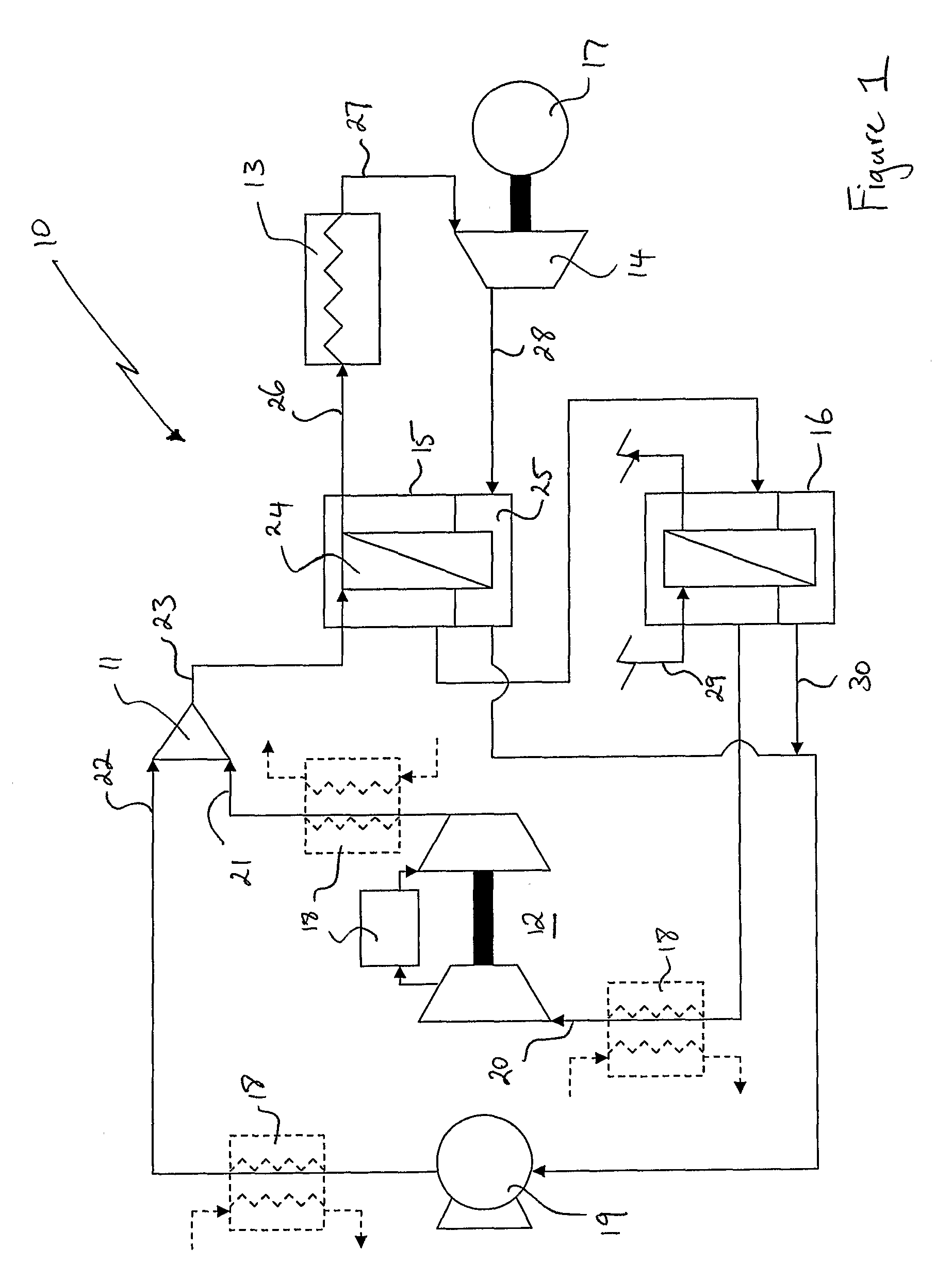

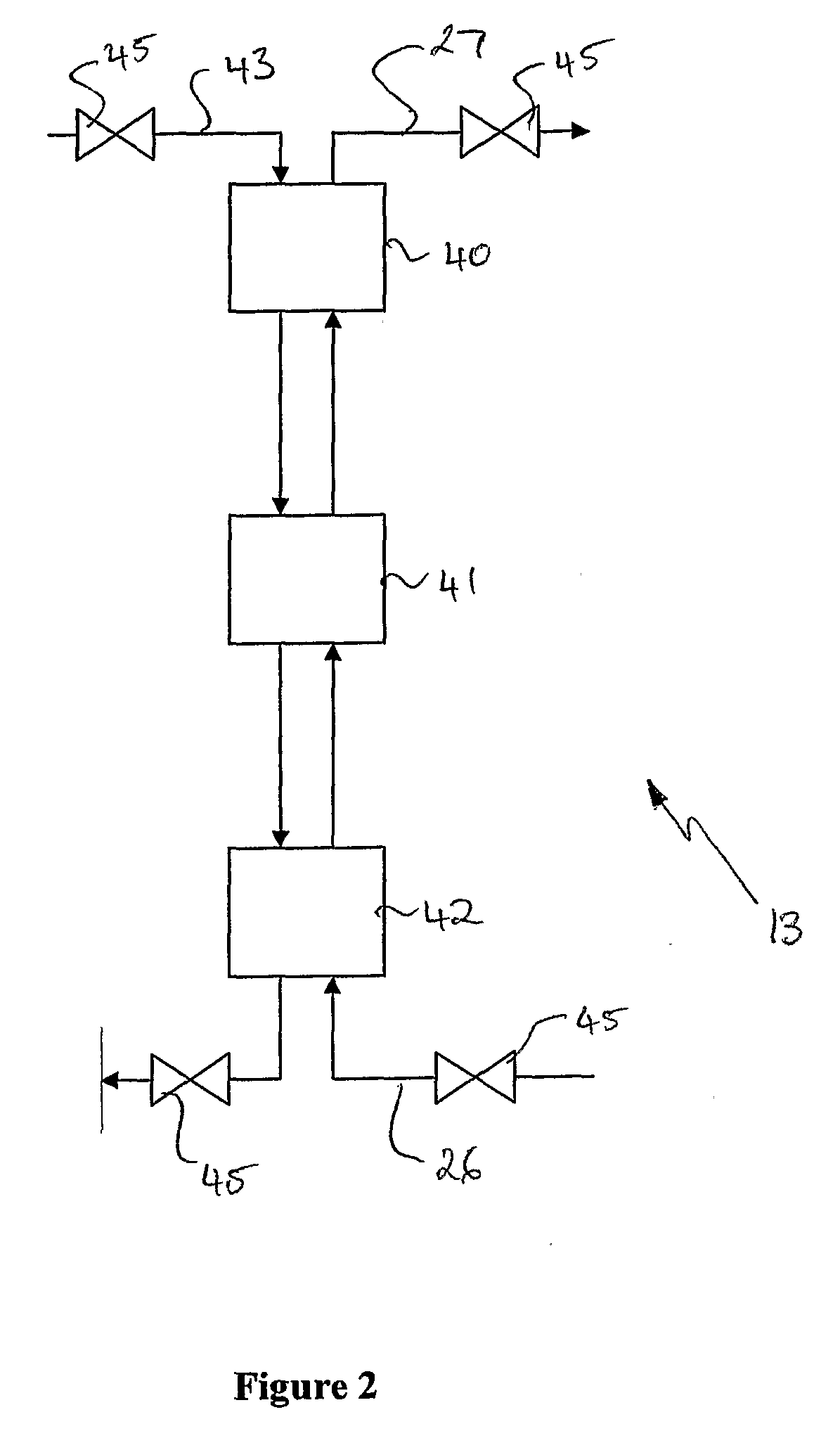

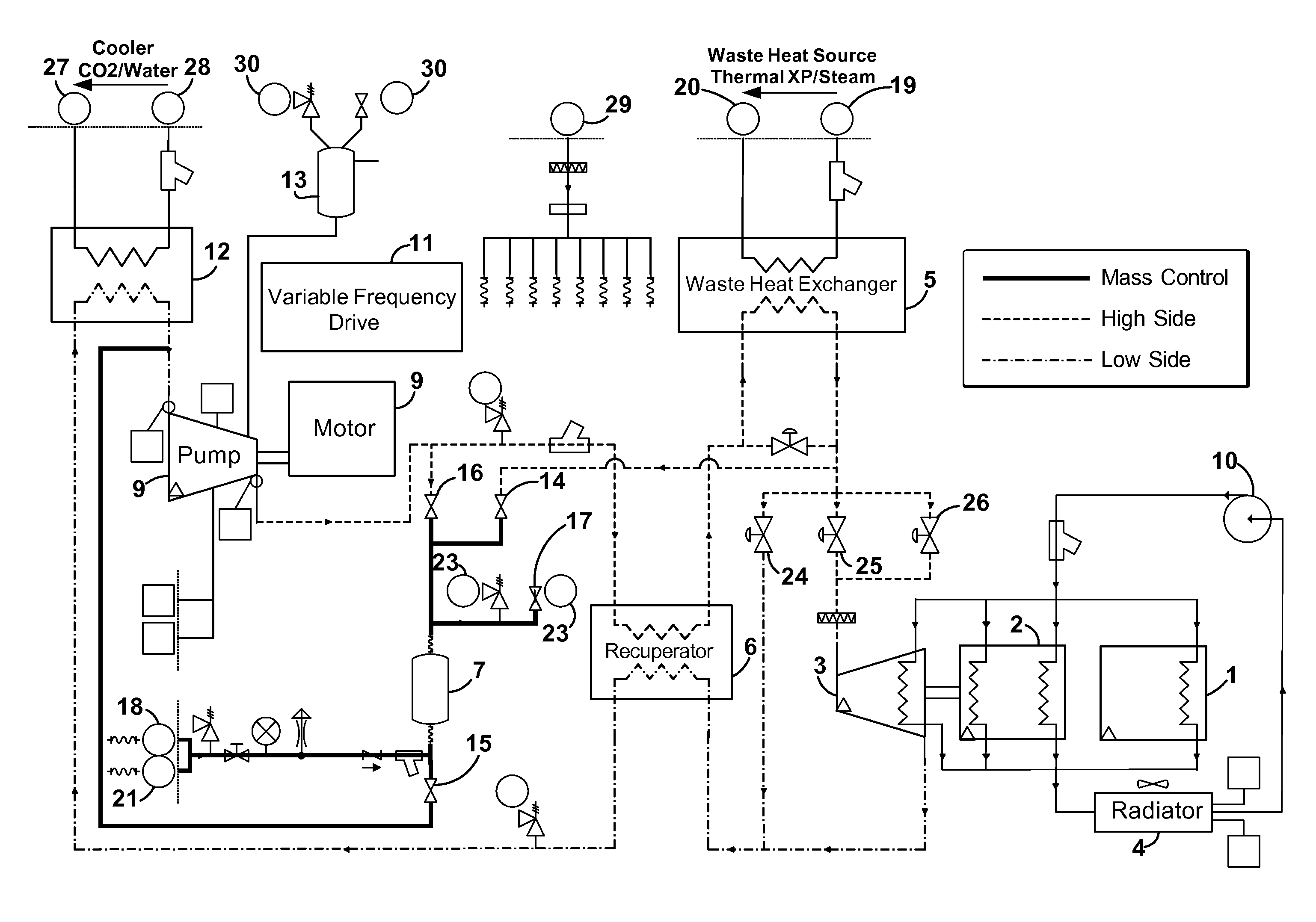

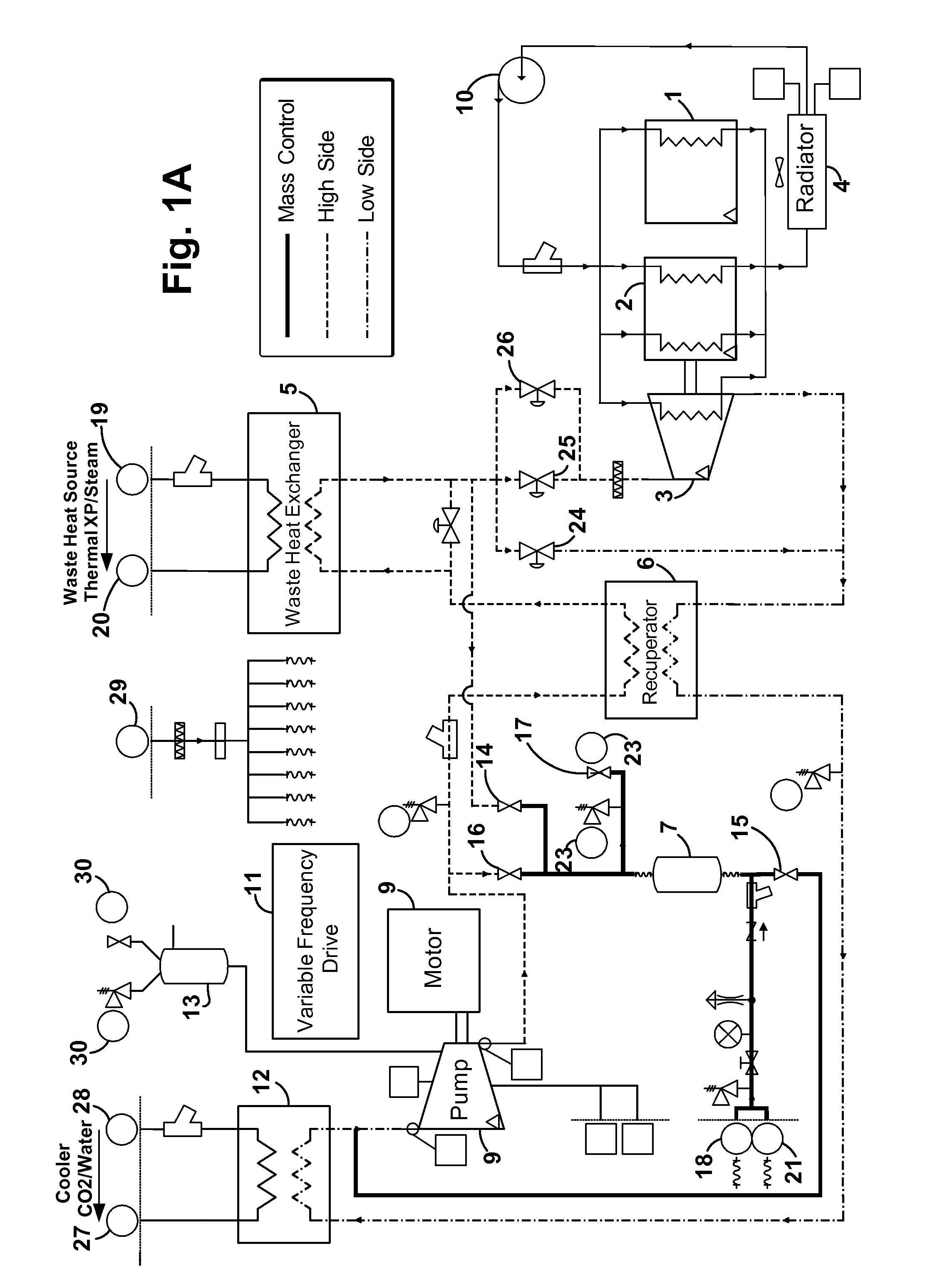

Parallel cycle heat engines

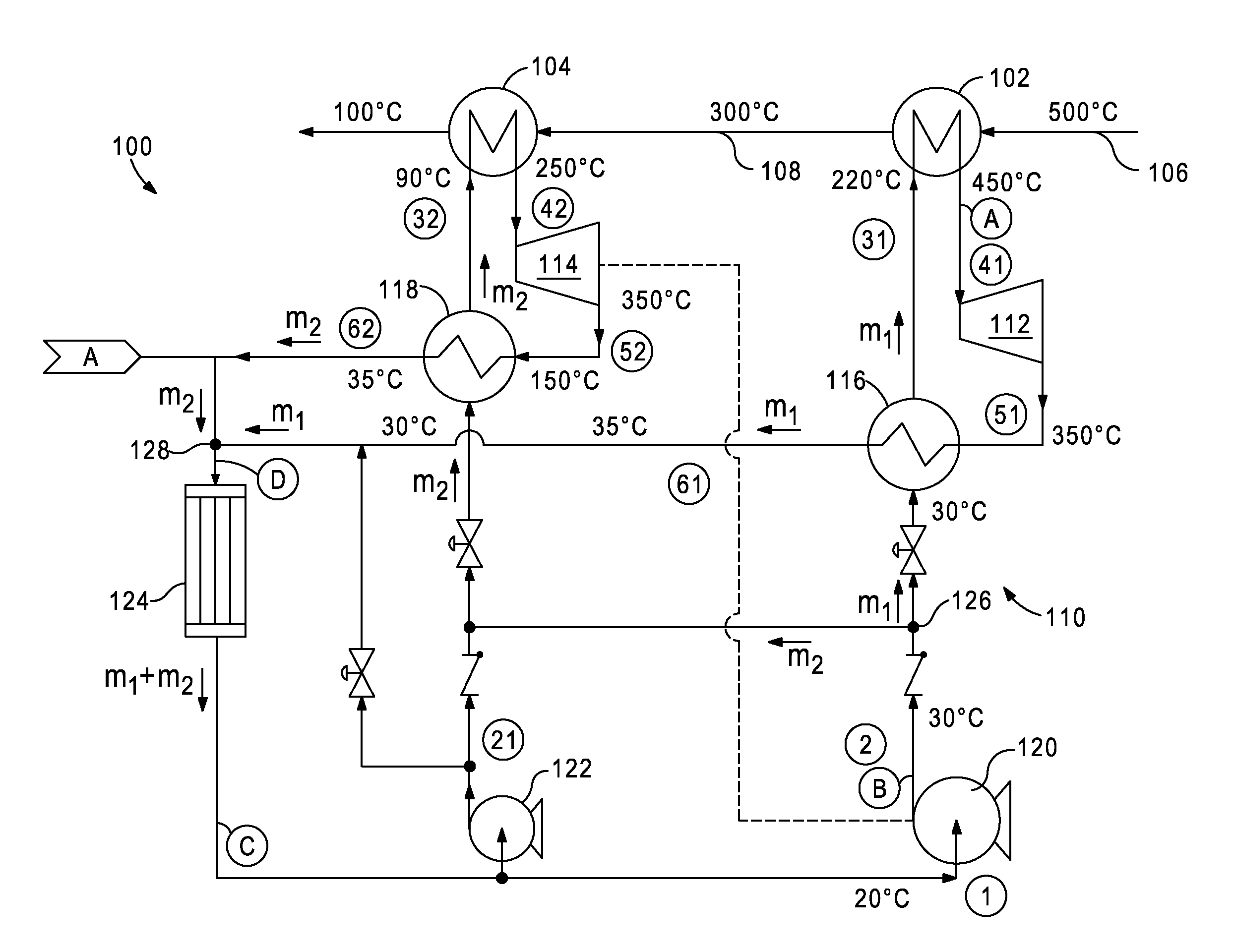

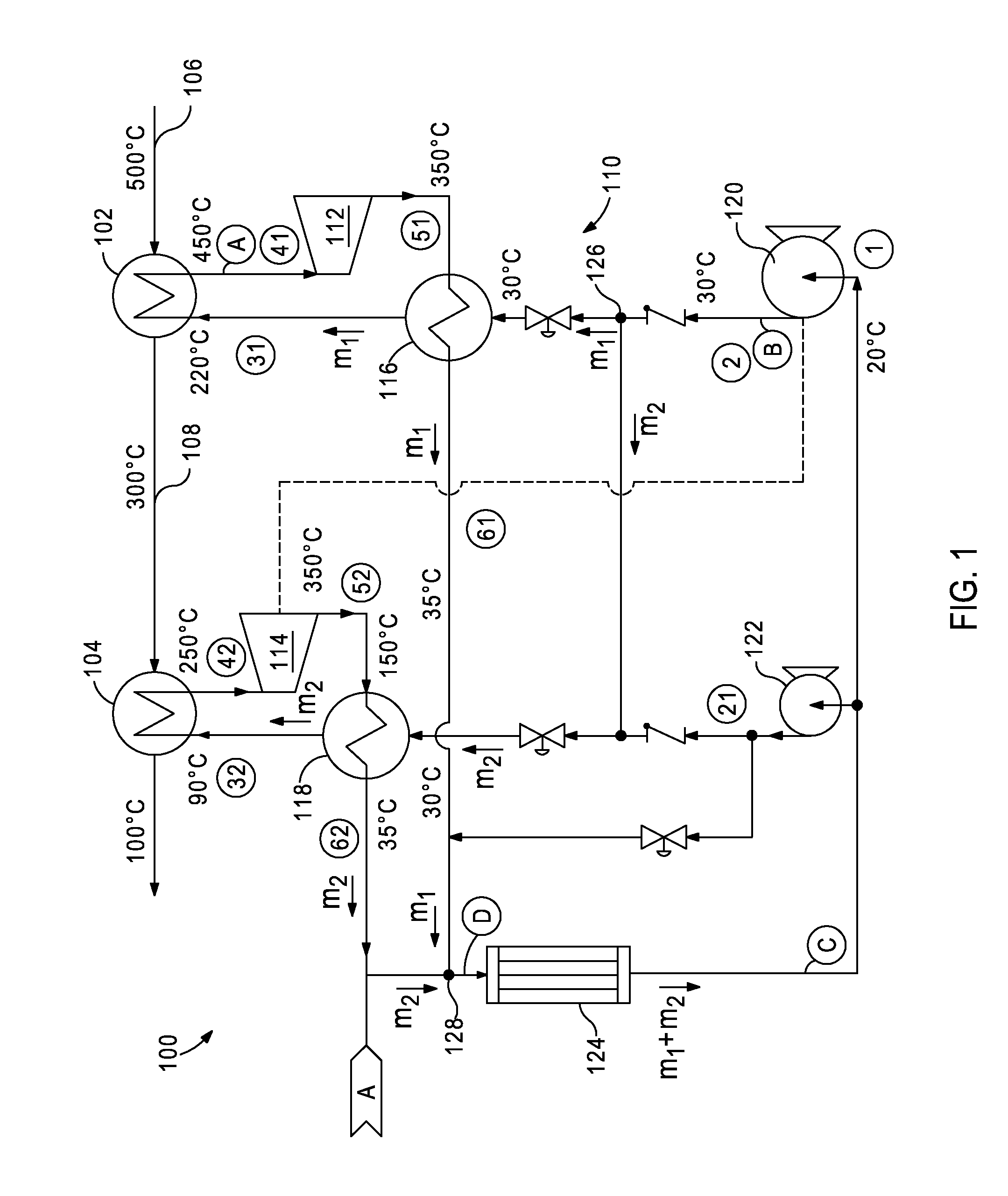

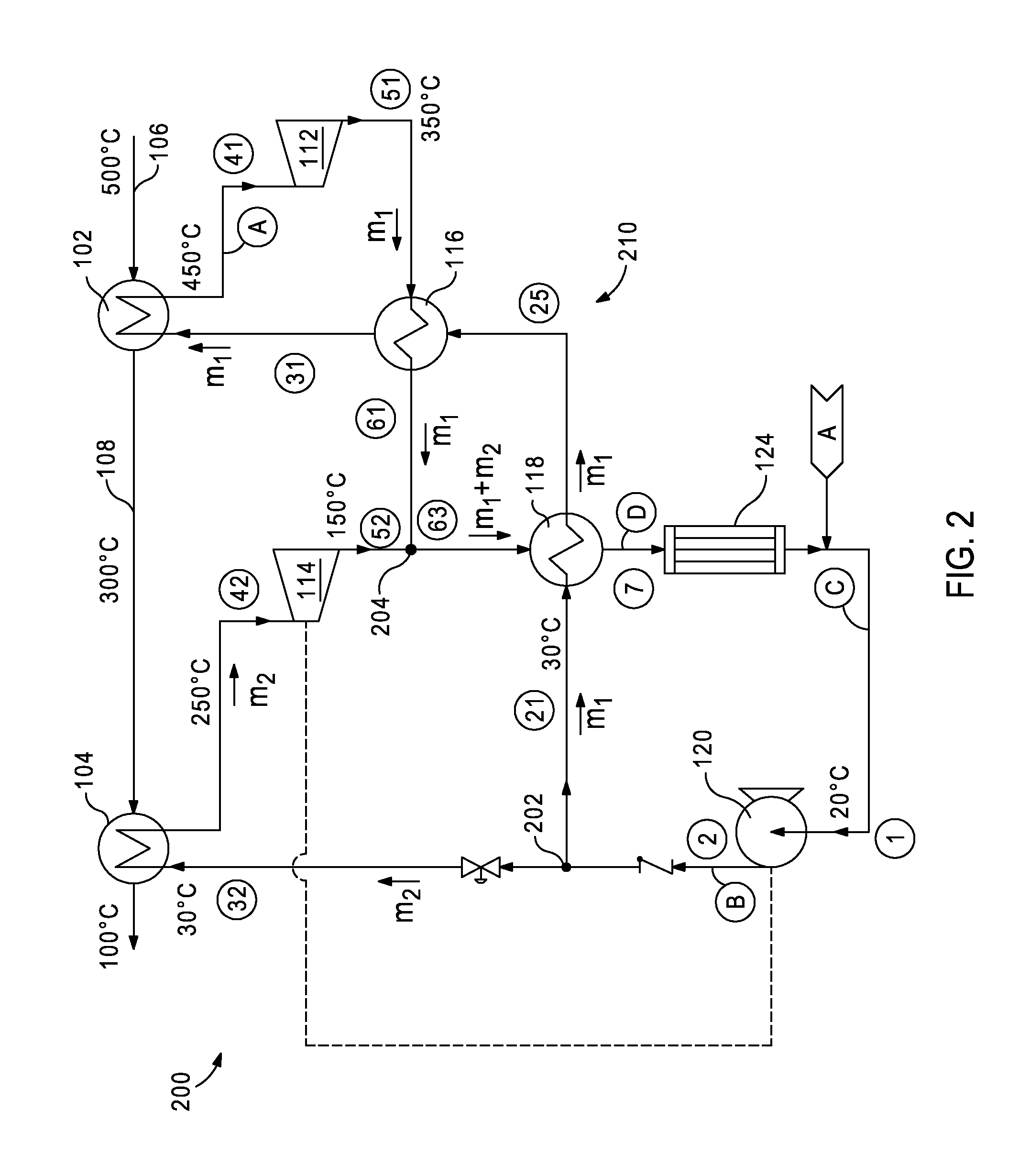

Waste heat energy conversion cycles, systems and devices use multiple waste heat exchangers arranged in series in a waste heat stream, and multiple thermodynamic cycles run in parallel with the waste heat exchangers in order to maximize thermal energy extraction from the waste heat stream by a working fluid. The parallel cycles operate in different temperature ranges with a lower temperature work output used to drive a working fluid pump. A working fluid mass management system is integrated into or connected to the cycles.

Owner:ECHOGEN POWER SYST

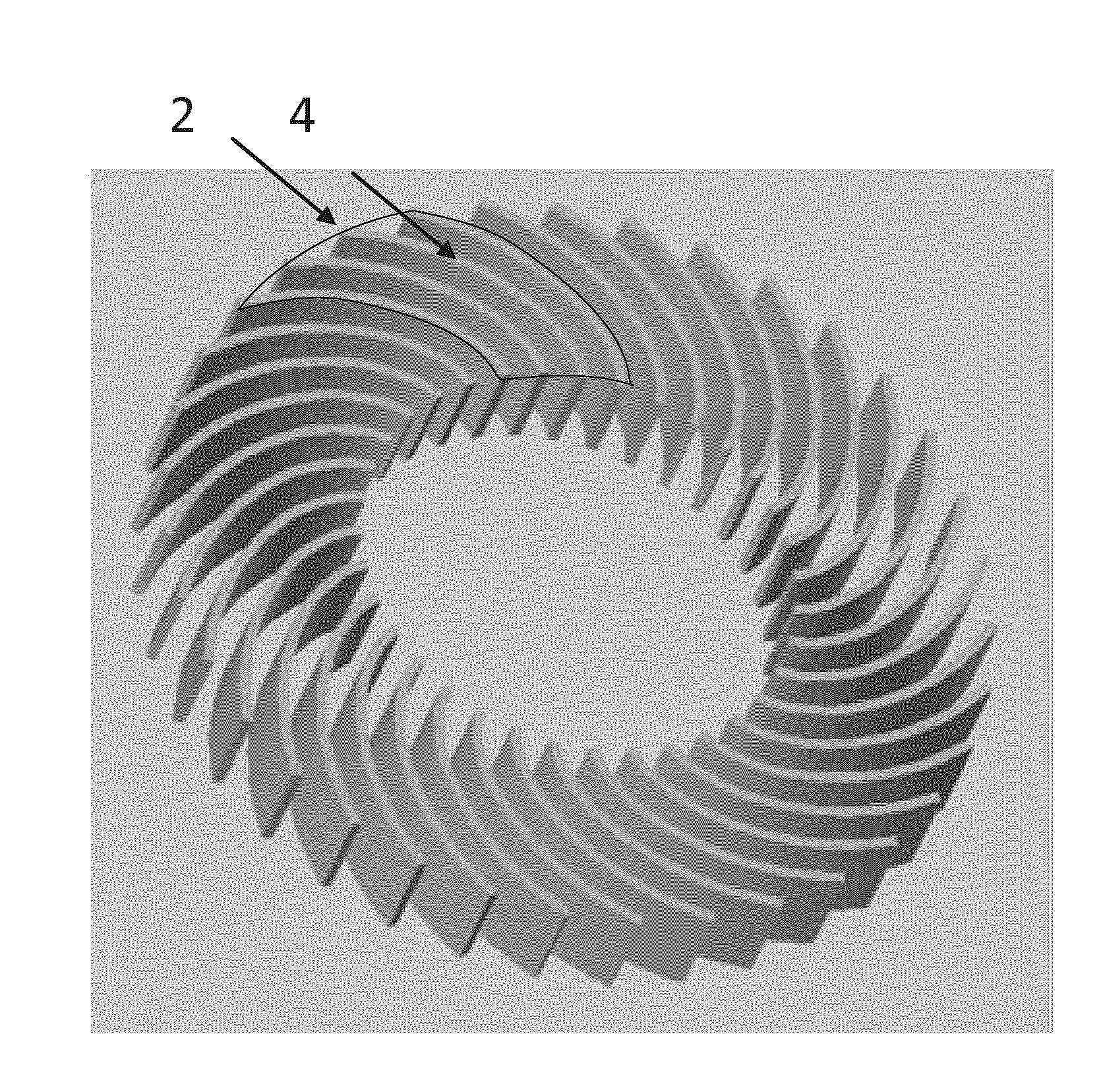

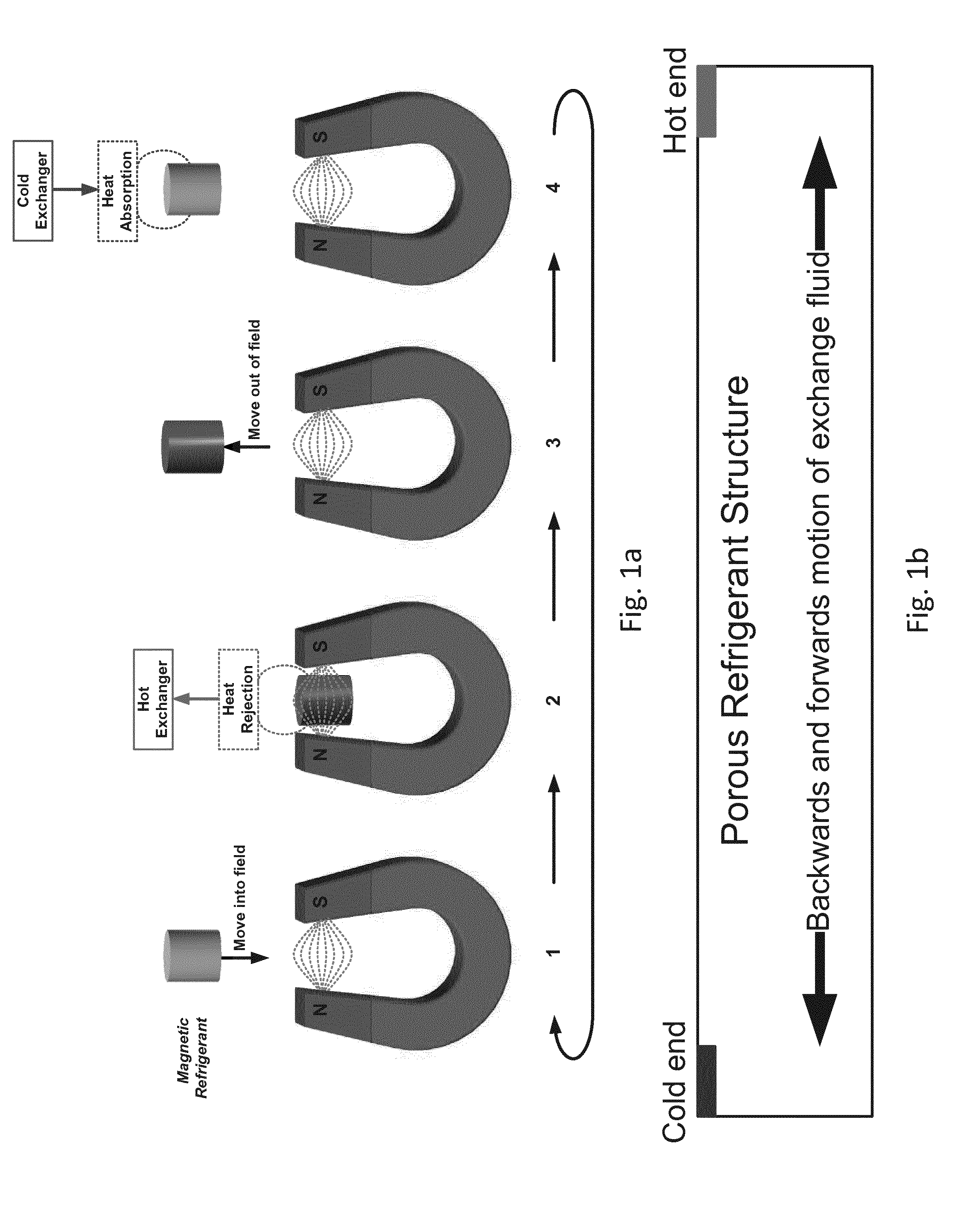

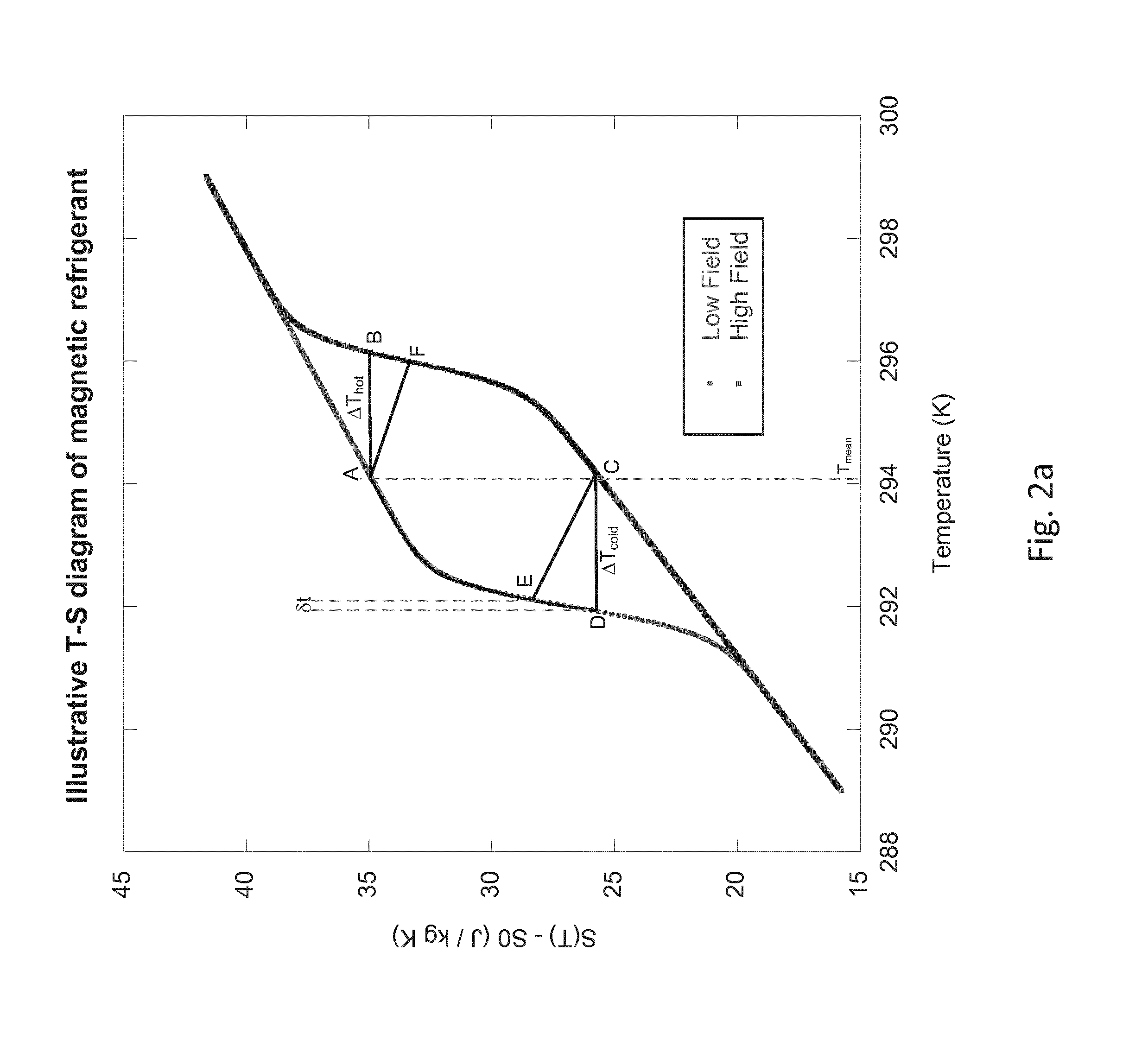

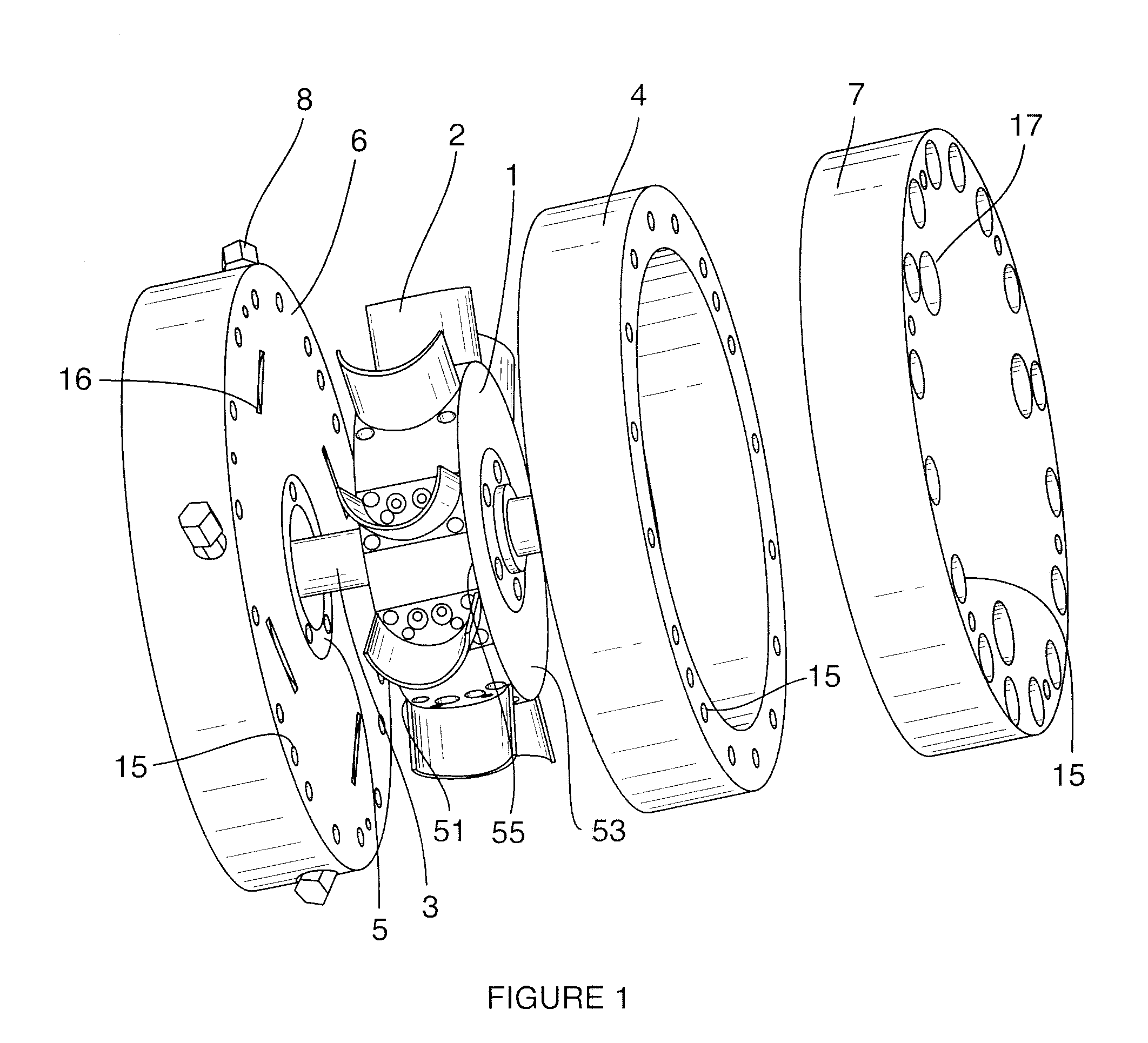

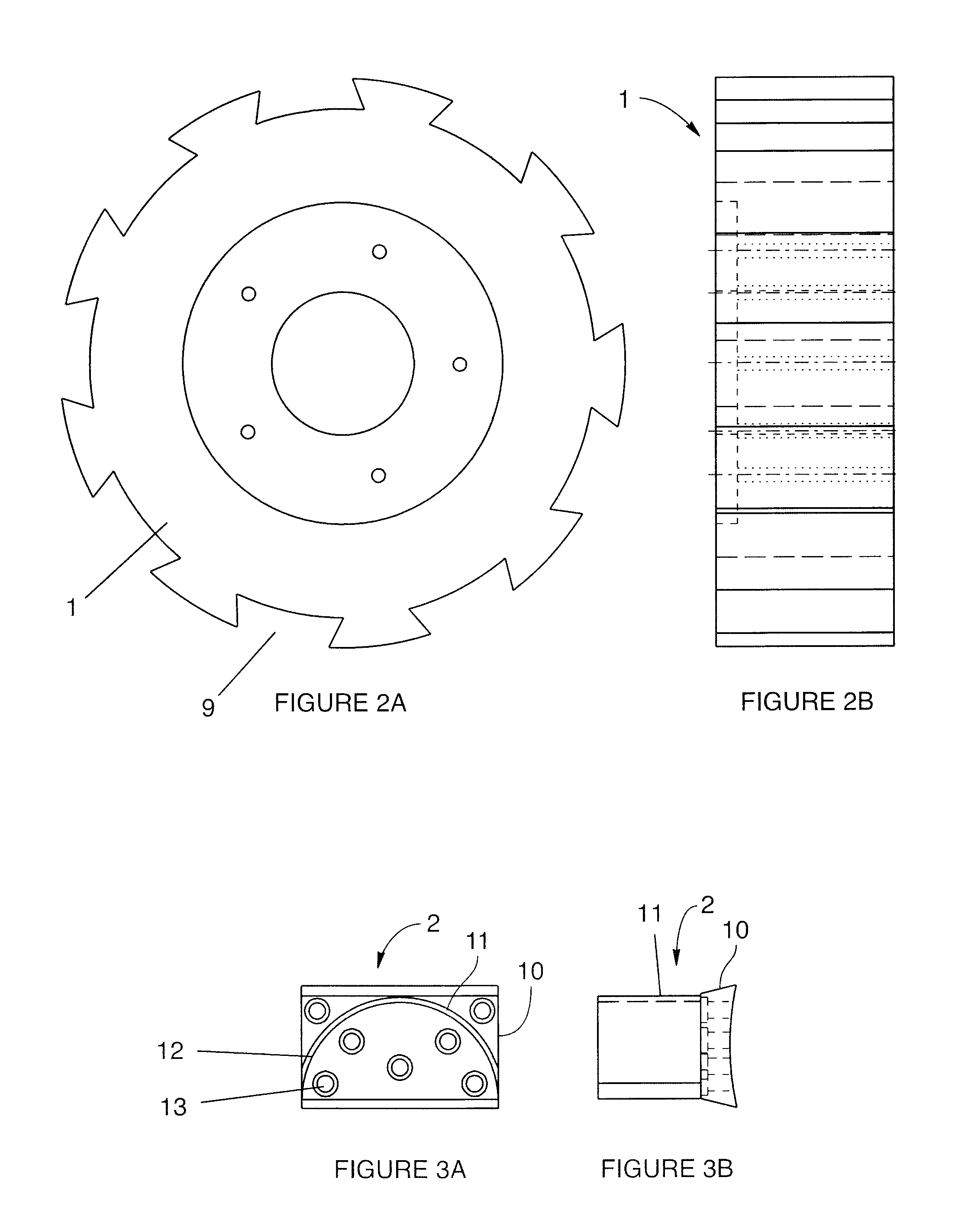

Multi-Material-Blade for Active Regenerative Magneto-Caloric and Electro-Caloric Heat Engines

ActiveUS20140216057A1Reducing HE lossLow-cost manufacturing processRoof drainageMachines using electric/magnetic effectsMulti materialCurve shape

The present invention describes the design and fabrication of Multi-Material-Blades used as active regenerative regenerators in active regenerative magneto-caloric or electro-caloric engines. The blades consist of a plurality of elements (2) that divide the blade body along its length. Each element (2) is made of a different magneto-caloric or electro-caloric material selected appropriately, and a plurality of dedicated channels (3) penetrates the blade body (1) and extends along the length of the blade. The dedicated channels (3) can be provided with fluid mixing structures, porous layers or hydrophobic coatings to reduce the HE loss in an active regenerative engine. The Multi-Material-Blades are obtainable by ink jet printing techniques to reduce costs. The Multi-Material-Blades can further have a curved shape to form an involute blade body (1). All measures can improve the performance of active regenerative magneto-caloric or electro-caloric engines, and lay the basis for commercial solutions.

Owner:CAMFRIDGE

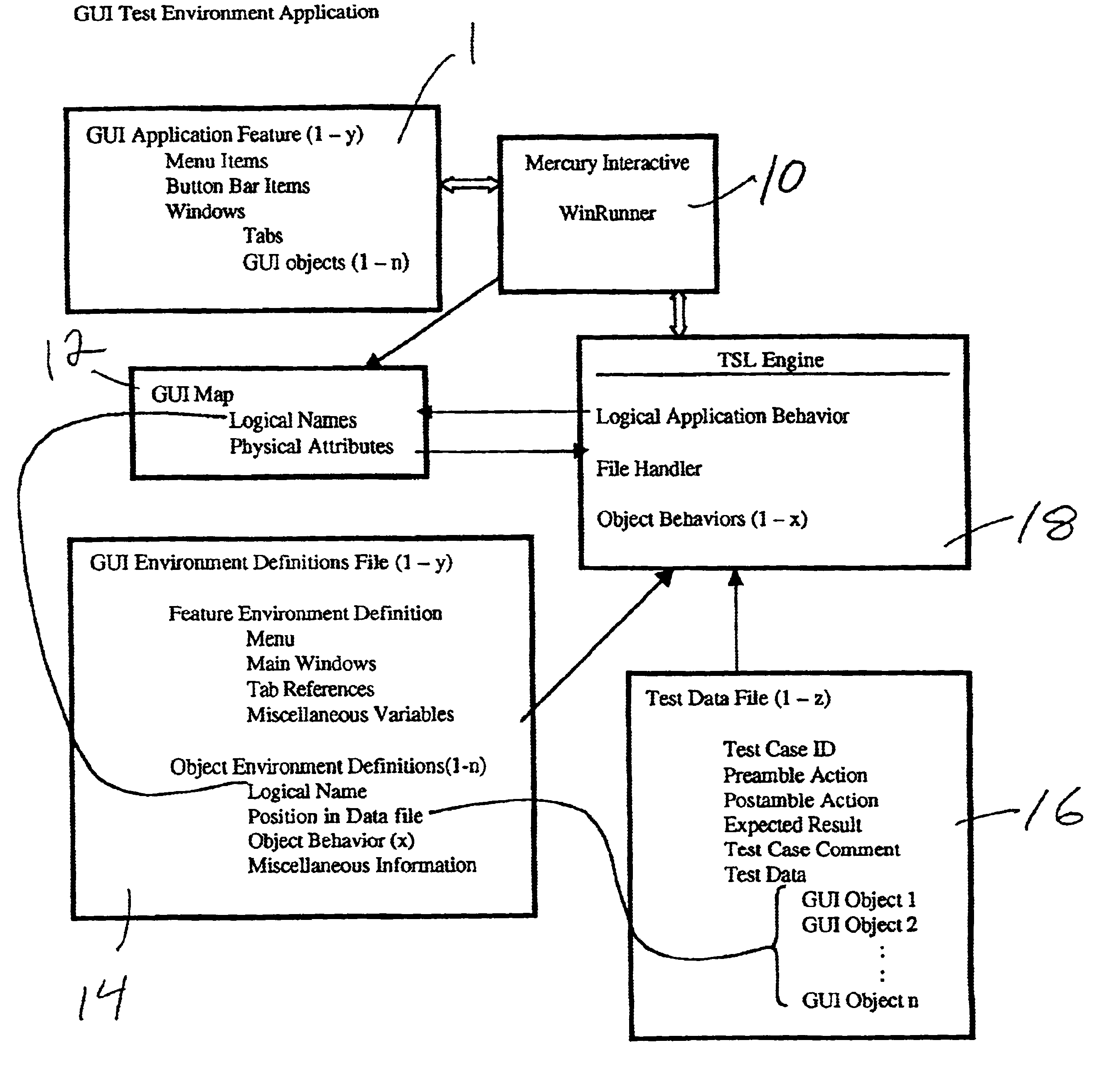

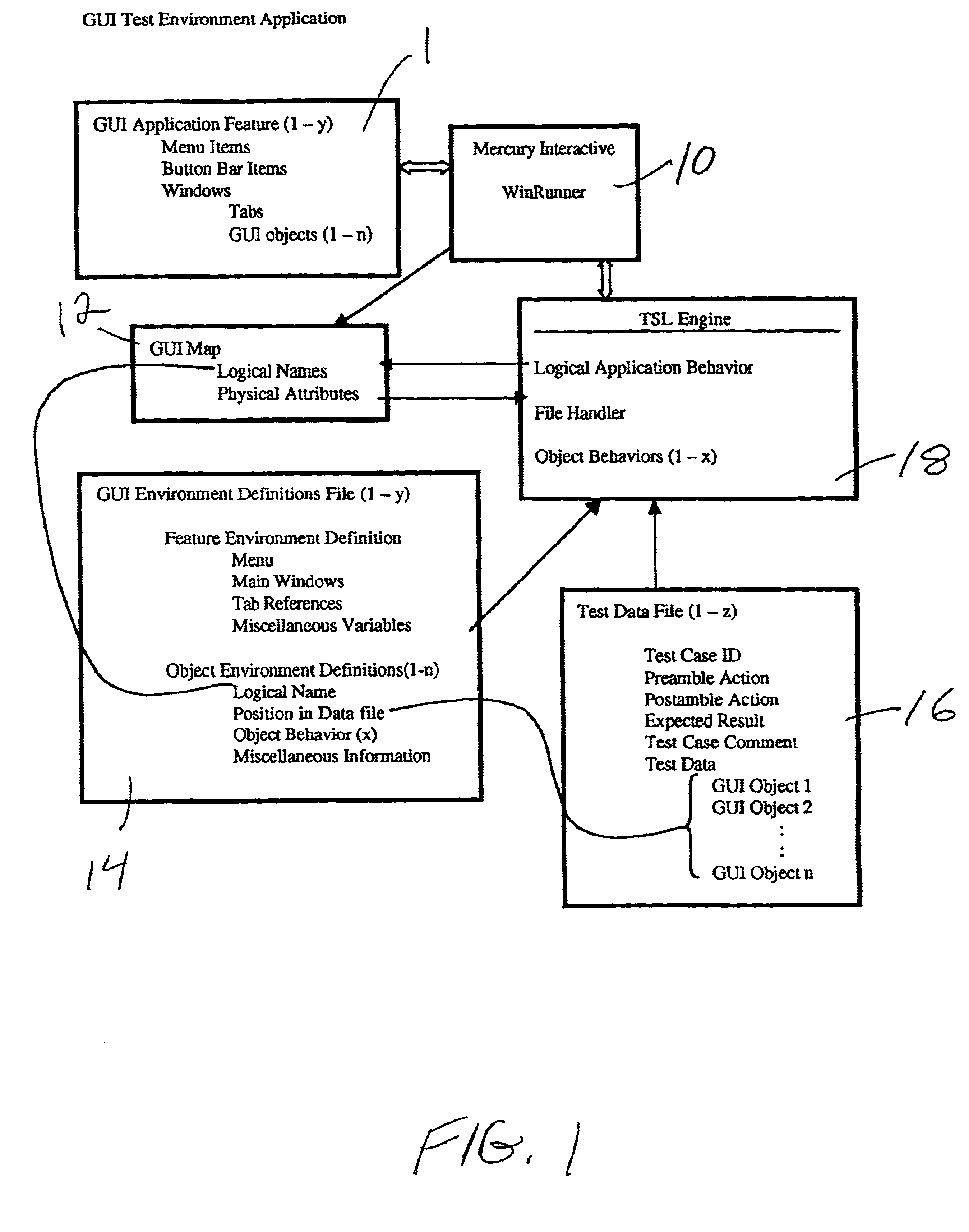

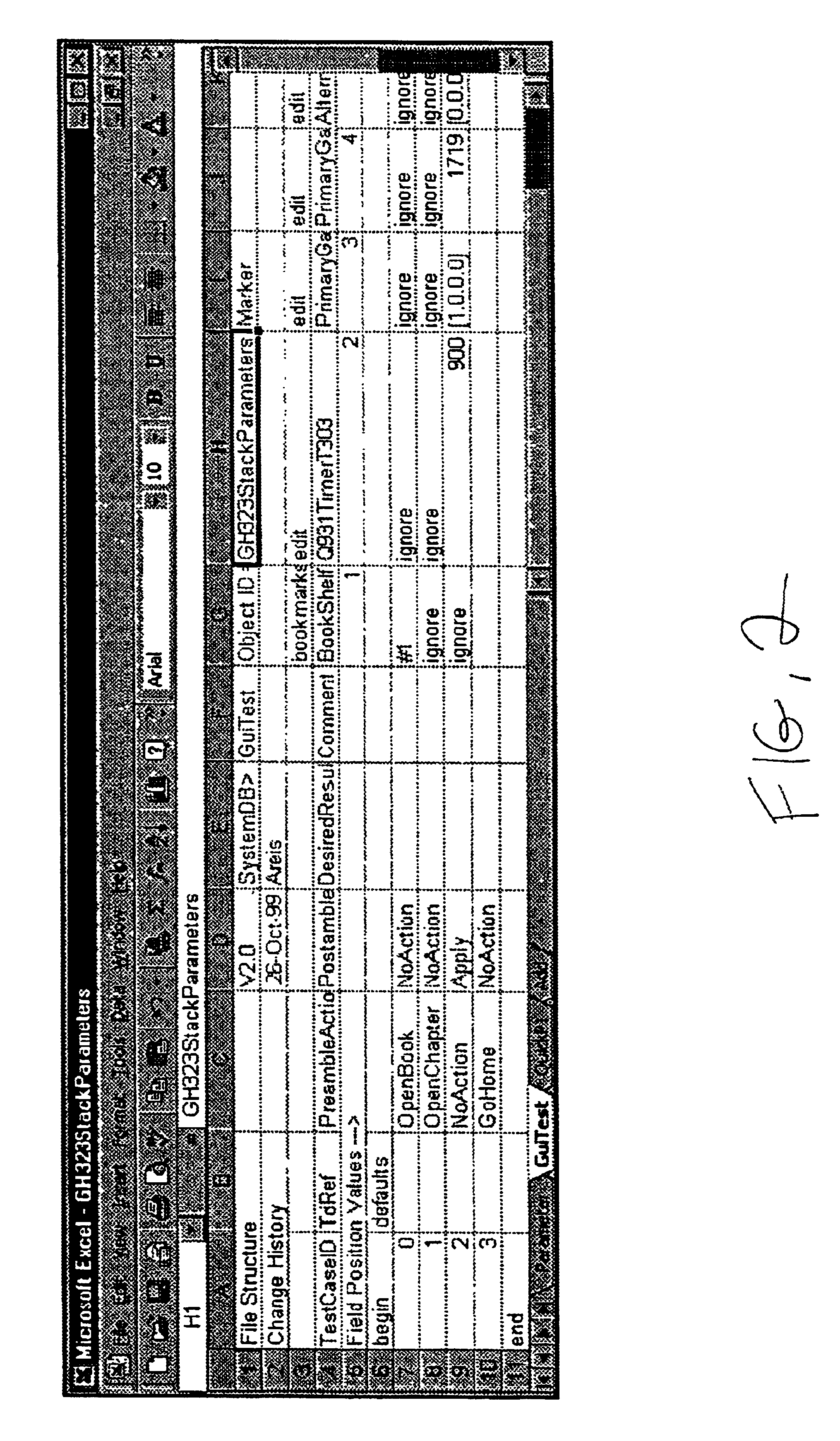

Environment based data driven automated test engine for GUI applications

InactiveUS6961873B2Maximum flexibilityReduce investmentSoftware testing/debuggingSpecific program execution arrangementsScripting languageElectronic form

The invention includes a scriptable GUI test tool which generates a GUI map (or which includes a utility which generates a GUI map), at least one environment definition (parameter) file, at least one test data (driver) file, and an automated test engine. A separate environment definition file is provided for each feature of the GUI. Each environment definition file provides the abstract details required by the test engine in order to support common processes for different applications. The test data file is organized into rows of data where each row defines a single test and each column represents a parameter. The automated test engine is composed of a plurality of library modules written in the scripting language of the scriptable GUI test tool. The ATE is driven by the test data file and calls upon the GUI map and environment definition file. According to the presently preferred embodiment, the scriptable GUI test tool is WinRunner®. The environment definition files and the test data files are preferably generated with a spreadsheet program such a Microsoft Excel® and saved as comma delimited text files.

Owner:UNIFY INC

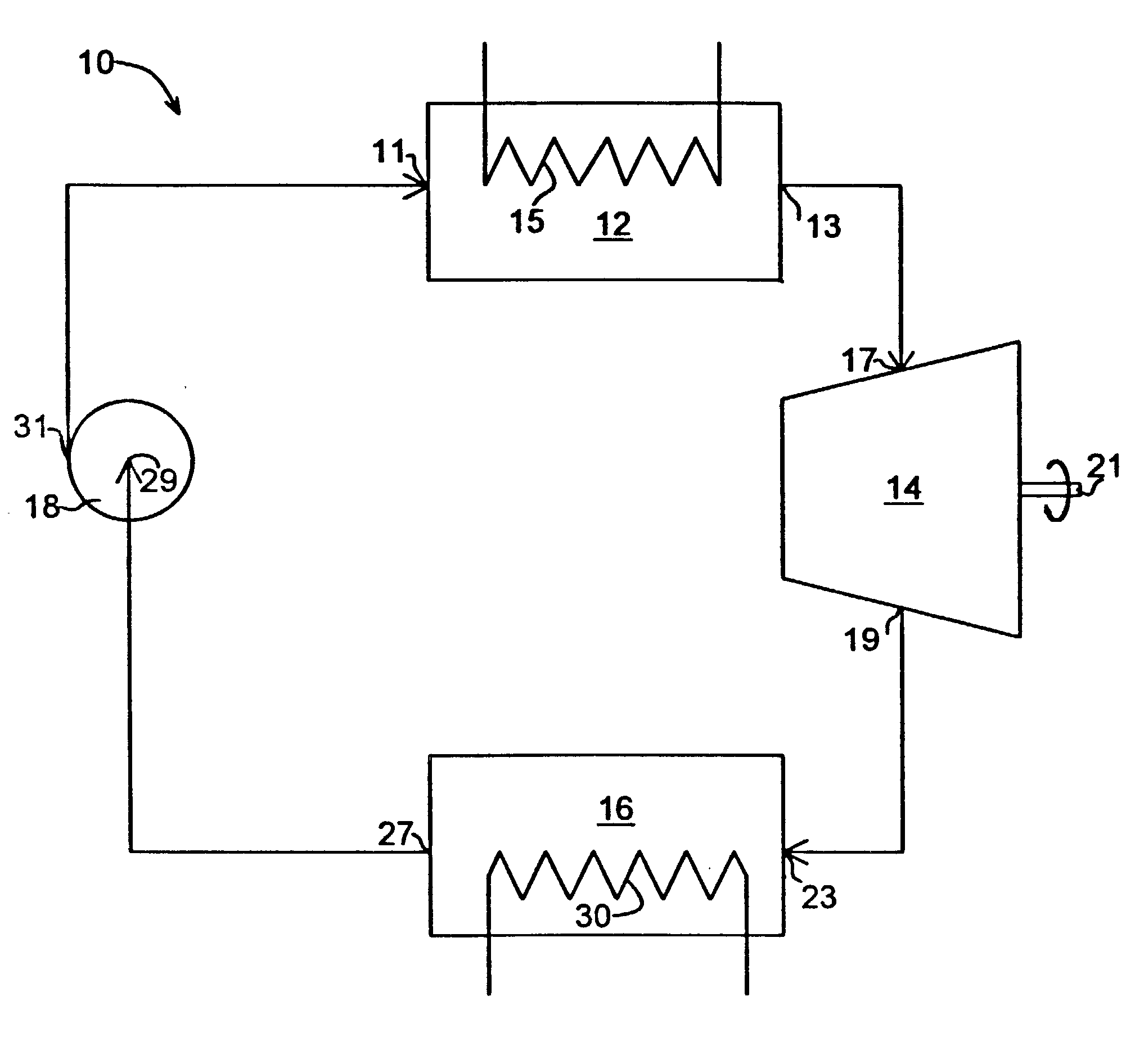

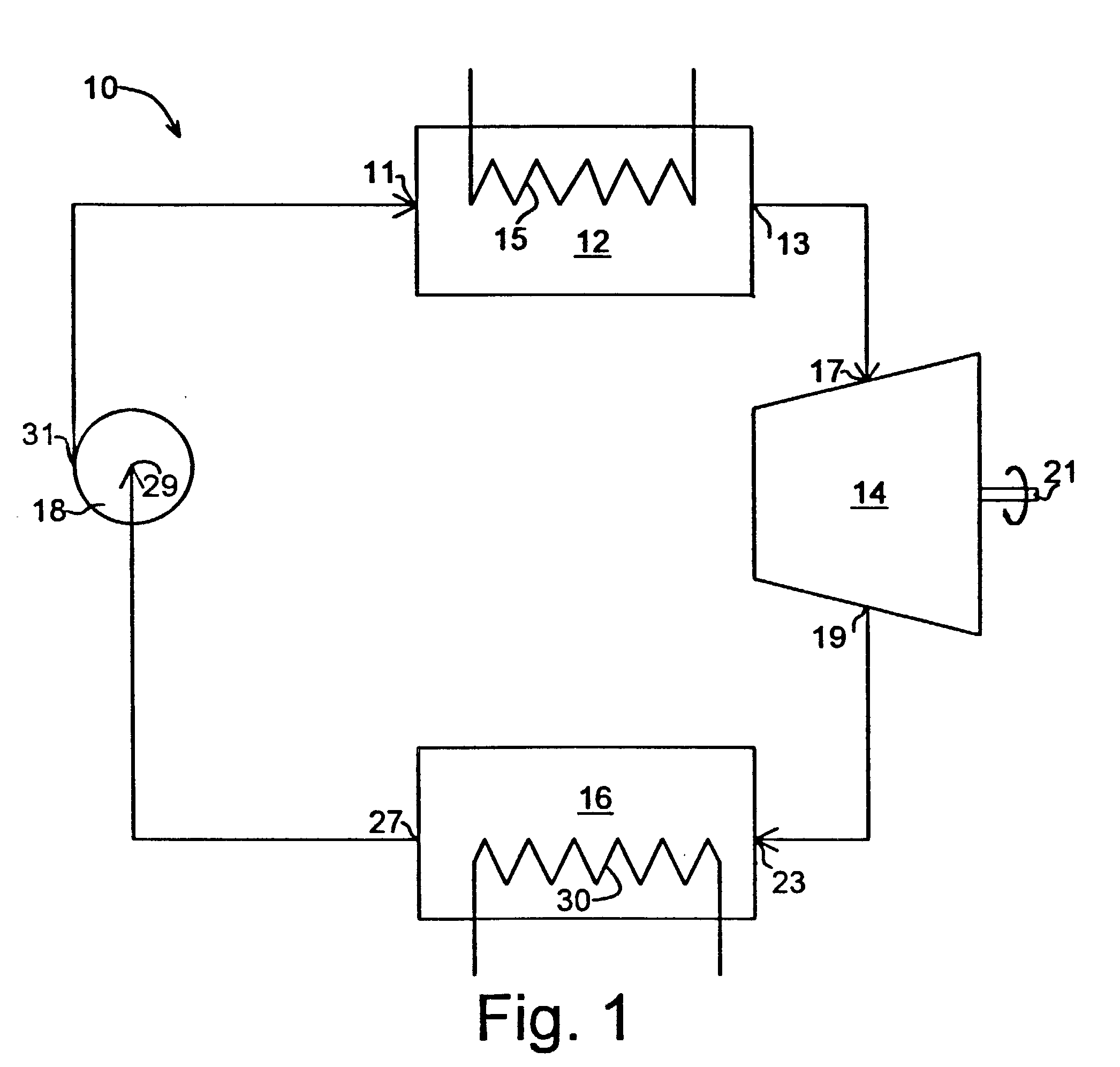

Heat engine and heat to electricity systems and methods

ActiveUS20100156112A1Efficiently and effectively produce powerFluid heatersInternal combustion piston enginesThermal energyWorking fluid

A waste heat recovery system, method and device executes a thermodynamic cycle using a working fluid in a working fluid circuit which has a high pressure side and a low pressure side. Components of the system in the working fluid circuit include a waste heat exchanger in thermal communication with a waste heat source also connected to the working fluid circuit, whereby thermal energy is transferred from the waste heat source to the working fluid in the working fluid circuit, an expander located between the high pressure side and the low pressure side of the working fluid circuit, the expander operative to convert a pressure / enthalpy drop in the working fluid to mechanical energy, a recuperator in the working fluid circuit operative to transfer thermal energy between the high pressure side and the low pressure side of the working fluid circuit, a cooler in thermal communication with the low pressure side of the working fluid circuit operative to control temperature of the working fluid in the low side of the working fluid circuit, a pump in the working fluid circuit and connected to the low pressure side and to the high pressure side of the working fluid circuit and operative to move the working fluid through the working fluid circuit, and a mass management system connected to the working fluid circuit, the mass management system, method and device having a working fluid vessel connected to the low pressure side of the working fluid circuit and configured to passively control an amount of working fluid mass in the working fluid circuit.

Owner:REXORCE THERMIONICS INC +1

High efficiency integrated heat engine-2 (heihe-2)

InactiveUS20090056670A1Improve efficiencyImprove conversion efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelWork periodWorking fluid

The present invention is a second kind of High Efficiency Integrated Heat Engine, or HEIHE-2 for short. HEIHE-2 is a reciprocal combustion engine integrated with both compound cycle and combined cycle. HEIHE-2 comprises triple compound cylinder structure, with the first cylinder and the second cylinder being the primary combustion and / or expansion cylinders; and the third cylinder being the secondary combustion and / or expansion cylinder. Power strokes driven by expansions of different working fluids such as air-fuel combustion products, steam and compressed air, are integrated into one engine block. Triple cylinder structure provides compound expansions of three (3) different fluids as to recover the energies that would be lost with the exhaust fluids or during braking. All of these make HEIHE-2 work around four (4) periods with six (6) different operation strokes. All four (4) working periods contain four (4) different power strokes but only two (2) of them consume the fuel. Thus the fuel conversion efficiency could be greatly increased, or even be doubled comparing with the conventional internal combustion engine (ICE).

Owner:ZHAO YUANPING +1

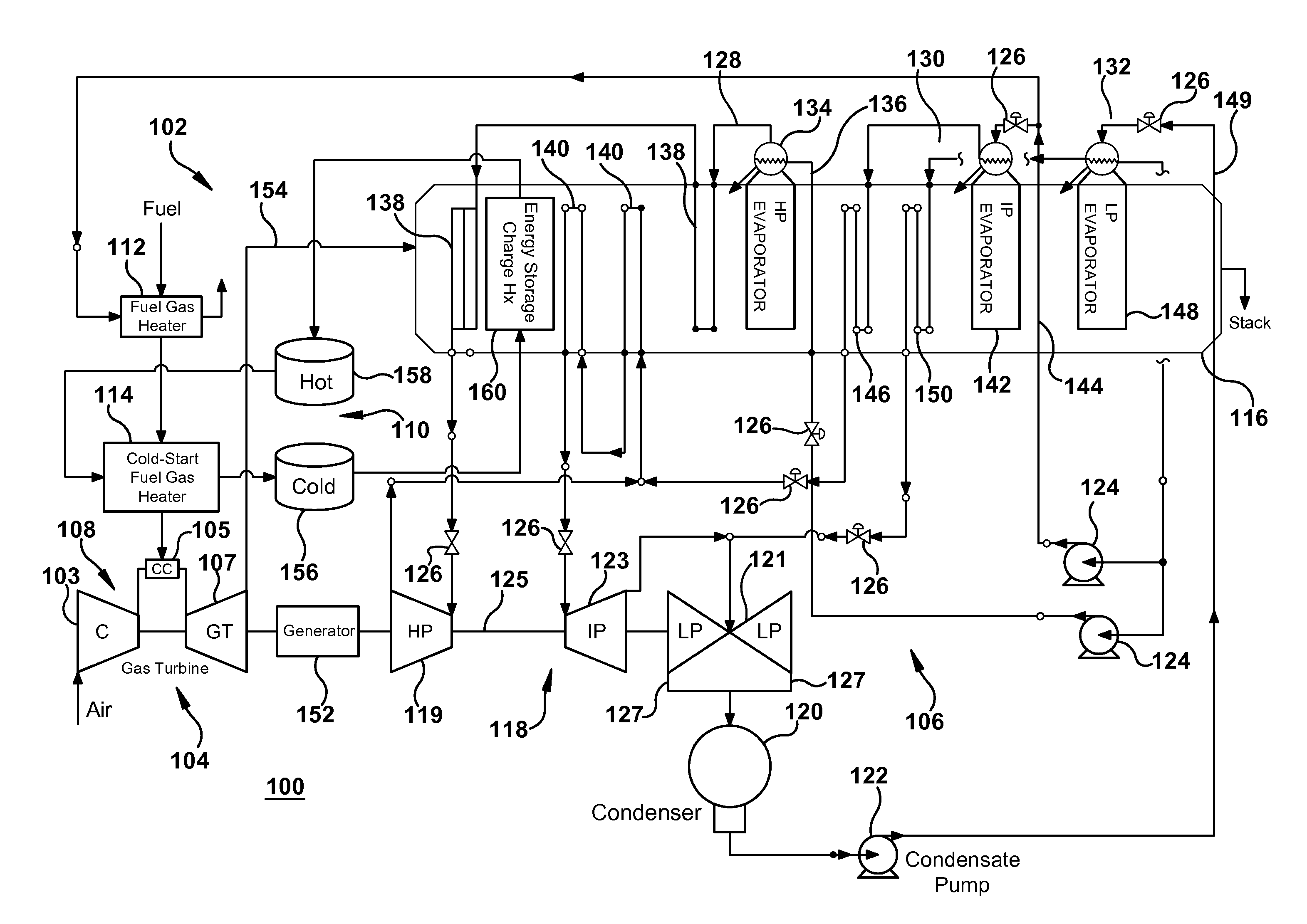

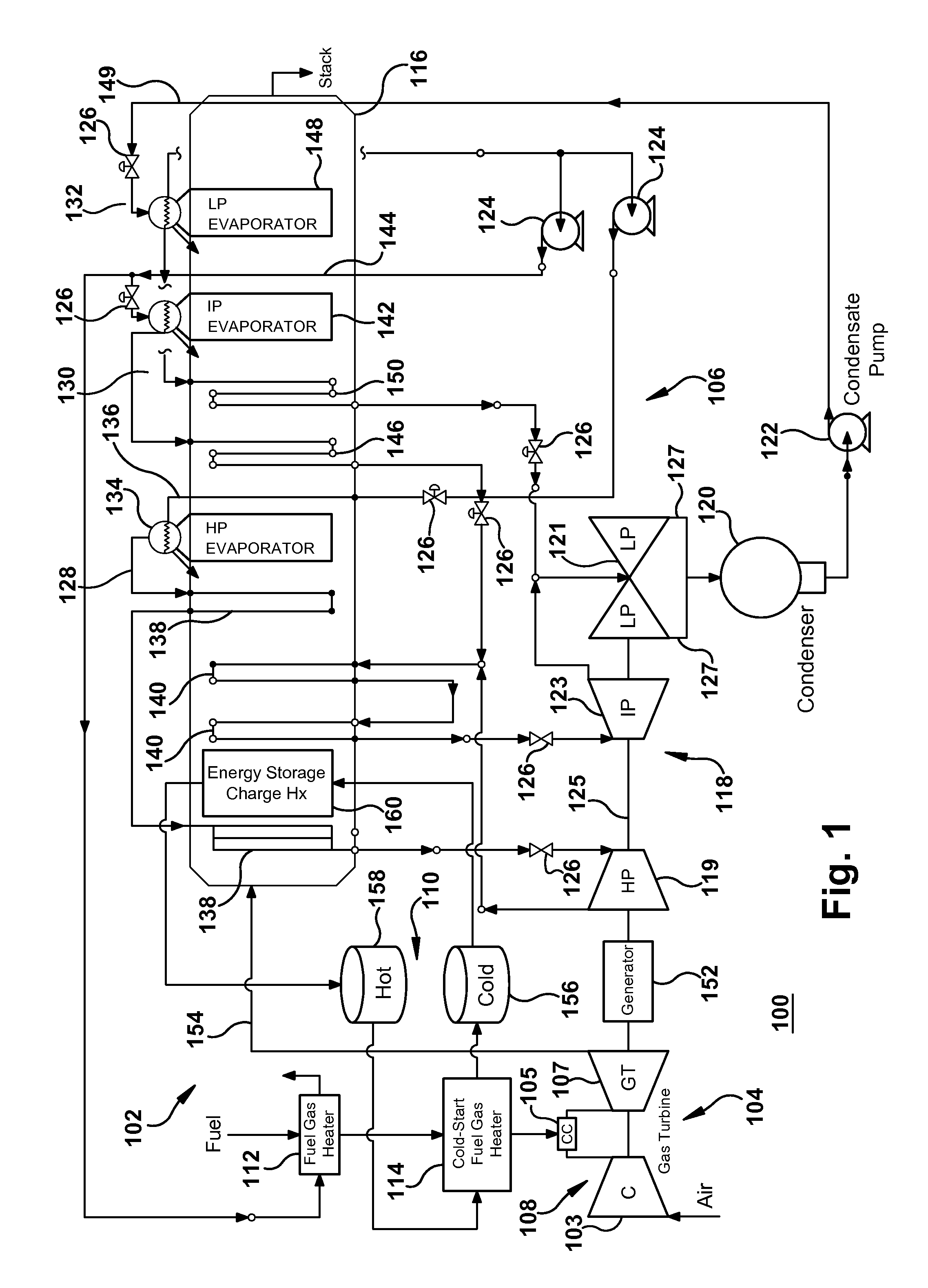

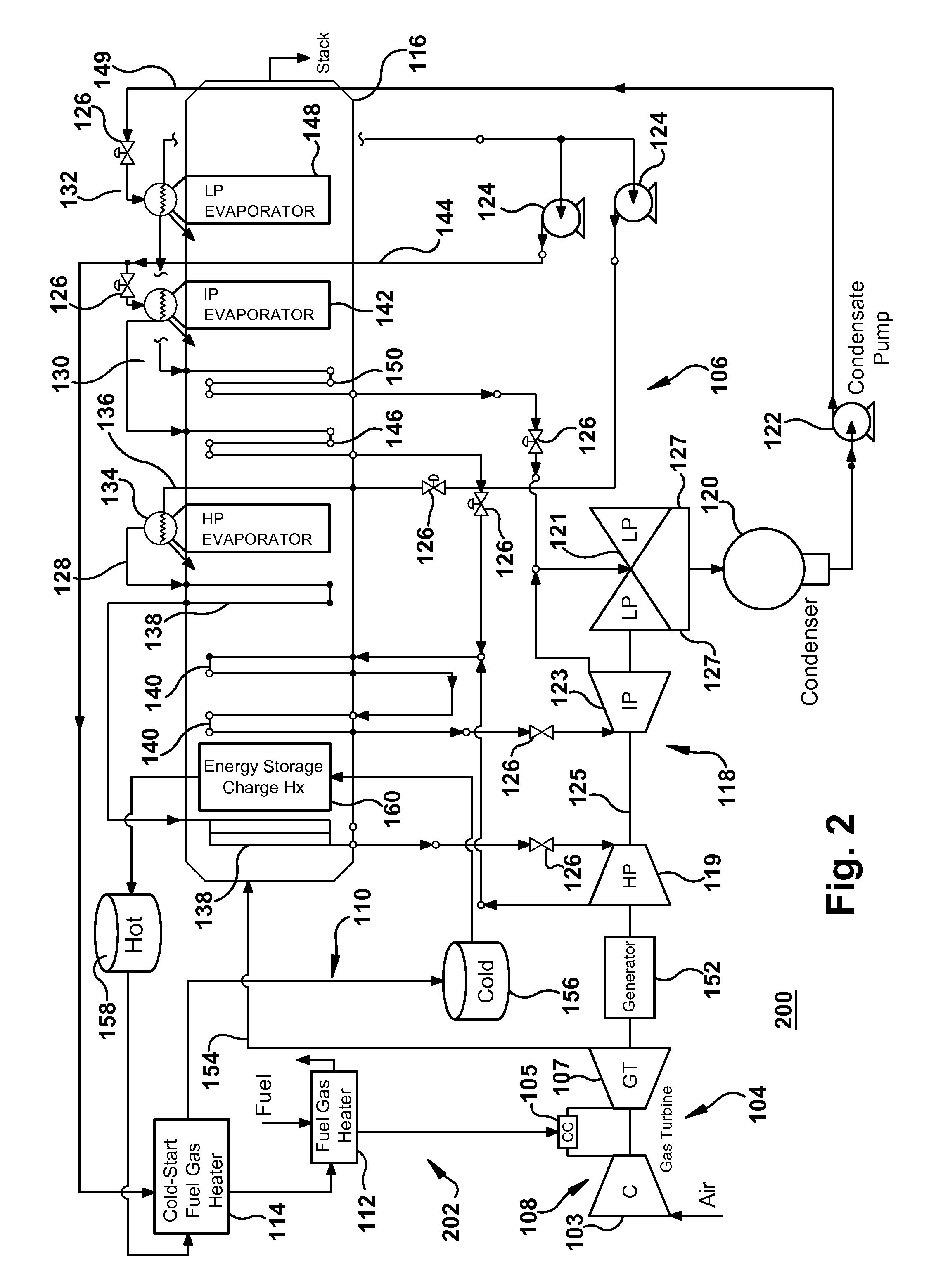

Fuel gas heating with thermal energy storage

Thermal energy storage containing thermal energy extracted from a bottom cycle heat engine is leveraged to heat fuel gas supplied to a gas turbine engine operating in a top cycle heat engine. Further, an extracted portion of a working fluid generated in a steam generation source of the bottom cycle heat engine can be used along with the thermal energy storage to heat fuel gas.

Owner:GENERAL ELECTRIC CO

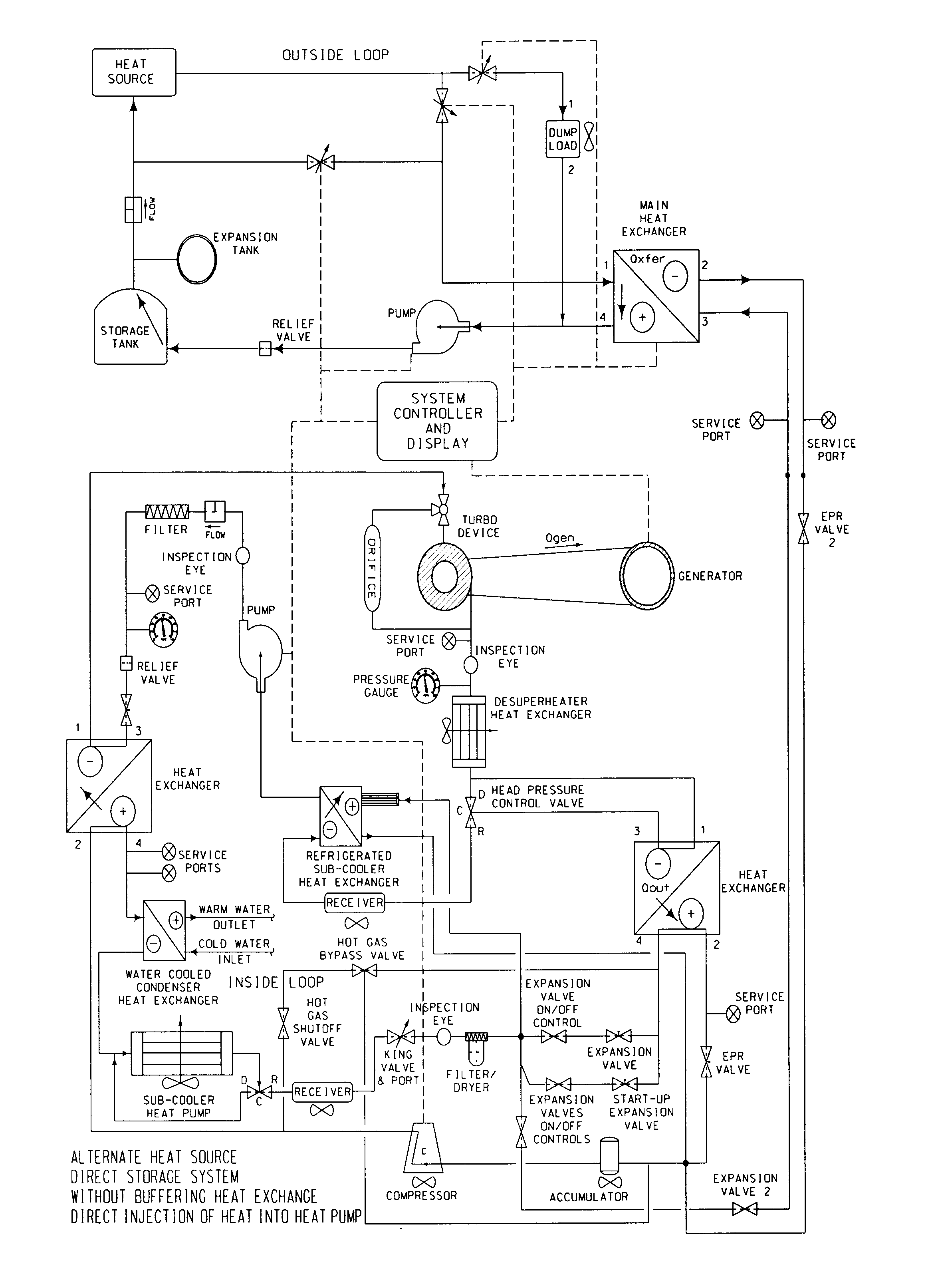

Thermodynamic power generation system

InactiveUS20110036091A1Large volumeEasy to produceAuxillary drivesRotary non-positive displacement pumpsWorking fluidEngineering

A power generation system that includes a heat source loop, a heat engine loop, and a heat reclaiming loop. The heat can be waste heat from a steam turbine, industrial process or refrigeration or air-conditioning system, solar heat collectors or geothermal sources. The heat source loop may also include a heat storage medium to allow continuous operation even when the source of heat is intermittent. Heat from the heat source loop is introduced into the heat reclaiming loop or turbine loop. In the turbine loop a working fluid is boiled, injected into the turbine, recovered condensed and recycled. The power generation system further includes a heat reclaiming loop having a fluid that extracts heat from the turbine loop. The fluid of the heat reclaiming loop is then raised to a higher temperature and then placed in heat exchange relationship with the working fluid of the turbine loop. The power generating system is capable of using low temperature waste heat is approximately of 150 degrees F. or less. The turbine includes one or more blades mounted on a rotating member. The turbine also includes one or more nozzles capable of introducing the gaseous working fluid, at a very shallow angle on to the surface of the blade or blades at a very high velocity. The pressure differential between the upstream and downstream surfaces of the blade as well as the change in direction of the high velocity hot gas flow create a combined force to impart rotation to the rotary member.

Owner:AMERICAN THERMAL POWER

Plasma Centrifuge Heat Engine Beam Fusion Reactor

InactiveUS20080226011A1Improve responseReduce the temperatureNuclear energy generationPlasma techniqueField lineNuclear fusion

A system and apparatus for a magnetized plasma nuclear fusion reactor, incorporating special design features which induce a plasma heat engine cycle in a rapidly rotating plasma. The heat engine operates either continuously or by oscillations. A continuous heat engine is formed in the open field outside a field reversed configuration. The oscillatory system operates in synchronism with cyclic acceleration, collision, and deceleration of plasma masses to produce nuclear fusion reactions at an economically useful rate with a relatively small driving power required. A special magnetic field design is combined with applied electrical voltages at the end of the field lines to produce required conditions. Design features allow recovery of large fraction of collision heat which would otherwise be dissipated as a parasitic loss.

Owner:BARNES DANIEL C

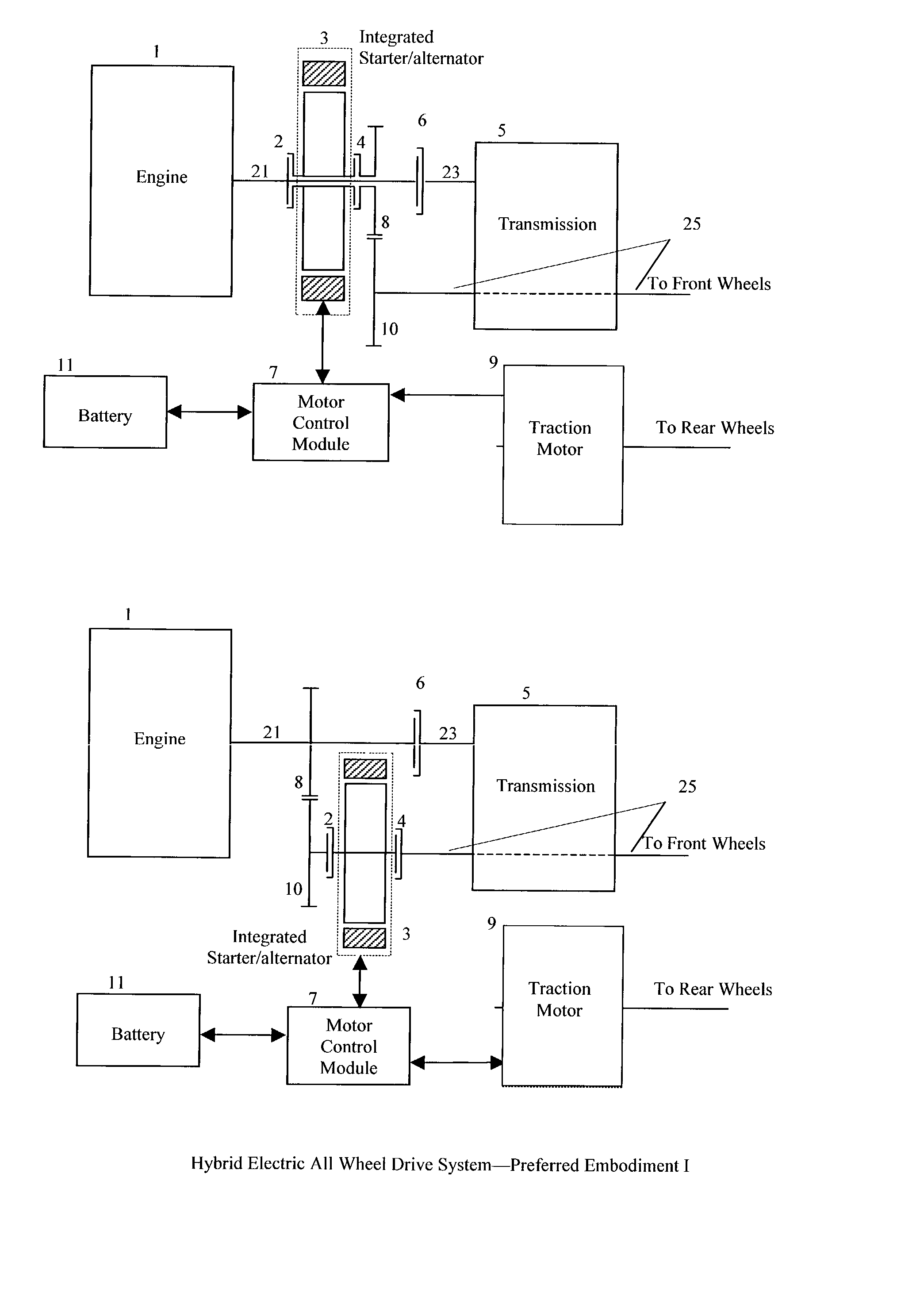

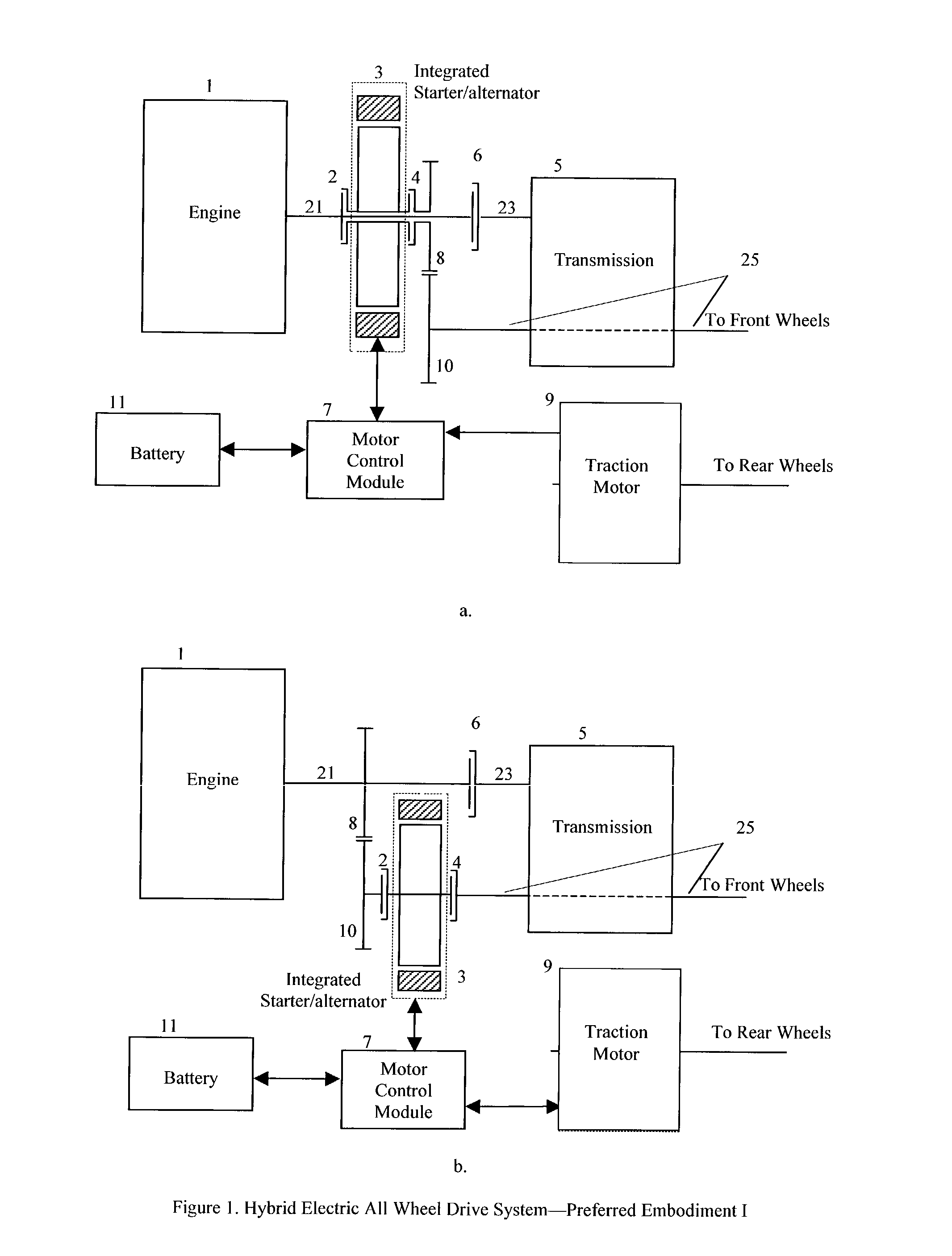

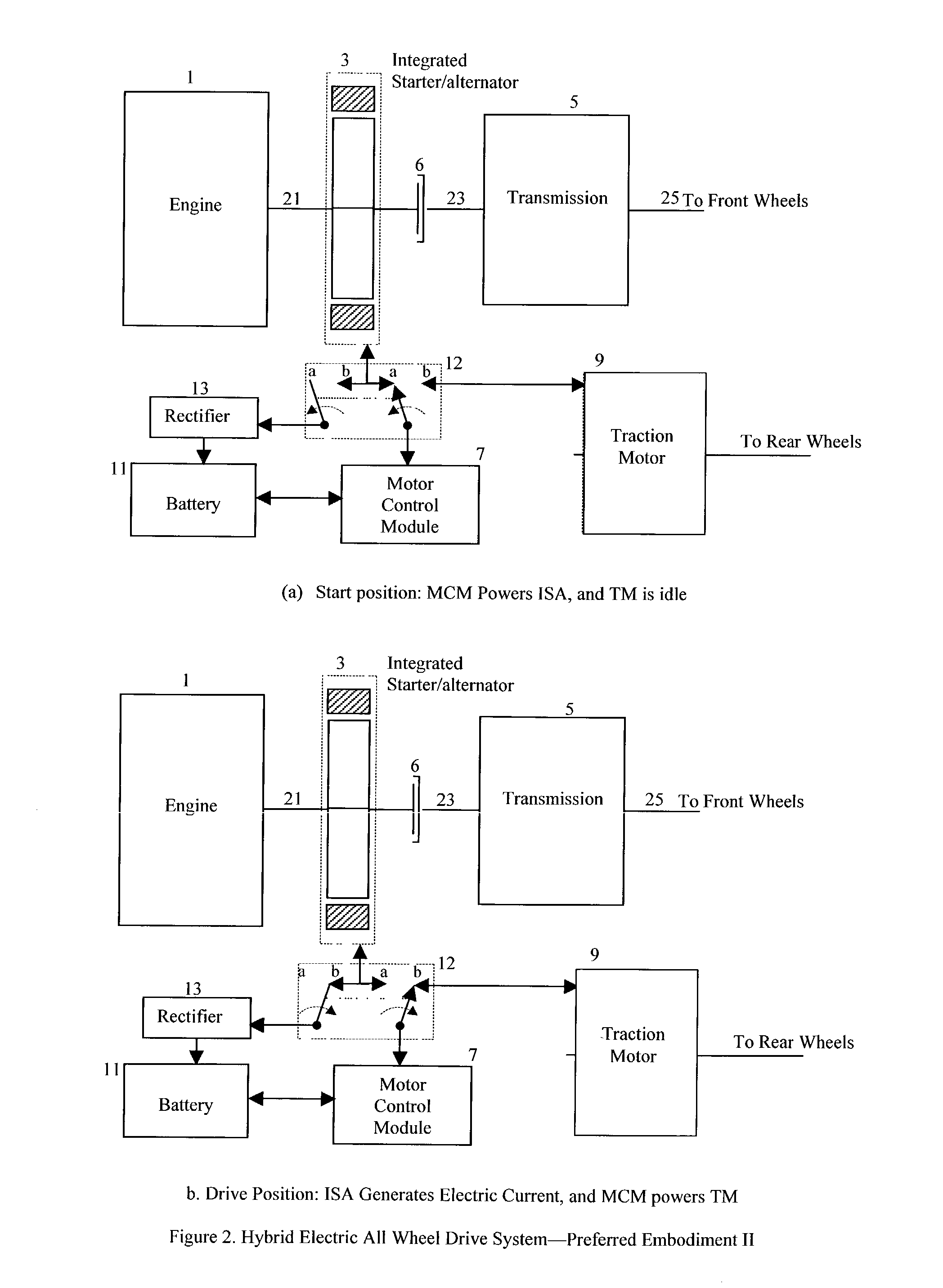

Hybrid electric all-wheel-drive system

InactiveUS20030019674A1Improve vehicle performanceEliminate needAsynchronous induction motorsPlural diverse prime-mover propulsion mountingEngineeringElectric power

The hybrid electric all-wheel-drive (HEAWD) system comprises a heat engine, a transmission, an integrated starter / alternator (ISA), a motor control module (MCM), a traction motor (TM), and a battery pack. The engine drives either the front wheels or the rear wheels, and TM drives the other pair of wheels. ISA starts and assists the engine or generates electricity. Both ISA and TM apply braking torque on the wheels and regenerate the vehicle kinetic energy into electricity during deceleration. MCM provides electric current to and controls both ISA and TM to work in their desired working modes. The battery stores the electric energy generated by the motors and provides electric power to the motors. A double-rotor traction motor provides the functions of a conventional traction motor plus an axle differential / torque coupling device.

Owner:DUAN ZHIHUI

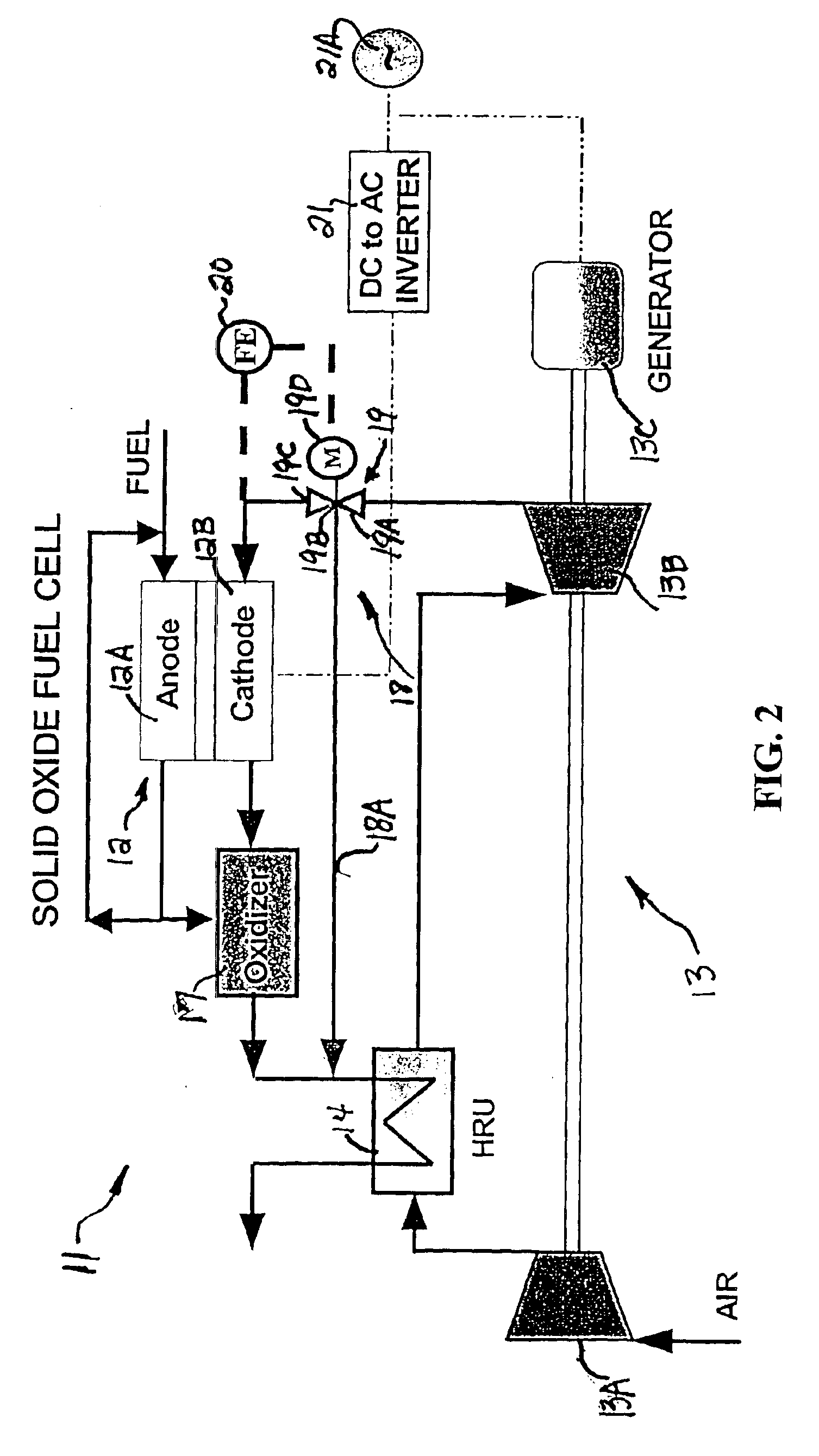

Enhanced high efficiency fuel cell/turbine power plant

ActiveUS6896988B2Improve efficiencyElectricity cogenerationFuel cell heat exchangePower stationCell system

A hybrid fuel cell system having a fuel cell and a heat engine having an expansion cycle and a compressor cycle and which is further adapted to include a bypass assembly for segmenting expanded oxidant supply gas from the expansion cycle of the heat engine into a first expanded oxidant supply gas portion and a second expanded gas portion and in which the first expanded oxidant supply gas portion is used for the fuel cell and the second expanded gas portion bypassed around the fuel cell.

Owner:FUELCELL ENERGY INC

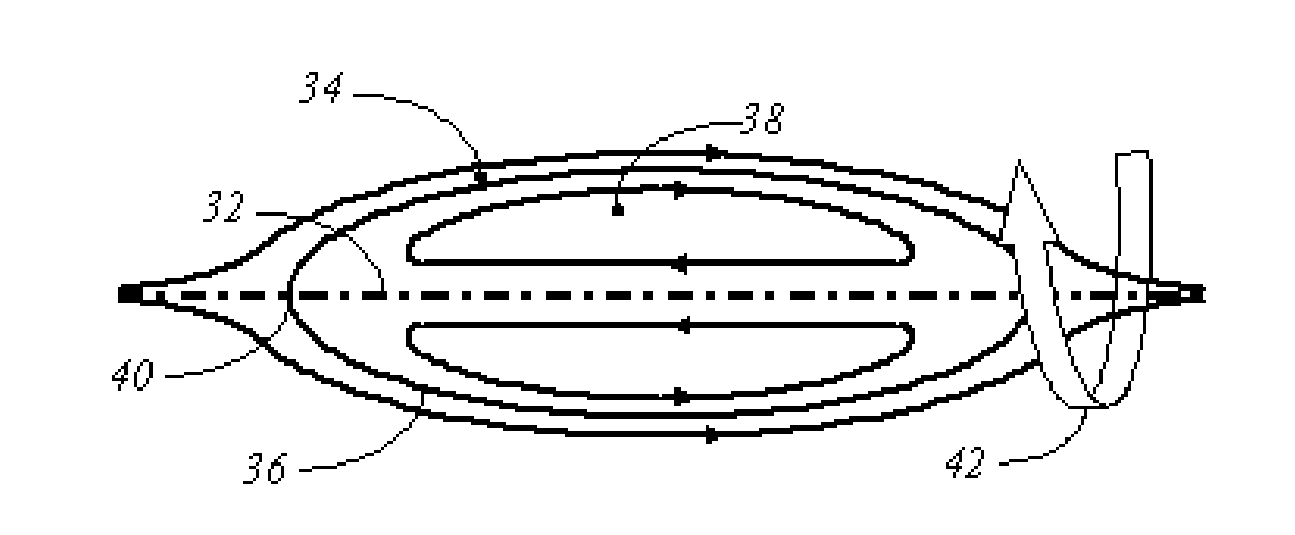

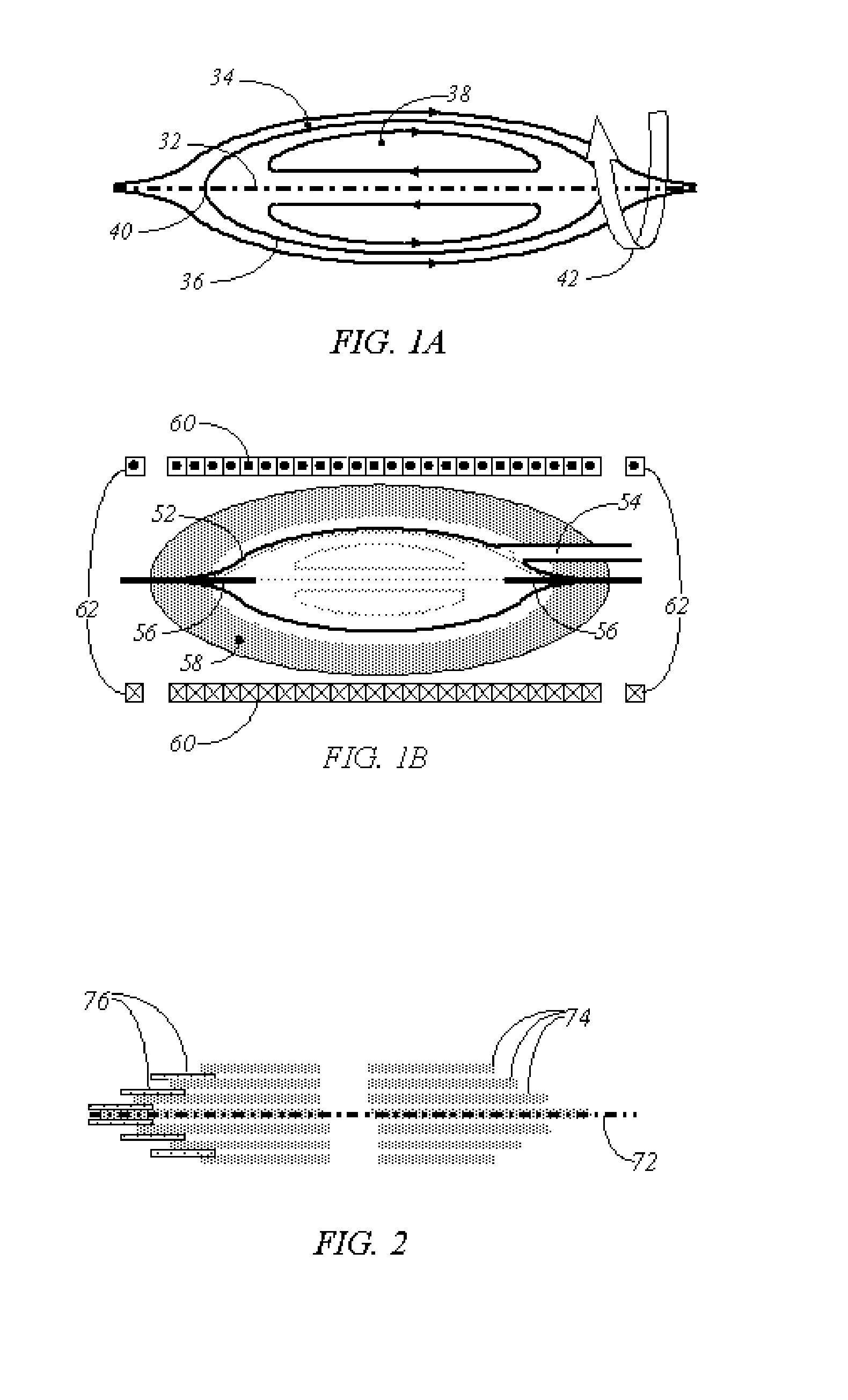

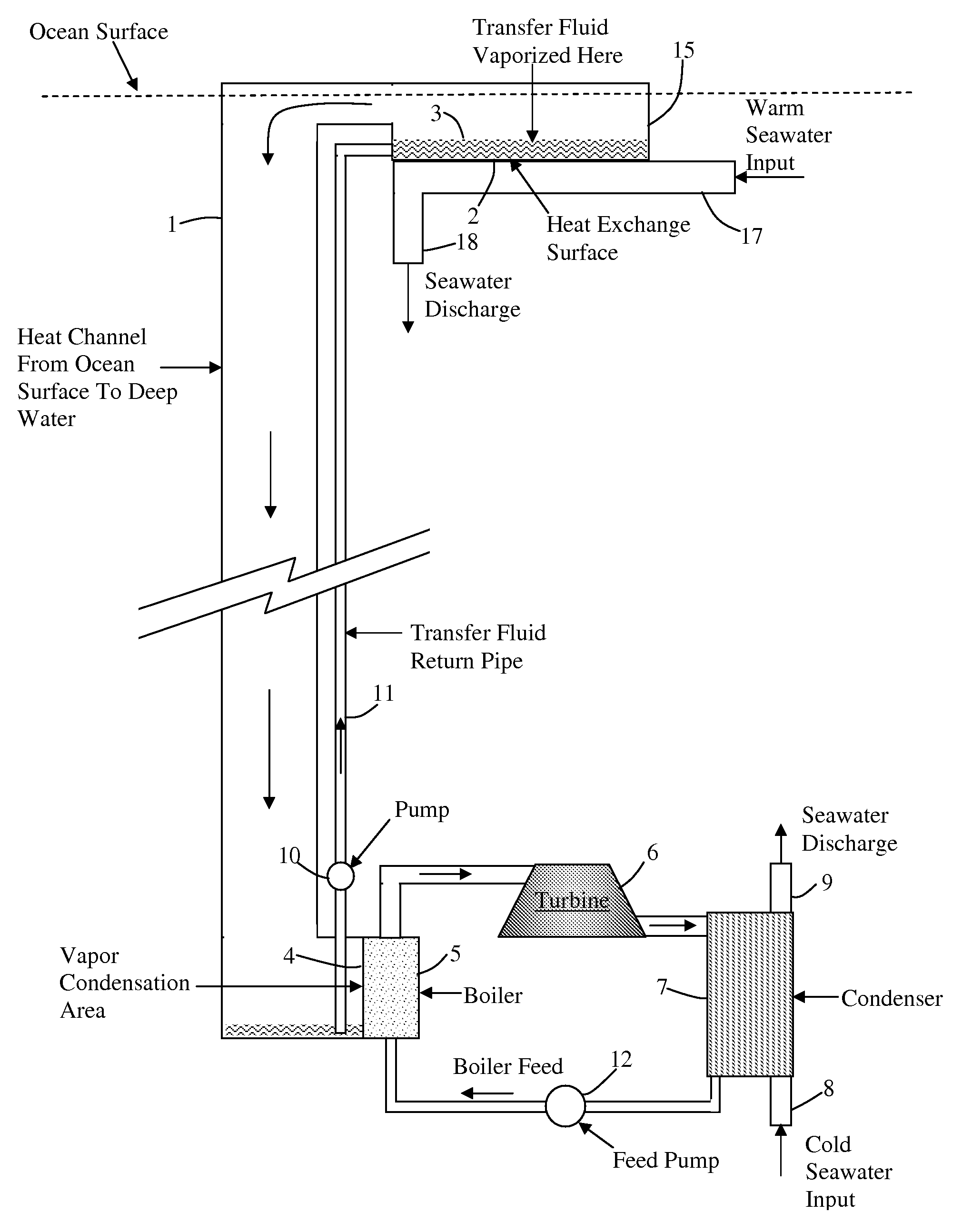

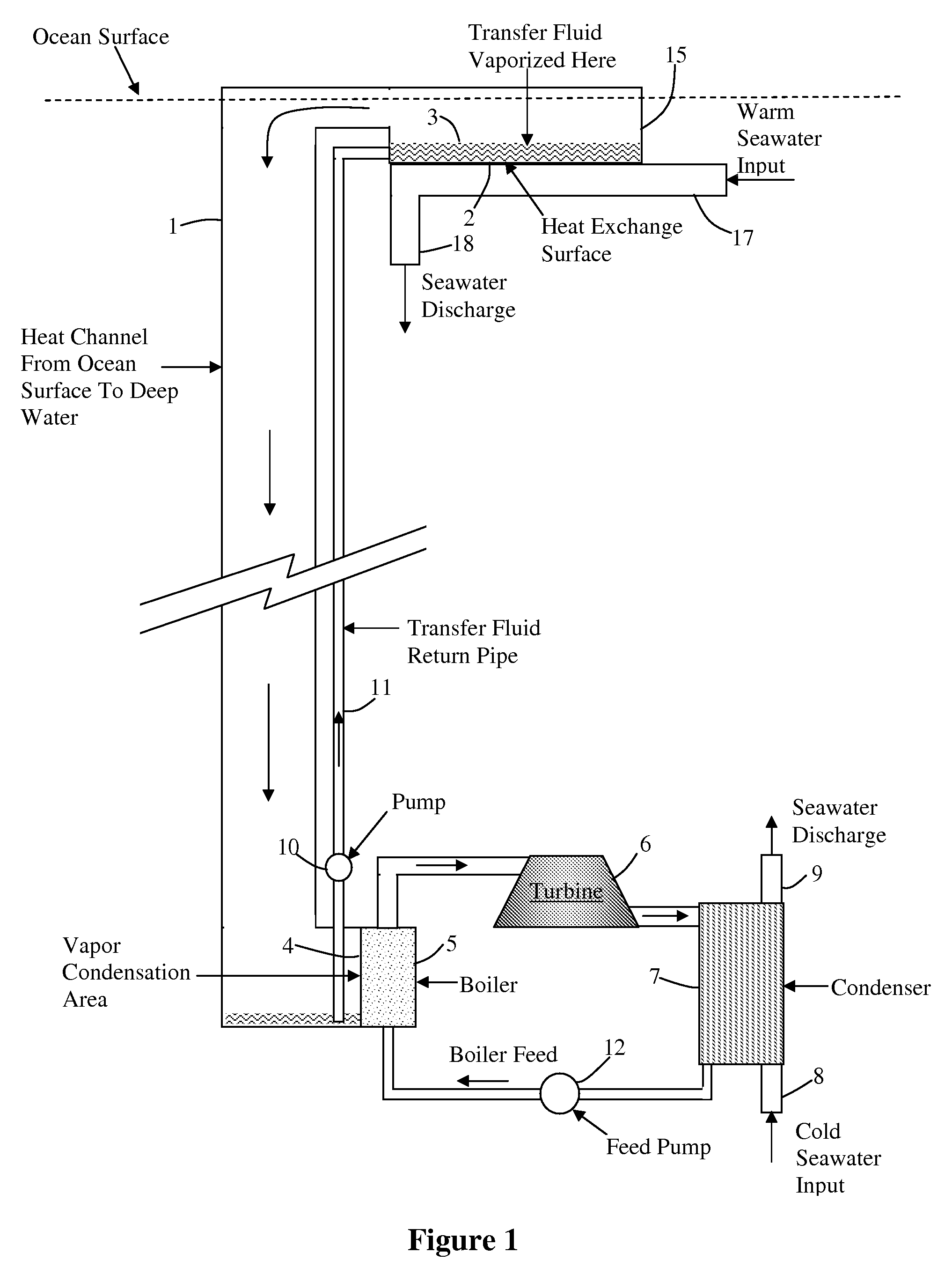

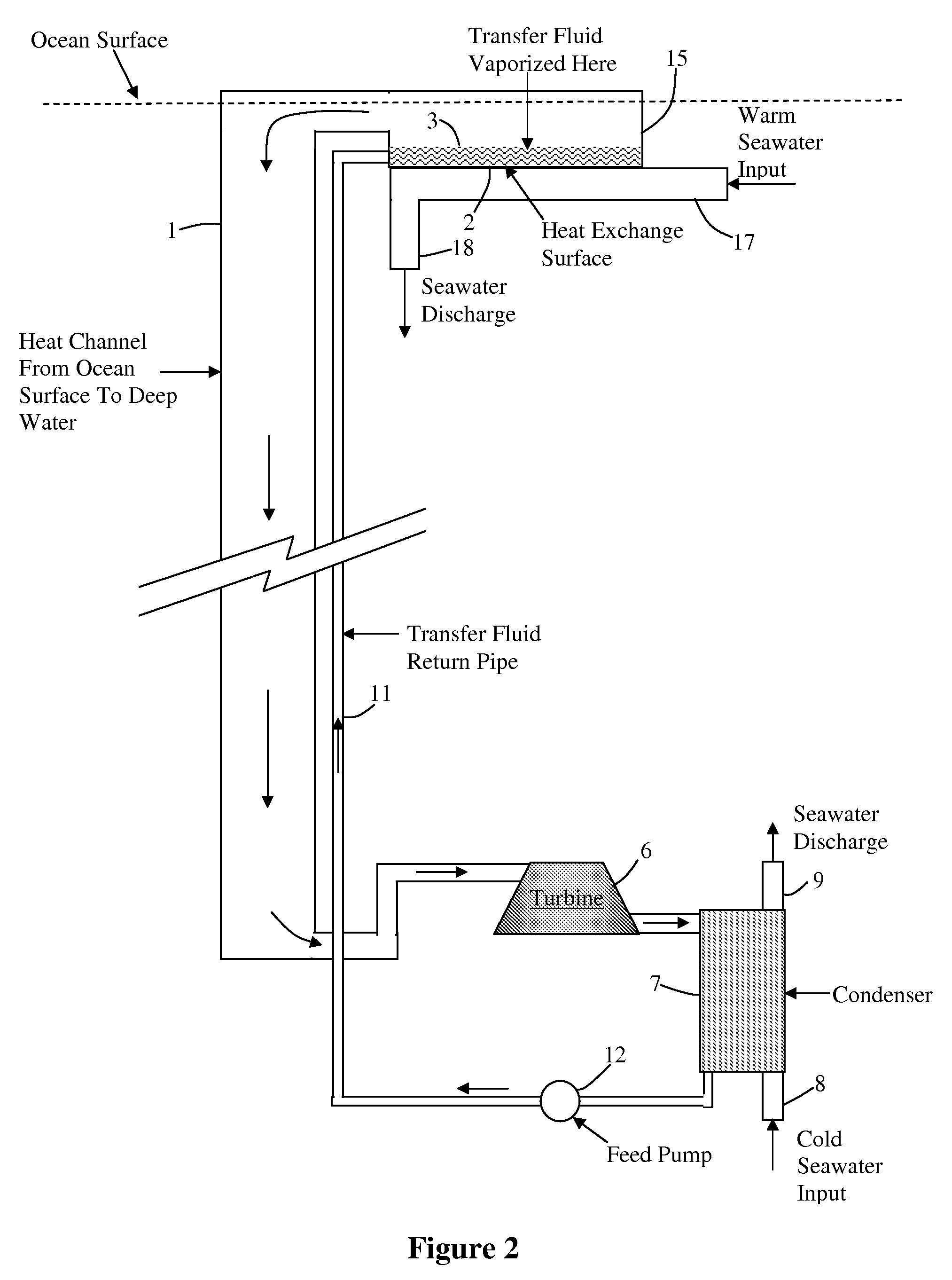

Heat transfer for ocean thermal energy conversion

InactiveUS20070289303A1Improve efficiencyMachines/enginesMechanical power devicesThermal energyOcean thermal energy conversion

For OTEC (Ocean Thermal Energy Conversion), rather than transfer huge quantities of cold water from deep in the ocean to the surface to provide a heat sink for a heat engine or for desalination, this invention provides a method of using small masses of low-boiling-point fluids to absorb heat in a heat exchanger near the ocean surface using the latent heat of evaporation and then depositing the latent heat of condensation in a deep ocean heat exchanger, using the cold seawater as a heat sink. The condensed liquid is pumped back to the ocean surface. The heat engine (turbine) and generator can be at the ocean surface, or it can be in deep ocean. By using a fluid that transfers heat by evaporation and condensation, much larger quantities of heat can be moved per kilogram of fluid than can be transferred by moving the same mass of seawater.

Owner:PRUEITT MELVIN L

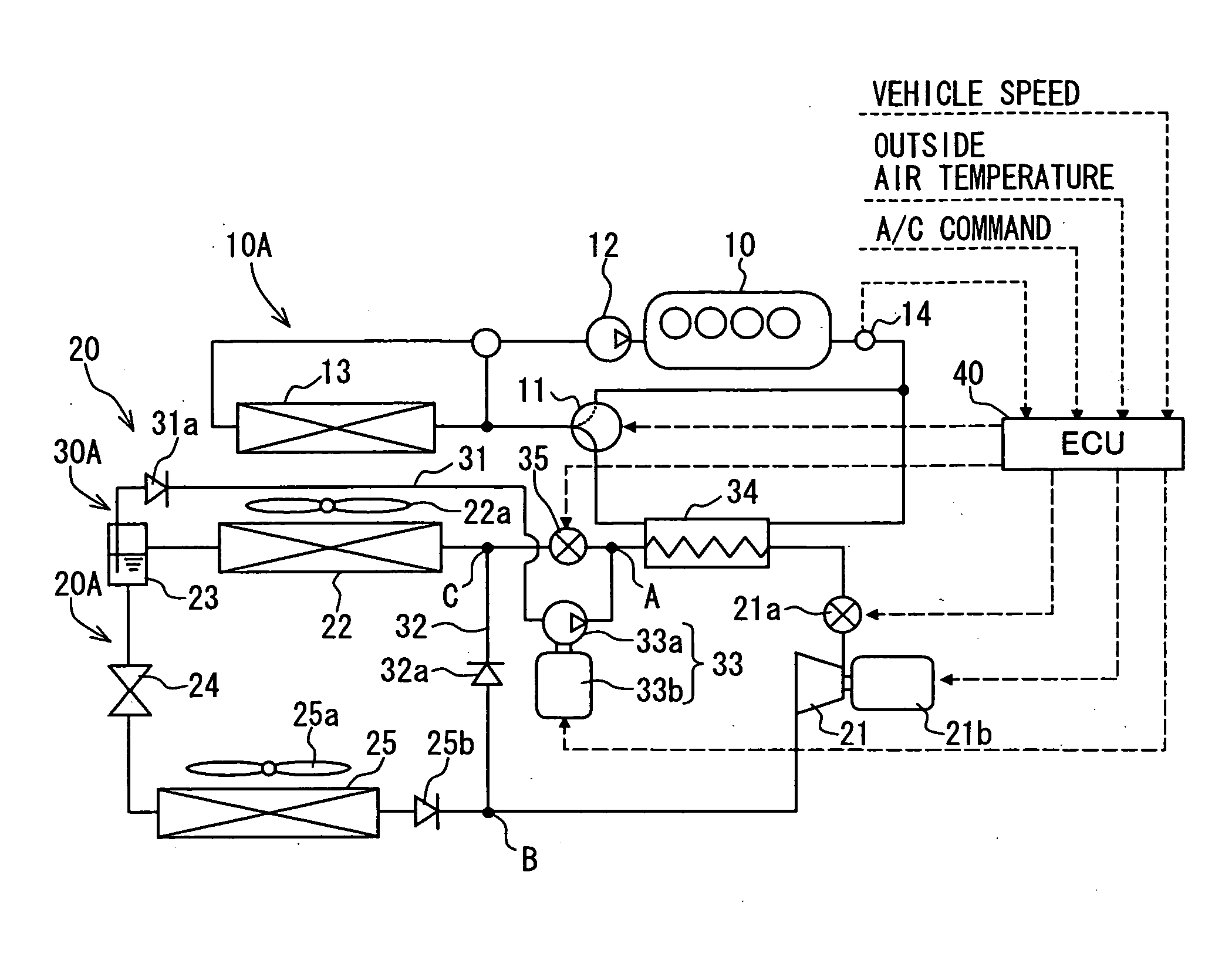

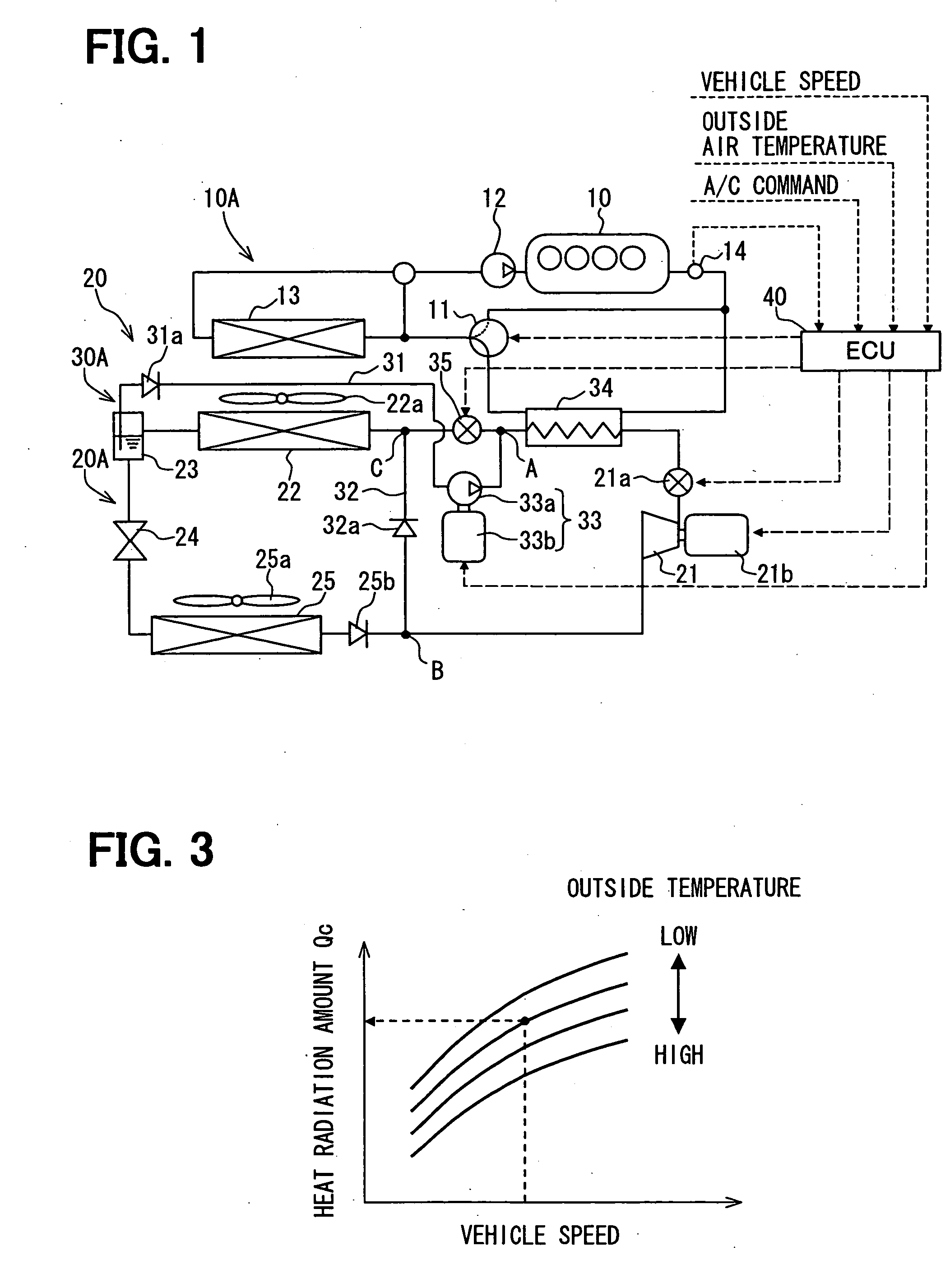

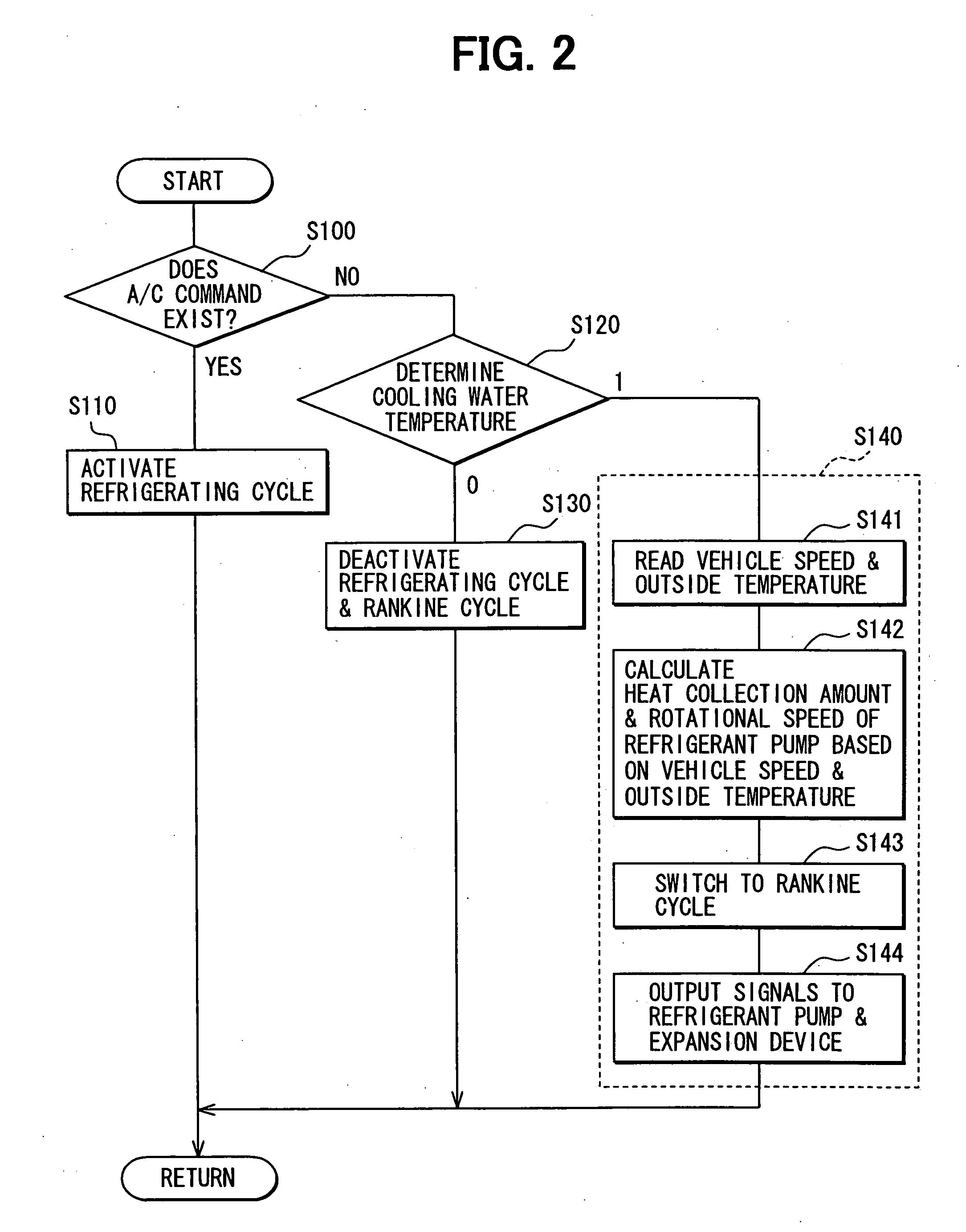

Device for utilizing waste heat from heat engine

InactiveUS20060225421A1Efficient collectionGenerate efficientlyInternal combustion piston enginesEngine componentsRefrigerantWaste heat

A device for utilizing waste heat from a heat engine comprises a Rankine cycle including a pump, a heating device, an expansion device, and a condenser device, and a controller for controlling an operation of the Rankine cycle. The controller calculates an optimum heat collection amount (Qho) as a heat value to be collected from waste heat of the engine, wherein the heat collection amount (Qho) is calculated as an optimum amount in relation to a potential maximum heat radiation amount (Qco) to be radiated at the condenser device. The controller calculates an optimum flow amount (G) of refrigerant corresponding to the optimum heat collection amount (Qho), so that a maximum driving power (L) is generated at the expansion device.

Owner:DENSO CORP

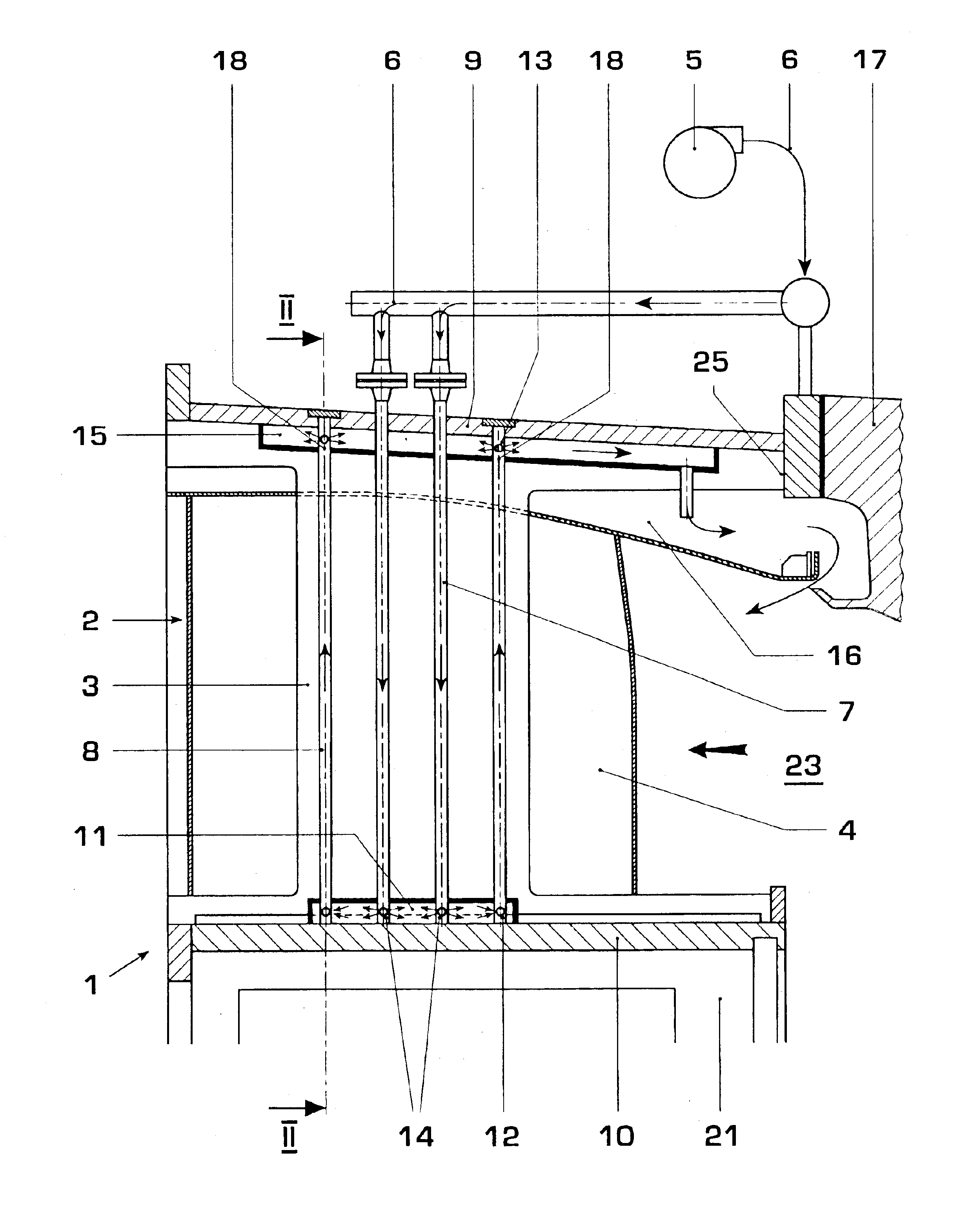

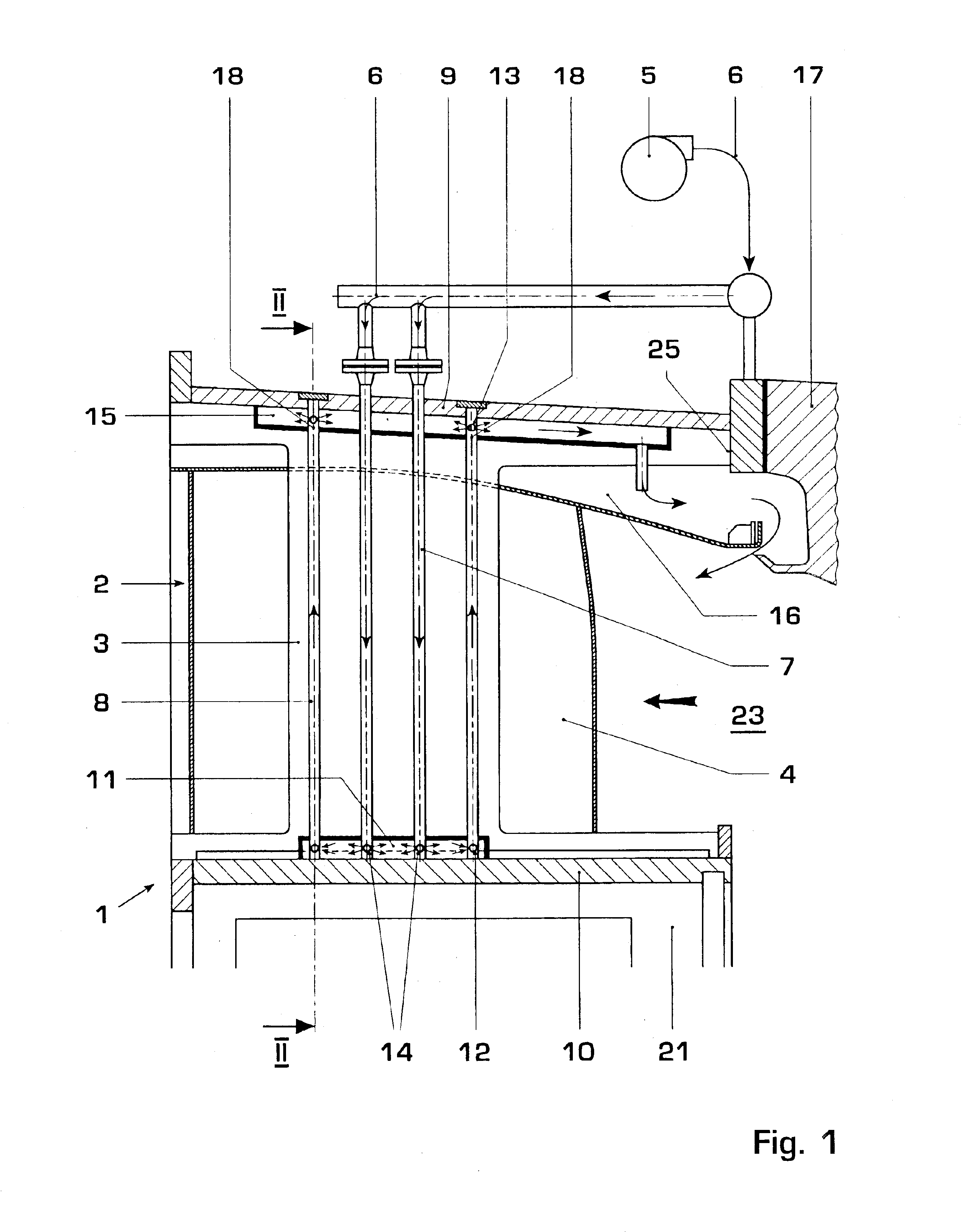

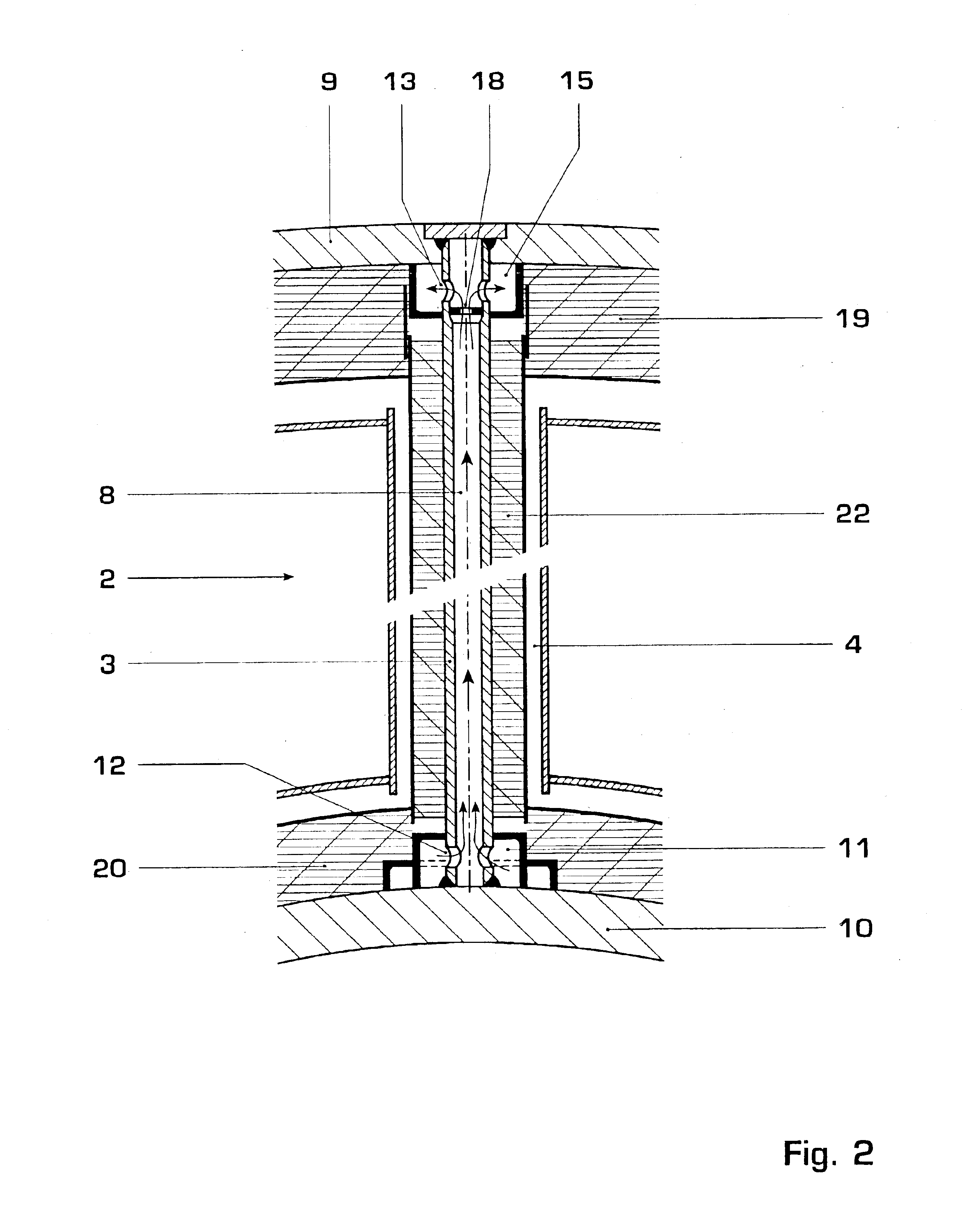

Exhaust gas housing of a thermal engine

InactiveUS7055305B2No impairment of operating conceptReduce temperature fluctuationsPump componentsTurbine/propulsion engine coolingExhaust fumesAnnular duct

In an exhaust gas housing (1) of a thermal engine, a radially outer housing casing (9) and a radially inner housing casing (10) arranged on the hub side are connected to one another via at least one thermally insulated carrying rib (3) acted upon by a cooling medium. A carrying rib (3) has at least two passage ducts (7) and (8) for the cooling medium, at least one passage duct (7) possessing a cooling medium supply (6) and at least one passage duct (8) possessing a cooling medium outlet (12), and these passage ducts (7) and (8) being in communicating connection in the radially inner hub-side end region via a deflection duct (11). The cooling medium is led from an external pressure source (5) through the carrying rib (3) to the region of the deflecting duct (11) arranged on the hub-side casing (10) and from there through the carrying rib (3) back again into a collecting duct (15) which issues preferably into an annular duct (26) for cooling the exhaust gas housing flange (24).

Owner:ANSALDO ENERGIA IP UK LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com