Patents

Literature

300results about "Thermoelectric device with dielectric constant thermal change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

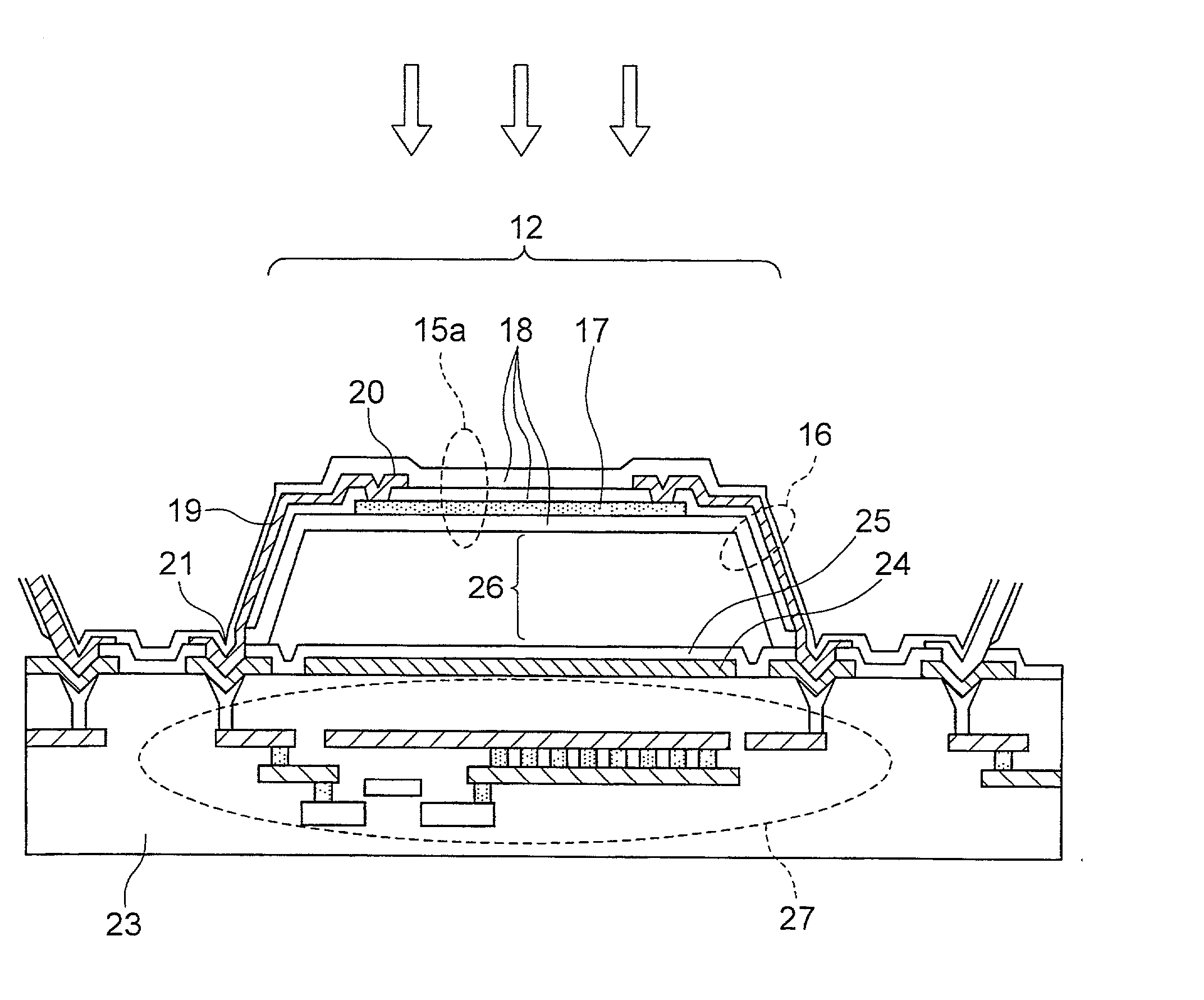

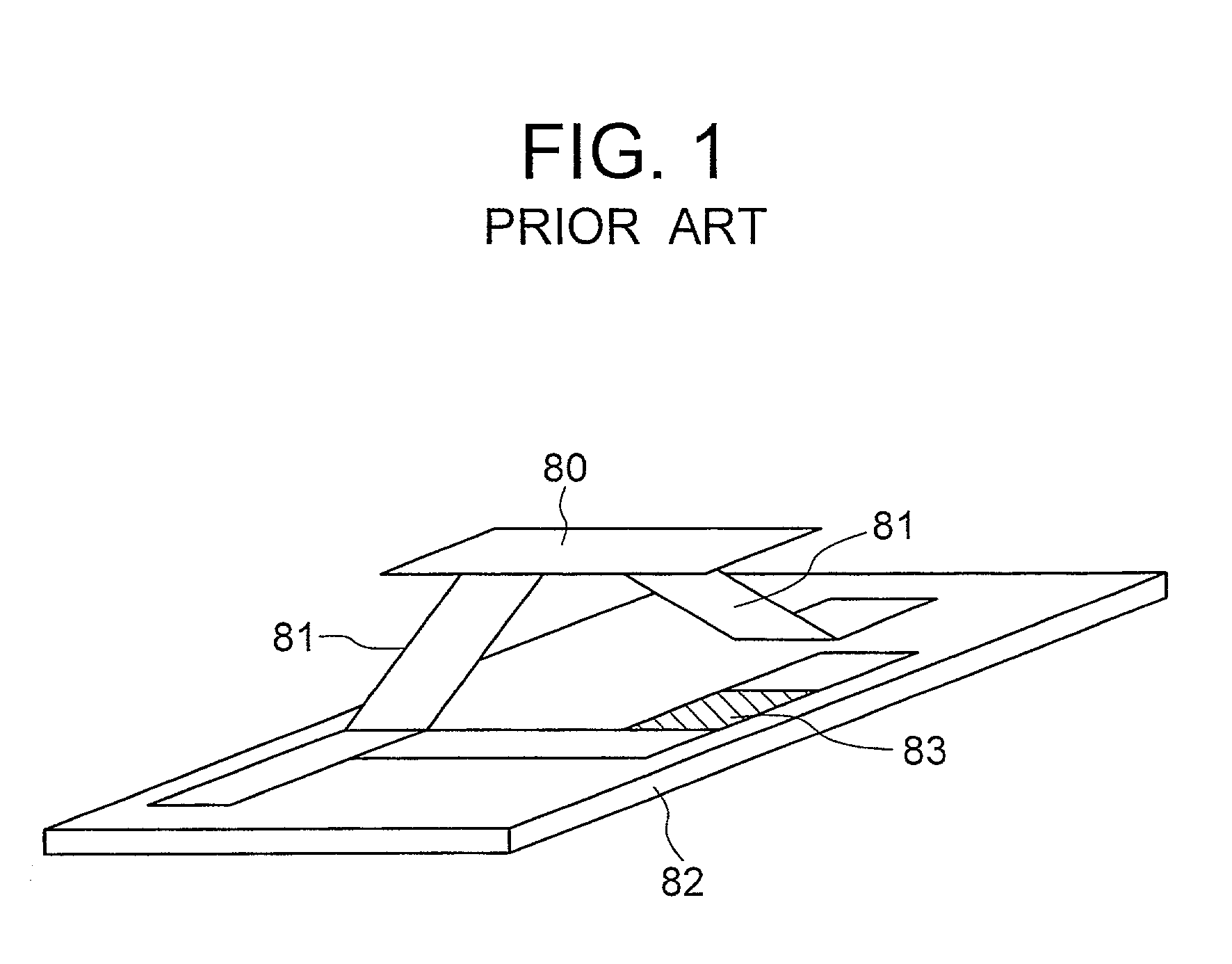

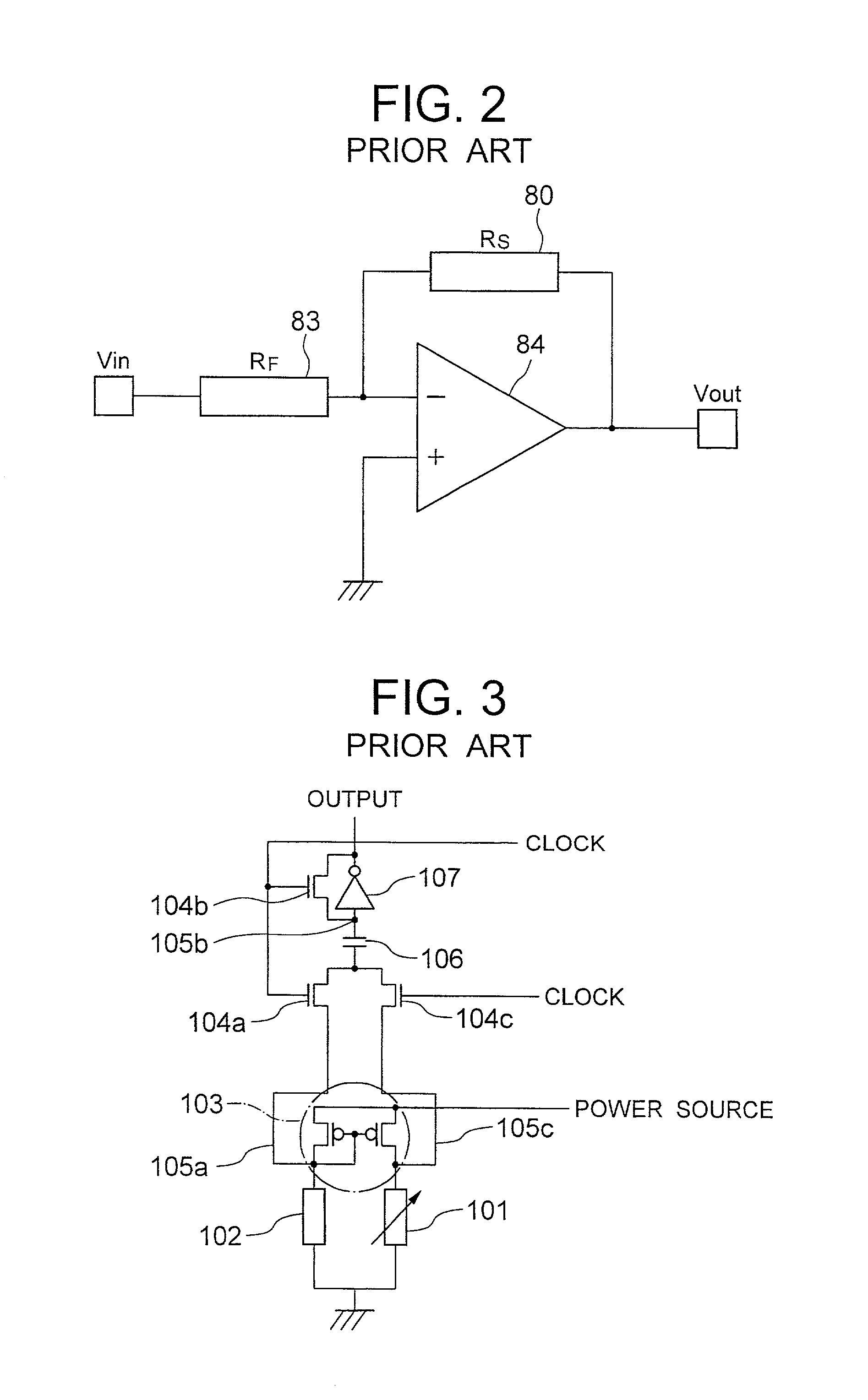

Electronic component having micro-electrical mechanical system

ActiveUS20050218488A1Thermoelectric device with dielectric constant thermal changeAcceleration measurement using interia forcesElectricityEngineering

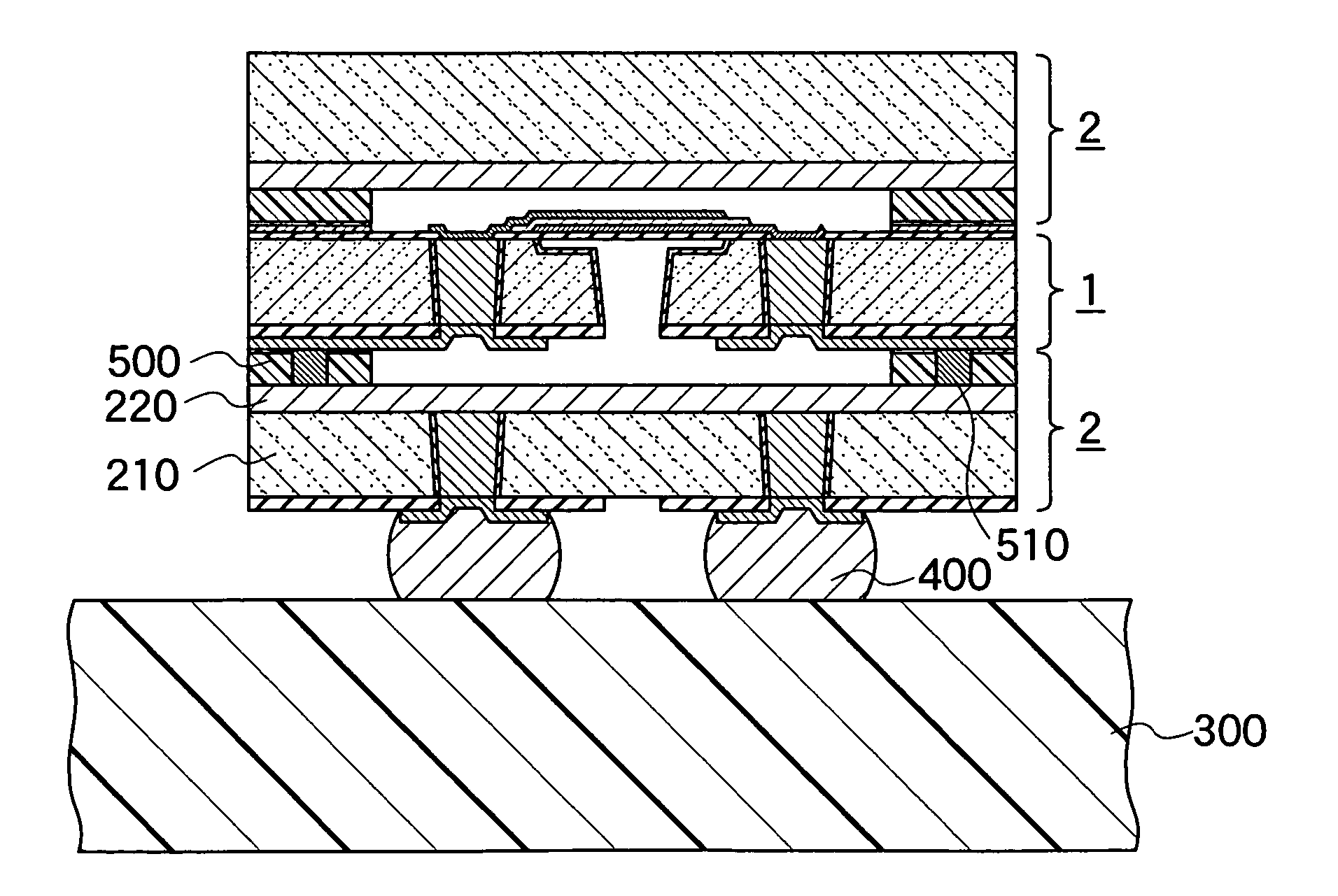

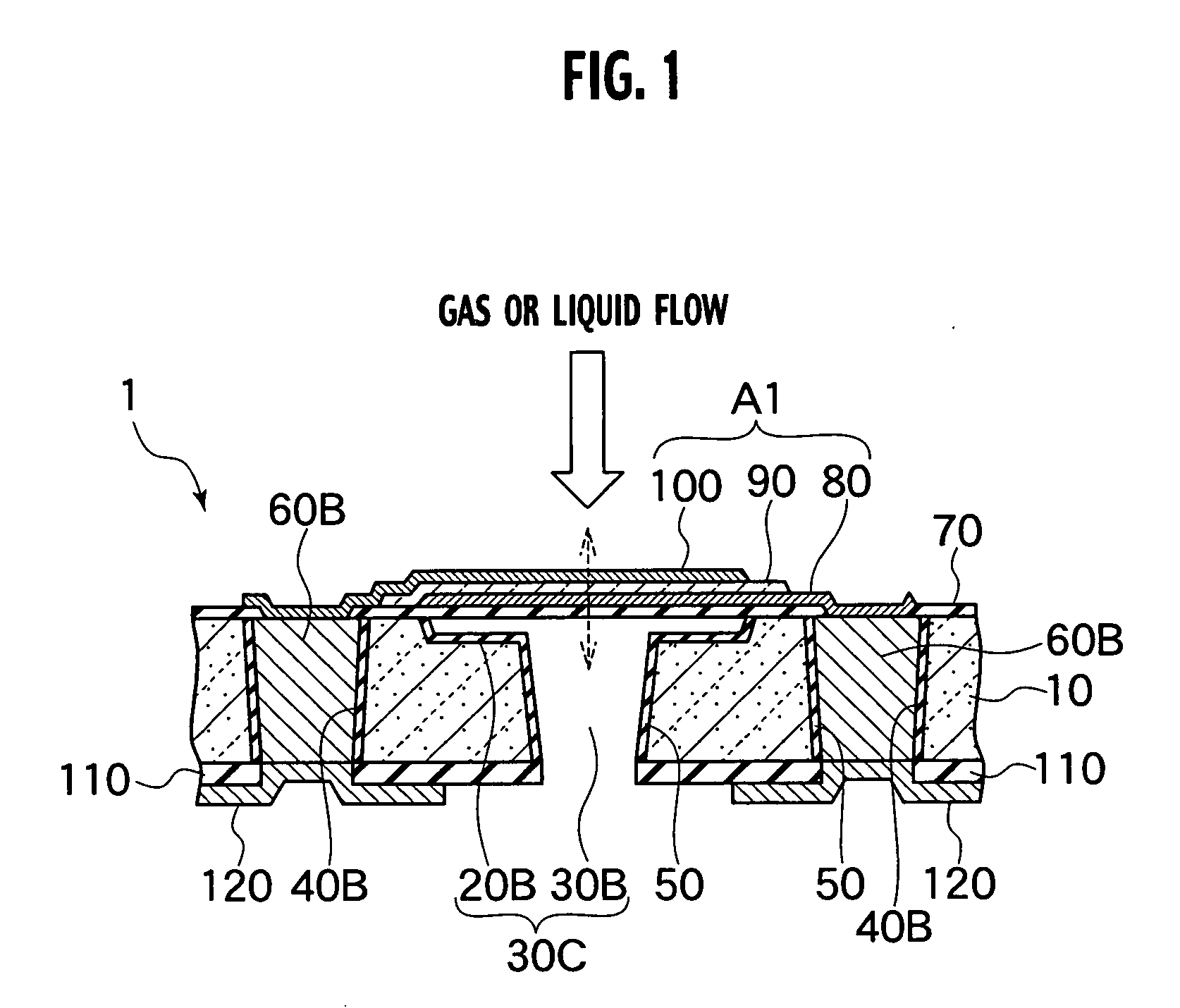

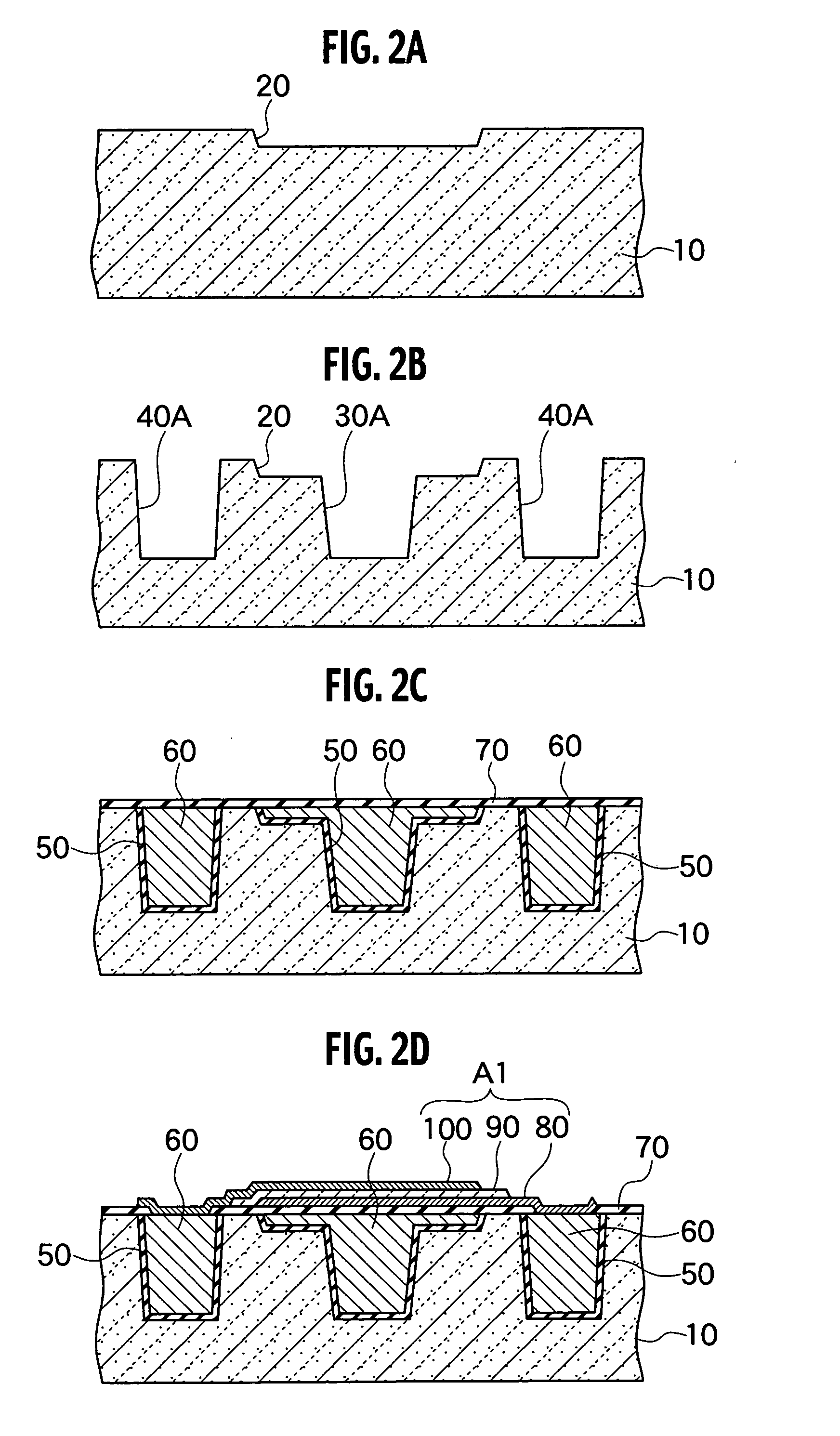

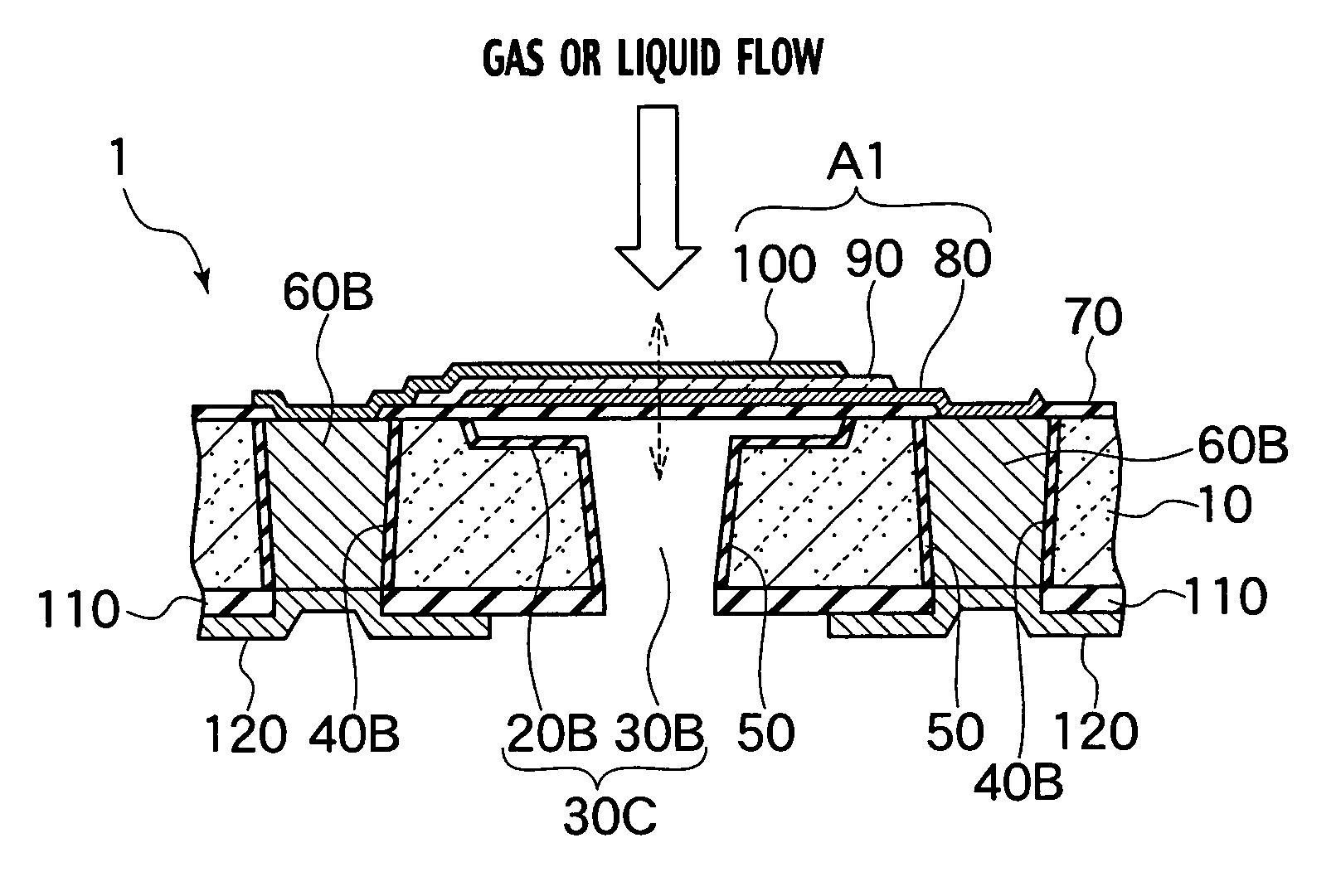

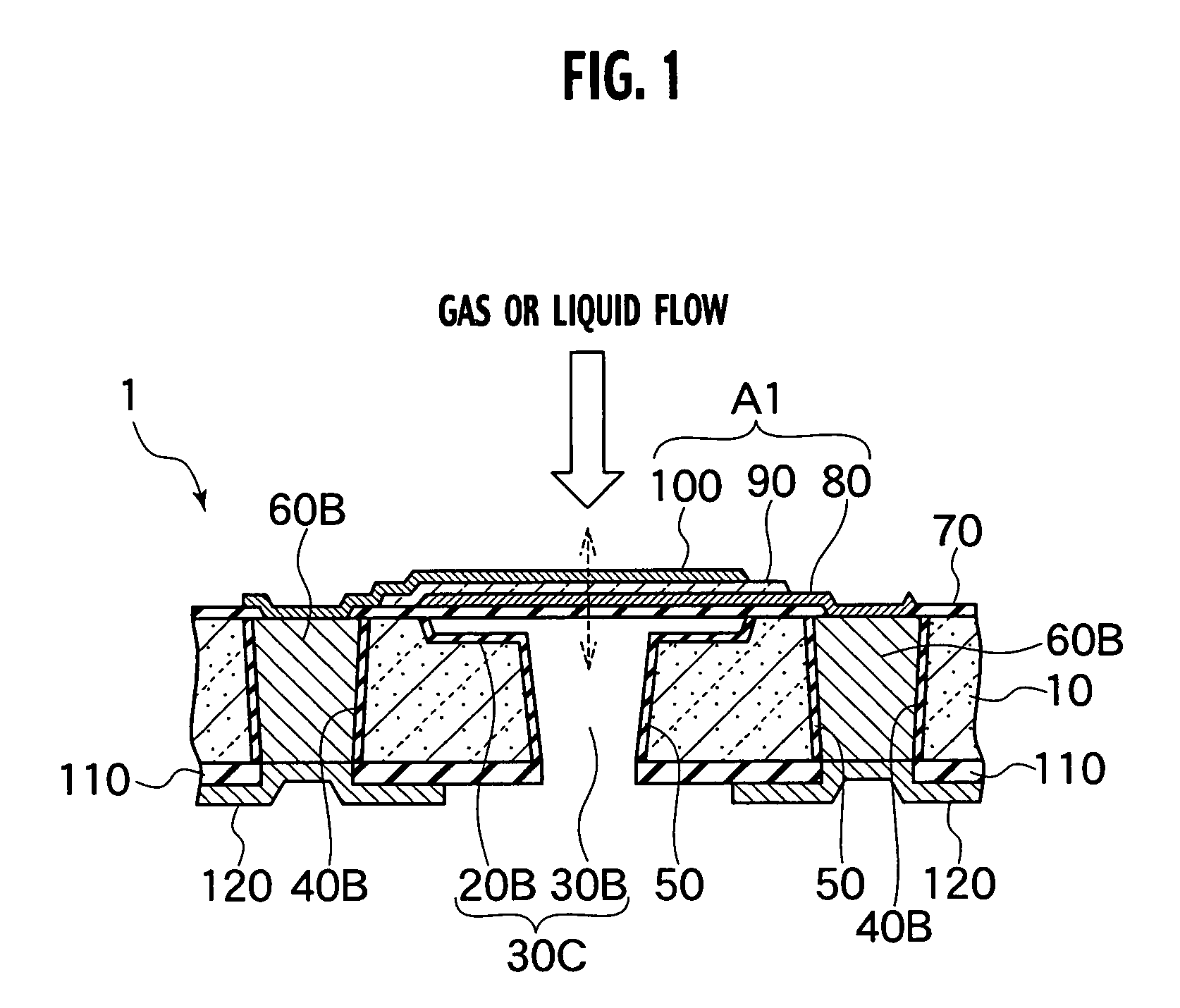

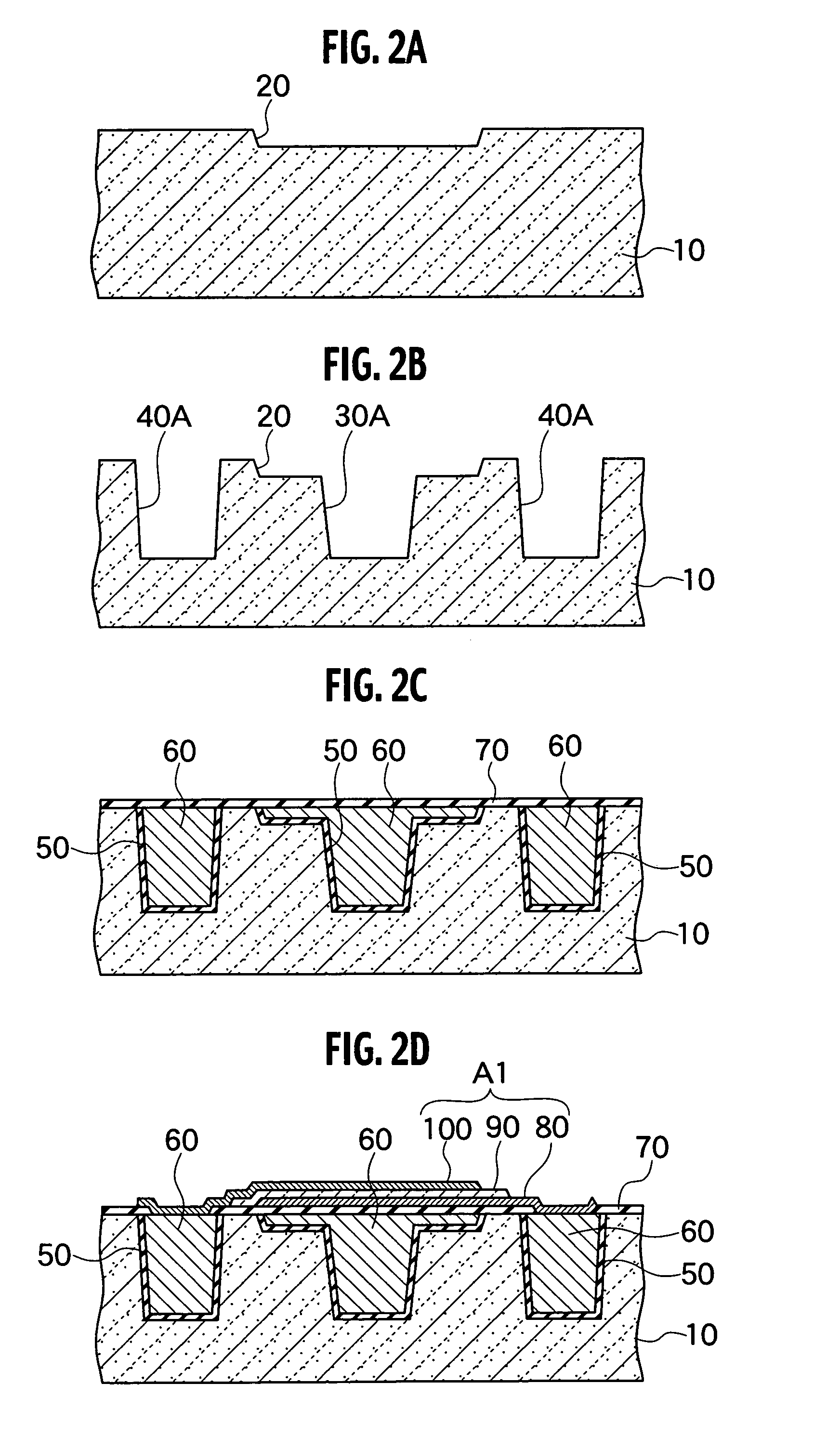

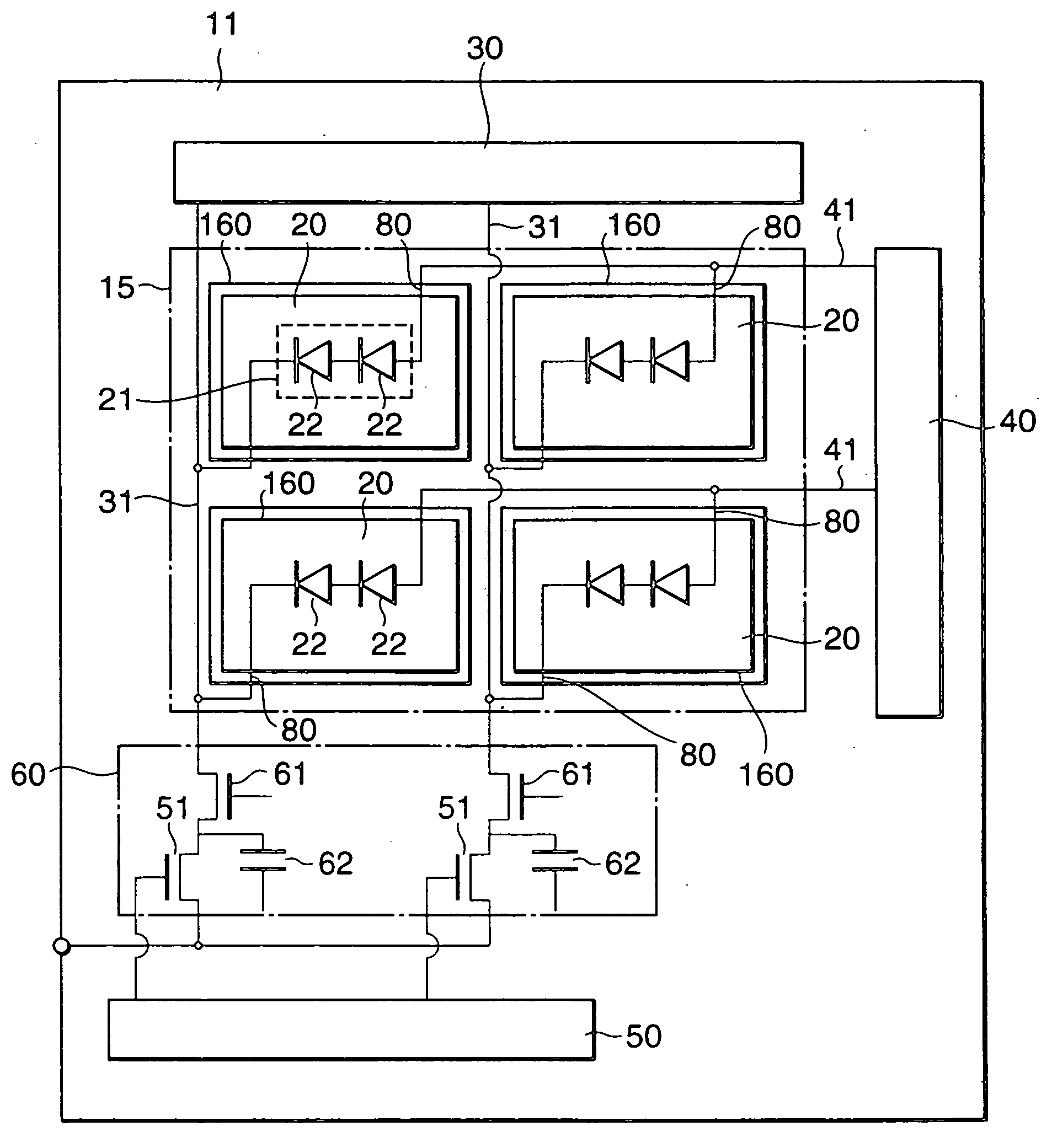

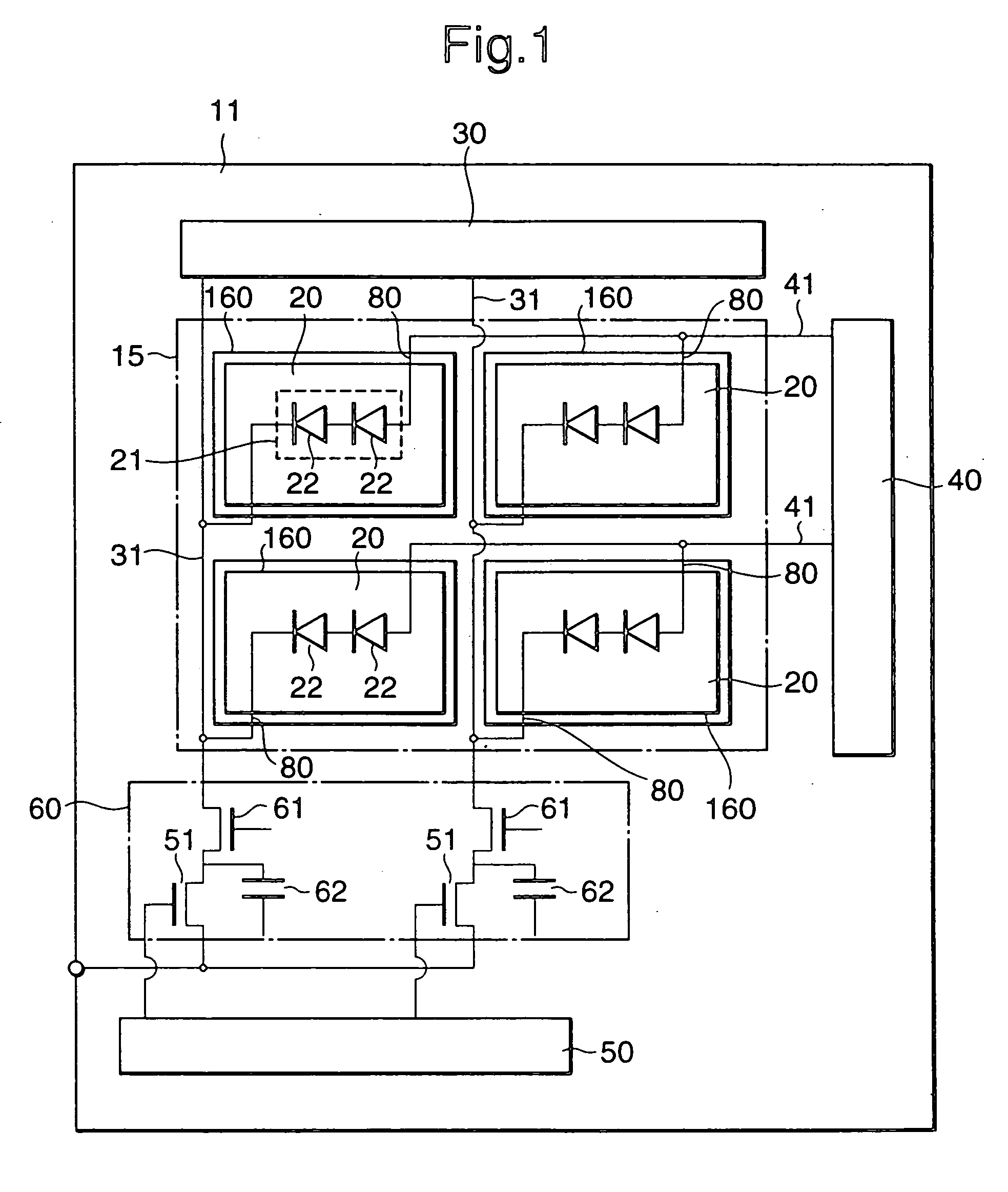

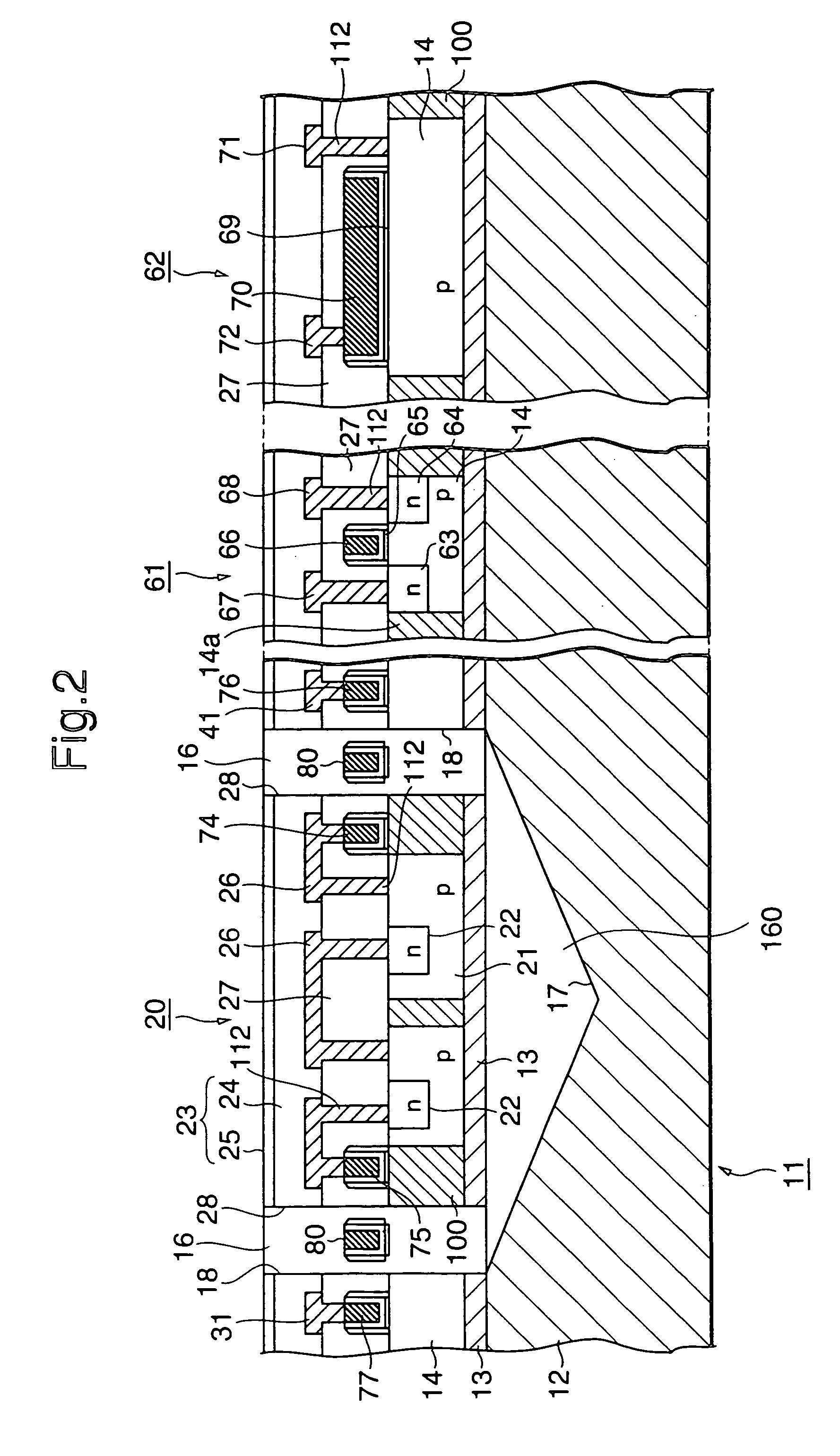

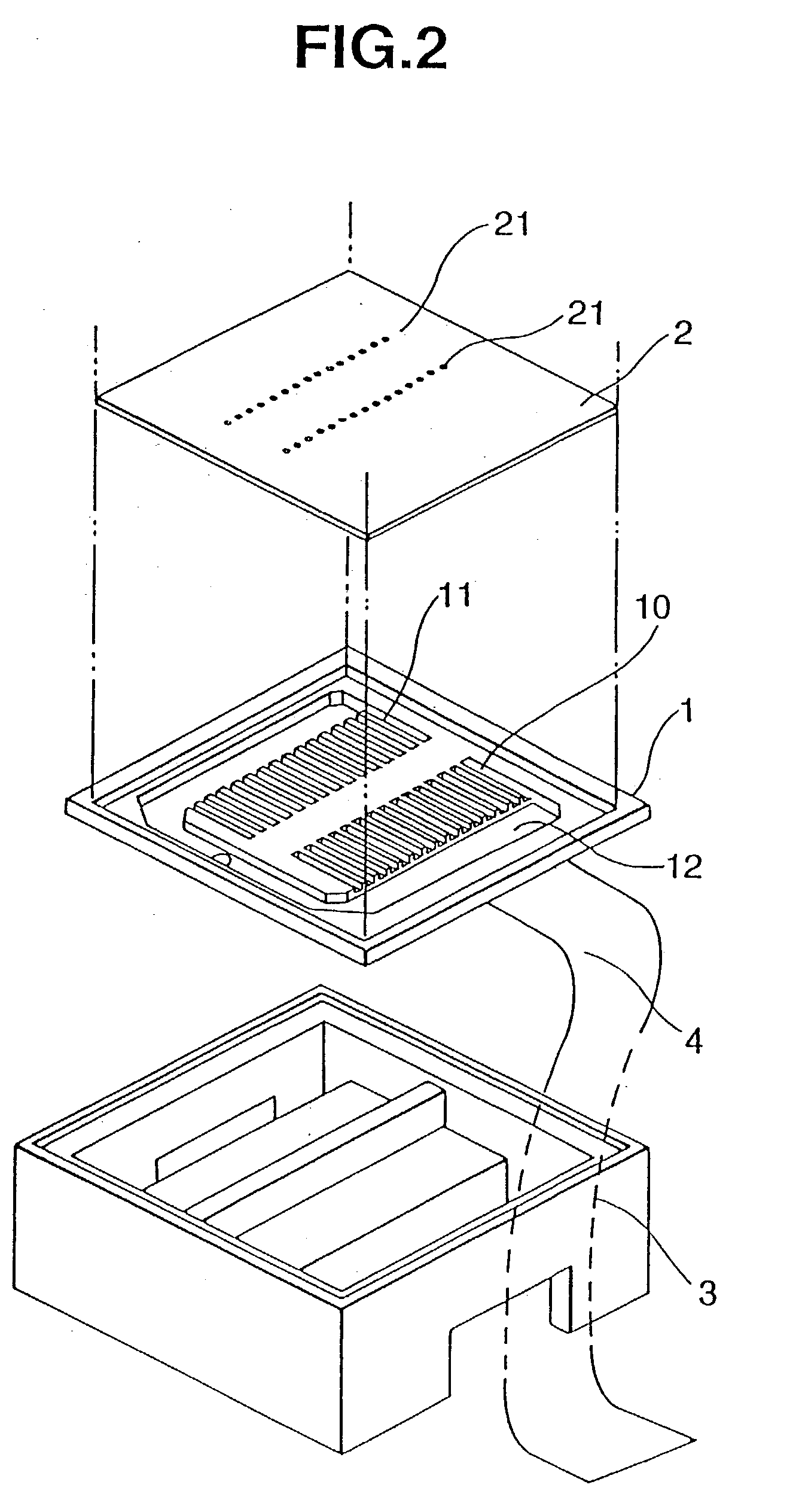

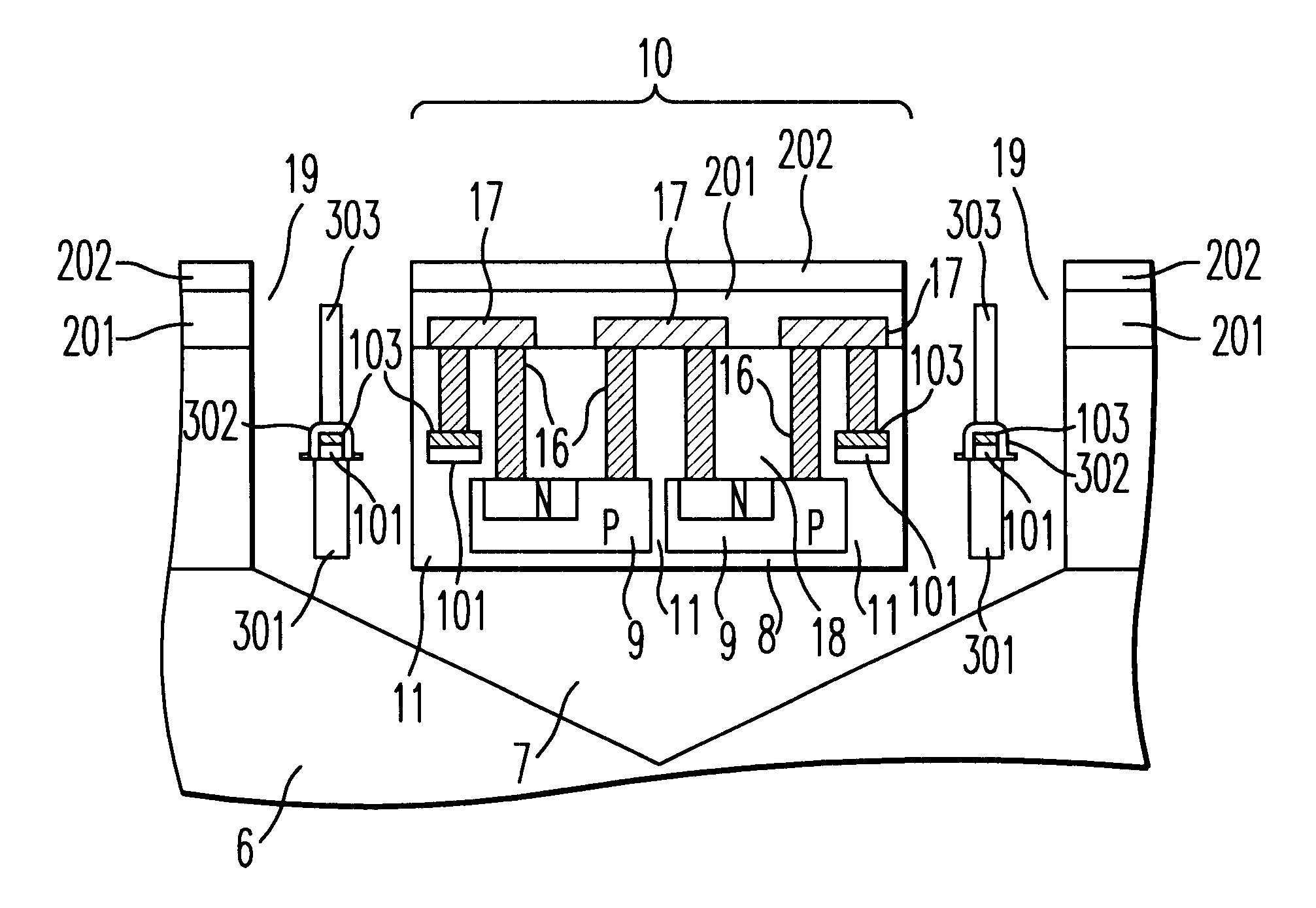

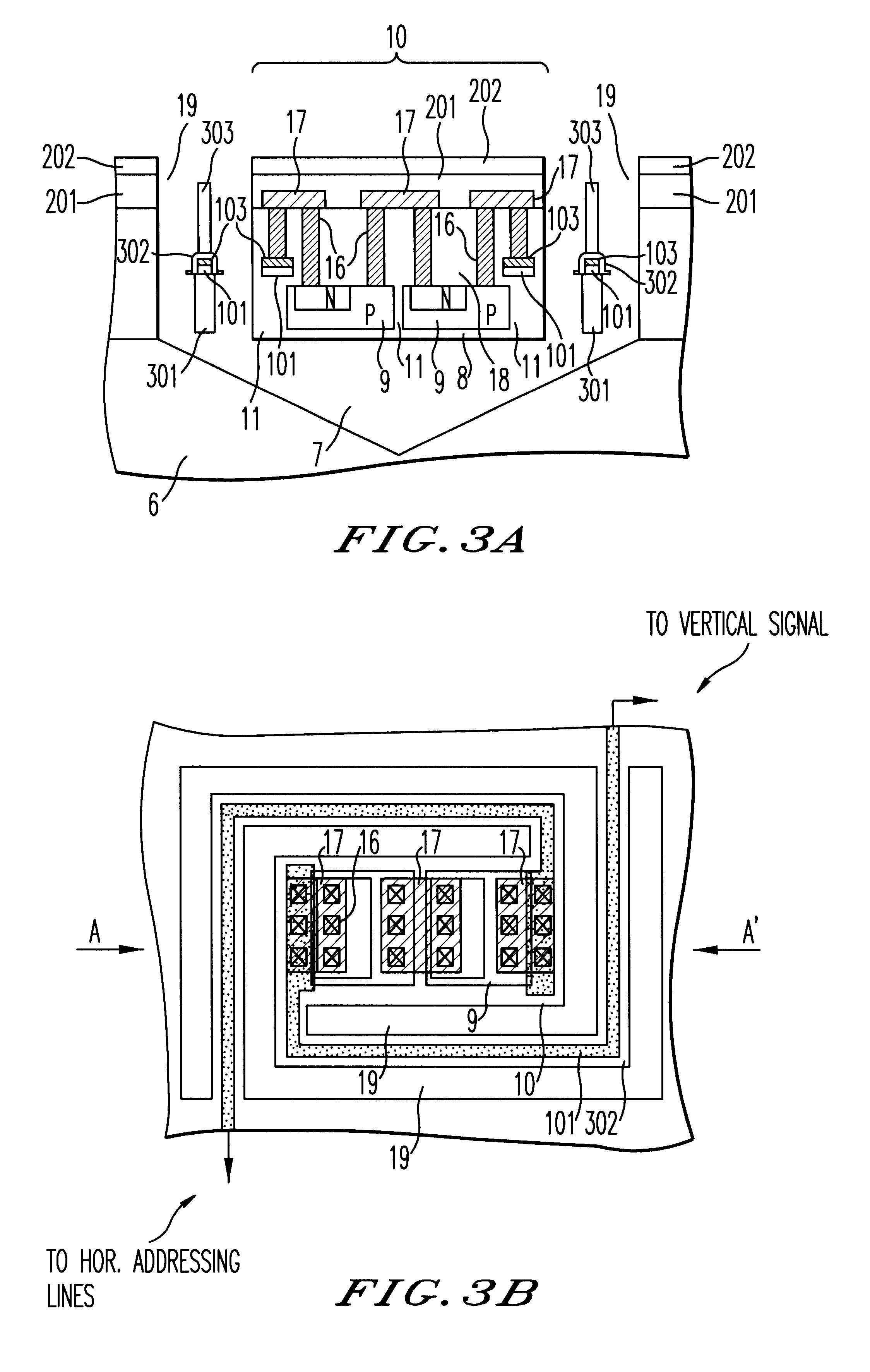

An electronic component includes a semiconductor substrate having a first surface and a second surface opposite to the first surface, a cavity that penetrates from the first surface to the second surface of the semiconductor substrate, and an electrical mechanical element that has a movable portion formed above the first surface of the semiconductor substrate so that the movable portion is arranged above the cavity. The electronic component further includes an electric conduction plug, which penetrates from the first surface to the second surface of the semiconductor substrate, and which is electrically connected to the electrical mechanical element.

Owner:KIOXIA CORP

Electronic component having micro-electrical mechanical system

ActiveUS7053456B2Thermoelectric device with dielectric constant thermal changeAcceleration measurement using interia forcesElectricityElectronic component

Owner:KIOXIA CORP

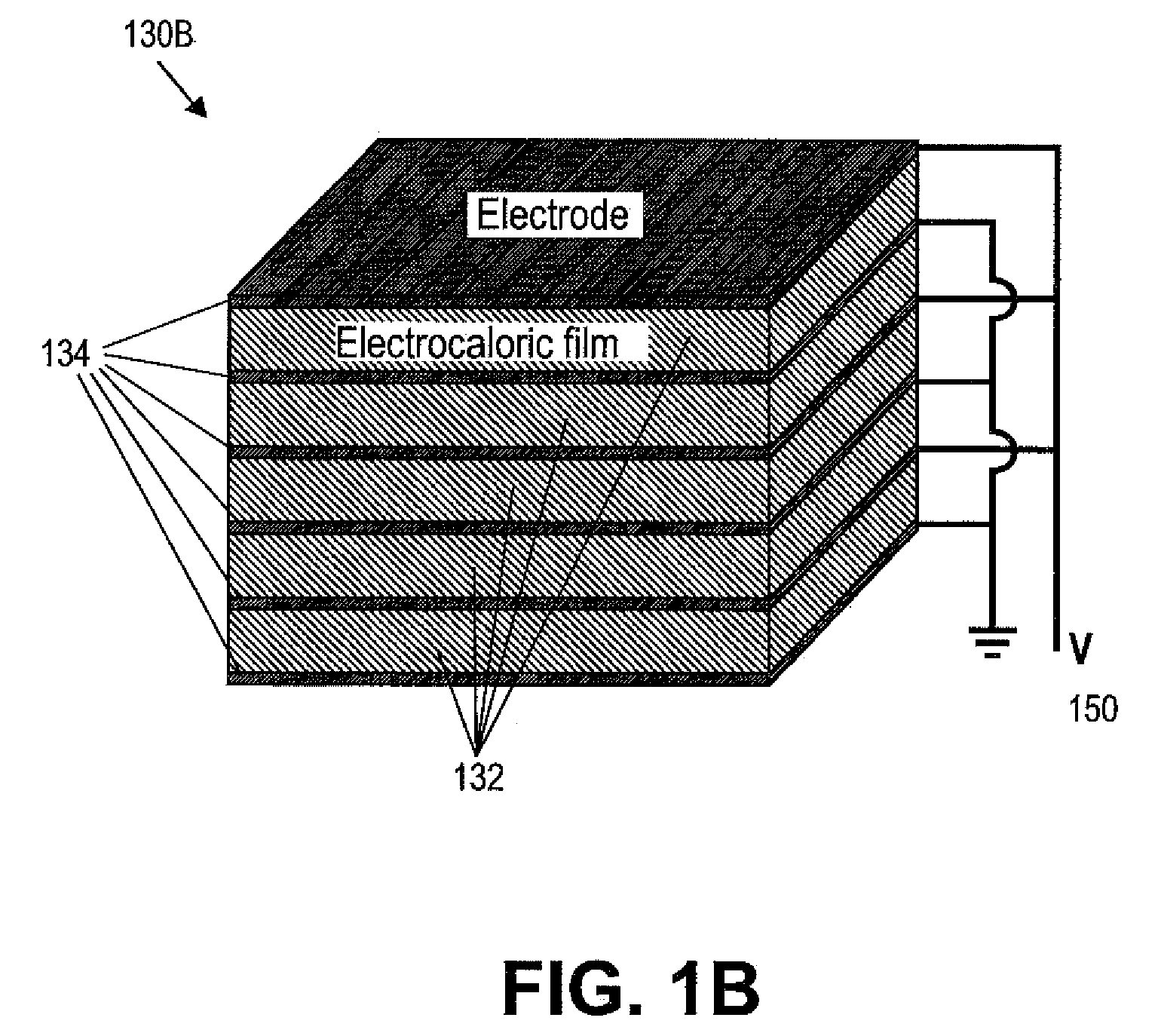

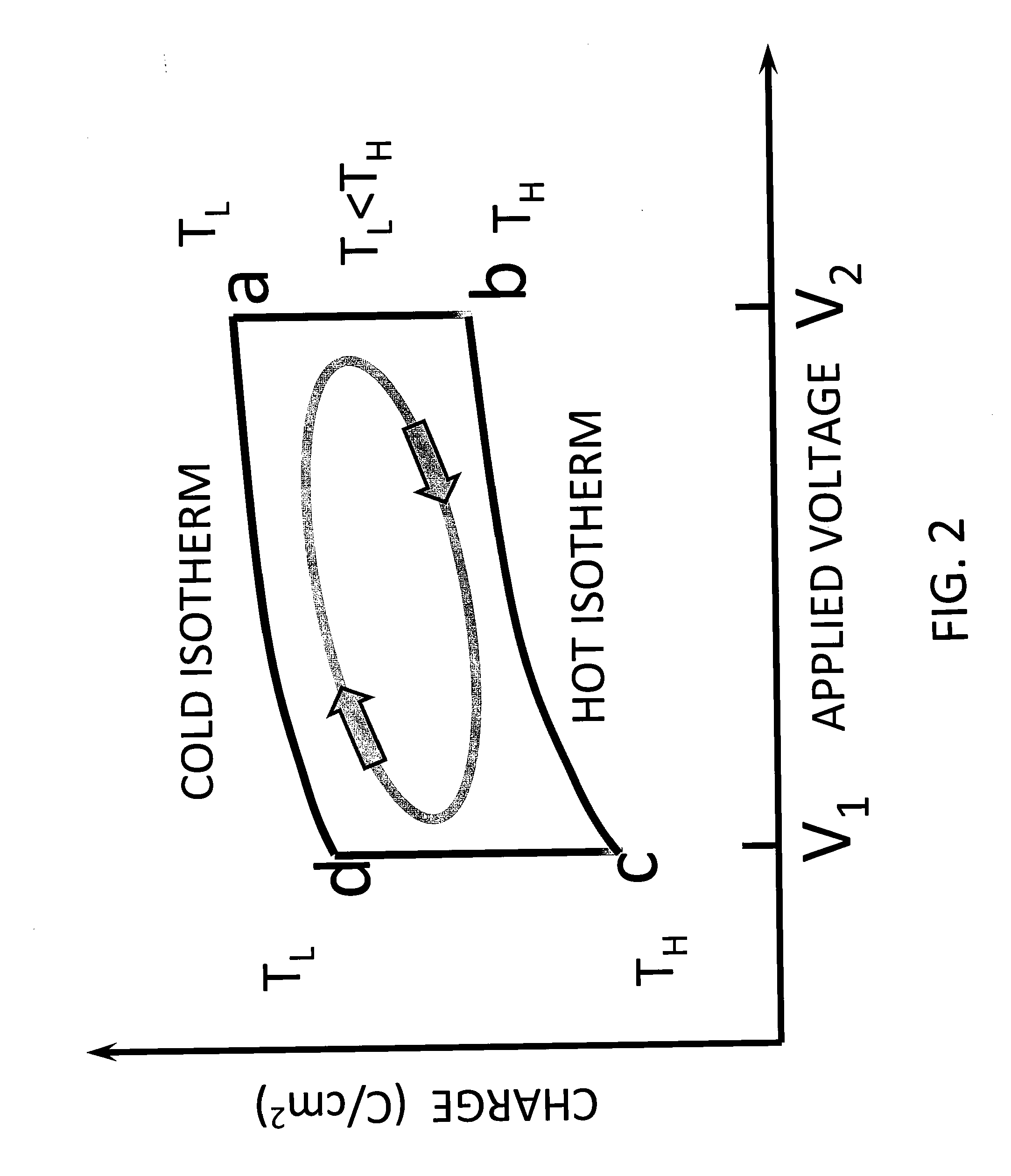

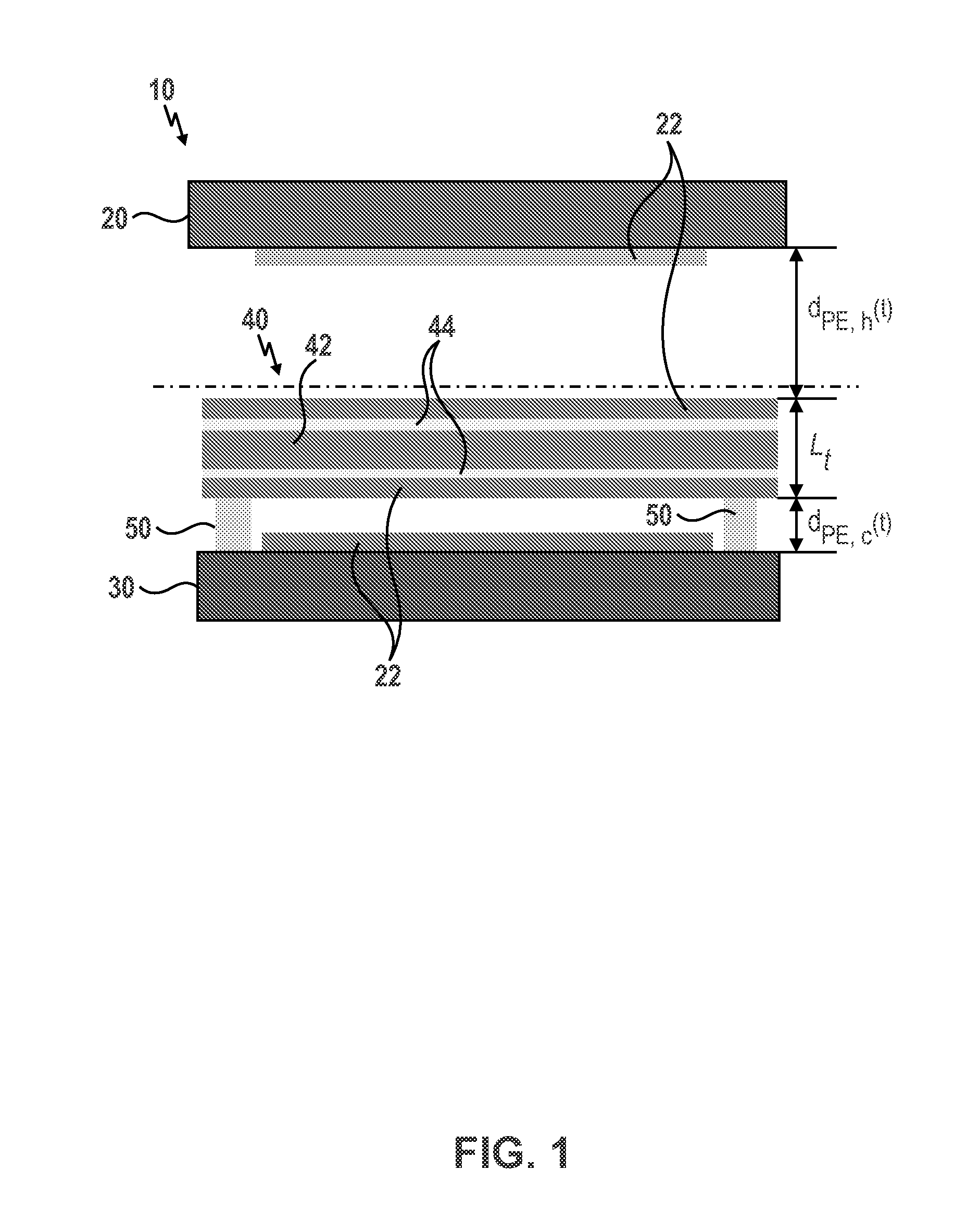

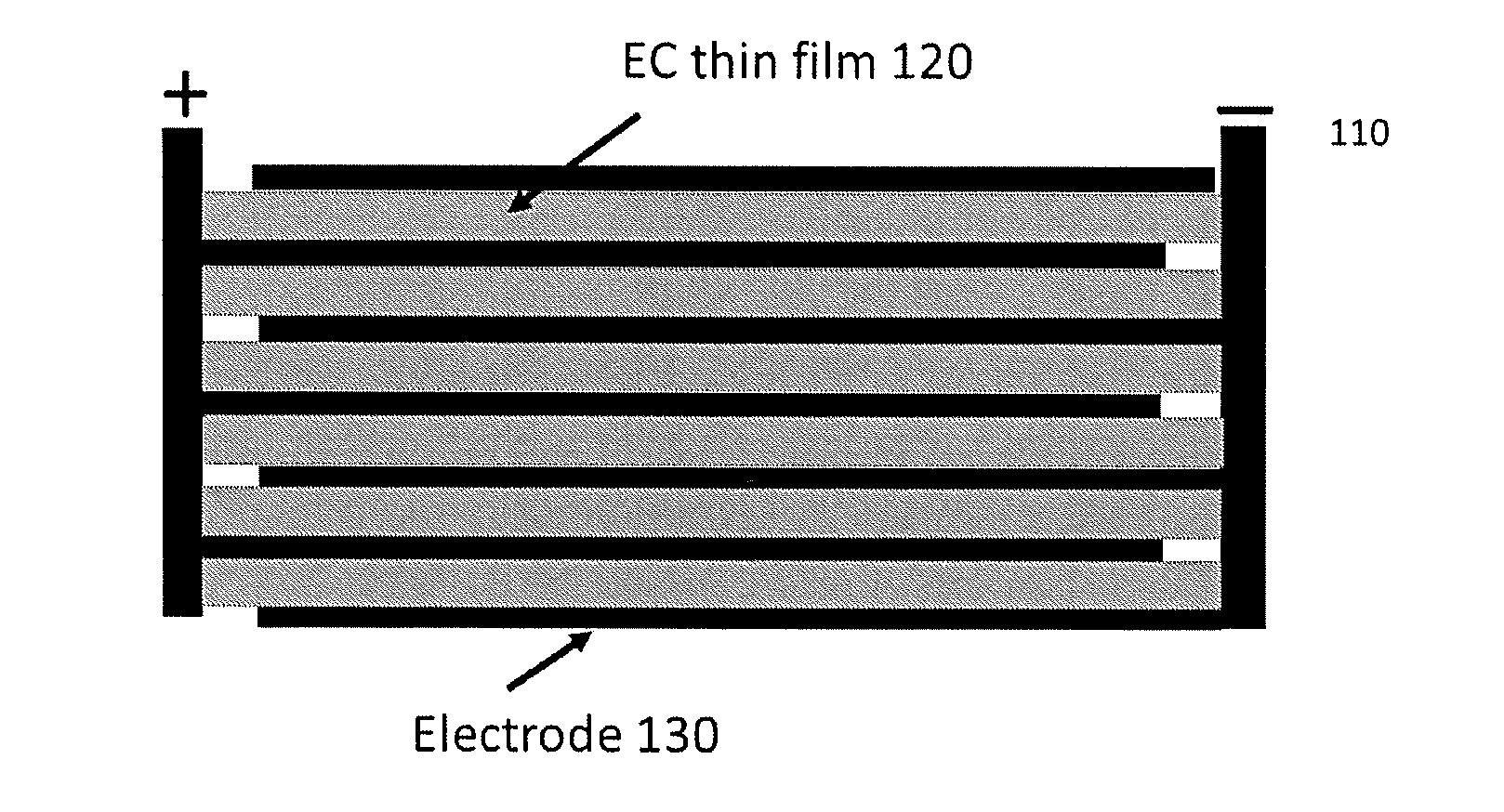

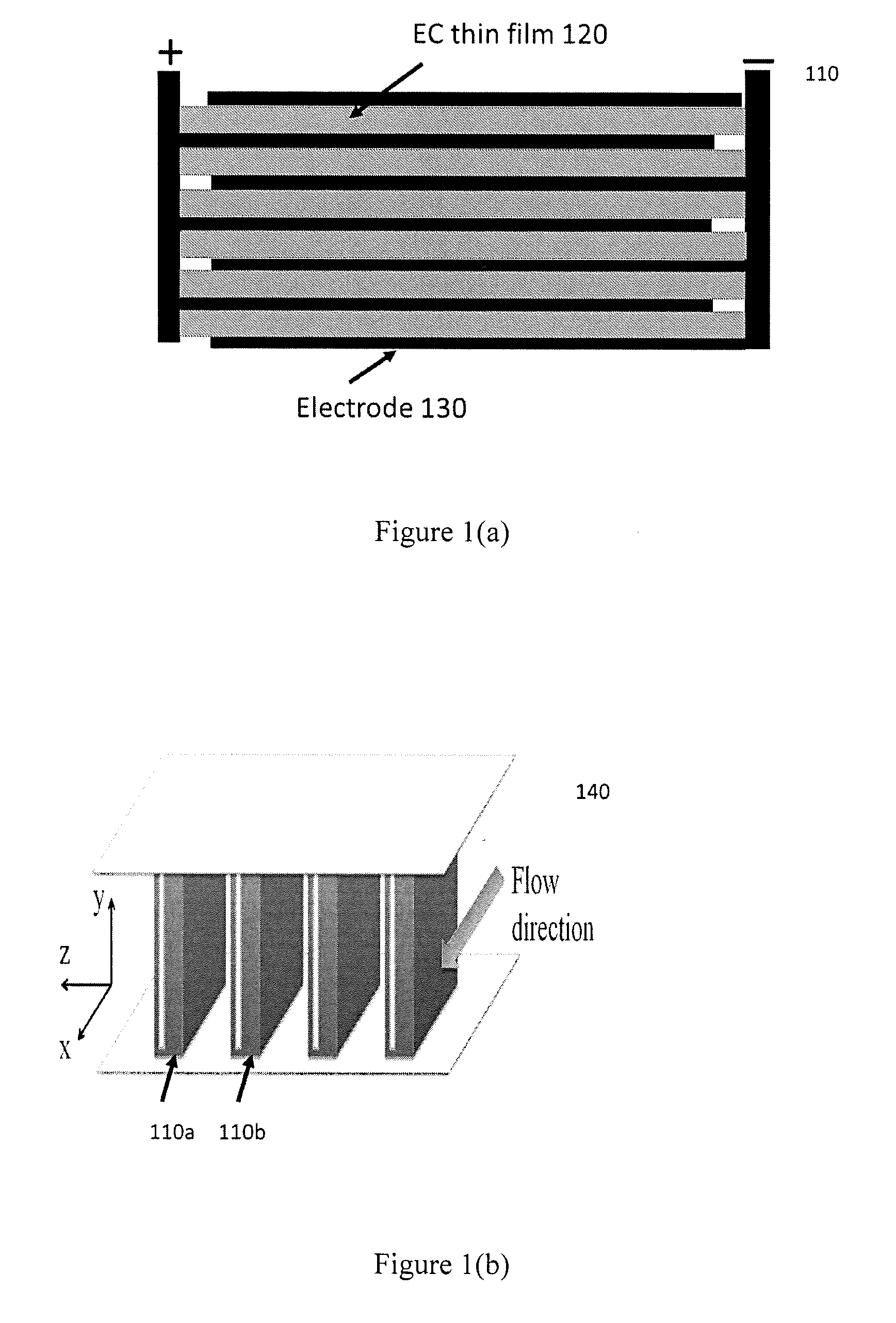

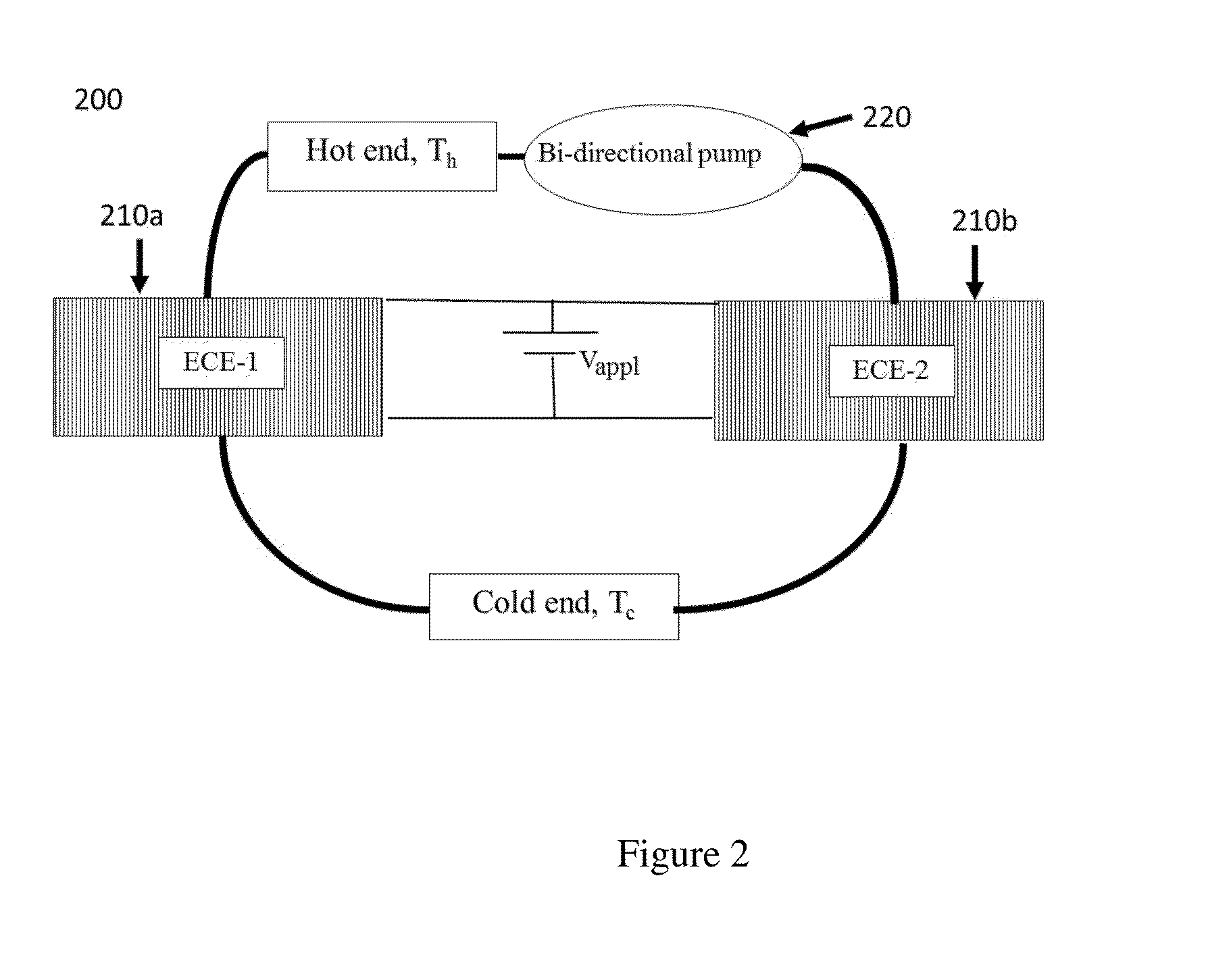

Electrocaloric refrigerator and multilayer pyroelectric energy generator

InactiveUS20100175392A1Thermoelectric device with dielectric constant thermal changeEnergy efficient heating/coolingEngineeringRefrigerated temperature

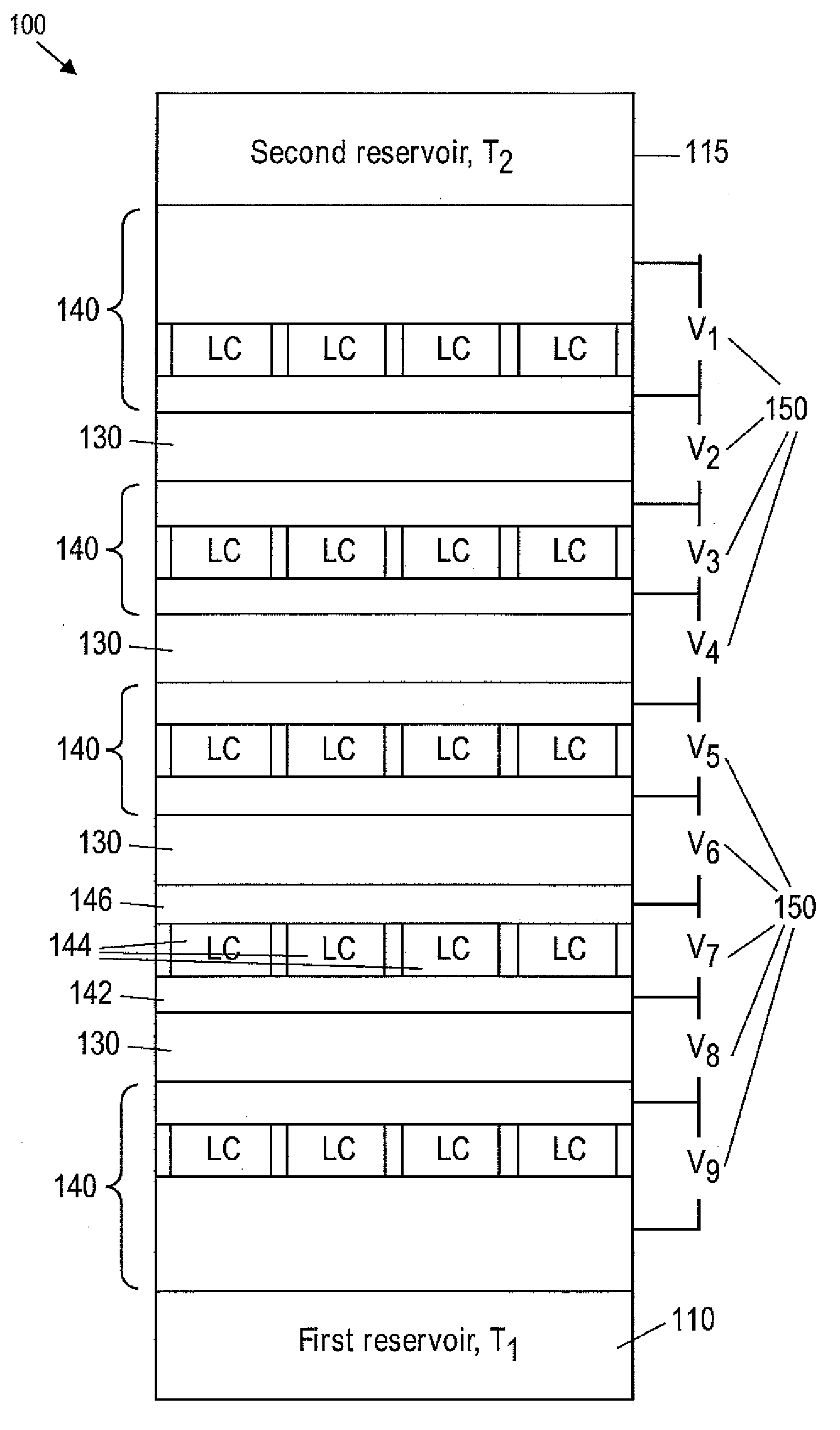

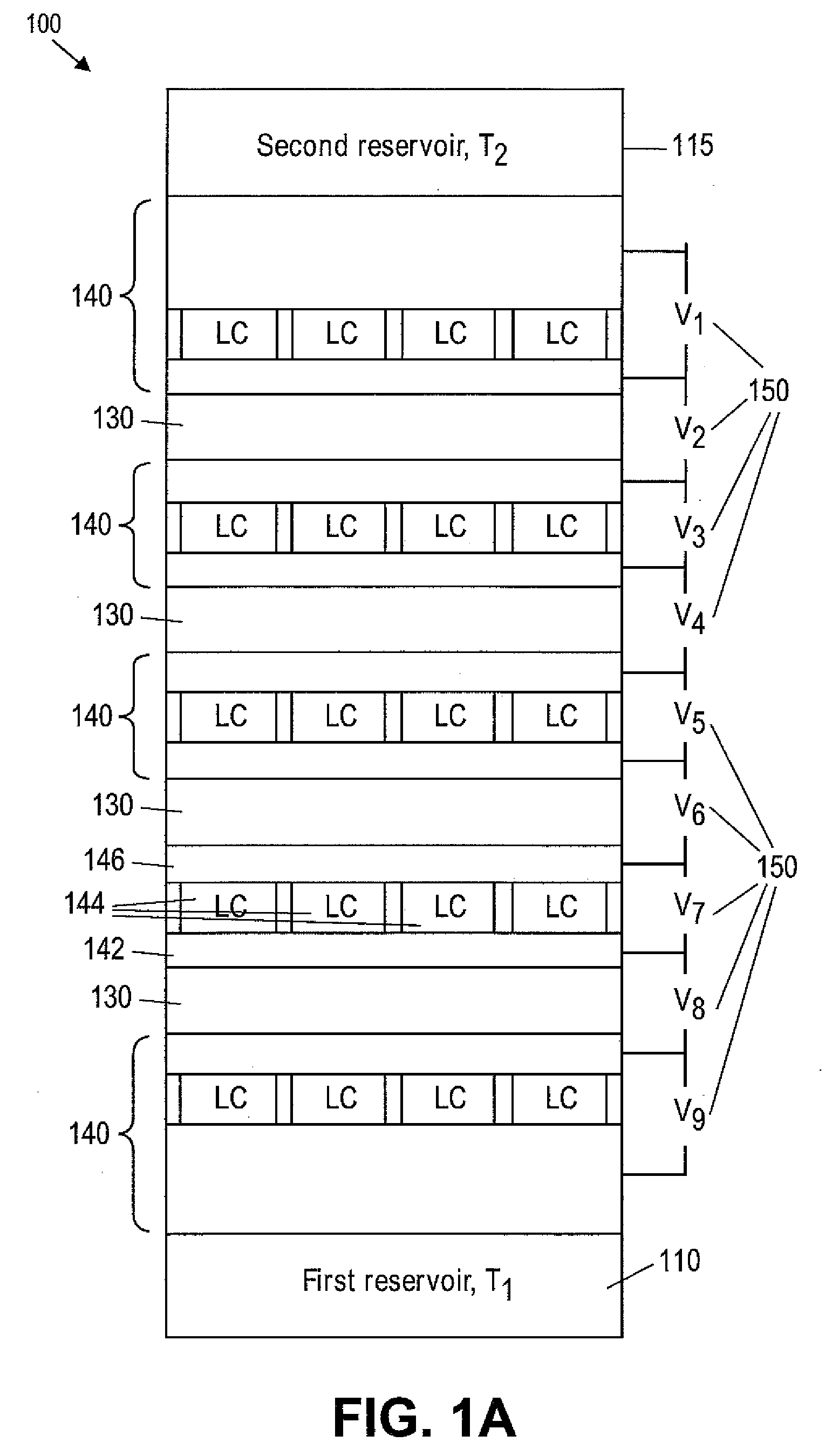

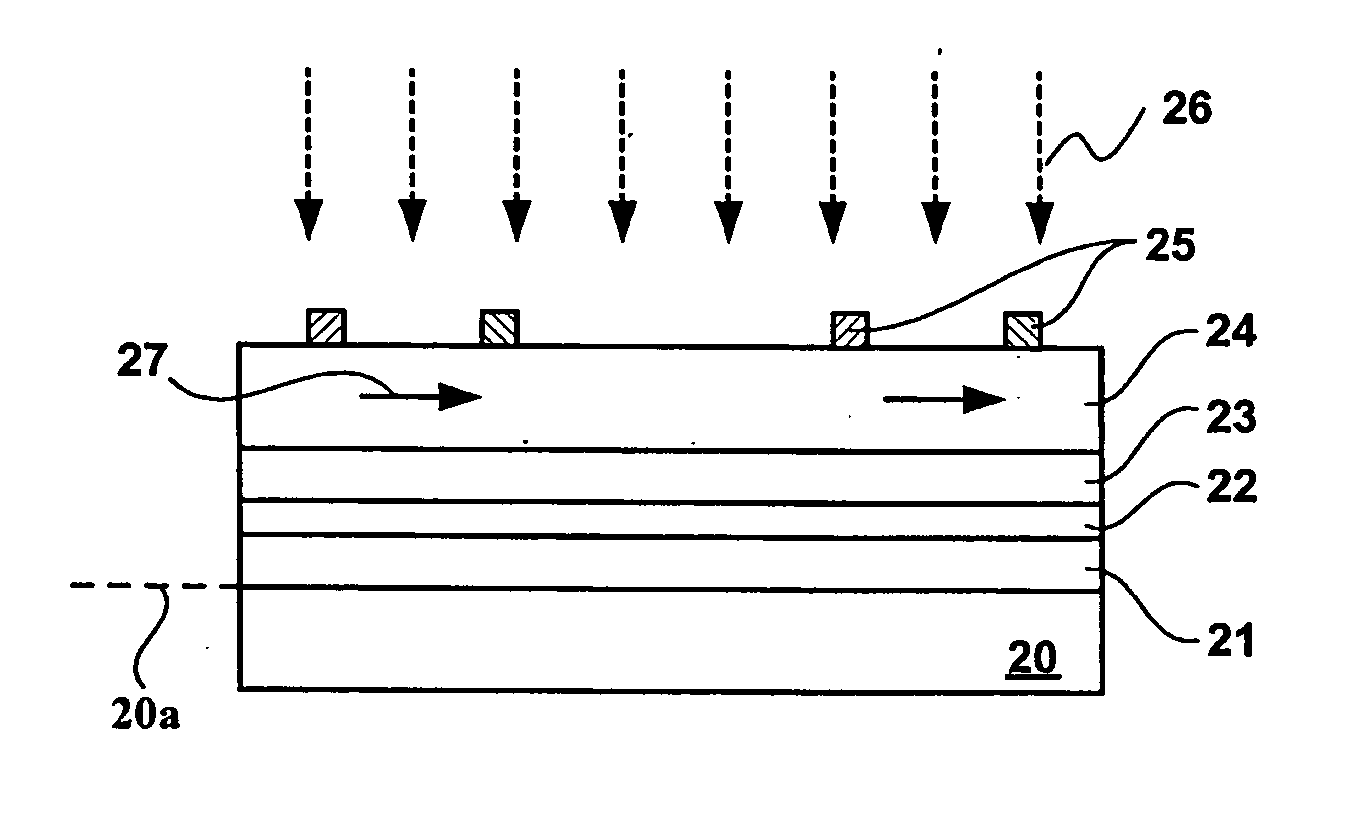

Provided are electrocaloric devices, pyroelectric devices and methods of forming them. A device which can be a pyroelectric energy generator or an electrocaloric cooling device, can include a first single-layer heat engine having a first side configured to be in contact with a first reservoir and a second side configured to be in contact with a second reservoir, wherein the first reservoir comprises a fluid. The device can also include a second single-layer heat engine having a first side in contact with the first reservoir and a second side in contact with a third reservoir and a channel disposed between the first single-layer heat engine and the second single-layer heat engine, the channel configured to transport the fluid from a first end to a second end. The device can further include one or more power supplies configured to apply voltages to the first and the second single-layer heat engine.

Owner:STC UNM

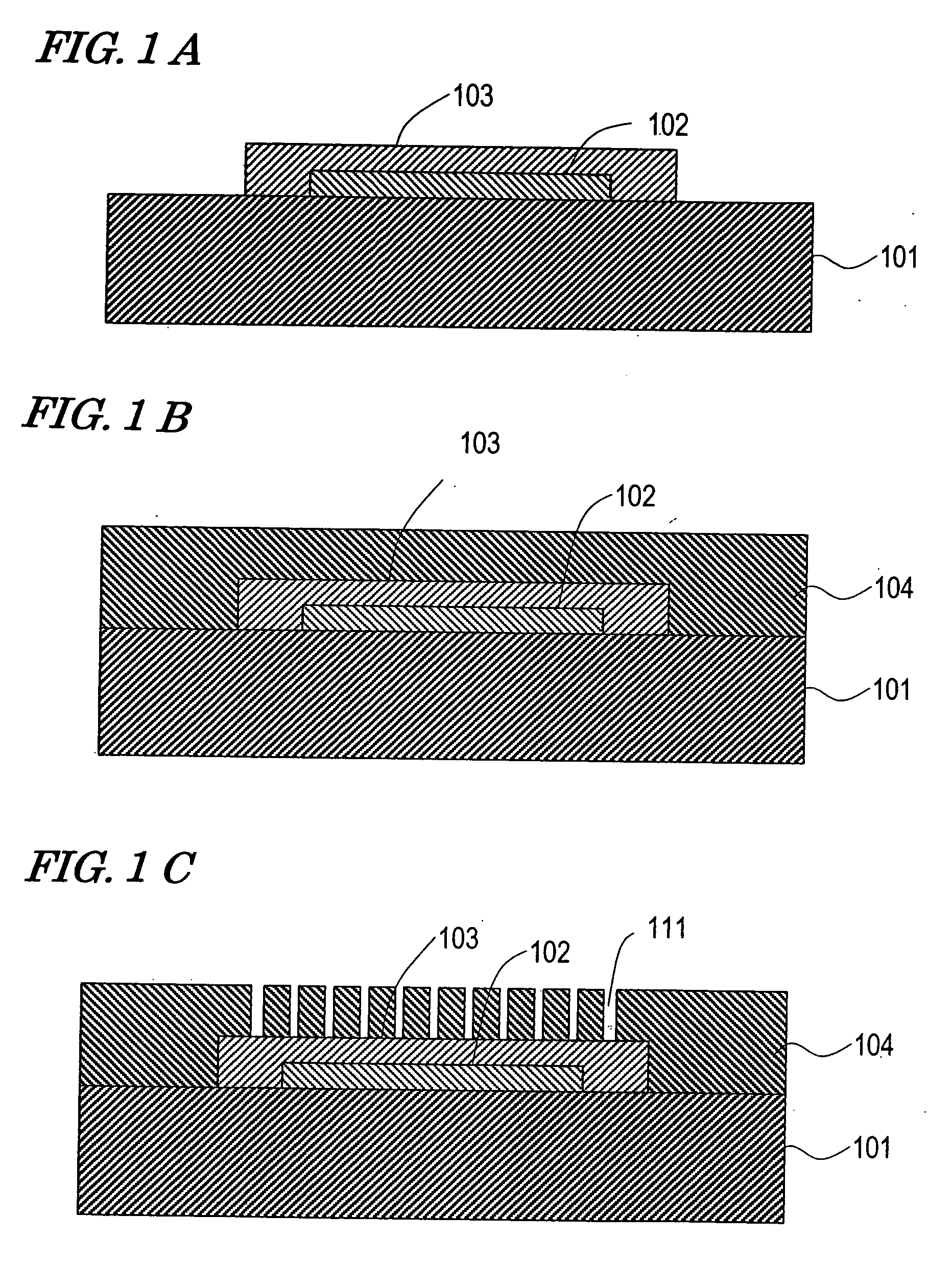

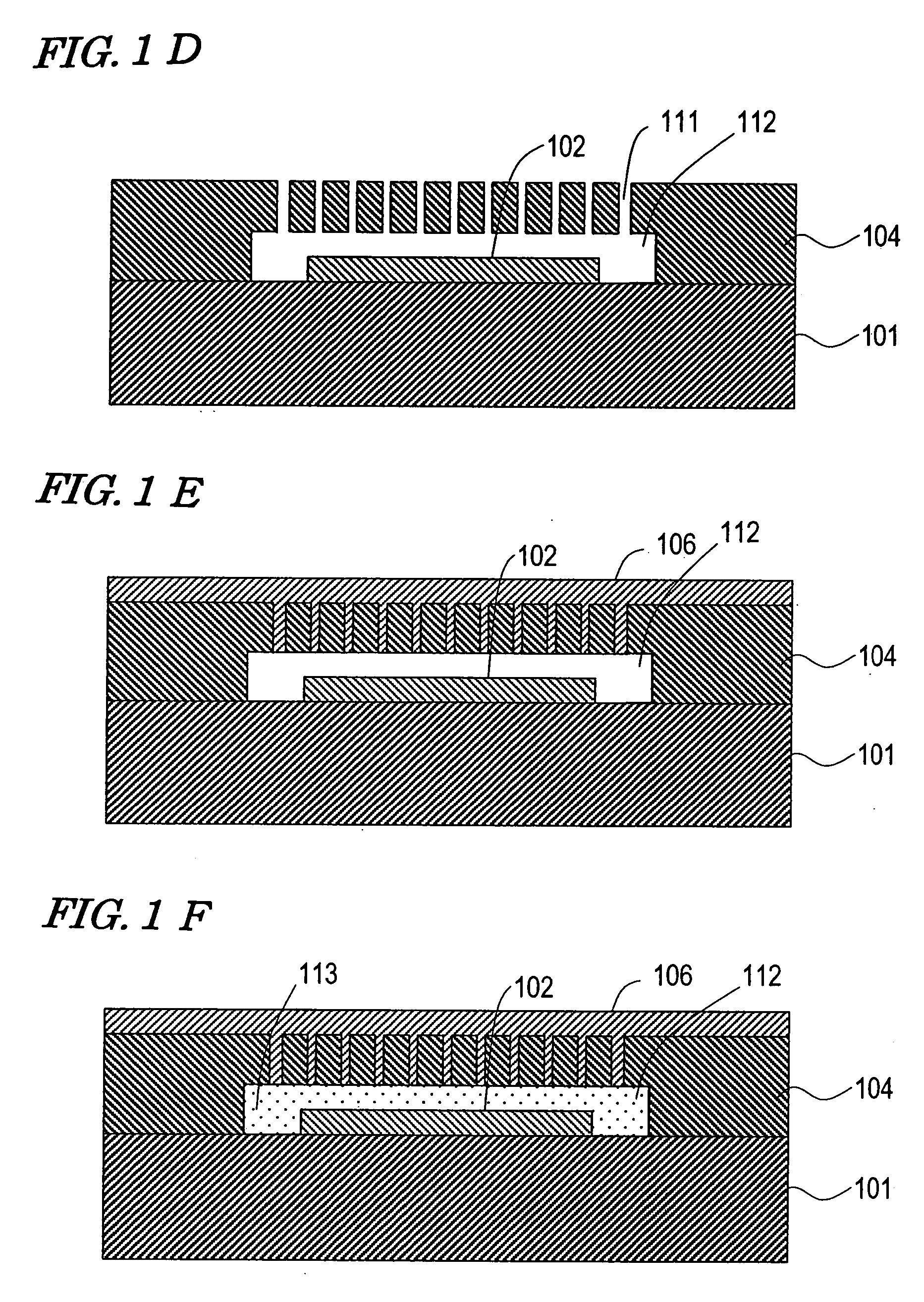

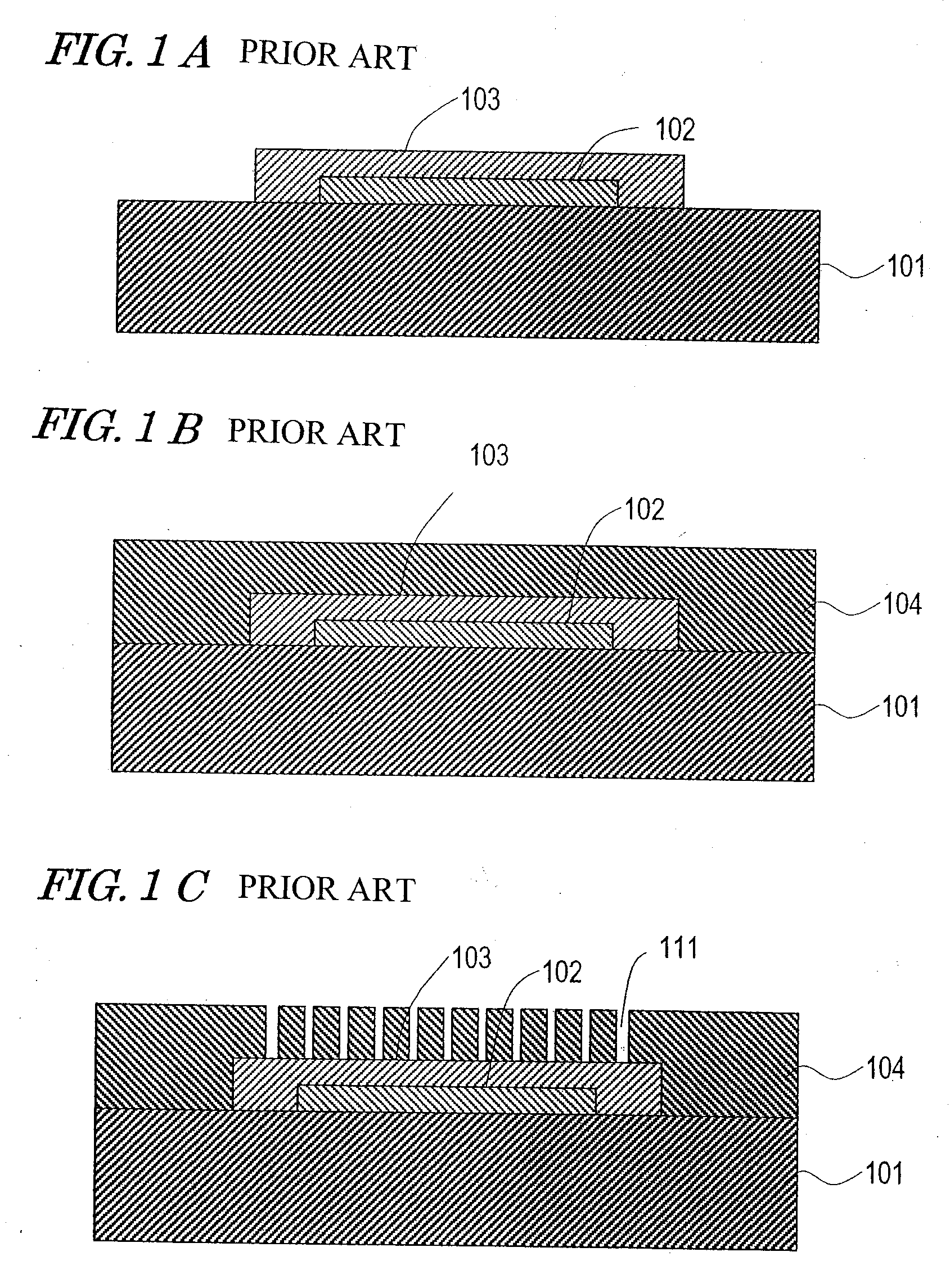

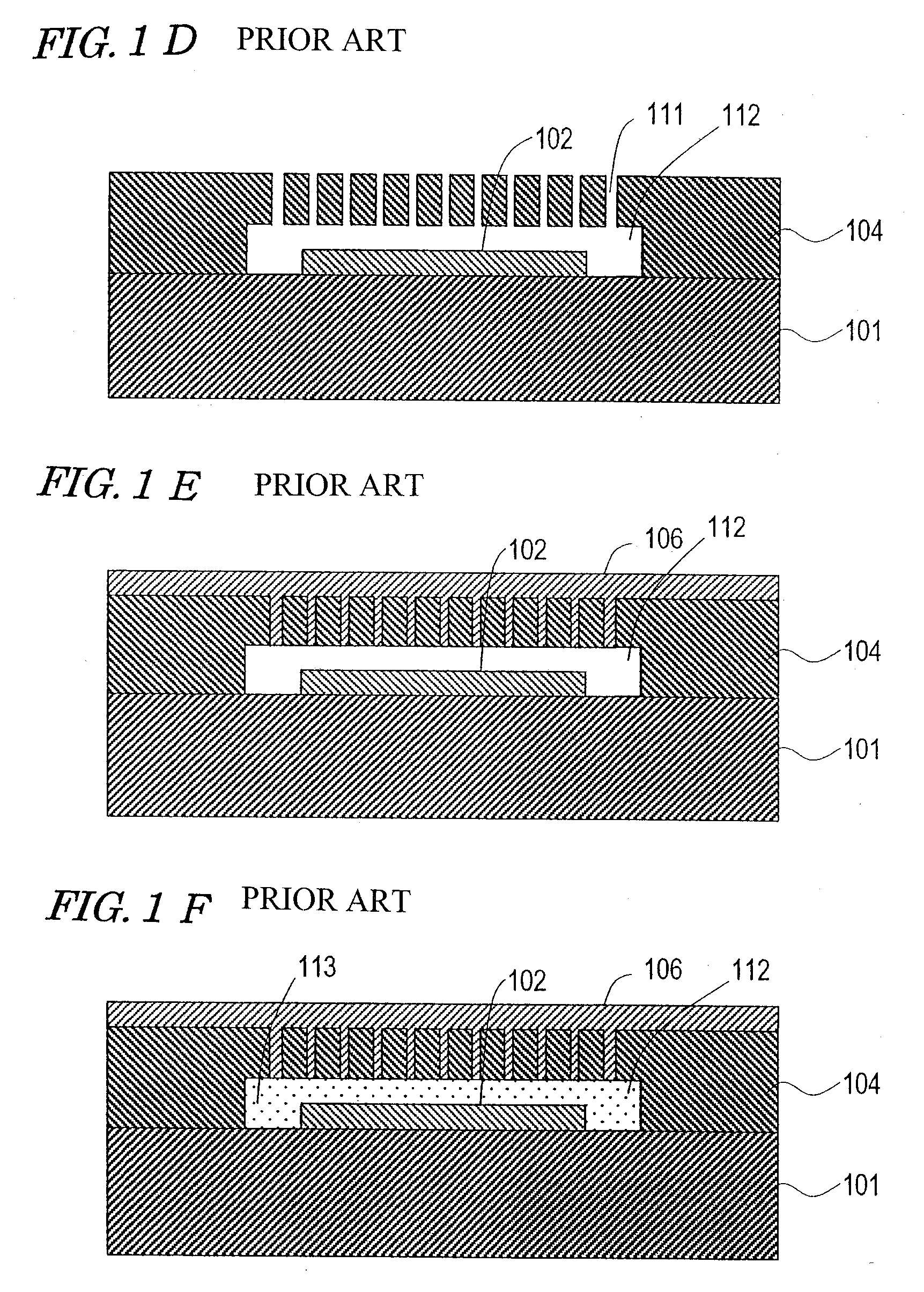

Electronic device and method of manufacturing the same

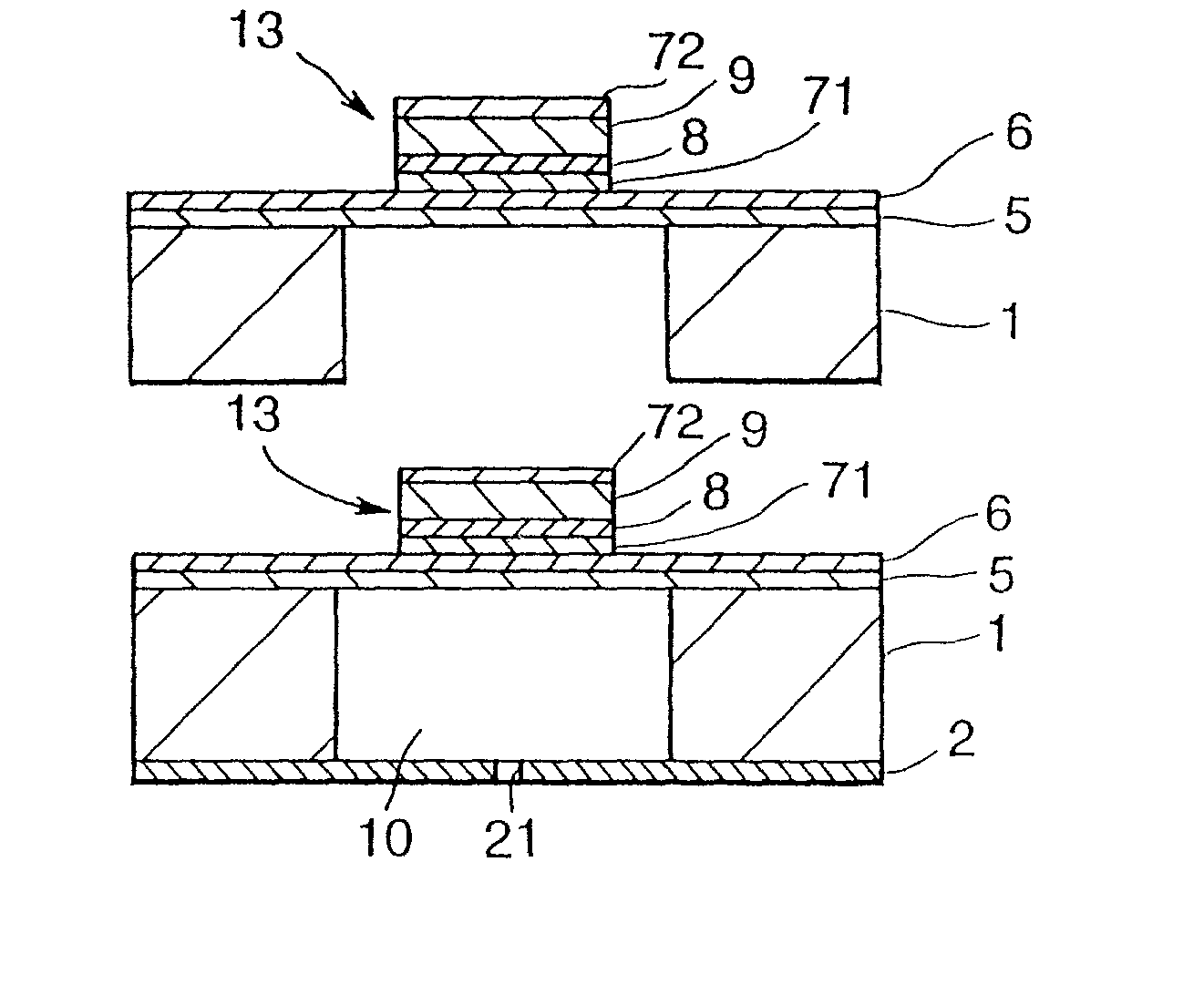

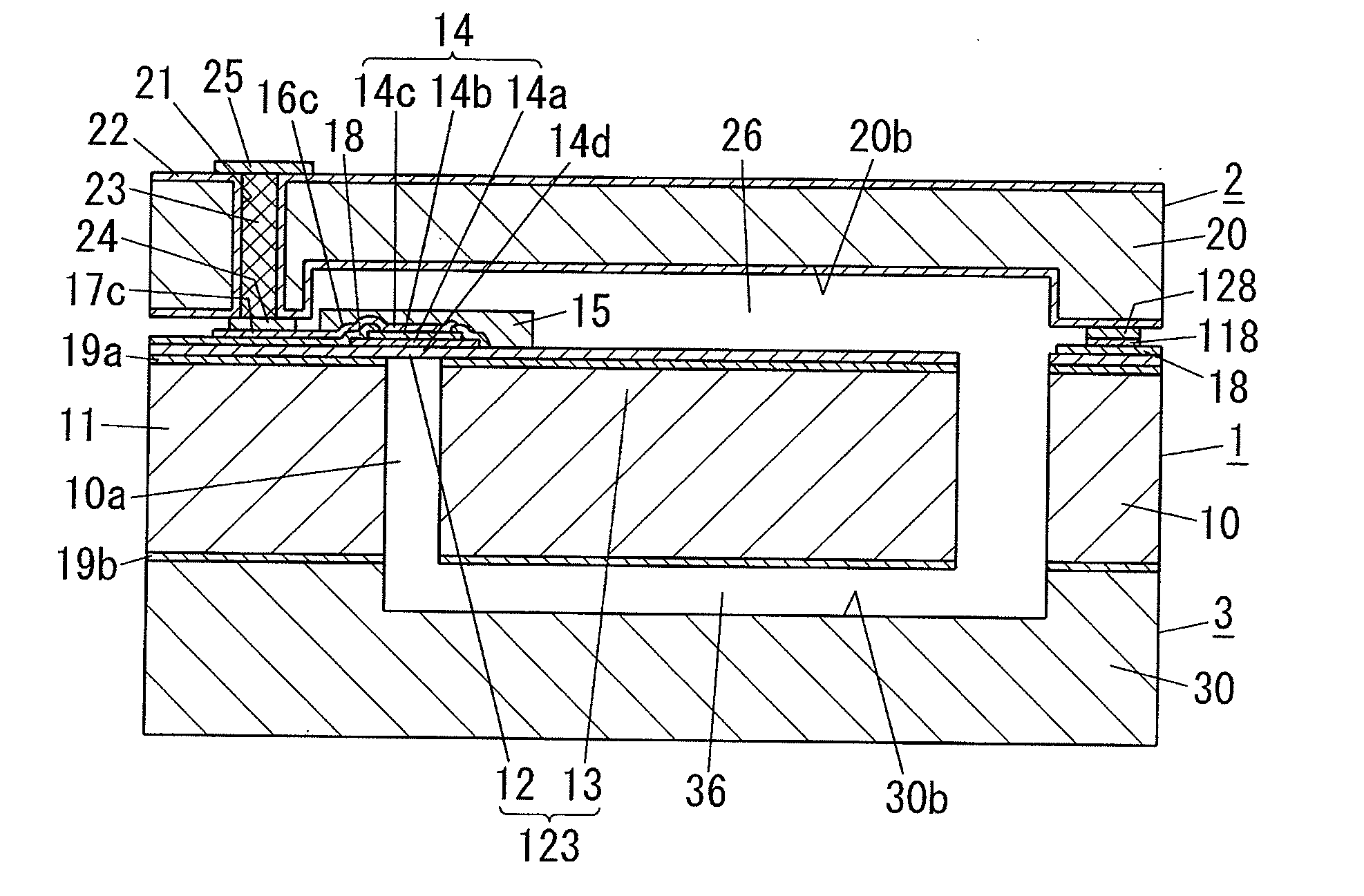

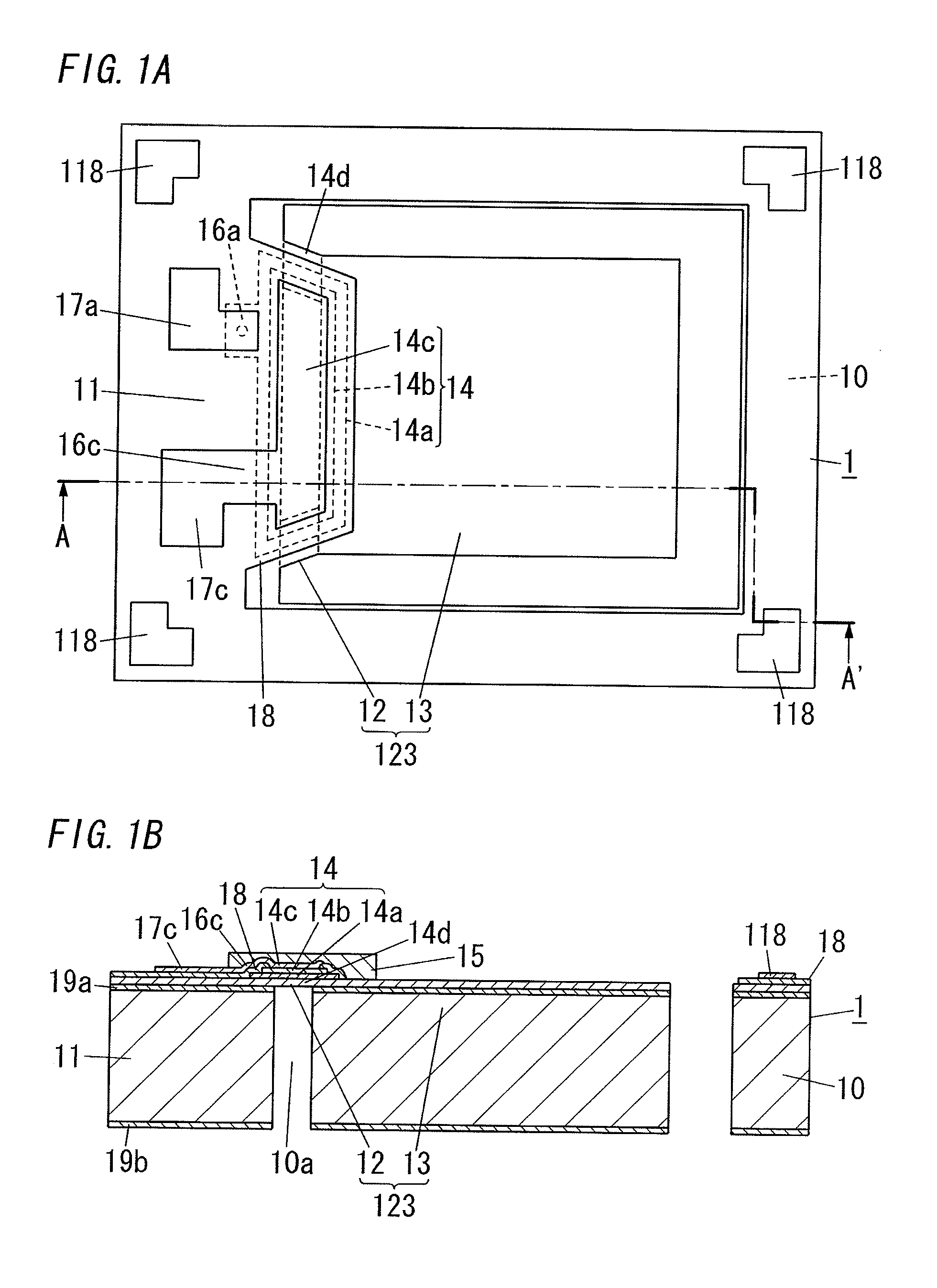

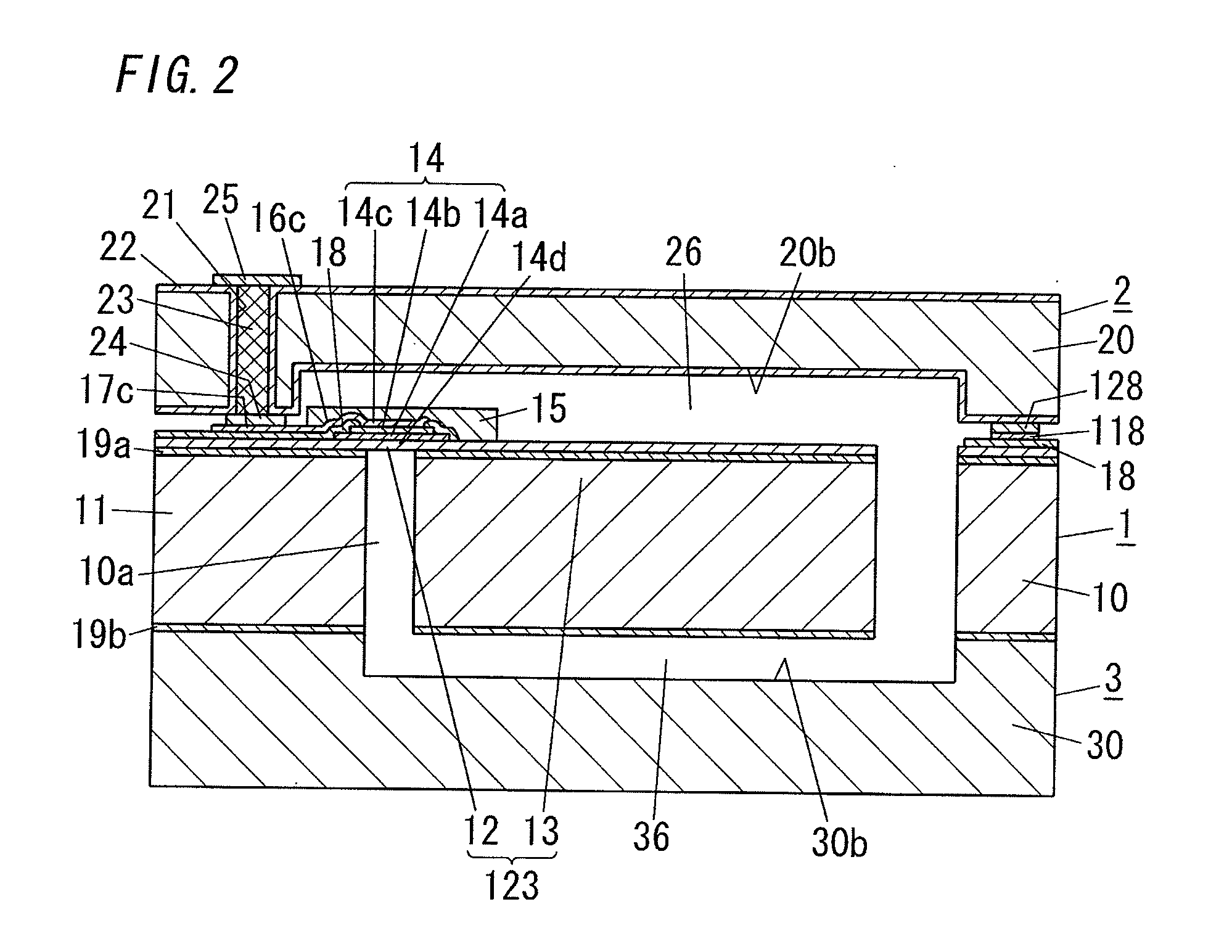

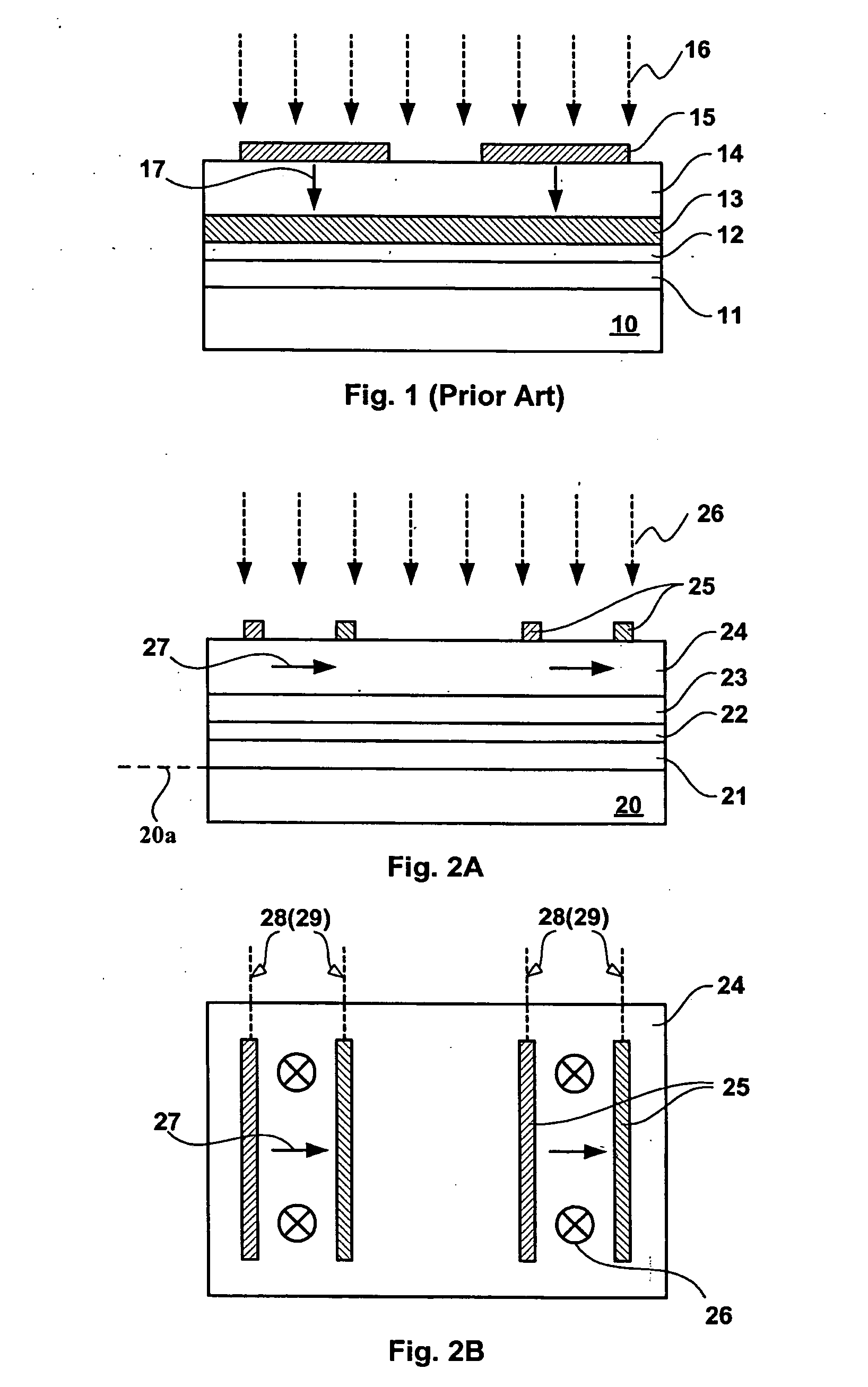

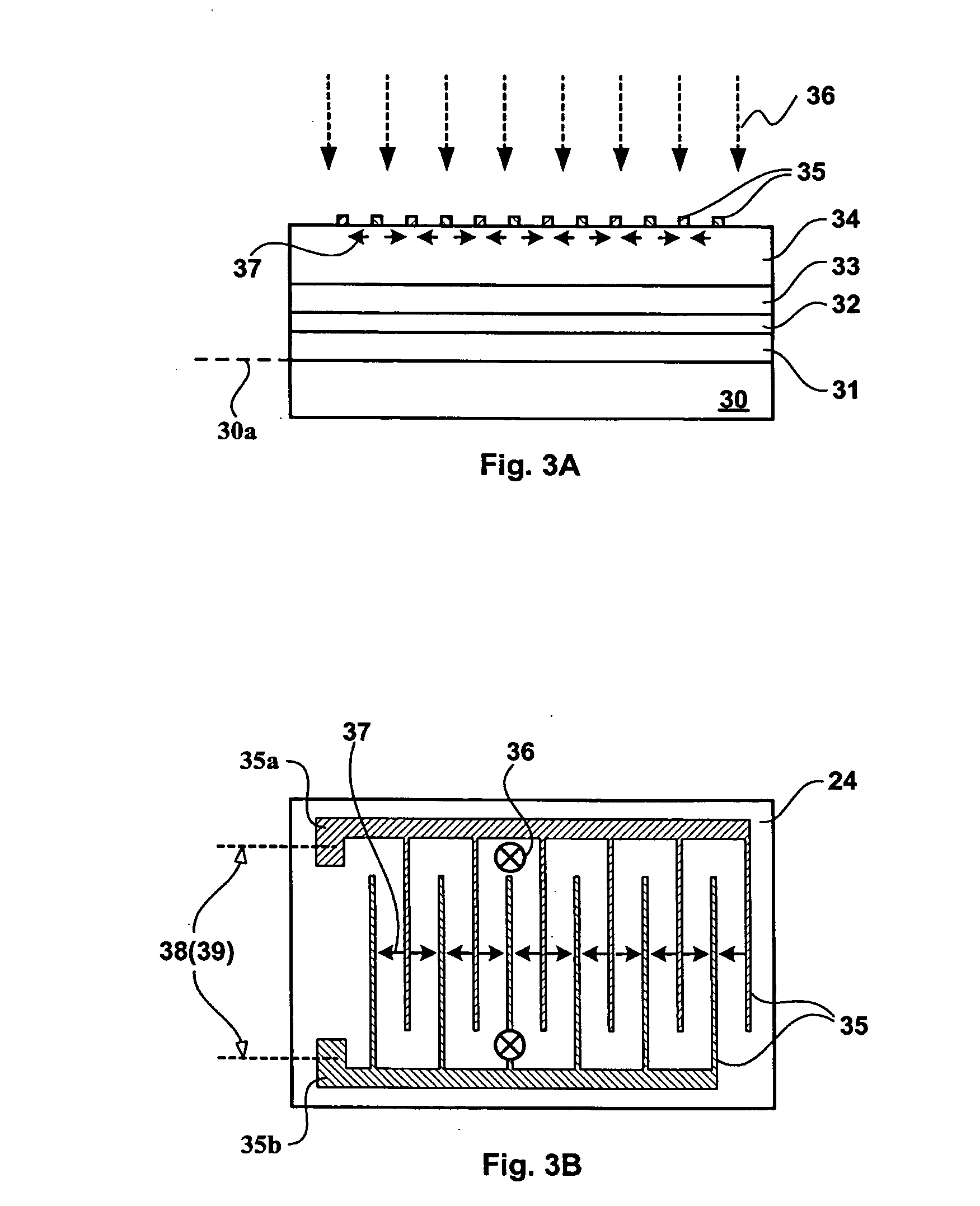

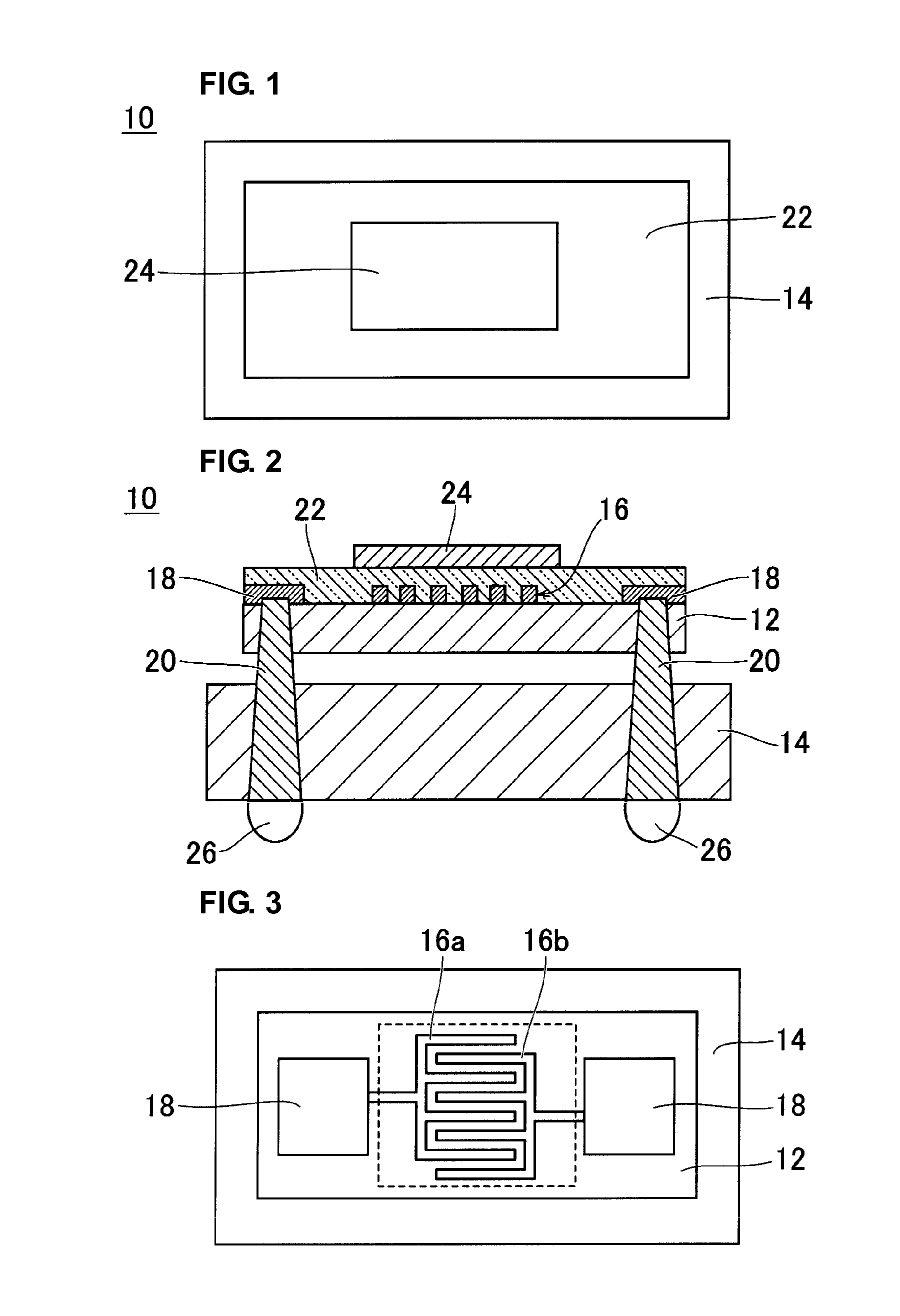

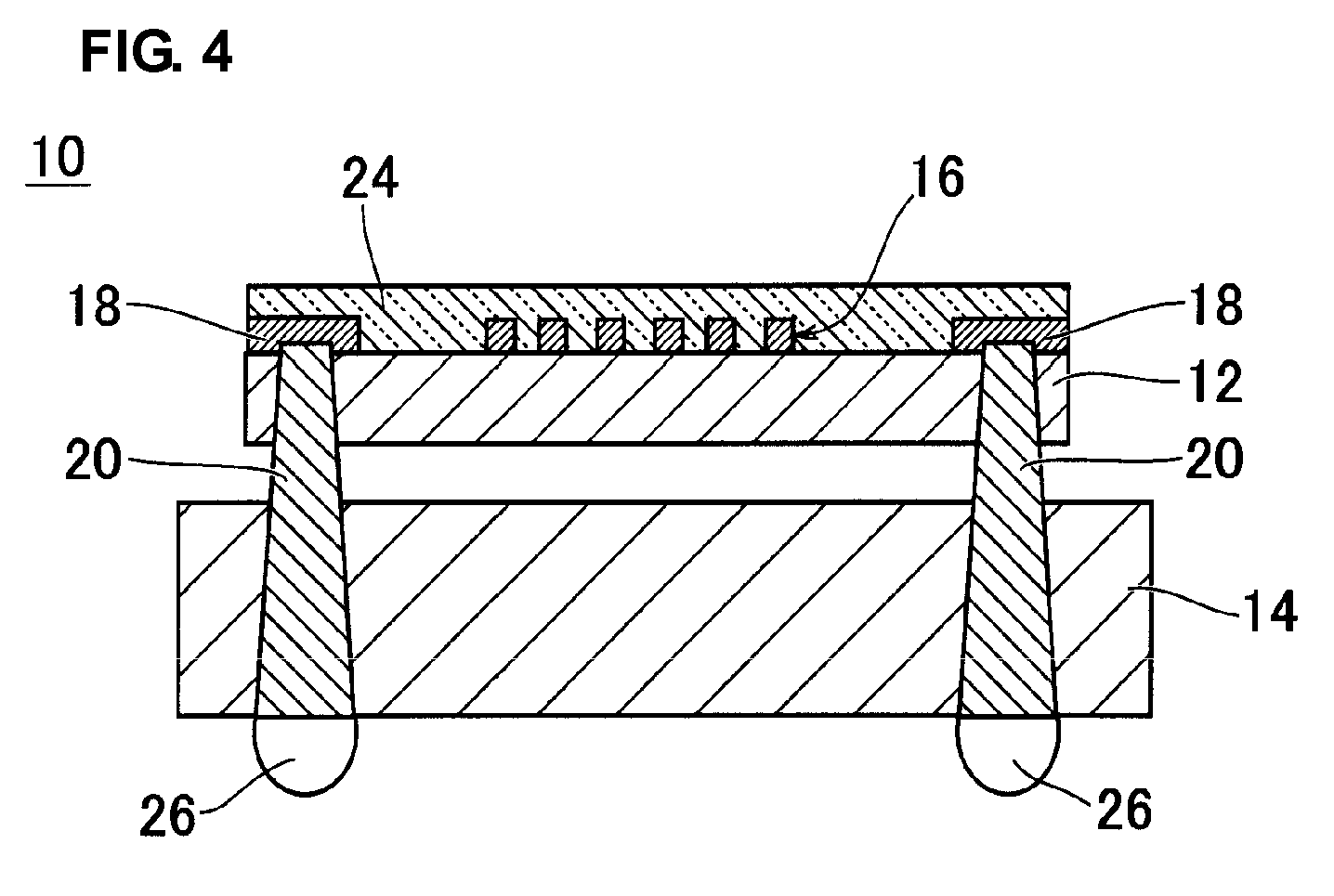

ActiveUS20050176179A1Small openingTelevision system detailsThermoelectric device with dielectric constant thermal changeSputteringHydrofluoric acid

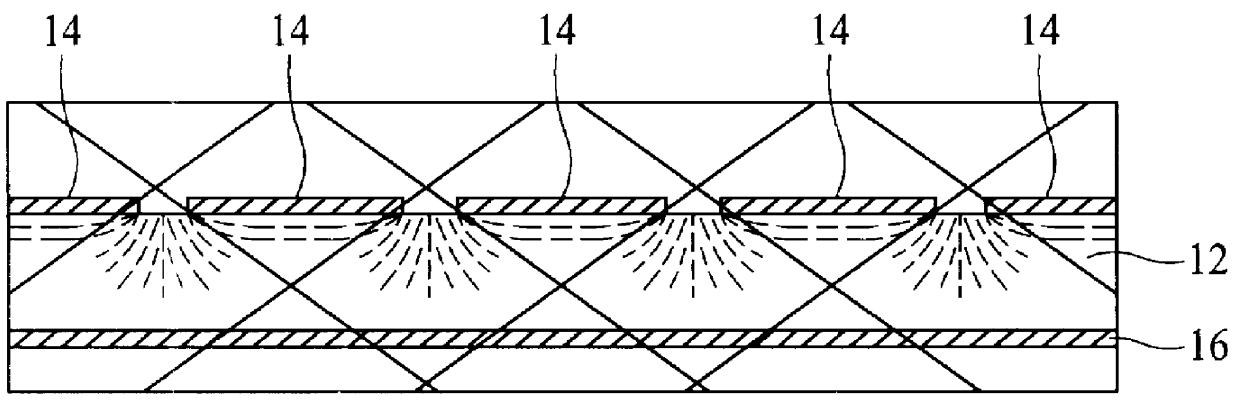

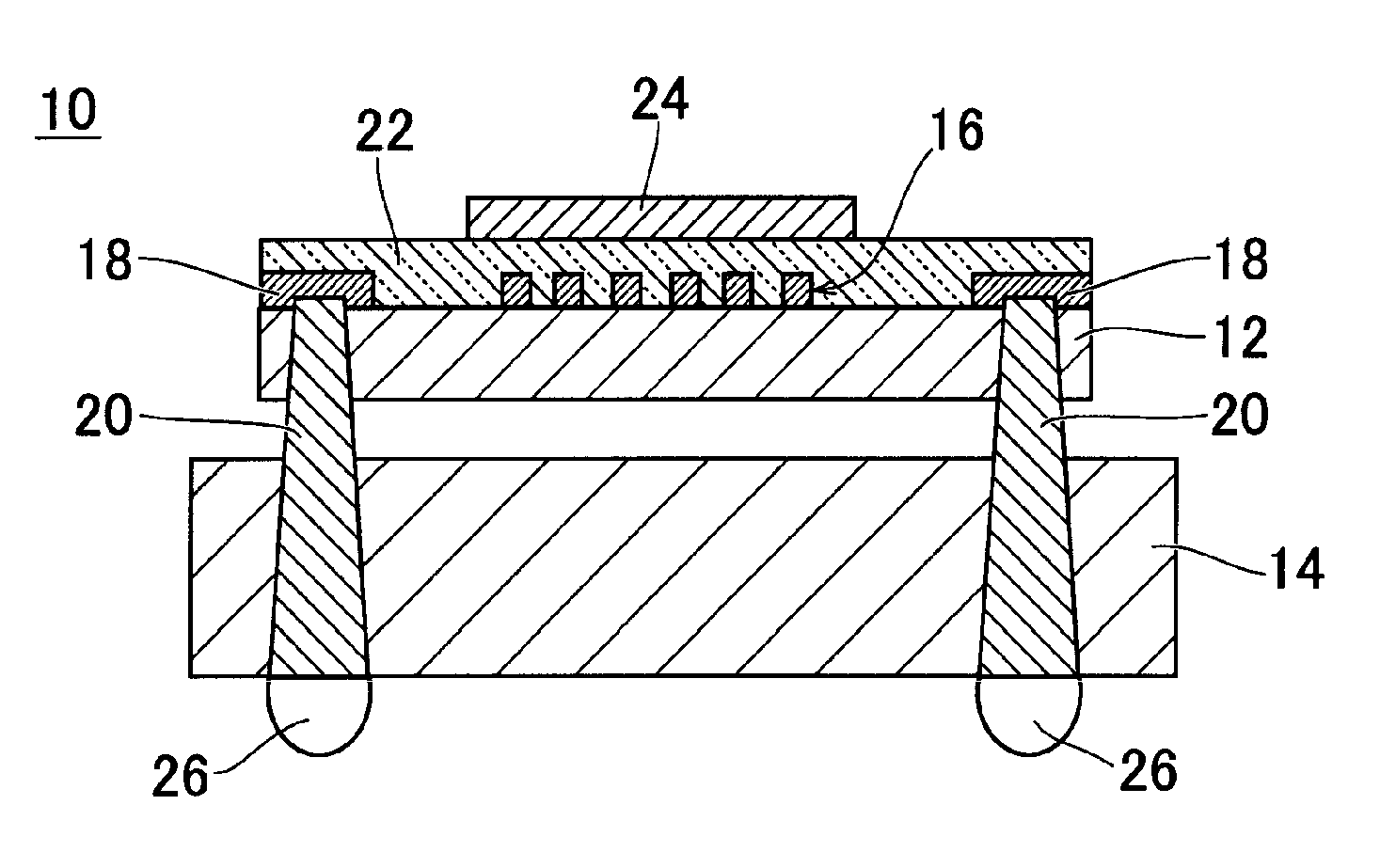

In the present invention, an etching hole 21 is formed in a polysilicon film 14 as a cavity-wall member. Through the etching hole 21, hydrofluoric acid is injected, so as to dissolve a silicon oxide film 13, thereby forming a cavity 22. In the cavity 22, a detecting unit 12 of a sensor is in an exposed condition. Next, by sputtering, an Al film 16 is deposited in the etching hole 21 and on an upper face of a substrate. Thereafter, a portion of the Al film 16 positioned on the polysilicon film 14 is removed by etching back, thereby leaving only a metal closure 16a of Al which closes the etching hole. The sputtering step is performed under a pressure of 5 Pa or less, so that the pressure in the cavity can be held to be low.

Owner:PANASONIC CORP

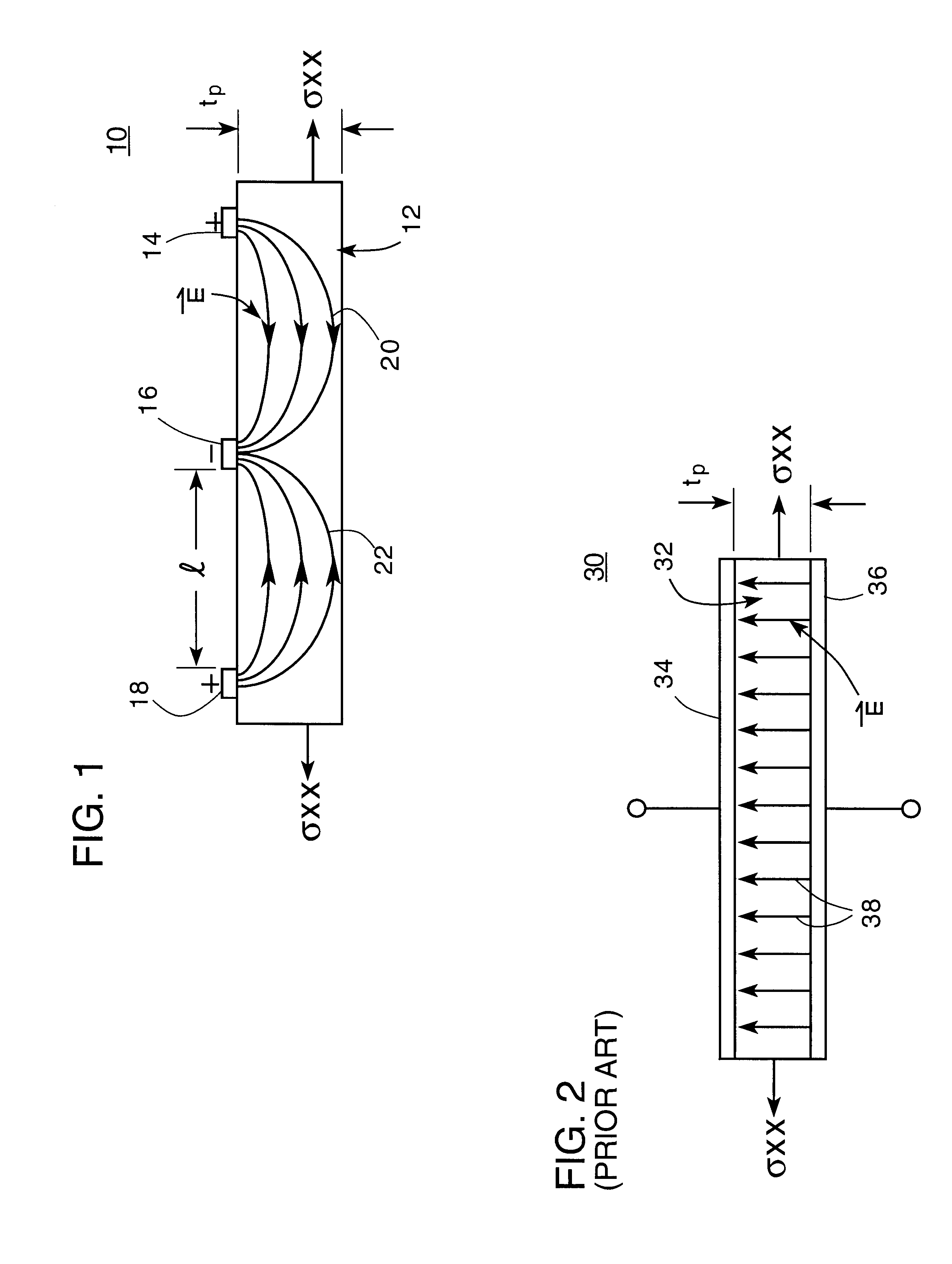

Ferroic transducer

InactiveUS6323580B1High sensitivityIncrease spacingThermoelectric device with dielectric constant thermal changePiezoelectric/electrostriction/magnetostriction machinesTransducerInterdigitated electrode

An interdigitated electrode ferroic transducer includes a film of ferroic material electrically polarized substantially in the plane of the film; and a set of interdigitated electrodes including at least two electrodes spaced from one another on the same side of the film and disposed at the termini of the polarization field.

Owner:CHARLES TARK DRAPER LAB INC THE

Thermo-sensitive infrared ray detector

InactiveUS20020040967A1Television system detailsThermoelectric device with dielectric constant thermal changeInfraredOptoelectronics

Owner:NEC CORP

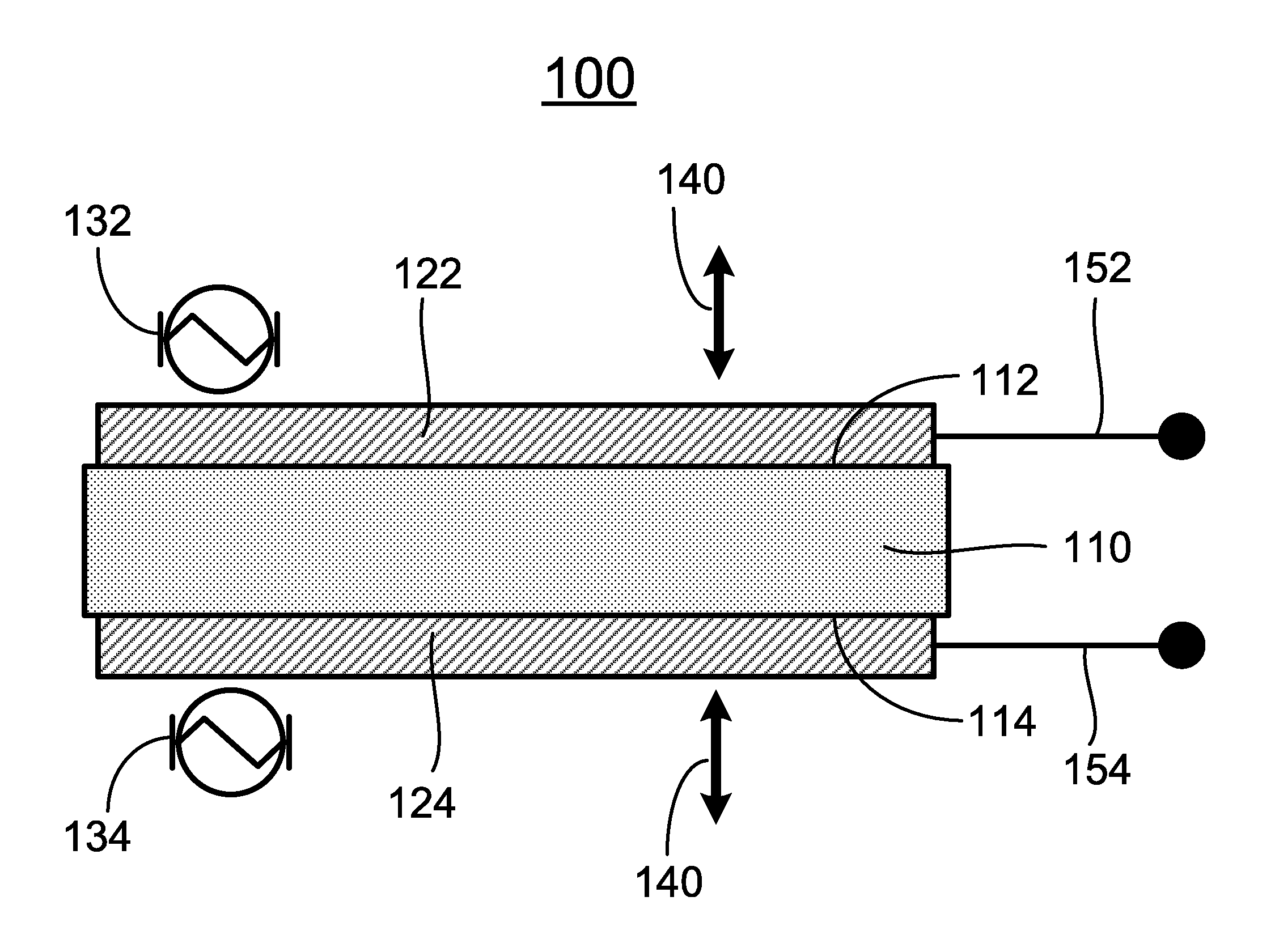

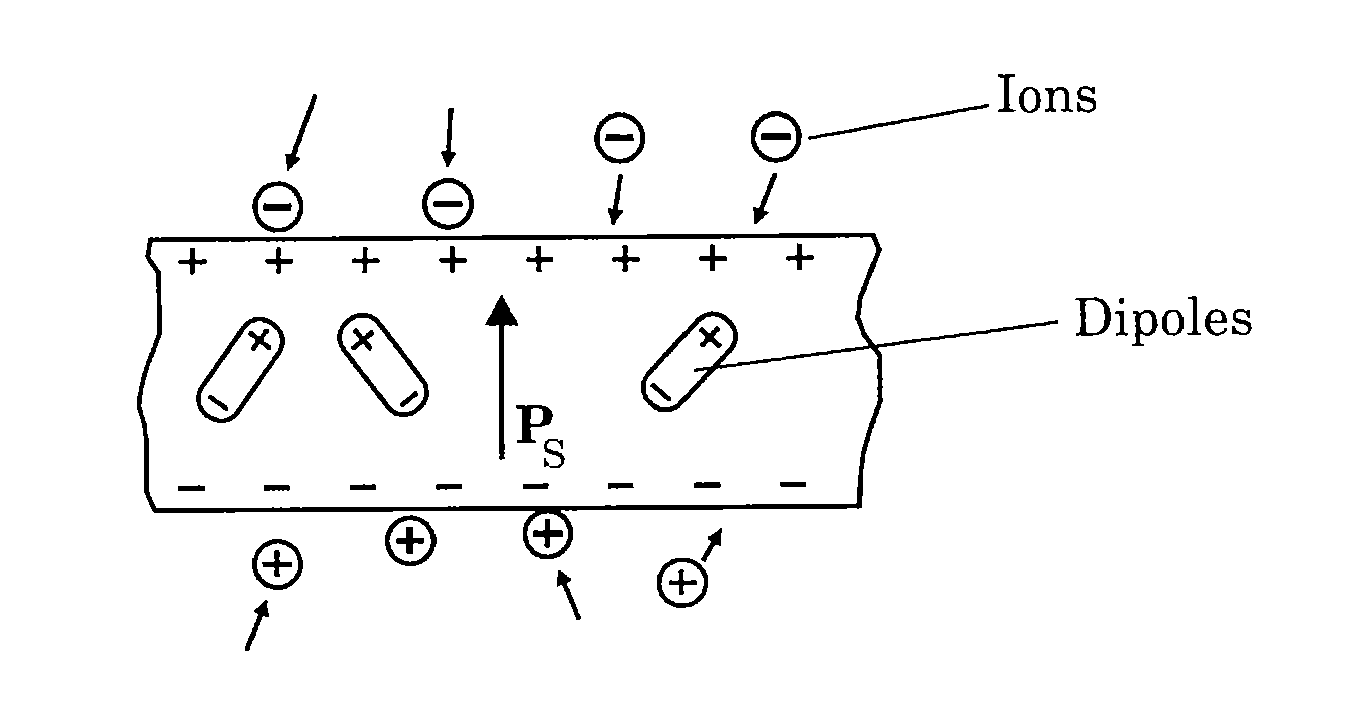

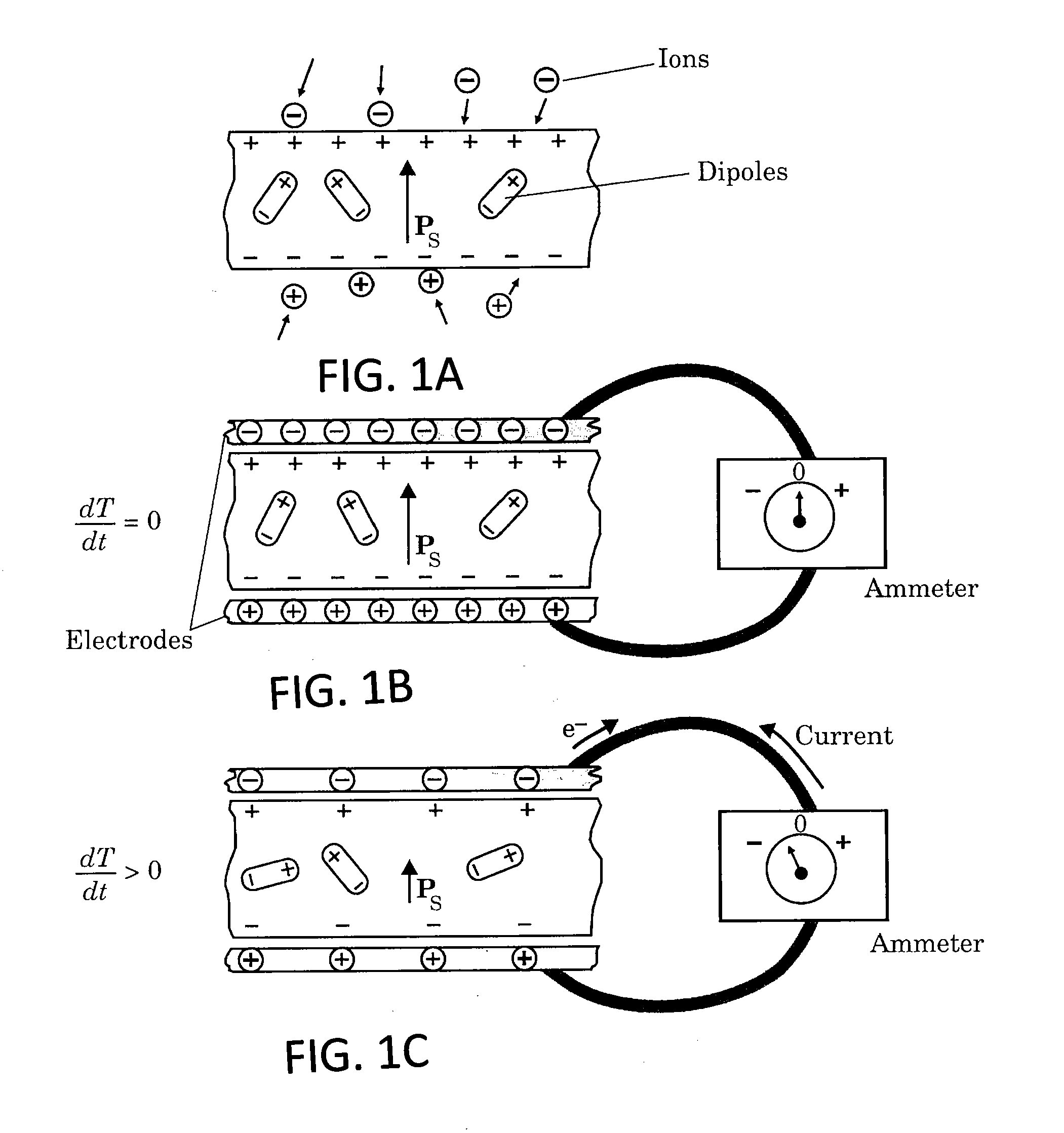

Apparatus and method for ferroelectric conversion of heat to electrical energy

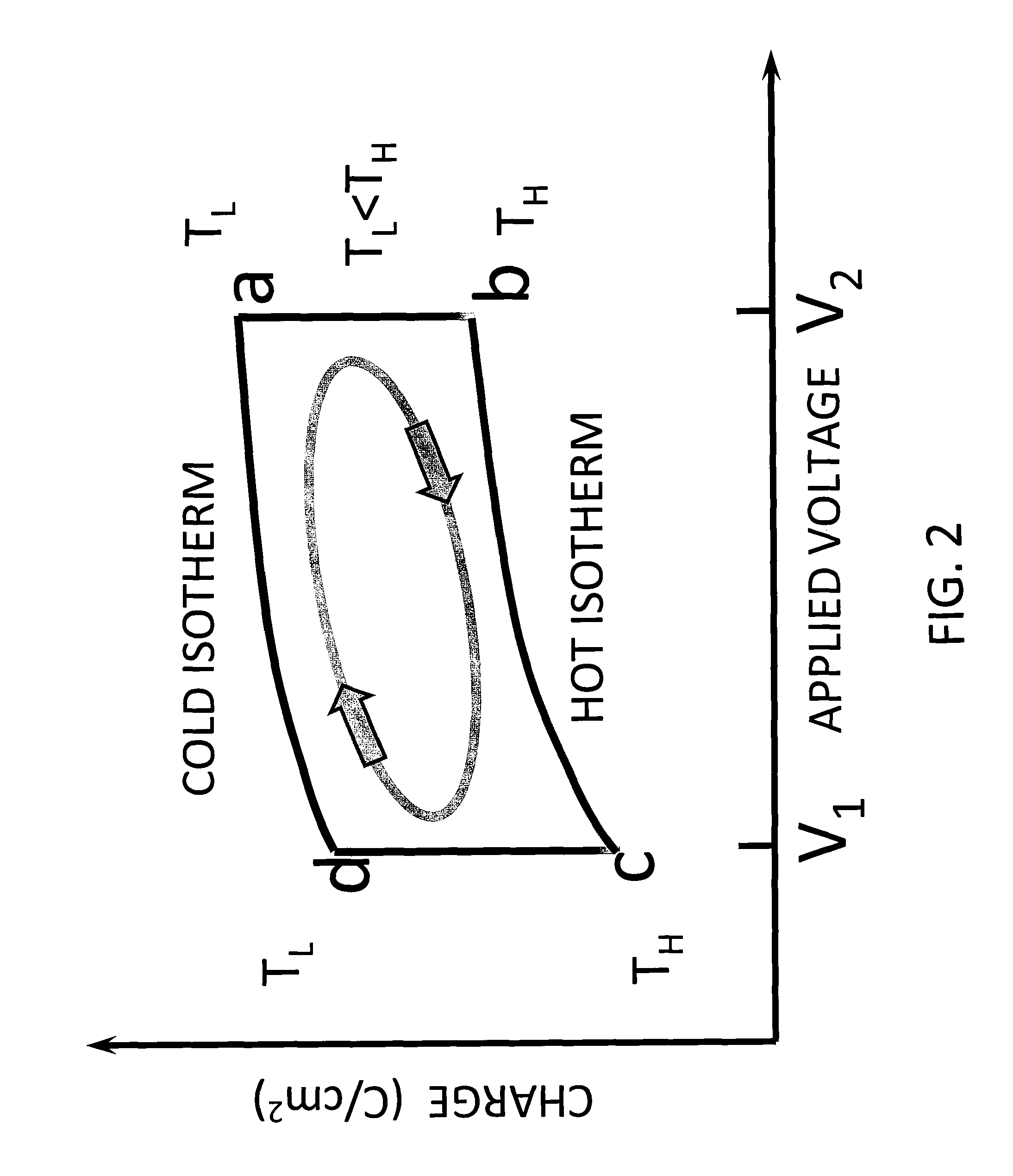

ActiveUS20100289377A1Robust conversionMaximum polarizationThermoelectric device with dielectric constant thermal changeThermal electric motorThermal energyEngineering

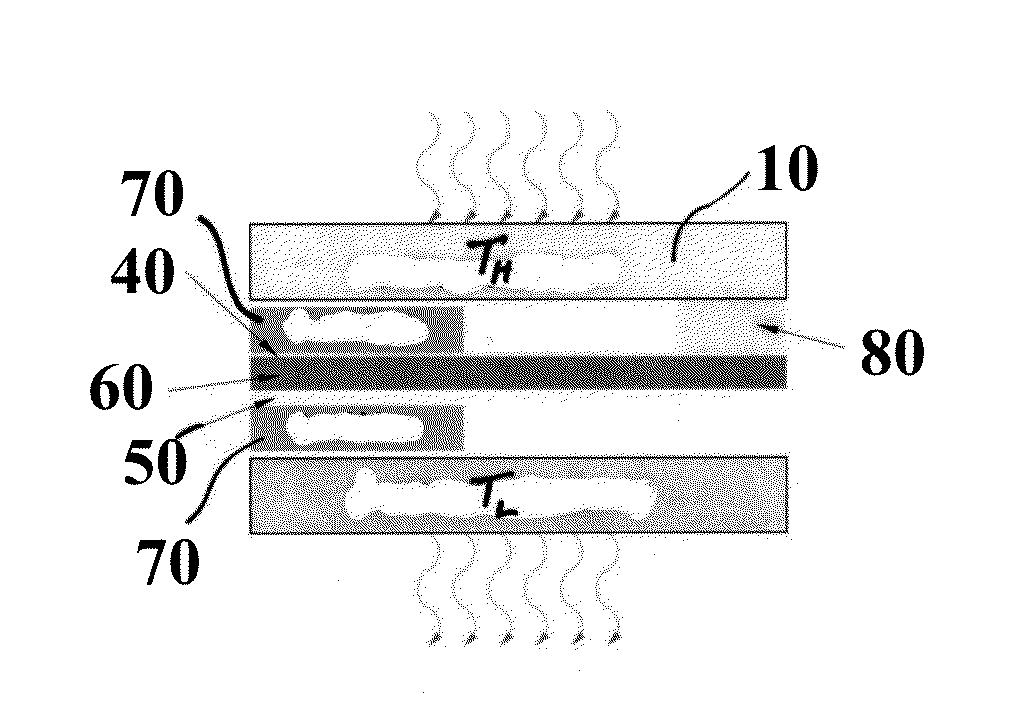

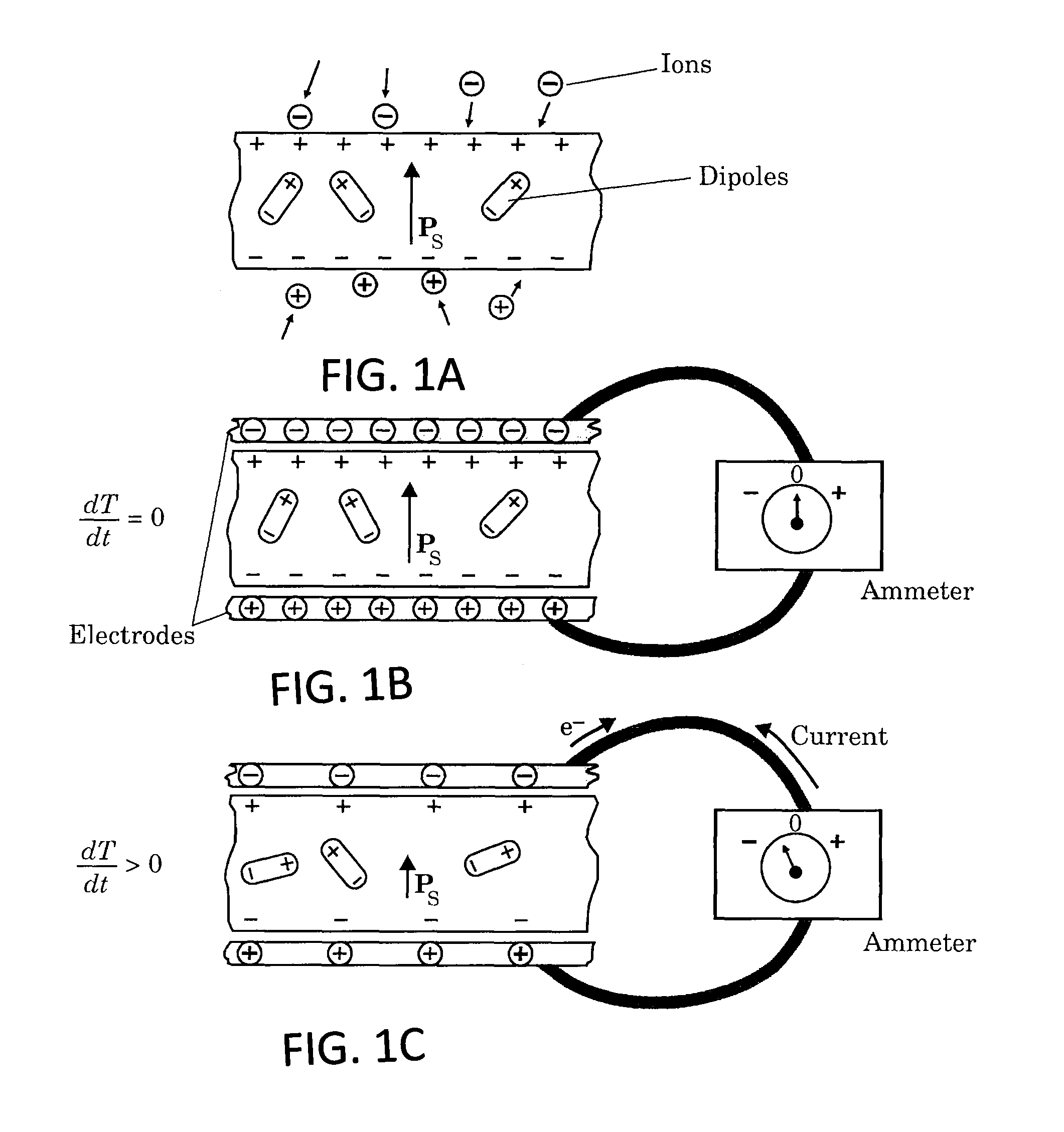

The present invention relates to a new method and apparatus for converting heat to electric energy. The invention exploits the rapid changes in spontaneous polarization that occur in ferroelectric materials during phase change. The invention permits robust and economical generation of electric energy from thermal energy, and it can be used in many different applications. In one aspect, the present invention relates to an apparatus for converting heat to electric energy comprising a pair of electrodes; a ferroelectric layer formed there between with a ferroelectric material characterized with a Curie temperature, Tc, such that when the temperature of the ferroelectric material is lower than Tc, the ferroelectric material is in a ferroelectric phase in which very powerful polarization is established spontaneously in the unit cells of the ferroelectric material, and when the temperature of the ferroelectric material is greater than Tc, spontaneous polarization is not established in the unit cells of the ferroelectric material; and a means for alternately delivering a flow of cold fluid and a flow of hot fluid to the ferroelectric layer so as to alternately cool the ferroelectric layer at a first temperature TL that is lower than Tc, and heat the ferroelectric layer at a second temperature TH that is higher than Tc, thereby the ferroelectric material of the ferroelectric layer undergoes alternating phase transitions between the ferroelectric phase and the paraelectric phase with temperature cycling.

Owner:THE NEOTHERMAL ENERGY

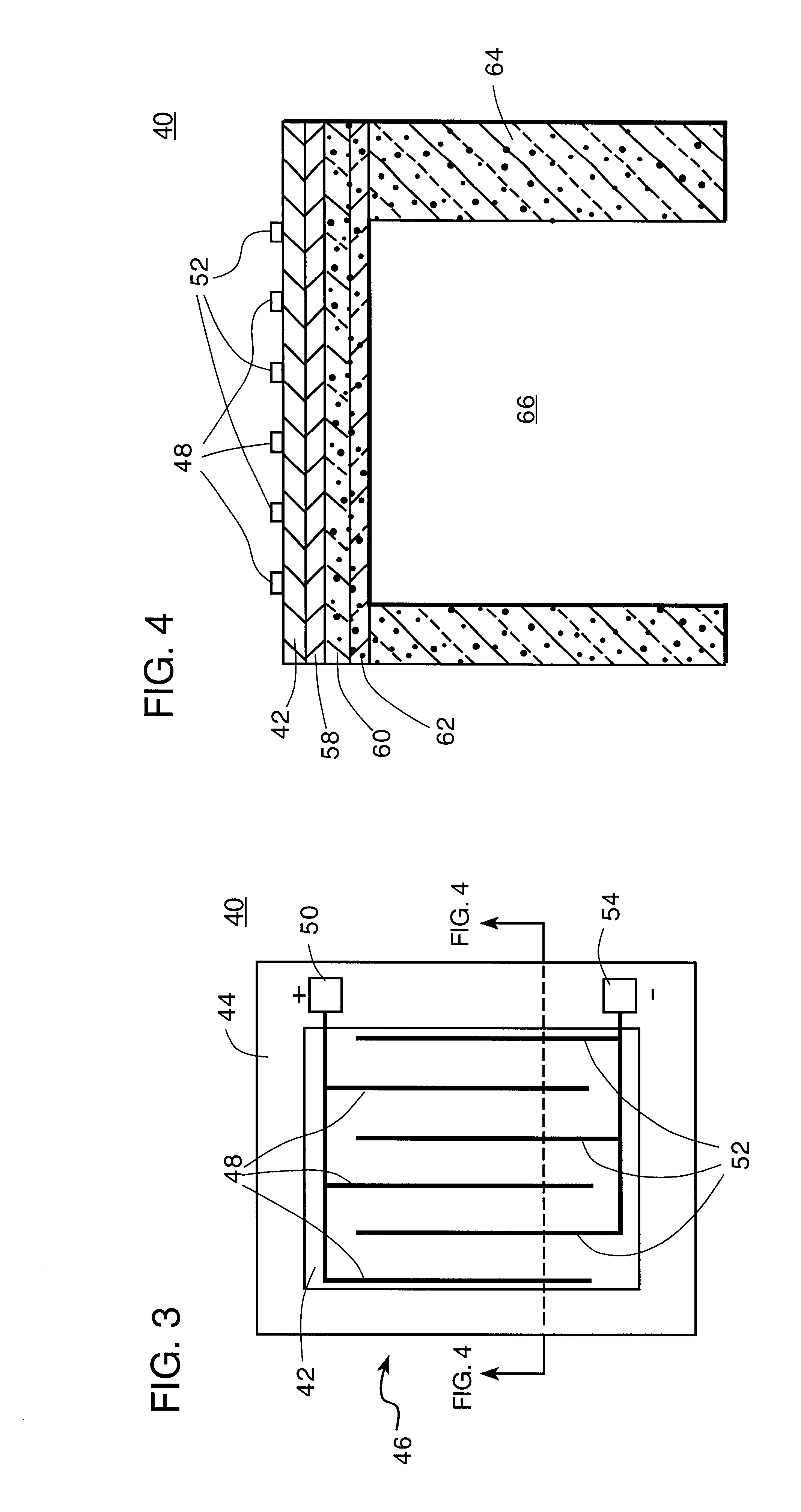

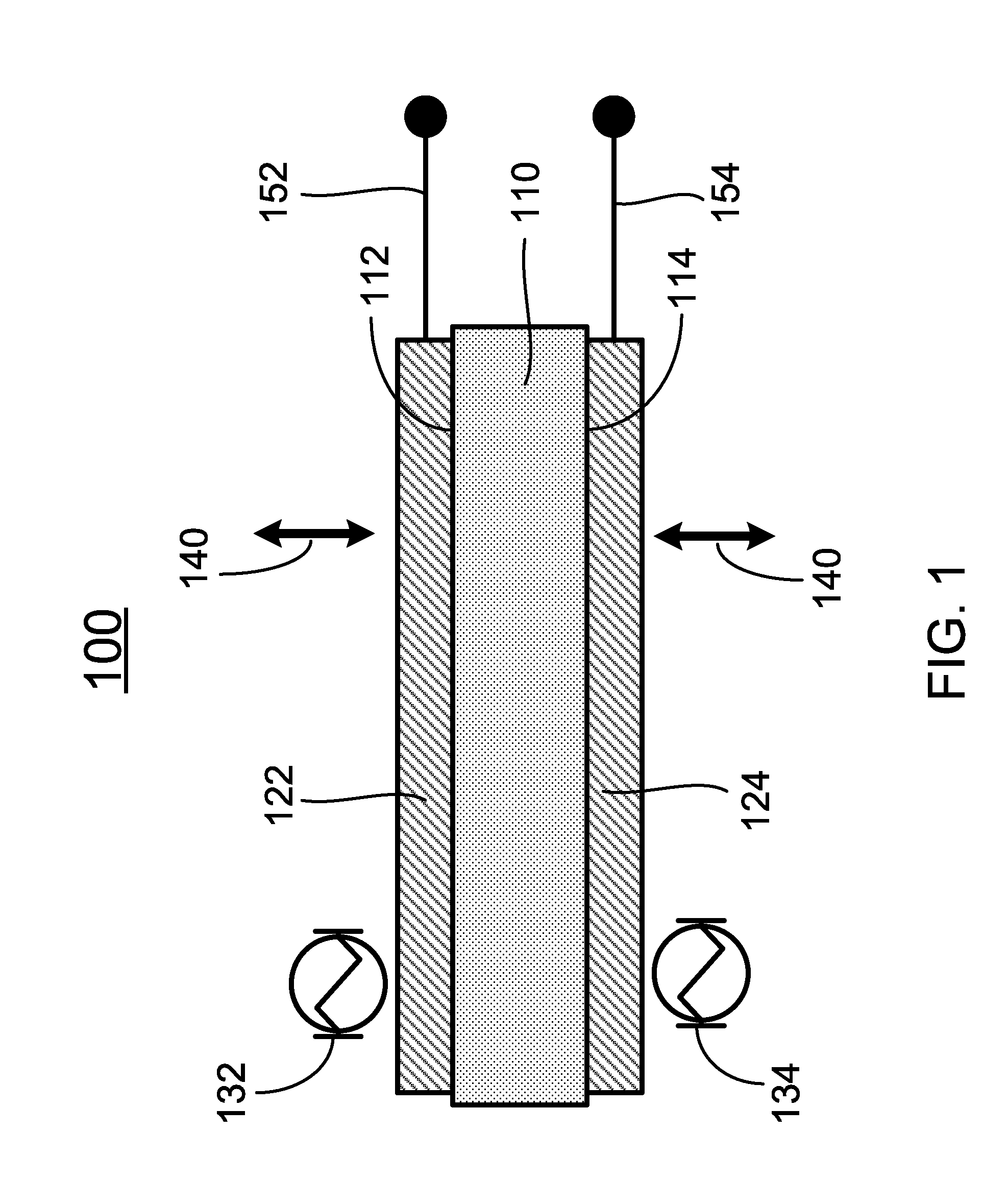

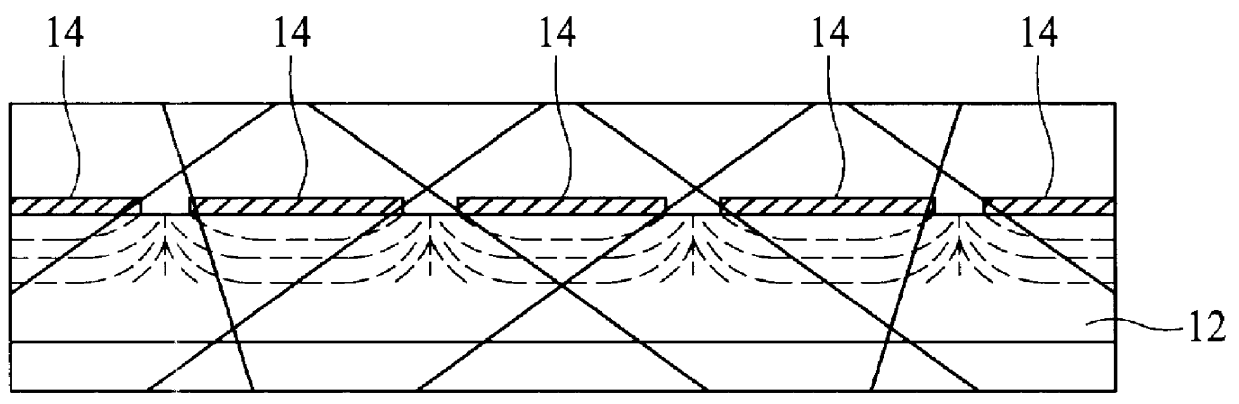

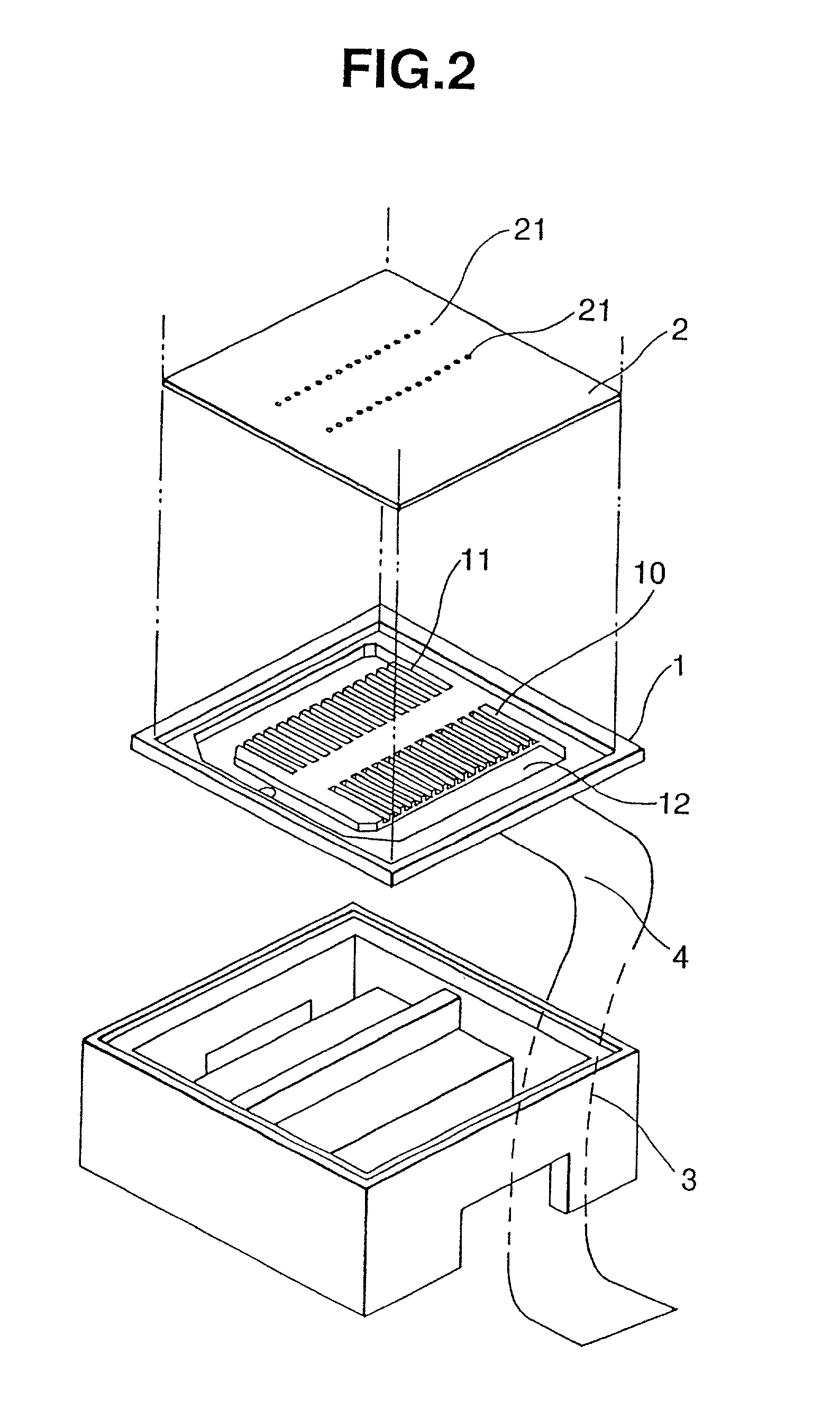

MEMS based pyroelectric thermal energy harvester

InactiveUS20120056504A1High quality electrical energySignificant reductionThermoelectric device with dielectric constant thermal changeThermal electric motorTemperature differenceDielectric layer

A pyroelectric thermal energy harvesting apparatus for generating an electric current includes a cantilevered layered pyroelectric capacitor extending between a first surface and a second surface, where the first surface includes a temperature difference from the second surface. The layered pyroelectric capacitor includes a conductive, bimetal top electrode layer, an intermediate pyroelectric dielectric layer and a conductive bottom electrode layer. In addition, a pair of proof masses is affixed at a distal end of the layered pyroelectric capacitor to face the first surface and the second surface, wherein the proof masses oscillate between the first surface and the second surface such that a pyroelectric current is generated in the pyroelectric capacitor due to temperature cycling when the proof masses alternately contact the first surface and the second surface.

Owner:UT BATTELLE LLC

Electronic device and method of manufacturing the same

ActiveUS20070298534A1Reduce internal pressureTelevision system detailsThermoelectric device with dielectric constant thermal changeSputteringHydrofluoric acid

In the present invention, an etching hole 21 is formed in a polysilicon film 14 as a cavity-wall member. Through the etching hole 21, hydrofluoric acid is injected, so as to dissolve a silicon oxide film 13, thereby forming a cavity 22. In the cavity 22, a detecting unit 12 of a sensor is in an exposed condition. Next, by sputtering, an Al film 16 is deposited in the etching hole 21 and on an upper face of a substrate. Thereafter, a portion of the Al film 16 positioned on the polysilicon film 14 is removed by etching back, thereby leaving only a metal closure 16a of Al which closes the etching hole. The sputtering step is performed under a pressure of 5 Pa or less, so that the pressure in the cavity can be held to be low.

Owner:PANASONIC CORP

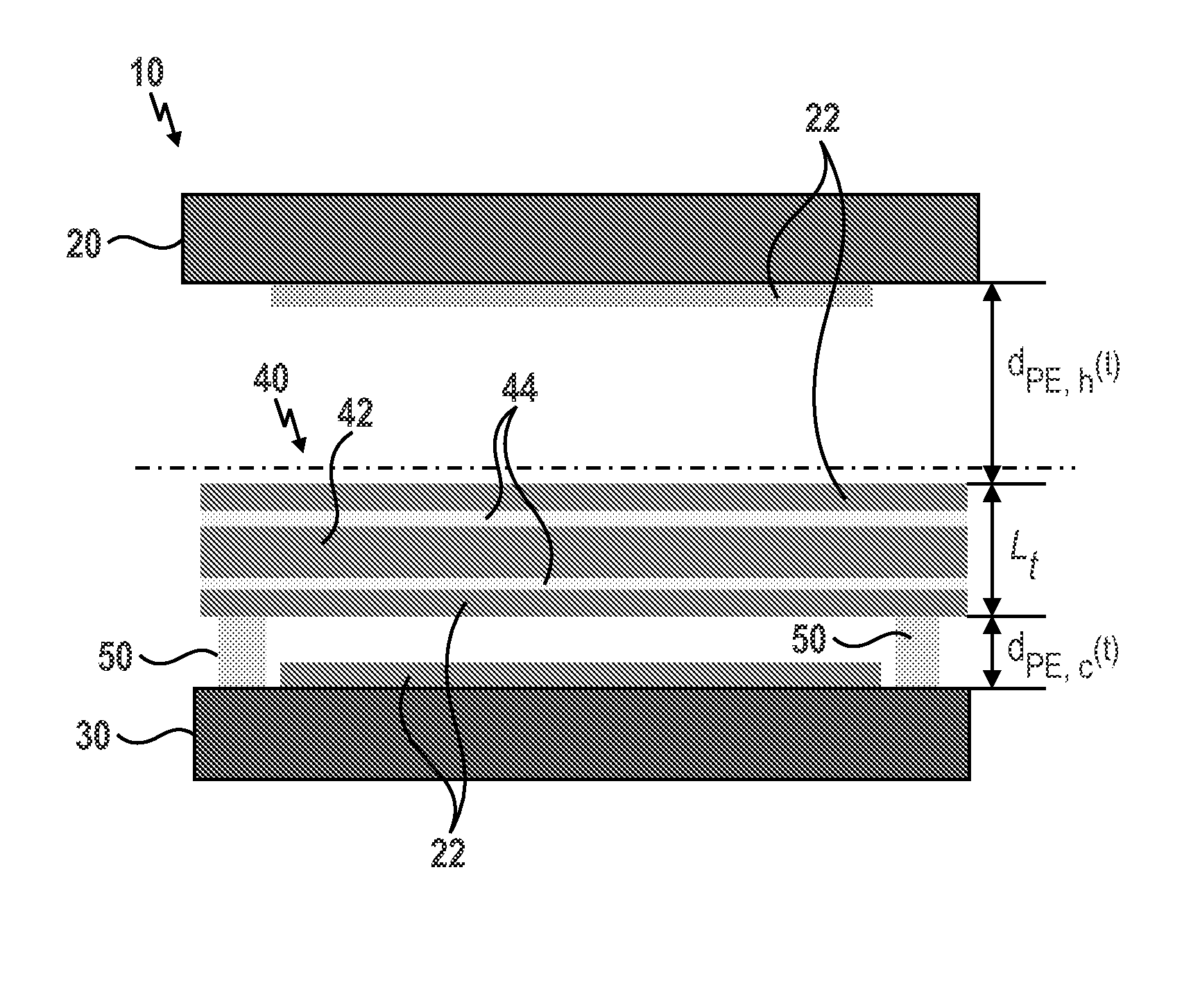

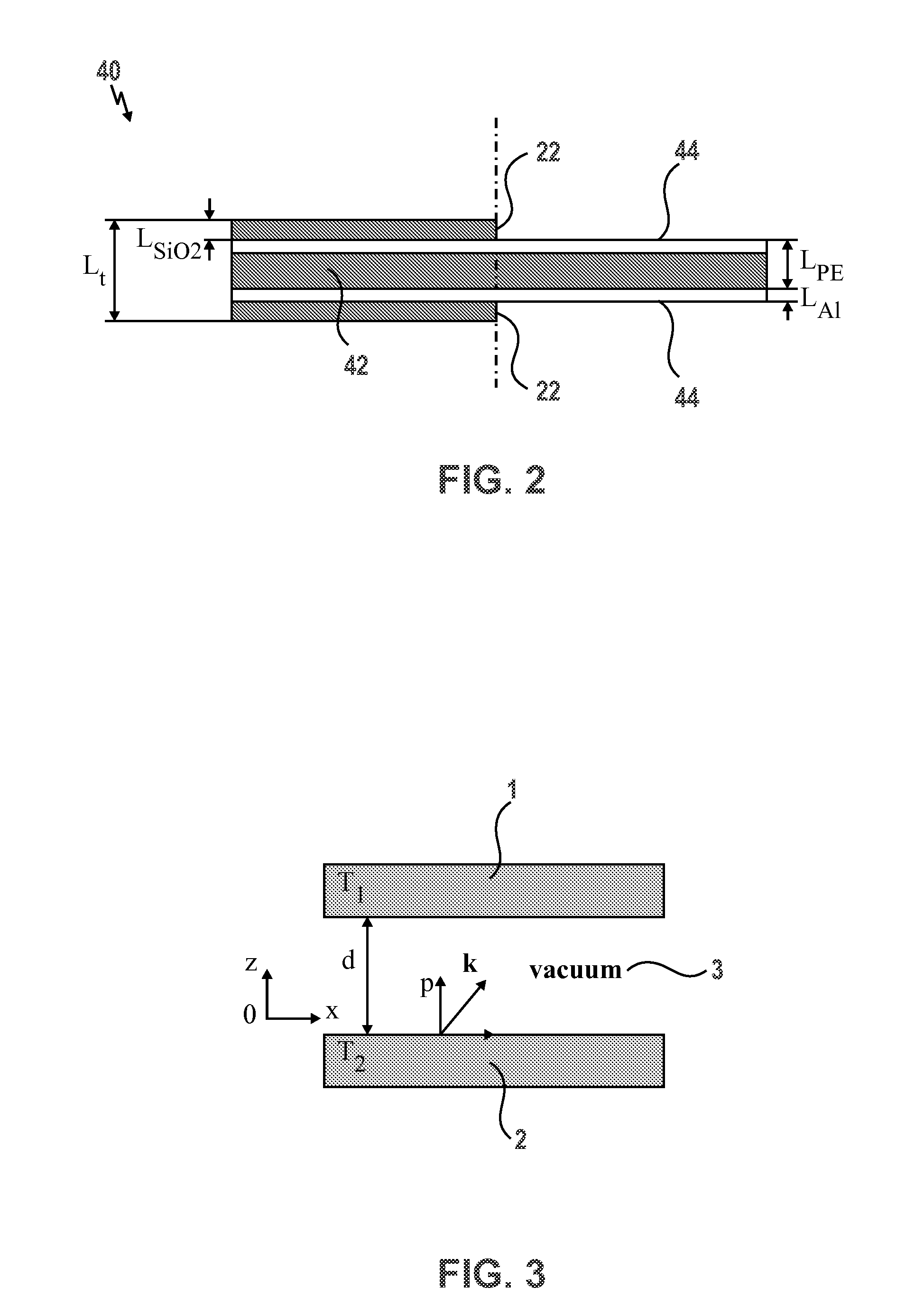

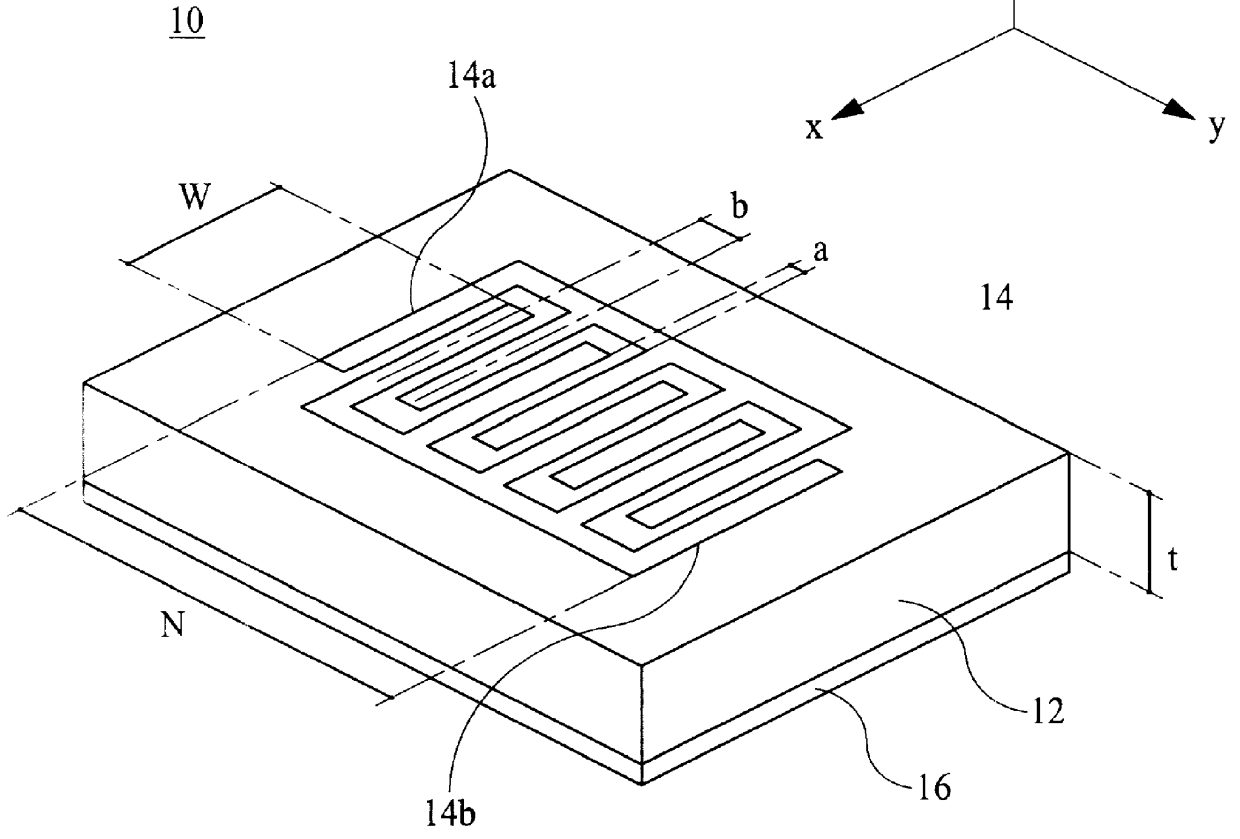

Direct conversion of nanoscale thermal radiation to electrical energy using pyroelectric materials

InactiveUS20110298333A1Minimize thermal contact resistanceEnhance radiative heat fluxThermoelectric device with dielectric constant thermal changeThermal electric motorComposite filmPower cycle

The embodiment provided herein are directed to a pyroelectric (PE) energy converter which is capable of combining nanoscale thermal radiation and pyroelectric energy conversion for harvesting low grade waste heat. The converter advantageously makes use of the enhanced radiative heat transfer across a nanosize gap to achieve high operating frequencies or large temperature oscillations in a composite PE plate. The PE energy converter generally comprises a hot source, a cold source, and a PE plate, wherein the PE plate oscillates between the hot and cold source and the PE plate can be subjected to a power cycle in the displacement-electric field diagram. The hot and cold sources of the converter can be coated with SiO2 absorbing layer to further enhance the radiative heat fluxes. The converter comprising a PE plate made of 60 / 40 P(VDF-TrFE) operated between 273 K and 388 K experiences a maximum efficiency of 0.2% and a power density of 0.84 mW / cm2. The converter comprising a PE plate made of 0.9PMN-PT composite thin films achieve a higher efficiency and a larger power output namely 1.3% and 6.5 mW / cm2, respectively, for a temperature oscillation amplitude of 10 K around 343 K at 5 Hz.

Owner:RGT UNIV OF CALIFORNIA

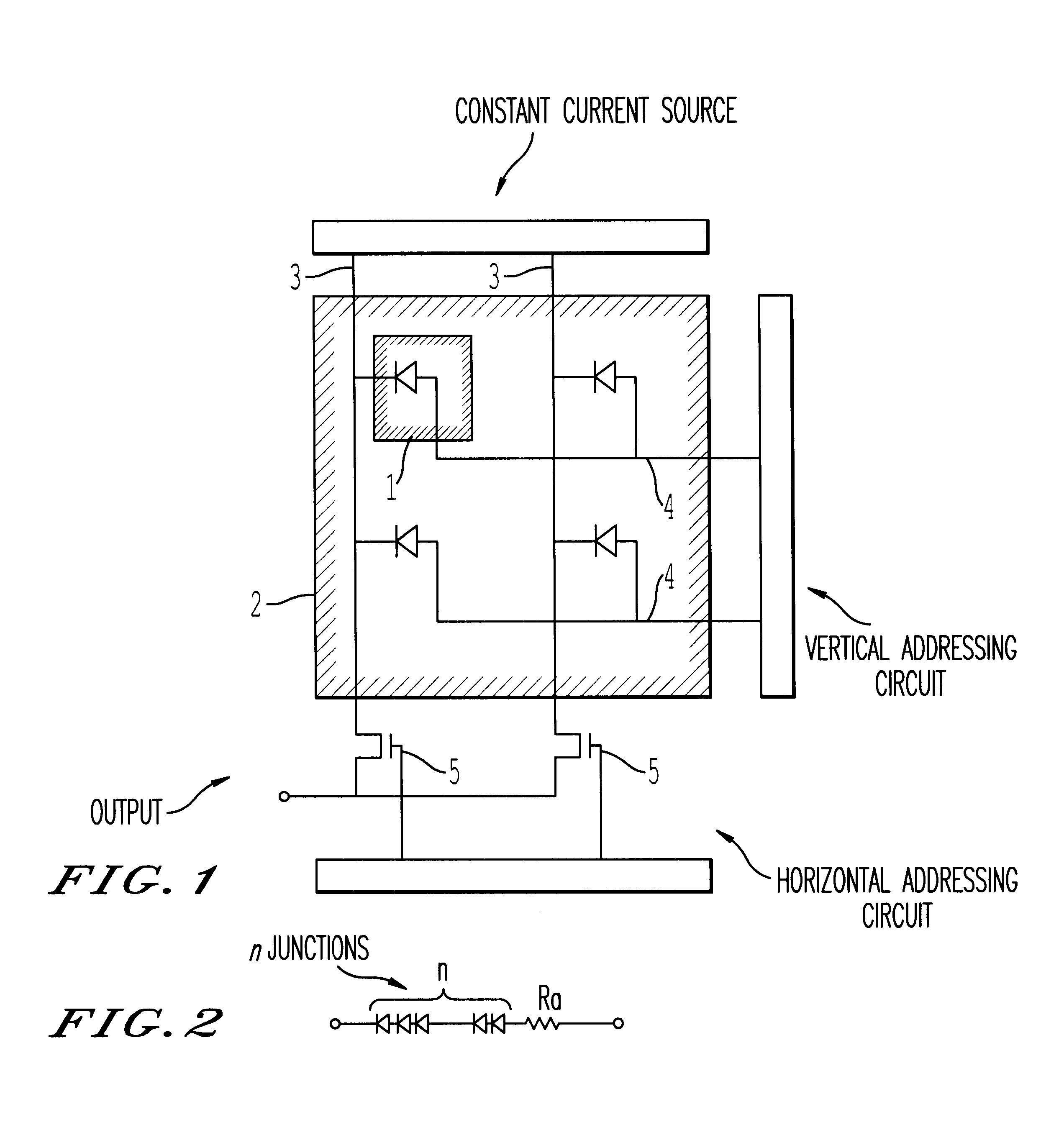

Pyroelectric infrared sensor device

InactiveUS6049080AAvoid problemsIncrease ratingsThermoelectric device with dielectric constant thermal changePhotometryTetragonal crystal systemThermoelectric materials

A pyroelectric infrared sensor device with improved sensitivity and relative detection rate and reduced manufacturing cost. The infrared sensor device includes a substrate of rectangular shape. The substrate is made of a pyroelectric material, such as tetragonal-system lead titanate pyroelectric ceramics. A pair of comb-shaped electrode patterns each having a set of parallel conductive open-ended fingers are disposed on the top surface of the substrate such that the open-ended fingers of one electrode pattern are spatially interdigitated in relation to those of the other. The paired comb-shaped electrodes have at least three finger pairs whereas the interelectrode distance corresponding to the gap between neighboring fingers is greater than 100 micrometers. These comb-shaped electrodes satisfying the criteria render the pyroelectric material, upon application of a DC voltage between them, substantially horizontally polarizable at or near the top substrate surface which acts as the infrared light receiving plane. An opposite electrode is on the entire bottom surface of the substrate. This electrode has portions insulatively overlapping the comb-shaped electrodes with the pyroelectric material being sandwiched therebetween.

Owner:MURATA MFG CO LTD

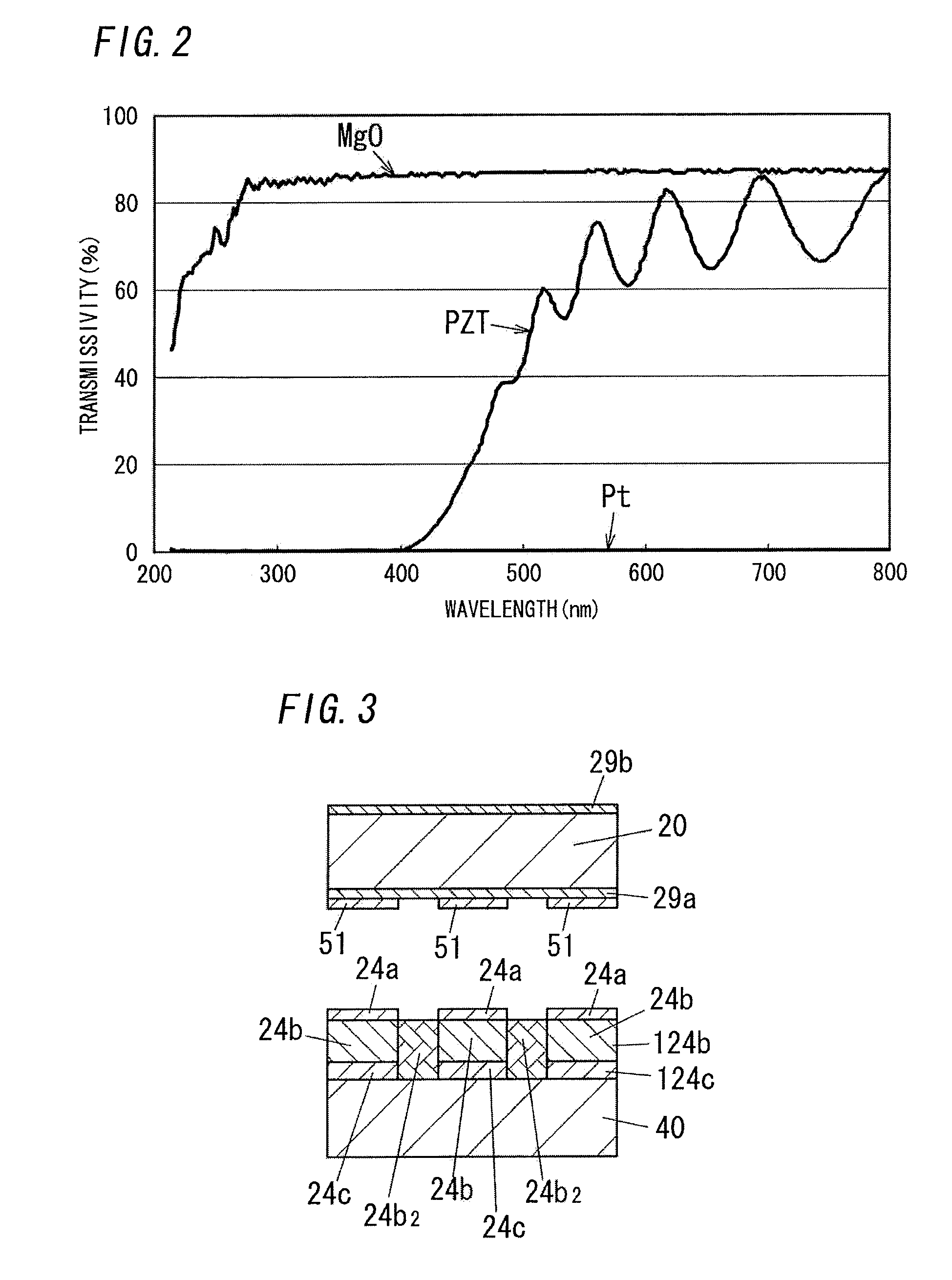

Ferroelectric Thin Films and Devices Comprising Thin Ferroelectric Films

InactiveUS20080165565A1Small sizeAddress rising pricesThermoelectric device with dielectric constant thermal changePiezoelectric/electrostrictive device manufacture/assemblyMicrometerFerroelectric thin films

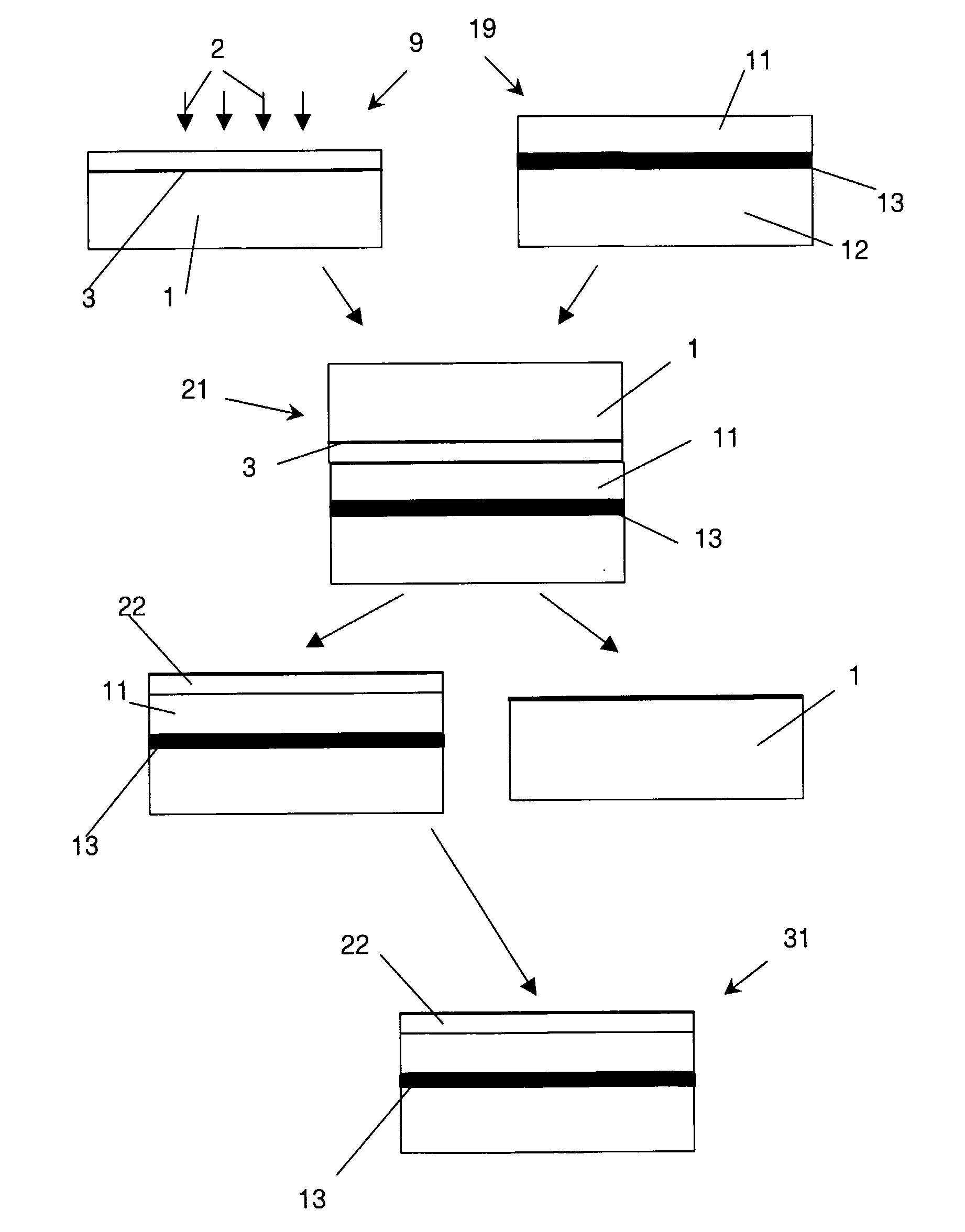

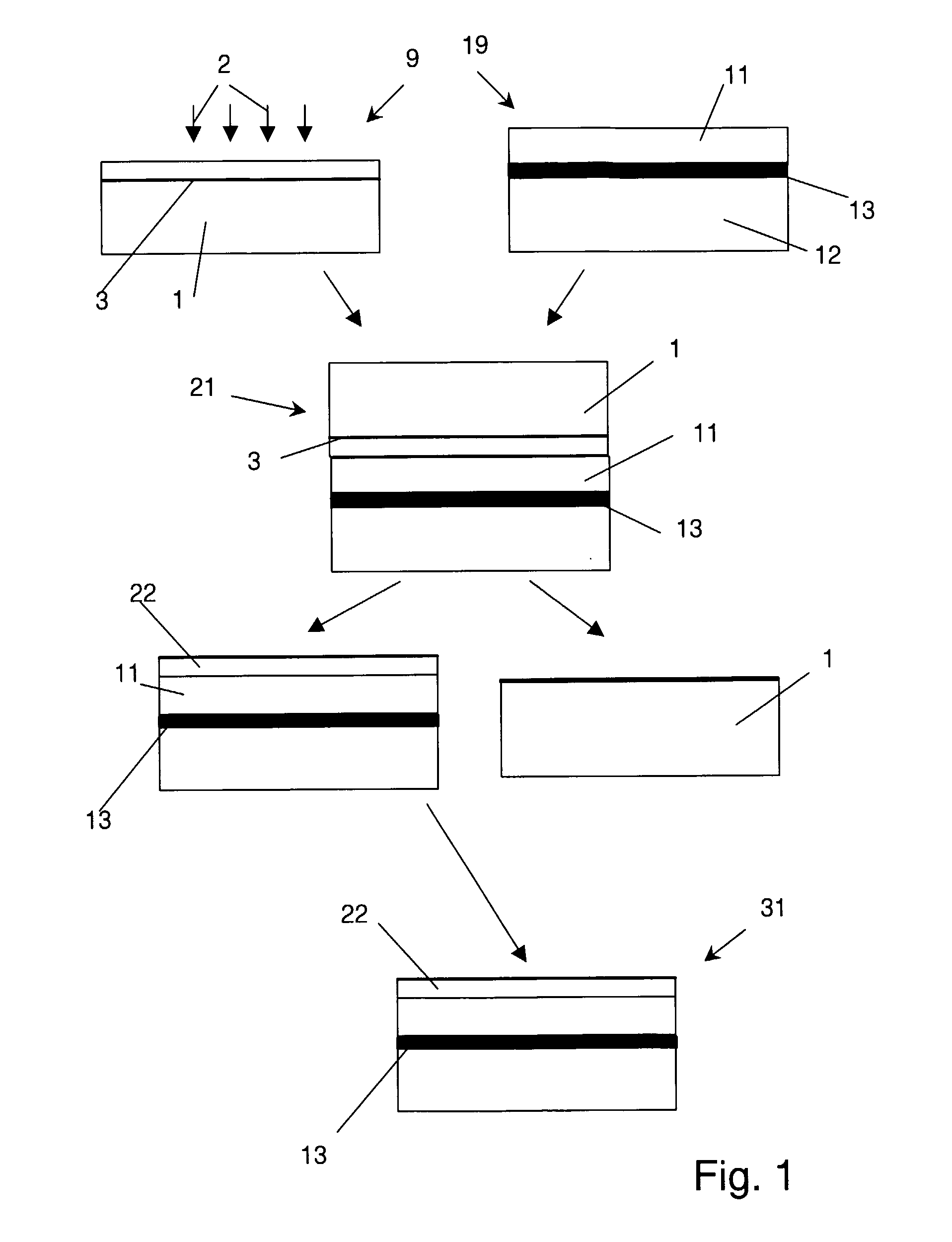

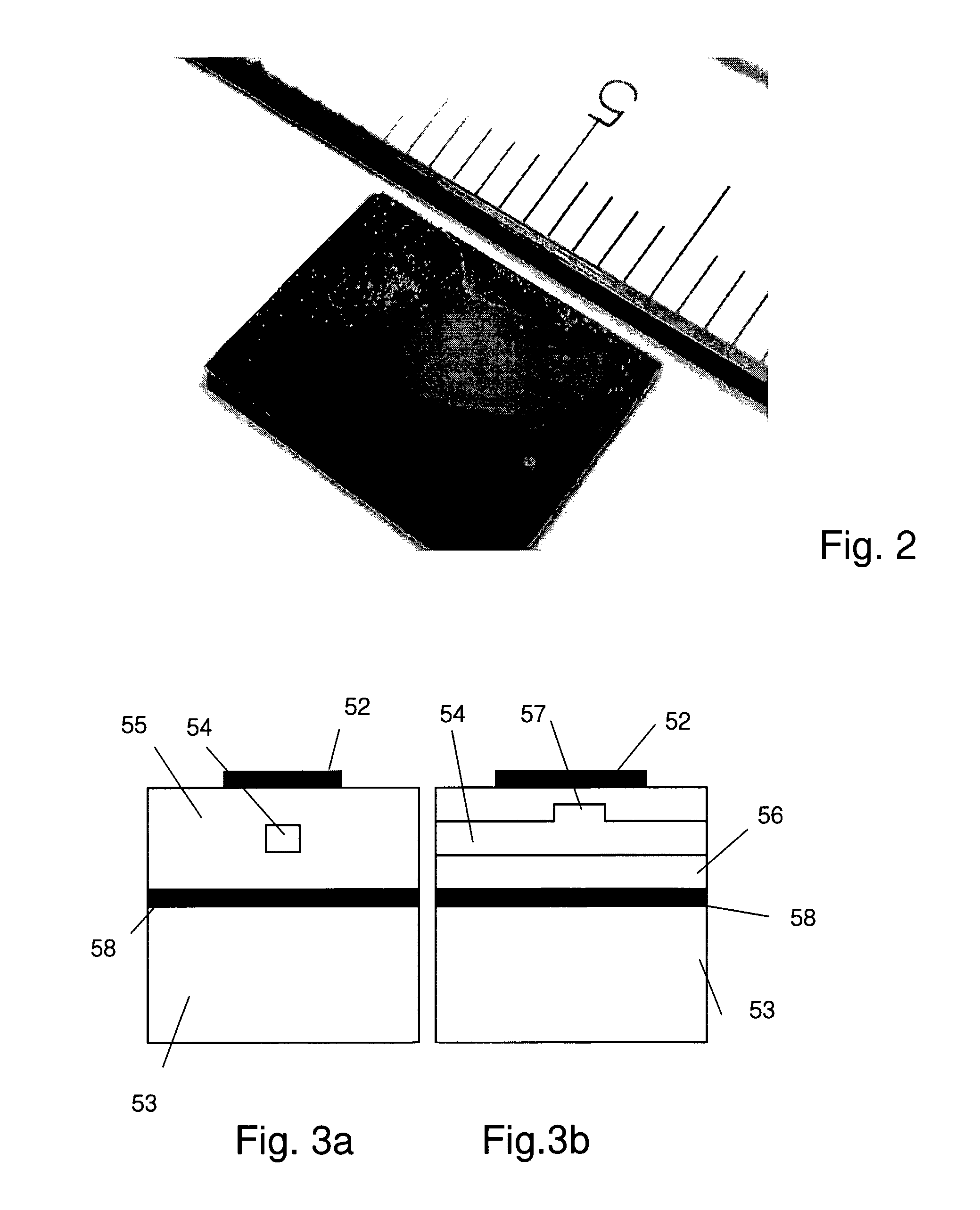

A method of producing a device with a ferroelectric crystal thin film on a first substrate including the steps of providing a ferroelectric crystal, of irradiating a first surface of the ferroelectric crystal with ions so that a damaged layer is created underneath the first surface, of bonding a block of material including the first substrate to the ferroelectric crystal to create a bonded element, wherein an interface is formed between the first surface and a second surface of the block, and of heating the bonded element and separating it at the damaged layer, so that a ferroelectric crystal layer remains supported by the first substrate. By this method, very thin films—down to thicknesses of a fraction of a micrometer—of ferroelectric crystals may be fabricated without jeopardizing the monocrystalline structure.

Owner:ETH ZZURICH

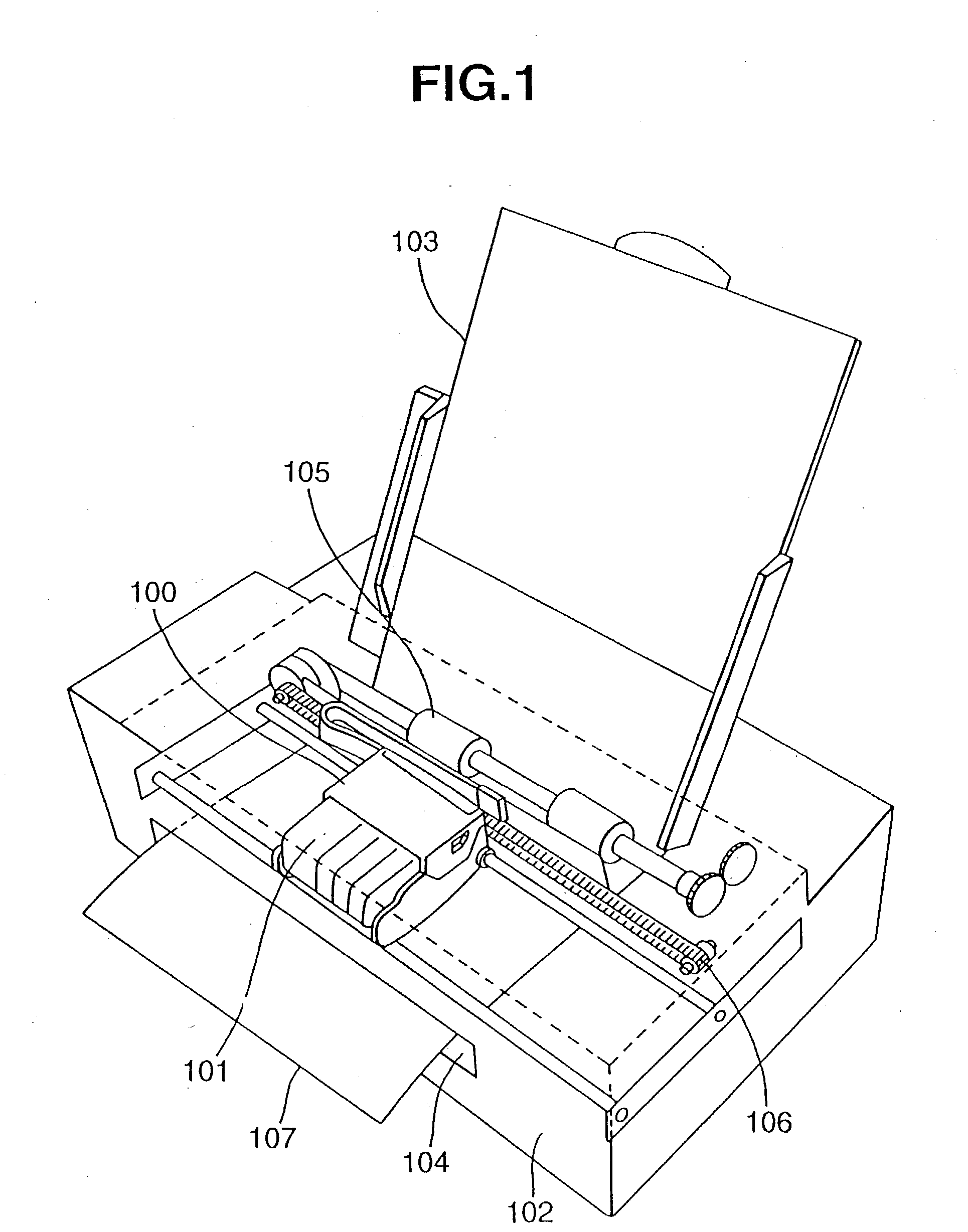

Method for manufactuing ferroelectric thin film device, ink jet recording head, and ink jet printer

InactiveUS20020123158A1Reliable drive characteristicReduce adhesionTransistorThermoelectric device with dielectric constant thermal changeIridiumFerroelectric thin films

It is an object of the present invention to control the crystal orientation of a ferroelectric thin film as dictated by the application of a ferroelectric thin film device. To accomplished the stated object, a bottom electrode containing at least iridium is formed over a surface preparation layer whose main component is zirconium oxide, and an ultra-thin titanium layer is laminated over the bottom electrode. An amorphous layer containing the elemental metal and elemental oxygen that constitute the ferroelectric is formed over the titanium layer, and a crystallized ferroelectric thin film is formed by heat treating this amorphous layer. If the thickness of the titanium layer is kept between 2 nm and 10 nm in the lamination thereof, the ferroelectric thin film will have a priority orientation of (100), and if it is kept between 10 nm and 20 nm, the ferroelectric thin film will have a priority orientation of (111).

Owner:SEIKO EPSON CORP

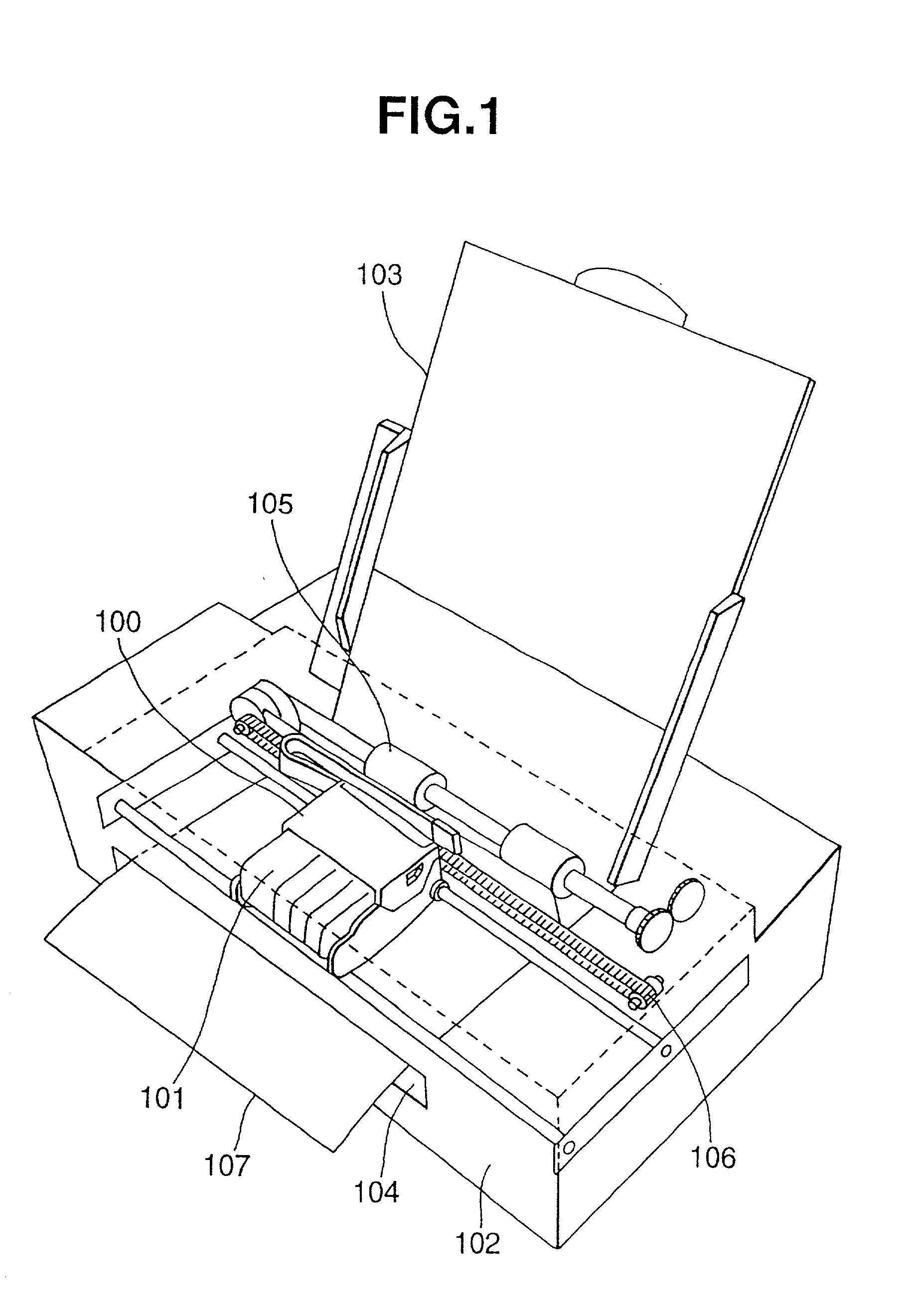

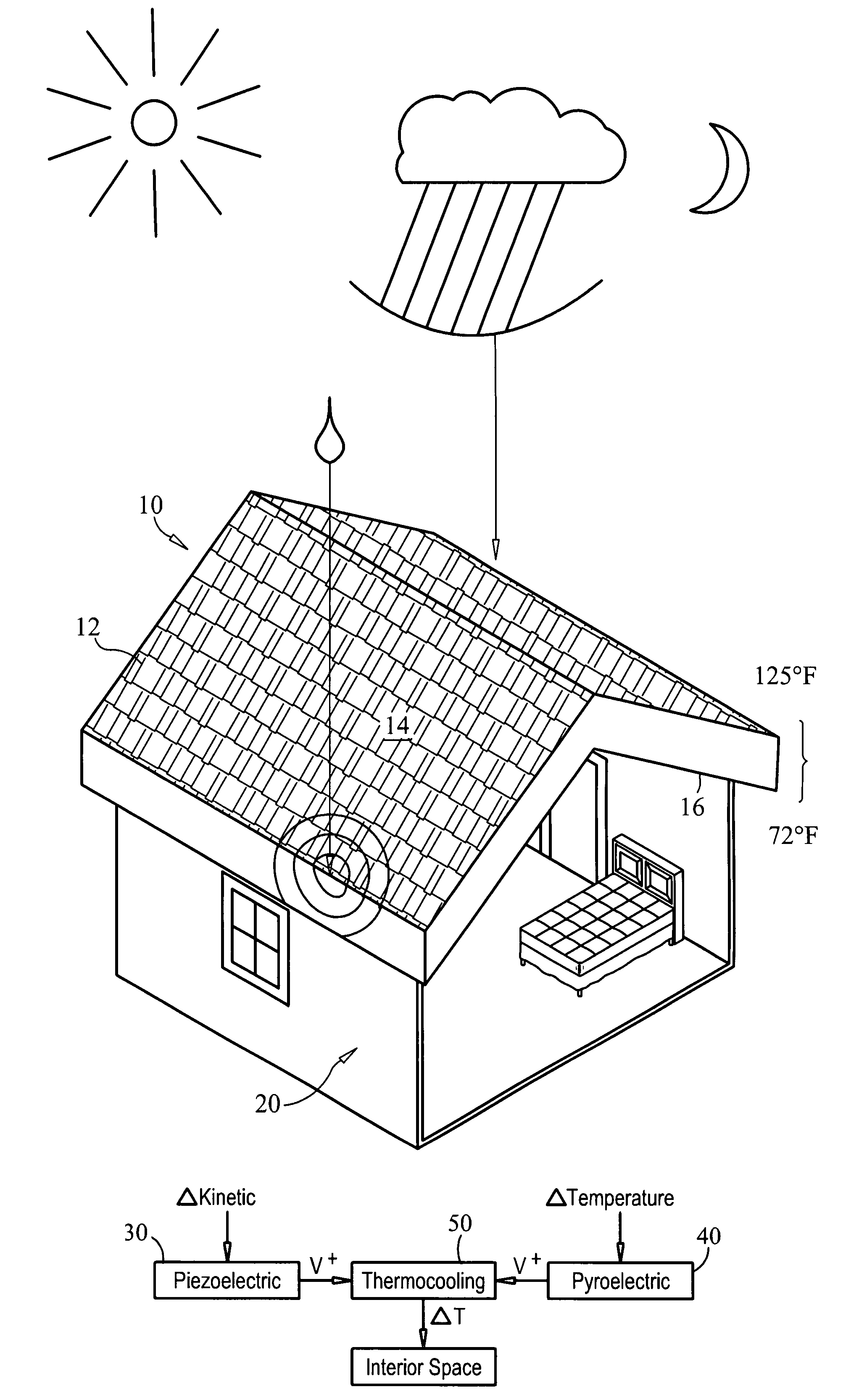

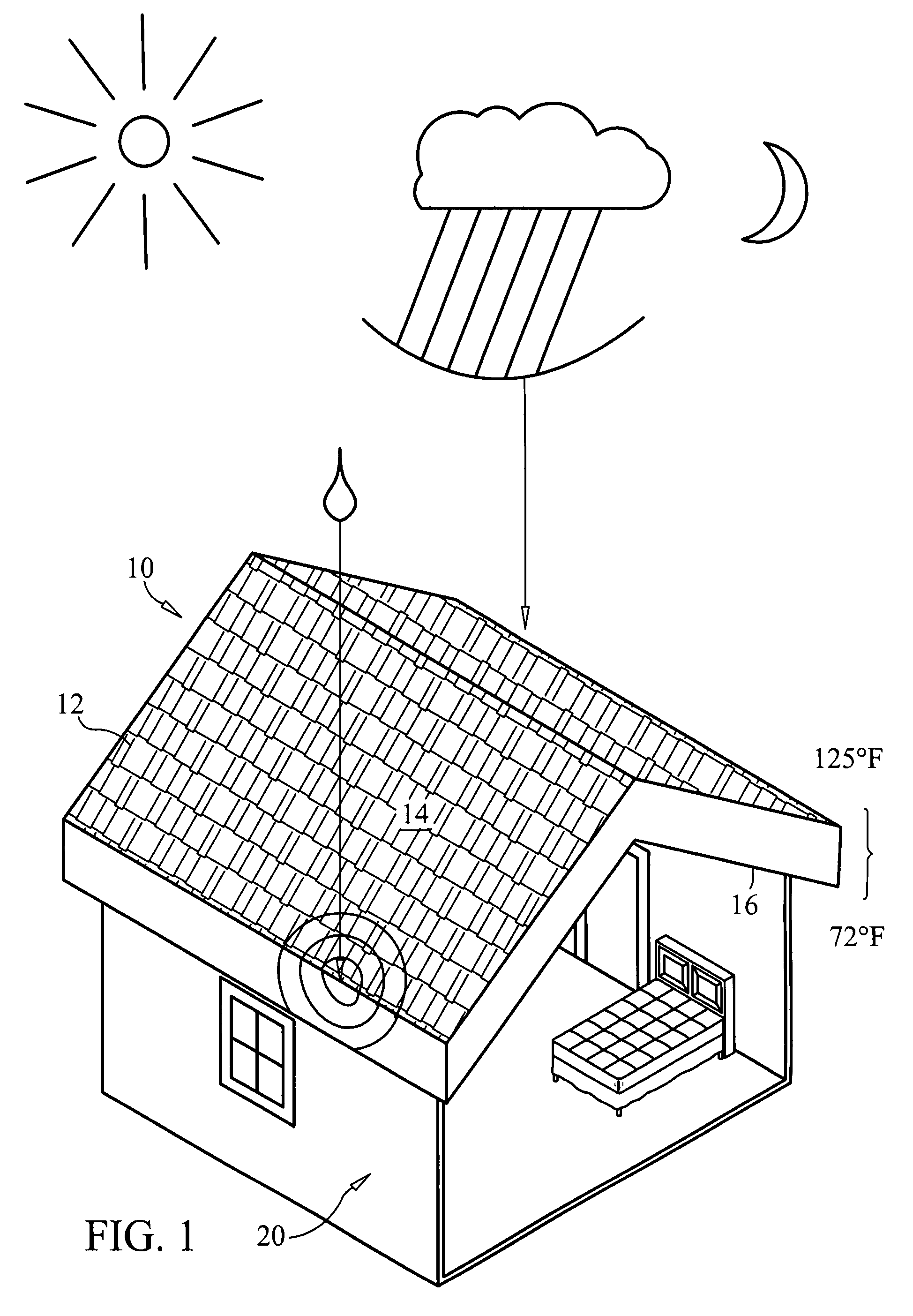

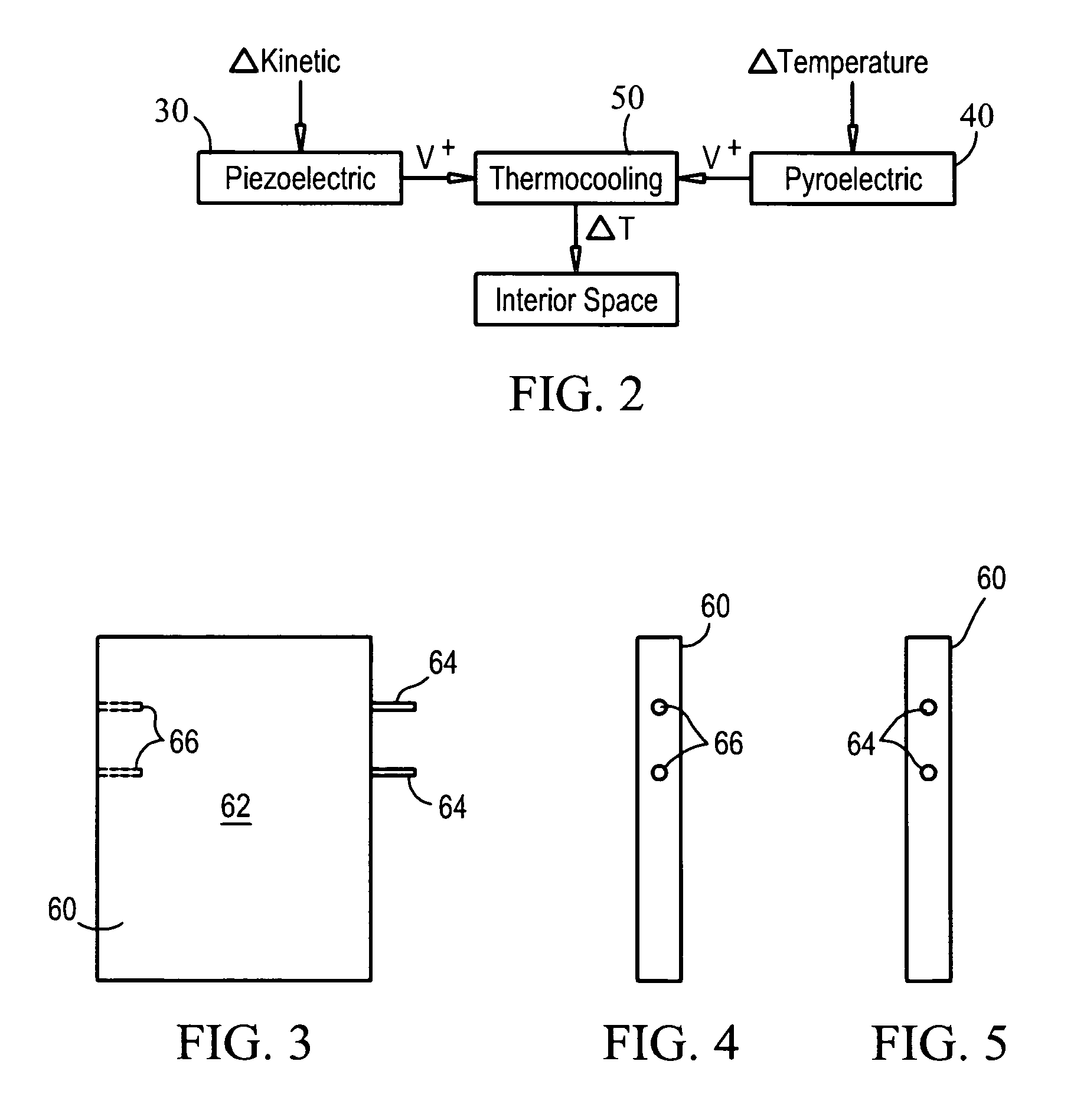

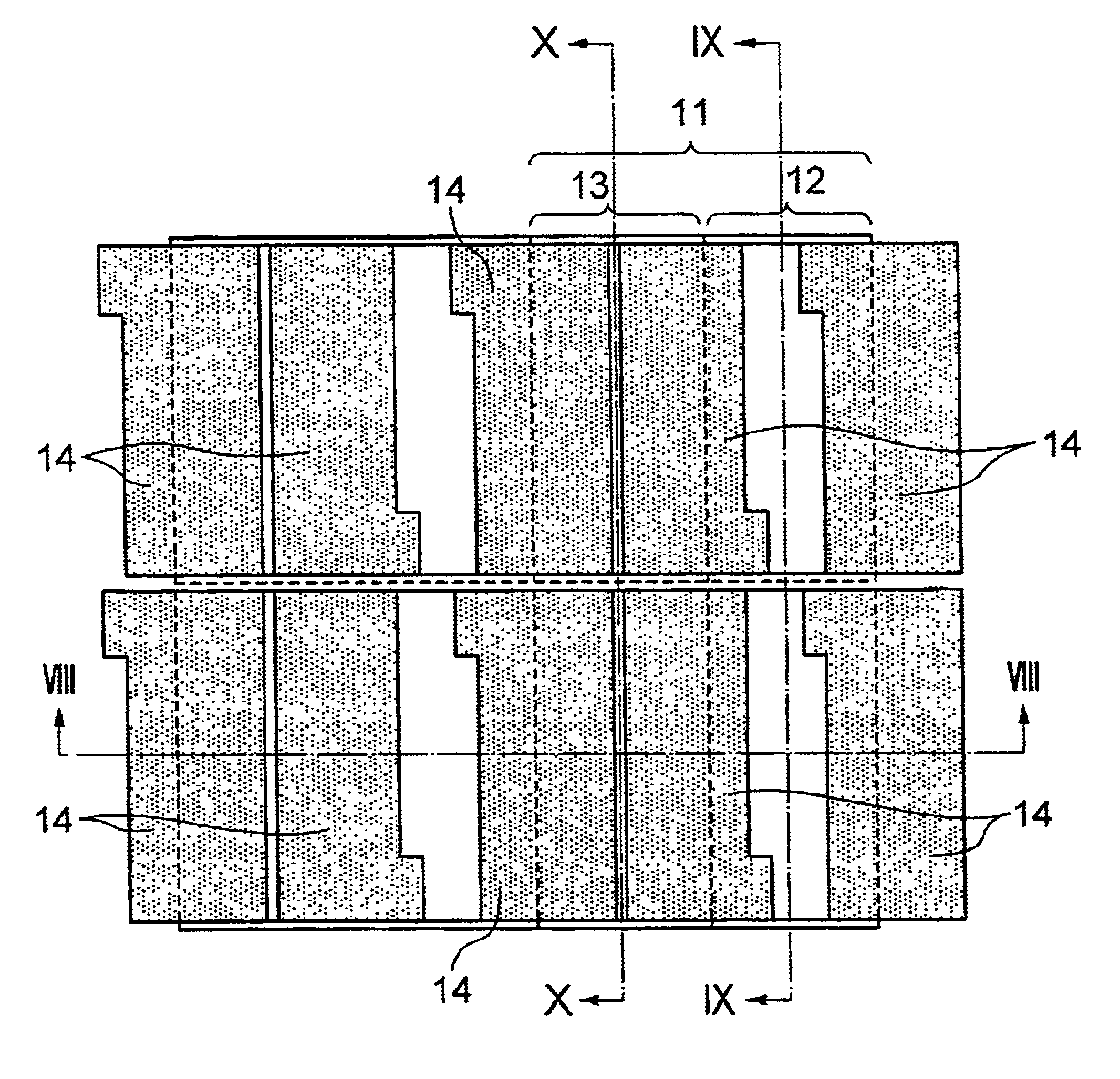

Apparatus and method for pyroelectric and piezoelectric power generation and thermoelectric heat transfer

ActiveUS7479727B1Simple and reliable processThermoelectric device with dielectric constant thermal changePiezoelectric/electrostriction/magnetostriction machinesThermoelectric coolingRoof tile

A roof system for a building is adapted to harness pyroelectric and piezoelectric effects to generate electric power. A roof system is provided wherein roof tiles, or other covering structure, are adapted with piezoelectric materials capable of converting mechanical energy from falling rain into electric energy by compression or deformation of the piezoelectric material, and further adapted with a pyroelectric system that generates electric power from temperature changes. The use of polyvinylidene fluoride, a material having both piezoelectric and pyroelectric characteristics, is discloses as a preferred material for accomplishing the goals of the present invention. The power generated supplies thermoelectric cooling systems that provide temperature conditioning of the building's interior space.

Owner:GRACE WINSTON

Thermo-sensitive infrared ray detector

InactiveUS6717147B2Television system detailsThermoelectric device with dielectric constant thermal changeInfraredOptoelectronics

Owner:NEC CORP

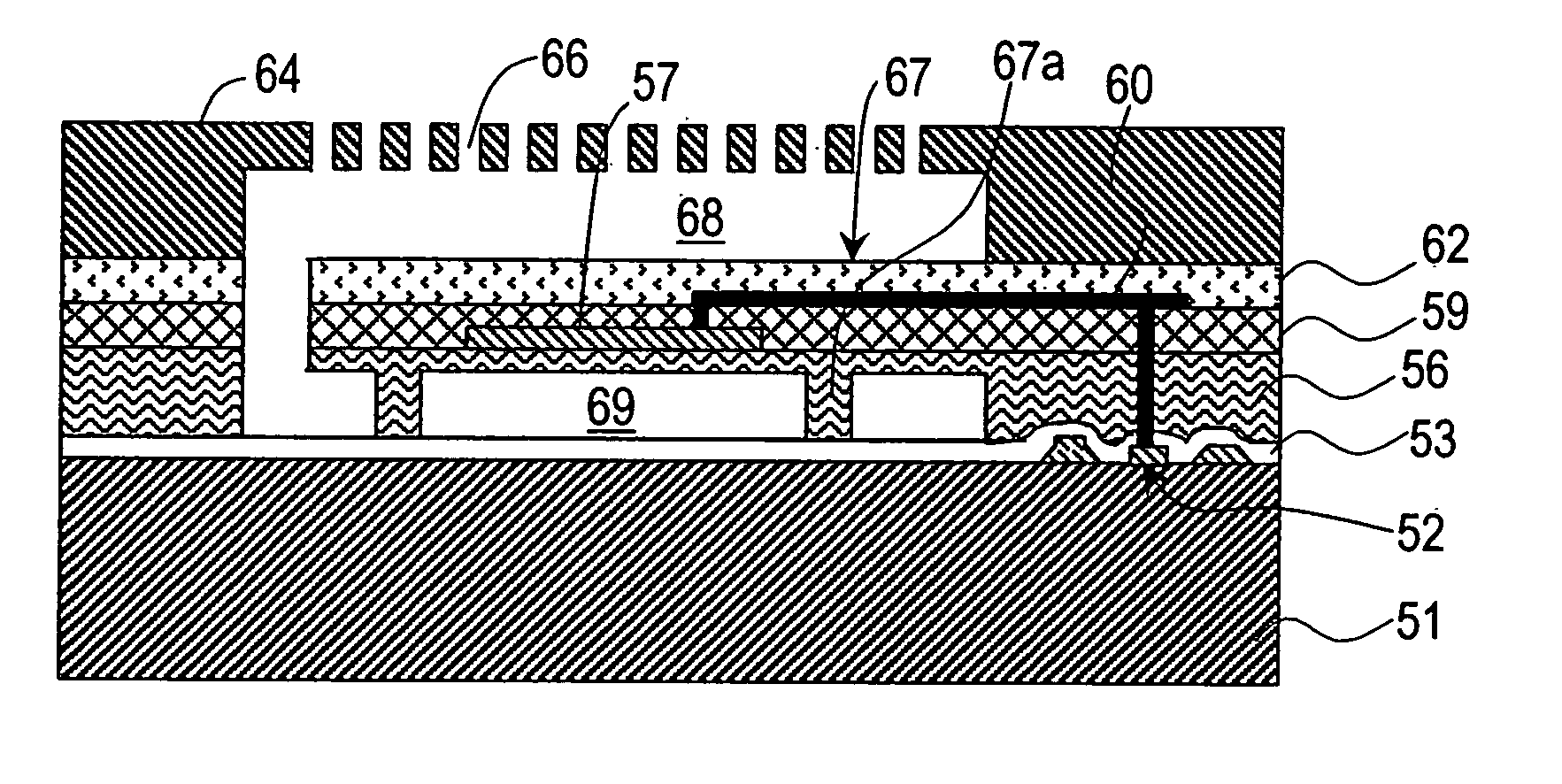

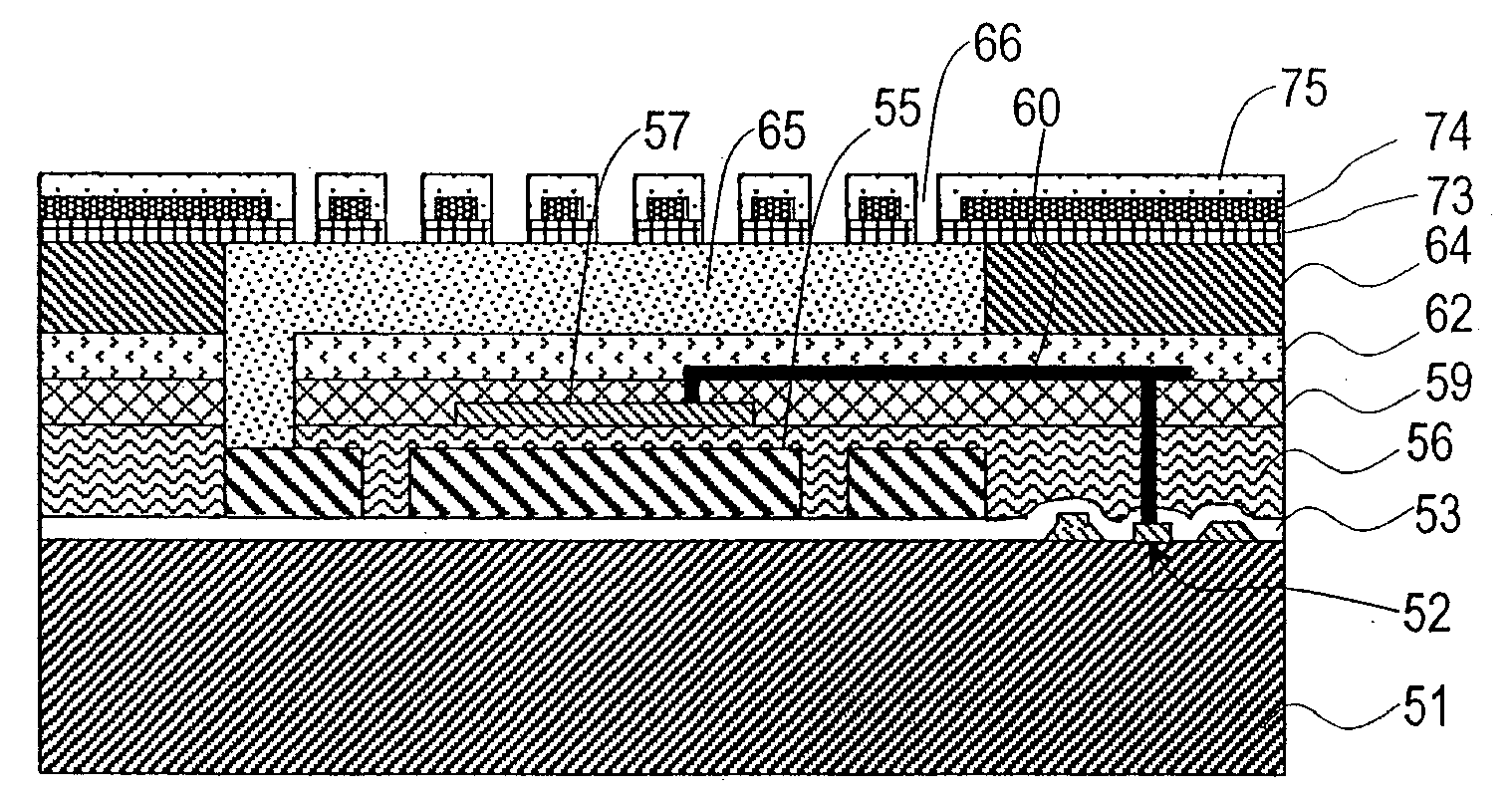

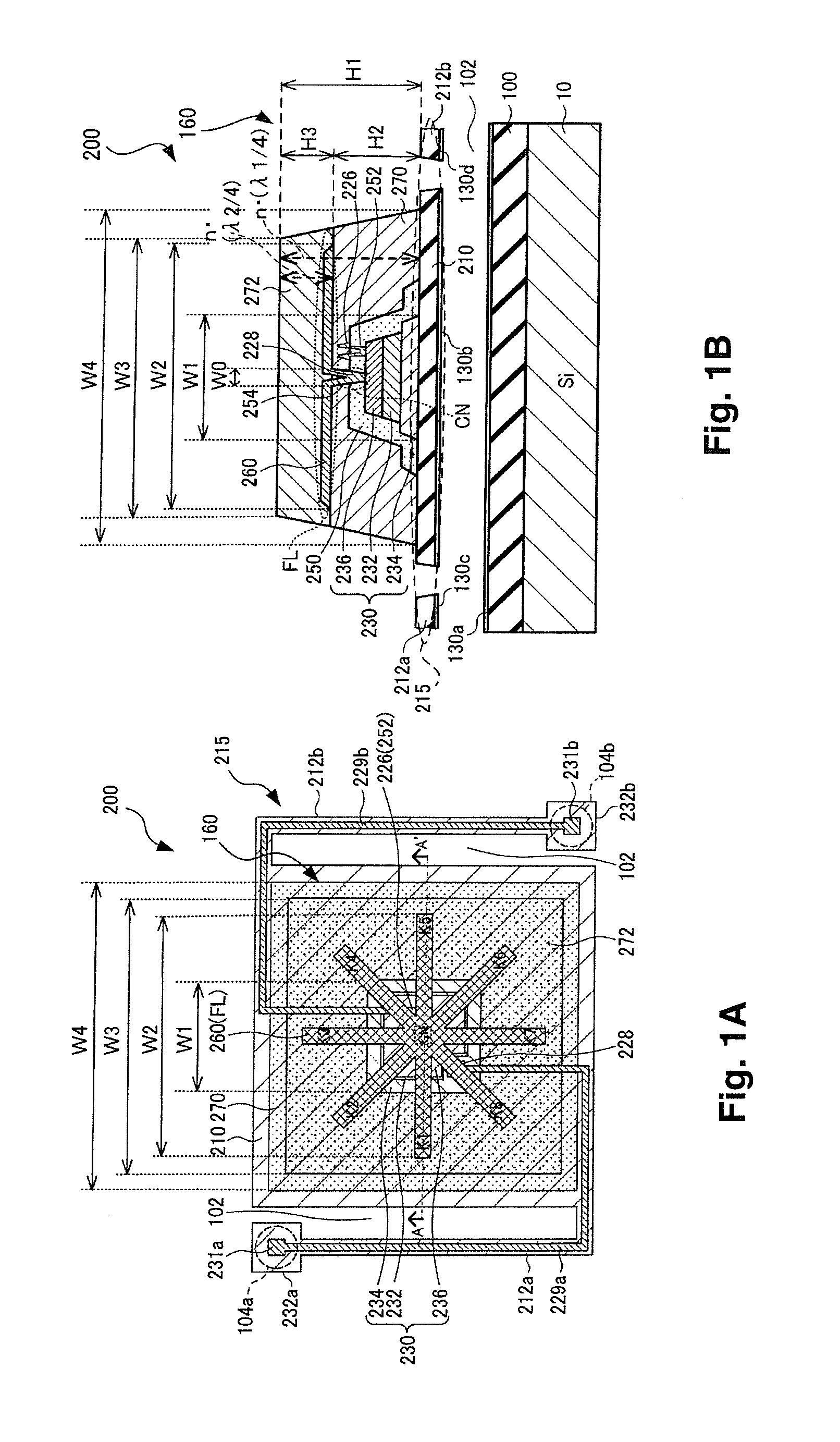

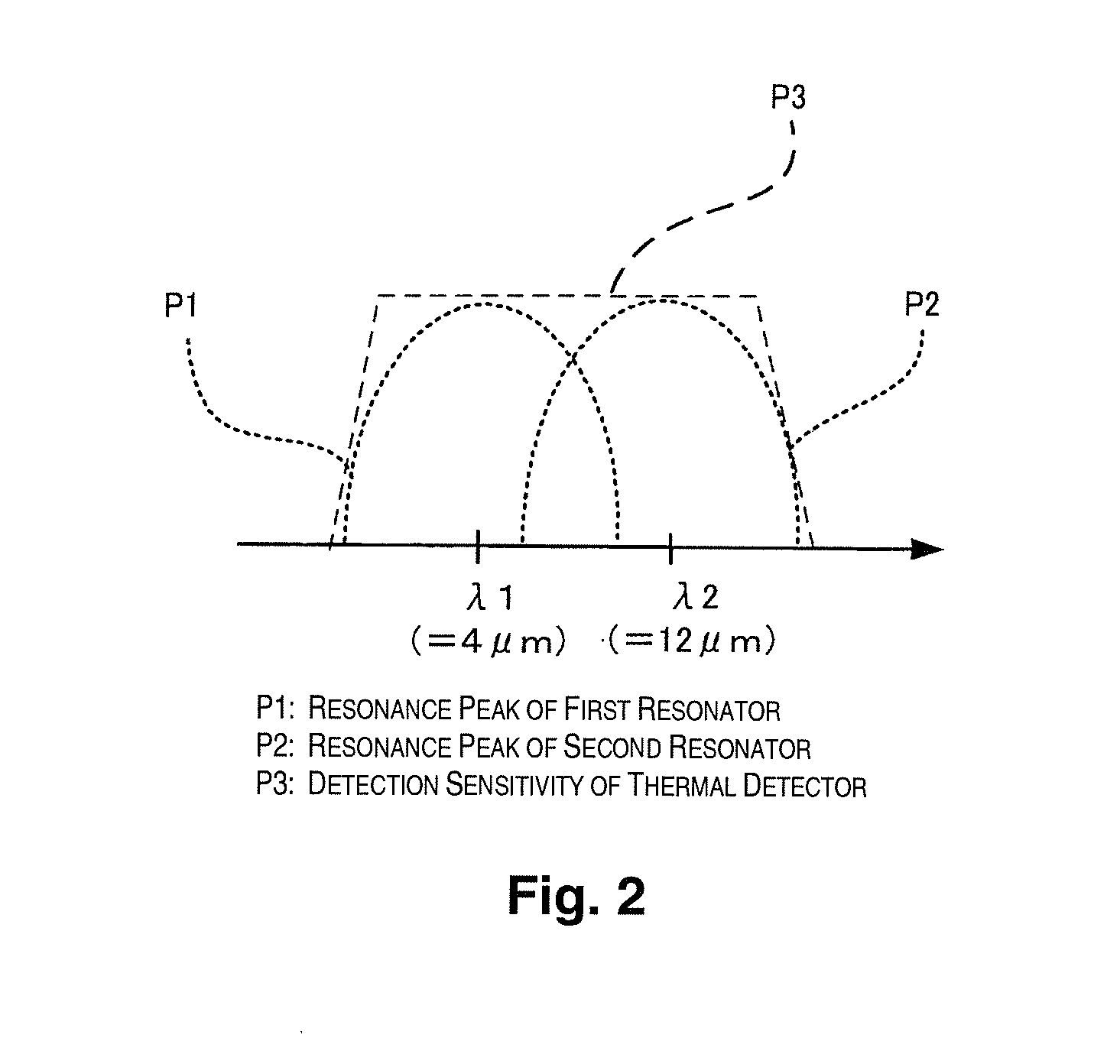

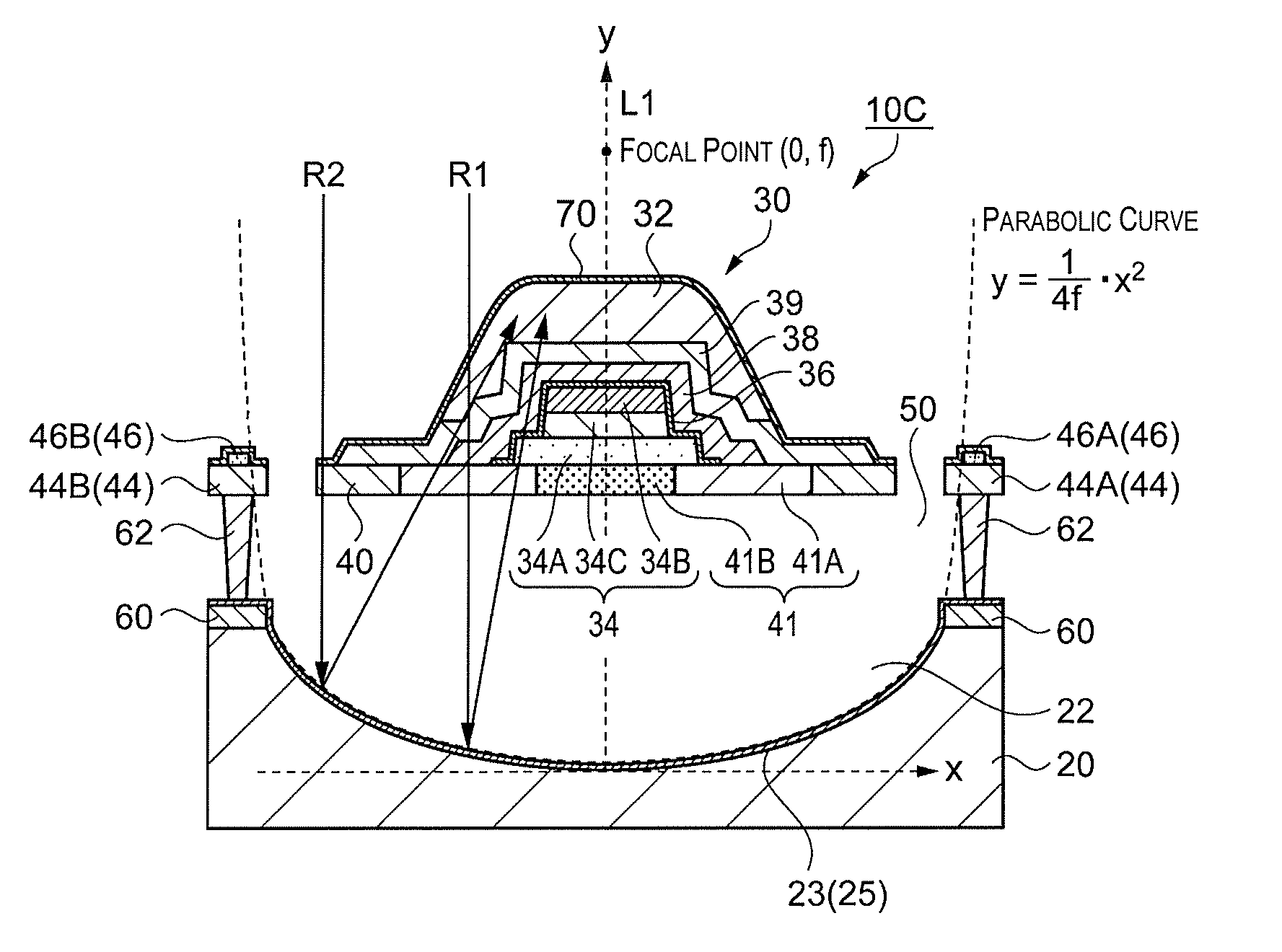

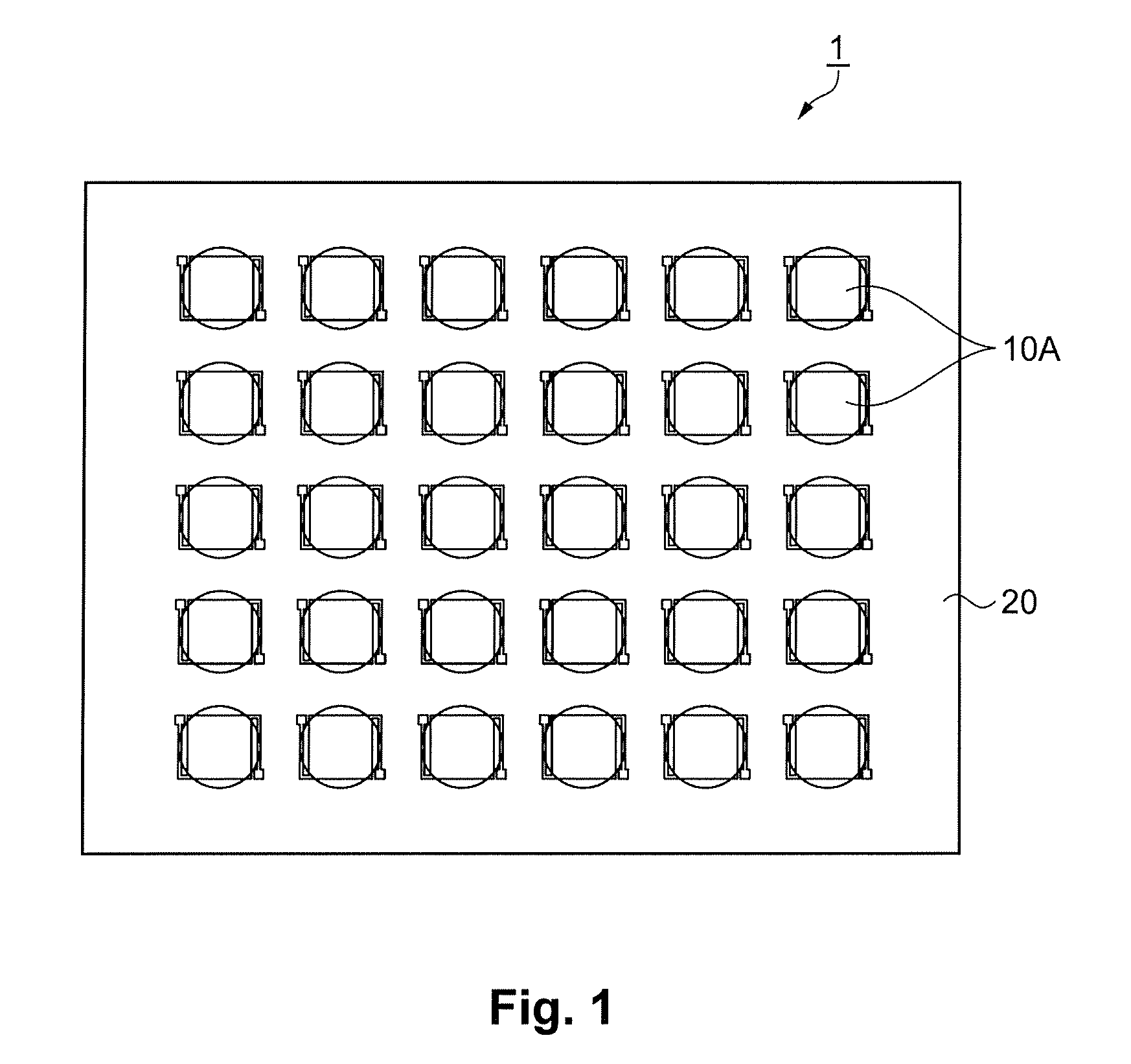

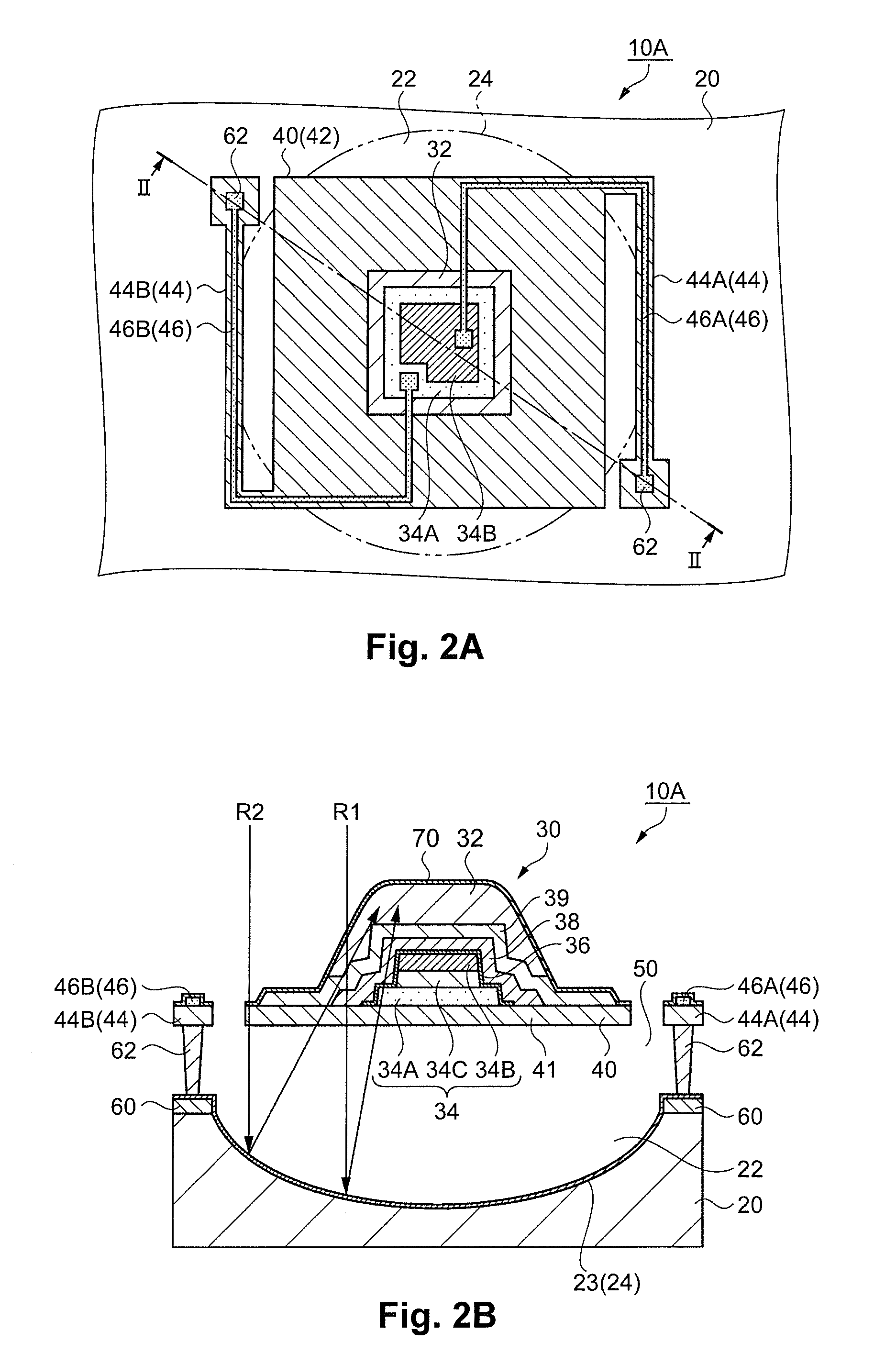

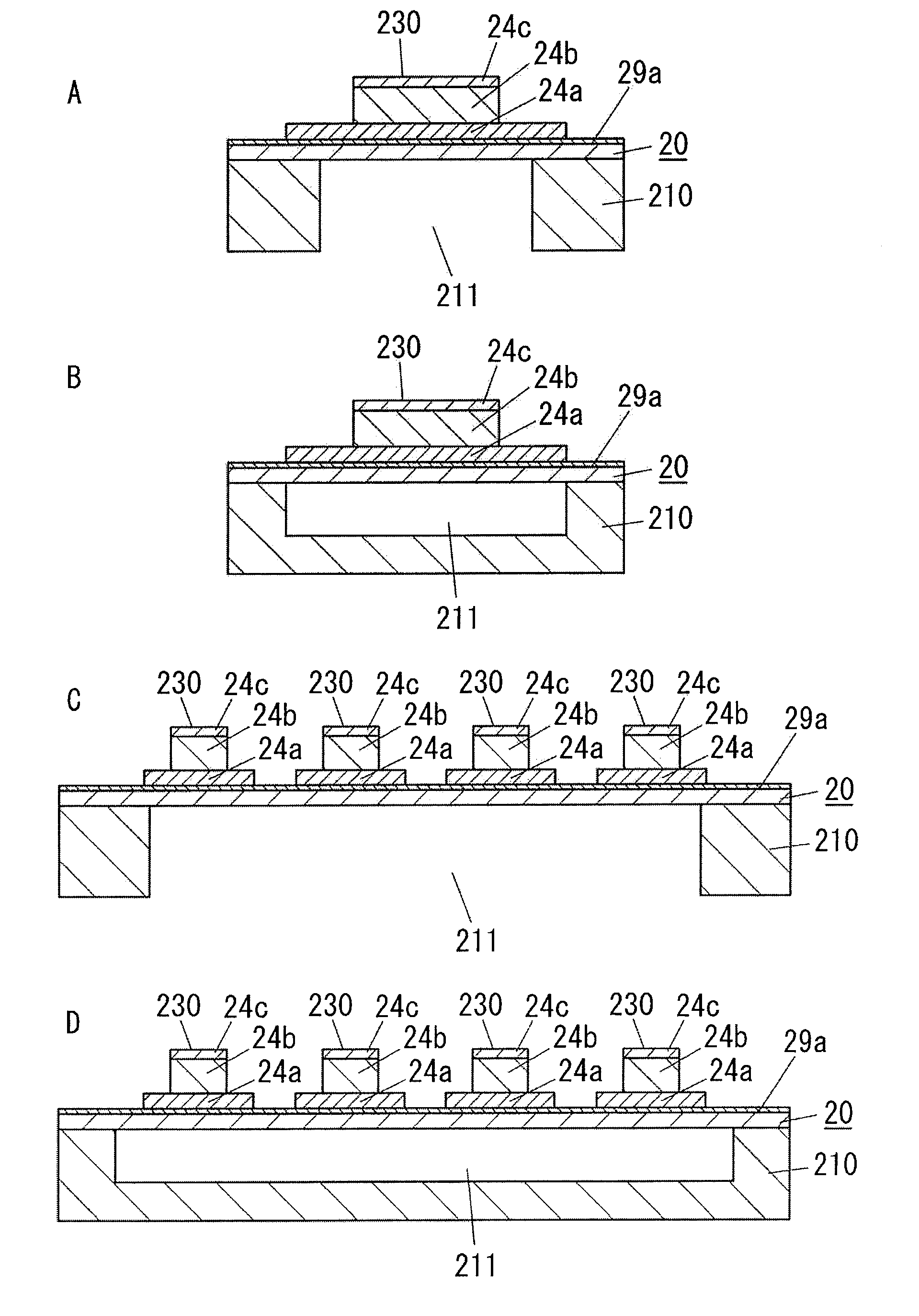

Thermal detector, thermal detection device, electronic instrument, and thermal detector manufacturing method

InactiveUS20120161003A1High detection sensitivityThermoelectric device with dielectric constant thermal changeThermoelectric device manufacture/treatmentPhysicsFirst light

A thermal detector includes: a substrate; a support member supported so that a cavity is formed between the substrate and the support member; a heat-detecting element supported on the support member; a thermal transfer member disposed over the heat-detecting element, and including a thermal collecting portion made of a material having light-reflecting characteristics and having a pattern with which a portion of light incident to a region defined by the support member as seen in plan view enters towards the support member, and a connecting portion connecting the thermal collecting portion to the heat-detecting element; a first light-absorbing layer contacting the thermal transfer member between the thermal transfer member and the support member; and a second light-absorbing layer contacting the thermal transfer member and disposed on the thermal transfer member.

Owner:SEIKO EPSON CORP

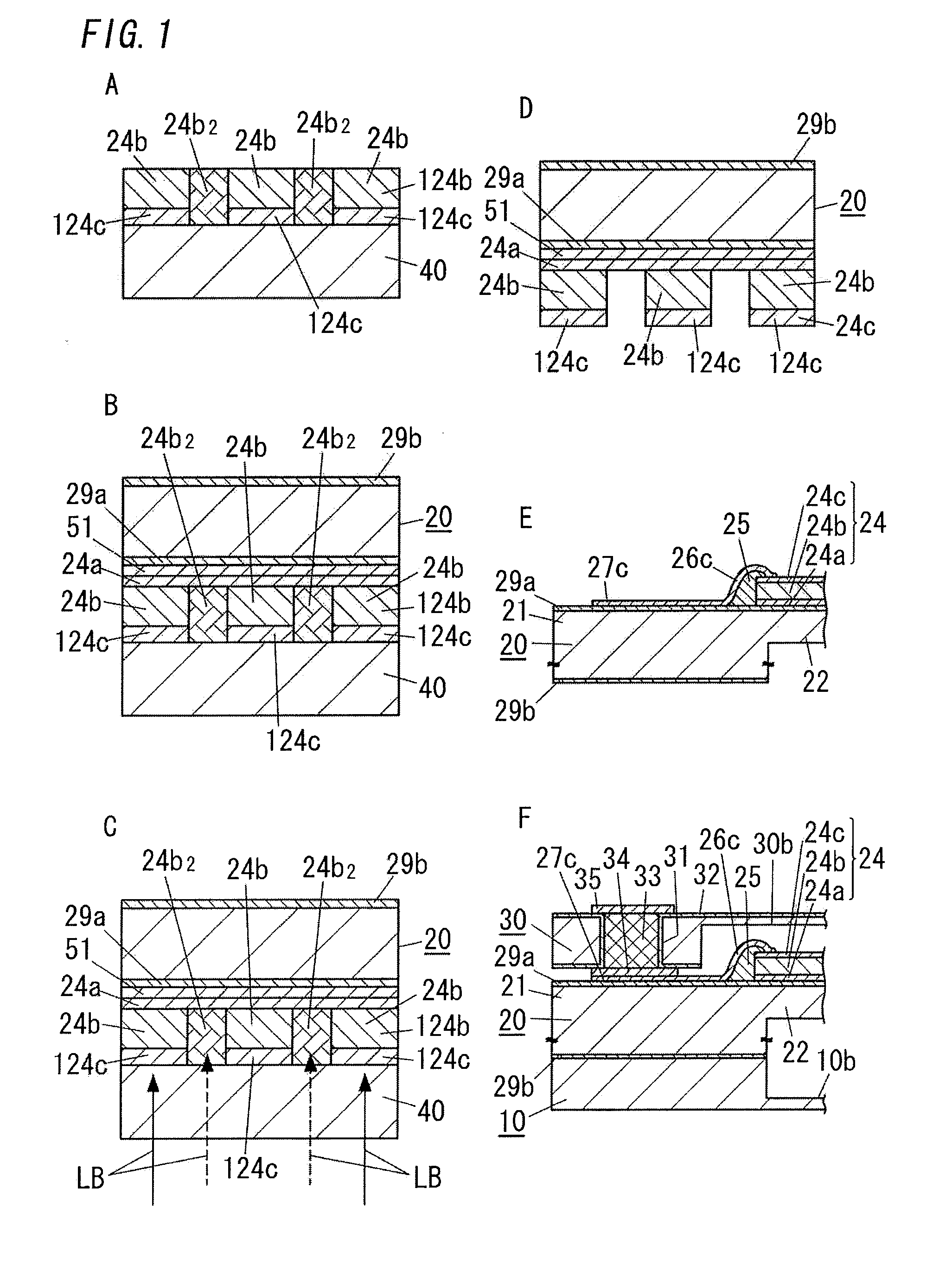

Ferroelectric device

InactiveUS20130032906A1High crystallinityImprove performanceTelevision system detailsThermoelectric device with dielectric constant thermal changeLattice constantSilicon

A ferroelectric device comprises: a silicon substrate (a first substrate); a lower electrode (a first electrode) formed on one surface side of first substrate; a ferroelectric film formed on a surface of lower electrode opposite to first substrate side; and an upper electrode (a second electrode) formed on a surface of ferroelectric film opposite to lower electrode side. The ferroelectric film is formed of a ferroelectric material with a lattice constant difference from silicon. The ferroelectric device further comprises a shock absorbing layer formed of a material with better lattice matching with ferroelectric film than silicon and provided directly below the lower electrode. The first substrate is provided with a cavity that exposes a surface of shock absorbing layer opposite to lower electrode side.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Thin film photovoltaic device

ActiveUS20060213549A1Thermoelectric device with dielectric constant thermal changePhotovoltaicsLight energyOptoelectronics

The present invention provides a thin film photovoltaic device and a method of forming a thin film photovoltaic device. The thin film photovoltaic device has a substrate, a thin film layer formed on the substrate and first and second electrodes formed on one side of the thin film layer. By applying an electric field over the first and second electrodes, the thin film layer is polarized in a direction parallel to the surface plane of the film. Upon exposure to light, the thin film layer converts light energy into electricity. According to the method, a thin film layer is formed on a substrate. A first electrode and a second electrode are formed on one side of the thin film layer. By applying an electric field over the first and second electrodes, the thin film layer is polarized in a direction parallel to the surface plane of the film.

Owner:AGENCY FOR SCI TECH & RES

MEMS based pyroelectric thermal energy harvester

InactiveUS8519595B2Significant reductionImprove powerThermoelectric device with dielectric constant thermal changeElectric discharge tubesPower flowTemperature difference

A pyroelectric thermal energy harvesting apparatus for generating an electric current includes a cantilevered layered pyroelectric capacitor extending between a first surface and a second surface, where the first surface includes a temperature difference from the second surface. The layered pyroelectric capacitor includes a conductive, bimetal top electrode layer, an intermediate pyroelectric dielectric layer and a conductive bottom electrode layer. In addition, a pair of proof masses is affixed at a distal end of the layered pyroelectric capacitor to face the first surface and the second surface, wherein the proof masses oscillate between the first surface and the second surface such that a pyroelectric current is generated in the pyroelectric capacitor due to temperature cycling when the proof masses alternately contact the first surface and the second surface.

Owner:UT BATTELLE LLC

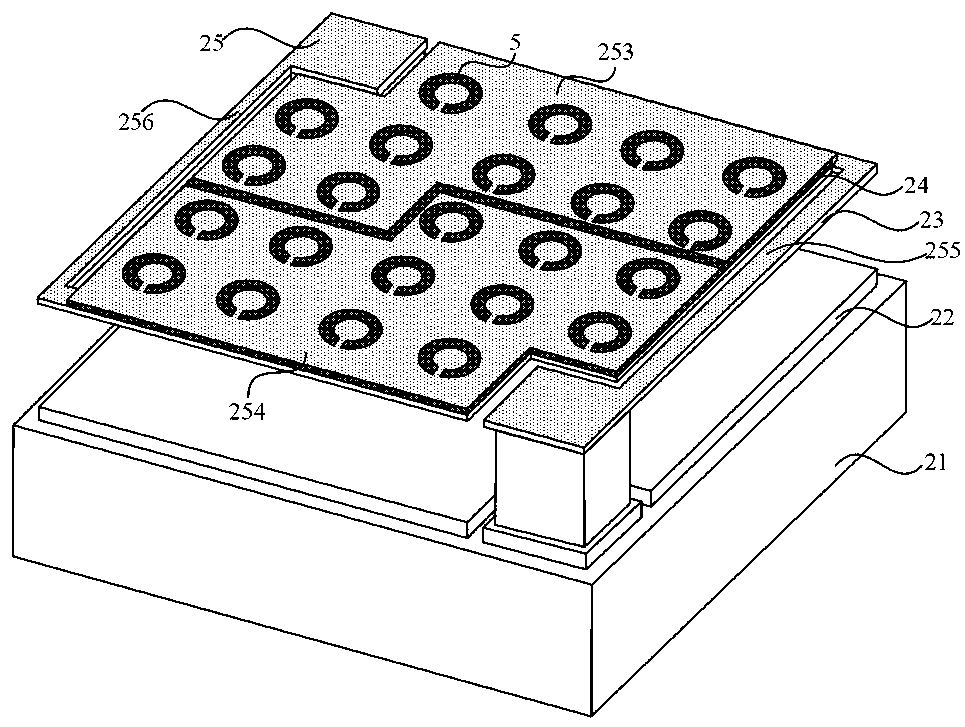

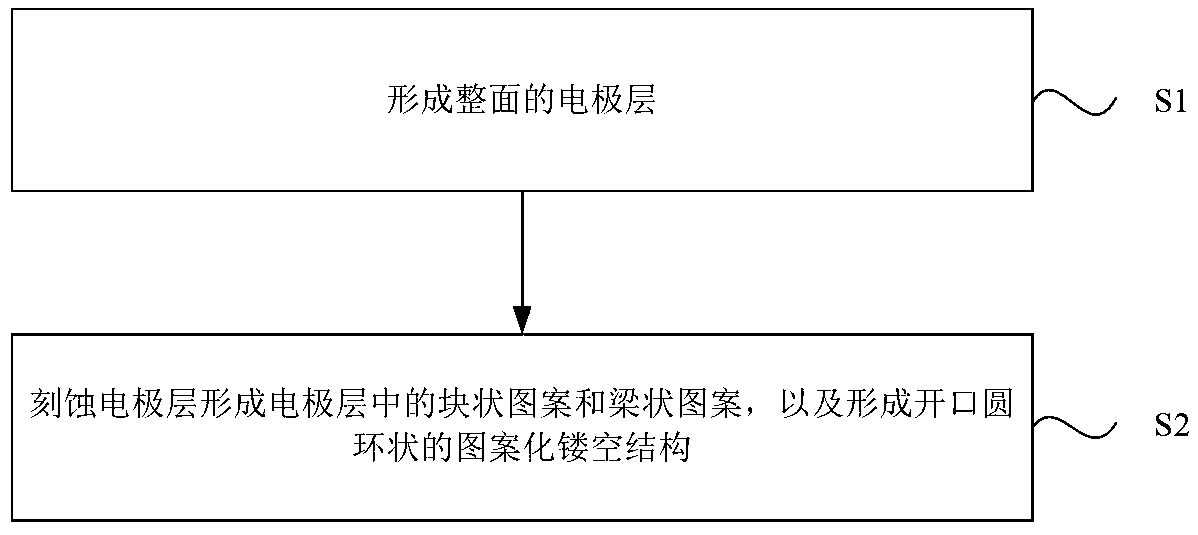

Infrared detector and preparation method thereof

ActiveCN111525023AImprove absorption propertiesHigh strengthThermoelectric device with dielectric constant thermal changeSolid-state devicesIr absorptionWave band

The invention relates to an infrared detector and a preparation method thereof. The infrared detector comprises a plurality of detector pixels arranged in an array, wherein each detector pixel comprises an electrode layer, the electrode layer is provided with a plurality of patterned hollow-out structures arranged in an array, the patterned hollow-out structures are in an open circular ring shape,and the infrared absorption spectrum section of the infrared detector is a wave band of 3 microns to 30 microns. By means of the technical scheme, wide-spectrum absorption of the infrared detector isachieved, so that the absorptivity of the infrared detector to temperature infrared radiation energy of a target object is greatly improved so as to make the infrared detector have high detection sensitivity.

Owner:BEIJING NORTH GAOYE TECH CO LTD

Infrared sensor device and manufacturing method thereof

InactiveUS20050061980A1Shorten the lengthHigh mechanical strengthTransistorThermoelectric device with dielectric constant thermal changeInfraredLight beam

A supporting beam line for supporting, afloat in a cavity on a semiconductor substrate, an infrared detection pixel comprising an infrared absorption portion for absorbing an incident infrared ray and converting it into heat and a thermoelectric conversion portion for converting a temperature change caused by the heat generated in the infrared absorption portion into an electric signal is formed by a damascene metal on the same layer as the gate of a damascene metal gate MOS transistor to be used in a peripheral circuit. The supporting beam line comprises a conductor line with U-shaped cross section inside which a metal is filled.

Owner:KK TOSHIBA

Infrared sensor and method for producing same

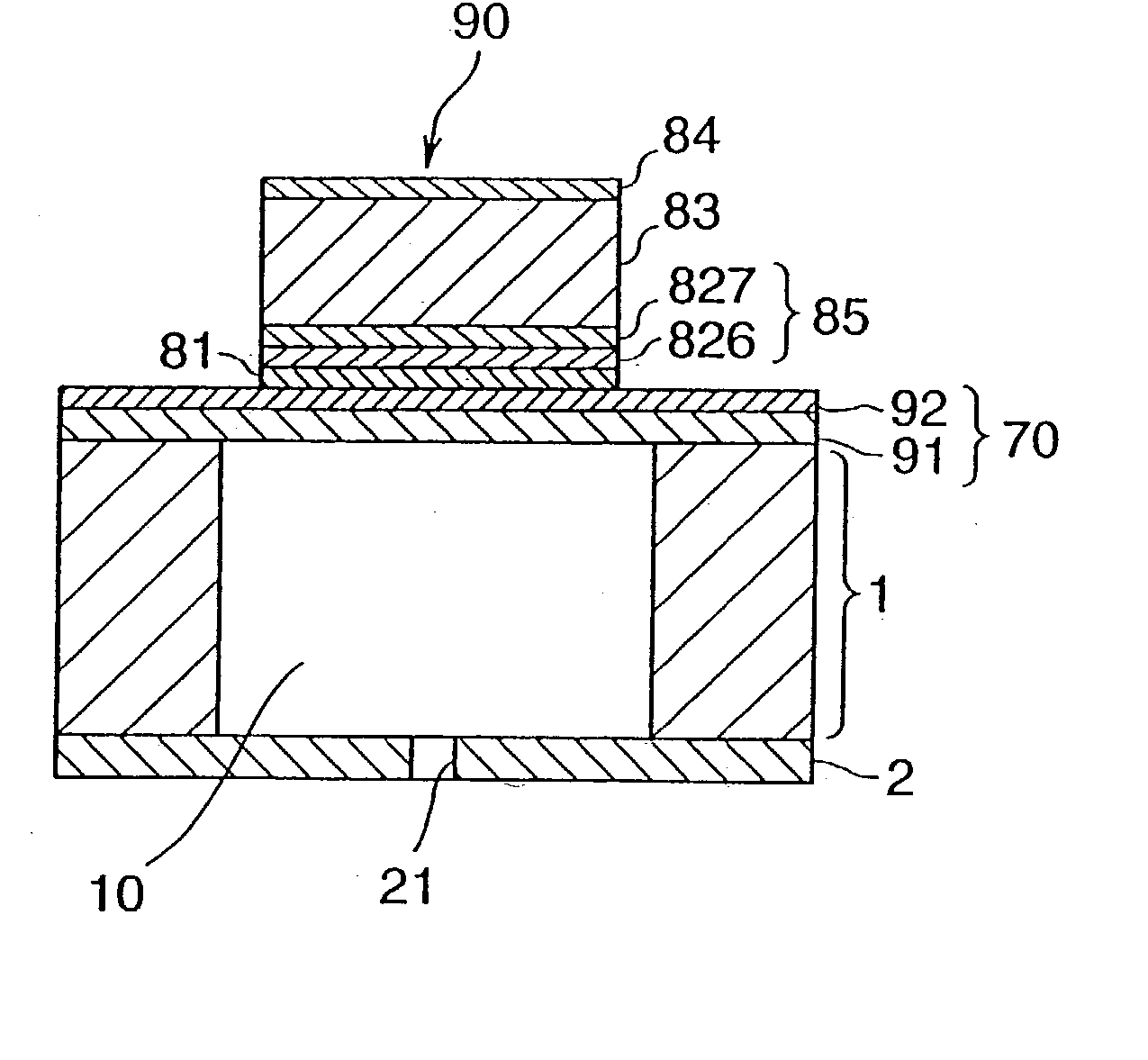

ActiveUS20090050808A1Improve insulation performanceSatisfactory responsivenessThermoelectric device with dielectric constant thermal changeMaterial analysis by optical meansThermoelectric conversionElectrical and Electronics engineering

An infrared sensor includes a first substrate made of a thermoelectric conversion material and a second substrate. The first substrate is supported by posts made of an electrode material while being spaced apart from the second substrate. A sensing electrode and lead portions connected thereto are provided on the first substrate. The sensing electrode and the lead portions are covered with an infrared-absorbing film. The posts are connected to the lead portions, and external terminal connection electrodes are connected to the posts.

Owner:MURATA MFG CO LTD

Method for manufacturing ferroelectric thin film device, ink jet recording head, and ink jet printer

InactiveUS20030092203A1Reliable drive characteristicReduce adhesionTransistorThermoelectric device with dielectric constant thermal changeIridiumFerroelectric thin films

It is an object of the present invention to control the crystal orientation of a ferroelectric thin film as dictated by the application of a ferroelectric thin film device. To accomplished the stated object, a bottom electrode containing at least iridium is formed over a surface preparation layer whose main component is zirconium oxide, and an ultra-thin titanium layer is laminated over the bottom electrode. An amorphous layer containing the elemental metal and elemental oxygen that constitute the ferroelectric is formed over the titanium layer, and a crystallized ferroelectric thin film is formed by heat treating this amorphous layer. If the thickness of the titanium layer is kept between 2 nm and 10 nm in the lamination thereof, the ferroelectric thin film will have a priority orientation of (100), and if it is kept between 10 nm and 20 nm, the ferroelectric thin film will have a priority orientation of (111).

Owner:SEIKO EPSON CORP

Method of making infrared sensor with a thermoelectric converting portion

InactiveUS6541298B2TransistorThermoelectric device with dielectric constant thermal changeInfraredPixel array

An infrared sensor including a substrate, a plurality of infrared detection pixels arrayed on a substrate with each of the infrared detection pixels including an infrared absorption portion formed over the substrate and configured to absorb infrared radiation, a thermoelectric converter portion formed over the substrate and configured to convert a temperature change in the infrared absorption portion into an electrical signal, and support structures configured to support the thermoelectric converter portion and the infrared absorption portion over the substrate via a separation space, the support structures having conductive interconnect layers configured to deliver the electrical signal from the thermoelectric converter portion to the substrate. The infrared sensor further includes a pixel selection circuit configured to select at least one of the infrared detection pixels which delivers the electrical signal and an output circuit configured to output the electrical signal delivered from selected infrared detection pixels via the conductive interconnect layers. The conductive interconnect layers include a material the same as a material of gate layers of the MOS transistors, and have a thickness similar to the gate layers.

Owner:KK TOSHIBA

Thermal detector, thermal detection device, and electronic instrument

ActiveUS20120211858A1Thermoelectric device with dielectric constant thermal changePhotovoltaicsElectronic instrumentEngineering

A thermal detector includes a substrate, a thermal detection element and a support member. The substrate has a recess part with a bottom surface of the recess part being a curved light-reflecting surface. The thermal detection element has a light-absorbing film. The support member supports the thermal detection element. The substrate and the support member are arranged to form a hollow part therebetween. The support member includes a light-absorbing part in which impurities are dispersed in polycrystalline silicon with the light-absorbing part being arranged in at least a part of a surface of the support member facing toward the hollow part so that the light-absorbing part being irradiated by light.

Owner:SEIKO EPSON CORP

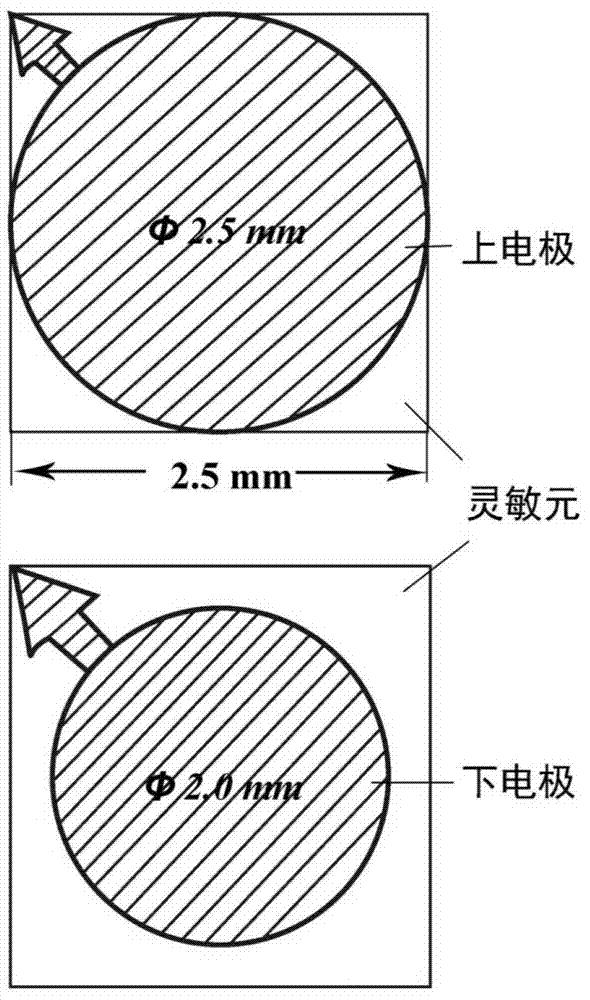

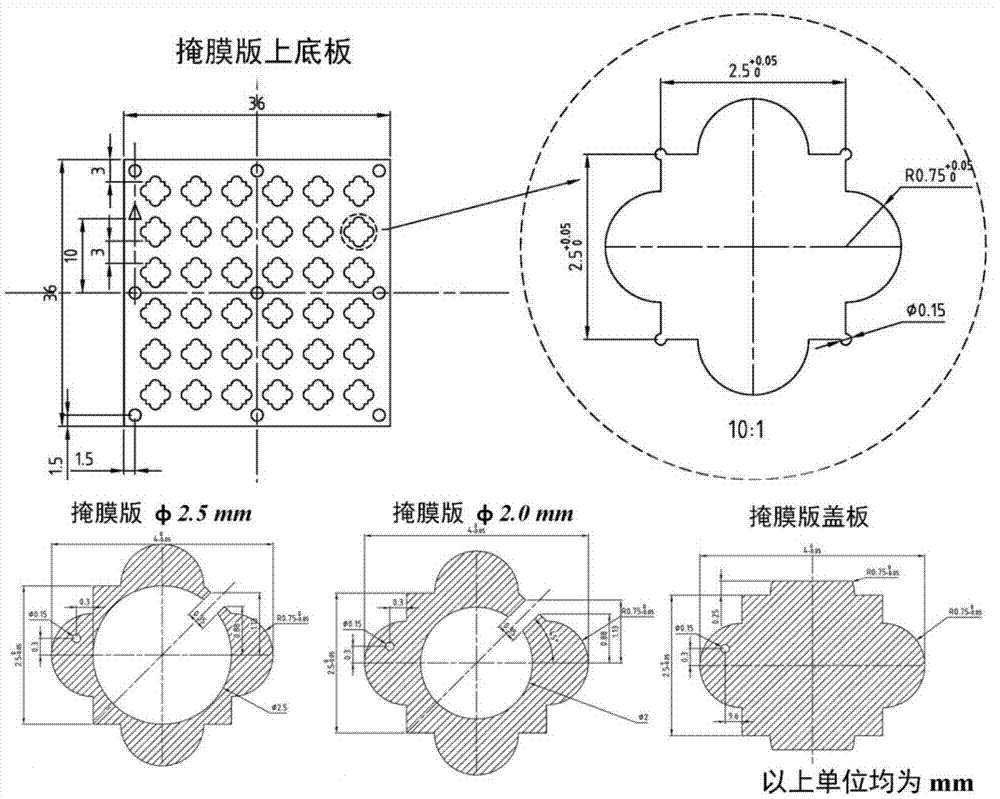

Relaxation ferroelectric monocrystal pyroelectric infrared detector and preparation method thereof

InactiveCN103943771AImprove response rateReduce noiseThermoelectric device with dielectric constant thermal changePolycrystalline material growthLow noiseResponsivity

The invention provides a relaxation ferroelectric monocrystal pyroelectric infrared detector and a preparation method thereof. The detector comprises a base, a shell, a sensing element, an upper electrode, a lower electrode, an absorbing layer and a current mode circuit, wherein the base is provided with pins, and the shell provided with a window and the base are packaged to form a holding space; the sensing element is arranged in the holding space and is made from relaxation ferroelectric monocrystal, and the thickness of the sensing elemtn is below 20 [mu] m; an upper electrode and a lower electrode are respectively arranged on the upper surface and the lower surface of the flexible element, the absorbing layer covers the upper electrode of the flexible element, and the current mode circuit is connected with the flexible element. The detector provided by the invention is high in response ratio, low in noise and high in detection ratio.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

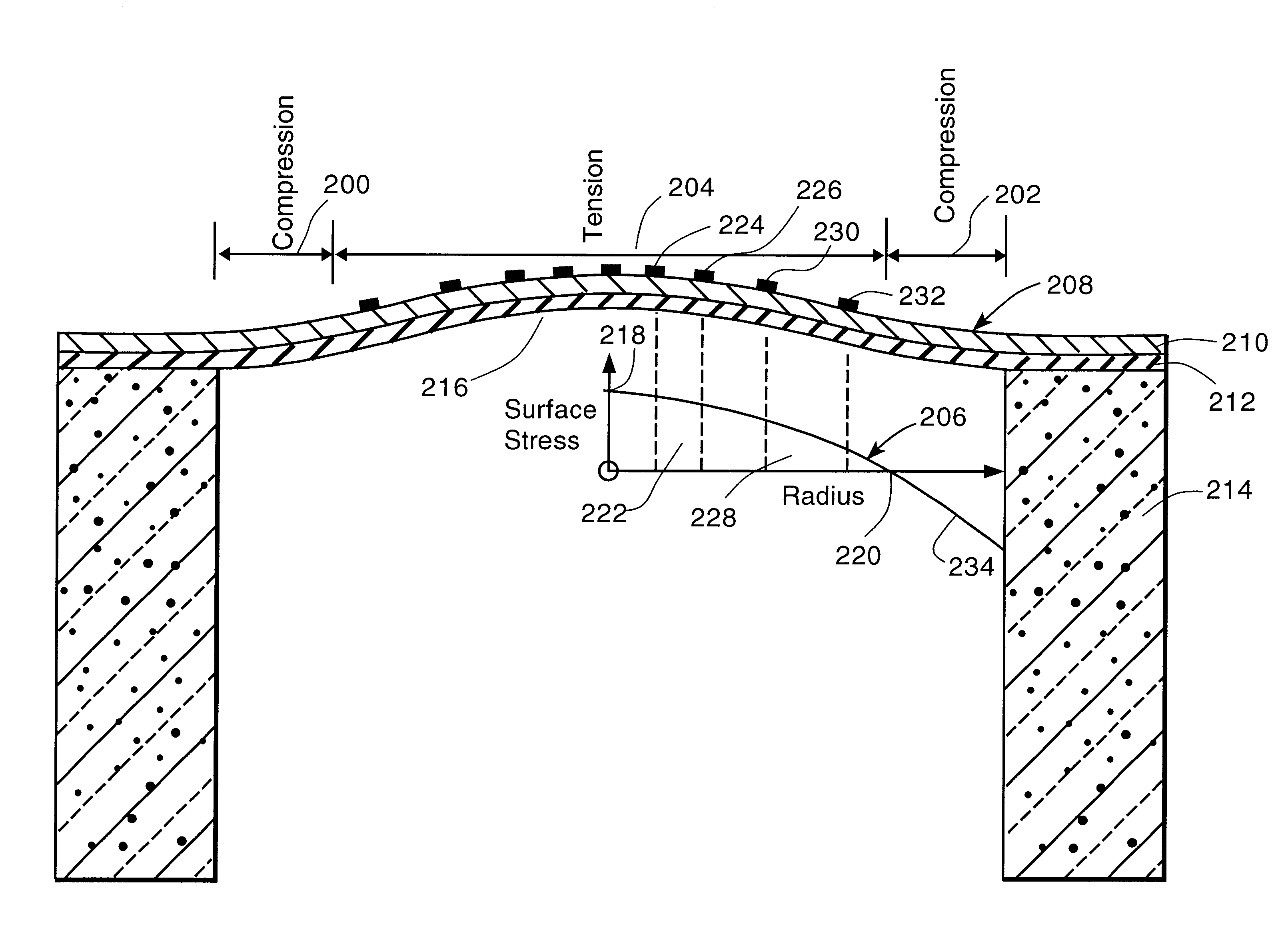

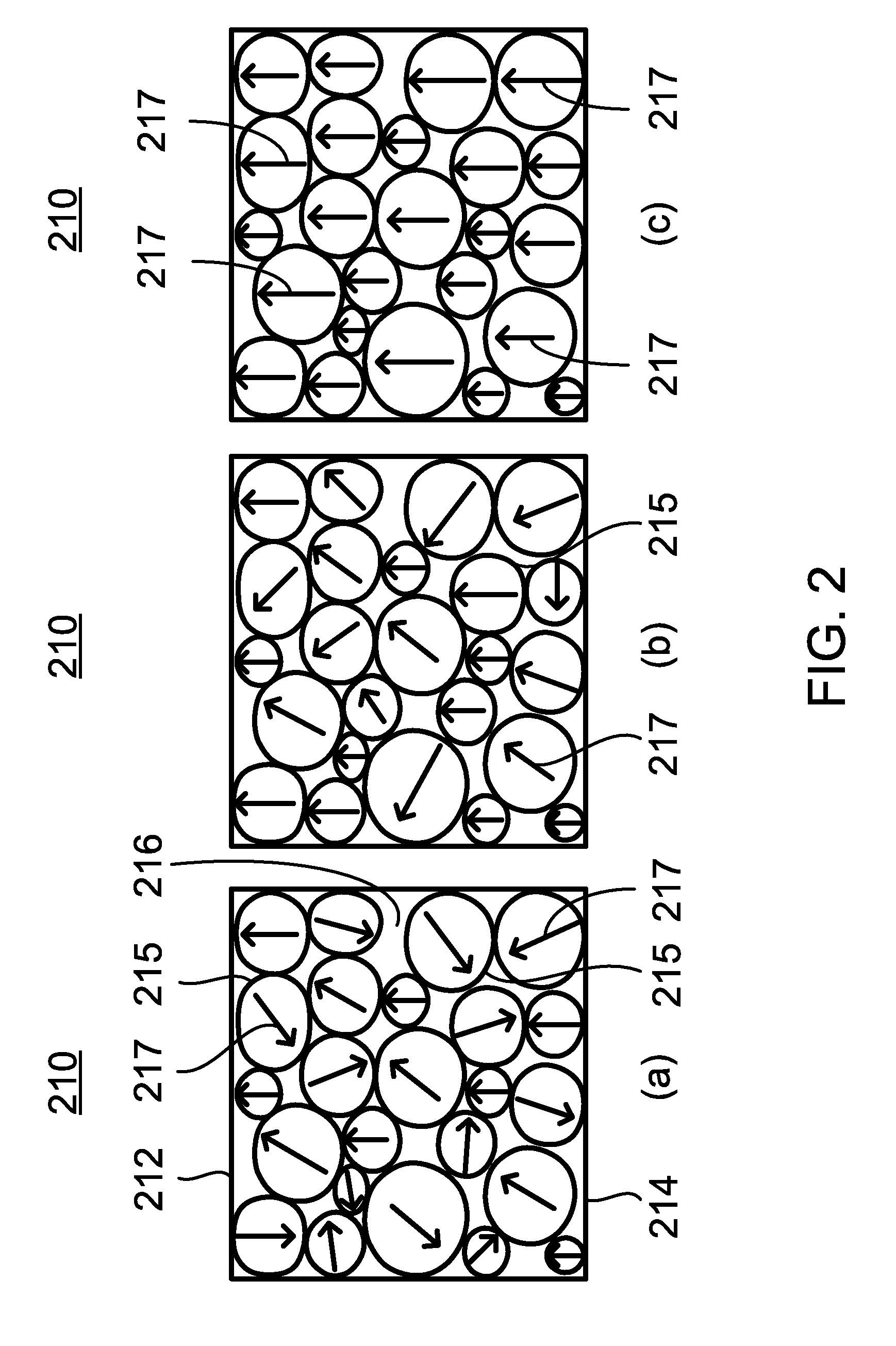

Methods to improve the mechanical performance of electrocaloric polymers in electrocaloric refrigerators

InactiveUS20160087185A1Increase elasticityReduce creepThermoelectric device with dielectric constant thermal changeMachines using electric/magnetic effectsFiberPolymer science

A cooling device utilizing the polymer composite materials possessing high electrocaloric effect and high elastic modulus are disclosed. Especially methods to enhance mechanical properties and reduce creep of the polymer composites with insulation fibers of high elastic modulus while maintain high electrocaloric effect.

Owner:NASCENT DEVICES

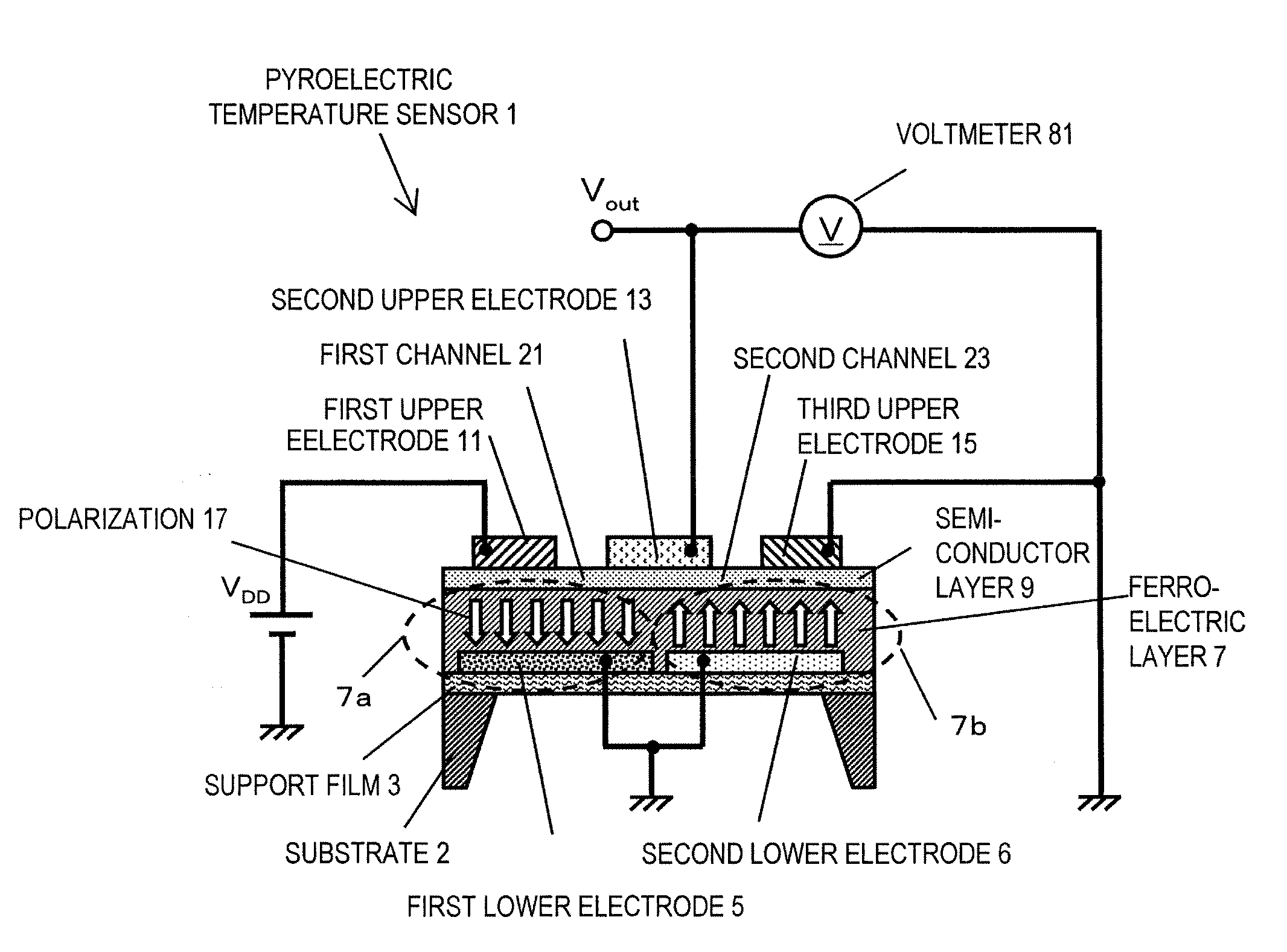

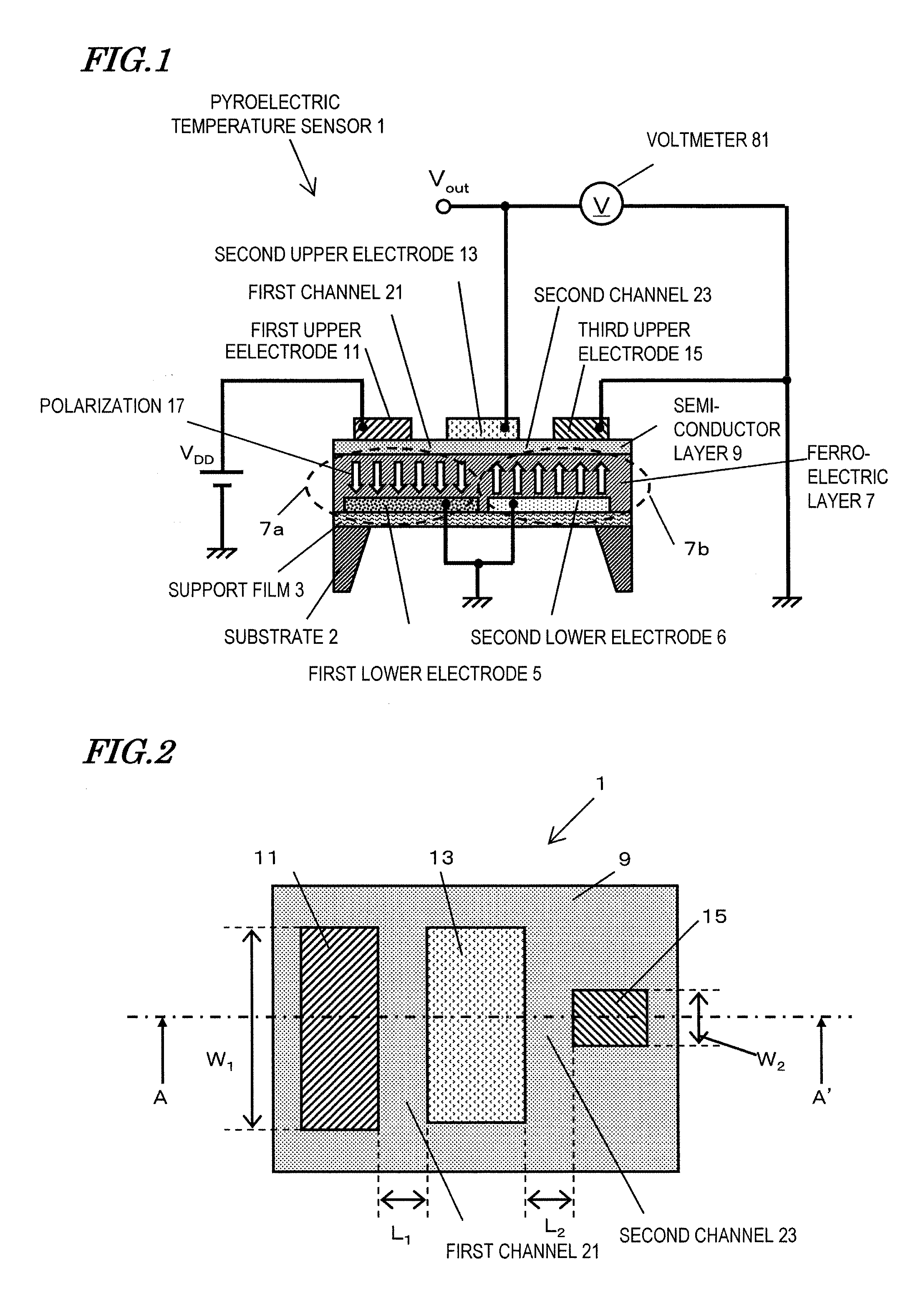

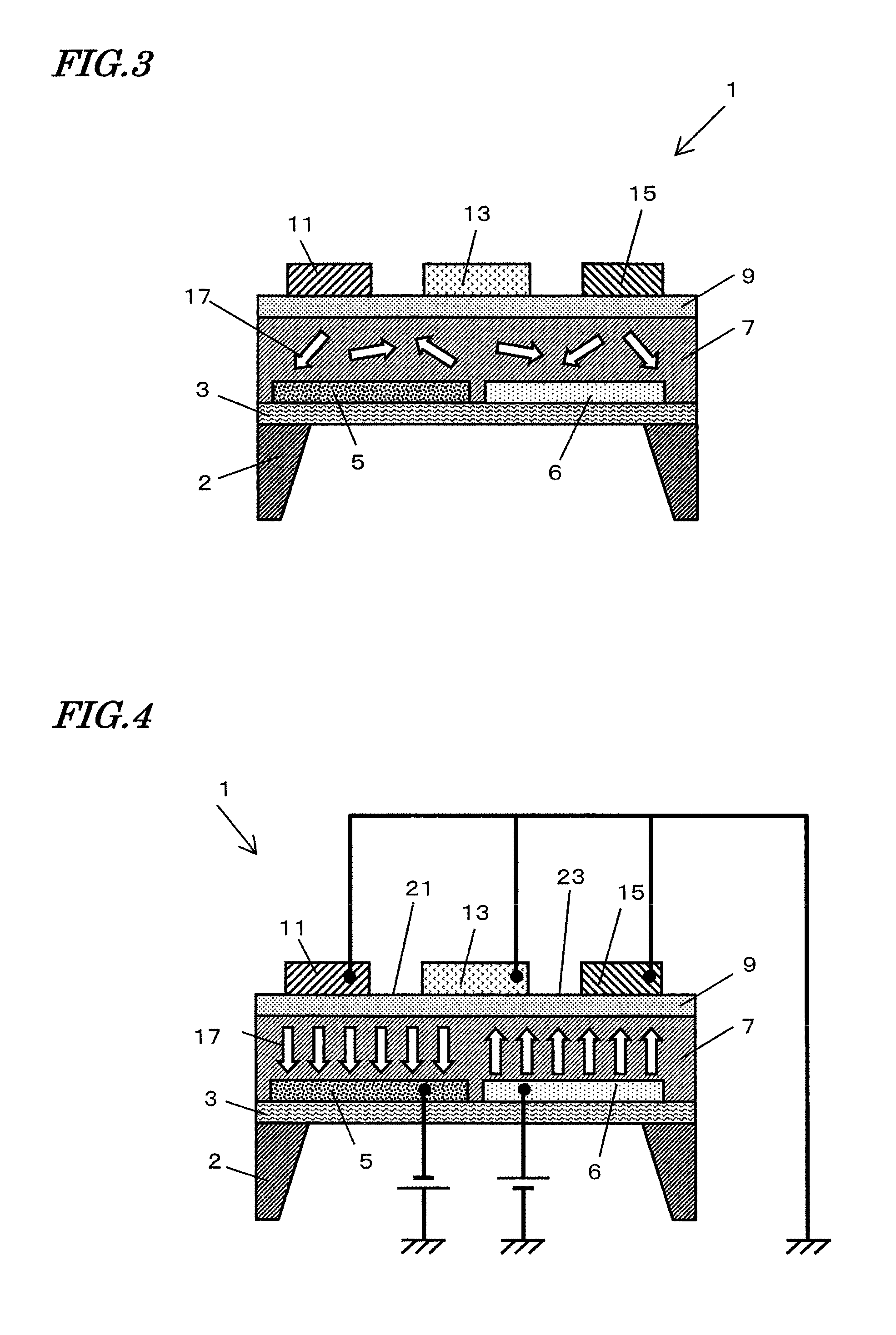

Pyroelectric temperature sensor and a method for measuring a temperature with the pyroelectric temperature sensor

ActiveUS20110299566A1High sensitivityThermoelectric device with dielectric constant thermal changeThermometers using electric/magnetic elementsSemiconductorMaterials science

A temperature sensor includes first and second lower electrodes, a ferroelectric layer having polarization, a semiconductor layer; and first to third upper electrodes. The second upper electrode is interposed between the first upper electrode and the third upper electrode in a plan view. The semiconductor layer includes a first channel disposed between the first upper electrode and the second upper electrode, and a second channel disposed between the second upper electrode and the third upper electrode. The ferroelectric layer includes a first ferroelectric part disposed below the first channel and a second ferroelectric part disposed below the second channel. A polarization direction of the first ferroelectric part is opposite to a polarization direction of the second first ferroelectric part. The temperature is calculated based on the output voltage from the second upper electrode and the voltage applied to the first upper electrode.

Owner:PANASONIC CORP

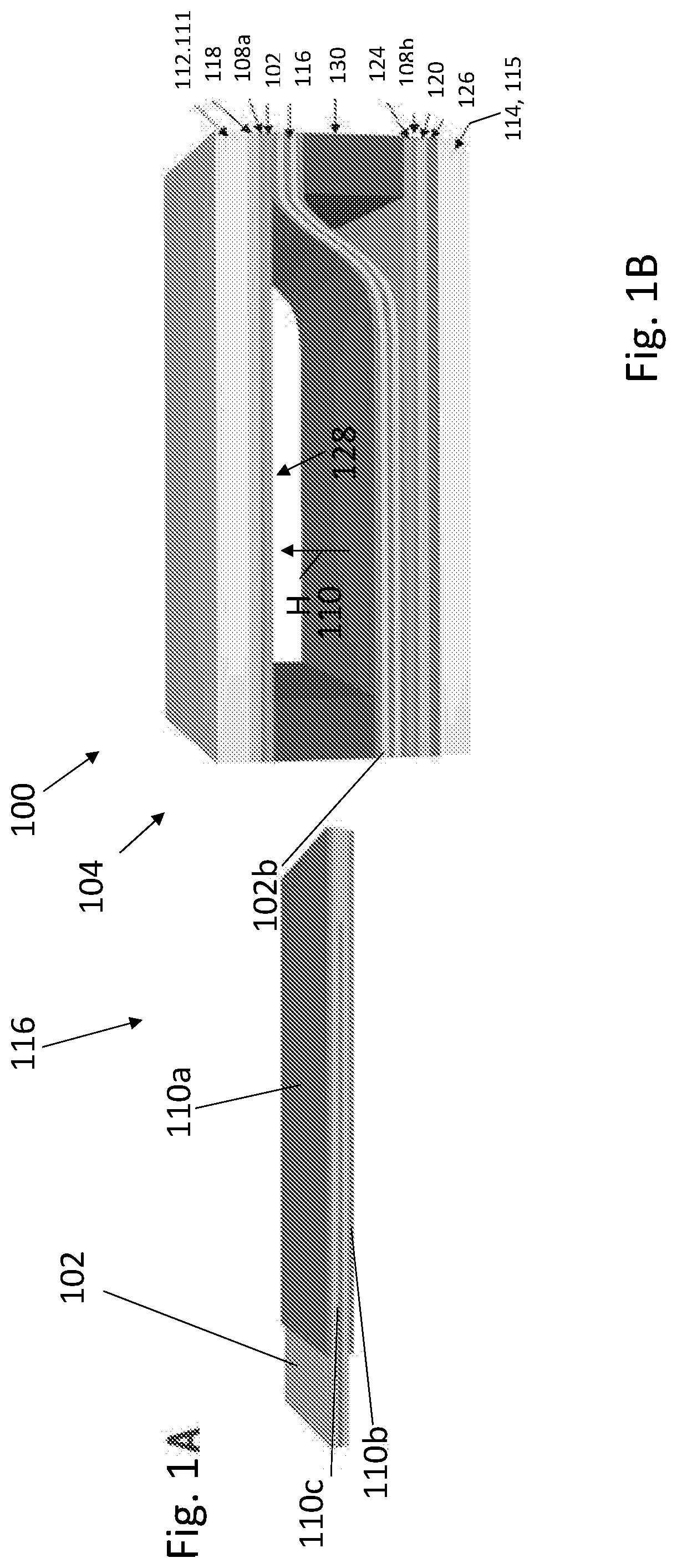

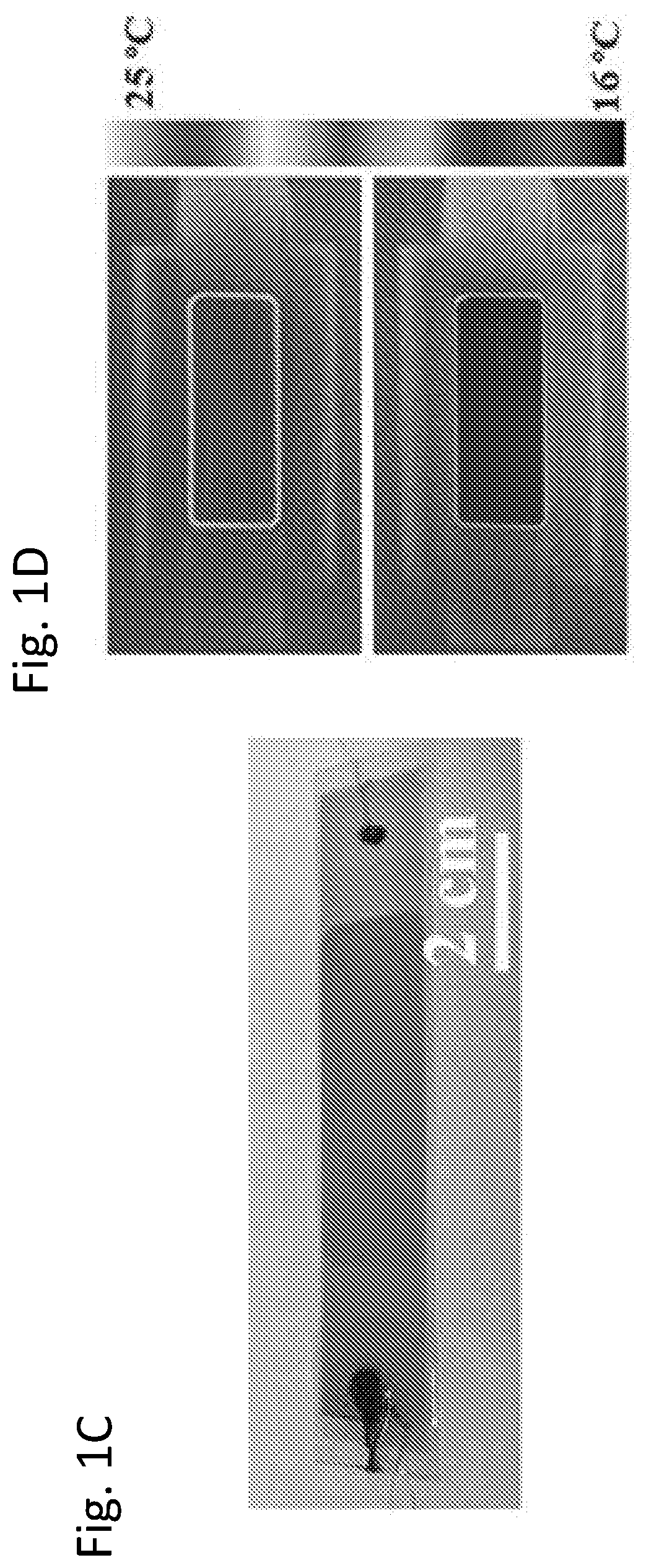

Electrocaloric cooling with electrostatic actuation

ActiveUS20210071917A1Leapfrogging performanceReduce power consumptionThermoelectric device with dielectric constant thermal changeSecondary cellsEngineeringCooling power

A solid-state heat transporting device including a heat transporting element whose uniformity of contact with one or multiple surfaces is controllable so that various amounts of heat may be transported to and from the one or multiple surfaces. The heat transporting element uses the electrocaloric effect to absorb and release the heat and the uniformity of contact is controlled using an electrostatic effect which may change the shape of the heat transporting element. In one embodiment, the heat transporting element is an electrostatically actuated P(VDF-TrFE-CFE) polymer stack achieving a high specific cooling power of 2.8 W / g and a COP of 13 (the highest reported coefficient of performance to date) when used as a cooling device.

Owner:SRI INTERNATIONAL +1

Method for manufacturing ferroelectric device

InactiveUS20130023063A1High crystallinityImprove performanceThermoelectric device with dielectric constant thermal changeSoldering apparatusLength waveLaser beams

A seed layer having a predetermined pattern is formed on a side of one surface of a second substrate, and a ferroelectric layer is formed on the side of the one surface of the second substrate. A lower electrode is formed on the ferroelectric layer, and the lower electrode and a first substrate are bonded via a bonding layer. A laser beam with a predetermined wavelength is irradiated from a side of other surface of the second substrate to transfer a ferroelectric film, which overlaps with the seed layer, of the ferroelectric layer and the seed layer onto the side of said one surface of the first substrate. The laser beam passes through the second substrate, is reflected by the seed layer, and is absorbed by a second portion of the ferroelectric layer. The second portion does not overlap with the seed layer.

Owner:PANASONIC CORP

Popular searches

Semiconductor/solid-state device details Fluid pressure measurement by electric/magnetic elements Semiconductor/solid-state device manufacturing Piezoelectric/electrostrictive device material selection Fluid speed measurement Flexible microstructural devices Microstructural device manufacture Semiconductor devices Impedence networks Piezoelectric/electrostrictive devices

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com