Patents

Literature

165results about How to "Reduce creep" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

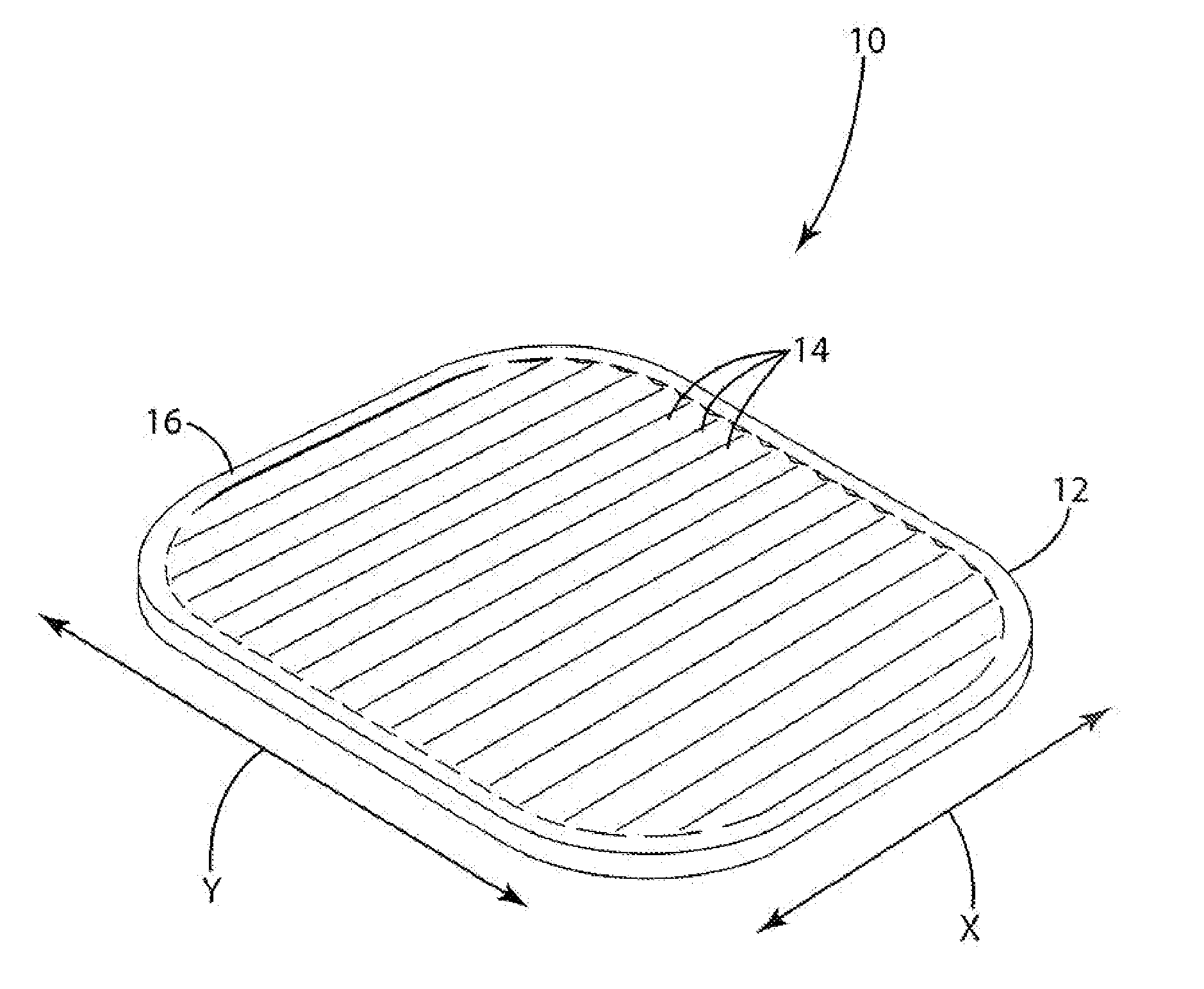

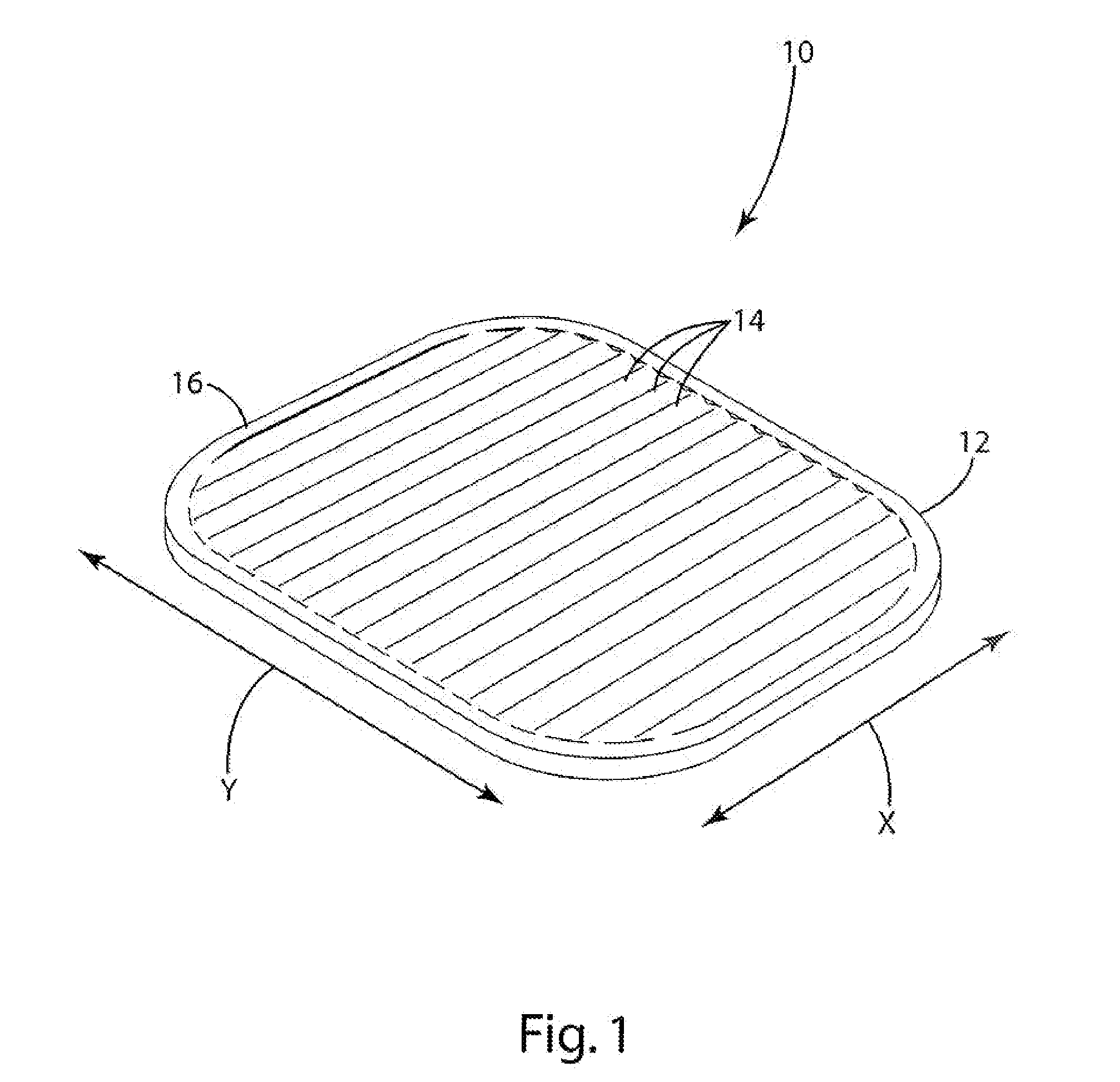

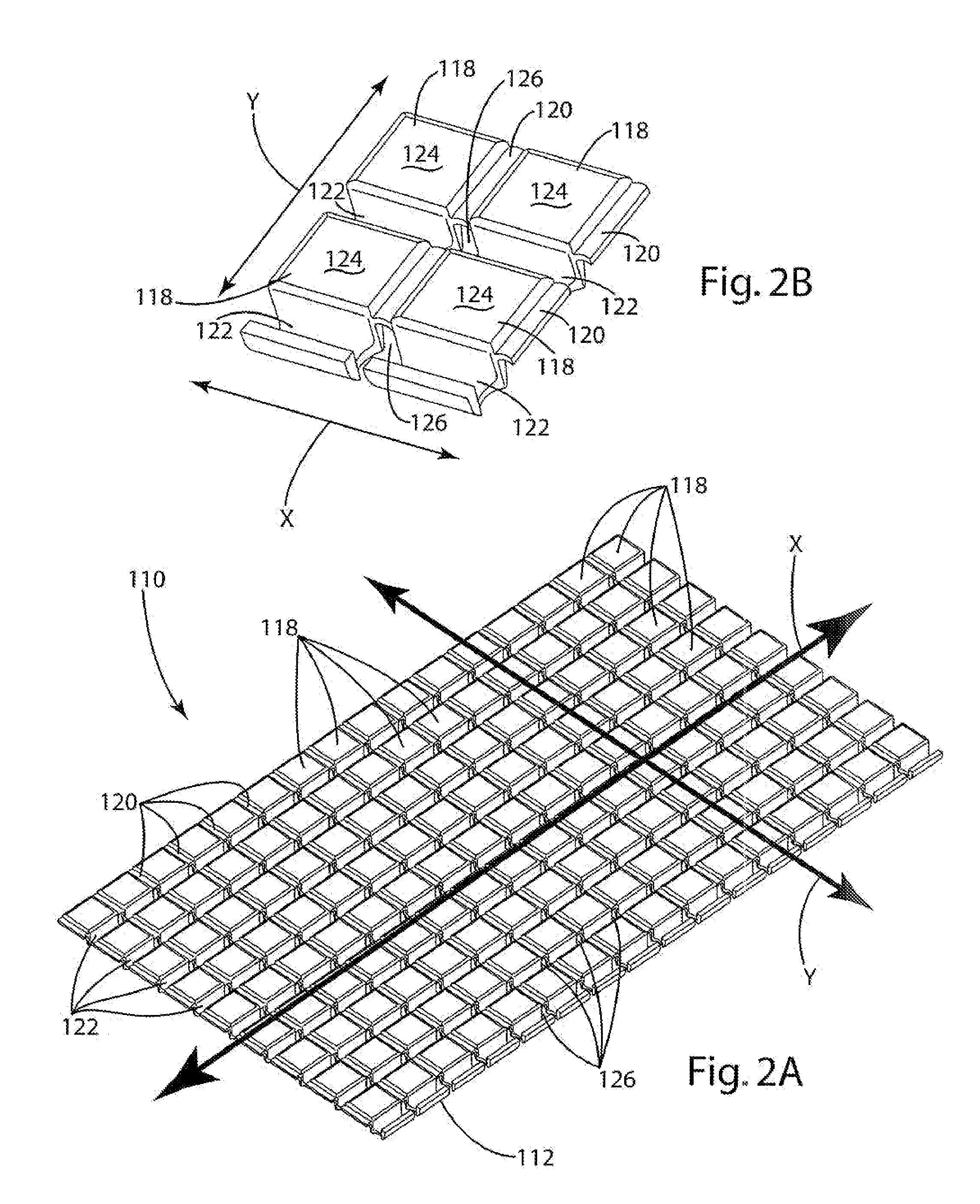

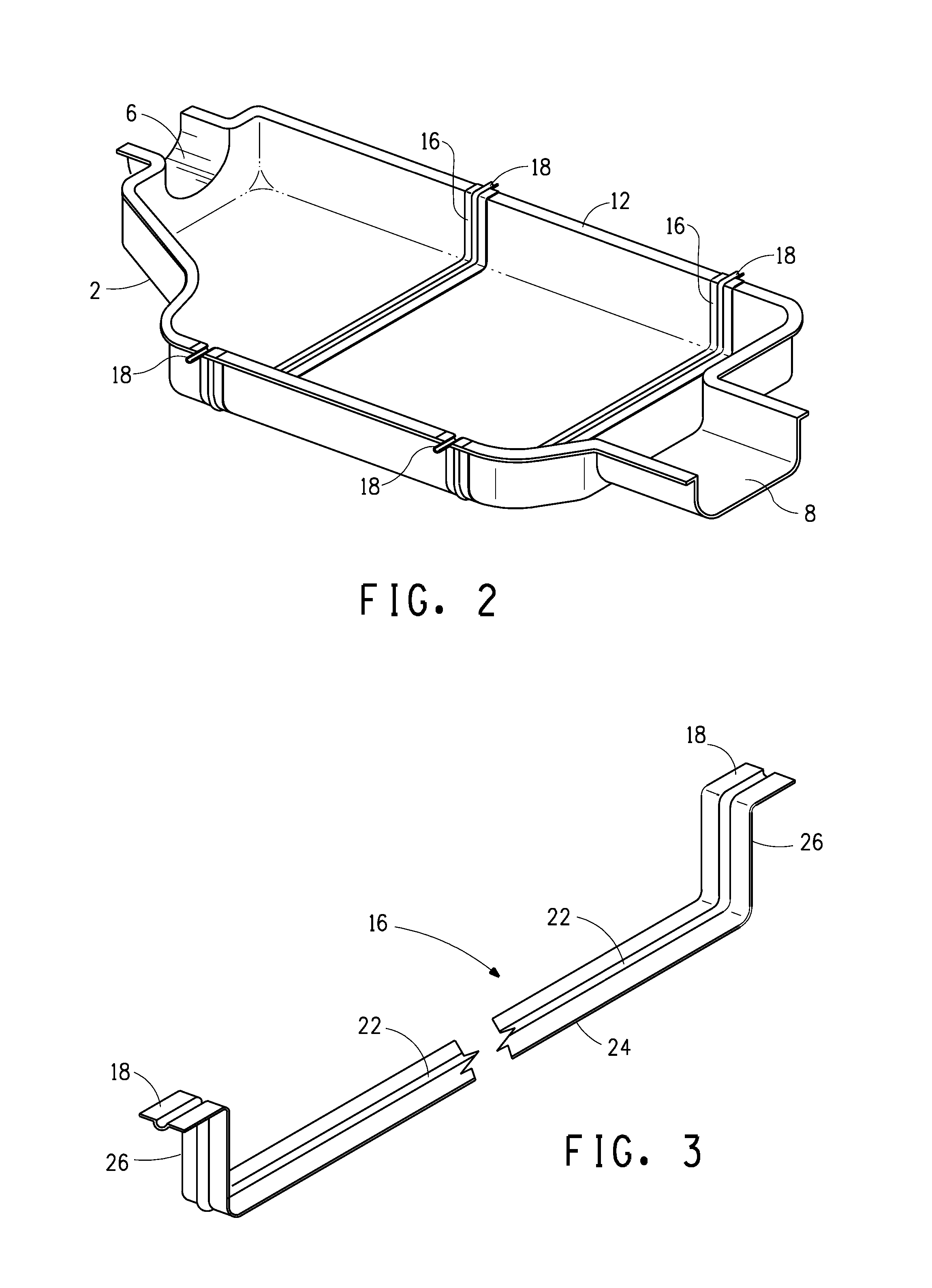

Load bearing surface

An elastomeric load bearing surface with different load support characteristics in different directions. In one embodiment, the surface includes an elastomeric membrane that is oriented in only a single direction, for example, by compression or stretching. In another embodiment, the surface includes mechanical structures, such as connectors and variations in thickness that vary the load support characteristics in different directions. In another embodiment, a surface is both oriented and includes mechanical structures.

Owner:ILLINOIS TOOL WORKS INC

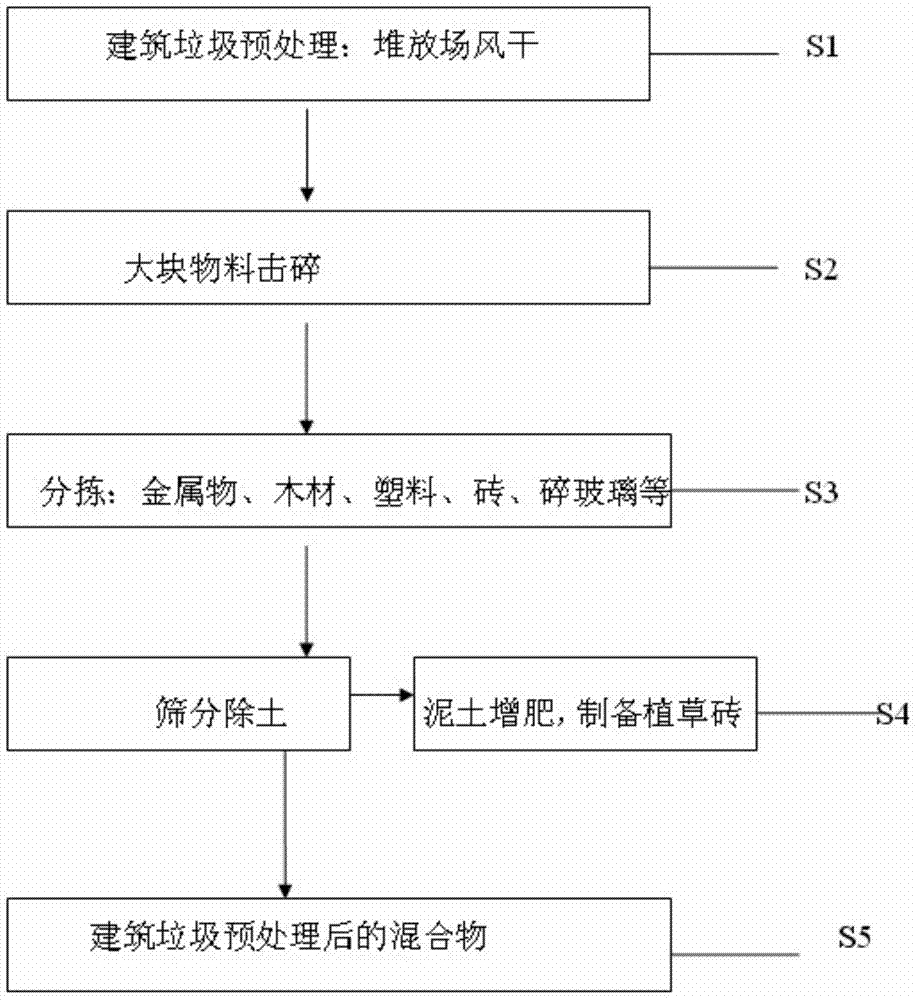

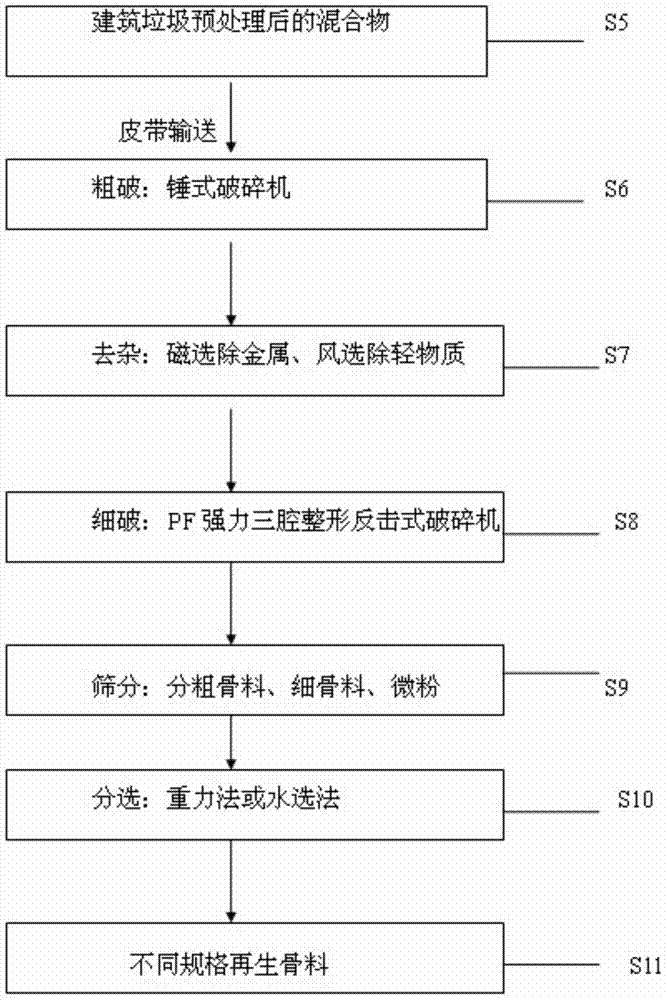

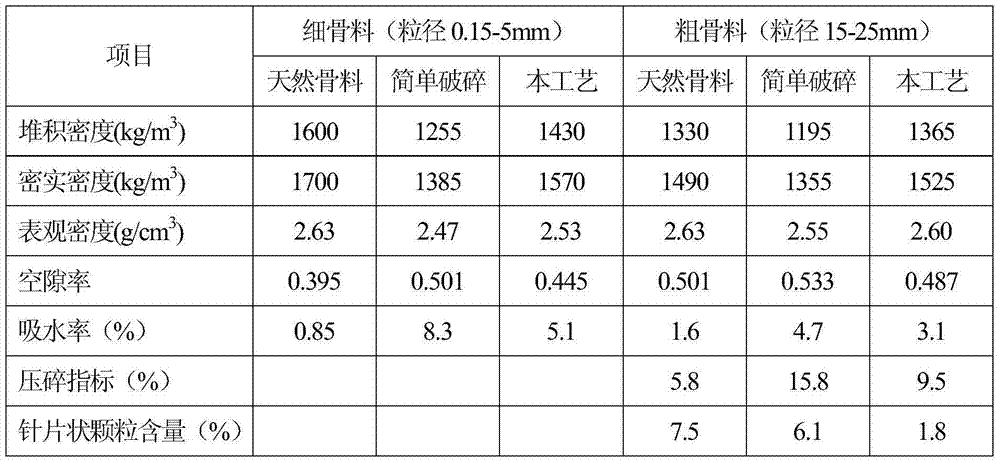

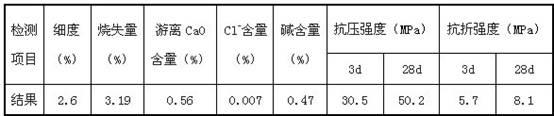

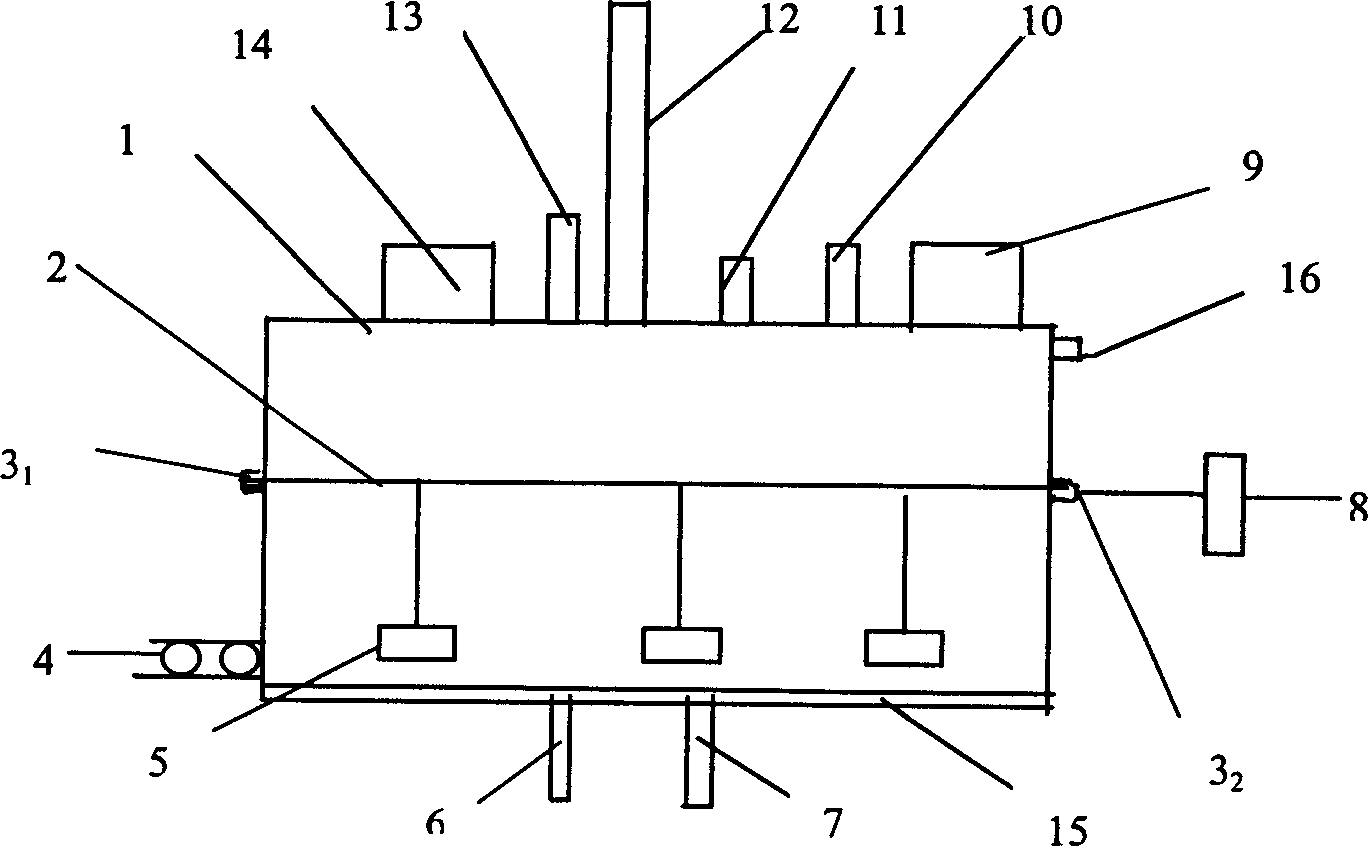

Ecological treatment technology for construction waste

The invention belongs to the field of recycling of construction waste, energy conservation and environment protection, and construction materials, and relates to an ecological treatment technology for construction waste, and particularly relates to the ecological treatment technology for construction waste and a preparation method for regenerated novel construction materials, which can efficiently use the construction waste and does not generate secondary pollution. The ecological treatment technology comprises the following steps of pretreating in a construction waste dump, namely, air drying the construction waste, crushing big blocks, sorting and removing soil through vibrating, adding a fertilizer in the soil to be used for filling grass planting bricks; preparing recycled aggregate, namely, crushing roughly, removing impurities, precisely crushing and simultaneously reinforcing and shaping the recycled aggregate, screening out the recycled aggregate with particle size less than 0.15mm as well as 0.15-5mm, 5-15mm and 15-25mm and micro powder for the secondary time, finally, separating the brick from concrete by a gravitational method or a hydraulic mineral beneficiation method according to different densities of the brick and concrete in the mixed recycled aggregate. Recycling and high value-added utilization of the construction waste are realized, and the ecological treatment technology gets major breakthrough in recycling industry of construction waste.

Owner:DALIAN HONG YUAN GREEN BUILDING MATERIALS

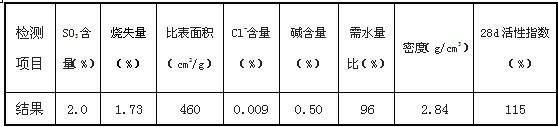

No-shrinkage grouting filler with adjustable performance

The present invention belongs to the field of building material, and is especially one kind of no-shrinkage grouting filler with adjustable performance. The no-shrinkage grouting filler is hydraulic mixture comprising Portland cement and fly ash or silica fume as cementing material, quartzite, water reducing agent, expanding agent, water loss reducing agent, early settling preventing agent and early contract preventing agent. It has high flowability, no settling, no weeping, micro plastic expansion, no shrinkage, no cracking, adjustable performance, and no plastic settling and other excellent performance, and may be applied widely in installing large precise equipment, large area leveling, emergency repair engineering, etc.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

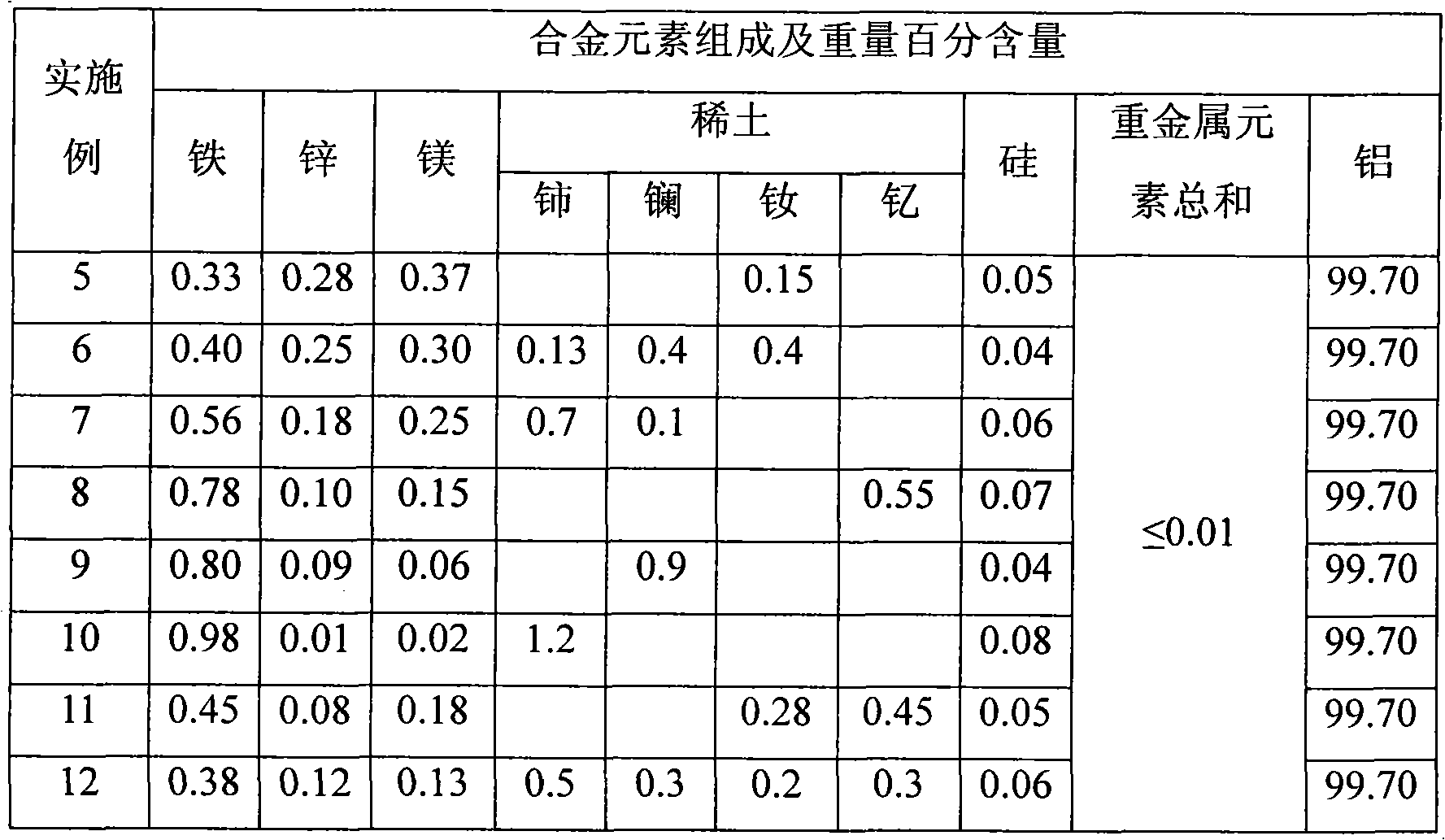

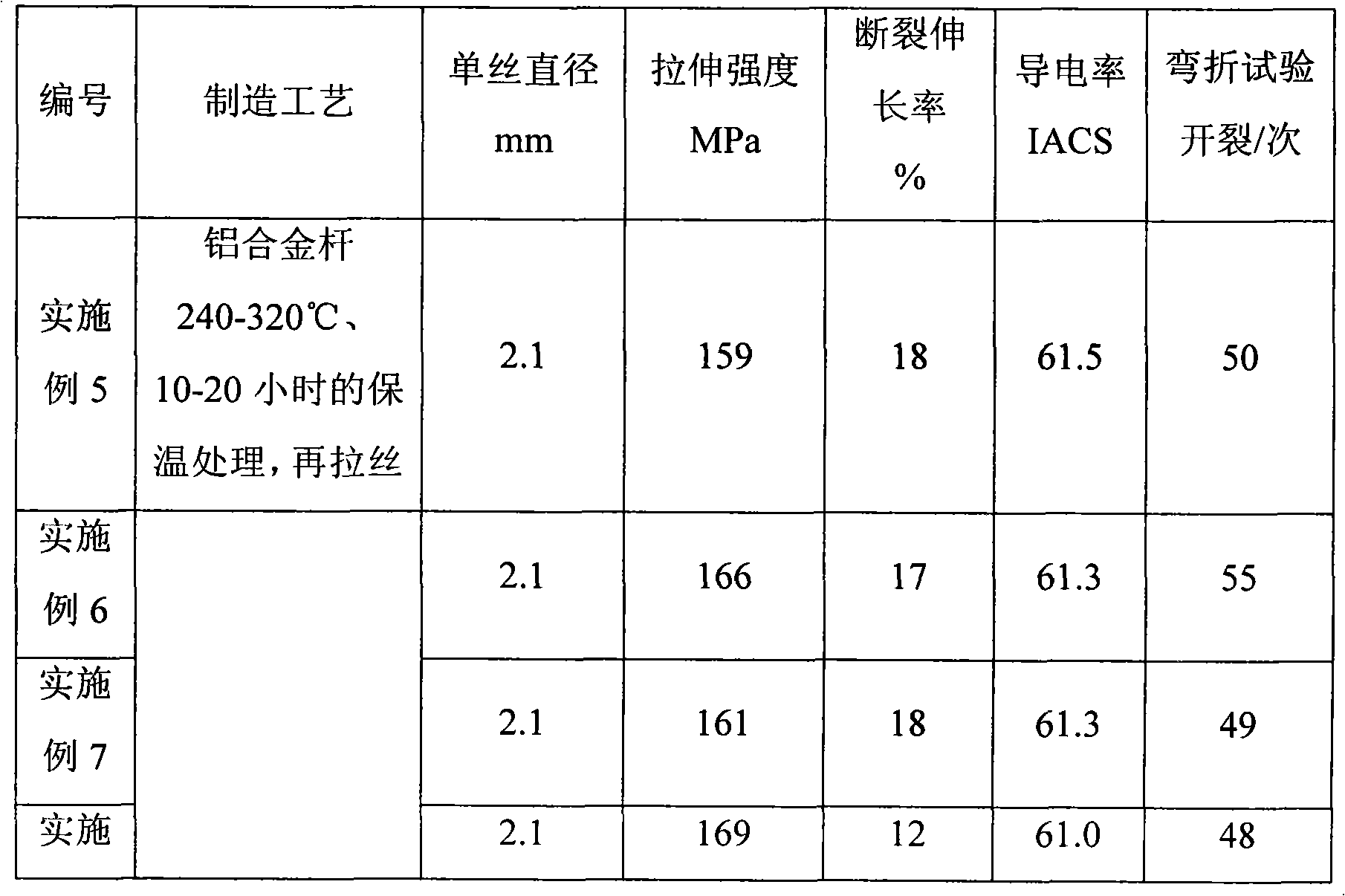

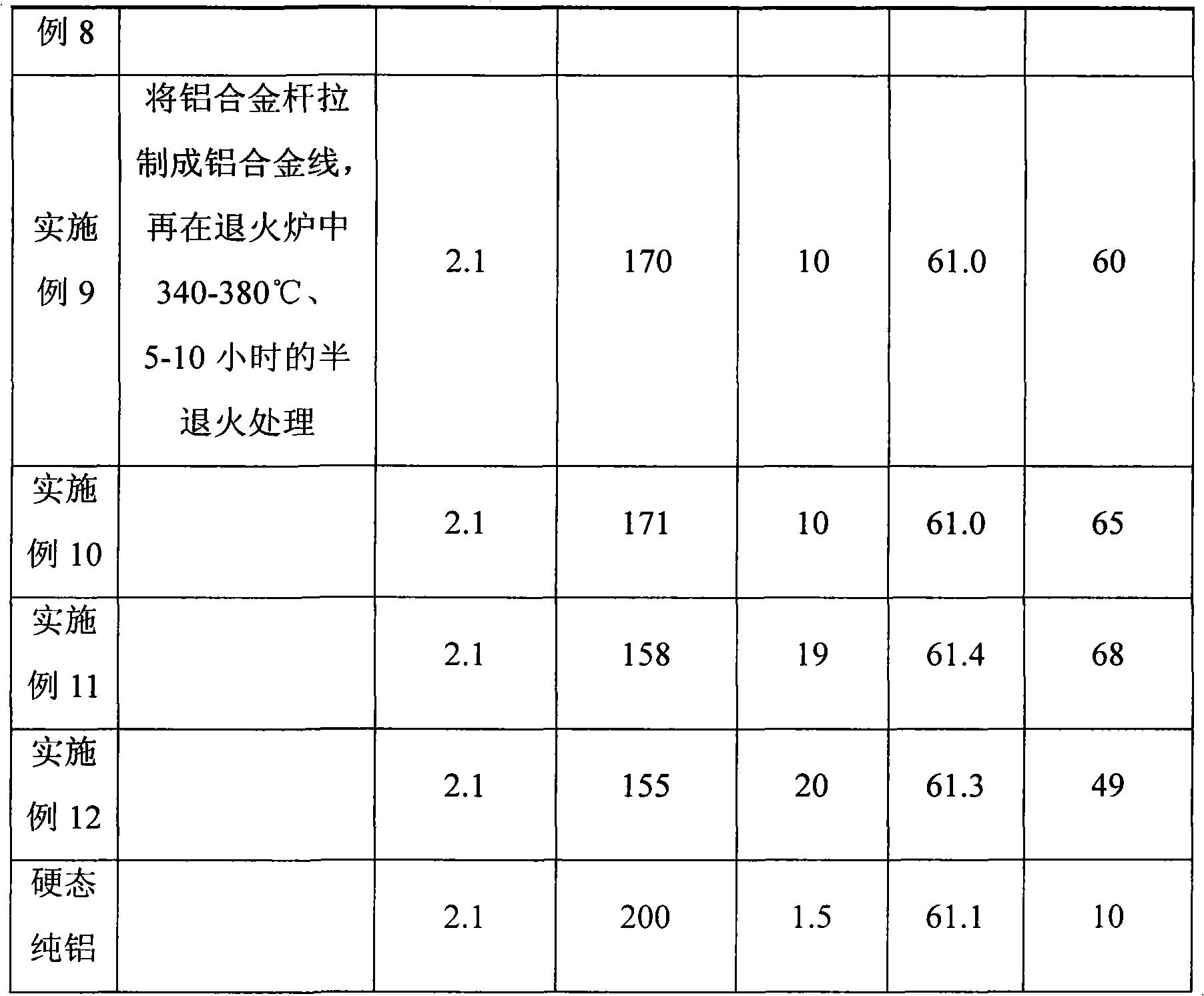

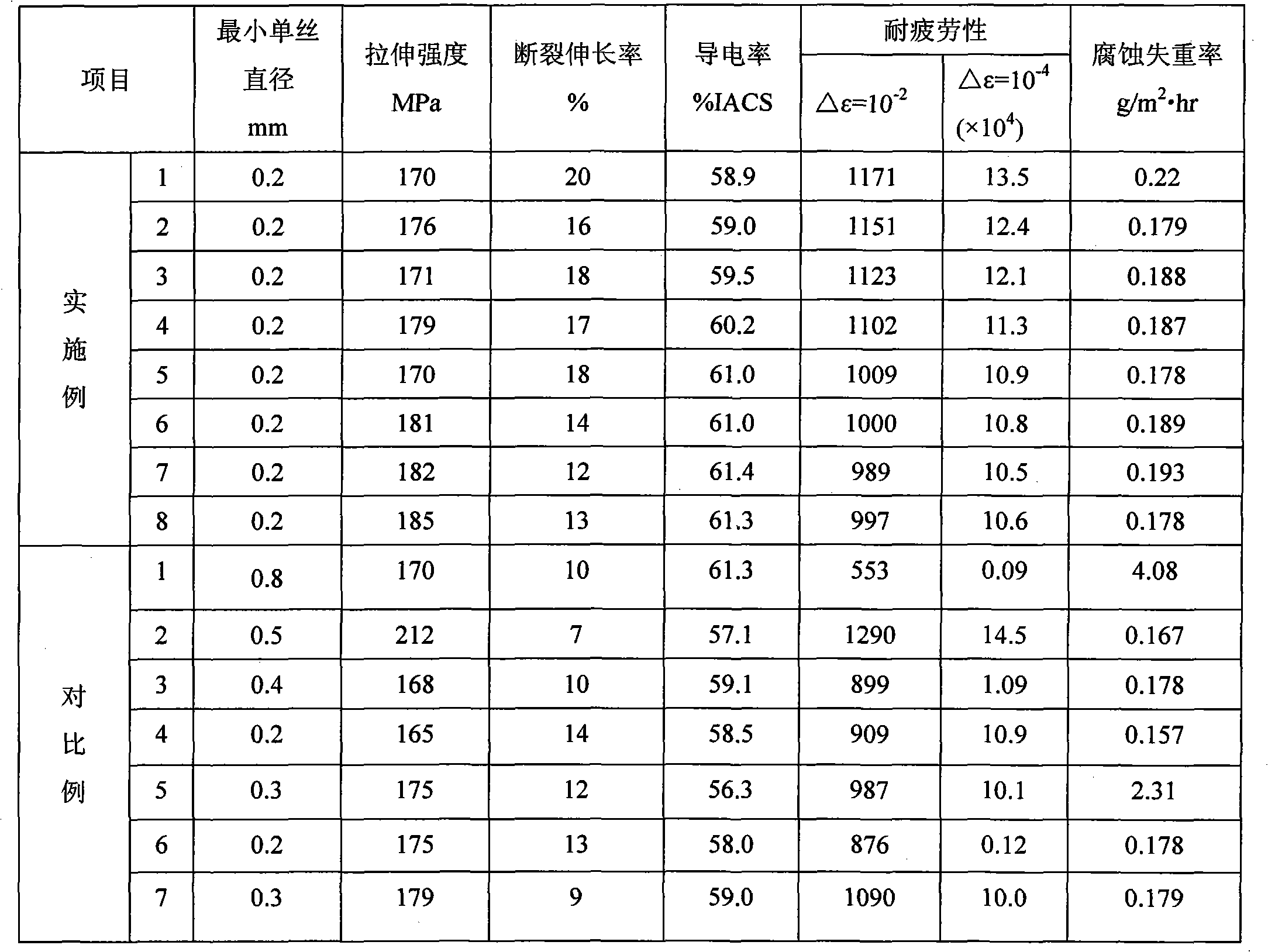

Al-Fe-Zn-Mg rare earth alloy wire and preparation method thereof

InactiveCN101880799AReduce defect densityGood match of strength and toughnessSingle bars/rods/wires/strips conductorsMetal/alloy conductorsAlloy elementRare-earth element

The invention discloses an Al-Fe-Zn-Mg rare earth alloy wire and a preparation method thereof. The aluminum alloy comprises the following elements: 0.3-1.2wt% of Fe, 0.01-0.3wt% of Zn, 0.01-0.4wt% of Mg, 0.1-1.5wt% of rare earth element and the balance of Al and inevitable impurities, wherein the rare earth element is composed of one or more of cerium, lanthanum, neodymium and yttrium. The preparation method of the aluminum alloy wire comprises the following steps: preparing an aluminum alloy rod through smelting, casting and rolling, performing insulation treatment in a heat holding cover at 240-320 DEG C for 10-20 hours, wiredrawing and extruding insulating material on the wire; or preparing an aluminum alloy rod through smelting, casting and rolling, drawing the aluminum alloy rod to prepare the aluminum alloy wire, performing semi-annealing treatment in an annealing furnace at 340-380 DEG C for 5-10 hours, and finally extruding insulating material on the wire. The aluminum alloy wire prepared by the method of the invention has excellent electrical property, mechanical property and corrosion resistance and can be used in the wire and cable conductors.

Owner:ANHUI JOY SENSE CABLE

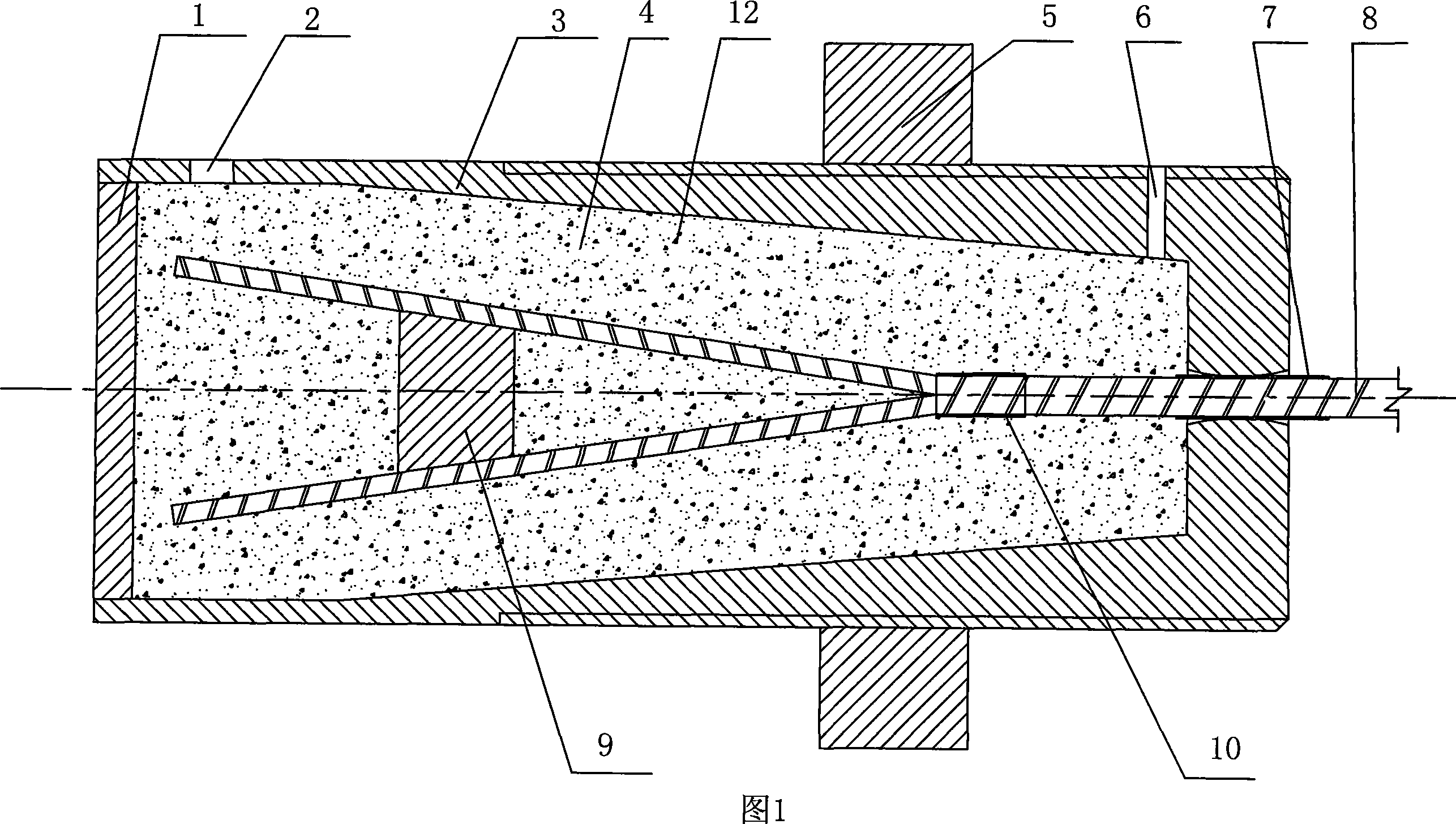

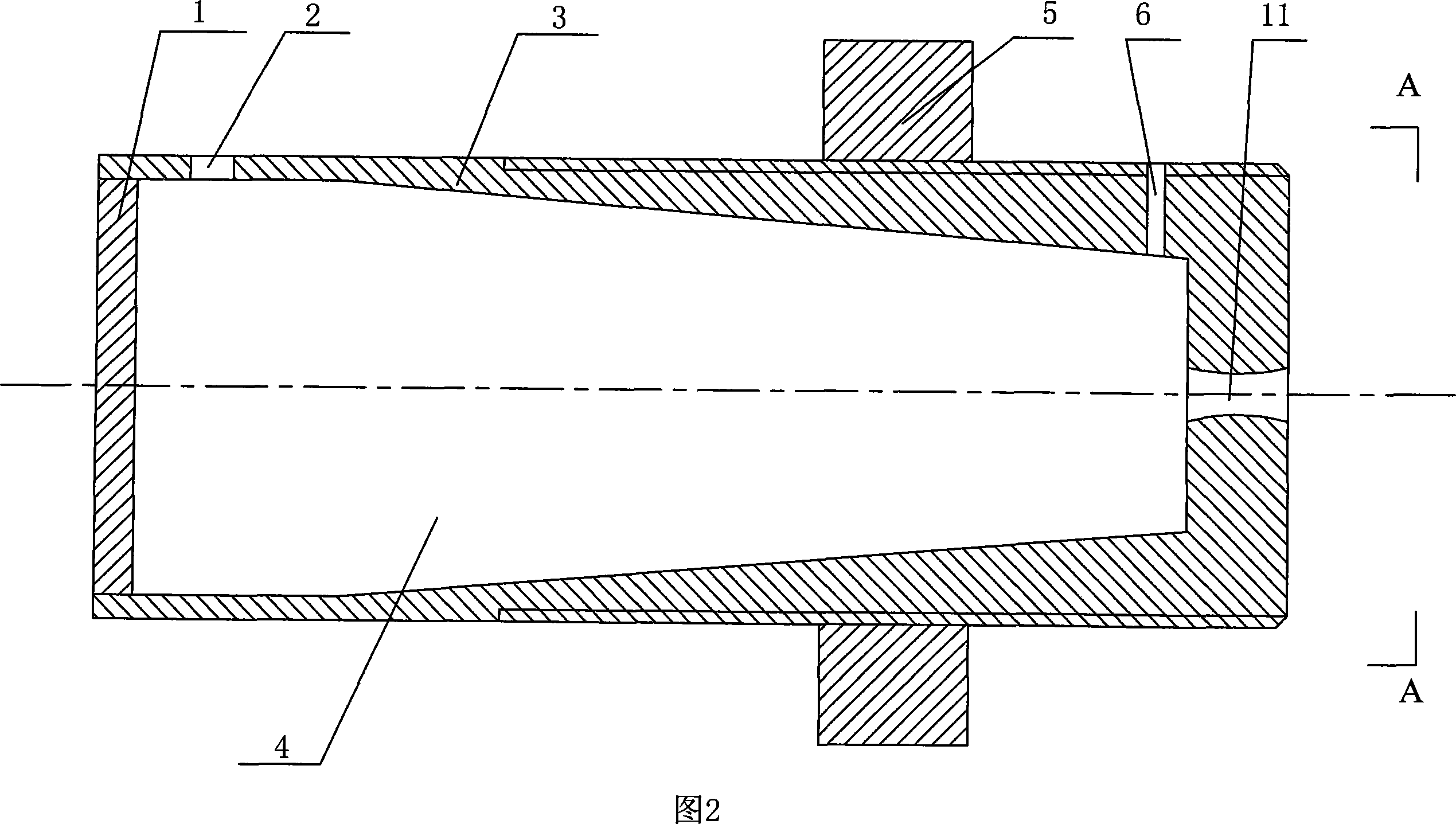

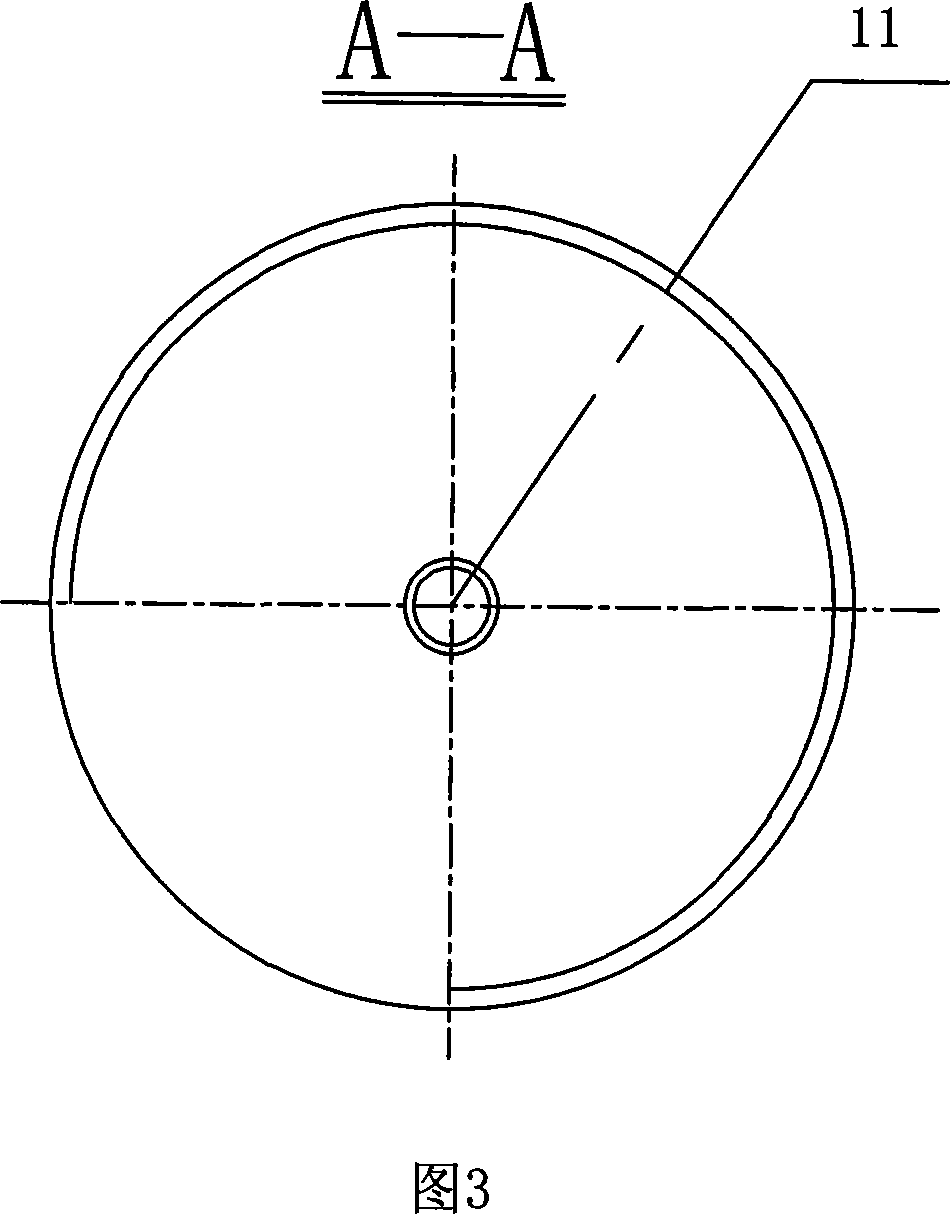

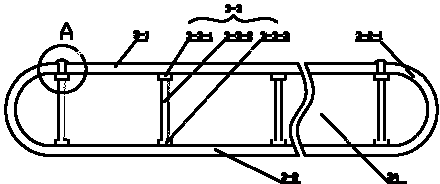

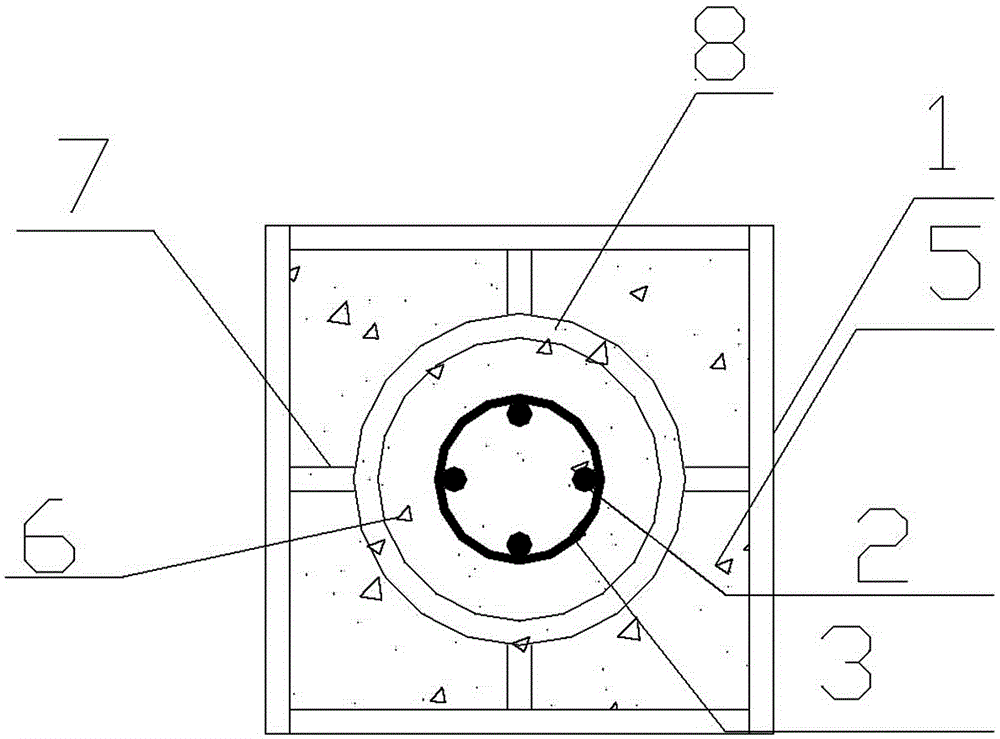

Bond type anchorage and anchoring method for anchoring fibre reinforced plastic reinforcement or bracing cable

ActiveCN101117838AHigh strengthHigh elastic modulusBuilding reinforcementsEngineeringFibre-reinforced plastic

The present invention relates to an adhesive anchoring unit and an anchoring method for anchoring fiber reinforcement plastic bar or cable, an end cover is arranged at one end of the anchoring unit and a sleeve with a locating hole is arranged at the other end of the anchoring unit. An internal cone chamber is arranged in the sleeve, and a nut is arranged surrounding the sleeve provided with a mortar filling hole and a ventilation hole. The fiber reinforcement plastic bar or cable passes through the locating hole and one end in the internal cone chamber was cut into two halves, which are inserted with a wedge to become a wedge form. A starting section of the half of one end of the bar or cable is coated with a retaining ring and the section passing through the locating hole is coated with a thin wall aluminum sleeve tube and active powder concrete is filled in the internal cone chamber of the sleeve. The method is described as follows: after the bar or cable shaft passes through the sleeve of the anchoring unit, a pretension is required on the sleeve, and the active powder concrete is added into the sleeve. The present invention improves anchoring performances of the adhesive media and the FRP bar, therefore, the anchoring length is reduced, the structure is simple, the use is convenient, the present invention is safe and reliable, the cost is low and the PRC manufacturing and maintenance is easy.

Owner:HUNAN UNIV

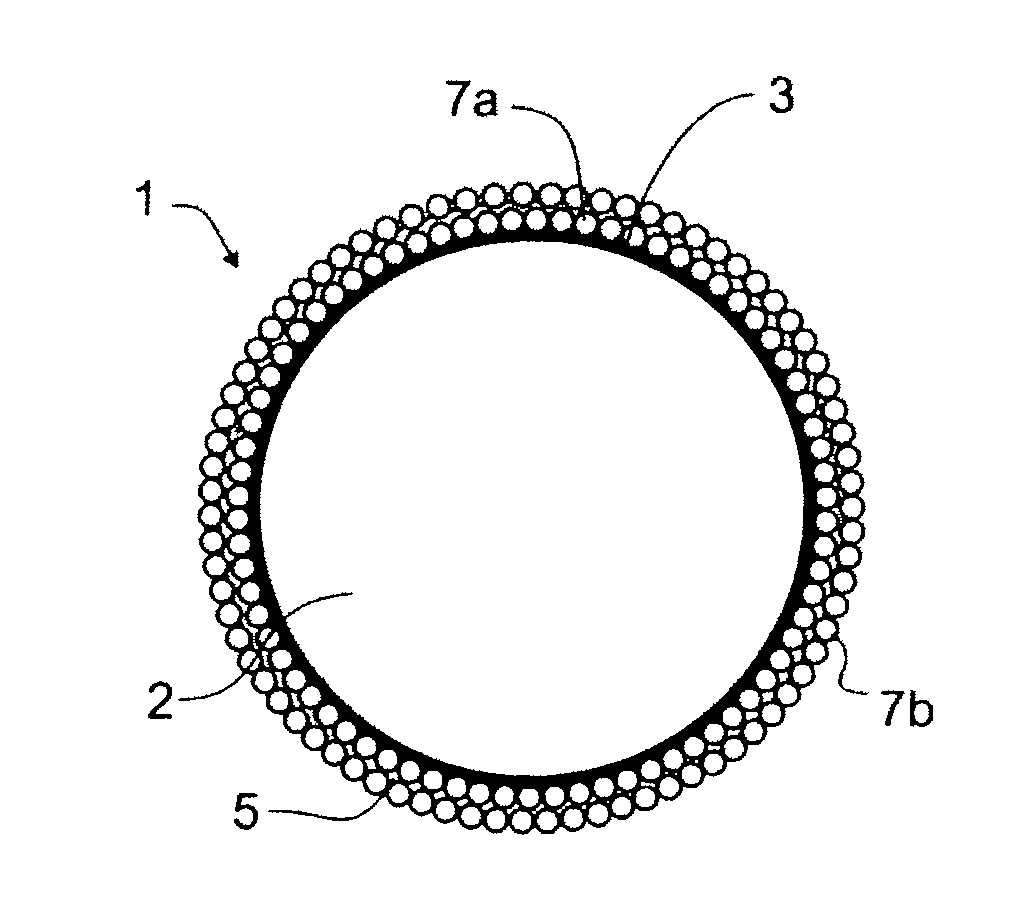

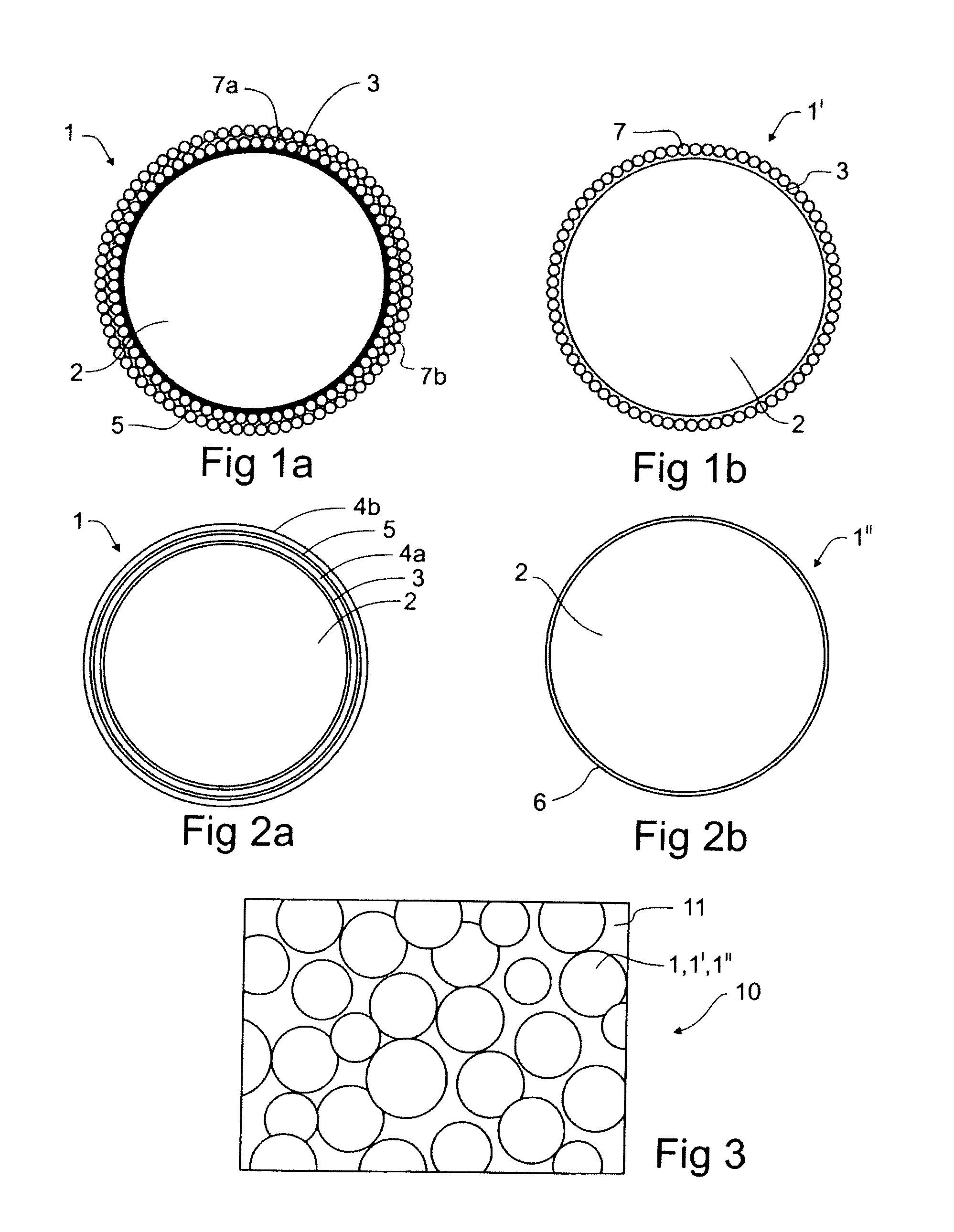

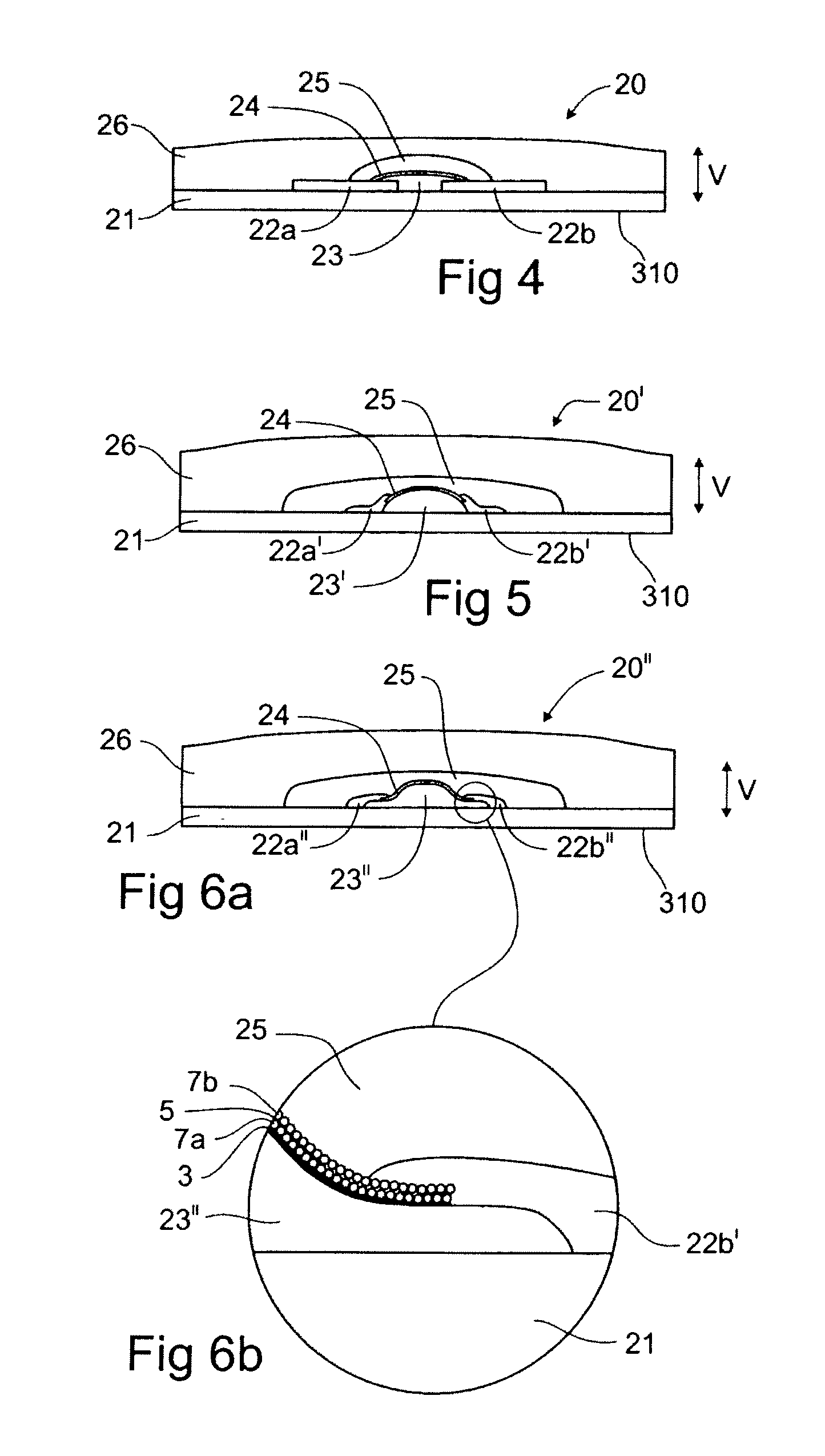

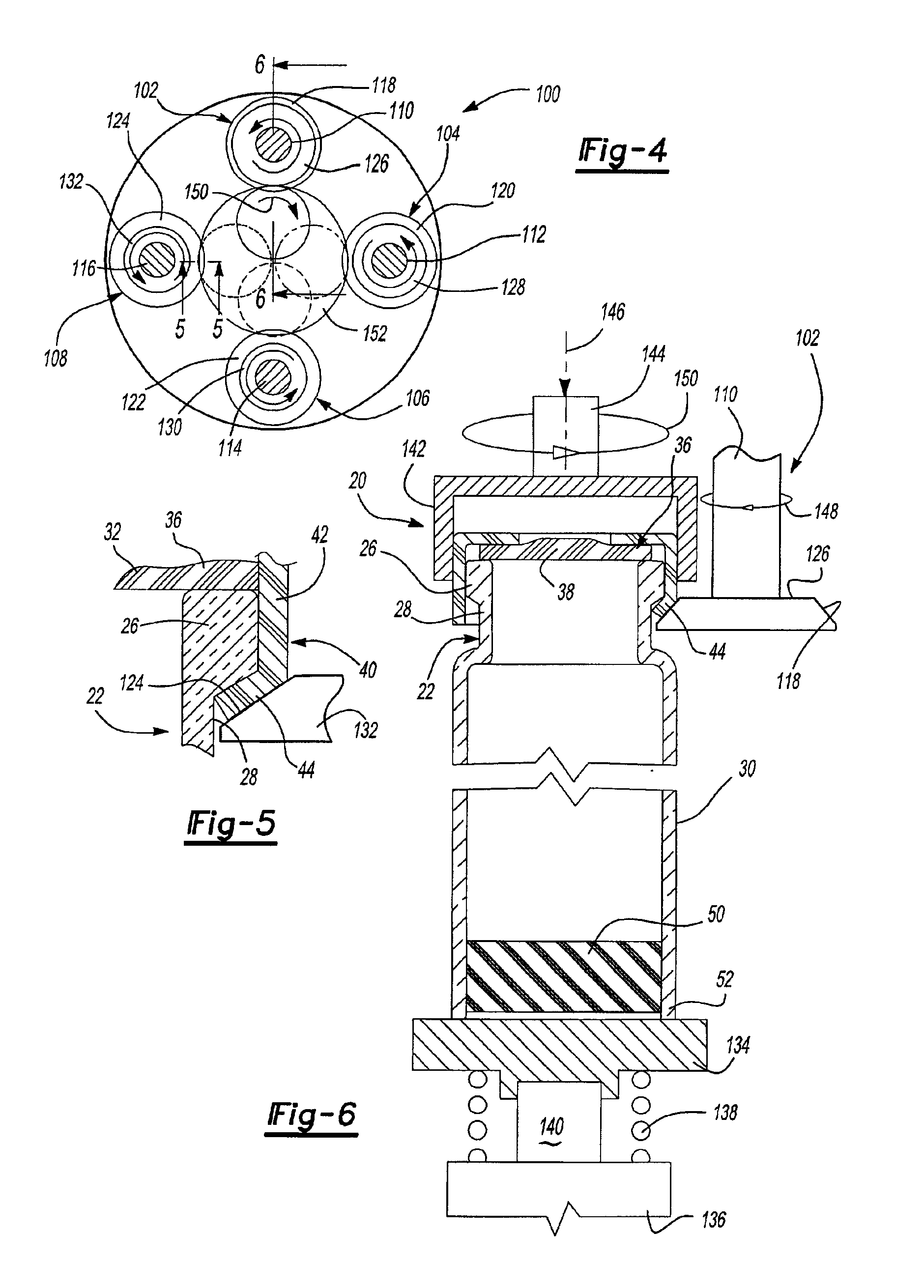

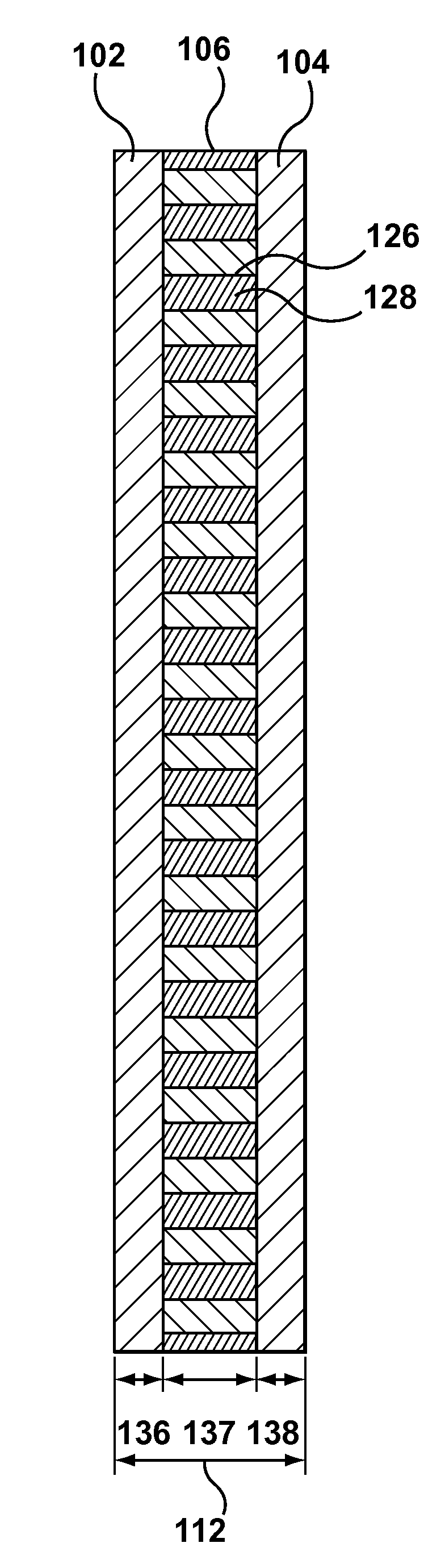

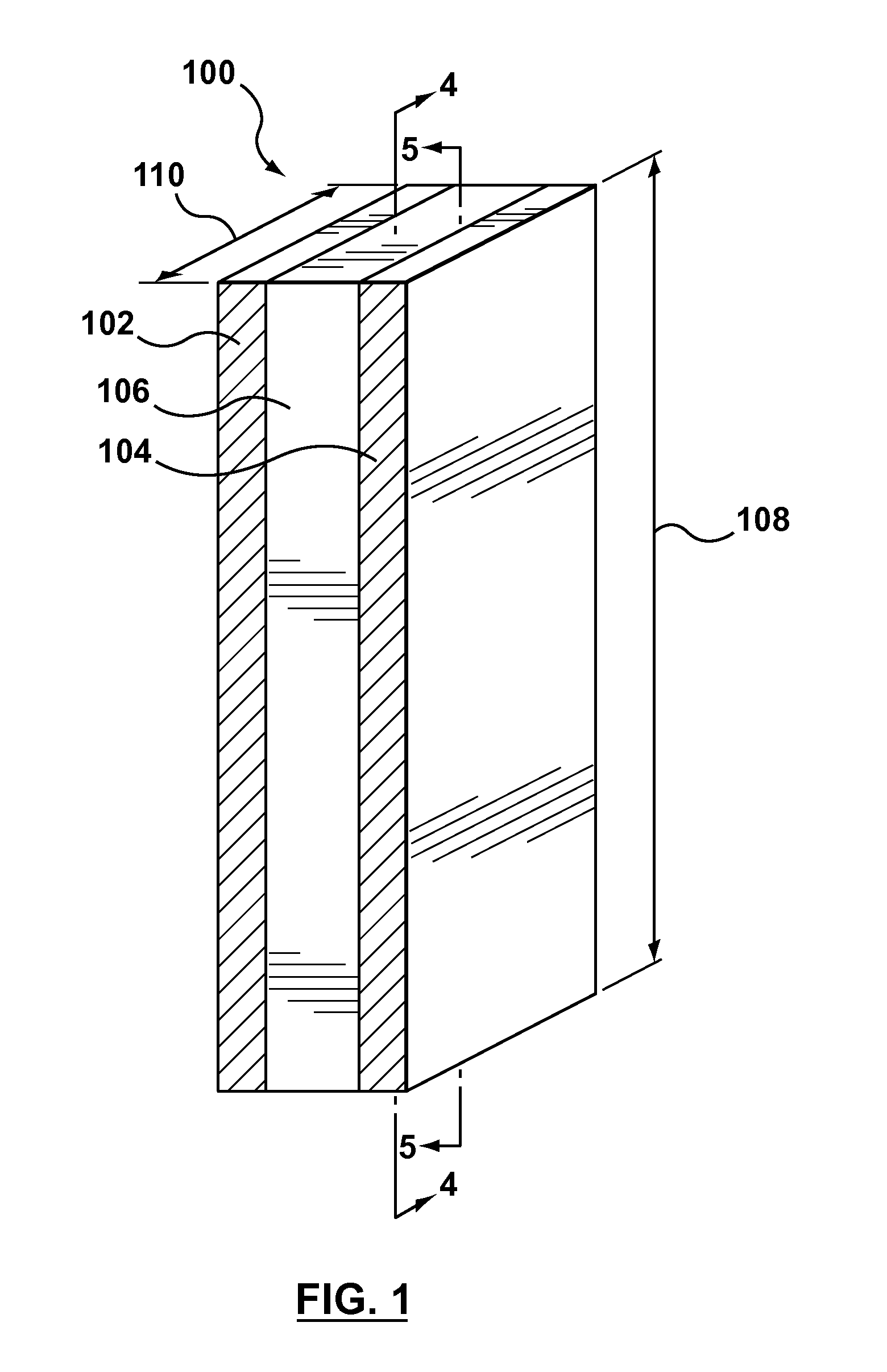

Elastomeric particle having an electrically conducting surface, a pressure sensor comprising said particles, a method for producing said sensor and a sensor system comprising said sensors

ActiveUS20100130889A1Reduce creepReduce hysteresisPneumatic massageFluid pressure measurement using ohmic-resistance variationElastomerSensor cluster

An elastomeric particle (1, 1, 1″) comprises a non-conducting elastomeric body (2) having an electrically conducting surface (4a, 4b, 6). Pressure sensor elements (20, 20′, 20″; 30, 30′, 30″, 30′″) comprising such elastomeric particles are disclosed, as well as sensor clusters (50″, 50′″, 50IV, 50V, 50VI, 50VII, 70) comprising such sensor elements. There is also disclosed a pressure sensor element (40, 40′, 40″, 40′″, 40IV, 40V, 40VI, 40VII), comprising a resistive element (44, 44′, 44″) providing a conduction path, a first electrode (42a, 42a-1, 42a-2, 42a-3, 42a-4, 42a-5, 42a-6), connected to the resistive element, a second electrode (42b, 42b′), which in a quiescent state is spaced from said first electrode, wherein the second electrode, when the pressure sensor element is subjected to a pressure, is arranged to contact said first electrode or said resistive element. Systems comprising such sensor elements and sensor clusters are disclosed, as well as methods of their fabrication.

Owner:SWELLING SOLUTIONS

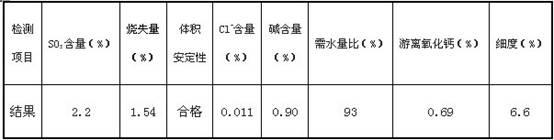

Ultra-high-performance concrete including regenerated fine aggregates and application method thereof

The invention discloses ultra-high-performance concrete including regenerated fine aggregates and an application method thereof. The ultra-high-performance concrete comprises the following raw materials: ordinary silicate cement, silica fume, quartz powder, fine aggregates and a water reducing agent with a mass ratio of 1:0.25-0.35:0.35-0.40:1.0-1.2:0.02-0.03:0.20-0.25, and the volumetric fraction of steel fiber is 0.5-3%. The fine aggregate comprises the following components in percentage by weight: 30-100% of regenerated fine aggregates and 0-70% of natural sand, wherein the regenerated fine aggregates belong to quasi-regenerated fine aggregates, with a particle range of 0.15-1.18mm or 0.15-4.75mm. The natural sand is replaced with regenerated fine aggregates, and thus exploitation of the natural sand can be reduced. The regenerated fine aggregates belong to solid waste, and are abundant in source, so that the regenerated fine aggregate ultra-high-performance concrete has good economic, social and environment-friendly benefits, and is applicable to large-scale popularization and application.

Owner:FUZHOU UNIVERSITY

Concrete composition containing ultra-fine carbonate rock powder and preparation method thereof

The invention discloses a concrete composition with hyperfine carbonate rock powder and allocating method, which comprises the following parts: polyvalent powder, additive, rough aggregate, fine aggregate and water, wherein the scale of polyvalent powder in per cubic meter concrete is 300kg / m3-550kg / m3, which contains 70kg / m3-150kg / m3 hyperfine carbonate rock powder, 20%-100% cement and mineral material.

Owner:北京恒坤混凝土有限公司 +2

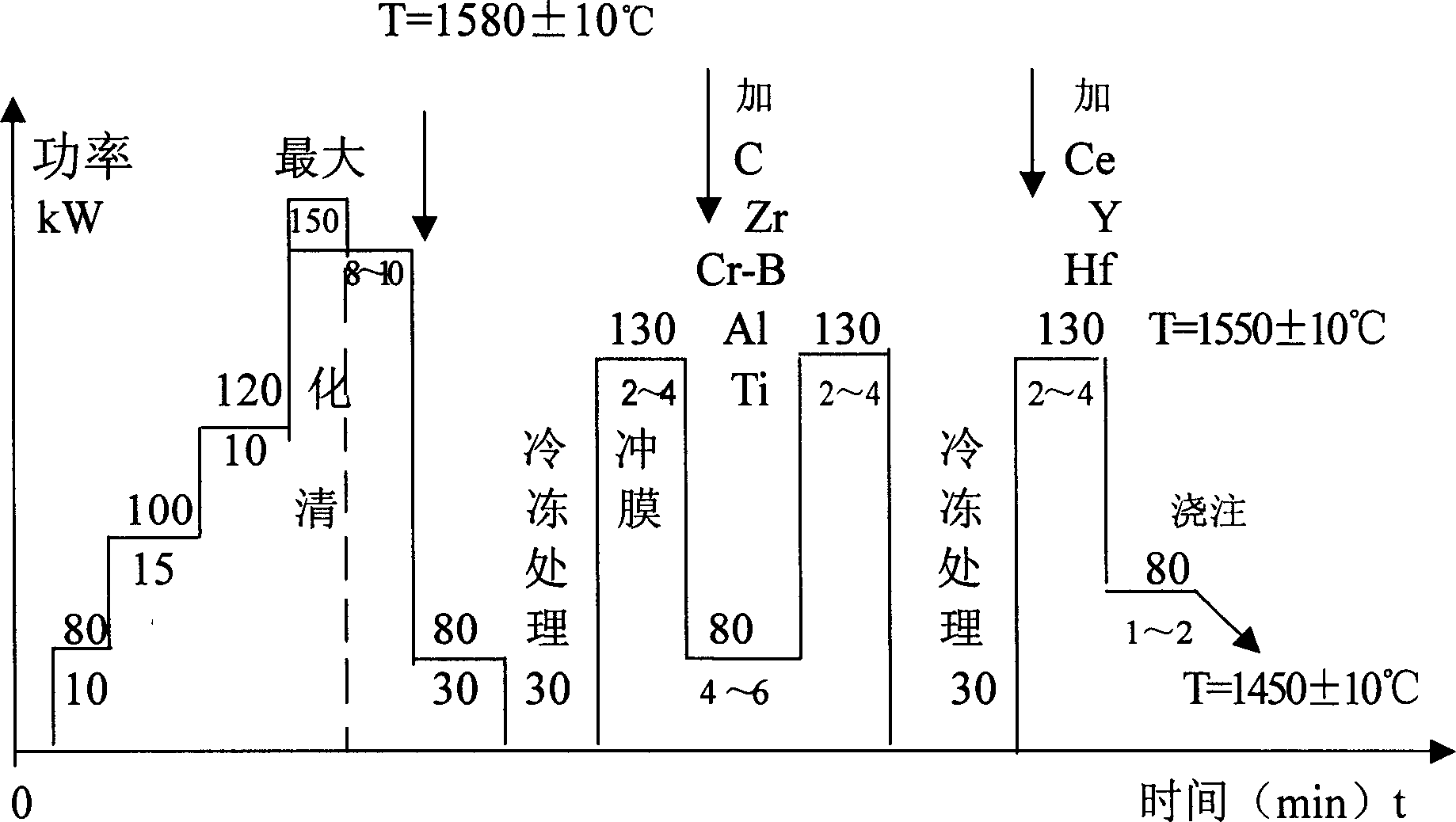

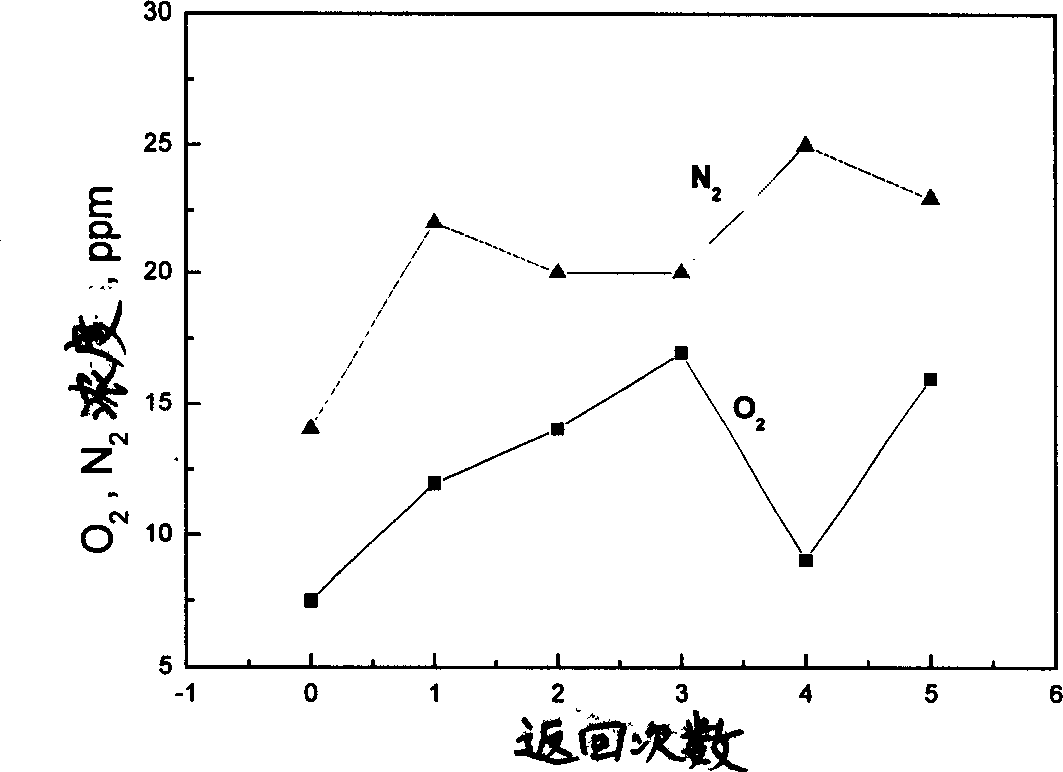

Vacuum smelting technology of hafnium containing nickel base casting high temperature alloy K488 reverse material alloy

InactiveCN1786228ADecreased tensile strength at room temperatureLower yield strengthRare-earth elementChemical composition

The invention relates to hafnium containing nickel base casting high temperature alloy K488 reverts alloy vacuum melting technique. It includes the following steps: melting reverts; pouring after melting, fining, cooling; using alumina ceramics filter screen to do the first filtration for alloy solution while pouring; adjusting the alloy solution component; mixing in proportion of 50% reverts and 50% fresh material; doing the first alloying treatment after melting, fining, cooling; adding dope material C, Cr-B inter-alloy, Al, Ti, Zr; doing the second alloying treatment after cooling; adding Ce, Y, Hf; and using alumina ceramics filter screen to do the second filtration for alloy solution while pouring to gain product. The technique adopts adding rare earth element method to purify reverting alloy. After many times returning melting, all of the alloy capability, chemical component, and impurity content can reach technical condition demand Q / 3B 1376-2005. The N content is far lower than 100ppm.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

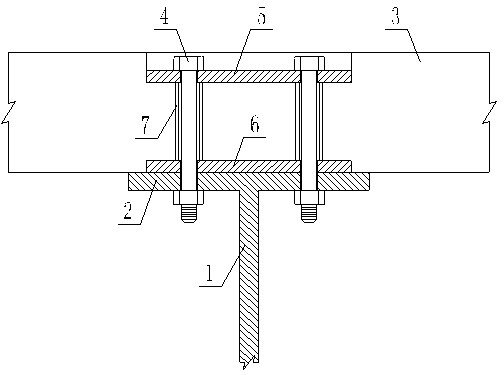

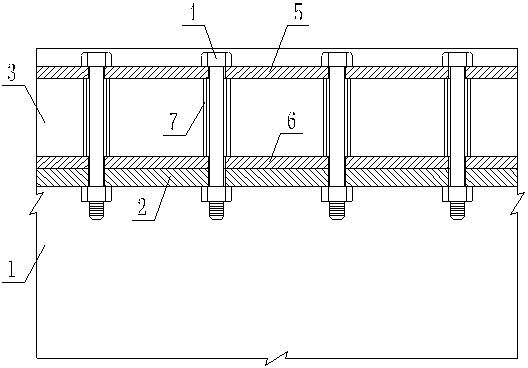

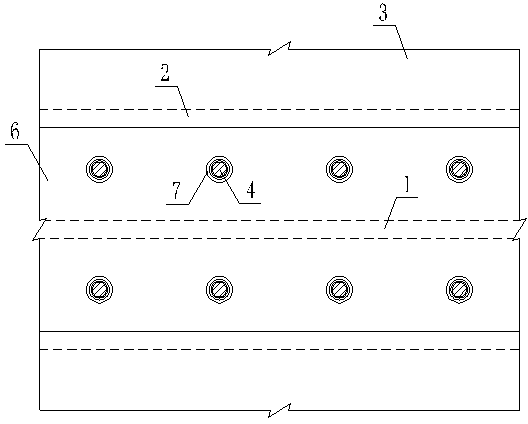

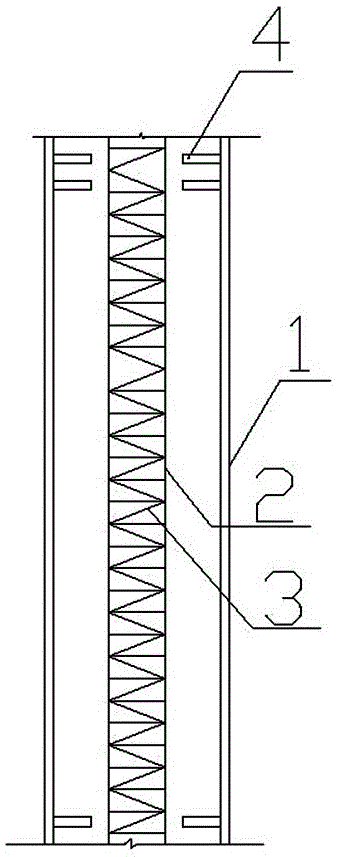

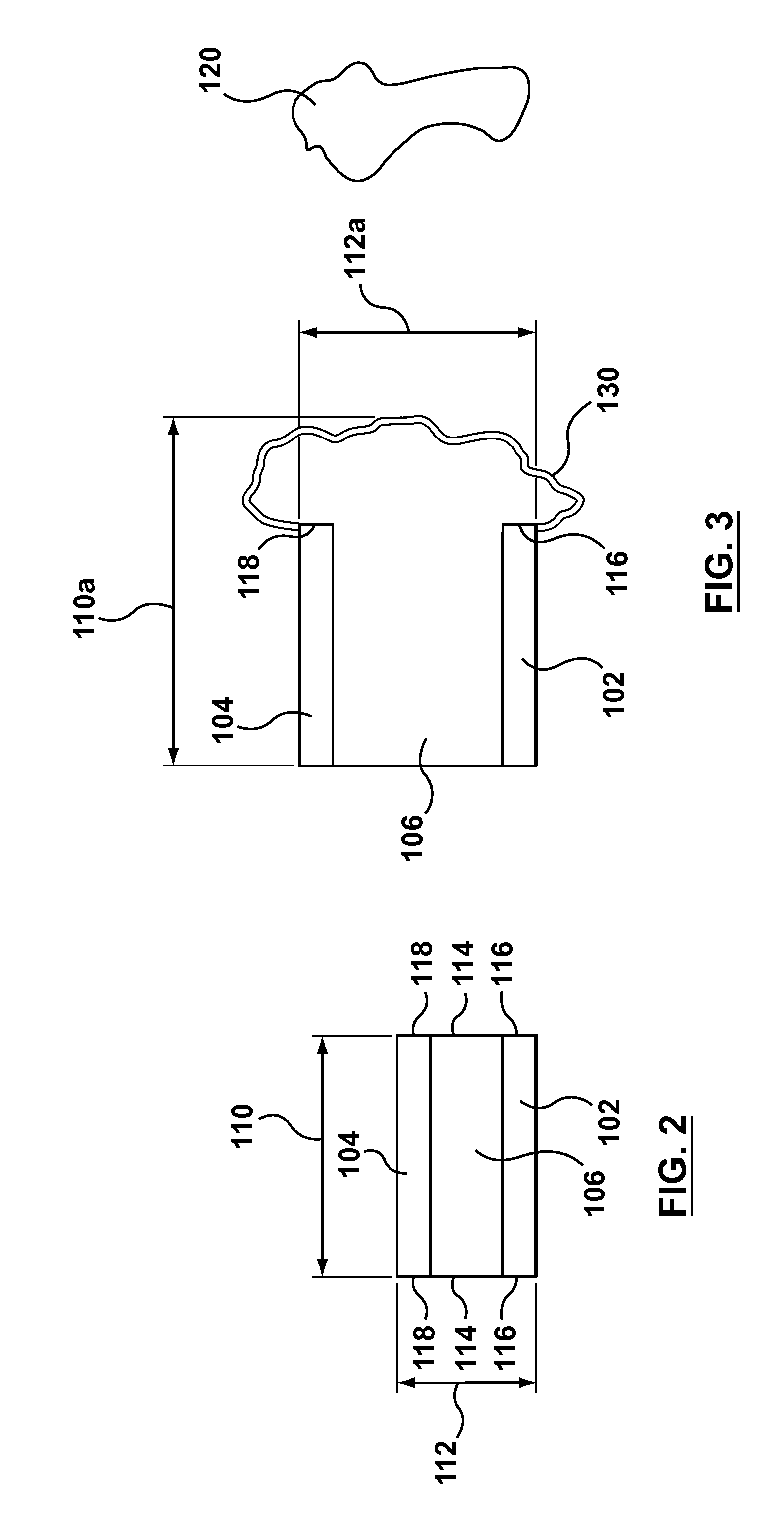

High-strength bolt shear key structure and constructing method thereof

InactiveCN103924674ARelieve pressureReduce creepBuilding material handlingPrecast concreteShear force

The invention discloses a high-strength bolt shear key structure and a constructing method of the high-strength bolt shear key structure. The high-strength bolt shear key structure comprises a steel beam composed of steel beam web plates and steel beam flange plates, a precast concrete plate, high-strength bolts and a connecting part formed by an upper cushion plate, a lower cushion plate and a supporting steel pipe, wherein the upper end and the lower end of the supporting steel pipe abut against and are fixed to the upper cushion plate and the lower cushion plate respectively, and the connecting part is cast in the precast concrete plate. The method includes the steps that the steel beam web plates and the steel beam flange plates are manufactured into the I-beam-type steel beam, meanwhile, the precast concrete plate is manufactured, the connecting part formed by the upper cushion plate, the lower cushion plate and the supporting steel pipe are cast in the designed position of the precast concrete plate, and the supporting steel pipe is clamped between the upper cushion plate and the lower cushion plate; the steel beam is paved with the precast concrete plate, and the supporting steel pipe of the connecting part serves as a formwork for hole drilling; the precast concrete plate and the steel beam flange plates are connected through bolts to be in an attached state, and the precast concrete plate and the flange plates can be connected through clamping force of the high-strength bolts.

Owner:SOUTHEAST UNIV

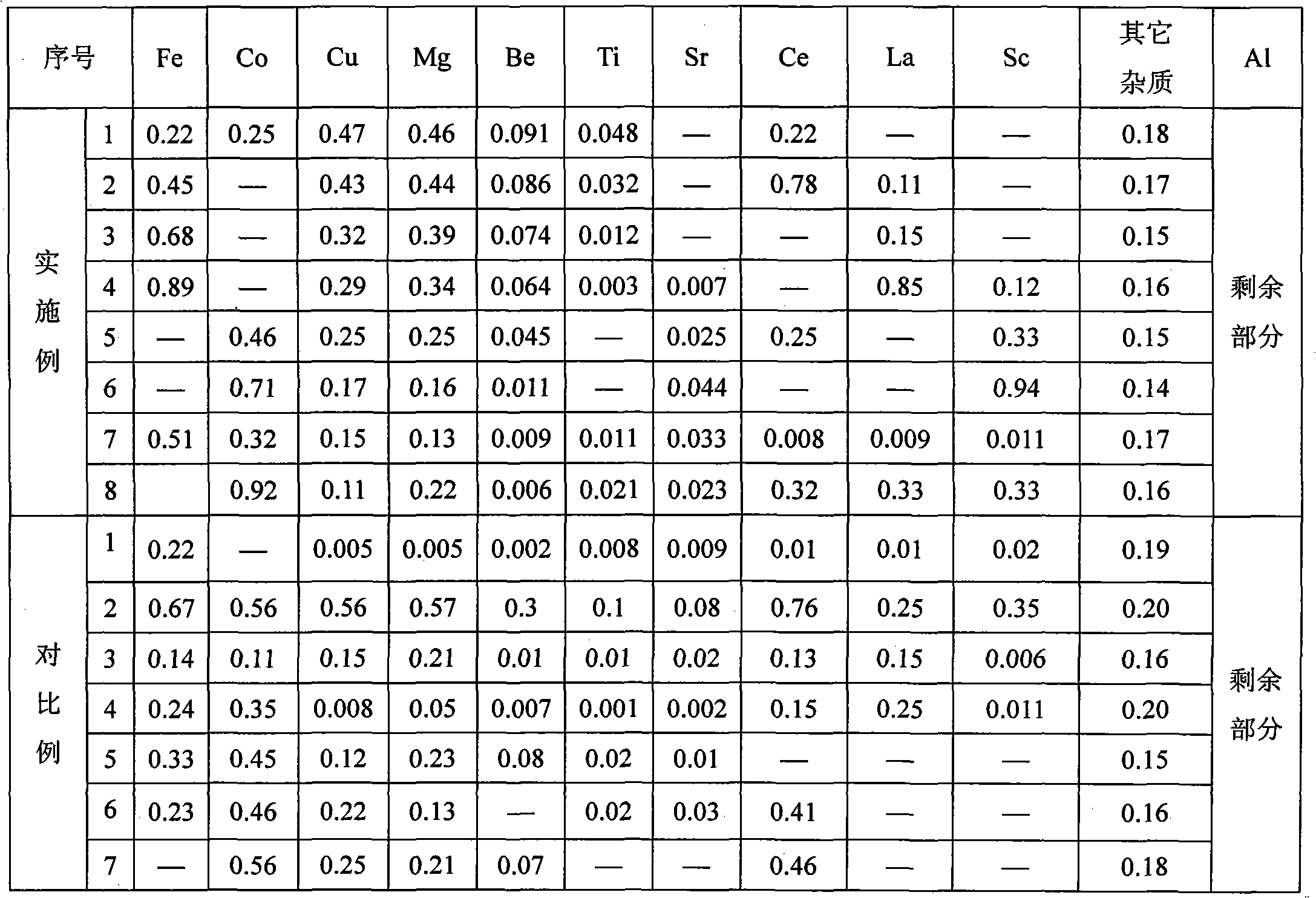

Conductor wire core aluminum alloy for welding machine cable and making method thereof

ActiveCN101921932AConductivity has little effectHigh tensile strengthMetal/alloy conductorsRare earthMaterials science

The invention discloses a conductor wire core aluminum alloy for a welding machine cable and a making method thereof. A conductor wire core is made of aluminum alloy materials. The aluminum alloy comprises the following compositions: 0.4-1.0wt percent of Fe or Co, 0.1-0.5wt percent of Cu, 0.1-0.5wt percent of Mg, 0.05-0.1wt percent of Be and 0.05-0.1wt percent of rare earth. An aluminum alloy wire harness is obtained by carrying out smelting, linecasting, rolling, intermediate annealing, drawing, bunch stranding and annealing on the alloy. The aluminum alloy wire core has the advantages of better conductivity, anti-fatigue performance, flexibility, bending performance and corrosion resistance and is suitable for the conductor wire core of the welding machine cable.

Owner:ANHUI JOY SENSE CABLE

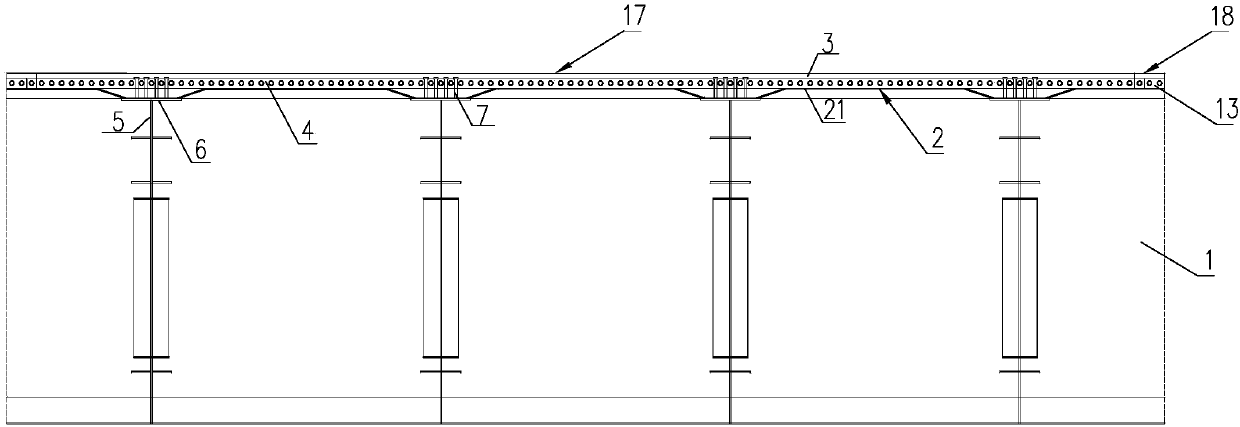

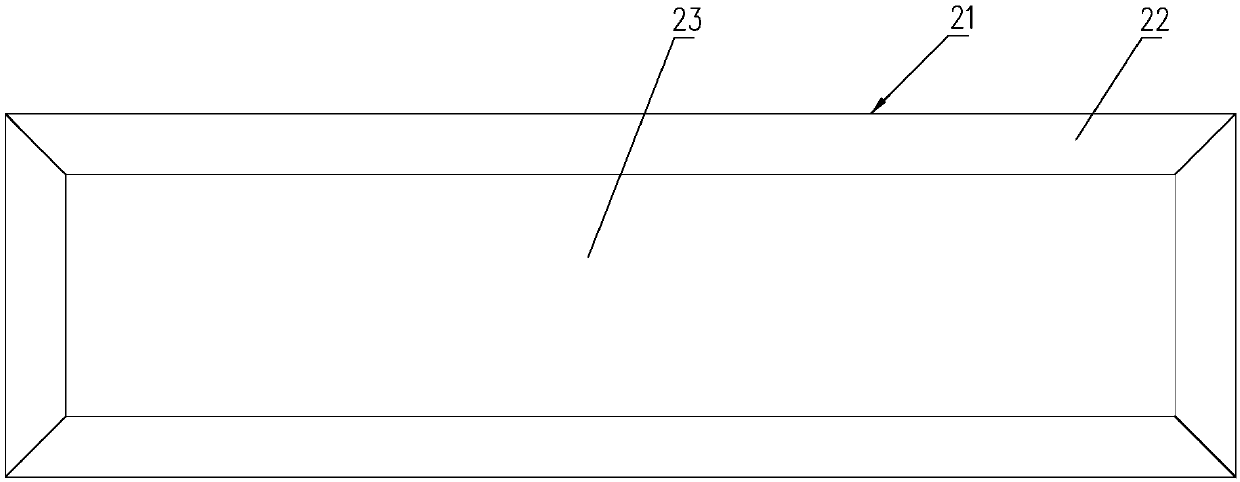

Ultra-high performance concrete (UHPC) combined deck slab with formwork

PendingCN107604815AHigh compressive strengthSmall water absorptionBridge structural detailsPrismRebar

The invention discloses an ultra-high performance concrete (UHPC) combined deck slab with a formwork. The UHPC combined deck slab is mainly formed by splicing of a plurality of unit plates. Each unitplate comprises a steel bottom plate and a UHPC slab body arranged on the steel bottom plate. Shear connecting pieces used for connecting the UHPC slab bodies are welded to the steel bottom plates. Each steel bottom plate is a flat thin-wall steel member in a quadrangular prism frustum shape. The adjacent steel bottom plates are connected with internal members of a main beam on the lower portionsof the deck slab, so that the steel bottom plates are connected into a whole. Steel bars connected into a whole are arranged on the upper portions of the shear connecting pieces in the forward direction of a bridge and the transverse direction of the bridge to form an upper edge force bearing steel net of the deck slab, the steel bottom plates and the shear connecting pieces become lower edge force bearing steel bars and shear steel bars of the deck slab correspondingly and serve as the bottom formwork jointly. The deck slab adopts UHPC so that the problems that in the prior art, cracking anddeck pavement damage are likely to occur can be effectively solved; and additionally the formwork engineering quantity can be reduced by a large margin, formwork mounting and demounting work is omitted, and thus the construction efficiency is improved.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

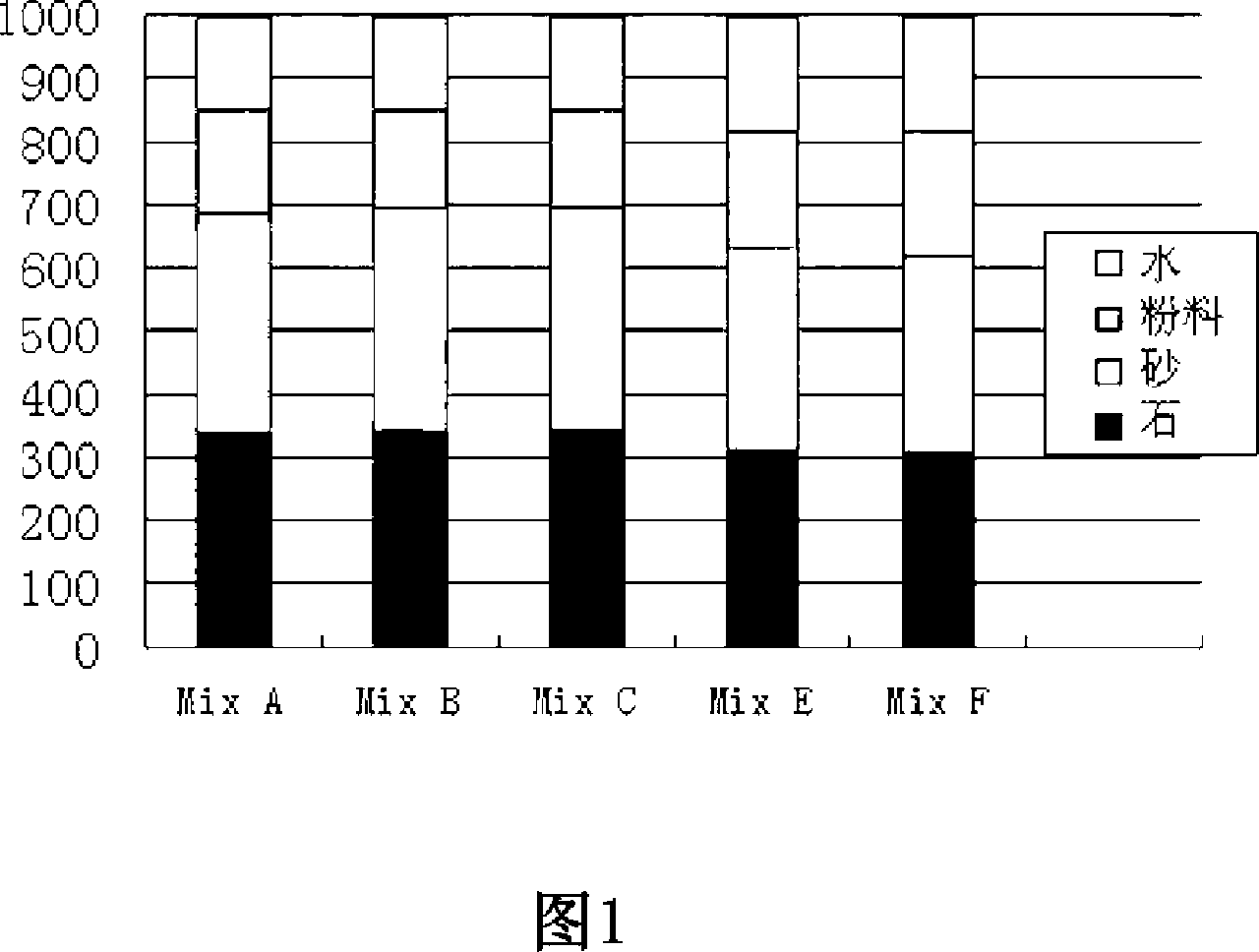

Low-creep C60 high-performance concrete

InactiveCN101891426AReduce usageImprove economySolid waste managementPortland cementSuperplasticizer

The invention discloses a low-creep C60 high-performance concrete material. Economic and reasonable 42.5 normal portland cement or portland cement is selected, and technologies of mixing grade I fly ash and grade S95 mineral powder, adding a polycarboxylic acid superplasticizer, and the like are adopted, thereby optimizing the proportioning of concrete, ensuring the economy and good placeability and mechanical property of concrete with low water to binder ratio, avoiding concrete cracking caused by low water to binder ratio, ensuring high durability of the concrete, effectively reducing the creep of concrete, reducing the prestressing loss, and ensuring the safety of the concrete structure.

Owner:CHINA RAILWAY HI TECH IND CORP LTD +1

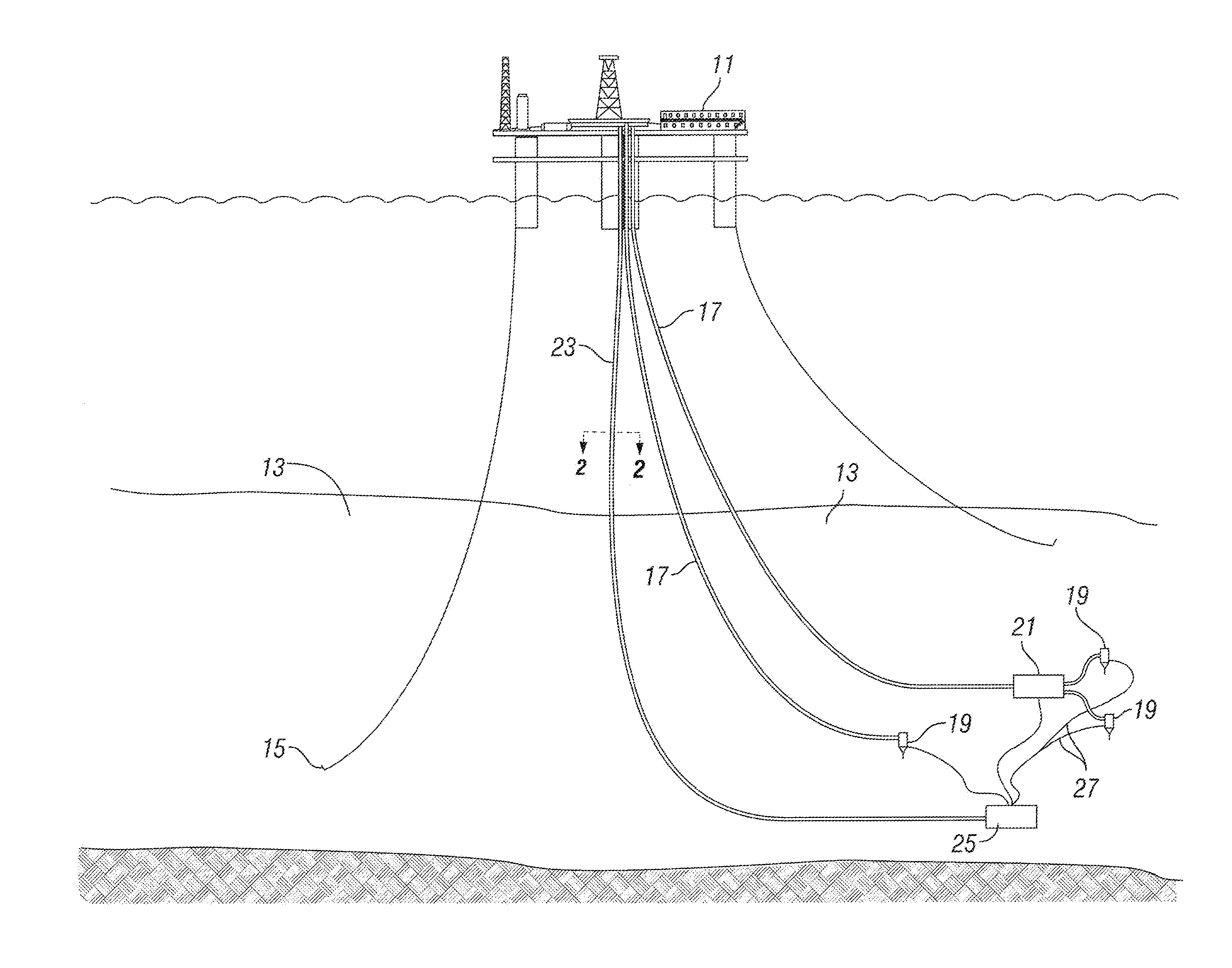

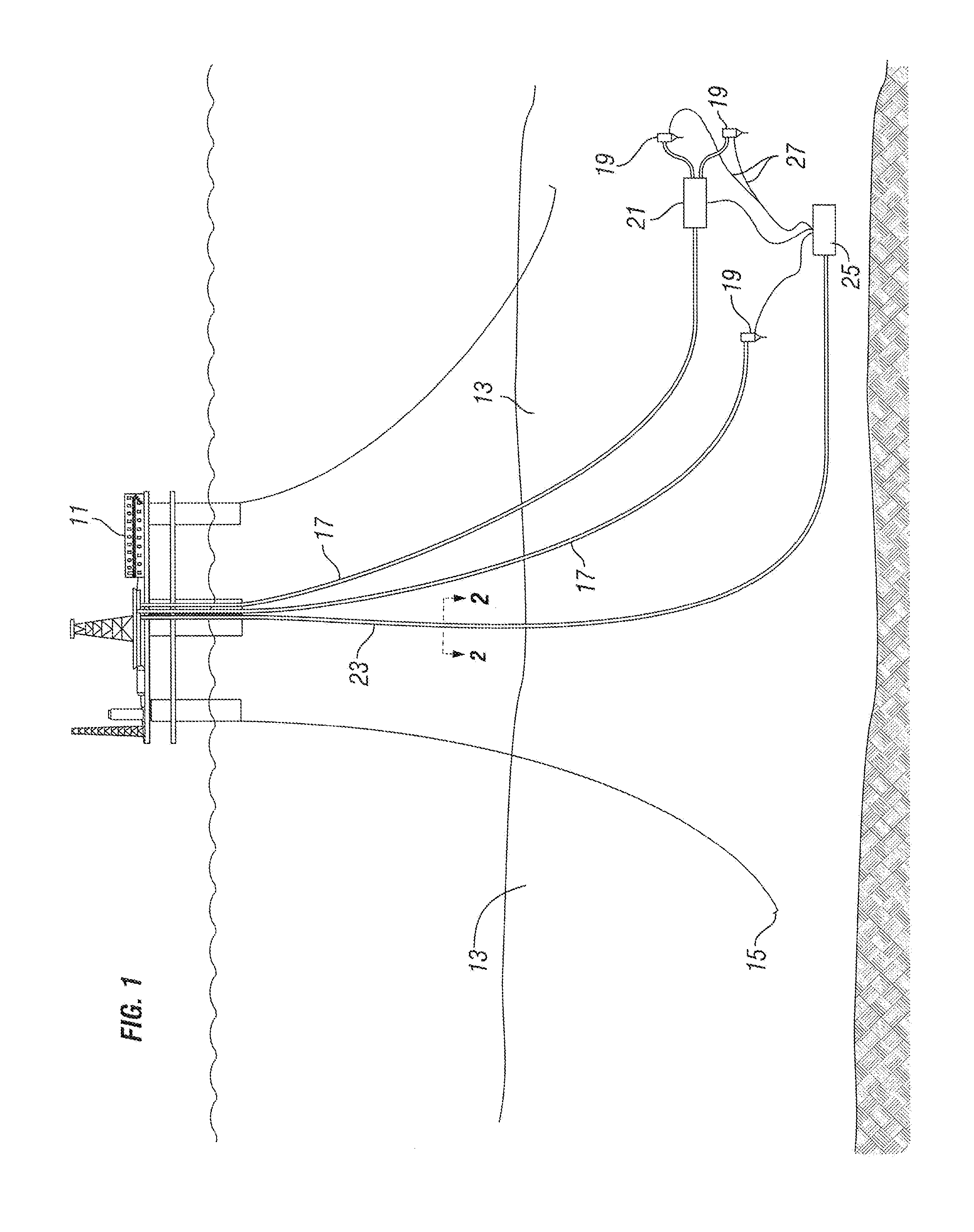

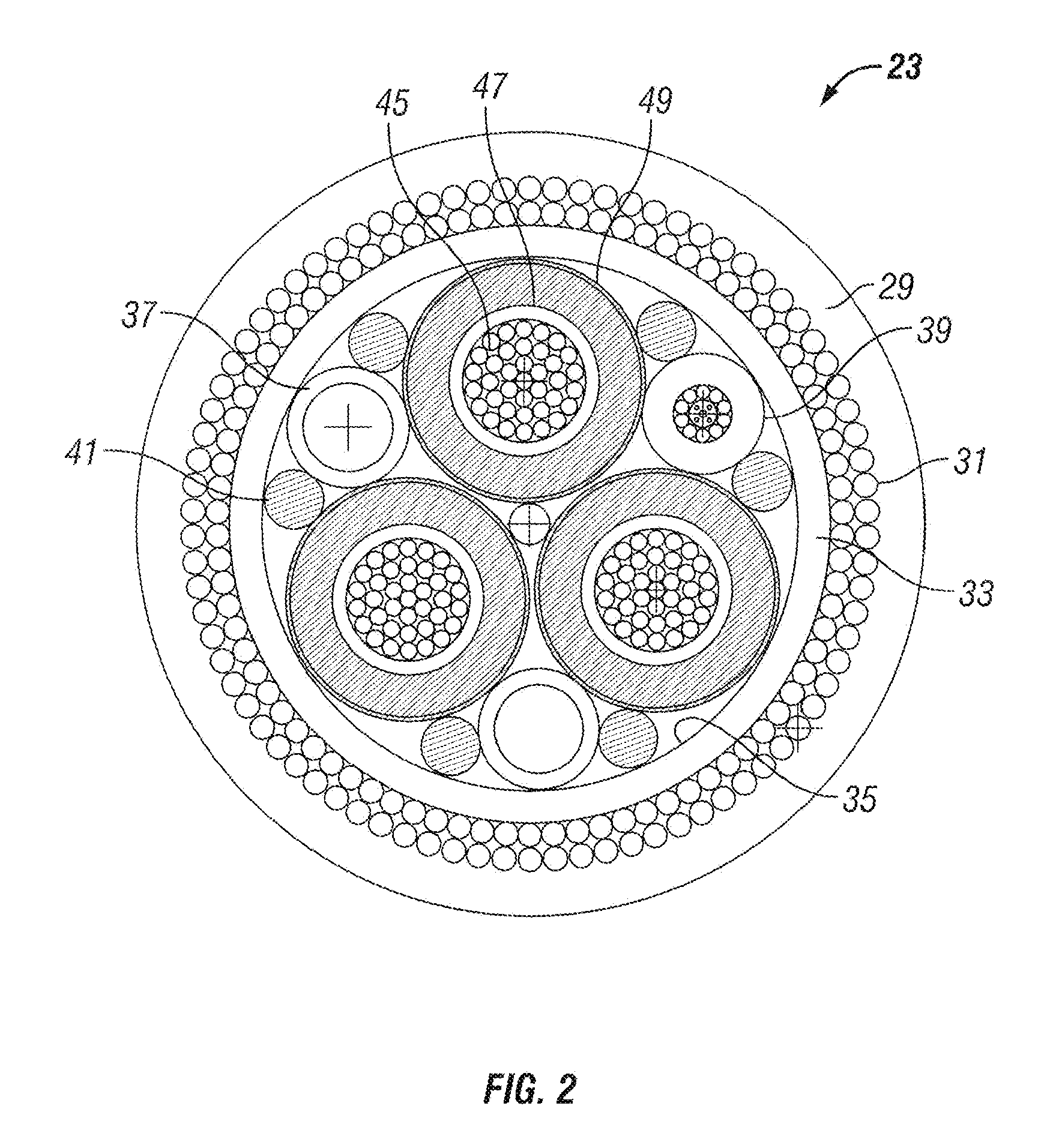

Subsea power umbilical

InactiveUS20090120632A1Increase frictionEliminate creepDerricks/mastsFluid removalElectrical conductorHydrogen

An umbilical assembly for supplying power to subsea equipment includes an electrical conductor to convey an electrical current to the subsea equipment. An insulator surrounds the conductor. A support member is positioned between the insulator and the conductor. The support member has either non-magnetic properties or low-magnetic properties because of its material composition. The support member is adapted to connect to a structure at the surface of the sea. The support member supports the weight of the conductor. The supporting of the weight of the conductor by the support member can be to reduce creep typically associated with the conductor supporting its own weight. The support member can be used to hermetically seal the conductor and prevent hydrogen migration along the conductor.

Owner:CHEVROU USA INC

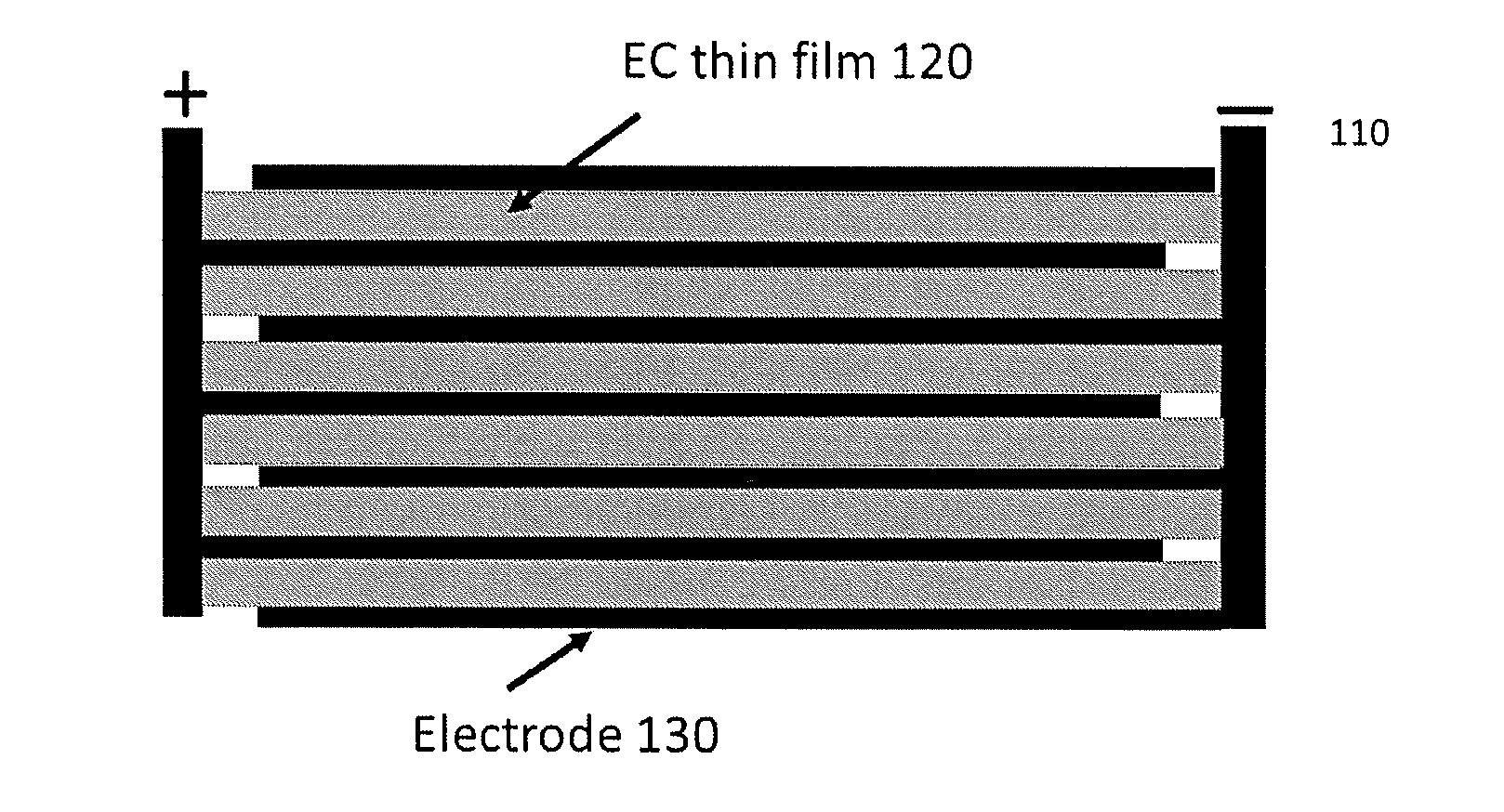

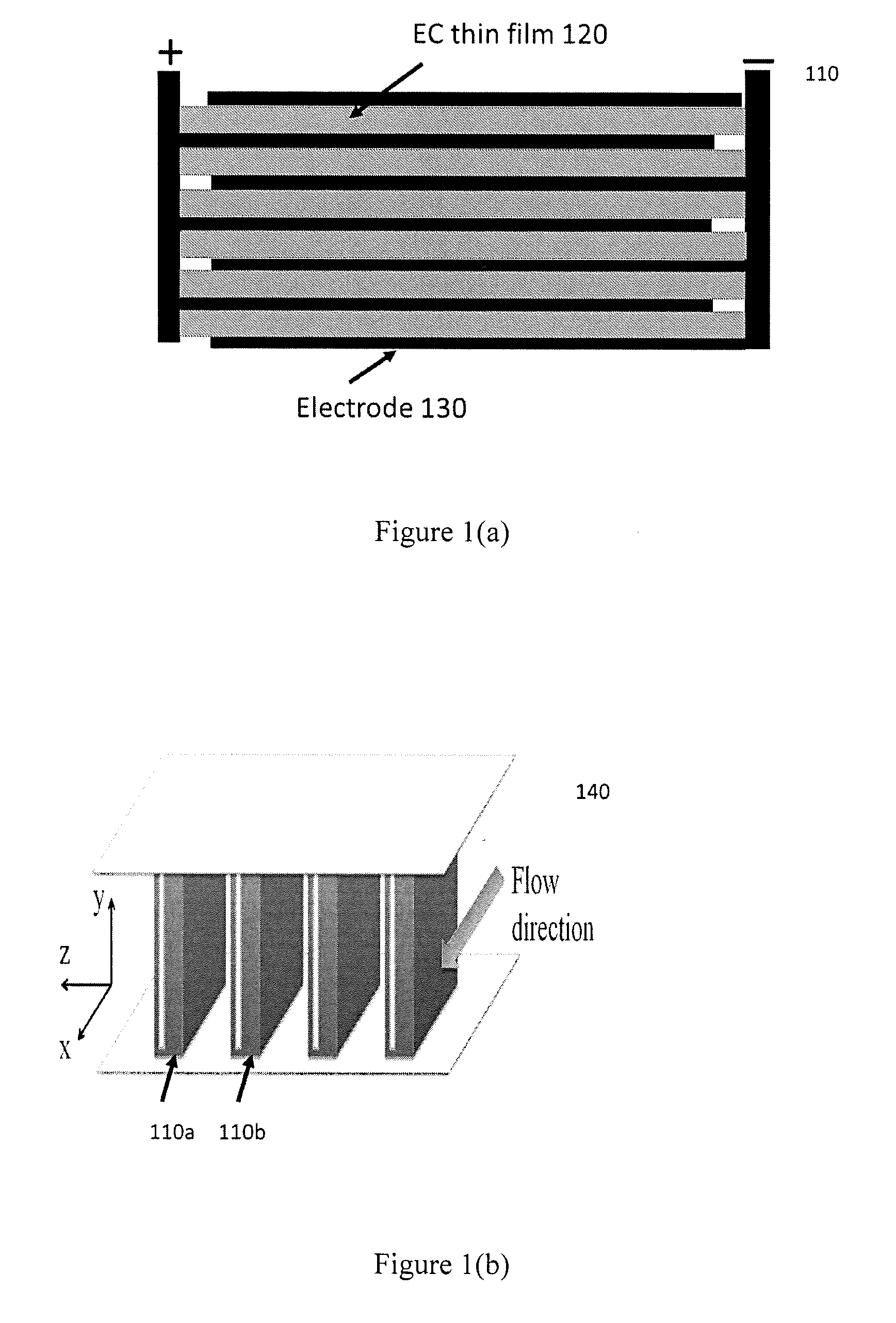

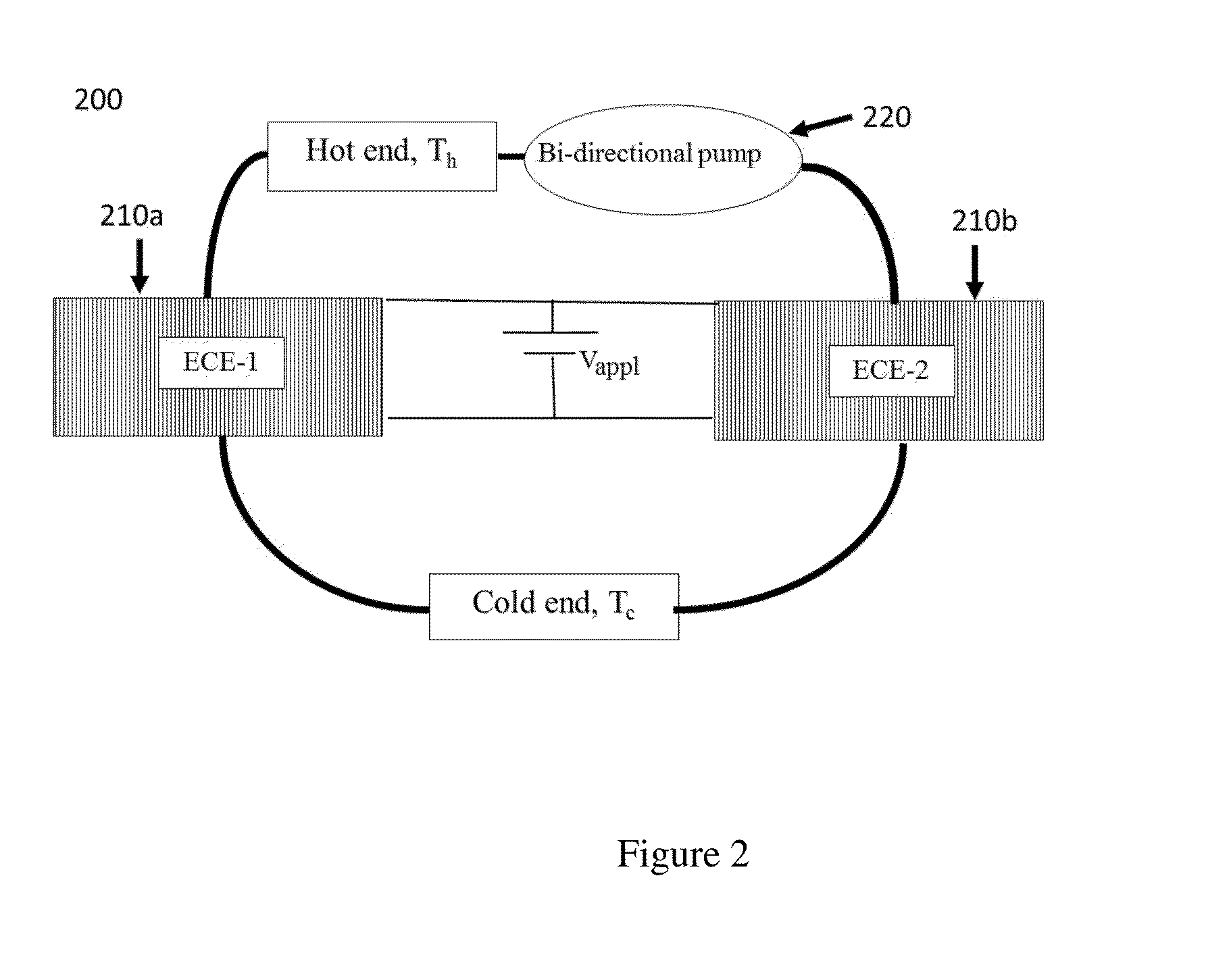

Methods to improve the mechanical performance of electrocaloric polymers in electrocaloric refrigerators

InactiveUS20160087185A1Increase elasticityReduce creepThermoelectric device with dielectric constant thermal changeMachines using electric/magnetic effectsFiberPolymer science

A cooling device utilizing the polymer composite materials possessing high electrocaloric effect and high elastic modulus are disclosed. Especially methods to enhance mechanical properties and reduce creep of the polymer composites with insulation fibers of high elastic modulus while maintain high electrocaloric effect.

Owner:NASCENT DEVICES

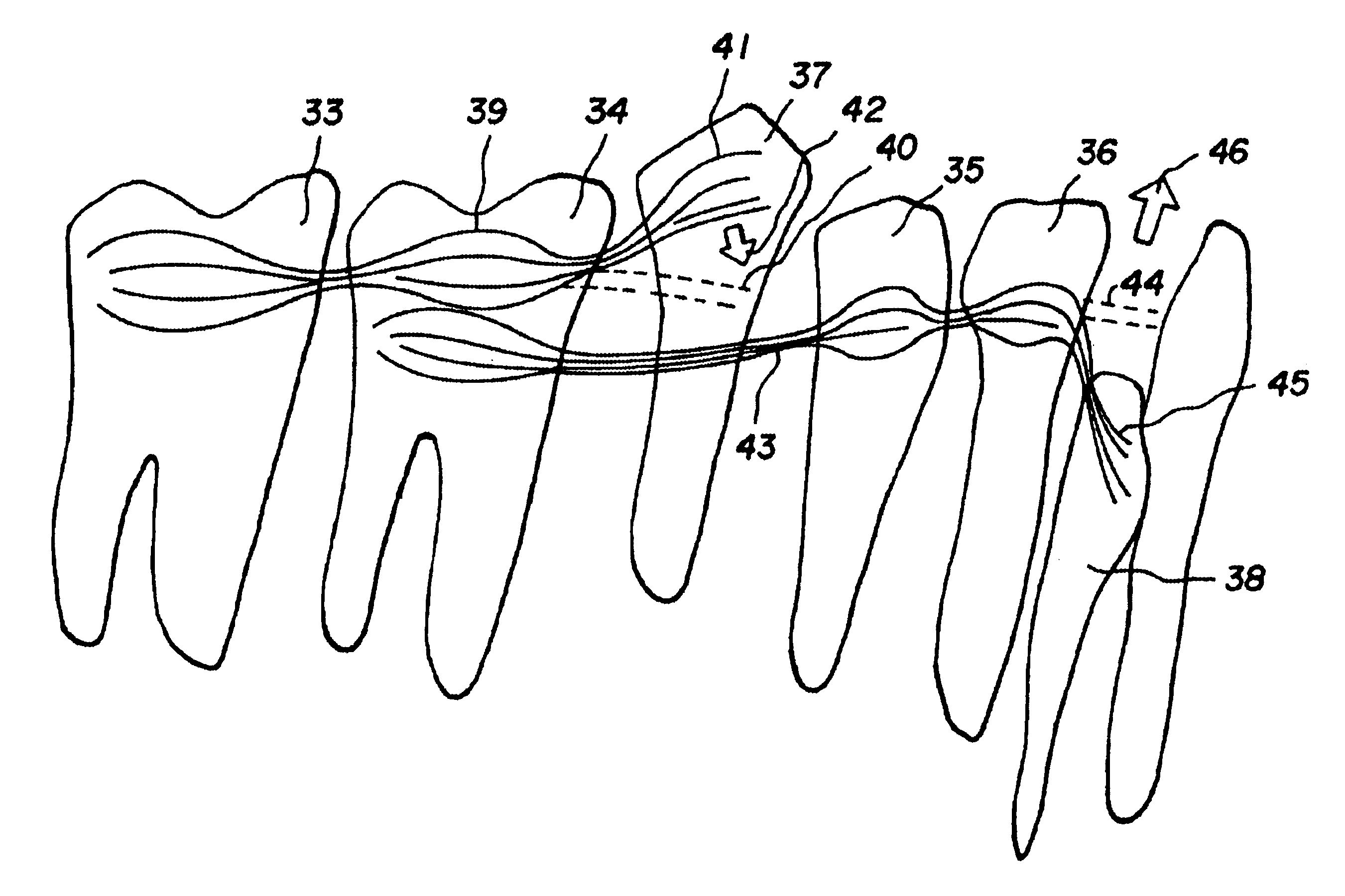

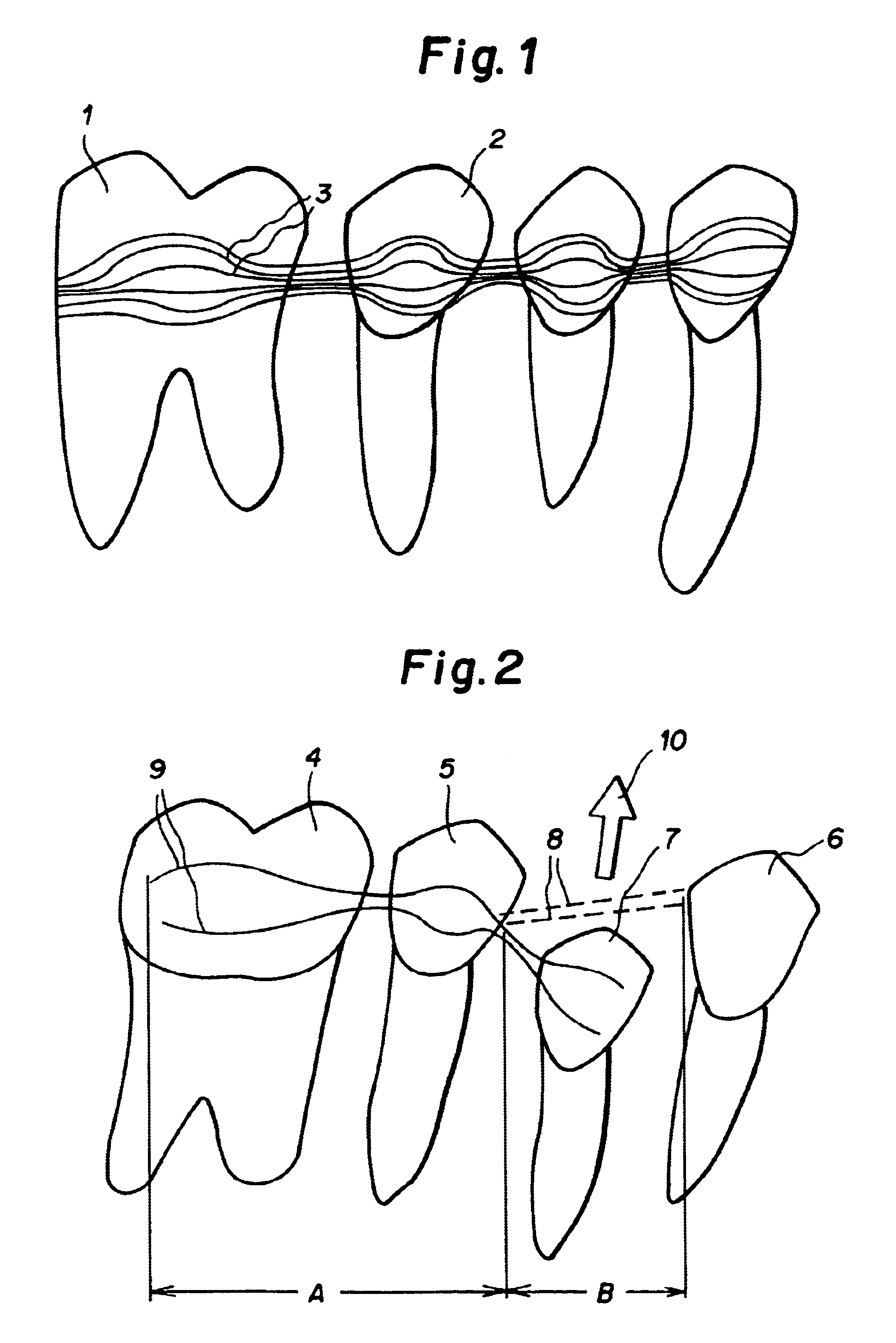

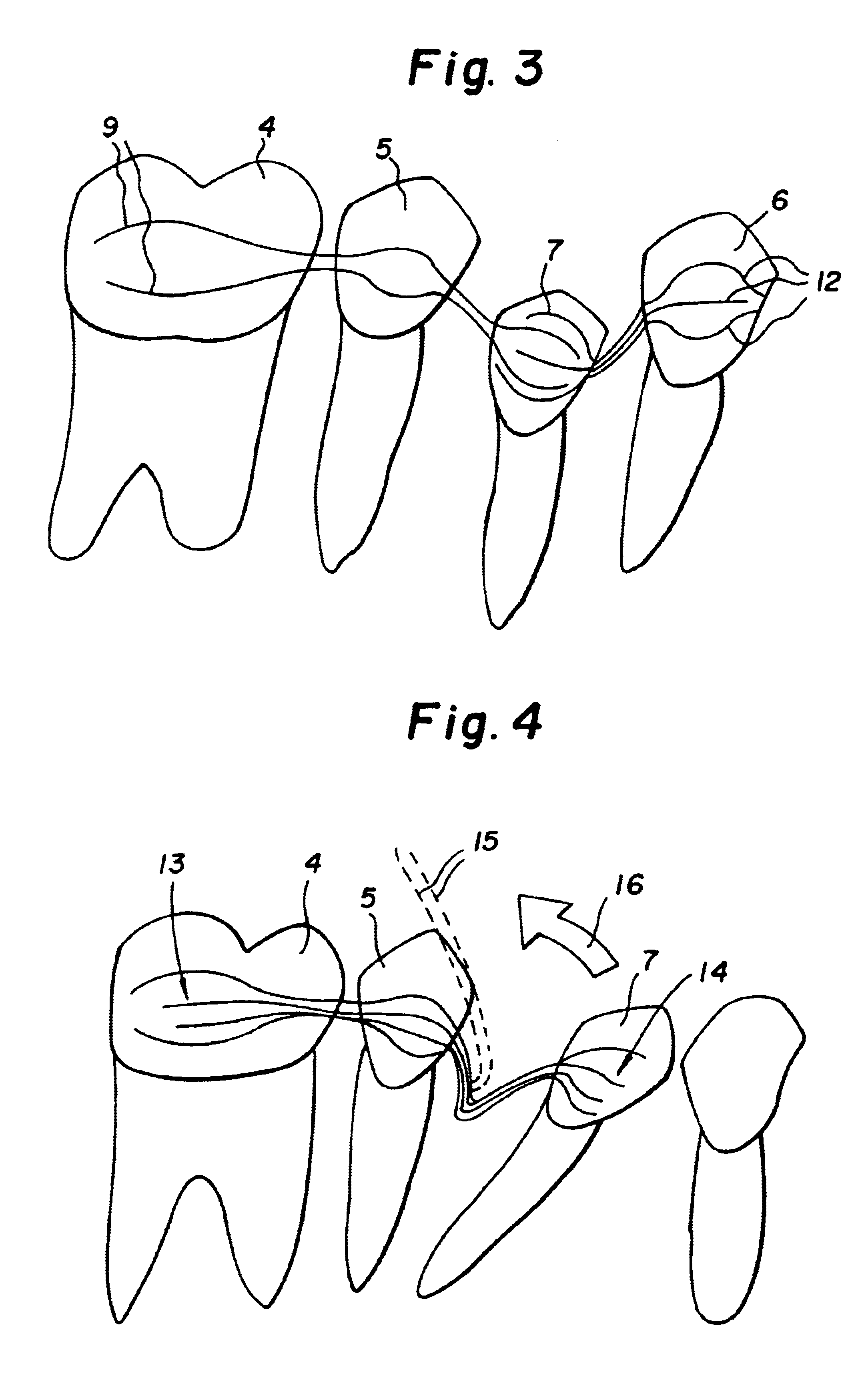

Orthodontic appliance

InactiveUS6733288B2Simple and reliable and aesthetic structureEasy maintenanceArch wiresDental toolsArch wiresFiber-reinforced composite

Owner:STICK TECH OY

Energy-saving anode for non-ferrous metal electrodeposition

An energy saving anode used in electro-deposition of nonferrous metal is characterized in that the energy saving anode used in electro-deposition of nonferrous metal comprises a metal-conductive base-plate and at least one block of composite structure which is compounded by a metal layer with porous structure, wherein the structure is frame type, sandwich type and slab lattice type. The energy saving anode not only can effectively reduce true current density of the anode in electro-deposition of the nonferrous metal, reduce overpotential for oxygen evolution of the anode and lower energy consumption, but also can reduce the quality of the anode, reduce the creep deformation and the deformation of the anode, form a more dense oxydic film on the surface, reduce the corrosion rate of the anode, extend the service length of the anode and improve the quality of the cathode products. The energy saving anode can make a full use of the existing anode without changing the structure of the groove and have no effect to the process flow, and the energy saving anode has low preparing cost and low investment.

Owner:CENT SOUTH UNIV

Steel box type composite beam forming method

Disclosed is a steel box type composite beam forming method. A split type processing method is utilized in a bottom box and a plug welding technology and an anti-deformation technology are utilized to effectively solve the problems of positioning of force transmission ribs, deformation of the bottom box and the like, and the prefabrication efficiency of steel-concrete composite bridges is improved by reasonably adjusting production processes. The adopted technical scheme of the steel box type composite beam forming method comprises utilizing steel plates as raw materials, leading the raw materials to be subjected to top plate forming, bottom box forming and wave plate forming, and performing assembling and welding to form a prefabricated steel box type composite beam. According to the steel box type composite beam forming method, assembly line production is utilized and large-scale processing and assembling of bottom boxes can be achieved in factories.

Owner:邢台路桥千山桥梁构件有限责任公司

Direct leaking stoppage fiber grouting material and preparation method thereof

The invention provides a direct leaking stoppage fiber grouting material and a preparation method thereof. The fiber grouting material is prepared from the following substances in percentage by weight: 15 to 20 percent of Portland cement, 40 to 45 percent of sodium silicate, 5 to 10 percent of fly ash or mineral waste residues, 25 to 30 percent of water, 3 to 4 percent of basalt fibers and 1 to 2 percent of retarder. The preparation method comprises the following steps: equally dividing the fly ash or the mineral waste residues into two parts according to the mass ratio; uniformly mixing one part of the fly ash or the mineral waste residues with the basalt fibers, the Portland cement and the water to obtain a mixed solution I; uniformly mixing the other part of the fly ash or the mineral waste residues with the sodium silicate to obtain a mixed solution II; slowly pouring the mixed solution II into the mixed solution I for uniformly mixing to obtain the fiber grouting material. The fiber grouting material provided by the invention can meet the requirements on three properties, namely groutability, controllability and permeability resistance, also has the advantages of high setting rate, high long-term strength and the like at the same time, and has a broad application prospect in related fields such as goaf, roads and foundation treatment.

Owner:LIAONING TECHNICAL UNIVERSITY

Civil aluminum alloy conductor, wiring and preparation method thereof

ActiveCN101937733AImprove corrosion resistanceStrong corrosion resistanceFlexible cablesMetal/alloy conductorsElectrical conductorManufacturing technology

The invention provides a method for manufacturing civil aluminum alloy wiring, belonging to the technical field of wire and cable design and manufacture. The manufacture method comprises the following steps: adding aluminum ingots, aluminum-iron master alloy, aluminum-boron master alloy and aluminum-rare earth master alloy into a shaft furnace; casting into a cast strip after smelting; rolling into an aluminum alloy rod through a rolling mill; preparing an aluminum alloy filament by the aluminum alloy through cold drawing; annealing, and performing extruded insulation on the aluminum alloy wire, wherein the insulation material is silane-crosslinked polyethylene; adding low halogen or halogen-free flame retardant during insulation; and performing warm water crosslinking or steam crosslinking treatment on the aluminum alloy wiring after the extruded insulation is completed. The aluminum alloy wiring has excellent conductivity, tensile property and bending performance; and the wire has better flame retardant performance and longer service life.

Owner:于贵良 +1

High-strength high-performance concrete and preparation method thereof

The invention discloses high-strength high-performance concrete, components of which comprise (by weight): 100-300 parts of cement, 50-100 parts of silica sand, 10-30 parts of nanometer magnesia, 10-20 parts of fly ash, 5-15 parts of nanometer calcium carbonate, 30-60 parts of a water reducer, 10-25 parts of lignin sulfonate, 2-12 parts of titanium fiber, 4-18 parts of polytetrafluoroethylene powder, 3-15 parts of sodium alginate, 10-30 parts of a silane coupling agent, 10-20 parts of glass fibre powder, 20-40 parts of ultrafine mineral powder and 50-100 parts of purified water. The inventionalso discloses a preparation method of the high-strength high-performance concrete. The method is simple for construction. The prepared concrete has high strength (strength is 45-60 Mpa), good anti-permeability and good durability. Meanwhile, the prepared concrete has excellent high crack resistance and impermeability. Thus, the hidden trouble that concrete cannot be used due to leakage and ponding caused by poor crack resistance and impermeability is avoided. Strength of concrete in middle and late stages is enhanced.

Owner:CHINA MCC17 GRP

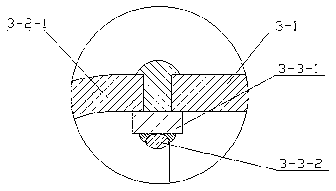

Vibration-free self-flowing dense concrete

InactiveCN101186480AExcellent working performanceWorkability is goodSolid waste managementRebarWork performance

The invention provides a C50 non-vibration self-flowing dense concrete used in the construction structures such as bridges, of which the mixing proportion by per cubic meter is that 375kg of concrete, 162kg of fly ash, 167kg of water, 767kg of sand, 901kg of gravel and 10.74kg of high efficiency water reducing agent; water-gel ratio is 0.325 and mortar-aggregate bond ratio is 0.352: 0.648; the invention can evenly and densely fill in a structure with dense concrete reinforcing bars and complicated physiques without stirring by relying on self weight of the concrete, which conquers the defect of structure quality of being not dense, etc.; the invention meets the requirements of C50 common concrete for working performance, mechanical property, impermeability, freezing resistance, Chloride ions diffusibility resistance, shrinkage and creep property, etc., and has good workability and little gradual loss in slump.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

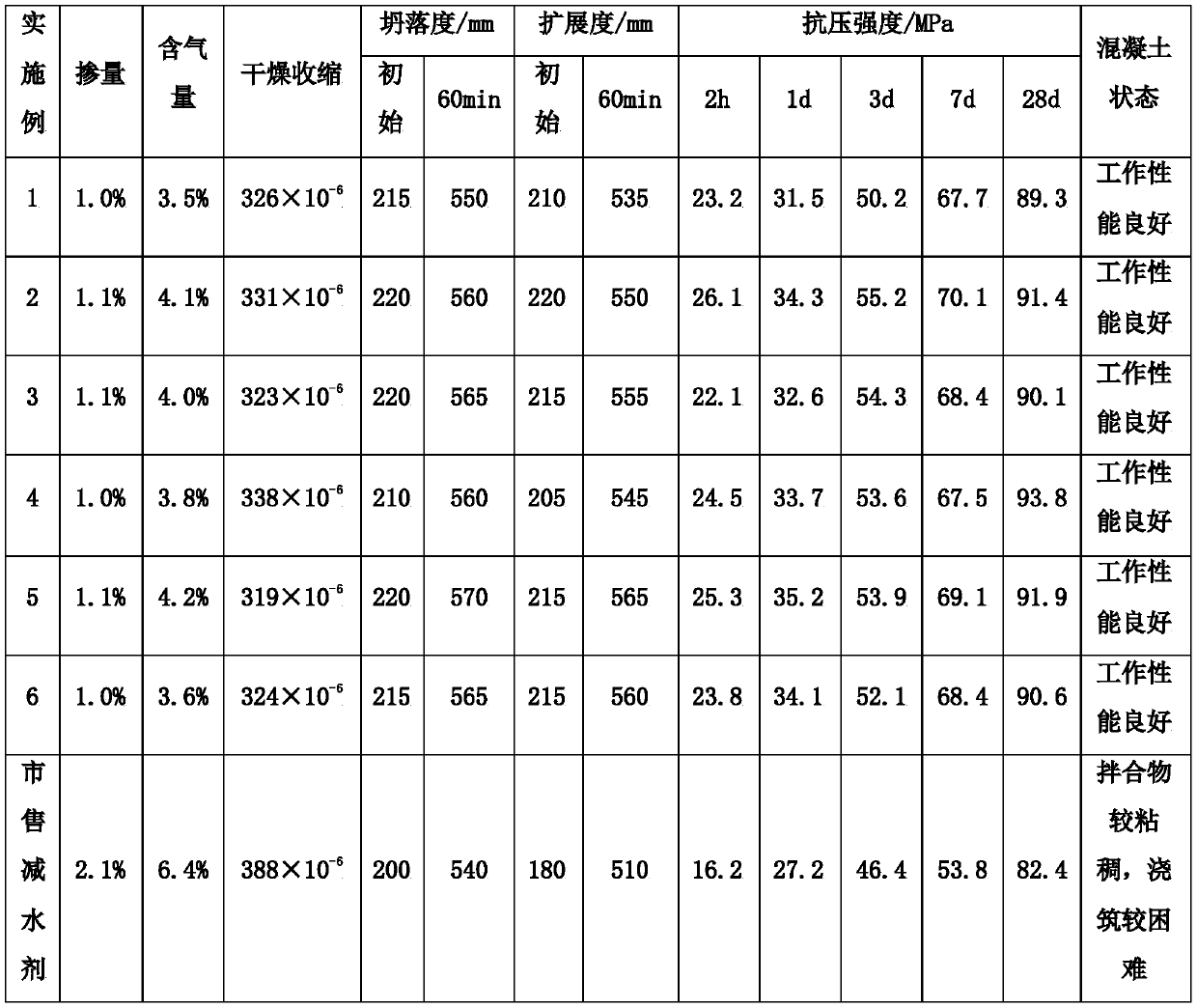

High efficiency concrete composite admixture

InactiveCN103588415ALate strengthDelay the initial setting and final setting time of concrete without affecting the later strengthSuperplasticizerWater reducer

The invention discloses a high efficiency concrete composite admixture, which comprises the following components: by weight, 5%-20% of triethanolamine, 10%-15% of sodium lignin sulfonate, 2% - 3% of a naphthalene-series high efficiency water reducer, 1% - 2% of bone glue, 5% - 15% of tartaric acid, 2% - 3% of rosin, 3% - 5% of sodium dodecyl benzene sulfonate, and the balance of water. The high efficiency concrete composite admixture has the advantages of simple process and excellent performances.

Owner:JIANGSU BAIRUIJI NEW MATERIAL

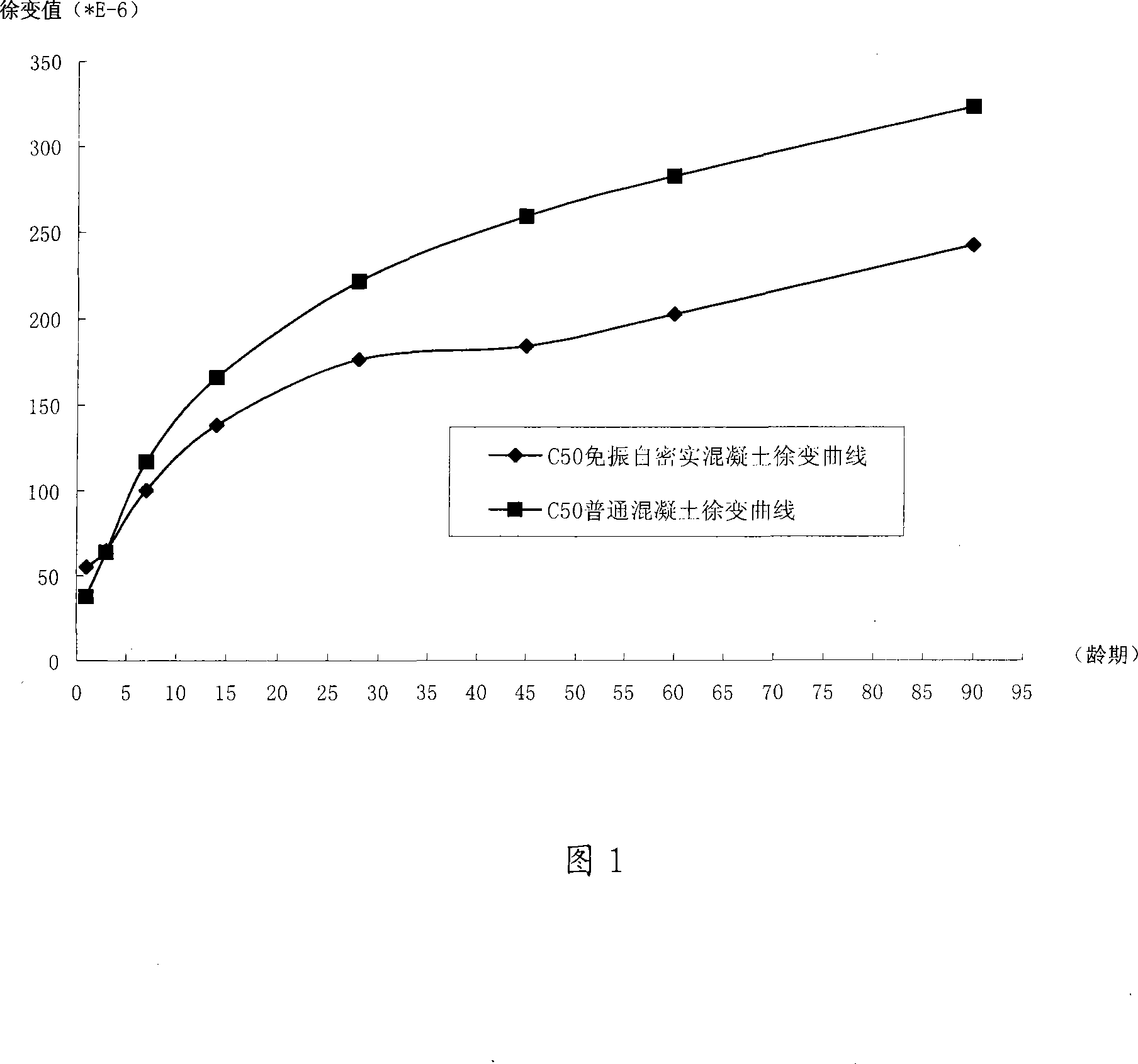

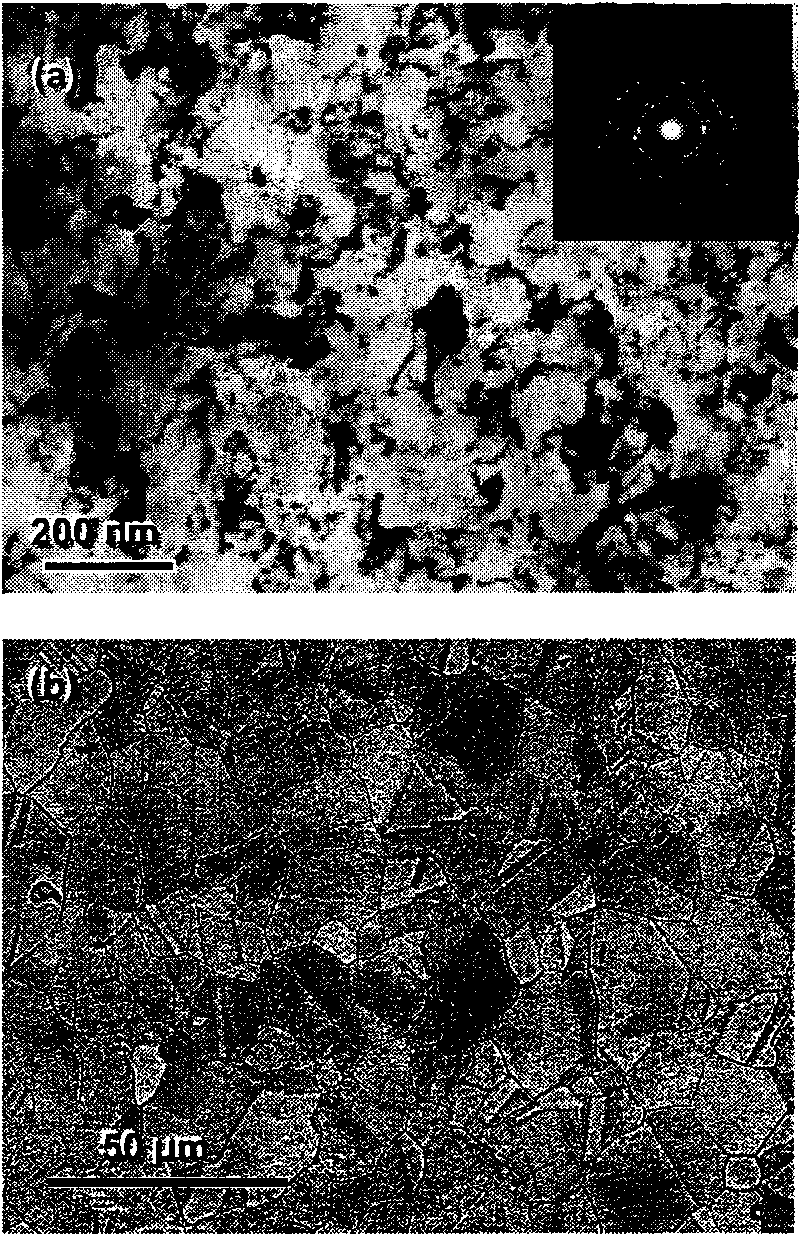

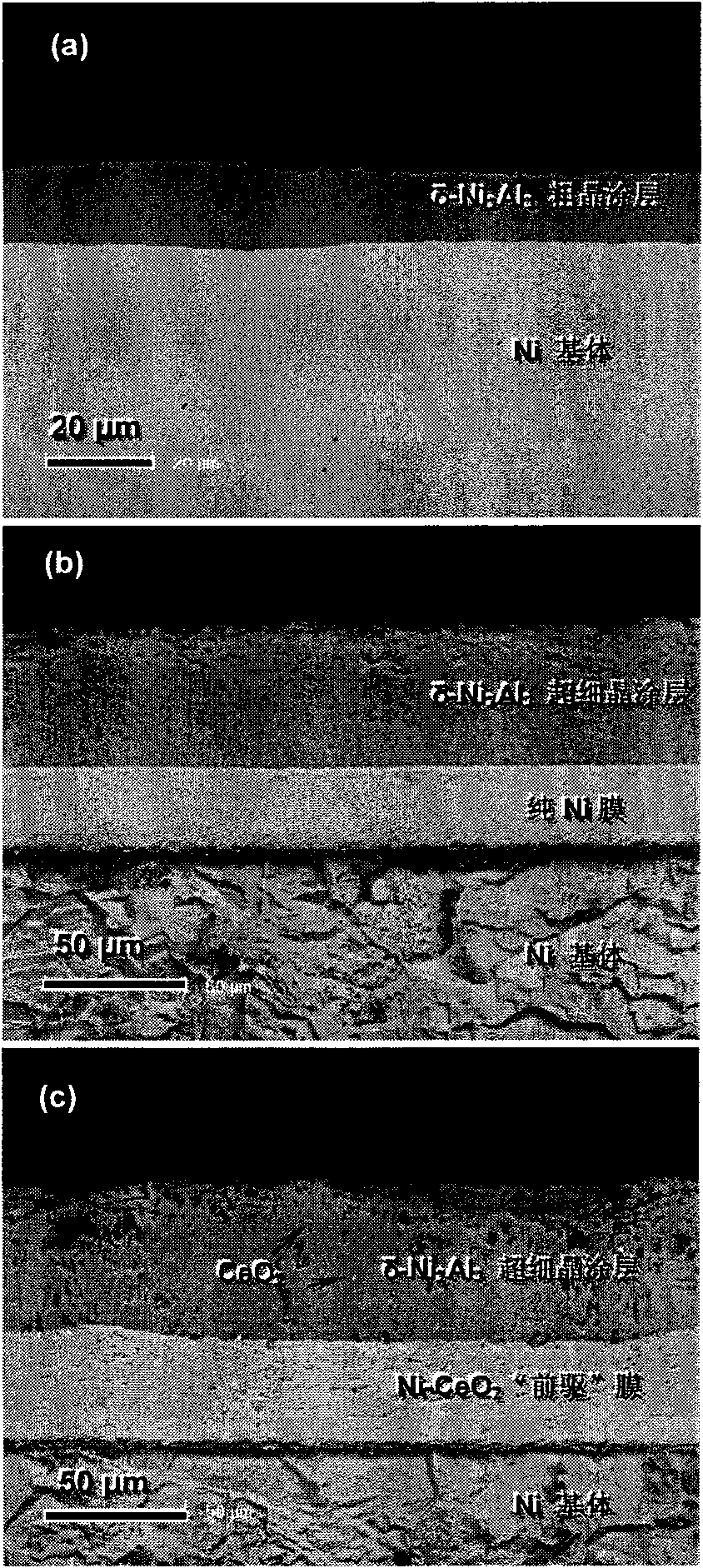

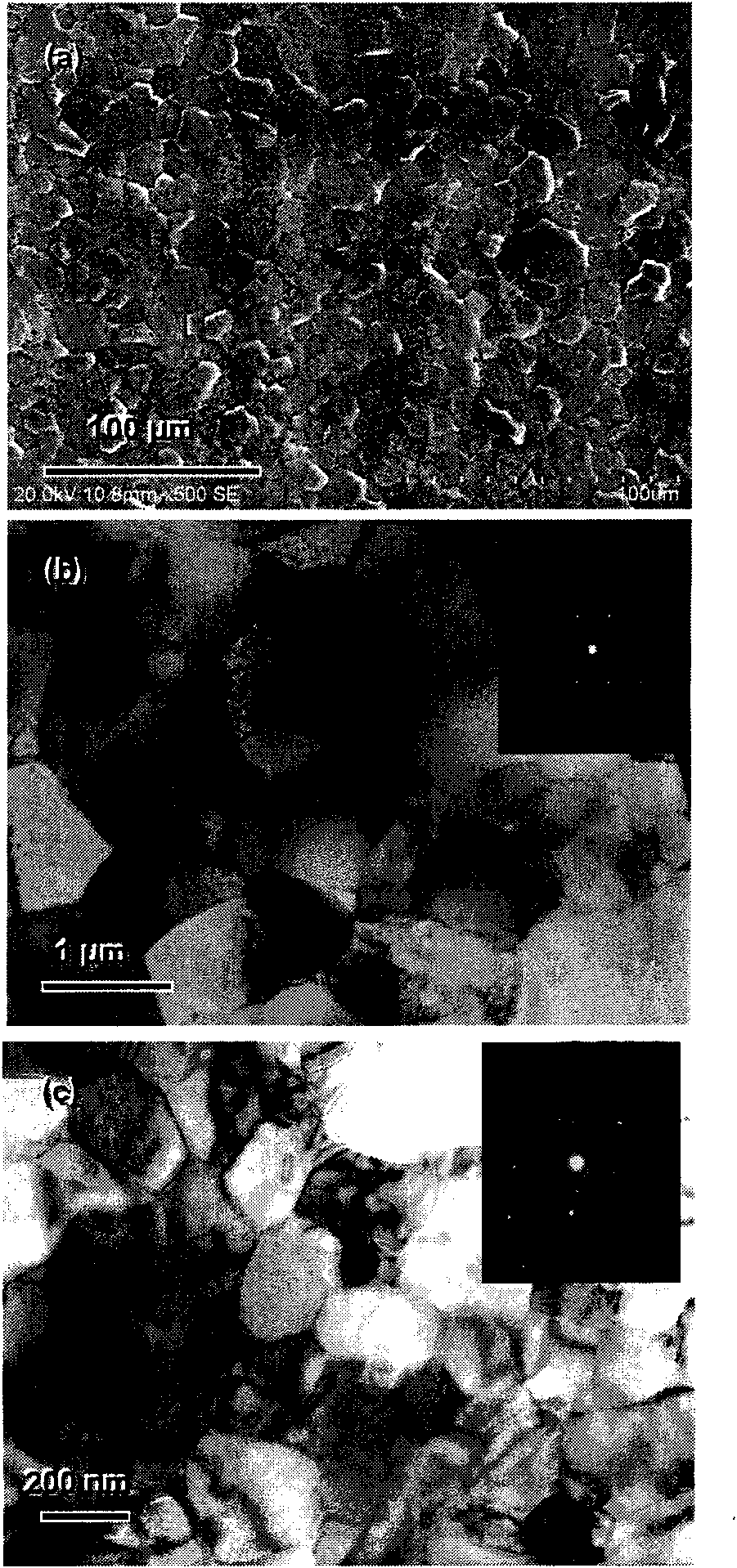

CeO2-diffused superfine crystalline delta-Ni2Al3 coating, and preparation method and application thereof

InactiveCN101988204AExpand the range of metal materialsSmall sizeElectrolytic coatingsSolid state diffusion coatingAlloy substrateCeo2 nanoparticles

The invention discloses a CeO2-diffused superfine crystalline delta-Ni2Al3 coating, and a preparation method and application thereof, which solve the problems of high temperature, weak Al2O3 layer bonding strength for the thermal growth of an alumetized coating, limitations to application, and the like of conventional alumetizing technology. The coating is prepared by the following two steps of: preparing an Ni-CeO2 nanometer compound precursor film with a nanocrystalline structure on a metal substrate, such as a low-carbon steel substrate, a low alloy steel substrate, an Ni-based alloy substrate or the like, by performing coelectrodeposition on Ni and CeO2 nanoparticles; and performing diffusion alumetizing on the precursor film at 500 to 700 DEG C to obtain the superfine crystalline CeO2 modified delta-Ni2Al3 coating. The coating consists of the following components in percentage by mass: 1 to 10 percent of diffused CeO2 nanoparticles and the balance of delta-Ni2Al3 phase. The CeO2-diffused superfine crystalline delta-Ni2Al3 coating of the invention can be applied to the metal substrate, such as the low-carbon steel substrate, the low alloy steel substrate, the Ni-based alloy substrate or the like, in an oxidizing atmosphere at the working condition temperature of less than 1,000 DEG C as a protective coating of a related part in a boiler, a heat exchanger, a gasifier or a garbage incinerator of a thermal power plant.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

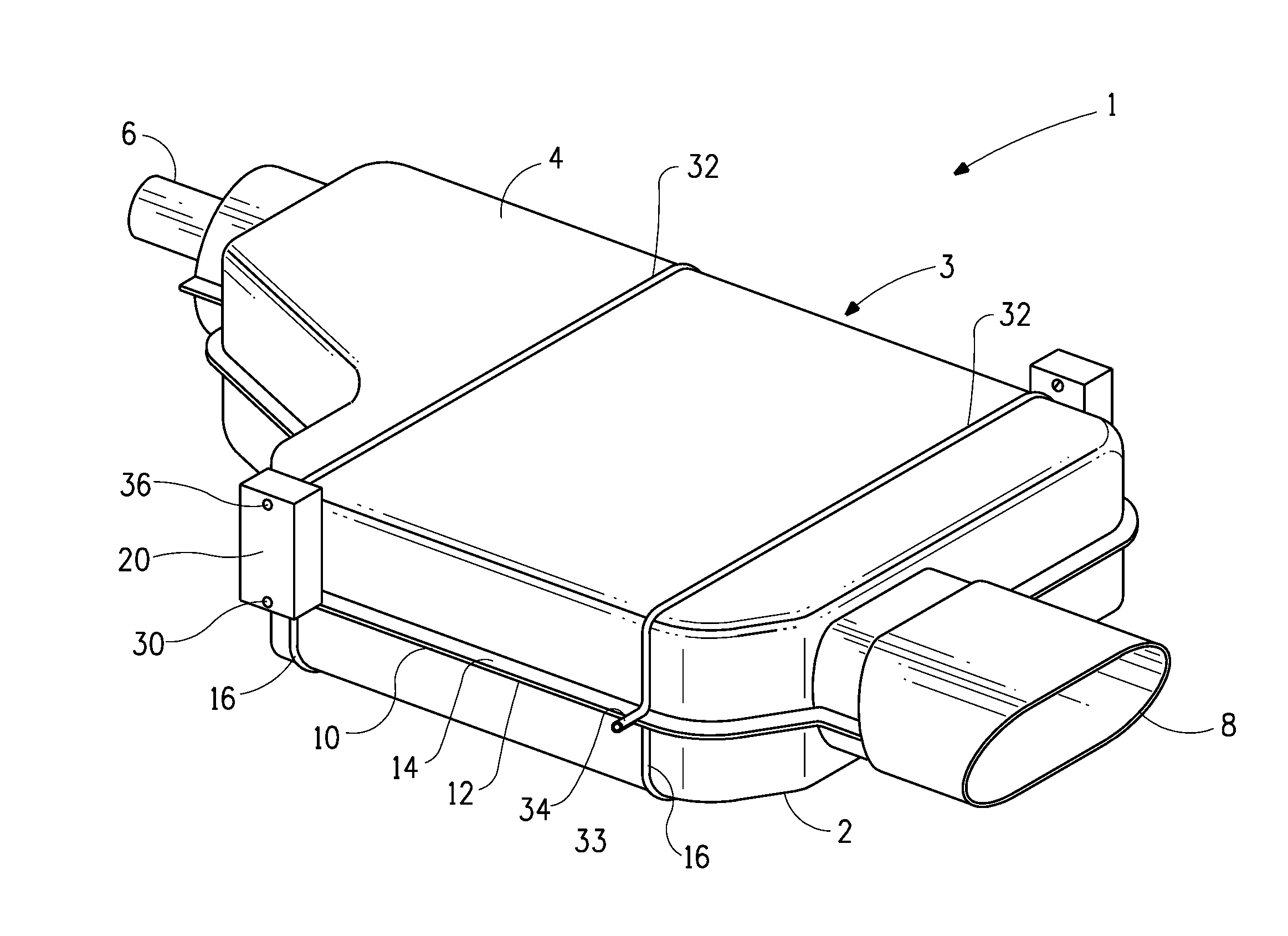

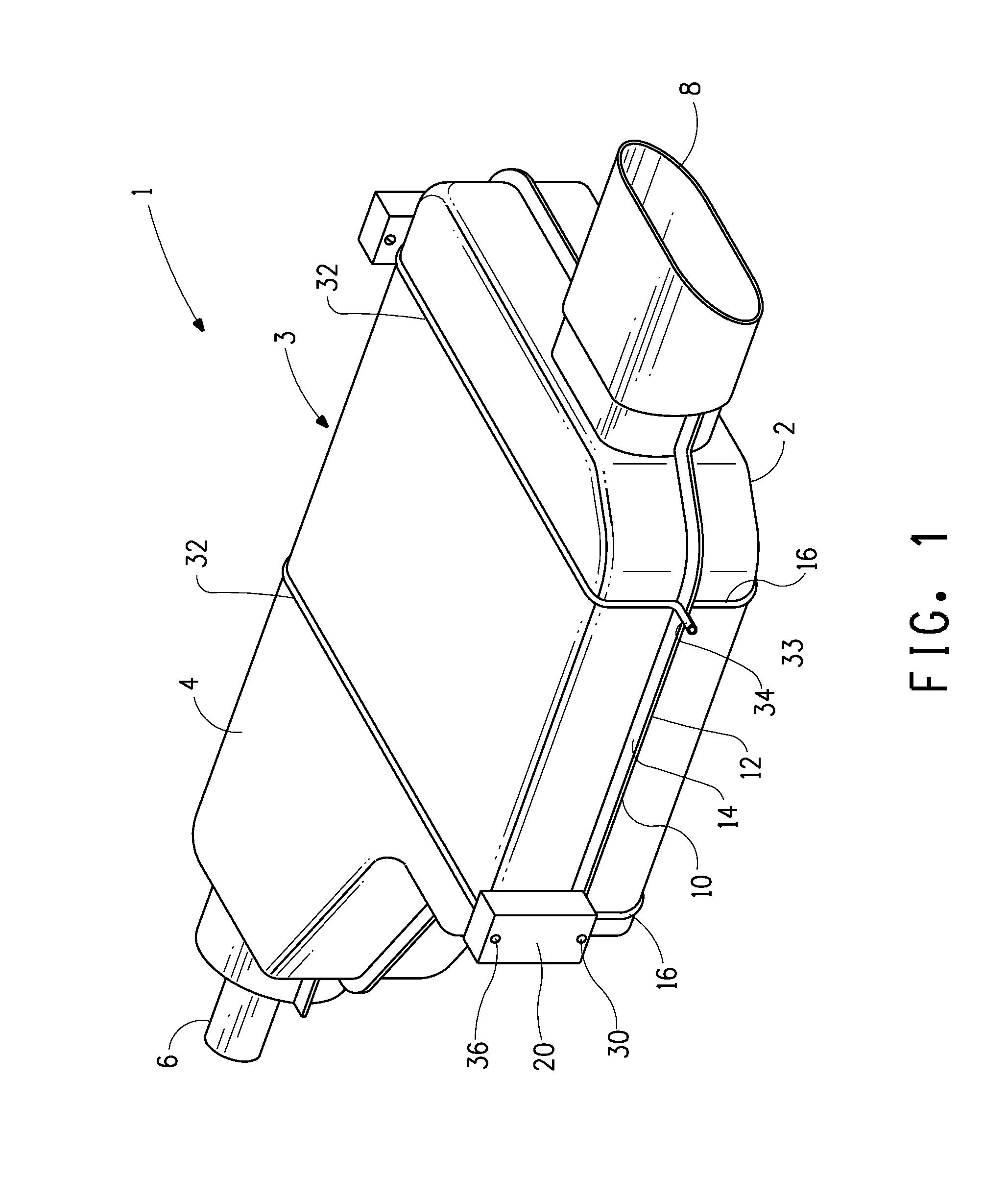

Muffler assembly and method of making

InactiveUS20120325578A1Improve adhesionReduce riskSilencing apparatusThermometers using physical/chemical changesPolymer compositesEngineering

A muffler 1 comprises a polymeric housing 3 and a support bracket 16 for mounting the muffler on a vehicle. The support bracket 16 is made of a polymer composite material comprising a polymer and fibres and is integrally formed with the housing 3. The muffler is made by a method comprising providing a support bracket 16 made of a polymer composite material comprising a polymer and fibres, and forming a polymer housing 3 by contacting molten polymer with the support bracket 16 to bond the support bracket to the housing.

Owner:EI DU PONT DE NEMOURS & CO

Preparation method of inorganic-organic composite particle and its special-purpose equipment

InactiveCN1515632AHigh hardnessHigh surface finishPigment treatment with macromolecular organic compoundsChemical LinkageInorganic particle

The present invention relates to a preparation method of inorganic-organic high-molecular composite particle and its special-purpose equipment. The inorganic particle can be directly reacted with organic high-molecular compound in a reactor still, under the action of mechanical energy and heat energy provided by reactor still the inorganic particle is reacted with organic high molecular to make chemical linkage, and one layer or several layers of organic high-molecular membranes can be formed on the surface of the particle so as to obtain the invented hydrophobic inorganic-organic high-molecular composite particle which can have an affinity for organic high-molecular material. Its special-purpose equipment is formed from horizontal reaction still with jacket, motor and control cabinet, etc.

Owner:WUHAN UNIV OF TECH

Polycarboxylate superplasticizer for machine-made sand concrete prestressed component and preparation method of polycarboxylate superplasticizer

The invention discloses a polycarboxylate superplasticizer for a machine-made sand concrete prestressed component and a preparation method of the polycarboxylate superplasticizer. The polycarboxylatesuperplasticizer is prepared from the following raw materials in parts by mass: 50-100 parts of polyether macromonomer, 20-40 parts of an ester macromonomer, 5-15 parts of maleic acid-beta-cyclodextrin, 5-15 parts of styrene, 30-60 parts of an acrylic monomer, 10-30 parts of unsaturated phosphate and 5-25 parts of an ammonium cation unsaturated monomer in a free radical polymerization manner so asto prepare a polymer with the molecular weight of 15000-80000; and 0-4 parts of an organic silicon defoamer, 0-10 parts of an early strength agent and 5-15 parts of a sacrificial agent are compounded, and then an alkaline solution is added for neutralization. The polycarboxylate superplasticizer has high tolerance to the stone powder content of machine-made sand concrete, good water reducing andviscosity reducing effects and an early strength function, meets the production requirements of machine-made sand concrete prestressed components in the fields of railways, highways, water conservancyand the like, and in particular, is used for preparing high-strength prestressed components with low water-binder ratios.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

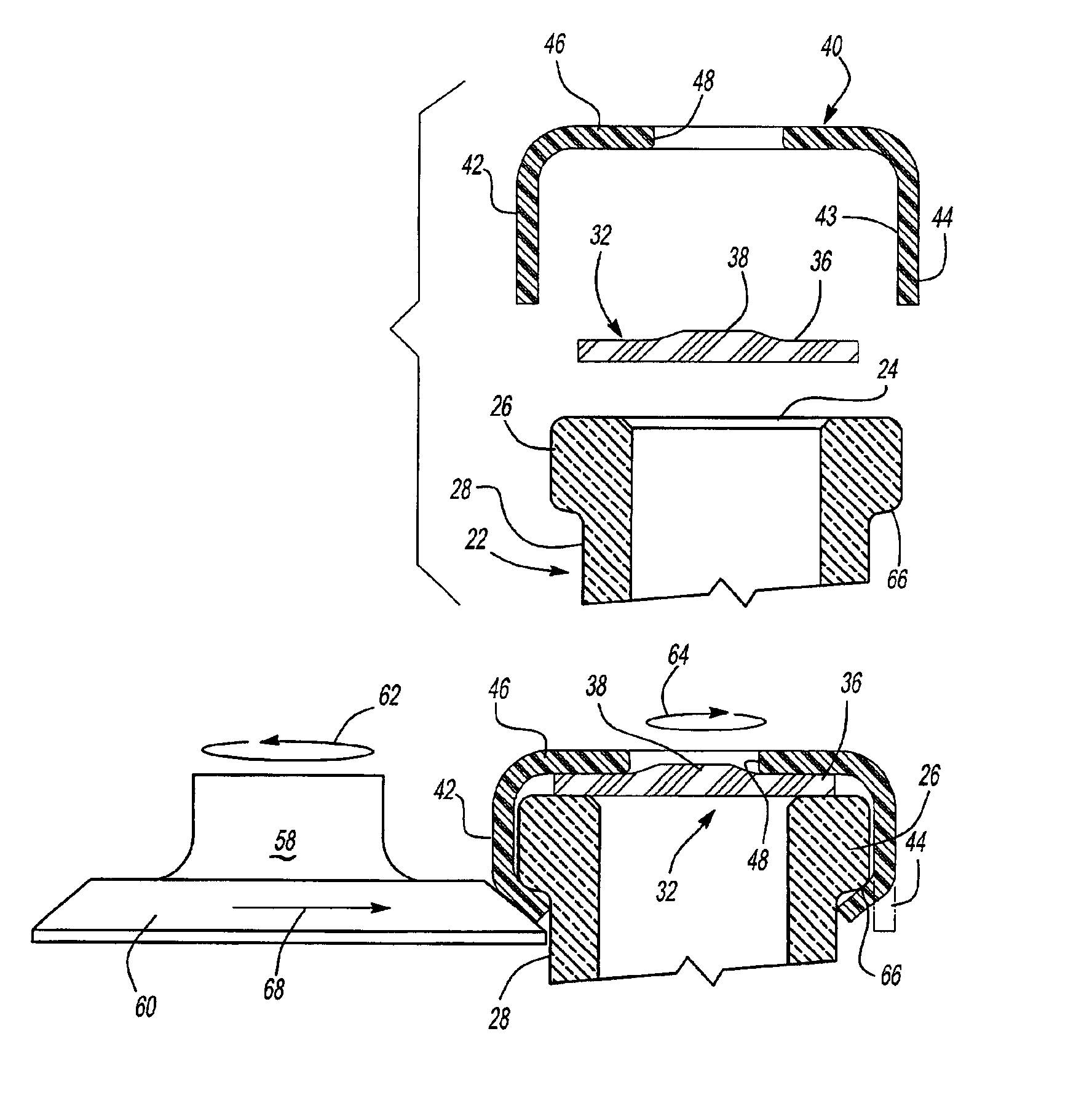

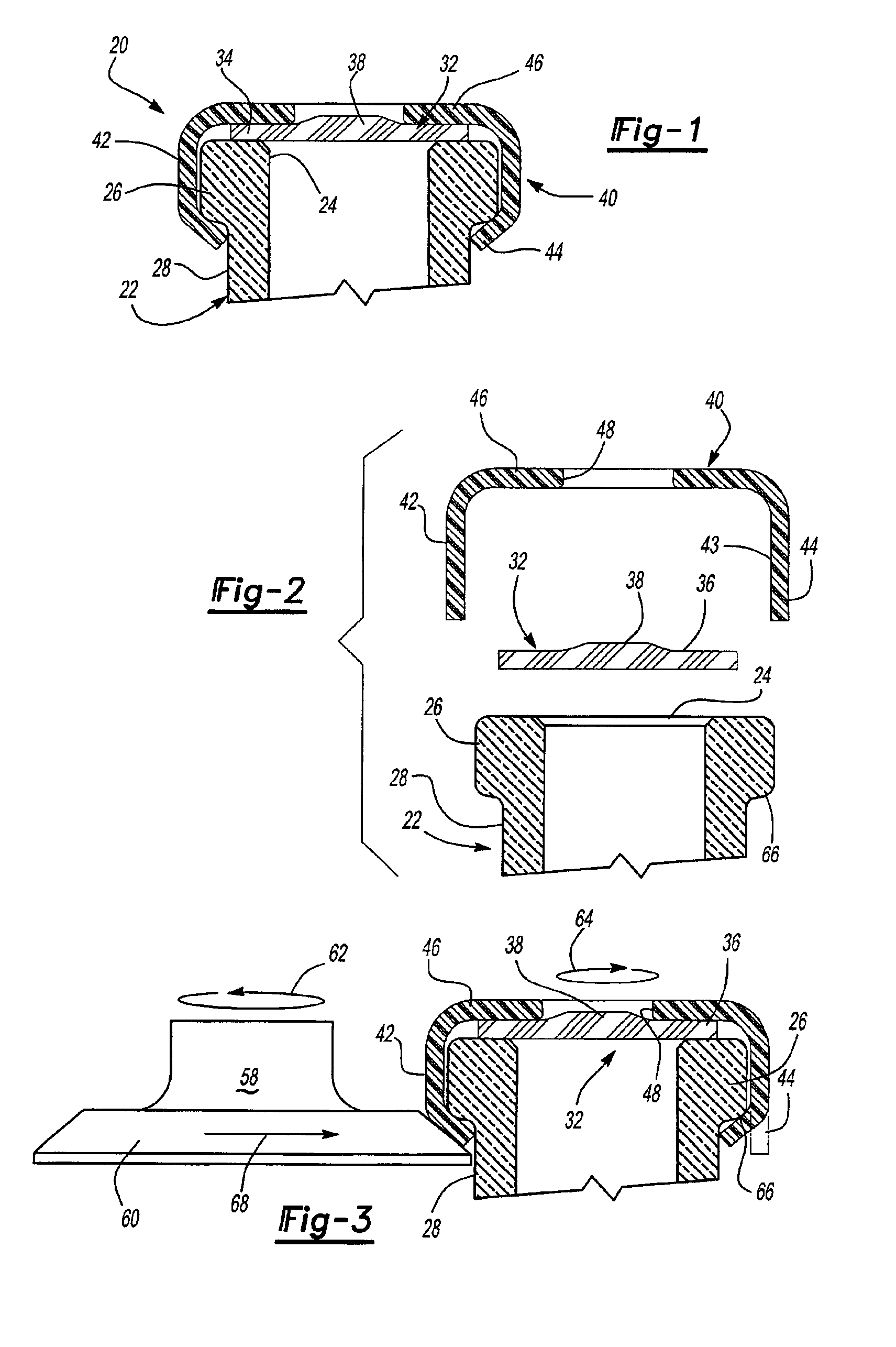

Method of sealing a cartridge or other medical container with a plastic closure

InactiveUS6904662B2Eliminate the problemEliminate hazardsCapsDiagnosticsEngineeringMechanical engineering

A method of sealing a cartridge having a barrel with a polymeric closure, wherein the polymeric closure includes a tubular collar portion and an integral radial portion, The method includes disposing the tubular collar portion over the radial rim portion of the barrel to surround the reduced diameter neck portion and incrementally rolling and radially deforming the tubular collar portion adjacent its free end into the reduced diameter neck portion with a crimping tool, wherein the polymeric closure is sufficiently malleable to permit radial deformation, yet sufficiently rigid and resistant to creep to retain its shape following deformation The crimping tool or tools include an inclined surface having a gradually decreasing angles of inclination which are driven against the tubular collar portion adjacent the free end and the cartridge assembly and crimping tool are relatively rotated.

Owner:BECTON DICKINSON & CO

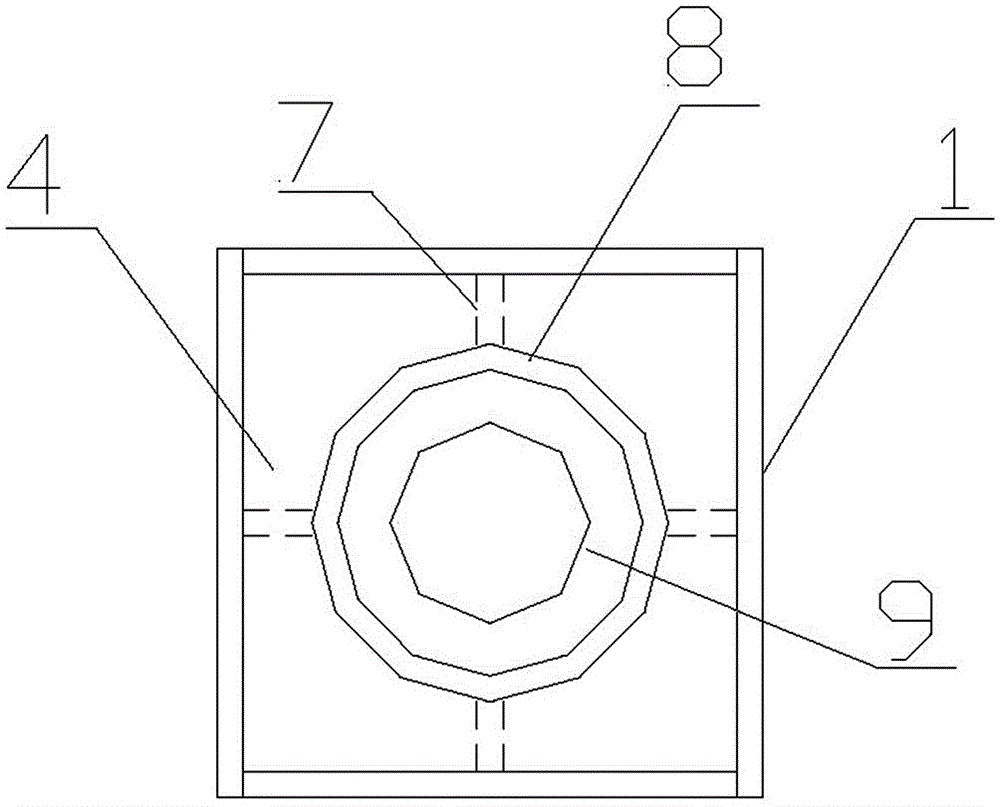

Space constraint multi-cavity pipe-in-pipe steel bar concrete huge column and construction method

ActiveCN105133793AImprove mechanical performanceWide range of sizesStrutsBuilding material handlingRebarMaterials science

The invention relates to a space constraint multi-cavity pipe-in-pipe steel bar concrete huge column and a construction method. A huge column comprises a core steel pipe concrete part and a steel-encased pipe concrete part. A core steel pipe forms an inner cavity. The inner cavity is filled with inner cavity concrete, and a steel bar frame is arranged through the middle part of the inner cavity. The core steel pipe and the steel-encased pipe form an outer cavity. The outer cavity is filled with outer cavity concrete, and at least a steel bar frame is arranged through the outer cavity. The core steel pipe and the steel-encased pipe are connected through a vertical connection plate and form a space steel pipe structure. The outer steel pipe of the huge column is connected with the inner steel pipe through the vertical connection plate, the space steel pipe structure is formed, and the force bearing performance of traditional steel pipe concrete can be raised effectively. The huge column has a strong anti-pressure capability, steel and concrete combined action performances are good under action of long-term load. The huge column has good earthquake resistant behavior, fireproof performance and construction convenience.

Owner:姚攀峰

Intumescent fire door edge system

InactiveUS8230659B2Increase the gap sizeHigh trafficSynthetic resin layered productsBuilding repairsMelting temperatureActivation temperature

An intumescent strip includes a first material layer and an opposing second material layer. A third material layer, formed from an intumescent material, is positioned between the first and second layers. The intumescent material includes a combination of intumescent particles suspended within a thermoplastic material. The intumescent particles have an activation temperature and are expandable when exposed to temperatures above the activation temperature. The thermoplastic material has a melting temperature that is lower than the activation temperature.

Owner:LANCOTEK PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com