Low-creep C60 high-performance concrete

A high-performance concrete, low-creep technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of increased prestress loss, etc., to achieve the effect of ensuring economical efficiency and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] In this example, according to the raw material composition described in the summary of the invention, 6 experimental groups of concrete were prepared, and the ratio data of each group are shown in Table 1.

[0046] Table 1 Low creep C60 high performance concrete mix ratio

[0047]

[0048] Guangxi China Resources 42.5 ordinary Portland cement is used for the cement in the above-mentioned cementitious materials, the fly ash is Class I fly ash of Taishan Power Plant, and the mineral powder is S95 finely ground mineral powder of Dongguan China Resources Cement Plant. See Table 2-4 for the technical indicators of cement, fly ash and slag used.

[0049] Admixture: JM-PCA(I) polycarboxylate high-efficiency water reducer produced by Jiangsu Bote New Material Co., Ltd., which has good compatibility with cement and other cementitious materials.

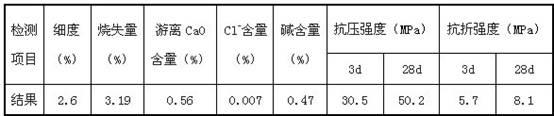

[0050] Table 2 The main technical indicators of Guangxi China Resources 42.5 cement

[0051]

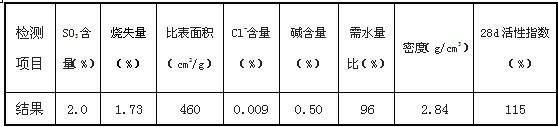

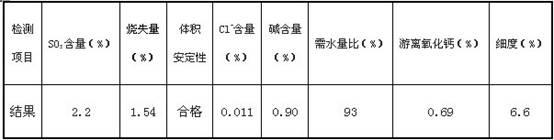

[0052] Table 3 Main technical ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sand rate | aaaaa | aaaaa |

| sand rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com