Patents

Literature

1713results about How to "Meet strength requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

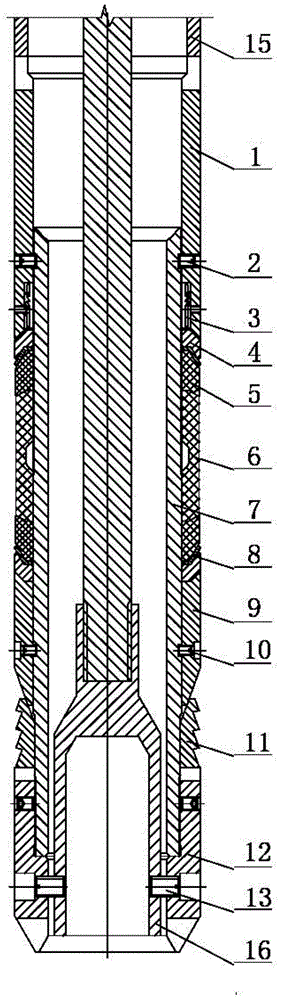

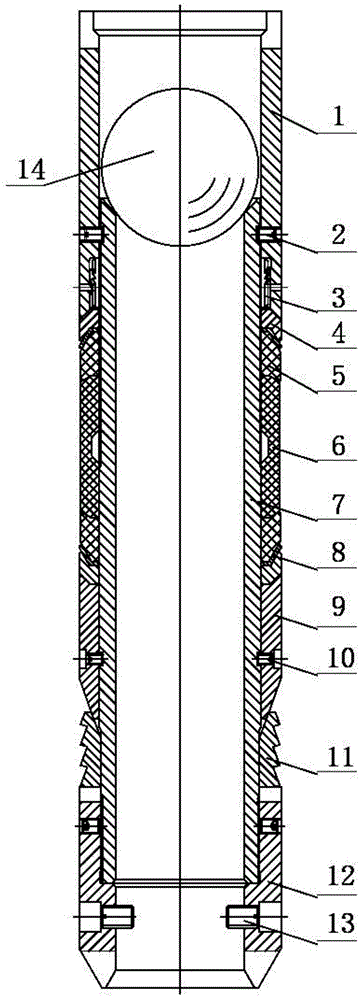

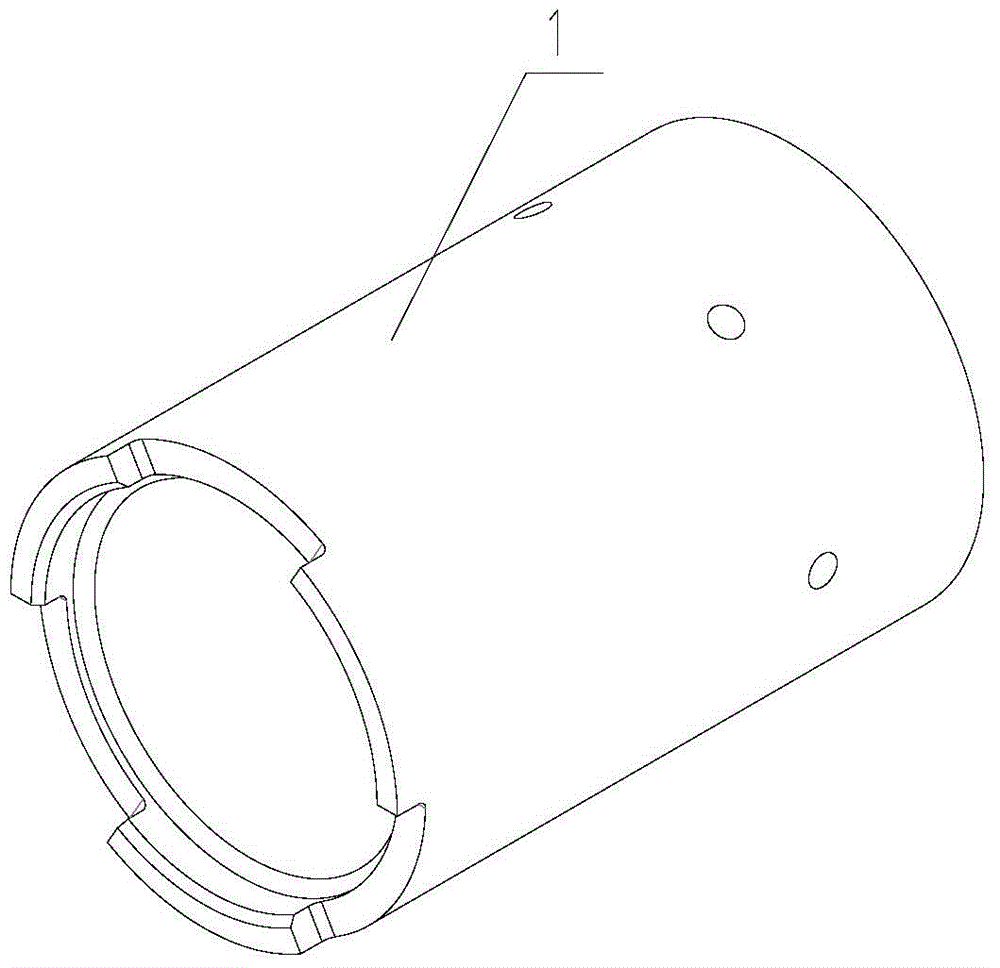

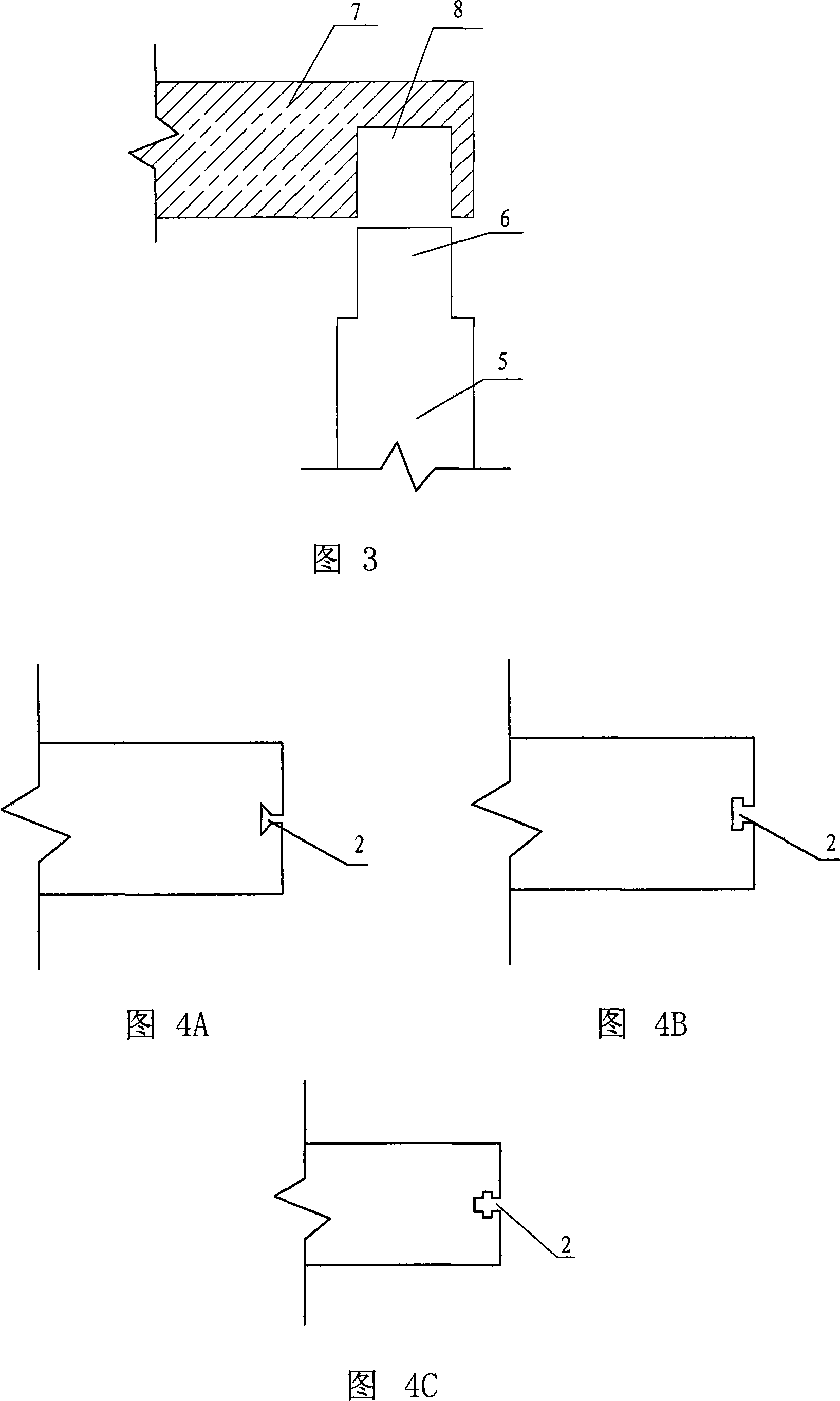

Bridge plug with large drift diameter and setting method of bridge plug

The invention discloses a bridge plug with a large drift diameter. The bridge plug comprises an upper joint, a central tube, a guiding shoe head and a bridge plug assembly; the upper joint is an annular part and is fixedly connected with the outer side of one end of the central tube in a sleeving mode; the central tube is a metal central tube, a soluble ball base is arranged at the end, close to the upper joint, of the central tube, and the central tube is a drillable metal part; the guiding shoe head is an annular part, is fixedly connected with the outer side of the other end of the central tube in a sleeving mode and is provided with a device used for being fixedly connected with a pull rod which is arranged in the bridge plug in a sleeved mode; the middle section of the central tube is sleeved with the bridge plug assembly which is located between the upper joint and the guiding shoe head. The invention further discloses a setting method of the bridge plug with the large drift diameter. The drilling polishing procedure of the bridge plug with the large drift diameter can be omitted, the problems of a long construction period, high operation cost and high construction risk brought by drilling polishing are solved, and the bridge plug is easier and more convenient to use and faster to construct.

Owner:JEREH ENERGY SERVICES

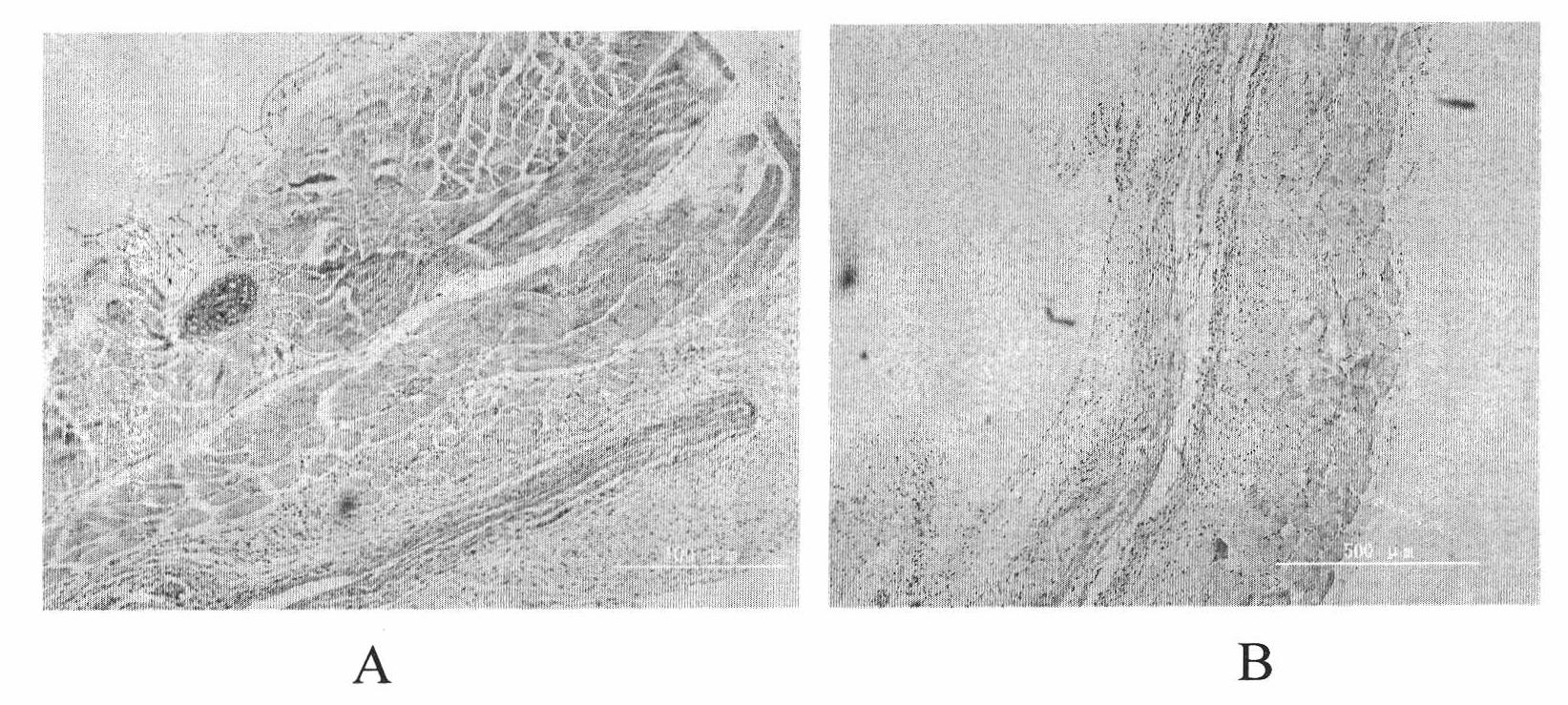

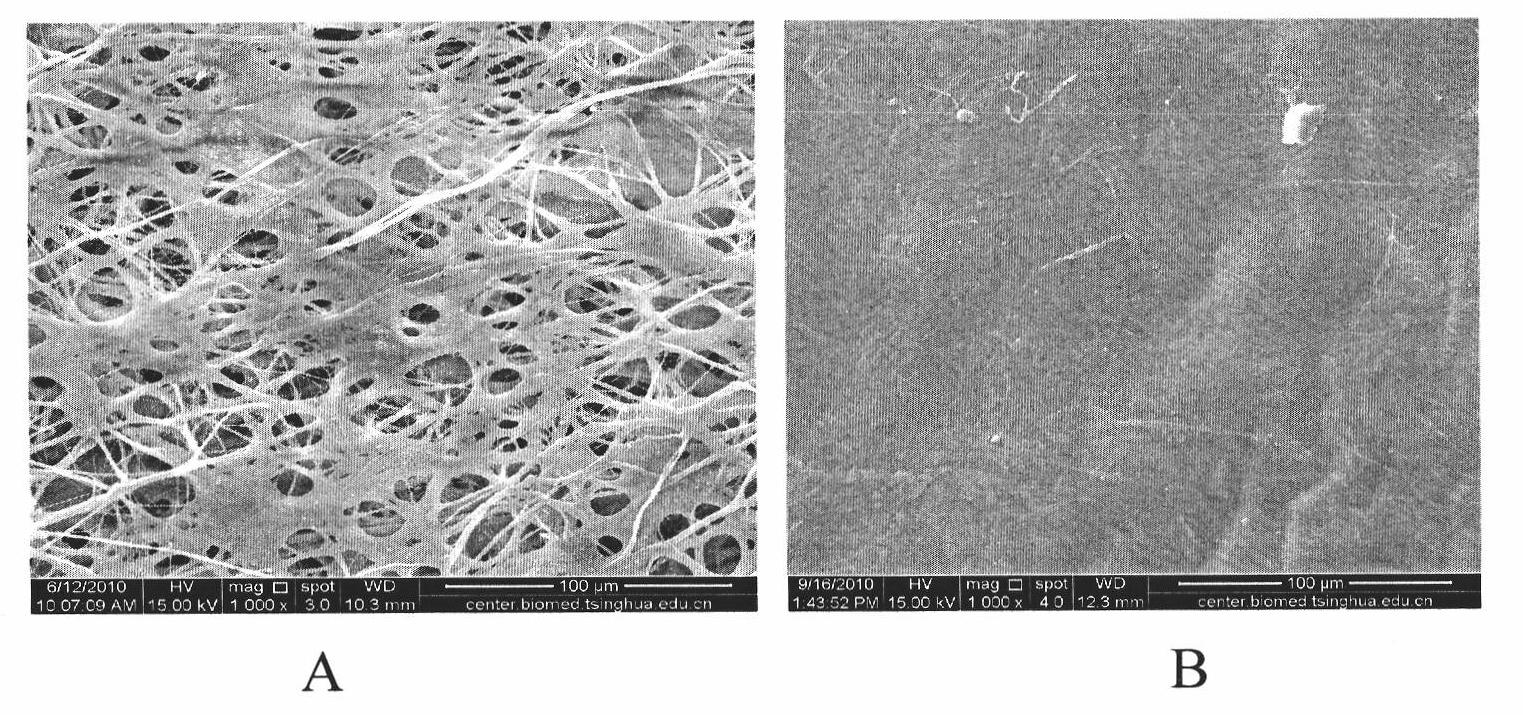

Small intestinal submucosa (SIS) soft tissue repair patch and preparation method thereof

InactiveCN102462561AImprove surface porosityImprove biological activityProsthesisTissue repairSoft tissue.FNA

The invention relates to a method for preparing a small intestinal submucosa (SIS) soft tissue repair patch, and the soft tissue repair patch prepared by the method. The invention also relates to application of the soft tissue repair path to tissue repair.

Owner:BEIJING MED ZENITH MEDICAL SCI CORP LTD

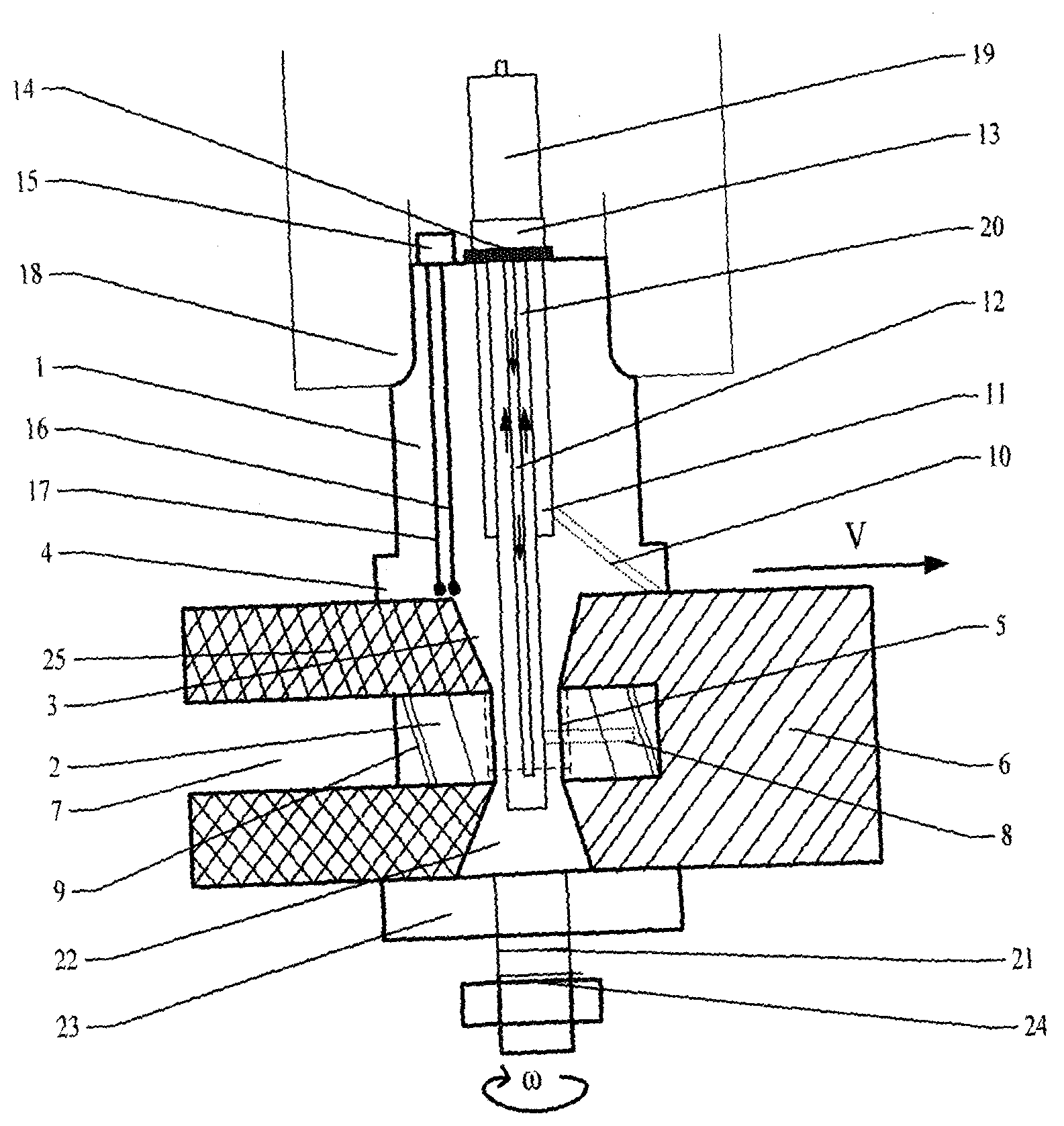

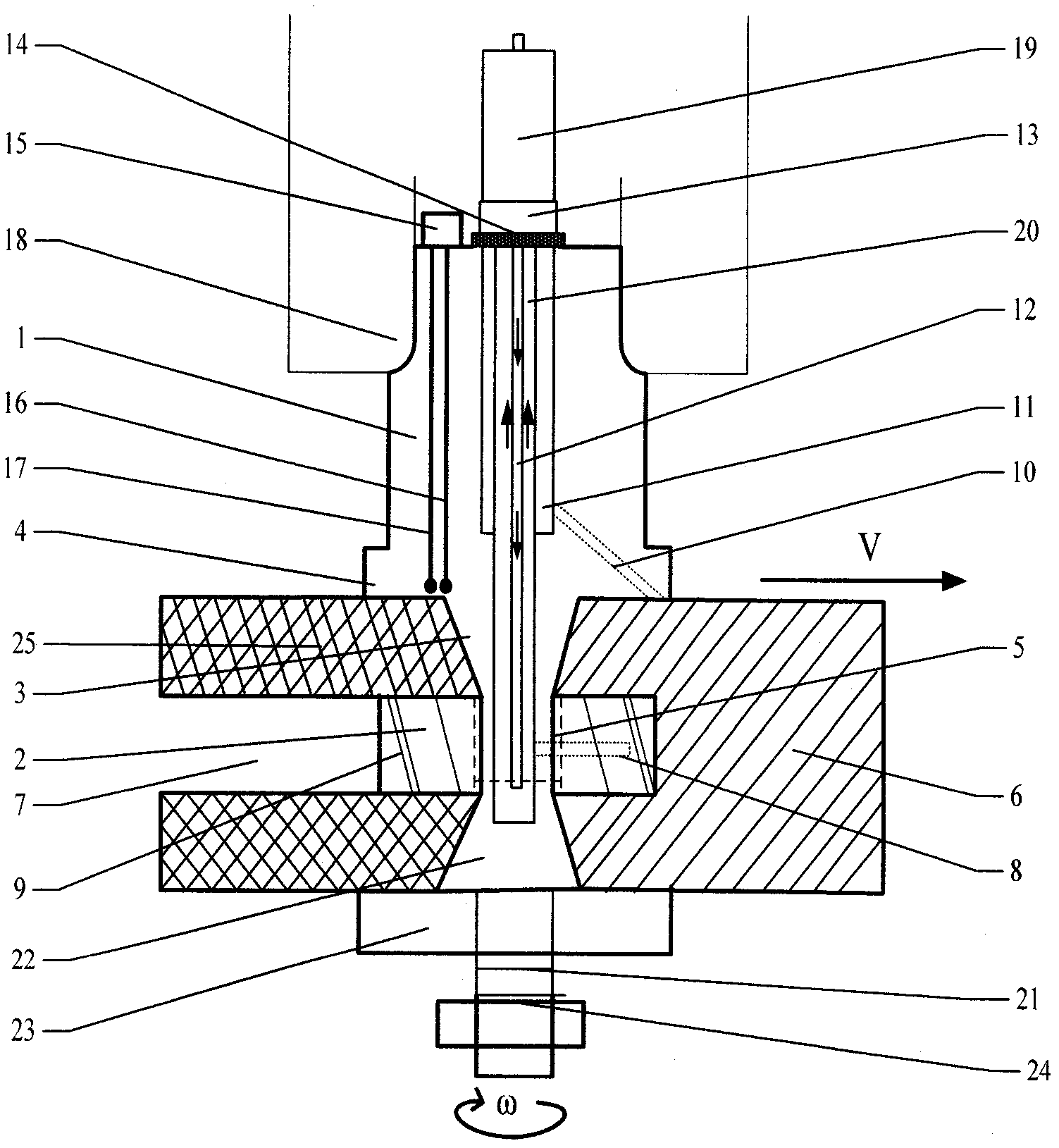

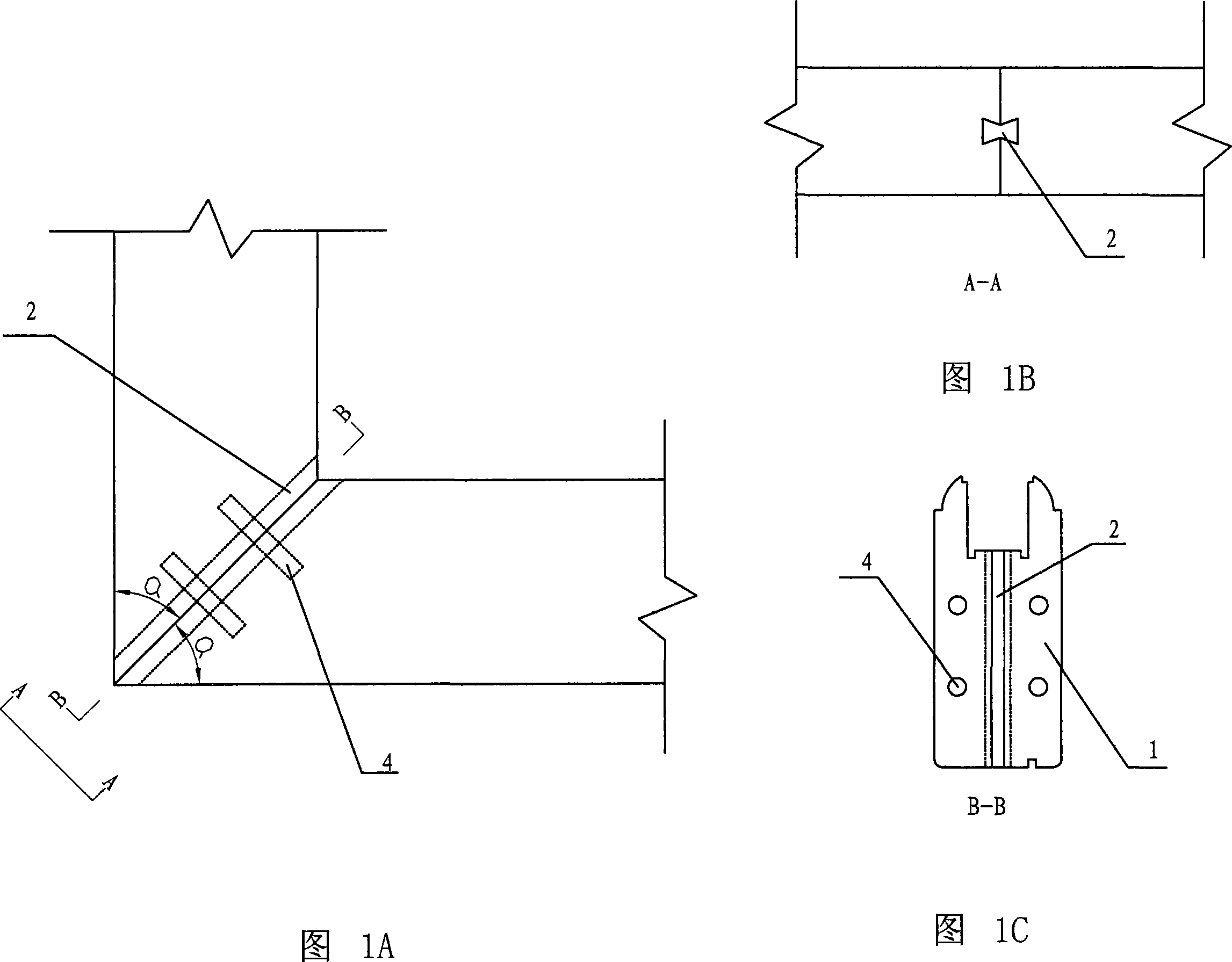

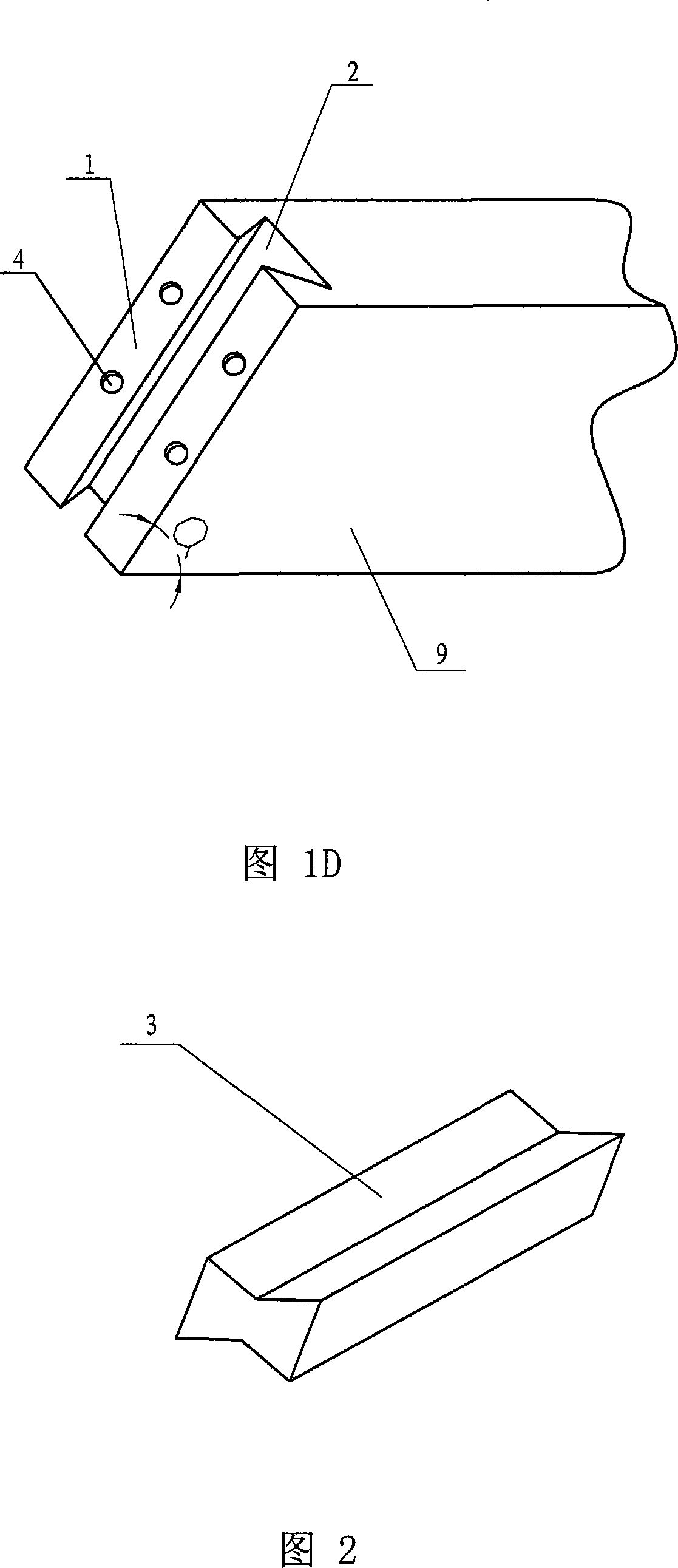

Cutting-stirring friction welding composite processing device for floating double-shaft-shoulder double-stirring needle and manufacture method thereof

InactiveCN102490018AEfficient coolingAvoid glitchesOther manufacturing equipments/toolsNon-electric welding apparatusInduction systemTemperature sensing

The invention discloses a cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and a manufacture method thereof, and particularly relates to a combined or composite processing device capable of simultaneously carrying out milling or cutting processing and stirring friction welding processing and a method thereof. The cutting-stirring friction welding composite processing device for the floating double-shaft-shoulder double-stirring needle integrates a cutting system or a milling system, a stirring friction welding system, a forced cooling system, a gas protection system, a temperature sensing system, a pressure induction system, a milling liquid supply system and a sensing-free system. The cutting-stirring friction welding composite processing device has functions of temperature control, gas protection, pressure detection, cooling liquid protection, milling head replacing and floating double-shaft-shoulder self-supporting stirring friction welding. The method for carrying out cutting-stirring friction welding composite processing on workpieces can meet strength requirements of mechanical processing of ferrous light metal materials, carbon steel materials and alloy steel materials. The cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and the manufacture method of the cutting-stirring friction welding composite processing device reduce manufacture procedures, save processing cost, have the advantages of being high in efficiency, excellent in quality, high in stability and saving in energy, break through limitation of conventional machining technology, form a new method and a new thought for machinery processing, and have wide application prospects in industries of heating, air conditioners, ice manufacture, freshness keeping, medicine preparation, construction, aquatic products and foods.

Owner:CHONGQING UNIV

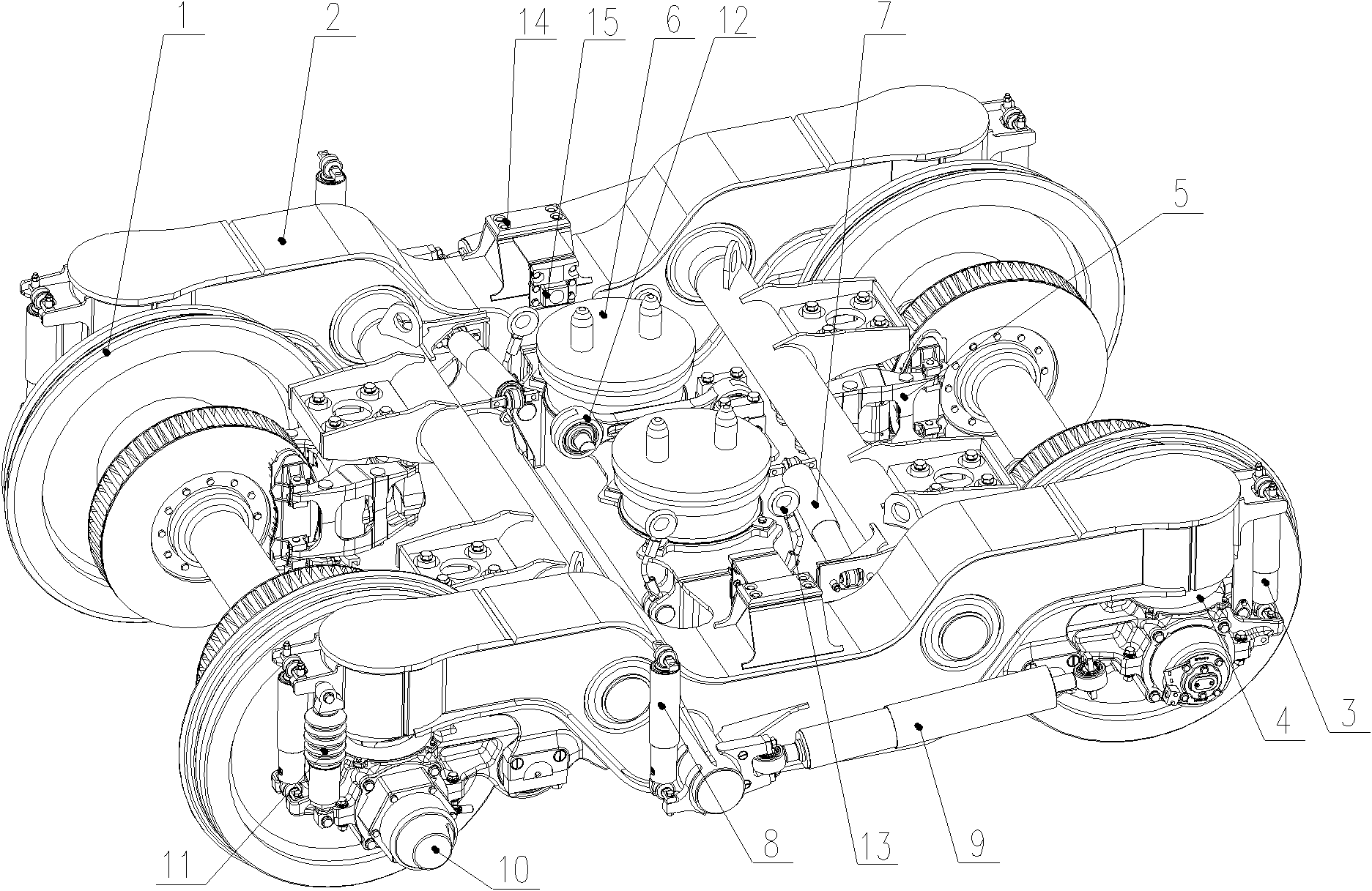

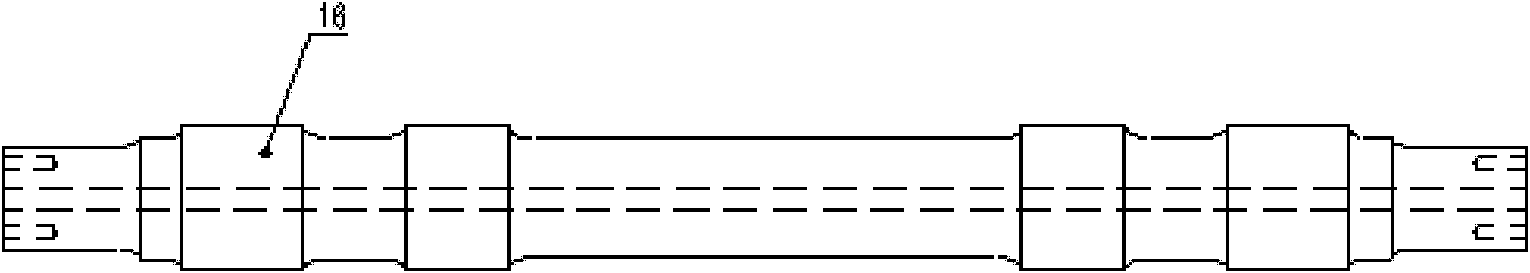

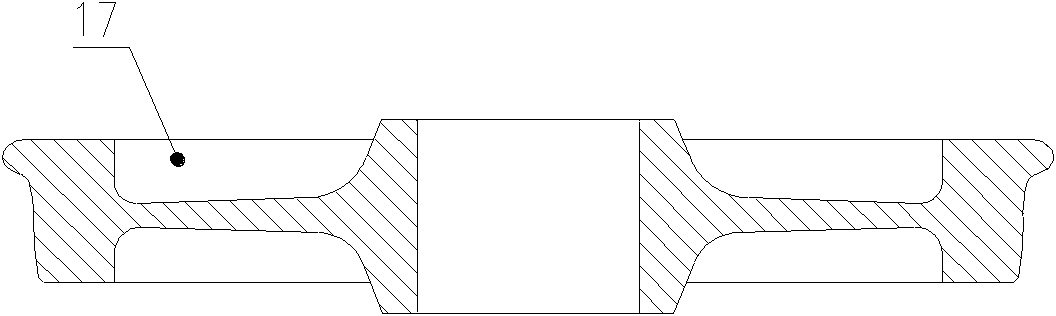

Bogie for high-speed rail wagon

ActiveCN102490755AImprove operational safety indicatorsSimple structureBogiesBogie-underframe connectionsTruckDouble stage

The invention discloses a bogie for a high-speed rail wagon. The bogie comprises a framework, wherein two transverse ends of the framework are connected with a wheel set through two single-stage suspension systems respectively; a double-stage suspension system and a foundation brake device are arranged on the framework; and the front side and the rear side of the framework are provided with an anti-snakelike damper respectively. By the bogie, two-grade requirements that the shaft weight is 16.5t when the speed of the wagon is 200km / h as well as the shaft weight is 18t when the speed of the wagon is 160km / h can be met simultaneously; and the bogie has the remarkable characteristics of simple structure, high popularity and reliable performance.

Owner:CRRC SHANDONG CO LTD

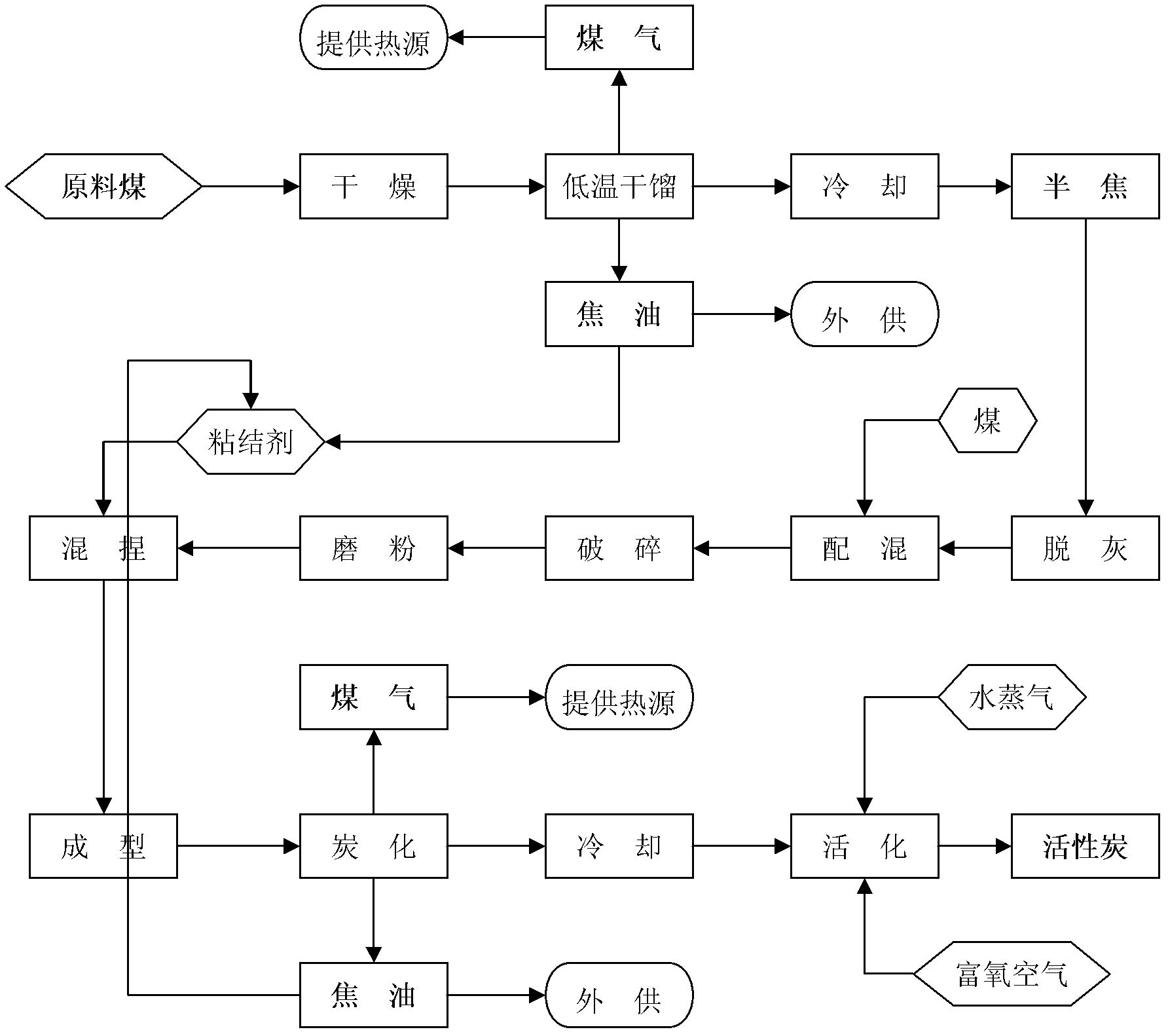

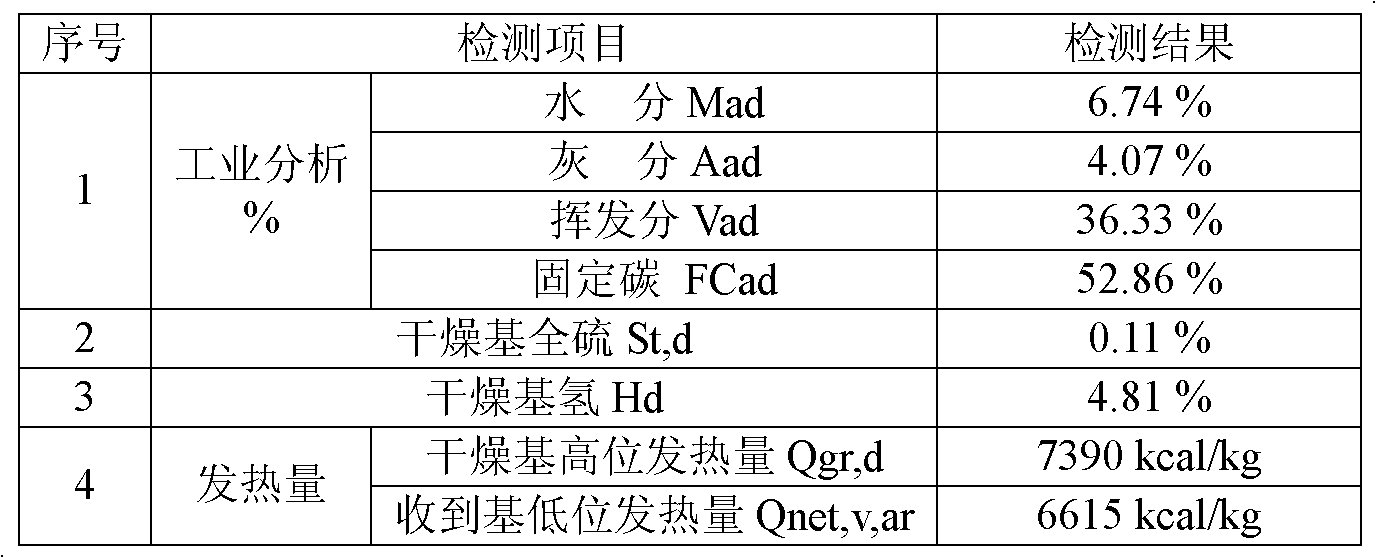

Method for preparing active carbon by using coal

The invention provides a method for preparing active carbon by using coal. The method comprises the following steps: after feed coal is dried, dry-distilled at low temperature and cooled, semicoke is obtained; deashing is carried out on the semicoke in which the ash content can not meet the production requirement of the active carbon; coal is mixed with certain viscosity into the semicoke which can not meet the strength of the active carbon according to the characteristics; after mixed with the coal, the raw materials are mixed fully by crushing and grinding; after a certain amount of binding agent is added, the powder is mixed and kneaded, and is pressed into a forming material with a special shape in forming equipment; the forming material enters a carbonization furnace by a conveying device, carrying out heat treatment, dry-distillation, heat cracking and condensation reaction at different temperature sections to prepare carbonized materials; the carbonized materials are conveyed to a cooling furnace for cooling by the conveying device; and the cooled carbonized materials are conveyed to an activating furnace, and is activated by utilizing an activating agent. The method has the advantages that the industrial chain for comprehensive utilization of subcannel coal is extended, the utilization bottleneck of the semicoke is broken, products with increasing market demand are produced, the strategic resources short in China can be effectively recovered, and large economic and social benefits can be created.

Owner:西安三瑞实业有限公司

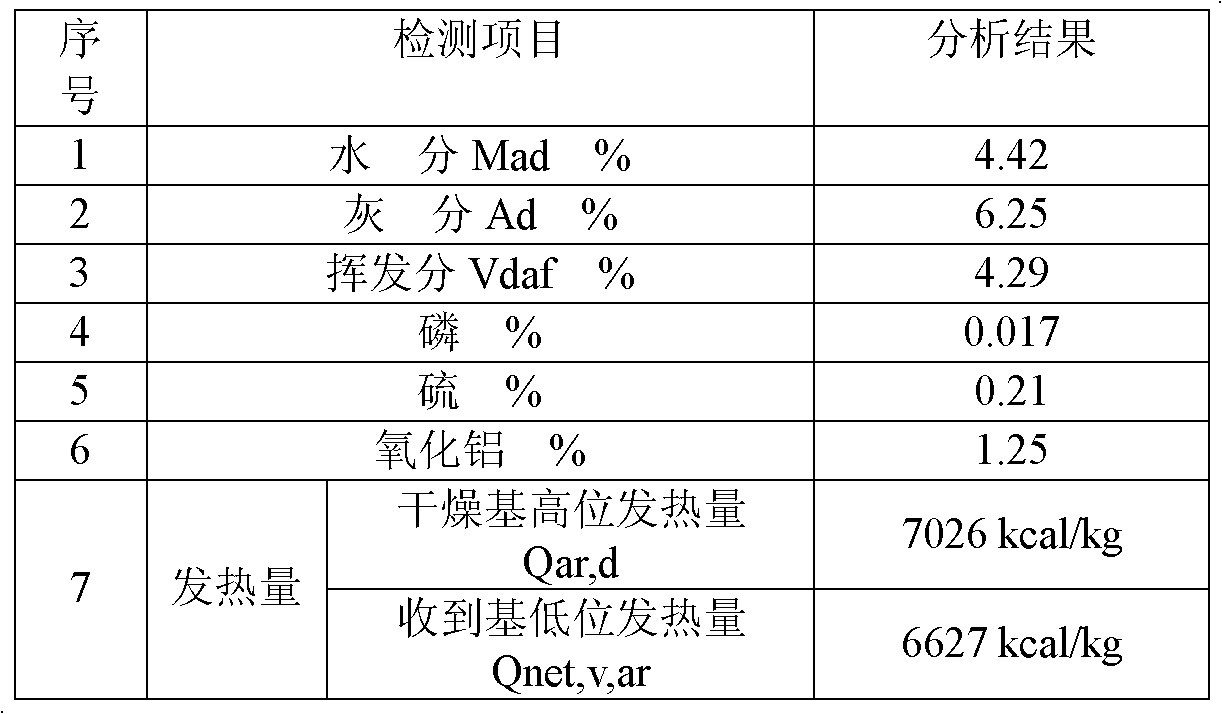

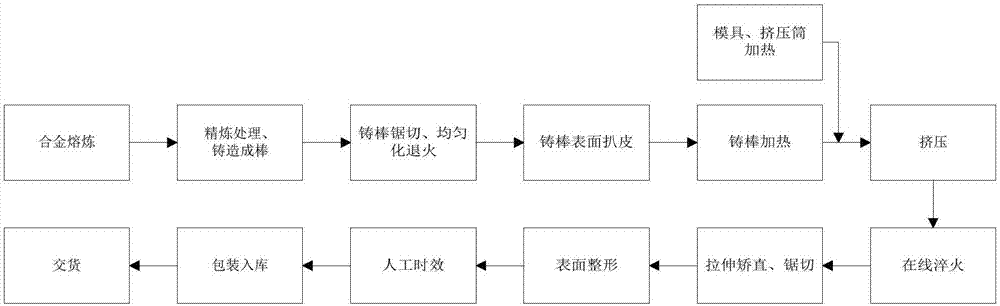

Aluminum alloy section for rail traffic car body skirtboard and manufacturing method of aluminum alloy section

InactiveCN107326227AGood mechanical propertiesReduce the failure rateExtrusion control devicesQuenchingRail transportation

An aluminum alloy profile for a rail transit car body skirt and a manufacturing method thereof, relating to the technical field of preparation of aluminum alloy profiles, the manufacturing method of the aluminum alloy profile for a rail transit car body skirt includes the following steps: alloy smelting, refining treatment, Casting into rods, sawing of cast rods, homogenization annealing, surface peeling of cast rods, heating of cast rods, extrusion, online quenching, stretching straightening, sawing, surface shaping, artificial aging, the manufacturing method strictly controls the process steps Each parameter can be mass-produced with qualified wall dimensions and good mechanical properties, meeting the strength requirements of aluminum alloy materials for rail transit car body skirts; the prepared aluminum alloy profiles for rail transit car body skirts can be specially used The production of rail transit car body skirts can reduce the occurrence of unqualified rates, improve production efficiency, and reduce manufacturing costs.

Owner:SHANDONG NANSHAN ALUMINUM +1

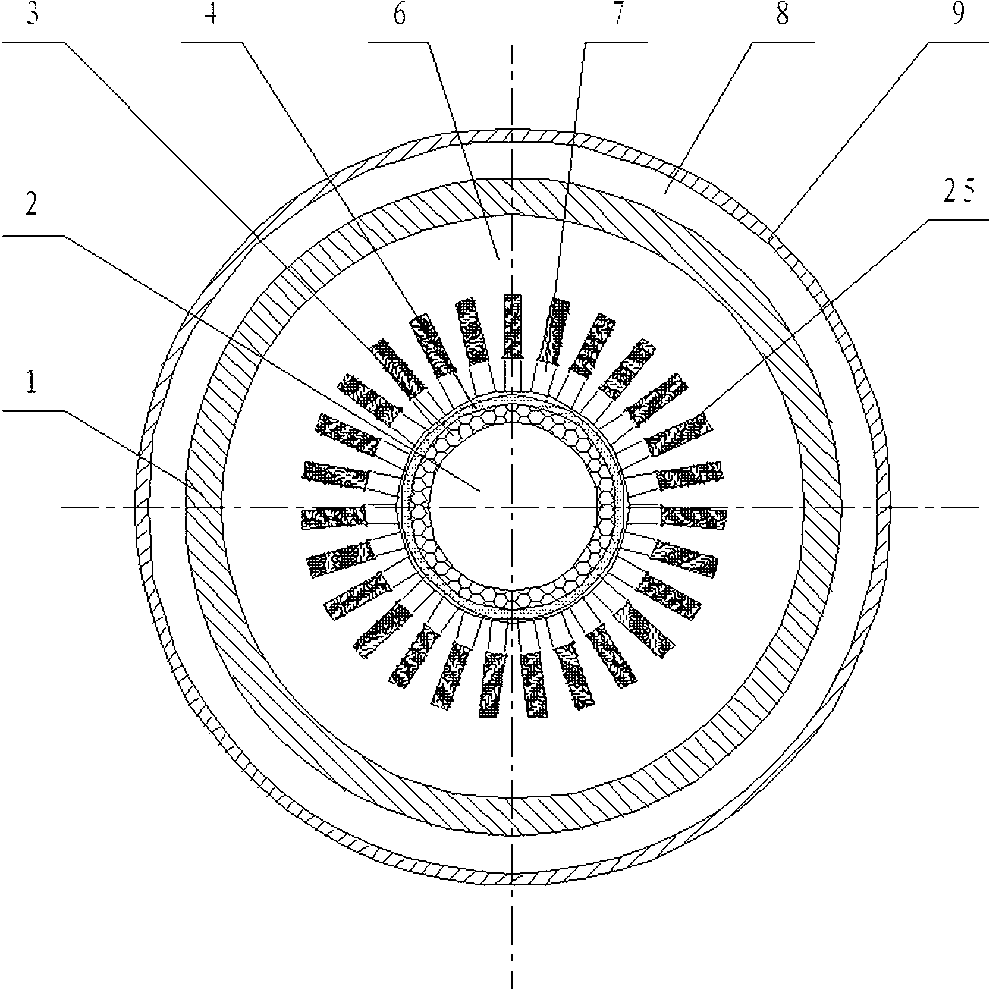

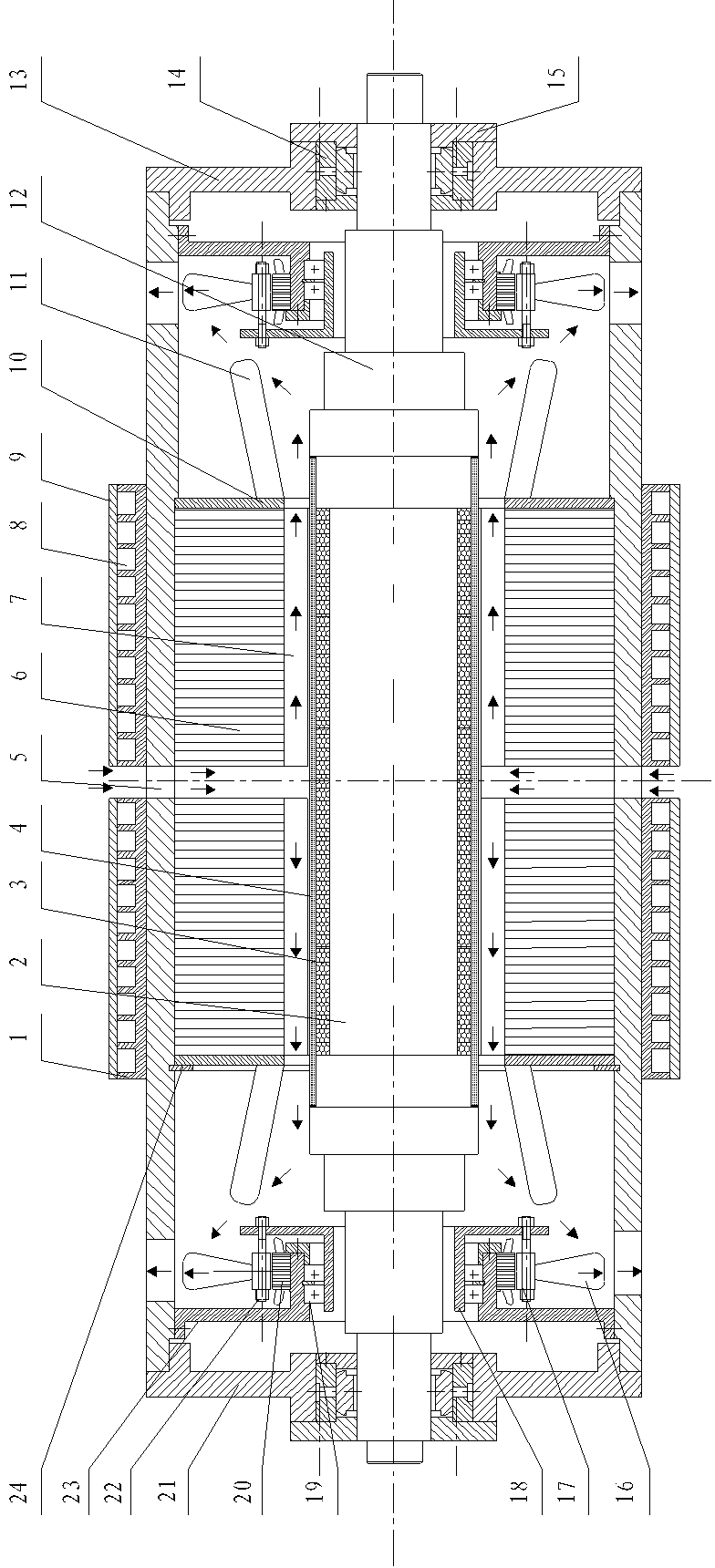

Air and water hybrid cooling high-speed permanent-magnet motor

InactiveCN102983680AReduce eddy current lossLow heat generationMagnetic circuit rotating partsMagnetic circuit stationary partsWater flowPermanent magnet motor

The invention discloses an air and water hybrid cooling high-speed permanent-magnet motor and belongs to the technical field of motors. The large-power high-speed permanent-magnet motor comprises a casing, a cooling water jacket, a stator core, a stator radial air duct, a stator inner air duct, a motor rotor, an outer rotor axial fan, an outer rotor fan fixing frame and two sliding bearings. The stator core is divided into two sections, the radial air duct is reserved in the middle, and the inner air duct is reserved in a stator slot close to the air gap position. The cooling water jacket is arranged outside the stator casing, a spiral water way is arranged in the water jacket, and water flows into the water way from the middle of the water way and flows out from a left spiral water outlet and a right spiral water outlet which are arranged at two ends of the water way. The air and water hybrid cooling high-speed permanent-magnet motor can mechanically solve the problem that a permanent magnet is broken when bearing large pulling stress during high-speed rotating, further solves the problems that the large-power high-speed motor is large in loss density, difficult in heat dissipation and over high in temperature rising, and prevents the permanent magnet from having irreversible demagnetization easily at high temperature.

Owner:SHENYANG POLYTECHNIC UNIV

Method for preparing high-loading iron cyanide complex/silicon dioxide hybrid materials

ActiveCN101041123AIncrease loadFast adsorption rateSilicon compoundsRadioactive decontaminationPotassiumSilicon dioxide

The invention relates to a preparing method for ferrocyanide with high load / silica hybrid material, belonging to a preparing method for radionuclide ion absorbing material. The method uses the salt solution with metal ion such as Mn, Sn, Ti, Fe, and Ni so on to react with potassium (sodium) ferrocyanide so as to obtain nanometer particle of ferrocyannide. The particle is fixed by silica solution in water system or is fixed by polymerization siloxane in organic solvent and proper inorganic acid, organic amine or amine water is added to obtain hybrid gel. The hybrid gel is dried, rubbed and screened to obtain ferrocyanide with high load / silica hybrid material. The high load of the material is high and the absorption to nuclide ion is strong. In addition, the material intensity can satisfy the demand of packed bed. The particle diameter can be controlled so as to avoid the problem that the water resistance of bed layer generated by ferrocyanide used alone is overlarge.

Owner:TSINGHUA UNIV

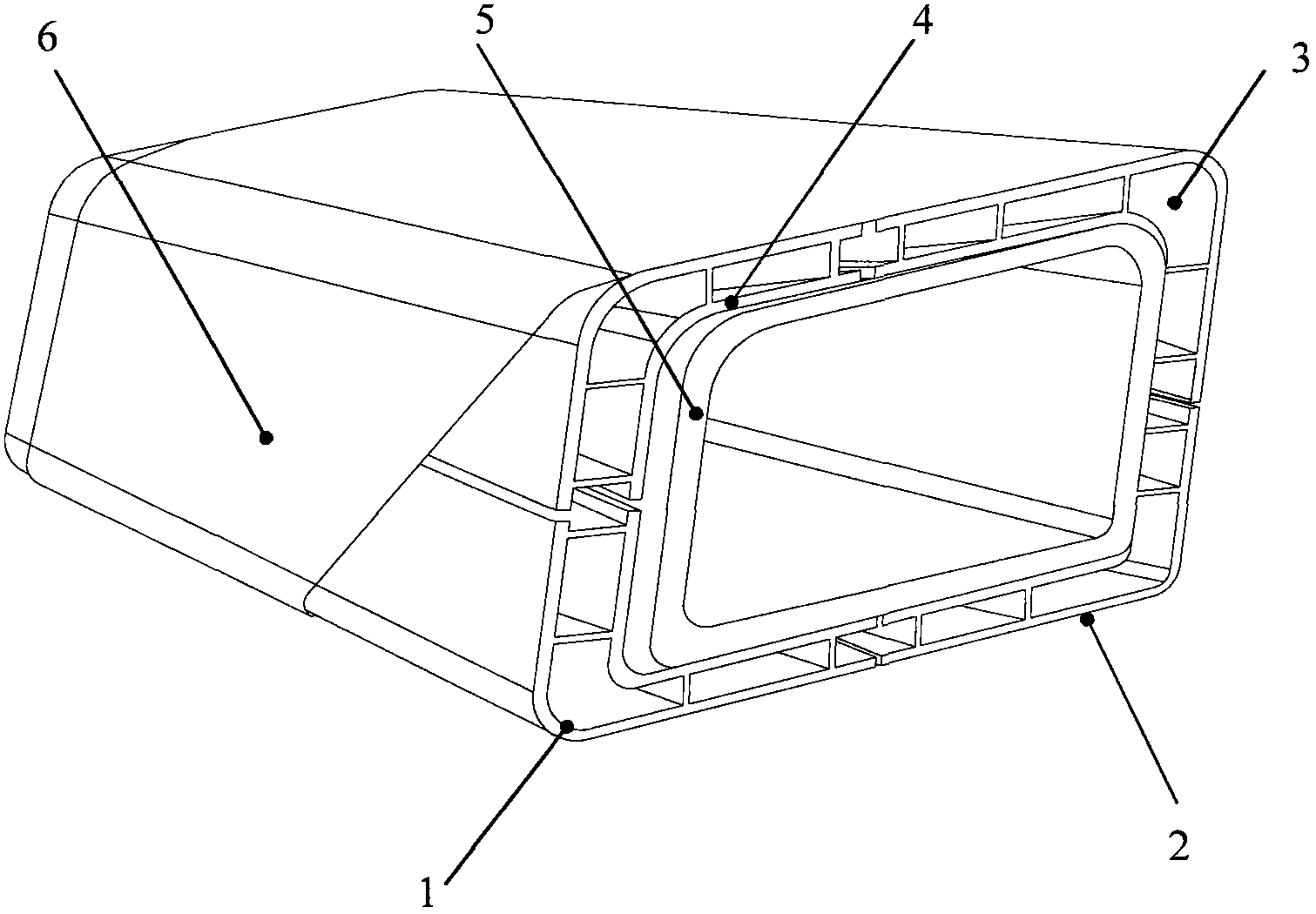

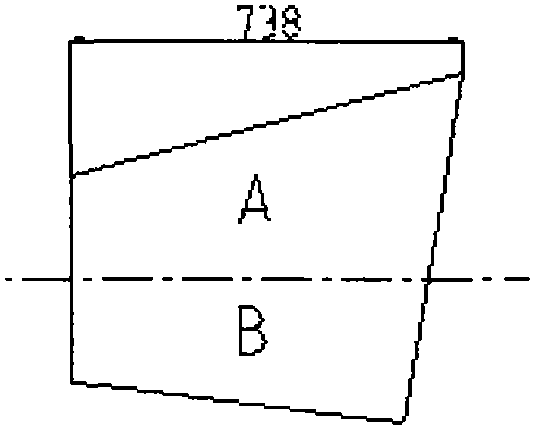

Integral forming method for thin-walled titanium alloy part with irregularly-shaped curved surface and die

InactiveCN102672435AOvercoming shape constraintsOvercome the processShaping toolsLaser beam welding apparatusTitanium alloyMetal

The invention belongs to the field of sheet metal and welding processing, and relates to an integral forming method for a thin-walled titanium alloy part with an irregularly-shaped curved surface. The integral forming method aims at overcoming the defects that the shape of parts processed through the prior art is limited or the procedure and the cost are higher, and effectively ensuring the precision forming of a thin-walled component with an irregular shape. The integral forming method comprises the steps as follows: a parting surface is determined; blanking is carried out; in the preforming step, a plate is bent from a flat into a circular arc through a bending die or a bending machine; welding is carried out; in the hot shaping step, a hot shaping die is put in the inner part of a part that is processed through the assembly welding under the ordinary temperature, and the part is supported tightly due to the dead weight of the die and is heated in a hot shaping machine; and in addition, a pressing machine applies pressure to the hot shaping die when the part is heated until material is softened, so as to enable the part to reach the needed size. The integral forming method comprehensively utilizes the advantages of various processes, can obtain the large-sized thin-walled titanium alloy part with the irregularly-shaped curved surface through only two weld joints, and achieves higher surface quality of the part.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

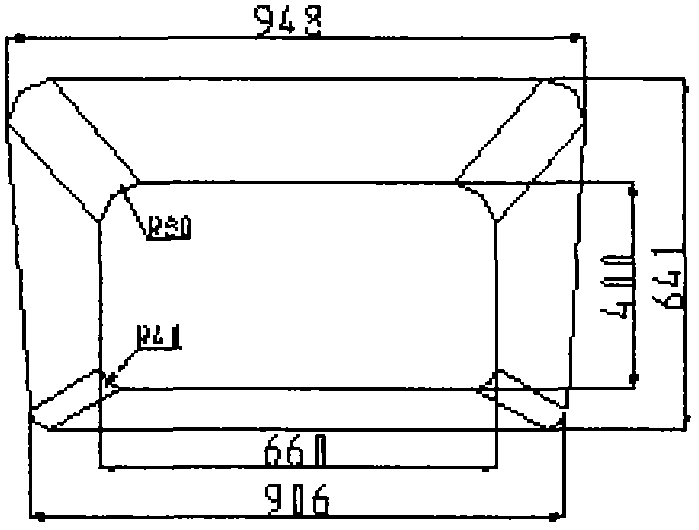

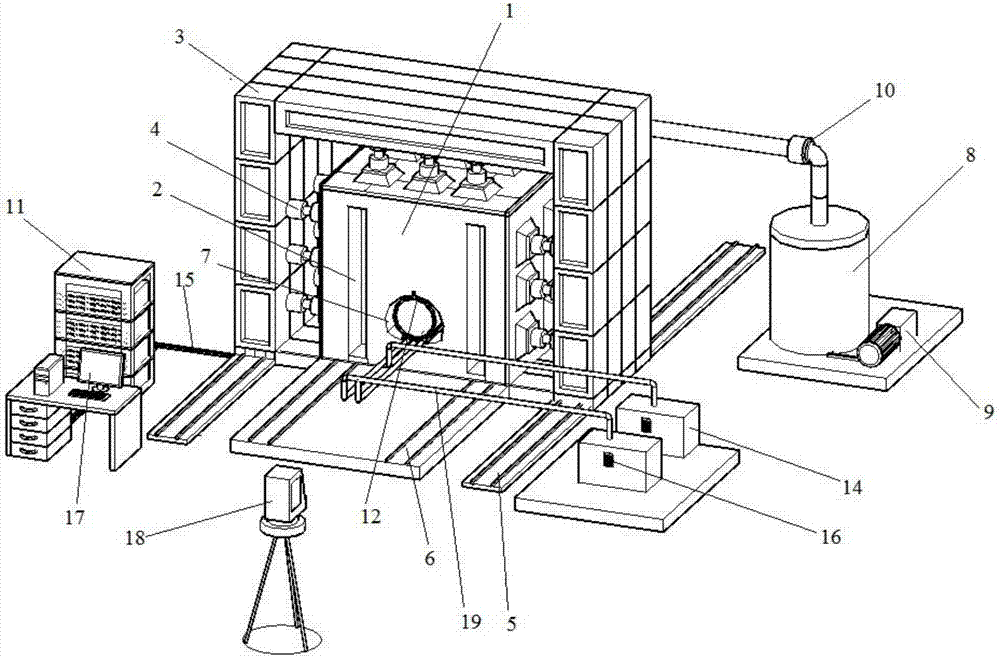

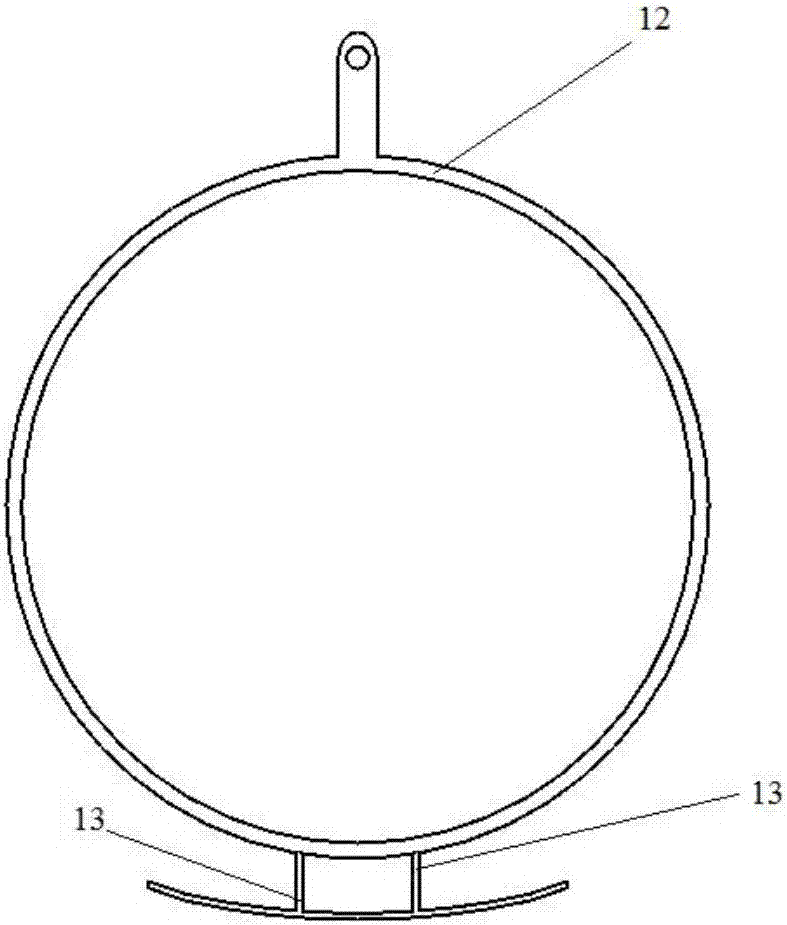

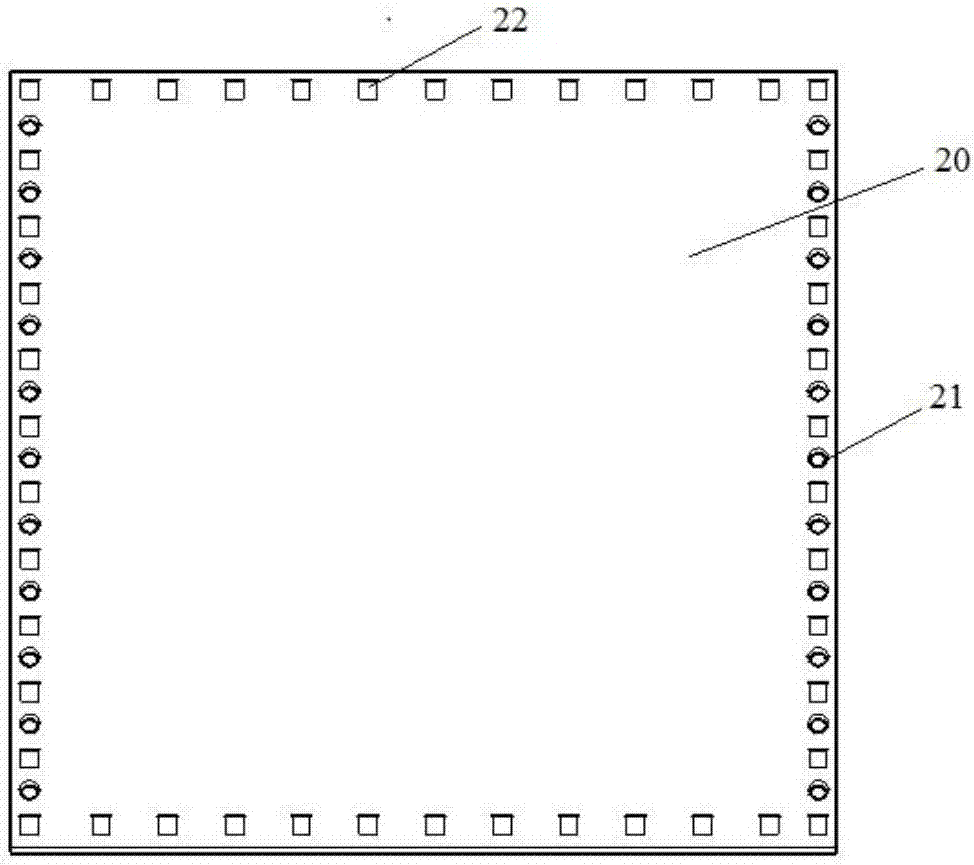

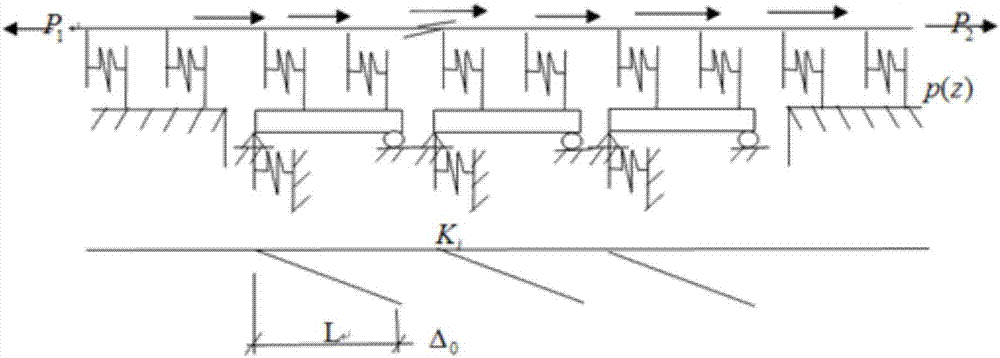

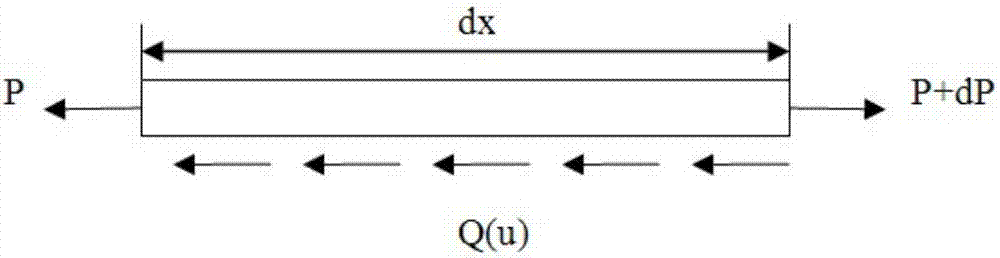

Real-time monitoring device for water-inrush and mud-burst disasters in tunnels and underground engineering and operation method

ActiveCN107144470ARealize visual monitoringRemovableMaterial strength using tensile/compressive forcesControl systemMonitoring system

The invention discloses a real-time monitoring device for water-inrush and mud-burst disasters in tunnels and underground engineering and an operation method. The real-time monitoring device comprises a model box, a ground stress simulation system, a water injection device, a monitoring system and a control system, wherein the model box is used for containing a water-body-containing similar material so as to simulate a rock body; the ground stress simulation system is used for applying a certain pressure to the water-body-containing similar material in a system of the model box and simulating a ground stress; the water injection device is used for injecting a certain amount of water into the water-body-containing similar material, a pressure controller and a flow control valve are mounted on the water injection device, are connected with a serve controller and are used for controlling simulated osmotic pressure at any time; the monitoring system comprises a sensor and a muddy water amount collecting device, the sensor is arranged in the model box, the muddy water amount collecting device is communicated to the inside of the model box, and the monitoring system is used for monitoring and collecting information before and after the occurrence of the water-inrush disasters in real time; and the control system is used for controlling the water injection device and simultaneously processing data collected by an information monitoring system.

Owner:SHANDONG UNIV

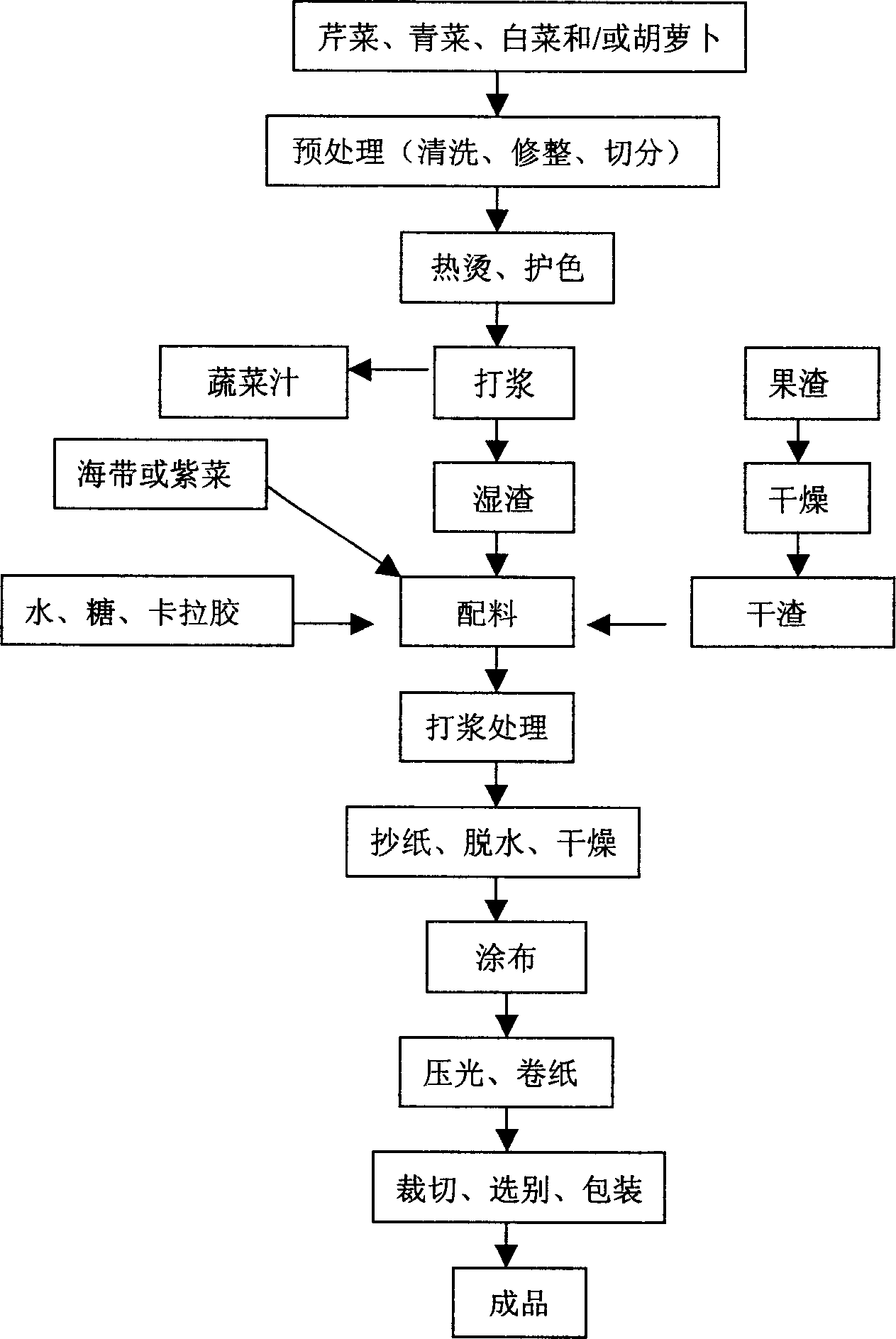

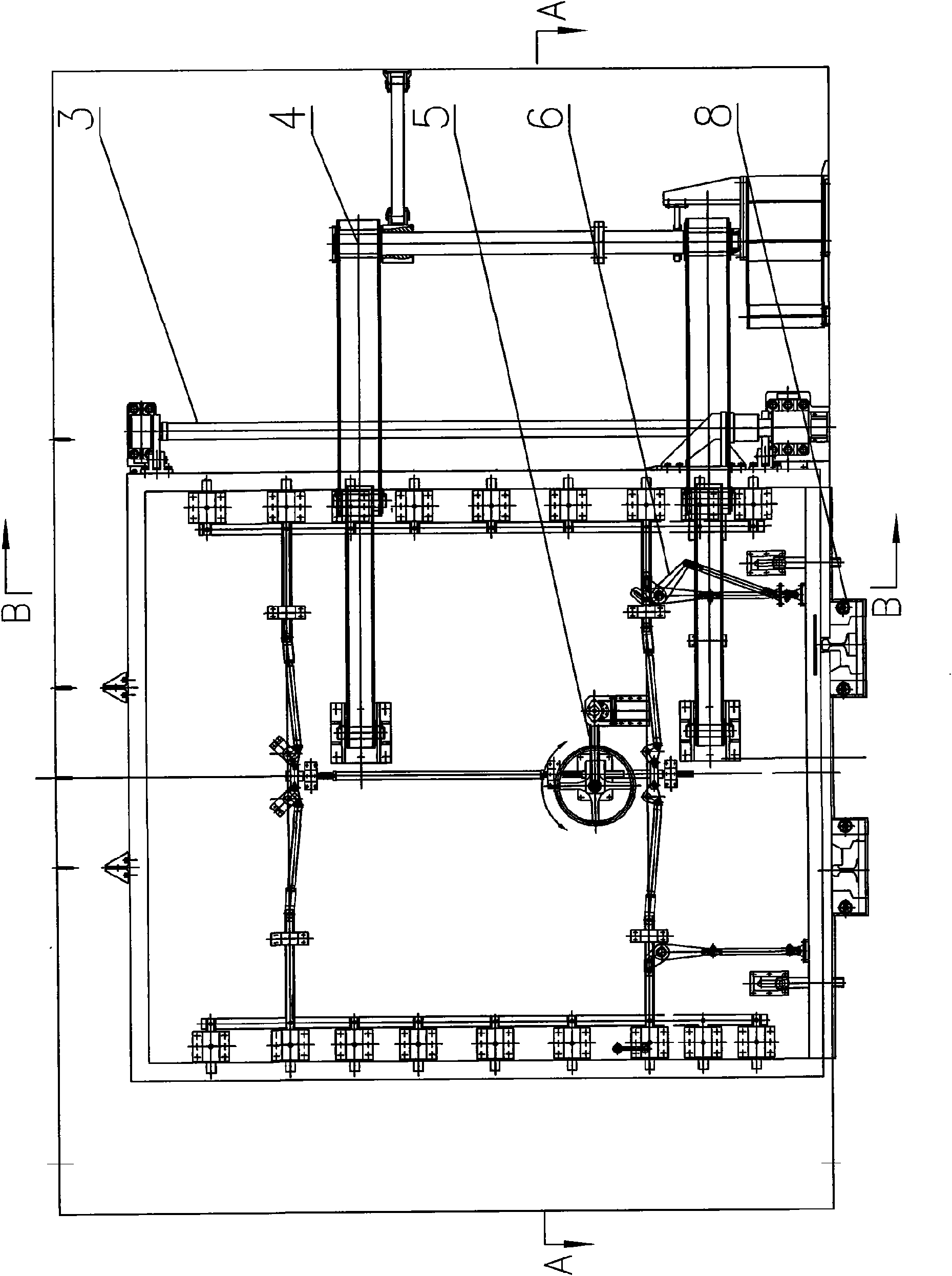

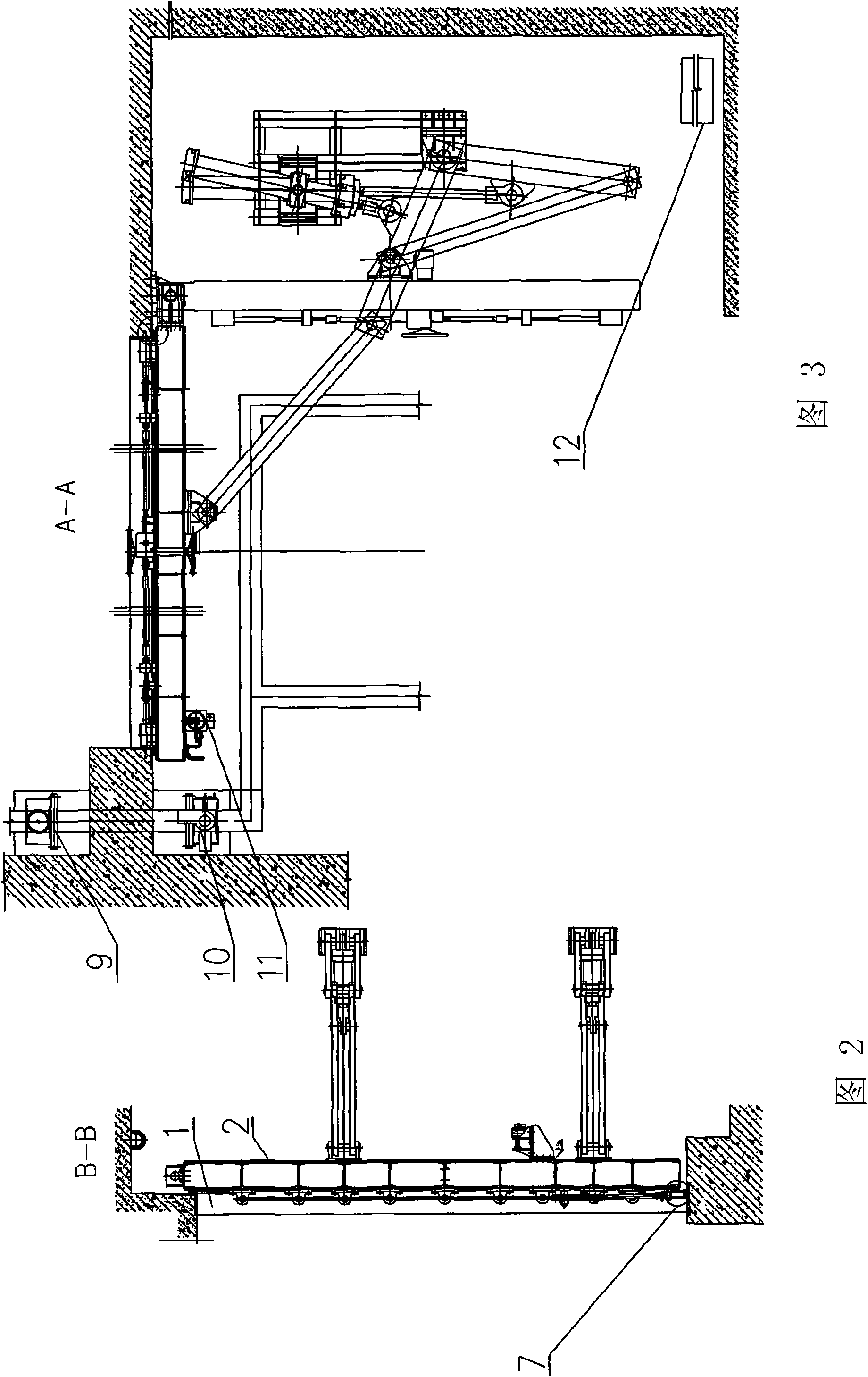

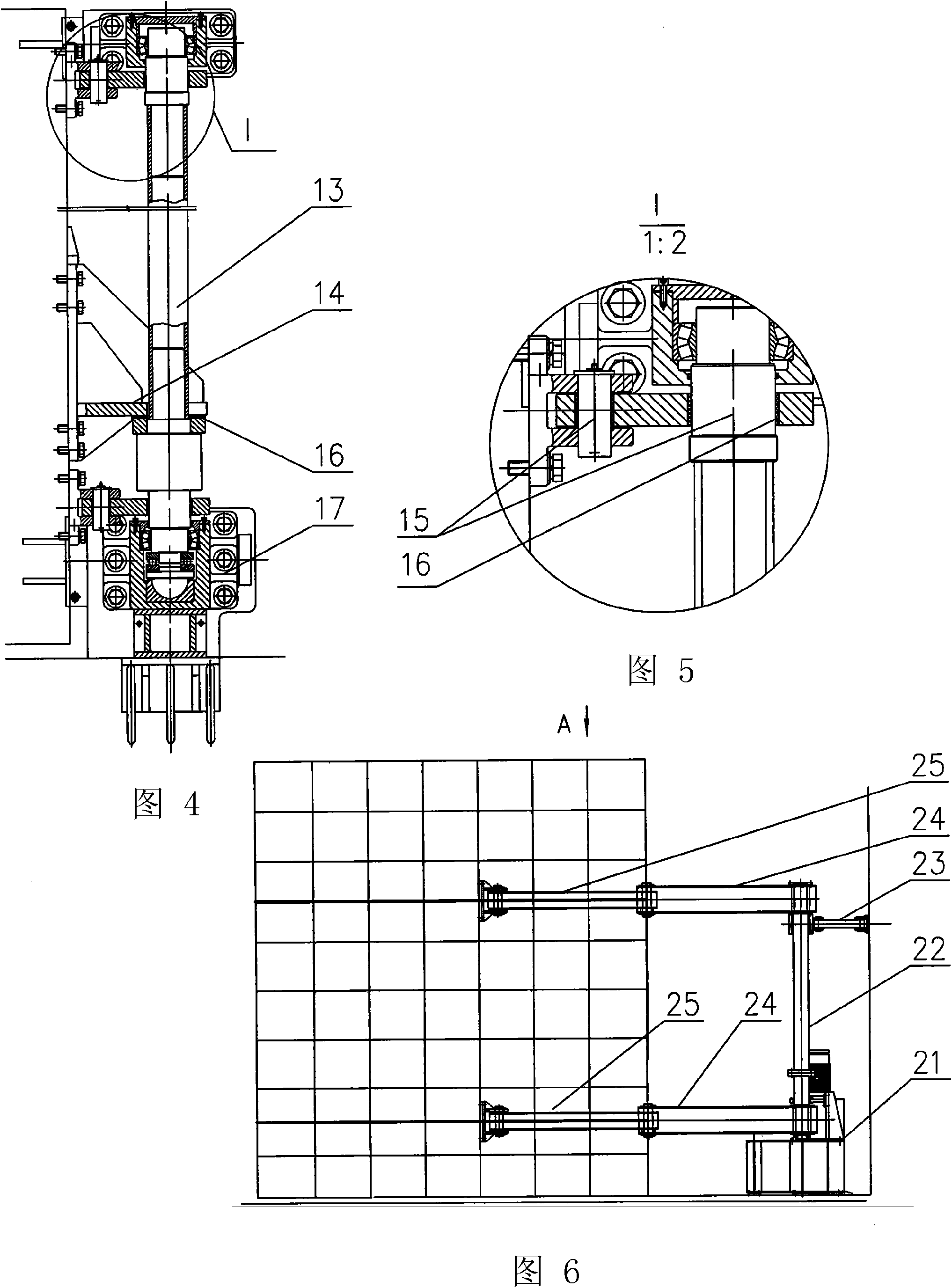

Preparation methodof edible package paper

The invention relates to an edibility packaging paper preparing method. It uses fruit processing tailings that apple and orange pomace, fresh vegetable that celery, cabbage, carrot etc as raw material, hydrophilic property high molecular material that polysaccharide, protein, antioxidant etc as auxiliary materials. The preparing method includes the following steps: preprocessing, blanching, color protecting, pulping, forming agent and protective agent adding, paper copying, dehydrating, drying, coating, burnish, coil paper, cutting, sizing, and packaging. The product can be used not only as fallow food to eat directly, but also as foods packing paper.

Owner:JIANGNAN UNIV

CO2 gas protection welding process of 800 MPa high-strength steel

InactiveCN102179601AUniform strengthUniform hardnessArc welding apparatusWelding/cutting media/materialsThumb oppositionOperability

The invention discloses a CO2 gas protection welding process of 800 MPa high-strength steel. The CO2 protection welding process is characterized by comprising the following steps of: (1) machining a joint: machining an X-shaped groove on the joint; (2) using a solid welding wire with the diameter of 1.2 mm and the tensile strength of 800 MPa, wherein the solid welding wire comprises the following chemical components in percentage by weight: 0.04-0.10% of C, 0.30-0.80% of Si, 1.30-2.0% of Mn, 0.40-1.0% of Ni, 0.20-0.50% of Cr, 0.20-0.60% of Mo, 0.30-0.80% of Cu, 0.05-0.20% of Ti, 0.002-0.010% of B, less than and equal to 0.020% of P, less than and equal to 0.015% of S, less than and equal to 0.03% of Als, and the balance of Fe and inevitable impurities; (3) setting a welding mode: adopting CO2 gas protection welding and a DC power supply opposition method; and (4) welding: carrying out one-side welding with back formation on a first welding line, and then carrying out multilayer multipass welding, wherein interlayer temperature is less than and equal to 160 DEG C. The invention has the advantages of simple process, high operability and low welding energy consumption and welding cost and can be widely used for the technical fields of the gas protection welding of the high-strength steel.

Owner:武钢集团有限公司

Hydraulic vertically rotary airtight flood and preventive partition door in metro running

ActiveCN101666242AOvercome the disadvantage of being thickMeet strength requirementsGasproof doorsMining devicesMonitoring systemEngineering

An airtight flood and preventive partition door used for civil defense in metro running mainly comprises a door leaf, a door frame, a hinge, a hydraulic drive device, a manual and electric locking device, a manual gate valve, a manual and electric gate valve, a support locking device, a monitoring device and the like. A hydraulic drive system drives the door leaf to open and close. The manual andelectric locking device can open and close the locks manually and electrically. The gate valve is used for sealing a drainage ditch passing by the partition door. The support locking device is used for supporting and safely locking the door leaf. A monitoring system is used for monitoring the water level and state of each component and controlling action of each component. The partition door simultaneously satisfies the requirements of civil defense and flood standards, is suitable for the characteristics of the metro running structure, occupies little space, has low overall cost, is characterized in that all the components can be used manually and electrically, can be monitored remotely and opened and closed easily and quickly, and has higher application value.

Owner:4TH DESIGN & RES INST OF ENGINEER CENT STAFF PLA +1

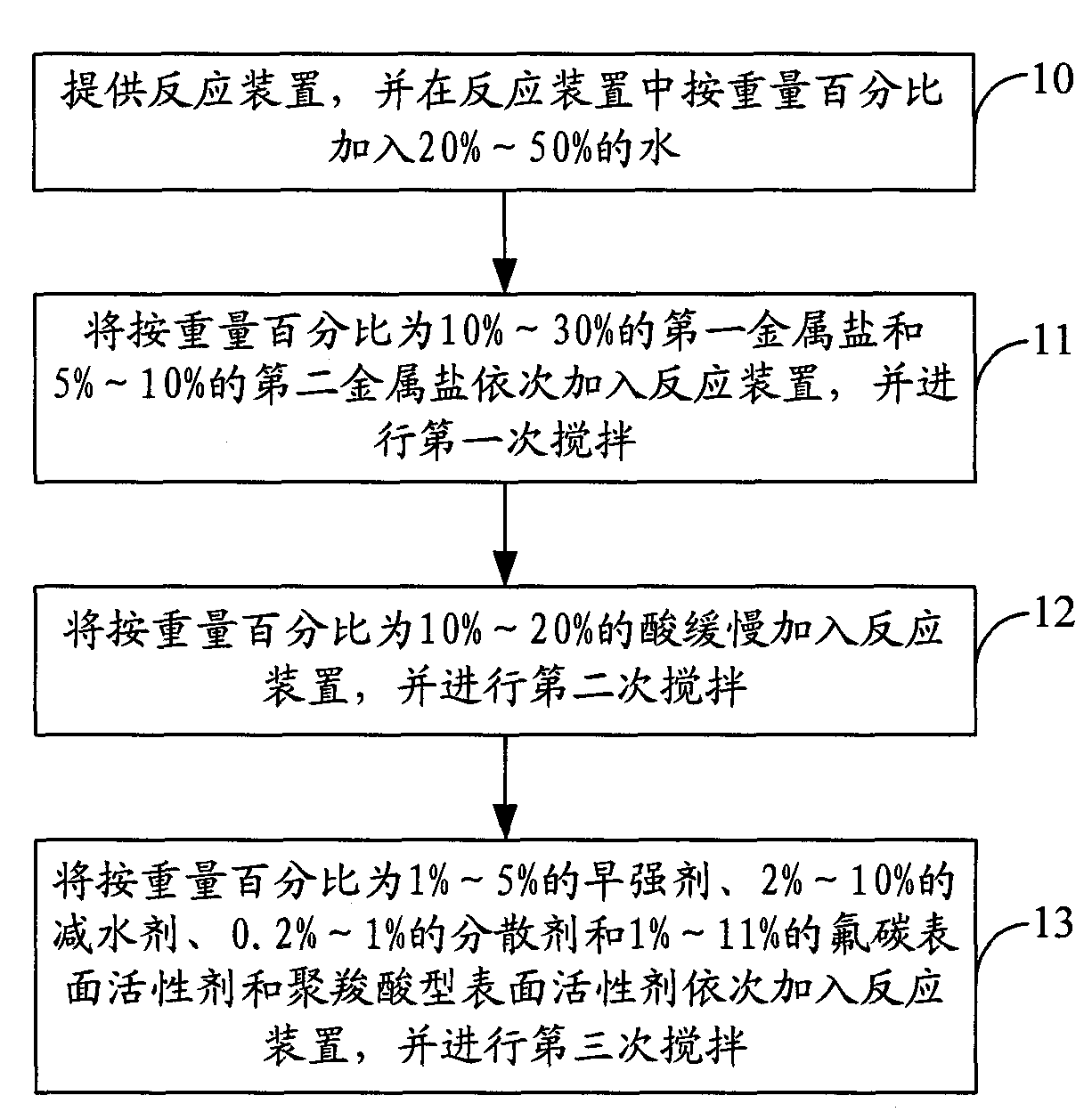

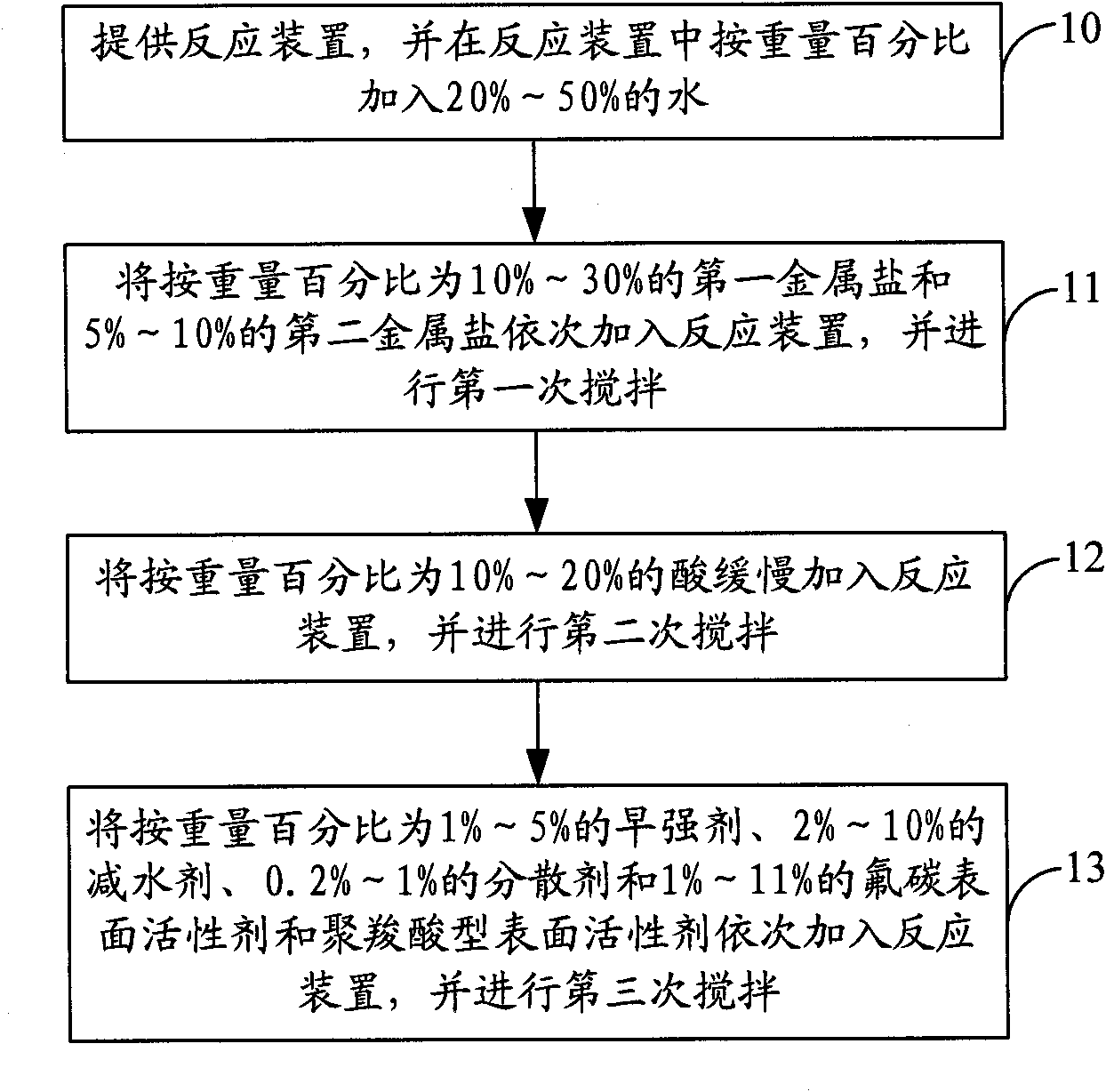

Soil and rock curing agent and manufacturing method thereof and road structure and manufacturing method thereof

InactiveCN101812300AReduced strength requirementsMeet strength requirementsIn situ pavingsRoads maintainenceWater resourcesCompressive strength

The invention relates to a soil and rock curing agent and a manufacturing method thereof and a road structure and a manufacturing method thereof. The soil and rock curing agent comprises a first metal salt, a second metal salt, water, acid, an early strength agent, a water reducing agent, a dispering agent, a fluorocarbon surfactant and a polycarboxylate surfactant. Widely distributed soil, decayed rock, building rubbish and tailing resource are main materials and the soil and rock curing agent is added, thereby being capable of reducing road cost; road roadbed, airport foundation, port foundation and water resource facilities built with the soil and rock curing agent have the advantages of short curing period, water resistance, cold resistance and hairline crack prevention, thereby improving compression strength and bending strength and greatly reducing construction cost.

Owner:田文利

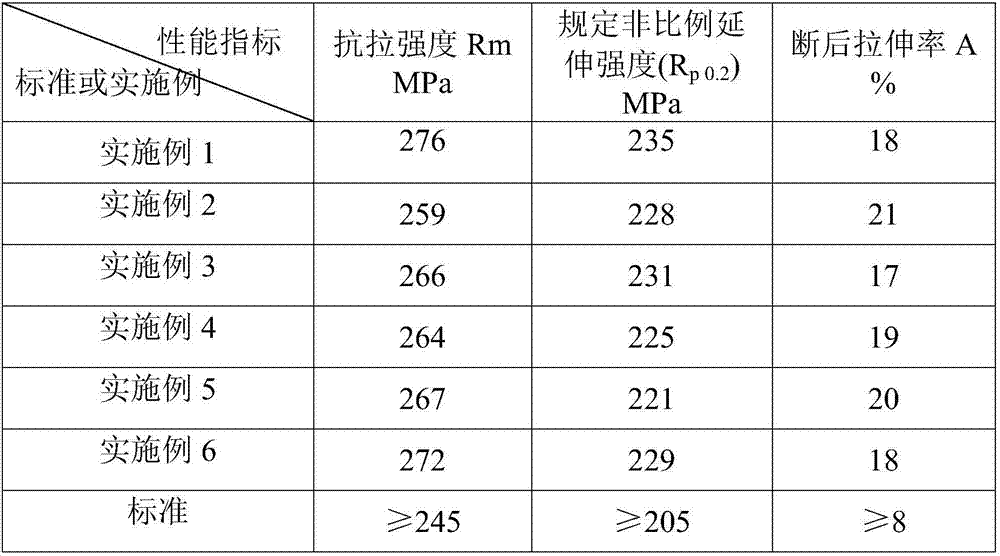

High-strength silicon, magnesium, manganese-aluminum bar and preparation method thereof

The invention relates to a high-strength silicon, magnesium, manganese-aluminum bar and a preparation method thereof and belongs to the field of metal materials. The high-strength silicon, magnesium, manganese-aluminum bar comprises the following components in percentage by weight: 1.1-1.25% of Si, 0.7-0.9% of Mg, 0.6-0.7% of Mn, 0.045-0.08% of Cu, 0.13-0.18% of Cr, 0.02-0.04% of Ti, less than or equal to 0.3% of Fe, less than 0.05% of other impurities and the balance of aluminum. The preparation method comprises the following steps: founding, homogenizing of a cast bar, extrusion and heat treatment. According to the invention, the high-strength silicon, magnesium, manganese-aluminum bar has higher mechanical properties than common silicon and magnesium series aluminum alloy through controlling the composition formula and the processing technology. The mechanical properties of the high-strength silicon, magnesium, manganese-aluminum bar are as follows: the tensile strength is greater than or equal to 380 MPa, the specified non-proportional extension strength is greater than or equal to 360 MPa, and the ductility A is greater than or equal to 10%; the high-strength silicon, magnesium, manganese-aluminum bar meets the strength requirement of high-end automobile aluminium alloy steering control arm material and can replace the imported material.

Owner:JIANGSU ASIA PACIFIC LIGHT ALLOY TECH CO LTD

Mobile phone curved glass panel and forming method thereof

ActiveCN104023099AFit tightlyComfortable fitGlass reforming apparatusTelephone set constructionsEngineeringGraphite

The invention discloses a mobile phone curved glass panel and a manufacturing method of the mobile phone curved glass panel. A curved glass panel body is formed by bending a mobile phone panel body toward the same side in an arc shape with the center line of the mobile phone panel body in the X-axis direction or the Y-axis direction as a center, or bending the periphery of the mobile phone panel body toward the same side in an arc shape with the center point of the mobile phone panel as the center, or the mobile phone curved glass panel comprises a main panel and curved panels. The curved panels are formed by bending one or more side edges of the main panel. The multiple curved panels are bent toward the same side relative to the main panel. The forming method includes the three steps of manufacturing a planar glass panel, manufacturing a graphite die and forming the curved glass panel. The good lubricating performance of graphite is used, through exerting certain pressure for deformation, heat deformation is achieved at the temperature below a glass softening point, the manufactured product is high in precision, the designing requirements of a 3D mobile phone glass panel are met, large-scale industrial production can be achieved, production cost can be reduced, and the requirement for personalized and fashionable mobile phones can be met for people.

Owner:LENS TECH

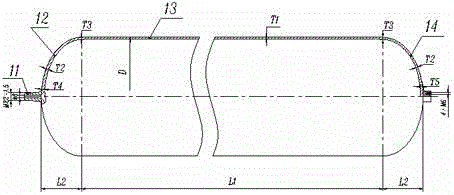

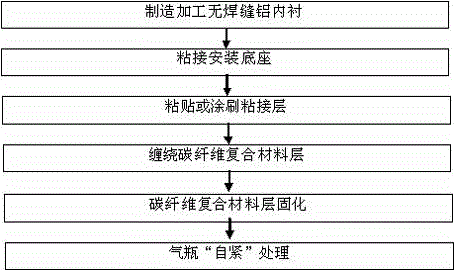

100 L carbon fiber wrapped aluminum-lined composite cylinder and manufacture method thereof

The present invention provides a 100 L carbon fiber wrapped aluminum-lined composite cylinder, including a weldless aluminum liner, a mounting base, an adhesive layer and a carbon fiber composite layer. The mounting base and the weldless aluminum liner form a smooth flattening winding mandrel; the external part of the mandrel is wound by the carbon fiber composite layer; and the adhesive layer is arranged between the mandrel and the carbon fiber composite layer and is used for firmly connecting the weldless aluminum liner and the carbon fiber composite layer. The composite cylinder has the advantages of large volume, high pressure resistance, high efficiency, light weight, high security, low cost and short manufacturing cycle. The present invention also provides a manufacture method of the carbon fiber wrapped aluminum-lined composite cylinder.

Owner:SHANGHAI INST OF SPACE PROPULSION

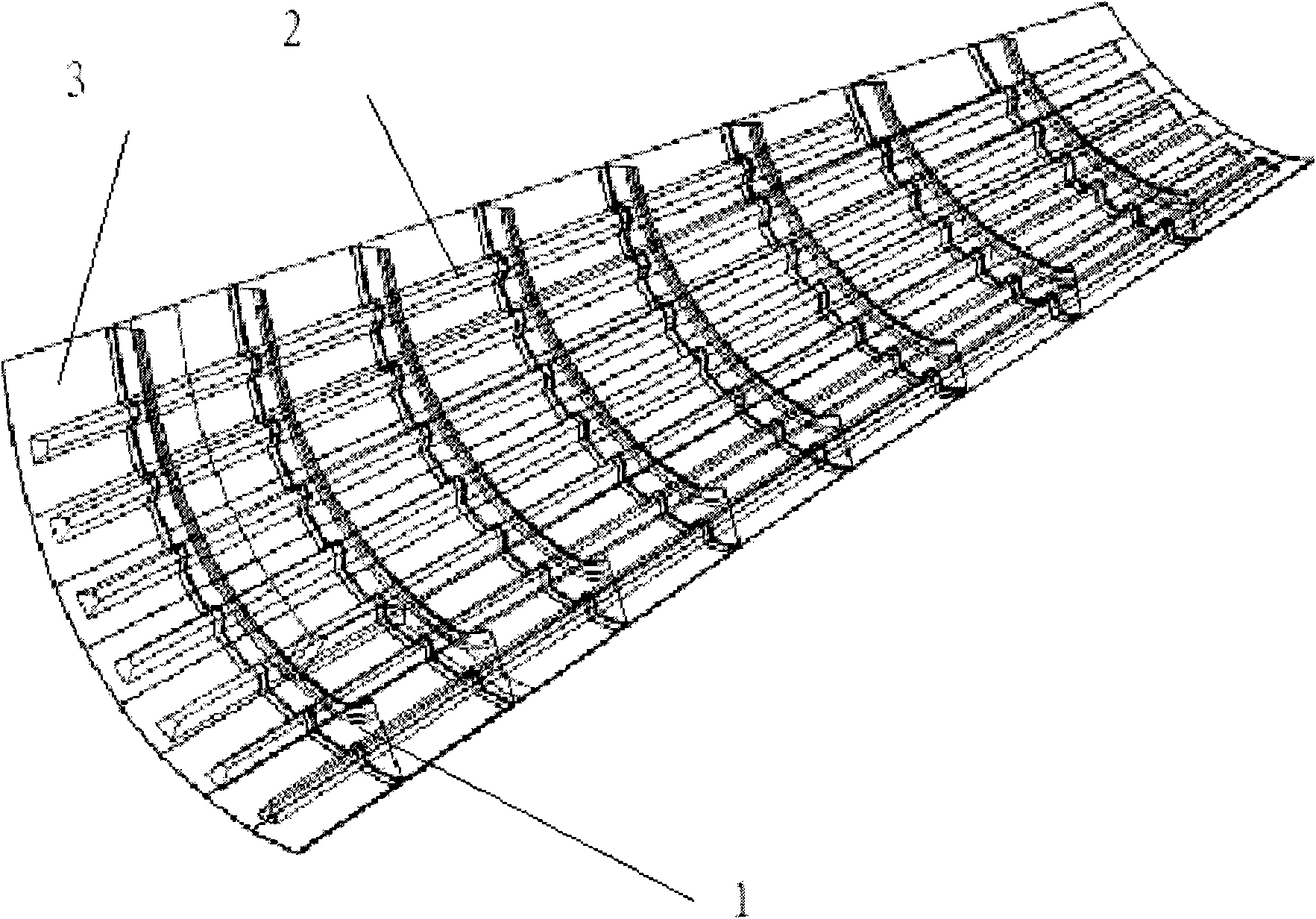

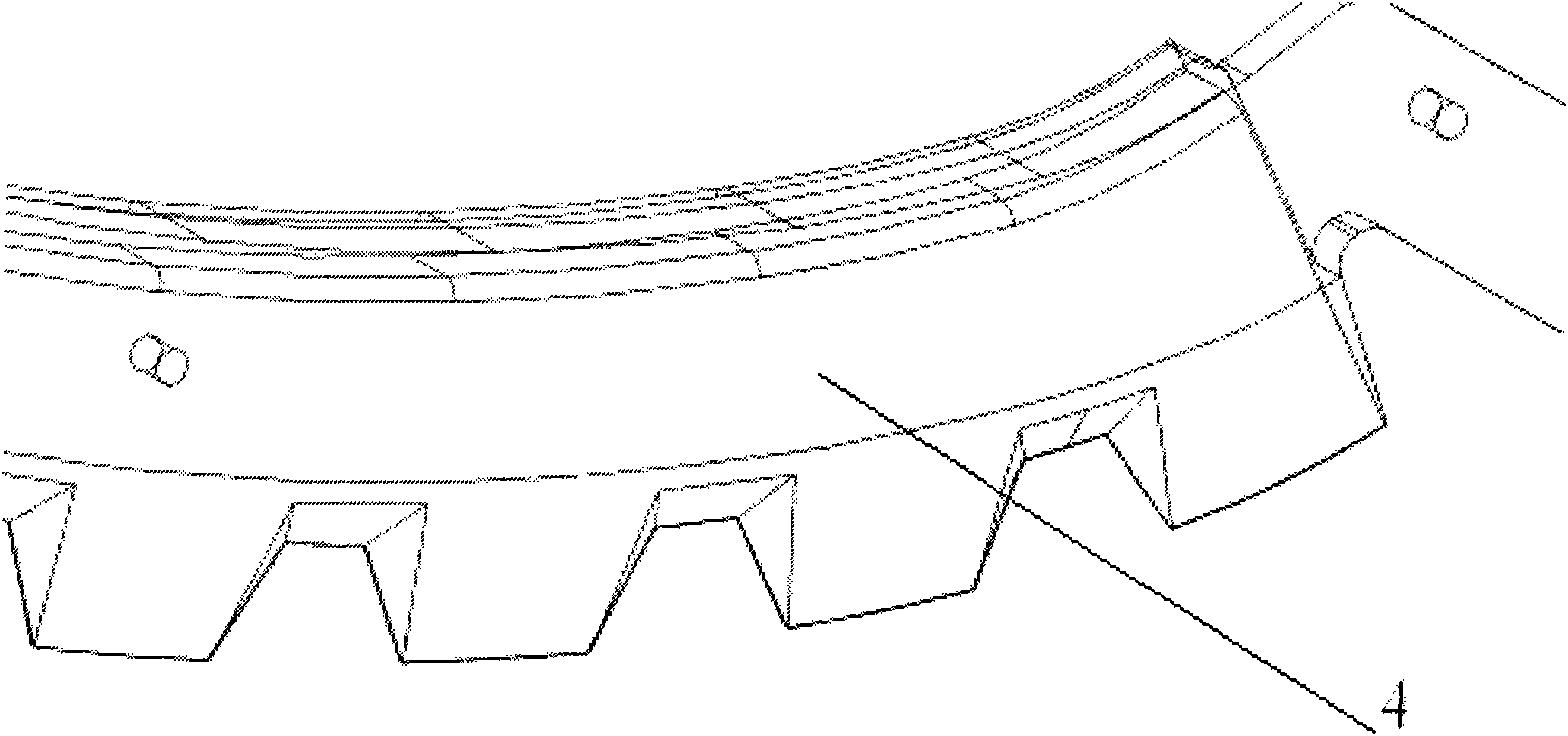

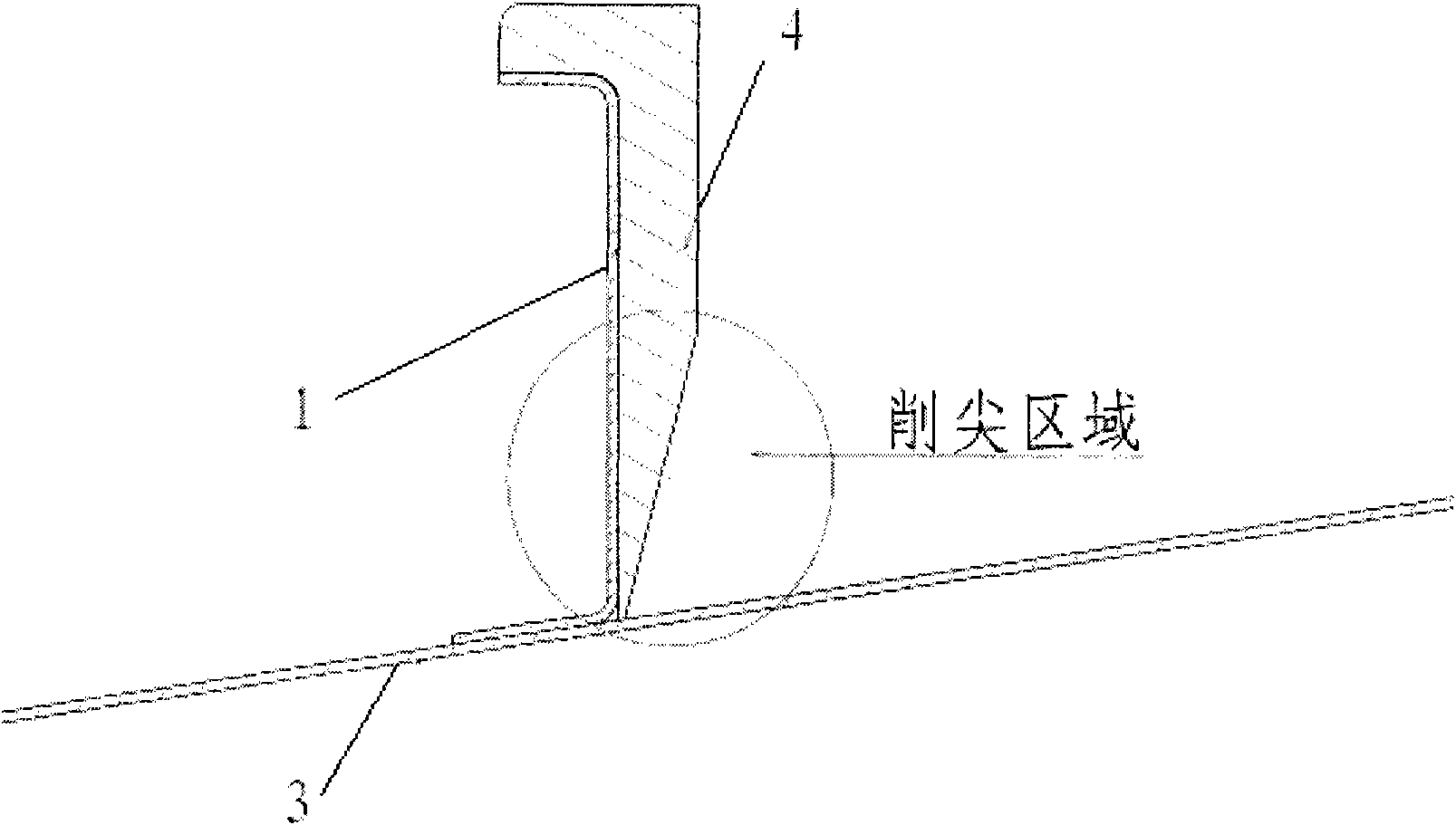

Method for forming frame, stringer and covering of composite material component through integrated co-curing

ActiveCN102114706AAchieving co-curing requirementsMeet strength requirementsDomestic articlesUltimate tensile strength

The invention belongs to the technical field of composite material forming, and relates to a method for forming a frame, a stringer and a covering of composite material through integrated co-curing. The method adopts advanced temperature-resistant pressure-resistant foams to fill the inner part of the stringer, so that the stringer and the covering can be completed through one-step paving and pasting; a positioning and curing tooling for the frame is adopted, and special sharpening processing is performed on the positioning and curing tooling, so that the pressurizing problem on a joint face of the frame and the stringer can be solved, and the integrated co-curing forming of the frame, the covering and the stringer can be achieved; in addition, a rubber lining film technology is adopted, so that the pressure uniformity of the inner complicated structure and the quality of the inner surface can be ensured. The method for forming the frame, the stringer and the covering of a composite material component through integrated co-curing solves the problem of cementing interfacial effect on the joint face of the frame, the stringer and the covering in the traditional secondary cementing forming, improves the product quality, and satisfies the strength requirement of large load of the structure.

Owner:JIANGXI CHANGHE AVIATION IND

Light-high-strength epoxy foam material and preparation method thereof

The invention relates to a light high intensity epoxy foaming material and a preparation method thereof. The material comprises the following compositions in weight percentage: 50 to 90 percent of an epoxide resin, 5 to 40 percent of an amine curing agent, 0.1 to 15 percent of azocompound and a hydrazine-type foaming agent, 2 to 20 percent of a toughener, 0.1 to 5 percent of a surface active agent, and 0 to 30 percent of a filling material. The foaming speed and the curing speed of an epoxy foaming curing system are coordinated by the 'prereaction' preparation technique and the 'postcuring' and sizing processes are performed further. Compared with the prior technique, the foam body prepared by the method has smooth surface, the internal bubble structure is compact and even, and the foaming material meets the intensity requirement and the related technical conditions of a fragile cap of various models of missile. At present, the foaming material has been applied to certain models of missile fragile caps and is in mass production; moreover, the foaming material can be applied in the related technical fields where light and high intensity products are required to be manufactured.

Owner:SHANGHAI RES INST OF MATERIAL

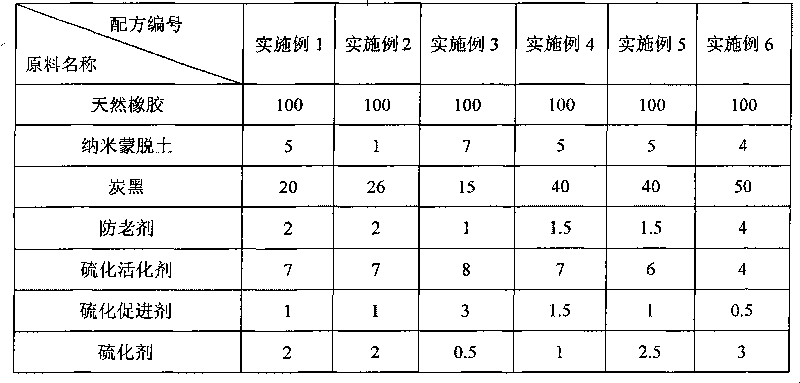

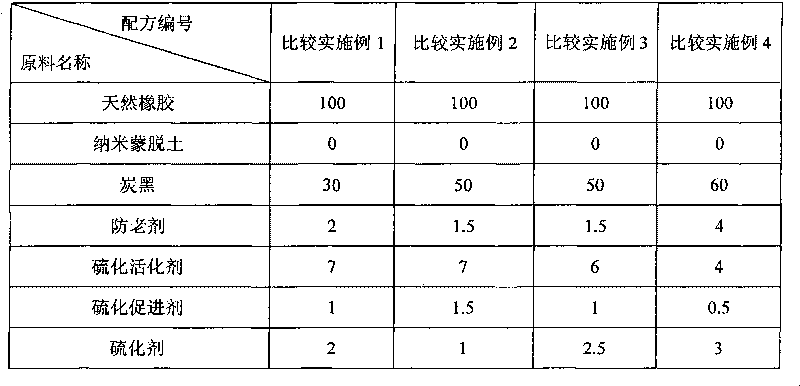

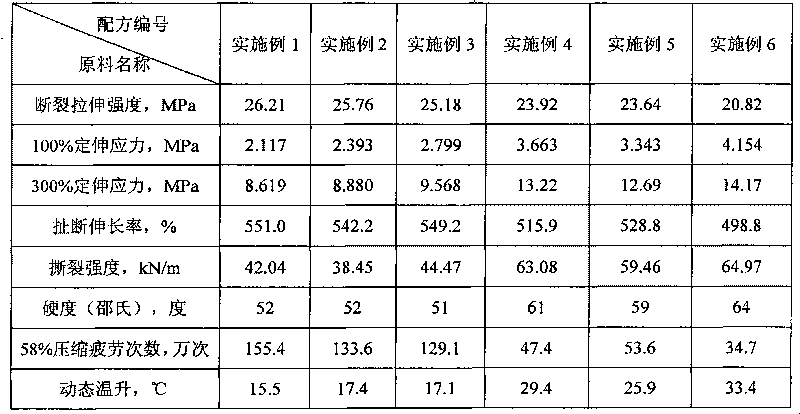

Fatigue-resisting natural rubber nano composite material and preparation method thereof

The invention discloses a fatigue-resisting natural rubber nano composite material and a preparation method thereof. The preparation method is characterized by comprising the following steps of: carrying out mechanical intercalation on 100 parts of natural rubber and 1-7 parts of nano montmorillonoid, then adding 4-8 parts of vulcanizing activator, 1-4 parts of anti-aging agent, 15-50 parts of carbon black packing, 0.5-3 parts of vulcanizing accelerator and 0.5-3 parts of vulcanizing agent, then adding gelatine into a flat-plate vulcanizing machine, and carrying out mould pressing for 10-30 minutes with the temperature of 135-155 DEG C and the pressure of 10-15MPa to obtain the fatigue-resisting natural rubber nano composite material. The invention substitutes the traditional high-structure carbon black packing by adopting the organic nano montmorillonoid, reduces the thermogenesis of the material under the dynamic loading effect and the same hardness by adopting less packing usage amounts, effectively prevents internal cracks of the material from generating and expanding by utilizing the layered structure of the nano montmorillonoid, and obtains a series of natural rubber materials with excellent fatigue-resisting performance without sacrificing the tensile breaking strength and the breaking elongation ratio of the material at the same time.

Owner:SICHUAN UNIV

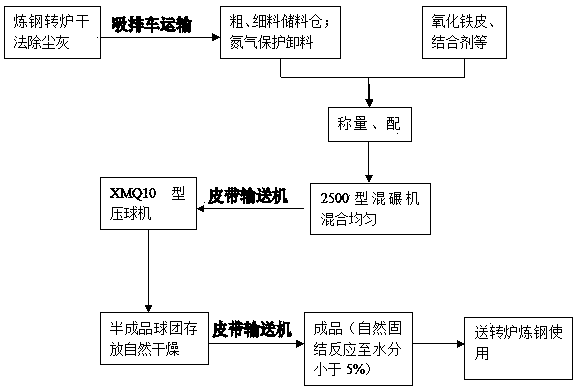

Technique for producing cold-bonded pellets from steel converter dust removal ash

The invention discloses a technique for producing cold-bonded pellets from steel converter dust removal ash, which comprises the following steps: separately collecting rough dust removal ash and fine dust removal ash of the steel converter, weighing iron scale, rough dust removal ash and fine dust removal ash in a mass ratio of (10-50):(20-80):(20-70), and uniformly mixing; adding the mixture into a magnesium chloride solution, and uniformly mixing, wherein the magnesium chloride solution accounts for 1-20 wt% of the total mass; and pelletizing with a pelletizer, stripping, and naturally solidifying to obtain the cold-bonded pellets. The dust removal ash does not need previous digestion treatment with water, thereby saving abundant water resources; the production technique is simple and feasible, and is implemented only by proportionally adding the inorganic weakly-alkaline binder into the iron scale, rough dust removal ash and fine dust removal, uniformly mixing and pelletizing; by using the inorganic weakly-alkaline binder, the finished cold-bonded pellets have the advantages of fewer impurities, low SiO2 content and high total iron content (not lower than 60%); and abundant cold-bonded pellets can be used in the steelmaking process, and the steelmaking process is not influenced by the addition amount.

Owner:CHONGQING ZHONGZHA METALLURGY RENEWABLE RESOURCESCO

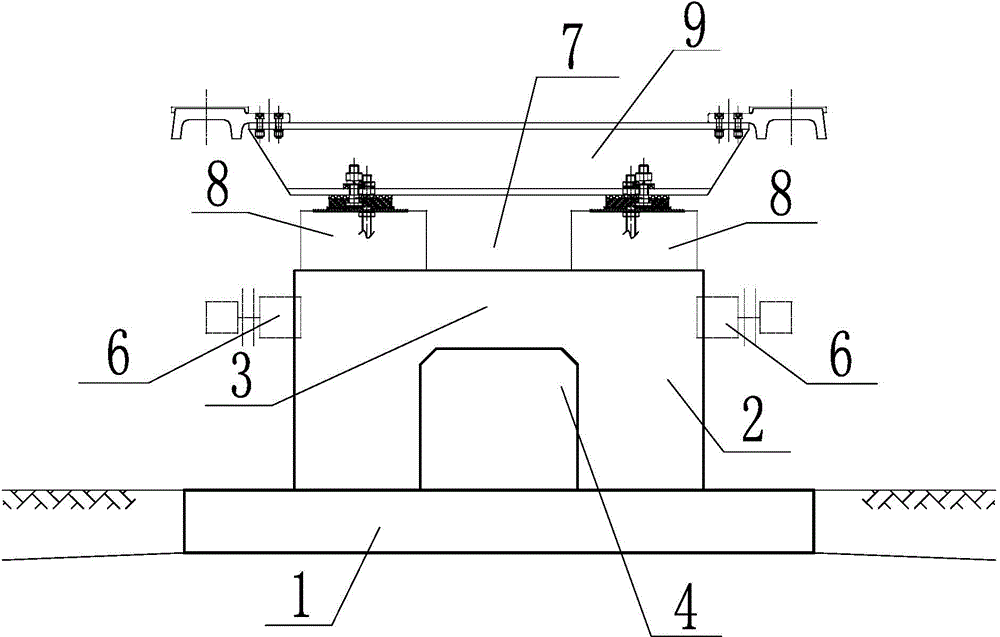

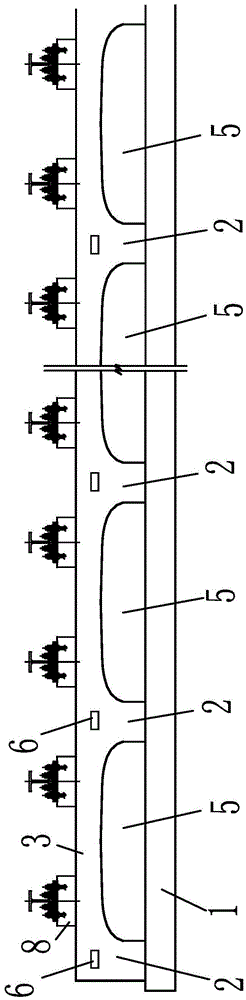

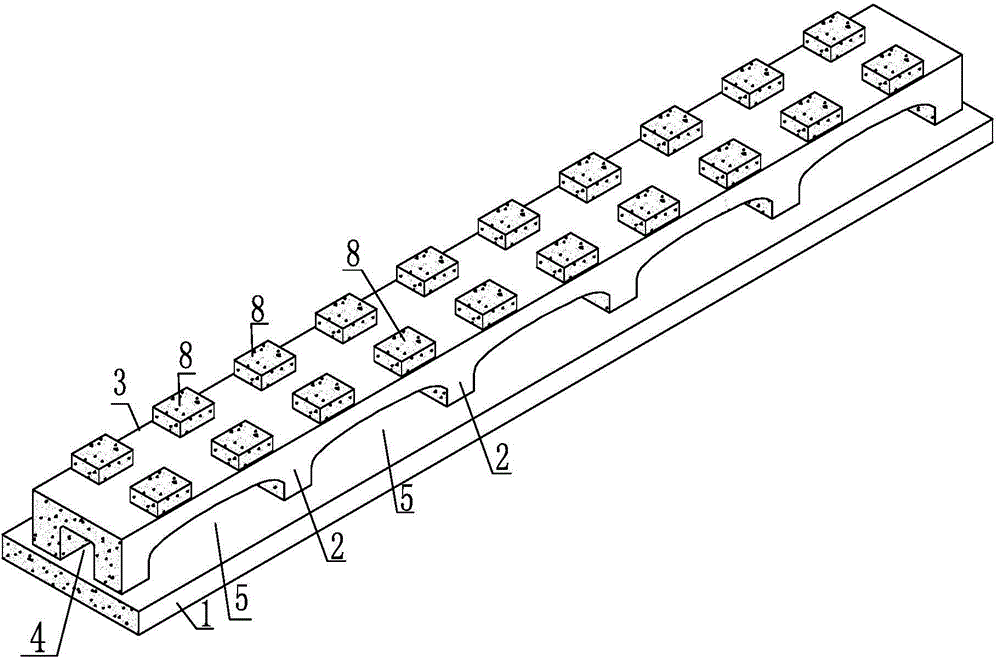

Medium-and-low speed magnetic levitation railway low route continuous arched supporting rail beam structure and construction method

ActiveCN104480803AMeet stability requirementsMeet strength requirementsBallastwayLow speedReinforced concrete

The invention discloses a medium-and-low speed magnetic levitation railway low route continuous arched supporting rail beam structure. The structure comprises a reinforced concrete bottom plate, a rail row, a plurality of rows of track rail supporting tables, a reinforced concrete top plate, flow guide rail brackets and a plurality of reinforced concrete arched posts, wherein a transponder mounting position is arranged between a left track rail supporting table and a right track rail supporting table in each row of track rail supporting tables; the flow guide rail brackets are arranged on the two sides of the reinforced concrete top plate; the reinforced concrete arched posts are arranged on the reinforced concrete bottom plate along the track line direction at equal intervals; the bottom of the reinforced concrete top plate is fixedly connected with the top of each reinforced concrete arched post; the rail row is arranged at the top of the reinforced concrete top plate through the track rail supporting tables; a transverse arch is arranged in each reinforced concrete arched post; a longitudinal arch is formed between every two adjacent reinforced concrete arched posts. The transverse drainage requirement on a low route at a dual-line road section is convenient to meet, and the difficulty on construction of a rail structure on the upper part can be reduced.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

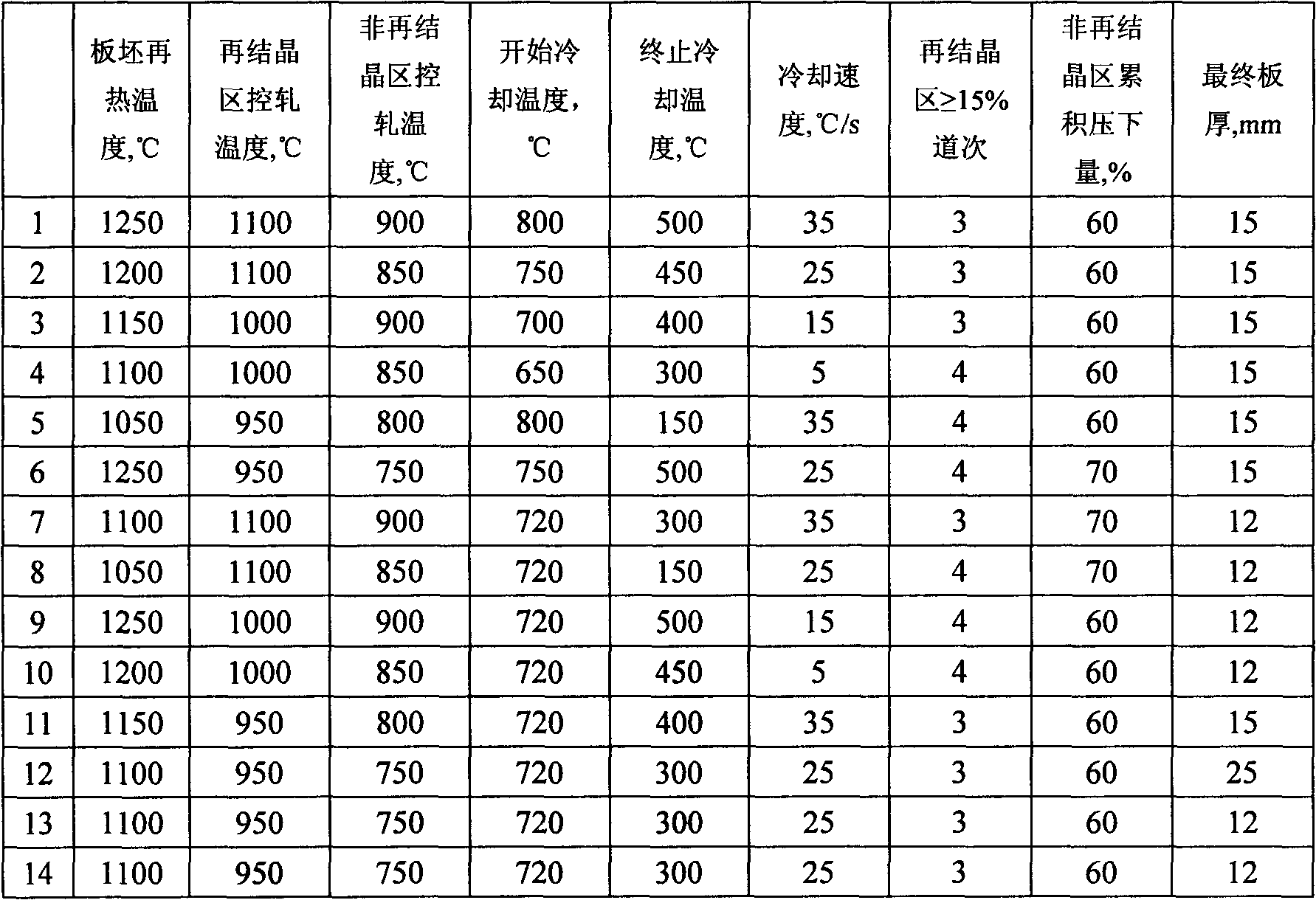

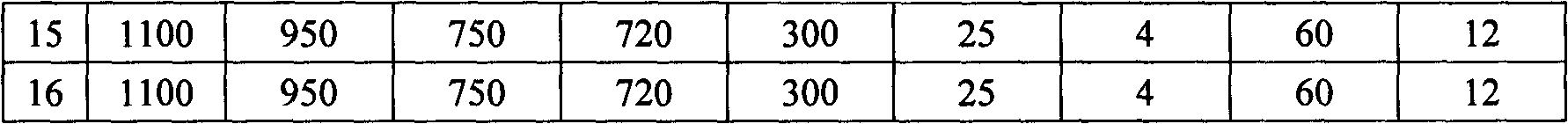

Strain design based pipe line steel X70 and its manufacturing method

ActiveCN102828125AExtend evenlyProper extensionTemperature control deviceImpurityHeating temperature

The invention discloses strain design based pipe line steel X70 and its manufacturing method. the steel comprises the following ingredients of: by weight, 0.06-0.10% of C, 0.1-0.6% of Si, 1.0-2.5% of Mn, P being less than or equal to 0.015%, S being less than or equal to 0.003%, Cr being less than 0.1%, 0.05-0.35% of Mo, 0.01-0.15% of Nb, 0.005-0.03% of Ti, 0.01-0.06% of Al, one or two components selected from 0-0.5% of Cu and 0-0.5% of Ni, and the balance Fe and unavoidable microscale impurities. The manufacturing method is characterized in that slab heating temperature is 1050-1280 DEG C by a controlled rolling and controlled cooling method; the temperature for controlled rolling in a recrystallization zone is controlled within the range of 900-1250 DEG C; the temperature for controlled rolling in a non-recrystallization zone is controlled within the range of 700-950 DEG C; initial cooling temperature is 650-800 DEG C; finish cooling temperature is 100-500 DEG C; and cooling rate is 5-35 DEG C / s. According to the invention, elements of V, B and the like are not added, and the total amount of Mo, Cu, Cr and Ni is low. In addition, subsequent heat treatment is not required, the process is simple and requires low cost, and production efficiency is high.

Owner:ANGANG STEEL CO LTD

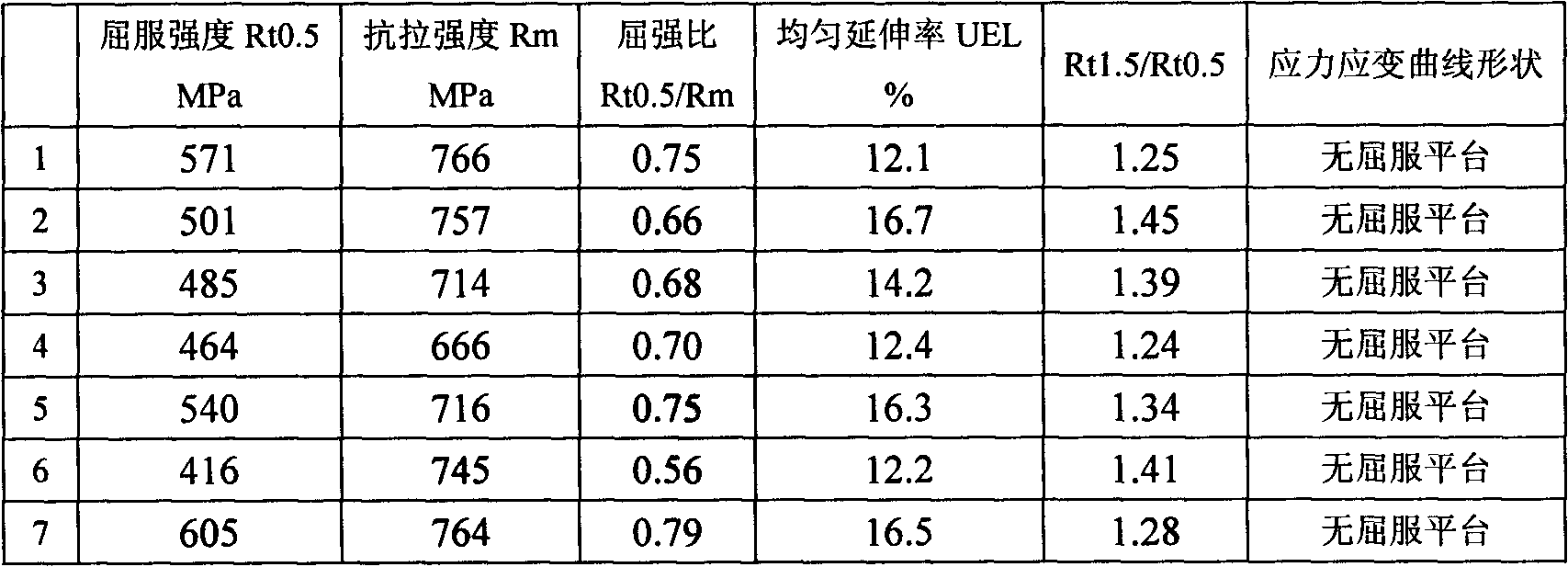

Bridge bearing mortar and production method thereof

The invention relates to a bridge bearing mortar and a production method thereof. The invention is characterized in that the bridge bearing mortar is prepared from the following raw materials in parts by weight: 45-60 parts of graded quartz sand, 30-40 parts of 42.5 sulfoaluminate cement, 5-15 parts of 42.5 Portland cement, 1-10 parts of U-shaped expanding agent, 0.1-1 part of water reducing agent, 0.1-0.5 part of water retention agent, 0.01-0.1 part of early-strength admixture, 0.2-1 part of retarder and 0.01-0.03 part of defoaming agent. The bridge bearing mortar has the characteristics of low cost, excellent performance, stable quality, high fluidity, short initial and final setting time, quick strength development and favorable micro-expansion, and can be widely used in the bridge bearing mortar for high-speed railways, highways, traffic bridges and other bridges and a production method thereof.

Owner:GUANGXI NANNING BAIRUITONG SYNTHESIS BUILDING MATERIALS TECH

Precision-investment casting method

InactiveCN101406932AGuaranteed compactnessMeet strength requirementsFoundry mouldsFoundry coresWaxMetallurgy

The invention provides a method for casting a fusible pattern precisely, which comprises the following steps: manufacturing a wax pattern in accordance with a cast product, wherein the wax pattern comprises a casting head and a core print corresponding to structures of an internal chill or an external chill; manufacturing a silicasol fusible pattern according to the wax pattern, and performing dewaxing and solidifying processes to obtain a shuttering which contains a reserved opening corresponding to the core print; placing the external chill or the internal chill which is designed well according to a dispersed thermal centre of the cast product into the shuttering from the reserved opening; pouring molten metal into a die cavity in the shuttering to obtain the cast product; cutting and separating the casting head of the cast product after the mould is opened, and removing the external chill or finishing a protruding part of the internal chill to obtain the finished product. The method is applicable in the field of casting high-precision parts.

Owner:泉州腾达精铸有限公司

Method for longitudinal stiffness control over high-pier large-span concrete continuous girder bridge and bridge

ActiveCN107201716AMeet vertical and horizontal control standardsProcess stabilityBridge structural detailsEngineeringFixed Bridges

The invention relates to the technical field of high-pier large-span concrete bridges, in particular to a method for longitudinal stiffness control over a high-pier large-span concrete continuous girder bridge and a bridge. The method for longitudinal stiffness control comprises a step a) of establishing a linear bridge pier integrated calculation model; a step b) of applying an analog load; a step c) of analyzing beam track acting force and jointless track stress deformation laws; and a step d) of determining longitudinal rigidity limits of a fixed bridge pier and track treatment measures. Therefore, beam shape arrangement and fixed pier rigidity are determined, a problem that in the prior art, it is difficult to control longitudinal stiffness of the high-pier large-span continuous girder bridge is solved, and the blank of the high-pier large-span girder bridge in the field of longitudinal stiffness control is filled. Meanwhile, normative standards of longitudinal linear stiffness limits of the high-pier large-span concrete continuous girder bridge are established, a reference and a basis are provided for bridge design and construction, so the design cost is reduced, and the actually built bridge meets specific usage environments.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

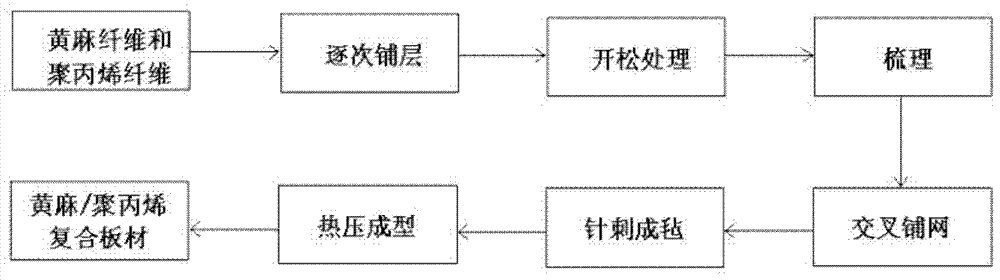

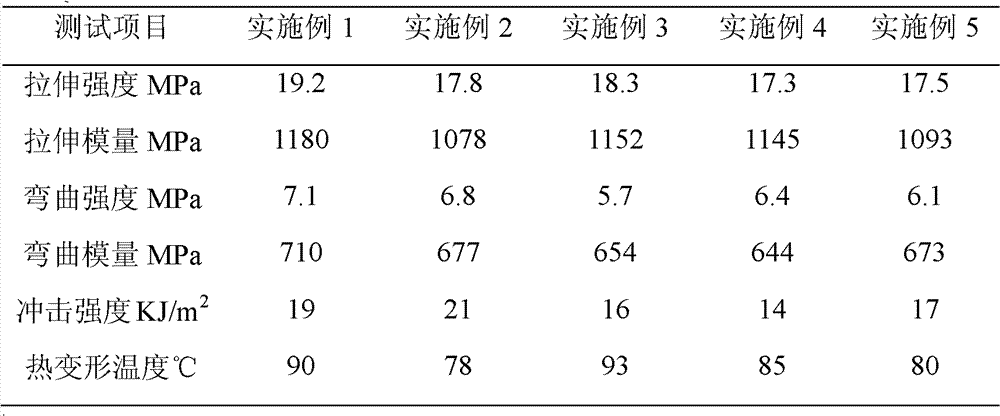

Natural fiber-reinforced thermoplastic composite material and preparation method and application thereof

ActiveCN102953231AEnvironmental performanceEasy to processVehicle componentsNon-woven fabricsAcute angleNatural fiber

The invention belongs to the technical field of composite materials, and relates to a thermoplastic composite material and a preparation method and application thereof. The thermoplastic composite material comprises the following components in percentage by mass: 40-60% of jute fiber and 40-60% of polypropylene fiber. Compared with the prior art, the composite material provided by the invention is environment-friendly and can be degraded naturally; with certain mechanical strength, the composite material can meet the requirement of the automotive trim material for strength; moreover, the composite material also has excellent processing performance and safety performance; and through the invention, the technological flow is shortened, the production efficiency is improved, and more importantly, the green and light automotive trim material is realized. Through the invention, the technological flow is simple, the composite material is easy to manufacture, and the raw materials are widely available and low in price, thereby being favorable for lowering the cost of the composite material; and moreover, a composite board has perfect toughness and does not form an acute-angle section after being broken, thereby being safe and reliable.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Method for manufacturing wooden sash section bar and method for assembling wooden window and door by using the same

InactiveCN101117874AImprove connection strengthReduce connection strengthCorner/edge jointsWindow/door framesEngineeringBuilding construction

A manufacturing method for assembling wood and door frame section material in field comprises the following steps: firstly, the wood is cut as per specified size and section shape; secondly, after cut, combination surfaces are formed on both ends of the wood, a key channel is formed at the combination surface, after the key channel is assembled into a frame parallel to the wood door section material and extended at the plane where is located and arranged between two surfaces of the frame, after the wood door and the window section material are matched at the corresponding combination surfaces, a pin key lock is used to fix with the adaptive key channel shapes; thirdly, surface treatment is done for wood of all the formed combination surfaces and key channels to be applicable for the wood door and the window section material for assembly at the construction site. The present invention is applicable for the manufacturing method for the wood door and the window section material in field and the method for assembling the wood door and the window with the section material for on-site arrangement. Structural strength of tenon is high, thus not damaging the surface of the section material and keeping the door and the window nice.

Owner:北京市木材厂有限责任公司

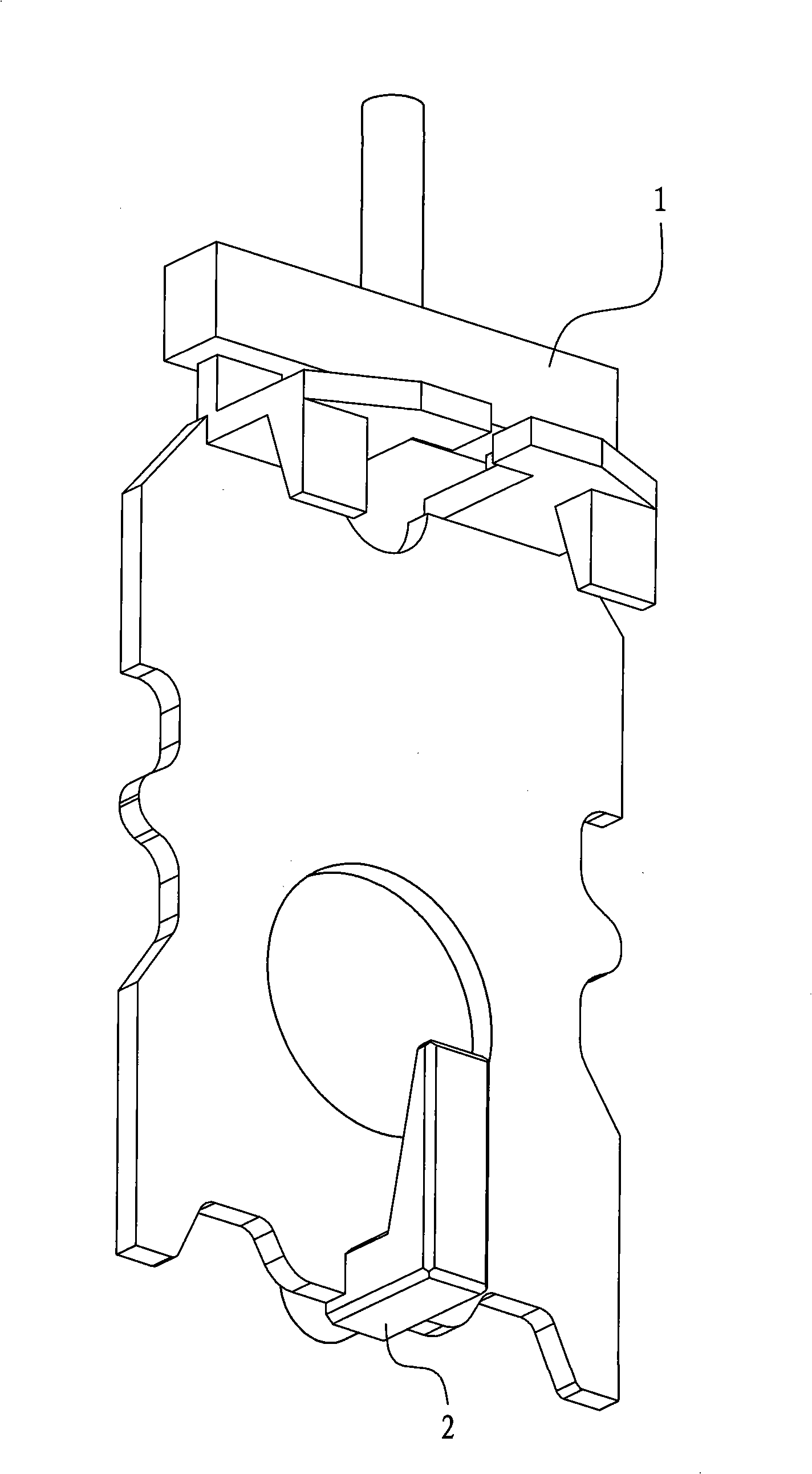

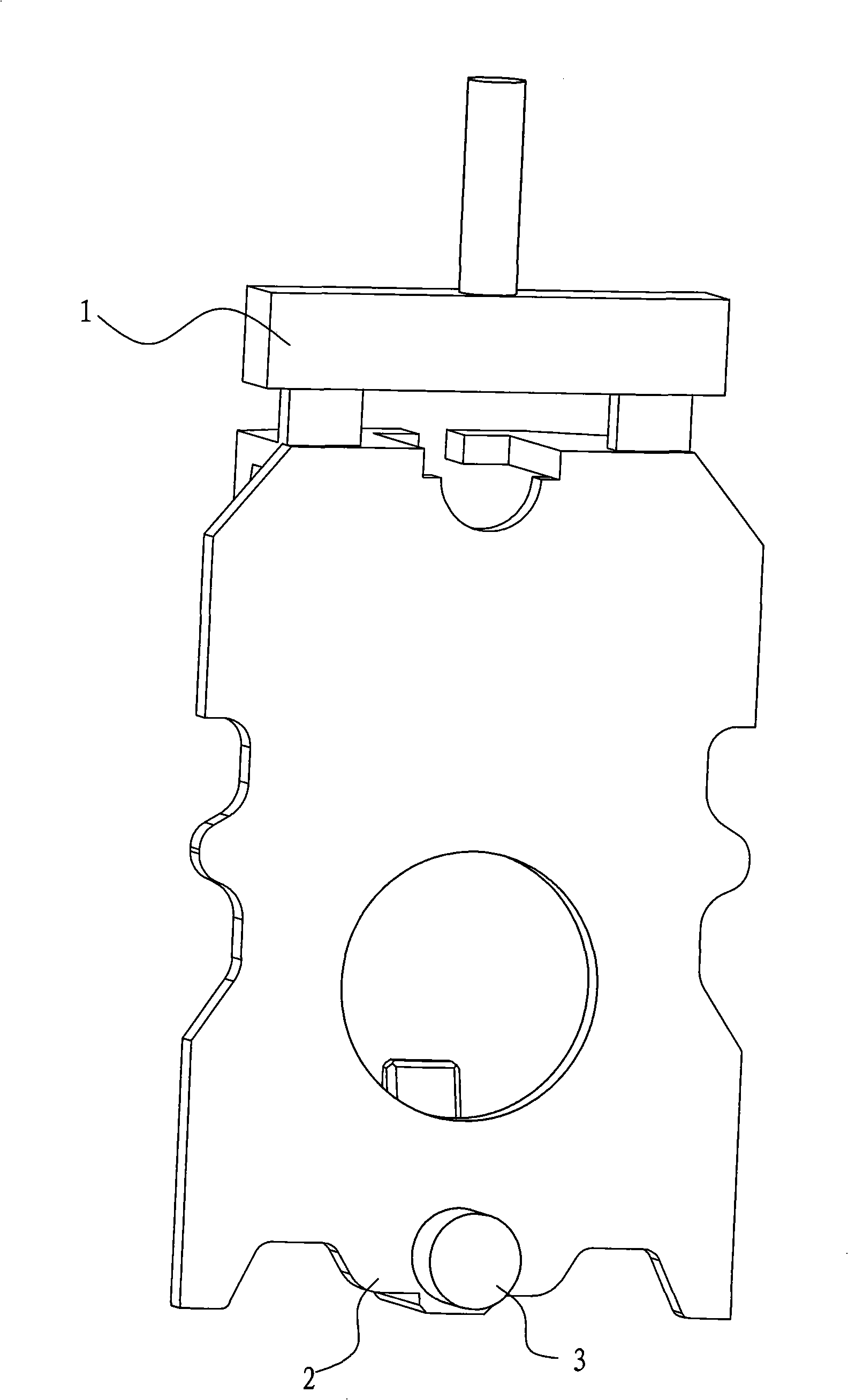

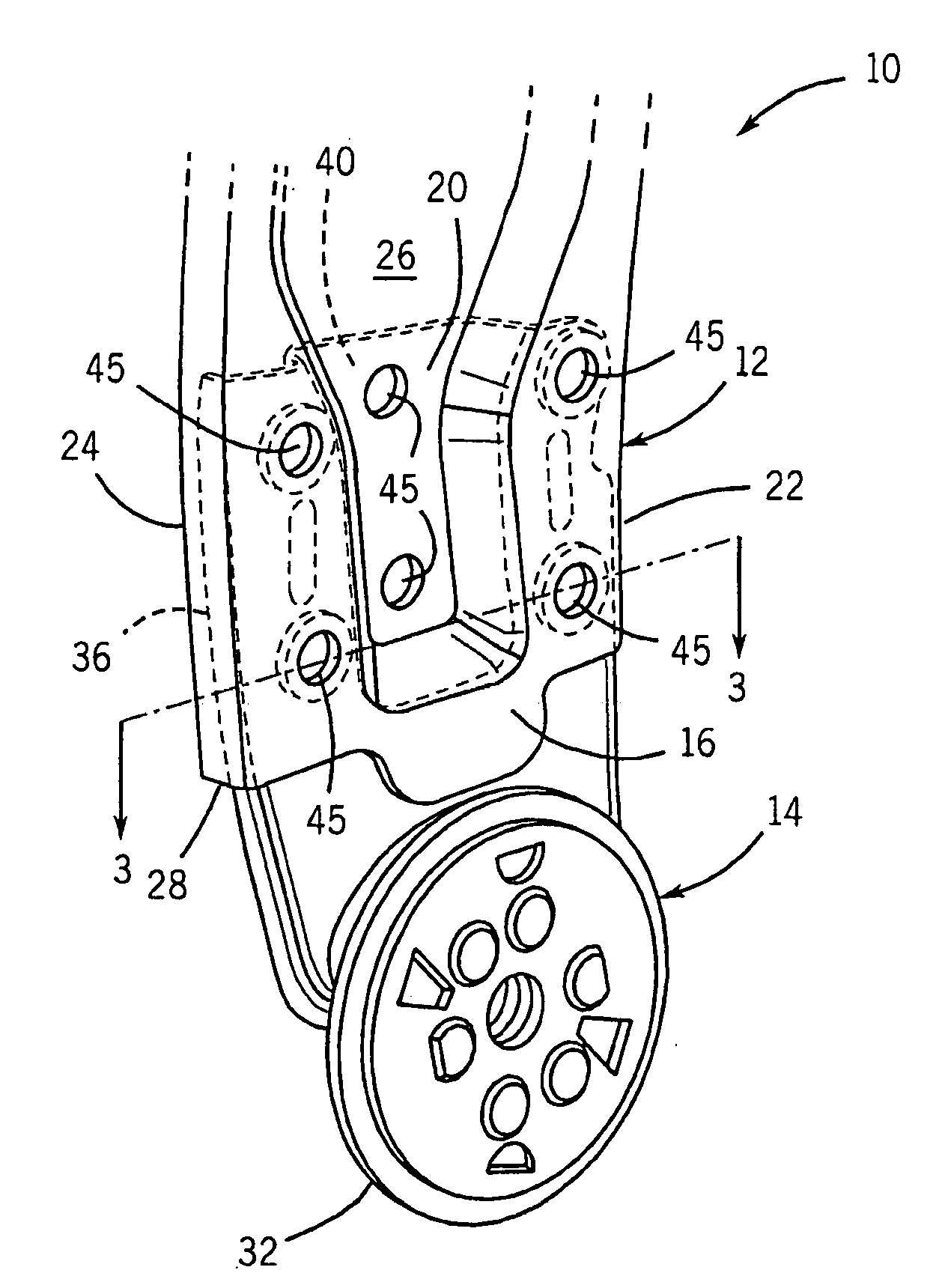

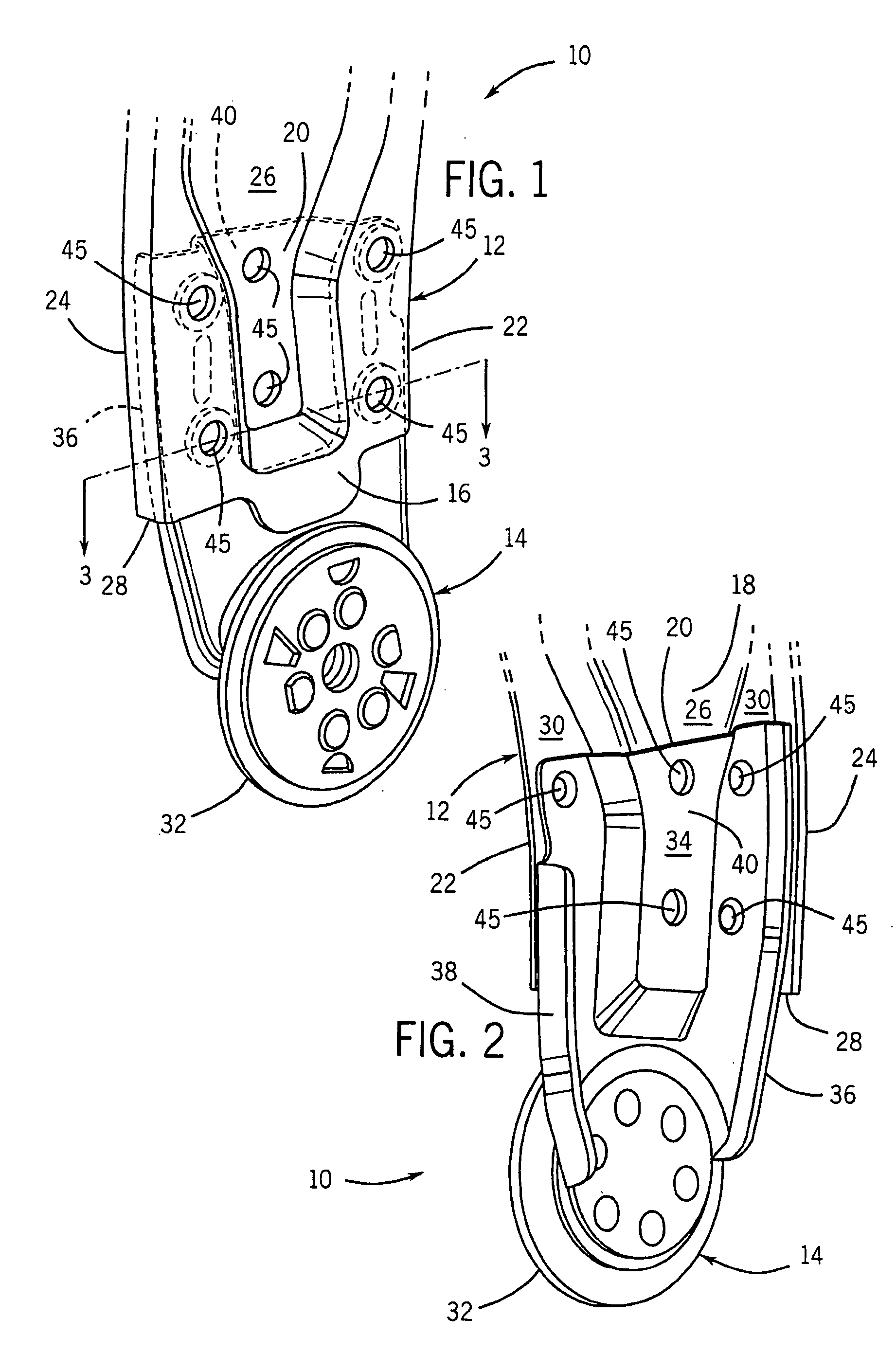

Mechanically locked recliners

Problems resulting from weld failures in the assembly of vehicle seats are reduced by providing a mechanical lock between a seat frame component and a recliner component. Because impact or impulse forced movement of the components is limited by the mechanical lock, reliance on welding alone is eliminated and the amount of welding done during assembly is reduced. The combined seat and recliner components can accordingly be assembled at reduced cost, and increased torsion moment in the side member resulting from the mechanical lock can further result in the mass (weight) of the system being reduced.

Owner:JOHNSON CONTROLS TECH CO

Toughening modifying method for polyphenyl ether/nylon 6 alloy

The invention discloses a toughening modifying method of polyphenylether / nylon 6 alloy. The polyphenylether grafted maleic anhydride is taken as the compatibilizer, which is made by melting grafted method. The mixture of the segmented copolymer of styrene- (ethylene-butylene)-styrene grafted maleic anhydride and the daiamidelastic body is taken as the toughener. The two above are mixed with the polyphenylether and nylon 6 in melting state and the polyphenylether / nylon 6 alloy can be obtained. The notch impact strength of the modified material can reach 1065 J / m, the elongation at break can reach 177 percent, the tensile strength can reach 43 MPa, the bending strength can reach 66.1 MPa and the flexural modulus can reach 1641 MPa.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com