Aluminum alloy section for rail traffic car body skirtboard and manufacturing method of aluminum alloy section

A technology of aluminum alloy profiles and rail transit, which is applied in the direction of manufacturing tools, metal extrusion control equipment, metal extrusion, etc., can solve the problems of many waste products, difficult size, large deformation, etc., to reduce manufacturing costs, reduce unnecessary The effect of pass rate and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

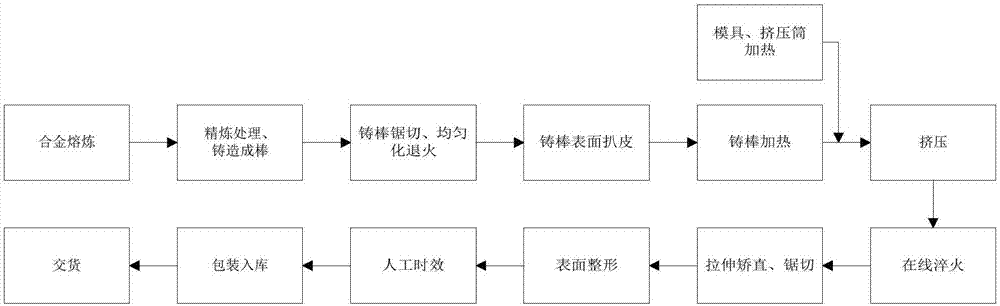

Method used

Image

Examples

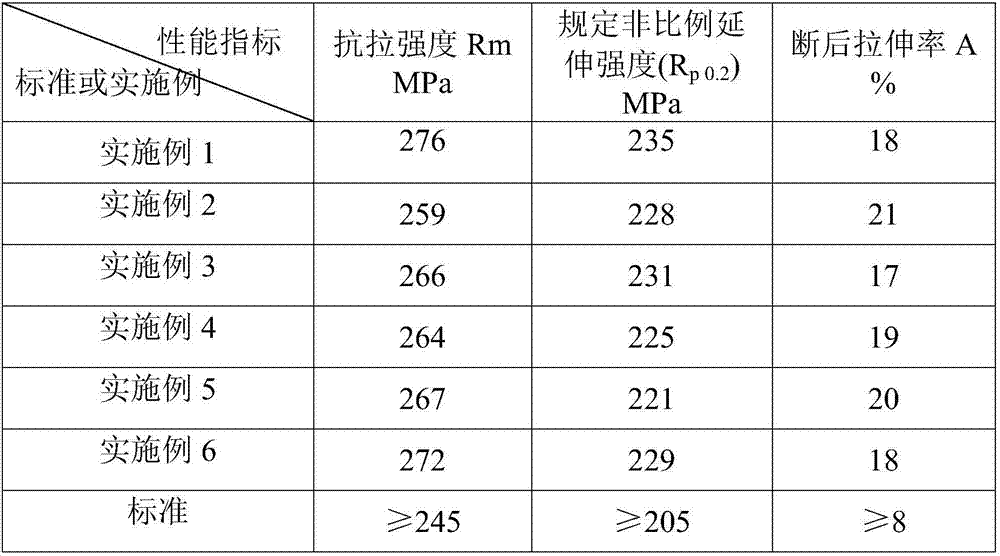

Embodiment 1

[0058] This embodiment provides an aluminum alloy profile for a rail transit car body skirt plate, which is obtained by the following manufacturing method:

[0059] a. Melting: put pure electrolytic aluminum liquid into a pouring melting furnace, add other alloy element components for melting, the melting temperature is 745°C, completely melt the raw materials, and obtain a uniform aluminum alloy melt, control The melt is composed of the following alloying elements by weight fraction: Si: 0.57%, Fe: 0.10%, Cu: 0.13%, Mn: 0.18%, Mg: 0.58%, Cr: 0.11%, Zn: 0.08%, Ti : 0.02%, Mn+Cr: 0.28%, other individual elements ≤ 0.05%, the total amount of other impurity elements ≤ 0.15%, the balance is Al.

[0060] b. Refining treatment: transfer the above melt to the holding furnace, and adjust the temperature of the melt to 740°C for refining treatment in the furnace: the volume ratio of the argon-chlorine mixed gas introduced is 75% for argon and 75% for chlorine 25%, the rotor speed is 3...

Embodiment 2

[0073]This embodiment provides an aluminum alloy profile for a rail transit car body skirt, the manufacturing method of the aluminum alloy profile for a rail transit car body skirt is roughly the same as that in Example 1, the difference lies in: this embodiment The melt in it, and the subsequent casting rods are composed of the following alloying elements by weight fraction: Si: 0.65%, Fe: 0.20%, Cu: 0.15%, Mn: 0.23%, Mg: 0.68%, Cr : 0.17%, Zn: 0.15%, Ti: 0.04%, Mn+Cr: 0.4%, other individual elements ≤ 0.05%, the total amount of other impurity elements ≤ 0.15%, the balance is Al, and finally the rail transit car body skirt Aluminum alloy profiles for panels.

Embodiment 3

[0075] This embodiment provides an aluminum alloy profile for a rail transit car body skirt, the manufacturing method of the aluminum alloy profile for a rail transit car body skirt is roughly the same as that in Example 1, the difference lies in: this embodiment The exit speed of the extruded profile used in the middle extrusion step is 2.4m / min, and finally the aluminum alloy profile for the rail transit car body skirt is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com