Patents

Literature

114results about How to "Product quality is light" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low coefficient of thermal expansion thermoplastic resin composition, preparation method and application thereof

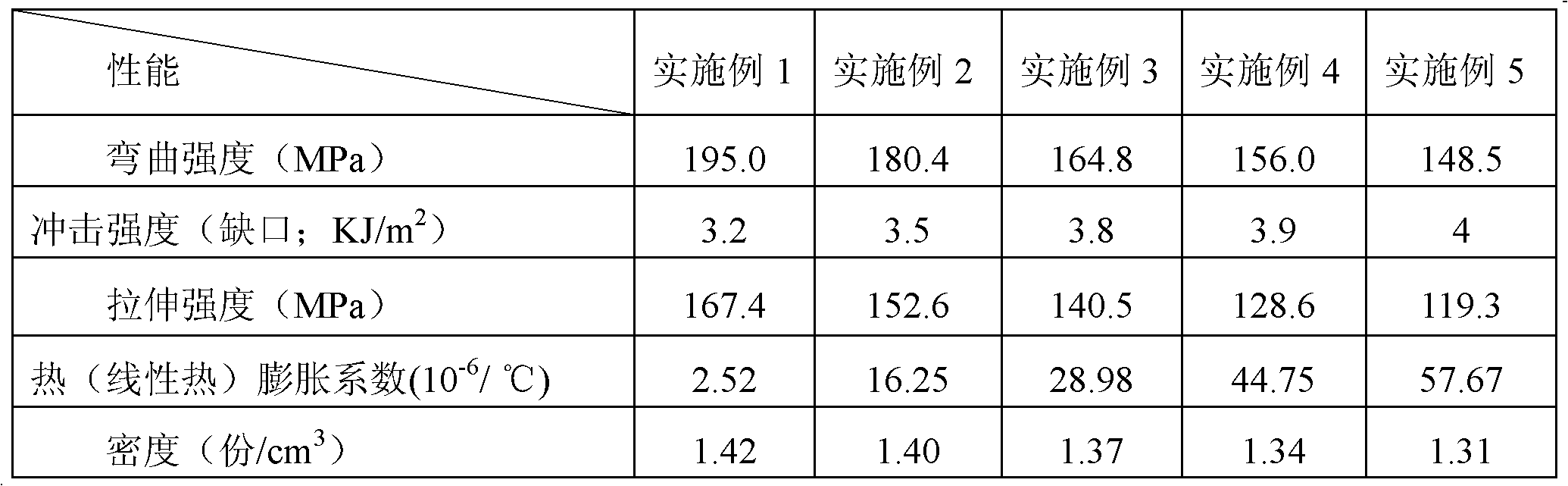

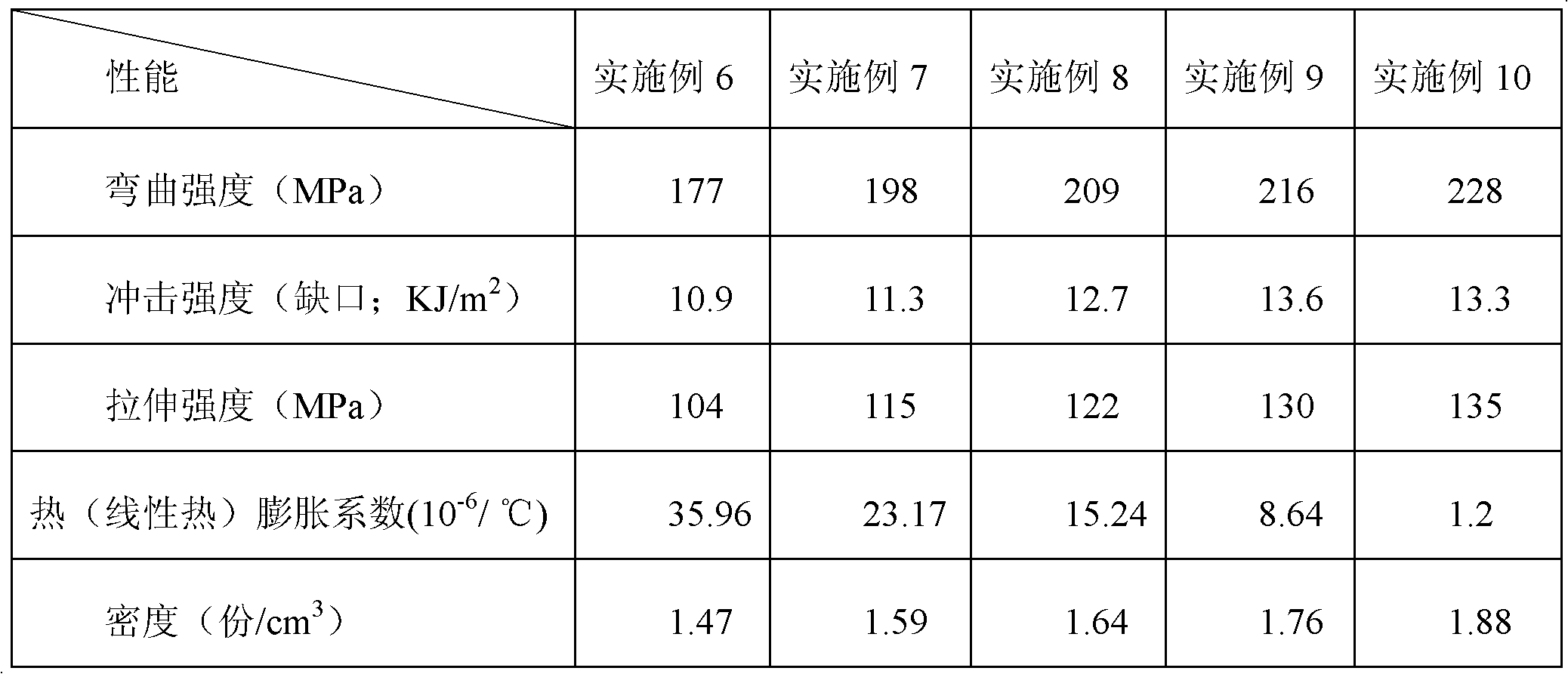

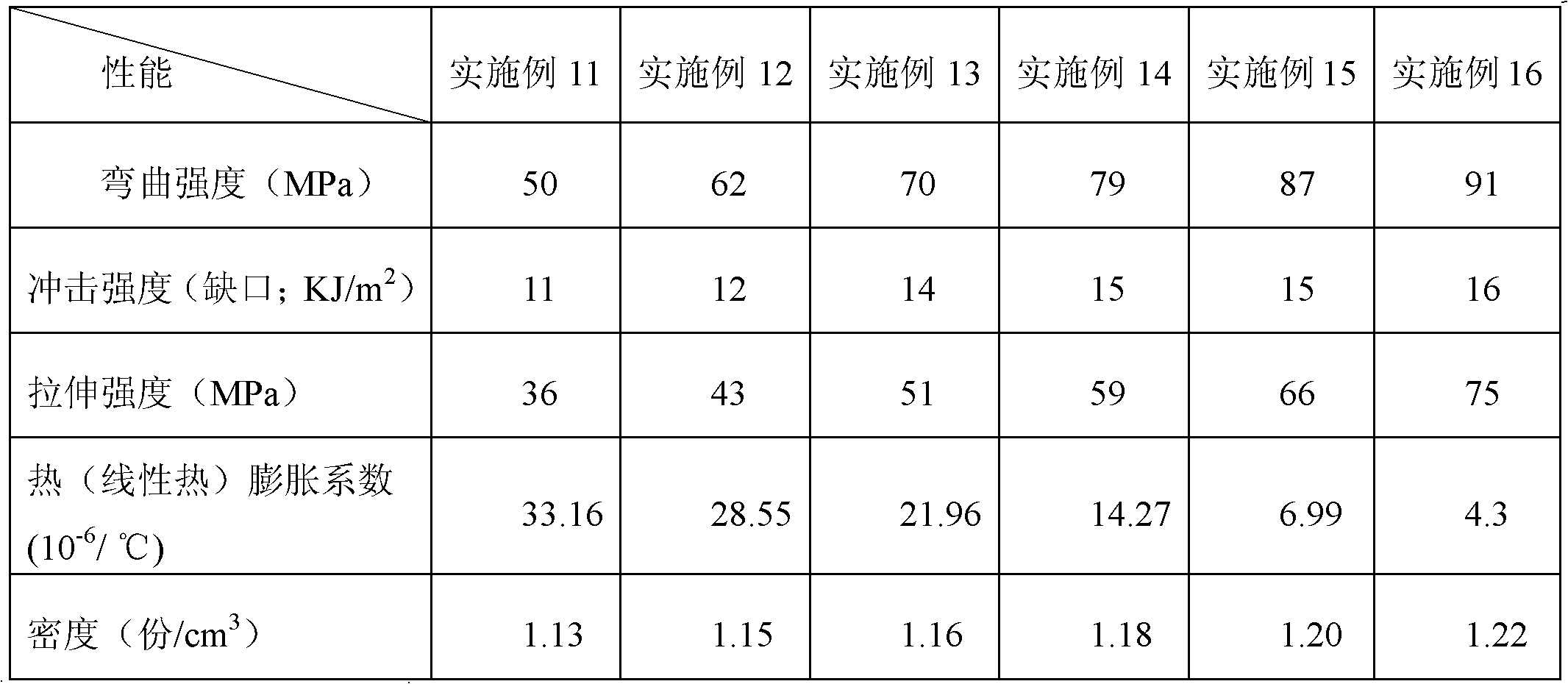

The invention belongs to the technical field of high polymer materials, and discloses low coefficient of thermal expansion thermoplastic resin composition, a preparation method and application of the low coefficient of thermal expansion thermoplastic resin composition. The resin composition is composed of, by weight, 340 to 900 parts of thermoplastic resin, 100 to 500 parts of carbon fibers, 0 to 5 parts of antioxygen, 0 to 5 parts of lubricating agent and 0 to 150 parts of flexibilizer. The preparation method comprises adding the 340 to 900 parts of the thermoplastic resin, the 0 to 5 parts of the antioxygen, 0 to 5 parts of the lubricating agent and the 0 to 150 parts of the flexibilizer to a high mixing machine to mix for 1 to 30 min, adding the mixture to a double-screw extruder, adding the 100 to 500 parts of the carbon fibers from the glass fiber feeding port or the side feeding port of the double-screw extruder to mix evenly, and carrying out extruding, dragging and prilling on mixed materials in the double-screw extruder to obtain the low coefficient of thermal expansion thermoplastic resin composition. The use of the low coefficient of thermal expansion thermoplastic resin composition applied to the fittings of a metal piece is provided. The thermoplastic resin is high in flexural modulus, tensile strength and impact strength, and low in linear expansion coefficient.

Owner:HEFEI GENIUS NEW MATERIALS

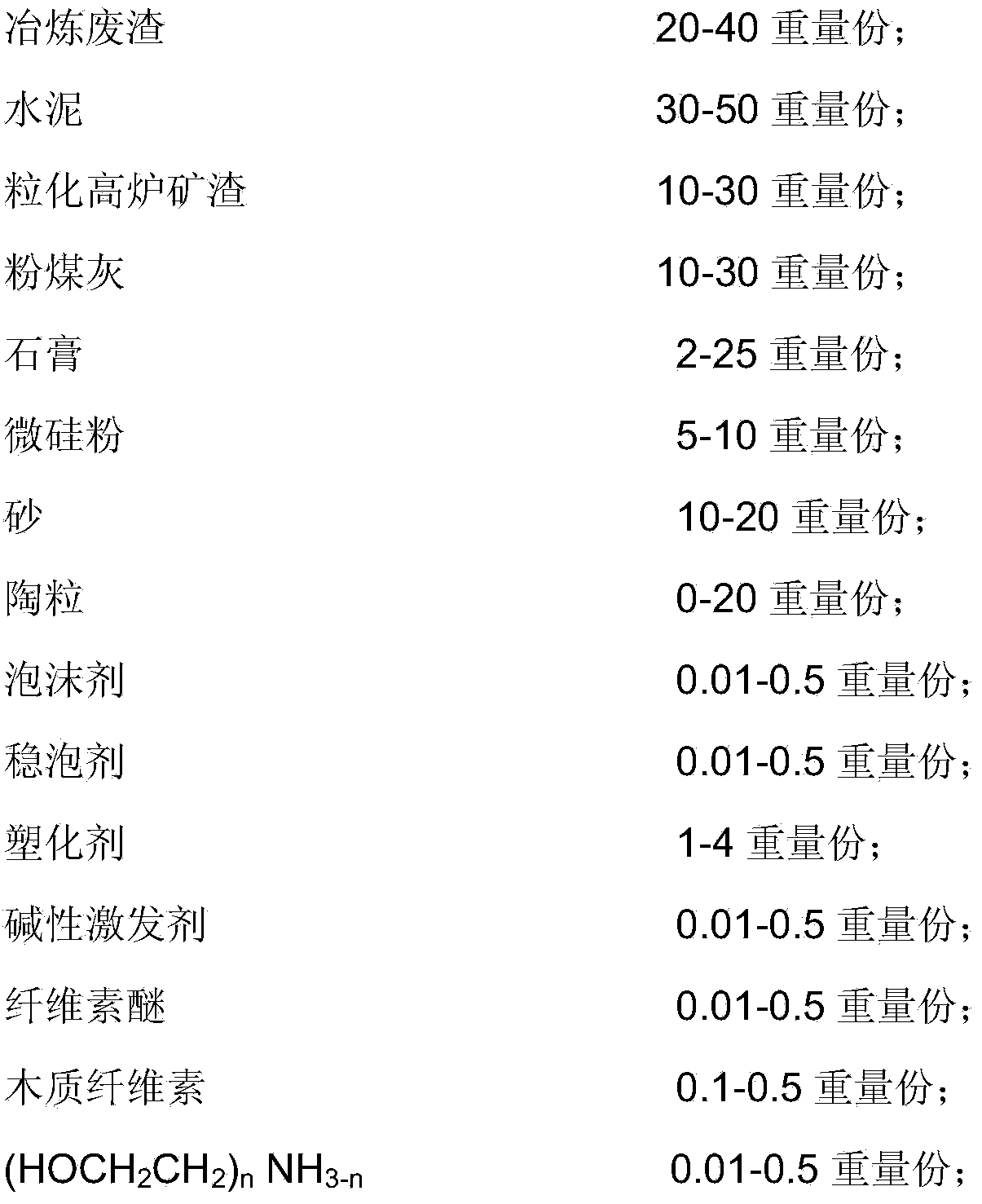

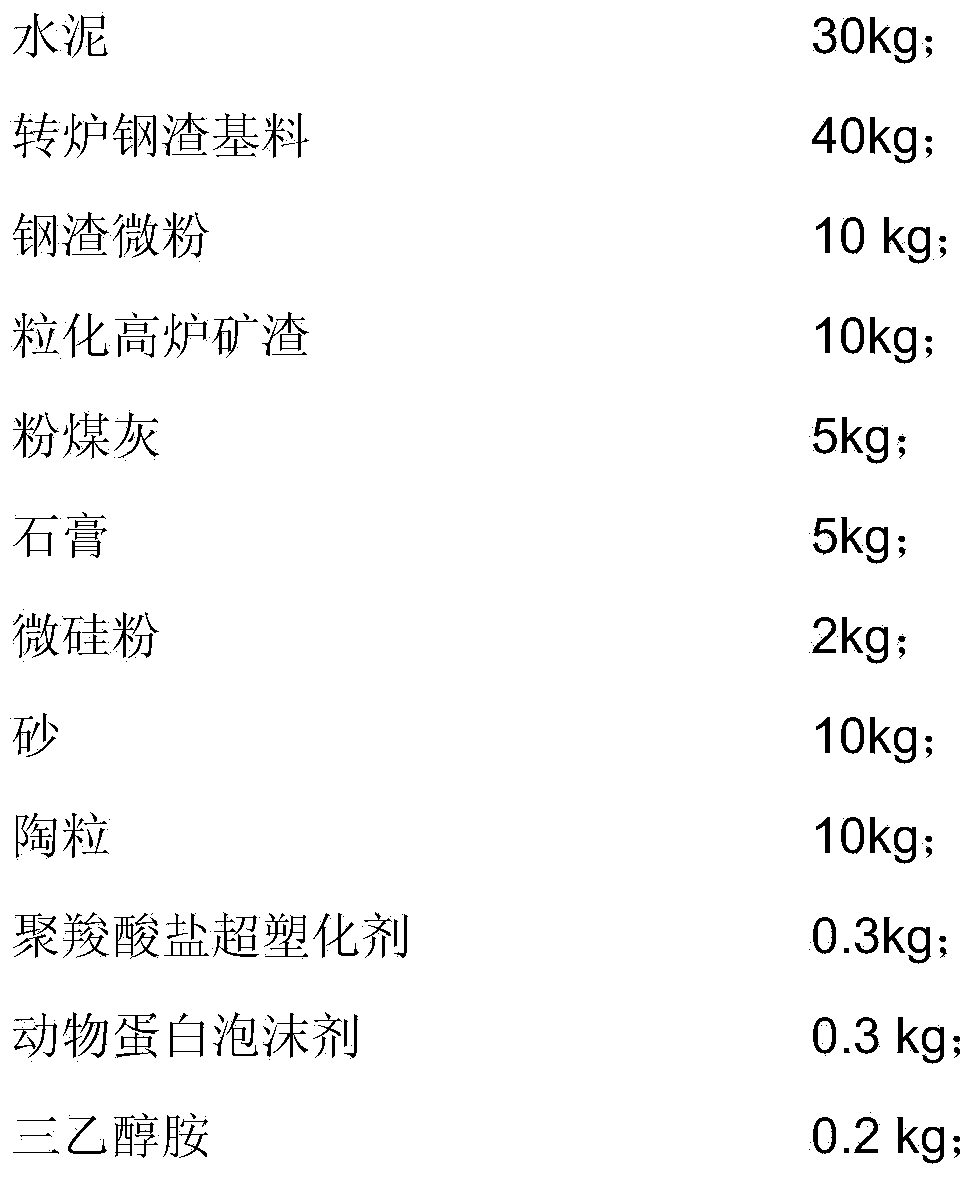

Smelting waste slag light composite artificial stone and production method thereof

ActiveCN104193399AImprove workabilityImprove pore structureSolid waste managementCeramic shaping apparatusSlagSlurry

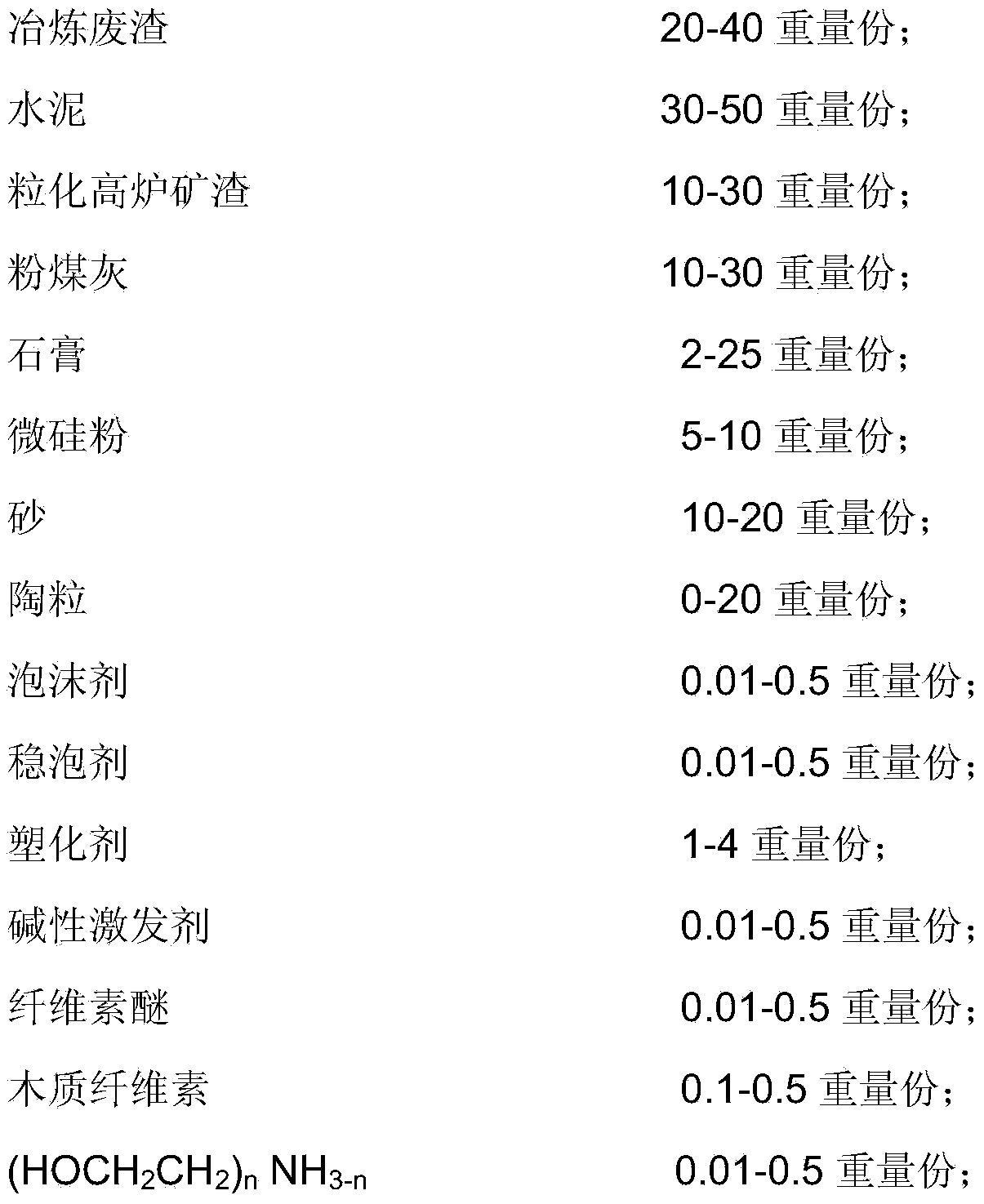

The invention provides a smelting waste slag light composite artificial stone which comprises a main body material prepared from structural slurry. The structural slurry comprises a base material, a cementing agent, water, a polymeric additive, an alkaline excitant and a foamer aqueous solution or a foam material. A production method of the smelting waste slag light composite artificial stone comprises the following steps: by pre-treating the smelting waste slag which is used as part of cementing agent and base material, introducing the foamer aqueous solution or the foam material; stirring the components; and casting and carrying out vibration molding in a die. The stone provided by the invention is scientific in formula and reasonable in process and has ecological environmental protection property, high mechanical strength, low cost and excellent operating performance. The self weight of the smelting waste slag light composite artificial stone is reduced, and the heat preserving and insulating properties and the soundproof, fireproof and saltpetering-preventing properties of the smelting waste slag light composite artificial stone are improved. The stone has extremely strong durability and color stability in various severe conditions.

Owner:SHANGHAI APE STONE

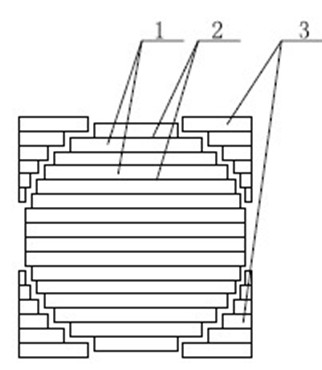

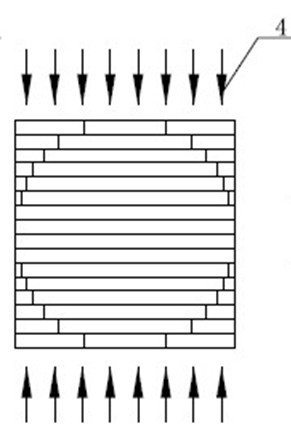

Structural glued-laminated timber round wooden column and manufacturing method thereof

InactiveCN102535752AReduce defectsIncreased dispersionStrutsWood working apparatusSolid woodAdhesive cement

The invention discloses a structural glued-laminated timber round wooden column and a manufacturing method thereof and belongs to the field of manufacturing of building materials. The structural glued-laminated timber round wooden column has a circular cross section and comprises member units and an adhesive layer, wherein the member units are in finger joint and are transversely spliced and fixedly stacked and adhered through the adhesive layer; texture of woods of the member units has consistent orientation; and the round wooden column has no knots, gaps, decayed parts, worm channels or other inherent natural defects of woods. The method comprises the step of manufacturing laminated wood employing small-specification wood sawn timber so as to manufacture the structural glued-laminated timber round wooden column. The problems that round wooden columns with any specification and size are difficult to obtain, stock columns easily crack and deform in the using process, the decayed parts, worm channels and other defects of the stock columns are difficult to overcome, and the like are effectively solved. The product can be used as a building bearing member, the wood materials are subjected to antiseptic treatment or are made of woods with high natural decay resistance; and the product can be used as a member for architectural ornament and decoration of outdoor or landscape garden wood buildings.

Owner:NANJING TECH UNIV

Vacuum continuous metalizing coating decoration process

InactiveCN102796986AMaterial unlimitedMeet individual needsVacuum evaporation coatingSputtering coatingUv protectiveLacquer

The invention discloses an environment-friendly plastic metalizing decoration process and belongs to the field of plastic decoration. The method comprises the following steps: a, cleaning a molded plastic part; b, coating primer, wherein the plastic part is coated with acrylate UV (ultraviolet) primer and then cured so that the uneven surface of a base material is flattened with the primer; c, coating a film in vacuum, wherein the plastic part is put into a vacuum film coating cavity of vacuum film coating equipment, the vacuum degree of the vacuum film coating cavity is controlled to be between 10<-2> and 10<-3>Pa, and performing vacuum continuous film coating after plasma dust collection; d, coating protective paint, wherein the plastic part is coated with the acrylate UV protective paint which is matched with the UV primer and then cured to form a paint film with a certain hardness; and e, pasting a film on the plastic part, and packaging the plastic part. The environment-friendly plastic metalizing decoration process produces less waste gas and waste water, is more environment-friendly than a conventional metalizing process; and the product has light weight, the appearance design of the product is free, and the individual requirement of consumers can be met.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

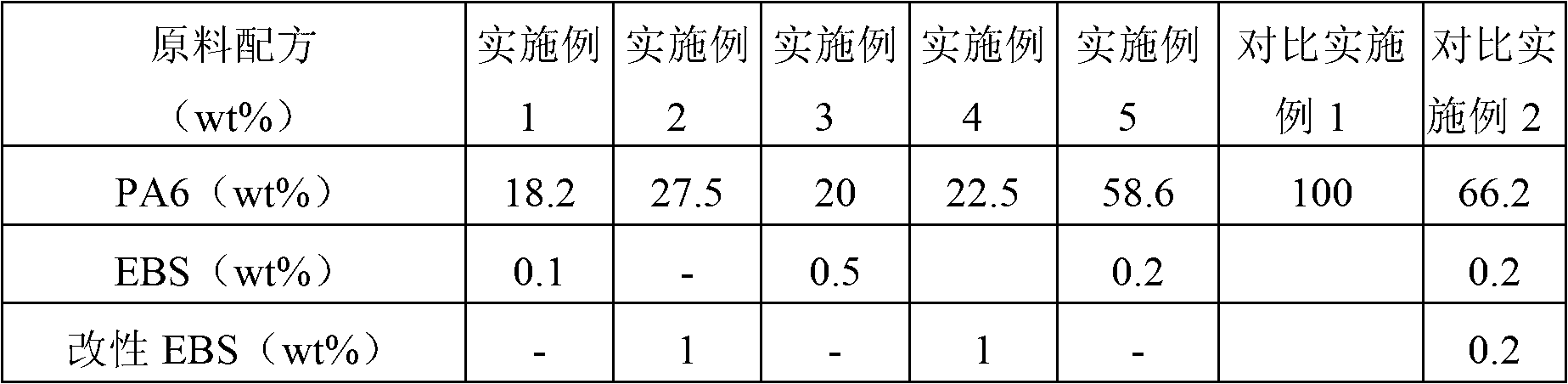

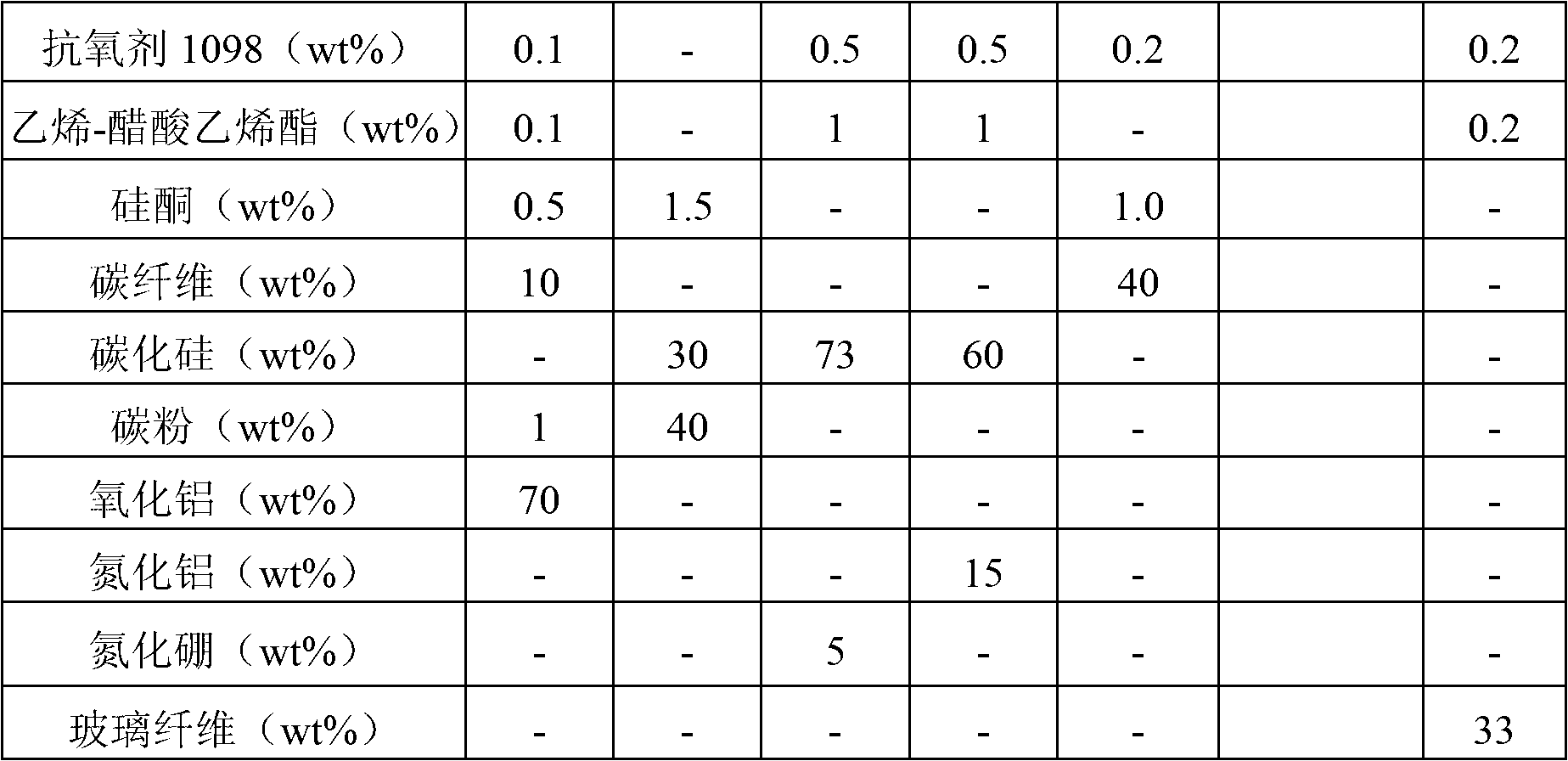

Heat conduction polyimide composite material, preparation method and application thereof

ActiveCN102796369AFast heat conductionLow costPoint-like light sourceLighting heating/cooling arrangementsFiberCarbon fibers

The invention provides a heat conduction polyimide composite material and a preparation method thereof. The heat conduction polyimide composite material comprises the following components in percentage by weight: 18.2-58.6 percent of polyimide, 0.1-1.0 percent of lubricating agent, 0.1-0.5 percent of antioxidant, 1.0-1.5 percent of surface modifier and 40-81 percent of heat conduction enhanced modifying agent, wherein the heat conduction enhanced modifying agent can be one, two or three of carbon fiber, carbon powder, silicon carbide, aluminum oxide, silicon carbide and aluminum nitride. The heat conduction polyimide composite material provided by the invention has excellent heat conduction, can be used for preparing a radiator part of a light emitting diode illuminating device, is low in cost, easy to process and form, and light in weight, can be recycled, and accords with the environment protection requirement. The preparation method provided by the invention is simple in process and is suitable for massive industrial production.

Owner:上海耐特复合材料制品有限公司

Environmentally-friendly plant fiber packing material

InactiveCN101654890AWide variety of sourcesLow pricePulp beating methodsWood working apparatusFoaming agentPlant fibre

The invention relates to an environmentally-friendly plant fiber packing material, and belongs to the field of packing materials. The environmentally-friendly plant fiber packing material is preparedby the following steps: putting plant fibers of agricultural waste straws, wheat stalks, bean stalks, devil's rush herb, corn stalks and the like into a closed container, adding water containing one or more of fungi into the container to soak the plant fibers in the water to be degraded, and then sealing the container and shaking the container for 5 to 7 days; taking the plant fibers out and beating the plant fibers; preparing the plant fibers, adhesive, softener, mildew-proof agent, foaming agent and waterproof agent in a weight ratio of (50-70): (1-2): (0.5-1): (0.5-1): (1-2): (0.5-1); bulking the materials into granules through bulking equipment, and blowing the granules into different models according to the packing requirements; or directly pressing the prepared materials into different packing models on a hot press. The environmentally-friendly plant fiber packing material has the advantages that the material totally uses the plant fibers of the straws, wheat stalks, bean stalks,devil's rush herb, corn stalks and the like, so the source is wide, and the price is low; the production process has no three wastes and does not influence the environment; the product is in accordance with the requirements of environmentally-friendly packing materials on light weight, pressure resistance, seismic resistance, moisture prevention and water prevention; and after discarding, the packing material can be naturally degraded, so the packing material is favorable for environmental protection.

Owner:李小龙 +2

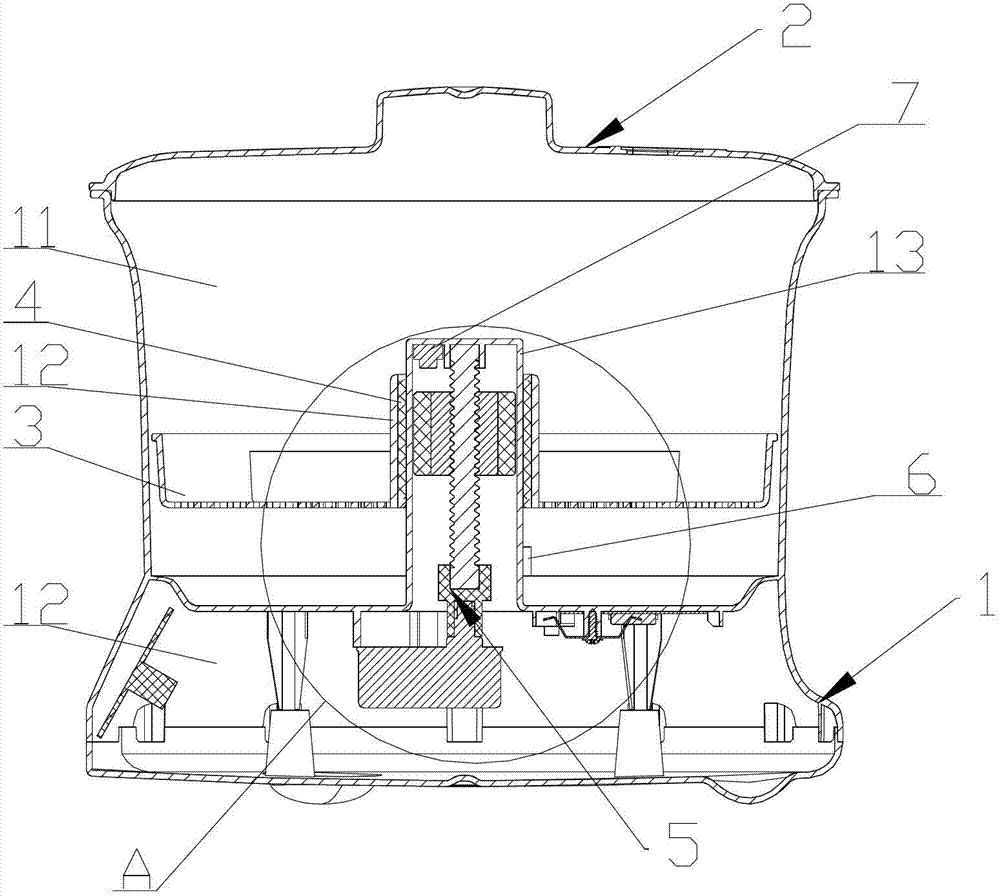

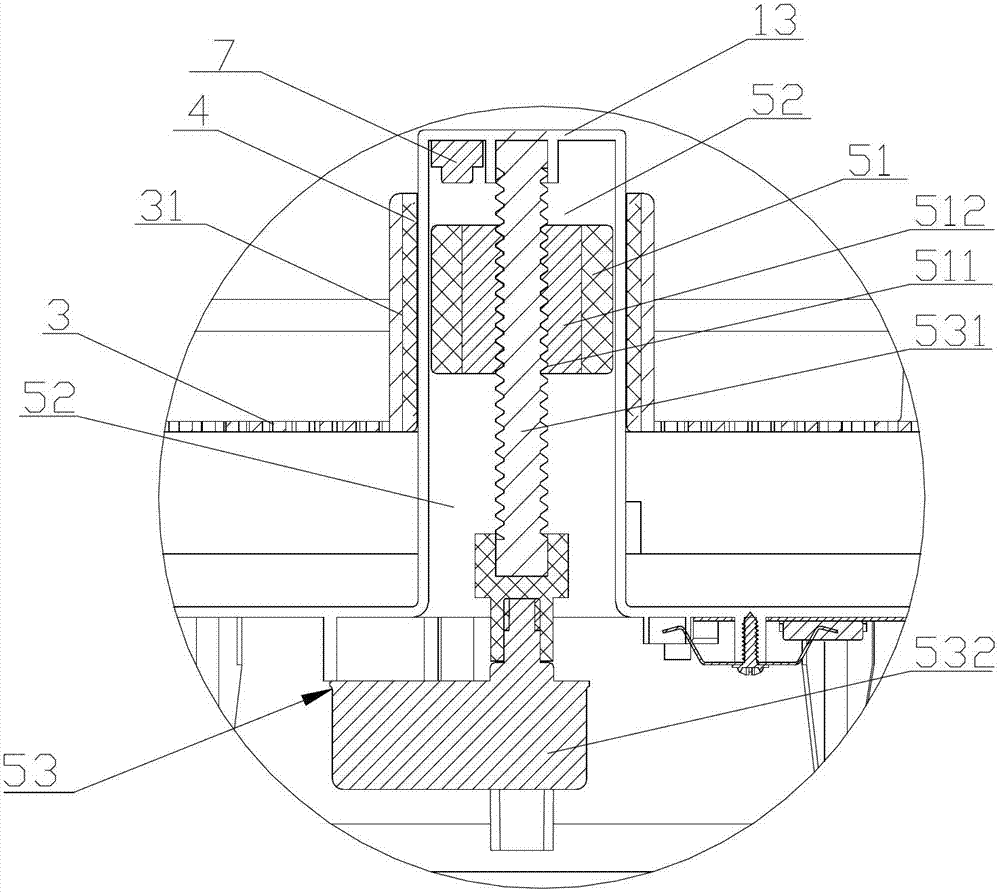

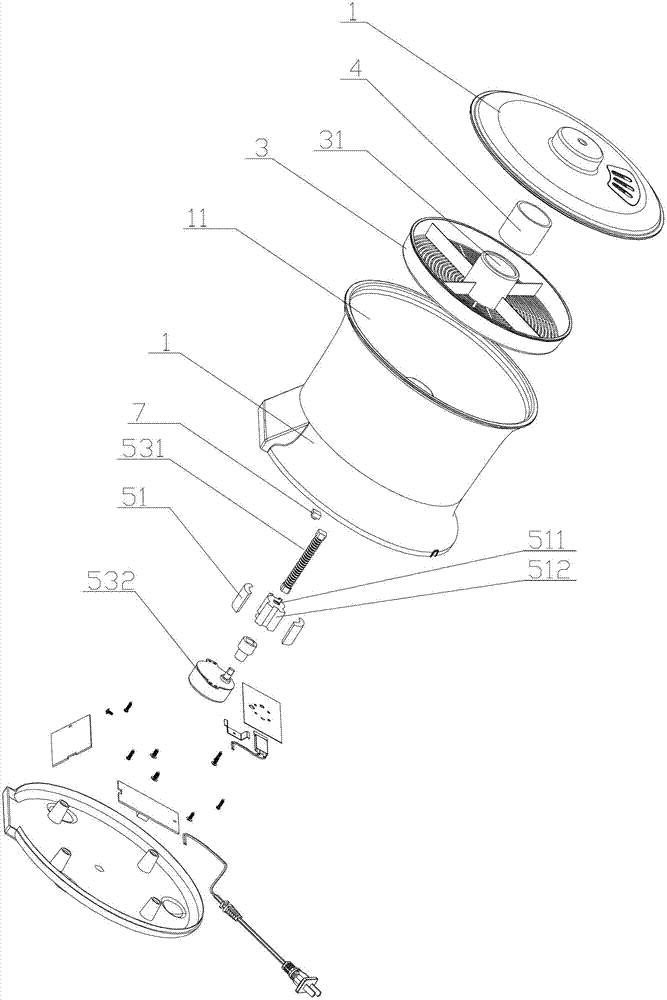

Lift bean sprouting machine and control method thereof

InactiveCN102845291AReduce volumeProduct quality is lightAgriculture gas emission reductionCultivating equipmentsAgeingEngineering

The invention relates to a lift bean sprouting machine and a control method thereof. The lift bean sprouting machine structurally comprises a shell, an upper cover and a seedling tray. A seedling chamber for raising bean sprouts and an electromechanical chamber for holding electromechanical parts are respectively arranged in the shell. A first part for controlling ascent and descent of the seedling tray is arranged on the seedling tray. A second part used with the first part to control ascent and descent of the seedling tray is disposed in the shell. The second part is a magnetic component capable of controlling up and down movement of the first part by magnetic force. The magnetic force can permeate most materials, so that the first part and the second part are disposed in two mutually isolated spaces respectively, namely technical water-electric isolation between the seedling chamber with the first part and the electromechanical chamber with the second part can be achieved. The technical defects that water in the seedling chamber possibly leaks into the electromechanical chamber to cause ageing, short circuit, electric leakage and the like to the electrical components in the prior art are overcome. The technical water-electric isolation is achieved.

Owner:BEAR ELECTRICAL APPLIANCE CO LTD

Ultralight rubber foam colloid particles and preparation method thereof

The invention relates to the field of shoe material manufacturing, and provides ultralight rubber foam colloid particles. The ultralight rubber foam colloid particles are prepared from, by weight, 20-40 parts of CPE-CM (chlorinated polyethylene), 12-18 parts of POE (polyolefin elastomers), 6.4-9.6 parts of EPDM (ethylene-propylene-diene monomer), 9.6-14.4 parts of EVA (ethylene vinyl acetate), 8-12 parts of natural rubber or isoprene rubber, 5.6-8.4 parts of filler, 0.24-0.36 part of stearic acid, 0.48-0.72 part of zinc stearate, 0.48-0.72 part of a DCP cross-linking agent, 0.64-0.96 part of zinc oxide, 0.96-1.44 parts of an AC foaming agent and 1.6-2.4 parts of a wear-resistant agent. Accordingly, the problems that an existing shoe material is poor in flexibility, fold resistance, anti-skid property and wear resistance, large in weight and like are solved.

Owner:许文谈

Method for manufacturing stalk-polystyrene composite thermal-insulated plate

The invention relates to a manufacture method for stalk-polystyrene compounding warming plate that includes the following steps: insolating the corn stalk, drying to make the water content below 5%, smashing the corn stalk to 5-10mm, mixing with polystyrene raw material according to weight ratio of 15-30:1, adding the mixture into plate mould, adding 100 degree centigrade vapor into mould to make polystyrene foaming, the light construction energy saving plate.

Owner:SHENYANG JIANZHU UNIVERSITY

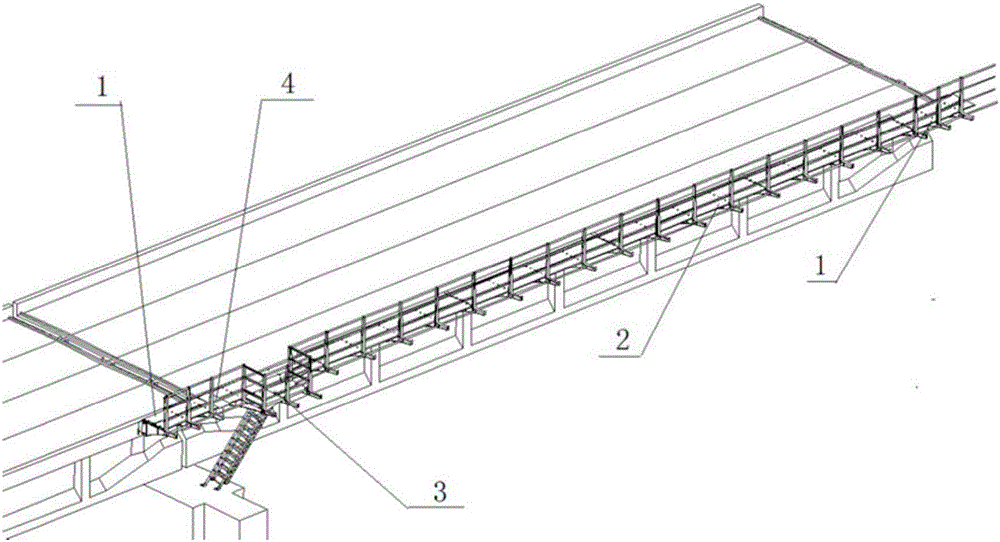

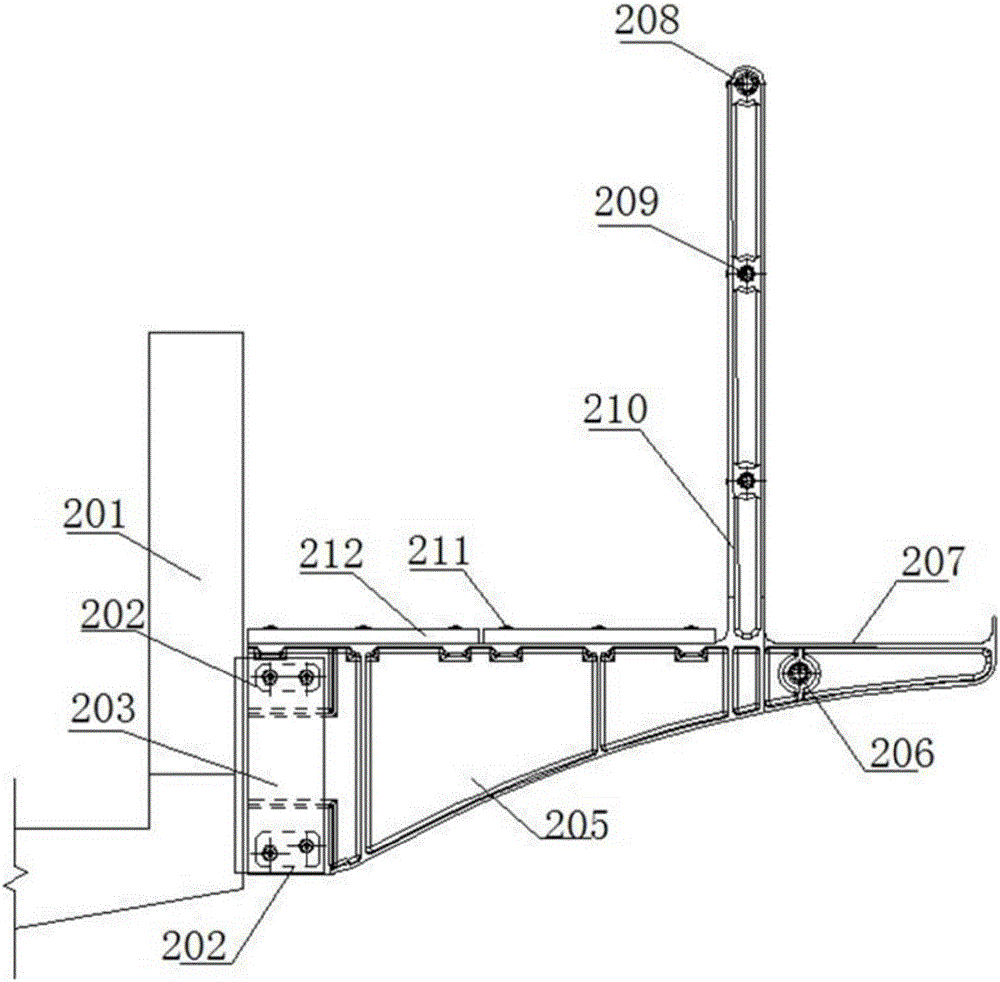

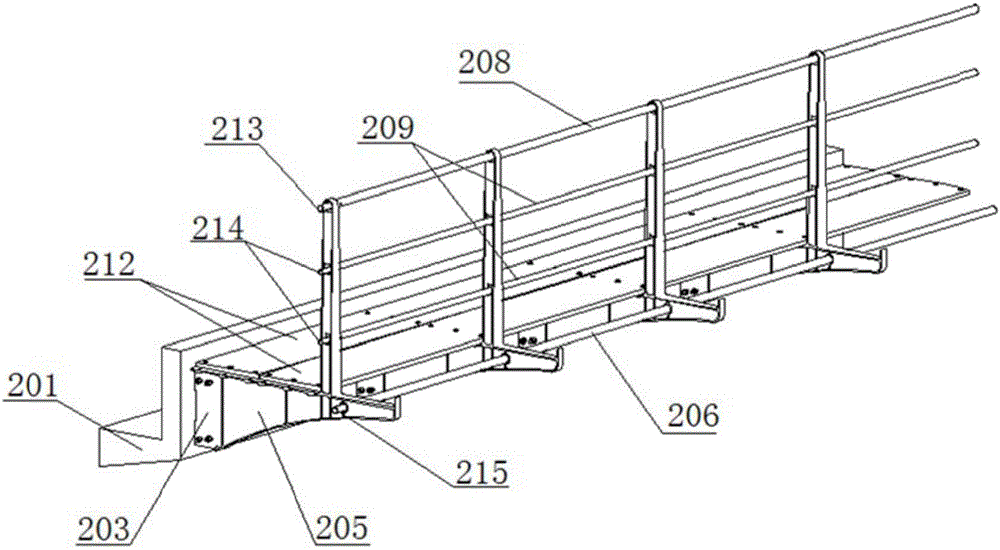

Concrete beam composite sidewalk

InactiveCN106592415ALightweight and high strengthLow costBridge structural detailsBridge materialsShaped beamPre stress

The invention relates to a concrete beam composite sidewalk which is a novel sidewalk with reinforced concrete and pre-stressed concrete T-shaped beams and plate-type beams for the railway and road. The invention especially relates to a concrete beam sidewalk which adopts the main components made from fiber reinforced composites and fully utilizes the advantages of all the components of the composite material. The concrete beam composite sidewalk comprises standard modules and beam end modules, wherein the beam end modules are located at the two ends of a concrete beam; a plurality of standard modules are arranged between the beam end modules at the two ends; the concrete beam composite sidewalk further comprises a beam end refuge platform module; the beam end refuge platform module instead of one beam end module is arranged at one end of the concrete beam. The concrete beam composite sidewalk can reduce the second phase dead load of the bridge, can increase the bearing capacity of the bridge and can reduce the maintenance cost of the deck ancillary facilities.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +5

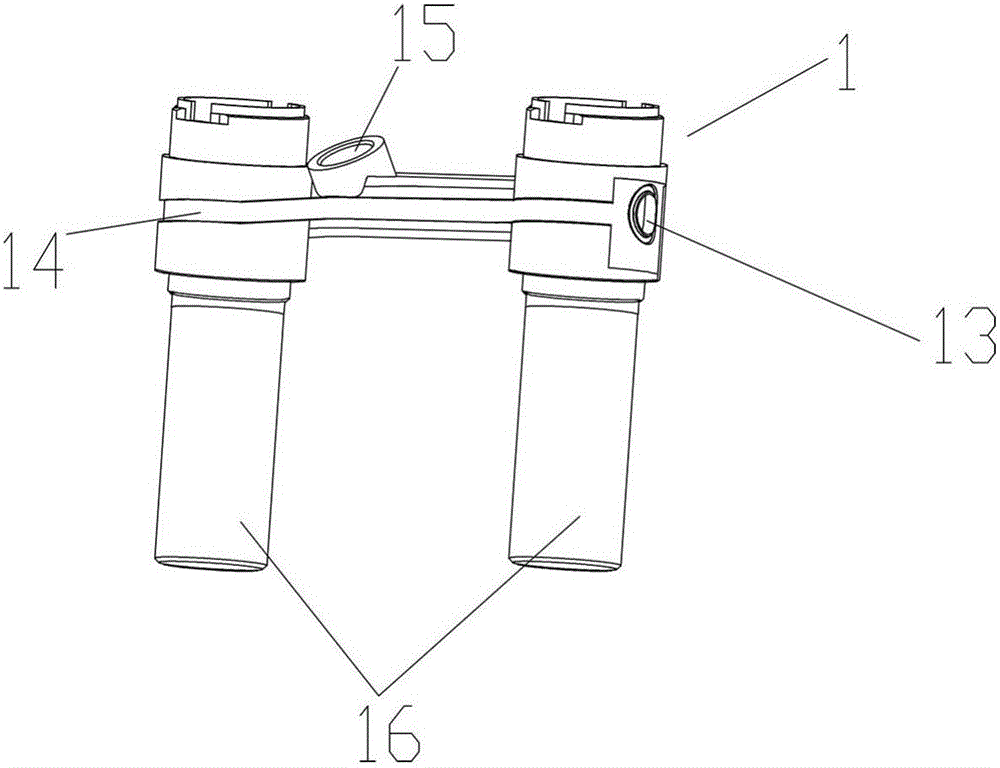

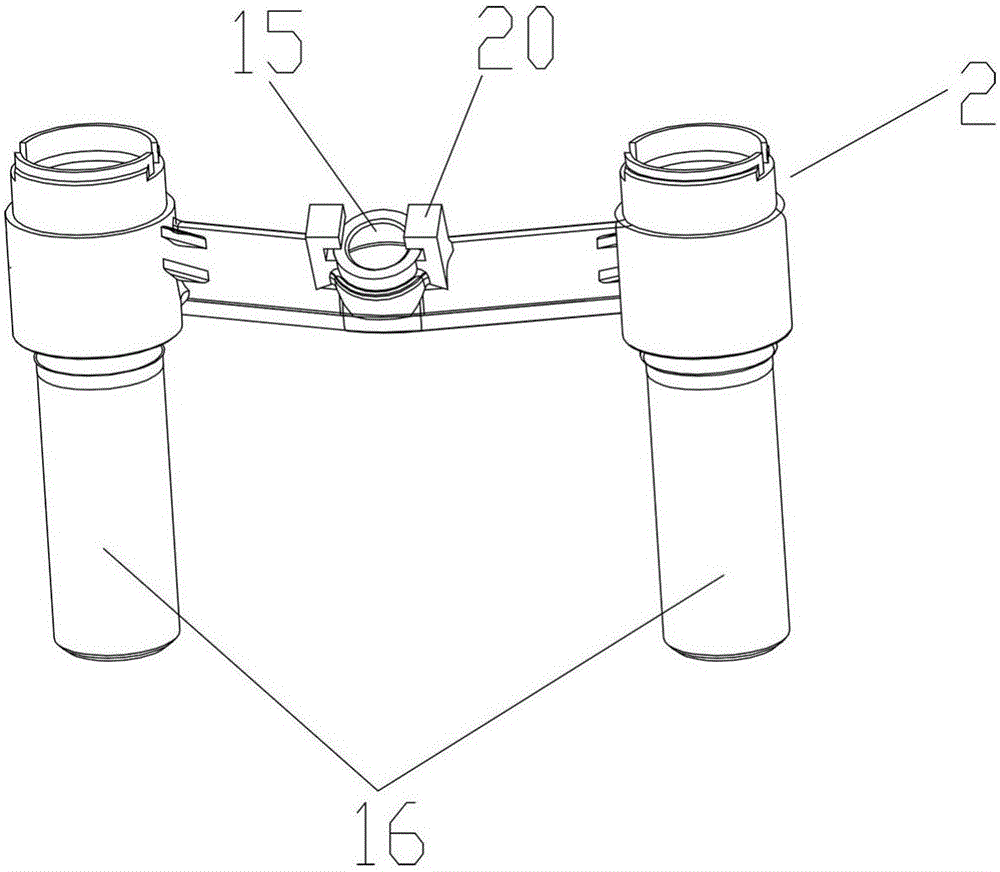

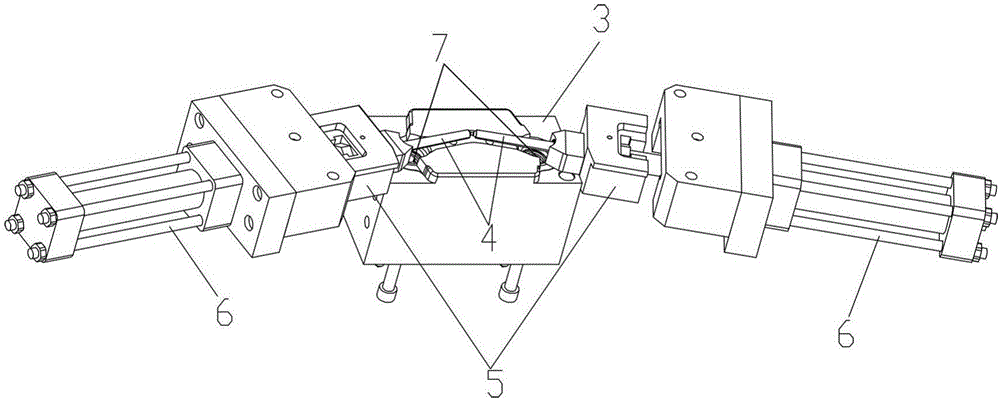

Integrated plastic faucet body forming method

ActiveCN106426736AEasy to prepareIncrease productivityDomestic articlesWork in processComposite material

The invention discloses an integrated plastic faucet body forming mold. The integrated plastic faucet body forming mold comprises a mold frame, a first static mold cavity, a second static mold cavity and a first moving mold core, wherein the first static mold cavity, the second static mold cavity and the first moving mold core are installed in the mold frame; after the first static mold cavity and the first moving mold core are combined, a first injecting molding is conducted, and a semi-finished product of an integrated plastic faucet is formed; and after the first static mold cavity and the first moving mold core is split, the second static mold cavity is combined with the first moving mold core, then a second injection molding is conducted, and a finished product of the integrated plastic faucet is formed. By adopting a manufacturing method of twice injection molding and integrated cladding forming in the finished product, the manufacture method is simple, producing efficiency and the yield of the finished product are high, the effect of fast and mass production is achieved, producing cost is reduced, and a metal connecting pin is added, so that a product is more firm, and the service life is prolonged.

Owner:深圳成霖实业有限公司

Heat insulation building material

InactiveCN103641416AQuality assuranceGuaranteed mechanical strengthSolid waste managementFoam concreteBuilding product

The invention relates to a heat insulation building material which comprises the following raw materials by mass percent: 20-40% of fine sand, 30-50% of cementing material, 10-40% of heat insulation material, 10-30% of mineral admixture and 5-10% of other auxiliary materials. A production technology of the heat insulation building material comprises the steps of mixing and stirring a shell cementing material, producing foam concrete, cutting and fixing the foam concrete and a heat insulation core body of a polystyrene foam plastic board, pouring, vibrating and molding shell slurry, and maintaining building blocks. The heat insulation building material can be used for replacing a great deal of solid clay bricks, thus saving a great deal of energy and land for China, being capable of consuming a great deal of industrial solid wastes and being beneficial to the environmental protection. The produced construction product has the excellent characteristics of being good in heat insulation property, light in self weight, high in strength, waterproof, impervious, low in shrinking percentage, long in service life, simple in construction and the like, thus being beneficial to the development of building energy conservation.

Owner:肖新颖

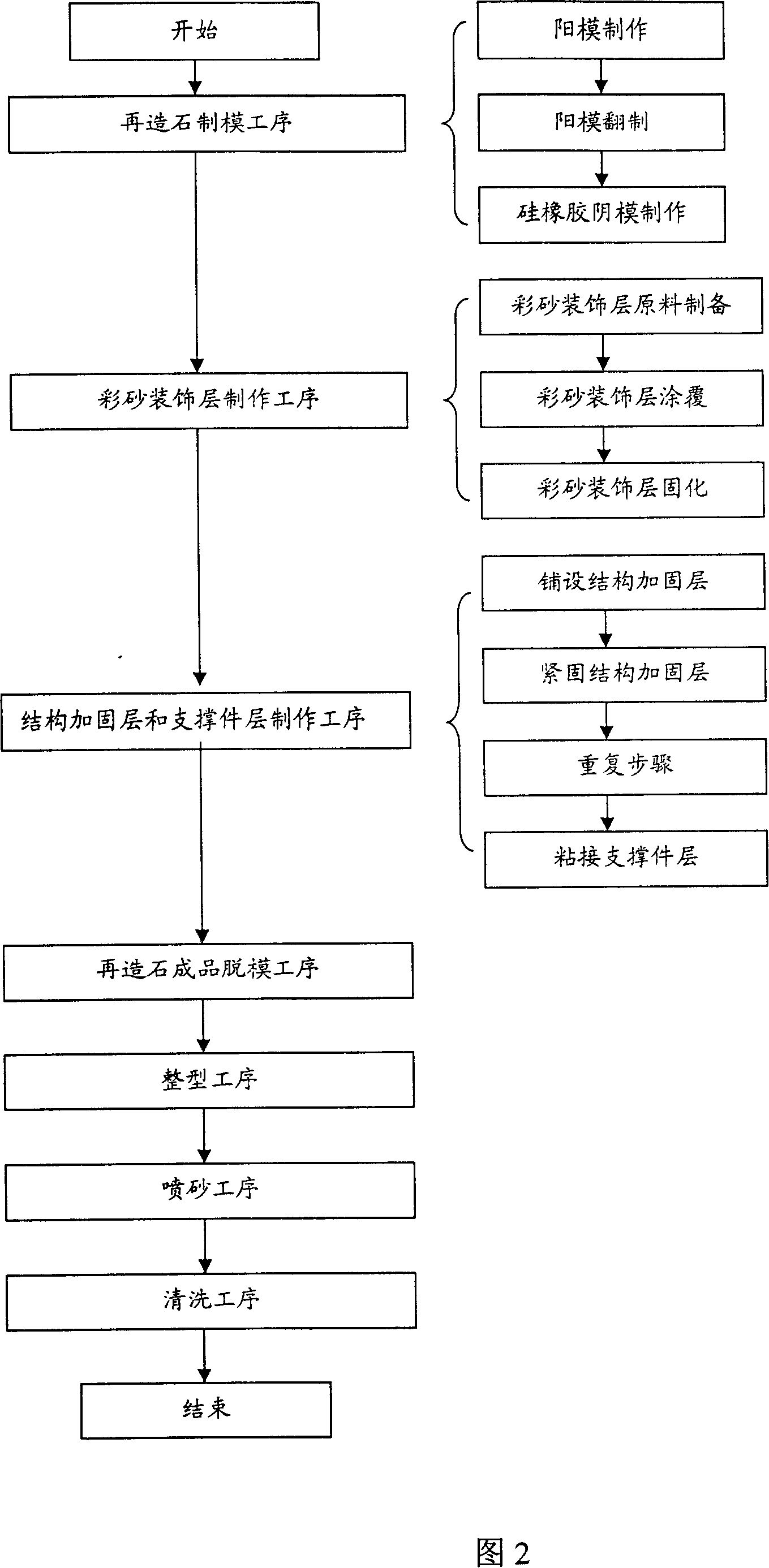

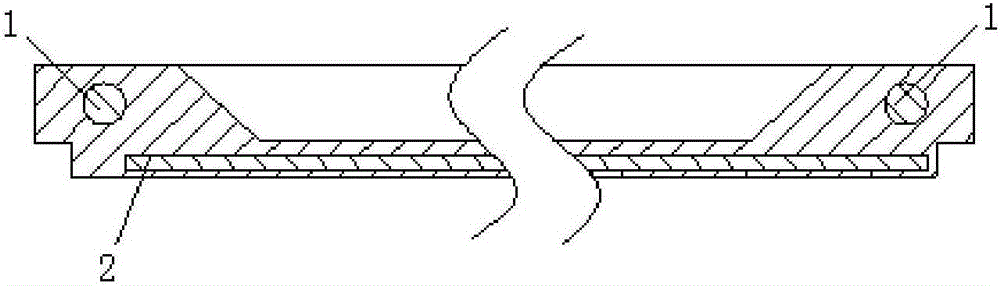

Reproduced stone and preparing method thereof

InactiveCN101121305AReduce the burden onSmall granularityOrnamental structuresSpecial ornamental structuresEngineeringPollution

The invention belongs to a building material product and a preparation method thereof, in particular to a reconstituted stone and a preparation method thereof. The structure of the reconstituted stone sequentially comprises: a colored sand decorative layer, a structural reinforcement layer and a support layer; A structural reinforcement layer is laid on the inner side of the decorative layer, and the structural reinforcement layer is used to reinforce the reconstituted stone sheet; the support layer is arranged in the structural reinforcement layer, and the support member is used for integrally fixing the reconstituted stone sheet . The invention solves the shortcomings of the traditional method, such as heavy weight, high temperature and other conditions, rough texture, single color, deformation and load-bearing, etc. specialty.

Owner:马珺

Polyvinyl chloride floorboard substrate and preparation method thereof

The invention discloses a polyvinyl chloride floorboard substrate and a preparation method thereof, belonging to the technical field of polyvinyl chloride boards. The polyvinyl chloride floorboard substrate solves the problems of high cost and poor quality in the existing product. The polyvinyl chloride floorboard substrate is prepared from 80-100 parts of polyvinyl chloride SG8 resin, 100-120 parts of heavy calcium carbonate, 50 parts of floorboard substrate moldboard reclaimed material, 7-8 parts of foaming regulator 903, 2-3 parts of foaming regulator 902, 2.8-4.9 parts of composite stabilizer, 0.6-1.2 parts of internal lubricant ZB-60, 0.35-0.7 part of polyethylene (PE) wax, 0.2-0.5 part of AP, 0.5-0.8 part of plasticizer OA3, 0.3-0.4 part of heat-release AC (azodicarbonamide) foaming agent, 1.4-1.6 parts of heat-absorption Zhongkai c-2 foaming agent, 2-5 parts of ferrite yellow powder and 2-4 parts of CPE (chlorinated polyethylene). The preparation method comprises the following steps: mixing, plastifying and foaming, and extruding to obtain the finished product. The product can be widely used in office buildings, shopping malls, schools, gymnasia, hospitals and other locations.

Owner:SHANDONG HUIFENG NEW MATERIAL TECH CO LTD

Color steel tile with graphite coating and preparation method thereof

ActiveCN106893440AFast dryingProduct quality is lightFireproof paintsAnti-corrosive paintsEpoxyPolyvinyl alcohol

The invention discloses a color steel tile with a graphite coating and a preparation method thereof. The color steel tile comprises a base plate located in a middle layer, and the two sides of the base plate are coated with coatings formed by graphite slurry. The graphite slurry is made of, by weight parts, 50-200 parts of fine flake graphite micro powder, 40-160 parts of cashew-nut oil modified phenolic resin or epoxy resin, 10-50 parts of polyvinyl acetal, 40-160 parts of alcohol, 2-10 parts of coupling agent, 2-10 parts of defoamer, 1-10 parts of plasticizer and 2-10 parts of liquid acrylonitrile butadiene rubber. The service life of the obtained color steel tile with the graphite coating can be greatly prolonged, problems that a conventional resin tile ages easily and is low in strength toughness and not resistant to flame and the like are solved; a problem that a conventional color steel tile is heavy in weight and difficult to install is solved; indoor and outdoor heat exchange rate can also be effectively increased, and a problem of high-temperature poor working environments of conventional color steel tile plants is solved; and a problem that at present, on the market the fine flake graphite is massively accumulated and is low in additional value is solved.

Owner:YICHANG XINCHENG GRAPHITE

High-crystal, light and high-strength gauge stuff ceiling

ActiveCN105082353ALight in massLow costCeramic shaping apparatusCement mixing apparatusEmulsionSurface finishing

A high-crystal, light and high-strength gauge stuff ceiling is prepared through the following steps that firstly, a stirring solution is prepared, namely, a polyving akohol solution, the copolymer emulsion of polyvinyl acetate and ethylene, a water reducer, a water-proofing agent, a retarder and a defoaming agent are mixed with water and stirred evenly; secondly, mixed powder is prepared, namely gypsum powder and white cement are evenly mixed; thirdly, gypsum pulp is prepared, namely the mixed powder is poured in a barrel containing the stirring solution, short-cut glass fiber filaments are added during stirring, and even stirring is performed; fourthly, pouring molding is carried out, namely the gypsum pulp is poured in a PVC mold for bottoming, leveling and bottom shielding, and glass fiber gridding cloth and glass fiber bars are placed, wherein the glass fiber bars are placed close to the edge of an inner cavity of the PVC mold, residual pulp is poured in the PVC mold and ironed through a mud plate, a PVC cover plate is placed during knocking, and the periphery is compacted; and after the residual pulp is finally set, the high-crystal, light and high-strength gauge stuff ceiling is obtained through maintaining, drying and surface processing. The high-crystal, light and high-strength gauge stuff ceiling has the beneficial effects of being light in weight, low in transporting and installing cost, high in safety coefficient and the like.

Owner:湖南安雅达建材科技有限公司

Production method of steaming-grade CPP film

The invention discloses a production method of a steaming-grade CPP film. The method comprises the following steps: (a) manufacturing a corona layer by weighing 19 to 21 parts of ternary polypropylene randon copolymer, manufacturing a core layer by weighing 59 to 61 parts of homo-polypropylene, manufacturing a heat seal layer by weighing 19 to 20 parts of ternary co-polypropylene, 0.5 to 0.64 part of a slipping agent and 0.08 to 0.22 part of anti-electrostatic agent, and mixing all raw materials for 3 minutes in a high-speed mixing machine; (b) plastically extruding the uniformly mixed materials at the temperature of 245 DEG C; (c) adhering a melt onto a cold roller by virtue of a high-pressure air knife, chilling the melt in a water bath at the temperature of 23 to 27 DEG C to form a cast sheet; (d) forming, and carrying out the thickness measurement feedback by utilizing an infrared system; (e) carrying out the corona spark treatment on the surface of the corona layer, enabling the corona tension to be 44 to 50 mN / m, and coiling the cast sheet at a speed of 60 to 70 m / min; (f) curing the cast sheet for 48 hours at the temperature of 27 to 28 DEG C. The product molded in the method is light in weight, resistant to impact, high in smoothness and clarity, resistant to abrasion, good in stress fracture resistance and excellent in chemical stability, insulation property and low-temperature heat seal property.

Owner:ANHUI SONGTAI PACKAGING MATERIALS

Quartz sand water permeable brick

The invention relates to a quartz sand water permeable brick, which is prepared from the following components in parts by weight: 230 to 337 parts of quartz sand, 32 to 54 parts of slag, 73 to 94 parts of cement, 12 to 15 parts of thermal insulating bead, 32 to 36 parts of water, 6 to 14 parts of mortar coagulator, 5 to 9 parts of dyeing agent, 11 to 13 parts of cementing agent, 2 to 6 parts of coloring agent, 340 to 531 parts of fine stone aggregate, 1 to 4 parts of pigment, 9 to 13 parts of cement enhancer and 12 to 14 parts of accelerator. The quartz sand water permeable brick has the advantages that a formula is scientific, and the material selection is convenient and easy. Waste expanded quartz sand with different specifications is taken as a main material, the weight of a product is lighter than that of a product prepared by adopting sandy gravel; the waste slag is used for extracting the thermal insulating bead which is then added in the product, so that the water permeation effect is higher. The quartz sand water permeable brick has excellent wear resistance; the product is bright and varicolored in color, is unfading, and is moldable in shape, and fully embodies diversity and individuation.

Owner:JIANGSU MINJIANG MINING CO LTD

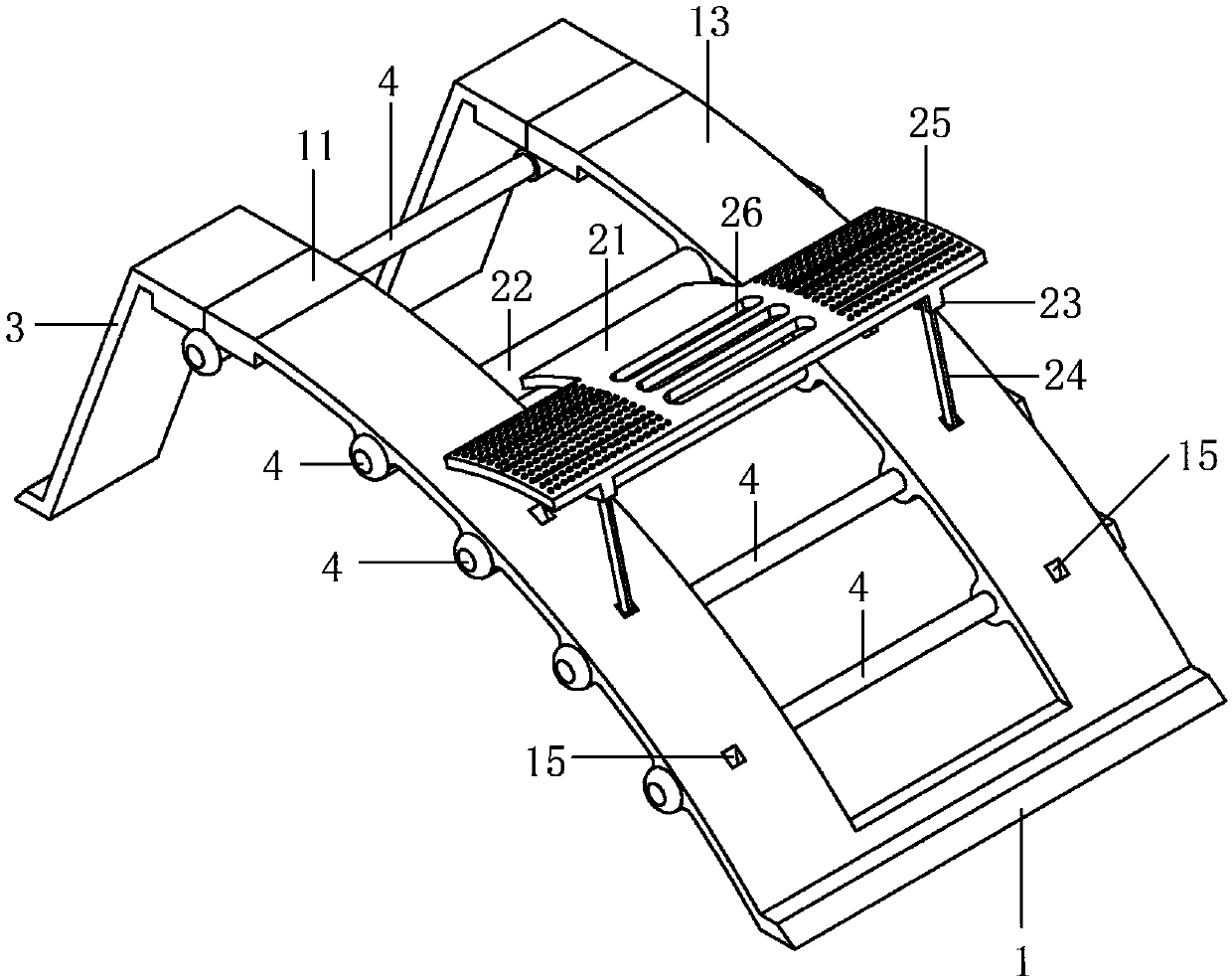

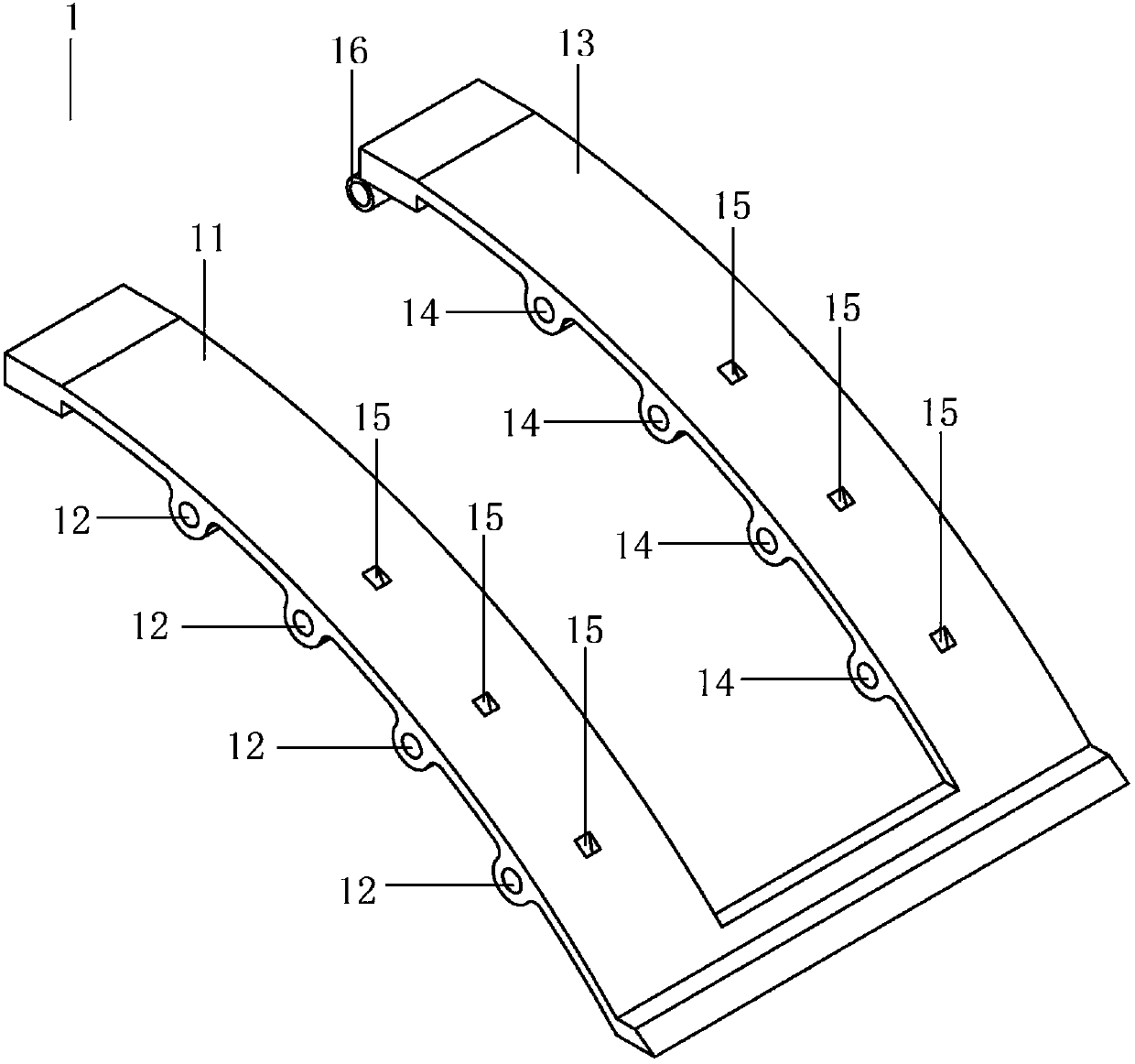

Toilet pedal device capable of preventing and relieving constipation

PendingCN107913019AProduct quality is lightNovel structural designBathroom accessoriesEngineeringToilet

The invention relates to a toilet pedal device capable of preventing and relieving constipation. The toilet pedal device comprises an arched supporting plate, a pedal plate, a support and connecting shafts. Four left connecting holes are formed in the lower end surface of a left arched plate of the arched supporting plate, and four right connecting holes are formed in the lower end surface of a right arched plate of the arched supporting plate. Three positioning grooves are formed in the upper end surface of the left arched plate as well as the right arched plate. The head of the left arched plate, as well as the head of the right arched plate, is fixedly connected with a bearing hole. The pedal plate is composed of a T-shaped, a rotating hole and regulating support rods; a rotary hole isfixedly connected to the head of the T-shaped plate, connecting units are respectively arranged at the left end and the right end of the tail of the T-shaped plate and connected with the regulating support rods; the upper side of the T-shaped plate is provided with anti-skid bumps, and the middle of the T-shaped plate is provided with three square through holes. The head of the support is fixedlyconnected with bearing holes; the head of each connecting shaft is provided with outer thread on the lateral side, and a nut is connected with the outer thread correspondingly. The toilet pedal devicehas the advantage that constipation can be prevented and relieved effectively by regulating the relative angel between the leg and the body in use of the toilet pedal device.

Owner:YUEYANG INTEGRATED TRADITIONAL CHINESE & WESTERN MEDICINE HOSPITAL SHANGHAI UNIV OF CHINESE TRADITIONAL MEDICINE

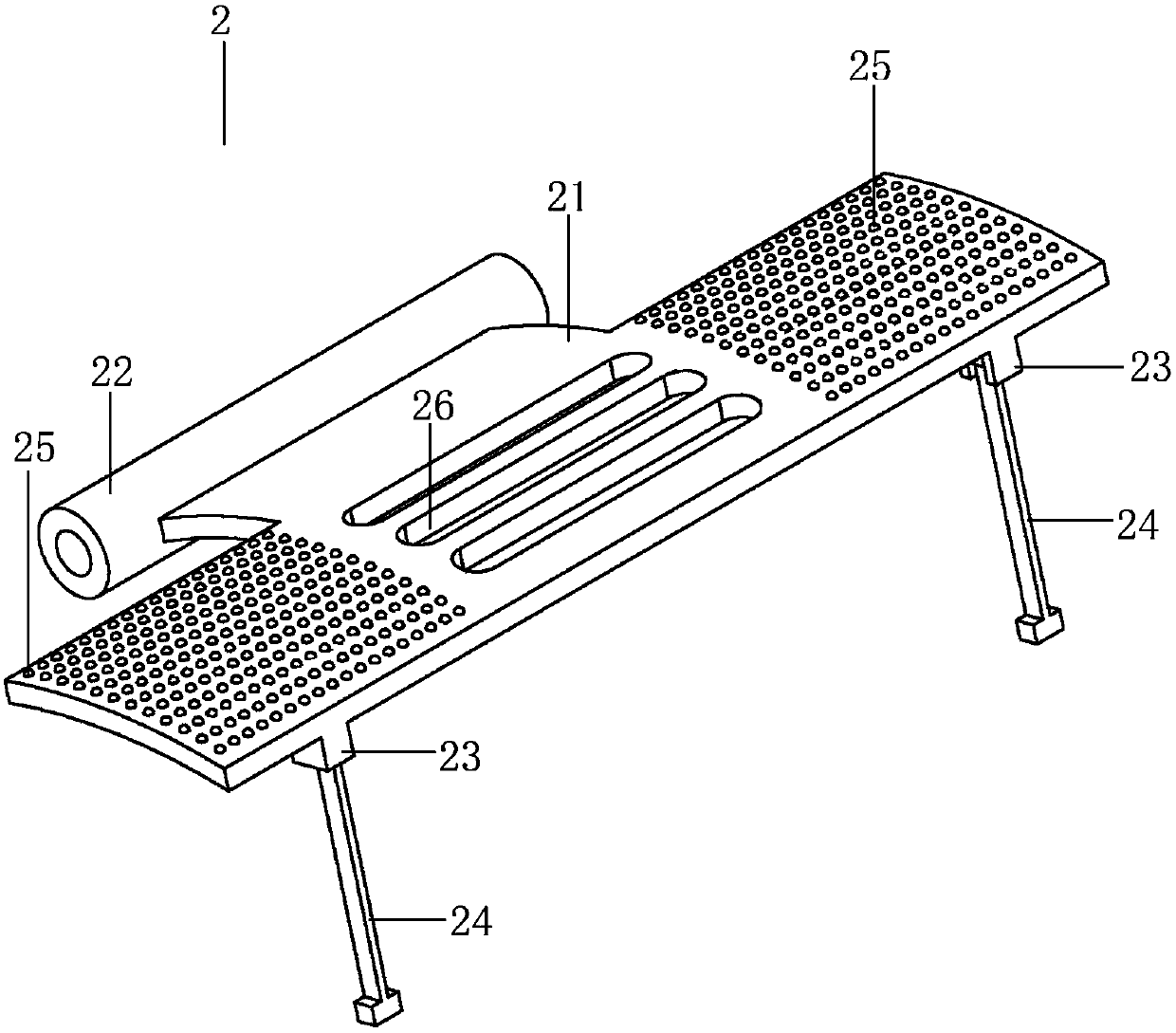

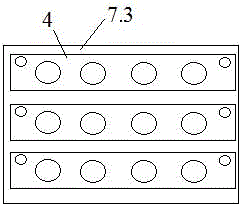

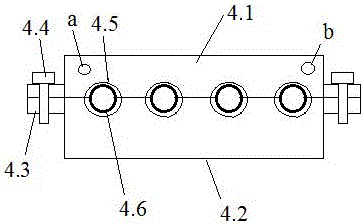

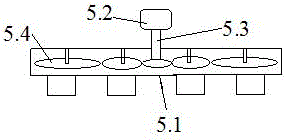

Equipment and method for preparing novel energy saving light wallboard

InactiveCN106182391ASuitable for useAvoid pollutionMouldsCeramic shaping plantsCompressive strengthTemperature resistance

The invention relates to building wallboard equipment and a preparation method, in particular to equipment and a method for preparing a novel energy saving light wallboard. The equipment for preparing the novel energy saving light wallboard is characterized by comprising a loading frame, a mixer, a grouting hopper, a mold, a pipe turning unit, a pipe drawing unit, a walking unit, a mold pressing unit and a total support frame; the loading frame is connected with the mixer; an outlet of the mixer is connected with the grouting hopper; the grouting hopper injects slurry into the mold through the mold pressing unit; the mold enters a plate dismounting area by passing through the pipe turning unit and the pipe drawing unit in sequence; and the walking unit is arranged at the lower part of the mold. The equipment has the beneficial effects of high efficiency of the preparation equipment, light mass of products prepared by the method, high compressive strength, adaption to high-rise buildings, excellent acid and alkali resistance, excellent temperature resistance, fire resistance, capability of recycling fly ash, prevention of environmental pollution, fast molding and high molding efficiency.

Owner:山东诺方建材有限责任公司

Thermal-insulating composite building coating for external wall and preparation method of coating

The invention discloses a thermal-insulating composite building coating for an external wall and a preparation method of the coating. The coating is prepared from components in parts by mass as follows: 40-50 parts of expanded perlite, 8-12 parts of aragonite sand powder, 8-12 parts of liquid sodium silicate, 2-4 parts of liquid potassium silicate, 3-7 parts of silica sol, 3-7 parts of deionized water, 2-4 parts of liquid lithium silicate, 3-7 parts of inorganic acid, 3-5 parts of an expanding agent, 8-12 parts of plant fiber powder and 8-12 parts of water. The thermal-insulating composite building coating for the external wall has the characteristics of low preparation cost, good effect and environment friendliness; tests show that the thermal conduction coefficient of the composite coating is 0.117 W / (m*K), and the density is 700-800 kg / m<3>. The coating is suitable for external thermal-insulation plastering engineering and internal thermal-insulation plastering engineering of walls, built by using reinforced concrete, aerated concrete, laid bricks, sintered bricks, non-sintered bricks and the like, of multistory and high-rise buildings and is also suitable for thermal-insulation improvement engineering of various old buildings currently.

Owner:胡进 +1

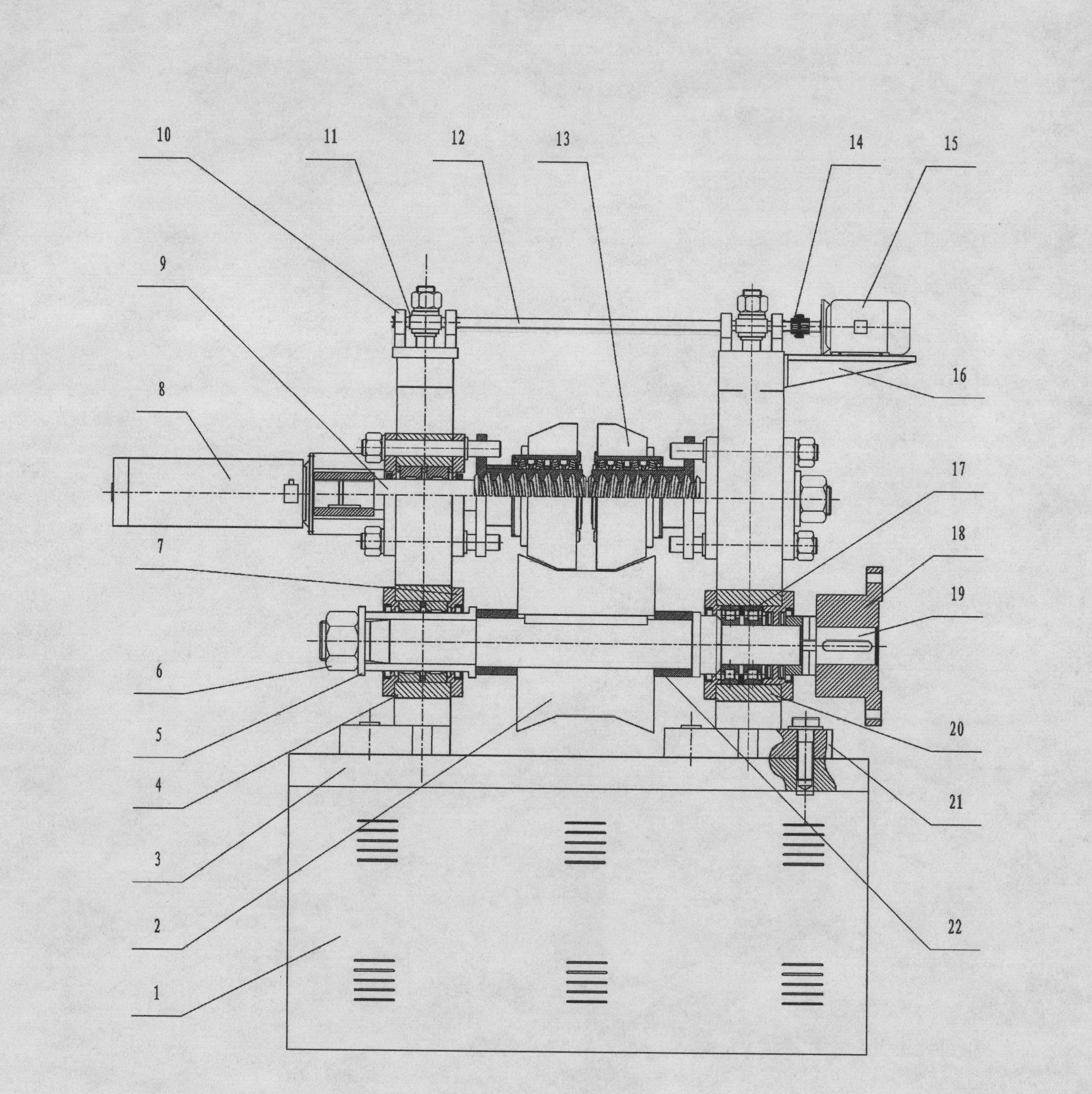

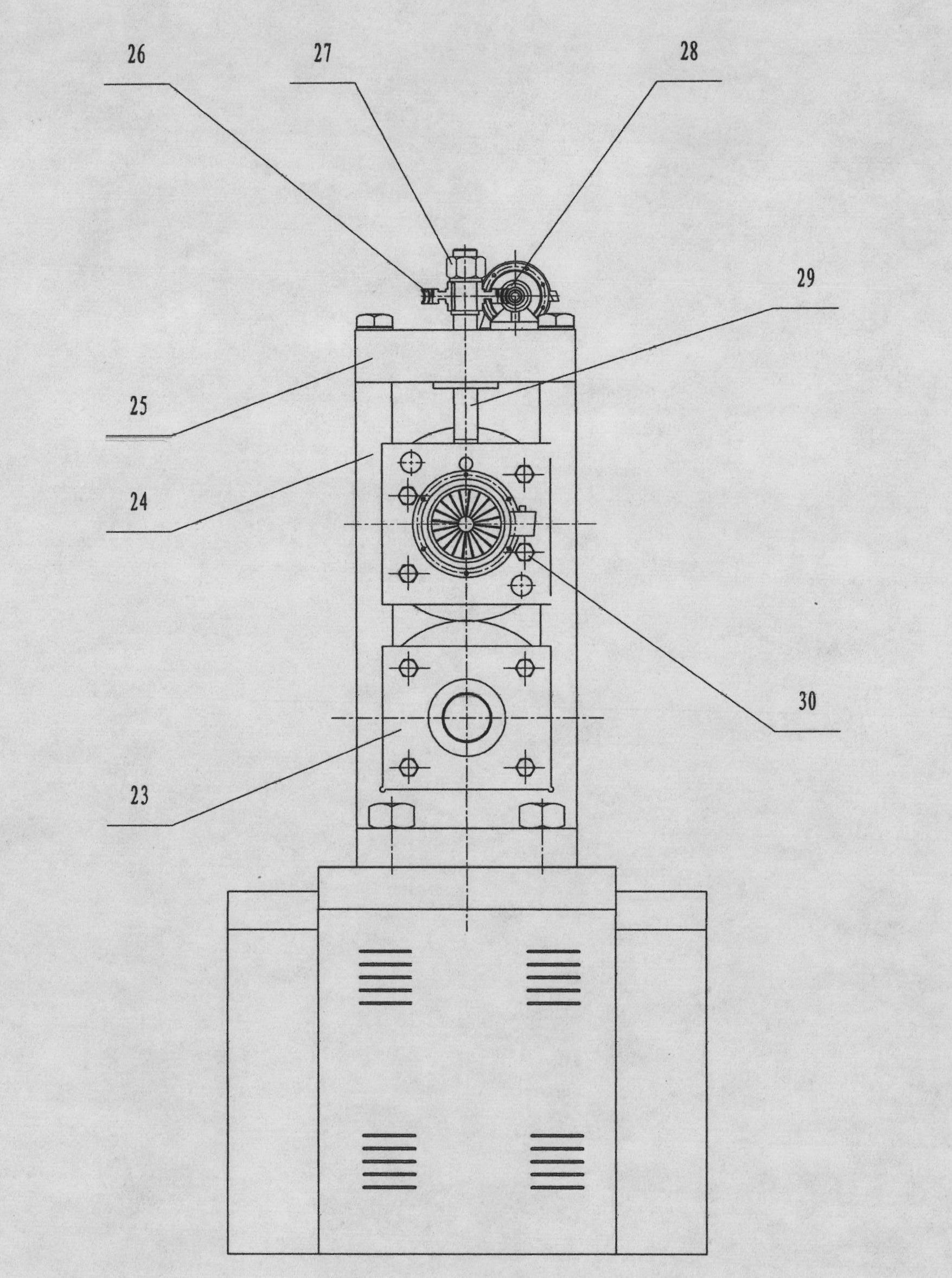

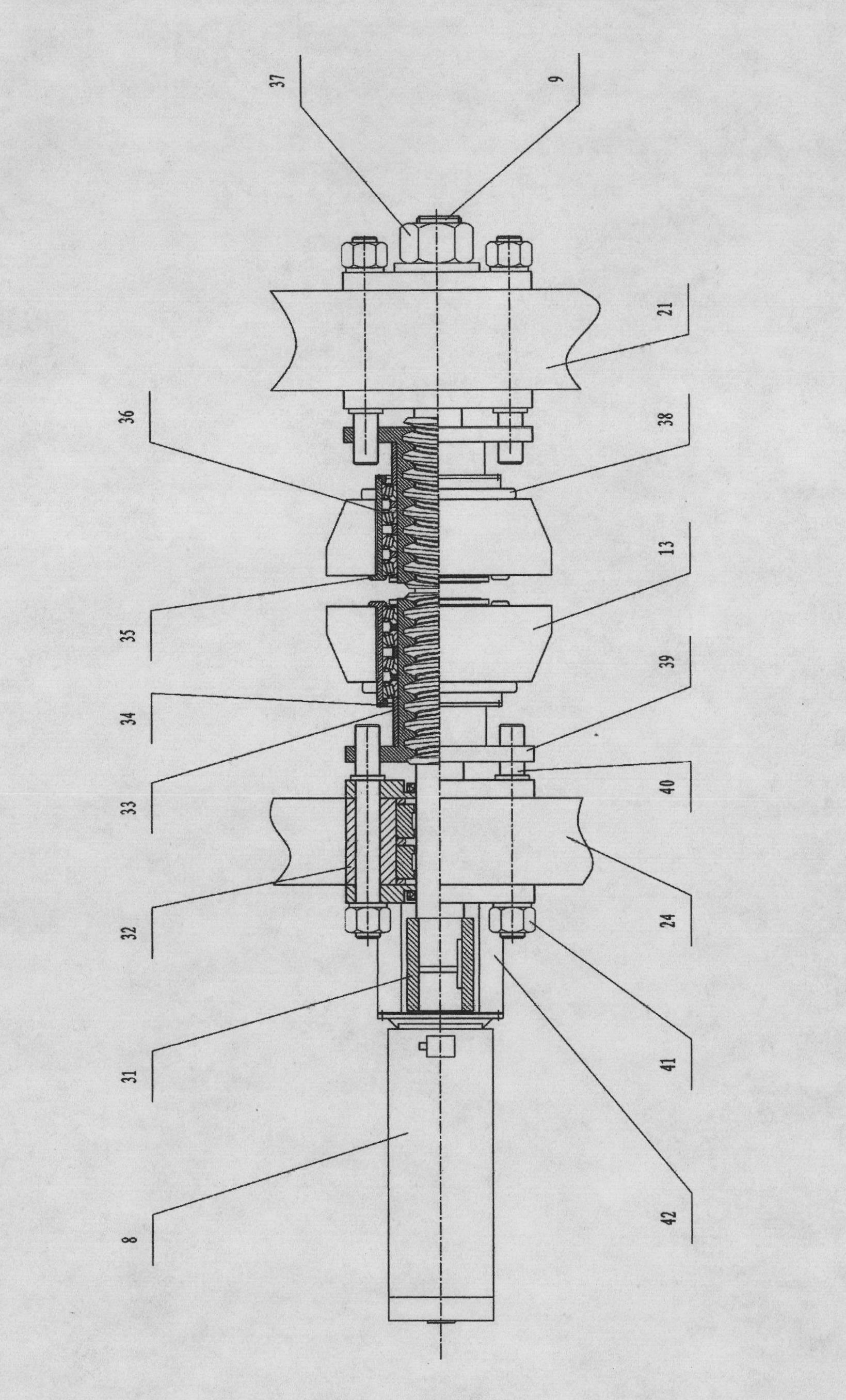

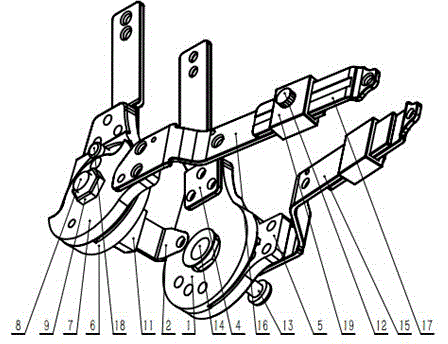

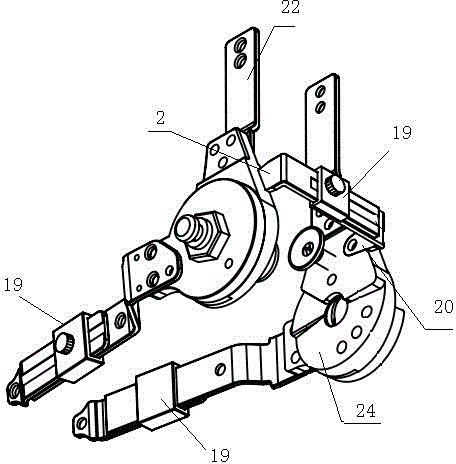

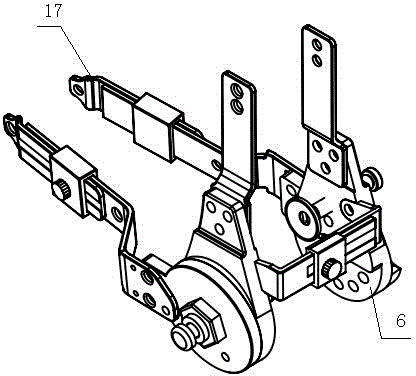

Roll-seam adjustable flexible roll bending forming device

The invention relates to a roll-seam adjustable flexible roll bending forming device, belonging to the field of roll bending forming equipment and aiming at solving the problems that vertical continuous variable-thickness plates cannot be formed in the current device, the production efficiency is low and the like. The main structure of the roll bending forming device comprises a tool case and a workbench, wherein two racks are arranged on the workbench, and a driving shaft system, a driven shaft system and a vertical adjusting device are assembled on the racks. Power is input from the shaft end of a driving shaft to driving a driving roll to rotate, so that a plate moves forwards. A driven roll is driven to rotate by friction force between the driven roll and the plate, and the plate continuously moves forwards and sequentially arranges roll groups for forming. The position of rolls is mainly controlled in real time through the driven shaft system and the vertical adjusting device, and the real-time adjustment for roll seams is realized. The roll bending forming device has the advantages of convenience for adjustment, high production efficiency, light quality of produced products and the like, and materials are fully utilized. The roll bending forming device is particularly suitable for roll bending forming for continuous variable-thickness plates along a rolling direction.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

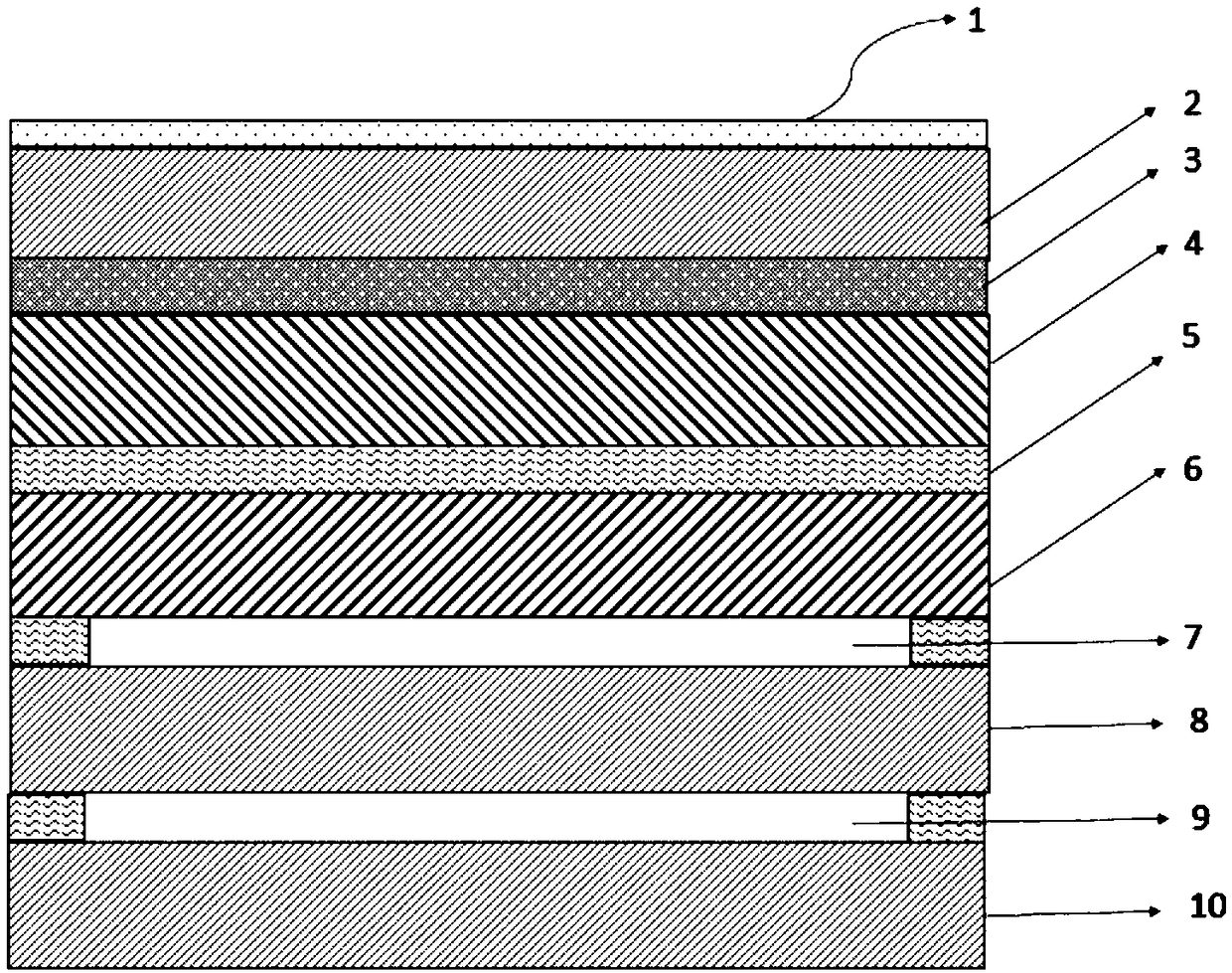

Bullet-proof glass and preparation method thereof

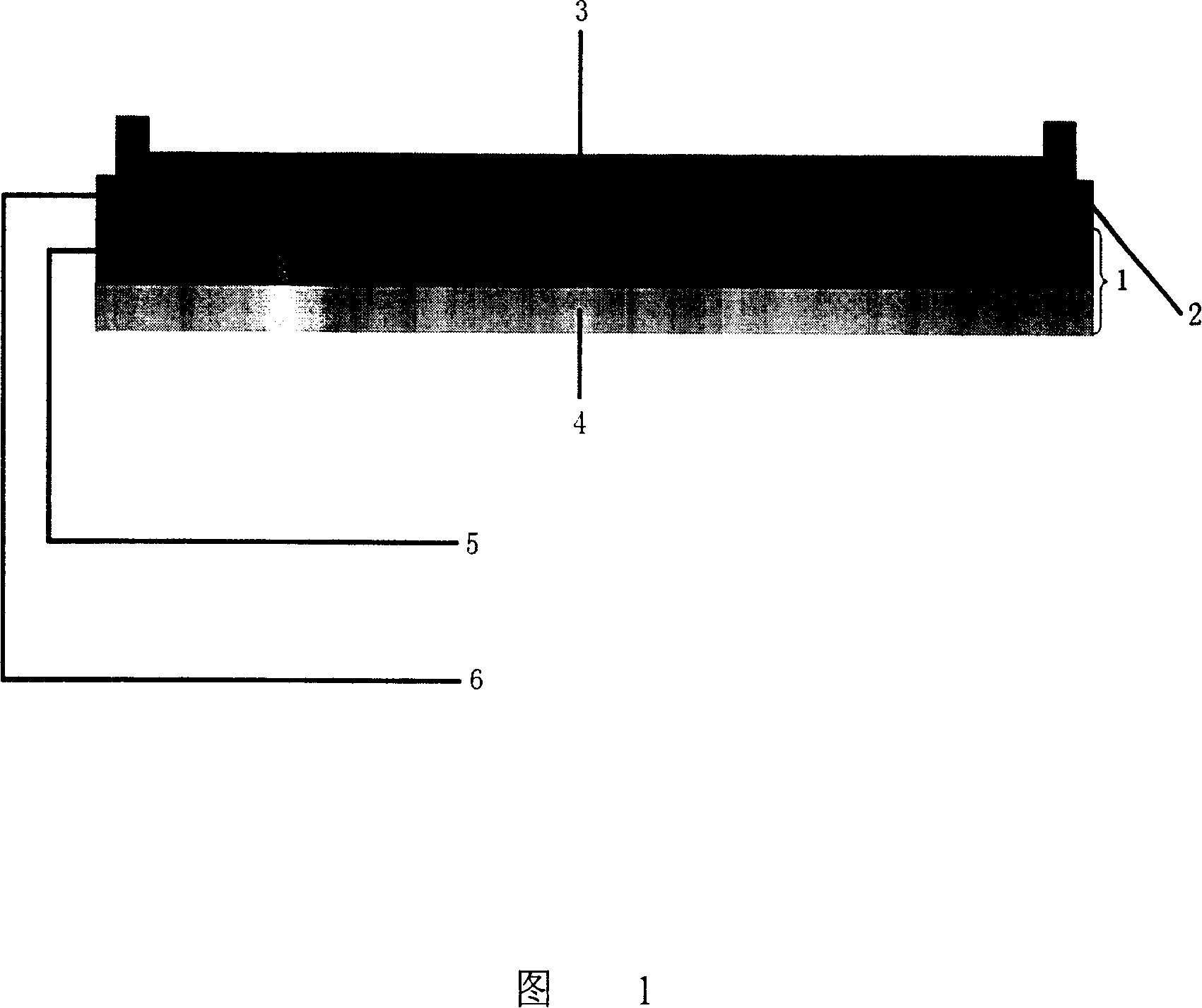

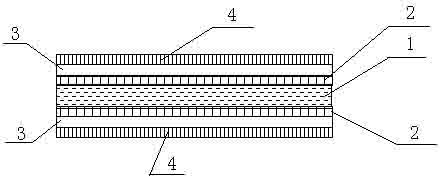

ActiveCN108943919AEffective barrierImprove thermal insulation performanceLamination ancillary operationsSynthetic resin layered productsChemistryFirst glasses

The invention belongs to the technical field of glass processing, and provides bullet-proof glass and a preparation method thereof. The bullet-proof glass comprises a first glass layer, a second glasslayer and a bullet-proof layer which are sequentially arranged; a first adhesive layer is arranged between the first glass layer and the second glass layer, and a second adhesive layer is arranged between the second glass layer and the bullet-proof layer; the first adhesive layer and the second adhesive layer are insulating adhesive layers; and the bullet-proof layer is provided with an insulating air layer. The bullet-proof glass has the beneficial effects that the insulating adhesive layers can be used for effectively insulating heat, and the insulating air layer can be used for further improving temperature preserving and insulating effects.

Owner:鸿翌科技有限公司

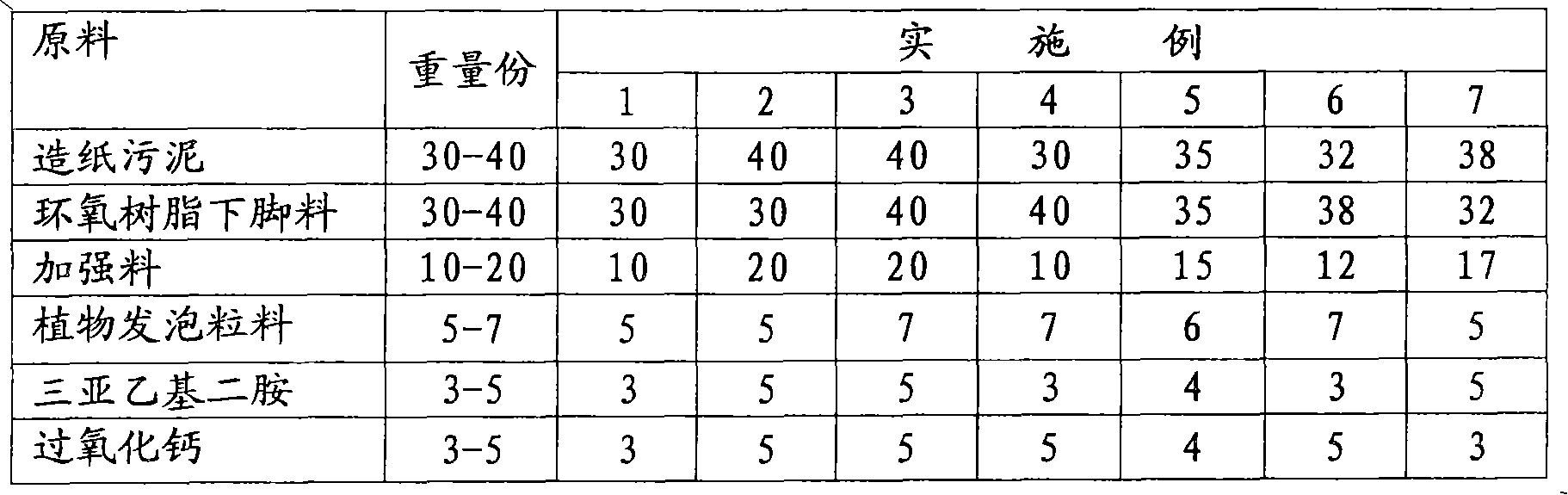

Production method of paper mill sludge landscape ornamental material

InactiveCN101575199ASolve the problem of raw materialsProduct quality is lightSolid waste managementEpoxyPaper mill

The invention discloses a production method of paper mill sludge landscape ornamental material, which is characterized by comprising the following raw materials according to parts by weight: 30 to 40 parts of paper mill sludge, 30 to 40 parts of epoxy resin leftover, 10 to 20 parts of reinforcing material, 5 to 7 of plant foaming granules, 3 to 5 of triethylenediamine and 3 to 5 parts of calcium peroxide. The production method comprises the following five steps of: first, preparing material; second, mixing; third, moulding and heat pressing; fourth, stacking and curing; and fifth, surface treatment. The prepared plank material is particularly applicable to be used as a flower bed boarding of the landscape area, is beautiful and elegant, and has low cost and water resistance and appropriate strength. The landscape ornamental plate is produced by the method, thus making waste profitable, not only solving the environmental problem, but also solving the problem of material for producing the artificial board; and the plank material has lighter weight and low energy dissipation in production.

Owner:潘金瓶

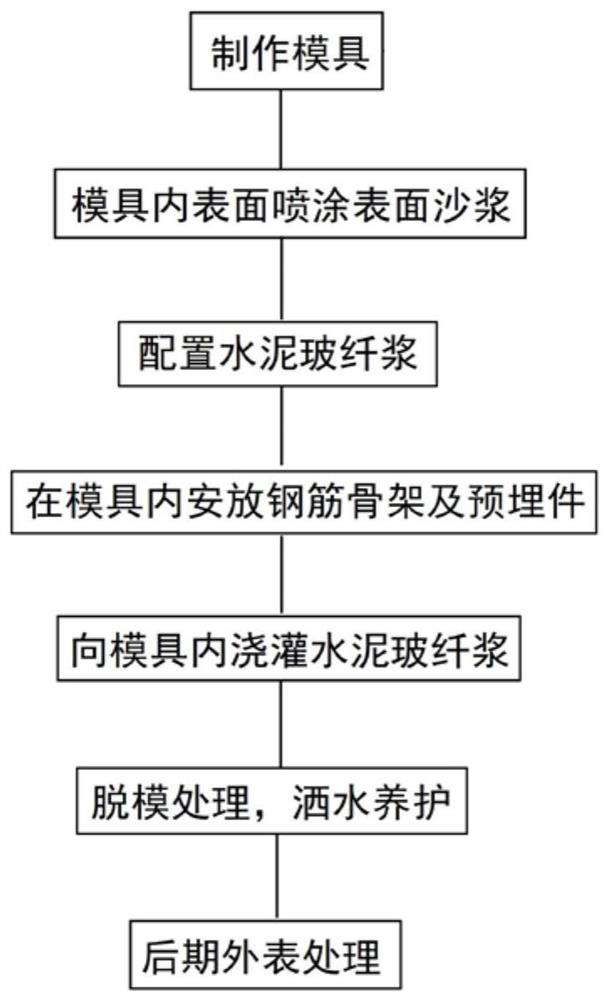

Manufacturing technology of component for building decoration

The invention discloses a manufacturing technology of a component for building decoration. The technology comprises following steps: a mold is made of a mold material according to design drawing requirements or models; a release agent is uniformly sprayed to inside of the mold, then cement, fine sand and water are mixed and stirred, and surface mortar is obtained and uniformly sprayed to the innersurface of the mold; cement, rock sand, water and alkali-resistant glass fibers are sufficiently continuously stirred and mixed, and cement and glass fiber slurry is obtained; a steel reinforcement framework is mounted in the corresponding position in the mold, an embedded part is embedded in the mold, and the cement and glass fiber slurry is poured into the mold; when the cement and glass fiberslurry is set to 70%-80%, mold release treatment is performed, and water sprinkling maintenance is performed to obtain the component. The technological process is mature and simple, the processing issimple and easy, and the component for the building decoration is low in cost and high in sculpturing property and can be applied to various landscape sculptures for factory mass production of the building decoration, and the prepared component for building exterior wall decoration can be used for exterior walls of various buildings to imitate European classical architecture.

Owner:上海驰艺装饰工程有限公司

Steaming and boiling-resistant composite casting polypropylene (CPP) film

InactiveCN107877966AProduct quality is lightImprove stabilityFlexible coversWrappersPolymer sciencePlastic packaging

The invention relates to the technical field of plastic packaging, in particular to steaming and boiling-resistant composite casting polypropylene (CPP) film. The casting polypropylene (CPP) film sequentially comprises a heat-seal layer, a core layer and a corona layer; the core layer is arranged between the heat-seal layer and the corona layer; the casting polypropylene (CPP) film comprises, by weight, 14%-20% of heat-seal layer, 55%-65% of core layer and 20%-25% of corona layer; the heat-seal layer is composed of 88%-95% of terpolymer polypropylene, 3%-8% of surfactant and 2%-5% of slippingagent, the core layer comprises 90%-96% of homo-polypropylene and 4%-10% of flexibilizer, and the corona layer comprises 50%-65% of homo-polypropylene, 20%-35% of terpolymer polypropylene, 5%-10% of metallocene POE and 5%-12% of anti-static coatings. The steaming and boiling-resistant composite casting polypropylene (CPP) film is good in stability, high in definition, good in impact resistance performance and not likely to crack and has good high temperature resistance performance.

Owner:ANHUI SONGTAI PACKAGING MATERIALS

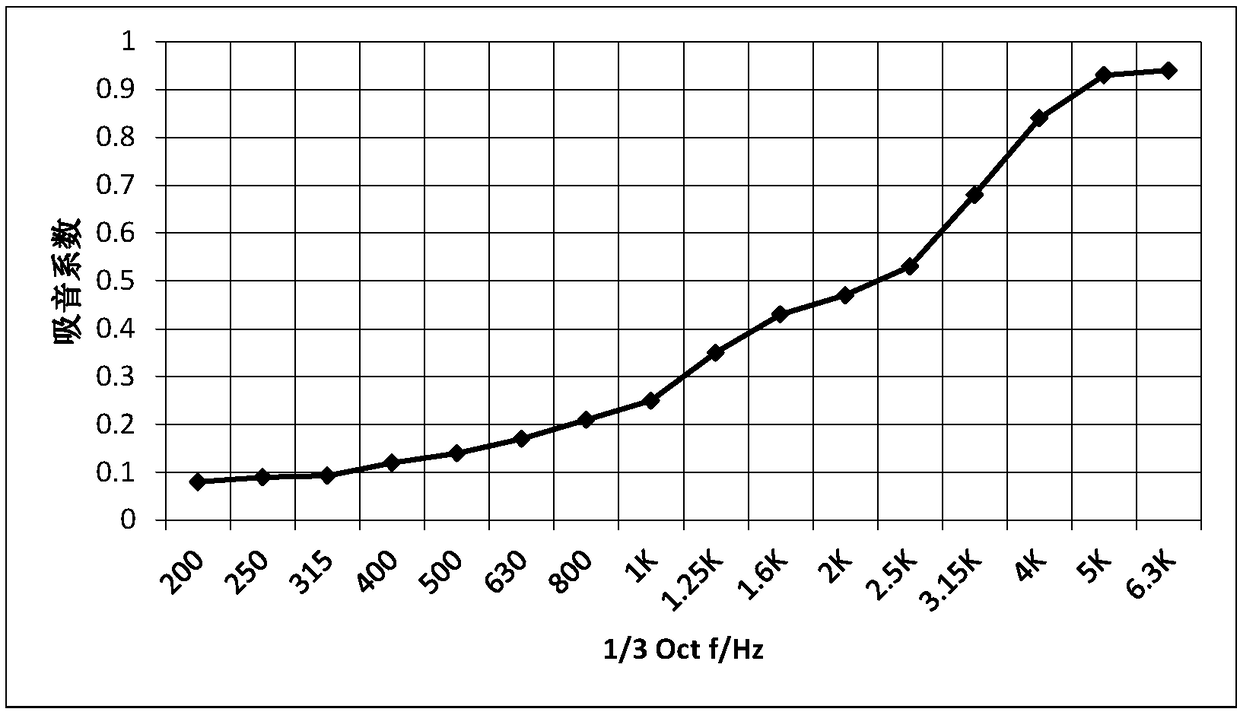

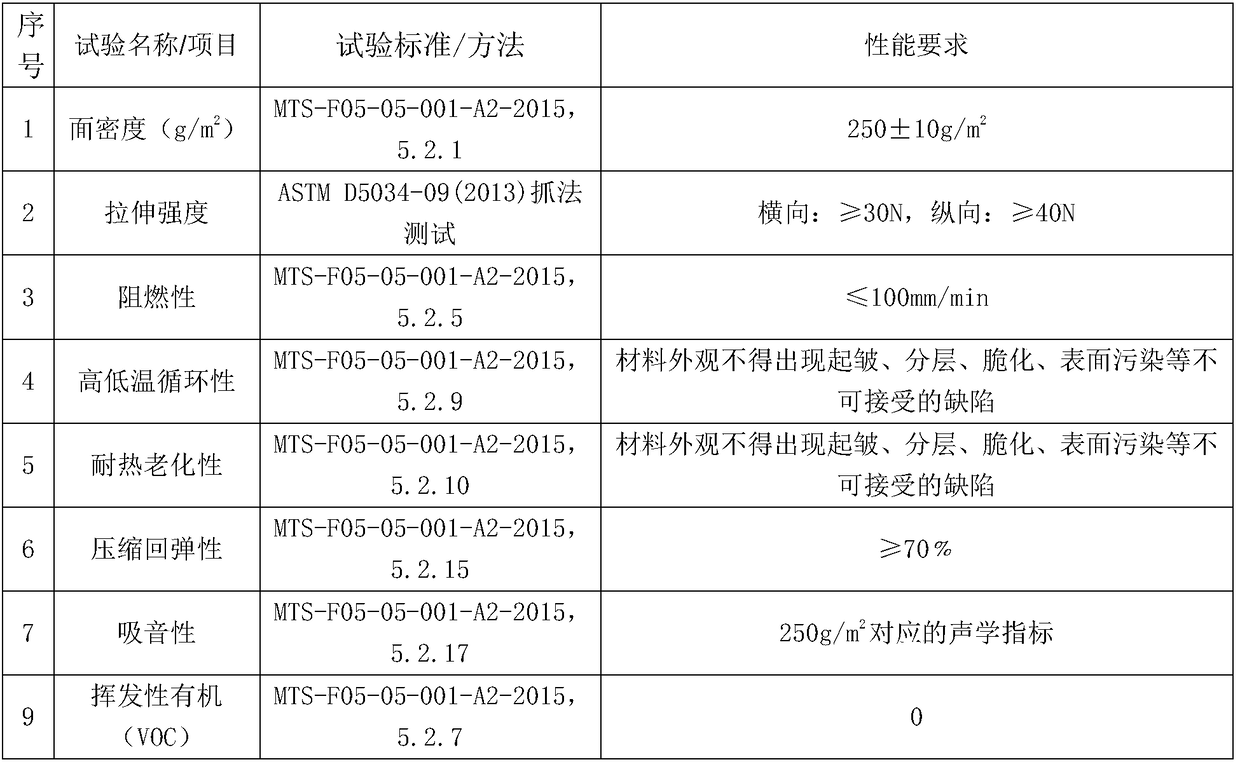

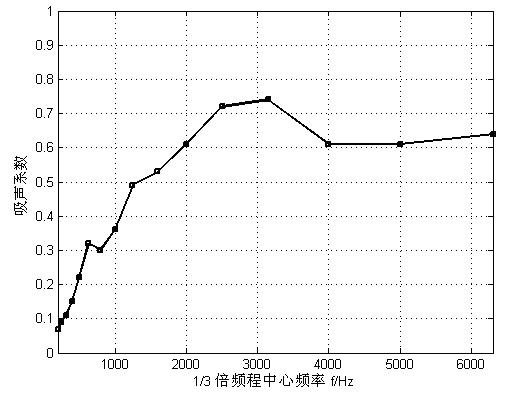

Multicomponent damping composite noise-absorbing cotton and preparation method thereof

ActiveCN108866814AHigh strengthBoost Shield AbsorptionPhysical treatmentFibre typesPolyesterAcoustic wave

The invention discloses multicomponent damping composite noise-absorbing cotton and a preparation method thereof, and belongs to the field of processing of damping and noise-absorbing materials. The multicomponent damping composite noise-absorbing cotton takes ES fiber, PET fiber and magnetic hollow polyester staple fiber as raw materials, meanwhile, low-melting point dacron thermofuse is added, meanwhile, the technologies of lapping, water-jetting, drying and sizing, and modification of hollow polyester staple fiber through an additional magnetic field and ultrasonic assistance are adopted, the whole preparation process utilizes the self performance of the materials to prepare the multicomponent damping composite noise-absorbing cotton, application of chemical reagents is reduced, the VOCcontent of the prepared product is lowered, the product is environmentally friendly and healthy, and meanwhile, the quantum effect of the magnetic hollow polyester stapler fiber nano Fe2O3 is beneficial for improving the fiber strength and the shield and absorption to acoustic waves.

Owner:芜湖跃飞新型吸音材料股份有限公司

Cubitus varus orthotics for children

InactiveCN103948461AImprove stabilityStrong anti-rotation effectMedical scienceClinical trialKnee orthosis

The invention provides a cubitus varus orthotics for children. The cubitus varus orthotics comprises upper arm support frames, which are symmetrically arranged and are positioned at the inner side and the outer side of an upper arm, an inner side forearm molding block and an outer side forearm molding block, wherein the upper arm support frames at the inner side and the outer side are respectively connected to the inner side forearm molding block and the outer side forearm molding block through hinge mechanisms, forcing screws, which are vertically connected, are respectively arranged on the inner lateral surfaces of the hinge mechanisms at the two sides, the screw at the outer side of an elbow is 2 cm from the axis of the corresponding hinge mechanism, and the screw at the inner side of the elbow is positioned at the axis of the corresponding hinge mechanism. The purpose of the invention is to achieve the double effect of fixing a fracture end and preventing cubitus varus through causing a patient child to wear the cubitus varus orthotics after restoration of condyle of humerus. After clinical trials, the cubitus varus orthotics has the advantages of high intensity, light weight, easiness in wearing, firm fixation, good permeability and convenience for clinical observation and adjustment, and the dual purposes of firmly fixing the fracture end and preventing the cubitus varus can be realized.

Owner:甘肃省中医院

Polyurethane composite plate

InactiveCN102350840AGood heat and sound insulationNo pollution in the processSynthetic resin layered productsVehicle componentsThermal insulationAdhesive

The invention discloses a polyurethane composite plate, which comprises a polyurethane plate, phenolic resin and a non-woven fabric, wherein the phenolic resin is compounded between the polyurethane plate and the non-woven fabric. The polyurethane composite plate has good thermal insulation and sound insulation effects without dust pollution; a great amount of adhesive is not required to be added in the preparation process, so thick odor in the pressing process is avoided; and the product is light.

Owner:LIYANG SHANHU IND CO LTD

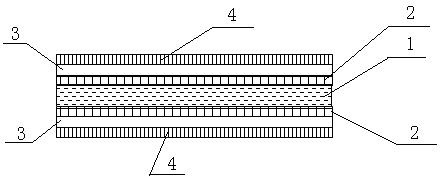

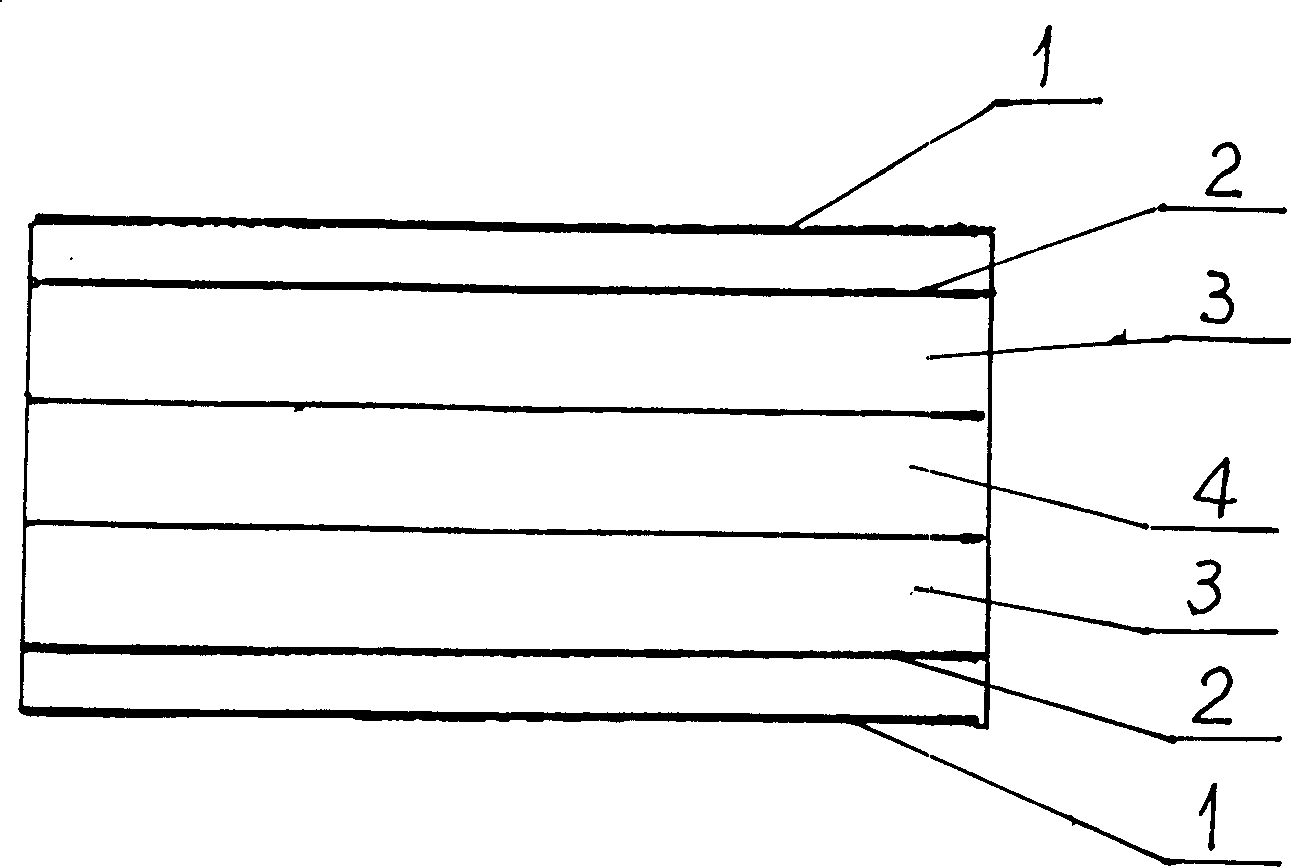

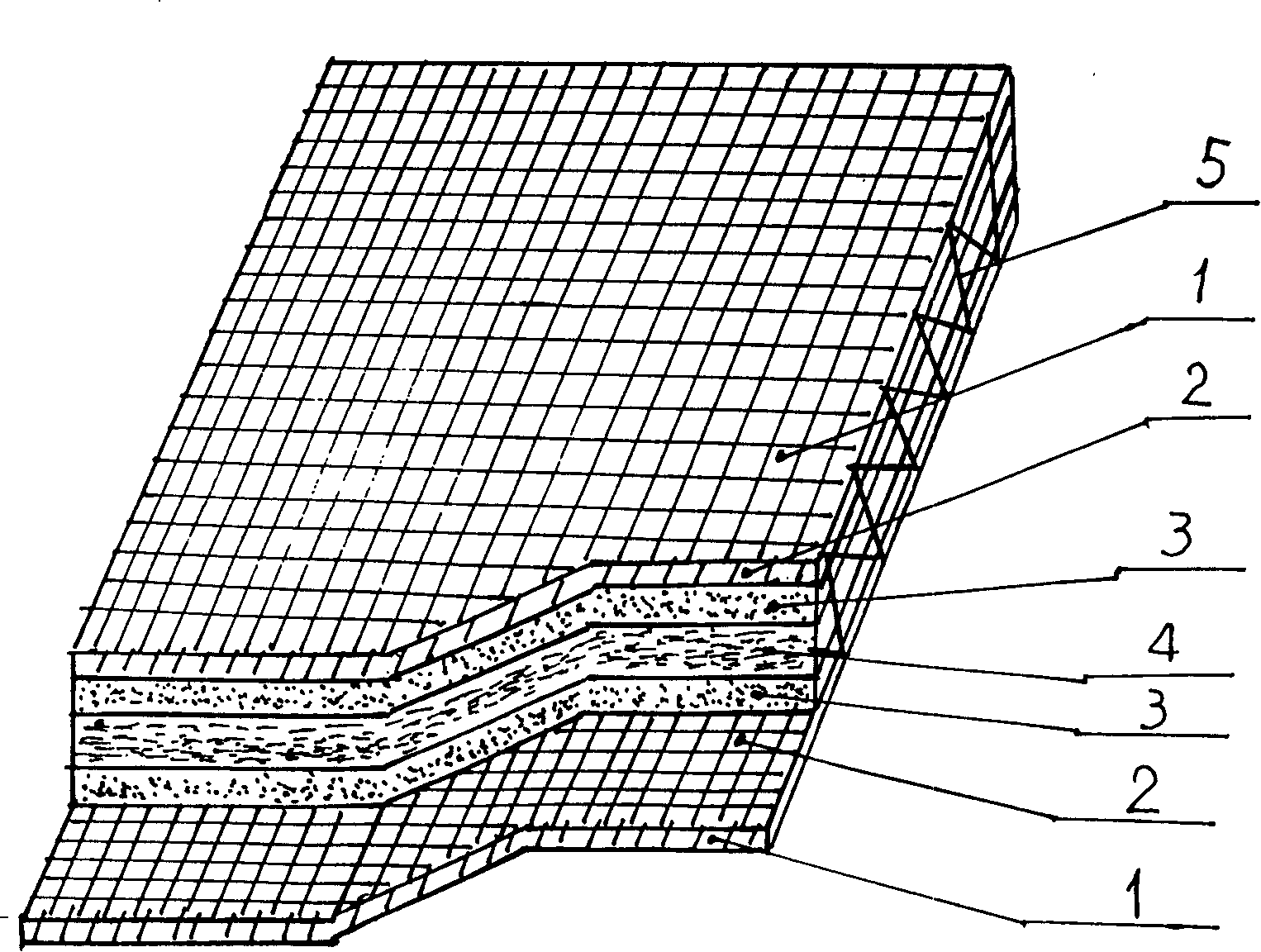

Double-layer steel net mineral cotton perlite sandwich composite lightweight wall plate

InactiveCN101191359ALight weightCondensation effect is strongBuilding componentsNon toxicitySandwich board

The present invention relates to a double-deck steel mesh mineral cotton perlite sandwich compound light wallboard; an upper cover coat and a lower cover coat are both double-deck steel meshes; a middle sandwich layer consists of a perlite lath, a mineral cotton lath and a perlite lath which are compounded; the compound middle sandwich layer is clamped and fixedly connected to form a grid sandwich board through the double-deck steel meshes of the upper cover coat and the lower cover coat. The invention has light volume weight, heat preservation, heat insulation, shock resistance, good sound absorption effect, non-toxicity and non-radioactivity, firmness, wear resistance, non-cracking and energy-saving and consumption-reducing performance, thereby the invention is an ideal fireproof and environment-friendly building material.

Owner:长沙市天心区广用珍珠岩建材厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com