Smelting waste slag light composite artificial stone and production method thereof

A technology of artificial stone and waste slag, which is applied in the direction of manufacturing tools, solid waste management, and other household appliances, etc. It can solve the problems of poor stability of steel slag, low utilization rate of steel slag, and influence on normal use, so as to facilitate sticking and dry hanging , low cost, improved ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The smelting waste slag base material of the present invention is pretreated according to the following steps:

[0049] Step 1, selecting undisturbed converter steel slag block with suitable particle size;

[0050] Step 2, using an impact crusher or an autogenous mill to crush to obtain fragments with a particle size less than 10mm;

[0051] Step 3, mixing the above fragments for homogenization;

[0052] In step 4, magnetic separation is used to remove some metal iron nuggets and RO phase slag with high FeO content, so as to obtain the required smelting steel slag base material.

[0053] The smelting waste slag cementing material of the present invention is obtained through the following pretreatment steps:

[0054] Step 1: Preliminary treatment of smelting waste slag is carried out according to the base material treatment method to obtain the smelting waste slag base material;

[0055] Step 2, use the combined grinding system composed of roller press and ball mill t...

Embodiment 2

[0068] The smelting waste slag base-material pretreatment step of the present invention is as follows:

[0069] Step 1, selecting the undisturbed open hearth furnace steel slag block with suitable particle size;

[0070] Step 2, using an impact crusher or an autogenous mill to crush to obtain fragments with a particle size less than 5mm;

[0071] Step 3, mixing the above fragments for homogenization;

[0072] In step 4, magnetic separation is used to remove some metal iron nuggets and RO phase slag with high FeO content, so as to obtain the required smelting steel slag base material.

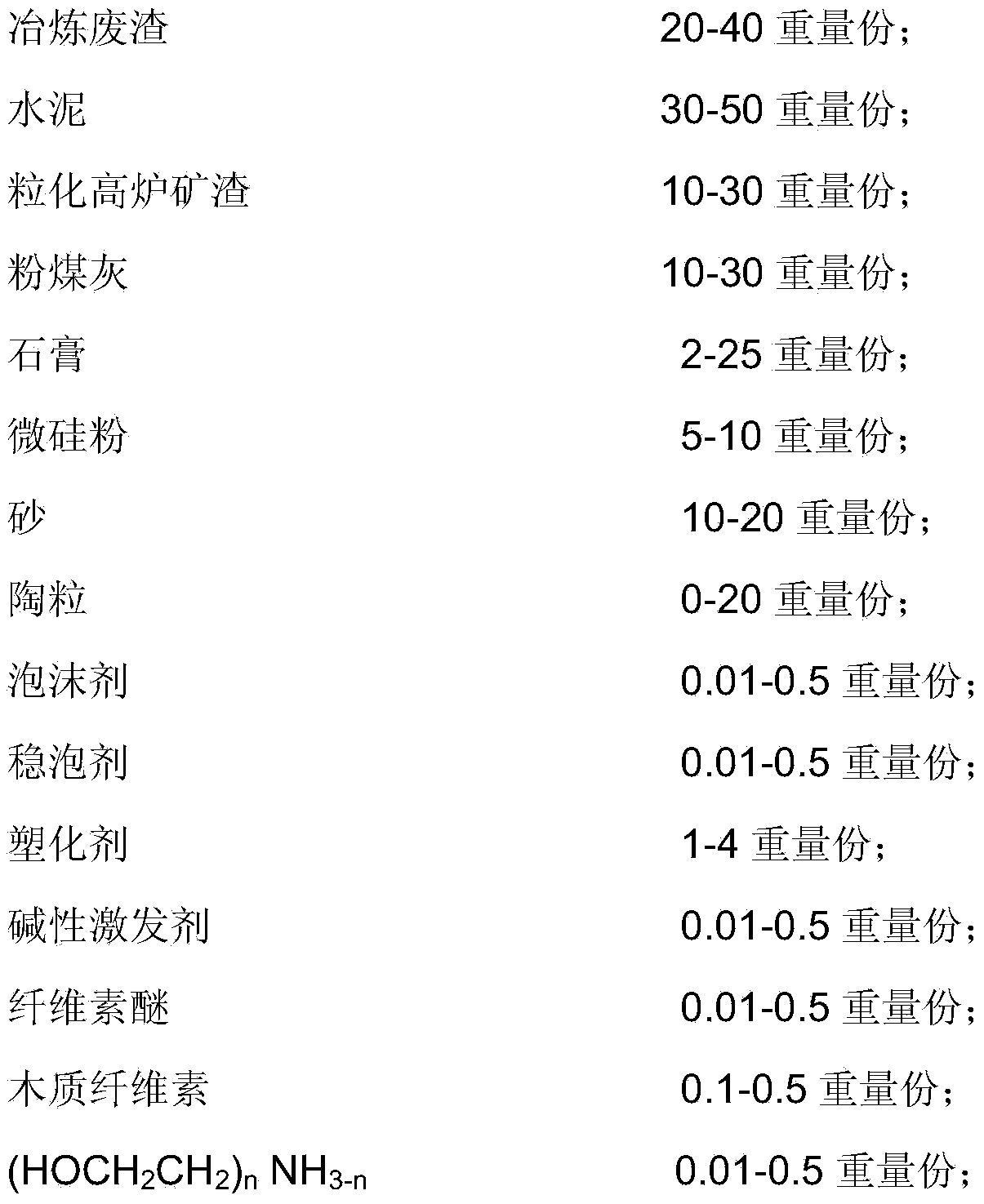

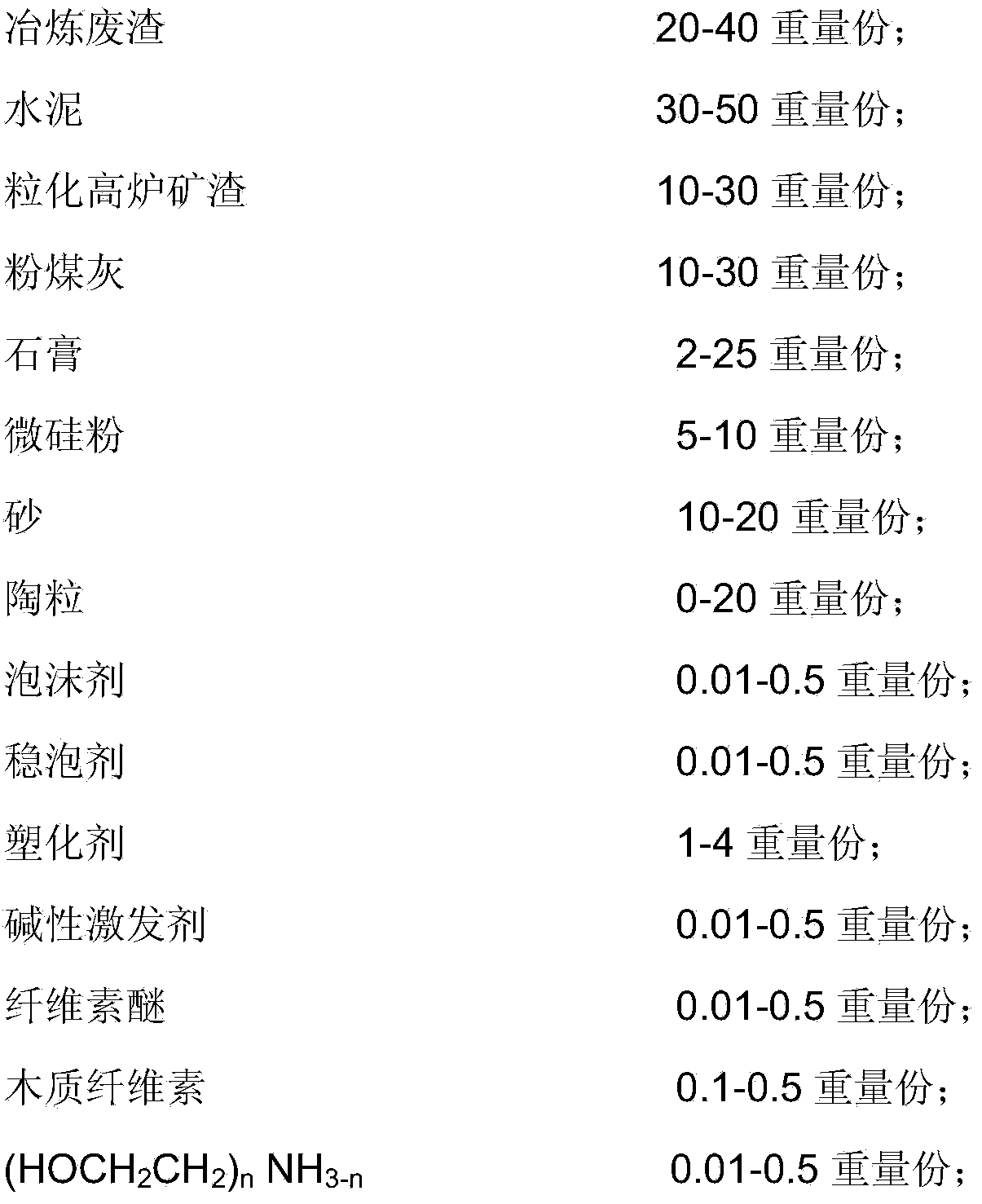

[0073] The structural slurry components of the composite artificial stone in this embodiment include:

[0074]

[0075]

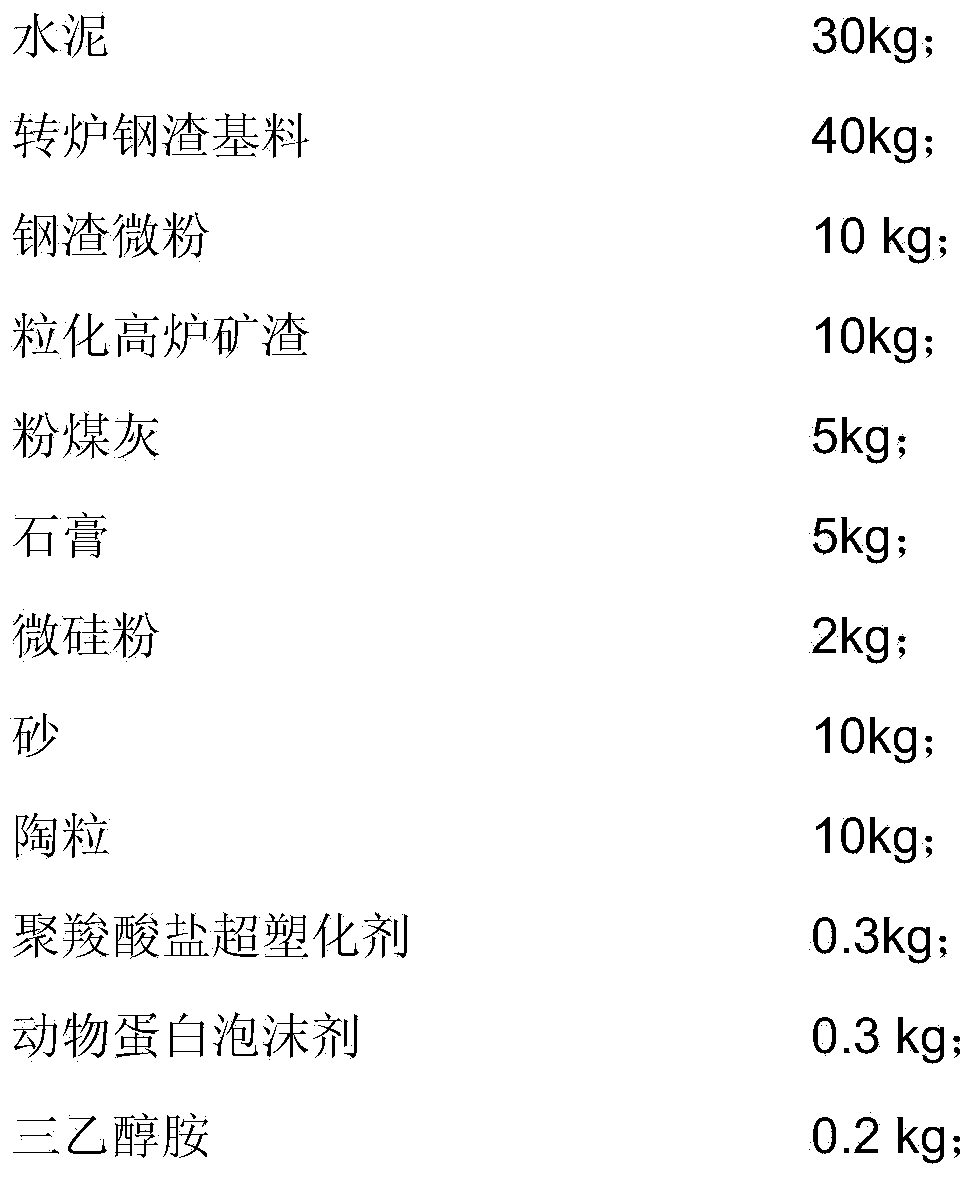

[0076] The production method of smelting waste slag lightweight composite artificial stone of the present invention, its step comprises the following:

[0077] Step 1, preparing color slurry, surface layer slurry or surface layer color paste, and intermediate layer s...

Embodiment 3

[0085] The smelting steel slag base material pretreatment step of the present invention is as follows:

[0086] Step 1, selecting the original non-ferrous metal ash block with suitable particle size;

[0087] Step 2, using an impact crusher or an autogenous mill to crush to obtain fragments with a particle size less than 5mm;

[0088] Step 3, mixing the above fragments for homogenization;

[0089] In step 4, magnetic separation is used to remove some metal iron nuggets and RO phase slag with high FeO content, so as to obtain the required smelting steel slag base material.

[0090] The smelting waste slag cementing material of the present invention is obtained through the following pretreatment steps:

[0091] Step 1: Preliminary treatment of smelting waste slag is carried out according to the base material treatment method to obtain the smelting waste slag base material;

[0092] Step 2, use the combined grinding system composed of roller press and ball mill to process the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com