Joint structure of iron framework and coupling member for connecting rectangular steel beam to rectangular steel column

a technology of connecting member and iron frame, which is applied in the direction of joists, girders, trusses, etc., can solve the problems of weakening and lowering workability, and achieve the effects of easy connection, enhanced workability and adjustable strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

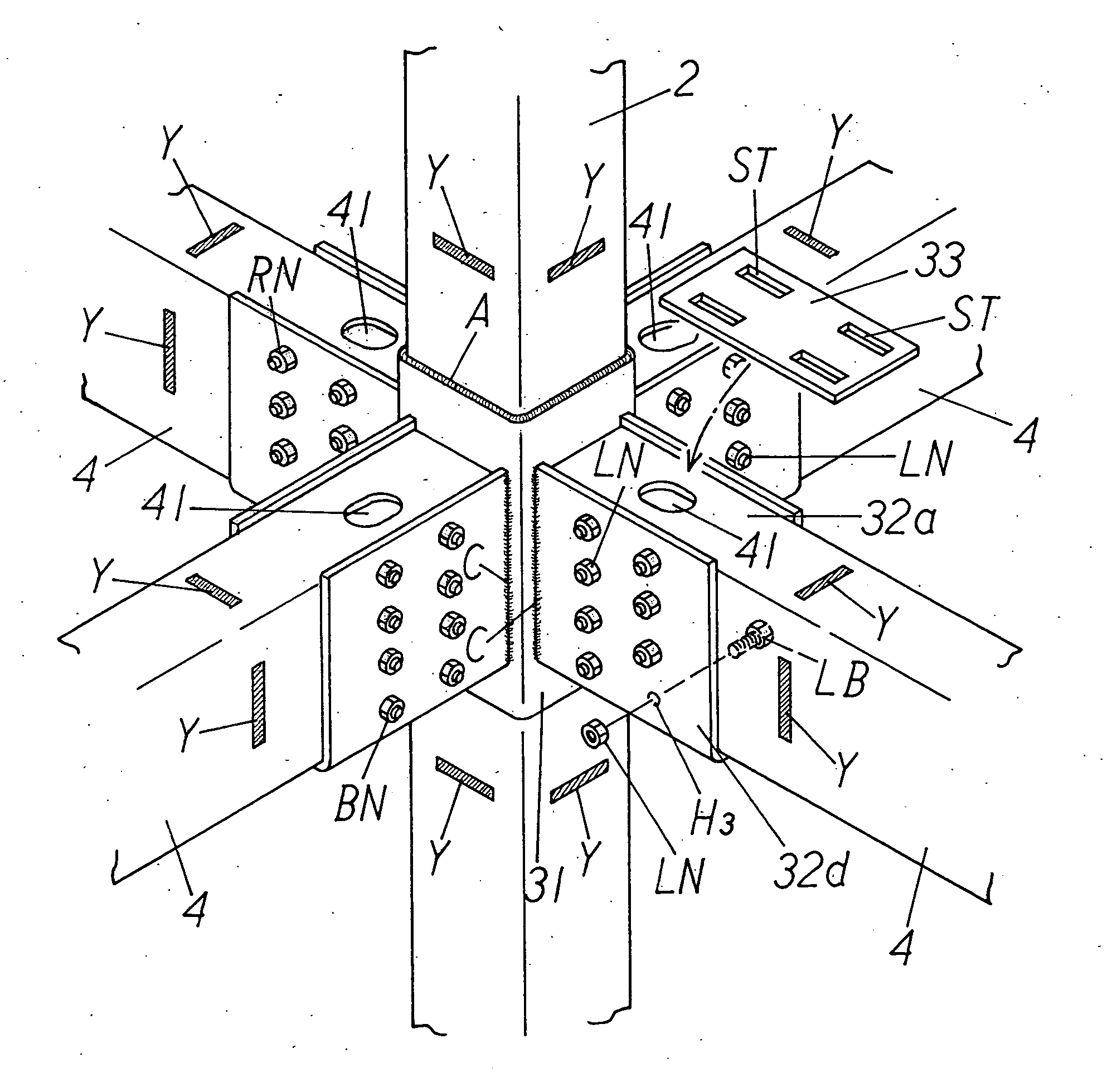

[0047] A joint structure of iron framework and a coupling member for connecting a rectangular steel beam to a rectangular steel column according to an embodiment of the present invention will be described with reference to drawings.

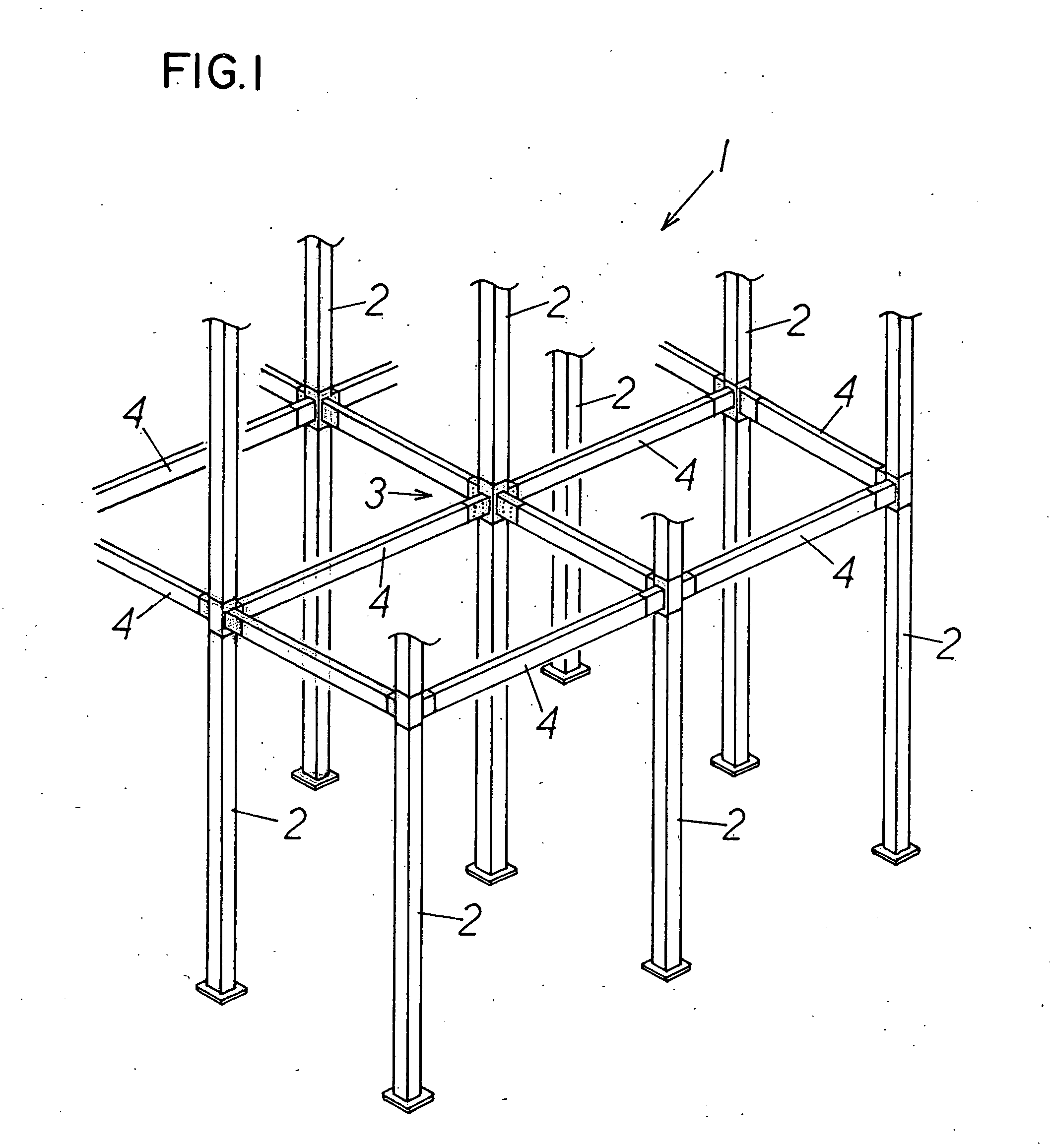

[0048] A reference numeral 1 shown in FIG. 1 denotes an iron framework structure constituted by connecting a hollow rectangular beam 4 to a hollow rectangular steel column 2 via a coupling member 3.

[0049] An outer shape of a cross-section crossing over a longitudinal direction of the hollow rectangular steel column 2 and an outer shape of a cross-section crossing over a longitudinal direction of the hollow rectangular steel beam 4 respectively assume a rectangular shape.

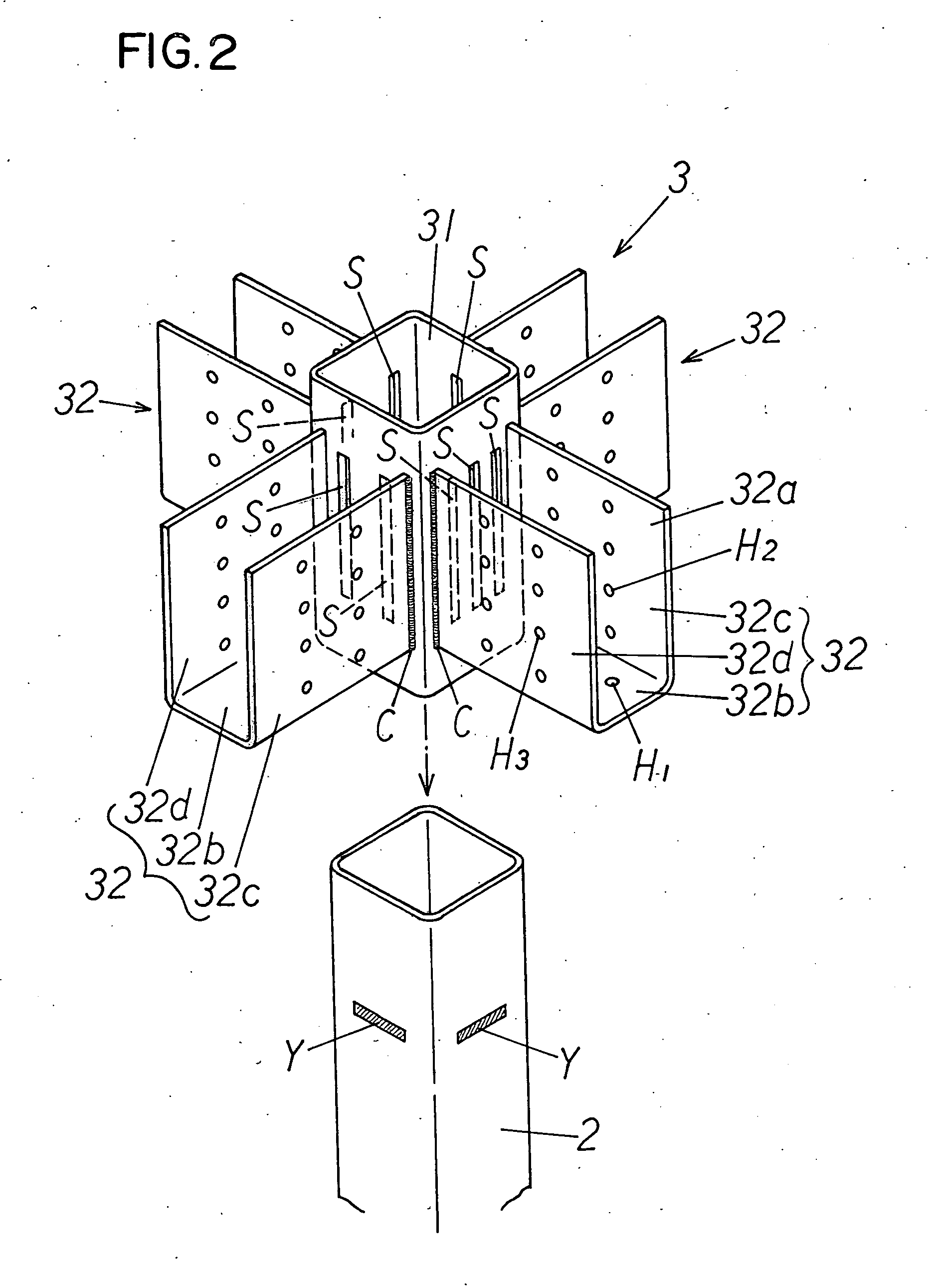

[0050] The coupling member 3 is used for connecting the hollow rectangular steel beam 4 to the hollow rectangular steel column 2. As shown in FIGS. 2 to 8, the coupling member 3 schematically includes: a rectangular cylinder (substantially rectangular sleeve) 31; U-shaped receiving memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com