Patents

Literature

4319 results about "Steel columns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

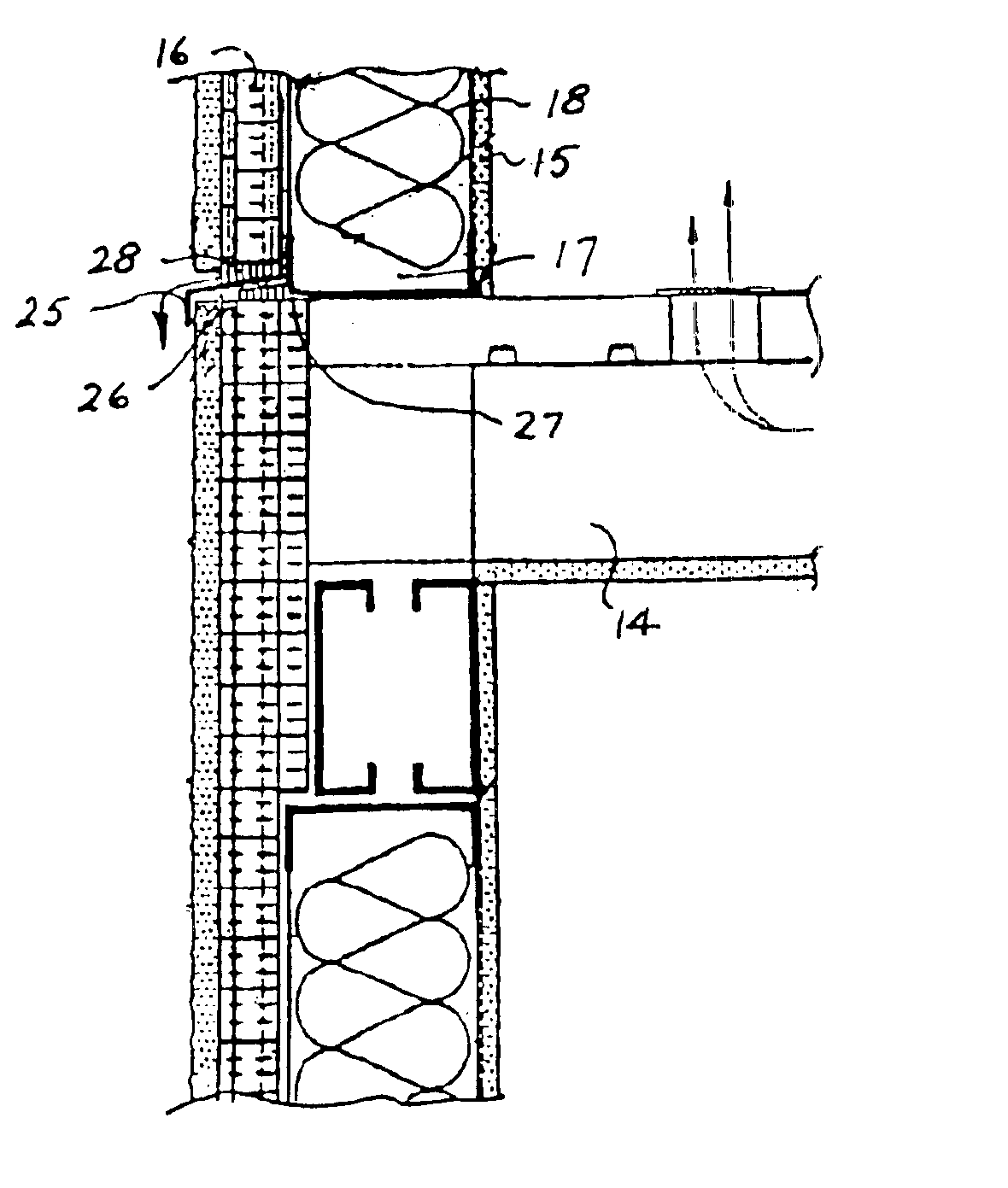

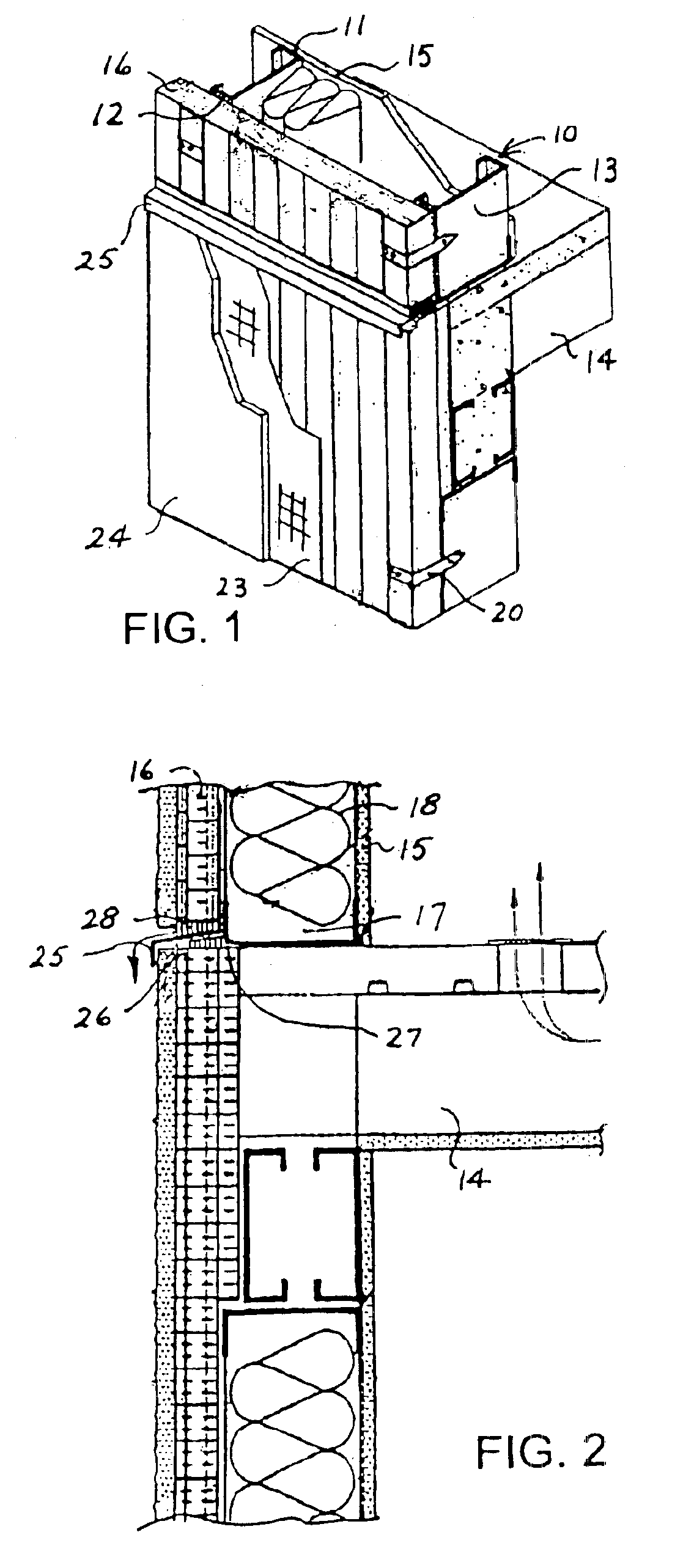

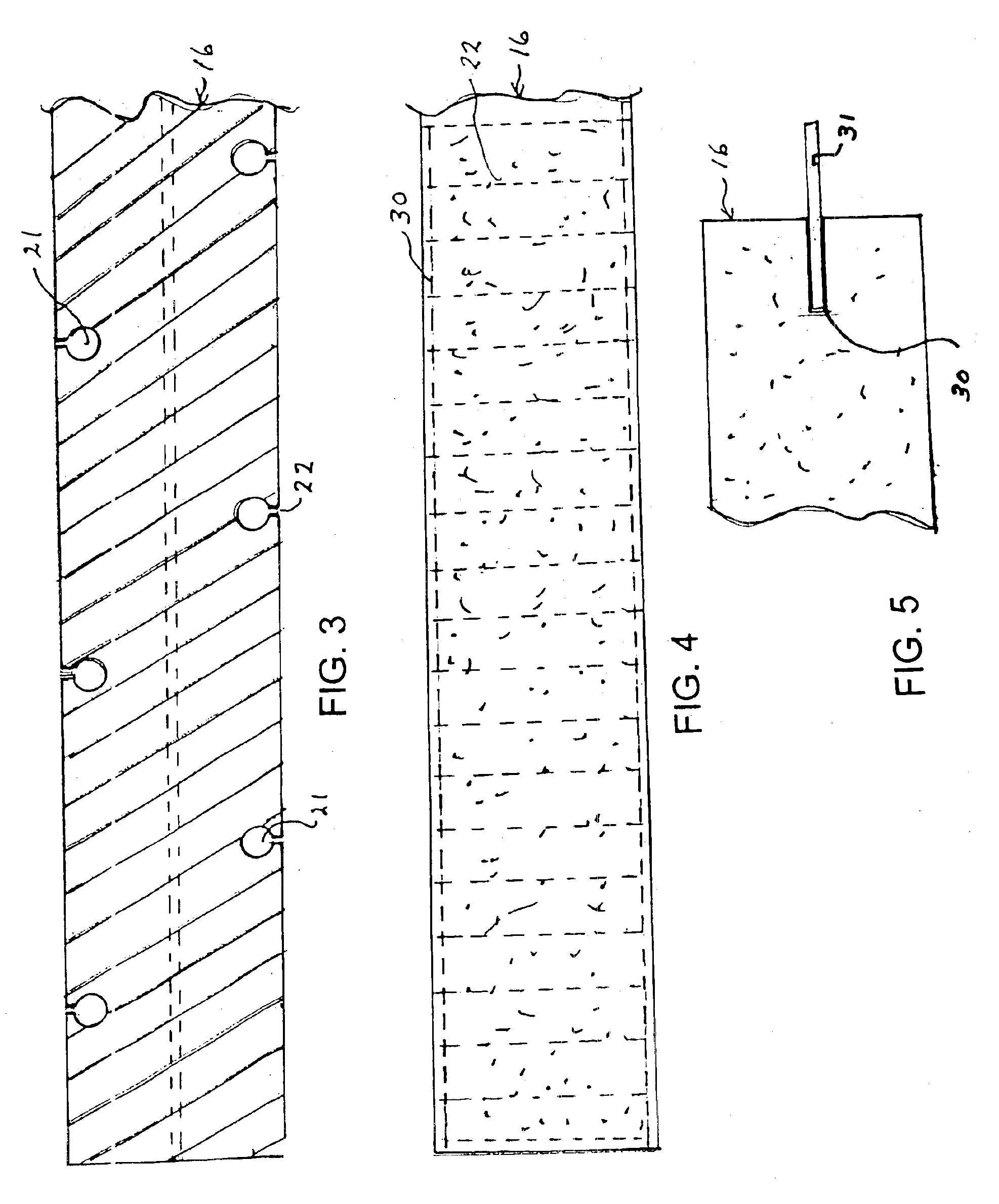

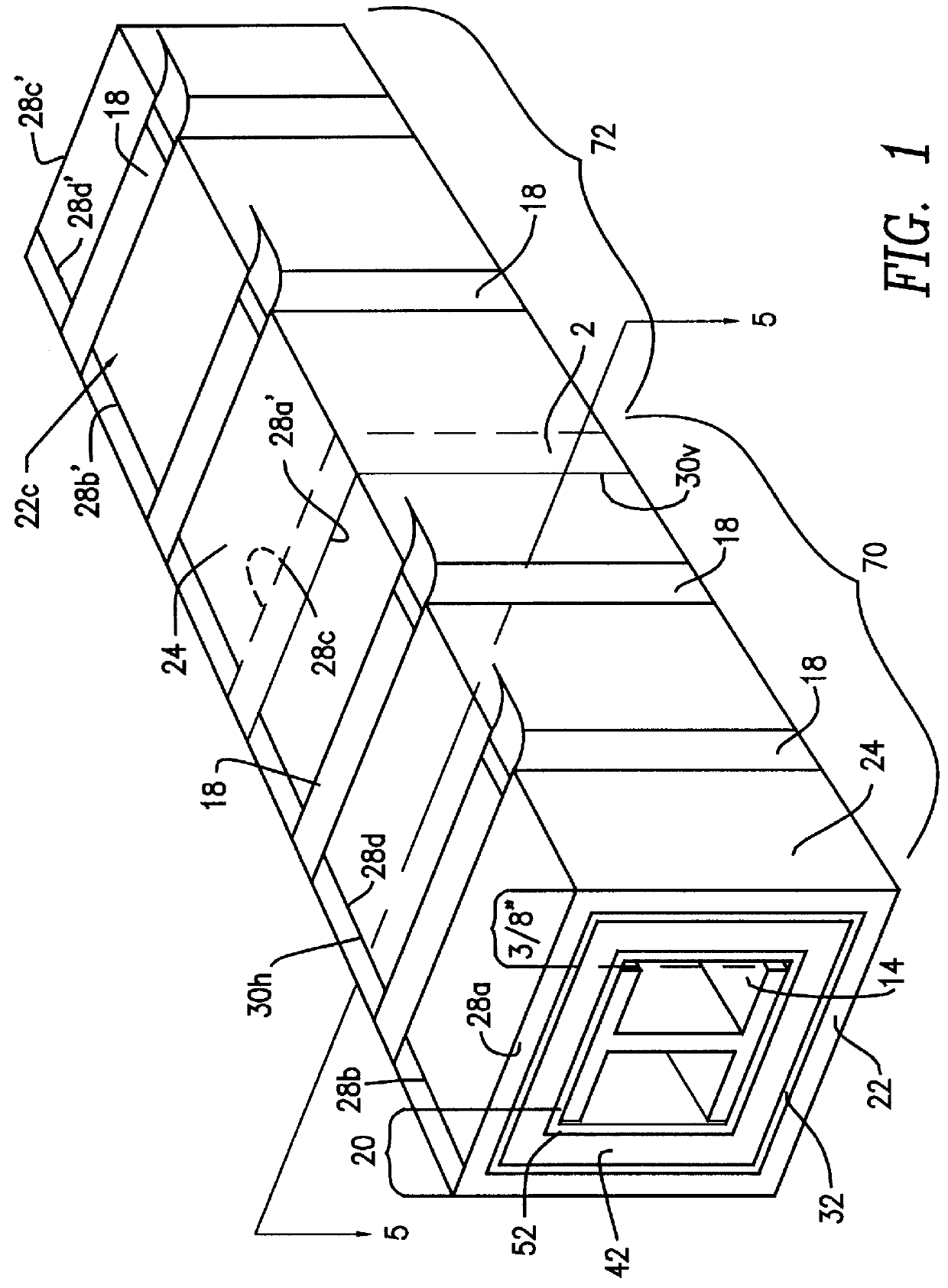

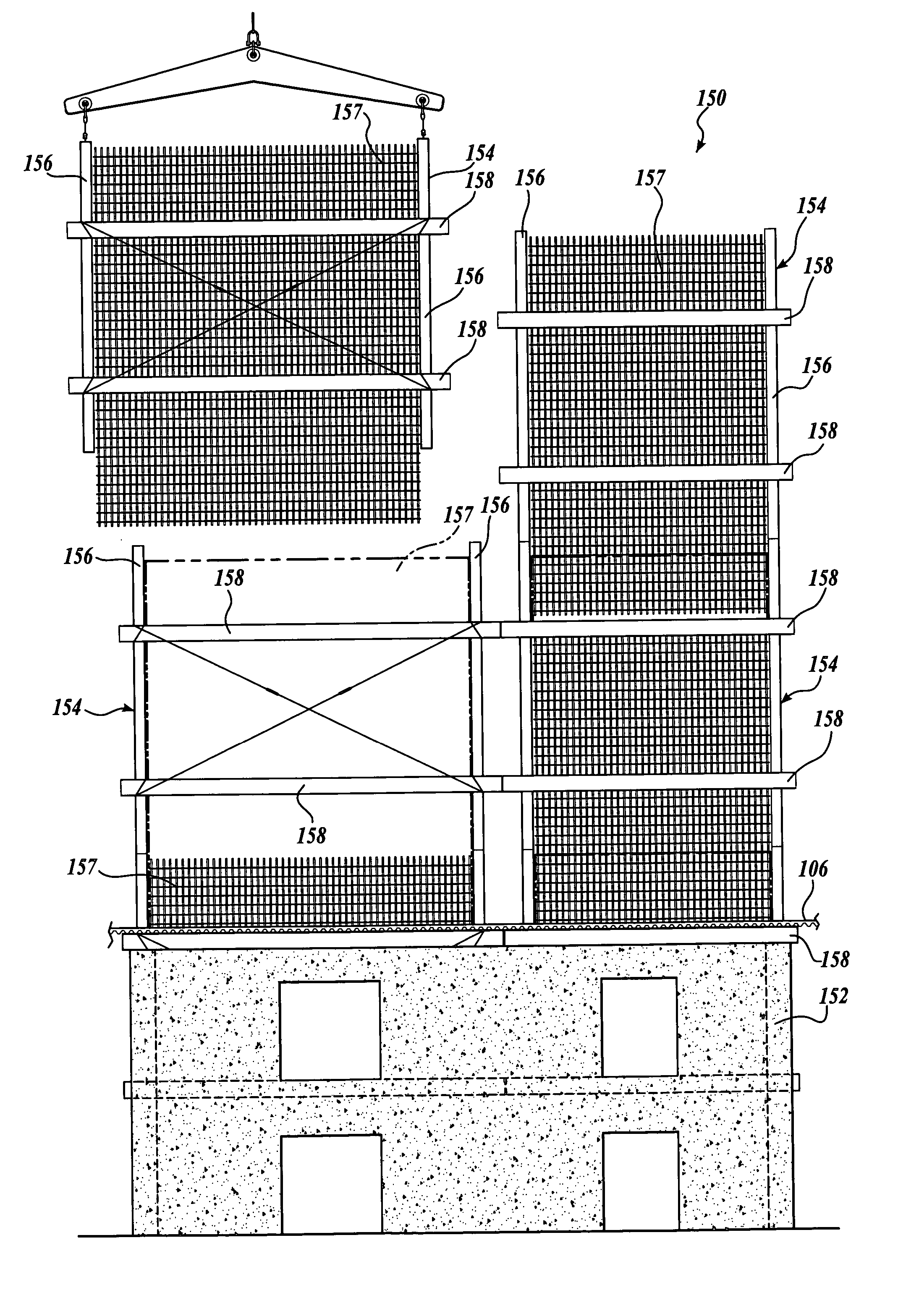

Exterior building cladding having rigid foam layer with drain channels

InactiveUS6886301B2Reduce conductivityStructural failureCeilingsConstruction materialInsulation layerSteel frame

A novel building construction is described for exterior building walls. The construction comprises an interior frame formed of a plurality of laterally spaced studs or beams, a layer of rigid insulation adjacent to the exterior side of this steel frame, exterior building cladding adjacent the exterior side of the rigid insulation and a plurality of low conductivity connectors, e.g. insulating plastic connectors or thin metal strips having an insulating plastic foam coating, extending through the layer of rigid insulation and connecting together the exterior cladding and the interior steel studs or beams. Vertical channels are formed adjacent both the inside and outside faces of the insulation layer to remove moisture. This provides the required structural strength with a minimum of thermal conductivity from the warm side to the cold side of the building envelope, while providing exterior drain channels and interior moisture removing channels.

Owner:SCHILGER HERBERT K

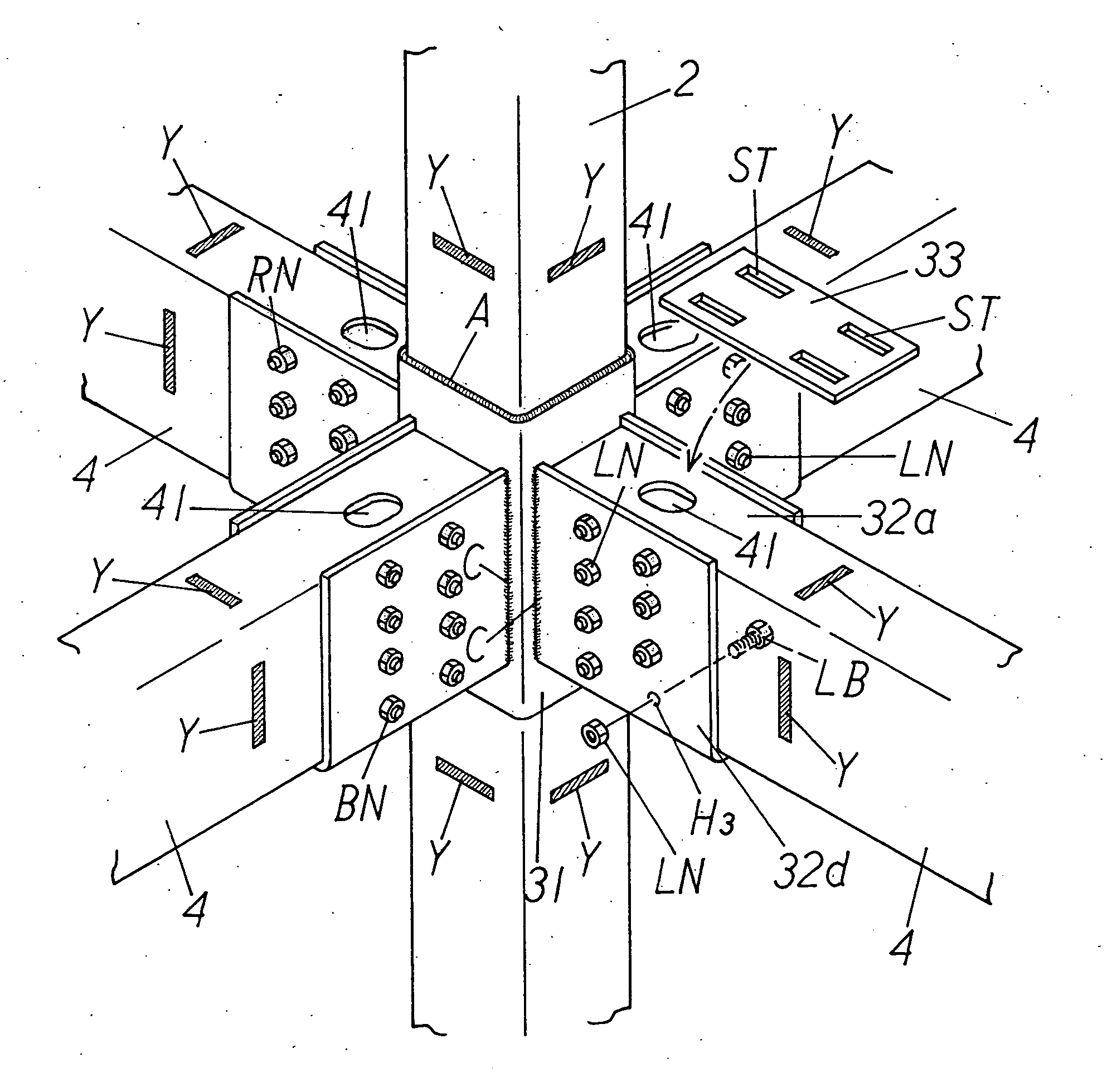

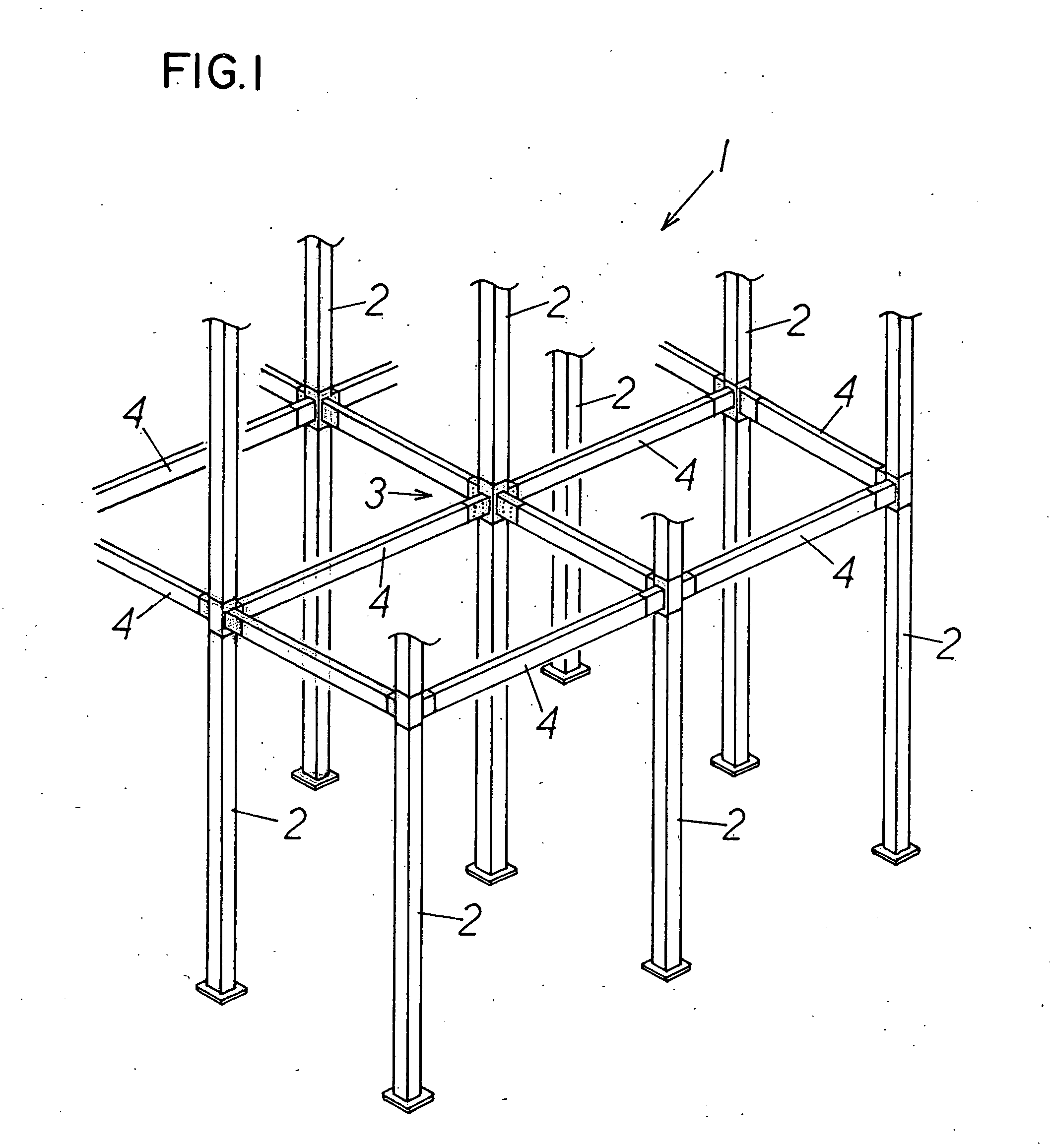

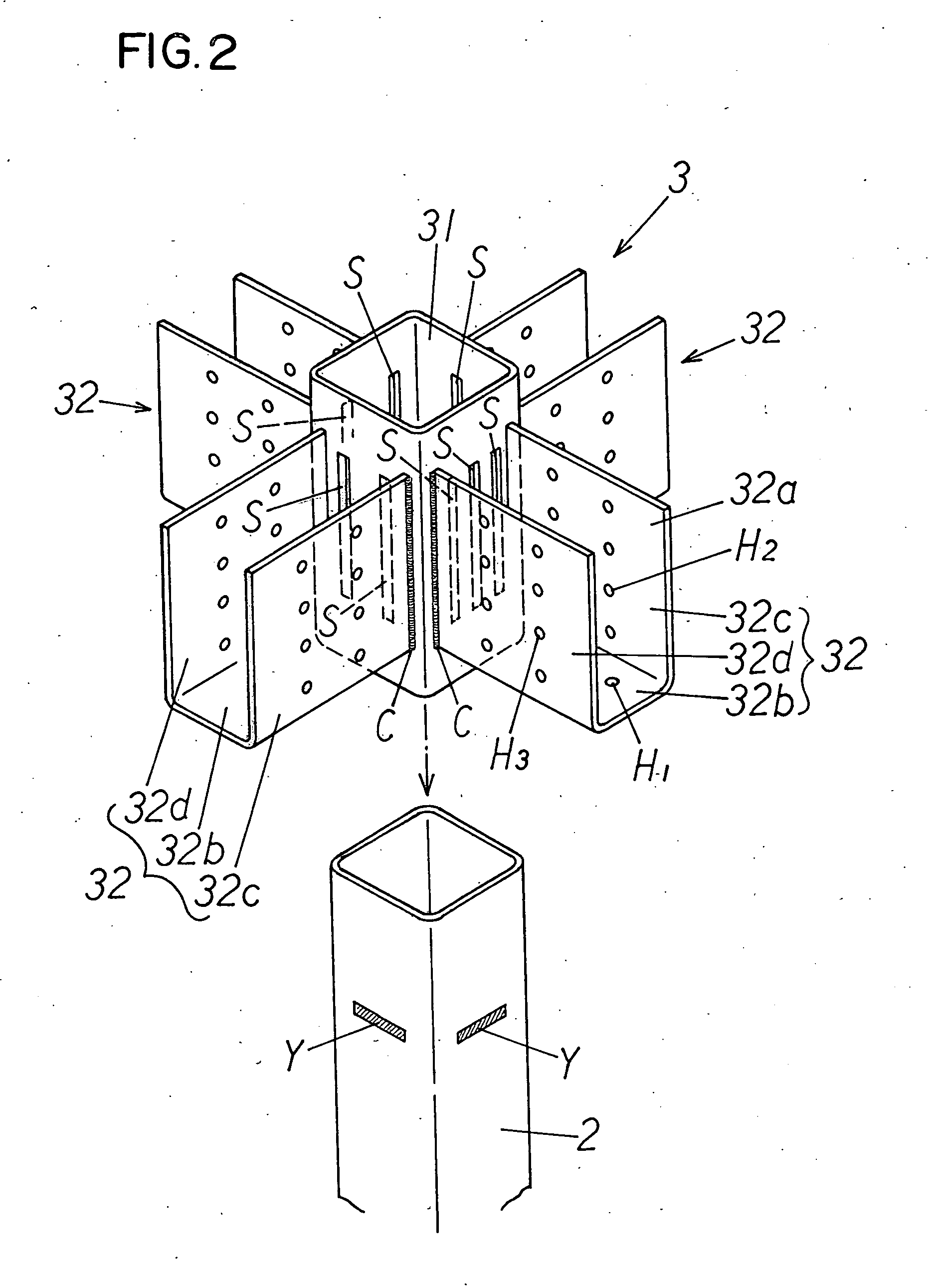

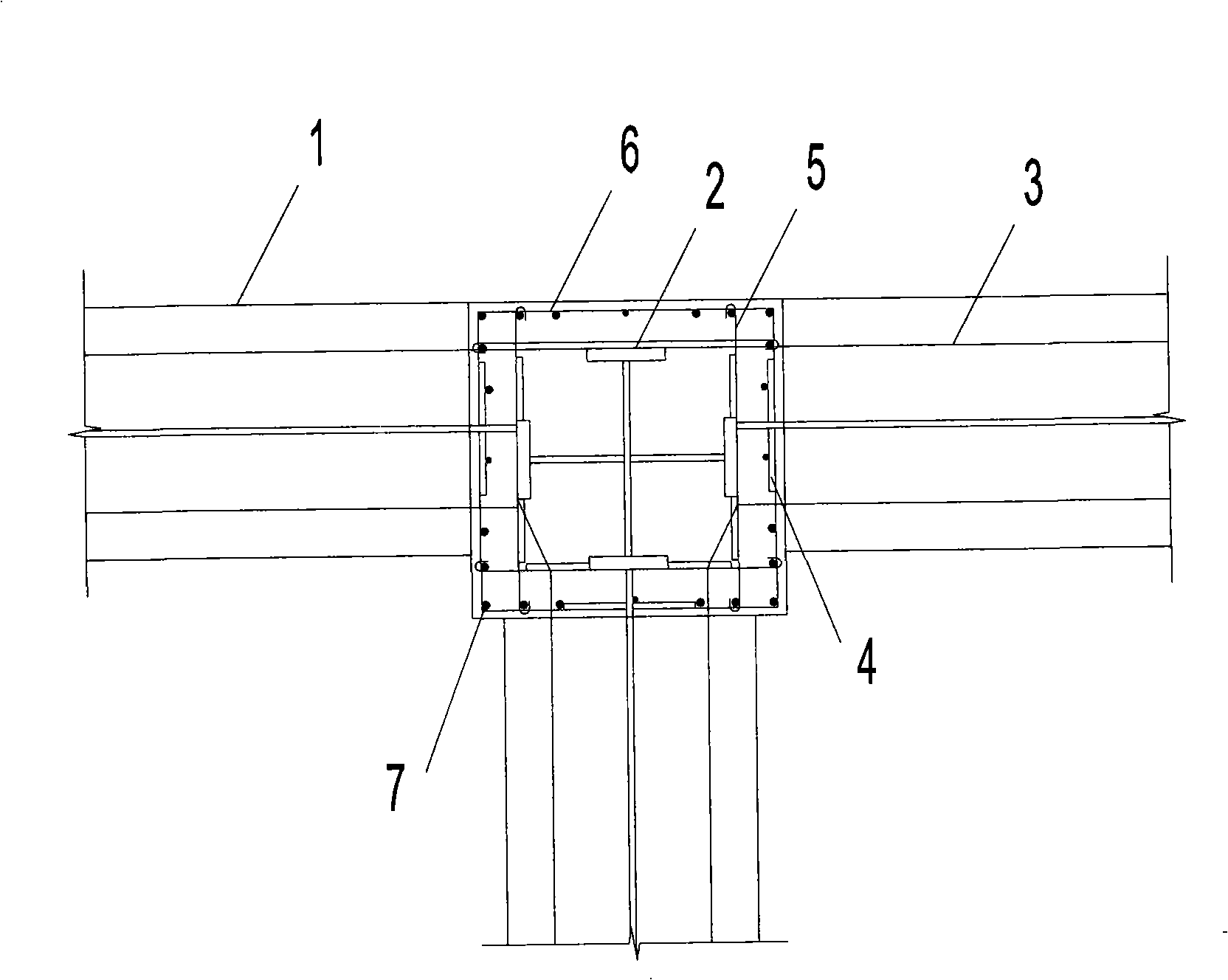

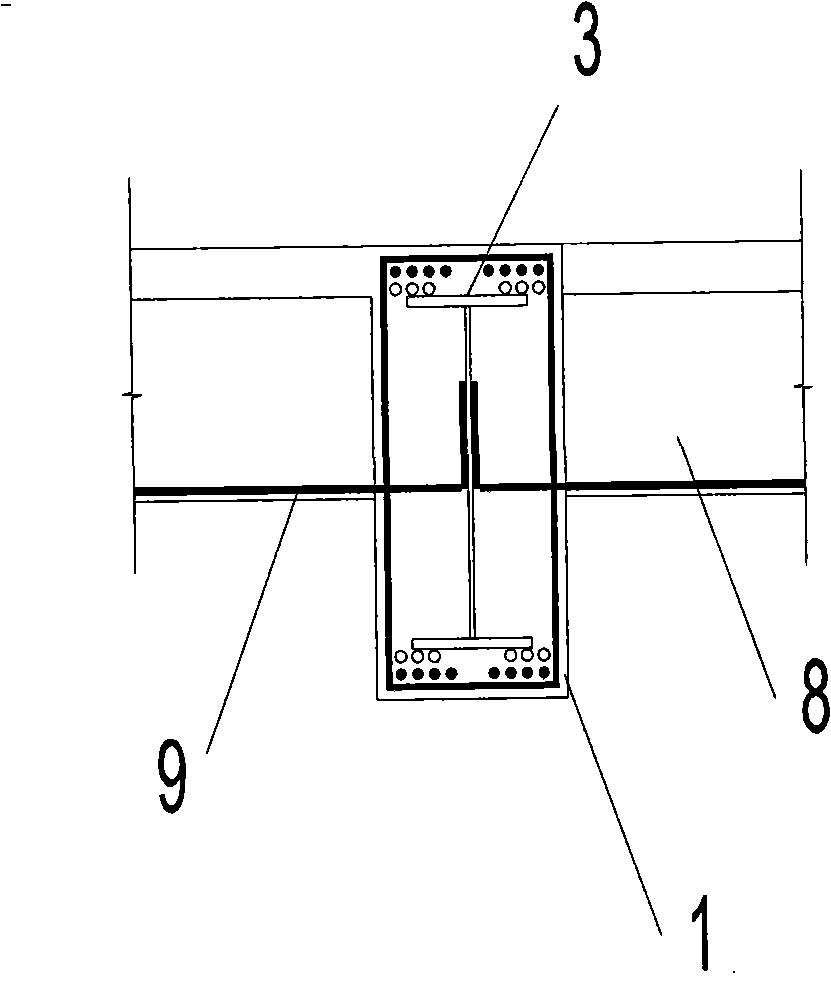

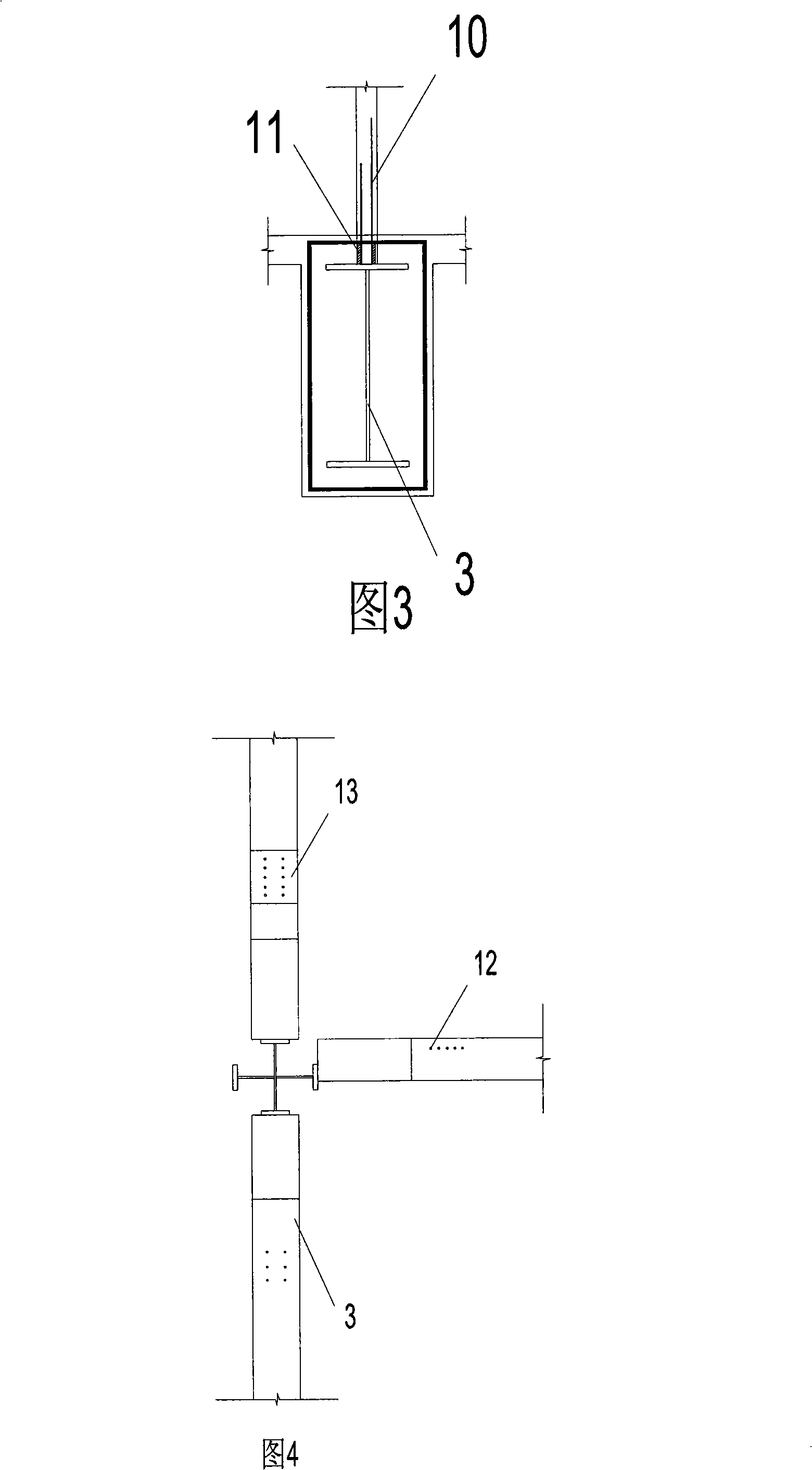

Joint structure of iron framework and coupling member for connecting rectangular steel beam to rectangular steel column

The present invention provides a joint structure of iron framework capable of enhancing workability and strength. The joint structure of iron framework 1 is a joint structure of iron framework for connecting a hollow rectangular steel beam 4 to a hollow rectangular steel column 2 via a coupling member 3. The coupling member 3 includes: a rectangular cylinder 31 fitted to an outer periphery of the hollow rectangular steel column 4 and firmly attached to the hollow rectangular steel column 4; a U-shaped receiving member 4 provided to a side surface of the rectangular cylinder 31 for connecting the hollow rectangular steel beam 4, the U-shaped receiving member 32 having a bottom portion 32b protruded from the side surface of the rectangular cylinder 31, having a U-shaped opening portion 32 located to face upward, having a U-shaped end surface firmly attached to the side surface of the rectangular cylinder 31; and a lid 33 firmly attached to the U-shaped receiving member 32 in a state of covering the upper surface of the hollow rectangular steel beam 4 mounted in the U-shaped receiving member 32.

Owner:HIRAGAKI MINORU

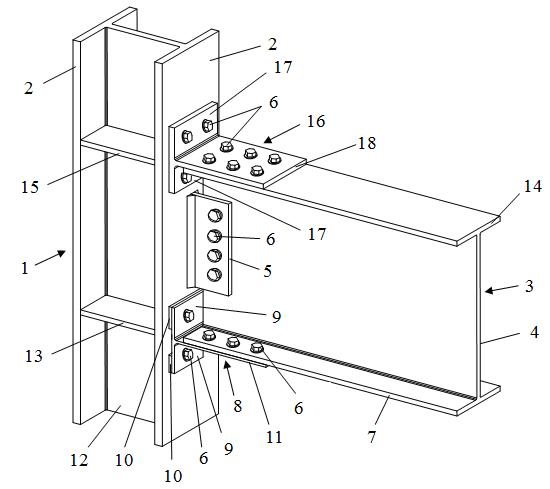

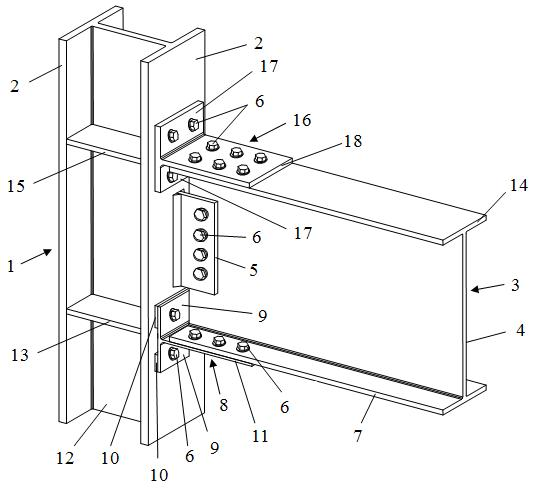

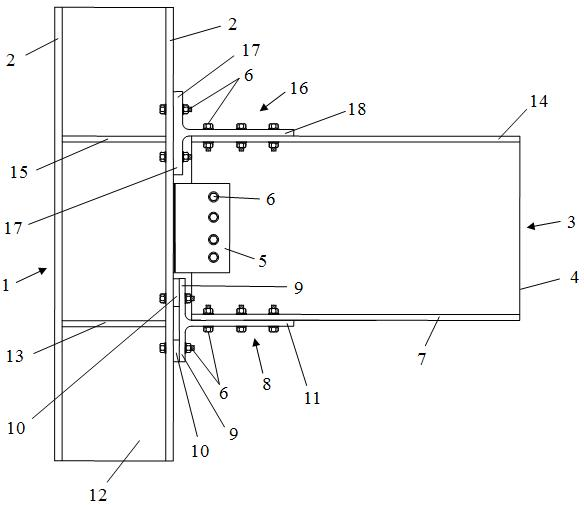

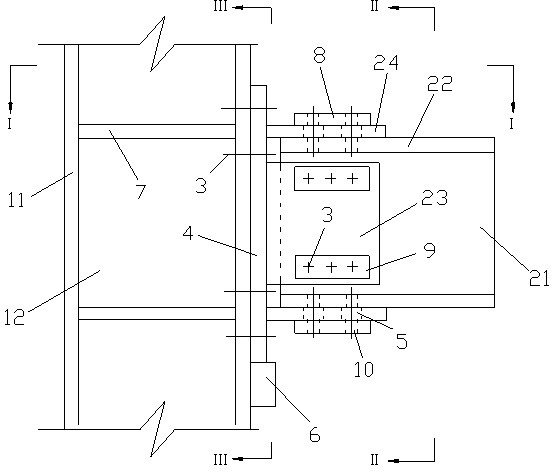

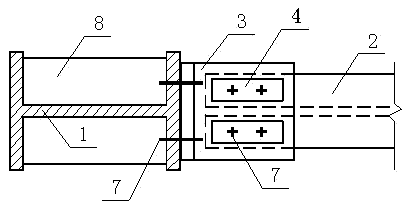

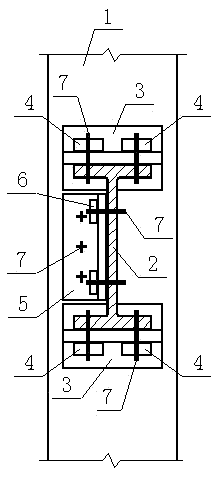

Easily repaired steel-structure beam-column node

InactiveCN101812872ASolve the lack of ductilitySolve the problem prone to brittle failureShock proofingHigh intensitySteel columns

The invention relates to an easily repaired steel-structure beam-column node, in particular to an easily repaired steel-structure beam-column node which is applied in the field of structural engineering and particularly used in high-intensity earthquake-proof areas. The node comprises an upright H-shaped steel column and an H-shaped steel beam of which the end part is vertically connected on a side wing plate of the H-shaped steel column, and is characterized in that: connecting ends of a belly plate of the H-shaped steel beam and the side wing plate of the H-shaped steel column are connected by a reinforced connecting plate closely contacted with the belly plate of the H-shaped steel beam and high-strength bolts penetrating the reinforced connecting plate, the reinforced connecting plate is in welding connection with the side wing plate of the H-shaped steel column, and both sides of the connecting end of a bottom side wing plate of the H-shaped steel beam are in locked connection with the H-shaped steel column by a T-shaped connecting plate and penetrating high-strength bolts respectively; and the T-shaped connecting plate is transversely arranged, upper and lower ends of the T-shaped connecting plate in the vertical direction are in locked connection with the side wing plate of the H-shaped steel column by a washer and the penetrating high-strength bolts respectively, a transverse plate of the T-shaped connecting plate is supported on the lower part of the bottom side wing plate of the H-shaped steel beam and locked by the penetrating high-strength bolts. The structure can effectively avoid brittle failure, has good ductile fracture characteristic, and can be widely applied to structures of earthquake areas, particularly the high-intensity earthquake-proof areas; and the easily repaired steel-structure beam-column node of the invention also has the advantages of convenient construction and convenient after-earthquake repairing.

Owner:FUZHOU UNIV

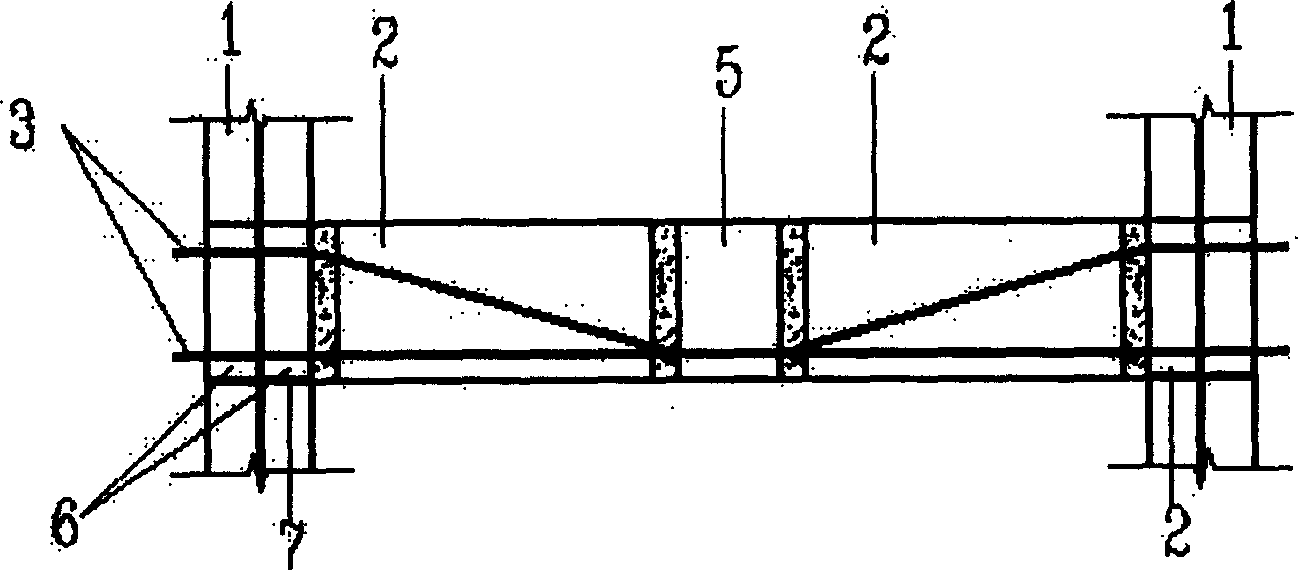

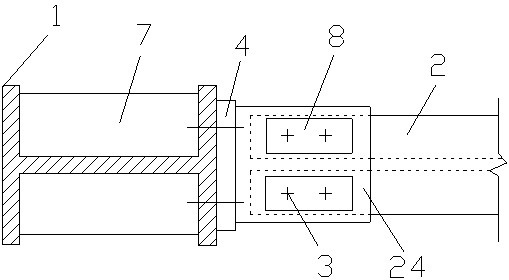

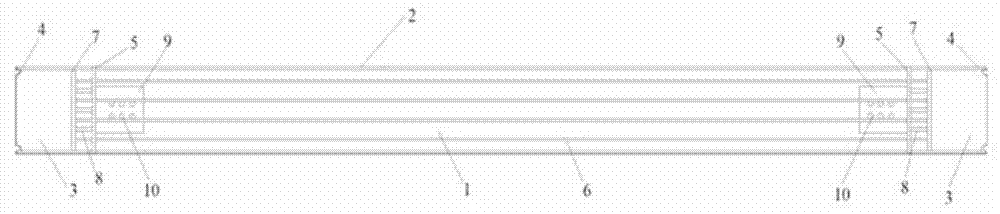

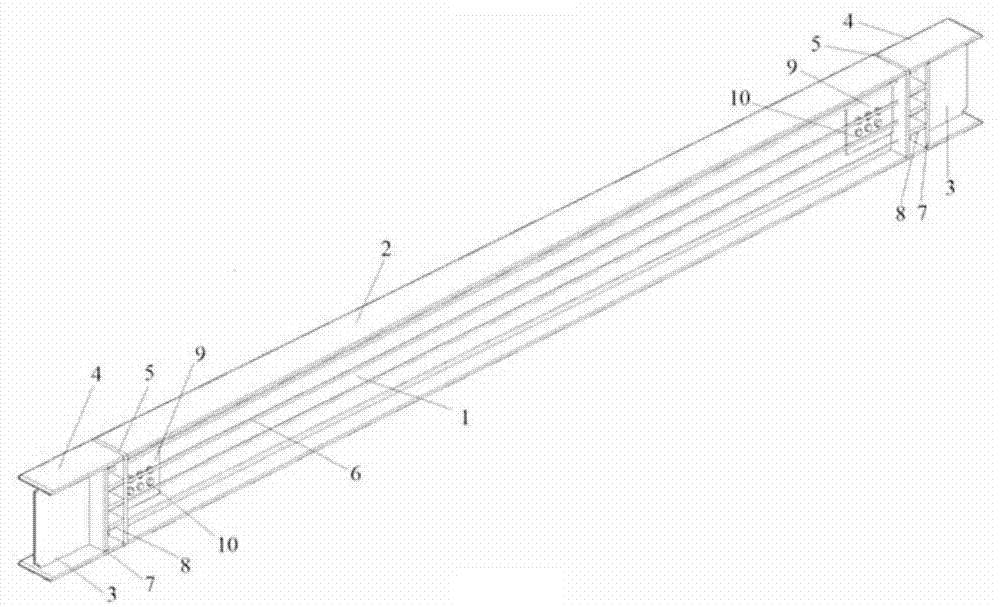

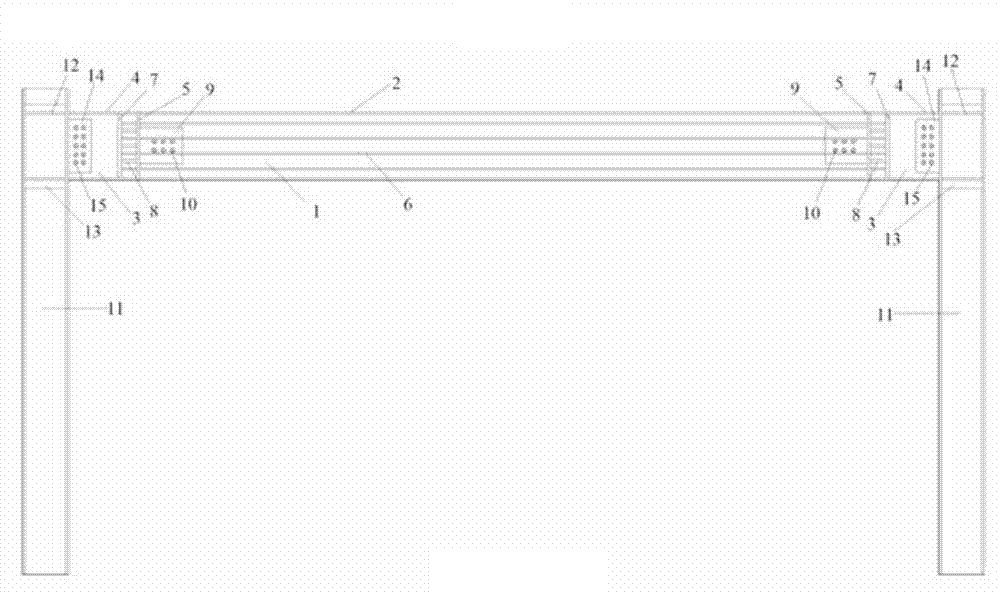

Steel frame precast prestressed beam column joint with post-earthquake recovering function

InactiveCN102817413AEasy constructionImprove construction qualityBuilding material handlingShock proofingPre stressSteel frame

The invention relates to a steel frame precast prestressed beam column joint with a post-earthquake recovering function. The joint comprises a steel frame column, a short beam section, a beam column connection device and an energy consumption device, wherein the steel frame column comprises a steel column, a column reinforced rib and a column reinforced plate; the short beam section comprises a short beam section web, a short beam section flange and a short beam section flange reinforced plate; the beam column connection device comprises a short beam section web reinforced rib, a prestressed cable and a beam end top plate; the energy consumption device comprises two channel steels and a high-strength bolt; and the two short beams are integrally connected with the column in a factory through a tension prestressed cable and two short beam section web reinforced ribs. When the earthquake action achieves a certain degree, the contact surface of the beam and the column is opened; the high-strength bolt is in friction energy dissipation so as to avoid destroying main components, such as beams and columns After the earthquake, the beams can be recovered to the former vertical position under the action of the prestress.

Owner:BEIJING UNIV OF TECH +1

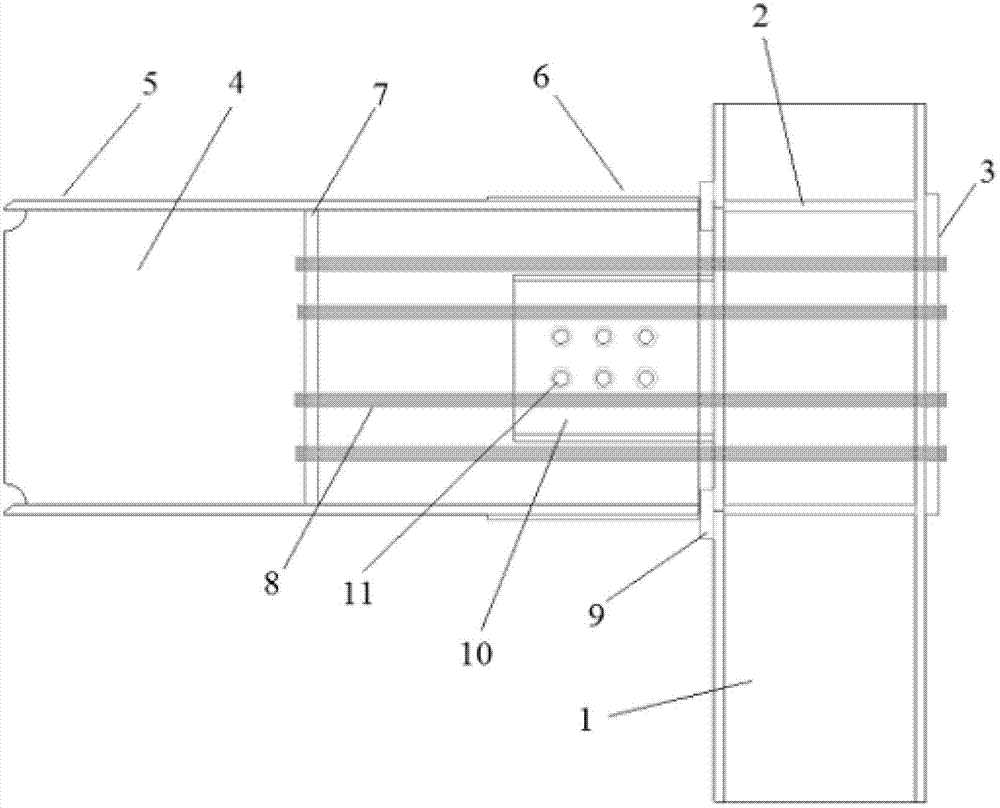

High-ductility steel structure beam column node in angle steel connection and construction method of high-ductility steel structure beam column node

ActiveCN102363979AIncreased ductile deformation capacityImprove energy consumptionBuilding material handlingShock proofingHigh intensitySteel columns

The invention relates to a high-ductility steel structure beam column node in angle steel connection and a construction method of the high-ductility steel structure beam column node. The invention is characterized in that: upper and lower flange plates of an H-shaped steel beam are respectively connected with a steel column by using flange angle steel, a flange steel cushion plate and a friction type high-strength bolt; a web plate of the H-shaped steel beam is connected with the steel column by using web plate angle steel, a web plate steel cushion plate and the friction type high-strength bolt; bolt holes in a flange angle steel branch and a web plate angle steel branch, which are connected with the H-shaped steel beam, are long circular holes; horizontal reinforcing ribs are arranged, at a joint of the steel column and the H-shaped steel beam, inside the steel column; and a gap is reserved between an end head of the H-shaped steel beam and the steel column. The high-ductility steel structure beam column node has quite high ductile deformation capacity and excellent energy-dissipation capacity; and connection welded beams are not formed on beam column members, so that the brittle failure of the steel beam or the steel column in a node area under the action of a seldom-occurring earthquake is avoided. Furthermore, the high-ductility steel structure beam column node has the advantages of convenience for construction, simple and quick in repair operation after the earthquake, low in repair cost and the like.

Owner:FUZHOU UNIV

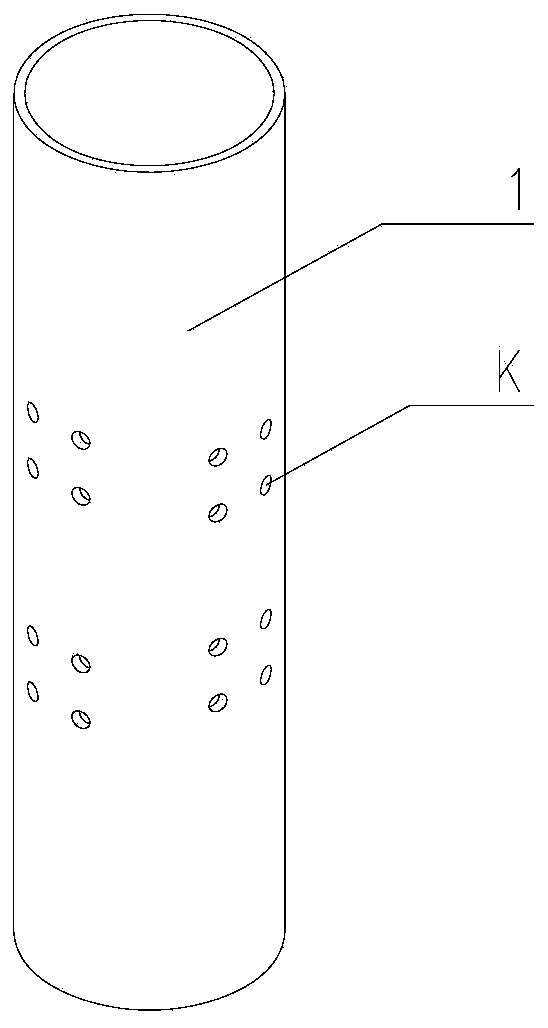

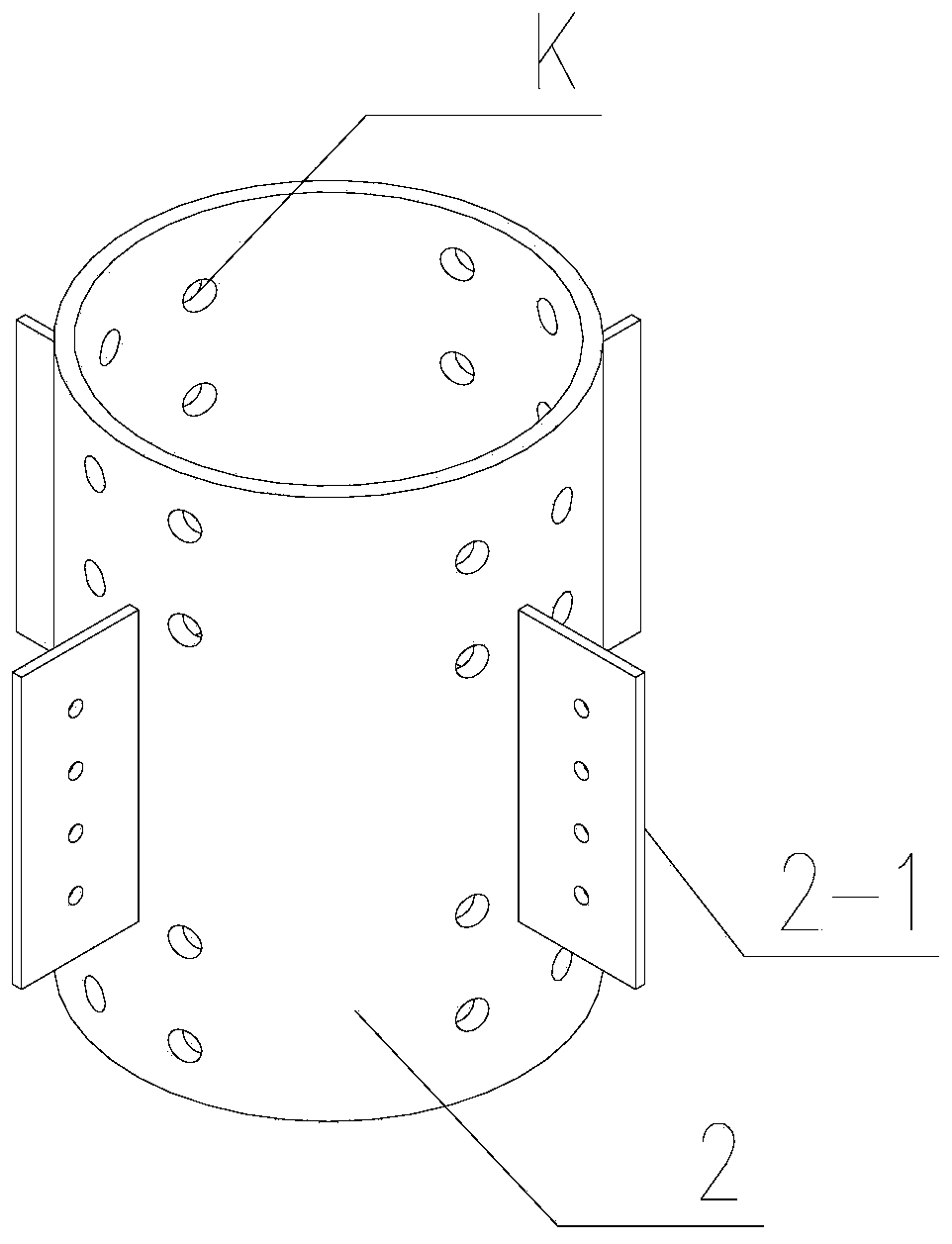

Production process method of pipe whip restraint steel structure of main power house of nuclear power station conventional island

ActiveCN101862942AImprove perforation rateReduce distortionArc welding apparatusBoring/drilling machinesNumerical controlGusset plate

The invention belongs to the technical field of pipe whip restraint steel structures of main power houses of nuclear power station conventional islands, in particular to a production process method of the pipe whip restraint steel structure of the main power house of the nuclear power station conventional island, which comprises the lofting process, the marking-off and scribing process, the cutting processing process, the bevel processing process, the hole-making process, the correction process, the polishing surface, the material splicing process, the pre-splicing process of a steel member, the assembly process, the processing process of a friction surface, the welding process of the steel structure and the anti-slip test of the friction surface of the steel member before leaving a factory, sandblasting, derusting and coating of a base coat are carried out in the factory, and the production of the steel structure is divided into the production processing of a welded H-shaped steel column, the production of a steel beam, the assembly and the welding of a support part, the production of a combined steel beam, the assembly and the welding of a girder box body and an inclined support below the girder box body, and the assembly and the welding of a pipe whip restraint key. The production process method can improve the drilling precision, utilize a numerical control planar drilling machine to complete the drilling on a gusset plate, determine a variety of processing processes and welding process parameters, and ensure the dimension of the member after the assembly and the smooth proceeding of field installation.

Owner:EAST STEEL STRUCTURE BRIDGE

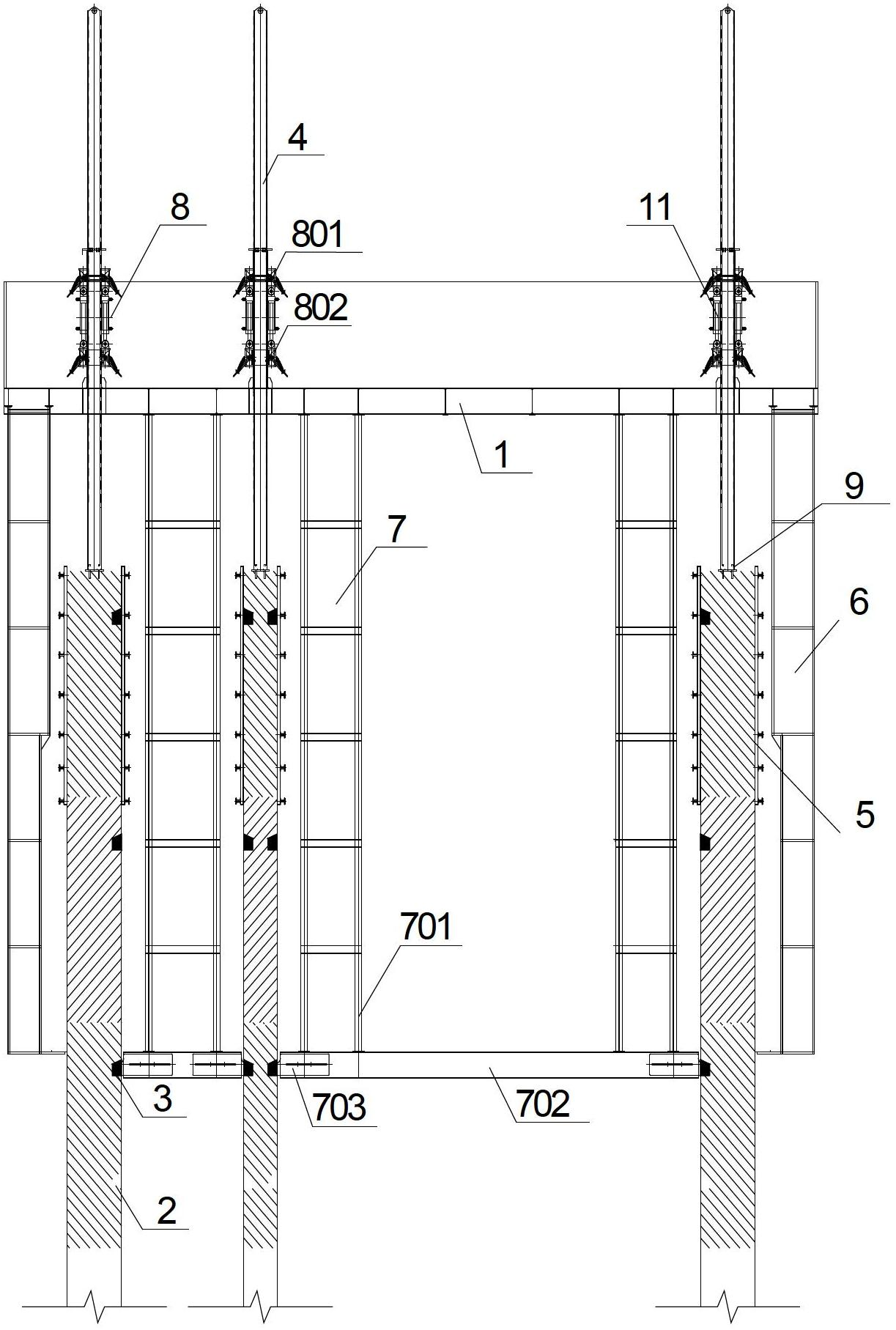

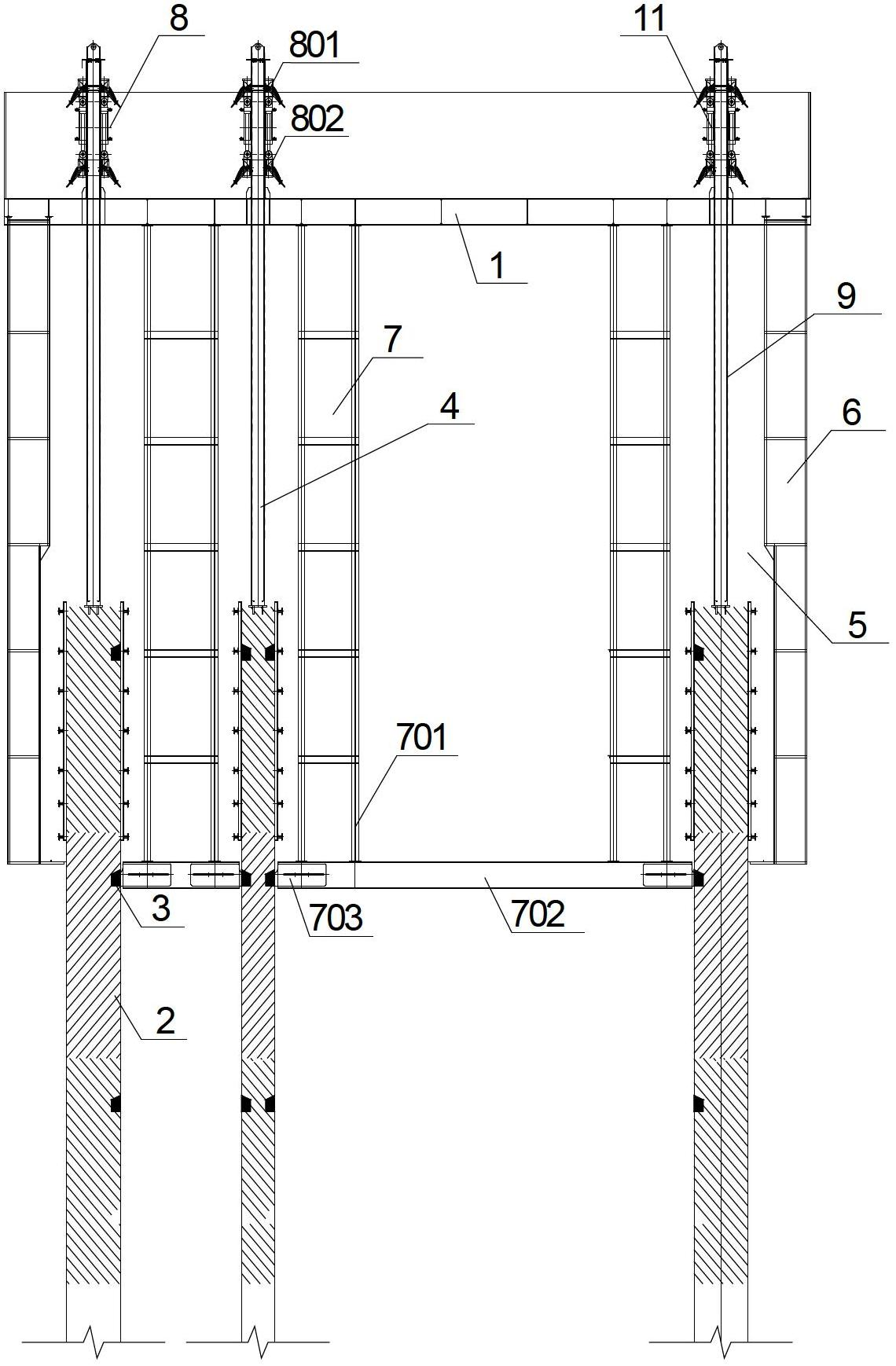

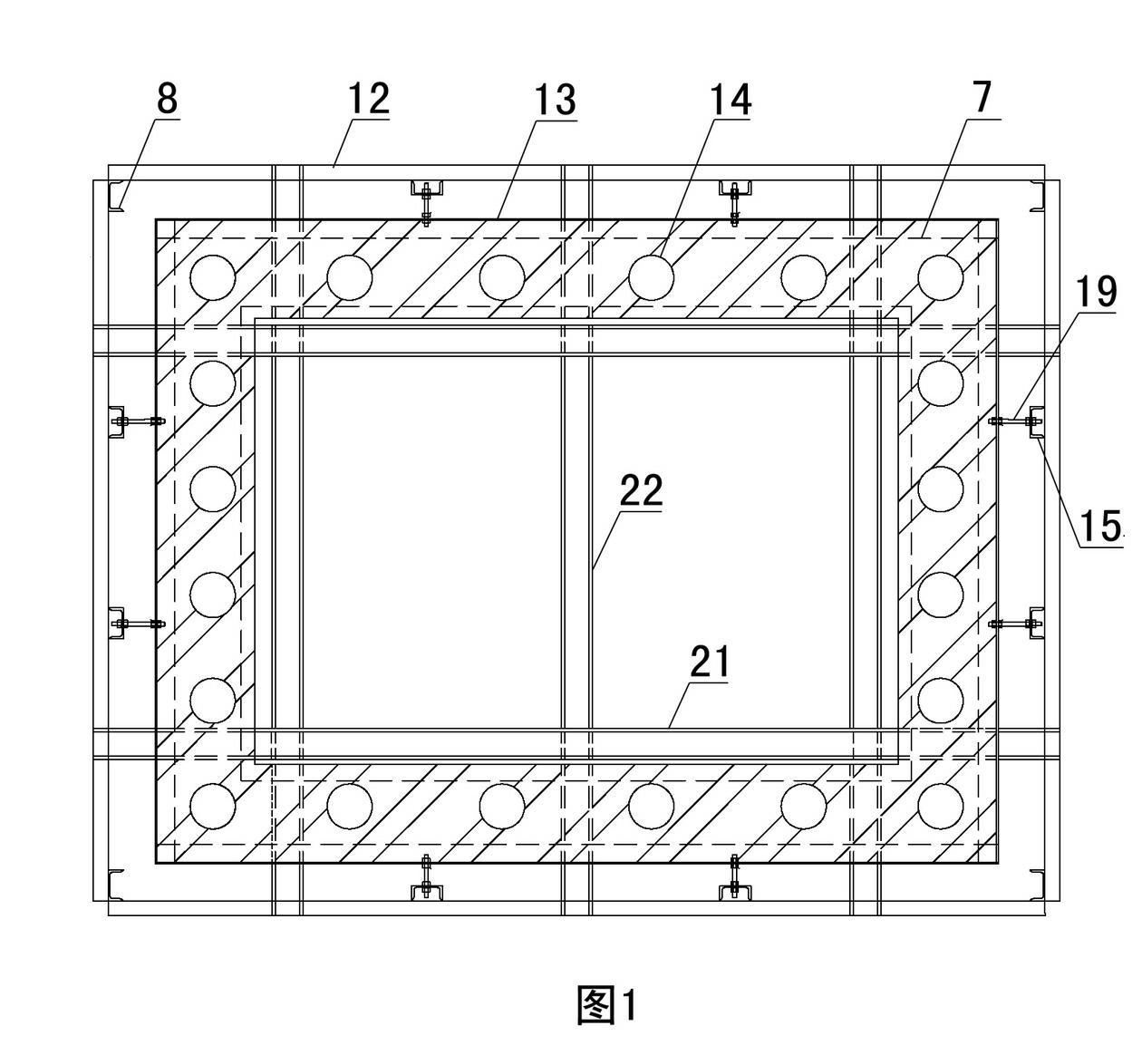

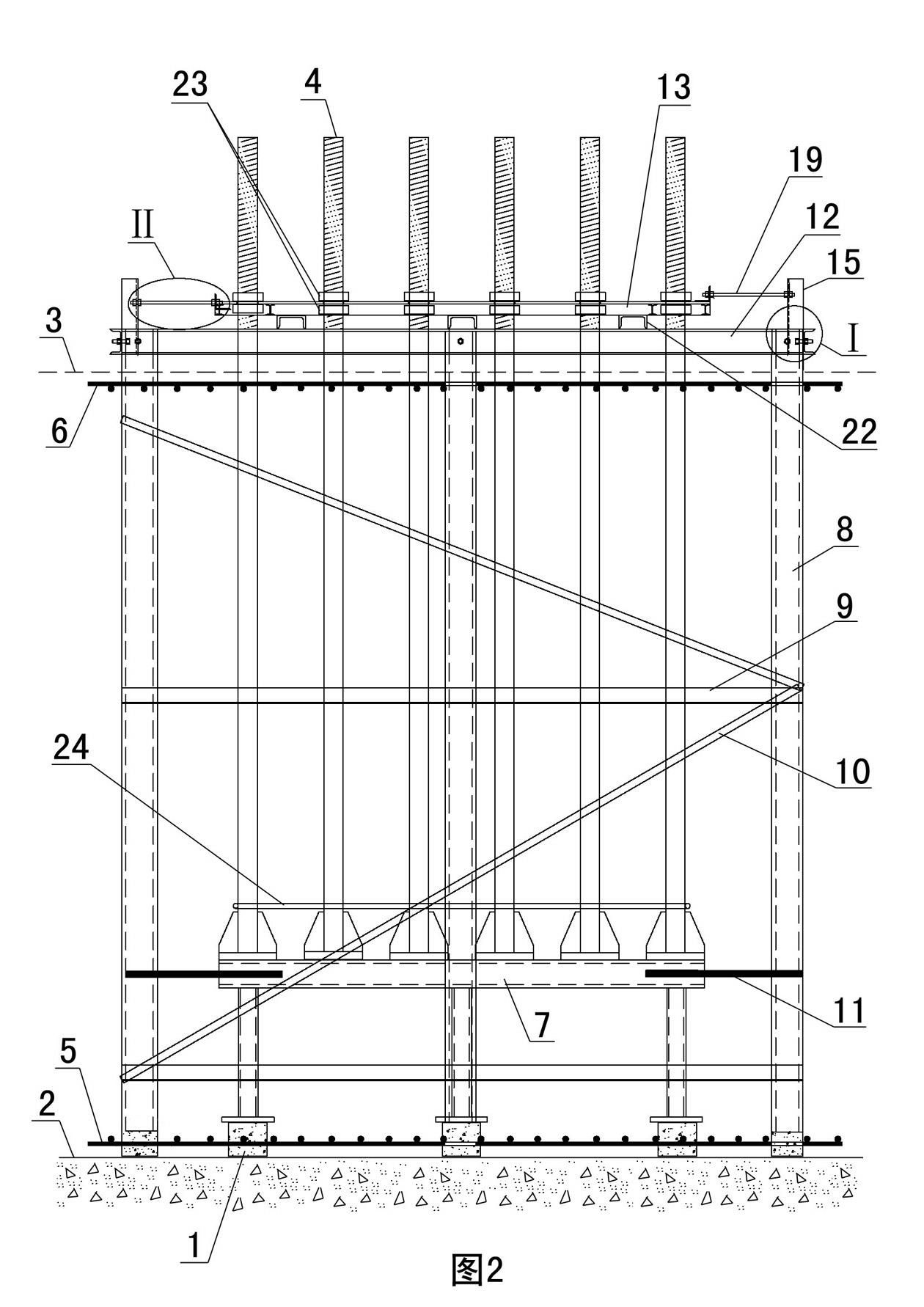

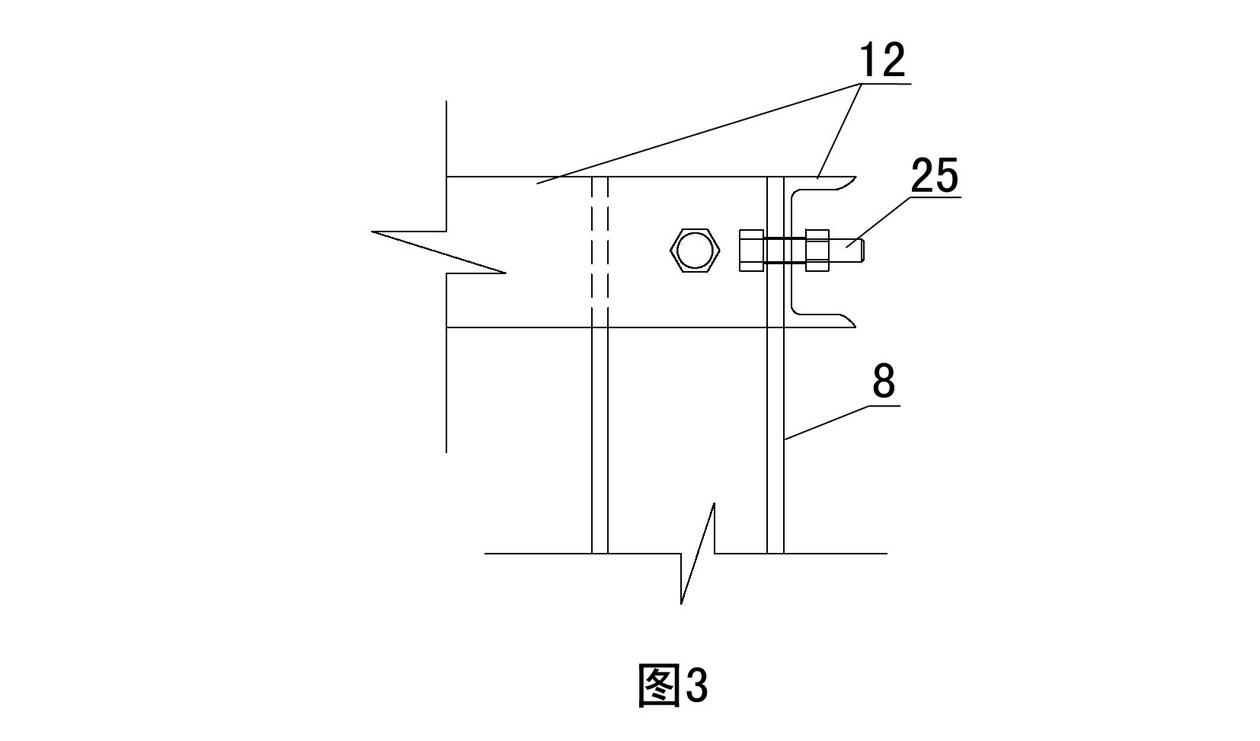

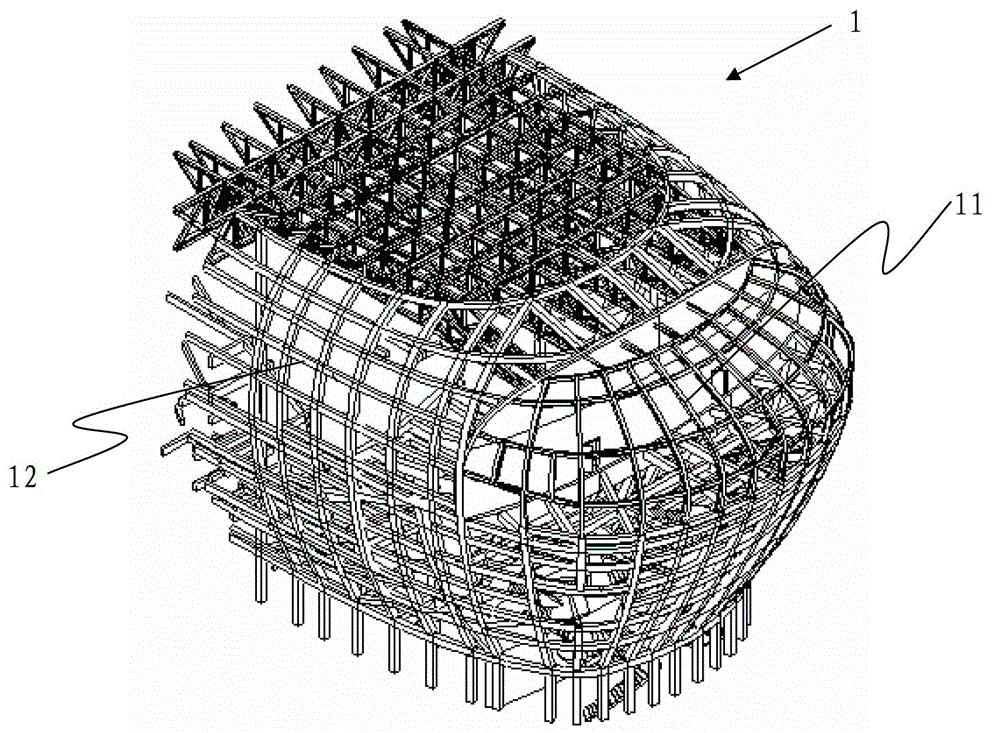

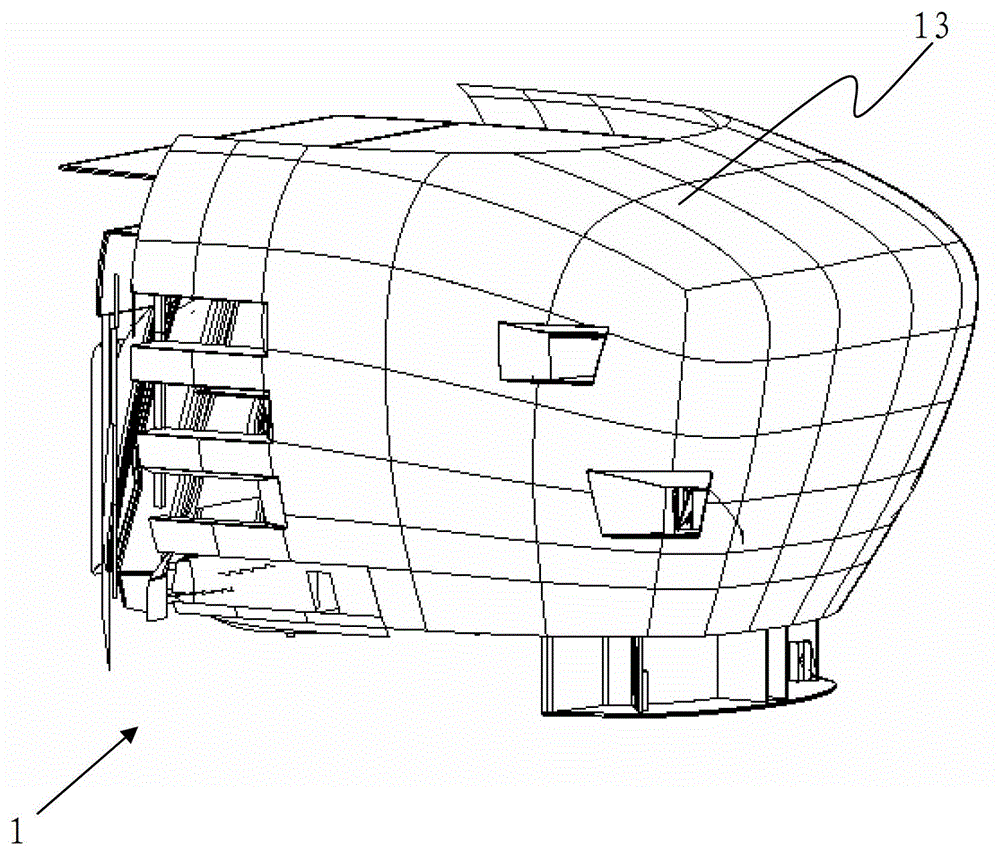

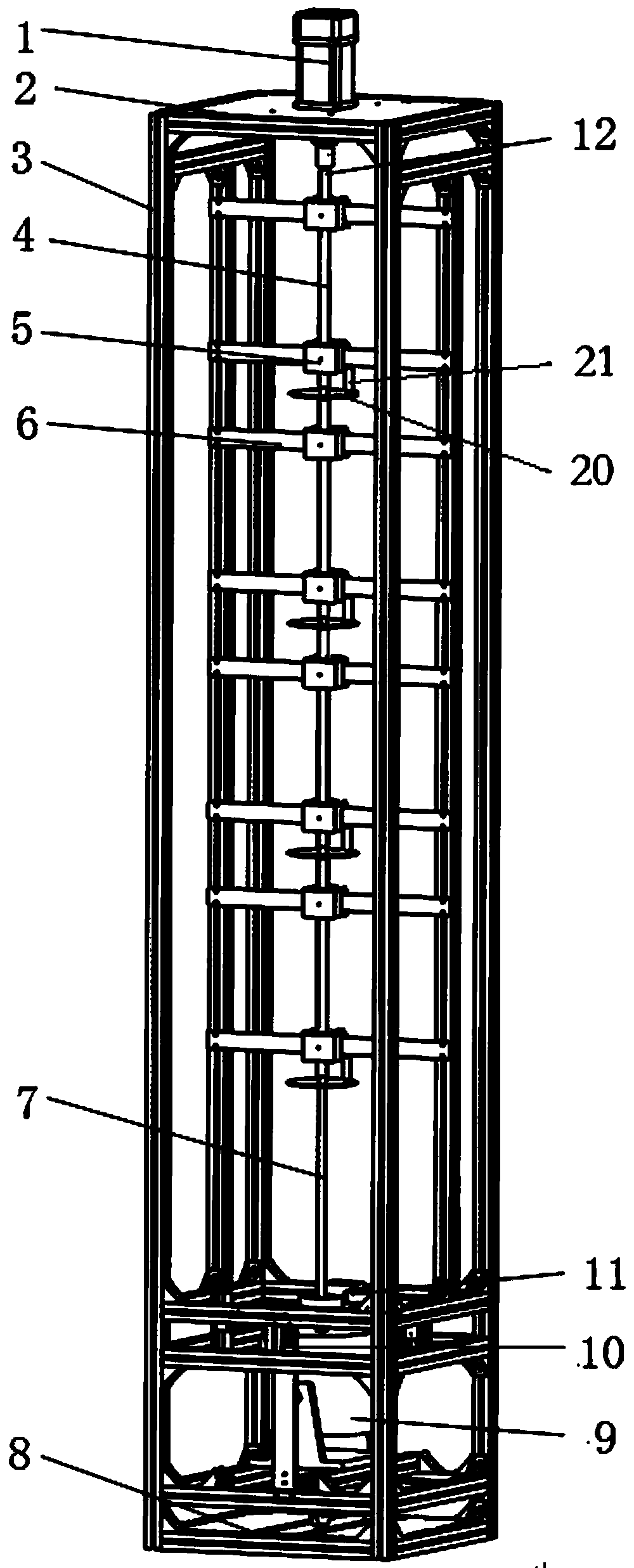

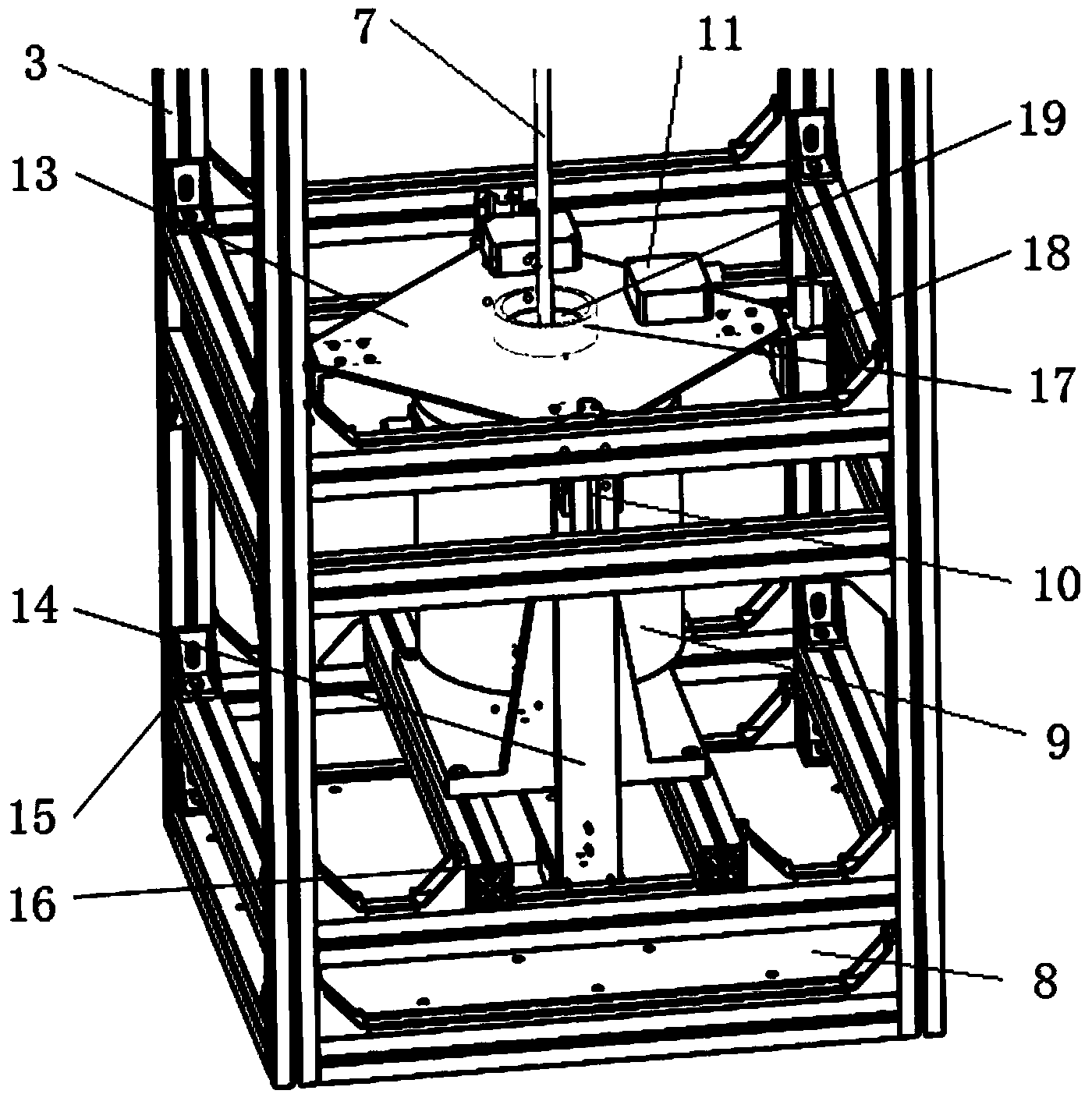

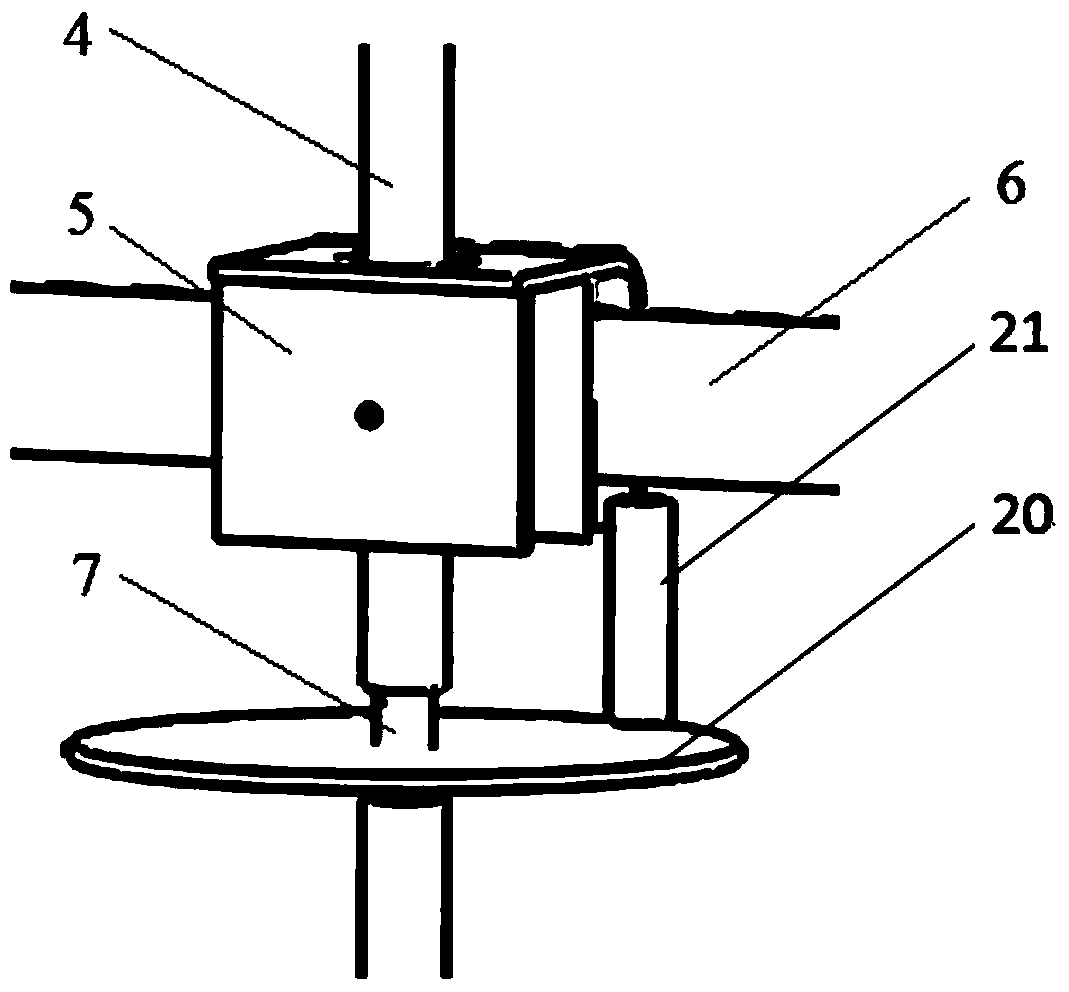

System for alternatively supporting whole lifting steel platform formwork by steel column casing rack and construction method

ActiveCN102677889AClimb achievedAchieve hydraulic climbForms/shuttering/falseworksBuilding material handlingSupporting systemArchitectural engineering

The invention discloses a system for alternatively supporting a whole lifting steel platform formwork by a steel column casing rack. The system comprises a steel platform, a template system, a scaffold system, a support system and a climbing system, wherein the support system comprises a casing rack support and a steel column support; the climbing system comprises climbing boosts and a hydraulic system; preformed core column holes are distributed on a core cylinder structure at intervals along the height direction; the casing rack support is fixedly arranged under the steel platform; the steel column support is fixed in the preformed core column holes under the construction state to serve as the support of a steel platform formwork under the construction state; under the climbing state, the steel column support is fixed to the upper end part of the concrete core cylinder structure and is used as the support of the steel platform formwork under the climbing state; and under the construction state, the steel column support is fixed to the steel platform by the climbing boosts. According to the system, the steel platform formwork system can greatly reduce the construction cost and save the engineering material by the whole hydraulic climbing supported by the tool type steel columns.

Owner:SHANGHAI CONSTRUCTION GROUP +1

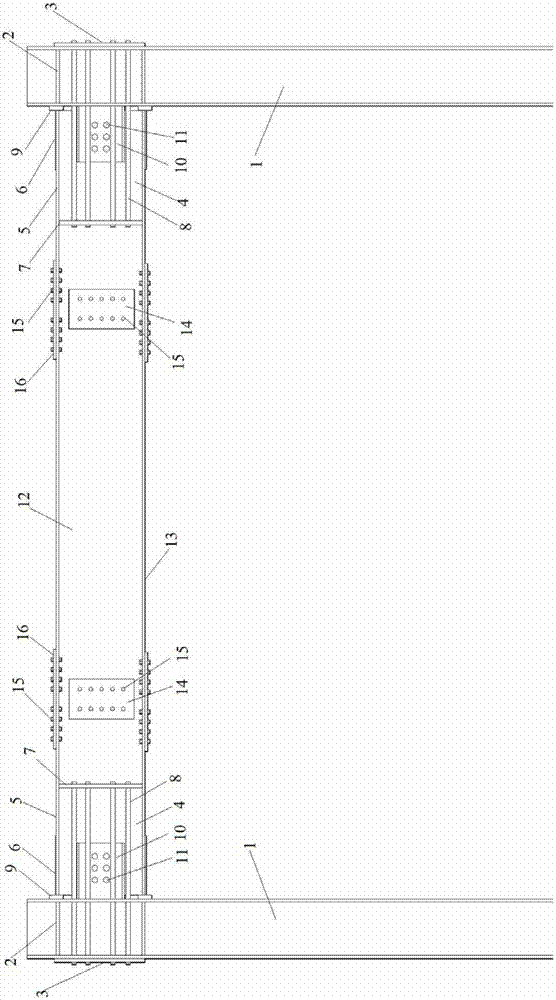

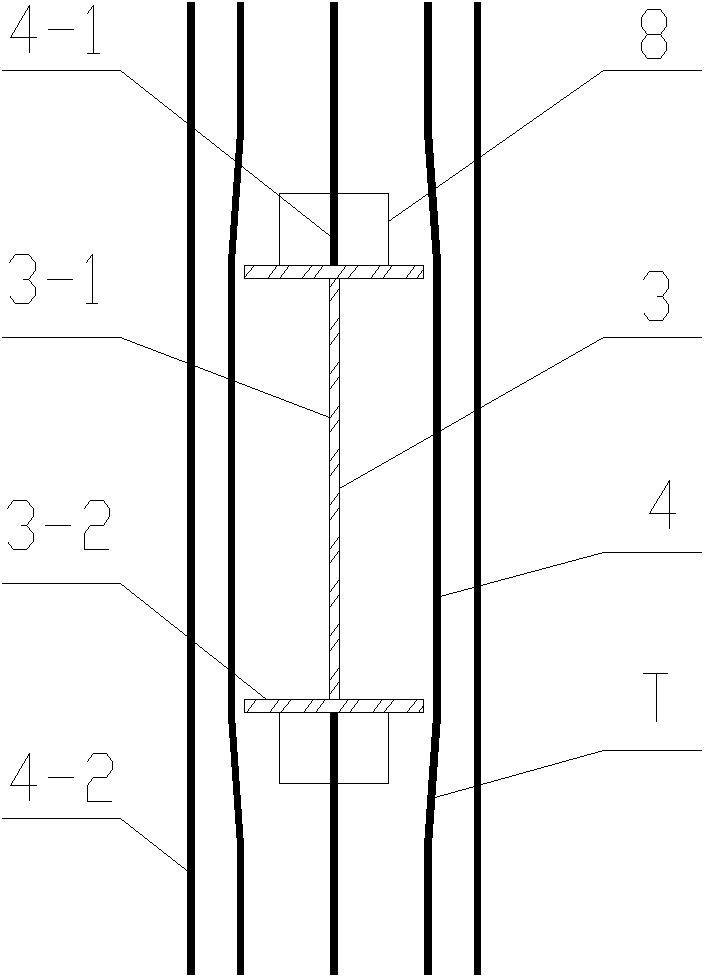

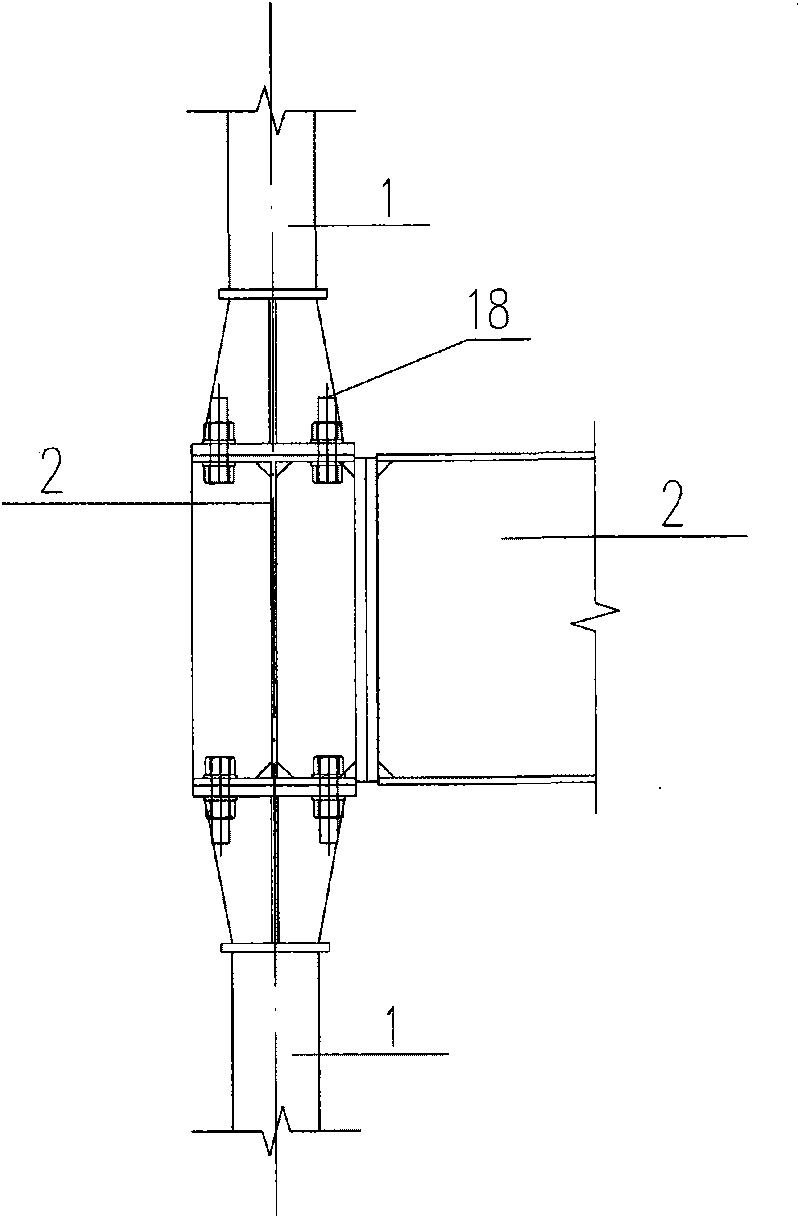

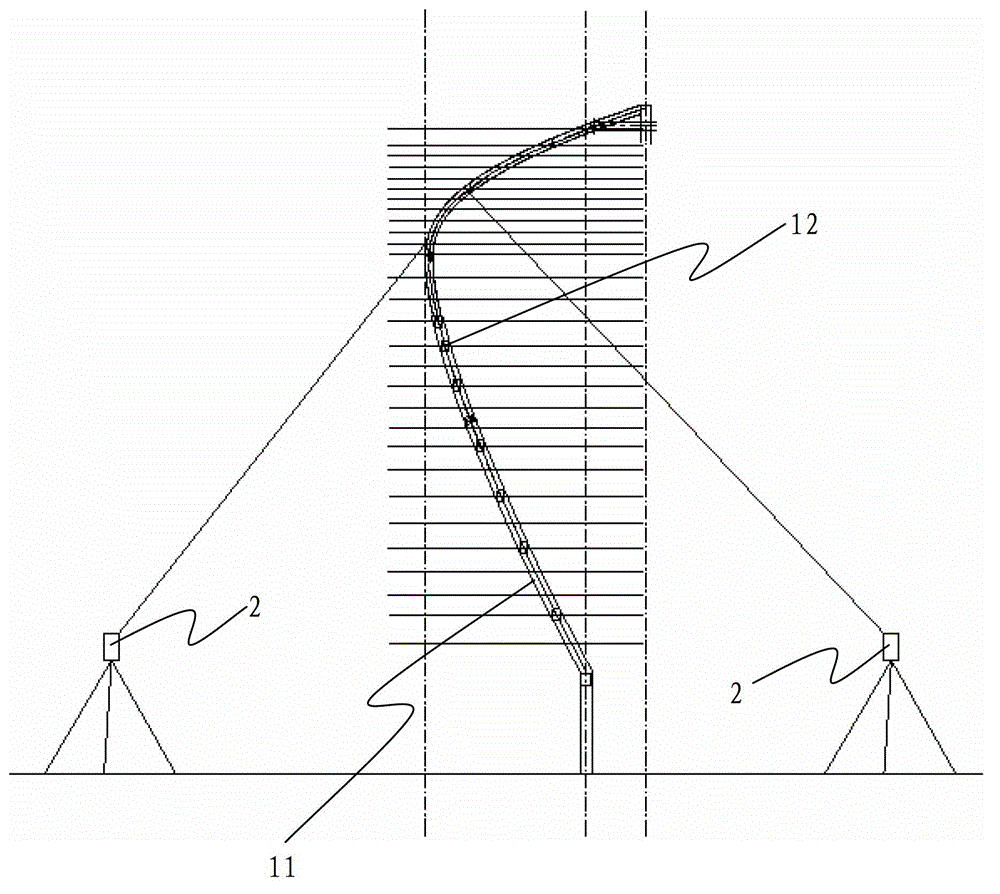

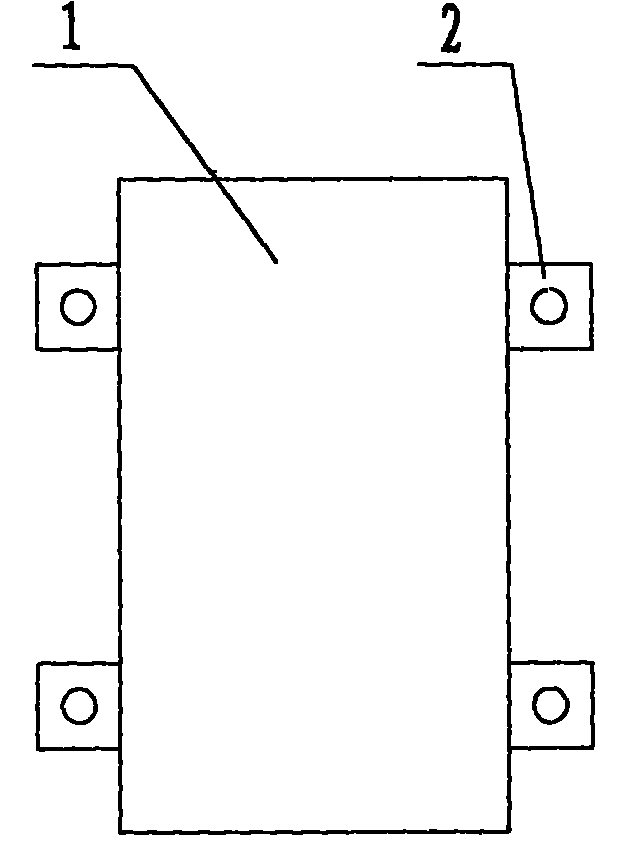

Connecting device of steel column butt joint and installing method

InactiveCN101906849ASpeed up the installation processReduce temporary fixturesStrutsBuilding material handlingButt jointSteel columns

The invention discloses a connecting device of a steel column butt joint and an installing method, belonging to the field of steel structure construction. The connecting device comprises two lug plates, two connecting clamp plates and bolts, wherein bolt holes are arranged on the two lug plates; the two connecting clamp plates are provided with bolt holes corresponding to the bolt holes on the two lug plates; and the two lug plates are arranged between the two connecting clamp plates and are fixedly connected into an integral structure through the bolts and the connecting clamp plates. The invention also provides an installing method of an incline steel column butt joint. The connecting device can be used in the butt joint of incline steel columns and is fixed on the butt joint of an upper steel column and a lower steel column to ensure that the upwards-inclining upper steel column is temporally fixed on the lower steel column through the connecting device without arranging a rigid support and pulling a cable wind rope and other temporary fixed facilities, thereby reducing the temporary fixed facilities used in the butt joint of incline steel column members, improving the installation progress of the construction of the steel structure, and shortening the construction period.

Owner:CHINA CONSTR SCI & IND CORP LTD

Steel-steel concrete fully prefabricated assembling structure

InactiveCN1554839AEnsure safetyImprove bearing capacityBuilding constructionsHigh strength concreteFloor slab

The fully prefabricated assembled steel-steel concrete structure includes two kinds of assembling forms. The first one is fully prefabricated assembled steel column-steel concrete structure, and its prefabricated steel column consists of H-shaped steel column, reinforcing concrete ribs, supporting steel plate and prestress-shearing force friction nodes with shear resisting strips. The second one is fully prefabricated assembled prefabricated steel pipe-concrete column-steel concrete structure, and the prefabricated steel pipe-concrete column consists of steel pipe with square cross section, micro expanding high strength concrete cast inside the steel pipe and shear resisting strips attached to the outer wall of the steel pipe to form preshearing force-friction type nodes. The present invention has raised antiseismic performance, area utilization, construction efficiency, fireproof performance, low cost and small member size, and is suitable for various buildings.

Owner:KUNMING UNIV OF SCI & TECH

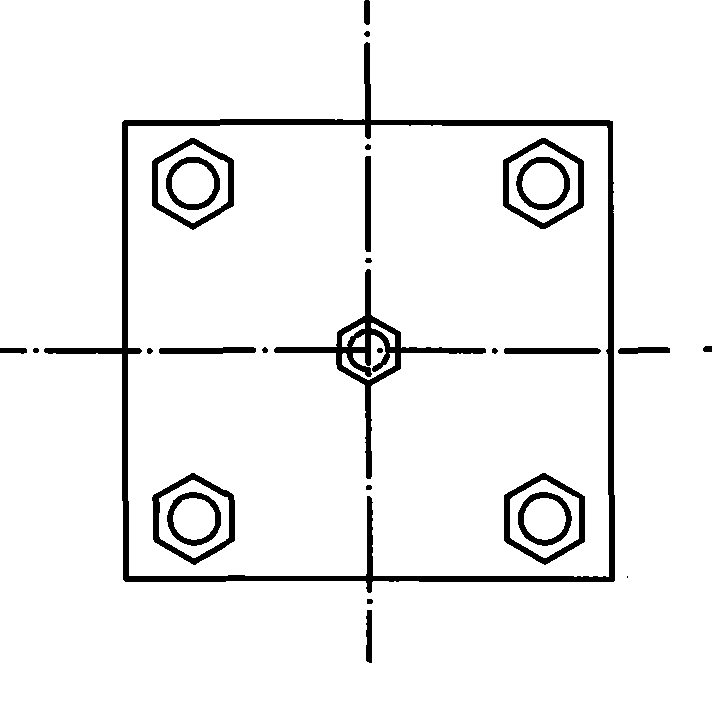

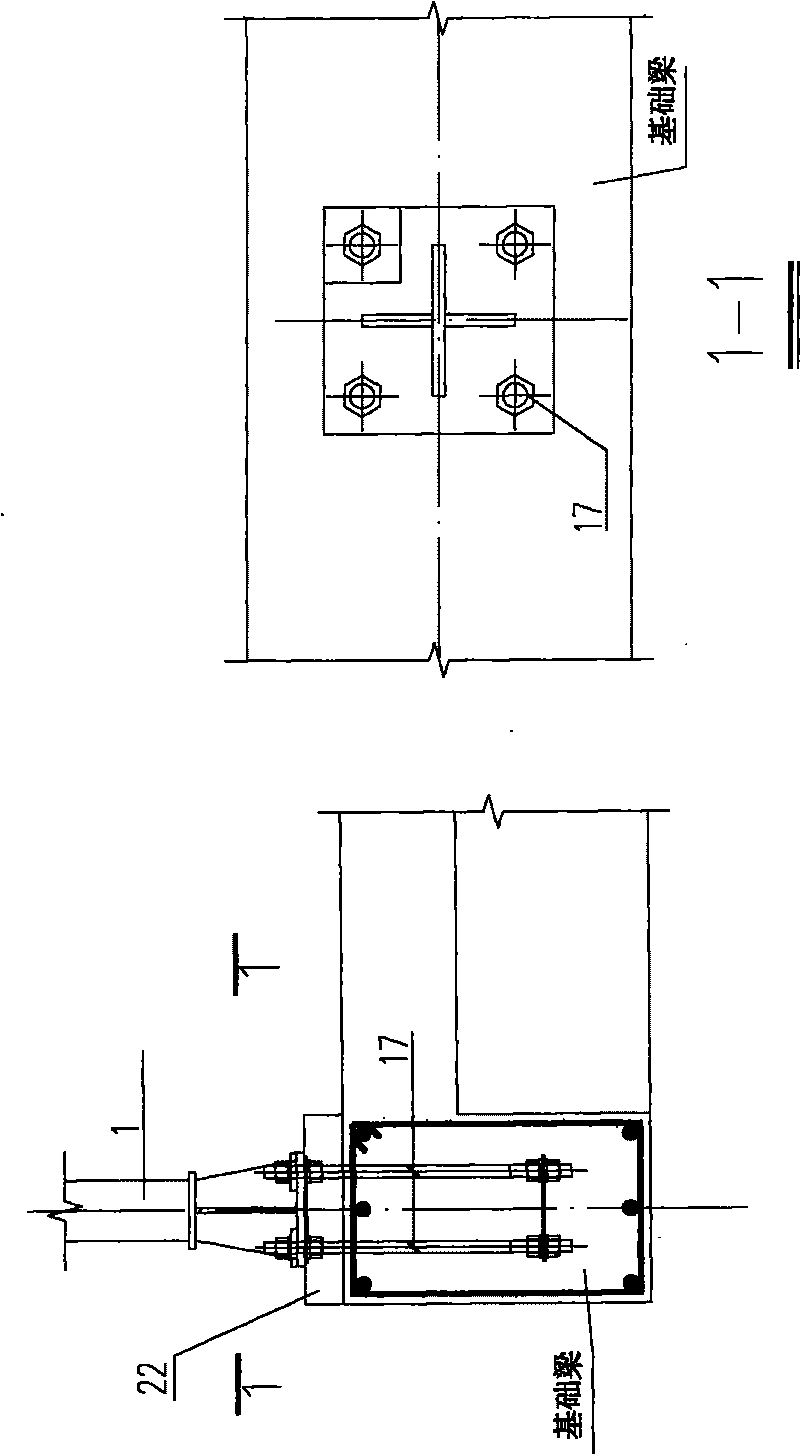

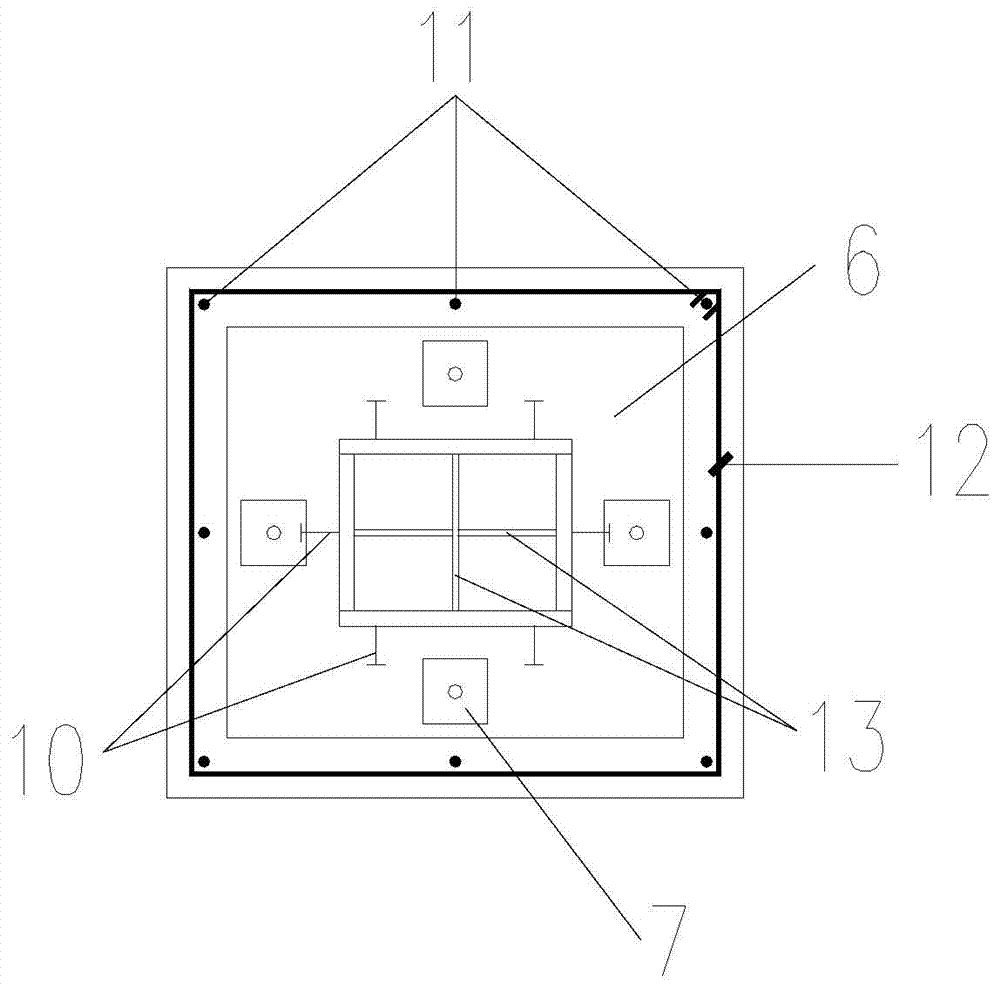

Precise positioning frame for large steel columns and equipment foundation fixing bolts and construction method of precise positioning frame

InactiveCN102561712AEasy to installGuaranteed installation accuracyFoundation engineeringBuilding material handlingBraced frameSteel columns

The invention discloses a precise positioning frame for large steel columns and equipment foundation fixing bolts and a construction method of the precise positioning frame. The precise positioning frame comprises a supporting frame for placing the fixing bolts; a profile steel bracket is surrounded at the outer side of the supporting frame; the profile steel bracket comprises vertical rods, connecting rods, a profile steel bracket top frame and a positioning sleeve frame placing platform, wherein the vertical rods are distributed at intervals, each connecting rod is connected between every two adjacent vertical rods, the profile steel bracket top frame is detachably connected between upper end parts of the vertical rods through a connecting bolt, and the positioning sleeve frame placing platform is connected on the profile steel bracket top frame; the fixing bolt positioning sleeve frame is laid on the positioning sleeve frame placing platform; and a positioning hole is arranged on the fixing bolt positioning sleeve frame. The positioning frame ensures that large steel structure column bolts or large equipment foundation fixing bolts are more precise to install, the defect that bolts can be adjusted and fixed only before concrete is cast and cannot be precisely adjusted during the casting of concrete in the traditional process is avoided, moreover, the positioning frame can be partly turned over to be operated, so that the construction cost is saved, and the construction progress is accelerated.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Fire and heat protection wrap for structural steel columns, beams and open web joists

A fire and heat protection wrapping system is described for wrapping structural steel such as steel columns, beams and open web joists used in steel construction of all types of edifices. The protection wrapping system includes a concentric composite laminate structure having a plurality of concentric layers for the protection of structural steel components which are exposed to high temperatures of up to five hours (5 hrs) in duration. The plurality of concentric layers includes an outer first layer, an inner second layer, an inner third layer and an inner core fourth layer for wrapping the structural steel component. The outer first layer is a fiberglass textile having an intumescent coating resistant to heat, water and impact. The inner second layer is a metal foil layer for reflecting heat and eliminates the convection transfer of heat. The inner core third layer is a low conductivity refractory blanket for reducing the transmission of heat. The inner core fourth layer is a metal foil layer for reflecting heat and eliminating the convection transfer of heat.

Owner:NO FIRE ENG

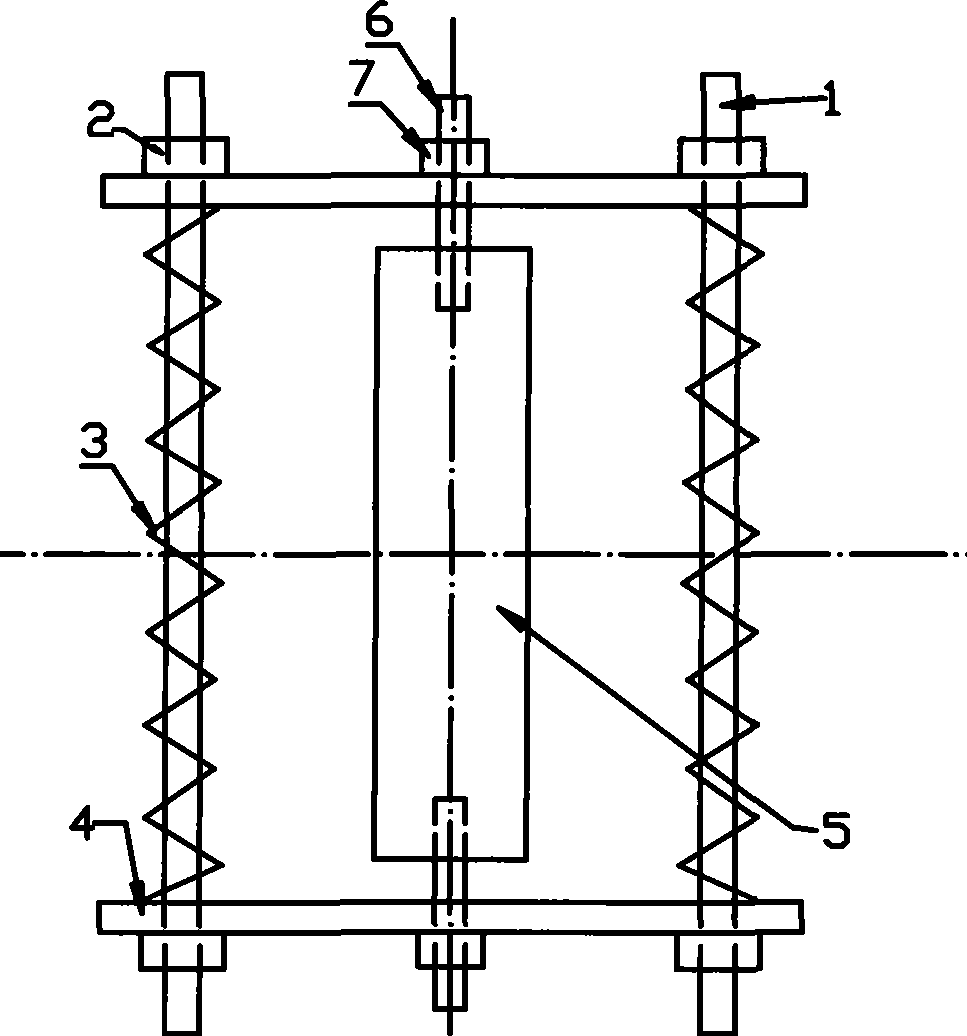

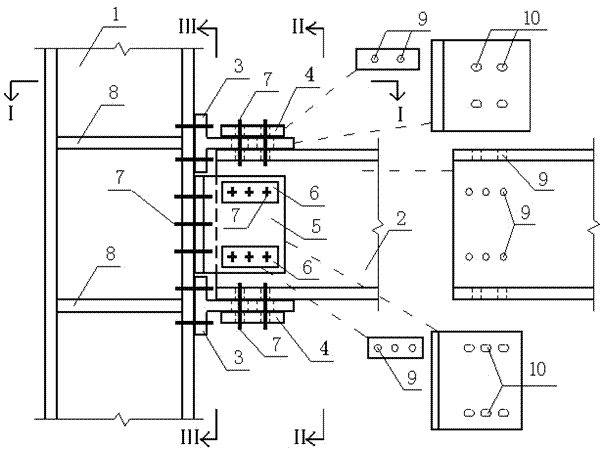

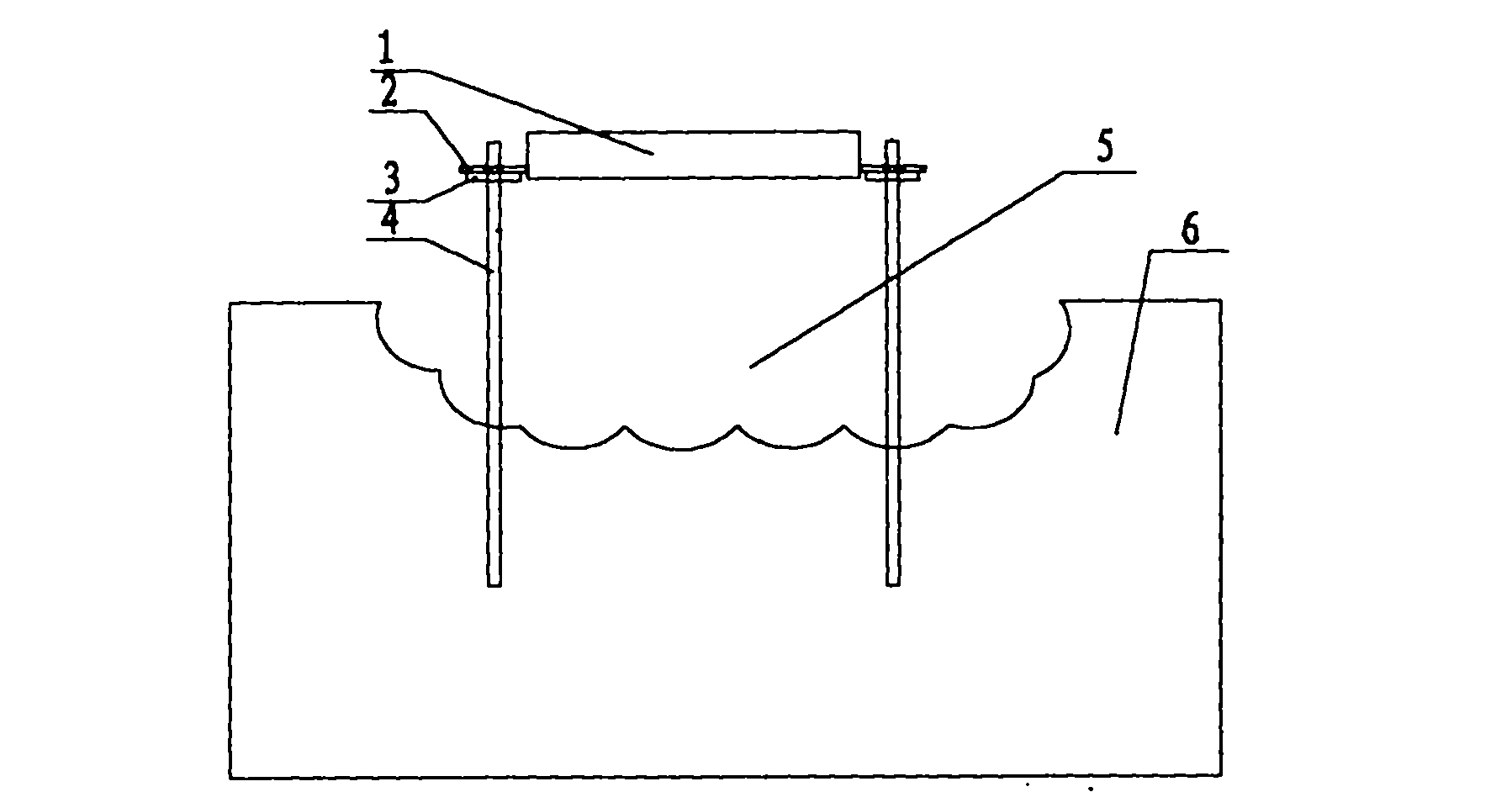

Uniaxial tension loading unit for testing concrete carbonizing performance under tensile stress and testing method

InactiveCN101387634AContinuous uniaxial tensionAchieve carbonization resistance durabilityMaterial testing goodsStrength propertiesSheet steelEngineering

The invention discloses a single shaft tension loading device for testing the carbonation property of the concrete under tensile stress and a test method, wherein the hex nuts pre-embedded at the axis of two ends of the tested element connect the cylinder or rectangle tested element between two parallel steel plates, four same compressed springs are sheathed on four steel columns of the diameters smaller than the inner diameter of the springs, the two steel plates can parallel move between the four steel columns, the material parameters and the compressed quantity of the springs can be used to calculate the axial tensile load on the tested element, the tested element is axially patched with three stress sheets to find the actual tensile stress at different parts. The characteristic parameters of the springs can be changed to obtain the carbonation test parameters under different tensile stresses.

Owner:SOUTHEAST UNIV

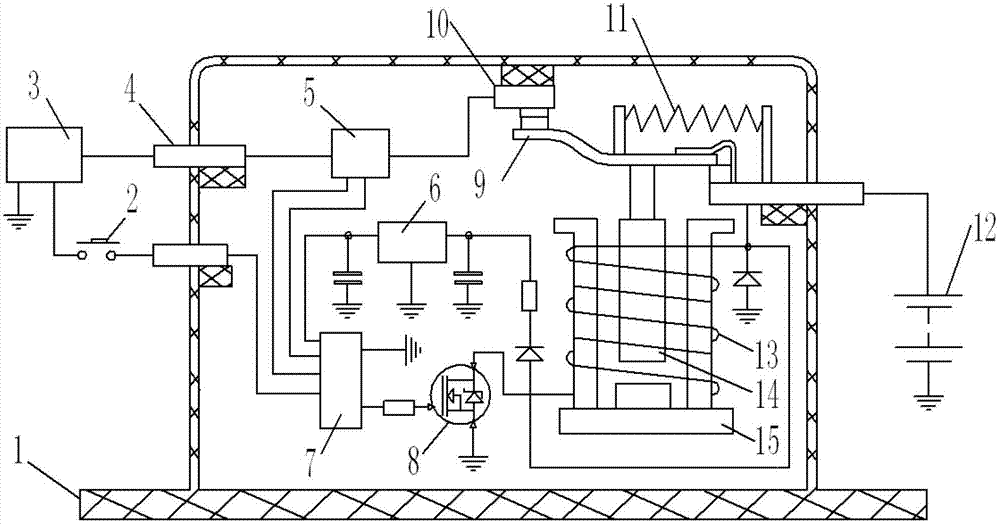

Normally-closed type power supply main switch device and automatic power off method of automatic short circuit

ActiveCN102903580AImprove securityArrangements responsive to excess currentProtective switch operating/release mechanismsPower flowSteel columns

The invention relates to a normally-closed type power supply main switch device which comprises a shell (1), a current sampling unit connected with an integral load, a main control chip (7), a movable contact (9) and a static contact (10), wherein a magnetic coil (13) is wound on an iron core (15) and a steel column (14), and the magnetic coil (13) is supplied with power by a storage battery (12). The normally-closed type power supply main switch device is characterized by also comprising switch parts respectively connected with the magnetic coil (13) and the main control chip (7); the current sampling unit is respectively connected with the static contact and the main control chip; and the main control chip (7) collects a signal of a start switch (2) and a current signal of the current sampling unit for controlling the switch parts.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

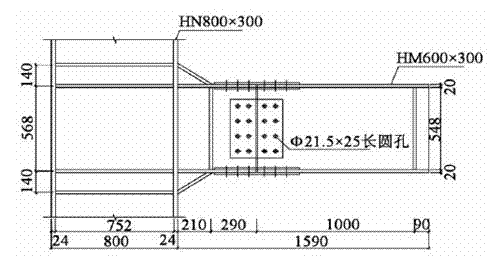

Reamed steel structure beam-column joint connected via end plate and construction method for same

ActiveCN102444211AStrong ductile deformation abilityImprove energy consumptionBuilding material handlingShock proofingSteel columnsBeam column

The invention relates to a reamed steel structure beam-column joint connected via an end plate and a construction method for the same. The reamed steel structure beam-column joint connected via an end plate comprises a steel column and an H-section steel beam, which is characterized in that: a steel column flange is connected with the end plate via a friction-type high-strength bolt; the end plate is connected with a steel beam web via a steel beam web connection plate; the end plate is connected with an upper steel beam flange and a lower steel beam flange via a steel beam flange connection plate; the steel beam web connection plate and the steel beam flange connection plate are welded on the end plate via groove full penetration welds; oblong holes are disposed on the steel beam web connection plate and the steel beam flange connection plate; the steel beam web connection plate and the steel beam flange connection plate are connected with the steel beam web and the steel beam flange via friction-type high-strength bolts; and the steel column flange is provided with a shear-resisting support plate on the bottom of the end plate. The reamed steel structure beam-column joint connected via an end plate and the construction method for the same disclosed by the invention can remarkably enhance the ductile deformability and energy dissipation capability of the joint under the function of a rare earthquake, and have the advantages of being convenient in construction, easy to repair after an earthquake etc.

Owner:FUZHOU UNIV

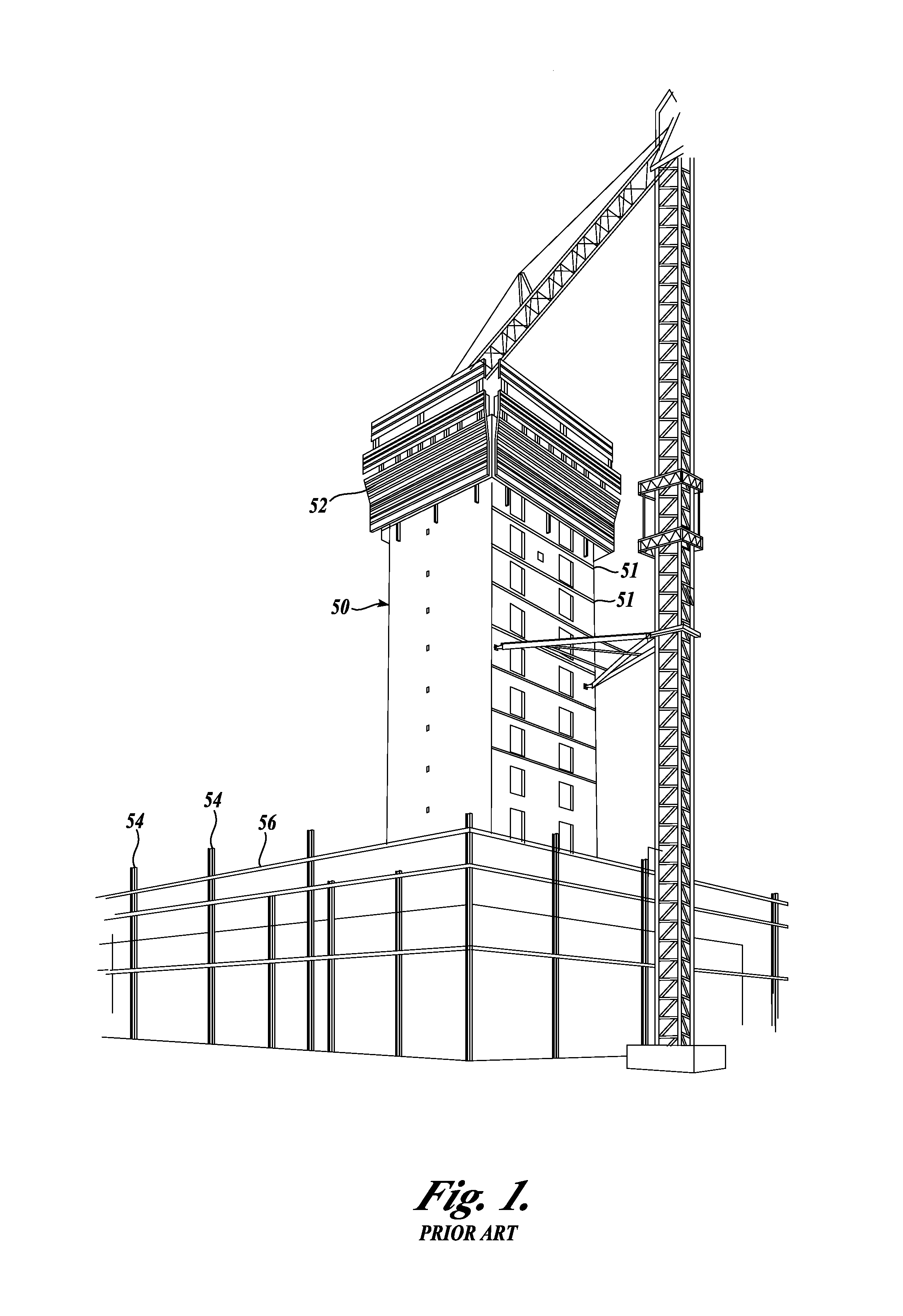

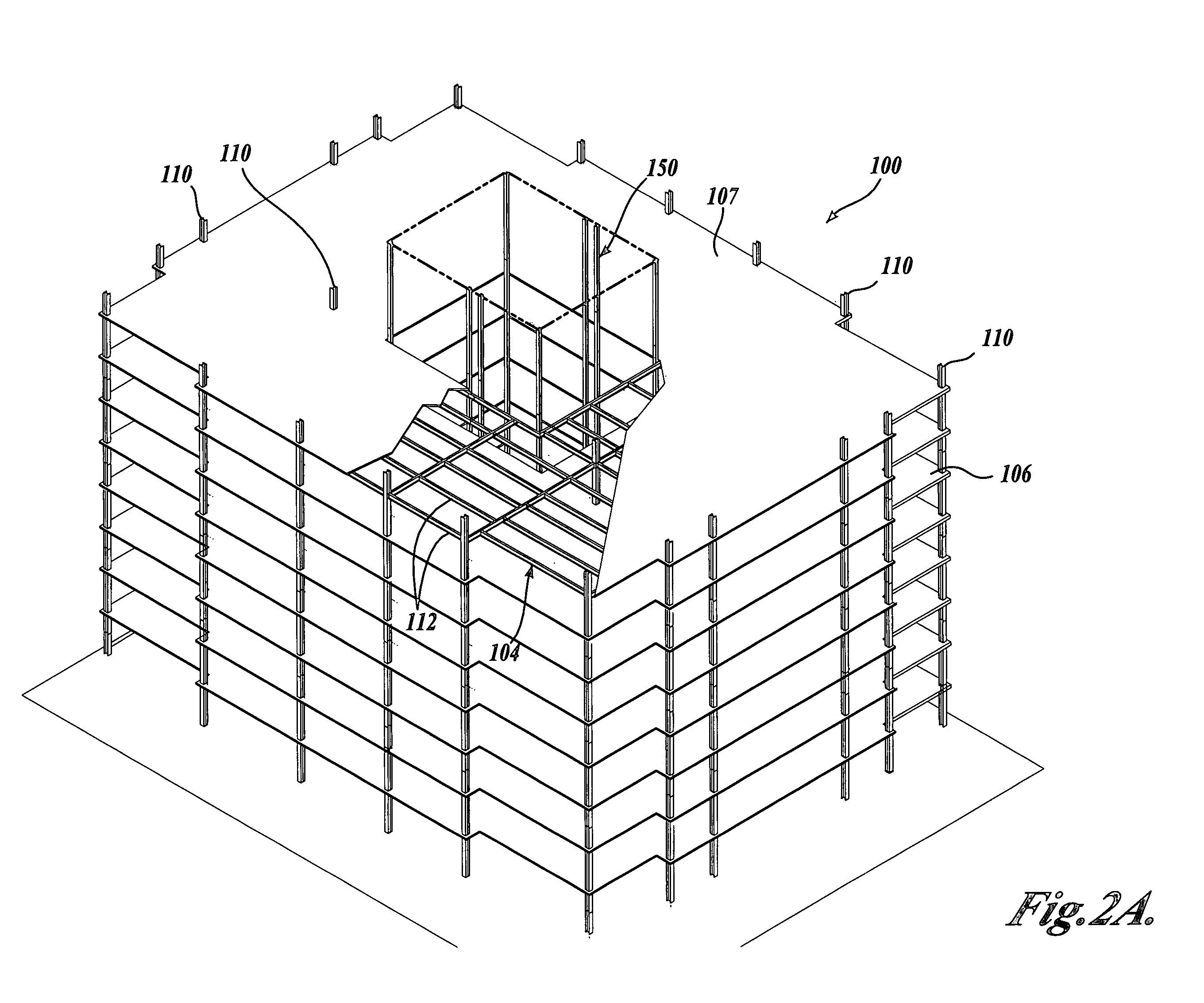

Method of constructing a concrete shear core multistory building

InactiveUS7444793B2Quick installationImproves Structural IntegrityPublic buildingsBuilding repairsRebarSteel columns

Method for constructing concrete shear core buildings wherein a steel erection structure is built having steel columns and beams. The steel erection structure is made from pre-assembled segments that include the steel reinforcing bar for the concrete shear core. A peripheral steel structure is also constructed and the steel floors are built, cooperatively supported by the steel erection structure and the peripheral structure. Forms are positioned generally about the steel reinforcing bars and at least a portion of the steel erection structure. Concrete is poured in the volume defined by the forms, to build a portion of the concrete shear core. In a preferred embodiment, the steel erection structure and peripheral steel structure proceed approximately seven to nine floors ahead of the concrete shear core, and the concrete shear core is sized to support the completed building without accounting for the additional structural support provided by the steel erection structure.

Owner:W LEASE LEWIS

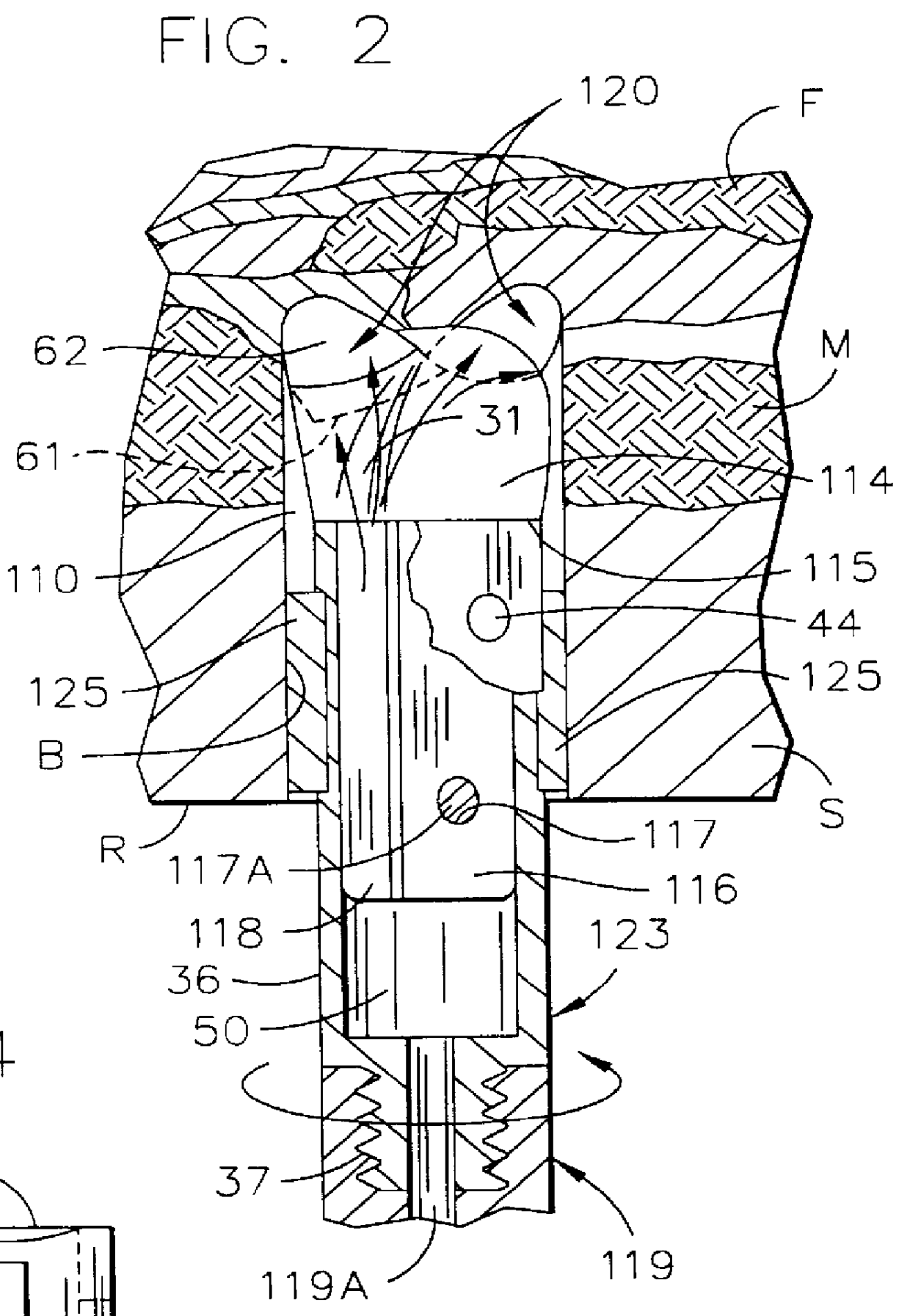

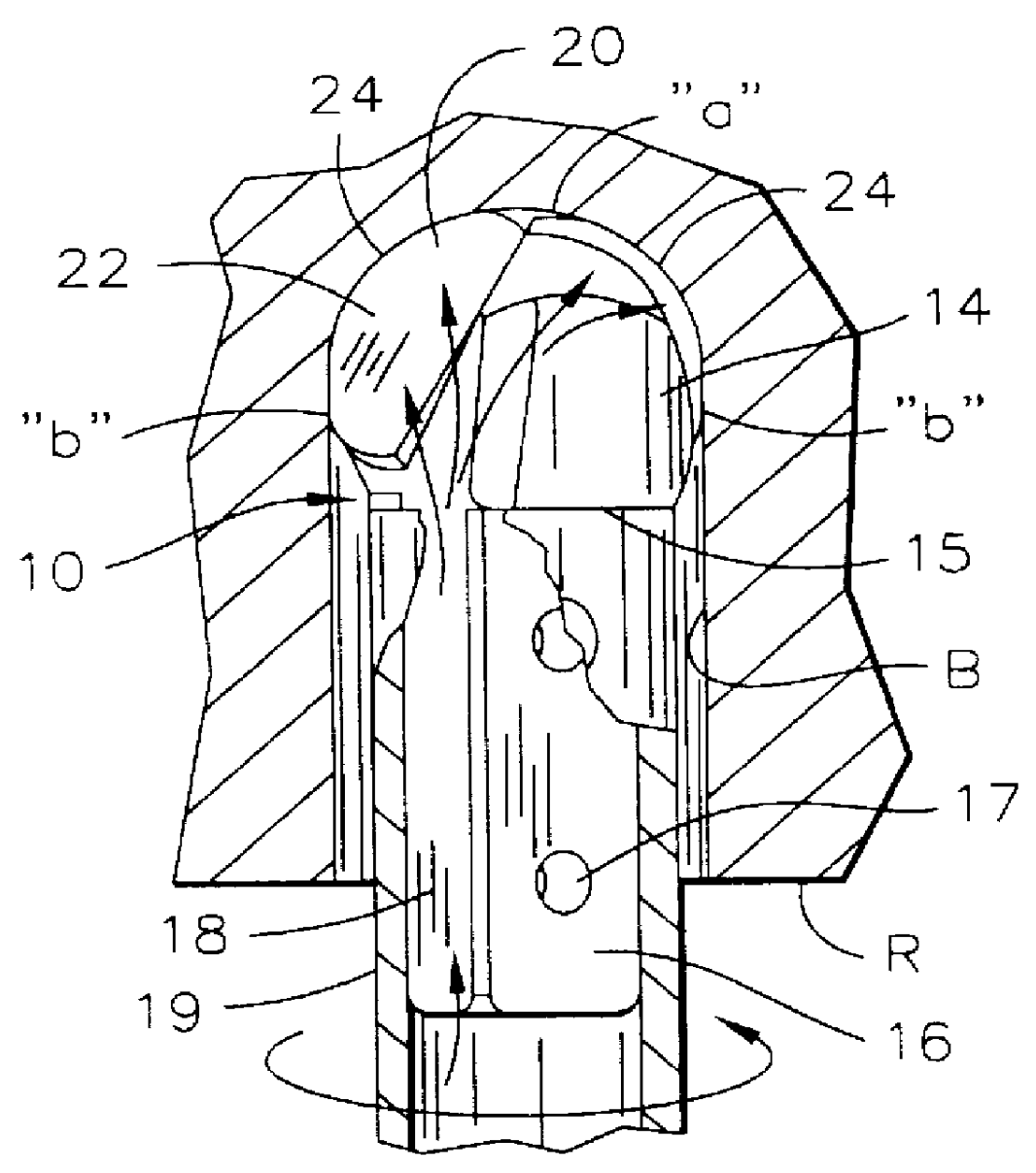

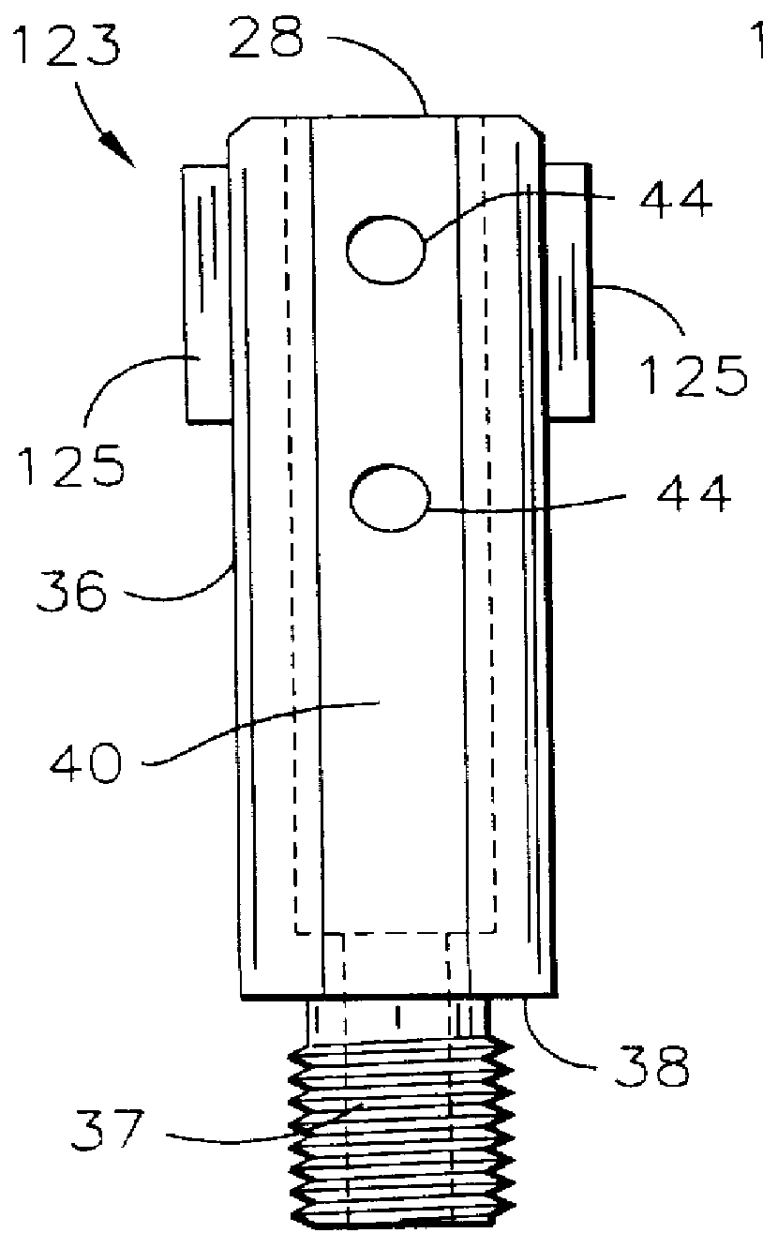

Rotary drilling systems

A rotary system having a sectional drill steel column connecting a drilling machine and rotary drill bit and being constructed and arranged to accommodate internal fluid flow to the drill bit without pressure loss, and which column employs a coupler section having both threaded and multi-faced ends for joining adjacent drill steel sections; and further having supplemental bore reamers adjacent to the drill bit to maintain design bore dimensions and accommodate fluid flow and removal of cuttings.

Owner:DOVER BMCS ACQUISITION CORP +1

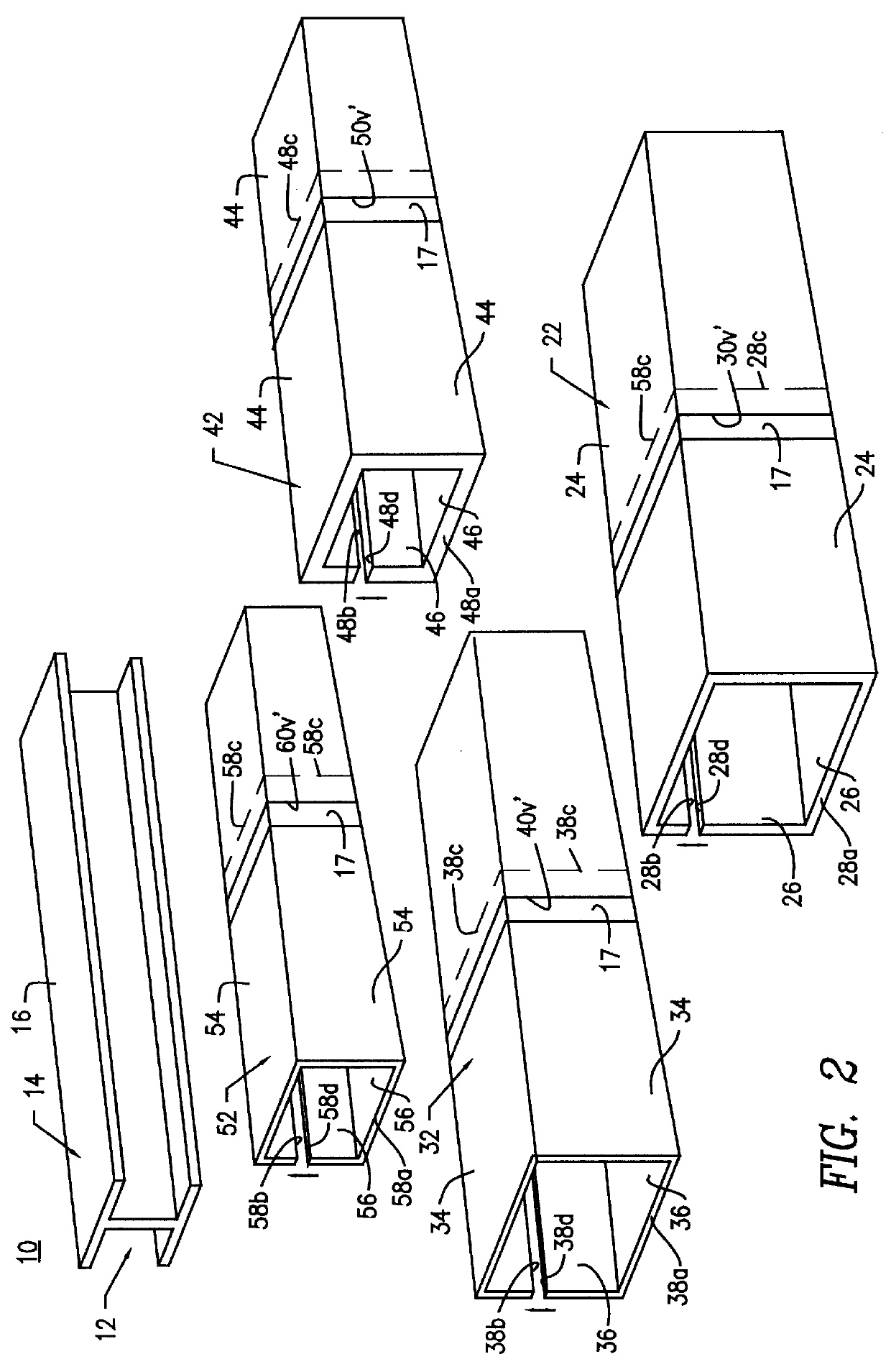

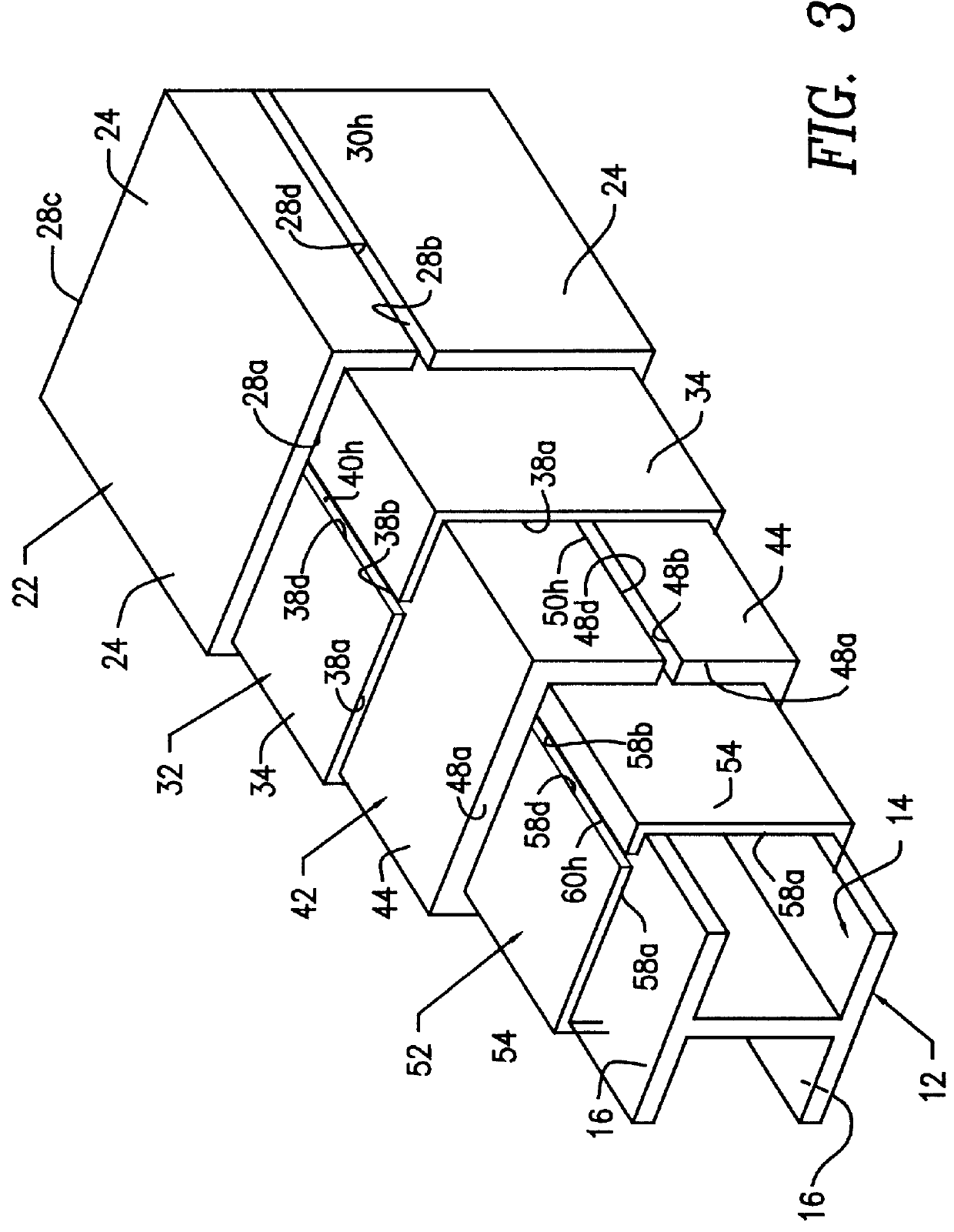

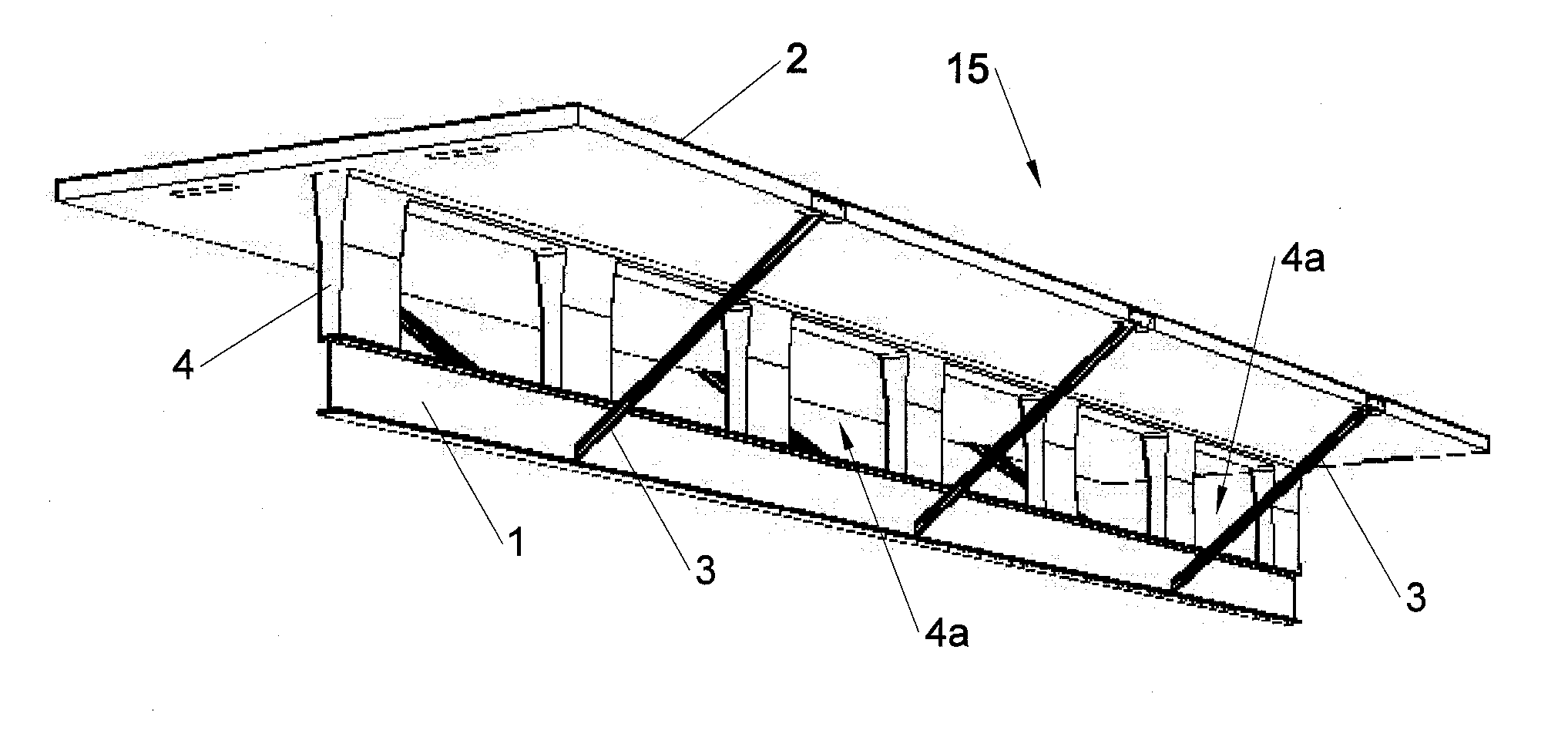

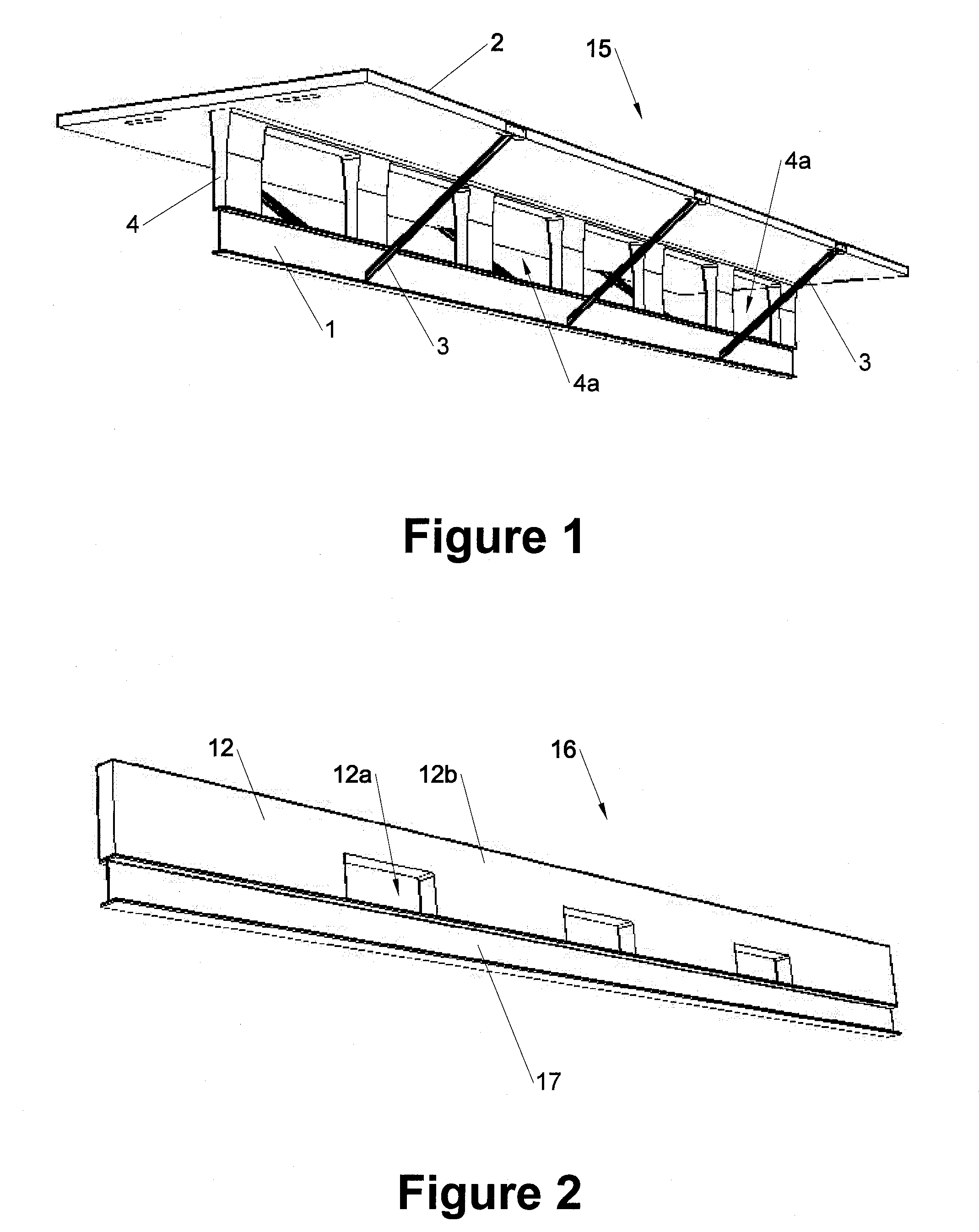

Precast composite structural floor system

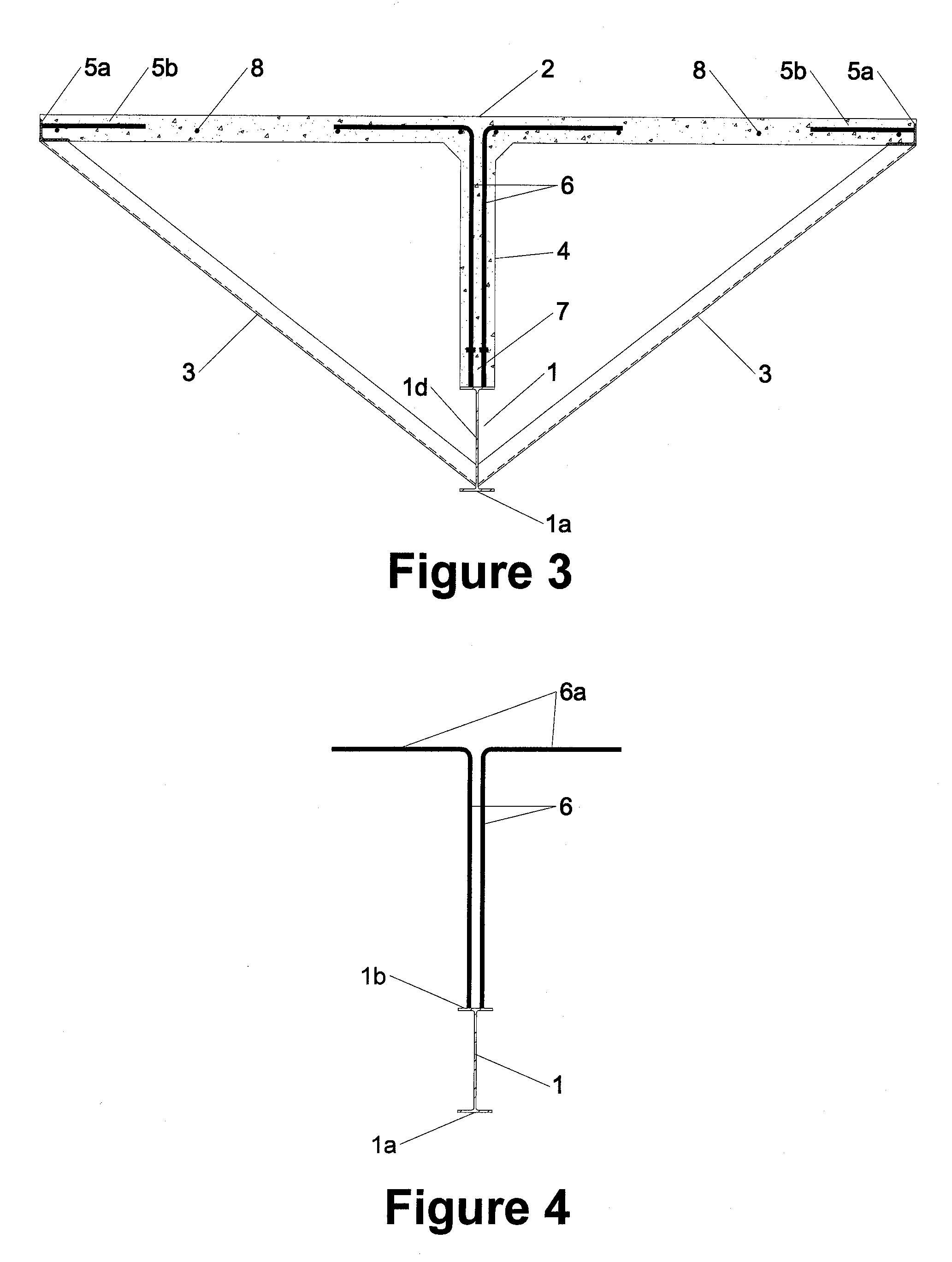

ActiveUS20090288355A1Reduce weightQuick and efficientBuilding roofsWallsComposite constructionFloor slab

A precast composite flooring system utilizes girders and floor panels having steel lower structures placed in tension and concrete upper structures places in compression. Openings through a stem wall allow ducts, pipes, and conduits to be run therethrough. The system provides reduced weight over conventional precast or pour in place systems, allowing further reduction in the weight and size of other building components. The floor deck does not use tensioning strands, allowing openings to be formed at nearly any stage of construction and with reduced concern over cutting steel reinforcement. The floor panels and girders bolt together and bolt to a steel column frame, allowing for more efficient assembly.

Owner:VELOCITY I P

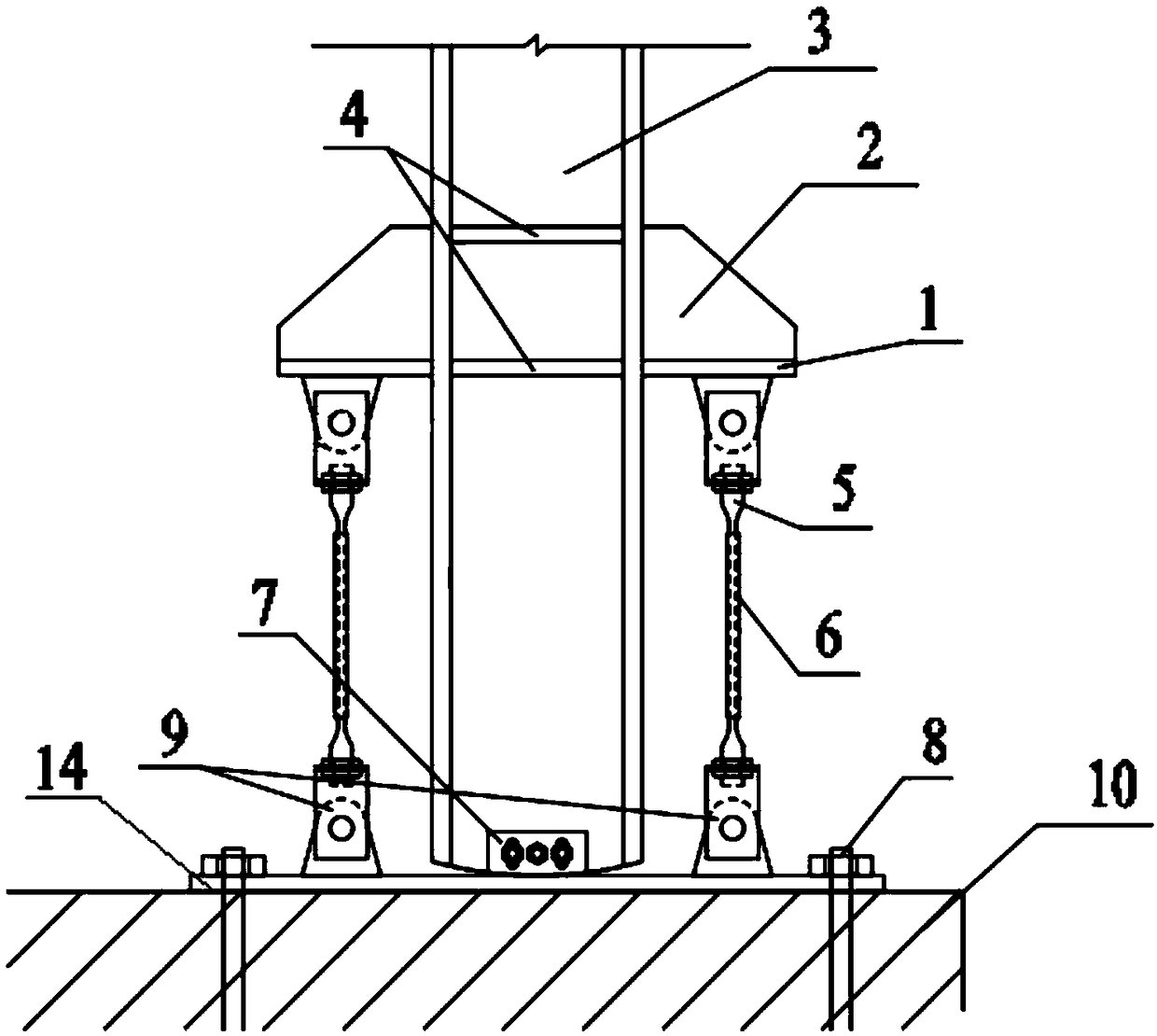

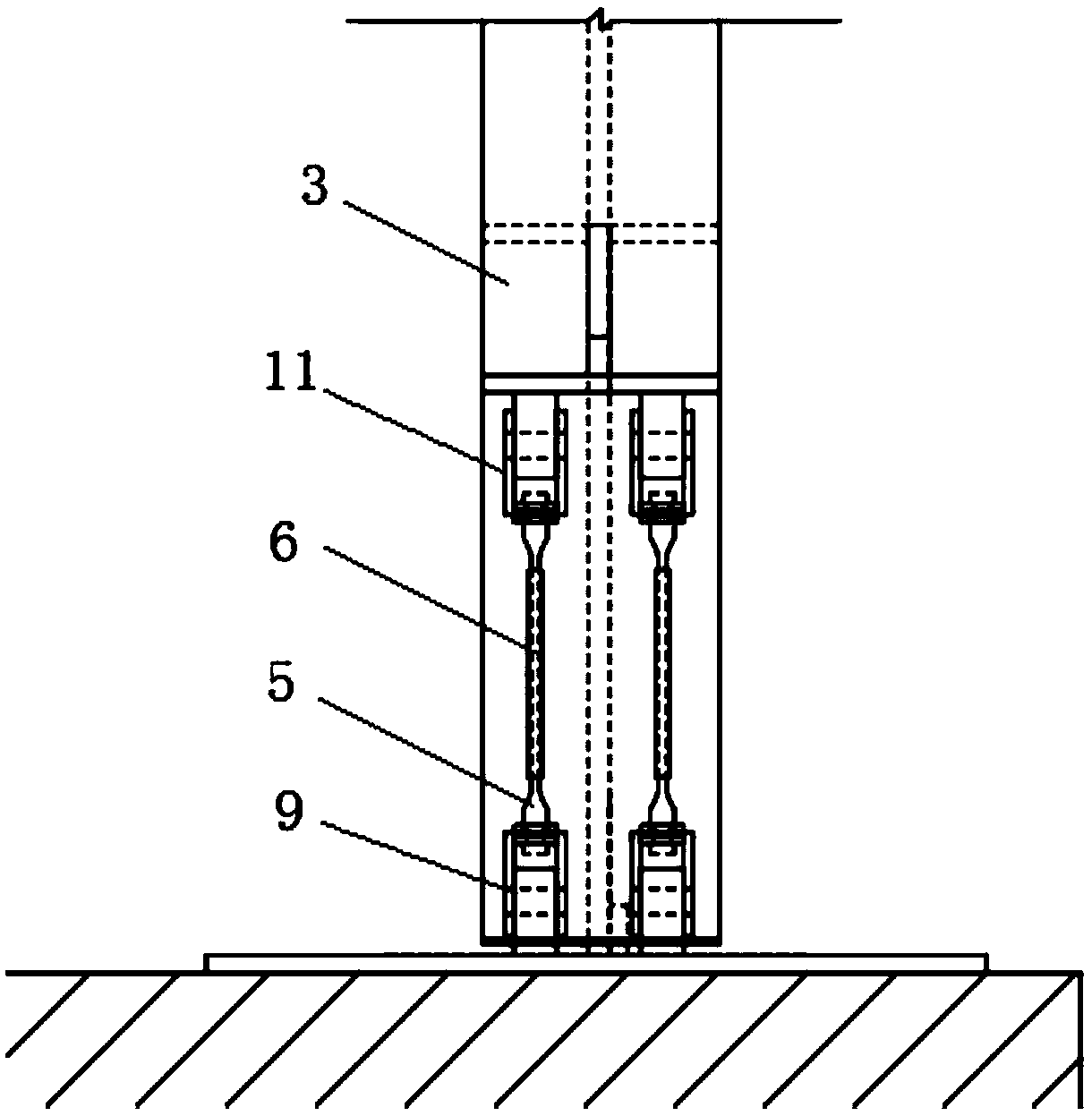

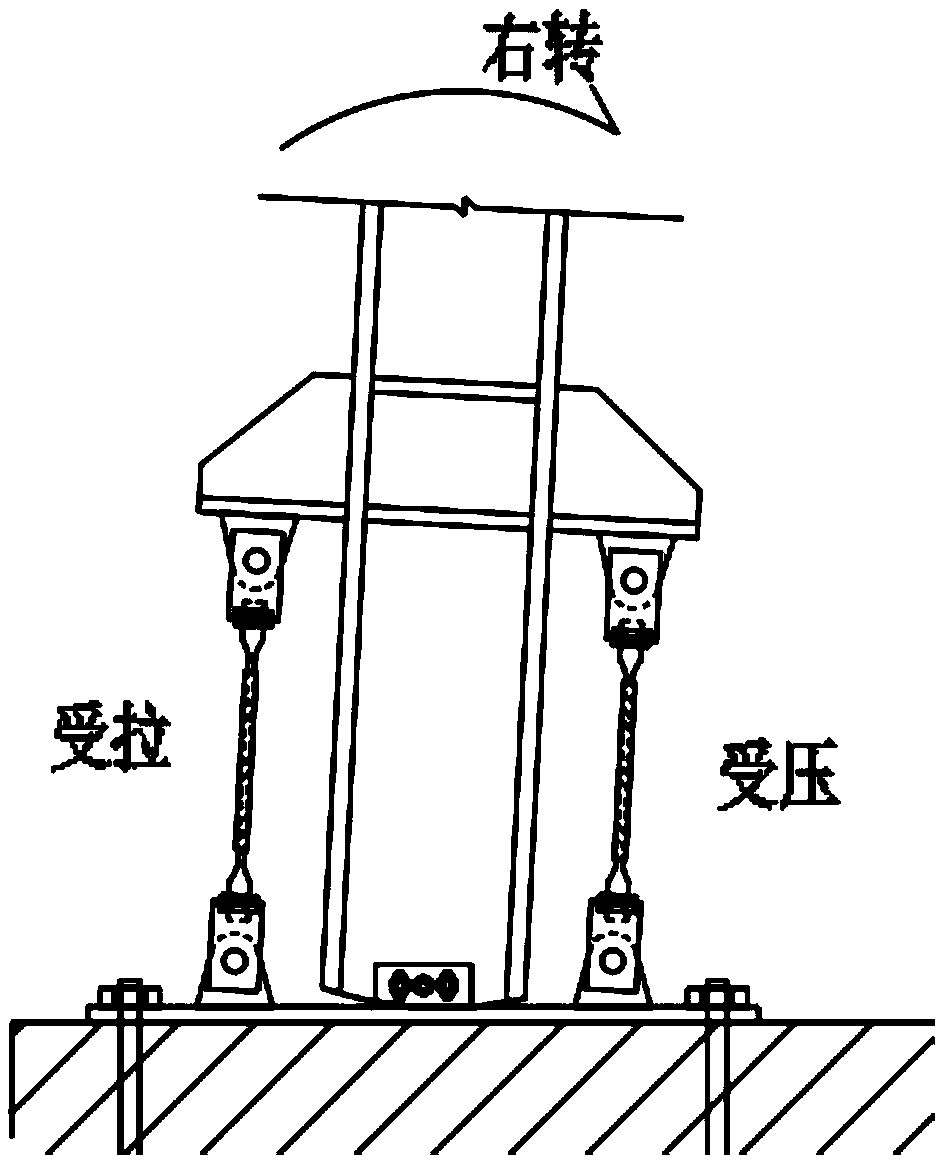

Self-resetting column foot node based on shape memory alloy bar and steel structure building

ActiveCN109057018AImprove bearing capacityDoes not lose initial stiffnessProtective buildings/sheltersShock proofingShape-memory alloyAlloy

The invention discloses a self-resetting column foot node based on a shape memory alloy bar and a steel structure building. The self-resetting column foot node solves the problems in the prior art ofhigh rigidity after the nominal yield of the node and easy loss of initial rigidity after an earthquake occurs, and has the advantages of good energy consumption performance and self-resetting capability under the action of earthquake load, after suffering from an excessive deformation or at low temperature, the initial rigidity is not lost, and the structural steel column and the column foot nodeare not damaged; according to the technical scheme, the self-resetting column foot node and the steel structure building comprises a concrete foundation, a bottom plate is fixed on the upper part ofthe concrete foundation, the bottom plate is connected with a vertical supporting column through an anti-shear connecting plate, the two sides of the support column are symmetrically provided with ananchor plate, the anchor plate and the bottom plate are connected with a shape memory alloy rod through a hinged support, the shape memory alloy rod provides an energy consumption performance and a self-resetting performance for the nodes while providing rotational rigidity; the circumference of the shape memory alloy rod is coated with a sleeve, and the sleeve can restrain the buckling of the shape memory alloy rod under compression so as to improve the ductility and bearing capacity of the shape memory alloy rod when the shape memory alloy rod is pressed.

Owner:SHANDONG UNIV

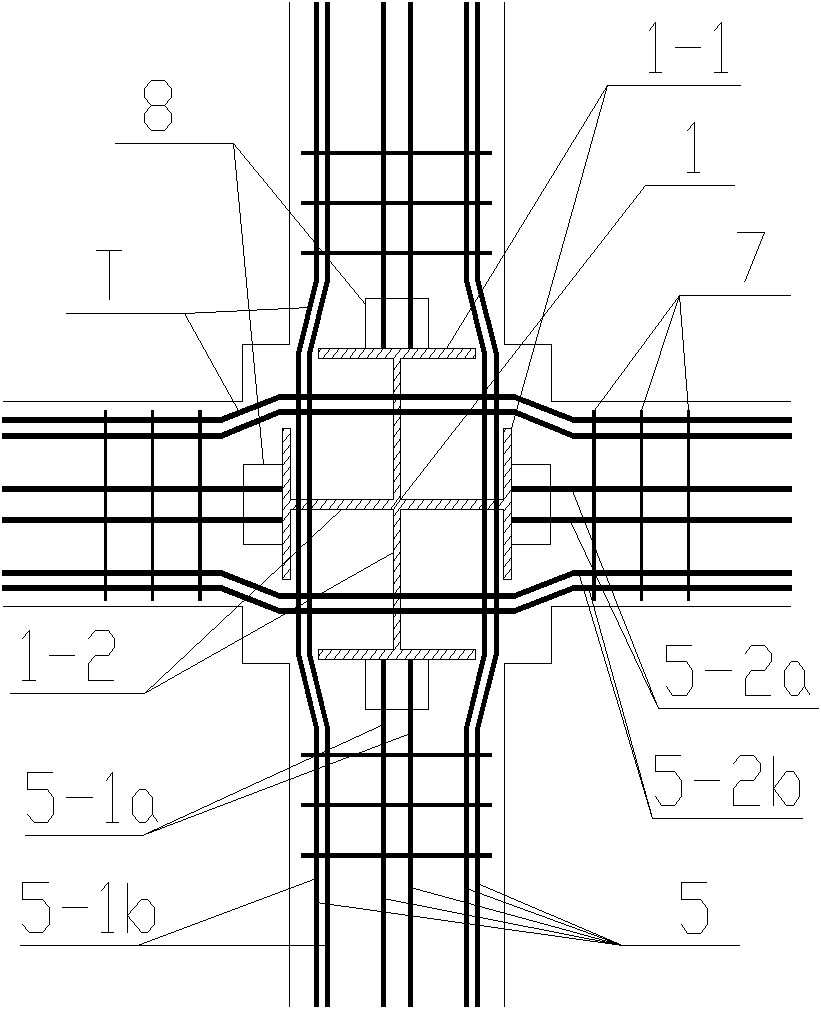

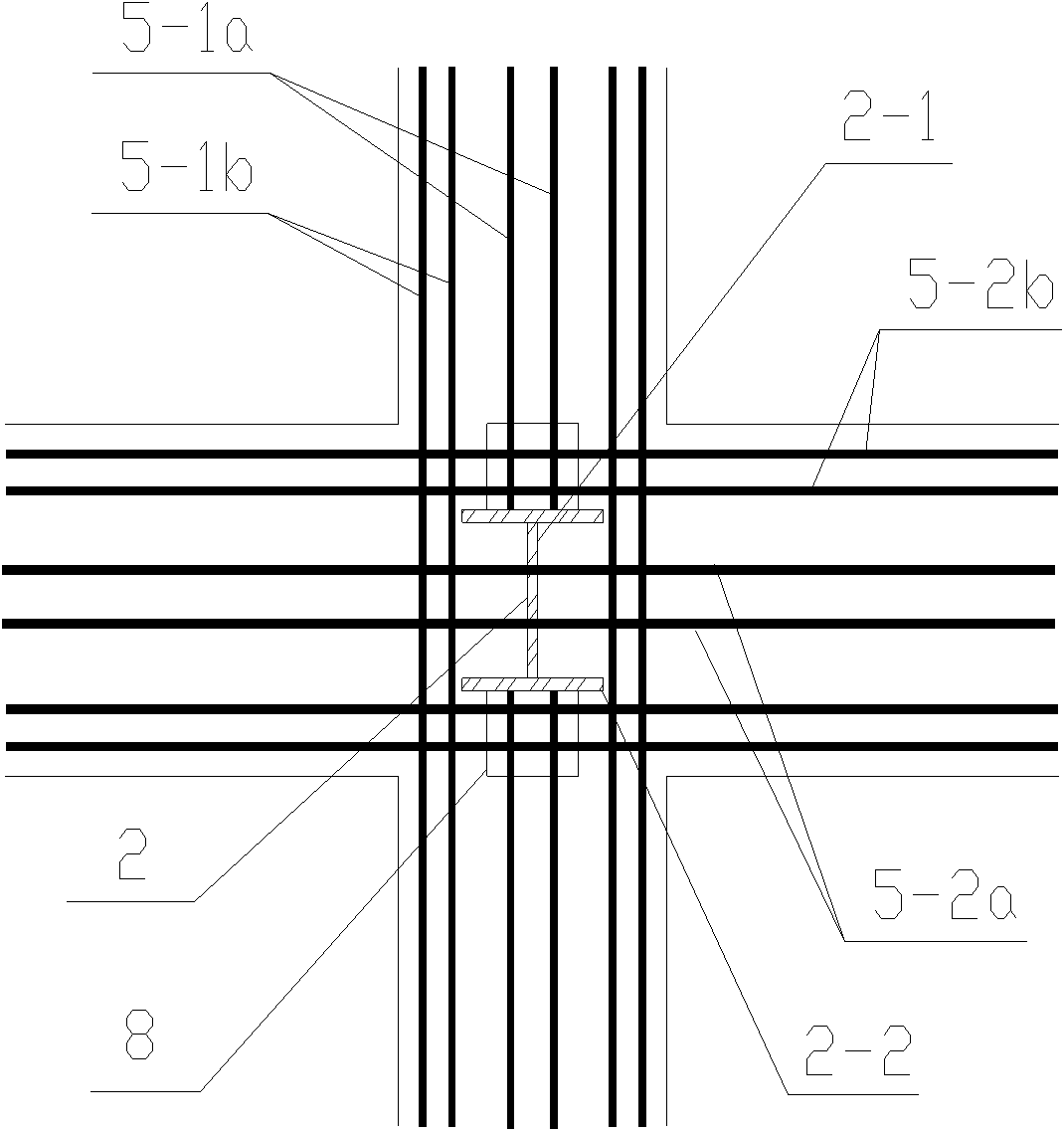

Construction method for formed steel reinforced concrete beam-column nodes

InactiveCN102322101AImprove project qualityImprove carrying capacityBuilding constructionsConcrete beamsRebar

The invention relates to a construction method for formed steel reinforced concrete beam-column nodes, belonging to the technical field of industrial and civil building construction. According to the invention, the problem for arranging and binding intricate and complicated steel bars and corresponding formed steel in formed steel beam and formed steel column connection node domains is creatively and sequentially solved; the boring of formed steel wing plates is avoided; the up-and-down adjusting and the bending for horizontal bars of X beams and Y beams can be realized through enabling the horizontal / longitudinal bars of the X beams and the Y beams to intersect with the formed steel columns and opening vertical long-strip holes on web plates of the formed steel columns; the area of the openings on the web plates of the formed steel columns is controlled to exceed 20% of that of the sectional area of the web plates, thus the negative influence on the strength of the web plates of the formed steel columns because of the openings is reduced to the maximum; and hoop bars are orderly arranged on the upper surfaces of column stiffening plates at intervals at the spatial staggered positions of column main bars, the column stiffening plates and column hoop bars, thus the number of steel bar joints is reduced. The construction method provided by the invention not only increases the construction efficiency, but also ensures to enhance the project quality and the node domain bearing capacity for the beam-column connection of formed steel reinforced concrete structures.

Owner:HUBEI HONGYI BUILDING DECORATION ENG

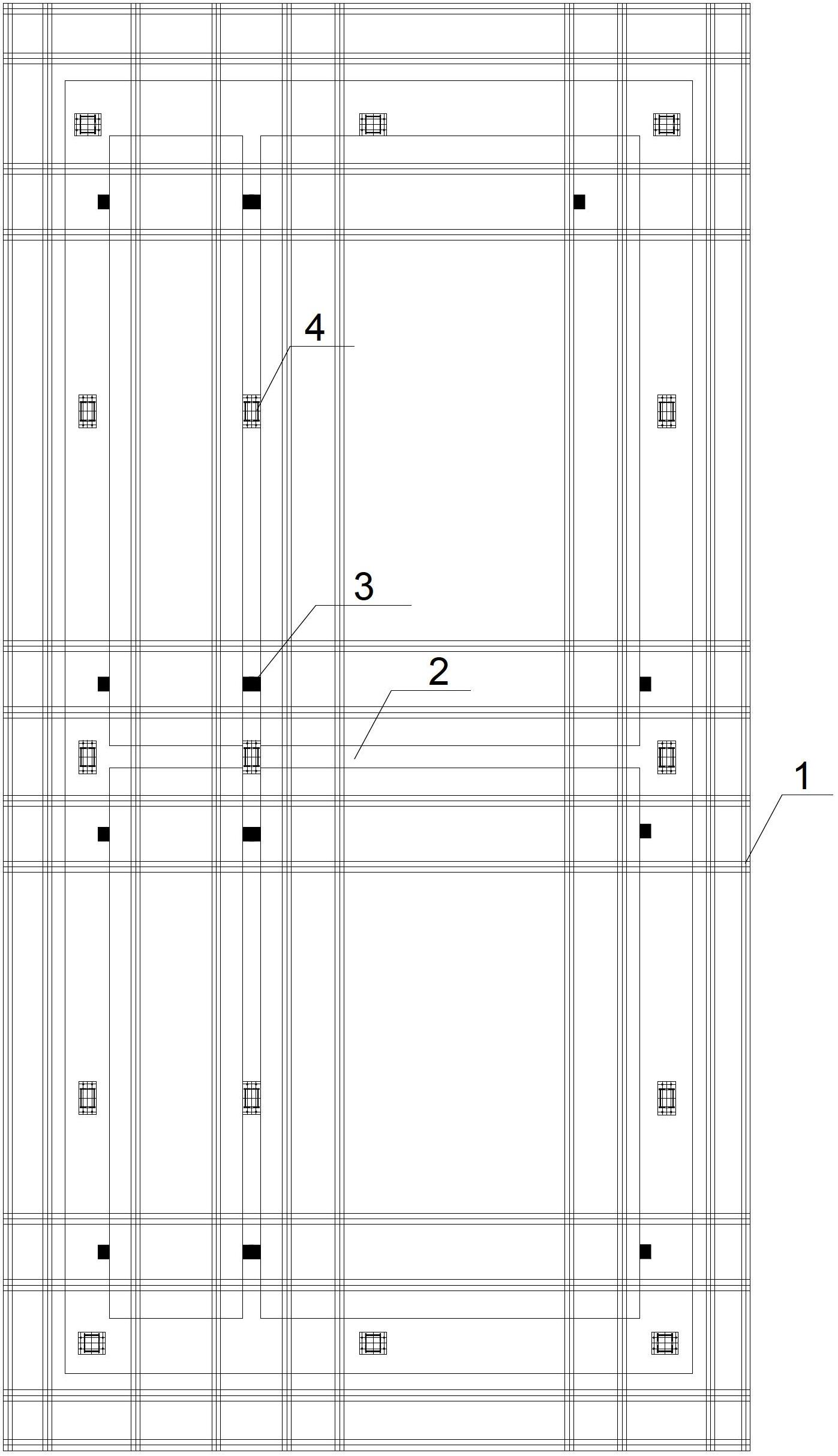

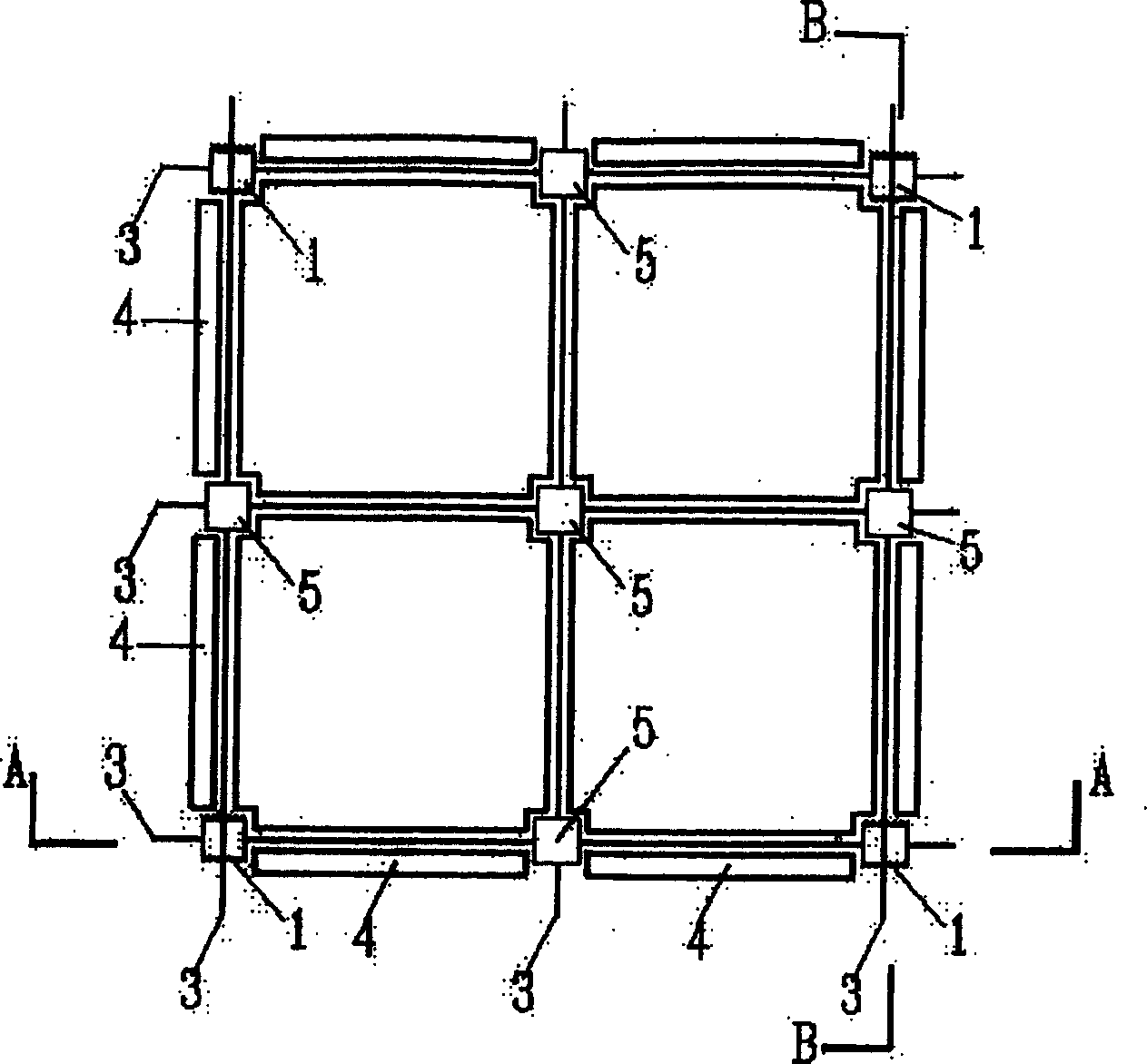

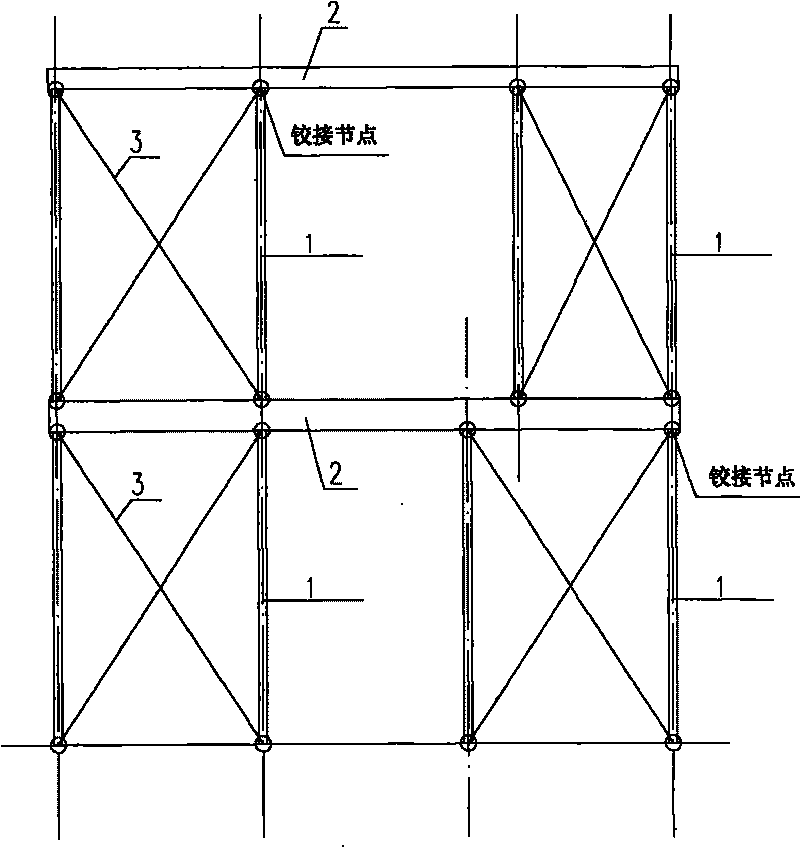

Structural system of industrial low storied dwelling

ActiveCN101748903AReasonable forceAvoid wastingBuilding constructionsDwelling buildingFloor slabSimple component

The invention belongs to the field of building structures, and in particular relates to a structural system of an industrial low storied dwelling adopting modularized design, factory production and field mounting. The structural system of the industrial low storied dwelling comprises steel columns, steel girders, inter-column supports, steel girder horizontal supports, floor slabs, connecting nodes between the steel columns and a foundation, the connecting nodes between the steel columns and the steel girders, the connecting nodes between the steel columns and the inter-column supports, the connecting nodes between the steel girders and the steel girder horizontal supports, rigid connection nodes between the steel girders, the connecting nodes between the steel girders and the floor slabs, roofing surrounding systems and wall surface surrounding systems, wherein the steel columns are connected with the foundation through pre-embedded bolts; the steel columns are connected with the steel girders through bearing type high-strength bolts; the steel columns are connected with the inter-column supports through ordinary bolts; the steel girders are connected with the steel girder horizontal supports through the ordinary bolts; the steel girders are in fully rigid connection through continuous girders; the slabs are connected with the steel girders through male pins or special fasteners; and each of the roofing surrounding systems and the wall surface surrounding systems is of a block type. The structural system of the invention has the characteristics of clear stress of the structure, simple component connection, convenient and quick mounting, attractive appearance, good rationality and economical efficiency of unit steel amount, and is favorable for industrial production.

Owner:宝业集团浙江建设产业研究院有限公司

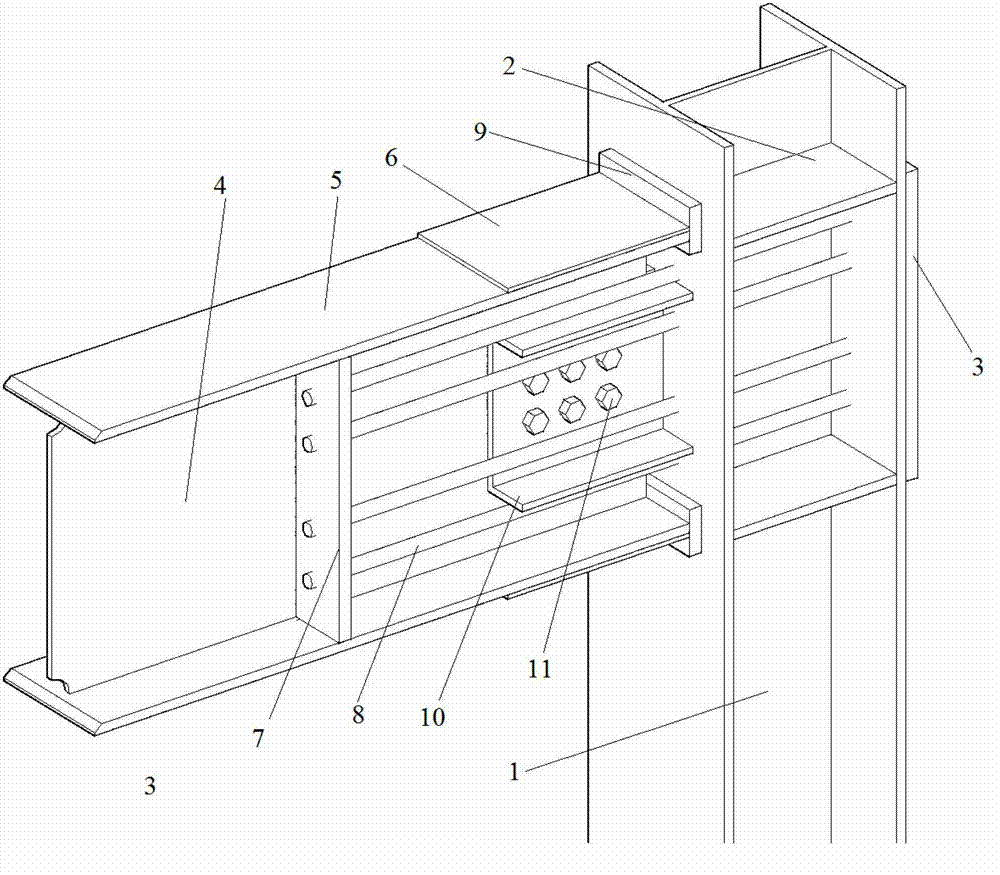

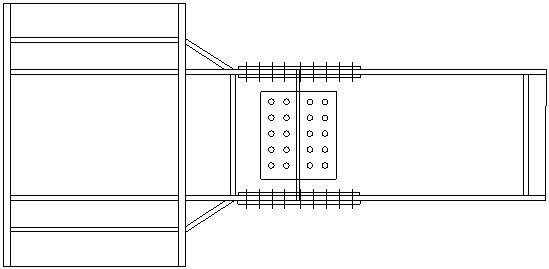

Hole-expanding type steel structure beam column node in short T-shaped steel connection and connection method of hole-expanding type steel structure beam column node

ActiveCN102363978AIncreased ductile deformation capacityImprove energy consumptionBuilding material handlingShock proofingSteel columnsBeam column

The invention relates to a hole-expanding type steel structure beam column node in short T-shaped steel connection. The hole-expanding type steel structure beam column node comprises two pieces of short T-shaped steel, a steel column and an H-shaped steel beam of which the end is vertically connected to a flange plate of the steel column, wherein a web plate of the short T-shaped steel is connected with the flange plate of the H-shaped steel beam; and the flange plate of the short T-shaped steel is connected with the flange plate of the steel column. The hole-expanding type steel structure beam column node is characterized by also comprising a flange steel cushion plate, wherein the flange steel cushion plate connects the web plate of the short T-shaped steel and the flange plate of the H-shaped steel beam by using a friction type high-strength bolt; the flange plate of the short T-shaped steel is connected with the flange plate of the steel column by using the friction type high-strength bolt; and a bolt hole in the web plate of the short T-shaped steel is a long circular hole. The invention also relates to a connection method of the hole-expanding type steel structure beam column node in the short T-shaped steel connection. The steel structure beam column node has quite high ductile deformation capacity and excellent energy-dissipation capacity; and the brittle failure of the steel beam or the steel column in a node area under the action of a seldom-occurring earthquake can be prevented.

Owner:FUZHOU UNIV

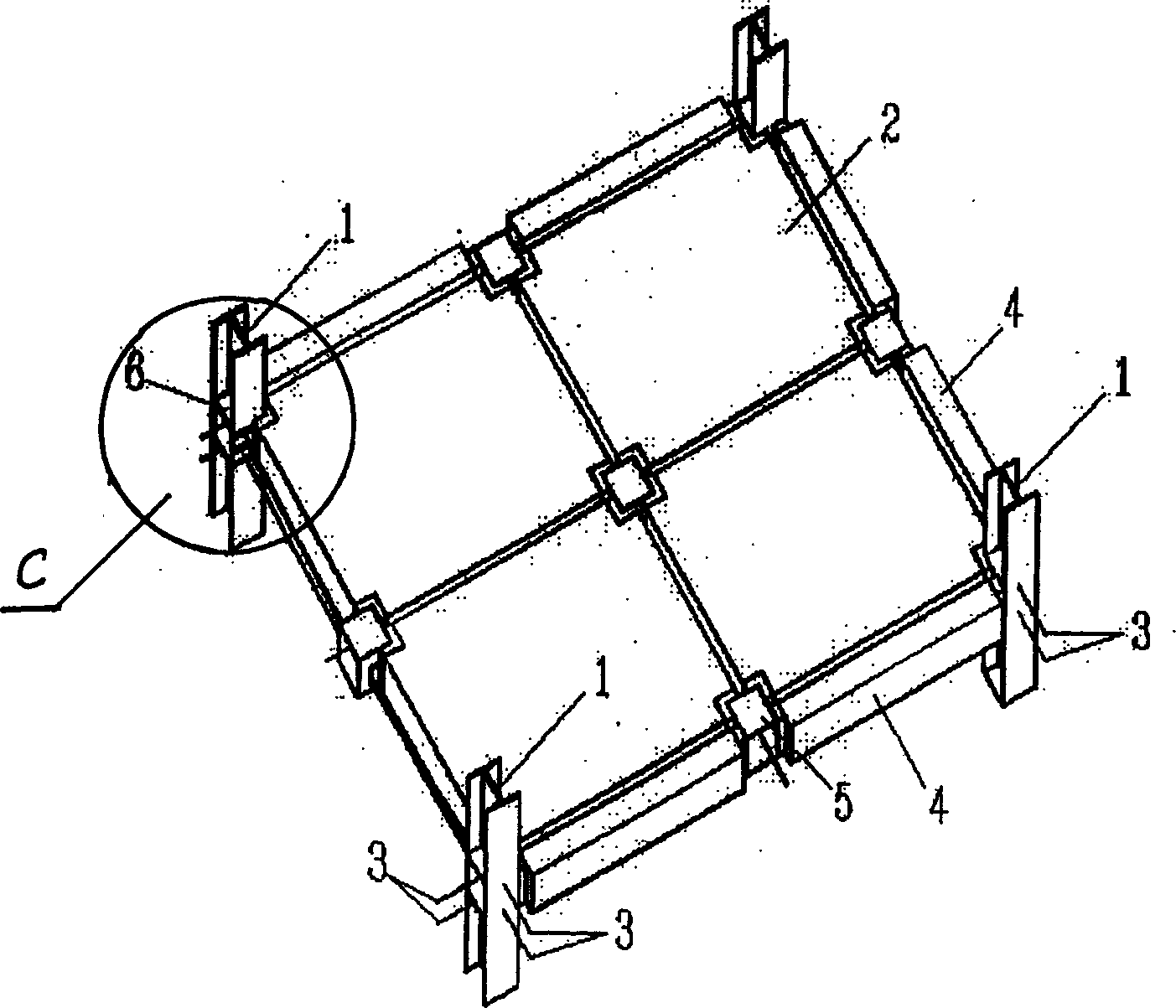

Novel prefabricate prestressed steel frame girder-column pitch point with post-earthquake self-reset function

ActiveCN103088918ARestoring structure and functionEasy constructionShock proofingPre stressSteel frame

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

High-rise building frame supported sectional steel concrete girder-like structural transfer floor construction method

InactiveCN101333825ASolve the difficulty of tyingSolve the problem of binding difficultiesBuilding constructionsConcrete beamsRebar

Disclosed is a construction method of the support frame steel concrete girder structure transfer floor for the high-rise buildings, which relates to the high-rise building structural transferring technology. Reinforced plates are welded on a profiled steel girder column flange plate and a profiled steel column flange plate; a profiled steel column stirrup is machined to an open stirrup which is welded on the reinforced plate. A perforation hole used for the stirrup to be inserted into is preset on the web plate of the profiled steel column; an angle table is welded on the profiled steel column flange plate; reinforced steel bars are in lap welding with the angle table. In the intersection of a non-frame girder and the profiled steel girder, the reinforced steel bars disconnect a bent anchor on the profiled steel girder web plate; wall body reinforced plates are generally welded on the upper flange wall body of the profiled steel girder; both sides of the wall body reinforced steel bars are welded on the wall body reinforced plates. Perforation holes used for the stirrup to be inserted into are prearranged on the upper flange of the profiled steel girder for the reinforced steel bar parts of the upper column and the concealed column of the profiled steel concrete girder; tie bars are welded with the tie bar reinforced plates. Spilt bolts are welded on both sides of the profiled steel web plate to reinforce the profiled steel concrete girder mould plate. The construction method of the support frame steel concrete girder structure transfer floor for the high-rise buildings has the advantages that the important technical problem the support frame steel concrete girder structure transfer floor in the construction process of the high-rise buildings is solved; the intensity, rigidity and the vibration resistance of the profiled steel concrete girder are reinforced.

Owner:BEIJING SHOUGANG CONSTR GROUP +1

Construction method of large-sized arc-shaped wall

The invention discloses a construction method of a large-sized arc-shaped wall. The method mainly comprises the following steps of: measuring and positioning; erecting a scaffold; mounting an arc-shaped in-column section steel column; binding a steel bar on the periphery of the section steel column; measuring and positioning, mounting an arc-shaped annular beam inner steel bar on the section steel column, and binding and fixing; mounting and fixing an arc-shaped column and an arc-shaped annular beam template on the steel bar; pouring concrete to form the arc-shaped column and an arc-shaped annular beam; measuring and manufacturing an arc-shaped plate; and mounting and fixing the arc-shaped plate on the arc-shaped column and the arc-shaped annular beam. According to the construction method of the large-sized arc-shaped wall, vertical sectioned construction is adopted, inner section steel and a steel bar structure of the arc-shaped column and the arc-shaped annular beam are erected layer by layer; the template is bound and is poured and molded; the poured arc-shaped column and the arc-shaped annular beam are continually provided with the upper-layer arc-shaped column and the arc-shaped annular beam; and finally, the arc-shaped plate which is designed and manufactured outside a field is mounted on the arc-shaped column and the arc-shaped annular beam, and process improvement can be carried out according to implementation effects.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

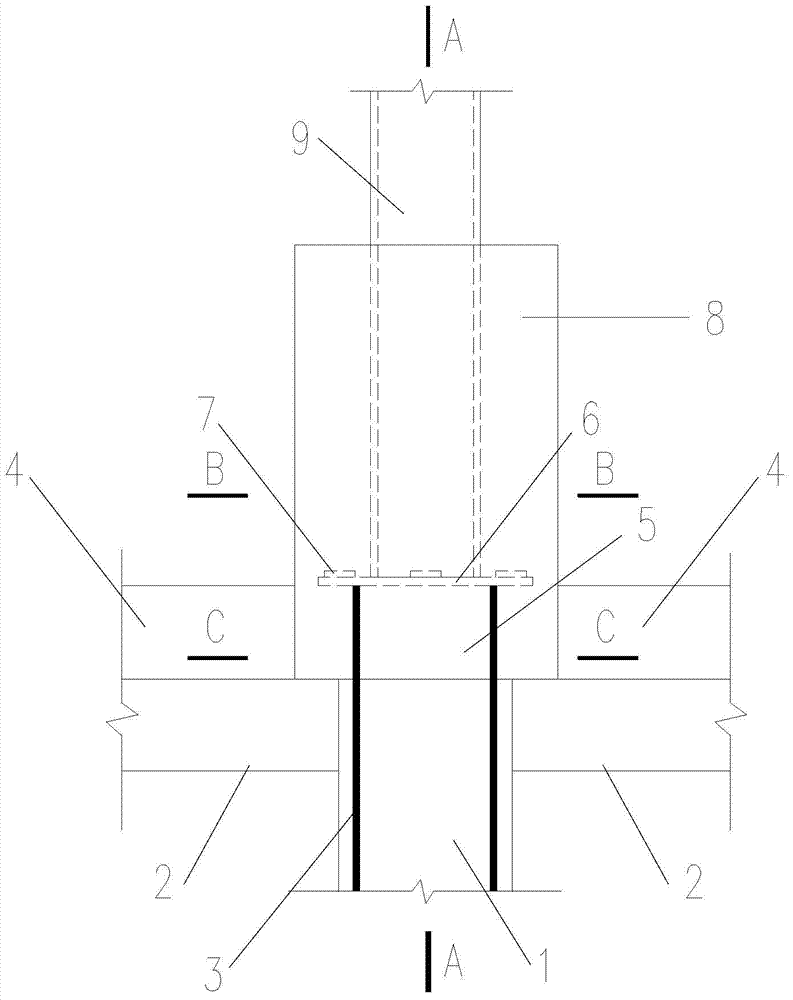

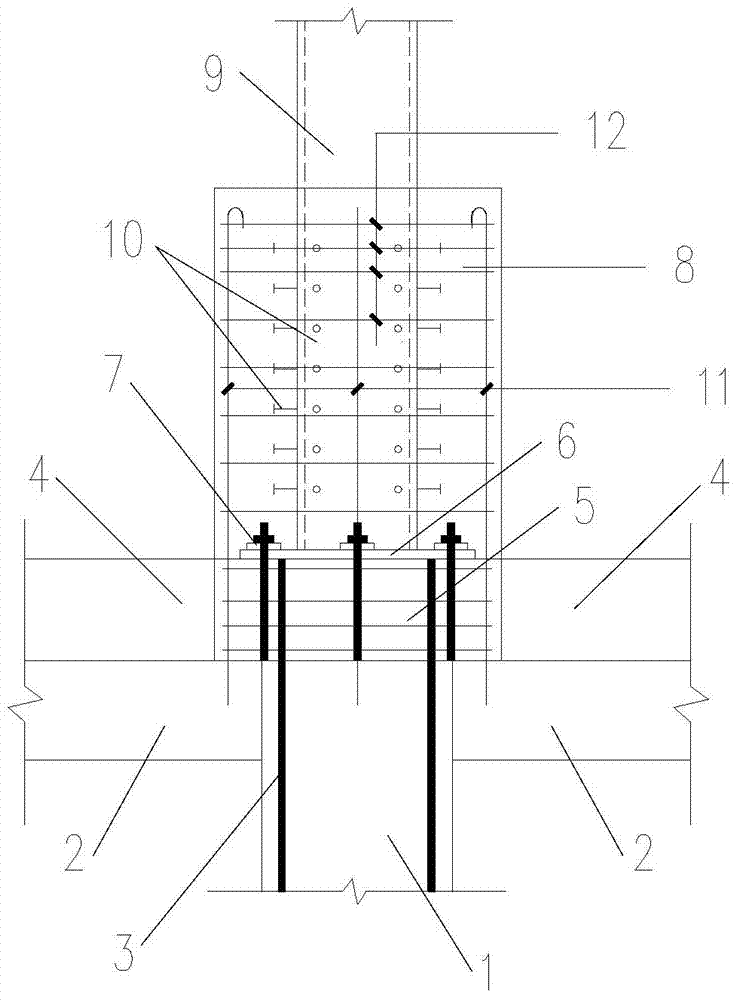

Layer added steel framework column base node on top of multi-layer concrete framework structure and construction method thereof

InactiveCN103669598AFacilitate adjustment and determinationSolve installation problemsBuilding constructionsReinforced concrete columnRebar

The invention provides a layer added steel framework column base node on the top of a multi-layer concrete framework structure and a construction method thereof; the column base node comprises a section of concrete column head (5) which is cast on an original reinforced concrete column (1) and the top of a beam (2) which is connected with the original reinforced concrete column, has an enlarged cross section and is connected with a steel column (9), and a ring beam (4) which is cast together with the concrete column head (5); an anchor bolt (7) and a longitudinal bar (3) are buried in the concrete column head (5); the root of the longitudinal bar (3) is implanted into the reinforced concrete column (1); a bottom plate (6) at the bottom of the steel column (9) is fixed with the concrete column head (5) through the anchor bolt (7); an outsourced reinforced concrete column (8) at the bottom of an outsourced steel column is cast on the top of the concrete column head (5). According to the layer added steel framework column base node on top of the multi-layer concrete framework structure and the construction method thereof, the connection rigidity of a column base is improved, so that the internal force which is produced by the added layer of an upper steel structure is effectively transmitted to an original structure, meanwhile the connection integrity on an interface between new and old structures is improved, and the anti-seismic performance of the structure is improved.

Owner:ANHUI TIANZHU CONSTR GRP +1

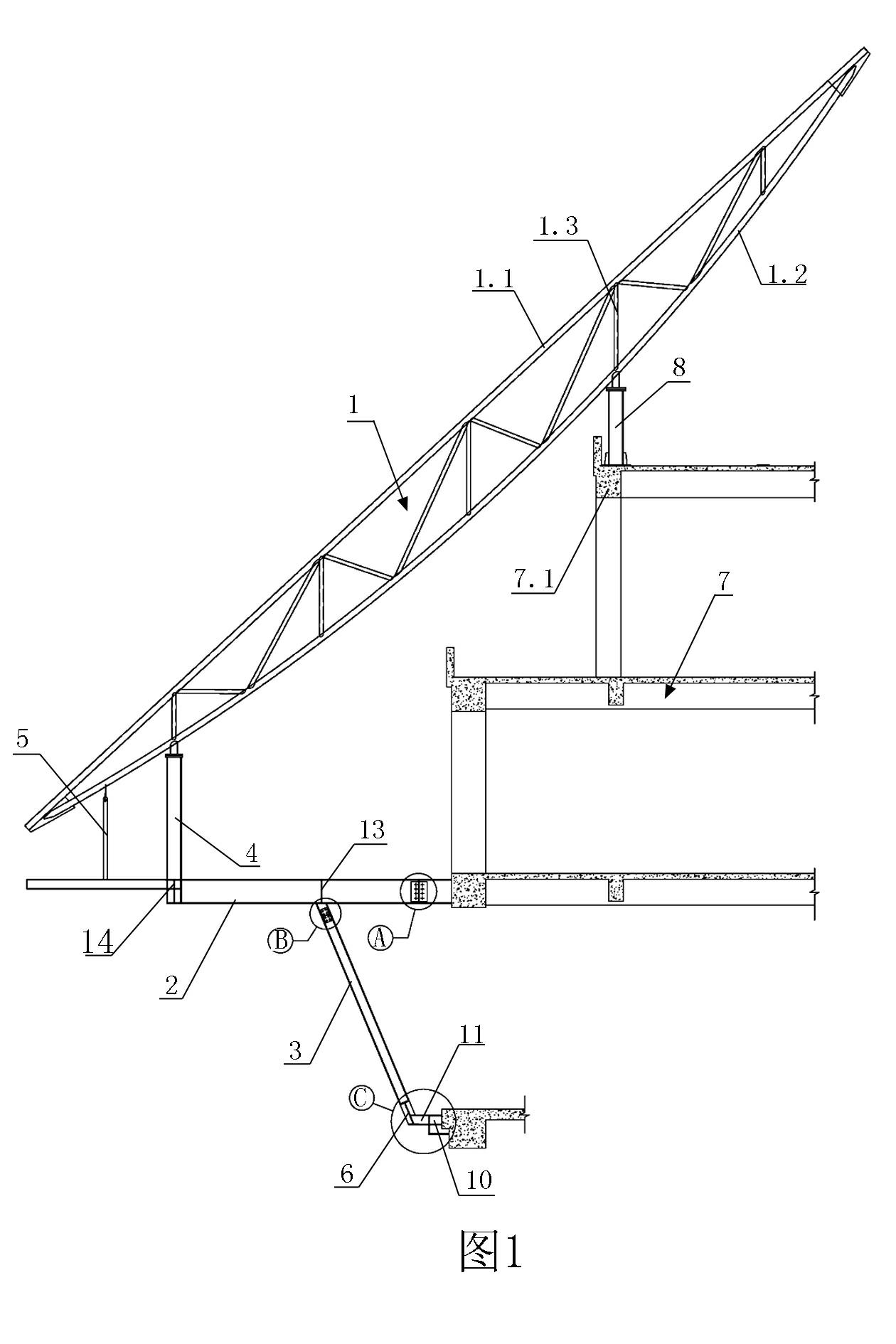

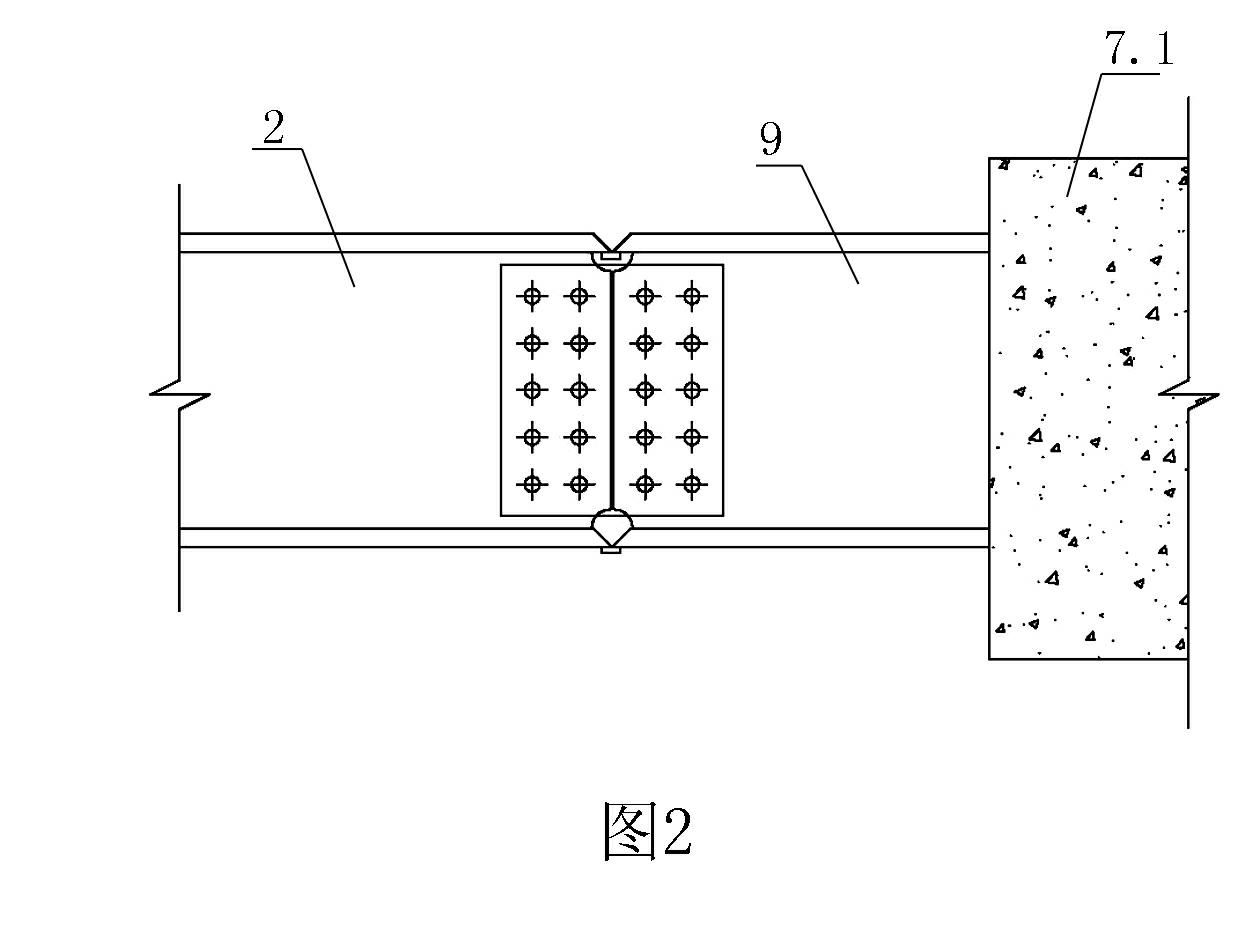

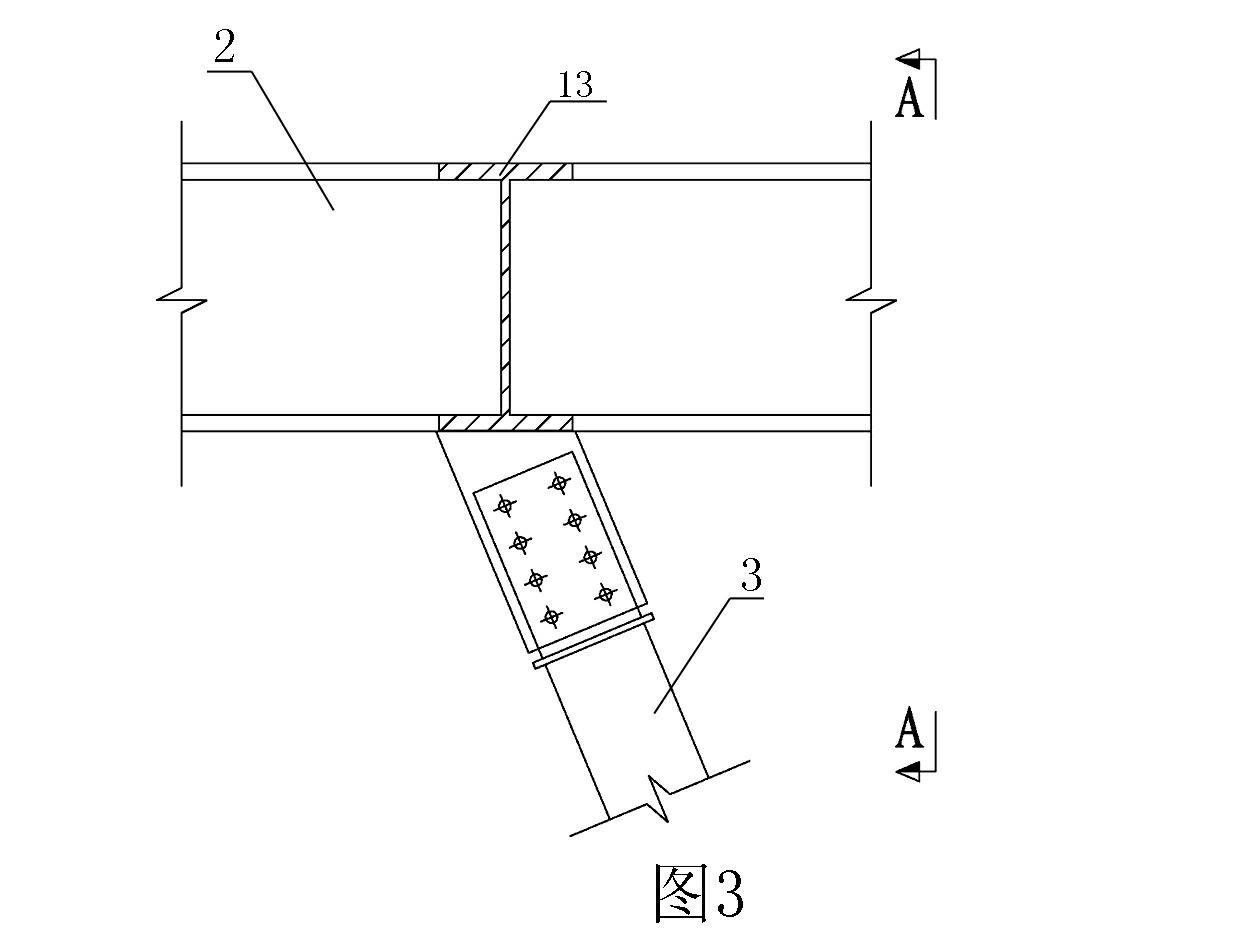

Cornice steel skeleton and bracket steel skeleton for large-span big roof of pseudo-classic architecture and construction method of cornice steel skeleton and bracket steel skeleton

InactiveCN102635209AEasy to installGuaranteed accuracyRoof coveringArched structuresEngineeringStructural engineering

The invention discloses a cornice steel skeleton and a bracket steel skeleton for a large-span big roof of a pseudo-classic architecture and a construction method of the cornice steel skeleton and the bracket steel skeleton. The steel skeletons are slantingly mounted at a cornice part of a main structure, and comprise the cornice skeleton and the bracket skeleton, wherein the cornice skeleton is a pipe truss, and an inclined plane support roof is formed by a lower support steel column, a low support steel-pipe column and an upper support column, the rigid connection is formed between the pipe truss and the above three parts; and the bracket skeleton is composed of an inclined strut for the bracket, a horizontal beam for the bracket and a needle beam for the bracket, the inclined strut for the bracket and the horizontal beam for the bracket are vertical in space, and the needle beam for the bracket is horizontally arranged. During construction, the integral assembling on ground and the segmental hoisting are adopted, during the hoisting, a reversible chain is adopted for adjusting so that to ensure the construction precision, then the steel skeleton is hoisted to a preset position for butt assembly in the air. With the adoption of the steel skeletons provided by the invention, the architectural shape of the pseudo-classic large-span roof can be perfectly realized, the construction process is safe and reliable, and the steel skeletons are suitable for the structure and the construction of the large-span roof of the pseudo-classic architecture.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU +1

Experimental device for researching drill column dynamic characteristic

InactiveCN103712790AResearch is accurate and feasibleMachine part testingCircular discElectric machinery

The invention relates to an experimental device for researching a drill column dynamic characteristic. The experimental device comprises a main machine frame, a well-wall-simulating assembly, a rotary assembly, a disc assembly, an excitation assembly, a weighing assembly and a detecting device. The well-wall-simulating assembly comprises an organic glass tube, a fixing clamping and a clamp mounting plate. The rotary assembly is provided with a motor, a driver, a coupler, a thin steel column and a top mounting plate, the rotary assembly penetrates through the whole main machine frame, the disc assembly comprises a disc and a cylinder, the disc is arranged on a floating platform, and the disc conducts rotary movement in the cylinder. An exciter in the excitation assembly excites the bottom of the disc according to the input signal type to simulate interaction of a drill head and rocks at the bottom of a borehole. The detecting device comprises a whirling motion track and a transverse vibration and longitudinal vibration detecting device. The experimental device for researching the drill column dynamic characteristic can simulate the vibration and deformation situations of a drill column and determine the parameters of the rotating speed, the bit pressure similarity ratio and the like according to the dynamic similarity ratio and the geometric similarity ratio.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

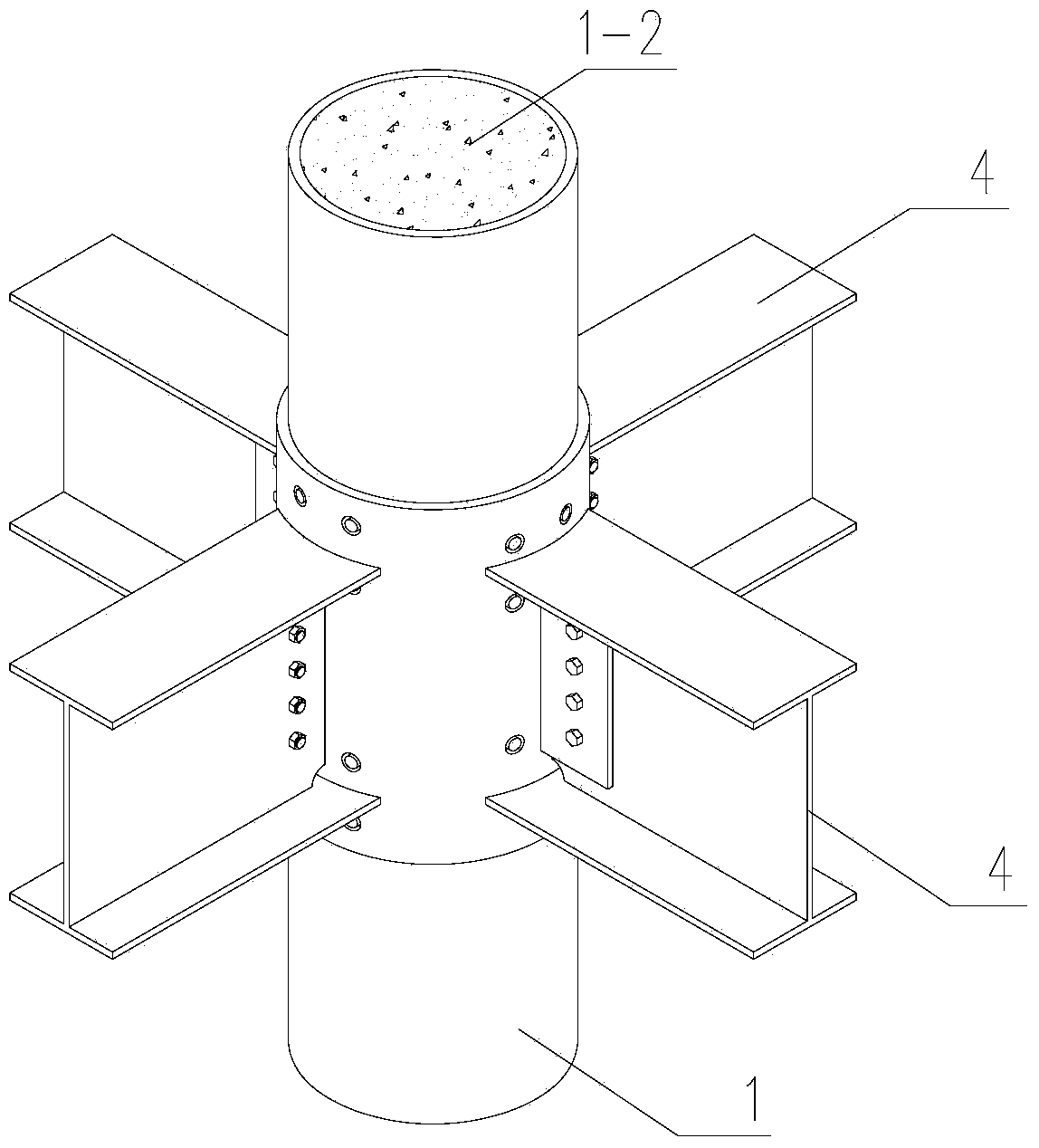

Connection joint of concrete filled steel tubular column and beams

InactiveCN104032838AIncrease stiffnessGuaranteed continuityBuilding constructionsSteel barSteel columns

The invention provides a connection joint of a concrete filled steel tubular column and beams, and belongs to the field of architectural structures. The peripheral surface of a steel column jacket at the connection joint bodies of the concrete filled steel tubular column and the beam ends is sleeved with a steel sleeve in a matched mode, the edge of the upper end and the edge of the lower end of the steel sleeve are fixedly welded to the steel column jacket, the peripheral surface of the steel sleeve is radially connected with steel connection boards corresponding to the beam ends at intervals, a circle of upper opposite-pull steel bar hole set and a circle of lower opposite-pull steel bar hole set which are correspondingly through are formed in the periphery of the steel sleeve and the inner layer of the steel column jacket, opposite-pull steel bars correspondingly penetrate through the upper opposite-pull steel bar hole set and the lower opposite-pull steel bar hole set, and namely an upper opposite-pull steel bar grid net and a lower opposite-pull steel bar grid net are formed in the steel column jacket of the concrete filled steel tubular column; the steel connection boards and the sleeve wall of the steel sleeve outside the concrete filled steel tubular column are correspondingly connected with webs of H-type steel connectors at the beam ends and upper and lower wing edge board ends respectively, and the concrete filled steel tubular column and the beams are connected in an integrated mode after a concrete layer in the steel column jacket of the concrete filled steel tubular column is poured. According to the connection joint, the overall strength of the concrete filled steel tubular column is enhanced by enhancing the joint bodies.

Owner:HUBEI HONGYI STEEL CONSTR ENG

Flat shim plate-adjustable grouting installation method

ActiveCN101871265AImprove construction qualityShort construction periodFoundation engineeringBuilding material handlingSteel columnsScale height

The invention relates to a flat shim plate-adjustable grouting installation method, belonging to a method for installing a steel column or a device. The method comprises the following steps: symmetrically welding rectangular plates with holes on the back and forth of the left side and the right side of a flat shim plate at intervals; cutting a grouting pit outside the foundation bolt or the preset hole of the concrete foundation of an installation device; arranging four screw holes which are arranged into a rectangle in the grouting pit; correspondingly and vertically plugging four screws the upper ends of which are respectively screwed with a regulating nut into the four screw holes; correspondingly sheathing the holes on the four rectangular plates of the flat shim plate onto the four screw in a penetrating mode so that the flat shim plate is supported on the regulating nuts; utilizing the regulating nuts to regulate the scale height and the levelness of the flat shim plate; leveling the flat shim plate for the fist time, arranging a grouting box on the foundation surface at the periphery of the grouting pit and placing a grouting material into the grouting box; when the grouting material is prehardened, utilizing the regulating nuts to accurately level the flat shim plate so that both the scale height and the levelness of the flat shim plate reach the installation requirements. When the steel column or the device is installed, an inclined shim plate is not needed for leveling, thus the method is convenient and speedy.

Owner:CHINA MCC17 GRP

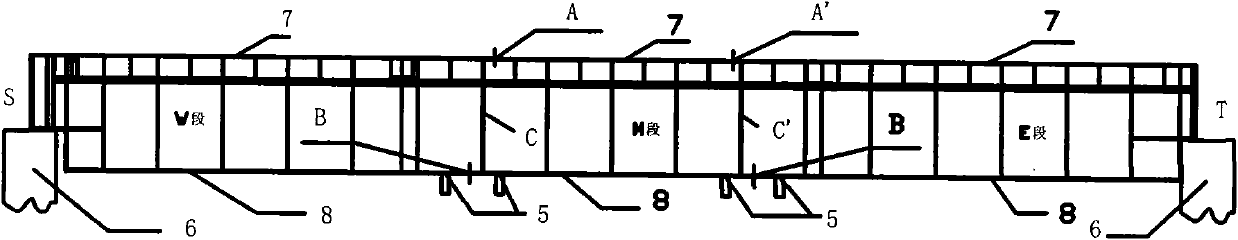

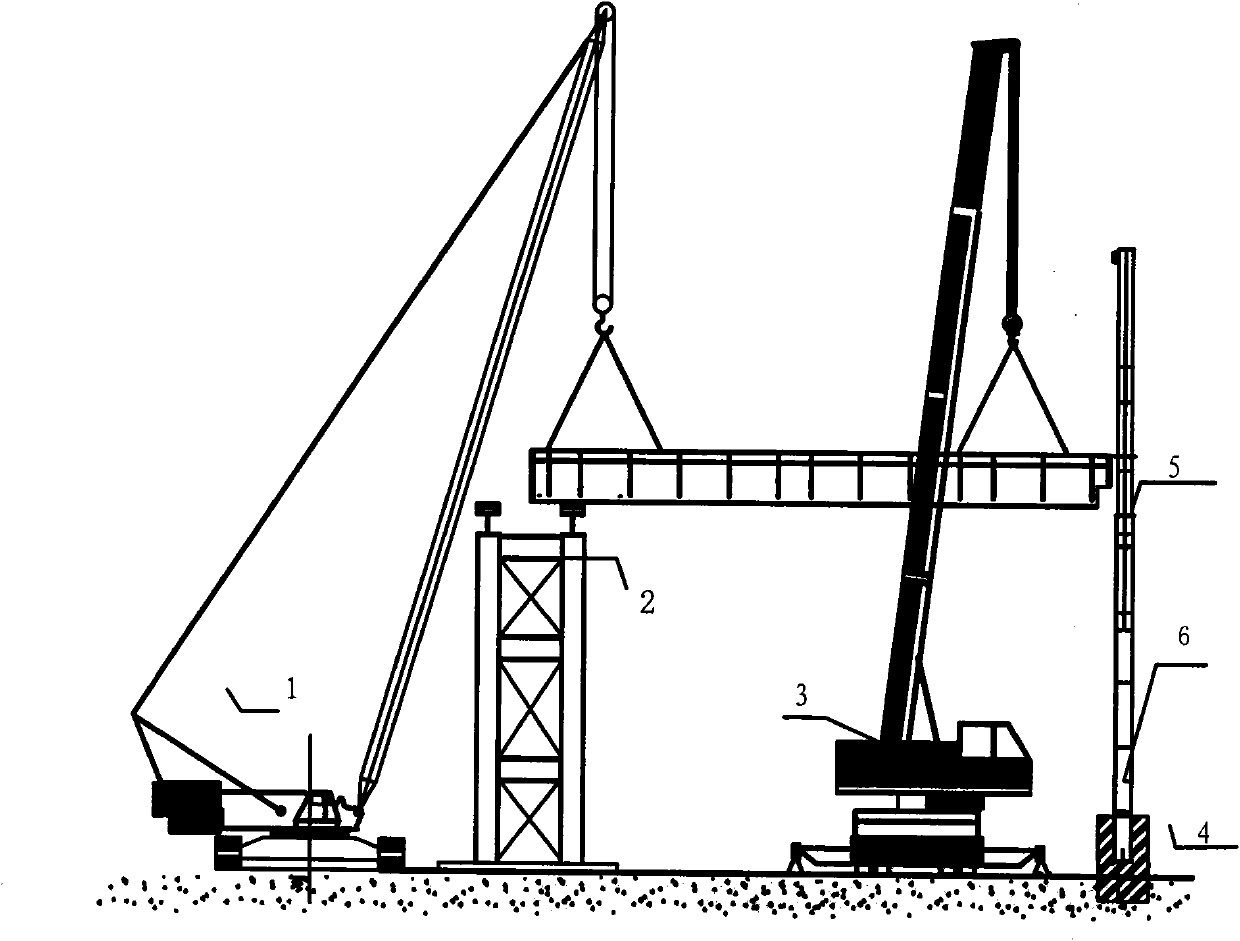

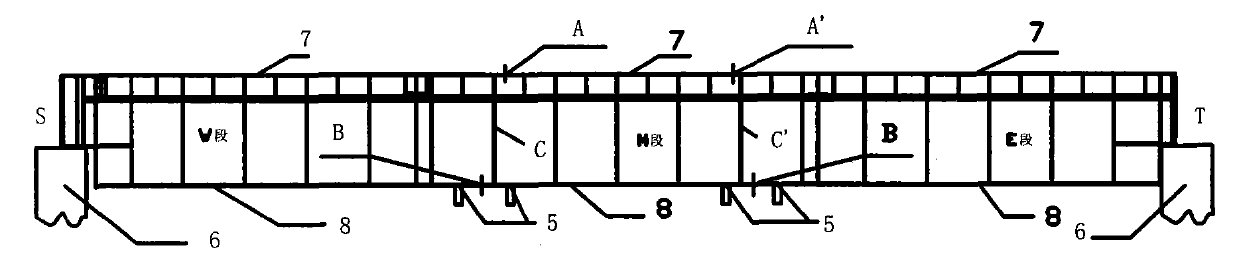

Onsite splicing and mounting method for extra-large and overweight box crane girders

ActiveCN102086000AImprove the quality of look and feelGood lookingLoad-engaging elementsSteel columnsTruck

The invention discloses an onsite splicing and mounting method for an extra-large and overweight box crane girder. The box crane girder consists of three sections, namely a W section, an M section and an E section, wherein the three sections of girders are connected on two steel columns; and the onsite splicing and mounting method for the crane girder is characterized by comprising the following steps of: 1, respectively assembling the three sections of the girders in a factory before the box crane girder enters the site, arranging two brackets at positions of splicing interfaces of the three sections on the box crane girder according to the lengths of the three sections between the two steel columns, arranging a lifting jack on a platform of the brackets, and measuring positioning lines on crossbeams of the brackets; and 2, splicing and mounting the box crane girder on site and at high altitude, namely manufacturing the extra-large and overweight box girder into the three sections of the girders in the factory, introducing the sections into the site according to a lifting sequence of the W section, the M section and the E section, directly lifting the sections by employing a 120t crawler crane and a 260t truck crane, lifting to right places by sections, splicing and welding, and unloading and detaching the brackets after the box crane girder passes the welding construction defect detection.

Owner:MCC5 GROUP CORP SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com