Layer added steel framework column base node on top of multi-layer concrete framework structure and construction method thereof

A technology of frame structure and column foot joints, which is applied in the direction of building structure and construction, can solve the problems of difficulty in determining the position of planting reinforcement, affecting the seismic performance of the structure, and being unsuitable for the bearing capacity of rigid column footing, so as to increase the embedding capacity, Avoid sudden changes in stiffness and increase the effect of integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

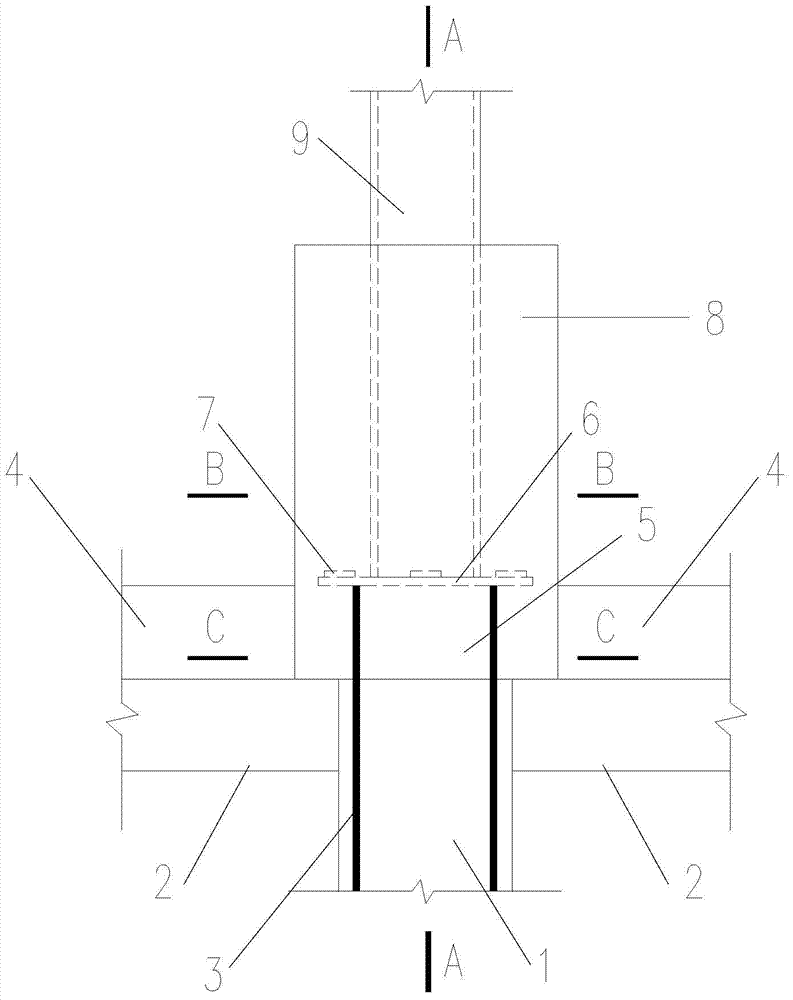

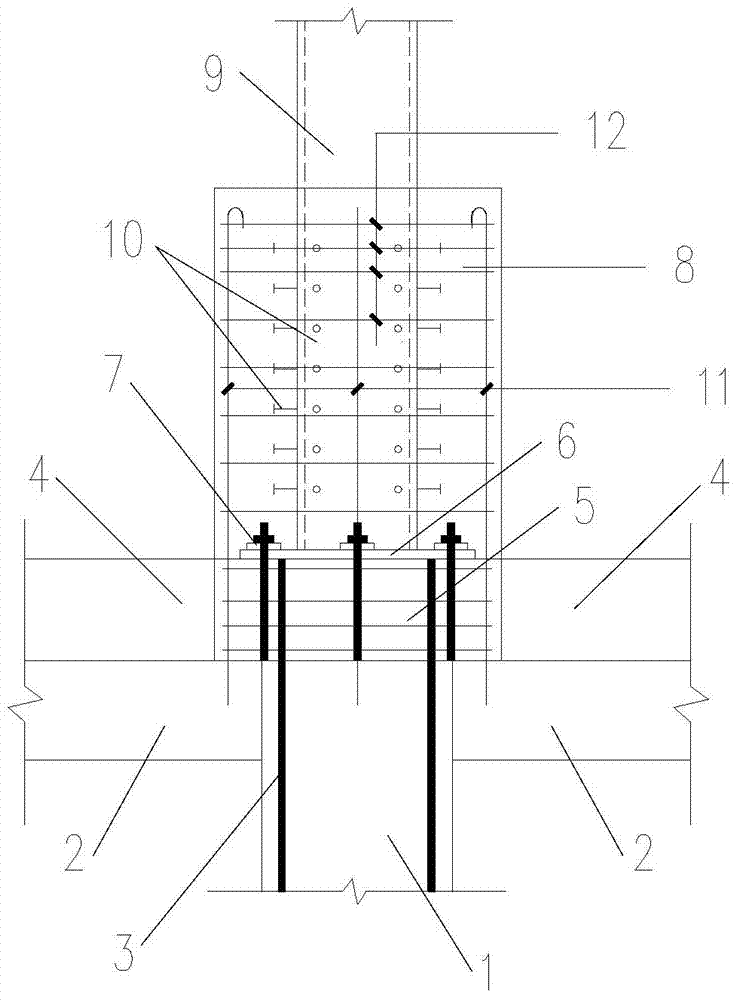

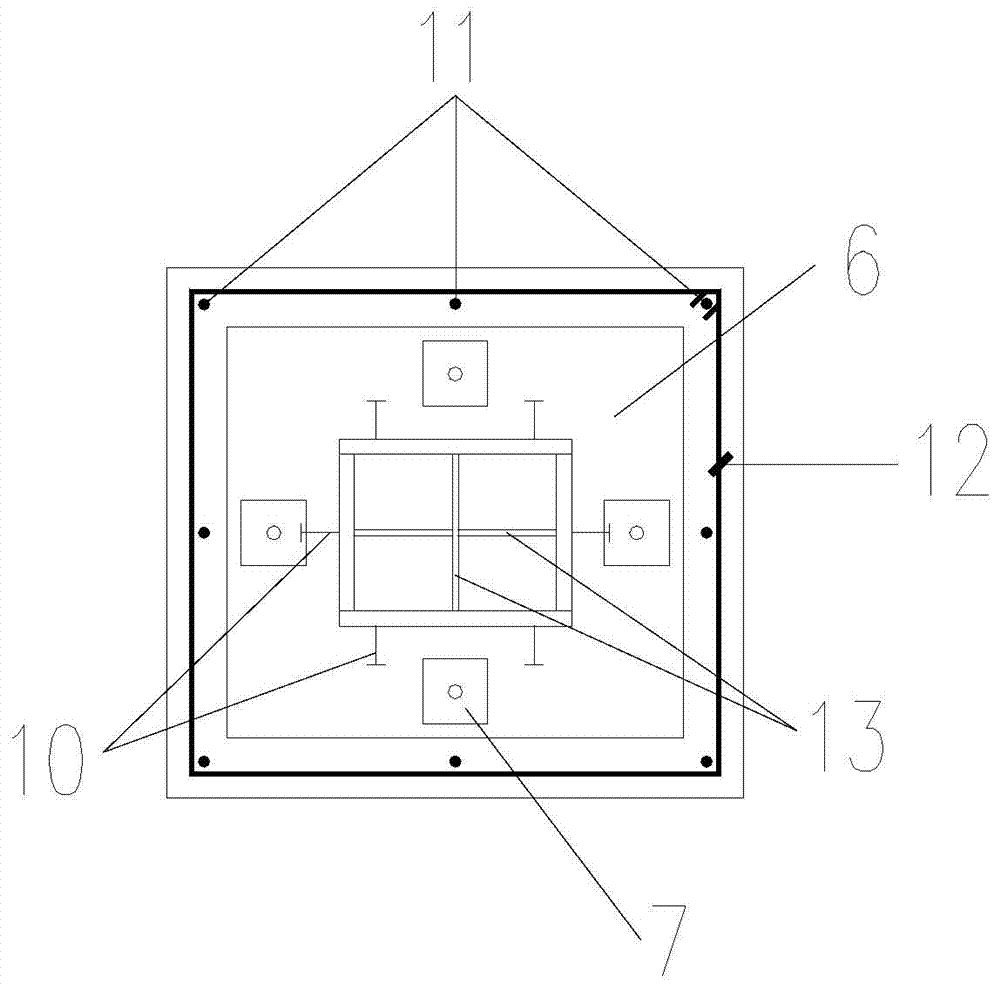

[0027] Such as Figure 1-Figure 4 As shown, the column base node of the added layer steel frame includes the original reinforced concrete column 1 and the original concrete beam 2, and the top of the original reinforced concrete column 1 of the original concrete beam 2 is poured with a section of enlarged concrete column head 5 for connecting the steel column 9 and The ring beam 4 is poured integrally with the concrete column head 5; the concrete column head 5 is embedded with anchor bolts 7 and longitudinal bars 3, and the roots of the longitudinal bars 3 are embedded in the reinforced concrete column 1; the bottom plate 6 at the bottom of the steel column 9 passes through the ground Anchor bolt 7 is fixed to concrete column head 5, the height of the connection between the anchor bolt and the steel column bottom plate is adjustable, and the longitudinal bar 3 is welded to the steel column bottom plate; the top of the concrete column head 5 is poured with an outsourced reinforc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com