Patents

Literature

3270 results about "Sash window" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sash window or hung sash window is made of one or more movable panels, or "sashes", that form a frame to hold panes of glass, which are often separated from other panes (or "lights") by glazing bars, also known as muntins in the US (moulded strips of wood). Although any window with this style of glazing is technically a sash, the term is used almost exclusively to refer to windows where the glazed panels are opened by sliding vertically, or horizontally in a style known as a "Yorkshire light", sliding sash, or sash and case (so called because the weights are concealed in a box case).

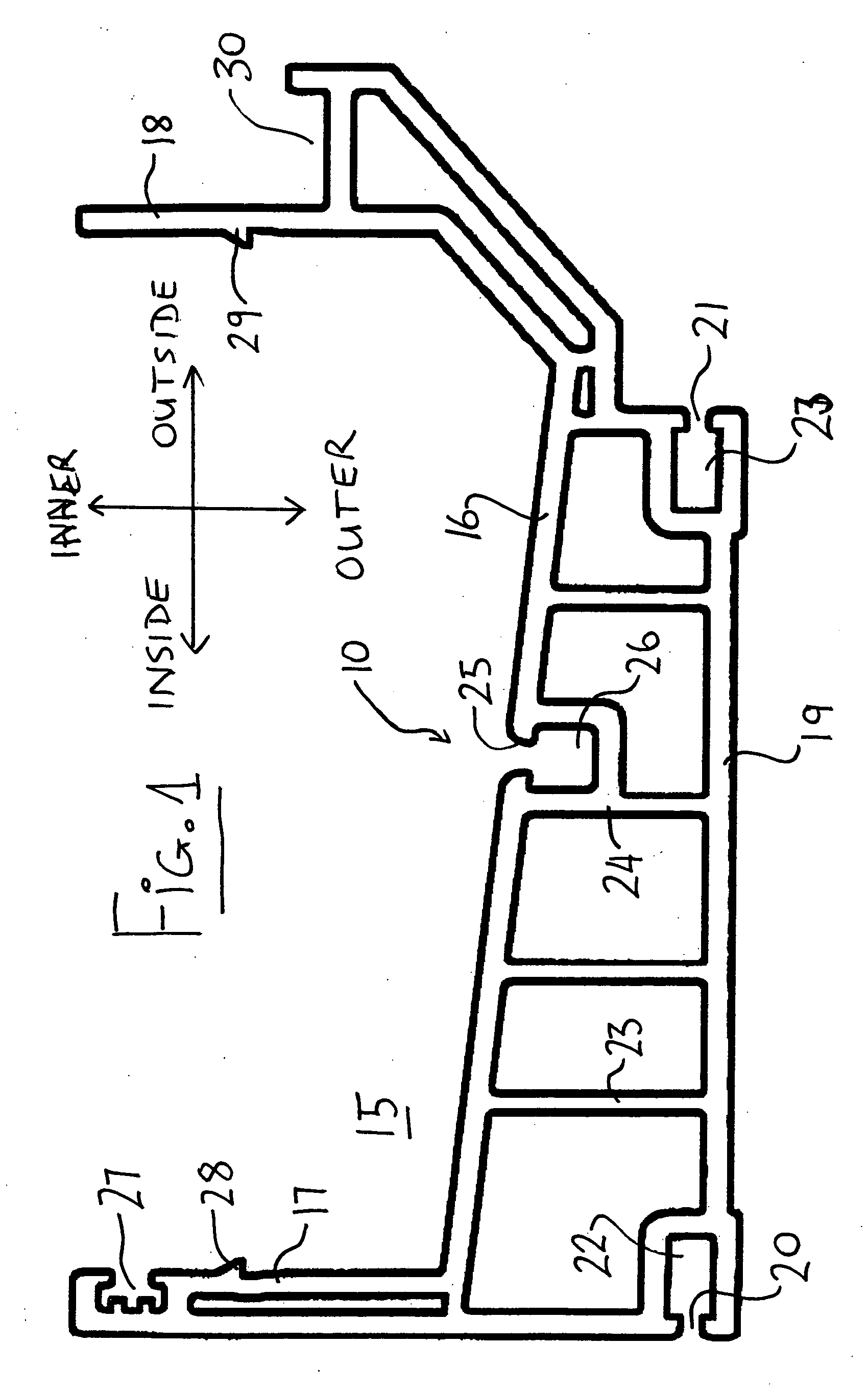

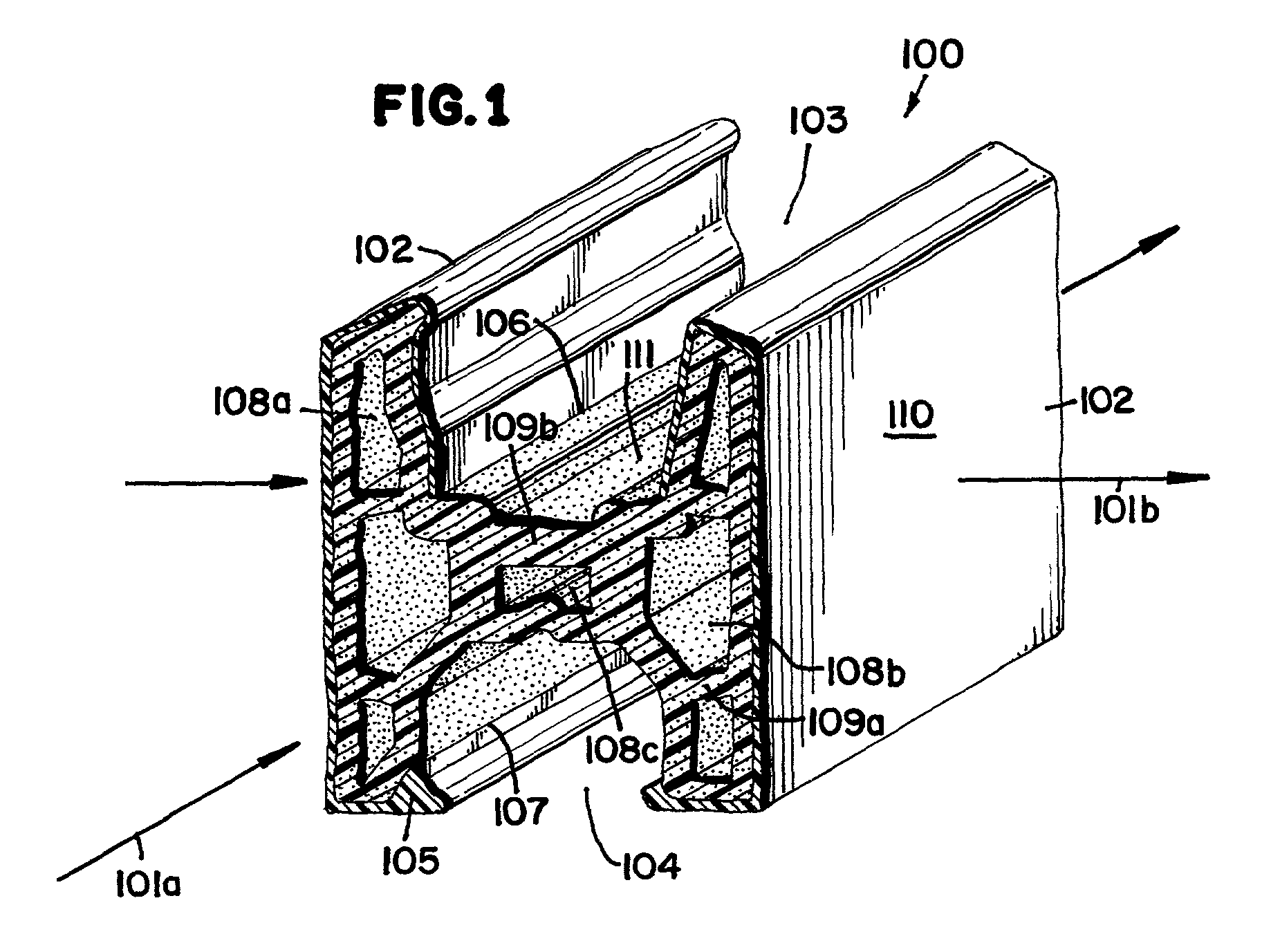

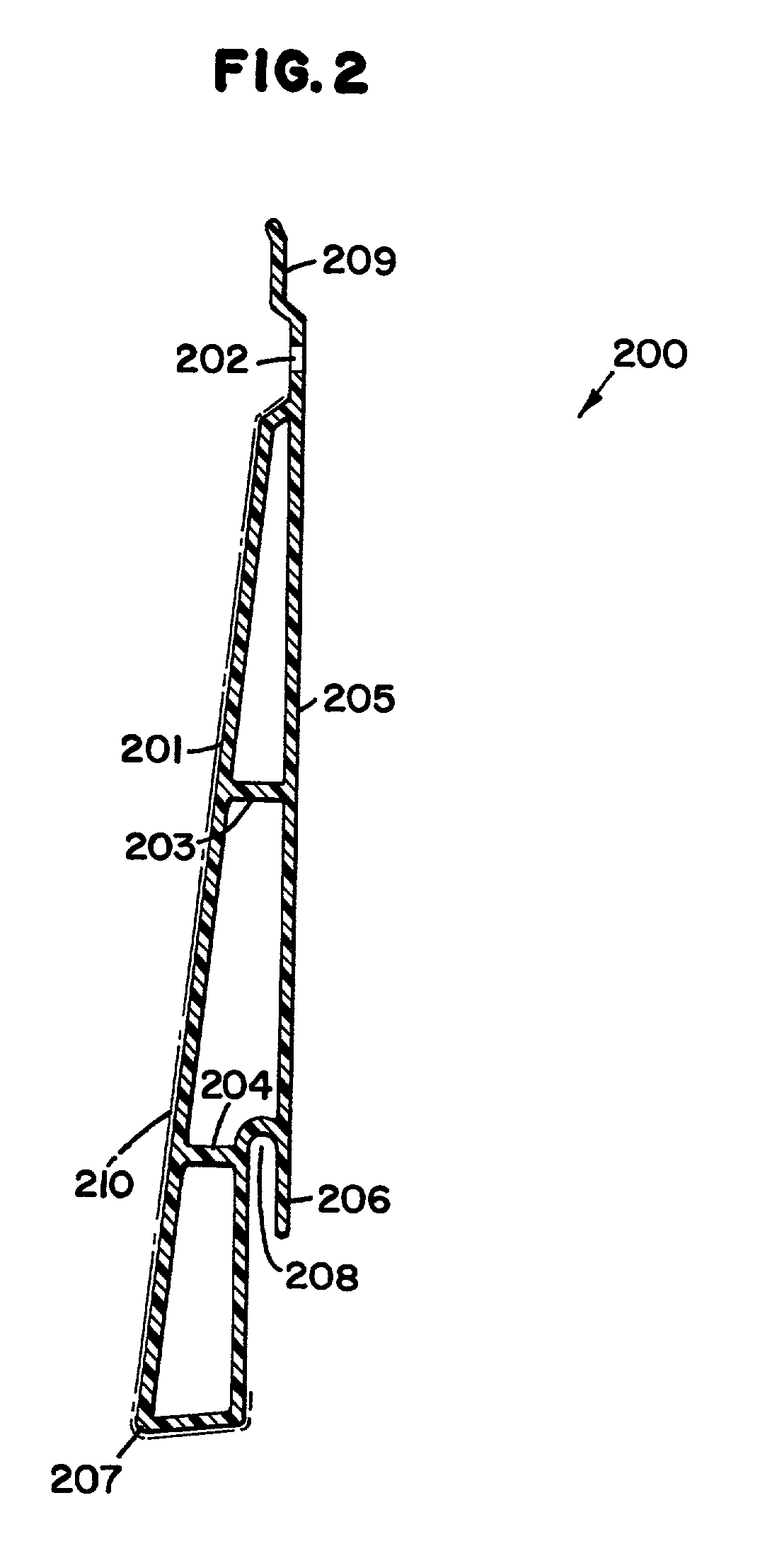

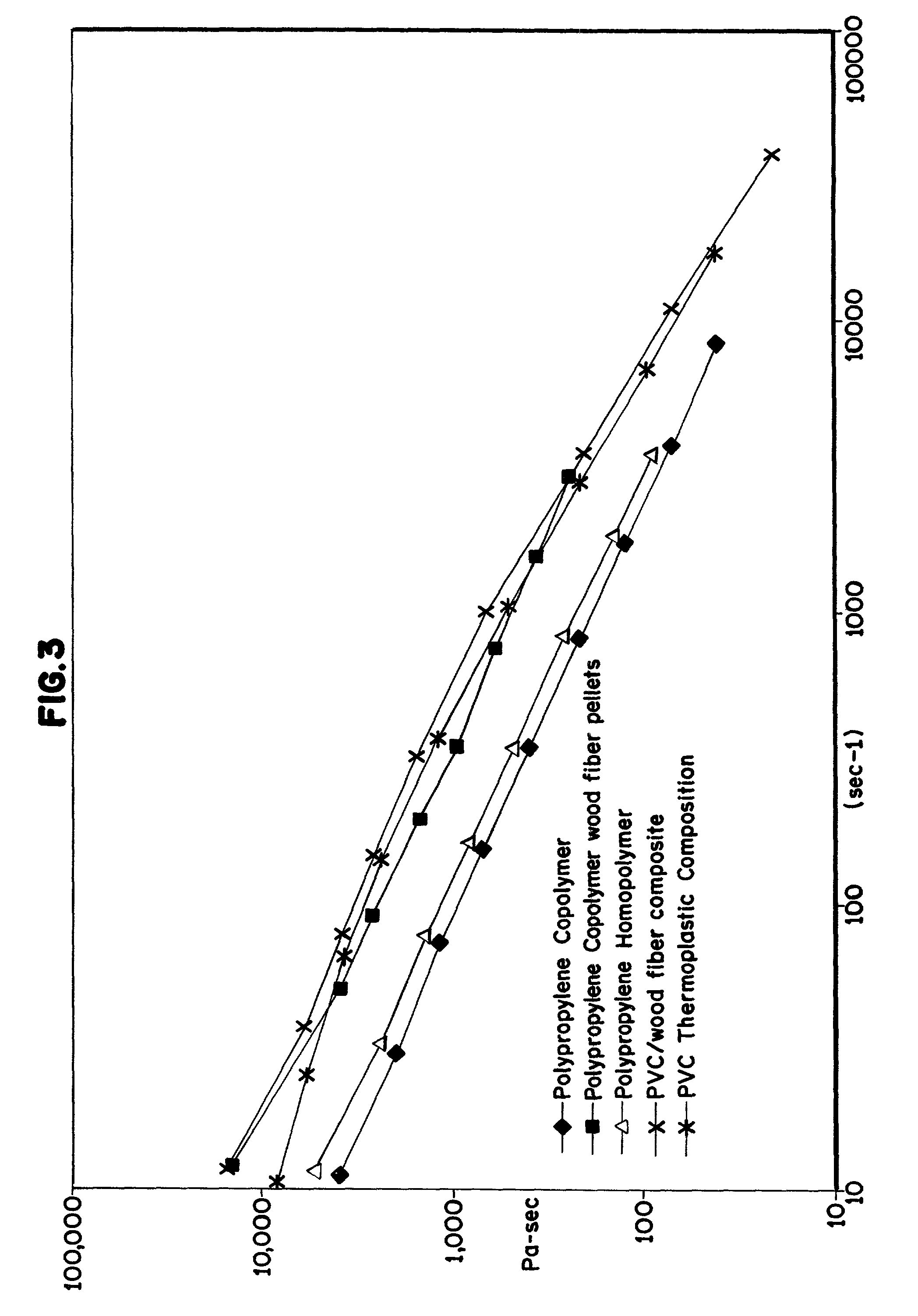

Polyolefin wood fiber composite

InactiveUS6265037B1Improve mechanical propertiesImproved chemicalConstruction materialCovering/liningsPolyolefinEngineering

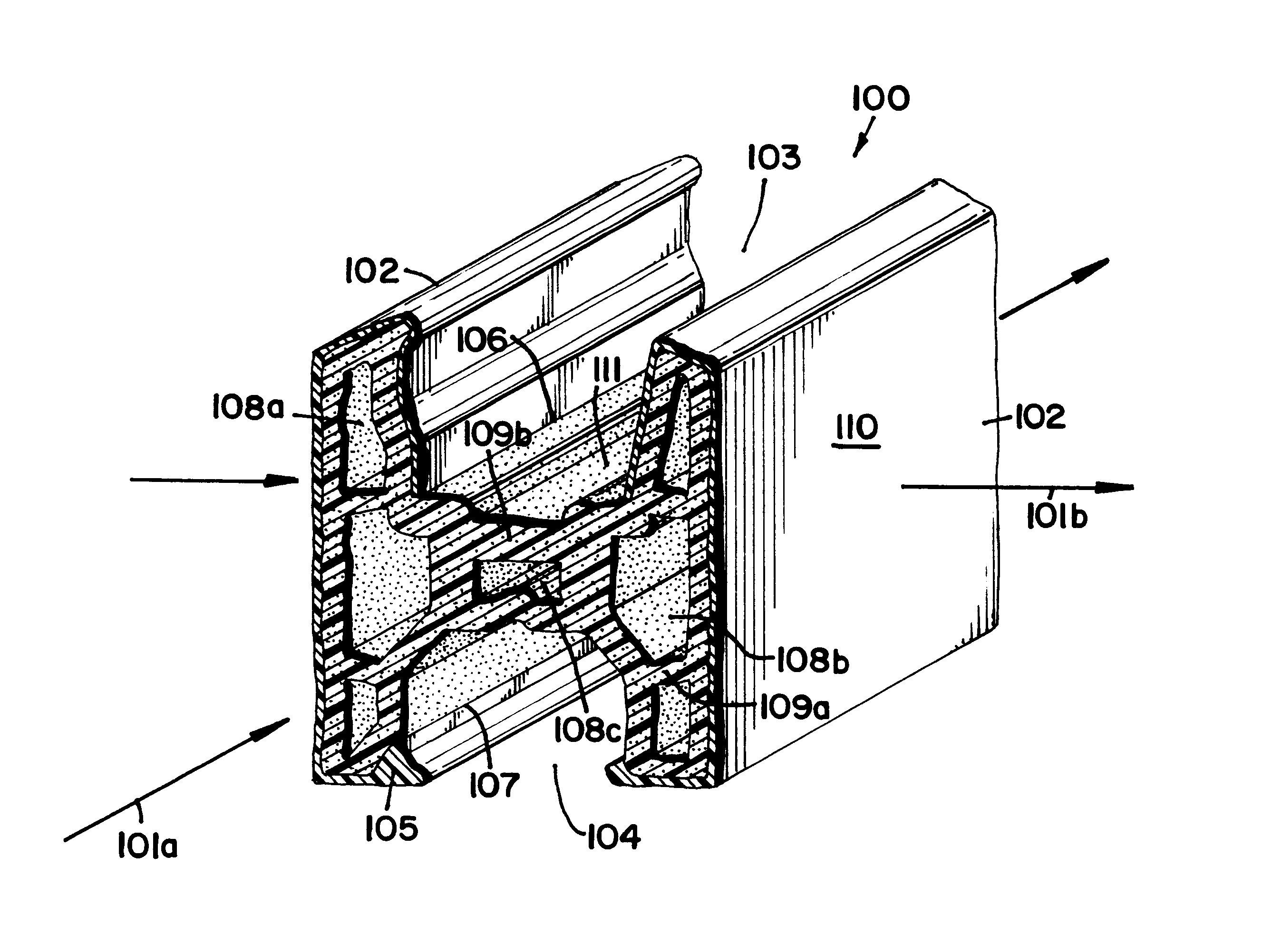

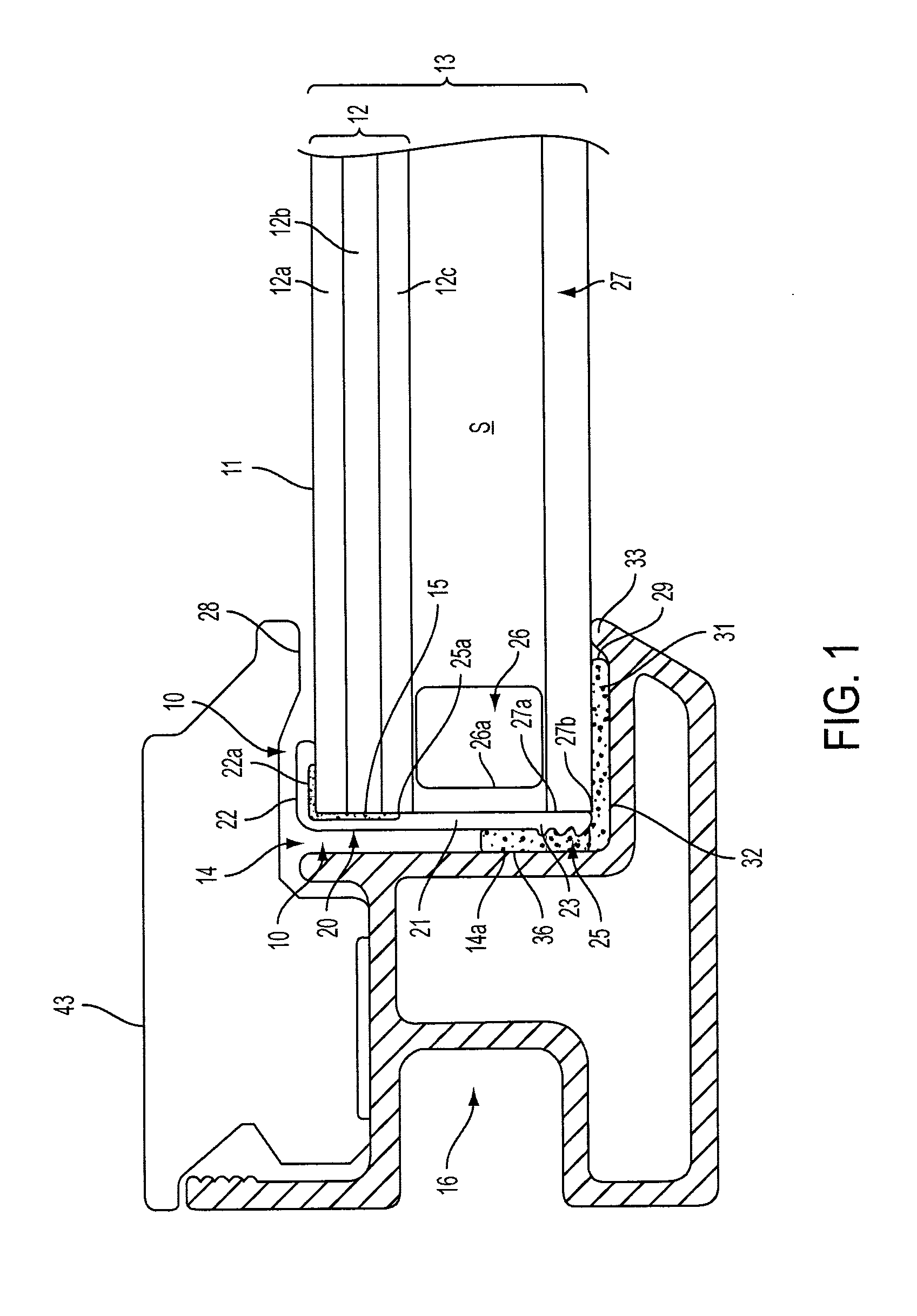

An improved composite structural member comprising a complex profile structural member, made of a composite comprising a polypropylene polymer and a wood fiber. The material is useful in conventional construction applications. The complex profile, in the form of an extruded thermoplastic composite member can be used in residential and commercial structures as described. Preferably, the structural member is used in the manufacture of the fenestration components such as windows and doors. Such linear members are designed with specifically configured cross-sectional shapes to form structural elements in the fenestration units. Structural elements must possess sufficient strength, thermal stability and weatherability to permit the manufacture of a structurally sound window unit that can be easily installed into a rough opening but can maintain its attractive appearance and structural integrity over the life of the window unit often twenty years or more. The structural member comprises a hollow complex cross-section with at least one structural web or one fastener web formed within the component. The exterior of the extruded component has a visible capstock layer and is shaped and adapted for installation in rough openings. The exterior also contains shape and components capable of supporting the elements of the fenestration unit such as a window, sash or movable door unit. The improved polypropylene structural members have unique advantages and can be assembled in thermoplastic weld processes.

Owner:ANDERSEN CORPORATION

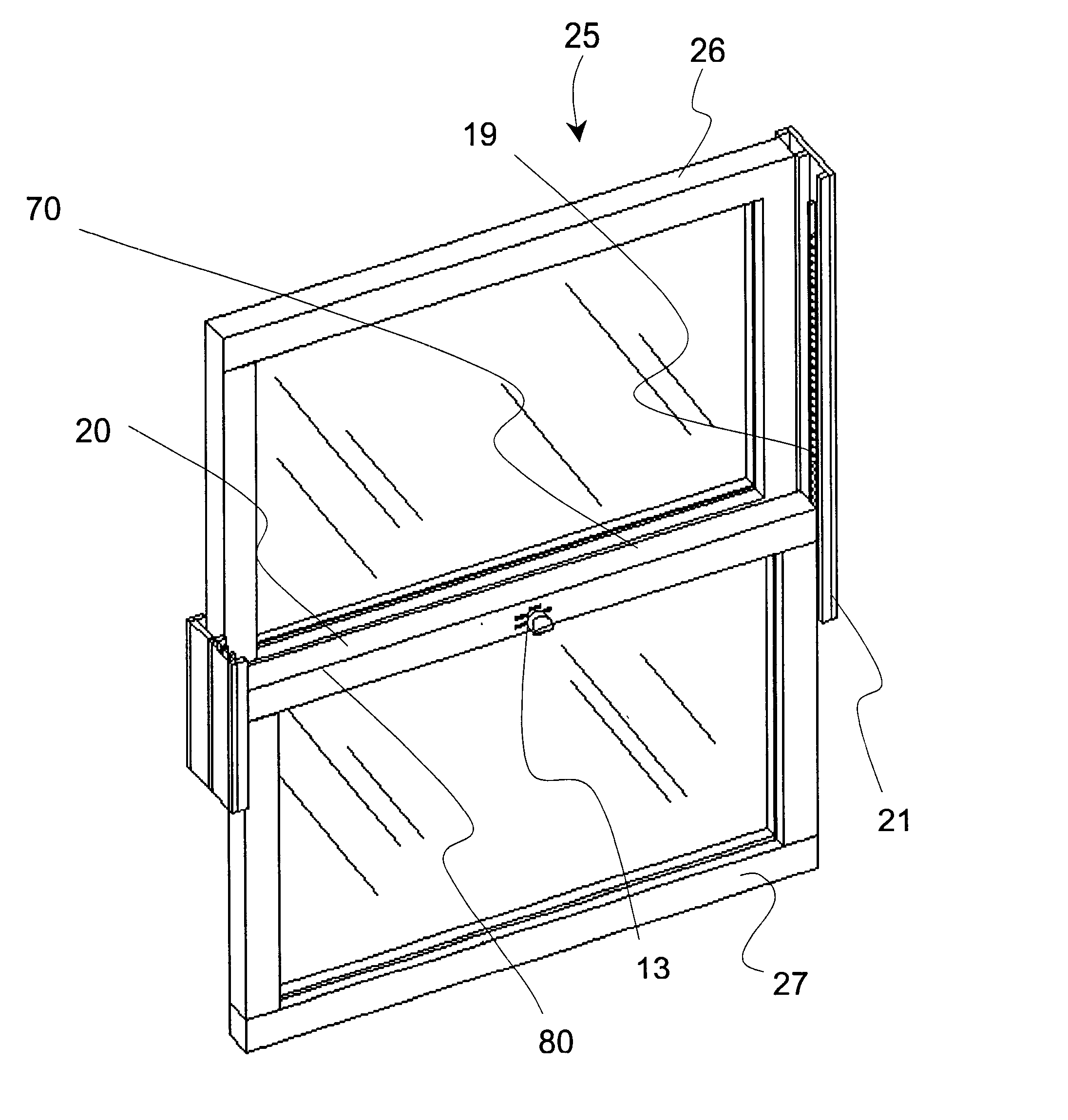

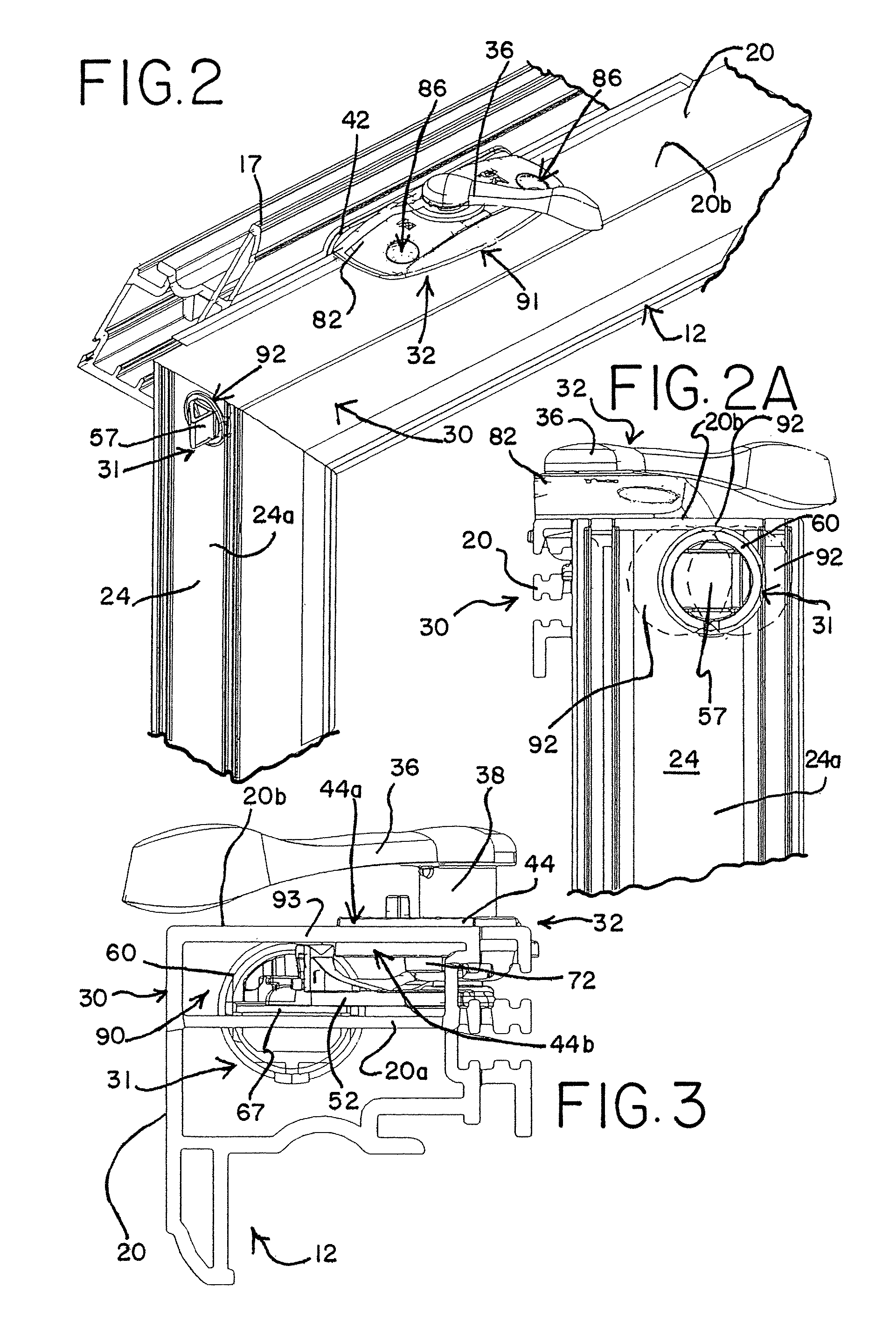

Window latch system

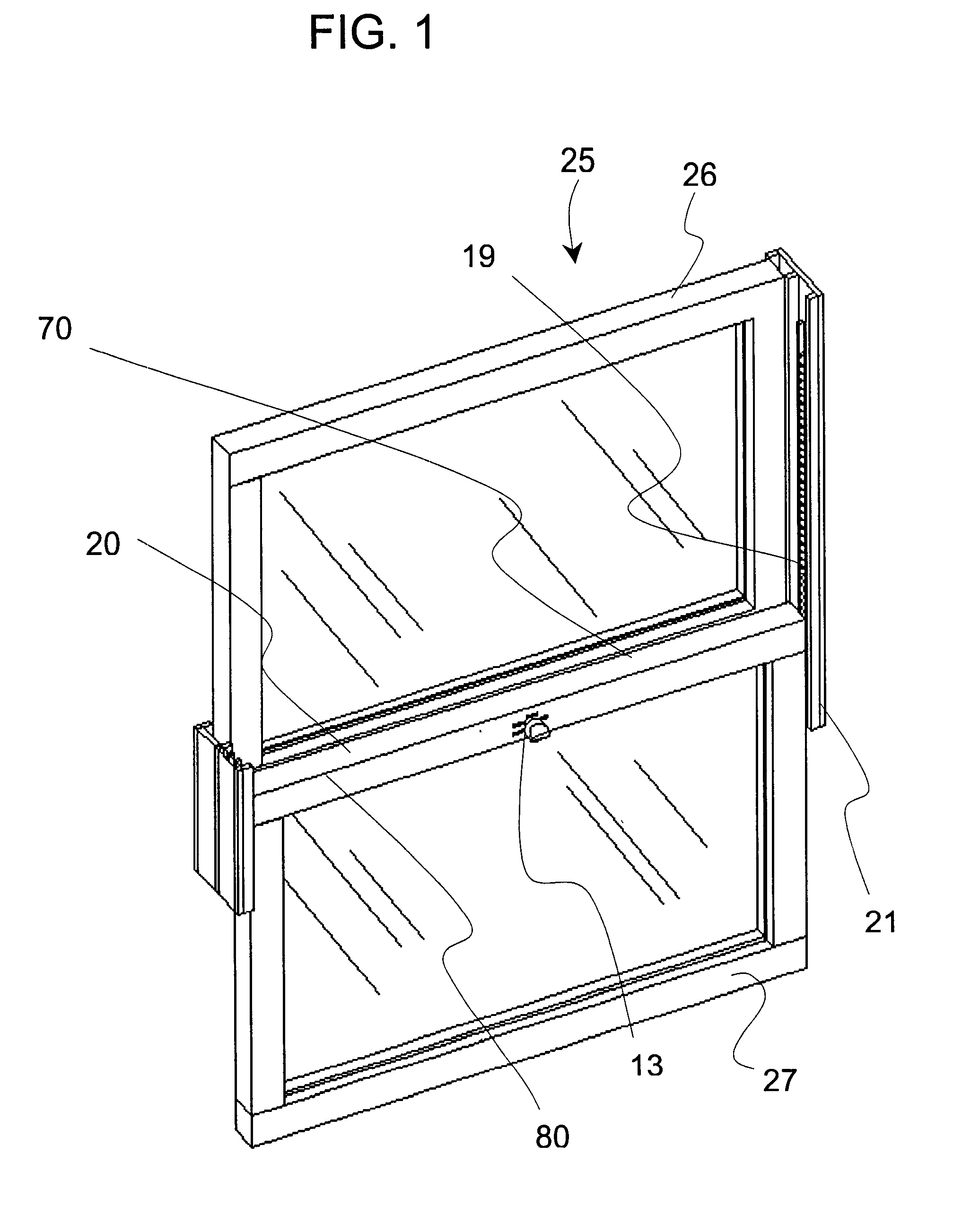

A sliding latch and locking mechanism, for windows and doors, whereby the latching mechanism provides a means for discrete position retention of a sliding window or door and provides an increased measure of security. The latching system combines four modes of operation i.e. lock, close only, raise (free sliding), and tilt to provide angular pivoting of window sash, that allow three levels of security, i.e. fully locked, close only with discrete positions maintained, and raise or lower without discrete positions maintained (free sliding). The latching system security levels are accomplished by means of a selector knob positioned to the desired mode of operation. Also, a mechanism is integrated to provide interlocking in the fully closed position with the upper or adjacent window or door sash.

Owner:ELLIOTT GORDON W

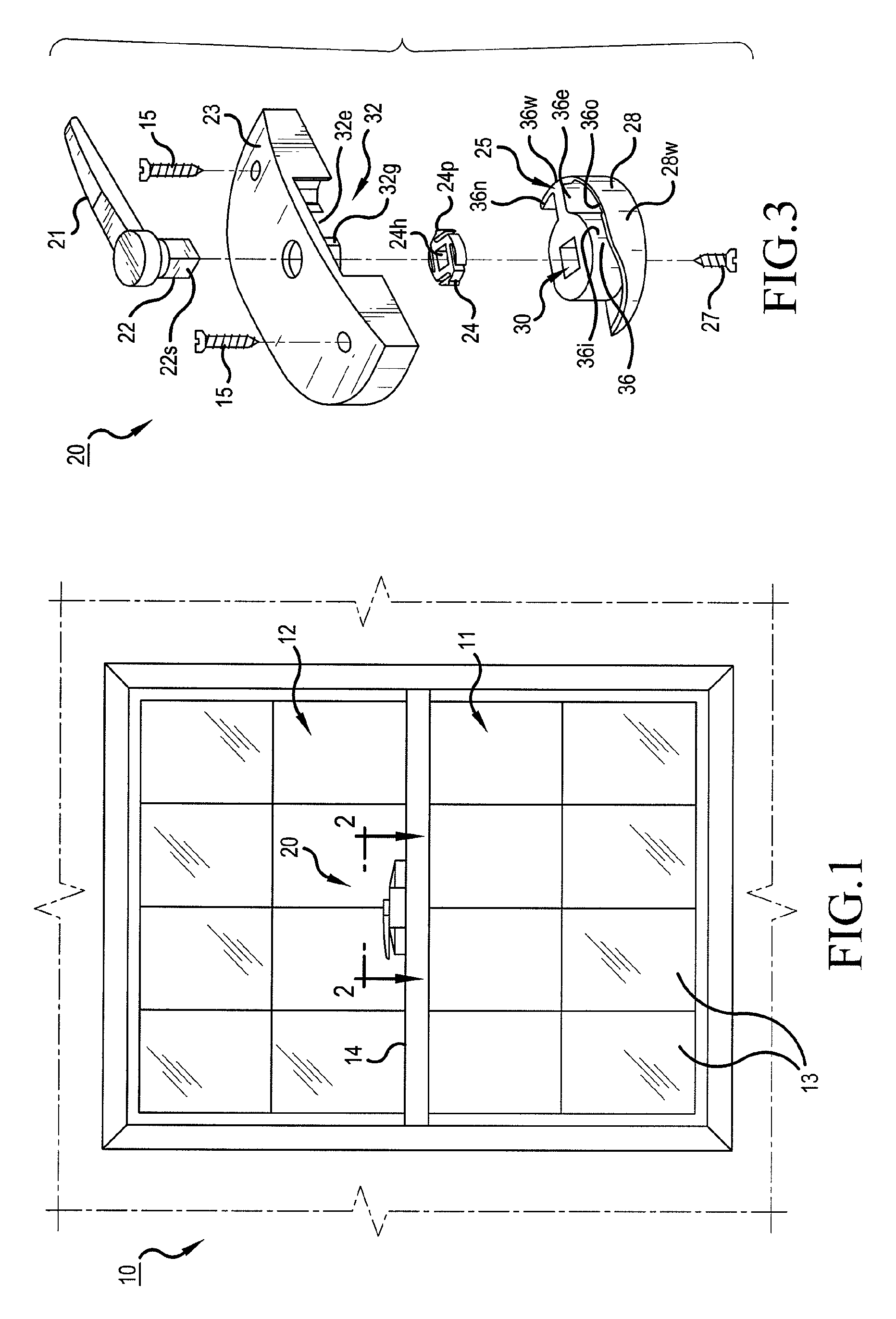

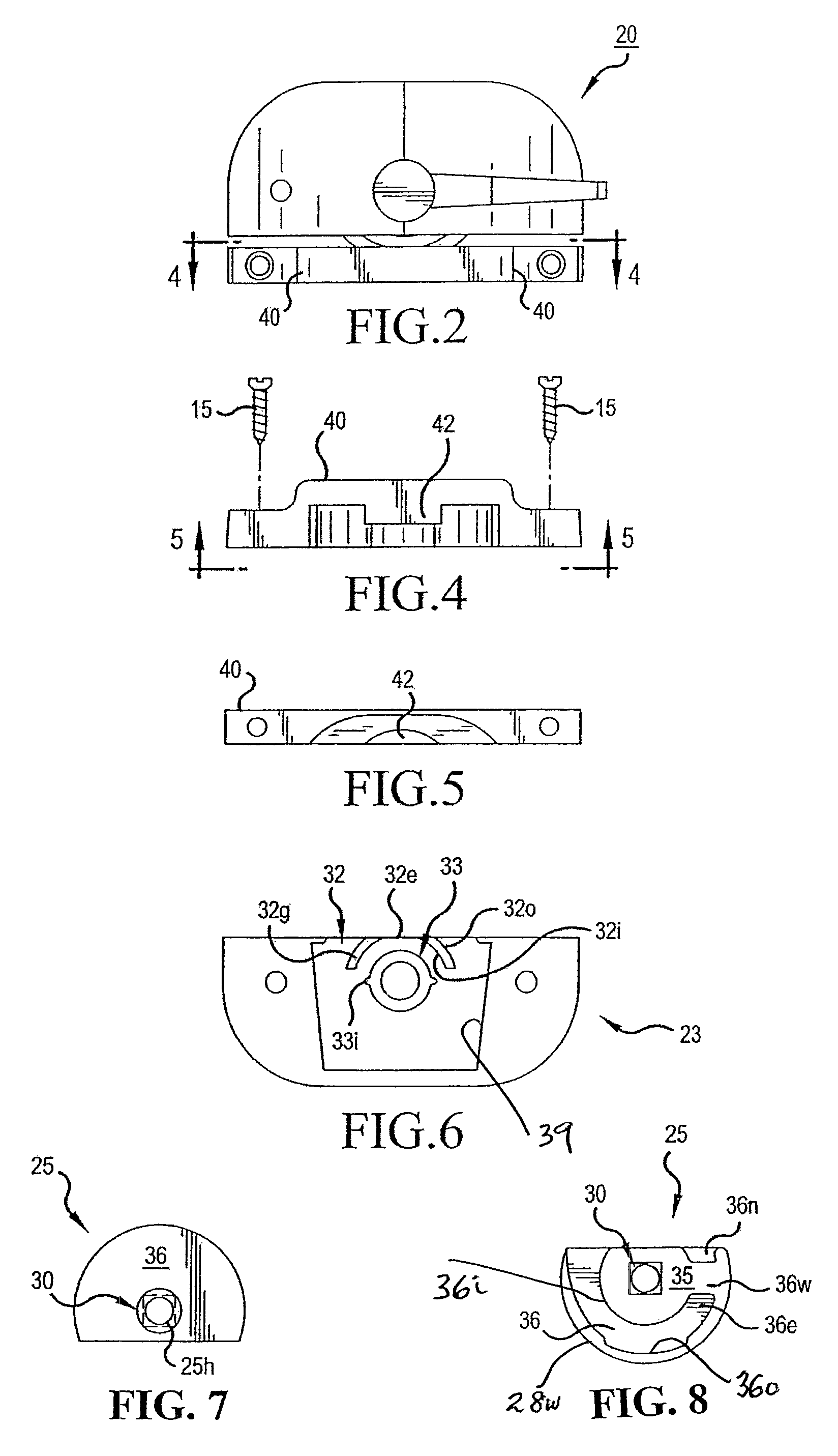

Tilt window latch assembly

Owner:WEATHER SHIELD MFG

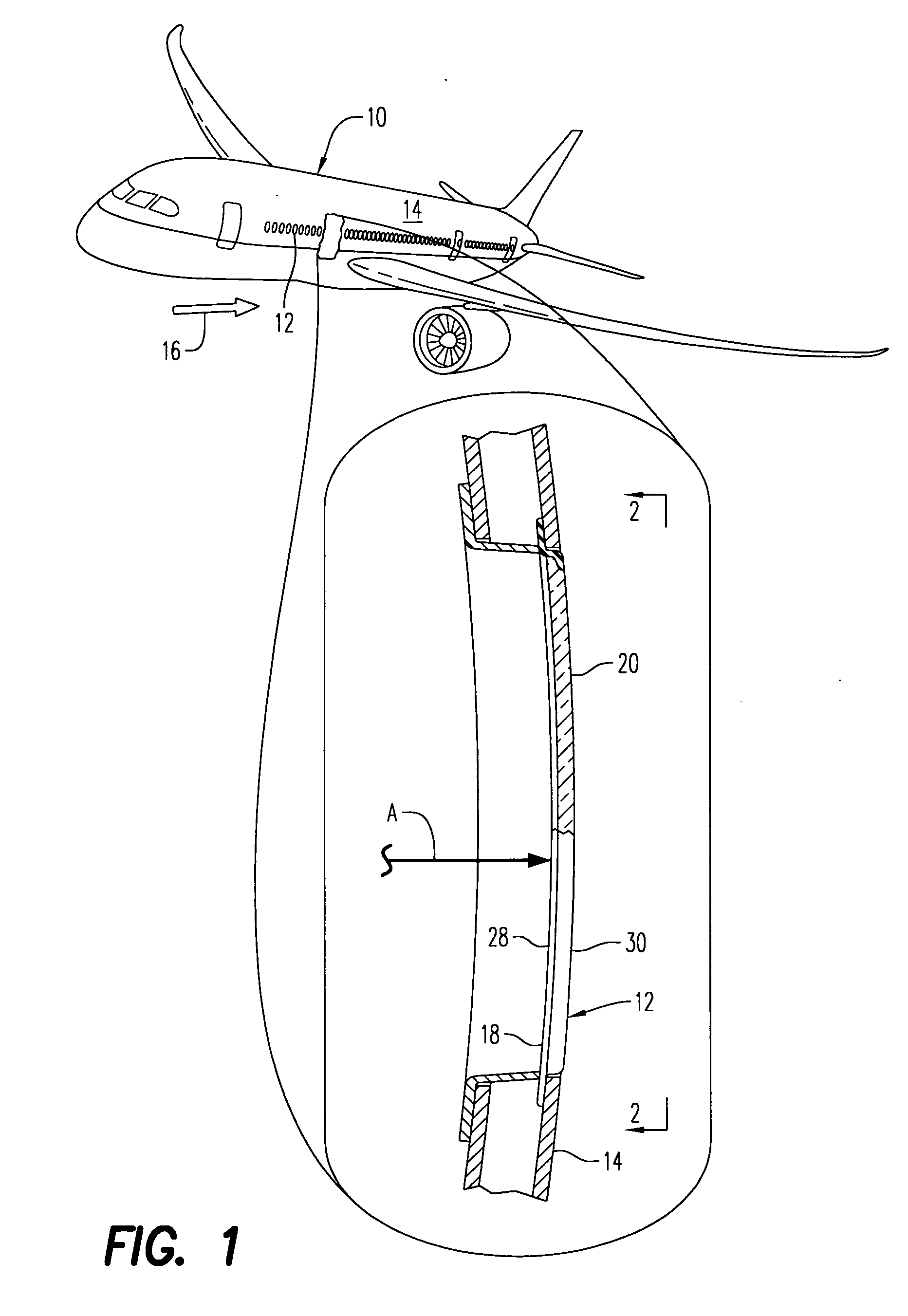

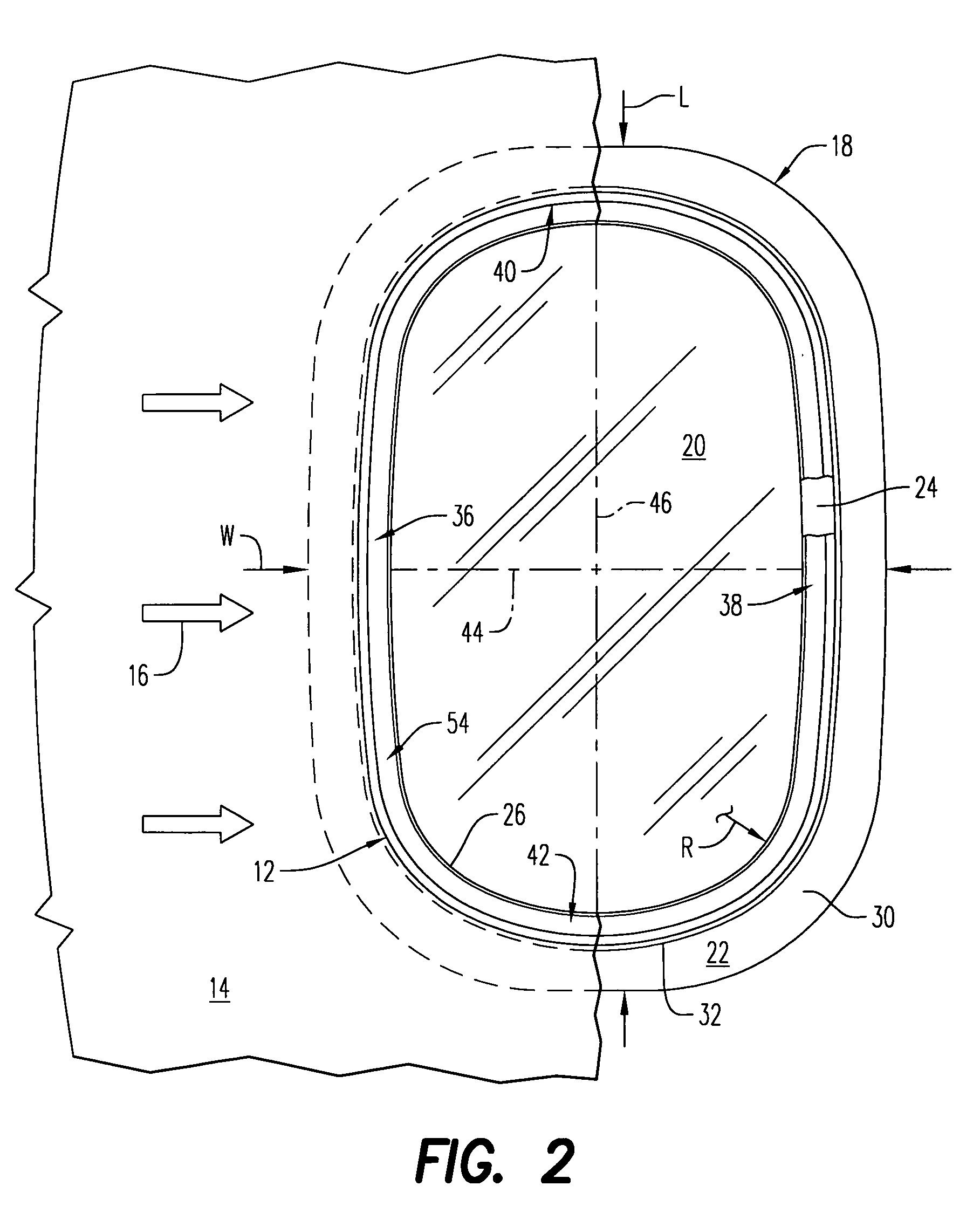

Composite aircraft window frame

An aircraft window frame includes a laminated outer rim and inner sash having a central aperture for receiving a window pane. The sash is transversely offset from the rim and they include different layers between the opposite inboard and outboard sides of the frame.

Owner:NORDAM GROUP

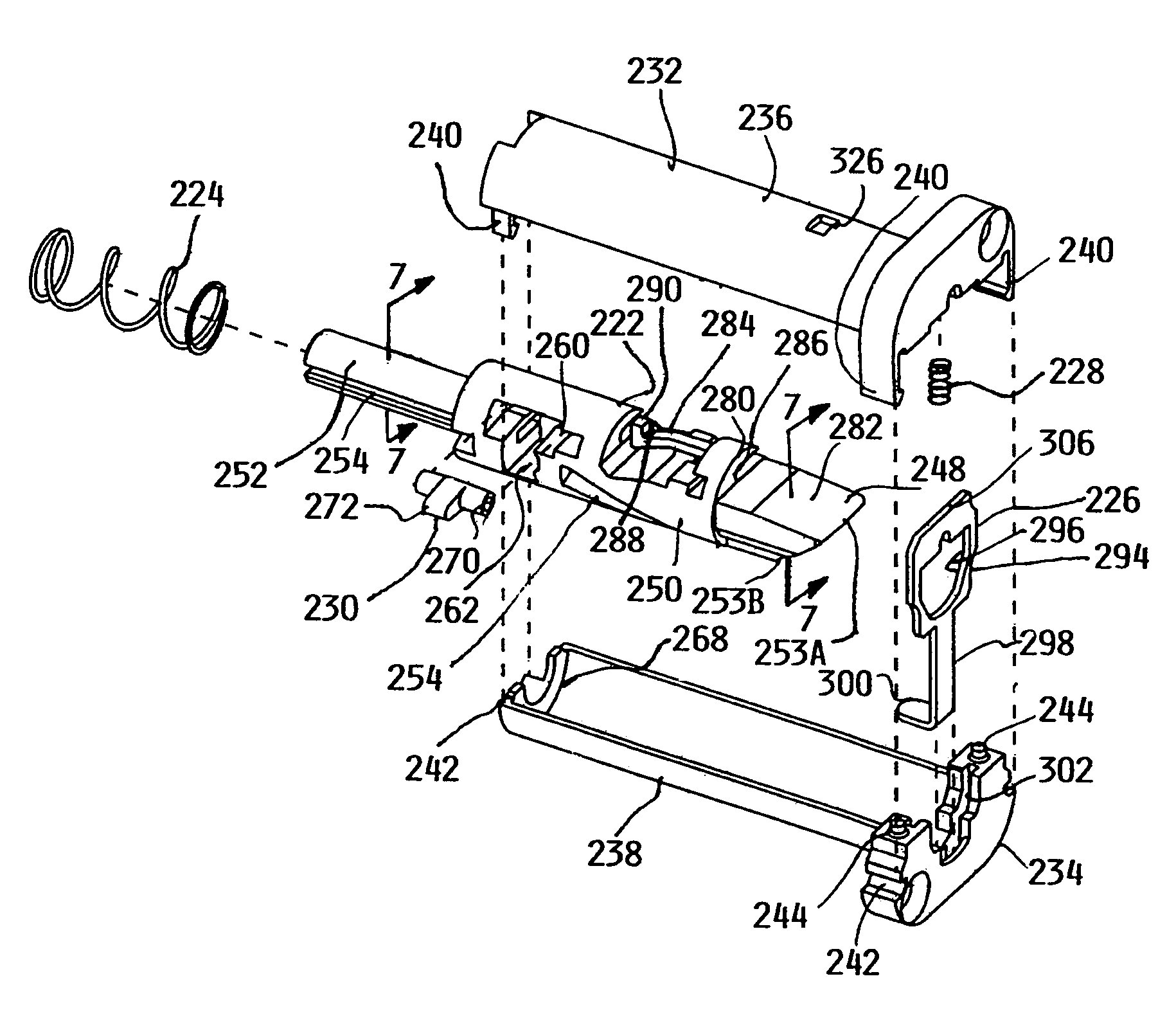

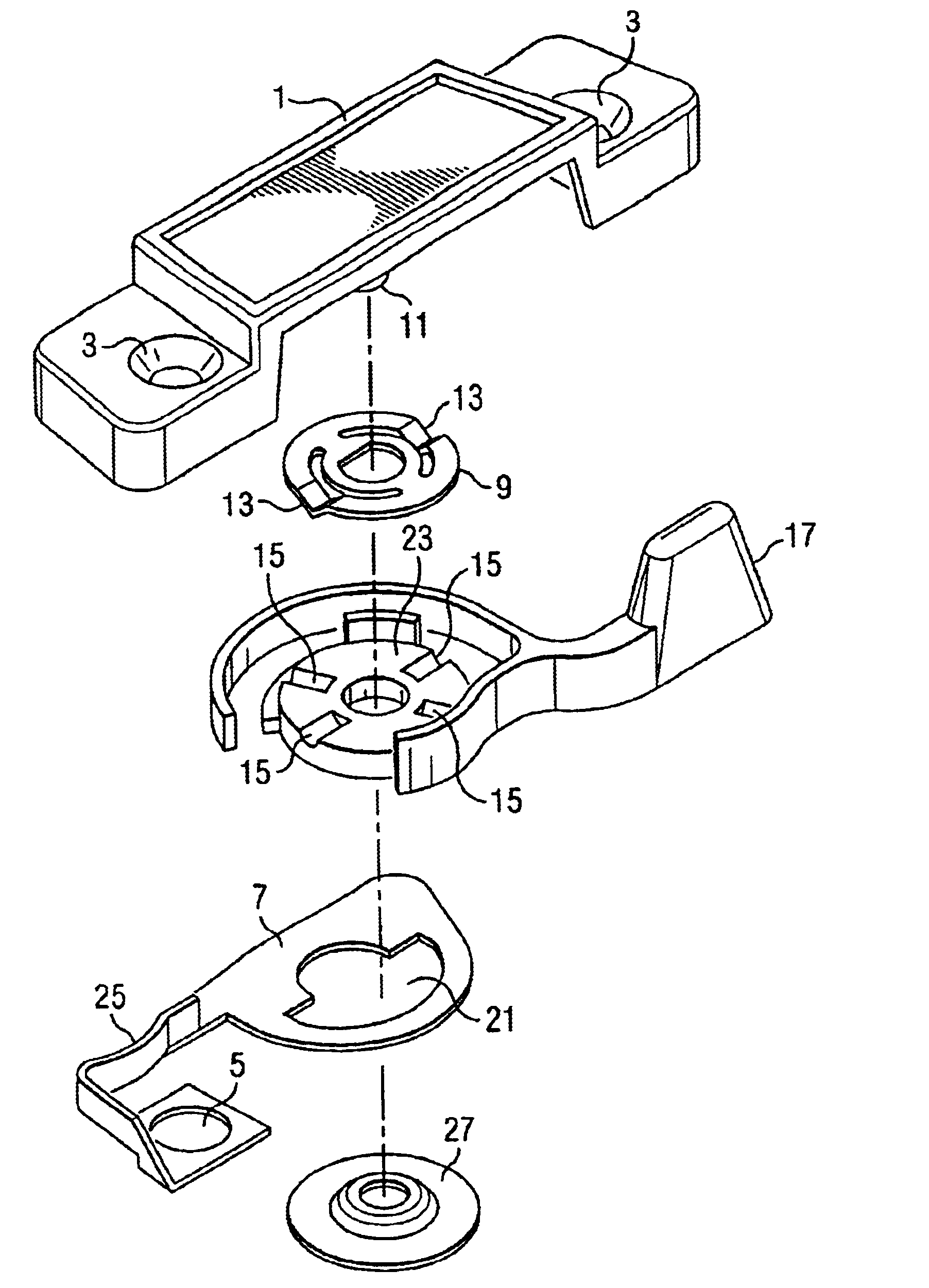

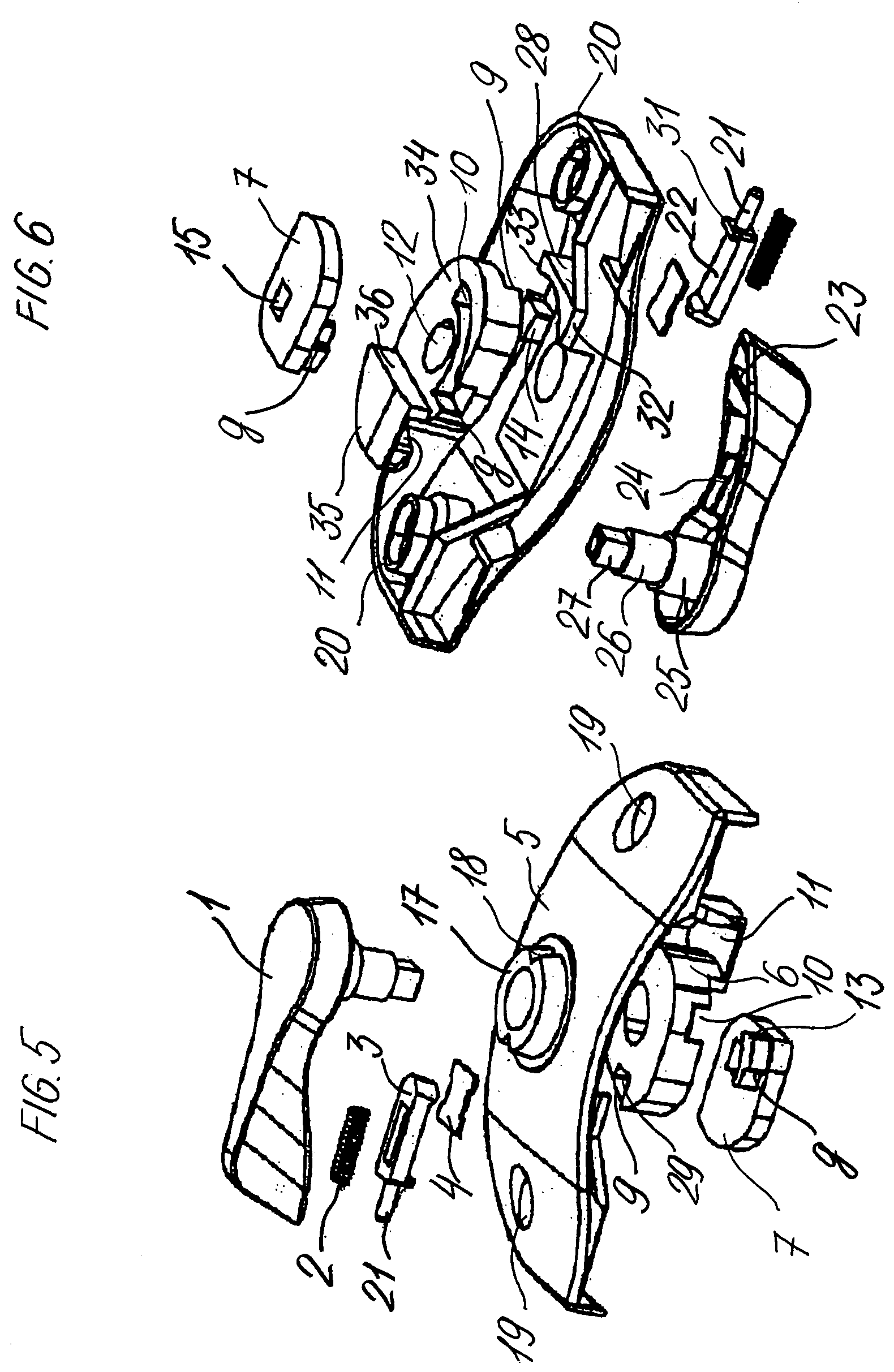

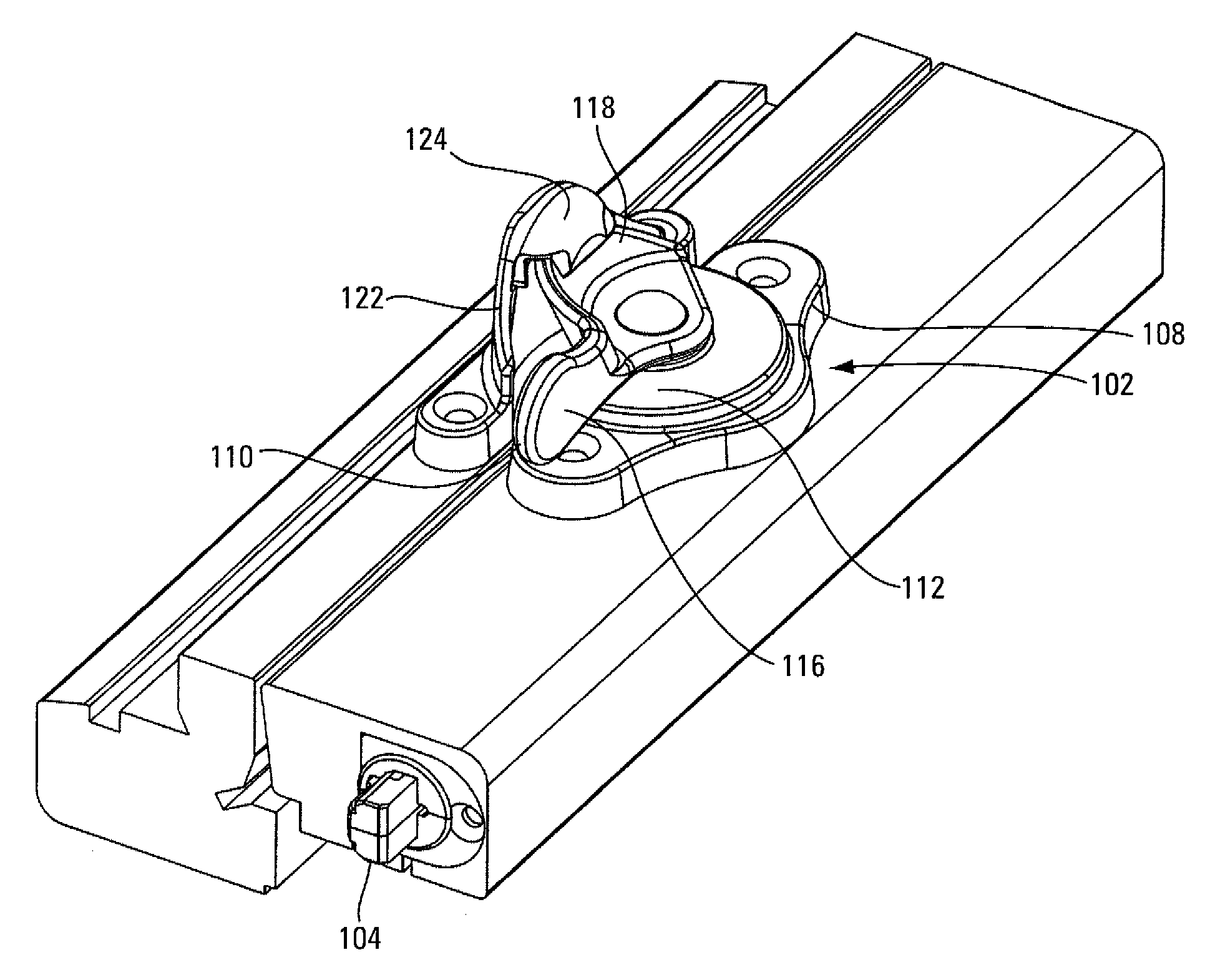

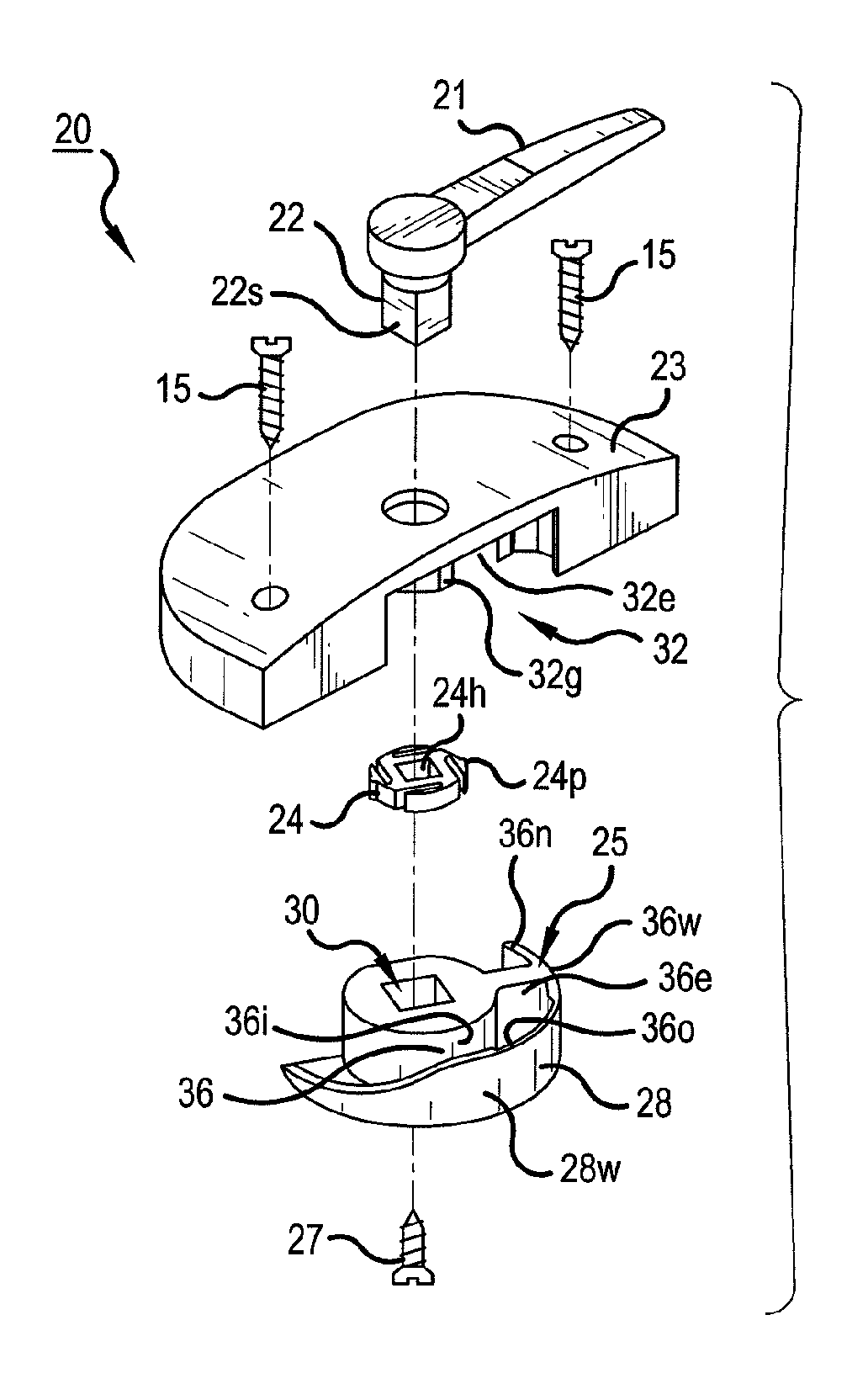

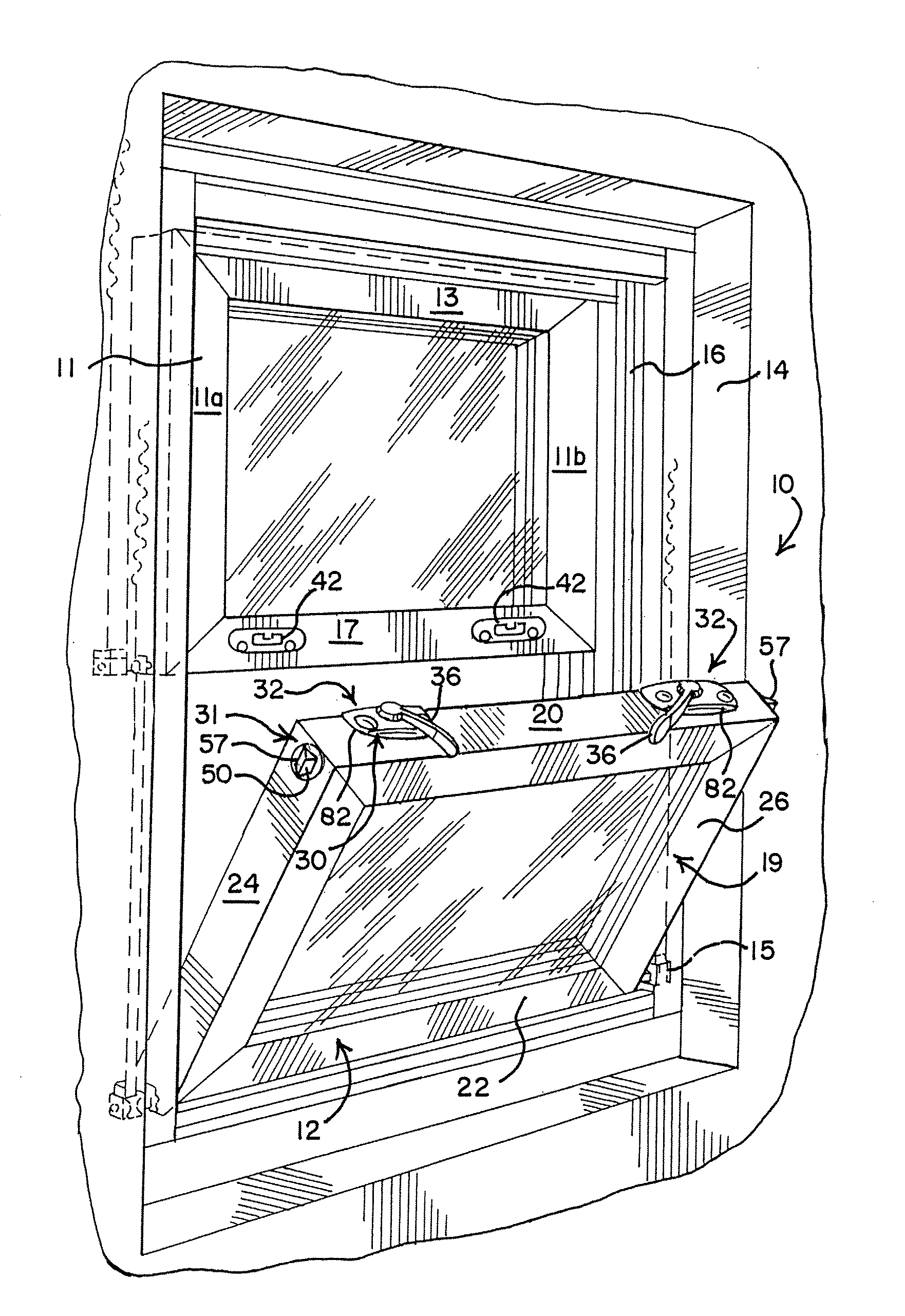

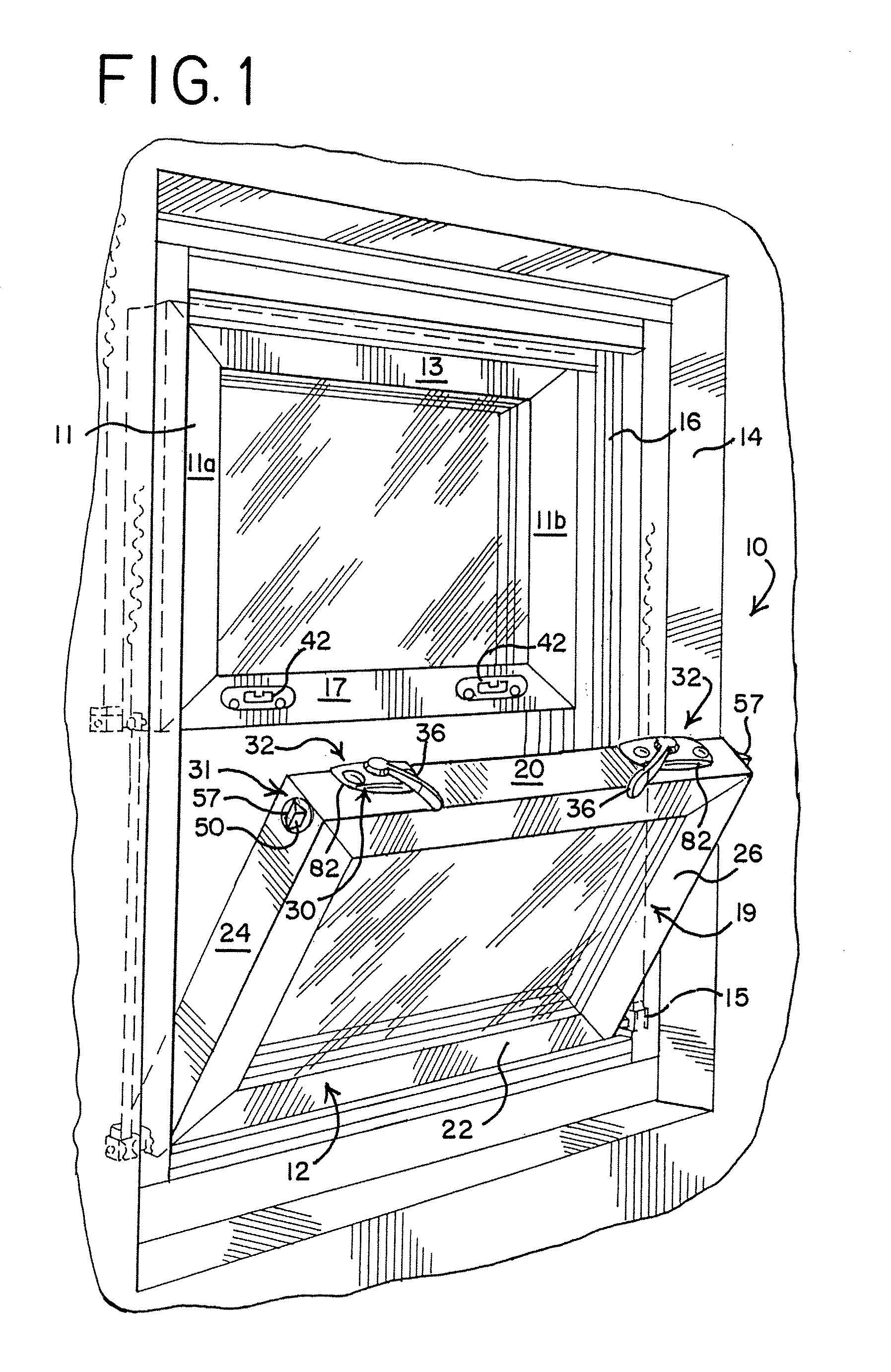

Integrated tilt/sash lock assembly

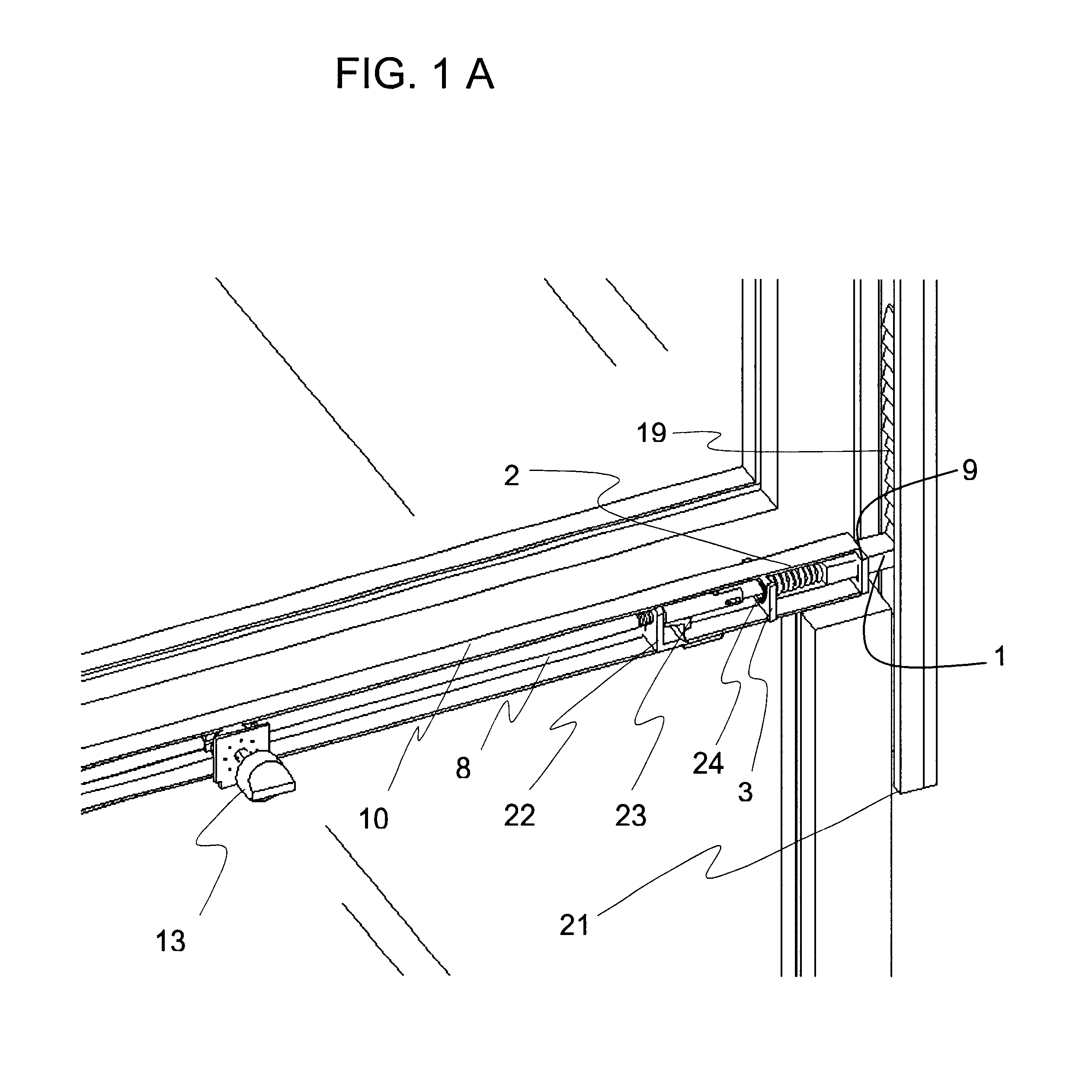

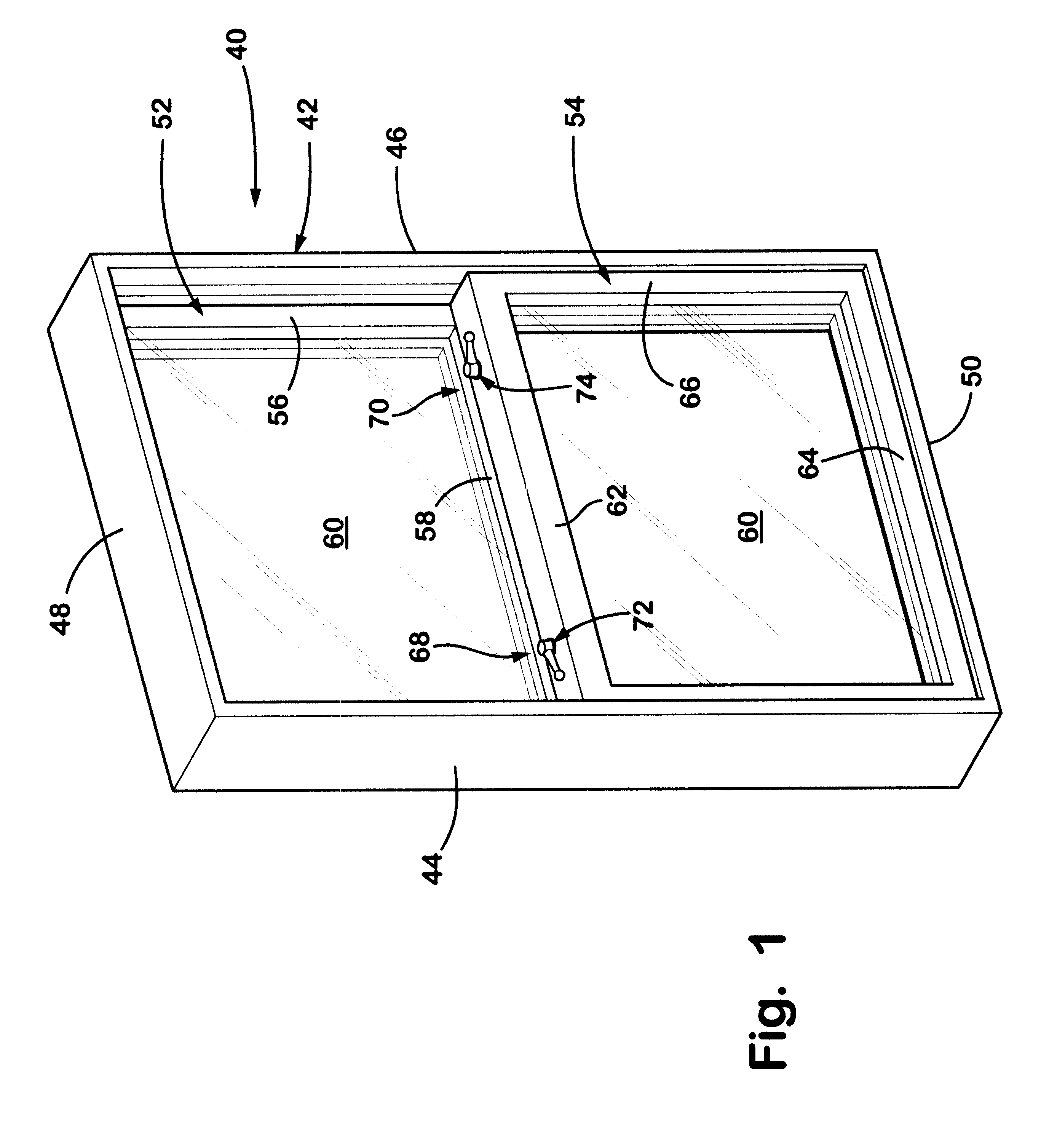

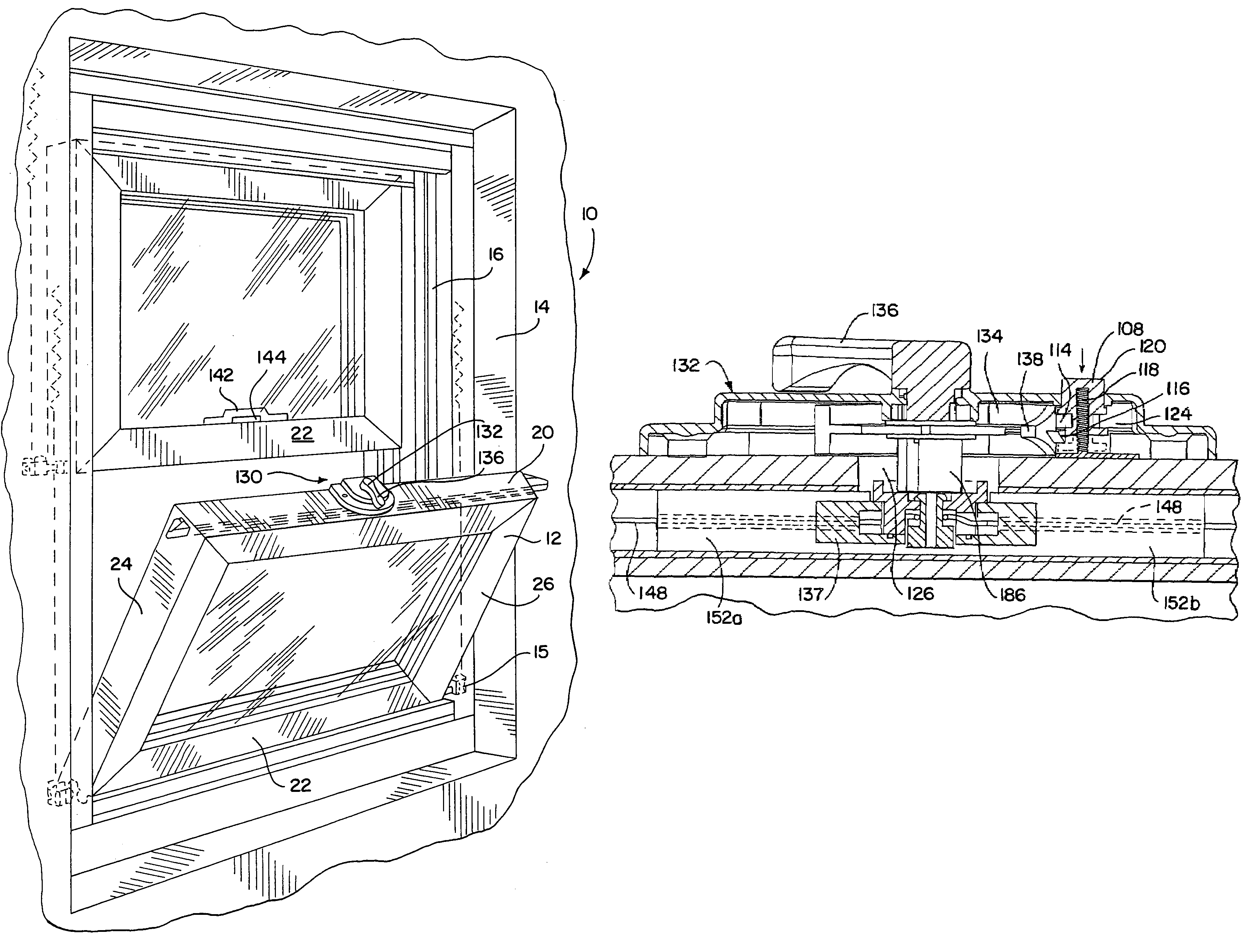

An integrated tilt / sash lock assembly for a sash window is disclosed. The sash window assembly has an upper sash window and a lower sash window slideable within a master frame, the integrated assembly has a keeper adapted to be connected to the upper sash window. A rotor assembly is adapted to be supported by the lower sash window, the rotor assembly having a rotor connected to a spool. A latch bolt is adapted to be supported by the lower sash window and is adapted to engage the master frame. A connector has a first end connected to the spool and a second end connected to the latch bolt. An actuator is connected to the rotor assembly. The actuator has a locked position wherein the rotor engages the keeper. The actuator is moveable to an unlocked position wherein the rotor assembly is disengaged from the keeper, and is further moveable to a tiltable position wherein the connector retracts the latch bolt from the master frame.

Owner:ASHLAND HARDWARE LLC

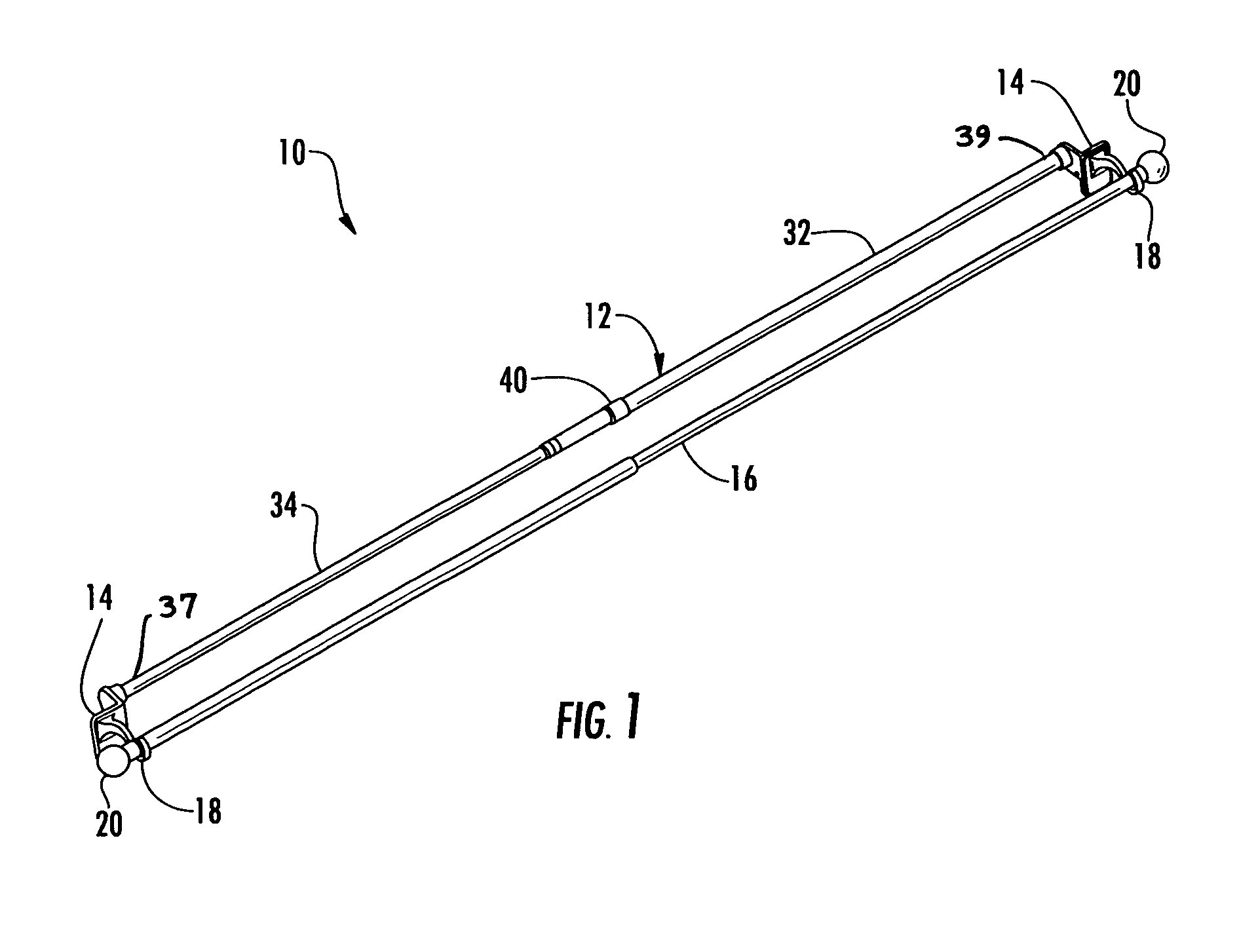

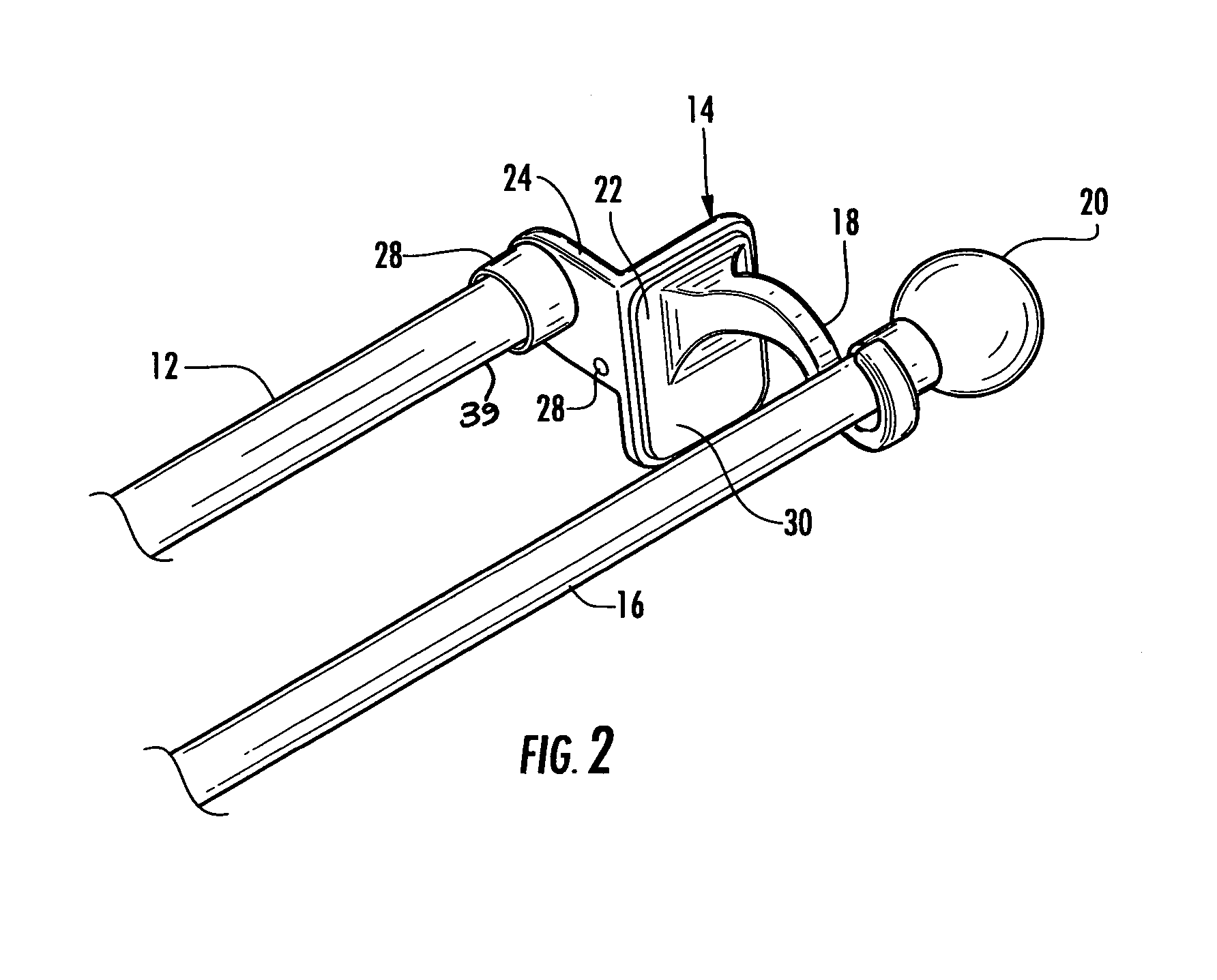

Tool-less double curtain rod assembly

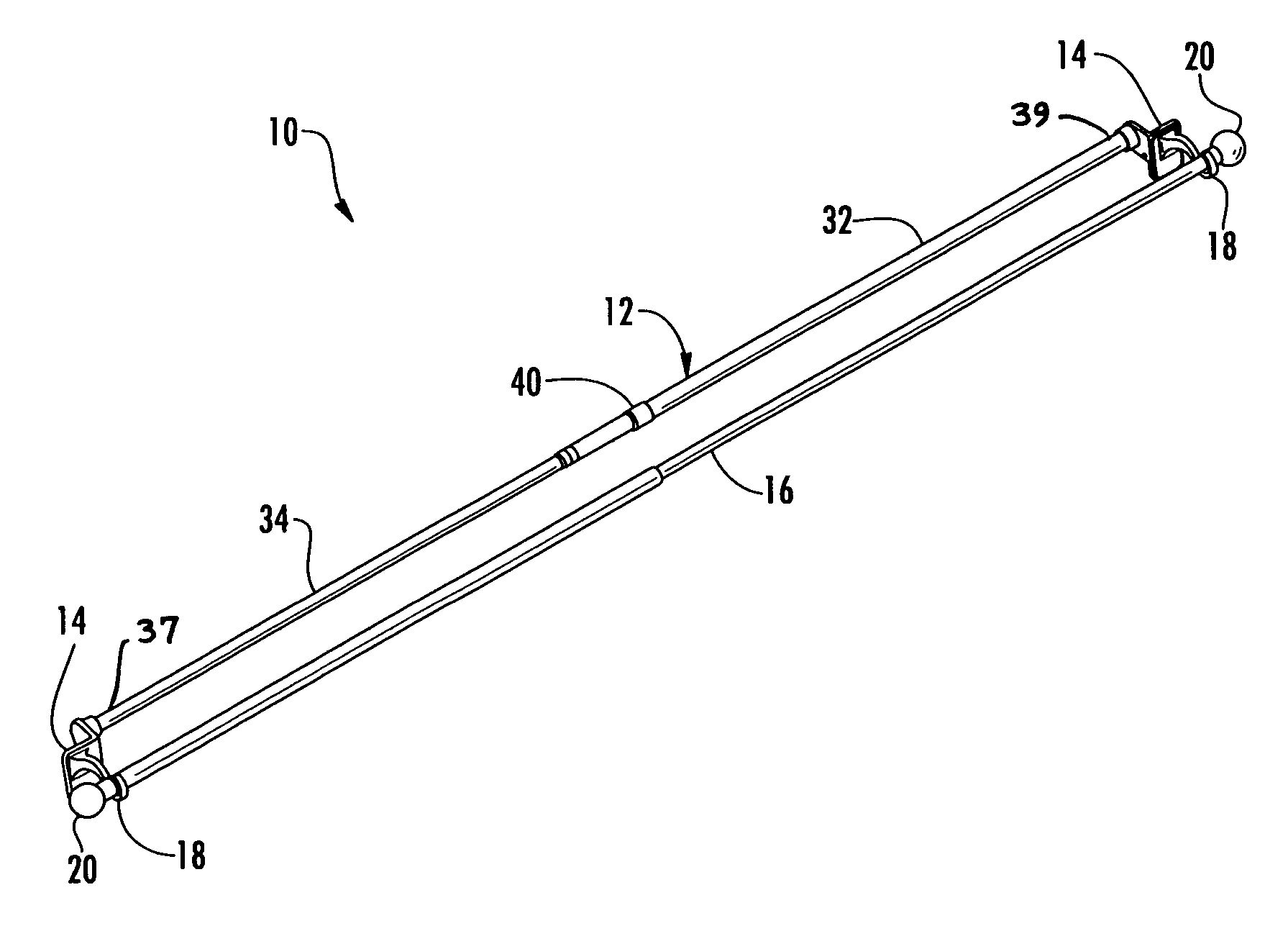

A curtain rod assembly for a window having a window casement is disclosed. The curtain rod assembly includes left and right brackets. Each bracket has a curtain rod support extending therefrom. An adjustable support rod is coupled to the left and right brackets. The adjustable support rod is configured and arranged to brace the left bracket and the right bracket against the window casement. A decorative curtain rod is suspended between the curtain rod supports.

Owner:KENNEY MFG

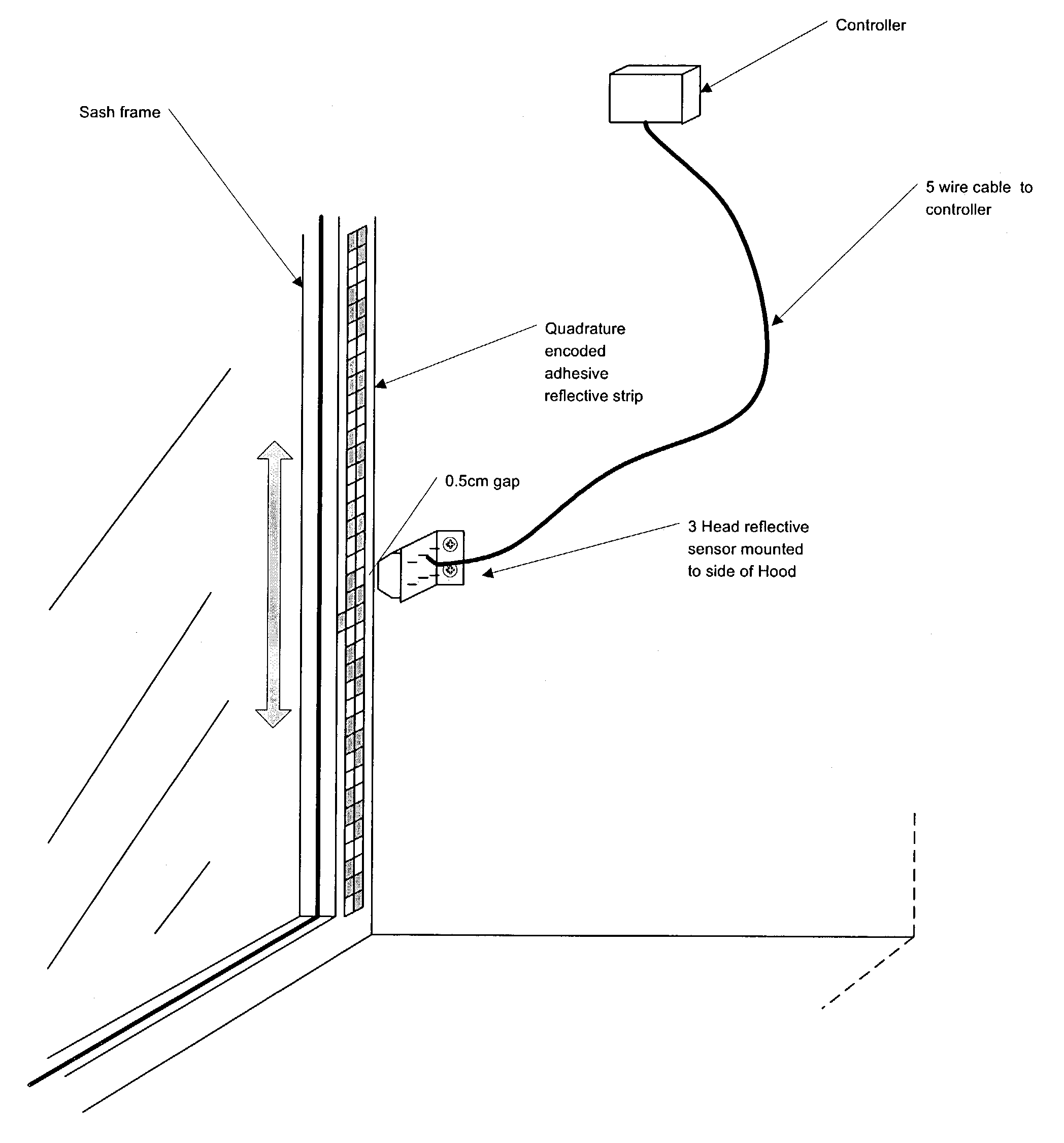

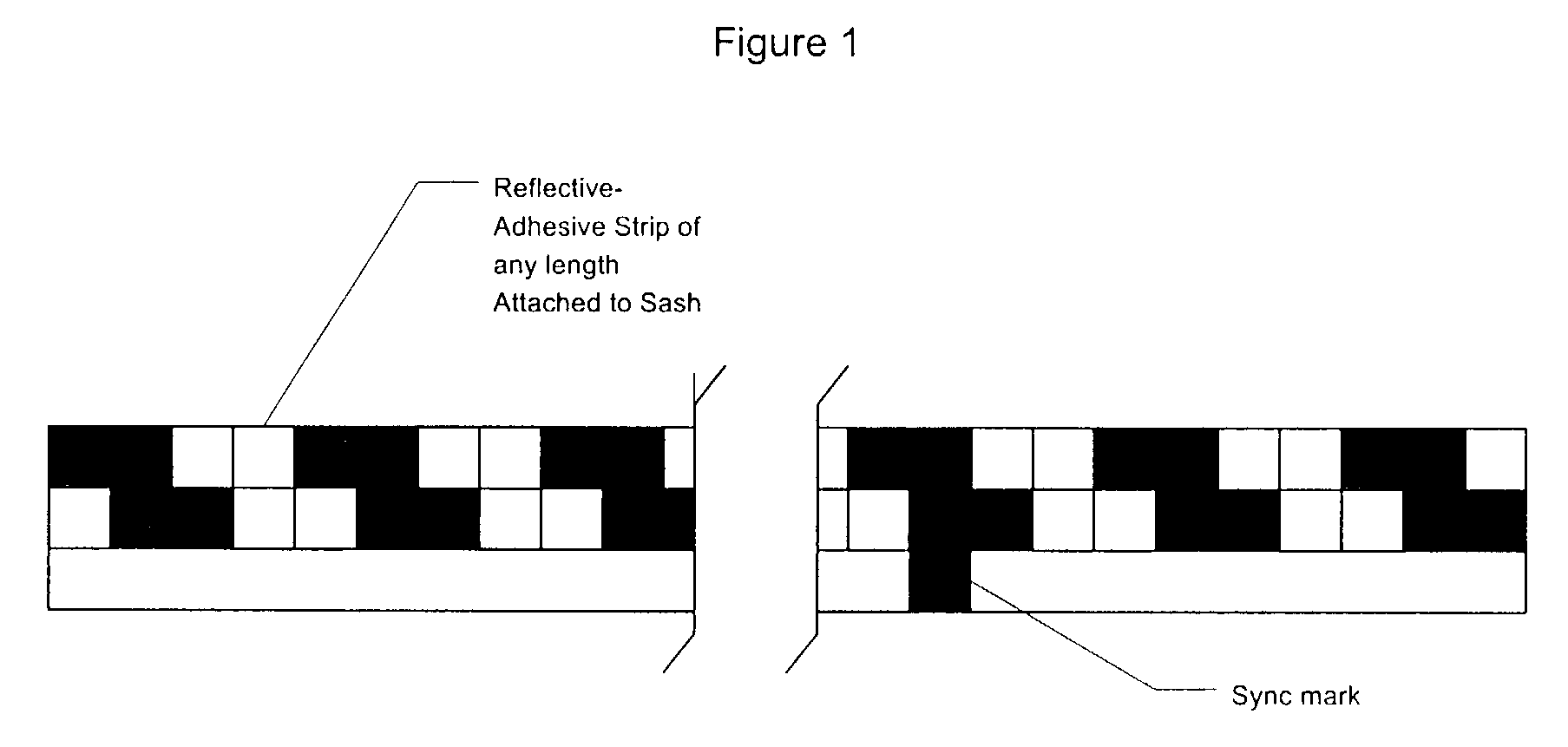

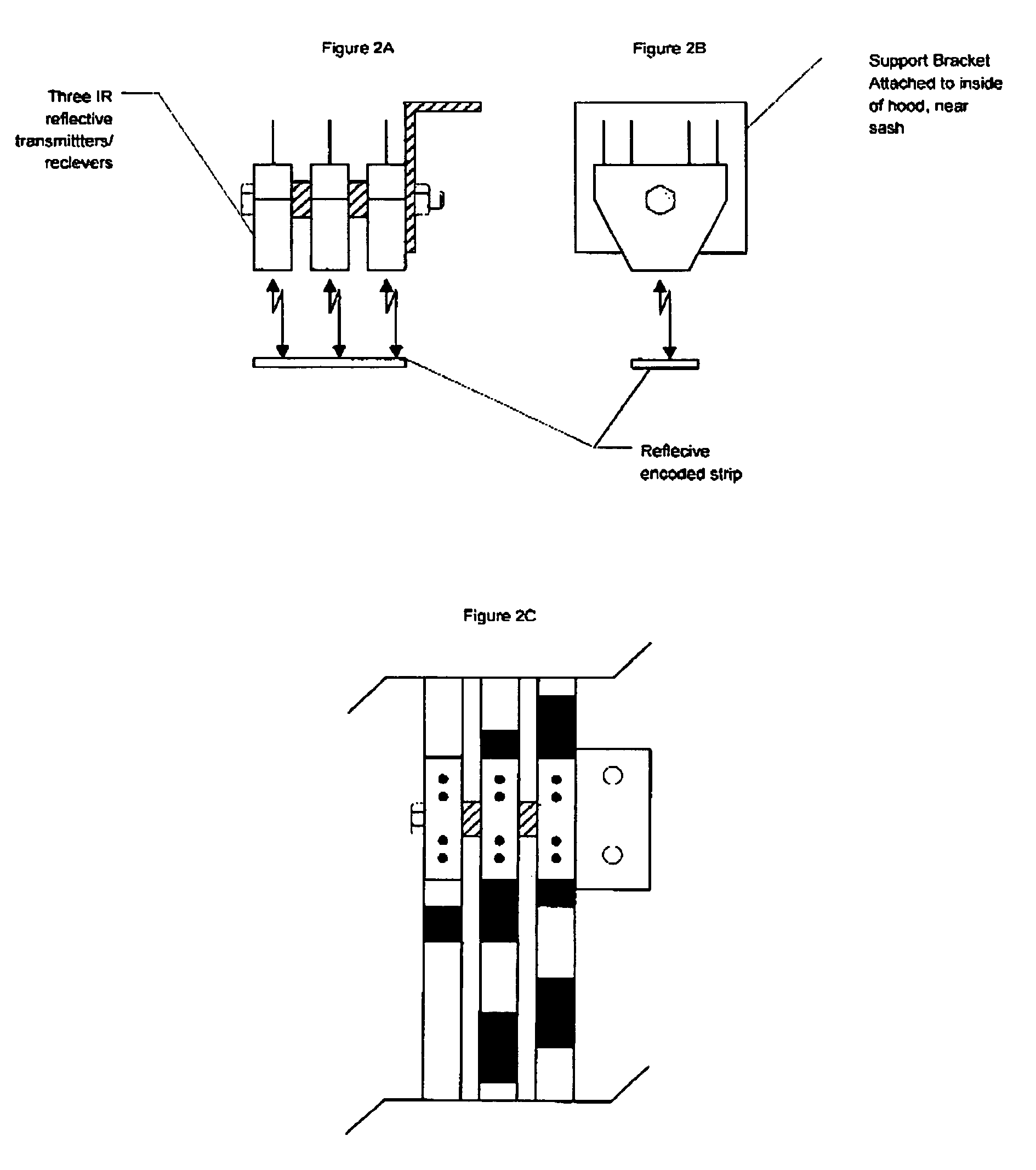

Optical sash sensing system for fume hoods

InactiveUS6994619B2Domestic stoves or rangesSpace heating and ventilation safety systemsSash windowControl signal

A fume hood optical sash sensing system for controlling the flow of air into a fume hood to maintain a constant face velocity by utilizing an optical sensing device mounted inside the fume hood that can sense the movement of a sash based on repeatable reflexive tape to produce an output control signal that corresponds to sash movement to produce desired airflow into the fume hood. The system includes an optical sensing device with a light source, reflexive tape with a repetitive, quadrature encoded pattern, a smart controller device that receives output control signals from the optical sensing device, and an actuation device capable of receiving the output signal from the controlling device to control the damper device that will result in constant face velocity across the face of the sash.

Owner:TRIATEK HLDG

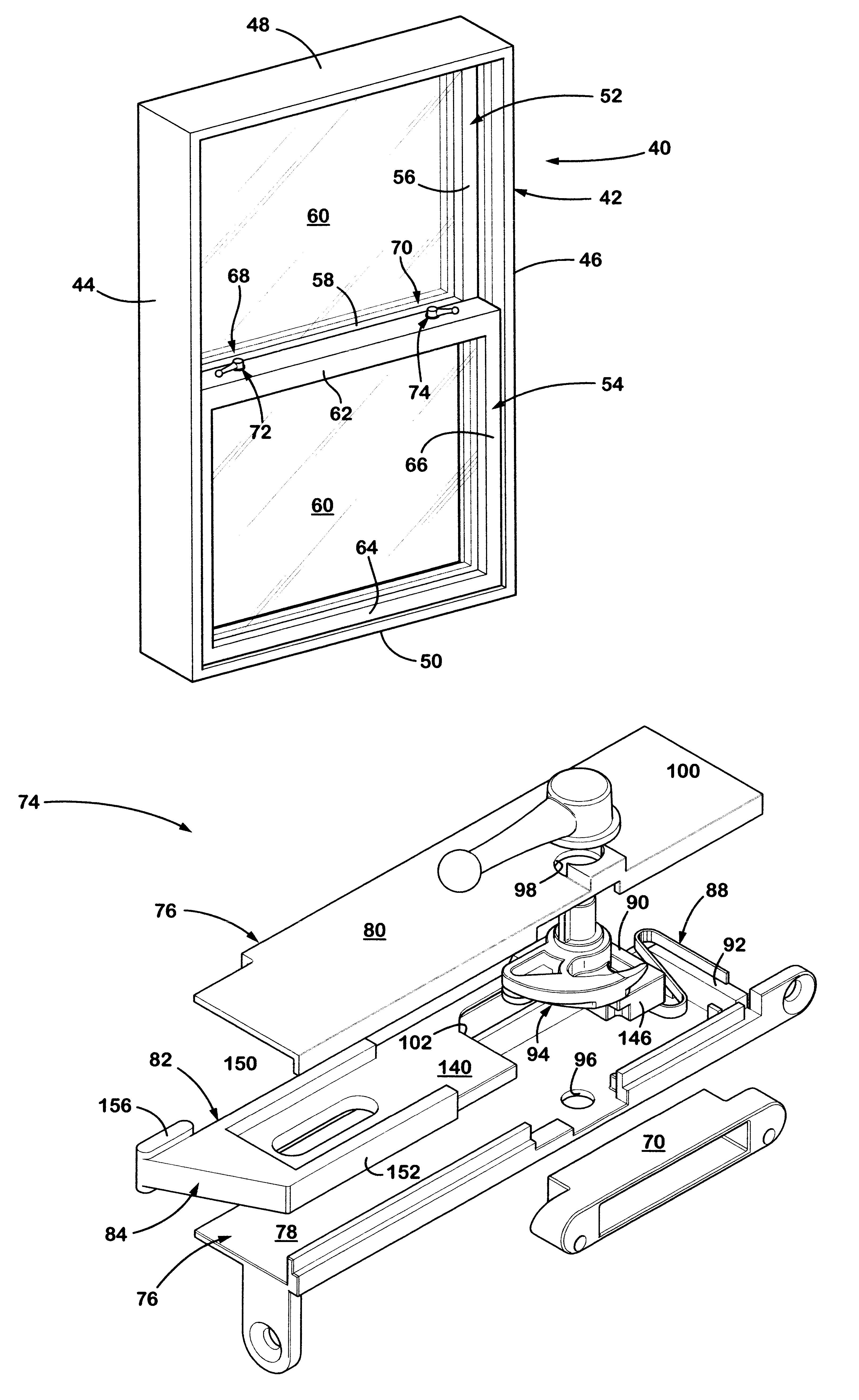

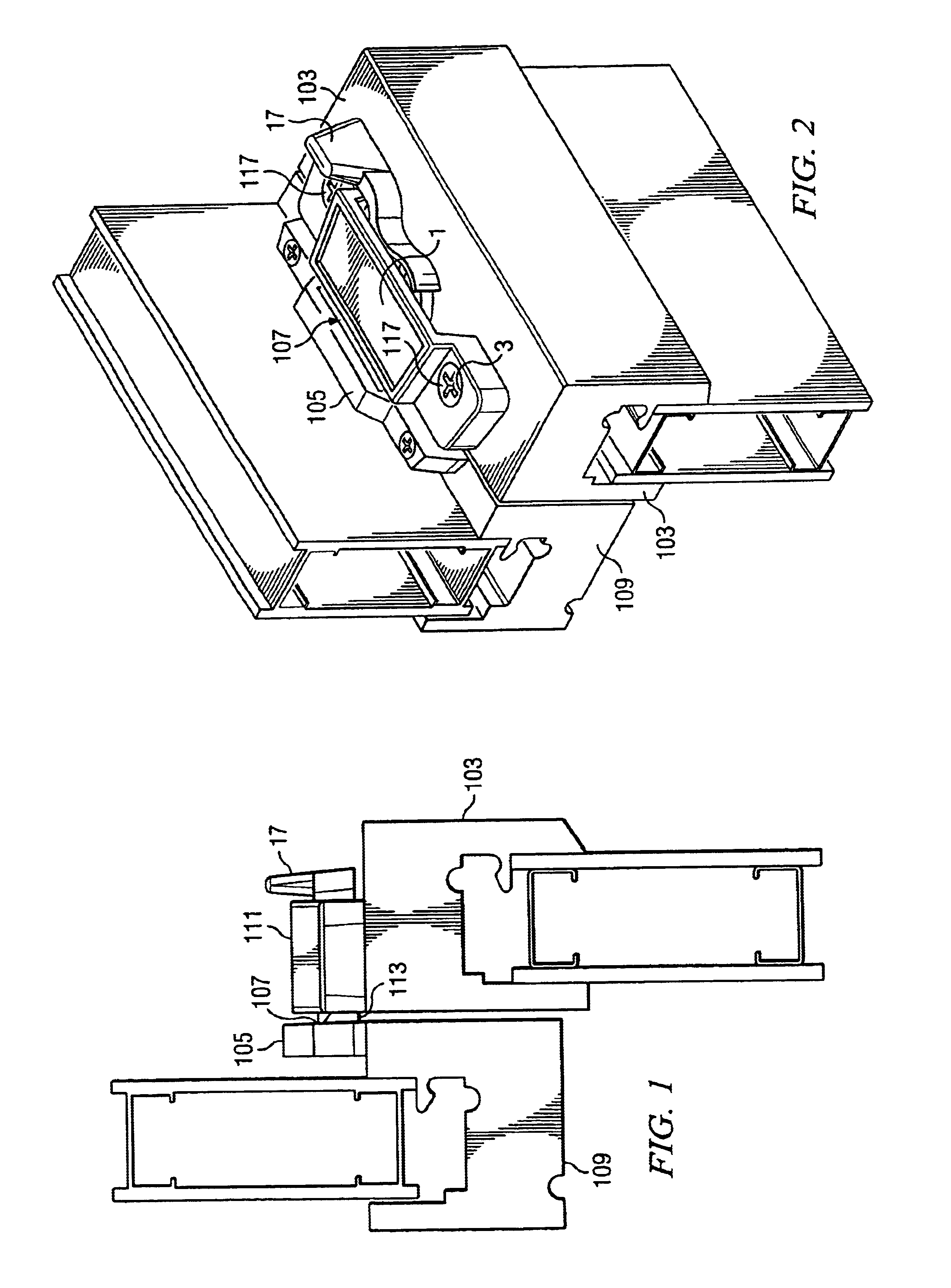

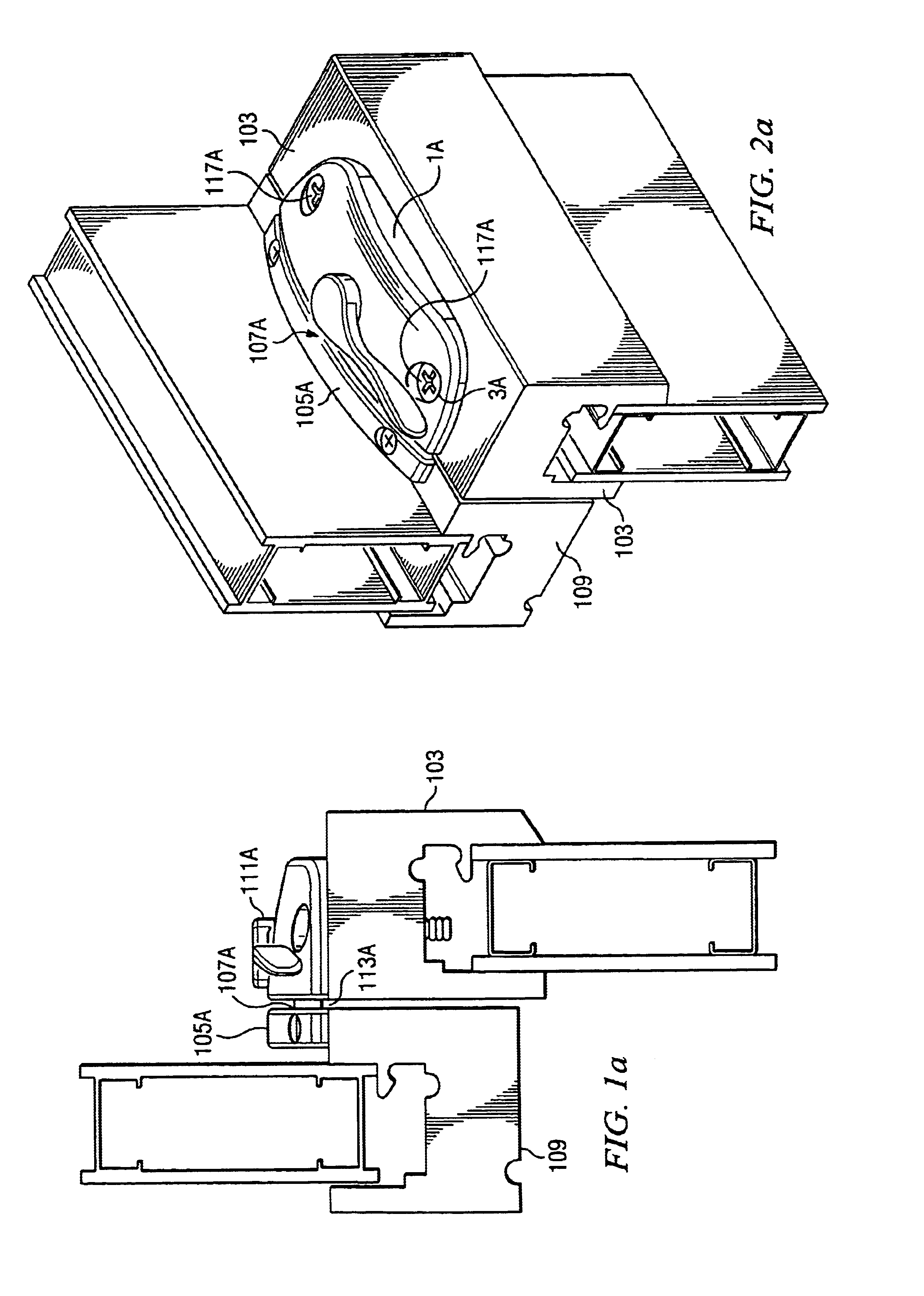

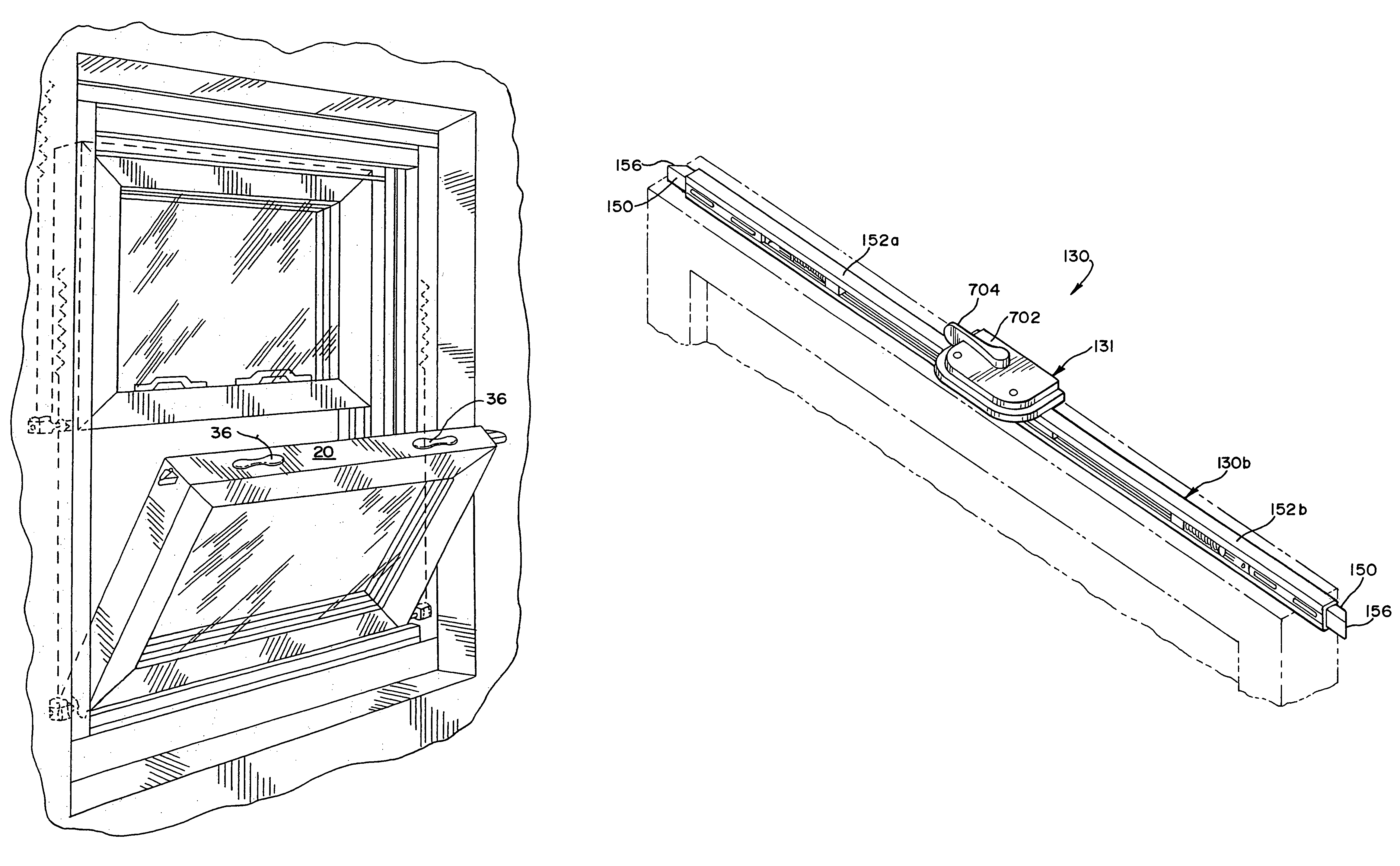

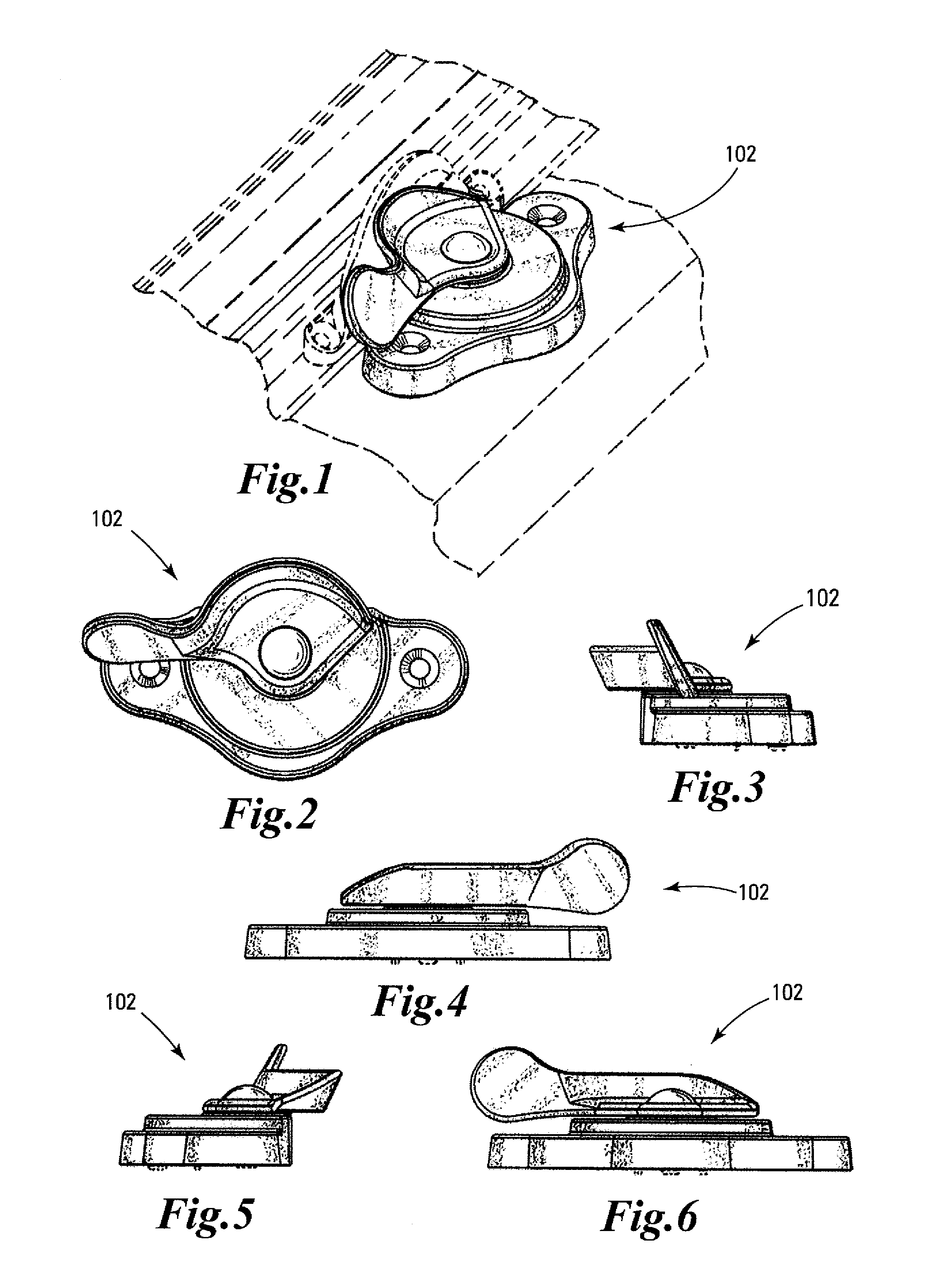

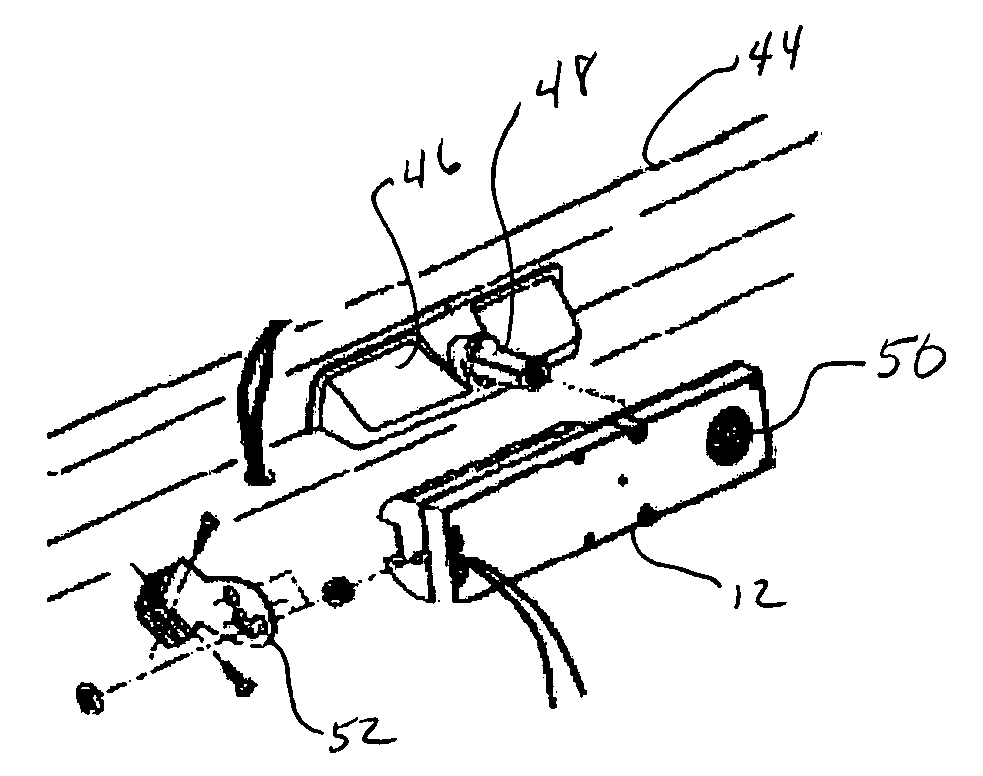

Integrated lock and tilt-latch mechanism for a sliding window

ActiveUS7322619B2Easy to installEnable tilting of the sashWing fastenersMechanical controlsSash windowSlide window

A low-cost combination tilt-lock-latch mechanism for a sliding window that combines ease of installation and adjustment with simplicity of use. The mechanism includes at least one tilt-latch mechanism adapted for mounting in the window sash. The tilt-latch mechanism includes a housing and a plunger having a latch bolt portion retractable within the housing. A plunger latch member automatically latches the plunger in a retracted position to enable tilting of the sash. Further, the mechanism may include an actuator mechanism and a flexible linking member. The tilt-latch may include a locking member adjustable from outside the housing of the tilt latch, to lock the flexible linking member to the plunger, thereby operably coupling the actuator mechanism with the tilt-latch.

Owner:TRUTH HARDWARE

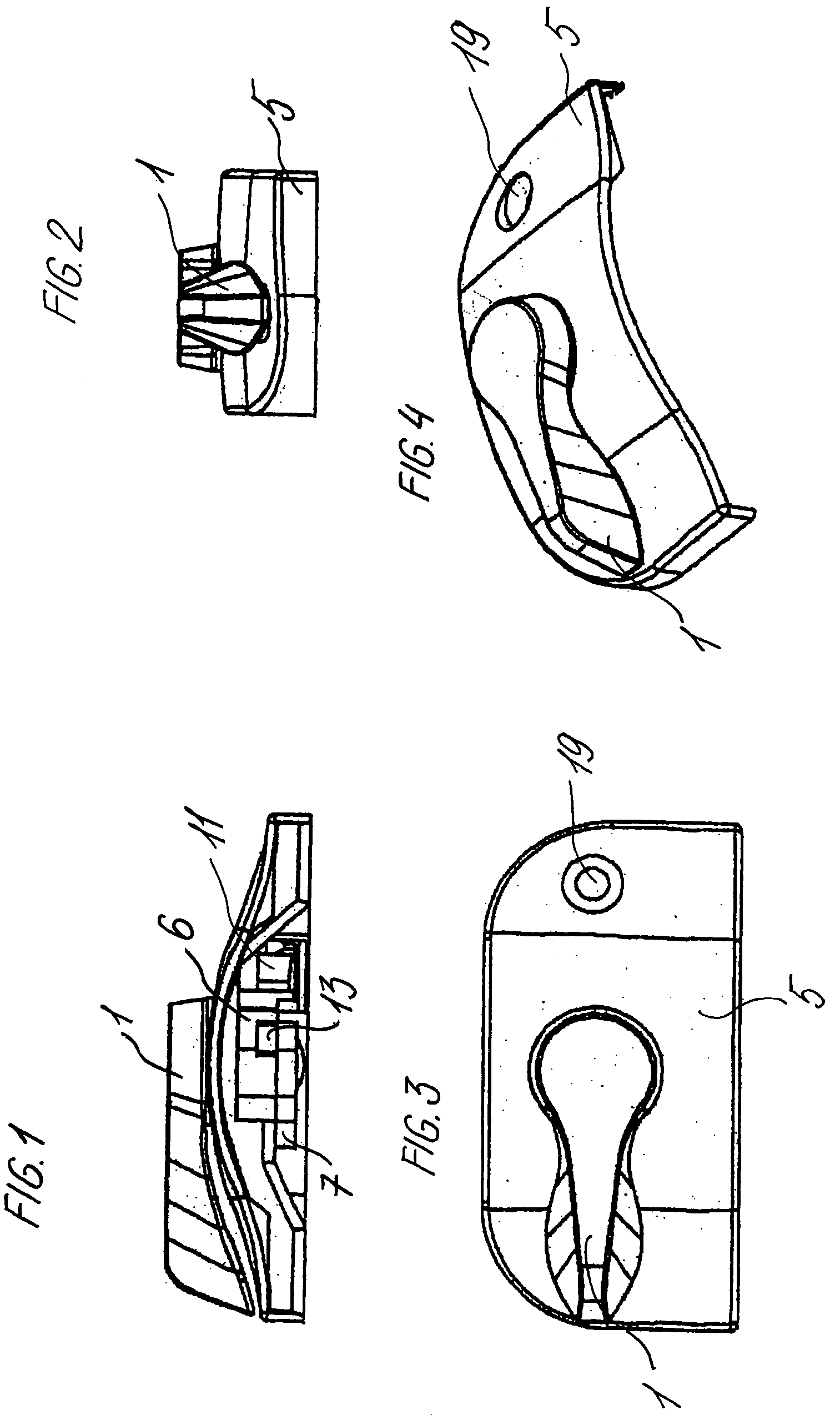

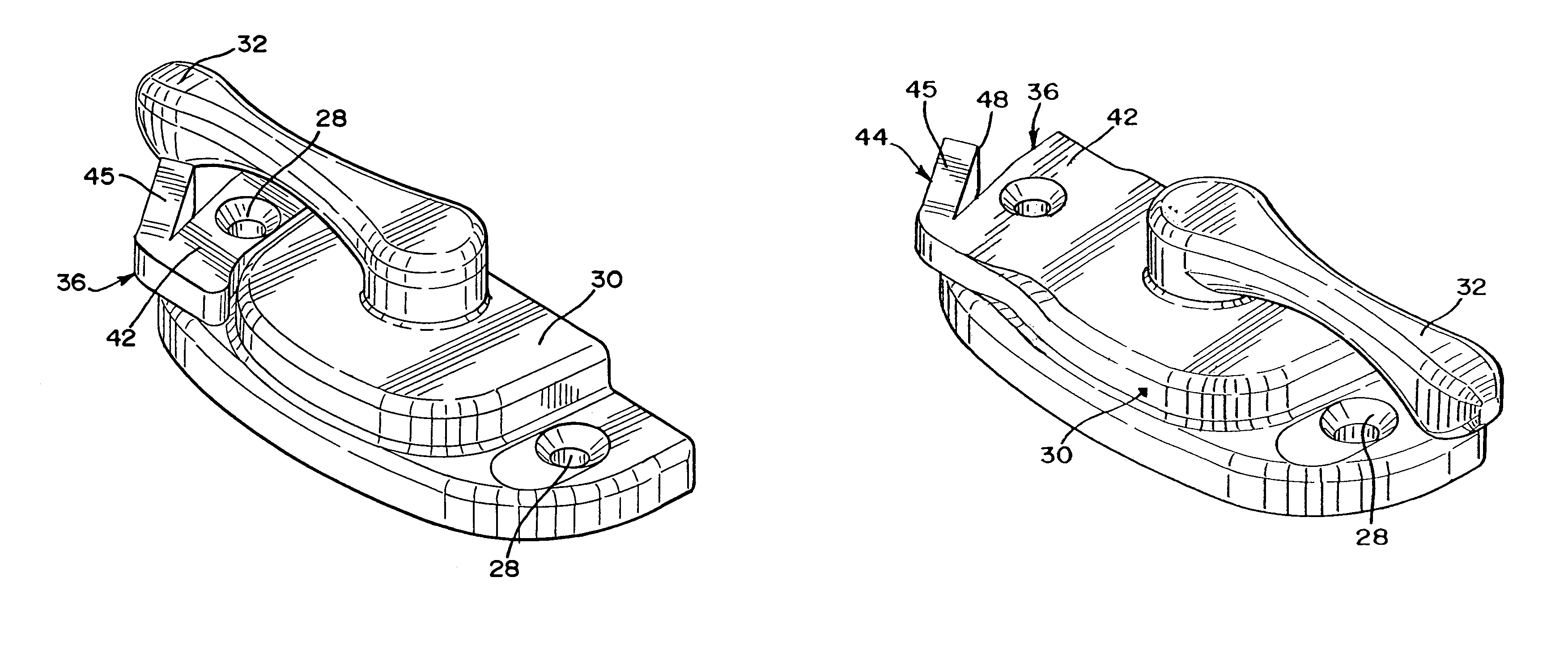

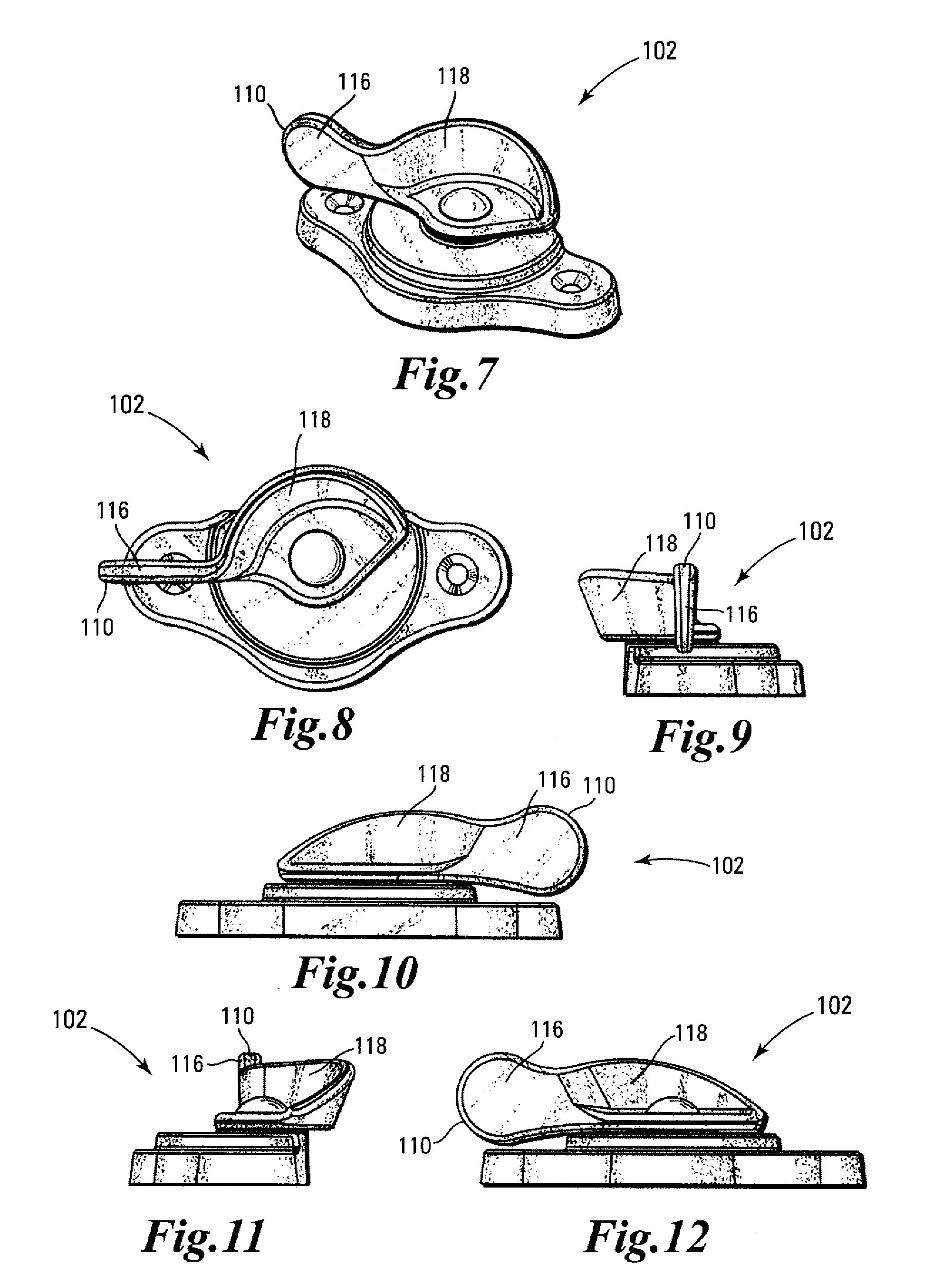

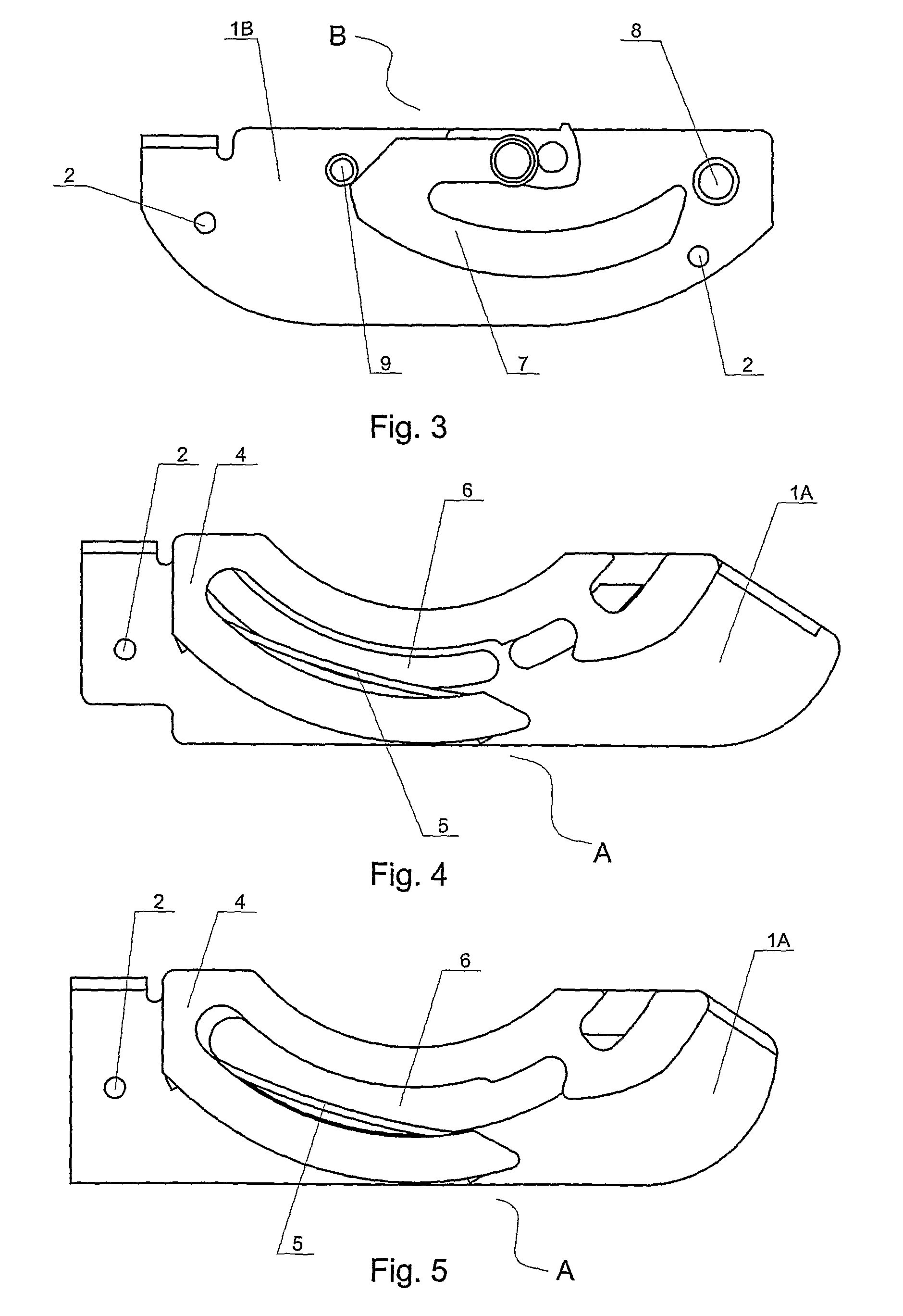

Sash lock

InactiveUS6871886B2Convenient preloadCost-effective and feasibleBuilding locksWing fastenersSash windowDetent

A sash lock apparatus which includes a keeper disposable on a first window sash and having a keeper aperture therein for lockingly receiving therein a selectively retractable element from a sash lock and the sash lock having the selectively retractable element disposable on a second window sash wherein the first and second window sashes are disposed for movement in a direction parallel to each other. The sash lock includes a rotatable lever having a tab extending therefrom and a spring slide deformable by rotation of the rotatable lever and movement of the tab against the spring slide for selectively causing a portion of the spring slide to enter and retract from the aperture to cause locking and unlocking of the first and second window sashes relative to each other. The spring slide includes a central aperture, the tab extending into the central aperture, rotation of the tab with the rotatable lever causing deformation of the spring slide and one of movement of the spring slide into or out of the keeper aperture. The housing has a shaft secured to the spring slide, the rotatable lever being rotatable about the shaft. The spring slide is preferably a spring steel slide. The apparatus may further include a member having member detents therein and secured to the shaft and rotatable member detents disposed on the rotatable member for entry into at least one selected member detent upon rotation of the rotatable member to one of an open or closed position.

Owner:HOWARD BERGER CO +1

Window sash latch

Owner:VISION INDS GROUP

Integrated tilt/sash lock assembly

An integrated tilt / sash lock assembly for a sash window is disclosed. The sash window assembly has an upper sash window and a lower sash window slideable within a master frame, the integrated assembly has a keeper adapted to be connected to the upper sash window. A rotor assembly is adapted to be supported by the lower sash window, the rotor assembly having a rotor connected to a spool. A latch bolt is adapted to be supported by the lower sash window and is adapted to engage the master frame. A connector has a first end connected to the spool and a second end connected to the latch bolt. An actuator is connected to the rotor assembly. The actuator has a locked position wherein the rotor engages the keeper. The actuator is moveable to an unlocked position wherein the rotor assembly is disengaged from the keeper, and is further moveable to a tiltable position wherein the connector retracts the latch bolt from the master frame.

Owner:ASHLAND HARDWARE LLC

Locking window

InactiveUS7063361B1Avoid compressionHinder intentional attempted movementConstruction fastening devicesFastening meansSash windowActuator

A locking window having a window frame and a window latch for use with the window is disclosed. The window latch, which is adapted to be attached to the window using a distinct fastener, is selectively movable between a first open position and a second locked position to secure the window sash in the closed position. The window latch includes an actuator arm, a locking arm, a non-compressible pivot and a housing. A pivot location is situated at the union of the actuator arm and the locking arm. The pivot location permits the actuator arm and the locking arm to be selectively movable between a first closed position and a second open position. The housing may include a securing feature for maintaining the housing substantially set relative to the window while at the same time permitting the actuator arm and the locking arm to be selectively movable between a first closed position and a second open position.

Owner:HUGHES SUPPLY OF THOMASVILLE

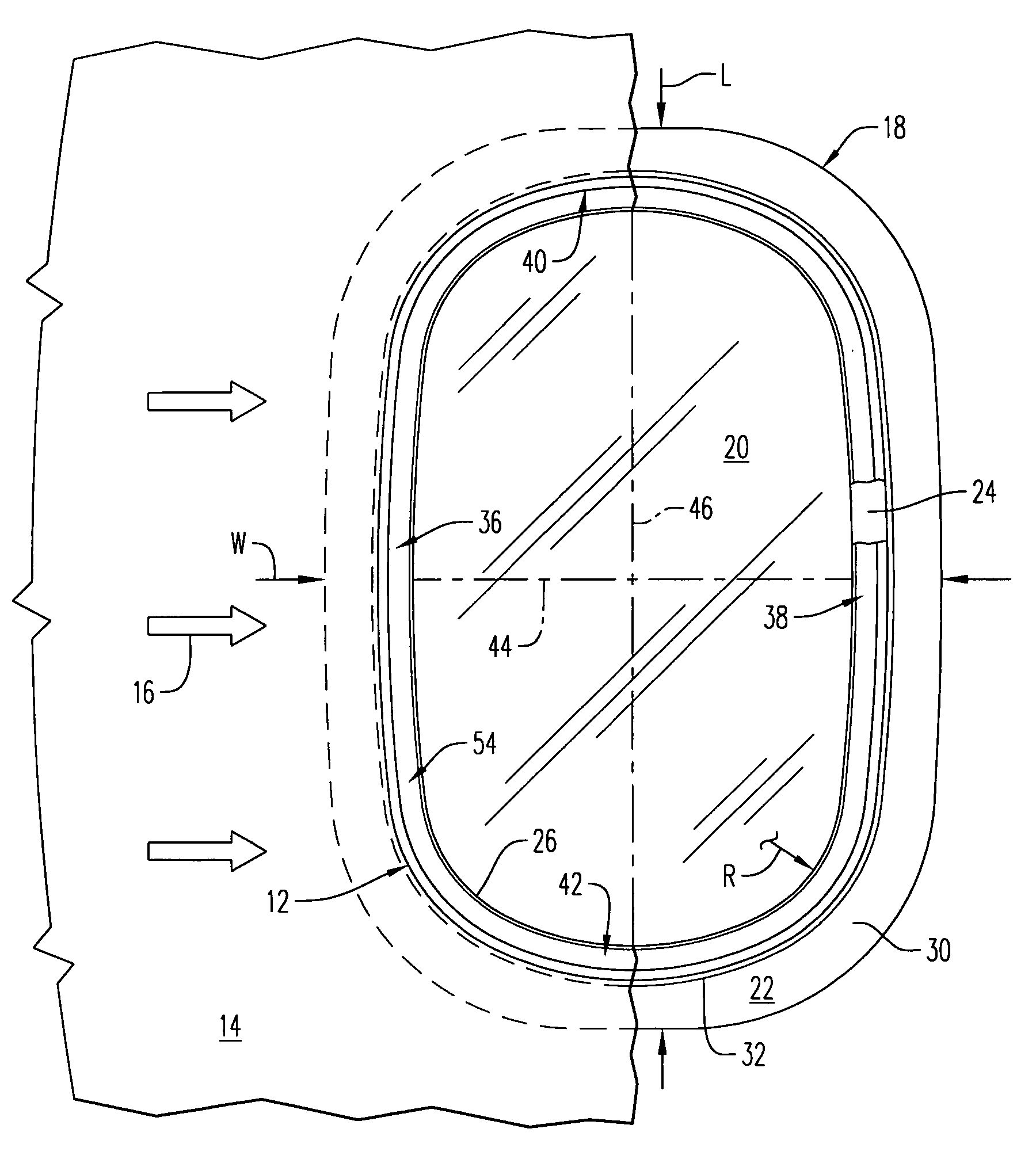

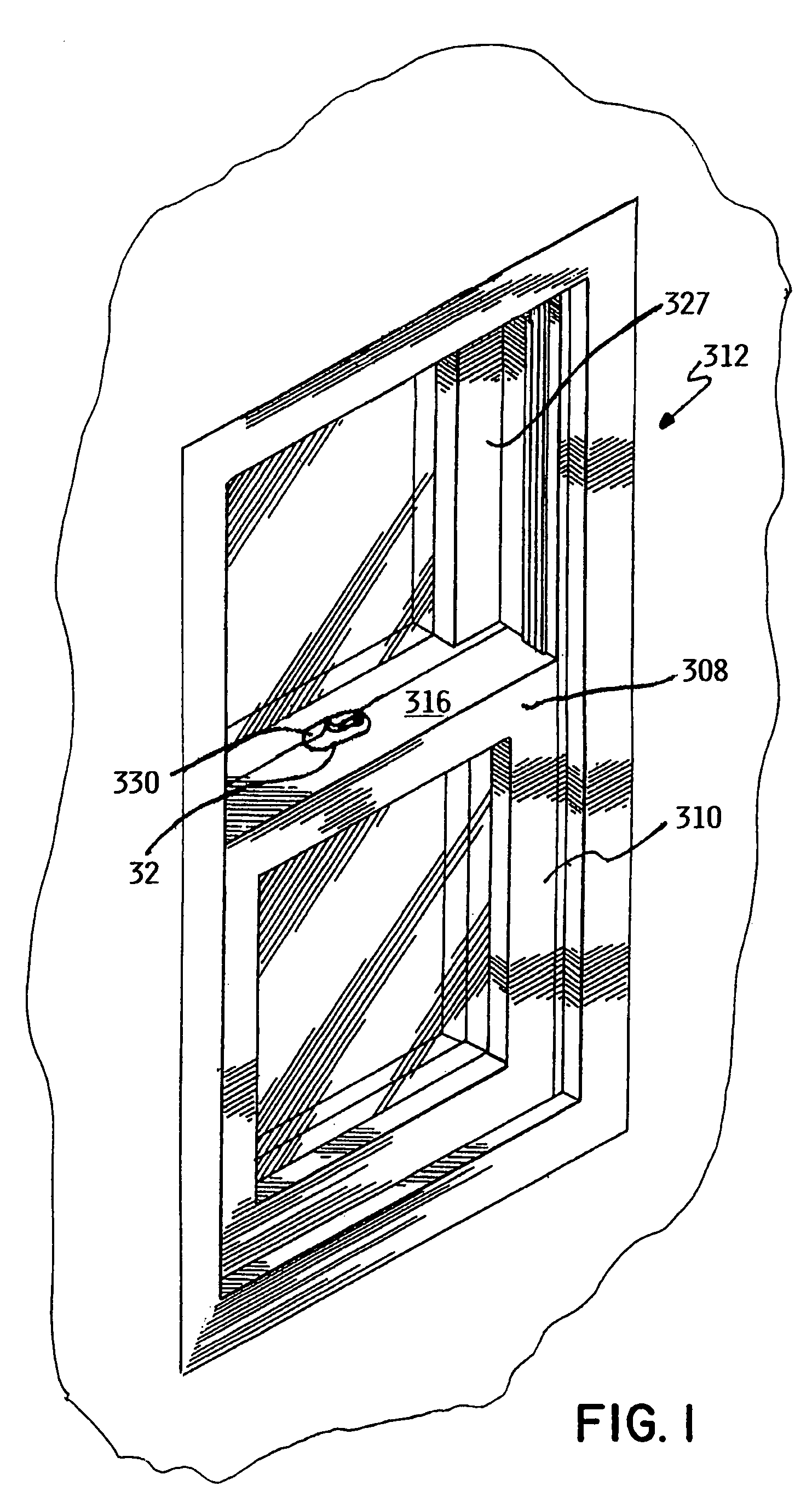

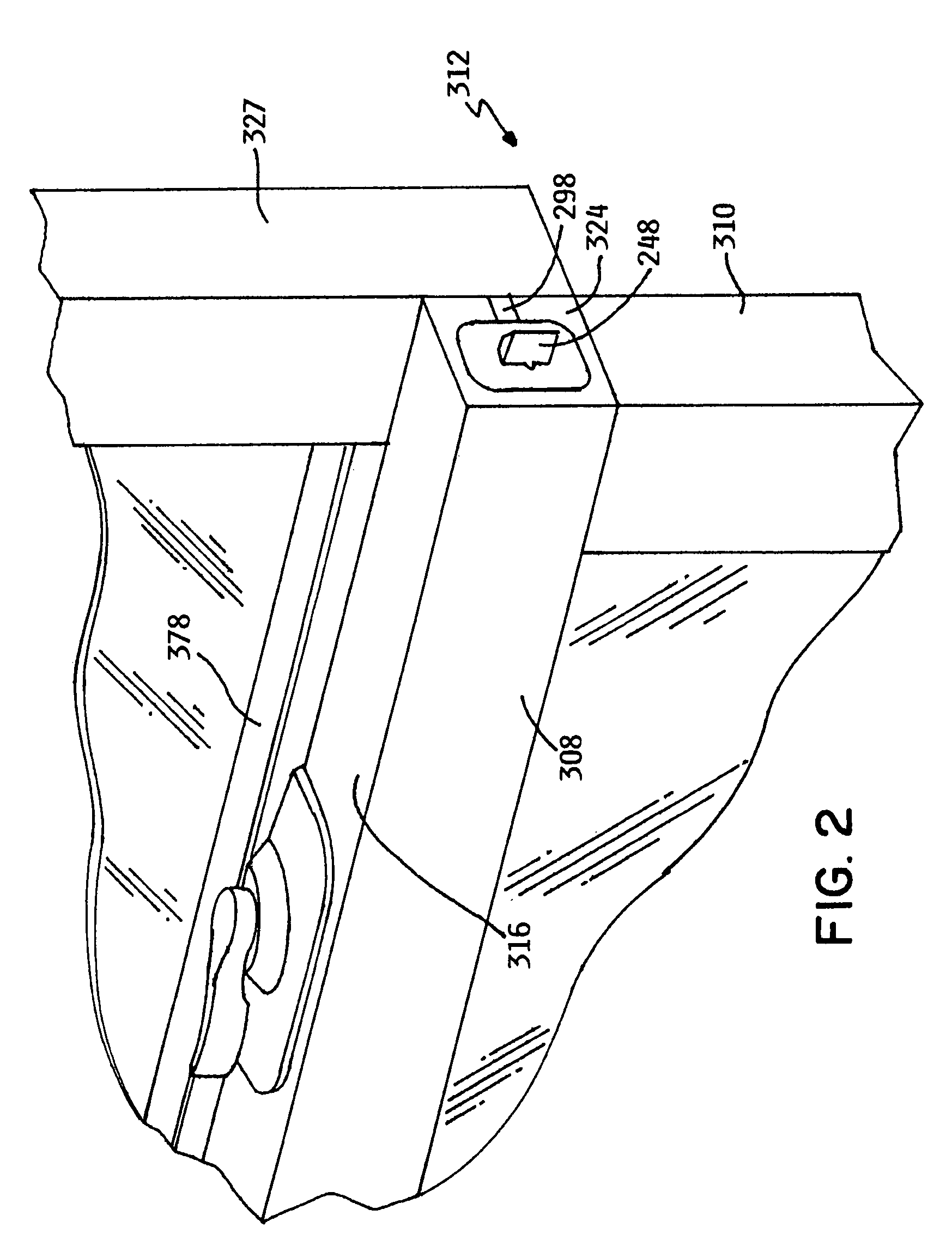

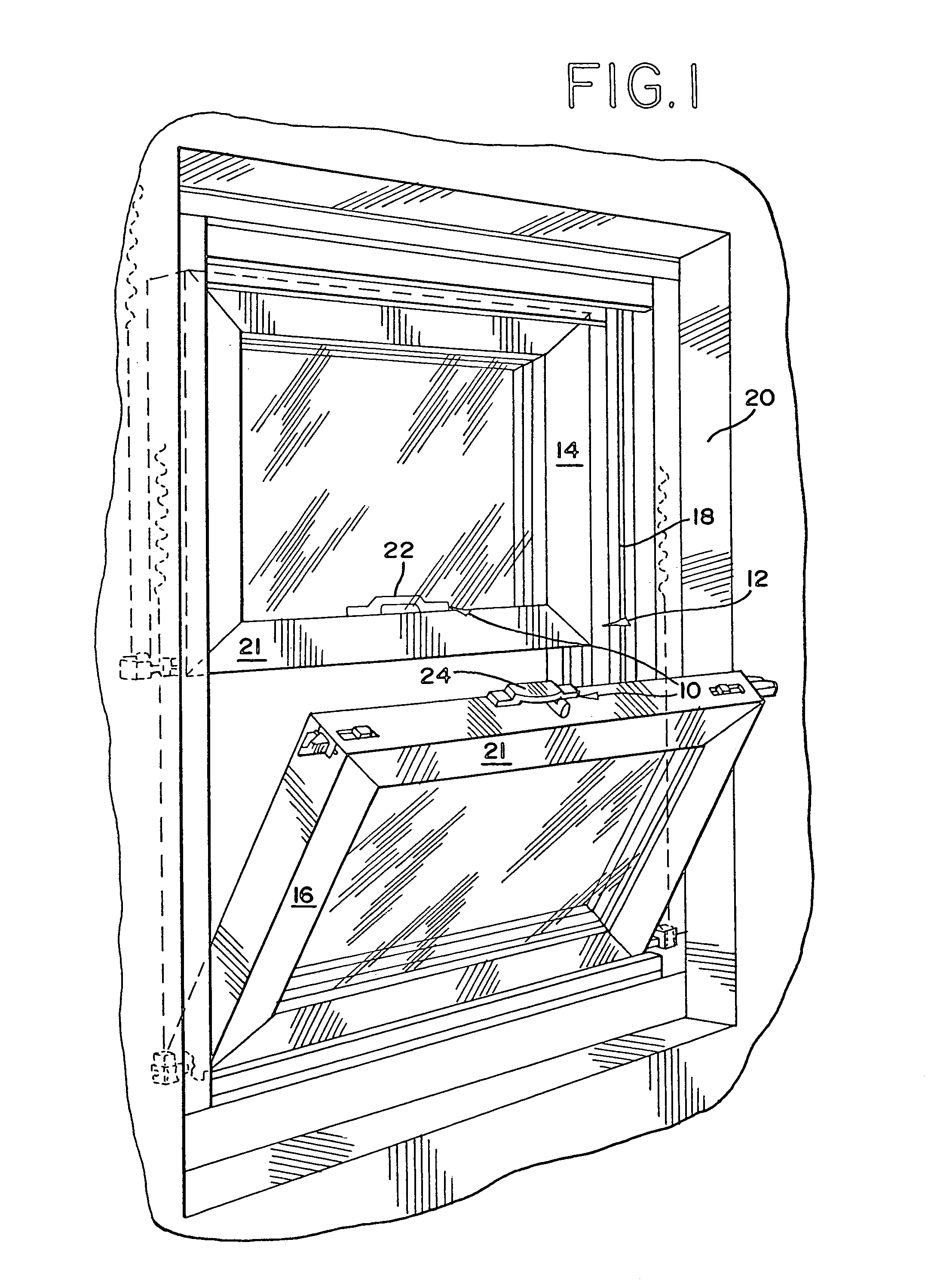

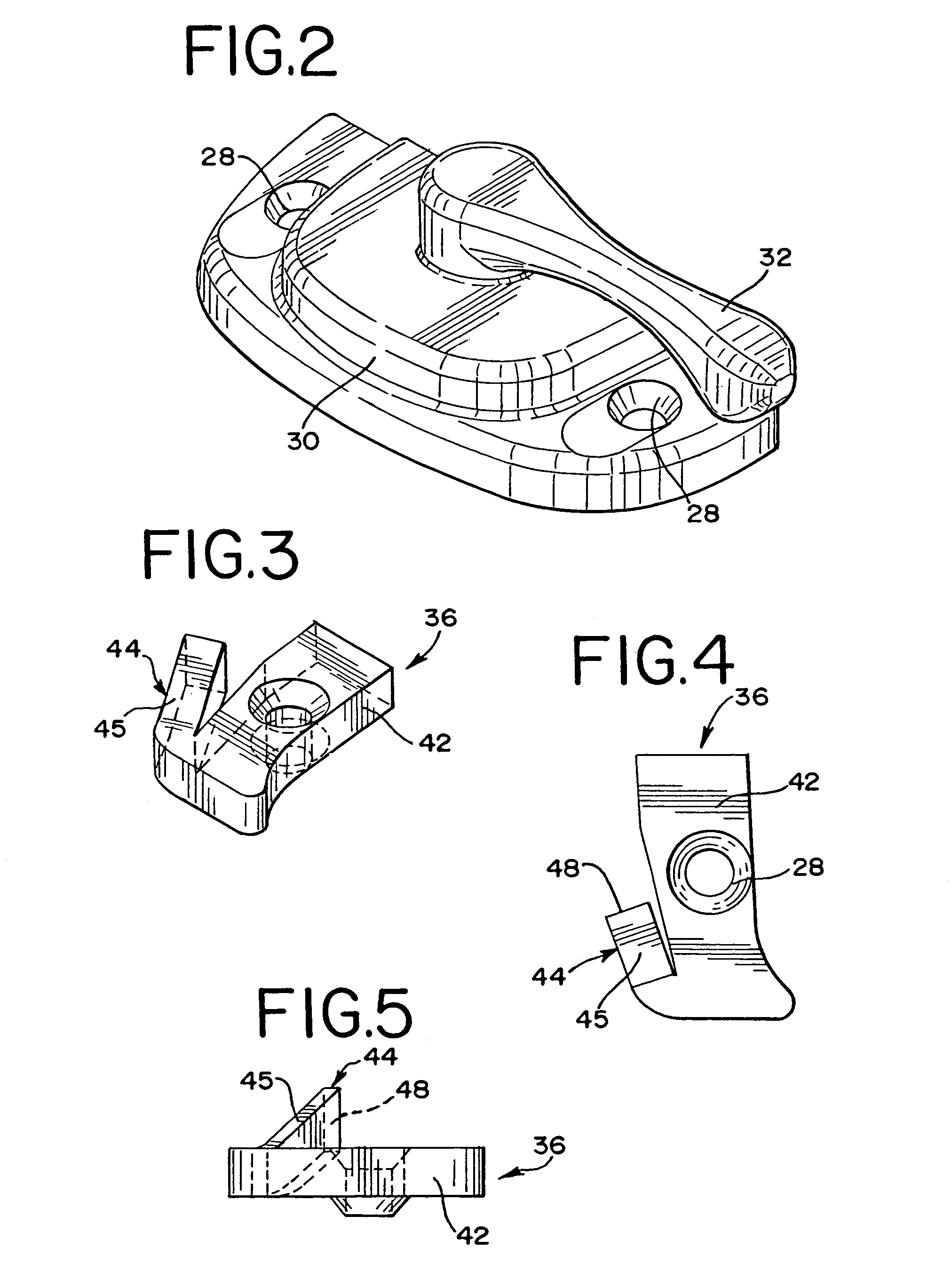

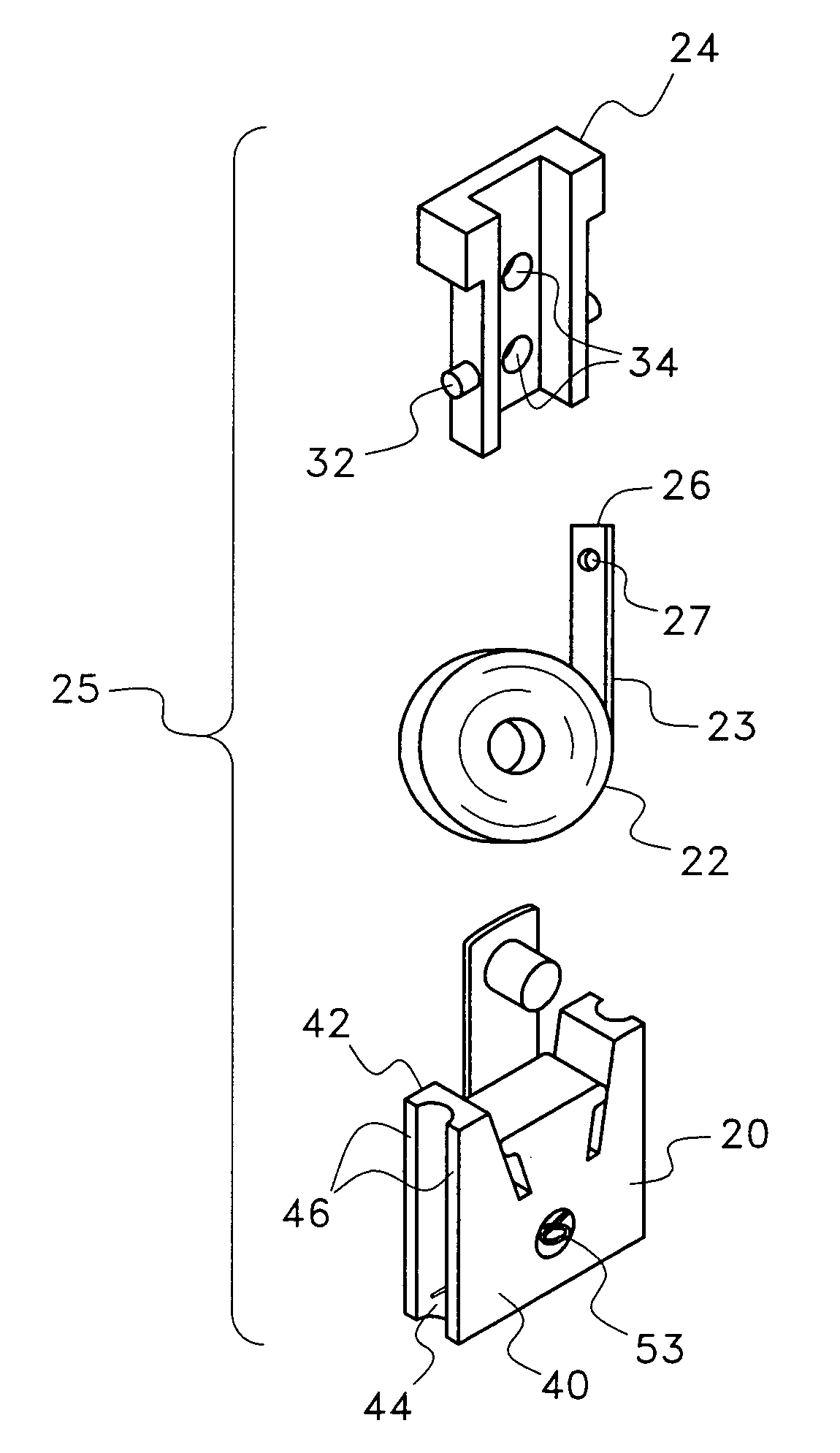

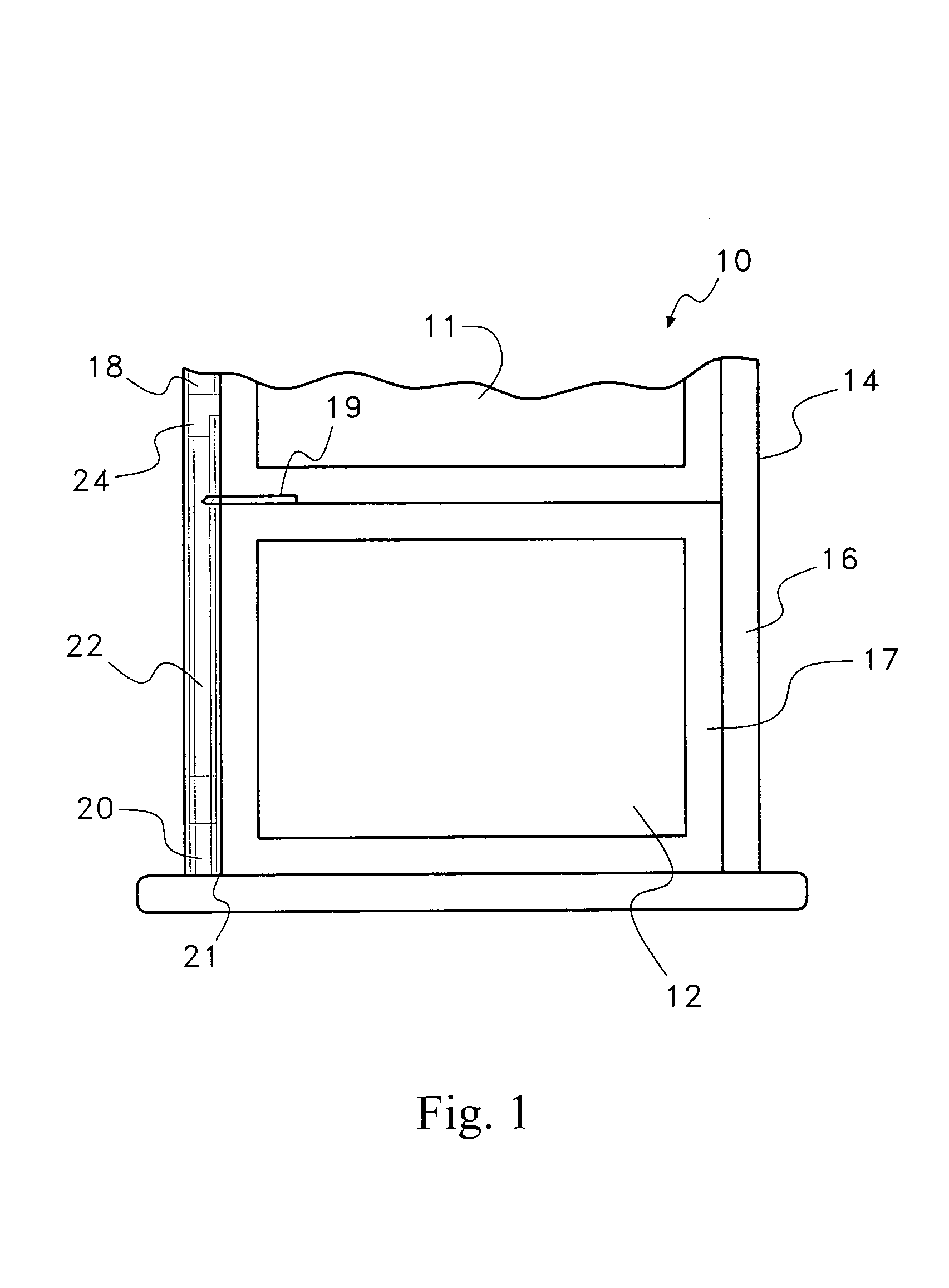

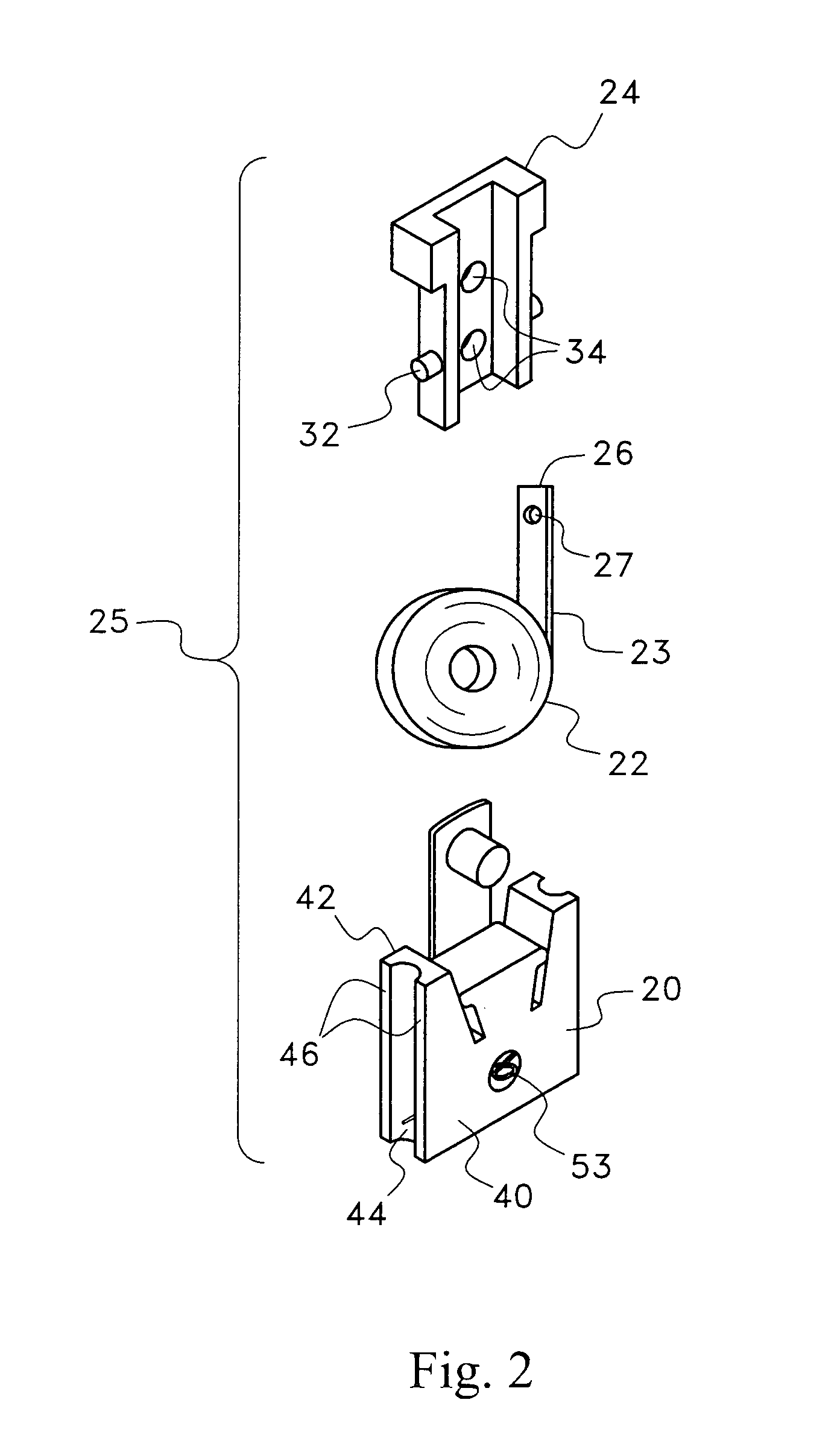

Forced entry resistance device for sash lock

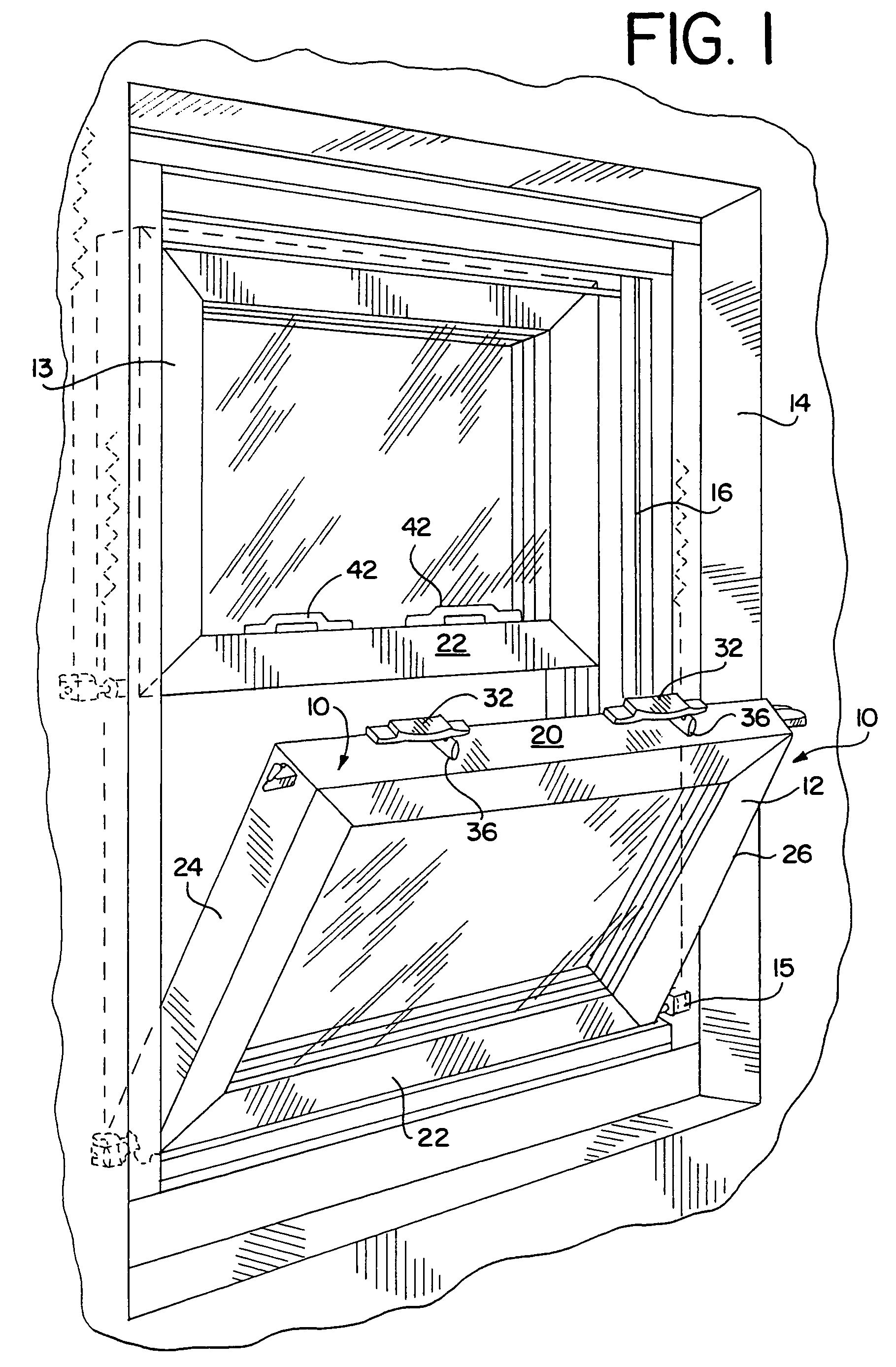

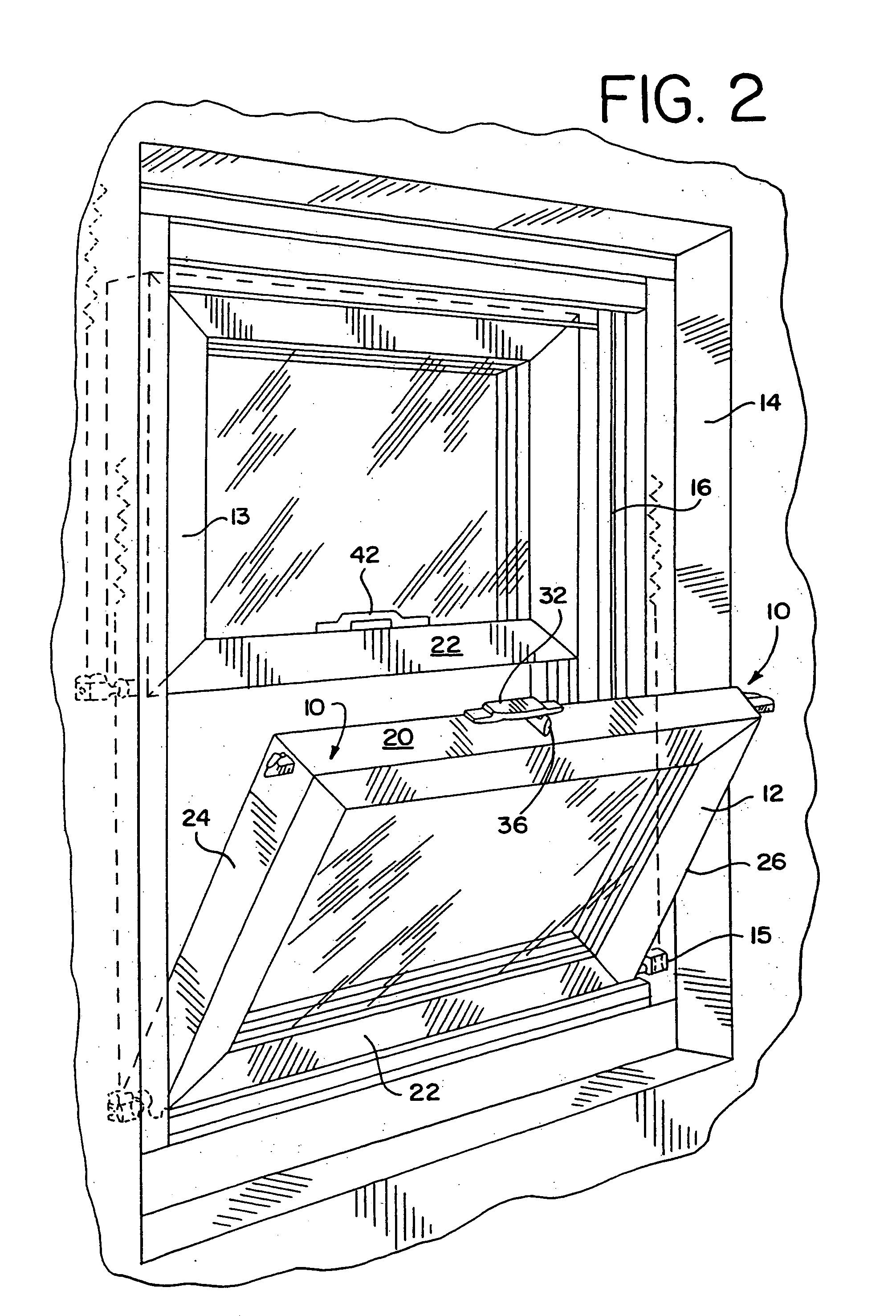

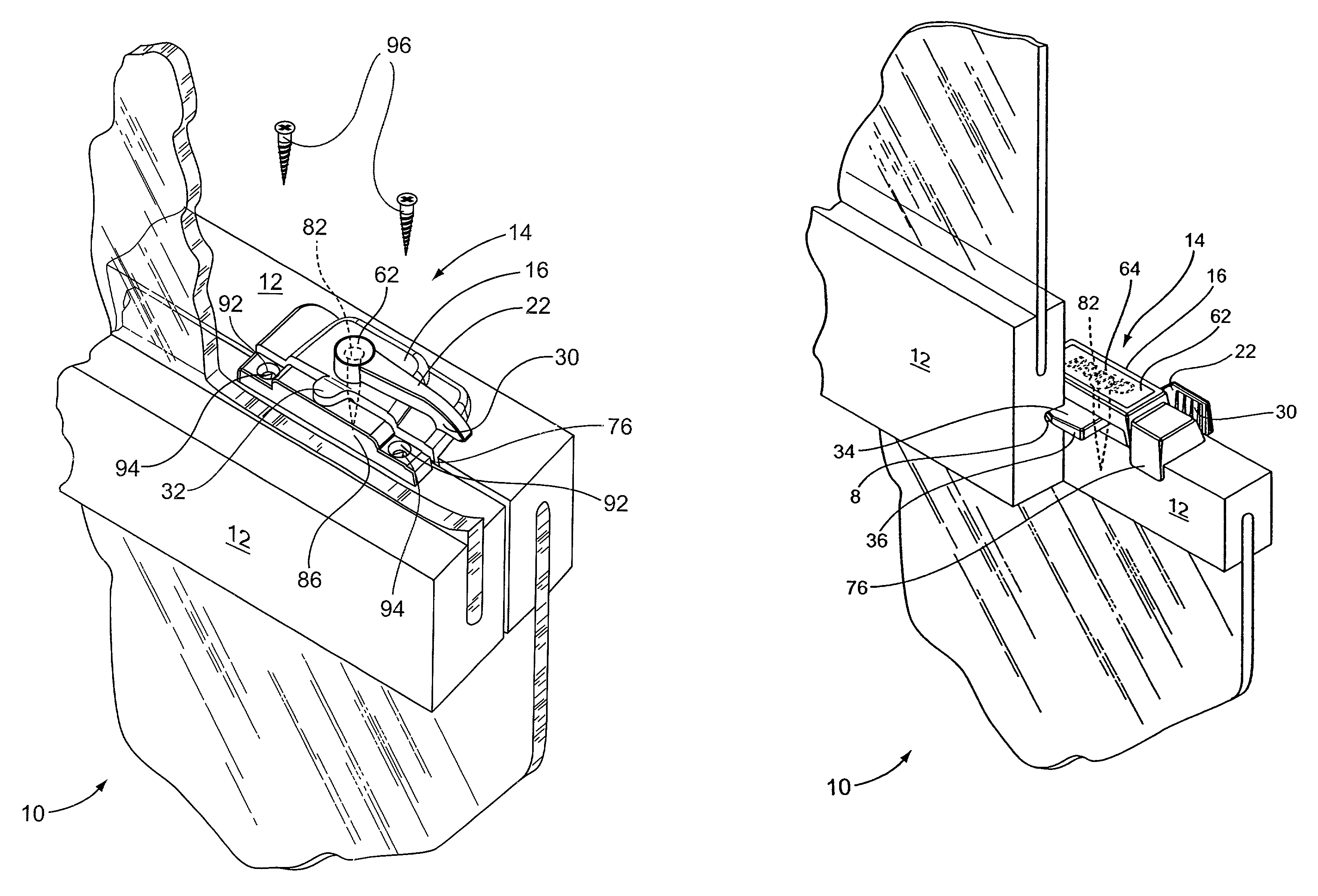

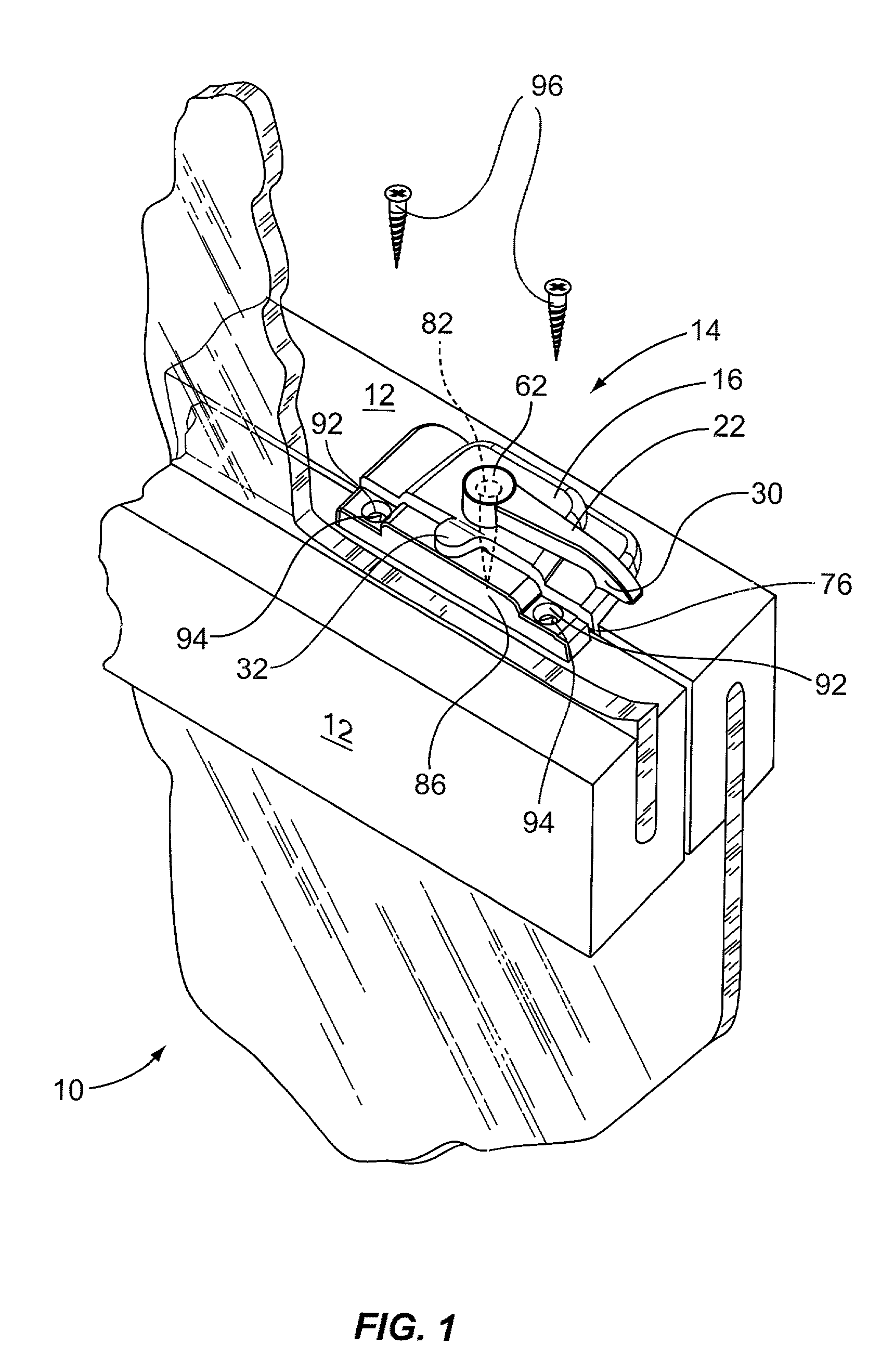

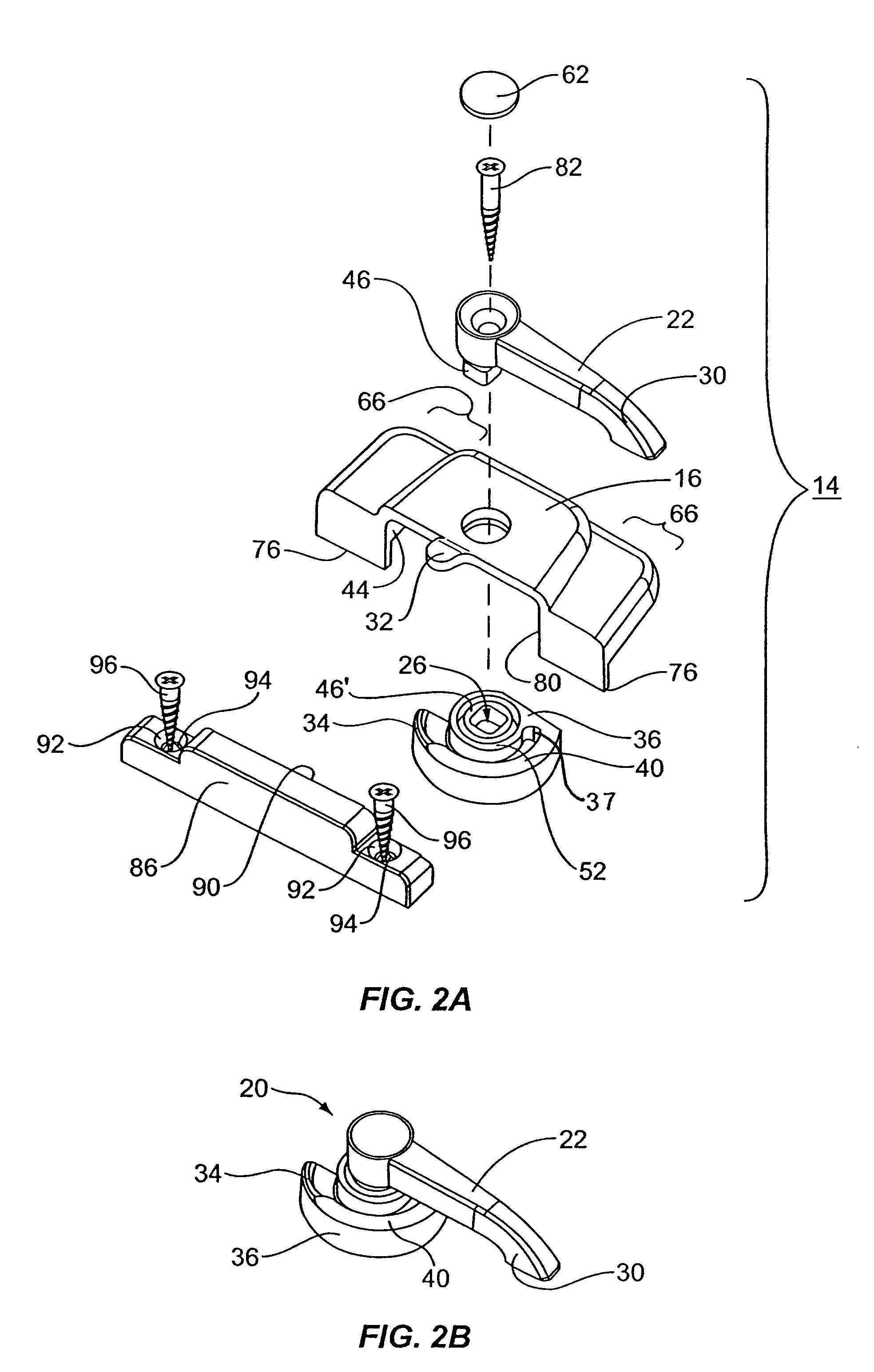

A sash lock (10) for a sash window assembly (12) is provided. The sash window assembly (12) includes an upper sash window (14) and a lower sash window (16), each of the sash windows (14), (16) mounted within opposed guide rails (18) on a master frame (20), wherein at least one of the sash windows (14), (16) is slidable within the frame (20) relative to the other sash window (14), (16). The sash lock (10) of the present invention includes a keeper (22) adapted for mounting on one of the sash windows (14), (16). The keeper (22) includes a keeper surface. The sash lock (10) also includes a locking assembly (24) adapted for mounting on the other of the sash windows (14), (16). The locking assembly (24) comprises a housing (30) having an aperture (33), an actuator arm (32) rotatable between an unlocked position and a locked position and a cam (34) having a cam surface (40) for engaging the keeper surface. A shaft (35) is also provided extending through the aperture (33) and coupling the actuator arm (32) to the cam (34) such that the actuator arm (32) and cam (34) are rotatably mounted to the housing (30). A tab (44) mounted to the housing is also provided wherein the tab (44) engages the actuator arm (32) to retain the actuator arm (32) in its locked position.

Owner:NEWELL OPERATING COMPANY

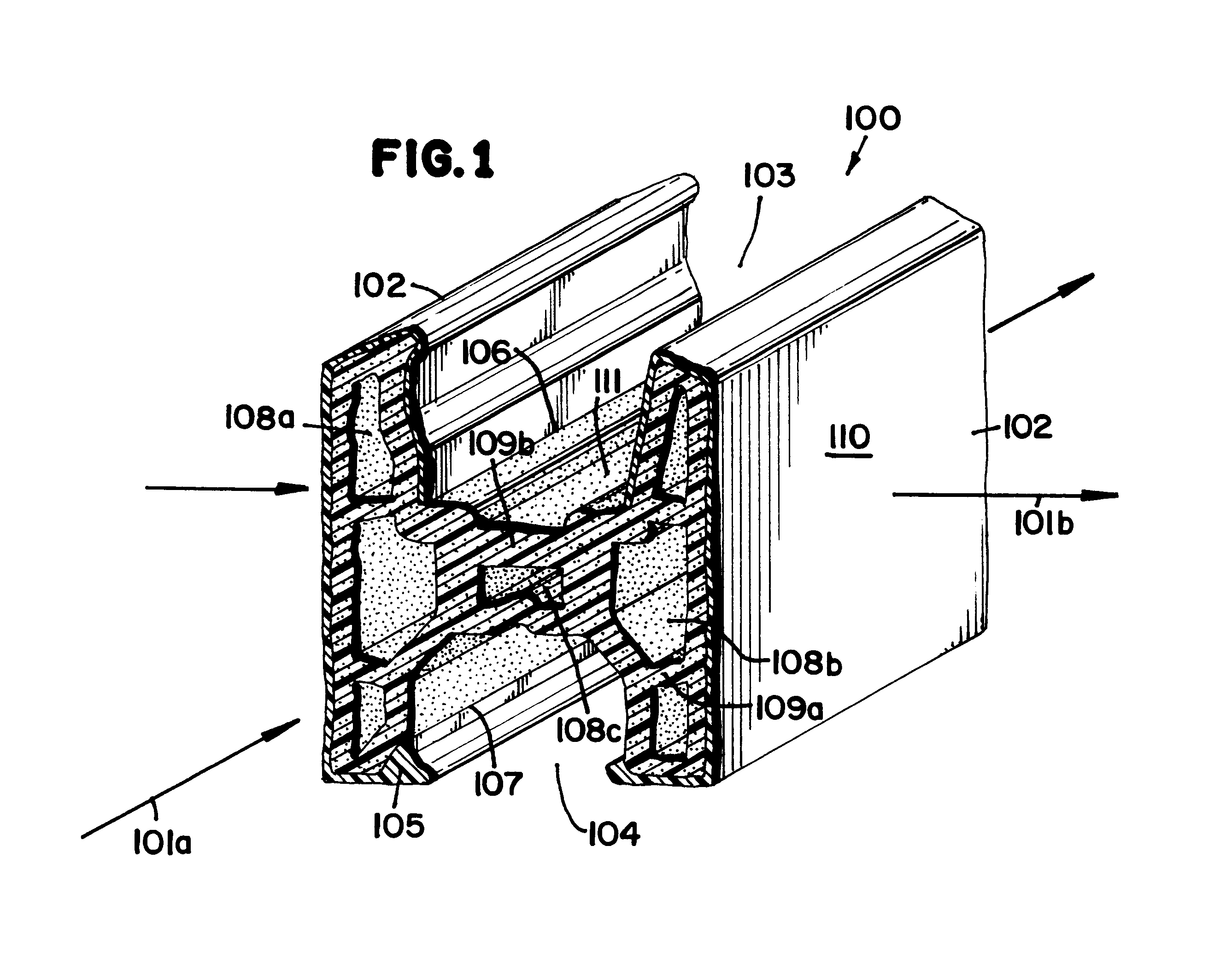

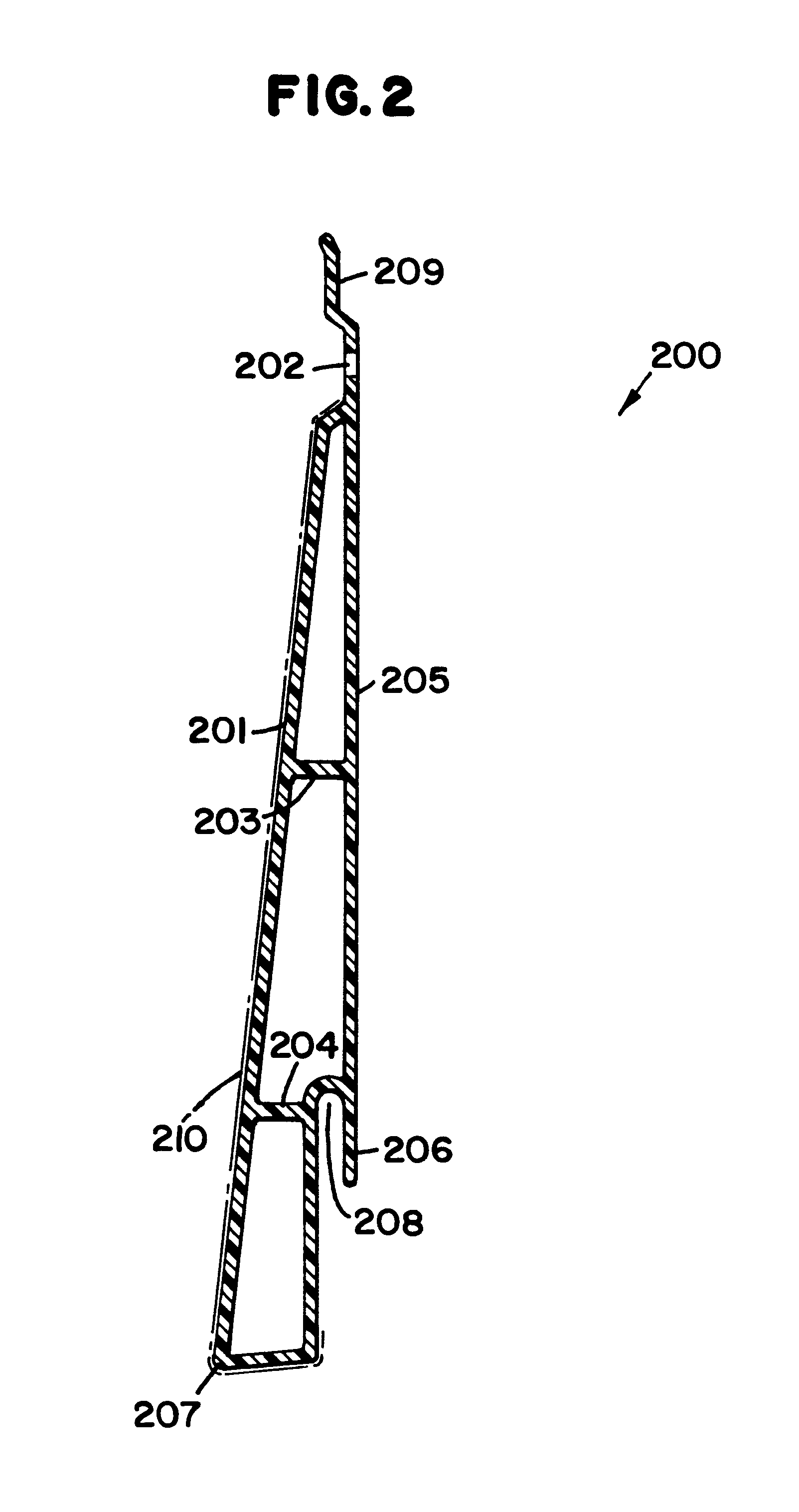

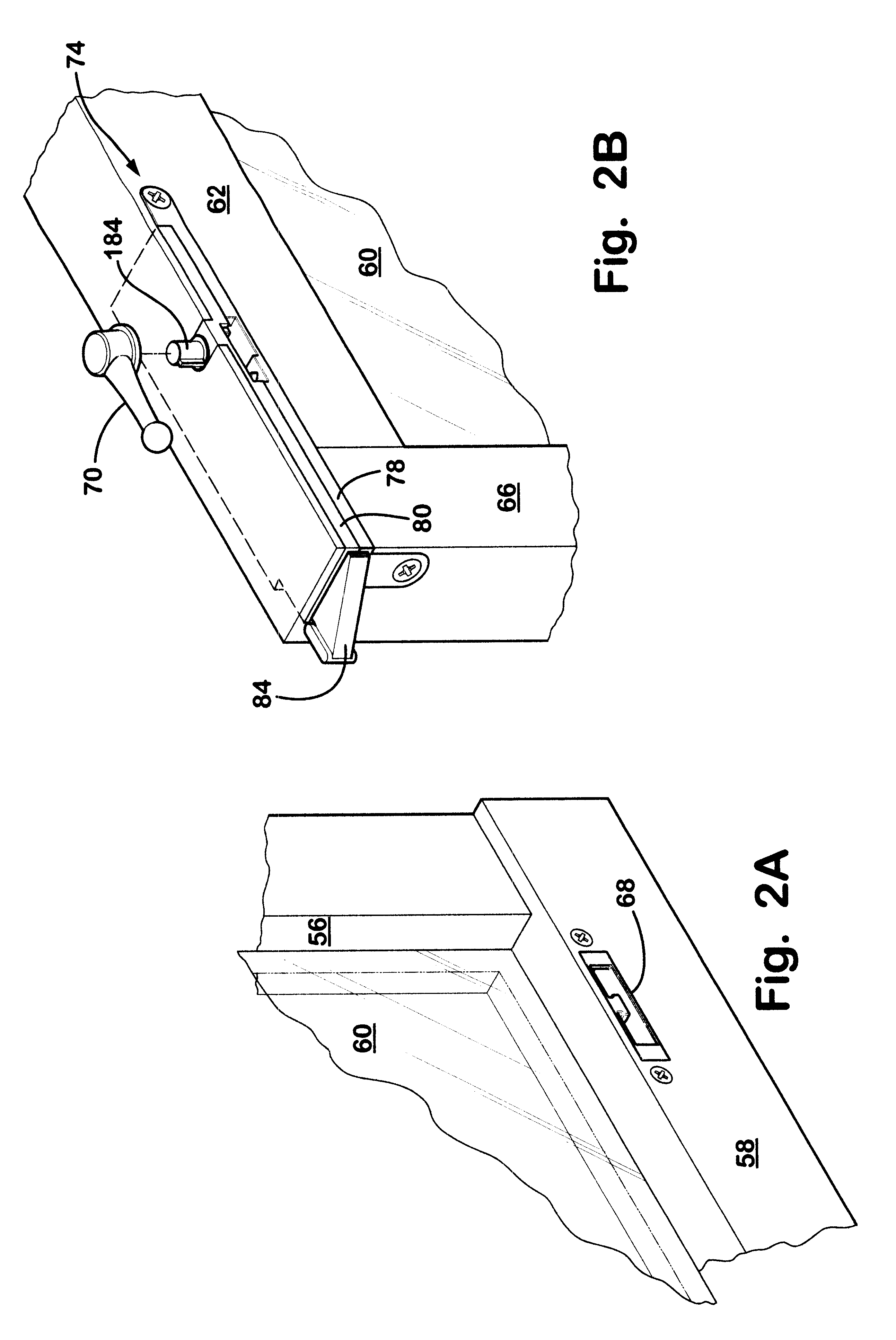

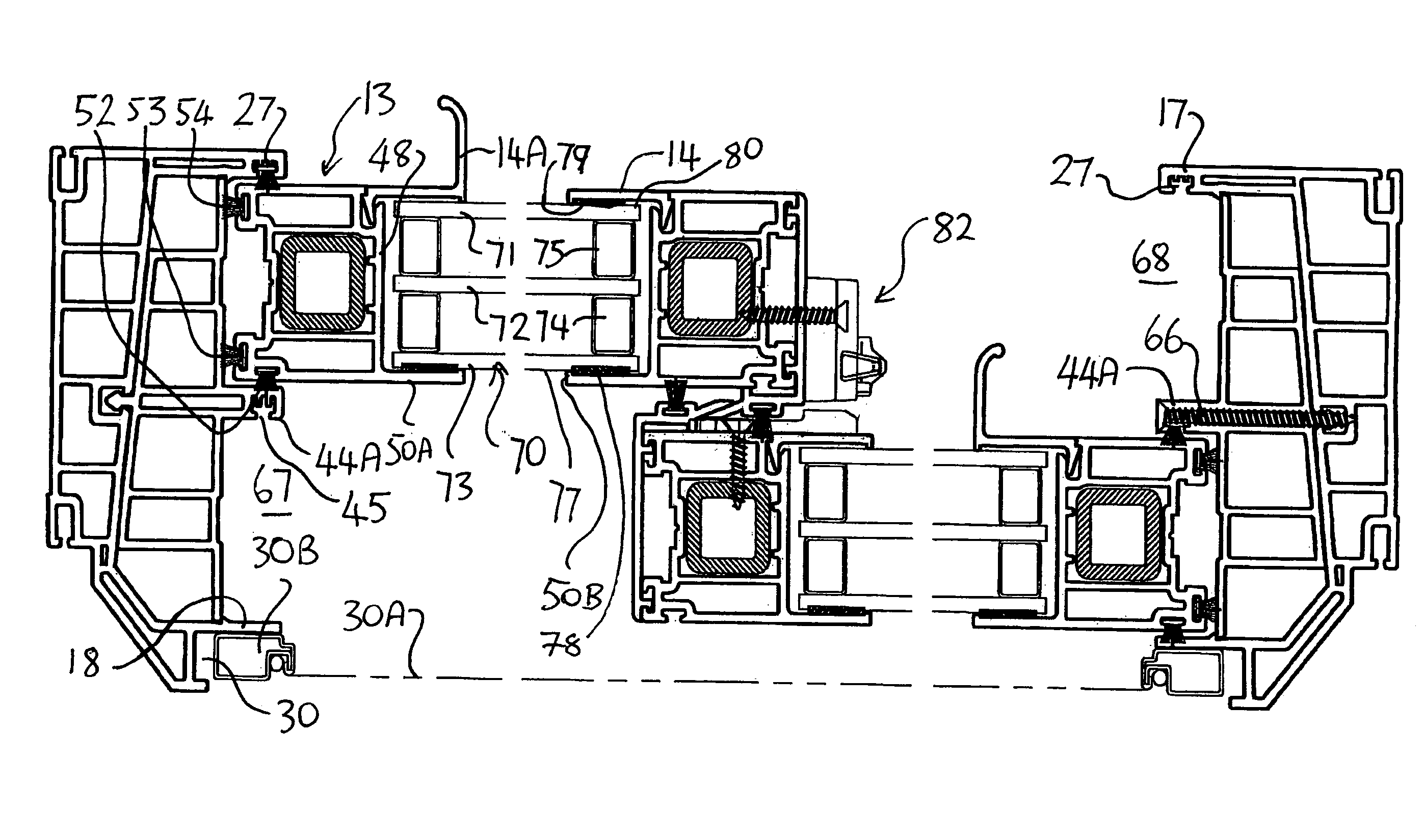

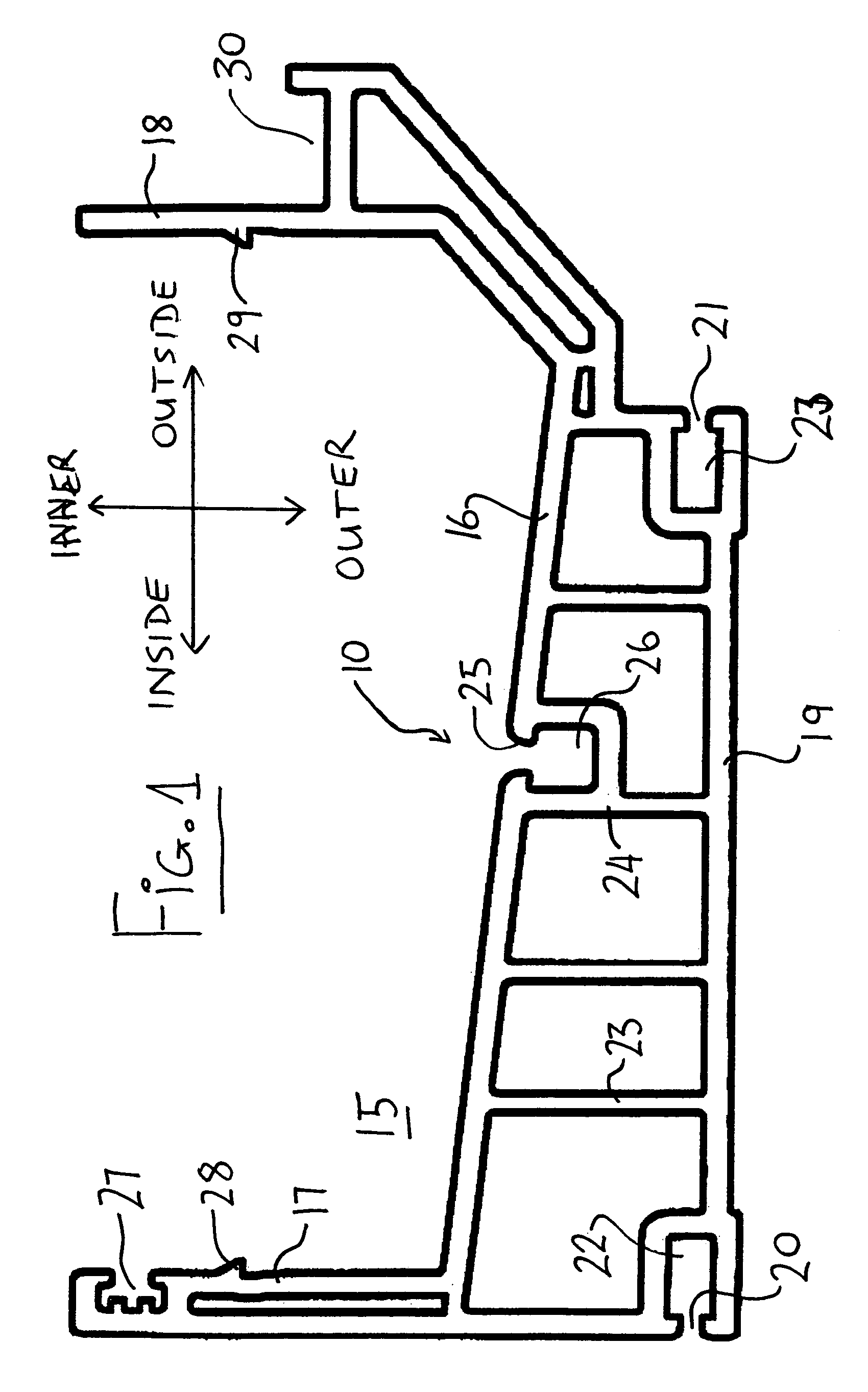

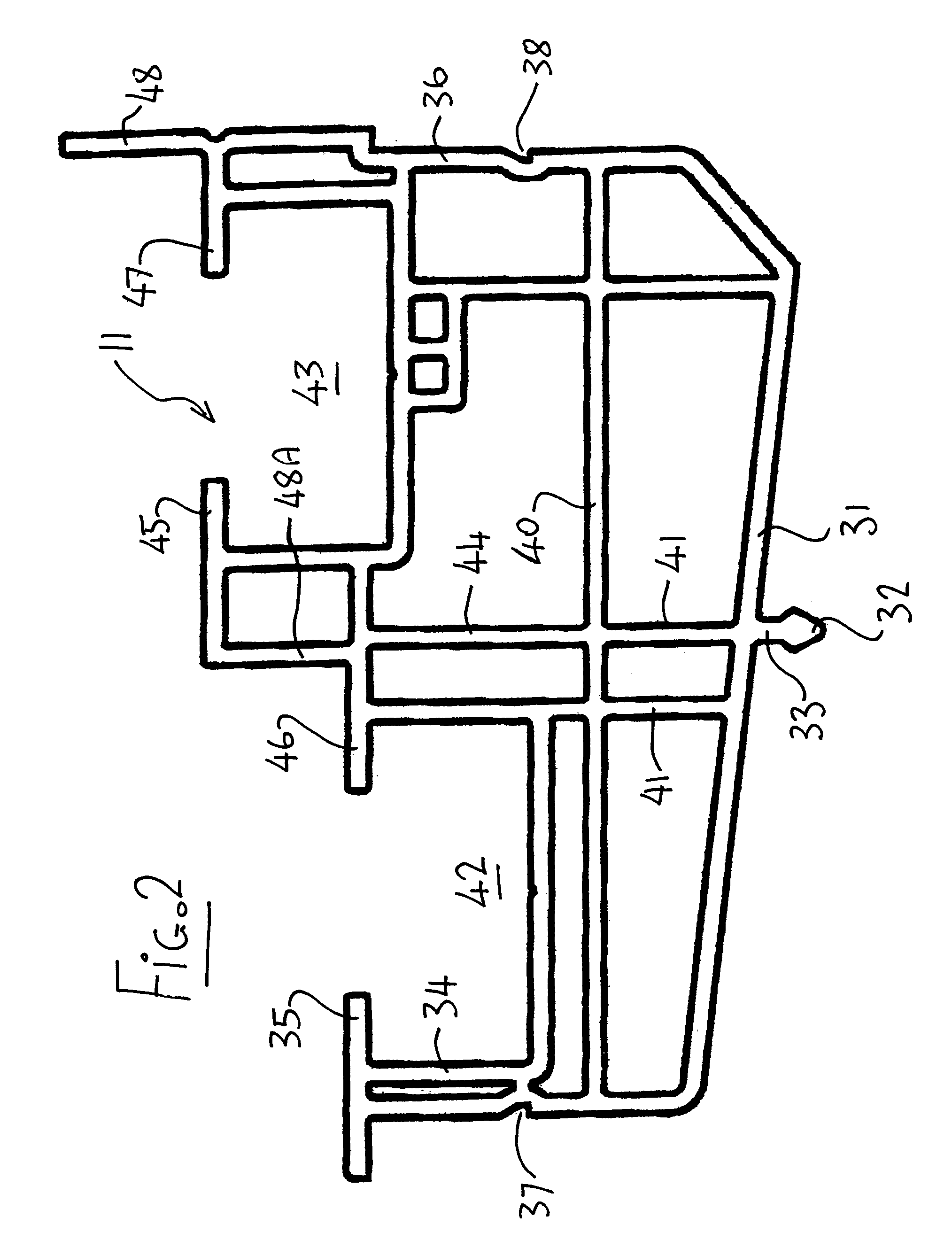

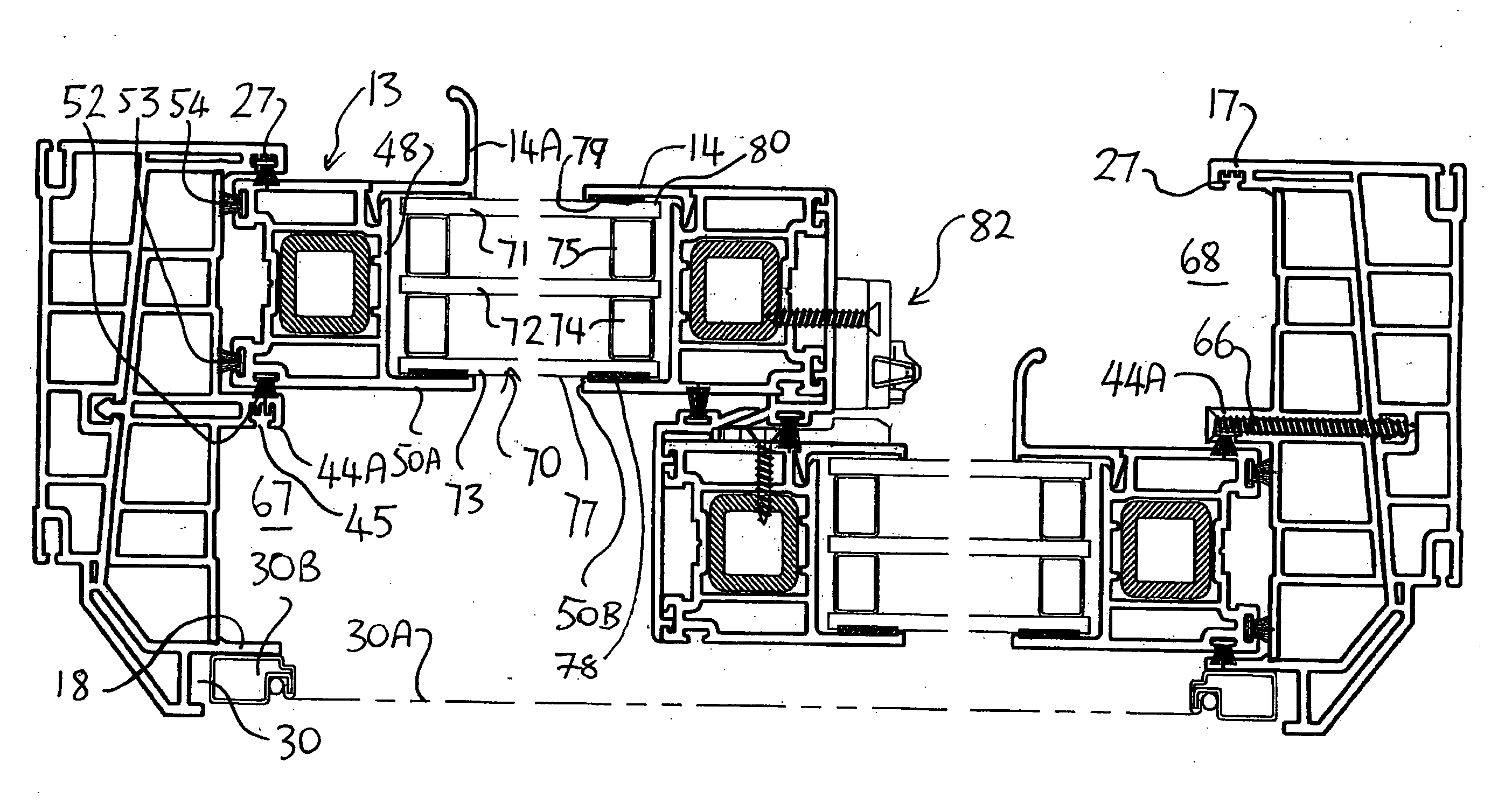

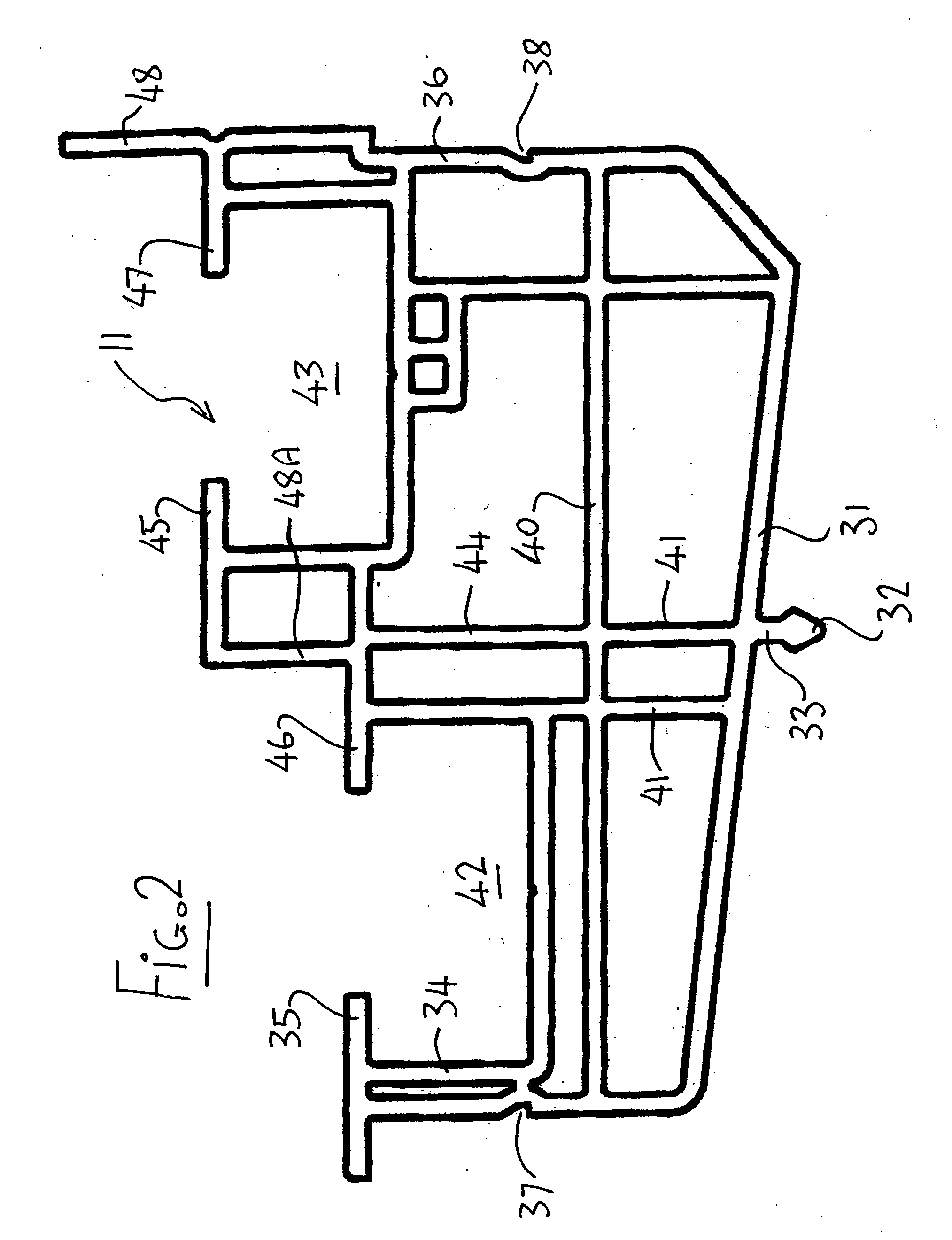

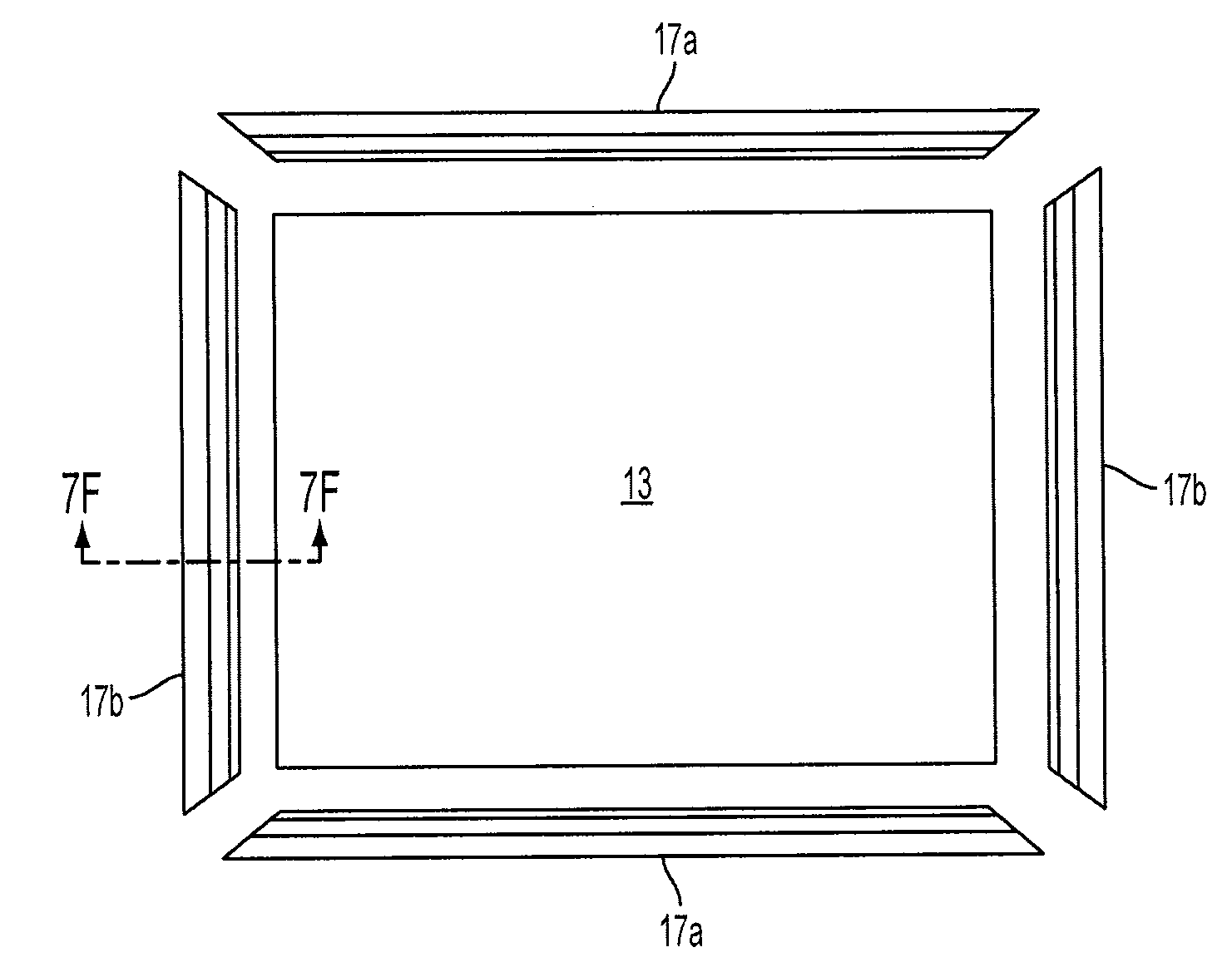

Extruded profile system for forming sliding fenestration products

A combination of profiles for forming slider and double hung sash windows or patio doors includes a common outer profile and two different inner profiles so that one inner profile can be used to form the double hung and the other to form the slider. This allows the slider top inner to be cut away to form a floating section resting on the top of the sash. This allows the drain holes to be formed separately in the inner and the outer to be longitudinally offset to prevent direct air penetration. The sash frame is formed with a removable glass stop on one side which snaps into engagement at right angles to the glass surface of the sealed unit to allow formation of a tri-pane with 0.5 inch spacing and to allow the use of two strips of adhesive one on each side of the sealed unit with no need for drainage.

Owner:HI TECH ENERGY WINDOWS

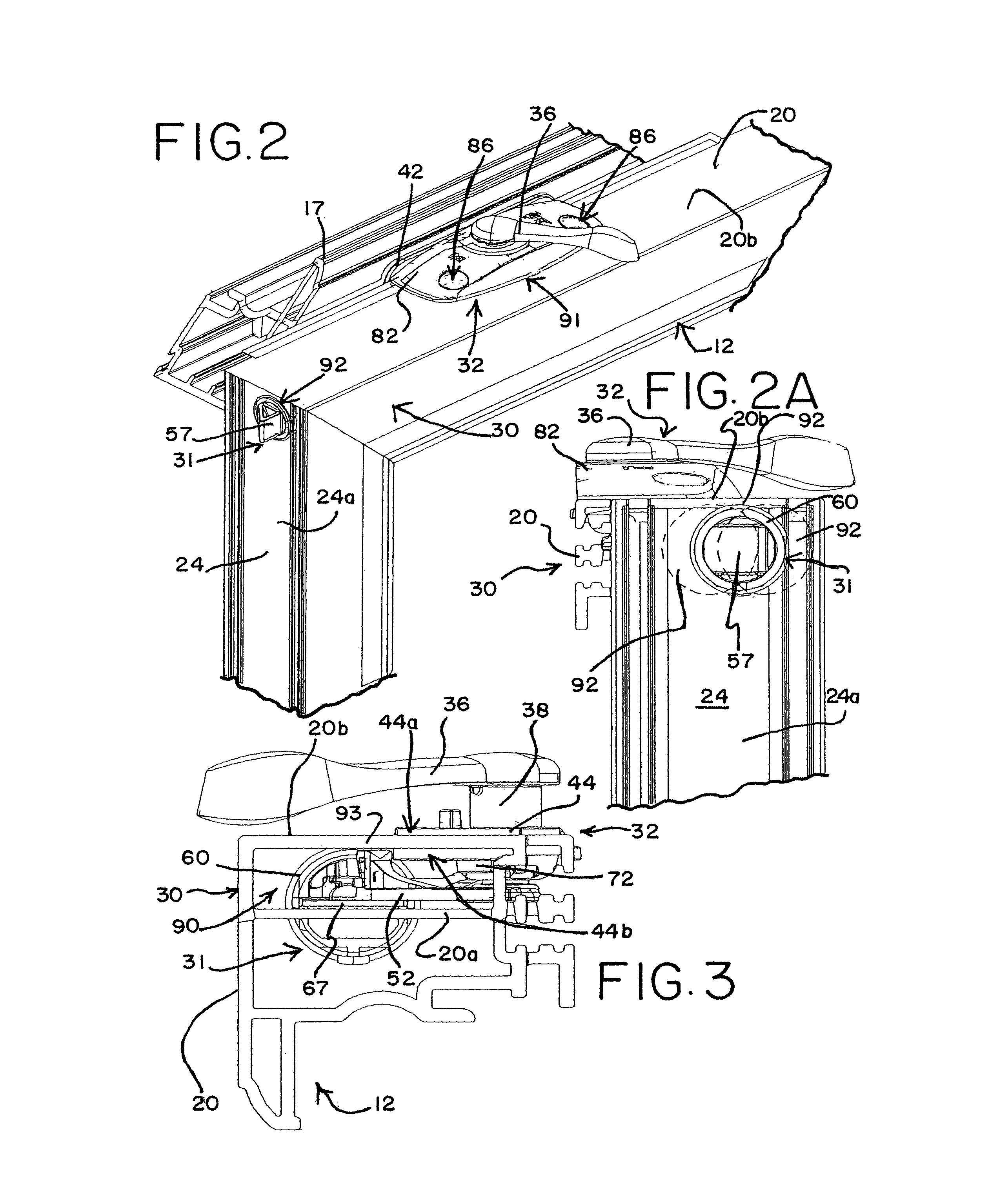

Integrated lock and tilt-latch mechanism for a sliding window

An integrated lock and tilt-latch mechanism for a sliding window including an actuator assembly operably connected by a flexible linking member to at least one tilt-latch mechanism adapted for mounting in a window sash. The actuator assembly includes a control lever that rotates a sweep cam and a selectively rotates a spool, thereby locking or unlocking the sliding window or actuating the tilt-latch mechanism. At least one biasing member causes the control lever to favor locked or unlocked positions over intermediate and tilt positions.

Owner:TRUTH HARDWARE

Extruded profile system for forming sliding fenestration products

A combination of profiles for forming slider and double hung sash windows or patio doors includes a common outer profile and two different inner profiles so that one inner profile can be used to form the double hung and the other to form the slider. This allows the slider top inner to be cut away to form a floating section resting on the top of the sash. This allows the drain holes to be formed separately in the inner and the outer to be longitudinally offset to prevent direct air penetration. The sash frame is formed with a removable glass stop on one side which snaps into engagement at right angles to the glass surface of the sealed unit to allow formation of a tri-pane with 0.5 inch spacing and to allow the use of two strips of adhesive one on each side of the sealed unit with no need for drainage.

Owner:HI TECH ENERGY WINDOWS

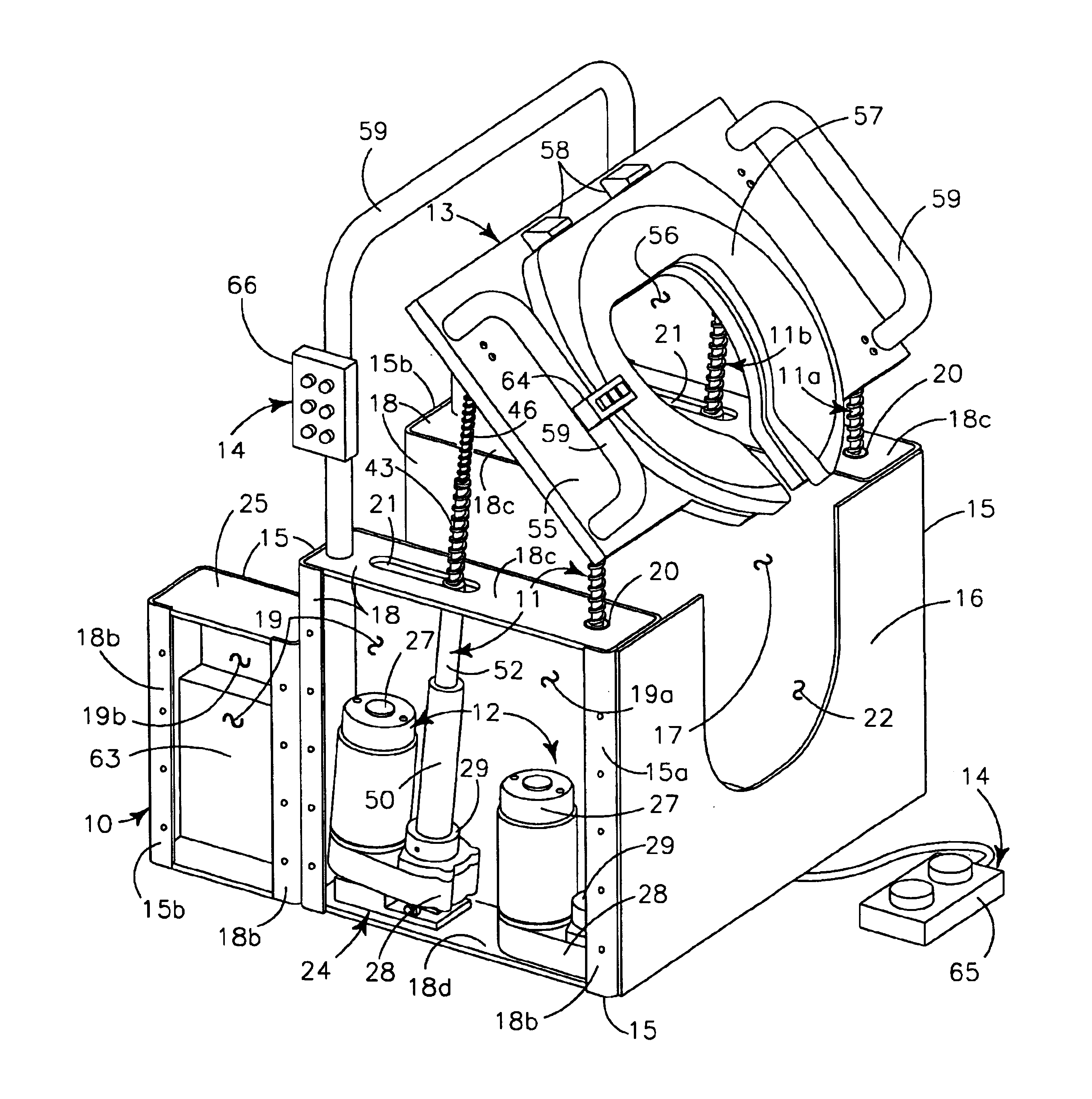

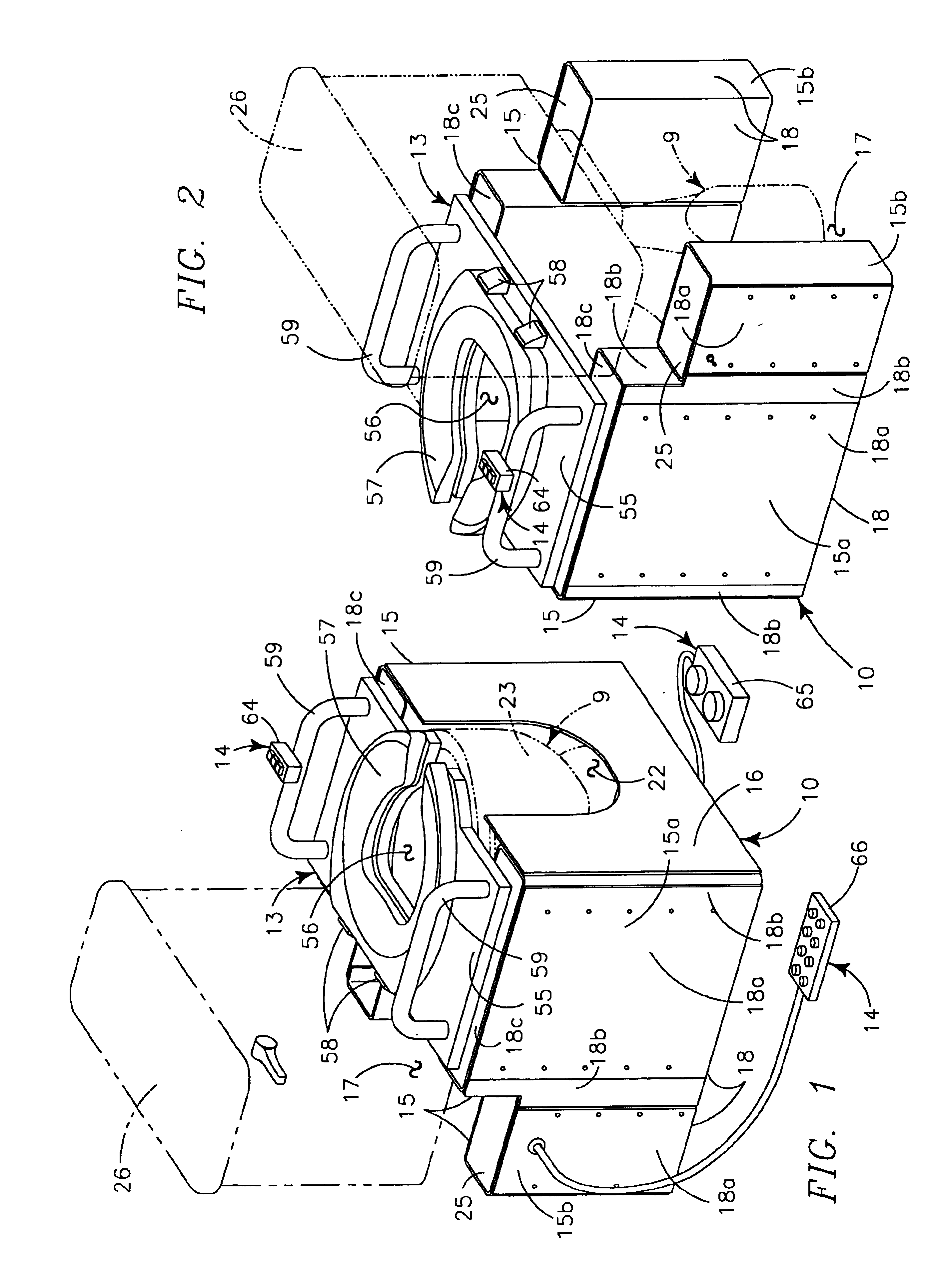

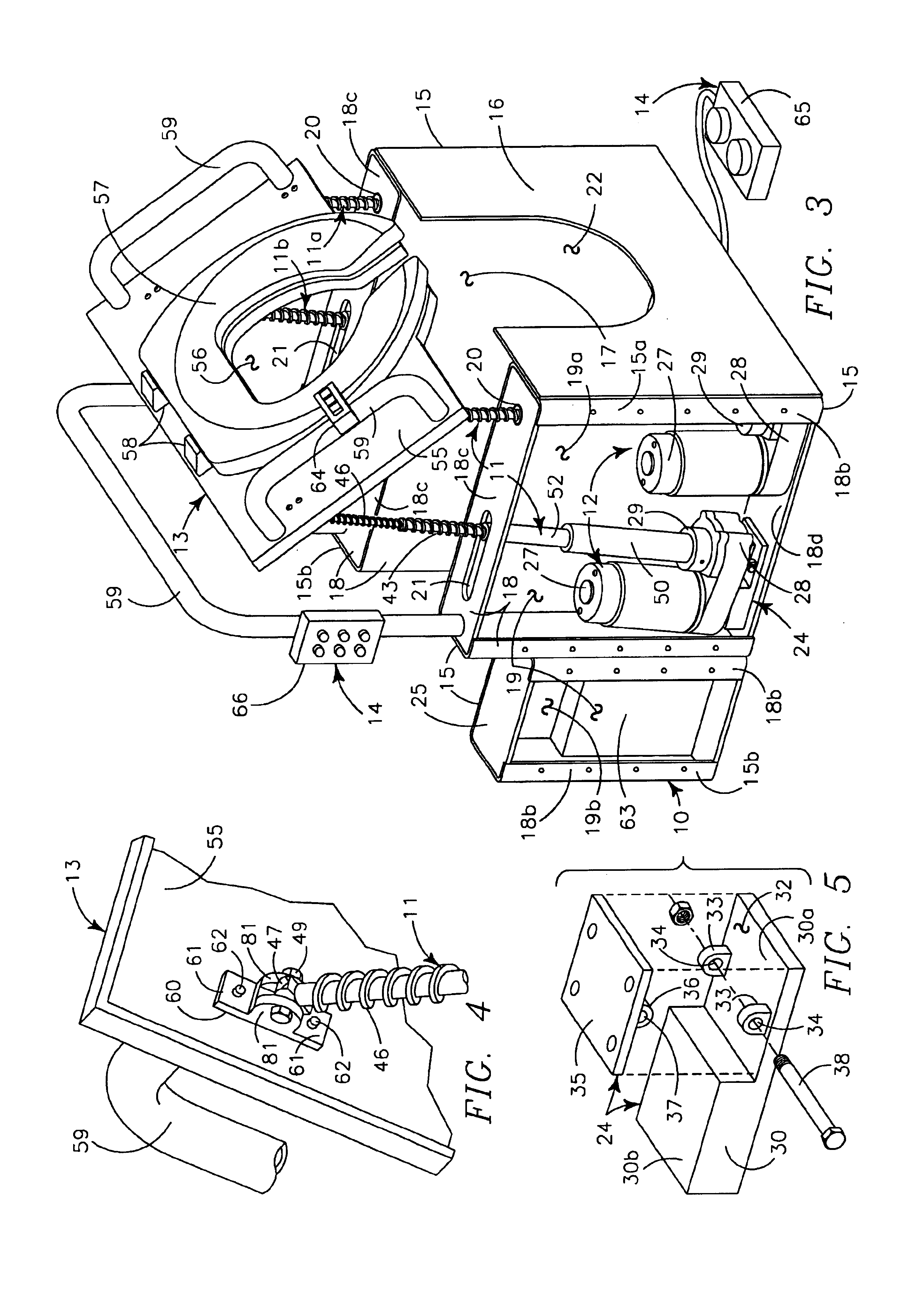

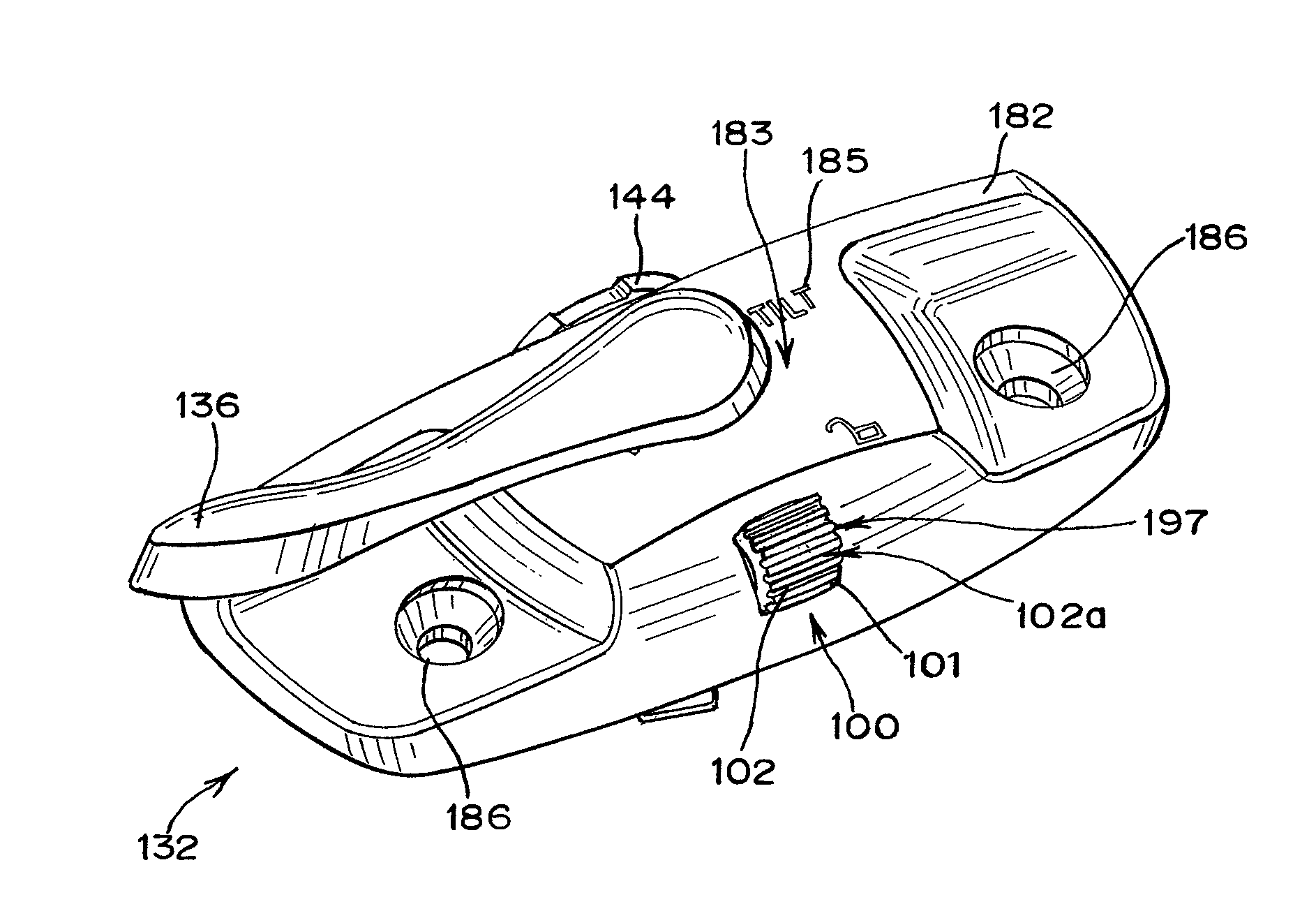

Powered auxiliary toilet seat lift

InactiveUS6754917B1Manual correctionEasy to useWheelchairs/patient conveyanceBathroom coversSash windowJackscrew

A powered auxiliary toilet seat lift provides a U-shaped casement formed by two similar elongate side members interconnected by a forward end plate to fit about a toilet stool and support a toilet seat structure thereabove for vertical and forwardly and downwardly angulated motion. Each casement side member is peripherally defined to create an internal chamber carrying similar elongately spaced lateral pairs of forward and rearward compound jackscrews that pivotally interconnect with the toilet seat structure thereabove. Powering mechanism provides separate electric motors powering each jackscrew that are controlled by a computerized feedback type circuitry for manually selectable or pre-programed motion of the toilet seat structure.

Owner:MCFARLANE DARRIC

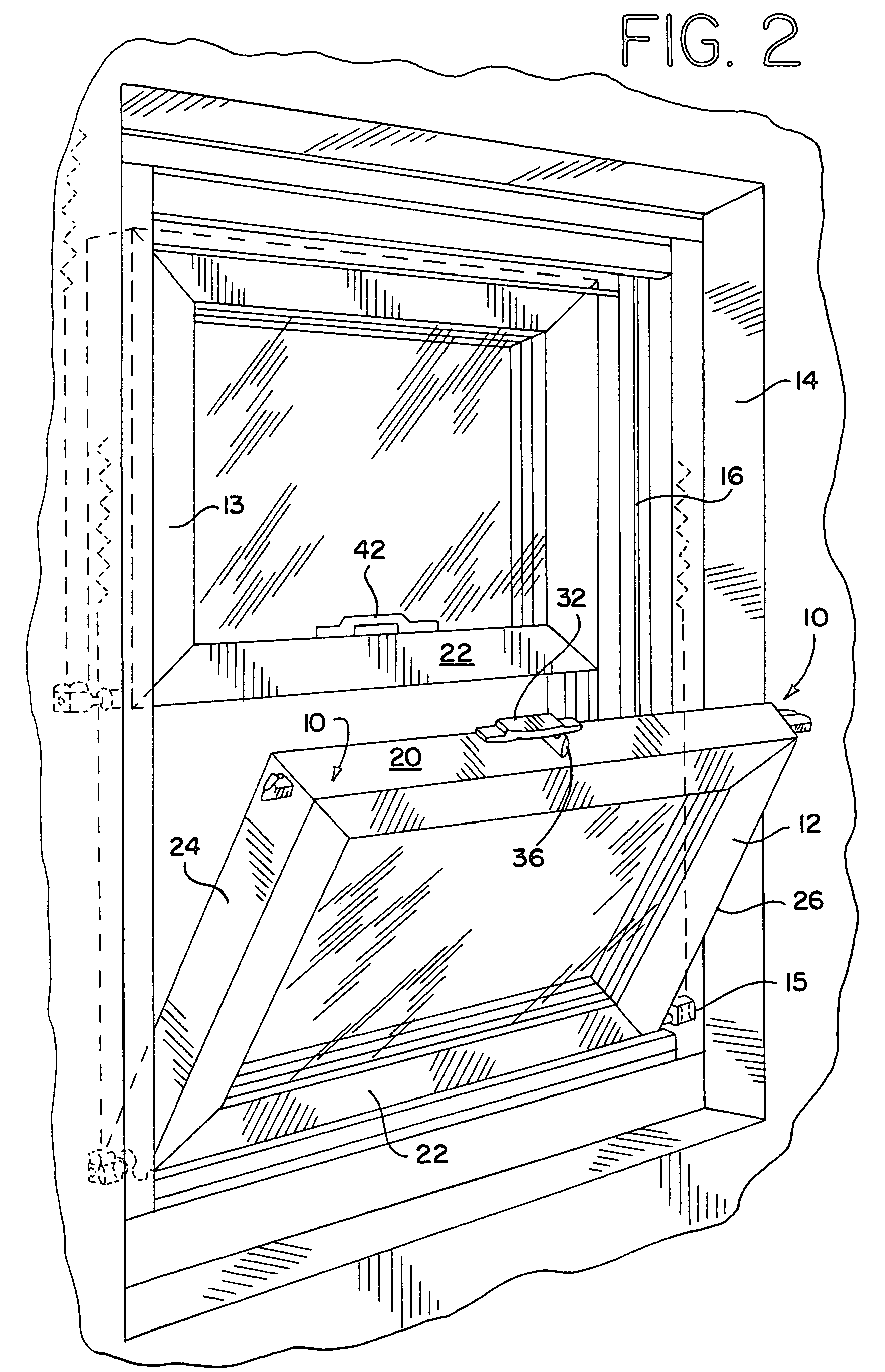

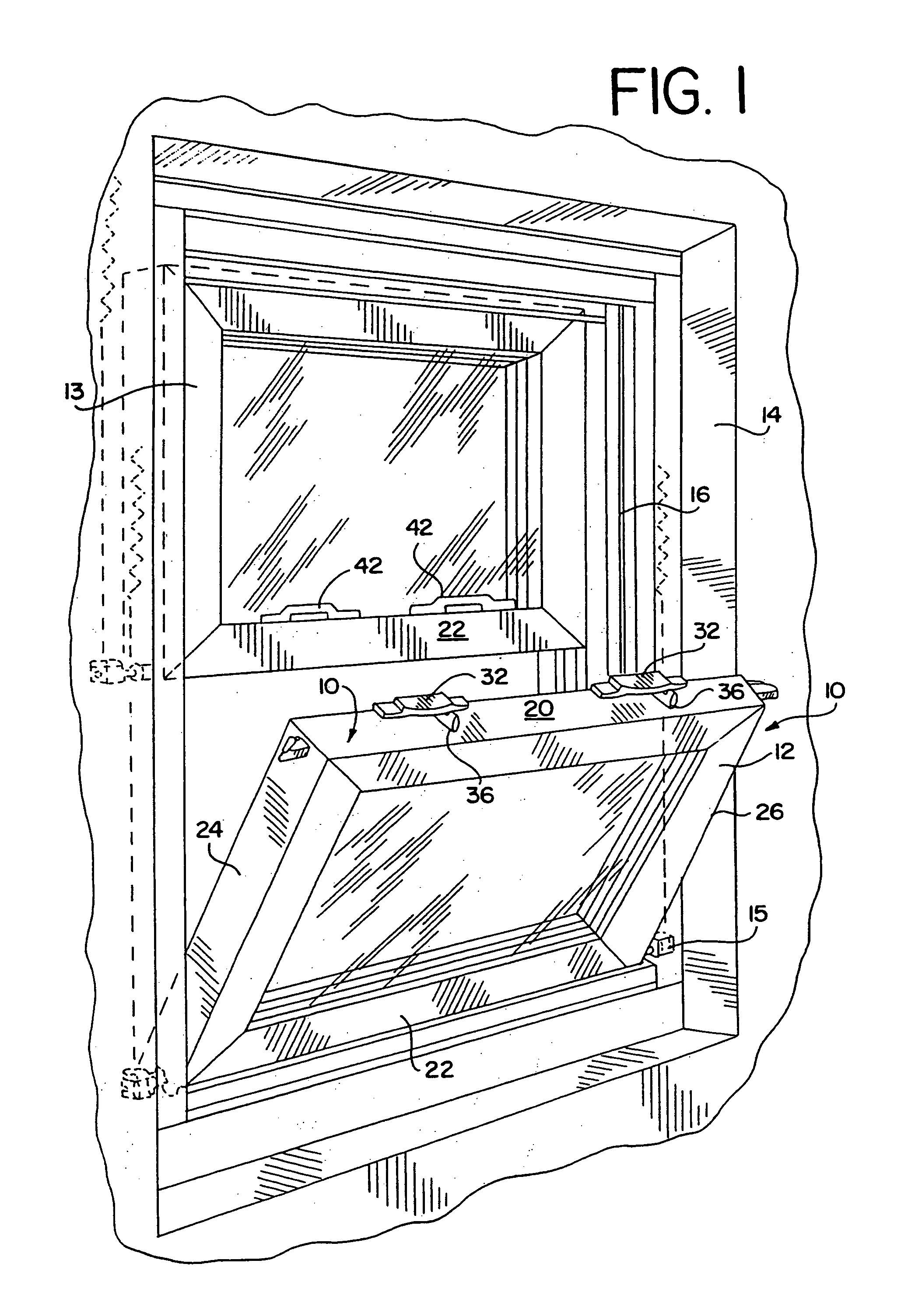

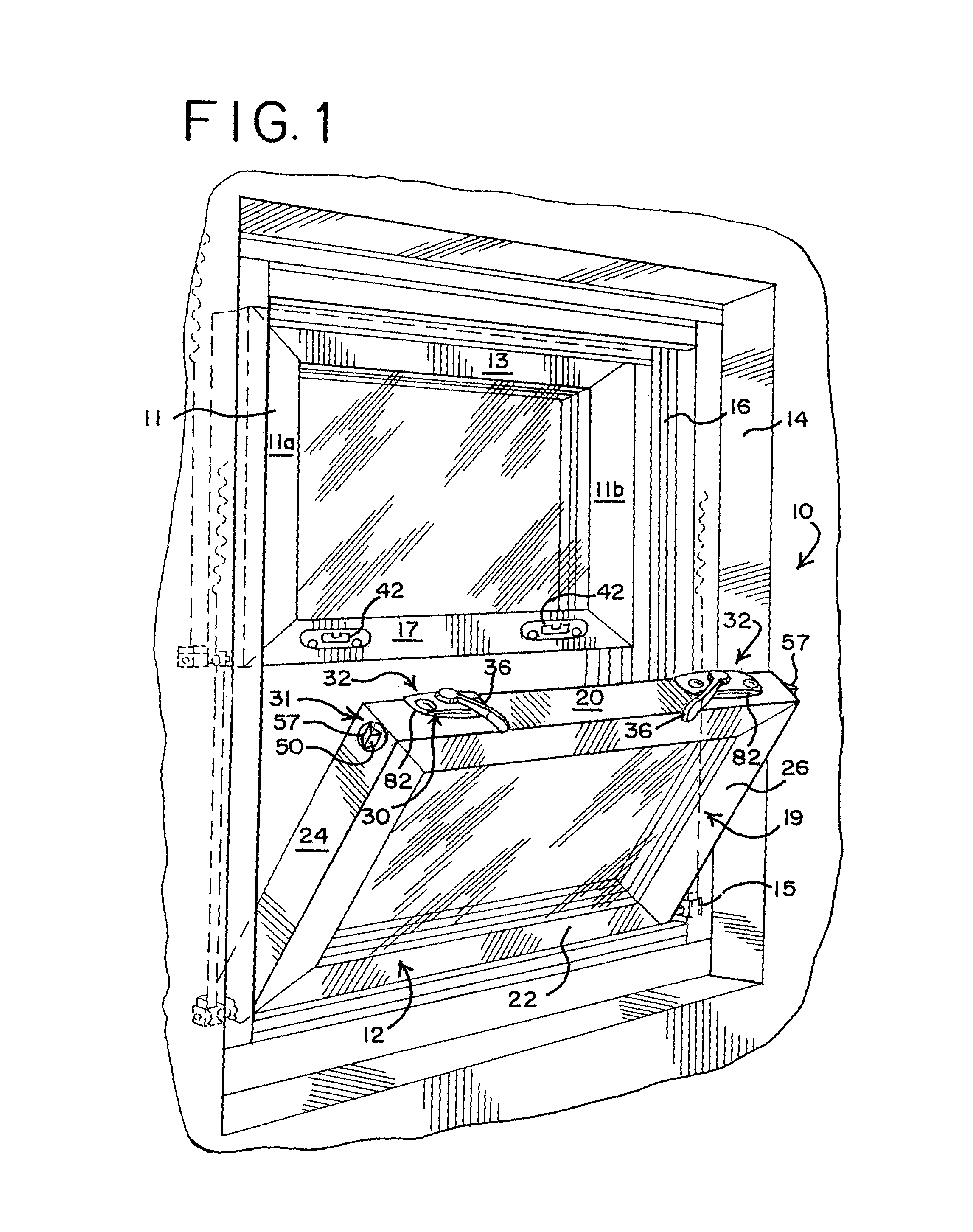

Locking system for a double-hung window

A double-hung window construction includes a window jamb and a pair of sashes slidably movable within the window jamb. A pivot member pivotally connects each sash to the window jamb such that the sash can tilt relative to the window jamb around the pivot member. A combined locking and tilting mechanism is attached to each sash. The mechanism is movable between a locked position preventing sliding or tilting of the window, an operative position permitting sliding of the sash and preventing tilting of the sash, and a tilting position which allows the tilting movement of the sash. Each locking and tilting mechanism is independent of the operation of the remaining locking and tilting mechanism.

Owner:THERMAL GARD INC

Security lock for a sash type window

A security lock having a housing and a cam. The housing includes an indent with a pair of guide portions. The cam is positioned within the indent and includes an axle port. A shaft of an axle is adapted to be inserted into the axle port so that the cam and the axle are rotatable together. The cam includes a sweep arm and a channel disposed on an upper surface of the sweep arm. The sweep arm has an outer wall that is either elongate-shaped or semicircular-shaped. The channel has a semi-circular-shaped inner wall and an elongate-shaped outer wall. Upon rotation of the axle, the cam rotates about the guide portions into a locked posture in the housing. The elongate-shaped outer wall of the channel allows the security lock to be self-locating when the housing and a keeper are misaligned when installed, respectively, on opposing window sashes.

Owner:LAWRENCE BARRY G

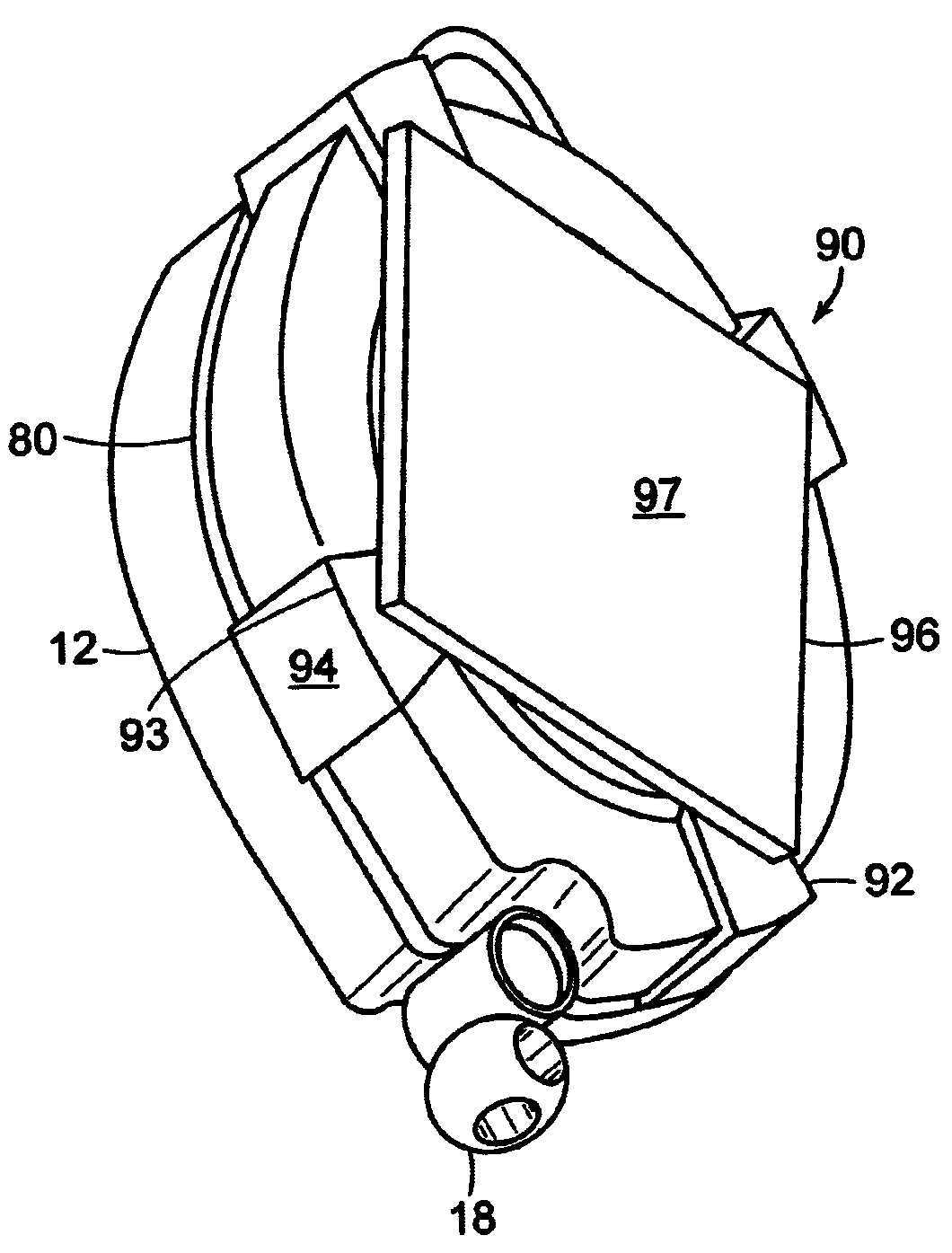

Integrated tilt/sash lock assembly

An integrated sash lock and tilt latch assembly is mounted in a sash window having a top rail, a base, and two stiles connected together at their extremities. The integrated assembly contains a sash lock mechanism, a tilt latch mechanism, and a connector. The sash lock mechanism includes an actuator movable to adjust the assembly among a locked position, an unlocked position, and a tiltable position, and a rotor coupled to the actuator. The tilt latch mechanism includes a tilt latch housing supported by the top rail and a latch bolt slidably supported by the tilt latch housing and moveable between an extended position and a retracted position. At least a portion of the tilt latch housing has a generally circular cross-section. The connector has a first end of operably coupled to the latch bolt and a second end operably coupled to the sash lock mechanism.

Owner:ASHLAND HARDWARE LLC

Polyolefin wood fiber composite

An improved composite structural member comprising a complex profile made of a composite comprising a polyolefin polymer and a wood fiber. The material is useful in conventional structural applications. The complex profile, in the form of an extruded thermoplastic composite member can be used in residential and commercial structures as described. Preferably, the profile is used in the manufacture of the fenestration components such as windows and doors. Such linear members are designed with specifically configured cross-sectional shapes to form structural elements in the fenestration units. Structural elements must possess sufficient strength, thermal stability and weatherability to permit the manufacture of a structurally sound window unit that can be easily installed into a rough opening but can maintain its attractive appearance and structural integrity over the life of the window unit often twenty years or more. The structural member comprises a hollow complex cross-section with at least one structural web or one fastener web formed within the component. The exterior of the extruded component has a visible capstock layer and is shaped and adapted for installation in rough openings. The exterior also contains shape and components capable of supporting the elements of the fenestration unit such as a window, sash or movable door unit. The improved polypropylene structural members have unique advantages and can be assembled using thermoplastic weld processes.

Owner:ANDERSEN CORPORATION

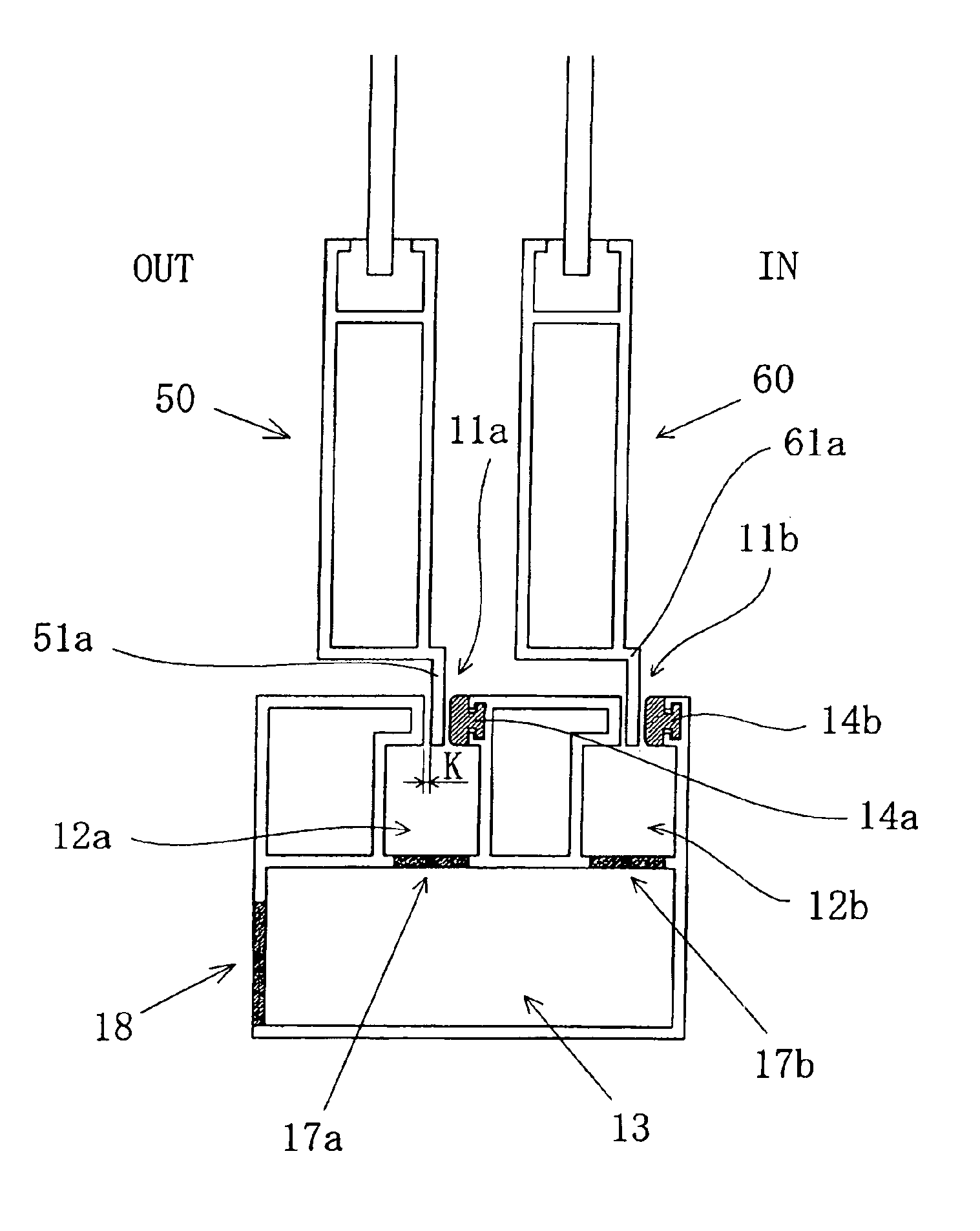

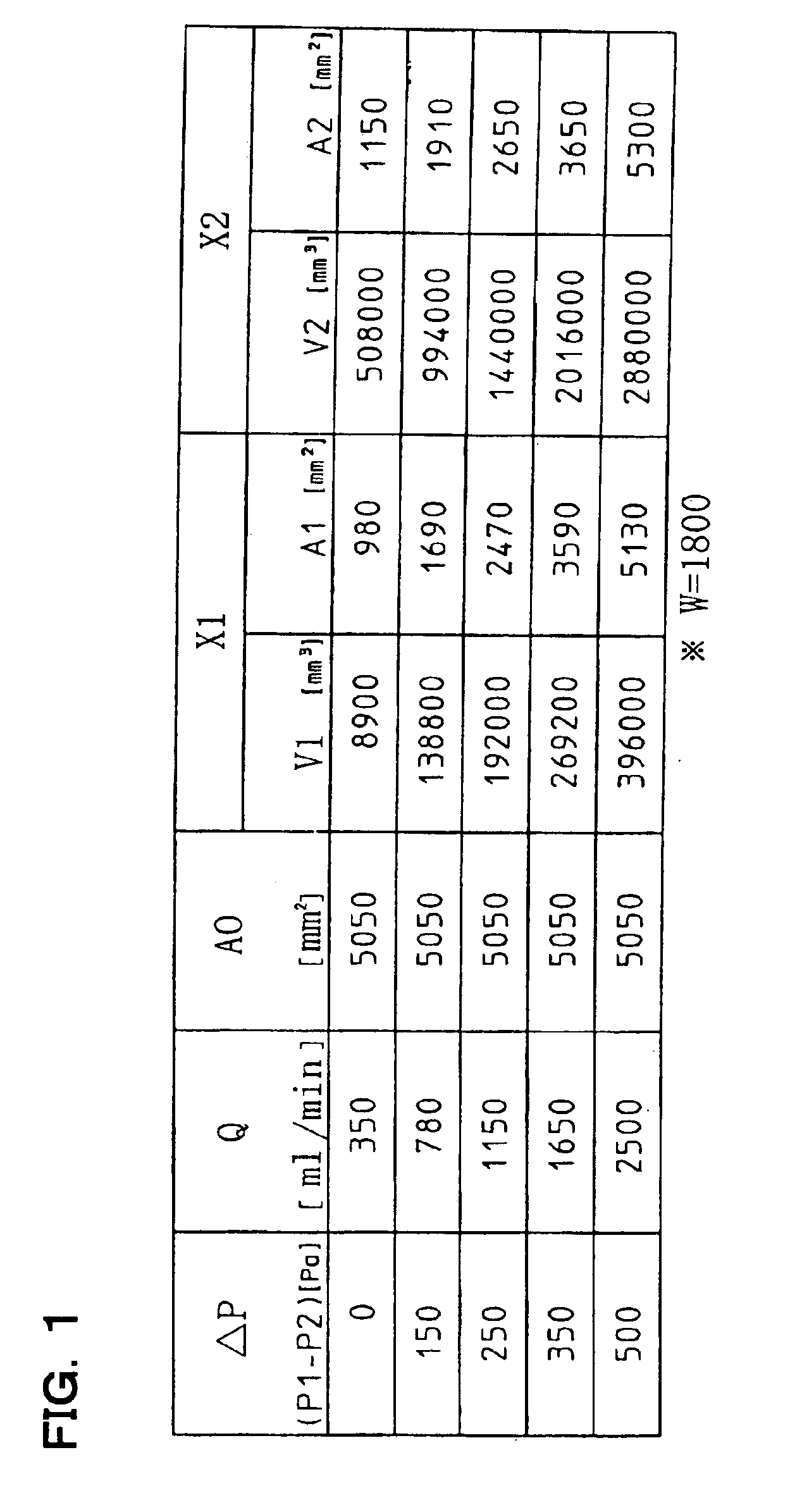

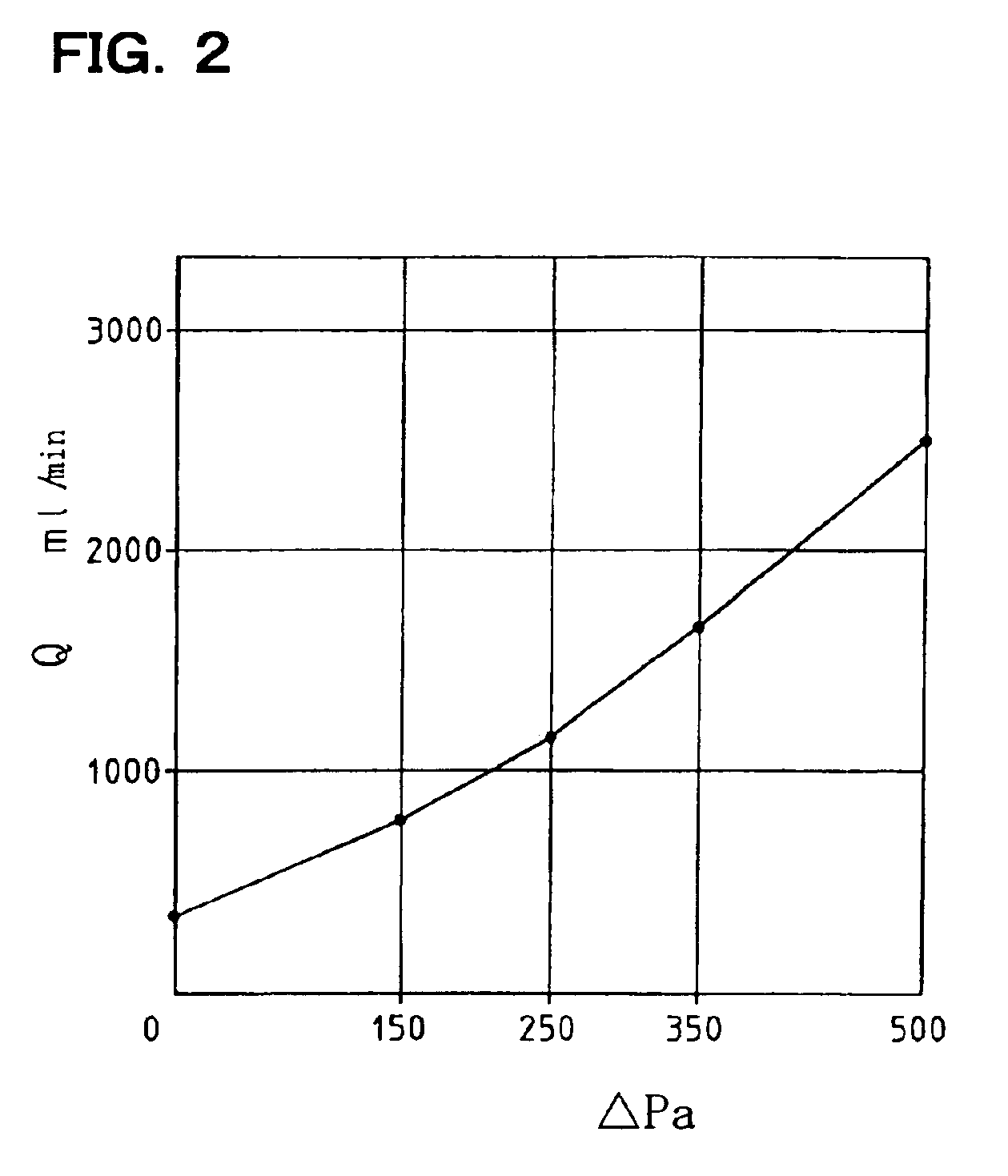

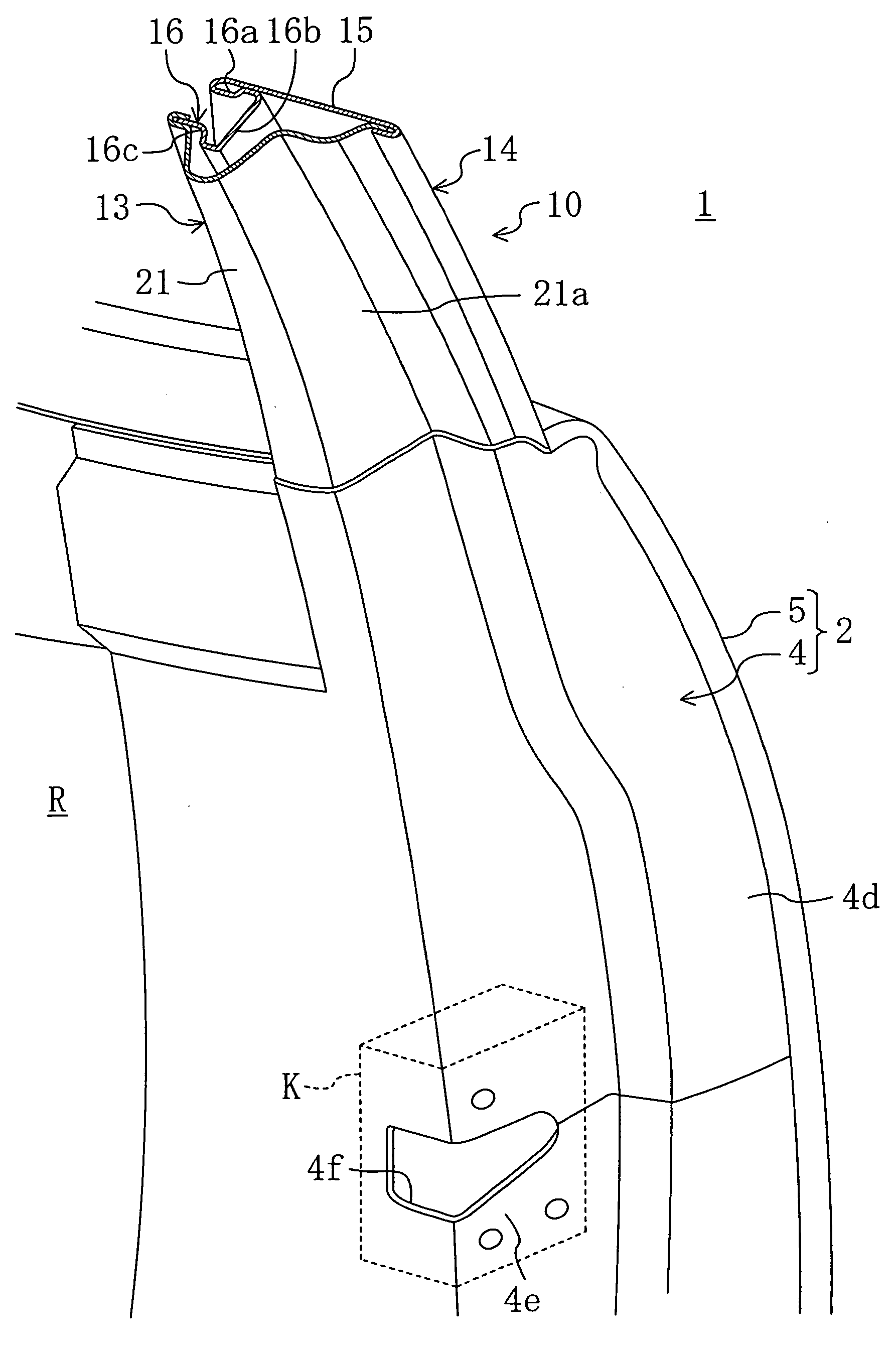

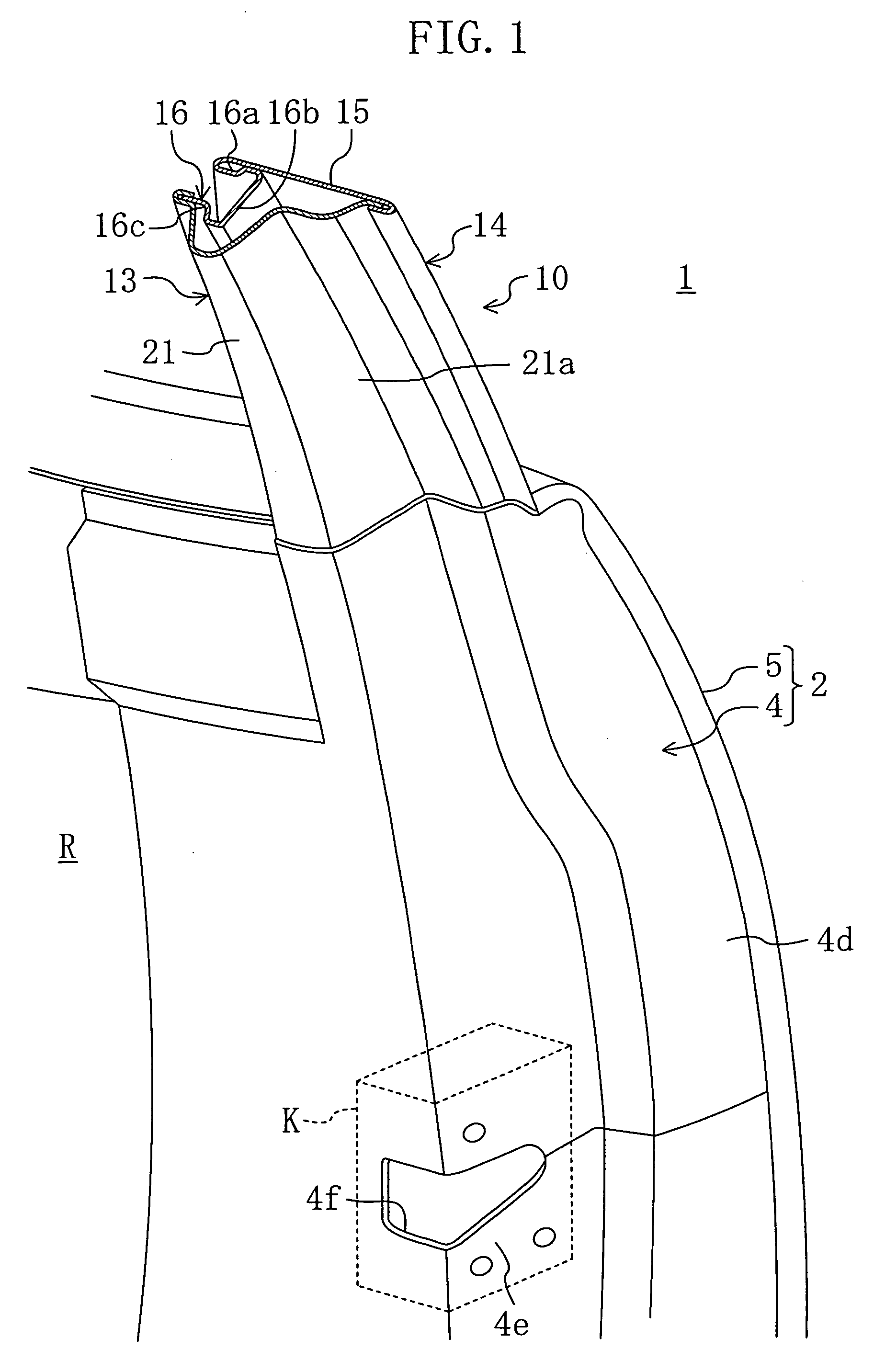

Outdoor window

InactiveUS6883279B2Superior in drainage of rainwaterHigh in watertightness against indoor water leakageCondensed water drain-offSealing arrangementsSash windowEngineering

Owner:TATEYAMA ALUMINUM IND

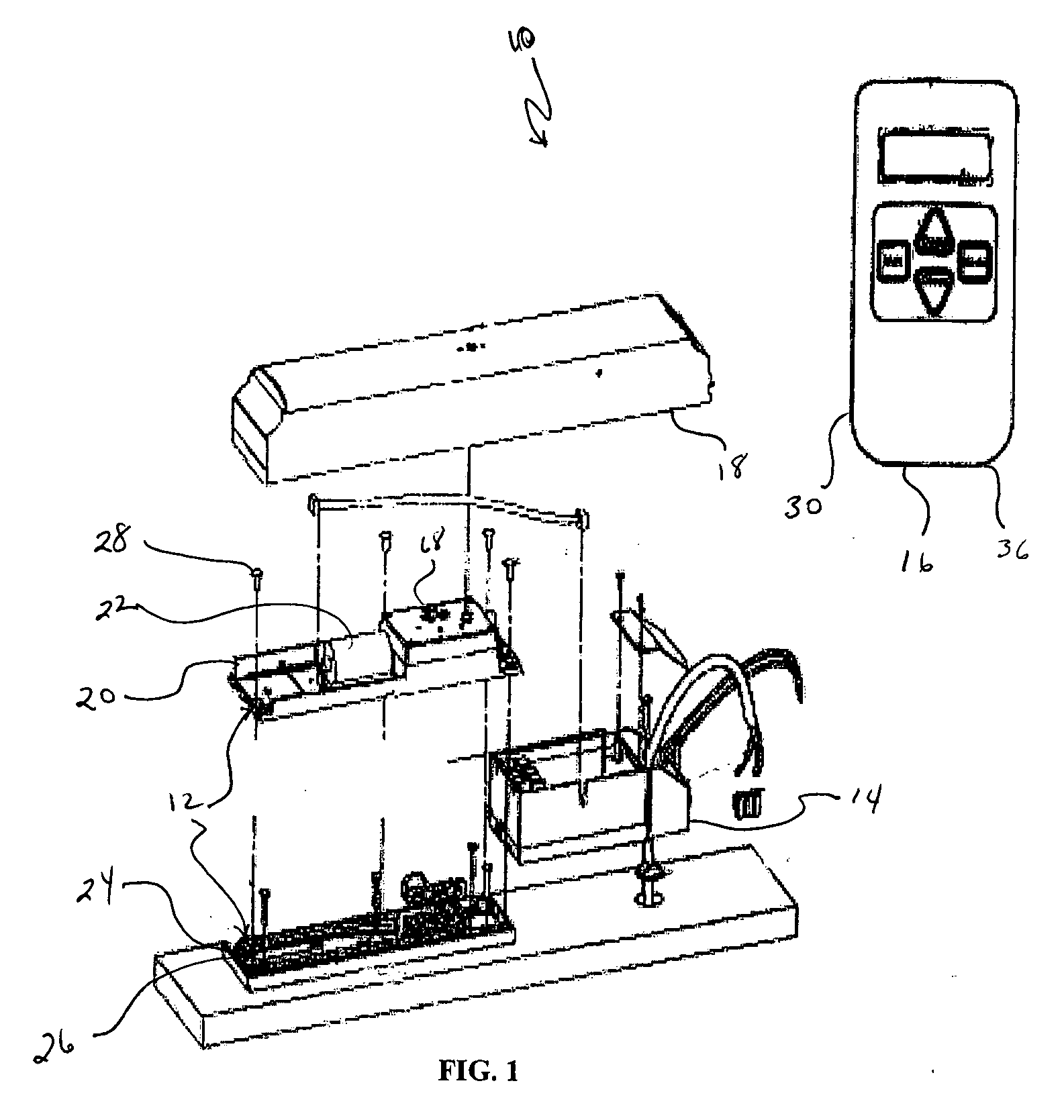

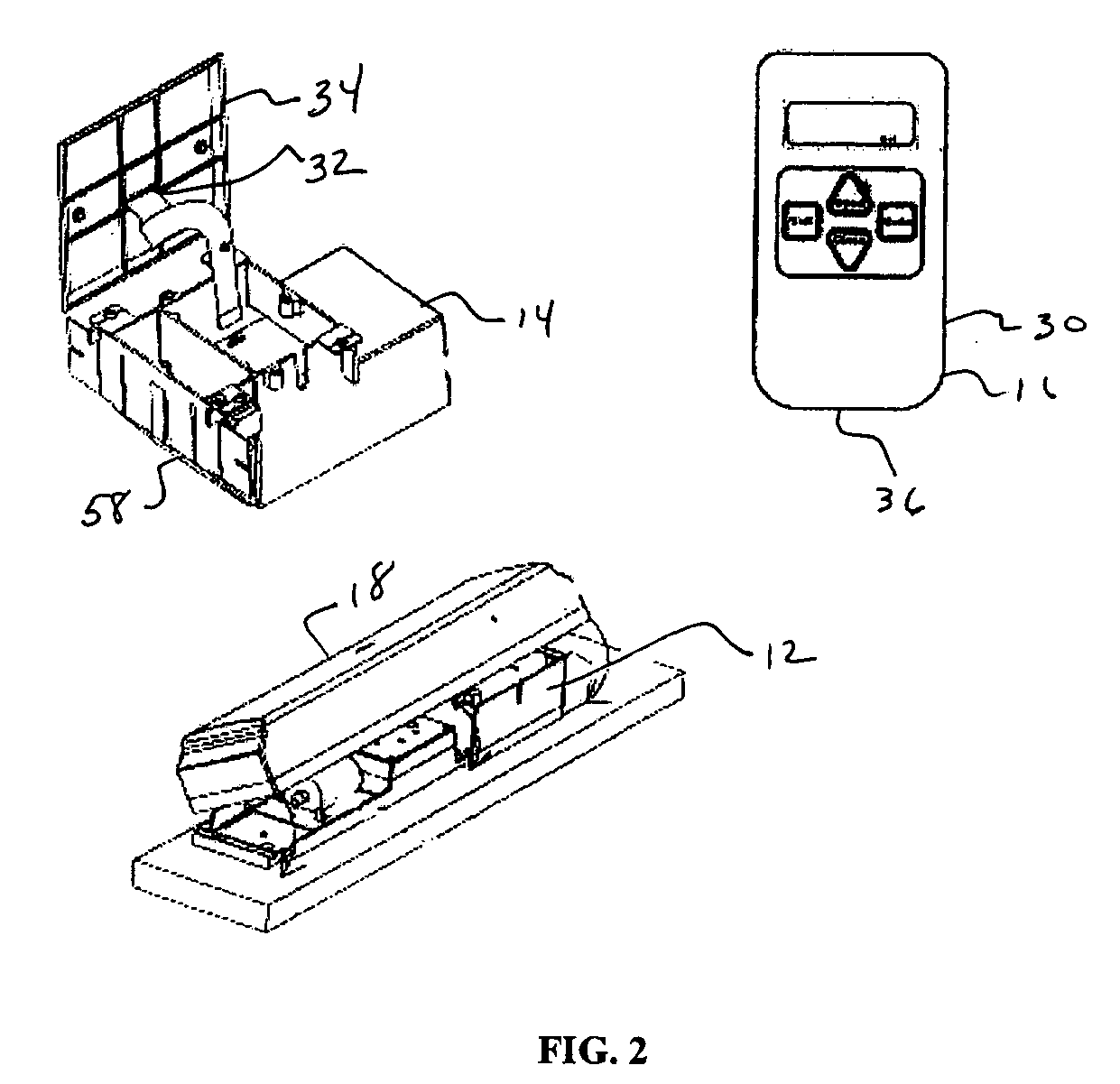

Integrated power window and skylight operating systems

InactiveUS20070271848A1Easy to installAssist in energy savingMan-operated mechanismPower-operated mechanismSash windowOperator control unit

An operable fenestration operating system for a structure including a window or skylight having a frame, an operable sash and presenting a resistance force opposing opening and closing of the sash. A motorized operator is coupled with the frame and the sash to selectively open and close the sash. The invention includes an operator control unit communicatively connected to the motorized operator. The operator control unit includes a processor, a sensor for sensing the magnitude of the resistance force, a pulse width modulation circuit for supplying electrical power to the motorized operator. The processor varies the torque output of the motorized operator using the pulse width modulation circuit in response to the sensed parameter.

Owner:TRUTH HARDWARE

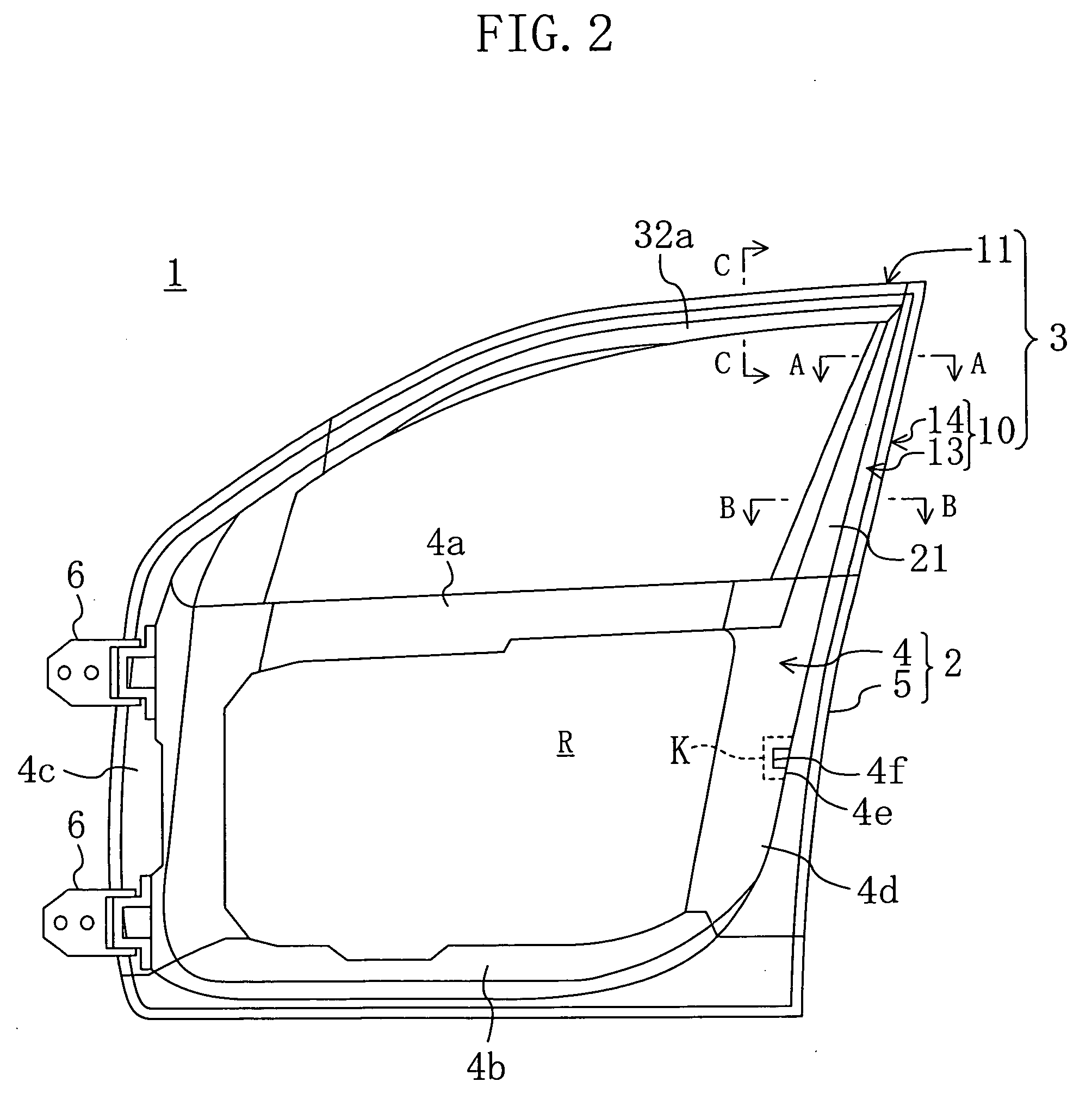

Vehicle door

Owner:HIROTEC CORP

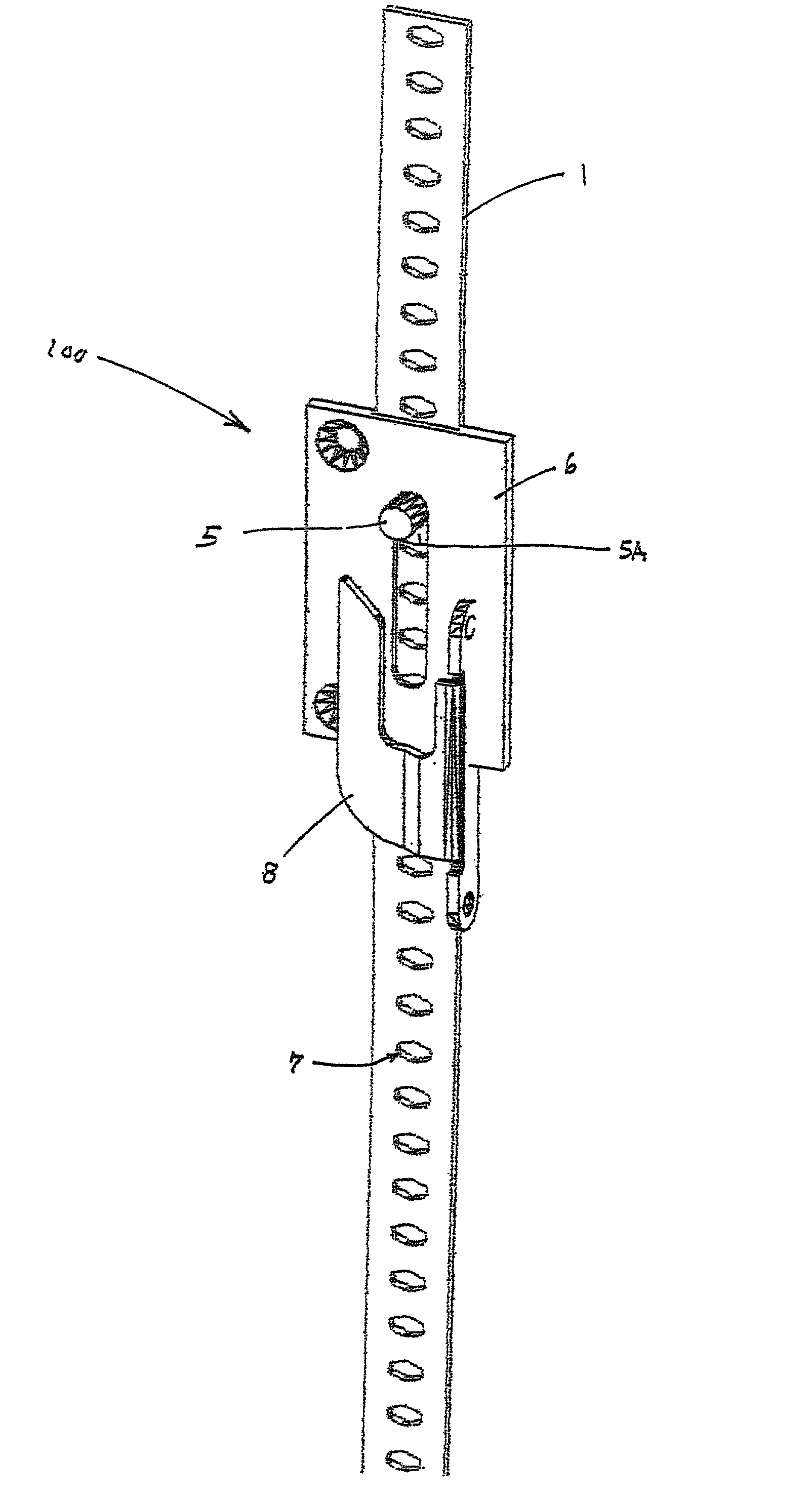

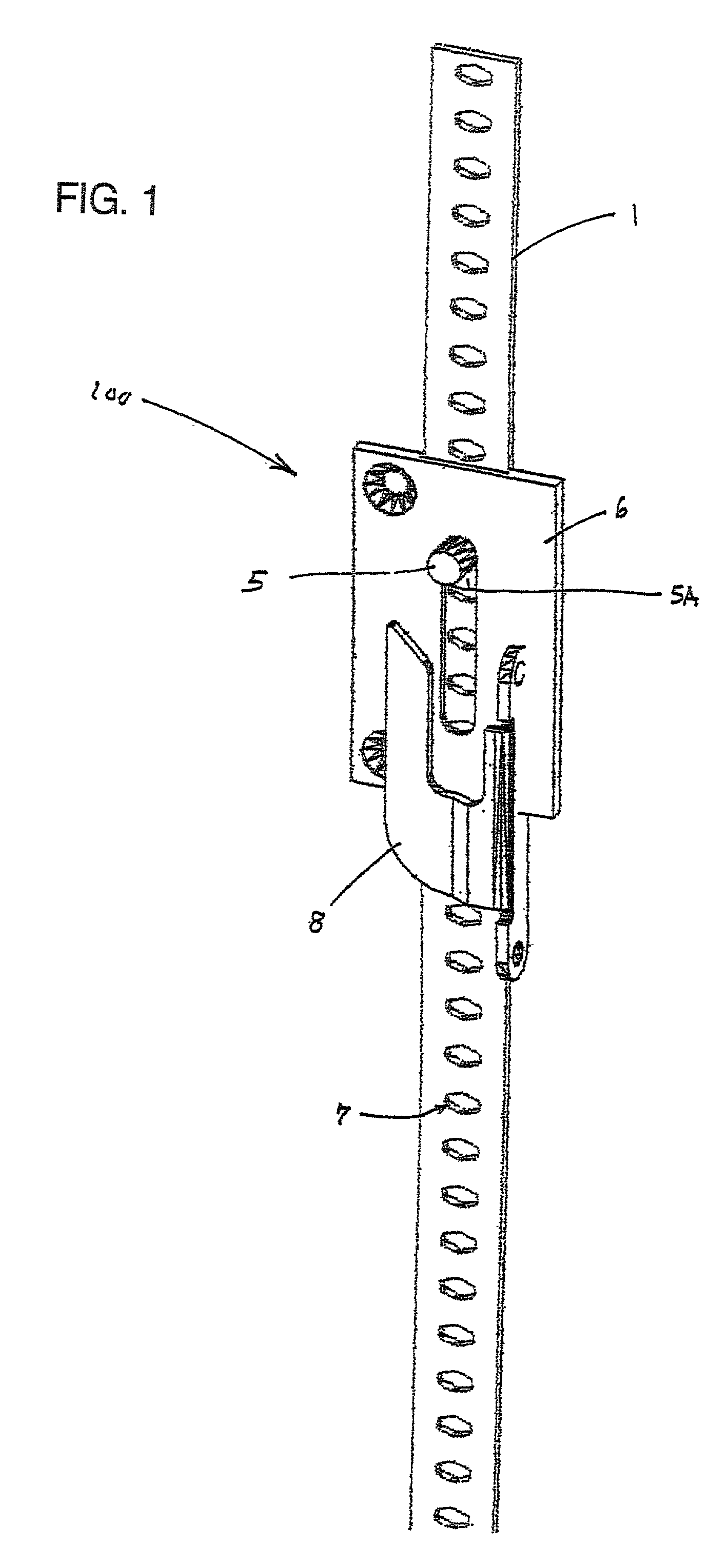

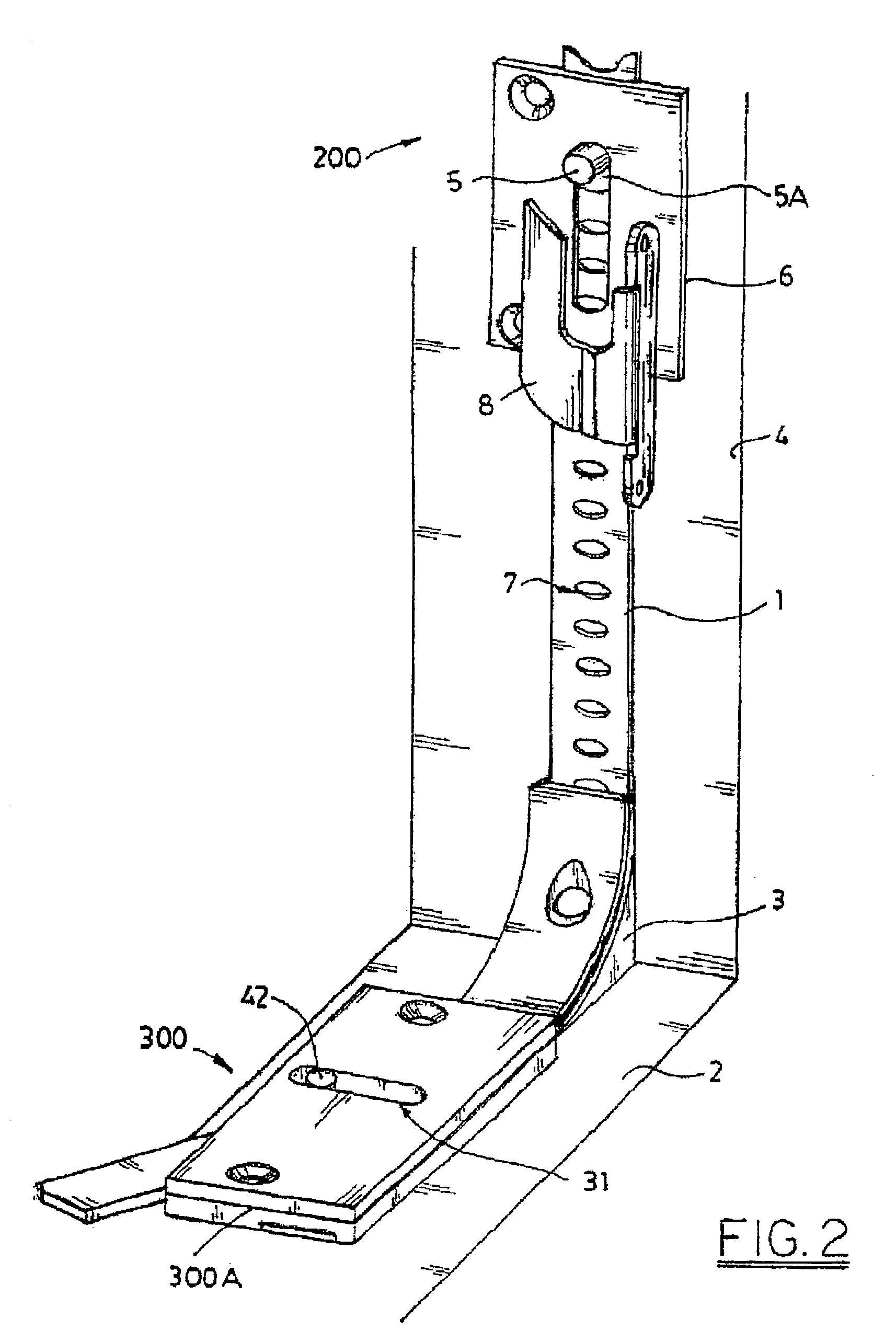

Fenestration locking system

InactiveUS7004515B2Easy to adaptEliminates any permanent connectionGearingWing fastenersSash windowEngineering

This fenestration locking system for a swinging sash or door is characterized by the use of a linear member running continuously from an actuating assembly to a locking pin assembly. The linear member can be a flexible linear member, allowing it to convey motion to the locking pin assembly around corners. The locking pin assembly has a moveable locking pin with an actuator and an extension that can engage a keeper. The linear member has multiple actuator engagement sites along its length where the actuator of the locking pin can engage the linear member. The linear member can then be used to move the locking pin with respect to the locking pin assembly so that the extension can engage or disengage a keeper. The locking pin assembly can be mounted on a fenestration frame and the keeper opposingly mounted on a window or door mounted in the fenestration frame. Alternately, the keeper can be incorporated into the fenestration frame and the locking pin assembly opposingly mounted on the window or door mounted in the fenestration frame.

Owner:CALDWELL MFG NORTH AMERICA

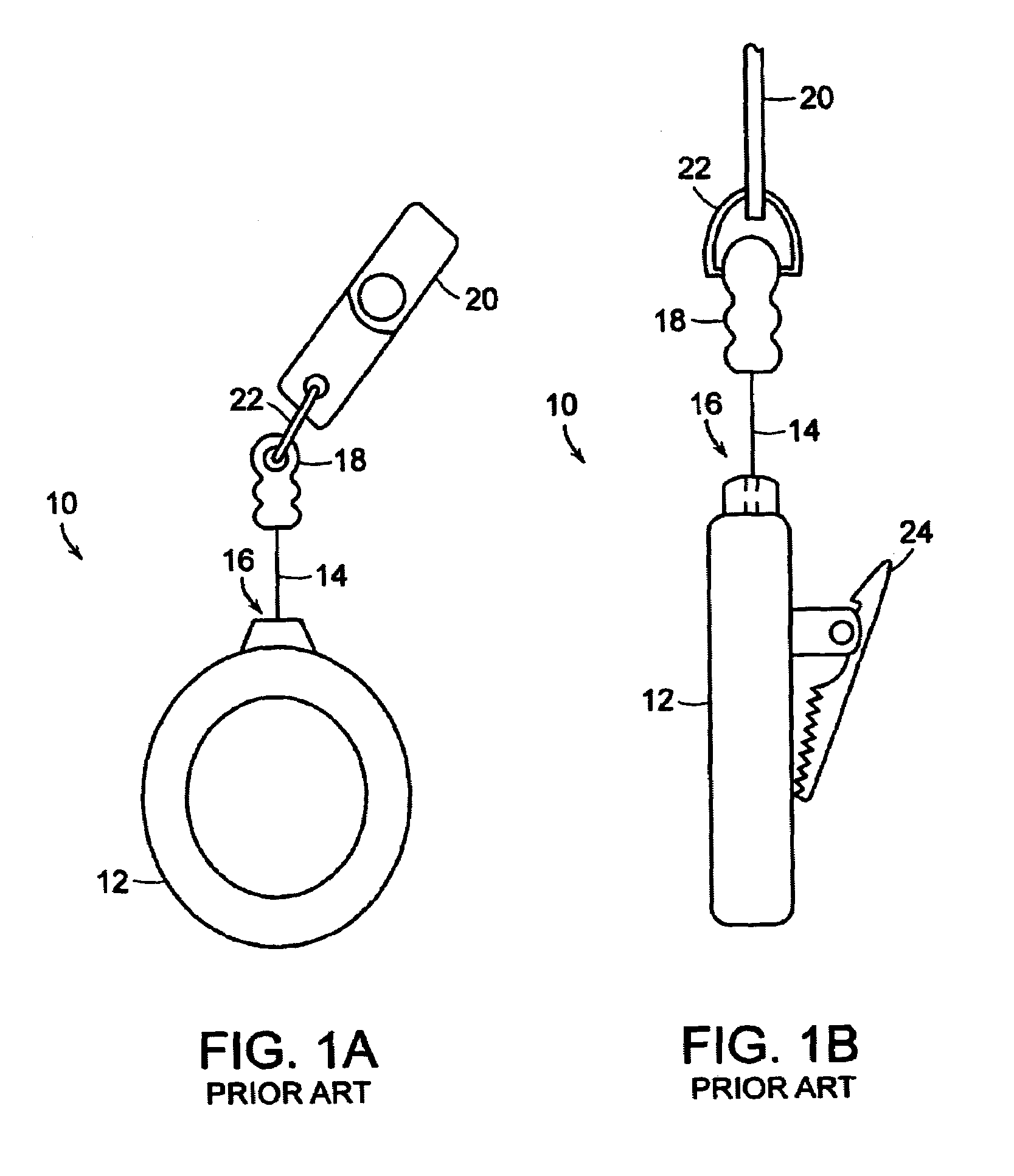

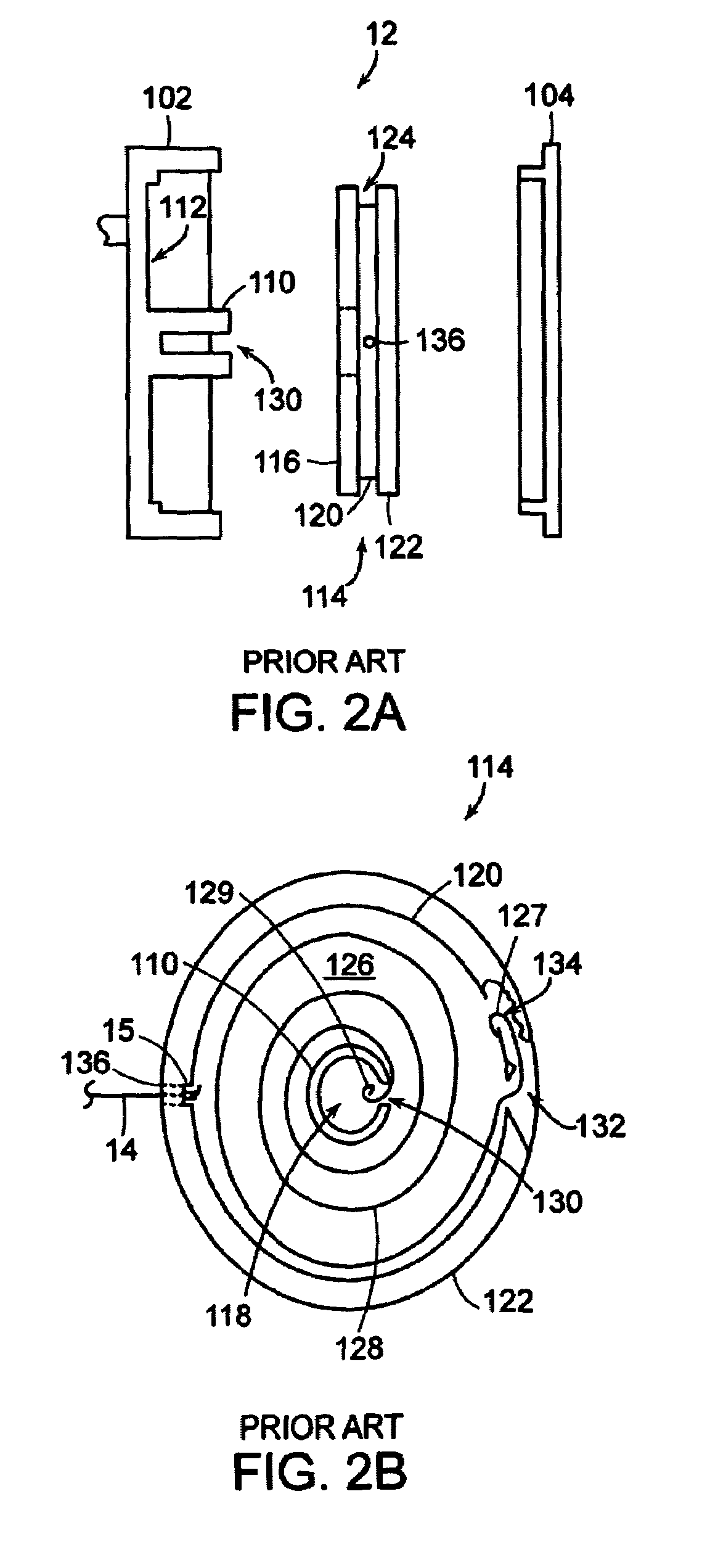

Retractable badge reel with billboard display

InactiveUS7007882B2Reduce capacitySolve the lack of tensionTravelling carriersHoldersSash windowMechanical engineering

A retractable badge reel with a billboard designed to display a logo, such that unadorned badge reels can be manufactured separately from the billboards that contain the logos. The billboard is optionally removable, allowing the logo being displayed to be changed without having to produce new retractable badge reels in their entirety. In another embodiment, a billboard designed to display a logo is adapted to be installed over the face of an existing retractable badge reel, such that the logo on the existing unit is hidden and the new logo on the billboard is instead displayed. A casement comprising the billboard and a back housing member have a mating portion that mates with a bob mating portion of a bob attached to the exterior end of the retractable cord to prevent the bob from shifting or twisting when the cord is in the retracted position.

Owner:COMPREHENSIVE IDENTIFICATION PRODS

Laminated glass retention system

A laminated glass retention system for securing a laminated glass subassembly within a window sash or frame member or door panel or similar component includes a retention member applied to the laminated glass subassembly. The retention member generally can include a leg portion that engages of the laminated glass subassembly, and can further include a base portion that is coupled to the frame member in which the laminated glass subassembly is seated. The retention member helps retain the insulating glass subassembly within its frame member when subjected to high winds and wind-borne debris.

Owner:ANDERSEN CORPORATION

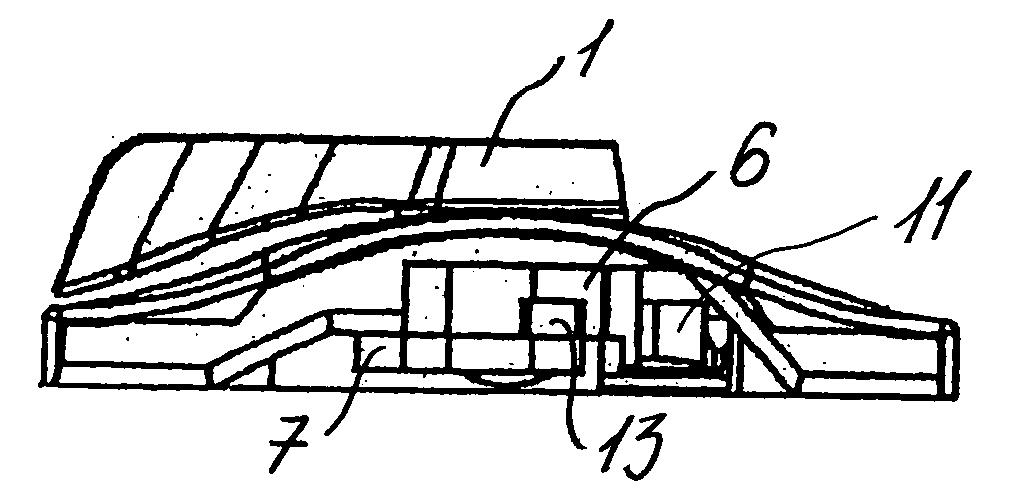

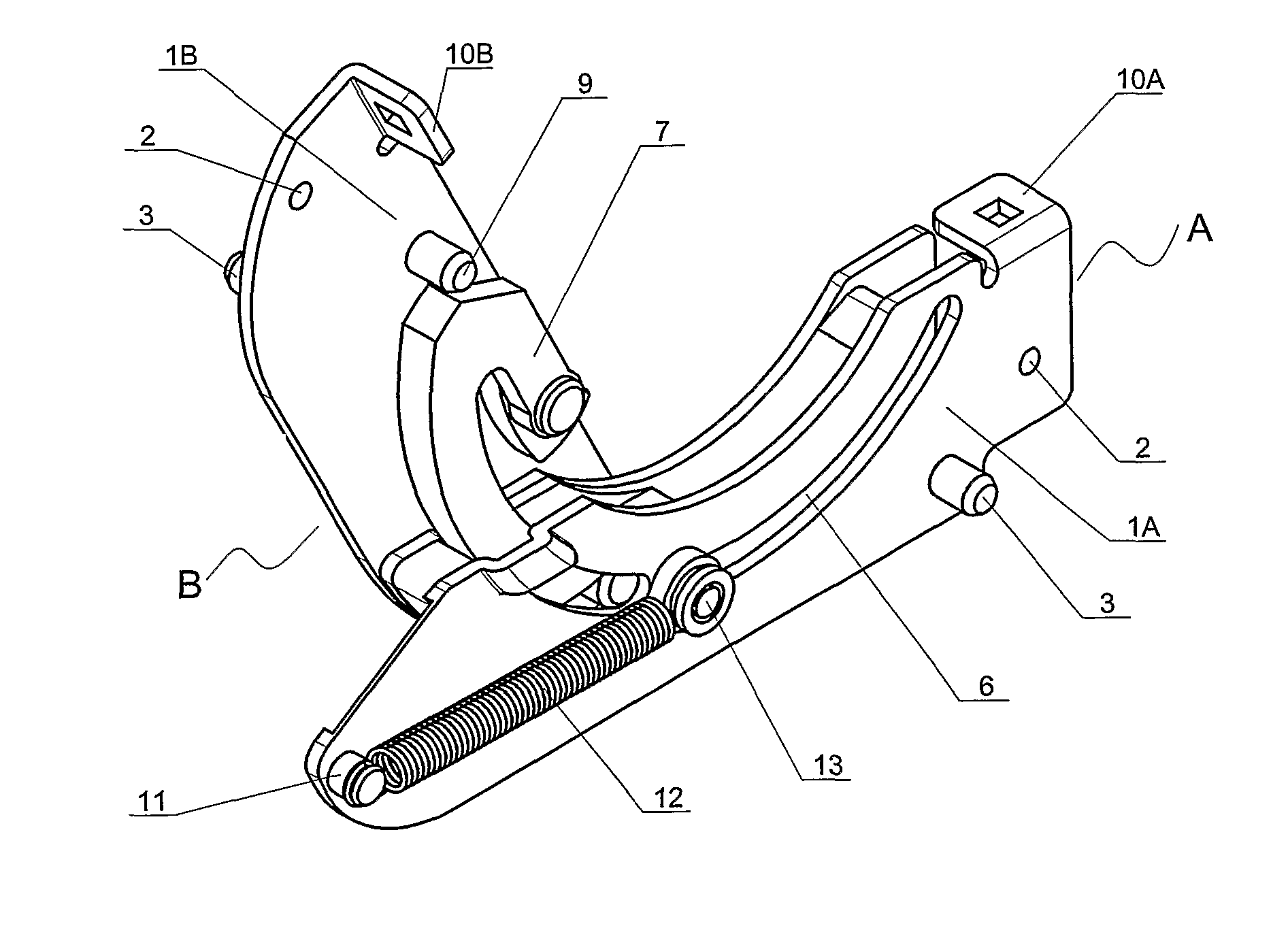

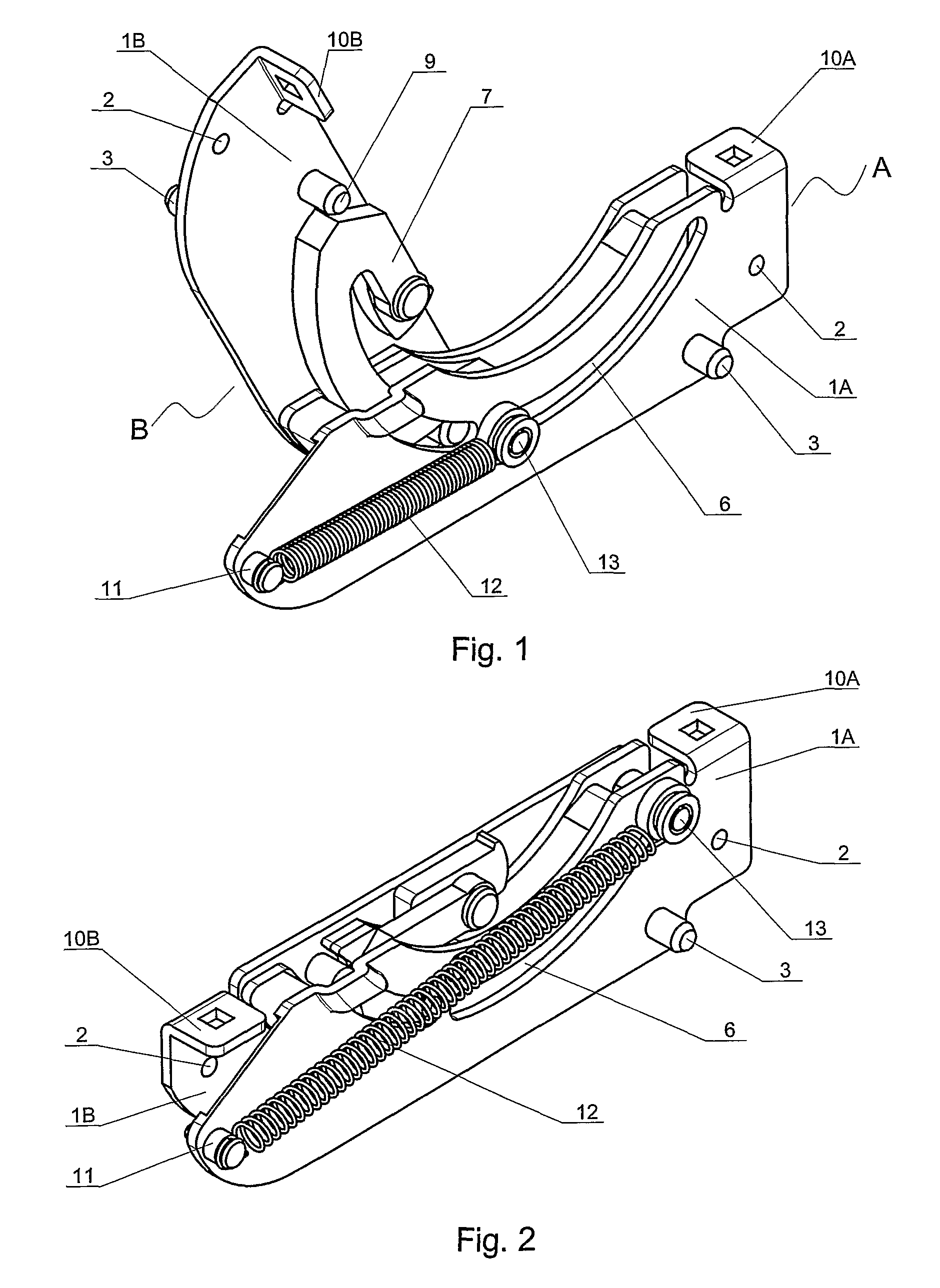

Hinge for a roof window with a pivot sash

A pivot hinge for roof windows with a sash pivoting around the axis located between the upper and the lower member of a window, has a balancing system, which ensures the state of equilibrium of a window sash when its centre of gravity is located outside the sash rotating axis and the friction spring of the hinge is unable to hold the sash pivoted in each its position. At the same time the window fittings, its assembly, installation in a roof and its appearance remain unchanged. Also the method of separating of both hinge parts (taking a sash out of a window frame) remains unchanged.

Owner:FAKRO PP SPOLKA Z O O

Sash lock with forced entry resistance

A sash lock mechanism includes a handle, a housing adapted to be supported by a sash window assembly, the housing having an opening receiving the handle therethrough, and a rotor coupled to the handle. The rotor is moveable between at least a locked position and an unlocked position by movement of the handle. The sash lock mechanism also includes a locking mechanism that contains a pivotable member pivotably connected to the housing. The pivotable member is pivotable between a first position and a second position. When the rotor is in the locked position and the pivotable member is in the first position, the pivotable member confronts the rotor to prevent movement of the rotor to the unlocked position. When the pivotable member is in the second position, the pivotable member does not prevent movement of the rotor.

Owner:ASHLAND HARDWARE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com