Patents

Literature

737 results about "Fume hood" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fume hood (sometimes called a fume cupboard or fume closet) is a type of local ventilation device that is designed to limit exposure to hazardous or toxic fumes, vapors or dusts.

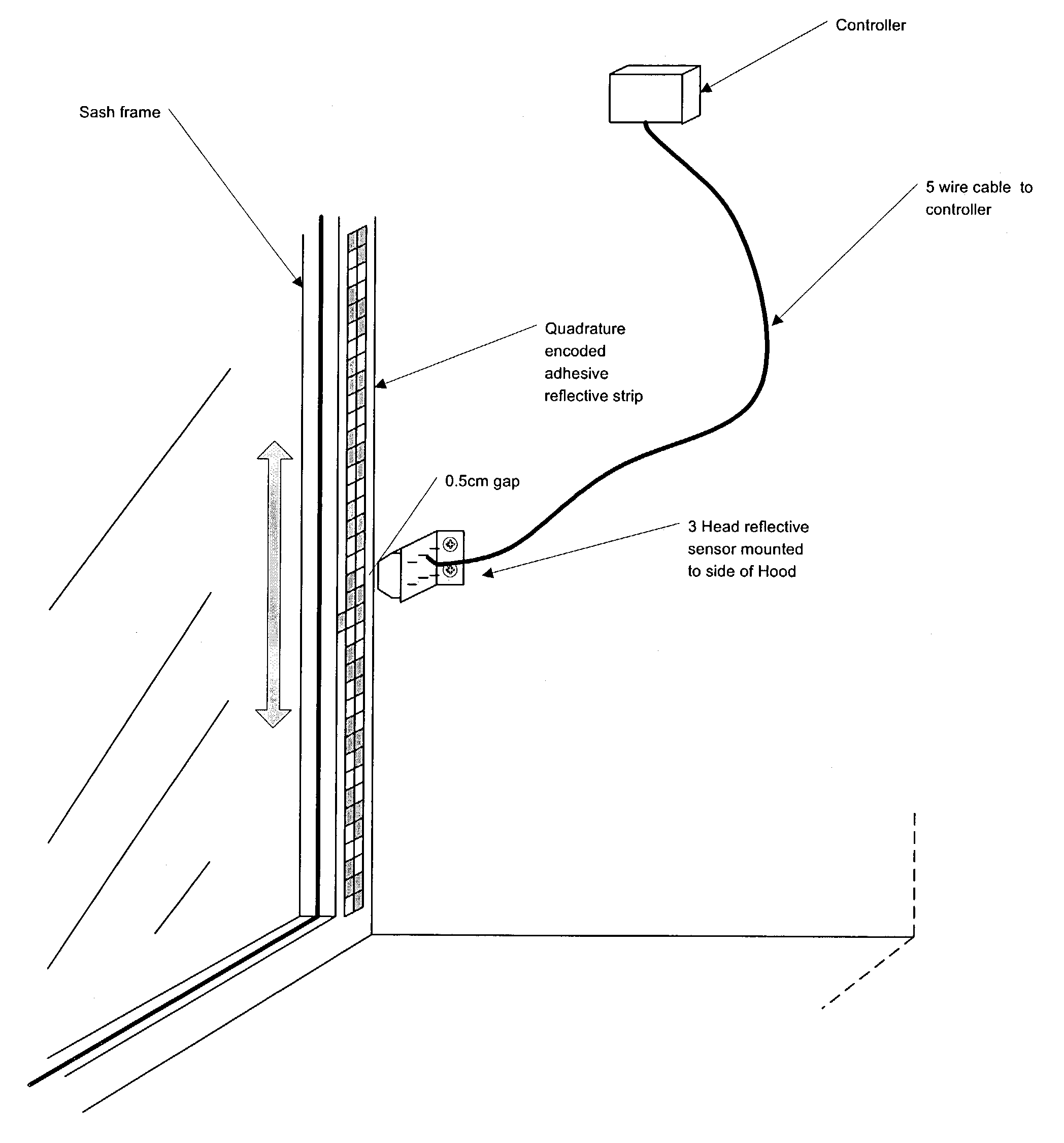

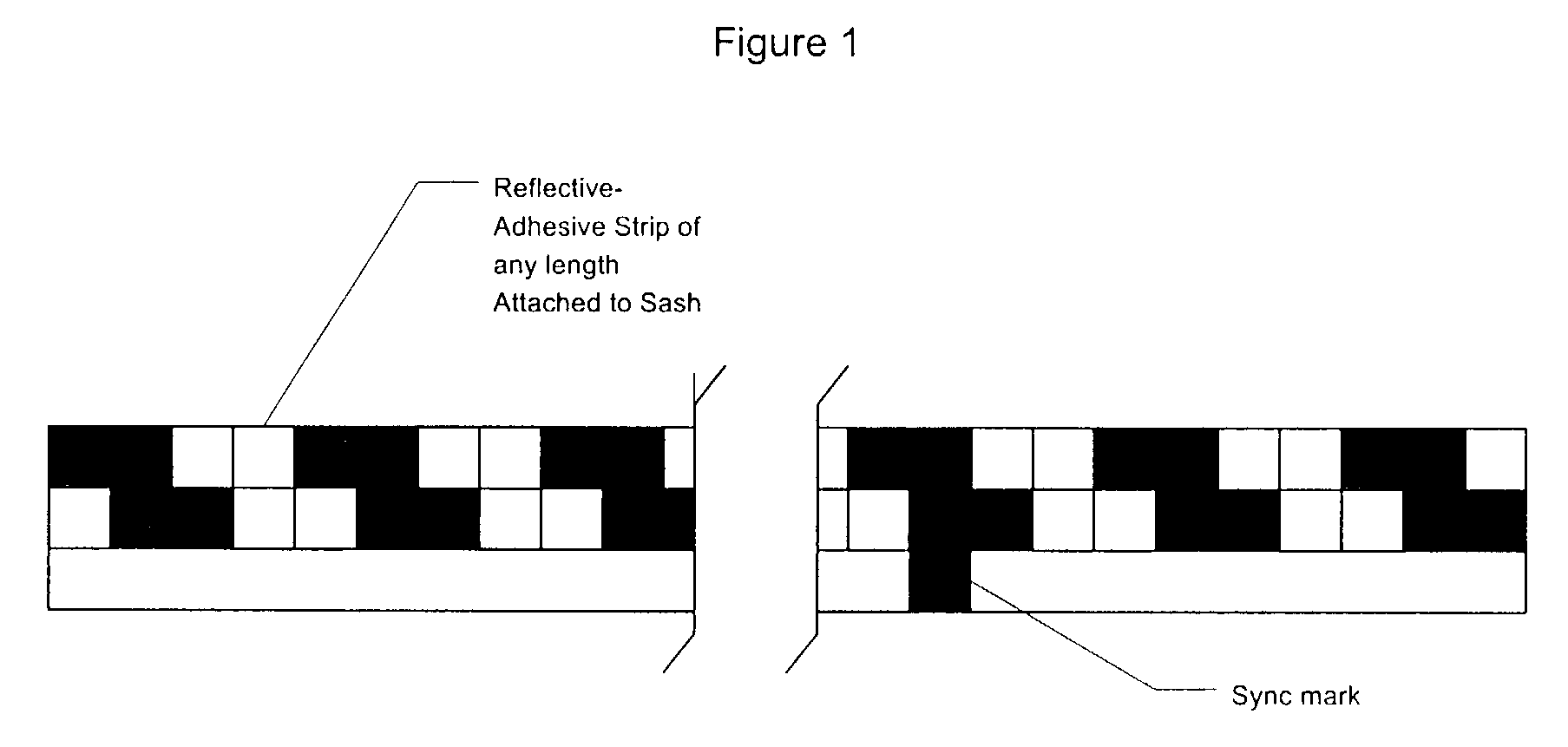

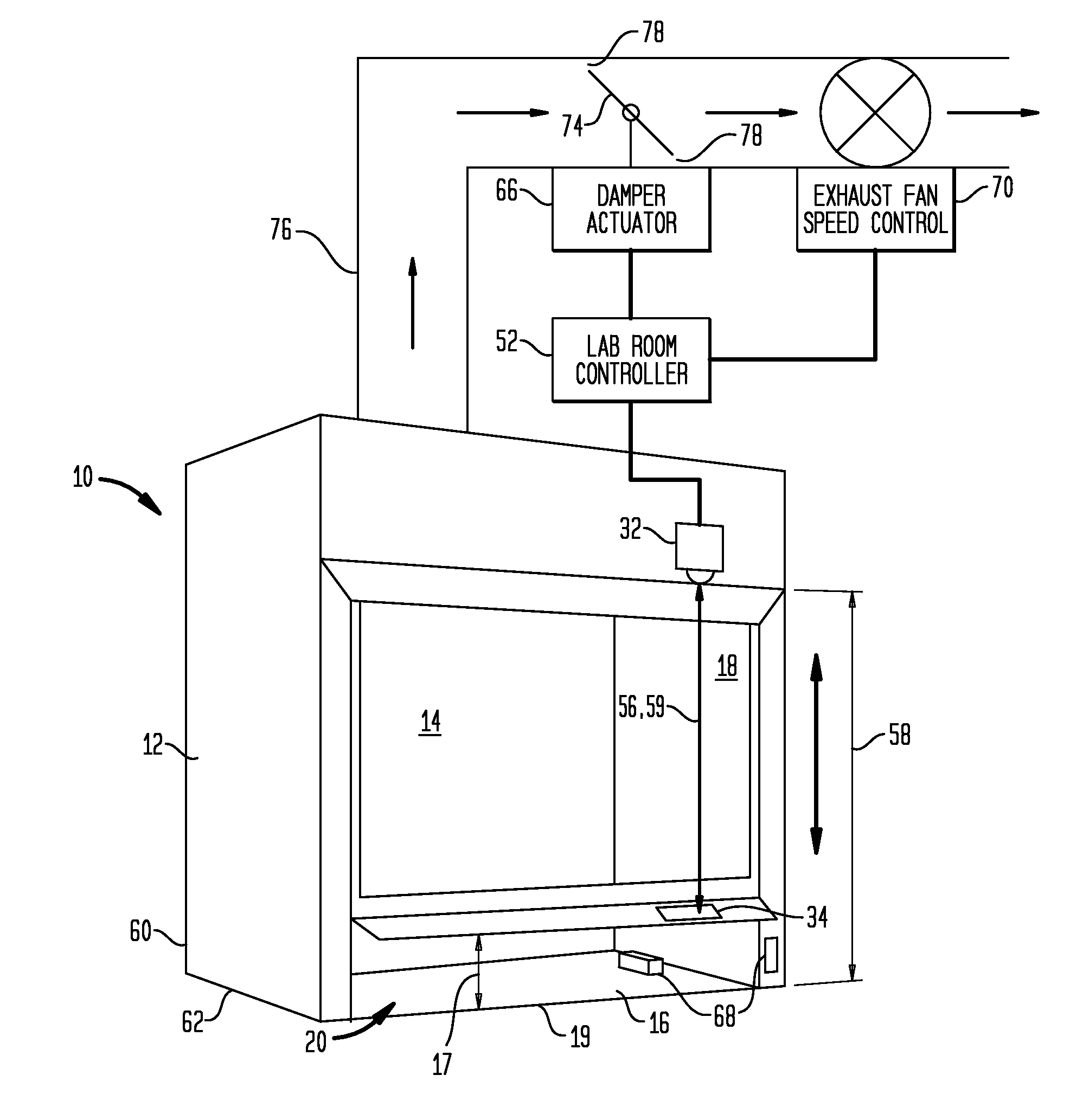

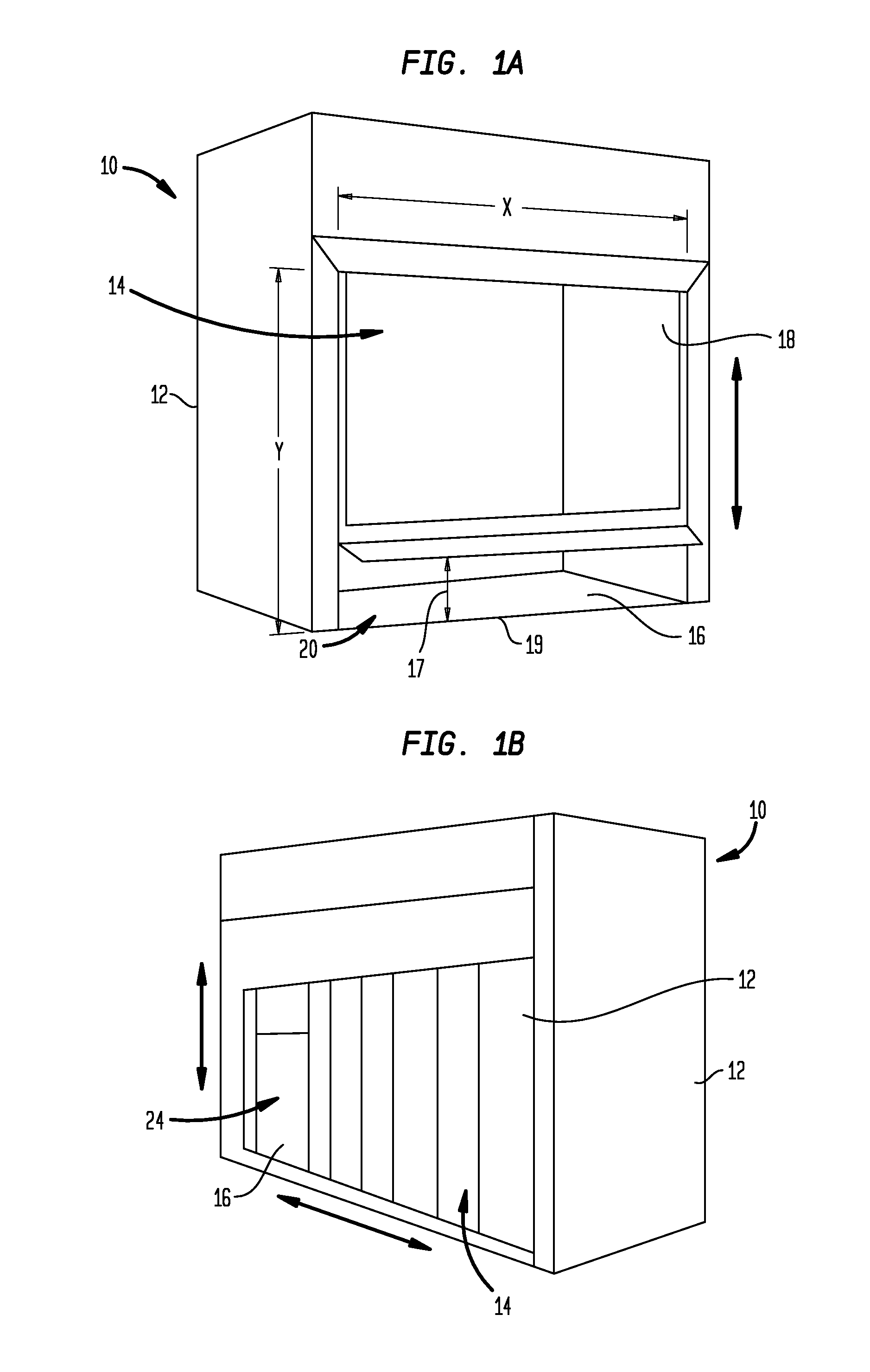

Optical sash sensing system for fume hoods

InactiveUS6994619B2Domestic stoves or rangesSpace heating and ventilation safety systemsSash windowControl signal

A fume hood optical sash sensing system for controlling the flow of air into a fume hood to maintain a constant face velocity by utilizing an optical sensing device mounted inside the fume hood that can sense the movement of a sash based on repeatable reflexive tape to produce an output control signal that corresponds to sash movement to produce desired airflow into the fume hood. The system includes an optical sensing device with a light source, reflexive tape with a repetitive, quadrature encoded pattern, a smart controller device that receives output control signals from the optical sensing device, and an actuation device capable of receiving the output signal from the controlling device to control the damper device that will result in constant face velocity across the face of the sash.

Owner:TRIATEK HLDG

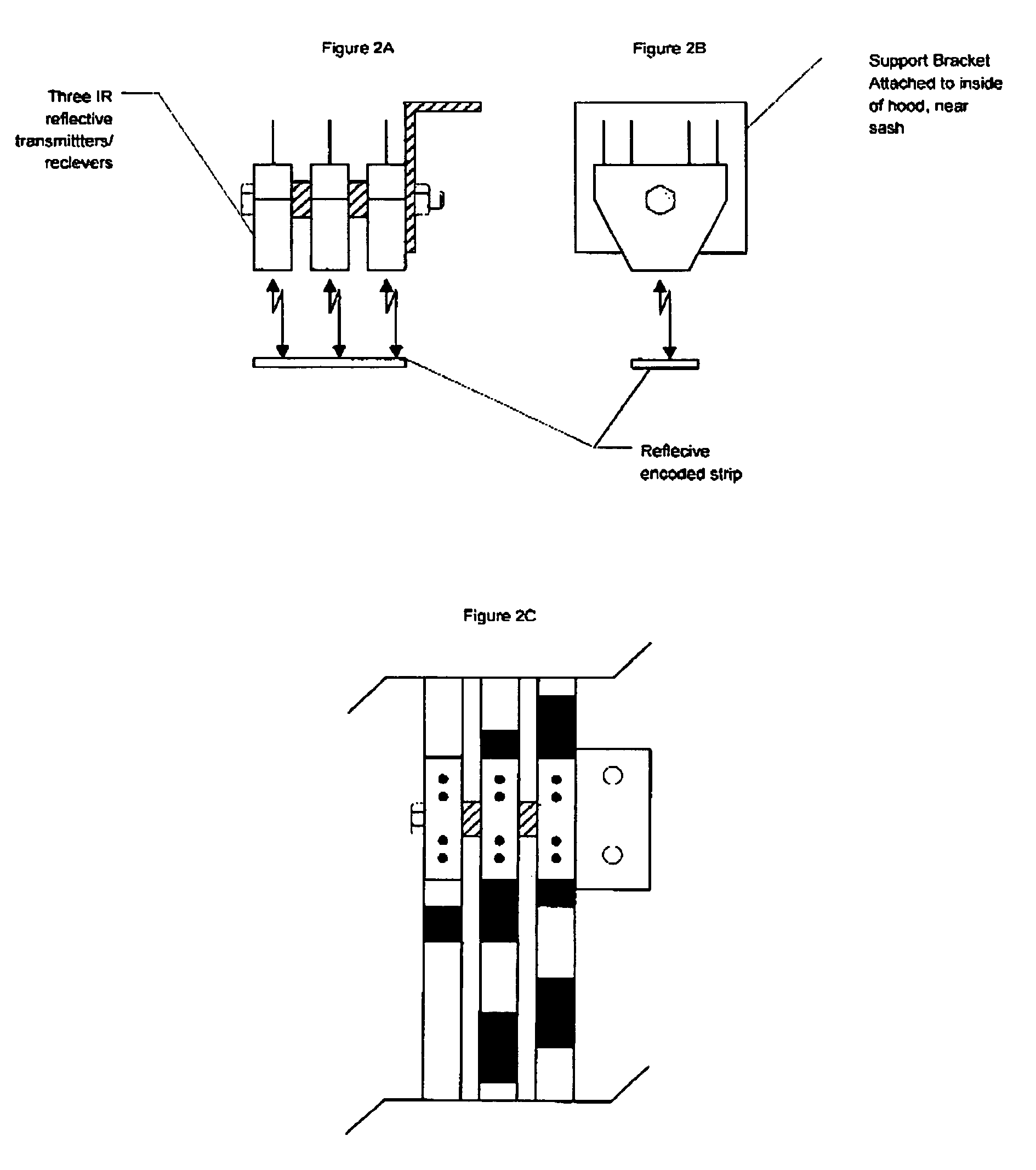

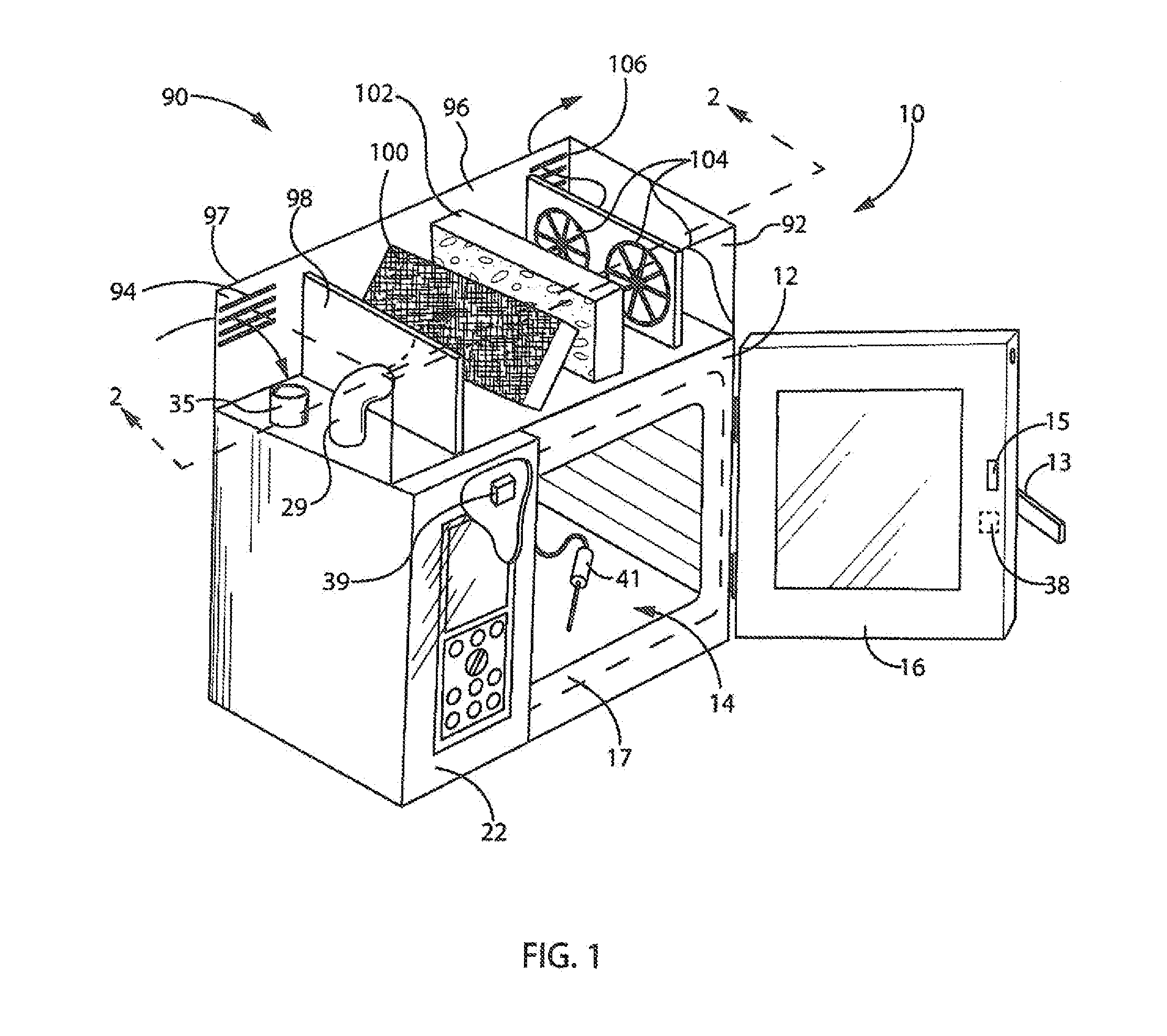

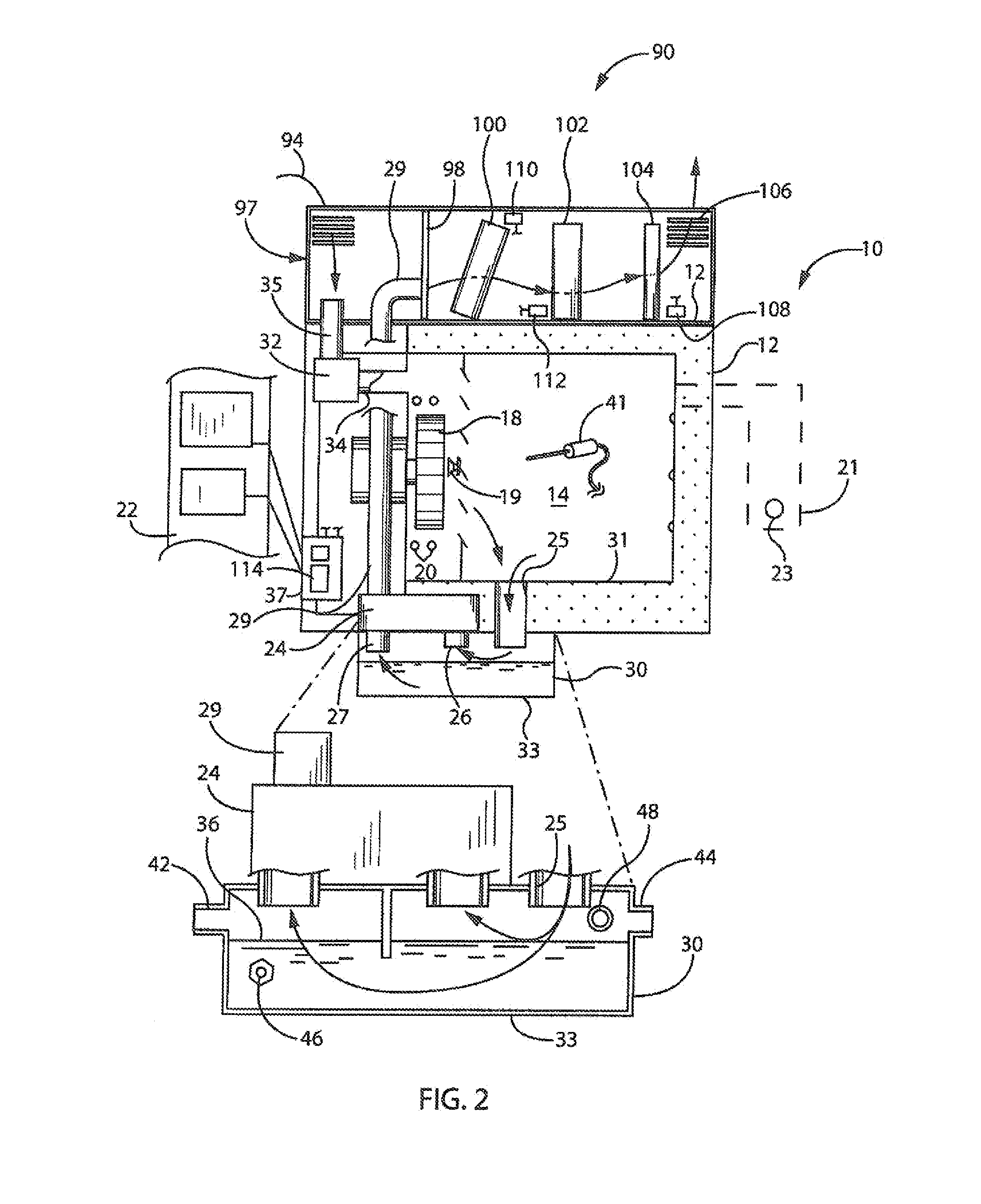

Ventless oven hood for combination oven providing rapid access

ActiveUS20150059595A1Suppress mutationAir-treating devicesDomestic stoves or rangesRapid accessProcess engineering

A ventless fume hood is integrated with an oven to anticipate a conclusion of the cooking schedule executed by the oven and in this way to provide direct venting of the oven cavity before the oven door is opened. Proper venting of a multimode combination oven may be thereby performed and the door may be opened up immediately upon conclusion of the cooking schedule without the delay otherwise required to collect cooking fumes escaping through the partially open door.

Owner:ALTO SHAAM

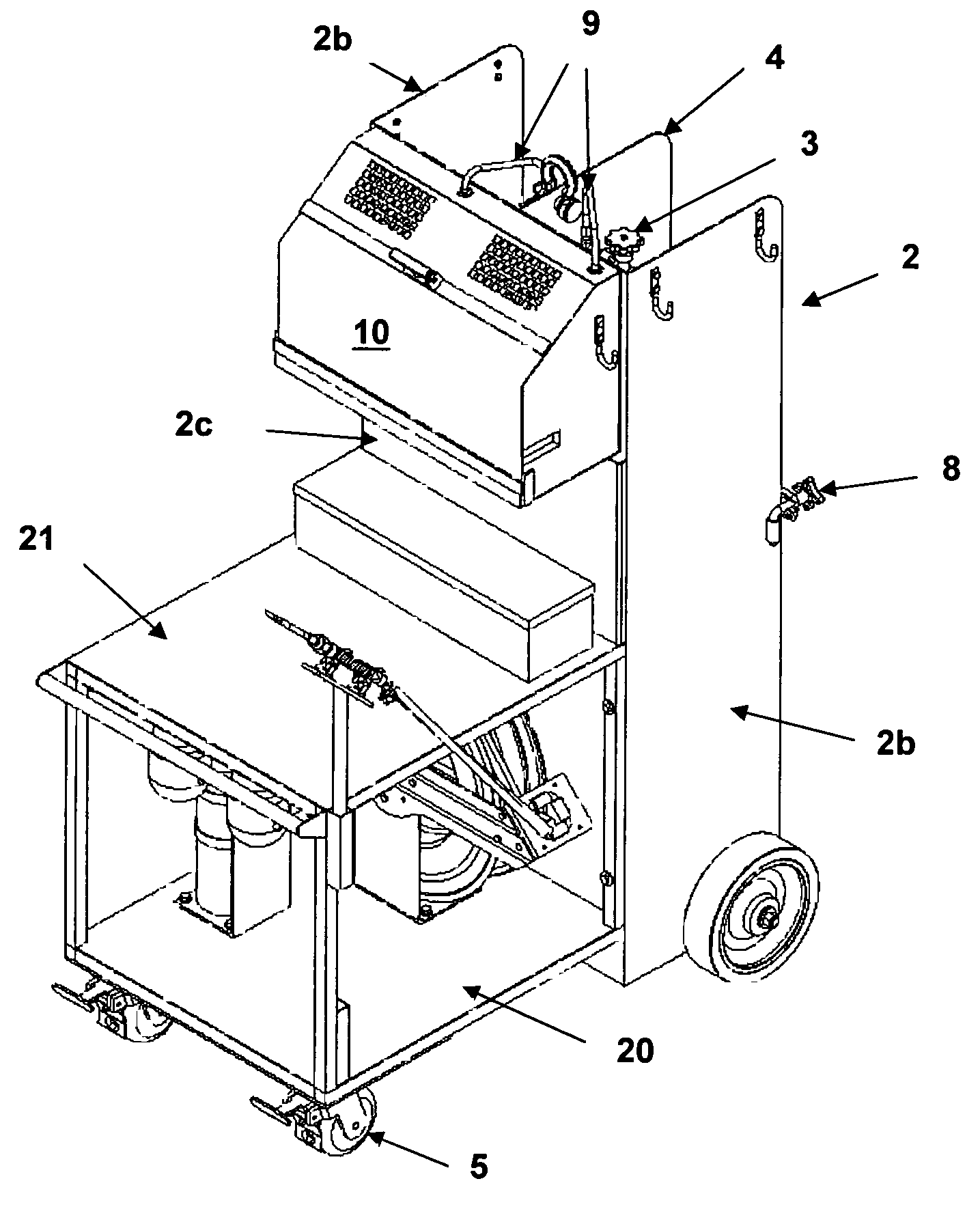

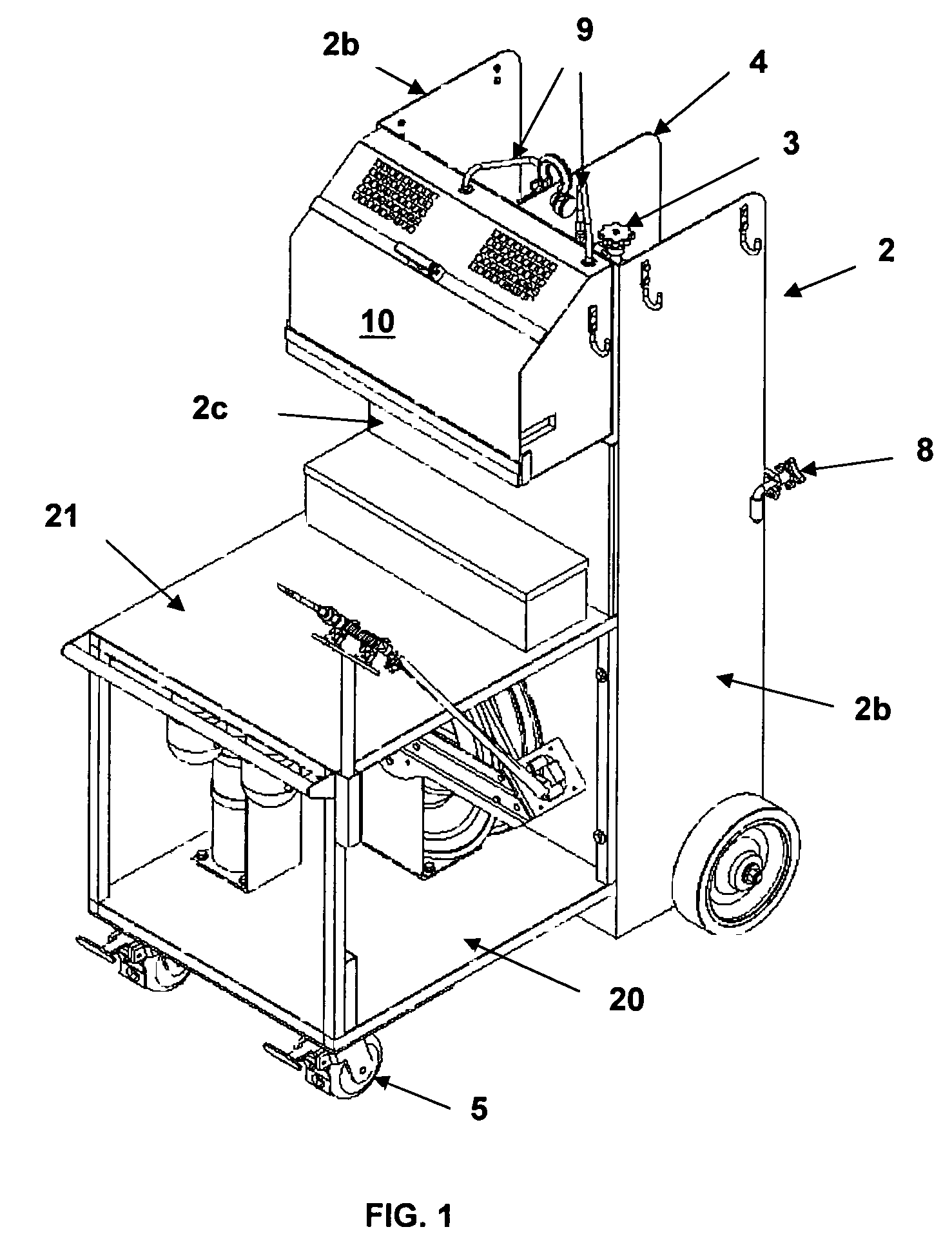

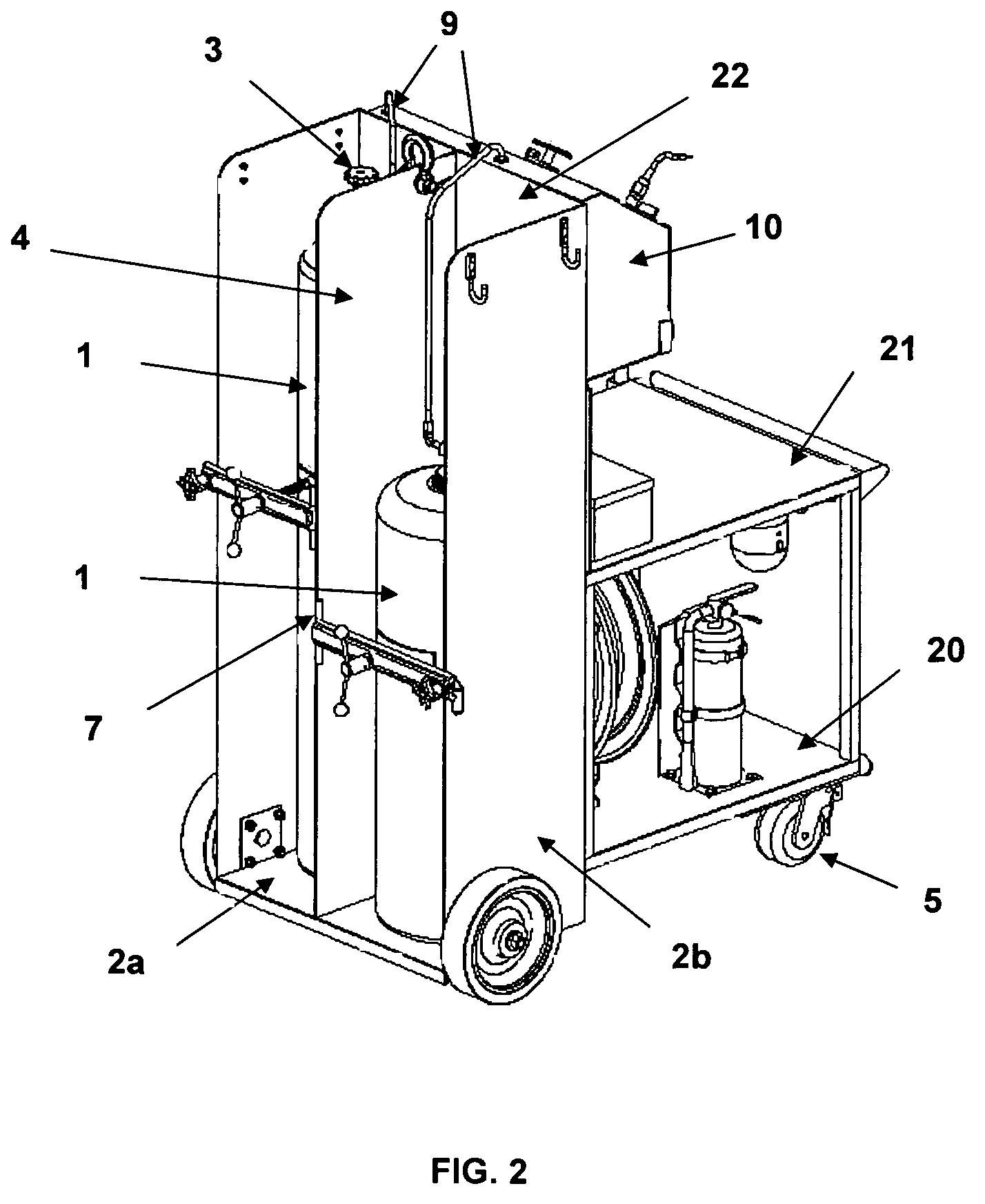

Safety welding cart

ActiveUS7252297B1Improve protectionReduce decreaseCarriage/perambulator with single axisHand carts with one axisGas cylinderFume hood

A safety welding cart structure having a metal box for holding pressurized gas cylinders, a firewall separating the cylinders, individual clamping devices to secure the cylinders, and shelves extending from the back of the box forming a cart set upon a four-wheeled base, which includes two positive-locking swivel casters. The regulators are contained within a ventilated cabinet and the hoses are wound about a reel.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

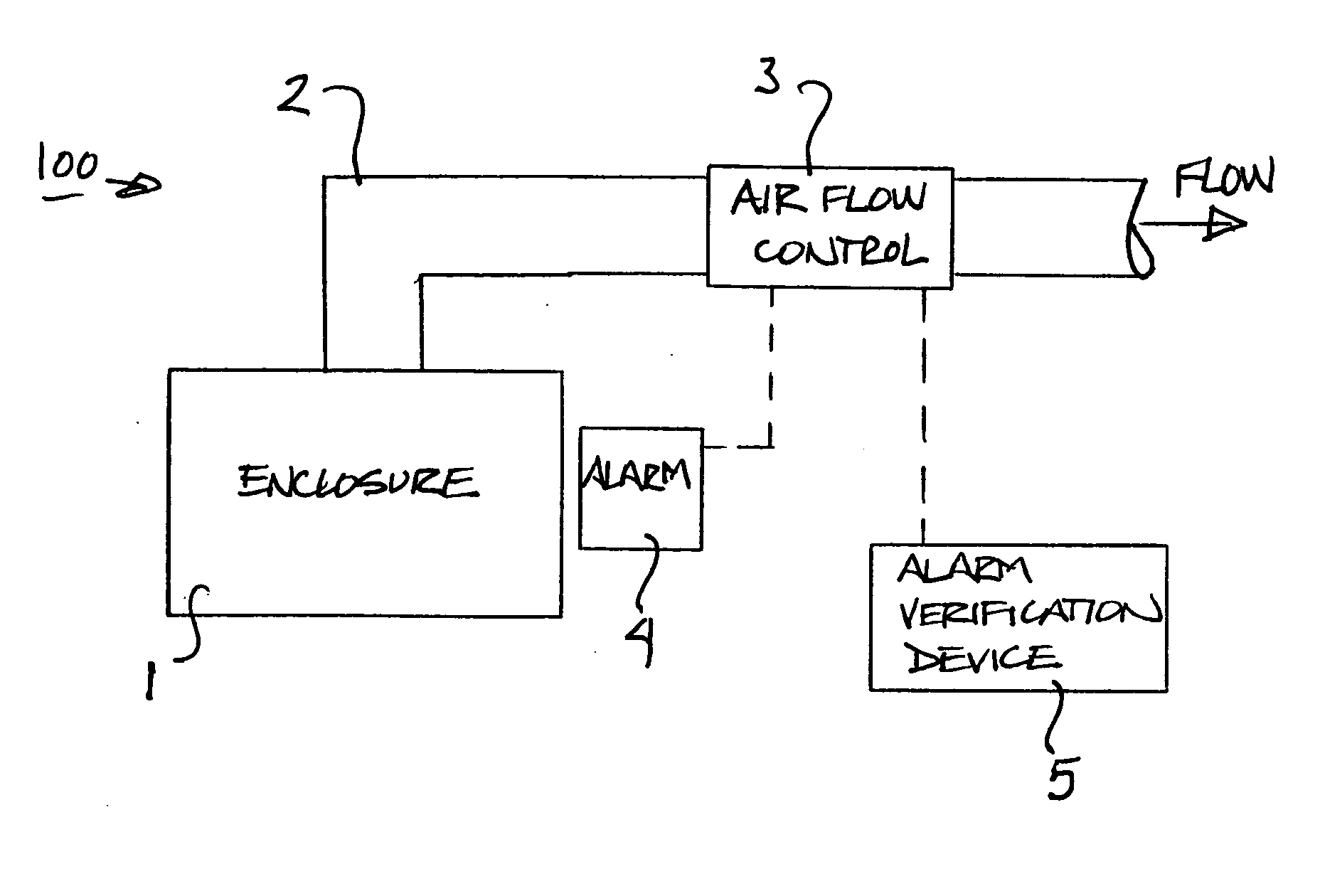

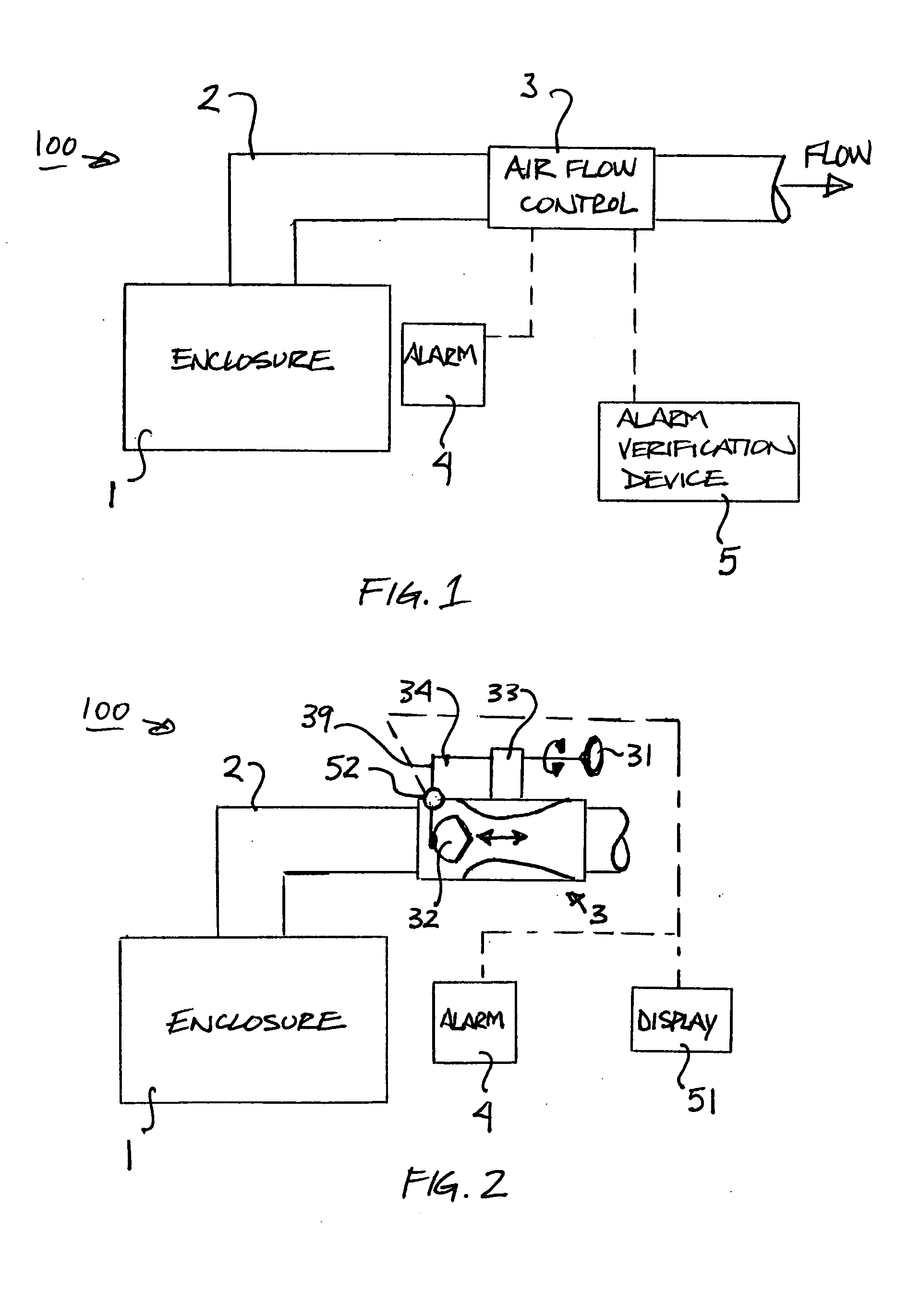

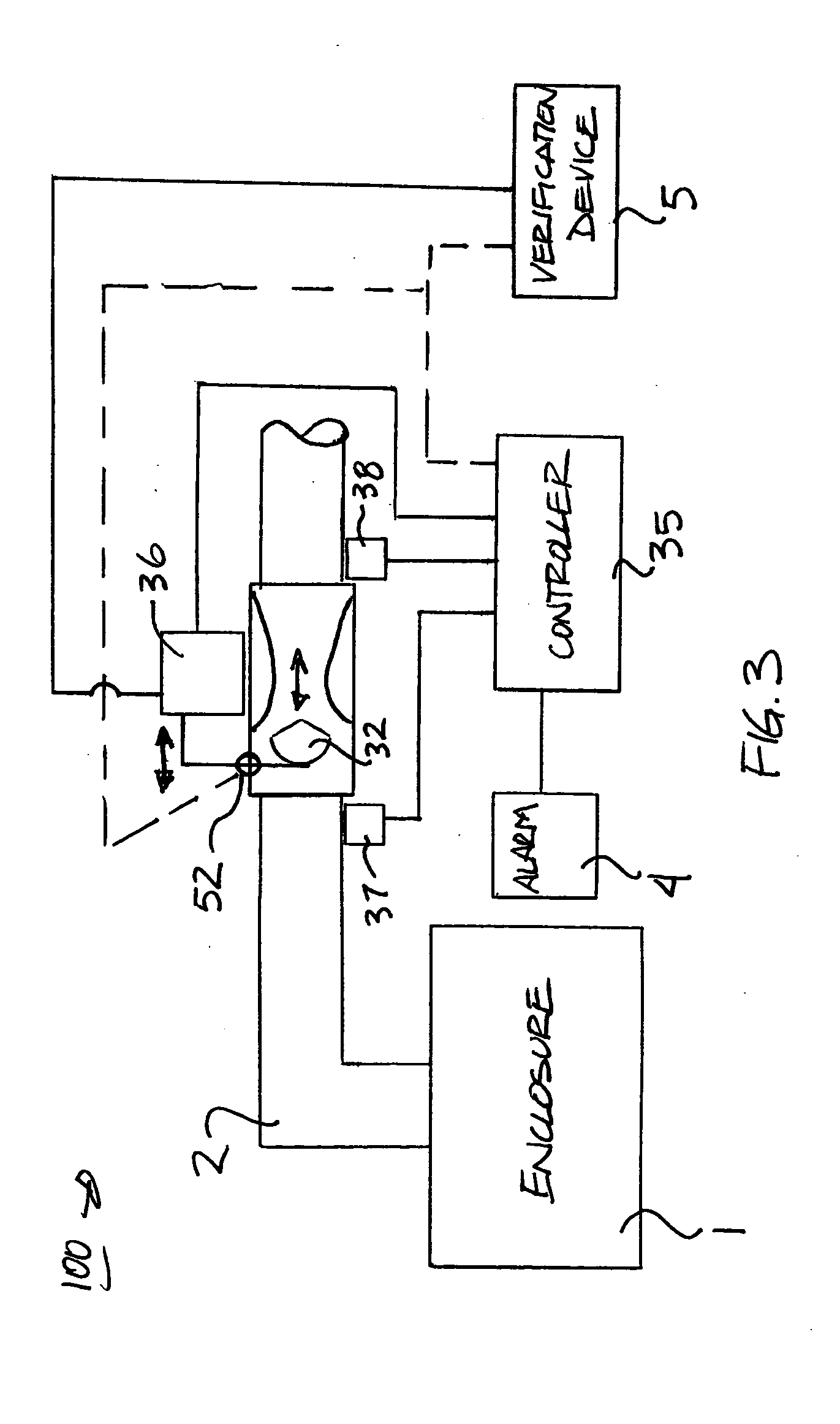

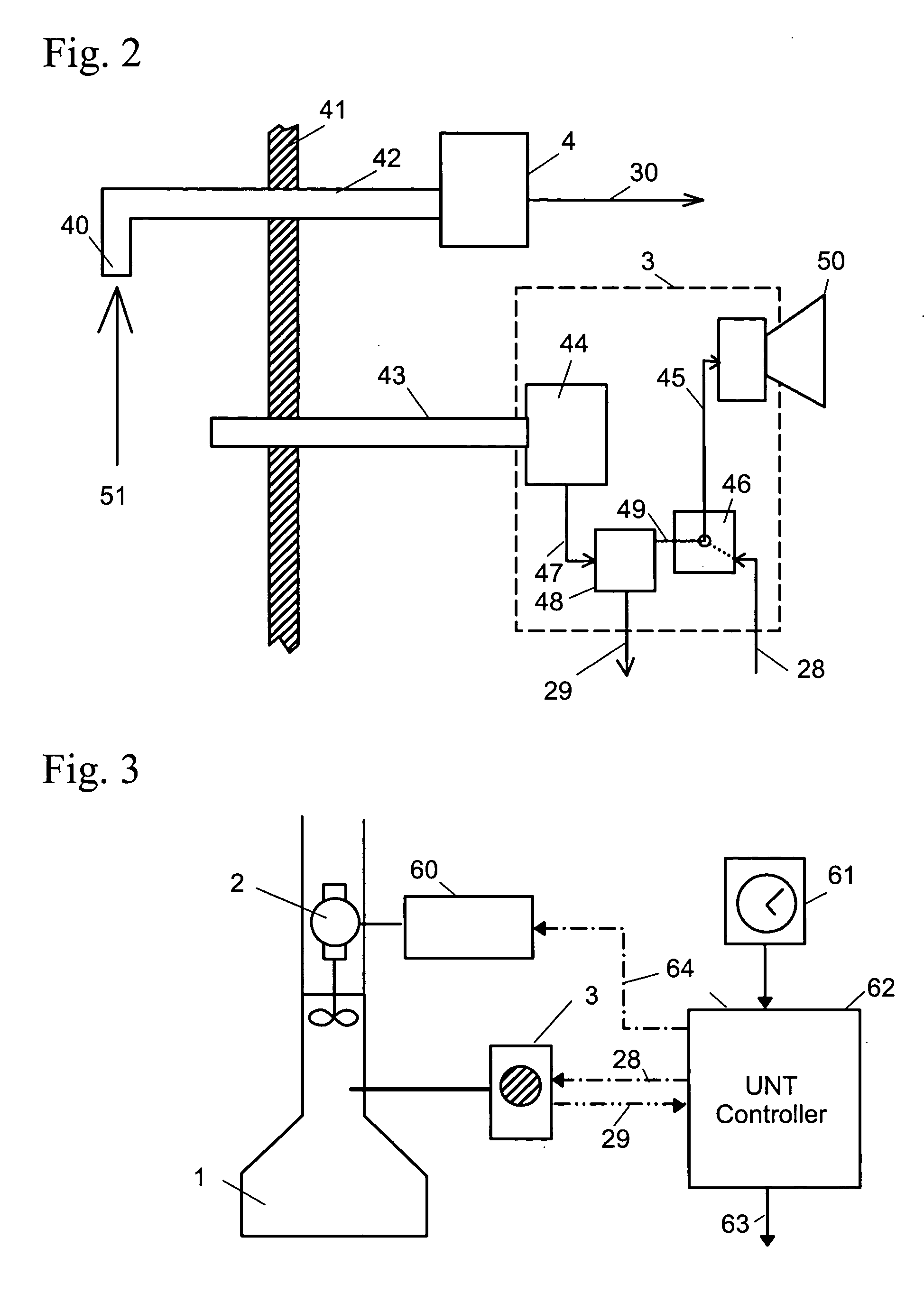

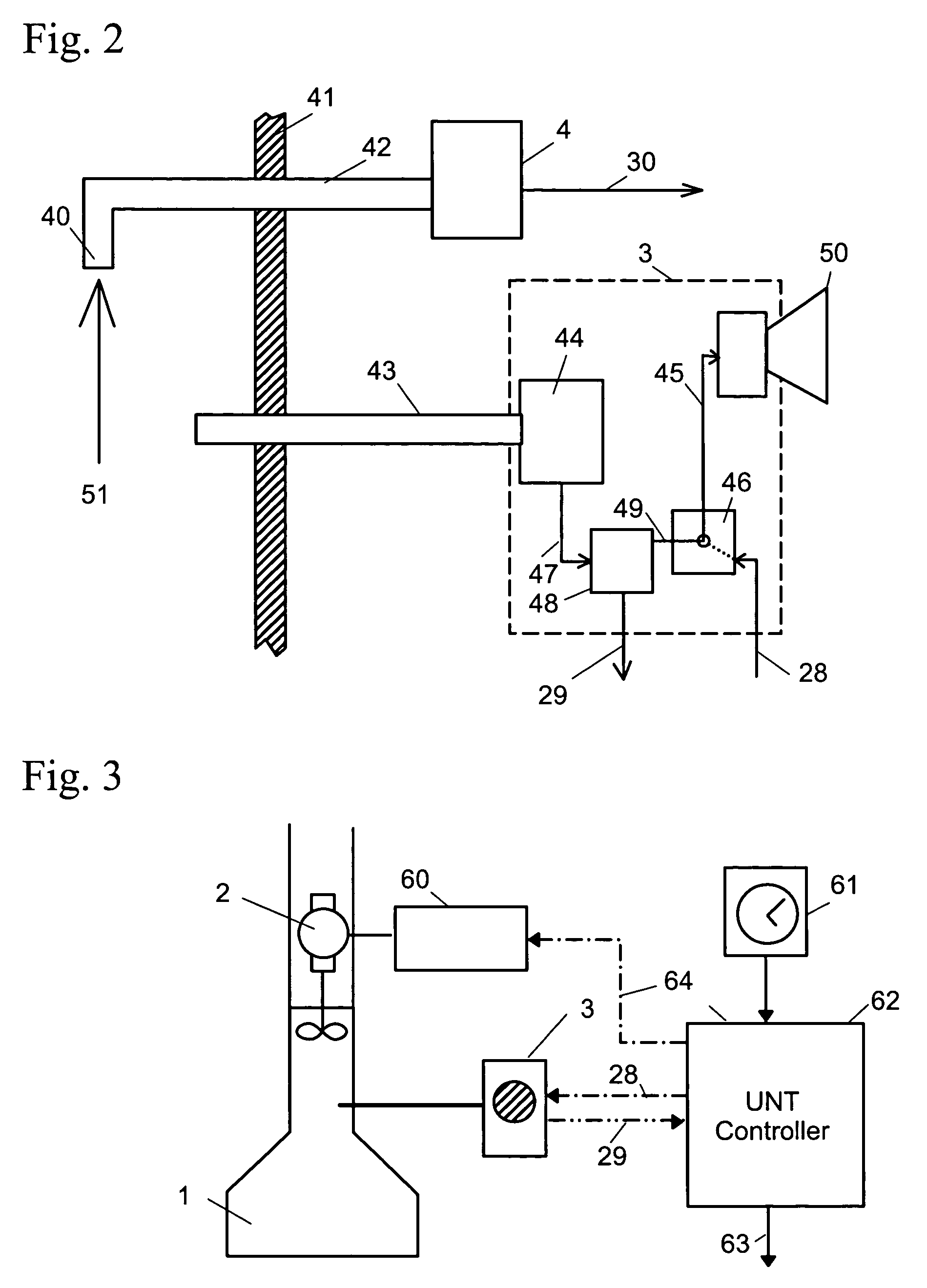

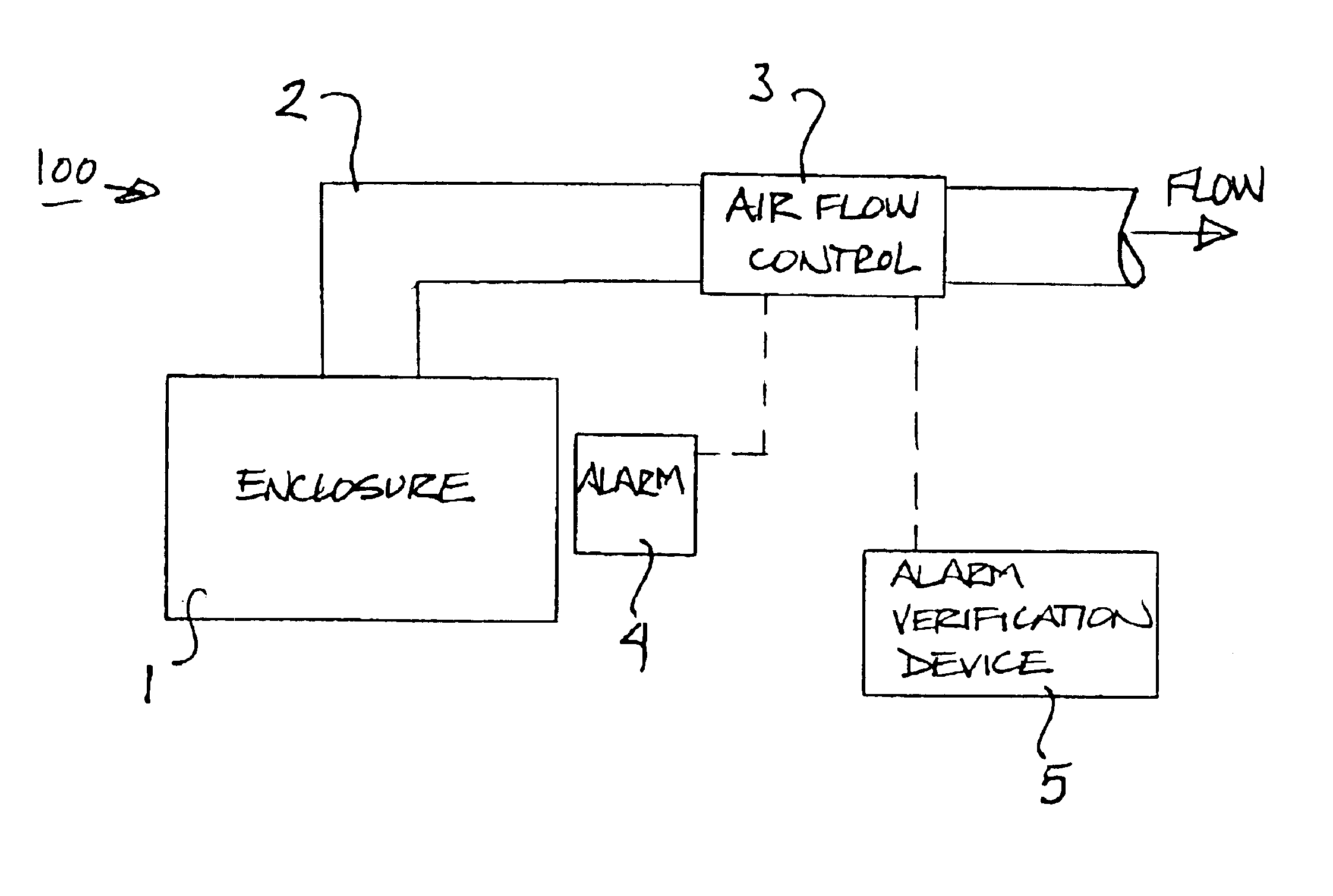

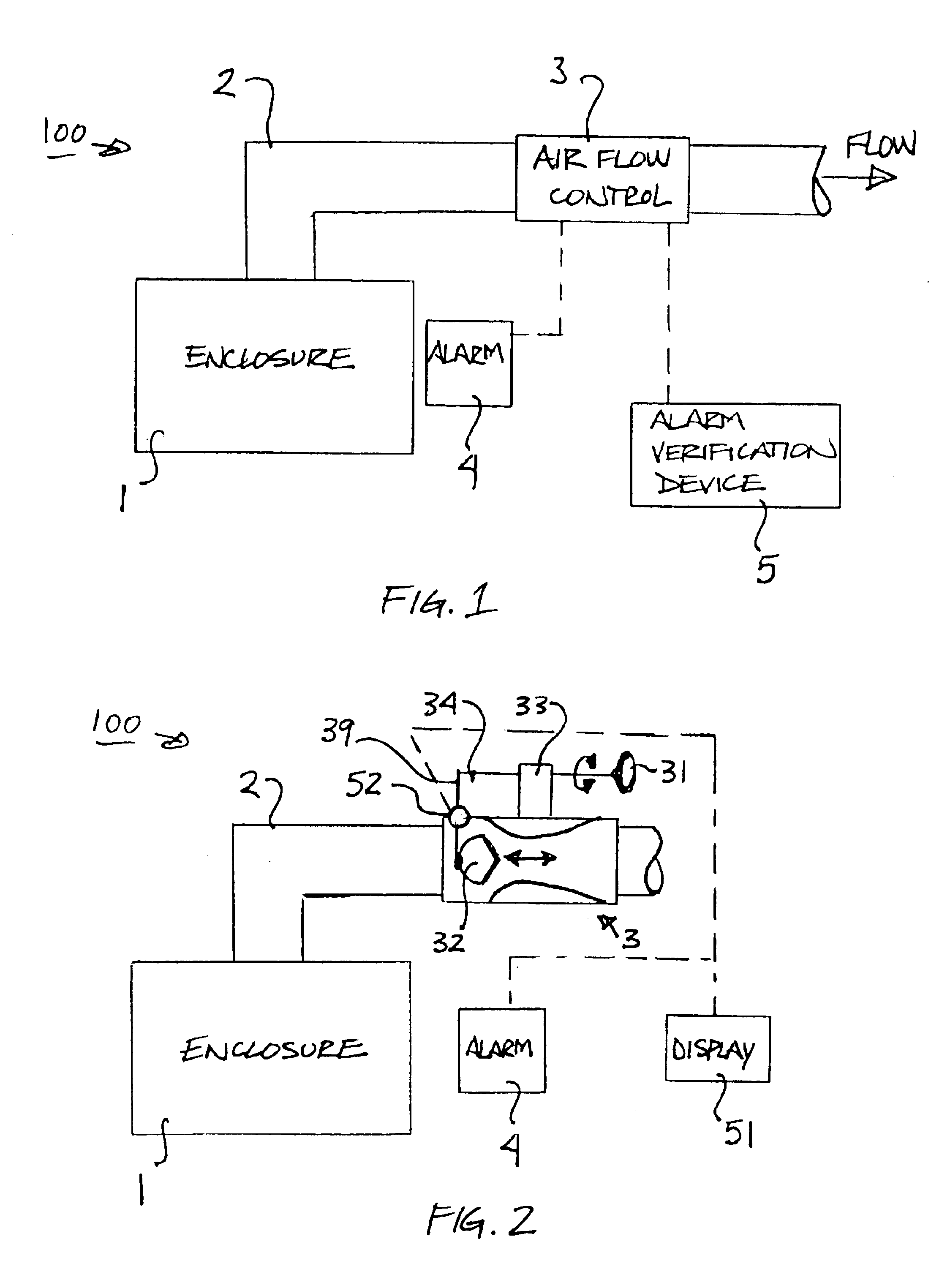

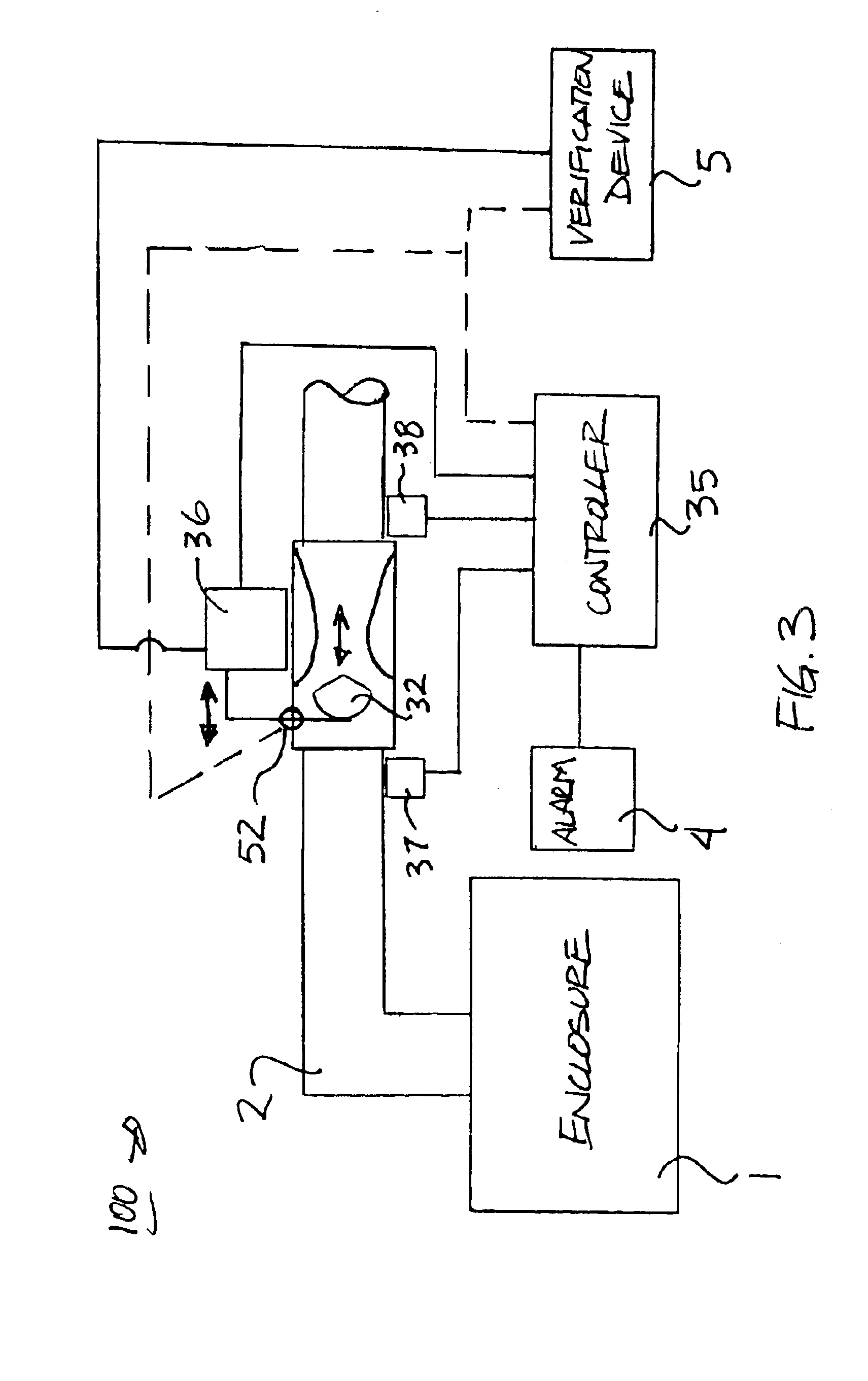

Method and apparatus for alarm verification in a ventilation system

ActiveUS20050024216A1Mechanical apparatusSpace heating and ventilation safety systemsFume hoodBiosafety cabinet

Method and apparatus for testing the operation of an alarm for a ventilated enclosure, such as a fume hood or bio-safety cabinet. Flow of gas being exhausted from the enclosure may be adjusted to a known value below or above a threshold value at which the alarm provides an indication that flow is unacceptably low or high. Adjustment of flow to the known value may be performed without requiring a manual measurement of flow, e.g., by performing a traverse in a duct leading from the enclosure.

Owner:PHOENIX CONTROLS

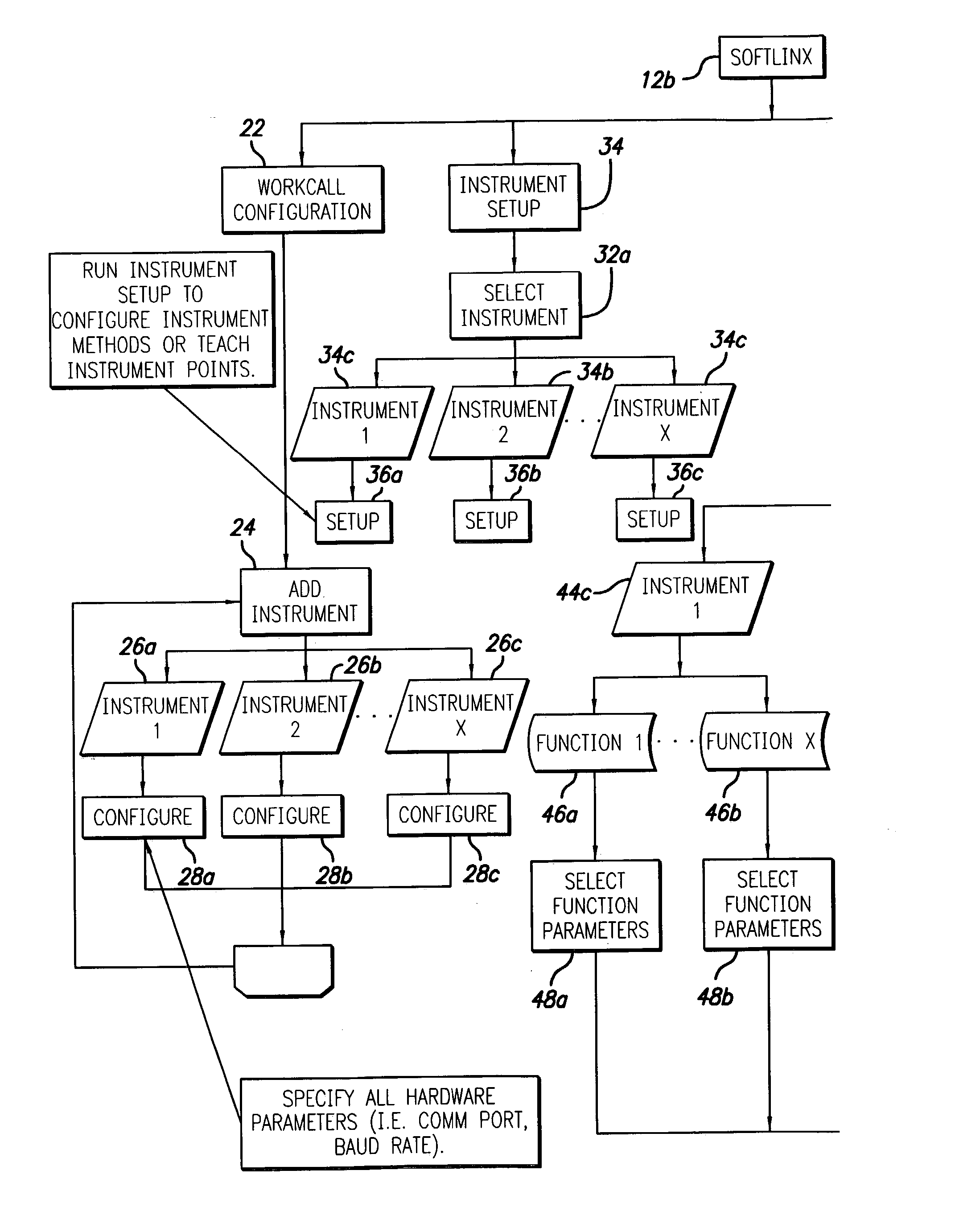

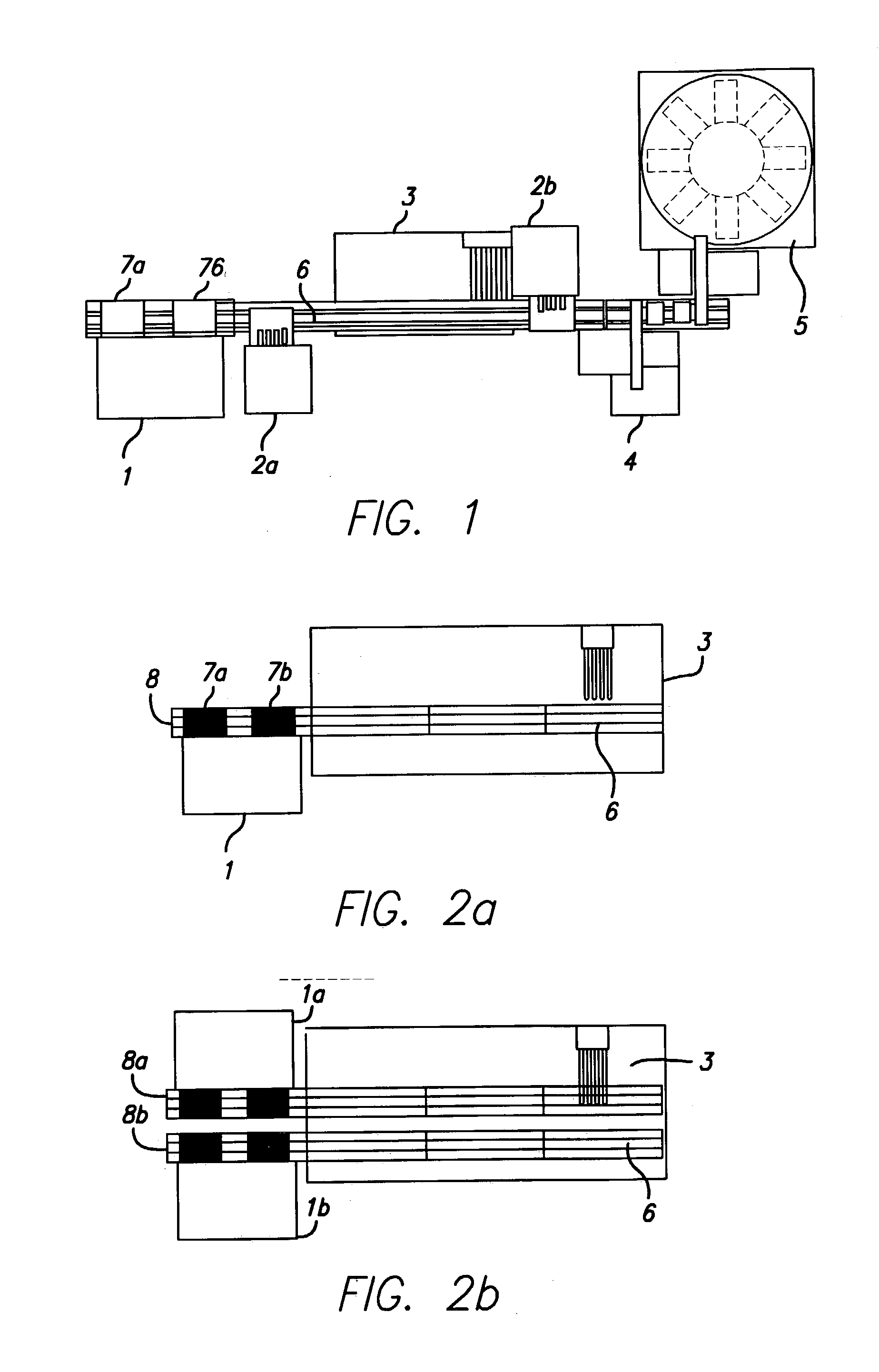

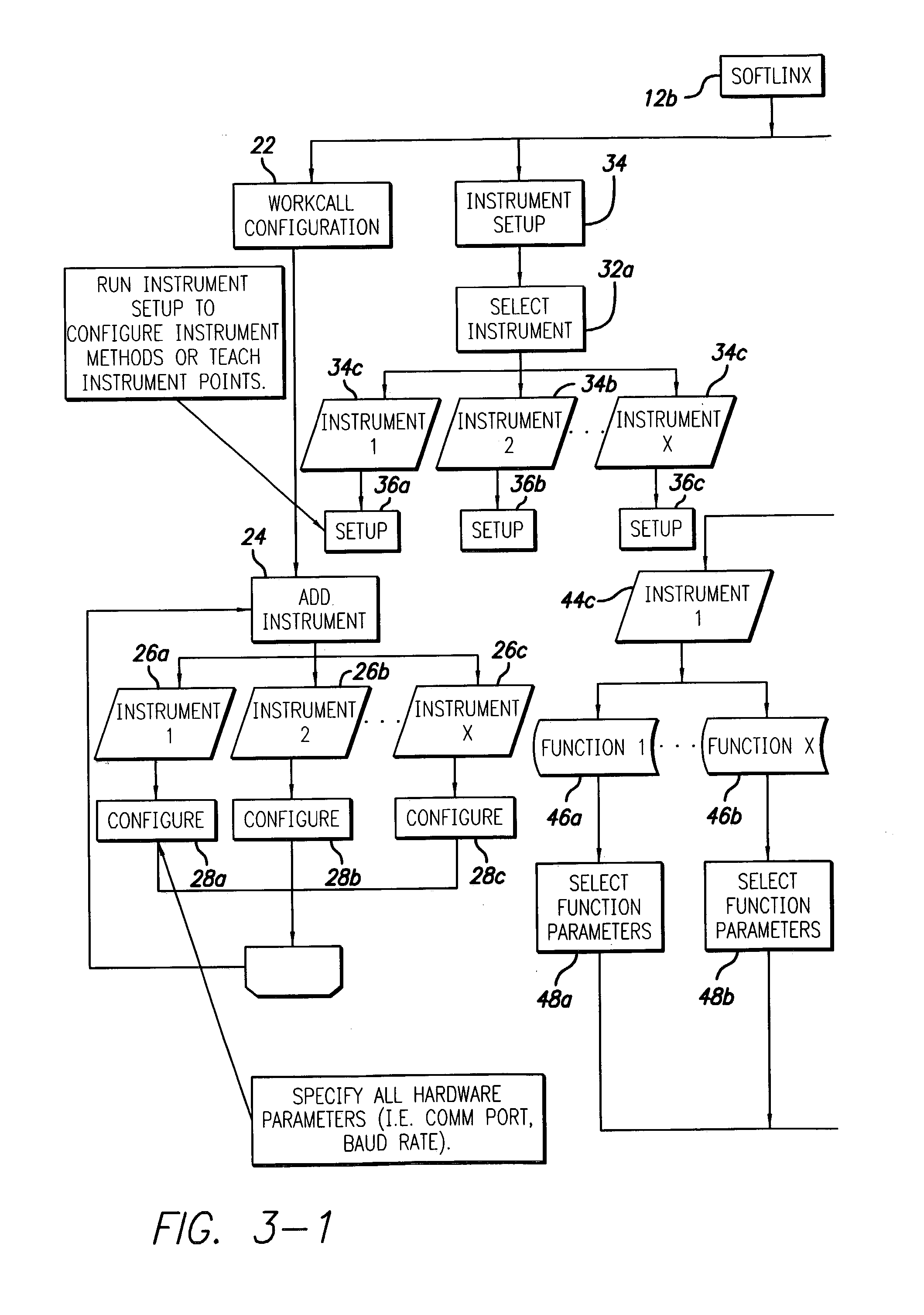

Modular equipment apparatus and method for handling labware

InactiveUS20030225477A1Move quicklyRapidly be moved into and out of position for washingDigital data processing detailsMaterial analysisLaboratory deviceElectrical connection

This invention discloses a system and method useful in moving labware between laboratory devices, such as liquid handlers, readers, washers, dispensers, sealers, incubators, microarrayers and labeling devices, such a bar code labelers, to aid in automation of laboratory tasks and assay procedures. Work cells addressing particular laboratory tasks comprise modular components such as stack links, track links, arm links and laboratory devices, such as washers or plate readers. Based upon the required flow of labware movement, the individual modular components are selected and interconnected to create a high-speed work cell. The work cells are easy to configure and setup and permit configuration on available bench top space or within other small spaces, such as laboratory fume hoods. All mechanical and electrical connections between the module components of the work cell are self-contained within the system. A mechanically robust and simple design of the work cell configuration permits reliable walk away automation.

Owner:HUDSON CONTROL GROUP

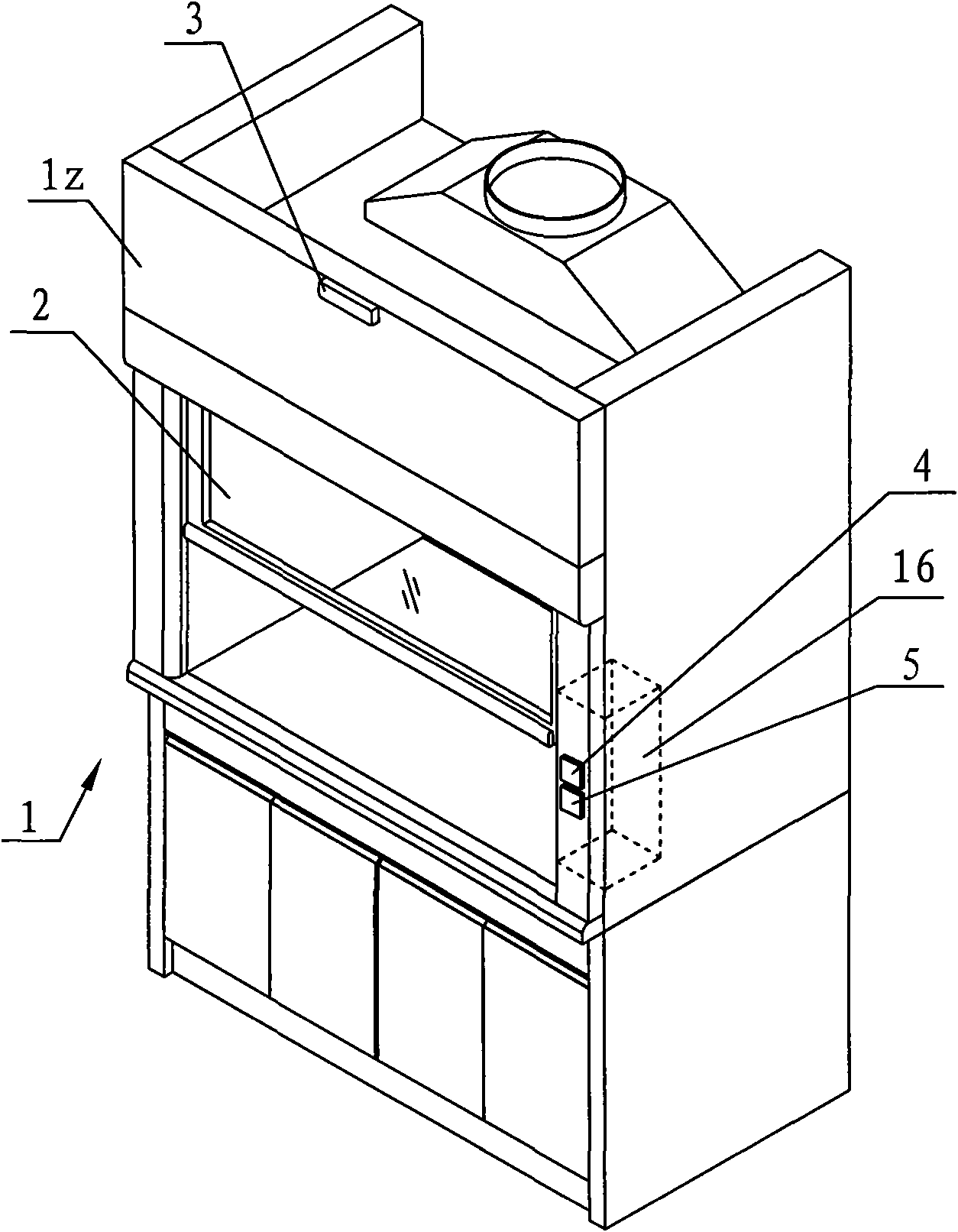

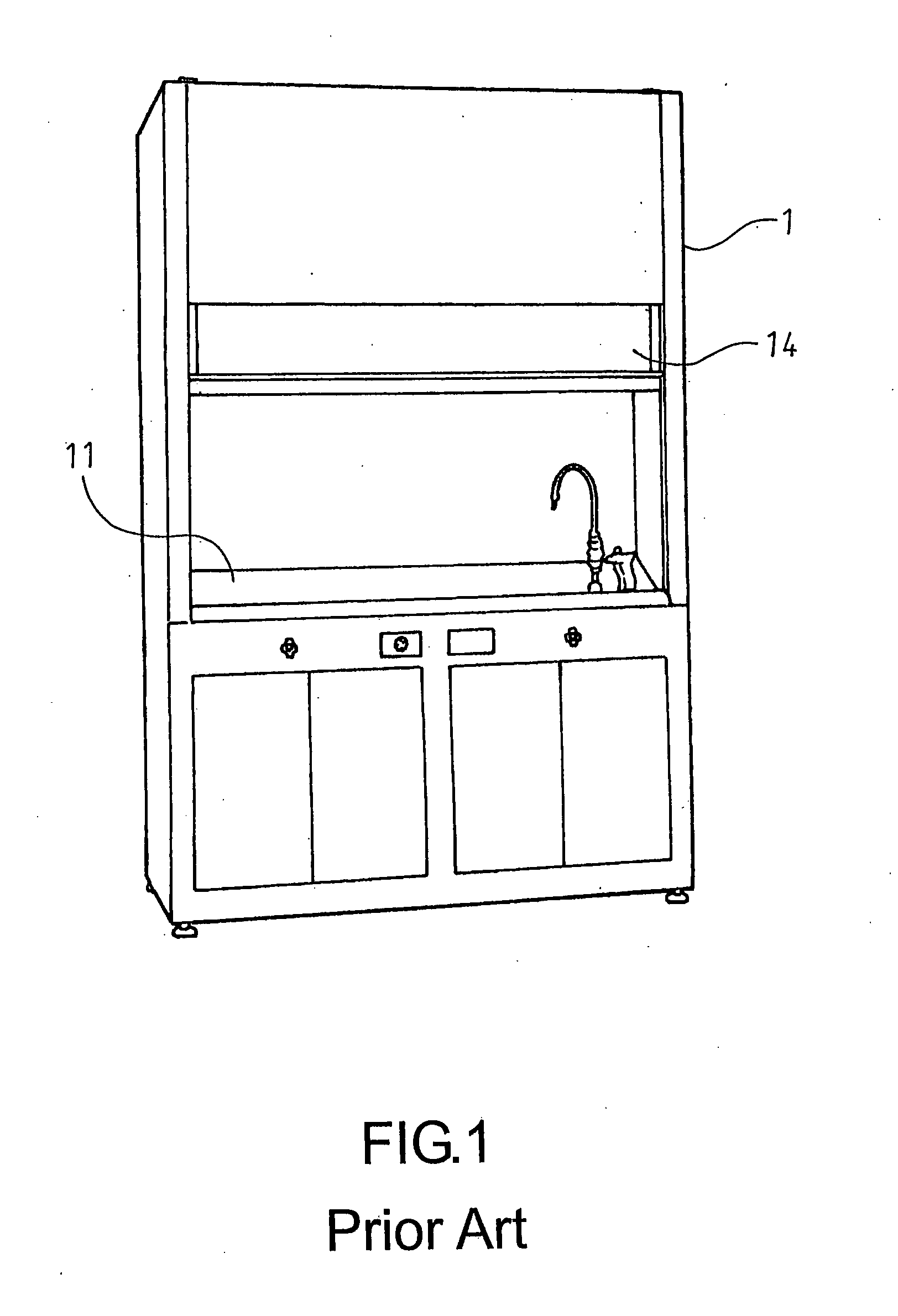

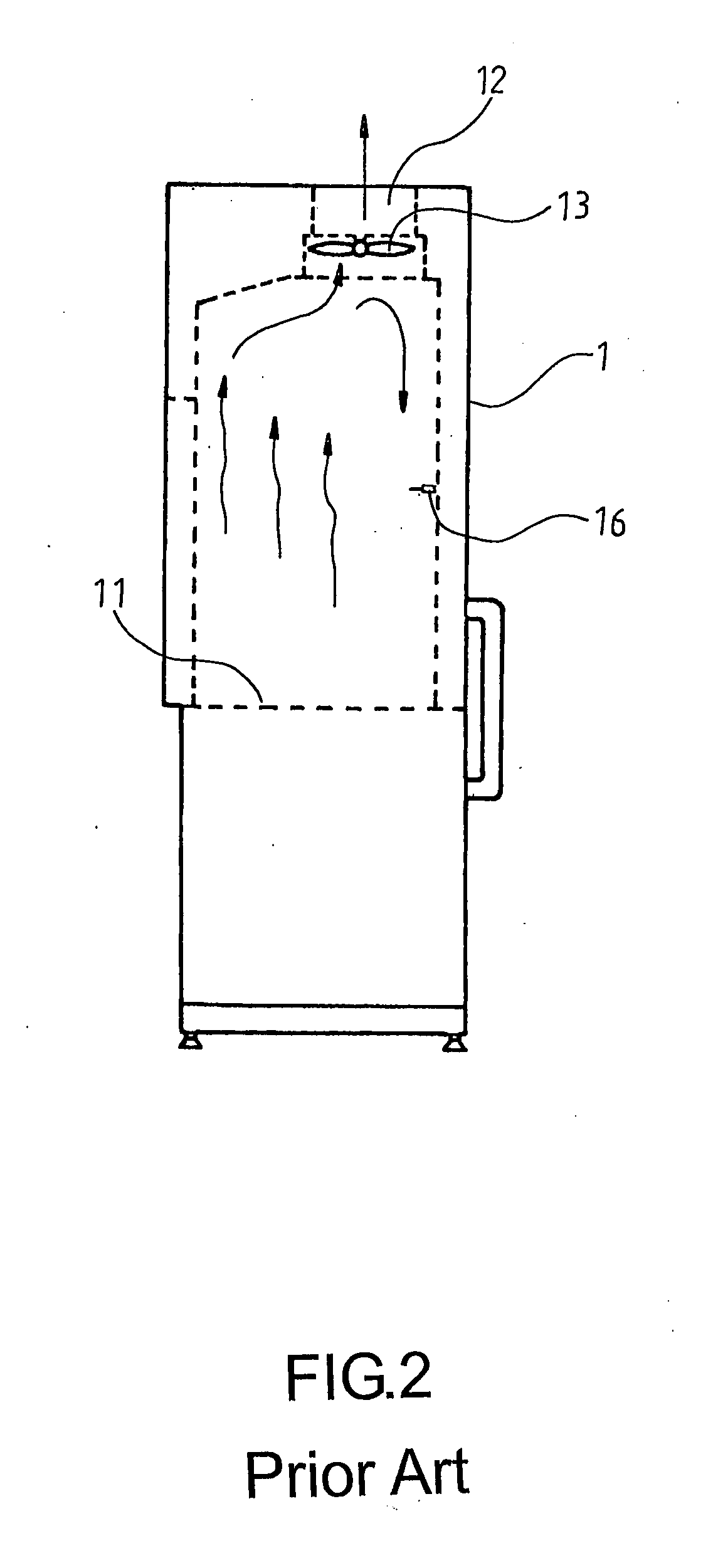

Laboratory ventilated cabinet

InactiveCN101537376ARealize automatic openingAvoid the disadvantages of having to switch manuallyDirt cleaningEnclosures/chambersInfraredFume hood

The invention discloses a laboratory ventilated cabinet which comprises a cabinet body, a window door, a central control unit and an infra-red detector, wherein the window door is arranged on the front face of the cabinet body, the central control unit is arranged on the cabinet body, the infra-red detector is arranged on a frame of the window door positioned on the front surface of the cabinet body, electrical signals of the infra-red detector are connected to the central control unit, electrical signals output by the central control unit control a drive mechanism of the window door, the infra-red detector detects infra-red input signals, so that the window door can automatically start when persons approach and automatically close when persons leave. The invention has high intellectualization and is convenient to operation and suitable for various laboratory ventilated cabinets.

Owner:李保标

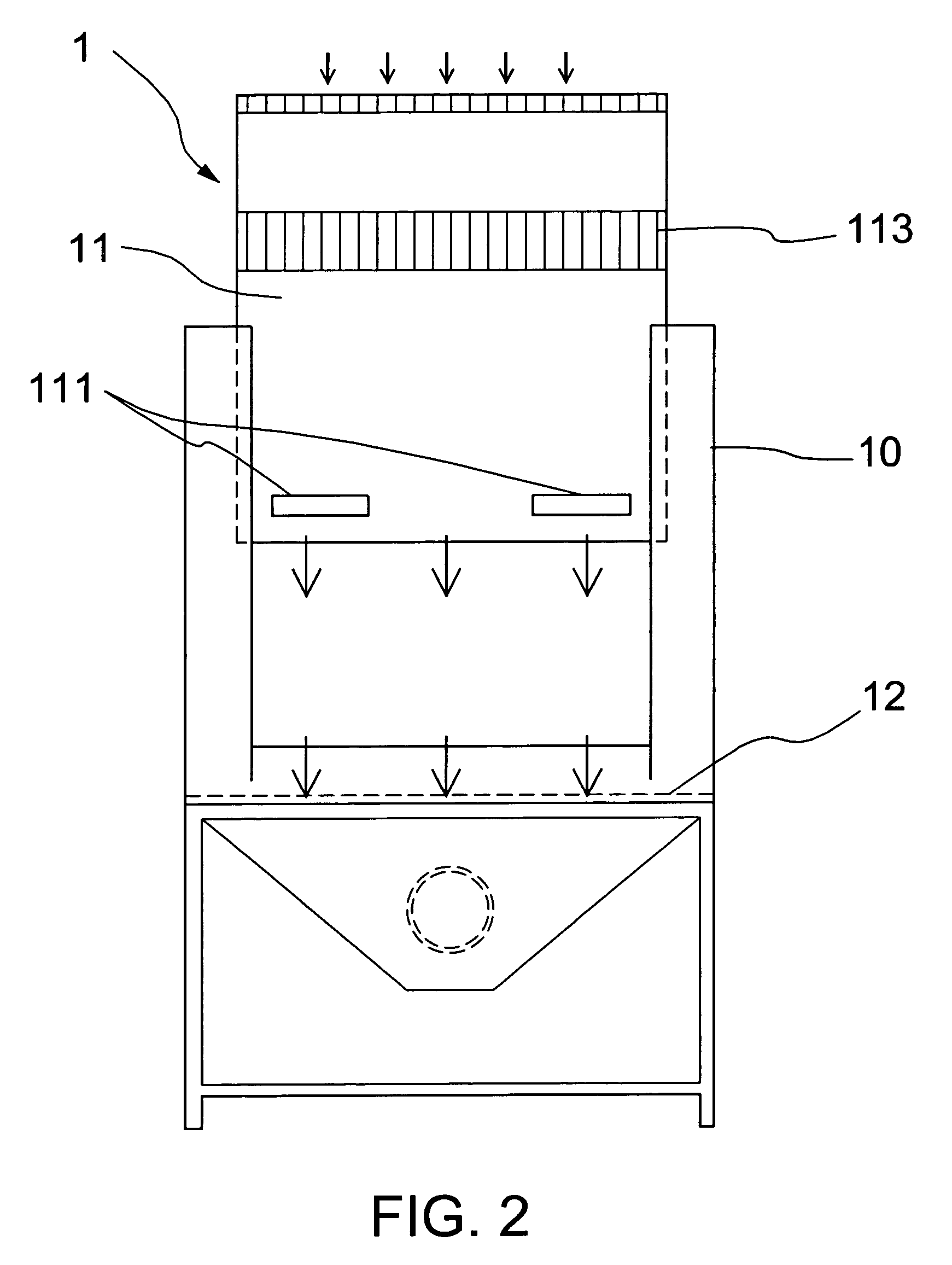

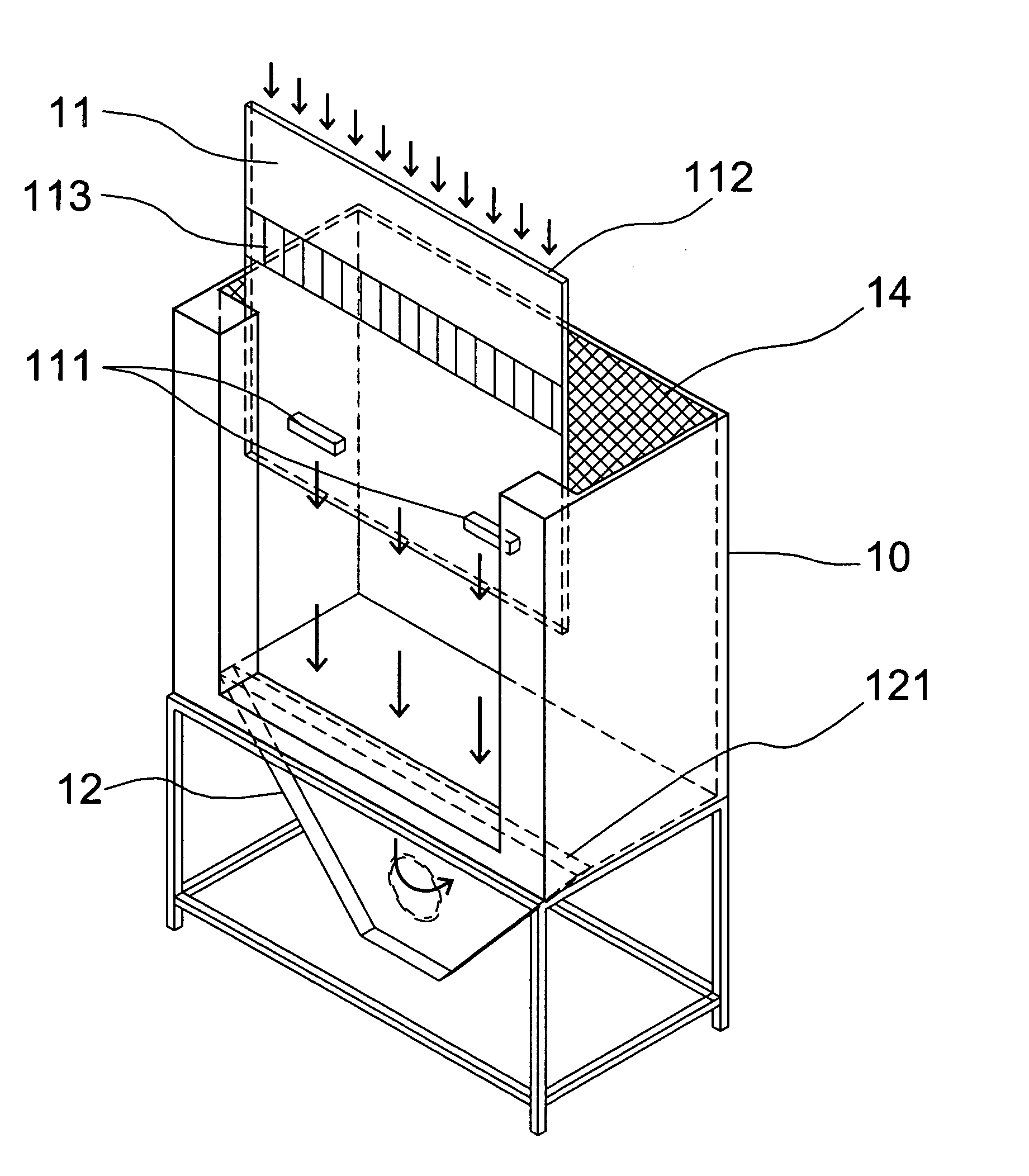

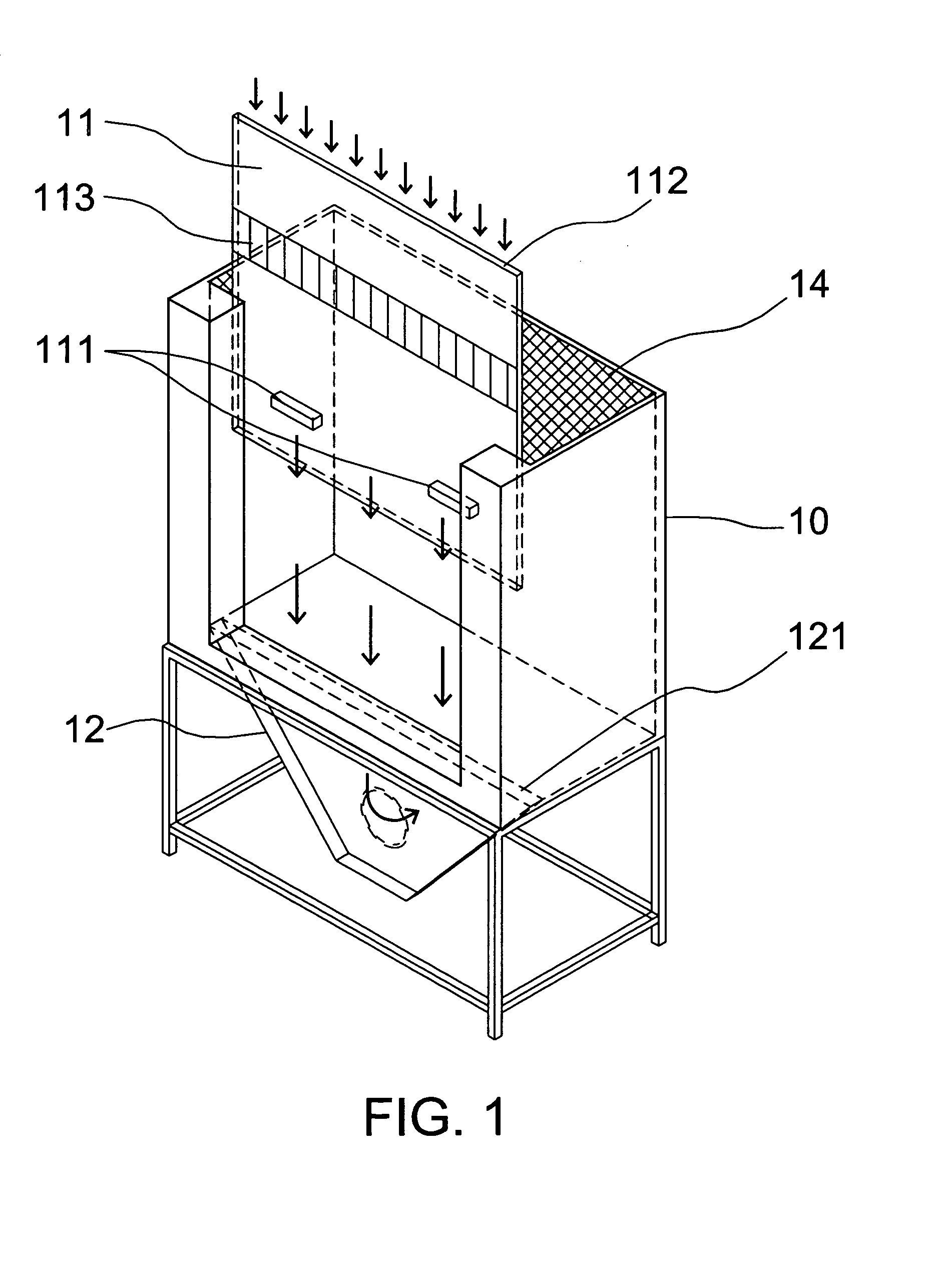

Air-isolator fume hood

InactiveUS7318771B2Save energyExhaust fastDomestic stoves or rangesSpace heating and ventilation safety systemsFume hoodEngineering

Owner:INST OCCUPATIONAL SAFETY & HEALTH COUNCIL LABOR AFFAIRS EXECUTIVE YUAN

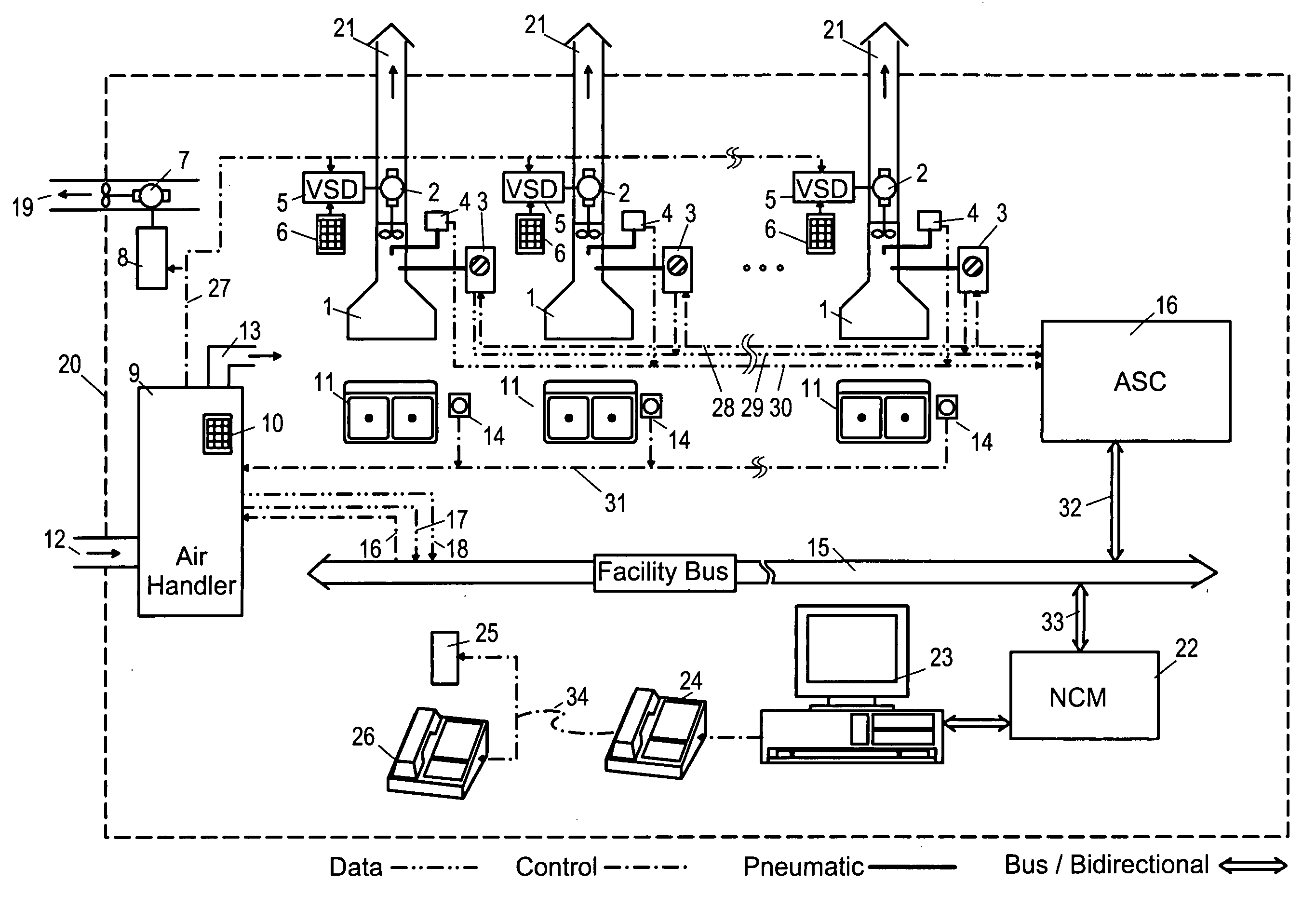

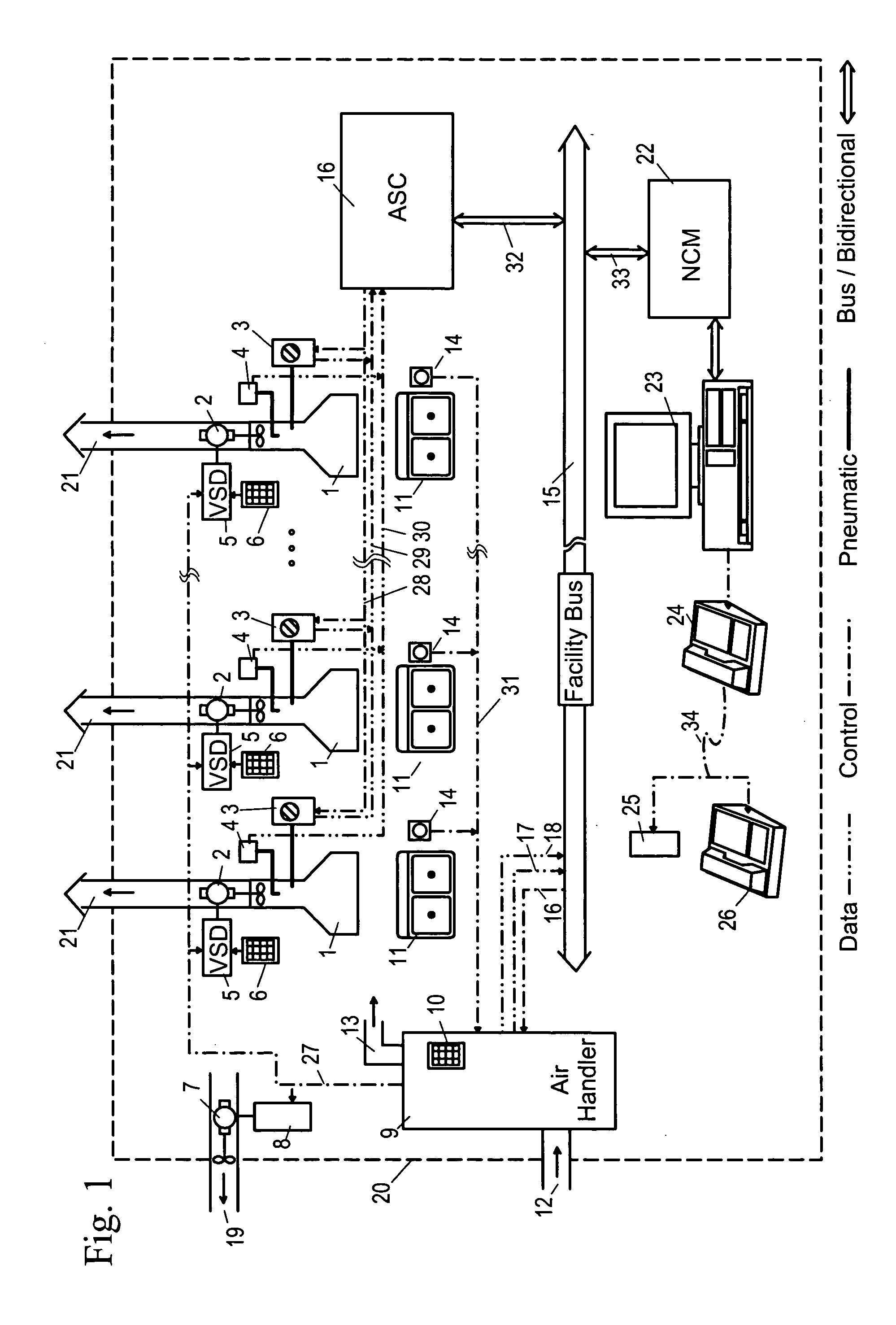

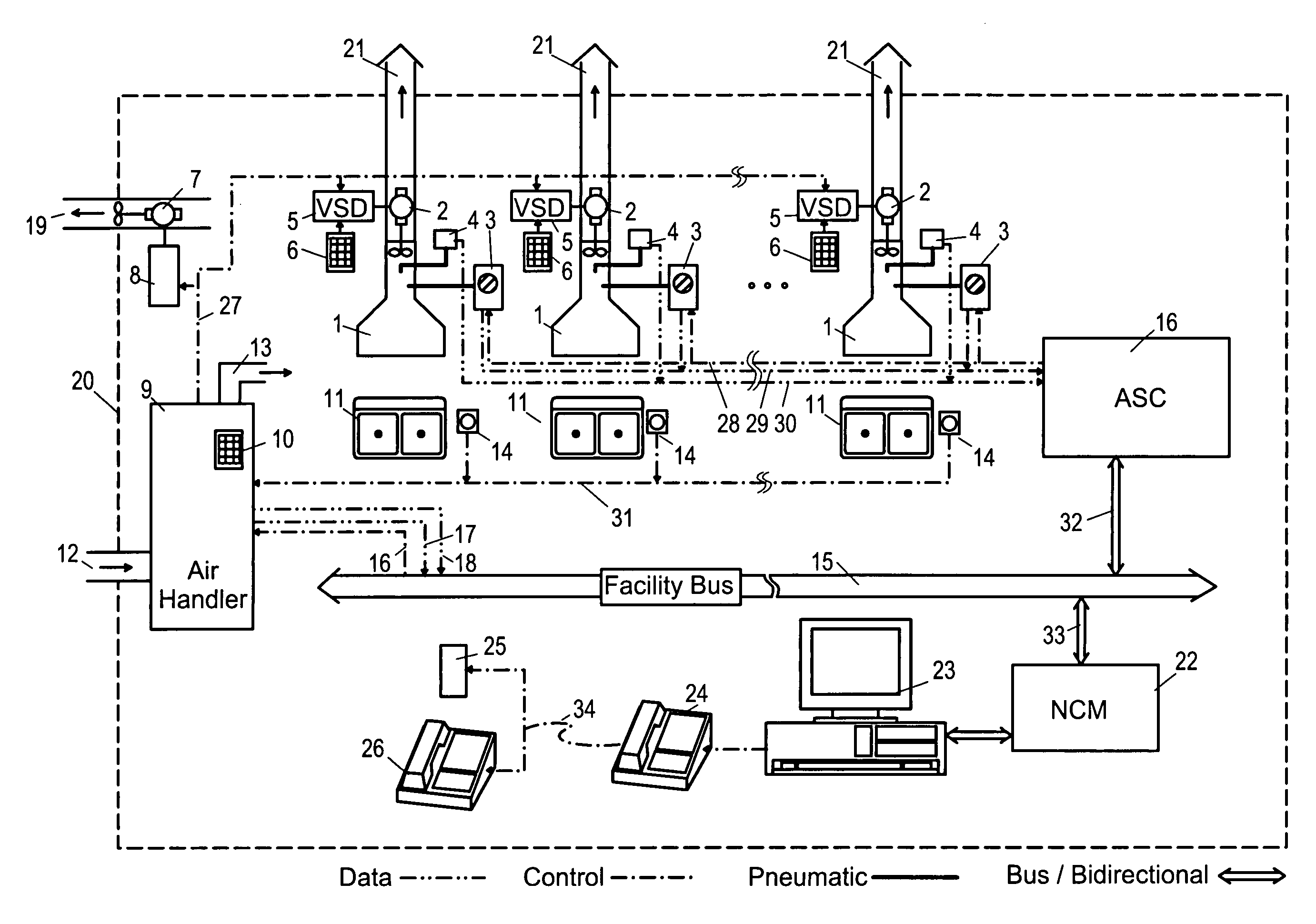

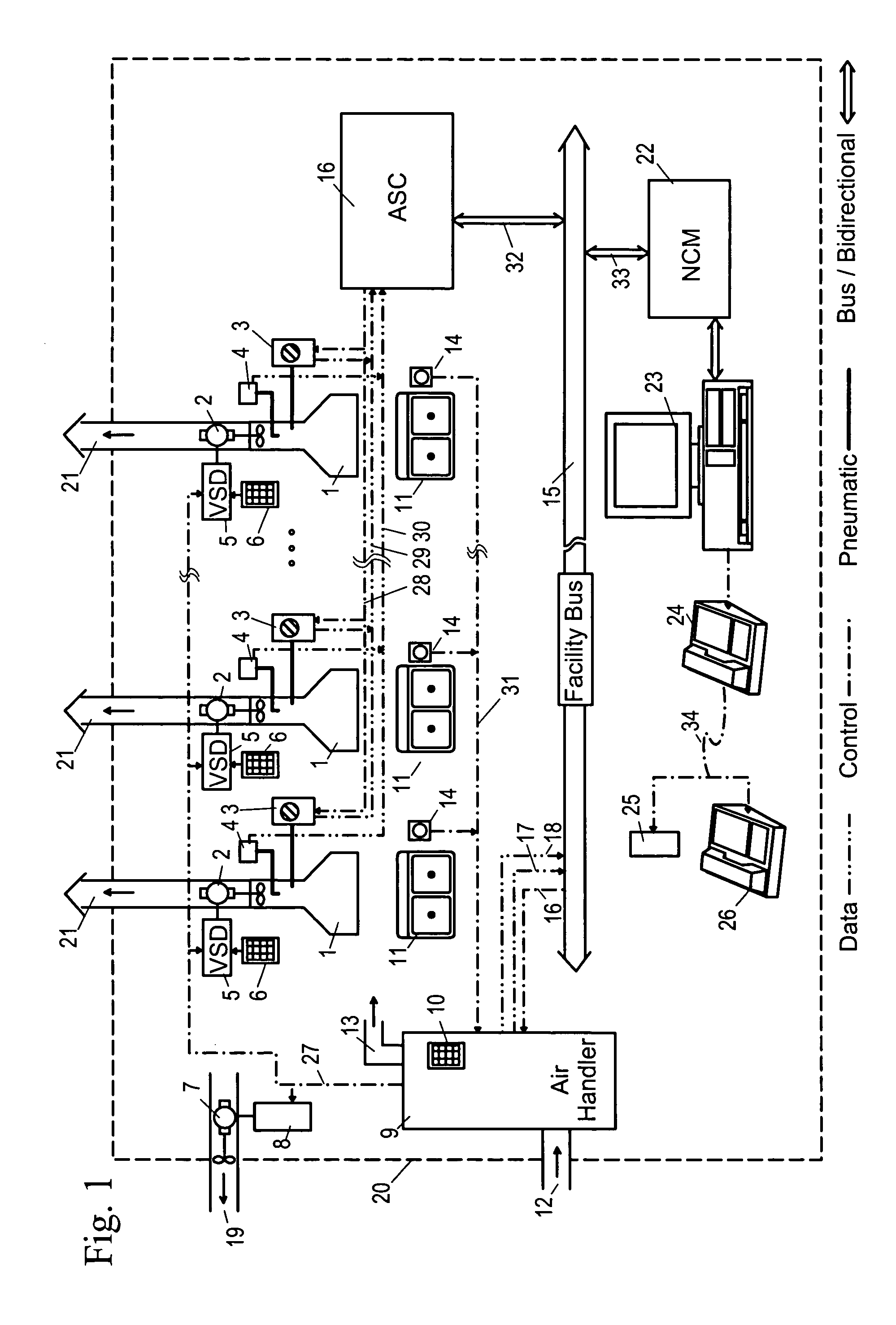

Air flow monitoring and control system with reduced false alarms

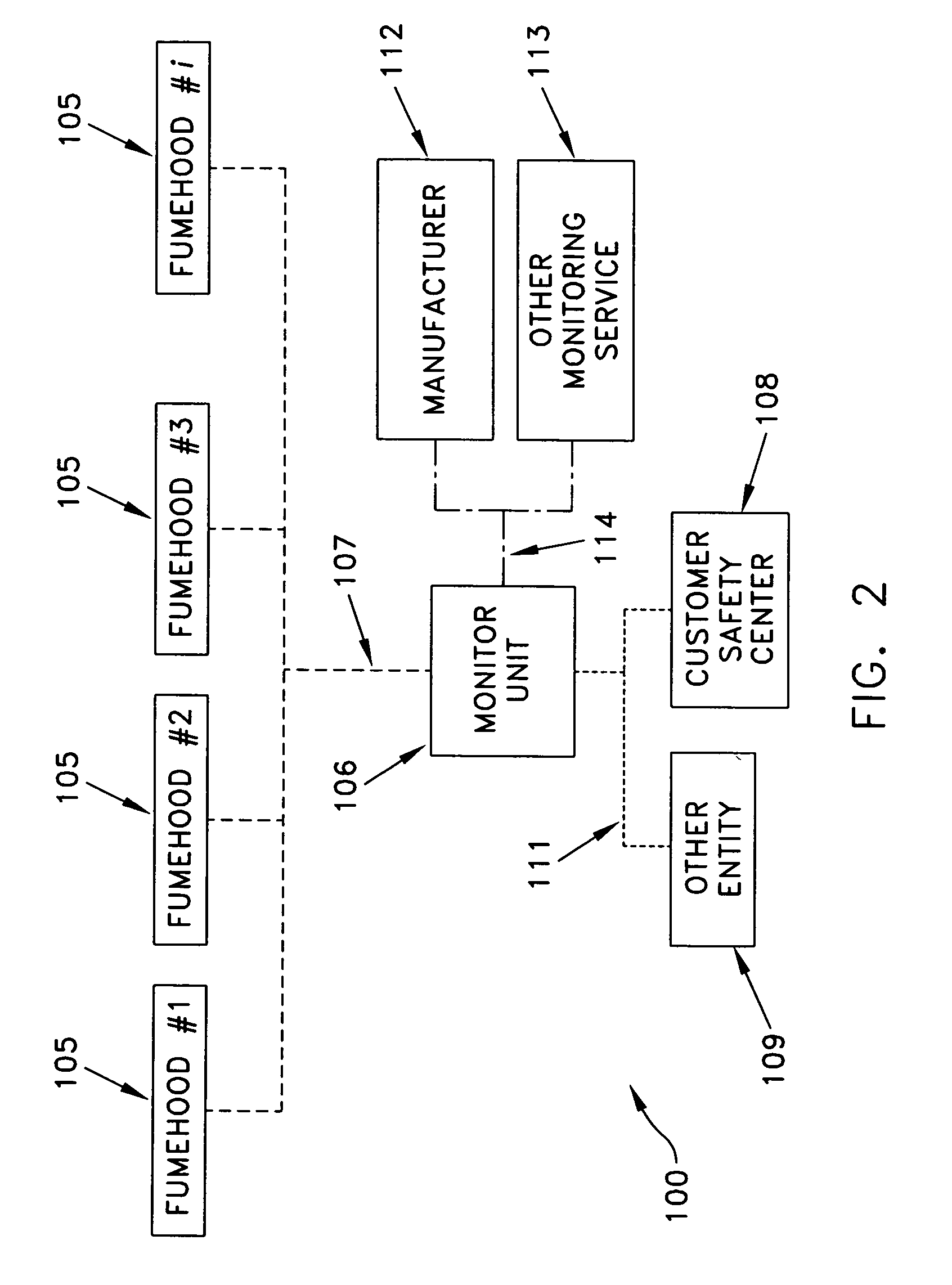

InactiveUS20050048896A1Reduce airflowReduce in quantityMechanical apparatusLiquid surface applicatorsControl systemDialer

An air flow monitoring and control system with reduced false alarms includes an alarm sensor for monitoring air flow in a fume hood or the like, set to provide a warning if air flow drops below a predetermined amount. A local controller monitors the alarm, and disables it when the hood is set to reduced air flow, whether by a local timer or by command of a central control system. Optionally, the controller itself can operate a variable speed drive to reduce air flow on a timed basis, and the controller can communicate with facility management through a dialer or the Internet, or can interface with a central control for the facility through a facility bus.

Owner:CORNELL RES FOUNDATION INC

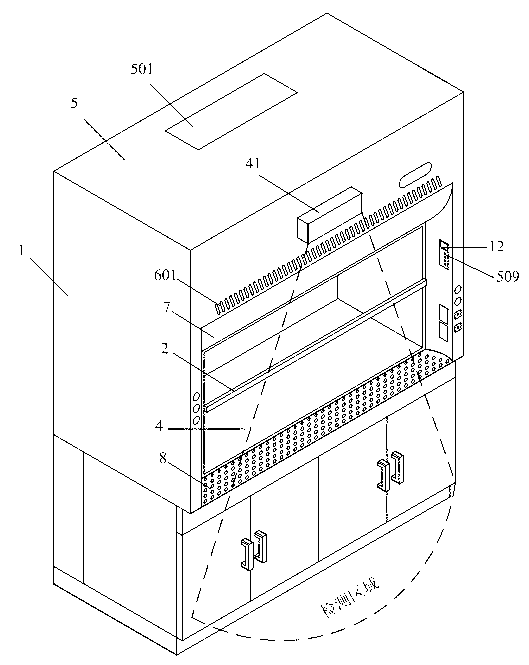

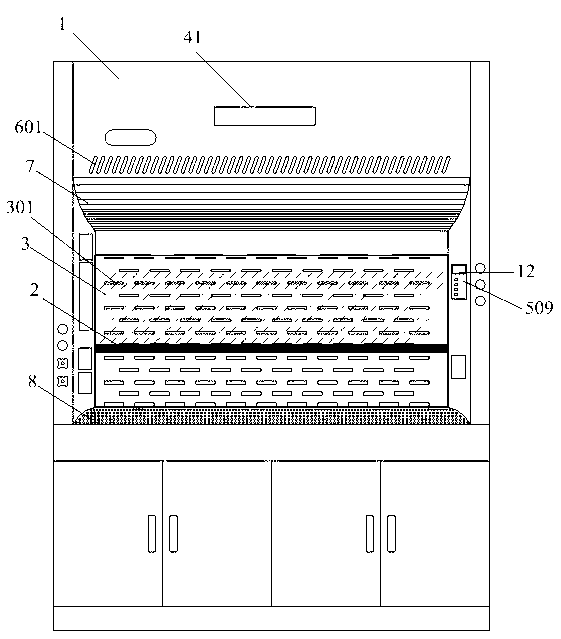

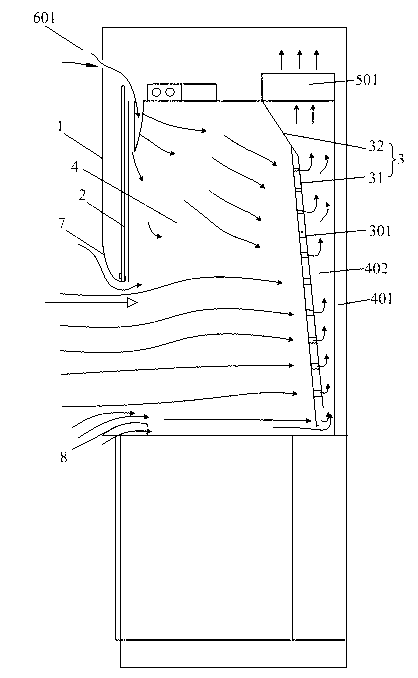

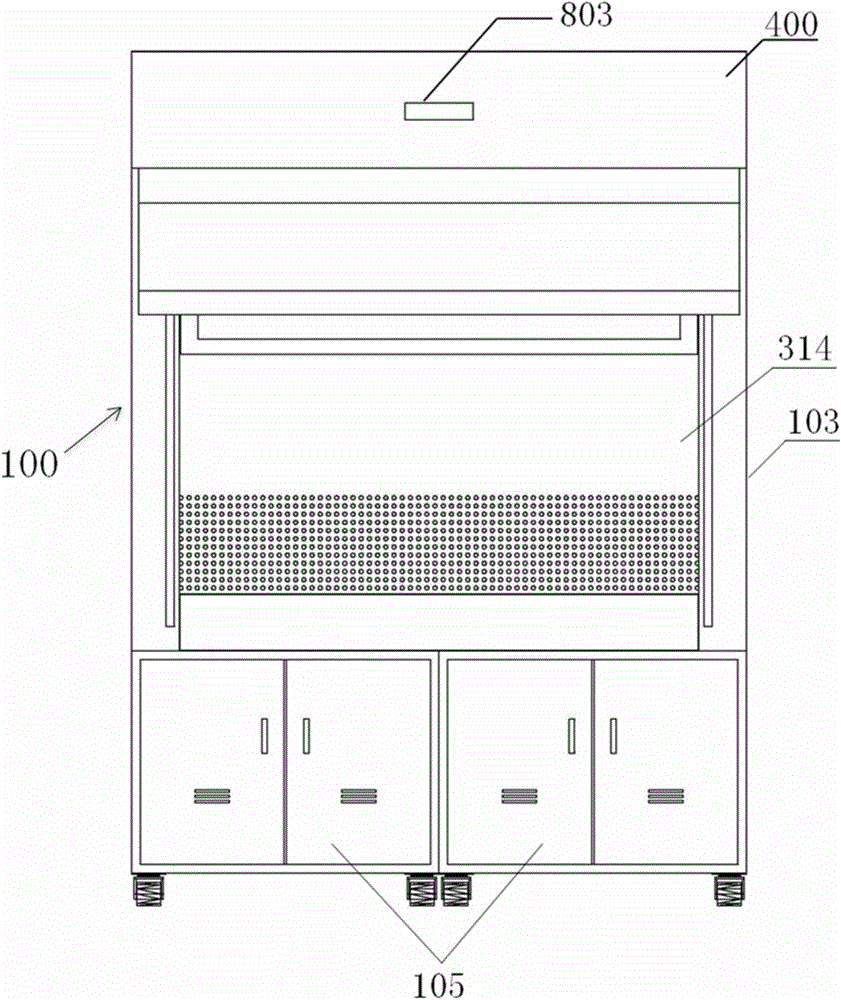

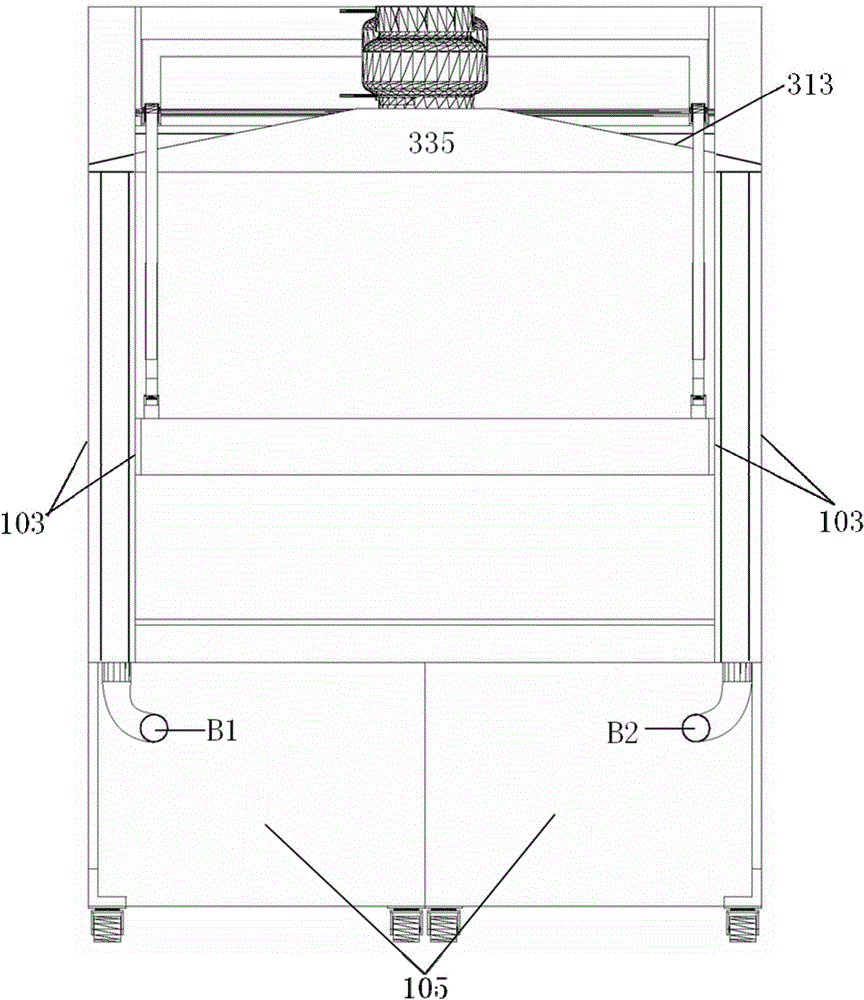

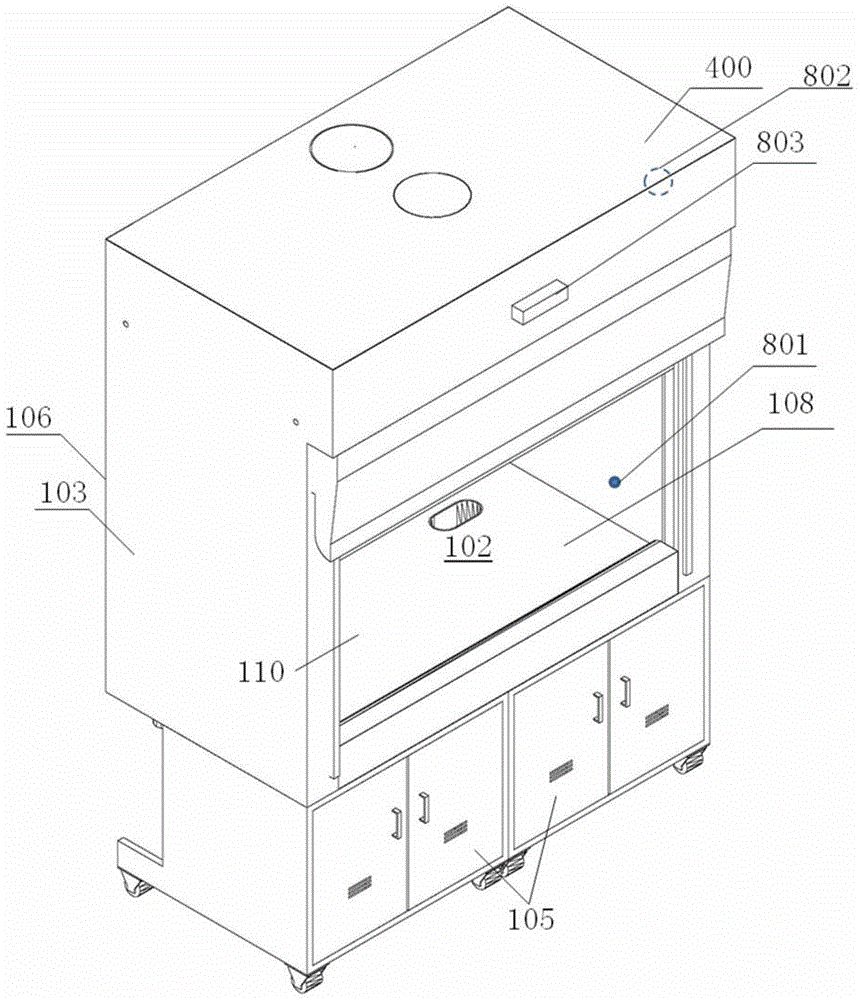

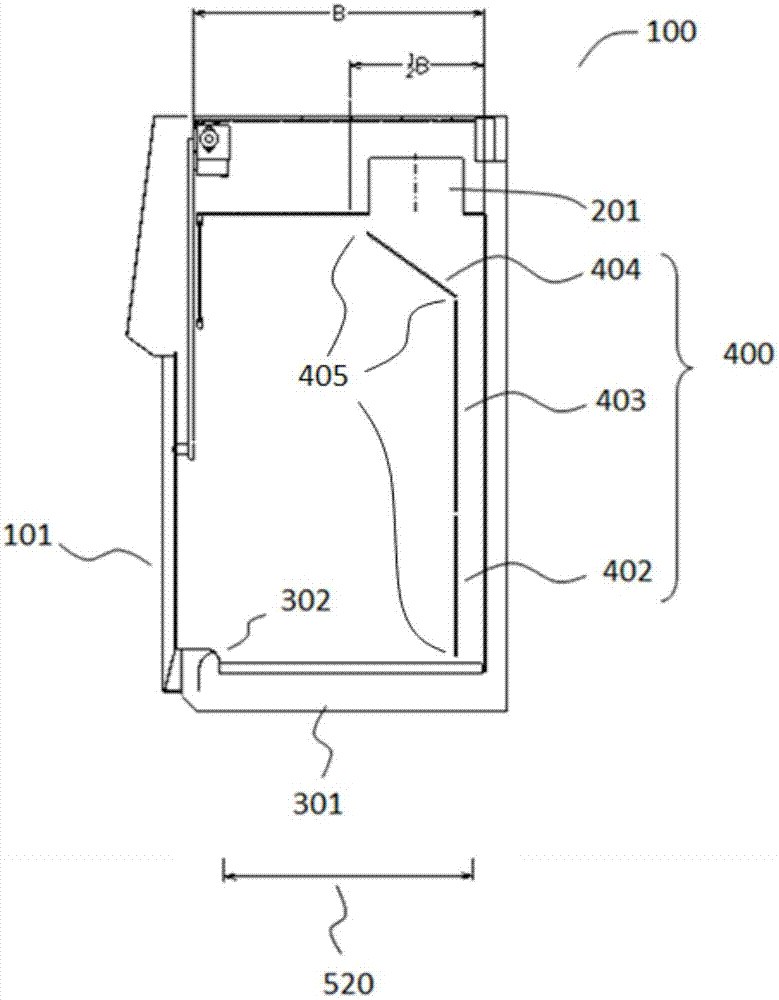

Novel energy-saving environment-friendly numerical-control fume hood of laboratory

The invention discloses a novel energy-saving environment-friendly numerical-control fume hood of a laboratory. The novel energy-saving environment-friendly numerical-control fume hood comprises a cabinet, a sliding window, a deflector and a numerical control system. The deflector is provided with a plurality of guide holes; air outside the fume hood flows into an inner cavity of the cabinet after the sliding window is opened; and under guiding of the deflector, gas generated in a testing area is exhausted from the guide holes of the deflector. The numerical control system comprises an automatic sliding window controller, a non-contact sliding window controller, a face velocity controller and a system controller. The automatic sliding window controller is used for detecting whether operators work in an operation area in front of the fume hood or not so as to automatically increase or decrease openness of the sliding window. The non-contact sliding window controller is used for the operators to open the sliding window to a required position in a non-contact way. The face velocity controller is used for regulating exhaust rate of the fume hood automatically according to the openness of the sliding window, and sending the exhaust rate and running states of the fume hood to the system controller so as to regulate running frequencies of an exhaust fan and an air supplement fan.

Owner:GUANGZHOU SUIJIAN LAB TECH CO LTD +2

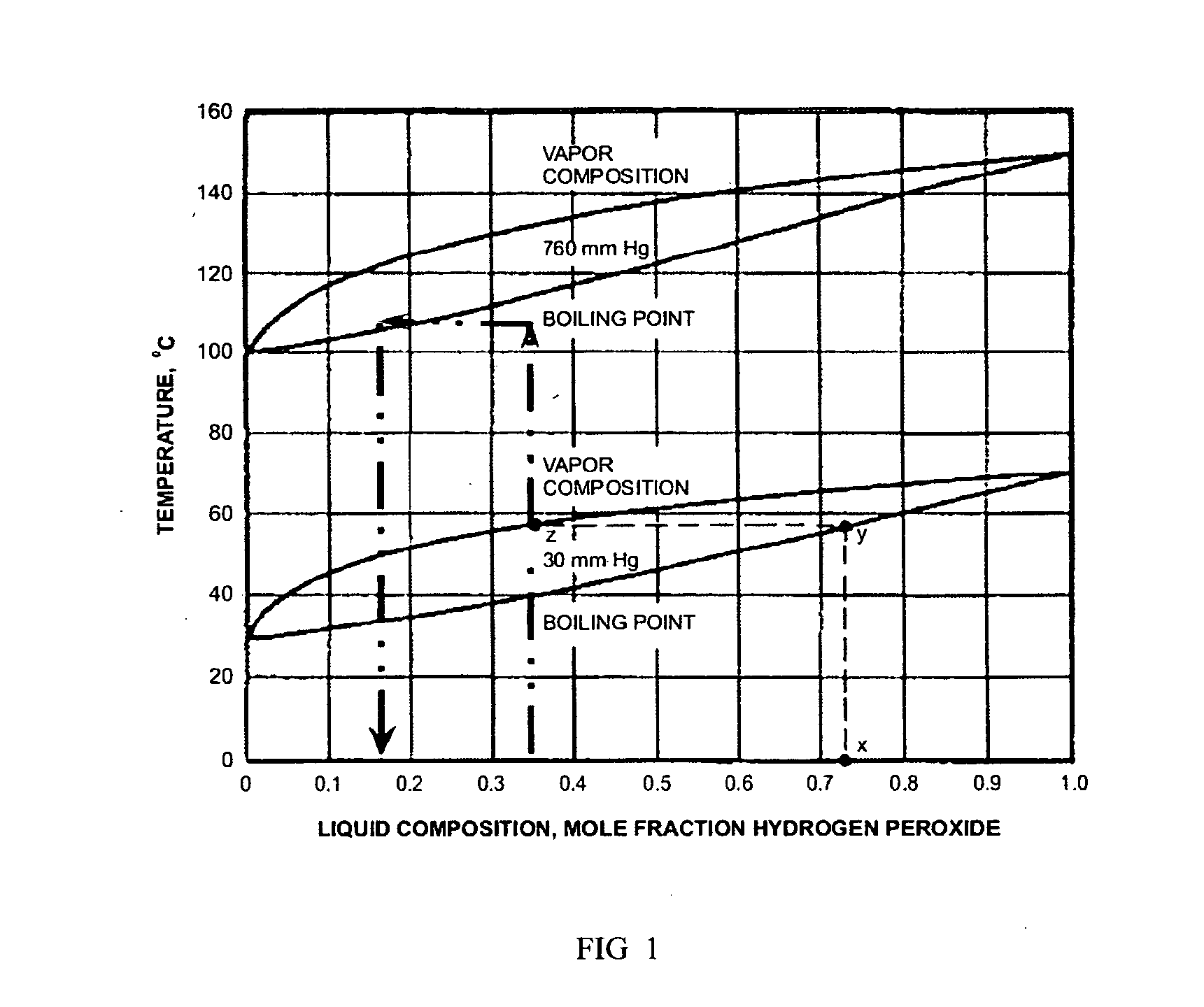

Integrated Automatic Humidity Control And Decontamination System For Incubators And Other Laboratory Equipment

The present invention relates generally to an integrated system and method for humidity control and vapor-phase decontamination of laboratory equipment with a multi-component vapor, one component of which is water vapor. The laboratory equipment can be a sealable enclosure such as an incubator, isolator, glove box, clean room, fume hood, safety cabinet, or centrifuge. The carrier gas flow is preferably in a multiple-pass, closed-loop recirculating mode. The humidity control and decontamination can be carried out automatically without user intervention for an indefinite period of time once the system has been installed, the required utilities connected and the desired settings including temperature and humidity level programmed.The integrated humidity control and decontamination system can be retrofitted onto existing laboratory equipment.

Owner:ESCO TECH ASIA PTE

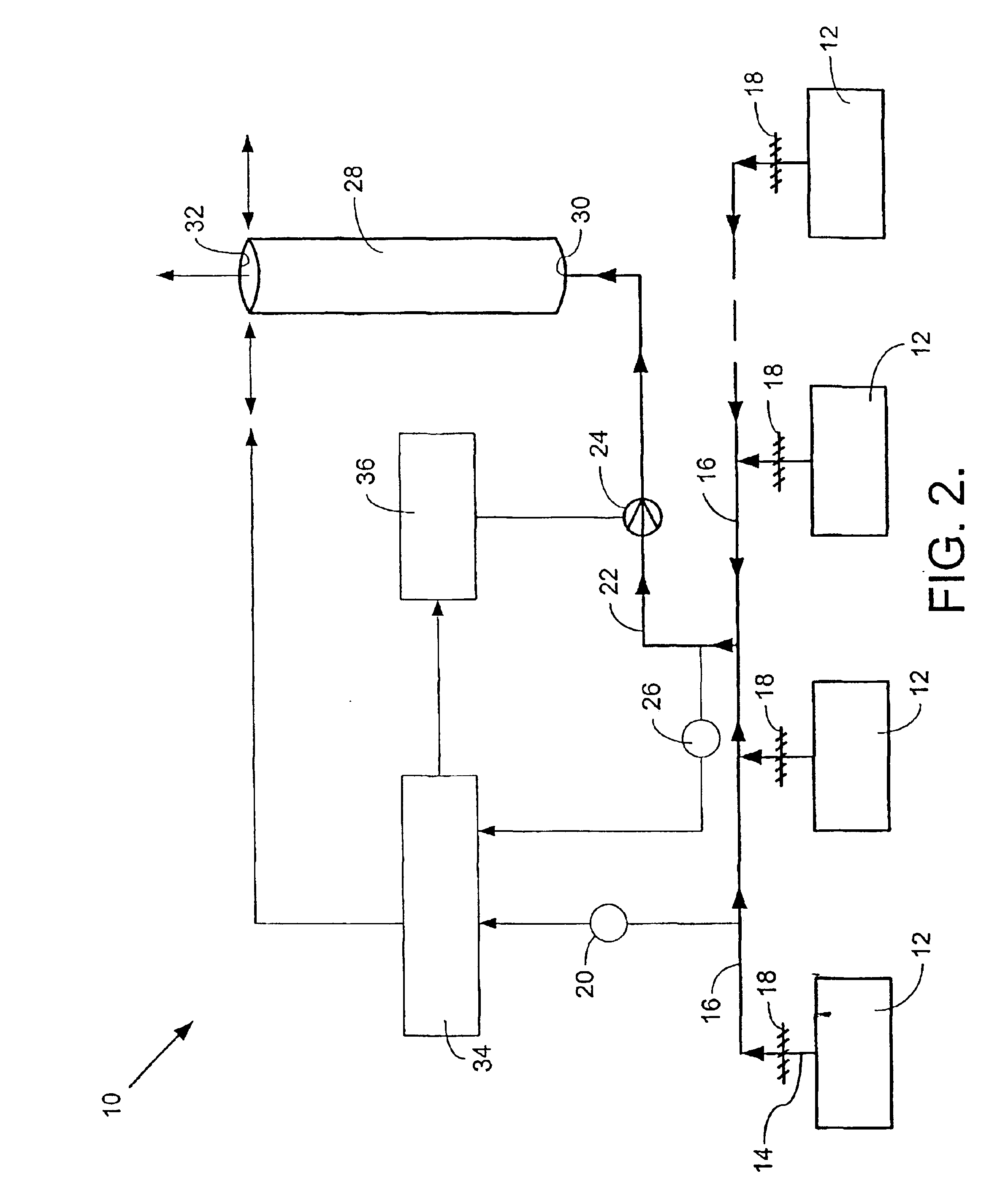

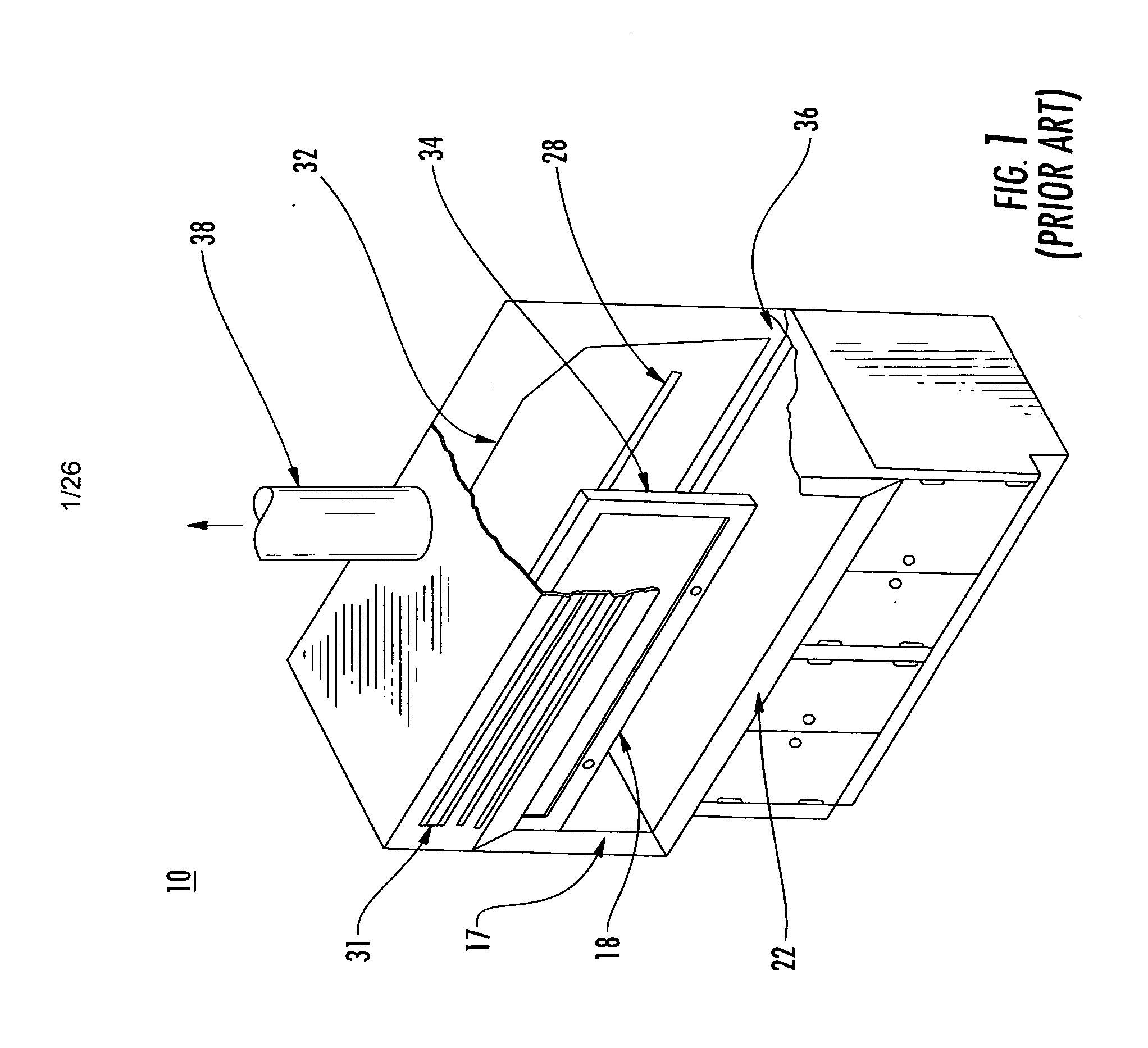

Fume hood exhaust stack system

InactiveUS6890252B2Constant momentumConstant velocityDomestic stoves or rangesSpace heating and ventilation safety systemsMomentumAtmospheric air

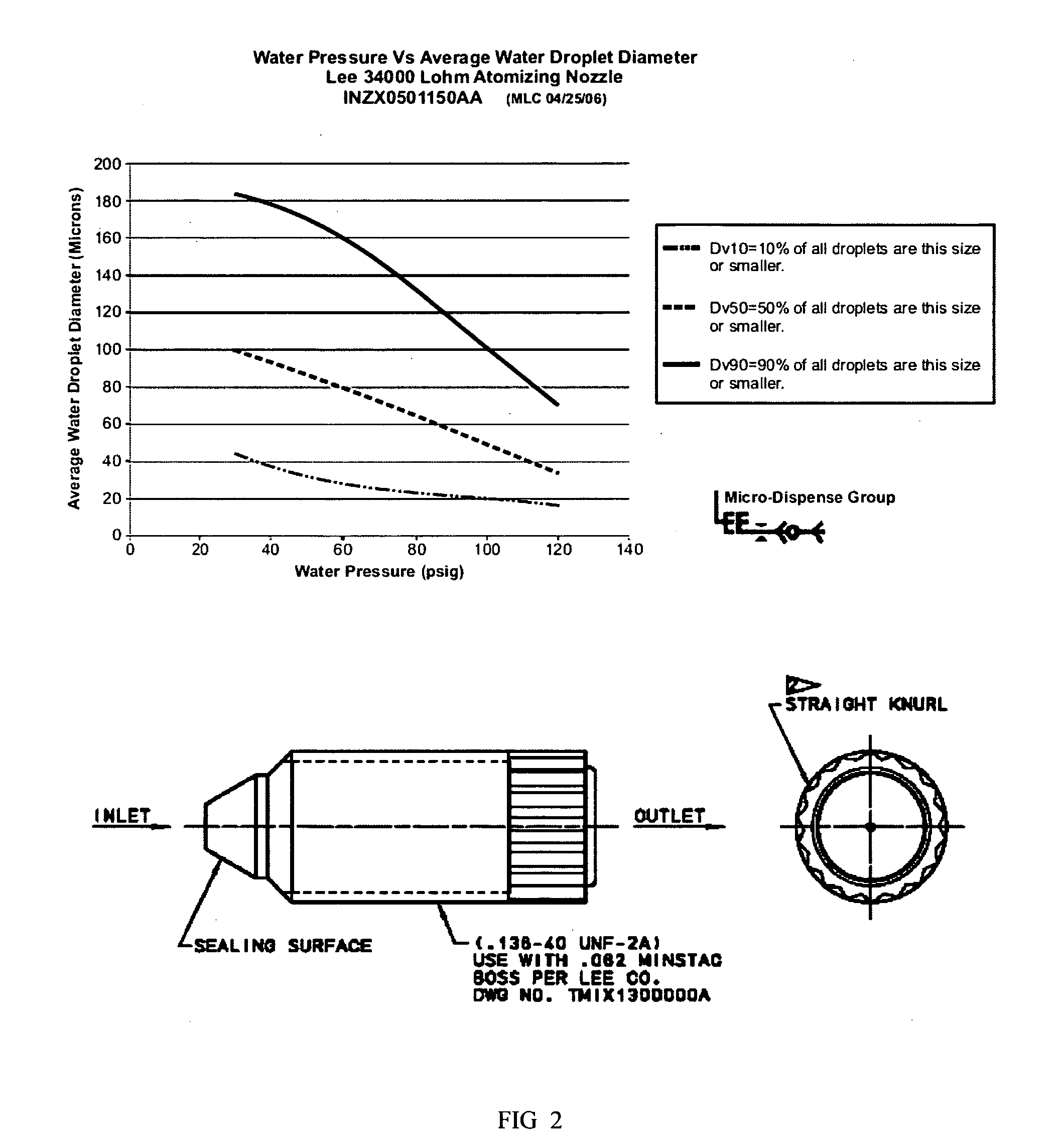

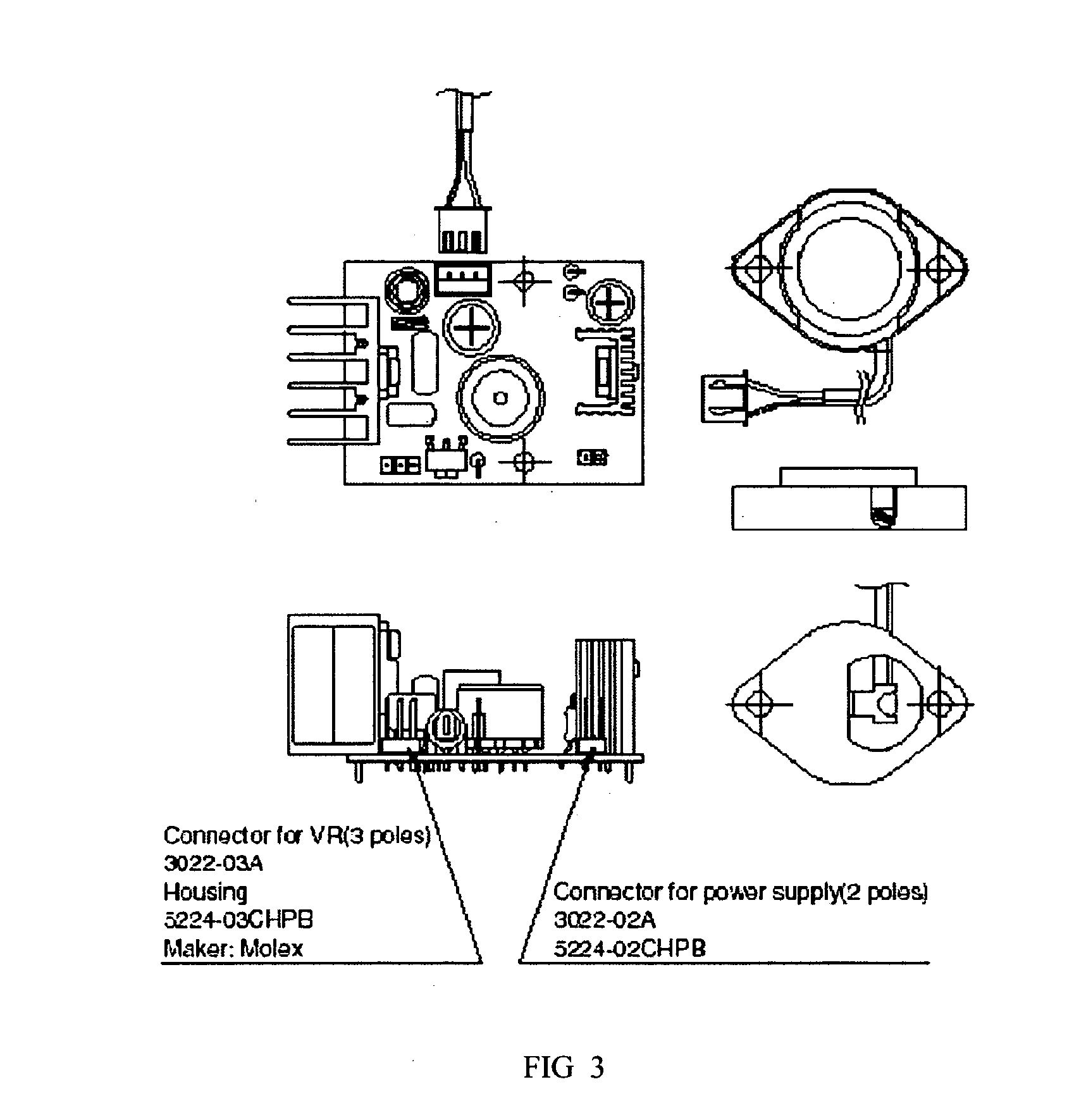

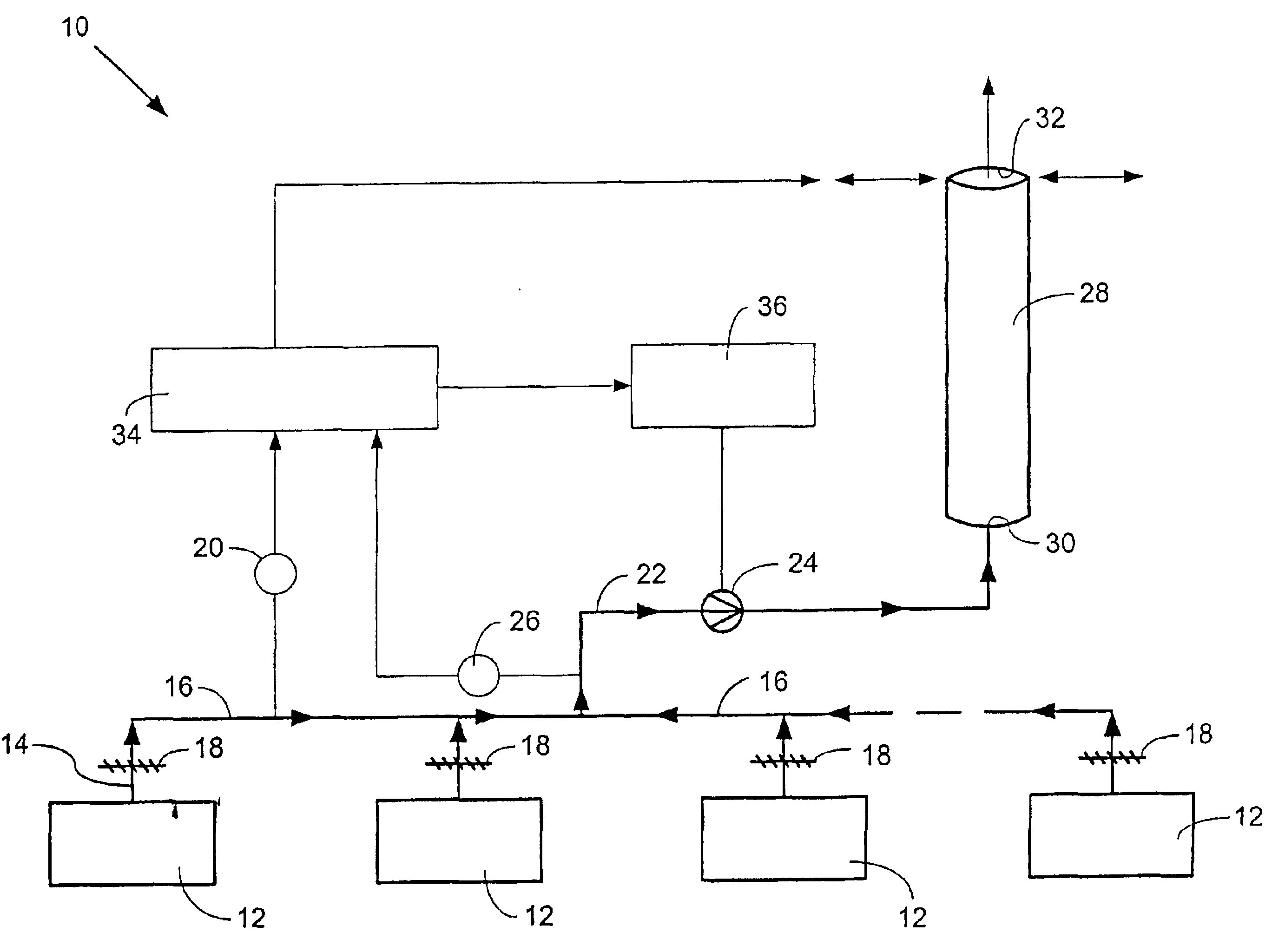

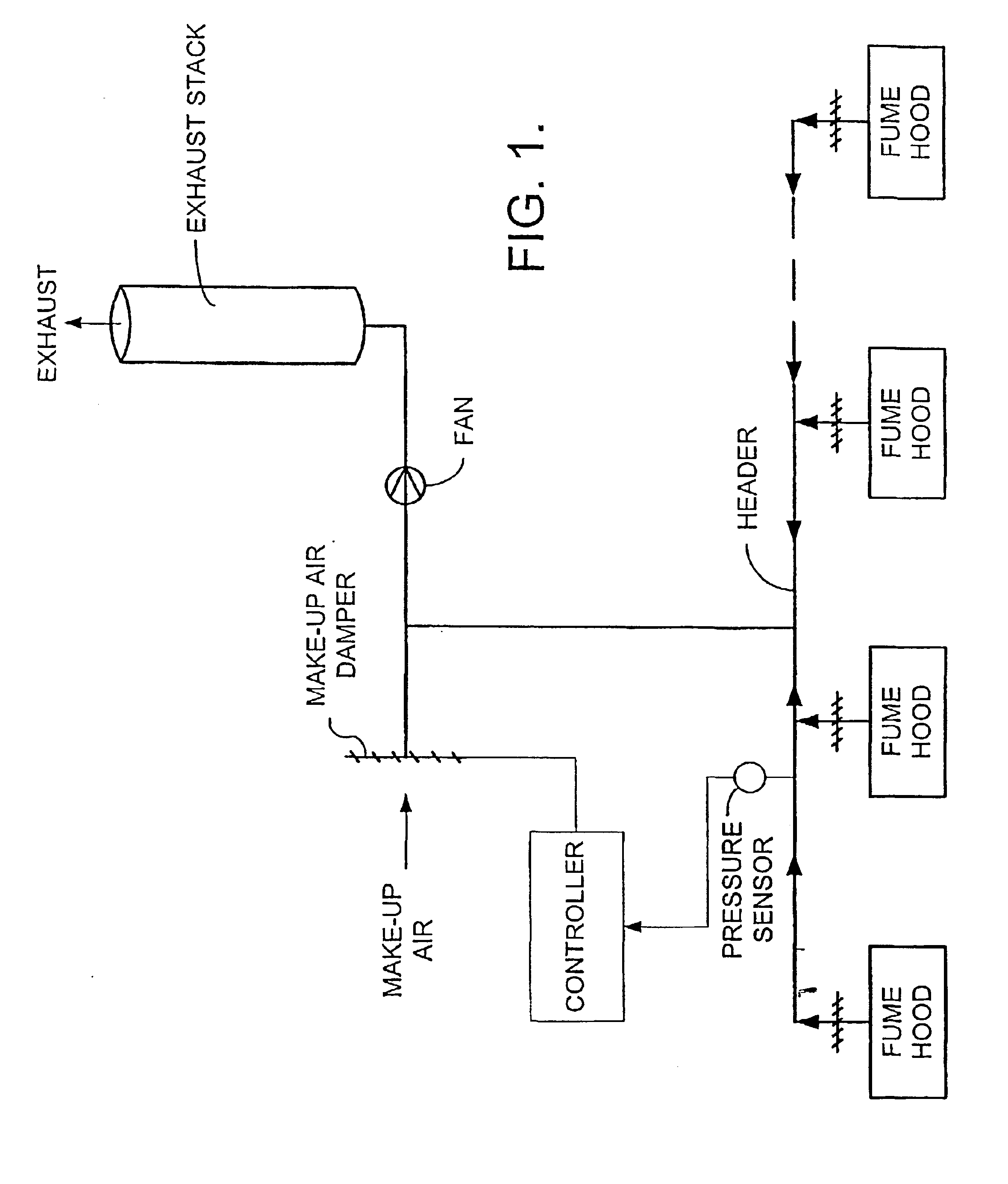

A fume hood exhaust stack system (10) and method utilize a variable speed fan (24) and an exhaust stack (28) having an adjustable cross-sectional area. Toxic exhaust from one or more fume hoods (12) is conveyed through a header (16) to the fan. The fan forces the exhaust through the exhaust stack, and the exhaust is then discharged into the atmosphere at a sufficient velocity and momentum to ensure that the exhaust reaches an environmentally sound altitude. A variable speed drive (36), programmable controller (34), flow signals (26), and static pressure and total pressure signals (20) are utilized to modulate the speed of the fan and the area of the exhaust stack to maintain the desired fan inlet pressure and exhaust velocity.

Owner:LIU MINGSHENG

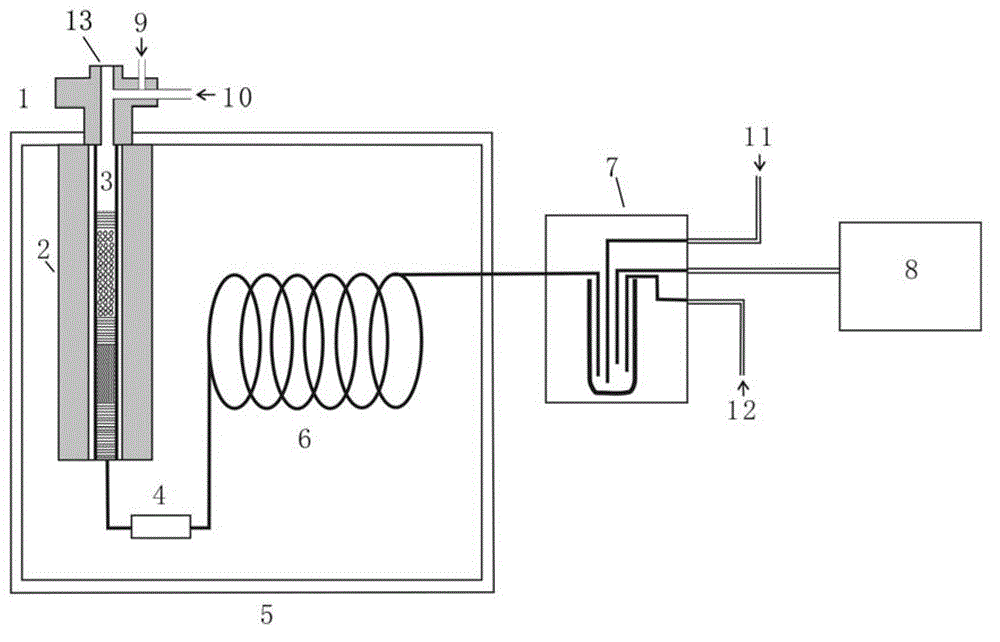

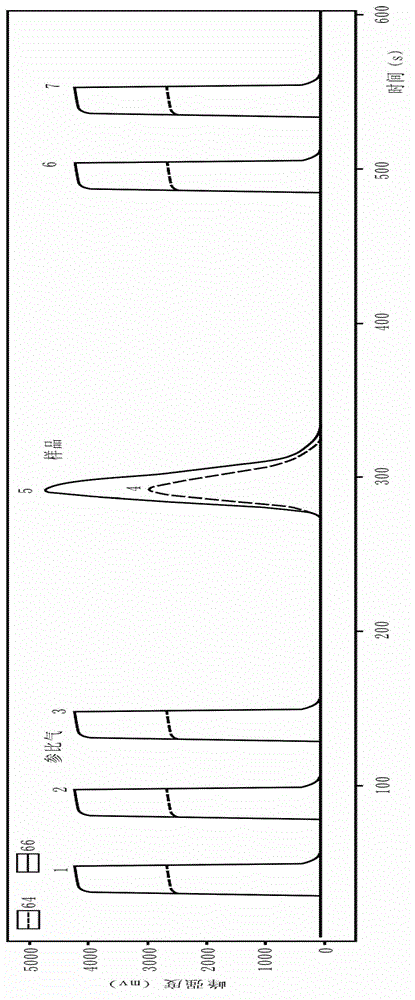

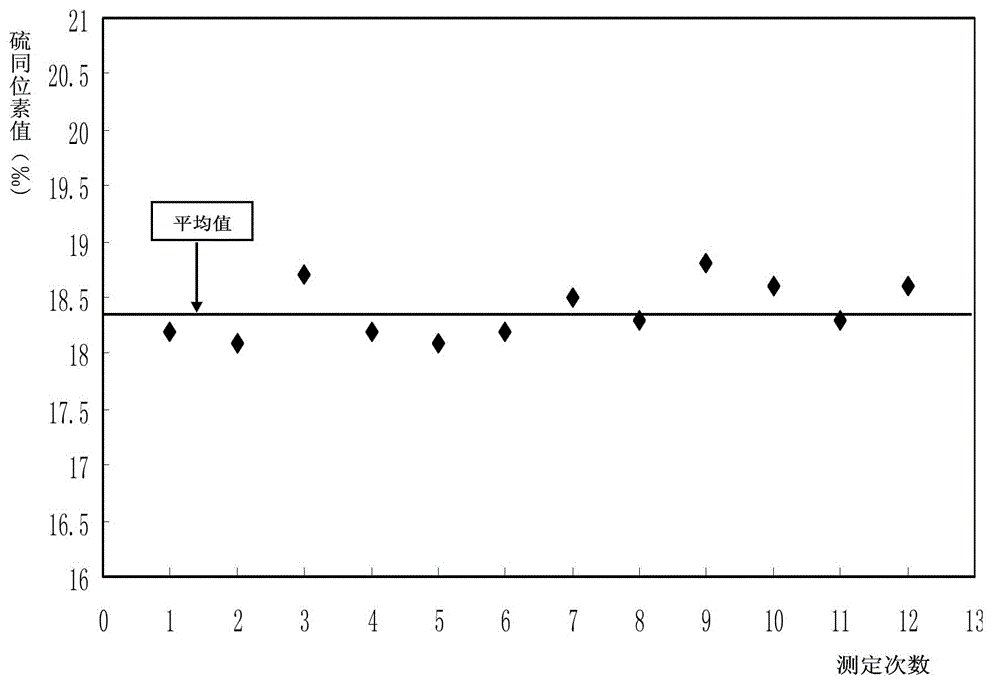

Online analysis method for sulfur isotope of hydrogen sulfide gas in natural gas

ActiveCN102749382ARealize direct and automatic conversionEasy to operateMaterial analysis by electric/magnetic meansElement analysisContinuous flow

The invention relates to an online analysis method for sulfur isotope of hydrogen sulfide gas in natural gas. The method comprises the steps of collecting a natural gas sample; heating oxidation furnace of an elemental analyzer to 1,020 DEG C; heating a chromatographic column box to 50 DEG C; introducing reference gas into a stable isotope ratio mass spectrometer, adjusting center magnetic field of the peak with mass / charge ratio of 66, and storing the magnetic field value; connecting a steel cylinder filled with the natural gas sample with a sampling valve, placing in a ventilating hood, and switching on the ventilating hood; taking the natural gas sample with an airtight sample injector; injecting the natural gas sample into a sample inlet; introducing the natural gas sample into a high-temperature oxidation tube with carrier gas, to be oxidized into carbon dioxide, water and sulfur dioxide gas, carrying the mixed gas with carrier gas through a dewatering tube for water removal; separating the dewatered mixed gas with a gas chromatographic column, sequentially introducing into a stable isotope ratio mass spectrometer through a continuous flow interface, measuring sulfur isotope composition, and generating spectrogram.

Owner:PETROCHINA CO LTD

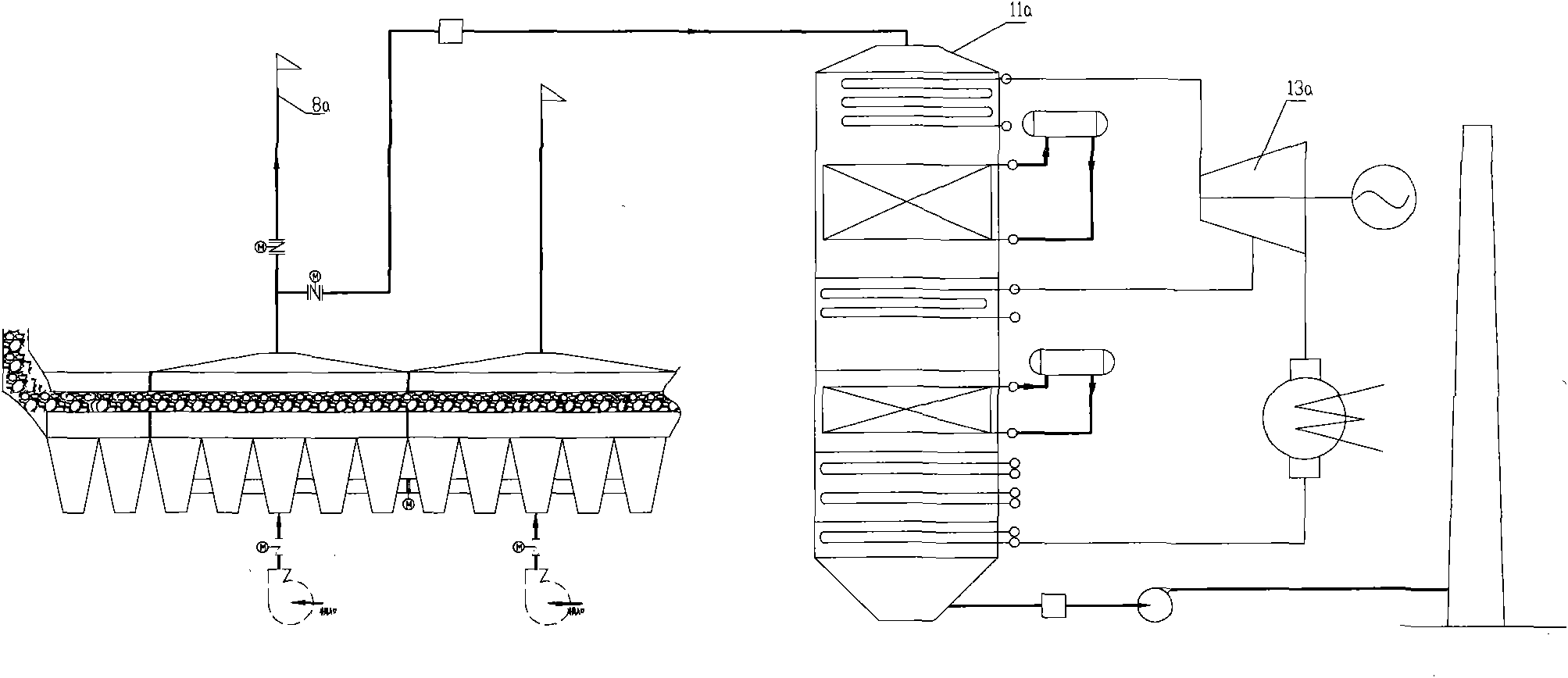

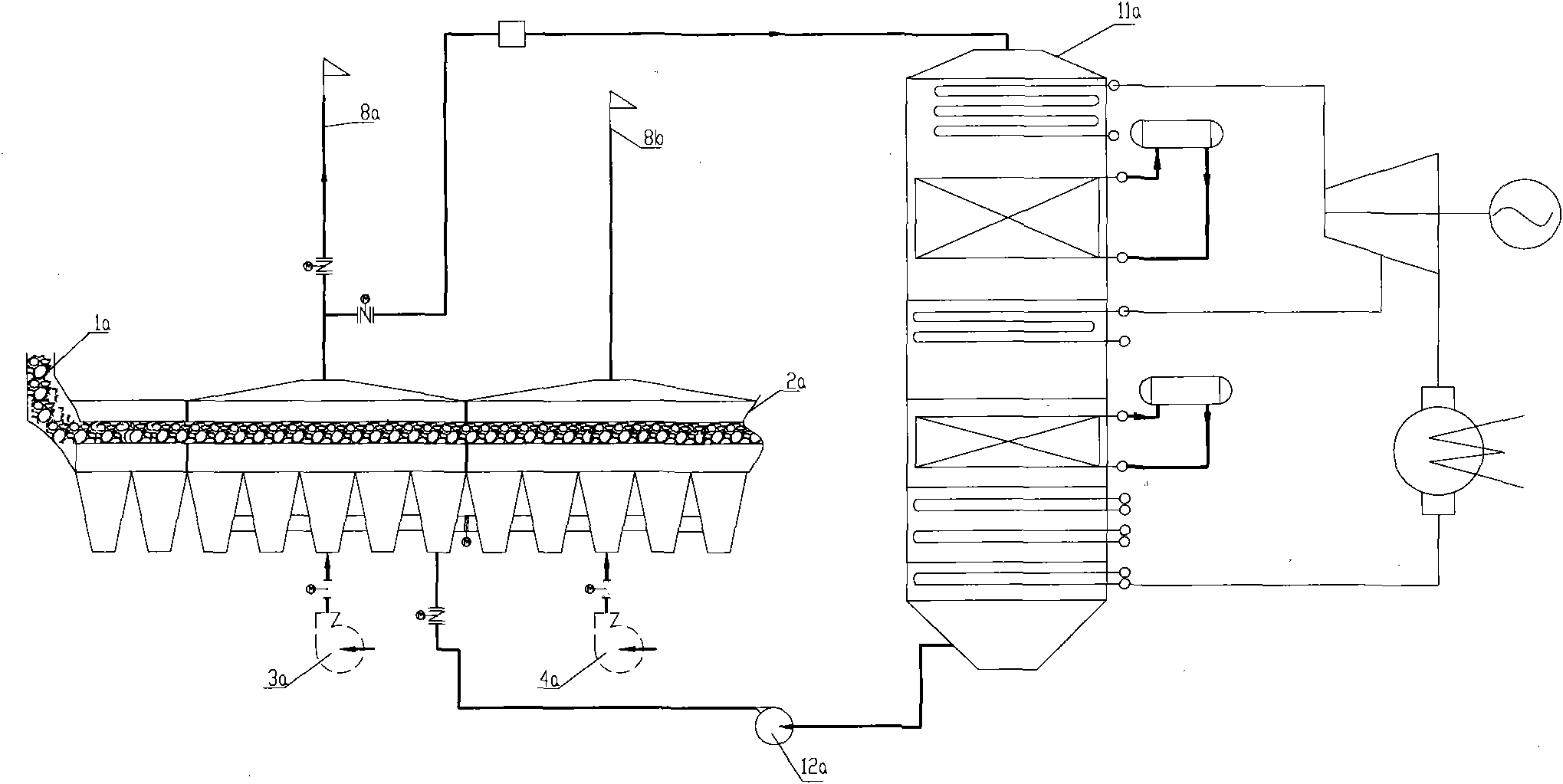

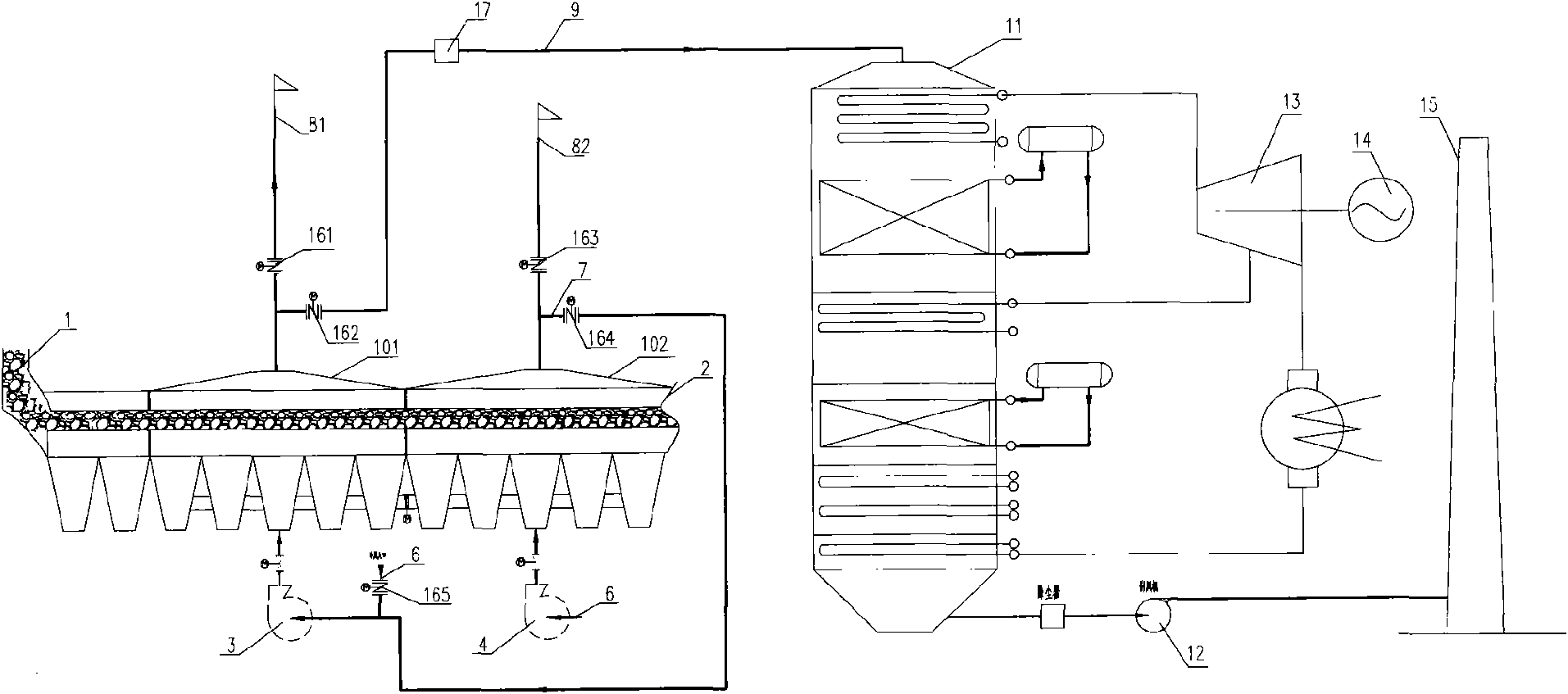

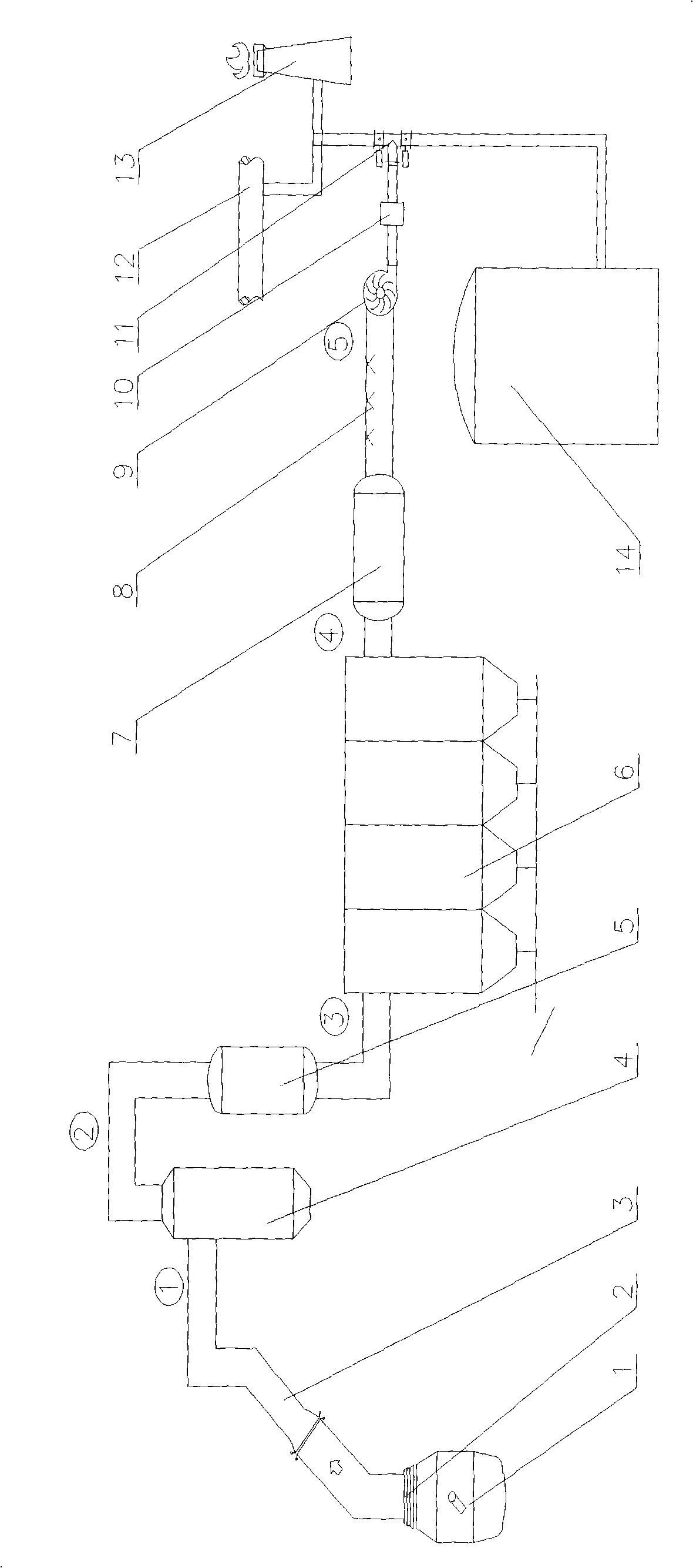

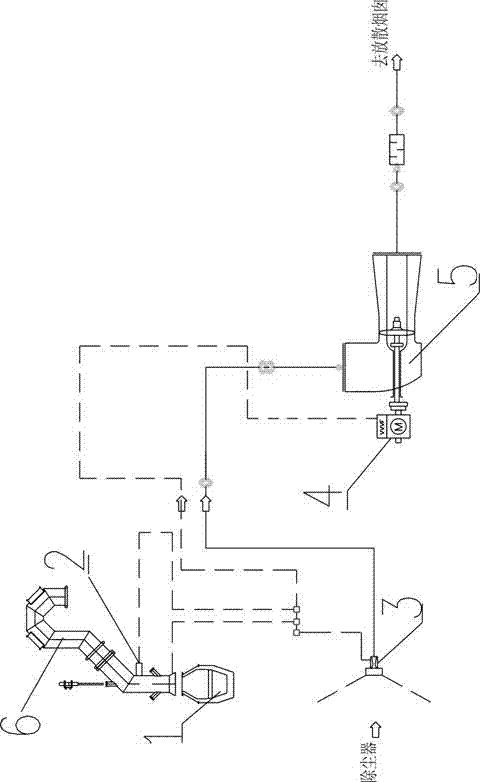

Power generation system using waste heat of sintering circular cooler

InactiveCN101672578AImprove reuse efficiencyWill not affect the performance of sintering processIncreasing energy efficiencySteam engine plantsExhaust fumesFume hood

A power generation system using waste heat of a sintering circular cooler comprises a first fume hood, a second fume hood, an air pipe, a first air blower, a first fume pipeline, a double-pressure waste heat boiler and a steam compensating steam turbine. The first fume hood is arranged at a low temperature zone of a circular cooler; the second fume hood is arranged at a high temperature zone of the circular cooler; the air pipe is communicated with the first fume hood and a cooling air conduit at the high temperature zone of the circular cooler; the first air blower superposes outdoor coolingair with fume discharged from the low temperature zone of the circular cooler in the air pipe as cooling air of the high temperature zone of the circular cooler; the first fume pipeline is used for communicating the second fume hood with an air line of the double-pressure waste heat boiler; the double-pressure waste heat boiler is used for converting the fume in the first fume pipeline into high pressure steam and lower pressure steam, the high pressure steam enters a high pressure section of the steam compensating steam turbine for doing work, and the lower pressure steam enters a low pressure section of the steam compensating steam turbine for doing work; and the steam compensating steam turbine is used for driving a generating unit to generate power. The invention provides a power generation system using waste heat of a sintering circular cooler, and the system is used for improving inlet temperature of the waste heat boiler without affecting properties of sintering processes.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

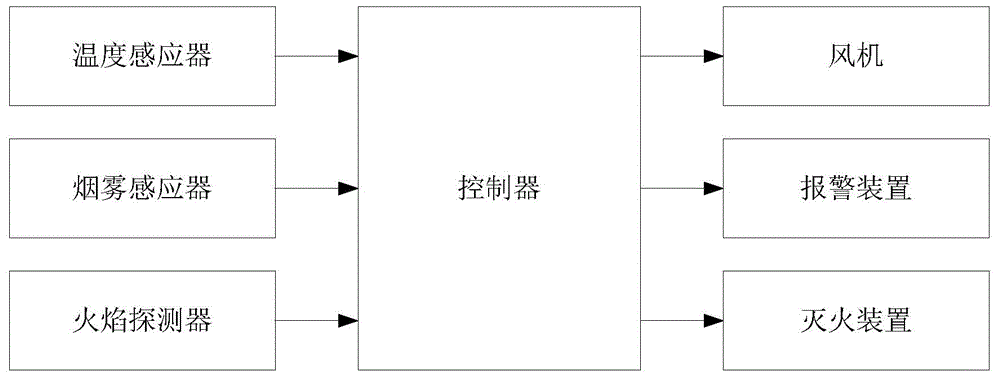

CIT ventilation cabinet with temperature-proof smoke-proof and fire-extinguishing functions

The invention discloses a CIT ventilation cabinet with temperature-proof smoke-proof and fire-extinguishing functions. A temperature sensor and a smoke sensor are arranged at an air outlet part, are respectively used for detecting the real-time temperature value and the real-time smoke quantity inside a cabinet body and are respectively connected to a controller, the controller is used for controlling the rotating speed of a fan according to detection signals of the temperature sensor and the smoke sensor, a flame detector is arranged inside the cabinet body, is used for detecting flame light signals inside the cabinet body and is connected to the controller, a fire extinguishing device is arranged at the side part of the cabinet body and comprises a plurality of spraying mechanisms and a water supply mechanism, the spraying mechanisms are connected with the water supply mechanism through a pipeline, in addition, a control valve is arranged on the pipeline, and the controller is connected with the control valve and is used for controlling the work state of a warning device and the fire extinguishing device according to the detection results of the flame detector. According to the CIT ventilation cabinet, the temperature and the smoke in the ventilation cabinet can be precisely monitored and effectively controlled.

Owner:杭州共享实验科技发展有限公司

Air flow monitoring and control system with reduced false alarms

InactiveUS7001263B2Reduce in quantityReduce airflowMechanical apparatusLiquid surface applicatorsTraffic capacityControl system

An air flow monitoring and control system with reduced false alarms includes an alarm sensor for monitoring air flow in a fume hood or the like, set to provide a warning if air flow drops below a predetermined amount. A local controller monitors the alarm, and disables it when the hood is set to reduced air flow, whether by a local timer or by command of a central control system. Optionally, the controller itself can operate a variable speed drive to reduce air flow on a timed basis, and the controller can communicate with facility management through a dialer or the Internet, or can interface with a central control for the facility through a facility bus.

Owner:CORNELL RES FOUNDATION INC

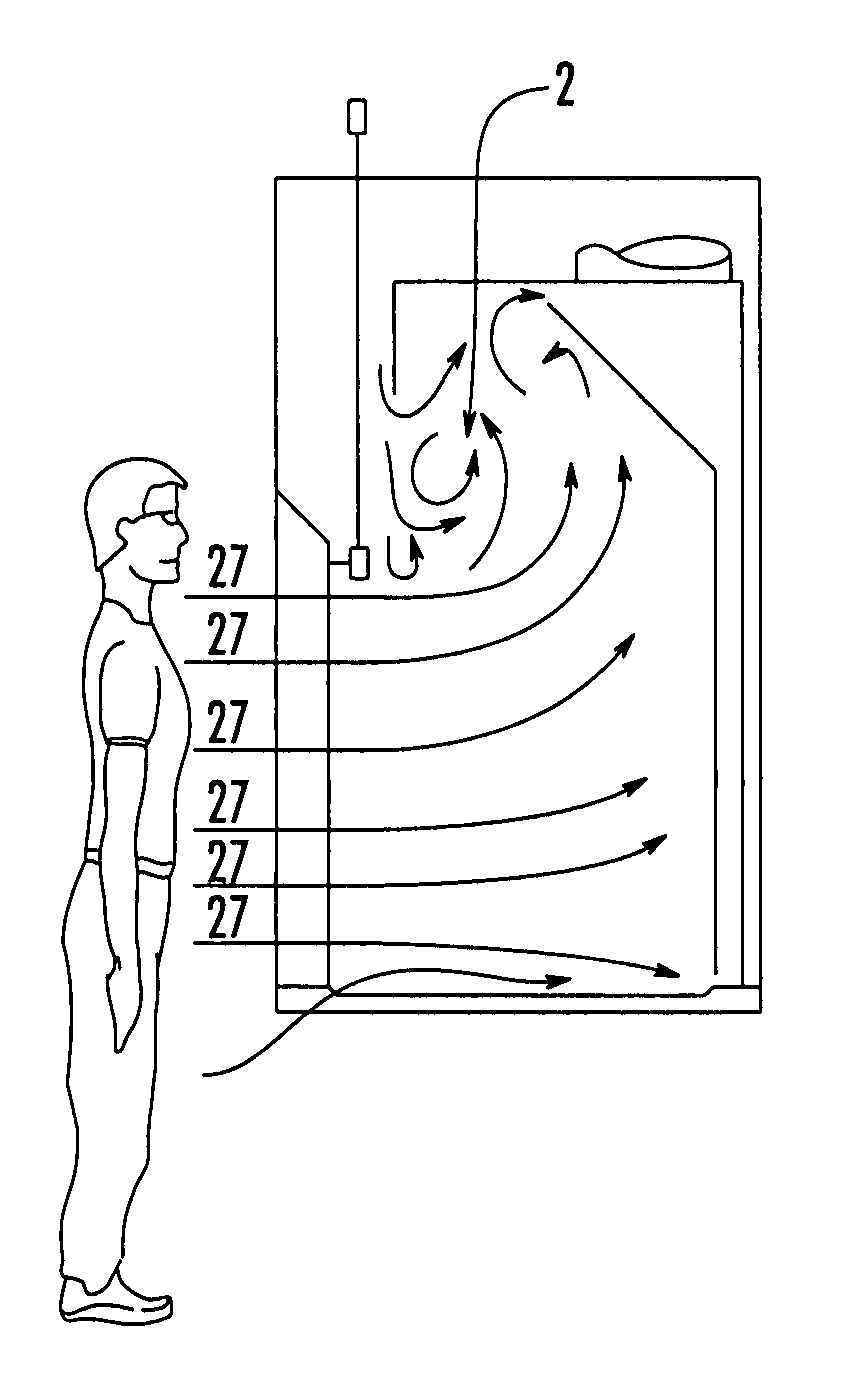

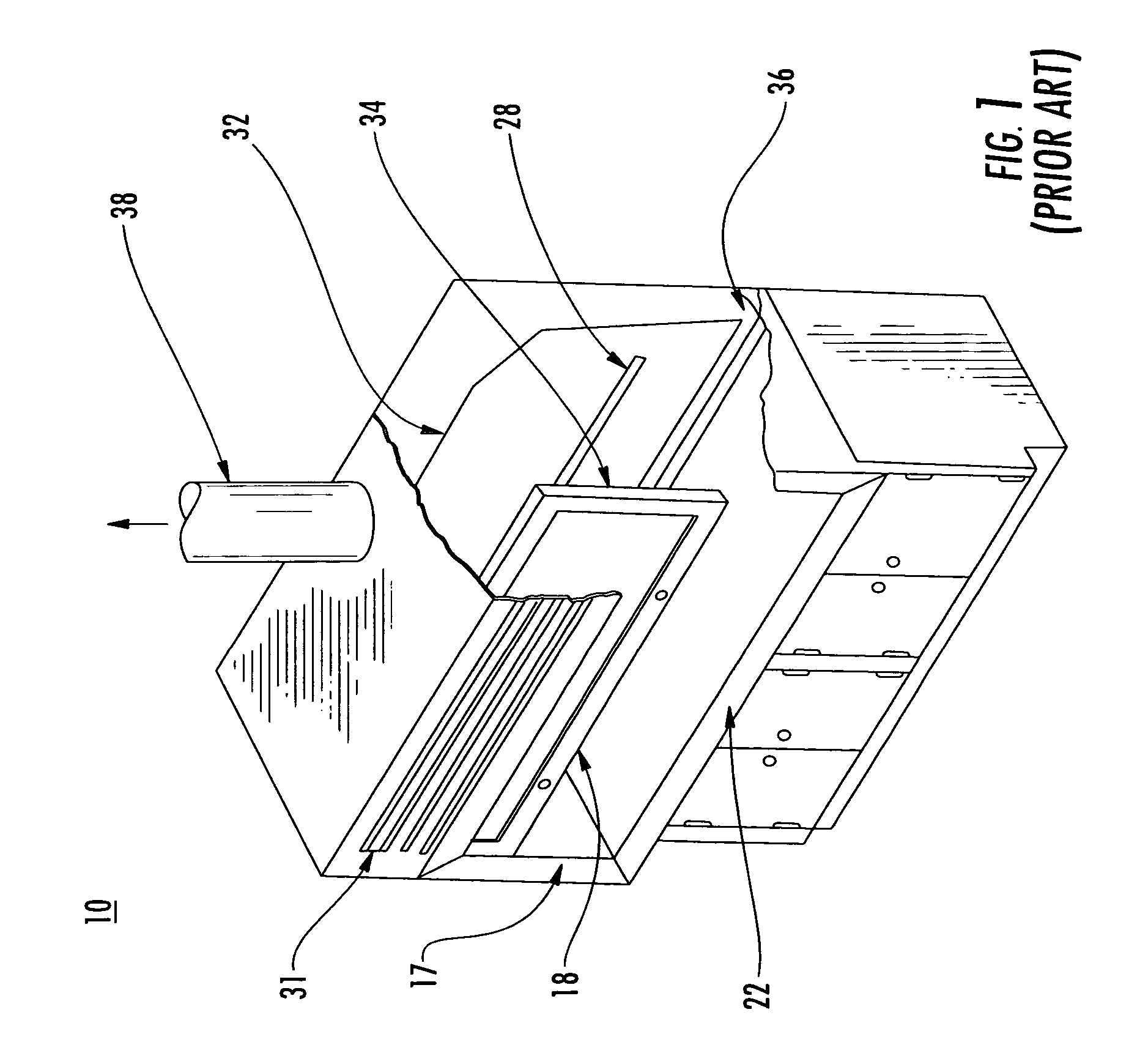

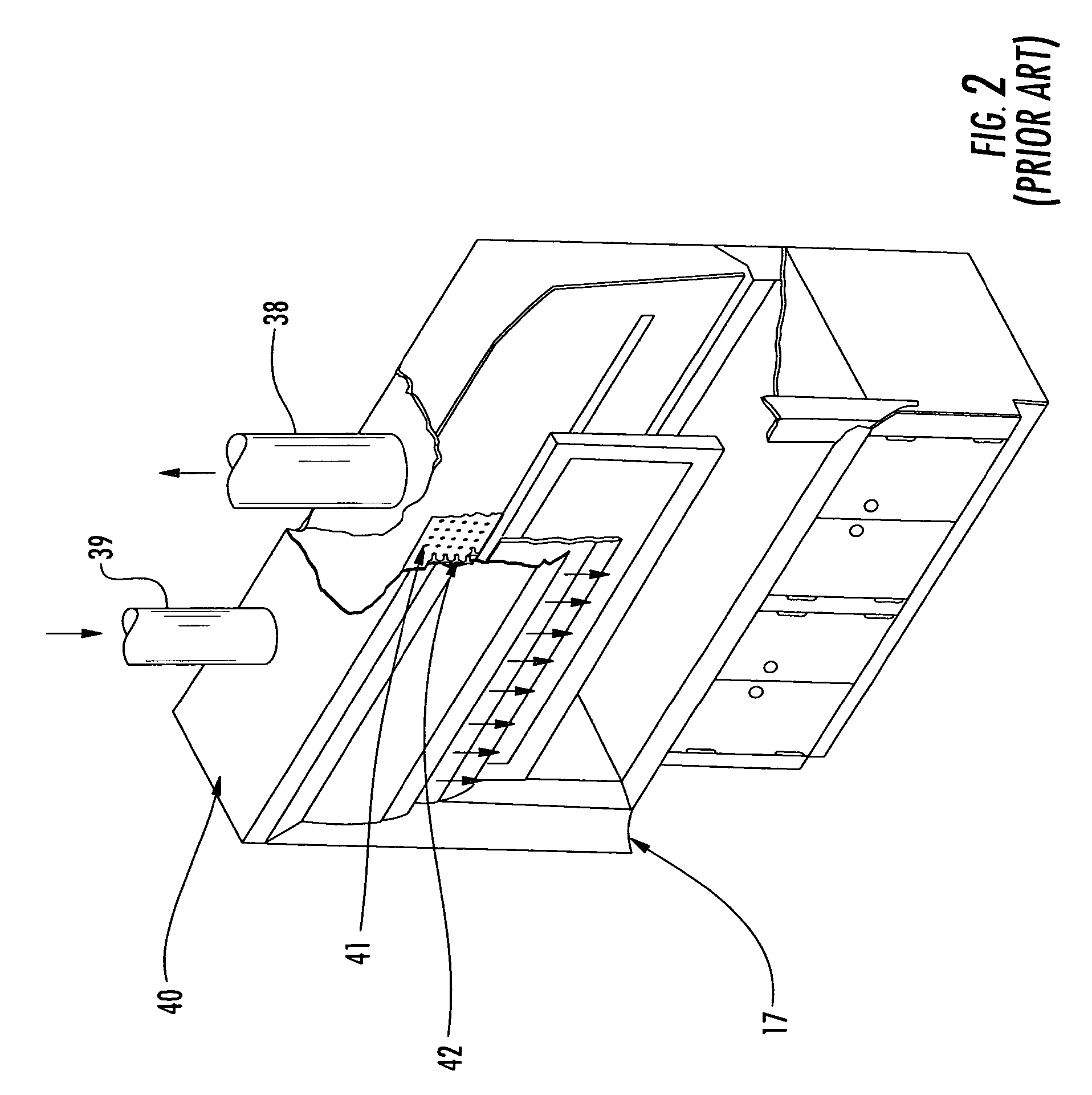

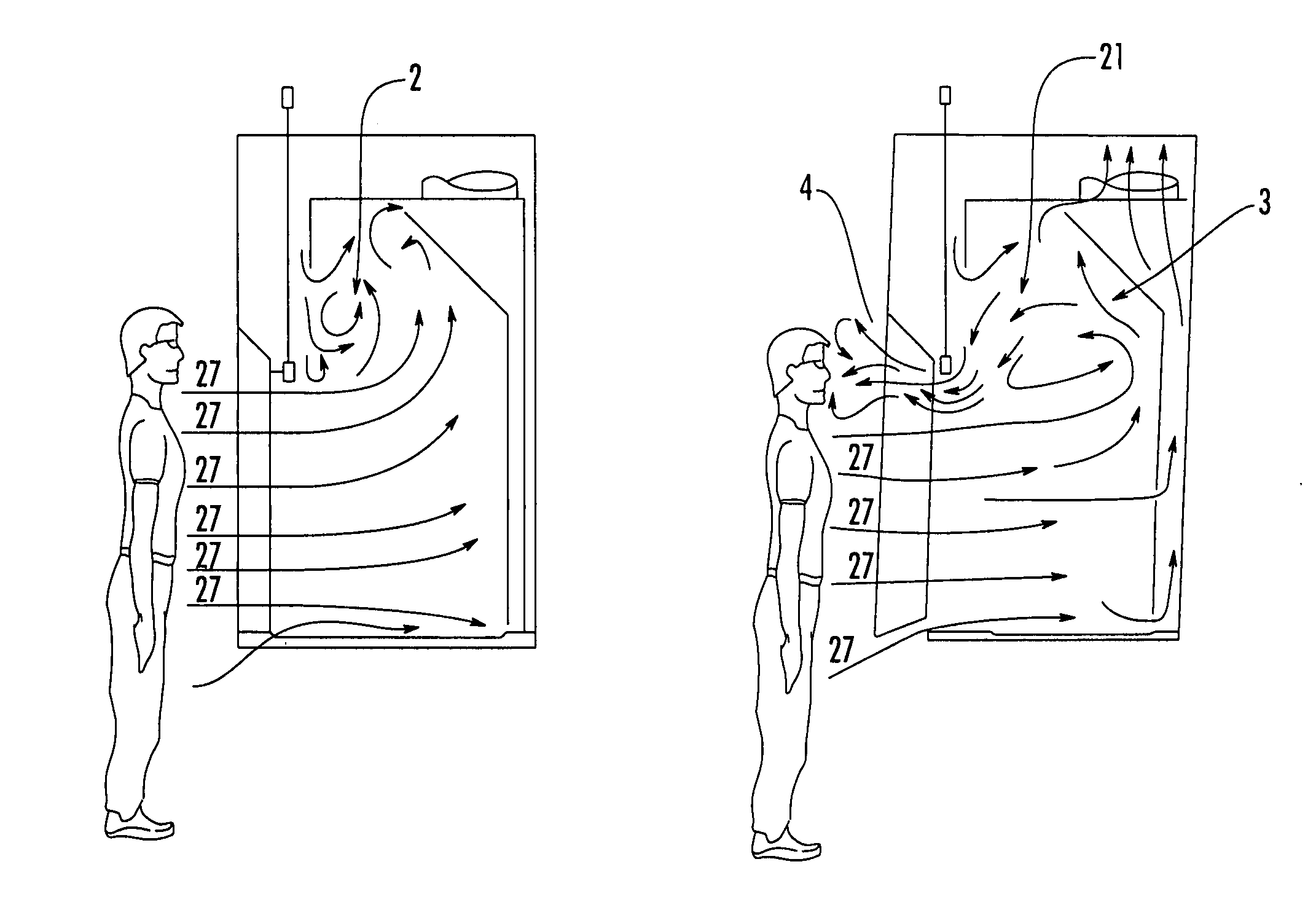

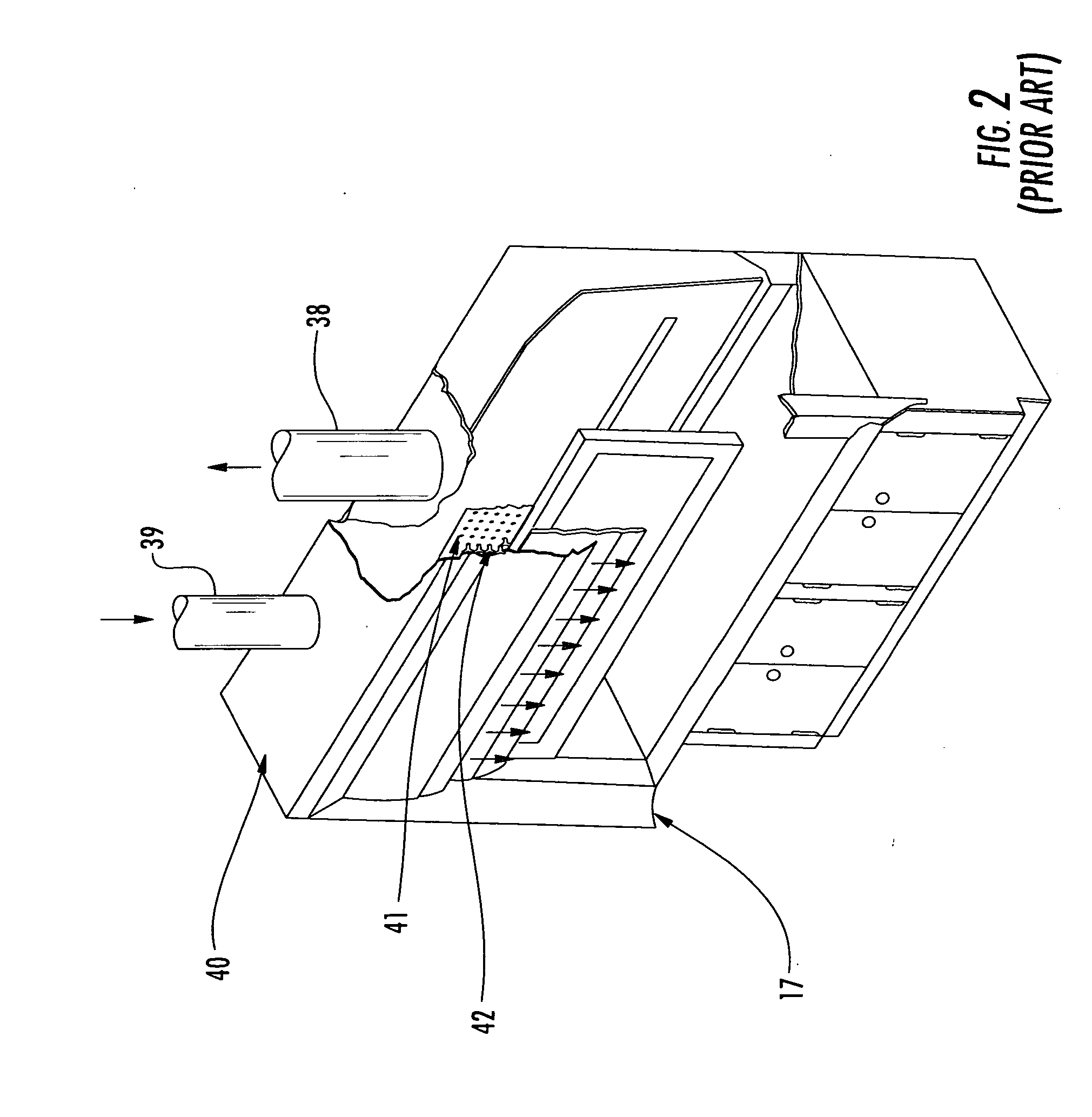

Converting existing prior art fume hoods into high performance low airflow stable vortex fume hoods

ActiveUS7470176B2Save energyImprove performanceDomestic stoves or rangesSpace heating and ventilation safety systemsFume hoodEngineering

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

Converting existing prior art fume hoods into high performance low airflow stable vortex fume hoods

ActiveUS20070087677A1Save energyImprove performanceDomestic stoves or rangesSpace heating and ventilation safety systemsEngineeringFume hood

The present invention provides a method and conversion kits, that include all necessary components, to convert any style existing prior art fume hood into a stable vortex high performance low airflow fume hood that can accommodate varying size prior art fume hoods without altering the fume hood envelope or customizing the conversion kit. The articulating rear baffle can be lifted out for cleaning debris that collects in baffle conduit. The conversion can be accomplished without drilling mounting holes into an asbestos liner and can be applied on any size or style prior art fume hood. The present invention also provides a new fume hood incorporating the features of the method and kit.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

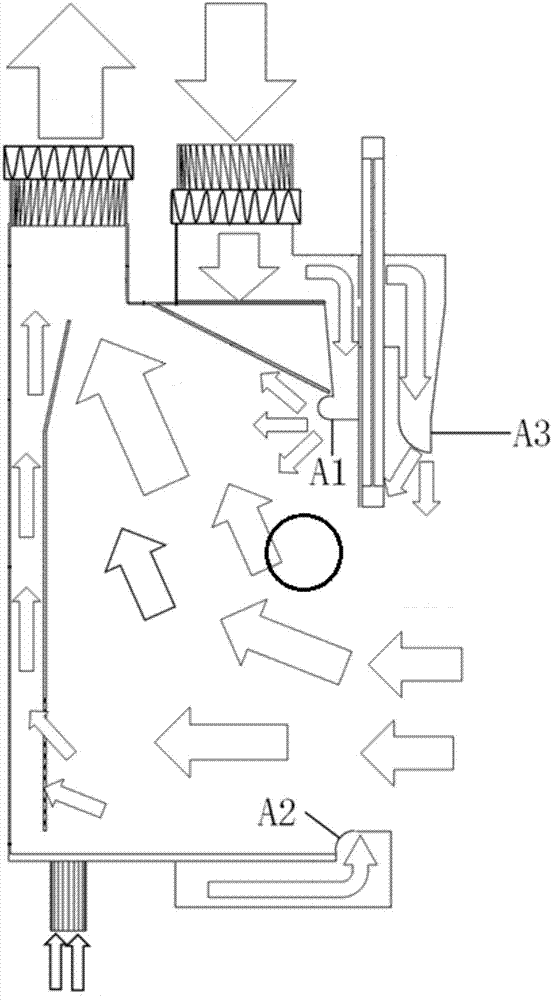

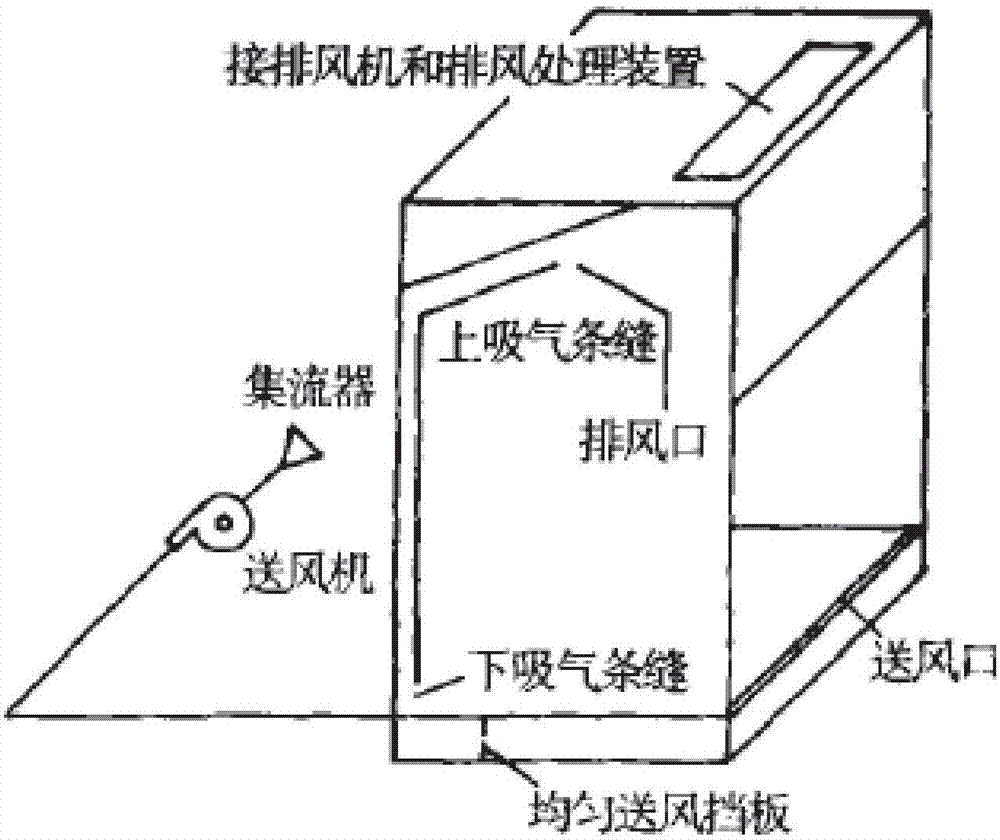

Ventilation hood

ActiveCN106140769AReduce installation costsReduce maintenance costsDirt cleaningExhaust valveHazardous substance

The invention provides a ventilation hood which is capable of reducing air-conditioning energy consumption, restraining hazardous substance effusion from a working chamber, and achieving the effects of low installation cost and high consistency of product quality. The ventilation hood comprises a hood body, an air supplement system and an air exhaust system; an inner chamber of the hood body is used as the working chamber, and a front opening opened towards indoor environment is formed in the front wall of the hood body; the air supplement system is connected with an air supplement passage of a building for working chamber air supplement; the air exhaust system is connected with an air exhaust passage of the building, and air entering the working chamber through the front opening and air entering the working chamber through the air supplement system are exhausted from the working chamber; the positions, on the upper portion and the lower portion of the hood body, of the air supplement system are each provided with at least an air supplement opening, and the air supplement openings supply air towards the working chamber; a top module is arranged on the hood body, and an air supplement draught fan and an air supplement valve for the air supplement system and an air exhaust draught fan and an air exhaust valve for the air exhaust system are arranged inside the top module; and air supplement passages which connect the air supplement draught fan and the air supplement valve with the air supplement openings communicate with one another.

Owner:E3 GREEN TECH CO LTD

Process for the removal of ethylene oxide from air

A process for removal of ethylene oxide (EO) from ambient air laden with EO is passed through a zeolite-based removal media, which preferrably consists of the acid form of zeolite ZSM-5, herein referred to as “H-ZSM-5.” The process described herein may be applied to many forms, configurations and uses, such as, for example, gas masks, fume hood ventilation filters, cartridge filters, etc. Preferably, the H-ZSM-5 is configured within an apparatus in such a manner that the stream containing EO is brought into sufficient contact with the zeolite to remove the EO from the airstream.

Owner:GUILD ASSOCS

Converter coal gas dry-method bag-type dust collecting and waste heat recovery method

InactiveCN101671757AReduce power consumptionSave investmentManufacturing convertersIncreasing energy efficiencyRecovery methodWaste heat recovery unit

The invention belongs to the technical field of separating operation and heating engineering, and in particular relates to a converter coal gas dry-method bag-type dust collecting and waste heat recovery method which is characterized in that: dusty high-temperature converter coal gas from a converter passes through a movable fume hood and an evaporation cooling duct to enter in a rough de-dustingfacility, and then the coal gas carries out dust removal and temperature reduction by a heat pipe exchanger and a dry-method bag-type dust collecting device, the coal gas which carry out dust removaland temperature reduction is treated differently according to different constituents of the converter coal gas after temperature reduction is carried out by a spraying device and constituent analysisis carried out. The invention can carry out effective recovery utilization to the converter coal gas, and the waste gas of the converter coal gas is fully utilized, thereby achieving energy-saving andenvironmental-protection purposes under the condition of low investment and high efficiency (dust content of the purified dust is less than 5mg / Nm<3>).

Owner:CISDI ENG CO LTD

Automatic fire extinguishing equipment of a fume hood

InactiveUS20110308825A1Achieve effectPrevent channelingDomestic stoves or rangesLighting and heating apparatusEngineeringFume hood

Automatic fire extinguishing equipment of a fume hood includes a cabinet having a workbench, a vent pipe, and ventilation equipment. In front of the cabinet is a window panel. Top rim of the workbench has first and second detection elements, and automatic fire extinguishing equipment mechanisms. The ventilation equipment contains a fire damper. When fire occurs at the workbench from experiments, the first detection element detects a fire signal first to issue alarming sound (or alerting flash) promptly, the ventilation equipment shutdowns, with the fire damper closed for closing the vent pipe. When the second detection element detects a smoke or high temperature signal, the window panel is closed, with the automatic fire extinguishing equipment mechanisms activated automatically to terminate flame, thereby preventing thick smoke or flame from channeling into the vent pipe to spread the fire, and preventing the fume hood from starting a cascade of fire.

Owner:ACXING INDAL CO LTD

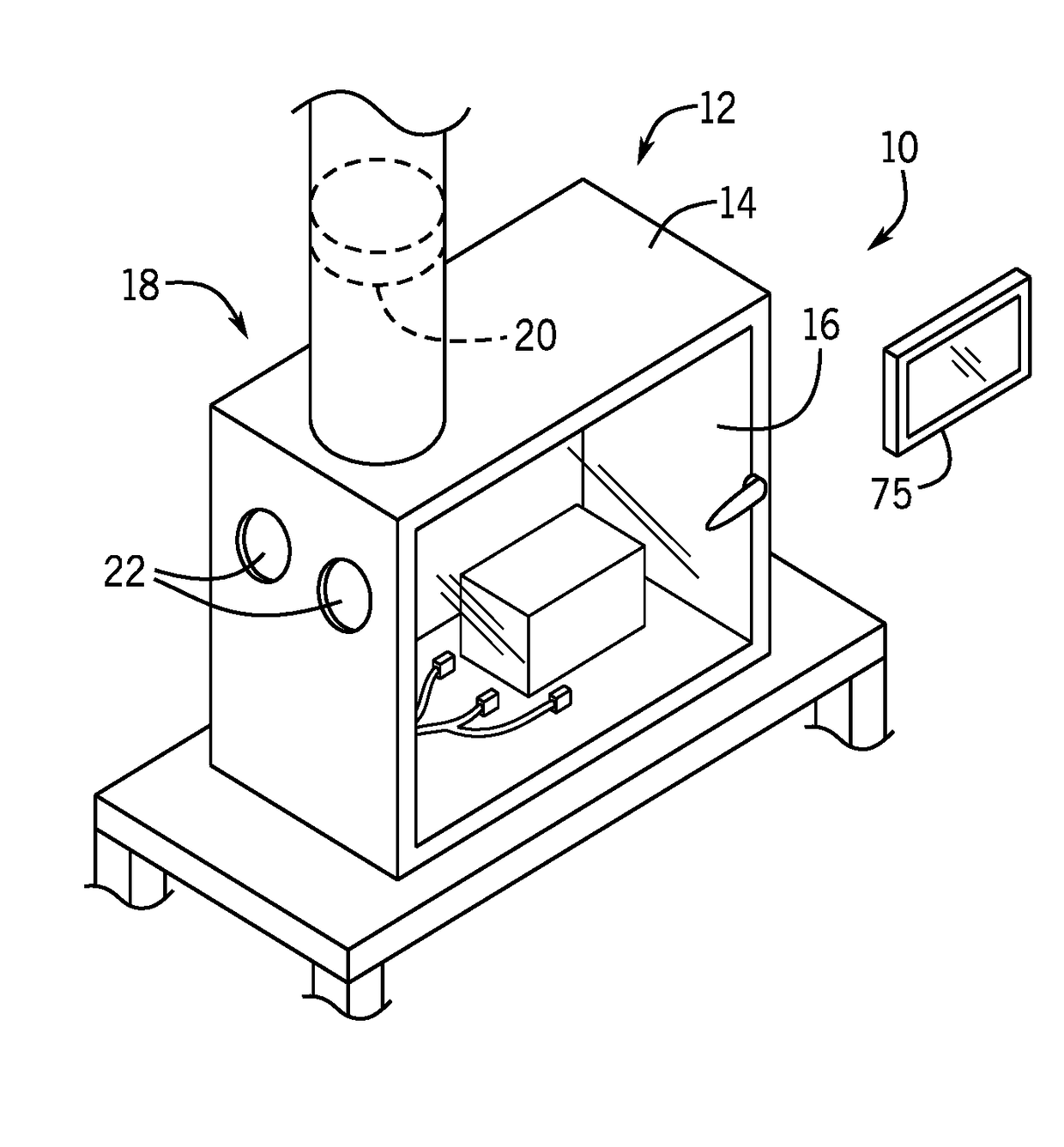

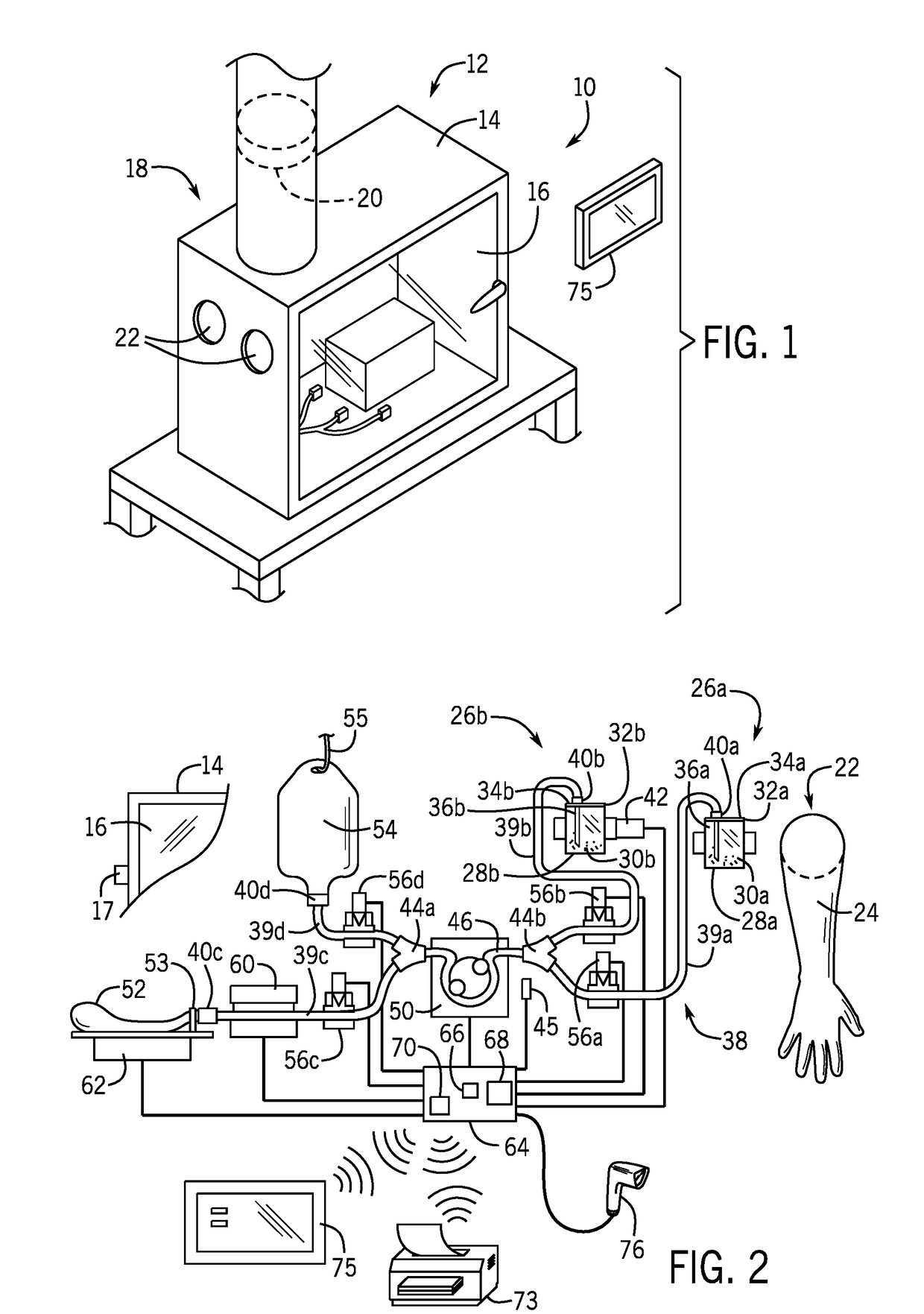

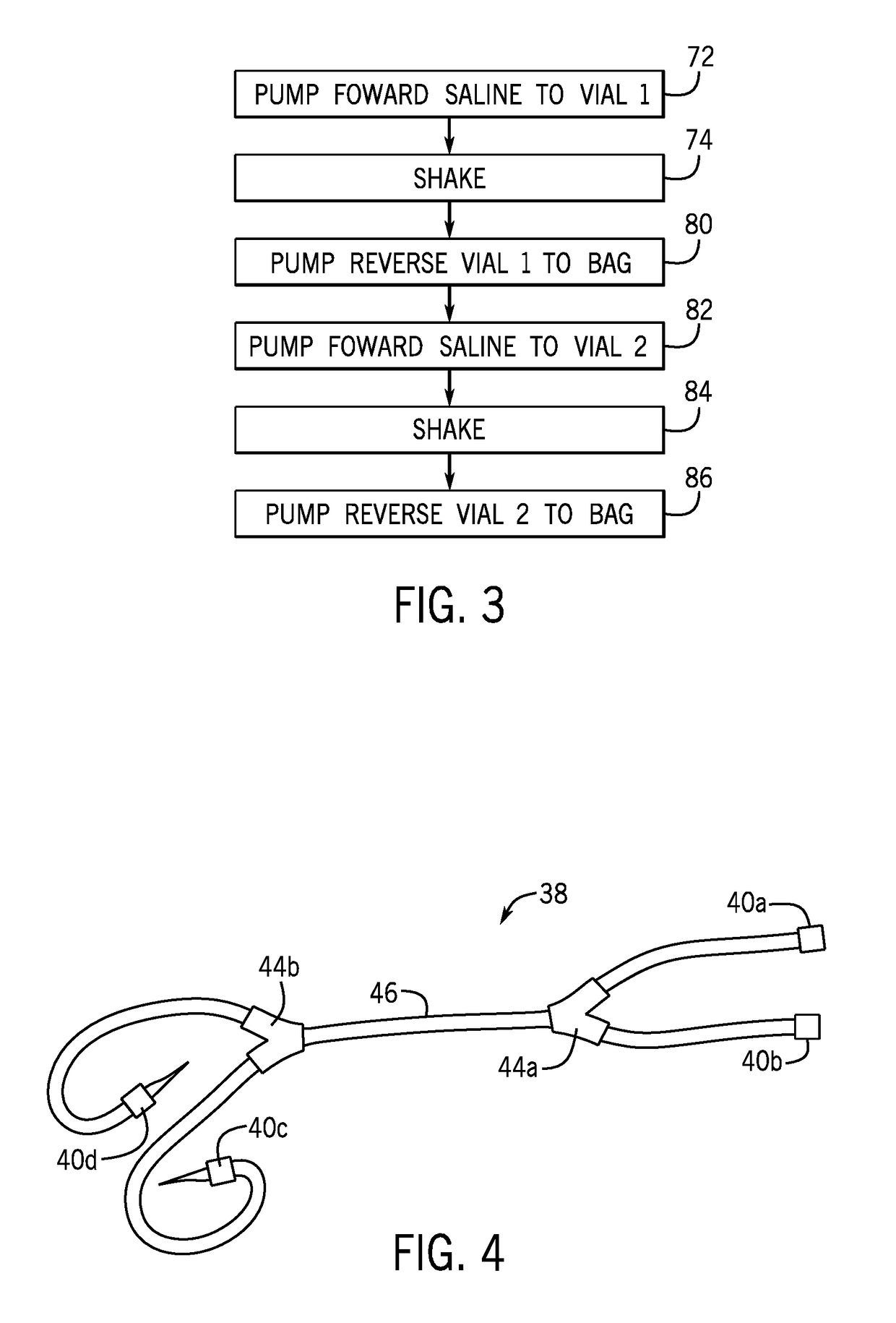

Isolatable Automatic Drug Compounding System

ActiveUS20180133667A1Minimizing chanceLow costShaking/oscillating/vibrating mixersMixing methodsOperational systemAdditive ingredient

A low-cost drug compounding system that can practically fit inside of a fume hood or the like is provided. The system can use a single pump operable in forward and reverse directions (or multiple pumps) to compound complex mixtures particularly including those requiring the creation of solutions from dry or powdered ingredients. A wireless link allows operation of the system remotely. In one embodiment, the system uses a disposable mixing tube set that can be discarded after mixing while still attached to the base ingredient containers used for the compounding thereby minimize the chance of personnel exposure.

Owner:ZYNO MEDICAL

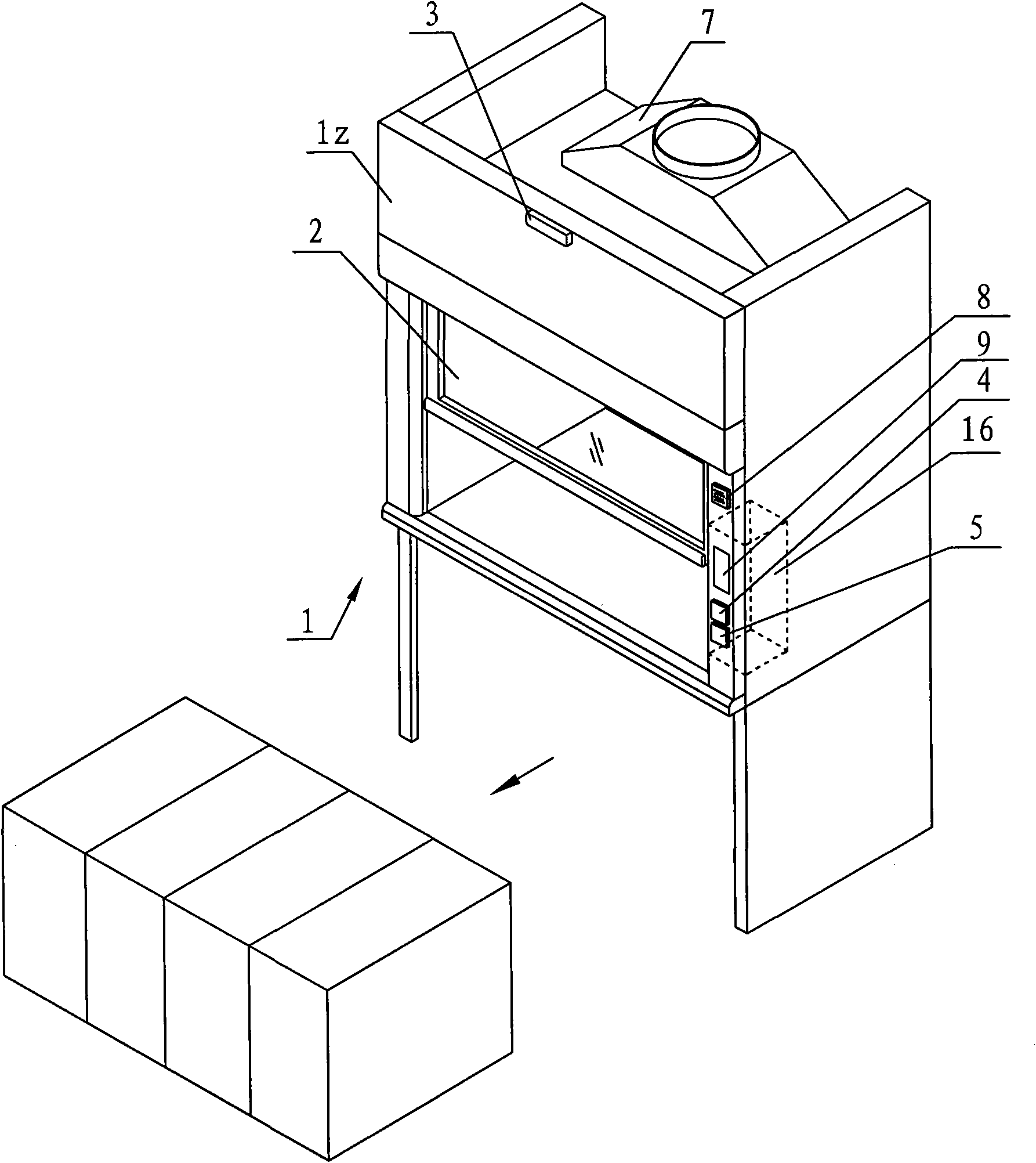

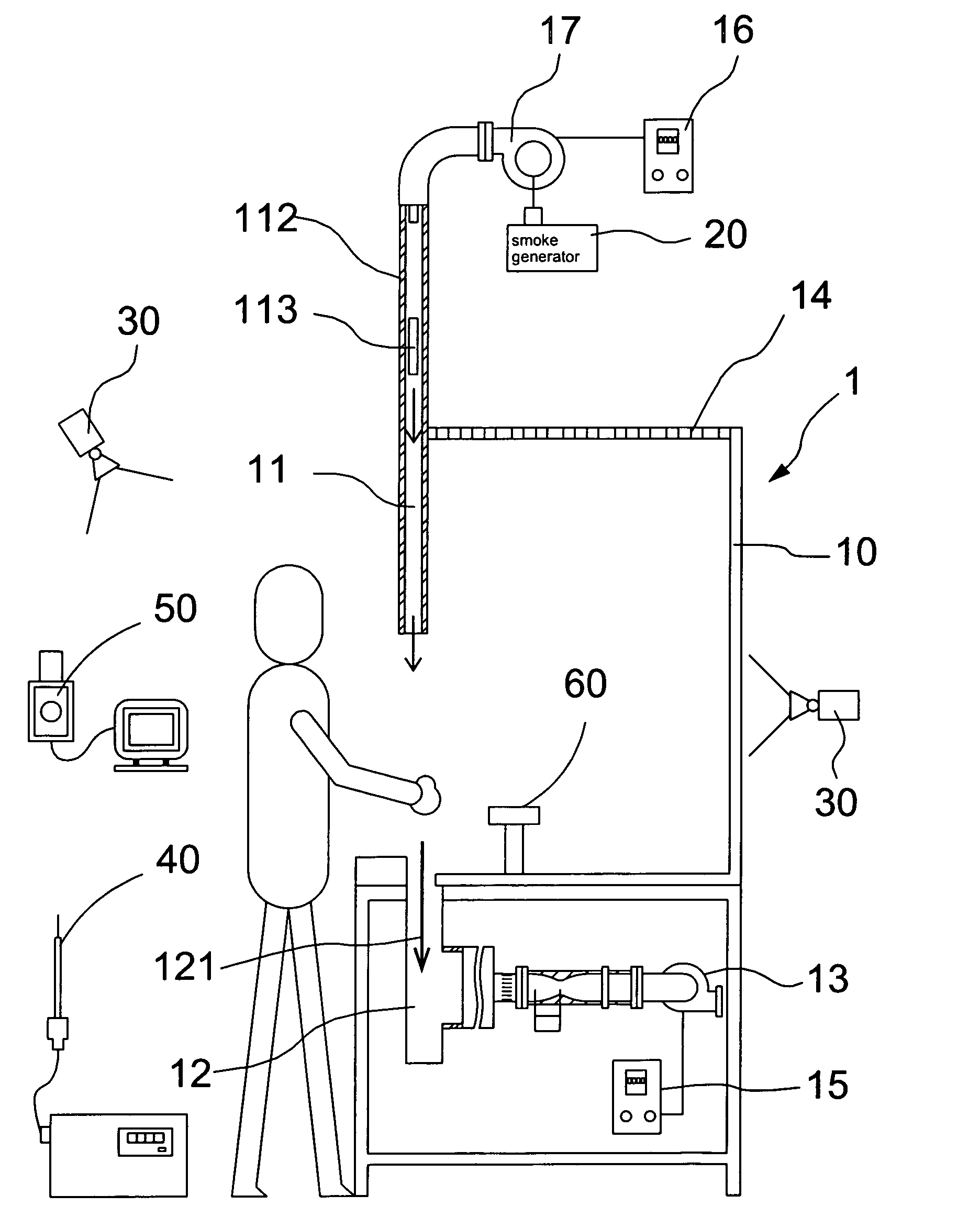

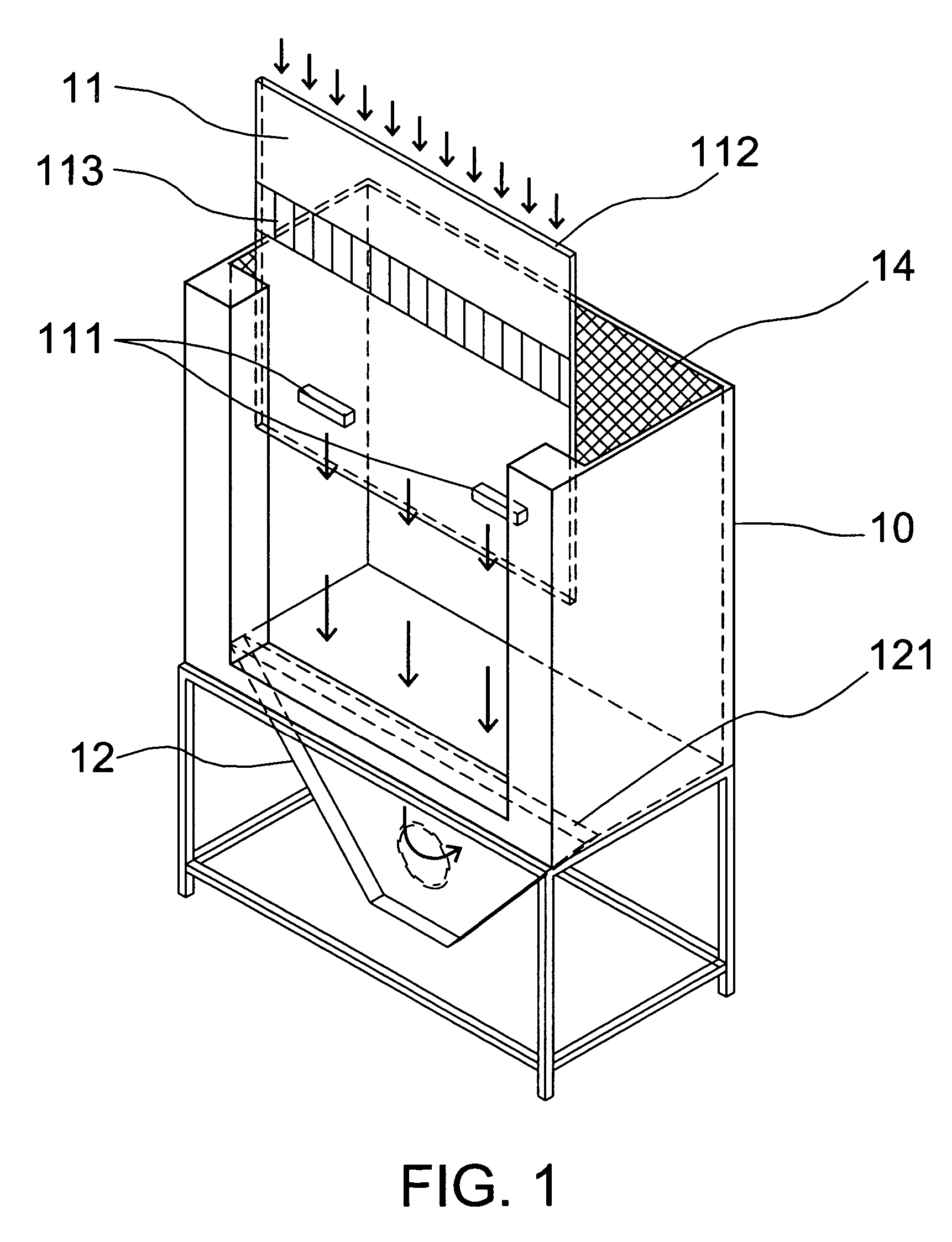

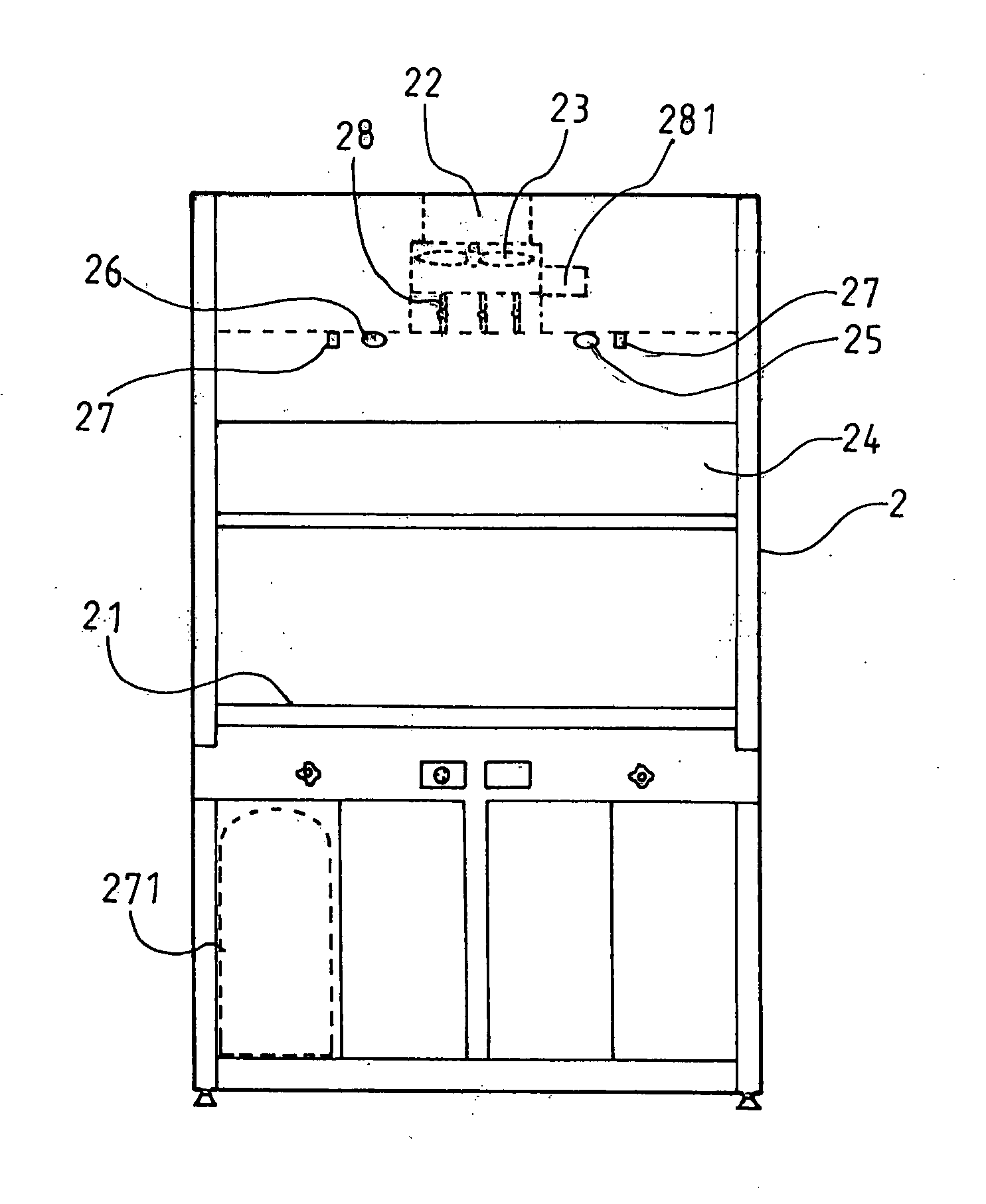

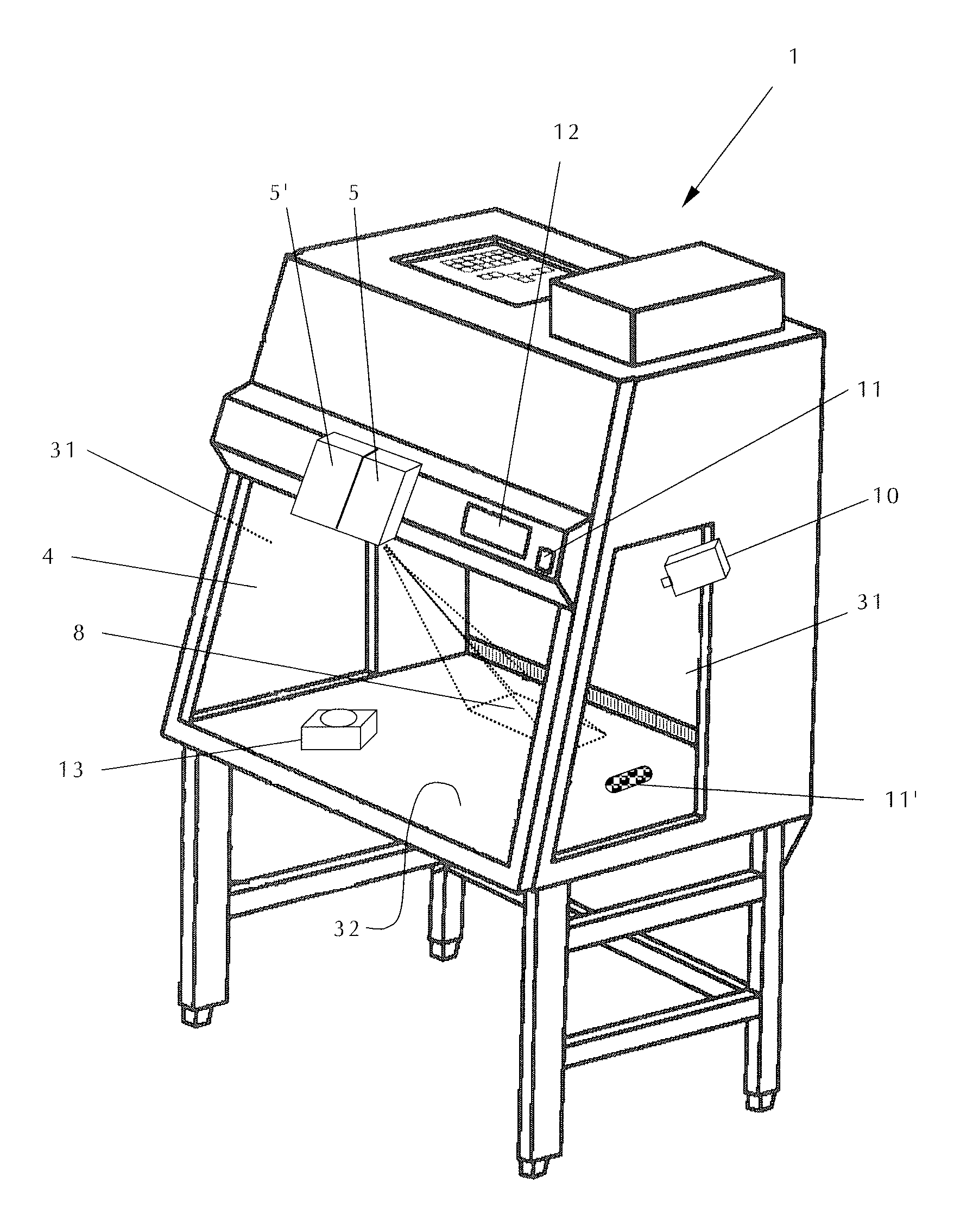

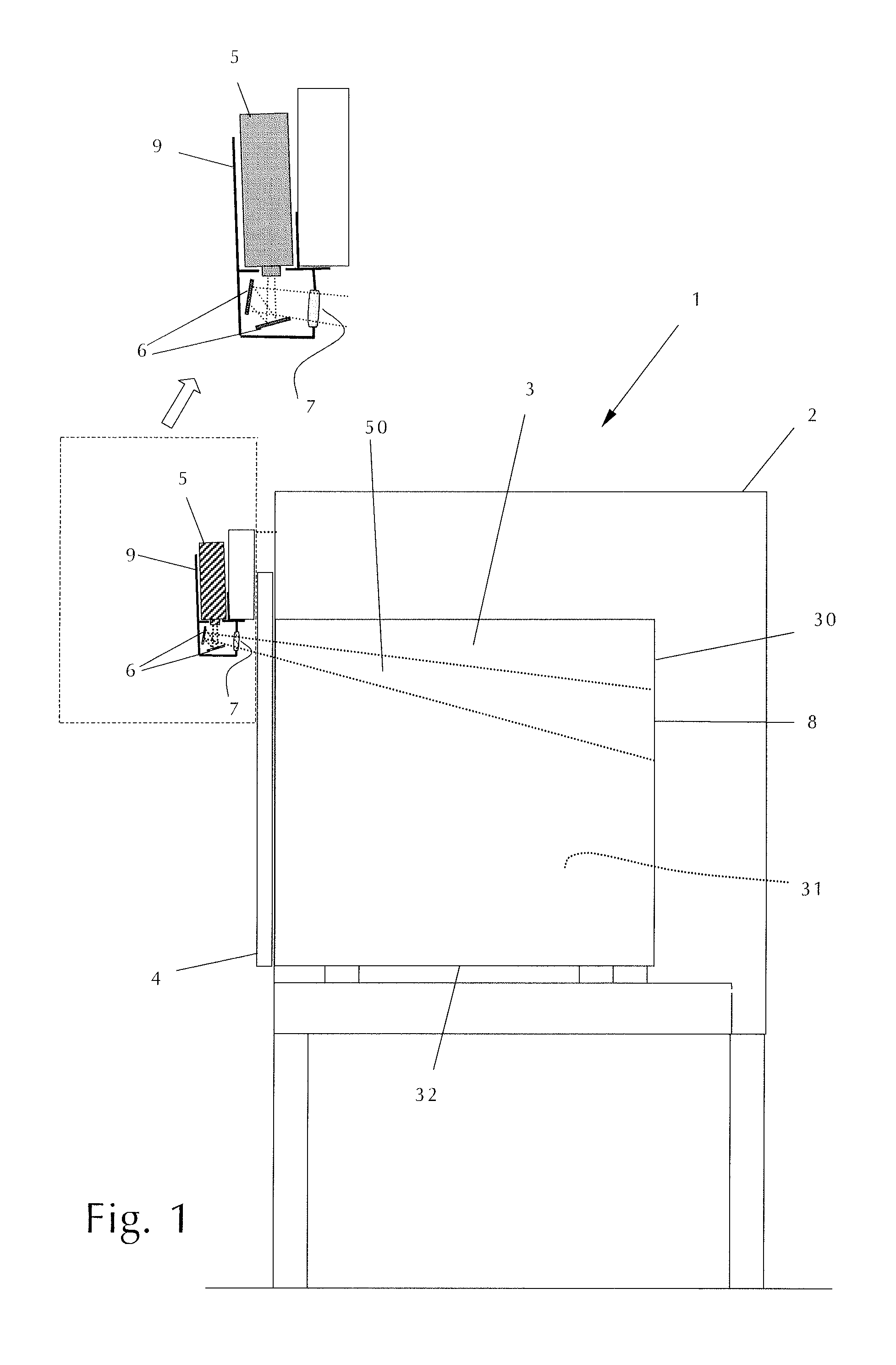

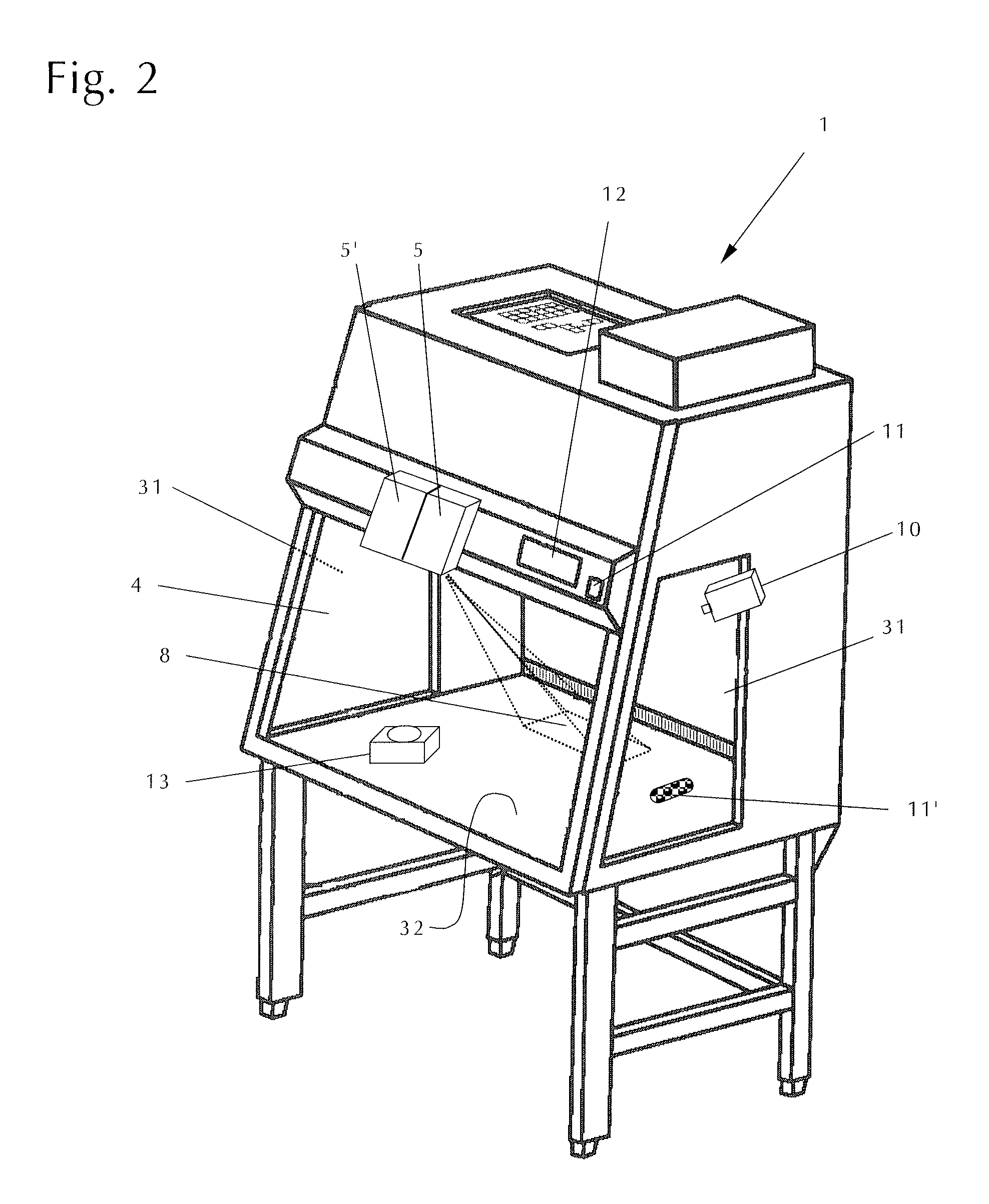

Laboratory Fume Hood With A Projection Apparatus

InactiveUS20130052927A1Avoiding impairment to air circulationEasy to cleanCombination devicesDomestic stoves or rangesEngineeringFume hood

The present invention relates to a laboratory fume hood, especially a safety cabinet, comprising a working space which is enclosed by a housing and which is closable by an especially movable front window. It comprises a projection apparatus in order to project an image into the working space.

Owner:THERMO ELECTRONICS LED GMBH

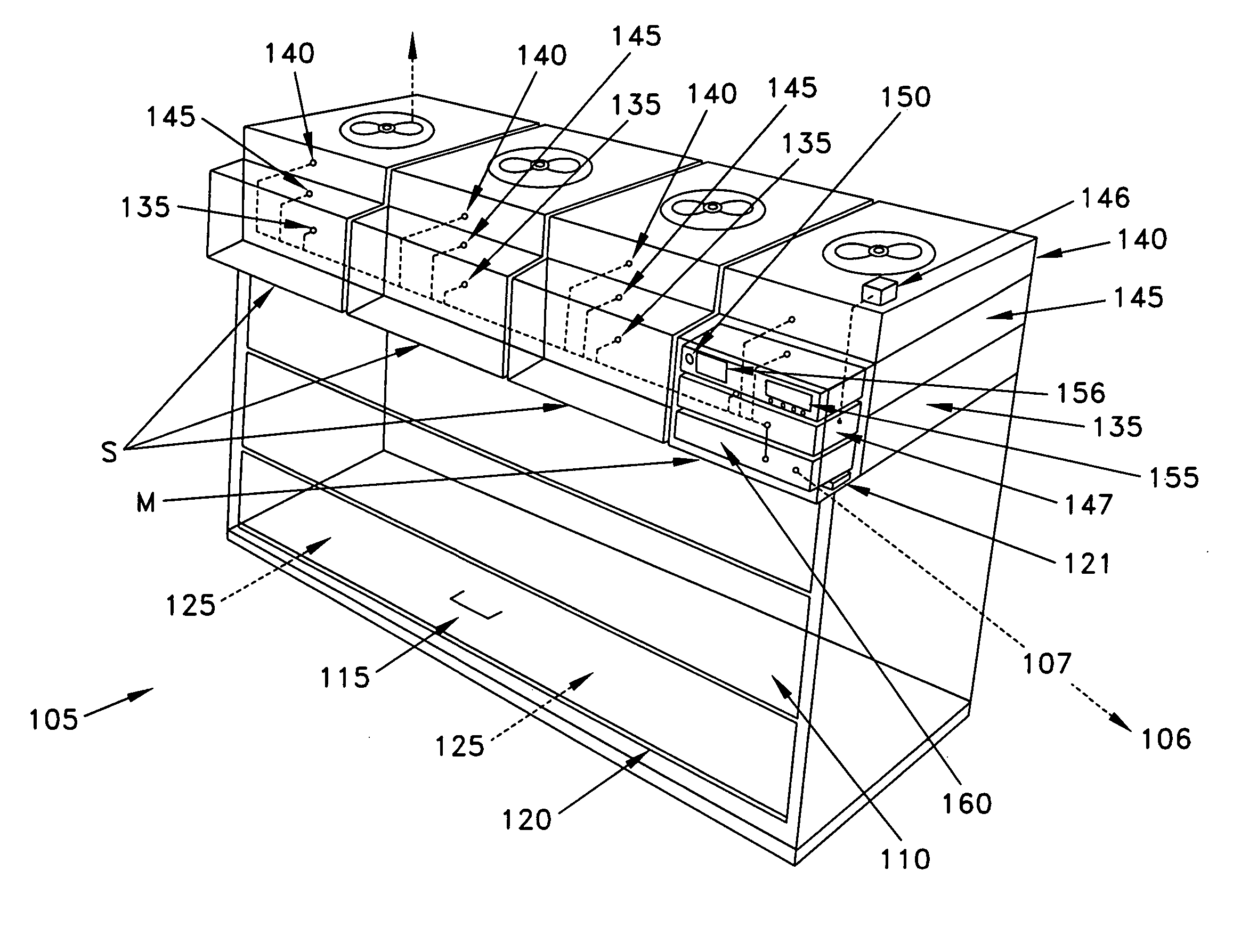

Ductless fumehood system

A ductless fumehood system comprising: at least one ductless fumehood comprising a housing; a workspace formed within the housing; a door for selectively closing off the workspace; an air inlet for introducing air into the workspace; a master module for receiving air from the workspace, purging unwanted substances from that air, and then exhausting that filtered air to the ambient room atmosphere; and a slave module for receiving air from the workspace, purging unwanted substances from that air, and then exhausting that filtered air to the ambient room atmosphere; wherein the slave module is in communication with the master module such that the master module central processing unit is capable of (i) controlling the operation of the active elements of the slave module, (ii) detecting a function failure of the slave module, and (iii) activating the master module alarm in the event of a failure within that slave module.

Owner:FIPAK RES & DEV

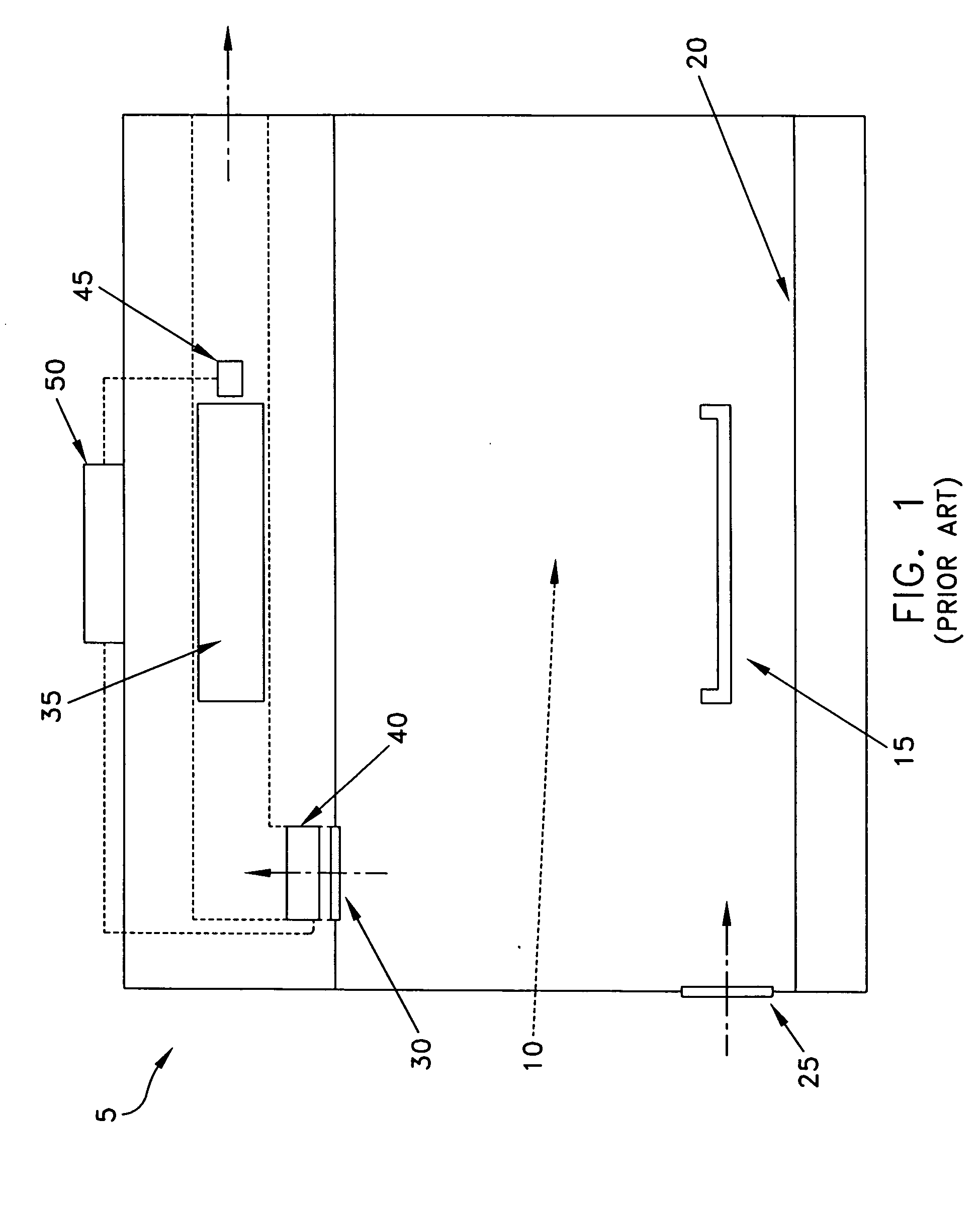

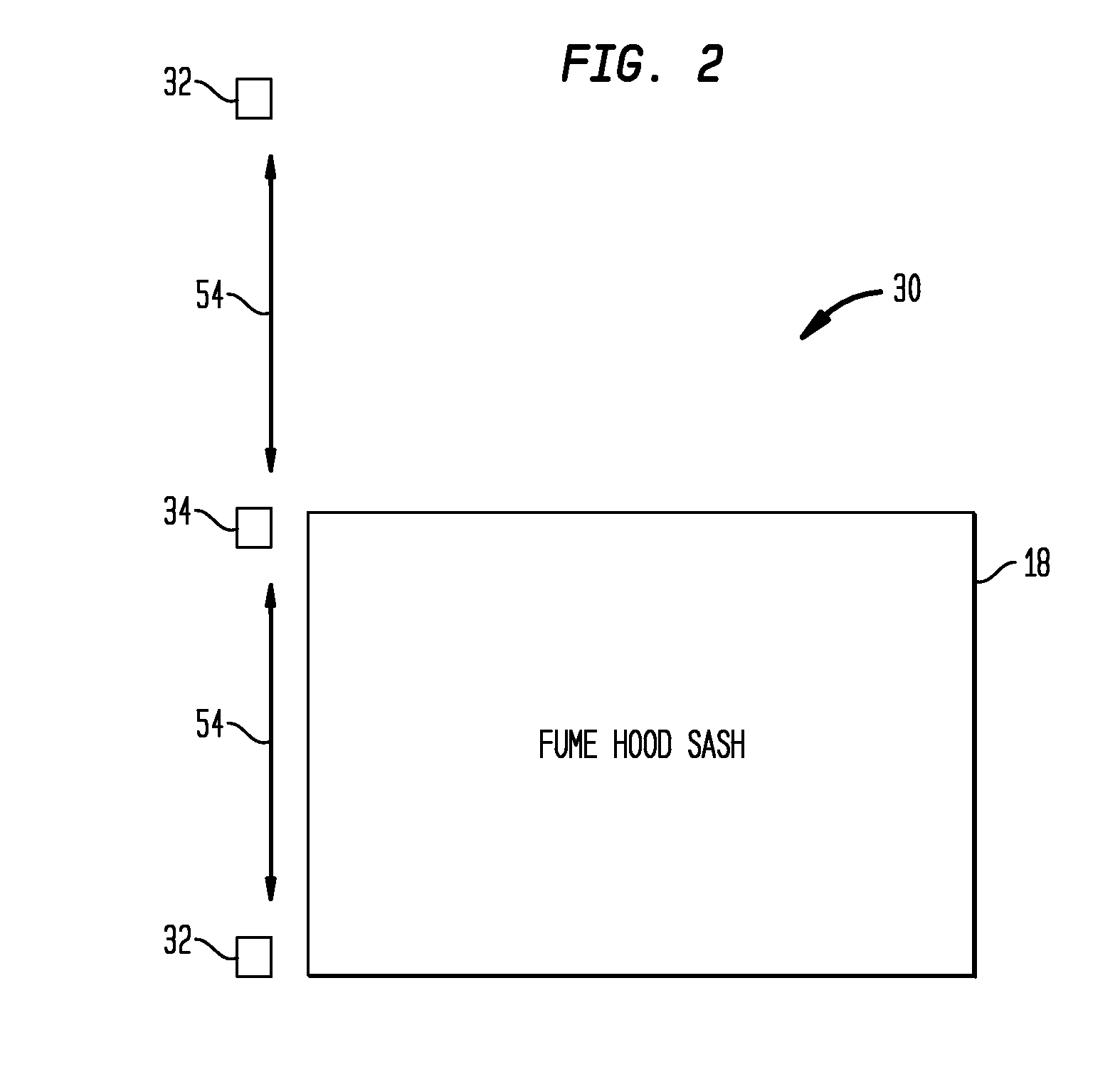

System for detecting a position of a fume hood sash

A method for determining a height of a sash opening formed by a movable sash in a fume hood. The method includes providing a laser device on the hood and providing a reflector on the sash. In addition, the method includes positioning the sash in an open position to form the sash opening and measuring a first distance between the laser device and the reflector when the sash is in the open position. The method also includes calculating the sash height based on the first distance.

Owner:SIEMENS IND INC

Air-isolator fume hood

InactiveUS20070021047A1Save energyExhaust fastDomestic stoves or rangesSpace heating and ventilation safety systemsEngineeringFume hood

Owner:INST OCCUPATIONAL SAFETY & HEALTH COUNCIL LABOR AFFAIRS EXECUTIVE YUAN

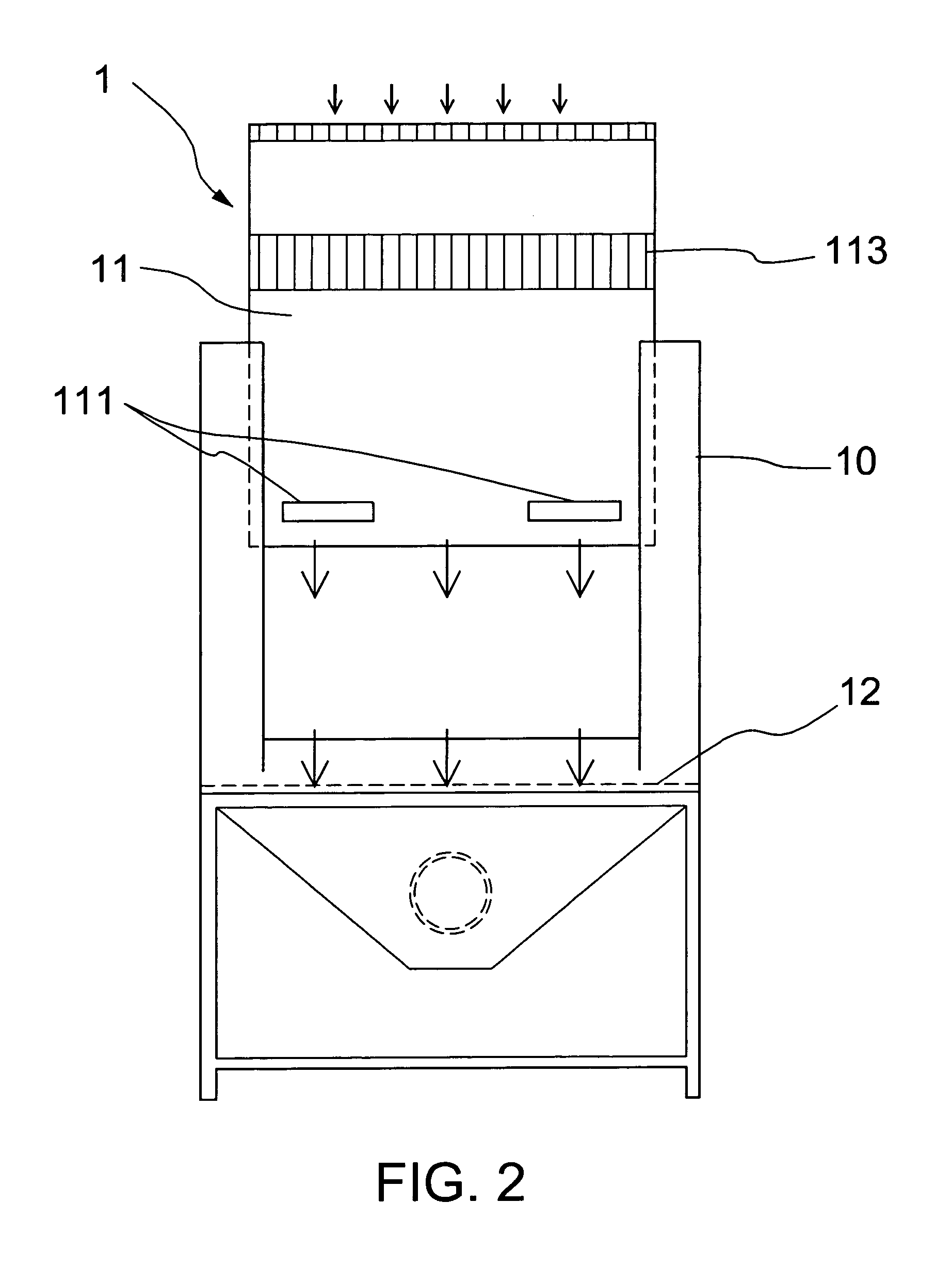

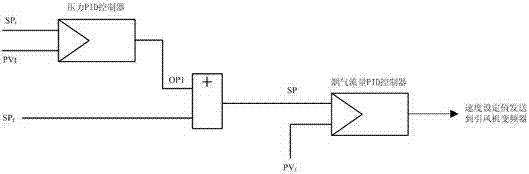

Control method of draught fan for dry dust removal of converter gas

InactiveCN102888488AEasy to trackHas non-linear characteristicsManufacturing convertersFrequency changerStart time

The invention provides a control method of a draught fan for dry dust removal of converter gas, which comprises the following steps: in a phase other than converter oxygen blowing, transmitting a rotation speed percentage set value to a draught fan frequency changer in a fume flow control mode; in a converter oxygen blowing phase, setting an oxygen blowing start time; and when the oxygen blowing time exceeds the oxygen blowing start time, using a pressure PID (proportional-integral-derivative) controller and a fume flow PID controller in a cascade control mode combining fume flow control and converter mouth fume hood micro-differential pressure control, wherein the output quantity of the pressure PID controller is used for compensating for the set value of the fume flow PID controller, and the output value of the fume flow PID controller is used for controlling the rotation speed of the draught fan frequency changer. The method enables the draught fan to be in a good working state, ensures the recovery quantity of converter gas and ensures that the draught fan for dry dust removal of converter gas has high dynamic response, high tracking accuracy and favorable stability.

Owner:丰镇新枫冶金有限公司

Ventilation cabinet

ActiveCN107497815APrevent overflowEliminate potential safety hazardsDirt cleaningFume hoodMechanical engineering

Owner:E3 GREEN TECH CO LTD

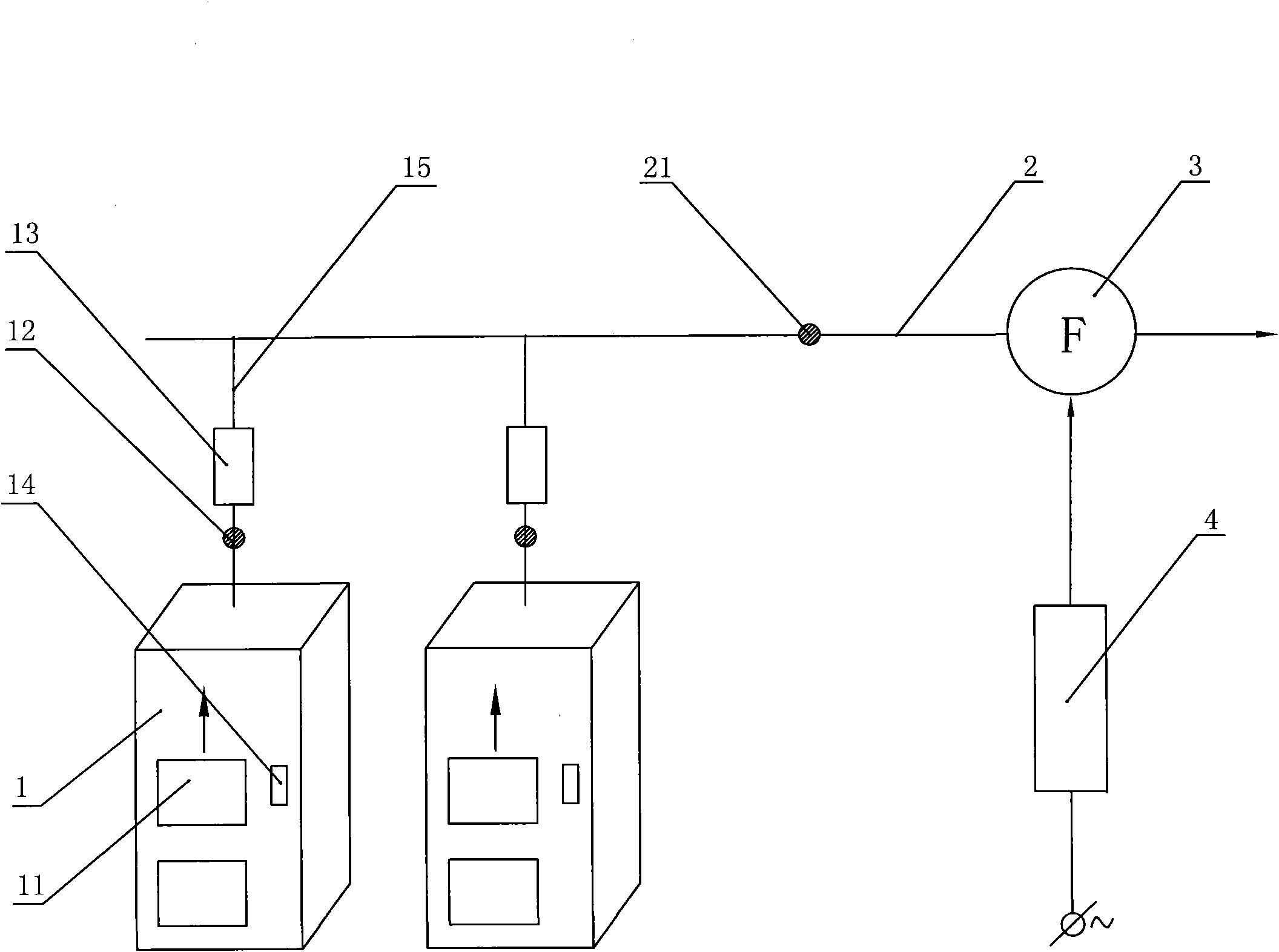

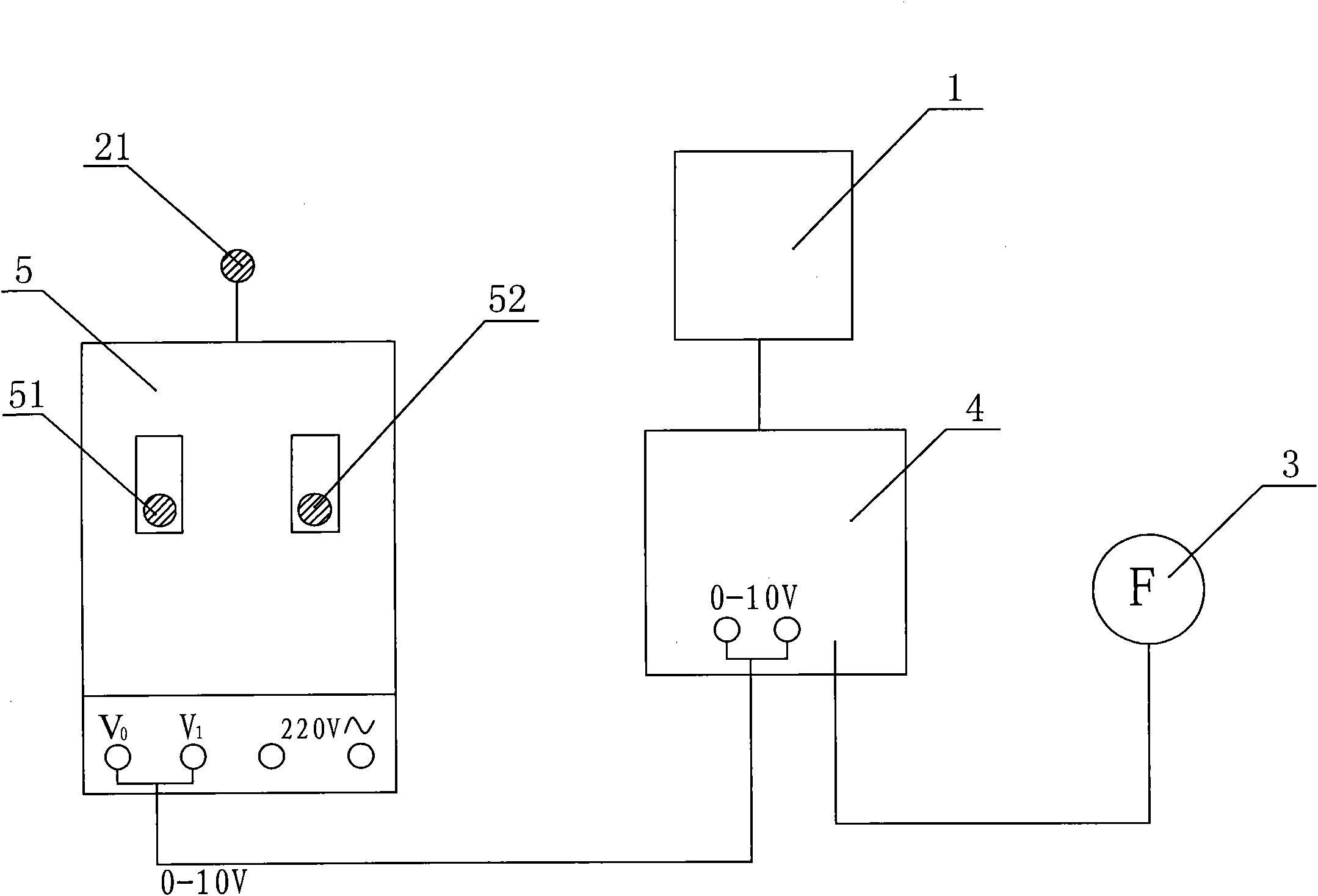

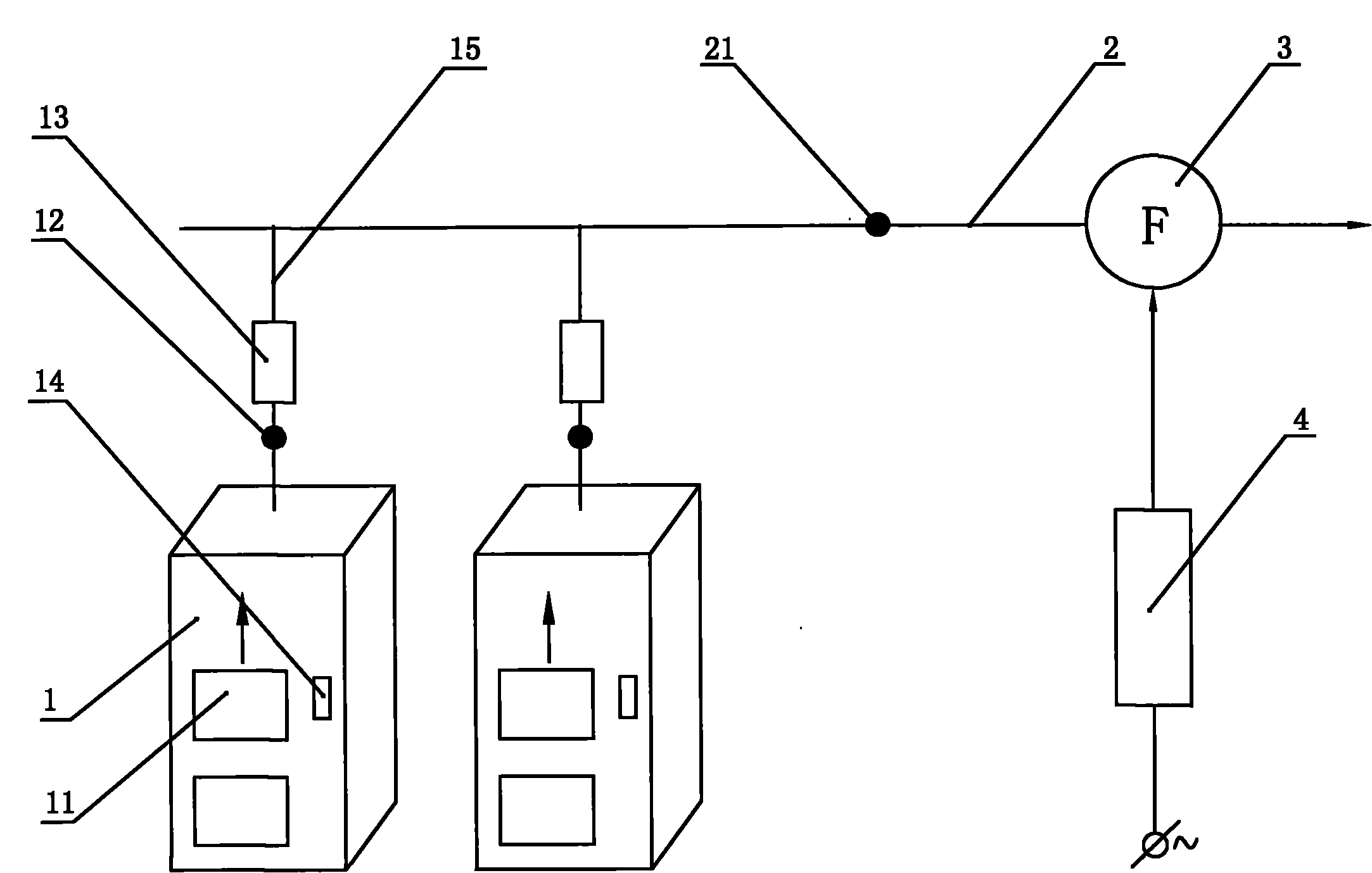

Multi-ventilated-case cooperating exhaust control system

The invention relates to a multi-ventilated-case cooperating exhaust control system which comprises an exhaust fan and more than two ventilated cases, wherein the exhaust fan is arranged on a main ventilation pipeline, and the more than two ventilated cases are communicated with the main ventilation pipeline. The invention is characterized in that a first differential pressure sensor is arranged in front of an inlet of the exhaust fan, a wind pressure signal in the main ventilation pipeline is transferred to a first signal modulator by the first differential pressure sensor, a modulation signal is transferred to a frequency changer by the first signal modulator, and the exhaust fan is dragged by the frequency changer. The invention not only can realize the control for the gas speed in the pipeline and the exhaust flow speed of the ventilated cases, but also has the advantage of reliable and accurate control and saves the energy consumption of the fan through a method for detecting the air pressure in the ventilation pipeline and by automatically controlling the rotating speed of the fan after signal modulation. The invention can be used in a multi-ventilated-case cooperating laboratory exhaust system.

Owner:广东科艺普实验室设备研制有限公司

Method and apparatus for alarm verification in a ventilation system

InactiveUS6914532B2Mechanical apparatusSpace heating and ventilation safety systemsTraffic capacityEngineering

Method and apparatus for testing the operation of an alarm for a ventilated enclosure, such as a fume hood or bio-safety cabinet. Flow of gas being exhausted from the enclosure may be adjusted to a known value below or above a threshold value at which the alarm provides an indication that flow is unacceptably low or high. Adjustment of flow to the known value may be performed without requiring a manual measurement of flow, e.g., by performing a traverse in a duct leading from the enclosure.

Owner:PHOENIX CONTROLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com