Patents

Literature

411results about How to "Improve reuse efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

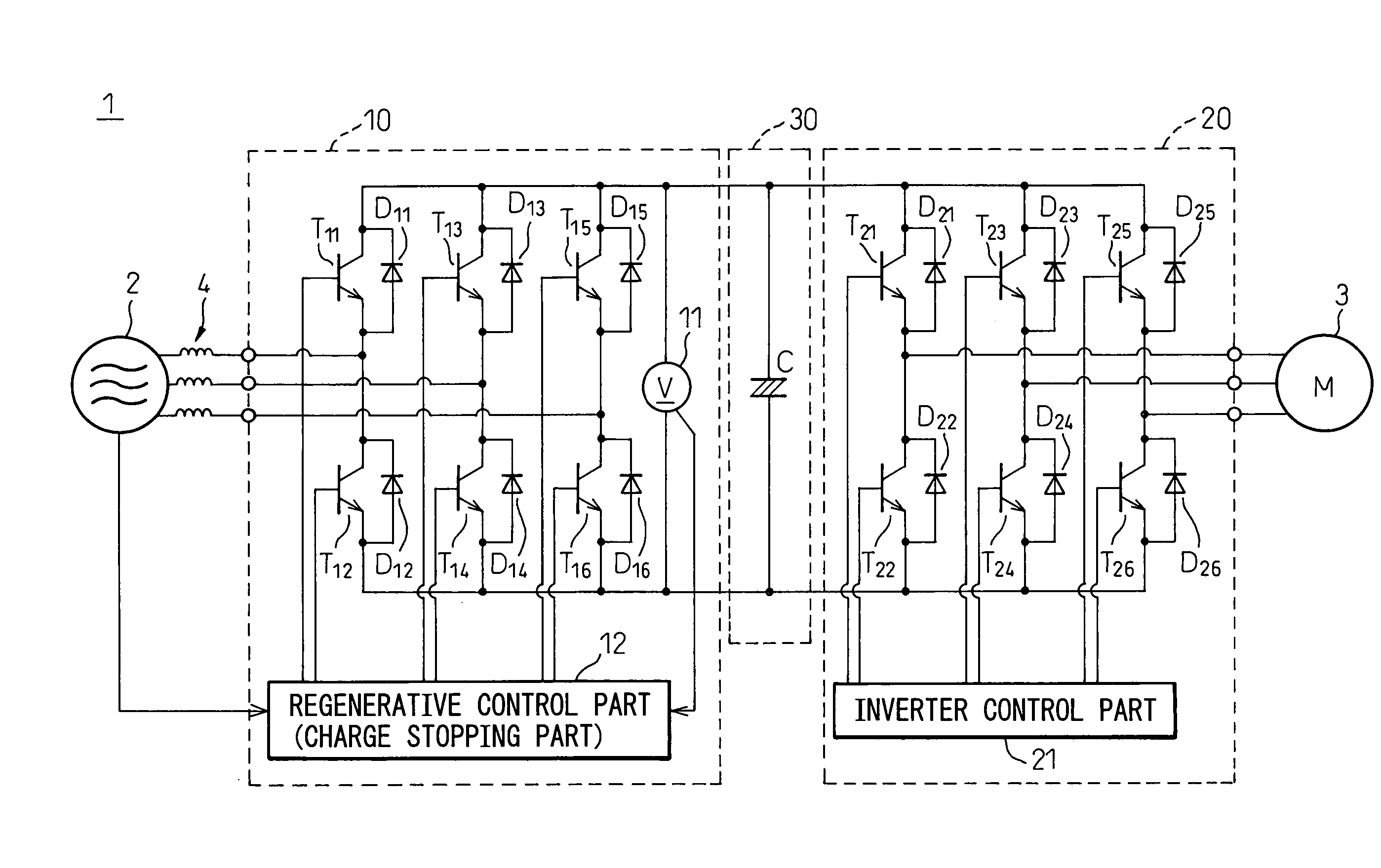

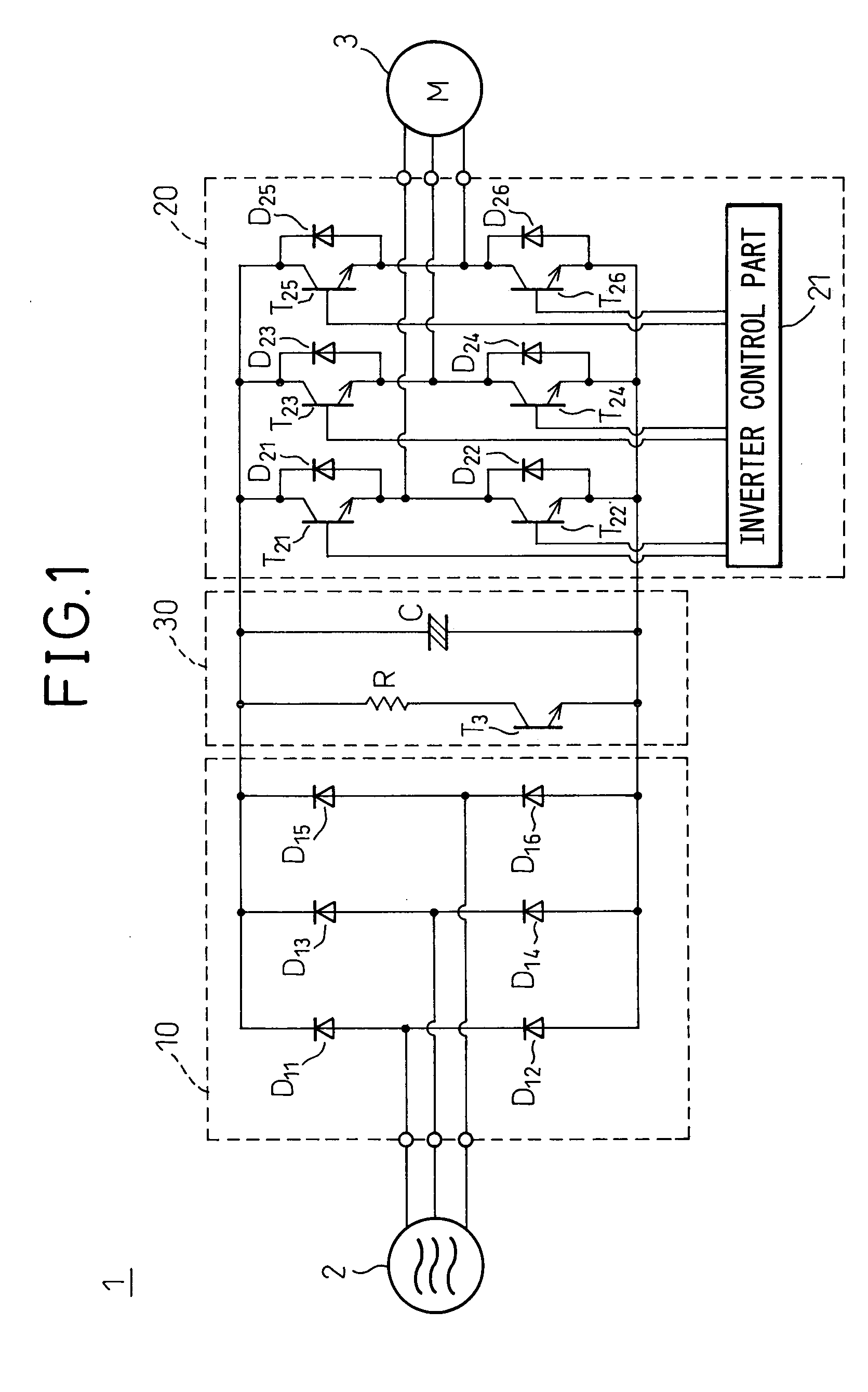

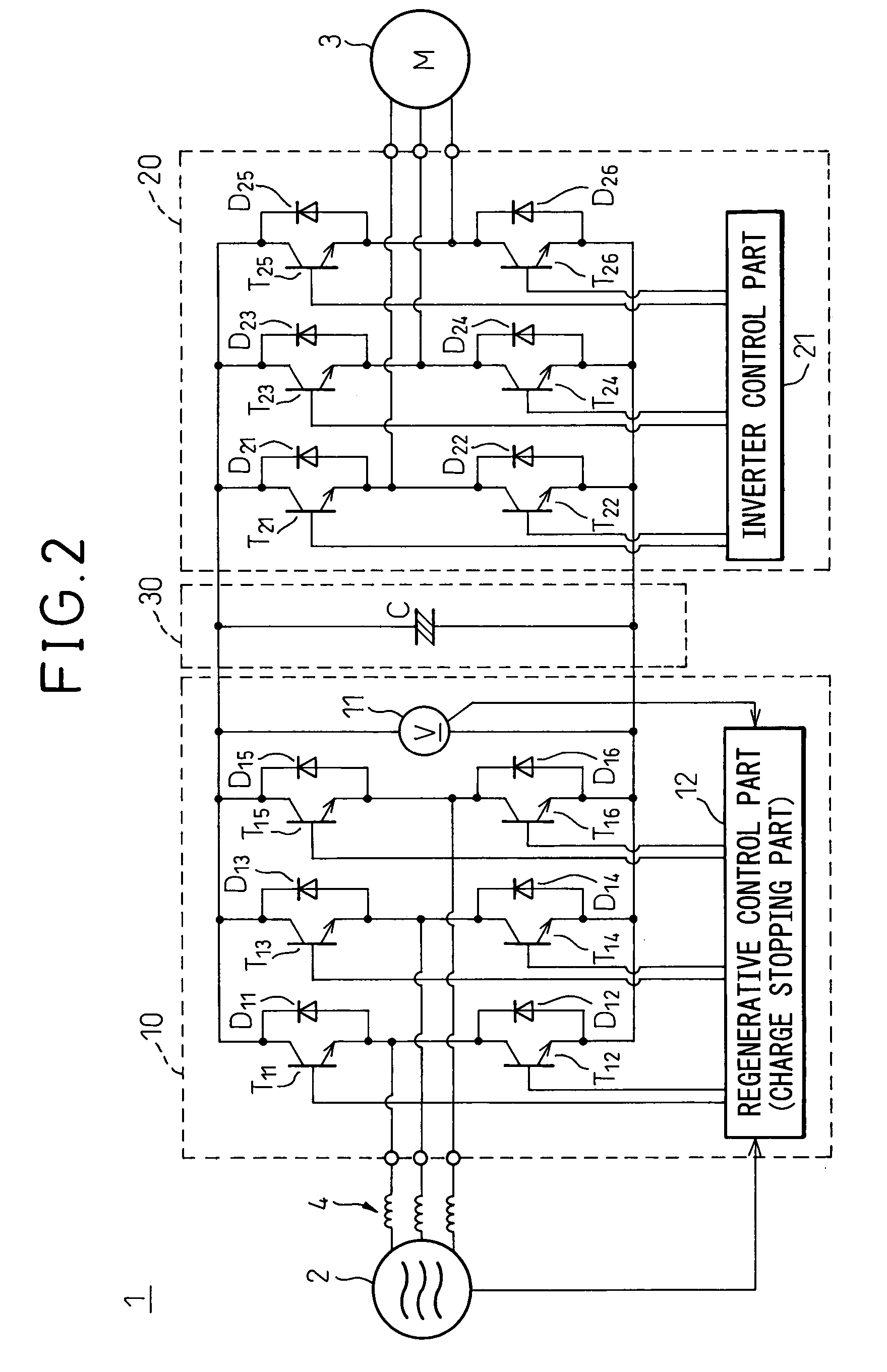

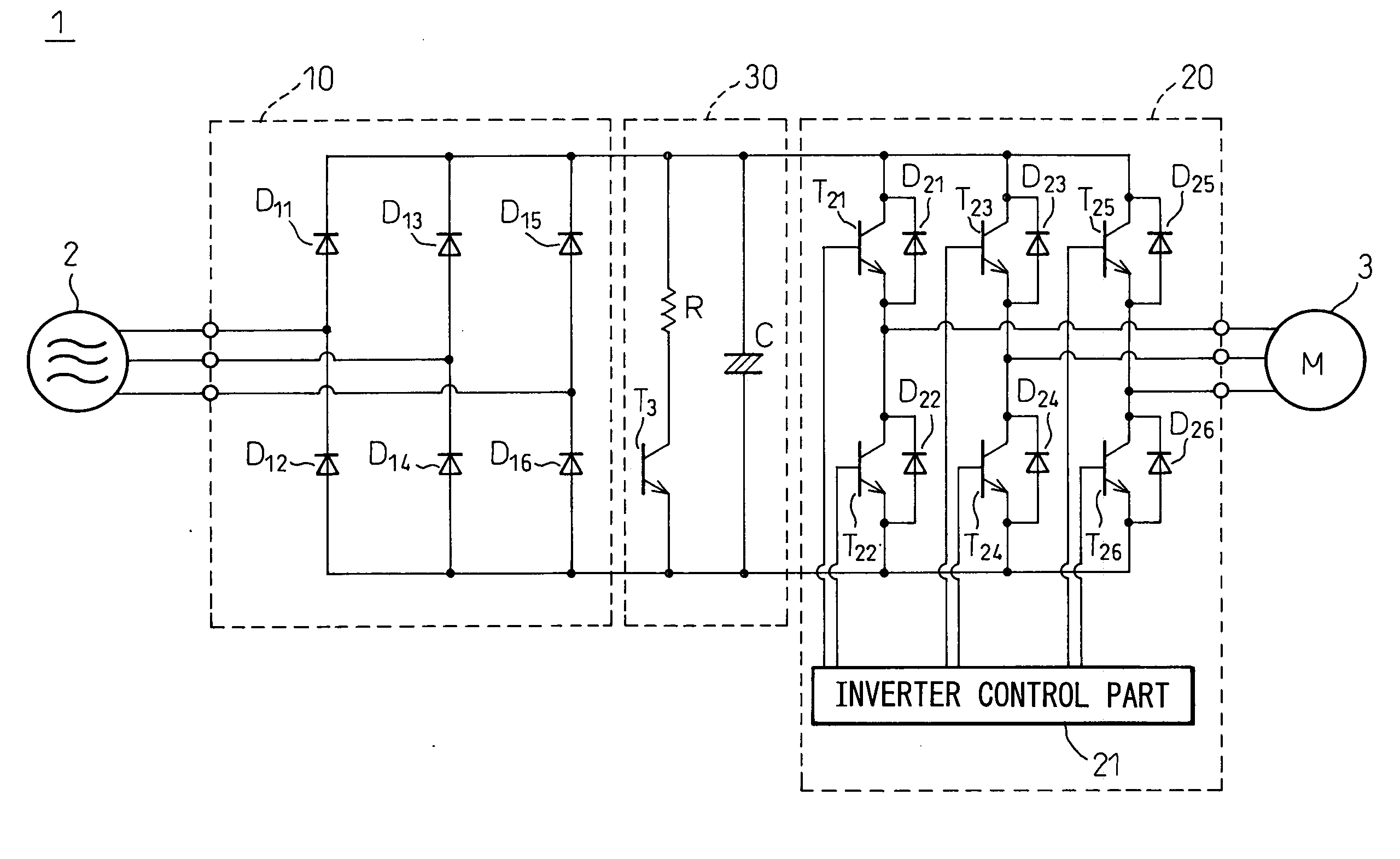

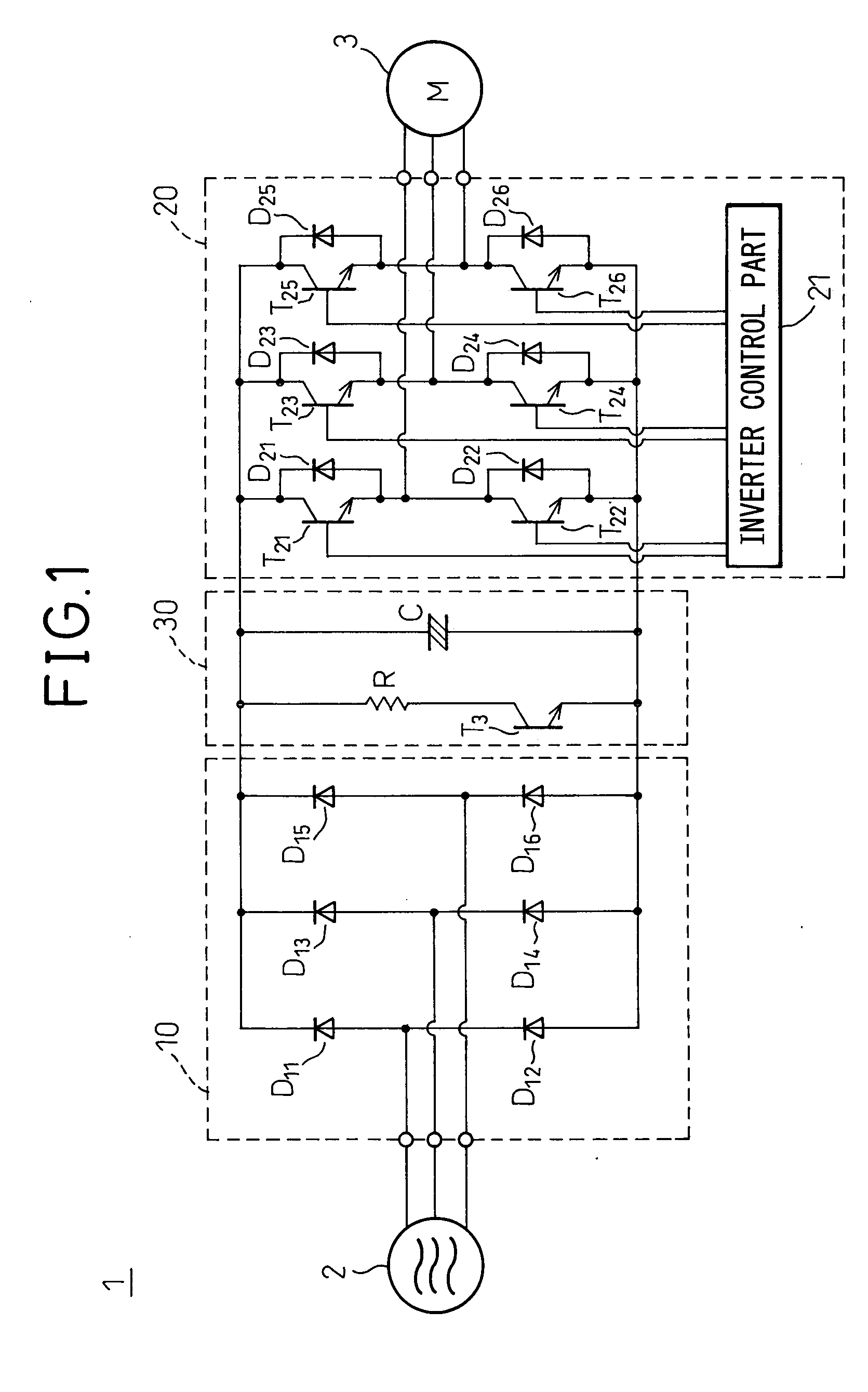

Converter apparatus, inverter apparatus, and DC link voltage control method

ActiveUS7135835B2High energyImprove charging capacityBatteries circuit arrangementsVector control systemsEngineeringDc link voltage

The invention is directed to the provision of a converter apparatus, an inverter apparatus, and a DC link voltage control method, wherein the upper limit value of the DC link voltage that rises due to regenerative energy occurring from a motor is set high, thereby increasing the regenerative energy to be stored in a DC link. The converter apparatus (10) comprises: a voltage detection part (11) for monitoring the DC link voltage occurring across the DC link (30); and a charge stopping part (12) for stopping charging a power storage part (C) when the detected value of the DC link voltage exceeds a predetermined upper limit voltage as the motor (3) is decelerated.

Owner:FANUC LTD

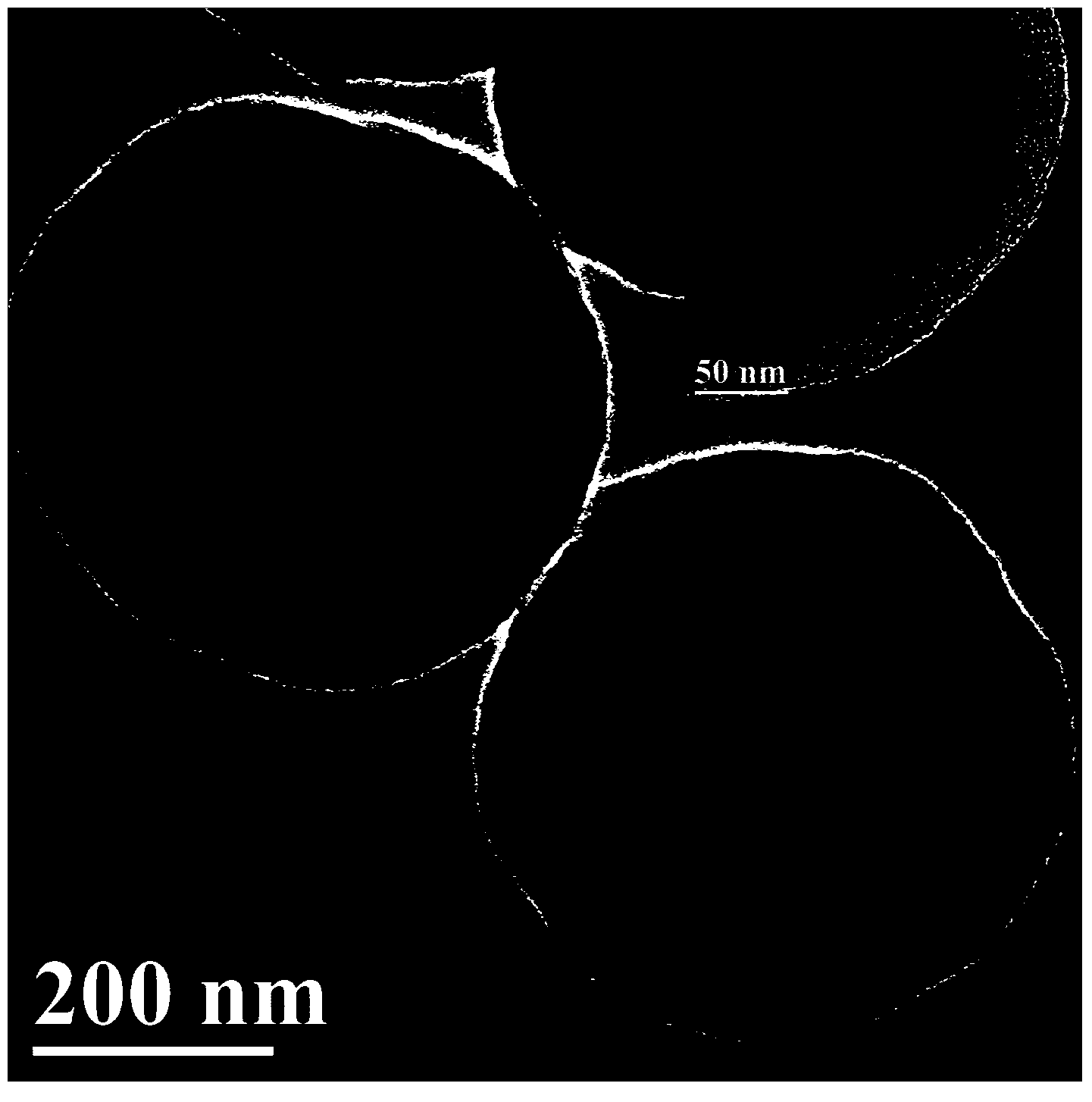

Magnetic zeolite imidazate metal organic skeletal material, preparation thereof and application to liquid phase condensation catalytic reaction

InactiveCN103638979APromote rapid formationShorten the timeCarboxylic acid nitrile preparationOrganic compound preparationMetal-organic frameworkSuperparamagnetism

The invention provides a magnetic zeolite imidazate metal organic skeletal material, preparation thereof and application to liquid phase condensation catalytic reaction, and the invention belongs to the field of magnetic zeolite imidazate metal organic skeletal material technology. The invention employs FeCl3.6H2O to prepare Fe3O4 core with superparamagnetism, and cetyl trimethyl ammonium bromide is used as a template, and sodium silicate is used as silicon source of SiO2 casing layer, and a SiO2 casing layer with meso pores is formed on Fe3O4 using supersonic wave, and template is roasted and removed under N2 after drying, and magnetic SiO2@Fe3O4 nanospheres are prepared. imidazate metal organic skeletal structure is formed on surface of magnetic core SiO2@Fe3O4 with Zn or Co metal ions and 2-methylimidazole or benzimidazole ligand by in-situ self assembly using supersonic wave, and the magnetic ZIFs@SiO2@Fe3O4 material is obtained. The ZIF material is used for liquid phase condensation reaction catalysis.

Owner:BEIJING UNIV OF CHEM TECH

Metal-organic framework materials with magnetic cores and preparation and application thereof

InactiveCN103521269APromote rapid formationShorten the timeMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMetal-organic framework

The invention provides metal-organic framework materials with magnetic cores and preparation and application thereof, and belongs to the technical field of magnetic metal-organic framework materials. FeCl3 6H2O is adopted for preparing superparamagnetic Fe3O4 cores, cetyl trimethyl ammonium bromide is used as a template agent, sodium silicate is used as silicon sources of SiO2 shell layers, mesoporous SiO2 shell layers are formed on the surfaces of the Fe3O4 cores by adopting an ultrasonic wave method, the template agent is removed by roasting under protection of N2 after drying, and magnetic SiO2@Fe3O4 nanospheres are prepared. The SiO2@Fe3O4 nanospheres are used as cores, an in-situ self-assembly mesh structure IRMOFs is carried out on the surfaces of the SiO2@Fe3O4 cores through Zn metal ions and organic carboxylic acid ligands by adopting the ultrasonic wave method. The novel MOFs materials can be used as catalysts of liquid phase catalysis reaction, and also have application values in the aspects of adsorption, separation, biological medicine and the like.

Owner:BEIJING UNIV OF CHEM TECH

Loaded nano-copper magnetic catalyst used for catalysis of solution of formaldehyde for preparing hydrogen and preparation method thereof

InactiveCN101862656AHigh activityImprove reuse efficiencyCatalyst carriersHydrogenHydrazine compoundFORMALDEHYDE SOLUTION

The invention relates to a loaded nano-copper magnetic catalyst used for catalytic conversion of aqueous solution of formaldehyde for preparing hydrogen and a preparation method thereof. The method comprises the following steps of: preparing magnetic Fe3O4 from low-cost FeCl2.4H2O and FeCl3.6H2O; coating a layer of SiO2 on the surface of the Fe3O4 to prepare a magnetic Fe3O4@SiO2 catalyst carrier; dispersing the magnetic Fe3O4@SiO2 in a copper ammonia complex; and reducing the dispersed substance by using a hydrazine hydrate to obtain a Cu / Fe3O4@SiO2 magnetic catalyst having a nano-scale Cu active ingredient. High-purity hydrogen can be obtained under a room temperature condition by applying the Cu / Fe3O4@SiO2 magnetic catalyst to the catalytic reaction of the solution of formaldehyde for preparing hydrogen and the separation of the catalyst from reactants can be realized easily by adding a magnetic field outside. Simultaneously, the catalyst can be reused repeatedly.

Owner:BEIJING UNIV OF CHEM TECH

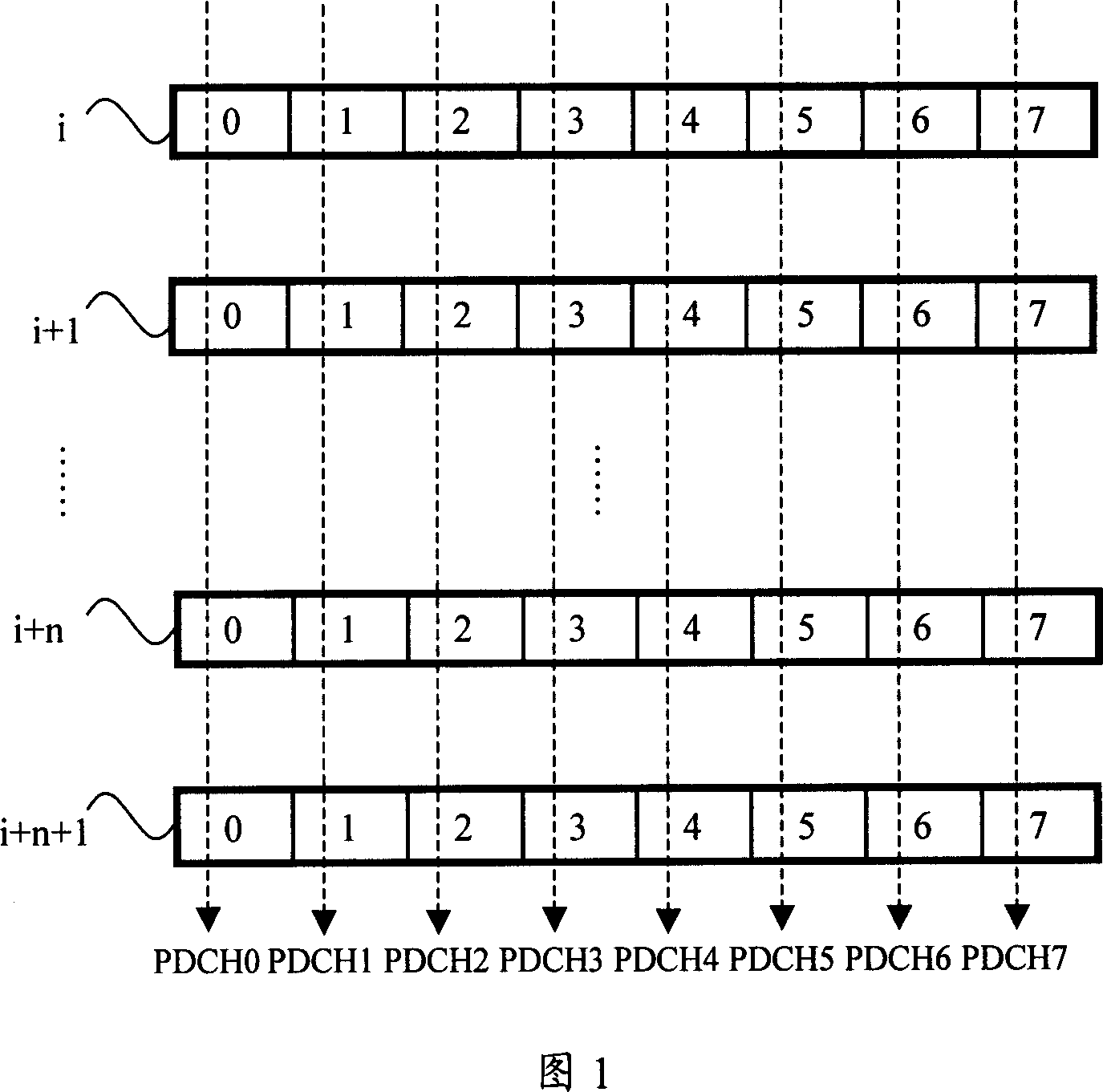

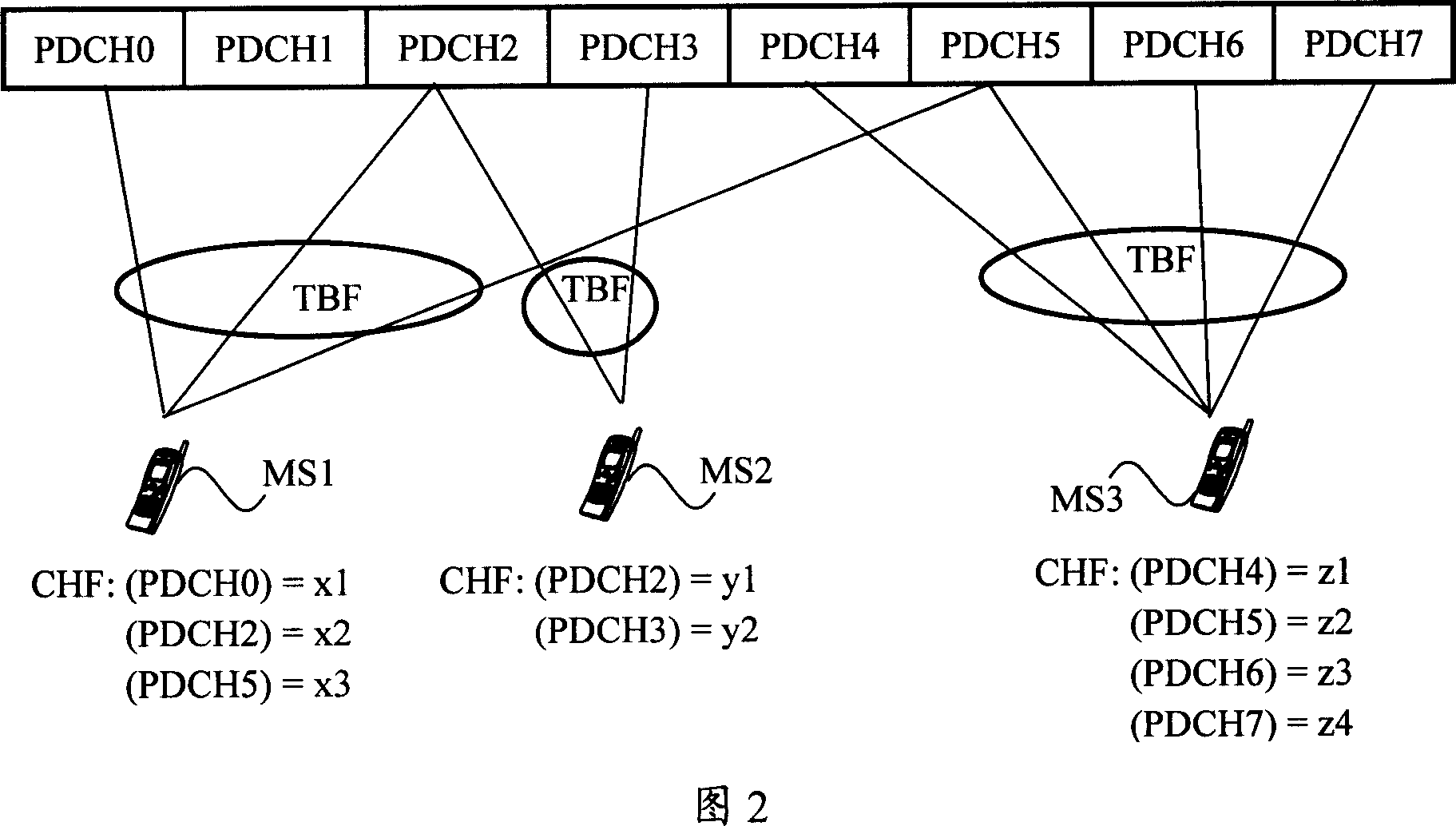

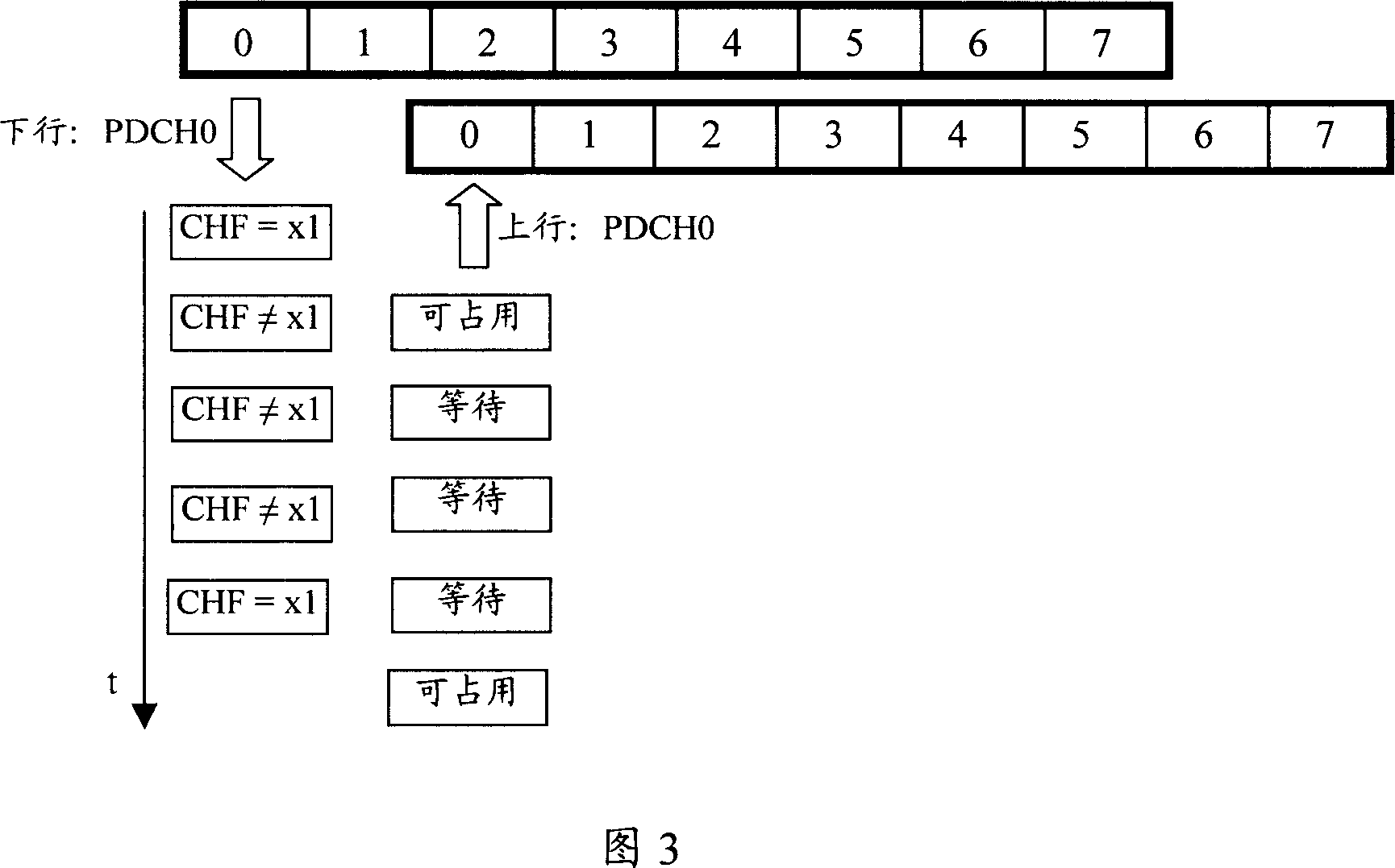

Distribution method of uplink block data channel and data transmitting method

ActiveCN101047426ASolve wasteImprove reuse efficiencyRadio transmission for post communicationData switching networksTelecommunicationsDistribution method

A method for distributing uplink packet data channel includes making expansion on USF controlling distribution of uplink channel and furthermore adding time slot distribution identification for distributing time slot at specified time interval on USF and utilizing added time slot identification to distribute different time slot in the same time interval of the same PDCH different user for service.

Owner:HUAWEI TECH CO LTD

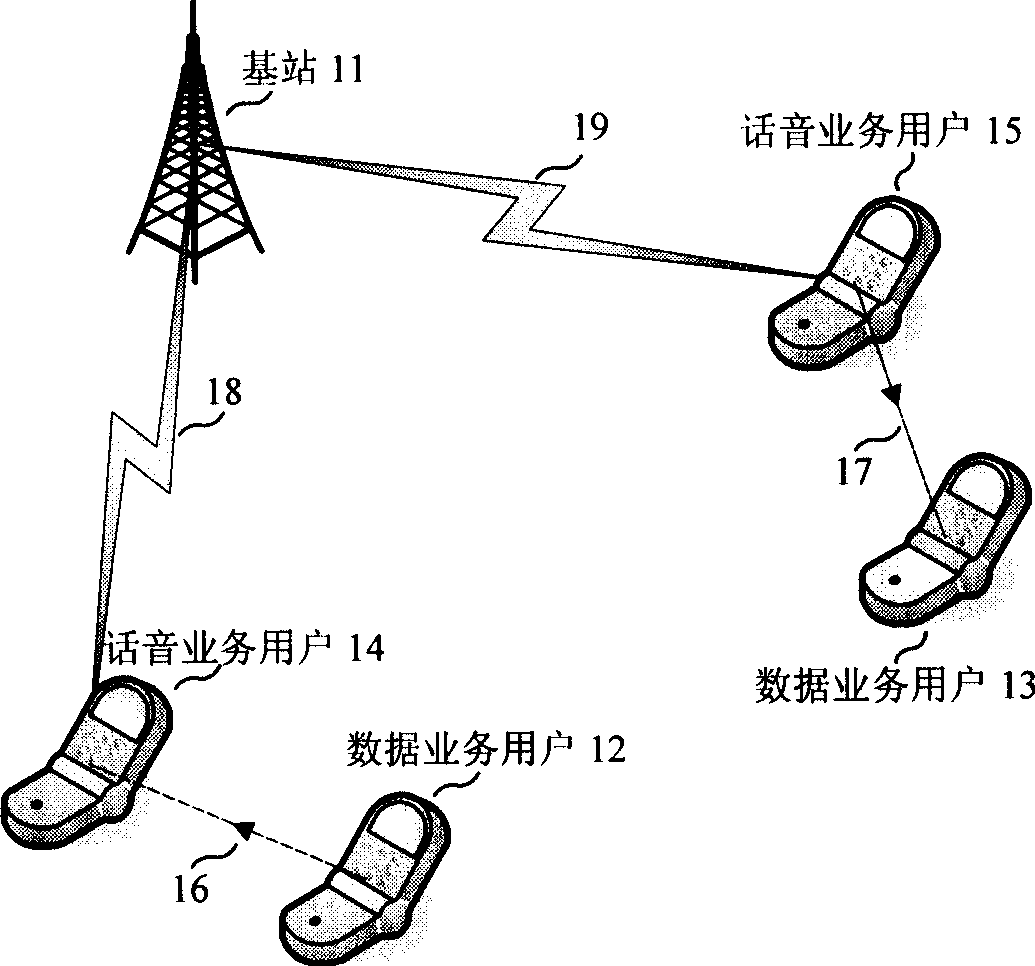

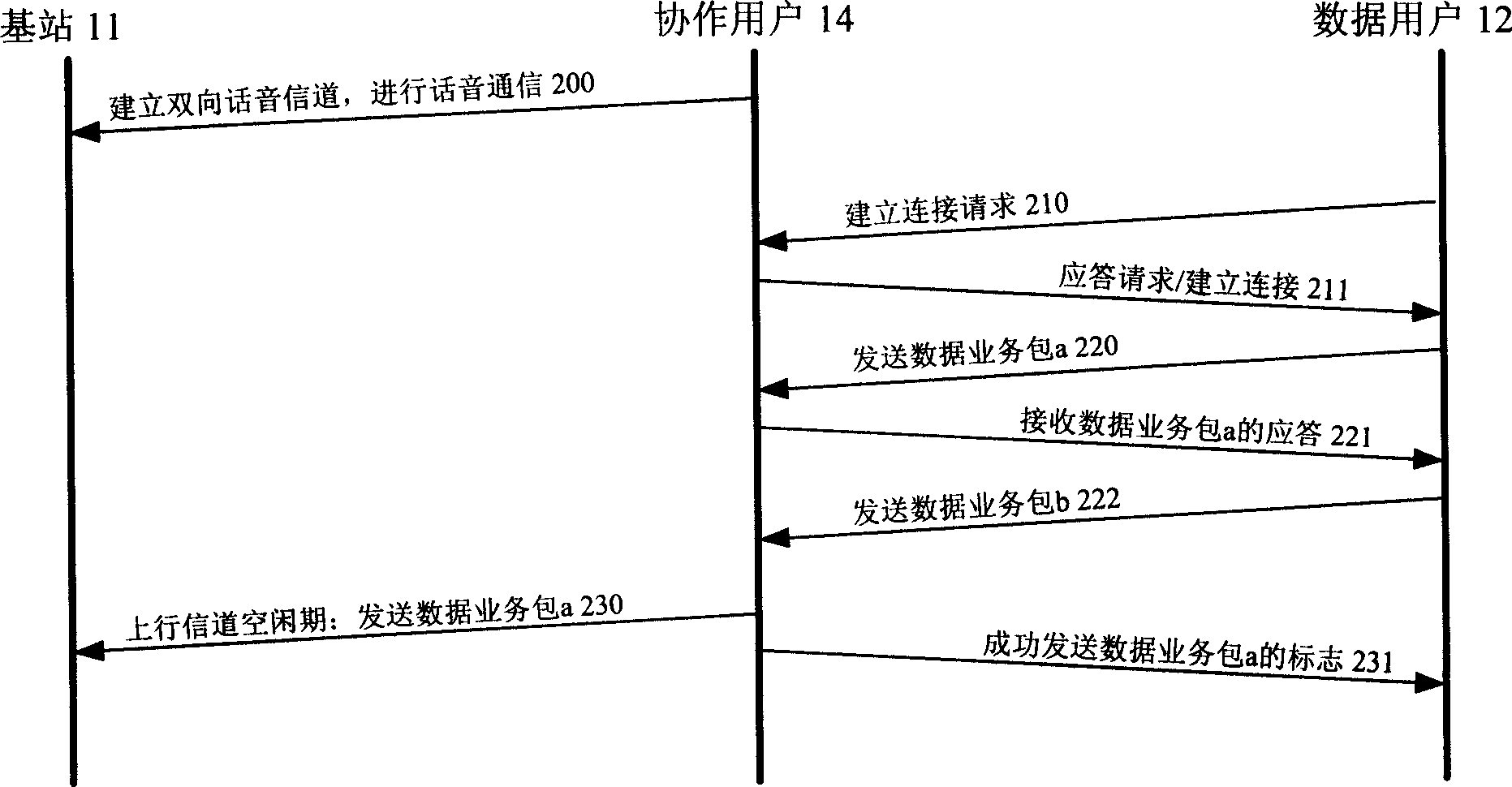

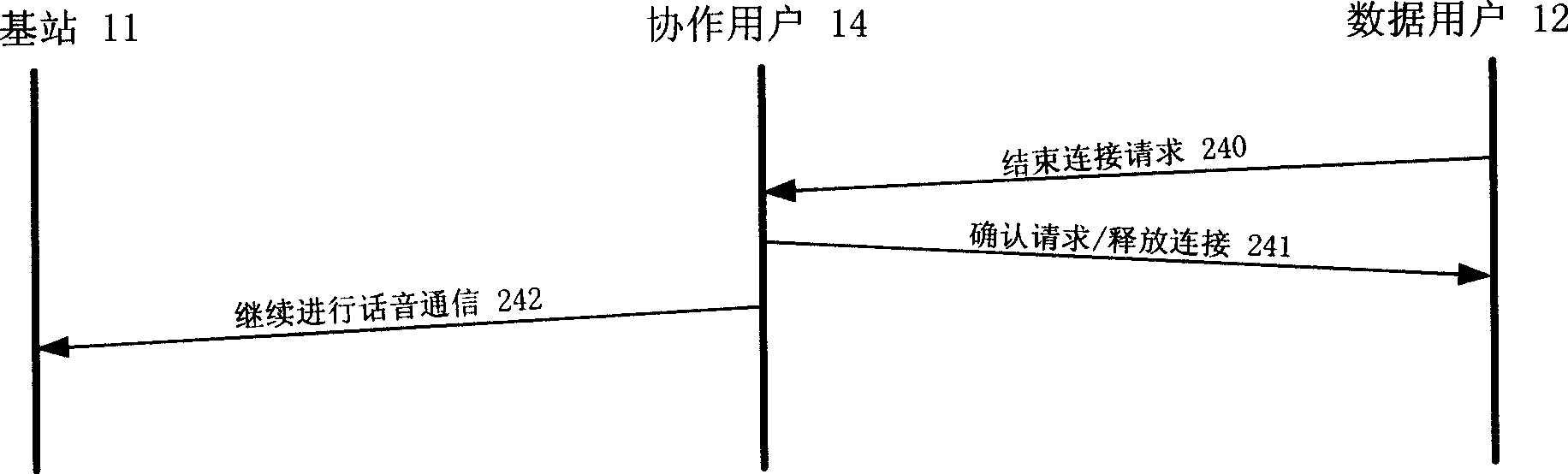

Multi-user cooperation transmission data traffic method based on service characteristic

InactiveCN101370301AImprove channel usage efficiencyReduce the probability of service responseRadio/inductive link selection arrangementsData switching networksService qualityData traffic

The invention discloses a method for multiuser collaborated transmission for data based on service features, characterized in that short distance connection is established between voice user and data user, voice user can serve as collaborated user, employs voice channel for accomplishing uplink and downlink transmission during idle period of voice. The invention effectively promotes voice channel utilization efficiency without influencing voice service quality, can improves data service quality when telephone traffic is busy.

Owner:UNIV OF SCI & TECH OF CHINA

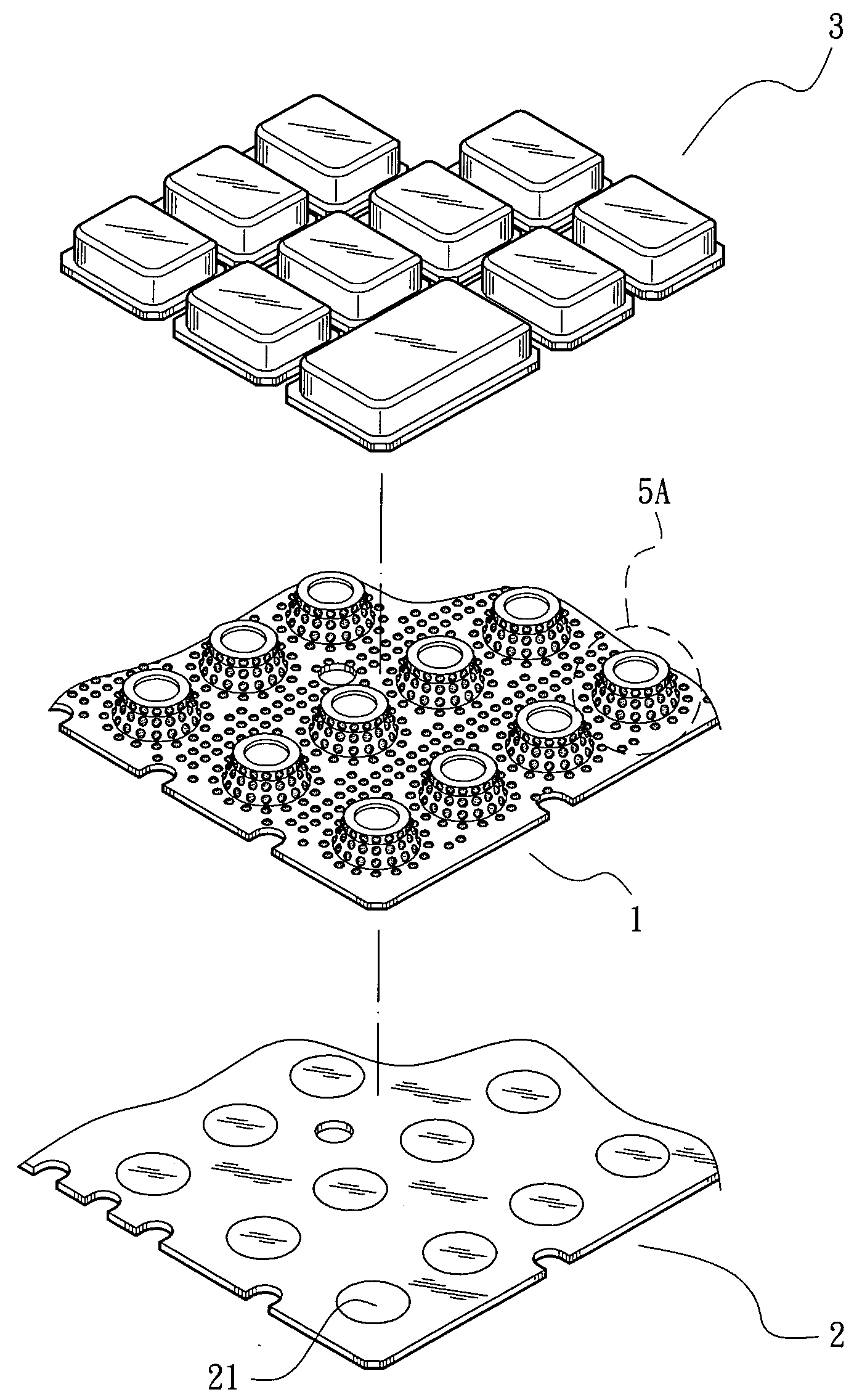

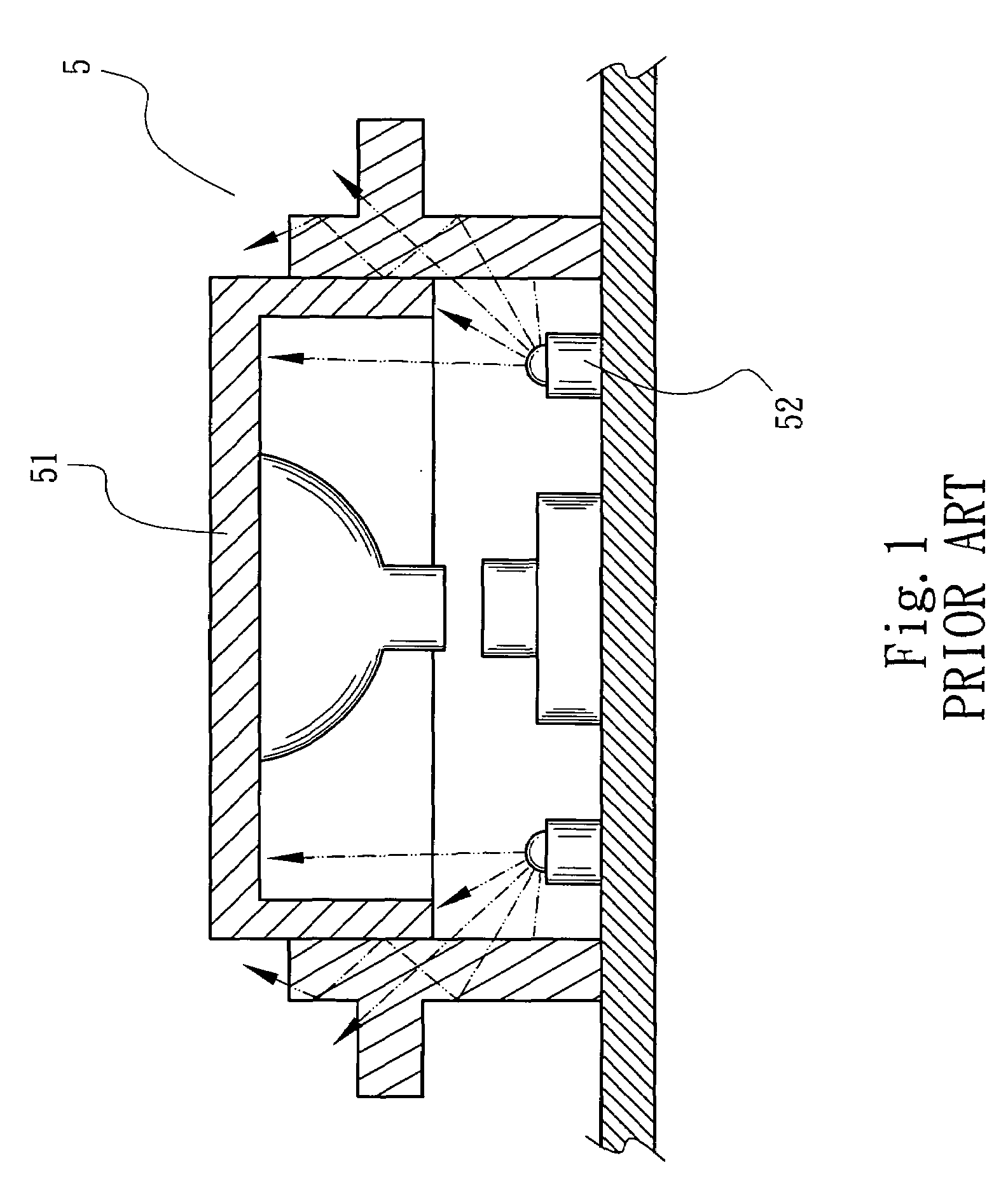

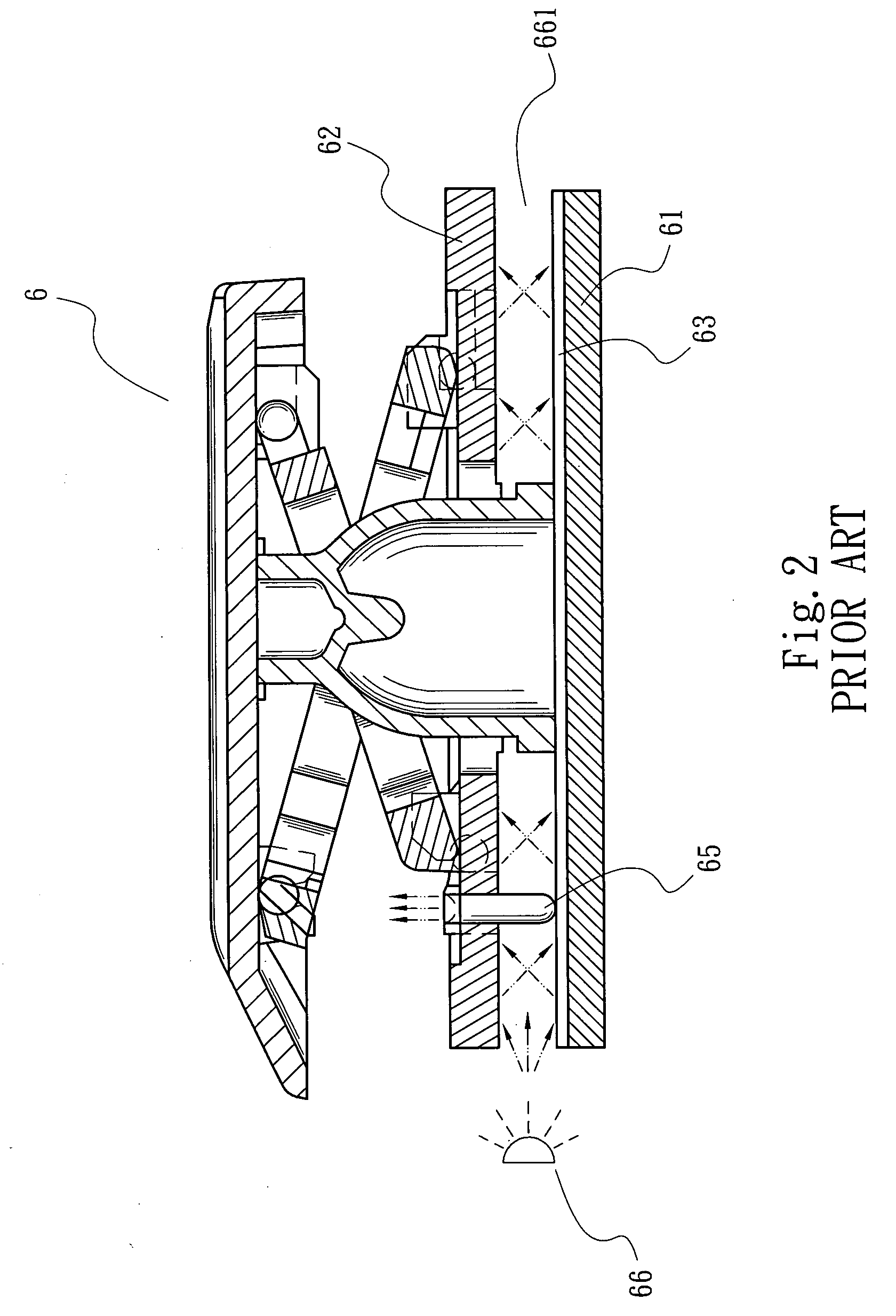

Light guide structure for a keyboard

InactiveUS20100148996A1Enhance uniform backlight illuminationAvoid shadowsLegendsElectronic switchingLight guideLight reflection

A light guide structure for a keyboard. The light guide structure includes a transparent rubber sheet. Multiple resilient support sections are formed on the rubber sheet in alignment with press keys of the keyboard respectively. Multiple diffusive reflection units are disposed on a surface of the rubber sheet and circumferences of the resilient support sections. The diffusive reflection units are boss sections protruding from the surface of the rubber sheet or recessed sections formed on the surface of the rubber sheet. Each diffusive reflection unit has a surface coated with a light reflection layer for reflecting light. When the light is reflected by external components back to the surface of the rubber sheet, the light reflection layers of the diffusive reflection units that are boss sections or recessed sections will again effectively reflect the light to enhance backlight brightness of the press keys and peripheries thereof.

Owner:KINPO ELECTRONICS

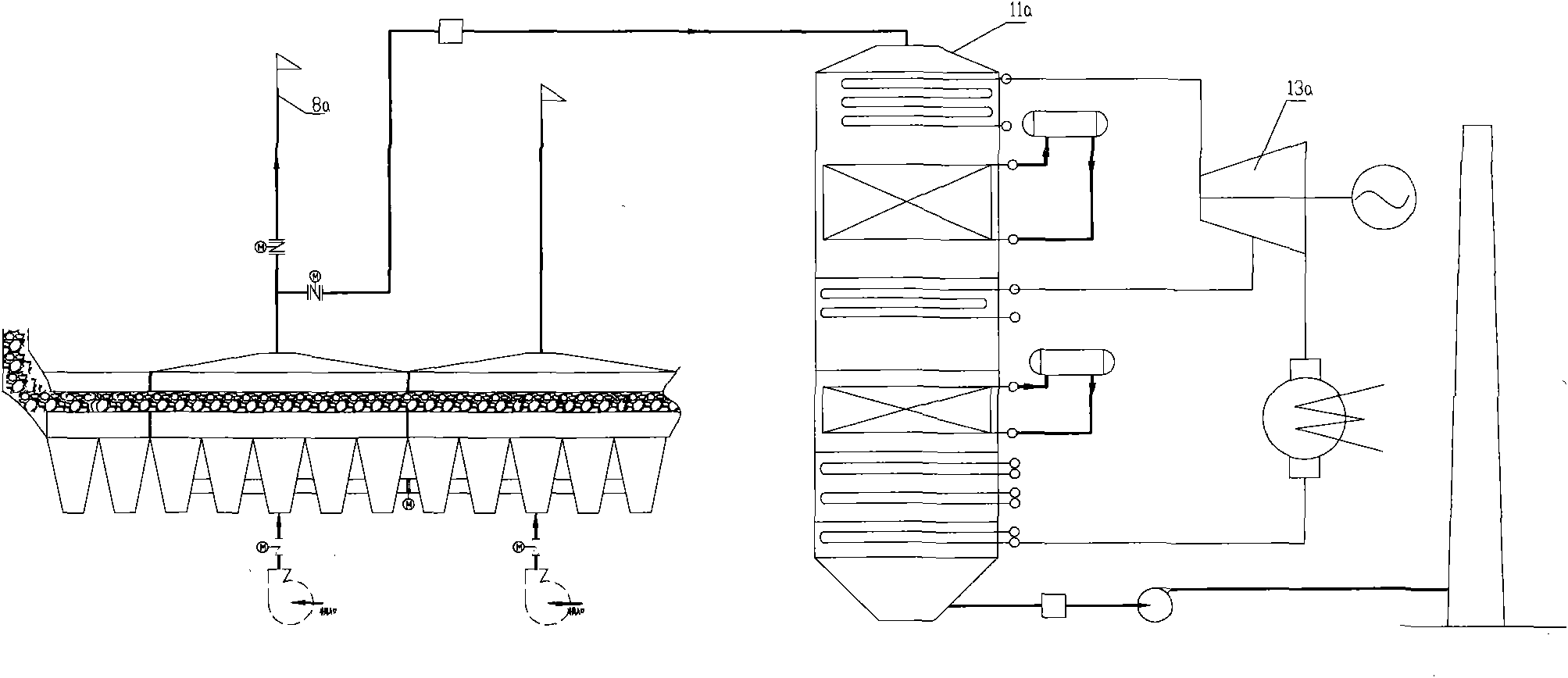

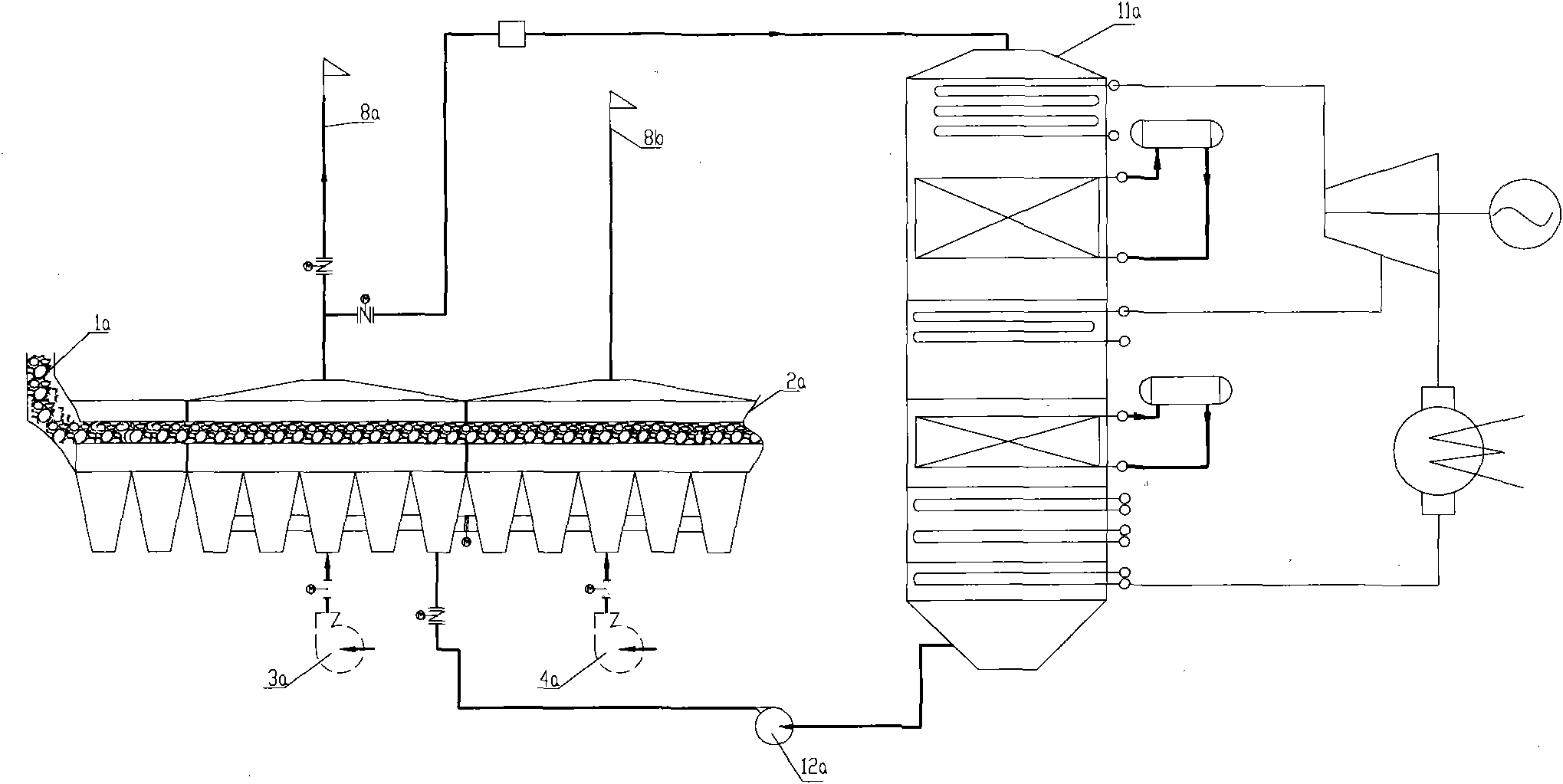

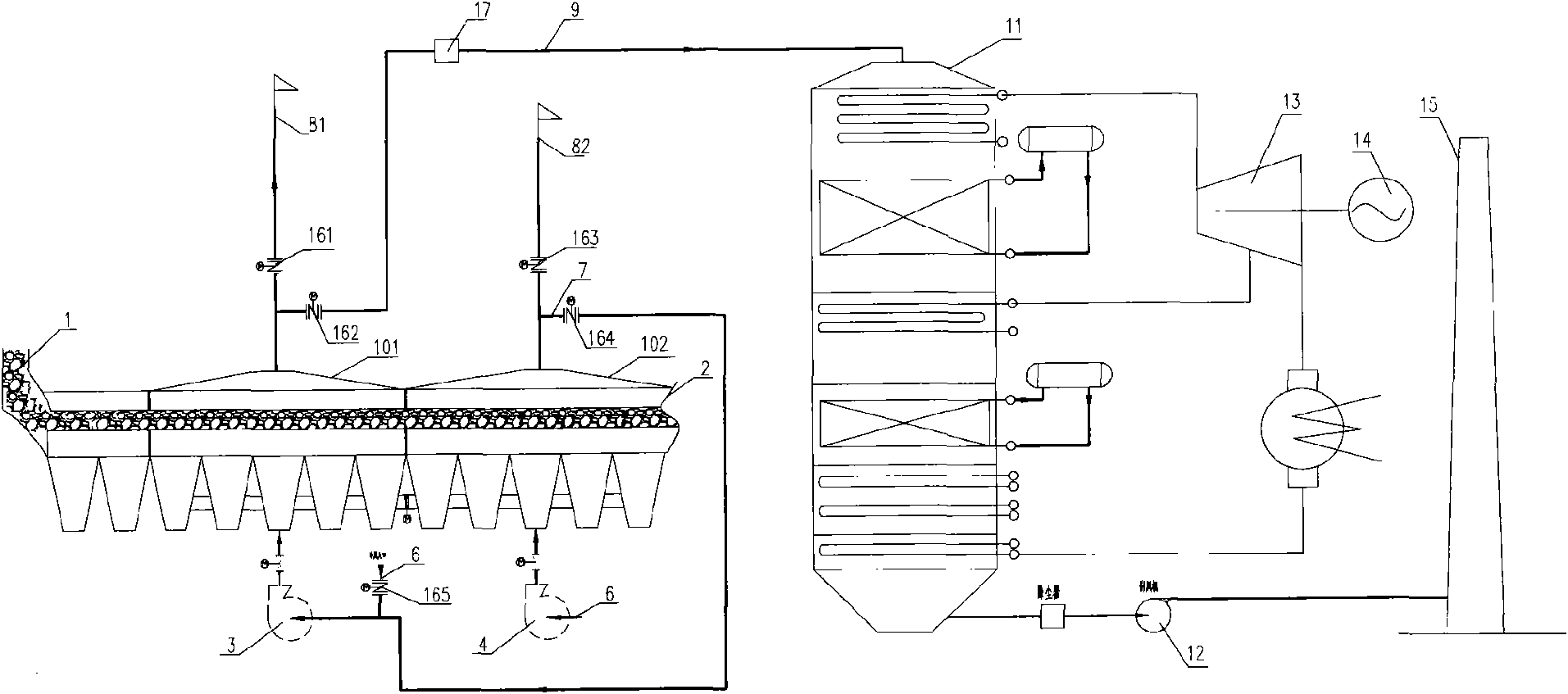

Power generation system using waste heat of sintering circular cooler

InactiveCN101672578AImprove reuse efficiencyWill not affect the performance of sintering processIncreasing energy efficiencySteam engine plantsExhaust fumesFume hood

A power generation system using waste heat of a sintering circular cooler comprises a first fume hood, a second fume hood, an air pipe, a first air blower, a first fume pipeline, a double-pressure waste heat boiler and a steam compensating steam turbine. The first fume hood is arranged at a low temperature zone of a circular cooler; the second fume hood is arranged at a high temperature zone of the circular cooler; the air pipe is communicated with the first fume hood and a cooling air conduit at the high temperature zone of the circular cooler; the first air blower superposes outdoor coolingair with fume discharged from the low temperature zone of the circular cooler in the air pipe as cooling air of the high temperature zone of the circular cooler; the first fume pipeline is used for communicating the second fume hood with an air line of the double-pressure waste heat boiler; the double-pressure waste heat boiler is used for converting the fume in the first fume pipeline into high pressure steam and lower pressure steam, the high pressure steam enters a high pressure section of the steam compensating steam turbine for doing work, and the lower pressure steam enters a low pressure section of the steam compensating steam turbine for doing work; and the steam compensating steam turbine is used for driving a generating unit to generate power. The invention provides a power generation system using waste heat of a sintering circular cooler, and the system is used for improving inlet temperature of the waste heat boiler without affecting properties of sintering processes.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

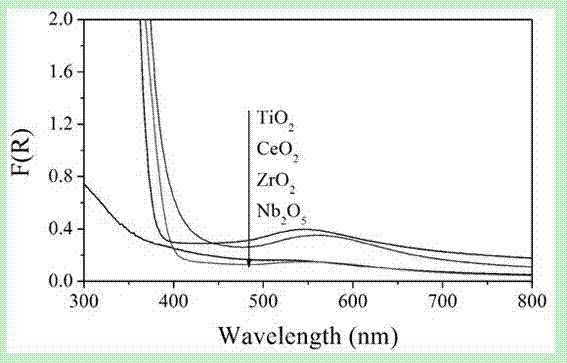

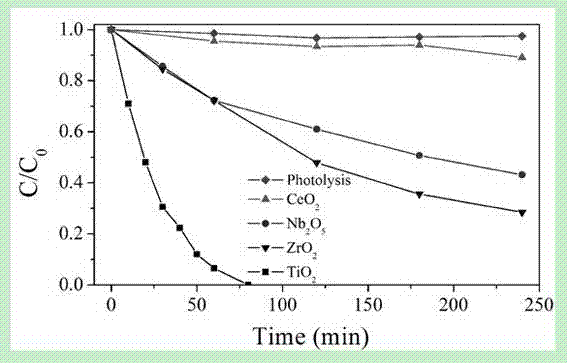

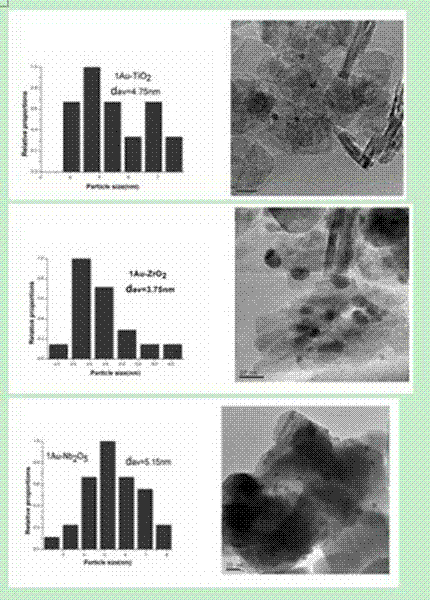

Preparation method of visible light catalyst with surface plasmon effect and application thereof

InactiveCN102350346AEfficient depositionControllable sizeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive componentNanoparticle

The invention relates to a preparation method of a visible light catalyst with a surface plasmon effect and application thereof. The active component of the visible light catalyst is a precious metal Au, and the carrier is one of TiO2, CeO2, Nb2O5, SiO2, Ta2O5, Al2O3 and ZrO2, wherein, Au accounts for 0.2-5% in mass content, and the particle size of Au particle is 2-20nm. Preparation of the catalyst consists of two steps: the first step is to prepare a carrier; the second step is to prepare an Au / TiO2 (CeO2, SiO2, Al2O3, Nb2O5, Ta2O5, ZrO2) visible light catalyst with a plasmon effect througha sol precipitation method. Au nanoparticles prepared by the method of the invention have good dispersibility, easily controllable size, high active component utilization rate, as well as the effect of high efficiency photocatalytic degradation of organic pollutants by visible light.

Owner:FUZHOU UNIV

Converter apparatus, inverter apparatus, and DC link voltage control method

ActiveUS20060033466A1Increase reusable regenerative energyHigh energyBatteries circuit arrangementsDC motor speed/torque controlLimit valueDc link voltage

The invention is directed to the provision of a converter apparatus, an inverter apparatus, and a DC link voltage control method, wherein the upper limit value of the DC link voltage that rises due to regenerative energy occurring from a motor is set high, thereby increasing the regenerative energy to be stored in a DC link. The converter apparatus (10) comprises: a voltage detection part (11) for monitoring the DC link voltage occurring across the DC link (30); and a charge stopping part (12) for stopping charging a power storage part (C) when the detected value of the DC link voltage exceeds a predetermined upper limit voltage as the motor (3) is decelerated.

Owner:FANUC LTD

Preparation method of bismuth oxyhalide/ titanium dioxide composite photocatalyst

InactiveCN103464181AImprove photocatalytic activityReduce contentPhysical/chemical process catalystsDispersed particle separationTitanium dioxideTitanium

The invention relates to a preparation method and application of a novel photocatalysis material. On the basis of the action principle of semiconductor heterojunction, bismuth oxyhalide and titanium dioxide are composited to obtain a novel titanium based photocatalysis material with the characteristics of high catalytic activity, wide applicability and good stability. The preparation method adopted by the invention is simple and efficient and is easy to implement, and the use amount of the bismuth oxyhalide is less and is about 1-3%, therefore no increase of overmuch cost may be caused. The photocatalysis material obtained by the reaction is a porous nano particle with larger specific surface area, good dispersibility and high degree of crystallinity. In addition, the photocatalytic activity of the bismuth oxyhalide / titanium dioxide composite photocatalyst is very excellent, and either under ultraviolet or visible light irradiation, the bismuth oxyhalide / titanium dioxide composite photocatalyst can show high degradation performance both on gas phase and liquid phase organic matters.

Owner:NO 63971 TROOPS PLA

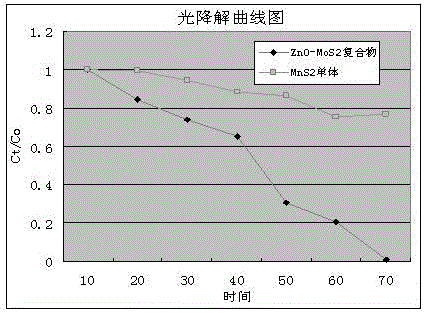

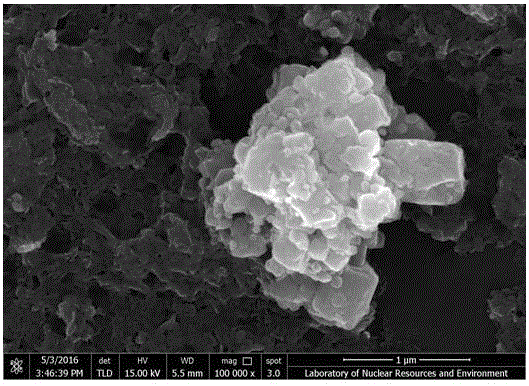

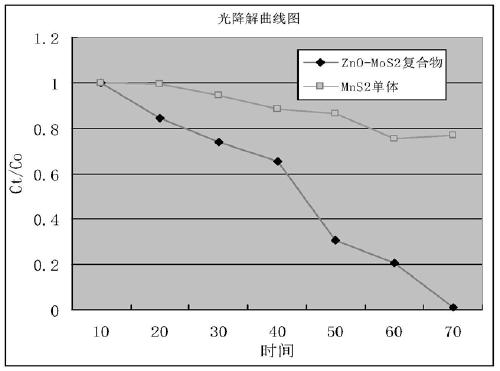

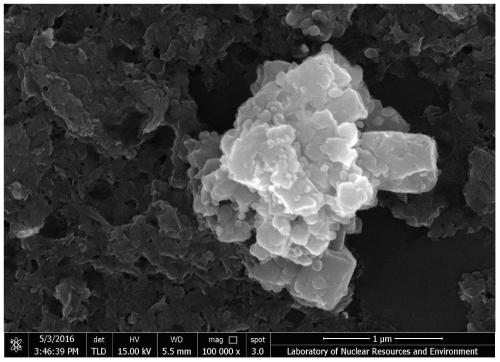

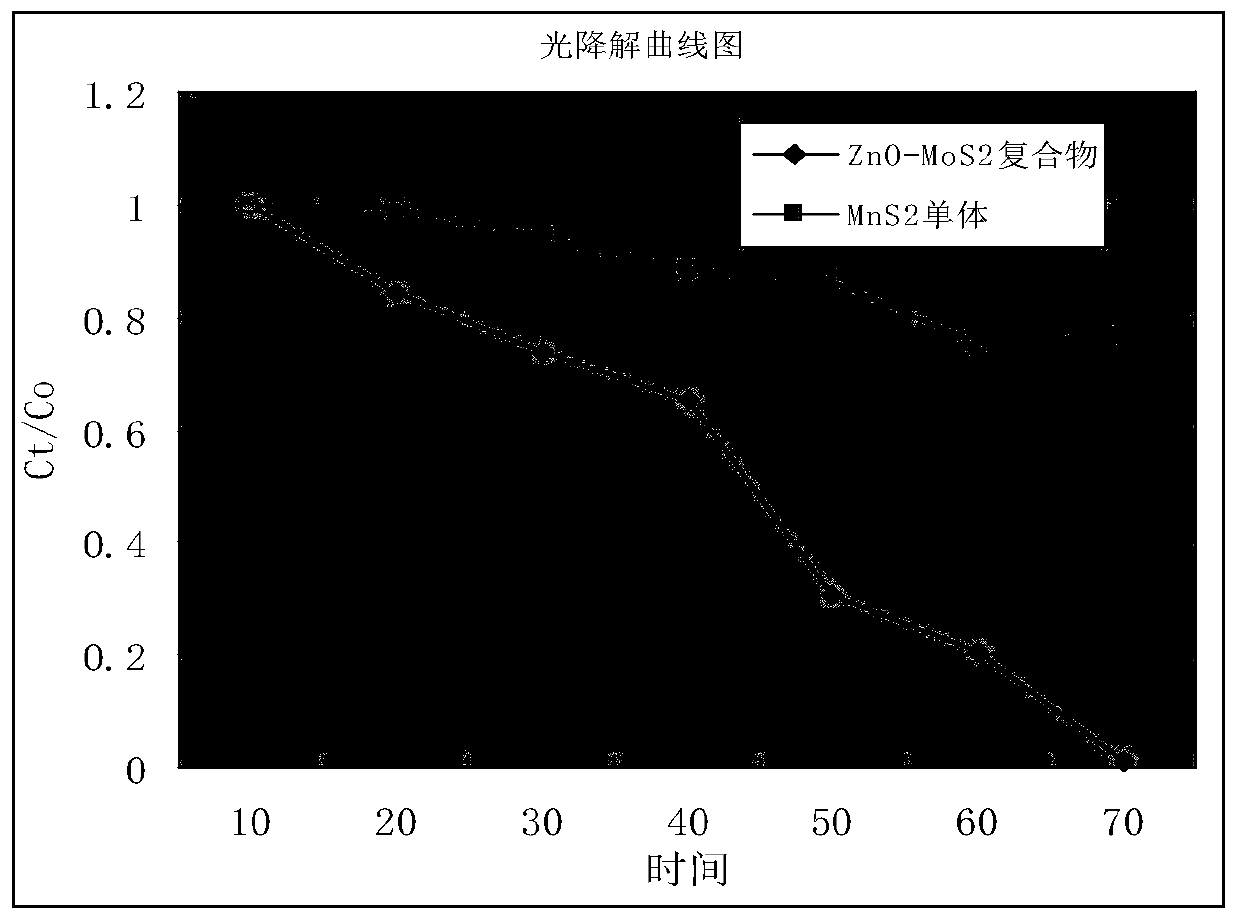

Preparation method of ZnO/MoS2 nanosheet compound photocatalyst

InactiveCN106391059AIncrease profitCompletely degradedPhysical/chemical process catalystsWater/sewage treatment by irradiationSodium molybdateWastewater

The invention relates to a preparation method of a ZnO / MoS2 nanosheet compound photocatalyst. The photocatalyst with low price and high efficiency is obtained by doping a small amount of zinc oxide into molybdenum disulfide; specifically the photocatalyst is prepared by reacting the zinc oxide, sodium molybdate dehydrate and thioacetamide through a hydrothermal method. The ZnO / MoS2 nanosheet compound in the invention can quickly degrade organic pollutants, particularly dye organic pollutes, in waste water into non-pollution substances such as H2O and CO2 under normal temperature, normal pressure and illumination, and the ZnO / MoS2 nanosheet compound has lasting photocatalytic activity.

Owner:NANCHANG HANGKONG UNIVERSITY

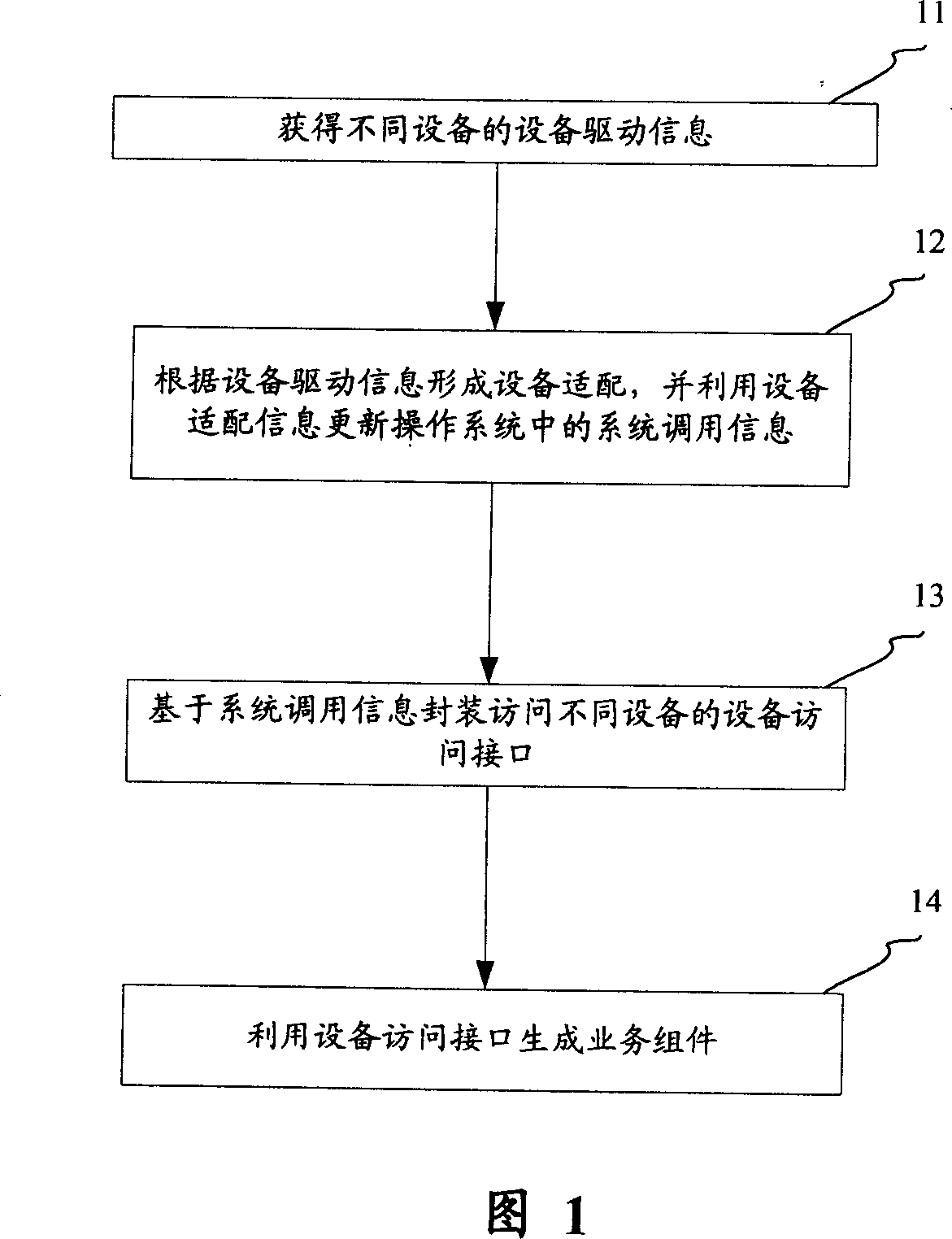

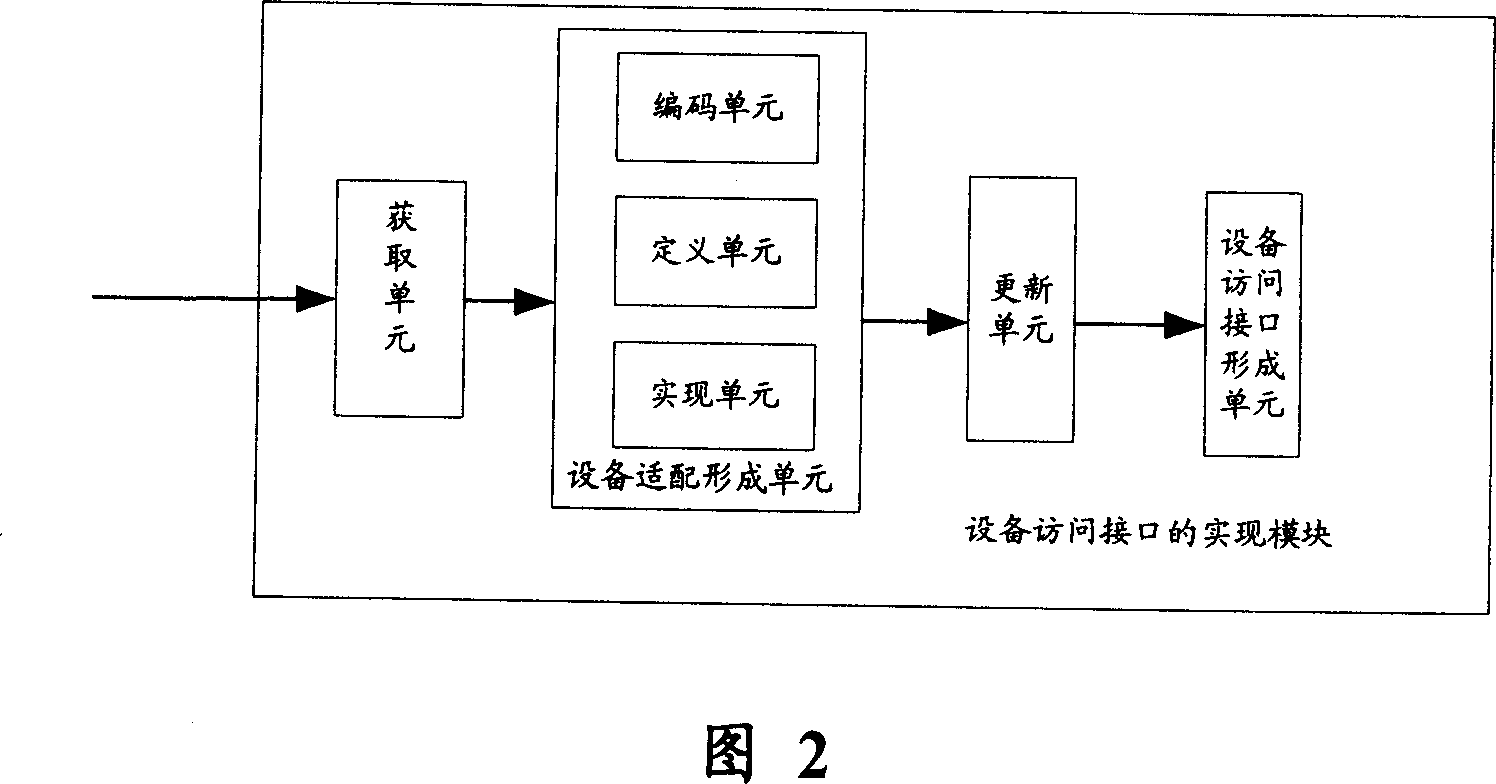

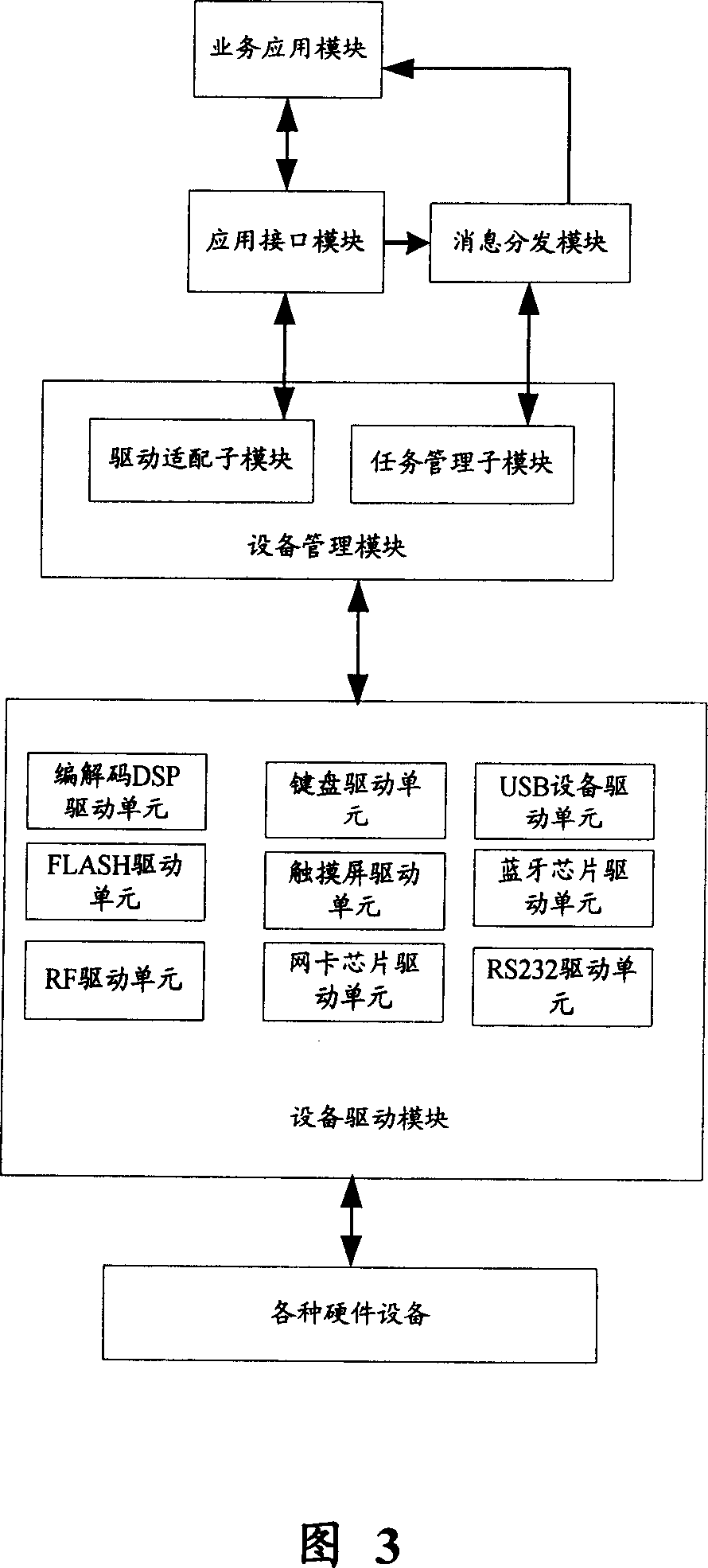

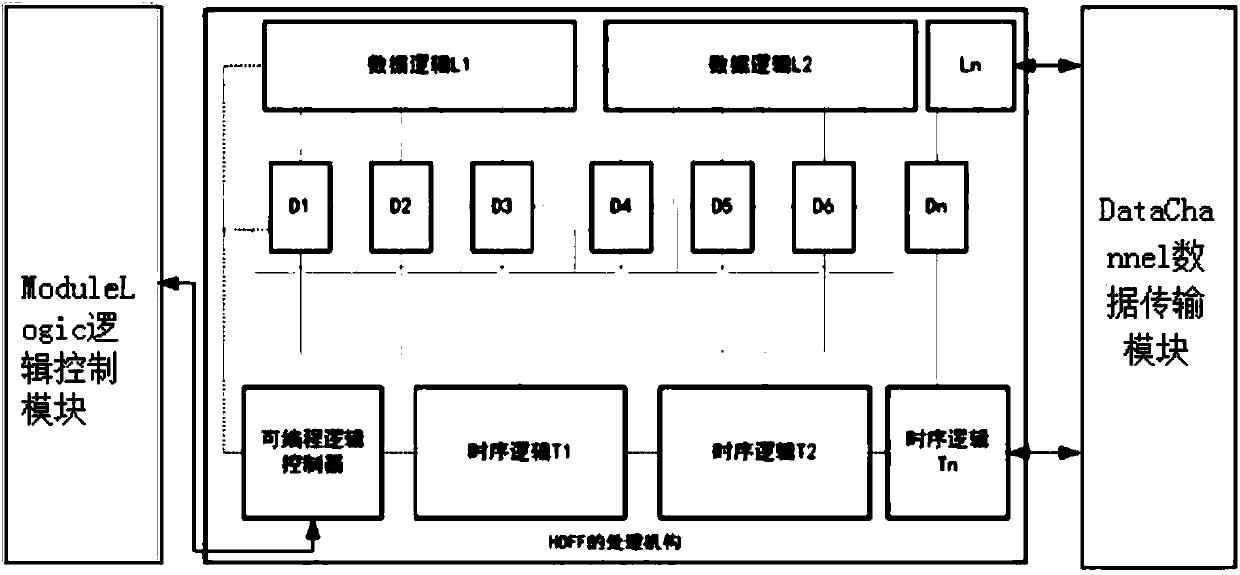

Module and method for realizing equipment access interface, equipment access system and method

ActiveCN1933425AIncrease portability and reusabilityImprove reuse efficiencySpecial service for subscribersData switching networksTelecommunicationsAccess method

A method for realizing device access interface includes obtaining unit driving information of different units and forming unit adaptive information according to obtained driving information then utilizing formed adaptive information to update system call information in operation system, packaging unit access interface used for calling on different units based on updated system call information. The unit access system and its access method are also disclosed.

Owner:HUAWEI TECH CO LTD

Magnetic nanosphere with mesoporous shell and quick preparation method thereof

InactiveCN103464065APromote rapid formationShorten the timeMicroballoon preparationMicrocapsule preparationSuperparamagnetismAmmonium bromide

The invention relates to a magnetic nanosphere with a mesoporous shell and a quick preparation method thereof, which belongs to the technical field of magnetic nanospheres. A Fe3O4 core with superparamagnetism is prepared from FeCl3.6H2O, then a mesoporous SiO2 shell is quickly formed on the surface of the magnetic Fe3O4 core with an ultrasonic wave method by taking hexadecyl trimethyl ammonium bromide as a template agent and taking low-cost sodium silicate as a silicon source for wrapping the SiO2 shell on the surface of the magnetic Fe3O4, and finally, the template agent is removed by roasting under the protection of N2, thus obtaining the magnetic SiO2@Fe3O4 nanosphere with the mesoporous SiO2 shell and large specific surface area. The magnetic nanosphere has good application prospects in the aspects of magnetic adsorption, precious metal recovery, target administration carriers, bioprotein separation and the like.

Owner:BEIJING UNIV OF CHEM TECH

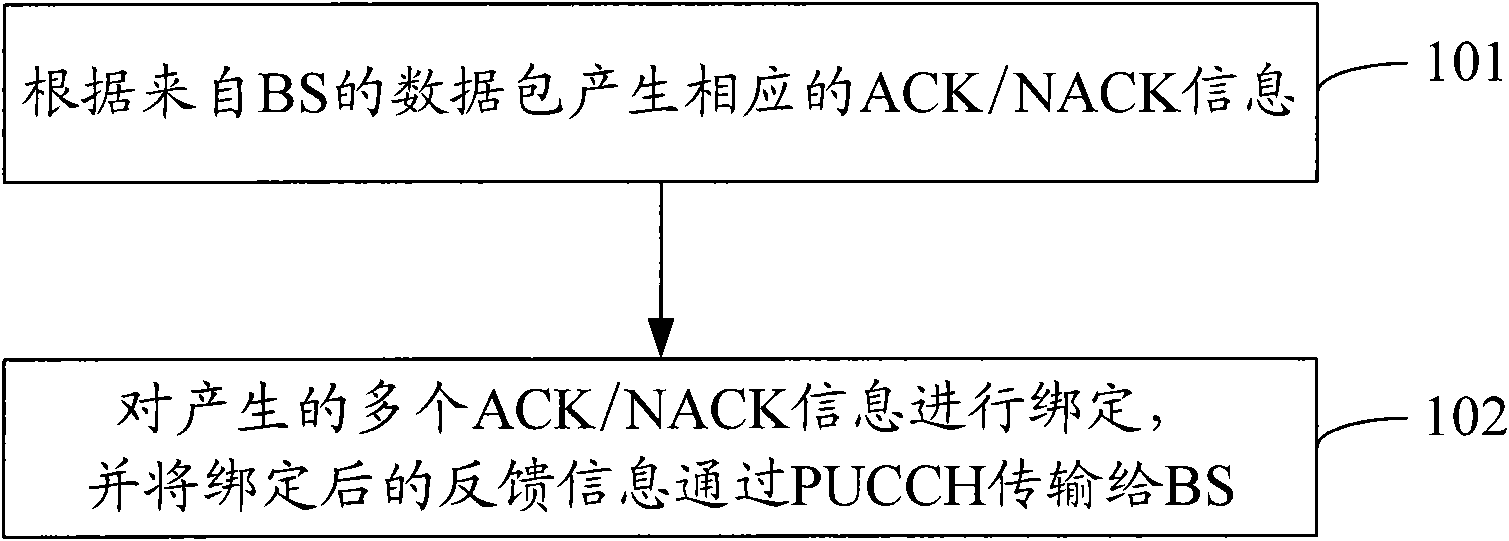

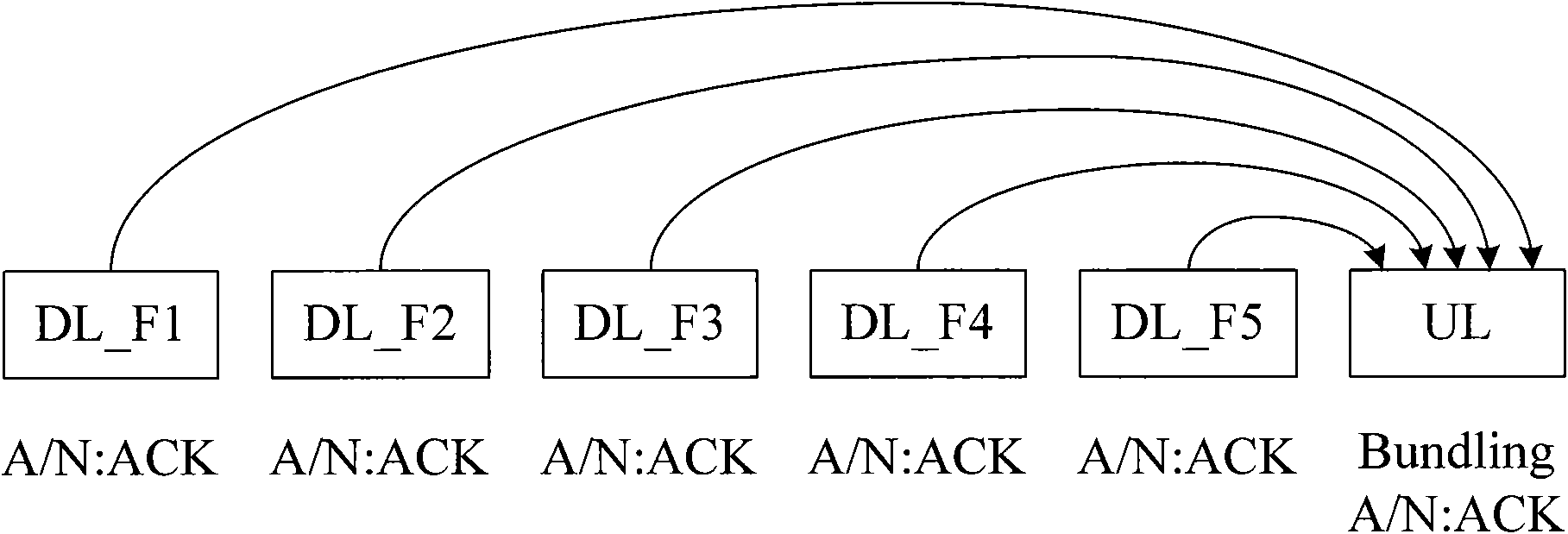

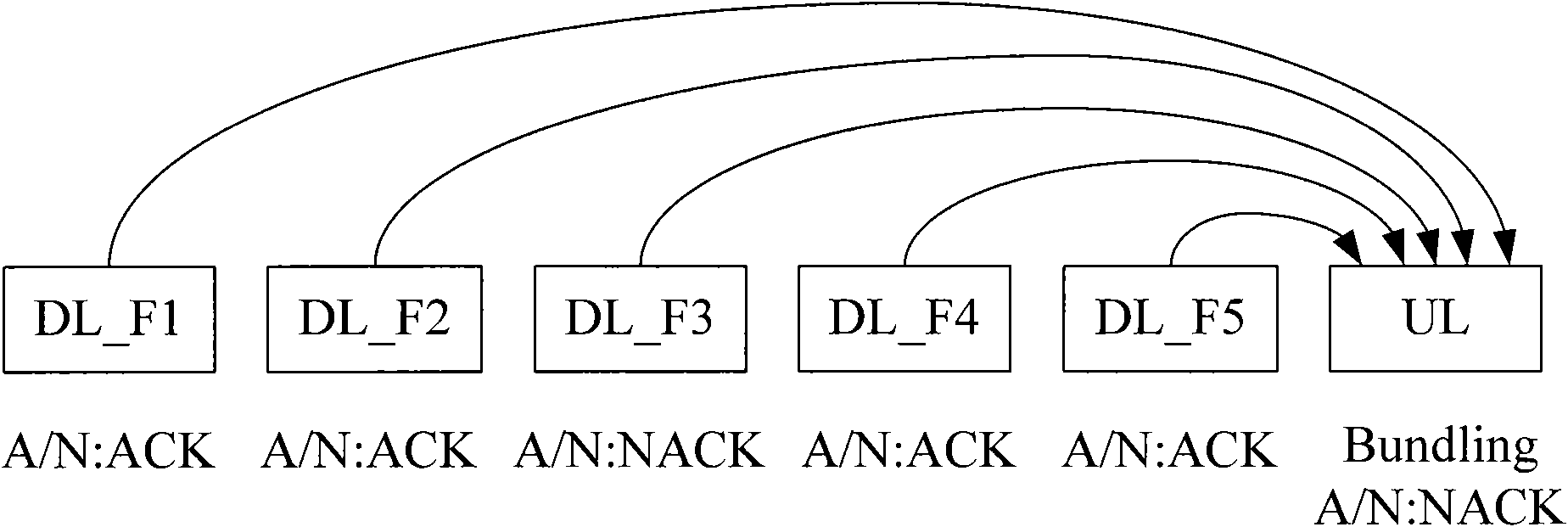

Information feedback method, system and user equipment

InactiveCN101777971AImprove reuse efficiencyReduce in quantityError prevention/detection by using return channelNetwork packetCarrier signal

The invention discloses an information feedback method, which comprises the following steps: generating corresponding acknowledgement character / non-acknowledgement character (ACK / NACK) information by user equipment (UE) according to a data pack sent by a base station (BS) through work carrier waves; binding a plurality of generated ACK / NACK information; and transmitting the bound feedback information to the BS through a physical uplink control channel (PUCCH). The invention also discloses an information feedback system and the user equipment. Through the binding operation executed on the ACK / NACK information, the invention improves the reuse efficiency of the ACK / NACK information, and saves resources.

Owner:ZTE CORP

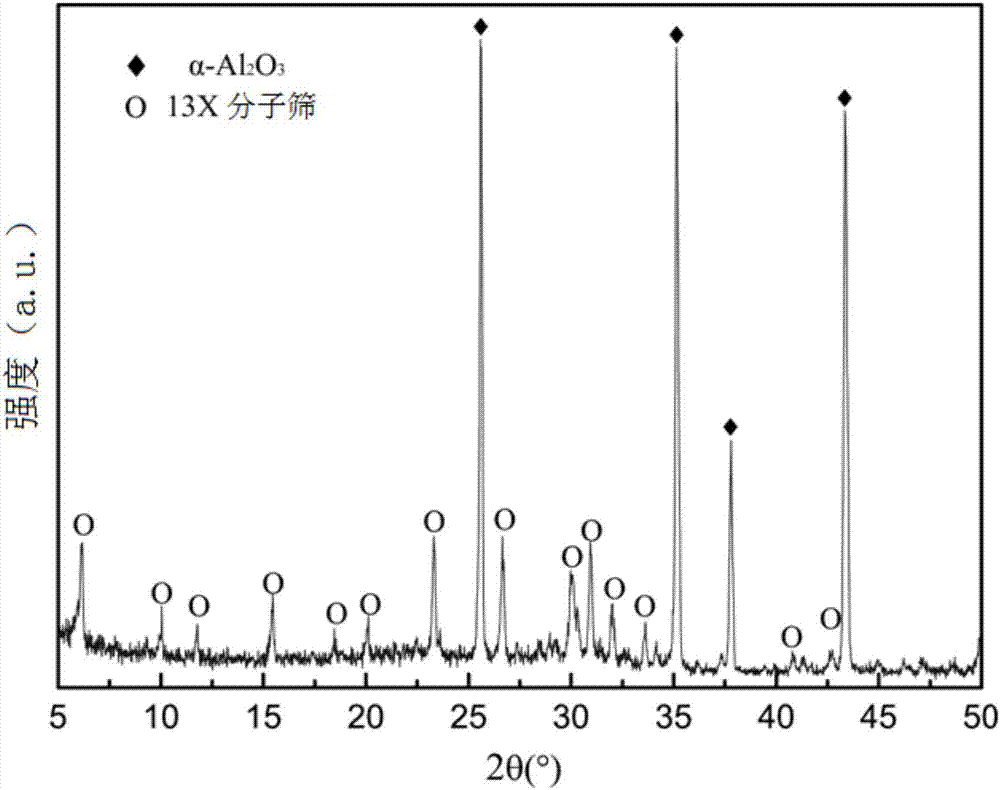

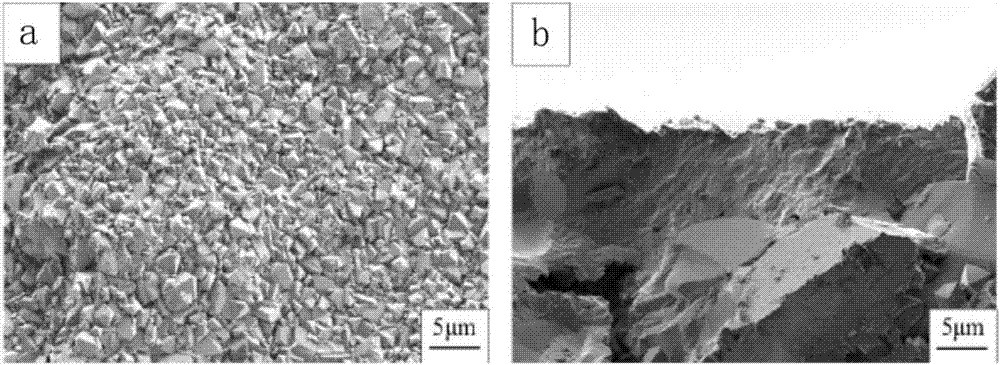

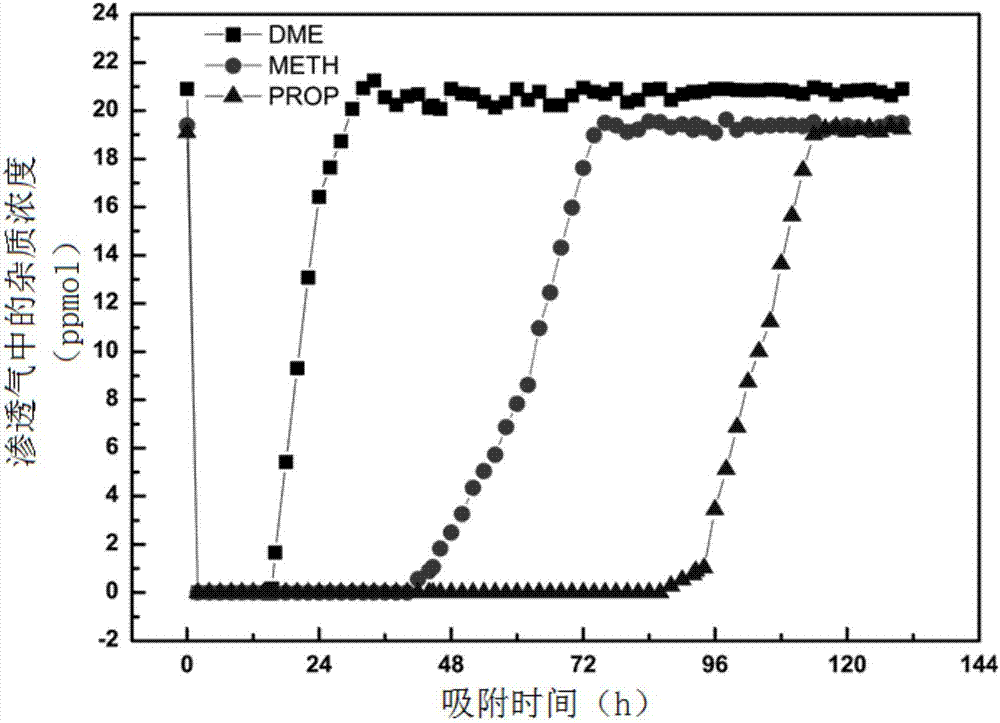

Molecular sieve ceramic membrane material for olefin purification as well as preparation method and application of molecular sieve ceramic membrane material

ActiveCN107970781AReduce mass transfer resistanceReduce energy consumptionSemi-permeable membranesOther chemical processesMolecular sieveBonding strength

The invention relates to a molecular sieve ceramic membrane material for olefin purification as well as a preparation method and application of the molecular sieve ceramic membrane material. In the molecular sieve ceramic membrane material, the particle sizes of molecular sieve particles supported on the surface of the ceramic material are 0.1-3 [mu]m, and the thickness of a molecular sieve layeris 3-5 [mu]m; during preparation, ceramic material pretreatment, molecular sieve seed crystal pre-coating and sealed crystallization are sequentially carried out; and the molecular sieve ceramic membrane material is used for removing a polar oxygenated compound in a gaseous olefin flow to be 1ppm or below. Compared with the prior art, the molecular sieve ceramic membrane material prepared by the preparation method of the invention has the molecular sieve layer with higher mechanical strength, larger specific surface area and uniform thickness, in addition, the molecular sieve layer has no longitudinal or horizontal cracks, has no air pores in the surface and is high in bonding strength and not easy to fall off; and when the polar oxygenated compound in the olefin flow is adsorbed, the purification depth is 1ppm or smaller, so that not only is the mass transfer resistance lower, but also the energy consumption is lower, and the regeneration capacity is high.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

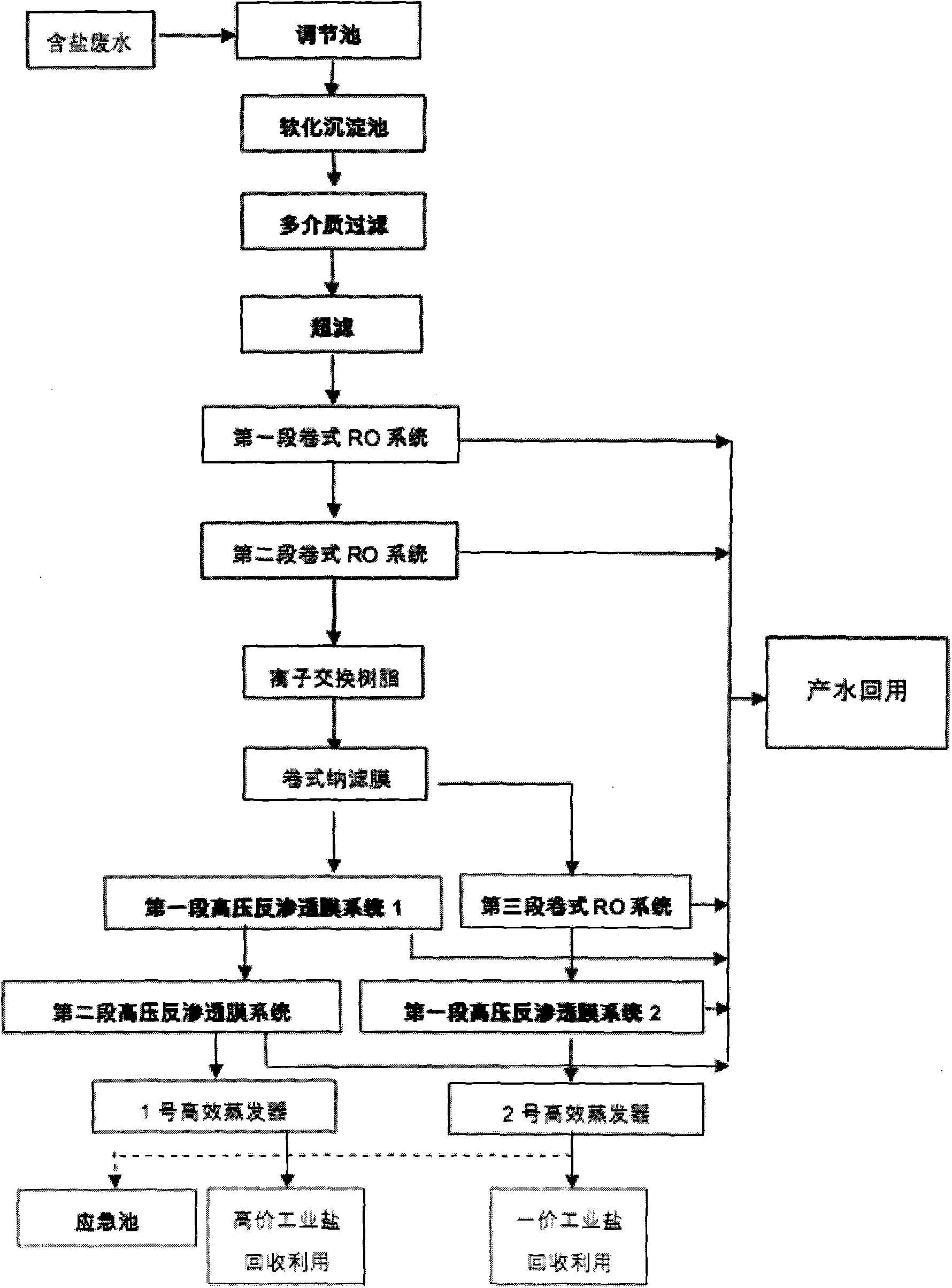

Salt-containing wastewater treatment method

ActiveCN103833172ASolve the problem of pollutionAvoid badWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisHigh concentrationIon exchange

The invention discloses a salt-containing wastewater treatment method. The wastewater goes through an adjusting tank, a softening sedimentation tank, a multi-medium filter, an ultrafiltration device, a first-section roll type reverse osmosis system, a second-section roll type reverse osmosis system, an ion exchange device, a roll type nanofiltration membrane device, a high-pressure reverse osmosis membrane system, a third-section roll type reverse osmosis system and an efficient evaporator. The treatment method disclosed by the invention has the advantages of strong anti-pollution capacity, solution of blocking problem, high concentration multiple, high recycling efficiency, high treatment efficiency, high automation degree, investment saving and low operation cost.

Owner:BEIJING NEWBIOLINK TECH DEV

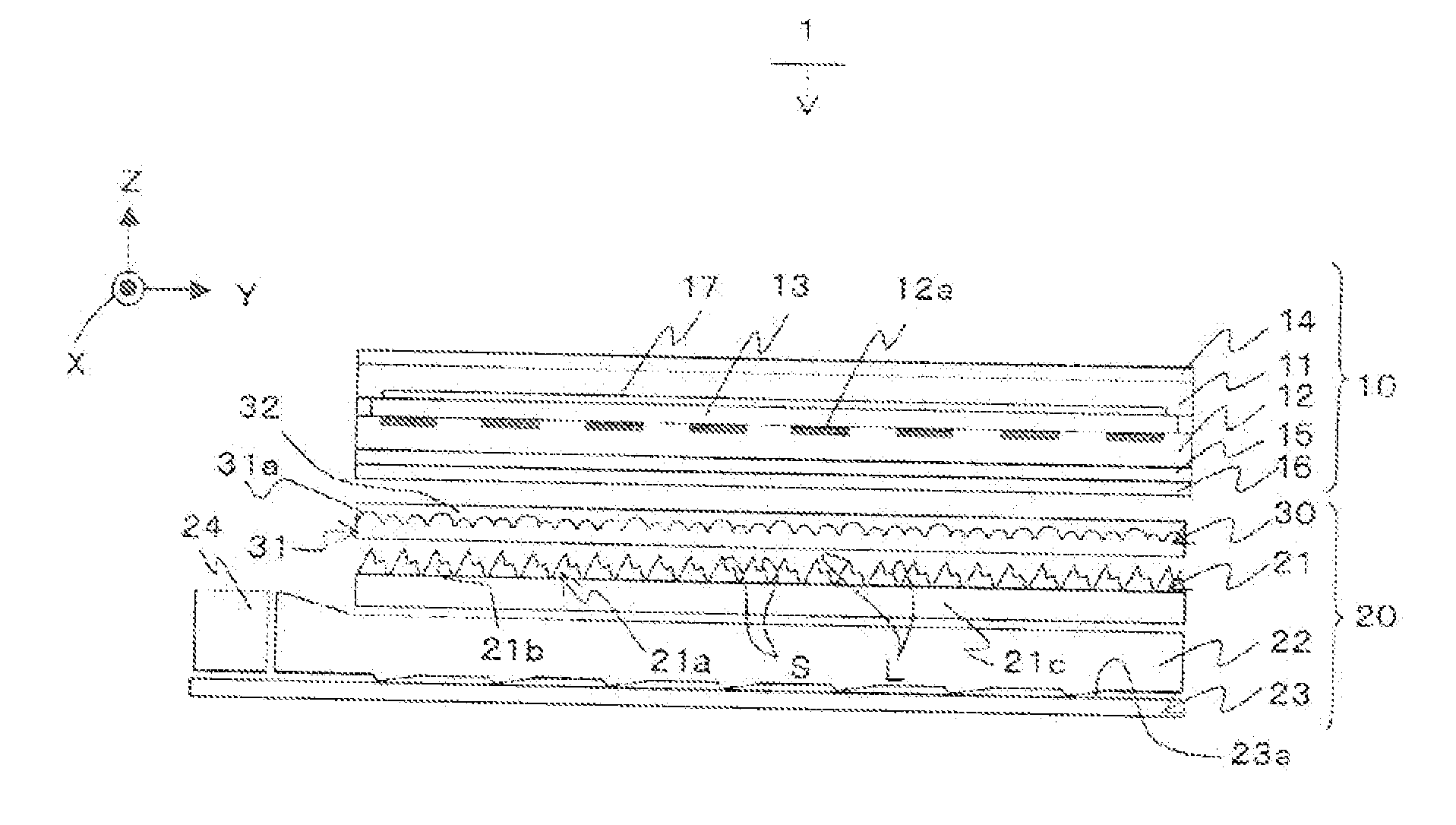

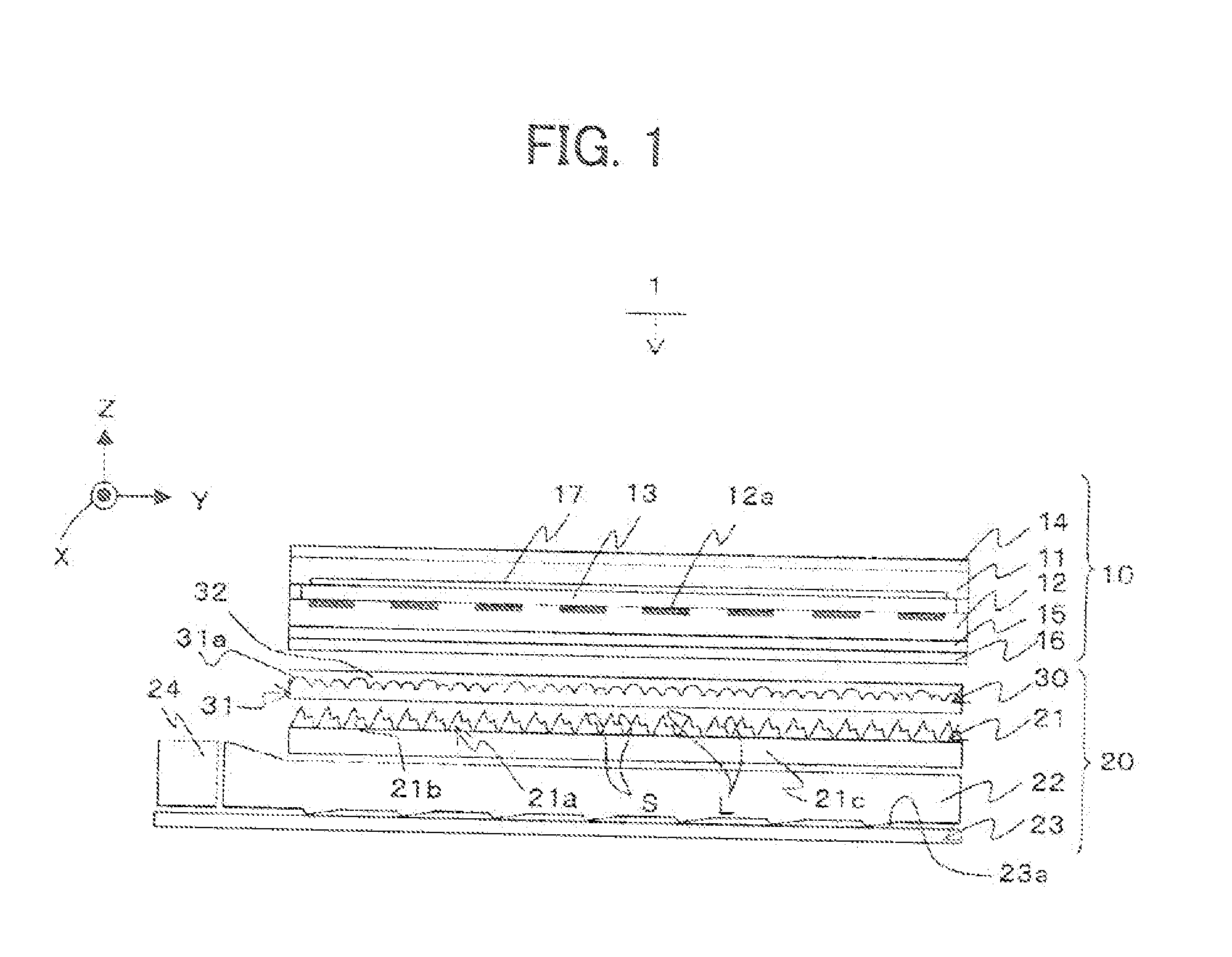

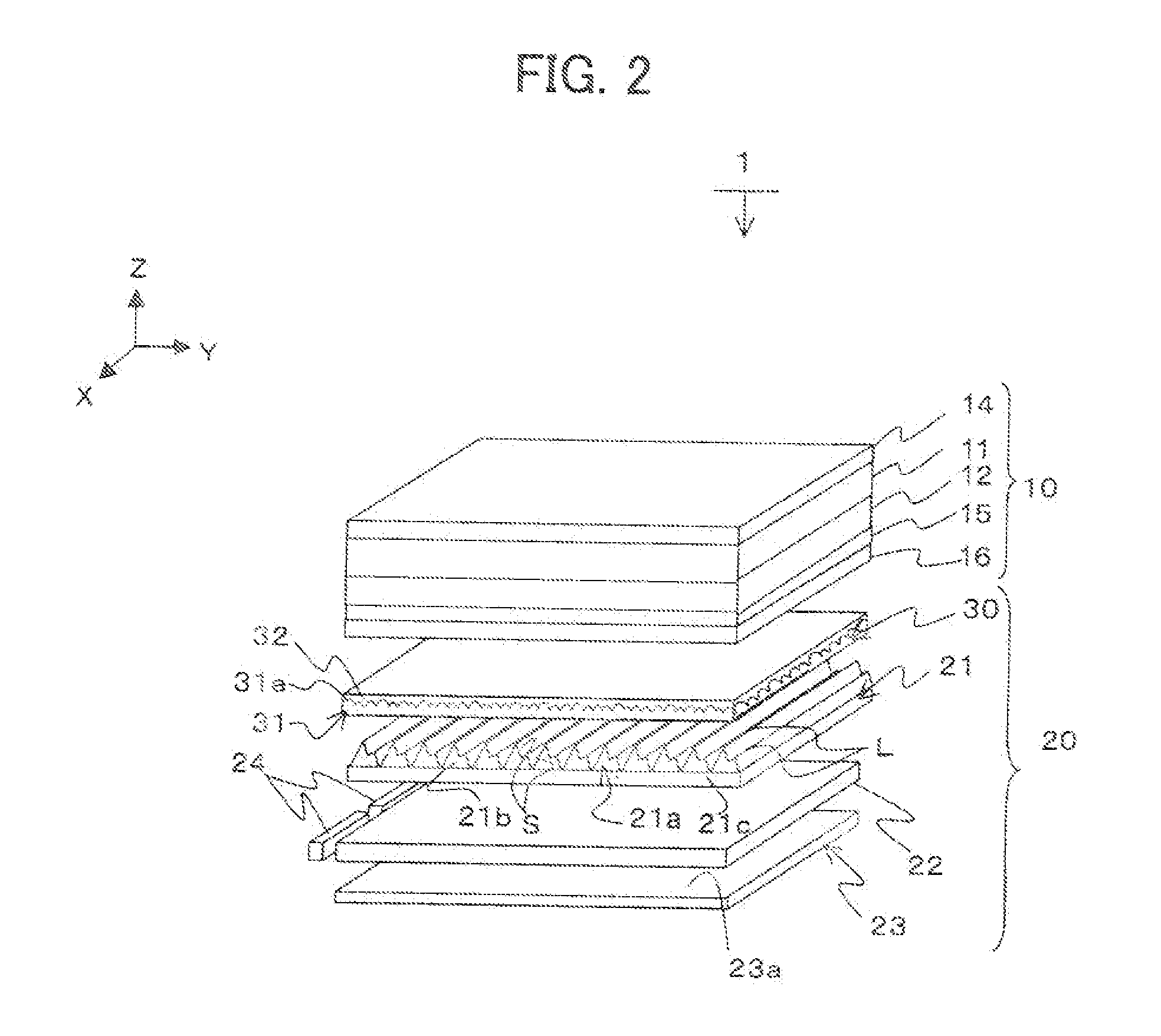

Liquid crystal display device

ActiveUS20120069272A1Improve reuse efficiencyReduce power consumptionNon-linear opticsOptical elementsLiquid-crystal displayBi-isotropic material

The backlight has an anisotropic diffusion sheet disposed between the reflective polarizing plate and the optical path converter. The anisotropic diffusion sheet includes a refractive index anisotropic diffusion sheet stretched in an absorption axis direction in which a concave-convex portion is formed on a surface of the reflective polarized plate, and an isotropic material part laminated on a surface of the concave-convex part. The isotropic material part has an isotropic reflective index. The refractive index of the isotropic material part is the same as the refractive index in the transmission axis direction perpendicular to a stretching direction of the refractive index anisotropic sheet.

Owner:JAPAN DISPLAY INC

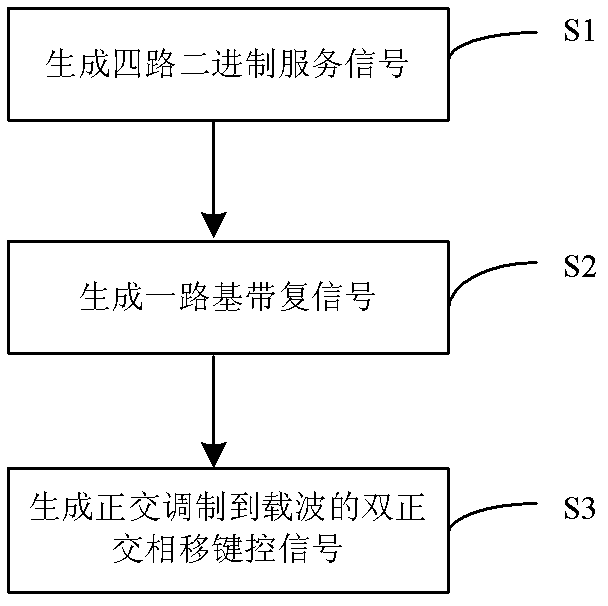

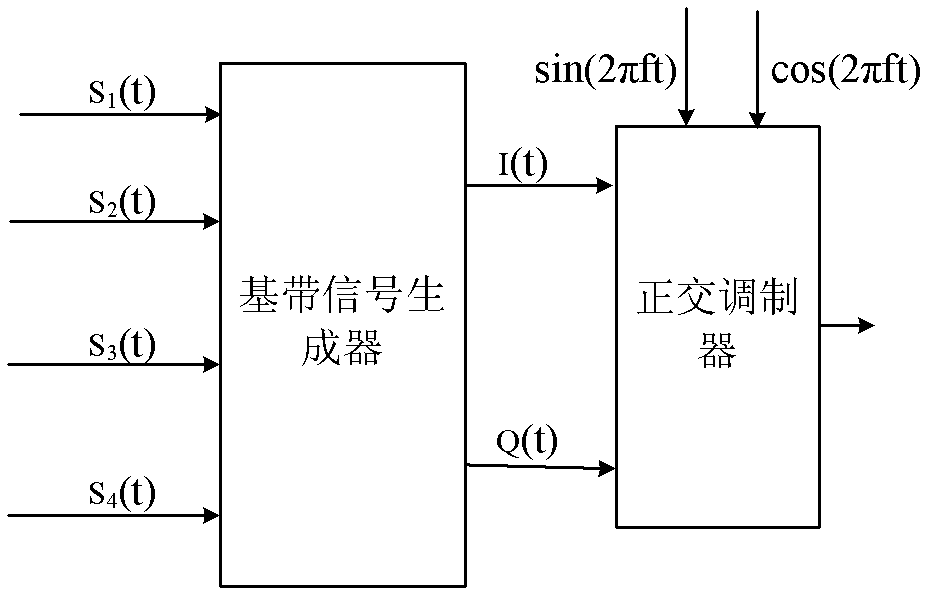

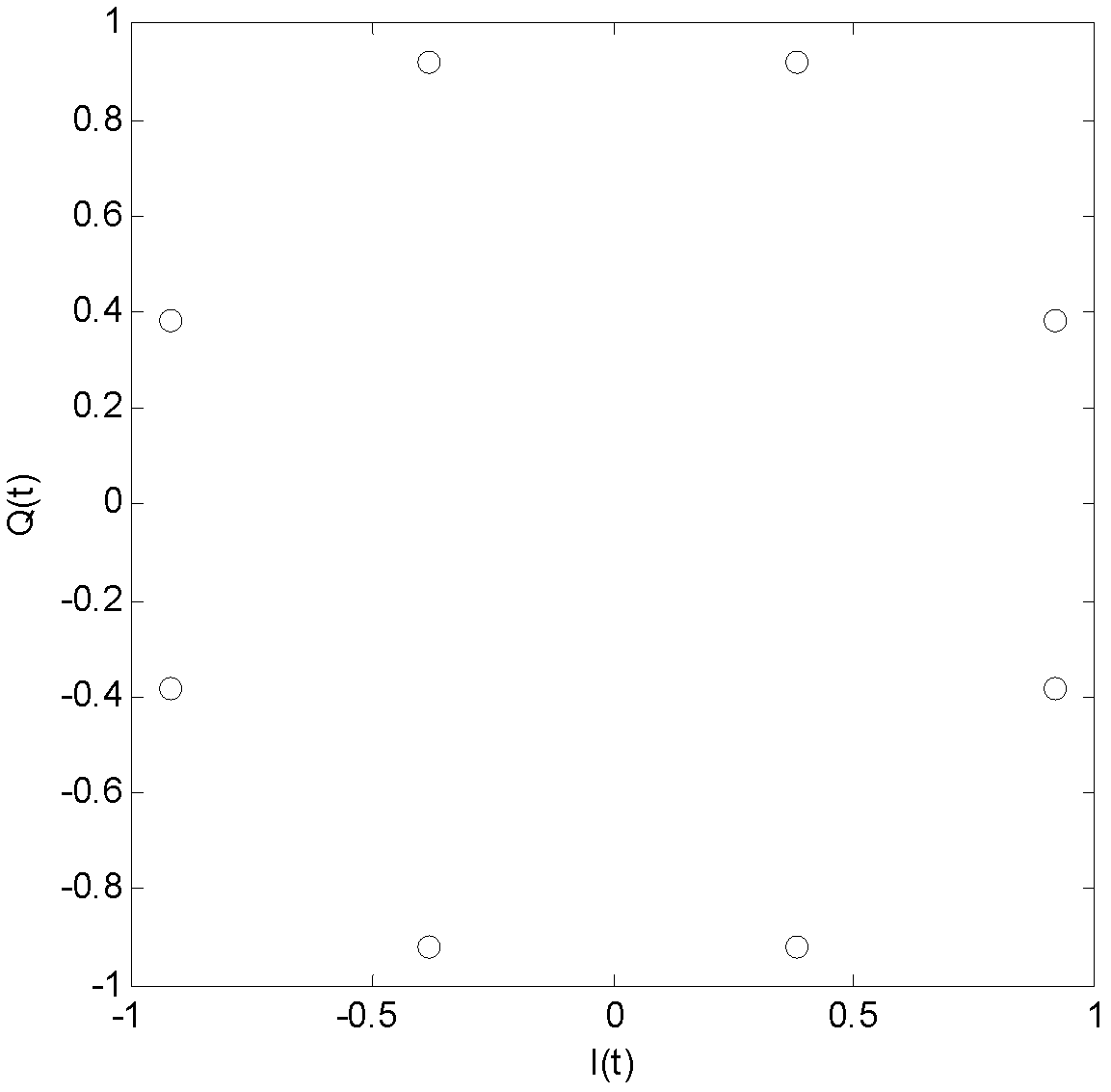

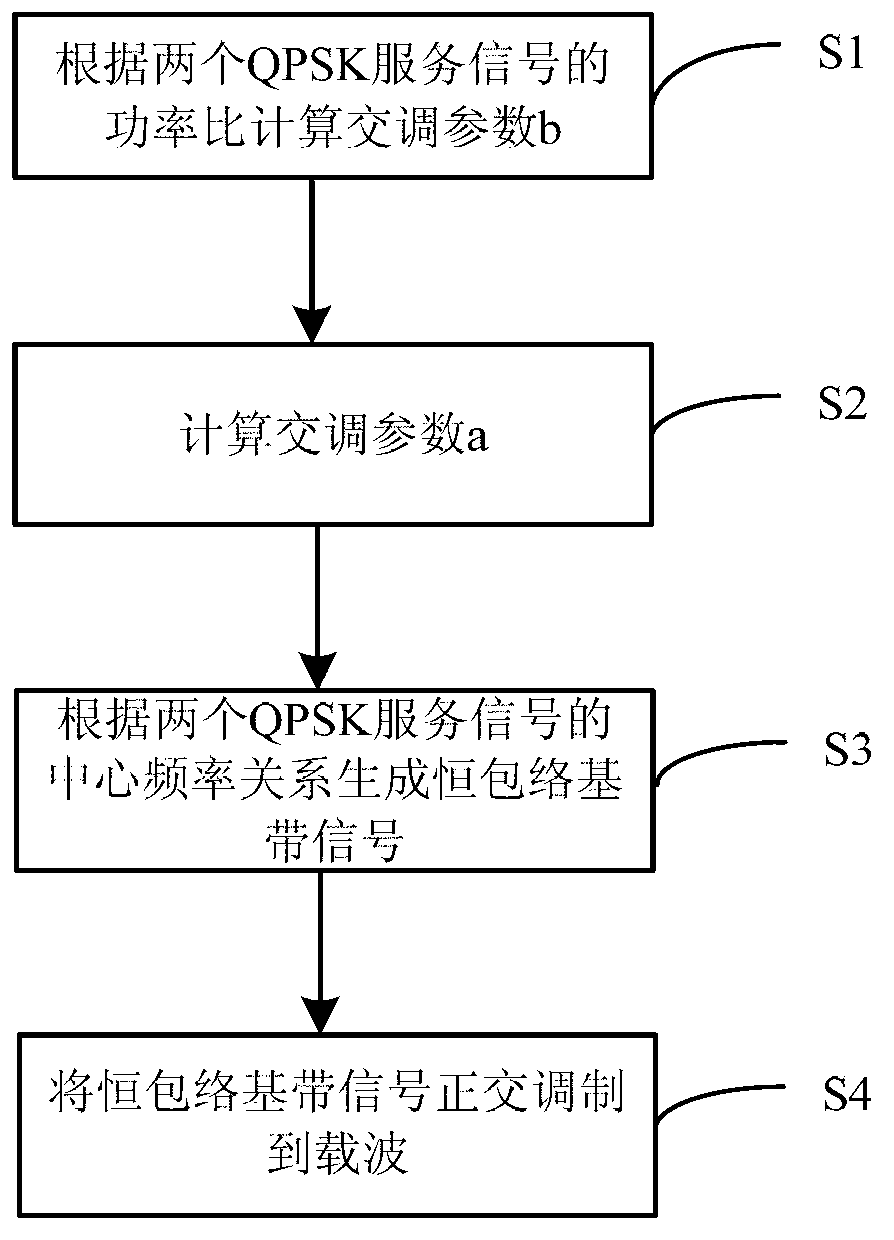

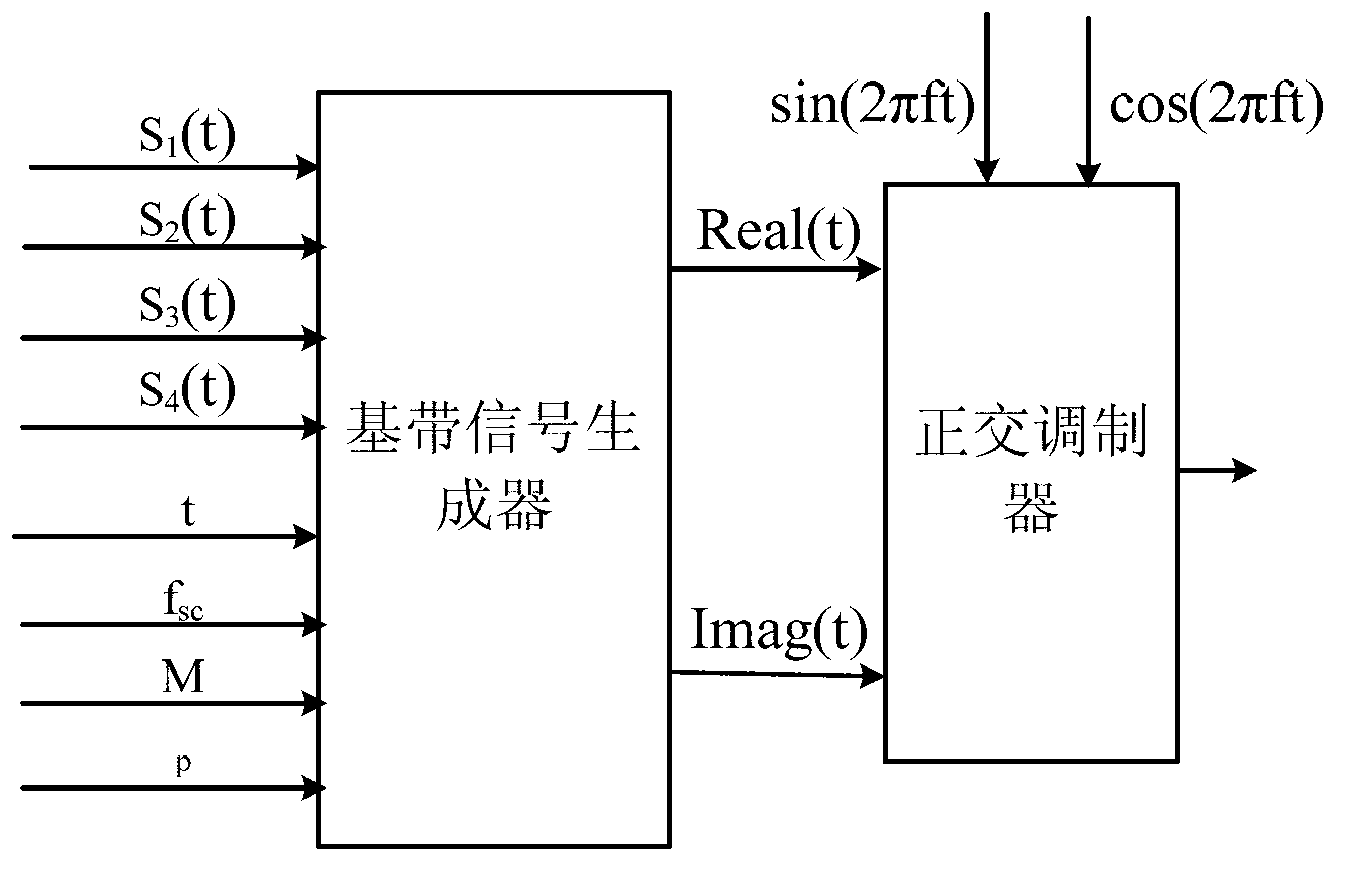

Method and device for modulating dual-quadrature phase shift keying signal

ActiveCN102437985AImprove reuse efficiencySimple stepsPhase-modulated carrier systemsSignal channelsCarrier signalPhase shifted

The invention provides a method for modulating a dual-quadrature phase shift keying signal. The method comprises the following steps of: generating four paths of irrelevant equipower binary service signals S1(t), S2(t), S3(t) and S4(t); combining the four paths of irrelevant equipower binary service signals into a path of base band complex signal S(t) by using the following shown in the specification; and performing quadrature modulation on a real signal and a virtual signal of the base band complex signal S(t) so as to form the dual-quadrature phase shift keying signal. In the method, the four service signals are modulated on the same carrier, so that the constant signal envelopment and the high multiplexing efficiency are realized, and the emission quality and the power efficiency of sequential signals are improved.

Owner:NAT UNIV OF DEFENSE TECH

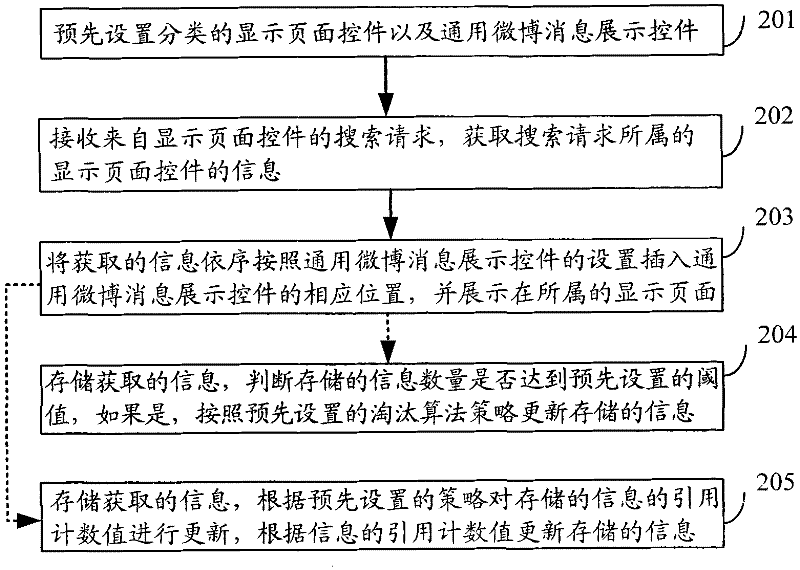

Method and device for searching microblog message

InactiveCN102446193AShorten the timeSave storage spaceData switching networksSpecial data processing applicationsMicrobloggingWorld Wide Web

The invention discloses a method for searching a microblog message, comprising the following steps of: presetting classified display page controls and a universal microblog message show control; receiving a search request from a display page control and obtaining the information of the display page control to which the search request belongs; and interpolating all the obtained information into the corresponding positions of the universal microblog message show control orderly according to the settings of the universal microblog message show control, and showing the same on the respective display pages. The invention also discloses a device for searching a microblog message. With the method and the device provided in the invention, the time of searching a desired microblog message by a user can be reduced, and the experience of the user is enhanced.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Preparation method of Ce2S3/TiO2 nanosheet composite photocatalyst

InactiveCN110038592AEasy to useEasy to recyclePhysical/chemical process catalystsWater/sewage treatment by irradiationWastewaterCerium

The invention relates to a preparation method of a Ce2S3 / TiO2 nanosheet composite. According to the method, a small amount of titanium dioxide is doped into cerium sesquisulphide to obtain a cheap andefficient photocatalyst, and specifically, the Ce2S3 / TiO2 nanosheet composite is prepared from titanium dioxide, cerium nitrate hexahydrate and thioacetamide through a hydrothermal method and a calcination reaction. The Ce2S3 / TiO2 nanosheet composite involved in the invention is capable of rapidly degrading organic pollutant, especially dye organic pollutant in wastewater into pollution-free substances such as H2O and CO2 under normal temperature, normal pressure and illumination, and has lasting photocatalytic activity.

Owner:NANCHANG HANGKONG UNIVERSITY

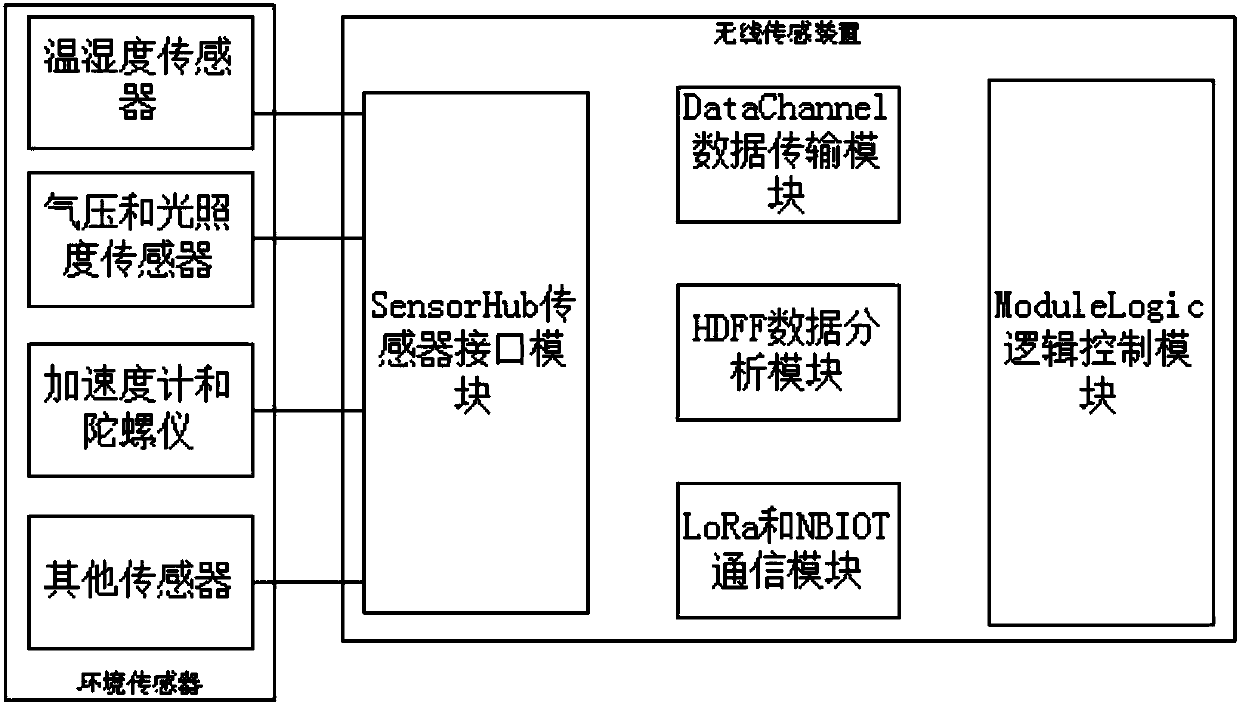

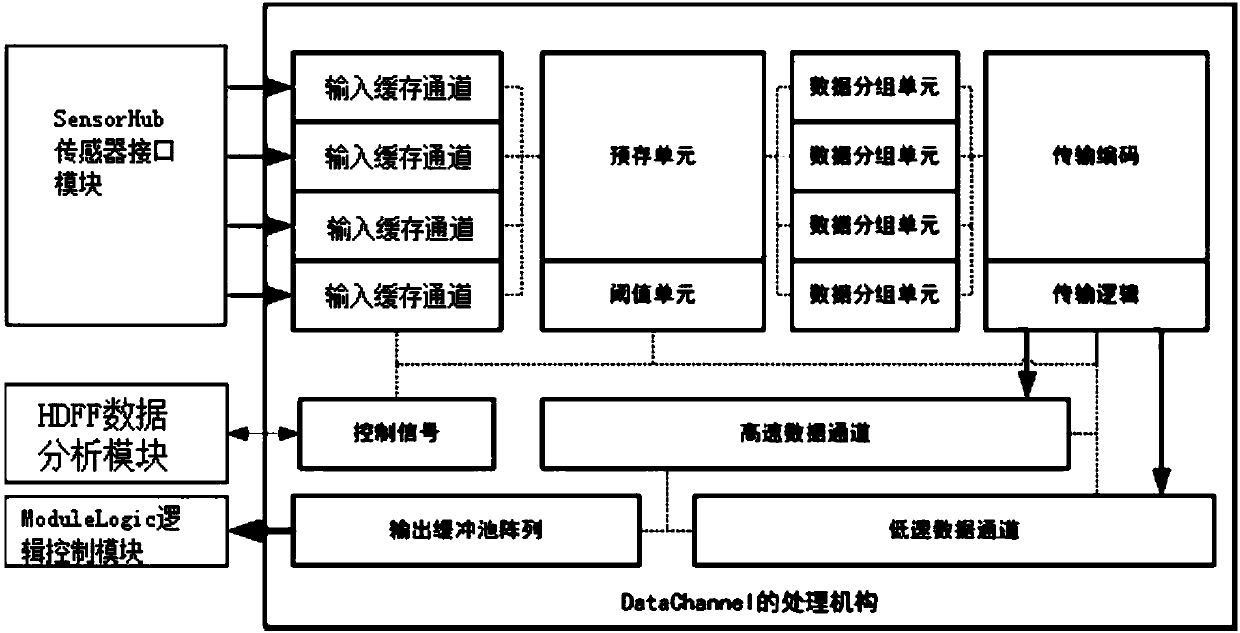

Low-power consumption intelligent wireless sensor and control system thereof

ActiveCN107566468AAvoid complexityReduce power consumptionTransmission systemsTransmissionLine sensorOriginal data

The invention provides a low-power consumption intelligent wireless sensor and a control system thereof. The control system is used for controlling multiple wireless sensing devices; the wireless sensing device comprises a SensorHub sensor interface module, a DataChannel data transmission module, a ModuleLogic logic control module, an HDFF data analysis module and a LoRa and NBIOT communication module; multiple interfaces of the wireless sensing device can be connected with multiple kinds of sensors simultaneously, uniformly preprocess and convert data of the sensors, include universal compatible interfaces of the sensors and are reused on a hardware circuit maximally; and data processing model logic is contained, the process that the original data of the sensors is calculated to obtain model results is processed on local equipment without uploading all the mass original data to a background to be processed, and therefore the bandwidth burden and the background complexity are avoided.

Owner:山西农谷科芯农业科技有限公司

Nano-Pd magnetic catalyst, its preparation method, and its use in liquid phase catalysis reaction

InactiveCN103586048AAvoid churnHigh activityOrganic compound preparationCarboxylic acid esters preparationActive componentSodium silicate

The invention relates to a nano-Pd magnetic catalyst, its preparation method, and its use in a liquid phase catalysis reaction, and belongs to the technical field of nanometer magnetic catalysts. A super-paramagnetic Fe3O4 core is made, a layer of meso-porous SiO2 is formed on the layer of the magnetic Fe3O4 core by adopting an ultrasonic wave method with cetyltrimethylammonium bromide as a template and sodium silicate as a silicon source, the obtained material is dried, and the material is roasted under the protection of N2 to remove the template in order to prepare a magnetic SiO2@Fe3O4 nanosphere. A Pd catalysis active component is assembled on the meso-porous SiO2 shell on the surface of the magnetic SiO2@Fe3O4 nanosphere by adopting the ultrasonic wave method with the magnetic SiO2@Fe3O4 nanosphere as a core to prepare the magnetic Pd / SiO2@Fe3O4 catalyst. Pd catalysis active component particles are embedded in meso-porous SiO2 to form a highly dispersed nano-Pd catalysis active component, so the activity of the catalyst is improved, and the loss of Pd in the reaction process is avoided.

Owner:BEIJING UNIV OF CHEM TECH

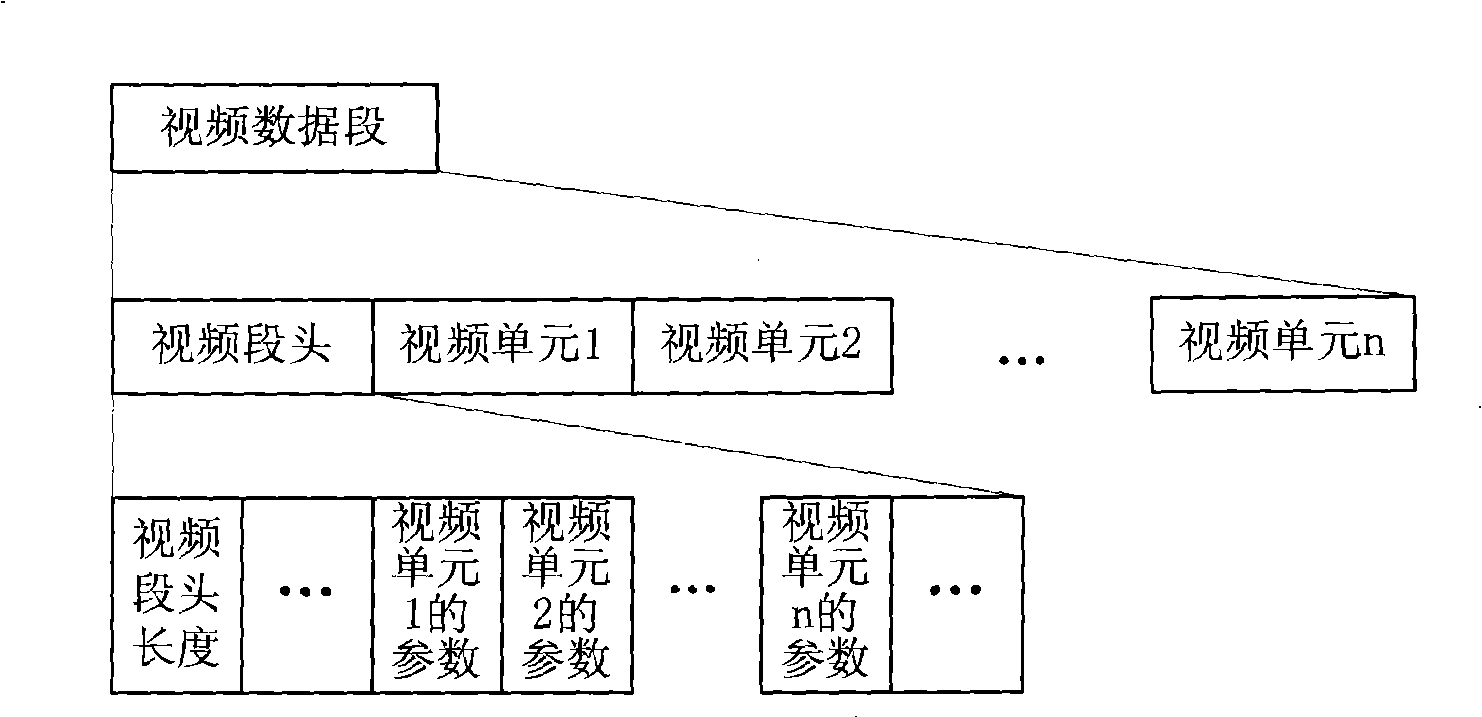

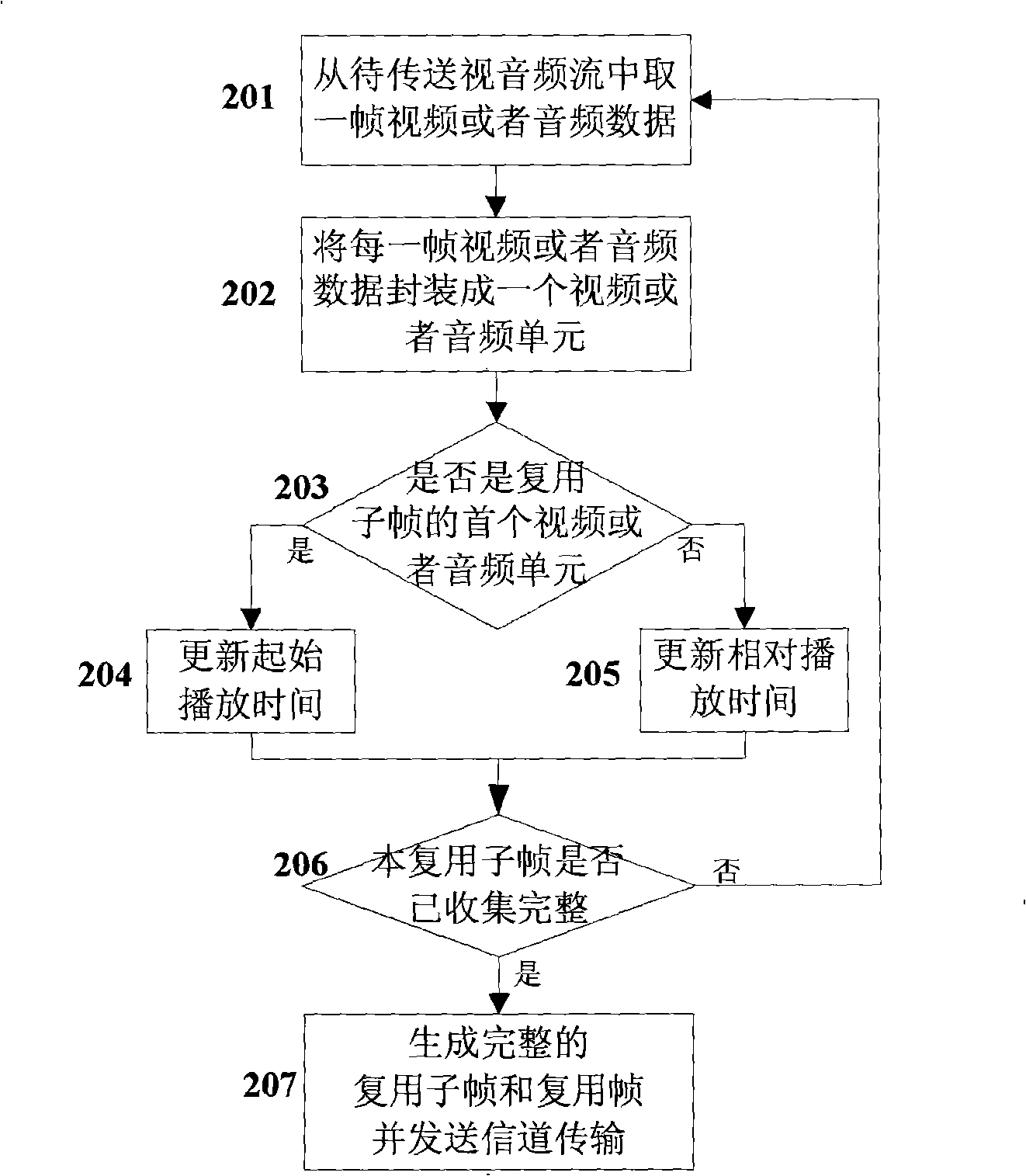

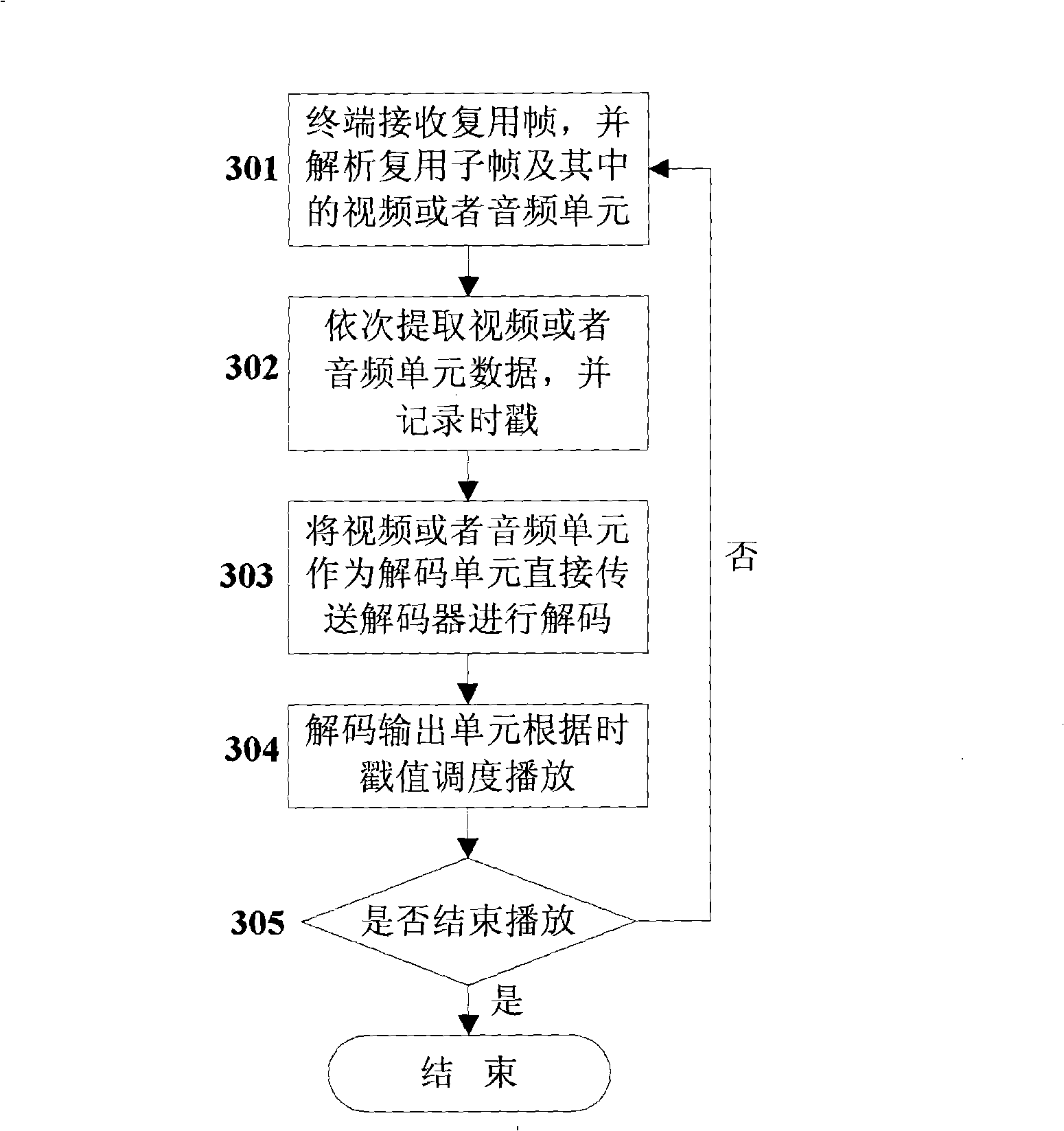

Transmission method and system for video/audio data flow

InactiveCN101272500AImprove reuse efficiencyImprove demultiplexing performancePulse modulation television signal transmissionTime informationMultiplexing

The invention discloses a transmission method and a system of a video-audio data stream, which relates to the mobile streaming media field. The transmission method of the video-audio data stream proposed by the invention orderly writes one frame data which can be decoded and is provided with the same time stamp into a multiplex subframe after being encapsulated into a video or an audio unit from a video or an audio stream waiting to be transmitted according to the frame boundary, The playing time information of each video or audio unit is recorded in the multiplex subframe, and the generated multiplex subframe is sent to a terminal. The method of the invention can increase the CMMB multiplexing efficiency, reduce the playing delay of the terminal and improve the de-multiplexing performance of the terminal.

Owner:ZTE CORP

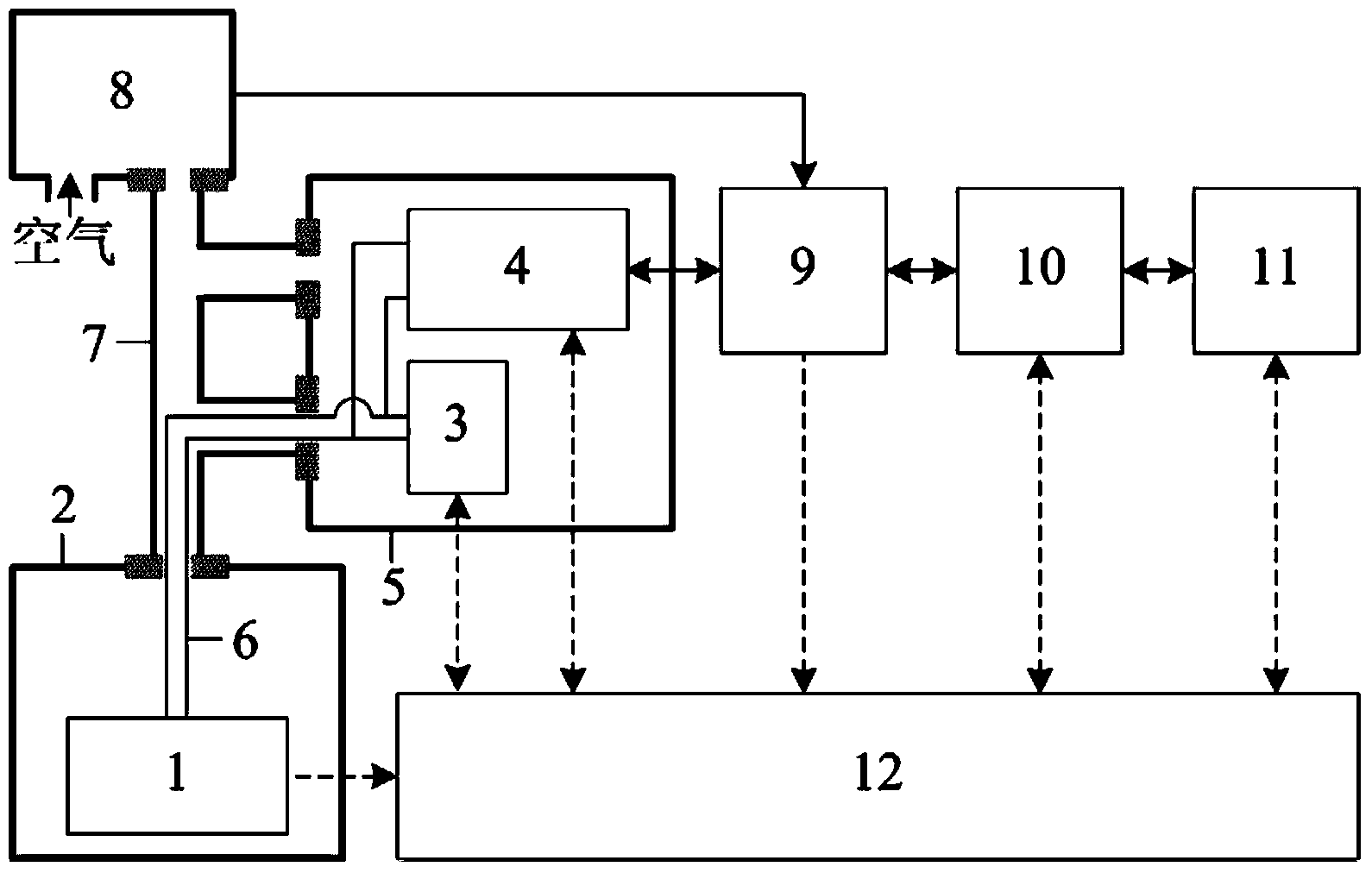

Energy recycling system and method for liquid hydrogen fuel cell car

InactiveCN103754130AImprove recycling efficiencyImprove reuse efficiencyElectrodynamic brake systemsVehicular energy storageFull bridgeControl system

The invention discloses an energy recycling system and method for a liquid hydrogen fuel cell car. The system comprises a superconducting coil, a superconducting switch, a full-bridge type direct current chopper, a superconducting current lead, a direct current link capacitor, a DC-AC bilateral transducer, a vehicle-mounted motor and a measurement and control system, wherein the superconducting coil is immersed in a liquid hydrogen container, the superconducting switch and the full-bridge type direct current chopper are installed in a low-temperature Duval, and the superconducting current lead, the direct current link capacitor, the DC-AC bilateral transducer, the vehicle-mounted motor and the measurement and control system are arranged in a low-temperature hydrogen pipeline. The superconducting current lead is used for connecting the superconducting coil, the superconducting switch and the full-bridge type direct current chopper. The low-temperature hydrogen pipeline is used for connecting a liquid hydrogen fuel cell, the liquid hydrogen container and the low-temperature Duval. Compared with the prior art, the energy recycling system has the advantages that the superconducting coil is cooled directly through vehicle-mounted liquid hydrogen, the superconducting current lead, the superconducting switch and the full-bridge type direct current chopper are cooled directly through the low-temperature hydrogen produced through gasification of the vehicle-mounted liquid hydrogen, a supermumetal energy storing device is actually used in the liquid hydrogen fuel cell car, the brake energy recycling and reutilizing ratio of the car is improved, and staring time and accelerating time of the car are shortened.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

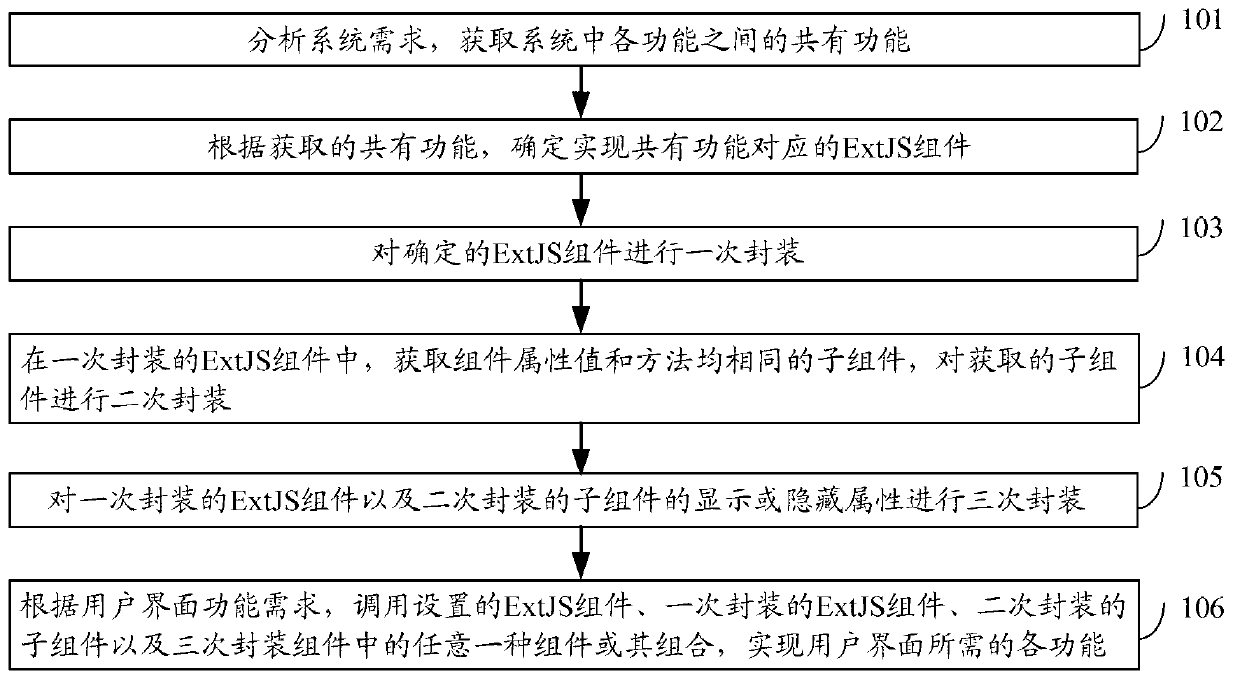

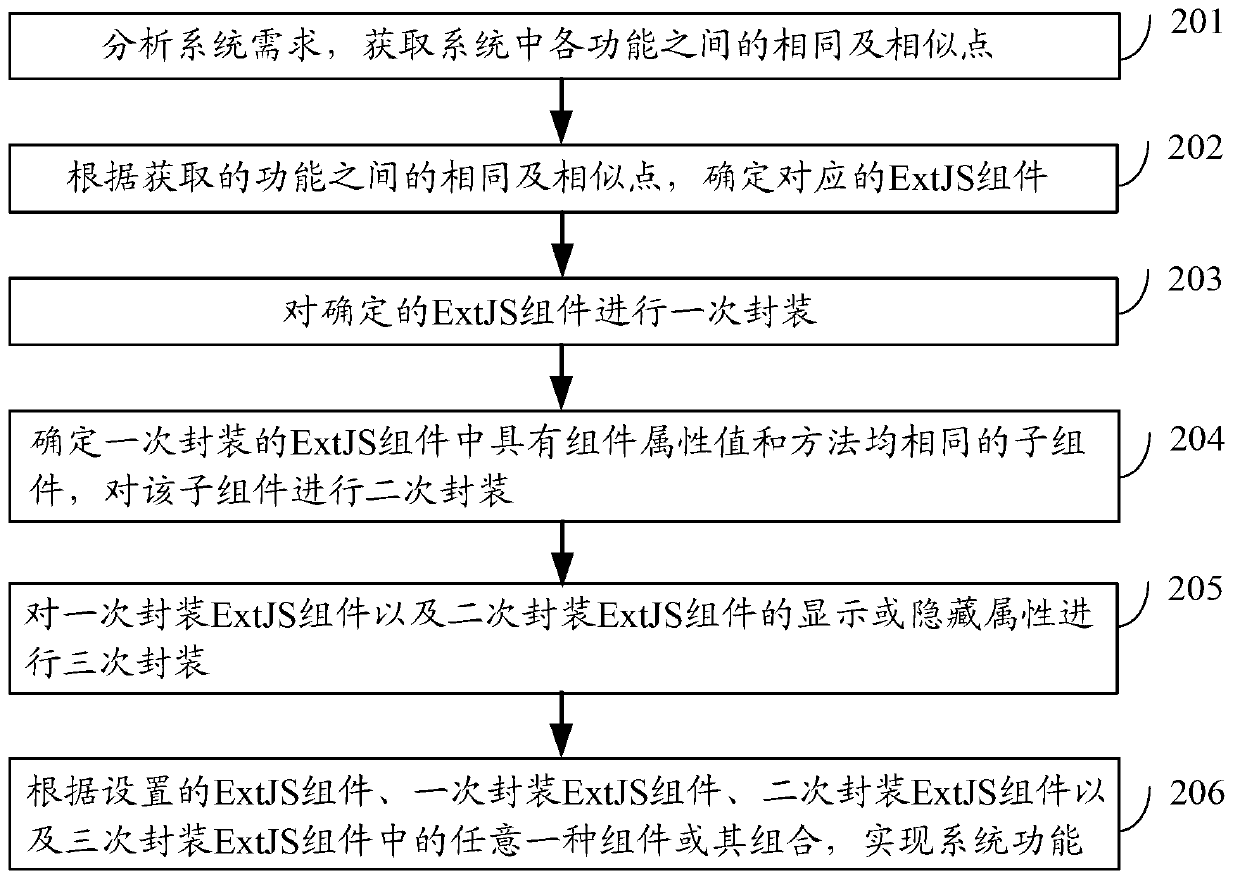

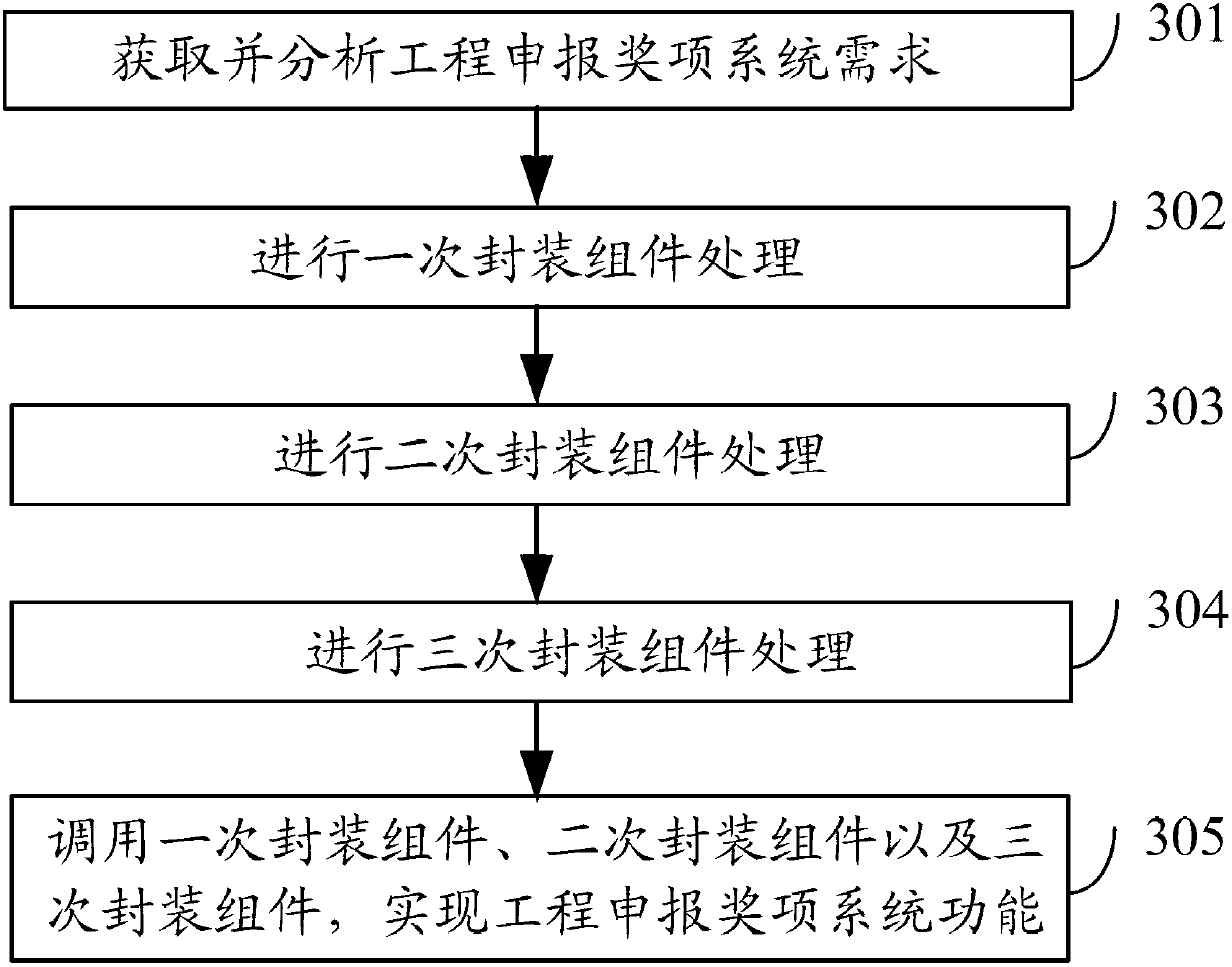

Module reuse achievement method based on module packaging

ActiveCN103345387ARealize system functionsReduce workloadSpecific program execution arrangementsEmbedded systemSystem requirements

The invention discloses a module reuse achievement method based on module packaging. The module reuse achievement method based on the module packaging comprises the steps of (1) analyzing the system requirement, obtaining a common function of functions in a system, (2) determining a corresponding ExtJS module for achieving the common function according to the obtained common function, (3) carrying out primary packaging on the determined ExtJS module, (4) obtaining sub-modules with the same module attribute value and the same method in the ExtJS module after the primary packaging, carrying out secondary packaging on the obtained sub-modules, (5) carrying out third packaging on shown or hidden attributes of the ExtJS module after the primary packaging and the sub-modules after the secondary packaging, and (6) calling any one or the combination of the set ExtJS module, the ExtJS module after the primary packaging, the sub-modules after the secondary packaging and a module after the third packaging to achieve the functions needed by a user interface according to the functional requirement of the user interface. When the module reuse achievement method based on the module packaging is applied, efficiency of the module reuse can be improved.

Owner:NO 15 INST OF CHINA ELECTRONICS TECH GRP

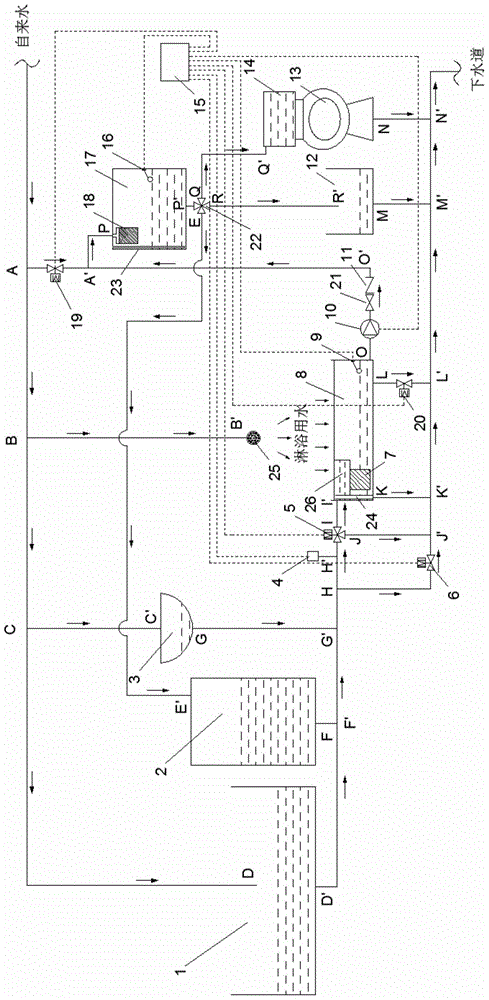

Bathroom sewage omni-directional recycling and automatic cyclic utilization system

InactiveCN104695513AMaximize recoveryNo wasteDomestic plumbingMultistage water/sewage treatmentAutomatic controlWater storage tank

A bathroom sewage omni-directional recycling and automatic cyclic utilization system comprises a sanitary ware sewage module, a primary recycling and processing module, a secondary recycling and processing module and a recycled water reuse module. The primary recycling and processing module comprises a primary lower water storage tank with a primary filter device. The secondary recycling and processing module comprises a secondary high water storage tank with a secondary filter device. Sewage generated by the sanitary ware sewage module enters a sewer or a sewage isolation chamber, the sewage in the sewage isolation chamber enters the primary lower water storage tank after being filtered through the primary filter device and then is conveyed to the secondary high water storage tank through a water pump to be secondarily filtered through the secondary high water storage tank, and secondarily filtered water is conveyed to the recycled water reuse module to achieve reuse. The bathroom sewage omni-directional recycling and automatic cyclic utilization system further comprises a pipe valve conveying module and an automatic control module, so that automatic cyclic utilization is achieved, and water resources are saved.

Owner:XI'AN PETROLEUM UNIVERSITY

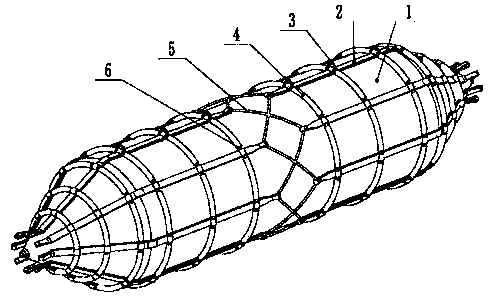

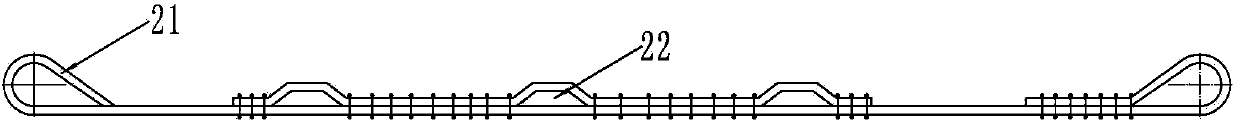

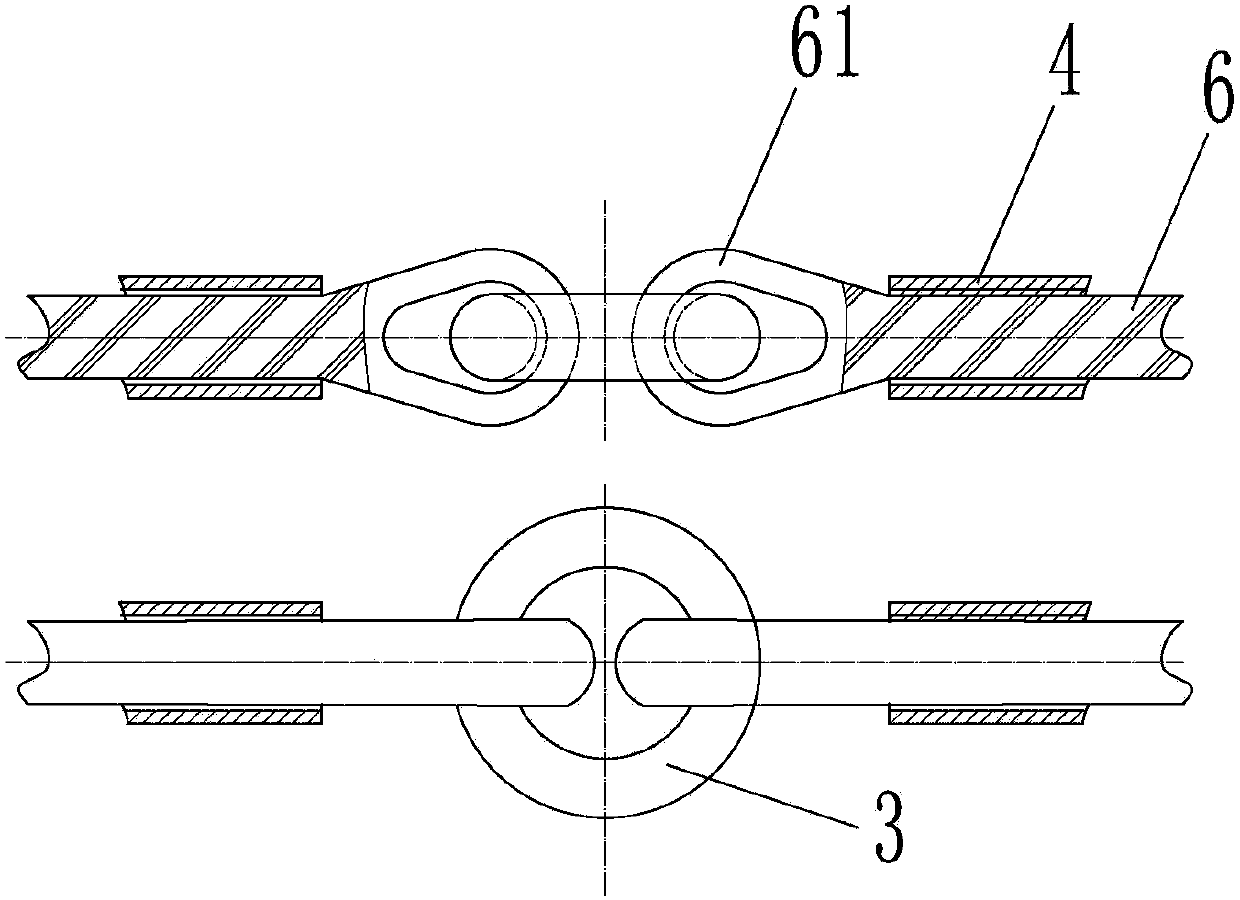

Net cover structure of engineering air bag

InactiveCN103963937ARealize buoyancy aid bindingEnsure safe workVessel salvagingSpecial purpose vesselsMarine engineeringMechanical engineering

The invention discloses a net cover structure of an engineering air bag. The movable net cover structure is formed by longitudinal hanging bands 2 and transverse hanging bands 5. The transverse hanging bands 5 penetrate through inner holes of rubber pipes 4 and fixing holes in the longitudinal hanging bands 2 to realize even distribution and limiting, on the circumference of a bag body, of the longitudinal hanging bands 2 in the circumferential direction. The two ends, located on the air bag 1, of each longitudinal hanging band 2 are provided with hanging lugs, the other end of each longitudinal hanging band 2 is located in the middle of the bag body and longitudinal tensioning of the longitudinal hanging bands 2 is realized by winding rope 5 in a crossed mode. The net cover structure can be fixedly bonded on an air bag with any diameter, and multi-point bearing binding of lateral floating force when the air bag is placed horizontally and single-point bearing binding of axial floating force when the air bag is placed longitudinally are realized. The net cover structure can be installed, disassembled and transported on the air bag easily, and the problem that floating-assisting binding cannot be conducted on large-diameter air bags is solved. The net cover structure is reasonable in stress, improves the construction safety, is high in reutilization rate, reduces construction investment and has wide application prospects in the fields such as ocean engineering construction and boat fishing.

Owner:SHANDONG NANHAI AIRBAG ENG

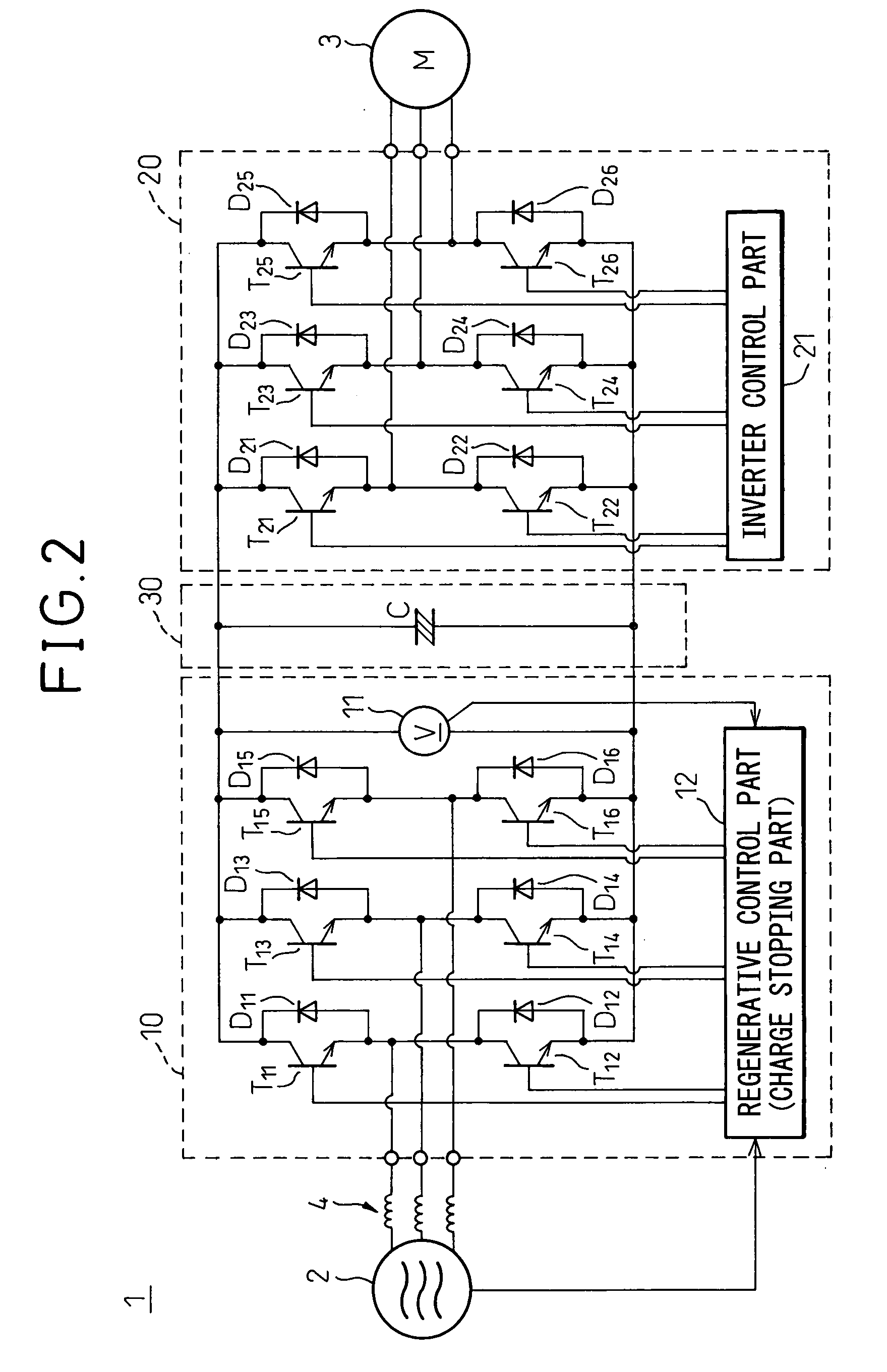

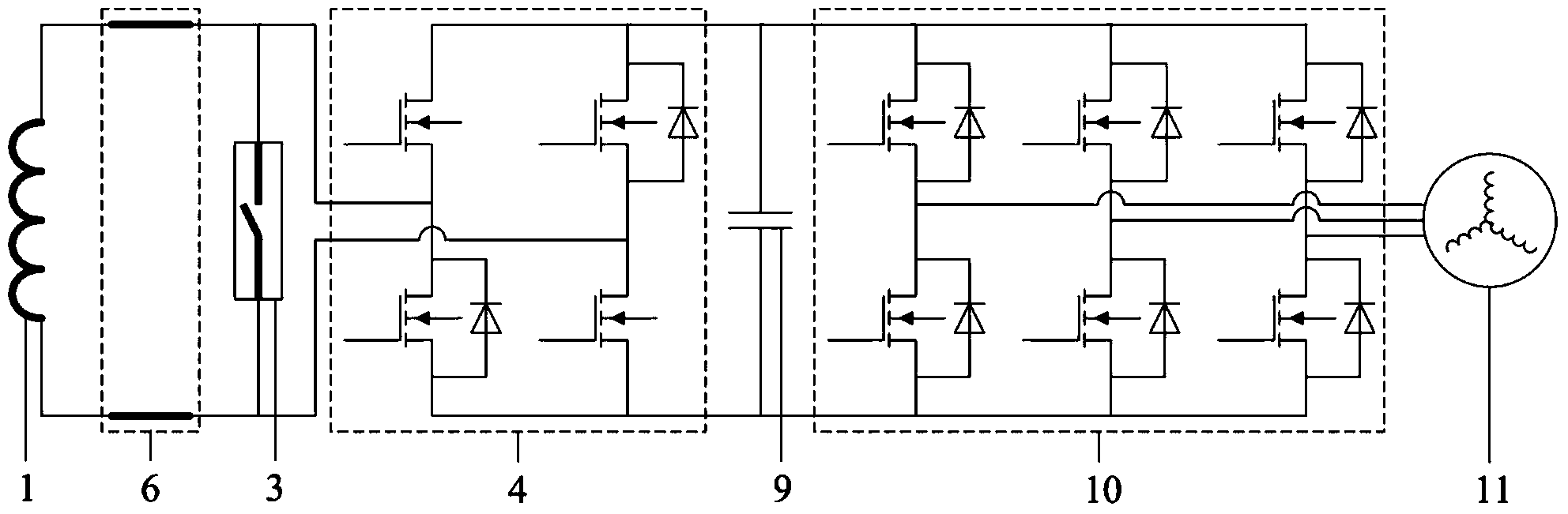

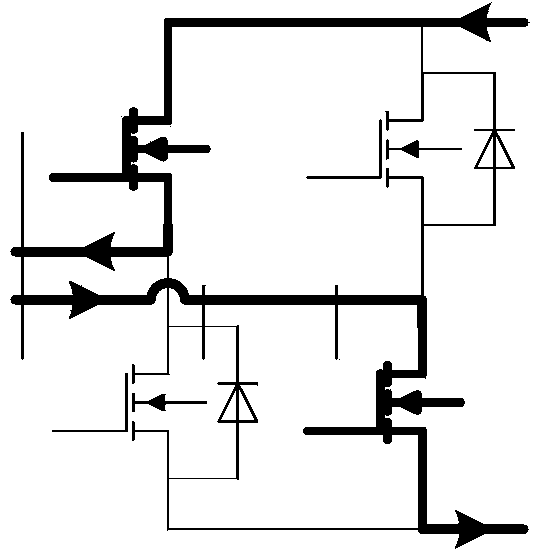

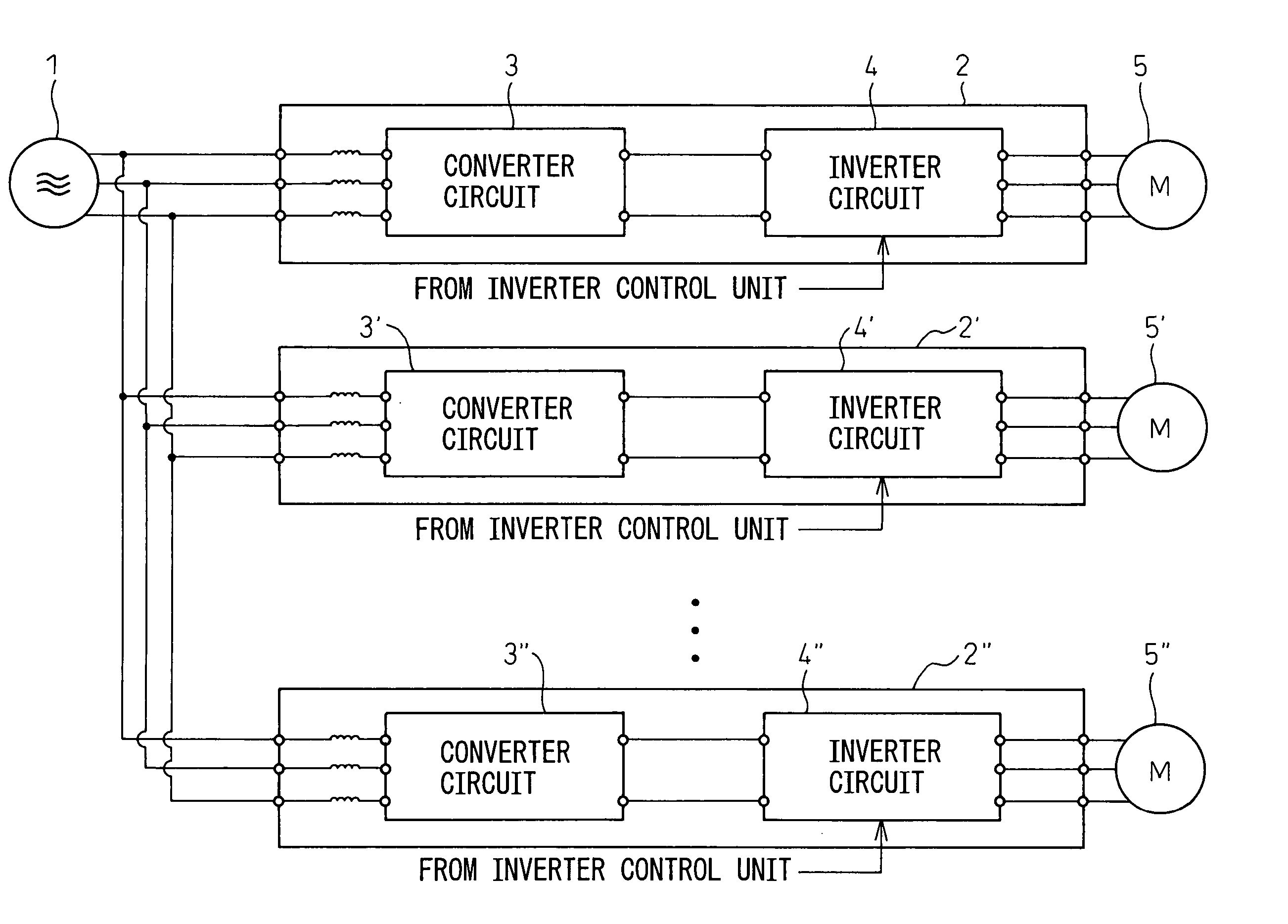

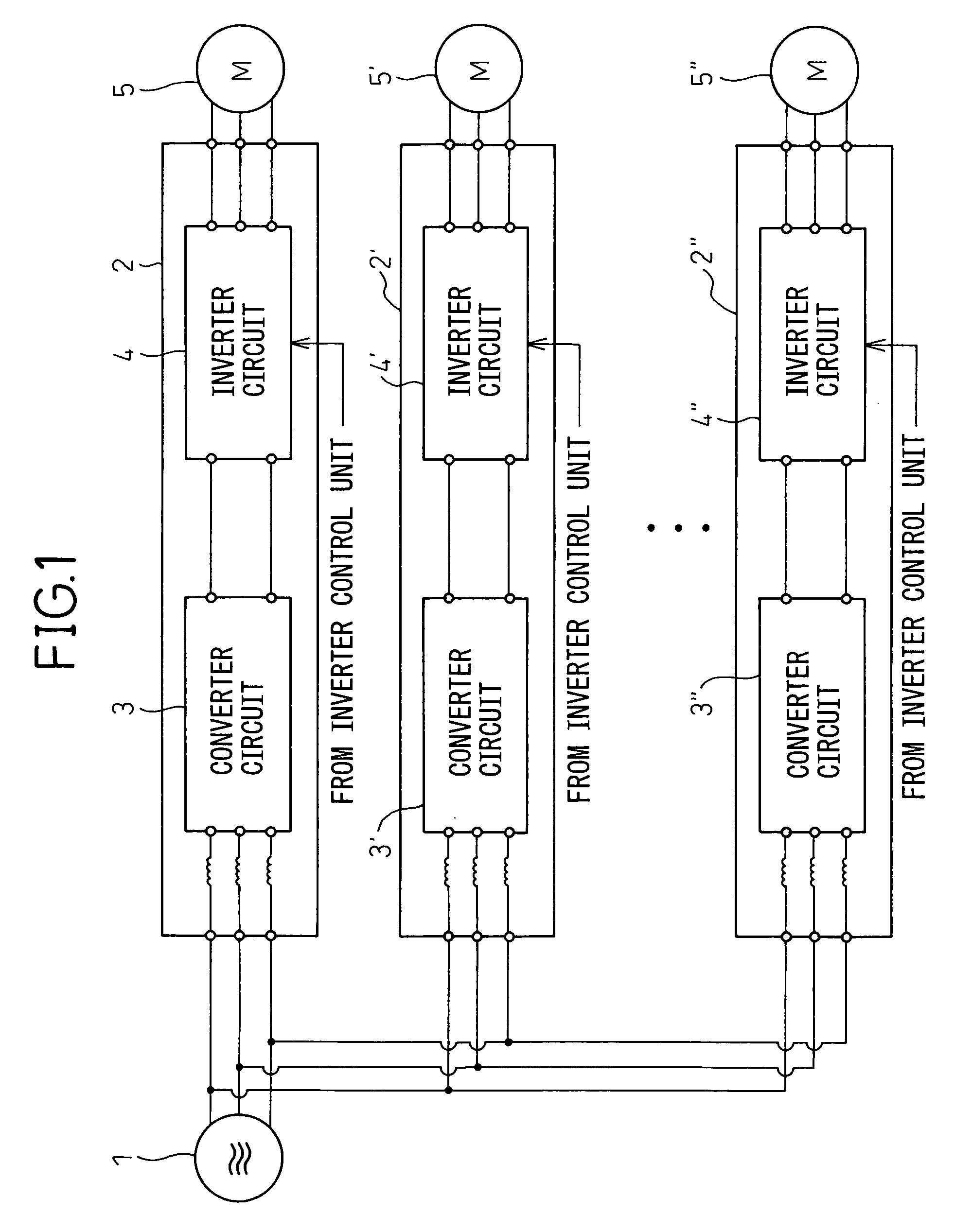

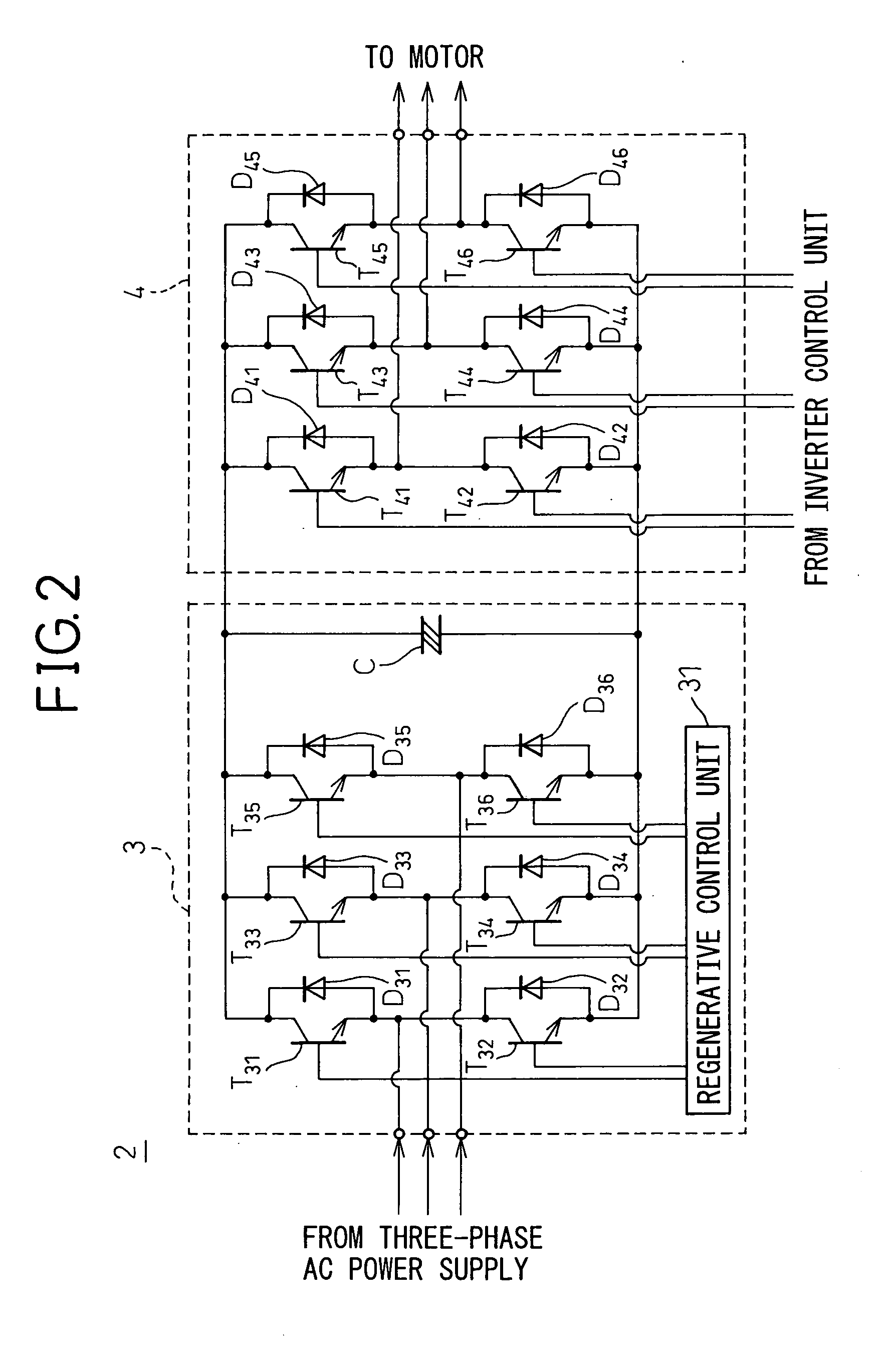

Servo motor driving apparatus and servo motor driving method

InactiveUS20060038524A1Improve reuse efficiencyMultiple ac dynamo-electric motors controlField or armature current controlMotor driveAlternating current

An object of the present invention is to provide a servo motor driving apparatus and a servo motor driving method for driving a plurality of servo motors, wherein provisions are made to improve the reuse efficiency of servo motor regenerative energy. The servo motor driving apparatus (2) comprises: a plurality of inverter circuits (4, 4″, 4″) which supply AC power to the plurality of servo motors (5, 5′, 5″), respectively; a converter circuit (3) which supplies electric power in common to the inverter circuits (4, 4′, 4″); and an inverter control unit (6) which, when giving an acceleration command to any one of the servo motors, gives a deceleration command to another one of the servo motors at the same time.

Owner:FANUC LTD

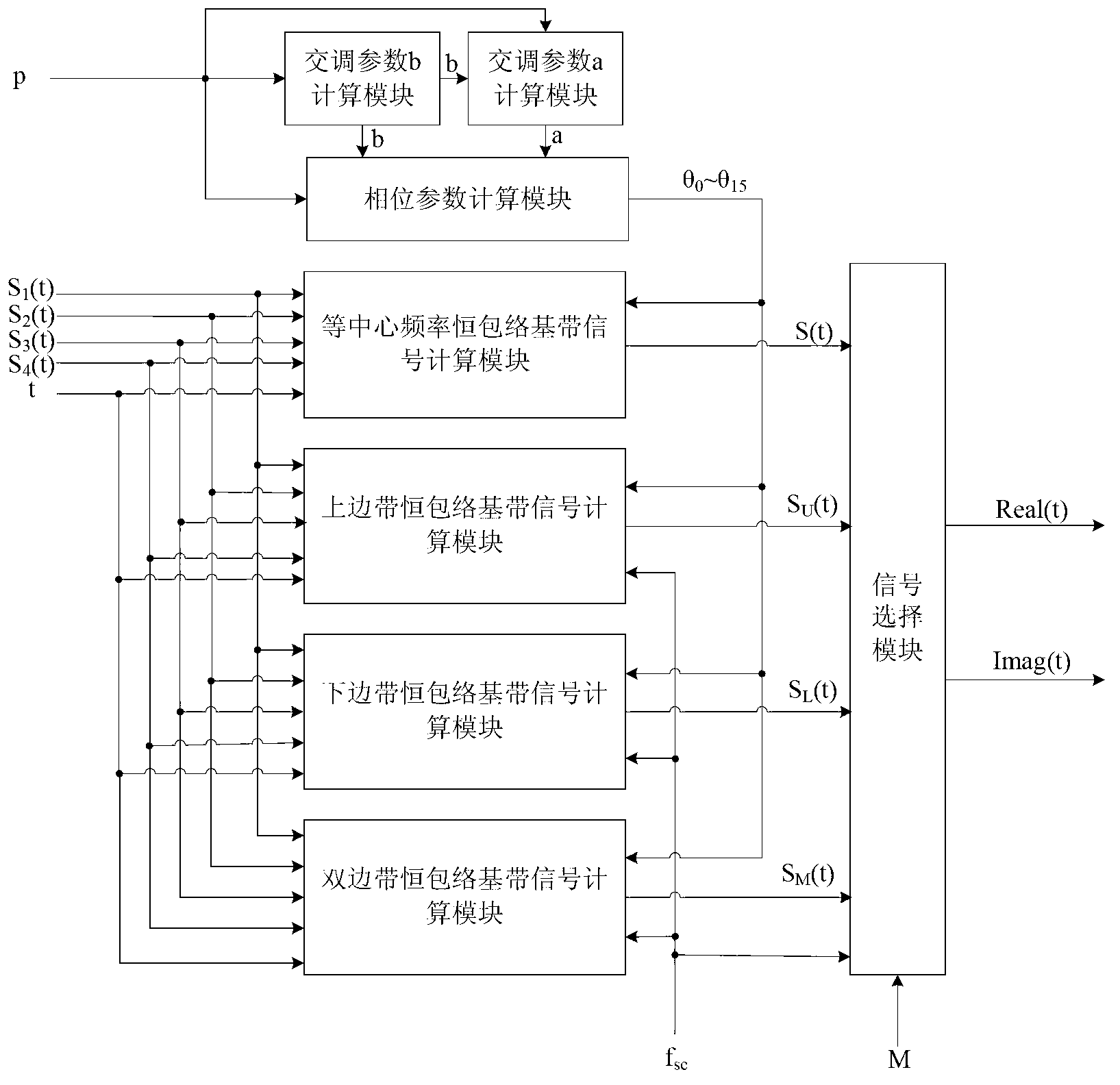

Non-equal power quadrature phase shift keying signal modulation method and device

ActiveCN103297380AIncrease flexibilitySimple stepsMultiple carrier systemsQuadrature modulatorCarrier signal

The invention provides a non-equal power quadrature phase shift keying signal modulation method and device. The modulation method includes four steps of S1, calculating an intermodulation parameter b according to power ratio of two quadrature phase shift keying service signals; S2, calculating an intermodulation parameter a; S3, generating constant envelope baseband signals according to center frequency relation of the two quadrature phase shift keying service signals; S4, modulating the constant envelope baseband signals to a carrier in a quadrature manner. The modulation device comprises a baseband signal generator and a quadrature modulator. The baseband signal generator combines two channels of non-equal power quadrature phase shift keying service signals into one channel of constant envelope baseband signals. The quadrature modulator modulates the constant envelope base signals in a quadrature manner and outputs the same. The two non-equal power quadrature phase shift keying service signals are modulated to one carrier according to the given power ratio and the center frequency relation, constant signal envelope and high multiplexing efficiency are realized, and signal transmitting quality and power efficiency are improved.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com