Patents

Literature

358results about How to "Controllable size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing nanometer silica micropowder

InactiveCN101659393AControllable sizeReduce manufacturing costNanostructure manufactureIndustrial scaleFilter cake

The invention discloses a method for preparing nanometer silica micropowder, and relates to the technical field of nano-powder preparation. The method comprises the following steps in particular: carrying out magnetic separation and acid pickling on quartz sand raw material after coarse grinding to remove impurity, wherein, the mass fraction of the silicon dioxide in the quartz sand is not less than 99.5%; carrying out wet process grinding to obtain grinding slurry; and naturally sedimenting after deironing by magnetic separation; separating sediment by the mechanical settlement method; and then sending the sediment back to the step of wet process grinding for grinding anew; meanwhile, adding dispersing agent into suspended matter slurry with the sediment thereof being removed; adopting high energy ultrasound dispersion; filter pressing the suspending liquid to obtain filter cakes; grinding the filter cakes by adopting extra-fine grinding method; speeding up sediment by centrifugal separation to separate extra-fine grinding sediment; sending the extra-fine grinding sediment to the step of extra-fine grinding for grinding anew; removing extra-fine grinding size of the sediment; obtaining filter cakes by filter pressing; drying to obtain the nanometer silica micropowder; and realizing size grading of the nanometer silica micropowder by adjusting centrifugal separation speed. Themethod of the invention has simple process and convenient operation, is suitable for industrial scale continuous production; the size of the nanometer silica micropowder can be controlled, and products with different specifications can be conveniently produced.

Owner:JIANGSU UNIV

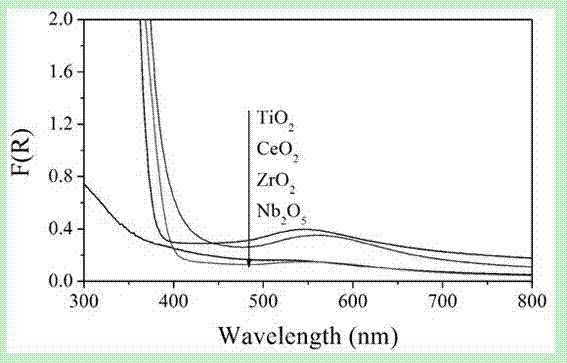

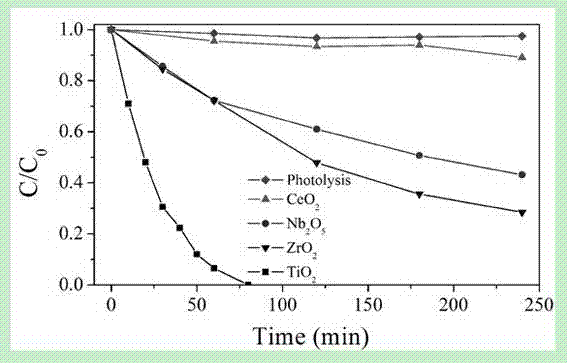

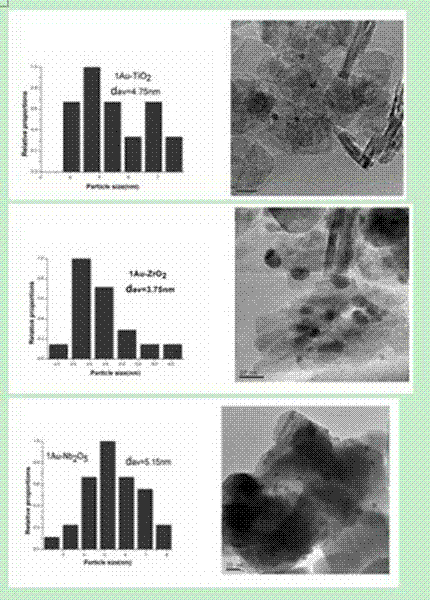

Preparation method of visible light catalyst with surface plasmon effect and application thereof

InactiveCN102350346AEfficient depositionControllable sizeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive componentNanoparticle

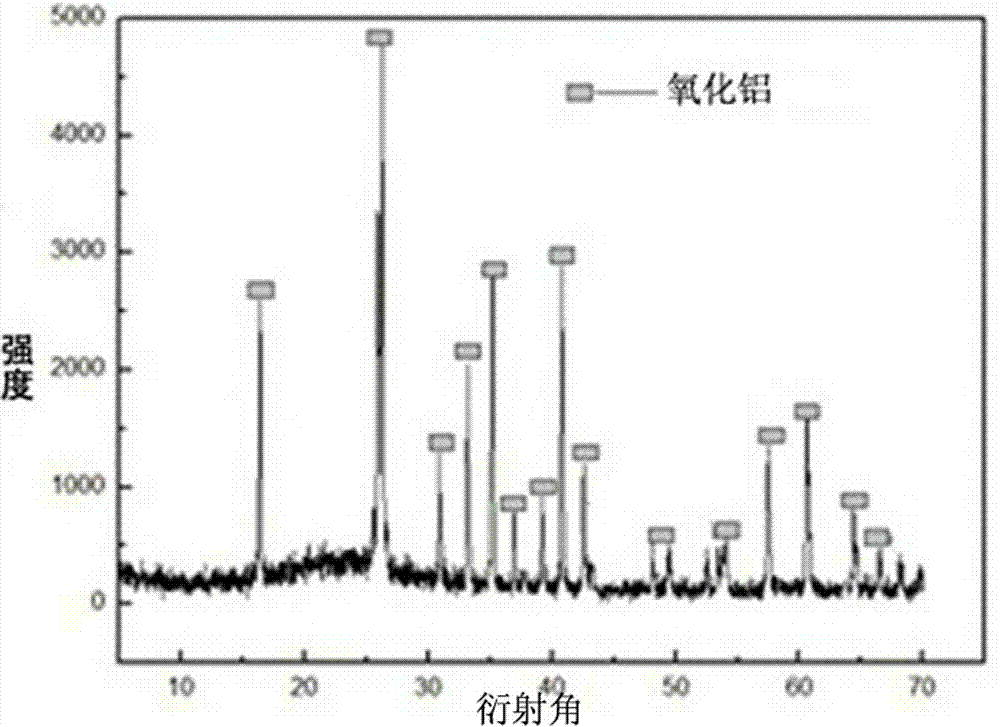

The invention relates to a preparation method of a visible light catalyst with a surface plasmon effect and application thereof. The active component of the visible light catalyst is a precious metal Au, and the carrier is one of TiO2, CeO2, Nb2O5, SiO2, Ta2O5, Al2O3 and ZrO2, wherein, Au accounts for 0.2-5% in mass content, and the particle size of Au particle is 2-20nm. Preparation of the catalyst consists of two steps: the first step is to prepare a carrier; the second step is to prepare an Au / TiO2 (CeO2, SiO2, Al2O3, Nb2O5, Ta2O5, ZrO2) visible light catalyst with a plasmon effect througha sol precipitation method. Au nanoparticles prepared by the method of the invention have good dispersibility, easily controllable size, high active component utilization rate, as well as the effect of high efficiency photocatalytic degradation of organic pollutants by visible light.

Owner:FUZHOU UNIV

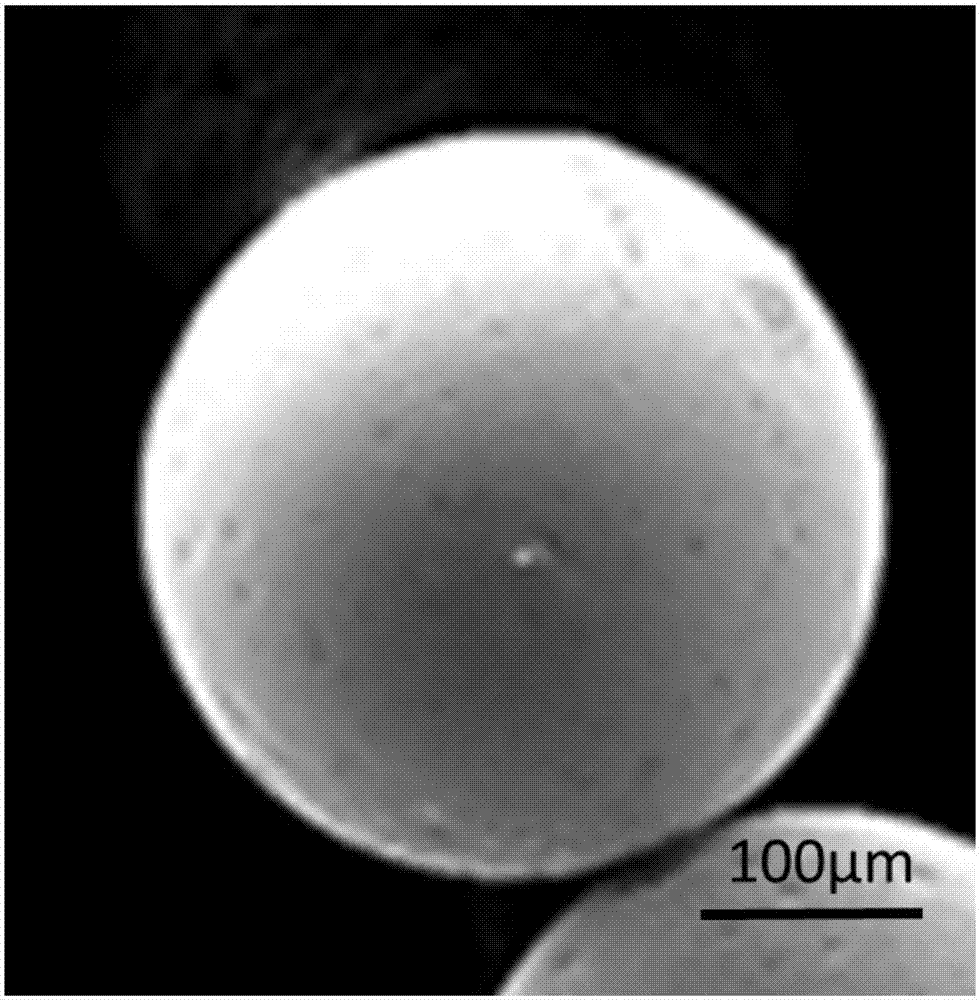

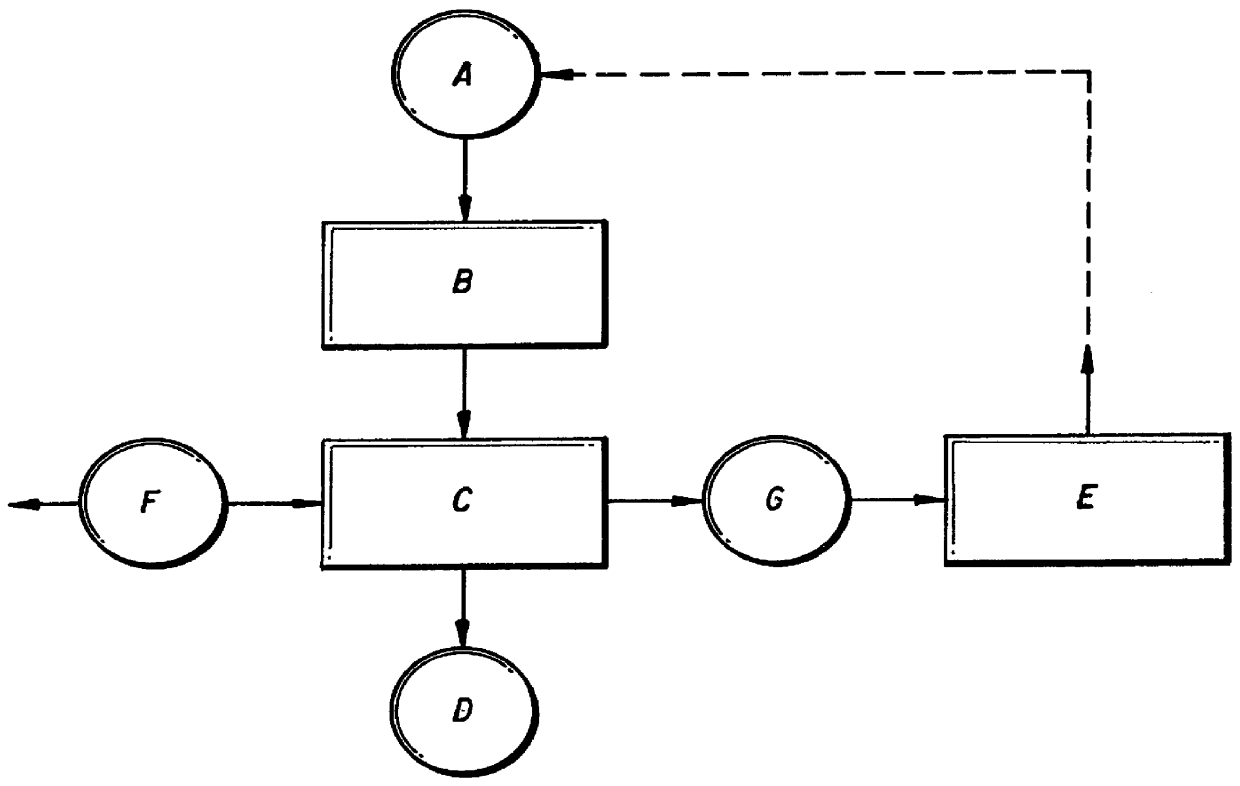

Method for self-assembling preparing colloidal photonic crystals and improving mechanical stability

InactiveCN101280455ALarge specific surface areaMeet the requirements of special useFrom gel stateMicroballoon preparationEvaporationSolvent

Disclosed is a self-assembly and preparation device of colloidal photonic crystals and the method thereof to improve the mechanical stability; the colloidal particle solution is distributed to a continuous phase and in the formation of colloidal solution droplets. Through the evaporation of the solution in the droplet, the colloidal particle in the solution is self-assembled to become the colloidal photonic crystal while the droplet is taken as a template. For the mechanical stability of the photonic crystal, the mutual cementation of the colloidal particles inside a crystal is greatly enhanced through the heat treatment. The three-dimensional colloidal photonic crystals with high mechanical stability and prepared through such a method has a potential value in the aspects of size exclusion chromatography, enzyme or zymophore, adsorption medium, bio-molecule detection carrier, filter, light switches, photonic paper and so on.

Owner:SOUTHEAST UNIV

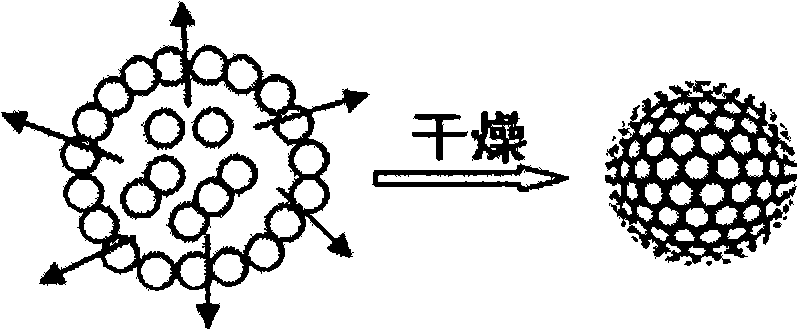

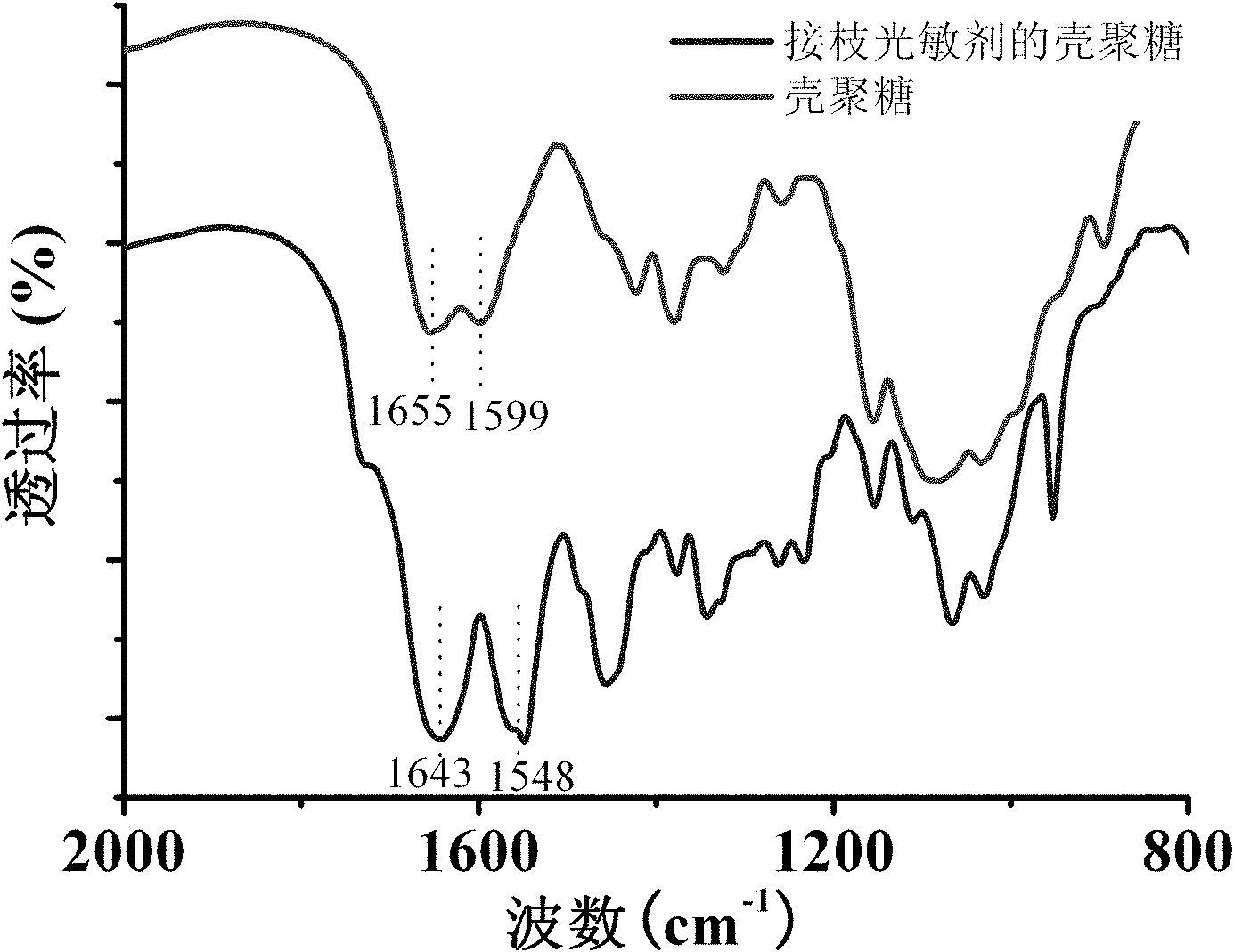

Photosensitive microcapsule used for photodynamic therapy and preparation method thereof

InactiveCN102133208AIncrease surface chargeEasy to assembleEnergy modified materialsPharmaceutical non-active ingredientsCancer cellMicrosphere

The invention discloses a photosensitive microcapsule used for photodynamic therapy and a preparation method thereof, belonging to the technical field of photosensitive polymer thin film materials. The photosensitive microcapsule is prepared by the following steps: firstly, preparing photosensitive polymer materials of photosensitizer molecule graft polymer, and then adopting the layer self assembly technology, assembling polyelectrolyte materials with opposite charges on a microballoon template, and preparing a hollow capsule assembled by a plurality of capsule walls, wherein materials of the capsule walls include natural polymer glycan (CHI) or glucan directly grafted with photosensitizer by chemical bonds. The photosensitive microcapsule has good biocompatibility, fixes photosensitive molecules, can kill cancer cells effectively, can be applied to (Photodynamic Therapy) PDT, and is good in water dispersion and uniform in particle size, high in single-state oxygen content yield under the illumination of beams with specific wavelength, simple in process and easy in operation.

Owner:BEIJING UNIV OF CHEM TECH

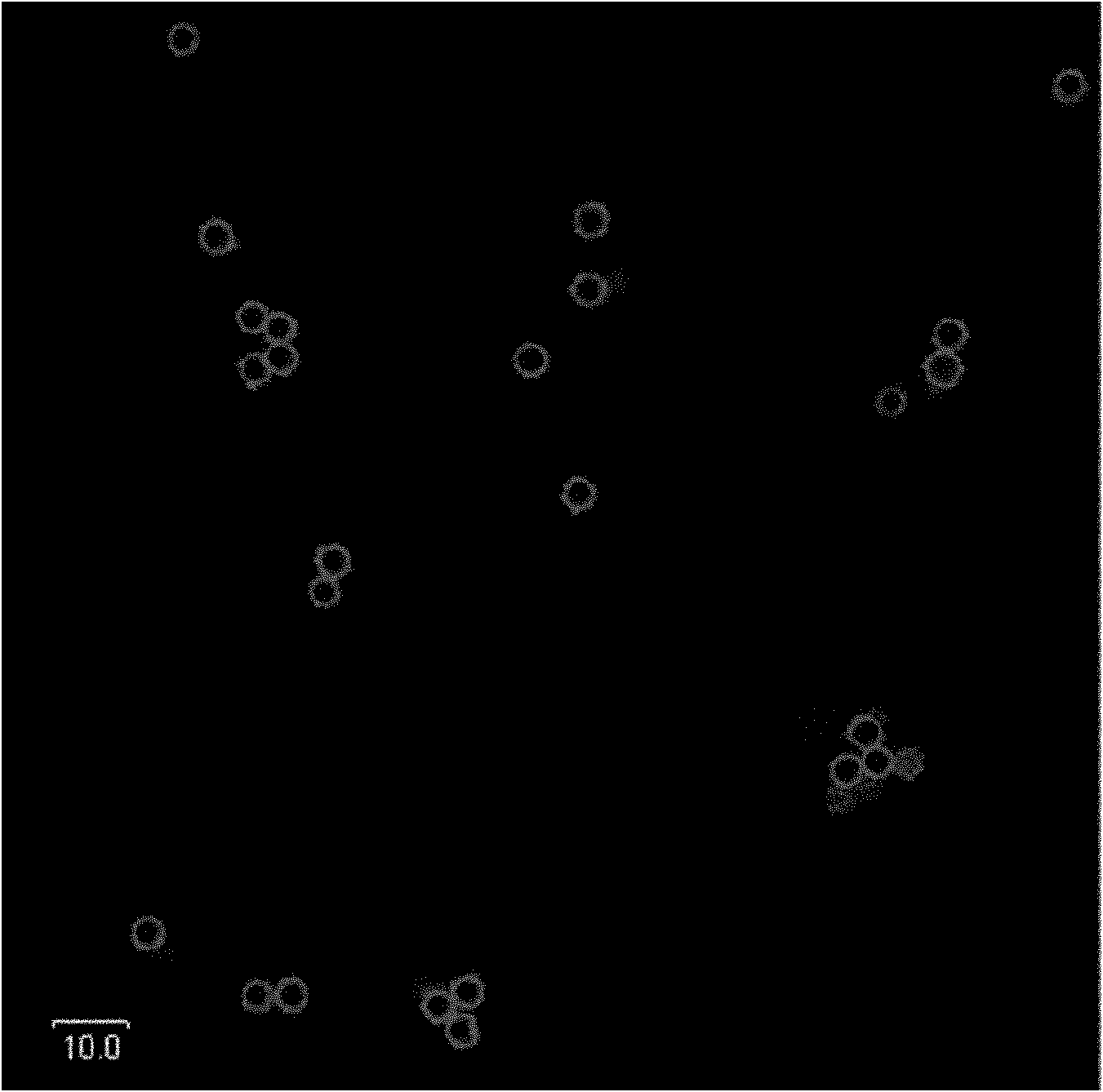

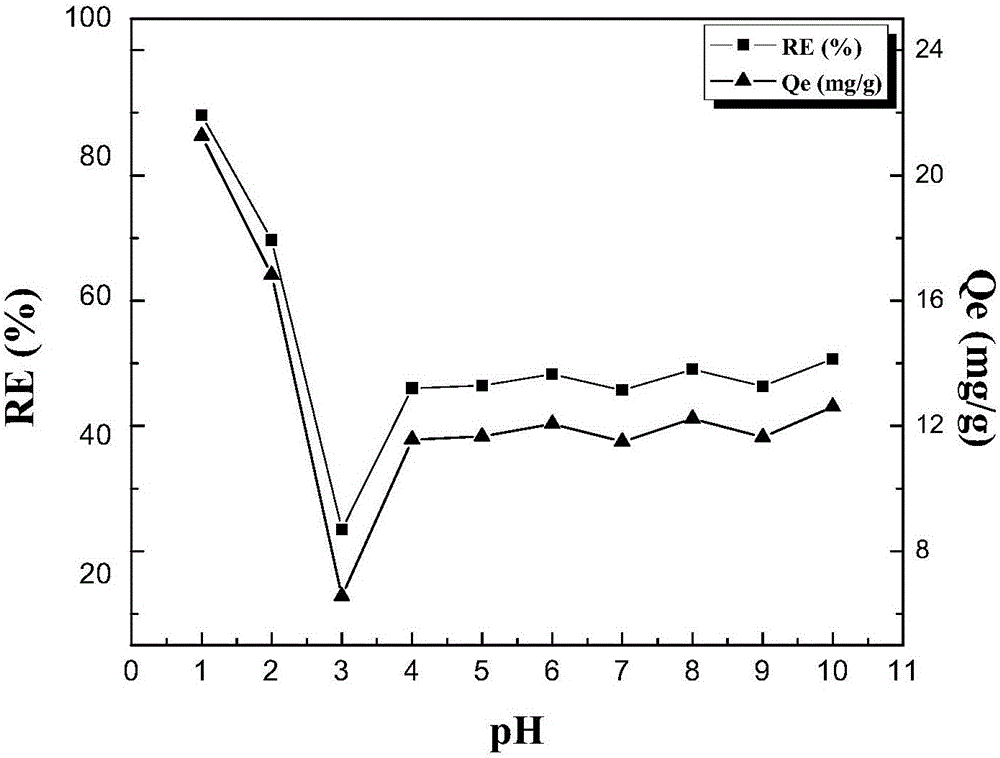

Double metal loaded sodium alginate/carboxymethylcellulose double-functional microballoon adsorbing material and preparation method thereof

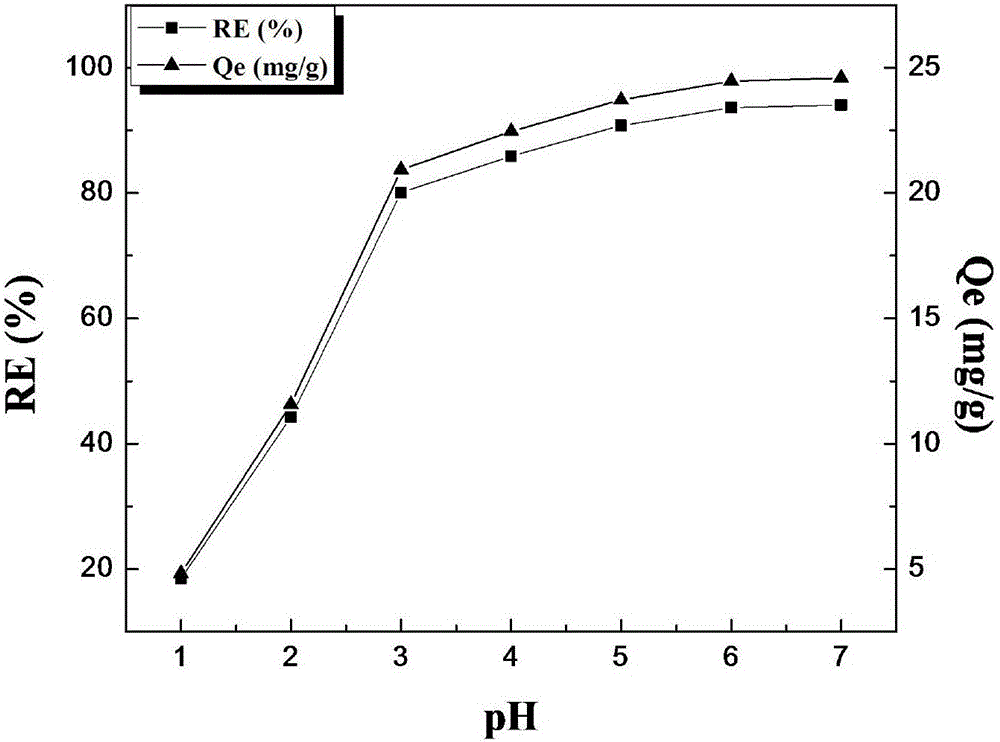

ActiveCN105013450ASimple adsorption operationLow costOther chemical processesAlkali metal oxides/hydroxidesIonCompound (substance)

The invention discloses a double metal loaded sodium alginate / carboxymethylcellulose double-functional microballoon adsorbing material and a preparation method thereof. The method comprises the following steps: dissolving sodium alginate and carboxymethylcellulose at a mass ratio of (5-20) to 1 in deionized water, and stirring so as to obtain 1-3wt% compound colloidal sol; electronically spraying the compound colloidal sol into a receiving device containing a 1-20wt% metal ion solution by using an electronic spraying device, stirring, and filtering to obtain metal ion doped gel microballoons; and leaching the gel microballoons, then soaking the leached gel microballoons in a 5-25wt% aluminium chloride solution, stirring to obtain a mixture, adding 0.1-3 parts by volume of a cross-linking agent into the mixture, stirring, filtering, leaching and stoving so as to obtain the double metal loaded sodium alginate / carboxymethylcellulose double-functional microballoon adsorbing material. The preparation method has the characteristics of being simple, low in cost, environmentally friendly, and the like; the material prepared by adopting the method disclosed by the invention has the good application prospect in the aspects of water treatment and the like in fields of chemical engineering, agriculture, environment protection and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

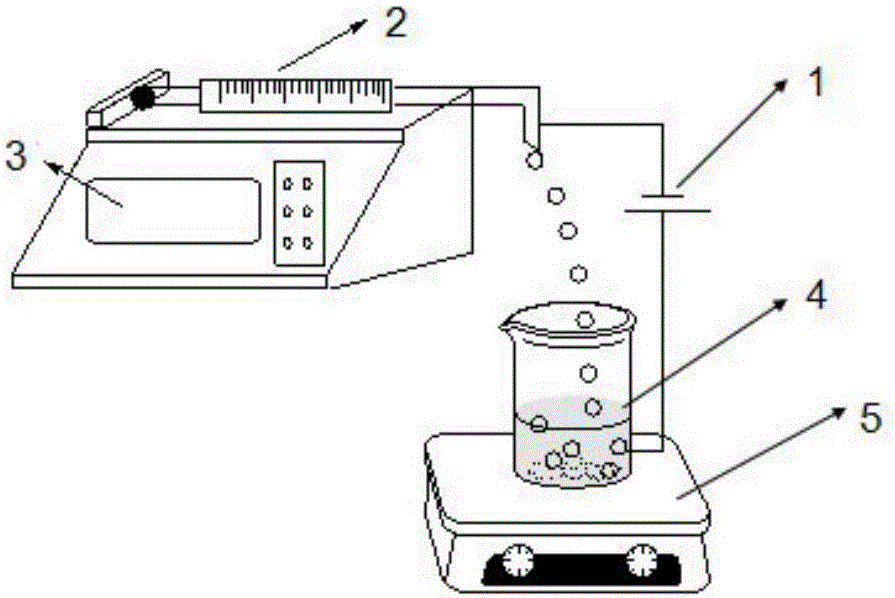

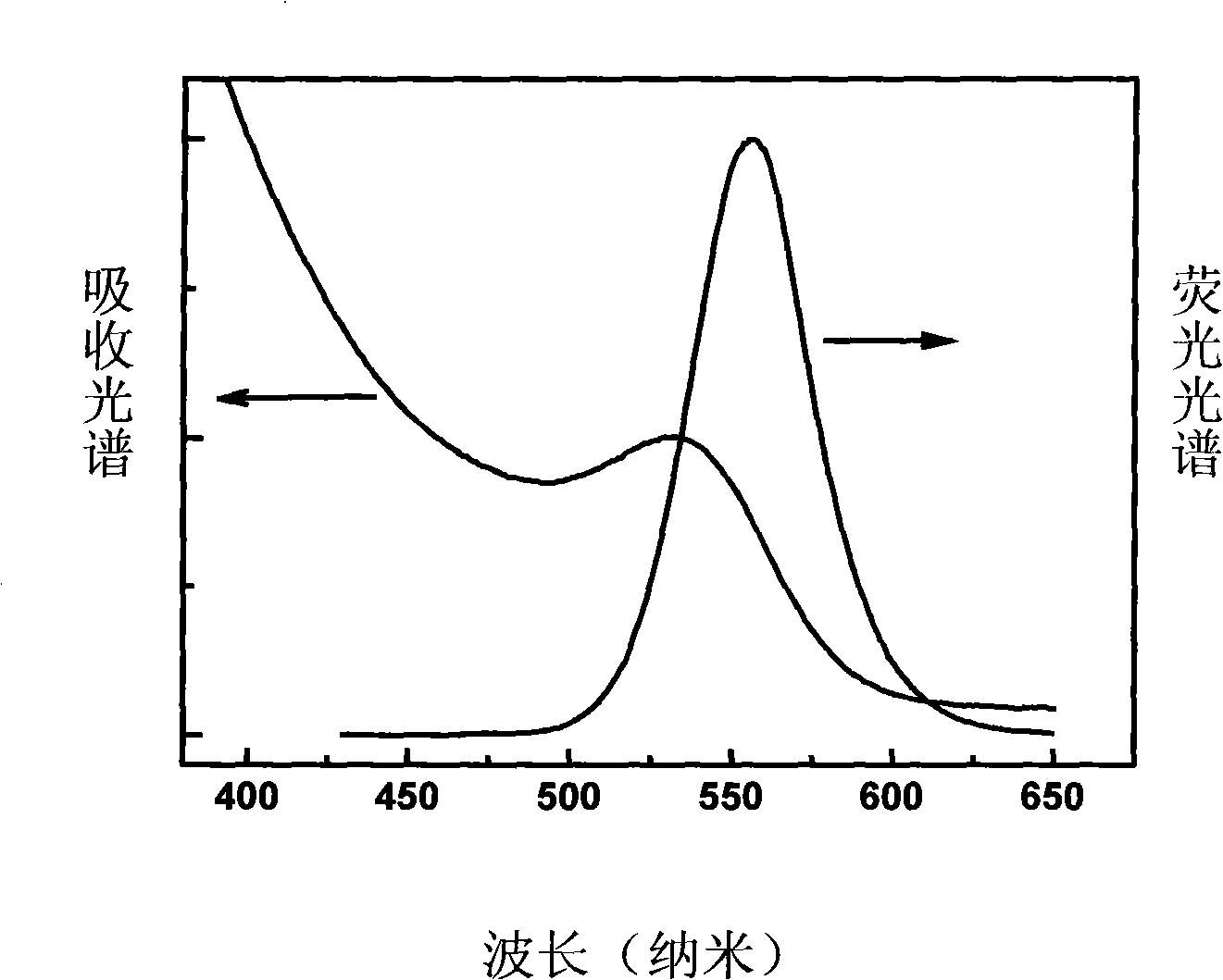

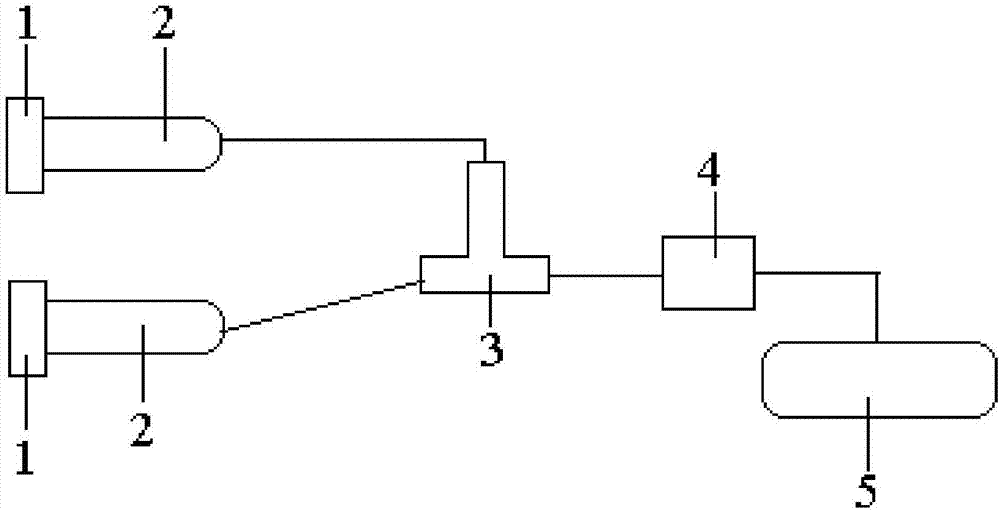

Method for rapidly preparing water-soluble quantum dot by ultrasonic spraying method

InactiveCN101525534AContinuous productionControllable sizeLuminescent compositionsQuantum yieldCadmium Cation

The invention relates to a method for rapidly preparing a water-soluble quantum dot by an ultrasonic spraying method with continuous production, which comprises the following steps that: cadmium ions or zinc ions and hydrogen (or selenide) telluride or sodium hydrogen telluride (or selenide) react to obtain a precursor solution of cadmium (zinc) telluride (selenide) through the complexation of a mercapto compound. An ultrasonic atomizer is used to atomize the precursor solution to form fogdrops of the precursor solution, and the fogdrops flow through a device with constant temperature to react to obtain the water-soluble quantum dot. The method has the advantages of high speed and continuous quantum dot production, the prepared quantum dot has high fluorescence quantum yield (between 20 and 50 percent), and good monochromaticity of luminescence (the peak width at half height of a fluorescence spectrum within the range of visible light is between 30 and 40nm), and the size of nano-particles can be easily controlled by changing the temperature and flow rate, thereby realizing the adjustment to luminescence peak positions (between 400 and 700nm).

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

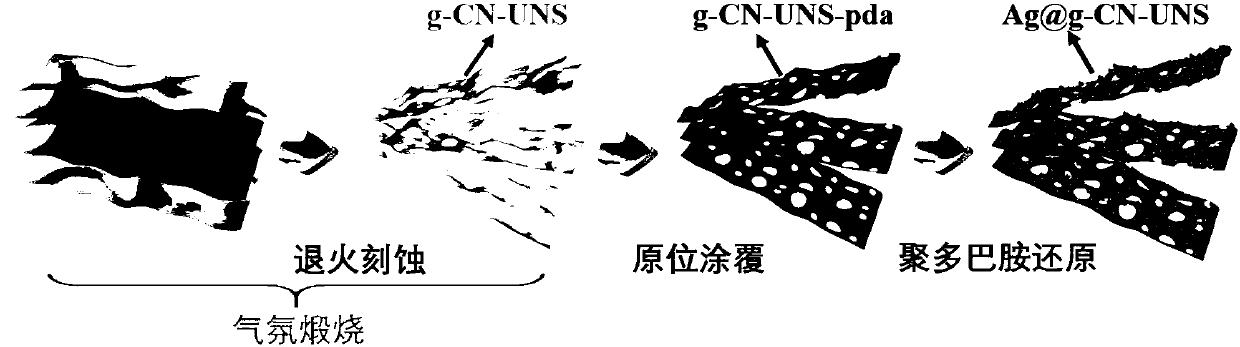

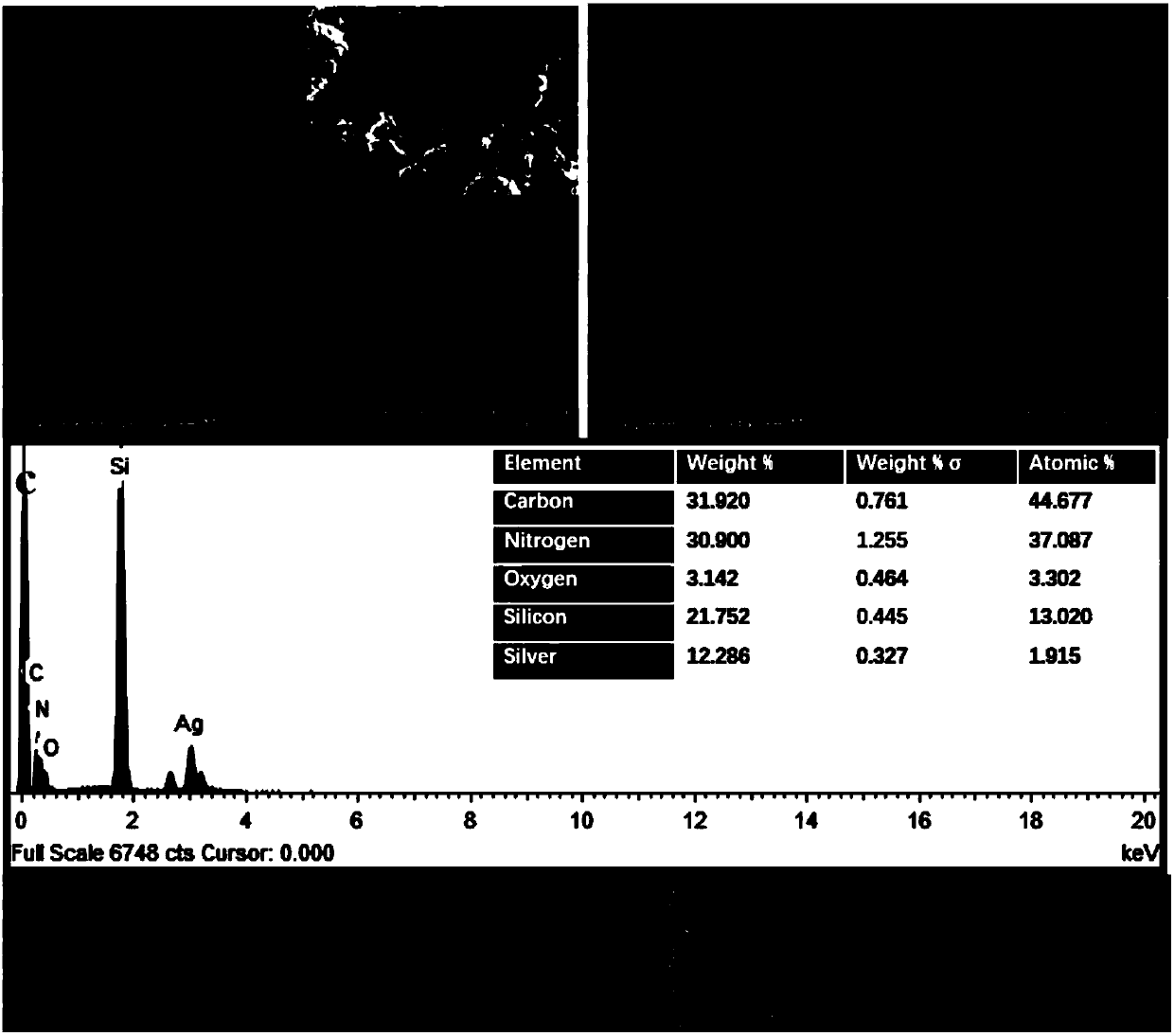

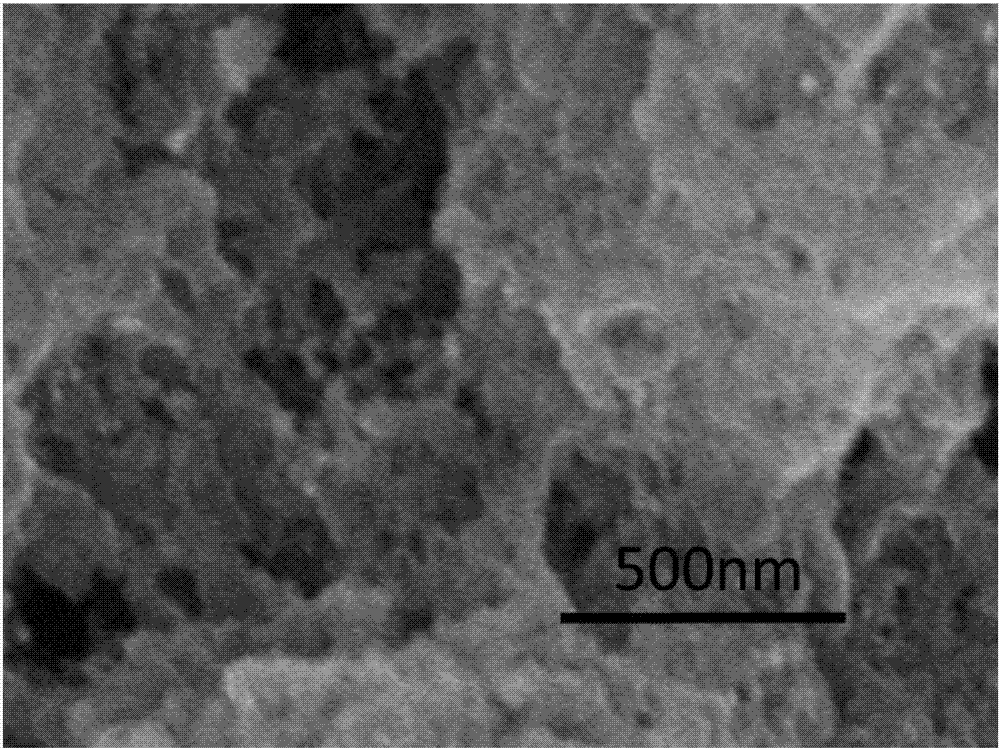

Preparation method and application of novel silver-nanoparticle modified ultrathin graphite phase carbon nitride catalyst

InactiveCN107684924AThe process is simple and easy to operateControllable sizePhysical/chemical process catalystsWater/sewage treatment by irradiationPhotocatalytic degradationUrea

The invention discloses a preparation method and application of a novel silver-nanoparticle modified ultrathin graphite phase carbon nitride catalyst. The method includes: subjecting urea to heat treatment to obtain lump graphite phase carbon nitride; subjecting the lump graphite phase carbon nitride to secondary heat treatment to obtain an annealing etched ultrathin graphite phase carbon nitridelayer; structuring a bionic mussel polydopamine biocoating on ultrathin graphite phase carbon nitride by adopting an impregnation method; based on polydopamine modification and by the aid of reducibility of silver nanoparticles, loading the silver nanoparticles on the surface of the ultrathin graphite phase carbon nitride. The two-dimensional ultrathin graphite phase carbon nitride layer is prepared by adopting the high-temperature annealing method, the silver nanoparticles are prepared by adopting the green bionic method of self-polymerization polydopamine, and good prospects of the novel composite high-activity photocatalyst are displayed in the field of organic pollutants like photocatalytic degradation of methylene blue and phenol.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST

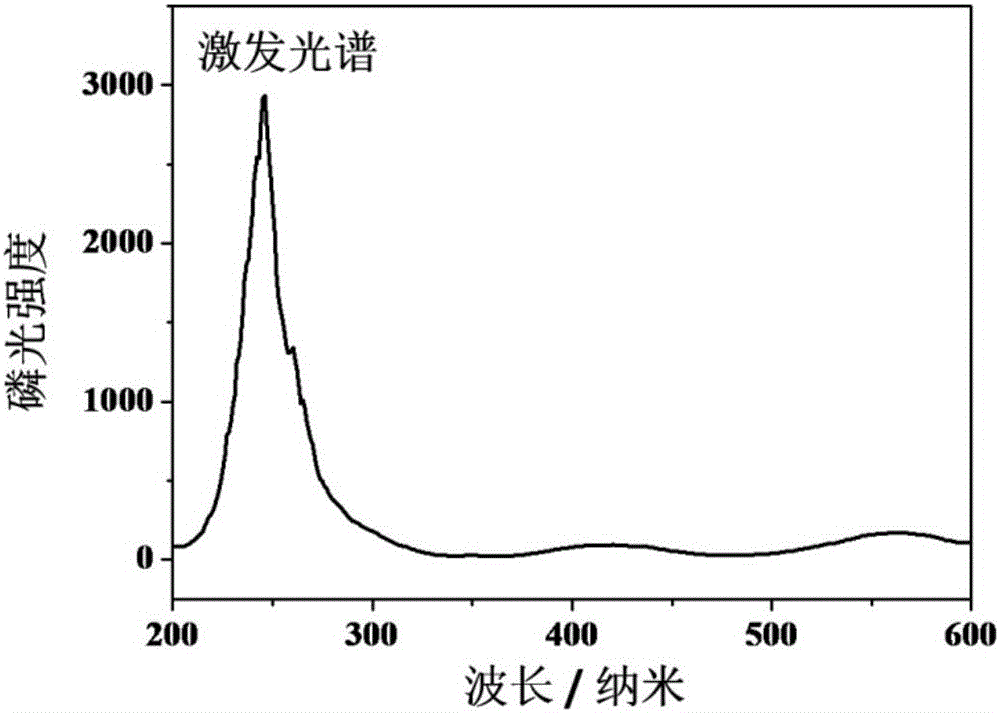

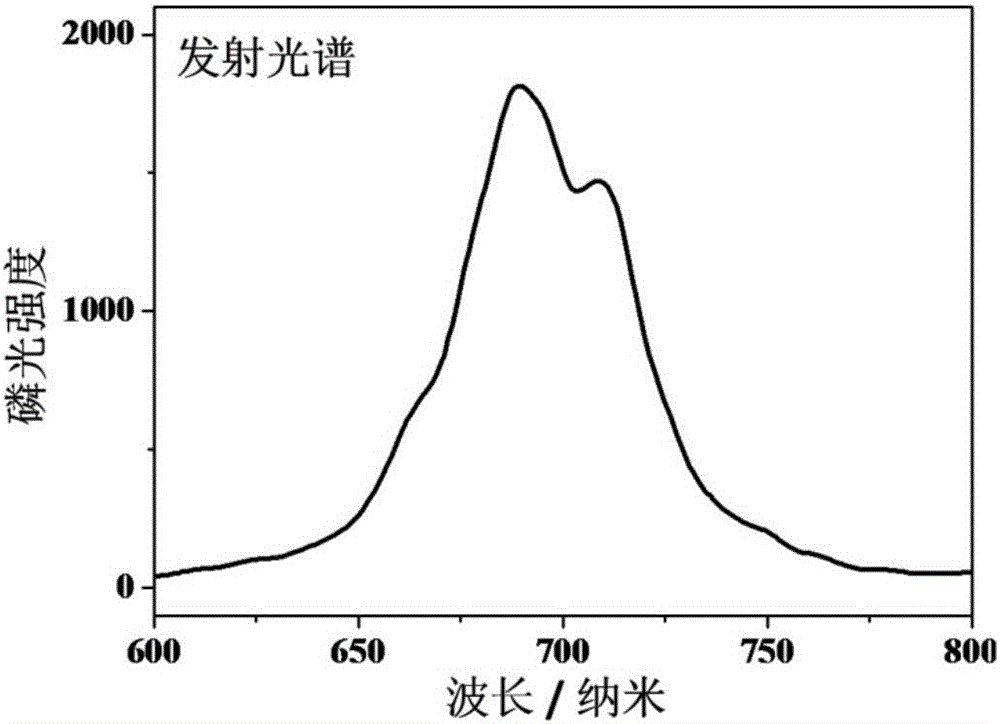

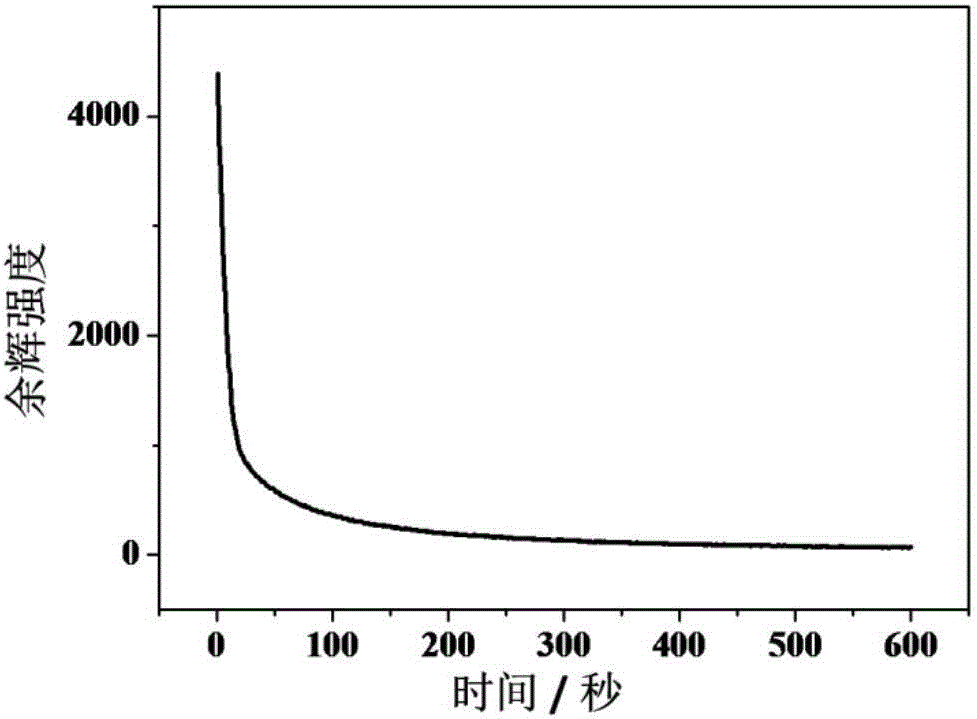

Preparation method of near-infrared long afterglow luminescent nanometer particle

InactiveCN106590656AControllable sizeSmall particle sizeLuminescent compositionsMuffle furnaceZinc glycinate

The invention relates to a preparation method of a near-infrared long afterglow luminescent nanometer particle. The near-infrared long lasting phosphorescent nanometer particle is prepared by adopting a mesoporous silica template method. The preparation method of the near-infrared long afterglow luminescent nanometer particle comprises the steps of firstly preparing mesoporous silica through a hydrothermal method; then adopting the silica as a carrier, adopting gallium and germanium zinc glycinate as a base material, uniformly stirring with a mixed solution codoped by chromium ions and rare earth ions, centrifugally separating, drying at the temperature of 80 DEG C, and carbonizing through a muffle furnace at the temperature of 550 DEG C; then using a sodium hydroxide solution for dissolving and removing a silica template in a sample, centrifugally separating a product once again, drying at the temperature of 80 DEG C, and finally calcining through the muffle furnace at the temperature of 700 DEG C; and preparing the near-infrared long afterglow luminescent nanometer particle with the average grain diameter being less than 10 nanometers. The preparation method of the near-infrared long afterglow luminescent nanometer particle provided by the invention has the advantages that the near-infrared long afterglow luminescent nanometer particle prepared by the method has excellent properties that the grain size is controllable, the grain diameter is smaller, an emission spectrum is within a near-infrared light area, the afterglow time is long, and the like; and the preparation method of the near-infrared long afterglow luminescent nanometer particle provided by the invention is simple to operate and low in cost, does not require reducing atmosphere during a preparation process, and has no pollution on the environment.

Owner:喀什大学

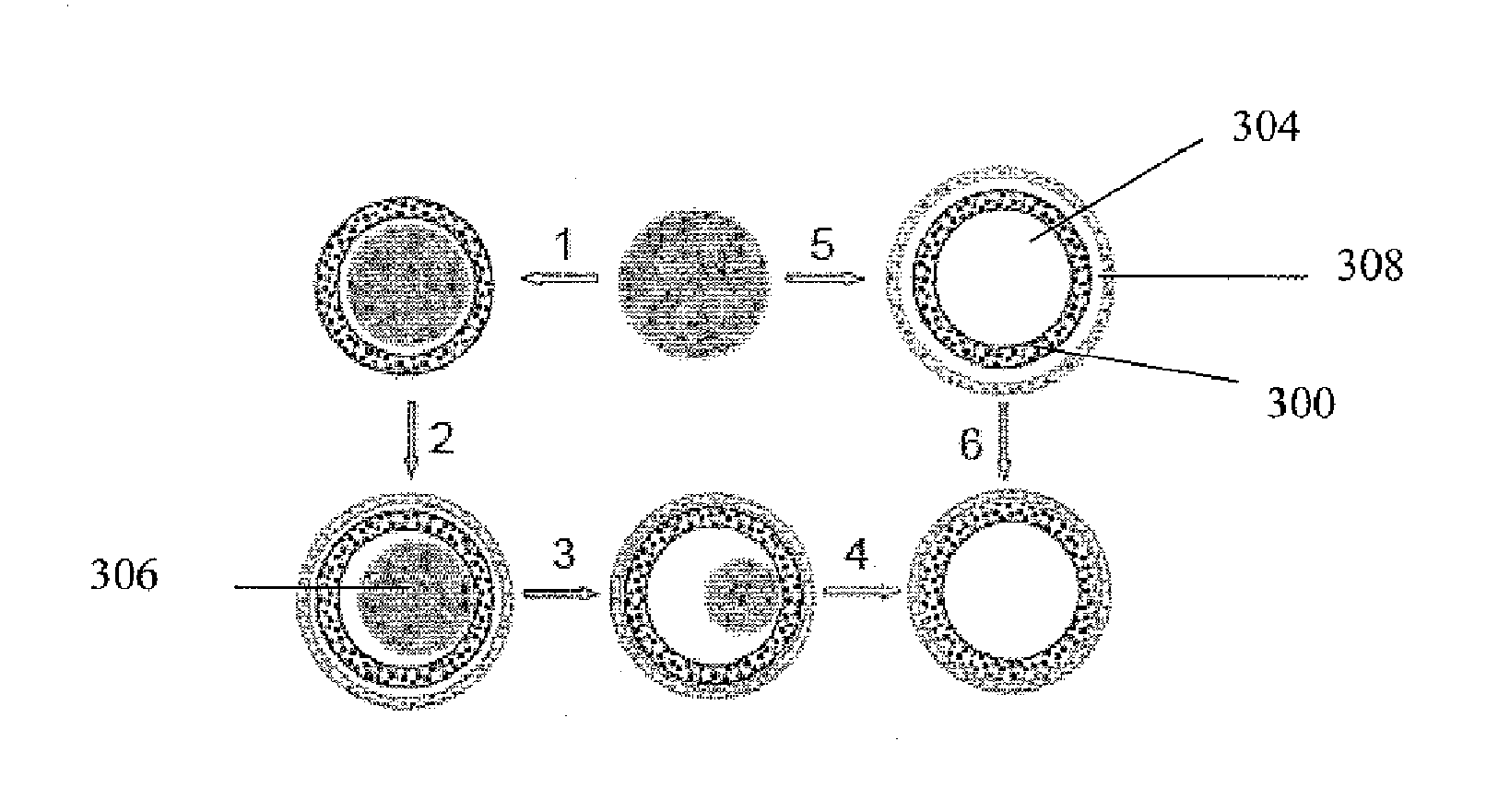

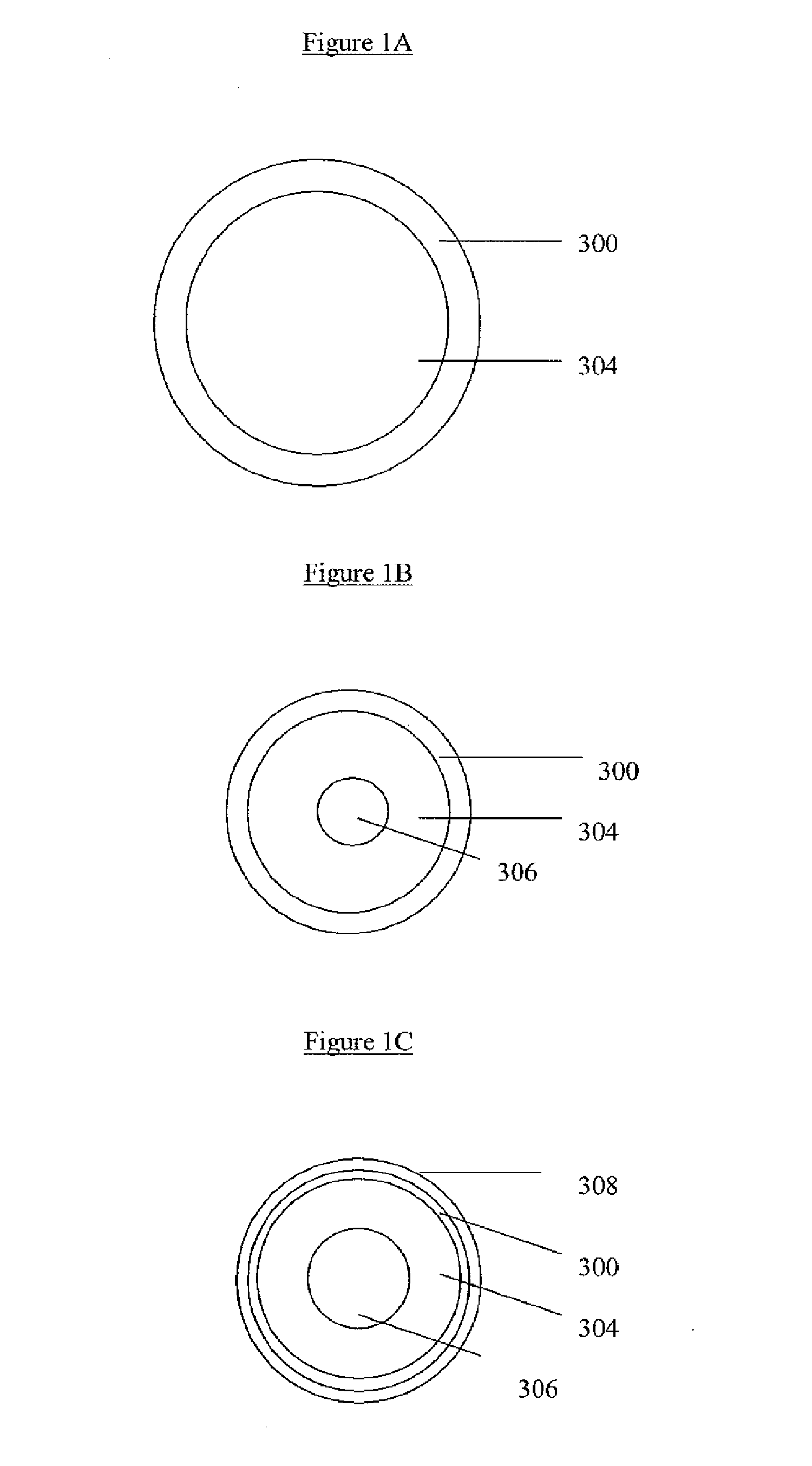

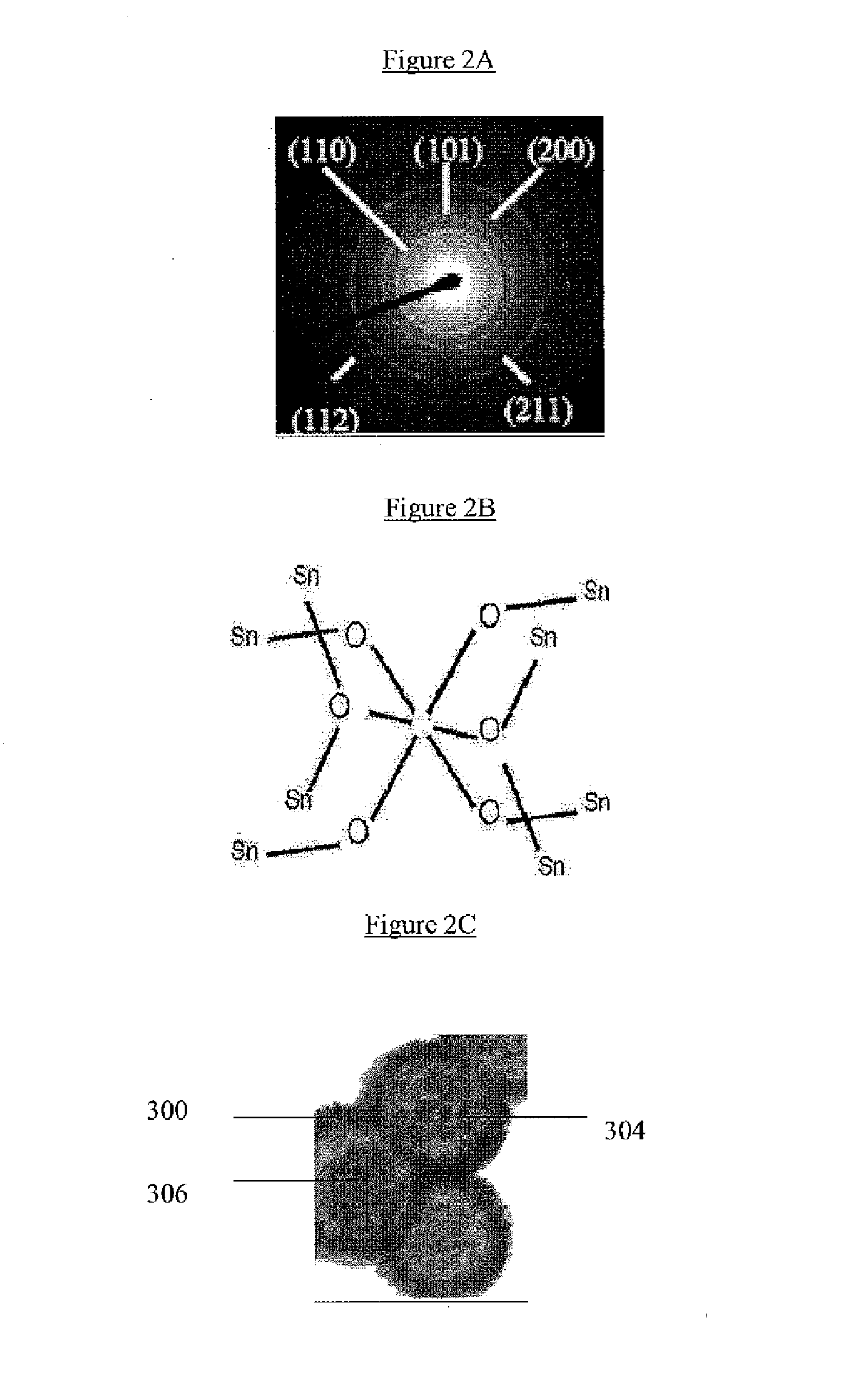

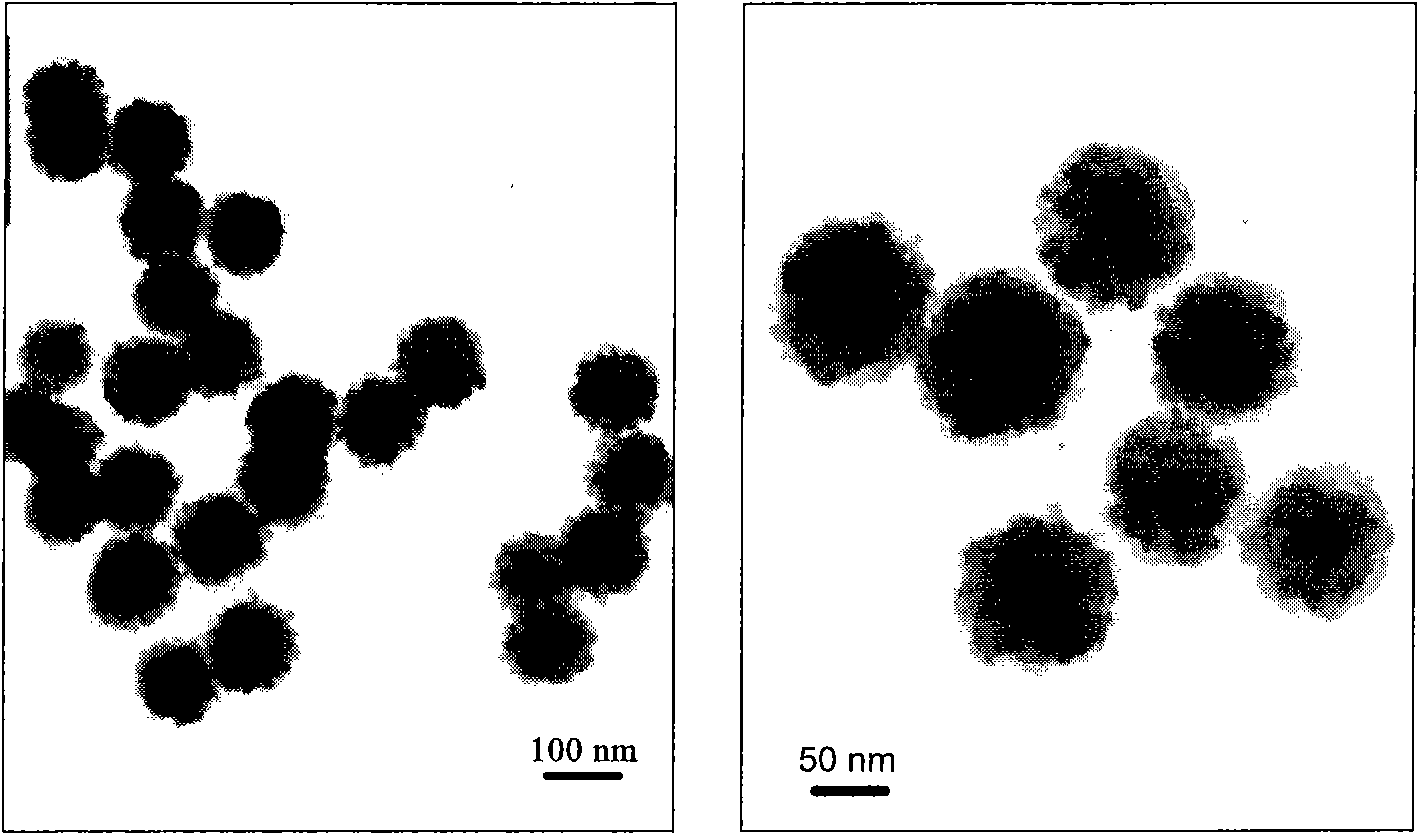

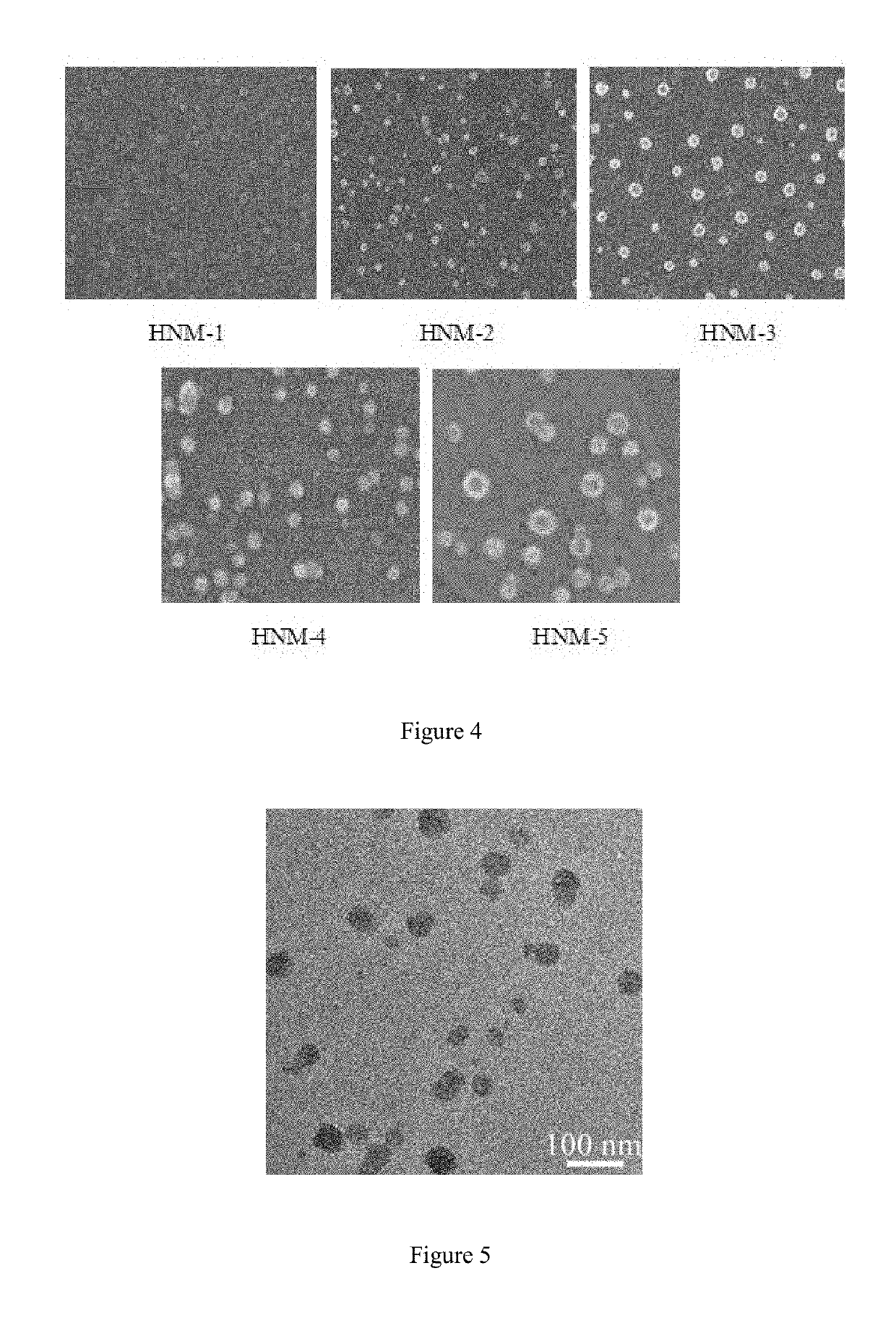

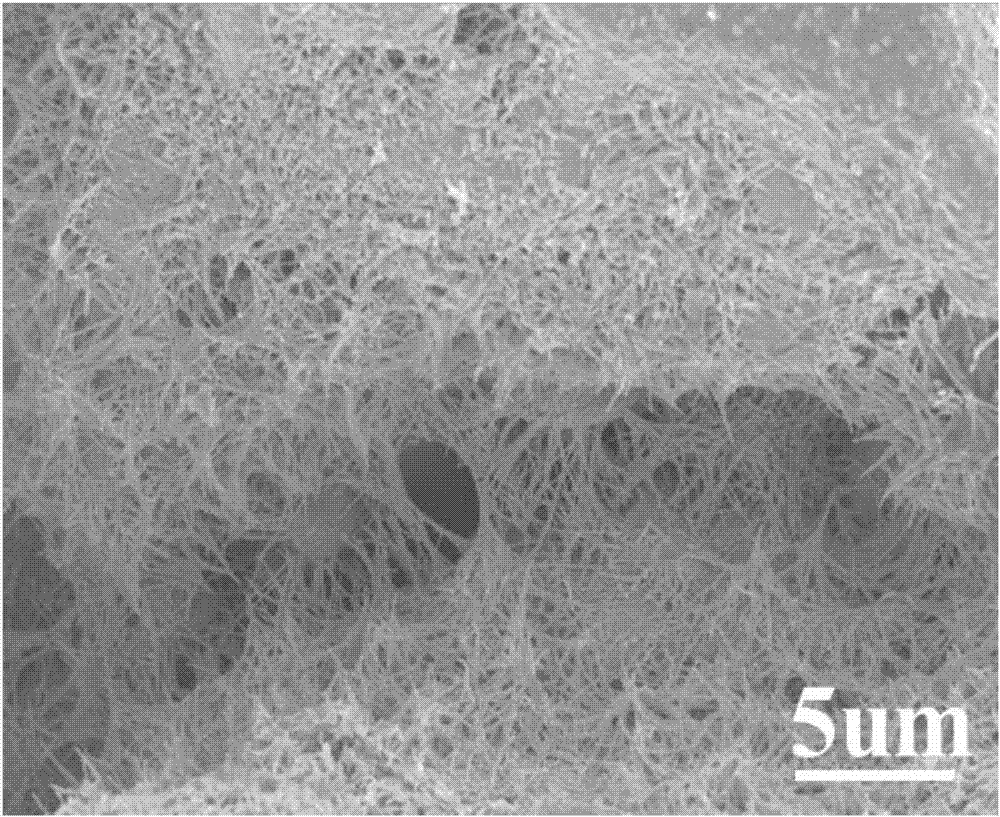

Nanostructured Metal Oxides Comprising Internal Voids and Methods of Use Thereof

InactiveUS20130130109A1Controllable sizeGood heat and electrical conductivity propertySilver accumulatorsMaterial nanotechnologyNanoparticleNanostructured metal

Owner:CORNELL RES FOUNDATION INC

Organic modified nanometer complex oxide material and preparation method thereof

InactiveCN101597437AUniform particle sizeControllable sizePigment treatment with non-polymer organic compoundsIonNanometre

The invention discloses an organic modified nanometer complex oxide material and a preparation method thereof. The SiO2 microsphere is taken as a substrate, an inorganic metal oxide is embedded in the bulk phase of the SiO2 microsphere and an organic group is connected to the surface of the inorganic metal oxide; the organic modified nanometer complex oxide material is expressed in a general formula MeOg-SiO2, wherein Me is short for Metal, and Og is short for Organicgroup; and Me is one or more of Co, Mn, Cu, Fe, V, Ti, Cr, Ni, Zn, Zr and Al and Og is one or more of methyl, ethyl, propyl, vinyl, chloroallyl, naphthyl, phenyl, trifluoropropyl, fluorophenyl and pentafluorophenyl. The operational process is simple and easy to control. Since the metallic ion and the organic group are respectively introduced on the bulk phase and the surface of the SiO2 simultaneously, the invention has the broad prospect on the application aspects of nano-devices and functional material.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

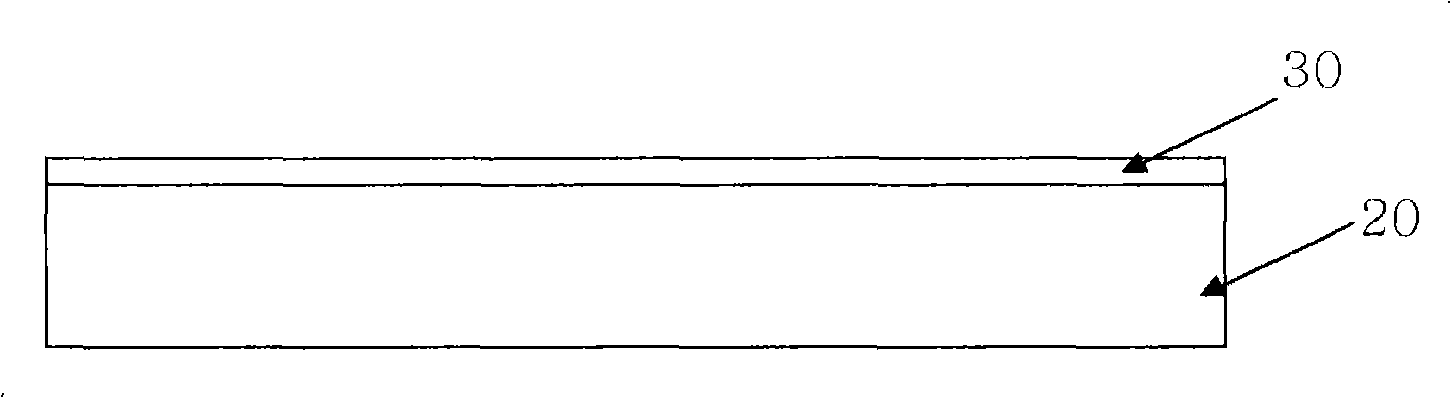

A preparing method of a platinum nanometer particle/titanium dioxide nanotube array, an electrode, a non-enzymatic glucose sensor and a composite material

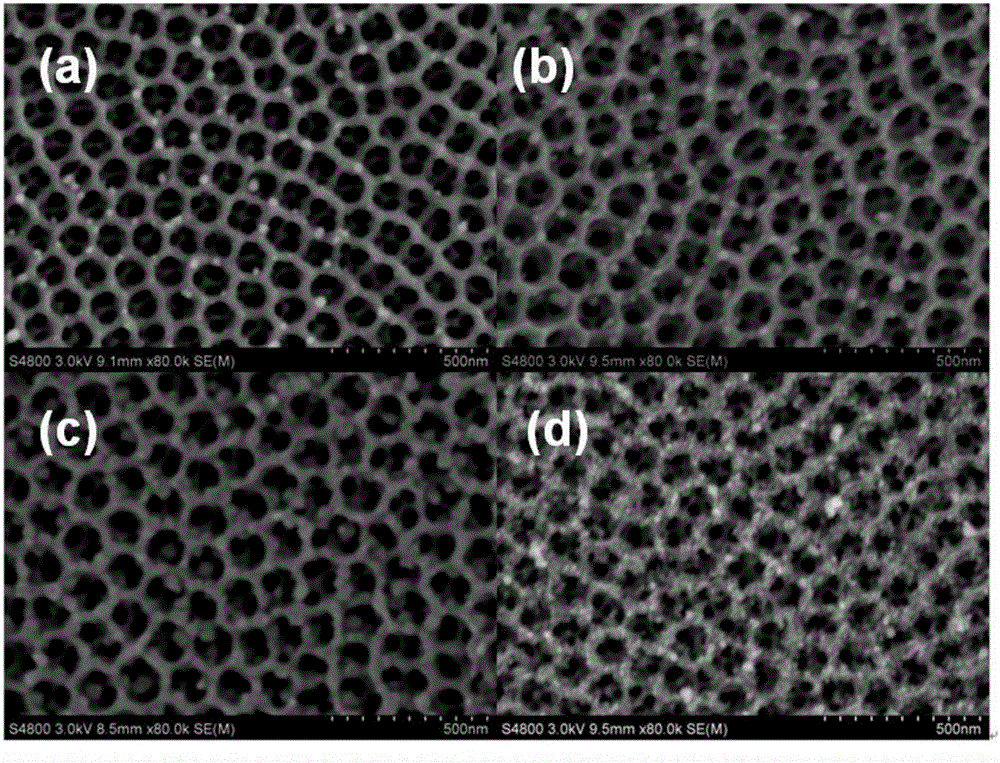

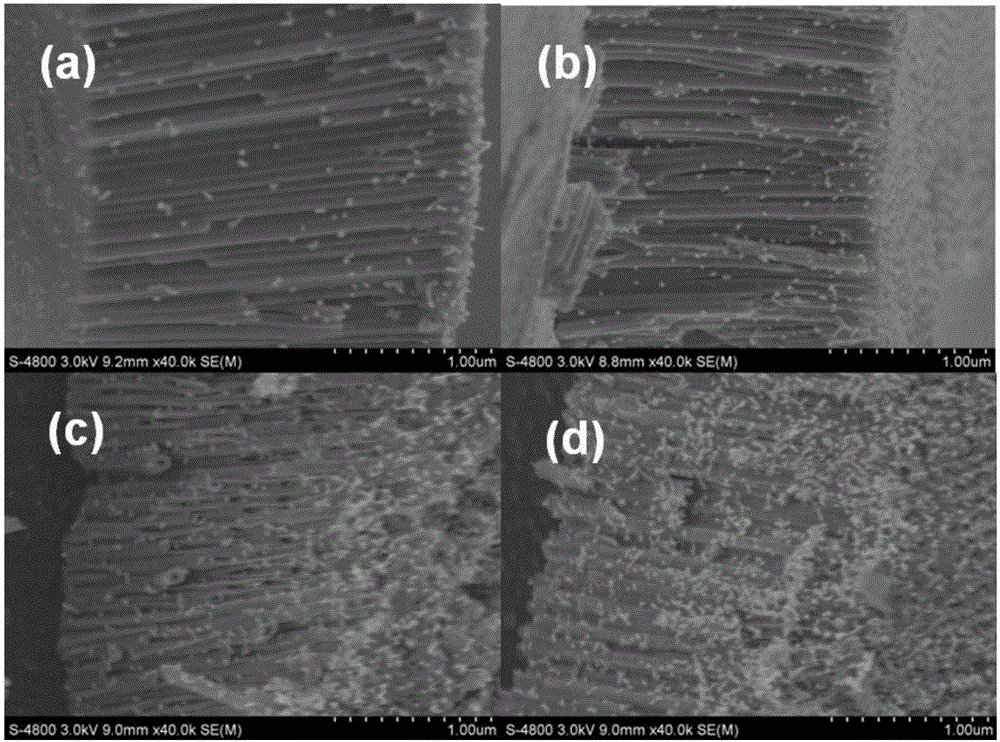

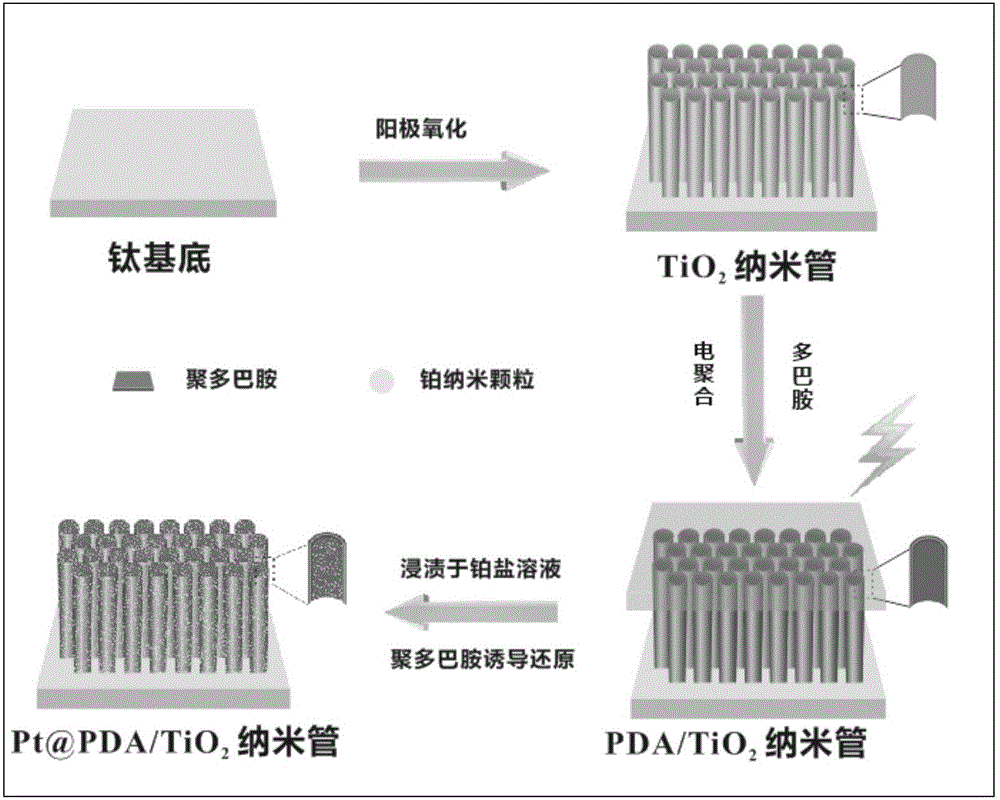

ActiveCN106167912ATime-consuming to solve the processSolve for uniformityElectrolysis componentsSurface reaction electrolytic coatingGlucose sensorsTio2 nanotube

A preparing method of a platinum nanometer particle / titanium dioxide nanotube array, an electrode, a non-enzymatic glucose sensor and a composite material are disclosed. The method includes S1), pretreating a titanium sheet, S2) preparing a TiO2 nanotube array through an anodizing manner, S3) preparing a biomimetic polydopamine coating on TiO2 nanotubes through adopting an electropolymerization manner, S4) based on the polydopamine coating and by utilizing the reducibility of itself, loading platinum nanometer particles onto the surface of the titanium dioxide nanotubes and S5) performing performance testing of the non-enzymatic glucose sensor by utilizing the prepared working electrode. According to the platinum nanometer particle / titanium dioxide nanotube array, a composite of the platinum nanometer particles and the titanium dioxide nanotubes is prepared through reduction by adopting a polydopamine electropolymerization manner. The platinum nanometer particle / titanium dioxide nanotube array can be used for manufacturing the non-enzymatic glucose sensor finally. Through a manner of reducing the platinum nanometer particles by the electropolymerization-loaded biomimetic polydopamine, problems that auto-agglutination in traditional polydopamine dipping methods is long in time, poor in uniformity, and the like are overcome.

Owner:SUZHOU LAVENNANO TECH INC

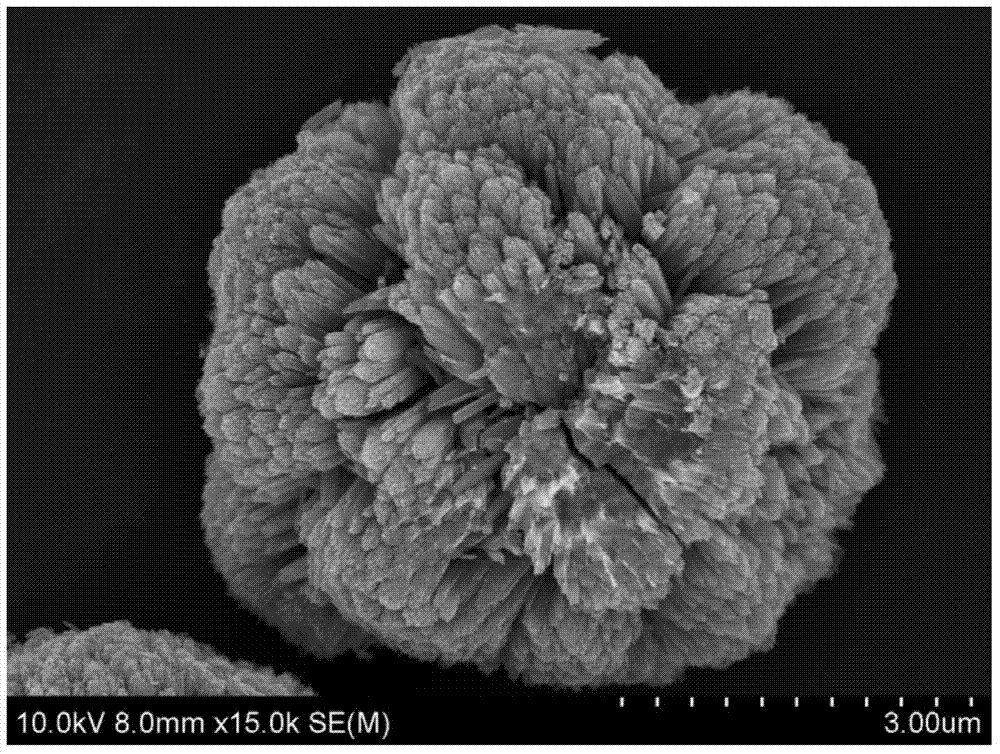

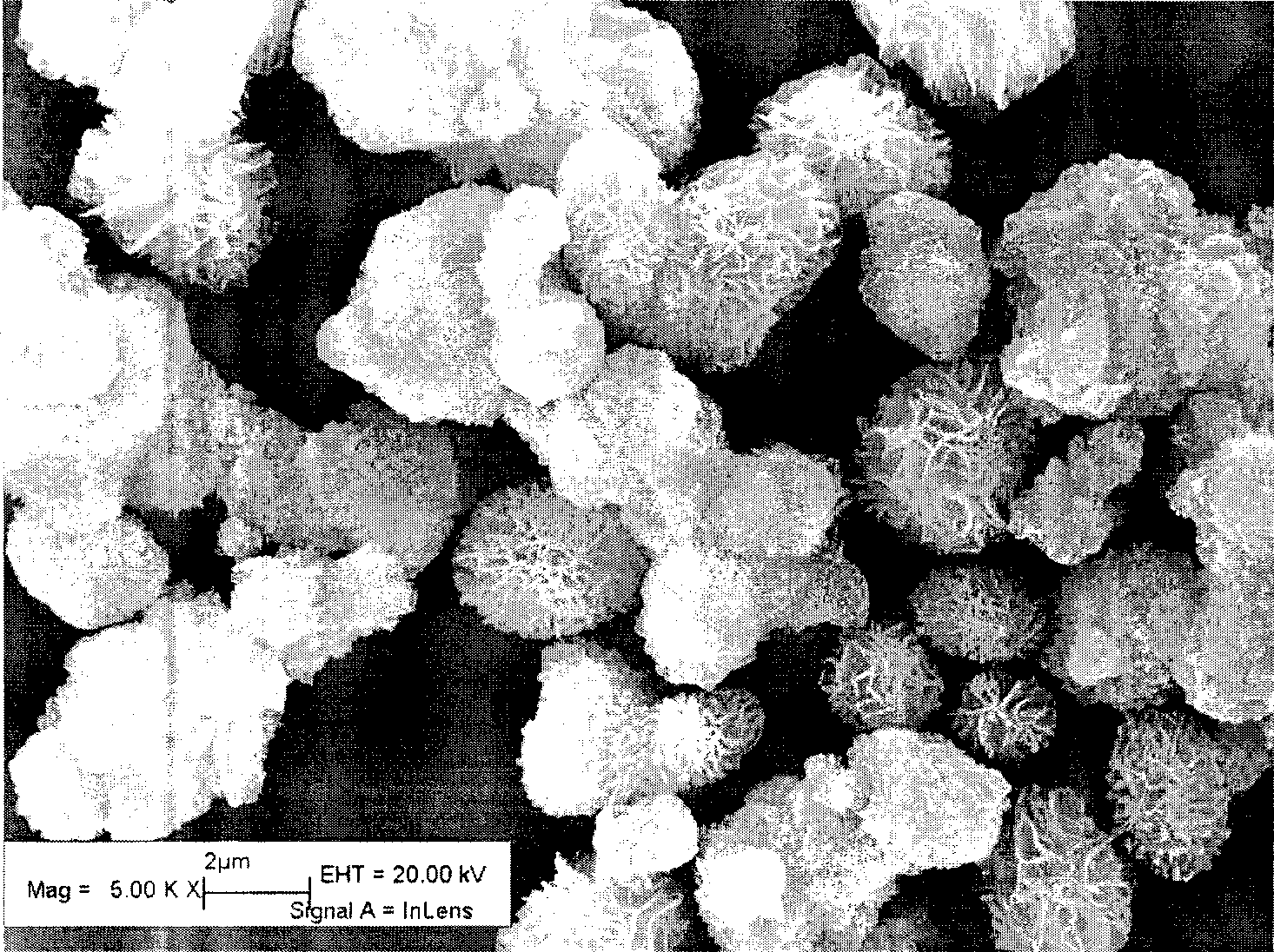

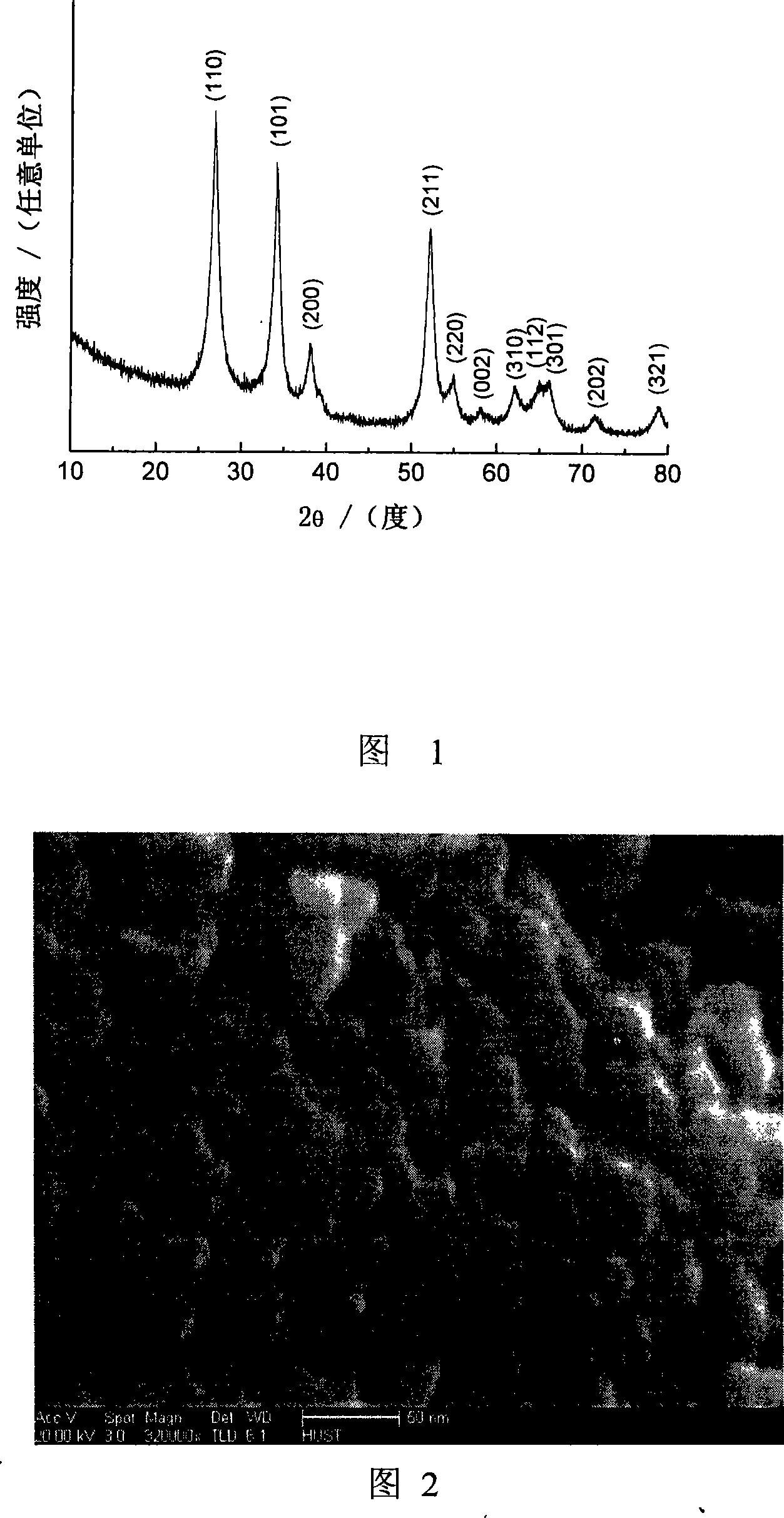

Controlled preparation method of ordered titanium dioxide nano-material

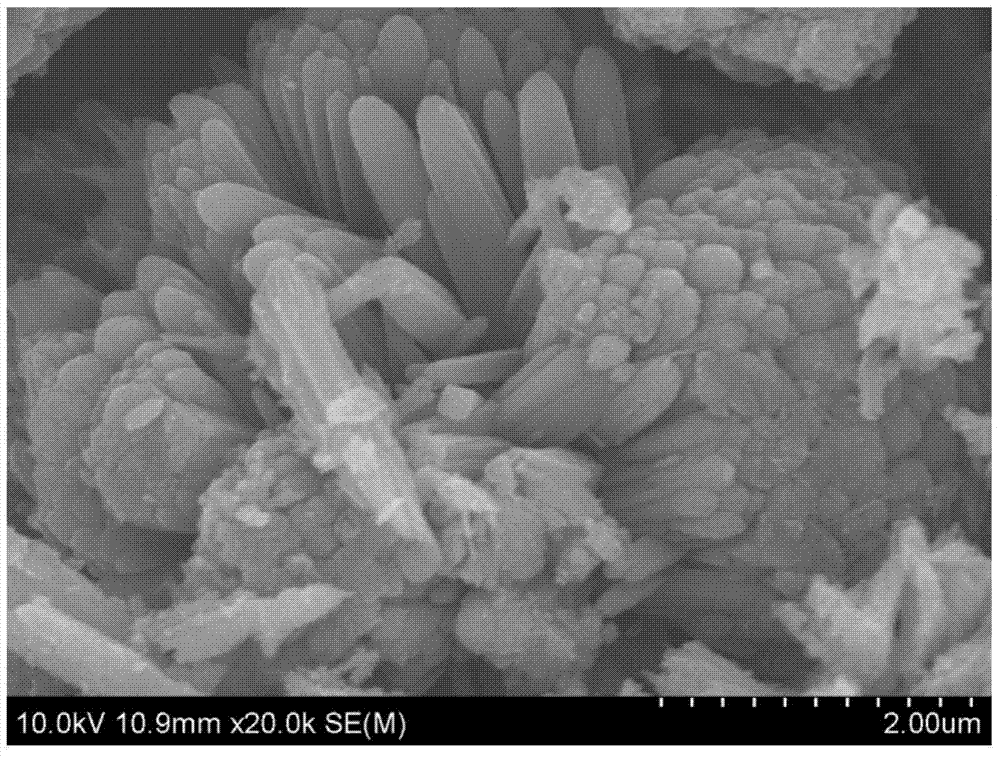

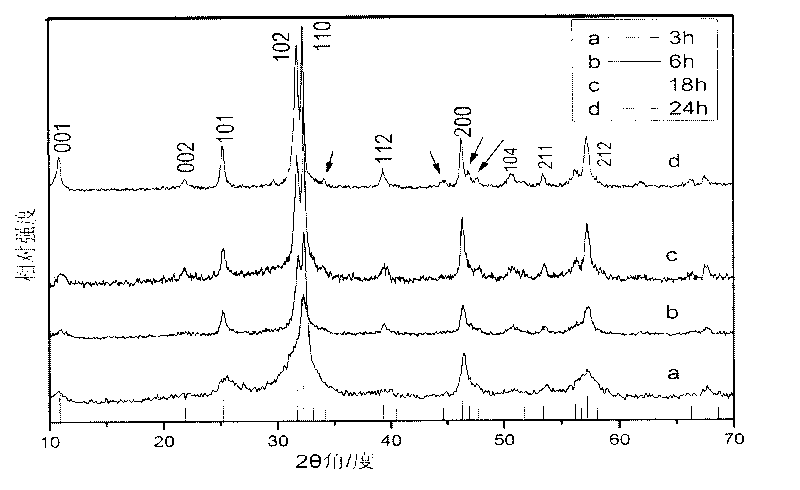

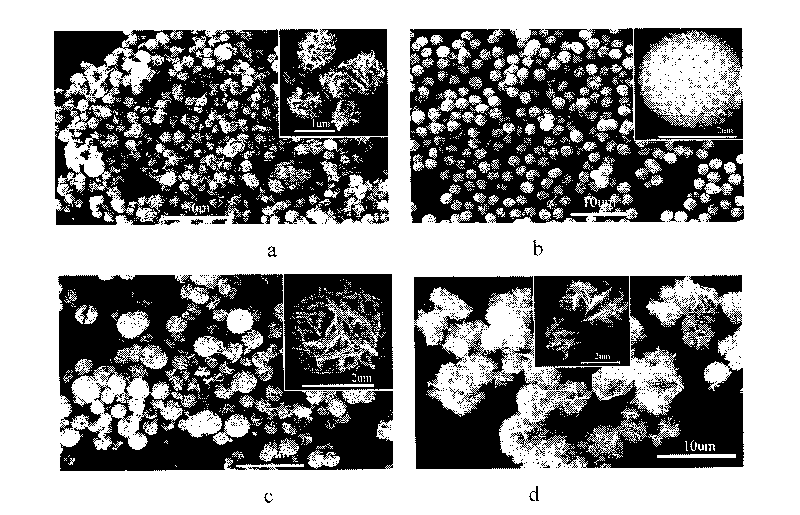

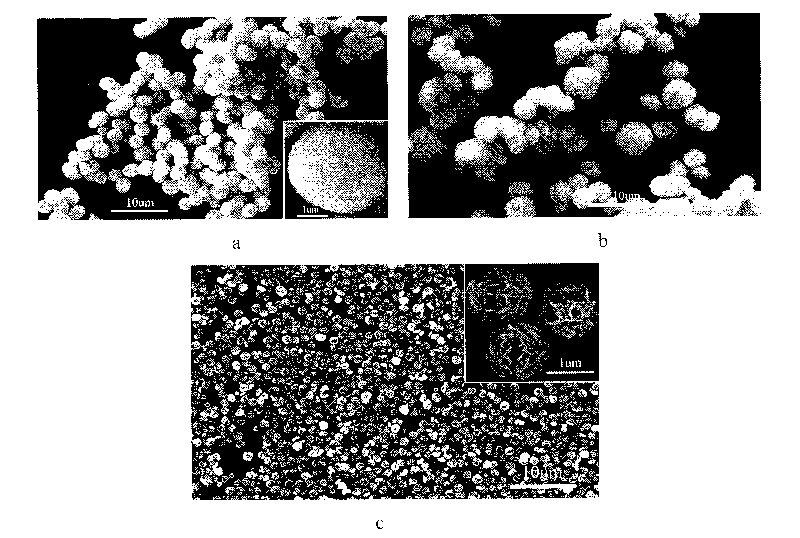

InactiveCN104118908AMaterials are readily availableEasy post-processingMaterial nanotechnologyTitanium dioxideNano structuringNanorod

The invention provides a controlled preparation method of an ordered titanium dioxide nano-material. The method comprises the following steps: preparing a mixed solution from acid and deionized water; dripping a titanium source into the mixed solution, intensively stirring to hydrolyze the titanium source quickly, and uniformly mixing the titanium source and the mixed solution; performing a hydrothermal reaction on the uniformly mixed suspension; washing precipitate with distilled water and absolute ethanol after the reaction is finished; and drying to obtain an ordered titanium dioxide nano-rod cluster, nano-flower or nano-ball. According to the preparation method, no surfactant is needed, and titanium dioxide nano-structures with different shapes and different crystal forms can be successfully prepared in an acid environment; in addition, the preparation method has the advantages of simple process and flow, wide parameter adjustable range, strong repeatability, low cost and the like.

Owner:SHANGHAI JIAO TONG UNIV +1

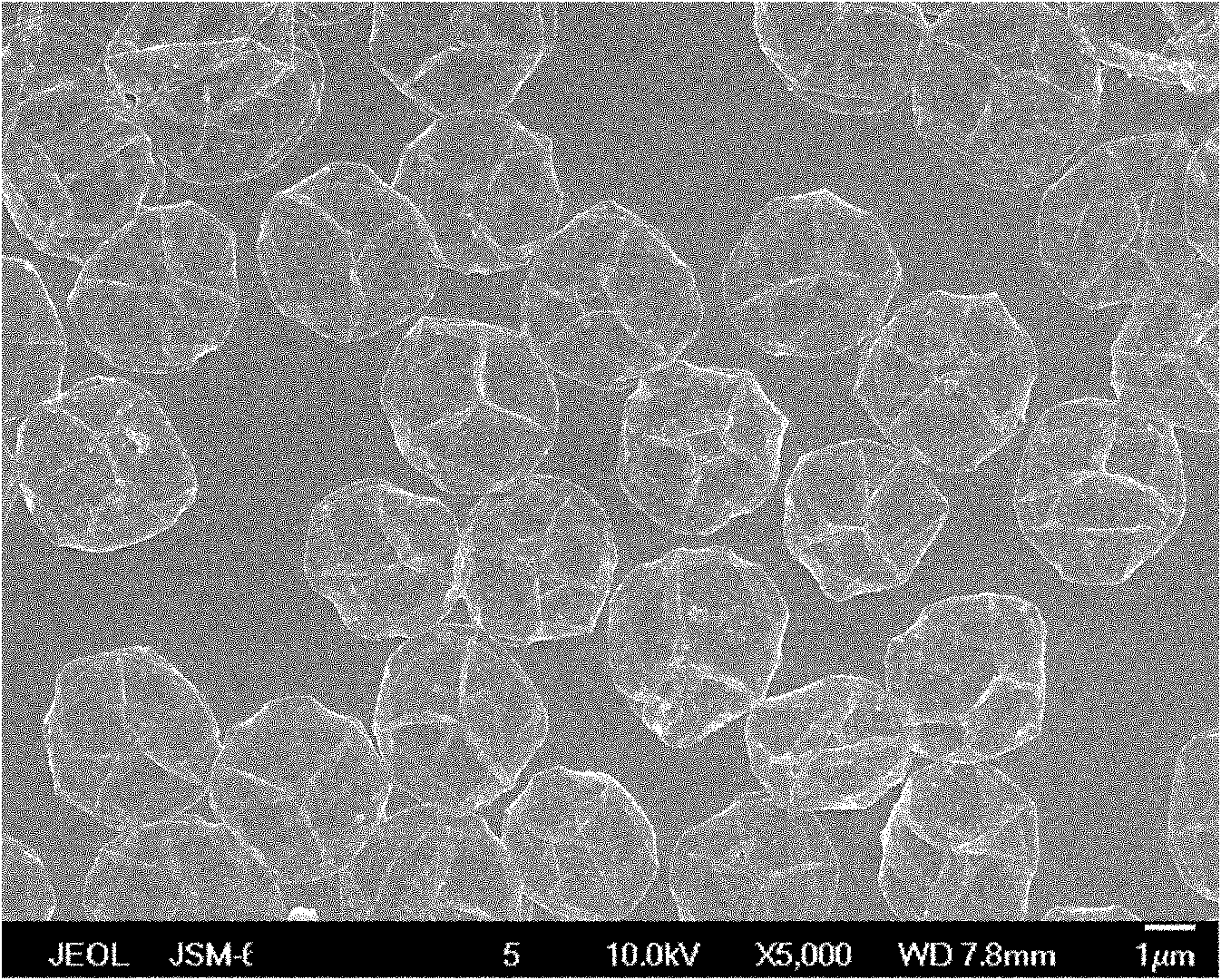

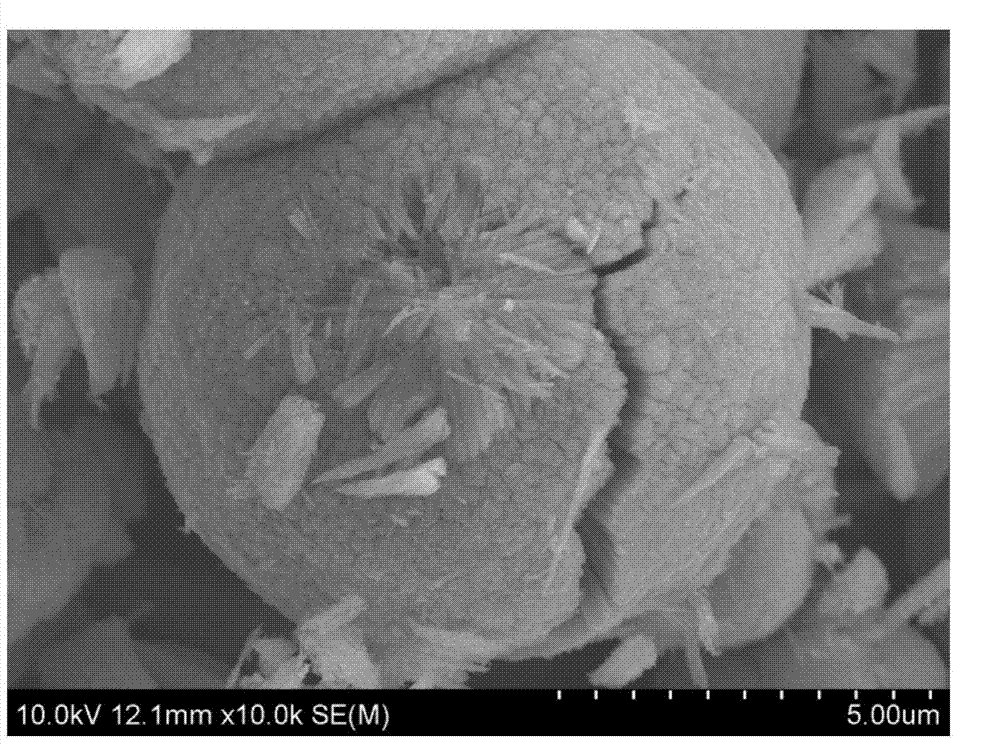

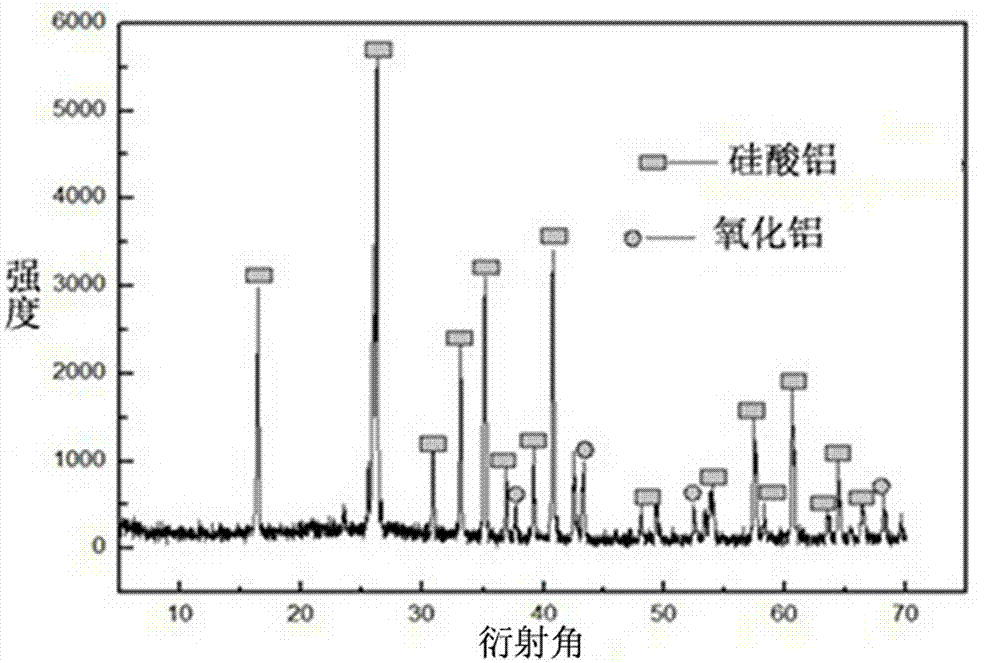

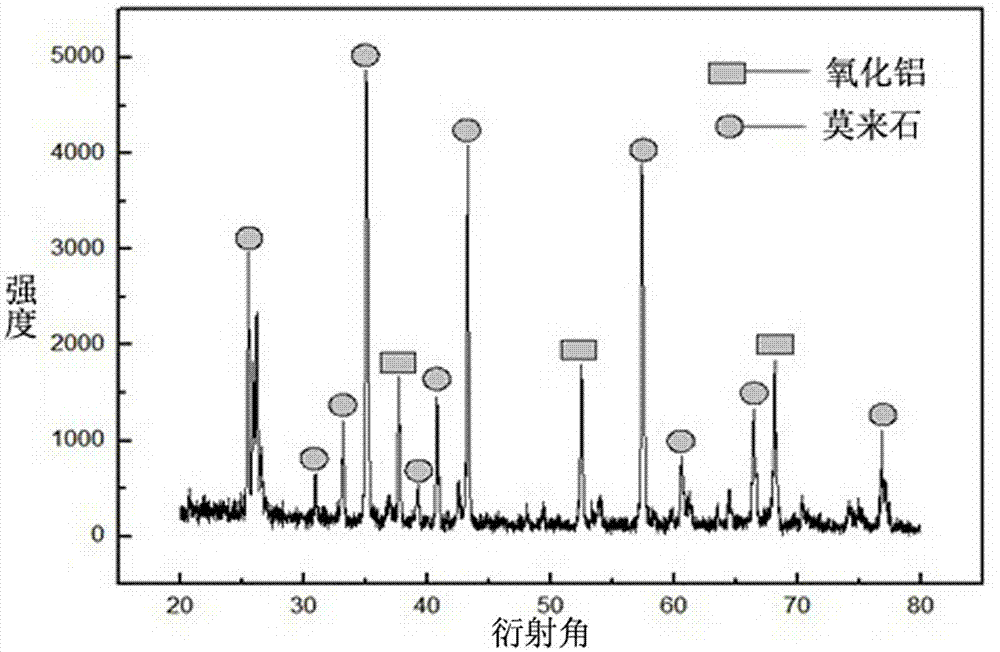

Porous oxide ceramic heat insulating material for kilns and preparation method of porous oxide ceramic heat insulating material

The invention discloses a porous oxide ceramic (aluminum silicate, mullite, alumina ceramics) prepared according to a foam in-situ consolidation method. Porous aluminum silicate, mullite, alumina ceramics each are made from the following raw materials: kaolin, bauxite, silicon micropowder, aluminum oxide and quartz, as well as a gas-generating agent (metal aluminum powder, rosin soap or sodium lauryl sulfate, polyvinyl alcohol or sodium carboxymethyl cellulose, agar), a foaming agent, a foam stabilizer and a forming agent. The porous oxide ceramic is prepared by the following steps: (1) preparation of ceramic slurry; (2) foaming of the slurry; (3) in-situ injection-consolidation forming of the slurry; and (4) drying and burning of formed blanks. The porous oxide ceramic heat insulating material has a uniform distribution of porosity and is good in heat-insulating effect and thermal shock resistance. According to the method, the process is simple, the cost is low, heat insulating materials for high-temperature kilns working in different temperatures (1200-1600 DEG C) can be produced, the heat insulating material product is not liable to chalking or cracking during long-term use, and the service life of the porous oxide ceramic heat insulating material is prolonged when compared with that of the existing kiln heat insulating material.

Owner:WUHAN UNIV OF TECH

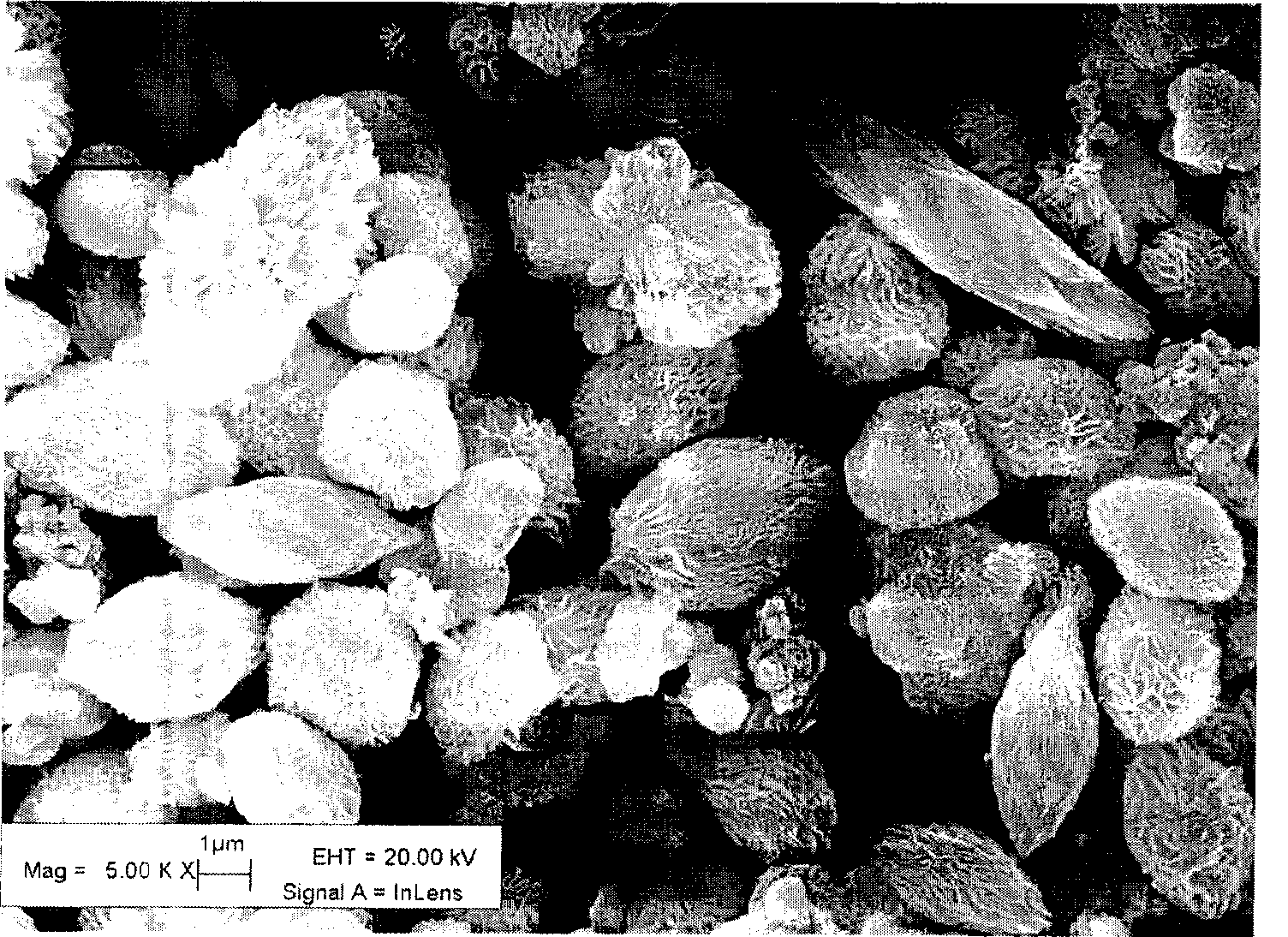

Method for preparing nano-sheet assembled bismuthyl bromide superstructure by adjusting and controlling surfactant

InactiveCN101691672ASimplify operation stepsSimple processPolycrystalline material growthFrom normal temperature solutionsSolventChemistry

The invention belongs to the fields of nano / micron material preparation technology and hydro-thermal synthesis technology, and particularly relates to a method for preparing a nano-sheet assembled bismuthyl bromide superstructure by adjusting and controlling a surfactant. The method comprises the following steps: using bismuth nitrate, sodium bromide or hexadecyl trimethyl ammonium bromide as a reactant, adding PEG4000 or PVP4000 as an adjusting and controlling agent, using ethanediol as a solvent, preparing a precursor solution under ultrasonic agitation, and moving the precursor solution into a hydro-thermal reaction kettle in a packing ratio of between 60 and 80 percent; putting the hydro-thermal reaction kettle filled with the mixture into a box-type resistance furnace, heating the kettle to a temperature of between 90 and 150 DEG C, keeping the temperature for 2 to 48 hours, taking the kettle out of the furnace, and cooling the kettle to the room temperature naturally; and washing and centrifugally separating the mixture in the kettle to obtain the required product. The method has the advantages of simple process, easy construction of a whole preparation system, simple and convenient operation, easily controlled condition, low cost, easily controlled product shape and size, high purity, good crystallinity and convenient processing of the product, and is suitable for large scale industrial production.

Owner:TONGJI UNIV

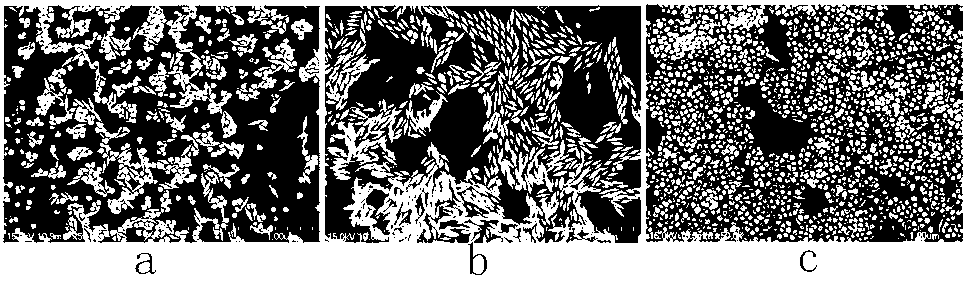

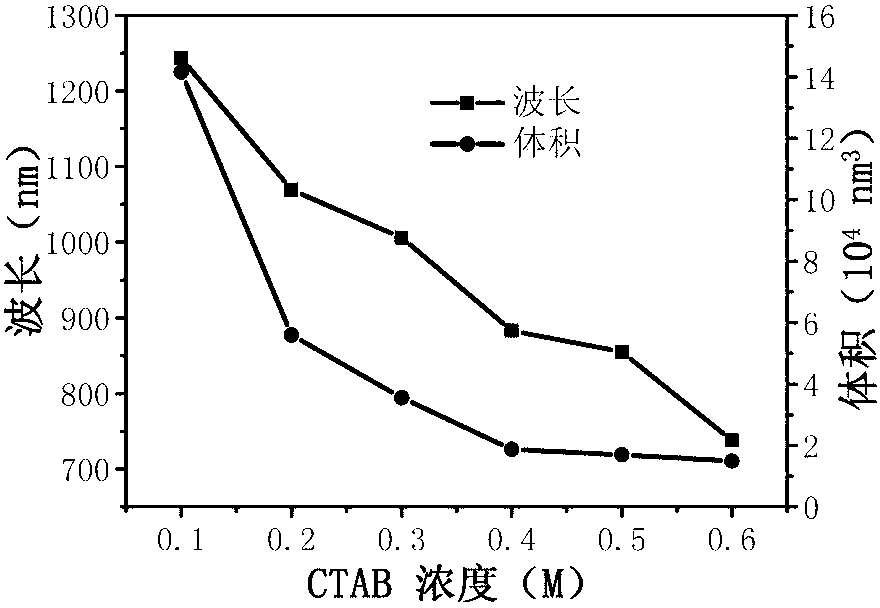

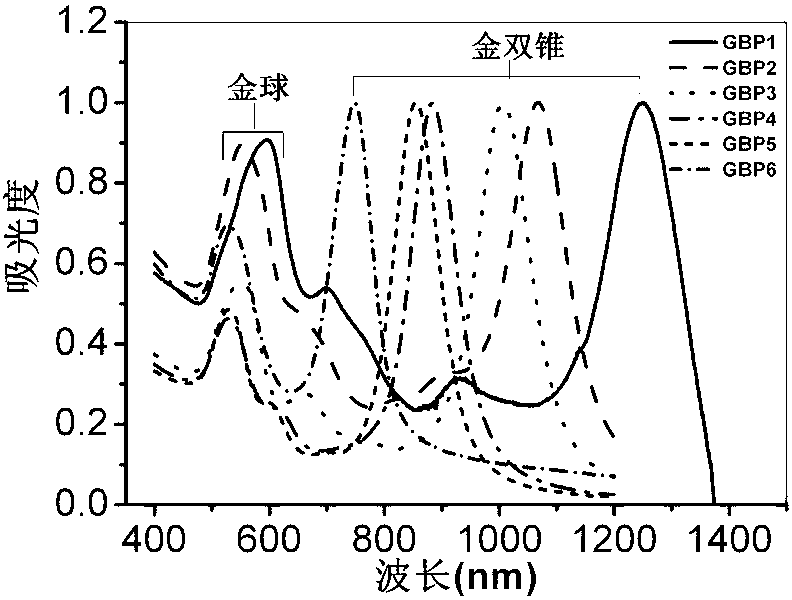

Purification method for gold nano-particles with double-cone structures

InactiveCN103240420AImprove purification efficiencySimple methodExtinction crossPurification methods

The invention discloses a purification method for gold nano-particles with double-cone structures. The gold nano-particles with stable citric acid serve as seeds, water solution of cationic surface active agents with silver nitrate serves as a growth system, initial gold nano-particle products with the double-cone structures are prepared by a seed growth method, centrifugally concentrated and then added into hexadecyl trimethyl ammonium bromide water solution with the concentration of 0.1M-0.6M, the volume of the initial gold nano-particle products is as same as that of the hexadecyl trimethyl ammonium bromide water solution, the initial gold nano-particle products are uniformly mixed and separated into an upper layer and a lower layer after standing for 24 hours, and the obtained lower layer is provided with pure gold double-cone nano-particle products with the plasma resonance wavelength ranging from 700nm to 1300nm. The double-cone nano-particles with different sizes are purified by adjusting the concentration of hexadecyl trimethyl ammonium bromide, the method is simple, convenient, easy to operate and high in purification efficiency, industrial production can be realized, and the obtained products have large local electric field enhancement and extinction cross sections and can be applied to the technical field of optics and biology.

Owner:SUZHOU UNIV

Radiating, thermal insulating and decorating integrated composite plate

A radiating, thermal insulating and decorating integrated composite plate is composed of a vacuum insulated panel and a surface layer, and the vacuum insulated panel is sealed inside the surface layer by adopting thermoplastic formation. Raw materials of the surface layer comprise 20 to 40 parts of infrared reflection pigment, 10 to 20 parts of hollow particles with aluminized surfaces, 15 to 25 parts of aerogel, 30 to 58 parts of organic resin, 0.15 to 0.25 part of a wetting agent, 0.3 to 0.4 part of a dispersing agent, 0.2 to 0.8 part of a foam breaking agent, 0.03 to 0.12 part of a corrosion remover, 0.03 to 0.12 part of a mould inhibitor, 0.5 to 1.1 part of a thickening agent, 1.2 to 2.4 parts of a coalescing agent, and 0.3 to 0.15 part of a PH value adjusting agent. The surface layer serves as a decorating layer, a radiating and thermal insulating layer, as well as a protecting layer for an STP or VIP core material, and a high intensity alkali-resisting fiberglass fabric covers a plate surface adhered to a base wall. According to the radiating, thermal insulating and decorating integrated composite plate, the combination of a radiating layer and an thermal insulating layer can be achieved, thermal insulation can be performed from three aspects of stopping heat conduction, preventing thermal convection and preventing thermal radiation, and the thermal insulation effect is improved greatly; moreover, the decorating layer, the protecting layer and the decorating layer are combined into a whole, materials are saved and the construction is simple.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

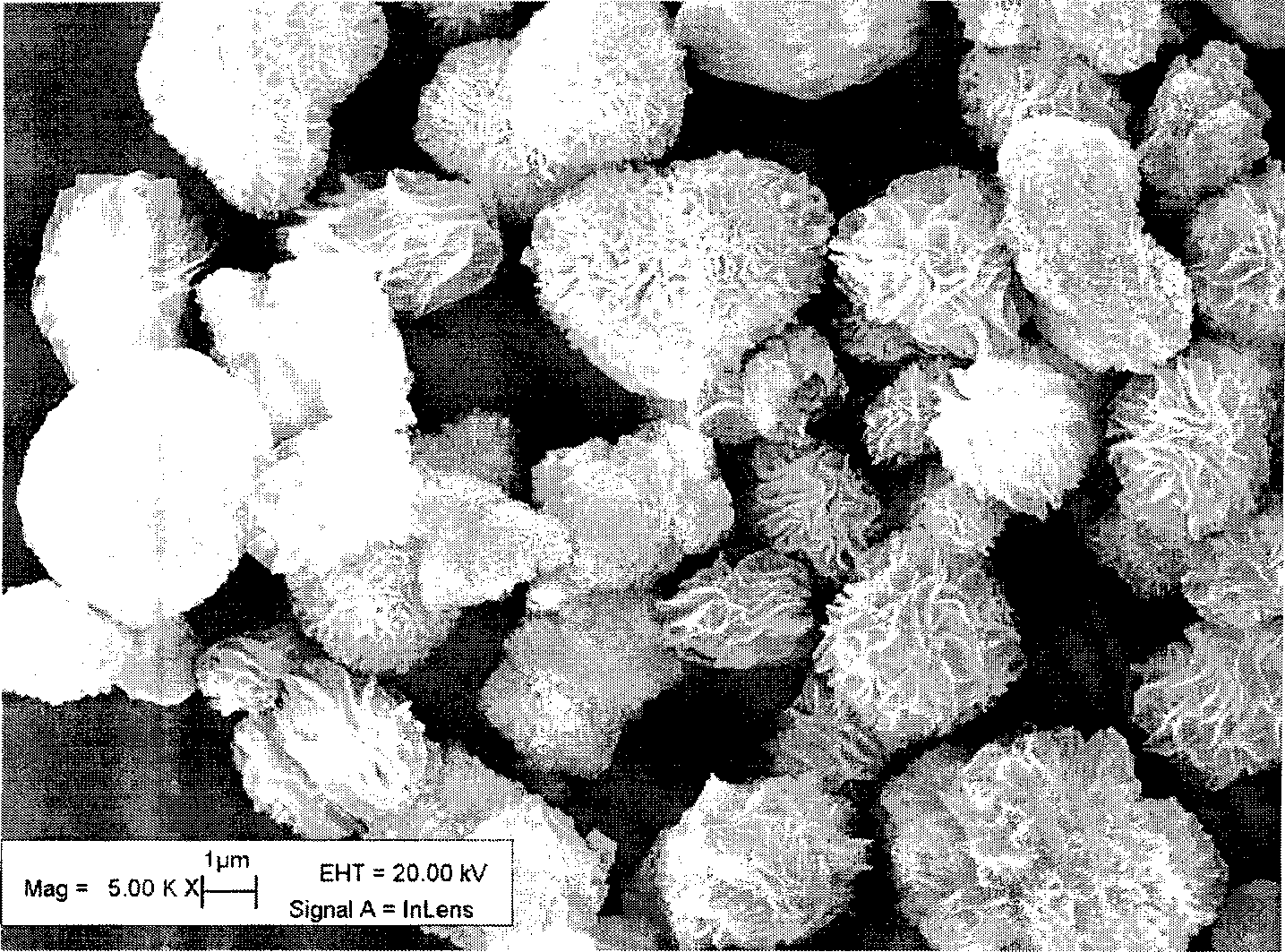

Process for producing flower shaped indium hydroxide powder having high specific surface area

InactiveCN101508462AHigh specific surface areaControllable sizeGallium/indium/thallium compoundsUreaChemistry

The invention relates to a method for preparing flower indium hydroxide with high specific surface area, which belongs to the technical field of inorganic material preparing process. The method uses In water soluble salt as an indium source, urea as an alkali source and sodium dodecyl sulfate as a surfactant to prepare indium hydroxide powder by a hydro-thermal method, wherein the compositions react at a constant temperature for 12 to 24 hours under a low-temperature hydrothermal condition of between 90 and 105 DEG C; and precipitate is obtained through filtration after the reactant is cooled to room temperature, and is washed, centrifugally precipitated and dried to obtain the flower high specific surface area indium hydroxide assembled by nanometer flakes. The method has the advantages that the method prepares the flower indium hydroxide by the low-temperature hydro-thermal method, not only can make crystal sufficiently grow under unrestricted condition with advantages of high specific surface area, controllable appearance and size of the crystal, perfect crystal and the like, but also can obtain powder body with specific surface area of between 20 and 40 mg; and XRD diffraction indicates that a main crystal phase is In(OH) and grows with preferred orientation along (100) direction, and impurity phase is InOOH with content totally less than 12 percent. The system has excellent application prospect in microelectronics, photoelectricity, sensing devices, catalysts, alkaline cells and other fields.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing magnetic porous carbon spheres through microfluidic method

InactiveCN106927510AControllable sizeUniform particle sizeMaterial nanotechnologyFerroso-ferric oxidesPolystyrene microsphereEnvironmentally friendly

The invention relates to a method for preparing magnetic porous carbon spheres through a microfluidic method and aims at solving the technical problems that an existing preparation method of porous carbon spheres is complicated in operation and strict in preparation condition, and that the prepared porous carbon spheres are uneven in particle sizes, relatively small in particle size and poor in dispersity, are not recyclable, and are not round in shape. The method comprises the steps of (1) preparing a disperse phase; (2) preparing microspheres; and (3) carrying out carbonization treatment. The microspheres prepared through the method are controllable in size, uniform in particle size and consistent in shape and form; and micropores prepared by employing polystyrene microspheres as a template are consistent in aperture and are in a honeycomb form. The method is novel and unique, simple in operation and small and easy in post-processing, the process is safe and non-toxic, and the method is environmentally friendly.

Owner:HEILONGJIANG UNIV

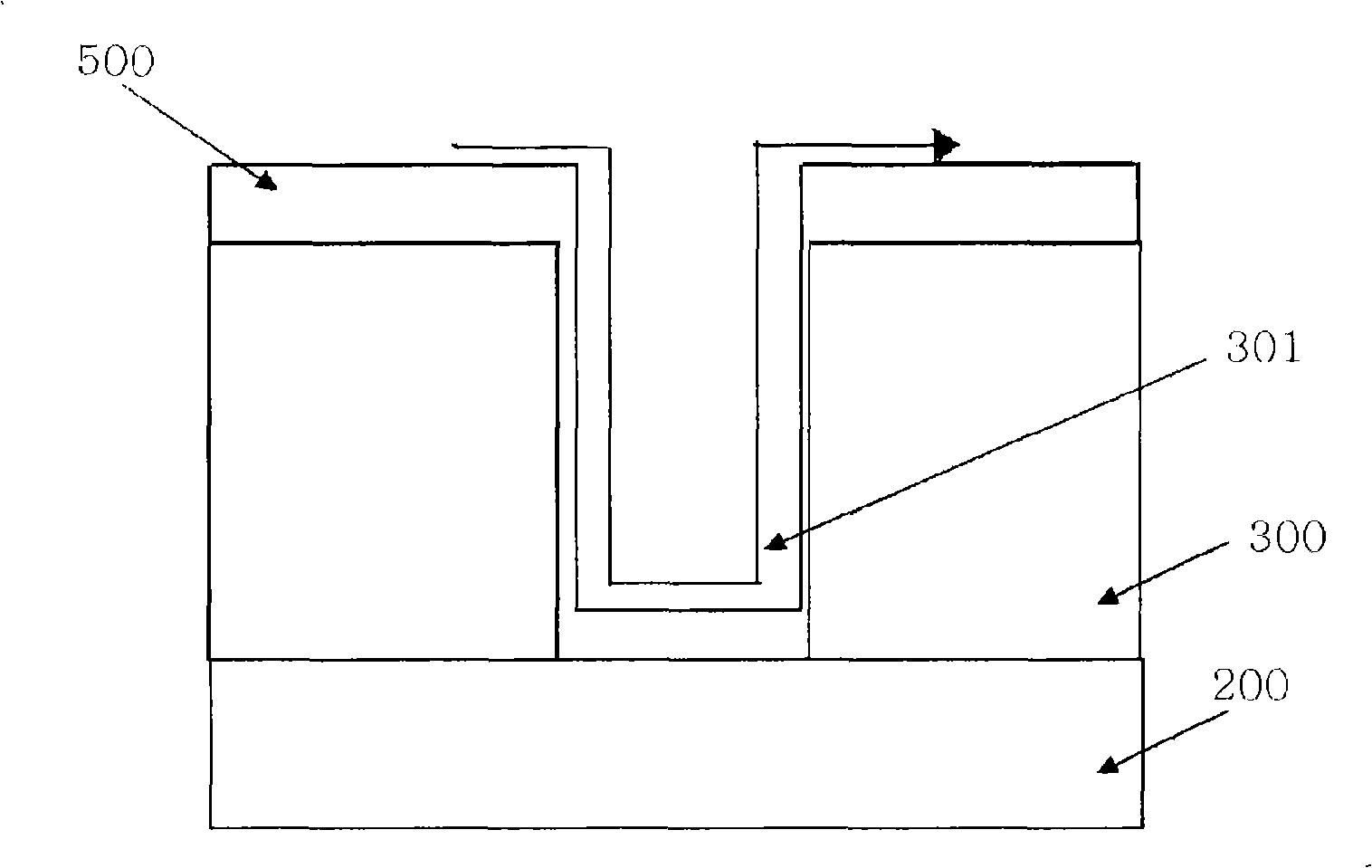

Method of manufacturing organic light emitting device and organic light emitting device manufactured by using the method

ActiveCN101496192AAvoid shiningEasy to controlSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsOrganic light emitting device

Disclosed is a method of manufacturing an organic light emitting device, an organic light emitting device manufactured by using the method, and an electronic device including the organic light emitting device. The method includes (a) forming an insulating layer on a lower electrode, (b) etching the insulating layer to form an opening ranging from an upper surface of the insulating layer to the lower electrode so that an overhang structure having a lowermost circumference that is larger than an uppermost circumference is formed, (c) forming a conductive layer on an upper surface of the lower electrode in the opening and a surface of the insulating layer other than the overhang structure, (d) forming an organic material layer on the conductive layer formed on the upper surface of the lower electrode in the opening, and (e) forming an upper electrode on an upper surface of the conductive layer disposed on the upper surface of the insulating layer and an upper surface of the organic material layer.

Owner:LG DISPLAY CO LTD

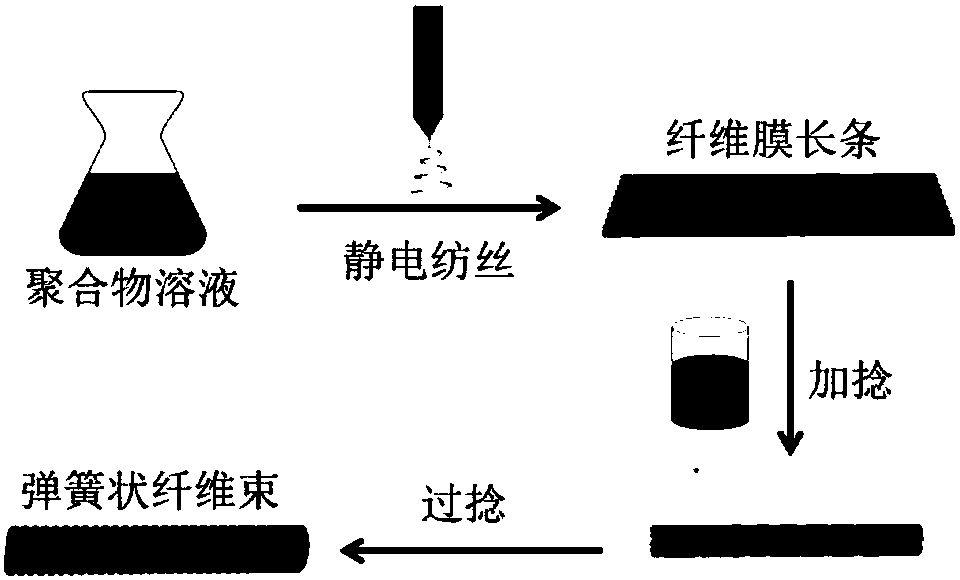

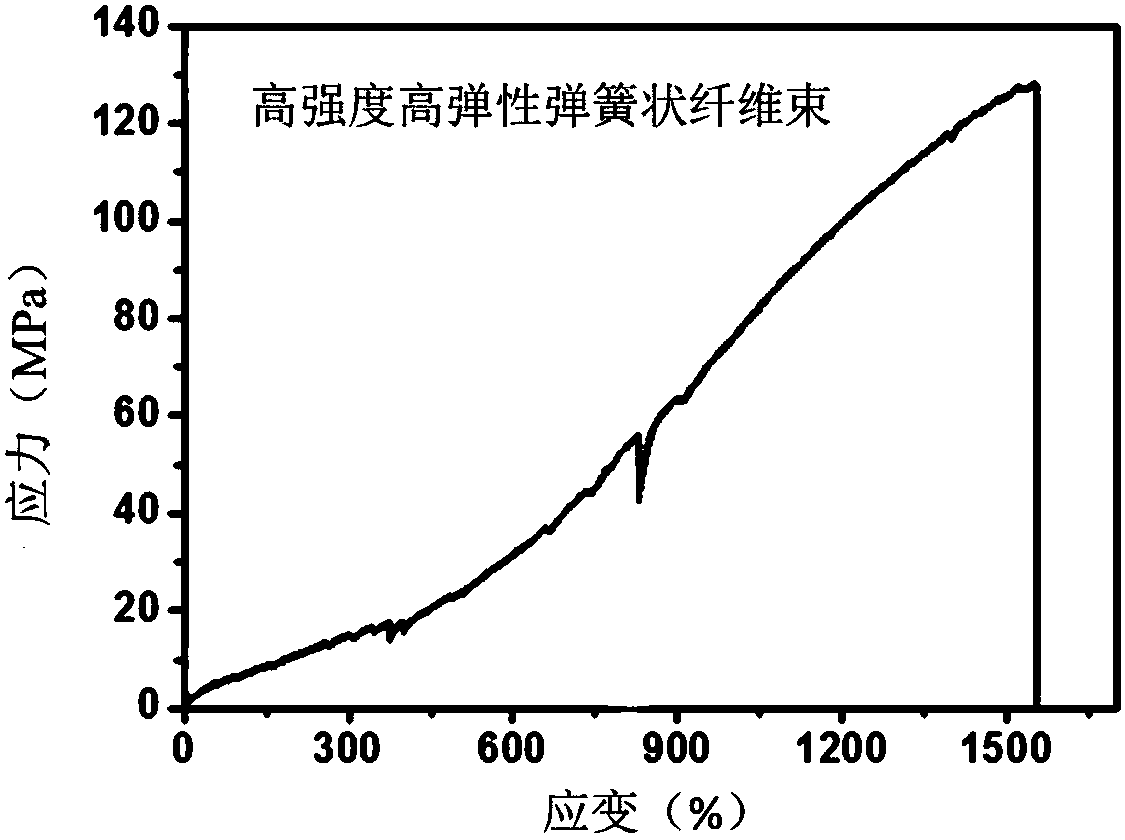

Preparation method for spring-like fiber bundle with high strength and high elasticity

InactiveCN107858780AHigh strengthStable structureFibre typesFilament/thread formingTensile strainPolymer science

The invention discloses a preparation method for a spring-like fiber bundle with high strength and high elasticity. Electrospinning and twisting technologies are adopted, and corresponding plasticizeris added in a preparation process. The fiber bundle is successfully prepared by the preparation method. The fiber bundle is of high mechanical strength, good flexibility and high tensile strain. Polymer is adopted as raw material of the fiber bundle, and by adding the corresponding plasticizer, the spring-like fiber bundle with high strength and high elasticity is acquired. The fiber bundle has astable structure and controllable dimensions and mechanical properties, and does not self-entangle and self-unwind, which is expected to be used in fields of woven conductive fabrics, stretchable sensors and flexible electronics.

Owner:BEIHANG UNIV

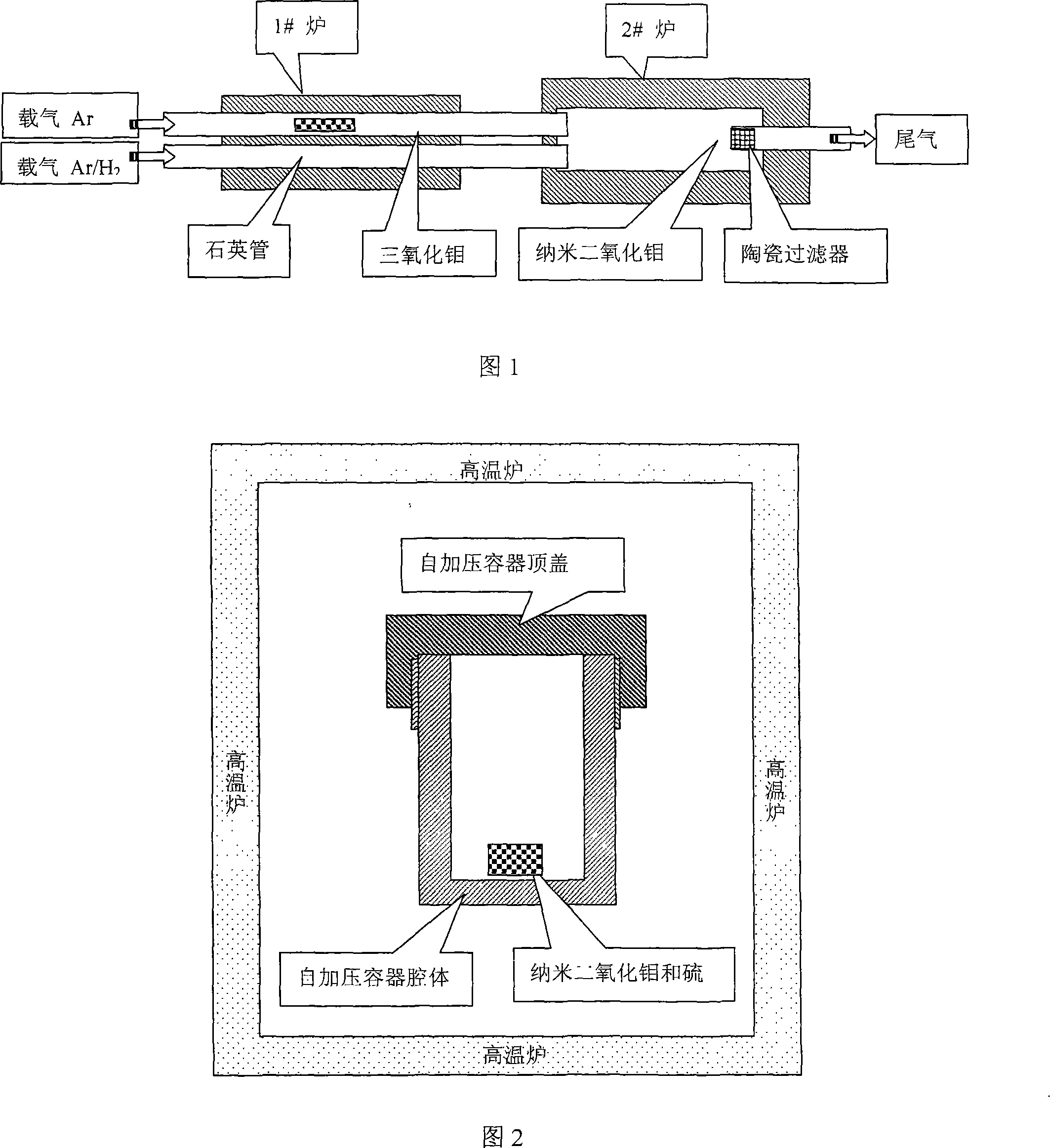

Method for preparing nano molybdenum disulfide with fullerene structure

The invention discloses a method for preparing nano molybdenum disulphide with a fullerene structure. The method comprises the following steps sequentially: by using industrial molybdenum trioxide as raw material, argon as carrier gas and hydrogen as reducing agent, molybdenum dioxide nano particle is generated by gas-phase reaction; the nano molybdenum disulphide and elemental sulfur are reacted under the condition of high temperature self-pressurization to produce powder material of the nano molybdenum disulphide with the fullerene structure; the molybdenum dioxide is nano particle generated directly by the reaction of the molybdenum trioxide after gasification under 700 to 1,000 DEG C with the hydrogen under 400 to 950 DEG C; the molybdenum disulphide with the fullerene structure is compound molybdenum disulphide by the self-pressurization reaction of the nano molybdenum dioxide and elemental sulfur in a vessel under 500 to 950 DEG C. The method for preparing the nano molybdenum disulphide with the fullerene structure has the advantages of simple process, high production efficiency, low cost of the raw material and product and short reaction time and the method can easily control the size of the molybdenum dioxide nano particle.

Owner:CHANGAN UNIV

Metal or metal oxide comprising a surface-bonded organic shell, and a method for preparing the same

ActiveUS20140124696A1Not easy to disperseEasy to reuseMaterial nanotechnologyPigmenting treatmentNitrogenMaterials science

An organically surface-bonded metal or metal oxide material including an inorganic metal or metal oxide and an organic material. The organic material is coated on the surface of the inorganic metal or metal oxide. The inorganic metal or metal oxide and the organic material are linked through a strong chemical bond. The strong chemical bond includes a covalent bond between a metal in the inorganic metal or metal oxide and a nitrogen in the organic material.

Owner:BEIJING GIGNANO BIOINTERFACE

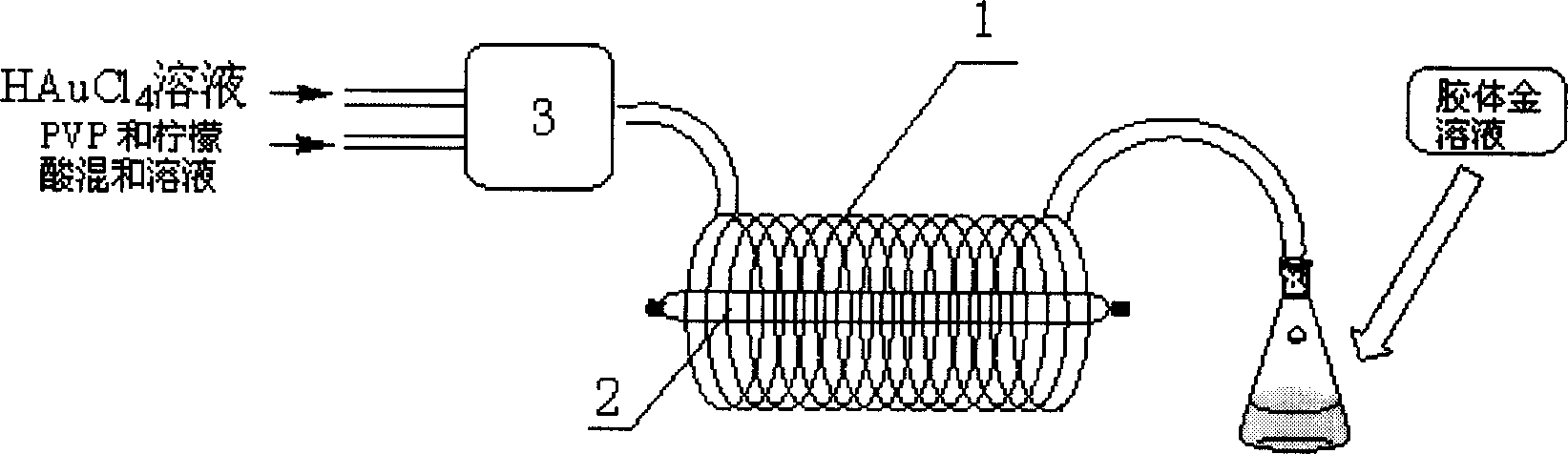

Method for preparing gold colloidal nanaparticles

The invention relates the method for preparation of nanometer gold particle, comprising the following step: making the mixture solution of PVP and citric acid, adding chlorauric acid solution, and injecting the mixture solution into quartz coiled pipe which is irradiated by ultraviolet lamp, the radiated wave length of ultraviolet lamp being 253.7-300nm, and the power of ultraviolet lamp being 14-2000W. Using the method, the grain-size distribution of nanometer gold particle is homogeneous, the particle sizes are easy to control, the least mean particle diameter is 1.5nm, and no poison material and the polluted material are produced.

Owner:XI AN JIAOTONG UNIV

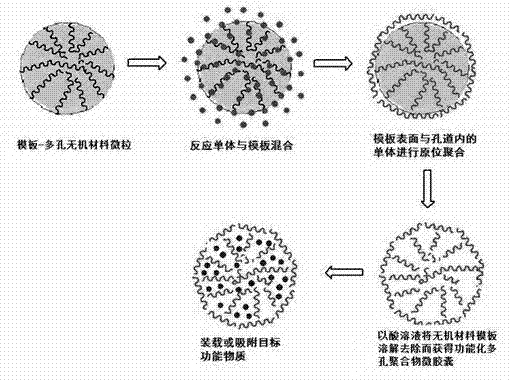

Porous functional microcapsule, preparation method and application

InactiveCN103566846AControllable sizeUniform sizeOther chemical processesAlkali metal oxides/hydroxidesIn situ polymerizationMicroparticle

The invention discloses a porous functional microcapsule, a preparation method and application. The porous functional microcapsule, taking porous inorganic microparticles as a template, is prepared from various monomers which are taken as wall material raw materials through mixing the template and the wall material raw materials, implementing in situ polymerization and removing the template. The microcapsule, due to thick capsule wall and many active groups, has the characteristics of being easy for loading of functional materials, and controllable and adjustable in release of the functional materials.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

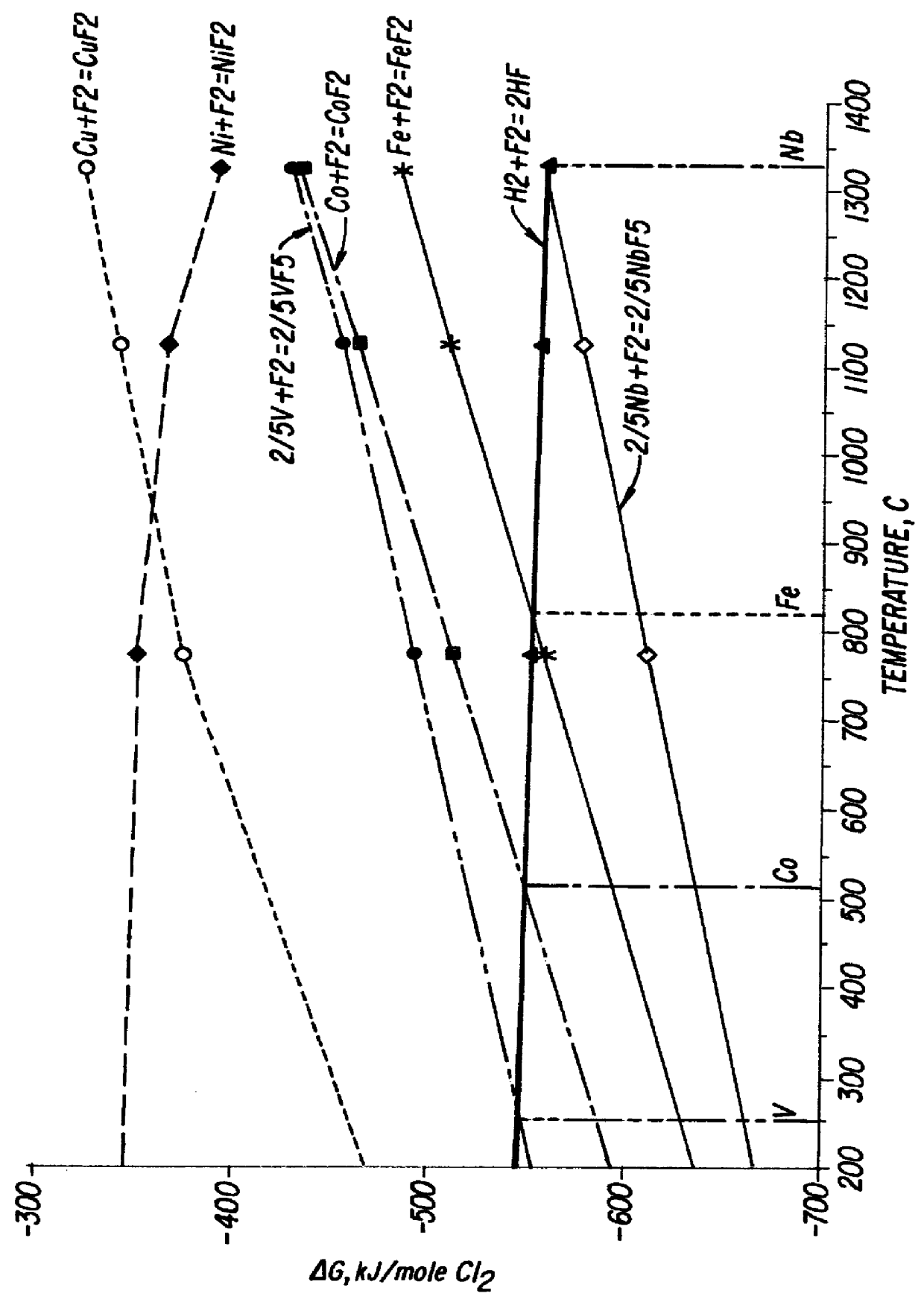

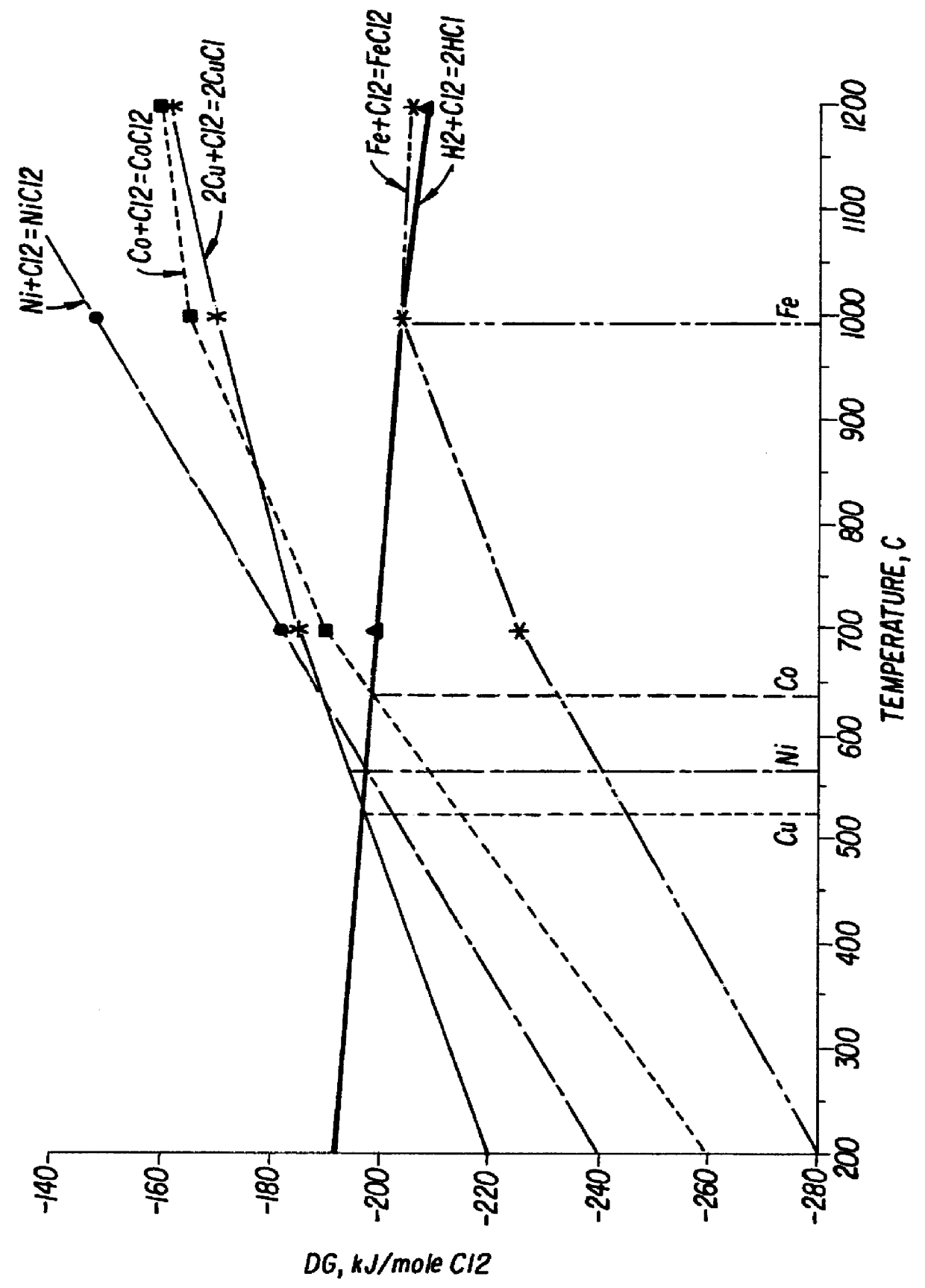

Process for manufacturing of metallic powder

InactiveUS6090179ASimple processSimple and efficient and inexpensiveProcess efficiency improvementHalogenDecomposition

A process for manufacturing of metal powder from a halogen containing chemical compound of the metal. The process involves thermal treatment of the compound within a closed reactor and in non-oxidizing atmosphere so as to induce decomposition of the compound and formation therefrom of a metal halide and a reduction agent capable to reduce the metal halide to elemental metal which can be collected in the form of fine powder. By variation of condition of the thermal treatment like temperature, pressure, duration and by choosing particular type of the compound it is possible to control the size and purity of the powder as well the powder particles shape.

Owner:REMPTECH

Method for preparing nano metal oxide ceramic thin/thick film

The invention discloses a preparation method for nanometer metal oxide ceramic thin or thick coating, comprising steps in sequence: first, a mixed solution with metallic cation, organic monomers, cross-bonding agents, and initiating agents is prepared; second, gelatin is catalyzed; third, sizing agent is prepared for coating; fourth, coating is carried out; fifth, heat treatment is carried out. By adopting the cheap inorganic salts as raw materials, the nanometer metal oxide ceramic thin or thick coating has the advantages of simple technical process, easy operation, high efficiency, excellent repeatability, easy control for the size of the metal oxide grain and the thickness of the coating by adjusting the technological parameters, effectively avoiding mutual contact and agglomeration of the grains, meanwhile overcoming the shortcomings of high requirements upon experimental facilities and high cost in the common film preparing technique, thus providing with excellent universality and commonality, and also applicable to the preparation of the multi-layer composite nano-metal oxide thin or thick ceramic coating. In addition, the prepared thin or thick coating has a net-type loose porous structure, and the crystallization is excellent. The crystallized grains with narrowly distributed sizes are in sphere or sphere-like shapes, and are particularly suitable for the preparation of gas or humidity sensors.

Owner:HUAZHONG UNIV OF SCI & TECH

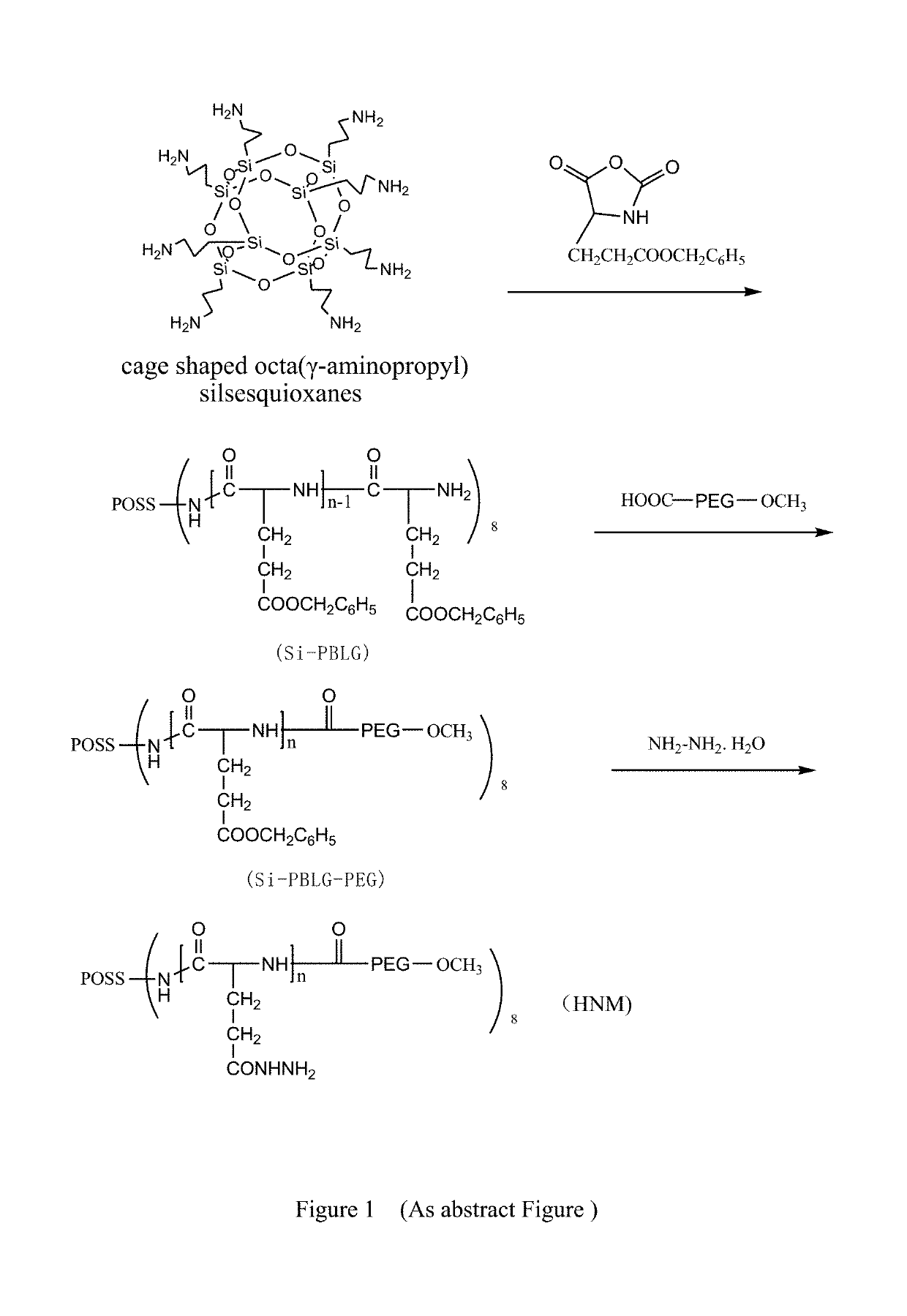

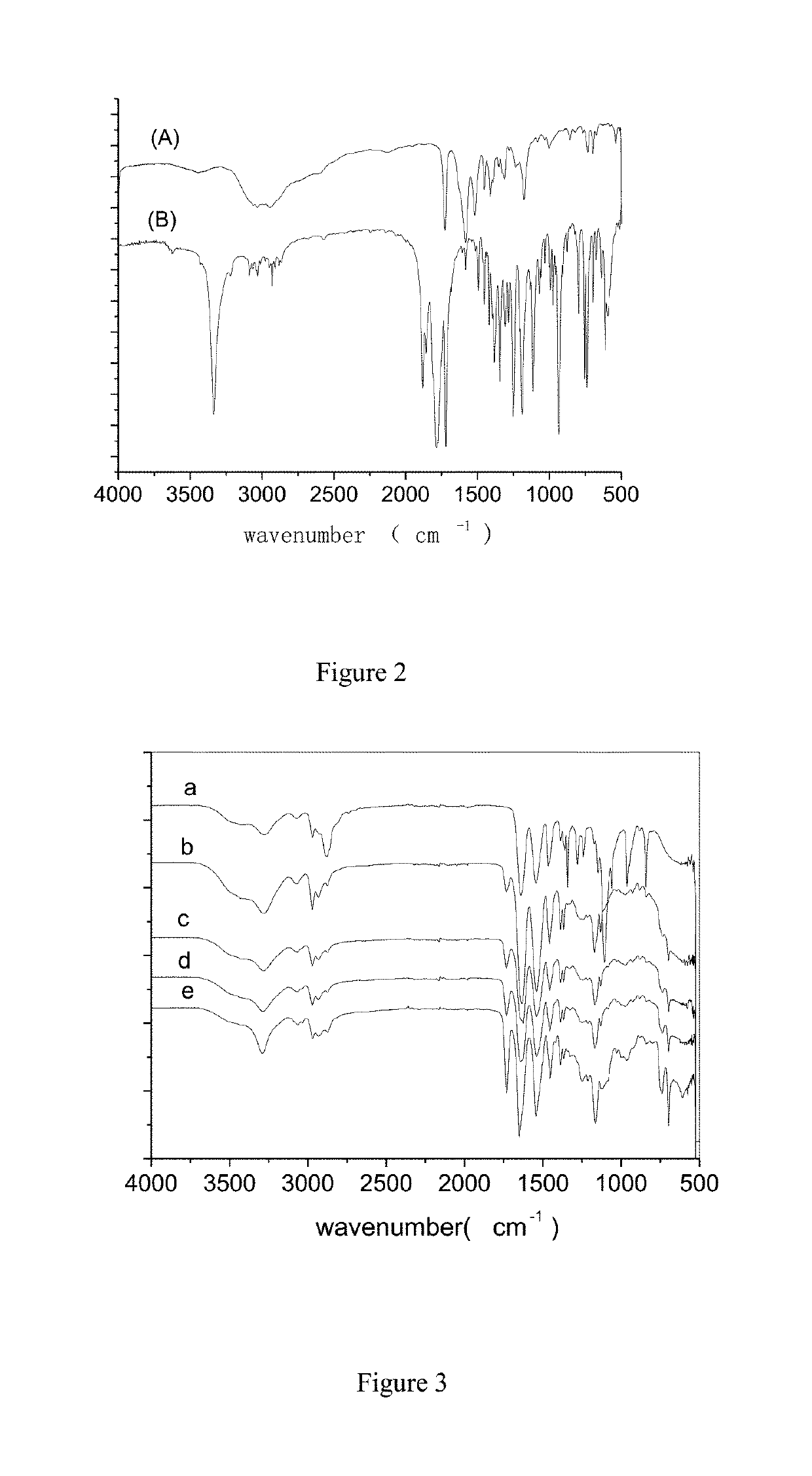

A method for preparation of hybrid amphiphilic star copolymer nano micelles

ActiveUS20190110987A1Structural rulesControllable sizeOrganic active ingredientsEmulsion deliveryHydrazine compoundSide chain

Hybrid amphiphilic star copolymer nano micelles are prepared in the invention. Cage shaped octa(γ-aminopropyl) silsesquioxanes is selected as the inorganic part, and L-glutamic benzyl ester-five membered ring anhydride is ring-opening polymerized by the initiation of amino groups on the surface of cage shaped octa(γ-aminopropyl) silsesquioxanes, producing copolymers with cage shaped octa(γ-aminopropyl) silsesquioxanes as nucleus and poly (L-glutamic-benzyl ester) as arms. The copolymers reacts with monomethoxy poly (ethylene glycol) carboxylic acid by condensation. Finally, the benzyl groups in the side chains of poly (L-glutamic acid-benzyl ester) are converted into hydrazine groups by acylhydrazination to obtain hybrid amphiphilic star copolymer nano micelles. The micelles can load doxorubicin, they are safe to human body and have good application prospects.

Owner:JIANGNAN UNIV

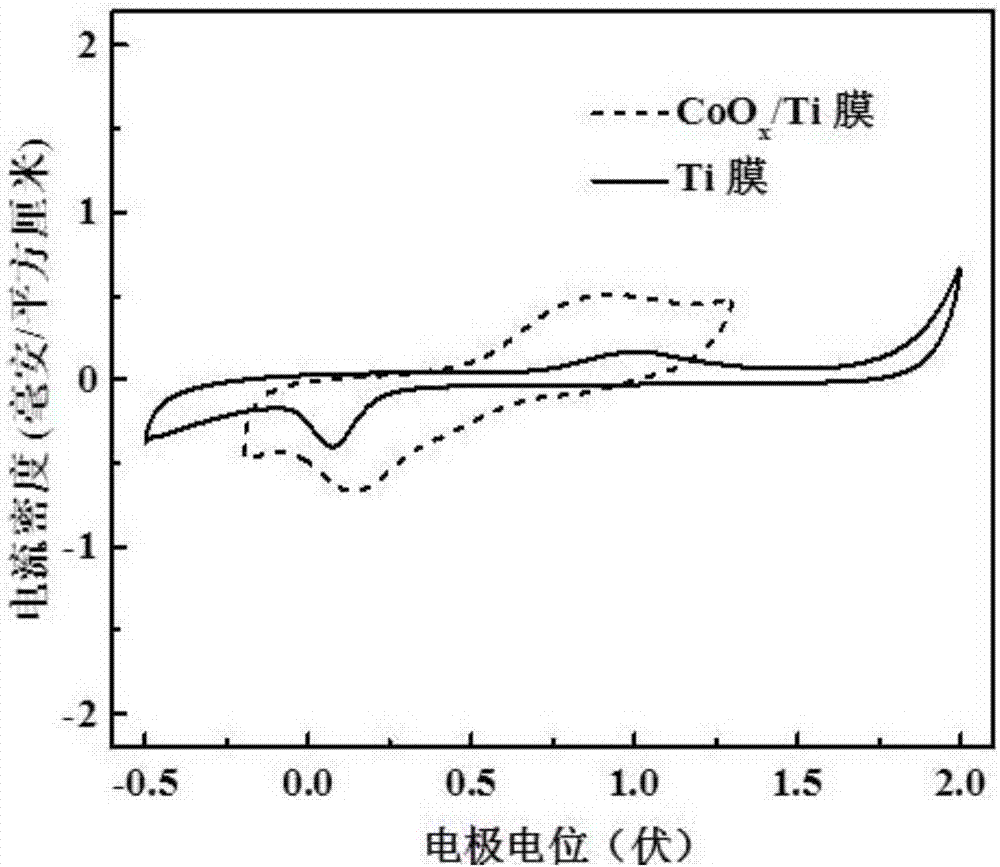

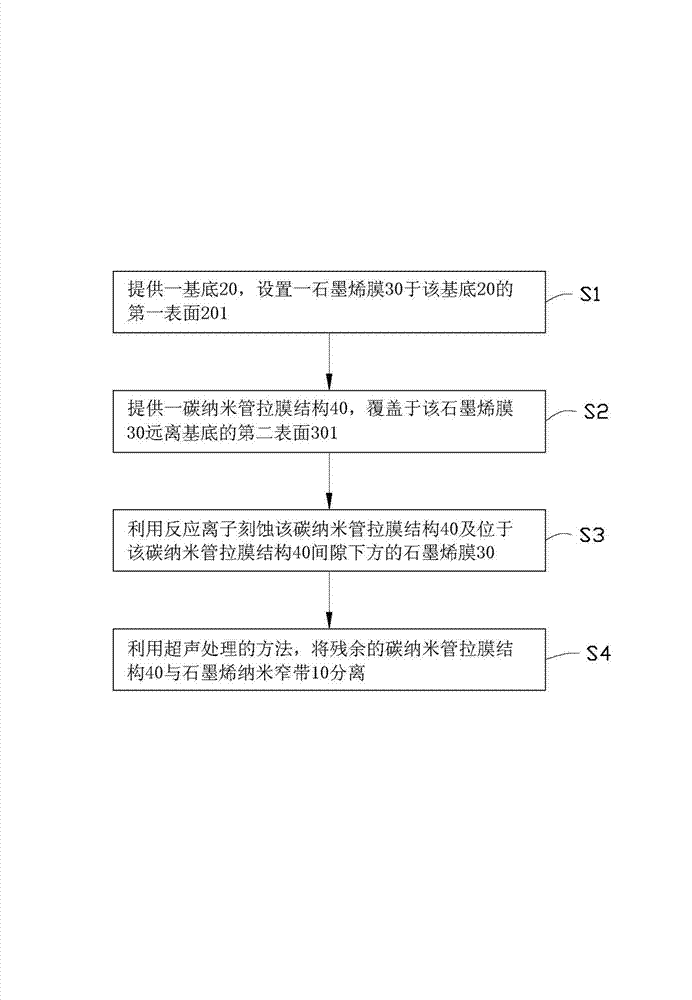

One-dimensional metallic oxide loaded titanium-based electro-catalysis film, preparing method and catalytic application

ActiveCN107059050ALoad method is simpleEasy to operateWater treatment parameter controlWater contaminantsElectricityNanowire

The invention relates to a one-dimensional metallic oxide loaded titanium-based electro-catalysis film, a preparing method and catalytic application and belongs to the field of film preparing and organic electrochemical synthesis. A micropore electric conduction film serves as a base film; a hydrothermal method is firstly adopted for conducting in-situ growth of a one-dimensional metallic oxide nanowire precursor structure on the surface of the base film; then an in-situ loaded one-dimensional metallic oxide nanowire structure is obtained on the surface of the titanium-based film through high-temperature roasting treatment, and a three-dimensional porous metal film electrode is prepared; and the three-dimensional porous metal film electrode serves as an anode assembly electro-catalysis reactor, and good catalytic performance is shown in the aspects of alcohol electrochemical oxidization synthesis for aldehyde preparing or acid organic electrochemical synthesis and water treatment. The method is simple and effectively, the cost is low, regulation of the catalyst feature is controllably achieved, the electrochemical performance and the catalytic performance of the obtained film electrode are good, and the problems that the feature, the size and other characteristics of catalyst particles are hard to control, the action force of the catalyst particles on the base film is weak, and stability and current efficiency of the film electrode are poor are solved effectively.

Owner:TIANJIN POLYTECHNIC UNIV

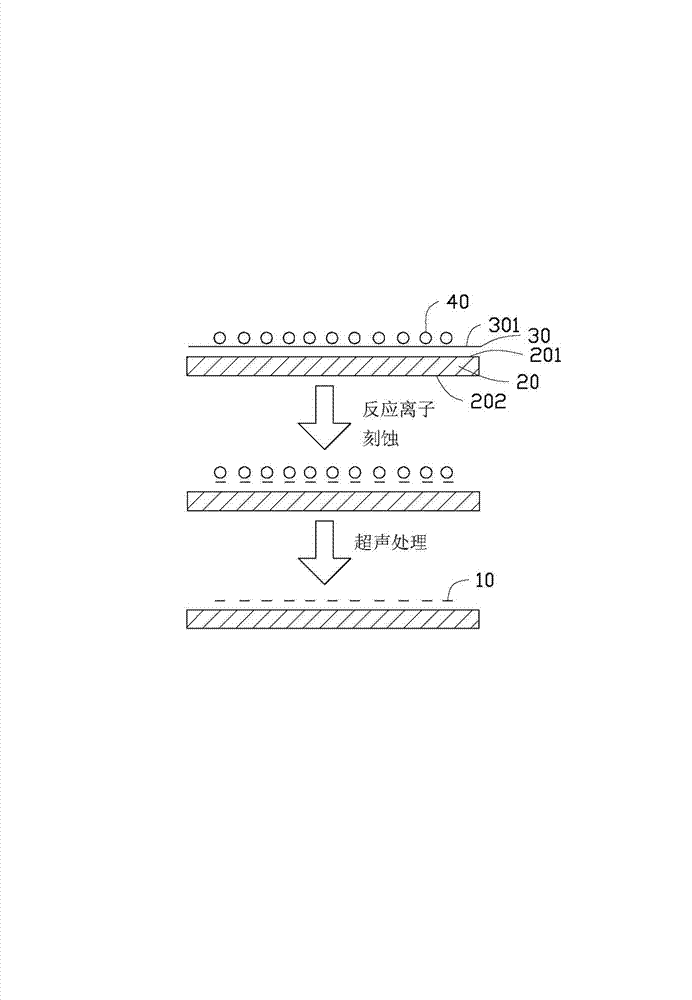

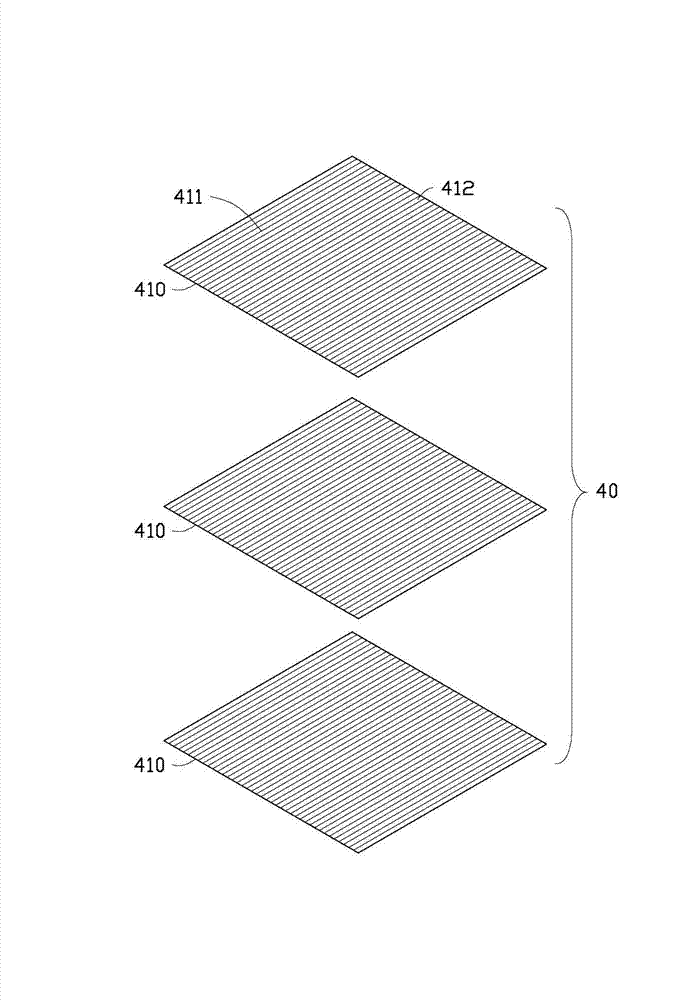

Preparation method of narrow graphene nanoribbons

ActiveCN103359723AEasy to manufactureControllable sizeMaterial nanotechnologyGraphene nanoribbonsCarbon nanotube

A method for making a strip shaped graphene layer includes the following steps. First, a graphene film is located on a surface of a substrate is provided. Second, a carbon nanotube structure is disposed on the graphene film. The carbon nanotube structure includes a plurality of carbon nanotube segments and a plurality of strip-shaped gaps between the adjacent carbon nanotube segments. Third, the graphene film exposed by the strip-shaped gaps is removed by a reactive ion etching method.

Owner:TSINGHUA UNIV +1

Combined manufacturing method of building exterior-wall thermal-insulation material

ActiveCN103570328AControllable sizeDeformation controllableClimate change adaptationPassive housesPumice dustThermal insulation

The invention relates to a building exterior-wall thermal-insulation material obtained by a combined manufacturing method and the combined manufacturing method. Raw materials of the building exterior-wall thermal-insulation material comprise an aggregate, a high-temperature binder and a low-temperature binder. The aggregate comprises expanded perlite, expanded vermiculite, pumice, expanded clay, expanded shale, expanded volcanic ash and expanded raw materials having a large amount of pores. The high-temperature binder comprises 45-60wt% of SiO2, 4-8wt% of Al2O3, 10-15wt% of CaO, 5-12wt% of B2O3, 1-8wt% of Na2O, 1-8wt% of K2O and 1-4wt% of ZnO. The low-temperature binder comprises water glass and bentonite. The combined manufacturing method has the characteristics that 1, in plate manufacture, the size and deformation can be controlled easily and the building exterior-wall thermal-insulation material is superior to foam light thermal-insulation materials; 2, compared with the foam thermal-insulation material manufacturing method utilizing a series of technological parameters such as a sintering temperature to control a heat conduction coefficient, the combined manufacturing method provided by the invention realizes heat conduction coefficient control only by raw material selection; 3, a sintering temperature is controlled in a range of 700-900 DEG C; and 4, in plate production, a roller kiln direct firing technology is utilized and kiln tools such as a base plate and a saggar are avoided so that a sintering heat utilization rate is high.

Owner:咸阳陶瓷研究设计院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com