Preparation method and application of novel silver-nanoparticle modified ultrathin graphite phase carbon nitride catalyst

A graphite phase carbon nitride, silver nanoparticle technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of easy recombination of photogenerated electrons and holes, low photon quantum efficiency, photocatalysis problems such as low efficiency, to achieve good chemical stability and reusability, improve catalytic ability, and the effect of simple and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

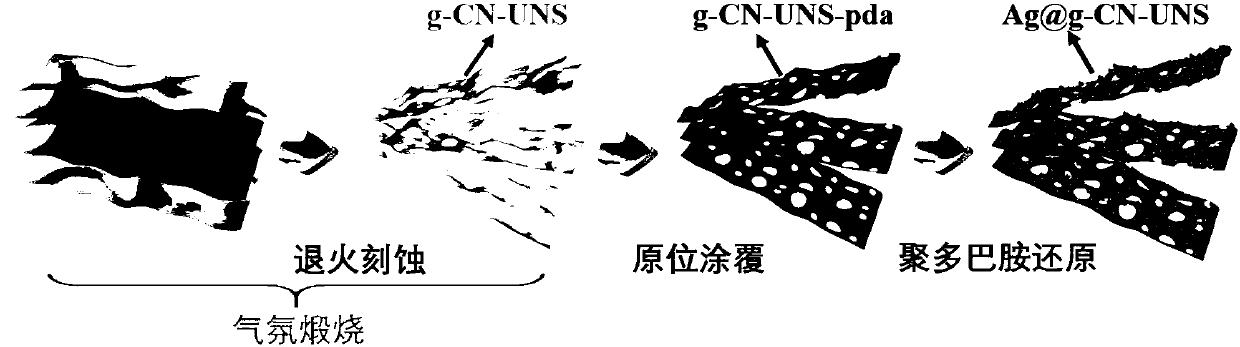

[0035] see figure 1 , figure 1 It is a schematic flow chart of the preparation method of the novel silver nanoparticle modified ultrathin graphite phase carbon nitride catalyst of the present invention. Such as figure 1 As shown, the present invention provides a kind of preparation method of novel silver nanoparticles modified ultrathin graphite phase carbon nitride catalyst, comprising the following steps:

[0036] Using urea as a precursor, the bulk graphite phase carbon nitride was prepared by high temperature heat treatment;

[0037] Preparation of ultrathin graphitic carbon nitride sheets;

[0038] A biomimetic polydopamine coating was loaded on ultra-thin graphitic carbon nitride sheets by dipping self-polymerization;

[0039] Based on the modification of polydopamine, using its own reducibility, silver nanoparticles are loaded on the surface of ultra-thin graphite phase carbon nitride sheets, and a new type of silver nanoparticles modified ultra-thin graphite phase ...

Embodiment 1

[0060] This implementation case shows the preparation method of a novel silver nanoparticle modified ultra-thin graphite phase carbon nitride catalyst according to the following steps:

[0061] (1) Obtain massive graphite phase carbon nitride by heat-treating urea: Weigh 10 g of urea and put it into a crucible, heat-treat it in a muffle furnace, the treatment temperature is 550°C, the constant temperature time is 2 hours, and the heating rate is 0.5°C / min After the reaction, cool to room temperature, take out the sample and seal it up.

[0062] (2) Convert the massive graphite phase carbon nitride into an ultra-thin graphite phase carbon nitride sheet by secondary high-temperature annealing and etching: put the massive graphite phase carbon nitride prepared in (1) into the crucible , continue to do heat treatment in the muffle furnace, the treatment temperature is 550°C, the constant temperature time is 2 hours, the heating rate is 2°C / min, after the reaction is completed, coo...

Embodiment 2

[0077] This implementation case shows the preparation method of a novel silver nanoparticle modified ultra-thin graphite phase carbon nitride catalyst according to the following steps:

[0078] (1) Obtain massive graphite phase carbon nitride by heat-treating urea: 10 g of urea is weighed and put into a crucible, and heat-treated in a muffle furnace at a treatment temperature of 570° C., a constant temperature time of 2 hours, and a heating rate of 0.5° C. / min. After the reaction, cool to room temperature, take out the sample and seal it up.

[0079](2) Convert massive graphite phase carbon nitride into ultra-thin graphite phase carbon nitride sheets by secondary high-temperature annealing and etching: put the massive graphite phase carbon nitride prepared in (1) into the crucible , continue to do heat treatment in the muffle furnace, the treatment temperature is 550 ° C, the constant temperature time is 1 hour, and the heating rate is 2 ° C / min. After the reaction is comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com