Conductive hydrogel based on nanocellulose-polyacrylamide-metal ions as well as preparation method and application of conductive hydrogel

A polyacrylamide and nanocellulose technology, applied in the field of sensors, can solve the problems of imperfect influence of hydrogel performance, and achieve the effect of excellent self-healing performance, simple process and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

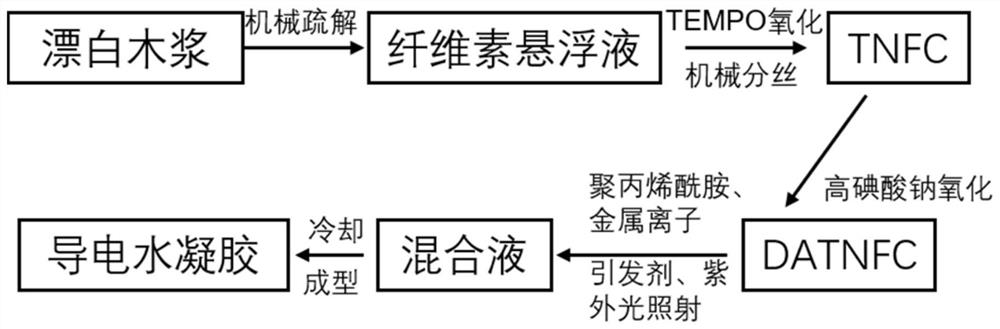

[0041] A kind of preparation method of the conductive hydrogel based on nanocellulose-polyacrylamide-metal ion (flow process see figure 1 ), including the following steps:

[0042] (1) Preparation of nanocellulose suspension: Take 30g of bleached coniferous wood pulp and add it to 100g of water, use a Valli beater to process it for 6 minutes without hanging heavy objects, and then add 0.48g 2,2 to the cellulose suspension , 6,6-tetramethylpiperidin-1-oxyl group (TEMPO) and 3g NaBr, add sodium hypochlorite solution (the consumption of sodium hypochlorite is added by 13.5mmol / g cellulose, effective in sodium hypochlorite Chlorine content is 194.3g / L), by adding 1M NaOH, the pH value of the reaction is maintained at 10.0, after reacting for 1h, adding 50mL of absolute ethanol to terminate the reaction to obtain a cellulose suspension, and using a high-pressure homogenizer to homogenize under 90bar pressure for 10 TEMPO-nanocellulose (TNFC) containing carboxyl groups was obtained...

Embodiment 2

[0045] A method for preparing a conductive hydrogel based on nanocellulose-polyacrylamide-metal ions, comprising the following steps:

[0046] (1) Preparation of nanocellulose suspension: Take 30g of bleached coniferous wood pulp and add it to 100g of water, use a Valli beater to process it for 6 minutes without hanging heavy objects, and then add 0.48g 2,2 to the cellulose suspension , 6,6-tetramethylpiperidin-1-oxyl group (TEMPO) and 3g NaBr, add sodium hypochlorite solution (the consumption of sodium hypochlorite is added by 13.5mmol / g cellulose, effective in sodium hypochlorite Chlorine content is 194.3g / L), by adding 1M NaOH, the pH value of the reaction is maintained at 10.0, after reacting for 1h, adding 50mL of absolute ethanol to terminate the reaction to obtain a cellulose suspension, and using a high-pressure homogenizer to homogenize under 90bar pressure for 10 TEMPO-nanocellulose (TNFC) containing carboxyl groups was obtained after the second time; 15g of sodium p...

Embodiment 3

[0049] A method for preparing a conductive hydrogel based on nanocellulose-polyacrylamide-metal ions, comprising the following steps:

[0050] (1) Preparation of nanocellulose suspension: Take 30g of bleached coniferous wood pulp and add it to 100g of water, use a Valli beater to process it for 6 minutes without hanging heavy objects, and then add 0.48g 2,2 to the cellulose suspension , 6,6-tetramethylpiperidin-1-oxyl group (TEMPO) and 3g NaBr, add sodium hypochlorite solution (the consumption of sodium hypochlorite is added by 13.5mmol / g cellulose, effective in sodium hypochlorite Chlorine content is 194.3g / L), by adding 1M NaOH, the pH value of the reaction is maintained at 10.0, after reacting for 1h, adding 50mL of absolute ethanol to terminate the reaction to obtain a cellulose suspension, and using a high-pressure homogenizer to homogenize under 90bar pressure for 10 TEMPO-nanocellulose (TNFC) containing carboxyl groups was obtained after the second time; 15g of sodium p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com