Patents

Literature

352results about How to ") The process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing graphene by using supercritical fluid

ActiveCN102115078AThe process is simpleLow costBulk chemical productionSingle layer grapheneCvd graphene

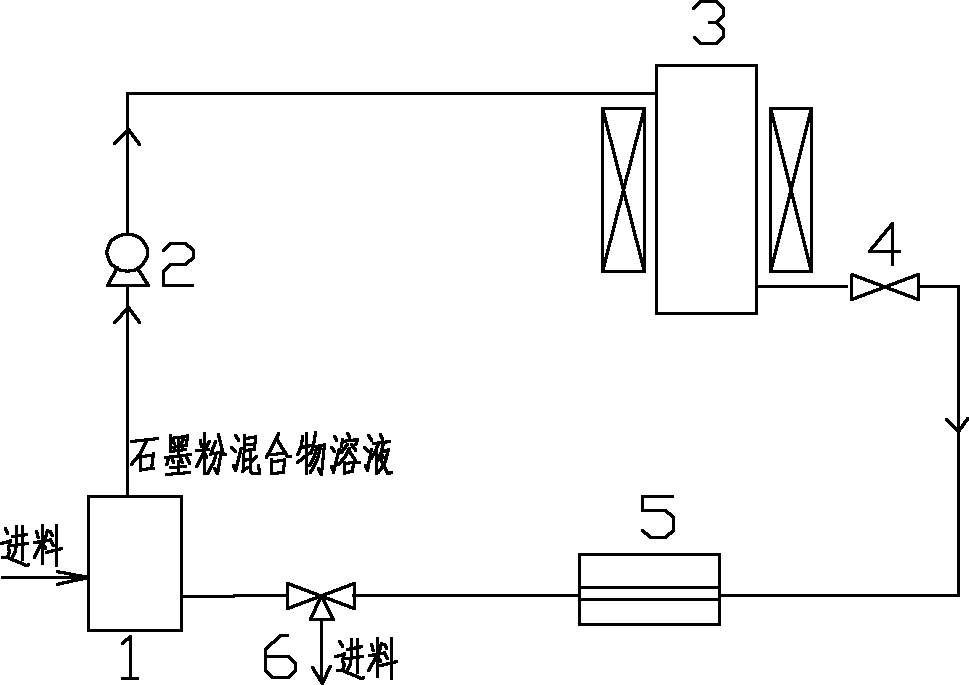

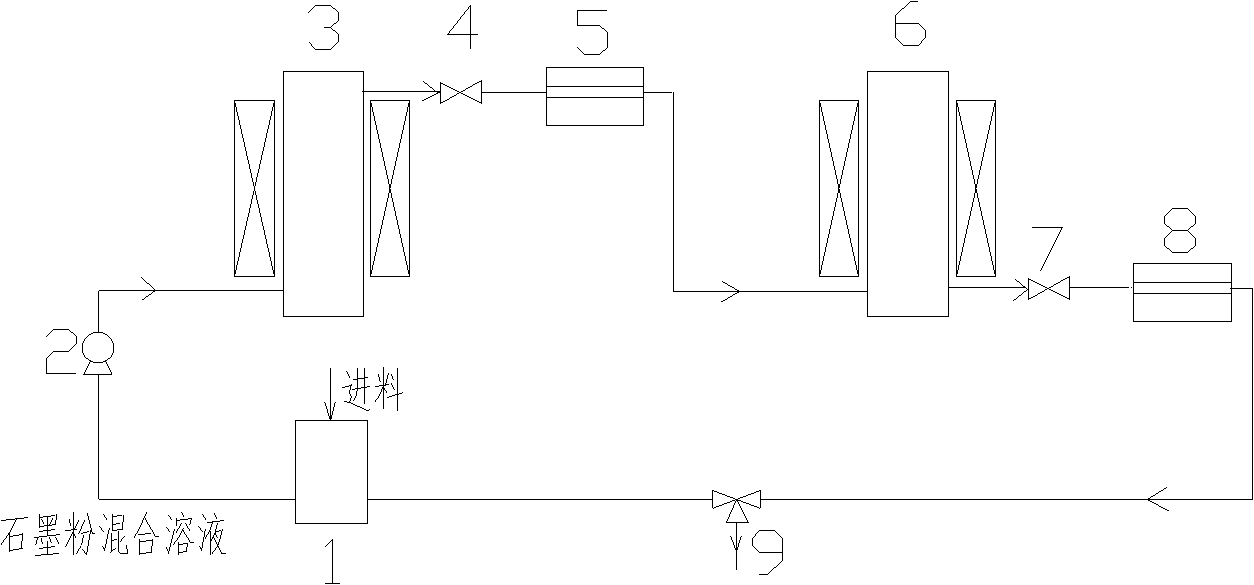

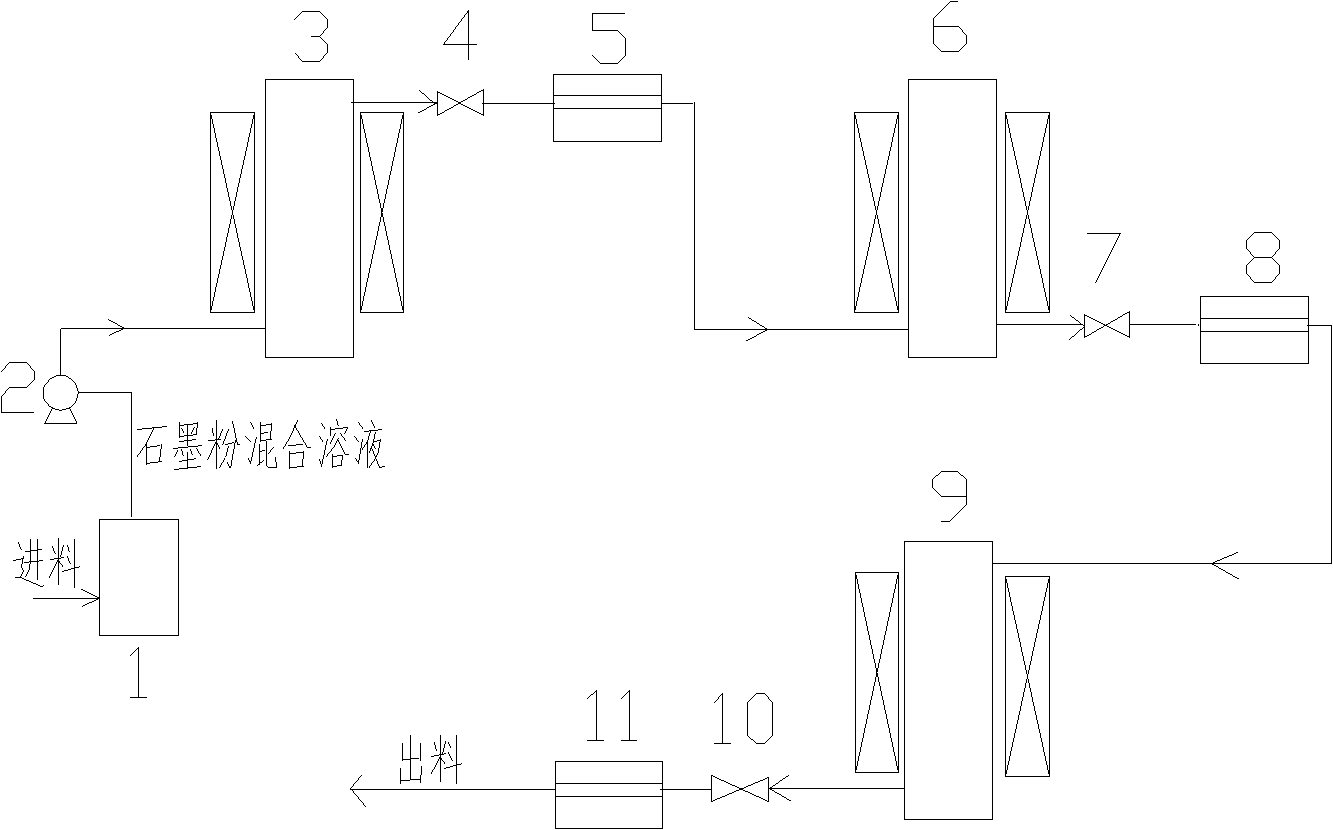

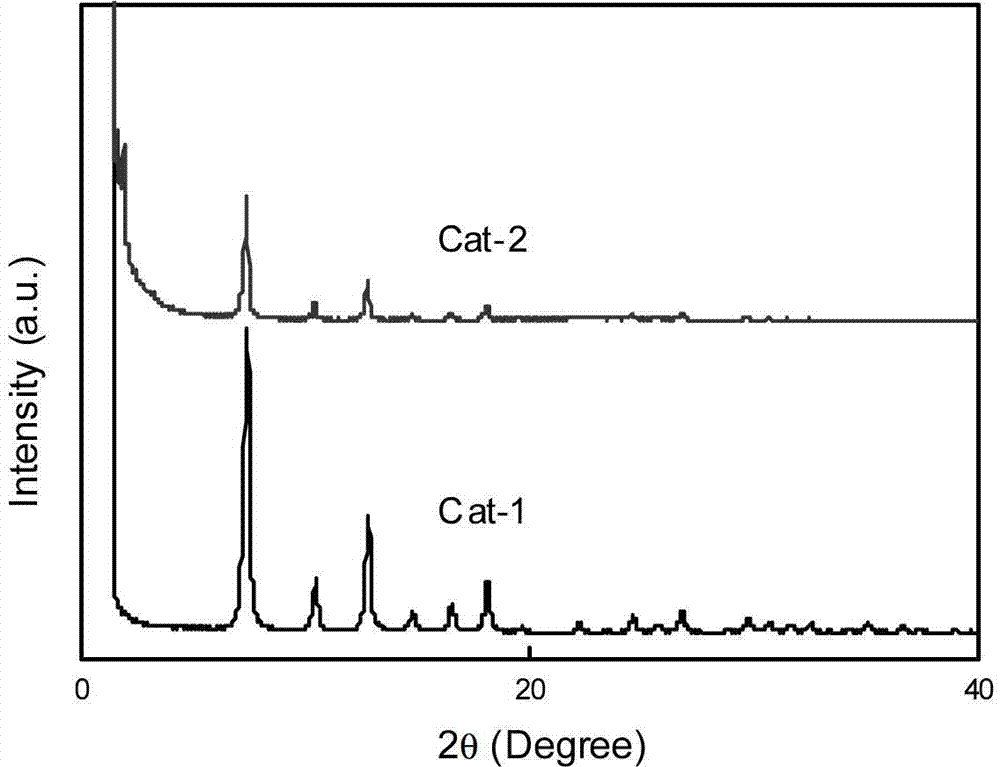

The invention discloses a method for preparing graphene by using a supercritical fluid, which relates to the technical field of novel nano materials. The graphene is prepared by repeatedly and circularly treating and cooling graphite powder dispersion liquid. Graphene of less than eight layers, prepared by the method, accounts for 90-95 percent and single-layer graphene accounts for over 10 percent; meanwhile, continuous operation is performed, so that mass production can be realized, and the graphene has the advantages of simple process, nontoxicity and lower cost.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method for novel gasoline sweetening adsorbent and application of novel gasoline sweetening adsorbent

ActiveCN102895954AIncreased mercaptan removal rateThe process is simpleOther chemical processesHydrocarbon oils refiningIonSolvent

The invention relates to a preparation method for a novel gasoline sweetening adsorbent and an application of the novel gasoline sweetening adsorbent. The preparation method for the novel gasoline sweetening adsorbent comprises the following steps of: evenly mixing a solvent, a metal ion precursor with a mesoporous material; ageing; adding an organic ligand; performing hydrothermal crystallization treatment; then, performing suction filtration, washing and drying on a product produced after the hydrothermal crystallization treatment to obtain a zeolite imidazole framework material / mesoporous material compound; and performing preforming shaping and crushing screening on the zeolite imidazole framework material / mesoporous material compound to obtain the gasoline sweetening adsorbent. According to the zeolite imidazole framework material / mesoporous material compound provided by the invention, the specific surface area of a zeolite imidazole framework material is high, and meanwhile, zeolite imidazole framework material is highly dispersed on the mesoporous material, and thereby, the problem of diffusional limitation caused by agglomeration is effectively solved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Tissue culture method of ginseng adventitious root

InactiveCN101606487AHigh yieldThe process is simplePlant tissue cultureHorticulture methodsNatural disasterGinseng

The invention discloses a tissue culture method of ginseng adventitious root, comprising the steps of induction, amplification and successive transfer culture of ginseng callus; the induced callus is inoculated on the prepared solid culture medium and added with plant growth regulator to be cultured for 3-4 weeks under the conditions of sterility, the temperature of 23-25 DEG C and keeping in dark place; the amplified callus is inoculated on the prepared solid culture medium and added with proper plant growth regulator to be cultured for 3-5 weeks under the conditions of sterility, the temperature of 23-25 DEG C and keeping in dark place, and then the adventitious root can be formed; the formed adventitious root is picked out and inoculated on the prepared liquid culture medium and added with the plant growth regulator to be cultured for 4-5 weeks under the conditions of sterility, room temperature and sunshine. The method has higher actual significance than ginseng cell cultivation, and the growth speed of the adventitious root is much higher than that of the original root; furthermore, the production rate of active secondary metabolite of the adventitious root is high and stabler and is not influenced by natural environment such as natural disaster and the like; the tissue culture method also has the characteristics of simple technique process, high inductivity, good repeatability, rapid propagation of the adventitious root, etc.

Owner:TIANJIN UNIV

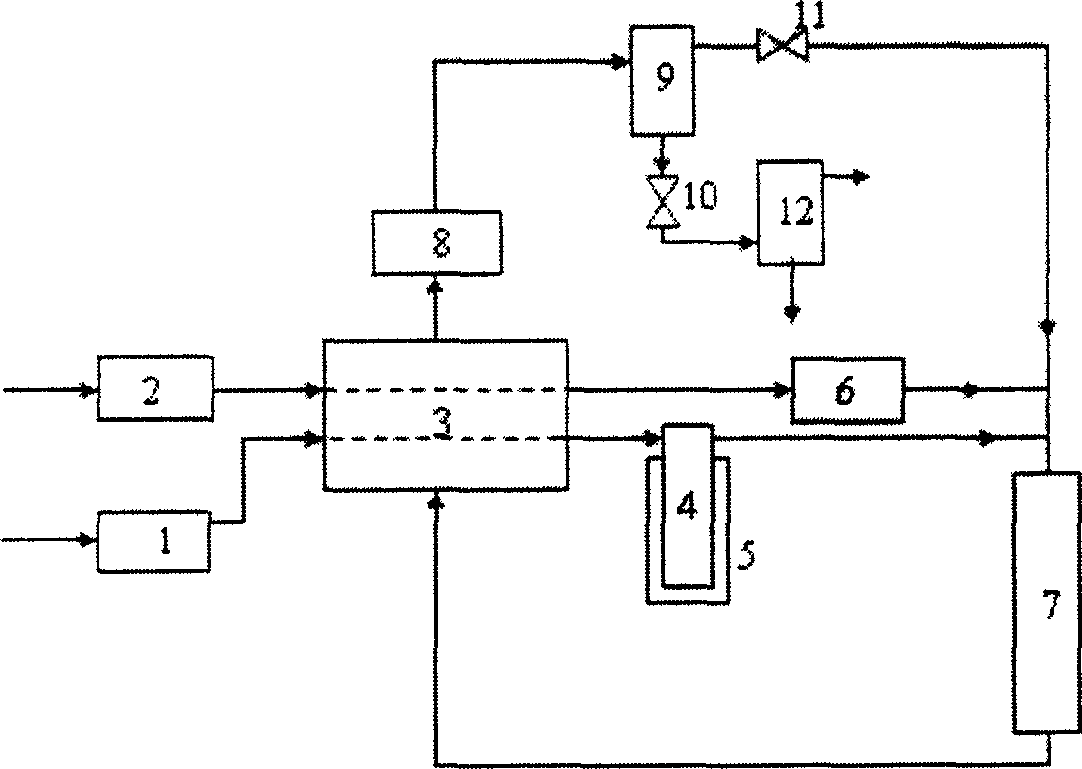

Method of sewage oxidation treatment using supercritical water

ActiveCN1730414AThe process is simpleEasy to operateMultistage water/sewage treatmentWater/sewage treatment by oxidationChemistryPollutant

The invention discloses a process for oxidation treatment of waste-water through hypercritical water which comprises, pressurizing the waste water to 22.1-30 MPa, preheating to 300-370 deg. C, loading the waste-water to a demineralizing equipment, elevating temperature to 450-650 deg C for desalinization, pressurizing the fluid containing oxidizing agent to 22.1-30 MPa, elevating the temperature to 550-650 deg. C, mixing the oxygen-containing fluid with desalinized waste-water and loading into hypercritical reactor, controlling the temperature between 550-650 deg. C, pressure between 22.1-30.0MPa, holding for 10-40 seconds, and carrying out hypercritical oxidation reaction.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

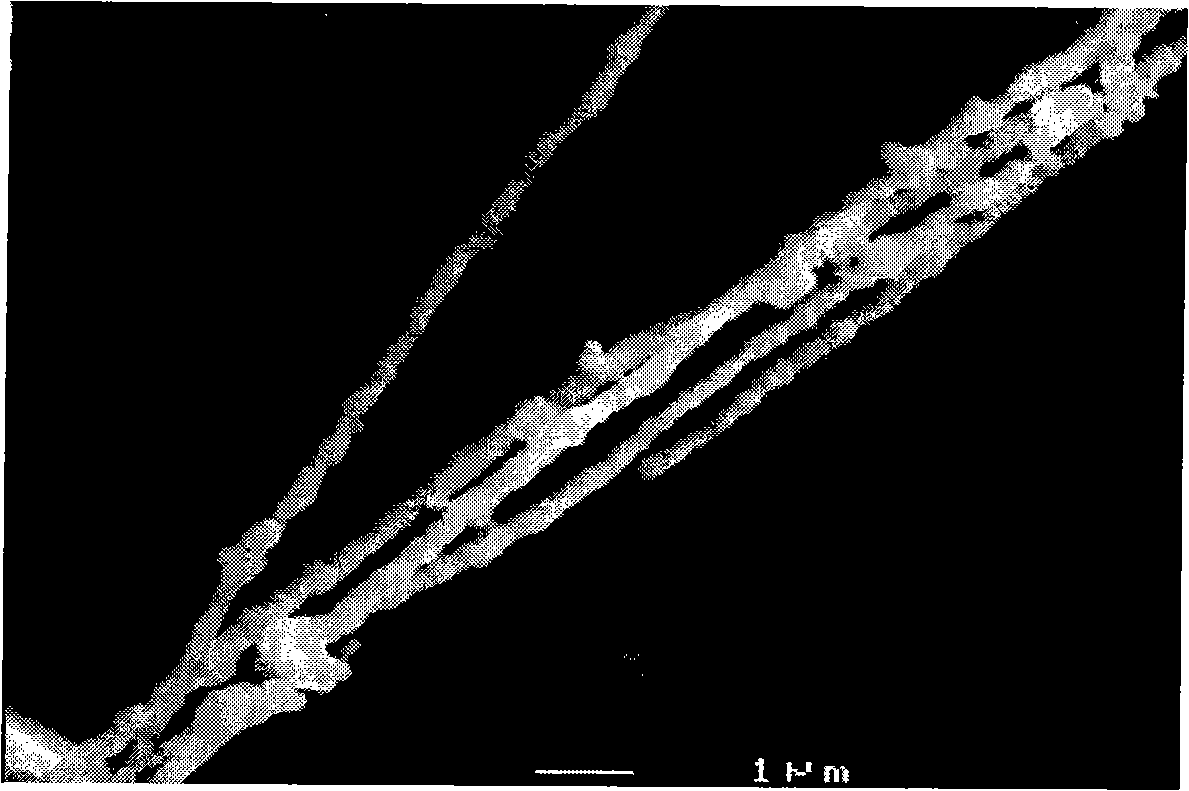

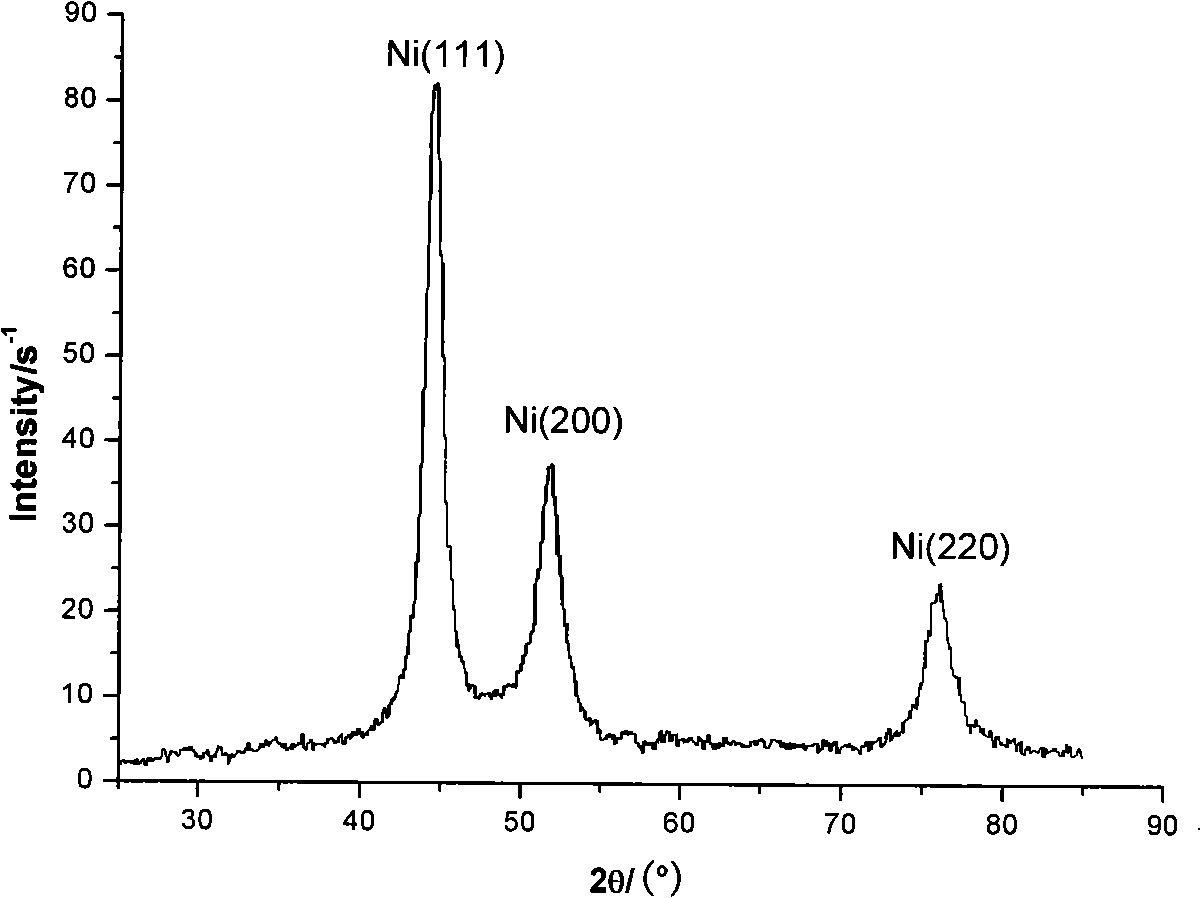

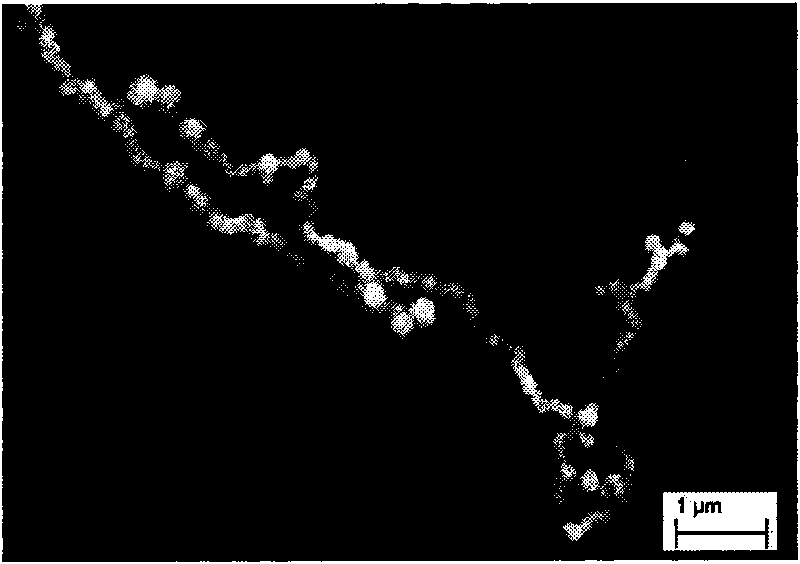

Method for preparing metallic nickel nano-wire

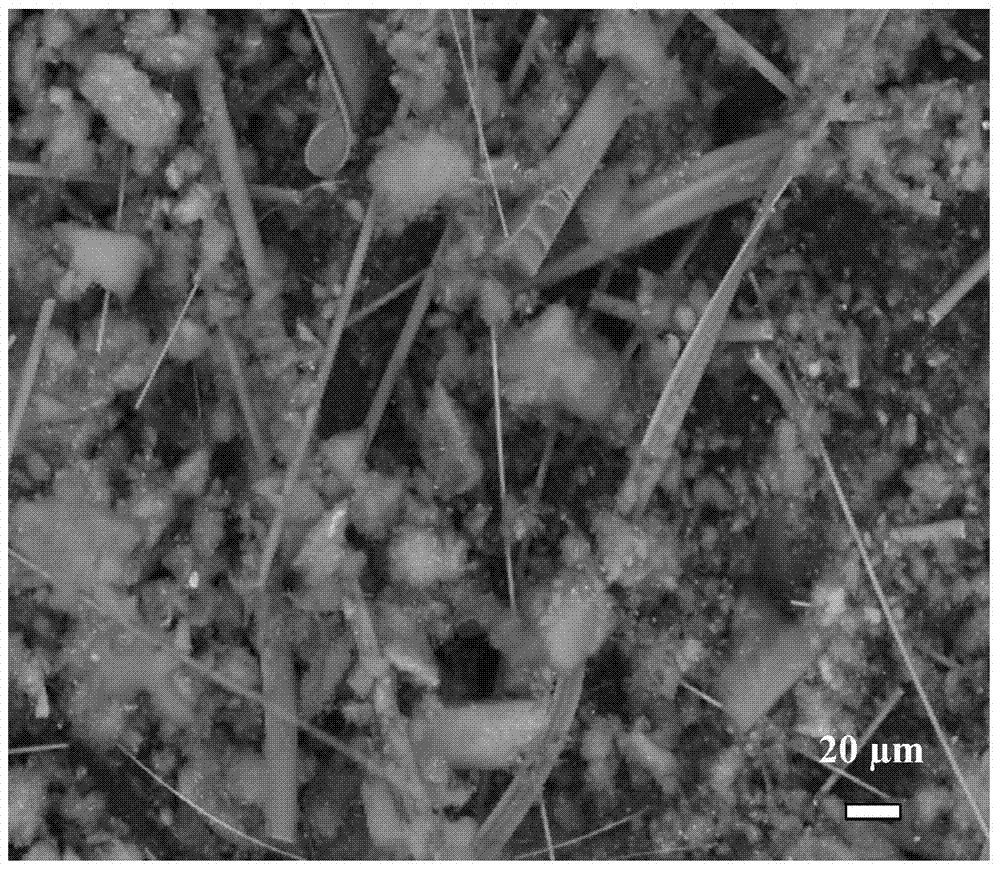

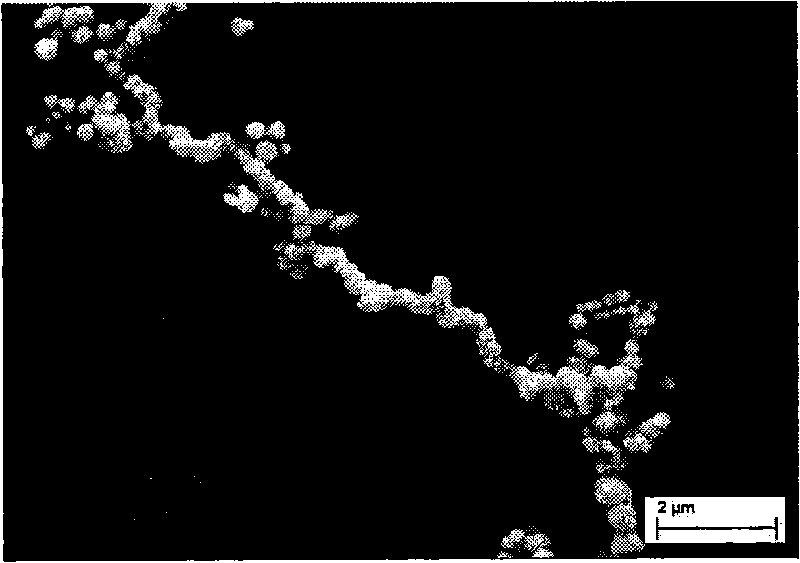

The invention discloses a chemical preparation method of nickel nano-wire which belongs to the field of the nanometer technology. The invention utilizes the mixed solution of water and ethanol to prepare the nickel ion solution which reacts with sodium hydroxide solution to generate nickel hydroxide precipitation, then utilizes hydrazine hydrate to dissolve precipitation and reduces the nickel ion under the heating condition and in the applied uniform magnetic field, finally the nickel nano-wire is assembled. Compared with the prior art, using the invention can prepare the nickel nano-wire which is 217 to 1900 nanometer in diameter, 15 to 69 micrometer in length, 20 to 300 in length-diameter ratio and has the composition of pure nickel. The invention has the advantages that the beforehand preparation process of formwork is not required, the chemical process is simple, the preparation cycle is short, the preparation cost is low and the mass preparation can be realized.

Owner:SHANGHAI JIAO TONG UNIV

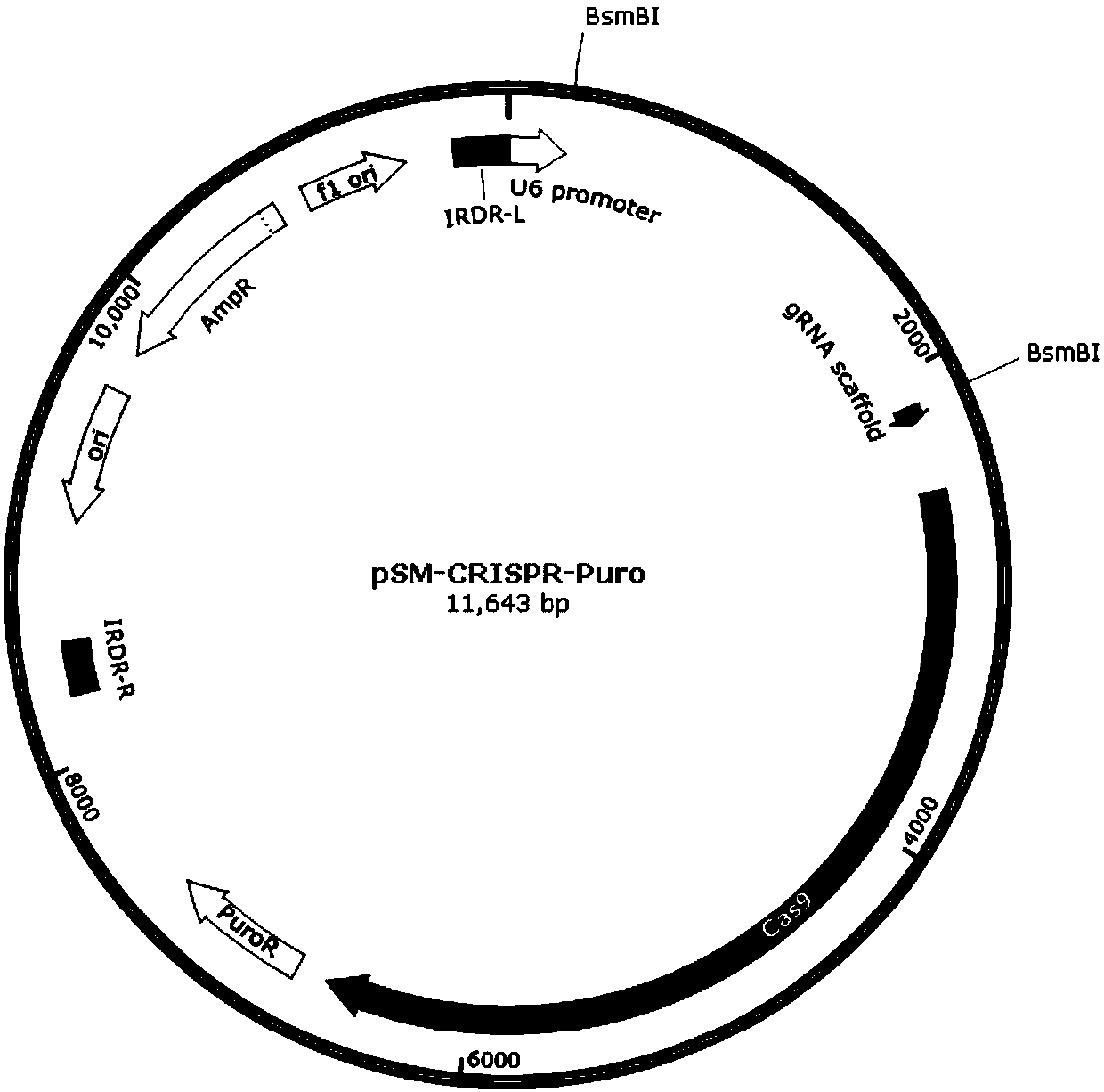

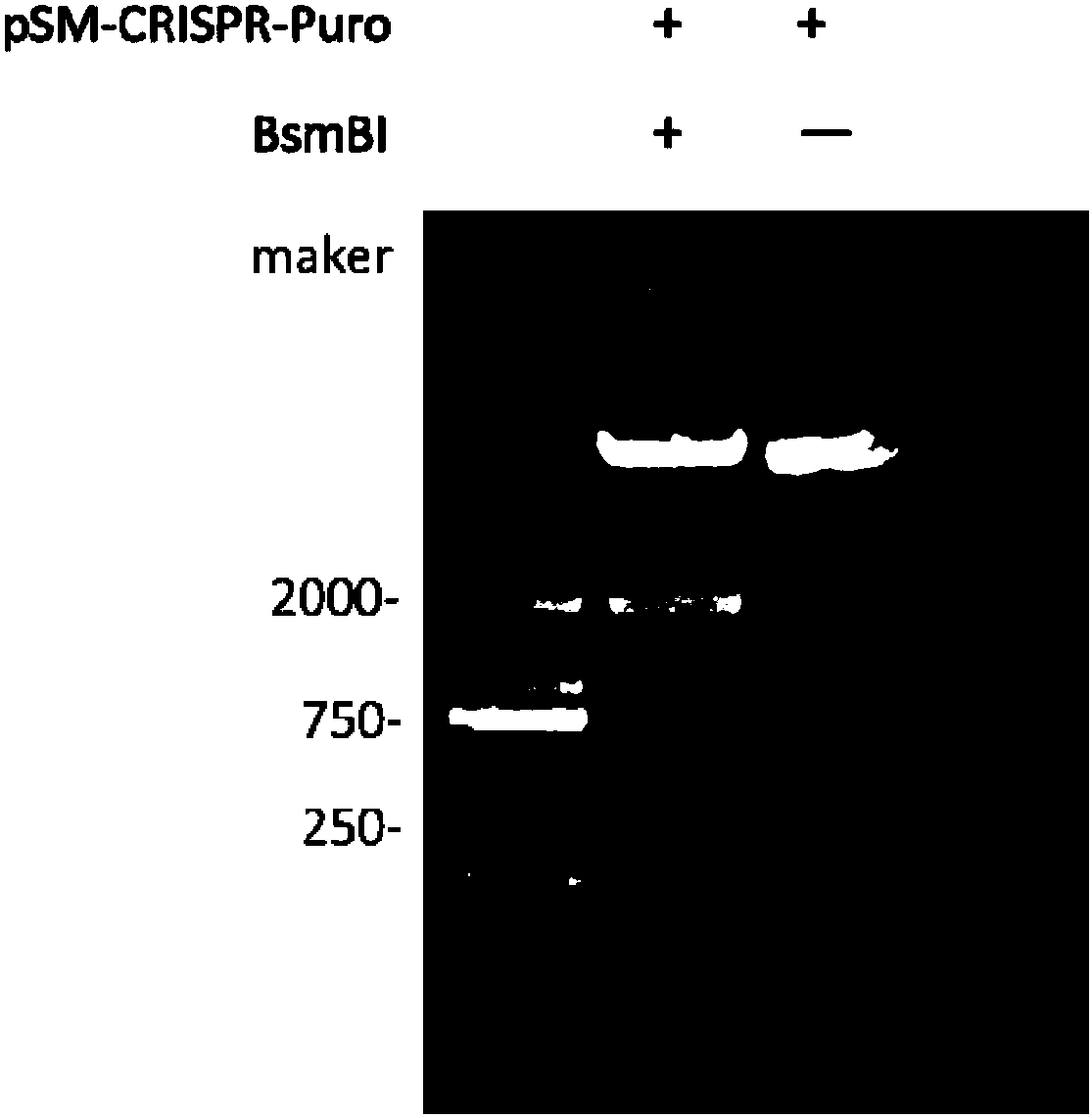

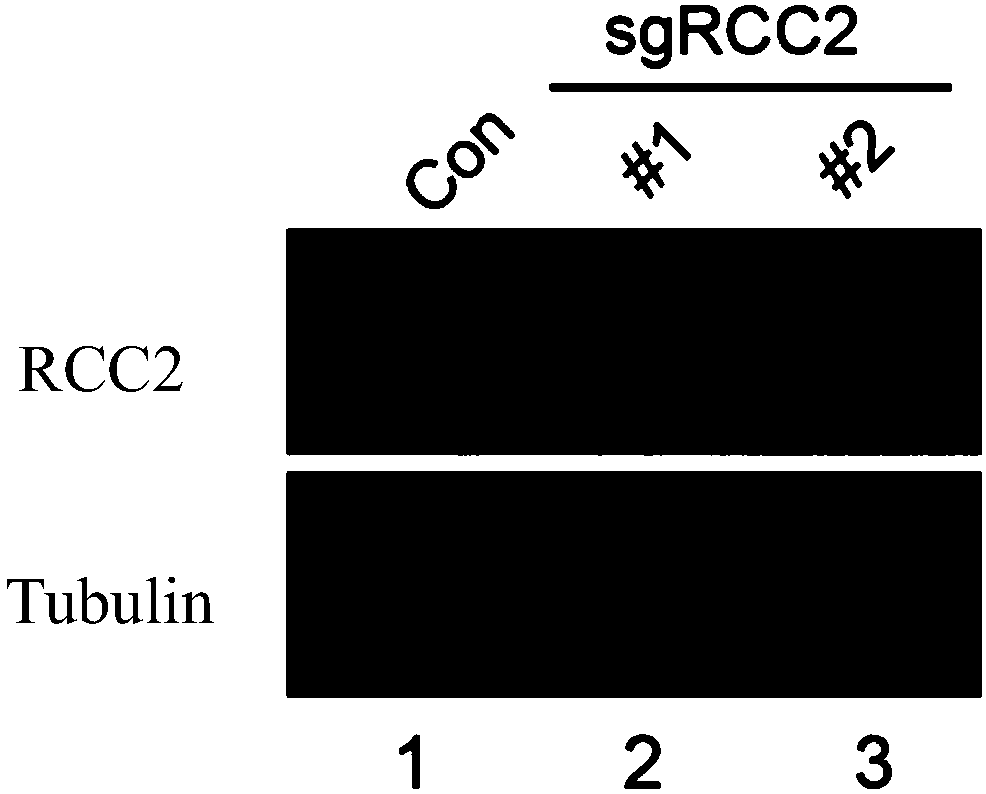

Stable knockout single plasmid vector with coordination of transposon and CRISPR/Cas9 system and application of stable knockout single plasmid vector

InactiveCN107686848ASimplify the build processThe process is simpleHydrolasesStable introduction of DNAStable cell lineBiology

The invention discloses a stable knockout single plasmid vector with coordination of transposon and a CRISPR / Cas9 system and application of stable knockout single plasmid vector and belongs to the field of gene engineering. The single plasmid vector is a double-stranded circular plasmid containing an IRDR-L-IRDR-R box, and the IRDR-L-IRDR-R box comprises an IRDR-L sequence, a promoter, a gRNA scaffold sequence, a Cas9 protein sequence, a resistance screening gene sequence and an IRDR-R sequence. The single plasmid vector provided by the invention can realize expression of sgRNA and a Cas9 protein only needing once construction and once transfection. A method is simple in process, is efficient and rapid, greatly simplifies a plasmid construction flow, shortens an experiment period and improves the working efficiency. The vector provided by the invention carries a transposase recognition sequence, does not use a virus, can conveniently, rapidly and safely establish a gene knockout stablecell line and is beneficial to screening stable cell lines by comprising the puromycin screening resistance.

Owner:SUN YAT SEN MEMORIAL HOSPITAL SUN YAT SEN UNIV

Soldering boat deck steel in high intensity by large line energy, and manufacturing method

InactiveCN101050502ASimple chemical compositionThe process is simpleRoll mill control devicesMetal rolling arrangementsChemical compositionHigh intensity

This invention relates to a method for producing high-strength ship plate steel suitable for high heat input welding. The chemical compositions of the ship plate steel are: C 0.01-0.18 wt.%, Si 0.05-0.4 wt.%, Mn 1.0-1.8 wt.%, Als 0.001-0.06 wt.%, Nb 0.01-0.08 wt.%, Ti 0.01-0.08 wt.%, N 0.002-0.012 wt.%, B 0.0001-0.0030 wt.%, one or more of Ca, Mg and Zr 0.0001-0.030 wt.%, P less than 0.015 wt.%, S less than 0.010 wt.%, Fe and impurities. The method comprises: keeping the oxygen content in the molten steel at 10-600 ppm, performing deoxidation with Fe-Ti alloy or metal Ti after steelmaking, adding one or more of Ca, Mg and Zr, performing final deoxidation with Al wire, adding B, casting, homogenizing, rolling, relaxing, and cooling online. The obtained ship plate steel has such advantages as simple chemical compositions, simple process, and high heat input welding, and is suitable for producing ships.

Owner:WUHAN UNIV OF SCI & TECH

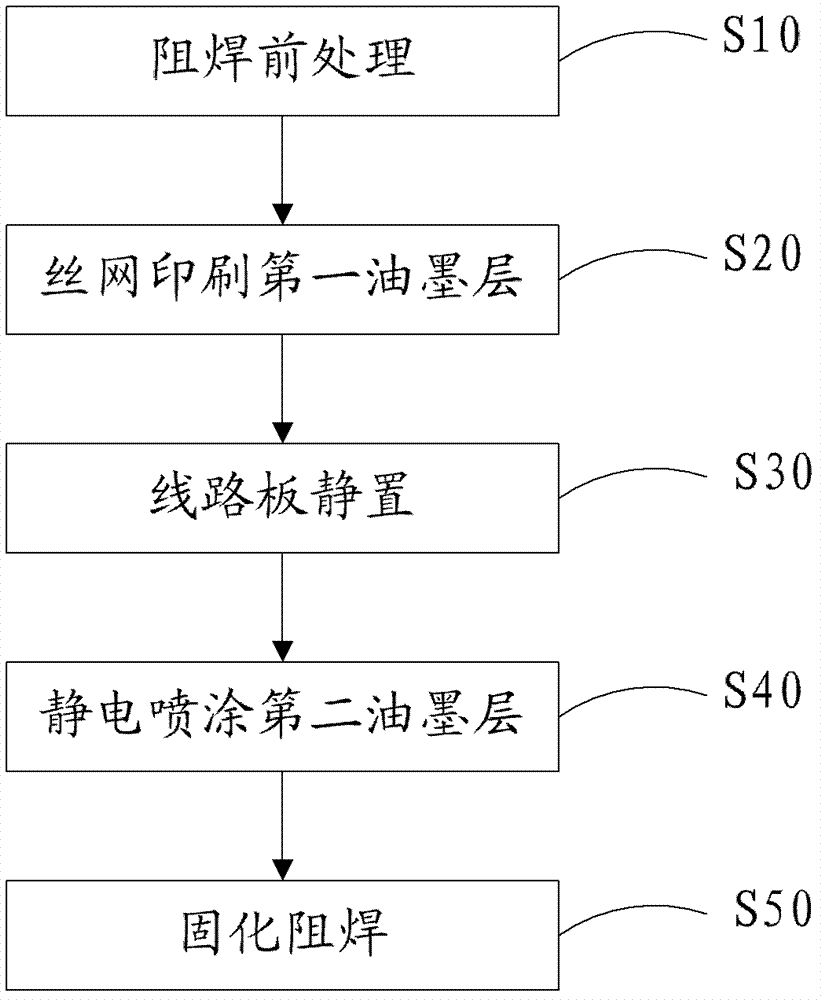

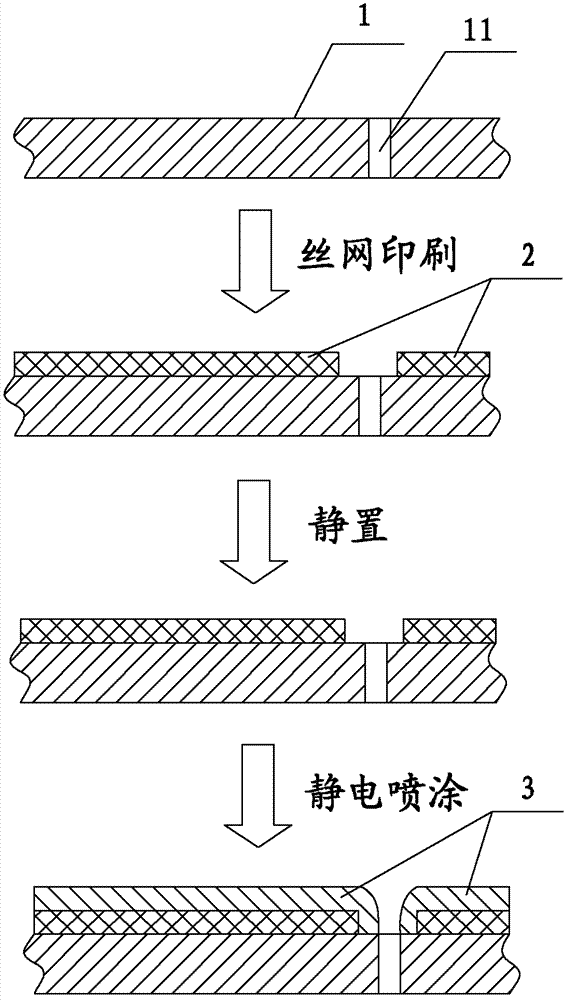

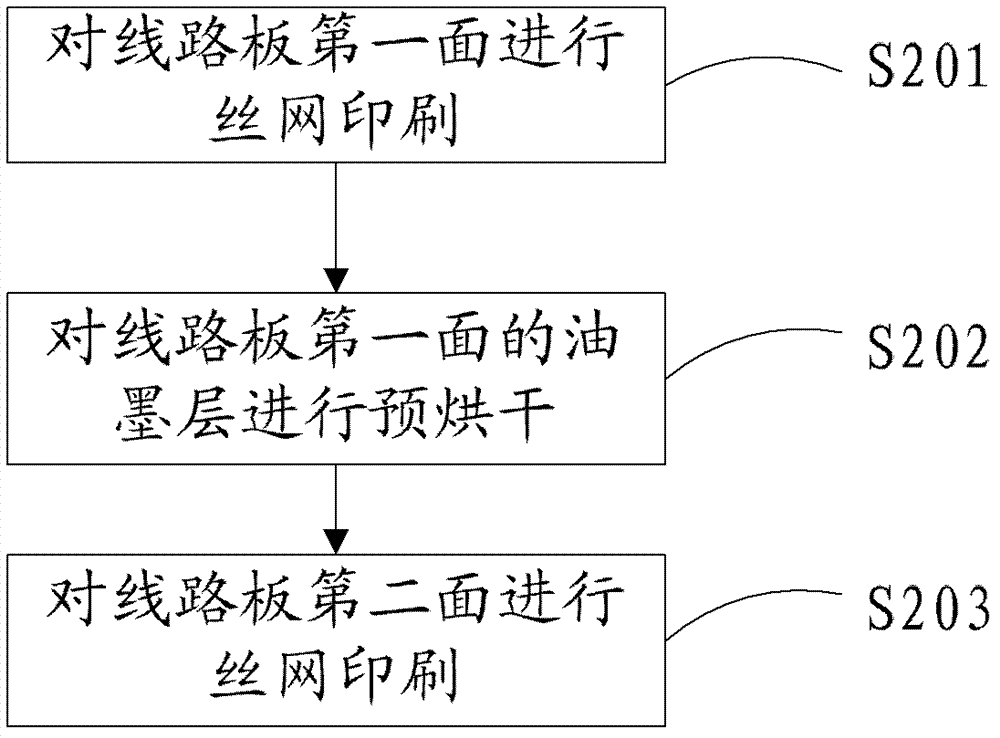

Solder resisting method for circuit board

InactiveCN103096633AExtended service lifeThe process is simpleNon-metallic protective coating applicationEngineeringWire mesh

The invention discloses a solder resisting method for a circuit board. The solder resisting method for the circuit board includes the following steps, a step 20 is that a first ink layer is printed in a silk-screen printing mode, more specifically, a silk screen with blocking points is utilized for printing the first ink layer, the blocking points cover holes in the circuit board, each blocking point is 0.13 to 0.17 millimeter longer than the diameter of each hole in the circuit board, and the thickness of the first ink layer is 35 micro meters to 40 micro meters; a step 30 is that a standing process is carried out on the circuit board; a step 40 is that a second ink layer is painted in an electrostatic spraying mode, more specifically, the electrostatic spraying technology is utilized for spraying the second ink layer on the circuit board, the second ink layer covers the first ink layer, and the thickness of the second ink layer is 40 micro meters to 50 micro meters; and a step 50 is that a solder resisting curing process is carried out, more specifically, the first ink layer and the second ink layer are exposed, developed and cured. The solder resisting method for the circuit board integrates the advantages of two solder resisting technologies, namely silk-screen printing and electrostatic spraying, the requirement that no solder resisting ink enters the holes of the circuit board is met, the technological processes are simple, and processing efficiency is high.

Owner:SHENNAN CIRCUITS

Preparation method of immune base and antigen or antibody immunoassay method

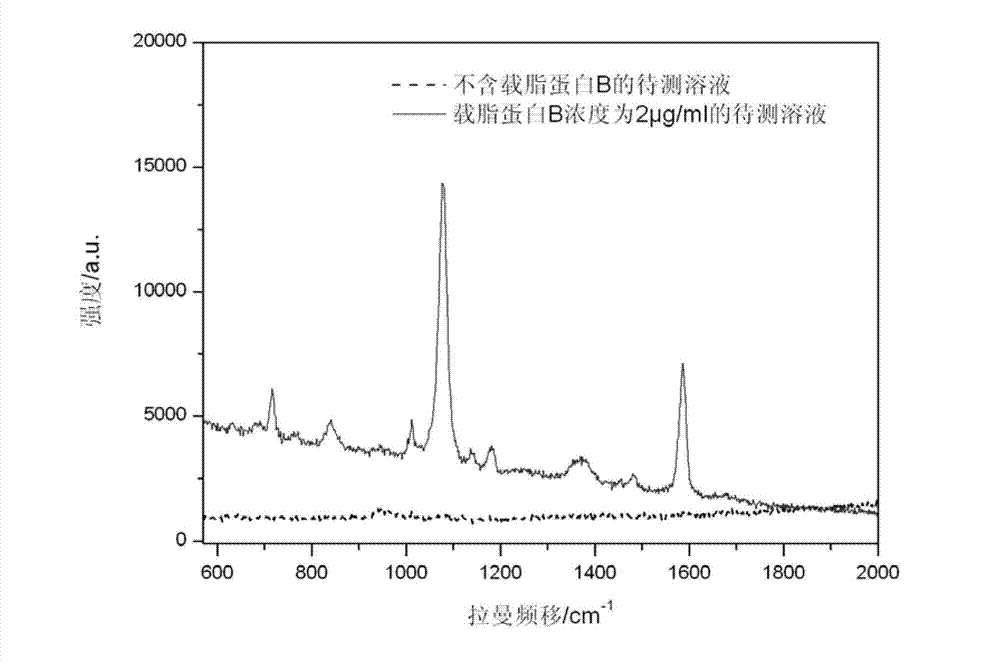

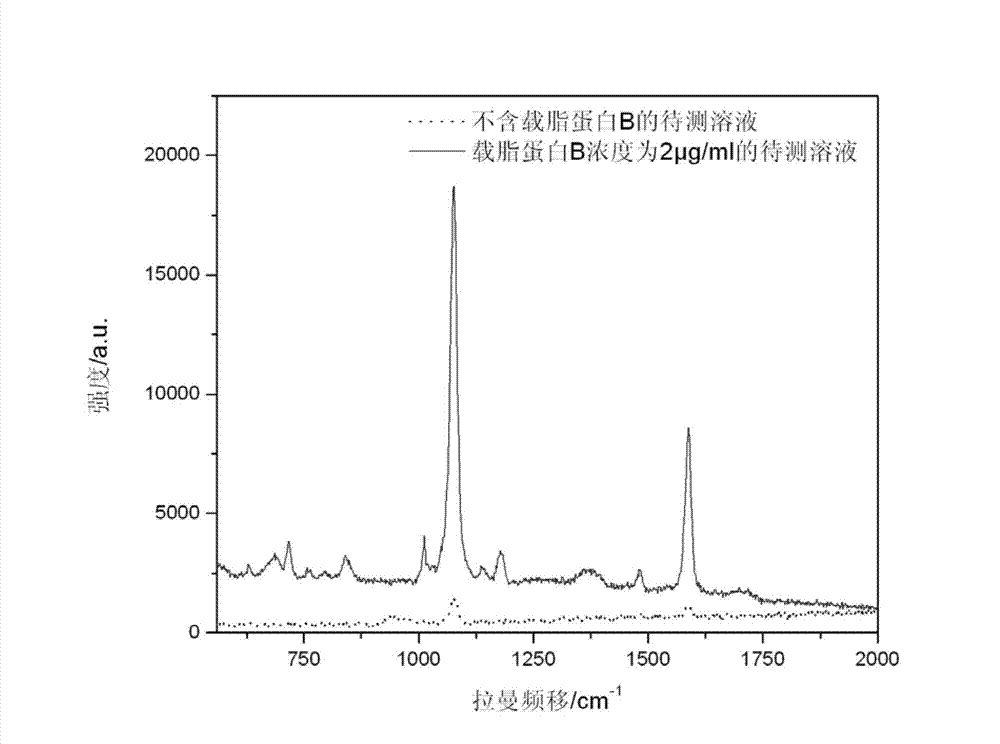

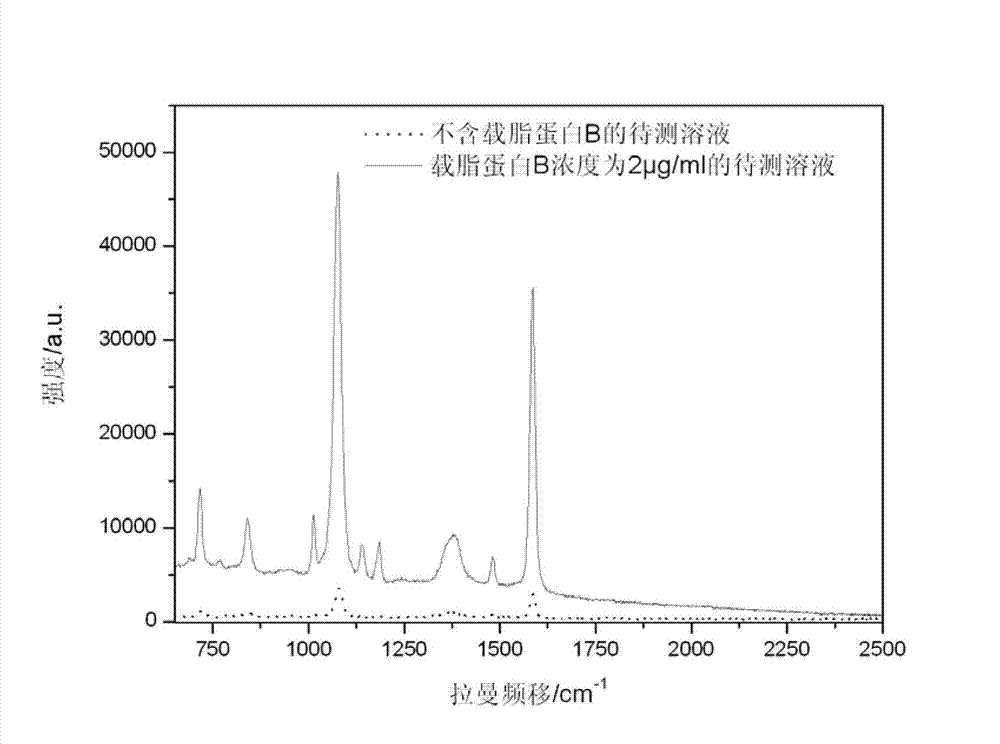

ActiveCN103116019AThe process is simpleLow costRaman scatteringImmune complex depositionRaman scattering

The invention discloses an immune base preparation method and an antigen or antibody immunoassay method. According to the immune base preparation method, a silicon slice is modified by using gold or silver nanoparticles, and antibodies / antigens are modified on the surfaces of the gold or silver nanoparticles, thereby being used for capturing antigens / antibodies to be assayed. According to the antigen or antibody immunoassay method, an immune base which is prepared by using the immune base preparation method and gold or silver nanoparticle immunoprobes is used, an immune base-antigen / antibody-immunoprobe three-layer sandwich structure is formed through an antigen-antibody immune complex reaction, and the assay on the antigens / antibodies to be assayed is realized in a manner that the characteristic dactylograms of Raman markers on the surfaces of the immunoprobes are assayed by using a surface-enhanced Raman scattering effect of the gold or silver nanoparticles. The method has the advantages that the sensitivity of the immunoassay can be greatly improved and the assay on high-flux multiple antigens / antibodies can be carried out.

Owner:NINGBO UNIV

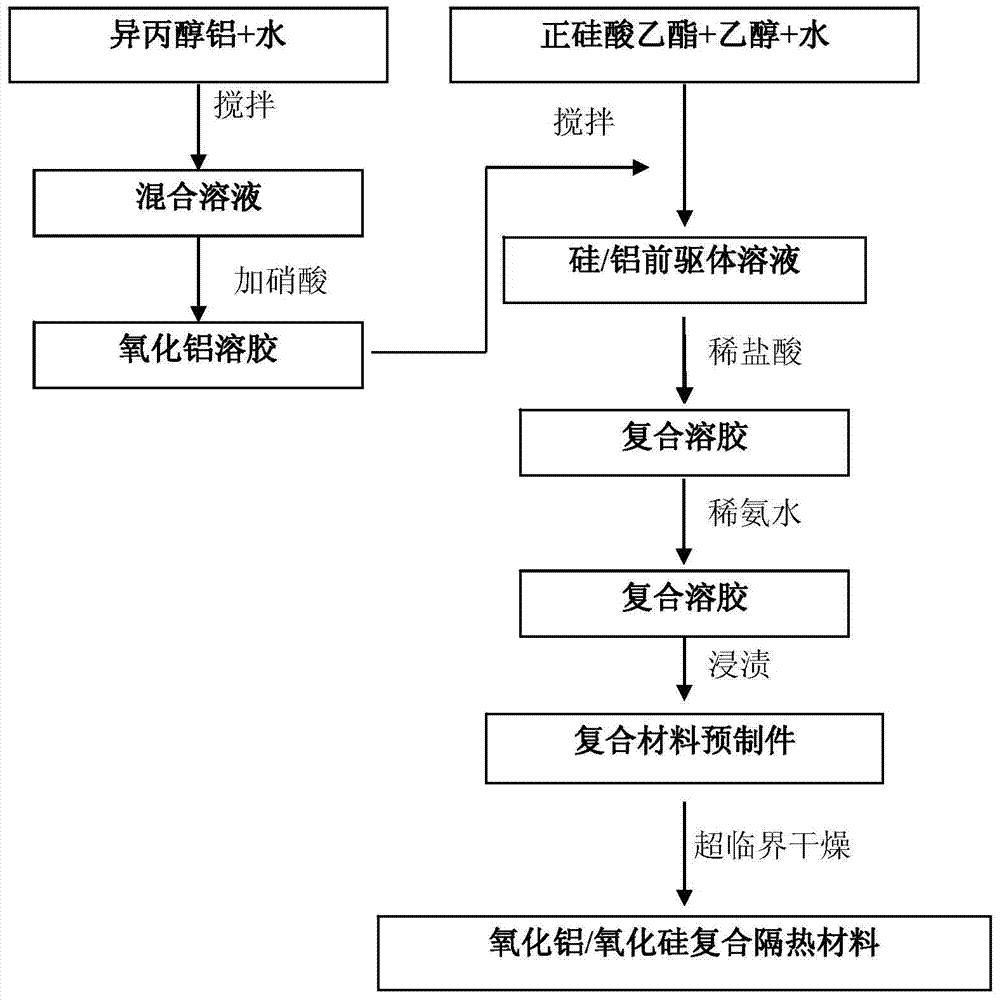

Method for preparing aluminum oxide-silicon dioxide flexible aerogel thermal insulation felt

ActiveCN103542230AThe process is simpleLow costThermal insulationPipe protection by thermal insulationThermal insulationSupercritical drying

The invention discloses a method for preparing aluminum oxide-silicon dioxide flexible aerogel thermal insulation felt. The method includes the following steps that an aluminum source is placed in water for conducting hydrolysis reaction and condensation polymerization to obtain stable aluminum oxide sol; a silicon source, water, alcohol and the aluminum oxide sol are mixed to obtain aluminum oxide-silicon dioxide sol through the hydrolysis reaction and the condensation polymerization under the action of catalysts; the aluminum oxide-silicon dioxide sol is poured to a fiber prefabricated part to form a sol dipped prefabricated part, supercritical drying is conducted on the sol dipped prefabricated part under the condition that the aluminum oxide-silicon dioxide sol is condensed or not, and then the aluminum oxide-silicon dioxide flexible aerogel thermal insulation felt is prepared, wherein the molar ratio of the aluminum source to water is 1:30-300. The method for preparing the aluminum oxide-silicon dioxide flexible aerogel thermal insulation felt is simple in technological process and low in cost.

Owner:余煜玺

Method for producing high-aluminum steel plate blanks

The invention provides a method for producing high-aluminum steel plate blanks. The method comprises the following steps: primarily smelting, wherein in the process, argon serves as bottom blowing gas and the end-point carbon content is controlled to be not less than 0.06 weight percent; strictly controlling the slag discharge amount in the tapping process, performing deoxidation alloying and recarburization on molten steel and slagging; performing ladle furnace (LF) refining, conveying the molten steel to an LF station, and feeding an aluminum wire for the first time while weakly stirring by using the argon; after feeding aluminum for the first time, stirring by using the argon, adjusting the temperature, adding aluminum (Al) particle to diffuse and deoxidize, so as to guarantee white slag operation, and feeding aluminum for the second time; performing Ruhrstahl and Heraeus (RH) vacuum treatment and component fine adjustment on the molten steel after feeding the aluminum for the second time, so as to adjust the Al content to be over 1.5 weight percent and adjust other alloy component content to be within the required range; and injecting the molten steel into a tundish, pouring the molten steel into a plate blank continuous casting crystallizer from the tundish and finishing the continuous casting production to obtain the high-aluminum steel plate blanks.

Owner:LAIWU IRON & STEEL GRP

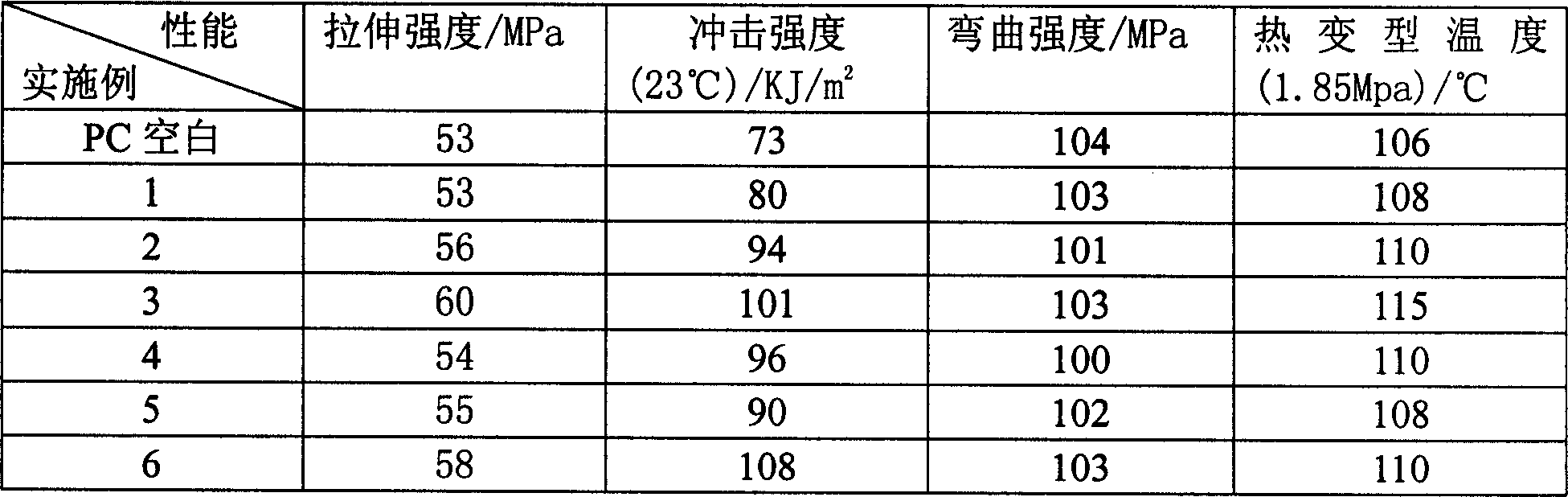

Acrylic ester modifier and preparation and use in bisphenol A poly carbonate

The acrylic ester modifier is prepared through drying nano silica, nano calcium carbonate, nano zinc oxide, nano zinc sulfide, nano titania or nano cadmium sulfide, adding silane as coupling agent and xylene to react under the xylene refluxing temperature, letting stand to separate lower layer matter, drying the lower layer matter to obtain nano alkylated particle as the acrylic ester modifier. The nano alkylated particle is mixed with emulsifier and deionized water, and through heating under nitrogen protection to 70 deg.c, dropping initiator, acrylic ester monomer to react, cooling, spray drying, modified acrylic ester is obtained. The weight ratio between modifier and the acrylic ester monomer is 2-10 to 90-98. The present invention can raise the performance of polymer.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

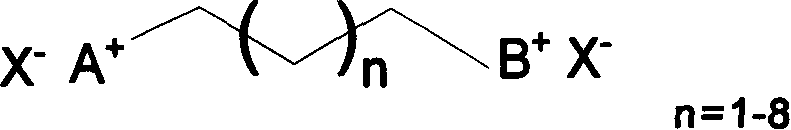

Fluoride-free low-acid zwitterion quartz sand reverse flotation process

The invention relates to fluoride-free low-acid zwitterion quartz sand reverse flotation process, which is characterized by comprising following steps: (1) pretreatment; (2) flotation: adjusting the pH (potential of hydrogen) value of ore pulp to 4-5 by sulfuric acid, performing air agitation, adding 40g / t-80g / t of positive ion collecting agent and 60g / t-75g / t of foaming agent, stirring and removing foams in primary flotation; and adjusting the pH value of the ore pulp to 9-10 by 200g / t-300g / t of sodium carbonate, performing air agitation, adding 80g / t-150g / t of negative ion collecting agent,then adding 60g / t-75g / t of foaming agent, stirring and removing foams in secondary floatation; and (3) washing ores in a flotation tank by water until the ores are neutral, and drying the ores to obtain quartz sand concentrates. The flotation collecting agents are fine in selectivity, the process is simple, cost is low, the purity of the quartz sand is high, the content of iron and aluminum impurities is low, and the problem that traditional fluoride and high-acid process damages equipment and environments is avoided in a flotation process.

Owner:陕西合兴硅砂有限公司

Method for producing rear passivation double-sided solar cell

InactiveCN102800745AThe process is simpleGood industry prospectsFinal product manufactureSemiconductor devicesEtchingEngineering

The invention discloses a method for producing a rear passivation double-sided solar cell. The method sequentially comprises the following steps of: positive cleaning, making a texture surface, forming a PN junction through diffusion, performing periphery and rear etching, evaporating a positive SiNx anti-reflection film, evaporating a rear passivation film or / and SiNx [11] passivation film or other passivation films, performing screen printing on a back electrode, performing screen printing on a positive electrode, and sintering. The method for producing the rear passivation double-sided solar cell has the advantages that the compounding rate of the rear surface can be greatly reduced, the back reflection is improved, and the more photon-generated carriers are collected. Compared with processes such as photoetching, laser sintering and laser opening, the method is simple in process flow and suitable for mass production. The actual working and generating efficiency can be effectively improved. The used equipment is compatible with the traditional solar cell equipment, the equipment does not need to be increased, the process cost is low, the capacity is high, and the method has good industry prospects.

Owner:TIANWEI NEW ENERGY HLDG +1

Method for recycling molybdenum of molybdenum-contained waste catalyst

ActiveCN101724758AThe process is simpleSimple equipmentProcess efficiency improvementAmmonium molybdateChemistry

The invention relates to a method for recycling molybdenum of a molybdenum-contained waste catalyst, which comprises the following steps of: roasting and pulverizing the molybdenum-contained waste catalyst; then mixing and roasting with an alkaline substance; extracting by using mixed acid; depositing by using an alkaline solution; depositing the molybdenum in an ammonium molybdate way; further dissolving the ammonium molybdate by using ammonia water and readjusting the pH value to obtain an ammonium molybdate sediment; and drying to obtain the ammonium molybdate product. The method is particularly suitable for the process of extracting high-purity ammonium molybdate by using a aluminium-based molybdenum-contained waste catalyst, and has simple process, high maneuverability, low energy consumption and stable quality of the prepared product.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Synthesis of cyclic carbonic ester

InactiveCN1817877AMild reaction conditionsThe process is simpleOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsIonEpoxide

Synthesis of cyclic carbonic acid ester is carried out by taking epoxide and carbon dioxide as raw materials without organic solvent, utilizing binary catalyst with transition metal salt and bidentate ionic liquid, cycloaddition reacting at 313.15-483.15K and 0.1-5.0Mpa and synthesizing cyclic carbonic acid ester. It is simple and clean, has higher recovery rate and selectivity and can be re-used.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

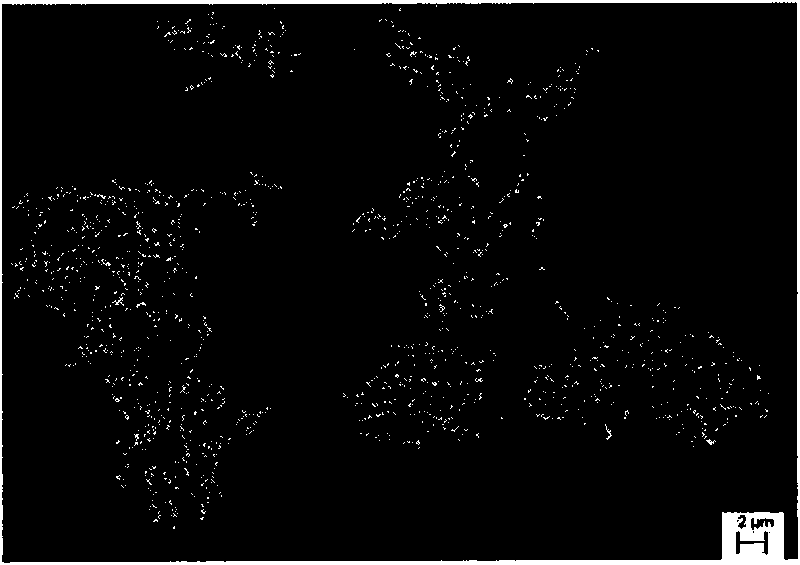

Chemical preparation method of metal cobalt nanowire

InactiveCN101698234AThe process is simpleMild reaction conditionsSurface-active agentsChemical preparation

The invention discloses a chemical preparation method of a metal cobalt nanowire, relating to a preparation method of metal cobalt powder. The method adopts a soft mould method to prepare the metal cobalt nanowire in a self-assembly way. The method is characterized of comprising the steps of: jointly forming into the soft mould with ethanediol and surface active agent; taking hydrazine hydrate as reducing agent to reduce cobalt ions in cobalt salt into cobalt atoms; and directionally growing cobalt crystal nucleus under the function of the soft mould to form into linear shape. The diameter of the prepared cobalt nanowire is 100-800 nm, length is 2.0-10.0 um, length-diameter ratio is 12-25, and powder is pure cobalt. The method has simple technology and low cost, can realize large-scale economic preparation, and provides precondition for the practical use of the cobalt nanowire.

Owner:UNIV OF SCI & TECH BEIJING

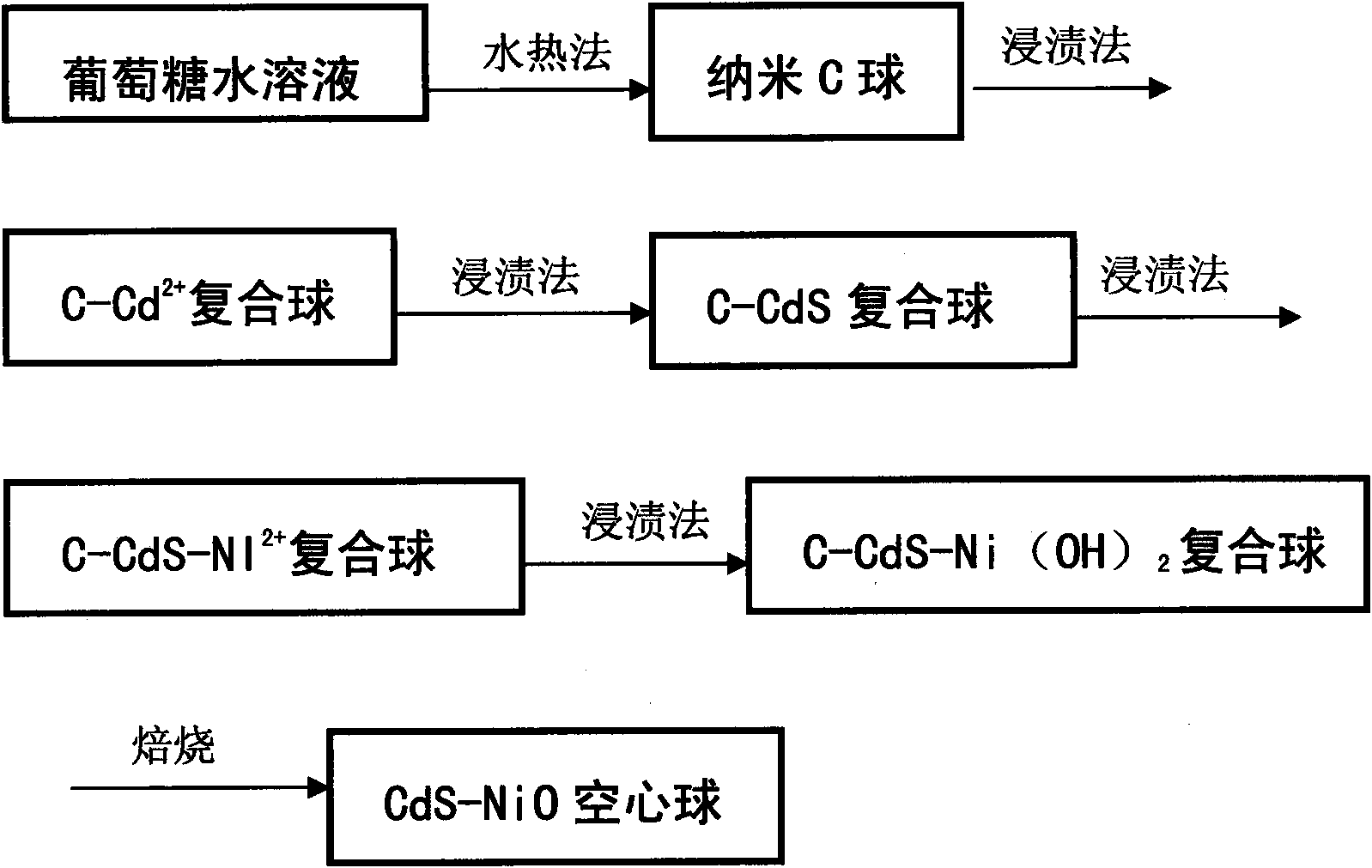

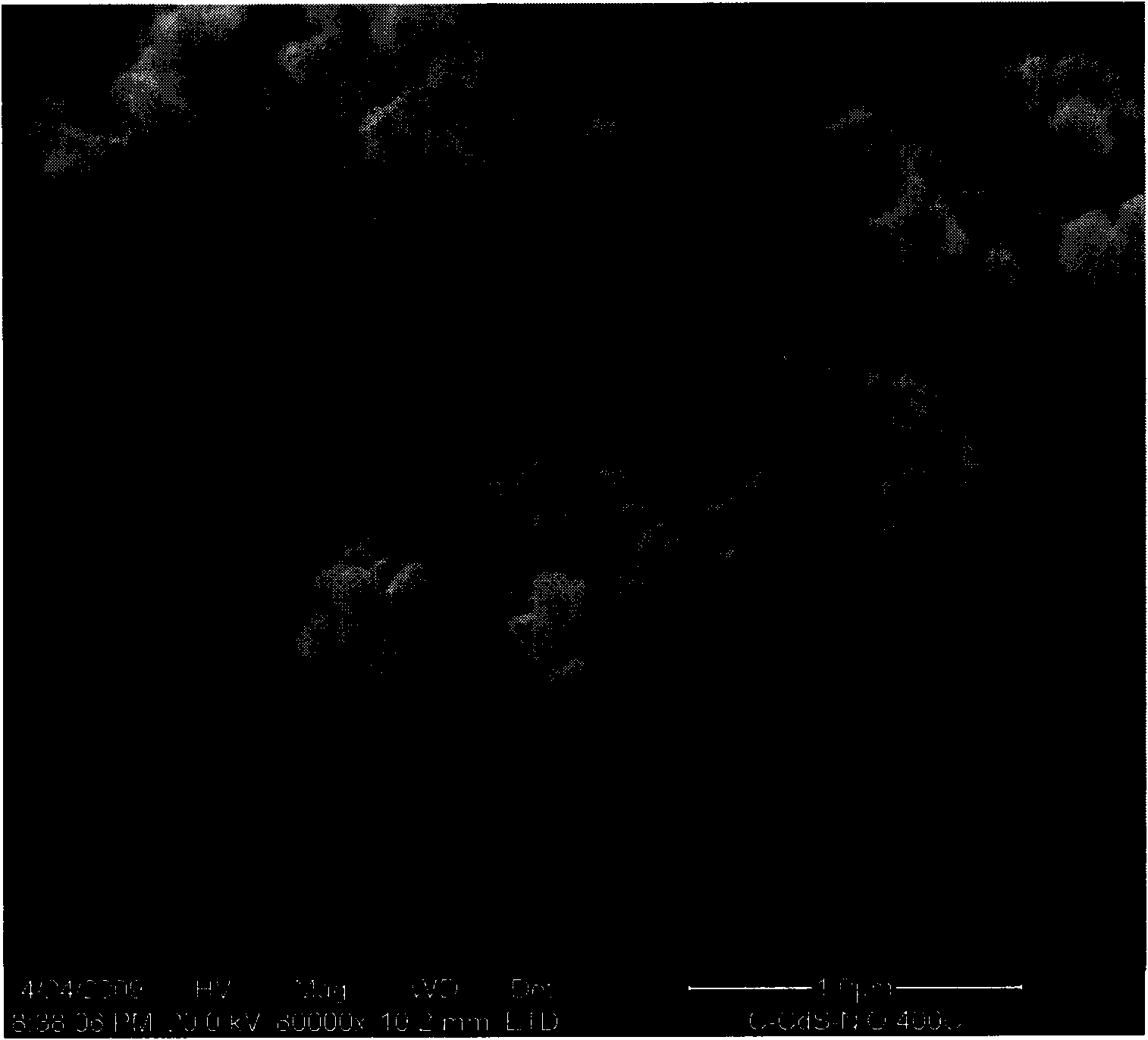

Preparation for p-n junction hollow sphere and application in photocatalytic hydrogen production by water decomposition

InactiveCN101623645AThe process is simpleImprove transmission efficiencyEnergy inputCatalyst activation/preparationDecompositionChemistry

The invention discloses preparation for p-n junction hollow sphere TiO-CdS nanophase compound material and application in photocatalytic hydrogen production by water decomposition; the method uses inexpensive cadmium source and nickel source, adopts a hydrothermal method, a synthesis method, and a four-step impregnation method for compounding an n-NiO semiconductor and a p-CdS semidconductor to prepare the p-n junction hollow sphere TiO-CdS nanophase compound material; and the technical process is simple and practicable and can realize scale production. The p-n junction hollow sphere TiO-CdS nanophase compound material is used as photocatalyst for solar energy visible light catalyzing hydrogen production by water decomposition, speeds up the conveying rate of photo-generated electrons and substantially increases yield of the hydrogen production.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

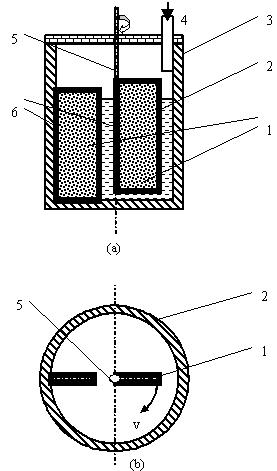

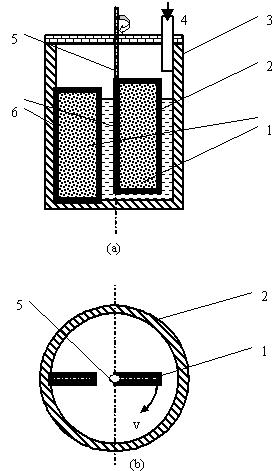

Method and apparatus for preparing sheet-type metal pwoder by atomized drop deformation

The present invention relates to a method for preparing flake metal powder by means of atomizing liquid drop deformation. Said method includes the following steps: heating and melting metal raw material, then making the molten metal be passed through the discharge spout of crucible bottom portion according to stable flow rate of 3-30g / sec. And be poured onto the center of disk rotated at high speed, the rotating speed of the disk is 1000-5000 rpm, under the action of centrifugal force atomizing and forming so as to obtain the invented product. Said equipment comprises, smelting crucible, rotating disk atomizer, drive motor, atomizing chamber, bearing and water-cooling chamber.

Owner:UNIV OF SCI & TECH BEIJING

Densification method of porous workpiece

The invention discloses a densification method of a porous workpiece. The method comprises the following steps: placing the porous workpiece in a jacket, and performing seal welding on a joint between the jacket and an end cover; performing leak detection for the jacket; after the tightness of the jacket is ensured, filling glass powder in the jacket, and shaking to be solid; vacuumizing the jacket and performing seal welding on a suction pipe to obtain a compact; performing hot isostatic pressing treatment on the compact; and after a hot isostatic pressing hearth is cooled, taking out the compact, and removing the glass and the jacket from the surface of the workpiece to obtain a dense workpiece. The method with a metal jacket and glass powder as force transfer media, can be used for processing any porous workpieces with complicated shapes and relative density being less than 90%, and is particularly suitable for densifying sintering pieces and castings such as SLS / SLM and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

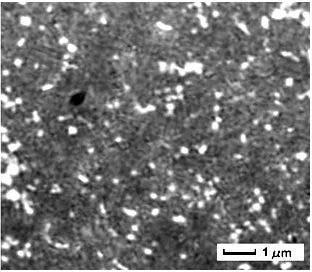

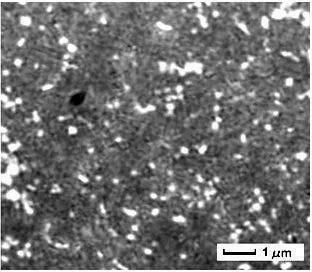

Iron-based composite material reinforced by in-situ titanium carbide grains and preparing method thereof

The invention discloses an iron-based composite material reinforced by in-situ titanium carbide grains and a preparing method thereof. The preparing method is characterized in that: high-strength high-toughness spheroidal graphite cast iron is used as a matrix, in-situ grown submicron titanium carbide grains are used as reinforcing grains, and the titanium carbide grains are uniformly distributedon the spheroidal graphite cast iron matrix to obtain a high-strength high-toughness iron-based composite material; and iron powder, titanium powder and carbon powder are fully mixed by utilizing a mechanical alloying method to form composite powder, spheroidal graphite cast iron is molten and treated by a conventional method, the composite powder is added to molten iron during secondary inoculation in proportion, constant temperature is kept for 5-10min and casting is carried out to obtain a cast-state composite material, and the cast-state composite material is subjected to isothermal quenching heat treatment to obtain the iron-based composite material. According to the iron-based composite material prepared by the method disclosed by the invention, the in-situ titanium carbide grains are small in size and uniformly distributed on the matrix so as to ensure the characteristics of high strength and high toughness of the iron-based composite material.

Owner:JIANGSU TANGCHEN AUTOMOBILE PARTS

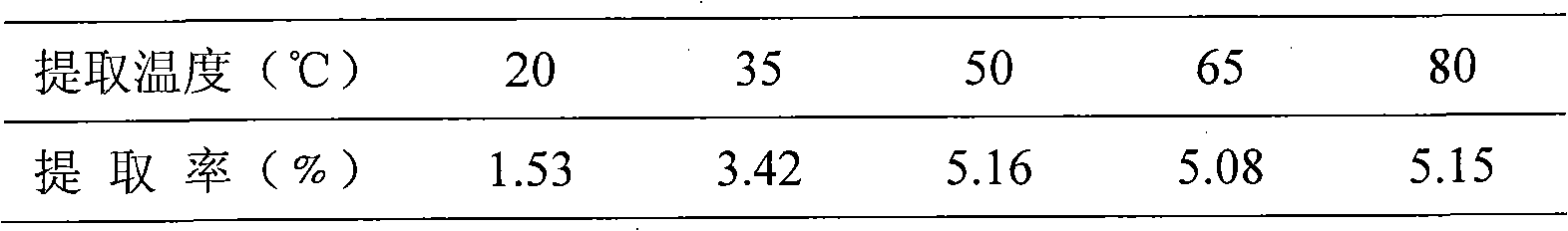

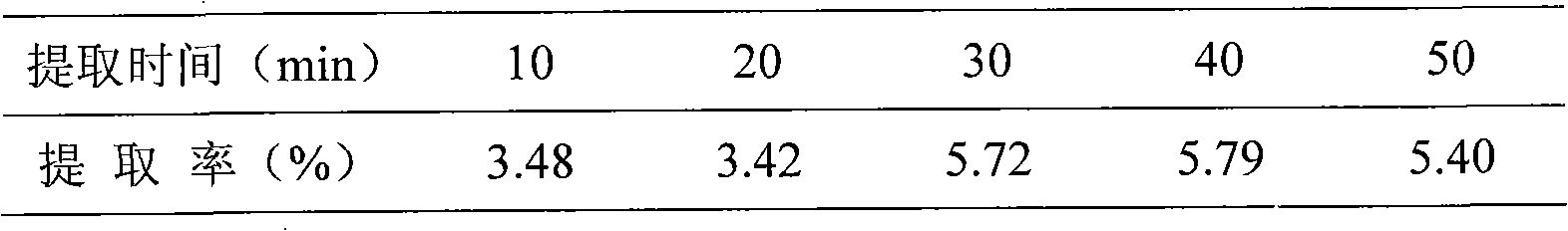

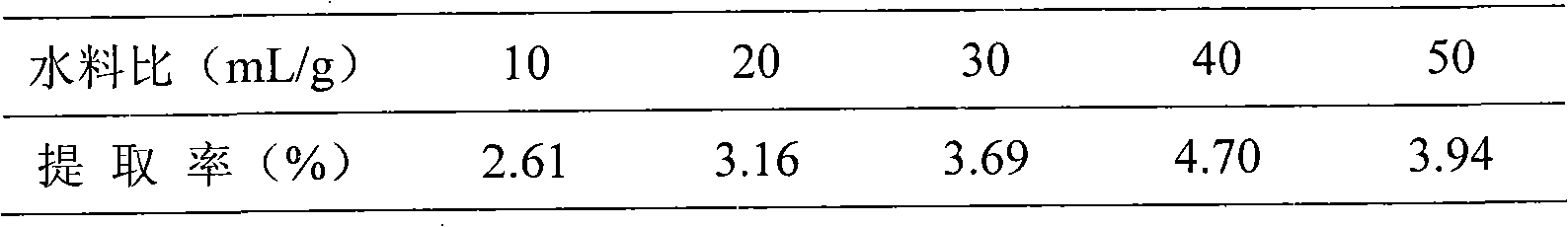

Method for extracting white mushroom lentinan assisted with ultrasonic wave

InactiveCN101891836AThe process is simpleOvercoming production season constraintsAntibacterial agentsAntinoxious agentsUltrasonic assistedWater assisted

The invention relates to a method for extracting white mushroom lentinan assisted with ultrasonic wave, which comprises the following steps: drying and crushing the white mushroom sporocarp; extracting with hot water assisted by ultrasonic wave; taking supernate by centrifugation; concentrating under the reduced pressure; precipitating with ethanol; taking precipitate by centrifugation; removing protein by a Sevag method; concentrating under the reduced pressure; precipitating with ethanol; taking precipitate by centrifugation; removing pigment by a macroporous resin method; concentrating under the reduced pressure; and vacuum drying to obtain the extract of the white mushroom lentinan. The invention has mild extraction condition, does not damage the lentinan structure, and has high polysaccharose purity, simple technical process, no environment pollution and low energy consumption. Additionally, the invention takes the dried and crushed white mushroom sporocarp as raw materials for extracting and overcomes the defect of season limitation caused by the utilization of the fresh raw materials.

Owner:乔德亮

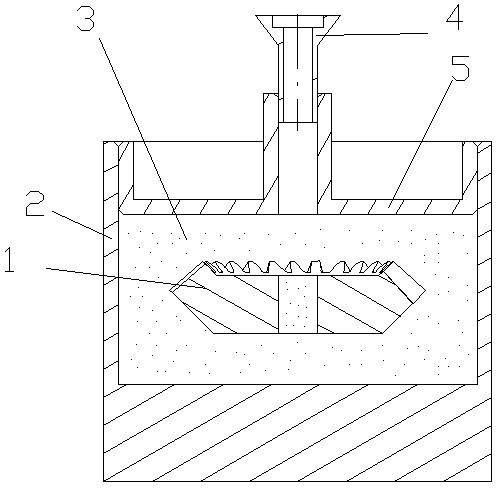

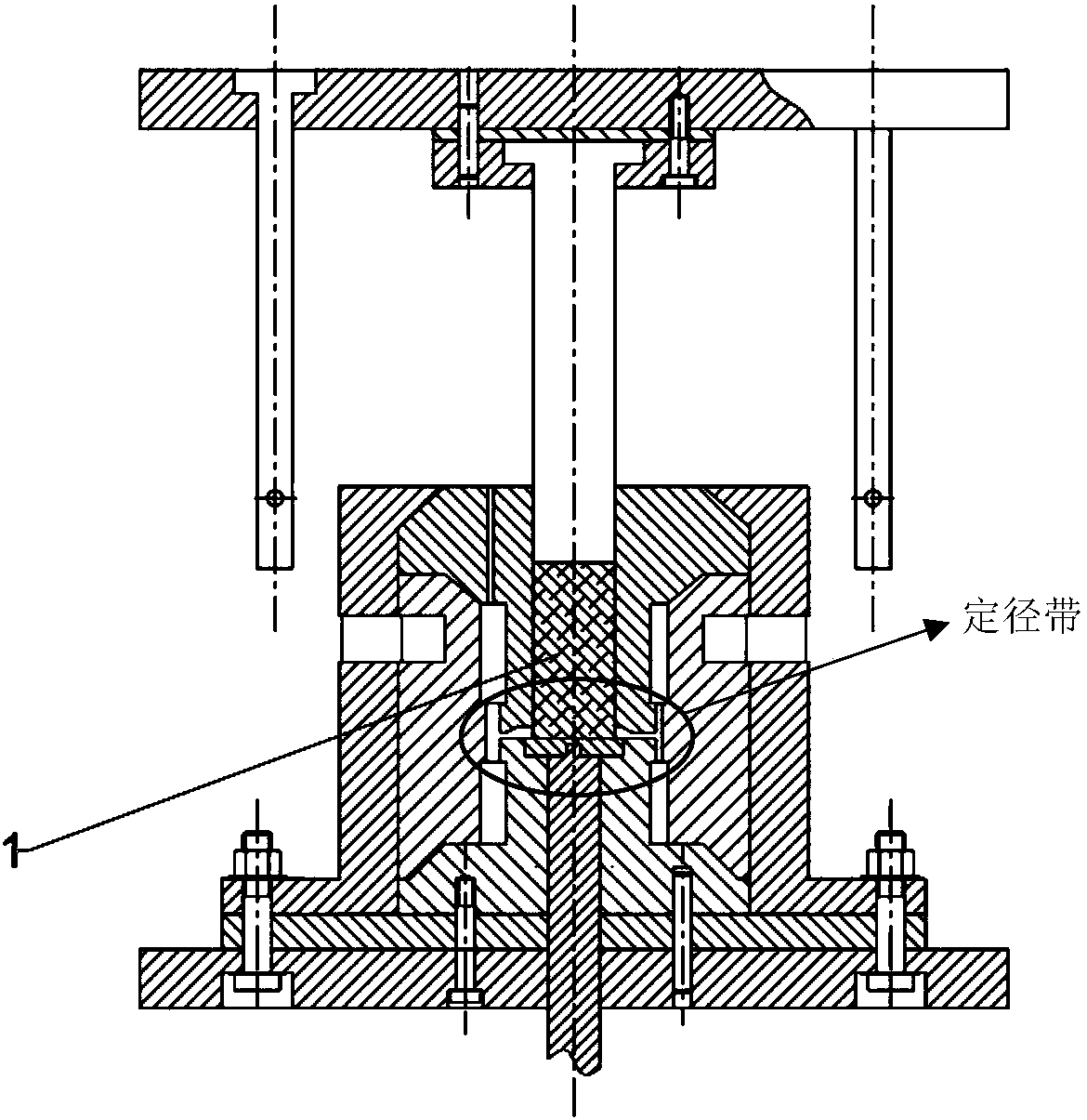

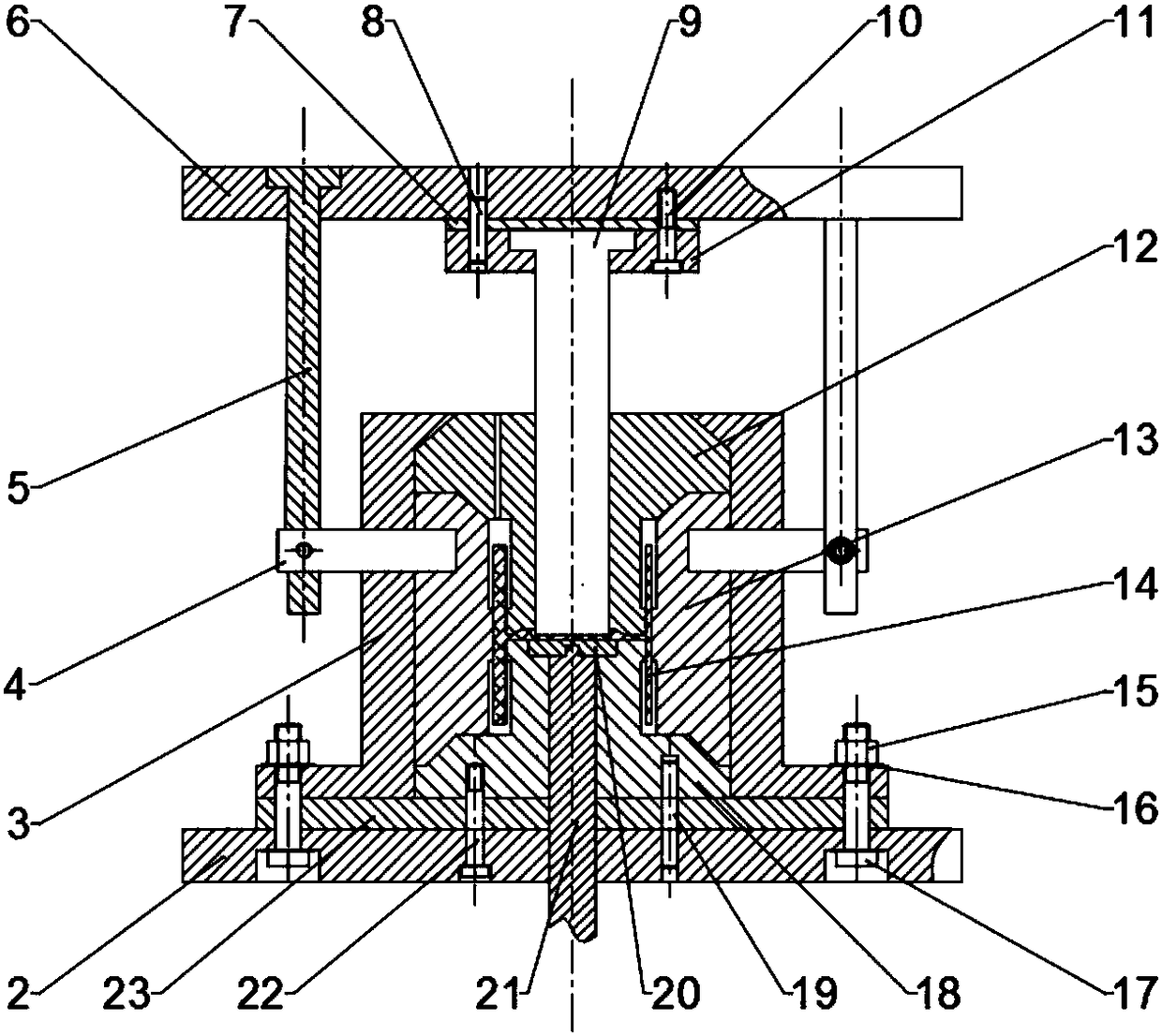

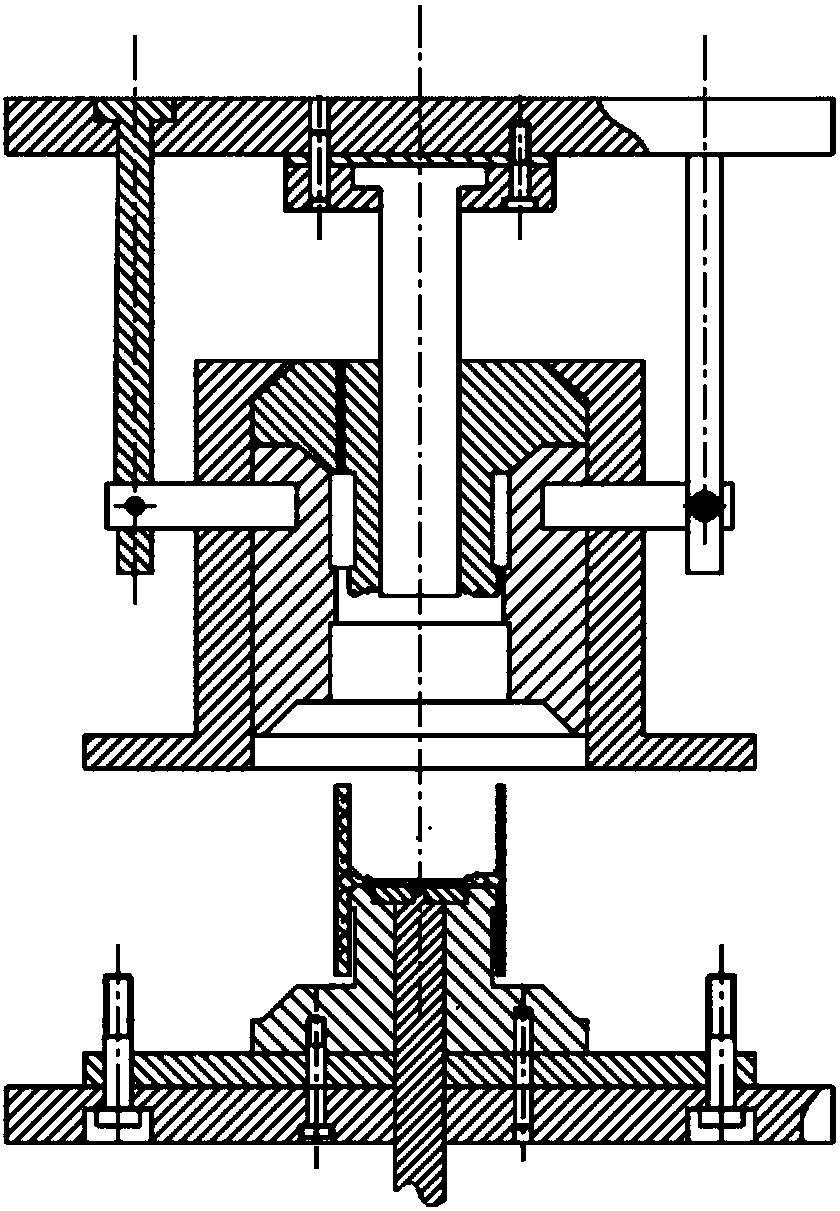

Strong plastic deformation extrusion molding device and method for magnesium alloy band rib barrel-type part

The invention provides a strong plastic deformation extrusion method and a molding device for magnesium alloy band rib barrel-type part, belonging to the technical field of plastic processing. A columnar billet is subjected to channel-changing corner extrusion for the first time to extend to a circumferential direction to form a circular rib and then subjected to the channel-changing corner extrusion for the second time to enter an up-down mold cavity to form a thin-walled cylinder provided with four longitudinal ribs. When a material is subjected to corner extrusion for multiple times, crystalline grains are constantly refined to generate strong plastic deformation to cooperate with the mold cavity to realize extrusion molding once and obtain the high-strength magnesium alloy band rib barrel-type part. The length of a diameter fixing band of an extrusion mold is shrunk so as to reduce friction between a formed part and a mold to decrease forming force. A longitudinal pull rod and a transverse shaft pin for special purpose are designed and cooperate with a mold structure, and after part molding is completed, the return stroke of a workbench on an extruder is utilized to disassemblethe mold and take out the formed part. A magnesium alloy barrel-type part, which has high strength, can be molded once, a circular rib and longitudinal bars therein can be used as support structures,and the designed part taking structure can be used for effectively solving the problem that a barrel-type extrusion part is difficult to take out.

Owner:UNIV OF SCI & TECH BEIJING

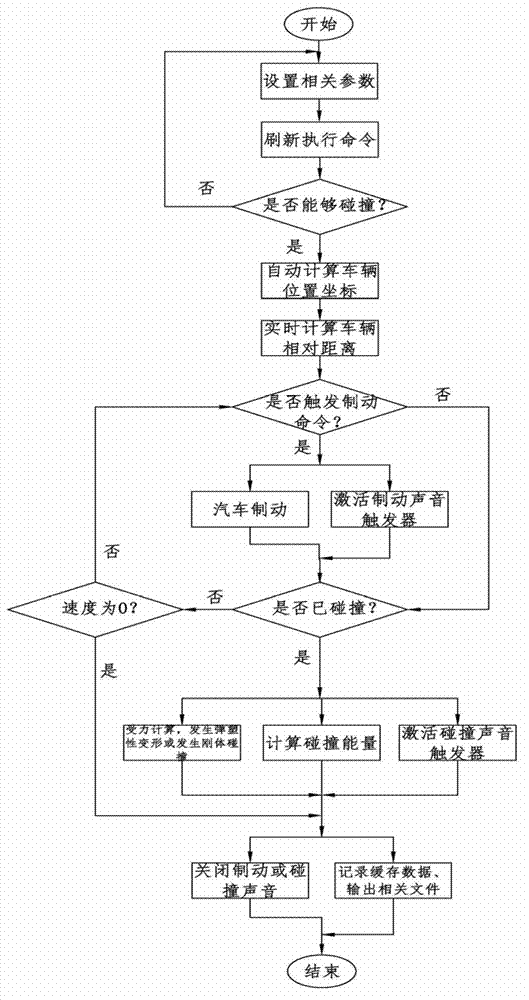

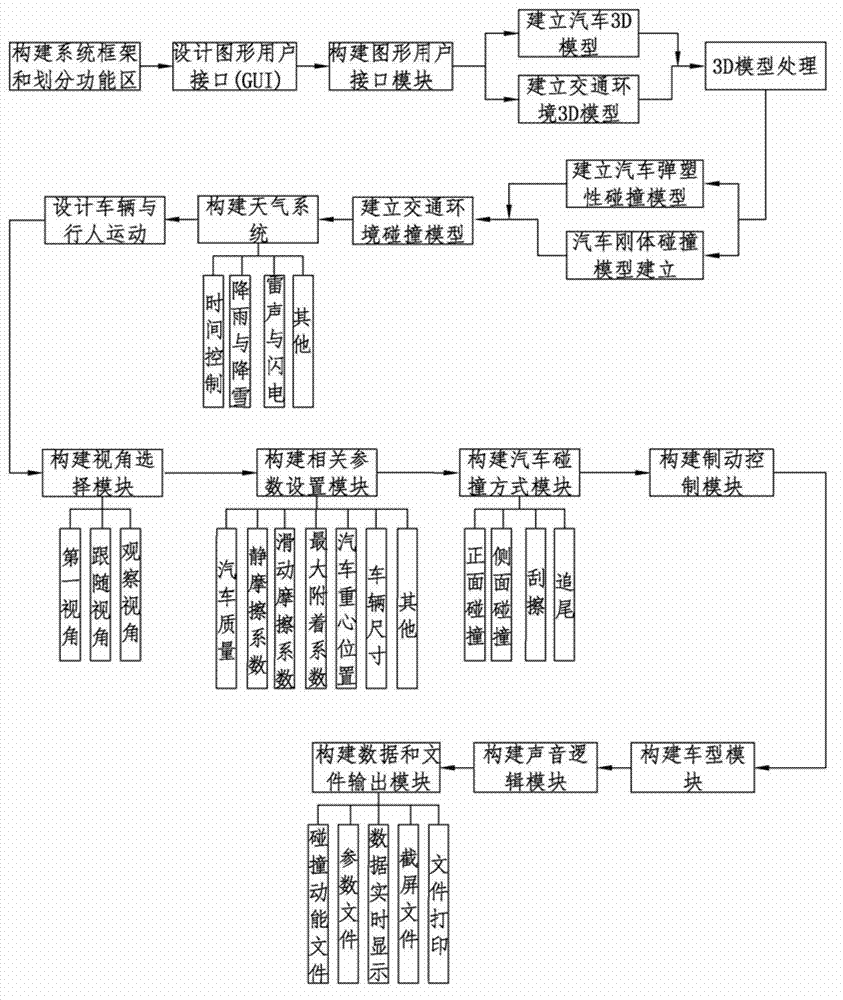

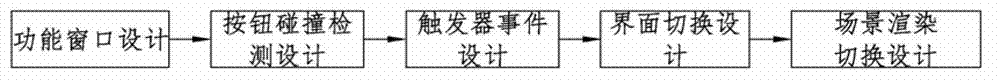

Motor vehicle collision accident simulation method

InactiveCN102930122AThe process is simpleReliable design principleAerodynamics improvementSpecial data processing applicationsAutomotive engineeringEngineering

The invention belongs to the technical field of motor vehicle collision accidents and relates to a motor vehicle collision accident simulation method. The method comprises the following steps: firstly setting motor vehicle collision parameters and inputting into a well-established computer simulation system which automatically calculates the motor vehicle collision parameters for further judgment and analysis; calculating stress condition, so as to judge whether elastic-plastic collision or rigid collision occurs; then calculating collision energy so as to activate a sound trigger to generate collision sound, and closing the motor vehicle braking or collision sound; and finally, recording the collision cache data, outputting and displaying collision energy files, screenshot files and parameter files, and terminating the collision process. The method provided by the invention has the advantages of simple technological process, reliable design principle, and real simulation scene, is favorable for analysis and judgment, and can be widely used for teaching, scientific research, accident analysis and other occasions.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method for purifying magnesium alloy melt

InactiveCN102031384AThe process is simpleEasy to operateProcess efficiency improvementMagnesium alloyMaterials science

Owner:JIANGSU UNIV

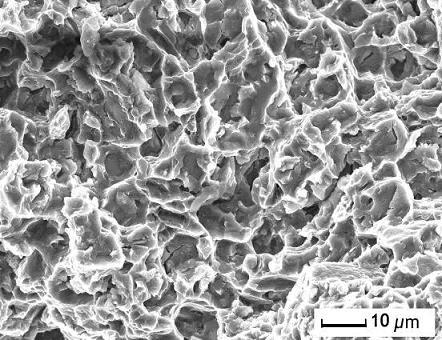

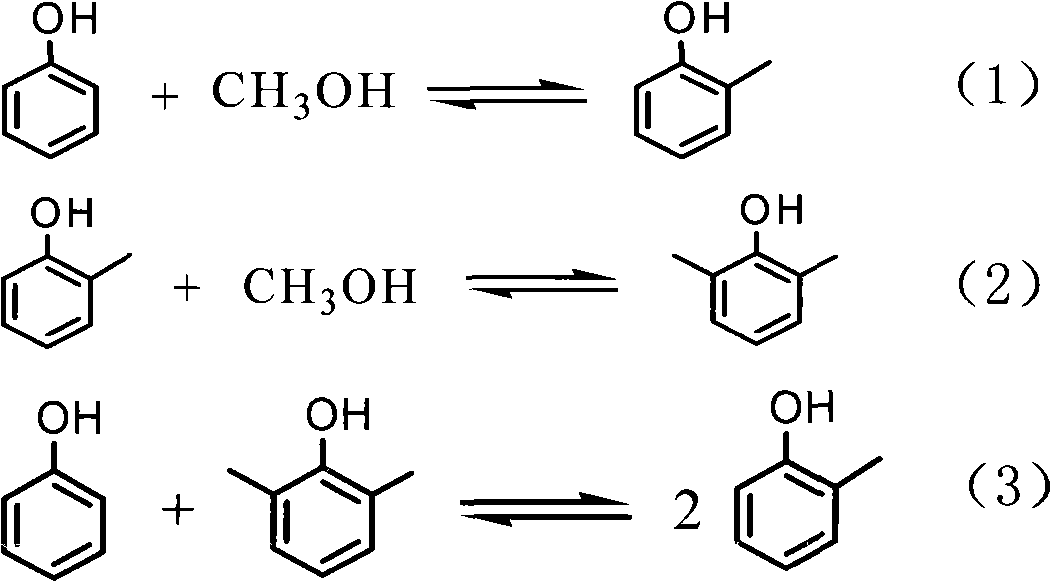

Method for preparing o-cresol

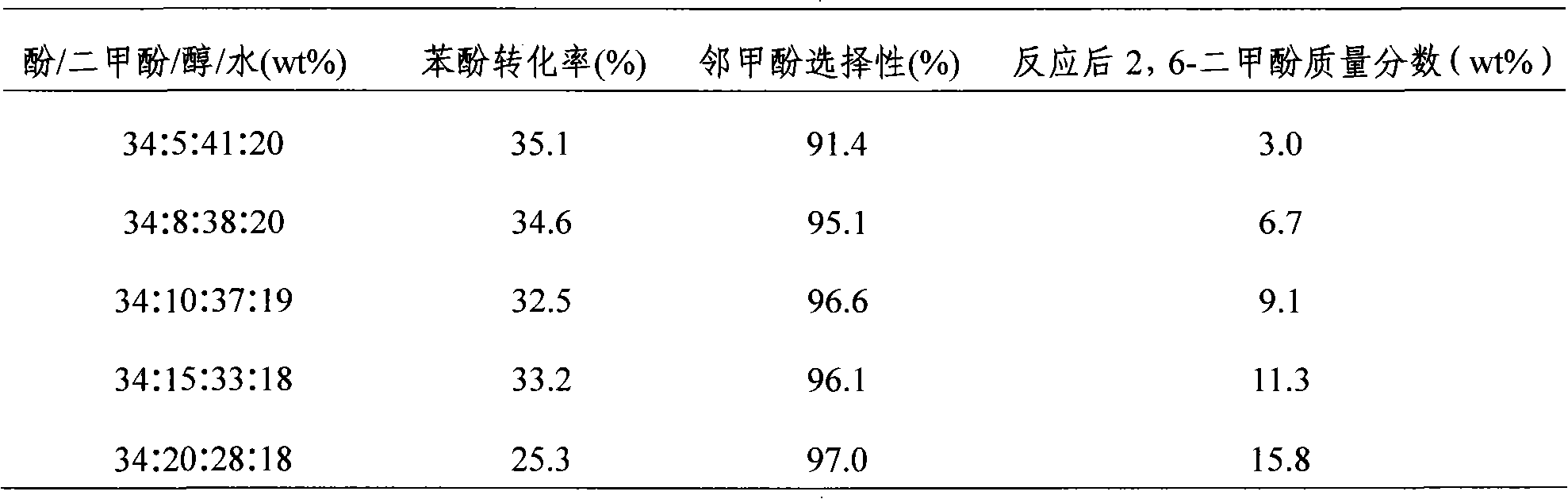

ActiveCN101514144AThe process is simpleHigh selectivityOrganic chemistryOrganic compound preparationReaction tubeP-Cresol

The invention discloses a method for preparing o-cresol, comprising the following steps: uniformly mixing phenol, 2, 6-dimethyl phenol and methanol with water by a mass ratio 34: (5-20): (33-46): (28-41), and then pumping the mixture into a reaction tube containing alkylate catalyst, introducing inert supporting gas to the reaction tube, and obtaining the o-cresol after condensating and recycling the reaction product. The reaction conditions comprise normal atmosphere, reaction temperature of 280 to 450 DEG C, and the airspeed of incoming stock of 0.8-1.8h. The method has advantages of simple technical process, high selectivity of o-cresol, relatively low selectivity of 2, 6-dimethyl phenol, no generation of by-products such as meta-cresol, p-cresol and anisole and long service life of the catalyst.

Owner:HUNAN XINLING CHEM CO LTD

Ultra hydrophobic surface preparation method

InactiveCN101417278AWide technical adaptabilityThe process is simplePretreated surfacesCoatingsSurface energyNanometre

The invention relates to a preparation method of a superhydrophobic surface, in particular to a method for preparing the superhydrophobic surface by compounding micron or sub-micron particles with nanometer pores or nanometer decorative surfaces and a low surface energy material. The method concretely comprises the following steps: the superhydrophobic surface is prepared by compounding the micron or sub-micron particles with nano-sized pores or surfaces decorated by nanometer and the low surface energy material; firstly activation is carried out to the particle surfaces by the existing mature surface activation technology so as to remove passivation membranes on the particle surfaces; then the low surface energy material, the micron or sub-micron particles after surface activation, a coupling agent and the like are evenly mixed, and the mixture is sprayed or painted on the surface to be processed according to needs; finally the hydrophobic surface is obtained after natural drying or being dried at a reasonable temperature. The method can solve the problem that the surface of a special shape is difficult to process in the prior art; the process is simple, thus being suitable for mass application; and the prepared hydrophobic surface has long service life.

Owner:JIANGSU UNIV

Multifunctional blended yarn and application of multifunctional blended yarn

The invention discloses a multifunctional blended yarn and an application of the multifunctional blended yarn. The multifunctional blended yarn comprises the components in parts by mass: 15-25 parts of pearl cellulose polyblend fibers, 15-25 parts of antibacterial fibers, and 50-70 parts of principle fibers; the pearl cellulose polyblend fibers comprise nanoscale pearl powders and viscose fibers; the antibacterial fibers are polyester fibers which contain an inorganic antibacterial agent or polyamide fibers which contain the inorganic antibacterial agent, wherein the inorganic antibacterial agent is of 1.5-3%, the polyester fibers or the polyamide fibers are of 98.5-97%; the principle fibers are at least one of cotton, acrylic fiber and nylon. The multifunctional blended yarn disclosed by the invention mixes multiple functions, namely an anti-ultraviolet function, an antibacterial function, moisture absorption and sweat releasing functions, and a far infrared ray emitting function; multiple functions are mixed and the manufacturing cost is reduced; the multifunctional blended yarn can be widely applied to fields such as home textile, clothing, socks and hats, and the application function and wearing comfort are improved obviously.

Owner:SHANGHAI NEW SPINNING TECH DEV CENT +1

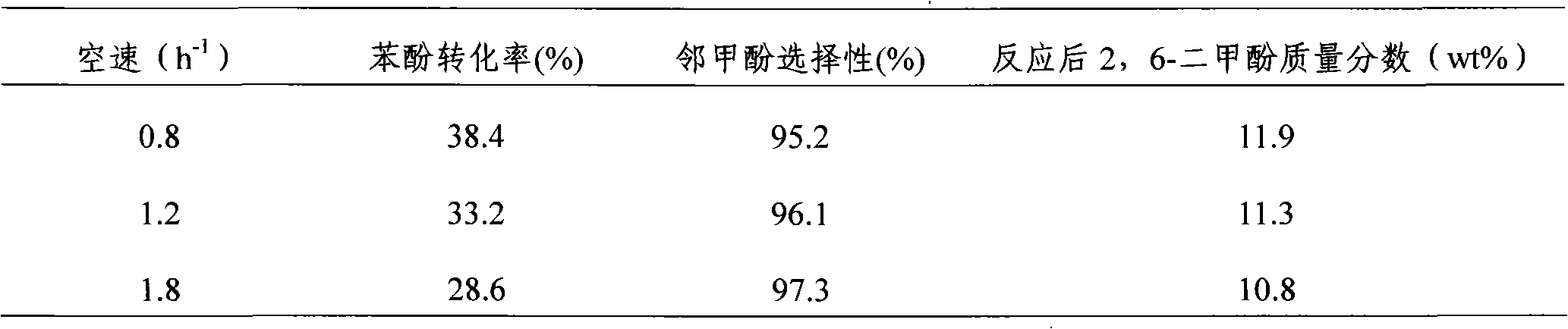

Coking wastewater treating process with zero discharge

ActiveCN104609632AThe process is simpleEasy to operate and manageMultistage water/sewage treatmentUltrafiltrationChemistry

The invention discloses a coking wastewater treating process with zero discharge. The coking wastewater treating process with zero discharge comprises the following steps: carrying out biochemical treatment, adsorbing by activated carbon, softening crystals, filtering by an ultrafiltration membrane, filtering by a reverse osmosis membrane, carrying out spray evaporation and the like. The coking wastewater treating process with zero discharge is simple in process, convenient in operation and management, high in automation degree and low in running cost, is capable of not generating secondary pollution, effectively treating coking wastewater, basically realizing wastewater zero discharge, completely eliminating environment disruption caused by organic matters, ammonia nitrogen, salts and the like in the wastewater and reusing all the wastewater with high quality, can be used as a wastewater treating full flow process of a newly-built coking enterprise and can also be abutted to the wastewater treating process of the traditional coking enterprise.

Owner:上海三夫工程技术有限公司

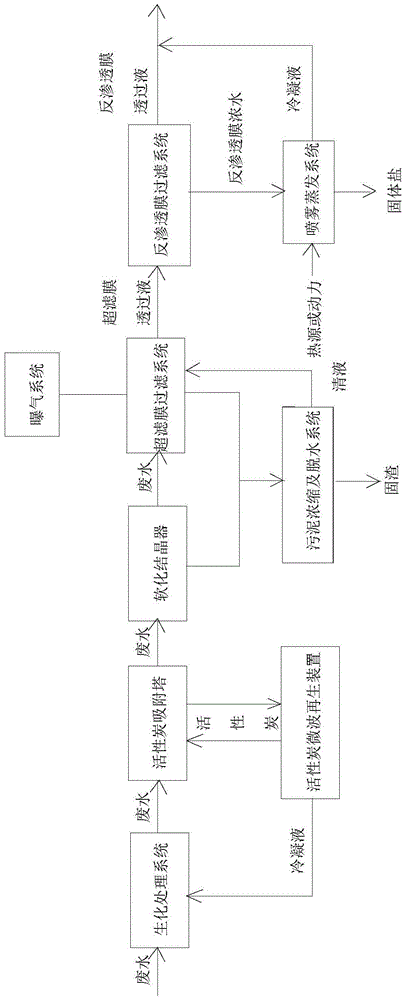

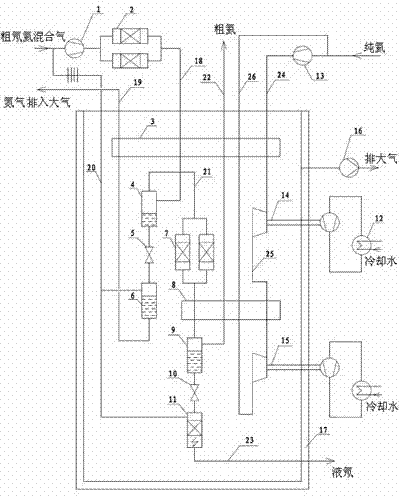

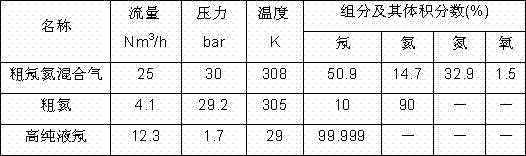

Method for extracting high-purity liquid neon

The invention provides a method for extracting high-purity liquid neon. A closed refrigeration circulating system consisting of a double-helium turbine expansion engine is adopted so as to realize cold supply. The method particularly includes pressurizing raw material gas and cooling the raw material gas; removing impurities such as nitrogen, oxygen and the like in the raw material gas by the aid of a low-temperature condensation method and an adsorption method and then obtaining neon and helium gas mixture; continuing cooling the neon and helium gas mixture, separating neon from helium by the aid of a low-temperature rectification method; and obtaining the high-purity liquid neon. The closed refrigeration circulating system consisting of the double-helium turbine expansion engine meets cold requirement during extraction of the liquid neon.

Owner:SHANGHAI QIYUAN GAS DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com