Patents

Literature

32results about How to "Short process cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

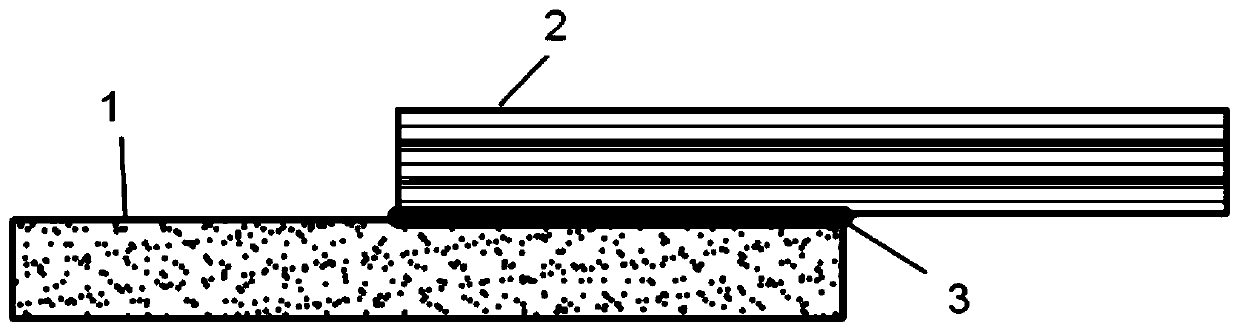

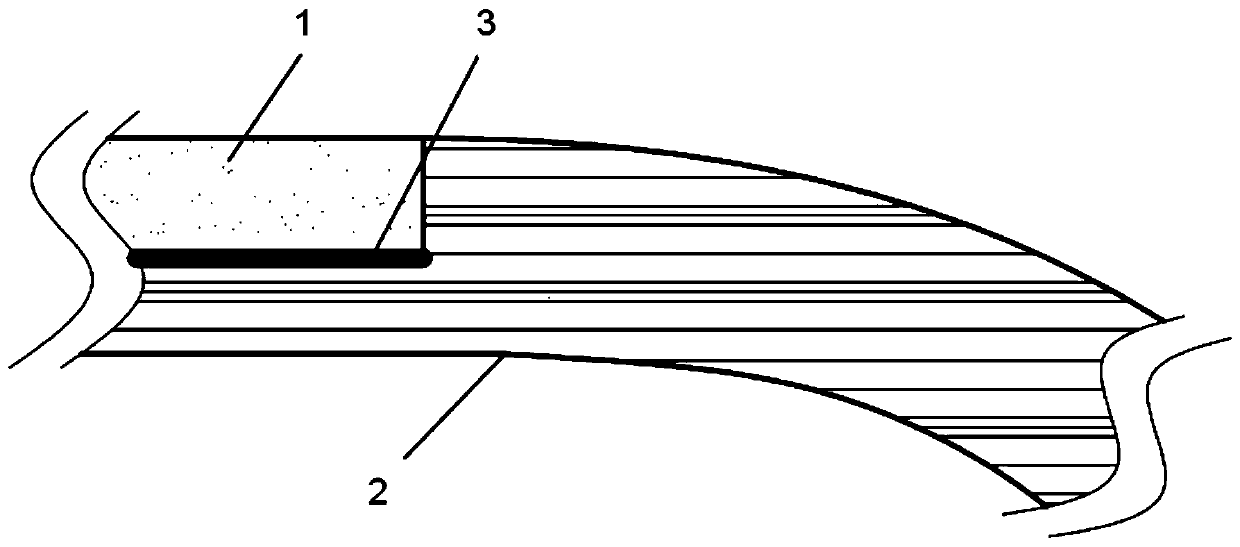

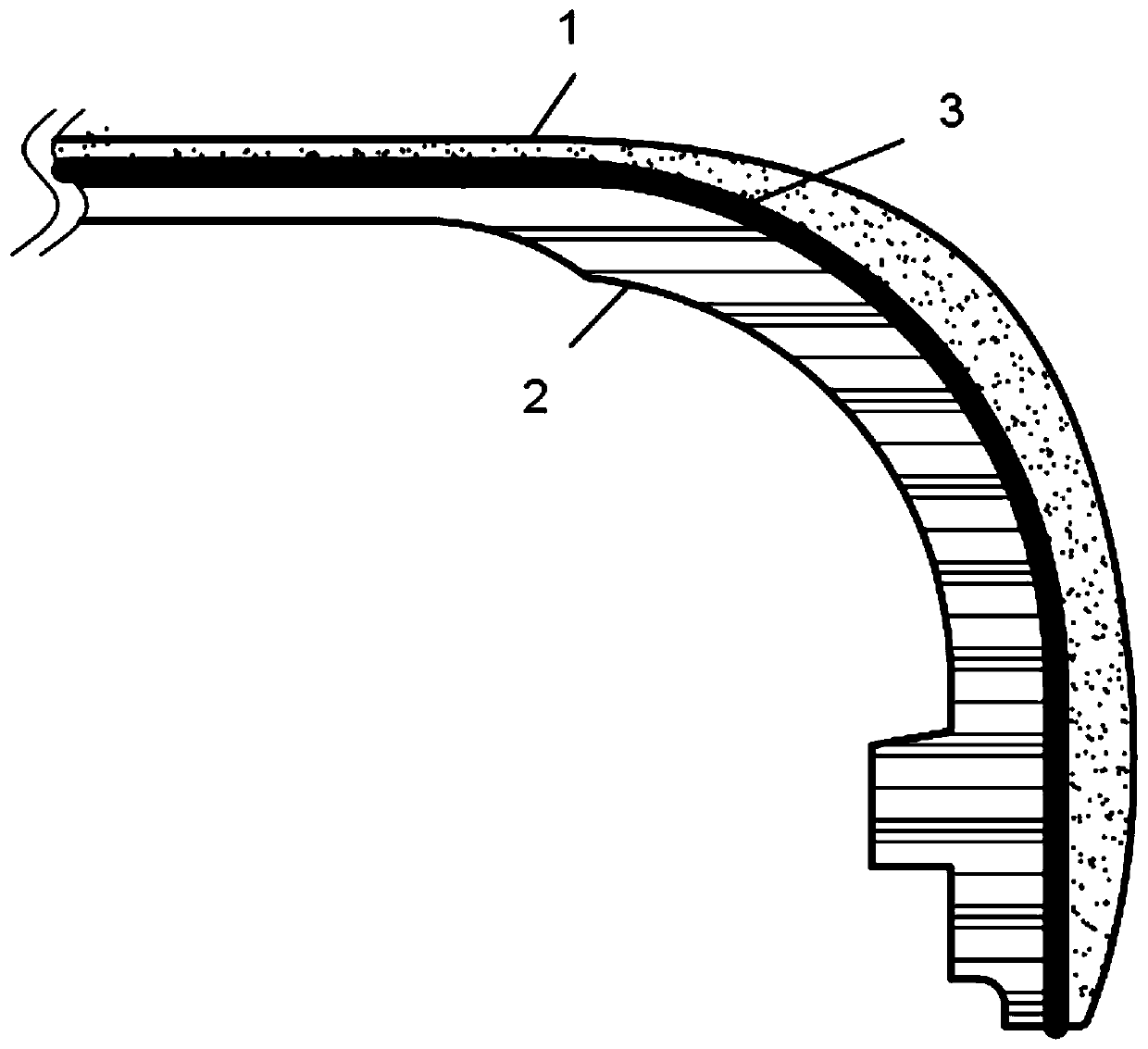

Bacterial cellulose porous thin film and preparation method thereof

ActiveCN104157815ASimple preparation processShort process cycleSecondary cellsCell component detailsThin membraneChemistry

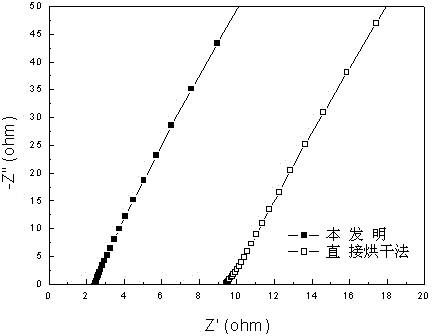

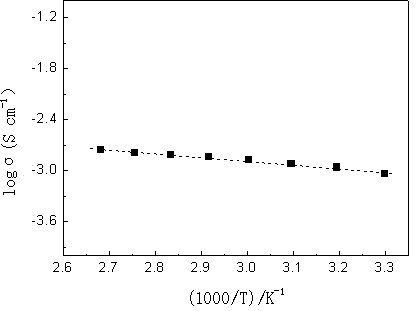

The invention provides a bacterial cellulose porous thin film for a lithium ion battery separator. The bacterial cellulose porous thin film is obtained by replacing water in a bacterial cellulose wet film with an organic solvent, then hot-pressing and drying. The bacterial cellulose porous thin film has the thickness of less than 40 microns and the porosity of greater than 50%. The invention further provides a preparation method of the bacterial cellulose porous thin film. The lithium ion battery separator prepared by the bacterial cellulose porous thin film has the characteristics of high porosity and high ionic conductivity, and is beneficial for promoting an industrialization process of the power lithium ion battery separator. The preparation method of the bacterial cellulose porous thin film has the advantages of being simple in preparation process, short in process period, and suitable for large-scale production.

Owner:HAINAN GUANGYU BIOTECH +1

Method and apparatus for preparing sheet-type metal pwoder by atomized drop deformation

The present invention relates to a method for preparing flake metal powder by means of atomizing liquid drop deformation. Said method includes the following steps: heating and melting metal raw material, then making the molten metal be passed through the discharge spout of crucible bottom portion according to stable flow rate of 3-30g / sec. And be poured onto the center of disk rotated at high speed, the rotating speed of the disk is 1000-5000 rpm, under the action of centrifugal force atomizing and forming so as to obtain the invented product. Said equipment comprises, smelting crucible, rotating disk atomizer, drive motor, atomizing chamber, bearing and water-cooling chamber.

Owner:UNIV OF SCI & TECH BEIJING

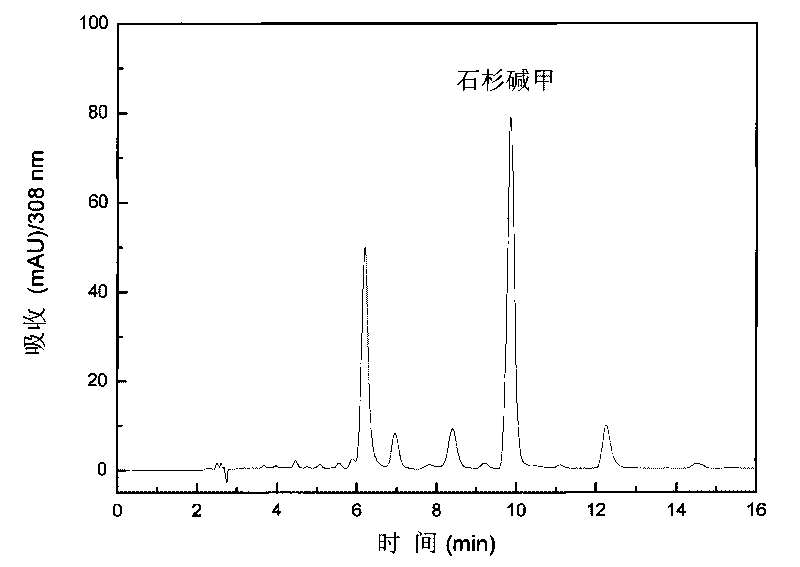

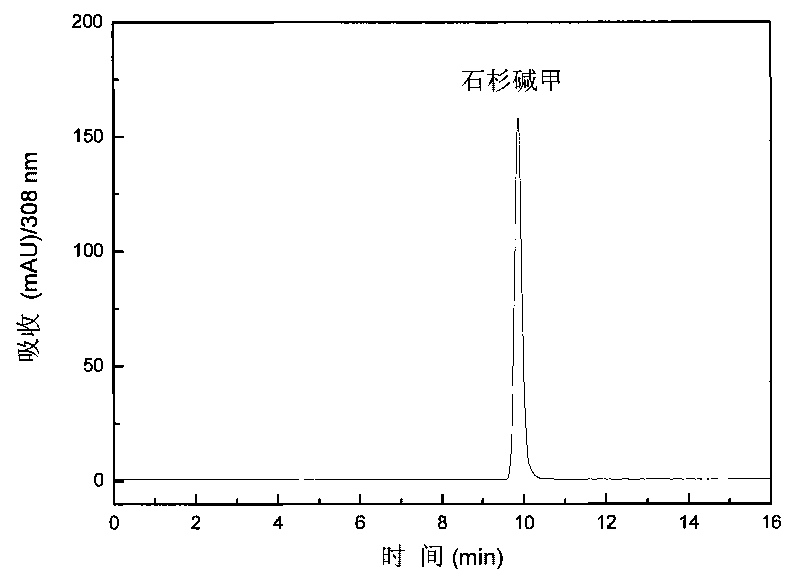

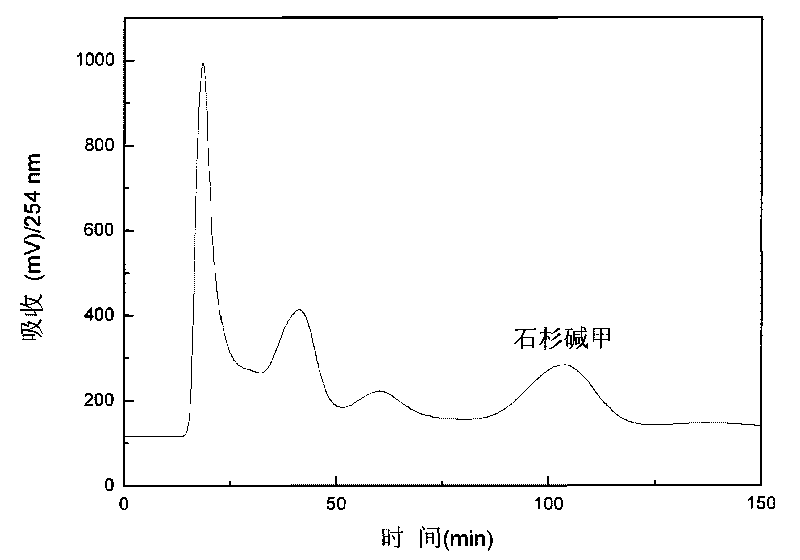

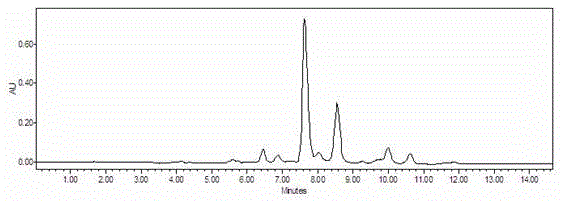

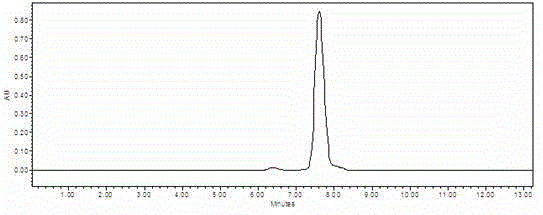

New method for extracting and separating high-purity huperzine A from thousand-layer column

InactiveCN101693689AEasy to operateShort process cycleNervous disorderOrganic chemistryChemistryPhosphate

The invention relates to a new method for extracting and separating high-purity huperzine A from a thousand-layer column. The method comprises the following three technological steps: first, the preparation of extract liquor, second, the pre-separation of macroporous resin, and third, the purification by high-speed countercurrent chromatogram. The preparation of the extract liquor comprises immersing the grinded thousand-layer column in acid liquor, implementing diacolation and ultrasonic extraction, and obtaining the extract liquor for further use. The pre-separation of the macroporous resin comprises regulating the pH value of the extract liquor to 8 to 10, delivering the extract liquor through a macroporous resin column, eluting the extract liquor with alcohol of different concentration, and obtaining extract extractum after recovering solvent with alcohol eluent. The purification by high-speed countercurrent chromatogram comprises taking petroleum ether, n-butyl alcohol and phosphate buffer as the solvent system to purify the extractum by a high-speed countercurrent chromatogram method, and obtaining the high-purity huperzine A.

Owner:LIAOCHENG UNIV

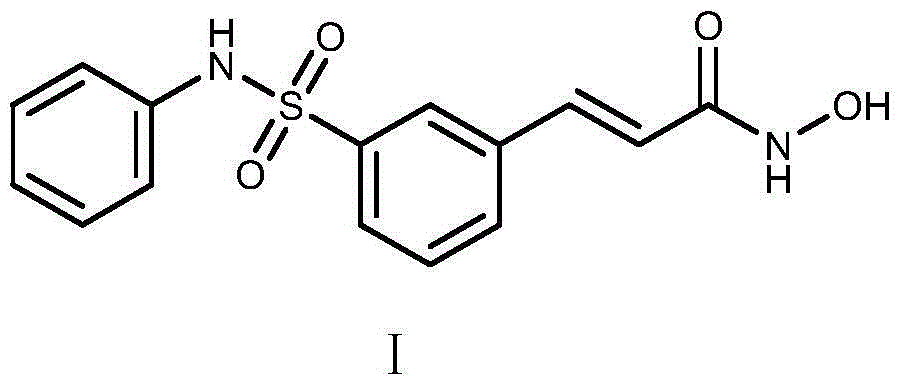

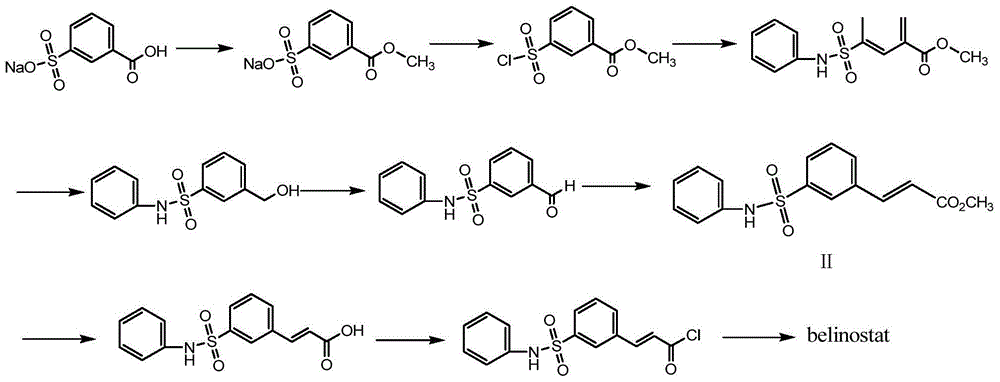

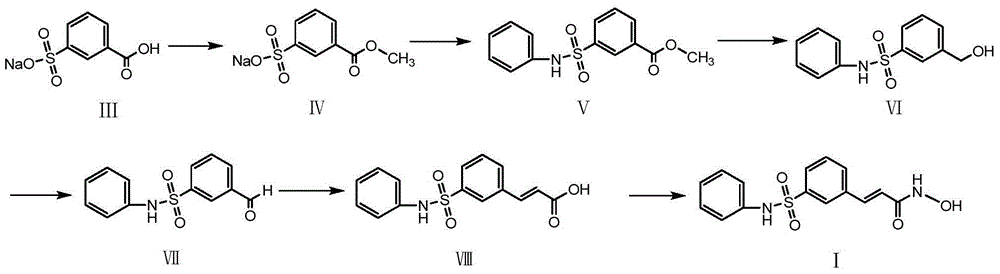

Belinostatsynthesis method suitable for industrial production

InactiveCN104478769AShort process cycleReduce lossSulfonic acid amide preparationHydroxylamine HydrochlorideChemistry

The invention provides an improved belinostatsynthesis method. According to the method, sodium m-carboxyl benzenesulfonate is taken as a starting material, and belinostat is prepared through six steps of esterification, acylation and aniline condensation, reduction, oxidation, Wittig-Horner condensation and hydrolysis as well as acylation and hydroxylamine condensation. With the adoption of the method, the production time is shortened, the reaction yield is increased, the production safety is enhanced, the environmental pollution is reduced, and the method is more suitable for industrial production.

Owner:深圳万乐药业有限公司

Chemical nitridation catalyst

InactiveCN102691030AImprovement of infiltrated tissueShort process cycleSolid state diffusion coatingAluminium silicateGram

The invention relates to a chemical nitridation catalyst which comprises the following components in proportion: 5 to 15 percent of calcium carbonate, 12 to 25 percent of sodium carbonate, 3 to 5 percent of calcium oxide, 10 to 30 percent of calcium chloride, 15 to 38 percent of ammonium chloride, 5 to 10 percent of rare earth carbonate and 10 to 15 percent of rare earth chloride. The seven compounds are uniformly mixed and put into a stainless steel pipe; two ends are plugged and locked by aluminium silicate fiber felts and spot-welded on the stainless steel pipe by stainless steel wafers; and the chemical nitridation catalyst is packaged every 200 grams and 300 grams. Discharged waste gas is reduced by about more than 52.5 kilograms, so that the environment is improved. The chemical nitridation catalyst is short in nitridation time and good in nitridation effect; electric energy is saved; a nitridation layer tissue is relatively thinned and dispersed; and the brittleness level, the nitride level and the looseness level can be well controlled.

Owner:远立贤

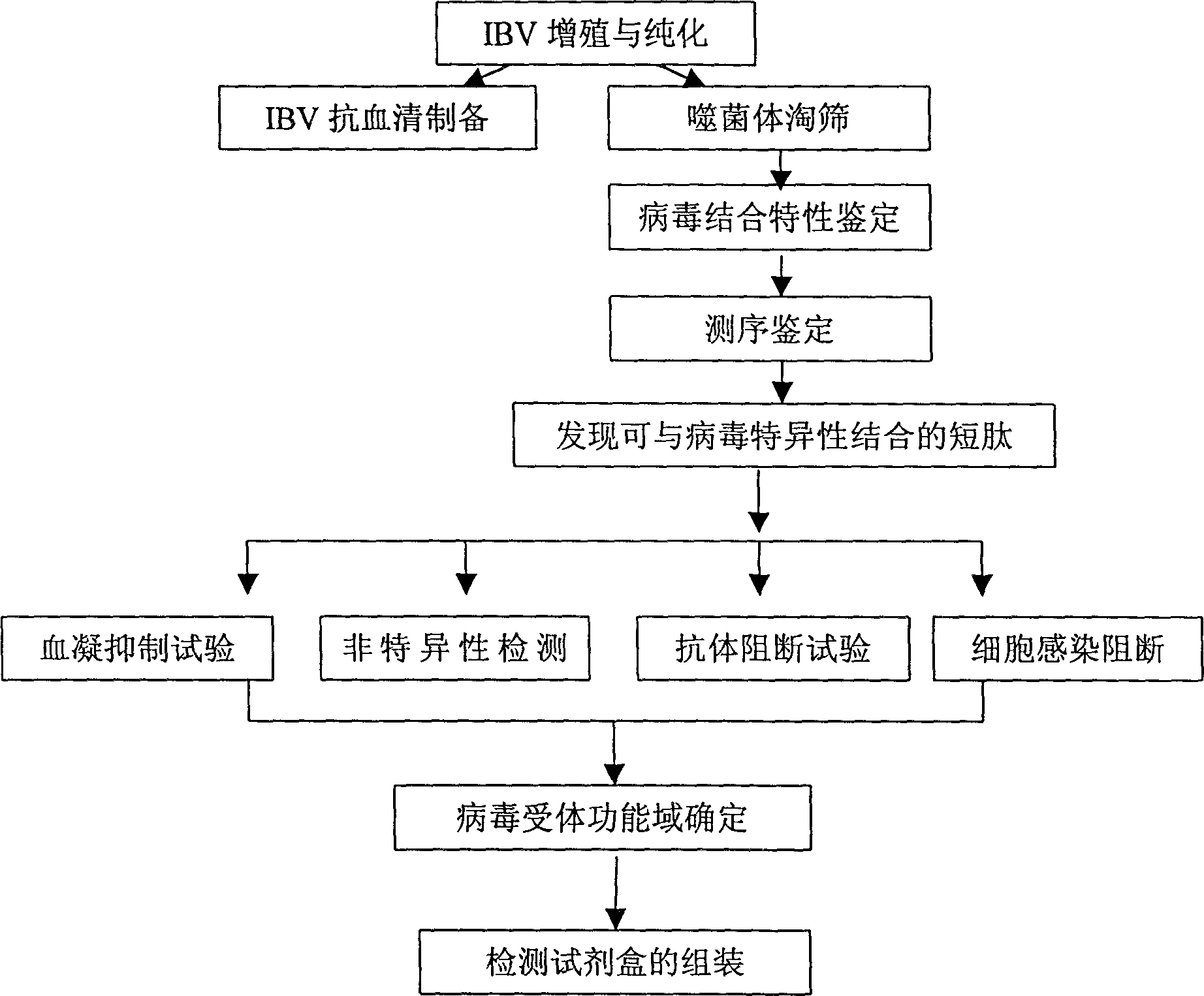

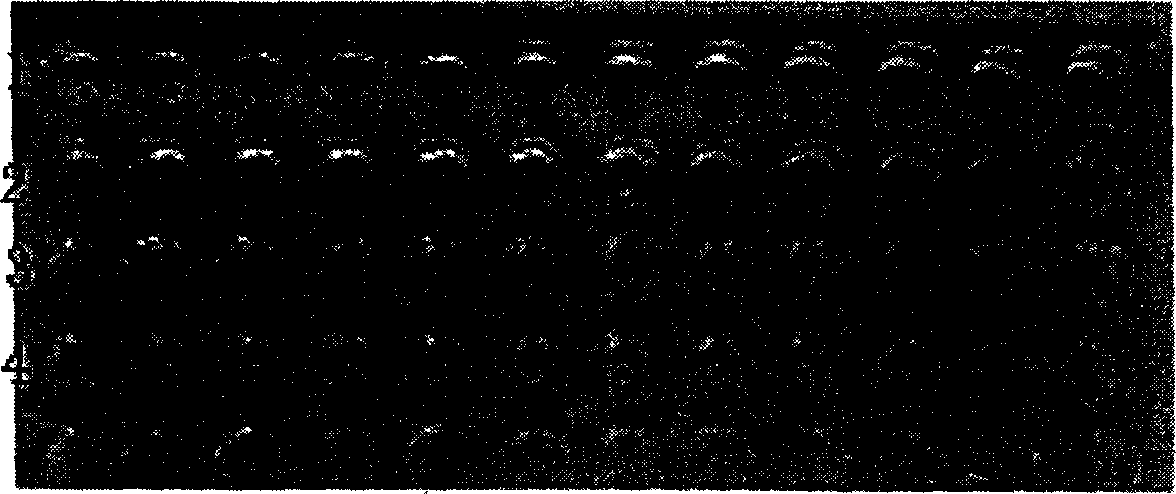

Bacteriophage containing short-peptide specifically combined with avian infectious bronchitis virus and use thereof

InactiveCN1721430AShort process cycleEasy to operateMicrobiological testing/measurementHybrid peptidesPeptideAvian infectious bronchitis

The present invention belongs to the field of animal virology technology, and is especially one kind of short peptide capable of combining specifically with chicken infectious bronchitis virus (IBV) H52, bacteriophage containing the short peptide and its preparation process. The short peptide has the amino acid sequence of GSHHRHVHSPFV, and may combine with chicken infectious bronchitis virus H52 specifically after passing through the substitution, deletion or addition of one or several amino acid residues. The present invention also includes the application of the bacteriophage in preparing IBV identifying and diagnosing kit, and the IBV identifying and diagnosing kit is used in the preventing and treating of chicken IBV.

Owner:HUAZHONG AGRICULTURAL UNIVERSITY

Nodular cast iron laser hardening technology

InactiveCN102477479AShort process cycleIncrease productivityMelting Point TemperatureAutomatic control

The invention relates to a laser hardening technology for a nodular cast iron workpiece. The laser hardening technology for the nodular cast iron workpiece comprises the steps of: fast scanning a workpiece surface by using a laser beam with high energy, and fast heating the workpiece surface by using the laser till the temperature of the workpiece surface is in the temperature range between an austenitic phase transition temperature of the workpiece and a melting point temperature of the workpiece. The hardening layer of the nodular cast iron workpiece has fine and dense textures; the hardness and wear-resisting property of the workpiece are largely improved; as laser quenching has a smaller heat affected zone on a substrate, the deformation and cracks of the workpiece are lightened, and the strengthening quality of the workpiece is high; meanwhile, the technological process is easy to realize automatic control.

Owner:HUNAN UNIV +2

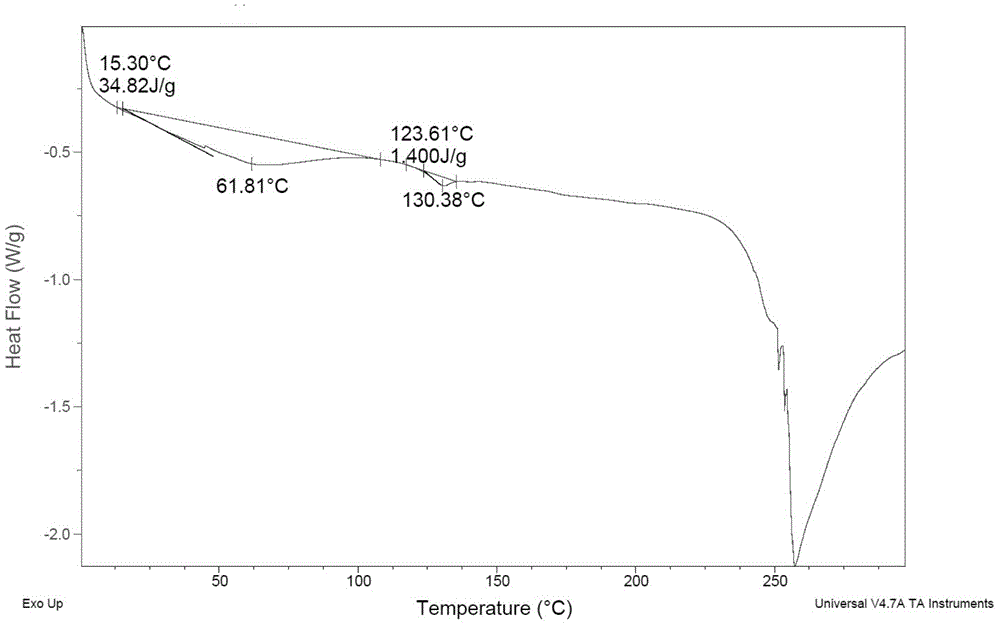

Ceramic earphone and manufacturing method thereof

The invention provides a method for manufacturing a ceramic earphone. The method comprises the following steps: pressurizing and mixing ceramic powder and an organic adhesive to form slurry, wherein the organic adhesive comprises 60-90 mass parts of POM, 10-20 mass parts of PE, 10-20 mass parts of EVA, 10-20 mass parts of PW and 5-10 mass parts of SA; extruding and granulating the slurry, thereby obtaining injection molding particles; performing injection molding on the injection molding particles by using a ceramic earphone mold, and generating a green body; performing catalytic degreasing on the green body, wherein the catalyst refers to 50-90 percent of nitric acid in the catalytic degreasing step; and sintering the degreased green body. According to the method disclosed by the invention, the organic adhesive with the components is adopted, and catalytic degreasing is performed in the subsequent step by using nitric acid, so that the production cycle is greatly shortened, the defects such as softening deformation and cracking are overcome, and the yield is improved.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

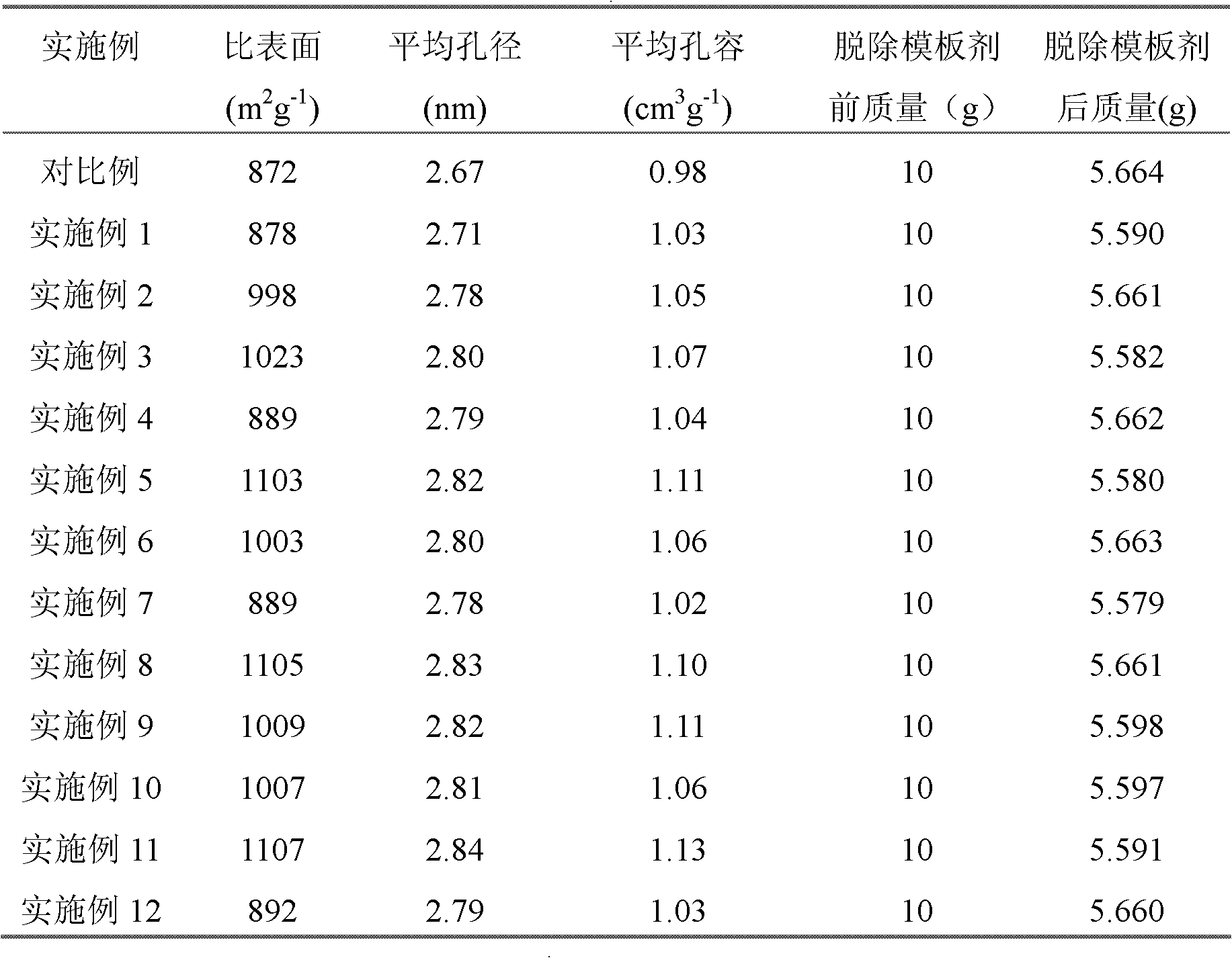

Method for rapidly removing organic templating agent in mesoporous material with solvent extraction method

InactiveCN103073015ASimplify operation stepsShort process cycleMolecular-sieve and base-exchange compoundsMolecular-sieve compoundsSoxhlet extractorOrganic solvent

The invention relates to a method for rapidly removing an organic templating agent in a mesoporous material with a solvent extraction method. According to the invention, a synthesized mesoporous material is acidified and is placed in a Soxhlet extractor; an organic solvent and an auxiliary agent are selected as extractants; and evaporation and refluxing are carried out, such that the templating agent is continuously extracted by the pure hot solvent. With the method provided by the invention, the organic templating agent in the mesoporous material can be rapidly removed, such that problems such as harsh experiment conditions, complicated operation steps, and long process cycle of existing solvent extraction methods are solved.

Owner:CHINA PETROLEUM & CHEM CORP

Method for separating and purifying pyrroloquinoline quinone disodium salt based on fermentation liquid composite salting-out

ActiveCN109180674AHigh filtration rateShort process cycleOrganic chemistryProduct recoveryActivated carbon

The invention discloses a method for separating and purifying pyrroloquinoline quinone disodium salt based on a fermentation raw material liquid. The method comprises: (1) primary filtration, (2) secondary filtration, (3) extraction of pyrroloquinoline quinone, (4) primary salting-out, (5) decolorization with activated carbon, (6) secondary salting-out, and (7) crystallization. The method has simple processes, realizes a low cost, can effectively shorten the product purification cycle, has a high product recovery rate and realizes the product purity of 99.5%.

Owner:福建康鸿生物科技有限公司

Mobile terminal component and preparation method thereof

ActiveCN110086898AImprove bindingImprove cohesionTelephone set constructionsHigh volume manufacturingMetallurgy

The invention discloses a mobile terminal component. The mobile terminal component comprises a ceramic component, a plastic component and a bonding layer; the bonding layer is used for connecting theceramic component and the plastic component; a gravel layer is arranged on the surface, making contact with the bonding layer, of the ceramic component, and the particle size D50 of gravel in the gravel layer ranges from 20 m to 400 m. According to the component, the binding force of the ceramic component and the plastic mold is high after injection molding, no offset or gap exists at the joint ofthe ceramic component and the plastic component, the problem that fine substances such as dust and scurf are adsorbed and embedded can be effectively avoided, and the texture and the aesthetic feeling of the ceramic-plastic composite component can be improved. The invention further provides a preparation method of the mobile terminal component, and the preparation method is simple in technological process, high in operability and suitable for mass production of the injection molding ceramic components in the mobile terminal mold.

Owner:CHAOZHOU THREE CIRCLE GRP

Preparation method of zinc manganate and graphene composite material

InactiveCN104934590AThe synthesis process is simpleShort process cycleCell electrodesSecondary cellsGraphite oxideAqueous solution

The invention relates to a preparation method of a zinc manganate and graphene composite material. The preparation method comprises the following steps: firstly preparing a graphite oxide water solution and a metal salt water solution, wherein the mole ratio of Zn(CH3COO)2.2H2O to Mn(CH3COO)2.2H2O in the metal salt water solution is 1: 2, and the molar concentration of the Zn(CH3COO)2.2H2O is 0.05-0.2 M; mixing the metal salt water solution and the graphite oxide water solution in a volume ratio of 1(5-7) under a stirring condition, transferring the mixture into a reaction kettle after uniformly mixed, wherein the temperature of the reaction kettle is 160-190 DEG C, and the reaction time is 6-12 h; and after the reaction kettle is cooled to room temperature, filtering, precipitating and washing the product with deionized water, and performing freeze drying on a sediment product to obtain an in situ synthesized ZnMn2O4 / graphene composite material. The preparation method is reasonable in technology, simple and convenient in operation, high in efficiency and low in preparation cost. The prepared zinc manganate and graphene composite material can serve as an anode material for a lithium ion battery, and has the characteristics of high specific area, high specific capacity and long cycle life.

Owner:HARBIN INST OF TECH AT WEIHAI +1

Method for extracting and degumming banana fiber by steam explosion technology

InactiveCN102277625ASimple processShort process cycleVegetable fibres from other vegetable matterBleaching apparatusChemistryShort cycle

The invention belongs to the field of textile industry, and relates to a method for extracting and degumming banana fibers by using steam explosion technology. Banana stalks are taken as raw materials, and after cutting, steam explosion extraction is performed to obtain banana crude fibers, and the banana crude fibers are soaked in alkali The pre-alkali treatment is carried out in the liquid, and then the banana fiber is obtained through steam explosion degumming, bleaching and post-treatment. The invention has a simple process and a short process cycle, uses discarded banana stalk resources in banana orchards as the main raw material, and has low cost. It adopts the combination of pre-alkali treatment and steam explosion, which not only effectively improves the banana fiber yield, but also reduces the banana fiber residue. At the same time avoiding environmental pollution, it opens up a new way to extract and degumming banana stem fibers, which is conducive to the comprehensive utilization of banana orchard waste resources and the further improvement of product added value.

Owner:HAIKOU EXPERIMENTAL STATION CHINESE ACAD OF TROPICAL AGRI SCI

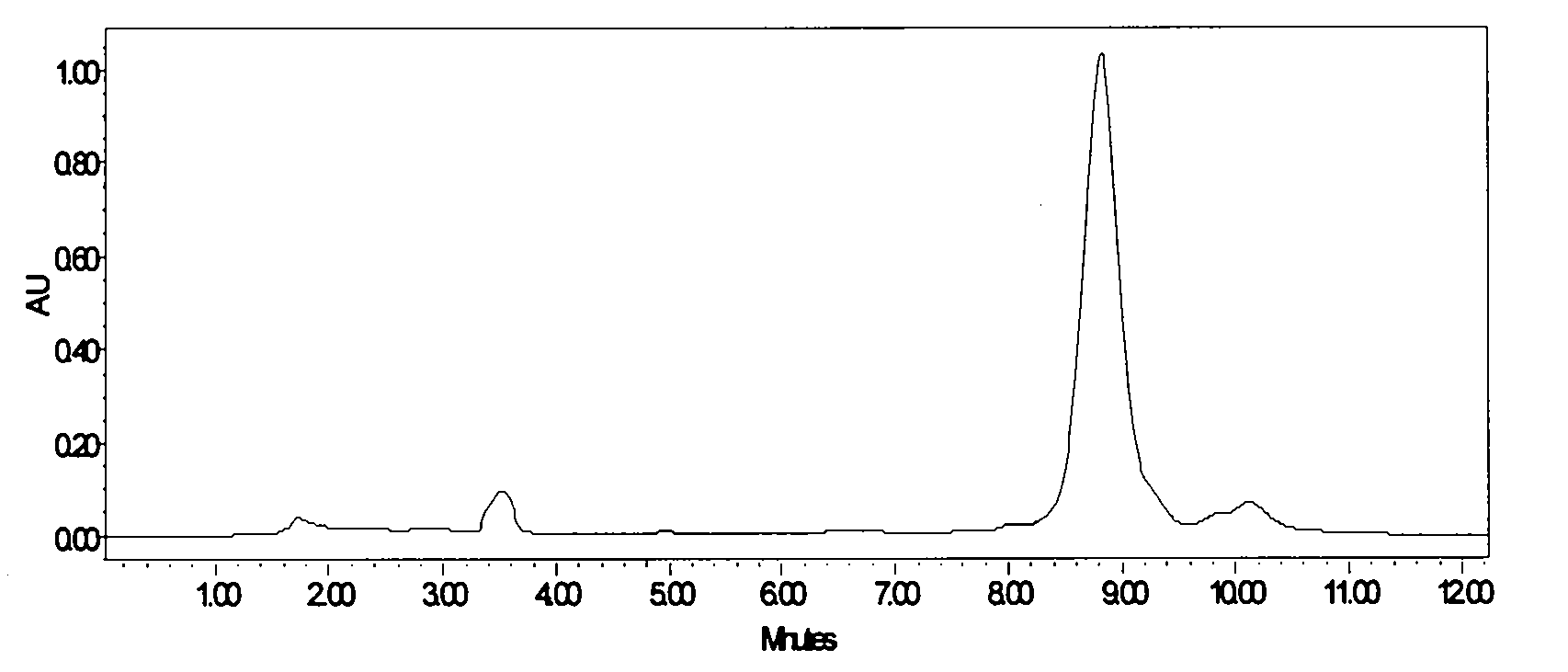

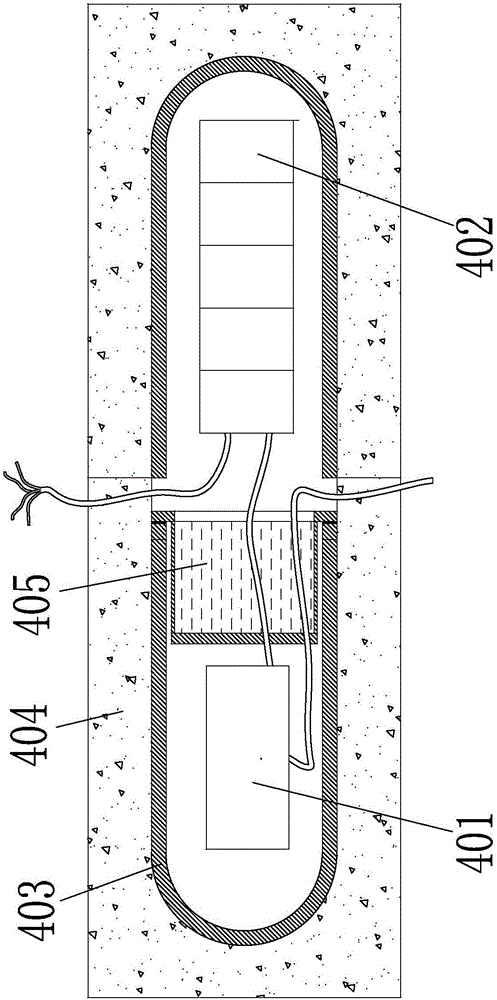

Preparation method of high-purity pneumocandin B0

ActiveCN103073622ASpeed up filteringShort process cyclePeptide preparation methodsChemistryGlarea lozoyensis

The invention discloses a method for preparing pneumocandin B0 by using a fermentation culture product of filamentous fungi glarea lozoyensis. According to the method, a filter aid is adopted; with steps such as leaching, discoloring, adsorption, crystallization, and the like, a pneumocandin B0 crude extract is obtained; and the crude extract is subjected to chromatographic separation by using polymer microspheres, such that the high-purity pneumocandin B0 product is obtained. The method provided by the invention has the advantages that: pneumocandin B0 is extracted and separated by using macroporous resin; the process is simple and feasible, and is suitable for industrialized productions; the polymer microspheres are used in chromatographic separation of the product for a first time, and high-purity pneumocandin B0 product can be prepared.

Owner:NCPC NEW DRUG RES & DEV

High-permeability porous ceramic membrane and preparation method thereof

InactiveCN103482999ALow raw material costShort process cycleCeramicwareClaywaresPotassium feldsparMicrowave sintering

The invention relates to a high-permeability porous ceramic membrane and a preparation method thereof, and belongs to the technical field of production of ceramic materials. The ceramic membrane comprises components in parts by weight as follows: 55-60 parts of kaolin, 20-25 parts of potassium feldspar, 5-8 parts of aluminum oxide, 5-8 parts of calcium carbonate, 1-3 parts of ammonium polymethacrylate and 1-3 parts of polyethyleneimine. The preparation method comprises the steps as follows: the components are weighed according to the proportion, uniformly mixed and stirred, melted in a frit furnace at the high temperature of 1,300 DEG C-1,350 DEG C, and then subjected to microwave sintering at the temperature ranging from 1,450 DEG C to 1,500 DEG C at the heating rate ranging from 20 DEG C / min to 25 DEG C / min, finally, heat preservation is performed at the high sintering temperature for 15-20 minutes, a melted liquid is quenched by cold water, and the high-permeability porous ceramic membrane is obtained. The ceramic membrane has good separation performance, reasonable price, high strength and wide application range.

Owner:崔劲

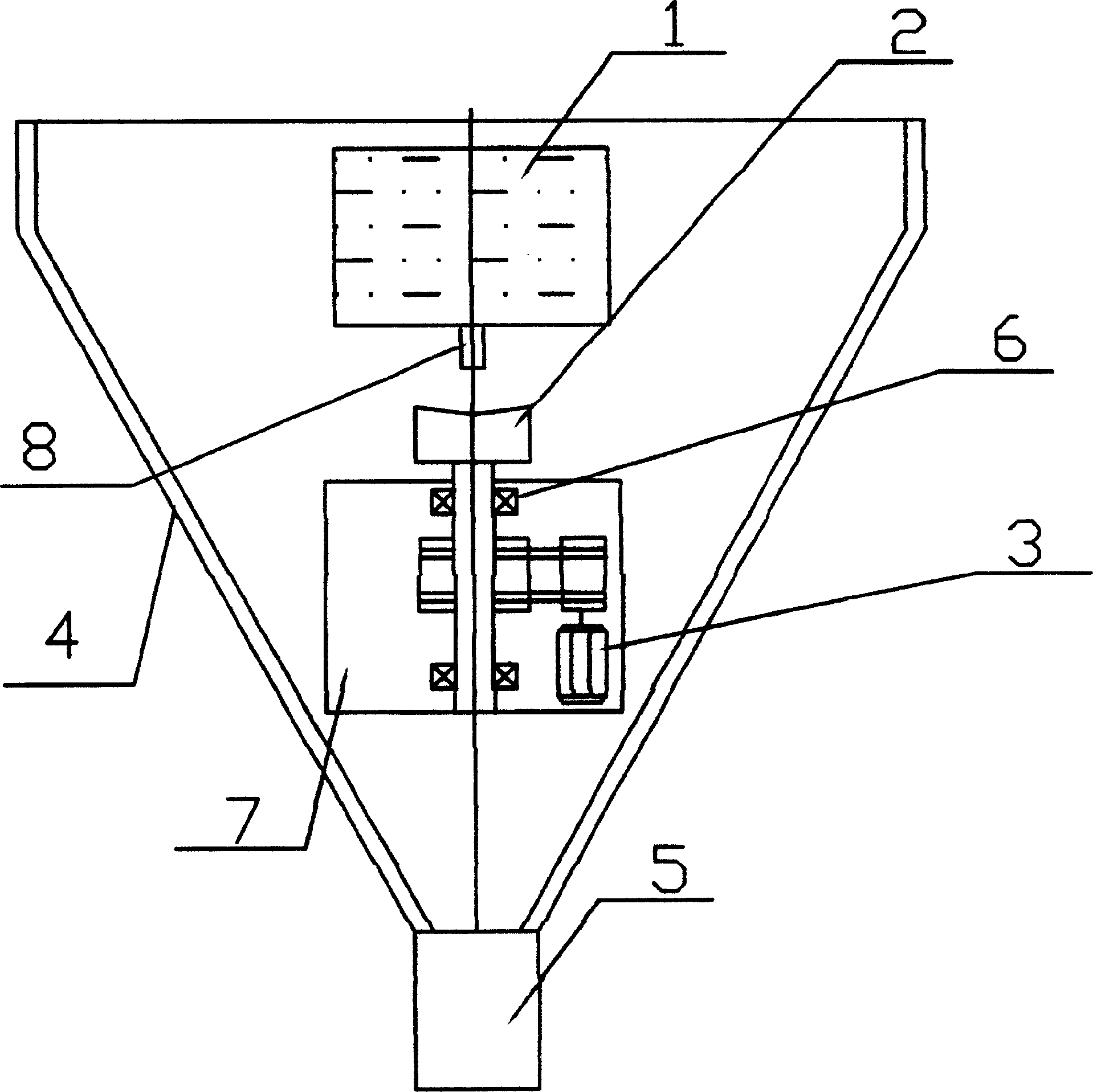

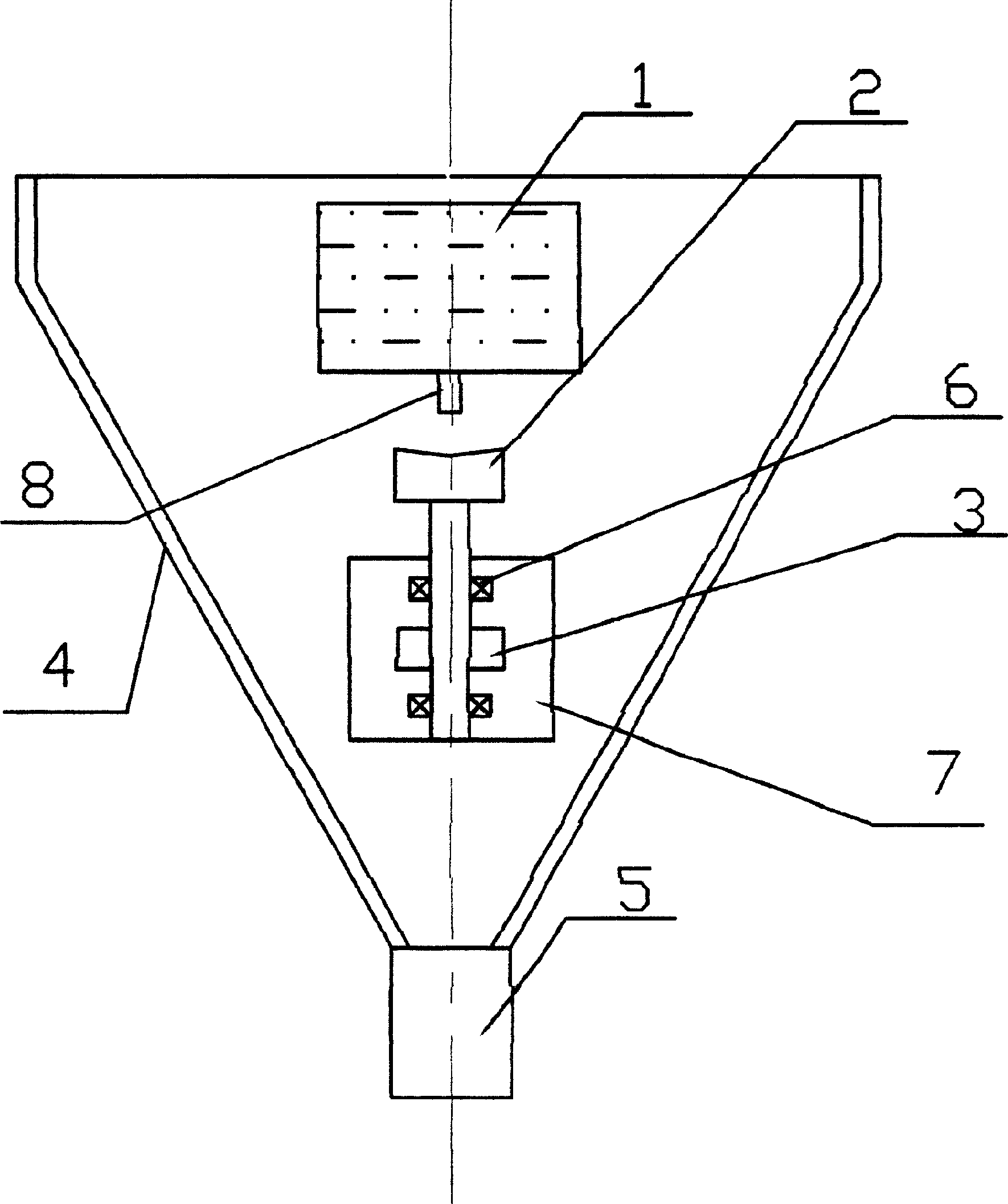

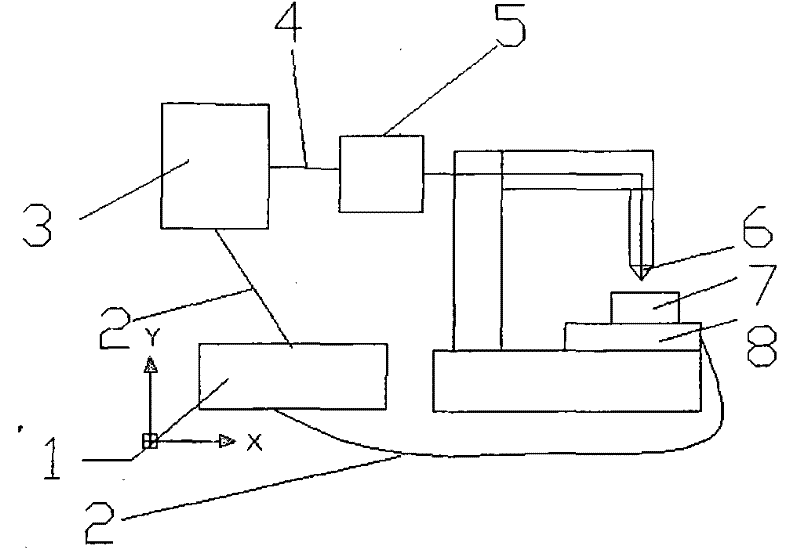

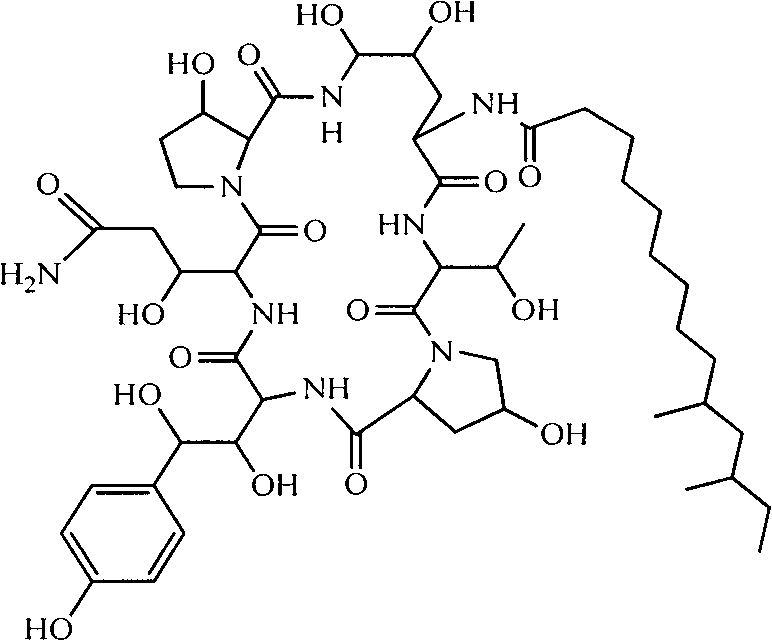

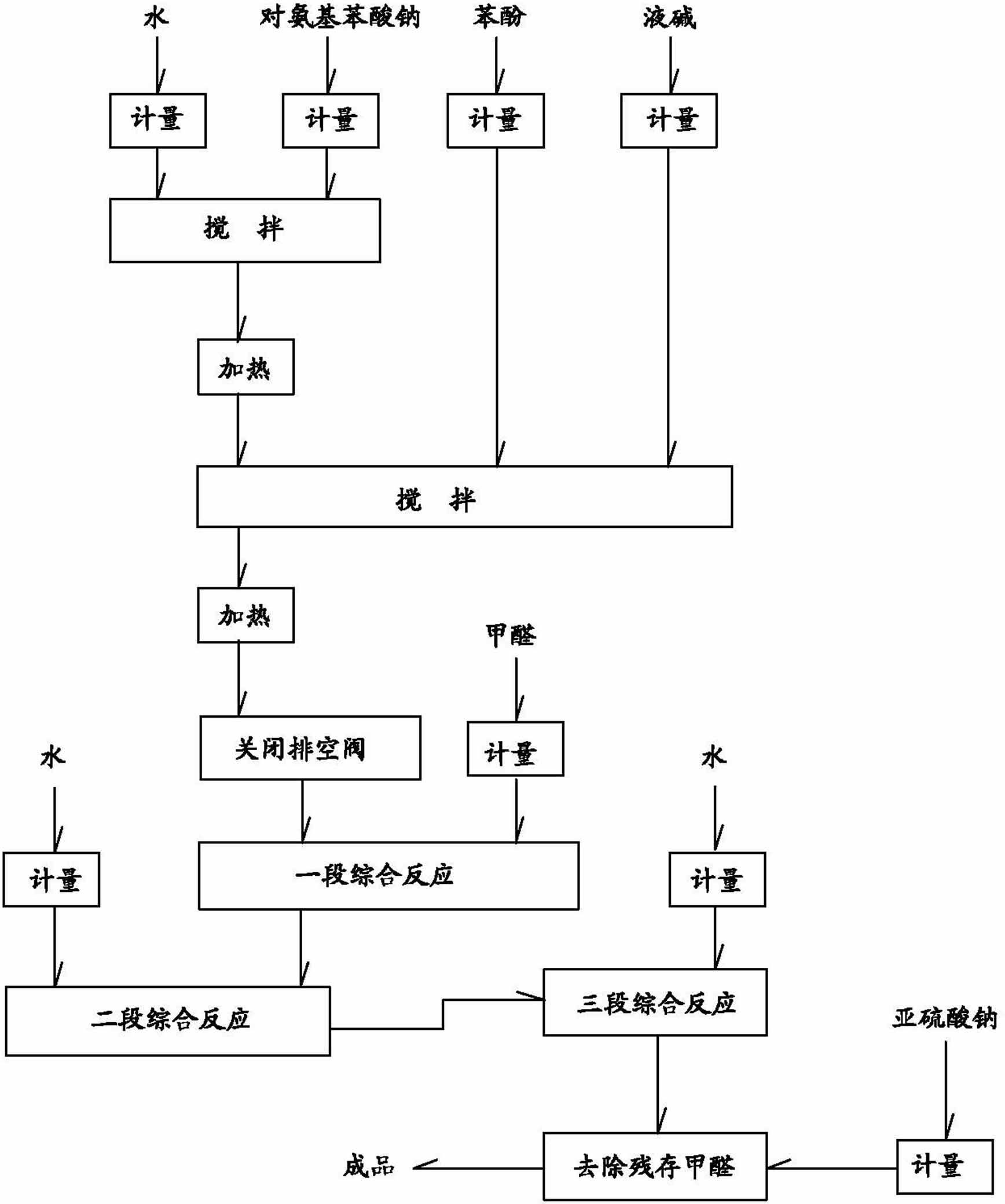

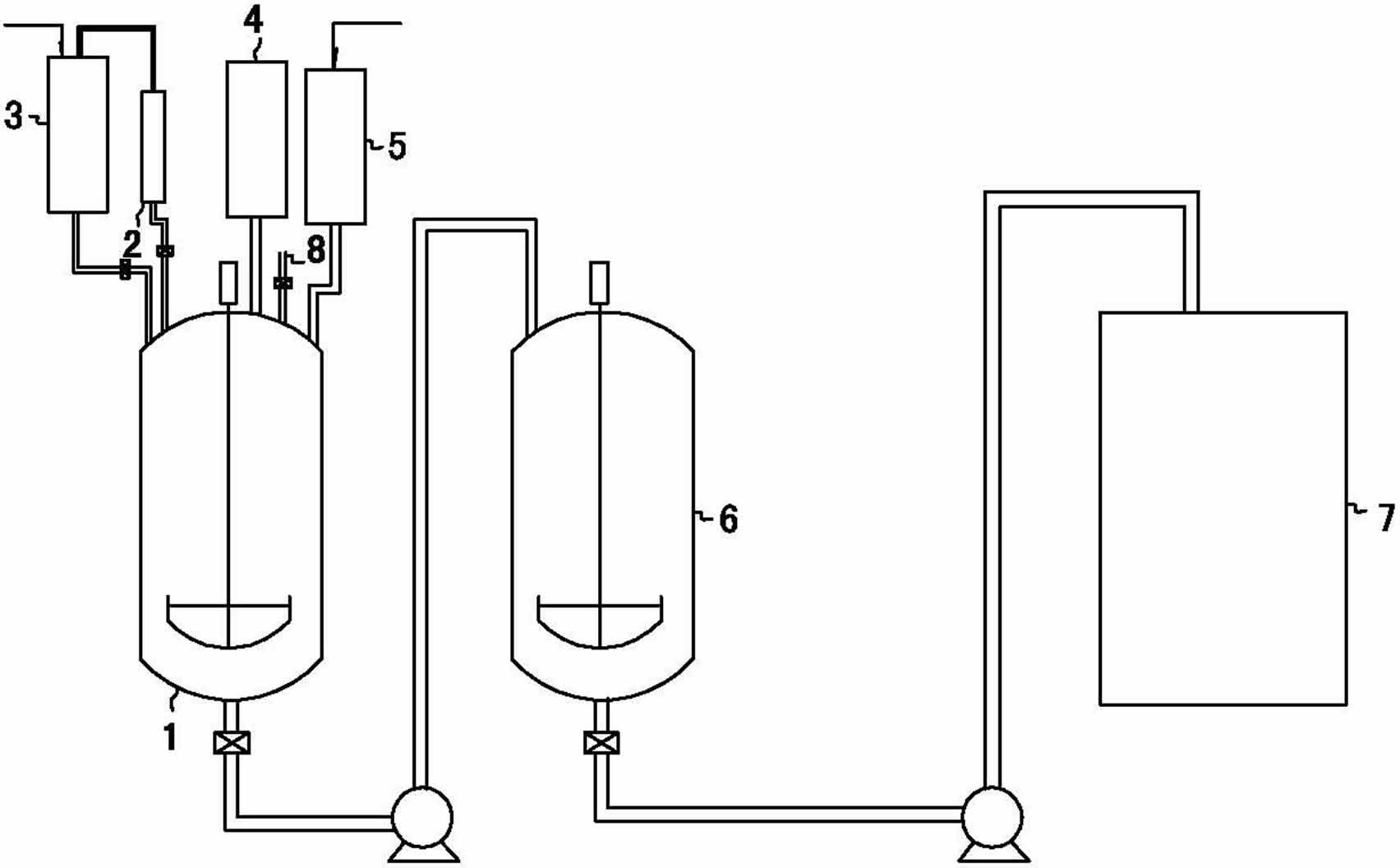

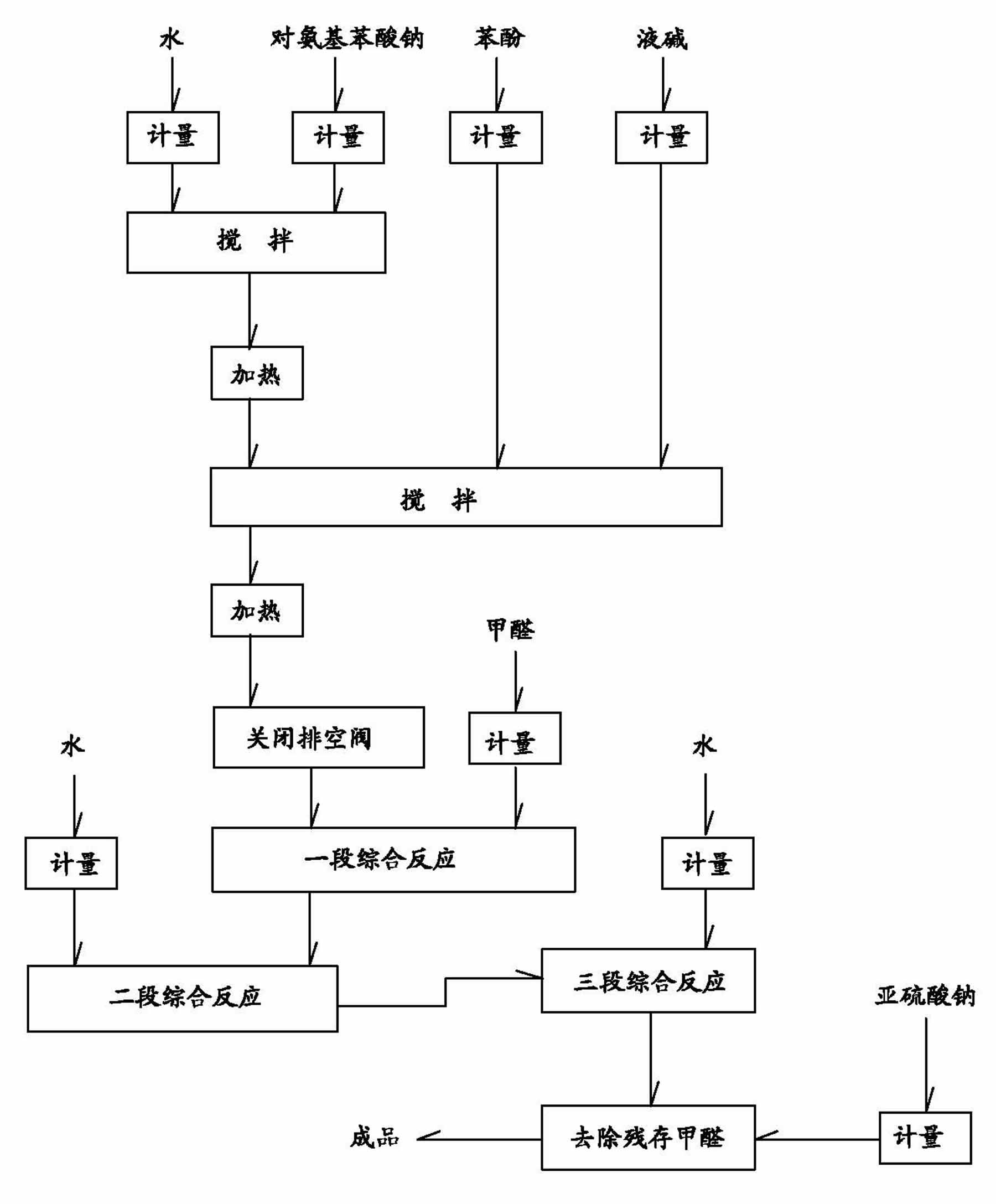

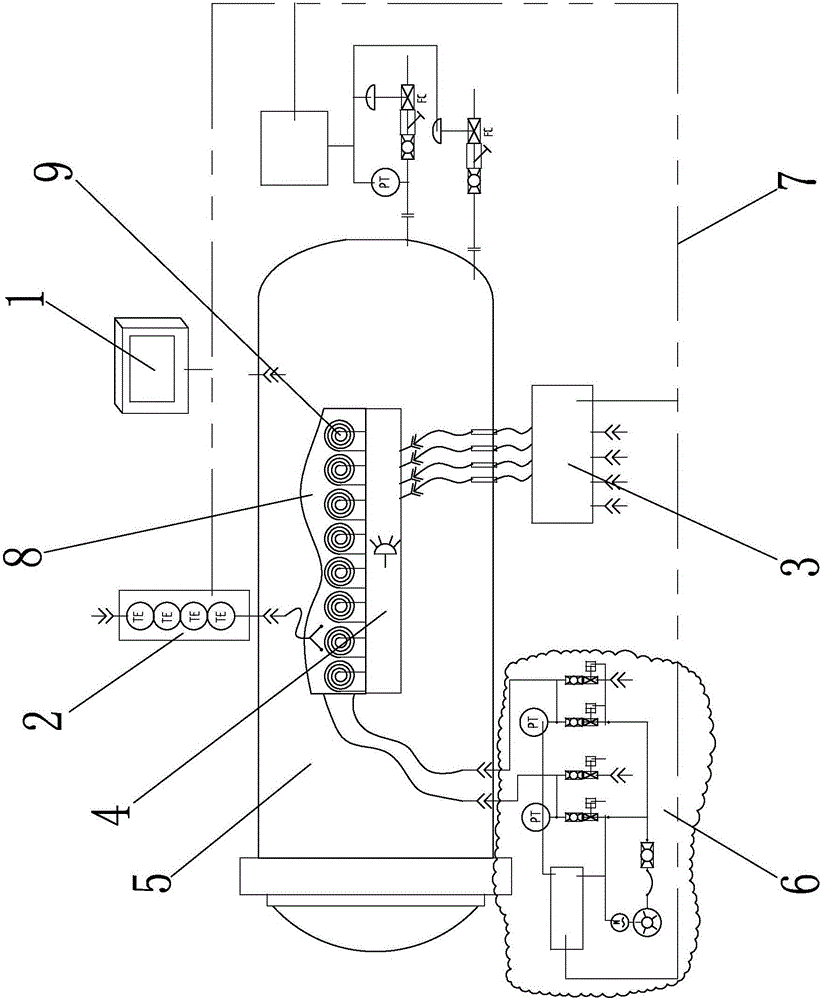

Method for producing sulfamate-series water reducing agent and equipment for producing sulfamate-series water reducing agent

The invention belongs to the technical field of production of water reducing agents for cement, and particularly relates to a method for producing a sulfamate-series water reducing agent and equipment for producing the sulfamate-series water reducing agent. The method for producing the sulfamate-series water reducing agent includes (1) adding water, sodium sulfanilate and caustic soda liquid into a reaction kettle; (2) adding phenol, heating, dripping formaldehyde into a system and realizing reaction; (3) adding water, cooling and realizing reaction; and (4) adding water, cooling and realizing reaction. The production equipment comprises the reaction kettle (1), a blending kettle (6), a formaldehyde metering tank (3), a water metering tank (4) and a caustic soda liquid metering tank (5), a material output end of the reaction kettle (1) is communicated with a material input end of the blending kettle (6), and an emptying valve (8) is fixedly disposed on the top of the reaction kettle (1). The production equipment further is provided with a condenser (2), and a port of the condenser (2) is respectively connected with a port of the formaldehyde metering tank (3) and a port of the reaction kettle (1). The method and the production equipment have the advantages of low raw material consumption, high production efficiency, fine quality of target products, high conversion rate and remarkable environmental protection efficacy.

Owner:辽宁岩砂晶建材有限公司

Equipment and process for forming composite material

InactiveCN105965916AReduce energy consumptionShort process cycleElectromagnetic inductionEngineering

The invention discloses equipment for forming a composite material. A master control system is connected with a controller provided for each module via a network, and used for sending running commands to the modules to run the modules; an electromagnetic output module receives the running commands sent by the master control system, and outputs electromagnetically induced current in a pulse mode; an electromagnetic power distribution and heating module distributes the current output by the electromagnetic output module to each heating module, so that the heating module heats a composite material forming mold in a specific combination manner and timing sequence; a pressurizing device is a pressure vessel or a mechanical pressurizing device; the composite material forming mold is placed in the pressurizing device, so that pressure can be exerted on the composite material laid on the composite material forming mold; and a vacuum control module having a vacuuming function is connected with the composite material mold via a pipeline, receives the commands of the master control system, and is used for vacuuming the composite material forming mold. The equipment has the advantages that the curing formation process cycle of the composite material is greatly shortened; and the transportation cost and the energy consumption are reduced.

Owner:山东中航泰达复合材料有限公司

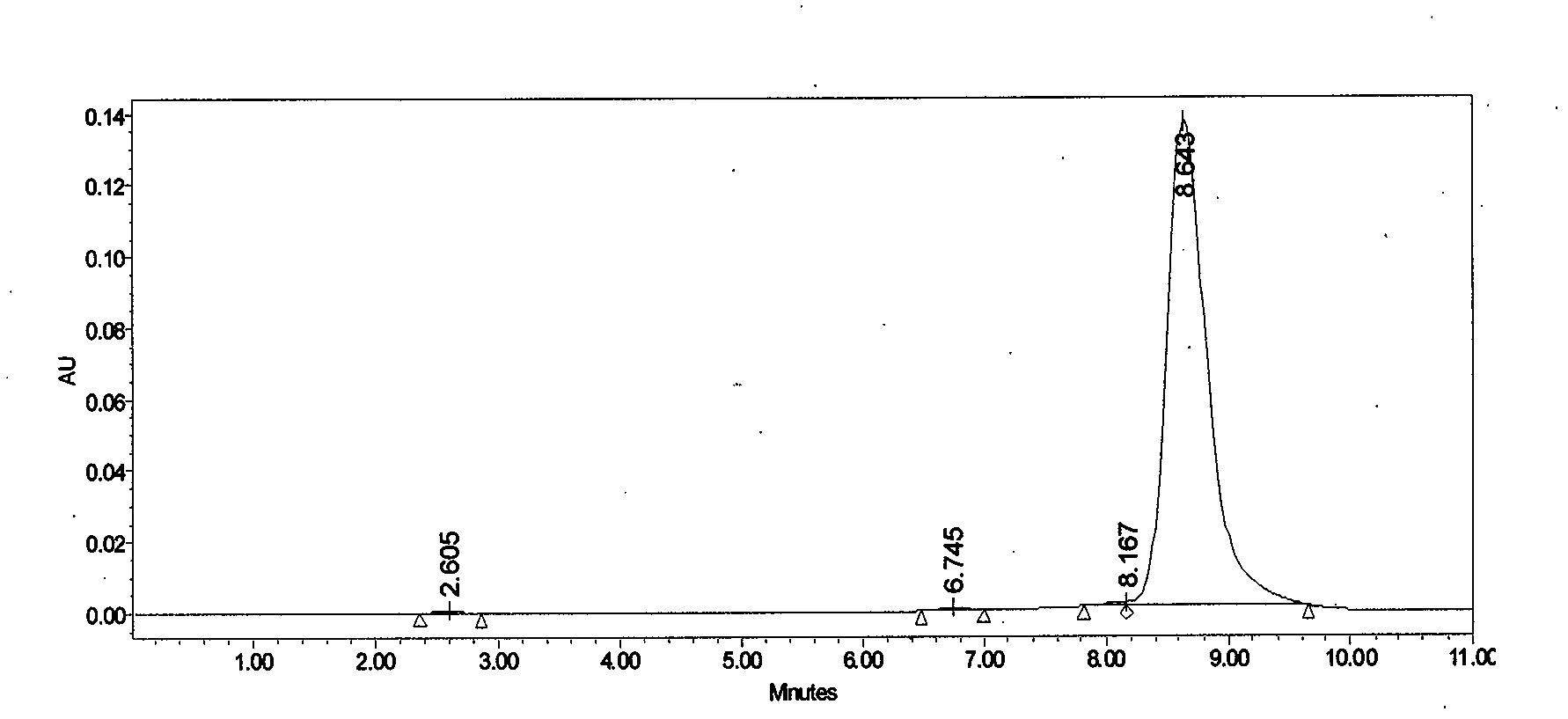

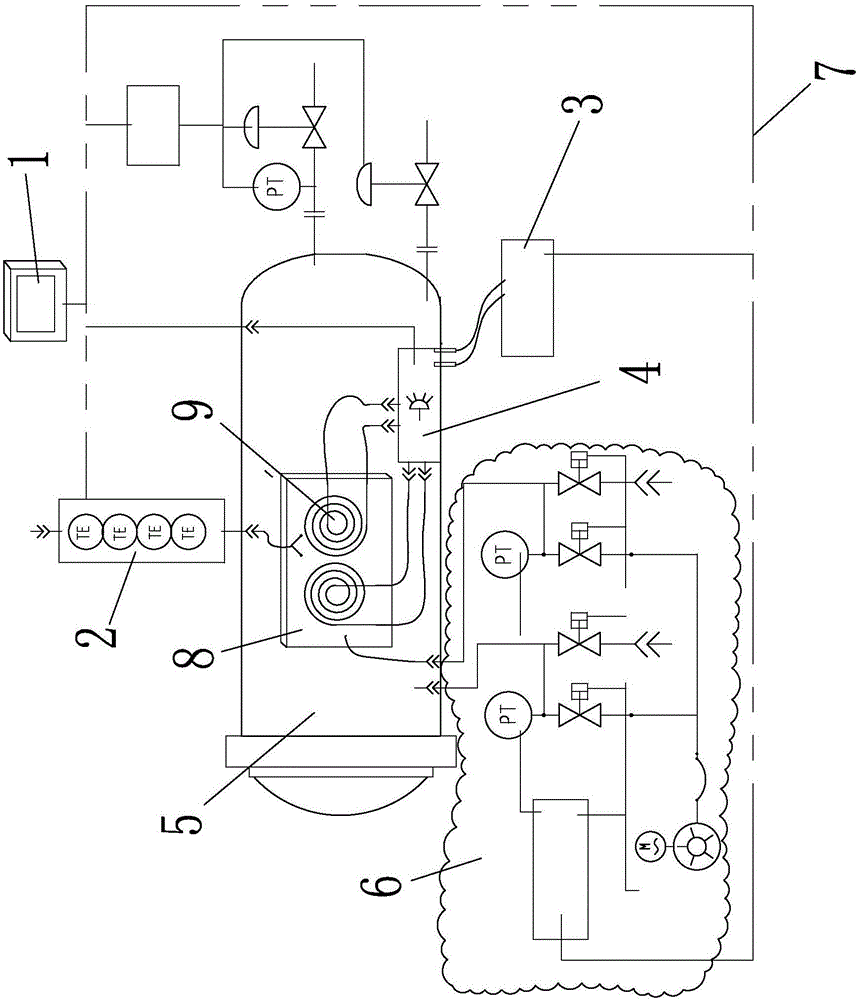

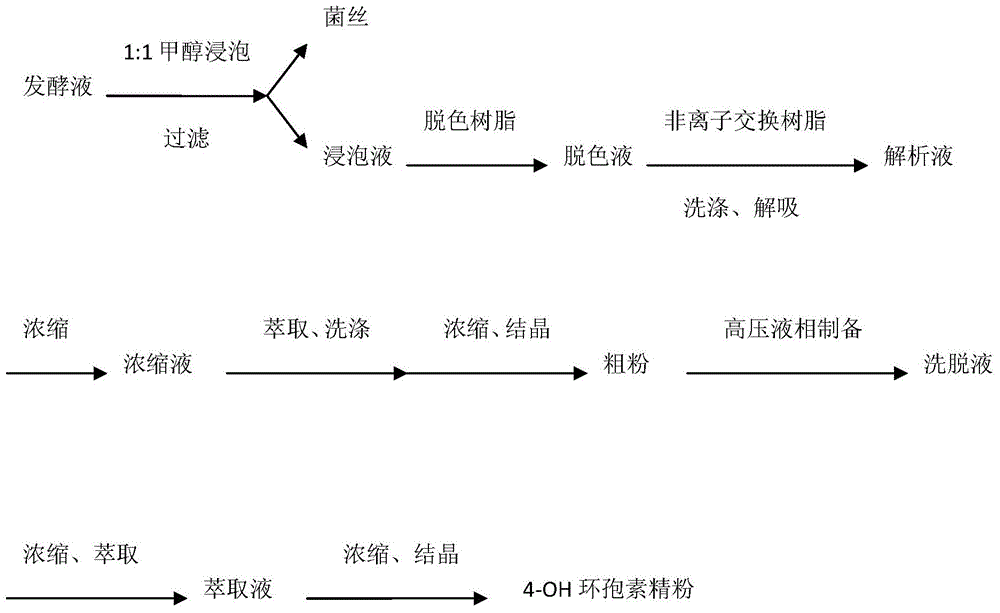

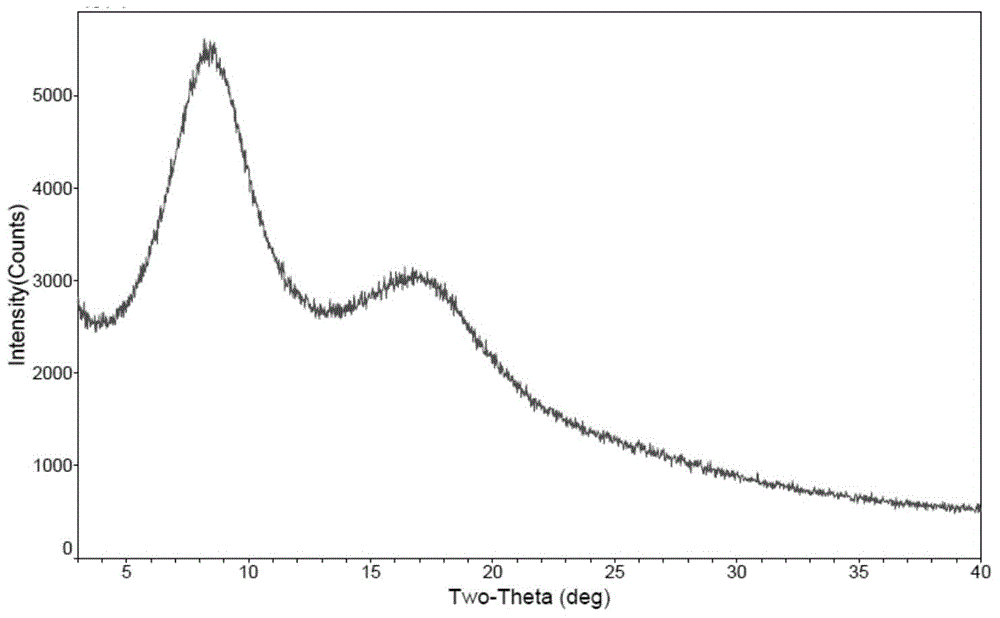

High purity 4-hydroxyciclosporin and purification and preparation method thereof

InactiveCN105646672AReduce difficultyShort process cyclePeptide preparation methodsChemistryHigh pressure

The invention discloses high purity 4-hydroxyciclosporin and a purification and preparation method thereof. The purification and preparation method comprises the following steps: extracting 4-hydroxyciclosporin, discoloring 4-hydroxyciclosporin extract by a discoloring medium, enriching by an adsorbing medium; carrying out high pressure chromatography preparation; and performing crystallization and purification. According to the purification and preparation method, an ion exchange resin discoloring technology, a macroporous adsorption resin enriching technology, and a high pressure chromatography purification technology are adopted; in each phase, a specific technology is chosen, technologies cooperate with each other, and a good technology effect is achieved.

Owner:SHIJIAZHUANG ZHONGTIAN BIOTECH +1

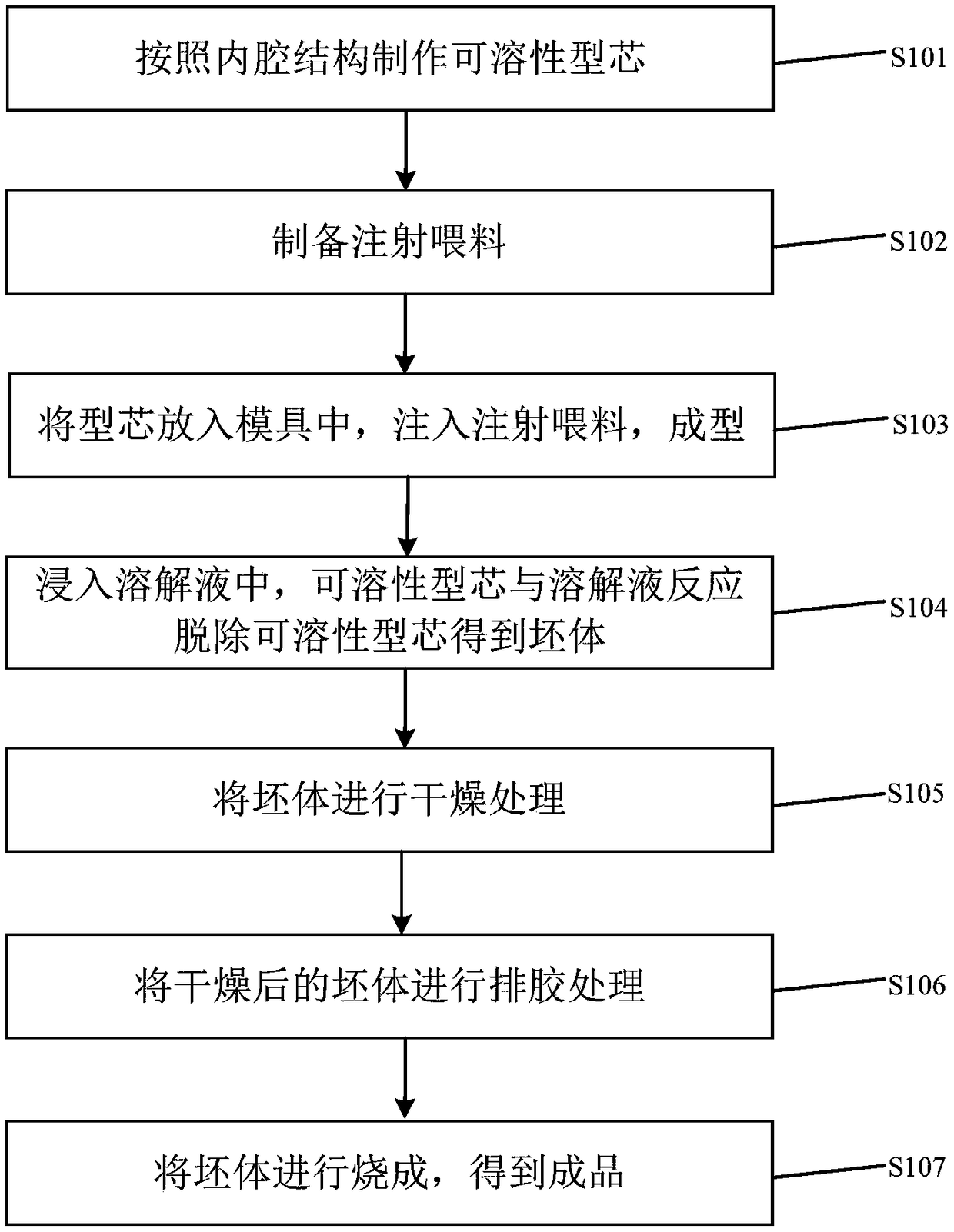

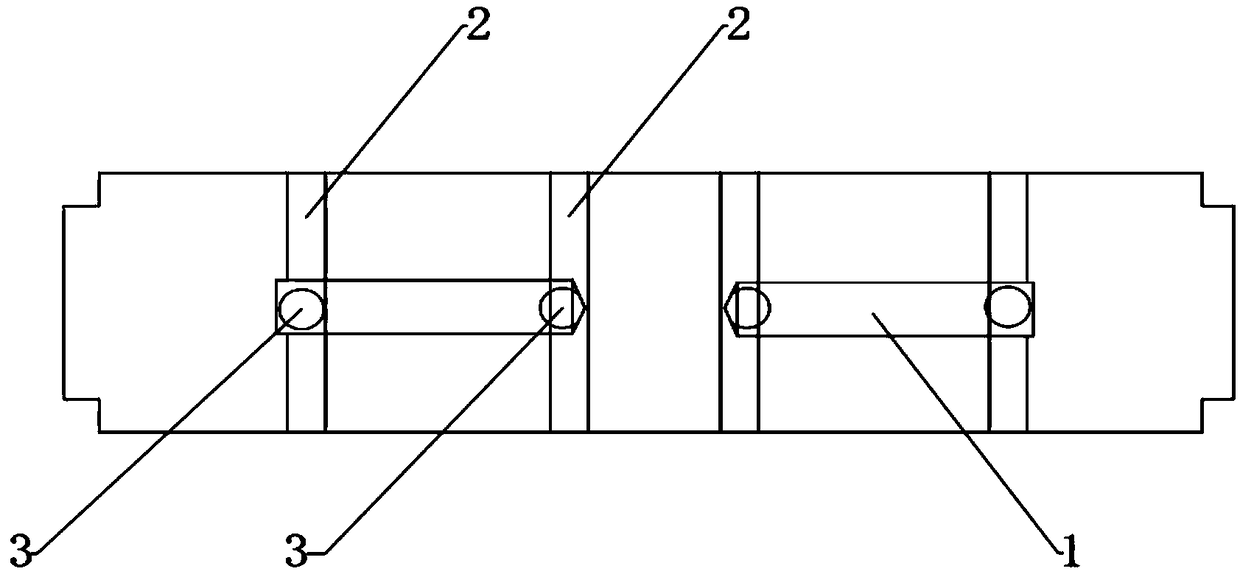

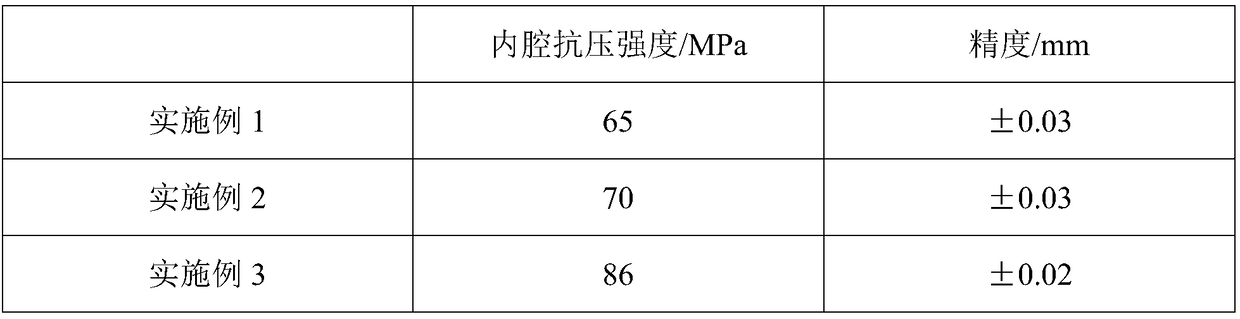

Ceramic component with cavity structure and preparing method of ceramic component

InactiveCN109227886AShort process cycleSimple methodCeramic shaping mandrelsCeramic shaping coresSintering

The invention discloses a preparing method of a ceramic component with a cavity structure. The method includes the steps of preparing a soluble core according to the cavity structure, preparing injection feed, placing the soluble core in a mold for injection molding, soaking the soluble core in a dissolving solution so that the dissolving solution and the soluble core can react, removing the soluble core to obtain a blank, and conducting drying and sintering. Accordingly, the invention further discloses the ceramic component with the cavity structure. The ceramic component is prepared throughthe preparing method. The method is simple, efficiency is high, the ceramic component can be produced on a large scale, and the prepared ceramic component is high in precision, high in strength and attractive in appearance.

Owner:广东金刚新材料有限公司 +1

Preparation method for Lepidium meyenii alkaloid

InactiveCN105732506AEasy to operateShort process cycleOrganic chemistryLepidium meyeniiCountercurrent chromatography

The invention relates to a preparation method for Lepidium meyenii alkaloid. The preparation method comprises the specific steps: (1) carrying out extracting; (2) carrying out impurity removal; (3) carrying out high-speed countercurrent purification; and (4) carrying out column-chromatography purification. The preparation method for rapidly and efficiently separating a Lepidium meyenii alkaloid monomer, disclosed by the invention, is a method for separating and preparing the Lepidium meyenii alkaloid monomer from Lepidium meyenii by using high-speed countercurrent chromatography and normal-phase chromatography. According to the preparation method, a crude Lepidium meyenii alkaloid extract is firstly subjected to impurity removal through chloroform extracting, then, is subjected to purification by the high-speed countercurrent chromatography and finally is further purified by using the normal-phase chromatography so as to obtain the Lepidium meyenii alkaloid monomer; and the process flow is green and environment-friendly and is free of severe hazards to environments, the operation is simple, the process cycle is short, reagents are saved, an eluant can be recycled, the production cost is reduced, and the extracting efficiency is high, so that the preparation method is applicable to industrial production.

Owner:HEILONGJIANG JOHNSUN BIOLOGICAL ENG CO LTD

Preparation method of sponge platinum

InactiveCN110964919AShort process cycleEasy to promoteProcess efficiency improvementPlatanic acidHydrogen peroxide

The invention discloses a preparation method of sponge platinum. The preparation method comprises the following specific steps that step 1, slurrying is carried out on crude chloroplatinate, heating is carried out, hydrochloric acid and sodium chlorate are added, and a mixed solution is obtained after stirring; step 2, the mixed solution is boiled and kept for the fixed time, ammonium chloride isadded, after the mixed solution is cooled, filtering is carried out, and high-purity ammonium chloroplatinate is obtained; and step 3, slurrying is carried out the high-purity ammonium chloroplatinate, the pH value is adjusted to 8-9, heating is carried out, hydrazine hydrate is added for reduction, and a platinum element is obtained; step 4, the platinum element in the step 3 is dissolved by using hydrogen peroxide, and a dissolved solution containing the platinum element is obtained; and step 5, precipitation is carried out on the dissolved solution in the step 4 by adopting an ammonium chloride step-by-step precipitation method, ammonium chloroplatinate is obtained, and then the ammonium chloroplatinate obtained through precipitation in the step 1 is calcined, and the sponge platinum isobtained. According to the method, impurity elements in the crude chloroplatinic acid ammonium are removed by adopting an aqueous solution chlorination method, and a hydrazine hydrate reduction-hydrochloric acid hydrogen peroxide dissolving-ammonium chloride step-by-step precipitation method is adopted to refine ammonium chloroplatinate to obtain the sponge platinum, and the whole process periodis short.

Owner:JINGMEN GEM NEW MATERIAL

Method for cultivating bean seedlings with specific effects

InactiveCN112673747AEasy to absorbShort process cycleCultivating equipmentsSoilless cultivationChinese herbologySeedling

The invention discloses a method for cultivating bean seedlings with specific effects. The method comprises the following steps of decocting traditional Chinese medicine liquid with the specific effects, namely selecting 0.5 kg of traditional Chinese medicinal materials with the specific effects, adding 2.5 kg of purified water, boiling with big fire, decocting with small fire to obtain 0.9-1.1 kg of traditional Chinese medicine liquid, and naturally cooling for later use; selecting seeds, namely removing broken, wizened and moth-eaten bean seeds, soil, stones and other impurities; soaking the bean seeds, namely adding 20 times of pure water into the traditional Chinese medicine liquid to obtain a traditional Chinese medicine diluent which can be used for soaking 16-19 kg of seeds, controlling the water temperature to be 30-35 DEG C, enabling the seed soaking time to be 6-7 hours until the bean seeds are fully swollen and have no wrinkles; performing cultivation, namely putting a clean container for sprout cultivation in a stable air place, not placing in a ventilated passage or an open air place, meanwhile, loading the bean seeds, covering the bean seeds with multiple layers of covering objects, and performing sprouting in the dark environment with the constant temperature ranging from 15 DEG C to 32 DEG C; performing tight covering; performing water drenching, namely, proving sufficient water for growth of the bean seedlings, supplying water through regular water drenching, adopting the traditional Chinese medicine diluent to replace common water, performing water drenching once every morning and evening, and performing continuous water drenching for watering the bean seedlings for four to five days; and harvesting.

Owner:胡宪明

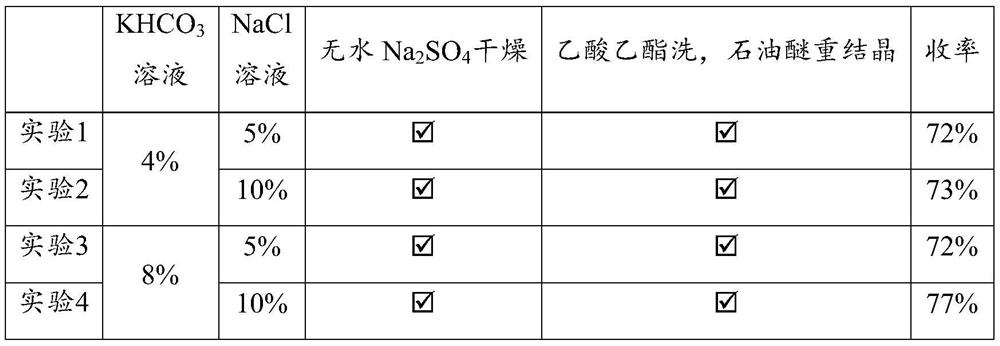

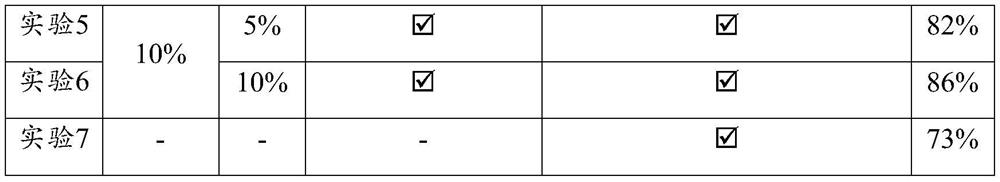

Preparation method and application of thyroxine-releasing hormone

PendingCN114516898AShort process cycleNo security riskPeptide preparation methodsBulk chemical productionHormoneRe crystallization

The invention provides a preparation method and application of a thyroxine release hormone, and relates to the technical field of polypeptide medicine preparation.The preparation method of the thyroxine release hormone comprises the steps that in the step of preparing Z-pGlu-His-Pro-NH2, acetonitrile is used for dissolving a concentrated product, crystals are separated out after low-temperature standing, and the Z-pGlu-His-Pro-NH2 is obtained; the conventional mode of recrystallization after two-time diethyl ether precipitation in the prior art is avoided, and the process period is short. In addition, a small amount of acetonitrile is used for dissolution, and reagents such as diethyl ether with a low flash point are not used. The method can be carried out in general areas and has no special requirements on plants. No safety risk exists, and industrialization can be achieved.

Owner:上海丽珠制药有限公司

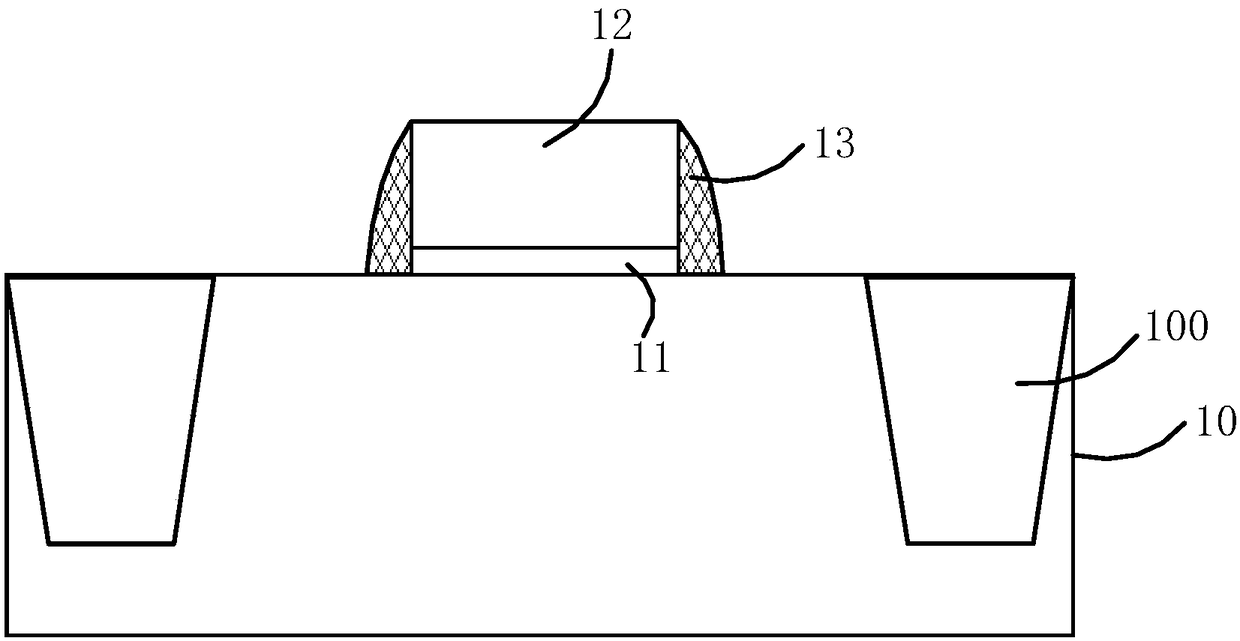

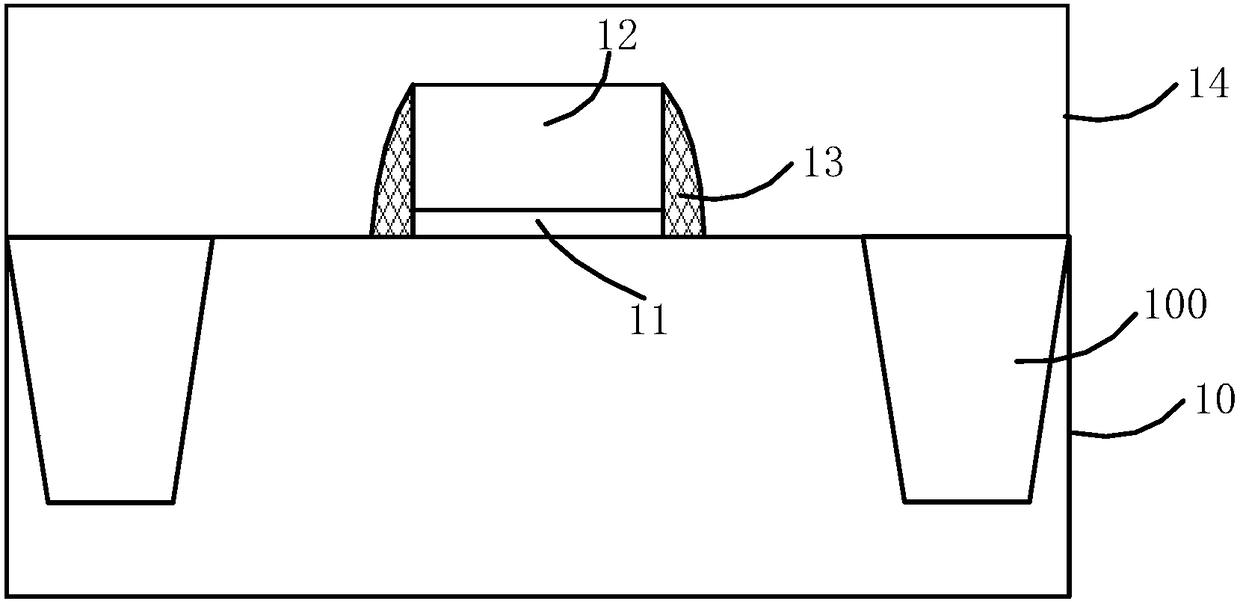

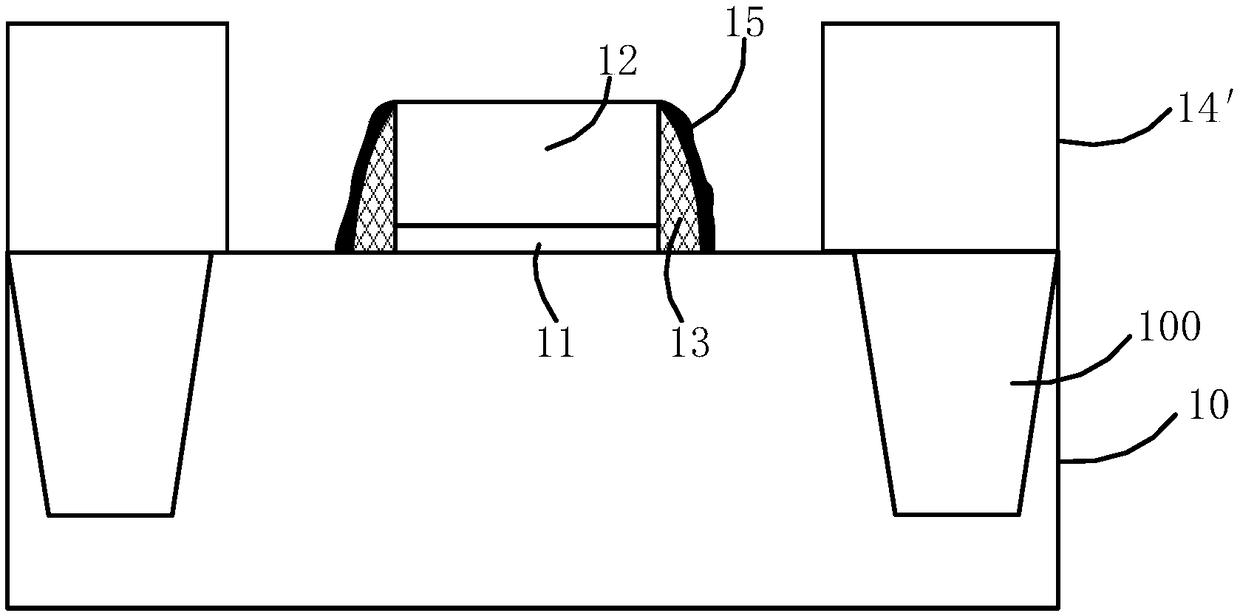

Semiconductor structure and production method thereof

ActiveCN108666222AShort process cycleGood activitySolid-state devicesSemiconductor/solid-state device manufacturingChemistryNitrogen

The invention discloses a semiconductor structure and a production method thereof. The production method comprises the steps of forming a nitrogen-containing compound layer on a substrate; carrying out a heat treatment process on the nitrogen-containing compound layer; and forming a photoresist pattern layer, wherein at least one part of nitrogen-containing compound layer is exposed out of the photoresist pattern layer. According to the production method, the heat treatment process is carried out on the nitrogen-containing compound layer before the photoresist pattern layer is formed, and theactivity of a nitrogen bond on the surface of the nitrogen-containing compound layer can be destroyed by the heat treatment process, so that the nitrogen bond does not react with air or a hydrogen bond in a cleaning process on the surface of the nitrogen-containing compound layer during the formation of the photoresist pattern layer, thereby preventing generation of residual gum. Therefore, CD ofthe semiconductor structure produced through the production method is stable and the semiconductor structure has good product quality and performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

The preparation method of beauverum

ActiveCN103898182BShort process cycleStrong controllabilityMicroorganism based processesPeptide preparation methodsCulture mediumsBeauvericin

The invention discloses a preparation method of beauvericin. The method comprises the steps of 1a, preparation of a fusarium LF061 seed solution preparation:inoculating a slant culture or spore liquid of strain LF061 into a seed culture medium, and culturing for 48-72 hours with a rotating speed of 120-160rppm at 28-32 DEG C to obtain the seed solution; 1b, preparation of beauvericin from the fusarium LF061 seed solution through fermentation: inoculating the seed solution of which the inoculation amount is 5-15% in percentage by volume into a liquid fermentation culture medium, wherein the fermentation temperature is 28-32 DEG C, the rotating speed is 120-160rpm, the ventilation volume is 10-30L / min, and the fermentation time is 96-144 hours; separating and refining obtained fermentation liquid to prepare beauvericin. According to the method disclosed by the invention, the beauvericin is produced through liquid fermentation, and the prepared beauvericin is high in purity and recovery rate and adaptable in industrial production.

Owner:NCPC NEW DRUG RES & DEV +1

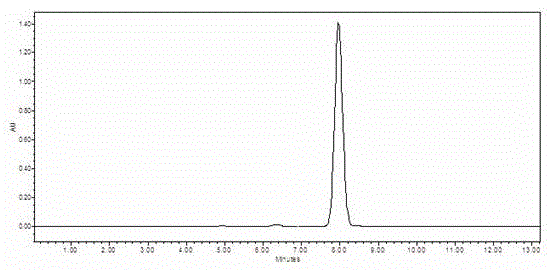

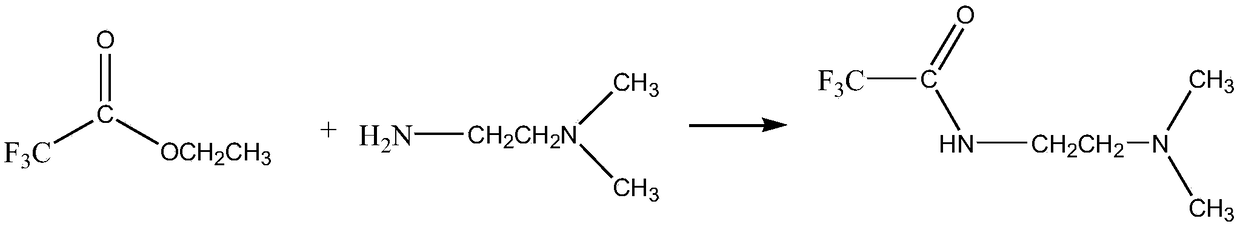

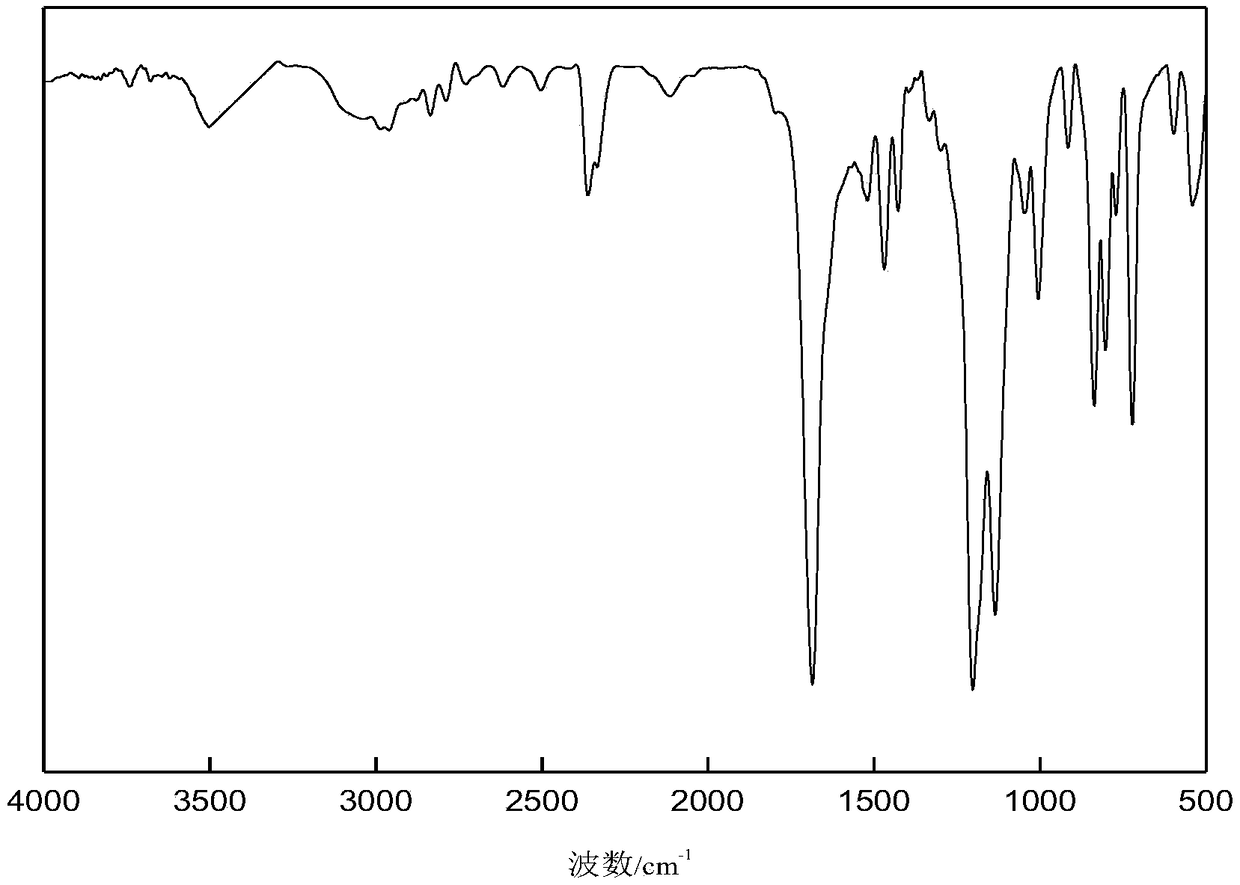

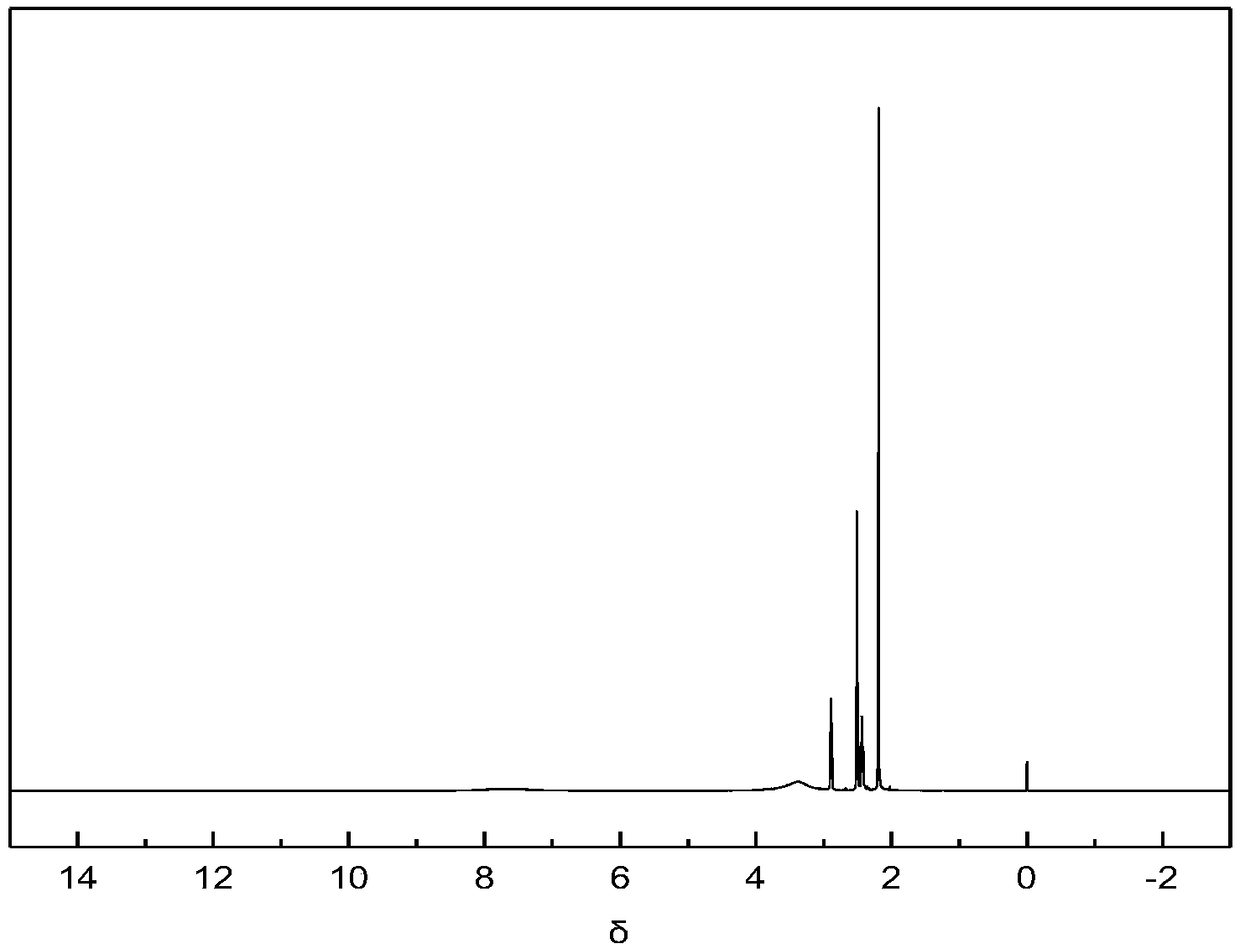

Fluorine-containing amide and preparation method thereof

InactiveCN109232290AThe reaction steps are simpleShort process cycleOrganic compound preparationCarboxylic acid amides preparationSolventEthyl ester

The invention discloses fluorine-containing amide and a preparation method thereof. The method comprises the following step: taking an aliphatic fluorine-containing intermediate ethyl trifluoroacetateand N,N-dimethylethylenediamine to make acylation reaction, so as to obtain the fluorine-containing amide. The ethyl trifluoroacetate and the N,N-dimethylethylenediamine are used as raw materials andwater is used as a solvent; the acylation reaction is carried out to generate the fluorine-containing amide; the preparation method has the advantages of simple reaction steps, short technology period, easiness for operation, low reaction temperature and easy-to-control process; the yield of the fluorine-containing amide prepared by the method can reach 99 percent.

Owner:SHAANXI UNIV OF SCI & TECH

Black pepper peel degumming strain and use thereof

InactiveCN101892184BShort process cycleEasy to operateBacteriaMicroorganism based processesHorticulturePollution

The invention relates to the technical field of microorganisms and discloses a black pepper peel degumming strain, which has a preservation number of CCTCC No.M2010184 and belongs to the class of bacilli. The invention also provides the use of the black pepper peel degumming strain in black pepper fruit peeling. The black pepper peel degumming strain is cultured for 4 to 52 hours, the culture solution of the black pepper peel degumming strain is centrifuged, the black pepper fruit is soaked in the supernate, and the peels of the black pepper fruits can be removed completely within two days. When the black pepper peel degumming strain is used for black pepper fruit peeling, the efficiency is high, energy is saved, pollution is relieved and a wide promotion value is achieved.

Owner:INST OF PROCESSING & DESIGN OF AROPROD OF HAINAN ACADEMY OF AGRI SCI

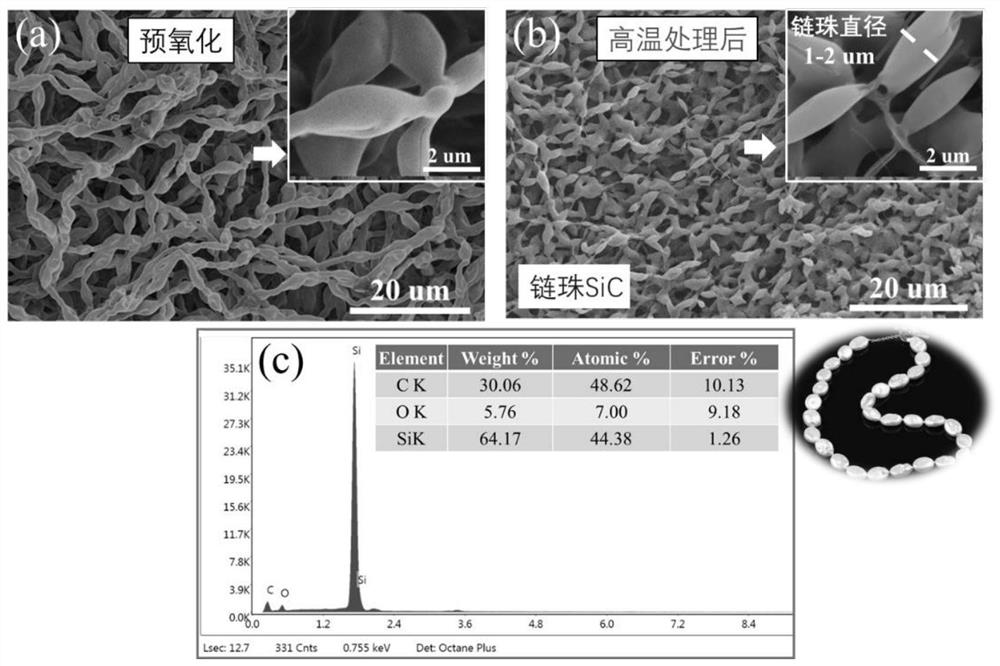

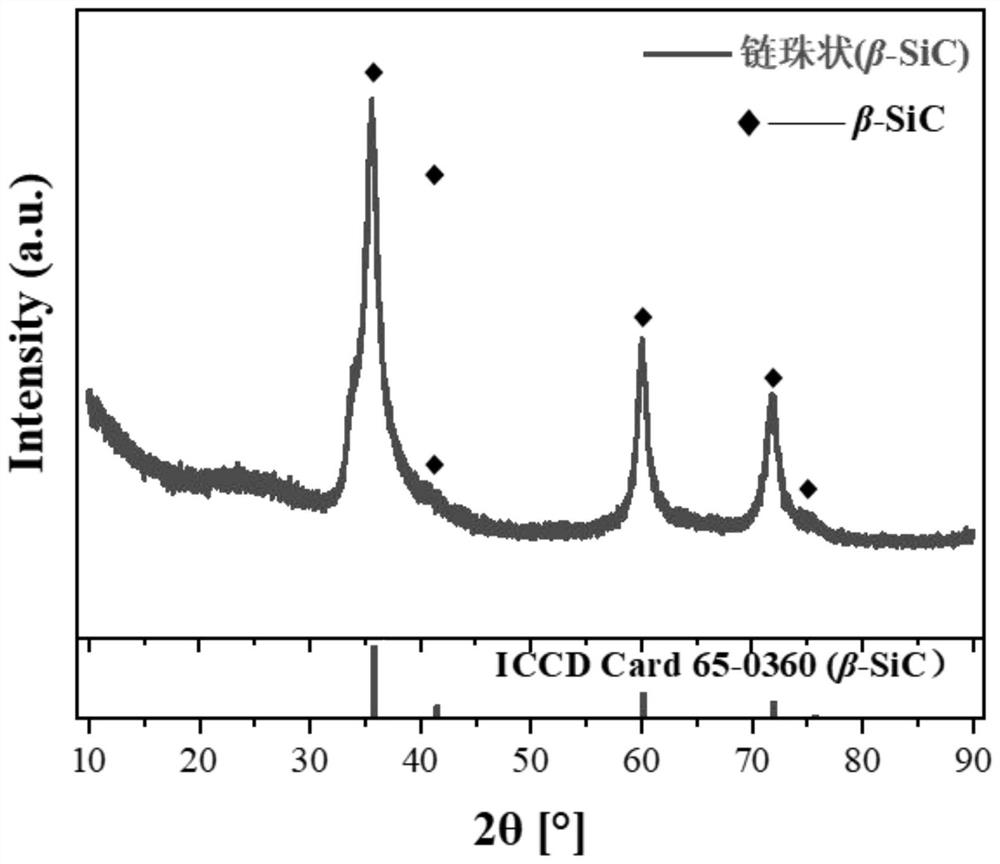

Chain-bead-shaped silicon carbide nano material and preparation method and application thereof

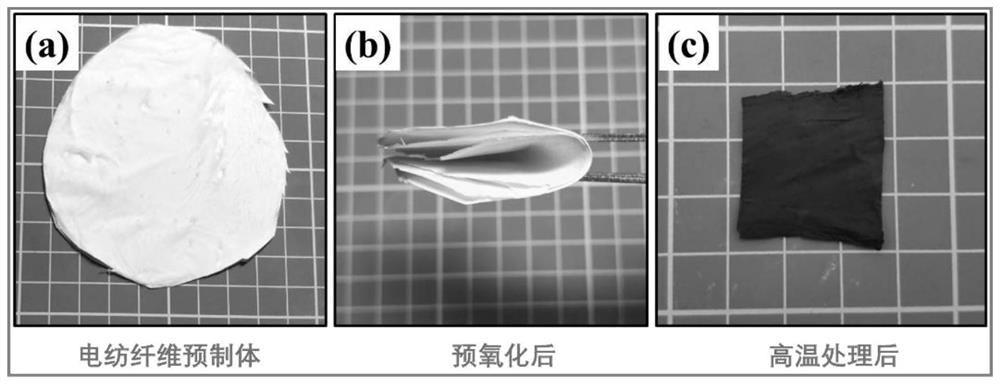

ActiveCN112661159AShort process cycleLow requirements for preparation conditionsCarbon compoundsElectrospinningCarbide silicon

The invention belongs to the field of silicon carbide nano materials, and particularly provides a chain-bead-shaped silicon carbide nano material and a preparation method and application thereof. A precursor solution is prepared by adopting a liquid phase method, then the solution is subjected to drawing and wire drawing under the action of electrostatic force through electrostatic spinning to obtain a one-dimensional SiC preform fiber membrane, and finally impurities are removed through heat treatment and crystallization is performed to obtain the large-scale continuous one-dimensional SiC nano material. The one-dimensional SiC nano material with the chain bead-shaped hierarchical structure prepared by the method is a high-quality raw material serving as a structural unit or a composite component. The electrical property of the material has huge application value in the aspects of energy storage and conversion, sensing, photoelectrons, field radiation and the like. The chain-bead-shaped hierarchical structure is expected to be used as a matrix reinforcement phase to improve the mechanical properties of the material.

Owner:CENT SOUTH UNIV

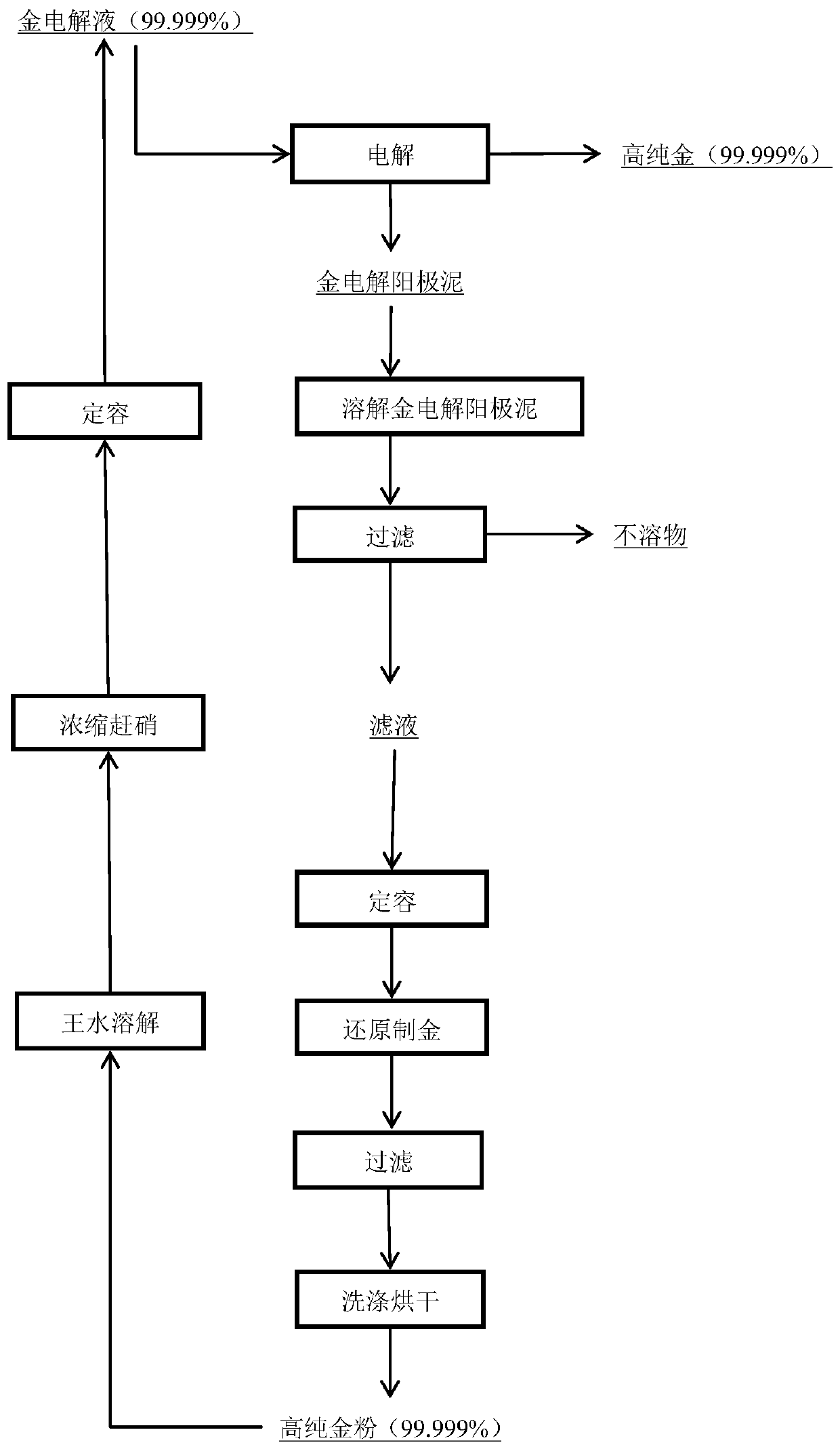

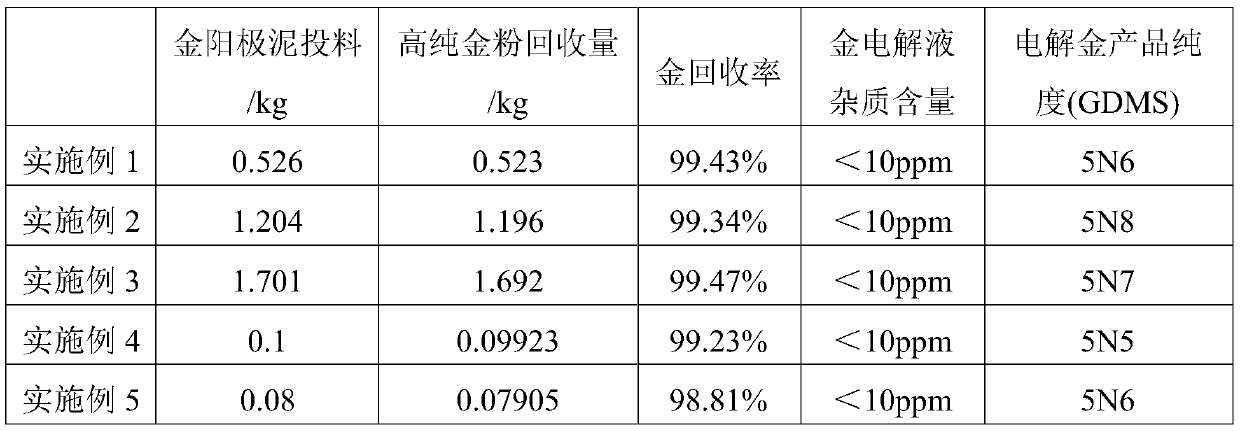

Method for preparing gold electrolyte through gold electrolysis anode mud

InactiveCN110863215AShort process cycleReduce volatile lossElectrolysis componentsPhotography auxillary processesPotassium hydroxideSodium sulfites

The invention discloses a method for preparing a gold electrolyte through gold electrolysis anode mud and belongs to the technical field of gold electrolysis anode mud treatment. The method comprisesthe following steps that (1) the gold electrolysis anode mud is dissolved; (2) reduction for gold preparation is performed; (3) gold powder is dissolved in aqua regia for preparing the gold electrolyte. In step (1), aqua regia or an iodine-potassium iodide solution is adopted for dissolving the gold electrolysis anode mud. The mass ratio of potassium iodide to iodine in the iodine-potassium iodidesolution is larger than or equal to 2:1. In step (2), sodium sulfite or potassium hydroxide is adopted for reduction for gold preparation. According to the method, the overall process of an electrolysis technology is simplified, the fund input is reduced, and the aims of reducing the cost and improving the effect are achieved.

Owner:GRIKIN ADVANCED MATERIALS

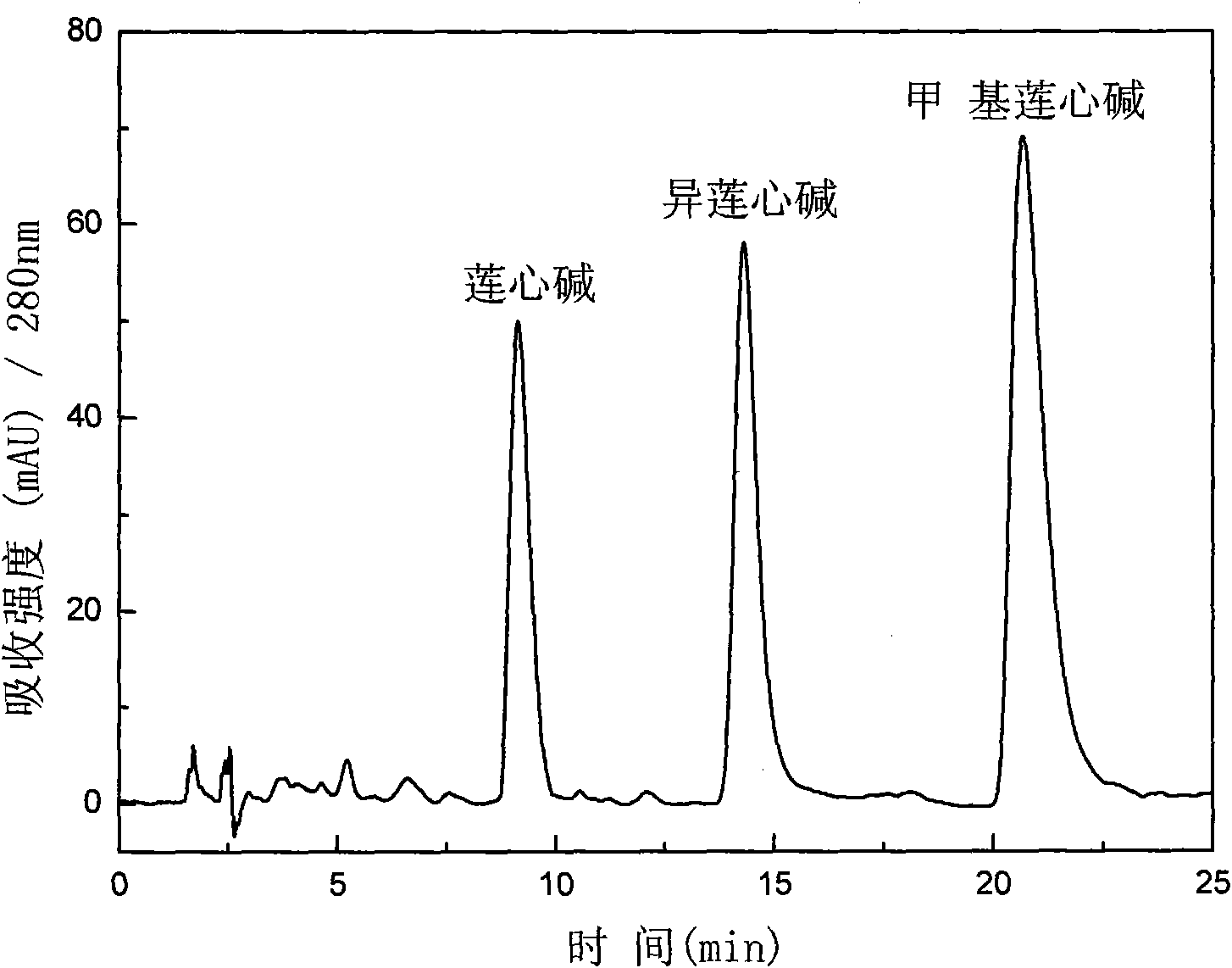

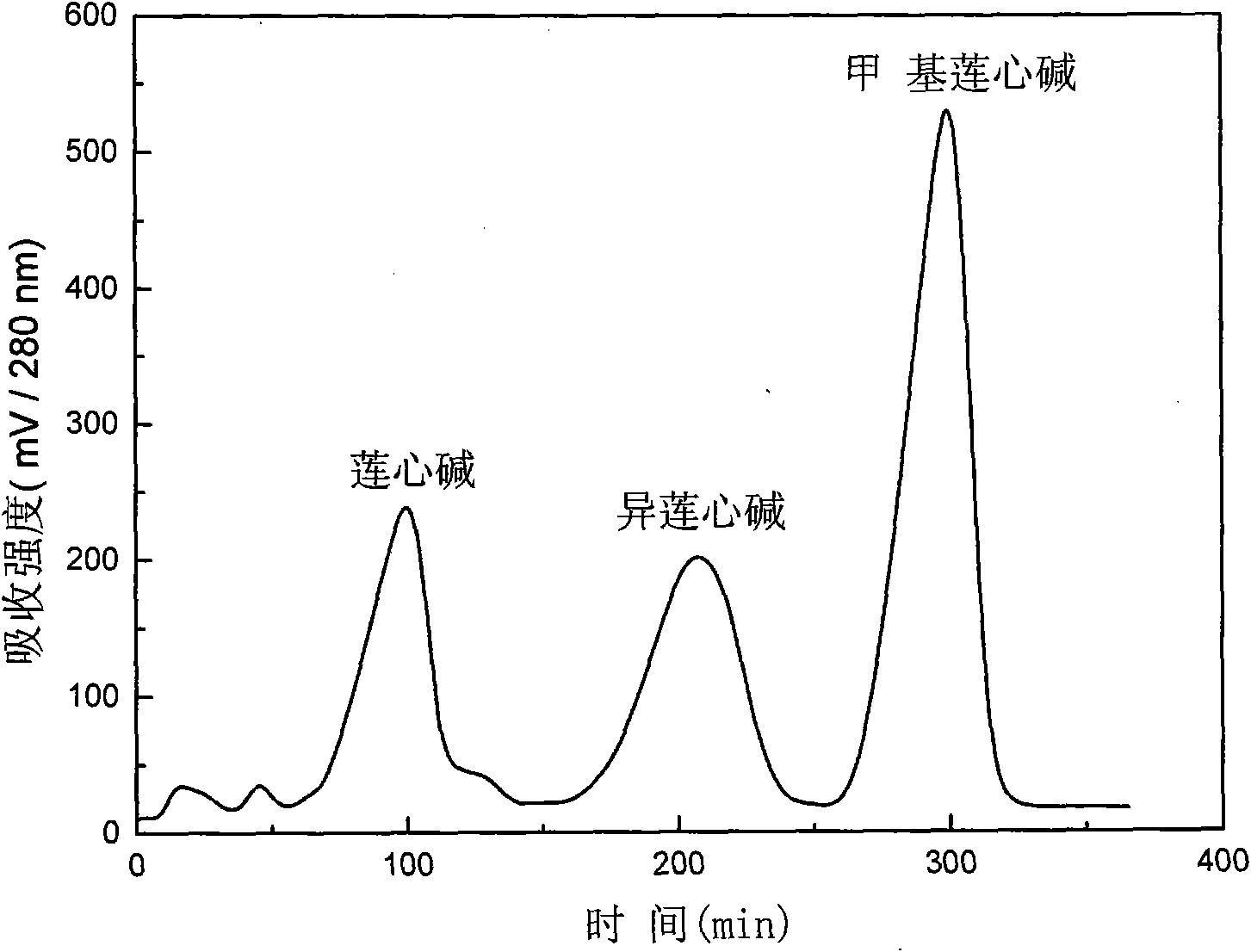

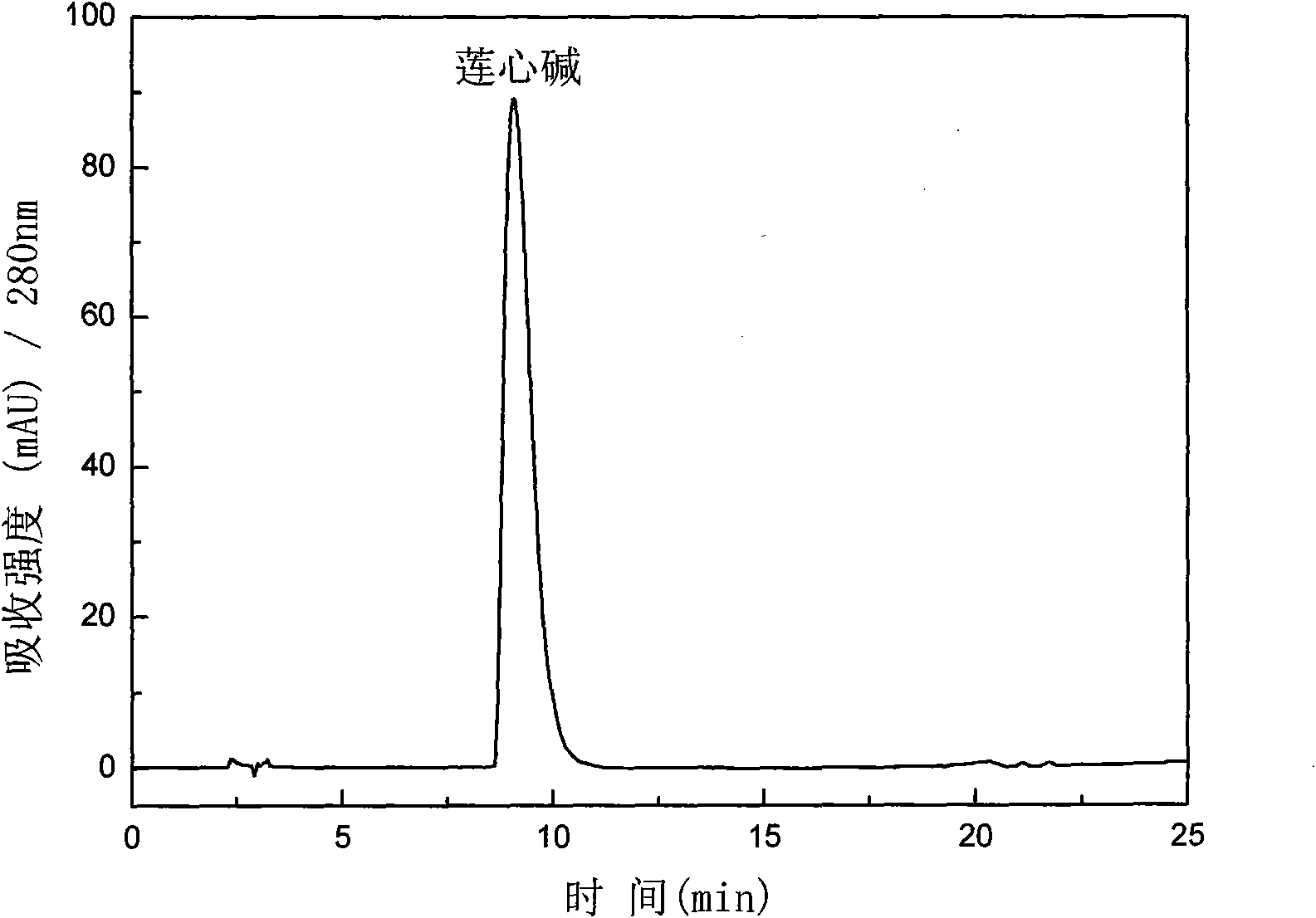

Method for extracting liensinine, isoliensinine and neferine from lotus plumule

InactiveCN101786984AEasy to operateShort process cycleOrganic chemistryChemical recyclingCounter currentChemistry

The invention relates to a method for extracting liensinine, isoliensinine and neferine from lotus plumule, which adopts the lotus plumule as a raw material and comprises the following steps of: (1) preparing a crude extract; (2) preseparating by adopting macroporous resin; (3) purifying by adopting a high speed counter current chromatography to obtain the liensinine, the isoliensinine and the neferine with the purity of more than 98 percent. By extracting alkaloid in a lotus plumule medicinal material by adopting ethanol, carrying out preseparation by adopting macroporous resin, adopting the ethanol as an eluant and carrying out purification by adopting the high speed counter current chromatography, the process is environmental-friendly without serious damage to the environment.

Owner:LIAOCHENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com