Chain-bead-shaped silicon carbide nano material and preparation method and application thereof

A technology of nanomaterials and silicon carbide, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., to achieve the effects of short process cycle, improved mechanical properties, and low requirements for preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

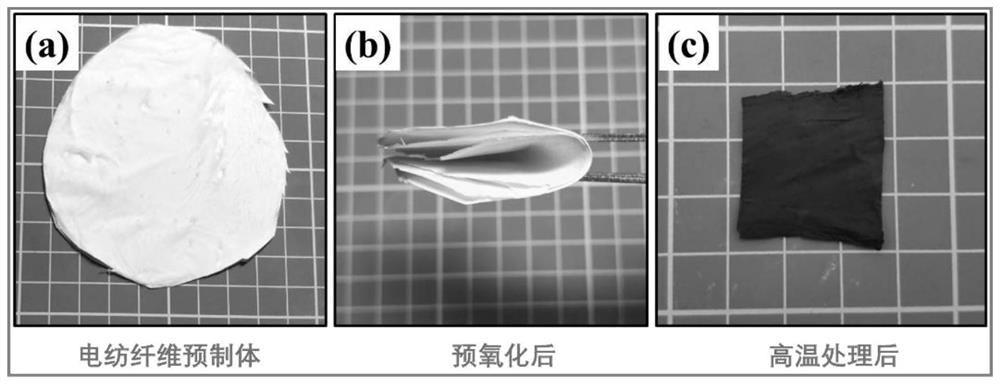

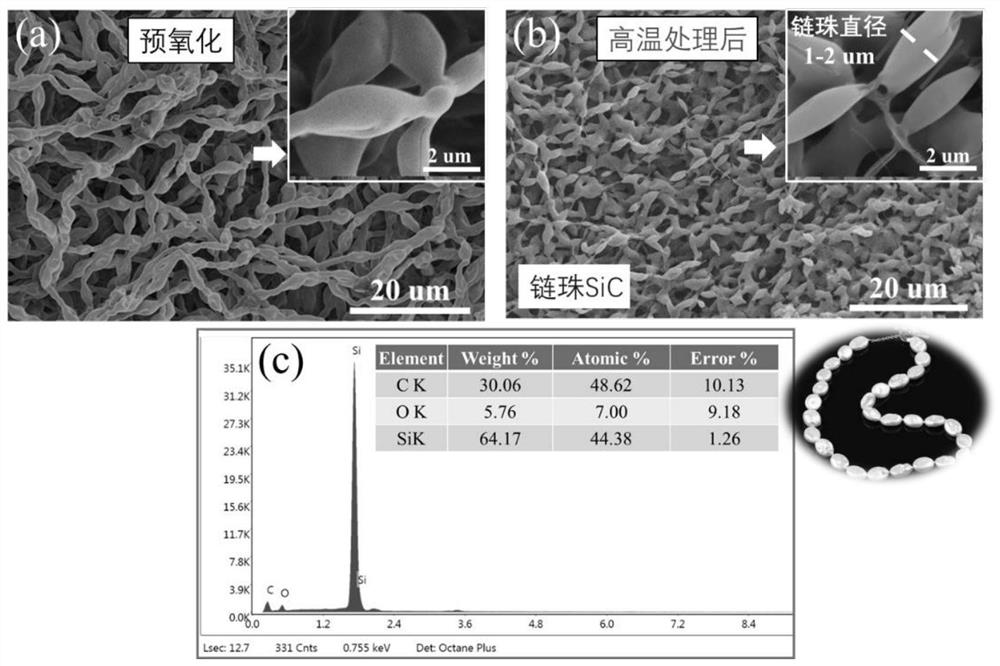

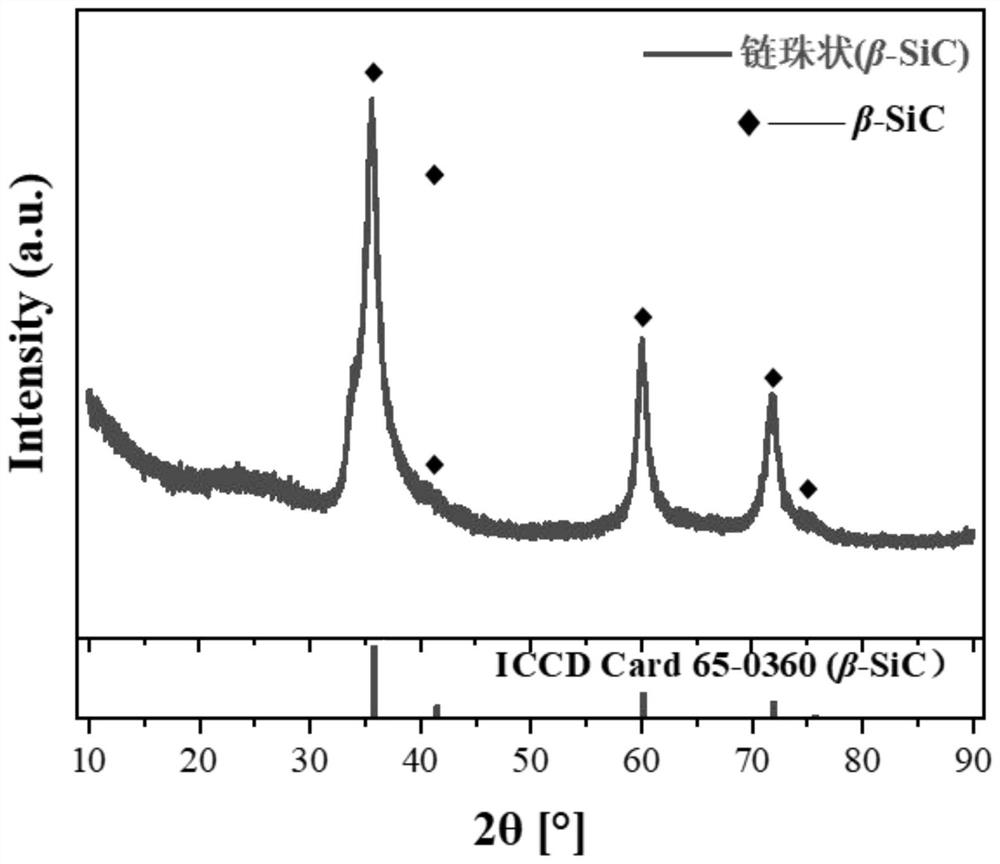

[0051] This embodiment provides a method for preparing a one-dimensional SiC nanomaterial with a chain bead-like hierarchical structure, and the preparation method is as follows:

[0052] S1. Configuration of pre-spinning solution

[0053] S1-1. Solute configuration

[0054] (1) Carbon source: polyacrylonitrile (PAN): 4.1 wt% (mass percentage);

[0055] (2) Silicon source: polycarbosilane (Polycarbosilane, PCS): 9.8 wt% (mass percentage).

[0056] S1-2. Solvent configuration:

[0057] Pre-spinning solvent content (the remaining part of the total solution, the solvent here is the mixed solvent of solvent 1 and solvent 2, the percentage is the percentage of each solvent formula, not the percentage of the total solution)

[0058] The solvent content is divided into two parts:

[0059] (1) Solvent 1: N, N-Dimethylformamide (N, N-Dimethylformamide, DMF) is the carbon source solvent: 10wt% (mass percentage); xylene is the silicon source solvent: 90 wt% (mass percentage) ;

[0...

Embodiment 2

[0071] Example 2 is basically the same as Example 1, except that the content of polyacrylonitrile is adjusted to 3%, and the content of polycarbosilane is adjusted to 12%, that is, the ratio of silicon source to carbon source is increased.

[0072] Among them, S1-2. Solvent configuration:

[0073] Pre-spinning solvent content (the remaining part of the total solution, the solvent here is the mixed solvent of solvent 1 and solvent 2, the percentage is the percentage of each solvent formula, not the percentage of the total solution)

[0074] The solvent content is divided into two parts:

[0075] (1) Solvent 1: N, N-Dimethylformamide (N, N-Dimethylformamide, DMF) is the carbon source solvent: 10wt% (mass percentage); xylene is the silicon source solvent: 90 wt% (mass percentage) ;

[0076] (2) Solvent 2: This solvent is a solubilizer, which is a mixed solvent of Tween 80 and high-purity ethanol, and the ratio of the two is 1:5;

[0077] Stir solvent 1 and solvent 2 in a ratio...

Embodiment 3

[0081] Example 3 is basically the same as Example 1, except that the content of polyacrylonitrile is adjusted to 5.2%, and the content of polycarbosilane is adjusted to 8.3%, that is, the ratio of silicon source to carbon source is reduced. The final microscopic appearance of the product is as follows: Figure 5 As shown, it can be seen that the structure is also in the shape of chain beads, but compared with Example 1, the connection between the chain beads is wider and thicker, and there is a phenomenon that the chain beads are agglomerated and agglomerated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com