Patents

Literature

9451 results about "Potassium hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium hydroxide is an inorganic compound with the formula KOH, and is commonly called caustic potash. Along with sodium hydroxide (NaOH), this colorless solid is a prototypical strong base. It has many industrial and niche applications, most of which exploit its caustic nature and its reactivity toward acids. An estimated 700,000 to 800,000 tonnes were produced in 2005. About 100 times more NaOH than KOH is produced annually. KOH is noteworthy as the precursor to most soft and liquid soaps, as well as numerous potassium-containing chemicals. It is a white solid that is dangerously corrosive. Most commercial samples are ca. 90% pure, the remainder being water and carbonates.

Method for preparing lithium cobaltate by directly using invalid lithium ion battery

InactiveCN102030375AReduce dispersionHigh purityCell electrodesCobalt compoundsElectrical batteryPotassium hydroxide

The invention provides a method for preparing lithium cobaltate by directly using an invalid lithium ion battery. The method comprises the following steps: crushing the invalid lithium ion battery or scraps generated when a lithium cobaltate battery is produced by a mechanical crusher at normal temperature; adding water and one or more of acetic acid, sulfuric acid, hydrochloric acid or nitric acid to produce mixed aqueous solution of the battery scraps and acid; filling the mixed aqueous solution into a hermetic pressure reactor, and controlling the temperature in the reactor to be between 50 and 150 DEG C; introducing or adding one leaching additive of sulfur dioxide or hydrogen, or adding hydrazine hydrate; stirring and leaching, cooling, and filtering; adding one precipitator of sodium carbonate, potassium carbonate and ammonium carbonate, or adding composite precipitator consisting of one of the sodium carbonate, the potassium carbonate and the ammonium carbonate and one of sodium hydroxide and potassium hydroxide to obtain mixture of lithium carbonate, cobalt carbonate and cobalt hydroxide; drying and calcining at high temperature to produce a lithium cobaltate product. The method is particularly suitable for the treatment scale of medium-sized and small enterprises, and is an effective method for directly materializing cobalt secondary resources.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

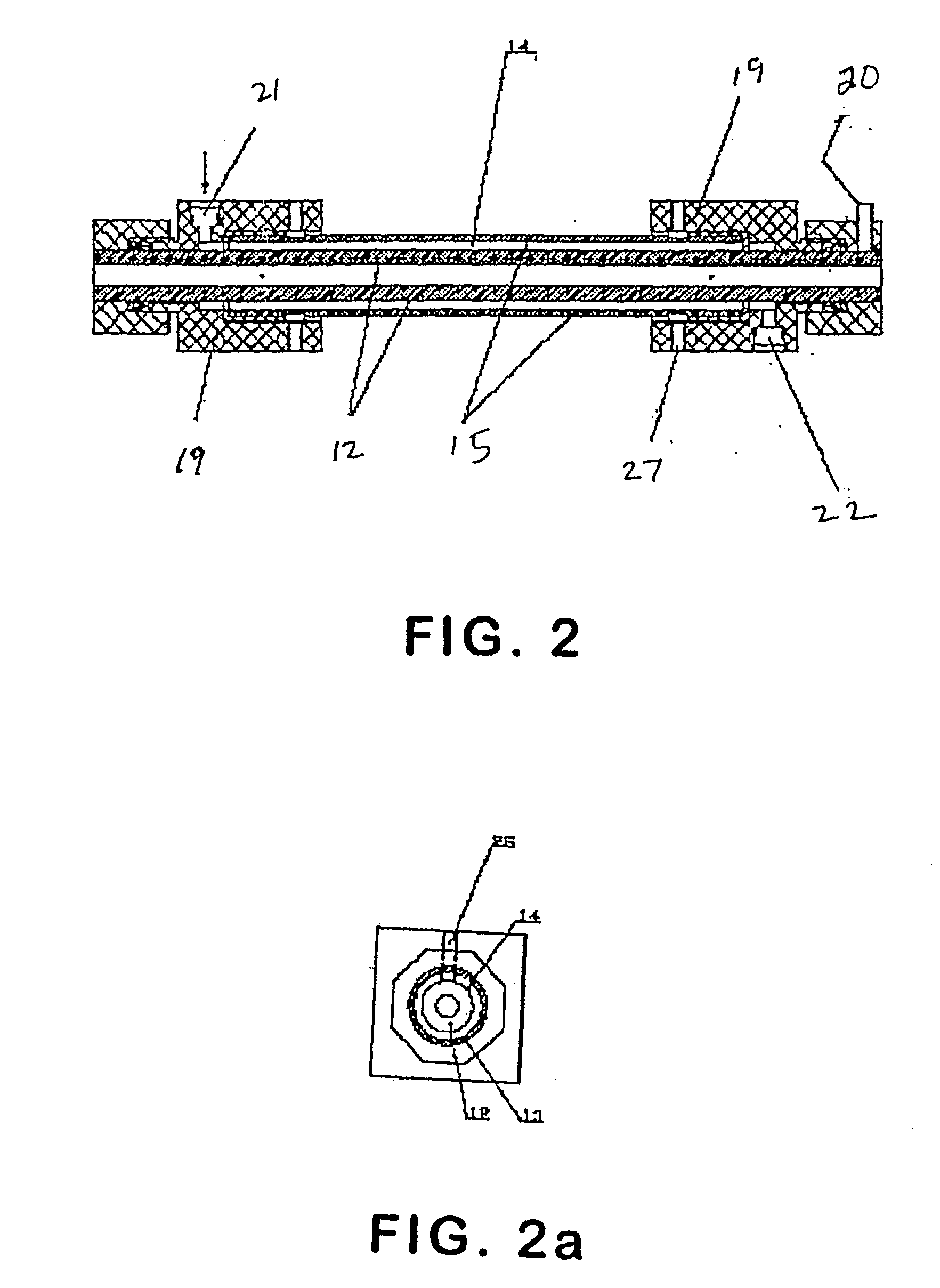

Transistor having notched fin structure and method of making the same

ActiveUS20120086053A1Semiconductor/solid-state device manufacturingSemiconductor devicesTetramethylammonium hydroxideEtching

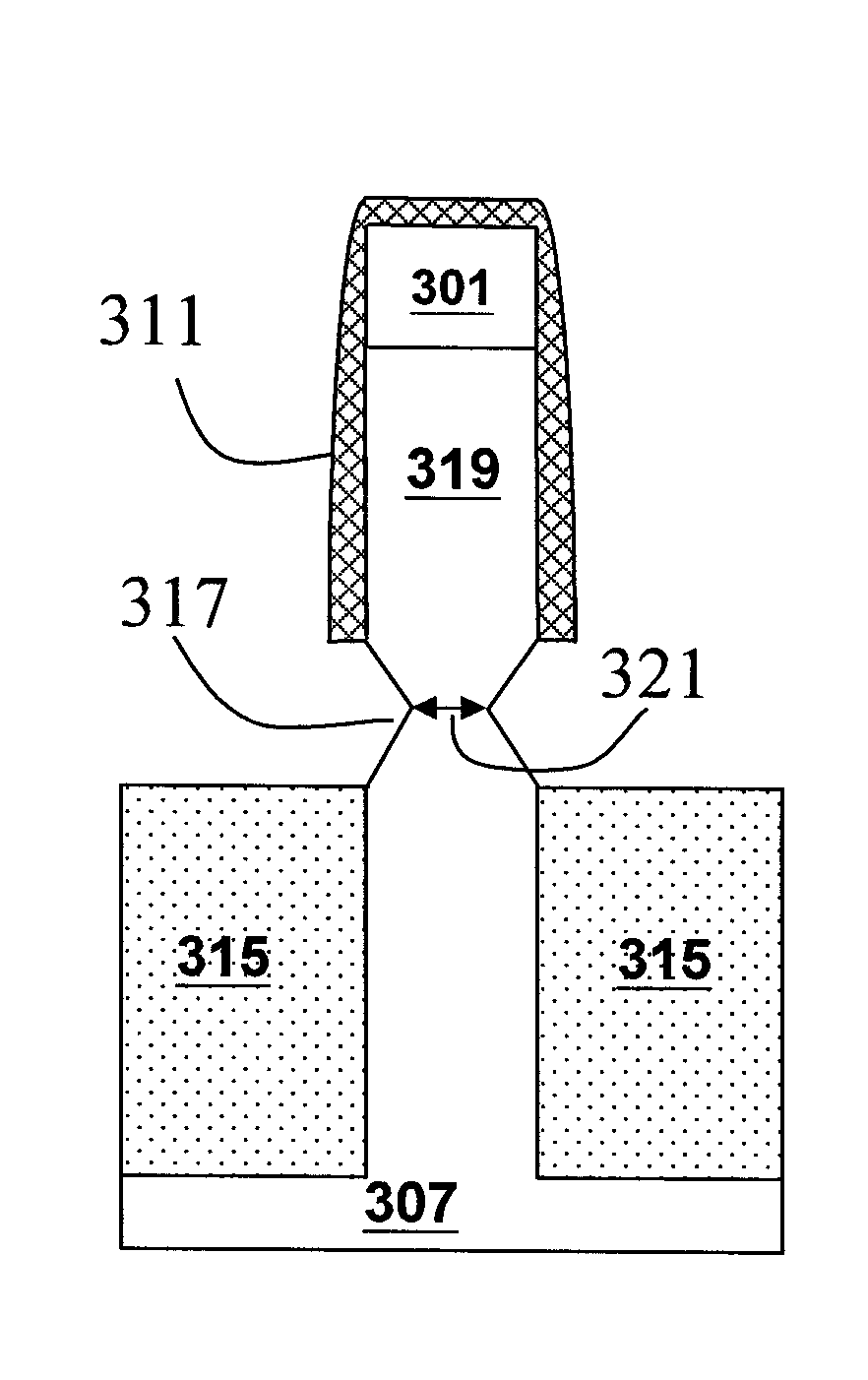

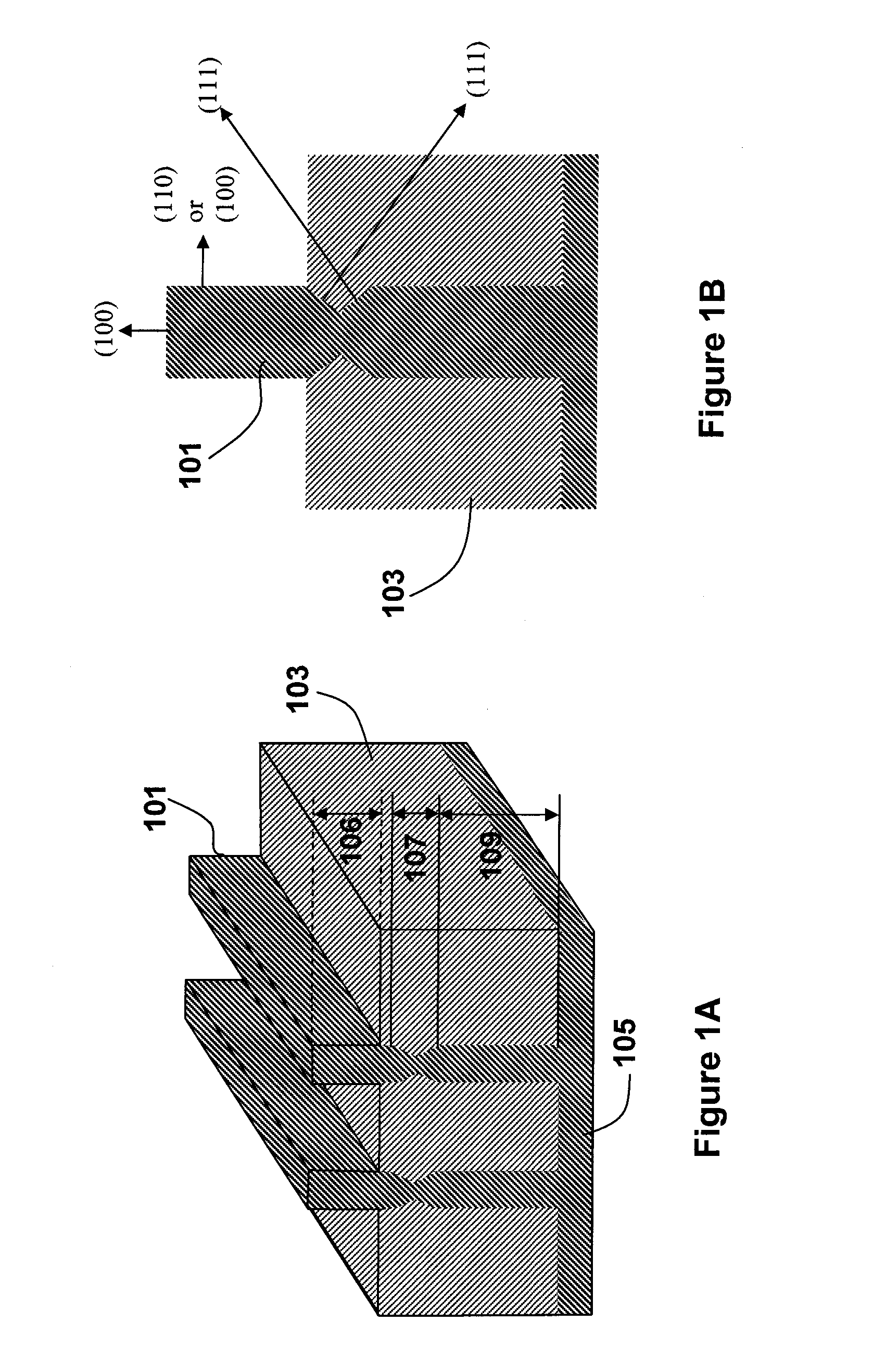

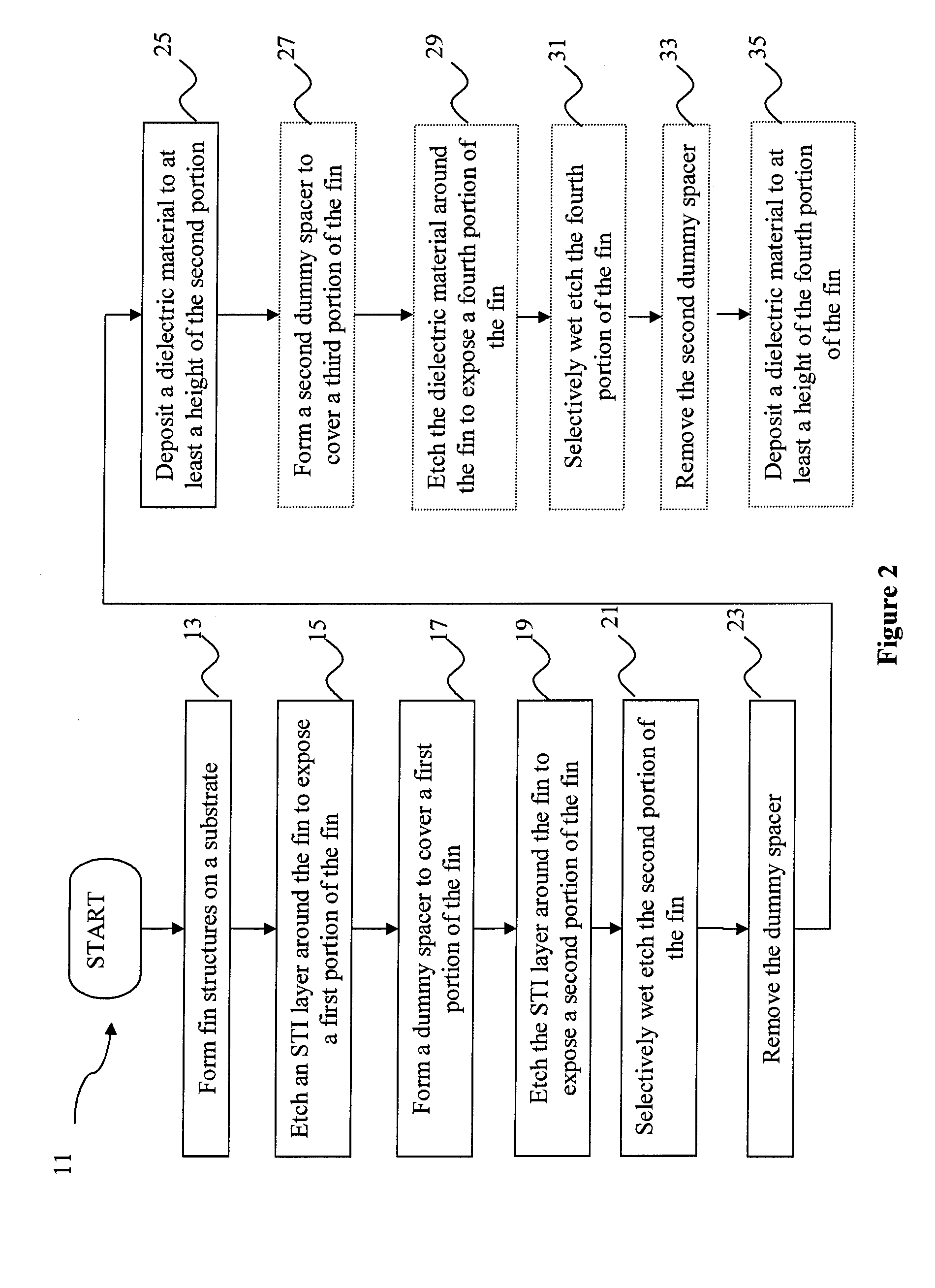

A transistor includes a notched fin covered under a shallow trench isolation layer. One or more notch may be used, the size of which may vary along a lateral direction of the fin. In some embodiments, The notch is formed using anisotropic wet etching that is selective according to silicon orientation. Example wet etchants are tetramethylammonium hydroxide (TMAH) or potassium hydroxide (KOH).

Owner:TAIWAN SEMICON MFG CO LTD

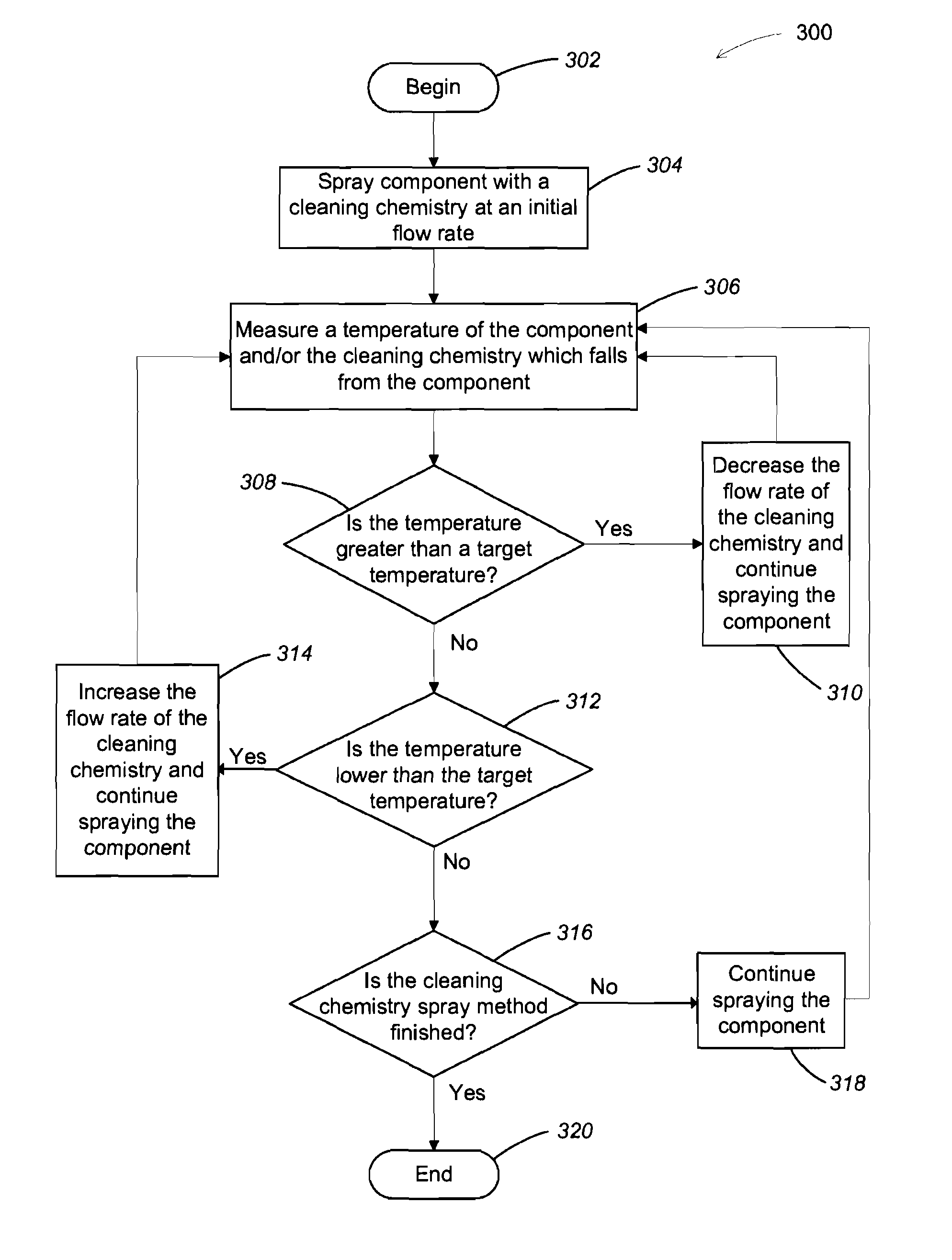

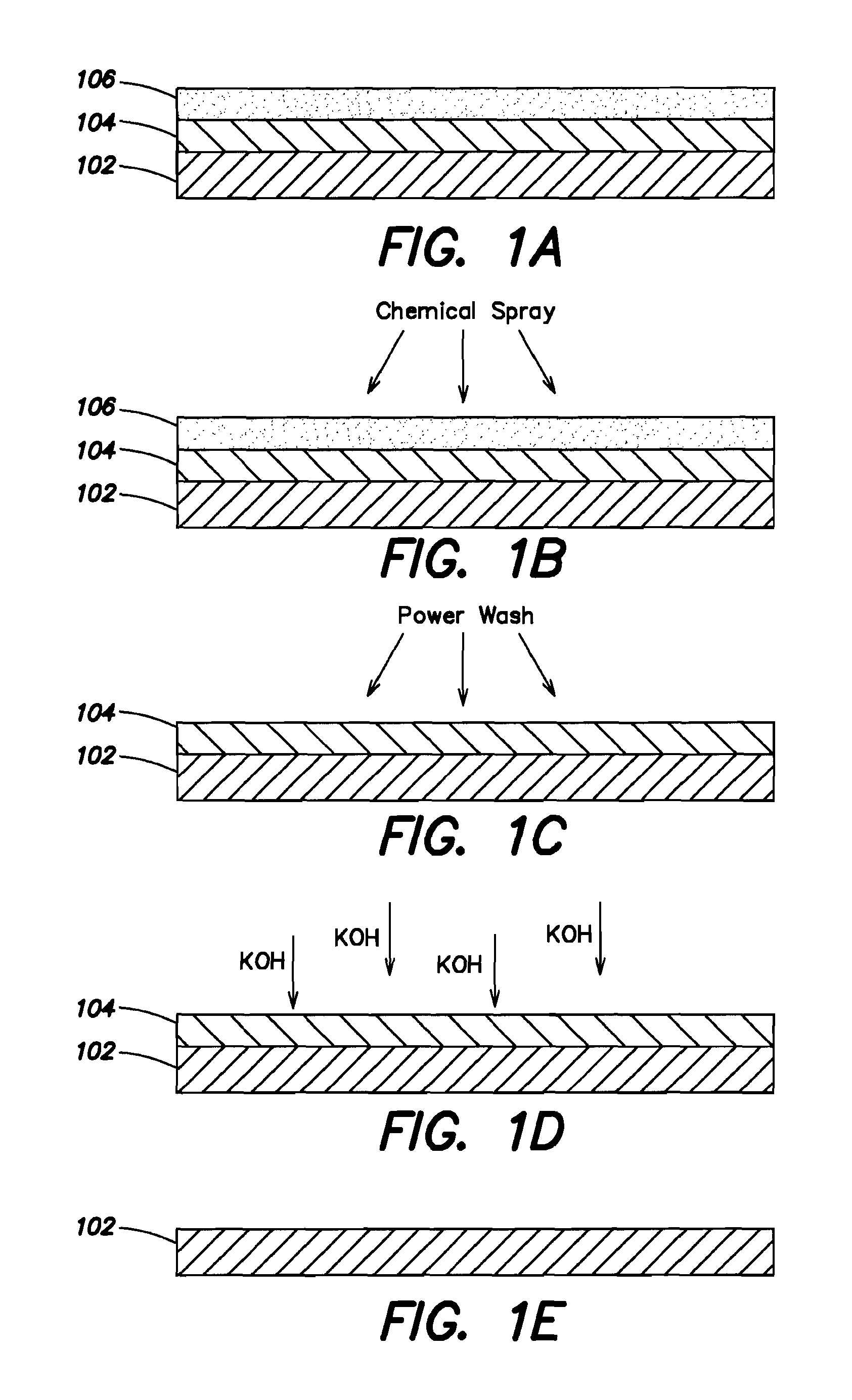

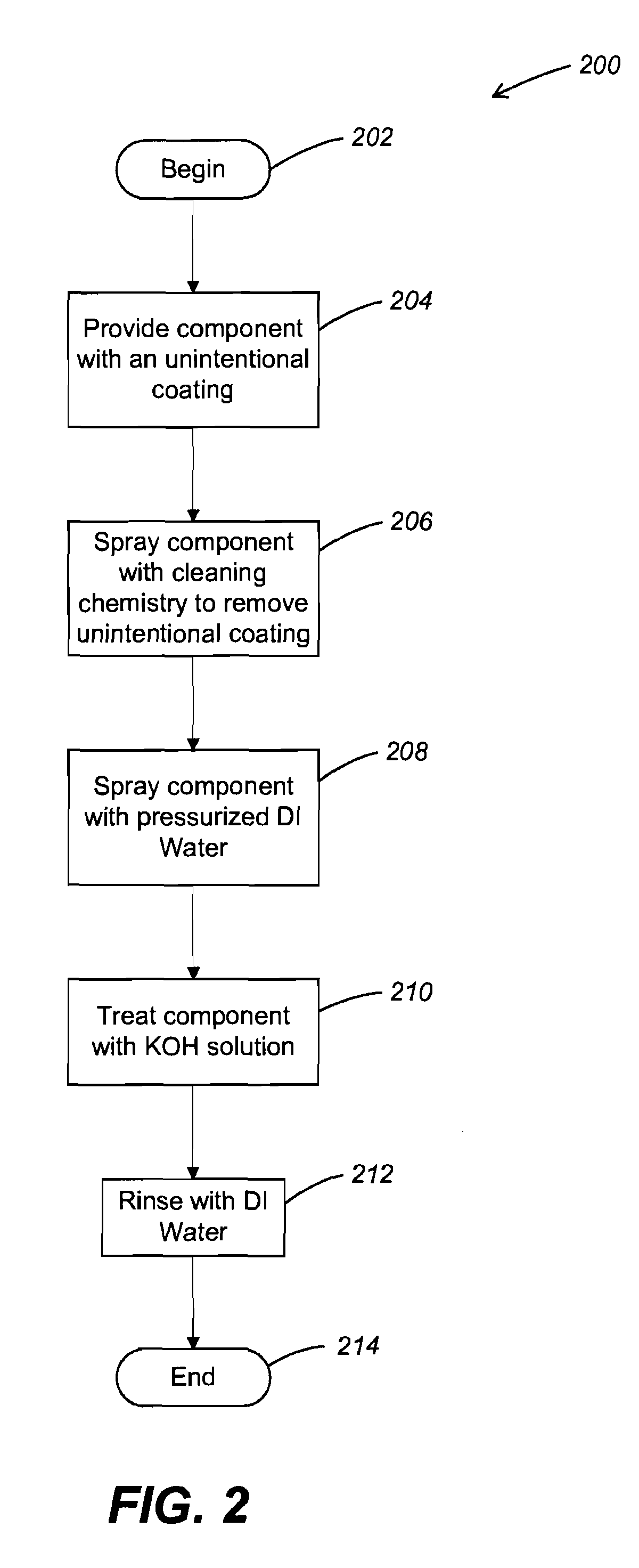

Methods and apparatus for cleaning deposition chamber parts using selective spray etch

Owner:QUANTUM GLOBAL TECH

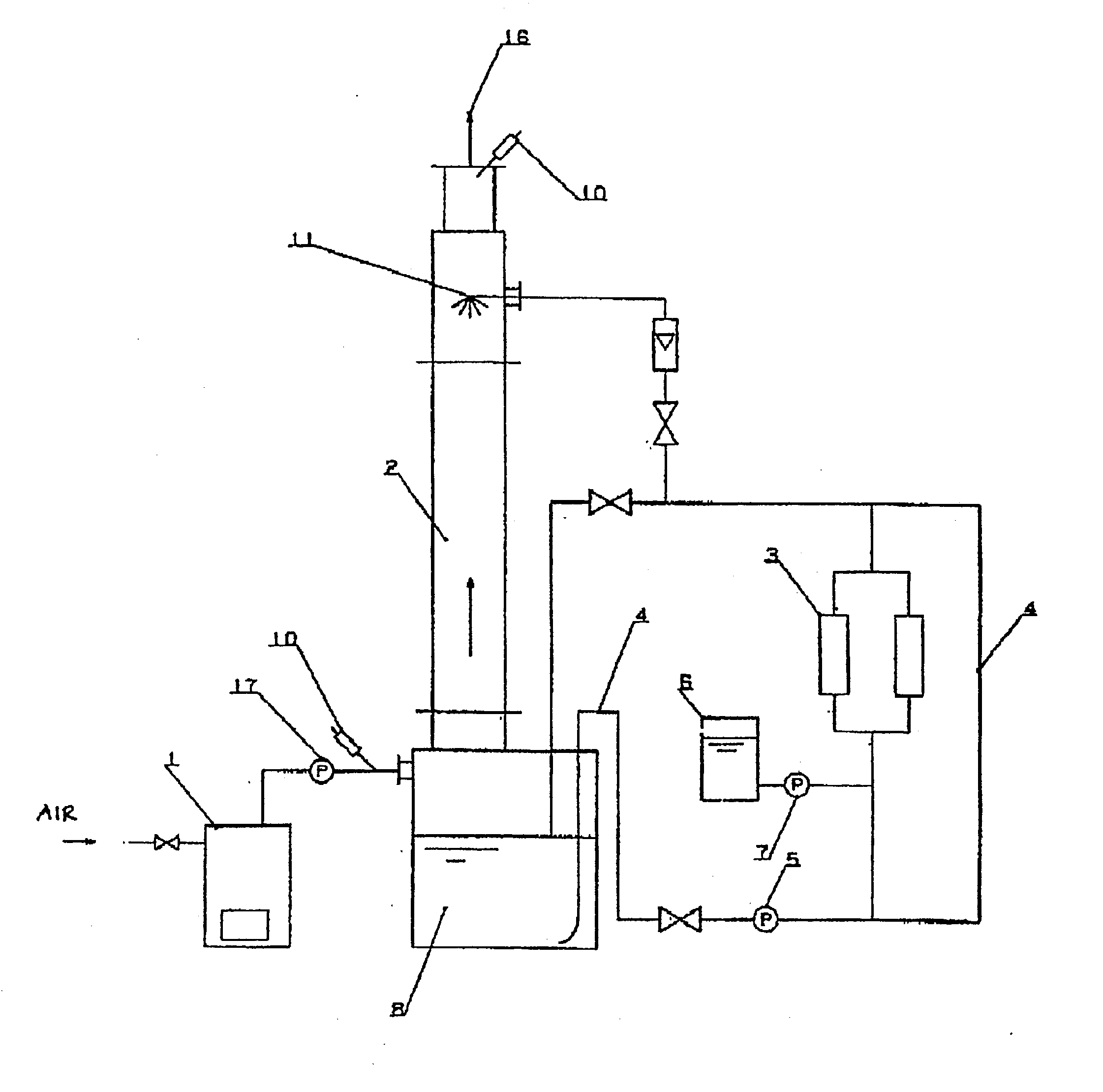

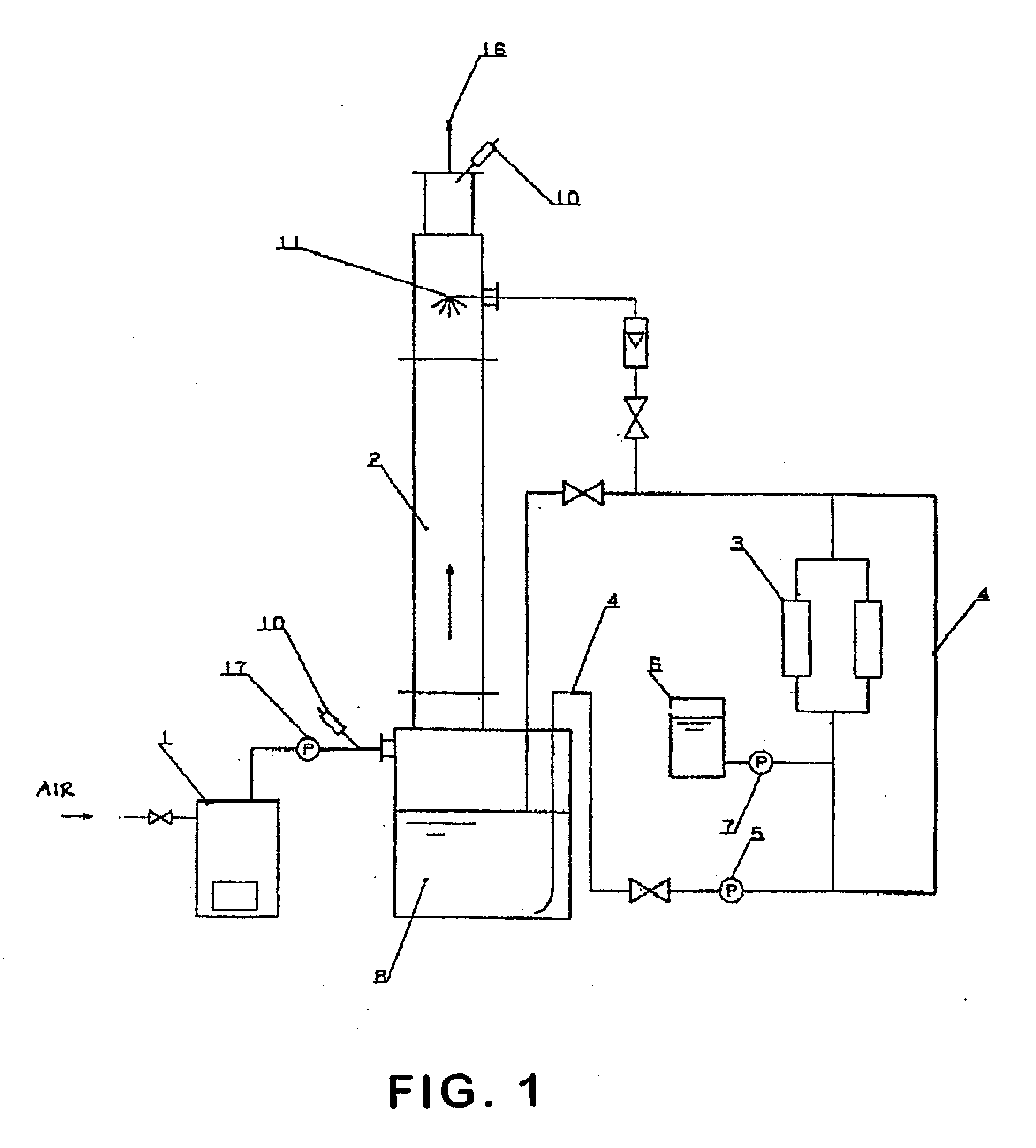

Method and device for deodorization and purification of exhaust gas or flue gas

InactiveUS20030164309A1Easy can be electrolyzedHigh densityCyanogen compoundsLighting and heating apparatusHazardous substancePotassium hydroxide

A method and device for removing, deodorizing and purifying odor, smoke and harmful substances from exhaust gas or flue gas employs a water solution containing hypohalogen acid such as hypochlorous acid soda, an alkaline electrolyte such as potassium hydroxide or sodium hydroxide and a saline electrolyte such as sodium chloride, potassium chloride, sodium bromide or potassium bromide which is electrolyzed to produce an electrolytic water solution which is fed to a deodorizing tower and brought into contact with exhaust gas or flue gas to remove odor, smoke and harmful substances in the exhaust gas or flue gas.

Owner:OMEGA CO LTD

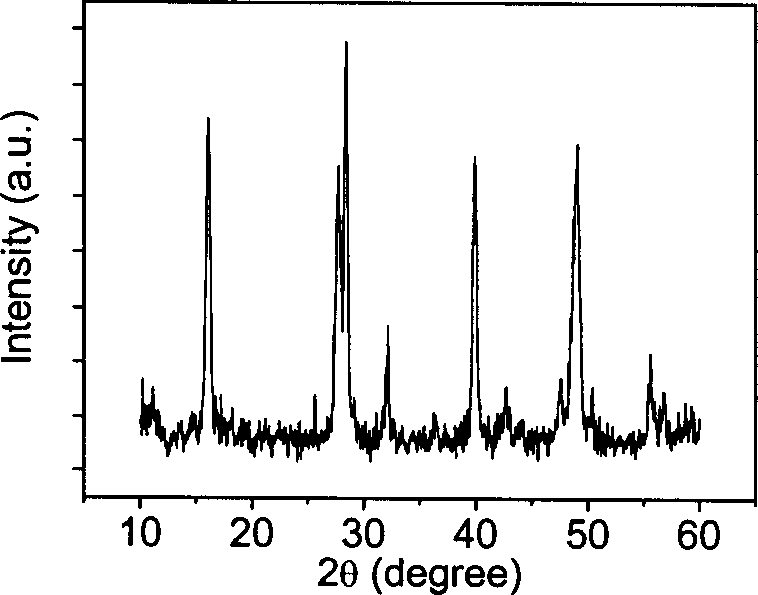

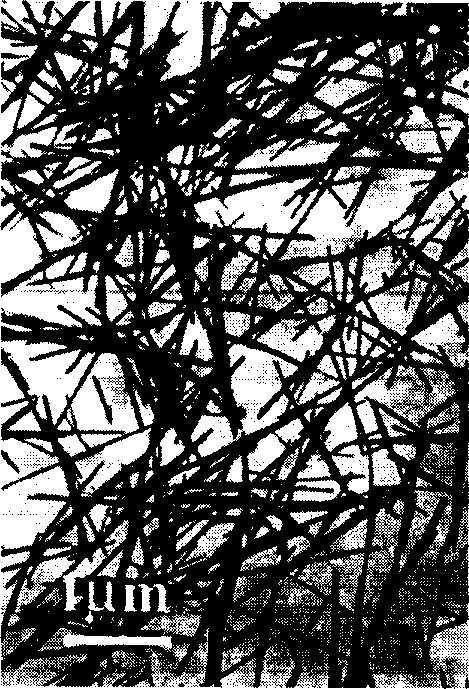

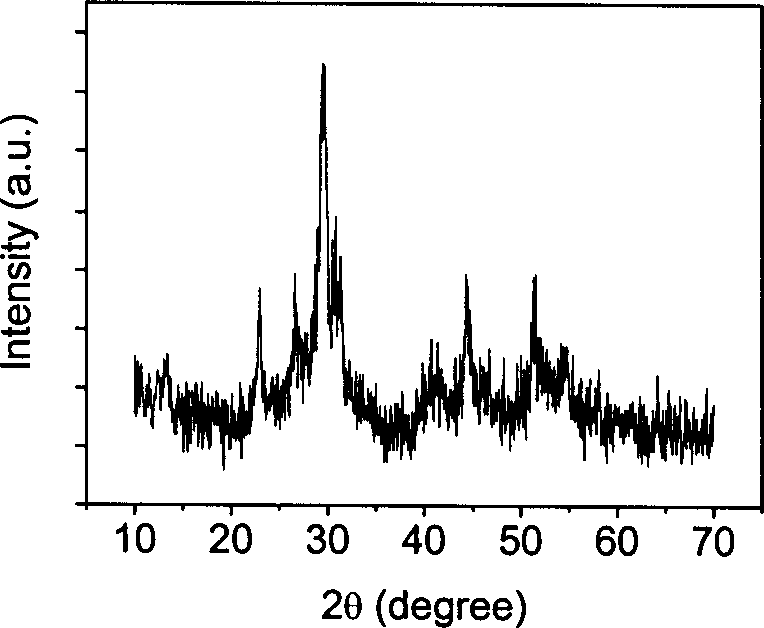

Synthesis process of nanostring and nanopowder of RE hydroxide or oxide

InactiveCN1403375ALarge specific surface areaSimple processRare earth metal compoundsRare-earth elementNanowire

Owner:TSINGHUA UNIV

Disinfectant glass wipe

InactiveUS20050026802A1Detergent mixture composition preparationDetergent compounding agentsAmmonium compoundsPotassium hydroxide

The present invention relates to disinfecting wipes or pads that can be use to treat or clean glass or other glossy surfaces. The disinfecting wipes or pads do not depend upon quaternary ammonium compounds for disinfection, but instead depend upon relatively low solvent levels and basic pH or relatively high levels of sodium hydroxide or potassium hydroxide.

Owner:THE GLAD PROD CO +1

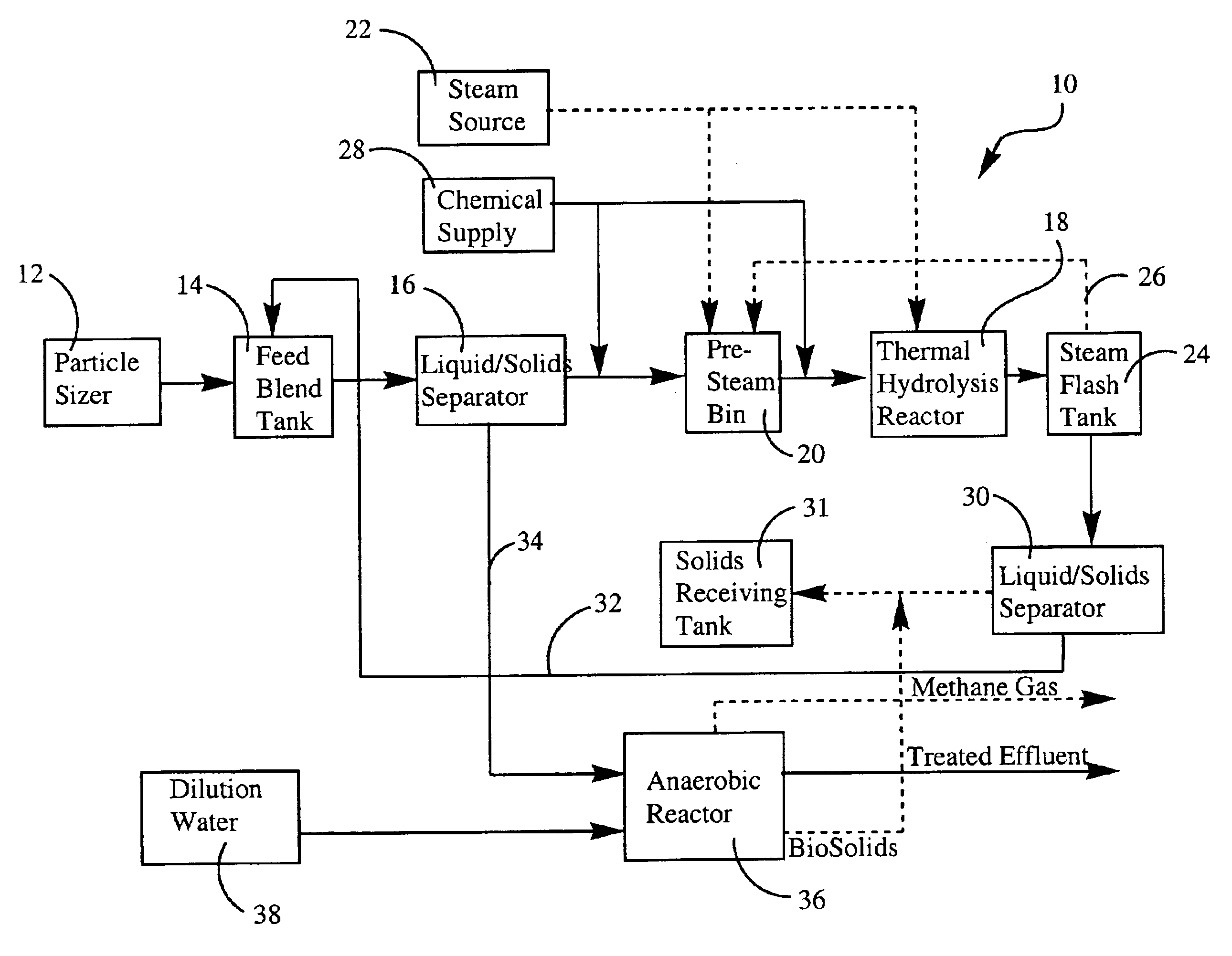

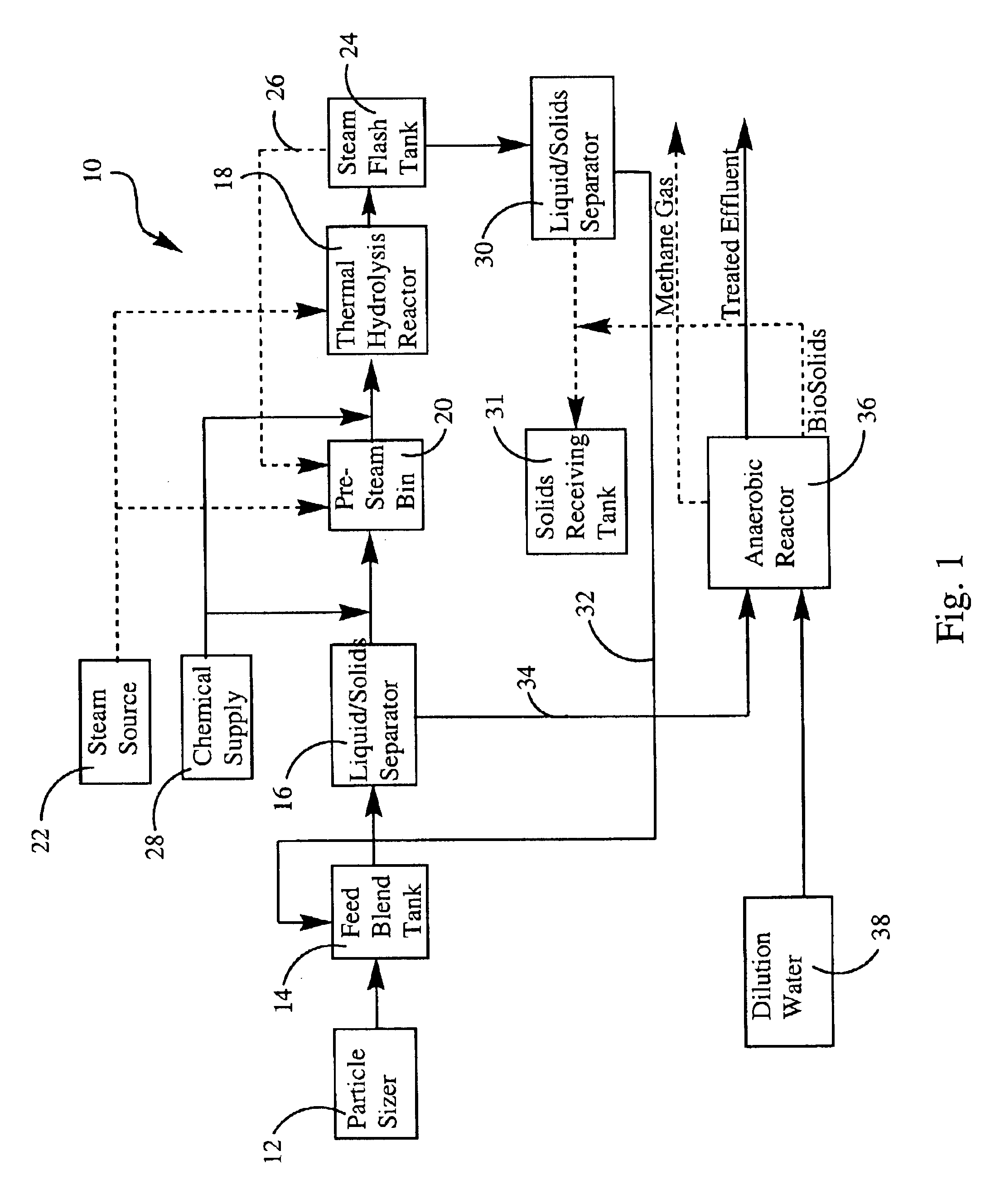

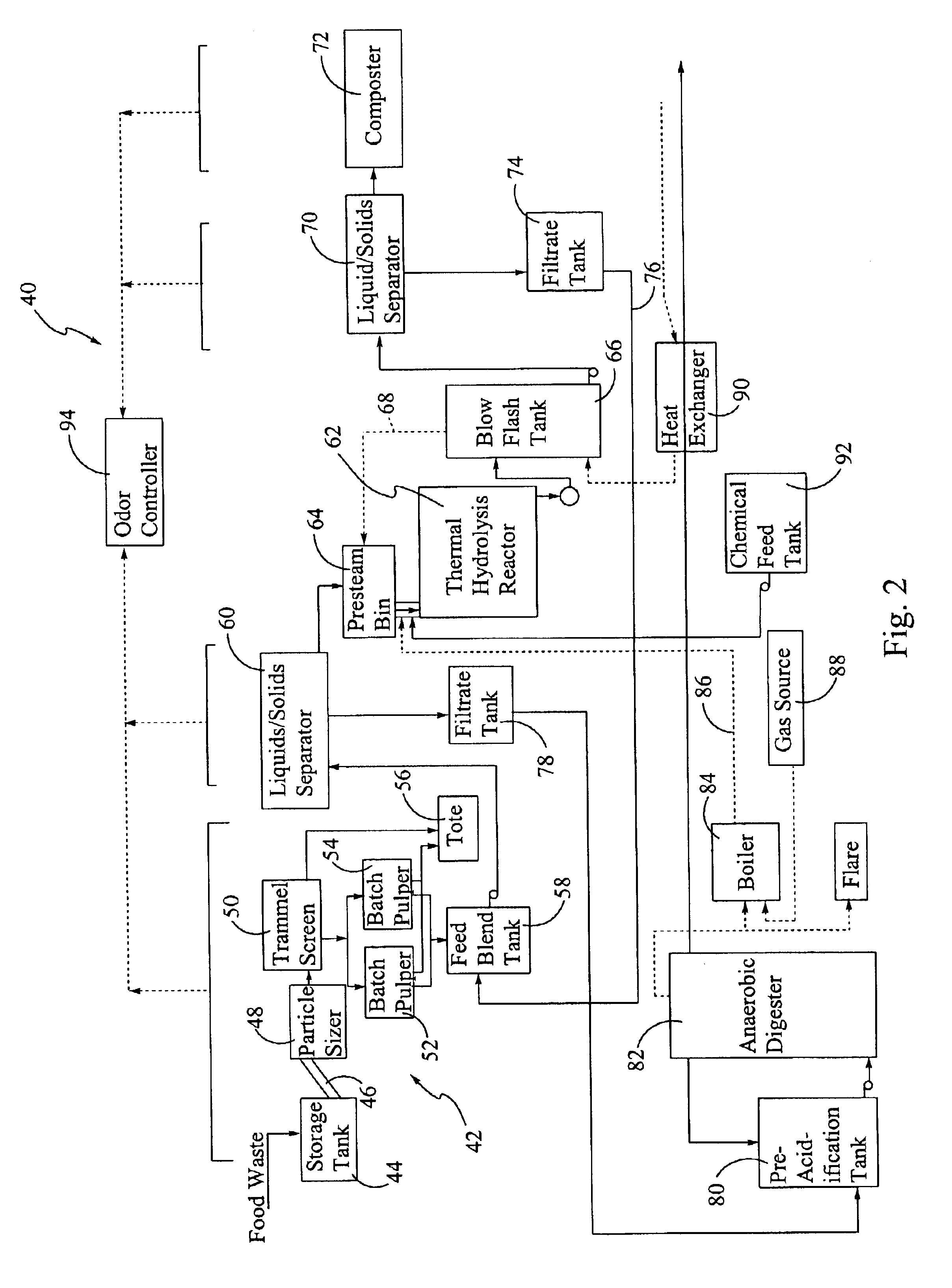

Method and apparatus for the treatment of particulate biodegradable organic waste

InactiveUS6905600B2Lower the volumeSaving in volume requirementBio-organic fraction processingBiological substance pretreatmentsPotassium hydroxideSaturated water vapor

A method for treating particulate biodegradable organic waste includes sizing the waste and adding a base prior to introducing the waste to a thermal hydrolysis reactor and hydrolyzing the waste at a temperature of about 130° C. or greater and a pressure greater than the saturated water vapor pressure to produce a slurry including solubilized organic material and residual solids. The solubilized organic material is separated from the residual solids using a liquid / solid separator and the solubilized organics are subjected to anaerobic digestion to produce a methane gas. The base is preferably potassium hydroxide (KOH) at a concentration of about 1%. The method may further include preheating the particulate biodegradable organic waste with latent heat of the separated solubilized organic material prior to thermal hydrolysis.

Owner:CH2M HILL

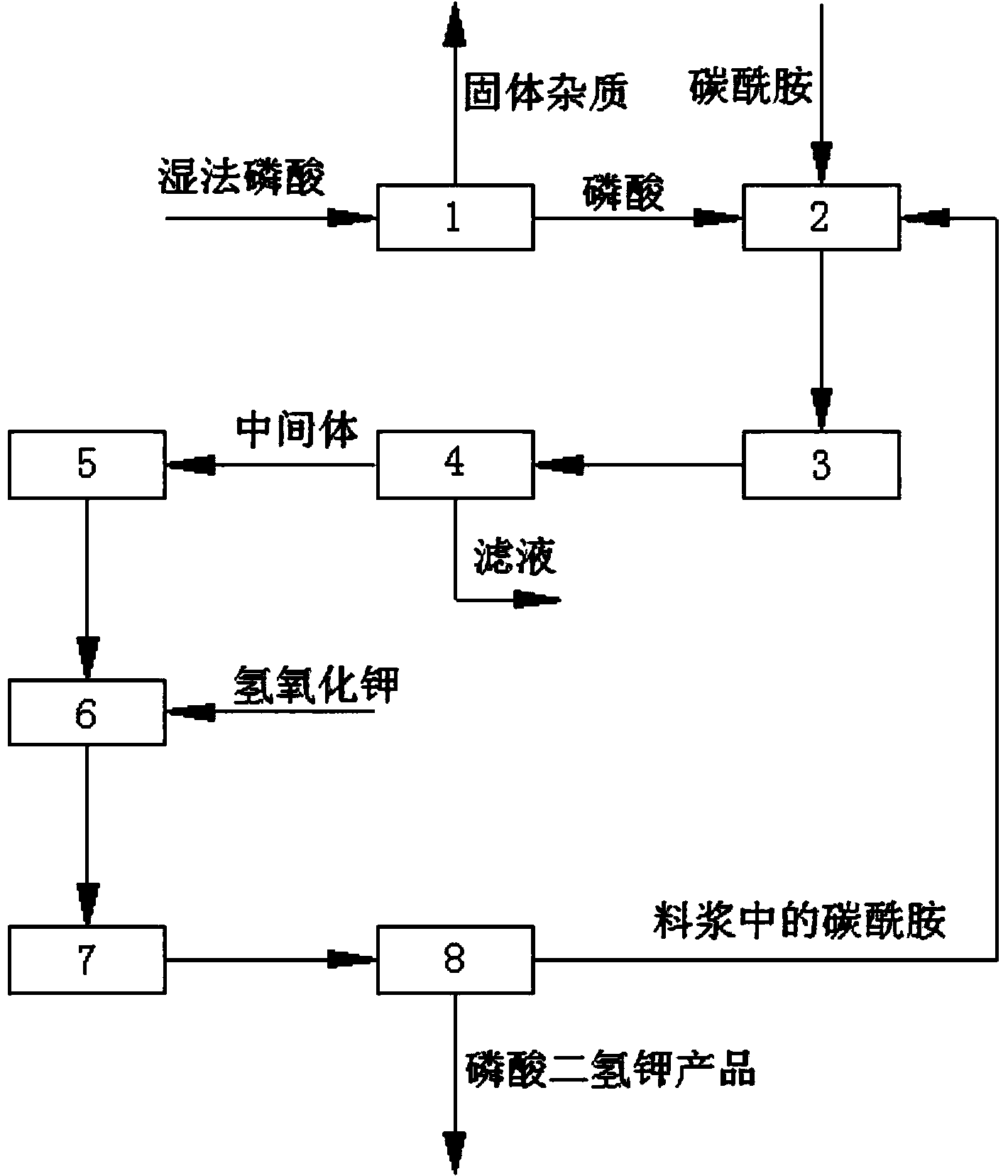

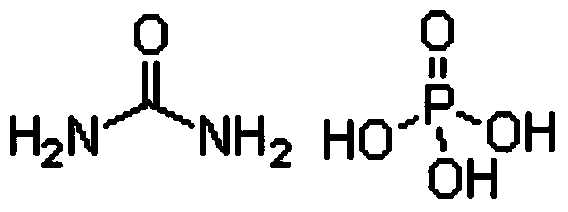

Method for preparing monopotassium phosphate by using wet-process phosphoric acid

InactiveCN103803518AReduce manufacturing costNo pollution in the processPhosphorus compoundsFertilizer mixturesEnvironmental resistanceHigh energy

The invention discloses a method for preparing monopotassium phosphate by using wet-process phosphoric acid. The method comprises the following steps: reacting carbonyl diamide and wet-process phosphoric acid to obtain an intermediate; reacting the intermediate and potassium hydroxide to prepare a monopotassium phosphate product. The method has the advantages of short process route, low energy consumption, stable product quality, low production cost, convenience in operation and safety in production. A side product, namely, slurry can be recycled completely, an entire production process is environment-friendly, clean and free from pollution, and no waste gas, waste water or waste residues are discharged. A response is made to the policy calling of energy saving, emission reduction and clean production, the problems of complex process, instable product quality, high energy consumption and environmental pollution existing in the prior art are solved, and the purity of the obtained monopotassium phosphate product is more than or equal to 98 percent.

Owner:GUIYANG KAILIN FERTILIZER CO LTD +1

Process for producing fluoroolefins

InactiveUS20030060670A1Preparation by hydrogen halide split-offOrganic chemistry methodsPhosphonium saltPtru catalyst

A process for producing a fluoroolefin of the formula: CF.sub.3CY.dbd.CX.sub.nH.sub.p wherein Y is a hydrogen atom or a halogen atom (i.e., fluorine, chlorine, bromine or iodine); X is a hydrogen atom or a halogen atom (i.e., fluorine, chlorine, bromine or iodine); n and p are integers independently equal to 0, 1 or 2, provided that (n+p)=2; comprising contacting, in the presence of a phase transfer catalyst, a compound of the formula: CF.sub.3C(R.sup.1.sub.aR.sup.2.sub.b) C(R.sup.3.sub.cR.sup.4.sub.d), wherein R.sup.1, R.sup.2, R.sup.3, and R.sup.4 are independently a hydrogen atom or a halogen selected from the group consisting of fluorine, chlorine, bromine and iodine, provided that at least one of R.sup.1, R.sup.2, R.sup.3, and R.sup.4 is halogen and there is at least one hydrogen and one halogen on adjacent carbon atoms; a and b are independently=0, 1 or 2 and (a+b)=2; and c and d are independently=0, 1, 2 or 3 and (c+d)=3; and at least one alkali metal hydroxide. The alkali metal hydroxide can be, for example, potassium or sodium hydroxide and the phase transfer catalyst can be, for example, at least one: crown ether such as 18-crown-6 and 15-crown-5; or onium salt such as, quaternary phosphonium salt and quaternary ammonium salt. The olefin is useful, for example, as an intermediate for producing other industrial chemicals and as a monomer for producing oligomers and polymers.

Owner:HONEYWELL INT INC

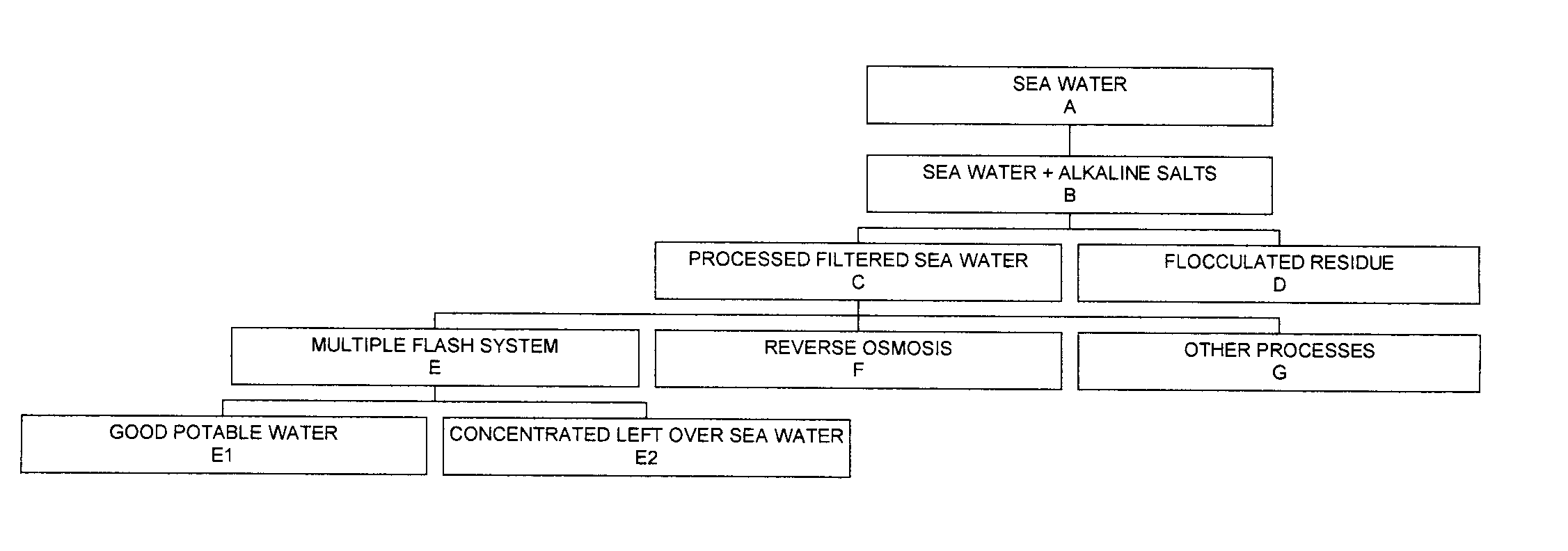

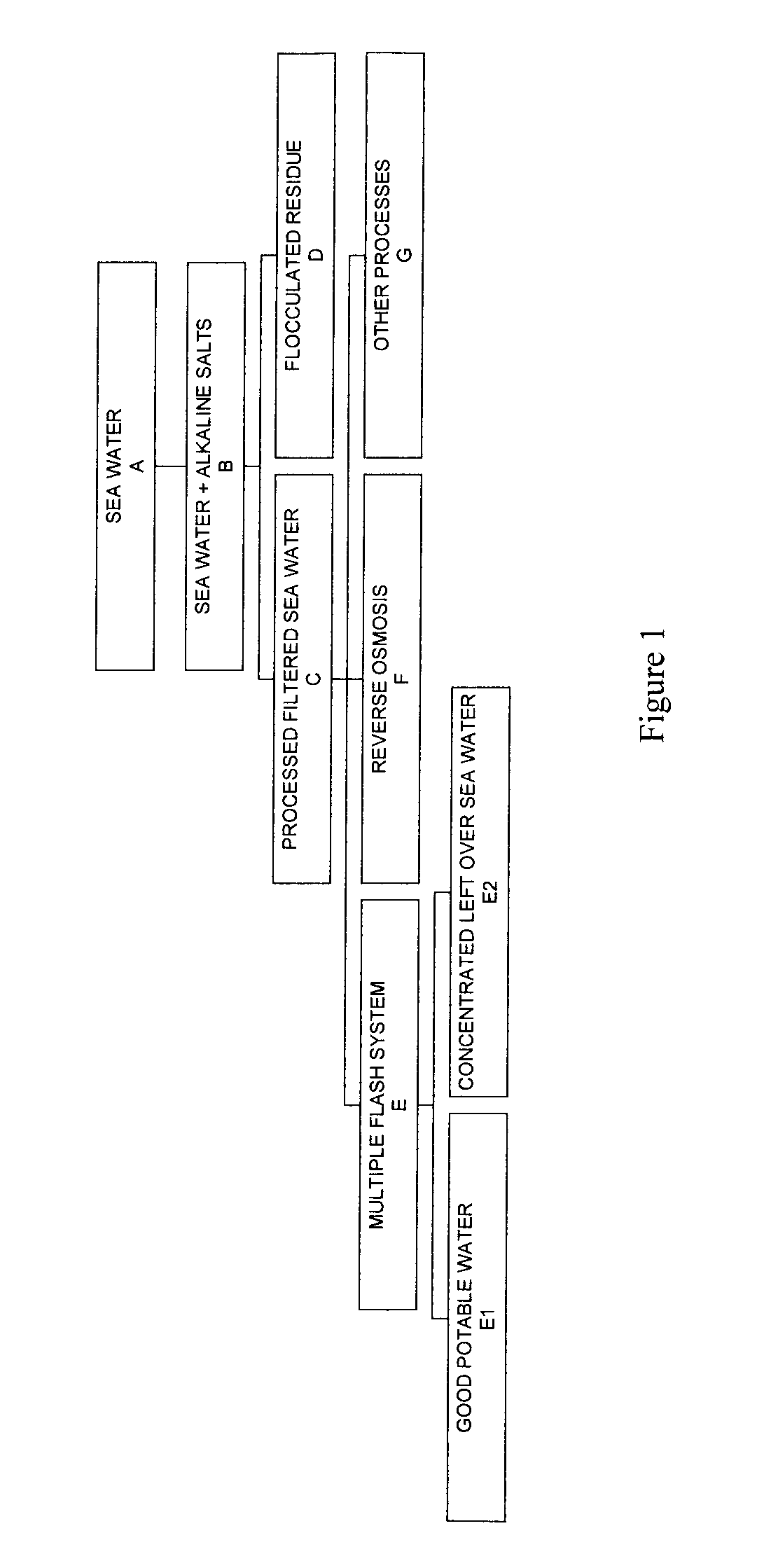

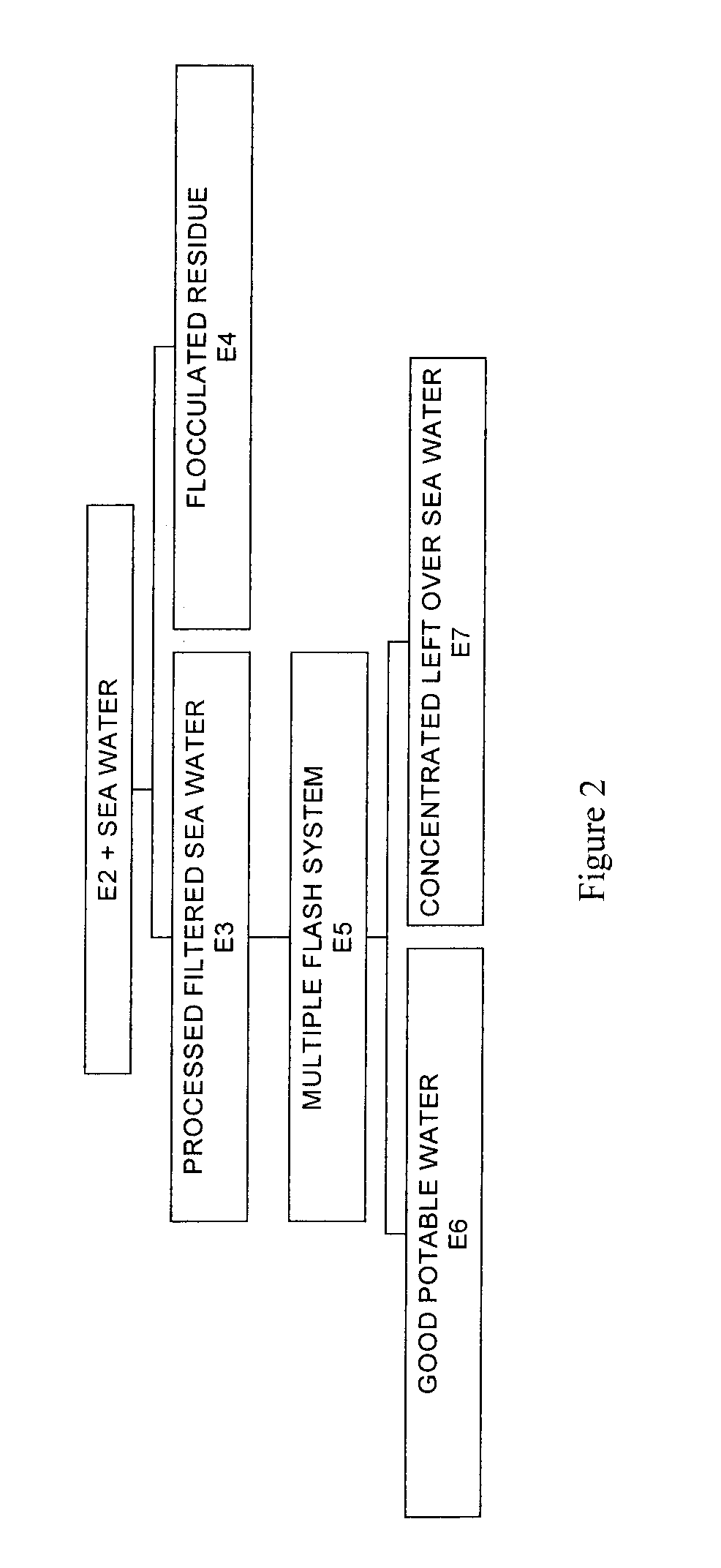

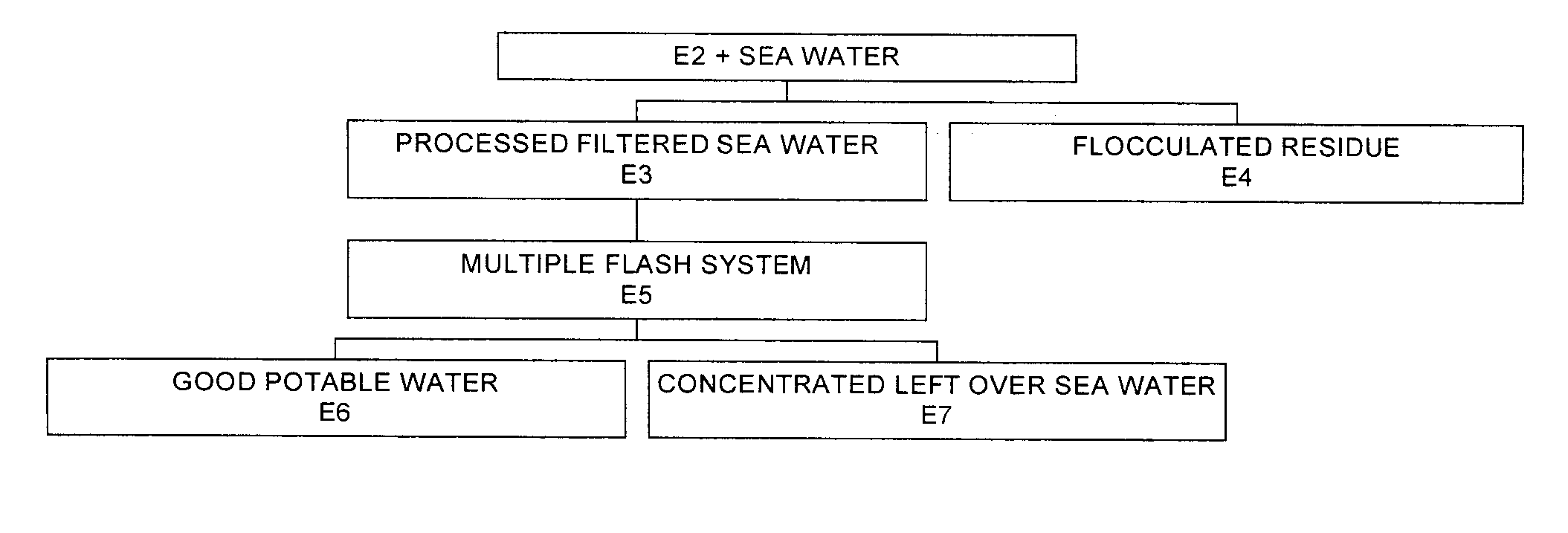

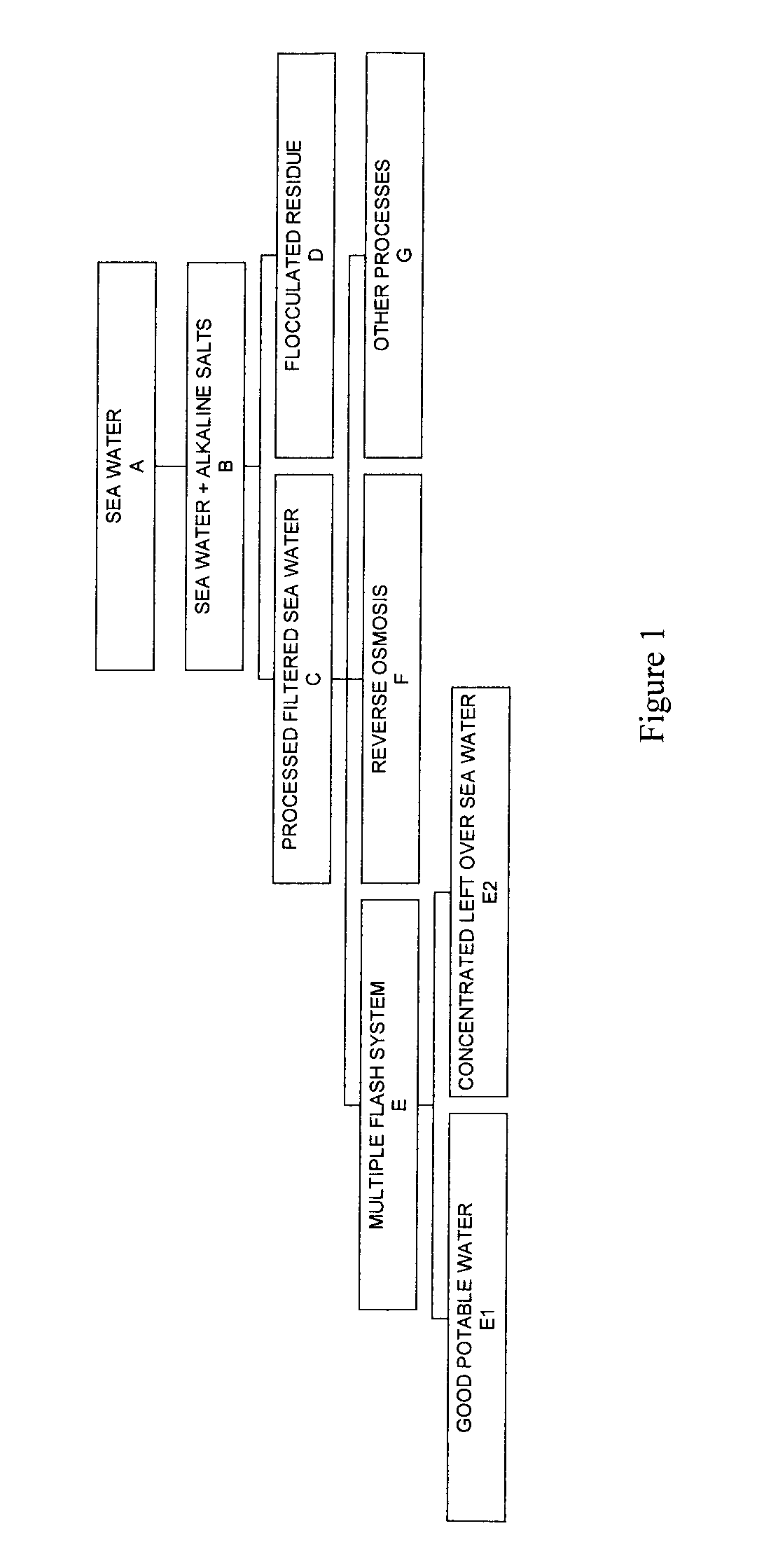

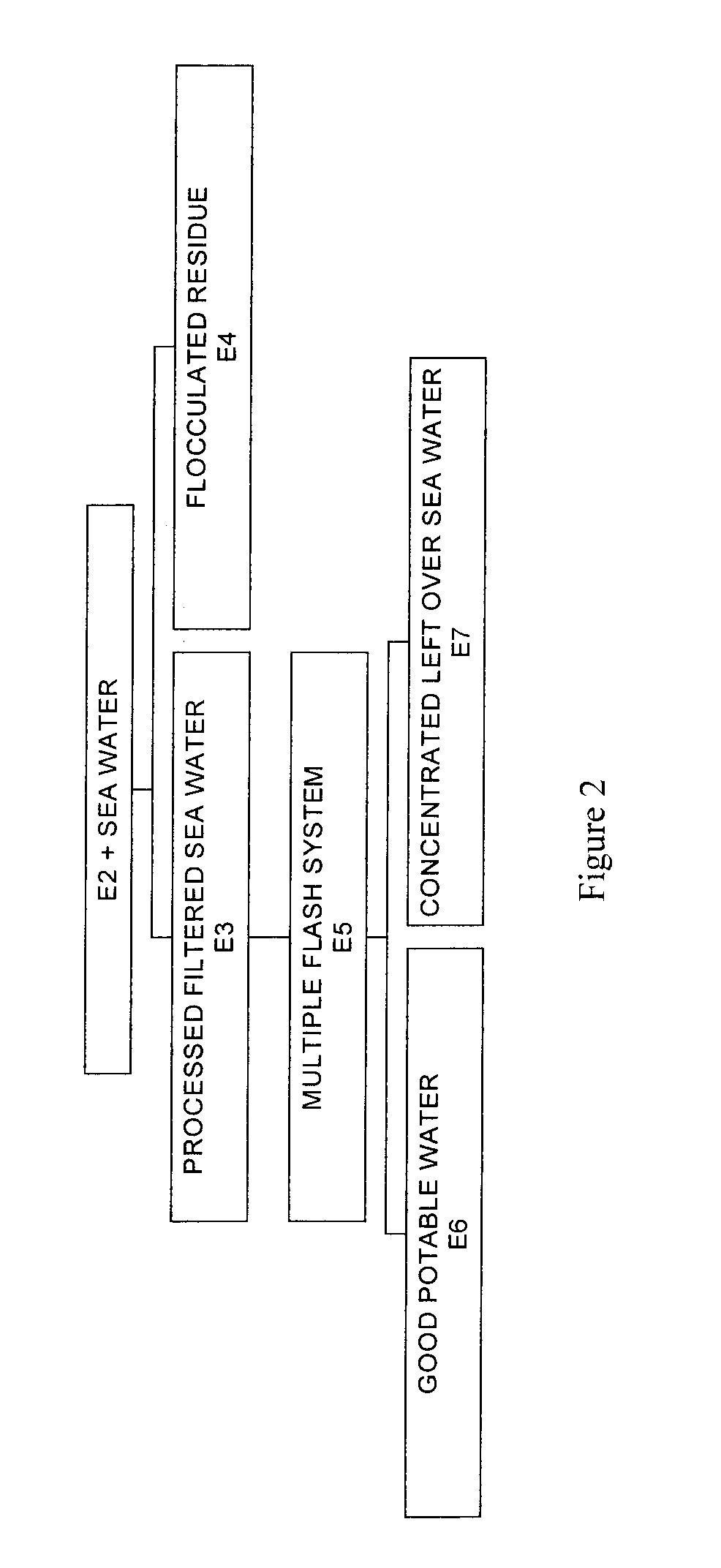

Process for pre-treating and desalinating sea water

ActiveUS20050098499A1Reduce maintenanceExtend equipment lifeGeneral water supply conservationSeawater treatmentCalcium bicarbonatePotassium hydroxide

Water containing dissolved salts, such as calcium sulfate, calcium chloride, magnesium sulfate, magnesium chloride, sodium carbonate, sodium chloride, sodium sulfate, calcium bicarbonate, and mixtures thereof, is treated to reduce the concentration of those salts. About 0.1 to about 60 g / L of sodium hydroxide, sodium carbonate, potassium hydroxide, potassium carbonate, calcium hydroxide, calcium carbonate, aluminum hydroxide, aluminum sulfate, aluminum potassium sulfate, and mixtures thereof is added to the water, whereby a precipitate forms in the water. The precipitate is separated from said water and the water is desalinated using reverse osmosis, flash evaporation, or another method. The process is preferably performed by first adding calcium oxide or calcium hydroxide, separating the precipitate that forms, then adding sodium hydroxide and sodium carbonate to form a second precipitate.

Owner:HUSSAIN MOHAMMED AZAM

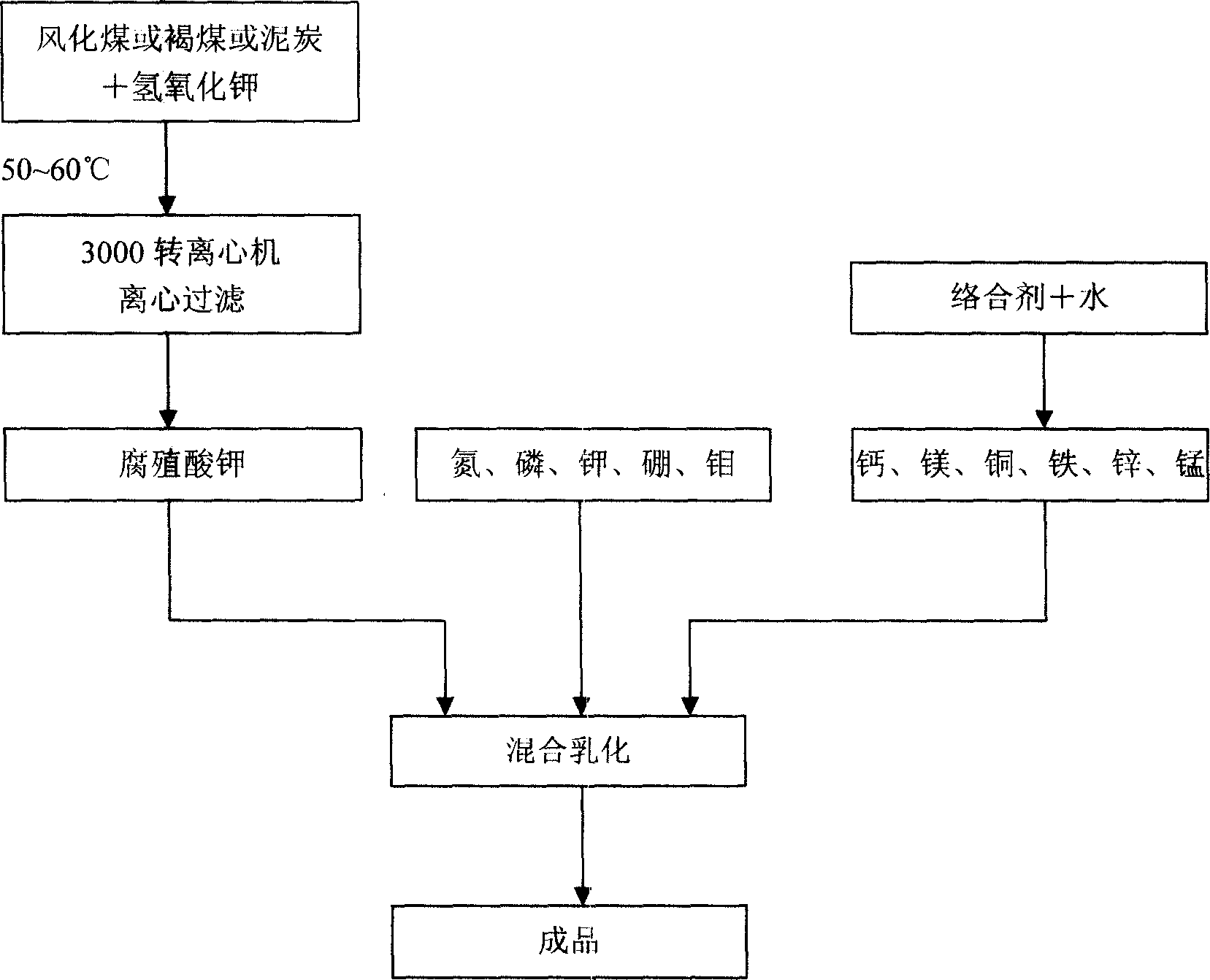

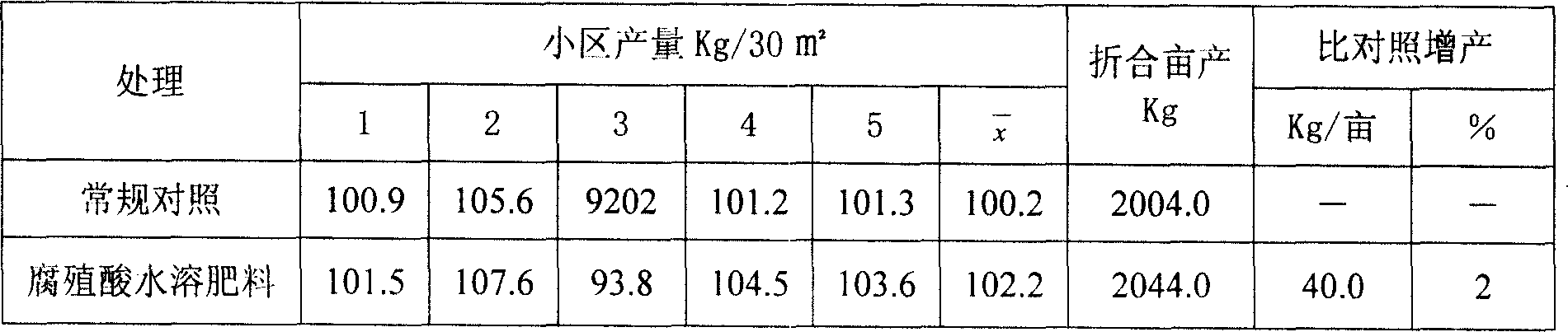

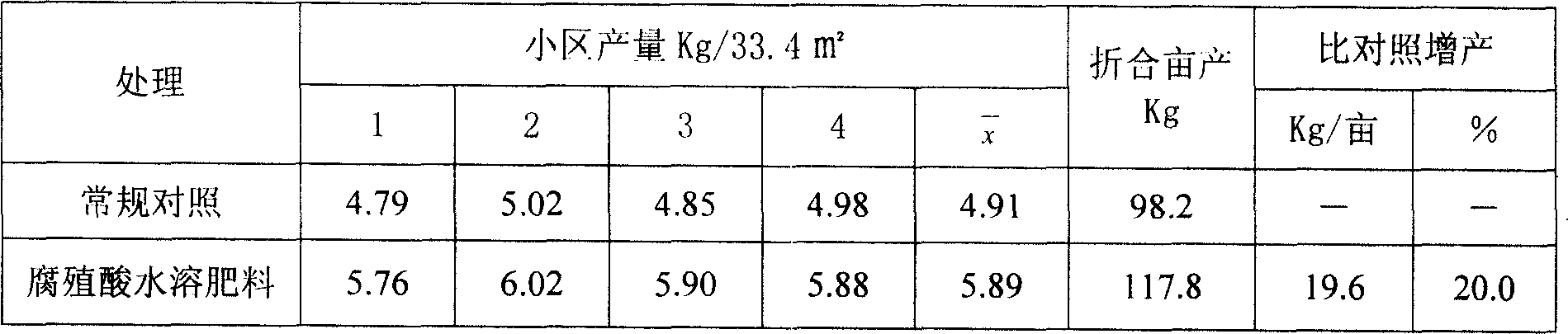

Method for preparing water solutable fertilizer containing humic acid

The invention relates to a manufacture method for water solubility fertilizer containing humus acid. It includes the following steps: adding water and raw material, and KOH as extracting agent, keeping temperature at 50-60 degree centigrade, distilling for 1-2 hours, taking centrifuging, filtering potassium humate, exhausting residue, dissolving N, P, K, and B, dissolving complex agent and adding Ca, Mg, Cu, Fe, Zn, and Mn, heating to dissolving; mixing the materials gained from the above steps, grinding for 3-4 hours under the effect of emulsification pump.

Owner:陕西鼎天济农腐殖酸制品有限公司

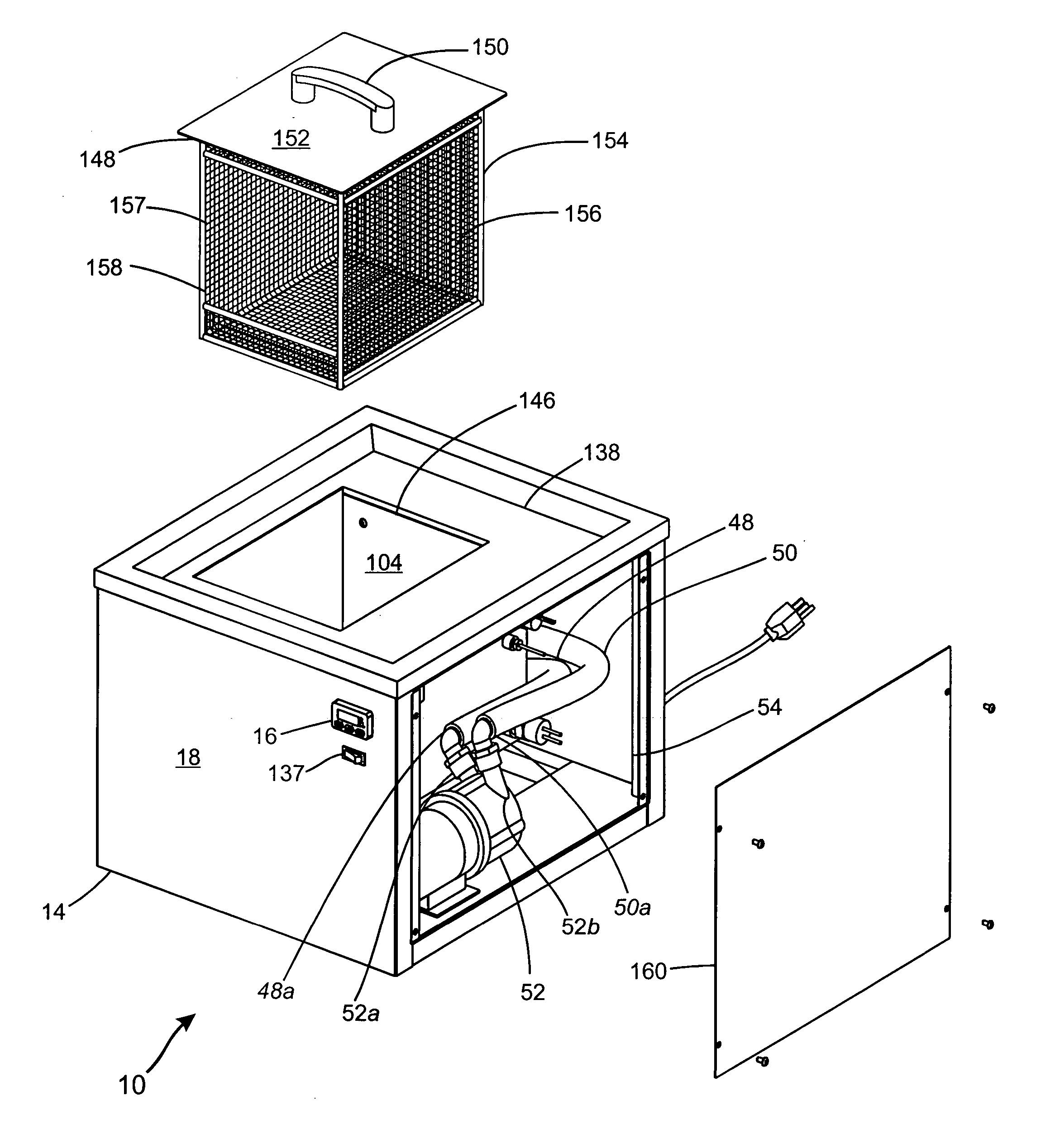

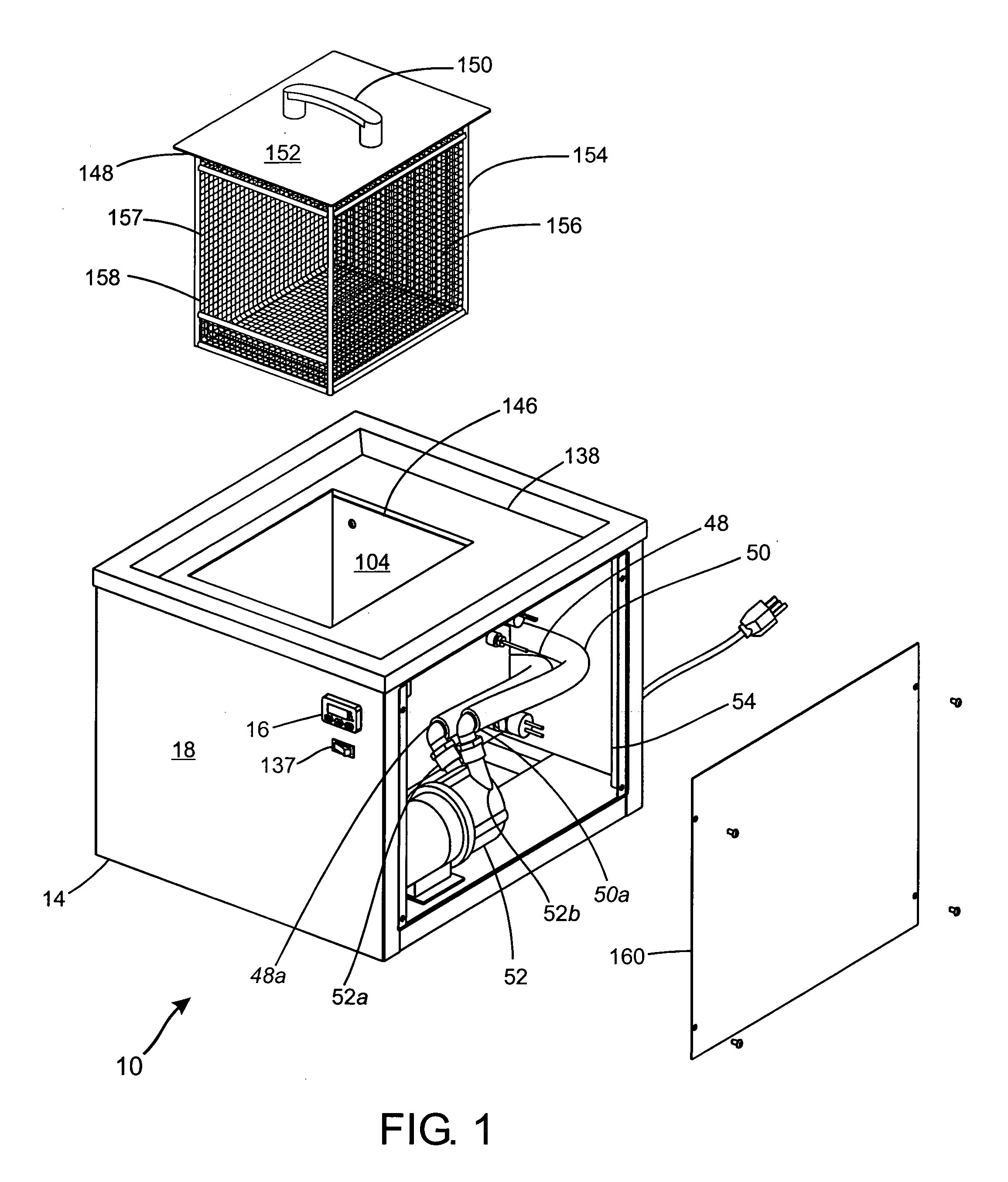

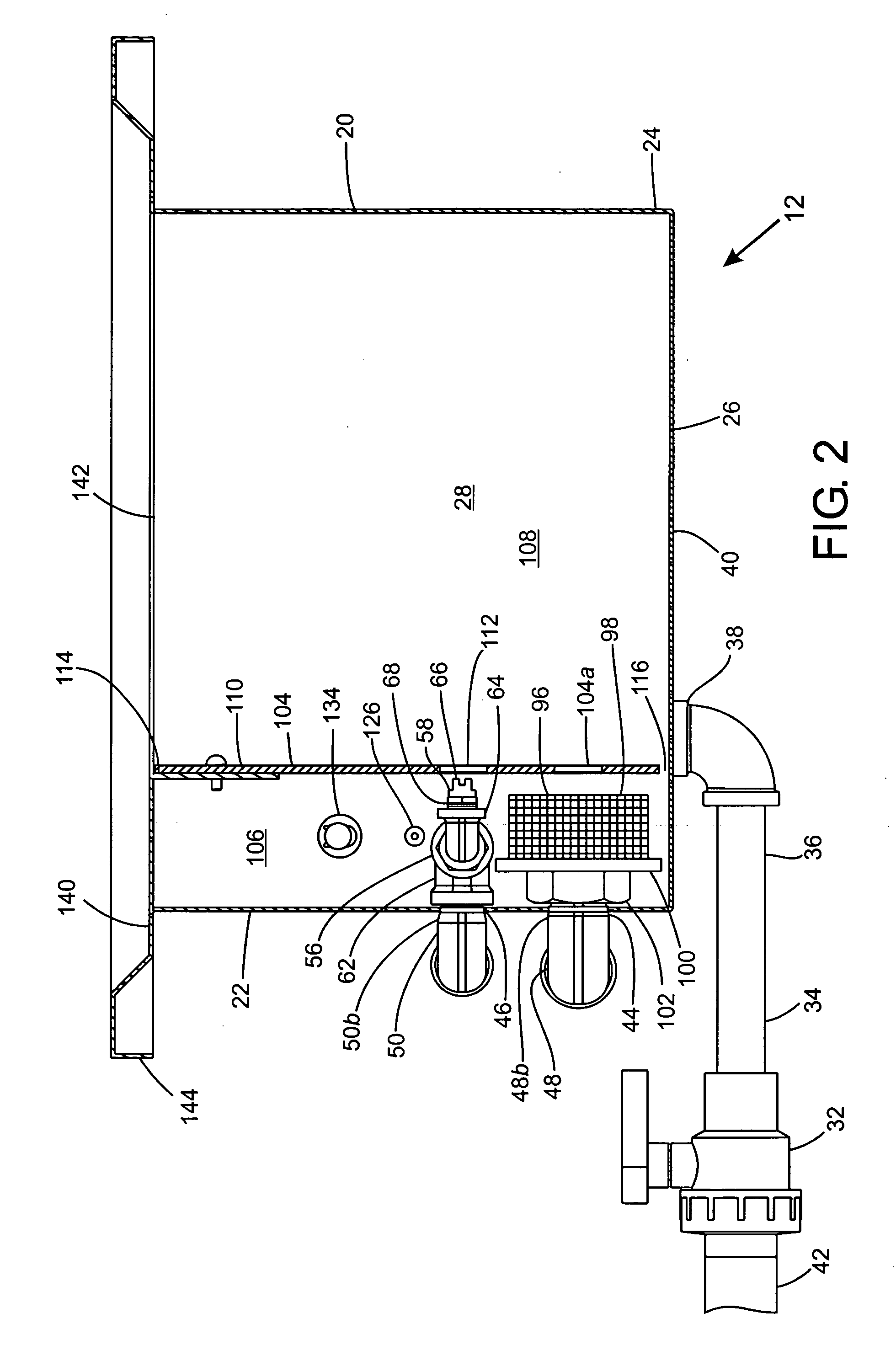

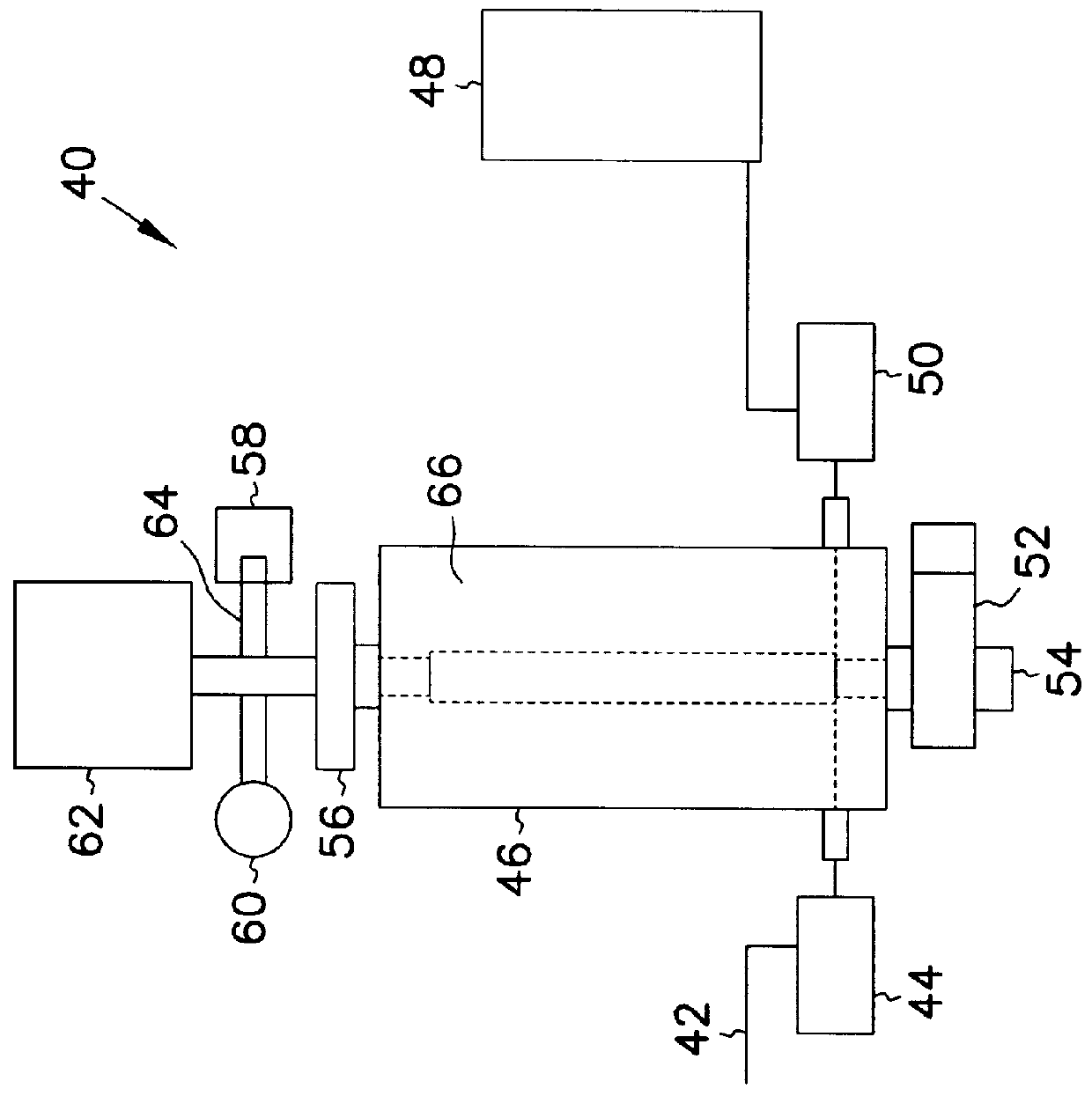

Apparatus and method of removing water soluble support material from a rapid prototype part

ActiveUS20050103360A1Low costEasy to useAdditive manufacturing apparatusHollow article cleaningSupport removalPotassium hydroxide

The support removal apparatus comprising in combination a retention tank having a manifold assembly comprising a plurality of nozzle heads in hydraulic communication with the discharge side of a pump, collectively configured for agitating an aqueous cleaning solution comprised of sodium or potassium hydroxide, sodium or potassium carbonate, and water; a heating element mounted within the retention tank for heating the aqueous cleaning solution to a predetermined temperature set point; a basket strainer mounted within the retention tank in hydraulic communication with the intake side of the pump to mitigate passage of small rapid prototype parts and residual support material therethrough and into the pump and manifold assembly; a work surface mounted atop the retention tank and having a movable lid fitted with a basket for containing small rapid prototype parts; a thermocouple for maintaining the temperature within a tolerable range for optimum removal of support material; a level indicator to ensure adequate solution level in the retention tank for operability of the pump and heating element; a cabinet having interface controller mounted on an exterior panel thereof for setting timer and heat functions; and a microprocessor having capabilities for making minute adjustments to the heating element via feedback from the thermocouple and controlling operation of the pump and heating element for a pre-set time interval.

Owner:TAFOYA DAVID JONATHAN

Process for pre-treating and desalinating sea water

ActiveUS7198722B2Extend equipment lifeReduce maintenanceGeneral water supply conservationSeawater treatmentCalcium bicarbonateReverse osmosis

Owner:HUSSAIN MOHAMMED AZAM

Watery zinc-aluminium heavy-duty coating in compounding squama shape and preparation method thereof

InactiveCN101525505AAchieve complete chrome-freeImprove bindingAnti-corrosive paintsPotassium hydroxideHeavy duty

The invention relates to a watery zinc-aluminium heavy-duty coating in a compounding squama shape and a preparation method thereof. The watery zinc-aluminium heavy-duty coating belongs to a bi-component coating and is prepared from organic-inorganic modified base stock and pigment according to a certain proportion by weight, wherein the organic-inorganic modified base stock contains silica sol, potassium hydroxide, silicone-acrylate emulsion, a pigment dispersing agent, a film forming addition agent and an antifoaming agent, and the balance is deionized water or distilled water; the pigment comprises squama-shaped zinc powder and squama-shaped aluminium powder; and the weight ratio of the organic-inorganic modified base stock to the pigment is 5: 1-2. The watery zinc-aluminium heavy-duty coating contains no chrome, can be solidified at the normal temperature, has environmental protection and low energy consumption and can be used for preparing thin coatings with high corrosion resistance, and the like.

Owner:HOHAI UNIV +1

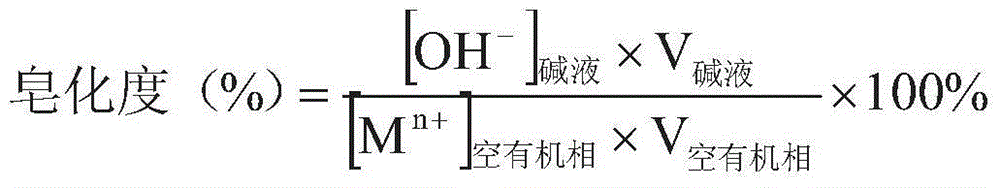

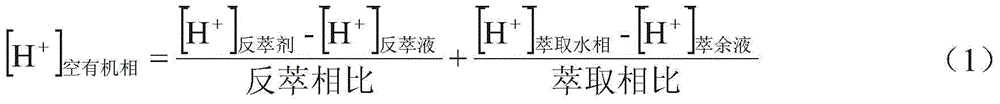

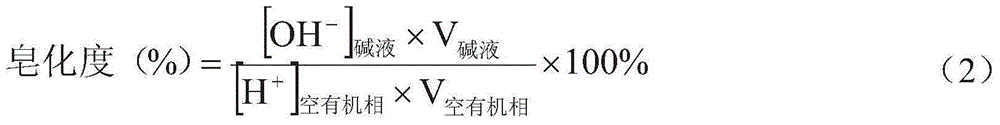

Regeneration method of lithium extraction system

InactiveCN104388677AGuaranteed recyclingSimple regeneration methodProcess efficiency improvementLithiumDiluent

The invention discloses a regeneration method of a lithium extraction system. The lithium extraction system is regenerated by virtue of alkaline saponification and the regeneration method comprises the following steps of mixing empty-loading organic phases subjected to lithium extraction and reverse extraction and alkaline liquor, saponifying and standing for separating phases to obtain a clarified and transparent regenerated and extracted organic phase, wherein the empty-loading organic phases comprise an extractant, a synergistic extractant and a diluent which are involved in the lithium extraction and reverse extraction processes; the synergistic extractant is iron chloride; and the alkaline liquor is any one of sodium hydroxide solution and potassium hydroxide solution. The regeneration method of the lithium extraction system disclosed by the invention has the advantages of simplicity in operation and good saponifying effect; when lithium is extracted by virtue of the saponified, regenerated and recycled extraction organic phase, the extraction efficiency of lithium is high and the extraction effect is good; and by the method, the recycling of the extraction organic phase for extracting lithium is achieved and the process flows of extracting, carrying out reverse extraction, regenerating and extracting for circularly extracting lithium are completed.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Cleaning composition and method for preparing the same

InactiveUS20060239952A1Good foam stabilization effectImprove propertiesCosmetic preparationsOrganic detergent compounding agentsNeutral Amino AcidsLong chain fatty acid

Cleaning compositions comprising (A) N-long-chain acyl neutral amino acid or a salt thereof, (B) N-long-chain acyl neutral amino acid dipeptide or a salt thereof, and (C) N-long-chain acyl neutral amino acid tripeptide or a salt thereof provide abundant foam, are excellent in foam retaining properties, and furnish a cleaned and dried body or hair with both a smooth feeling and a moist feeling. Compositions which further comprise (D) a higher fatty acid having 8 to 22 carbon atoms or a salt thereof exhibit enhanced creamy properties in foam quality. N-long-chain acyl neutral amino acids or salts thereof may be conveniently prepared by mixing a neutral amino acid, a long-chain fatty acid, and at least one of an alkaline substance selected from sodium hydroxide and potassium hydroxide, and maintaining the mixture with heating, while removing the water produced during the reaction, with no catalyst being employed.

Owner:AJINOMOTO CO INC

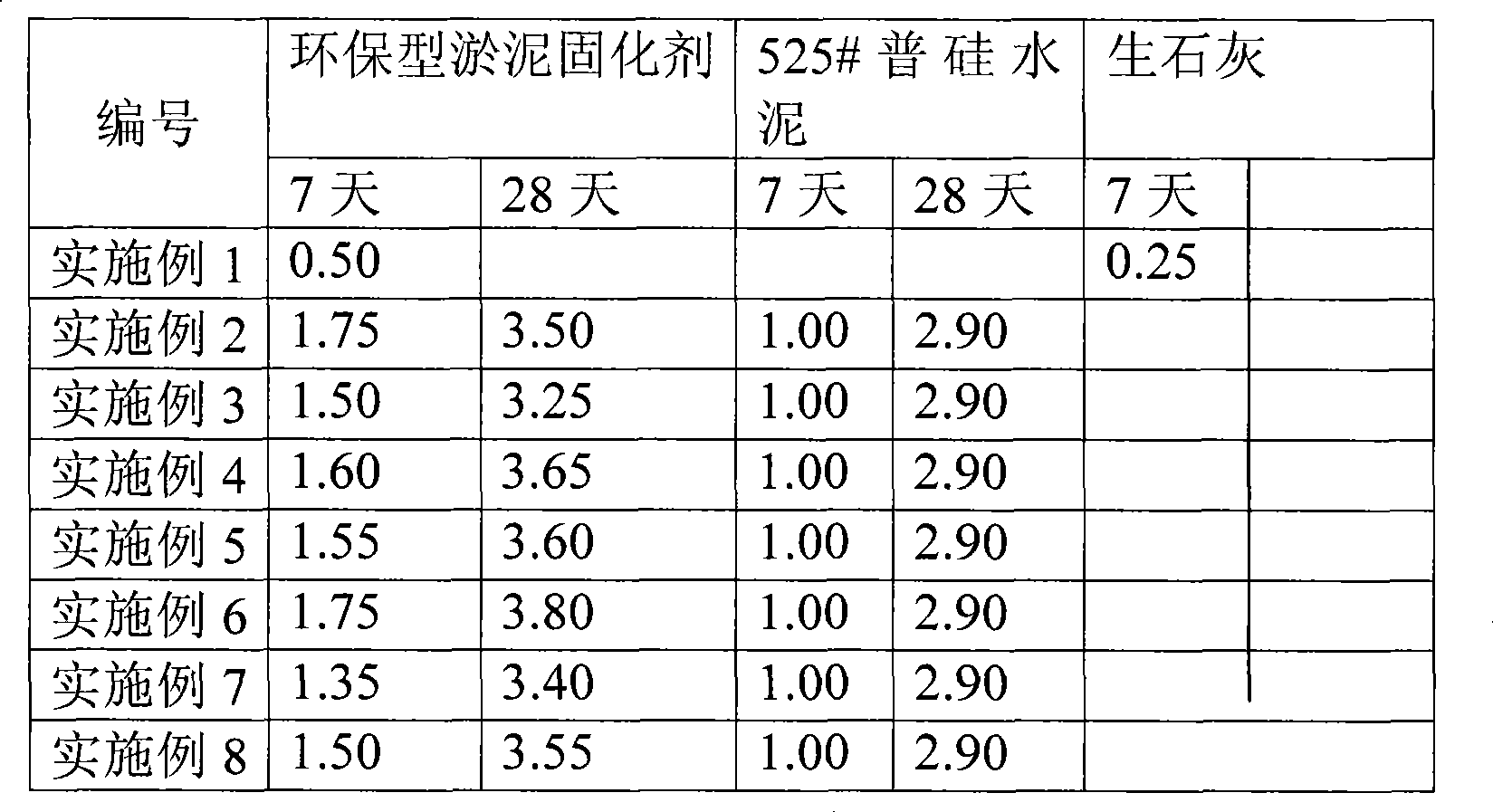

Environment-friendly type sludge firming agent

InactiveCN101381194AImprove curing abilityImprove curing effectSludge treatment by de-watering/drying/thickeningRoad engineeringSlag

The invention provides an environment-friendly silt curing agent, which is manufactured through the following steps: one or two among fly ash, calcium sulfate, sodium sulfate, sodium carbonate and potassium carbonate, one or two among slag, slag combination, potassium hydroxide, calcium oxide, sodium silicate or silicon dioxide, one or two among carbide slag, lime or gypsum, as well as one or two among triethanol amine surfactant, calcium lignosulfonate or sodium lignosulfonate form a plurality of optimal compound formulations according to respective attributes, are optimized, compounded, ground till the Brinell specific surface areas are between 300 and 900 m2 / kg respectively and then mixed, wherein particle sizes are between 0.00040 and 0.5 mm. As a large amount of waste is utilized, the curing agent saves raw materials, solves the problems about waste discharge and environmental pollution, controls waste through waste, and has important significance to environmental protection. The invention aims to provide the environment-friendly silt curing agent which has strong adaptability to a plurality of types of silt and soil, is good in curing effect, good in durability after curing and capable of utilizing industrial waste, and can be widely applied to fill engineering, embanking or embankment reinforcement engineering, road engineering and other fields.

Owner:天津渤海环保工程有限公司 +1

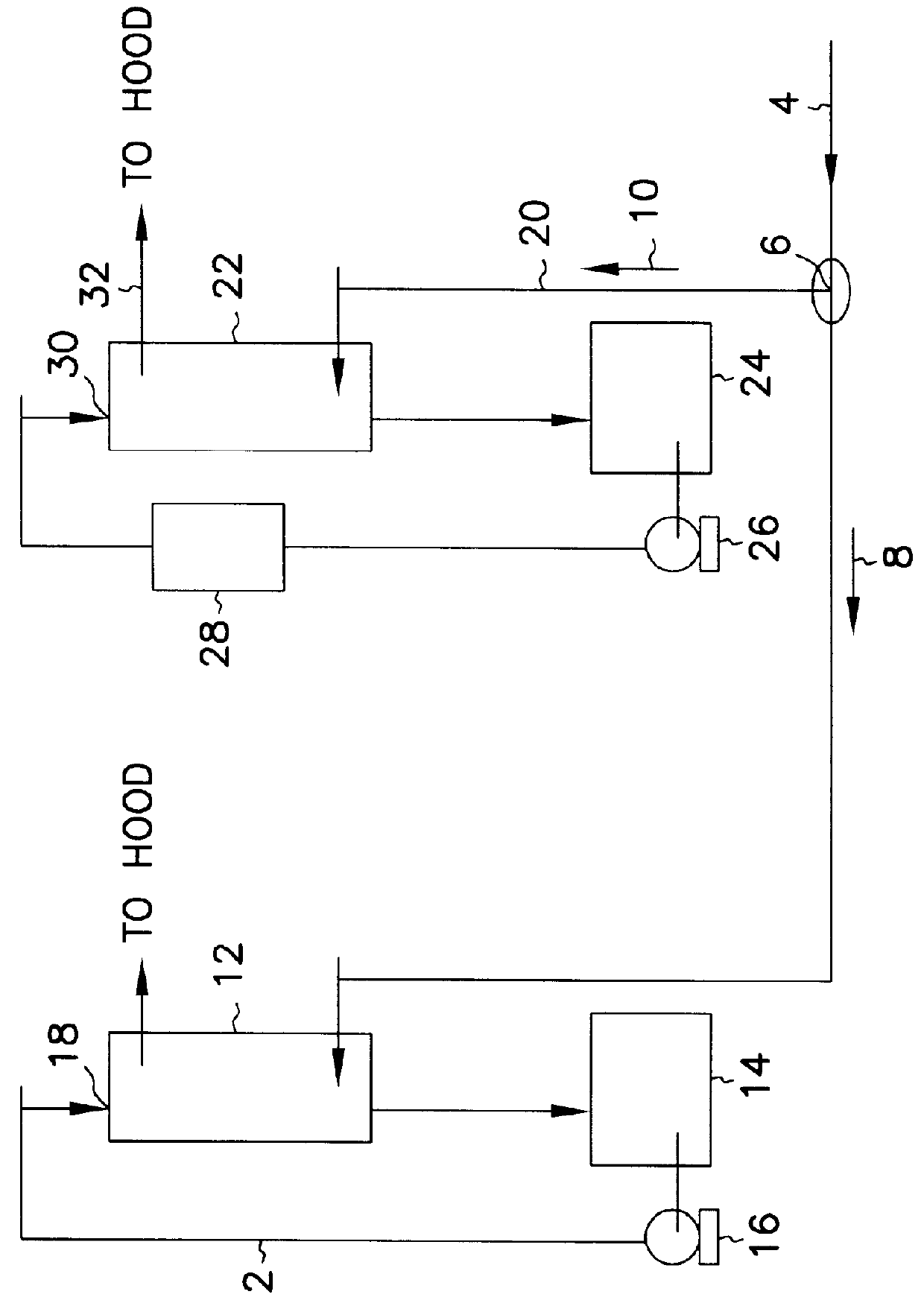

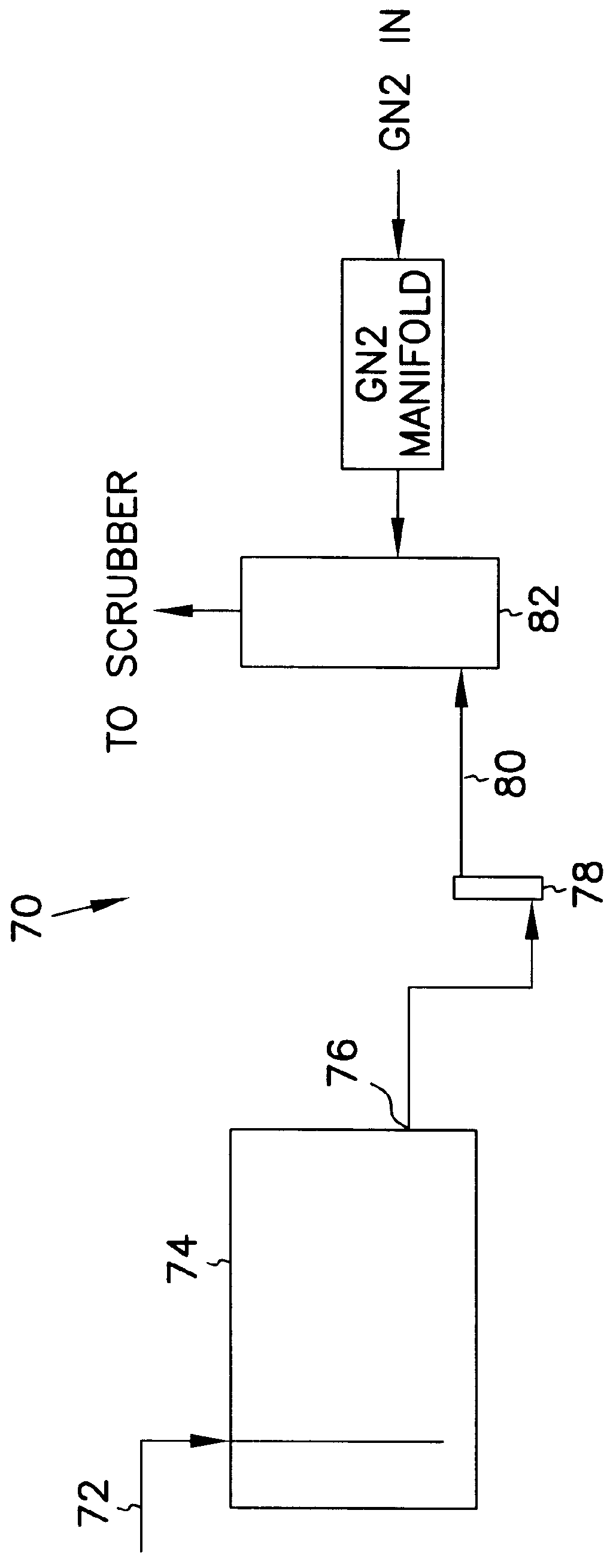

Process and equipment for nitrogen oxide waste conversion to fertilizer

The present invention describes a process for converting vapor streams from sources containing at least one nitrogen-containing oxidizing agent therein to a liquid fertilizer composition comprising the steps of: a) directing a vapor stream containing at least one nitrogen-containing oxidizing agent to a first contact zone, b) contacting said vapor stream with water to form nitrogen oxide(s) from said at least one nitrogen-containing oxidizing agent, c) directing said acid(s) as a second stream to a second contact zone, d) exposing said second stream to hydrogen peroxide which is present within said second contact zone in a relative amount of at least 0.1% by weight of said second stream within said second contact zone to convert at least some of any nitrogen oxide species or ions other than in the nitrate form present within said second stream to nitrate ion, e) sampling said stream within said second contact zone to determine the relative amount of hydrogen peroxide within said second contact zone, f) adding hydrogen peroxide to said second contact zone when a level of hydrogen peroxide less than 0.1 % by weight in said second stream is determined by said sampling, g) adding a solution comprising potassium hydroxide to said second stream to maintain a pH between 6.0 and 11.0 within said second stream within said second contact zone to form a solution of potassium nitrate, and h) removing said solution of potassium nitrate from said second contact zone.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION U S GOVERNMENT AS REPRESENTED BY THE ADMINISTATOR

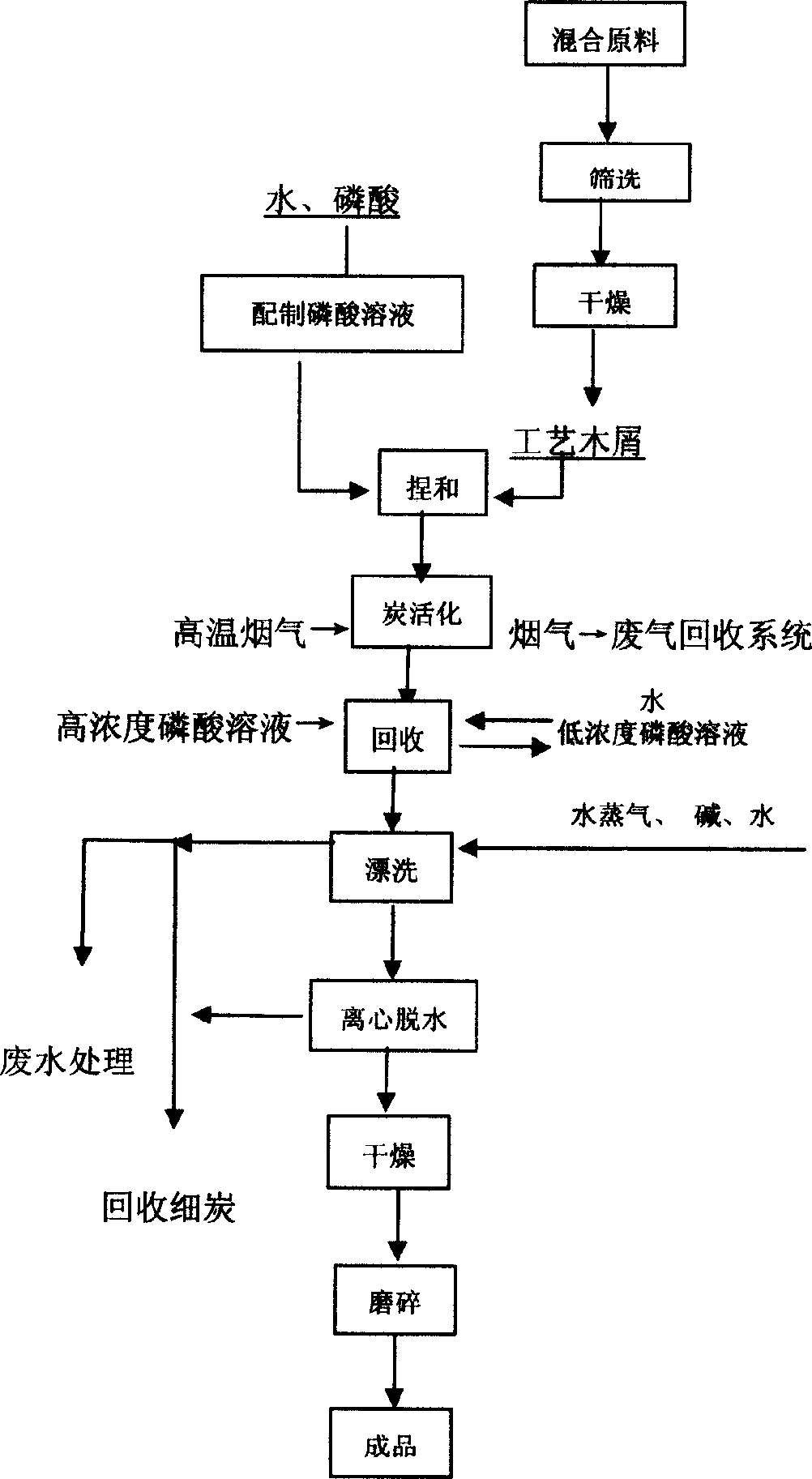

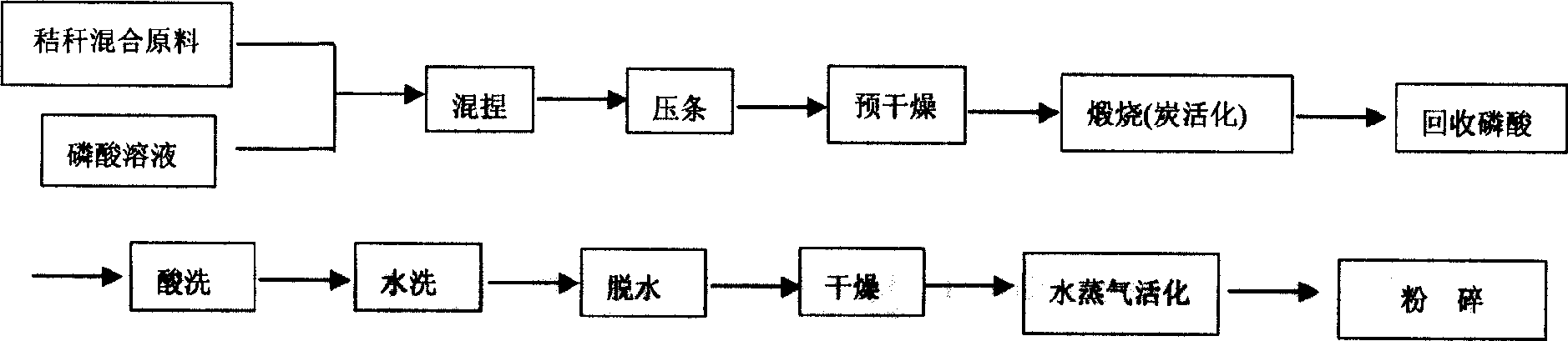

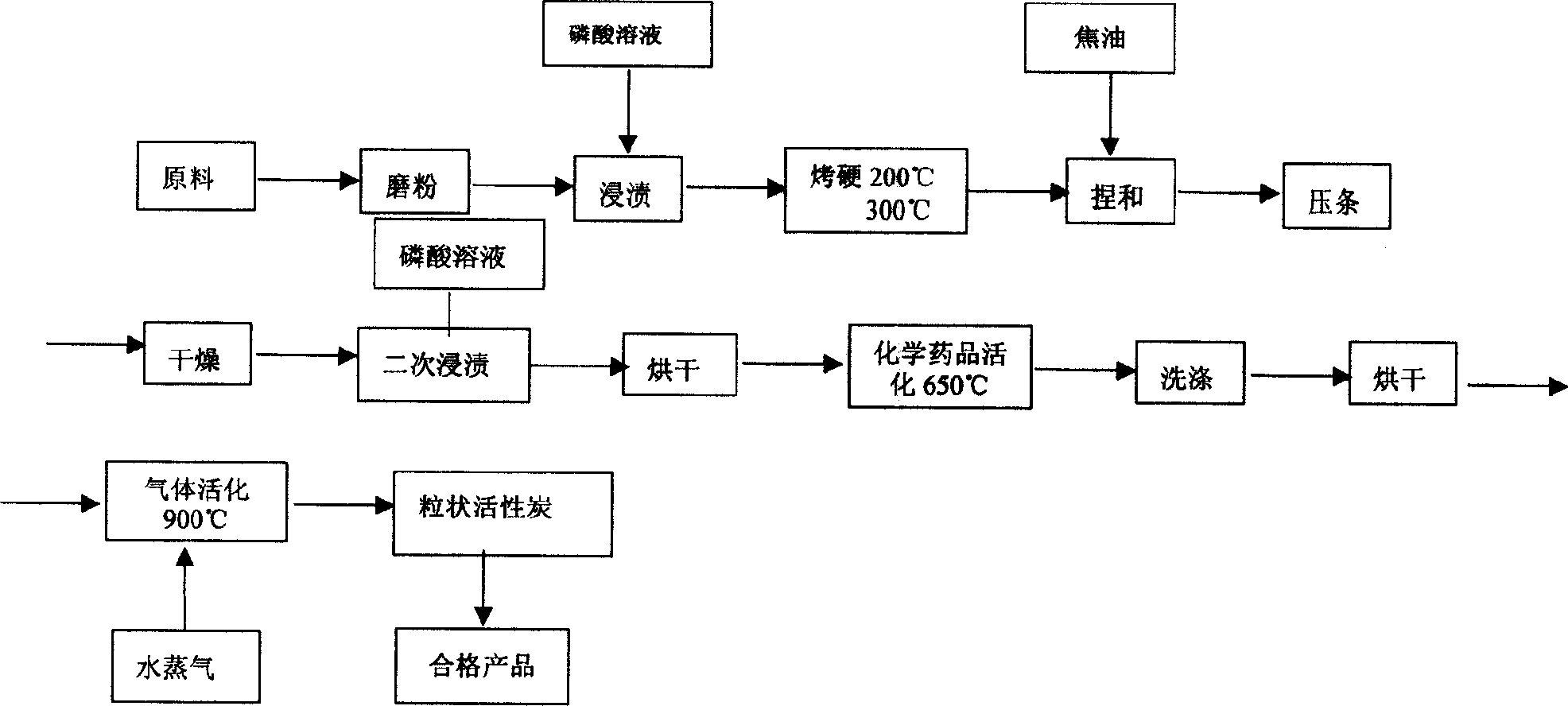

Active carbon producing process with mixed stalk material

The present invention discloses the active carbon producing process with mixed stalk material. The mixed stalk material of crop stalk, waste fruit branch and sawdust is produced into powdered or granular active carbon via phosphoric acid process and combined physical process. Or, the mixed stalk material is produced into powdered or granular active carbon in a chemical physical process with potassium hydroxide as activating agent and perchloric acid for pre-treatment of the material. The present invention has small investment scale, low cost, high utility and simple operation, and the product may be used widely.

Owner:NORTHWEST A & F UNIV

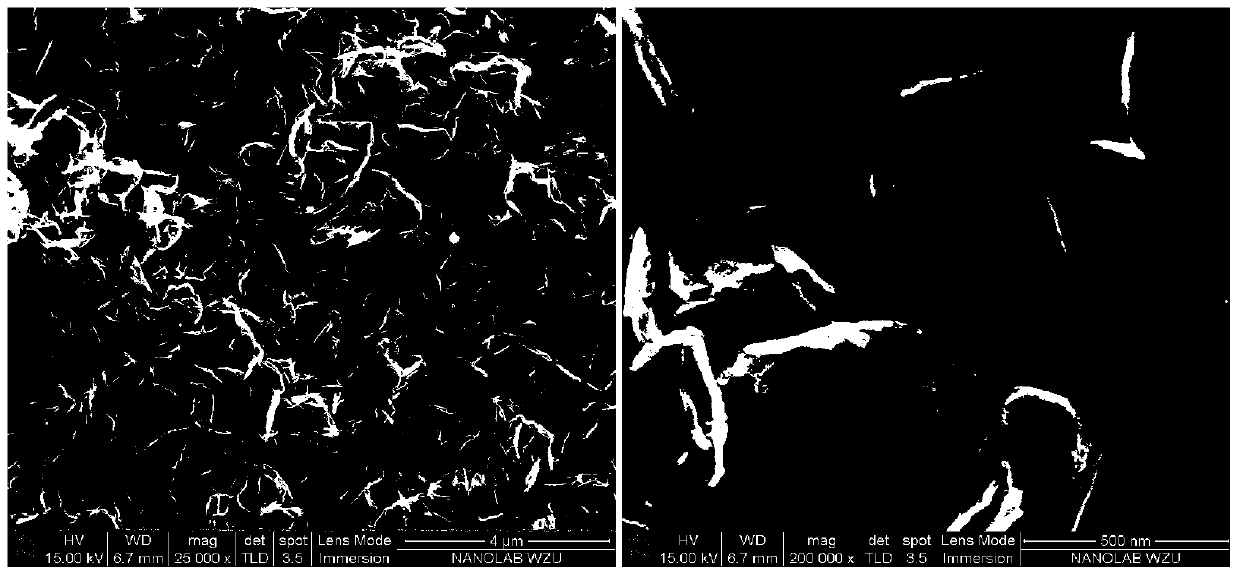

Graphene-based nitrogen-doped hierachical-pore carbon nanosheet/sulfur composite material for cathode of lithium sulfur battery, as well as preparation method and application of graphene-based nitrogen-doped hierachical-pore carbon nanosheet/sulfur composite material

ActiveCN103700859AIncrease loadNovel structureNon-aqueous electrolyte accumulator electrodesLi-accumulatorsElectrolytic agentElectrical battery

The invention discloses a graphene-based nitrogen-doped hierachical-pore carbon nanosheet / sulfur composite material for a cathode of a lithium sulfur battery, as well as a preparation method and application of the graphene-based nitrogen-doped hierachical-pore carbon nanosheet / sulfur composite material. The carbon nanosheet is a graphene-based nitrogen-doped hierachical-pore carbon nanosheet, and is prepared by the steps of growing poly-pyrrole on graphene oxide in situ, performing carbonization at high temperature, activating by using potassium hydroxide and forming pores, wherein the graphene oxide and nano-silicon dioxide serve as double templates; the thickness of the carbon nanosheet is 10 to 25 nm; the specific surface area is 800 to 1,600 m<2> / g; the pore diameter of the carbon nanosheet is distributed into the range of 0.8 to 6 nm in a concentrated way; the structure of the carbon nanosheet is a sandwich-like type which adopts graphene as the interlayer of the carbon nanosheet. The carbon nanosheet with abundant micro-pores, meso-pores and large specific surface area can load more sulfur active substances and can effectively inhibit dissolution of polysulfide. The ultrathin nanosheet, and the micro-pores and meso-pores guarantee diffusion of electrolyte and transmission of ions. According to the structure, the capacity, the cycling stability, the coulombic efficiency and the rate performance of the carbon nanosheet / sulfur composition material applied to the lithium sulfur battery are improved synergistically.

Owner:WENZHOU UNIVERSITY

Polishing composition and polishing method

InactiveUS20050205837A1Suitable for useOther chemical processesDecorative surface effectsColloidal silicaTetramethylammonium hydroxide

A polishing composition includes silicon dioxide, an alkaline compound, an anionic surfactant, and water. The silicon dioxide is, for example, colloidal silica, fumed silica, or precipitated silica. The alkaline compound is, for example, potassium hydroxide, sodium hydroxide, ammonia, tetramethylammonium hydroxide, piperazine anhydride, or piperazine hexahydrate. The anionic surfactant is at least one selected from a sulfonic acid surfactant, a carboxylic acid surfactant, and a sulfuric acid ester surfactant. The polishing composition can be suitably used in applications for polishing a silicon wafer.

Owner:FUJIMI INCORPORATED

Preferred materials for pigmented ink jet ink

InactiveUS6866379B2Measurement apparatus componentsDuplicating/marking methodsAddition polymerLithium hydroxide

An ink jet ink composition including from 40.0 to 99.0% by weight of water; from 0.1 to 20.0% by weight of a pigment dispersed with an oleoyl methyl taurine salt dispersant from 0 to 70.0% by weight of a water miscible co-solvent; and from 0.1 to 20.0% by weight of a water-reducible addition polymer; wherein the weight average molecular weight of the polymer is from 2,000 to 100,000; the acid number is from 50 to 400; and the acid group on the polymer is neutralized by an alkaline metal hydroxide such as lithium hydroxide, sodium hydroxide potassium hydroxide, or a mixture thereof; and wherein all weight percentages are based on the total weight of the ink composition. An ink jet printing method is also disclosed.

Owner:EASTMAN KODAK CO

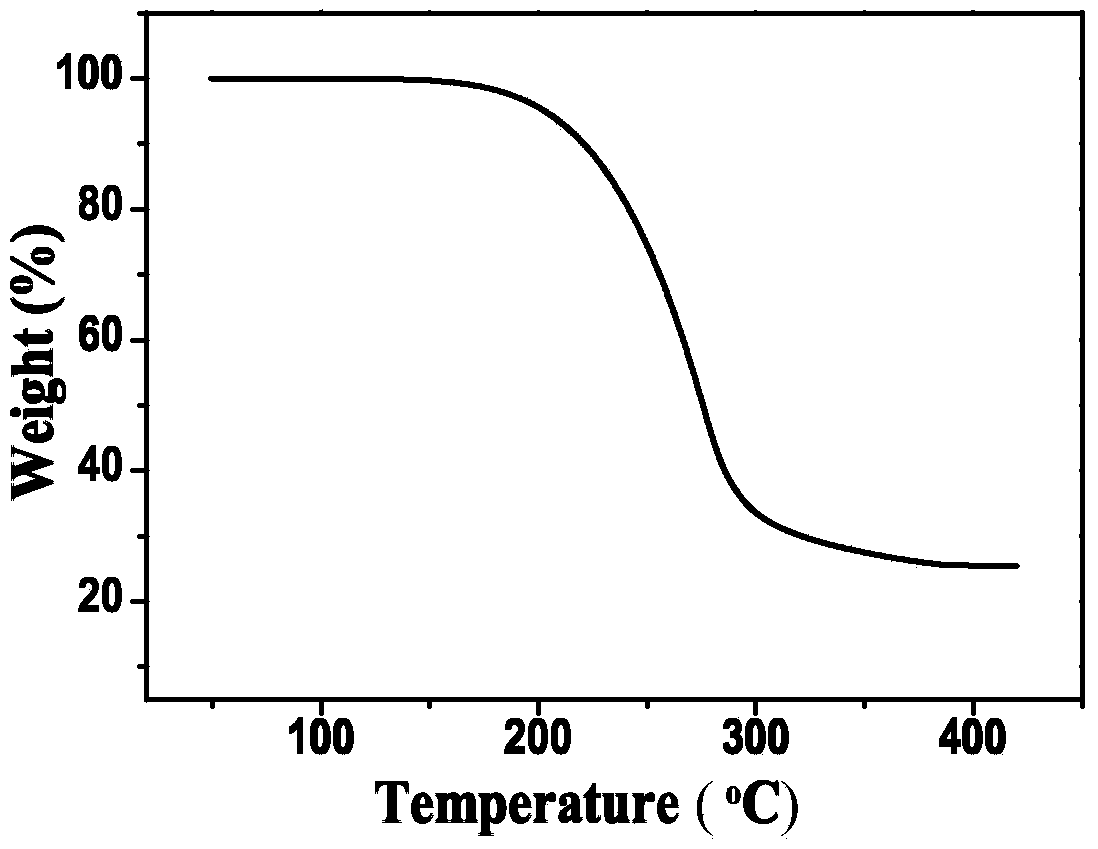

Synthetic process of herbicide dicamba

ActiveCN102942474AImprove one-way yieldImprove quality and efficiencyOrganic compound preparationCarboxylic compound preparationMethoxylaricinolic acidFixed bed

The invention relates to a preparation method of herbicide dicamba. The preparation method includes: (1) liquid potassium hydroxide and 2, 5-dichlorophenol are reacted according to molar ratio of 0.95:1-1:1 to obtain 2, 5-dichlorophenol potassium; (2) at the presence of anhydrous potassium carbonate and catalyst, the 2, 5-dichlorophenol potassium obtained in the step (1) is reacted with CO2 to generate 3, 6-dichlorosalicylic acid, pressure of CO2 is controlled to be 4-6MPa, reaction temperature ranges from 100 DEG C to 160 DEG C, and molar ratio of anhydrous potassium carbonate and 2, 5-dichlorophenol potassium is 1-2:1; and (3) in alkaline condition, at the temperature of 70-100 DEG C, the 3, 6-dichlorosalicylic acid obtained in the step (2) and chloromethane are reacted under the action of the catalyst through a tube fixed-bed reactor according to molar ratio 1:1-3.5, saponification and acidification are performed to obtain 3, 6-dichloro-2-methoxysalicylic acid, namely the dicamba. The process is high in reaction yield, simple in reaction condition, good in product quality, small in three wastes and low in energy consumption.

Owner:JIANGSU YOUJIA CHEM +2

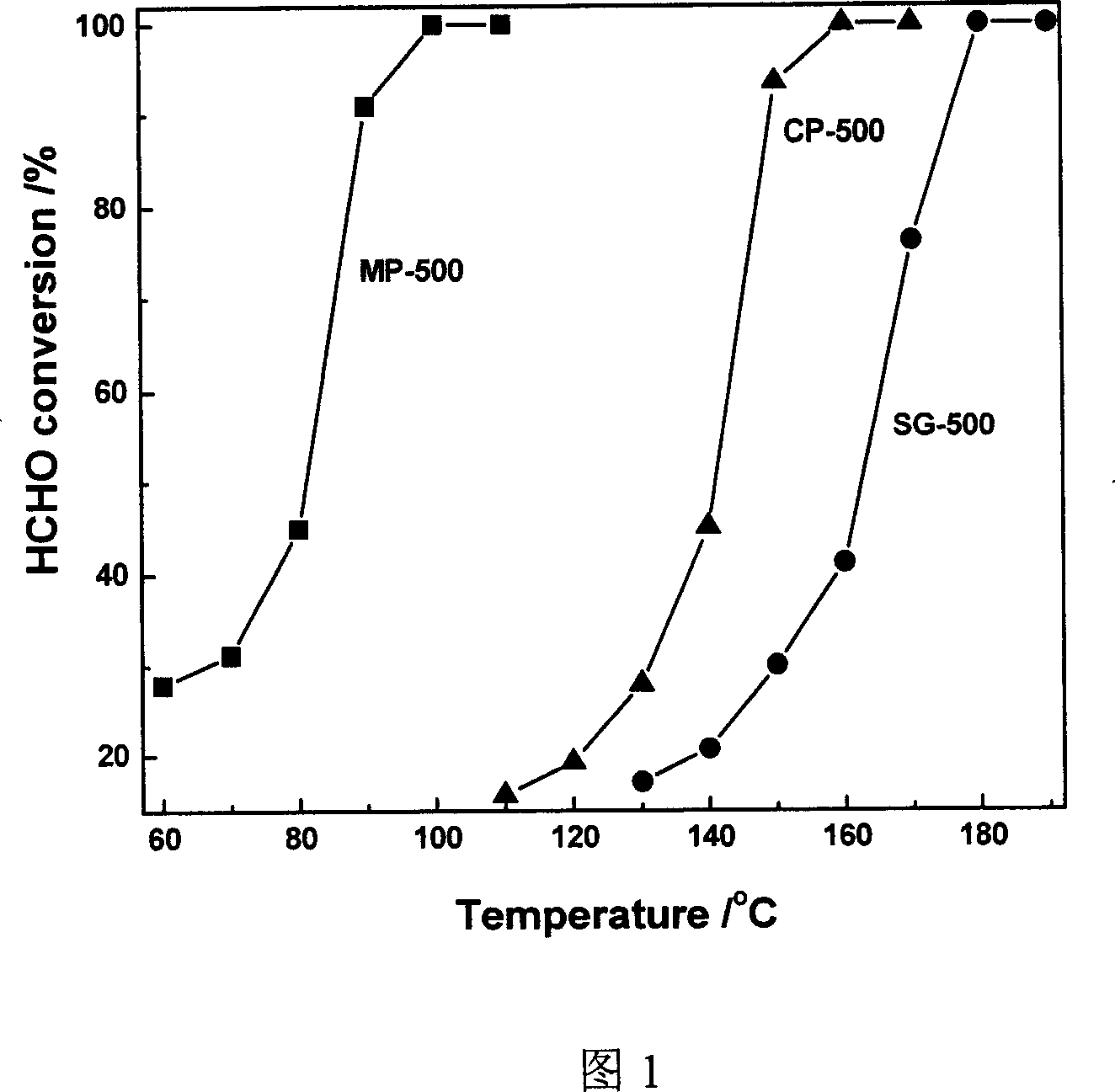

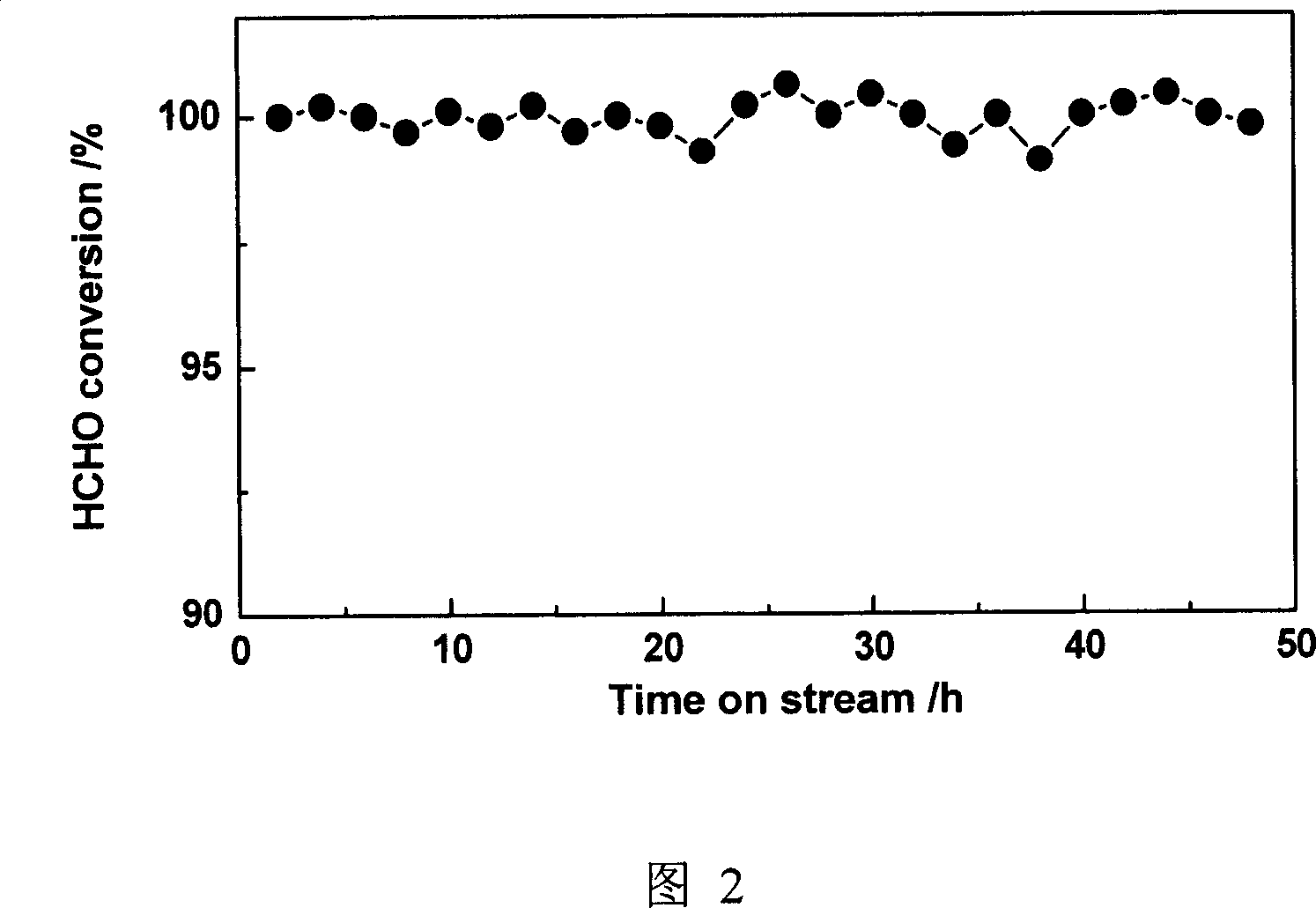

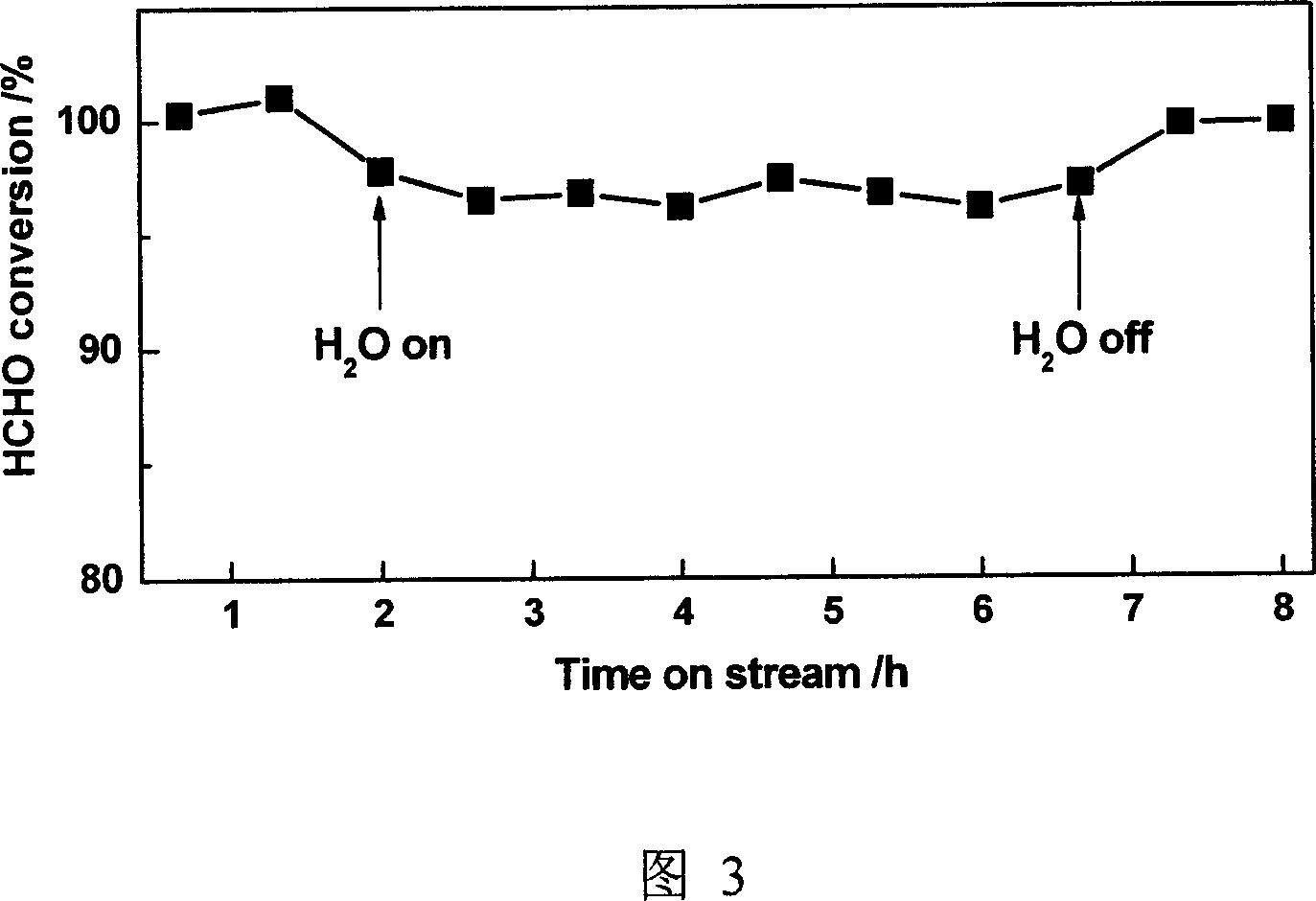

Manganese cerium composite oxide catalyst, its production and use

InactiveCN101028595AStrong interactionHigh activityDispersed particle separationCatalyst activation/preparationNitrateManganese

A composite Mn-Ce oxide catalyst for oxidizing the form-aldehyde into CO2 and H2O is prepared through adding soluble manganese nitrate in the solution of potassium permanganate and cerium ammonium nitrate while stirring, adding potassium hydroxide, stirring to obtain deposit, filtering, washing, drying at 80-120 deg.C and calcining.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

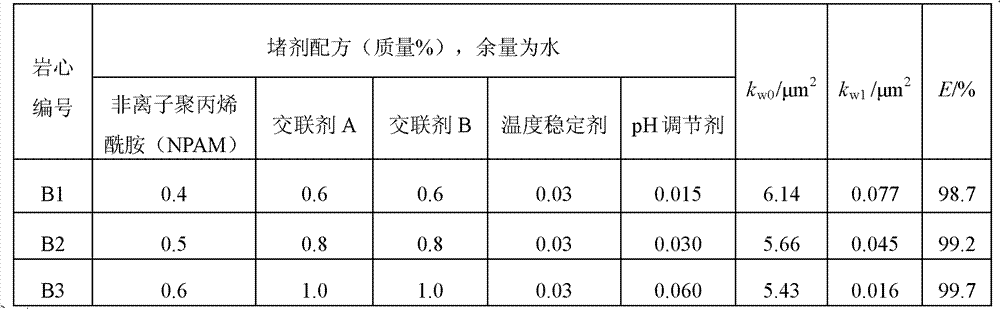

Gel plugging agent for deep profile control of higher temperature oil reservoir and preparation method of gel plugging agent

ActiveCN102807849AImprove temperature resistanceGelation time is shortDrilling compositionSodium bicarbonateCross-link

The invention relates to a gel plugging agent for deep profile control of a higher temperature oil reservoir, and a preparation method of the gel plugging agent. The gel plugging agent comprises 0.3-0.8 percent of nonionic polyacrylamide, 0.6-1.3 percent of a cross-linking agent A, 0.45-1.44 percent of a cross-linking agent B, 0.02-0.04 percent of a temperature stabilizer and 0.01-0.08 percent of a pH value regulator, wherein the cross-linking agent A is methenamine; the cross-ling agent B is hydroquinone or resorcinol; the temperature stabilizer is sodium thiosulfate, sodium bisulfite or sodium sulfite; and the pH regulator is sodium hydroxide, potassium hydroxide, sodium carbonate or sodium bicarbonate. The gel plugging agent disclosed by the invention has strong temperature resisting performance and can be used for the profile control operation of the high temperature oil reservoir with 100-160DEG C; the gel plugging agent has the characteristics of high strength after being gelatinized, stronger plugging capability for the stratum and favorable thermal stability; and in addition, after the gel plugging agent is stood at the temperature of 130 DEG C for 90 days, the strength change is little and gel breaking and hydration are avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

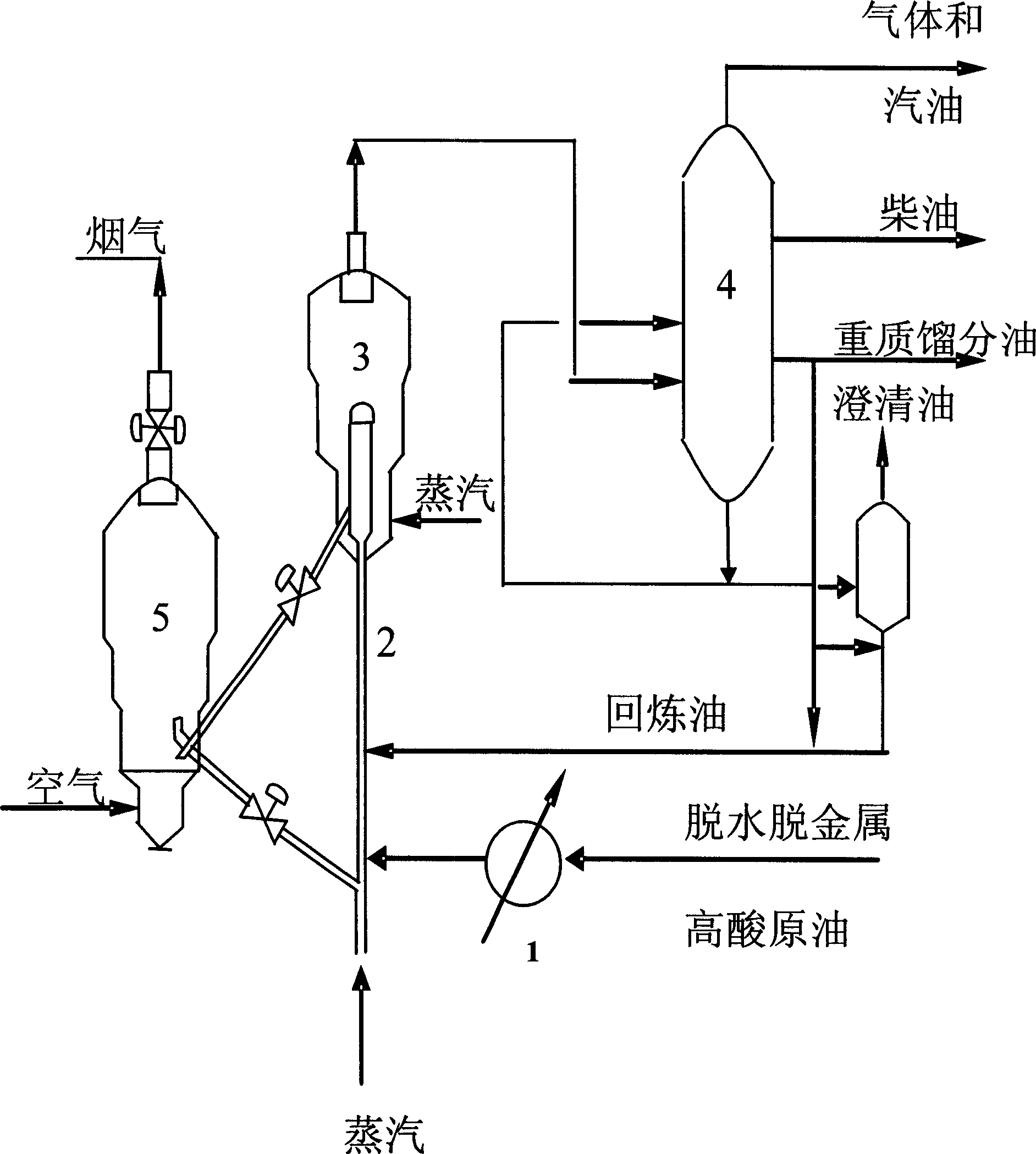

Method for processing crude oil with high acid value

ActiveCN1827744AEvenly distributedInhibition of harmful effectsCatalytic crackingPotassium hydroxideAcid value

A method for producing highly acid value crude oil consists of preheating the crude oil which is total acid number of more than 0.5mg potassium hydroxide per gram after the pretreatment and injecting them into the fluidized catalytic cracker to contact the catalyst, and reacting in catalytically cracked reaction condition, separating the oil gas and the catalyst, in which the oil gas is put into the subsequent separation system, while the catalyst can be circularly used after stripping and regenerating. The method is characterized in that it is of strong industrial practicability, low running cost and fine deacidification effect and so on.

Owner:CHINA PETROLEUM & CHEM CORP +1

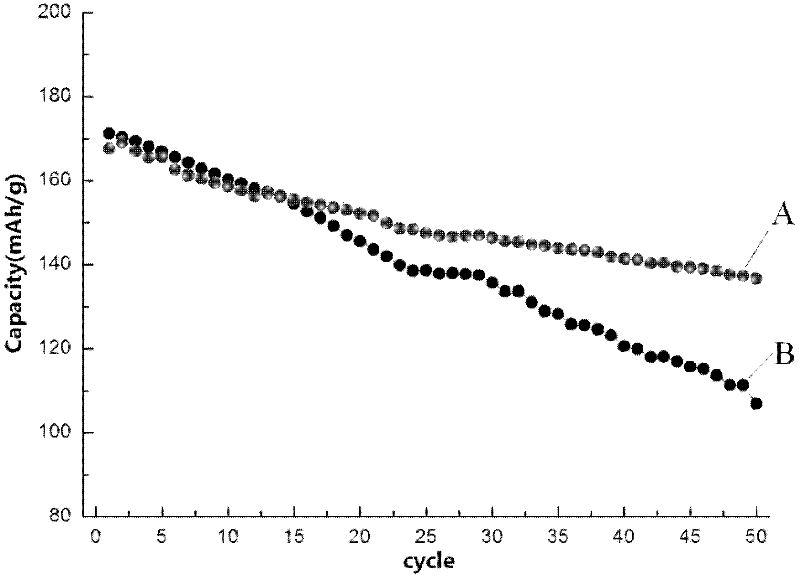

Preparation method of lithium-ion battery cathode material coated aluminum

InactiveCN102299299ACoating process conditions are easy to controlImprove high temperature stabilityCell electrodesNickel saltElectrical battery

The invention relates to a method for preparing aluminum-coated anode materials of lithium-ion batteries, which is characterized in that: firstly, soluble nickel salts, cobalt salts, and manganese salts are formulated into salt solutions, and then mixed with ammonia-water-mixed sodium hydroxide or potassium hydroxide solutions React to form precursor particles, wash and dry; add water to the dried precursor particles to prepare a flowable slurry, stir, and add trivalent aluminum salt solution and sodium hydroxide or potassium hydroxide solution dropwise to the slurry at the same time , to obtain the precursor of nickel hydroxide cobalt manganese coated with aluminum; then mix the precursor with lithium source, and then sinter to obtain the positive electrode material of lithium ion battery coated with aluminum. The present invention has the following obvious advantages: raw materials are easy to obtain; coated The process conditions are easy to control, and it is easy to obtain a relatively uniform coating body; the prepared positive electrode material can make the lithium ion battery have superior high temperature stability and better cycle characteristics.

Owner:深圳市天骄科技开发有限公司

Low-temperature scouring and bleaching agent and preparation method thereof and preprocessing technique

InactiveCN101037842AReduce the bleaching temperatureThe effect of the pretreatment process is obviousBleaching apparatusTextile treatment by spraying/projectingTextile printerBenzene

The present invention realtes to a low temperature scouring and bleaching agent belonging to the pretreatment process technology field of the textile printing and dyeing industry, a manufacturing method thereof and a pretreatment process. Said low temperature scouring and bleaching agent consists of promoter QR2010 consisting of carbon tetrachloride, acetic acid esters, alkyl benzenes, emulsifying agents and scouring agents; promoter QR2011 consisting of potassium hydroxide, carbonates and penetrating agents; and promoter QR2020 consisting of acyls and nitriles activating agents and builders. Said three promoters are prepared using routine methods and are deposited solely. When used, the three promoters, together with hydrogen peroxide, are mixed according to different proportions to prepare solutions. Said low temperature scouring and bleaching agent is capable of annealing, boiling and bleaching a variety of cotton as well as cotton blending textiles at any temperature ranging from 40 DEG C to 80 DEG C, and being processed at different scouring and bleaching equipments, with a whiteness of higher than 80% and a capillary effect of 10-20 cm. Compared with the process in existing, the amount used of hydrogen peroxide activating agent is 1 / 7 to 1 / 5 of that originally used, the total energy consumption is reduced, the tonnage of used water is decreased, and billet flaws such as holes bleached by oxygen and lycra folded crepes sourced and bleached are avoided.

Owner:SHANGHAI QIRUI TEXTILE CHEM

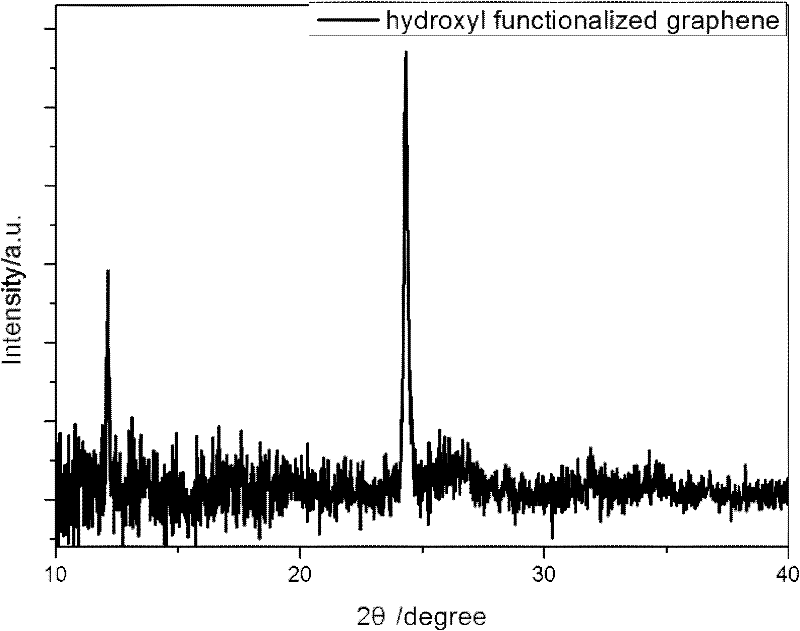

Low-temperature preparation method of hydroxy-functionalized graphene

InactiveCN102225759AThe internal structure is intactHigh degree of crystallinityNanotechnologyPotassium hydroxideEngineering

The invention relates to a novel and simple low-temperature preparation method of hydroxy-functionalized grapheme, belonging to the field of novel carbon nanomaterials. The preparation method provided by the invention comprises the following steps of: adding graphite powder and potassium hydroxide solid to a ball milling tank, then adding milling balls to the ball milling tank, placing the ball milling tank in a ball mill, continuously ball-milling under air blast and room temperature conditions at a speed of 200-400 r / min for 10-16 hours, transferring the ball-mill product to a sample bottle by deionized water, and then removing unreacted potassium hydroxide by deionized water until the solution was neutral. By using the preparation method provided by the invention, hydroxy-functionalized grapheme can be prepared at room temperature, and the hydroxy-functionalized grapheme has a lamellar structure, contains a large number of hydroxyl groups on the surface, well remained internal structure and a high crystallinity.

Owner:WENZHOU MEDICAL UNIV

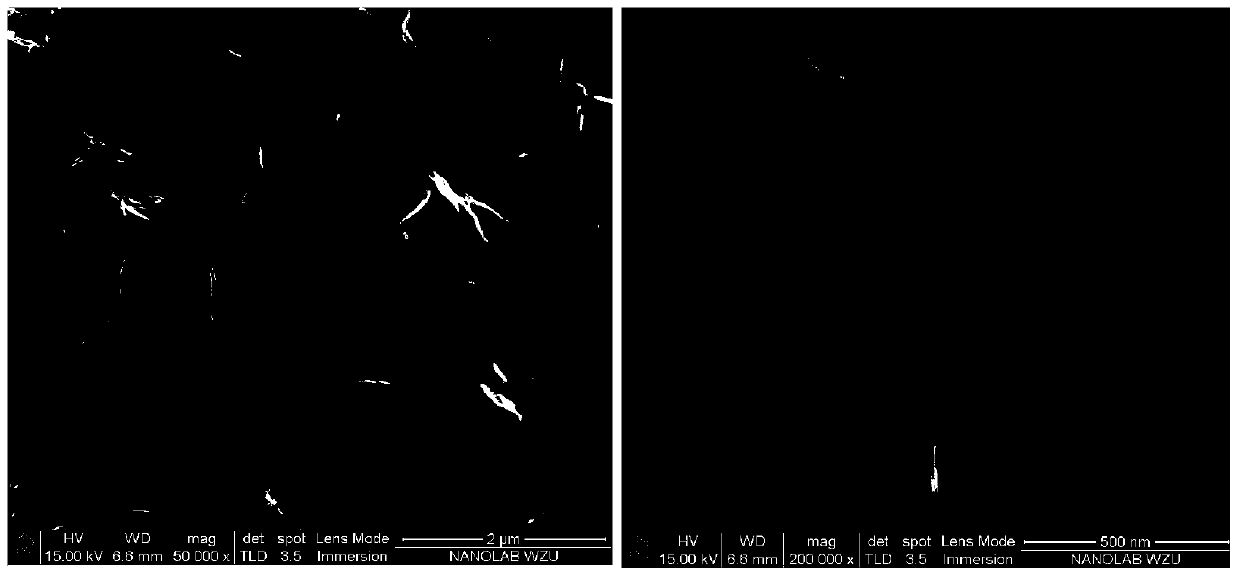

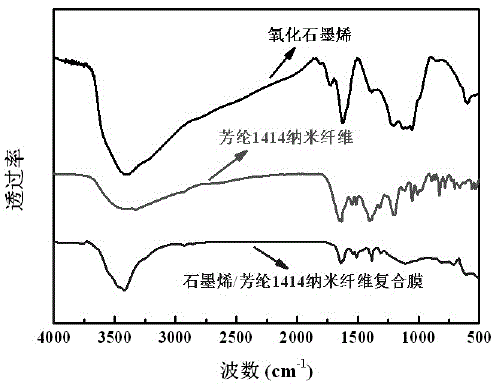

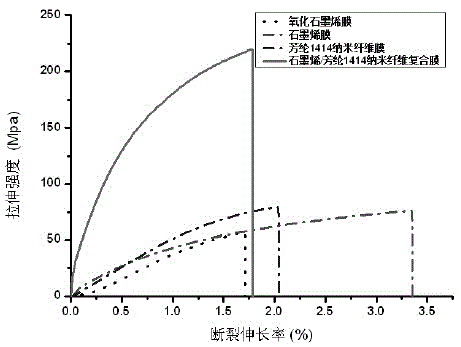

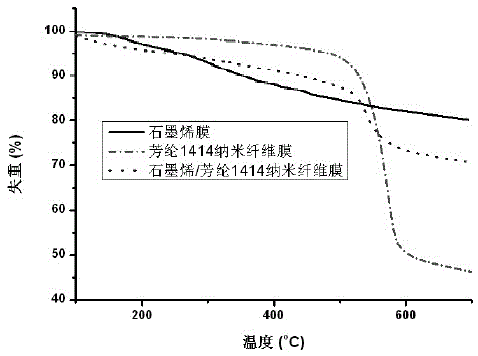

Preparation method for graphene/aramid fibre 1414 nano-fibre composite membrane

The invention discloses a preparation method for a graphene / aramid fibre 1414 nano-fibre composite membrane, comprising the following steps of: performing nano-fibrillation on aramid fibre 1414 yarns via the solution system of dimethyl sulfoxide and potassium hydroxide; slowly adding dimethyl sulfoxide solution for oxidizing graphene, sequentially centrifuging, dispersing, performing suction filtration and film formation, and thus obtaining oxidized graphene / aramid fibre 1414 nano-fibre composite membrane; and reducing via hydroiodic acid, washing, drying, and thus obtaining the graphene / aramid fibre 1414 nano-fibre composite membrane. The tensile strength and the Young modulus of the graphene / aramid fibre 1414 nano-fibre composite membrane obtained by the preparation method disclosed by the invention can achieve 209.4 Mpa and 29.5 GPa respectively, thus showing excellent mechanical property; simultaneously, the conductivity of the graphene / aramid fibre 1414 nano-fibre composite membrane can achieve 175 S / m, thus being excellent in conductance; and a thermogravimetric analysis shows that the graphene / aramid fibre 1414 nano-fibre composite membrane is good in heat stability.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com