Patents

Literature

77results about How to "Improve one-way yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthetic process of herbicide dicamba

ActiveCN102942474AImprove one-way yieldImprove quality and efficiencyOrganic compound preparationCarboxylic compound preparationMethoxylaricinolic acidFixed bed

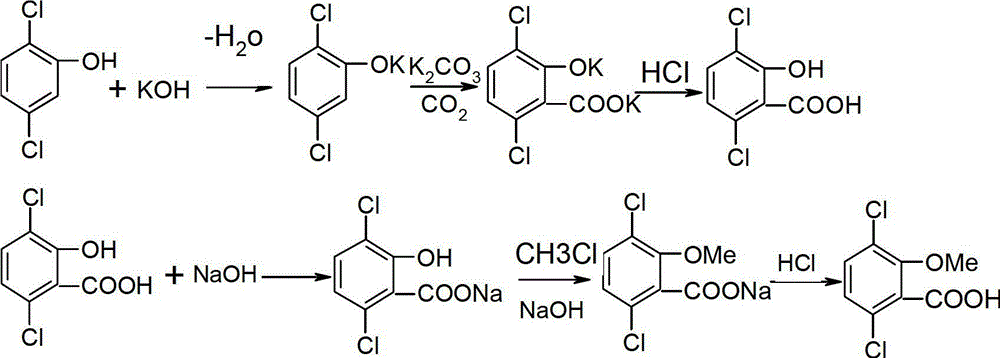

The invention relates to a preparation method of herbicide dicamba. The preparation method includes: (1) liquid potassium hydroxide and 2, 5-dichlorophenol are reacted according to molar ratio of 0.95:1-1:1 to obtain 2, 5-dichlorophenol potassium; (2) at the presence of anhydrous potassium carbonate and catalyst, the 2, 5-dichlorophenol potassium obtained in the step (1) is reacted with CO2 to generate 3, 6-dichlorosalicylic acid, pressure of CO2 is controlled to be 4-6MPa, reaction temperature ranges from 100 DEG C to 160 DEG C, and molar ratio of anhydrous potassium carbonate and 2, 5-dichlorophenol potassium is 1-2:1; and (3) in alkaline condition, at the temperature of 70-100 DEG C, the 3, 6-dichlorosalicylic acid obtained in the step (2) and chloromethane are reacted under the action of the catalyst through a tube fixed-bed reactor according to molar ratio 1:1-3.5, saponification and acidification are performed to obtain 3, 6-dichloro-2-methoxysalicylic acid, namely the dicamba. The process is high in reaction yield, simple in reaction condition, good in product quality, small in three wastes and low in energy consumption.

Owner:JIANGSU YOUJIA CHEM +2

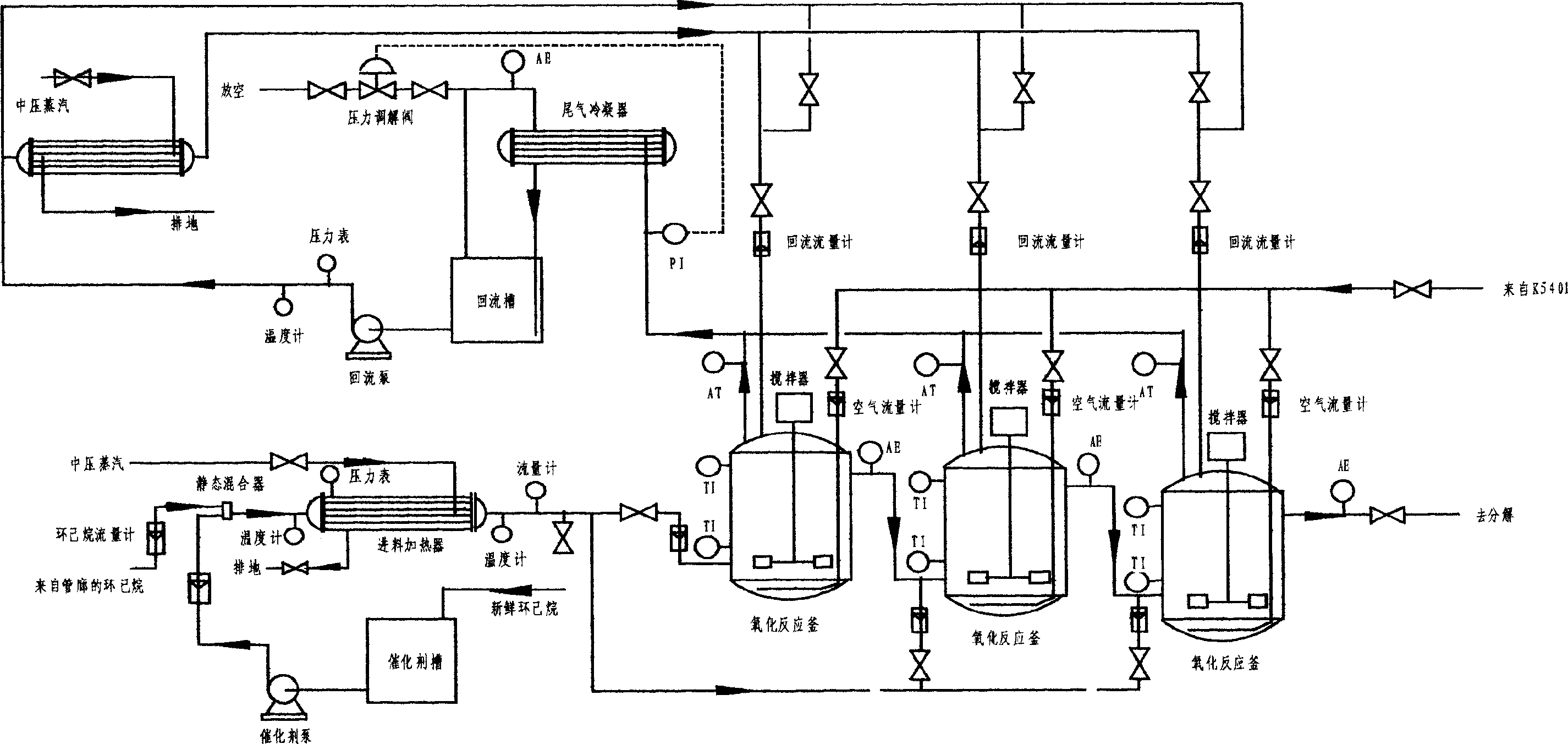

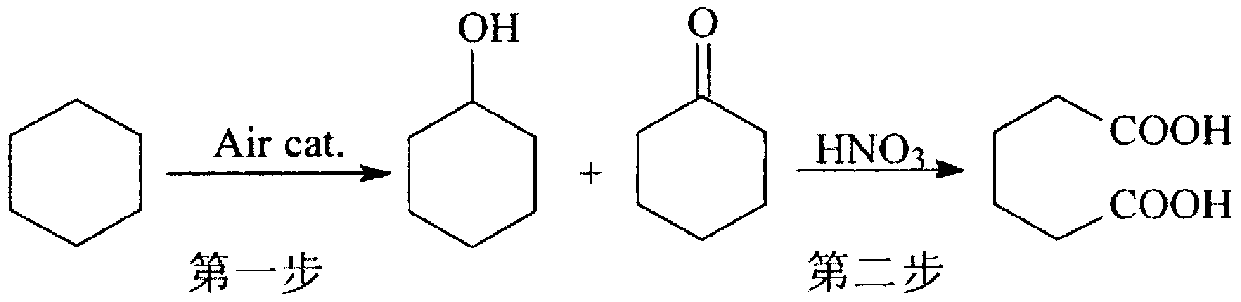

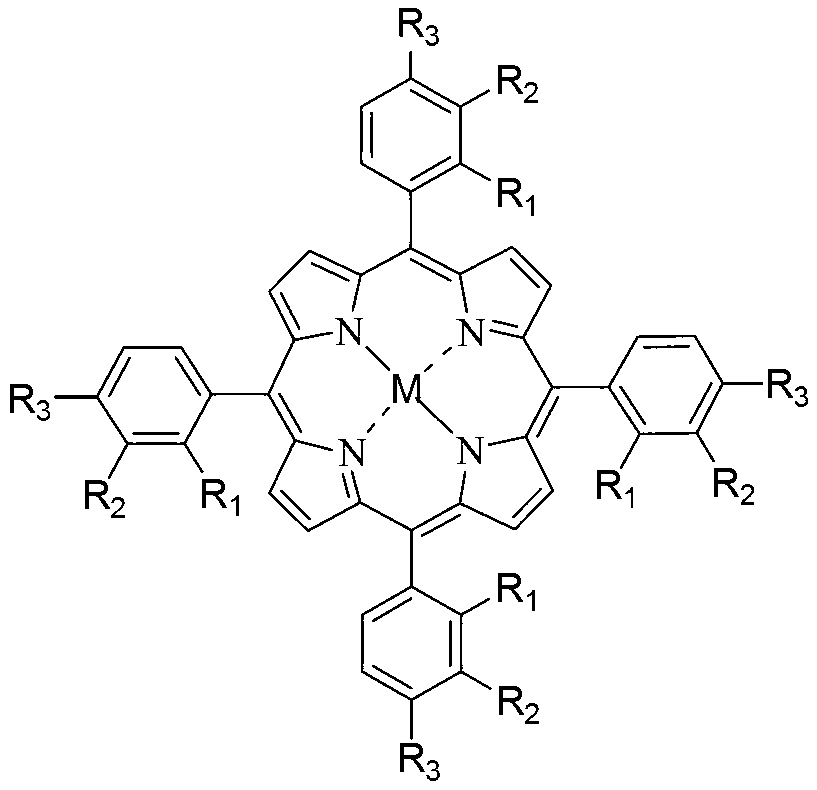

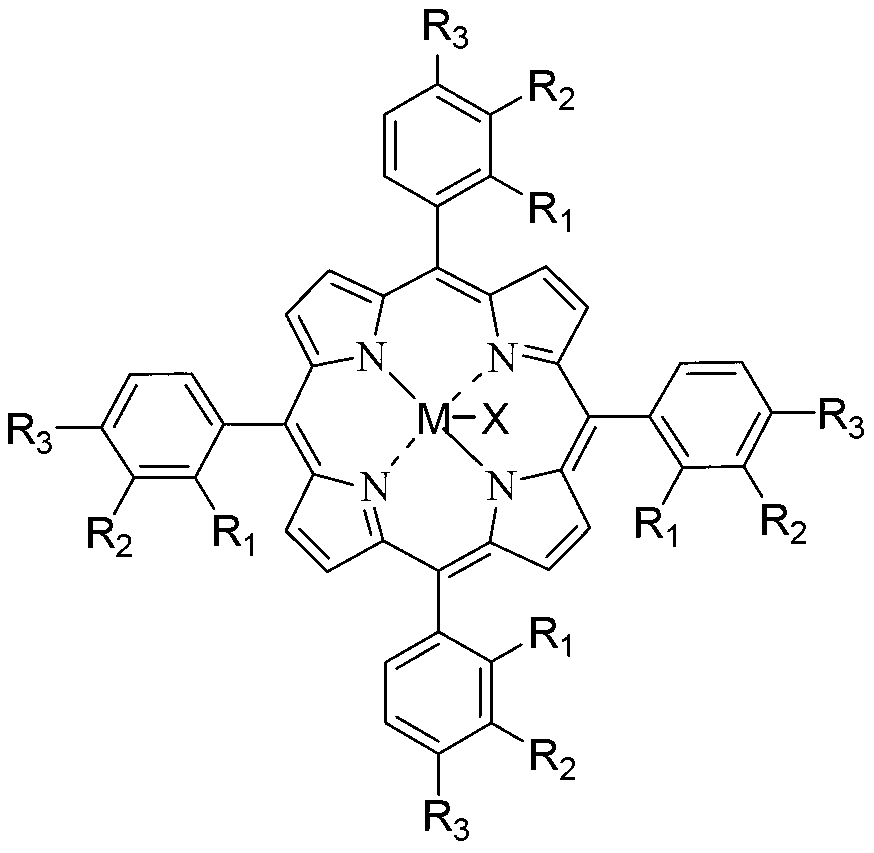

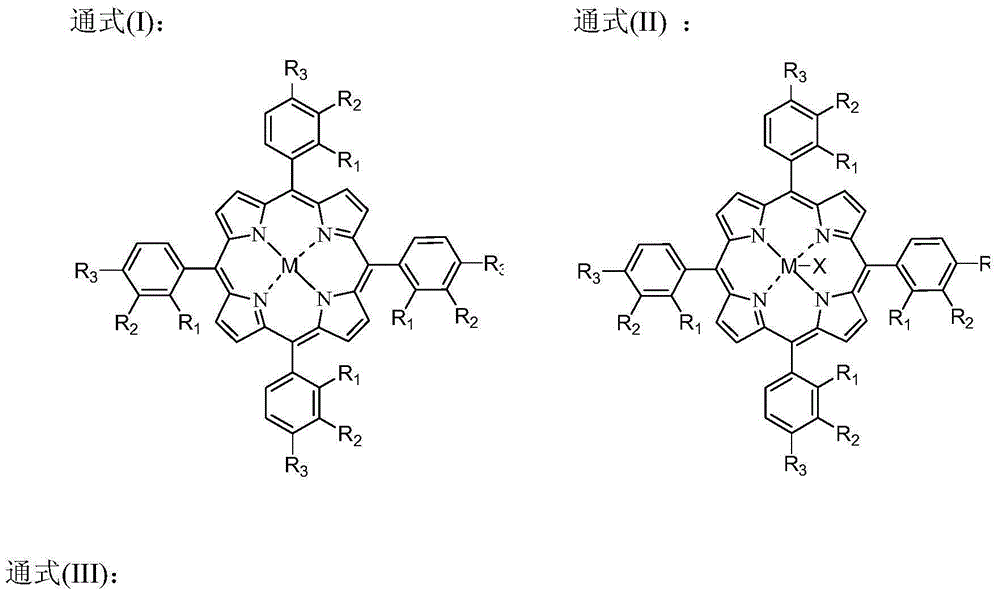

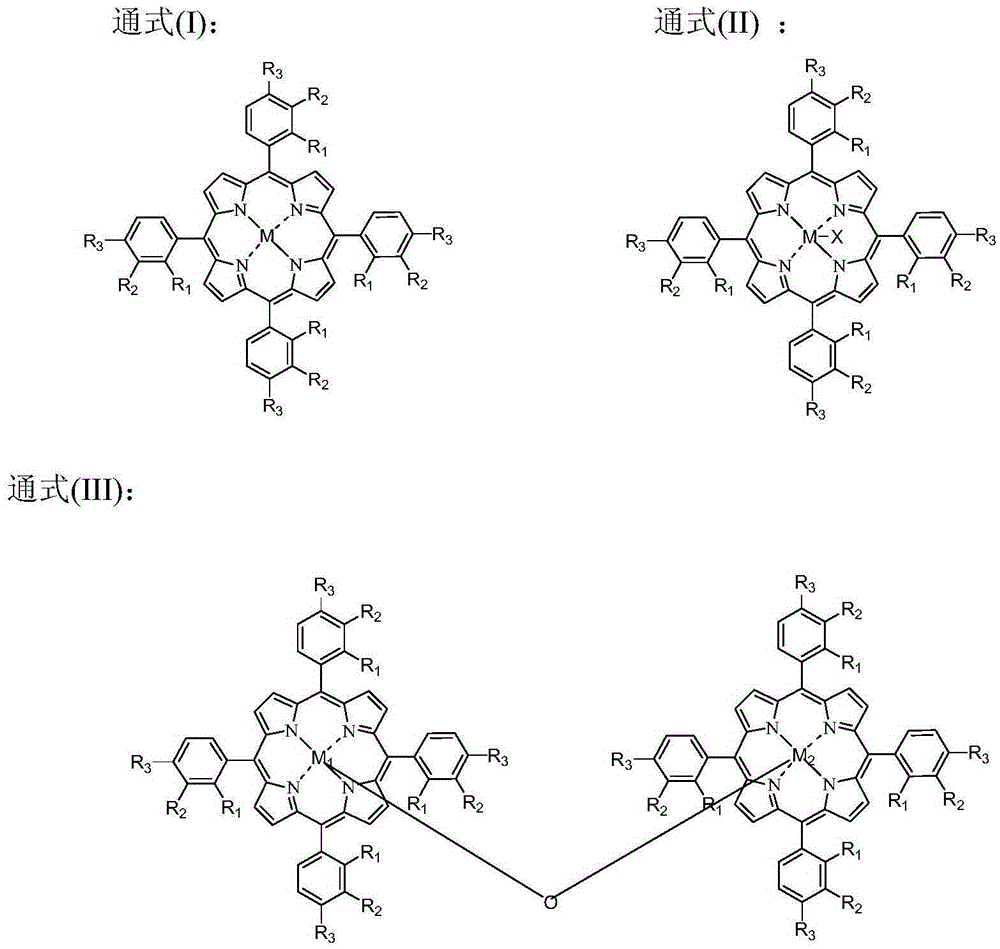

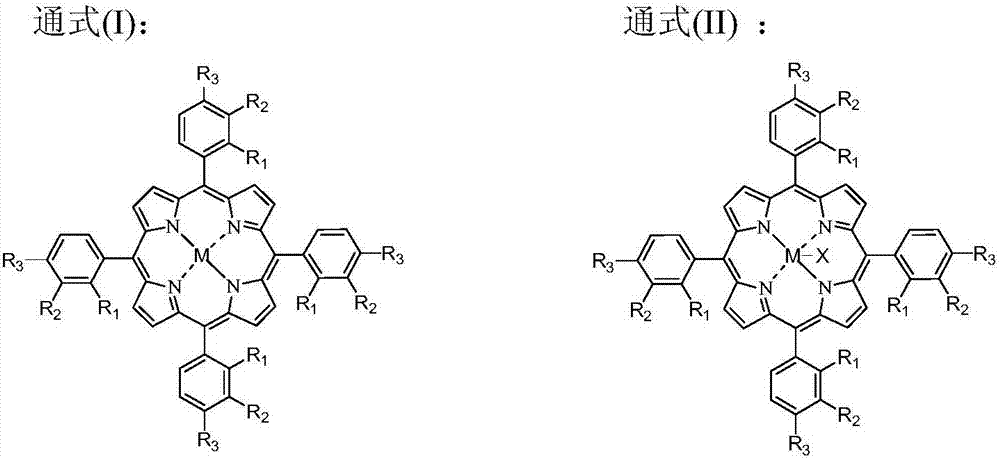

Catalyst oxdie cyclohexane process

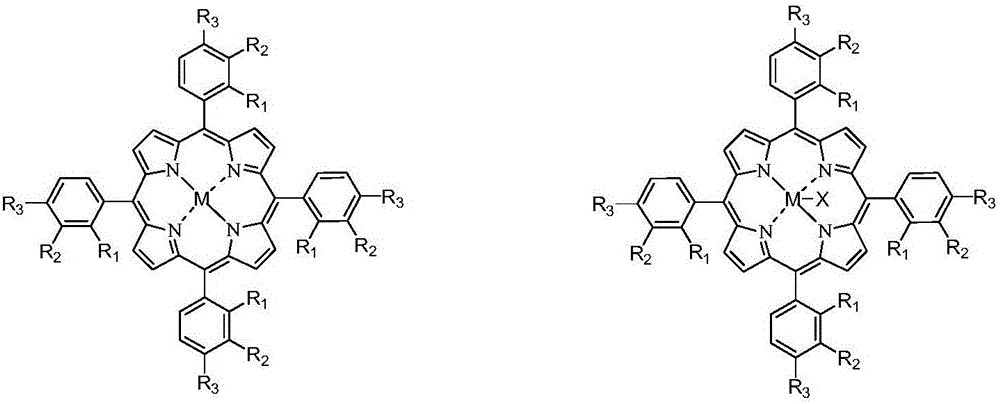

ActiveCN1530358AIncrease conversion rate per passImprove one-way yieldOxygen compounds preparation by hydrocarbon oxidationCyclohexanonePorphyrin

A process for preparing cyclohexanol, cyclohexanone and adipic acid by catalytic oxidization of cyclohexane under existance of metallic porphyrin catalyst and a certain temp and pressure through combination of different reactors is disclosed. Its advantages are high single-pass conversion rate of cyclohexane and total output rate, low energy consumption and cost, and no need of cyclohexanol or acetone solvent and cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP

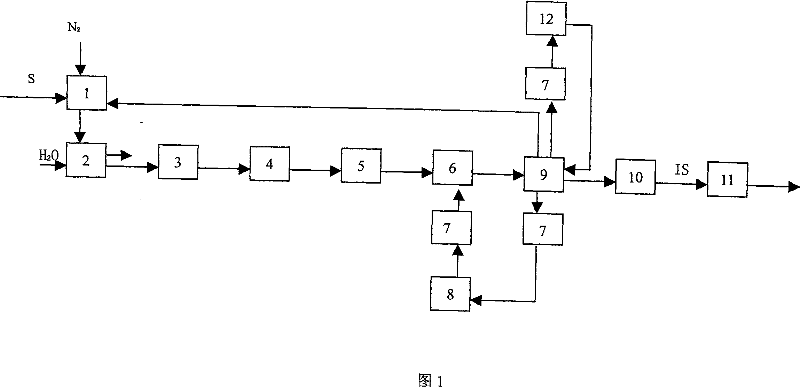

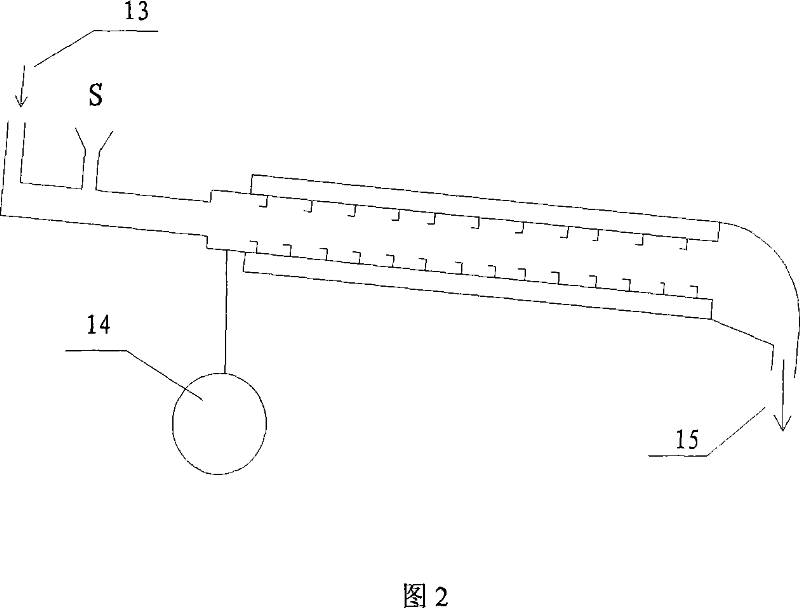

Preparation method of oil-filled insoluble sulphur

InactiveCN101037191AImprove one-way yieldColor has no effectSulfur preparation/purificationThermal insulationSolvent

The present invention relates to a preparation method of insoluble sulfur of special vulcanizing agent used for rubber, in particular to a preparation method of oil charge type insoluble sulfur, which comprises the steps of: using ordinary sulfur as raw material which is added with composite stabilizer; putting into a reaction kettle which is provided with a heating controller and a stirring device; nitrogen blanketting; melt polymerization at 200~300 DEG C; thermal insulation for 25~120 min; quenching, curing, drying, size reduction and sieving; extracting by using a mixed solvent as extractant, centrifugal separation of the liquid after extraction, fluidized drying of the residue, and then obtaining insoluble sulfur; and then executing oil charge to obtain oil charge type insoluble sulfur with high stability. The operation has a strong continuity, the recovery energy consumption of the extractant is low and the product has high thermal stability.

Owner:NANJING UNIV OF TECH

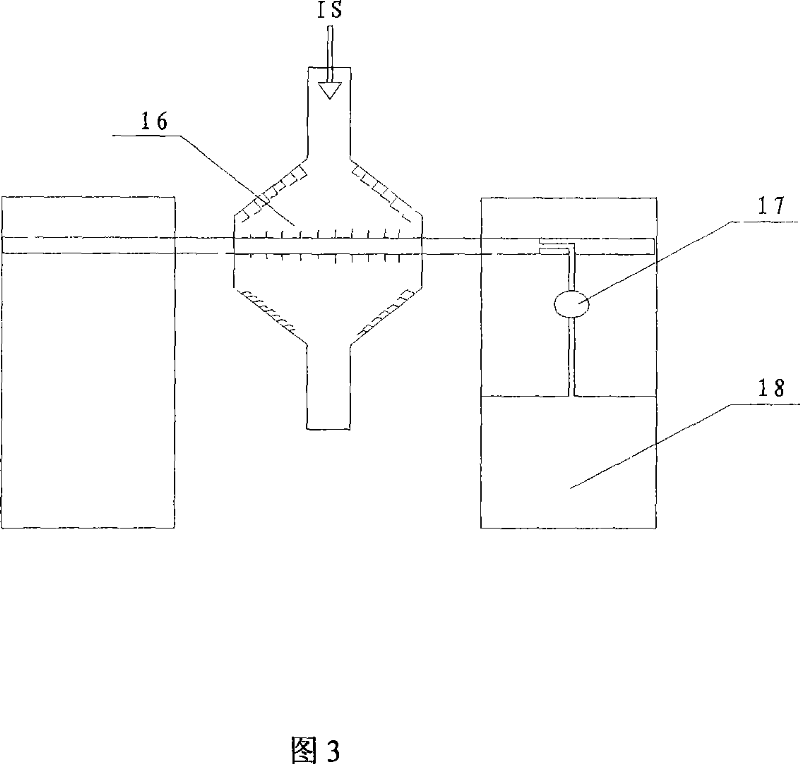

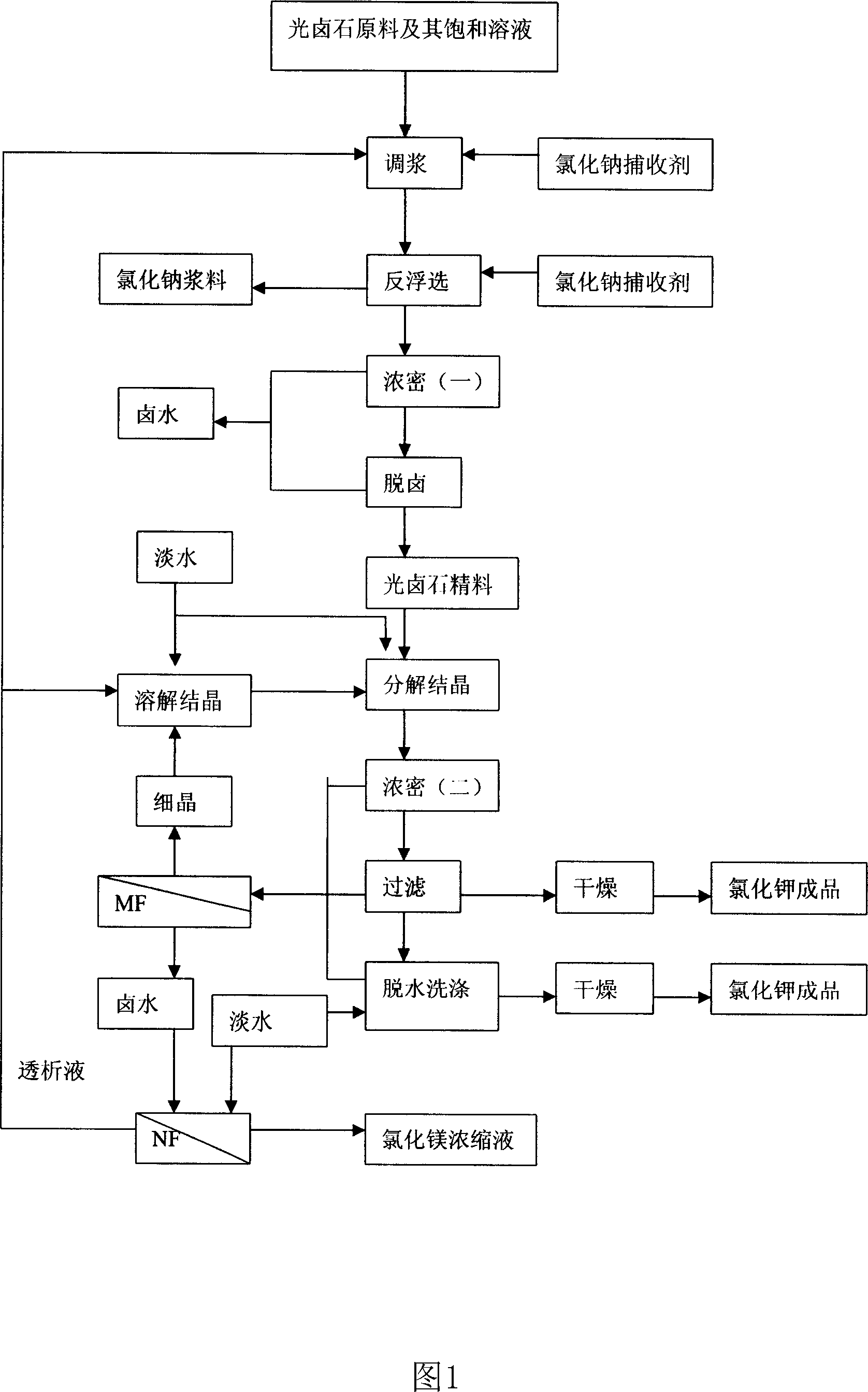

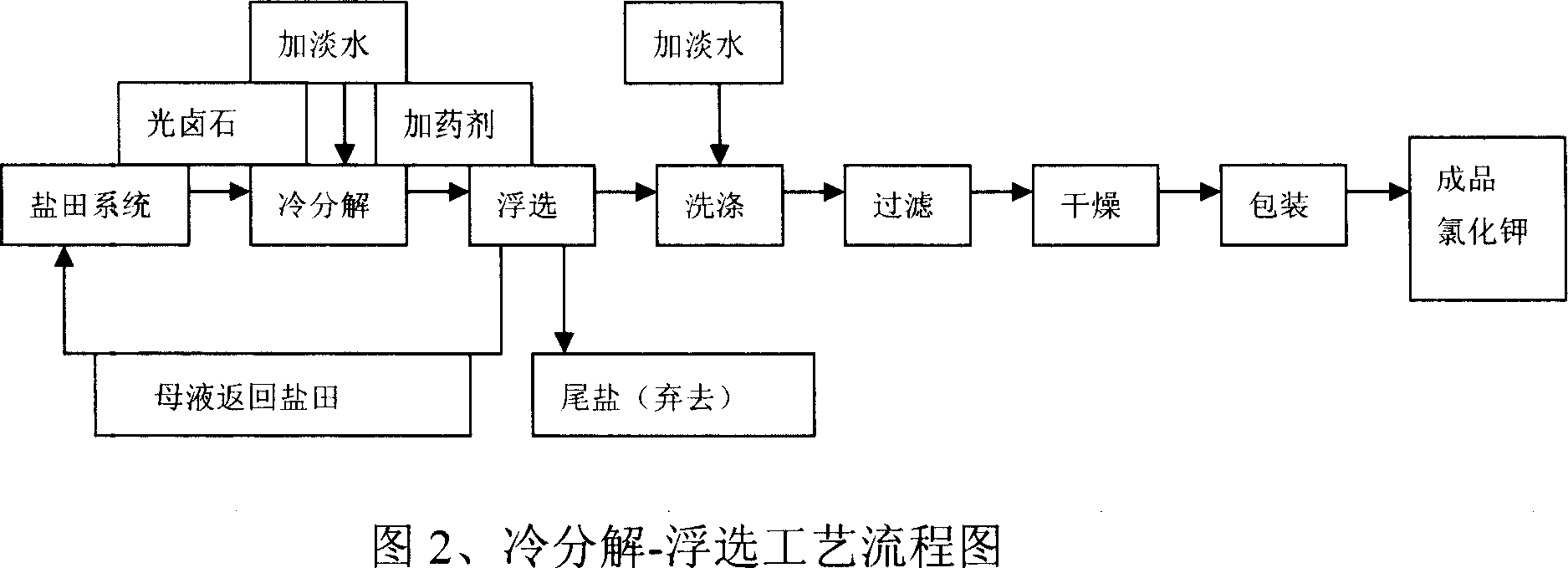

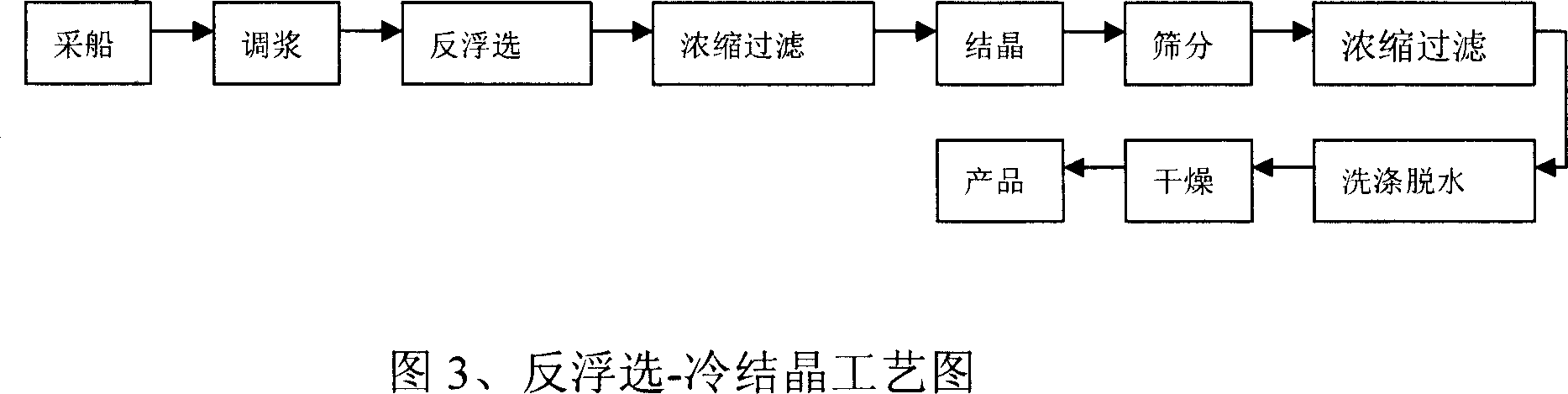

Reverse floatation-cold crystallization process for producing potassium chloride

InactiveCN101066769ALarge particlesQuality improvementAlkali metal chloridesAlkali metal halide purificationGranularityFresh water

The reverse floatation and cold crystallization process for producing potassium chloride includes the following four steps: 1. reverse floatation to prepare low sodium carnallite; 2. decomposing low sodium carnallite in fresh water, crystallizing, centrifugally filtering and drying to prepare potassium chloride product; 3. microporous membrane filtering to recover fine potassium chloride crystal, dissolving, returning to potassium chloride crystallizer for secondary crystallization to prepare potassium chloride; and 4. returning the bittern for reuse. The process has potassium chloride yield up to 80 %, great potassium chloride crystal granularity and high product quality, and is suitable for industrial production.

Owner:陈颖

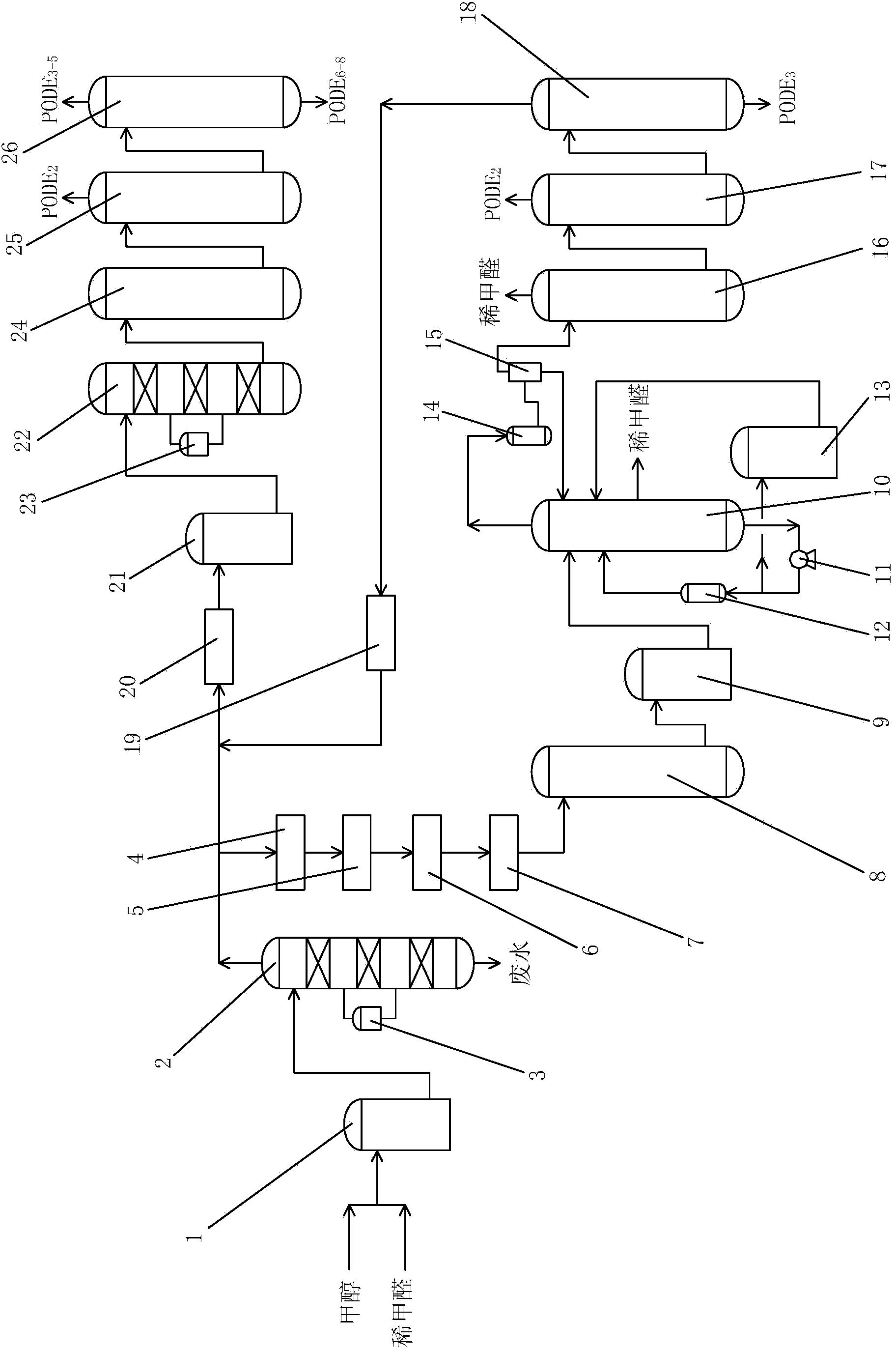

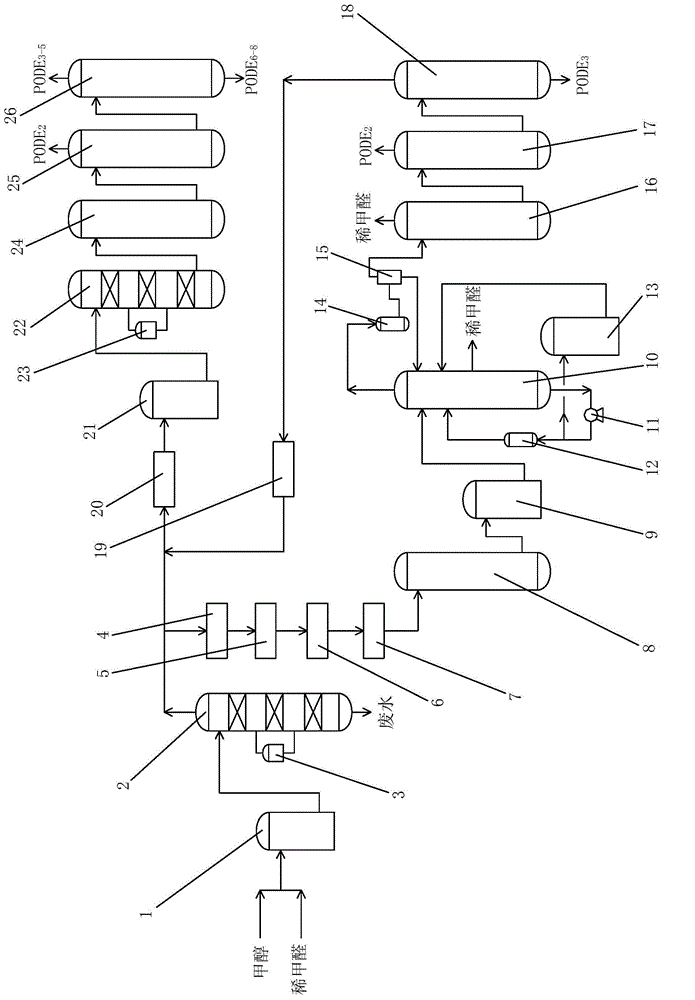

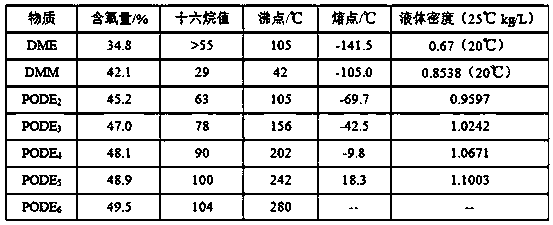

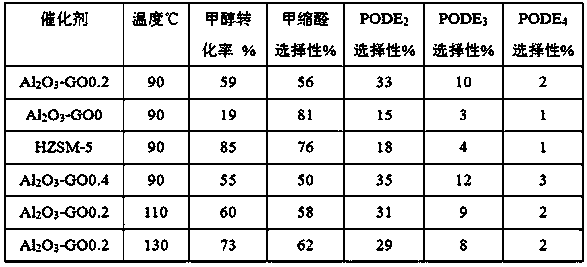

Method for synthesizing PODE through condensation, oxidation, polycondensation and etherification of methyl alcohol

ActiveCN104058940AHigh catalytic activityStrong selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemistryMethanol

The invention discloses a method for synthesizing PODE through condensation, oxidation, polycondensation and etherification of methyl alcohol. The method includes the steps that firstly, methylal with the mass purity of 85%-99.9% is prepared through a reaction of the methyl alcohol and diluted methanal; secondly, the methylal and air are catalyzed and oxidized by iron-molybdenum catalysts to prepare methanal with the mass purity of not less than 70%; thirdly, the methanal is subjected to polycondensation and then is refined to obtain triformol with the mass purity of not less than 99.9%; fourthly, the methylal and the triformol are subjected to etherification, reactive distillation and dehydration and are refined to obtain PODE3-8 with the mass purity of over 99%. By the adoption of the method, the single-pass yield of the PODE is increased from 40%-50% to 95%, the yield of the PODE3-8 is increased from 20% to 90%, product distribution is more reasonable, and the product purity is improved from 50% to 99%. The PODE is wide in application prospect and remarkable in economic, social and environmental benefit.

Owner:XIAN SHANGHUA TECH DEV CO LTD

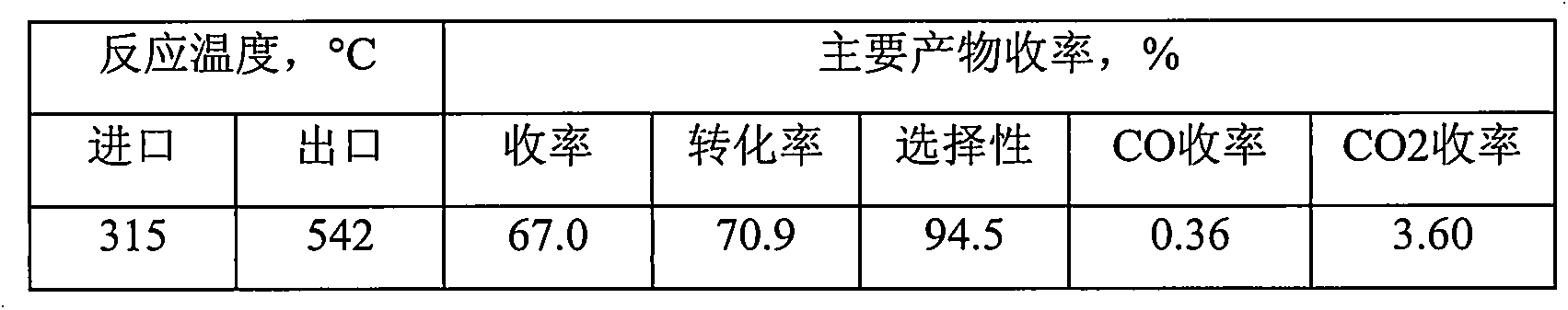

Method of preparing propylene and ethylene by catalytic cracking olefin

ActiveCN1927785AHigh activityConducive to gatheringBulk chemical productionHydrocarbon by hydrocarbon crackingRare earthReaction temperature

The present invention relates to process of catalytically cracking olefin to produce propylene and ethylene, and the process is superior to available technology, which has the problems of poor high temperature hydrothermal stability of catalyst with scaling, deactivation, etc. The technological scheme of the present invention is that C4 and C4+ olefin material is catalytically cracked to produce propylene at the reaction temperature of 450-650 deg.c, reaction pressure of -0.08 to 0.5 MPa and liquid space velocity of 0.5-15 / hr under the action of ZSM-5 molecular sieve catalyst containing RE metal and phosphorus oxide. The process may be used in industrial production of propylene through cracking olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

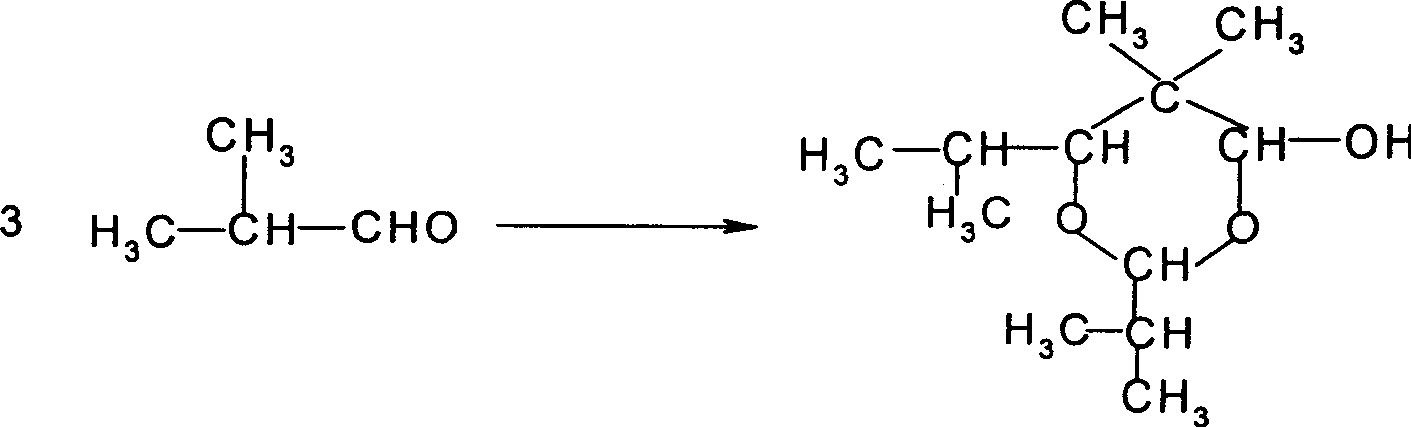

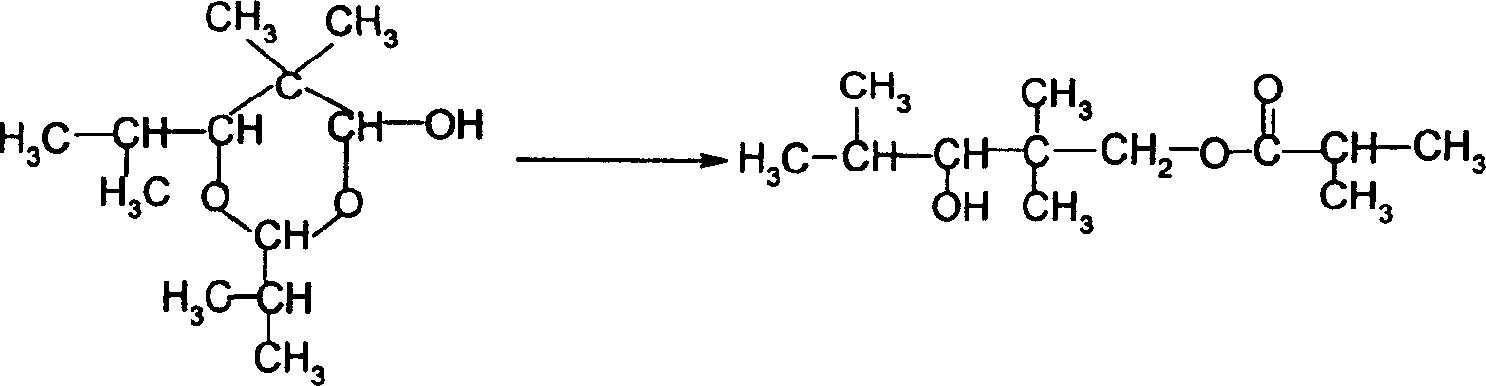

Production of 2,2,4-trimethyl-1,-3-pentadiol mono-isobutyric acid

InactiveCN1817850AImprove one-way yieldMild reaction conditionsPreparation by aldehyde oxidation-reductionHydrotalciteHomogeneous catalysis

Production of 2,2,4-trimethyl-1,3-pentanediol monoester isobutyrate is carried out by condensation pre-treating isobutyl aldehyde, and Knigcharlo reacting in molecule under the action of hydrotalcite-like solid catalyst to obtain the final product. It has high single-pass recovery rate, gentle reactive condition and no corrosion.

Owner:EAST CHINA NORMAL UNIV

FT synthesis sintered iron catalyst and preparation method and use thereof

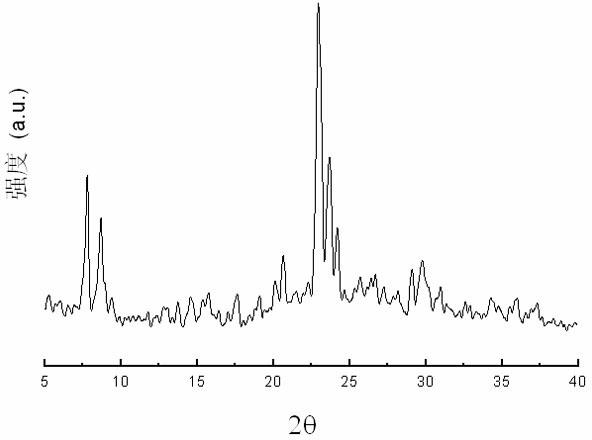

ActiveCN101391219ALow priceSimple processHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSilicon oxideHigh intensity

The invention relates to a Fischer-Tropsch synthesis fused iron catalyst as well as a preparation method and an application thereof, the catalyst is an iron-based catalyst, the weight percentage of iron (Fe) is between 50 and 85 percent, and the weight ratio Fe<3+> / 2Fe<2+> of substance of ferric iron to that of bivalent iron which is two times the weight of ferric iron is 0.5 to 1.5, and the invention also includes a co-catalyst having the compositions: aluminum oxide (Al2O3) 0.1 to 1.5g / 100gFe, magnesium oxide (MgO) 0.1 to 1.5g / 100gFe, potassium oxide (K2O) 0.2 to 1.2g / 100gFe, sodium oxide (Na2O) 0.1 to 2g / 100gFe, calcium oxide (CaO) 0.1 to 1.5g / 100gFe, and silicon oxide (SiO2) 0.5 to 2g / 100gFe. Compared with the prior art, the catalyst has the advantages of high strength, low methane selectivity, high olefin selectivity, simple production process, low production cost and applicable mass production.

Owner:YANKUANG ENERGY R&D CO LTD

Method for preparing adipic acid through co-catalytic oxidation of six-carbon oxygenated compound and cyclohexane

ActiveCN103254060AHigh selectivityLow priceOrganic compound preparationCarboxylic compound preparationSolventChemistry

The invention discloses a method for preparing adipic acid through co-catalytic oxidation of a six-carbon oxygenated compound and cyclohexane. According to the method, cyclohexane is used as a raw material, a six-carbon oxygenated compound is used as a co-oxidant, and one of transitional metal salt or oxide, N-hydroxyphthalimide and analogues, metal phthalocyanine and metalloporphyrin, or a mixture of several ones thereof is used as a catalyst, the mass ratio of the six-carbon oxygenated compound to the cyclohexane is (0.003-9):1, and the dosage of the catalyst is 1-100,000ppm of the total weight of the cyclohexane; and under the conditions that an oxygen-containing gas is continuously introduced, the reaction temperature is 80-155 DEG C, the reaction pressure is 0.1-1.2MPa and the reaction time is 0.4-4 hours, the cyclohexane is oxidized into adipic acid in a solvent in one step. The method disclosed by the invention has the advantages of mild reaction conditions, high once through yield of product, good selectivity and environmental protection.

Owner:上海立科化学科技有限公司

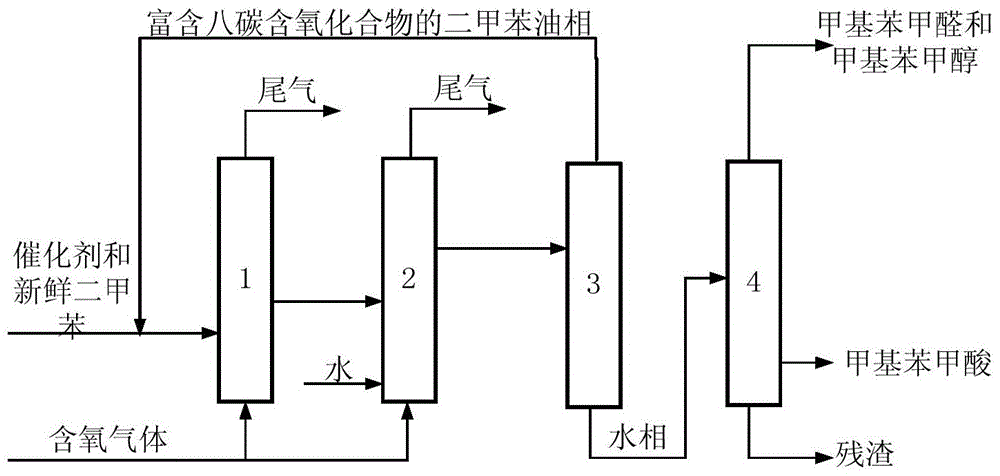

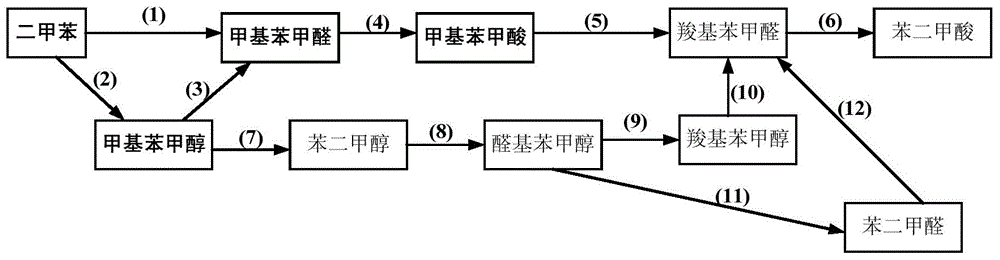

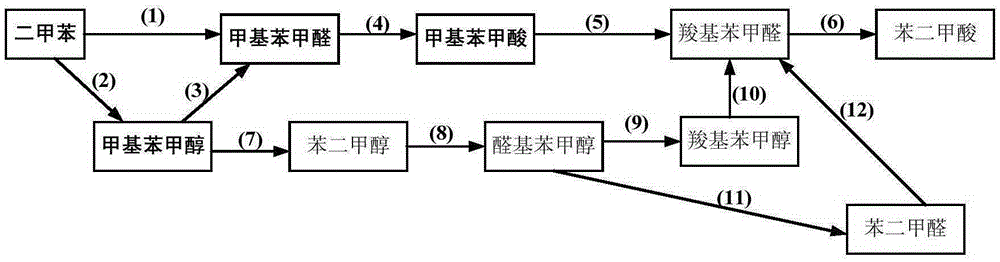

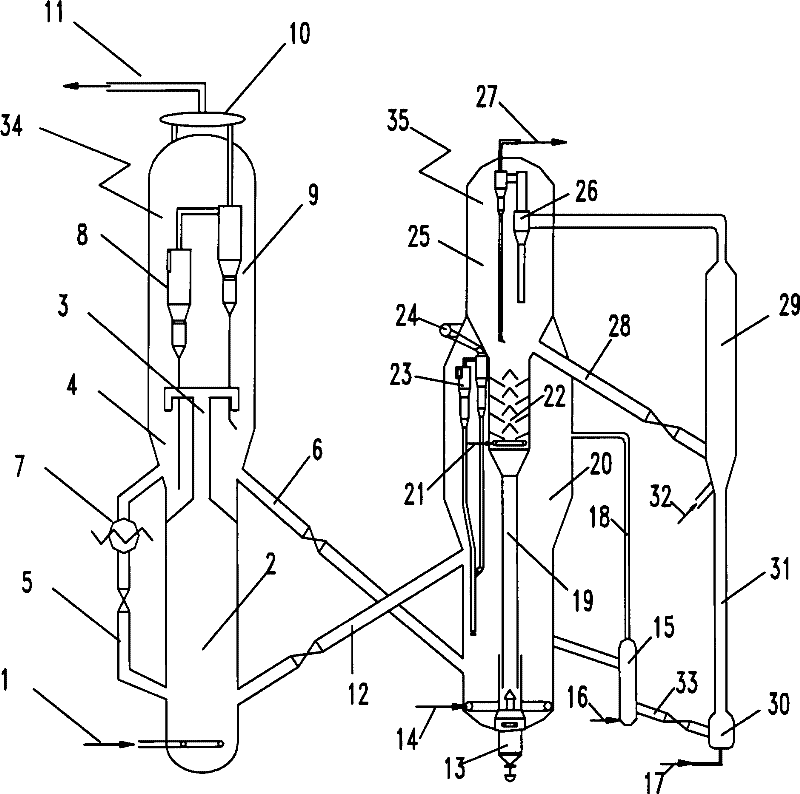

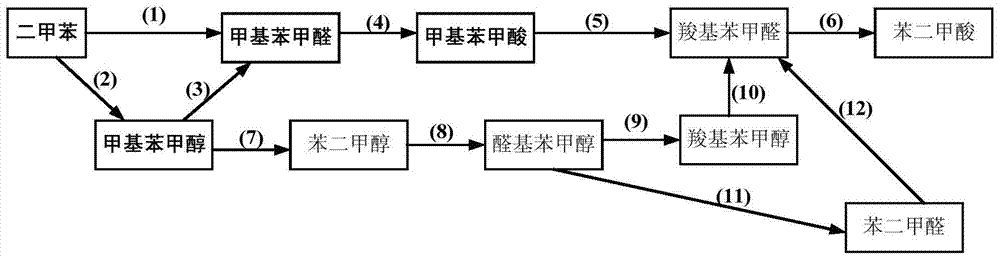

Coproduction method of methyl benzoic acid, methyl benzaldehyde, and methyl benzyl alcohol

ActiveCN105237344AHigh selectivityHigh activityPreparation by oxidation reactionsOrganic compound preparationBenzoic acidBenzaldehyde

The invention discloses a coproduction method of methyl benzoic acid, methyl benzaldehyde, and methyl benzyl alcohol. The method comprises the following steps: (1) primary oxidation: continuously introducing xylene, a catalyst and oxygen-containing gas into a primary oxidation reactor to carry out reactions to obtain a primary oxidation reaction liquid; (2) secondary oxidation: continuously introducing the primary oxidation reaction liquid into a secondary oxidation reactor, and continuously introducing water and oxygen-containing gas into the secondary oxidation reactor to carry out reactions to obtain a secondary oxidation reaction mixture; (3) liquid-liquid layering: introducing the secondary oxidation reaction mixture into a liquid-liquid layering device to carry out layering to obtain an oil phase in the upper layer and a water phase in the lower layer, and returning the oil phase to the primary oxidation reactor; (4) water phase separation: separating and purifying the water phase to obtain methyl benzoic acid, methyl benzaldehyde, and methyl benzyl alcohol. The method has the advantages of high raw material conversion rate, high product yield, good selectivity of target product, and environment-friendliness.

Owner:山东友道化学有限公司

Coproduction method of methyl benzyl alcohol, methyl benzaldehyde, and methyl benzoic acid

ActiveCN105237343AHigh activityHigh selectivityPreparation by oxidation reactionsOrganic compound preparationBenzoic acidBenzaldehyde

The invention discloses a coproduction method of methyl benzyl alcohol, methyl benzaldehyde, and methyl benzoic acid. The coproduction method comprises the following steps: mixing xylene, a co-oxidization agent (a C8 oxygen-containing compound), and a catalyst, and continuously introducing oxygen-containing gas to carry out reactions. By controlling the amount of the added oxygen-containing gas, the content of oxygen gas in tail gas is not more than 5%. The mass ratio of the co-oxidization agent (a C8 oxygen-containing compound) to xylene is 0.003-0.2:1, and the using amount of the catalyst is 10-10000 ppm of the weight of the xylene. The reaction temperature is 105 to 200 DEG C, the reaction pressure is 0.2 to 2.5 MPa, the reaction time is 0.4 to 5 hours, and the xylene is oxidized into a mixture of methyl benzyl alcohol, methyl benzaldehyde, and methyl benzoic acid in one step. The method has the advantages of mild reaction conditions, high product yield, good selectivity, green, and environment-friendliness.

Owner:山东友道化学有限公司

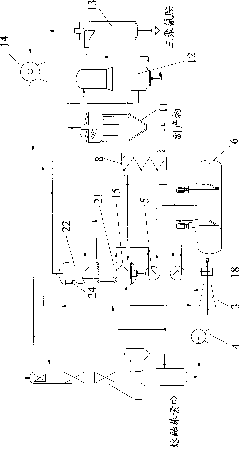

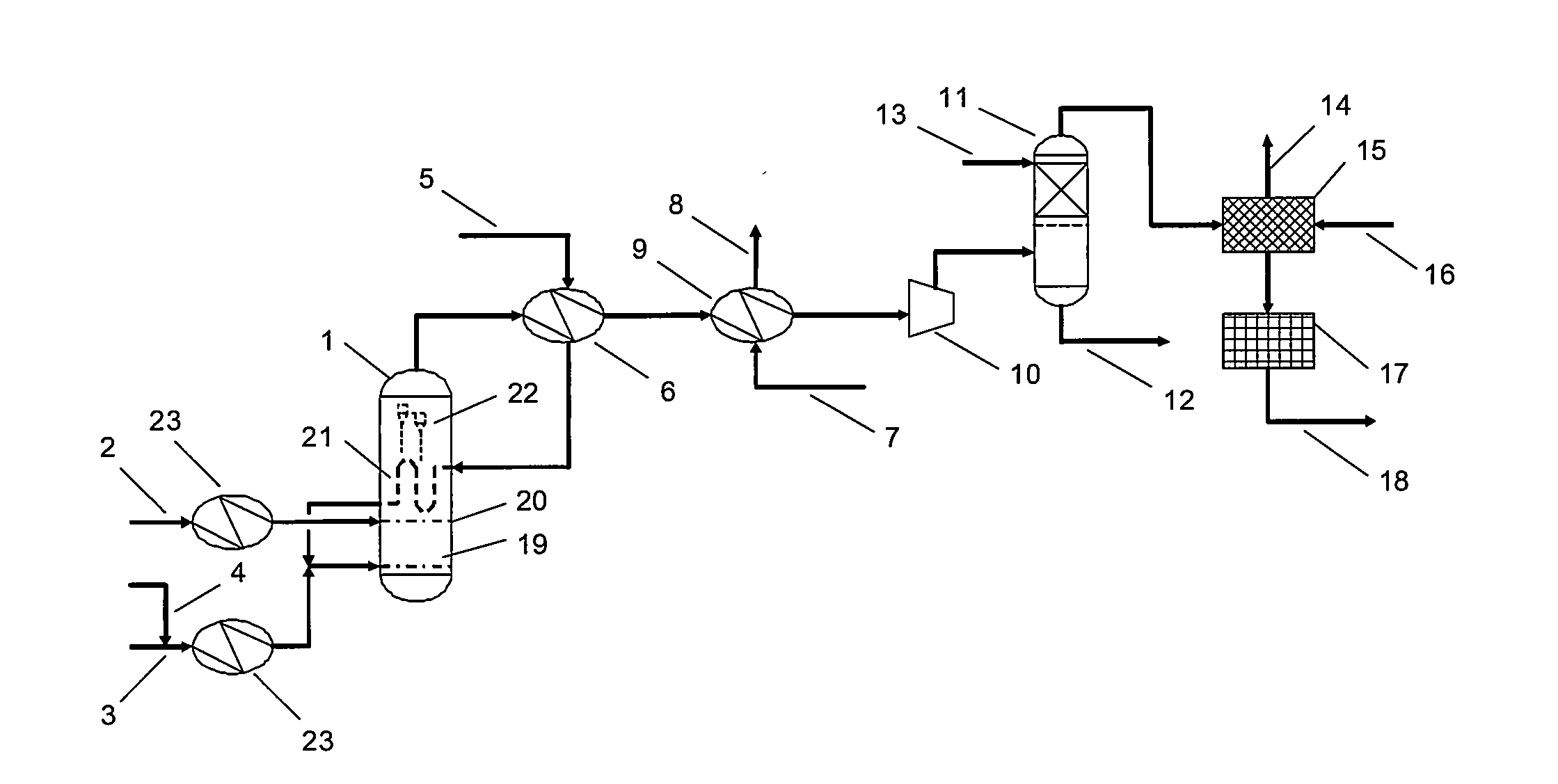

Method for catalytic conversion of methanol and naphtha into light olefins

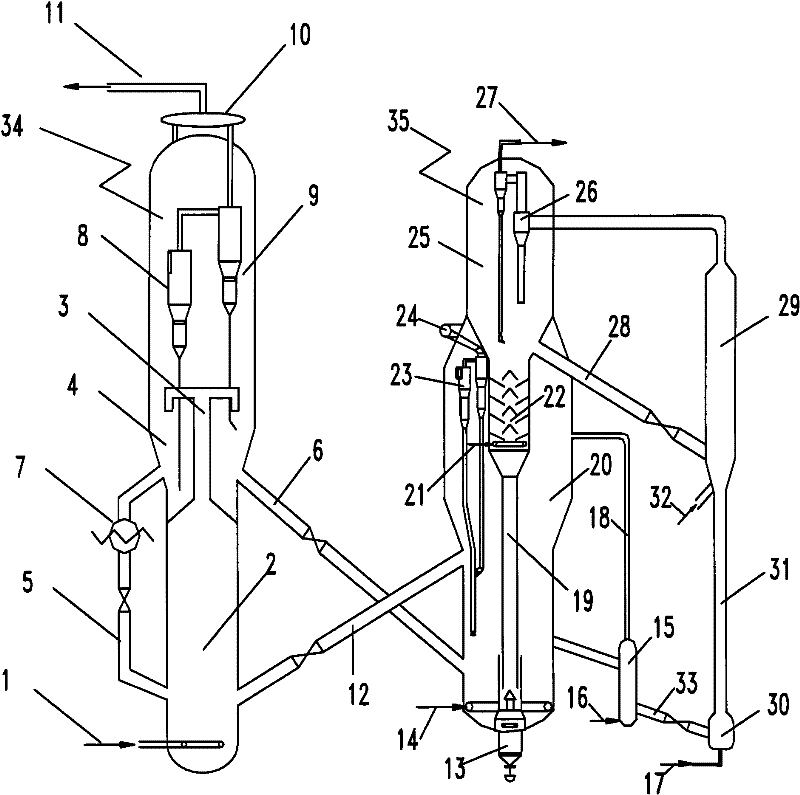

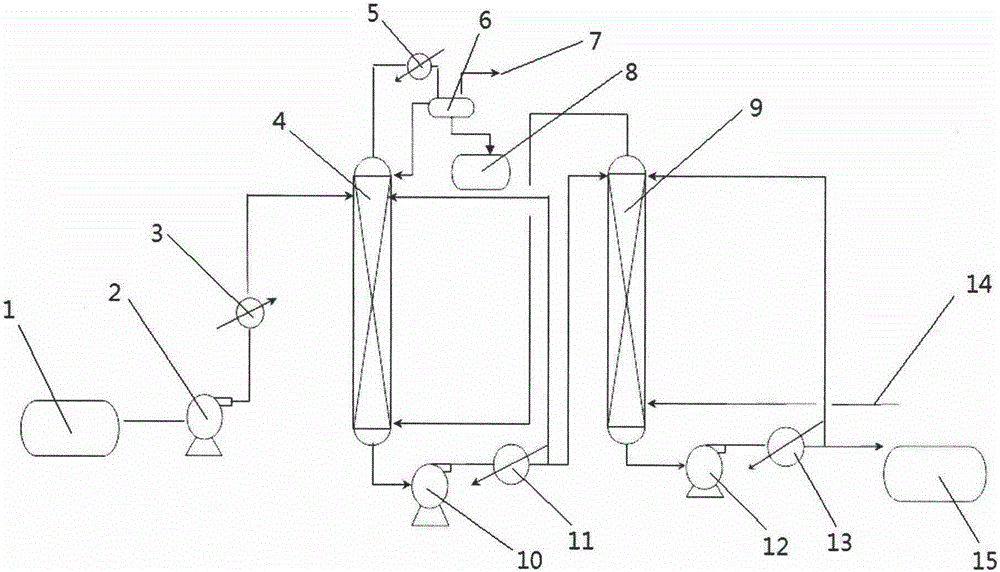

ActiveCN102276391AImprove one-way yieldHigh yieldCatalytic crackingHydrocarbon from oxygen organic compoundsNaphthaAlkene

The invention discloses a method for catalyzing and converting methanol and naphtha into low-carbon olefins, which is used for mainly solving the problem of low yield of the low-carbon olefins in the prior art. In a technical scheme adopted in the invention, a reaction device comprising a methanol reactor, a regenerator, a naphtha converting reactor, an auxiliary settlement steam stripping device, a gas-solid cyclone separator and a catalyst circulation pipeline is used for organically coupling a process for preparing olefins form the methanol and a process for catalytically pyrolyzing the naphtha to prepare the olefins, thus, the problem is favorably solved. The method can be used for industrial production of the low-carbon olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for co-producing methylbenzoic acid, methylbenzaldehyde and methylbenzyl alcohol

ActiveCN105237344BHigh selectivitySimple processPreparation by oxidation reactionsOrganic compound preparationBenzoic acidBenzaldehyde

The invention discloses a coproduction method of methyl benzoic acid, methyl benzaldehyde, and methyl benzyl alcohol. The method comprises the following steps: (1) primary oxidation: continuously introducing xylene, a catalyst and oxygen-containing gas into a primary oxidation reactor to carry out reactions to obtain a primary oxidation reaction liquid; (2) secondary oxidation: continuously introducing the primary oxidation reaction liquid into a secondary oxidation reactor, and continuously introducing water and oxygen-containing gas into the secondary oxidation reactor to carry out reactions to obtain a secondary oxidation reaction mixture; (3) liquid-liquid layering: introducing the secondary oxidation reaction mixture into a liquid-liquid layering device to carry out layering to obtain an oil phase in the upper layer and a water phase in the lower layer, and returning the oil phase to the primary oxidation reactor; (4) water phase separation: separating and purifying the water phase to obtain methyl benzoic acid, methyl benzaldehyde, and methyl benzyl alcohol. The method has the advantages of high raw material conversion rate, high product yield, good selectivity of target product, and environment-friendliness.

Owner:山东友道化学有限公司

A method for co-producing methyl benzyl alcohol, methyl benzaldehyde and methyl benzoic acid

ActiveCN105237343BHigh selectivitySimple processPreparation by oxidation reactionsOrganic compound preparationBenzoic acidBenzaldehyde

Owner:山东友道化学有限公司

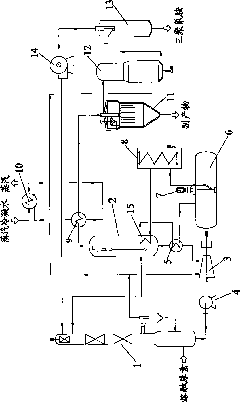

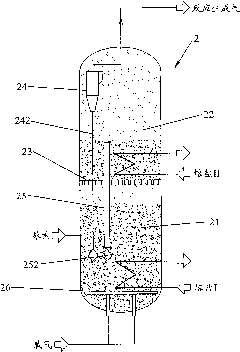

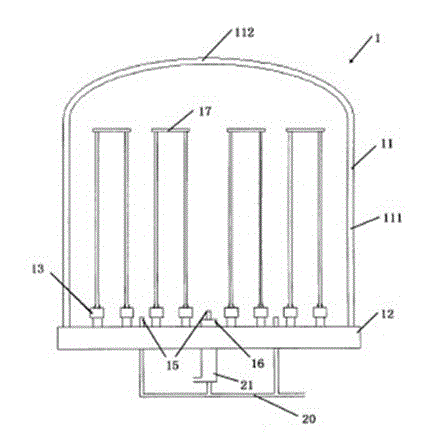

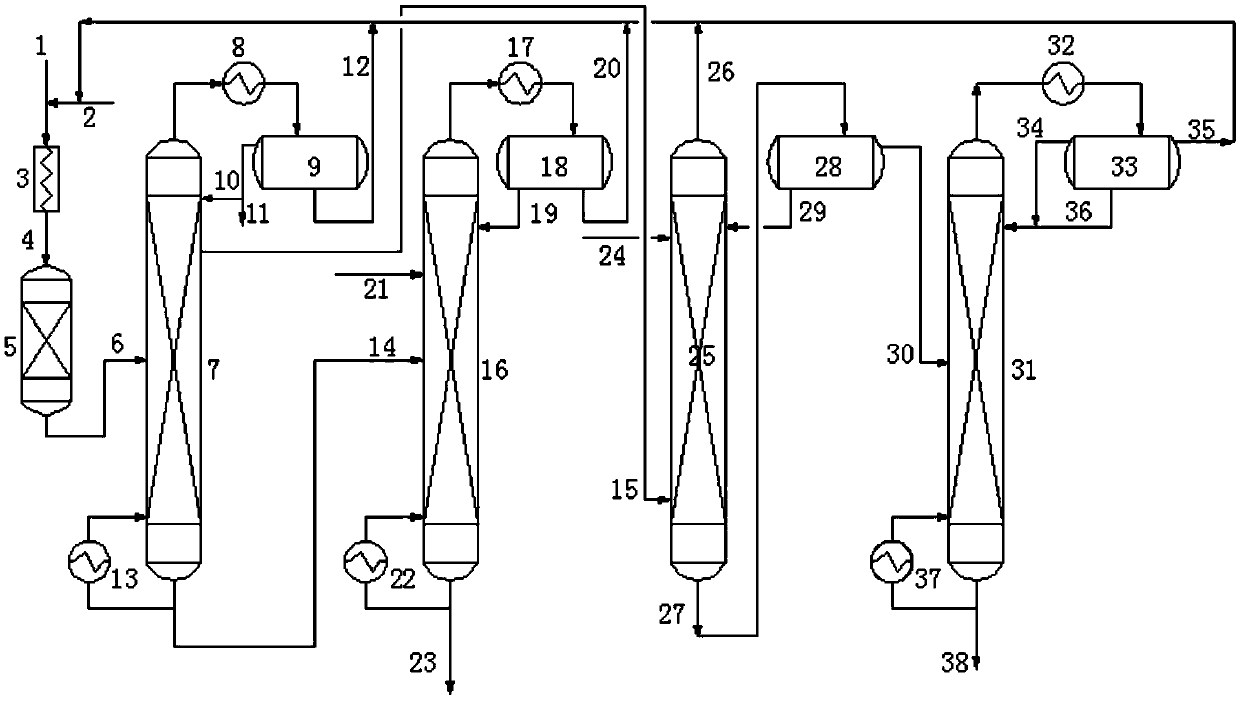

Reactor, system and method for producing tripolycyanamide

ActiveCN101822960AImprove one-way yieldReduce processing loadOrganic chemistryChemical/physical processesEngineeringProcess engineering

The invention relates to a reactor, a system and a method for producing tripolycyanamide. The invention relates to a reactor and a production system comprising the same. The reactor is a two-section cylindrical reactor and comprises a reaction section, a cooling section, a gas distributor arranged between the reaction section and the cooling section and a cyclone separator arranged on the coolingsection, wherein the reaction section and the cooling section are provided with catalysis reaction beds. The reactor and the system can improve the once through yield of products and reduce energy consumption.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD +1

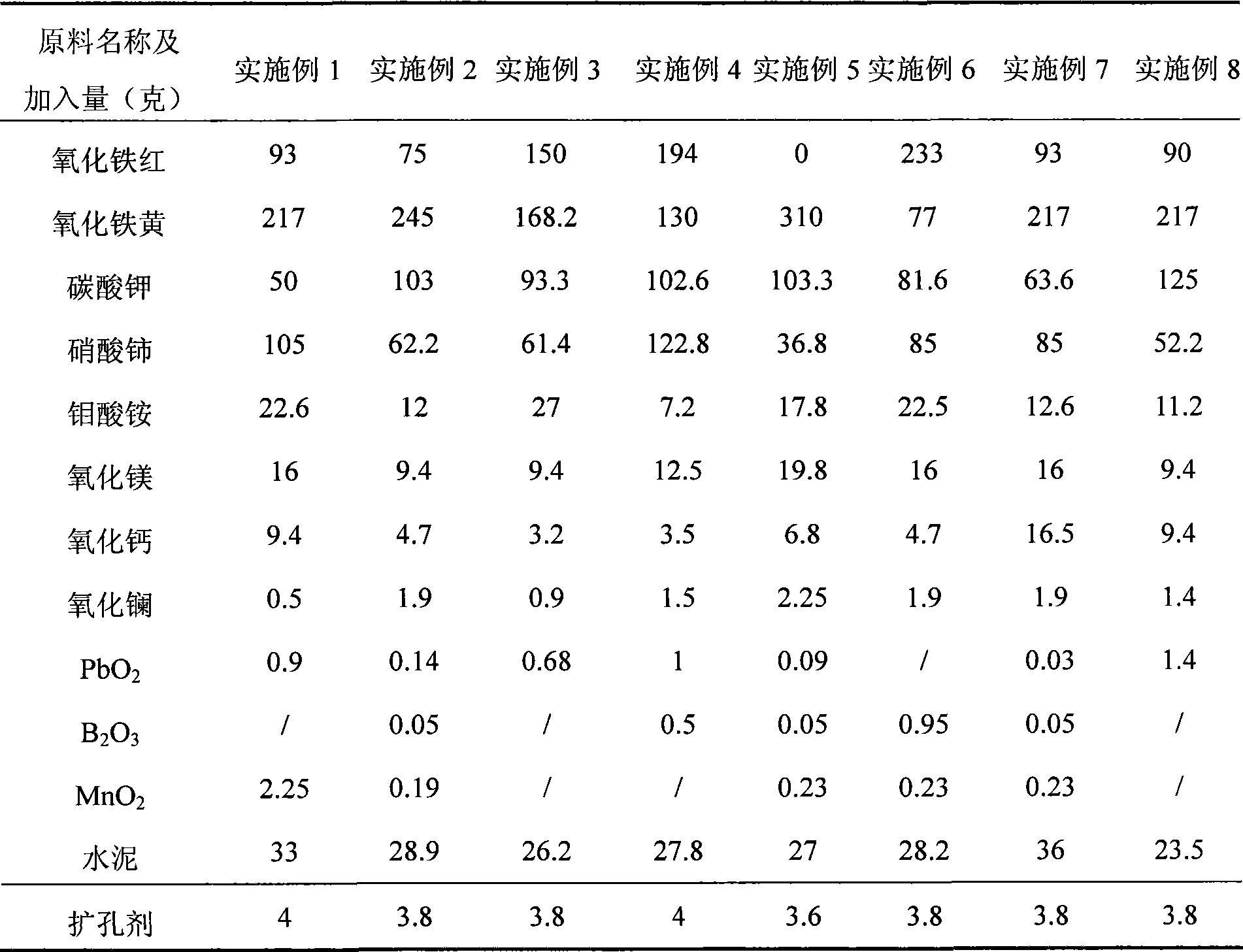

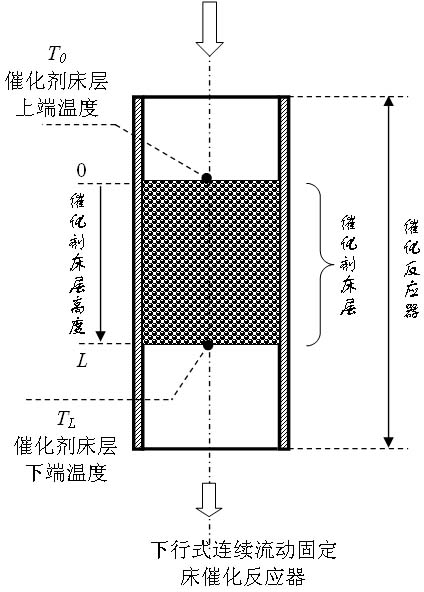

Alkyl-alkenyl arene production catalyst by high-selectivity dehydrogenation of alkyl aromatics

InactiveCN101455968AHigh selectivityImprove one-way yieldHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneDehydrogenation

The invention relates to a high-selectivity alkane alkenyl aromatic hydrocarbon catalyst prepared by dehydrogenating alkyl aromatic hydrocarbon, in particular to a styrene catalyst prepared by dehydrogenating phenylethane. The catalyst takes iron-potassium-cerium-molybdenum as a main system, and is characterized by comprising the following main active components by mass percentage: 1) 50 to 85 percent of Fe2O3; 2) 7 to 15 percent of K2O; 3)1 to 6 percent of MoO3; 4) 2 to 13 percent of CeO2; 5) 1 to 6 percent of MgO; 6) 0.5 to 5 percent of CaO; and 7) 0.05 to 0.9 percent of La2O3. The catalyst prepared especially when iron oxide consists of pigment-grade iron oxide red containing no crystal water and pigment-grade iron oxide yellow containing one crystal water in certain proportion and when potassium oxide and iron oxide are selected within a certain proportion range, has the advantages of maintaining high selectivity and simultaneously raising conversion rate so as to obtain high once through yield of styrene.

Owner:PETROCHINA CO LTD

Catalyst for preparing gamma-butyrolactone by normal pressure gas phase hydrogenation of maleic-anhydride and preparation process thereof

InactiveCN1669651AImprove conversion rateHigh selectivityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsHydrogenAdjuvant

The invention discloses a method for preparing a catalyst, which is used in making the gamma-butyrolactone with sym-form anhydride and hydrogen in normal temperature. The catalyst is made up of CuO, TiO2, Al2O3 and adjuvant, and can be prepared through coprecipitation or microemulsion. The catalyst does not have the toxic component Cr and belongs to the environment-friendly type, and it has high sym-form anhydride conversion rate and gamma-butyrolactone selective in high liquid hourly space velocity, which can reach to 100% individually, that is to say, the gamma-butyrolactone selective can remain 100% when the catalytic activity declining, and the gamma-butyrolactone has high monochromatic absorptivity.

Owner:EAST CHINA UNIV OF SCI & TECH

Catalyst for producing propylene and propane by converting ethanol and its preparation method and application

InactiveCN102274748AImprove one-way yieldHigh overall yieldMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePropene

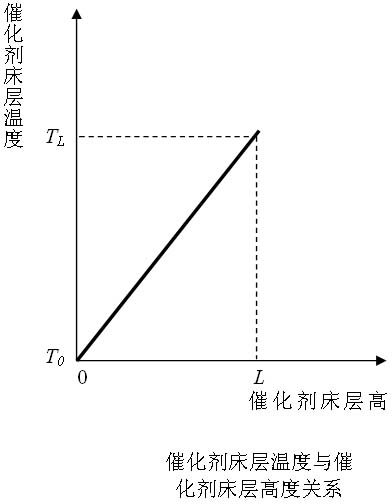

The invention discloses a catalyst for ethanol conversion to produce propylene and propane. The catalyst is a composite molecular sieve catalyst containing MOR, HZSM-5, Beta, Y, SAPO-34, SAPO-31, SAPO-11, MCM-22, MCM -41. Two or more components of SBA-15 molecular sieves, which contain at least HZSM-5 and SAPO-34 molecular sieves, and the mass ratio of HZSM-5 and SAPO-34 molecular sieves is 0.2-5. The total yield of propylene and propane in the product obtained by using the catalyst of the present invention is high, and by-product ethylene and butene can be adjusted by changing the reaction conditions. The ratio of propylene / ethylene in the product is due to the temperature distribution of the catalyst bed, so The reaction heat effect generated by ethanol conversion is better dispersed and utilized, and there are no hot spots in the catalyst bed.

Owner:NORTHWEST UNIV

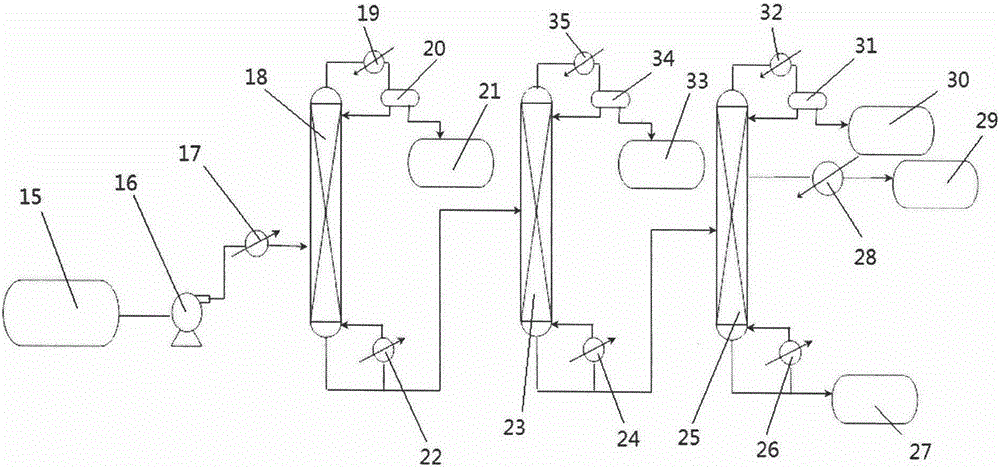

A process for continuously producing m-toluic acid

InactiveCN105061187AImprove reaction efficiencyIncrease production capacityOrganic compound preparationCarboxylic compound separation/purificationM-tolualdehydeWork flow

The invention discloses a process for continuously producing m-toluic acid. The process comprises a synthesizing production process corresponding to a synthesizing workshop section and a rectifying production process corresponding to a rectifying workshop section. The process for continuously producing m-toluic acid comprises a work flow of (1) synthesizing process, namely synthesizing by adopting a multi-level outer-loop serial connection process; and (2) rectifying process, namely rectifying by utilizing an m-xylene recovery tower, a m-tolualdehyde recovery tower and a m-toluic acid rectifying tower. The process has the advantages of reasonable structural design and continuous operation, a gaseous phase and a liquid phase are sufficiently contacted by means of countercurrent to react, so that the reaction efficiency can be greatly improved, the product production capacity in unit interval can be improved, and operation energy consumption can be reduced. Furthermore, the continuous rectification process can be used for greatly shortening the time for heating a to-be-separated mixture and remarkably inhibiting generation of deep byproducts, so that the once through yield can be greatly improved, and the production benefit can be remarkably increased.

Owner:JIANGSU PANOXI CHEM

Method for producing butadiene through mixing carbon C

InactiveCN103304359AImprove fluidization stateUniform temperature distributionHydrocarbonsHydrocarbon preparationButeneSeparation technology

The invention discloses a method for producing butadiene through mixing carbon C, mainly solving the problems of poor butene conversion per pass, low butadiene once through yield and large device energy consumption in the prior art. The following main technical schemes are adopted to realize the purposes: adopting a ferrite catalyst and a fluidized bed reactor reaction technology to carry out oxidative dehydrogenation on butene in a mixed carbon C so as to generate butadiene; exchanging heat with a desalted water by utilizing a gas generated after the reaction and generating a byproduct-steam, further cooling the gas to be about 110 DEG C, and filling the gas into a quench tower to remove impurities such as water, oxides and solid powder; condensing the quenched gas to be about 1.2MPa, absorbing and resolving to obtain crude butadiene; and treating the crude butadiene through utilizing a conventional butadiene extraction and separation technology so as to obtain a polymer grade butadiene product. By utilizing the method, the conversion per pass of the butene in the mixed carbon C is more than 90%, the butadiene selectivity is more than 95%, the device energy consumption is reduced by about 40%, and the device investment is saved about 20%, and the method can be applied to the field of butadiene industrial production.

Owner:王伟跃

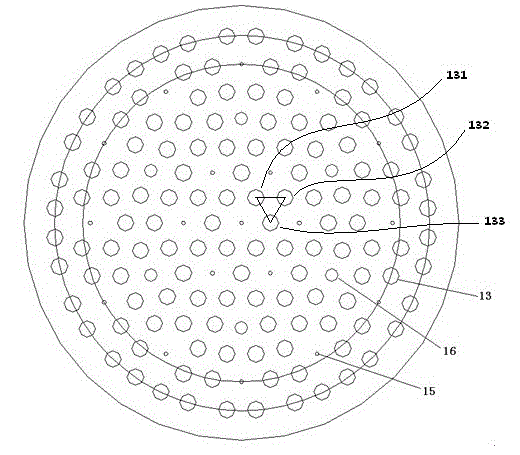

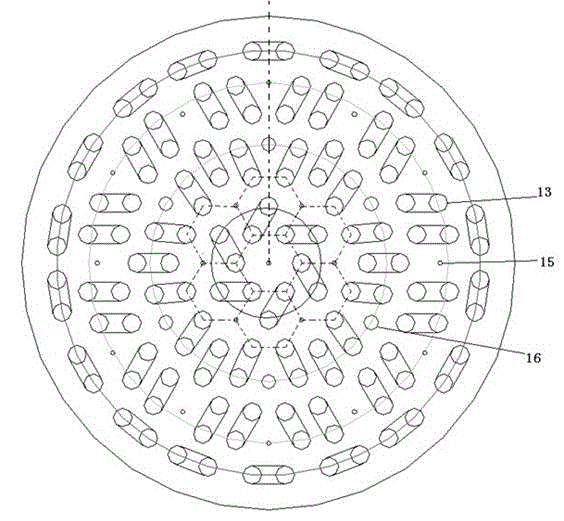

Reactor used for producing polycrystalline silicon

The invention discloses a reactor used for producing polycrystalline silicon. The reactor comprises a furnace tube with a cooling device, a chassis, and electrodes, raw material gas inlets and gas outlets positioned on the chassis. The reactor is characterized in that except the outermost electrodes close to the furnace tube, each electrode has 4 or 5 other adjacent electrodes and one or two adjacent gas inlets and / or outlets at distances of 150mm-300mm. A matrix formed by the electrodes, gas inlets and gas outlets is arranged as equilateral triangle and / or approximate equilateral triangle matrix. With the reactor, denser silicon core arrangement can be realized, thermal energy utilization rate in a reduction furnace can be improved, and more uniform flow field distribution is realized, such that polycrystalline silicon yield in each bath is improved, product surface quality is improved, and energy consumption is reduced.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV

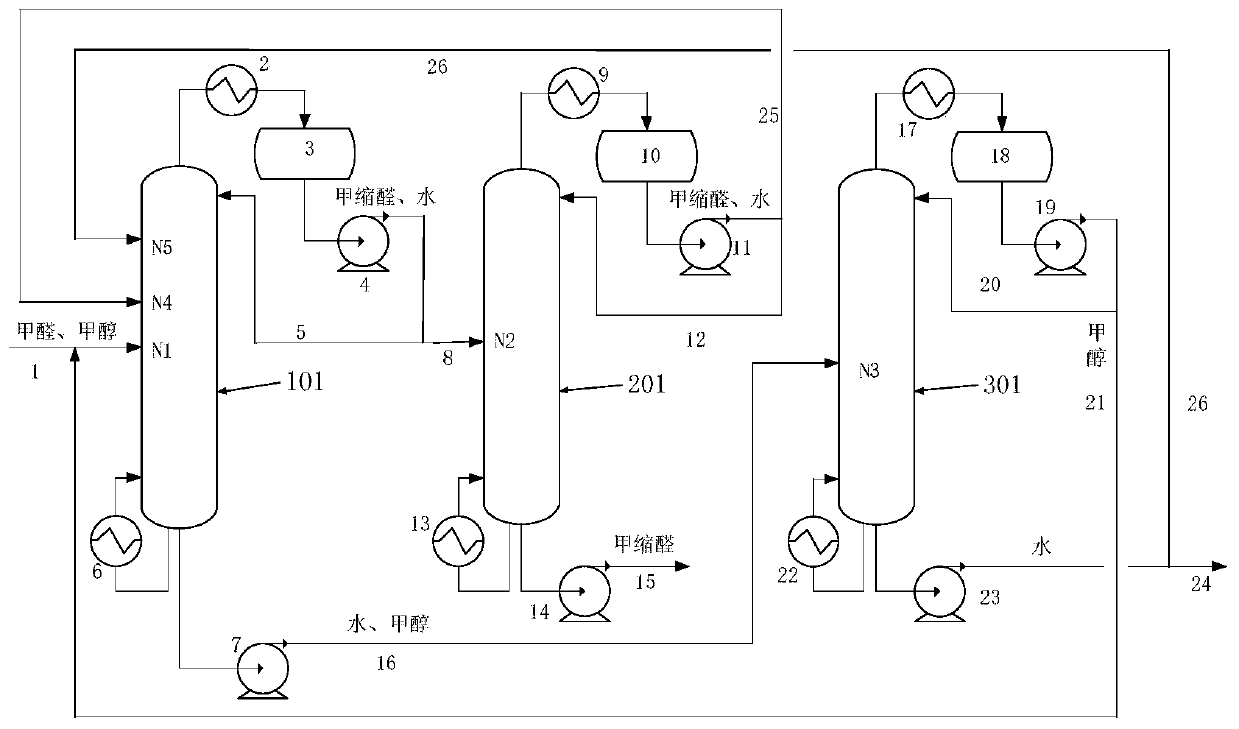

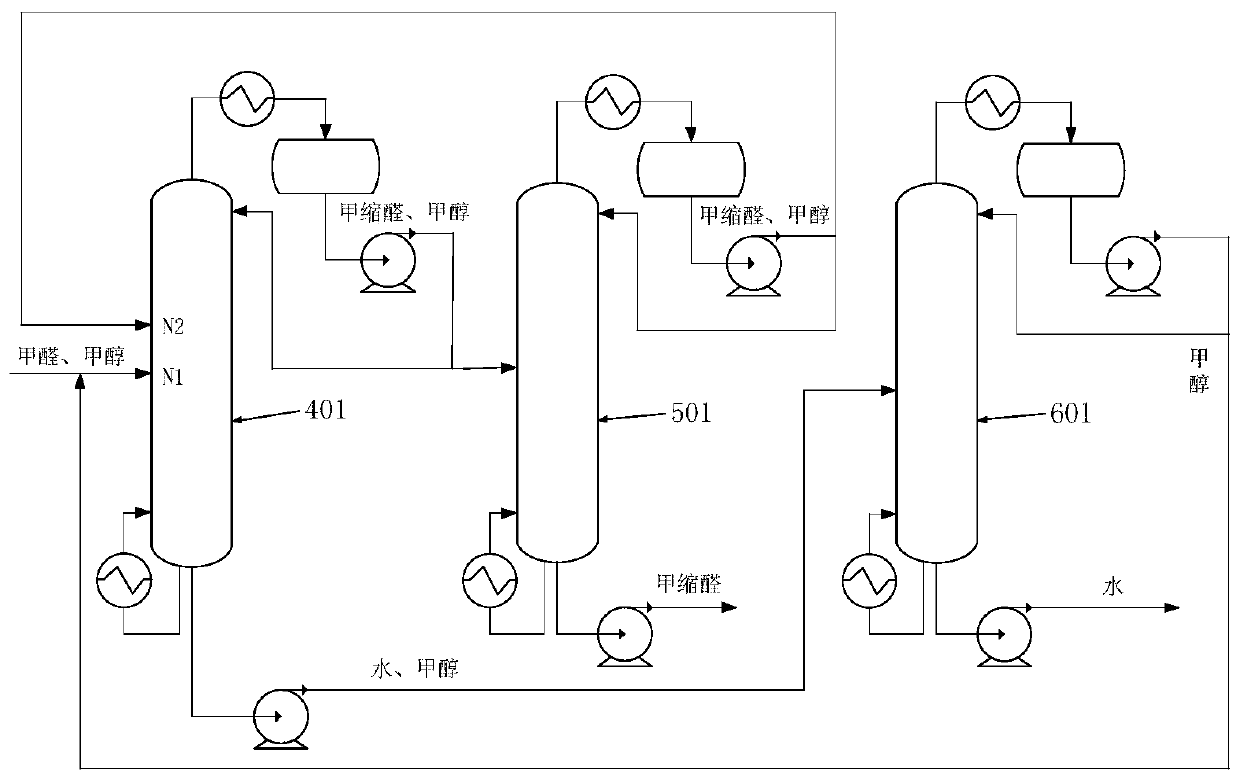

Device and process for preparing high-concentration methylal

ActiveCN111454135AReduce dosageWill not polluteOrganic chemistryOrganic compound preparationHigh concentrationEnvironmental engineering

The invention discloses a device and a process for preparing high-concentration methylal. The process comprises the following steps: a) respectively sending a mixture of formaldehyde and methanol, water and recycled crude methylal to a first rectifying tower for extractive reaction rectification to obtain an azeotrope of methylal and water at the top of the tower and obtain water and residual methanol at the bottom of the tower; b) sending the azeotrope of methylal and water discharged from the tower top to a second rectifying tower for pressurized rectification to obtain high-concentration methylal with the mass fraction of 99.9% or above at the bottom and obtain a methylal-water azeotrope with higher water content at the top, and feeding the methylal-water azeotrope back to the first rectifying tower for recovery; and c) feeding the material discharged from the bottom of the first rectifying tower to a third rectifying tower to recover methanol, partially circulating the water extracted from the bottom of the third rectifying tower to the first rectifying tower for recycling, and discharging the residual water as process wastewater. The method is used for synthesizing and preparing the high-concentration methylal; non-toxic and harmless water is used as an extracting agent and an entrainer, so that the technological process is simple, the single-pass yield of the high-concentration methylal is high, and the comprehensive energy consumption is low.

Owner:青岛迈特达新材料有限公司

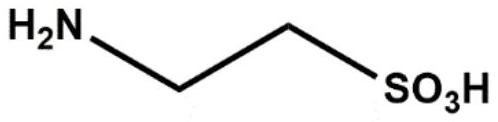

Method for preparing taurine from sodium isethionate

ActiveCN111689880AImprove catalytic selectivityHigh selectivityOrganic compound preparationSulfonic acids salts preparationSodium IsethionatePtru catalyst

The invention provides a method for preparing taurine from sodium isethionate. The method comprises the following steps of: efficiently catalyzing the ammonolysis reaction of sodium isethionate by using a Pd-C / Al2O3 heterogeneous catalyst with a shape selection function, and then conducting neutralizing, crystallizing, separating and the like to obtain a taurine product. Compared with a traditional basic catalyst, the catalyst provided by the invention can be used for limiting the generation of macromolecular by-products including disubstituted sodium taurate and trisubstituted sodium tauratethrough a unique pore channel structure, so that the selectivity of sodium taurate in the ammonolysis reaction is improved; meanwhile, due to the excellent catalytic performance of the catalyst, the temperature and the pressure of the ammonolysis reaction are effectively reduced, the reaction time is shortened, and the catalyst can be separated and recycled through simple filtration.

Owner:WANHUA CHEM GRP CO LTD

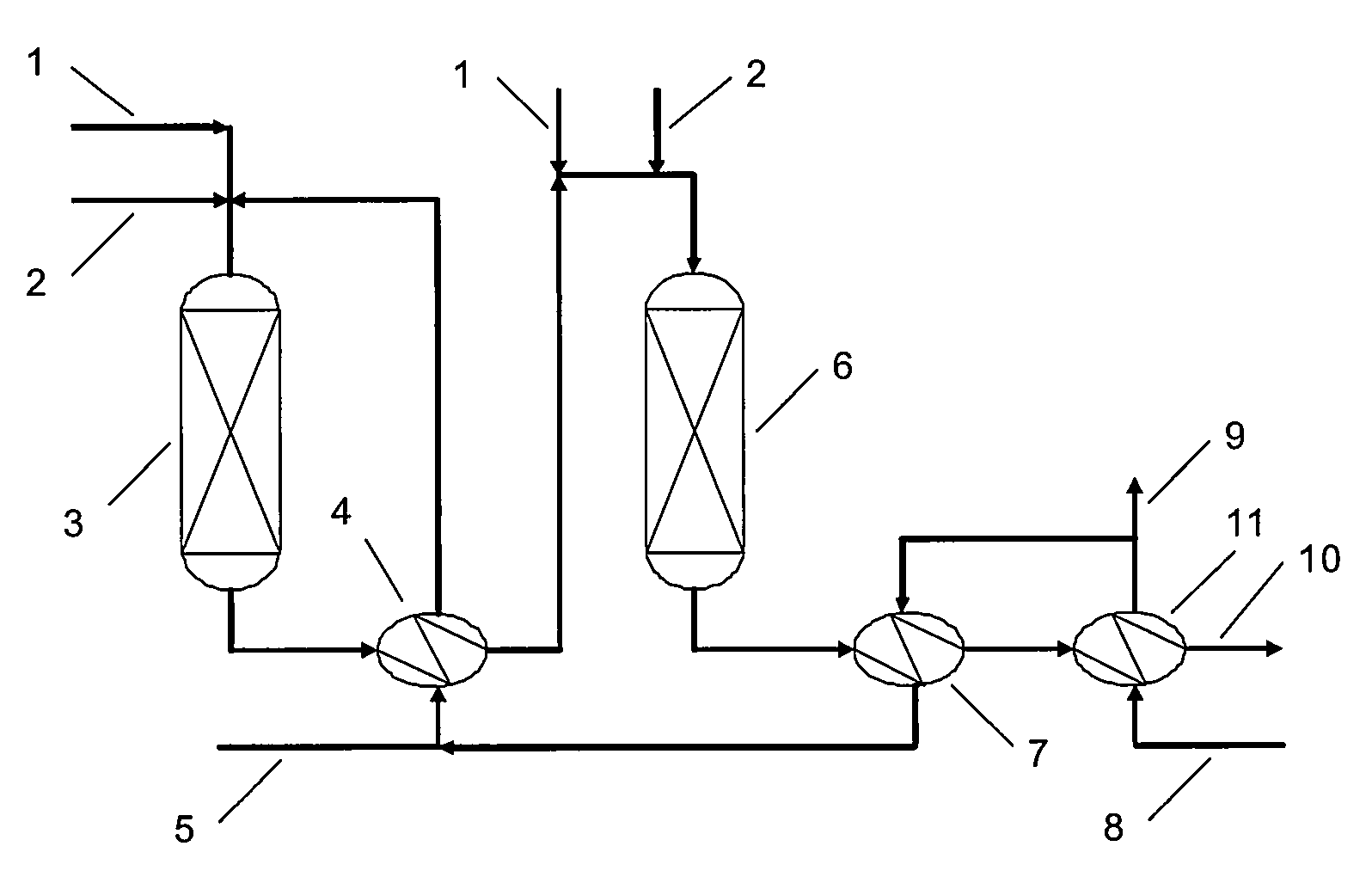

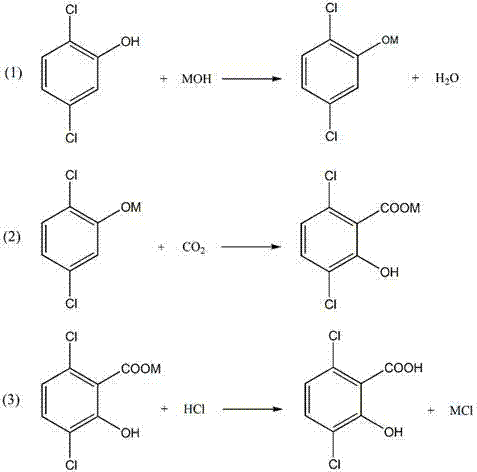

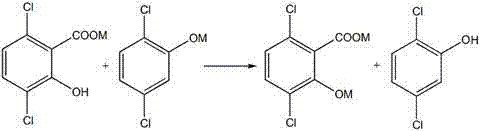

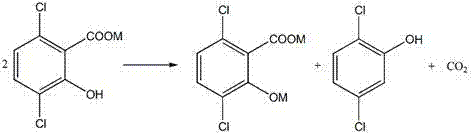

A method for increasing the yield of 3,6-dichloro-2-hydroxybenzoic acid

InactiveCN102295552AImprove one-way yieldShort reaction timePreparation from carboxylic acid saltsCarboxylationOrganic solvent

The invention belongs to a production technology of a dicamba intermediate, and relates to a method for preparing 3,6-dichloro-2-hydroxy benzoic acid by reacting 2,5-dichlorophenols salt with carbon dioxide in an organic solvent,the technology for increasing Kolbe-Schmitt carboxylation reaction yield by a secondary salt forming comprises the following steps: (1) preparing the raw material phenates and dehydrating; (2) performing a primary carboxylation reaction to the raw material phenates; (3) performing a salt forming and dehydration to by-product dichlorophenols; (4) carrying out a carboxylation reaction; (5) refining. Experiments show that the yield of 6-dichloro-2-hydroxybenzoic acid can reach 68.4%-70.5% after the secondary carboxylation, The method for increasing yield of 3,6-dichloro-2-hydroxybenzoic acid is capable of solving the unfavorable influence of dichlorophenols generated by the reaction, raising the reaction yield, minimizing the reaction time and saving the production cost.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Method for synthesizing polyoxymethylene dimethyl ether through condensation, oxidation, polycondensation and etherification of methanol

ActiveCN104058940BHigh catalytic activityEasy to separateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholReactive distillation

Owner:XIAN SHANGHUA TECH DEV CO LTD

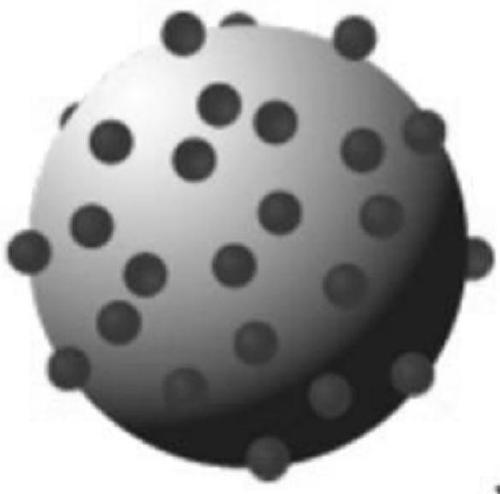

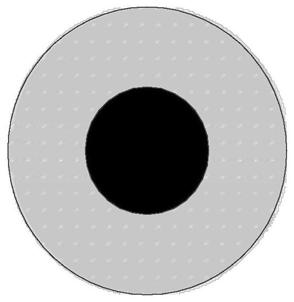

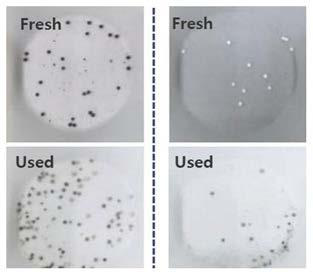

Yolk-eggshell SiO2-Al2O3 noble metal propane dehydrogenation catalyst and preparation method thereof

ActiveCN111437830AAvoid breakingImprove physical strengthHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsYolkPtru catalyst

The invention discloses a yolk-eggshell SiO2-Al2O3 noble metal propane dehydrogenation catalyst and a preparation method thereof. According to the catalyst, solid SiO2-Al2O3 microspheres are used as egg yolk; porous SiO2-Al2O3 hollow spheres are used as eggshells, yolk and eggshell layers are loaded with effective catalytic active components with different functions respectively, the obtained catalyst has a large specific surface area, the activity and selectivity of the catalyst are improved, the carbon deposition rate is reduced, and the one-way yield is increased; meanwhile, the catalyst has high strength, catalyst breakage caused by core coke generation of the catalyst is avoided, and the problems of blockage of inner and outer nets of a reactor, short operation period of the device and the like caused by catalyst breakage are effectively solved.

Owner:ZHEJIANG SATELLITE ENERGY CO LTD

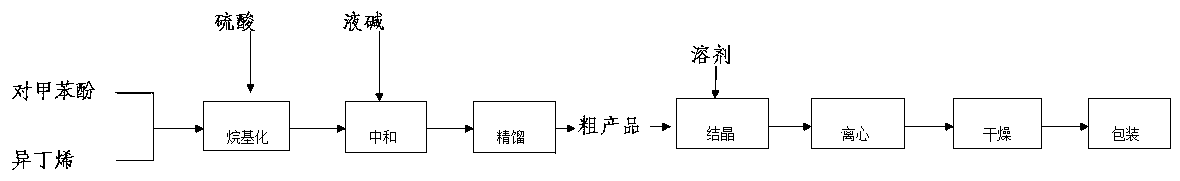

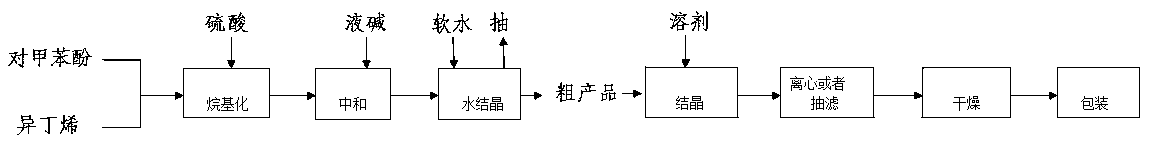

Preparation method of anti-aging agent 264

InactiveCN107602353AImprove one-way yieldReduce energy consumptionOrganic chemistryOrganic compound preparationAlkyl transferOrganic solvent

The invention discloses a preparation method of an anti-aging agent 264. Isobutene, p-cresol and concentrated sulfuric acid are subjected to alkylation reaction; then, sodium hydroxide is used for neutralization; next, soft water is added for product crude separation; a solvent is used for crystallization; centrifugation, filtering and drying are performed. The preparation method is characterizedin that the product crude separation adopts water crystallization. For the product crude separation, an organic solvent is not used during the product crude separation; the water is used and can be repeatedly used; the anti-aging agent 264 is not dissolved in water, so that the once through yield is high; the rectification is not needed, so that high temperature is not needed; the energy consumption is low; the equipment investment is low; the dangerous waste liquid is little.

Owner:郑程

Adjustable hydrophilic and hydrophobic catalyst for preparation of polymethoxydimethyl ether as well as preparation method and application thereof

ActiveCN110330414AFacilitate responsePromote separationOrganic chemistryMolecular sieve catalystsParaformaldehydeEther

The invention discloses an adjustable hydrophilic and hydrophobic catalyst for preparation of polymethoxydimethyl ether as well as a preparation method and application thereof. The catalyst comprisesa hydrophobic carrier and an active component, wherein the active component is a solid acid substance; the hydrophobic carrier accounts for 2 to 98 percent of the weight of the catalyst; and the active component accounts for 2 to 98 percent of the weight of the catalyst. The hydrophobic performance of the catalyst can be adjusted by adjusting the proportion of a hydrophobic agent to the active component. The catalyst prepared by the method can be applied to preparation of the polymethoxydimethyl ether through reaction of methanol and formaldehyde, wherein the methanol can be replaced by dimethyl ether, methylal and polymethoxydimethyl ether with low polymerization degree; the types of the formaldehyde can be a formaldehyde solution with different concentration, paraformaldehyde and trioxymethylene. The catalyst provided by the invention has the effect of adjusting distribution of polymethoxydimethyl ether products, can realize reasonable optimization of the hydrophilic and hydrophobicproperties of the catalyst according to production requirements, can realize reaction optimization and separation optimization and accords with the requirement of green chemical development.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Preparation method and system of sec-butyl alcohol

ActiveCN111377802AIncrease productionEasy to operateOrganic compound preparationPreparation by hydrolysisOil phaseSec-Butyl acetate

The invention provides a preparation method of sec-butyl alcohol. The method includes the steps of: feeding a mixture obtained after the hydrolysis reaction into a sec-butyl alcohol azeotropic distillation tower for separation; withdrawing a mixed material containing sec-butyl alcohol, sec-butyl acetate and water from the side line of the upper part of the sec-butyl alcohol azeotropic distillationtower, feeding the mixed material into a multi-stage extraction tower, adding an extracting agent chilled water to obtain a sec-butyl alcohol-containing water phase at the bottom of the tower, and withdrawing the water phase at the bottom of the tower; feeding the mixture into a liquid separation tank to obtain a sec-butyl alcohol oil phase at the upper layer of the liquid separation tank; and feeding the sec-butyl alcohol oil phase obtained at the upper layer of the liquid separation tank into a sec-butyl alcohol refining tower for refining, and adding entrainer water to obtain the high-purity product sec-butyl alcohol at the bottom of the tower. According to the method, sec-butyl acetate and sec-butyl alcohol are effectively separated, the yield of the sec-butyl alcohol obtained after separation reaches 99.5% or above, and the one-way yield of the sec-butyl alcohol is greatly increased and is increased to 85% or above from 50%.

Owner:HUNAN ZHONGCHUANG CHEM

Catalyst for preparing acrylic acid through propane selective oxidation and preparation method of catalyst

ActiveCN103691457ASmall particlesLarge specific surface areaPhysical/chemical process catalystsOrganic compound preparationActive componentPetrochemical

The invention belongs to the technical field of petrochemical engineering, in particular relates to a catalyst for preparing acrylic acid through propane selective oxidation and a preparation method of the catalyst. The catalyst has a formula of MoaVbTecNbdOx, wherein Mo, V, Te and Nb are active components; a : b : c : d is 1 : (0.2-0.3) : (0.2-0.3) : (0.1-0.2). When the catalyst is adopted to prepare the acrylic acid, the conversion rate of the propane and the once-through yield of the acrylic acid are high.

Owner:临沂星火知识产权服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com