Patents

Literature

41results about How to "High overall yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

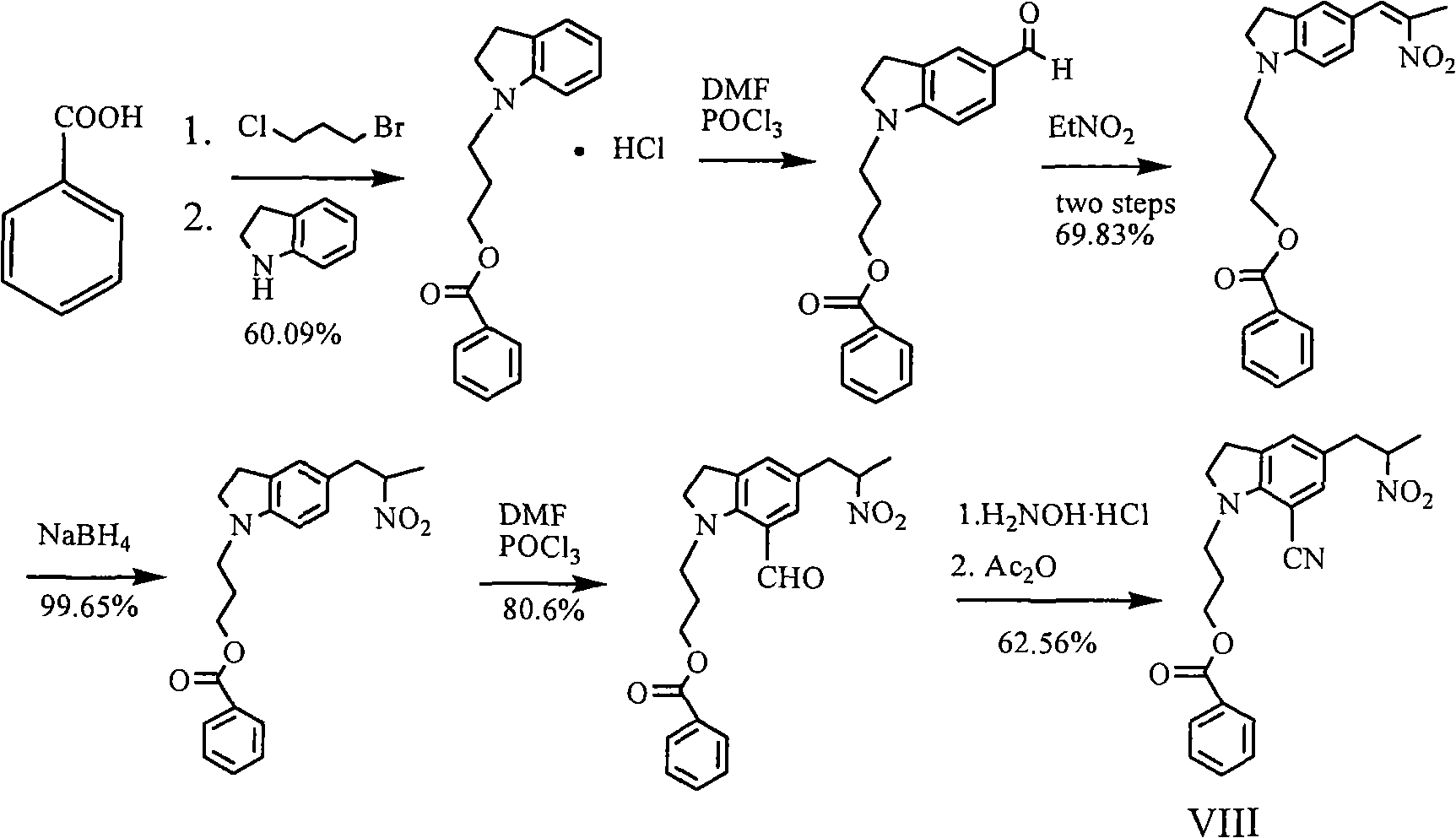

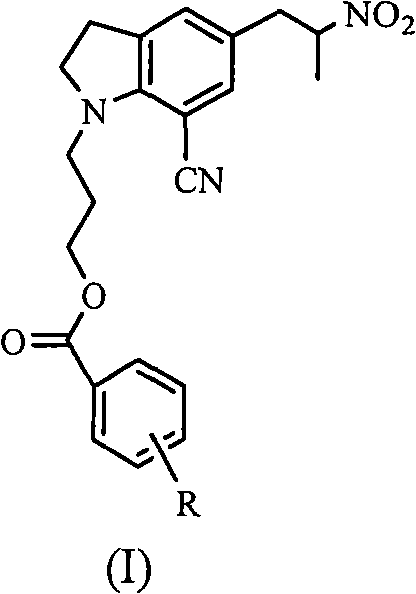

Indoline compound for preparing silodosin and preparation method thereof

The invention provides an indoline compound of 1-(3-substituted benzoyl alkoxypropyl)-5-(2-nitrylpropyl)-7-cyanophoric indoline and a preparation method thereof. The indoline compound can be used as an intermediate compound and is used for synthesizing silodosin. The indoline compound uses substituted phenylformic acid as a raw material, is prepared by multiple-step reaction, has high yield and is easy to industrially produce.

Owner:ZHEJIANG HUAHAI PHARMACEUTICAL CO LTD +1

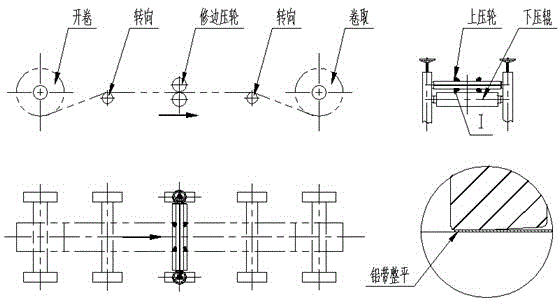

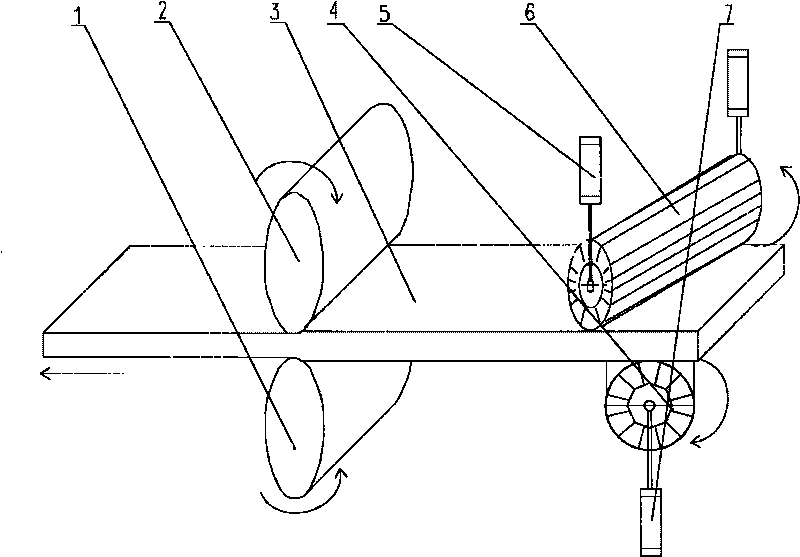

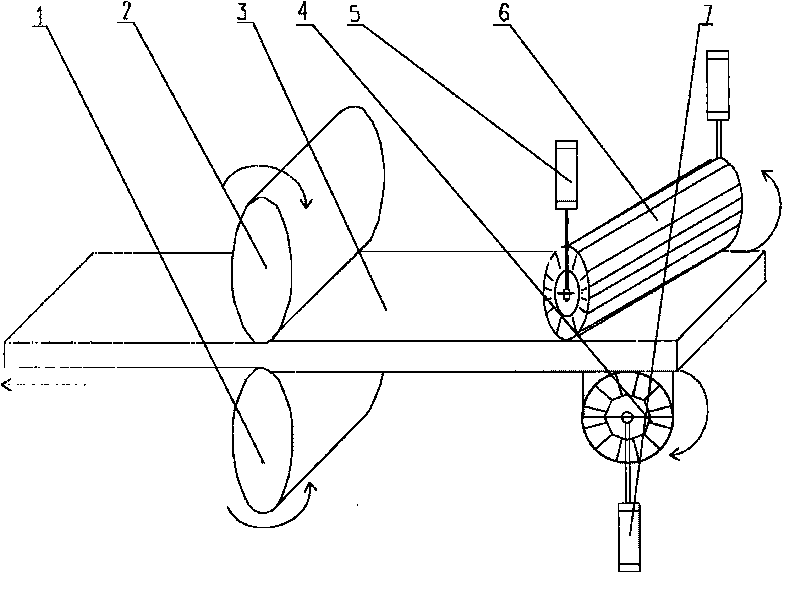

Novel process for on-line removing of scale at surface of hot-rolled copper plate belt

InactiveCN101698197ASuperiorRemove in timeWork treatment devicesCleaning using toolsSurface oxidationIngot

The invention discloses a novel process for the on-line removing of scale at the surface of a hot-rolled copper plate belt, which is a process for scraping, brushing and purging scale at the surface of a blank ingot during hot rolling. The process comprises the following steps: scraping and brushing the scale on the upper surface or the lower surface of a rolled piece (3) by a scraping and brushing roller at the inlet side and the outlet side of a working roller, scraping off the scale which already turns up because of hot rolling, and avoiding pressing into the inside of the rolled piece during rolling; the process can solve the long-term puzzling problem of the pressing-in of the scale in the hot-rolling process of a copper plate belt, can be used for common hot-rolling materials, also can be used for hot-rolling quenching materials, can lower the energy consumption and the cost, can improve the labour production conditions of workers and can better produce a blank used for a cold-rolling copper plate belt with no scale pressed into the surface.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

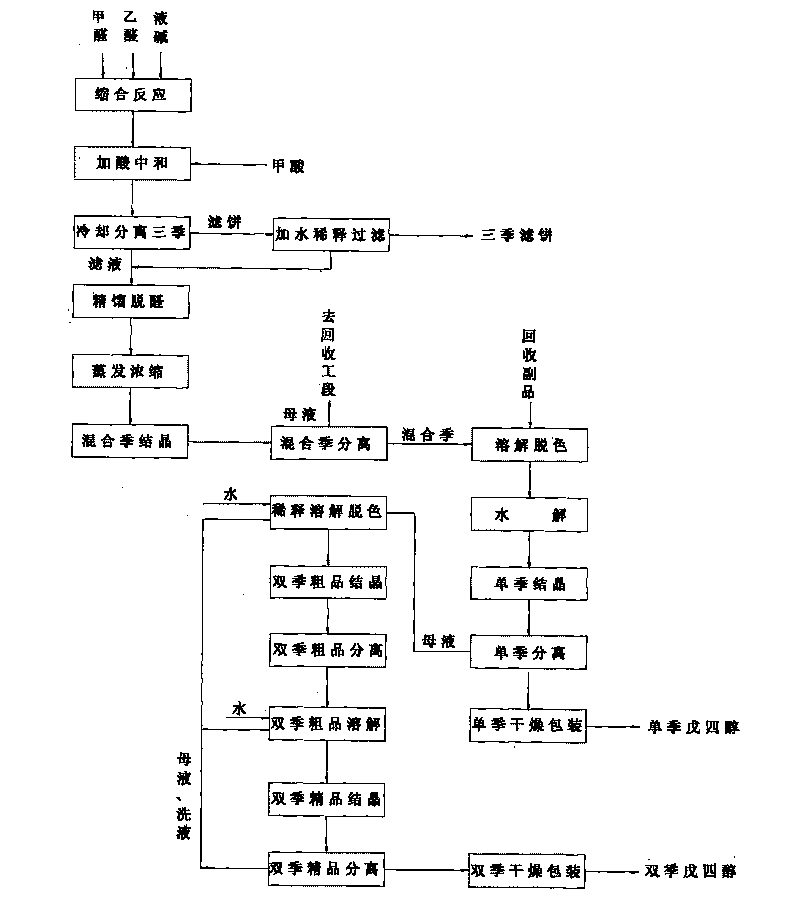

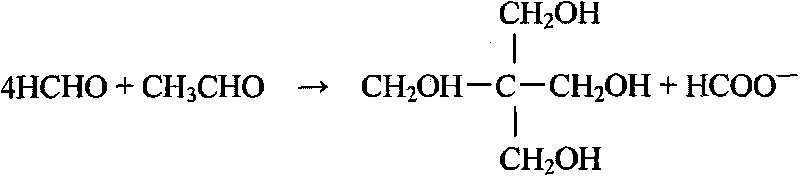

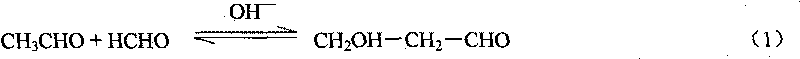

Method for preparing pentaerythritol and dipentaerythritol

ActiveCN101696158AHigh overall yieldImprove qualityOrganic compound preparationHydroxy compound preparationChemistryPentaerythritol

The invention relates to a method for preparing pentaerythritol and dipentaerythritol, which comprises the steps of: taking formaldehyde, aldehyde and sodium hydroxide as raw materials, controlling the reaction temperature according to a reaction mechanism, adopting a specific feeding program to control the mixture ratio of the raw materials for a reaction, and using formic acid for neutralization after the reaction is finished; and reducing the temperature of a reaction solution through the cooling, filtering tripentearythritol, then crystallizing to separate the pentaerythritol and a crude dipentaerythritol product respectively at a specified temperature through rectification dealdehyding, pressurized hydrolysis and evaporation concentration, and obtaining a refined dipentaerythritol product by refining the crude dipentaerythritol product. The method has a simple process, and reduces the generation of the tripentearythritol as much as possible on the premise of ensuring the yield of the dipentaerythritol and the total yield by accurately controlling the mixture ratio and the concentration of the raw materials, the reaction temperature and the feeding program; and the obtained pentaerythritol and dipentaerythritol have high quality, particularly the dipentaerythritol has high content, the content of the dipentaerythritol can reach over 90 percent, and the ash content is low and is only between 0.01 and 0.03 percent.

Owner:濮阳市鹏鑫化工有限公司

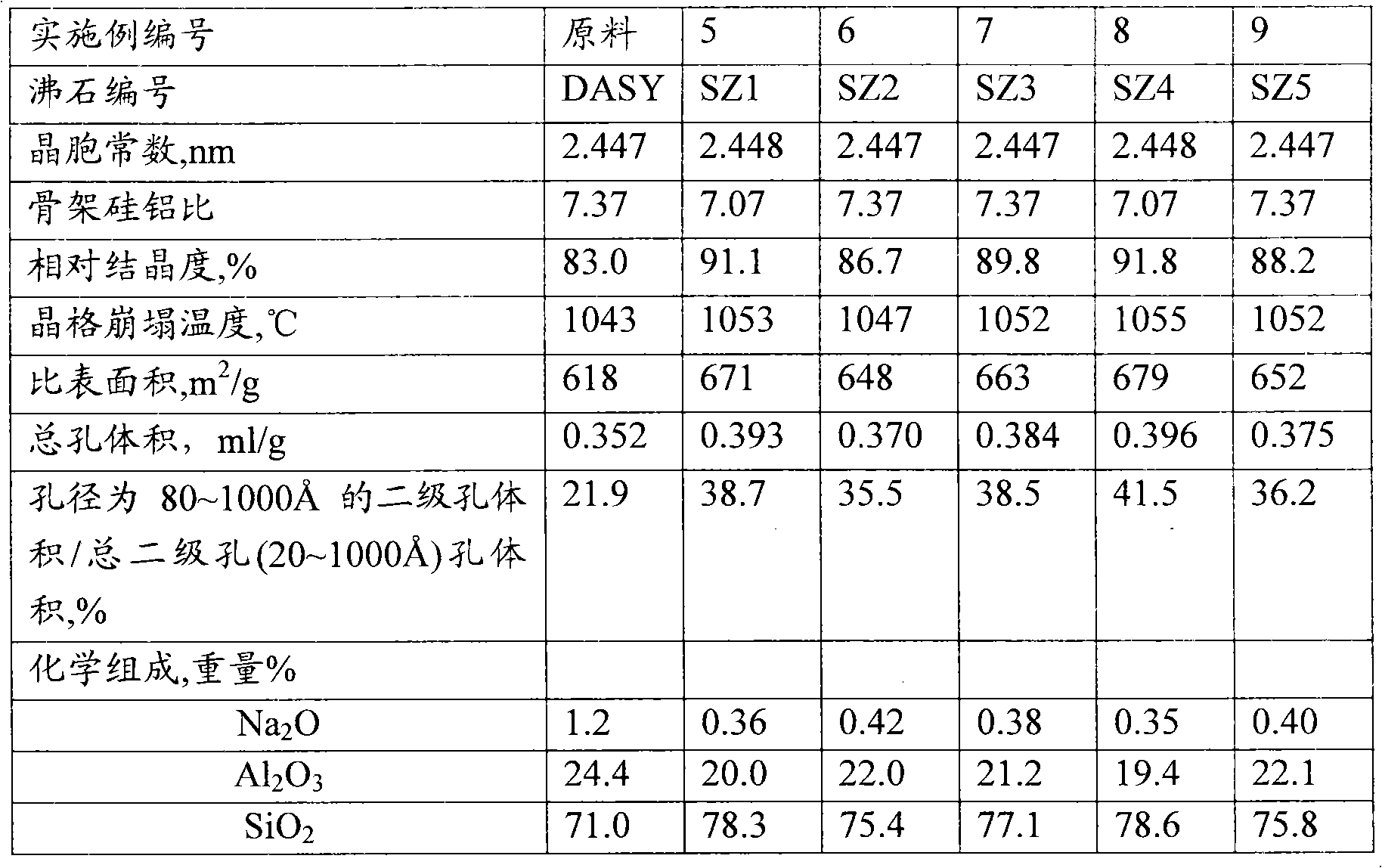

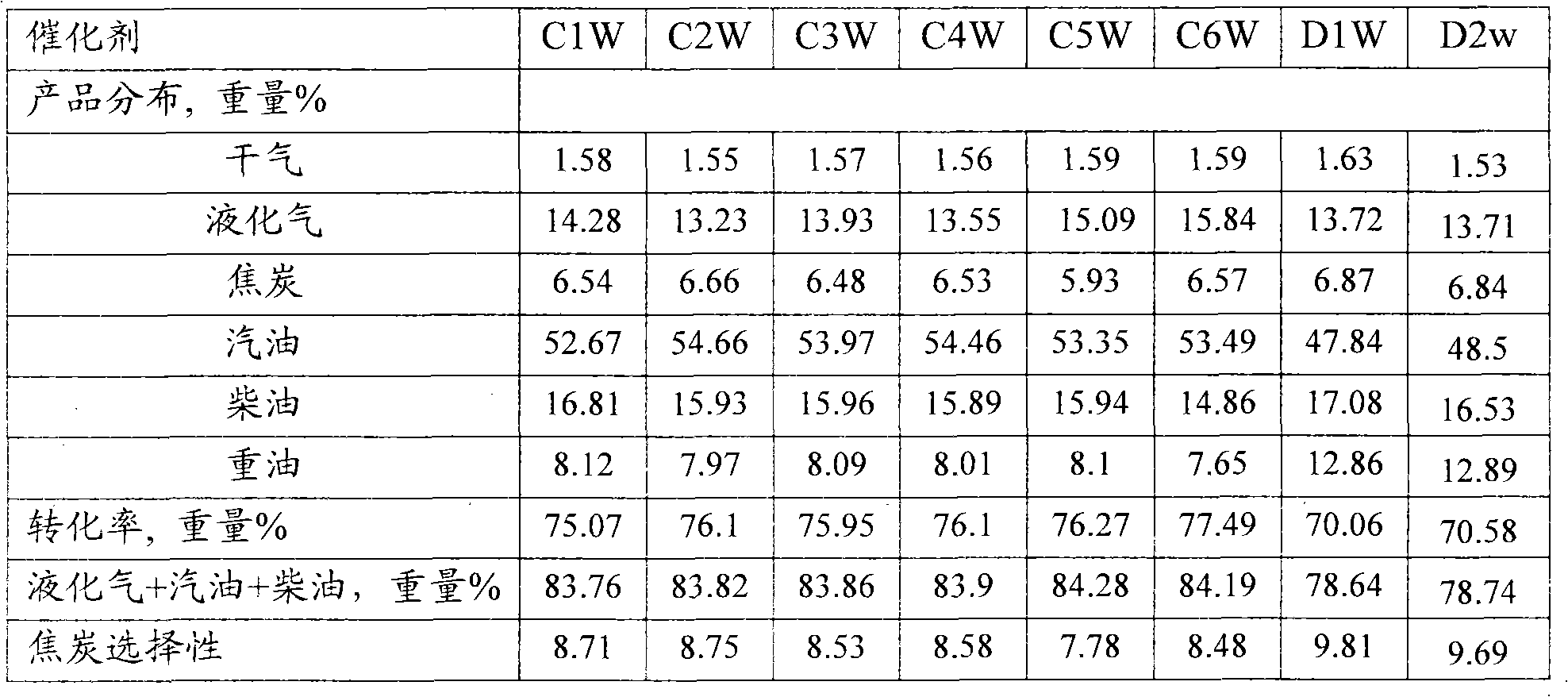

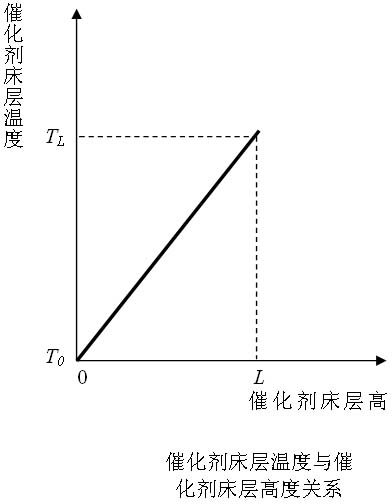

Heavy oil cracking catalyst and application thereof

ActiveCN101767029AGood coke selectivityHigh overall yieldCatalytic crackingMolecular sieve catalystsMetal pollutionFuel oil

The present invention relates to a heavy oil cracking catalyst and an application thereof. The catalyst comprises Y type zeolite and modified rectorite. The preparing method of the catalyst comprises the following steps: the modified rectorite is prepared by mixing rectorite, an auxiliary, water and acid; then, the catalyst is prepared by processing the modified rectorite and the Y type zeolite by mixing, pulping and spray drying. The auxiliary is selected from one or several of the compounds of La, Co, Zn, Cu and Ti, and the Y type zeolite comprises a modified super-stable Y type zeolite of which the ratio of silicon to aluminium is from 6 to 15 and the lattice constant is from 2.440nm to 2.458nm. The pore volume of secondary pores of which the pore diameter is from 80 to 1000 in the zeolite accounts for 30 to 60% of the pore volume of all secondary pores. The catalyst has high metal pollution resistant capability, high heavy oil conversion capability and good coke selectivity. The use of the catalyst for heavy oil catalytic cracking has the advantages of high conversion rate, high petrol yield and high total yield of liquefied gas, petrol and diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

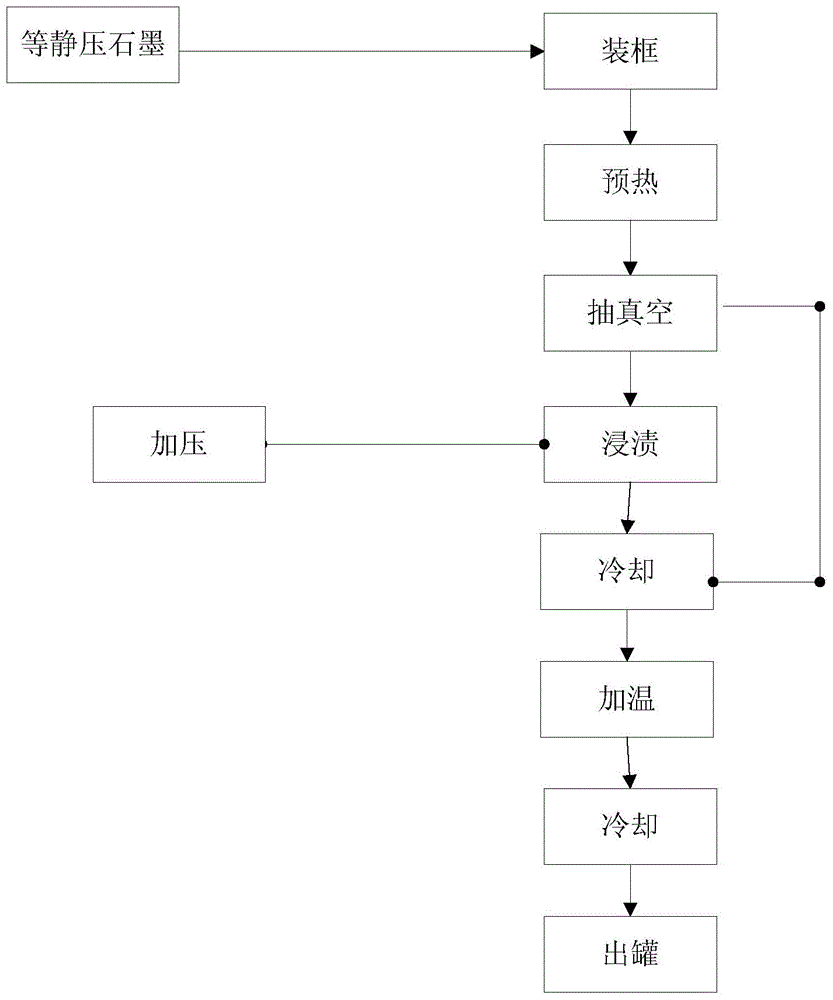

Impregnating method of preparing isostatic pressing graphite product

The invention discloses an impregnating method of preparing an isostatic pressing graphite product. The impregnating method comprises the following steps: preheating the isostatic pressing graphite product by raising the temperature from room temperature to 330 DEG C; placing the preheated isostatic pressing graphite product in liquid asphalt to form an impregnating system, and applying pressure to the impregnating system, wherein the temperature of the liquid asphalt is 180-220 DEG C; after the applied pressure remains unchanged, cooling the impregnating system under the condition of pressurization until the temperature is 50-60 DEG C; and heating the cooled impregnating system until the temperature of asphalt in the impregnating system is above a softening point, while stopping heating when the temperature of the surface of the product is at the softening point of the asphalt, meanwhile, reducing the pressure of the impregnating system, discharging the asphalt, then cooling the impregnating system again until the temperature is 60-80 DEG C, and finishing impregnation. According to the impregnating method disclosed by the invention, isostatic pressing graphite is uniformly and deeply impregnated in the impregnating process, the problems of cracking, bursting and the like in the whole impregnating process do not occur, the growth rate of the impregnated graphite product is increased, and the asphalt on the surface of the graphite product can be recycled again.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Synthesis method of 4-hydroxy-8-bromoisoquinoline

ActiveCN105693607AShort synthetic routeHigh overall yieldOrganic chemistry5-hydroxytryptamine receptorsDisease

The invention discloses a synthesis method of 4-hydroxy-8-bromoisoquinoline. The method comprises the following steps: mixing bromobenzylamine with a toluene solution, then adding p-toluenesulfonic acid and glyoxylic acid, heating, refluxing, dehydrating and condensing to generate a 2-bromobenzene imidoacetic acid crude product, adding polyphosphoric acid, simultaneously heating and stirring, pouring the product into water for filtering after the reaction is completed, washing filter cake with ethyl ether, then drying the filter cake. According to the synthesis method of 4-hydroxy-8-bromoisoquinoline, bromobenzylamine is used as the raw material; the synthesis route is simple; the process selection is reasonable; the raw material is simple and easily available; the operation and after-treatment are convenient; the total yield reaches up to 76%; the 4-hydroxy-8-bromoisoquinoline is easy to magnify and high in biological activity, can be used as a 5-hydroxytryptamine receptor, and has a strong effect of treating dementia and schizophrenia diseases.

Owner:SUZHOU KANGRUN PHARMA

Prepn of lutein fally ester and lutein

InactiveCN1810785ASimple processHigh overall yieldOrganic chemistrySolid sorbent liquid separationSolventAlkane

The present invention is the process of preparing lutein fatty ester from marigold extractum and preparing refined lutein product with lutein fatty ester. Marigold extractum is treated through dissolving in alkane solvent, adsorbing with macroporous adsorption resin, eluting with low toxicity mixed solvent comprising alkane and lower alcohol, rotary evaporation of the eluted liquid to recover solvent and vacuum drying, to obtain lutein fatty ester of 80-95 % content. The lutein fatty ester of 80-95 % content is further saponified under alcohol alkali condition for 2 hr, the reacted liquid is filtered, and the filter cake is washed with lower alcohol and water and vacuum dried to obtain lutein of 80-95 % purity. The process is simple and suitable for industrial production, and the solvent may be recovered and reused for low cost and environment friendship.

Owner:EAST CHINA UNIV OF SCI & TECH +1

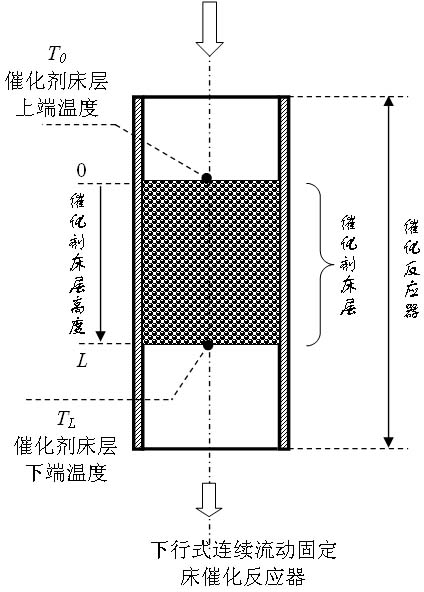

Catalyst for producing propylene and propane by converting ethanol and its preparation method and application

InactiveCN102274748AImprove one-way yieldHigh overall yieldMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePropene

The invention discloses a catalyst for ethanol conversion to produce propylene and propane. The catalyst is a composite molecular sieve catalyst containing MOR, HZSM-5, Beta, Y, SAPO-34, SAPO-31, SAPO-11, MCM-22, MCM -41. Two or more components of SBA-15 molecular sieves, which contain at least HZSM-5 and SAPO-34 molecular sieves, and the mass ratio of HZSM-5 and SAPO-34 molecular sieves is 0.2-5. The total yield of propylene and propane in the product obtained by using the catalyst of the present invention is high, and by-product ethylene and butene can be adjusted by changing the reaction conditions. The ratio of propylene / ethylene in the product is due to the temperature distribution of the catalyst bed, so The reaction heat effect generated by ethanol conversion is better dispersed and utilized, and there are no hot spots in the catalyst bed.

Owner:NORTHWEST UNIV

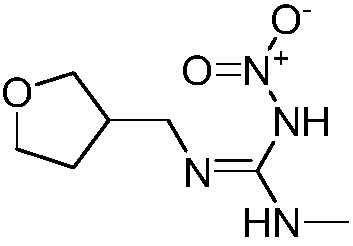

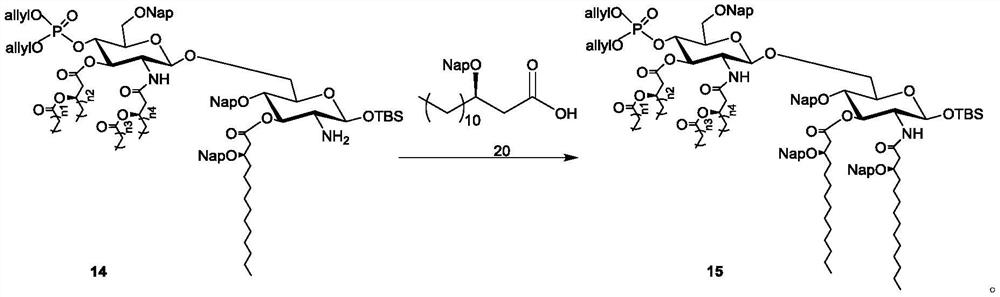

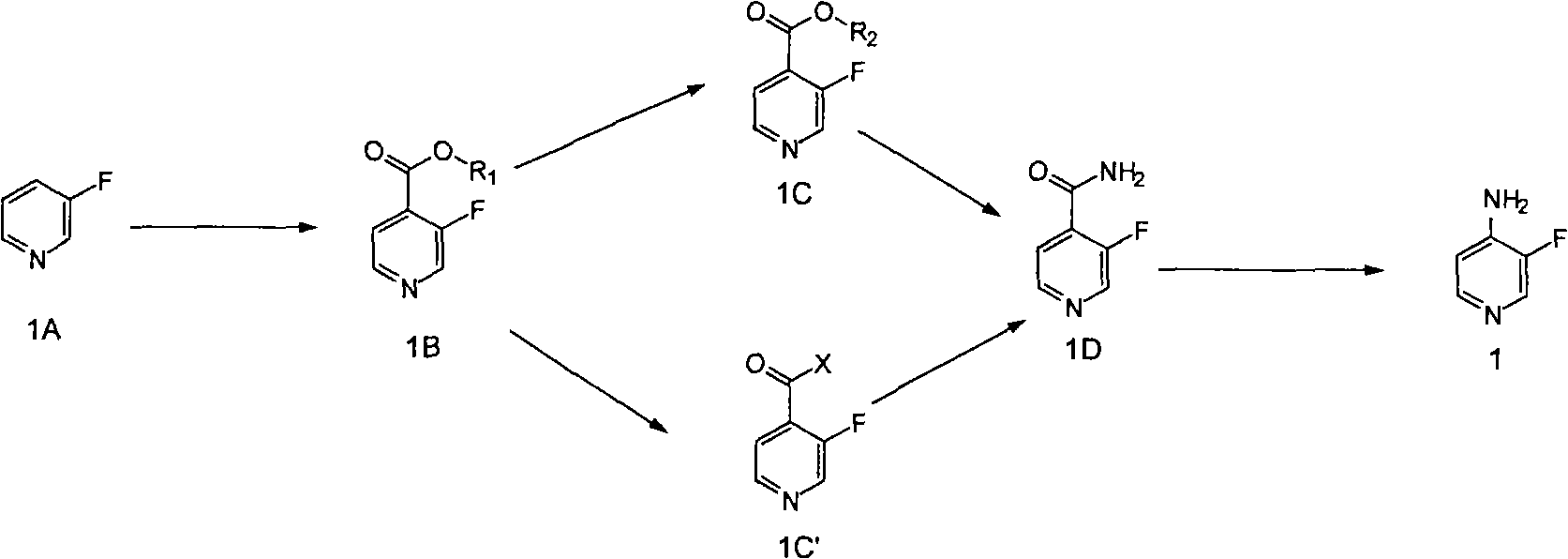

Preparation method of 5,6,7,8-tetrahydro-imidazo[1,5-a]pyrazine-1-carboxylic acid ethyl ester

ActiveCN102464661AShort synthetic routeHigh overall yieldOrganic chemistryEthyl esterDrugs synthesis

The invention relates to a preparation method of a 5,6,7,8-tetrahydro-imidazo[1,5-a]pyrazine-1-carboxylic acid ethyl ester derivative, mainly aiming at solving the technical problems of low yield, difficulty in purifying, inconvenience for experimental operation and the like existing in the conventional synthesis method. The preparation method comprises the following steps of: (1) preparing 2-methylthiopyrazine; (2) oxidizing methylthio; (3) closing a ring of methyl sulfuryl; and (4) hydrogenating and reducing pyrazine. A reaction formula is shown in the specifications. The 5,6,7,8-tetrahydro-imidazo[1,5-a]pyrazine-1-carboxylic acid ethyl ester derivative obtained by utilizing the preparation method disclosed by the invention is a useful intermediate or product synthesized by multiple medicaments.

Owner:WUXI APPTEC (TIANJIN) CO LTD

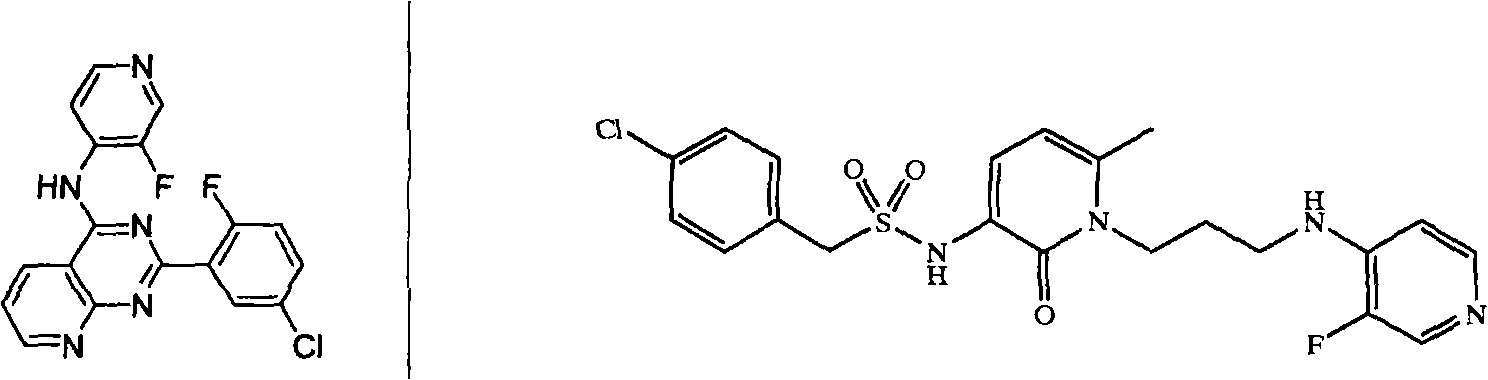

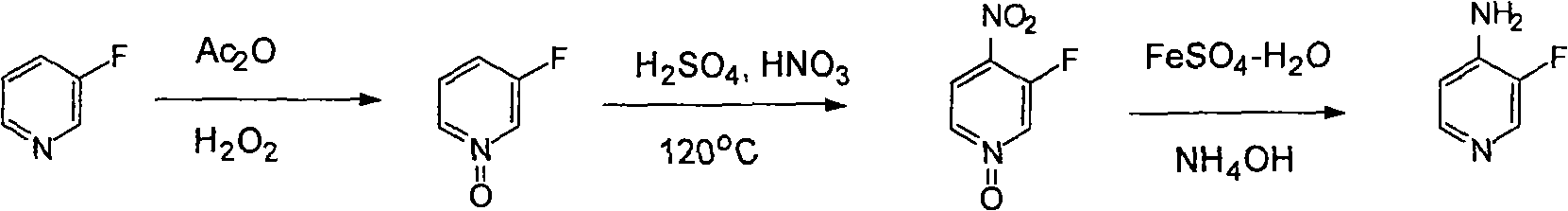

Synthesis method of 3-fluorine-4-aminopyridine

ActiveCN101863829AHigh overall yieldImprove securityOrganic chemistryDegradation reactionCarbon dioxide

The invention relates to 3-fluorine-4-aminopyridine, in particular to a synthesis method of the 3-fluorine-4-aminopyridine, mainly aiming at solving the technical problems of low yield, difficult separation and purification, easy explosion and the like of the existing synthesis method. The method has the technical scheme of: 1) taking 3-fluorine pyridine (1-A) as a raw material, using strong base to remove proton, carrying out reaction with carbon dioxide, and obtaining 3-fluorine-4-pyridine carboxylic acid or metal salt (1B); 2) carrying out esterification reaction on the compound (1B), and obtaining 3-fluorine-4-pyridine formic ether (1C); 3) carrying out ammonolysis reaction on the 3-fluorine-4-pyridine formic ether (1C), and generating 3-fluorine-4-pyridine carboxamide (1D); and 4) carrying out Hofmann degradation reaction on the 3-fluorine-4-pyridine carboxamide (1D), and generating the 3-fluorine-4-aminopyridine (1). The 3-fluorine-4-aminopyridine is an important intermediate for synthesizing multiple new medicines.

Owner:上海联友制药技术有限公司 +2

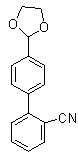

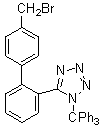

Preparation method of Olmesartan Medoxomil

Owner:湖南欧亚药业有限公司

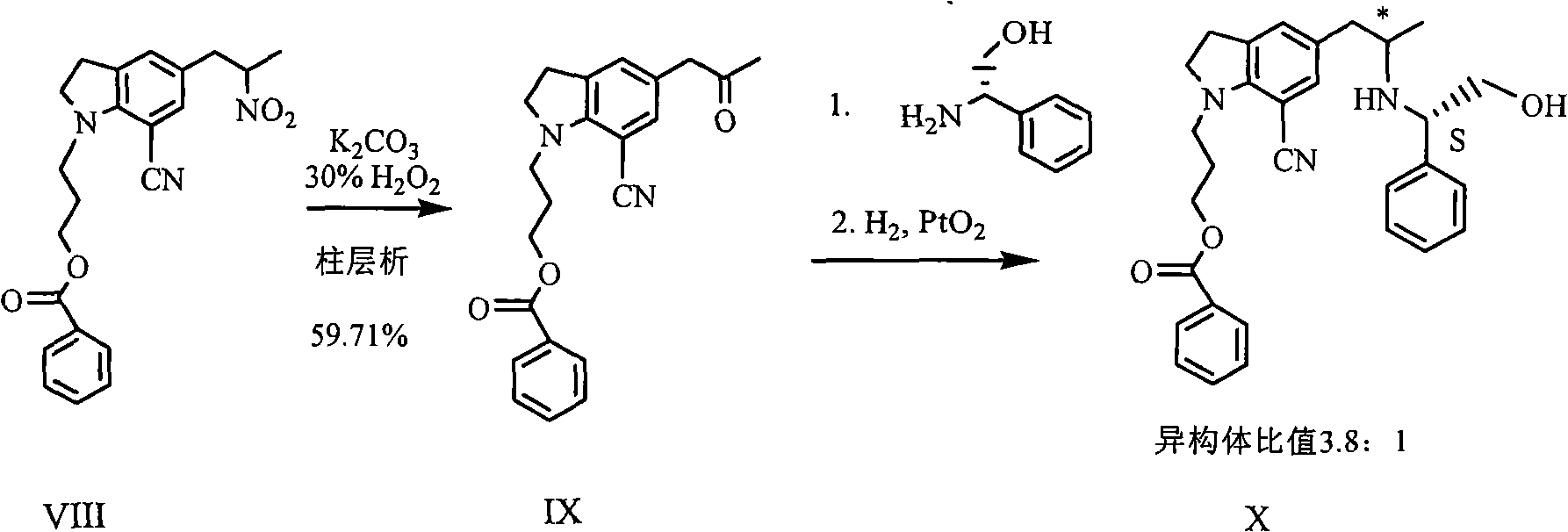

Method for synthesizing 4-[2-(trans-4-alkyl cyclohexyl )ethyl]cyclohexanone

ActiveCN103265417AFew reaction stepsHigh overall yieldCarbonyl compound preparation by oxidationMethyl formateActivated carbon

The invention discloses a method for synthesizing 4-[2-(trans-4-alkyl cyclohexyl )ethyl]cyclohexanone, comprising: reducting trans-4-alkyl cyclohexyl methyl formate which is used as a raw material under action of an aluminum / morpholine reducing agent, to obtain trans-4-alkyl cyclohexyl formaldehyde; carrying out witting reaction of trans-4-alkyl cyclohexyl formaldehyde with a 4-benzyloxy triphenyl benzylidene bromide phosphine salt under action of potassium tert-butoxide, to obtain 1-benzyloxy-4-[2-(trans-4-alkyl cyclohexyl )vinyl]benzene; under catalysis of palladium on activated carbon, hydrogenating 1-benzyloxy-4-[2-(trans-4-alkyl cyclohexyl )vinyl]benzene, to obtain 4-[2-(trans-4-pentyl cyclohexyl )ethyl]cyclohexyl alcohol; and oxidizing 4-[2-(trans-4-pentyl cyclohexyl )ethyl]cyclohexyl alcohol with hydrogen peroxide, to prepare 4-[2-(trans-4-alkyl cyclohexyl )ethyl]cyclohexanone compounds. The method has advantages of few steps, low cost and high overall yield, and oxidation reaction is carried out under green hydrogen peroxide, thereby avoiding serious environment pollution caused by a metal oxidation reagent.

Owner:XIAN CAIJING OPTO ELECTRICAL SCI & TECH

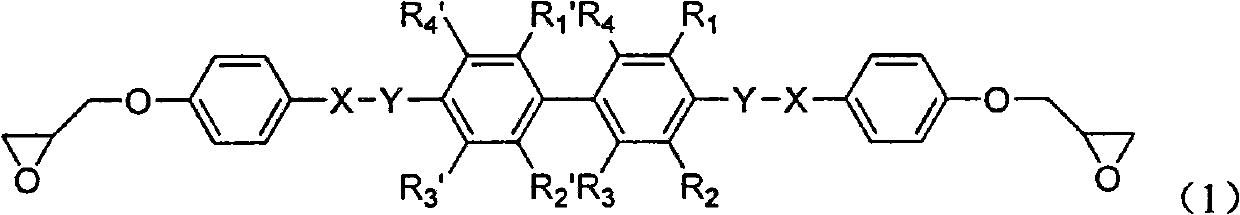

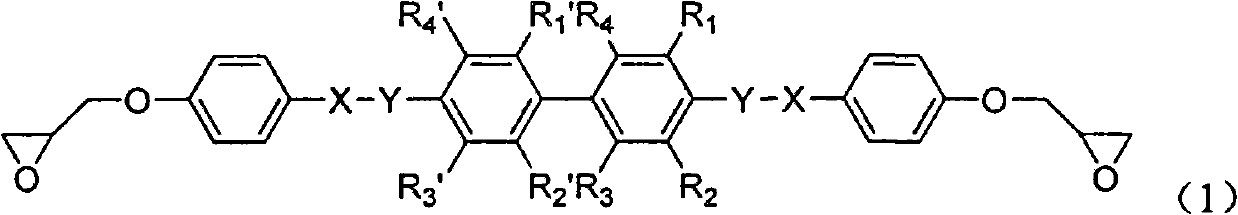

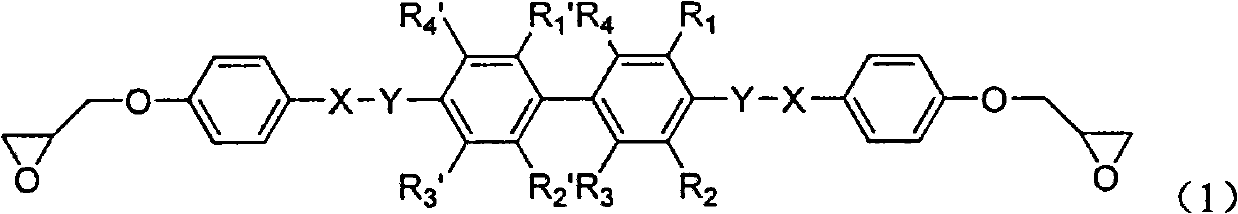

Biphenyl-containing compound liquid crystal epoxy resin and preparation method thereof

InactiveCN101962372AThe reaction steps are simpleHigh overall yieldLiquid crystal compositionsOrganic chemistryBenzeneLiquid crystal

The invention provides a biphenyl-containing compound liquid crystal epoxy resin and a preparation method thereof. The biphenyl-containing compound liquid crystal epoxy resin has a structure represented by a formula (1), wherein the -X-Y-, which represents a bridge bond for connecting an aromatic group to a rigid rod mesomorphic structure, may be -C(=O)-O- or-CH=N-; and R1, R2, R3 and R4 and R'1, R'2, R'3 and R'4 has a substituent group which may be -H, -F, -Cl, -Br, -CH3, -C2H5, -OCH3 or -OC2H5. The resin makes full use of the liquid crystal epoxy resin (LCER) thermal performance, and has high comprehensive mechanical performance. The preparation method comprises performing a reaction for generating bisphenol which a liquid crystal epoxy resin intermediate and reacting the bisphenol intermediate with epoxy chloropropane to form the liquid crystal epoxy resin.

Owner:SOUTH CHINA UNIV OF TECH

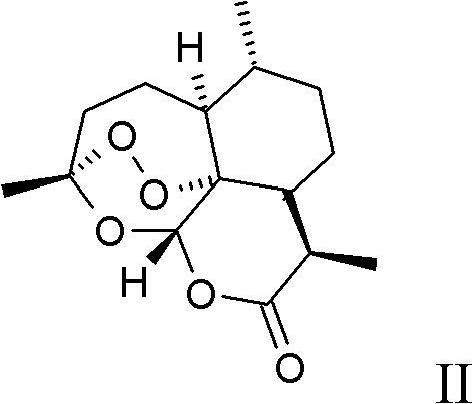

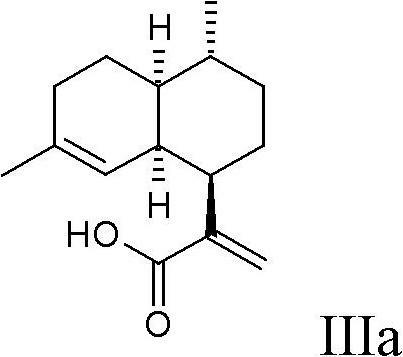

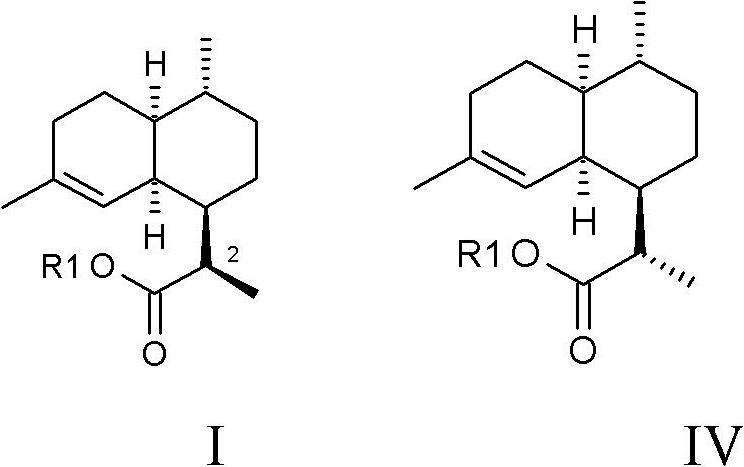

Process for the production of artemisinin intermediates

InactiveCN102612507AHigh overall yieldGood product purityOrganic compound preparationOrganic chemistry methodsChemistryDouble bond

This application relates to a process for the production of (2R)-dihydroartemisinic acid or (2R)-dihydroartemisinic acid esters from artemisinic acid or artemisinic acid esters, respectively, by diimine hydrogenation of the exocyclic CC-double bond, and use of said process in the production of the antimalarial drug artemisinin.

Owner:SANOFI SA

Preparation method of furanone

ActiveCN110372646AHigh overall yieldImprove extraction efficiencyOrganic chemistryEthyl acetateEthyl ester

The invention discloses a preparation method of furanone. The preparation method includes the steps that an acetone aldehyde solution is prepared, a 3,4-dihydroxy-2,5-hexanedione solution is prepared,3,4-dihydroxy-2,5-hexanedione is purified, semi-finished furanone is prepared, and finished furanone is prepared. The preparation method has the advantages that 1, the yield of the intermediate 3,4-dihydroxy-2,5-hexanedione and the total yield of the furanone can be increased through composite catalyst zinc powder, iron powder and manganese powder, 2, purity of the intermediate 3,4-dihydroxy-2,5-hexanedione is obviously increased by adding anhydrous sodium sulphate and sodium chloride composite powder, and 3, purity of the furanone can be obviously improved by combining extractant ethanol andethyl acetate.

Owner:安徽金轩科技有限公司 +1

Method for simultaneously preparing disperse red 3B and disperse red 60

InactiveCN102618059AHigh overall yieldGood economic benefitsAmino-hydroxy-anthraquinone dyesCyclohexanoneN-Butyl acetate

The invention relates to a method for simultaneously preparing disperse red 3B and disperse red 60, which includes the steps: adding at least one organic solvent, which is selected from o-dichlorobenzene, butyl acetate and cyclohexanone, into distillation residue generated in a traditional disperse red 60 preparation process, heating to 100-110 DEG C to lead the distillation residue to completely dissolve, then cooling the dissolved distillation residue to 75-80 DEG C with suction filtration, keeping filtrate, cooling the filtrate to be lower than 25 DEG C, separating out solid with suction filtration, and obtaining the disperse red 3B. The method is used for ingeniously processing the distillation residue generated during traditional disperse red 60 preparation into the disperse red 3B, so that turning waste into wealth is realized, total product yield is increased, economic benefits are remarkable, and environmental protection significance is great.

Owner:苏州市罗森助剂有限公司

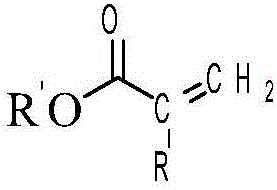

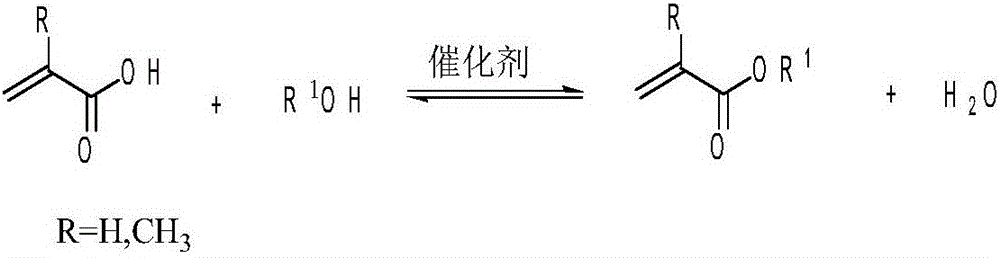

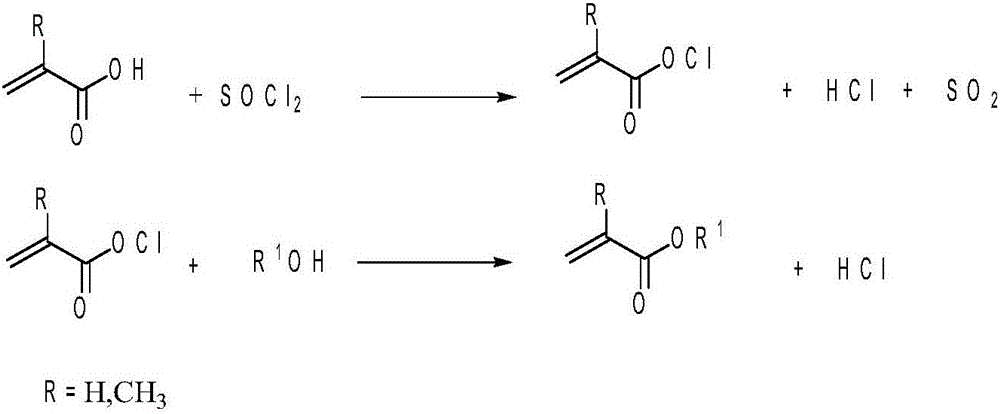

Method for synthesis of (meth)acrylate diluent

InactiveCN105837448AHigh overall yieldImprove processing powerPreparation by ester-hydroxy reactionOrganic compound preparationOrganic synthesisReaction conditions

The invention discloses a method for synthesizing (meth)acrylate diluent, which belongs to the field of organic synthesis. The (meth)acrylate and alcohol are used as raw materials, a reaction-rectification coupling process is adopted, and a copper wire mesh is used. The modified rectification column of packing, adding organic monotin catalyst, can obtain sufficient product purity and yield after simple post-treatment process. Compared with the traditional transesterification method, the method of the present invention can improve the total yield and processing capacity, utilize the reaction heat to supply the separation needs, reduce energy consumption, and reduce investment. The method of the invention is short in technical process, easy to obtain raw materials, simple in equipment and easy to control the reaction conditions. The method has mild reaction conditions, simple purification and purification process, stable and easy separation of products, and is not easy to cause polymerization.

Owner:CHANGZHOU UNIV

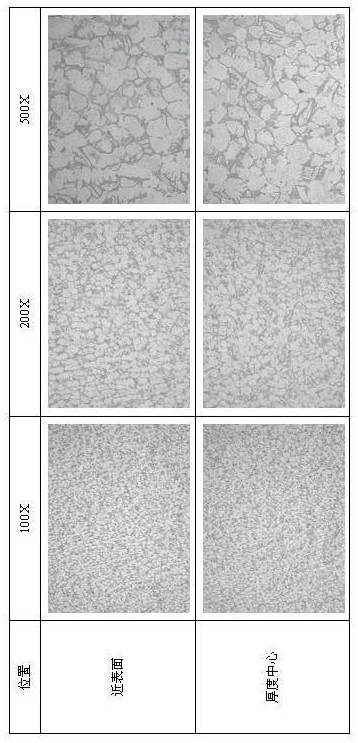

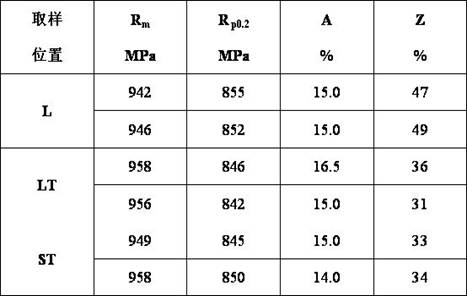

Forging machining method for super-large titanium alloy forging stock

PendingCN114178456AReduce processing costsHigh overall yieldMetal-working apparatusTitanium alloyMachining

The invention relates to the technical field of titanium alloy forging, in particular to an oversized titanium alloy forging stock forging machining method which is achieved through the steps of cogging forging, homogenizing forging, forging below T beta, finished product forging and the like. By the adoption of the forging method, batch production of the ultra-large TC4 titanium alloy forging stock with the single weight being 3000-5000 kg can be achieved on a high-speed forging machine, the total forging heating number of the forging stock is 8-10, the machining cost is reduced by about 17% compared with 14-16 times of forging of a traditional titanium alloy forging stock, the comprehensive yield is increased by about 7%, and the forging method is suitable for industrial production.

Owner:湖南湘投金天钛业科技股份有限公司

Production method for carrying out low boiler recycling on methyl acetoacetate

ActiveCN106748789AReduce lossHigh overall yieldOrganic compound preparationPreparation from ketenes/polyketenesProduct recoveryDiamine

The invention discloses a production method for carrying out low boiler recycling on methyl acetoacetate. The production method comprises the following steps: adding methanol and a catalyst triethylene diamine in a reaction kettle; carrying out heating reflux; dropwise adding diketene; keeping warm; cooling a reaction solution after a reaction is completed; adding concentrated sulfuric acid; keeping warm; filtering; carrying out continuous rectification on filtrate; rectifying a low boiler; adding acid in the low boiler for esterifying; rectifying the low boiler at normal pressure after carrying out the heating reflux for 1 to 2 hours; stopping rectifying after rising the kettle temperature to be 115 to 125 DEG C; cooling to 40 to 50 DEG C; neutralizing by using solid base; enabling a neutralized material to enter a conventional negative pressure rectifying system, and rectifying a methyl acetoacetate finished product, wherein the content of the methyl acetoacetate finished product is greater than 99.0 percent, the acidity is smaller than 0.05 percent, and the product recovery rate is 95 percent or above. According to the production method disclosed by the invention, loss of the methyl acetoacetate is reduced, the total yield of the methyl acetoacetate is increased, a resource can be recycled and reutilized, and the cost is reduced.

Owner:NANTONG ACETIC ACID CHEM

Continuous-casting and continuous-drawing processing technique of N6 nickel alloy wire

The invention relates to a continuous-casting and continuous-drawing processing technique of an N6 nickel alloy wire. The continuous-casting and continuous-drawing processing technique is characterized by comprising the following steps: during smelting and drawing, charging nitrogen into an upper space of melted metal; putting an electrolytic nickel plate and N6 alloy leftovers together into an intermediate-frequency smelting furnace; simultaneously adding graphite carbon of which the weight is 0.1 percent of the weight of the electrolytic nickel plate; controlling the temperature to be 1470+ / -20 DEG C to melt the metal; adding NiMg alloy according to a proportion of 0.4Kg / 100Kg for degassing; keeping the temperature; starting continuous-casting of a lead wire; regulating the ratio of pulse rotation length to stagnation distance to be 7:3 and regulating the drawing speed to be 2m / min to 5m / min; synchronously adding cooling water of which the pressure is 0.08Mpa to 0.12MPa. The continuous-casting and continuous-drawing processing technique of the N6 nickel alloy wire has the beneficial effects of reducing a plurality of processing steps such as peeling of a blank material, hot-rolling blooming and primary draw-molding of a wire ingot, prolonging the processing period of the wire and improving the comprehensive rate of finished products, and also lowering the processing cost of the wire.

Owner:中色创新研究院(天津)有限公司

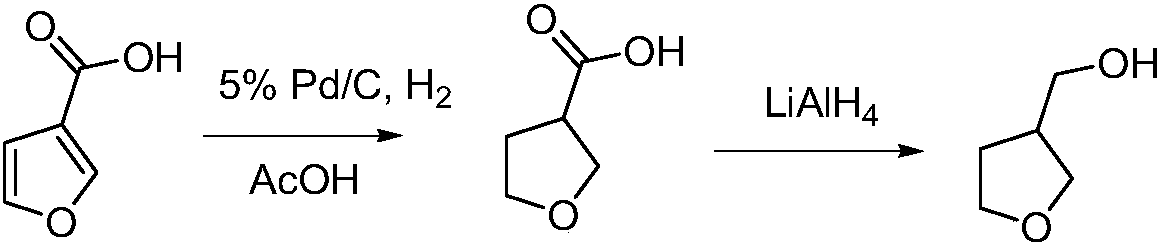

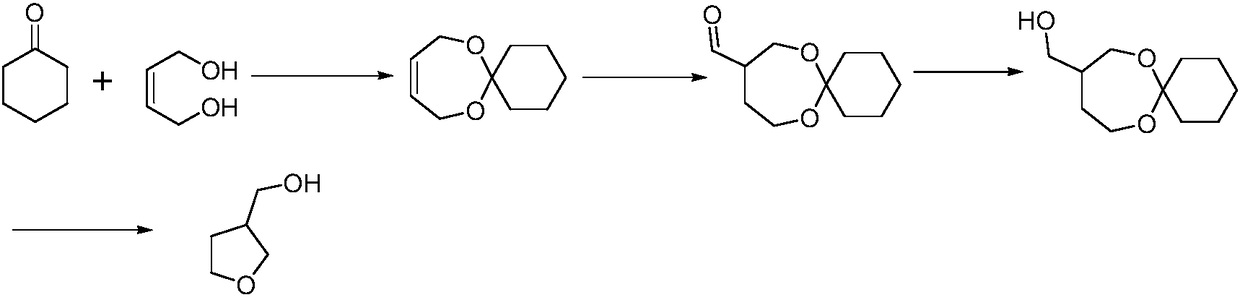

Production technology for 3-hydroxymethyltetrahydrofuran

The invention discloses a production technology for 3-hydroxymethyltetrahydrofuran, and belongs to the field of pesticide intermediate synthetic processes. The production technology is capable of using 2-butene-1,4-diol as a starting raw material, and synthesizing the 3-hydroxymethyltetrahydrofuran through a three-step reaction of dehydration cyclization, hydroformylation and reduction. The production technology is moderate in reaction conditions, low in cost, less in three wastes, and suitable for the industrial production.

Owner:HUBEI JINGHONG CHEM

Novel method for synthesizing adenine

InactiveCN107602558AHigh overall yieldReduce manufacturing costOrganic chemistryActivated carbonDichloroethane

The invention discloses a novel method for synthesizing adenine. The novel method comprises the following steps: (1) firstly, dispersing acetyl hypoxanthine into 1,2-dichloroethane; then adding the mixture into a reaction kettle; slowly adding anhydrous pyridine and triethylamine; stirring and raising the temperature to 110 DEG C to 120 DEG C; adding phosphoryl chloride and keeping heat and reacting for 50min to 80min; continually keeping the heat and reacting at 110 DEG C to 120 DEG C for 4h to 6h; then cooling to about 15 DEG C and standing; (2) filtering a reaction solution; then adding a mixed solution and carrying out aminolysis; drying to obtain an adenine crude product; (3) adding the obtained adenine crude product into the reaction kettle; after finishing feeding, raising the temperature to 80 DEG C and dissolving; after completely dissolving the adenine, adding active carbon and de-coloring; continually keeping the heat at 80 DEG C and de-coloring for 2h; filtering and separating the active carbon; (4) after filtering, carrying out the aminolysis, crystallization and drying to obtain an adenine pure product. The novel method disclosed by the invention takes the acetyl hypoxanthine as a raw material, and the raw material is a byproduct of a glutamic acid fermentation process and is cheap and easy to obtain; the total yield is improved.

Owner:SUQIAN YUANYANG BIOTECH

Method for preparing gallic acid and pyrogallic acid with tannin biomass

ActiveCN106146284AHigh analytical purityHigh overall yieldOrganic compound preparationPreparation from carboxylic acid esters/lactonesTanninBiomass

The invention provides a method for preparing gallic acid and pyrogallic acid with tannin biomass and belongs to the technical field of chemical production. A mixed solution of deionized water, absolute ethyl alcohol and formamide is utilized to carry out acid-base catalysis and special dissolvability in high-temperature liquid state, Chinese gall or tara is enabled to be decomposed into gallic acid or pyrogallic acid to undergo strongly acidic styrene type cation exchange resin reaction in the microwave environment after dehydration and ethanol removal, Chinese gall or tara is enabled to be hydrolyzed fully, and gallic acid and pyrogallic acid products processed via some processing steps are high in analysis purity and total yield. Test proves that the analysis purity of gallic acid and pyrogallic acid products are above 90wt% and 95wt%. Total yield of products is over 75%.

Owner:遵义市倍缘化工有限责任公司

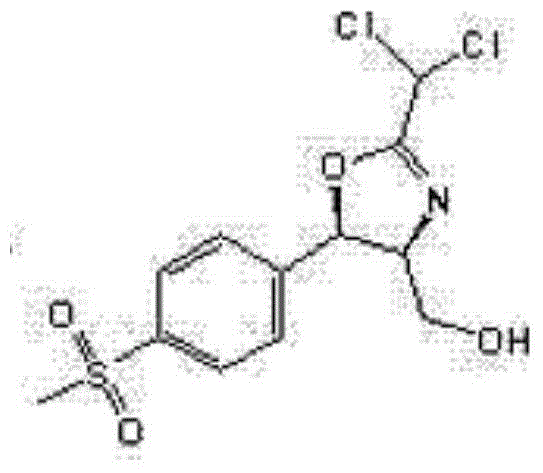

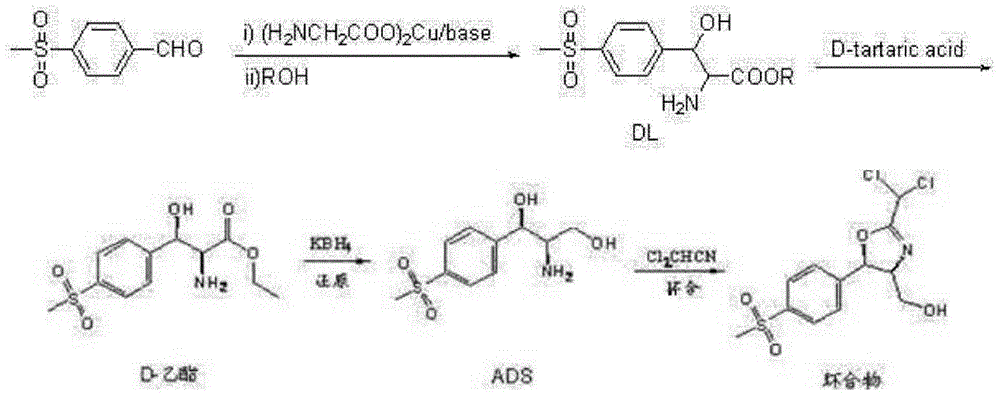

Synthetic method for (4R,5R)-2-bischloromethyl-4,5-dihydro-5-(4-methylsulfonyl)-4-oxazole methyl alcohol

The invention belongs to the technical field of synthesis of a florfenicol intermediate and particularly relates to a synthetic method for (4R,5R)-2-bischloromethyl-4,5-dihydro-5-(4-methylsulfonyl)-4-oxazole methyl alcohol. The method comprises the following steps that a sodium hydroxide water solution is added into 2-nitro ethyl alcohol in a dripped mode, then bromine is added, and the reaction is carried out to obtain 2-bromine-2-nitro ethyl alcohol; 2-bromine-2-nitro ethyl alcohol and ethyl alcohol are obtained, a hydrogenation catalyst is added, the mixture reacts with hydrogen, alcohols solvent is added, and then dichloroacetonitrile is added in a dripped mode for reaction; magnesium, tetrahydrofuran and 4- methylsulfonyl benzaldehyde are added to obtain a ring compound II; the ring compound II is subjected to an isomerization reaction in the alcohols solvent to obtain (4R,5R)-2-bischloromethyl-4,5-dihydro-5-(4-methylsulfonyl)-4-oxazole methyl alcohol. According to the method, a brand-new synthetic route is adopted, and generation of a large amount of copper-containing wastewater difficult to treat is avoided; hydrogen is adopted for reduction, generation of a large number of three wastes is avoided, cost is reduced, the total yield is high and is over 98%, benefits are increased, and environment is protected.

Owner:SHANDONG GUOBANG PHARMA

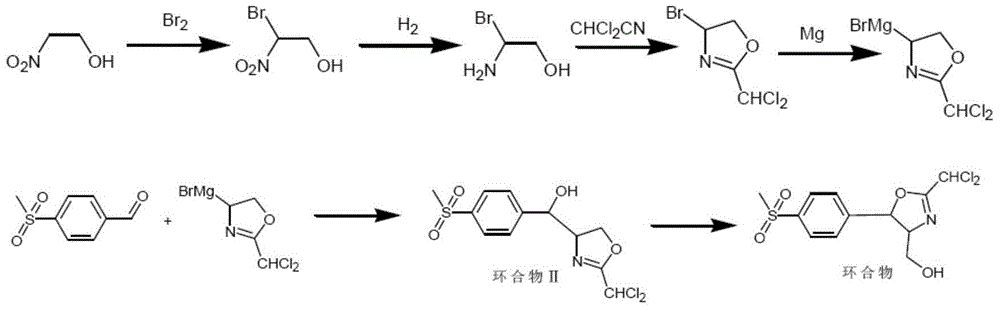

Total synthetic method of Talienbisflavan A

ActiveCN106588850AFew reaction stepsHigh overall yieldOrganic chemistryL-selectrideChemical synthesis

The invention relates to a total synthetic method of the proanthocyanidin natural product Talienbisflavan A and belongs to the field of chemical synthesis. The natural product Talienbisflavan A (see figures) is synthesized by: synthesizing dimeric catechin via acid catalyzed dimerization of formaldehyde, subjecting the dimeric catechin to DMP (Dess-Martin periodinane) oxidation and L-Selectride selective reduction to synthesize dimeric epicatechin, subjecting the dimeric epicatechin to coupling reaction with benzyl-protected gallic acid to synthesize dimeric epicatechin gallate, subjecting the dimeric epicatechin gallate to palladium / carbon debenzylation. The method of the invention has the advantages that reaction steps are few, total yield is high, product selectivity is good, and the method is suitable for industrial production.

Owner:威海创惠环保科技有限公司

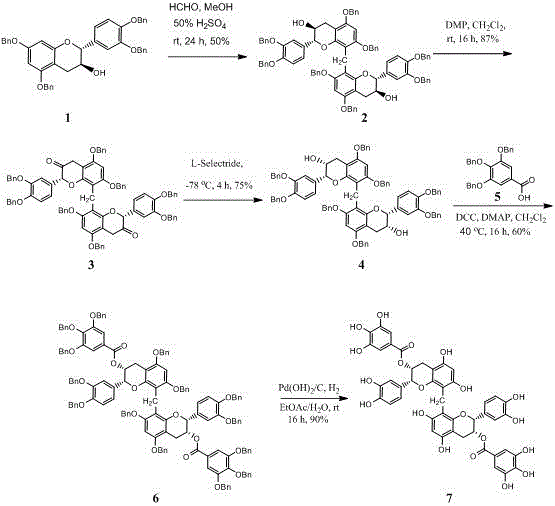

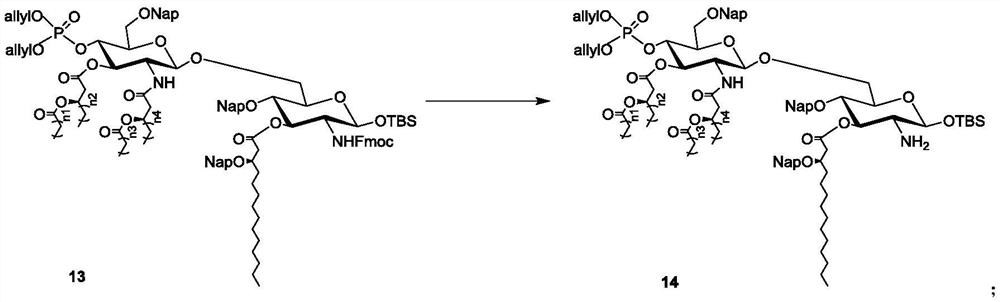

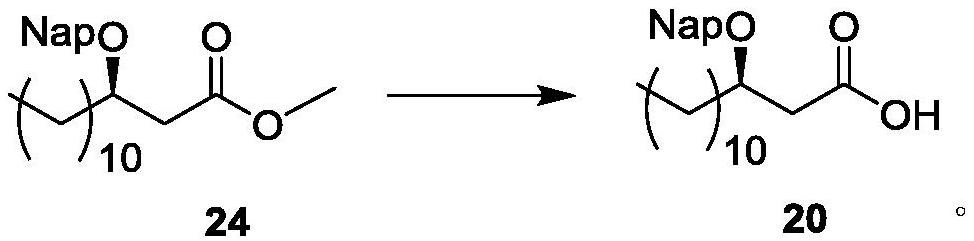

Intermediate, synthesis and application of vaccine adjuvant MPLA

PendingCN113527397AShort routeHigh overall yieldEsterified saccharide compoundsSugar derivativesPhosphoric acidMedicinal chemistry

The invention discloses an intermediate, synthesis and application of a vaccine adjuvant MPLA. According to the intermediate provided by the invention, an allyl phosphate ligand is used as a phosphate group source in MPLA, and Nap is used as a protecting group, so that the allyl phosphate ligand and the protecting group can be conveniently removed in subsequent operation; the synthesis route of the intermediate is short, and the total yield is obviously increased. A basis is provided for synthesis and amplification of MPLA.

Owner:SHANGHAI INST OF PHARMA IND +1

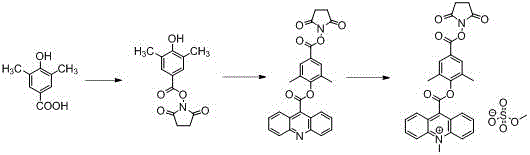

Synthesis of acridinium ester chemiluminescent substrate DMAE.NHS

InactiveCN106749185AThe reaction steps are simpleHigh overall yieldOrganic chemistryChemiluminescene/bioluminescenceSolventCarbonyl chloride

The invention aims to provide a synthesis method of a chemiluminescent substrate namely acridinium ester 9-((4-(((2,5-dioxo-1-pyrrolidinyl)oxy)carbonyl)-2,6-dimethylphenoxyl)carbonyl)-10-methyl acridine onium methyl sulfate (DAME.NHS). The chemical structure of DMAE.NHS is represented in the description. According to the synthesis method, 3,5-dimethyl-4-hydroxyl benzoic acid, N-hydroxyl succinimide, and acridine-9-carbonyl chloride are taken as the raw materials, and after two steps of esterification reactions, the reaction product is subjected to methylation to obtain the target compound. Compared with other synthesis method, the provided synthesis method has the advantages that the steps are few, the method does not need any pricy reagent or solvent, the reaction conditions are mild, the product yield and purity are high, and the synthesis method is suitable for massive production.

Owner:HUNAN NORMAL UNIVERSITY

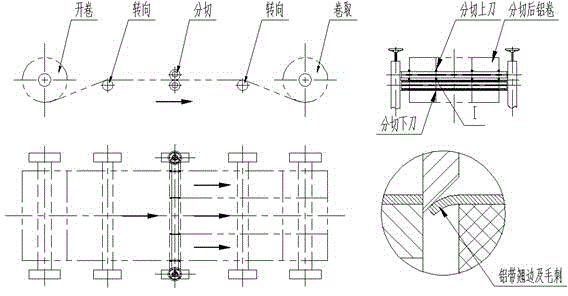

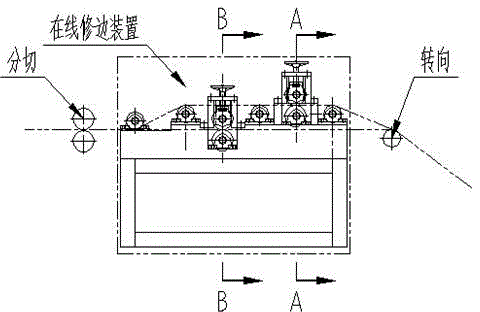

Split aluminum band on-line trimming apparatus

The invention discloses a split aluminum band on-line trimming apparatus, which comprises a double layer guiding trimming unit; each guiding trimming unit comprises an upper pinch roller, a lower pinch roller, a wallboard, a shaft, a frame, a feather key, an adjusting handwheel, a screw rod, a spherical guide groove ball bearing and a spherical ball bearing. Two aluminum bands interfere with each other when trimming because two split parallel aluminum bands have no slit therebetween, and a trimming wheel is wider than the aluminum bands when flanging. To solve the interference problem, the split parallel multiple aluminum bands are divided into 2 groups at intervals to an up and down guiding for trimming. The way of single off line trimming work of the split aluminum band is changed to working on-line multiple split aluminum bands at the same time, so that an off-line trimming work production line is saved; the trimming efficiency is improved by times; and the water of the aluminum bands in a production line operation cycle is reduced. The apparatus has the advantages of raising production efficiency, saving labor and time, saving electricity, reducing waste and improving comprehensive yield.

Owner:镇江龙源铝业有限公司

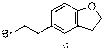

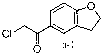

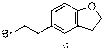

Synthetic technology of darifenacin intermediate 5-(2-bromomethyl)-2,3-dihydro-1-coumarone

ActiveCN102731449AHigh reaction yieldHigh overall yieldOrganic chemistryBulk chemical productionCarbonyl groupAcylation

The invention relates to the technical field of heterocyclic chemistry, especially to the technical field of oxygen-containing five-membered heterocyclic chemistry. The invention specifically relates to a synthetic technology of a darifenacin intermediate 5-(2-bromomethyl)-2,3-dihydro-1-coumarone. To realize the above synthetic technology, the invention provides a novel intermediate compound, which has a structure as shown in the formular (b), wherein R is a carbonyl protective group; and R is preferably alkyl, aryl or alkyloxy. Alkyl is preferably C1-C6 straight-chain alkyl or C5-C8 annular alkane. Aryl is preferably C6-C12 aryl. Alkyloxy is preferably C1-C6 alkyloxy. The compound as shown in the formula (b) is prepared by two-step reaction of acylation and nucleophilic substitution with 2,3-dihydro coumarone as a raw material. The darifenacin intermediate 5-(2-bromomethyl)-2,3-dihydro-1-coumarone can be prepared by two-step reaction of catalytic hydrogenation and bromination of the compound as shown in the formula (b).

Owner:ZHEJIANG JIUZHOU PHARM CO LTD

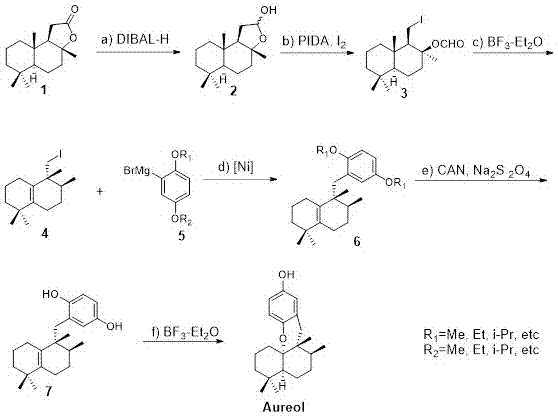

Method for synthesizing marine natural product Aureol

ActiveCN107954970AFew reaction stepsHigh overall yieldOrganic chemistry methodsChemical synthesisNickel

The invention relates to a method for synthesizing a marine natural product Aureol, and belongs to the field of chemical synthesis. Iodo substances 3 and 1-iodine-2, 5-di-alkoxy Grignard reagents 5 are used as starting materials, and the iodo substances 3 are generated from (+) sclareolide. The method includes generating rearrangement iodo substances 4 from the salvia sclarea iodo substances 3 andboron trifluoride diethyl ether; coupling the rearrangement iodo substances 4 and the 1-iodine-2, 5-di-alkoxy Grignard reagents 5 under the catalytic effects of nickel to construct key synthesis precursor frameworks 6 for the Aureol; carrying out known 2-step reaction on framework compounds 6 to obtain the marine natural product Aureol. The method has the advantages that the method includes few reaction steps, is easy and convenient to operate, good in product selectivity and suitable for industrial production, and the like.

Owner:HARBIN INST OF TECH AT WEIHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of 5,6,7,8-tetrahydro-imidazo[1,5-a]pyrazine-1-carboxylic acid ethyl ester Preparation method of 5,6,7,8-tetrahydro-imidazo[1,5-a]pyrazine-1-carboxylic acid ethyl ester](https://images-eureka.patsnap.com/patent_img/ffc819a5-75bf-437b-9ab0-dfe4a682f9e8/DEST_PATH_IMAGE007.png)

![Preparation method of 5,6,7,8-tetrahydro-imidazo[1,5-a]pyrazine-1-carboxylic acid ethyl ester Preparation method of 5,6,7,8-tetrahydro-imidazo[1,5-a]pyrazine-1-carboxylic acid ethyl ester](https://images-eureka.patsnap.com/patent_img/ffc819a5-75bf-437b-9ab0-dfe4a682f9e8/DEST_PATH_IMAGE009.png)

![Preparation method of 5,6,7,8-tetrahydro-imidazo[1,5-a]pyrazine-1-carboxylic acid ethyl ester Preparation method of 5,6,7,8-tetrahydro-imidazo[1,5-a]pyrazine-1-carboxylic acid ethyl ester](https://images-eureka.patsnap.com/patent_img/ffc819a5-75bf-437b-9ab0-dfe4a682f9e8/56454DEST_PATH_IMAGE010.png)

![Method for synthesizing 4-[2-(trans-4-alkyl cyclohexyl )ethyl]cyclohexanone Method for synthesizing 4-[2-(trans-4-alkyl cyclohexyl )ethyl]cyclohexanone](https://images-eureka.patsnap.com/patent_img/3c71d476-996f-4c83-a729-5789ac81a0f9/BDA00003139550500011.PNG)

![Method for synthesizing 4-[2-(trans-4-alkyl cyclohexyl )ethyl]cyclohexanone Method for synthesizing 4-[2-(trans-4-alkyl cyclohexyl )ethyl]cyclohexanone](https://images-eureka.patsnap.com/patent_img/3c71d476-996f-4c83-a729-5789ac81a0f9/BDA00003139550500021.PNG)

![Method for synthesizing 4-[2-(trans-4-alkyl cyclohexyl )ethyl]cyclohexanone Method for synthesizing 4-[2-(trans-4-alkyl cyclohexyl )ethyl]cyclohexanone](https://images-eureka.patsnap.com/patent_img/3c71d476-996f-4c83-a729-5789ac81a0f9/BDA00003139550500022.PNG)