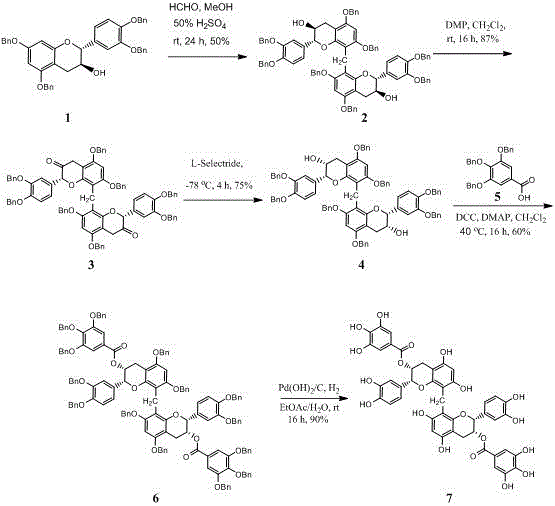

Total synthetic method of Talienbisflavan A

A total synthesis and tea element technology, applied in the direction of organic chemistry, can solve the problem of no compound synthesis report, etc., and achieve the effect of less reaction steps, good product selectivity and high total yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the synthesis of dimeric catechin (2, see accompanying drawing)

[0018] O-Bz catechin (1, 1.0 mmol) and 5 mL of dioxane were added to the reaction flask, and formalin (35.0 uL) and 50% concentrated H were added at room temperature 2 SO 4 (0.5 mL), stirred at room temperature for 24 hours, and TLC detected the end of the reaction. Add 20 ml of water to quench, shake and separate the liquids, extract the aqueous phase with ethyl acetate (20 mL x 3), combine the organic phases, dry over anhydrous sodium sulfate, filter, concentrate, and purify by column chromatography to obtain dimer catechu Prime (2, see accompanying drawing), yield is 50%.

Embodiment 2

[0019] Example 2: Synthesis of dimeric epicatechin (3, see accompanying drawing)

[0020] Dimeric catechin (2, 0.5 mmol) and 5 ml of dichloromethane were added to the reaction flask, DMP (1.25 mmol) was added at room temperature, stirred at room temperature for 16 hours, and the reaction was detected by TLC. Add 5 ml of 10% sodium thiosulfate solution to quench, shake and separate the liquids, extract the aqueous phase with ethyl acetate (10 mL x 3), combine the organic phases, dry over anhydrous sodium sulfate, filter, concentrate, and purify by column chromatography , to obtain dimeric epicatechinone (3, see attached figure), with a yield of 87%.

Embodiment 3

[0021] Example 3: Synthesis of dimeric epicatechin (4, see accompanying drawing)

[0022] Add dimeric epicatechin (3, 0.5 mmol) and 5 ml THF into the reaction flask, cool to -78°C, slowly add L-Selectride (1 mmol) dropwise at this temperature, stir at -78°C for 4 hours , TLC detects that the reaction is complete. Add 5 ml of water to quench, shake and separate the liquids, extract the aqueous phase with ethyl acetate (10 mL x 3), combine the organic phases, dry over anhydrous sodium sulfate, filter, concentrate, and purify by column chromatography to obtain dimerized form Tea element (4, see accompanying drawing), yield is 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com