Patents

Literature

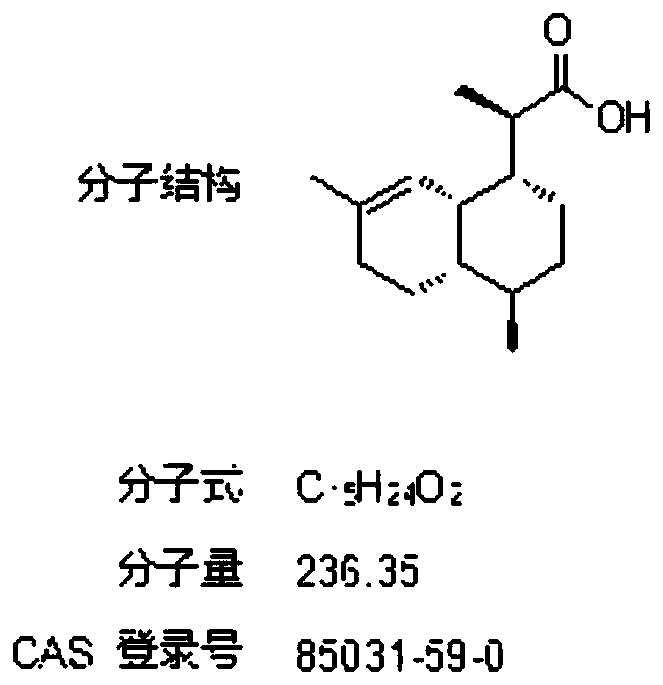

56 results about "Dihydroartemisinic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

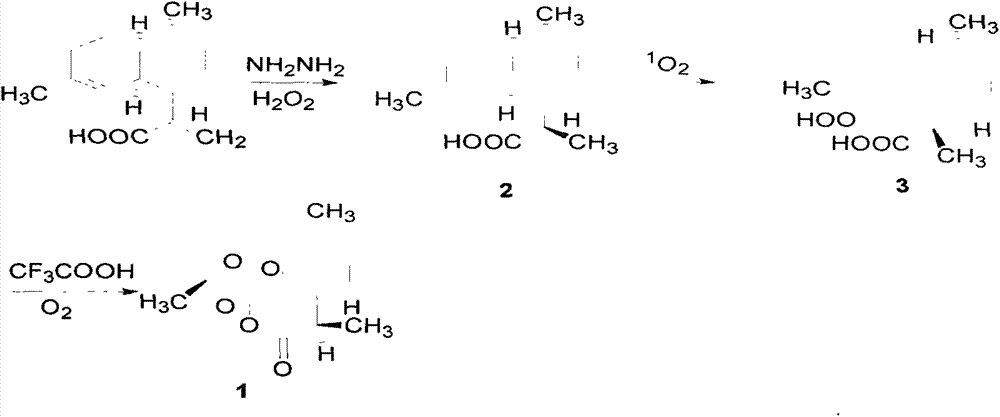

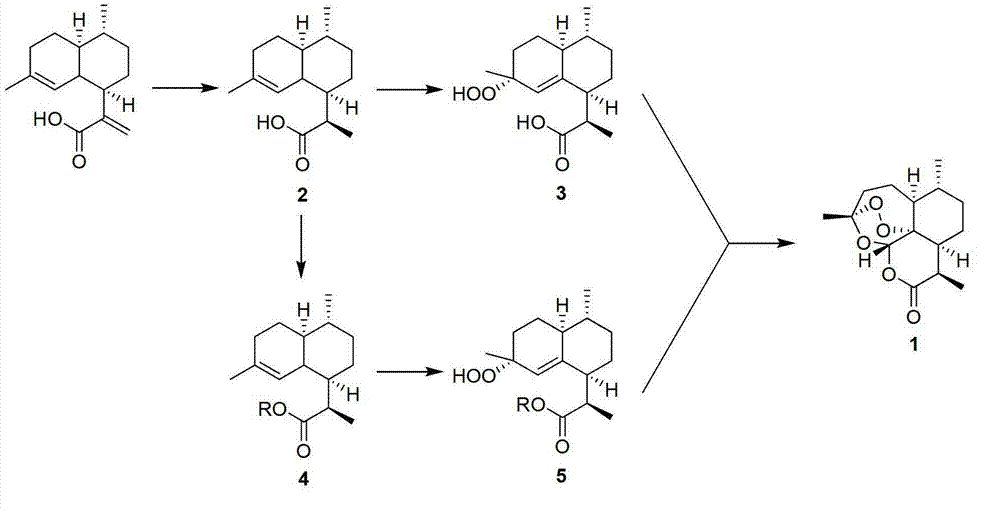

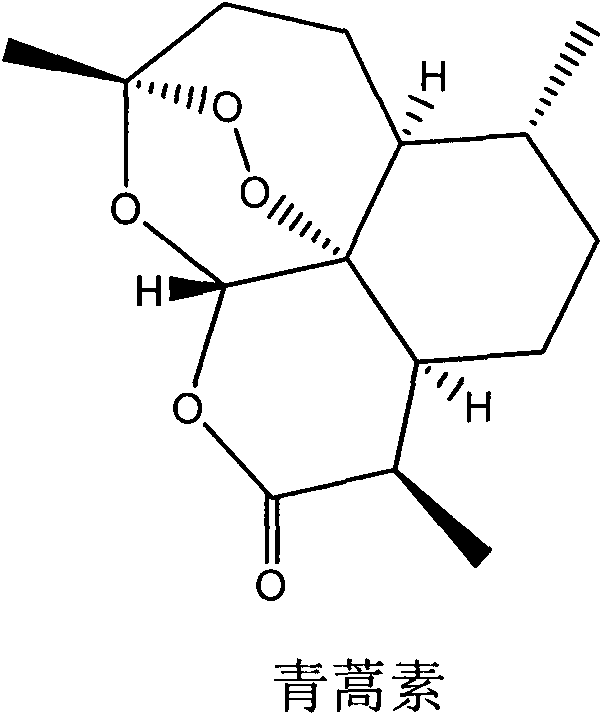

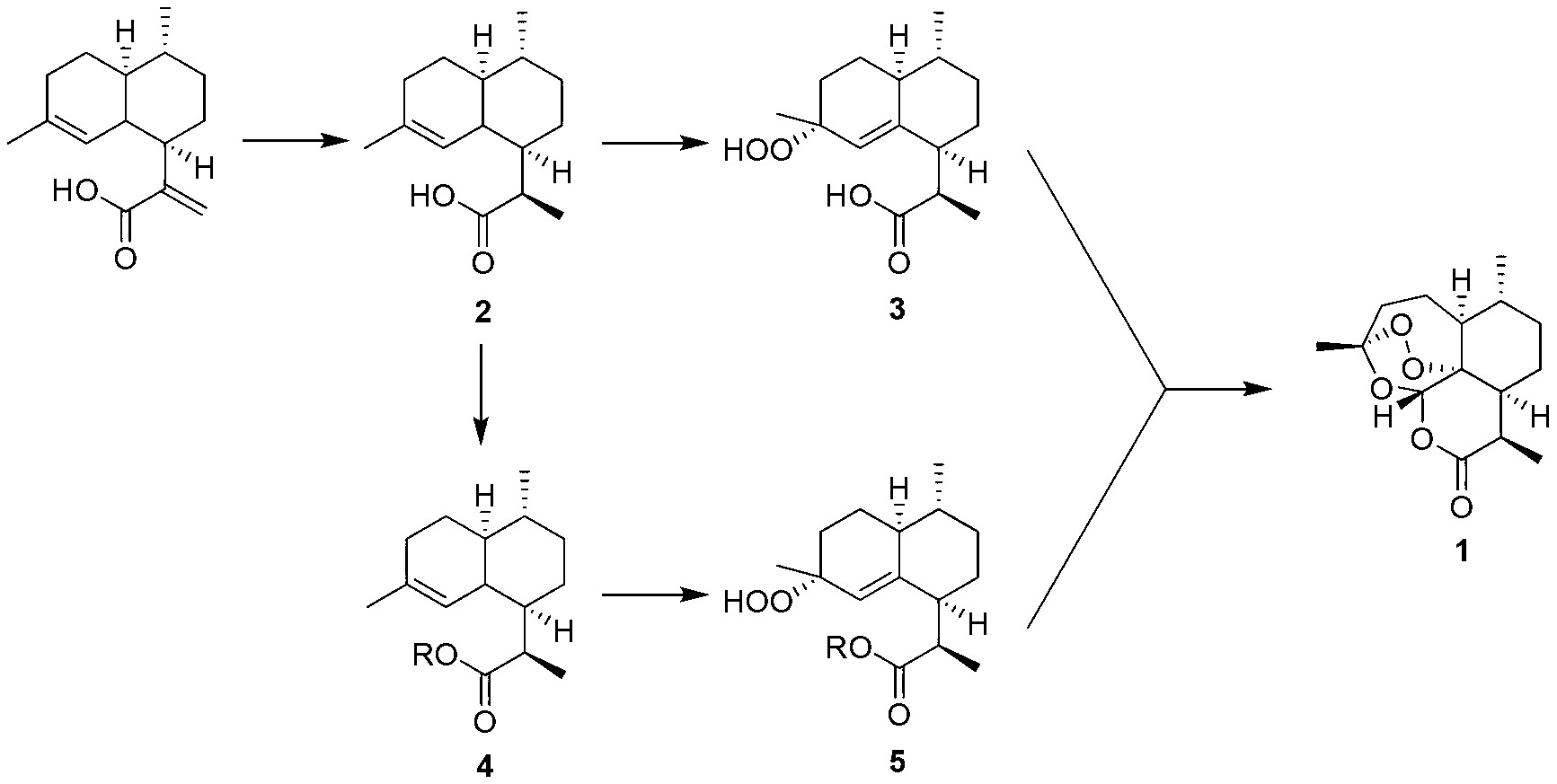

Method for preparing artemisinin through arteannuic acid

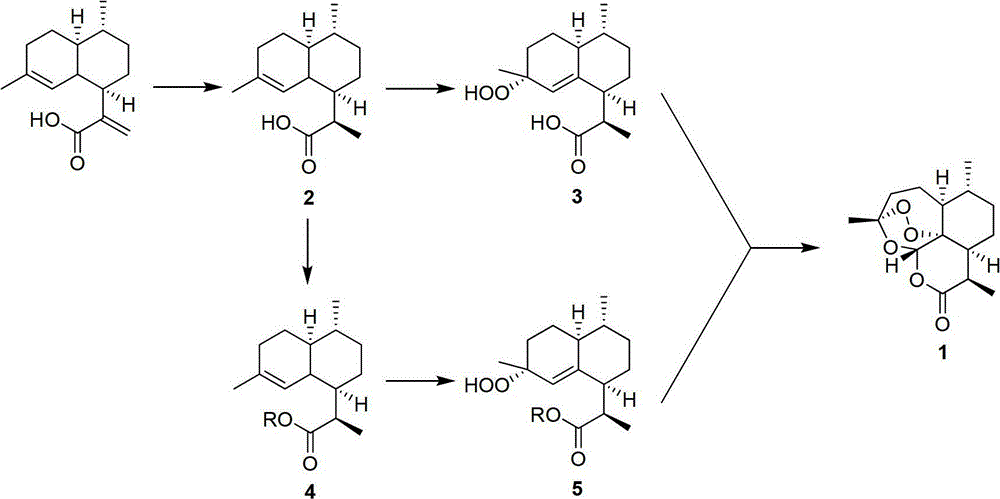

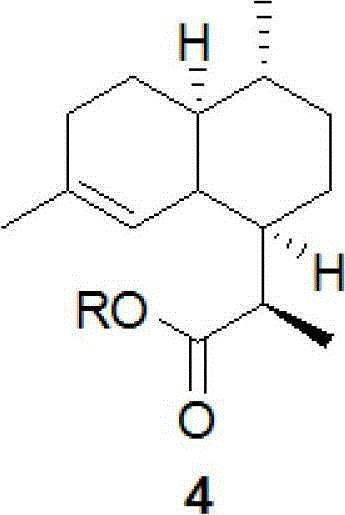

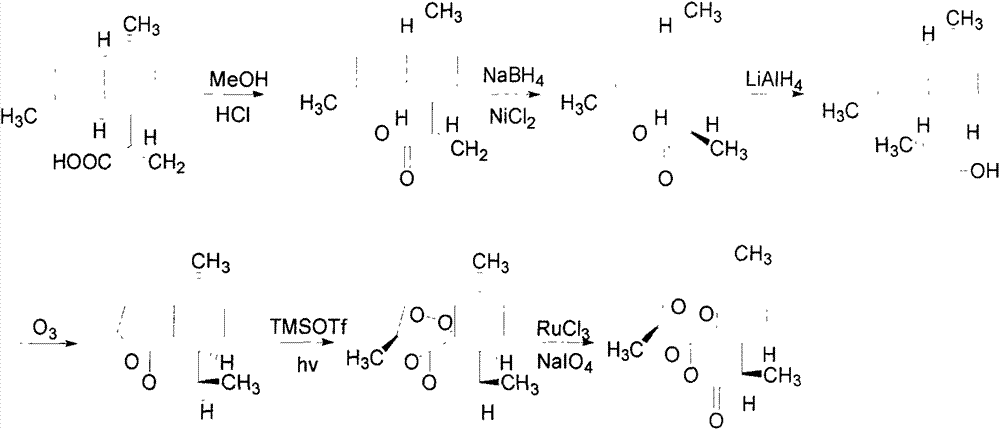

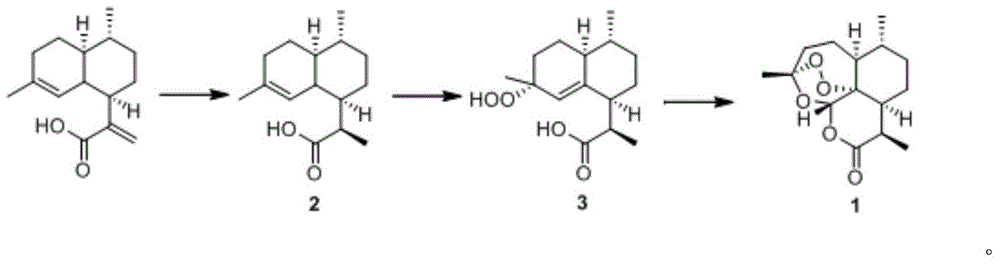

The invention discloses a method for preparing artemisinin through arteannuic acid. The method comprises the steps that first the arteannuic acid is processed to obtain a dihydroartemisinic acid under the effect of a reducing agent such as sodium borohydride / nickel chloride or a hydrogen / metal catalyst, and then the dihydroartemisinic acid is oxidized into a peroxided dihydroartemisinic acid through peroxide in the presence of the catalyst, and finally the target product artemisinin can be obtained with high yield under the catalyzing of the acid and the effect of oxygen; or a dihydroartemisinic acid derivative can be obtained from the dihydroartemisinic acid based on the protection on carboxyl, and the dihydroartemisinic acid derivative is oxidized into a relevant peroxided dihydroartemisinic acid derivative through the peroxide in the presence of the catalyst, and then the target product artemisinin can be obtained with high yield under the catalyzing of the acid and the effect of the oxygen. Compared with the prior art, the method for preparing the artemisinin through the arteannuic acid has the advantages as follows: the used agent has low cost, and is easy to obtain; the synthetic route is short; the reaction selectivity is high; the preparation process is environmental-friendly; the operation and post-processing are simple; the total yield is high; and the method for preparing artemisinin through the arteannuic acid is applied to industrial production.

Owner:SHANGHAI JIAO TONG UNIV

Method for extracting and purifying dihydroartemisinic acid from artemisinin wax oil

InactiveCN103694106AIncrease productionOrganic compound preparationCarboxylic compound preparationMolten stateSodium bicarbonate

The invention discloses a method for extracting and purifying dihydroartemisinic acid from artemisinin wax oil. The method comprises the following steps: adding wax oil into a sodium hydrogen carbonate water solution, heating, adjusting the pH value to be 9-9.5 by the saturated sodium hydrogen carbonate water solution after the wax oil is completely molten, stirring and conducting a centrifuging process; adding petroleum ether into centrifugal liquid, stirring, extracting and degreasing; heating a degreased alkali water solution to remove residual petroleum ether, adding hydrochloric acid for adjusting the pH value to be 5-6, naturally cooling to room temperature, and crystallizing; dissolving crystals by ethyl acetate, and re-crystallizing to obtain dihydroartemisinic acid. According to the method, waste wax oil can be effectively utilized and the yield of dihydroartemisinic acid can be increased.

Owner:湘西自治州奥瑞克医药化工有限责任公司 +1

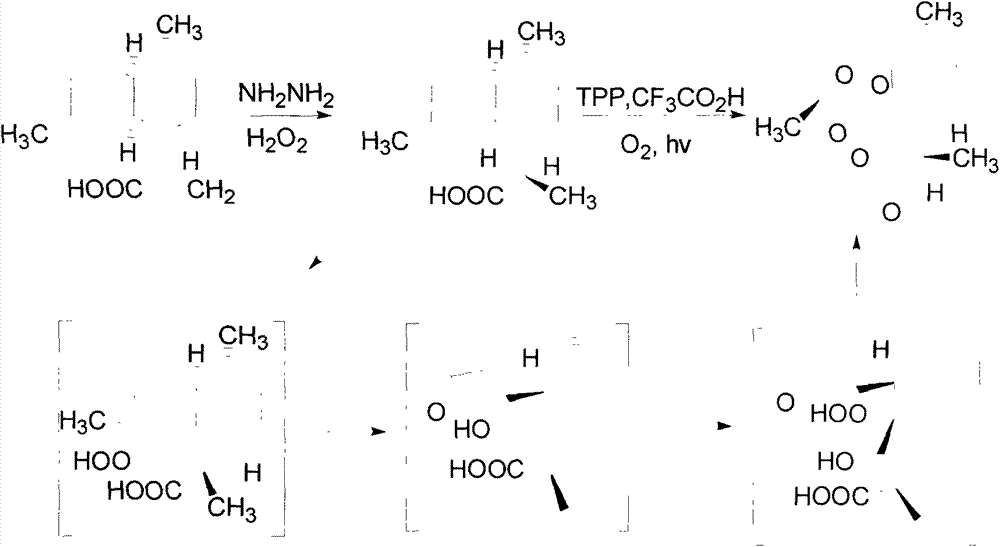

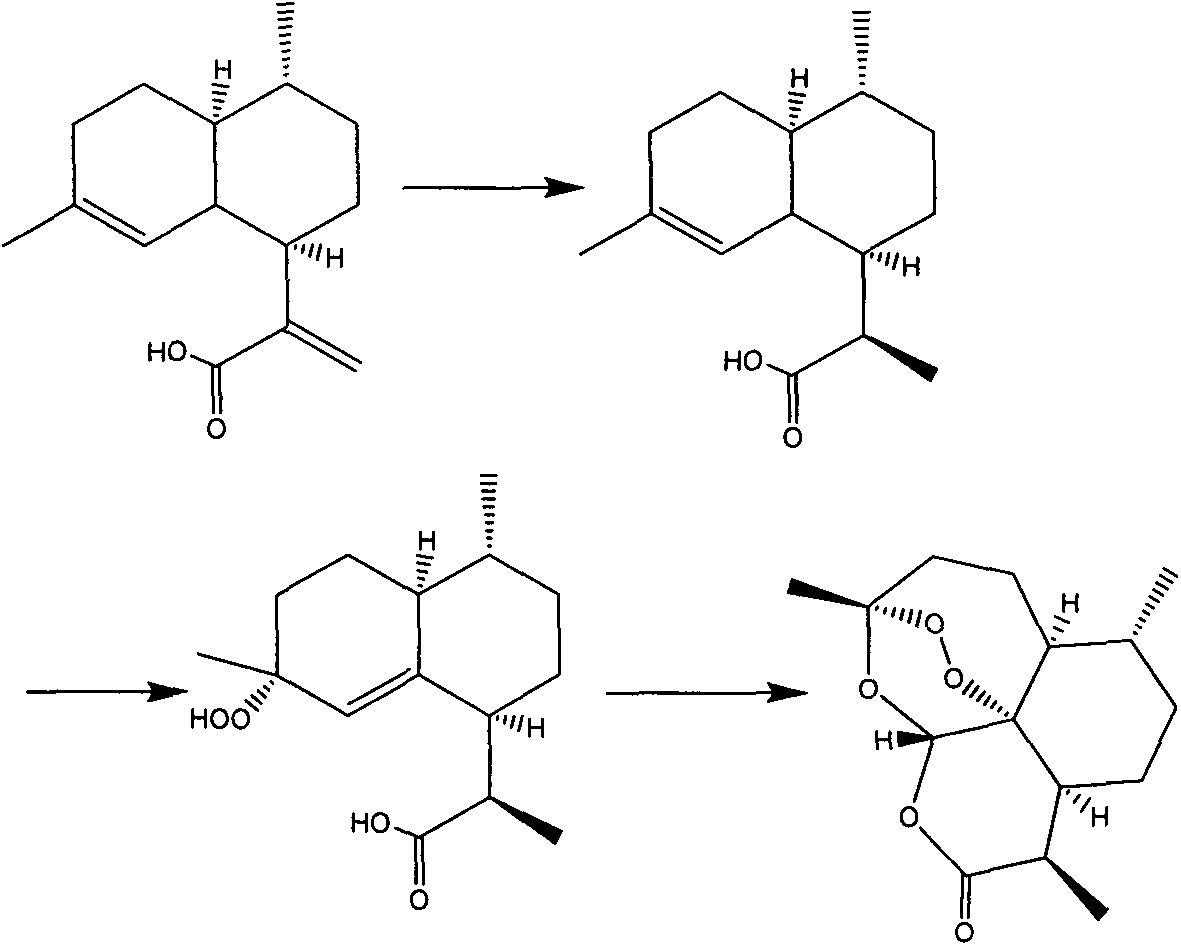

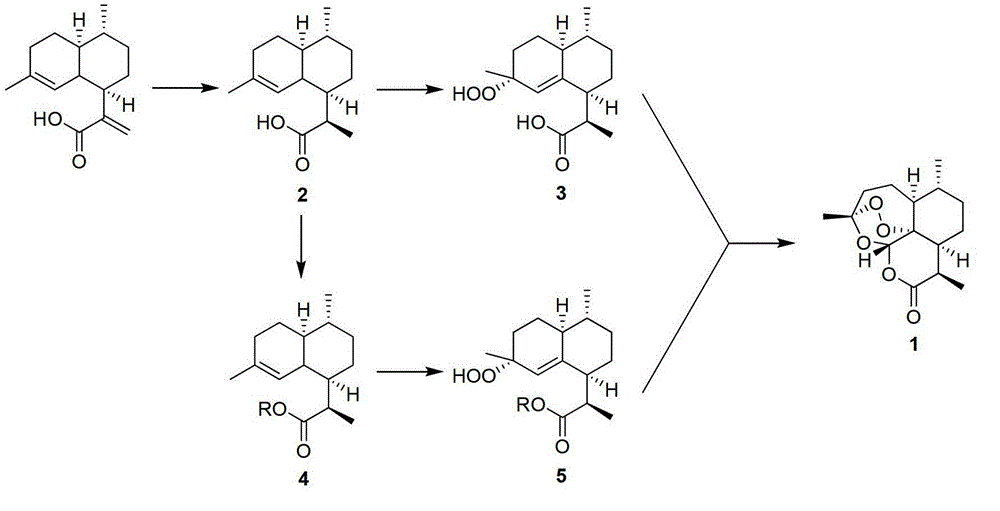

Method of semi-synthesizing artemisinin

InactiveCN103087074ARaw materials are easy to getShort processOrganic chemistryChemical reactionAlcohol

The invention relates to a method of semi-synthesizing artemisinin. The method comprises the steps of: reducing arteannuic acid into dihydro arteannuic acid by utilizing diimine produced in situ, oxidizing the dihydro arteannuic acid into peroxide alcohol by utilizing singlet oxygen produced in chemical reaction in situ, and then producing artemisinin under the action of oxygen and acid; or, obtaining dihydro arteannuic acid derivatives through protecting the dihydro arteannuic acid carboxyl, then oxidizing into corresponding peroxy alcohol under the action of the singlet oxygen produced in situ, and acting with the oxygen under the catalysis of acid to obtain artemisinin with high yield. A method of producing singlet oxygen in situ mainly comprises molybdate / peroxide, nitrile compound / peroxide, diacid iodobenzene / peroxide, peroxide-disulfate, and the like. With adoption of the method, the total yield can achieve up to 65%.

Owner:HUNAN KEYUAN BIO PRODS

Method for simultaneously extracting arteannuic acid and dihydroarteannuic acid from liquid waste after separation of artemisinin

ActiveCN103524527AAchieving Simultaneous ExtractionIncrease profitCarboxylic compound separation/purificationLiquid wasteDistillation

The invention discloses a method for simultaneously extracting arteannuic acid and dihydroarteannuic acid from liquid waste after separation of artemisinin. The method disclosed by the invention comprises the following steps: firstly, initially enriching arteannuic acid and dihydroarteannuic acid in artemisia apiacea liquid water by adopting a molecular distillation technology; then, further separating a molecular distillation product by adopting a solvent extraction method and an acid-alkali method to obtain an oily crude product; and finally, carrying out clathration on the oily crude product through urea to remove part of saturated and monounsaturated fatty acid, and repeatedly crystallizing to obtain mixed crystals of arteannuic acid and dihydroarteannuic acid with the total content which is not lower than 95%. Compared with the prior art, the method disclosed by the invention has the characteristics of high extraction efficiency, environment-friendliness, relatively low cost, strong implementability and applicability to industrial production.

Owner:GUANGZHOU HONSEA SUNSHINE BIOTECH CO LTD

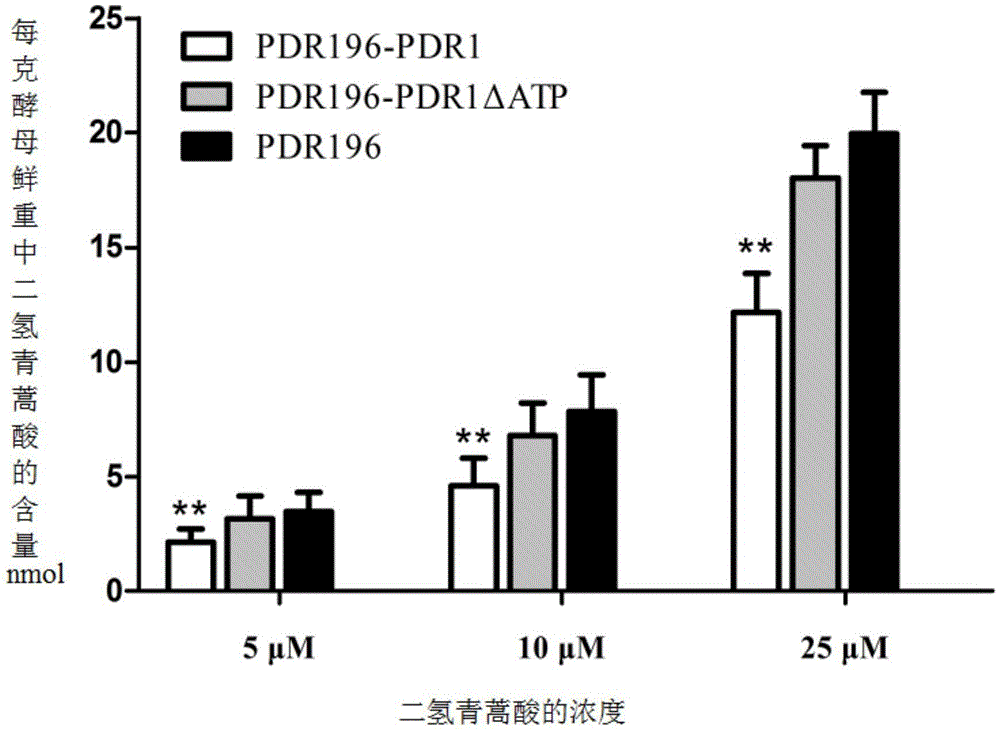

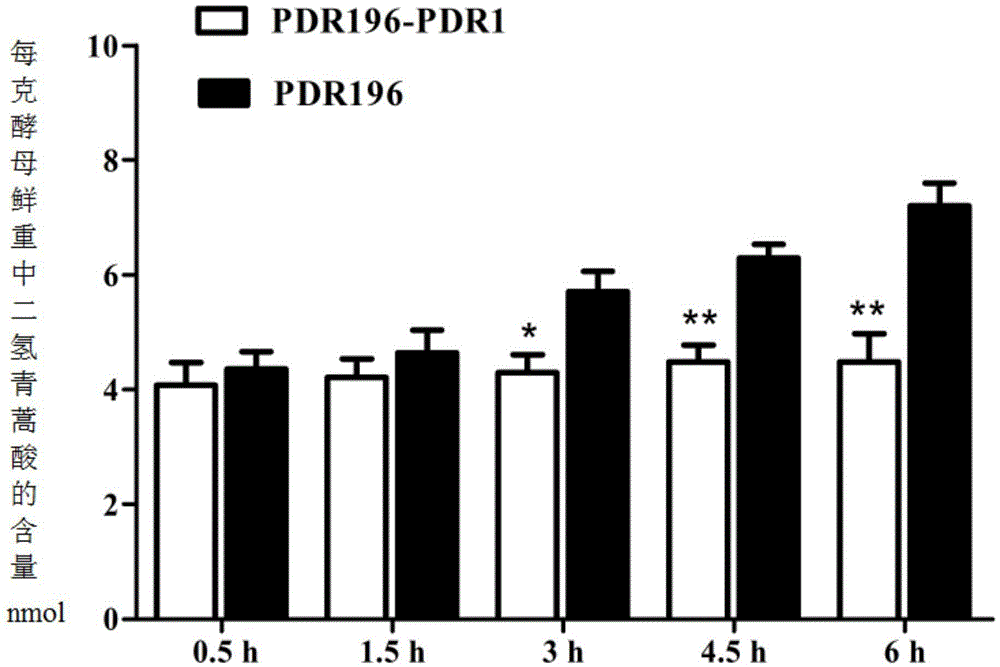

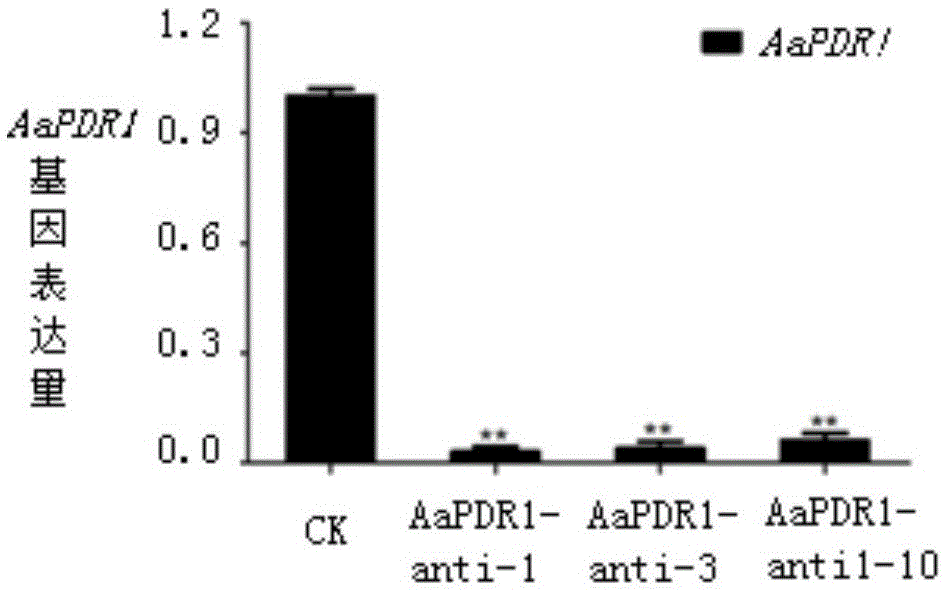

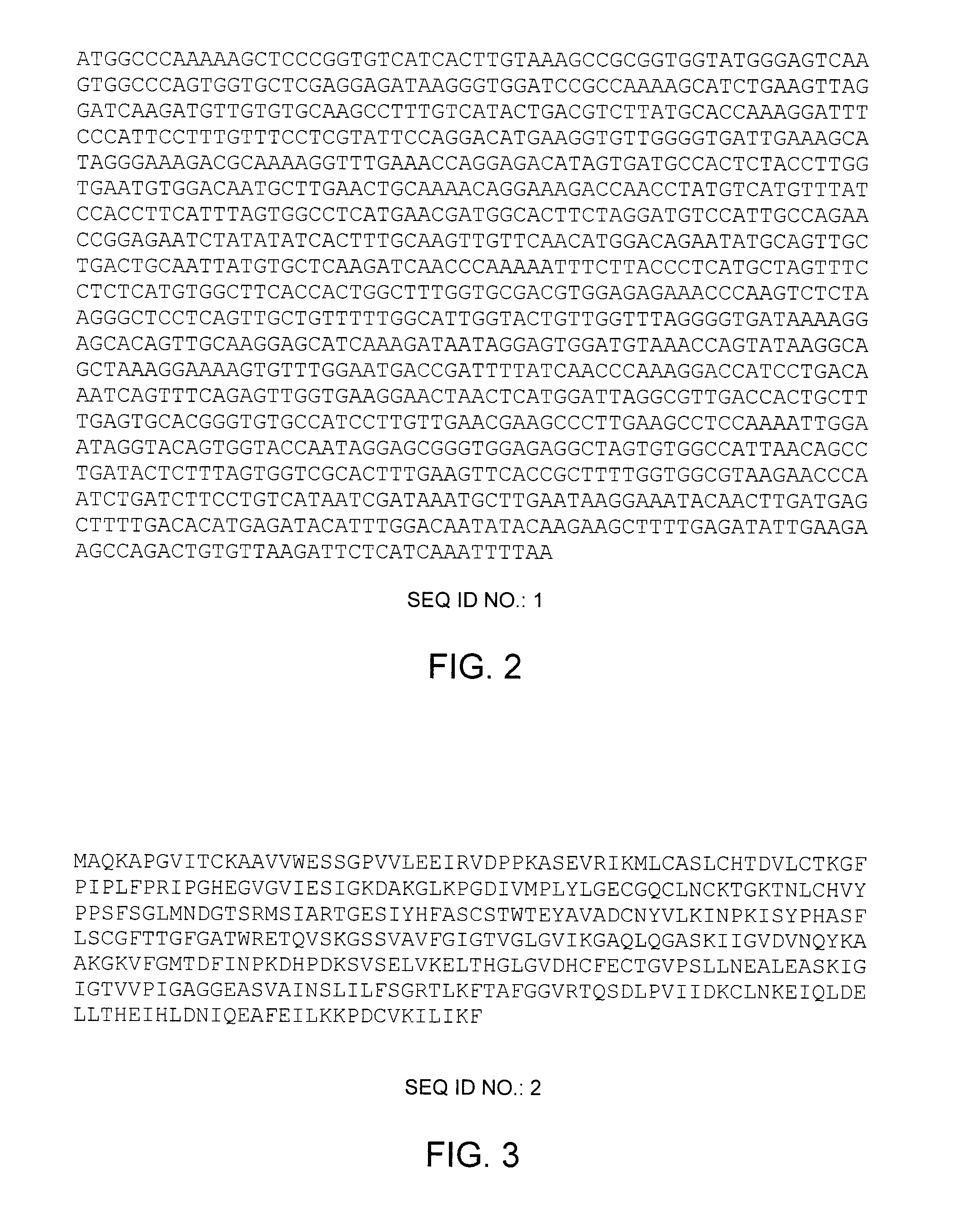

Artemisia annua L. PDR sub-family transport protein and functional verification method and application thereof

ActiveCN105585624AInhibit synthesisIncrease contentMicrobiological testing/measurementPlant peptidesBiotechnologyArtemisia annua

The invention discloses Artemisia annua L. PDR sub-family transport protein. Amino acid sequences of the protein comprise the amino acid sequence shown as SEQ ID NO:2 or the amino acid sequence of the protein is shown as SEQ ID NO:2 or nucleic acid codes crossed by the protein and complementary chains of nucleic acid of protein with the coded amino acid sequence shown in SEQ ID NO:2 under the highly-strict condition are achieved. Furthermore, the protein is named AaPDR1 by the inventor and is transport protein specifically expressed by Artemisia annua L. secreting type gladular trichomes, and it is proved through a yeast transport experiment and interference of Artemisia annua L. in the transport protein that the AaPDR1 participates in transporting an artemisinin synthetic route intermediate product dihydroartemisinic acid in Artemisia annua L.. The Artemisia annua L. PDR sub-family transport protein has great significance in providing high-yield and stable new drug resources for large-scale production of artemisinin.

Owner:SHANGHAI JIAO TONG UNIV

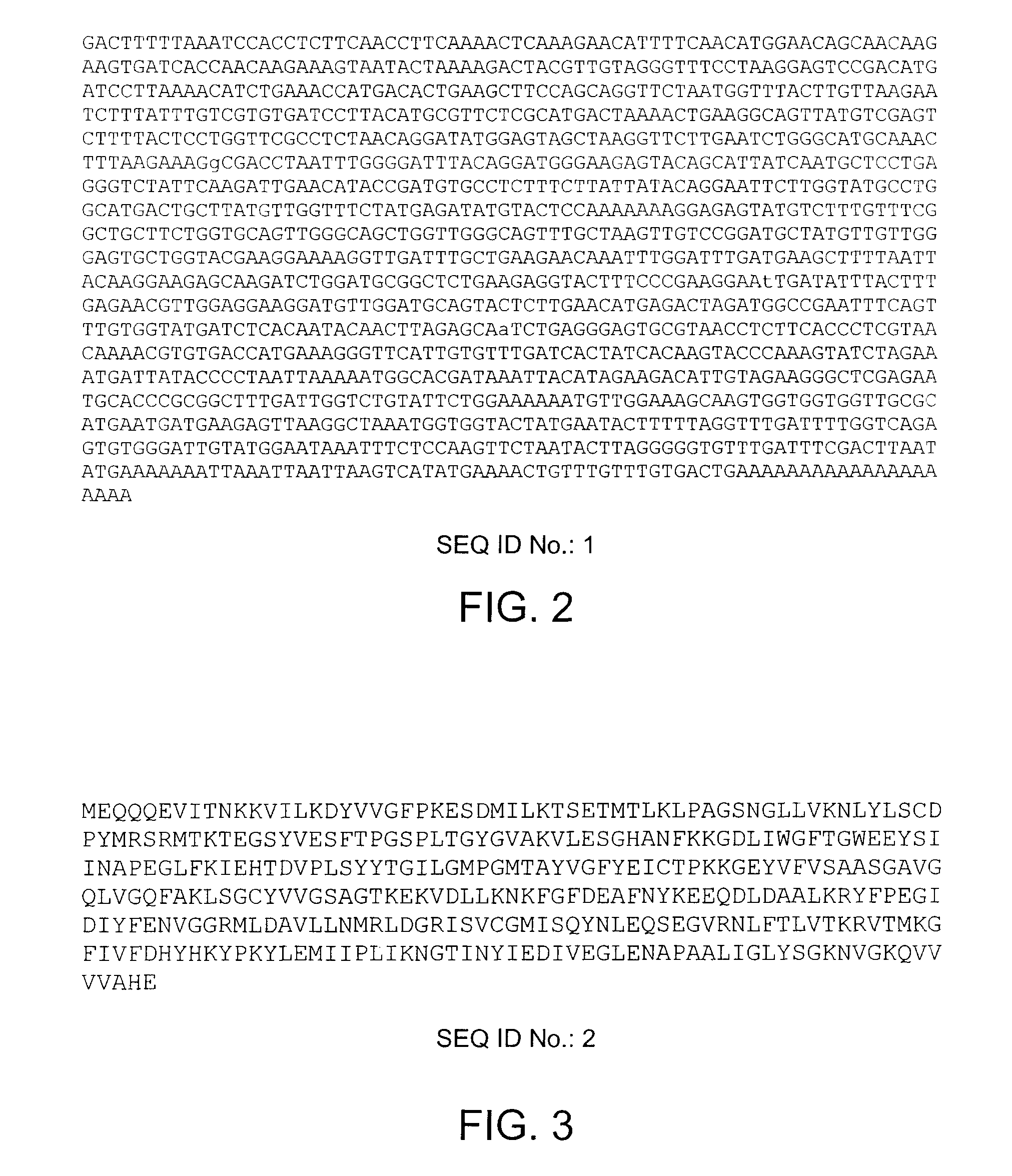

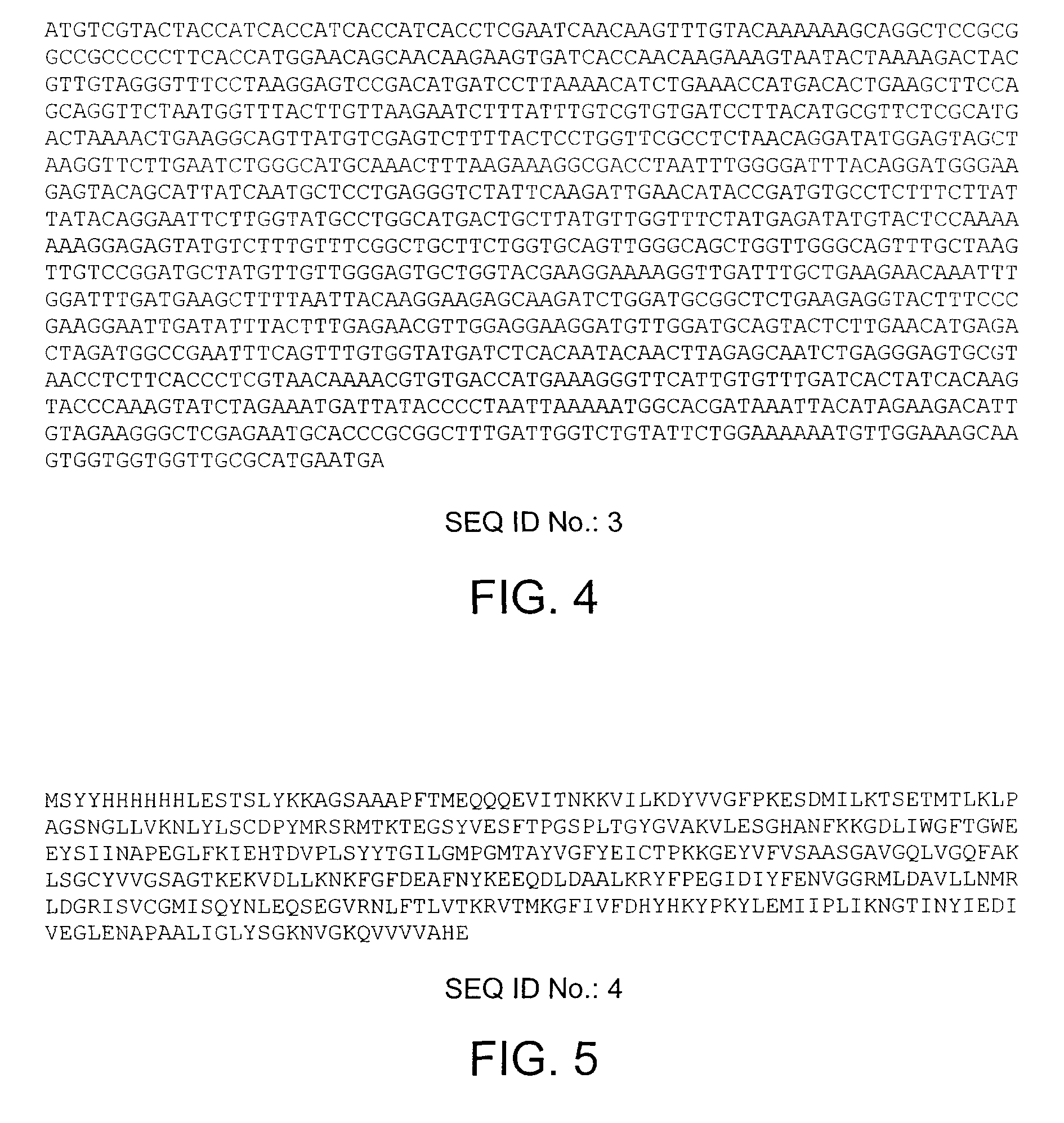

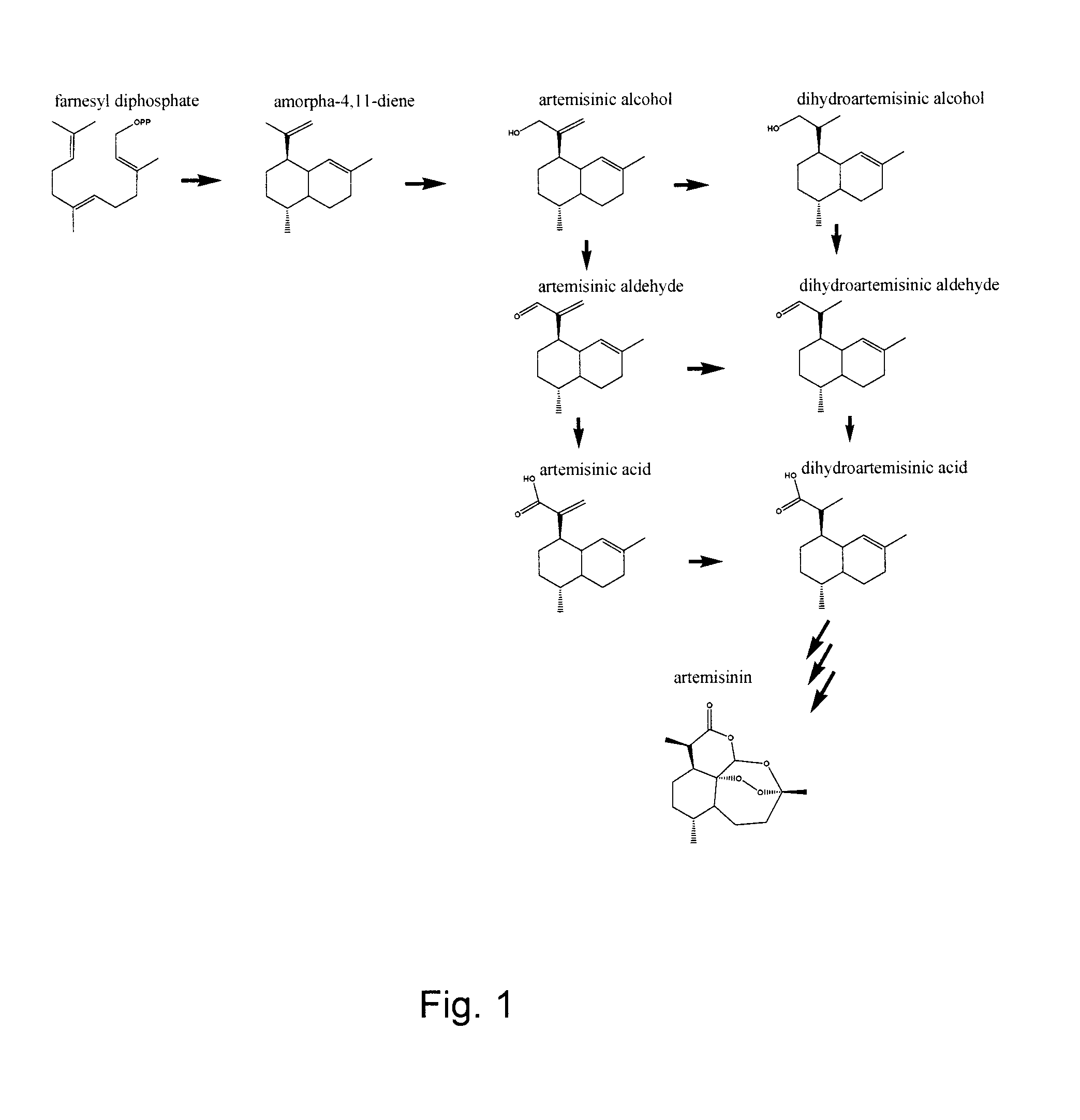

Nucleotide sequences encoding enzymes in biosynthesis of dihydroartemisinic acid

InactiveUS8207402B2Reduce in quantitySimple processSugar derivativesMicrobiological testing/measurementNucleotideProtein Artemis

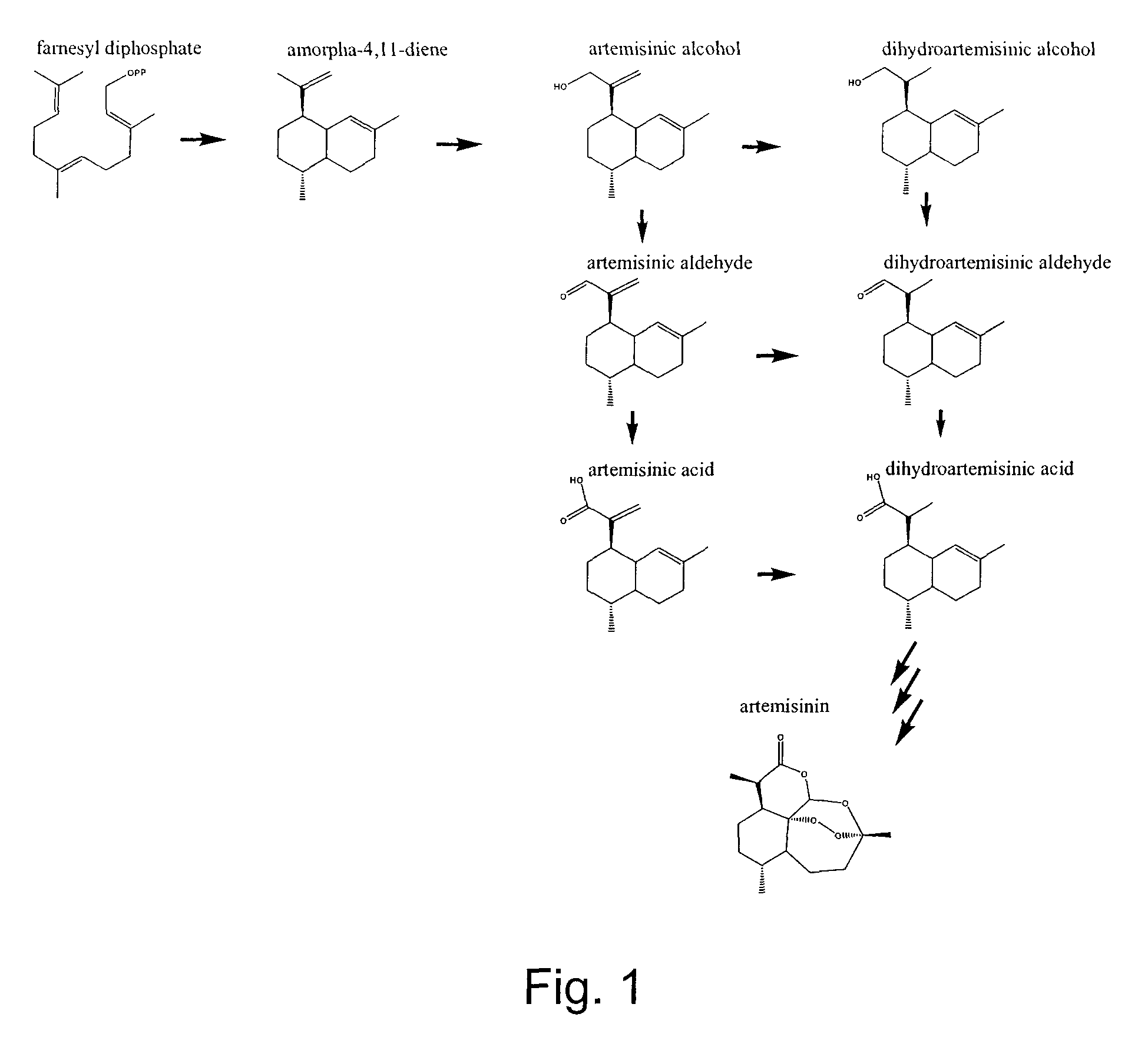

Isolated nucleic acid molecules cloned from Artemisia annua encode artemisinic aldehyde double bond reductase and artemisinic / dihydroartemisinic aldehyde dehydrogenase. Artemisinic aldehyde double bond reductase enzymatically reduces artemisinic aldehyde to dihydroartemisinic aldehyde. Artemisinic / dihydroartemisinic aldehyde dehydrogenase enzymatically oxidizes dihydroartemisinic aldehyde to dihydroartemisinic acid and artemisinic aldehyde to artemisinic acid. The nucleic acid molecules, and the enzymes encoded thereby, may be used in processes to produce dihydroartemsinic aldehyde, dihydroartemisinic acid or artemisinic acid in a host cell. Dihydroartemisinic acid is a late precursor to the a antimalarial compound artemisinin.

Owner:NAT RES COUNCIL OF CANADA

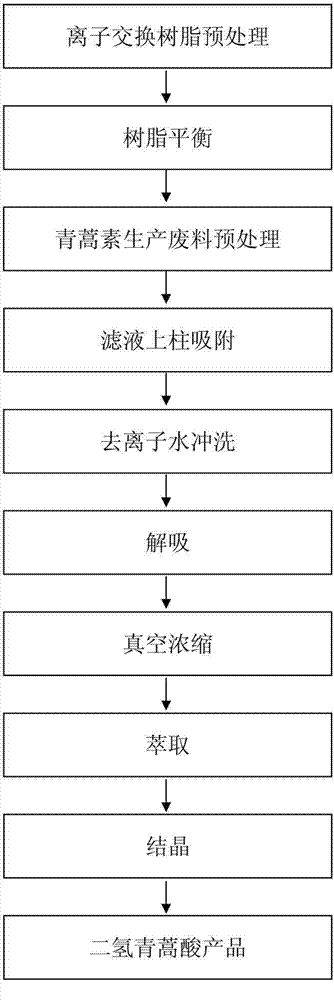

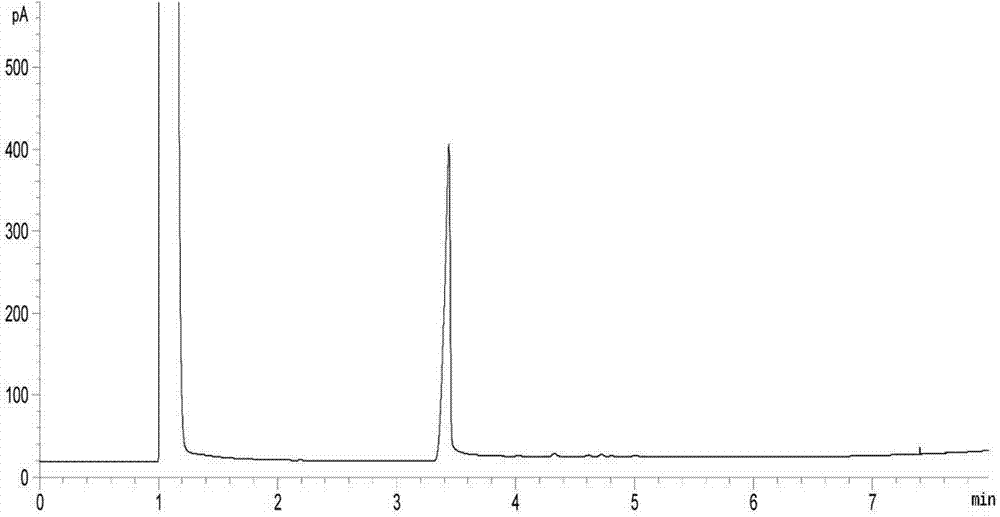

Method for separating refined dihydroartemisinic acid from artemisinin production waste through ion-exchange resin method

InactiveCN104230699AShorten the concentration timeReduce energy consumptionCarboxylic compound separation/purificationOrganic solventDesorption

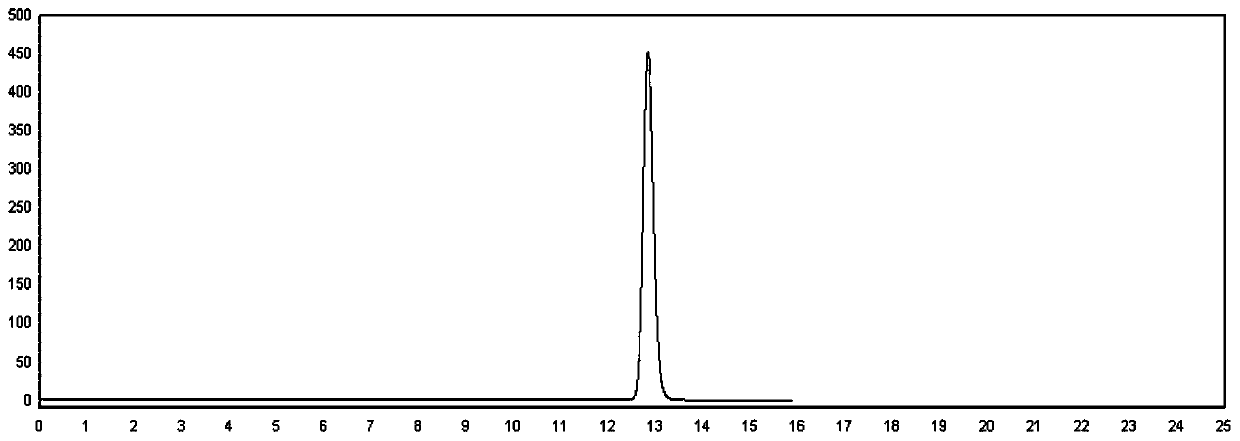

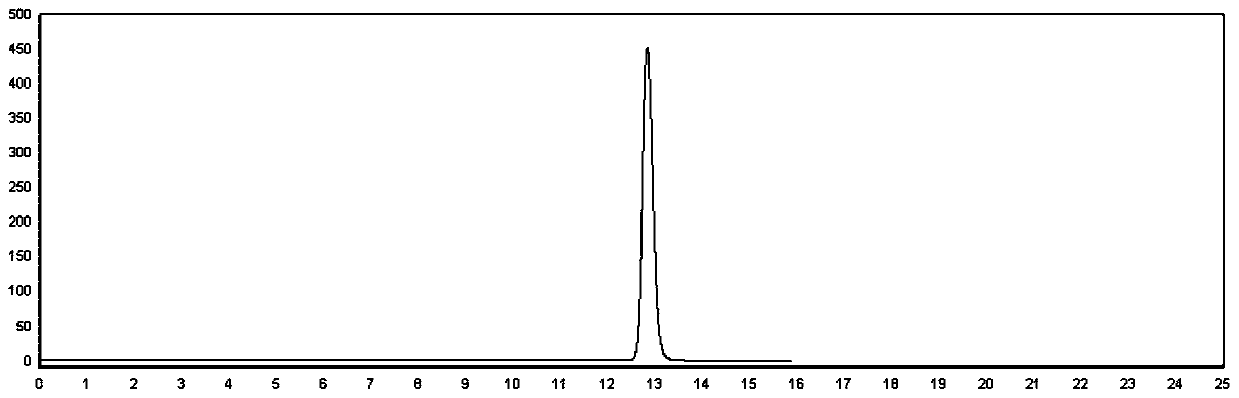

The invention discloses a method for separating refined dihydroartemisinic acid from artemisinin production waste through an ion-exchange resin method. The method for separating the refined dihydroartemisinic acid from the artemisinin production waste through the ion-exchange resin method comprises enabling the dried artemisinin production waste to be served as raw materials, dissolving through a sodium hydroxide solution, centrifuging to remove precipitate, obtaining supernatant liquor, gradually adding preprocessed and balanced processed anion exchange resin, flushing through deionized water, performing desorption, collecting eluent, perform vacuum concentration, performing extraction through organic solvent and finally obtaining high-purity dihydroartemisinic acid products through crystallization. According to the method for separating the refined dihydroartemisinic acid from the artemisinin production waste through the ion-exchange resin method, the artemisinin production waste is served as the raw materials firstly and the dihydroartemisinic acid is separated and purified through the ion-exchange resin method; the concentration time and energy consumption are reduced due to the vacuum concentration and organic solvent extraction combined technology, the product yield is increased, production costs are reduced, the product purity which is high is more than 99%; the recovery rate which is high in larger than 80%; the operation is convenient, the production is large, and industrial scale production is easy to achieve.

Owner:HUNAN AGRICULTURAL UNIV

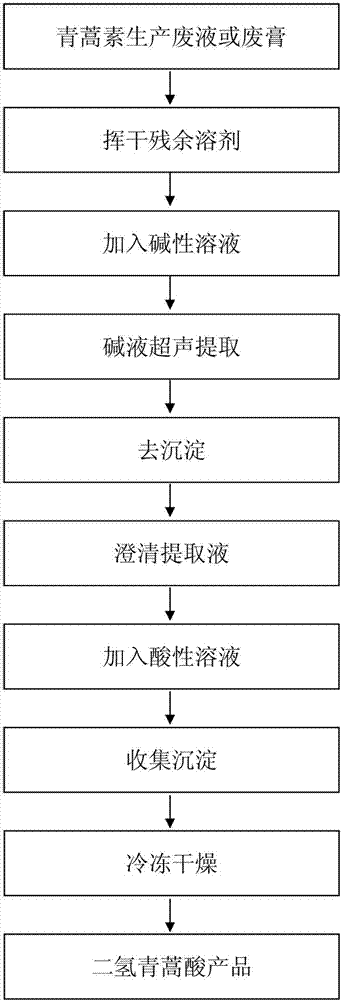

Separation of sihydroartemisinic acid from artemisinin production waste by means of alkali dissolution and acid deposition

InactiveCN104262137ASolve degradationImprove extraction efficiencyCarboxylic compound separation/purificationUltrasonic assistedFreeze-drying

The invention discloses separation of sihydroartemisinic acid from artemisinin production waste by means of alkali dissolution and acid deposition. The method comprises the following steps of: concentrating in vacuum to volatilize residual solvents in production waste liquid or waste paste by using the artemisinin production waste liquid or the waste paste as raw materials; ultrasonically extracting by using alkali solution; mixing extracting solution with one another and removing sediments to obtain supernate; adding acid solution into the supernate; collecting sediments; washing the sediments by using clean distilled water; freeze-drying to obtain a dry sihydroartemisinic product. A method for separating sihydroartemisinic from the artemisinin production waste is established at first, and then an ultrasonic-assisted extracting method is adopted, so that the extraction efficiency and the recovery rate are effectively improved; by utilizing a freeze-drying method, the problem of degradation of the sihydroartemisinic acid product caused in the traditional drying method is effectively solved; the purity of the product is more than 72 percent, and the recovery rate is more than 90 percent; moreover, the production capacity is high, and the industrialized production is easily realized.

Owner:HUNAN AGRICULTURAL UNIV

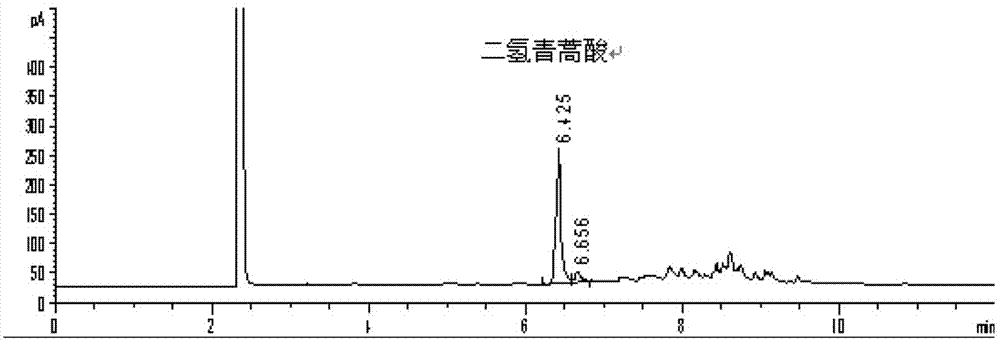

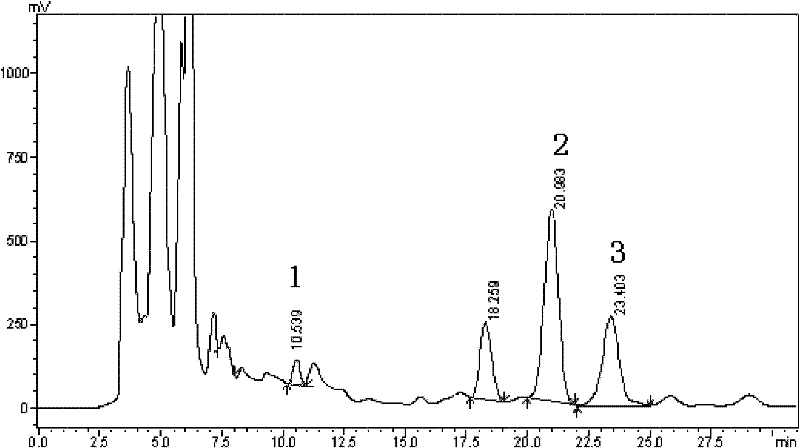

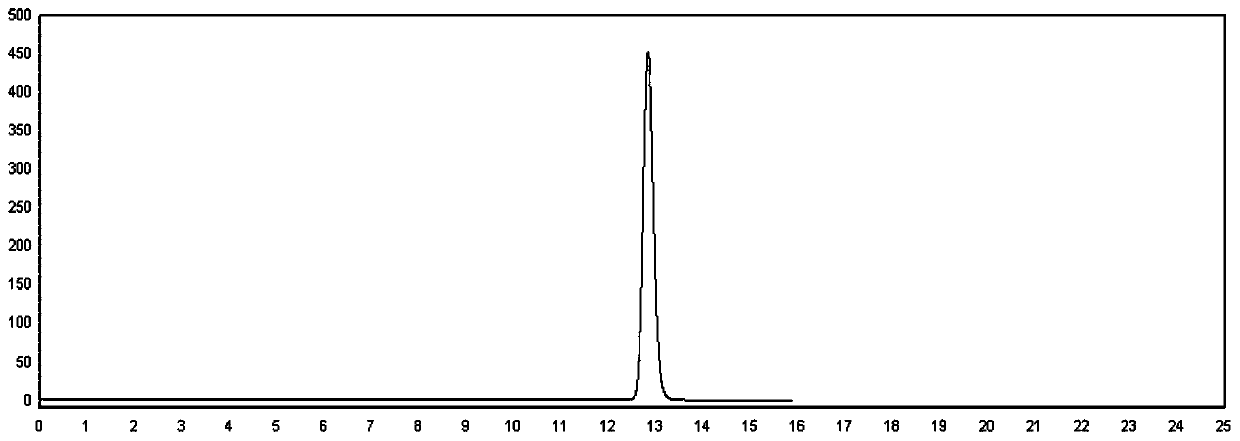

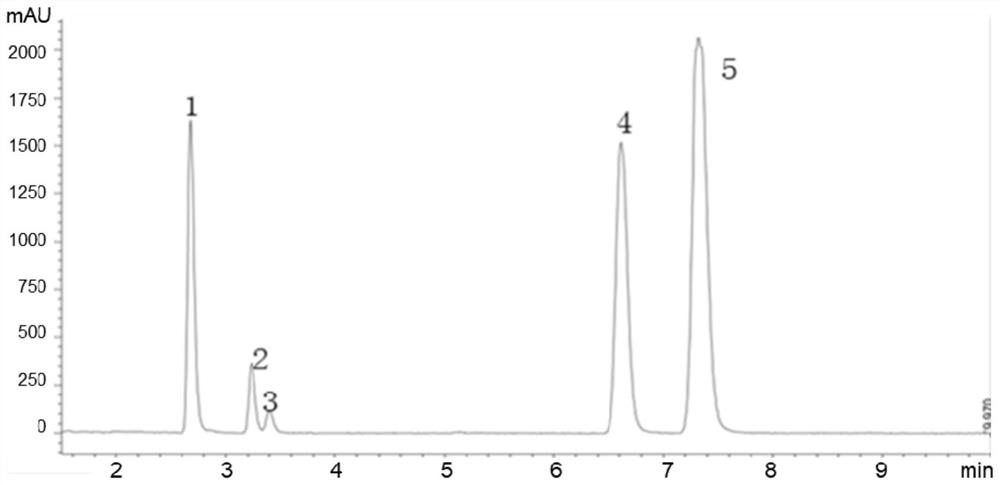

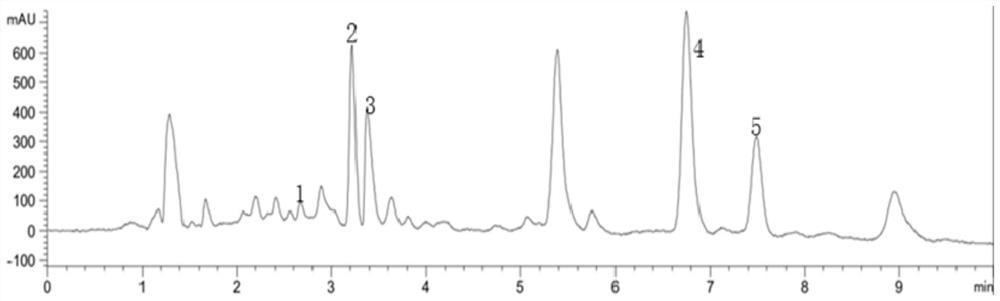

Method for separating and refining arteannuin, dihydro-artemisinic acid and artemisinic acid by reversed-phase high performance liquid chromatography

InactiveCN102153565AIncrease productionReduce manufacturing costHydroxy compound separation/purificationOrganic solventCrystallization

The invention relates to a method for separating and refining arteannuin, dihydro-artemisinic acid and artemisinic acid by reversed-phase high performance liquid chromatography. The method mainly comprises the following steps of: separating and purifying an artemisia apiacea crude extract extracted by organic solvent by reversed-phase high performance liquid chromatography, and concentrating and crystallizing to obtain pure products of the arteannuin, the dihydro-artemisinic acid and the artemisinic acid. The method is high in yield, separation efficiency and a separation speed, the pure products of the arteannuin, the dihydro-artemisinic acid and the artemisinic acid can be obtained simultaneously, and the purity can reach over 96 percent, so the method can be used for large-scale industrial production.

Owner:HUNAN AGRICULTURAL UNIV

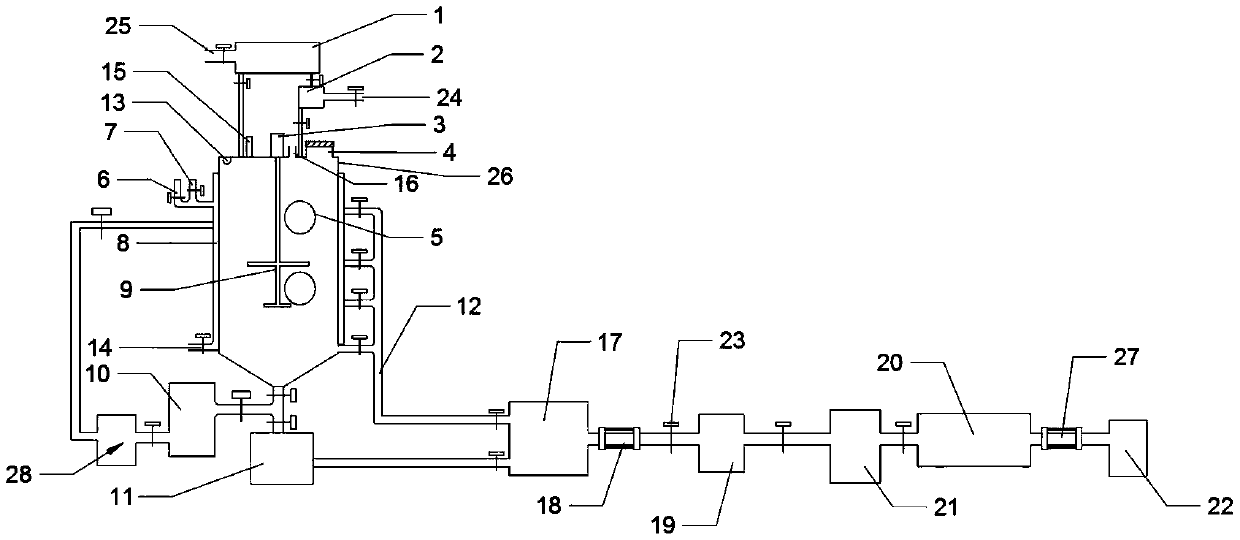

Method and apparatus for the synthesis of dihydroartemisinin and artemisinin derivatives

ActiveUS20160145265A1Improve scalabilityOrganic chemistryChemical/physical/physico-chemical stationary reactorsAlcoholDihydroartemisinin

The present invention is directed to a method for continuous production of dihydroartemisinin and also artemisinin derivatives derived from dihydroartemisinin by using artemisinin or dihydroartemisinic acid (DHAA) as starting material as well as to a continuous flow reactor for producing dihydroartemisinin as well as the artemisinin derivatives. It was found that the reduction of artemisinin to dihydroartemisinin in a continuous process requires a special kind of reactor and a special combination of reagents comprising a hydride reducing agent, at least one activator such as an inorganic activator, at least one solid base, at least one aprotic solvent and at least one C1-C5 alcohol.

Owner:MAX PLANCK GESELLSCHAFT ZUR FOERDERUNG DER WISSENSCHAFTEN EV

High-efficiency preparation method of anti-malarial medicine artemisinin

The invention discloses a high-efficiency preparation method of anti-malarial medicine artemisinin. The method comprises the following steps of: preparing dihydroartemisinic acid from artemisinin under the action of reducing agent sodium borohydride / nickel chloride or hydrogen / metal catalyst; oxidizing the dihydroartemisinic acid by peroxide in the existence of the catalyst to obtain oxidized dihydroartemisinic acid; and preparing the target product artemisinin with high yield under catalysis of acid and the action of oxygen. Compared with the prior art, the method has the advantages of low price and easy availability of reagents, short synthetic route, high reaction selectivity, environmentally-friendly preparation process, simplicity in operation and post-treatment and high total yield, and is suitable for industrial production.

Owner:SHANGHAI JIAO TONG UNIV

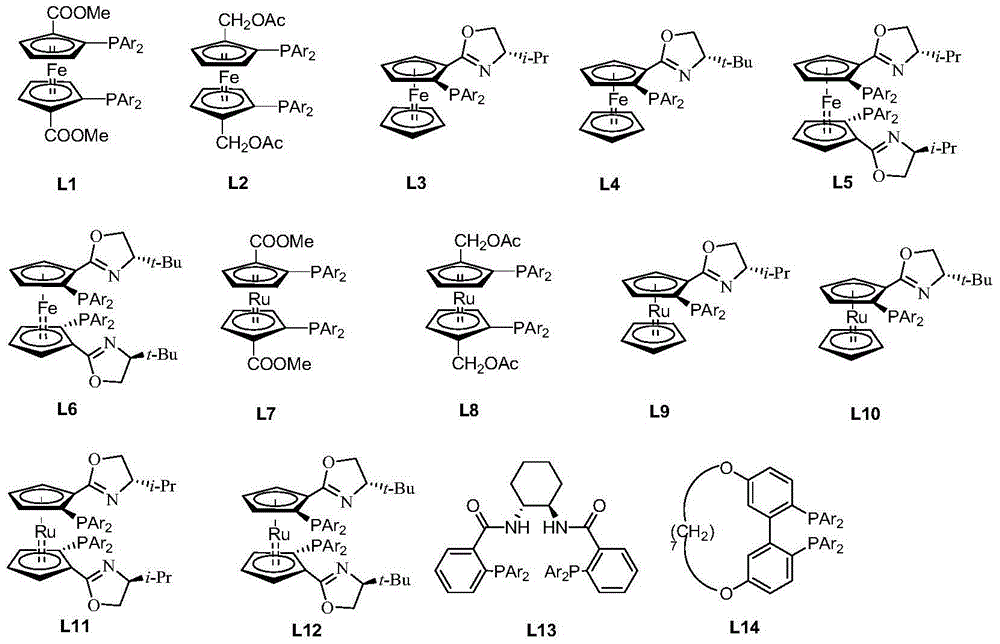

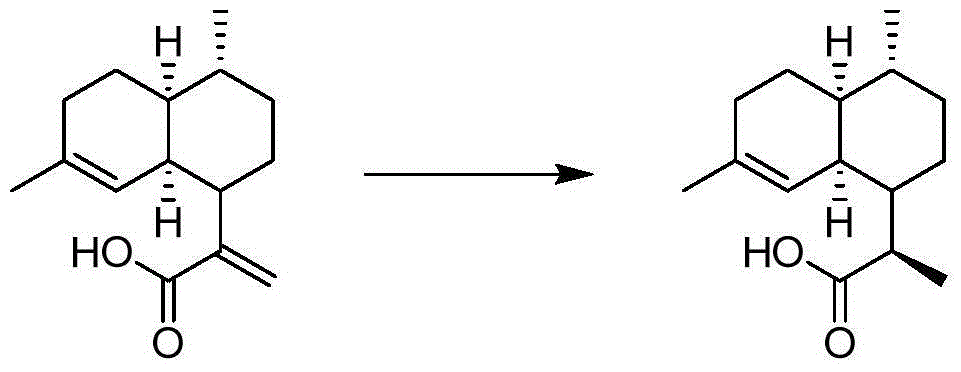

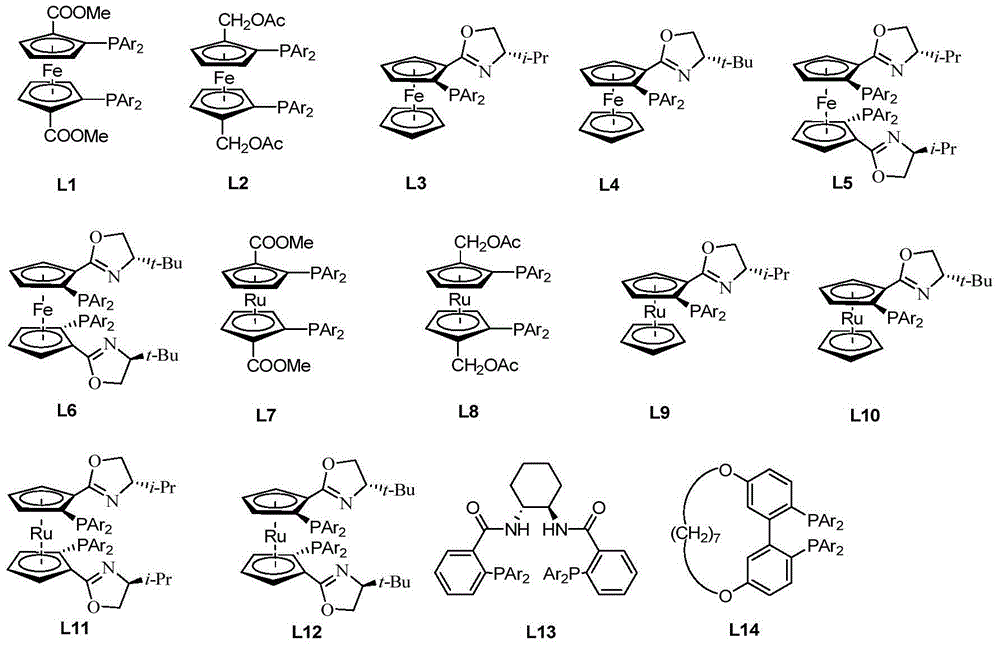

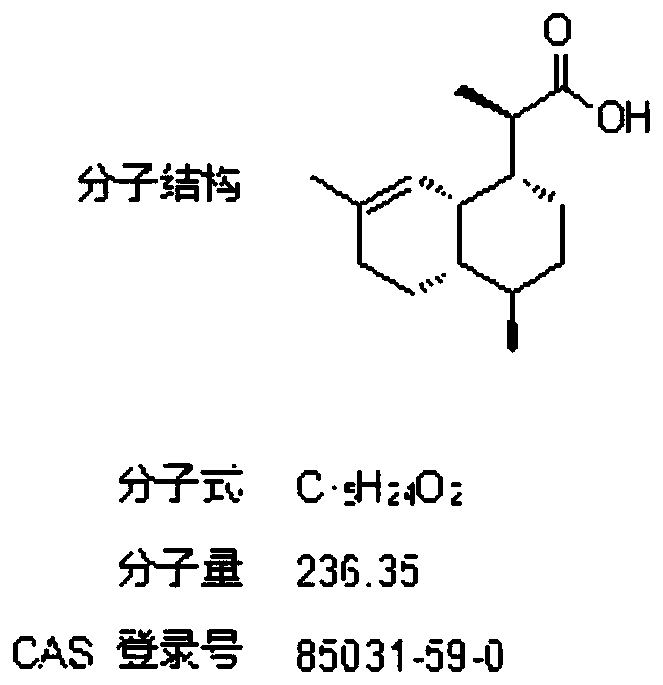

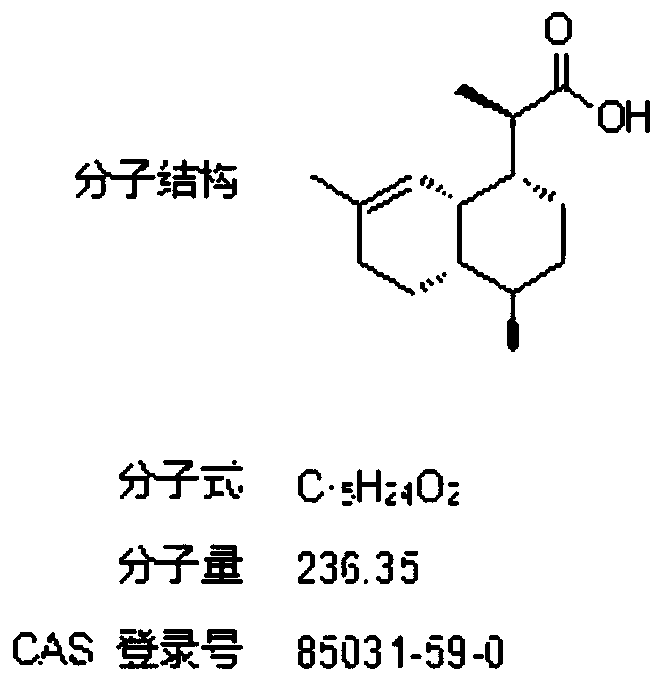

Asymmetric synthesis method of dihydroartemisinic acid from arteannuinic acid

ActiveCN105481684AEfficient synthesisLow costCarboxylic preparation by ozone oxidationArtemisic acidSynthesis methods

The invention discloses an asymmetric synthesis method of dihydroartemisinic acid from arteannuinic acid. The asymmetric synthesis method comprises the following steps: in the presence of a solvent and alkali and under the action of a chiral catalyst, performing asymmetric catalytic hydrogenation on the arteannuinic acid, so that the dihydroartemisinic acid is generated. According to the asymmetric synthesis method, the final conversion rate of arteannuinic acid is up to 100% and the diastereoselectivity is higher than 99.0%. The asymmetric synthesis method is easy to operate, good in selectivity, high in yield and very good in industrial application prospect.

Owner:SHANGHAI JIAO TONG UNIV

Method used for extracting dihydroartemisinic acid from artemisia apiacea wax oil

PendingCN110105195APromote crystallizationHigh yieldOrganic chemistry methodsCarboxylic compound separation/purificationFiltrationArtemisia annua

The invention discloses a method used for extracting dihydroartemisinic acid from artemisia apiacea wax oil. The method comprises following steps: 1, extracting filtering; 2, chromatography column processing; 3, extracting and impurity removing; 4, condensation and acid adjusting; 5, extraction and condensation; 6, crystallization pumping filtration; and 7, crude product refining. According to themethod, dihydroartemisinic acid is extracted and separated from artemisinin production by-product artemisia apiacea wax oil, chromatography is adopted to remove terpenes which possess structures similar to that of dihydroartemisinic acid and are not removed through saponification, and then condensation, extraction, and purification are carried out to produce the high quality dihydroartemisinic acid with a purity of 99% or higher. The method is capable of changing waste into valuables, increasing conversion efficiency of artemisinin from artemisia apiacea, saving artemisia annua raw material resource, reducing organic solving using amount, reducing pollution of artemisinin production process on the environment, and promoting artemisia annua resource comprehensive development and utilization.

Owner:湖南威嘉生物科技有限公司

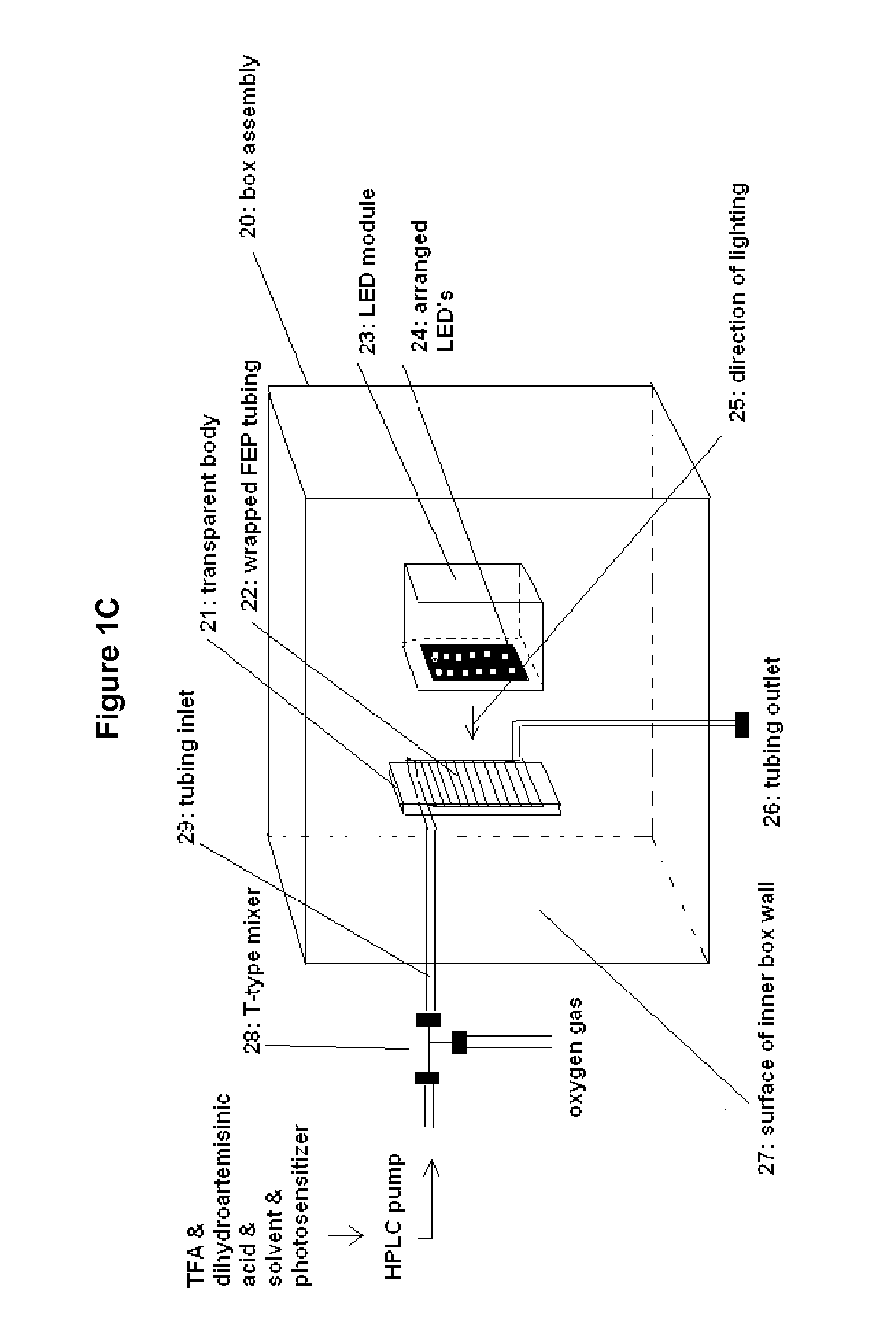

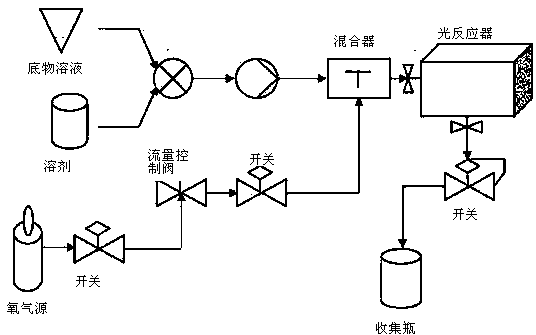

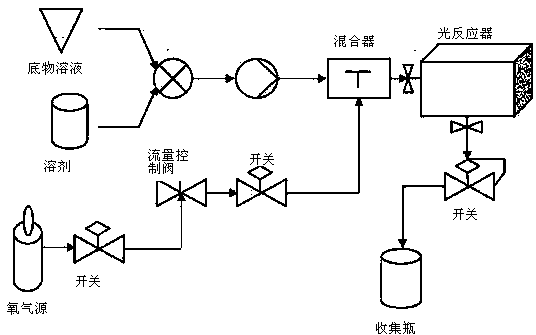

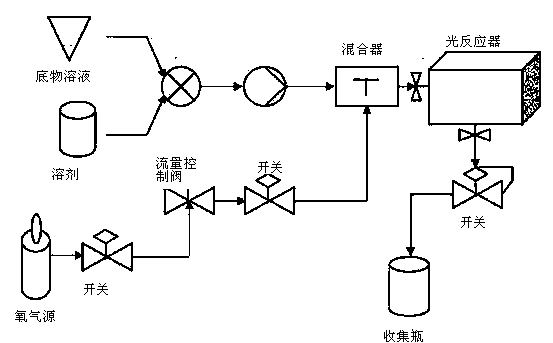

Method for preparing artemisinin by using residue obtained through extraction of artemisinin from sweet wormwood herb

ActiveCN103739608AImprove conversion rateReduce pollutionOrganic chemistryPhotosensitizerOrganic solvent

The invention relates to a method and equipment for preparing artemisinin by using residue obtained through extraction of artemisinin from sweet wormwood herb. The method comprises: 1) adopting an organic solvent to extract arteannuic acid and dihydroarteannuic acid from residue obtained through extraction of artemisinin from sweet wormwood herb; 2) adopting hydrazine hydrate to reduce the arteannuic acid obtained in the step 1) into a dihydroarteannuic acid crude product; 3) dissolving the dihydroarteannuic acid crude product obtained in the step 2) in an organic solvent, adding a photosensitizer and an acid catalyst, and adopting a light source to carry out a light oxidation reaction of the dihydroarteannuic acid so as to synthesize a artemisinin crude product; and 4) carrying out column chromatography and recrystallization purification on the artemisinin crude product obtained in the step 3). The invention further provides the equipment light oxidation reactor for performing the method. According to the present invention, the residue obtained through extraction of artemisinin from sweet wormwood herb is recycled so as to provide advantages of low environment pollution and resource saving; and the effective component in the residue obtained through extraction of artemisinin from sweet wormwood herb is completely utilized so as to increase the conversion rate of preparation of artemisinin from sweet wormwood herb.

Owner:湖南莱崔尔生物科技有限公司

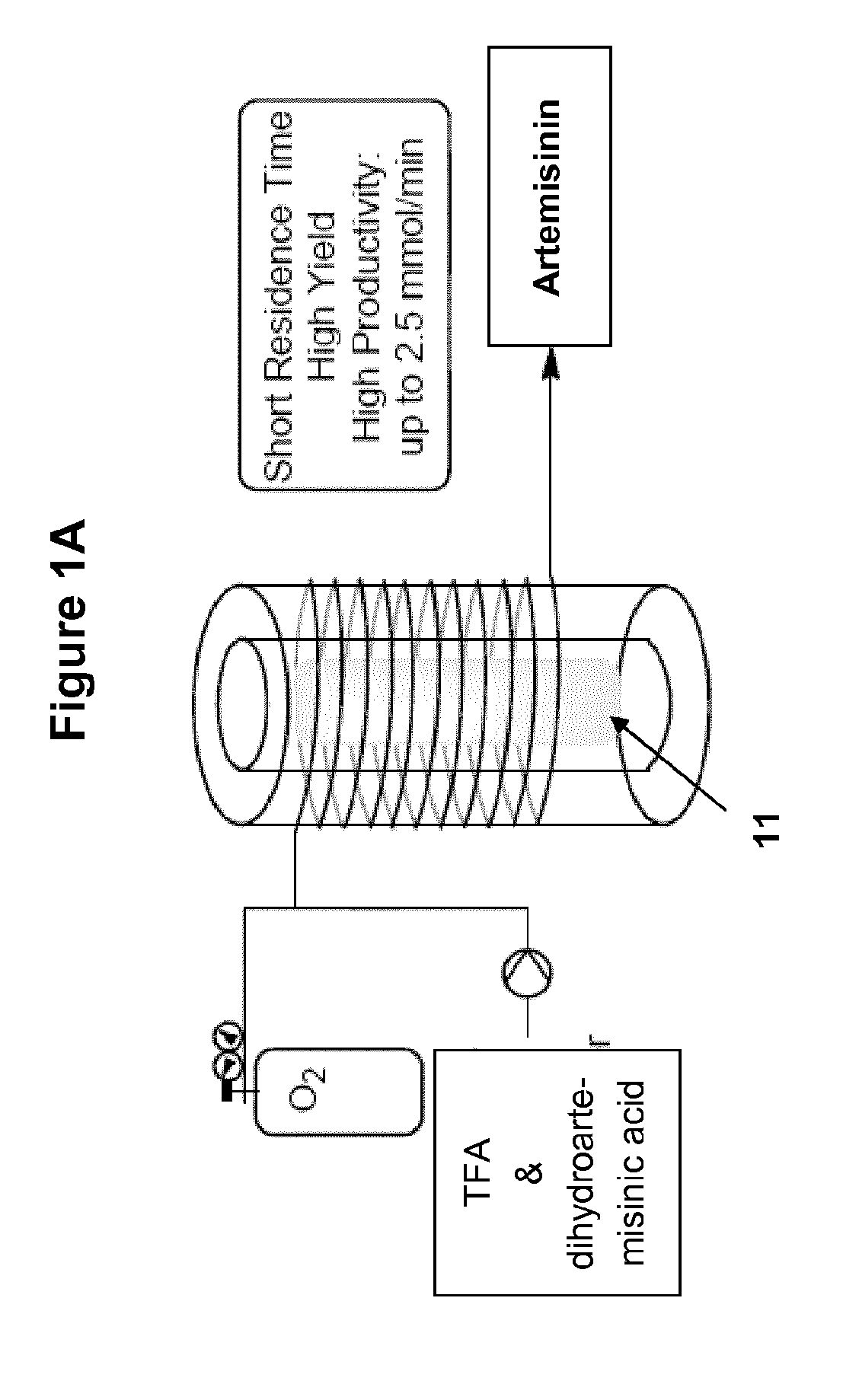

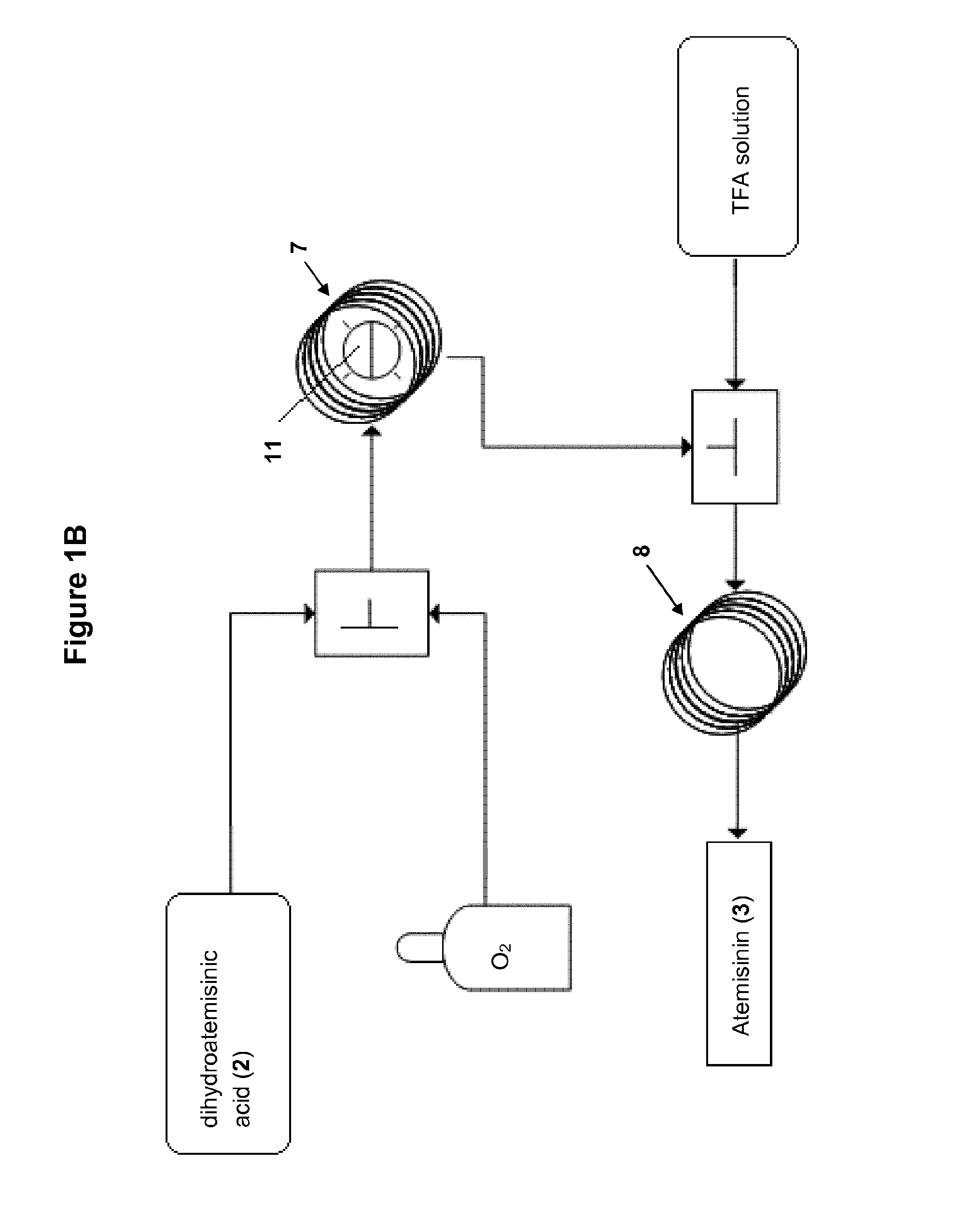

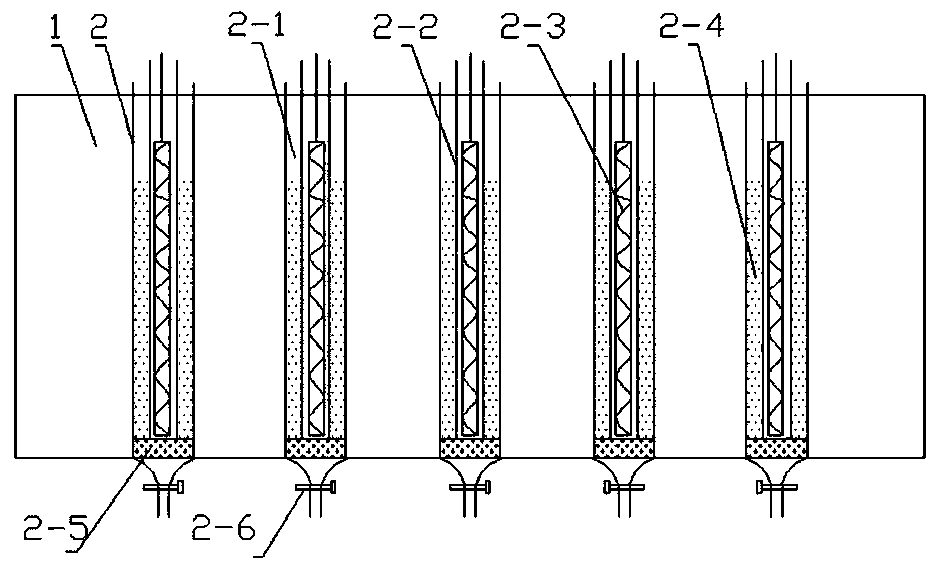

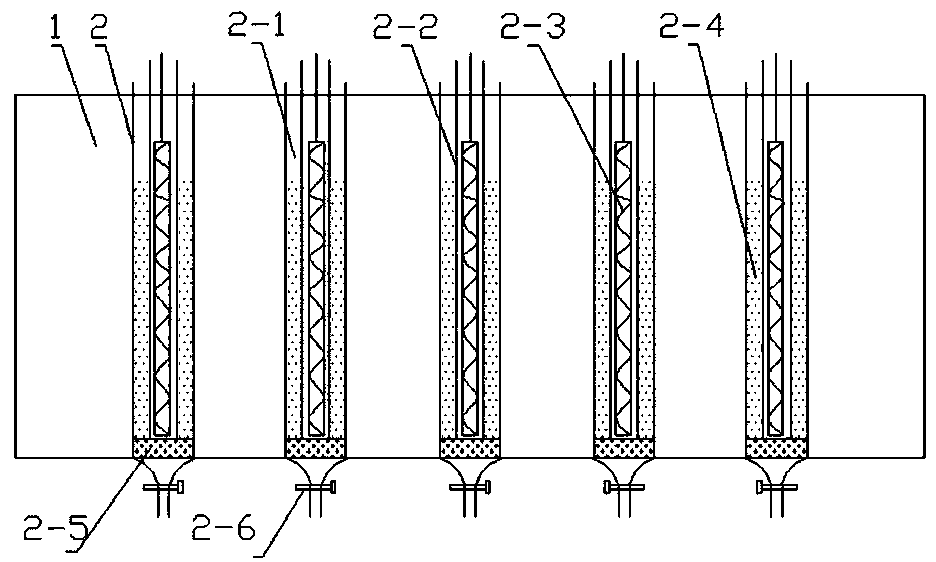

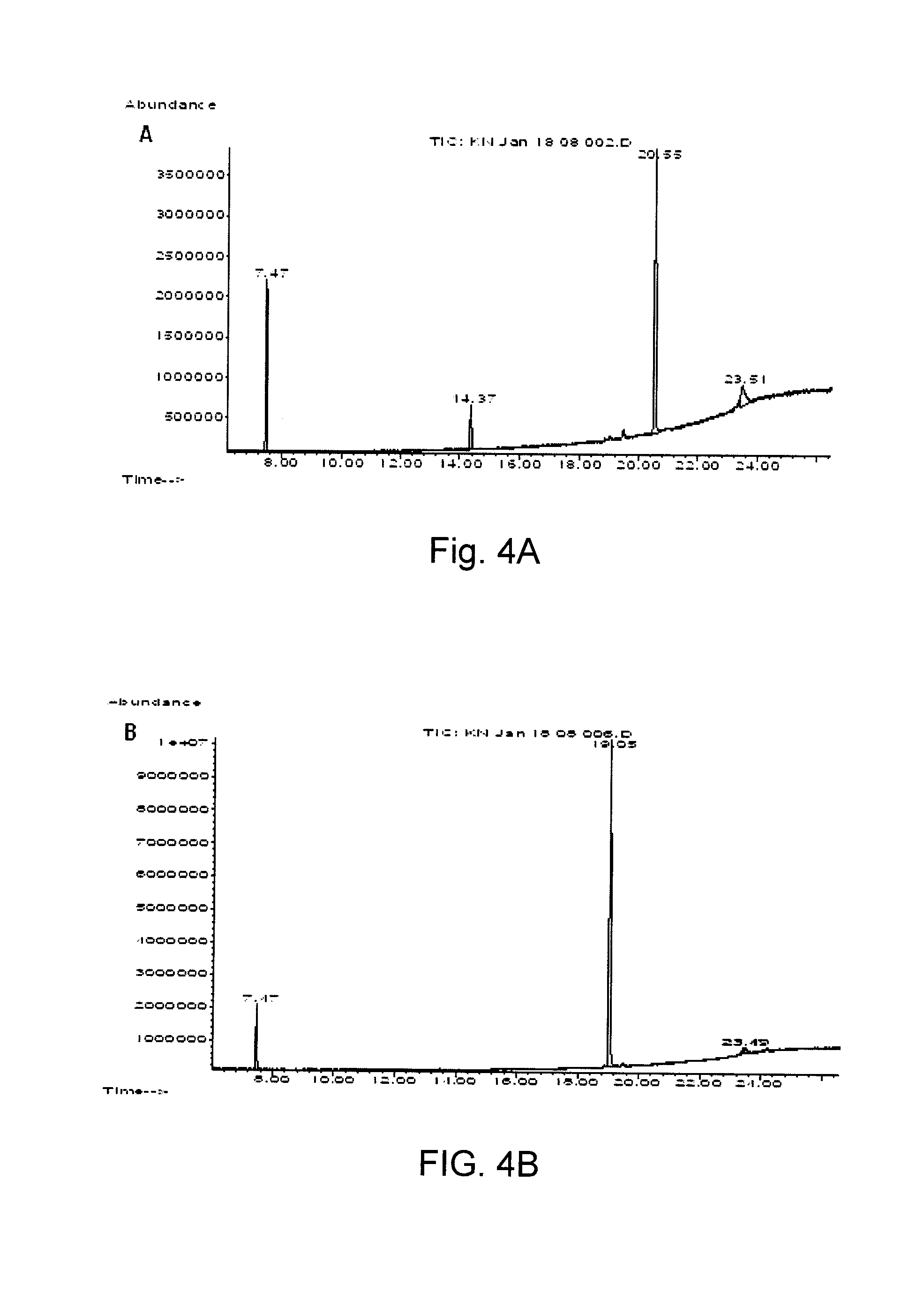

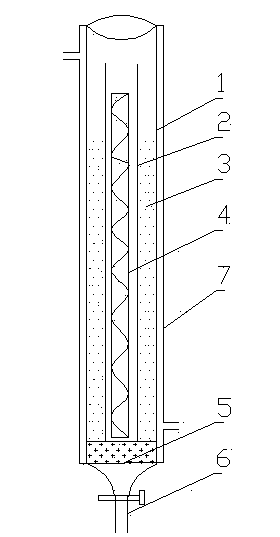

Method and equipment for scale production of artemisinin

ActiveCN103739609AHigh yieldIncrease profitOrganic chemistryEnergy based chemical/physical/physico-chemical processesArtemisininsPtru catalyst

The invention relates to a method and equipment for scale production of artemisinin. The method comprises: dissolving dihydroarteannuic acid in an organic solvent, adding a photosensitizer and an acid catalyst, adopting a light source to make the dihydroarteannuic acid be subjected to light oxidation so as to obtain peroxy alcohol of the dihydroarteannuic acid, carrying out acid catalysis so as to carry out Hock cut-off, and carrying out oxidation ring closing to produce the artemisinin, wherein the whole reaction or only the light oxidation reaction is performed in photosensitive oxidation reaction equipment. The present invention further comprises the photosensitive oxidation reaction equipment for performing the method. According to the present invention, the method has characteristics of low reaction temperature and high light source utilization rate, and the equipment has characteristics of high light source utilization rate, simple structure, low manufacturing cost, and high single-batch productivity.

Owner:HUNAN KEYUAN BIO PRODS

Facility for extracting dihydroartemisinic acid from waste oil generated in artemisinin production

PendingCN110143867AHigh purityRealize functionCarboxylic compound separation/purificationWater dischargeLiquid storage tank

The invention discloses a facility for extracting dihydroartemisinic acid from waste oil generated in artemisinin production. The facility comprises an extraction pot, a stirring device is arranged inthe extraction pot; the upper part of the body of the extraction pot is communicated with a cooling part; the body of the extraction pot is externally provided with an interlayer; the interlayer is communicated with a cooling water pipe, a steam inlet pipe, and a steam cooling water discharge pipe; the body of the extraction pot is provided with a plurality of material outlets at different heights; the material outlets are connected with a crude filtering device; the body of the extraction pot is communicated with the material inlet of a centrifuge through a bottom discharge pipe; the bottomdischarge pipe is also provided with a branch pipe that is communicated with a liquid storage tank; the discharge pipe of the centrifuge is communicated with the crude filtering device; and the crudefiltering device is communicated with a vacuum storage tank, a liquid pump, a fine filtering device, and a normal pressure storage tank through pipelines. The purity of dihydroartemisinic acid is high, after impurities and oil are removed by the facility. The recovery rate of waste oil can reach 96.2%.

Owner:HUNAN AGRICULTURAL UNIV +1

Method for separating and refining arteannuin, dihydro-artemisinic acid and artemisinic acid by reversed-phase high performance liquid chromatography

InactiveCN102153565BIncrease productionReduce manufacturing costHydroxy compound separation/purificationOrganic solventCrystallization

The invention relates to a method for separating and refining arteannuin, dihydro-artemisinic acid and artemisinic acid by reversed-phase high performance liquid chromatography. The method mainly comprises the following steps of: separating and purifying an artemisia apiacea crude extract extracted by organic solvent by reversed-phase high performance liquid chromatography, and concentrating and crystallizing to obtain pure products of the arteannuin, the dihydro-artemisinic acid and the artemisinic acid. The method is high in yield, separation efficiency and a separation speed, the pure products of the arteannuin, the dihydro-artemisinic acid and the artemisinic acid can be obtained simultaneously, and the purity can reach over 96 percent, so the method can be used for large-scale industrial production.

Owner:HUNAN AGRICULTURAL UNIV

Nucleotide sequence encoding an alcohol dehydrogenase from artemisia annua and uses thereof

An isolated nucleic acid molecule cloned from Artemisia annua encodes an alcohol dehydrogenase (Adh1). Artemisia annua Adh1 enzymatically oxidizes artemisinic alcohol to artemisinic aldehyde. The nucleic acid molecule, and the enzyme encoded thereby, may be used in processes to produce artemisinic aldehyde, dihydroartemsinic aldehyde, artemisinic acid and / or dihydroartemisinic acid in a host cell. Artemisinic aldehyde, dihydroartemisinic aldehyde, artemisinic acid and / or dihydroartemisinic acid can be chemically converted to the antimalarial compound artemisinin.

Owner:NAT RES COUNCIL OF CANADA

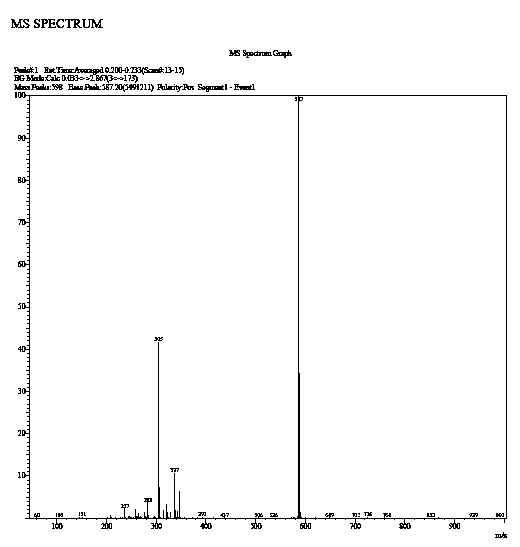

Method and equipment for preparing artemisinin by adopting dihydroarteannuic acid as raw material

ActiveCN103739610AIncrease productionSimple structureOrganic chemistryEnergy based chemical/physical/physico-chemical processesArtemisininsPtru catalyst

The invention relates to a method and equipment for preparing artemisinin by adopting dihydroarteannuic acid as a raw material. The method comprises: dissolving dihydroarteannuic acid in an organic solvent, adding a photosensitizer and an acid catalyst, adopting a light source to make the dihydroarteannuic acid be subjected to light oxidation so as to obtain peroxy alcohol of the dihydroarteannuic acid, carrying out acid catalysis so as to carry out Hock cut-off, and carrying out oxidation ring closing to produce the artemisinin, wherein the whole reaction or only the light oxidation reaction is performed in the photoreactor. The present invention further comprises the photoreactor for performing the method. According to the present invention, the method has characteristics of low reaction temperature, high artemisinin yield and high light source utilization rate, and the equipment has characteristics of simple structure, low manufacturing cost, and high single-batch productivity.

Owner:HUNAN KEYUAN BIO PRODS

Preparation method of low-energy consumption easy-industrial production high-purity dihydroartemisinic acid

InactiveCN110229059AReduce energy consumptionWide applicabilityCarboxylic compound separation/purificationRoom temperatureEnergy consumption

The invention belongs to the field of medicinal chemistry, and particularly relates to a preparation method of low-energy consumption easy-industrial production high-purity dihydroartemisinic acid. The method comprises the following steps: (1) performing extraction concentration; (2) performing extraction; (3) performing acidification; (4) performing extraction; (5) performing concentration; (6) performing primary crystallization; (7) performing decolorization; (8) performing recrystallization; and (9) performing drying. According to the preparation method of the dihydroartemisinic acid provided by the invention, the steps of extraction concentration, extraction and acidification do not need heating, the operation temperature is room temperature, heating is required only when reagents arerecovered, so that the energy consumption is lower; the preparation method does not need column chromatography, does not need to add special equipment, and has smaller investment, simple operation, and easy industrialization and promotion; and the purity of the dihydroartemisinic acid prepared by the preparation method all reaches 99%, the highest purity can reach 99.9%, and the yield of the dihydroartemisinic acid is about 75-80%.

Owner:长沙艾康生物科技有限公司 +1

Preparation method of artemisinin

The invention discloses a preparation method of artemisinin, wherein the preparation method comprise the steps: with artemisinic acid as a starting material, obtaining dihydroartemisinic acid under the hydrogen / metal catalyst action, then oxidizing dihydroartemisinic acid into arteannuic acid dihydrogen peroxide by hydrogen peroxide in the presence of sodium molybdate, and finally acting with oxygen under the catalysis of copper trifluoromethanesulfonate, to obtain the target product artemisinin with high yield. Compared with the prior art, the preparation method has the following advantages:the used reagents are cheap and easy to get, the synthetic route is short, the reaction selectivity is high, the preparation process is environmentally friendly, the operation and post-processing aresimple, the total yield is high, and the preparation method is suitable for industrialized production.

Owner:TIANJIN PACIFIC PHARMA

Low-energy-consumption easily-industrializable preparation method for high-purity dihydroartemisinic acid

InactiveCN110256237AReduce energy consumptionWide applicabilityChemical industryCarboxylic compound separation/purificationRoom temperatureEnergy consumption

The invention specifically relates to a low-energy-consumption easily-industrializable preparation method for high-purity dihydroartemisinic acid, belonging to the field of medicinal chemistry. The preparation method of the invention comprises the following steps of: (1) extraction and concentration; (2) extraction; (3) acidification; (4) extraction; (5) concentration; (6) primary crystallization; (7) decolorization; (8) recrystallization; and 9) drying. According to the preparation method for dihydroartemisinic acid in the invention, heating is not needed in the steps of extraction and concentration, extraction and acidification, operation temperature is room temperature, and heating is required only when reagents are to be recovered, so energy consumption is low; and the preparation method of the invention does not need treatment with a column or additional arrangement of special equipment, so investment is low, operation is simple, and the preparation method is easy to industrialize and promote. The purity of dihydroartemisinic acid prepared by using the preparation method of the invention reaches 99% or above and is as high as 99.9%, and the yield of dihydroartemisinic acid is about 75-80%.

Owner:长沙艾康生物科技有限公司 +1

Method for removing impurities in production process of high-purity dihydroartemisinic acid

InactiveCN110563573ATo achieve the effect of removing impuritiesSpeed up filteringCarboxylic compound separation/purificationImpurityEnergy consumption

The invention relates to the field of medicinal chemistry, in particular to a method for removing impurities in the production process of high-purity dihydroartemisinic acid. The method comprises thefollowing steps: (1) extracting and standing; (2) filtering and removing impurities; (3) concentrating; (4) extracting to remove impurities; (5) acidification; (6) extracting, standing and removing impurities; (7) concentration. The method for removing the grease impurities and the black colloidal impurities in the production process of the high-purity dihydroarteannuic acid is low in energy consumption, easy to operate, free of special equipment, small in investment and capable of effectively removing the impurities in the production process of the dihydroarteannuic acid.

Owner:长沙艾康生物科技有限公司 +1

A method for simultaneously extracting artemisinic acid and dihydroartemisinic acid from waste liquid after separation of artemisinin

ActiveCN103524527BAchieving Simultaneous ExtractionIncrease profitCarboxylic compound separation/purificationLiquid wasteLiquid water

Owner:GUANGZHOU HONSEA SUNSHINE BIOTECH CO LTD

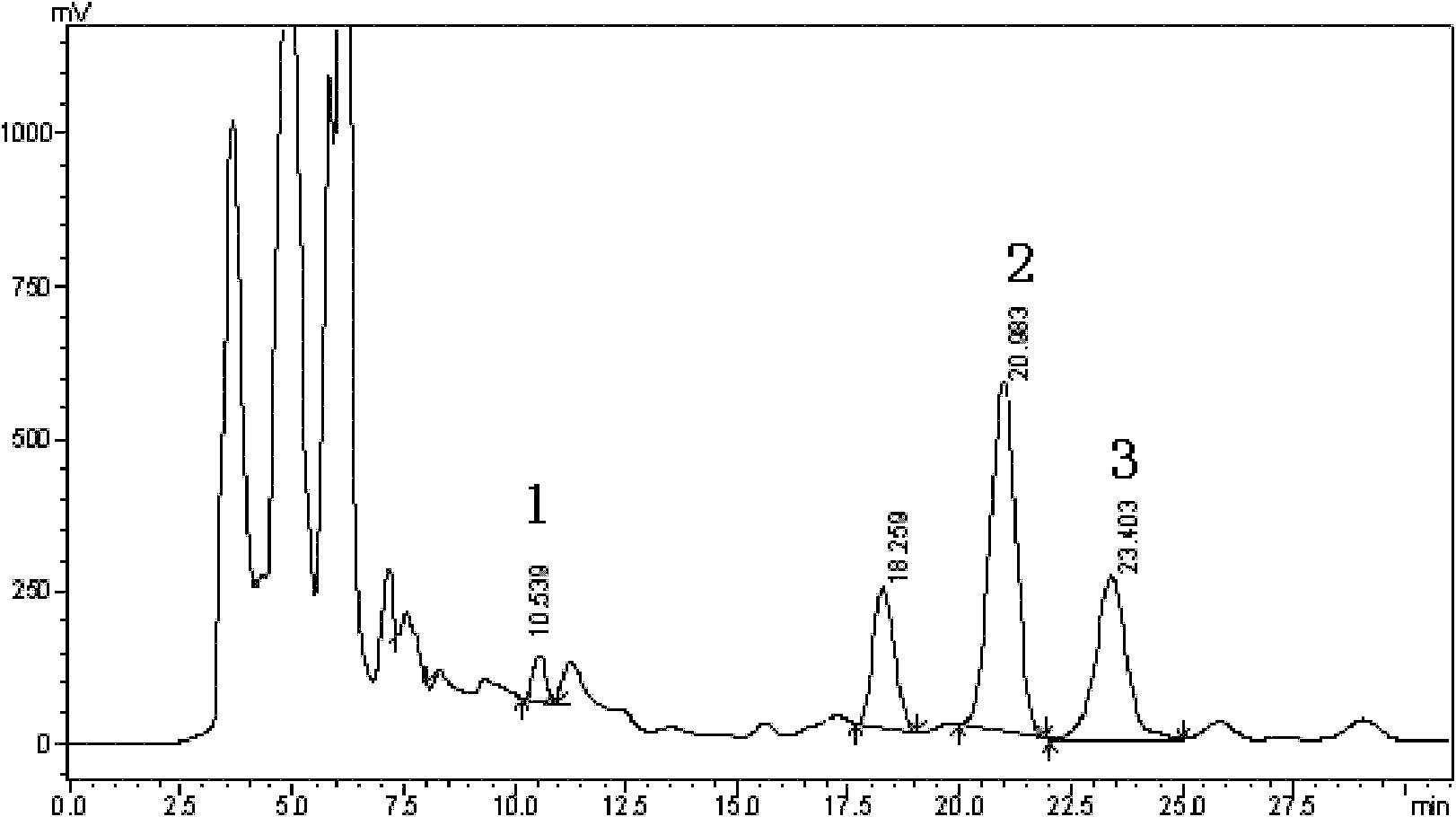

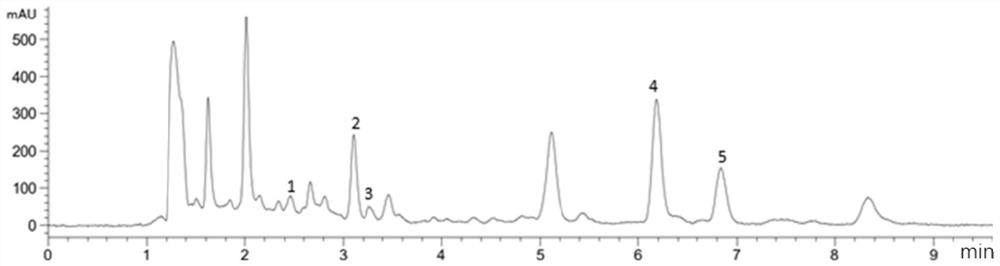

Artemisia apiacea sesquiterpene effective part and extraction and purification process thereof

ActiveCN112062776AEasy to operateLow costComponent separationOrganic chemistry methodsChemical compoundPharmaceutical drug

The invention relates to a sesquiterpene compound and an extraction and purification process thereof, in particular to a sesquiterpene effective part extracted from artemisia apiacea and an extractionprocess of the sesquiterpene effective part. The content of sesquiterpene in the artemisia apiacea sesquiterpene effective part is higher than 55%, and the artemisia apiacea sesquiterpene effective part mainly comprises the following compounds: 1: artemisinin B; 2: artemisinin; 3: artemisinin C, 4: artemisinic acid and 5: dihydroartemisinic acid. The sesquiterpene effective part can be used for preparing antimalarial drugs. The sesquiterpene effective part can also be used for preparing medicines with the effects of clearing deficiency heat, removing bone steaming, relieving summer heat, removing jaundice and the like. Meanwhile, the invention further provides a preparation method of the sesquiterpene effective part, and the method is simple, efficient and suitable for industrial application.

Owner:苏州满元生物科技有限公司

Method for separating and purifying dihydroartemisinic acid from artemisinin waste wax oil

PendingCN111533653AImprove separation efficiencyReduce separation costsCarboxylic compound separation/purificationActivated carbonFiltration

The invention discloses a method for separating and purifying dihydroartemisinic acid from artemisinin waste wax oil, which comprises the following steps: 1) adding purified water into the artemisininwaste wax oil, heating to remove residual organic solvent in the wax oil, cooling, adding petroleum ether, adding an alkaline substance to regulate the pH value, heating, refluxing and stirring; 2) cooling to room temperature, layering, removing an aqueous solution layer, centrifuging and concentrating; 3) adding an acidic substance to adjust the pH value; 4) adding petroleum ether, heating and stirring, cooling, standing for layering to obtain a petroleum ether layer, and performing extraction twice; 5) combining petroleum ether layers, concentrating under reduced pressure, cooling and crystallizing to obtain dihydroartemisinic acid white yellow coarse crystals; and (6) adding an ethanol solution having a concentration of 80% into the dihydroartemisinic acid white yellow coarse crystals,stirring until the dihydroartemisinic acid white yellow coarse crystals are completely dissolved, adding activated carbon, stirring for decolorization, carrying out suction filtration to remove the activated carbon, recovering ethanol, cooling the residual aqueous solution, crystallizing, carrying out suction filtration, and drying to obtain the high-purity dihydroartemisinic acid colorless crystals. The method is high in separation efficiency and simple in separation process, and the separated dihydroartemisinic acid is high in purity.

Owner:YUZHOU TIANYUAN BIOTECH CO LTD

Method for preparing artemisinin for malaria

ActiveCN103224501AGood stereoselectivityHigh purityOrganic chemistryAgainst vector-borne diseasesOxygenMalaria

The invention discloses a method for preparing artemisinin for malaria. Firstly, dihydro-artemisinic acid is obtained by artemisinic acid under the effect of a reducing agent such as sodium borohydride / nickel chloride or hydrogen / a metal catalyst, then, under the existence of the catalyst, the dihydro-artemisinic is oxidized to be peroxide artemisinic acid through peroxide, and finally, an objective product-the artemisinin can be obtained with high efficiency under the catalyzing of the acid and the effect of oxygen. Compared with the prior art, the method for preparing the artemisinin for malaria has the advantages that the reagent is cheap and easy to obtain, short in synthetic route, high in reaction selectivity, environment-friendly in the process of preparation, easy to operate, simple in post-processing, high in total collection efficiency and suitable for industrialized production.

Owner:SHANGHAI JIAO TONG UNIV

High-efficiency preparation method of anti-malarial medicine artemisinin

The invention discloses a high-efficiency preparation method of anti-malarial medicine artemisinin. The method comprises the following steps of: preparing dihydroartemisinic acid from artemisinin under the action of reducing agent sodium borohydride / nickel chloride or hydrogen / metal catalyst; oxidizing the dihydroartemisinic acid by peroxide in the existence of the catalyst to obtain oxidized dihydroartemisinic acid; and preparing the target product artemisinin with high yield under catalysis of acid and the action of oxygen. Compared with the prior art, the method has the advantages of low price and easy availability of reagents, short synthetic route, high reaction selectivity, environmentally-friendly preparation process, simplicity in operation and post-treatment and high total yield, and is suitable for industrial production.

Owner:SHANGHAI JIAOTONG UNIV

Method for preparing high-purity dihydroartemisinic acid by removing grease from crude dihydroartemisinic acid

ActiveCN110143864AReduce lossReduce manufacturing costCarboxylic compound separation/purificationChemical synthesisCentrifugation

The invention relates to the field of medicinal chemistry, in particular to a method for preparing high-purity dihydroartemisinic acid by removing grease from crude dihydroartemisinic acid. The methodof the invention comprises the following steps: (1) preliminary crystallization; (2) centrifugal degreasing; (3) dissolving for degreasing; (4) recrystallization; (5) decolorization and crystallization; (6) secondary decolorization and recrystallization; (7) drying; and (8) pulverizing and packaging. The method of the invention uses the crude dihydroartemisinic acid as a raw material, and can remove most of grease impurities in the crude dihydroartemisinic acid and prepare high-purity dihydroartemisinic acid through centrifugation via a centrifuge, solution extraction and multiple dissolutiondegreasing and crystallization. The method of the invention is simple to operate, capable of effectively removing grease impurities in the crude dihydroartemisinic acid, and easy to be industrializedand popularized; and the finally prepared dihydroartemisinic acid has a content of 99% or more and a purity of 99.9%, and can meet the needs of chemical synthesis, pharmaceutical preparation and thelike.

Owner:HUNAN AGRICULTURAL UNIV +1

Dihydroartemisinic acid synthesis technology

InactiveCN105622393AIncrease conversion rate per passHigh yieldCarboxylic preparation by ozone oxidationOrganic solventDiimine

The invention discloses a dihydroartemisinic acid synthesis technology. The technology comprises dissolving dihydroartemisinic acid in an organic solvent, adding hydrazine hydrate and a catalytic amount of a transition metal compound into the solution, adjusting a reaction temperature in a range of 65-100 DEG C, dropwisely adding hydrogen peroxide into the reaction solution so that the arteannuic acid is reduced into dihydroartemisinic acid through diimine produced in situ, and carrying out extraction and drying to obtain dihydroartemisinic acid. The technology has short synthesis reaction time and a high dihydroartemisinic acid yield.

Owner:QINGDAO SHOUTAI AGRI SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com