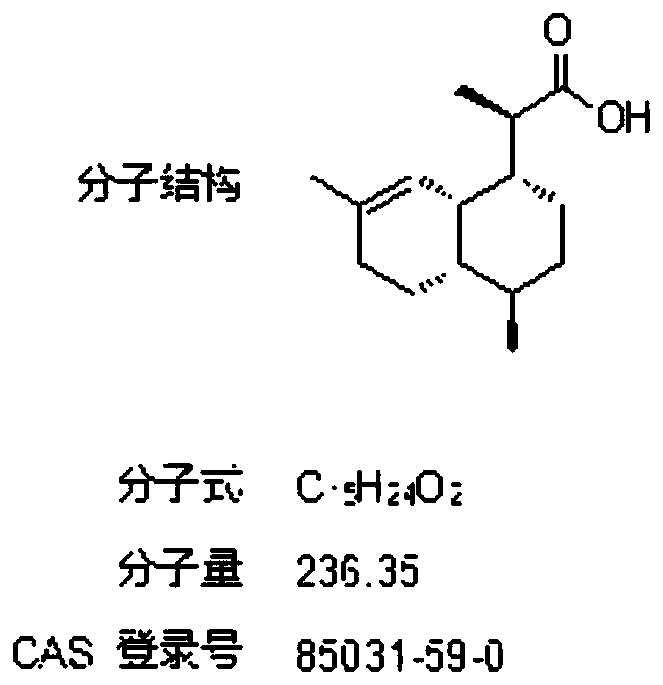

Low-energy-consumption easily-industrializable preparation method for high-purity dihydroartemisinic acid

A technology of dihydroartemisinic acid and low energy consumption, which is applied in the separation/purification of carboxylic acid compounds, chemical industry, organic chemistry, etc. Advanced problems, to achieve the effect of easy industrialization and promotion, wide application and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

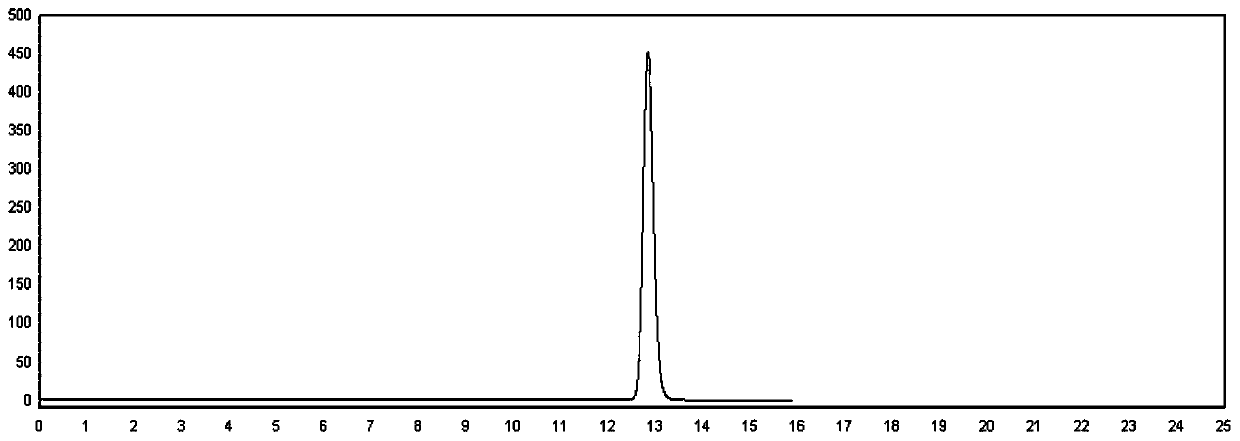

Image

Examples

Embodiment 1

[0039] A method for preparing high-purity dihydroartemisinic acid with low energy consumption and easy industrial production, comprising the following steps:

[0040](1) Extraction and concentration: take 400 g of waste oil without residual solvent used in the production of artemisinin after the concentration is complete, and its dihydroartemisinic acid content is 6.5% after detection, and add methanol with a volume concentration of 80% under the condition of stirring 12000ml of aqueous solution, the methanol aqueous solution contains sodium hydroxide with a mass volume ratio of 5%. Stir continuously at room temperature for 8h, let it stand for 4h, and centrifuge to obtain a clear golden yellow extract. The pressure is above -0.07MPa, 45°C Vacuum concentration to 600ml;

[0041] (2) Extraction: Add 600ml of petroleum ether to the alkaline water layer of the concentrated solution obtained in step (1), stir and extract for 2h, let stand for 1h, and separate the lower alkaline wa...

Embodiment 2

[0050] A method for preparing high-purity dihydroartemisinic acid with low energy consumption and easy industrial production, comprising the following steps:

[0051] (1) Extraction and concentration: take 100 kg of waste oil without residual solvent used in the production of artemisinin after the concentration is complete, and its dihydroartemisinic acid content is 6.9% after testing, and add ethanol with a volume concentration of 60% under the condition of stirring 3000L aqueous solution, the ethanol aqueous solution contains sodium bicarbonate with a mass volume ratio of 0.1%. Stir continuously at room temperature for 6h, let it stand for 2h, and centrifugally filter to obtain a clear golden yellow extract. The pressure is above -0.07MPa, 55°C Vacuum concentration to 200L;

[0052] (2) Extraction: Add 300L ethyl acetate to the alkaline water layer of the concentrated solution obtained in step (1), stir and extract for 0.5h, let stand for 2h, and separate the lower alkaline ...

Embodiment 3

[0062] A method for preparing high-purity dihydroartemisinic acid with low energy consumption and easy industrial production, comprising the following steps:

[0063] (1) Extraction and concentration: take 1000 kg of waste oil without residual solvent used in the production of artemisinin after the concentration is complete, and its dihydroartemisinic acid content is 6.9% after detection, and add acetone with a volume concentration of 40% under the condition of stirring 30000L aqueous solution, the methanol aqueous solution contains disodium bicarbonate with a mass volume ratio of 1%. Stir continuously at room temperature for 4h, let it stand for 6h, and centrifuge to obtain a clear golden yellow extract with a pressure of -0.07MPa or more, 65 ℃ Vacuum concentration to 2000L;

[0064] (2) Extraction: Add 3000L of dichloromethane to the alkaline water layer of the concentrated solution obtained in step (1), stir and extract for 1 hour, let stand for 0.5 hour, and separate the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com