Patents

Literature

1640 results about "Operation temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The operating temperature is the temperature which prevails inside equipment and piping during any intended operation. A process engineer determines the operating temperature.

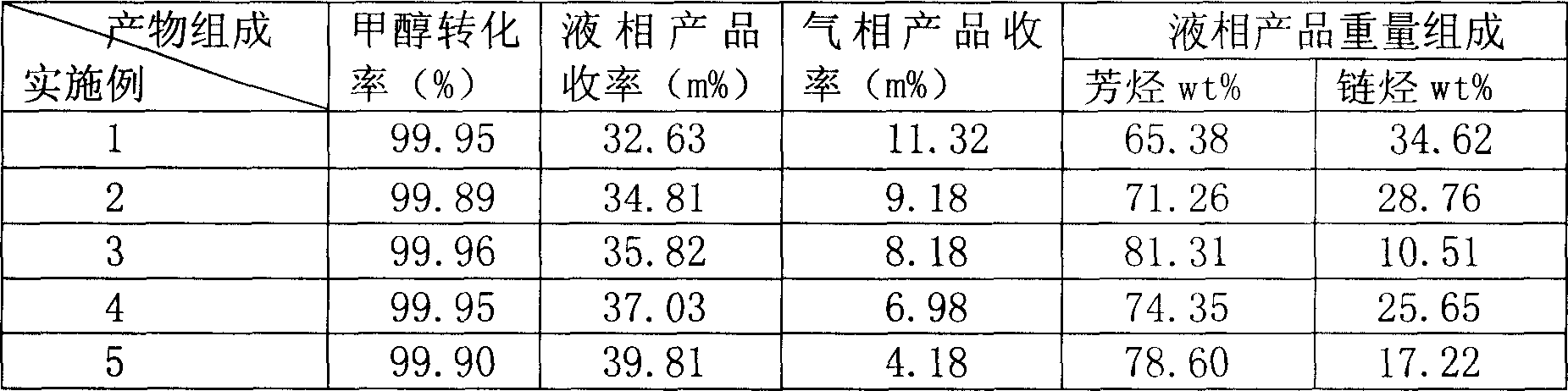

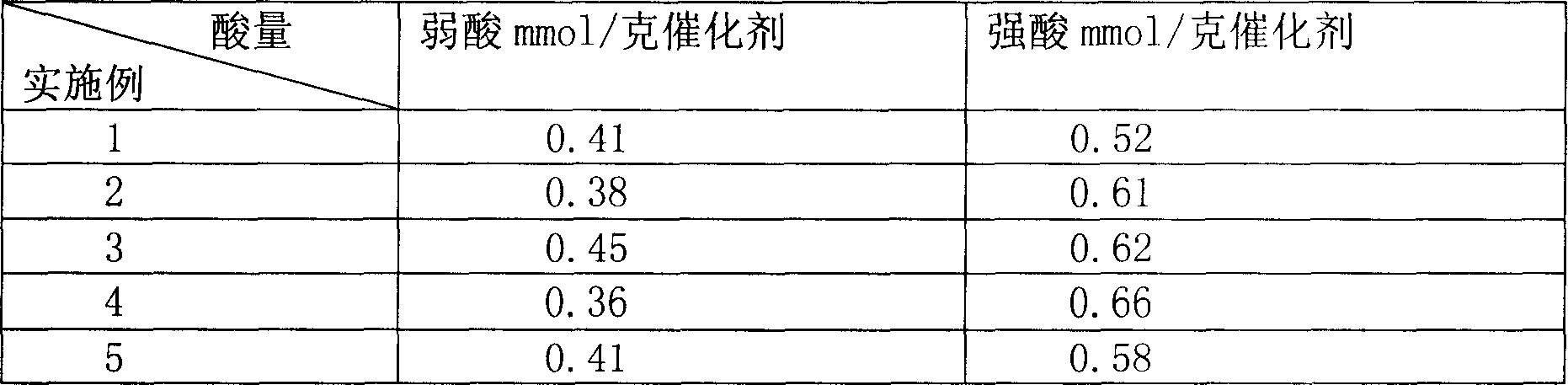

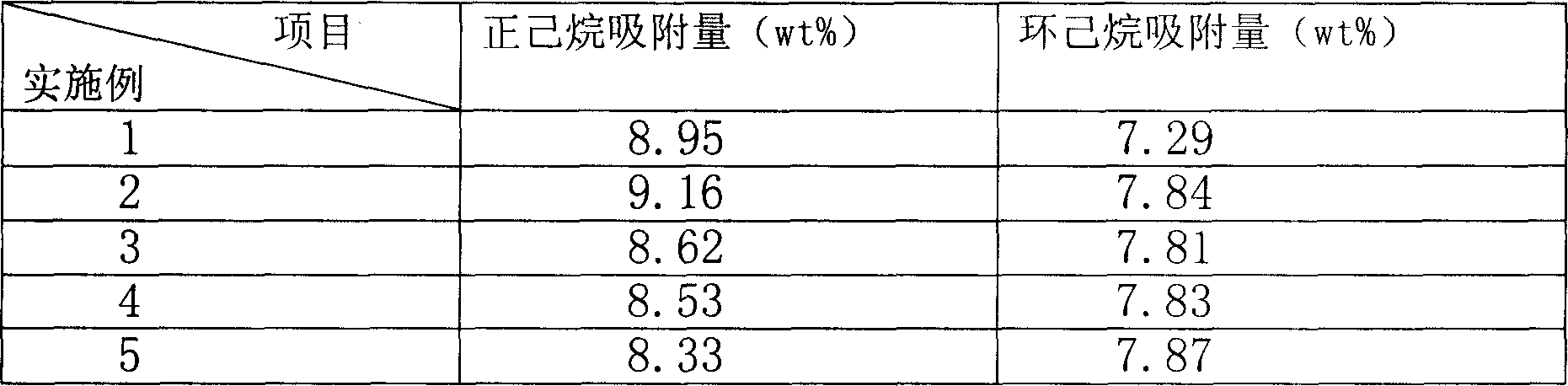

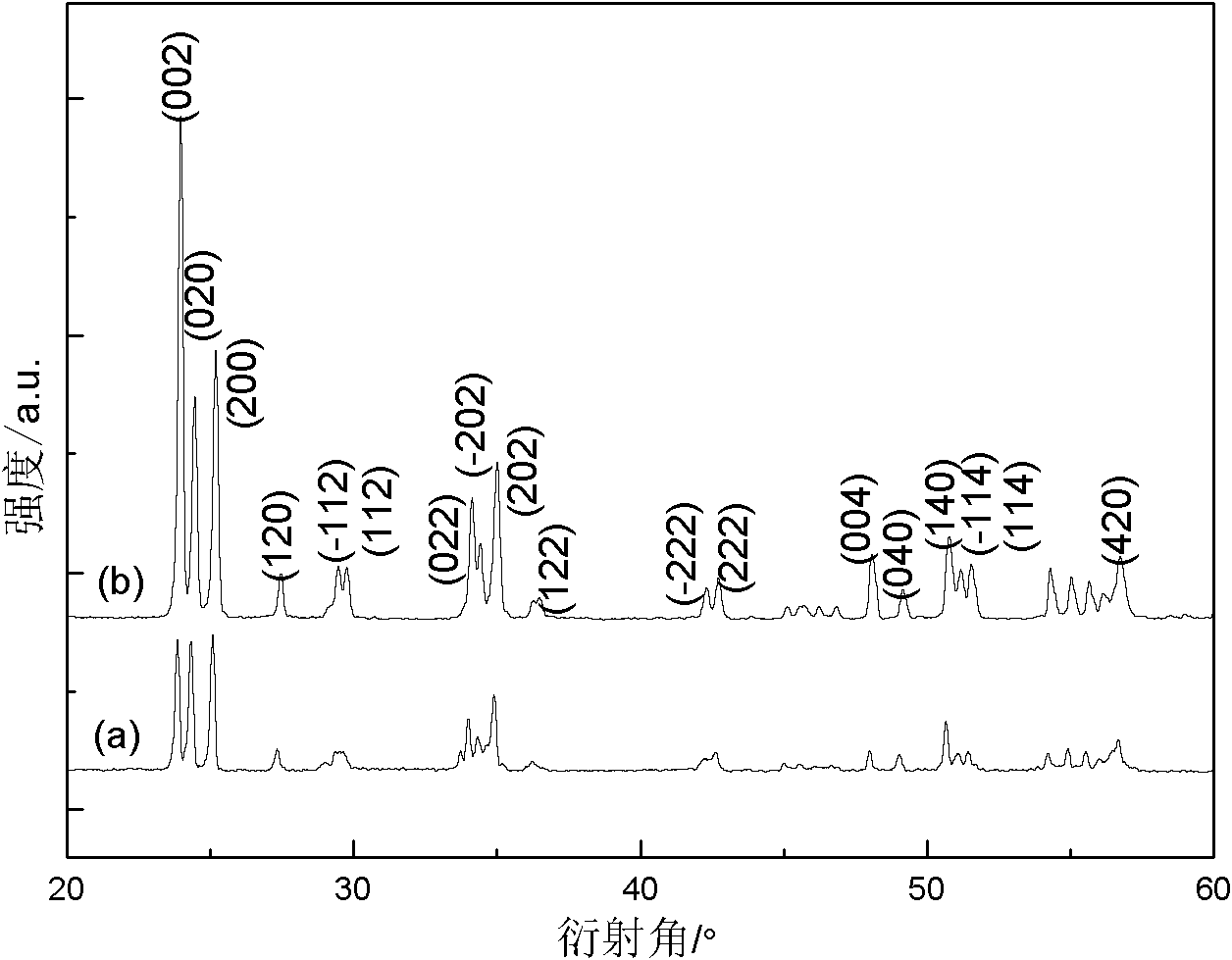

Process of methanol conversion for preparing arene and catalyst and catalyst preparation method

InactiveCN1880288AHigh selectivityHigh flexibility in process operationMolecular sieve catalystsHydrocarbonsGas phaseAromatic hydrocarbon

This invention relates to a process for transforming methanol to aromatic hydrocarbons, comprising: use methanol as raw material, with modified ZSM-5 molecular sieve as catalyst, under conditions of operation pressure 0.1-5.0Mpa, operation temperature 300-460Deg C, raw material liquid air speed 0.1-6.0h-1, transformed to products with aromatic hydrocarbons as main components; separate the gas-phase products lower carbon hydrocarbons from the liquid-phase C5+ hydrocarbons by cooling separation; the liquid-phase C5+ hydrocarbons then can be separated to be aromatic hydrocarbons and non-aromatic hydrocarbons by extracting separation. This invention is characterized of high total selectivity of aromatic hydrocarbons and flexible process operation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

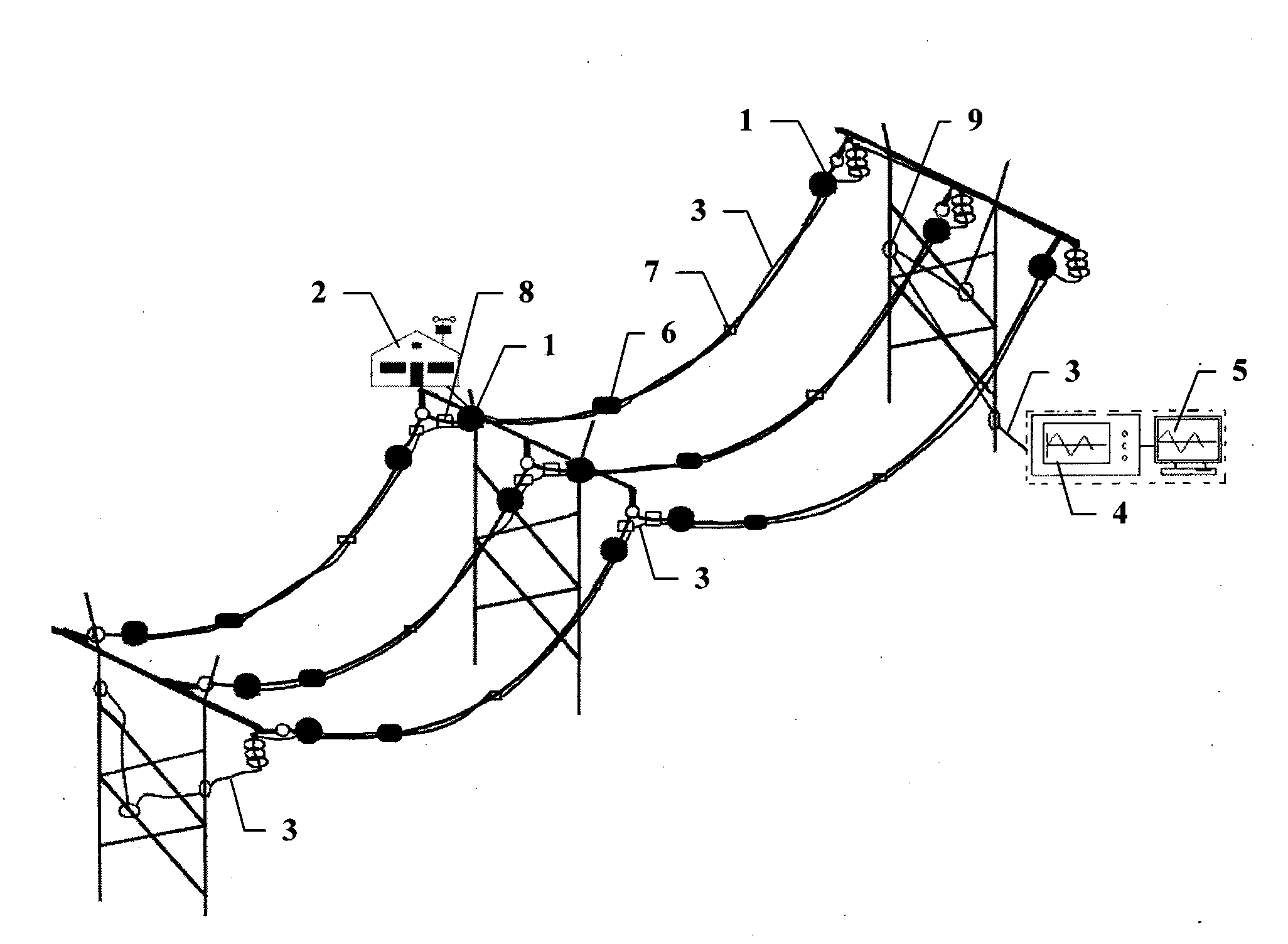

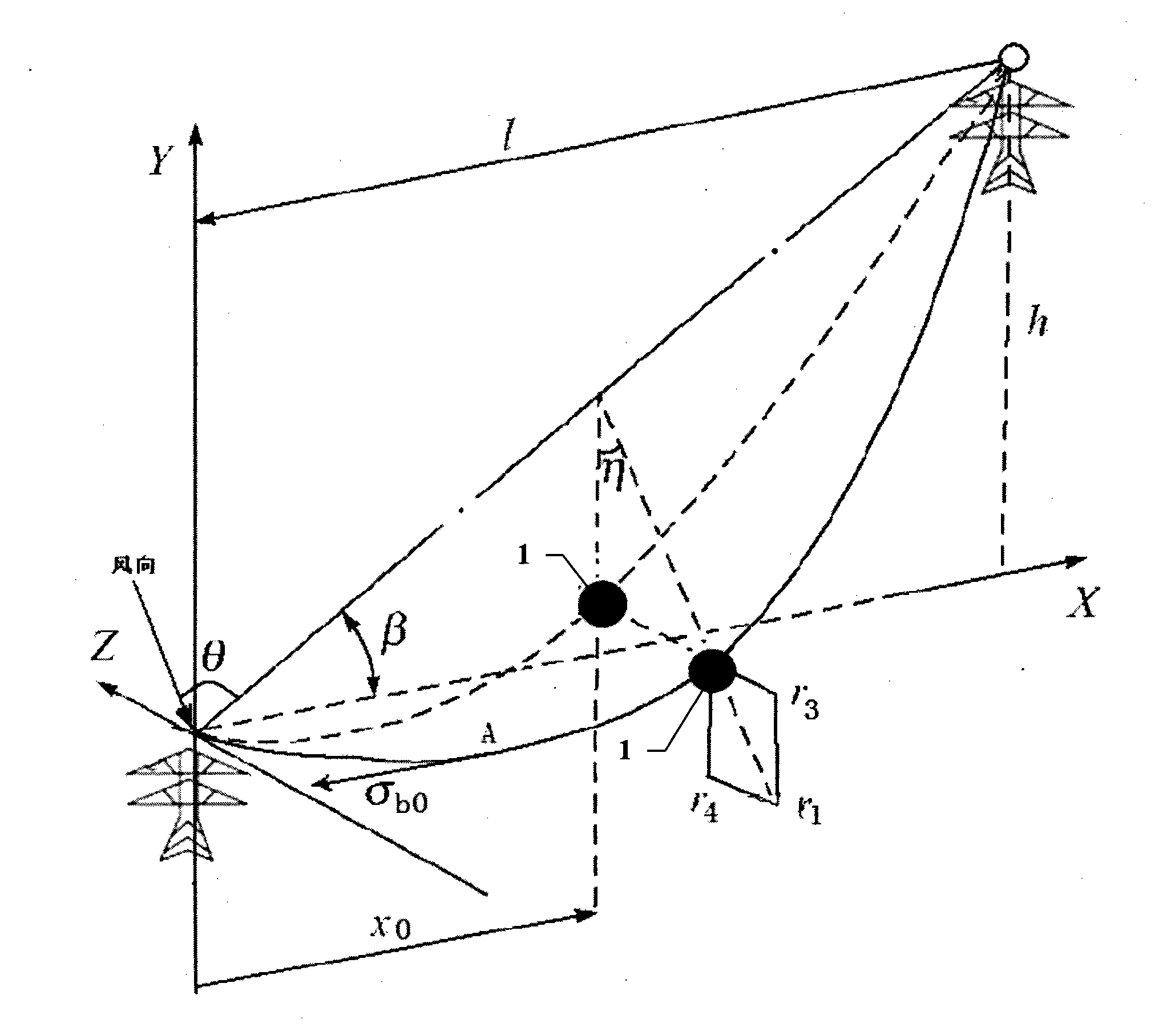

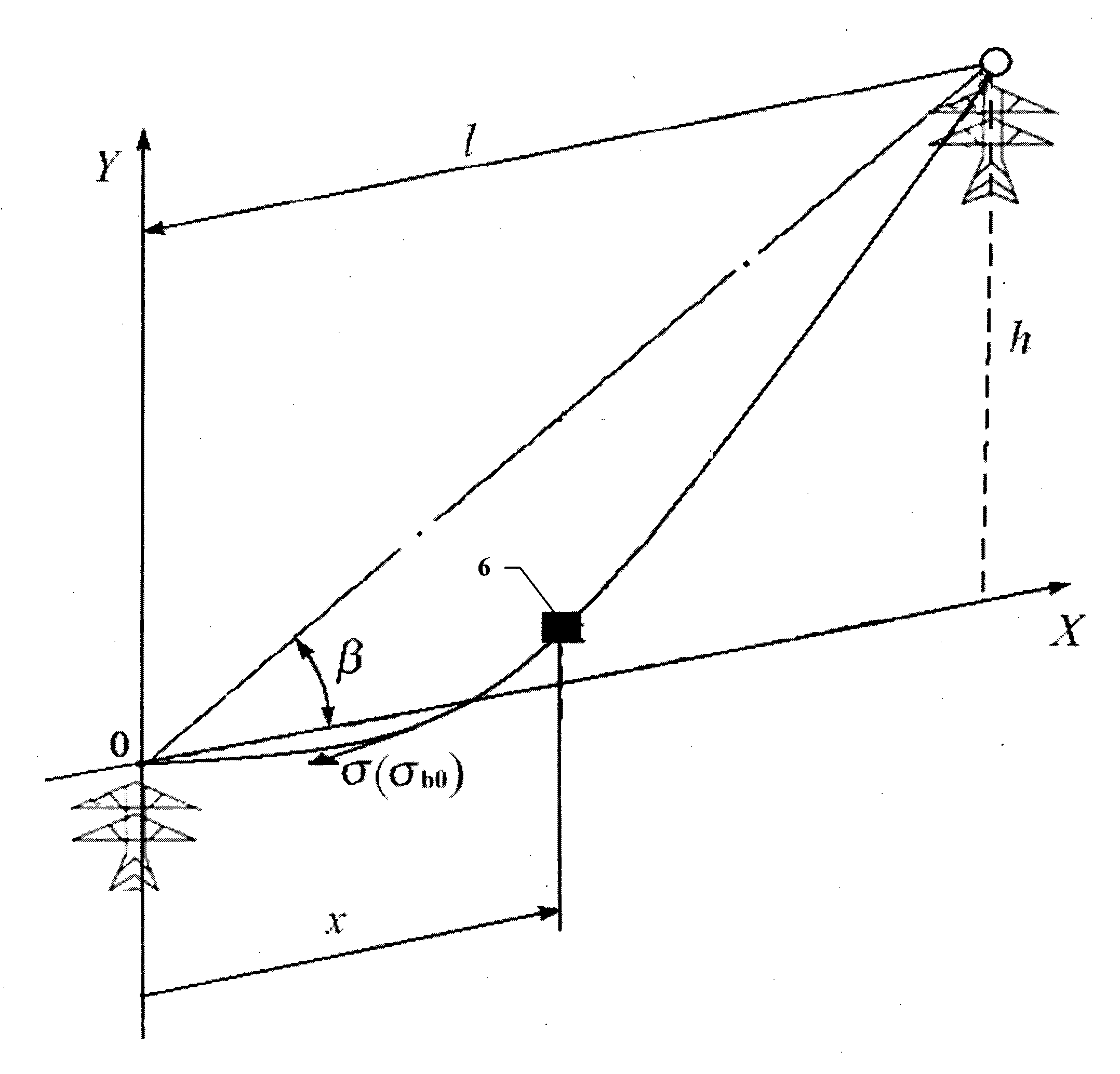

Device for monitoring state of power transmission line tower-line system

InactiveCN102042885AWide operating temperature rangeLong measuring distanceForce measurement by measuring optical property variationIndication of weather conditions using multiple variablesVibration amplitudeDistributed structure

The invention discloses a device for monitoring the state of a power transmission line tower-line system, which fully utilizes the advantages of corrosion resistance, wide operation temperature range, anti-electromagnetic interference, passivity, long measuring distance, reliable operation and long service life and the like of optical fiber sensors to configure the optical fiber sensors on a transmission conductor and a tower in a quasi-distributed structure for detecting the temperature, the strain and the acceleration of the transmission conductor and the multipoint stress variation on the tower which are transmitted to an optical modulator demodulator for demodulating and are sent to a computer analyzing and processing system for calculating to obtain the icing quality, the waving amplitude, the breeze vibration amplitude and frequency and the sag of the transmission conductor, and the inclination angle of the tower, thus realizing the simultaneous monitoring on the icing, the waving, the breeze vibration and the sag of the transmission conductor, and the inclination angle state of the tower, and being capable of finishing long-time reliable operation under the on-site severe environment conditions.

Owner:SICHUAN HUIYUAN OPTICAL COMM CO LTD

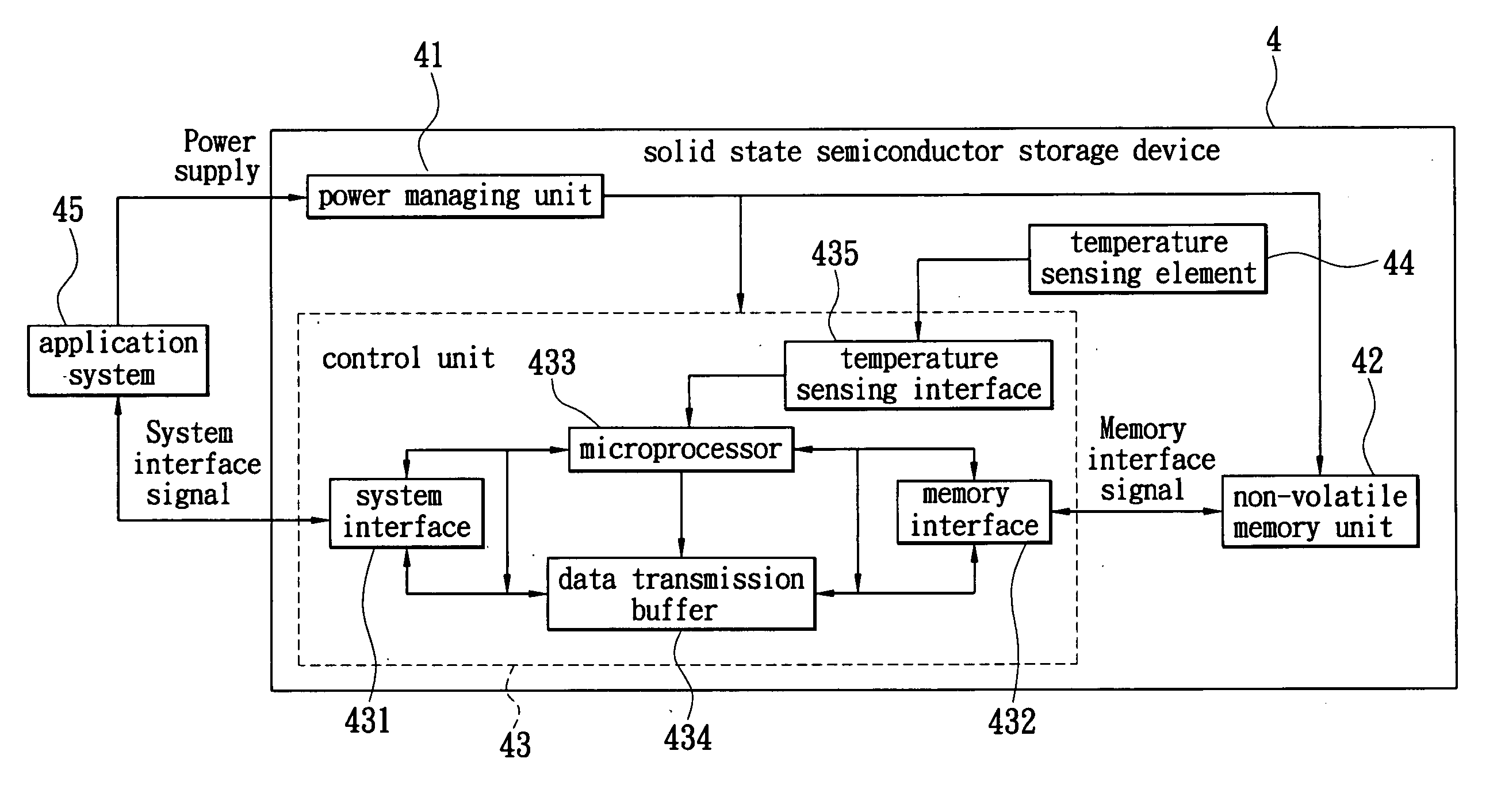

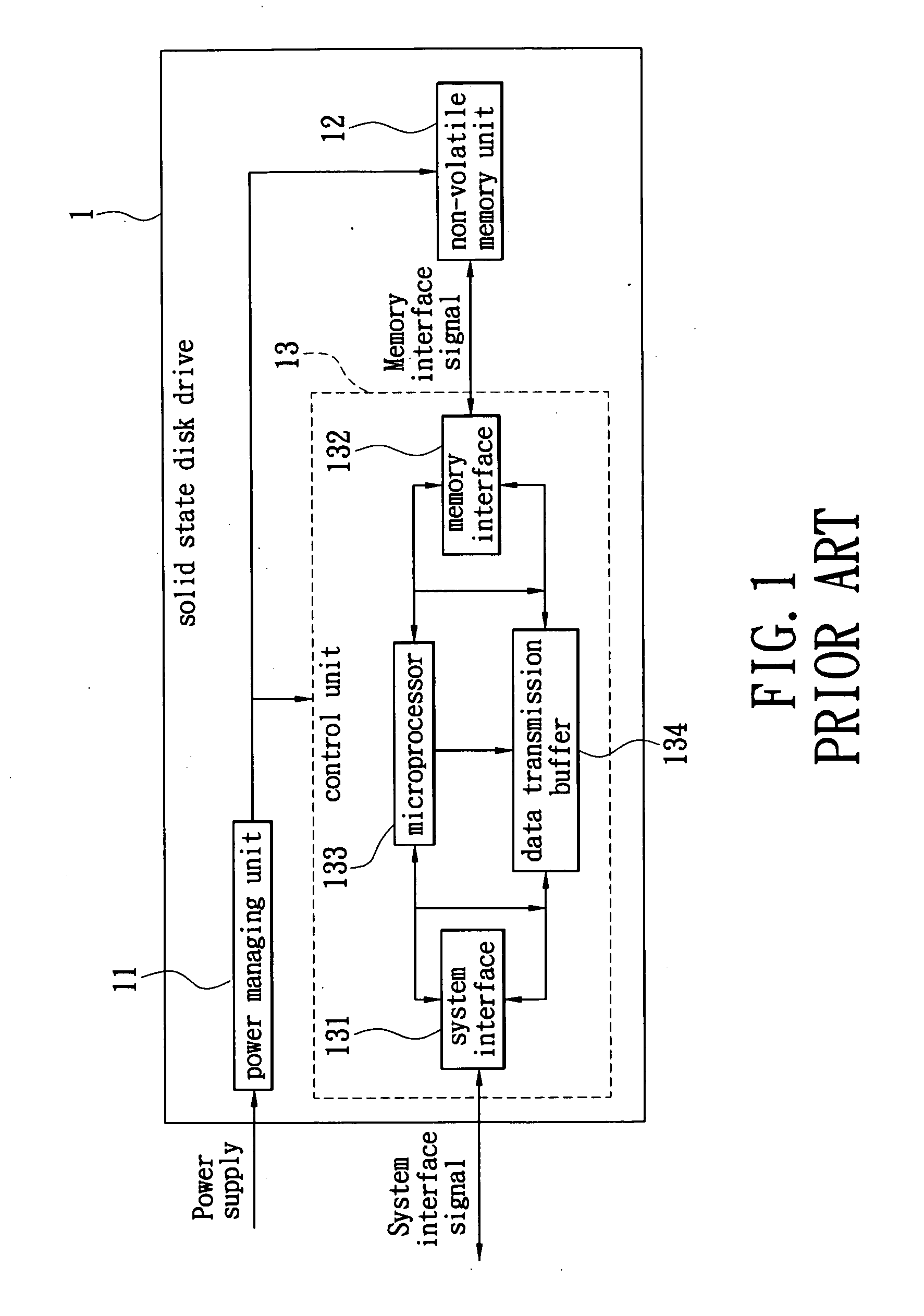

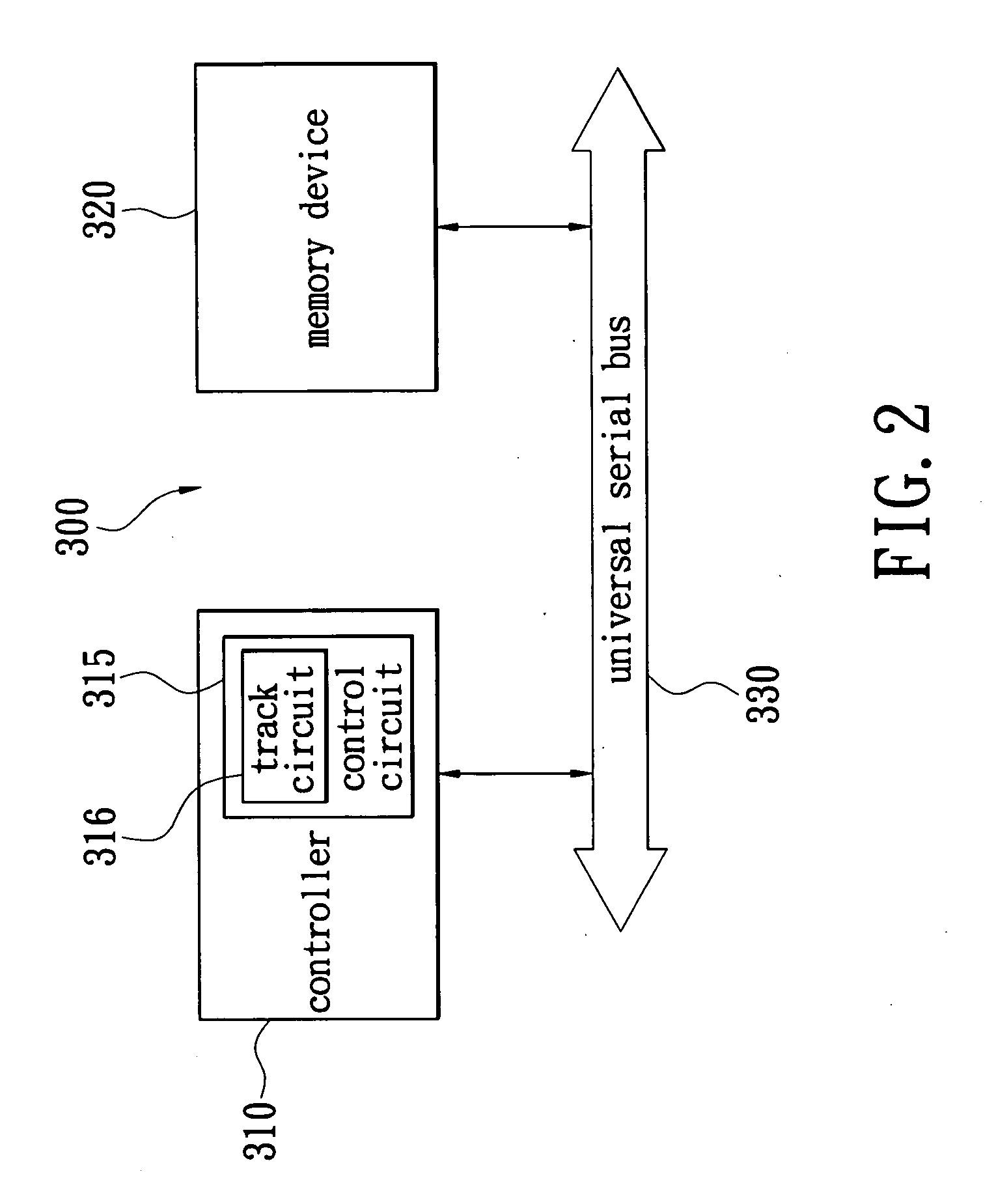

Solid state semiconductor storage device with temperature control function, application system thereof and control element thereof

ActiveUS20090091996A1Effective temperature controlDigital storageTemperature controlSemiconductor storage devices

A solid state semiconductor storage device with temperature control function comprises a non-volatile memory unit, a temperature sensing element, and a control unit. The temperature sensing element is used for sensing the operation temperature of the solid state semiconductor storage device so as to provide a temperature sensing signal to the control unit. According to the temperature sensing signal, the control unit controls the operation mode of the solid state semiconductor storage device for achieving the function of temperature control.

Owner:ADATA

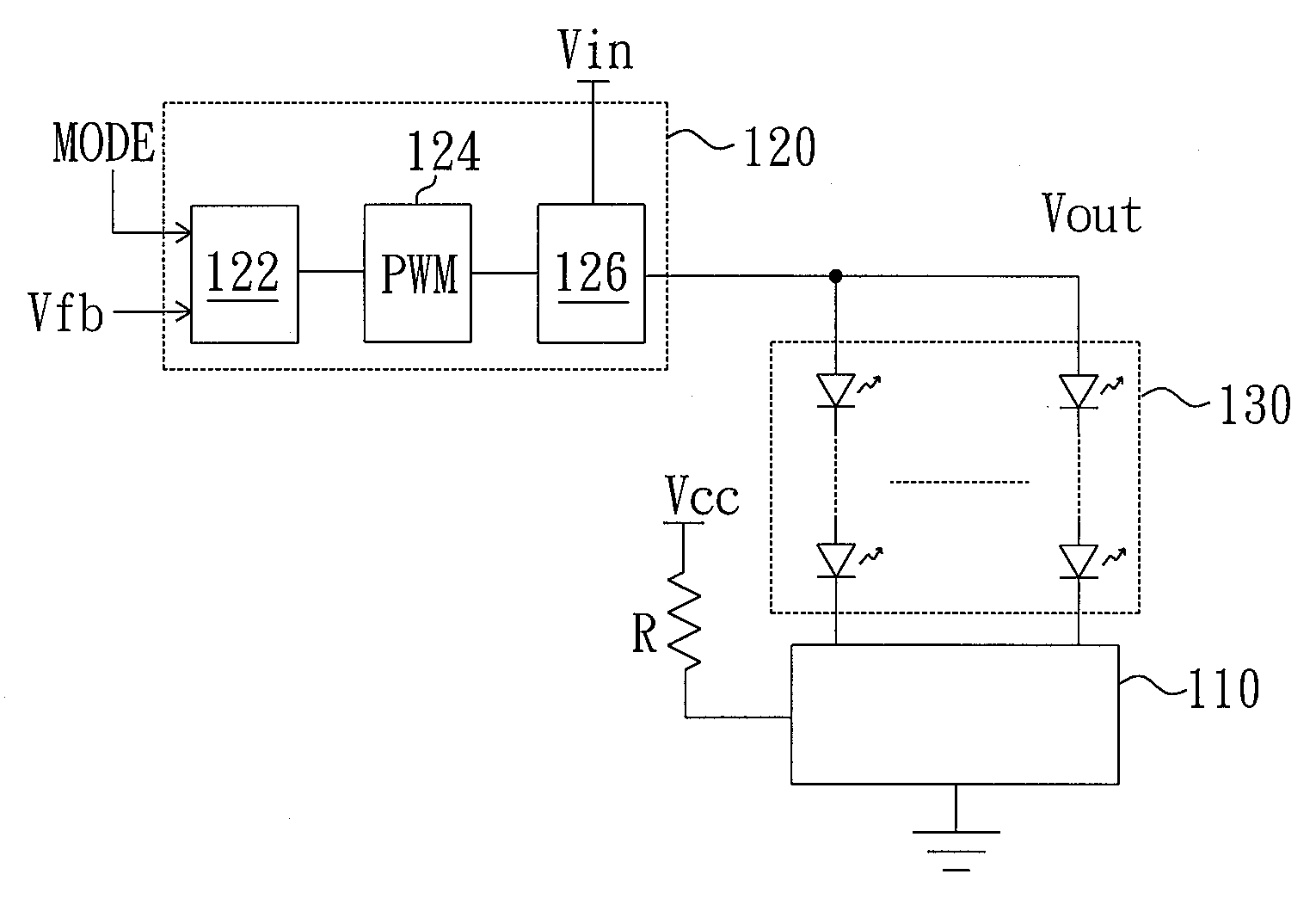

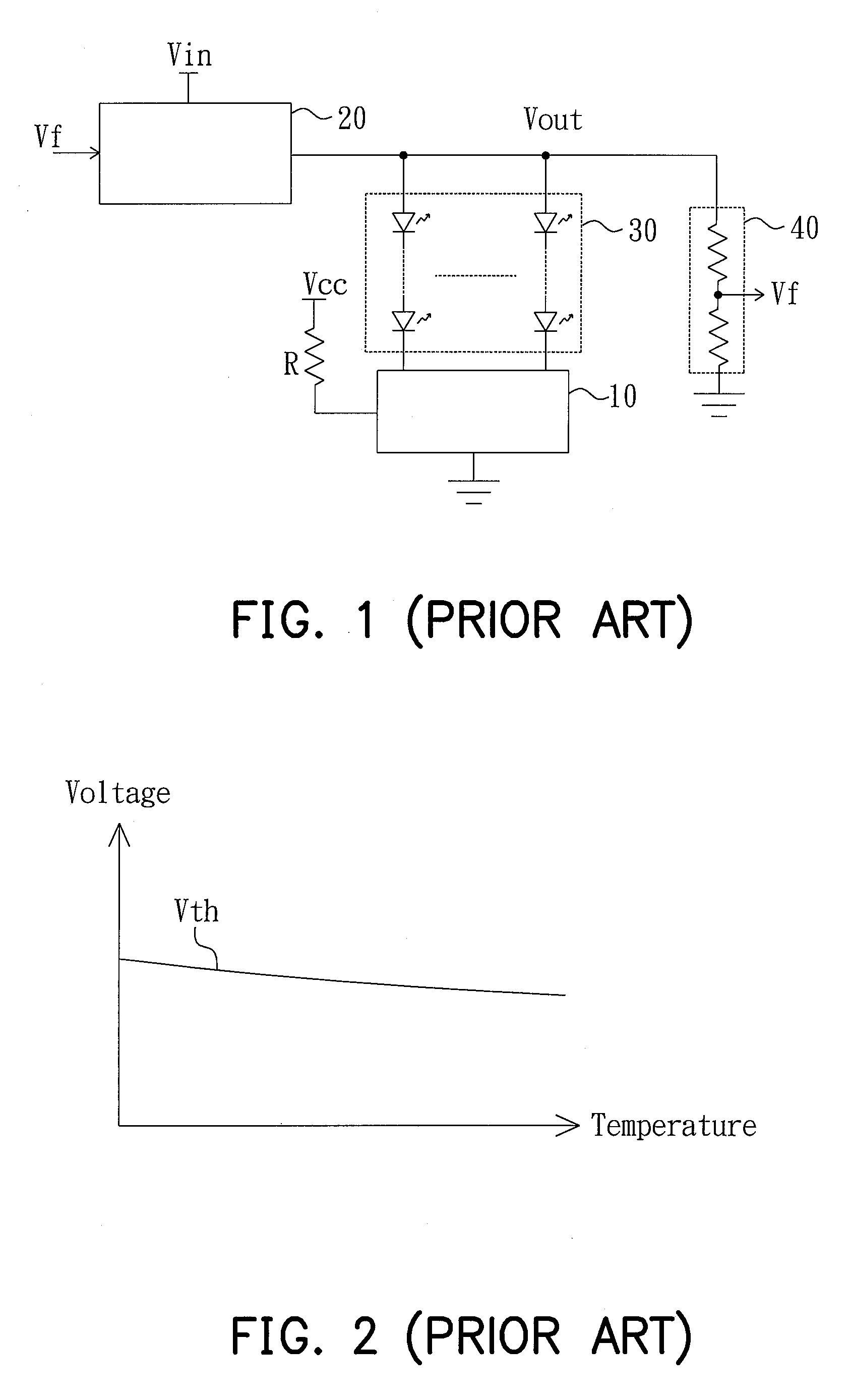

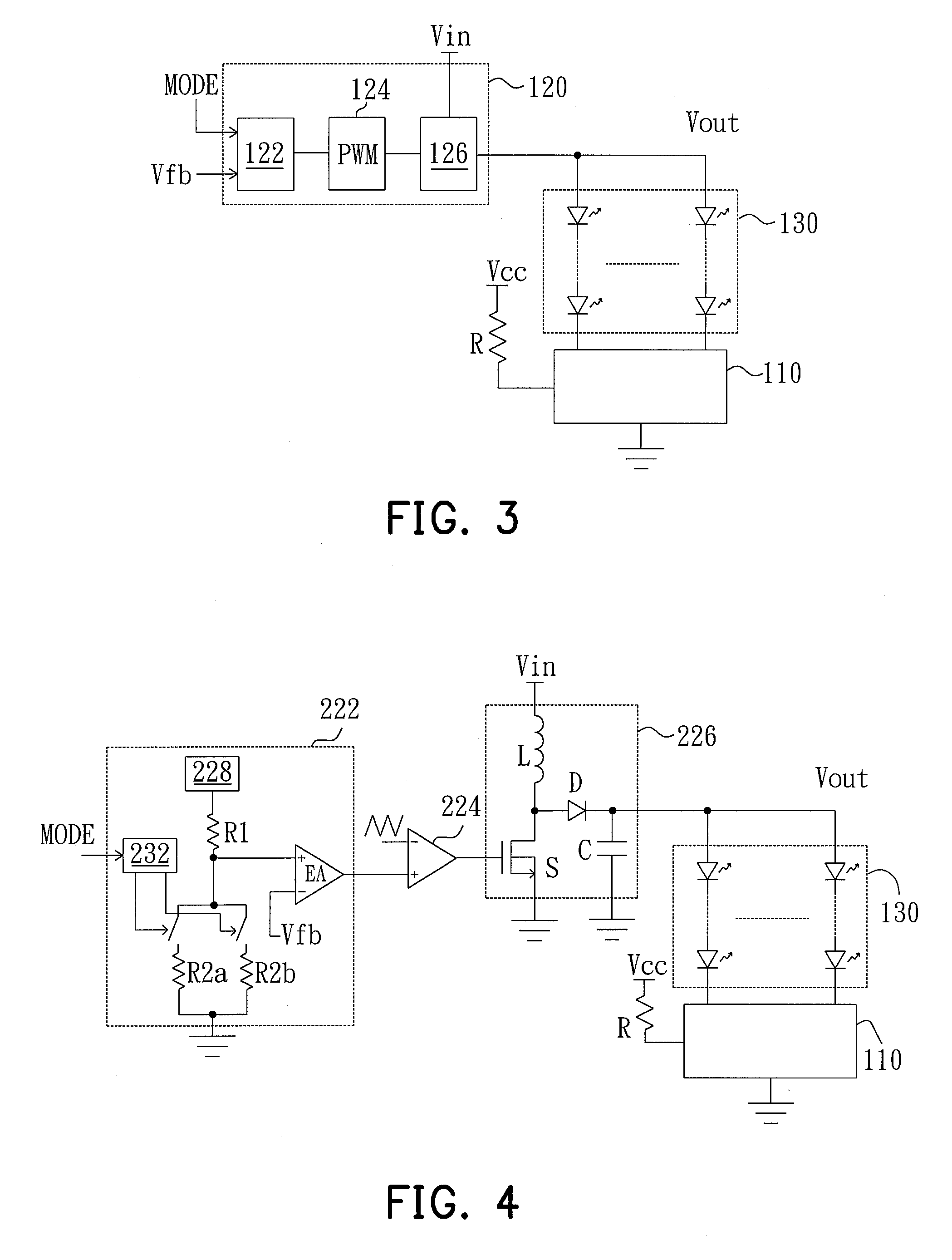

LED driving circuit and controller with temperature compensation thereof

InactiveUS20100141159A1Reduce output voltageIncrease working temperatureElectrical apparatusElectroluminescent light sourcesControl signalEngineering

The present invention provides an LED driving circuit with temperature compensation, comprising a power transforming circuit, an LED module and a controller. The transforming circuit receives an electrical power from an input power source and transforms it into an output voltage according to a control signal. The LED module is coupled to the transforming circuit. The controller generates the control signal according to an operation temperature and a voltage feedback signal indicative of the output voltage, and makes the output voltage decrease with increasing operation temperature. Therefore, the LED driving circuit of the present invention has an effect of temperature compensation that compensates the influence of the decreased driving voltage of the LED module due to temperature.

Owner:GREEN SOLUTION TECH CO LTD

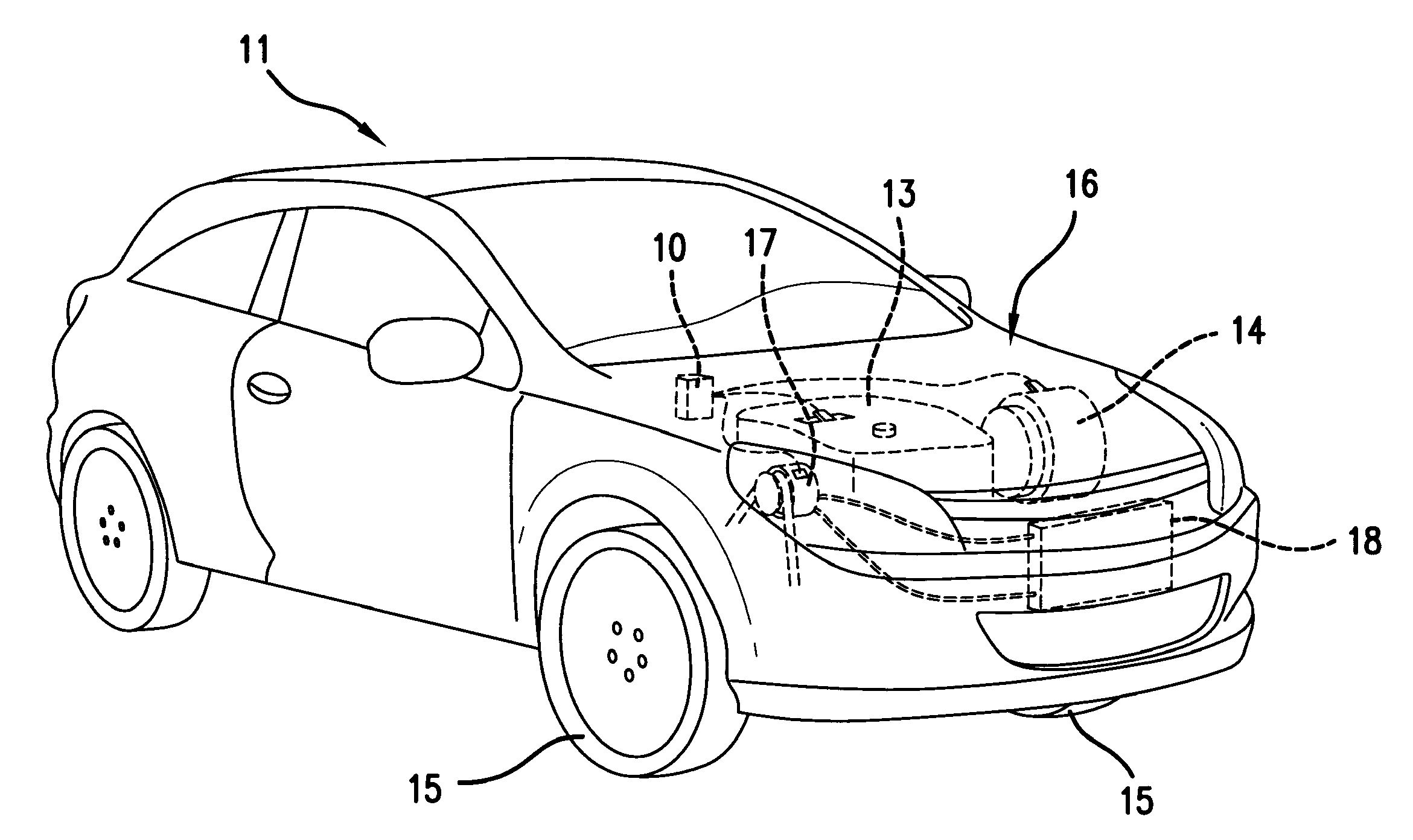

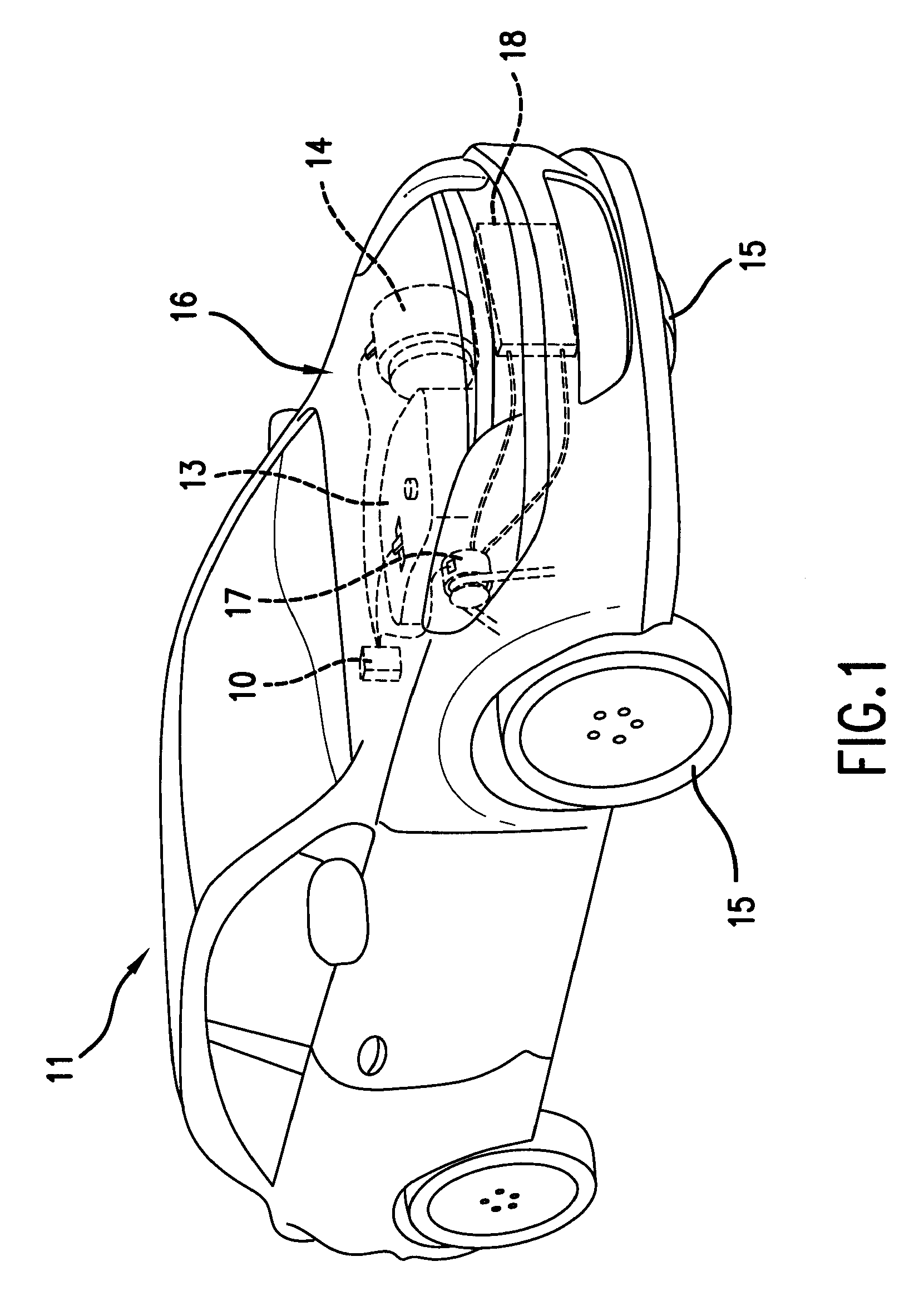

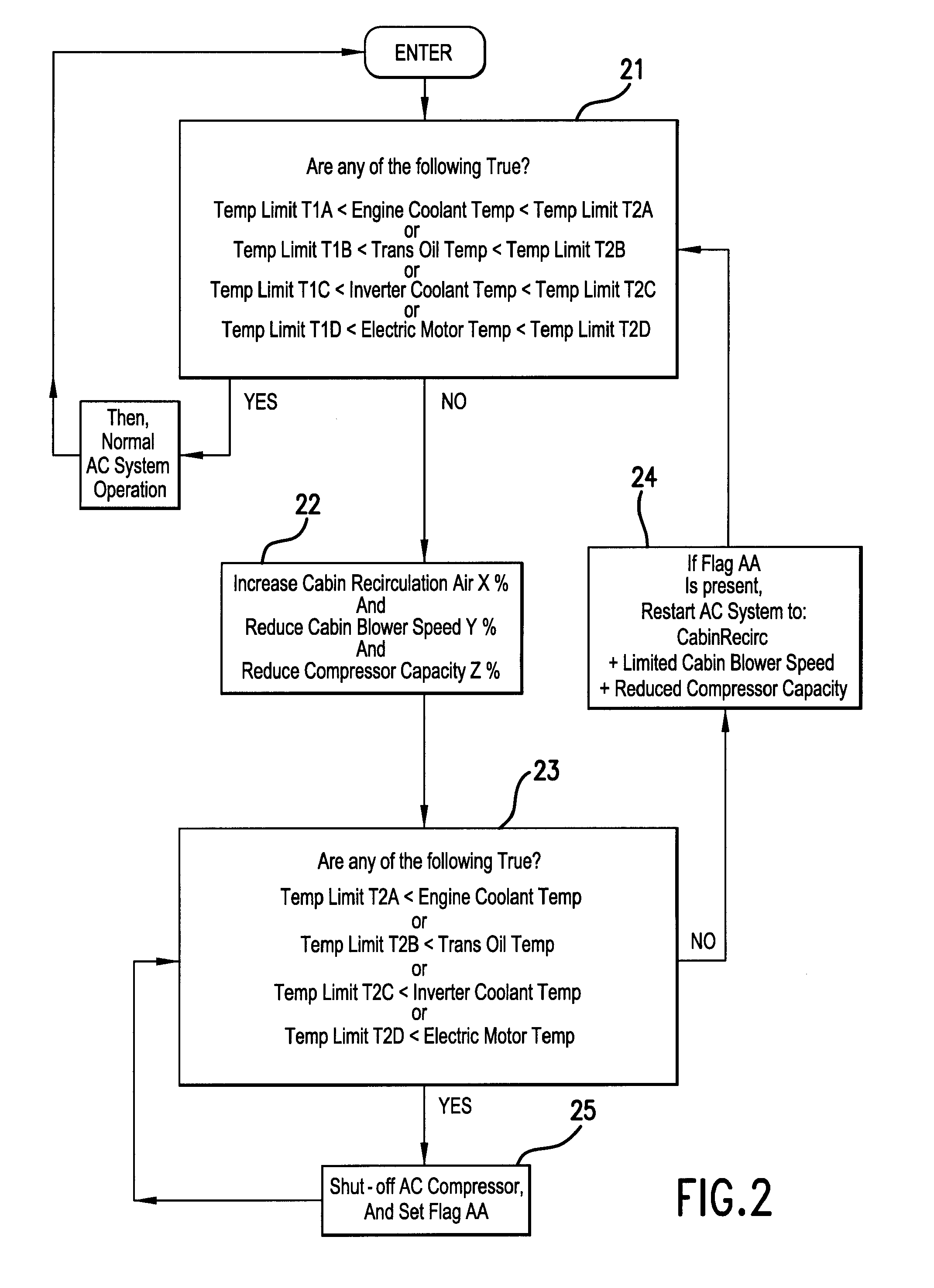

Methods of Optimizing Vehicular Air Conditioning Control Systems

InactiveUS20080034767A1Reduction in propulsion cooling system sizeReduce heat loadCompression machines with non-reversible cycleVehicle heating/cooling devicesElectric driveOperating temperature

Air conditioning system controls are optimized for an air conditioning system having a compressor in IC engine vehicles and in hybrid or fuel cell vehicles having electric drive motors by first determining the operating temperature of at least one of the following vehicle components: engine coolant and transmission oil for all types of vehicles, and for hybrid or fuel cell vehicles also determining the operating temperature of inverter coolant and the electric drive motors. At least one operating temperature is then compared to lower and upper temperature limits. If the operating temperature is outside of the temperature limits air conditioner heat load is reduced by at least one of the following steps: increasing cabin air recirculation, reducing cabin blower speed and reducing air conditioner compressor capacity. Subsequent to reducing air conditioner heat load, selected operating temperature or temperatures are monitored to determine if the operating temperature exceeds the upper temperature limit or limits. If the operating temperature or temperatures exceed the upper limit or limits the compressor is shut off.

Owner:GM GLOBAL TECH OPERATIONS LLC

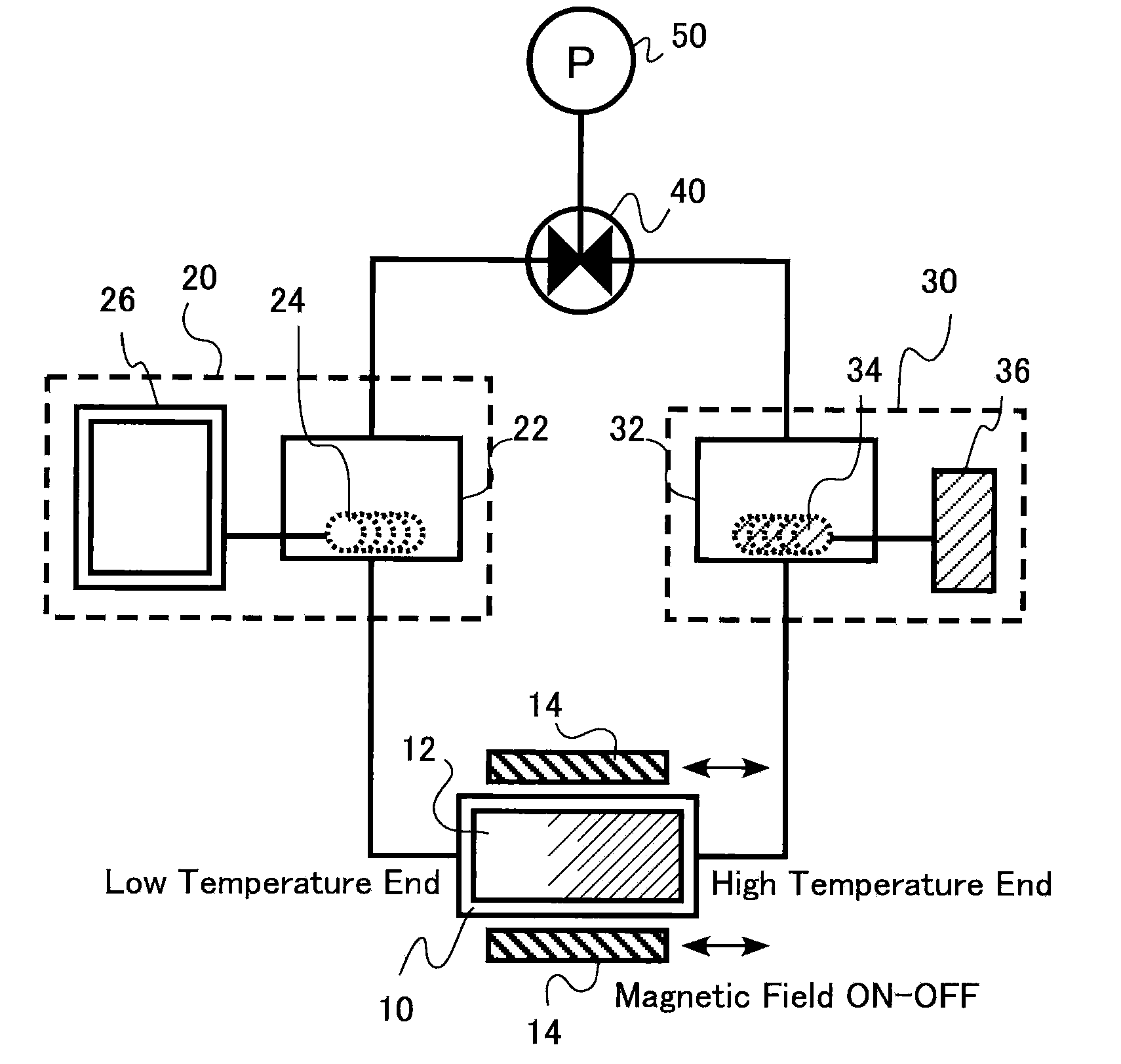

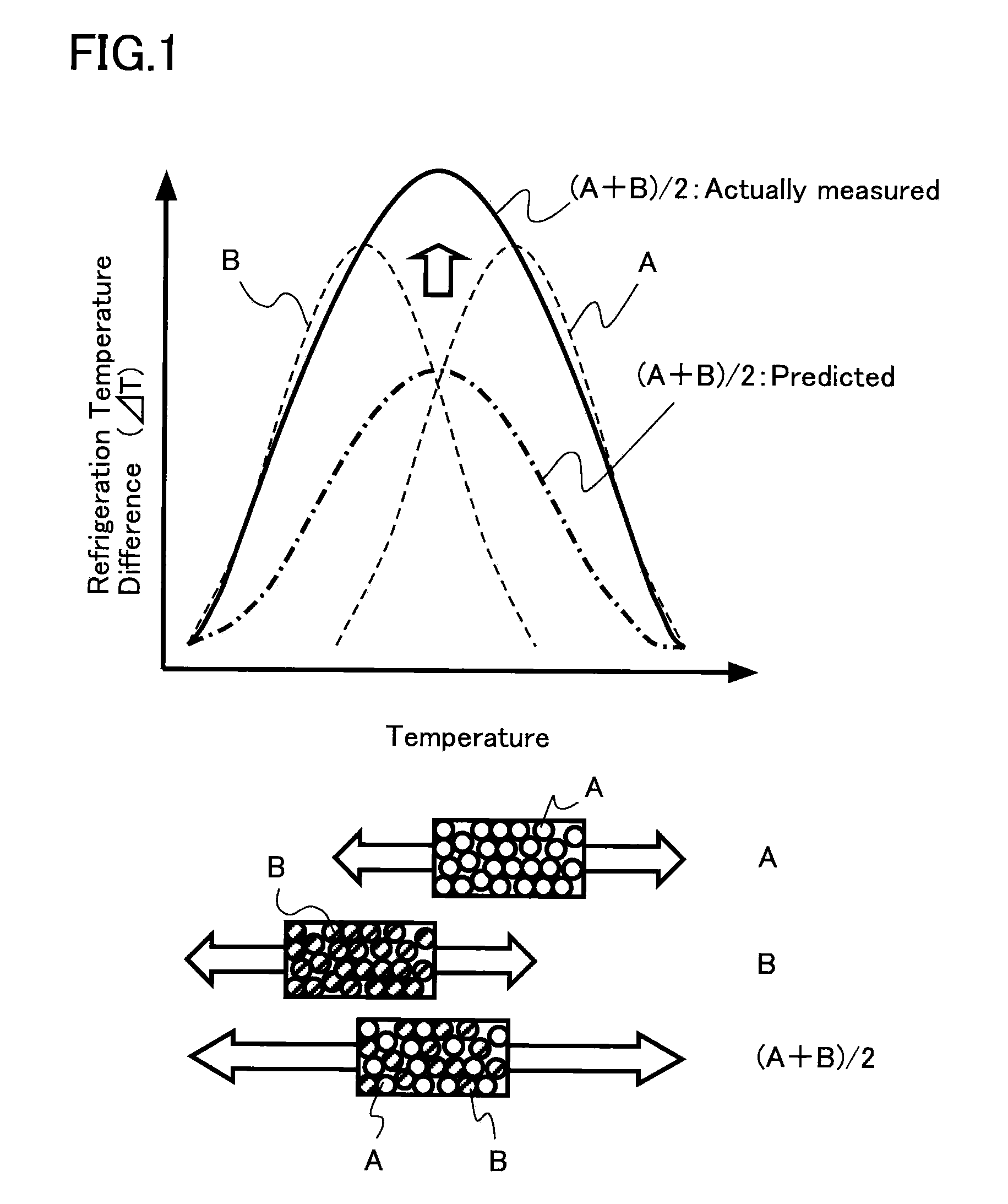

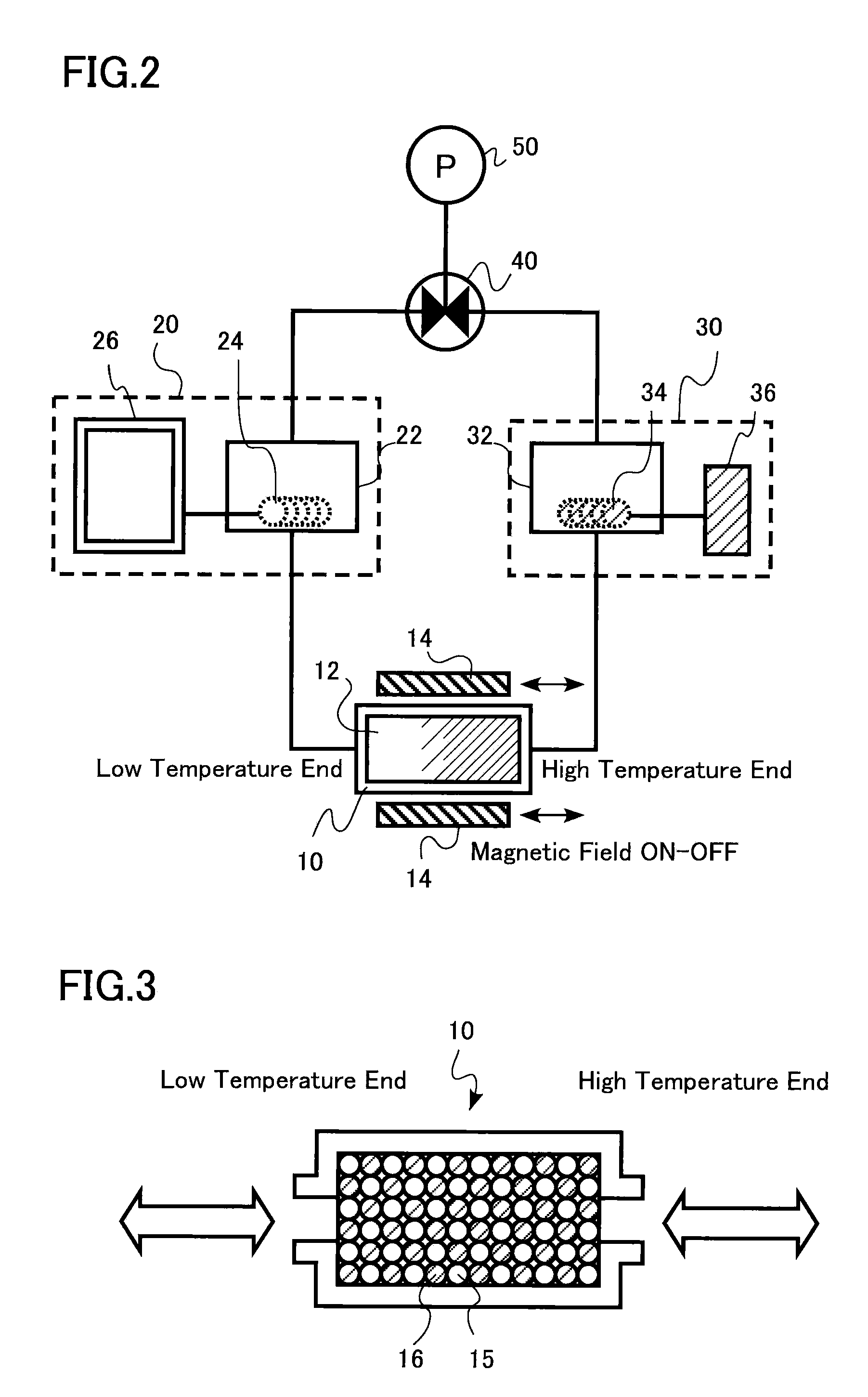

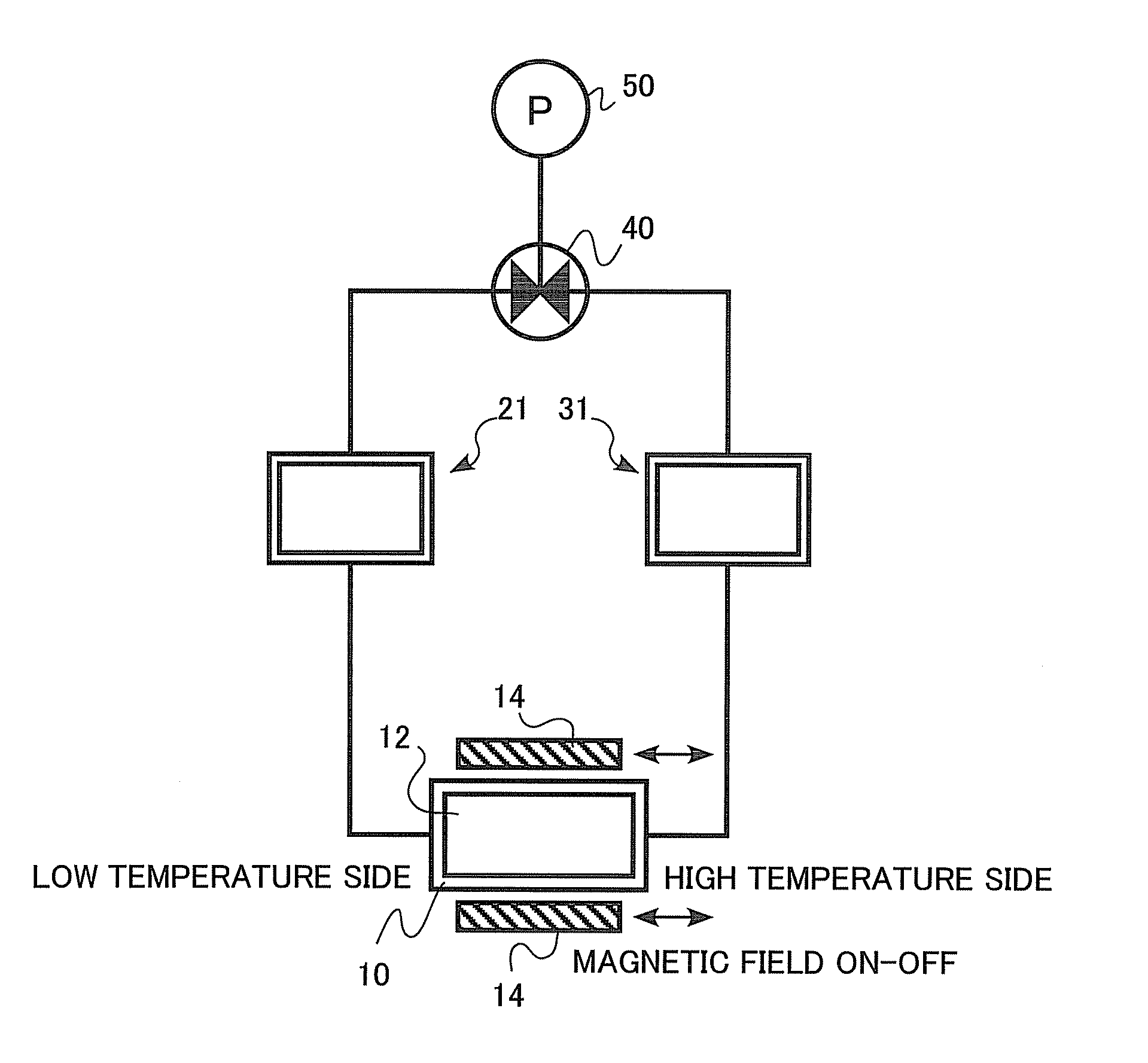

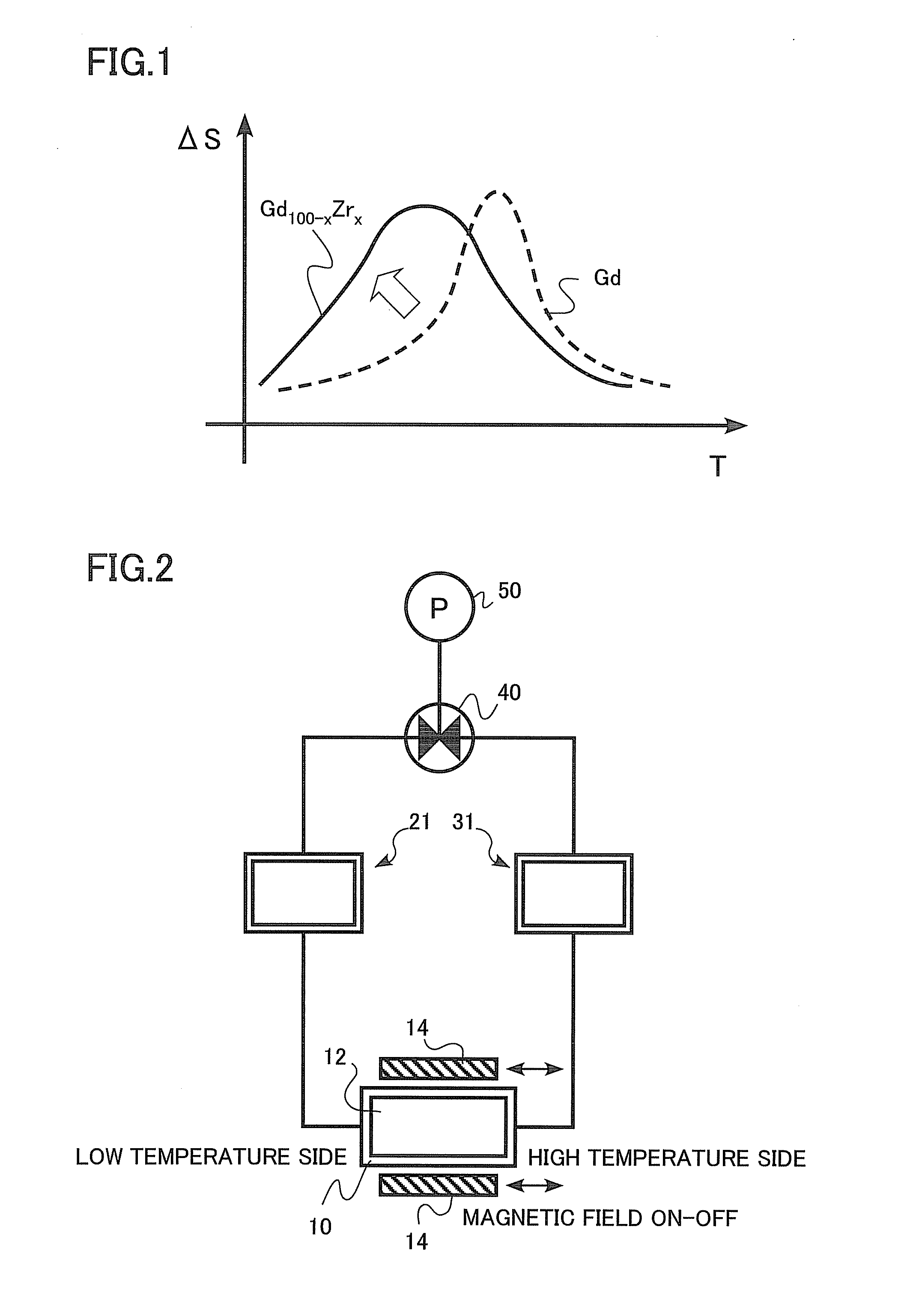

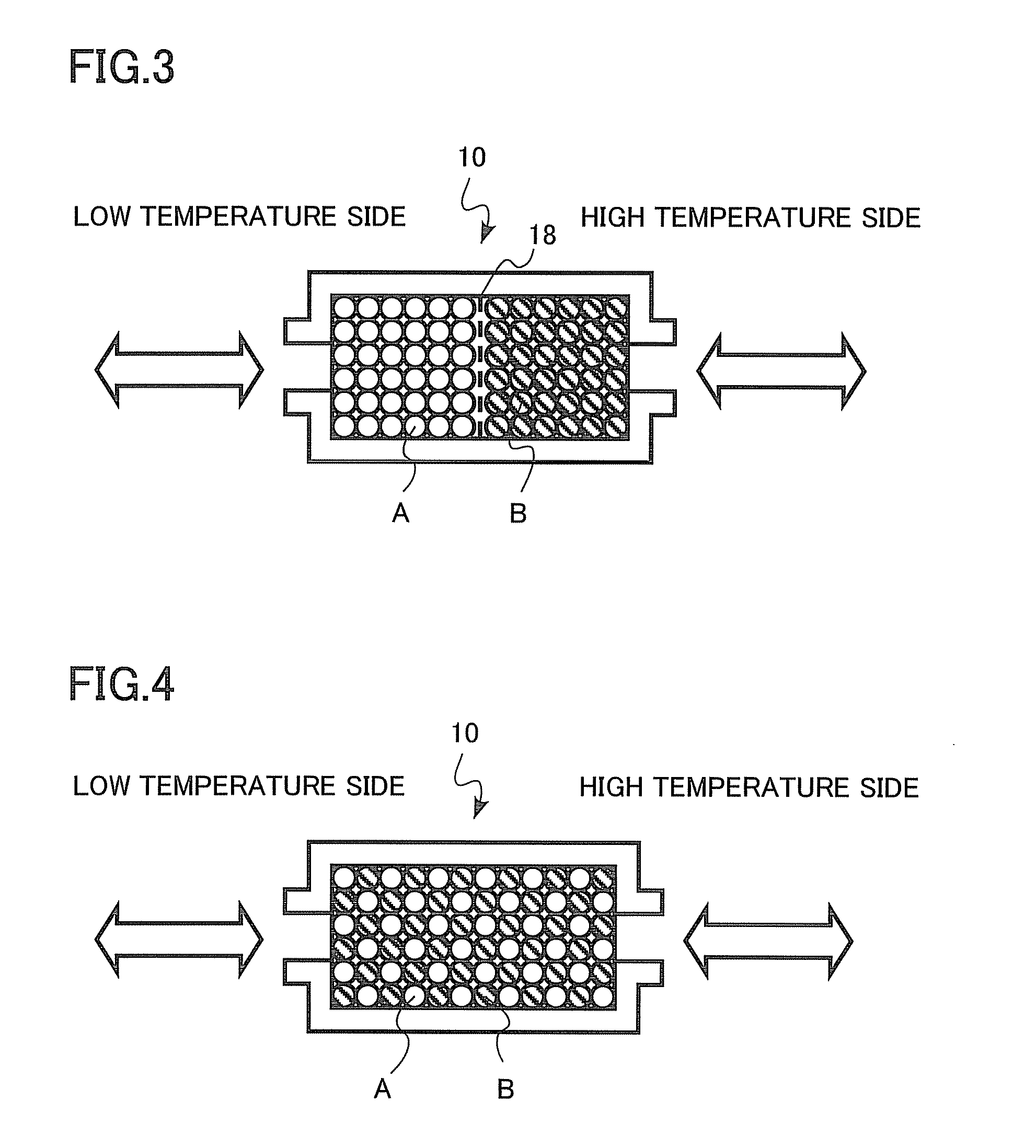

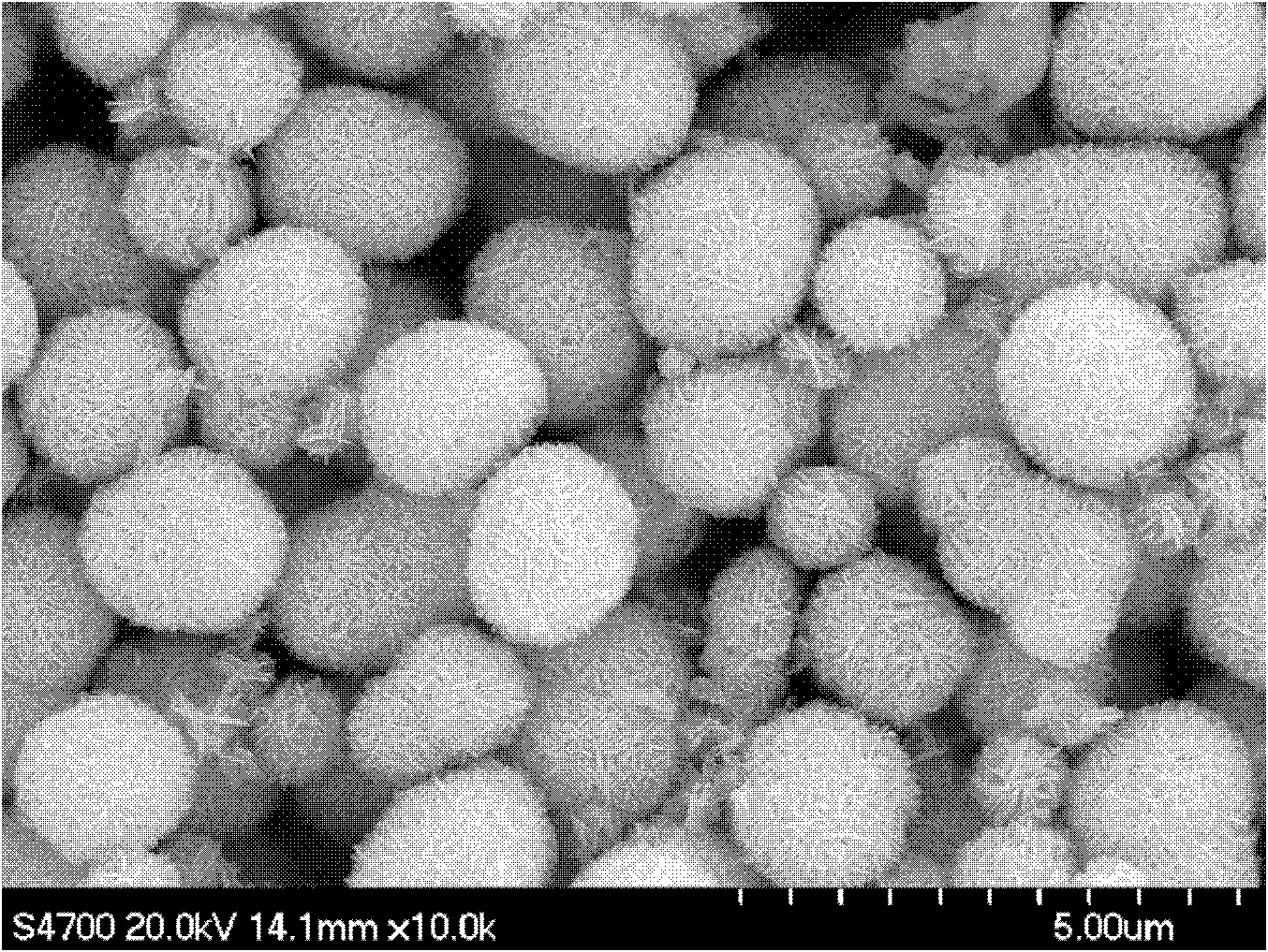

Magnetic material for magnetic refrigeration apparatus, amr bed, and magnetic refrigeration apparatus

InactiveUS20090217674A1Improve cooling efficiencyWide operationEnergy efficient heating/coolingMachines using electric/magnetic effectsMagnetic transitionsMaximum diameter

There are provided a magnetic material for a magnetic refrigeration apparatus, which improves magnetic refrigeration efficiency by the wide operation temperature range of it, AMR bed using the magnetic material, and a magnetic refrigeration apparatus. The magnetic material is used for the magnetic refrigeration apparatus using a liquid refrigerant, formed by approximately uniformly blending at least two kinds of magnetic particles having different magnetic transition temperatures, and the magnetic particles exhibit an approximately spherical shape with maximum diameter of 0.3 mm or more to 2 mm or less. The AMR bed is filled with the magnetic particles.

Owner:KK TOSHIBA

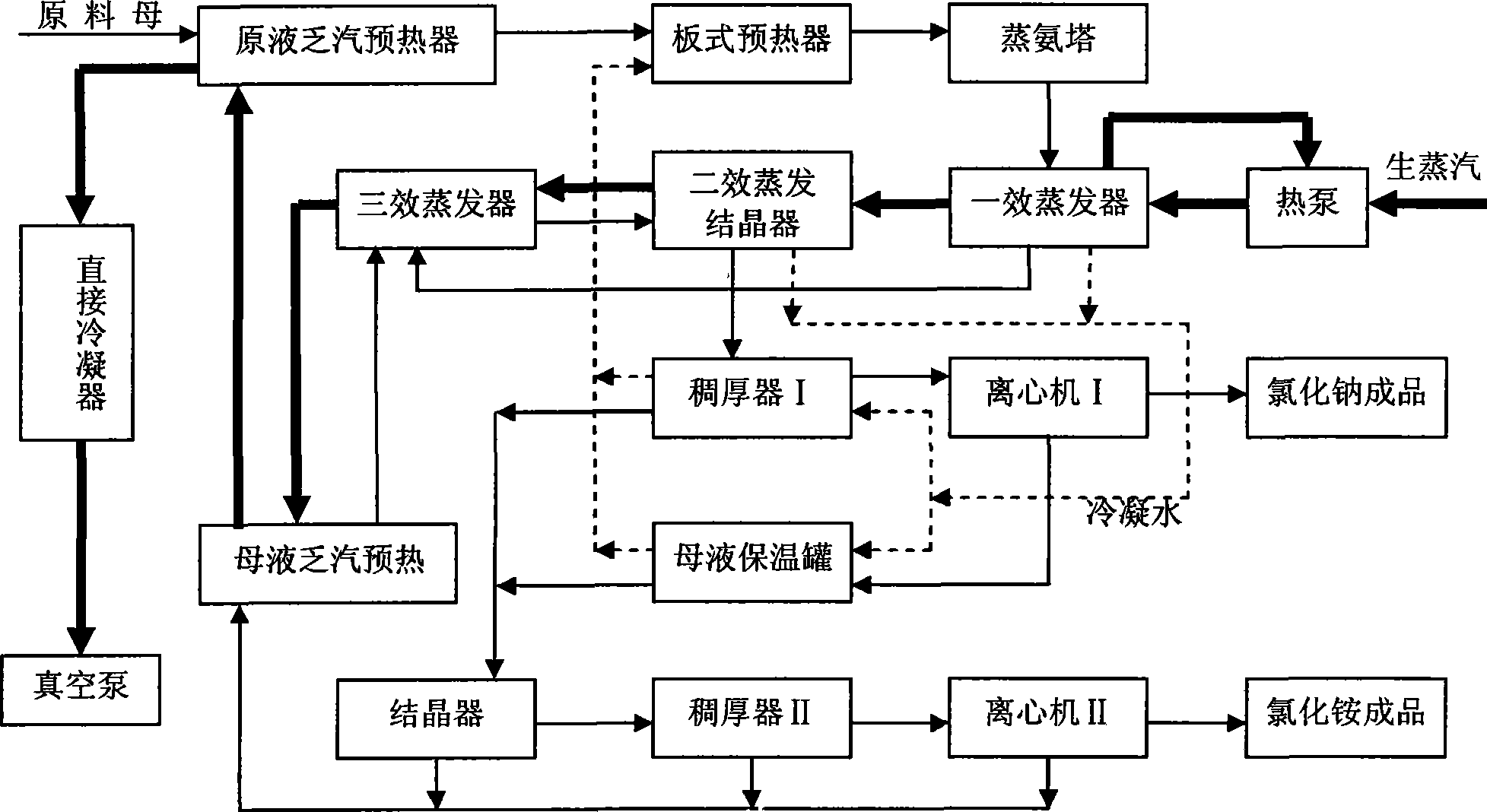

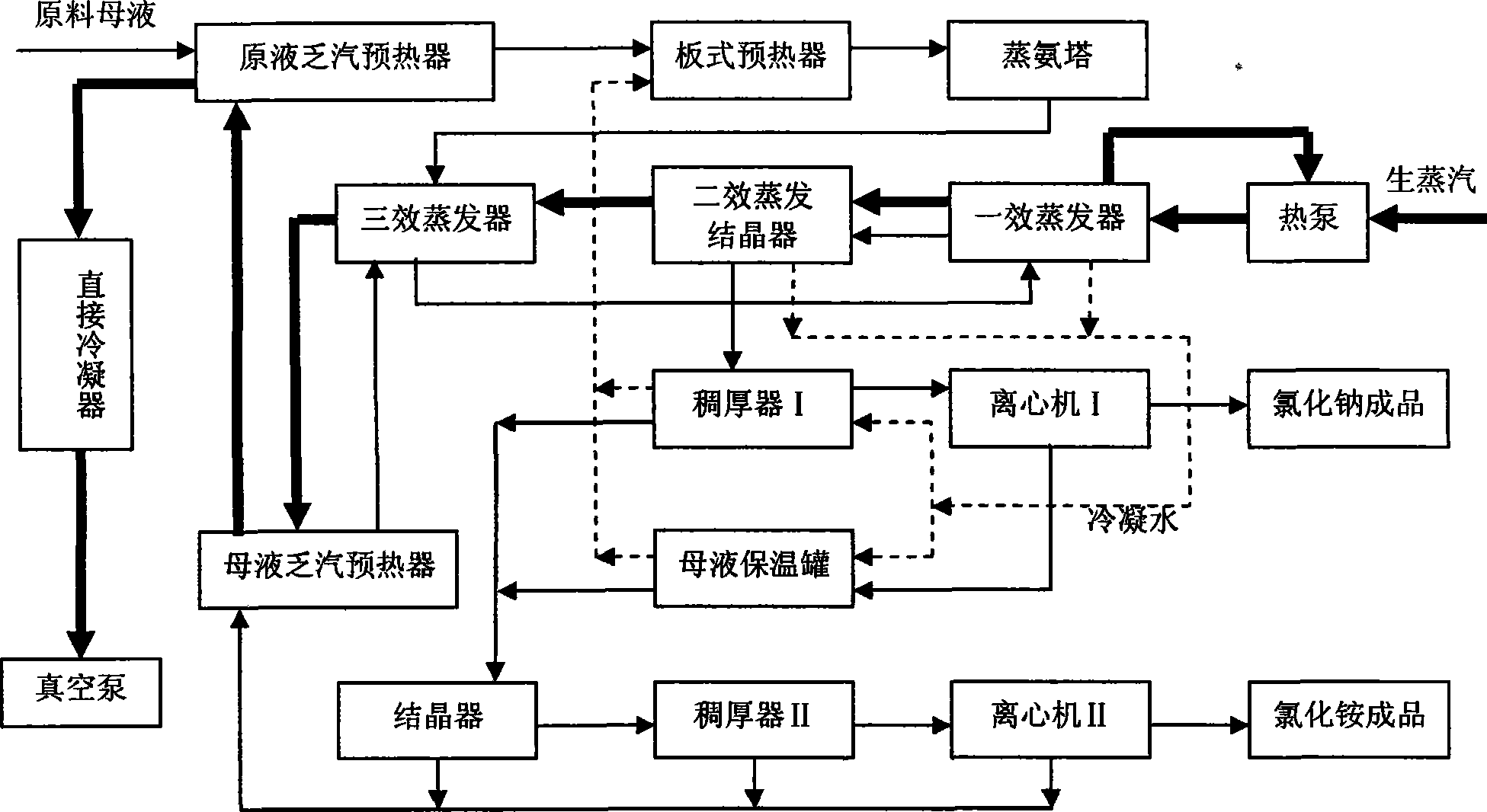

Process method for recovering ammonium chloride and sodium chloride from waste water containing ammonium chloride and sodium chloride

InactiveCN101544437AFully recycleReduce energy consumptionEnergy inputSolution crystallizationSodium bicarbonateDecomposition

The invention relates to a process method for recovering ammonium chloride and sodium chloride from waste water containing the ammonium chloride and the sodium chloride, which produces the ammonium chloride and the sodium chloride by using mother solution which is generated in a process for producing sodium bicarbonate by natural bittern double decomposition reaction and contains the ammonium chloride and the sodium chloride as raw materials. The method adopts ammonium still, evaporation, crystallization and separation process to treat, wherein the evaporation adopts multiple-effect, a heat pump and a vacuum evaporation process, and selects a falling film evaporator and a forced circulation type evaporator to perform triple-effect mixed-flow procedure, so that sodium chloride is crystallized and separated in the evaporation; and the ammonium chloride is crystallized and separated by cooling after the evaporation. The method effectively reduces the operation temperature of the equipment, can repeatedly use secondary steam and condensed water, reduces erosion of the ammonium chloride solution to the equipment, saves the energy, reduces the cost, improves the production efficiency, and reduces environmental pollution.

Owner:HEBEI UNIV OF TECH +1

Magnetically refrigerating magnetic material, magnetic refrigeration apparatus, and magnetic refrigeration system

ActiveUS20100058775A1Energy efficient heating/coolingMachines using electric/magnetic effectsMaximum diameterEngineering

There are provided a magnetic material for magnetic refrigeration improving a magnetic refrigeration efficiency by including a wide operation temperature range and a magnetic refrigeration apparatus and a magnetic refrigeration system using the magnetic material. The magnetically refrigerating magnetic material is formed of a magnetic material shown by a composition formula of Gd100-x-yZrxYy, wherein 0<x<3.4 as well as 0≦y≦13.5, and the magnetic refrigeration apparatus and the magnetic refrigeration system uses the magnetic material.It is preferable that the magnetic material be approximately spherical magnetic particles having a maximum diameter of 0.3 mm or more to 2 mm or less.

Owner:KK TOSHIBA

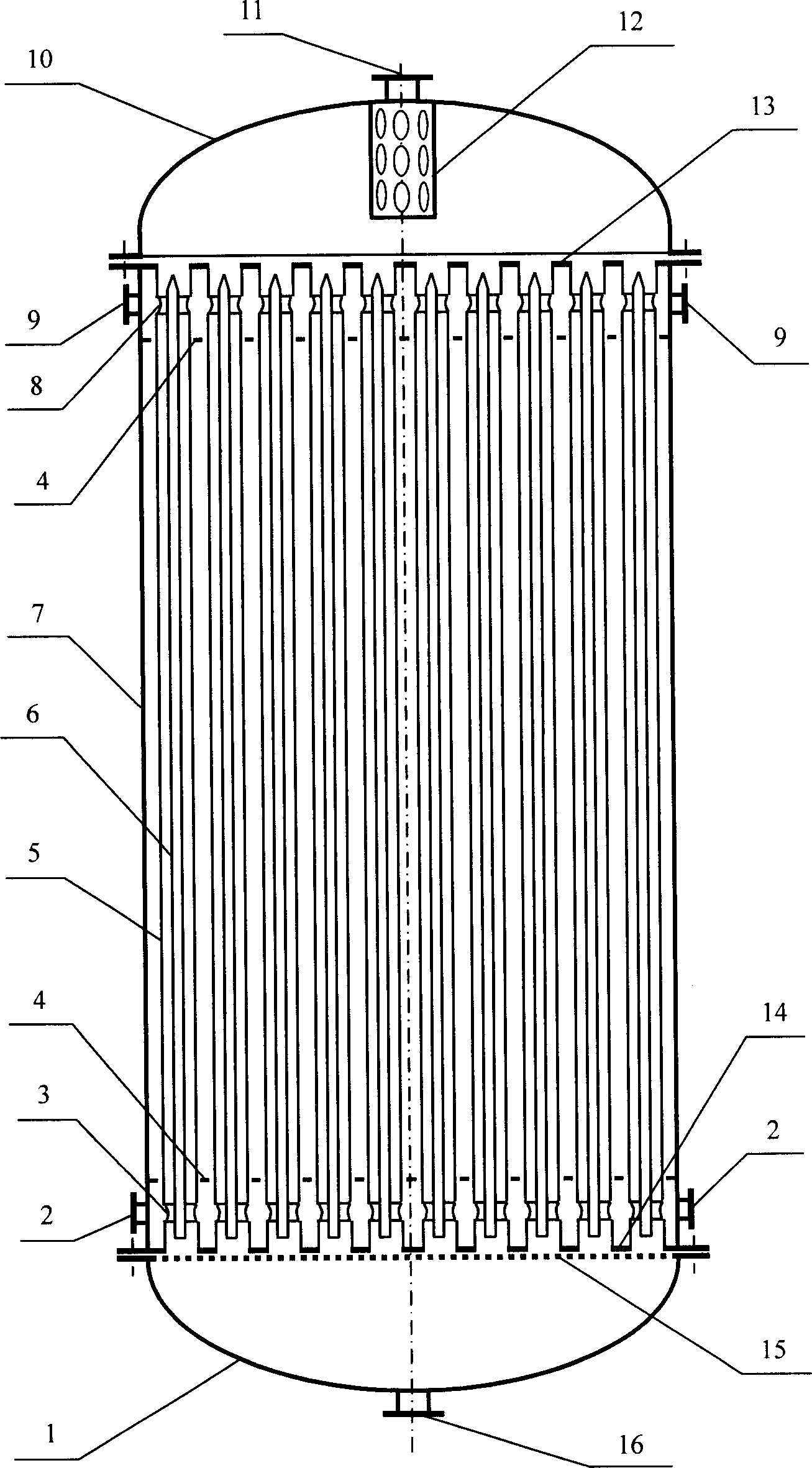

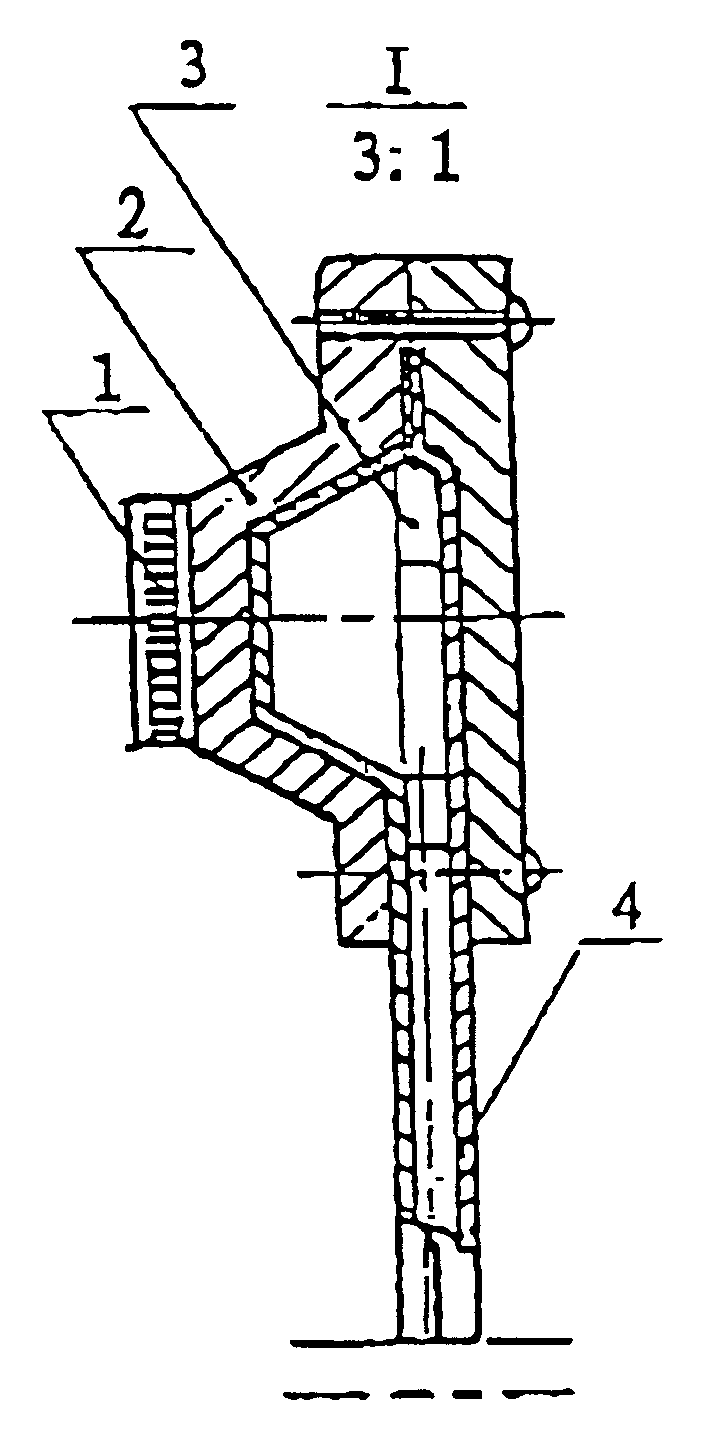

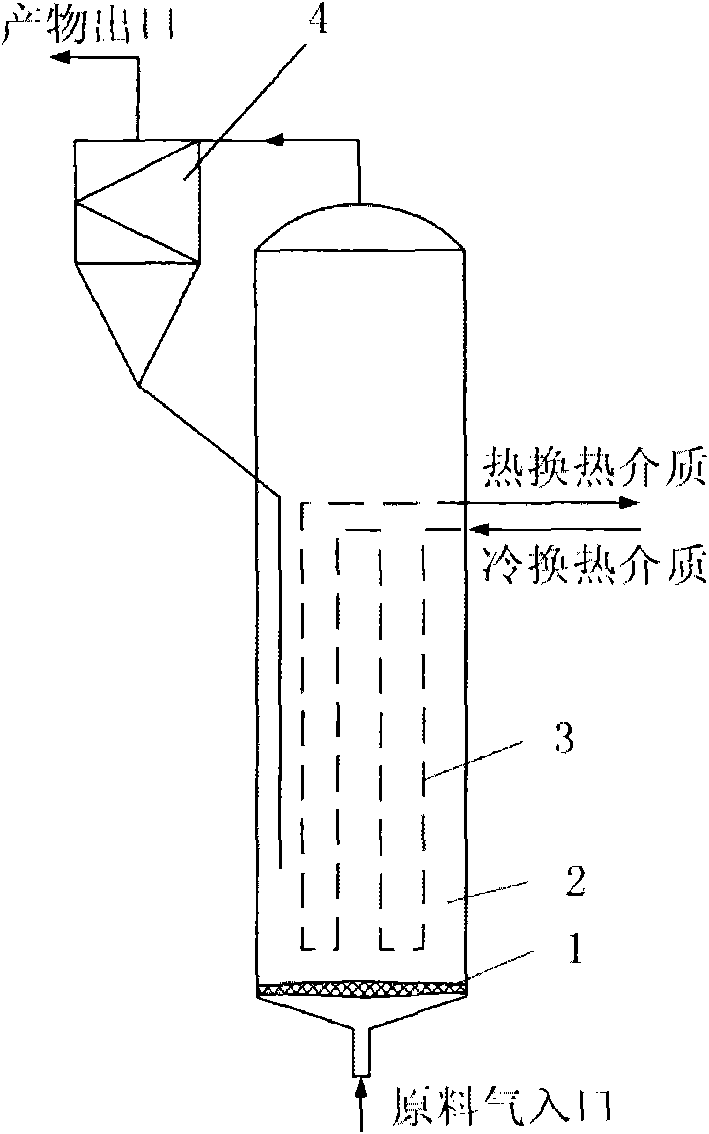

Non-hot spot calandria type fixed bed reactors

InactiveCN1736574AIncrease the heat exchange areaIncrease heat transfer areaChemical/physical processesReaction rateDiameter ratio

Disclosed is a non- thermal point tubular fixed bed reactor, which is technically characterized in that: every tube of the reactor adopts annular tube structure, the inner tubes being closed, the inner tube and outer tube being linked to the shell side of the reactor by canal, the catalyst being filled into the space between tubes to form a catalyst bed layer, the bottom and top of the tubes being equipped with a cooling medium distributing plate. The diameter ratio of the inner tube to outer tube can be regulated according to the reaction rate and the operation temperature to make the reaction heat transfer to the double- side. Dimension of opening of the cooling medium distributing plate and dimension of the opening of the side- wall of double terminals of inner tube can be regulated to control the distribution of cooling medium between inner tube and the shell side of reactor. With the invention, in the condition of no increasing the number of tubes largely, it can increase the heat- exchange area of the tubular fixed bed reactor and decrease the heat- exchange route.

Owner:TSINGHUA UNIV

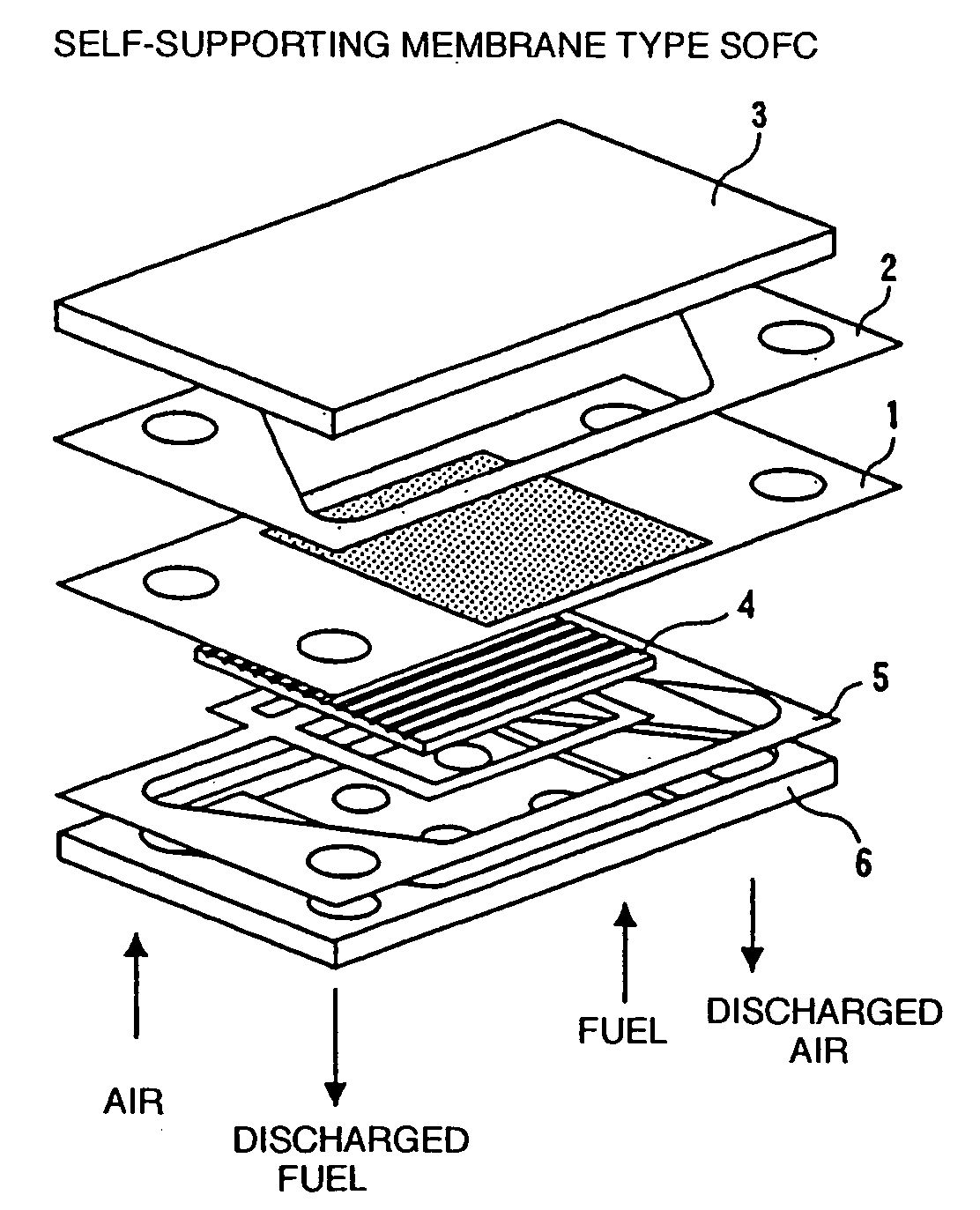

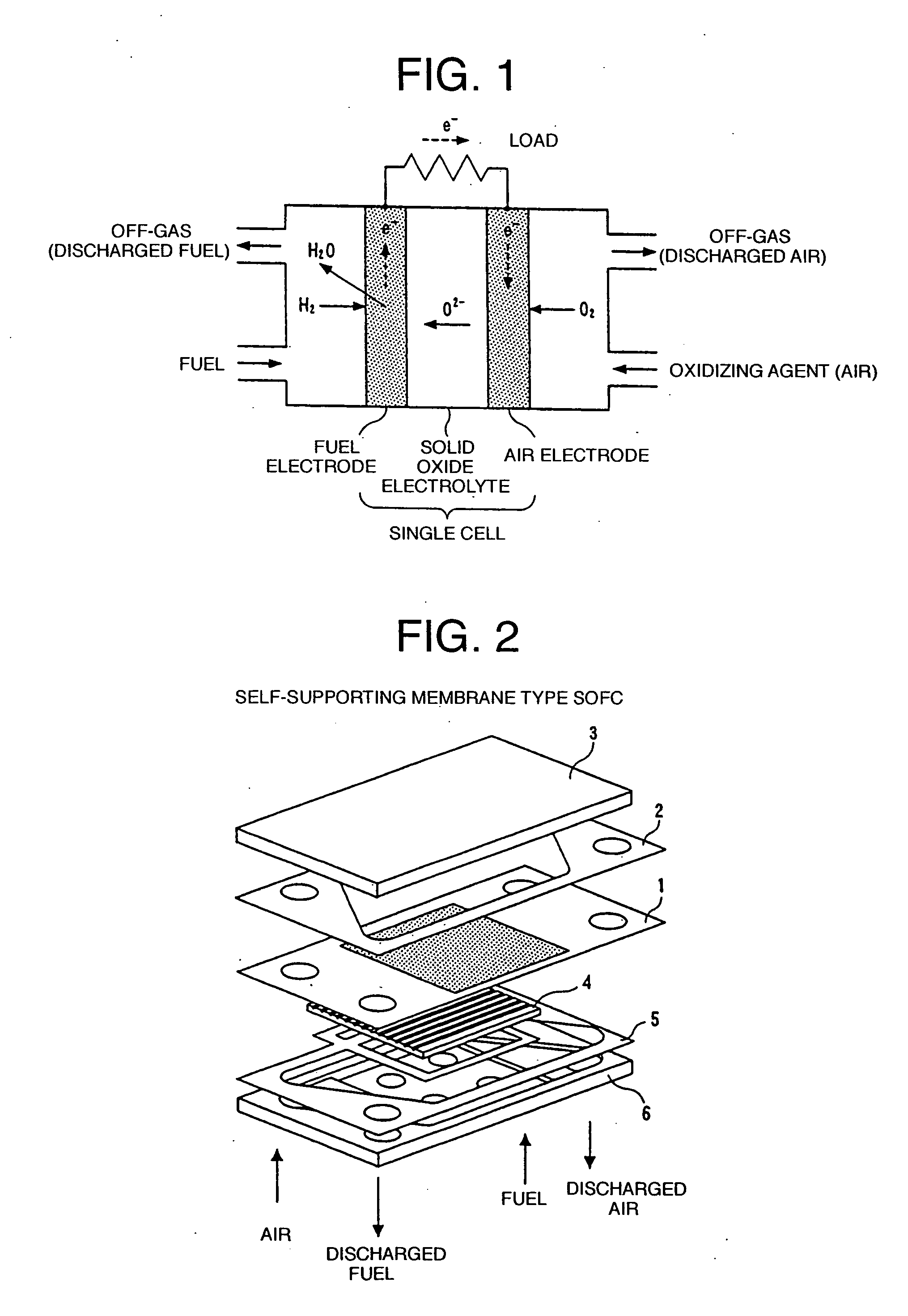

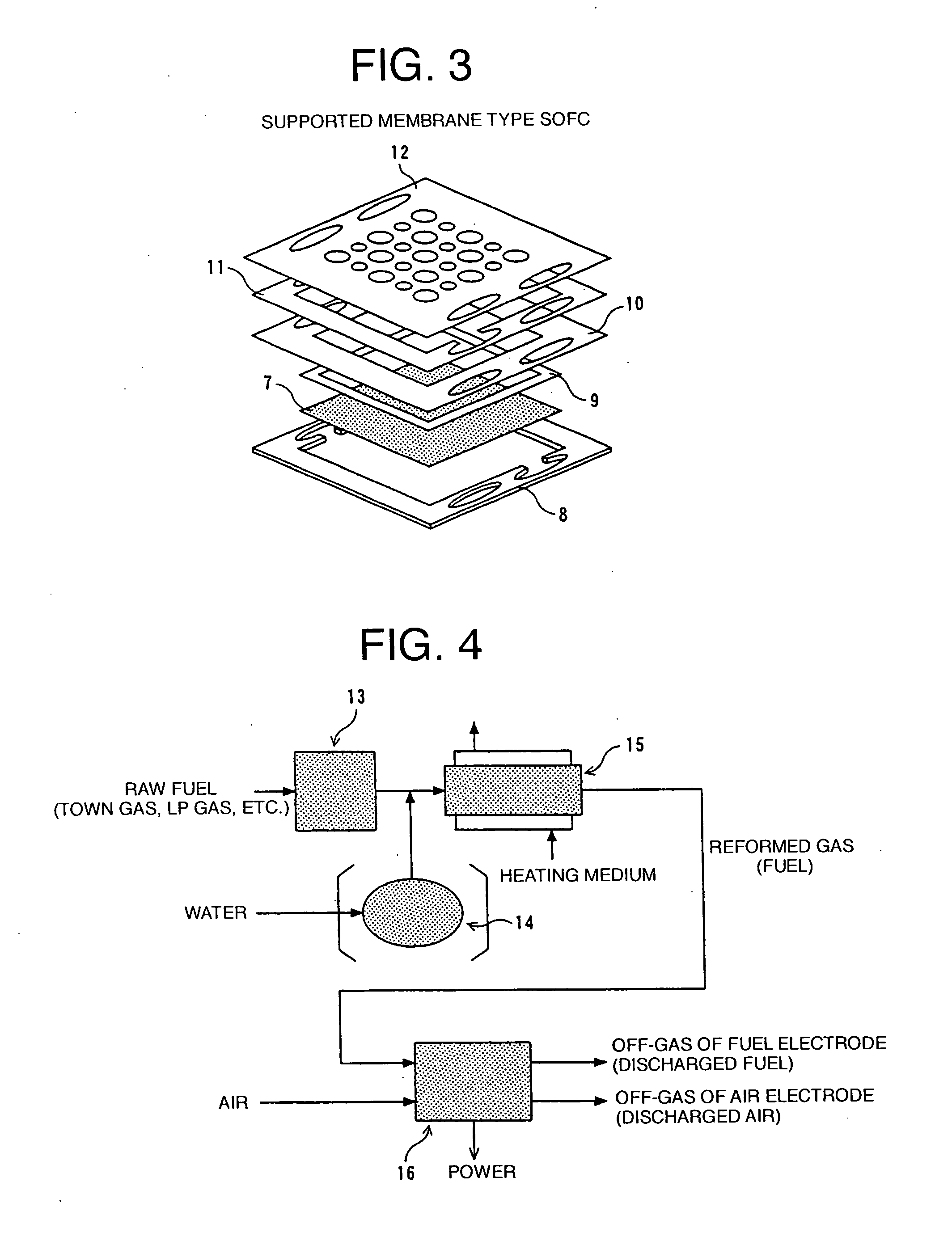

Solid oxide fuel cell system

There are provided a solid oxide fuel cell system comprising (a) a solid oxide fuel cell stack, (b) a preliminary reformer for removing hydrocarbons having two or more carbon atoms from a hydrocarbon fuel by converting the hydrocarbons having two or more carbon atoms into methane, hydrogen, and carbon monoxide, and (c) an integrated heat exchanger for catalytic combustion for heating either air or fuel, or both the air and fuel, to be guided to the solid oxide fuel cell stack, by use of a combustion gas formed by combusting discharged fuel with the use of discharged air, wherein component equipment described above are disposed in an adiabatic vessel and the integrated heat exchanger for catalytic combustion for use in the solid oxide fuel cell system. With the invention, an advantage of the preliminary reformer in combination with that of the integrated heat exchanger for catalytic combustion can be obtained, and heat loss of the SOFC system is eliminated or reduced as much as possible. In addition, with the integrated heat exchanger for catalytic combustion according to the invention, since air and / or fuel, to be fed to the SOFC stack, can be heated by controlling the maximum temperature achieved thereof, it is quite useful as an heat exchanger for an SOFC with operation temperature on the order of 850° C. or lower, particularly, for a supported membrane type SOFC, and further, the same is quite useful in making up an SOFC system because an inexpensive material can be used as a constituent material of a component equipment of the system, the system in whole can be reduced in size, and so forth.

Owner:TOKYO GAS CO LTD

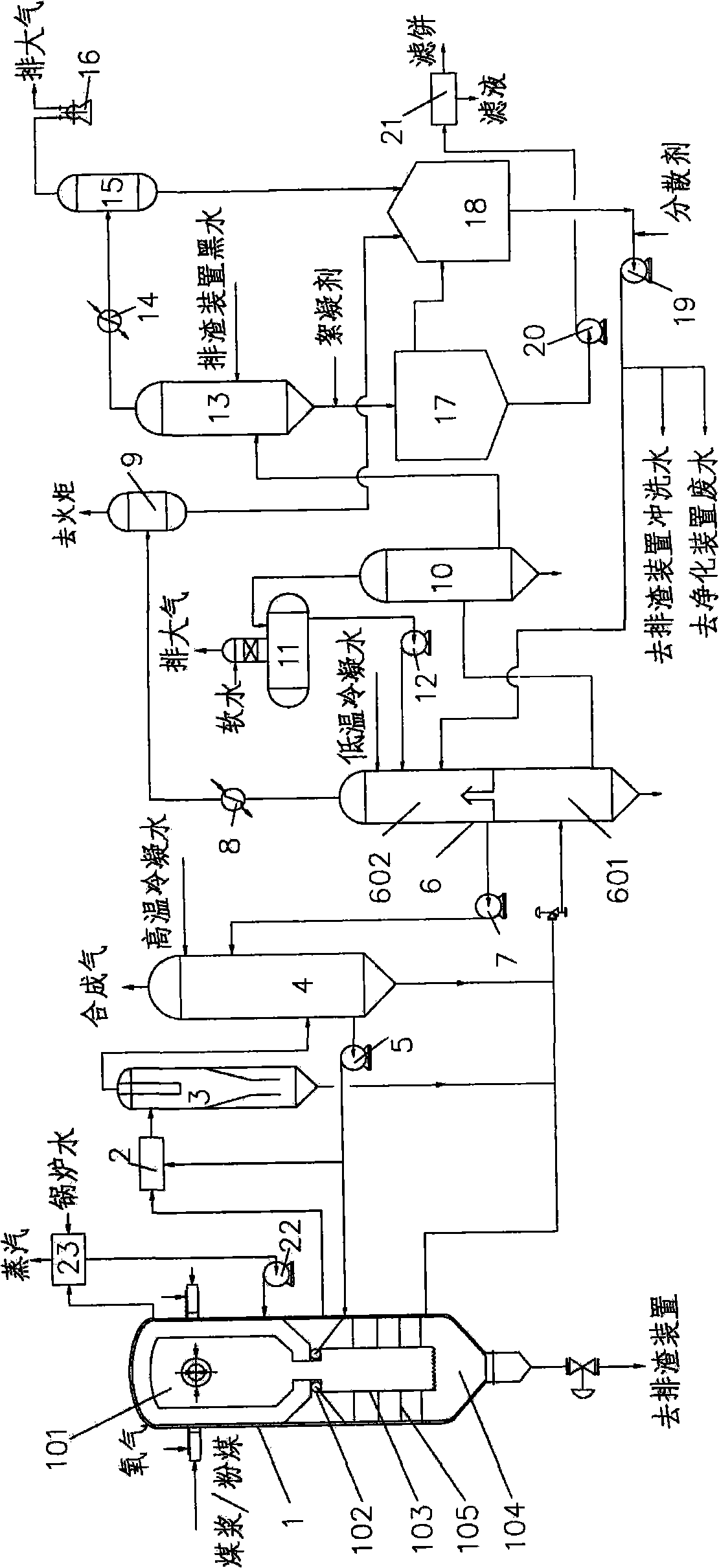

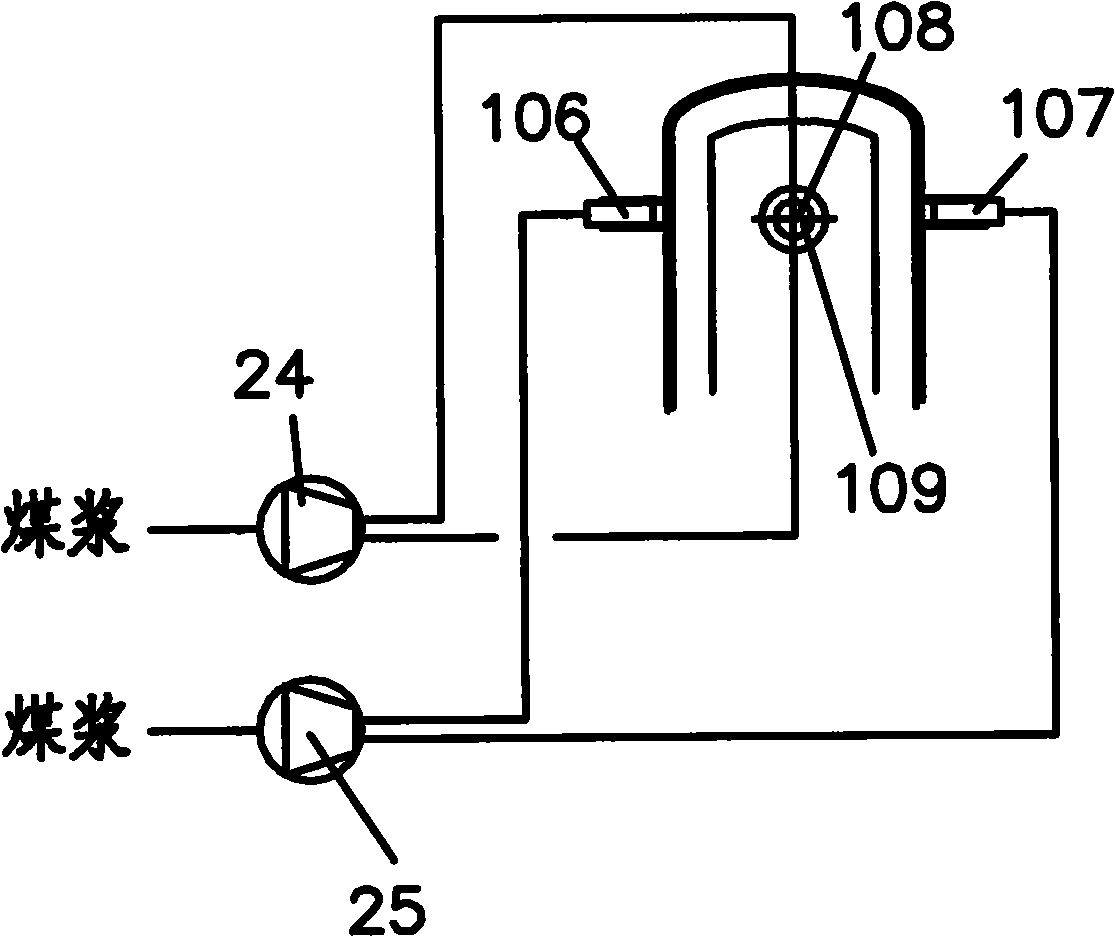

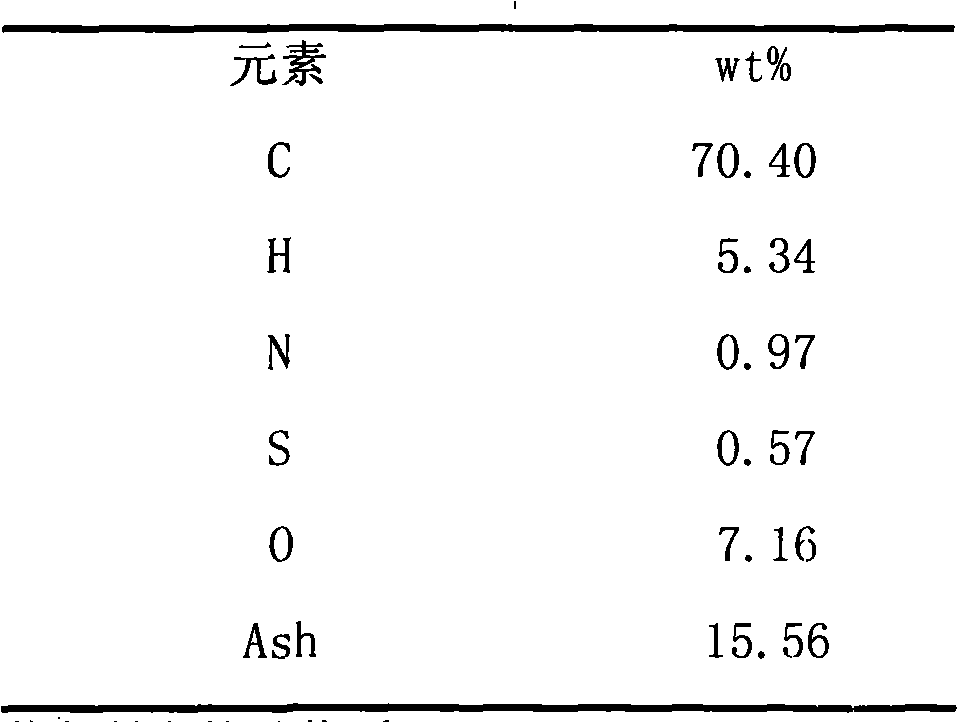

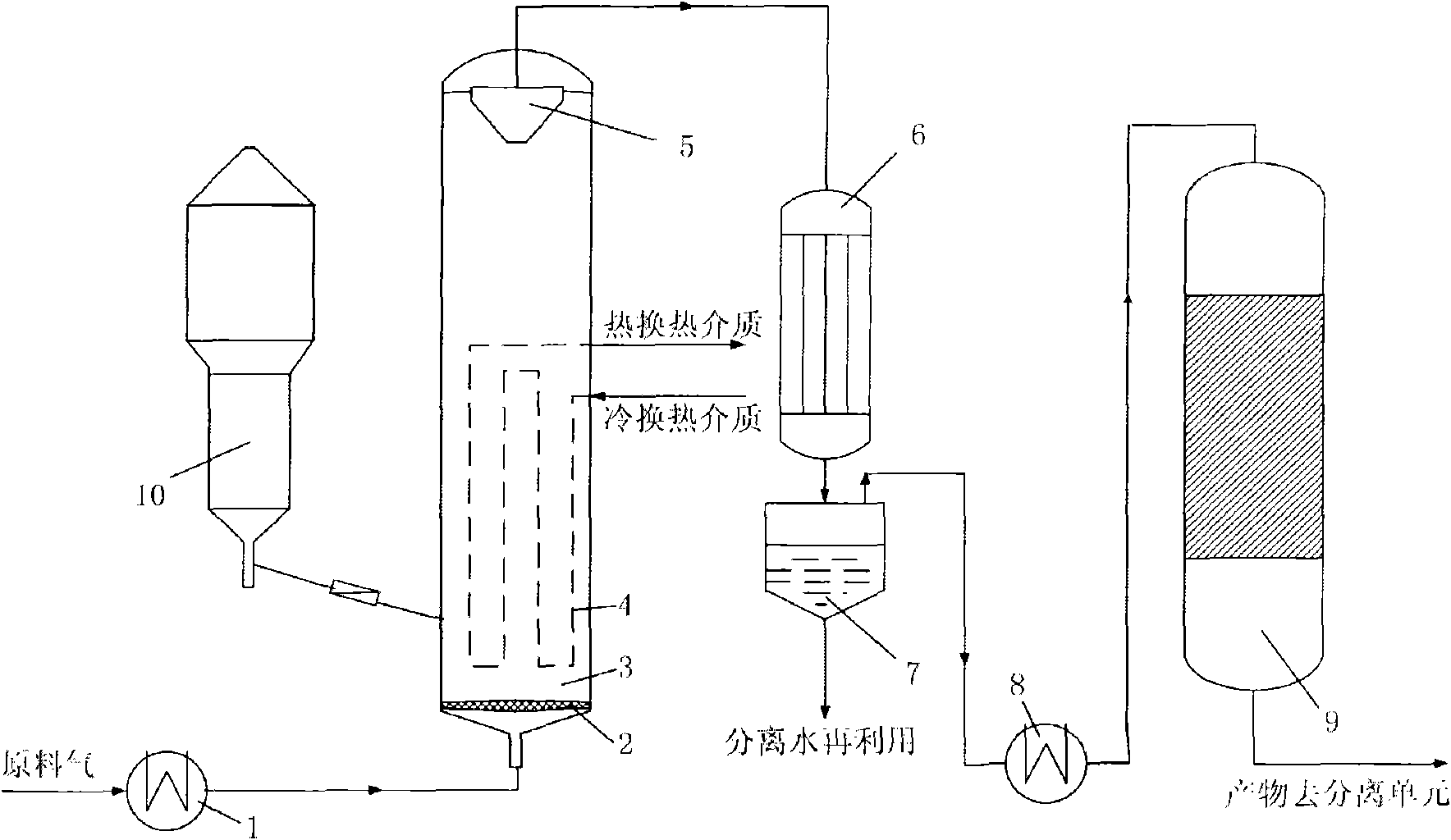

Gasification method of shock chilling type pulp or powder carbonaceous material

ActiveCN101298569AImprove water qualityReduce or eliminate emissionsChemical industryCombined combustion mitigationWater vaporWater quality

The invention discloses a gasification method of chilling slurry or powdery carbonic material. The method mainly consists of four technologies which are gasification in opposed multi-burner type, primary purification of synthetic gas, heat recovery and the treatment and recycling of black water, wherein, a gasification furnace is the core device of the method in the gasification process, which is provided with at least two pairs of opposed burners in uniform distribution and realizes the full gasification of the material under the operation pressure of 3-8 MPaG and the operation temperature of below 1200 DEG C-1700 DEG C. The invention has the following advantages: the carbon conversion rate in the gasification furnace is up to more than 90 percent, the effective gas content during slurry feeding is more than 84 percent and the effective content during powdery feeding is more than 90 percent; the ash content of the synthetic gas after primary purification is low, which can be lowered to below 1 mg / Nm<3>, thus having better water-gas ratio, i.e. the volume ratio of steam / synthetic gas (dry basis) is 1.3-1.5 / 1; the heat of the black water is totally recovered, the quality of ash water after purification is good and no fouling and clogging phenomena occur; the energy consumption, the oxygen consumption and the water consumption of the whole gasification process are relatively low, thus being capable of realizing long period stable operation with high efficiency.

Owner:EAST CHINA UNIV OF SCI & TECH

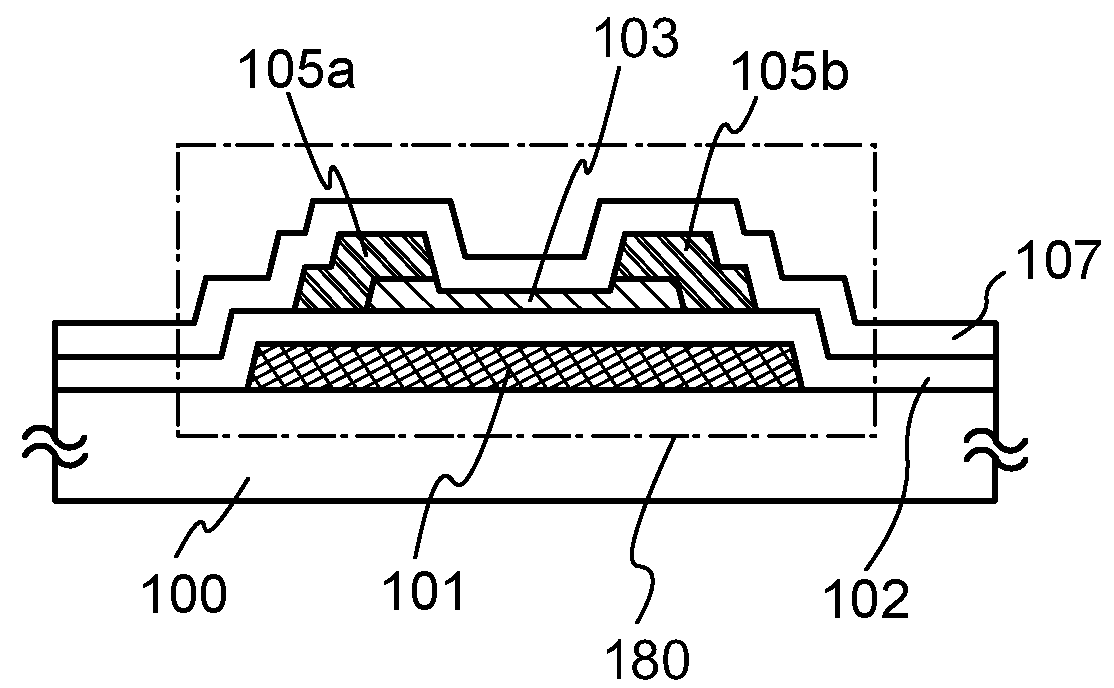

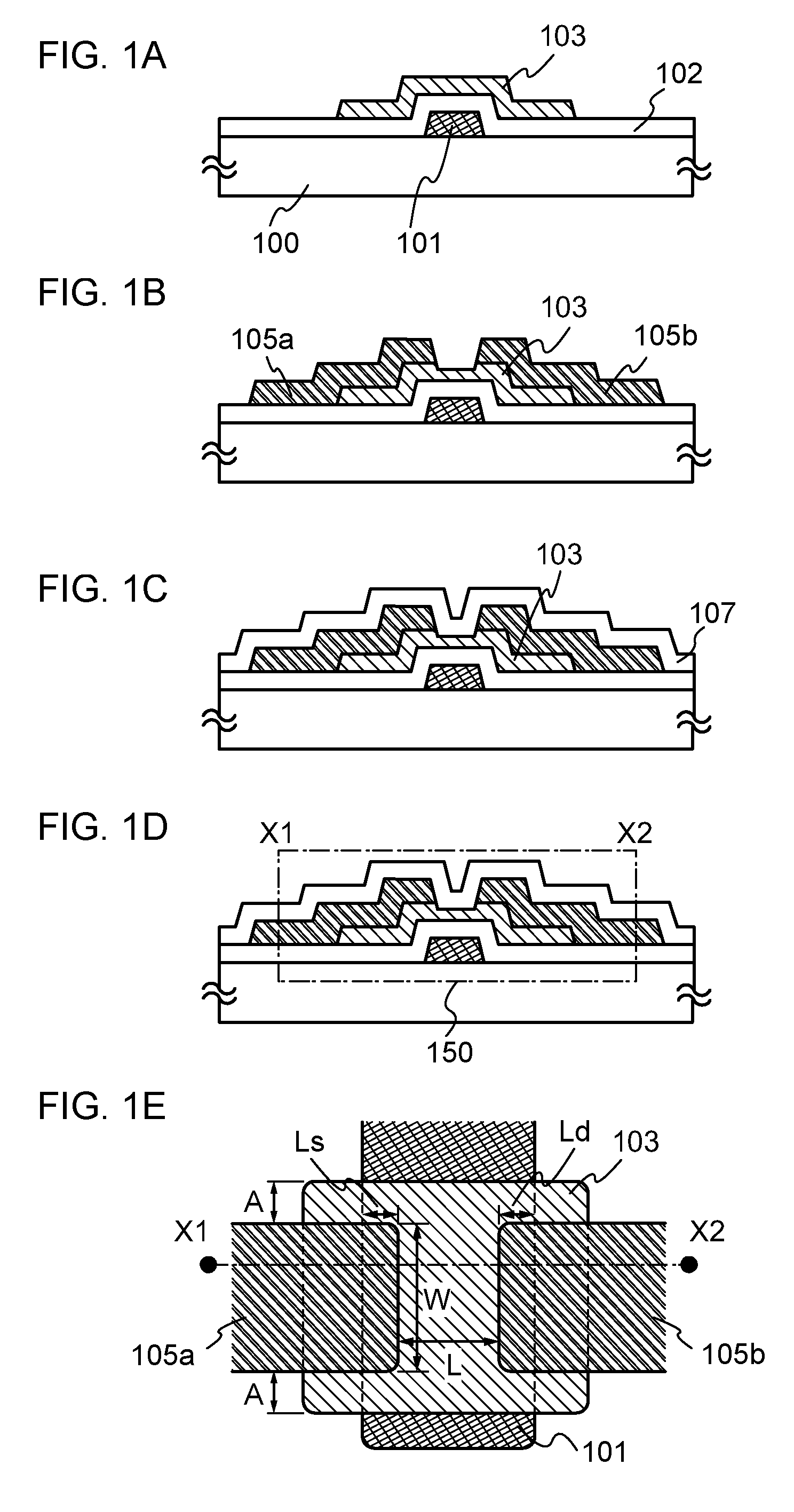

Semiconductor device and method for manufacturing the same

InactiveUS20110062435A1Excellent electrical propertiesStable characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialDisplay device

It is an object to provide a highly reliable thin film transistor with stable electric characteristics, which includes an oxide semiconductor film. The channel length of the thin film transistor including the oxide semiconductor film is in the range of 1.5 μm to 100 μm inclusive, preferably 3 μm to 10 μm inclusive; when the amount of change in threshold voltage is less than or equal to 3 V, preferably less than or equal to 1.5 V in an operation temperature range of room temperature to 180° C. inclusive or −25° C. to −150° C. inclusive, a semiconductor device with stable electric characteristics can be manufactured. In particular, in a display device which is an embodiment of the semiconductor device, display unevenness due to variation in threshold voltage can be reduced.

Owner:SEMICON ENERGY LAB CO LTD

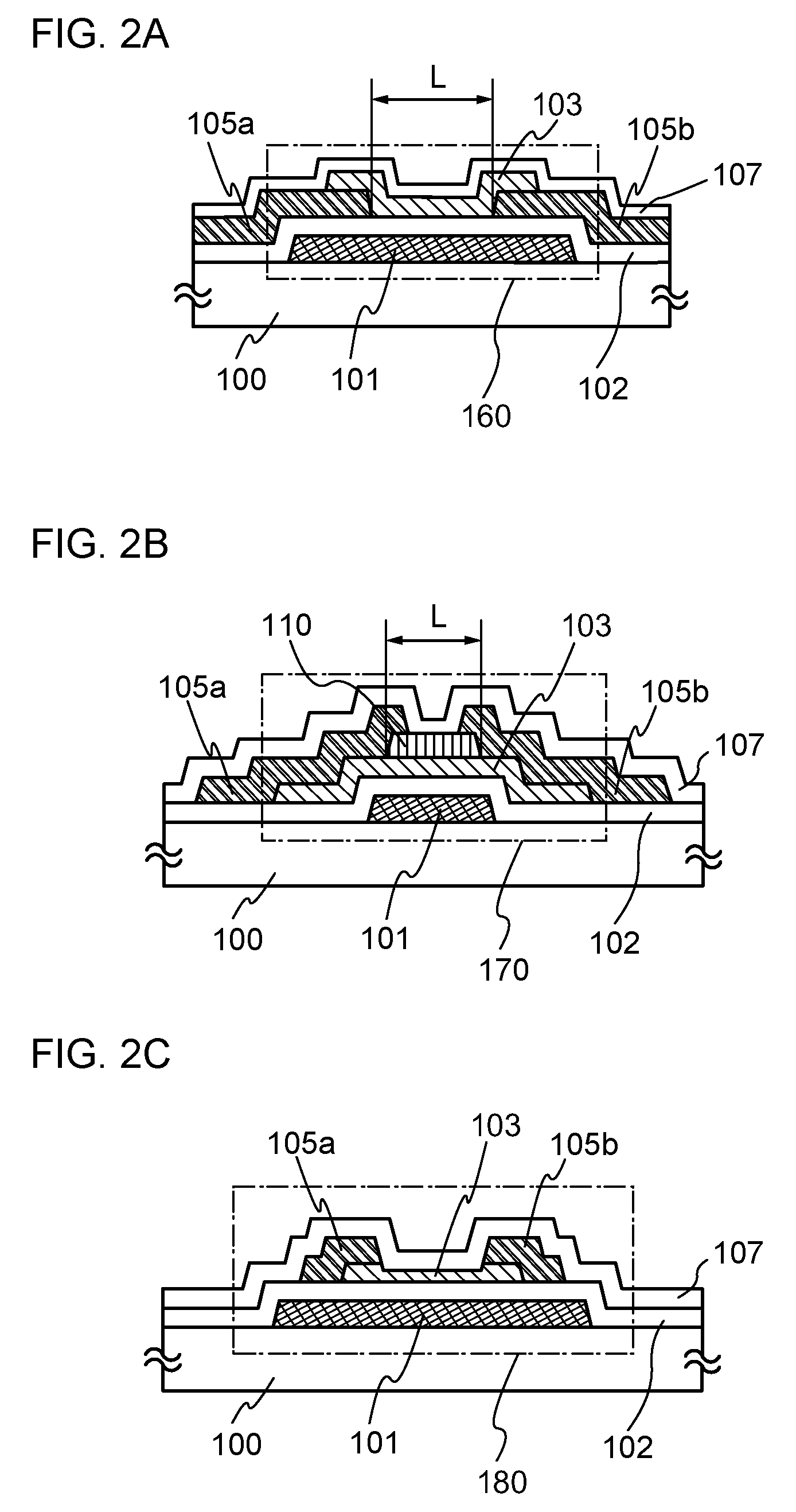

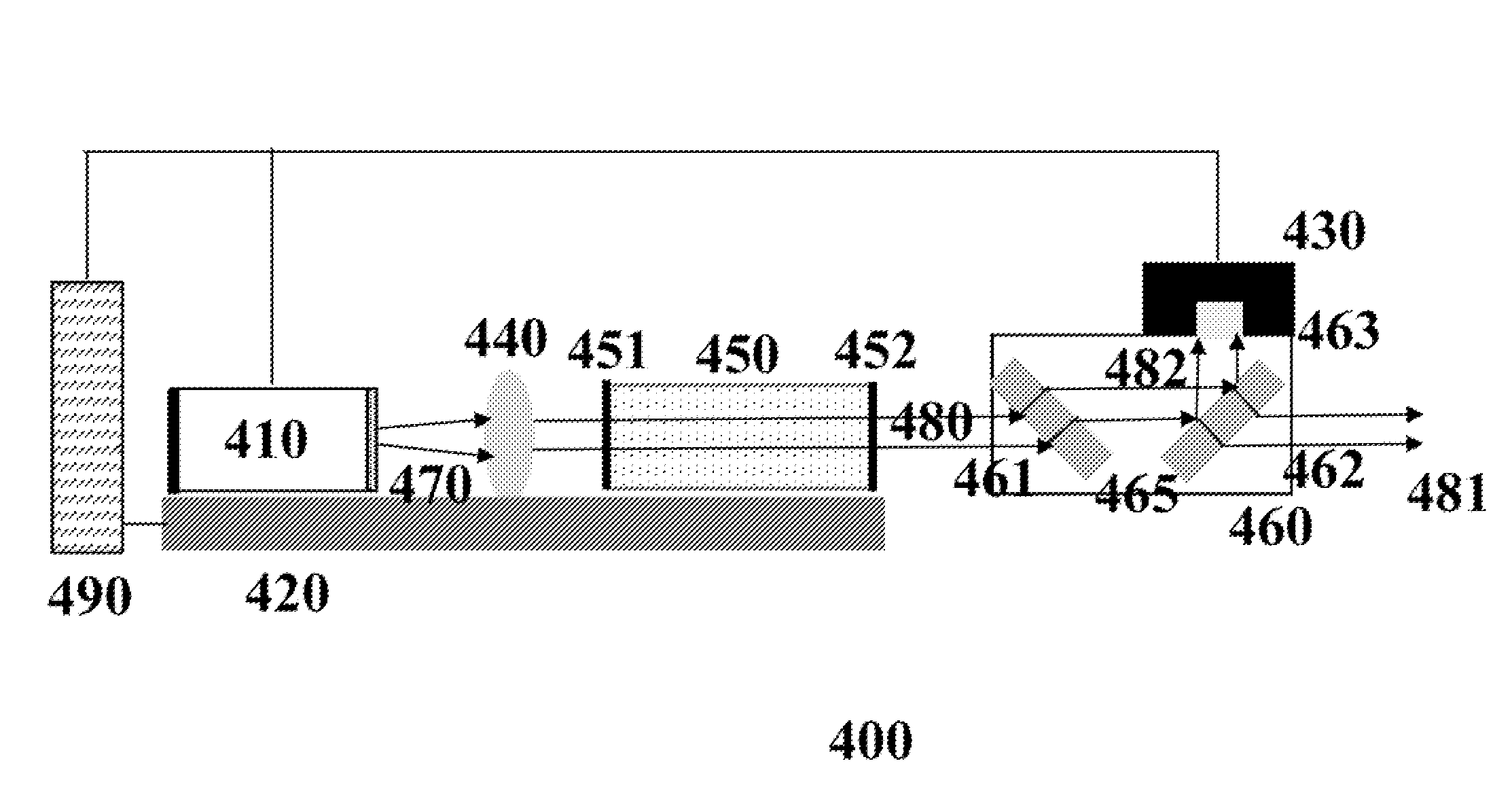

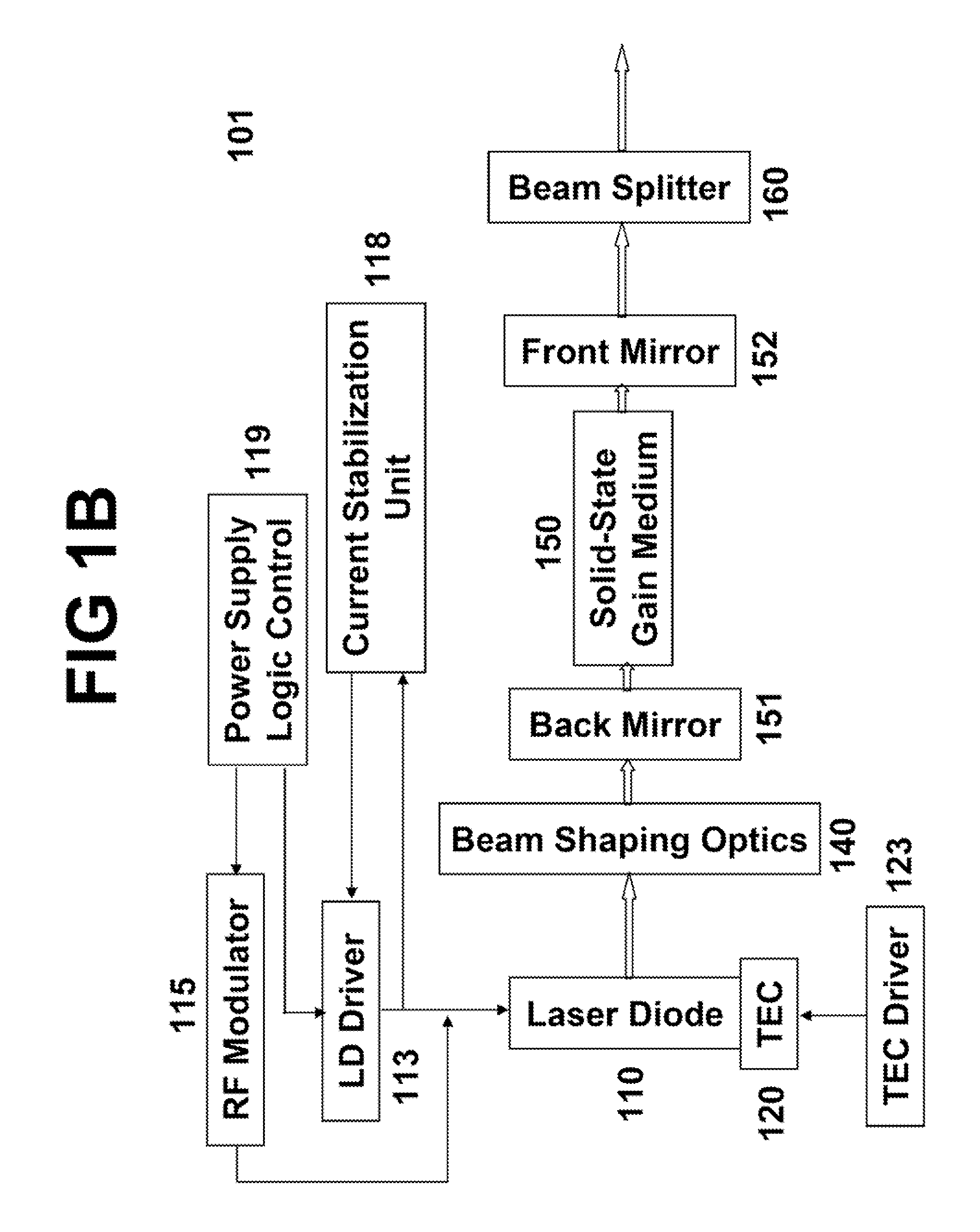

Wavelength and Intensity Stabilized Laser Diode and Application of Same to Pumping Solid-State Lasers

ActiveUS20090097507A1Avoid excessive perturbationLaser using scattering effectsActive medium shape and constructionLow noisePeak value

An efficient and low-noise solid-state laser is optically pumped by one or more laser diode(s) driven by RF modulated current. The solid-state laser operation is stabilized by the pump source stable in both spectrum and intensity, in conjunction with automatic power control wherein the feedback loop accurately reflects the true drift in the output power. Moreover, the pump efficiency is optimized and the optical noise is minimized by adjusting the diode operation temperature such that the pump wavelength coincides with the absorption peak of the gain medium. By internally or externally modulating the amplitude of the drive current, the pump diode(s) operate in pulsed mode with controllable shape, width, repetition rate, and pulse-to-pulse intervals, which enables essentially constant optical energy produced from each pulse of the solid-state laser in high repetition rates with variable pulse-to-pulse intervals.

Owner:PAVILION INTEGRATION

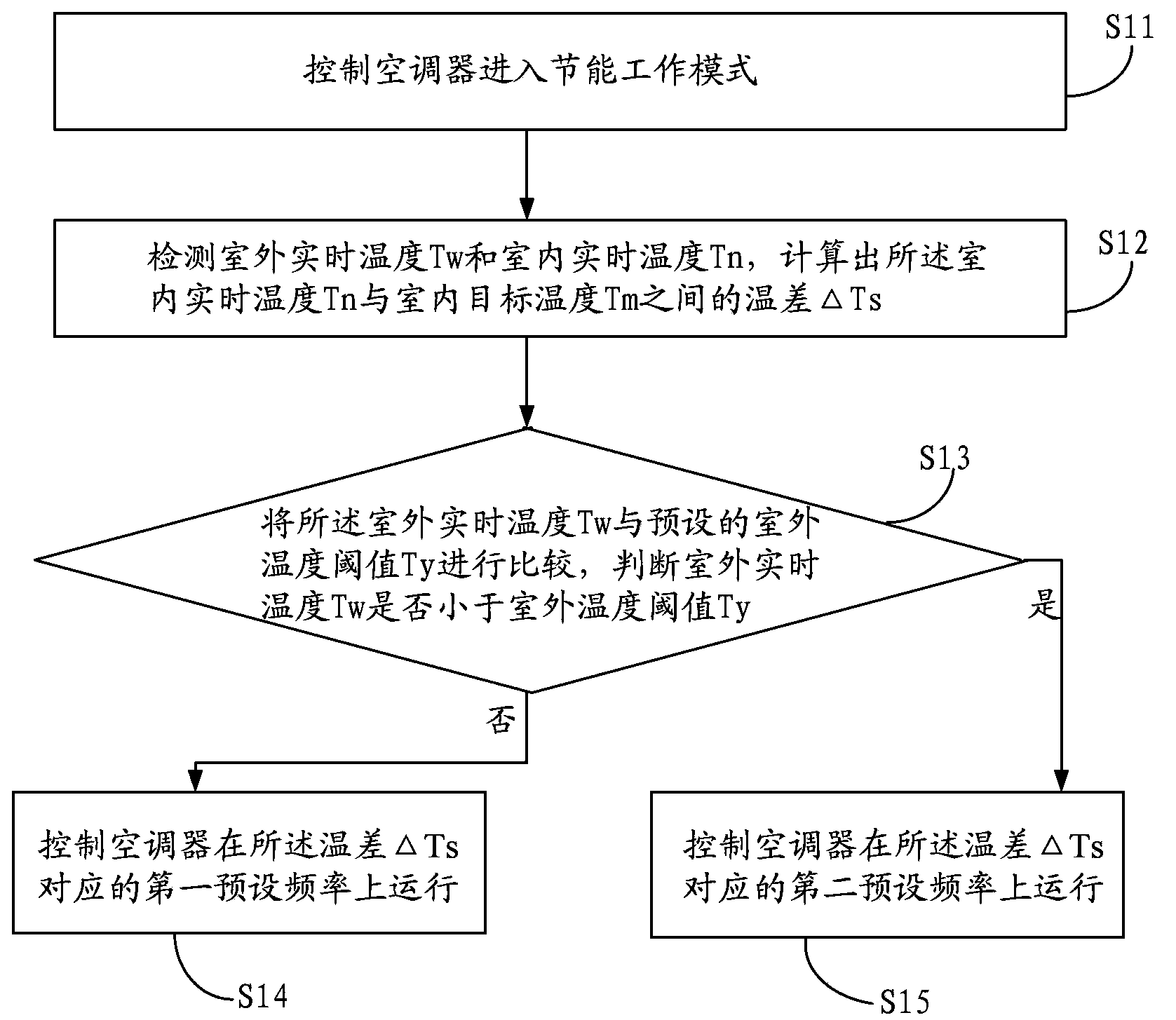

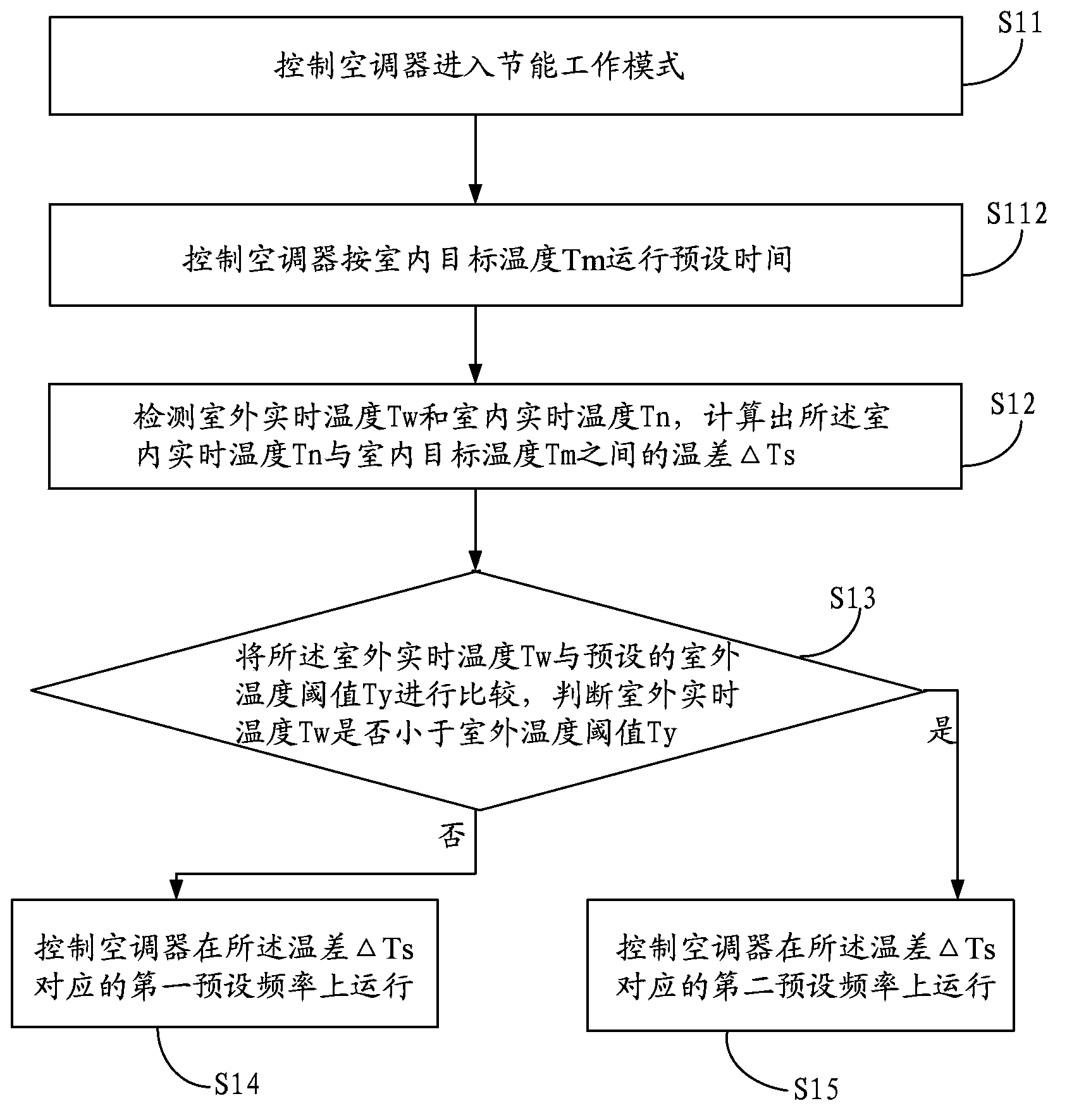

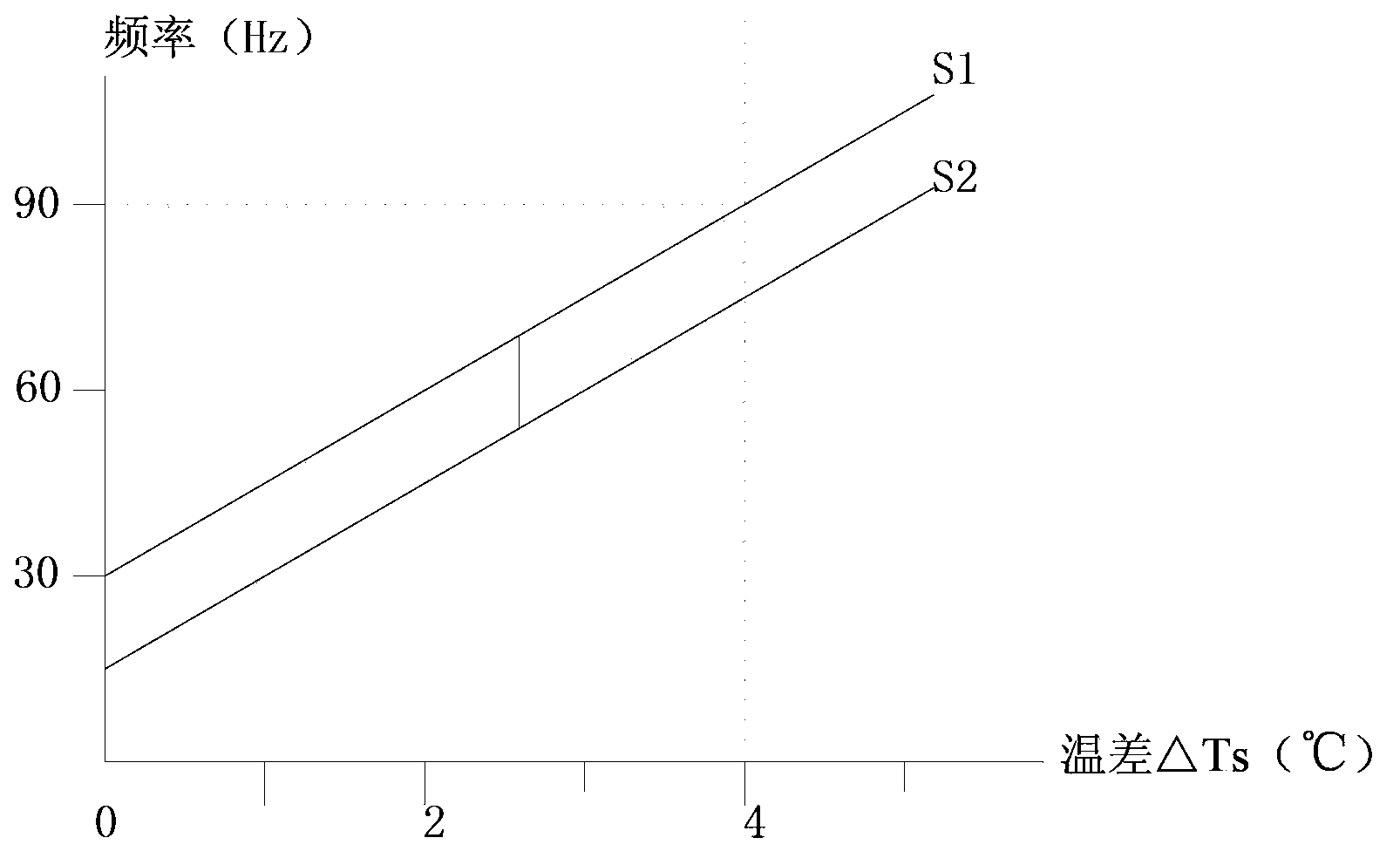

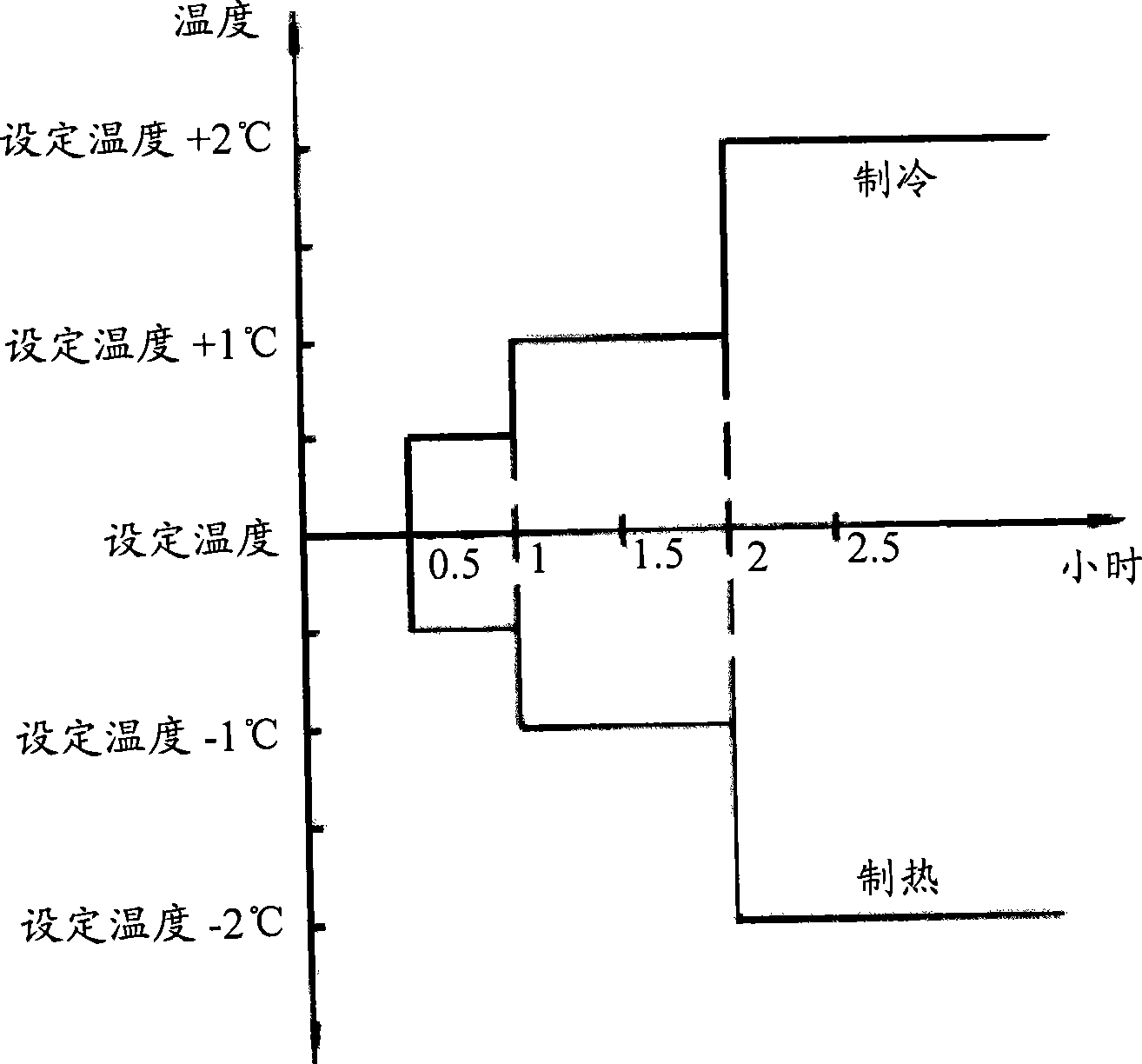

Control method of air conditioner

ActiveCN103388880AMeet energy saving needsImprove comfortSpace heating and ventilation safety systemsLighting and heating apparatusTemperature differenceEngineering

The invention belongs to the field of air conditioner control, and particularly relates to an energy-saving control method of an air conditioner. By using the control method of the air conditioner provided by the invention, according to the requirement of a user, outdoor real-time temperature Tw and indoor real-time temperature Tn are detected, the temperature difference delta Ts between the indoor real-time temperature Tn and the indoor target temperature Tm is calculated; according to a comparison result of the outdoor real-time temperature Tw and a preset outdoor temperature threshold Ty, the air conditioner is controlled to operate under a first preset frequency or a second preset frequency corresponding to the temperature difference delta Ts. The operation frequency of the air conditioner is adjusted anytime, the operation temperature of the air conditioner is controlled in the optimum comfortable state, the refrigeration and heating requirements of the user can be met, the user experience is improved, the power consumption of the air conditioner is reduced, and energy-saving and environment-protecting effects are realized.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

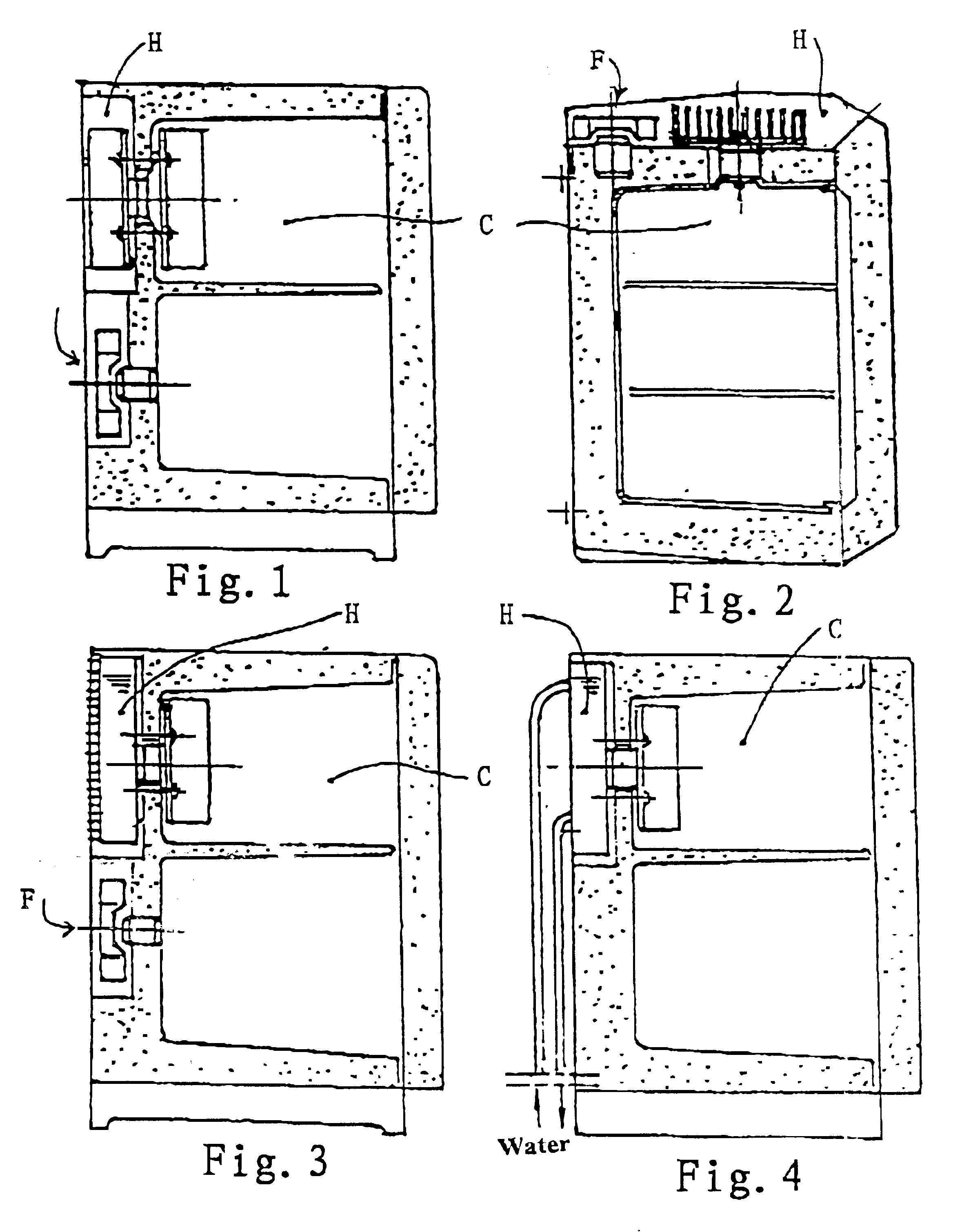

Thermoelectric cooling device using heat pipe for conducting and radiating

InactiveUS6351951B1Efficient and large conductionEfficient and large and dispersionHeat exhanger conduitsDomestic refrigeratorsThermoelectric coolingHeat conducting

A thermoelectric cooling device using heat pipes for heat conducting and dispersing, comprising a multi-bundle of the heat pipe conducting plates installed at the cold end of the thermoelectric cooling member and converged to condenser, a multi-bundle of the heat pipe heat exchangers installed at the hot end of the thermoelectric cooling member with fin plates or fin stripes and converged to the evaporator. It performs a fast cooling and heat dispersing by heat pipes and high efficient phase change and heat transport of the working medium. It can eliminate the heat exchange produced by the heat accumulation on the cold and hot ends, so as to run at the minimum operation temperature differences in order to obtain the maximum cooling capacity.

Owner:LUQUAN JIWEI ELECTRICAL APPLIANCE

TiO2 supported manganese-cerium composite oxide catalyst and preparation method thereof

InactiveCN101352680AHigh catalytic activityUniform particlesDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsDispersityAdditive ingredient

The invention discloses a manganese-cerium complex oxide catalyst loaded by TiO2, which takes nanometer titanium dioxide as a carrier and the manganese-cerium complex oxide loaded on the carrier as an active ingredient. The mole ratio of each ingredient is that Ti: Mn: Ce is equal to 1: (0.05 to 1): (0.05 to 1). The invention also discloses a preparation method of the catalyst, which adopts sol-gel preparation technology to promote the dispersity and strength of the two ingredients of manganese and cerium on a TiO2 carrier. Furthermore, the catalyst prepared by adopting the preparation method has the advantages of high catalytic activity and uniform particles; active substances is good in dispersity and is hard to sinter; when used in low-temperature SCR reaction, the catalyst can greatly lower the operation temperature and the operation cost of the SCR since the catalyst has a very high removal rate of NO at the temperature about 120 DEG C.

Owner:ZHEJIANG UNIV

Polylactic acid/thermoplastic starch extrusion blow molding film and its producing method and application

The invention discloses a polylactic acid / thermoplastic starch extrusion blown film, a relative production method and an application. The invention mixes polylactic acid, the copolymer fatty group-aromatic polyester, thermoplastic starch, flexibilizer, nucleating agent, lubricant, anti-oxidant, reinforcing agent and anti-ultraviolet agent into a twin-screw extruder, at suitable operation temperature and screw rod rotation speed, to be extruded and granulated, and uses extrusion blowing method to produce polylactic acid / thermoplastic starch extrusion blown film product. The inventive polylactic acid / thermoplastic starch extrusion blown film can be used as packaging film, clingfilm, one-time film and agricultural film. And the production method has simple process, easy operation, low cost, degradable property, easy treatment and reduced white pollution.

Owner:江苏橙桔生物降解塑料有限公司

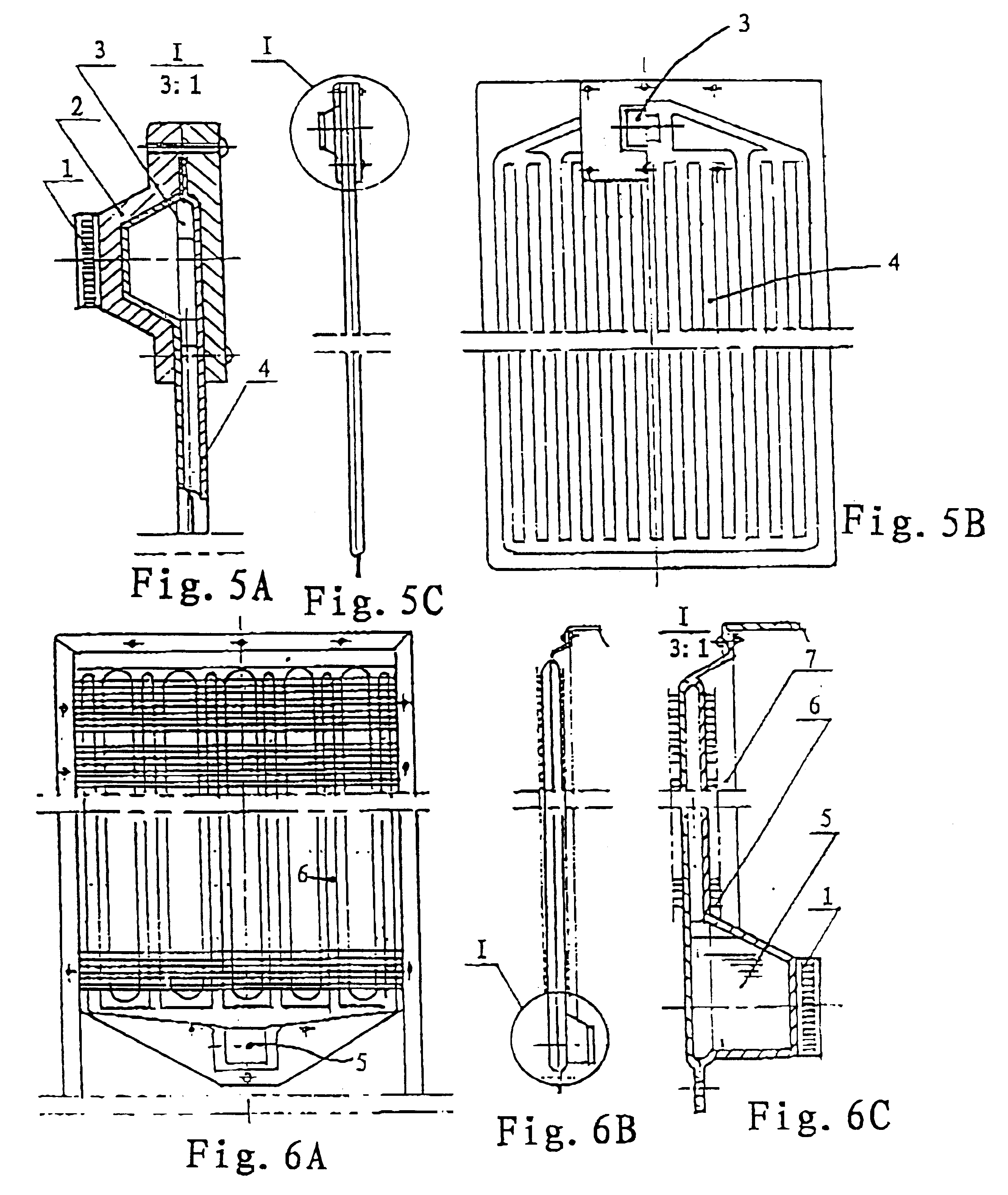

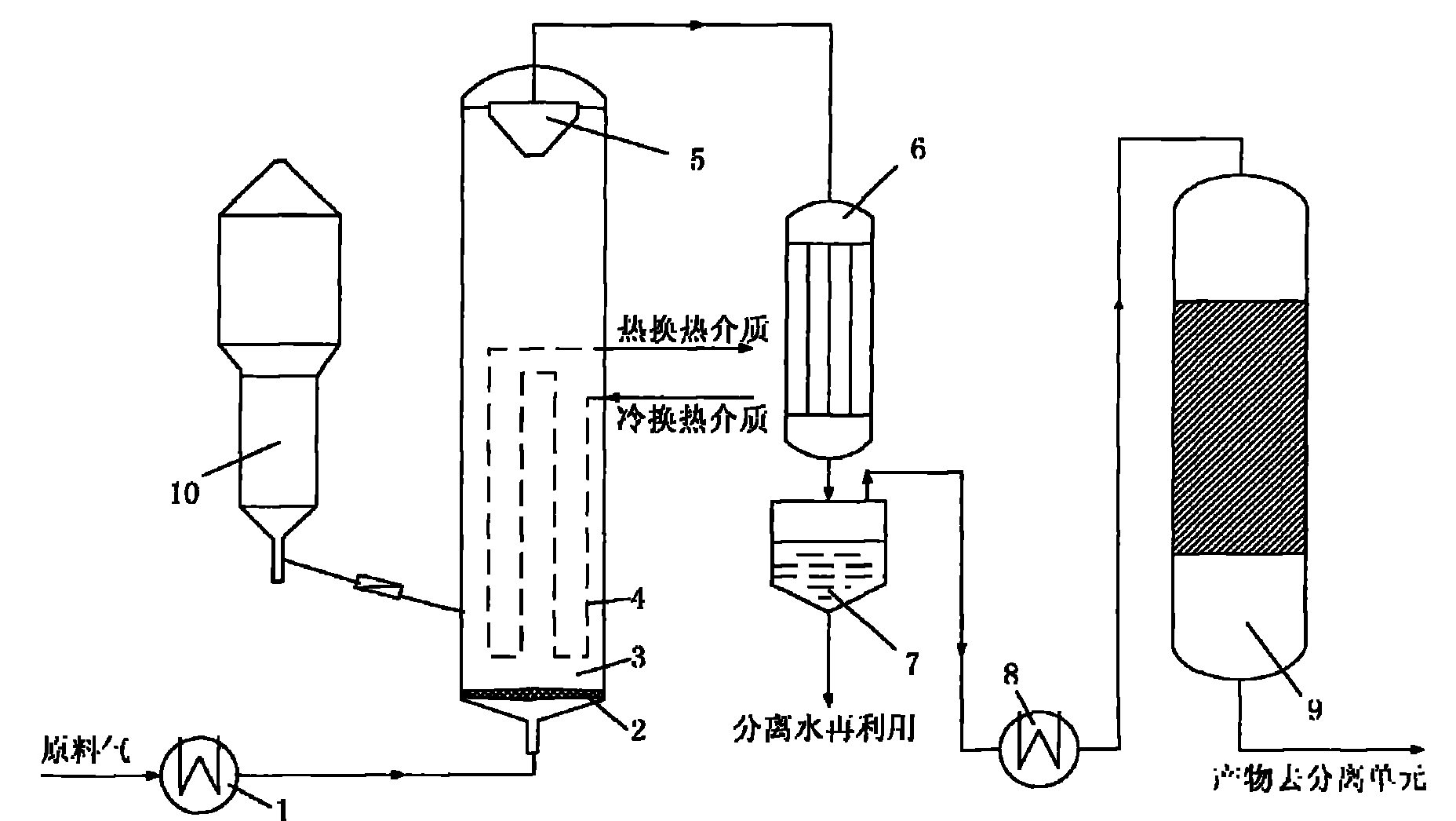

Method and device for catalyzing methanation of synthesis gas

ActiveCN101817716AIncrease productivityEasy to removeHydrocarbon from carbon oxidesSyngasMethanation

The invention relates to a method and a device for catalyzing methanation of synthesis gas. The method has the process characteristics that synthesis gas as a raw material firstly realizes the conversion rate of 60 to 95% in a built-in heat exchanger type fluid bed reactor, the reaction temperature is from 200 to 700 DEG C, the pressure is from 0.1 to 6.0 MPa, and the reaction airspeed is from 1000 to 50000 h<-1>; gas-solid separation is carried out on reaction products and a catalyst, and water therein is separated and enters a fixed bed reactor after temperature raise; and the rest raw material synthesis gas is converted to methane, the operation temperature is from 180 to 700 DEG C, the pressure is from 0 to 6.0 MPa, the reaction airspeed is from 500 to 600h<-1>, and the final raw material synthesis gas conversion rate reaches more than 98%. Compared with the fixed bed reactor adiabatic reaction process generally adopted currently, the process of the method has simpler process flow. The space time yield of the methane can be obviously improved, and the invention has better industrialized application value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

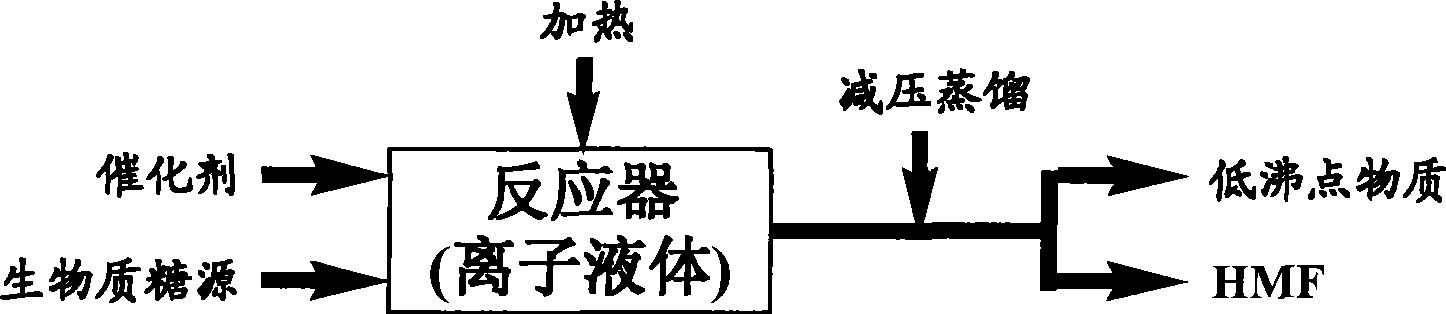

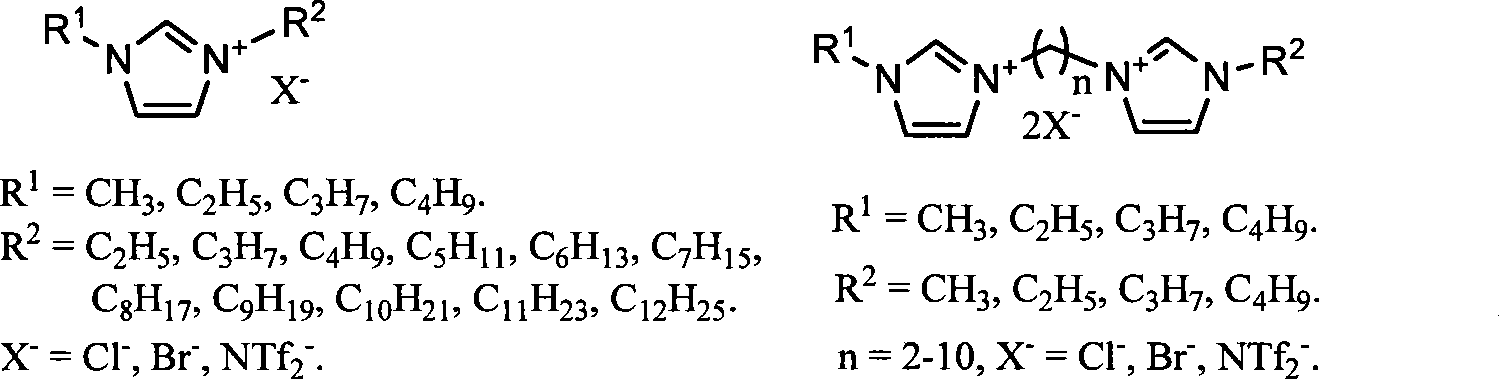

Method for preparing 5-hydroxymethyl-furfural

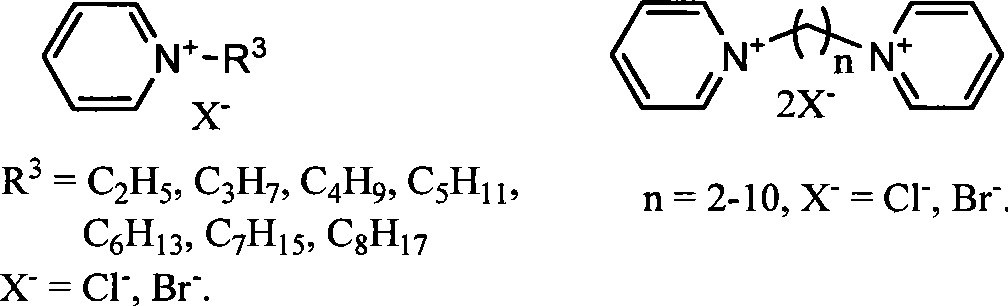

InactiveCN101456850ALow costCorrosion resistance requirements are not highOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAlternative fuelsSolvent

The invention relates to a method for preparing 5-hydroxymethylfurfural (HMF) by transforming a biomass saccharine source. The method comprises the following concrete steps: using an ionic liquid as a solvent, hexose or hexose source biomass as a raw material substrate, and acid as a catalyst, heating the mixture to react for 5 minutes to 20 hours at normal pressure, and then depressurizing and distilling the mixture under the condition that an operation temperature is not higher than 180 DEG C to obtain the HMF after the reaction is ended; and after the distilled remainder is cooled, directly adding the remainder into the biomass saccharine source, and repeating the processes of reaction and separation to obtain the HMF, so as to realize recycling of an ionic liquid catalyst system and semi-continuous preparation of the HMF. By using the method, once through yield of the HMF reaches as high as 94 percent. The method has the advantages of high selectivity, low acid consumption, mild condition, quick reaction, reusability of the ionic liquid, low cost, simple process, environmental protection, semi-continuous production and the like, and provides new technology for industrialized production of the HMF by transforming the biomass saccharine source, so as to develop a new path for preparing common chemicals in a large scale by using biomass resources and replacing fuels.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

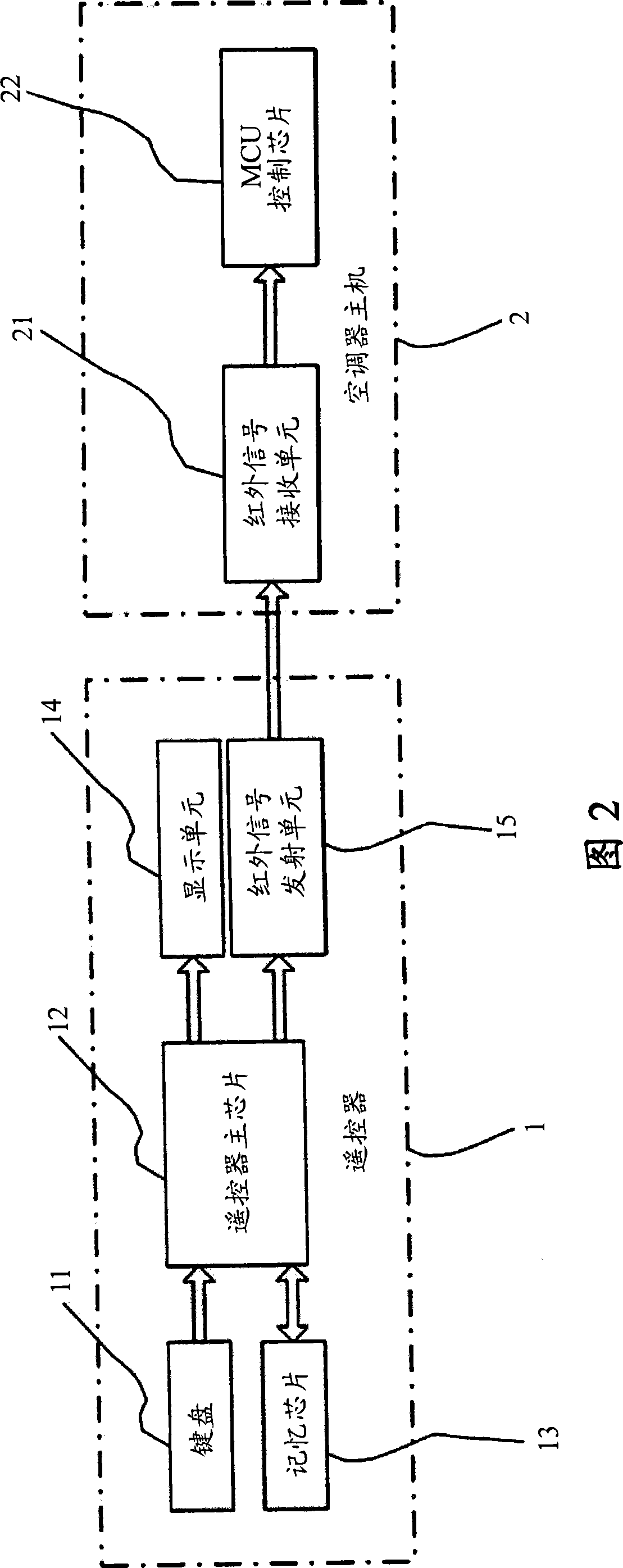

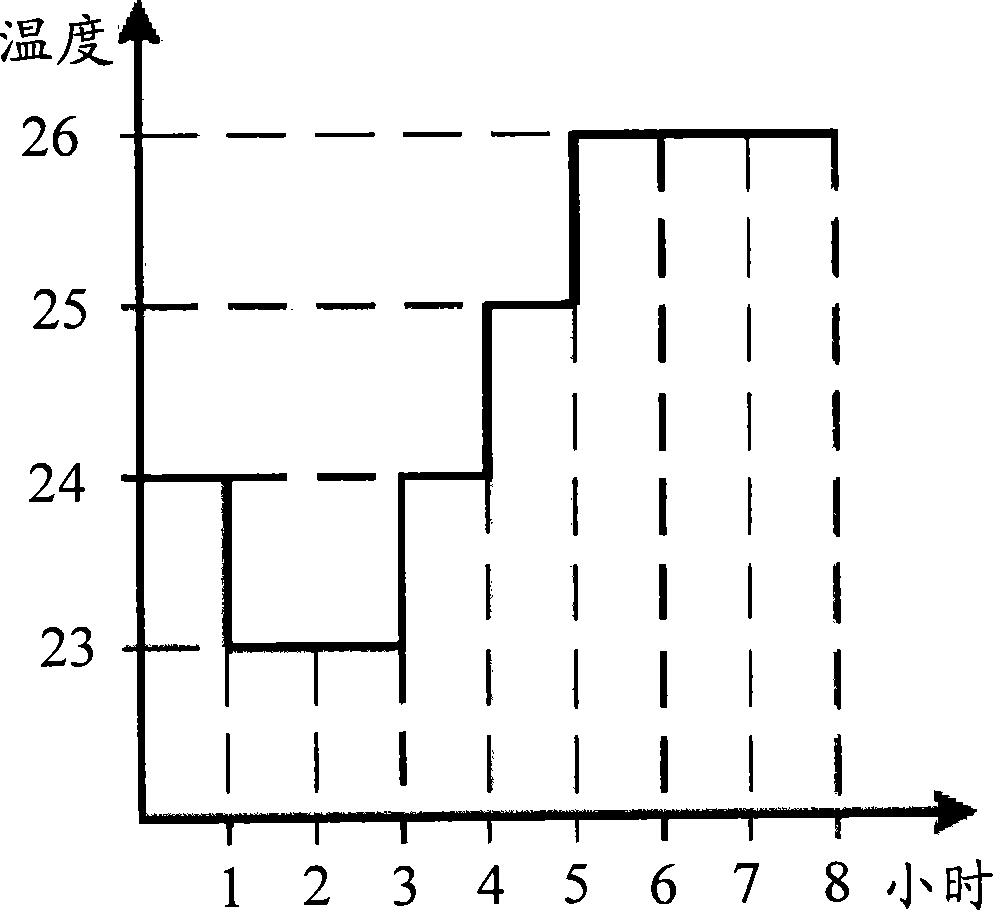

Method for controlling air conditioner to operate as custom curve

ActiveCN101382331ANon-electrical signal transmission systemsSpace heating and ventilation safety systemsMemory chipPersonalization

The invention discloses a method for controlling an air conditioner to operate according to a self-defined curve; the method comprises the following steps: the self-defined curve is set by a keyboard on a remote controller; data of the self-defined curve is stored in a memory chip; the data of the self-defined curve is sent to an infrared signal receiving unit of a main machine of the air conditioner and stored in a RAM, preset operation parameters are set in the corresponding time period according to the data of the self-defined curve, the main machine of the air conditioner is controlled to carry out the corresponding operation by the operation parameters, wherein, the step of setting the self-defined time-the temperature curve comprises: the set state is activated by entering the set mode; the start time and the operation time are set; the set temperature which is corresponding to the operation time is set and the set of a temperature point is completed; and the set of the self-defined time-the temperature curve is completed by the repeated set of a plurality of temperature points. The air conditioner can provide the personalized operation temperature and the operation mode of the air conditioner according to the needs of a user, thereby meeting the needs on the comfort of the user.

Owner:GREE ELECTRIC APPLIANCES INC

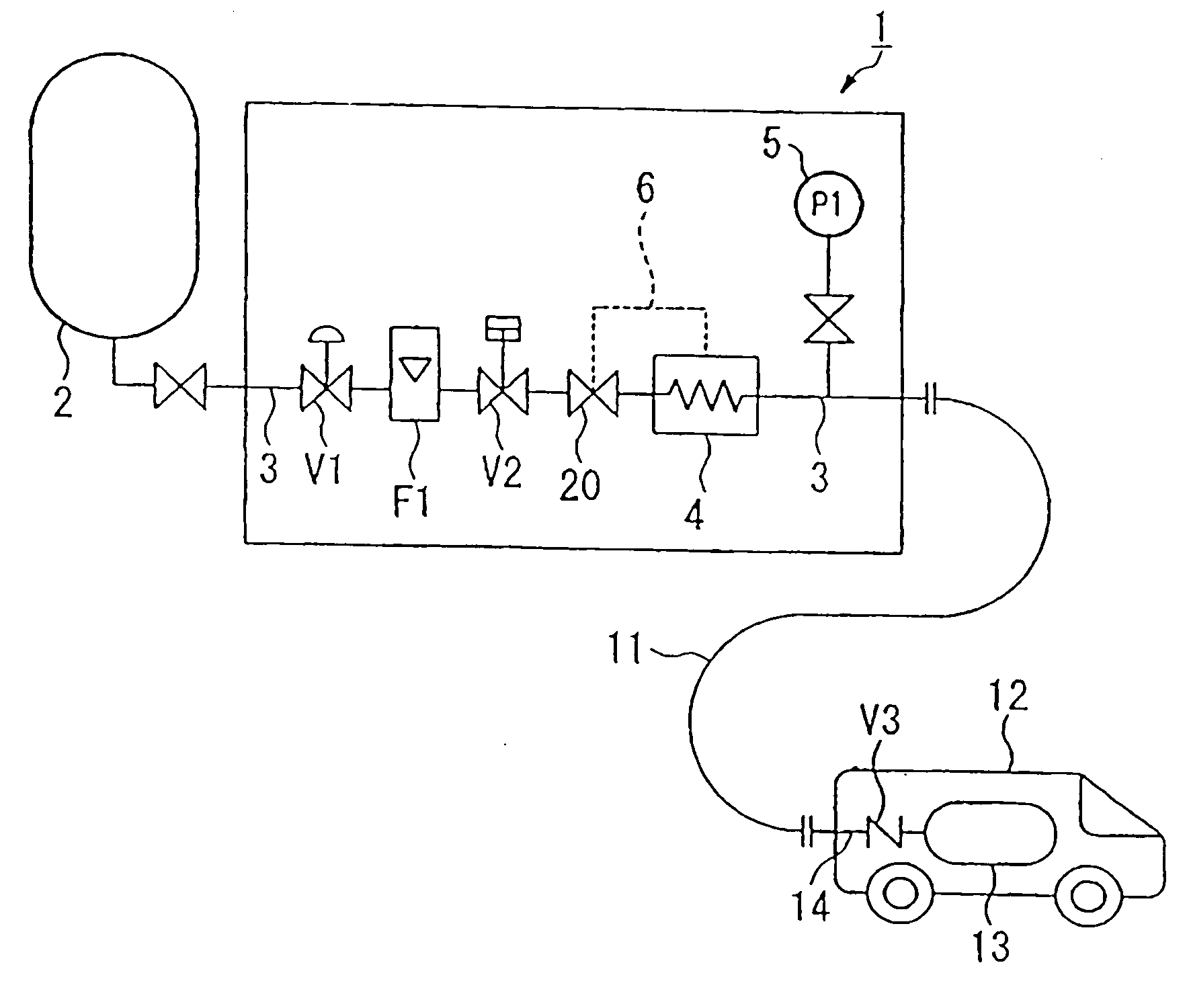

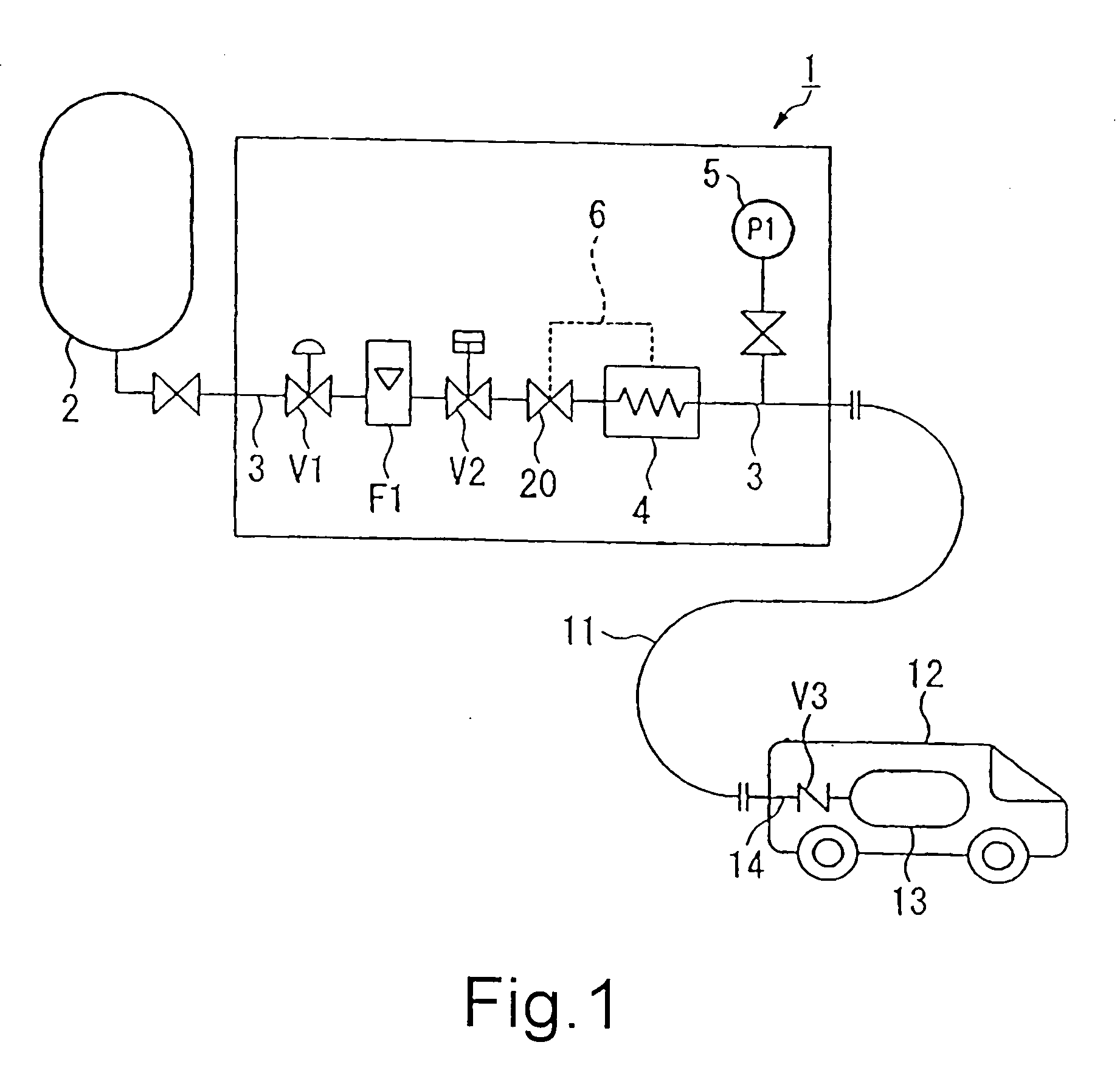

Apparatus and method for filling fuel

InactiveUS20060016512A1Safely and rapidly filledSimple structureGas handling applicationsLiquid transferring devicesFuel gasVALVE PORT

A fuel filling apparatus is provided. The fuel filling apparatus comprises an overfilling protective valve arranged in a fuel gas supply path for supplying a fuel gas to an automobile. The overfilling protective valve further comprises a fuel gas path, a valve unit for opening and closing the fuel gas path by a valve body, a valve body displacement means for displacing the valve body according to a filling pressure of the fuel gas, and a temperature modulating unit for modulating a temperature of the valve body displacement means. Even though a difference between the temperature of the fuel gas and the operation temperature of the overfilling protective valve is large, the temperature of the valve body displacement means can be maintained within the preset temperature range by the temperature modulating unit and the overfilling protective valve can be exactly operated under the preset pressure.

Owner:TAIYO NIPPON SANSO CORP

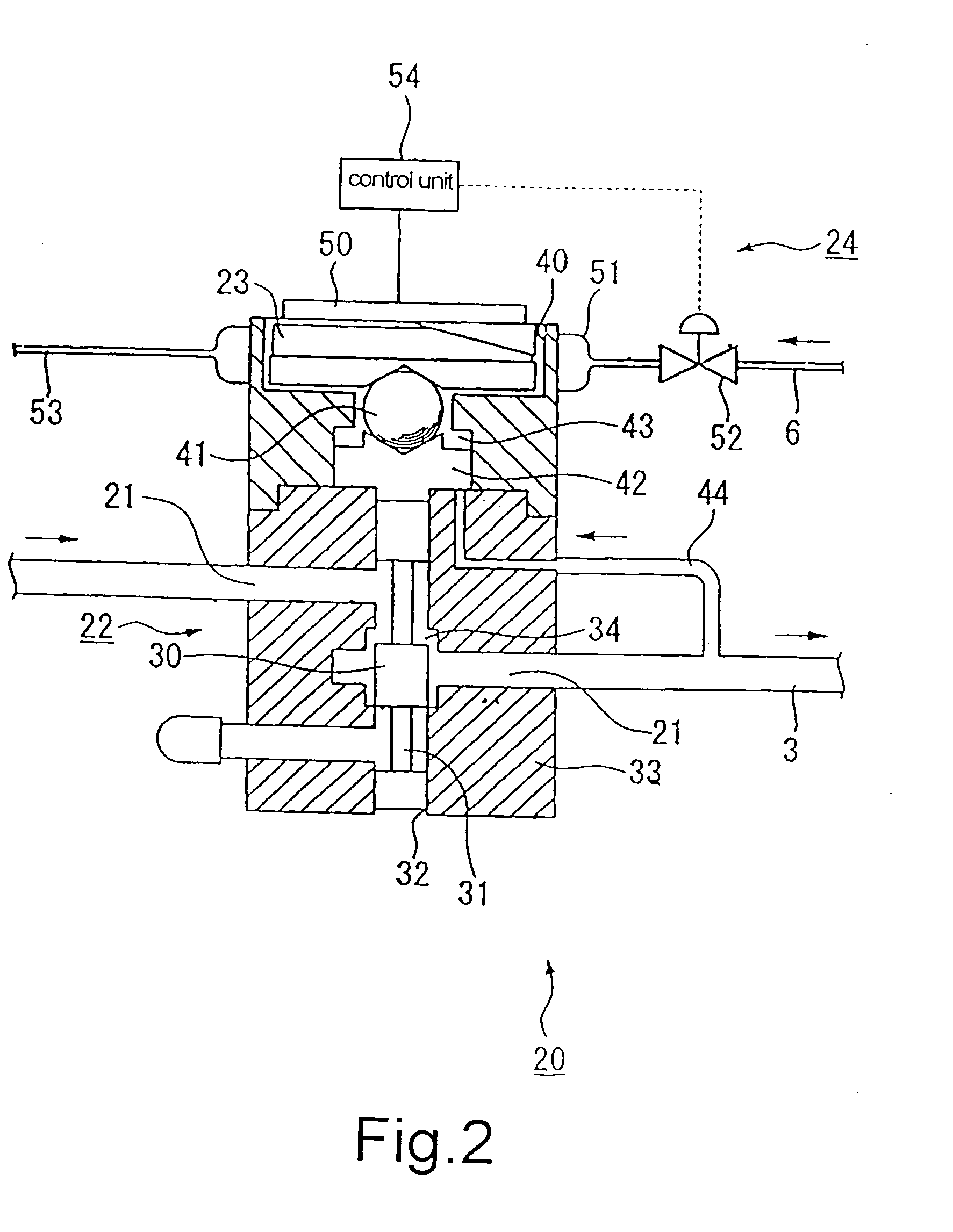

Method for decomposing vanadium slag with solution of potassium hydroxide under normal pressure

InactiveCN101812588ALow reaction temperatureImprove resource utilizationProcess efficiency improvementMass ratioSlag

The invention relates to a method for decomposing vanadium slag with solution of potassium hydroxide under normal pressure, which comprises the following steps: adding the vanadium slag or pre-treated vanadium slag, water and KOH into a reactor, controlling the mass ratio of the KOH to the vanadium slag and the concentration of solution of KOH, performing oxidation reaction in the presence of oxidizing gas, and controlling the reaction temperature and reaction time in the reaction process; diluting the obtained reaction slurry with a diluting agent to obtain mixed slurry which contains potassium hydroxide, potassium vanadium, potassium chromate and tailings; and performing filtering separation on the mixed slurry to obtain the tailings and vanadium and chromium-containing aqueous solution. The method is only operated under normal pressure, is easy to perform and has high safety; the operation temperature is far lower than the traditional vanadium extraction temperature; the extraction rate of vanadium is high; and synchronous extraction of chromium in the vanadium slag can be realized. The total amount of the vanadium in the tailings is 0.2-1 weight percent (based on the amount of V2O5) and the total amount of the chromium is 0.2-1 percent (based on the amount of Cr2O3).

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of aroma rapeseed oil

ActiveCN102936531AStrong fragranceRetain nutrientsFatty-oils/fats refiningFatty-oils/fats productionScreening proceduresAdditive ingredient

The invention discloses a preparation method of aroma rapeseed oil, wherein the preparation method comprises the following main procedures: selecting rapeseeds, removing impurities, and removing macadam and clods, wherein the impurity content is smaller than 0.1% and the rapeseed content in the screen underflow is smaller than 0.5% after the screening procedure; frying the rapeseeds at 140-145 DEG C; squeezing the rapeseeds through a squeezer and controlling the thickness of an oil cake to be smaller than 1.5mm to obtain crude oil; primarily deslagging the squeezed crude oil through an oil clarifying box, and pumping the crude oil in a blade filter to be filtered, wherein the insoluble impurity in the filtered crude oil is smaller than 0.2%; obtaining clean crude oil, controlling the operation temperature at 65-70 DEG C and controlling the water temperature at 70-75 DEG C to perform hydration degumming; washing the clean crude oil twice by virtue of softened water, drying and dewatering at vapor pressure of 4-5 Mpa; stirring the clean crude oil at a rotating speed of 30 r / min (revolutions per minute), and cooling until the oil temperature is lower than 80 DEG C; and filtering the clean crude oil in a frame filter to obtain the aroma rapeseed oil. The prepared rapeseed oil generates full-bodied fragrance, and the nutrition ingredients and physiological active ingredients in the rapeseed oil are kept to the maximum.

Owner:YUNNAN ZHENWEI GREASE

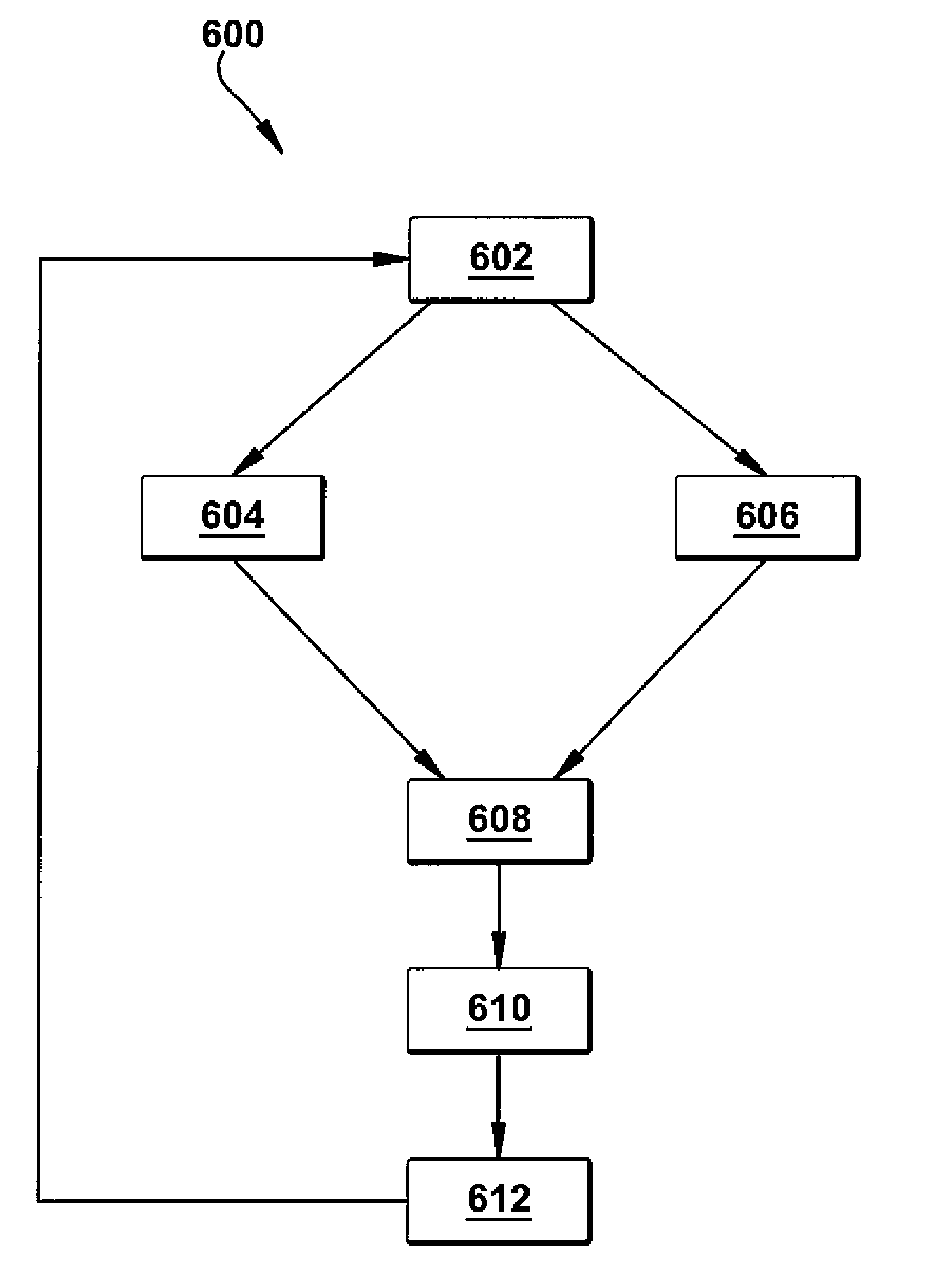

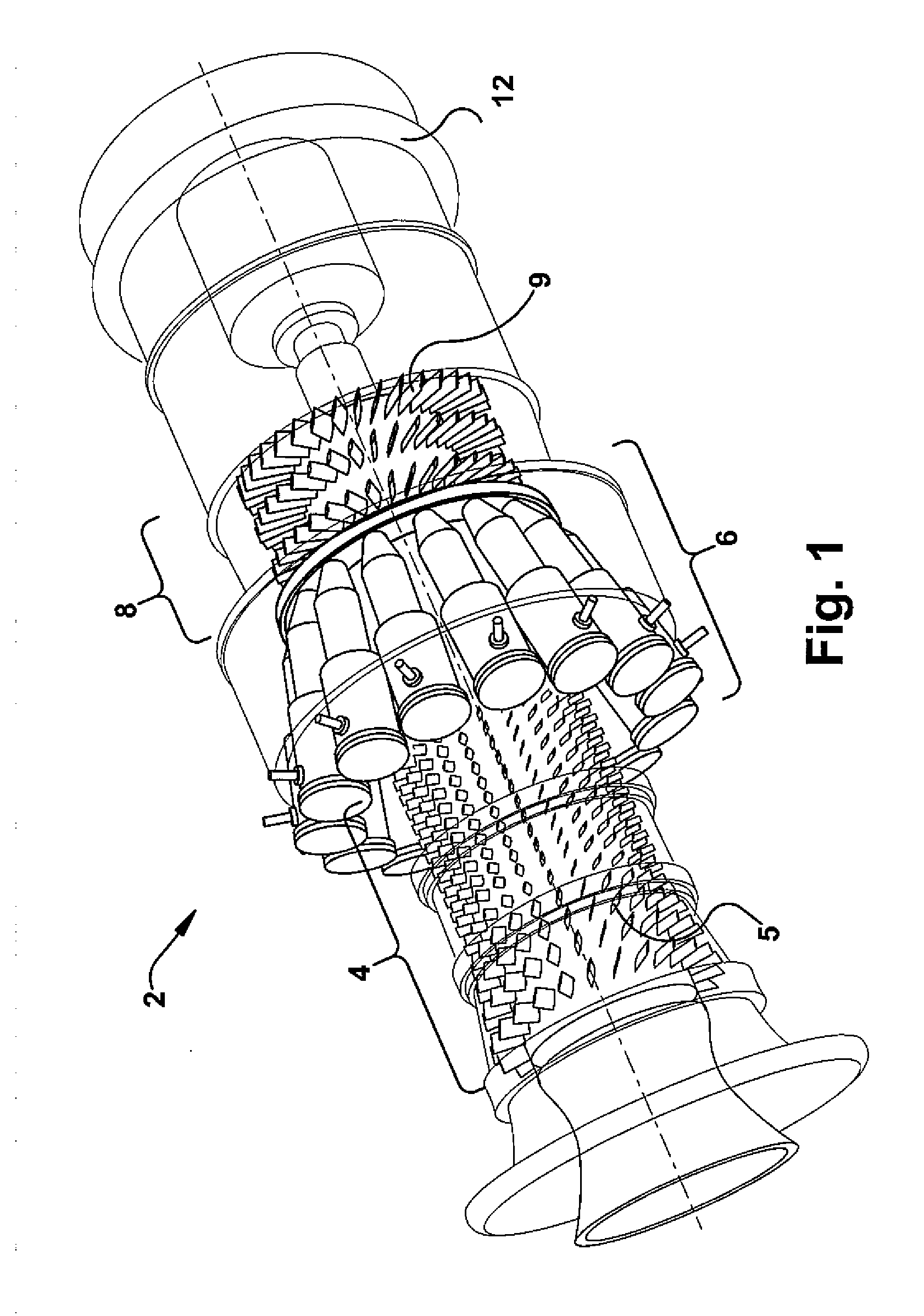

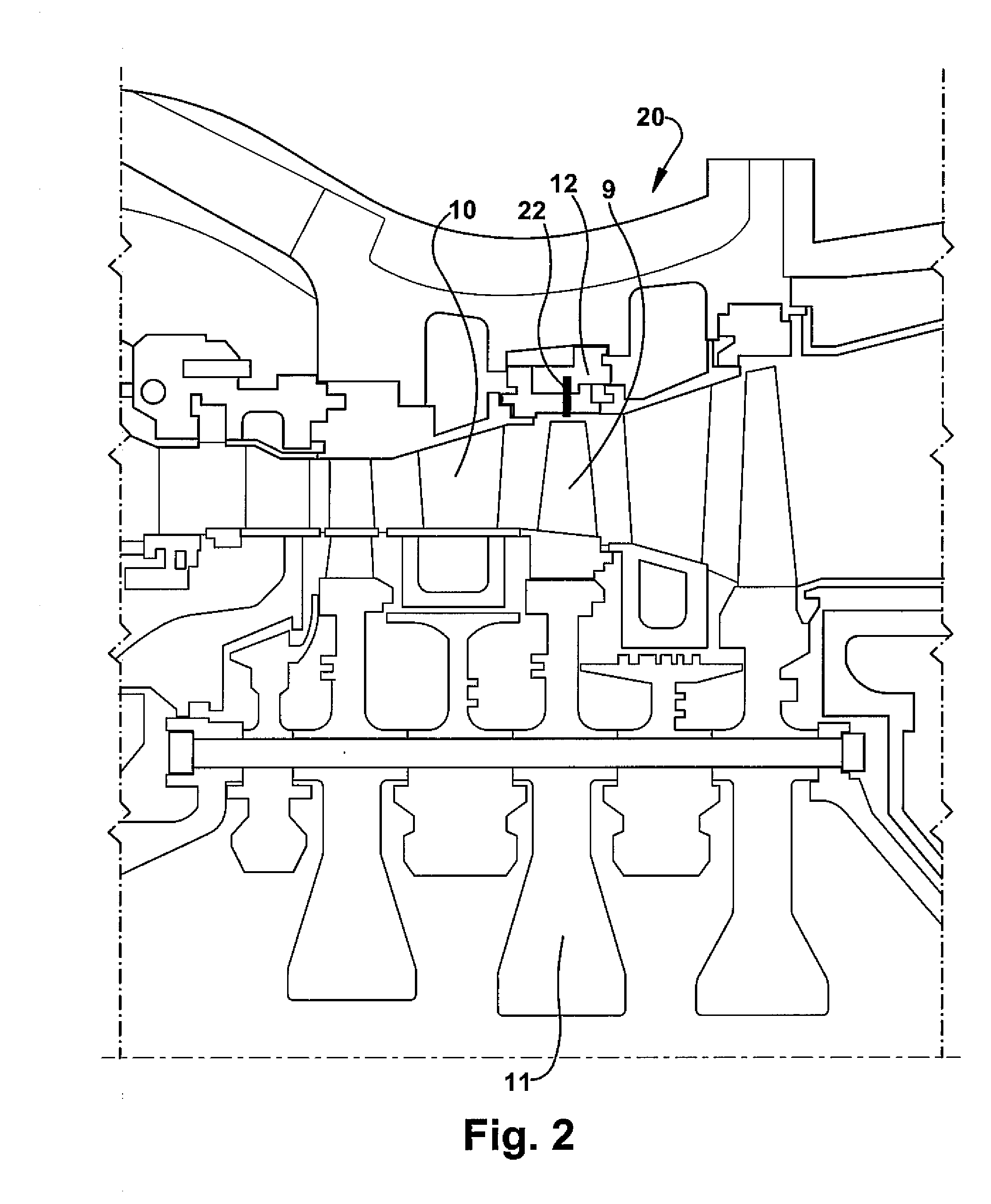

Method and systems for operating turbine engines

A method of operating a turbine, the method including the steps of: 1) gathering measured creep data for a blade while the turbine operates at different operating temperatures, the measured creep data comprising at least a measured creep rate for the blade (wherein the different operating temperatures include at least a first operating temperature and a second operating temperature); and 2) given the measured creep data for the blade while the turbine operated at the first operating temperature and the measured creep data for the blade while the turbine operated at the second operating temperature, determining whether operating the turbine at the first operating temperature or the second operating temperature is more economically efficient.

Owner:GENERAL ELECTRIC CO

Tungsten oxide nanoflake self-assembly nanosphere and application method and application of tungsten oxide nanoflake self-assembly nanosphere

InactiveCN102757095AEasy to operateMild experimental conditionsTungsten oxides/hydroxidesNanotechnologyMicrometerNitrogen dioxide

The invention provides a tungsten oxide nanoflake self-assembly nanosphere gas-sensitive material, a preparation method and application of the gas-sensitive material. Tungsten oxide nanoflake self-assembly nanosphere is successfully prepared by an ultrasonic method under the mild condition, the diameter of the tungsten oxide nanosphere ranges from 1 micrometer to 3 micrometers, and the tungsten oxide nanosphere consists of lamella structure units in a self-assembly manner. Compared with an existing method for preparing a tungsten oxide nanometer material, the method has the advantages of simple equipment, convenience in operation, mild experimental condition, low cost and the like. The prepared tungsten oxide nanoflake self-assembly nanosphere has high sensitivity and selectivity to low-concentration NO2 at low operation temperature, and is applicable to detecting trace nitrogen dioxide in environments.

Owner:BEIJING UNIV OF CHEM TECH

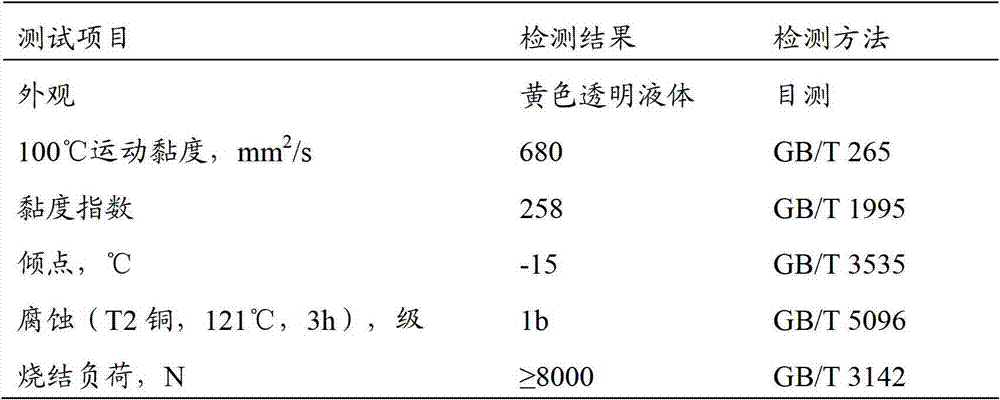

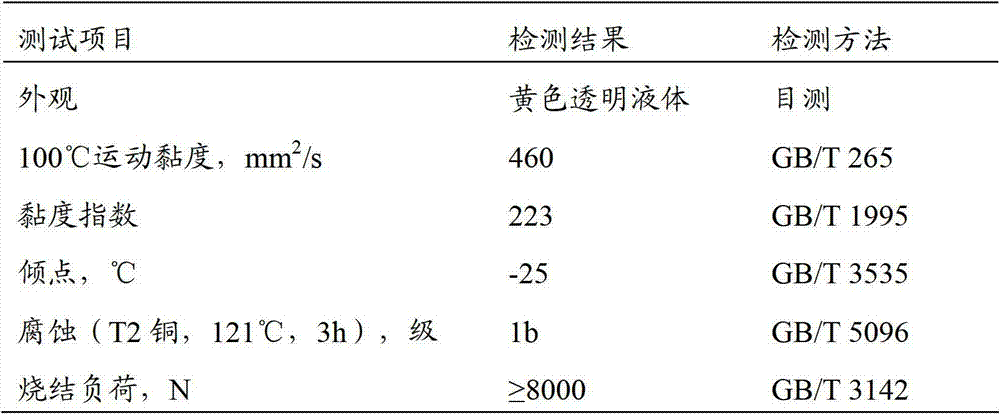

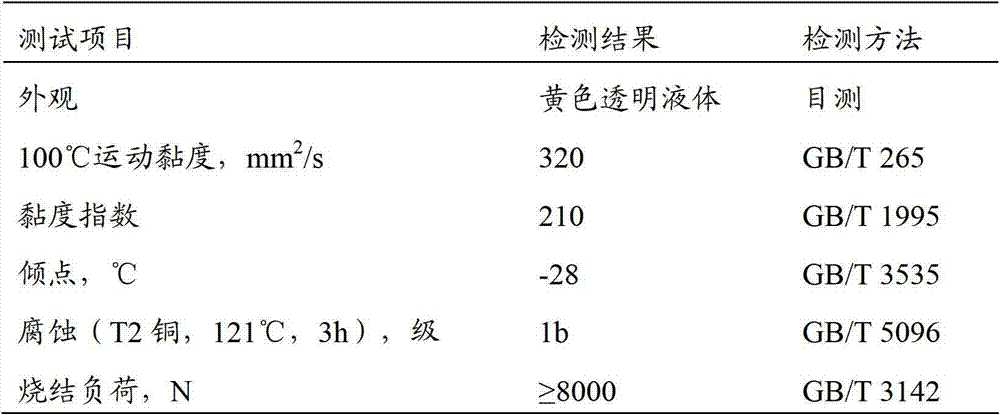

Open gear lubricant combination and preparation method thereof

ActiveCN102776056AImprove efficiencyIncrease viscosityLubricant compositionSolubilityViscosity index

The invention discloses an open gear lubricant combination which comprises high-viscosity synthetic base oil, synthetic ester base oil and an additive having a weight ratio of (55-93):(5-25):(2-20). Because the high-viscosity synthetic base oil has the characteristics of high viscosity index, better high-temperature and low-temperature performance and lower friction coefficient, and the synthetic ester base oil has the characteristics of low pour point and excellent solubility and perceptibility of the additive, the high-viscosity synthetic base oil and the synthetic ester base oil are matched in the invention, and a proper amount of additive is added, thus ensuring that the lubricant combination has the following characteristics: the lubricant combination has higher viscosity and excellent viscosity-temperature performance, and is beneficial to formation and maintenance of a lubricant film in the process of using oil products; under the condition of the same viscosity range, the open gear lubricant has excellent low-temperature flowing performance, thereby enlarging in use temperature range; and in use, the low-fluid friction of a gear pair in a load region can be caused, the operation temperatures of a gear and a gear transmission device are lowered, and the efficiency of the gear is increased.

Owner:CHINA PETROLEUM & CHEM CORP

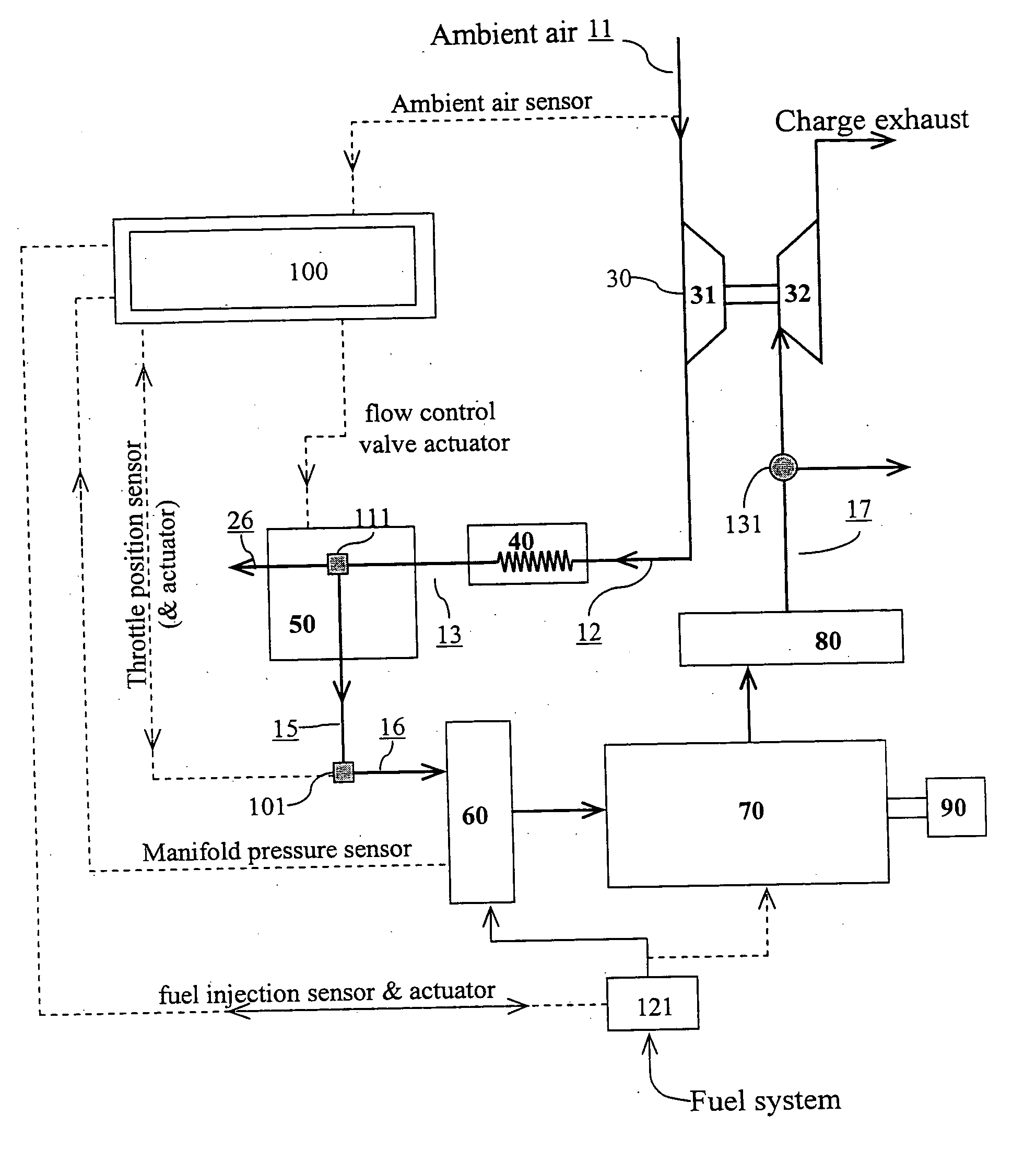

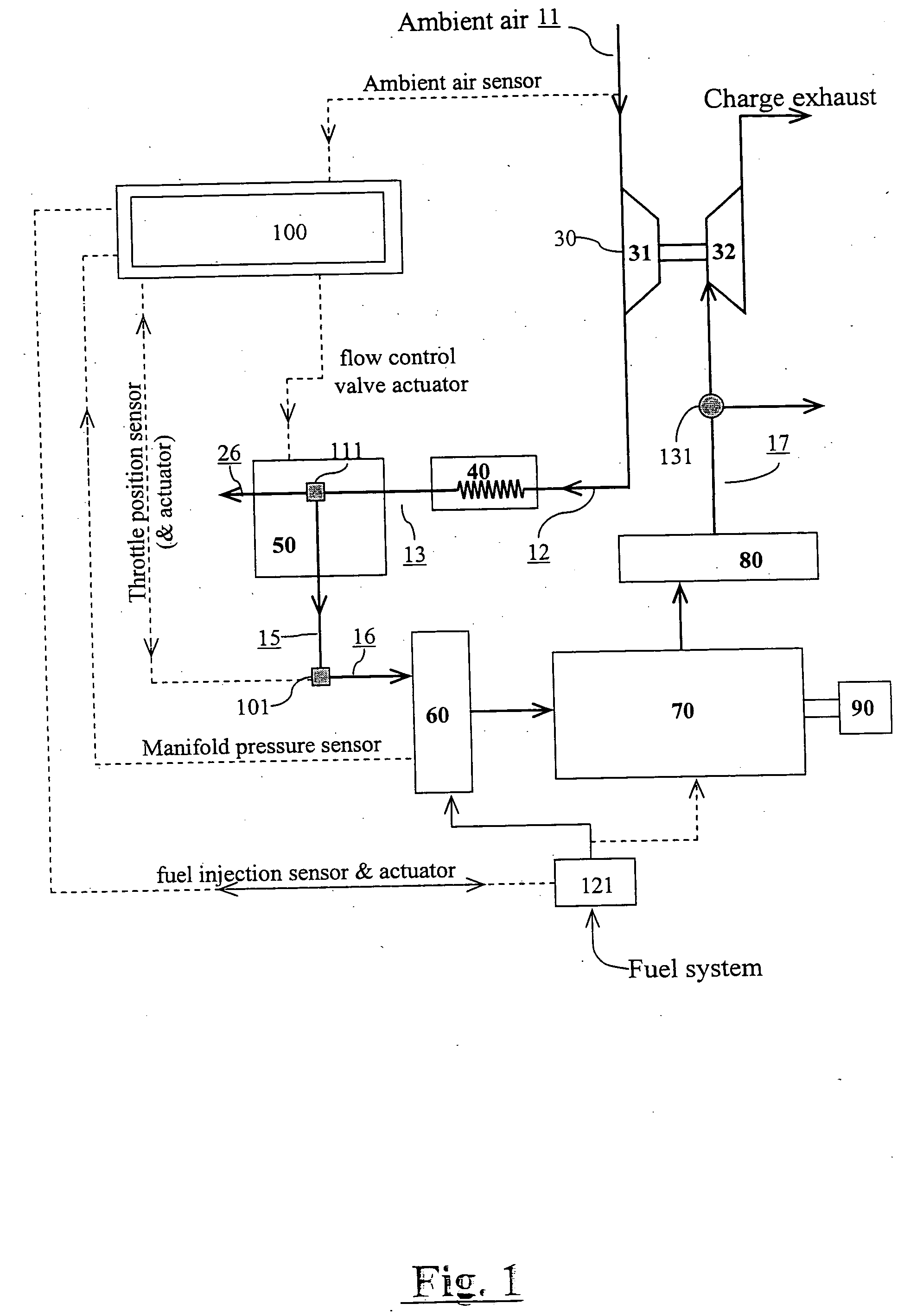

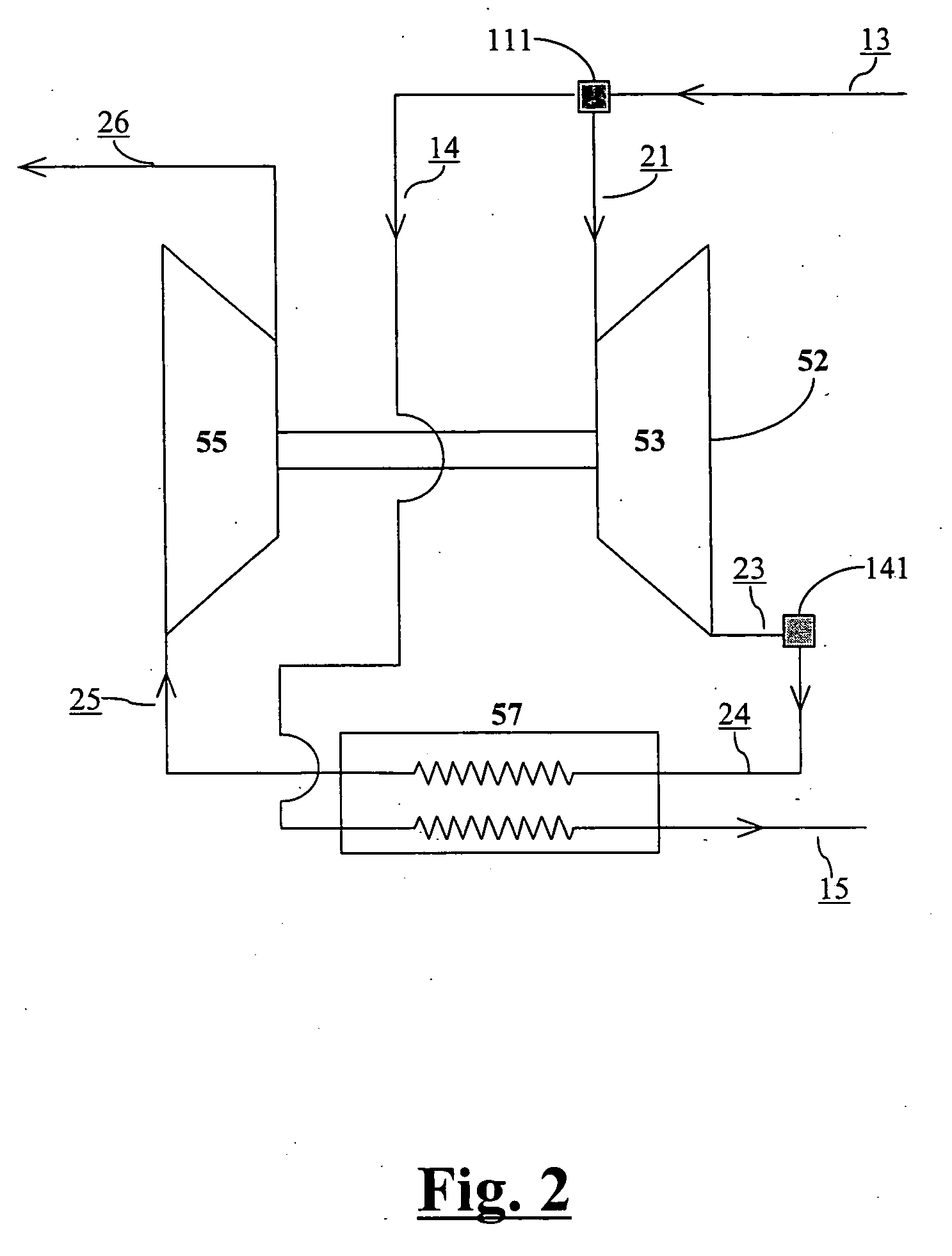

Supercharged intercooled engine using turbo-cool principle and method for operating the same

InactiveUS20050279093A1Easy to controlGuaranteed uptimeElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionCombustion

A supercharged and intercooled engine utilizing the turbo-cool principle and a method for operating the same is provided. The classical Carnot-Otto-Diesel paradigm for internal combustion engines is modified so internal combustion engines achieve highest performance in an optimal peak temperature range, which is lower than the typical peak operation temperatures of current gasoline engines and diesel engines. Turbo-cooling turbocharging systems provide for internal combustion engines operating within this peak temperature range by simultaneously controlling engine load-and-speed and intake-air temperature through the combined application of a primary load-and-speed control and a second operation control unit, primarily for intake air conditioning. This can be applied to gasoline engines, diesel engines, direct-injection gasoline engines, and homogeneous charge compression ignition (HCCI) engines.

Owner:LIN SHU WANG

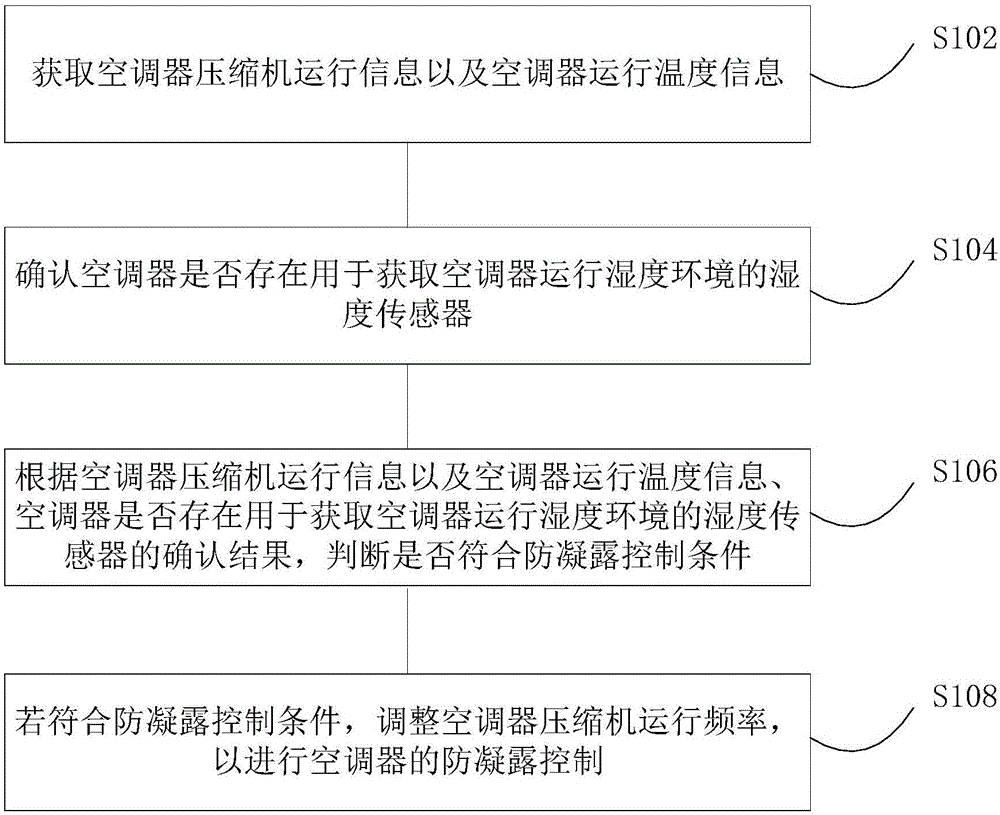

Control method and device for air conditioner

ActiveCN106765975ASolve the problem of relatively limited scope of applicationMechanical apparatusSpace heating and ventilation safety systemsEngineeringControl theory

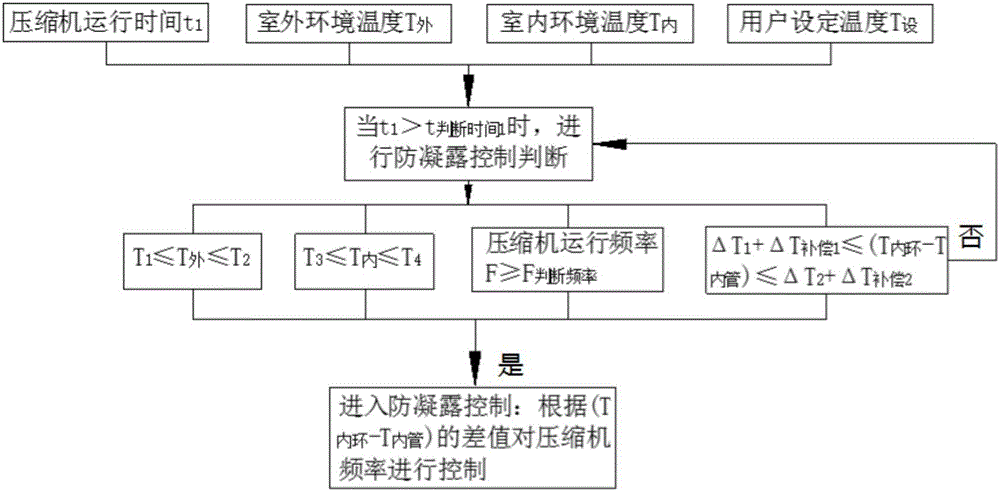

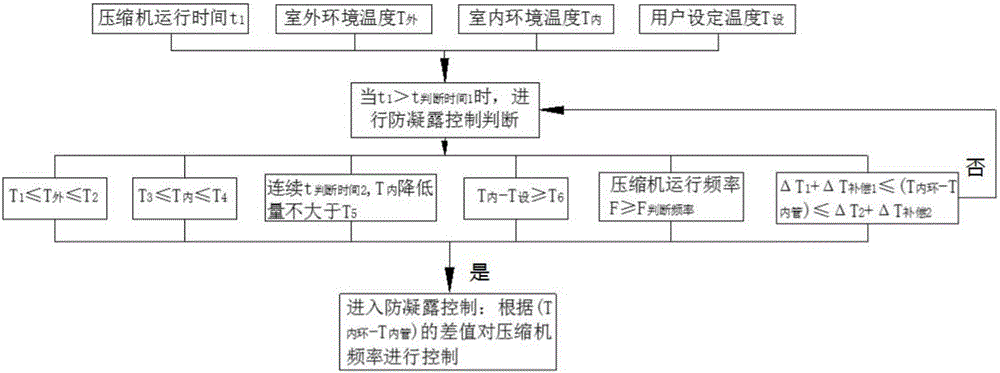

The invention discloses a control method and device for an air conditioner, wherein the method comprises the following steps of: obtaining operation information of a compressor of the air conditioner and operation temperature information of the air conditioner; confirming whether the air conditioner has a humidity sensor for obtaining an operation humidity environment of the air conditioner or not; judging whether a condensation prevention control condition is met or not according to the operation information of the compressor of the air conditioner, the operation temperature information of the air conditioner as well as the confirmed result about whether the humidity sensor for obtaining the operation humidity environment of the air conditioner exists or not; and if the condensation prevention control condition is met, regulating operation frequency of the compressor of the air conditioner to perform condensation prevention control on the air conditioner. The control method solves the problems that a control strategy for the condensation problem of the air conditioner in the prior art is only suitable for the air conditioner with the humidity sensor and range of application is relatively limited, so that the scope of application is expanded.

Owner:GREE ELECTRIC APPLIANCES INC

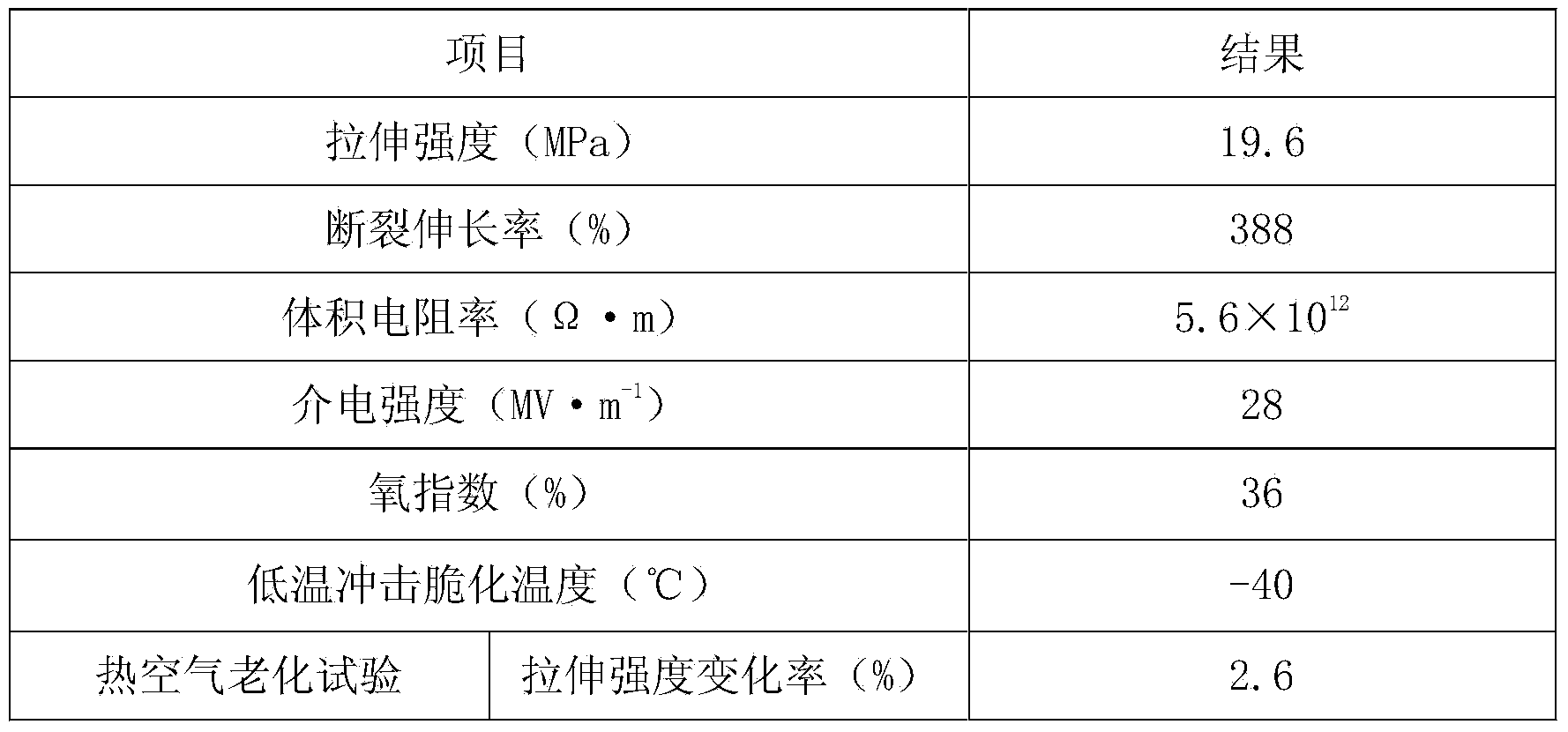

Oil-resistant cold-resistant ultraviolet-proof polyvinyl chloride/nitrile rubber composite cable material and preparation method thereof

InactiveCN103509274AImprove mechanical propertiesImprove toughnessRubber insulatorsPlastic/resin/waxes insulatorsDiethylene glycol monobutyl etherPolymer science

A disclosed oil-resistant cold-resistant ultraviolet-proofpolyvinyl chloride / nitrile rubber composite cable material is prepared from the following raw materials in parts by weight: 60-80 parts of SG-2 type polyethylene, 20-30 parts of POE, 30-50 parts of nitrile rubber, 15-20 parts of fluorubber, 10-15 parts of dioctyl phthalate, 5-10 parts of di(butylcarbitol)adipate, 0.5-1 part of dicumyl peroxide, 2-3 parts of triallyl isocyanurate, 1-2 parts of 2-mercaptobenzimidazole, 4-8 parts of titanium dioxide, 5-10 parts of paraffin oil, 2-3 parts of zinc oxide, 4-8 parts of microcrystalline paraffin and the like. The cable materials of the invention ahs excellent thermoset rubber apparence and thermoplastic elastomer characteristics, and good mechanical properties and low-temperature flexibility; the long-term suitable operation temperature is -40 DEG C to 105 DEG C; the cable material is capable of retarding flame, resisting oil, resisting acid and base, resisting wear, resisting weather, resisting ozone, resisting thermal aging and resisting ultraviolet ray, and is applicable as high-oil-resistance weatherable cable sheath materials.

Owner:安徽天民电气科技有限公司

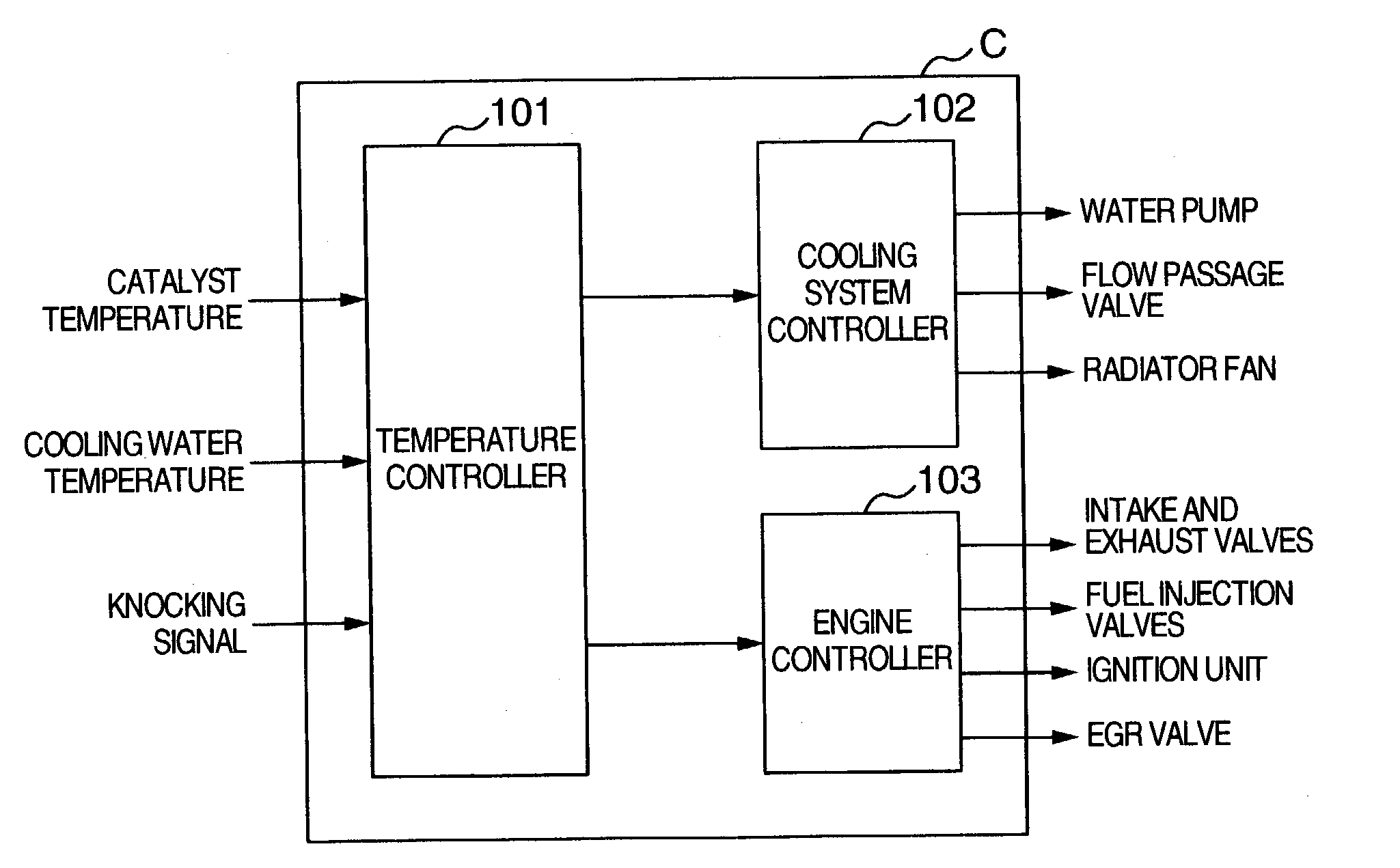

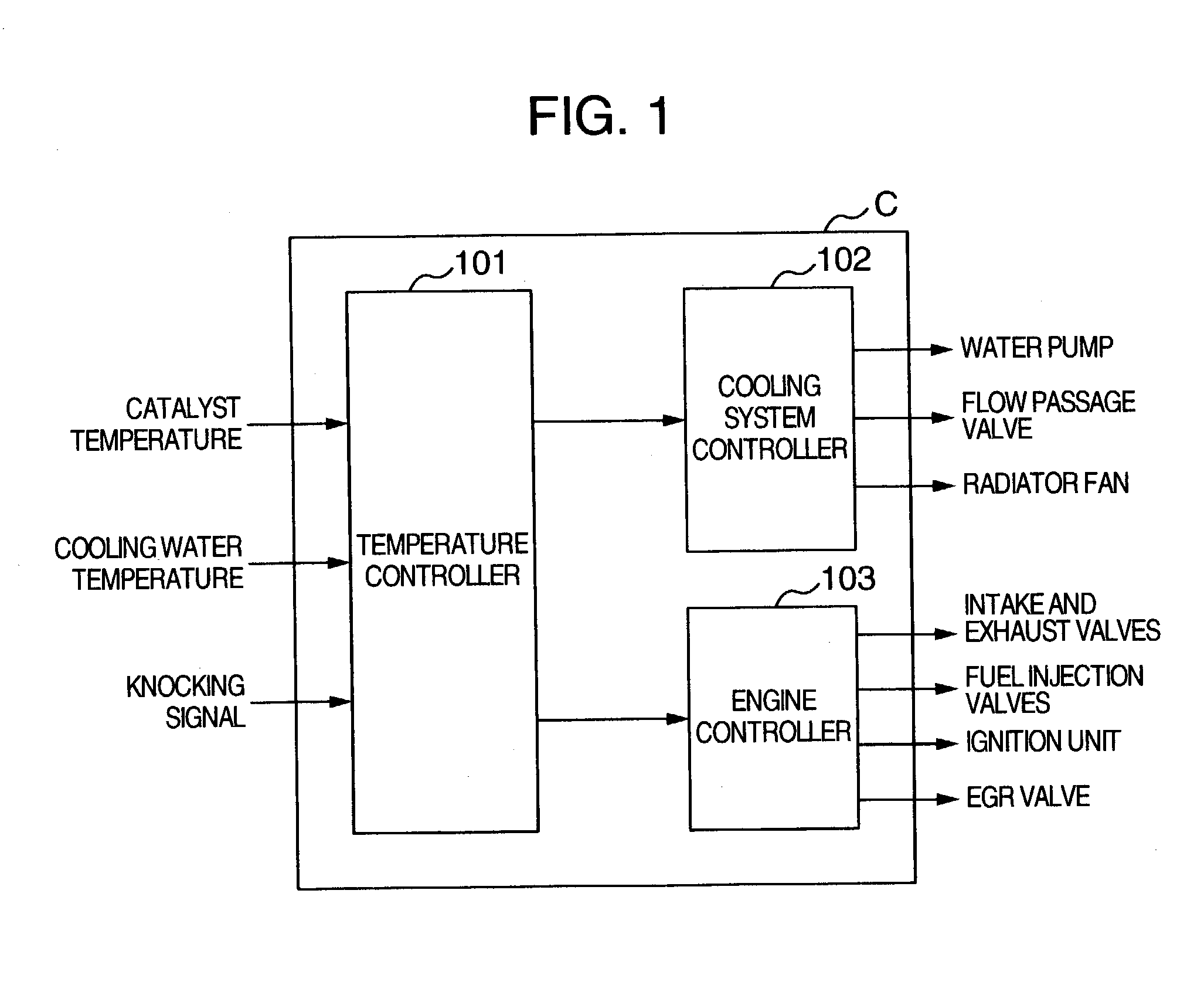

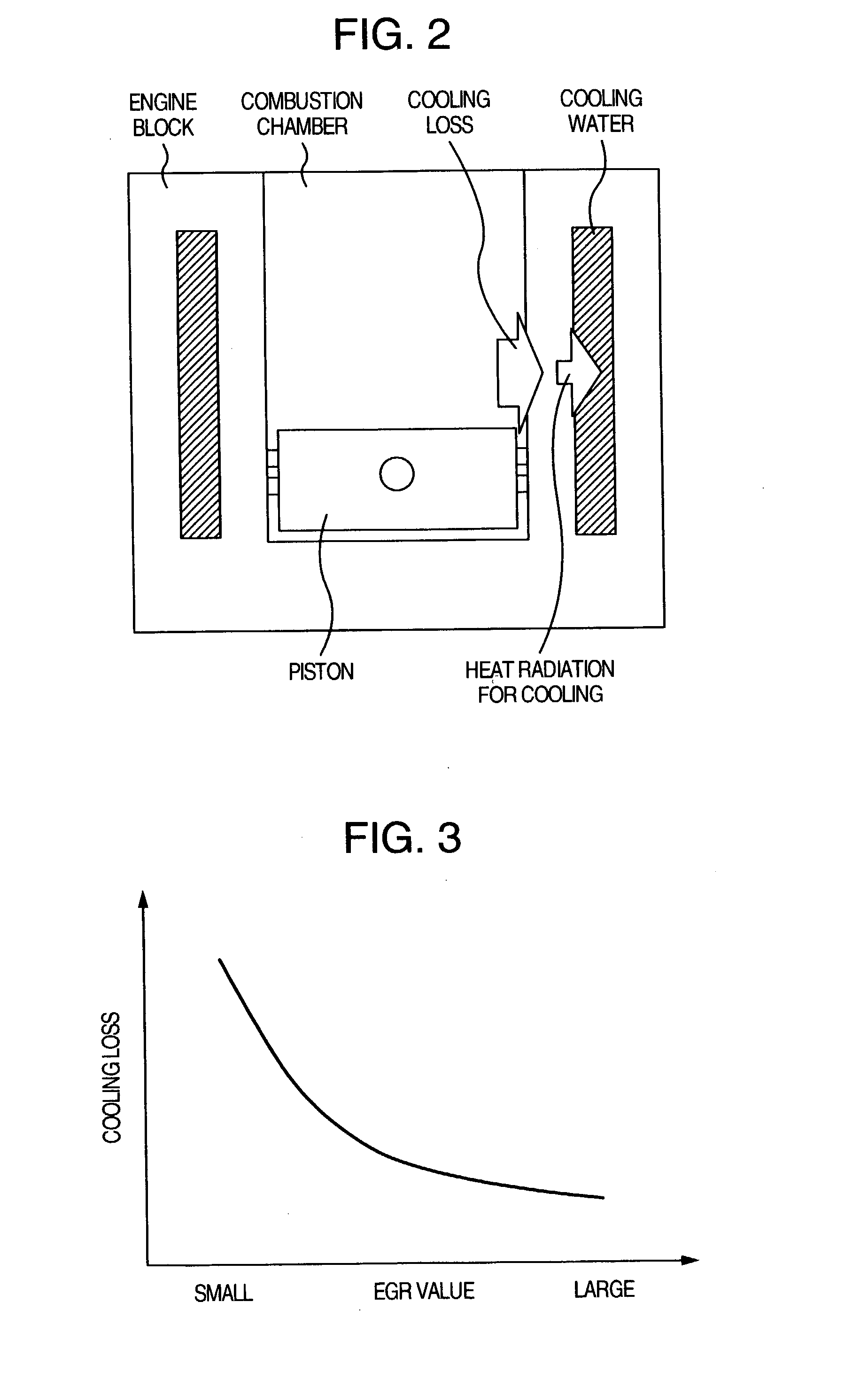

Control system for internal combustion engine with catalyst for purifying exhaust gas

There is provided a control system for an internal combustion engine, which aim for early warm-up of catalyst and the engine in order to control a cooling loss and a heat radiation for cooling in such a way that the warm-up of the catalyst is carried out prior to the warm-up of the engine. That is, if the temperature of the catalyst is not greater than an activation temperature, there is carried out at least one of (1) retardation control of the ignition timing, (2) stopping control of a water pump for engine cooling water, (3) lowering control of the flow rate of the cooling water, but if the temperature of the catalyst is higher than the activation temperature, there is carried out at least one of control of the water pump in accordance with a temperature of the cooling water and control of retardation of the ignition timing, until the temperature of the cooling water reaches a warm-up temperature which is a normal operation temperature of the engine.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com