Magnetic material for magnetic refrigeration apparatus, amr bed, and magnetic refrigeration apparatus

a technology of magnetic refrigeration and amr bed, which is applied in the direction of lighting and heating apparatus, machine operation mode, magnetic body, etc., can solve the problems of reducing working efficiency, affecting the environment, and cfc's substitutes also have adverse effects on the environment, so as to improve the efficiency of magnetic refrigeration and widen the effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

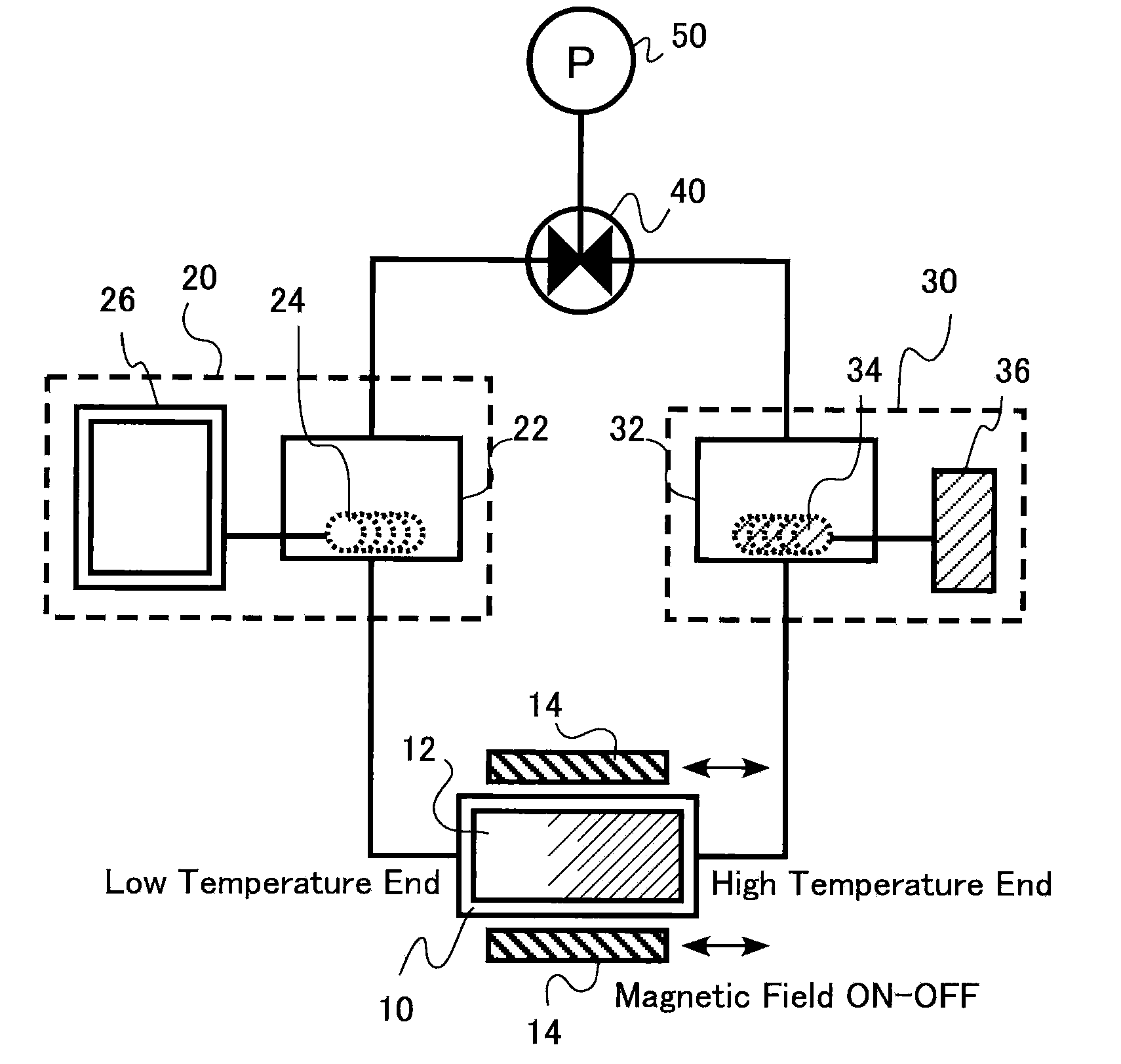

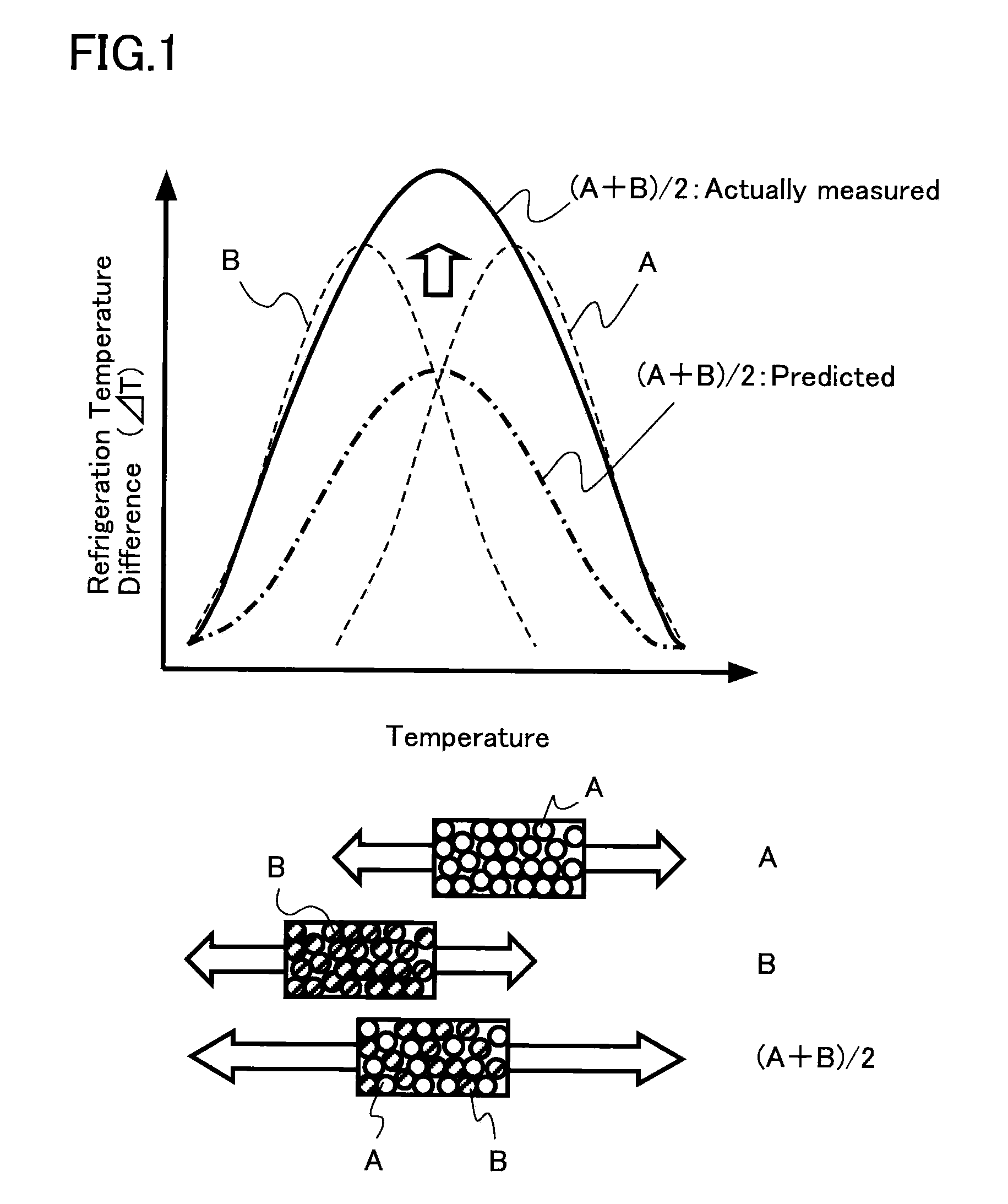

[0026]A magnetic material for a magnetic refrigeration apparatus of a first embodiment is a magnetic material for a magnetic refrigeration apparatus using a liquid refrigerant. At least two kinds of magnetic particles having different magnetic transition temperatures (Tc) are approximately uniformly blended. The magnetic particles exhibit an approximately spherical shape with a maximum diameter of 0.3 mm or more to 2 mm or less.

[0027]In the magnetic material of the first embodiment, two kinds of magnetic particles, for example, Gd particles having a magnetic transition temperature 293 (K) and Gd95Y5 particles having a magnetic transition temperature 283 (K), which is lower than that of the Gd particles, are approximately uniformly blended at a ratio of 1:1. Hereinafter, the difference between the magnetic transition temperatures of the two kinds of the magnetic particles is called a magnetic transition temperature difference (ΔTc).

[0028]The two kinds of the magnetic particles exhibi...

second embodiment

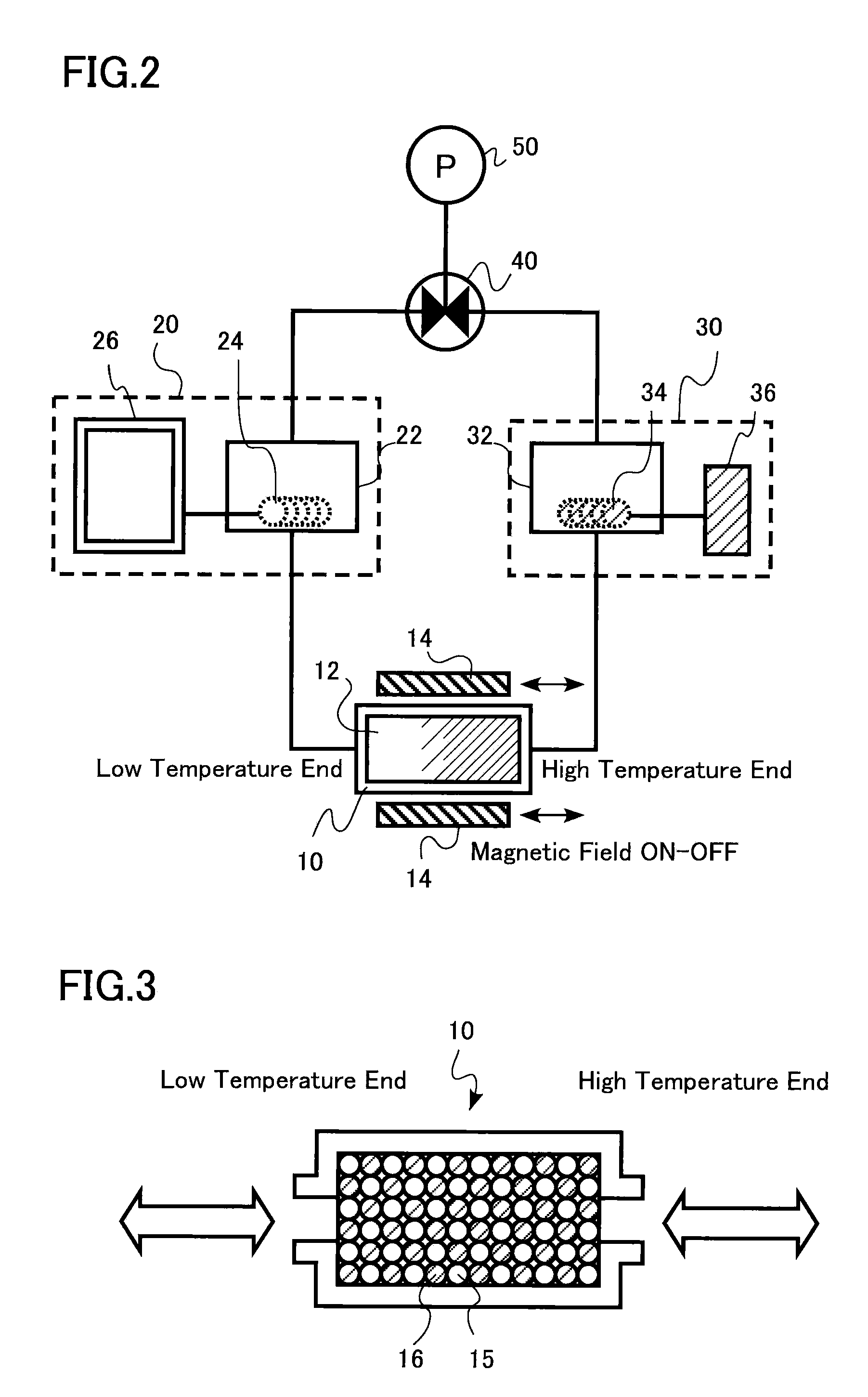

[0038]A magnetic refrigeration apparatus of a second embodiment is a magnetic refrigeration apparatus using a liquid refrigerant. The magnetic refrigeration apparatus has AMR bed filled with a magnetic material, a magnetic field generation means (device) for applying and removing a magnetic field to and from the magnetic material, a cooling block, and a radiating block. Further, the magnetic refrigeration apparatus has a refrigerant flow path formed by connecting the AMR bed, the cooling block and the radiating block configured to circulate the liquid refrigerant. The magnetic material with which the AMR bed is filled is formed by approximately uniformly bending at least two kinds of magnetic particles having different magnetic transition temperatures, and the magnetic particles has a feature in that they exhibit an approximately spherical shape with a maximum diameter of 0.3 mm or more to 2 mm or less. Note that since the magnetic material with which the AMR bed is filled is the sa...

example 1

[0056]AMR bed (hereinafter, called also a specimen vessel) was filled with a specimen, in which Gd95Y5 particles and Gd particles formed in a spherical shape and having a diameter of 0.3 mm or more to 2 mm or less were blended at a weight ratio of 3:1 (Gd ratio=25%), at a void ratio of 30% to 50%, and a refrigeration temperature difference (ΔT) was evaluated. Note that the magnetic transition temperature of the Gd95Y5 particles was 283 K, the magnetic transition temperature of the Gd particles was 293 K, and a magnetic transition temperature difference (ΔTc) was 10 K. The refrigeration temperature difference (ΔT) was evaluated by the following method.

[0057]The AMR bed was filled with the specimen so that the specimen did not easily move. Next, a thermocouple was inserted into the specimen vessel through a 0.8 mm φ hole formed to an upper lid of the vessel so that it was positioned in a central portion of the specimen vessel. Further, the specimen vessel was entirely covered with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com