Patents

Literature

4520results about How to "Improve packaging efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

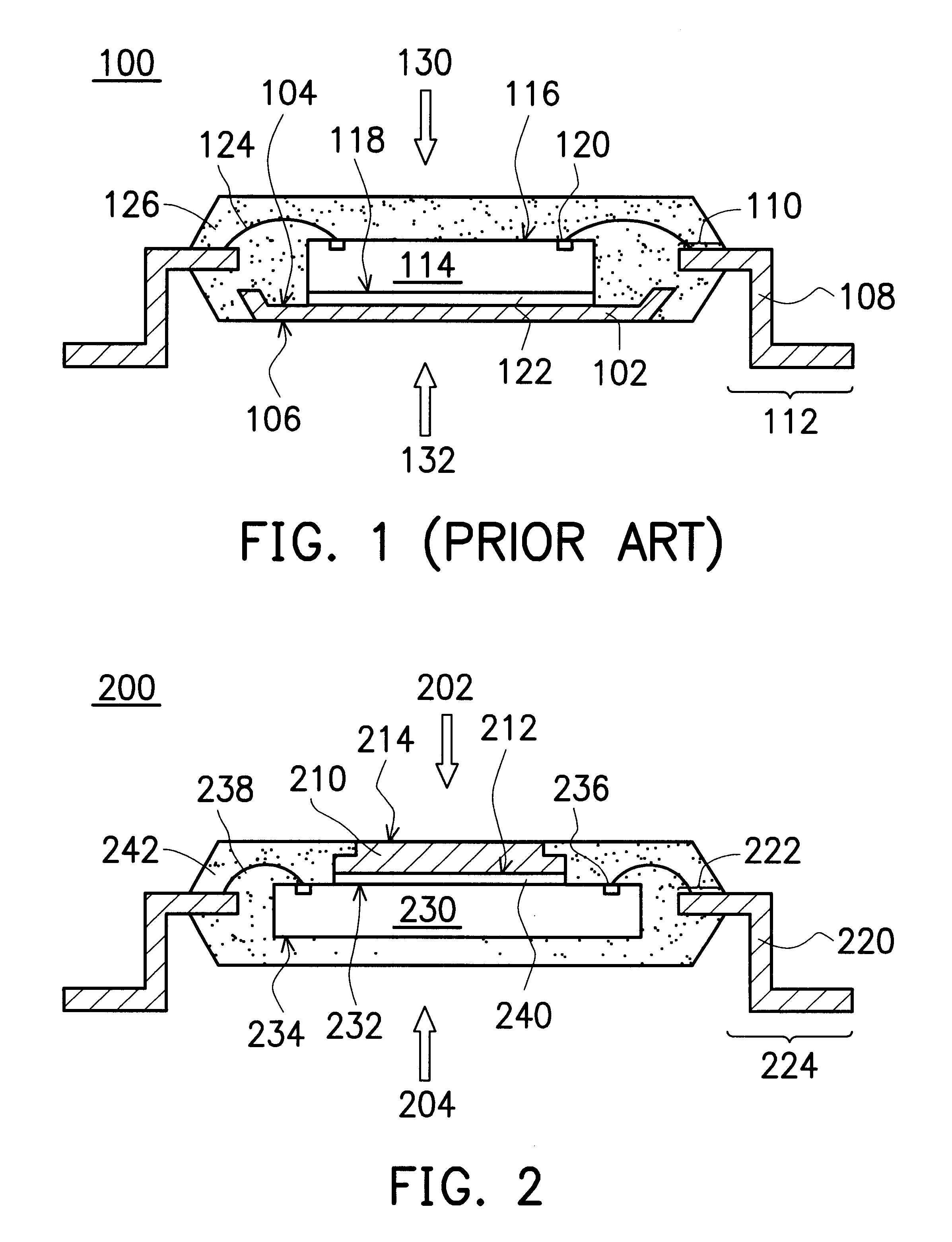

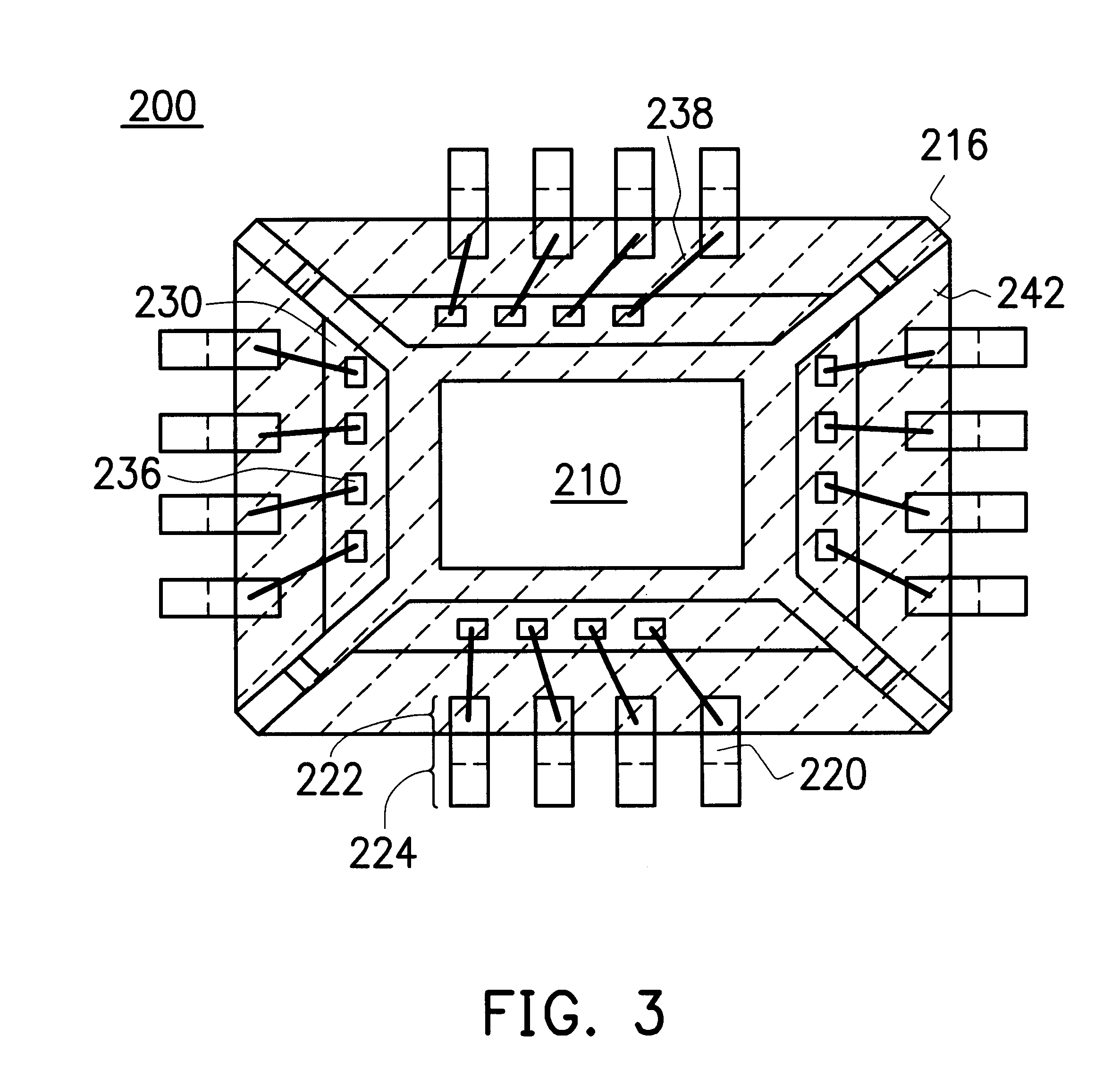

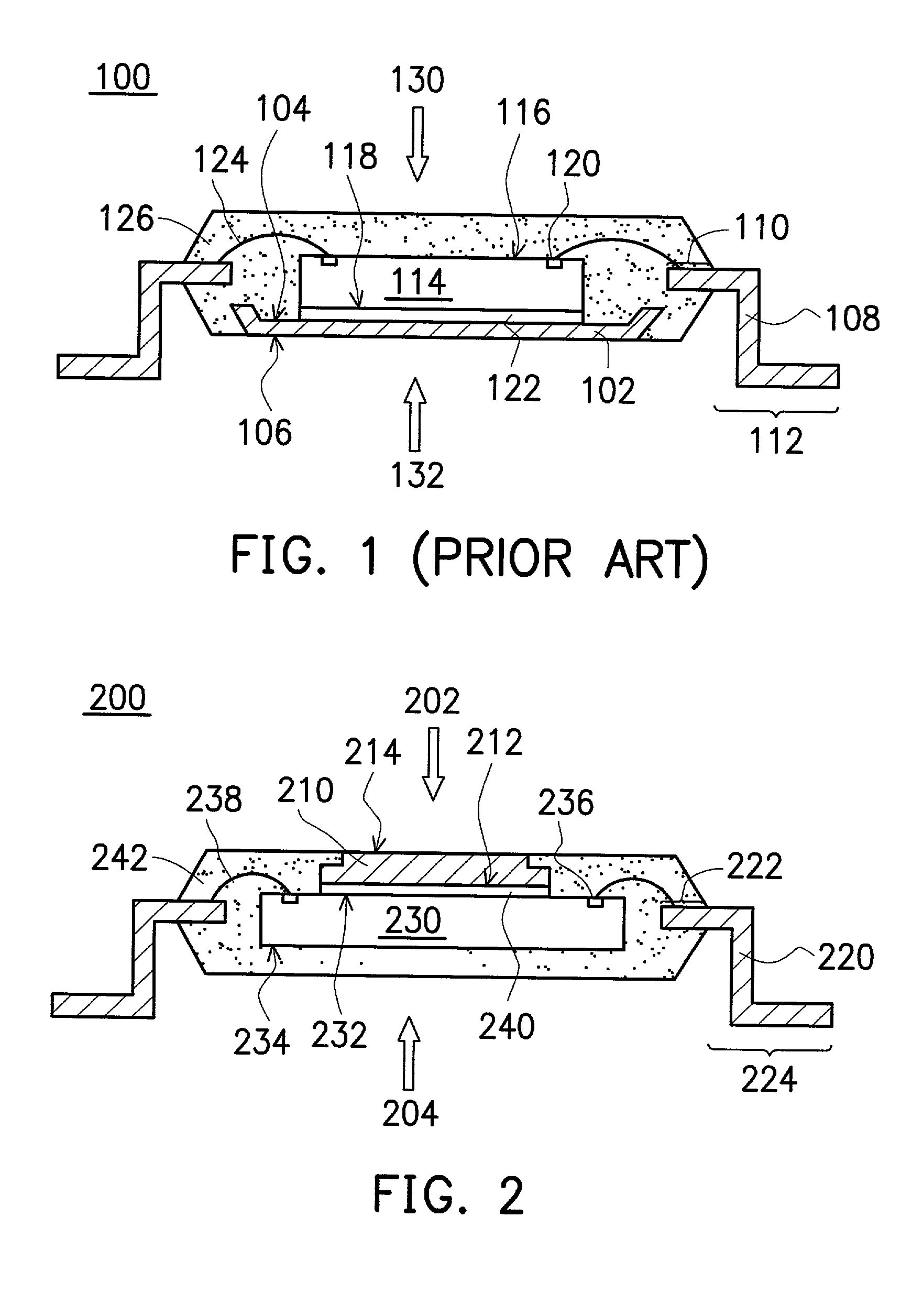

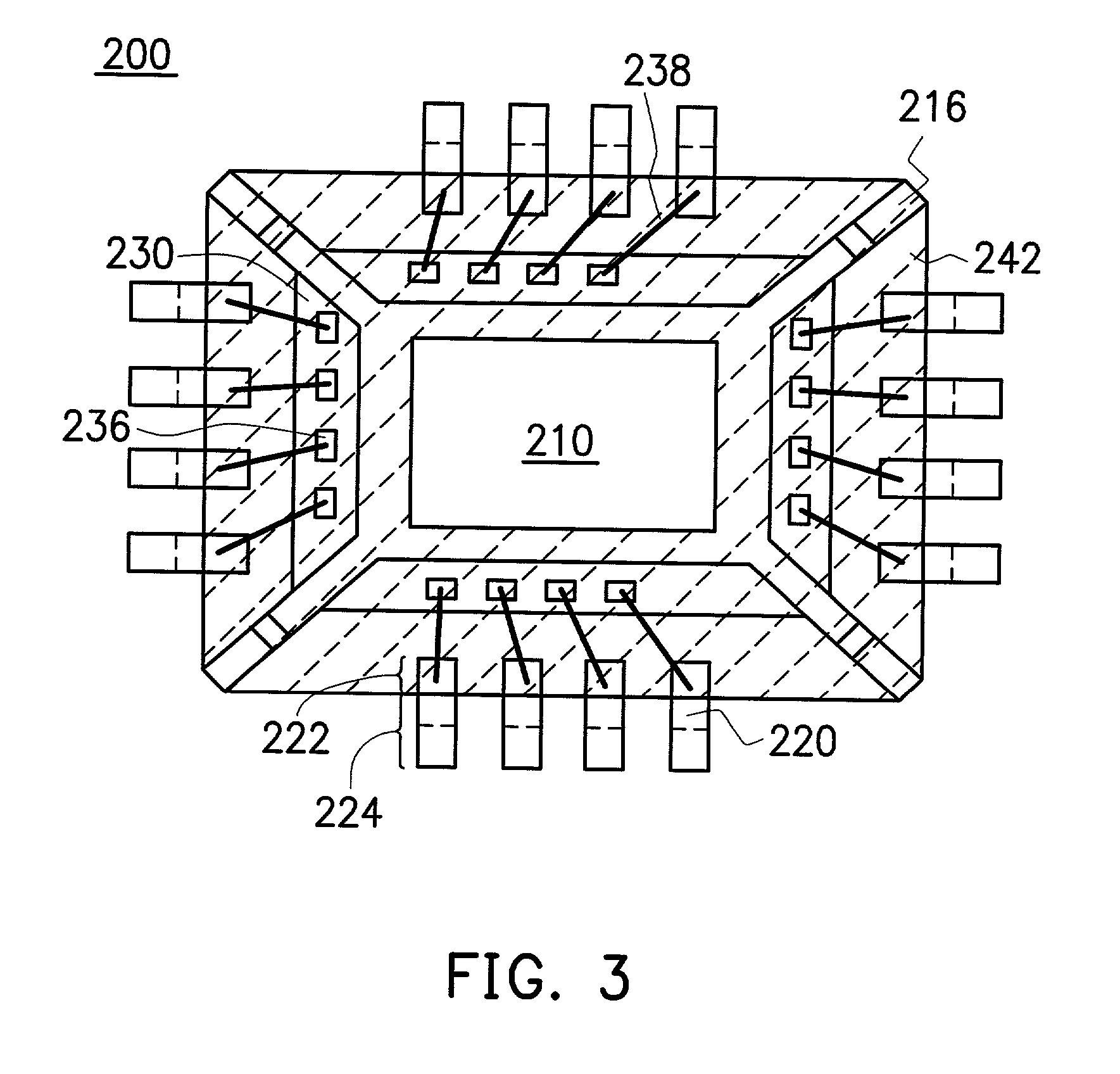

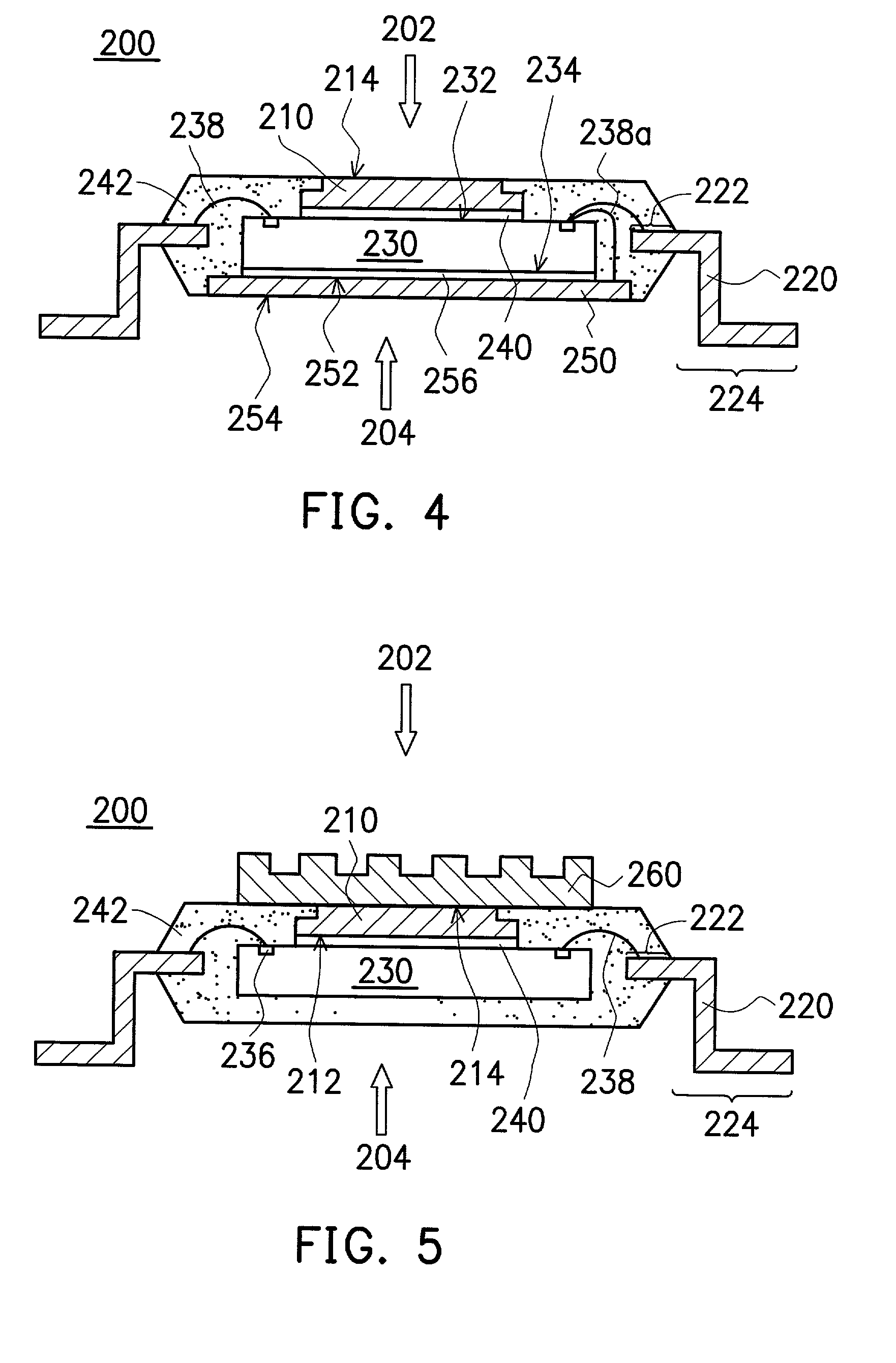

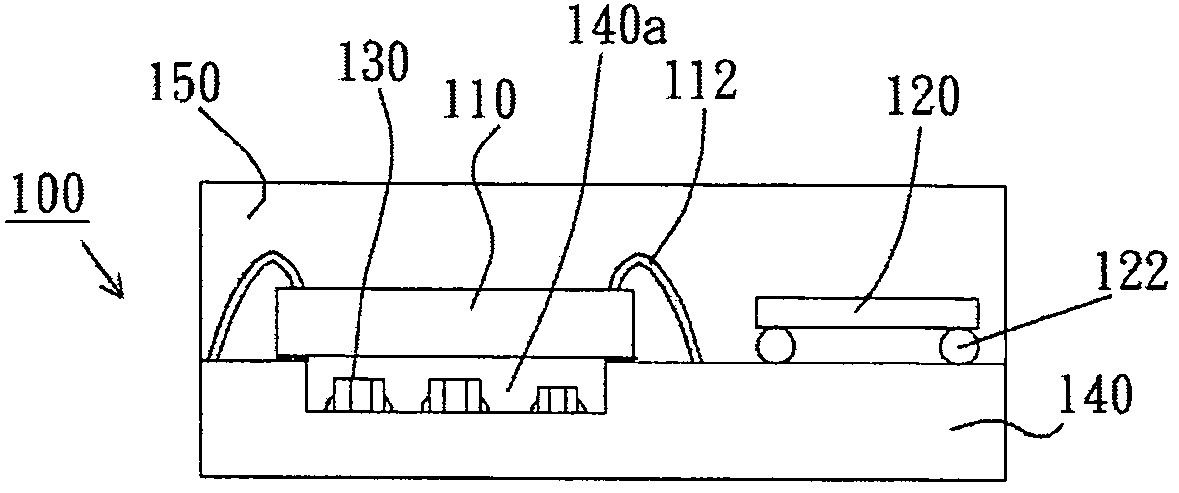

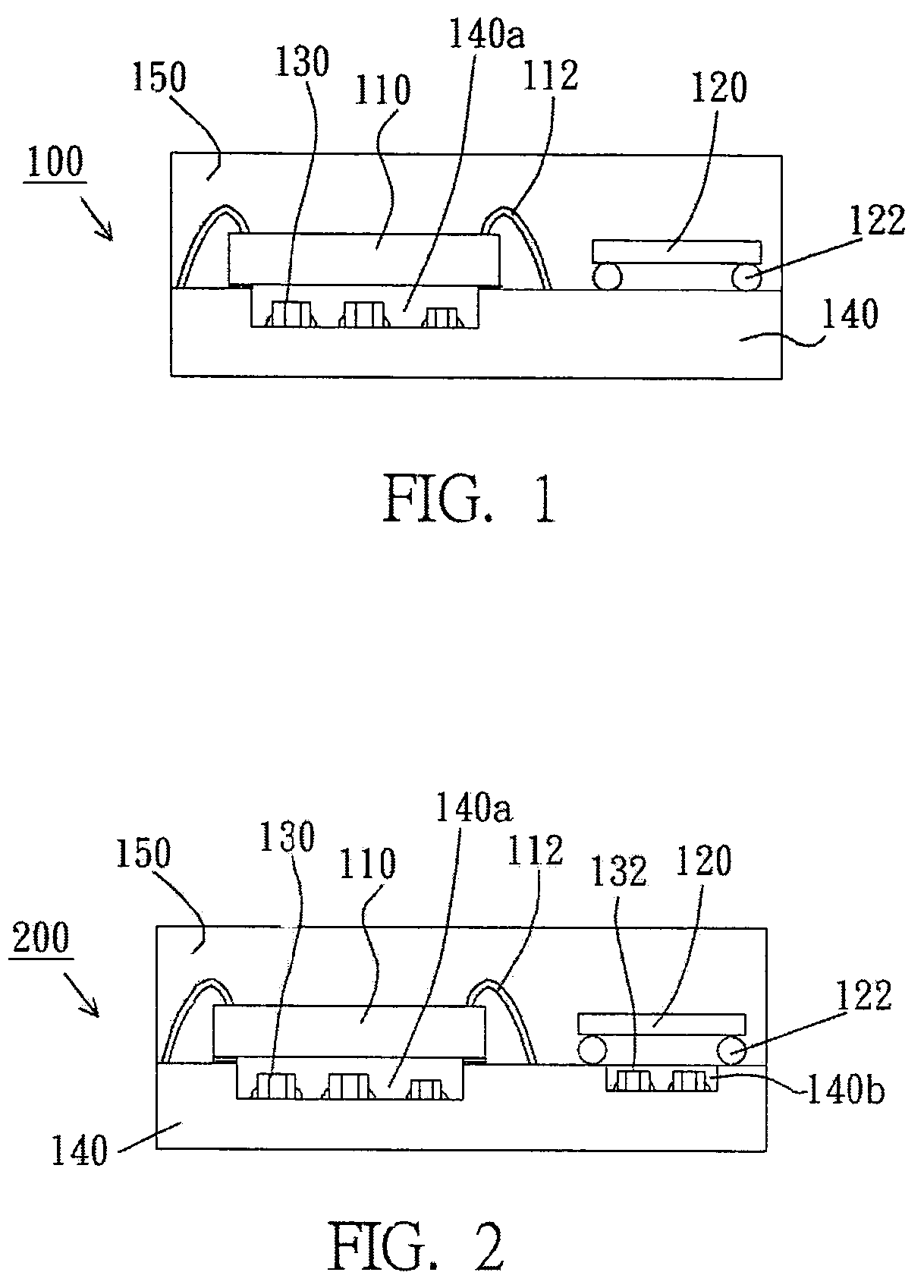

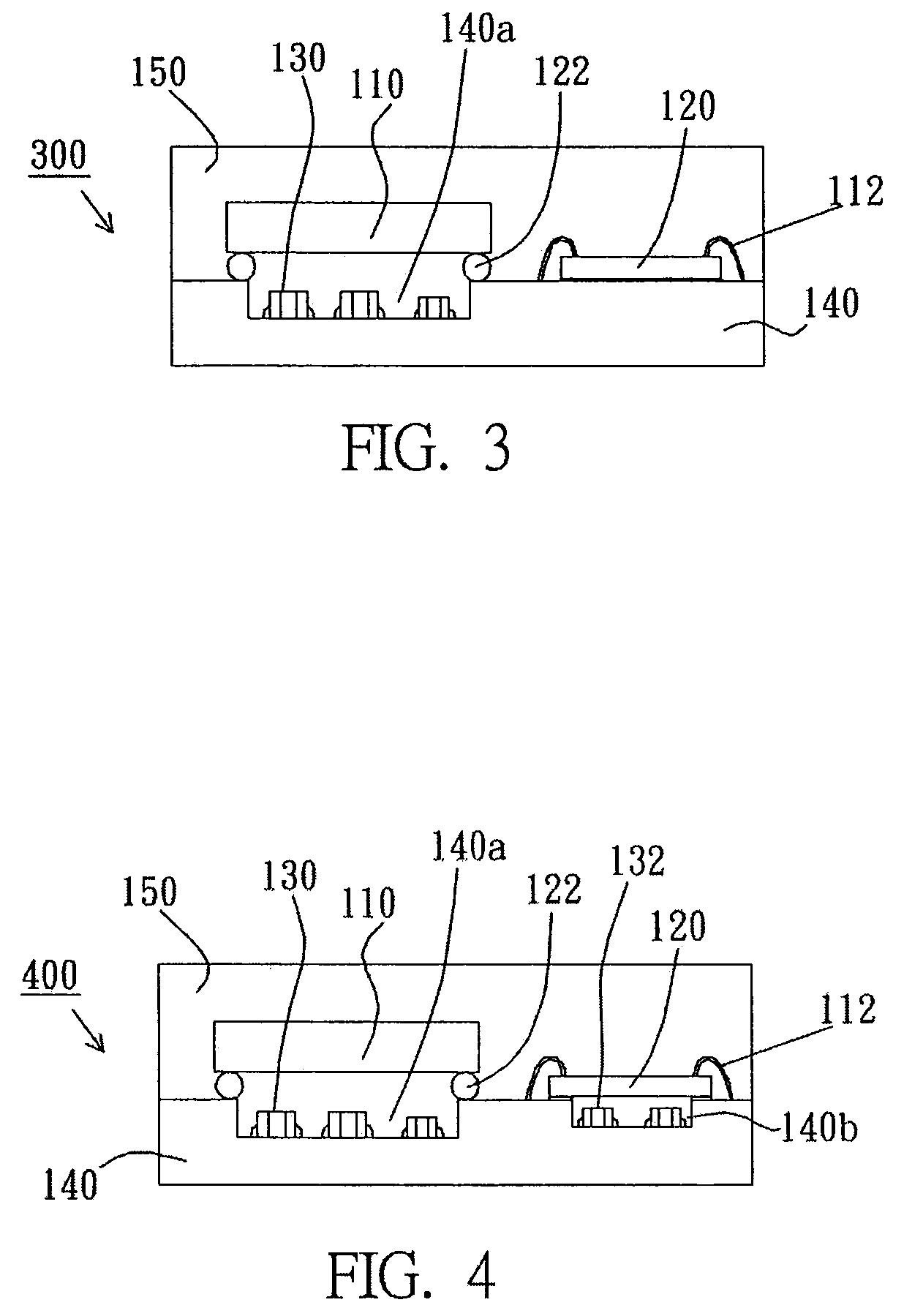

Semiconductor package having heat sink at the outer surface

InactiveUS6559525B2Easy to addImprove packaging efficiencySemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageLead frame

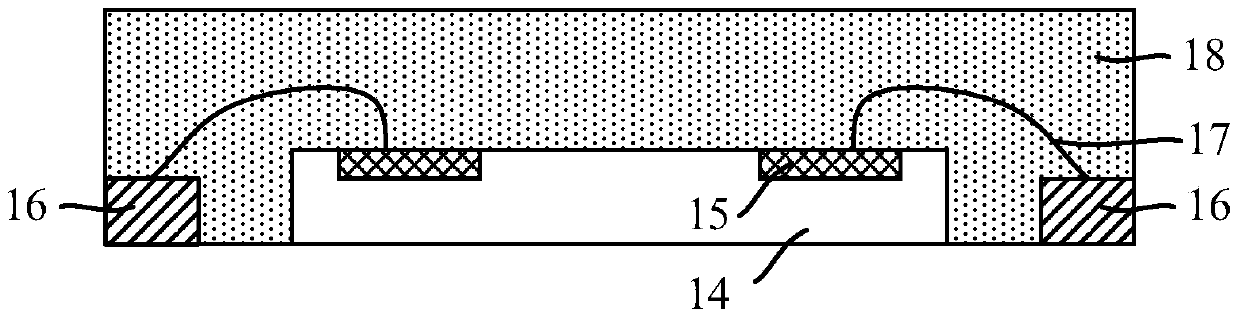

A semiconductor package having heat sink at the outer surface is constructed on a lead frame. The package comprises a chip, a die pad, a plurality of leads, a plurality of bonding wires, and a molding compound. The die pad has a first surface and a second surface, and the chip has its active surface bonded to the first surface of the die pad. The area of the die pad is smaller than the area of the chip in order to expose the bonding pads on the active surface of the chip. The leads having an inner lead portions and an outer lead portions are disposed at the periphery of the die pad, and the inner lead portions are electrically connected to the bonding pads by a plurality of bonding wires. The molding compound encapsulates the chip, the die pad, the inner lead portions of the leads, and the bonding wires. The second surface of the die pad is exposed on the top surface of the package structure while the outer lead portion of the leads is exposed at the side edge of the package structure.

Owner:SILICONWARE PRECISION IND CO LTD

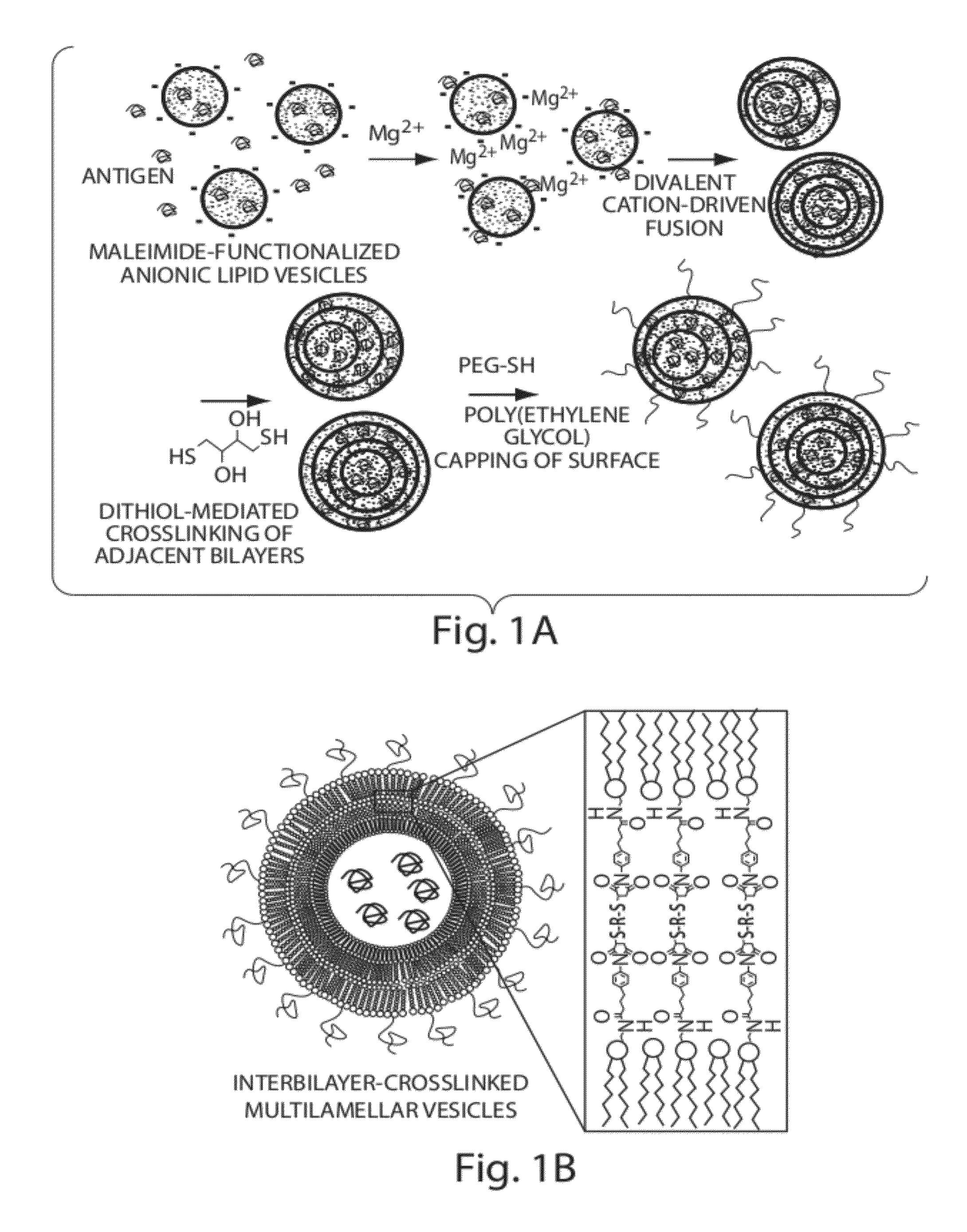

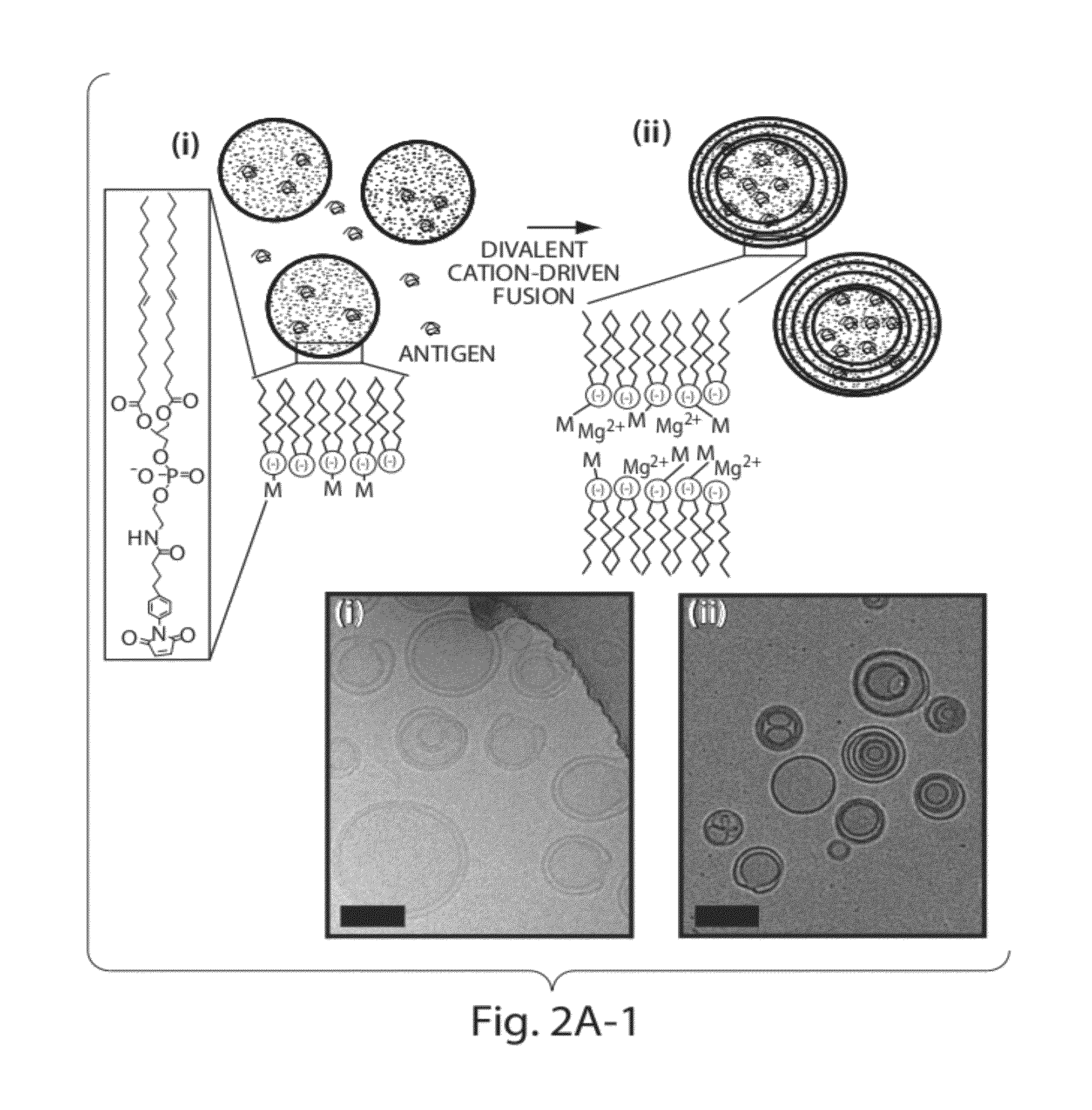

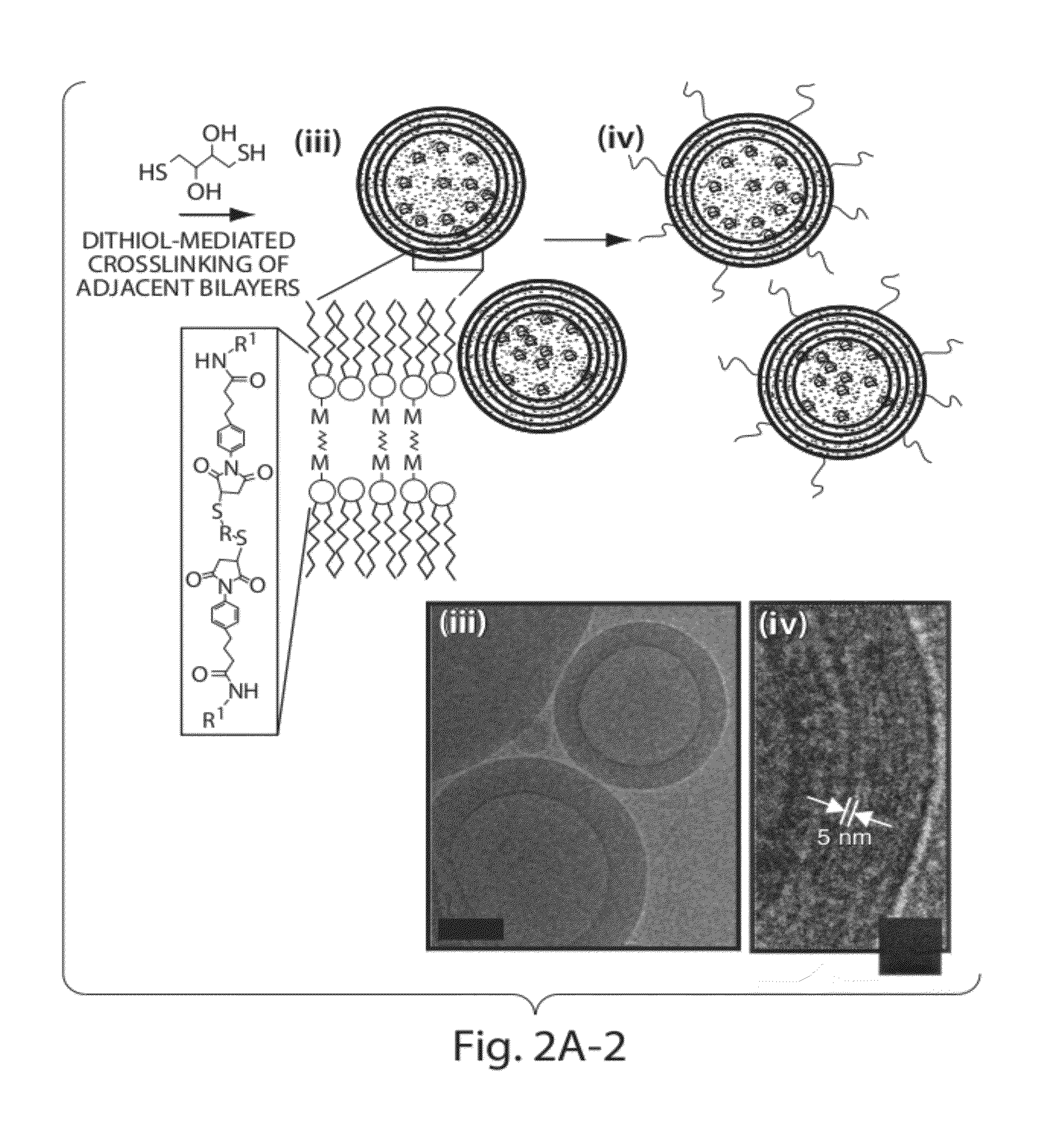

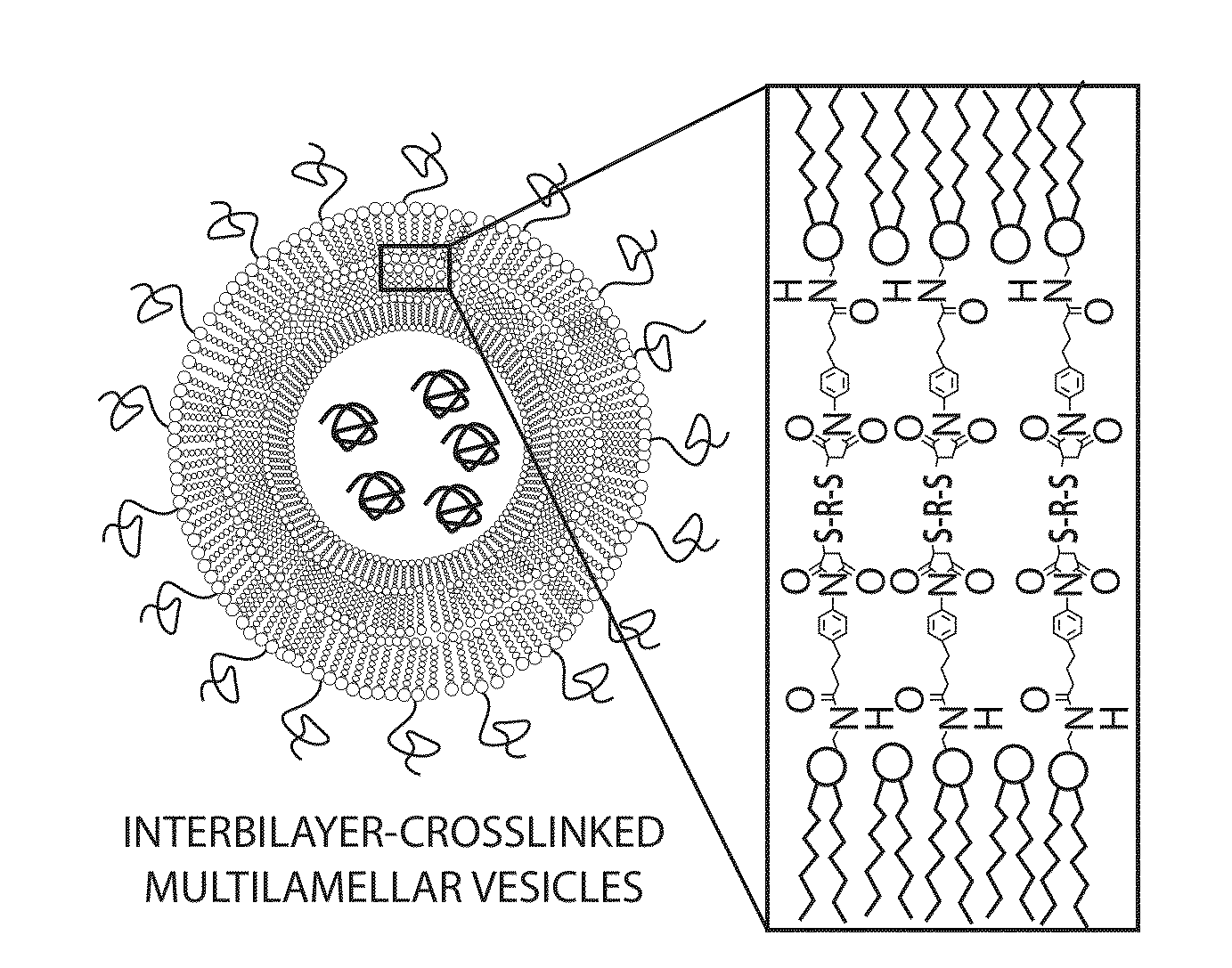

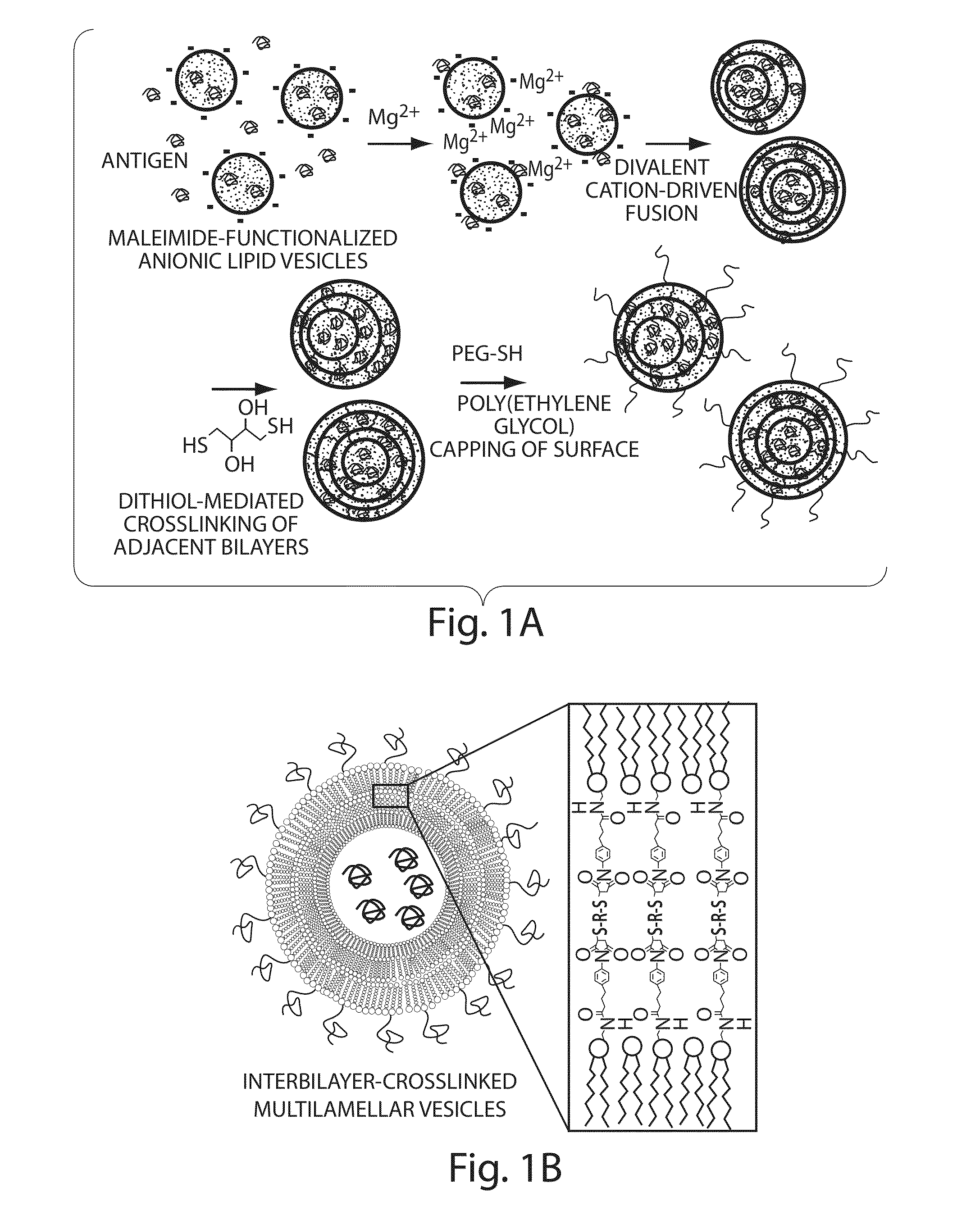

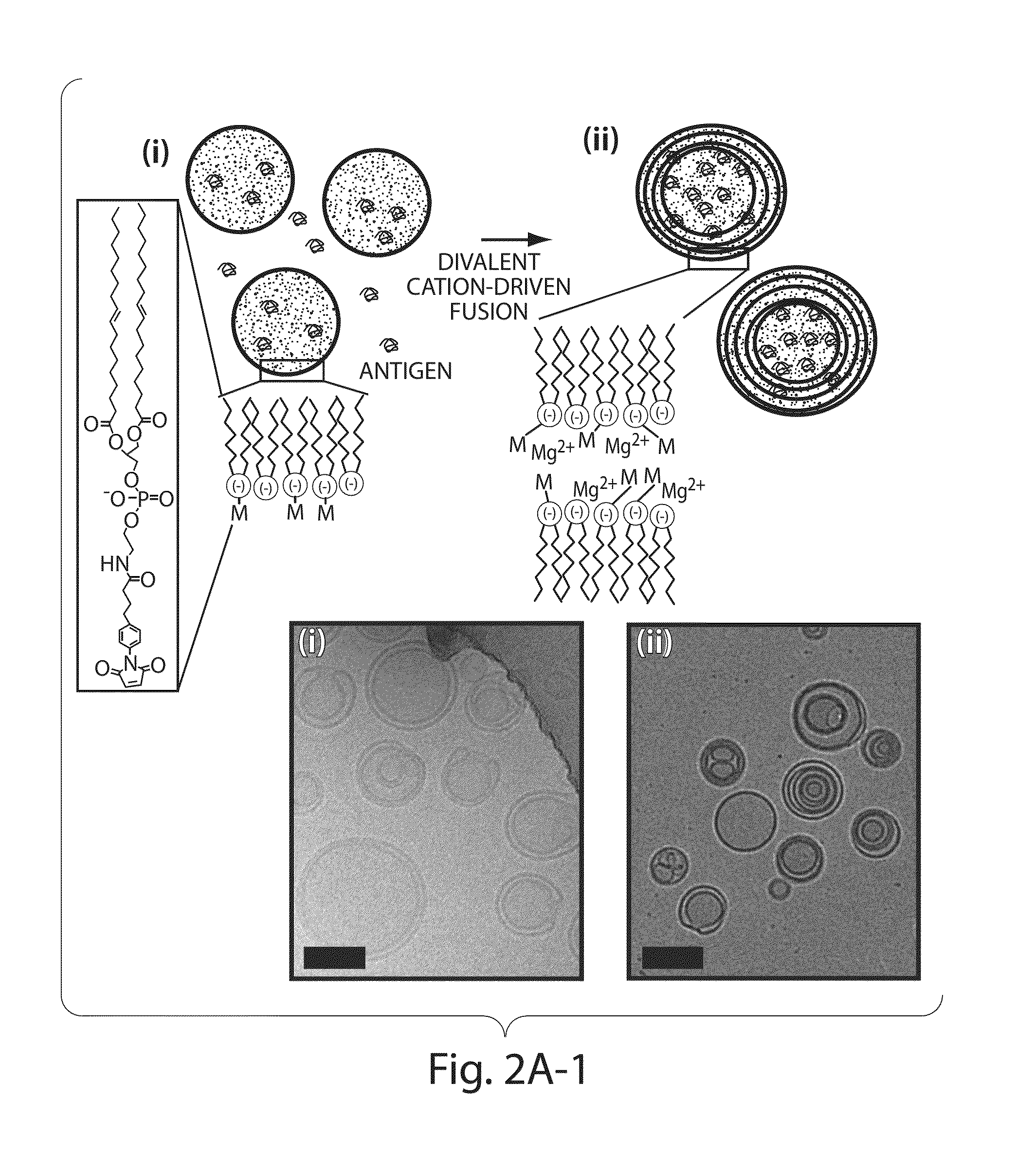

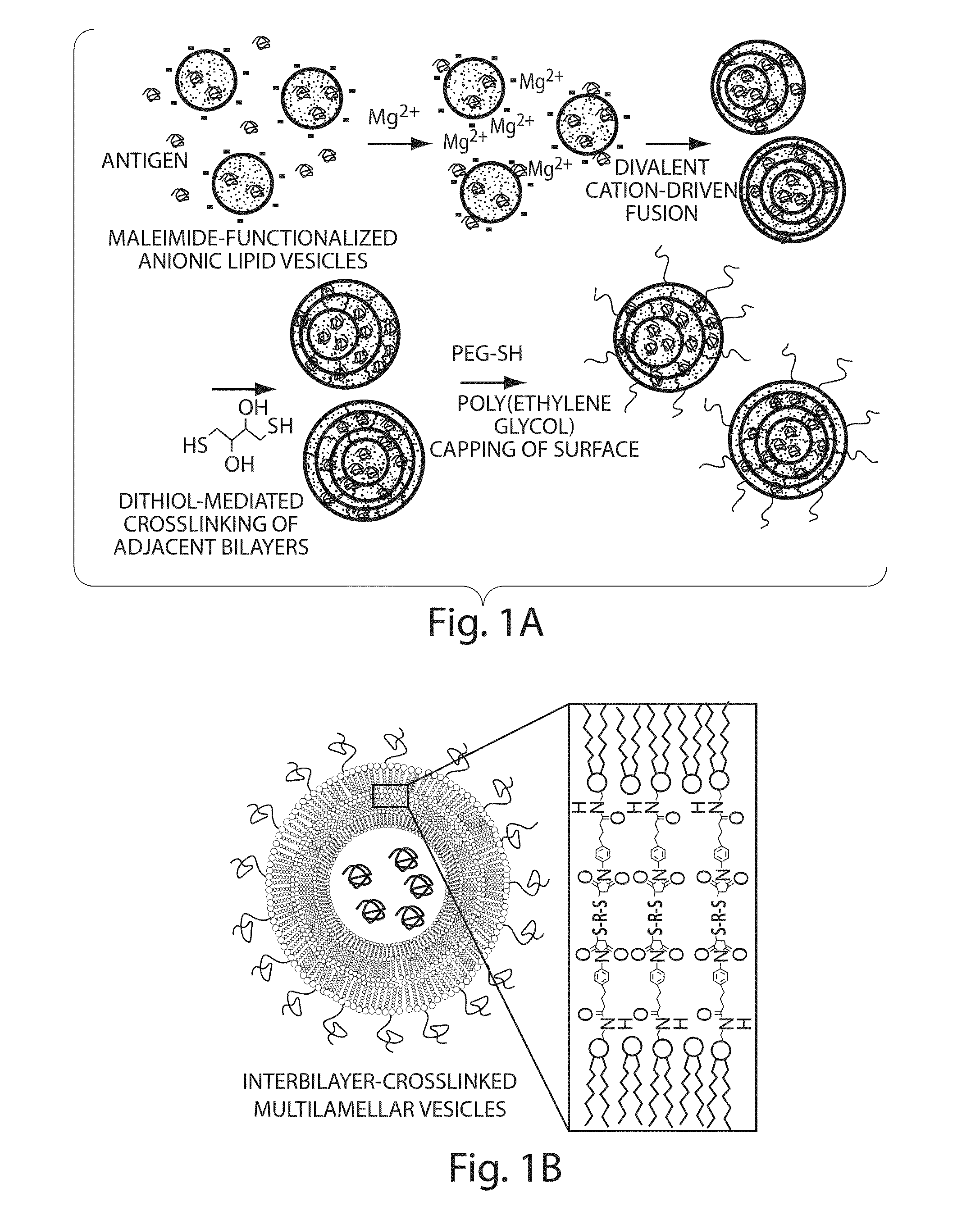

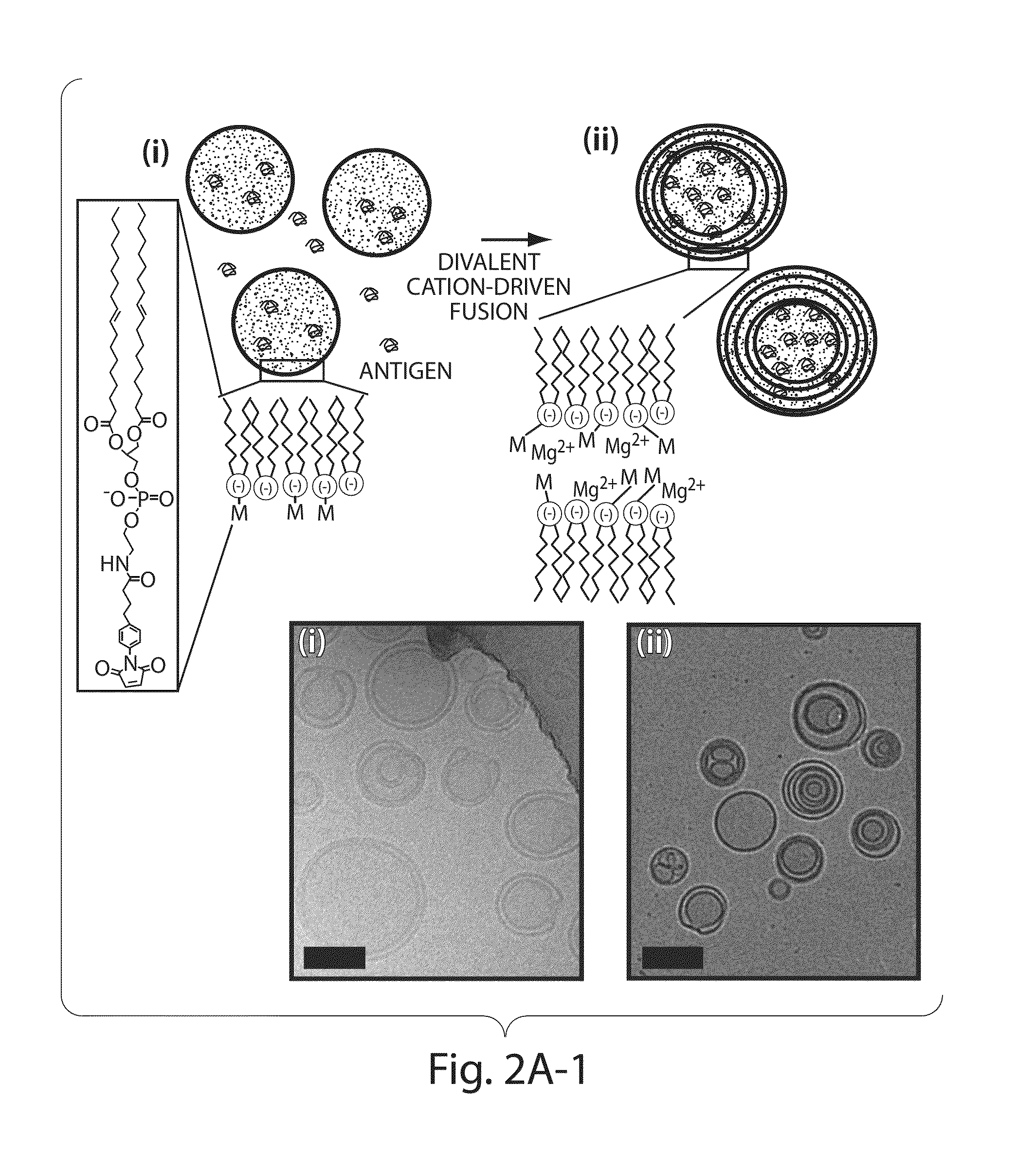

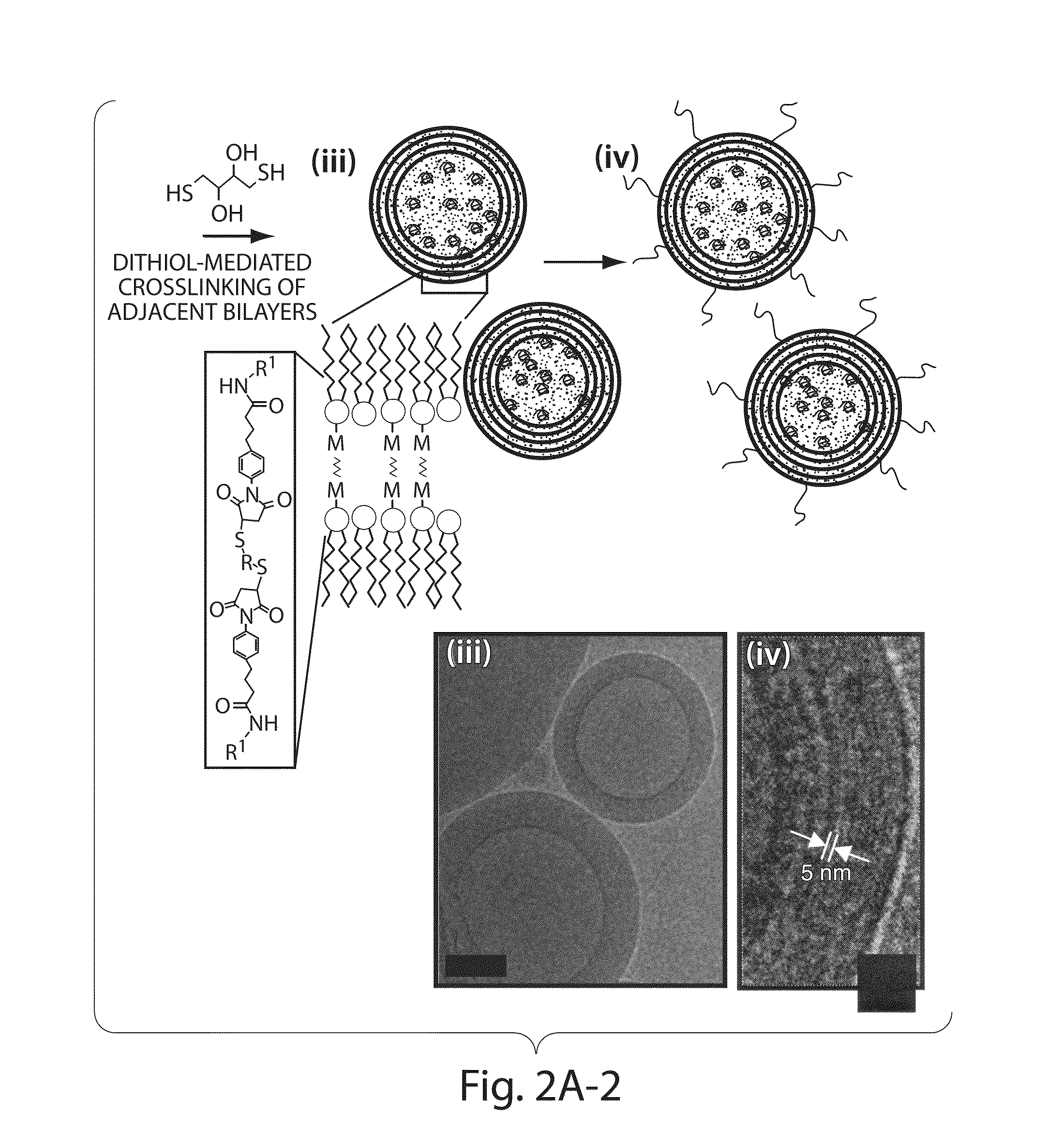

Lipid vesicle compositions and methods of use

ActiveUS20120177724A1Increase load capacityImprove the level ofPeptide/protein ingredientsMicroencapsulation basedAntigenVesicle/vacuole

The invention provides delivery systems comprised of stabilized multilamellar vesicles, as well as compositions, methods of synthesis, and methods of use thereof. The stabilized multilamellar vesicles comprise terminal-cysteine-bearing antigens or cysteine-modified antigens, at their surface and / or internally.

Owner:MASSACHUSETTS INST OF TECH +1

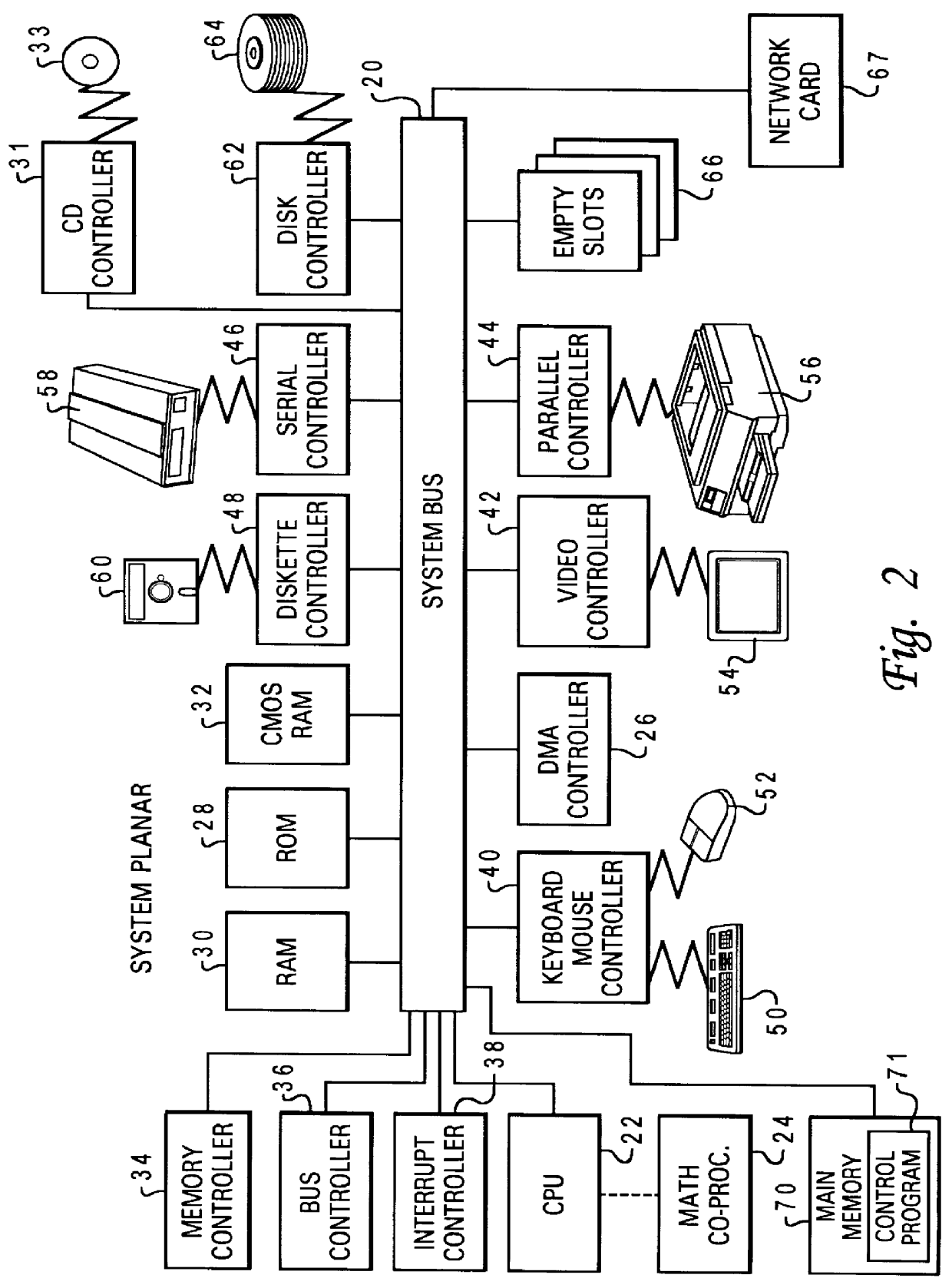

Method and system in a computer network for bundling and launching hypertext files and associated subroutines within archive files

InactiveUS6026437AReduce download timeImprove packaging efficiencyData processing applicationsMultiple digital computer combinationsClient-sideApplication software

A method and system in a computer network for dynamically bundling and launching hypertext files within archive files, wherein the computer network includes at least one client connectable to one or more servers. Initially, an archive file is established within the computer network wherein particular subroutines are maintained. Thereafter, a particular hypertext file is associated with a selected subroutine maintained within the archive file. The particular hypertext file and the selected subroutine are subsequently bundled together within the archive file. Thereafter, the archive file is automatically transmitted to the client from a server maintained within the computer network, in response to a client request to download the hypertext file, such that the subroutine and the hypertext file are downloaded within a single selected archive file from the server, thereby reducing download time and increasing data packaging efficiency. The subroutine may be composed of an applet and the hypertext file may be based on an HTML file having tags which point to particular applets and data associated with the applets.

Owner:IBM CORP

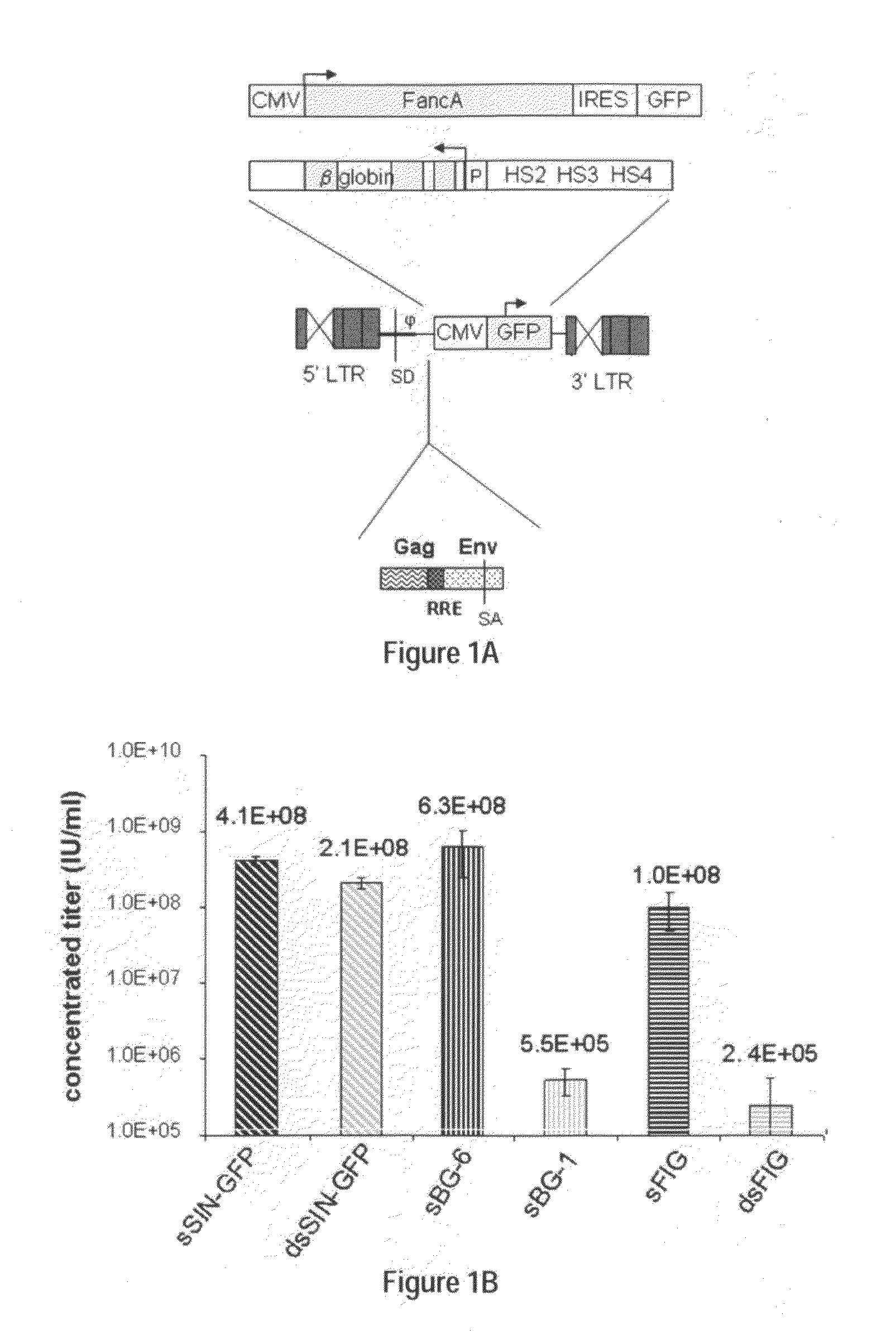

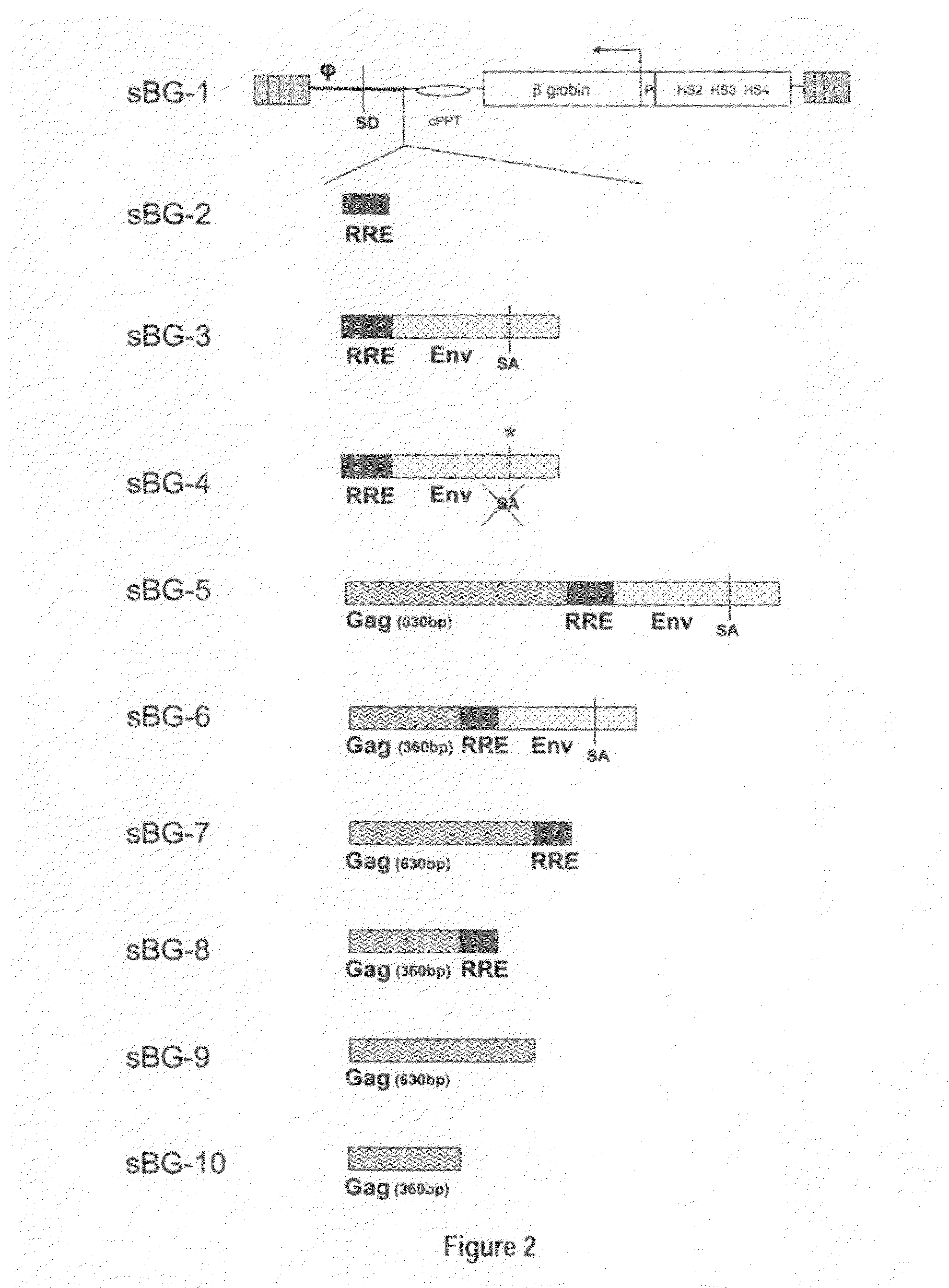

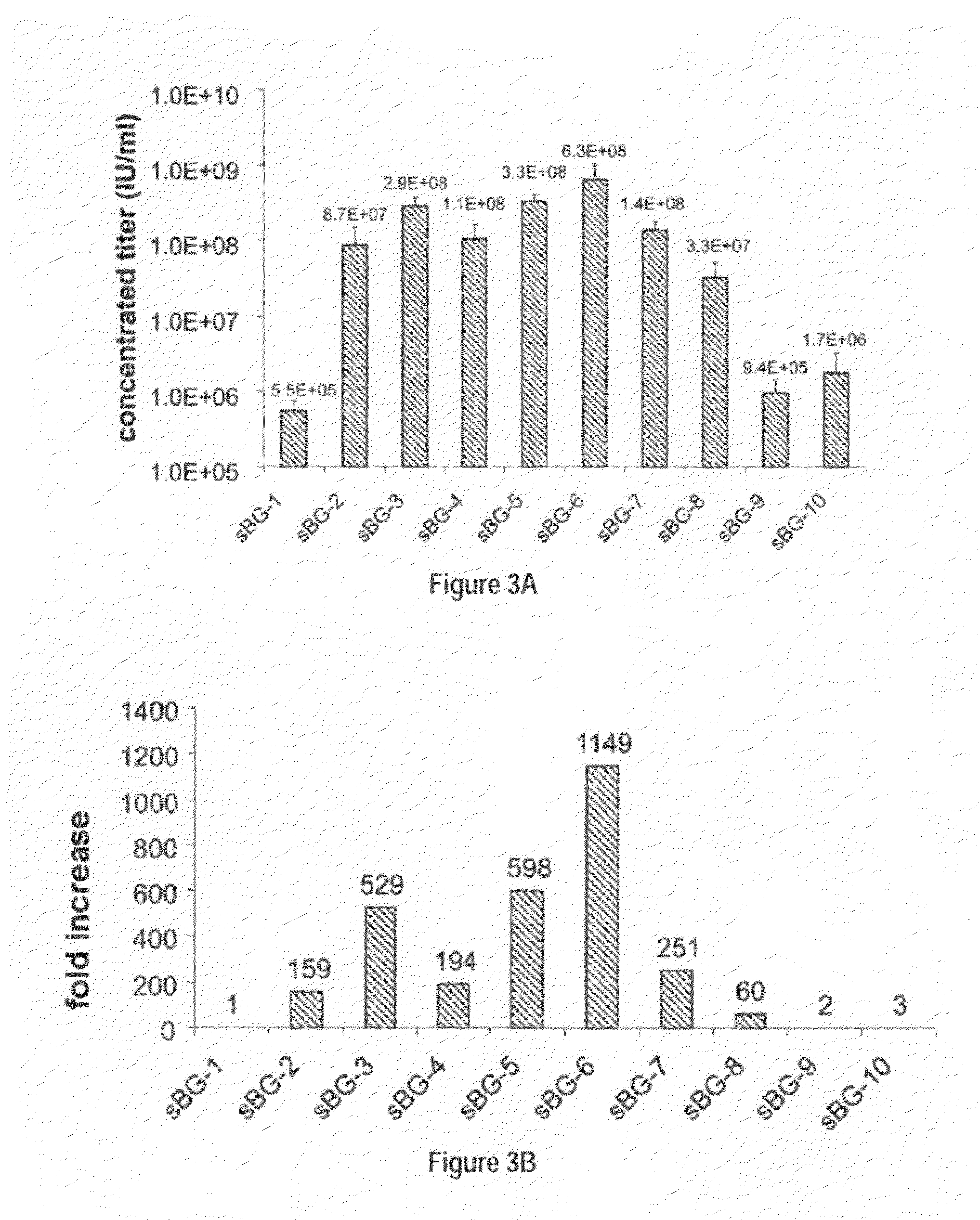

Optimization of determinants for successful genetic correction of diseases, mediated by hematopoietic stem cells

InactiveUS20110294114A1Improve stabilityImprove securityVectorsSugar derivativesNervous systemSickle cell anemia

Methods and compositions disclosed herein generally relates to methods of determining minimum hematopoietic stem cell (HSC) chimerism and gene dosage for correction of a hematopoietic disease; in particular, in in vivo models. The invention also relates to modified lentiviral expression vectors for increase a viral titer and various methods for increasing such titers as well as expression vectors capable of enhancing such titers. The invention also relates to CHS4 chromatin insulator-derived functional insulator sequences. The invention further relates to methods for genetic correction of diseases or reducing symptoms thereof, such as sickle cell anemia, a lysosomal storage disease. The invention further relates to a method of improving and / or correcting one or more central nervous system (CNS) abnormalities caused by one or more lysosomal storage disease. The invention further relates to methods of improving titer in transfection-based bioreactor culture production or transfection-based production systems using eukaryotic cells.

Owner:CHILDRENS HOSPITAL MEDICAL CENT CINCINNATI

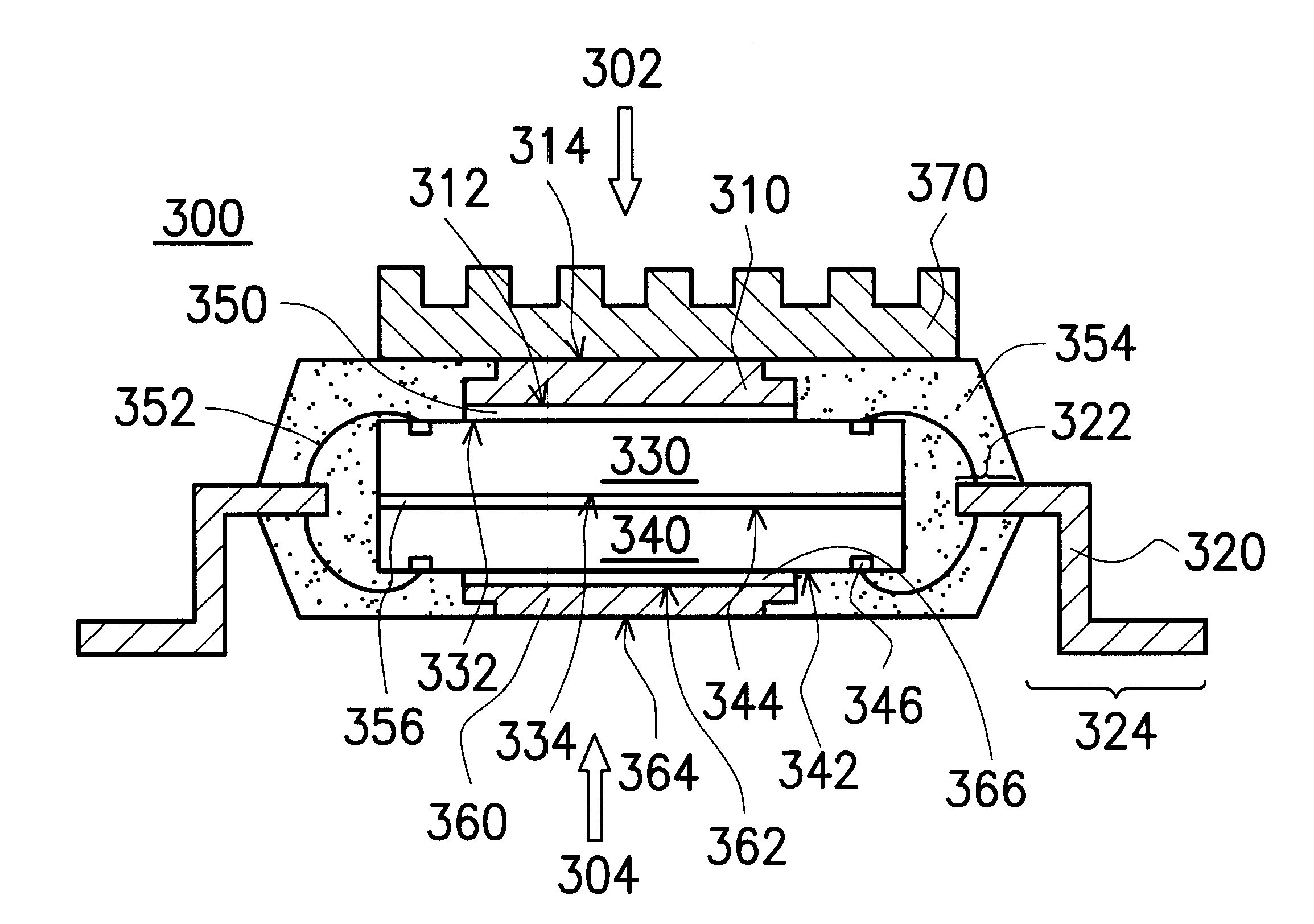

Semiconductor package having heat sink at the outer surface

InactiveUS20010045644A1Easy to addImprove packaging efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat spreader

A semiconductor package having heat sink at the outer surface is constructed on a lead frame. The package comprises a chip, a die pad, a plurality of leads, a plurality of bonding wires, and a molding compound. The die pad has a first surface and a second surface, and the chip has its active surface bonded to the first surface of the die pad. The area of the die pad is smaller than the area of the chip in order to expose the bonding pads on the active surface of the chip. The leads having an inner lead portions and an outer lead portions are disposed at the periphery of the die pad, and the inner lead portions are electrically connected to the bonding pads by a plurality of bonding wires. The molding compound encapsulates the chip, the die pad, the inner lead portions of the leads, and the bonding wires. The second surface of the die pad is exposed on the top surface of the package structure while the outer lead portion of the leads is exposed at the side edge of the package structure.

Owner:SILICONWARE PRECISION IND CO LTD

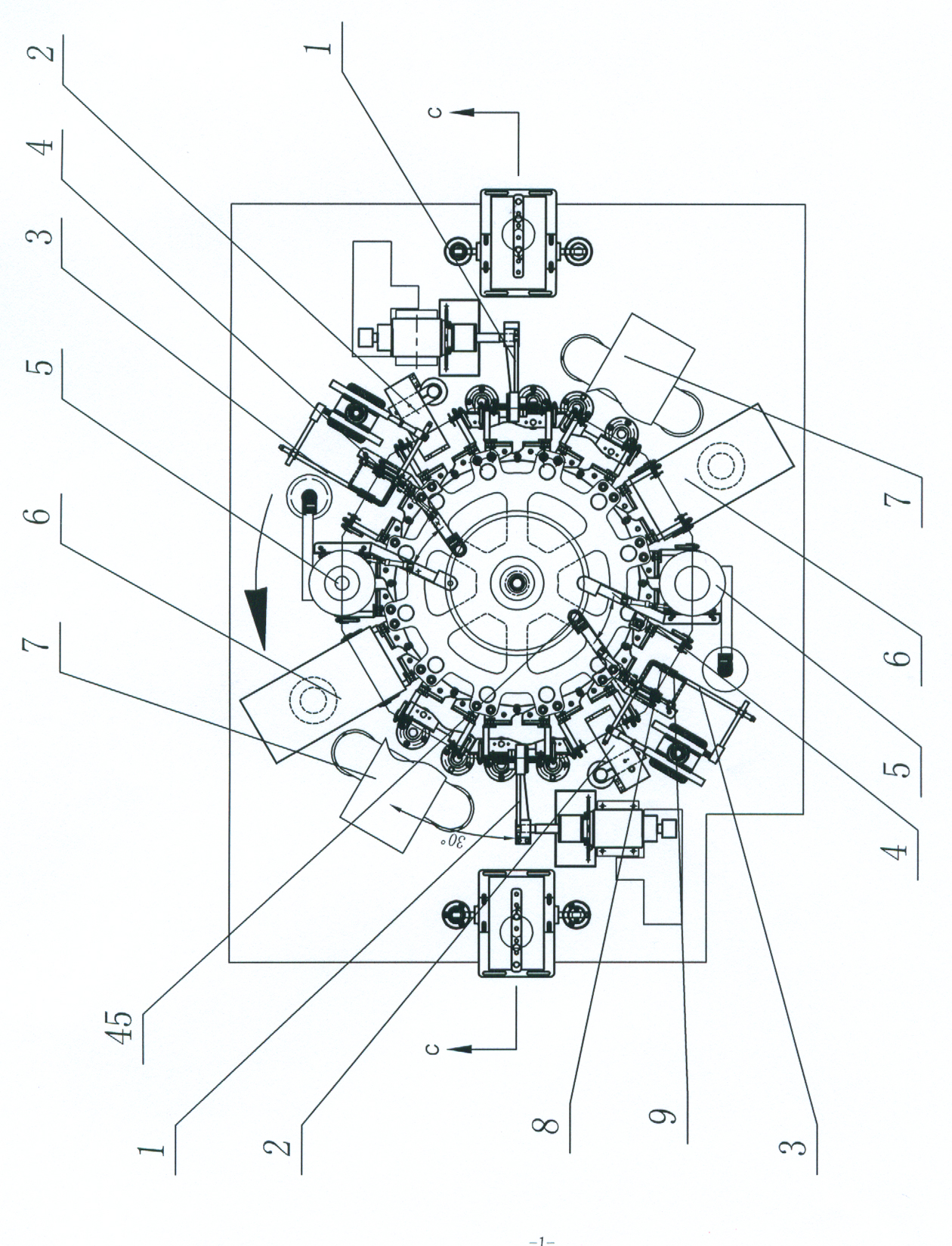

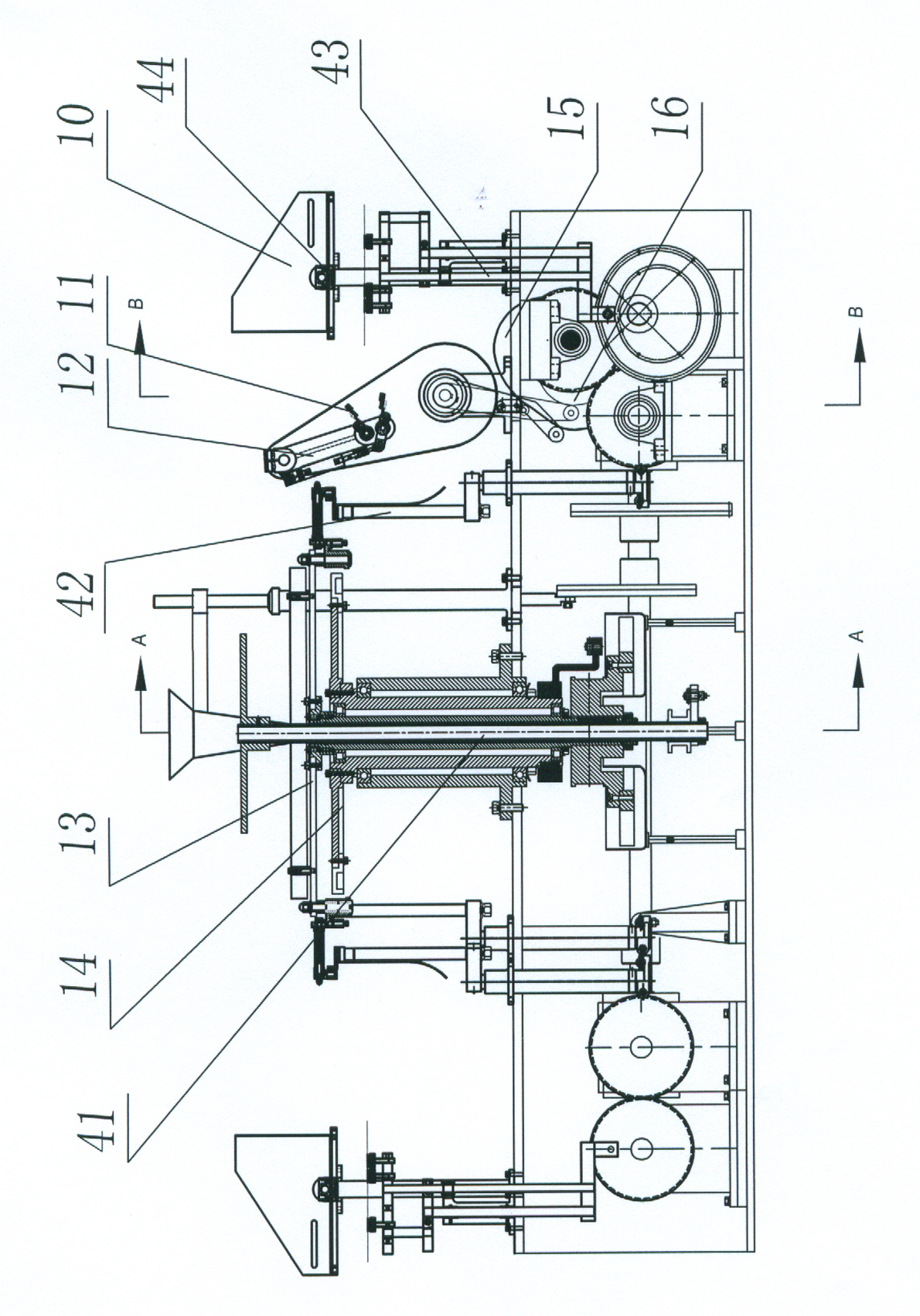

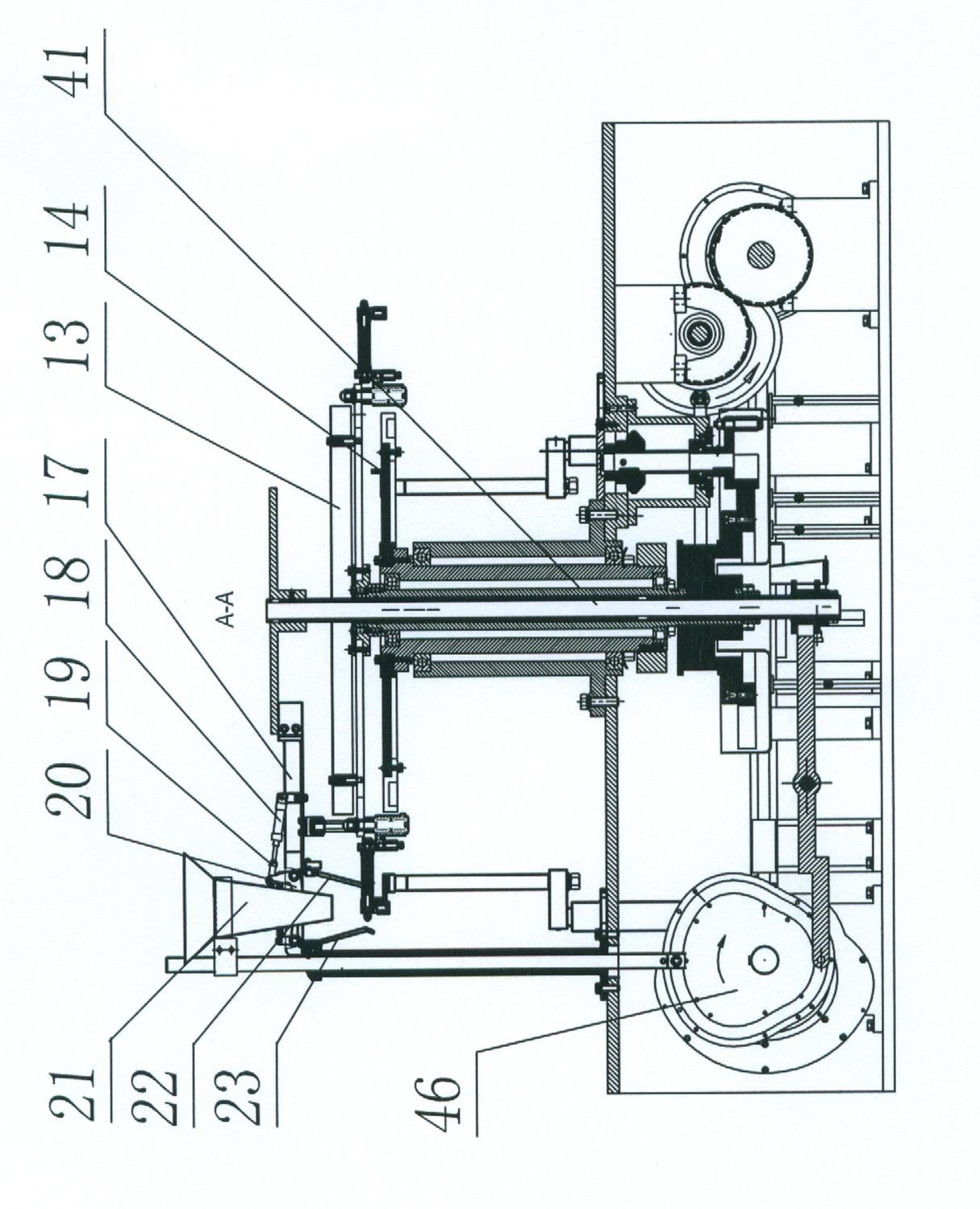

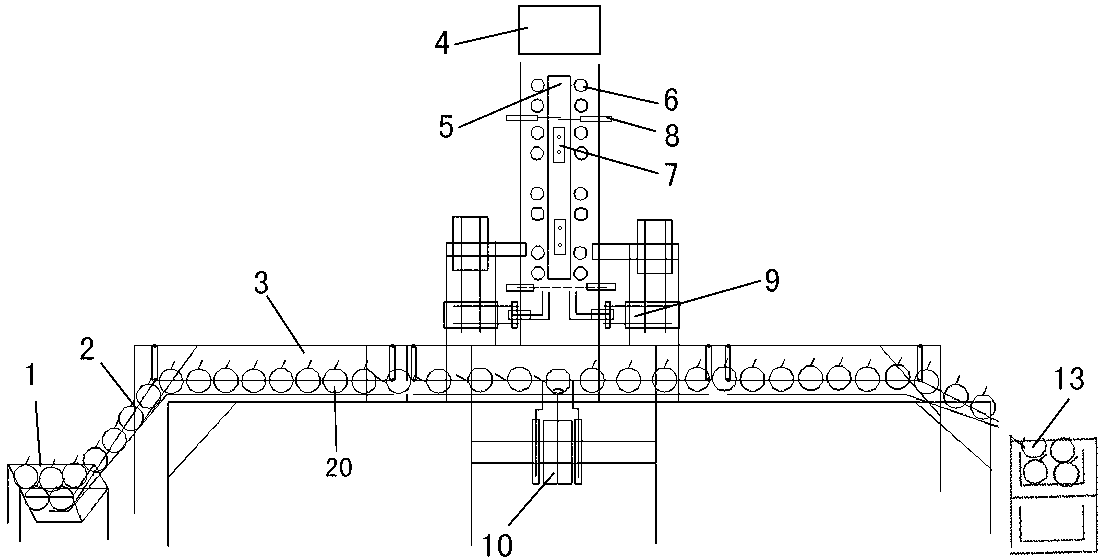

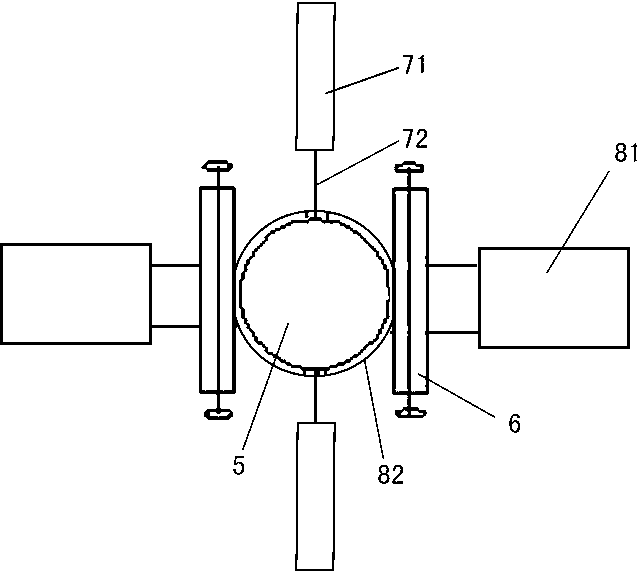

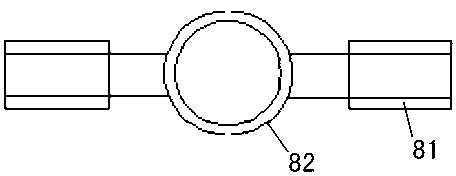

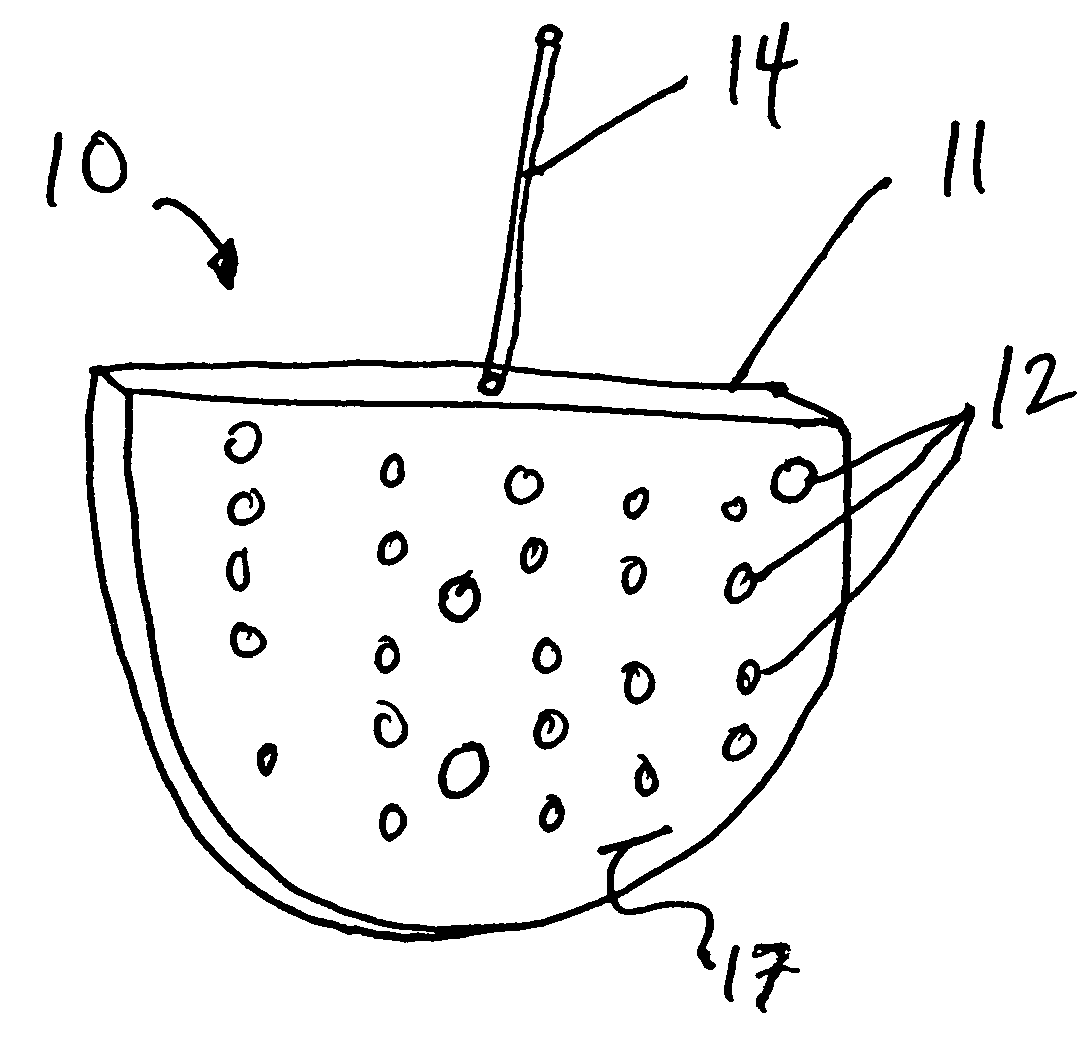

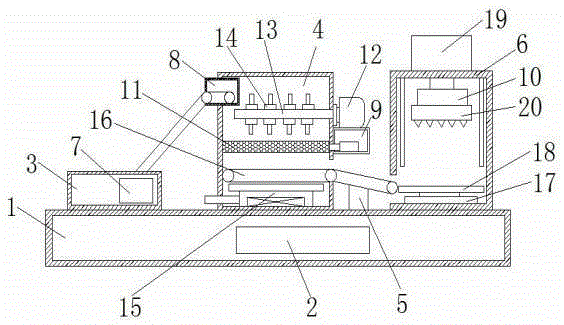

Full-automatic bag-feeding type packaging machine

InactiveCN101837845AImprove packaging efficiencyAvoid the problem of not being able to hold the bagWrapper supporting apparatusWrapper twisting/gatheringRotating discPackaging machine

The invention discloses a full-automatic bag-feeding type packaging machine, comprising a rotating disc (13), a large cam (14), a bag feeding device (1), a marking device (2), a bag opening device (3), a material charging device (5), a heat-sealing device (6), a bag discharging device (7) and a bag bracing device (4). A bag clamping device (39) is arranged at the edges of the rotating disc (13); the bag feeding device (1), the marking device (2), the bag opening device (3), the material charging device (5), the heat-sealing device (6) and the bag discharging device (7) are all arranged outside the rotating disc (13); and the bag bracing device (5) is of a swing arm type and is movably mounted on the rotating disc (13). The packaging machine is characterized in that the bag feeding device (1), the bag opening device (3), the material charging device (5), the heat-sealing device (6) and the bag discharging device (7) are symmetrically arranged around the central point of the rotating disc (13); and the bag bracing device (4) is symmetrically arranged around the central point of the rotating disc (13). The full-automatic bag-feeding type packaging machine with the structure has the advantages of stable performance and high production efficiency.

Owner:WENZHOU READOR MACHINERY

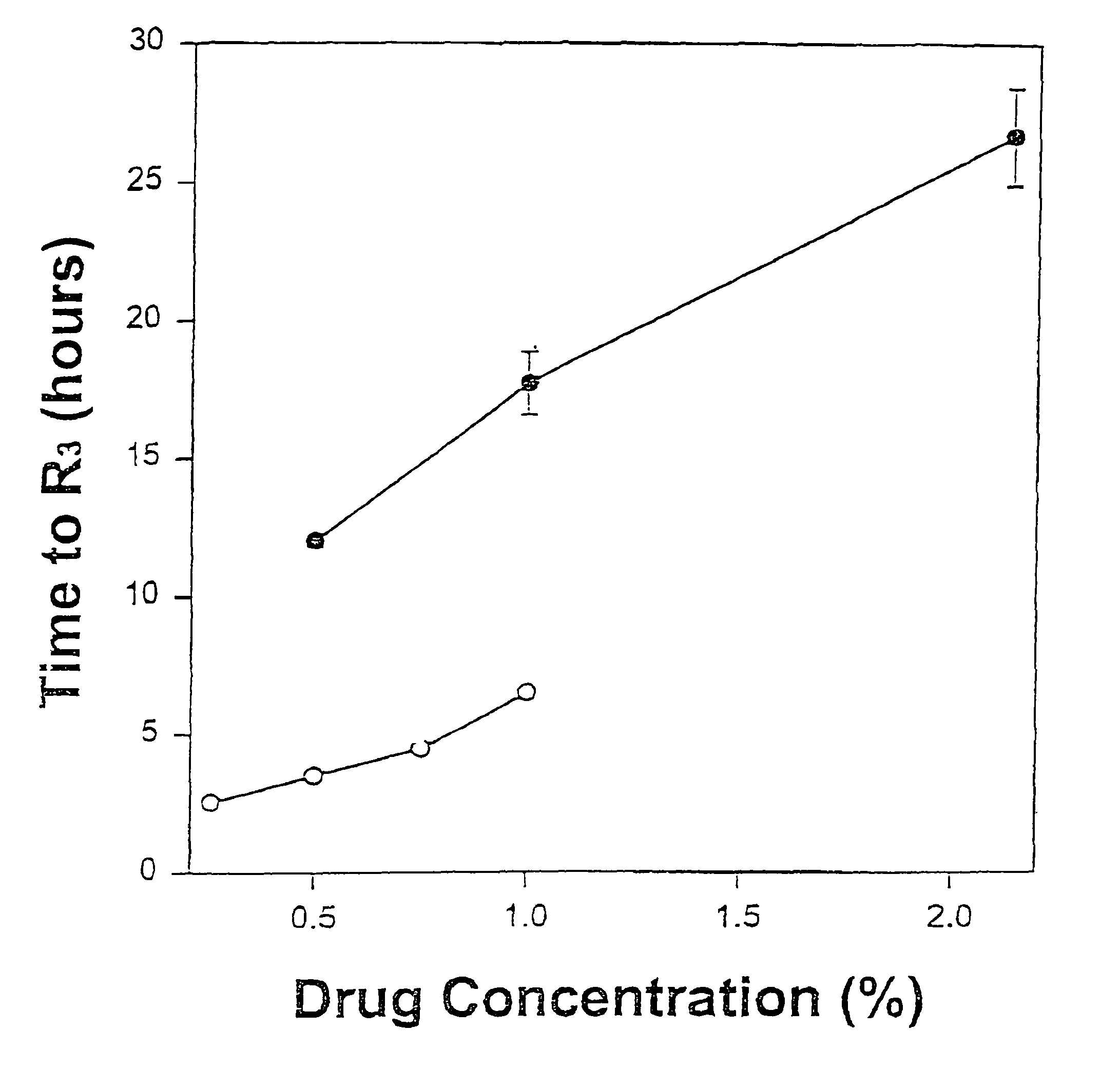

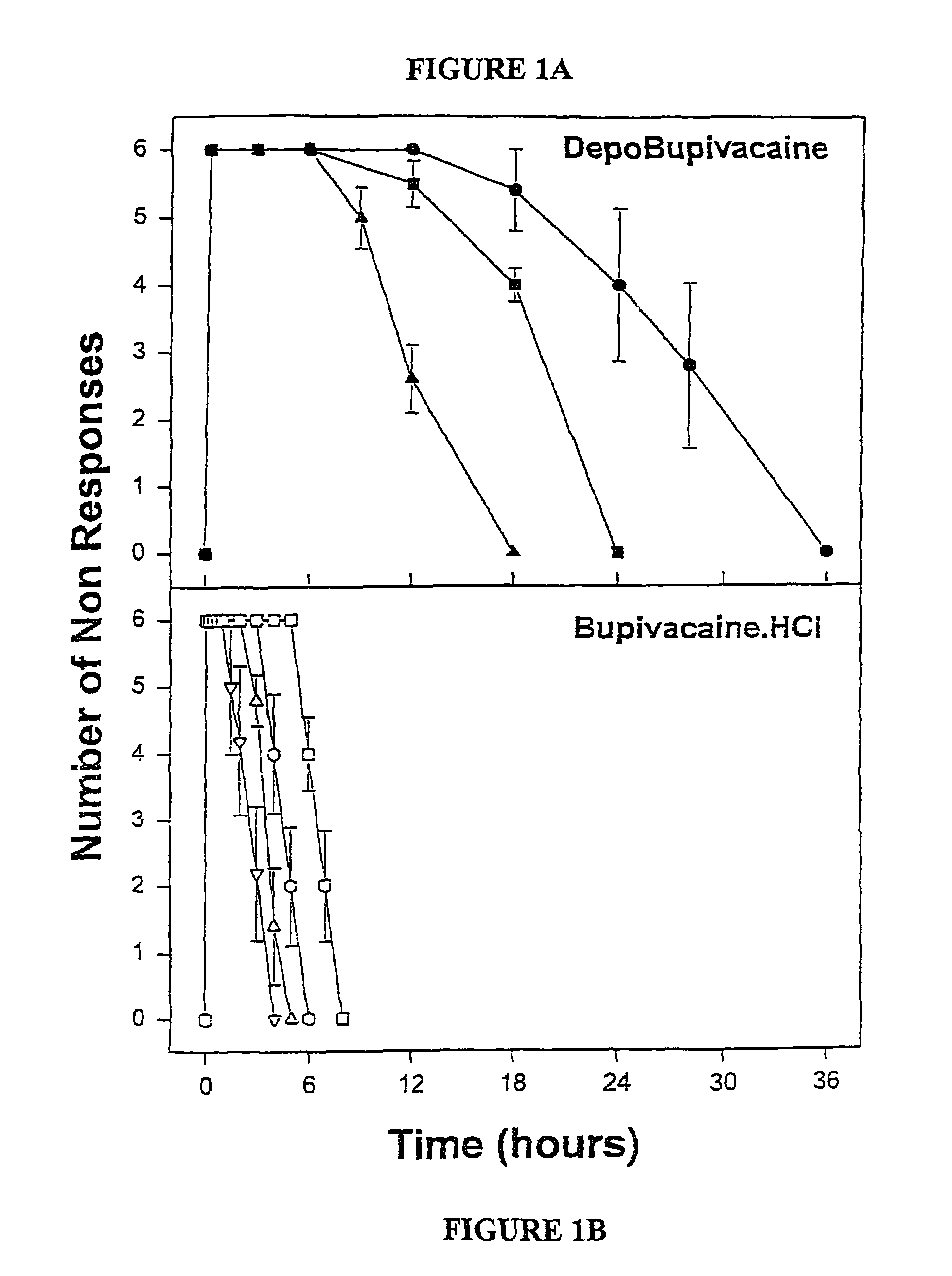

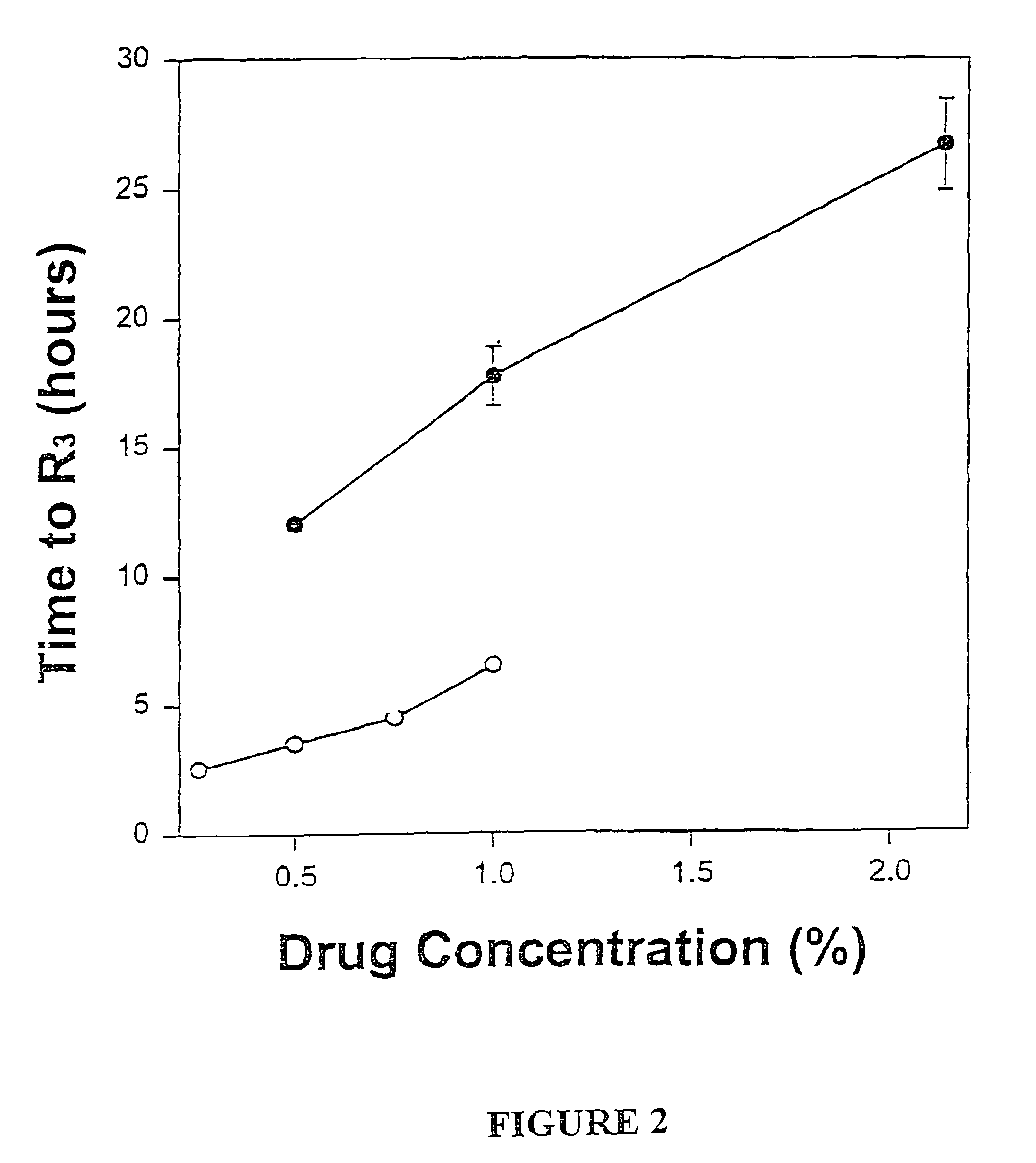

Sustained-release liposomal anesthetic compositions

InactiveUS8182835B2High acceptabilityImprove encapsulationInorganic non-active ingredientsAnaestheticsHalf-lifeMaximum tolerated dose

Owner:PACIRA PHARMA INC

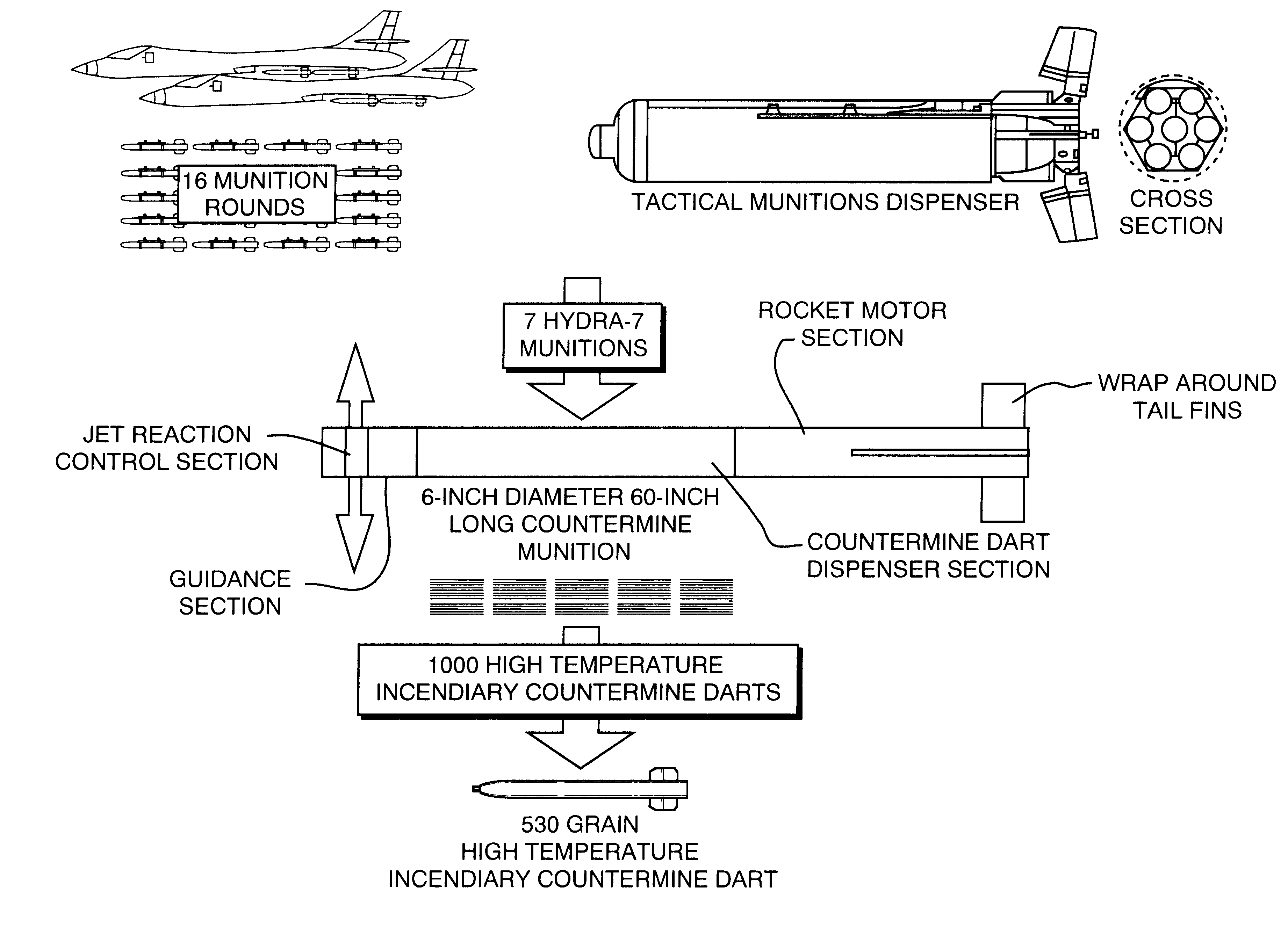

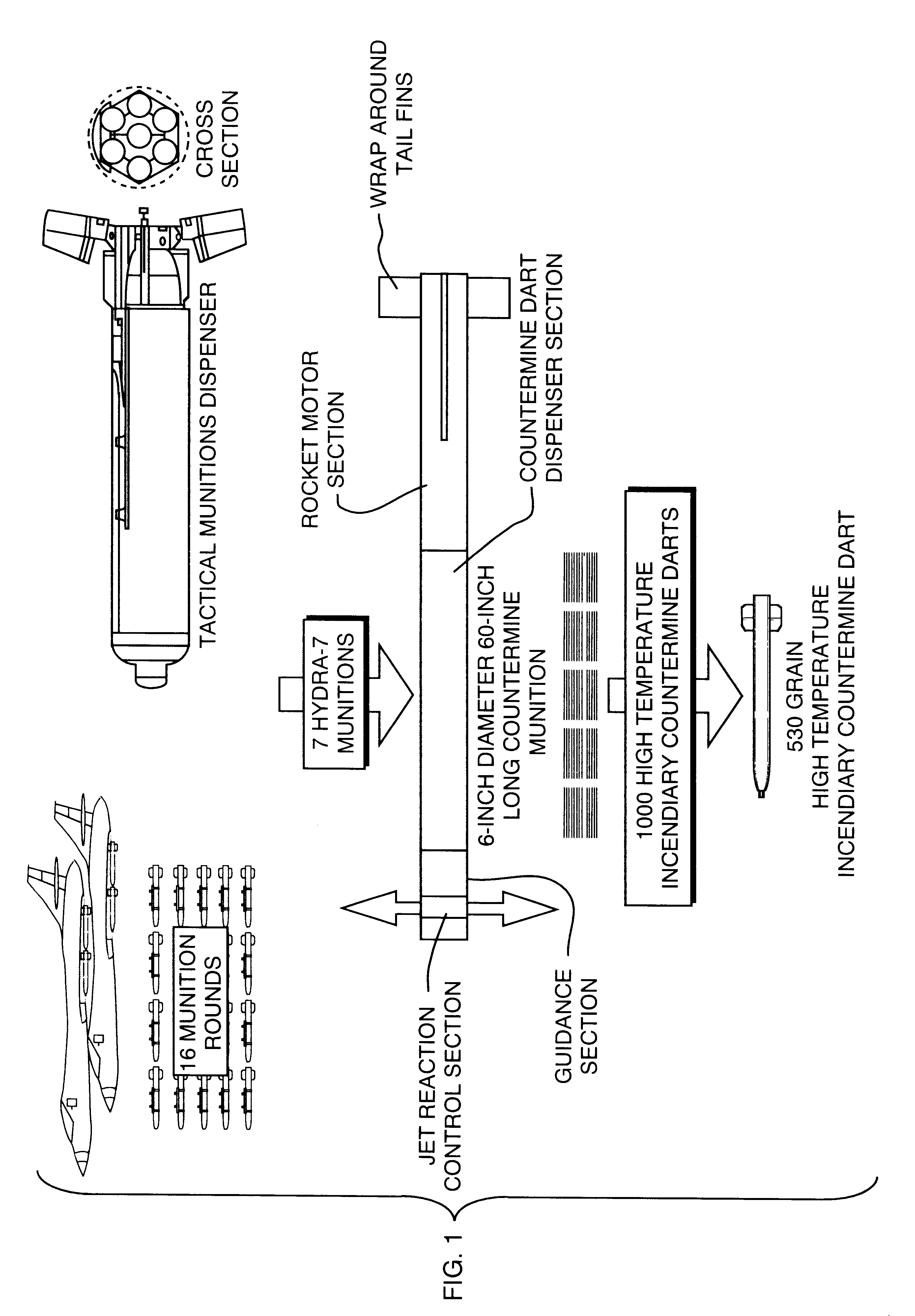

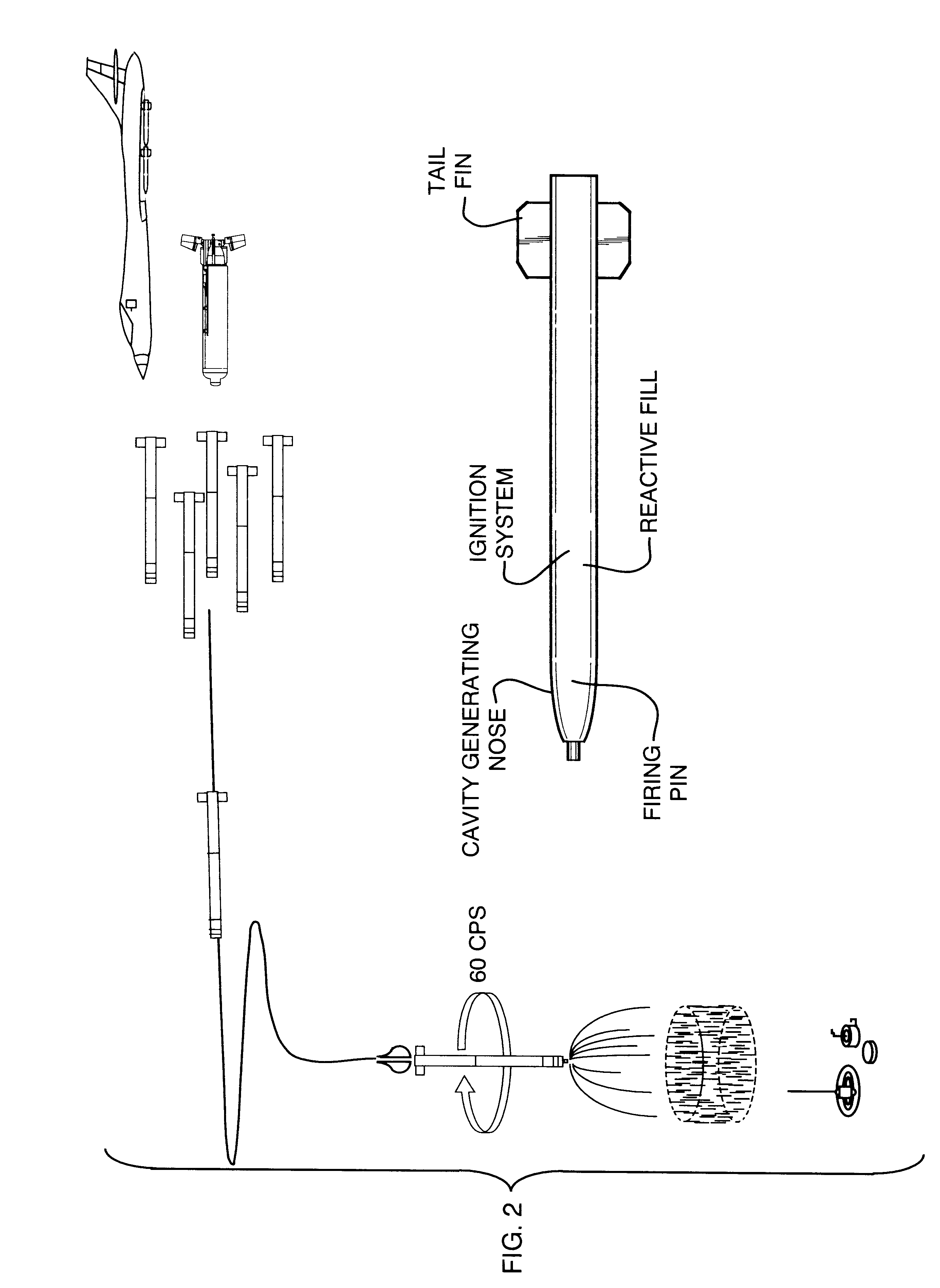

System for clearing buried and surface mines

Owner:LOCKHEED MARTIN ADVANCED PROJECTS

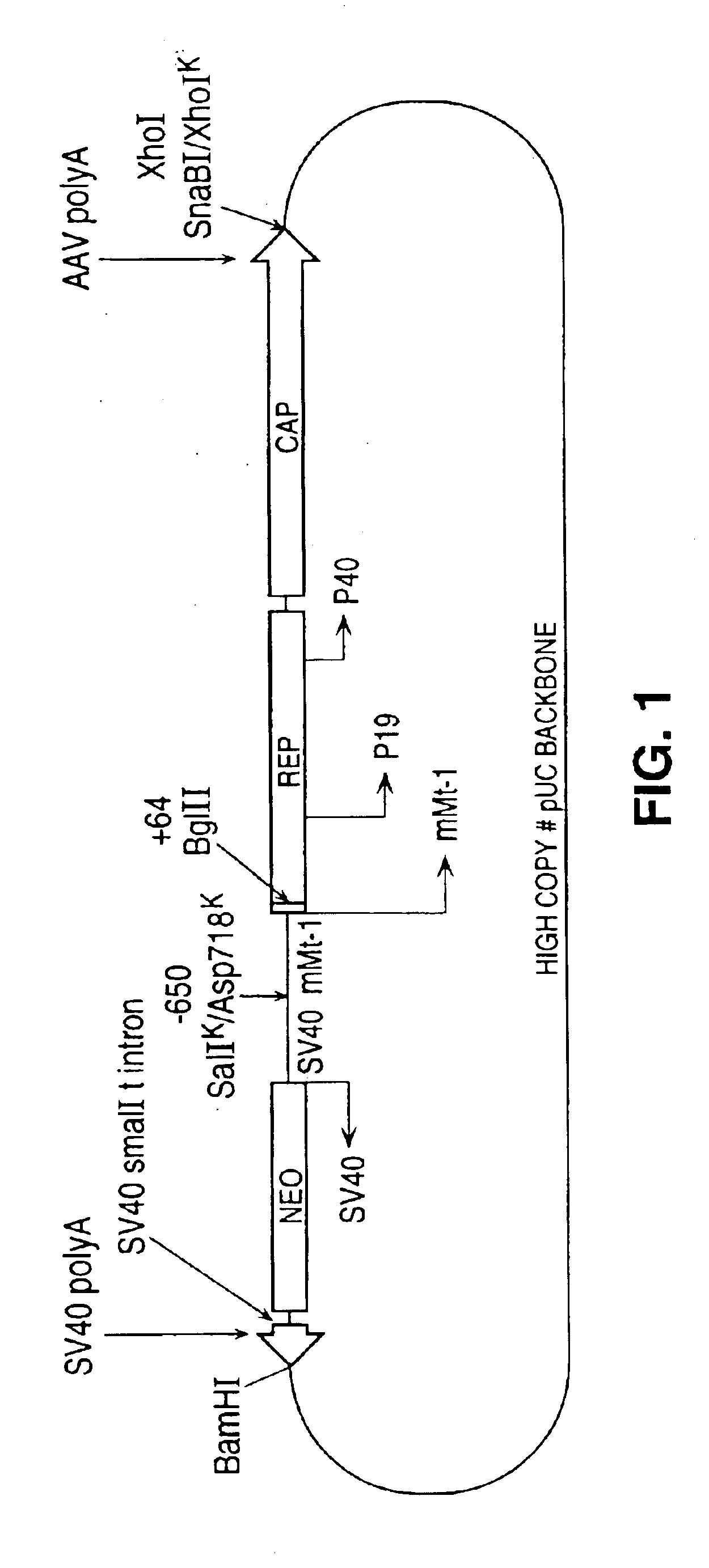

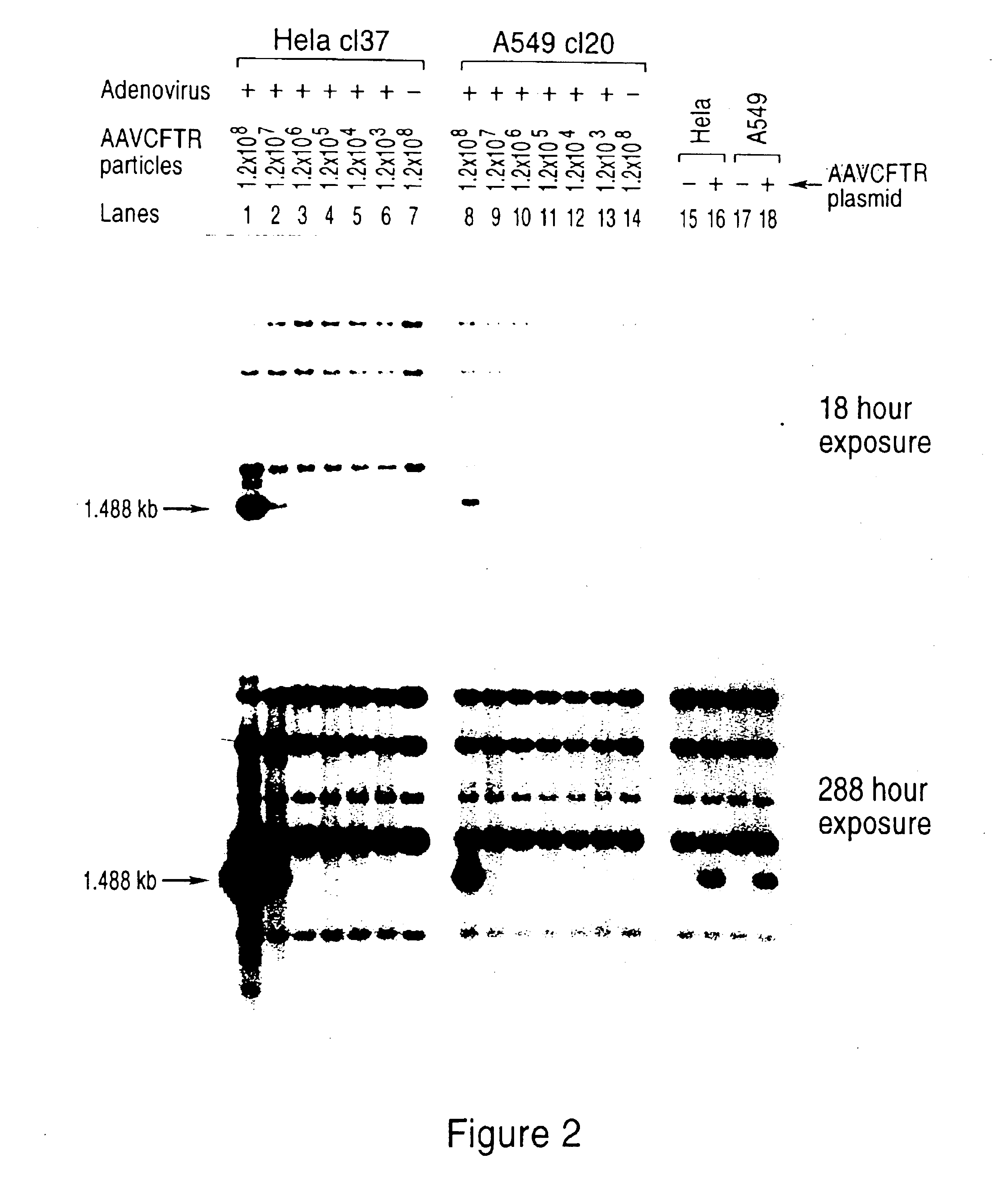

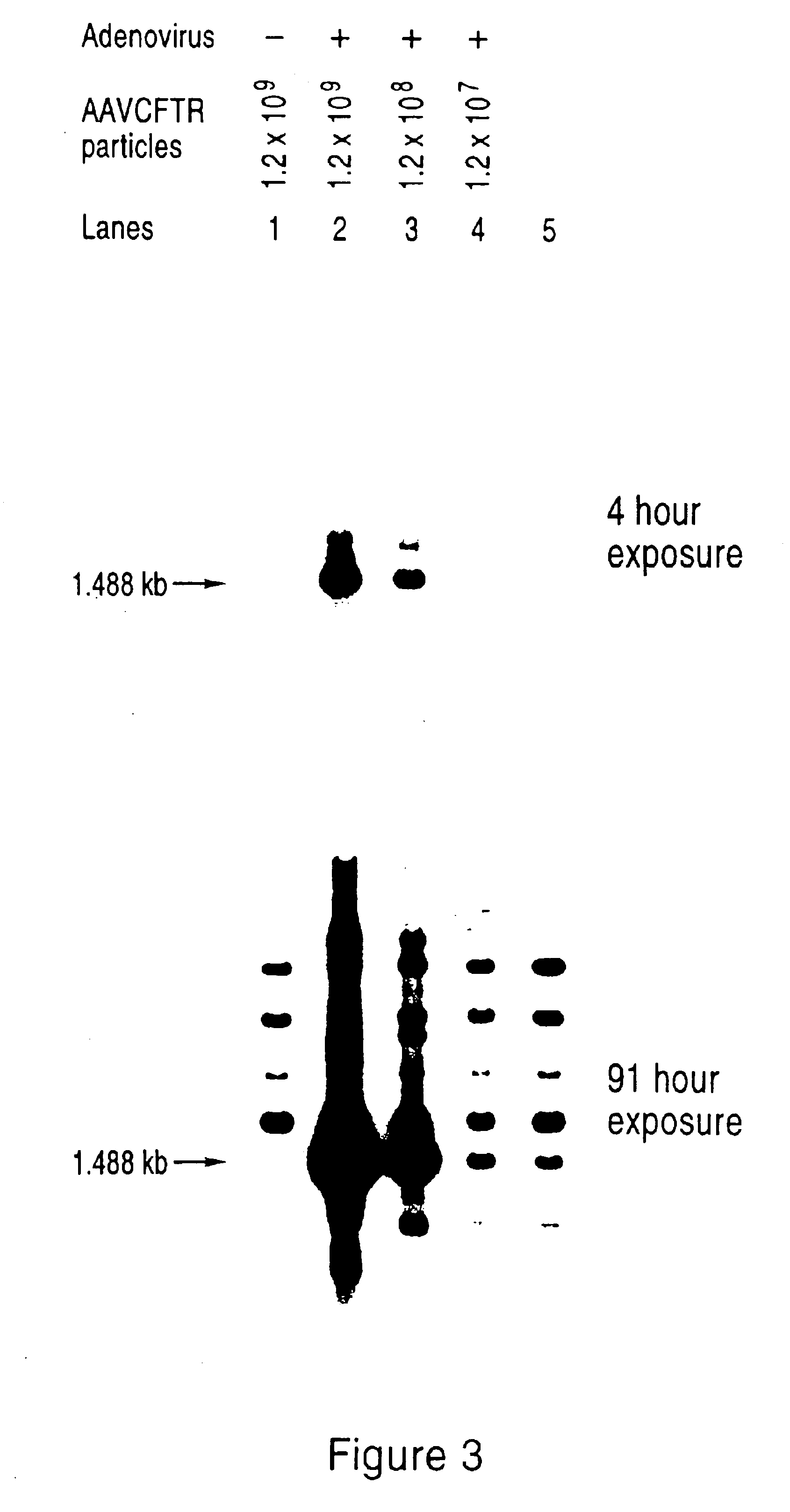

Packaging cell lines for generation of high titers of recombinant AAV vectors

InactiveUS6924128B2Not be easily manipulatedIncrease diversityBiocidePeptide/protein ingredientsGenes humanCell biology

AAV vectors may have utility for gene therapy but heretofore a significant obstacle has been the inability to generate sufficient quantities of such recombinant vectors in amounts that would be clinically useful for human gene therapy application. Stable AAV packaging cell lines have been elusive, mainly due to the activities of Rep protein, which down-regulates its own expression and can negatively affect the host cell. This invention provides packaging systems and processes for packaging AAV vectors that effectively circumvent these problems and that allow for substantially increased packaging efficiency.

Owner:TARGETED GENETICS CORPORTION

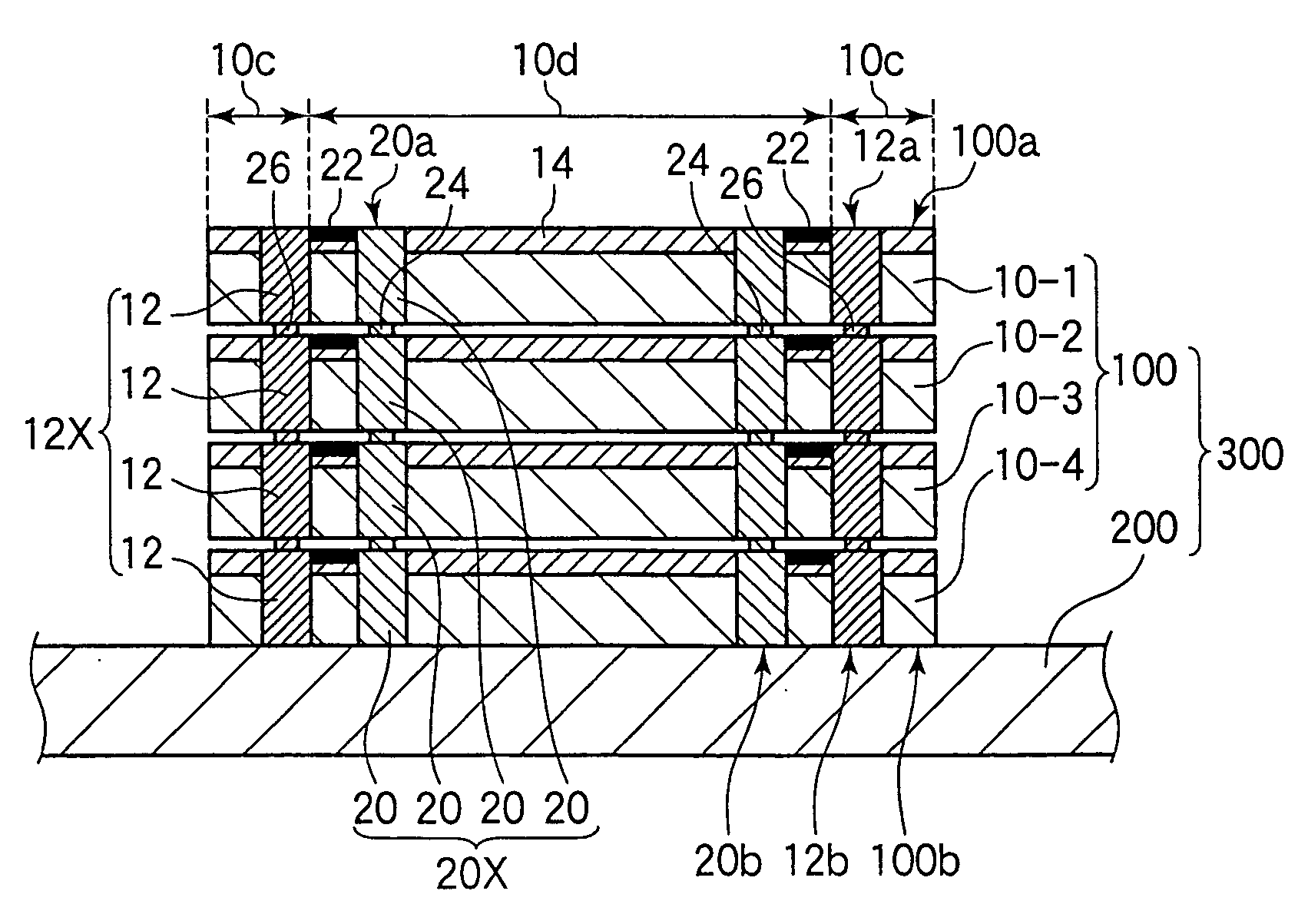

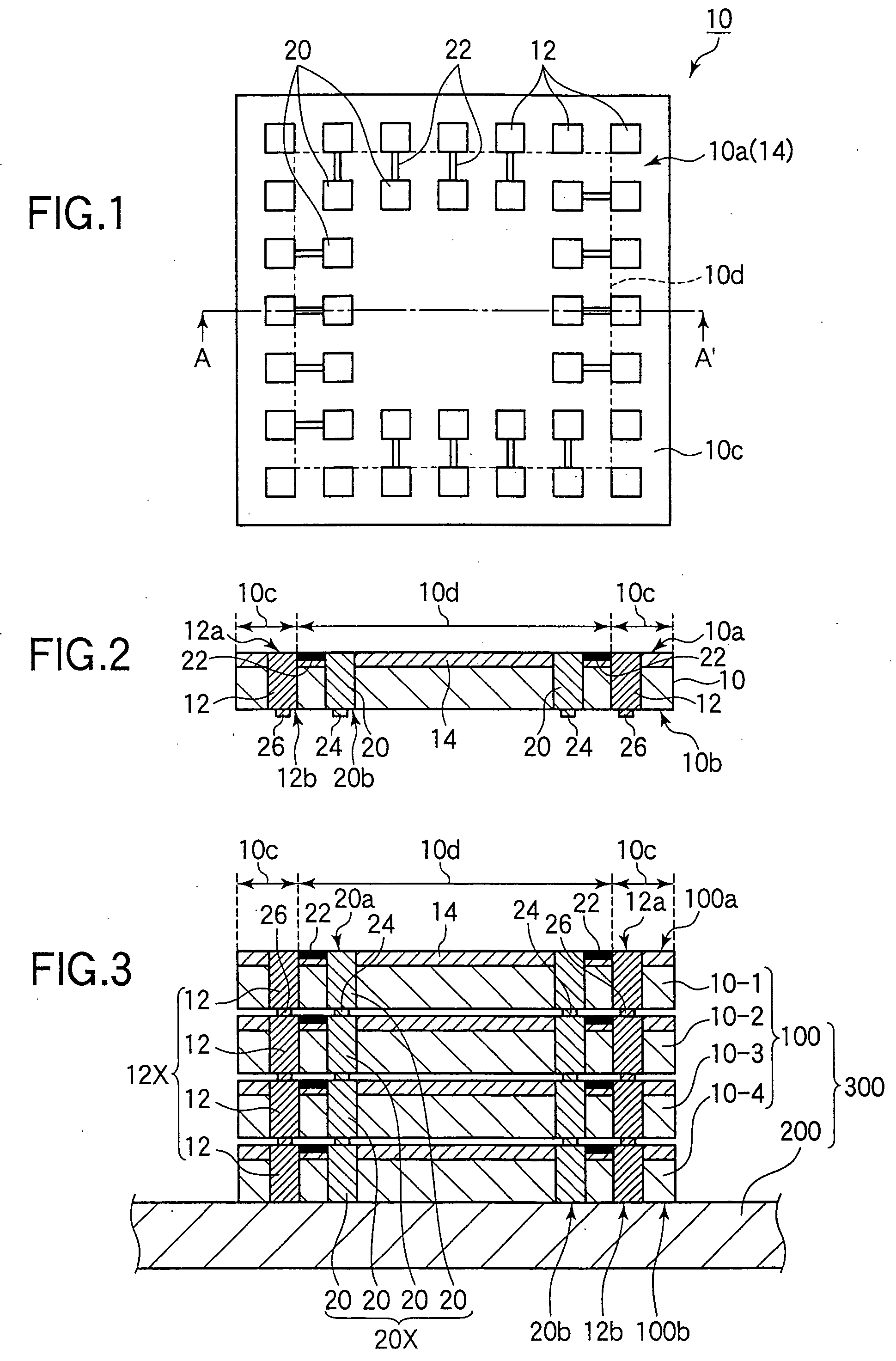

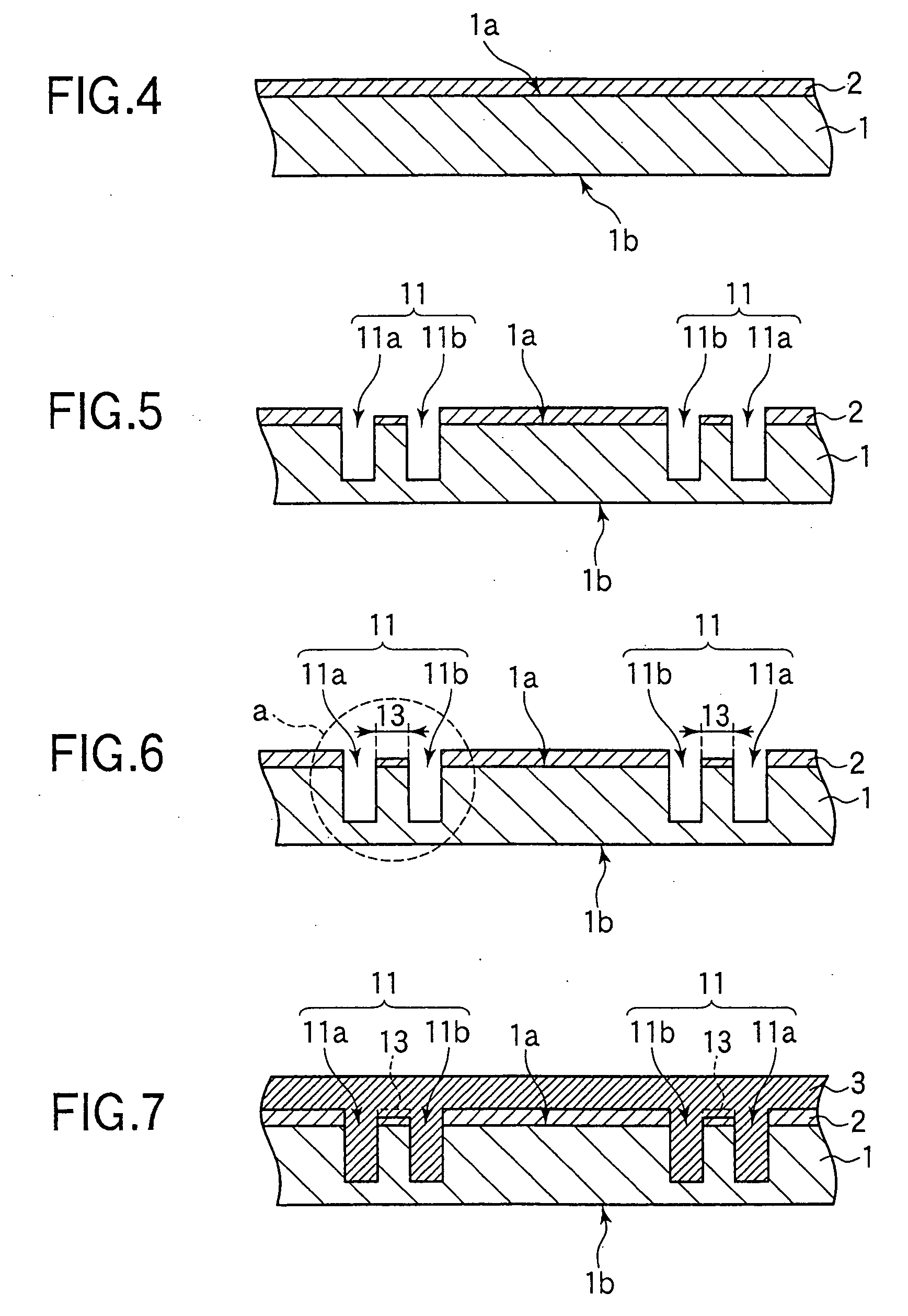

Semiconductor device, stacked structure, and manufacturing method

ActiveUS20060197181A1Improve cooling effectImprove packaging efficiencySemiconductor/solid-state device detailsSolid-state devicesDevice materialWafer dicing

An array of electrically conductive members, formed around the edges of a semiconductor device or chip, penetrate from one major surface of the device to the other major surface. In an area located inward of this array, a multiplicity of thermally conductive members also penetrate from one major surface to the other major surface. The semiconductor device can be manufactured from a semiconductor wafer by creating holes that penetrate partway through the wafer, filling the holes with metal to form the electrically conductive members and thermally conductive members, and then grinding the lower surface of the wafer to expose the ends of the electrically conductive members and thermally conductive members before dicing the wafer into chips. The thermally conductive members improve heat dissipation performance when semiconductor chips of this type are combined into a stacked multichip package.

Owner:TAIWAN SEMICON MFG CO LTD

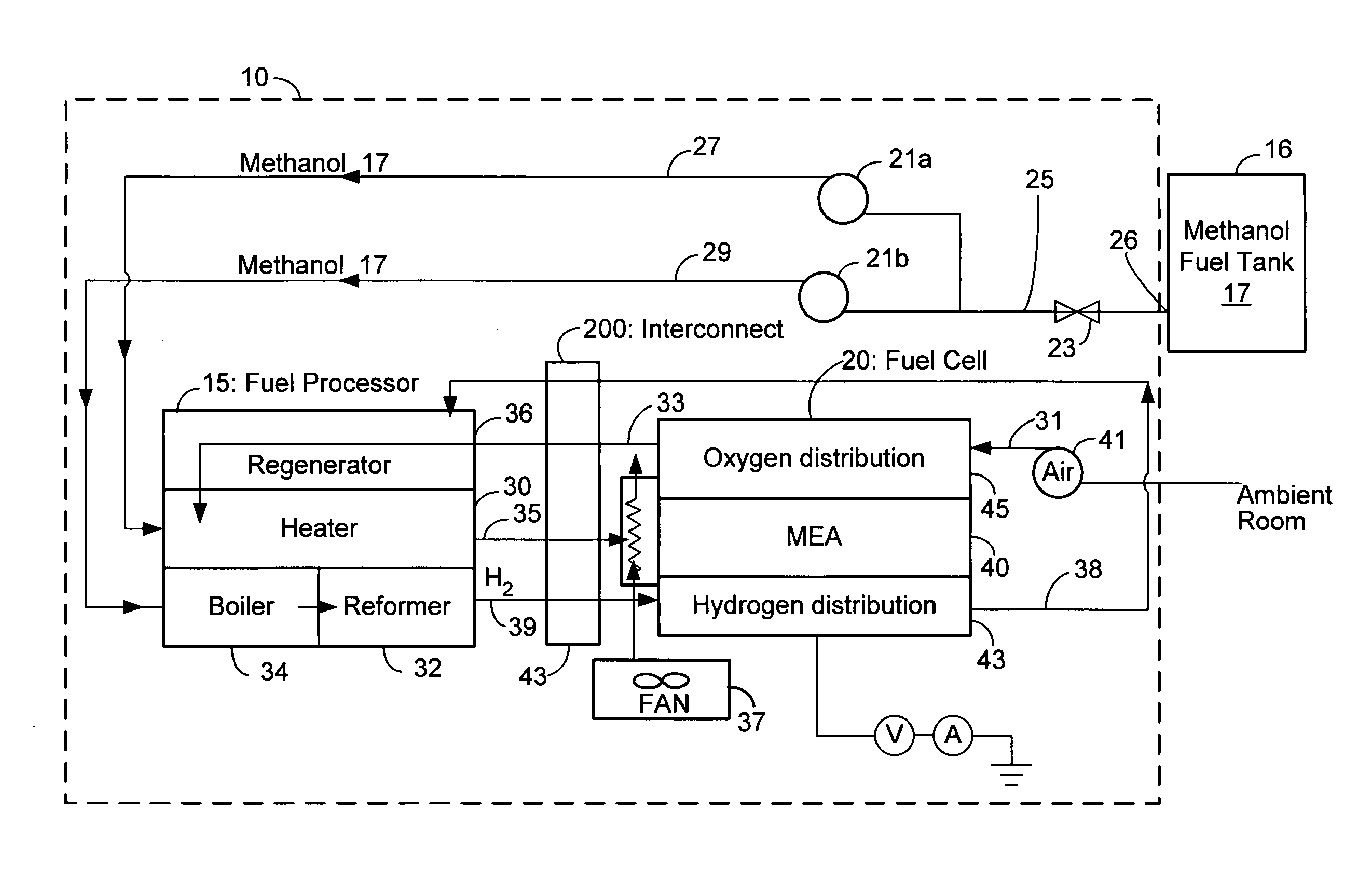

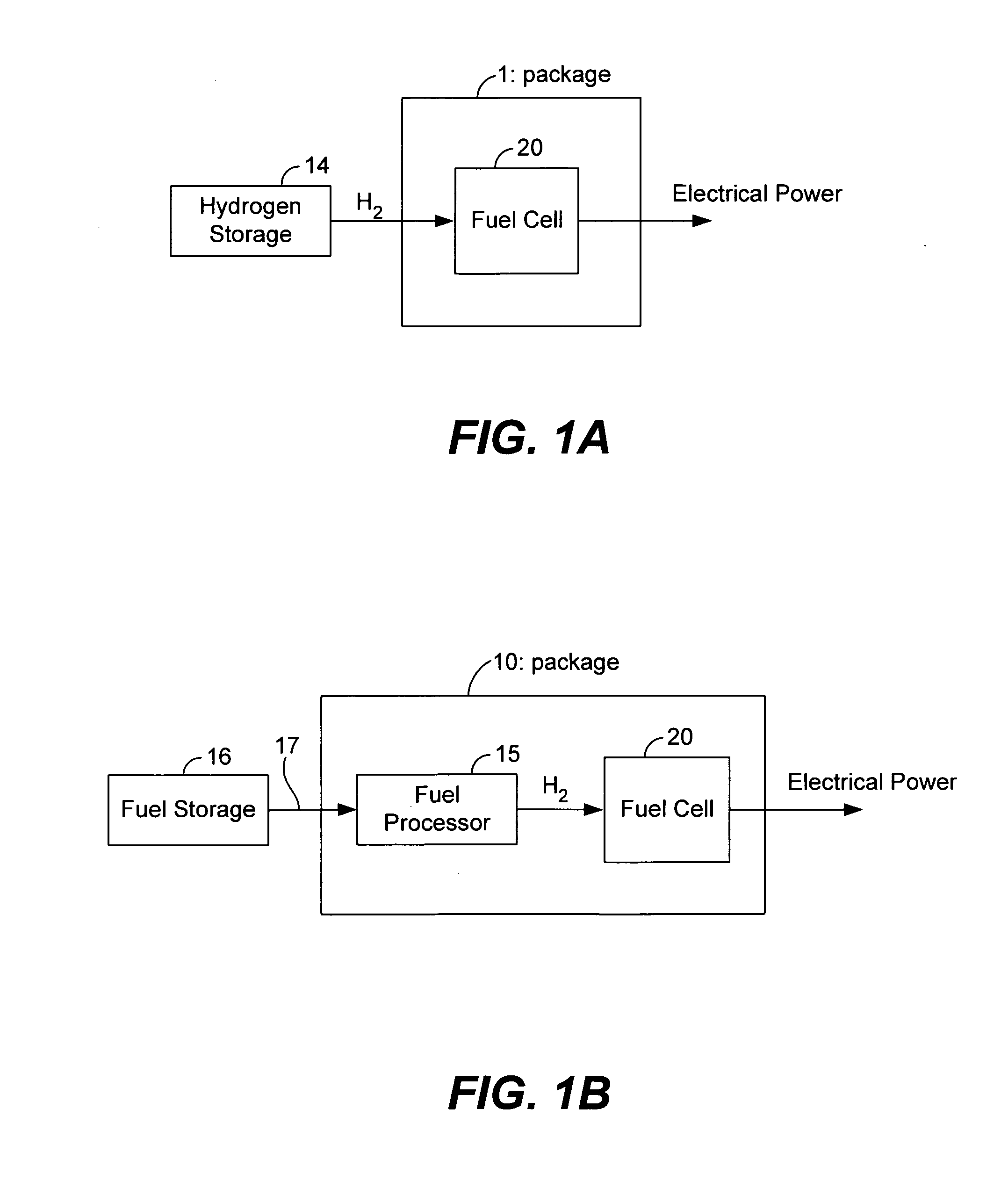

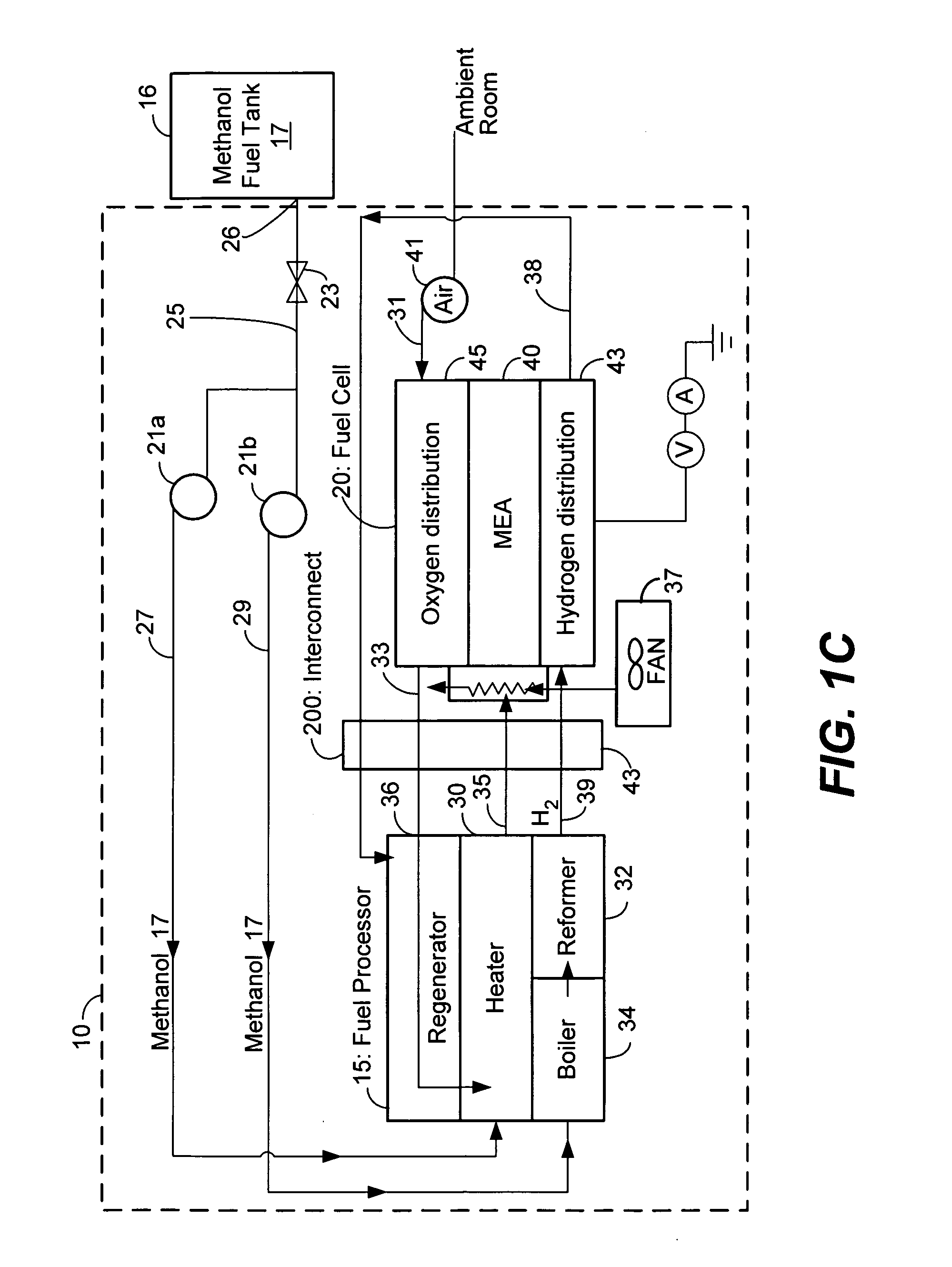

Compact fuel cell package

ActiveUS20060134470A1Decrease heat lossIncrease thermal efficiencyReactant parameters controlFuel cells groupingElectric energyUnit volume

The invention relates to a compact and portable fuel cell package. The package includes a fuel cell that generates electrical energy. Some packages also include a fuel processor that produces hydrogen from a fuel source. Fuel cell packages described herein provide power densities (power per unit volume or mass) at levels not yet seen. One package employs an interconnect disposed at least partially between a fuel cell and a fuel processor. The interconnect forms a structural and plumbing intermediary between the two. Given the portable size of fuel cell packages described herein, the invention is well suited to power portable electronics devices. One portable fuel cell package includes a tether, which allows electrical and detachable coupling to an electronics device.

Owner:ADVENT TECH LLC

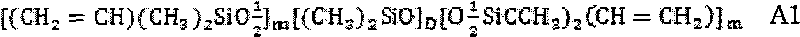

Organic silicon rubber encapsulating material for high-power LED

InactiveCN101747632AHigh light transmittance durabilityImprove temperature resistanceOther chemical processesSemiconductor devicesRefractive indexTackifier

The invention relates to an organic silicon encapsulating material for a high-power LED and a preparation method thereof. The organic silicon encapsulating material is prepared by mixing a component A containing vinyl polysiloxanes, a silicone resin component B, a component C containing hydrogen polysiloxane, a platinum catalyst component D, a component E of catalytic inhibitor of acetylene alcohols and a tackifier component F. The obtained encapsulating silicon rubber with different refractive indexes of level 1.4, level 1.5 and the like can be used for the encapsulation of various high-power LEDs and the encapsulation of other optical application. The organic silicon rubber encapsulating material for the high-power LED takes the silicone resin component B as a filling material, which not only enables that the silicone rubber has high transparency, high strength and high light transmittance, but also improves the temperature resistance, the yellowing resistance, and the durability of the high light transmittance of high-power LED products. The organic silicon rubber encapsulating material for the high-power LED can be prepared into two encapsulating forms of a single component and bi-component, which improves the adaptability and the encapsulating efficiency for encapsulating equipment and process procedures, and has the characteristics of reduced cost and convenient use.

Owner:陈俊光

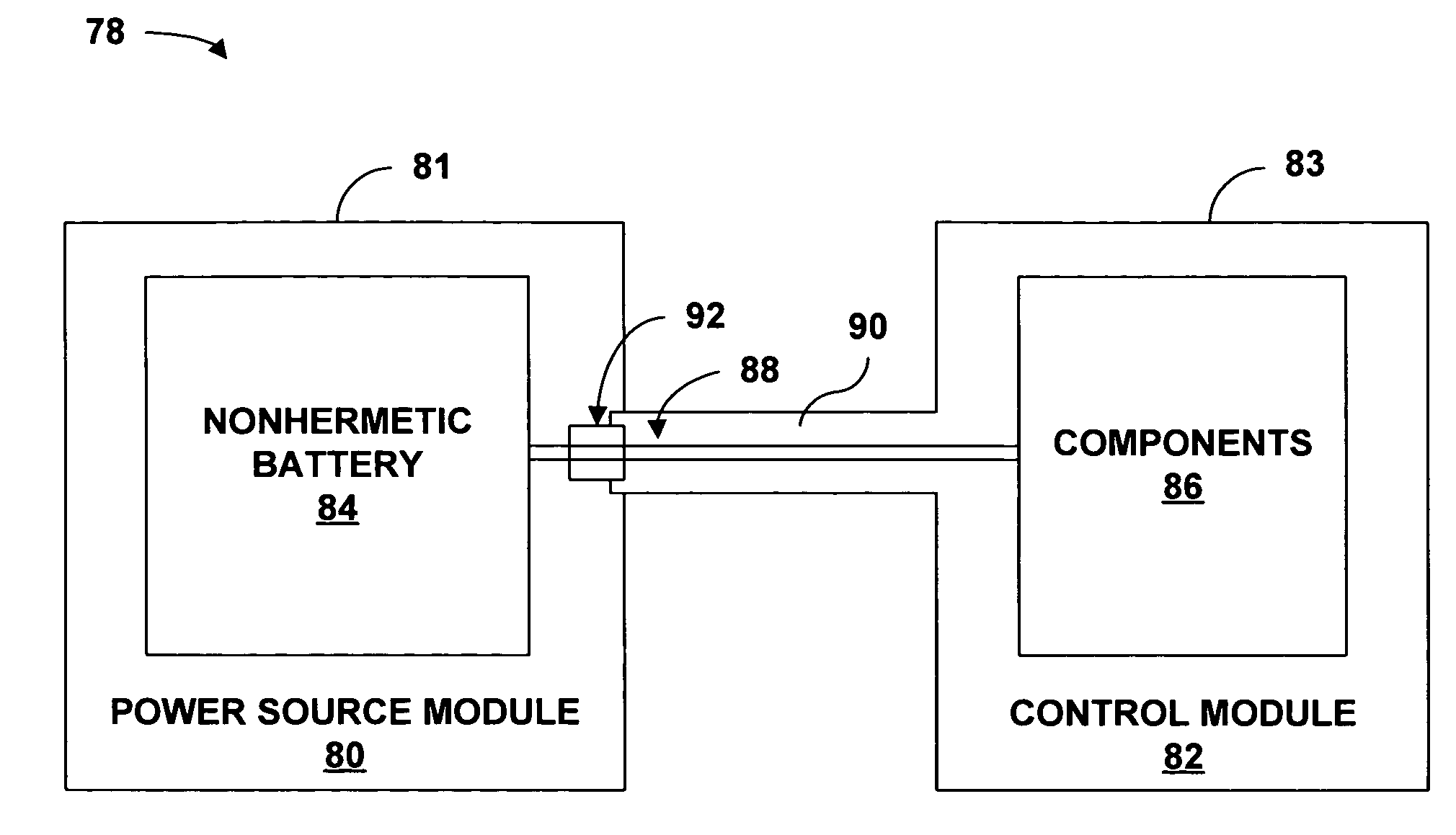

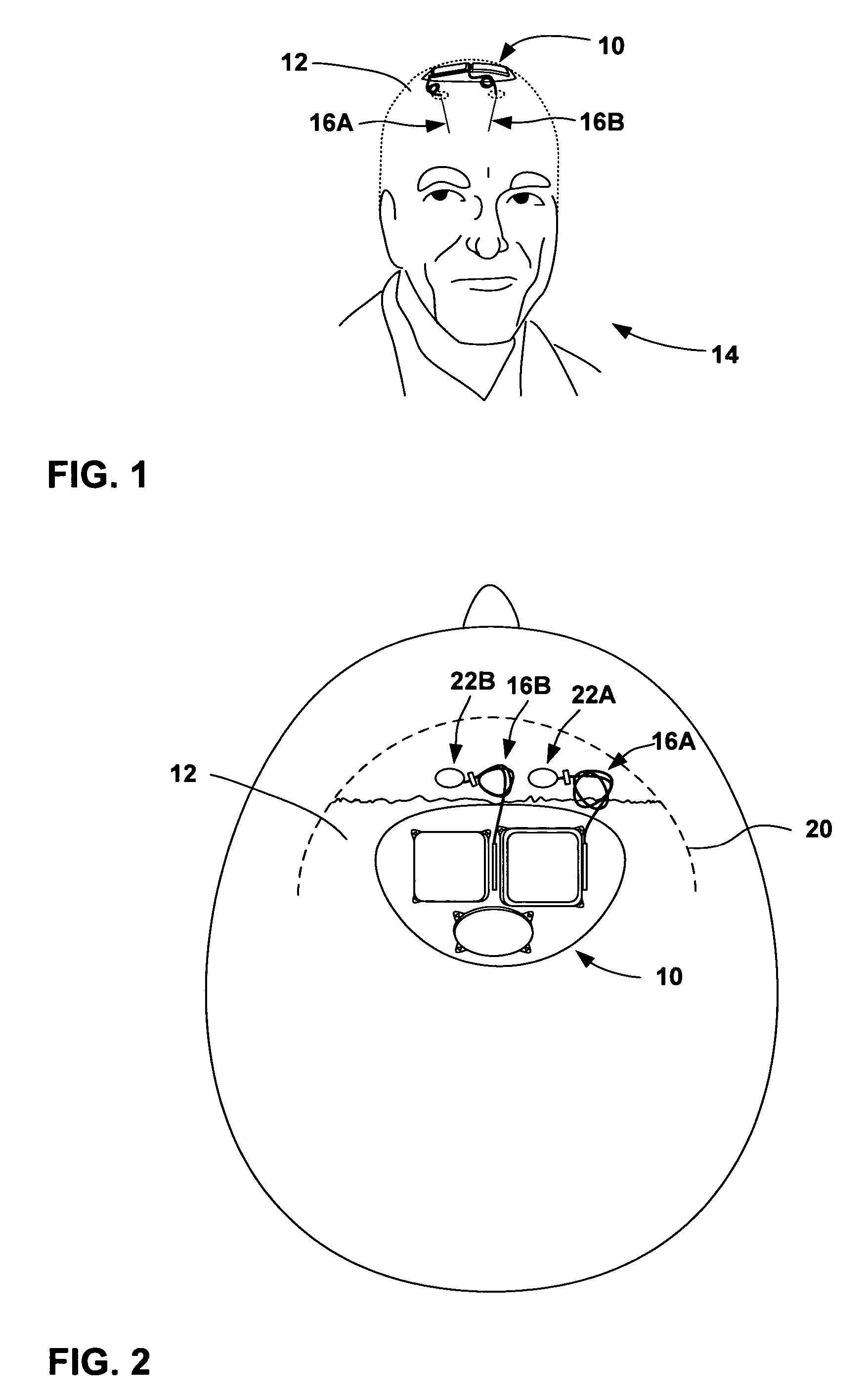

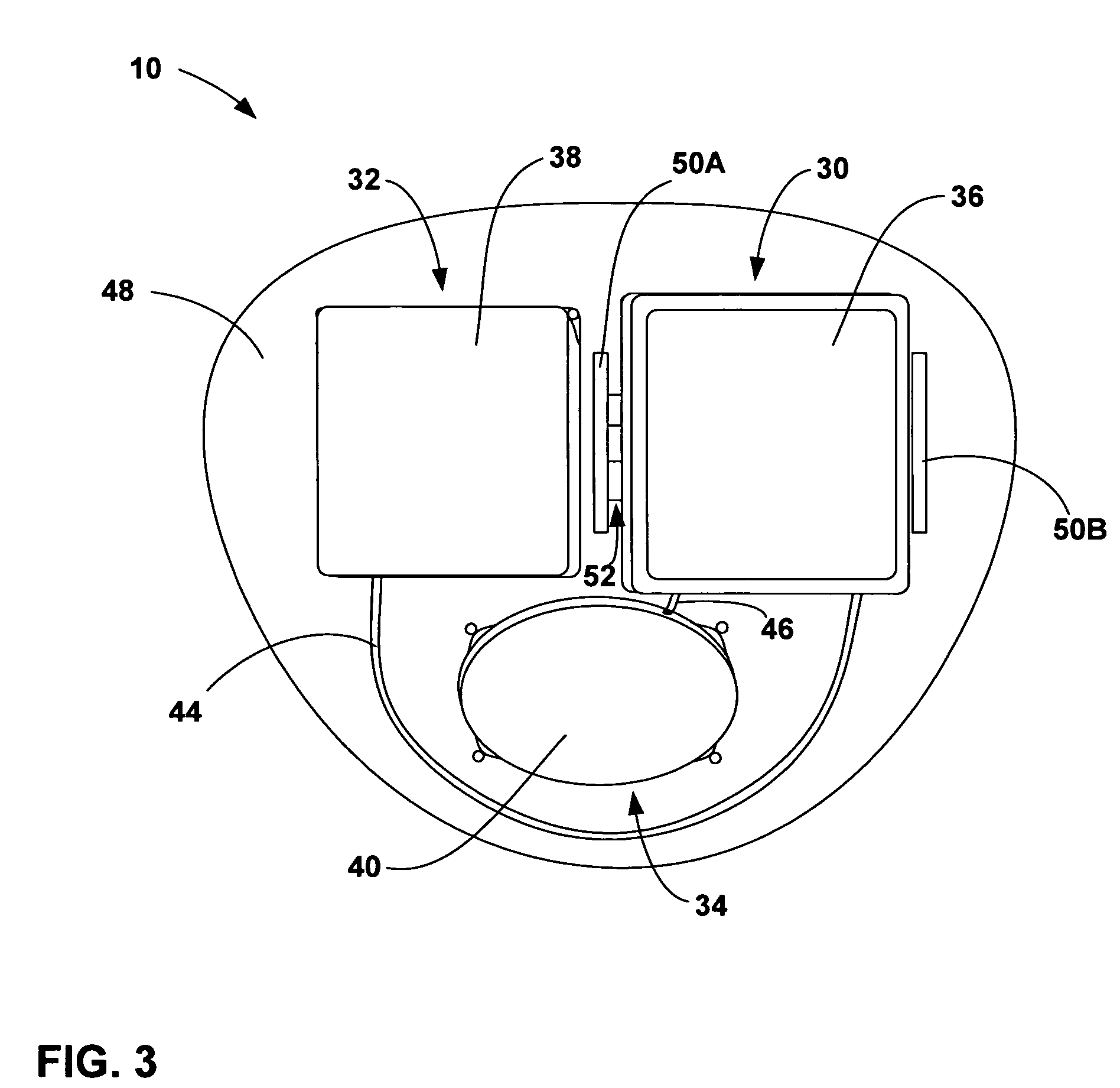

Implantable medical device with a nonhermetic battery

InactiveUS7263401B2Damage to componentEasy to useInternal electrodesHermetically-sealed casingsElectrical batteryEngineering

An implantable medical device (IMD) including a nonhermetic battery is described. The IMD includes components and a power source module that includes the nonhermetic battery. The IMD also includes a barrier to substantially impede movement of substances from the nonhermetic battery to the components. The barrier may include a hermetic feedthrough, a gel, a polymer, or a solid electrolyte within the nonhermetic battery, and a seal member. The barrier may also be a material that encapsulates the nonhermetic battery and a getter within the IMD. In some embodiments, the IMD comprises a modular IMD including an interconnect member. In that case, the barrier may include a material that fills at least a portion of a void defined by the interconnect member. A length and a cross-sectional area of the interconnect member may also act as a barrier.

Owner:MEDTRONIC INC

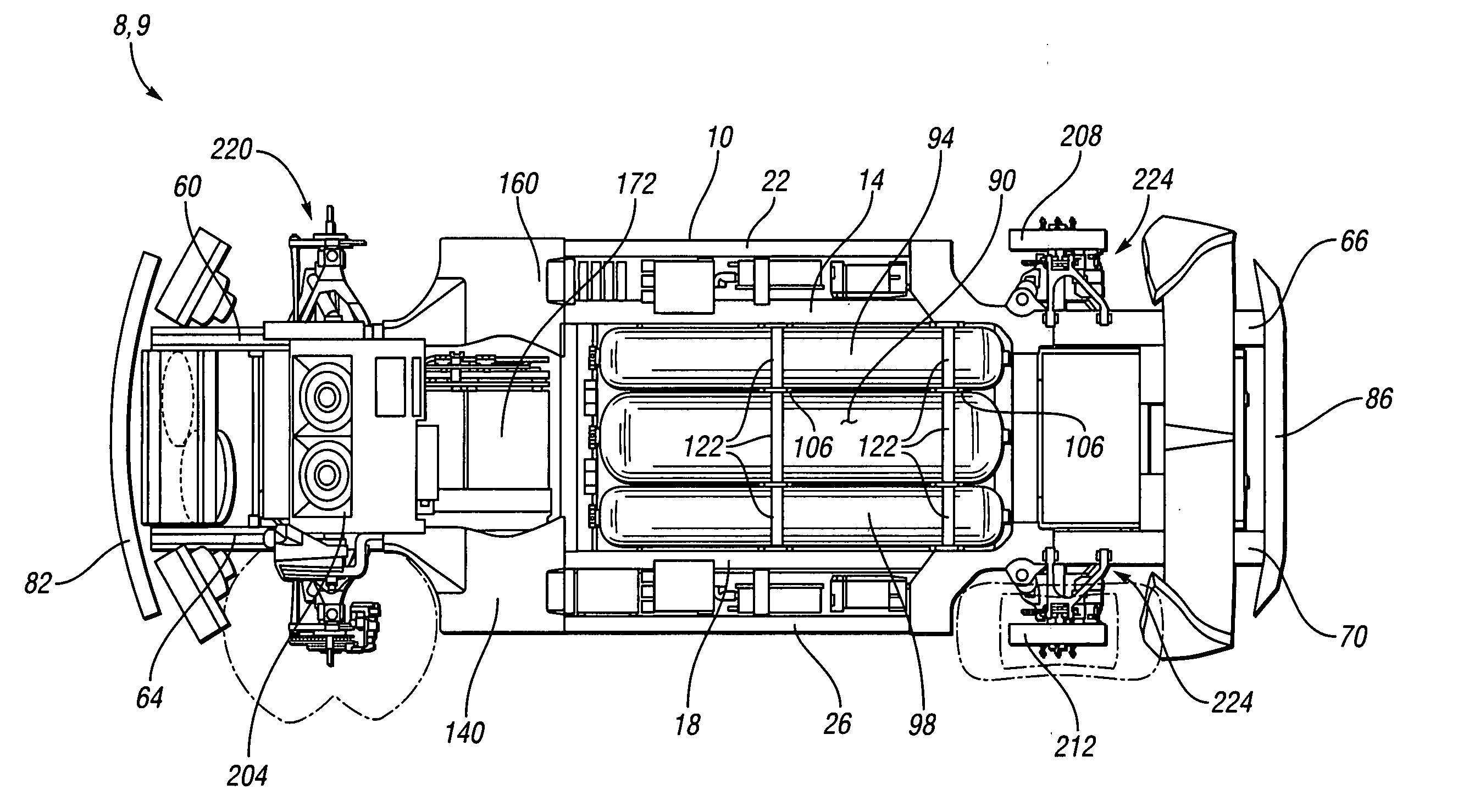

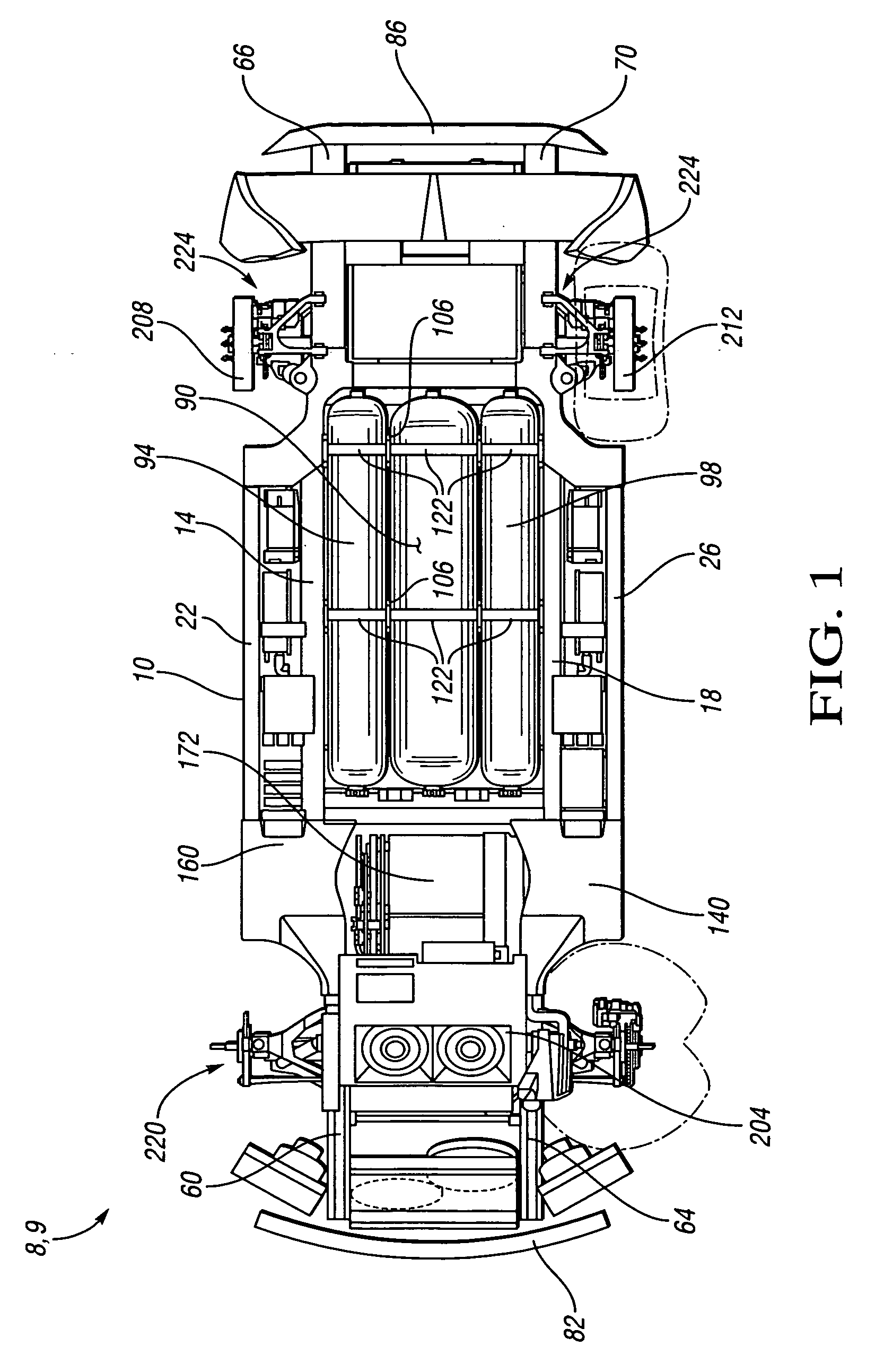

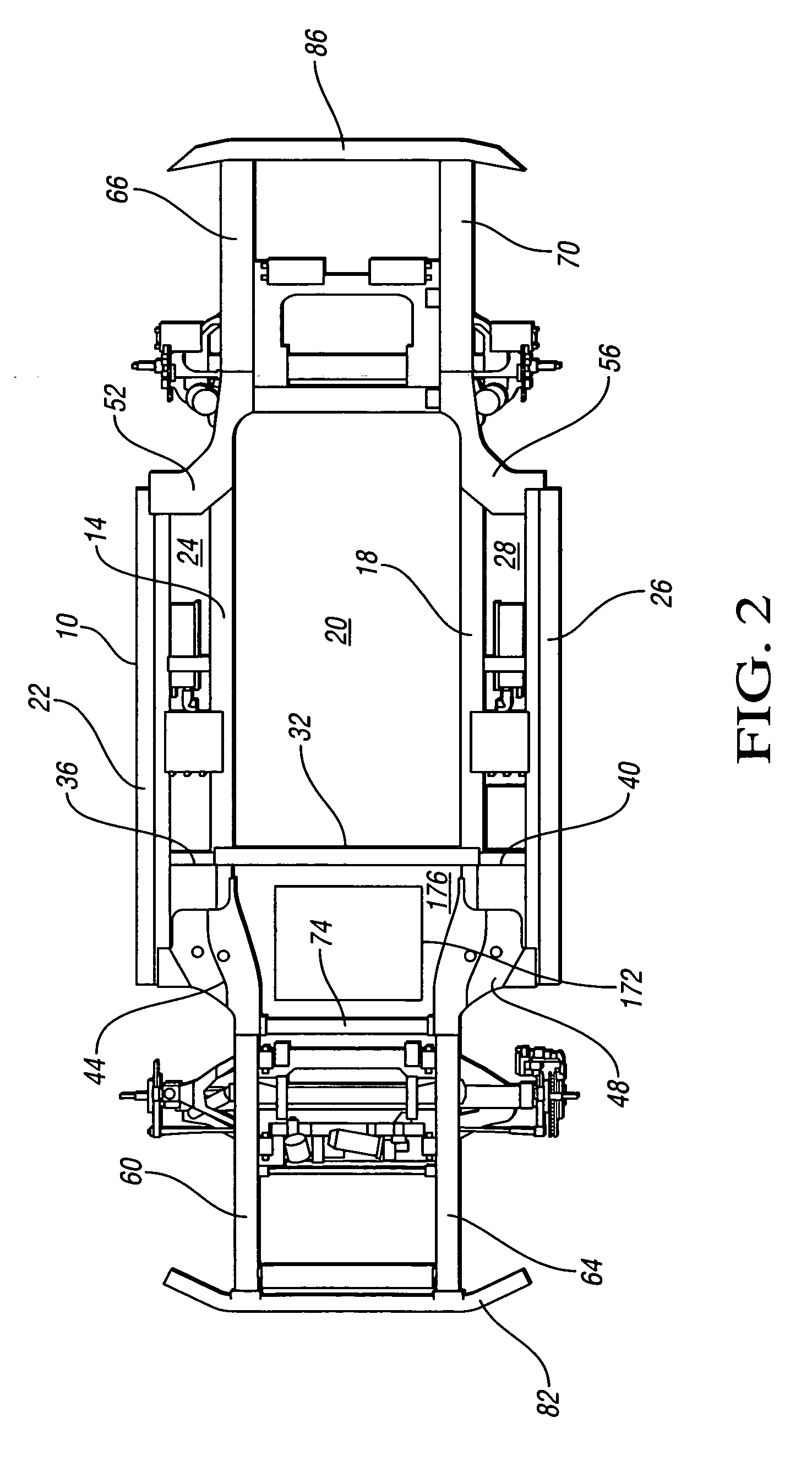

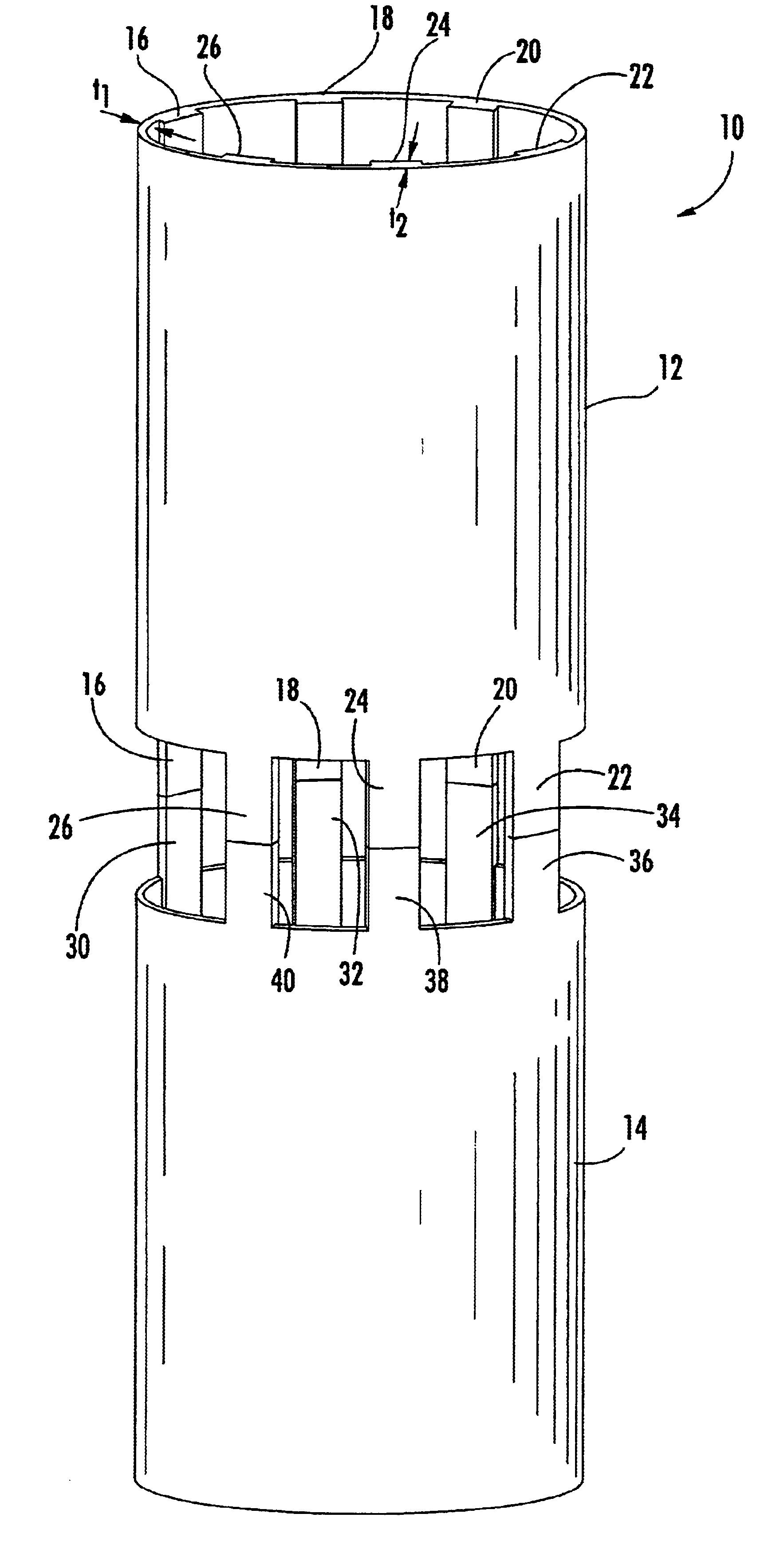

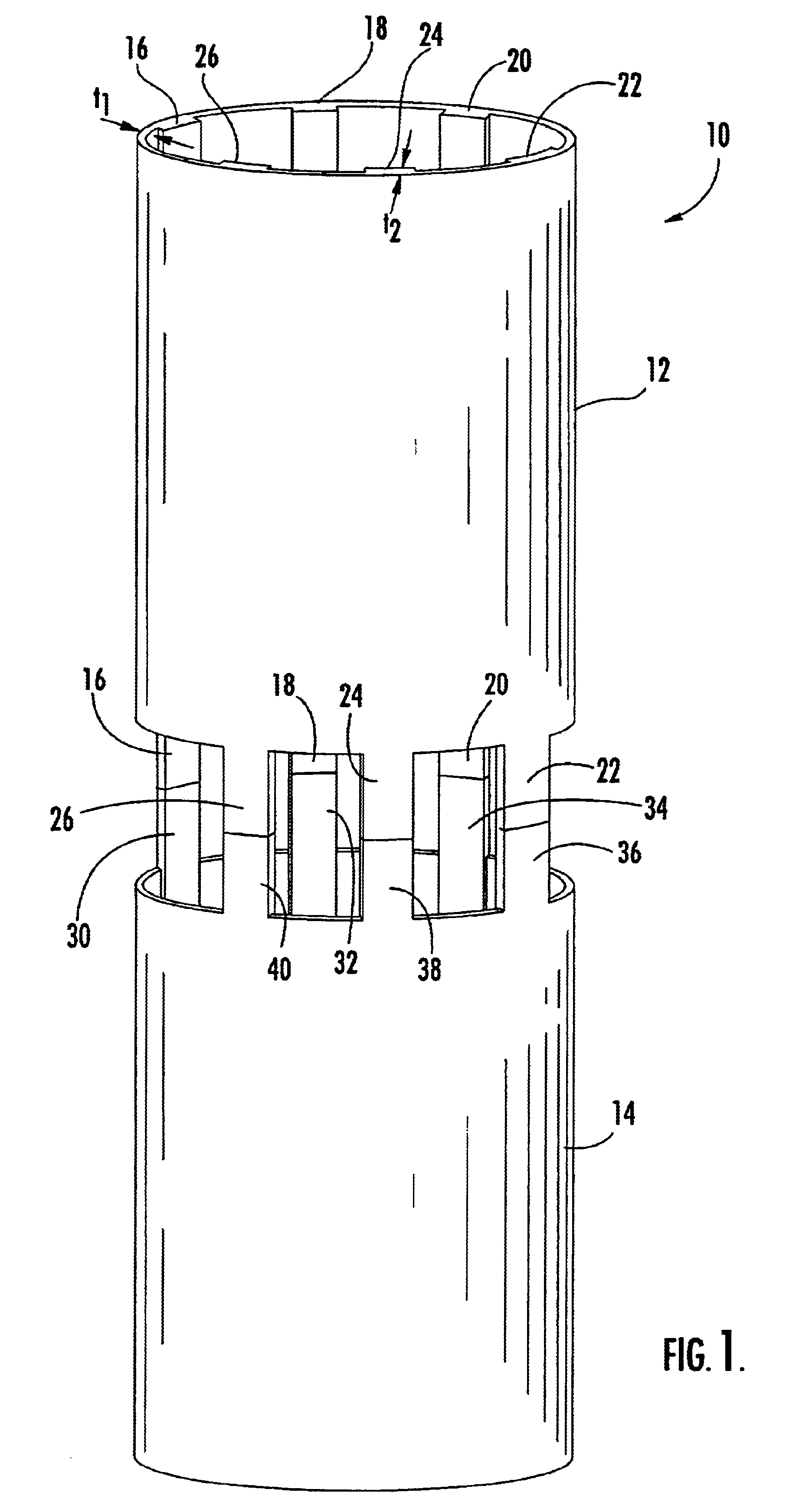

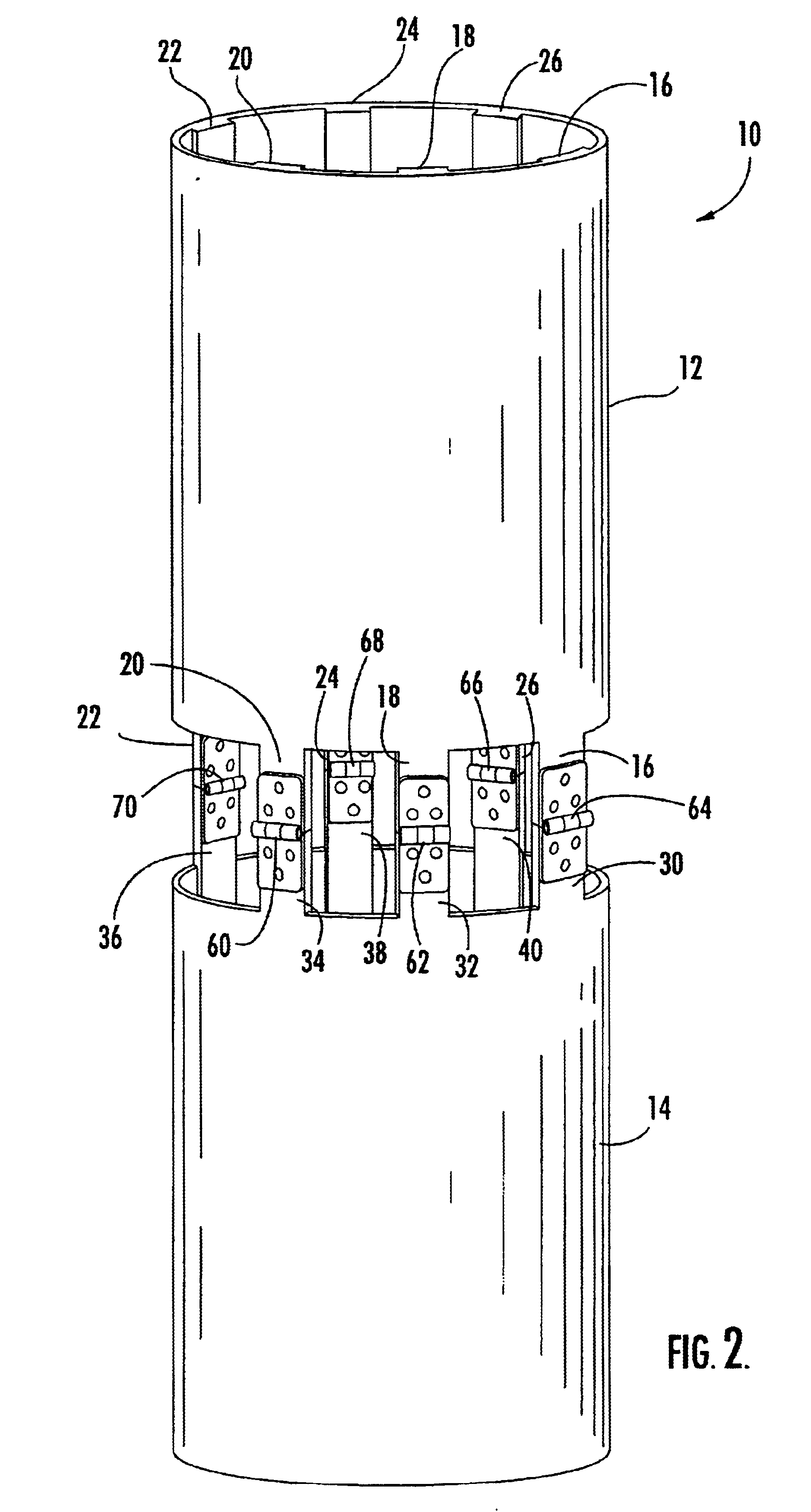

Compressed gas tank carrier assembly

InactiveUS20060061081A1Improve maintainabilityImprove usabilityReactant parameters controlTank vehiclesEngineeringHolding tank

A carrier assembly for a compressed gas storage tank includes a first yoke defining a first concavity, and a second yoke defining a second concavity. The first and second concavities are sufficiently aligned such that a tank is at least partially containable within both the first and second concavities. In an exemplary embodiment, the first yoke also defines a third concavity and the second yoke defines a fourth concavity; the third and fourth concavities are sufficiently aligned such that another tank is at least partially containable therein. Preferably, at least one flexible strap retains the tanks with respect to the yokes.

Owner:GM GLOBAL TECH OPERATIONS LLC

Lipid vesicle compositions and methods of use

ActiveUS20110229529A1Increase load capacityLong release profileOrganic active ingredientsVirusesDiagnostic agentVesicle/vacuole

Owner:MASSACHUSETTS INST OF TECH

Bagging and encasement all-in-one machine

InactiveCN103101638AFully automatedReasonable structurePackaging bottlesPackaging fruits/vegetablesControl systemPulp and paper industry

The invention provides a bagging and encasement all-in-one machine which comprises a conveyer system, a bagging system, a encasement system and a control system, wherein the conveyer system comprises a workbin, a loading material conveyor belt arranged at a position of an opening of the workbin, and a working table conveying device arranged in the back of the loading material conveyor belt. The bagging system is arranged in the middle of the working table conveying device, and comprises a net sleeve loading material roller, a net sleeve cylinder arranged below the net sleeve loading material roller, conveying rollers arranged on two sides including a left side and a right side of the net sleeve cylinder, fixed supports arranged on two sides including a front side and a back side of the net sleeve cylinder, a net sleeve cutter arranged on the upper middle portion of the net sleeve cylinder, a net sleeve expansion device arranged below the net sleeve cylinder, and a negative-pressure adsorption pushing device arranged below the working table conveying device which is arranged below the net sleeve expansion device. Compared with the prior art, the bagging and encasement all-in-one machine achieves automation of a bagging and encasement overall process, and is reasonable in structure, convenient to use and high in packaging efficiency.

Owner:郝保军

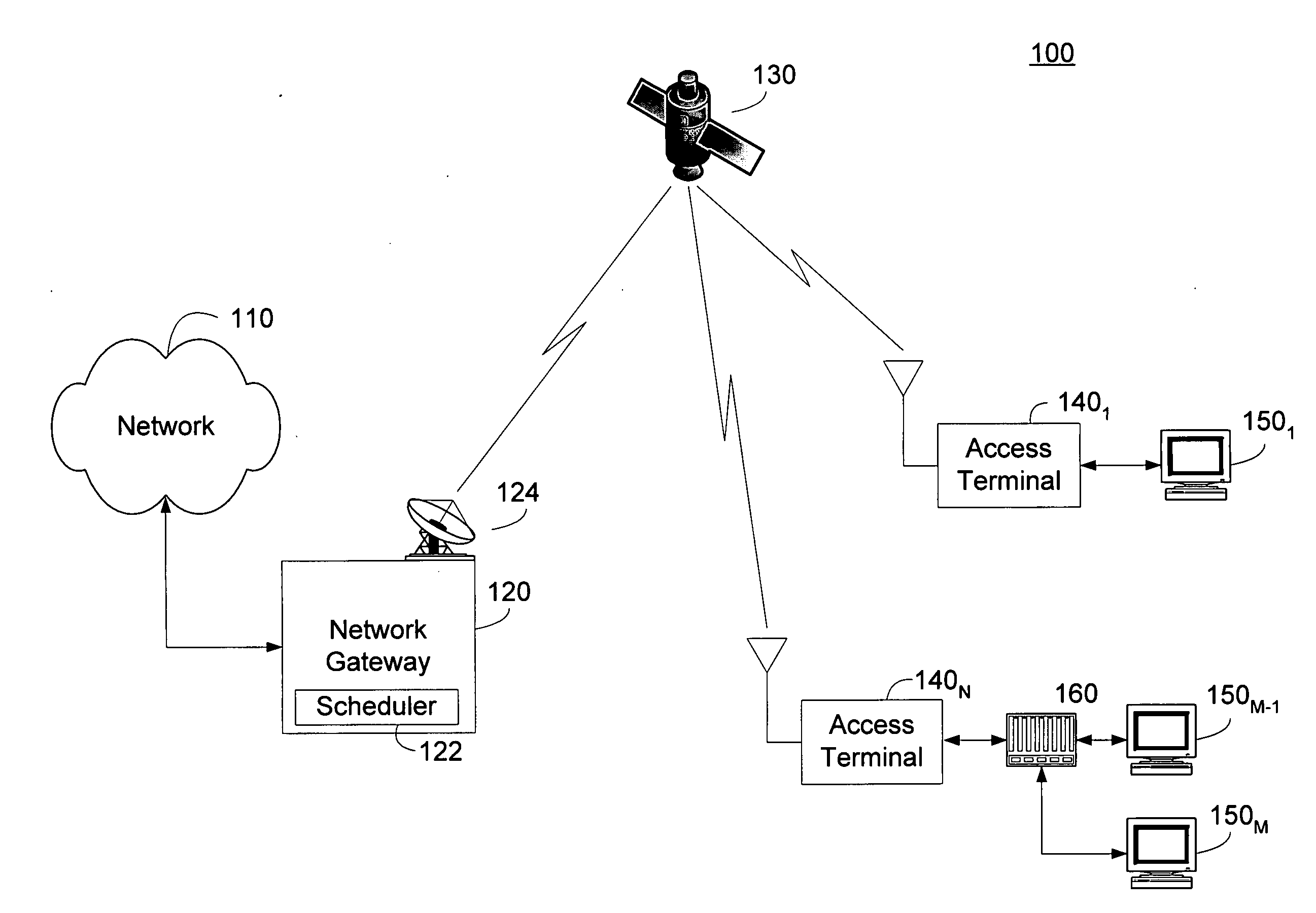

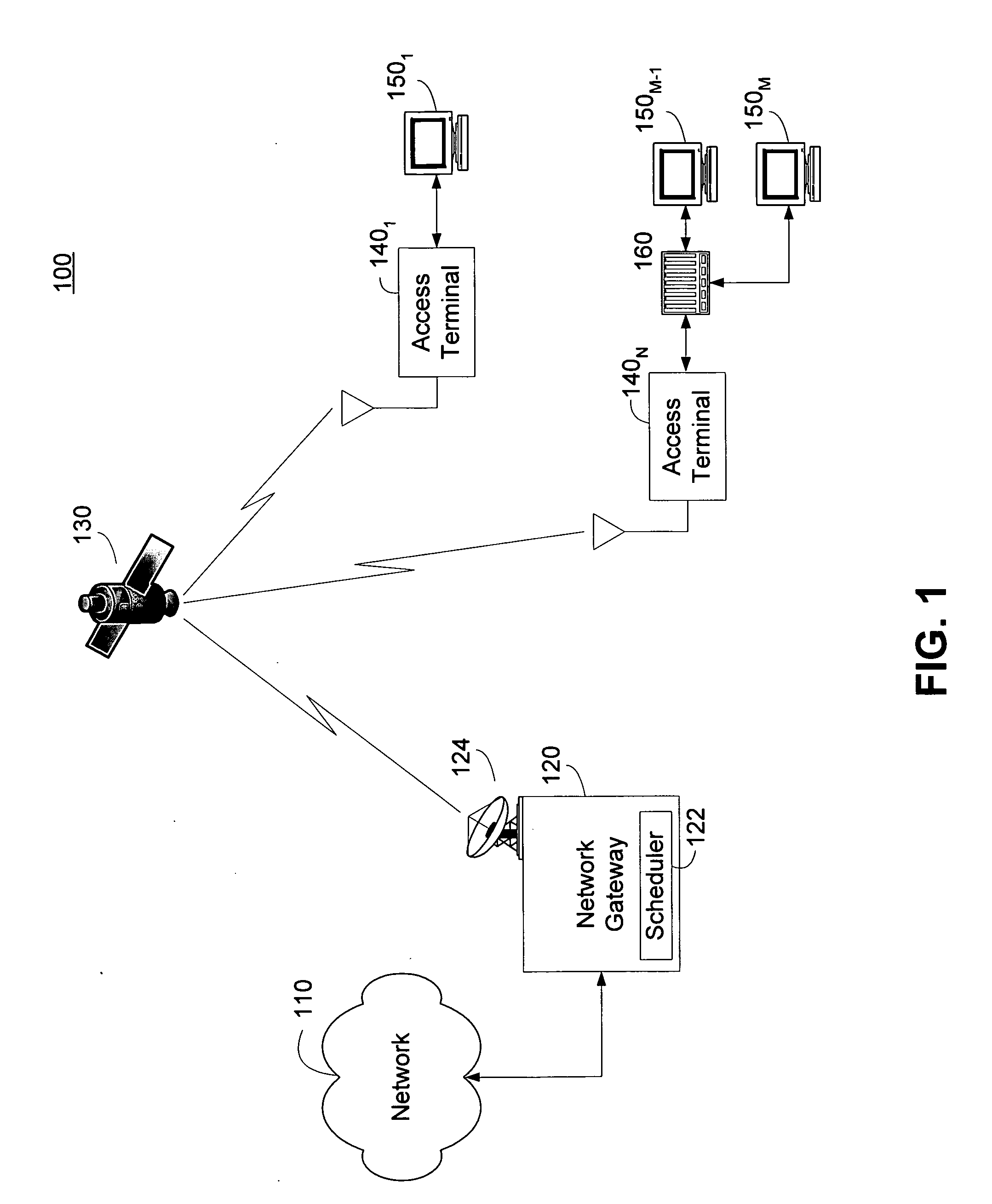

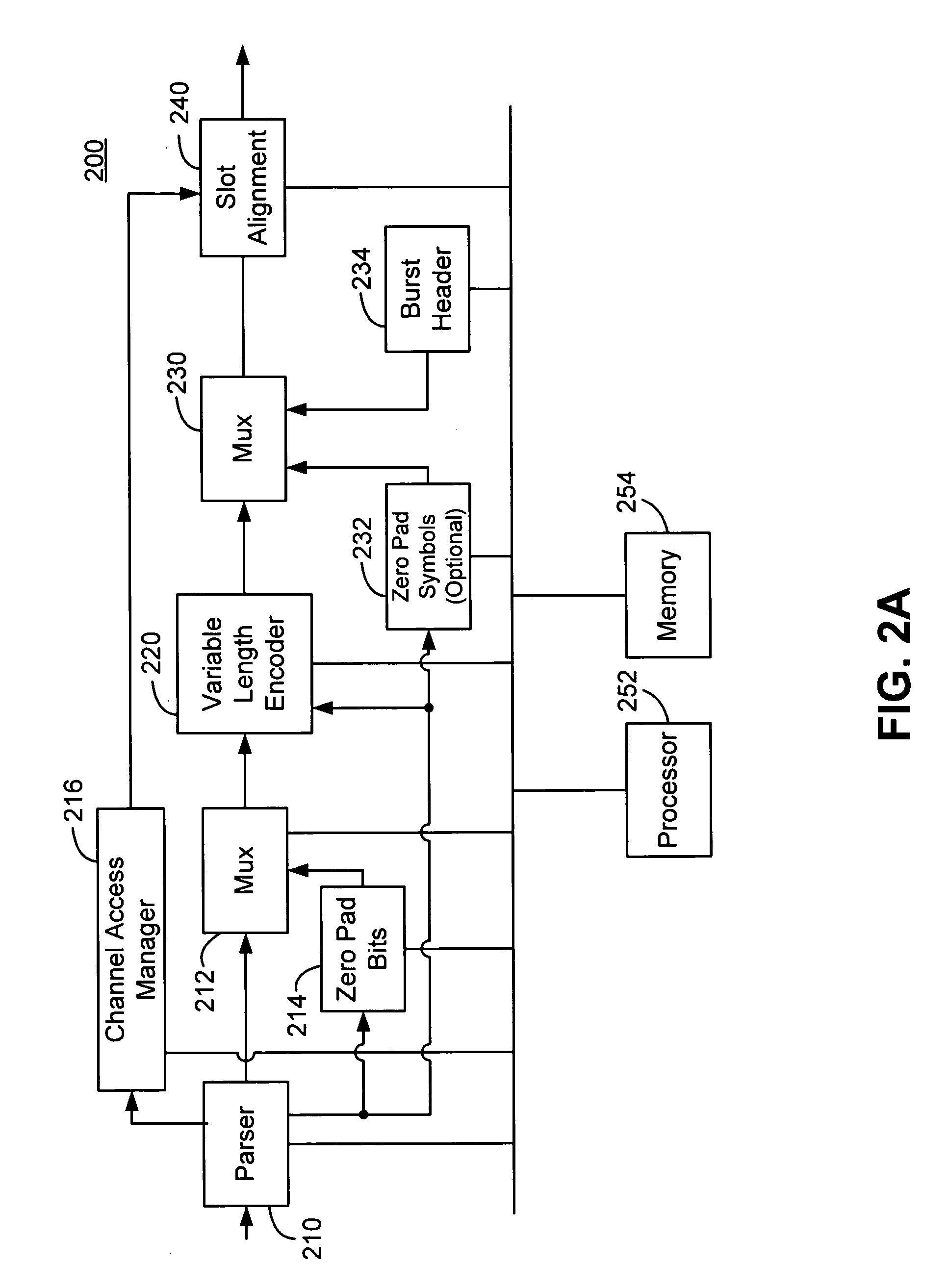

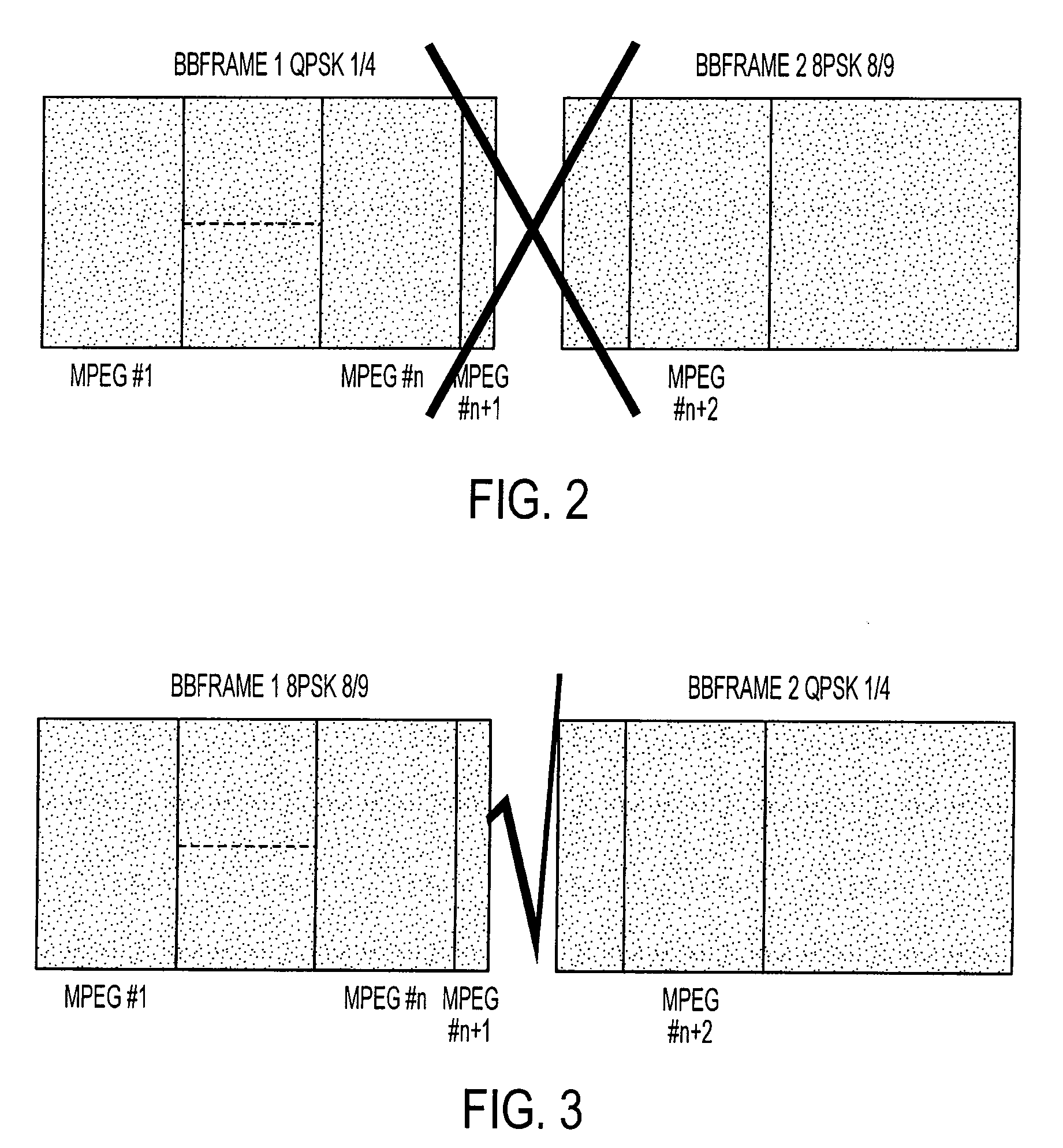

Variable length data encapsulation and encoding

ActiveUS20070126612A1Eliminate needImprove packaging efficiencyColor television with pulse code modulationError preventionComputer hardwareCoding block

Systems, apparatus, and methods of encoding variable length data for efficient transport over a wireless channel. A wireless terminal can determine a frame size to encode, and can encode and transmit the frame data as one or more encoded blocks selected from a family of block sizes. Each block size can correspond to a particular encoder rate. The frame is parsed into a number of segments having a block size selected from the family of block sizes. The block sizes are selected to maximize the spectral efficiency of the frame. Each segment is then encoded with an encoder corresponding to the block size and having a coding rate that is configured to provide a substantially equal energy per symbol for all of the blocks. The encoded blocks are then aggregated and the smallest block zero padded. The aggregate of encoded blocks can be transported in one or more bursts.

Owner:VIASAT INC

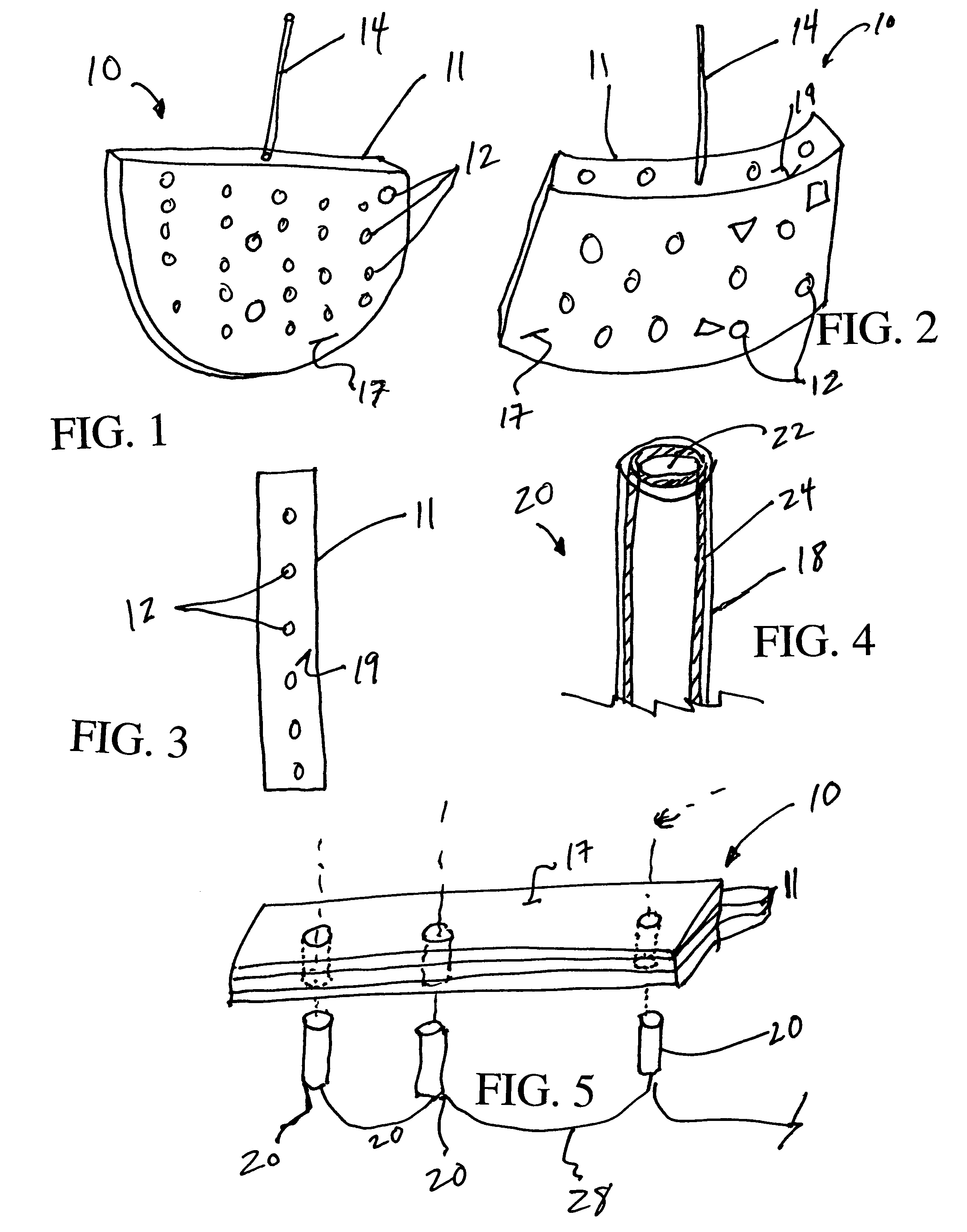

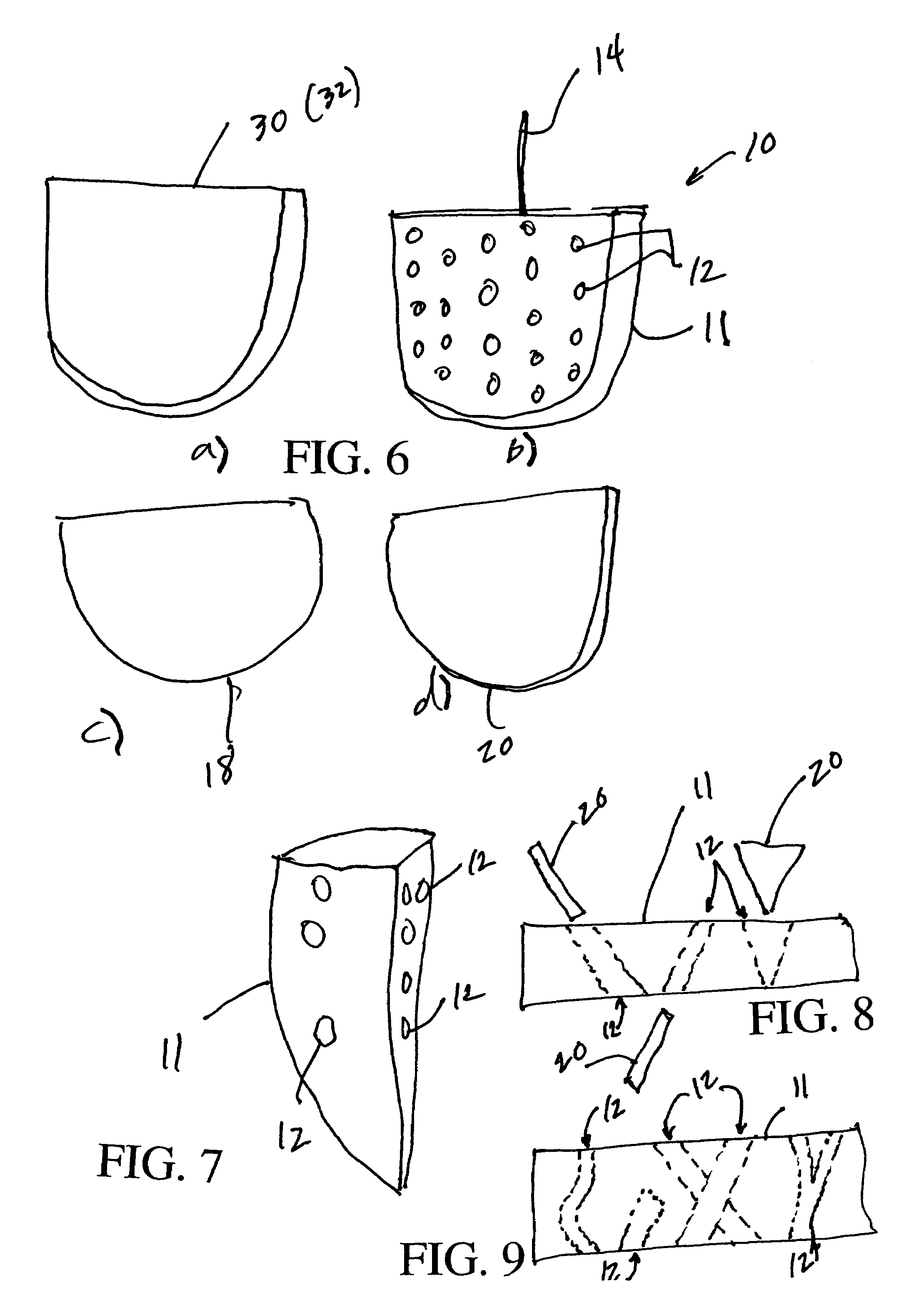

Advanced valve metal anodes with complex interior and surface features and methods for processing same

InactiveUS7342774B2Small shape flexibilitySmall sizeLiquid electrolytic capacitorsHeart defibrillatorsHigh voltage capacitorsHigh energy

The present invention generally relates to improved capacitors; in particular, the present invention provides advanced valve metal (AVM) anodes and methods for fabricating AVM anodes having complex surface and interior features for use in high energy density capacitors. Such anodes find use in high voltage capacitors incorporated into implantable medical devices (IMDs), among other uses. The AVM anodes may be pressed into virtually any arbitrary shape and may have a gradually changing (or substantially constant) density profile throughout the AVM anode. Such AVM anodes may also be perforated or shaped to receive one or more cathode members. The AVM anodes enhance packaging efficiency for compact high energy density capacitors.

Owner:MEDTRONIC INC

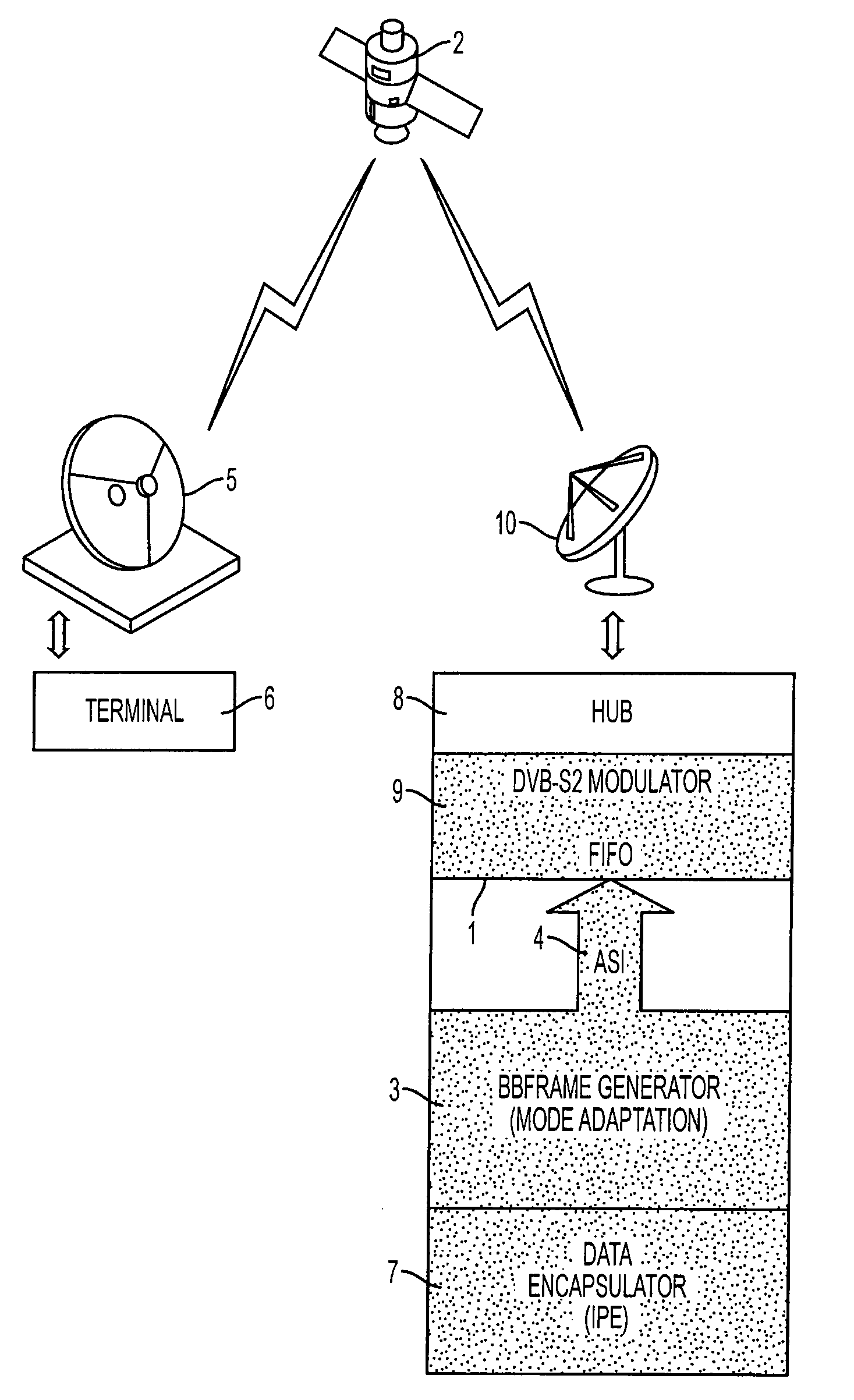

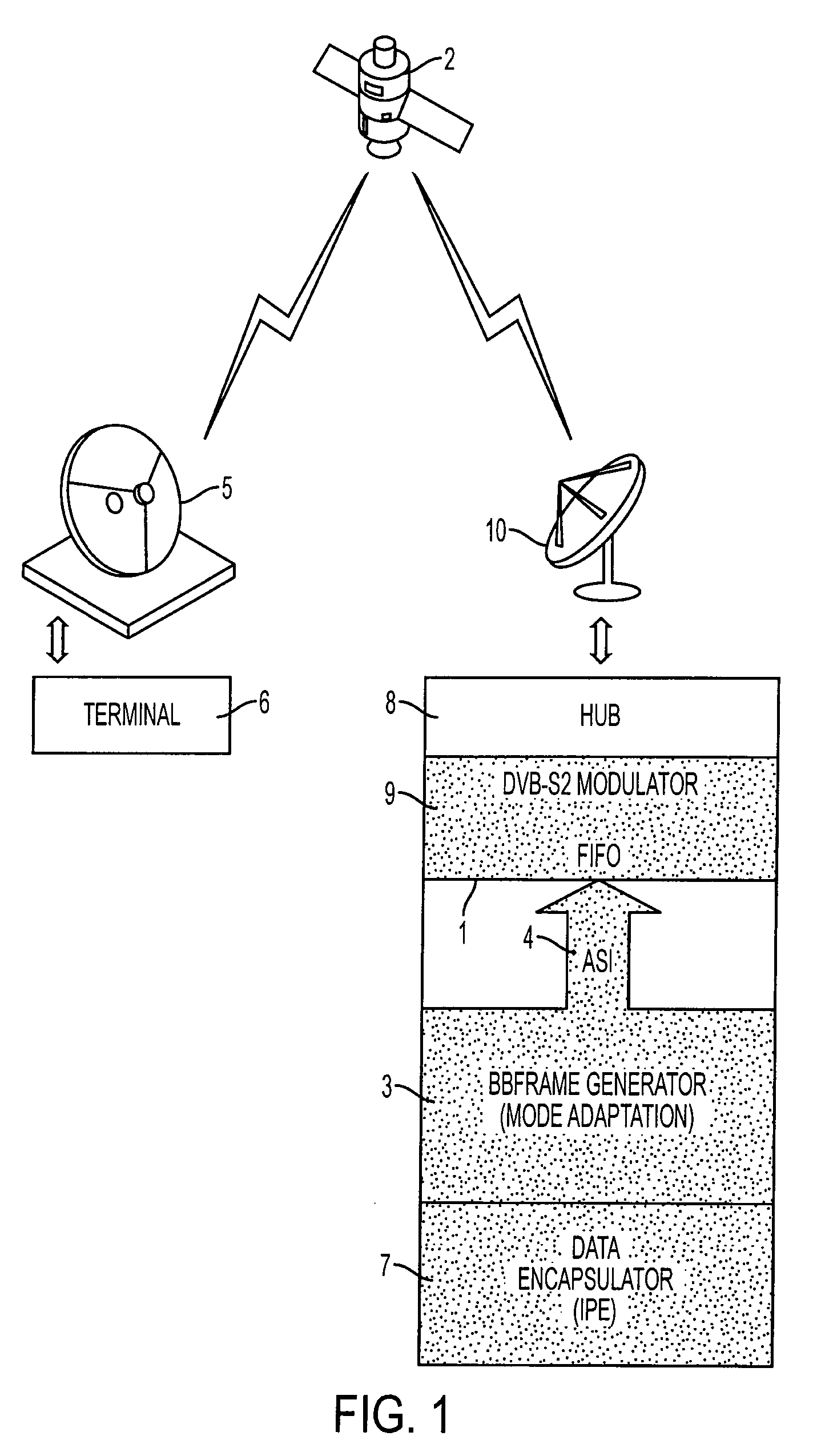

Packing Data Over An Adaptive Rate Link

ActiveUS20080049659A1Prevent overflowEnabling useTime-division multiplexFrequency-division multiplexComputer networkDVB-S2

Owner:GILAT SATELLITE NETWORKS

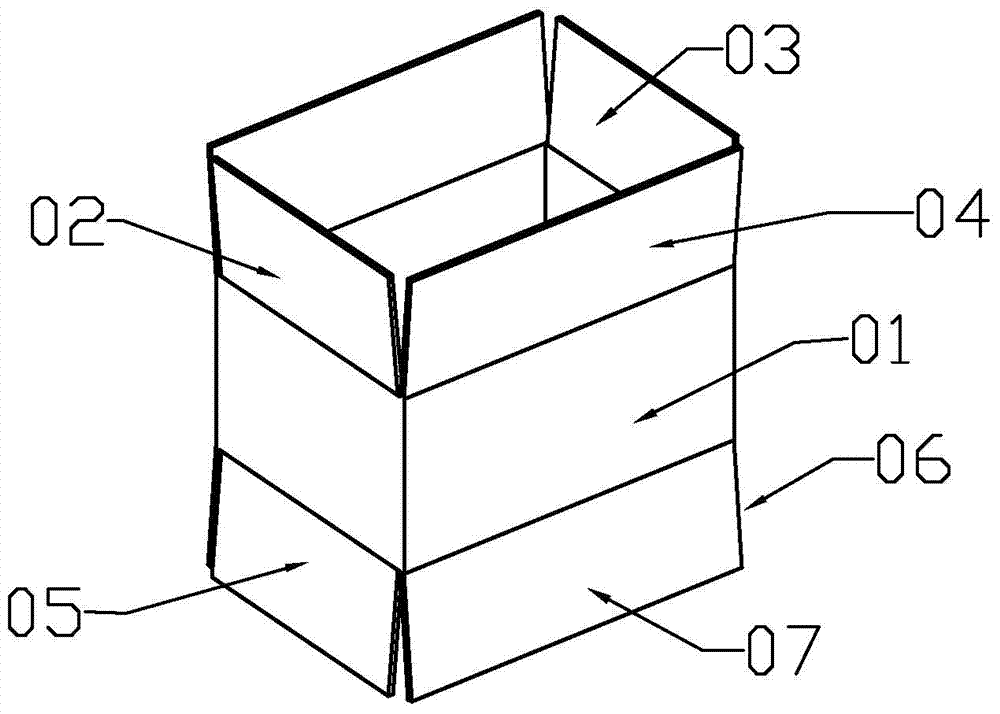

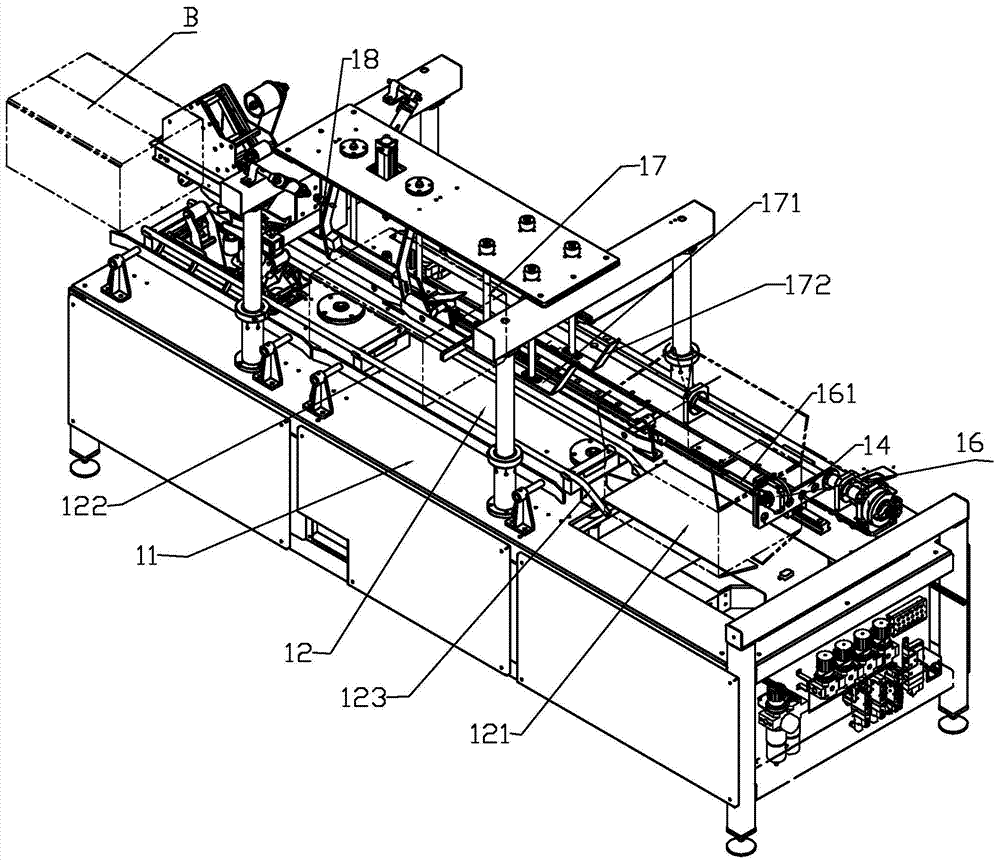

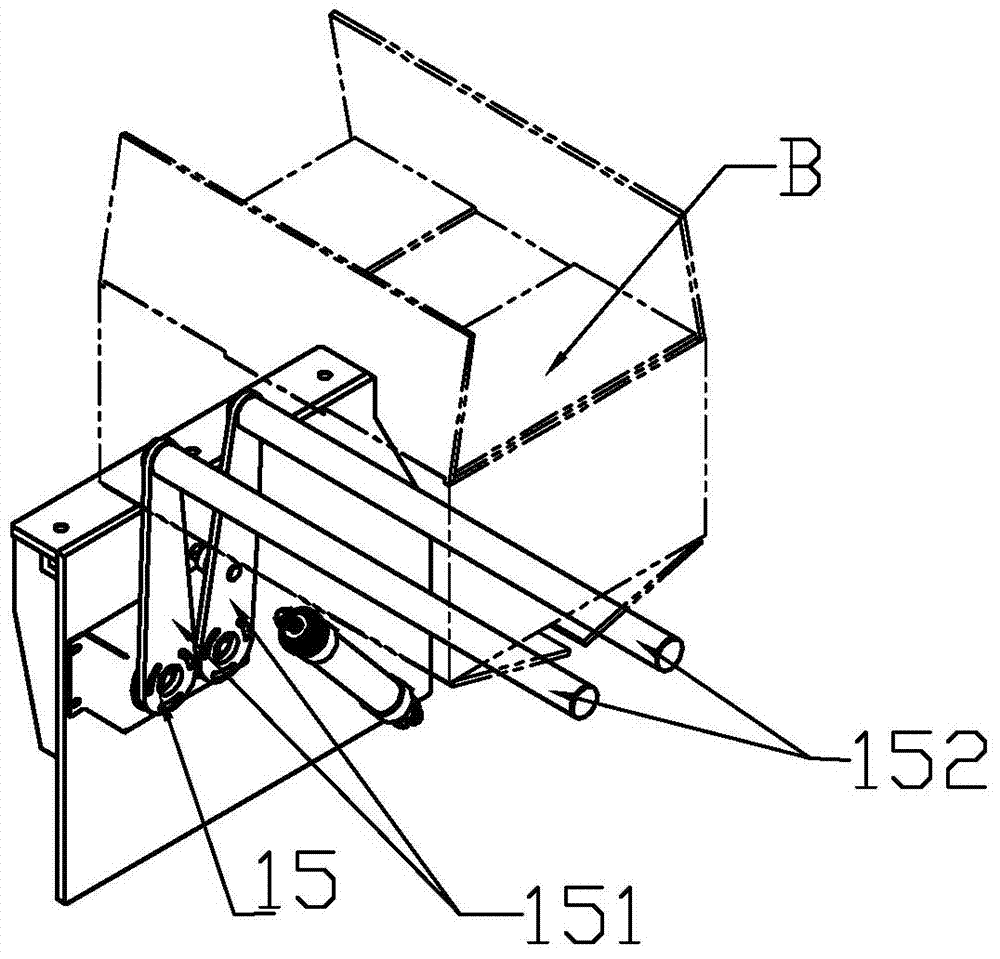

Packing box boxing and sealing device

ActiveCN104326118AReduce manual interventionImprove packaging efficiencyWrapper twisting/gatheringEngineeringManipulator

The invention relates to a packing machine, in particular to a packing box boxing and sealing device. The packing box boxing and sealing device comprises a horizontal transport passage which is arranged on a stander and a mechanical hand which is arranged above the transport passage; a supporting flat plate is arranged on the bottom of a rear section of the transport passage, a transport track is arranged on the bottom of a front section of the transport passage, and the rear end of the transport track is inclined downwards to form a guide section; the stander is also provided with a drive arm which can push a packing box to move forwards; the mechanical hand can drive the packing box to obliquely swing forwards and backwards above the supporting flat plate and to move up and down in the vertical direction; lower side sheet turnover mechanisms which can push two lower cover side sheets of the packing box to be turned inwards are arranged on the lower two sides of the supporting flat plate; an upper cover sealing mechanism which is used for turning an upper cover rear sheet, and an upper cover front sheet and upper cover side sheets of the packing box inwards and an adhesive tape sealing mechanism for sealing an adhesive tape are also arranged above the transport passage. By adopting the packing box boxing and sealing device, the sealing process of the packing box can be automatically completed, the packing efficiency can be improved, and the operating cost can be reduced.

Owner:JOYEA CORP

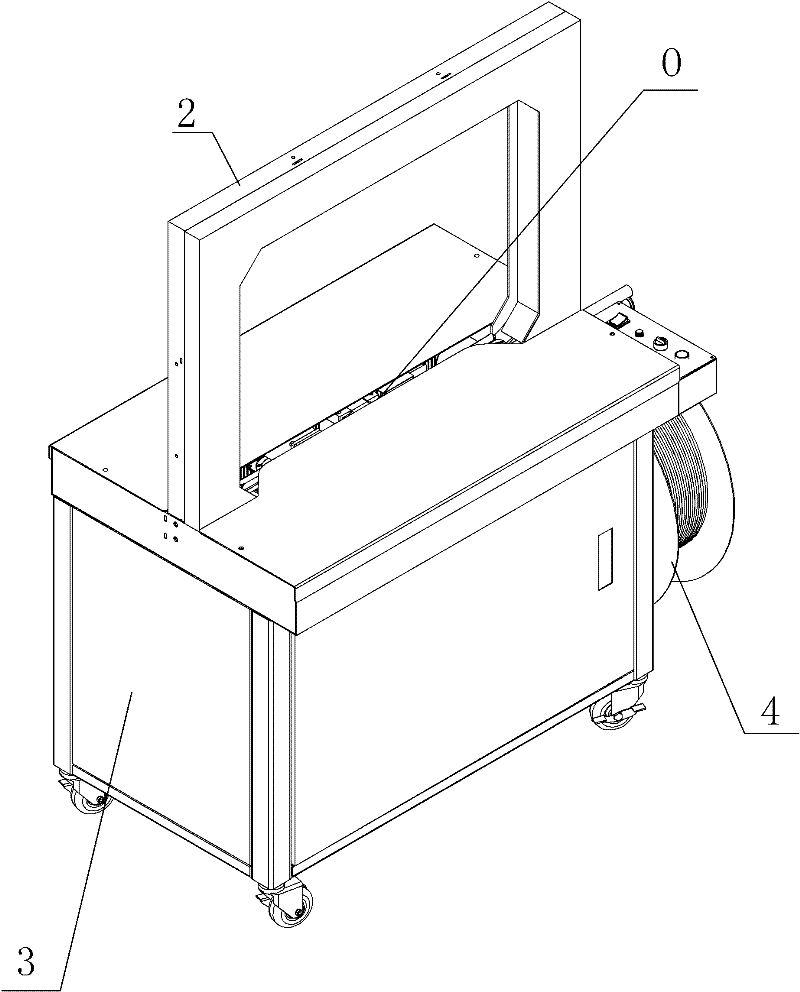

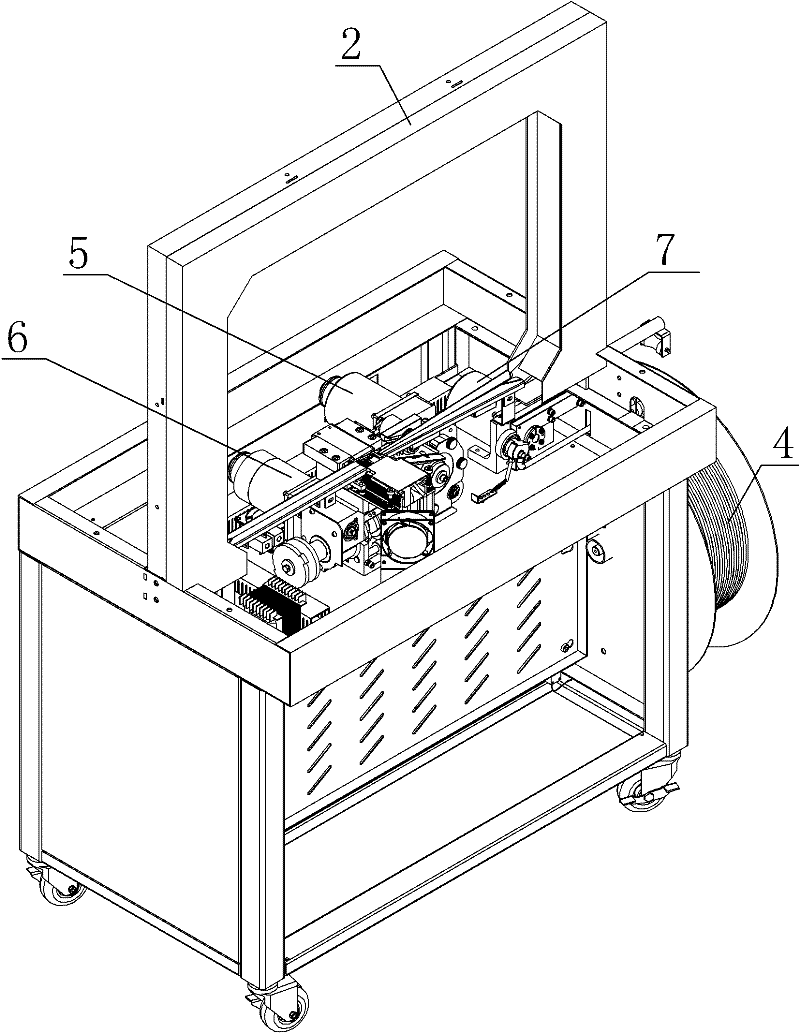

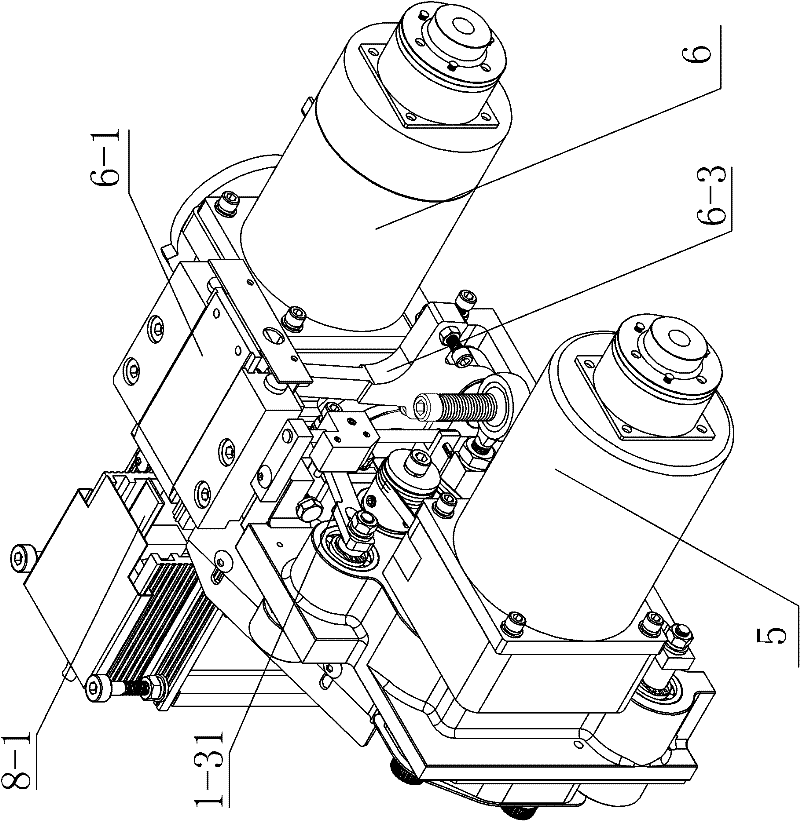

Novel packing machine

ActiveCN102530291AReasonable configurationEasy to controlBinding material applicationBundling machine detailsFixed frameEngineering

The invention provides a novel packing machine. A vertical mounting plate is arranged at the lower half part of the packing machine, a horizontal mounting plate is fixed at the upper part of the vertical mounting plate, a fixing frame is arranged at the upper half part of the vertical mounting plate and wraps the left part, right part and upper part of an article banding station, the mounting plates and the fixing frame are arranged on a rack of the packing machine, and a tape spool is arranged at the lower part of the packing machine; and a movement of the packing machine and a pre-sending belt device are arranged on the horizontal mounting plate, a retreating belt and tensioning belt device is arranged in the movement of the packing machine and comprises a retreating belt mechanism and a tensioning belt mechanism. According to the novel packing machine, all the functional devices are reasonable in configuration and convenient and simple in control, the packing quality can be improved, and the comprehensive improvement of the packing efficiency and the reliable work can be facilitated.

Owner:HANGZHOU YOUNGSUN INTELLIGENT EQUIP

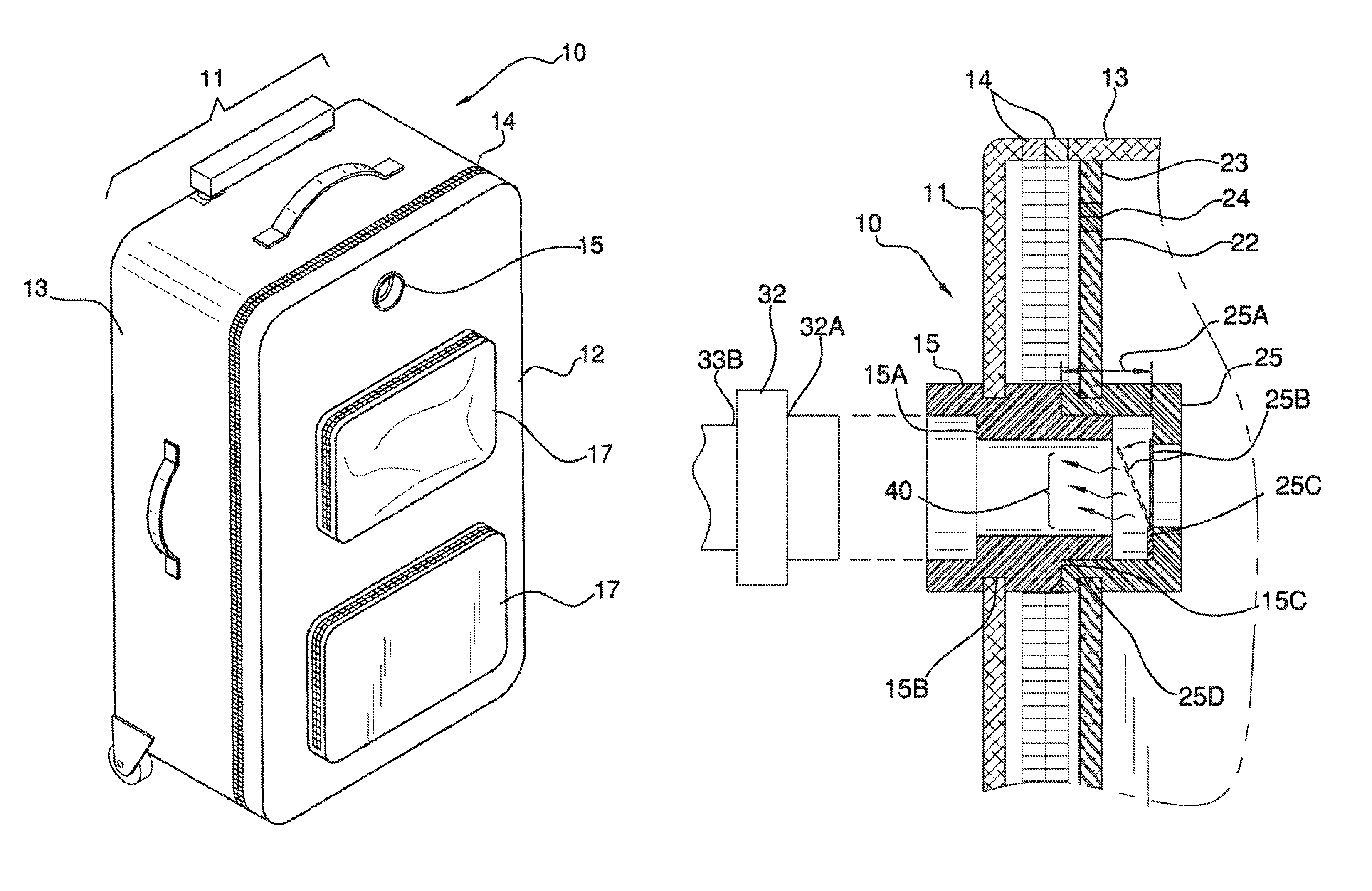

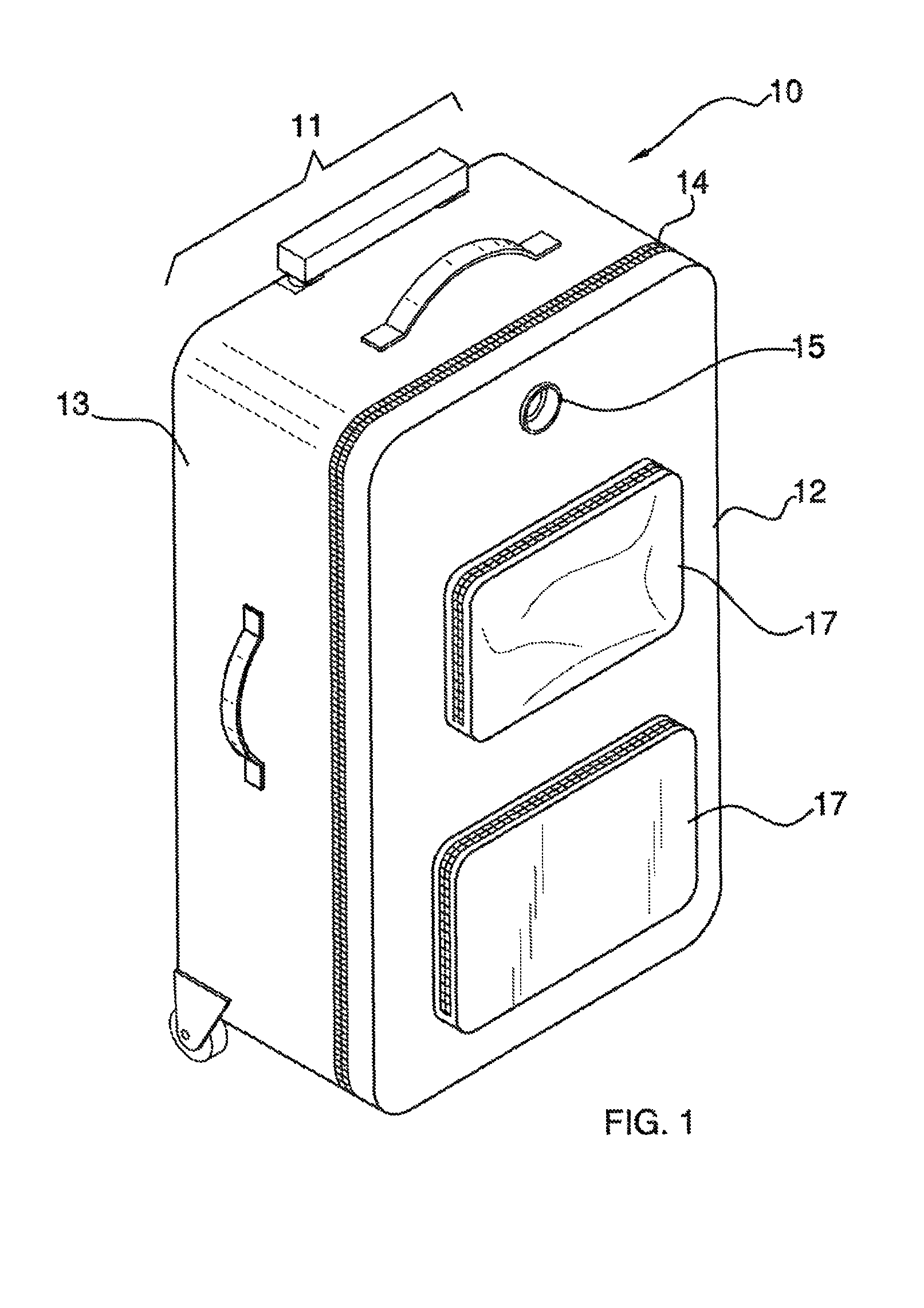

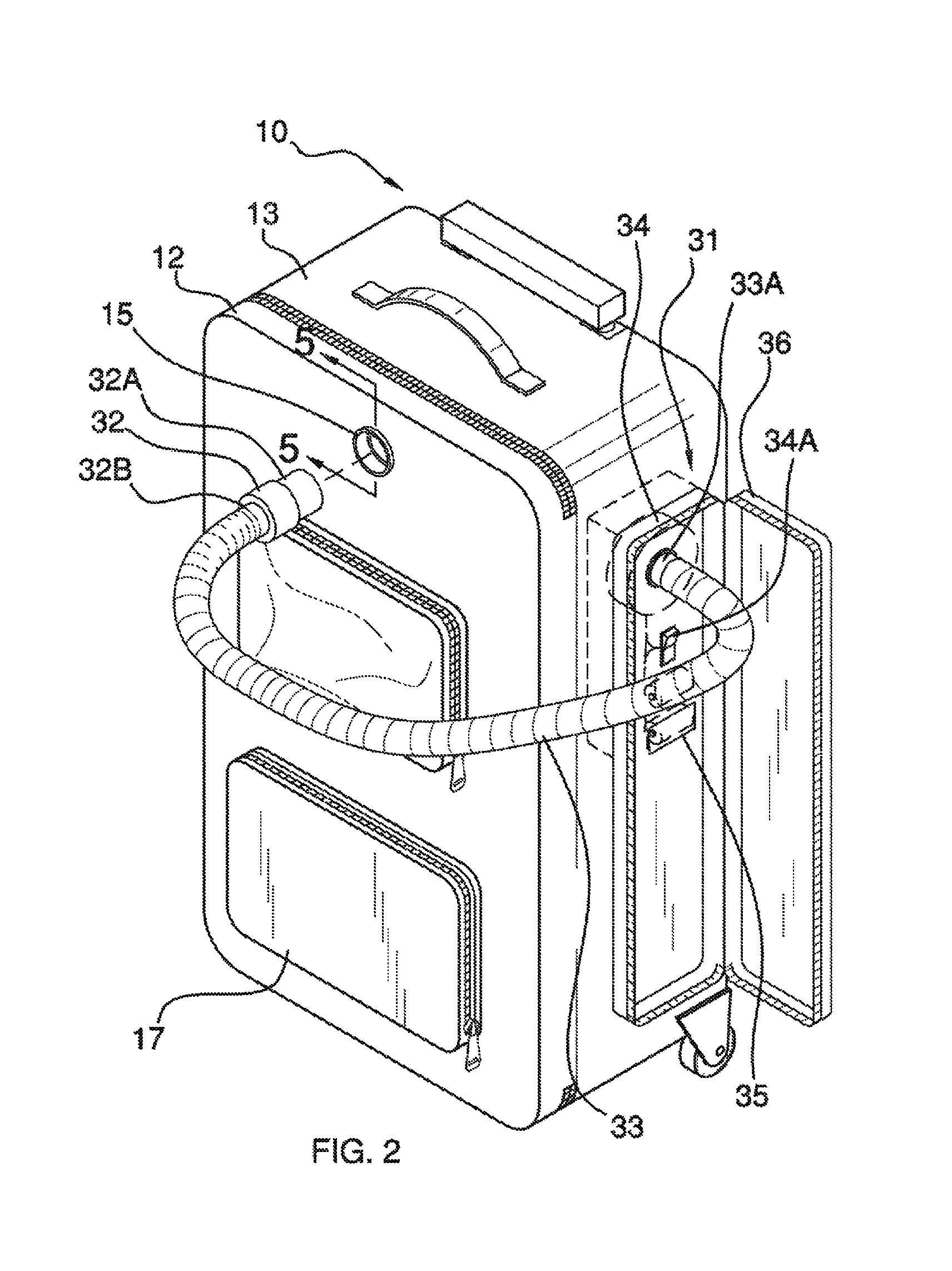

Luggage with integrated vacuum bags

Owner:EFRON CHAD

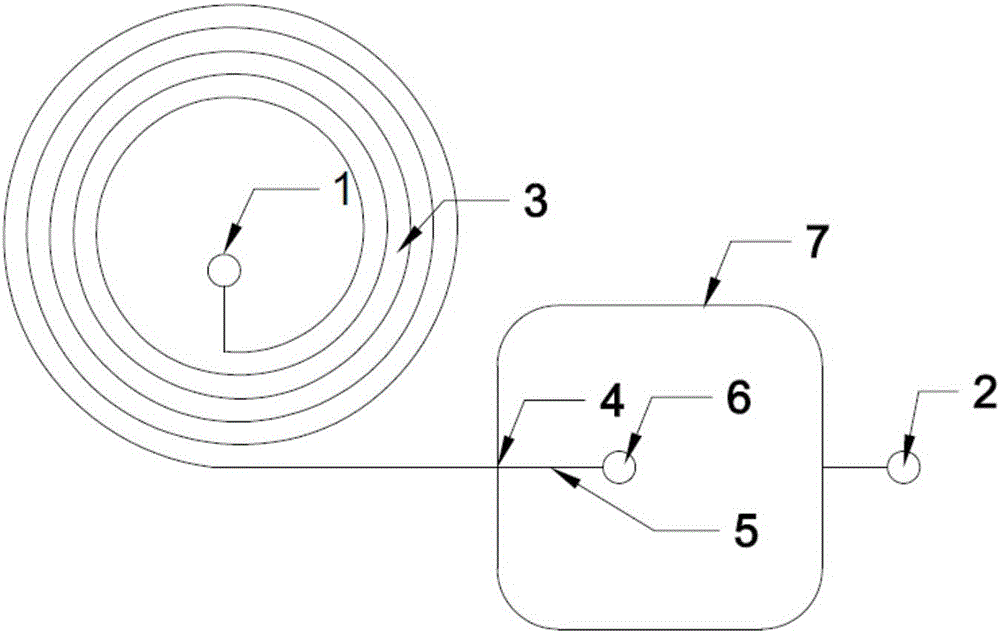

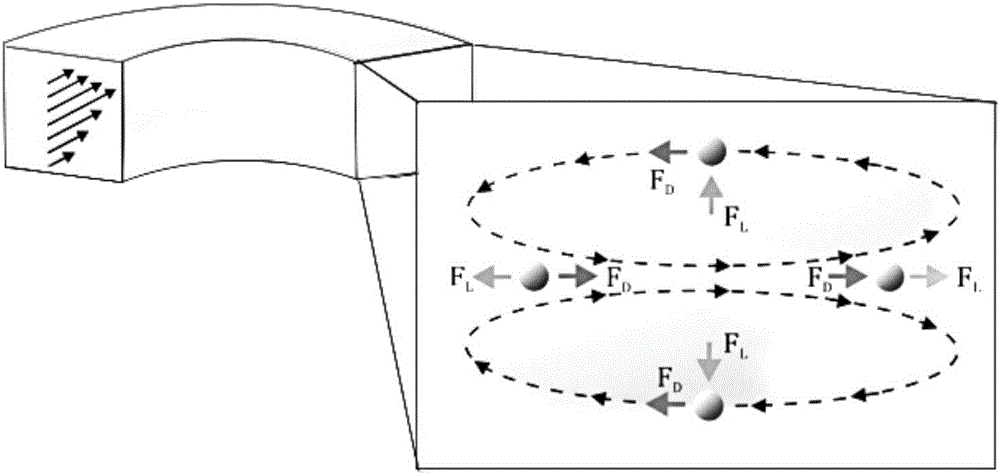

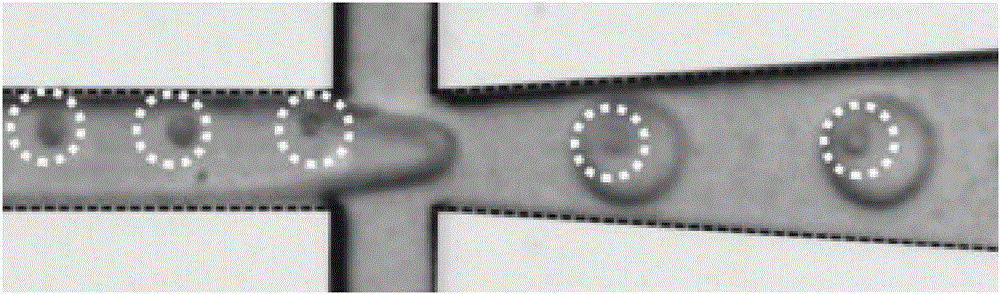

Micro-fluidic chip for single-cell isolation

ActiveCN105944775AImplement a single packageImprove packaging efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsOil phaseEngineering

The invention discloses a micro-fluidic chip for single-cell isolation. The micro-fluidic chip comprises a substrate and a micro-channel formed in the substrate, wherein the micro-channel comprises a cell sample feeding hole, a single-cell collecting pool, a cell separation unit and a liquid drop output channel, the cell separation unit and the liquid drop output channel are sequentially communicated between the cell sample feeding hole and the single-cell collecting pool, a liquid drop generation packaging unit is formed at the joint of the cell separation unit and the liquid drop output channel and is communicated with an oil phase conveying channel, and the cell separation unit is used for conveying cells arrayed in a single-row manner to the liquid drop generation packaging unit. According to the micro-fluidic chip, a cell solution is treated by virtue of a spiral disc type micro-channel, so that the cells can be arrayed in a pipeline in a single-row manner and can be singly packaged by virtue of the liquid drop generation packaging unit.

Owner:SUZHOU WENHAO MICROFLUIDIC TECH CO LTD

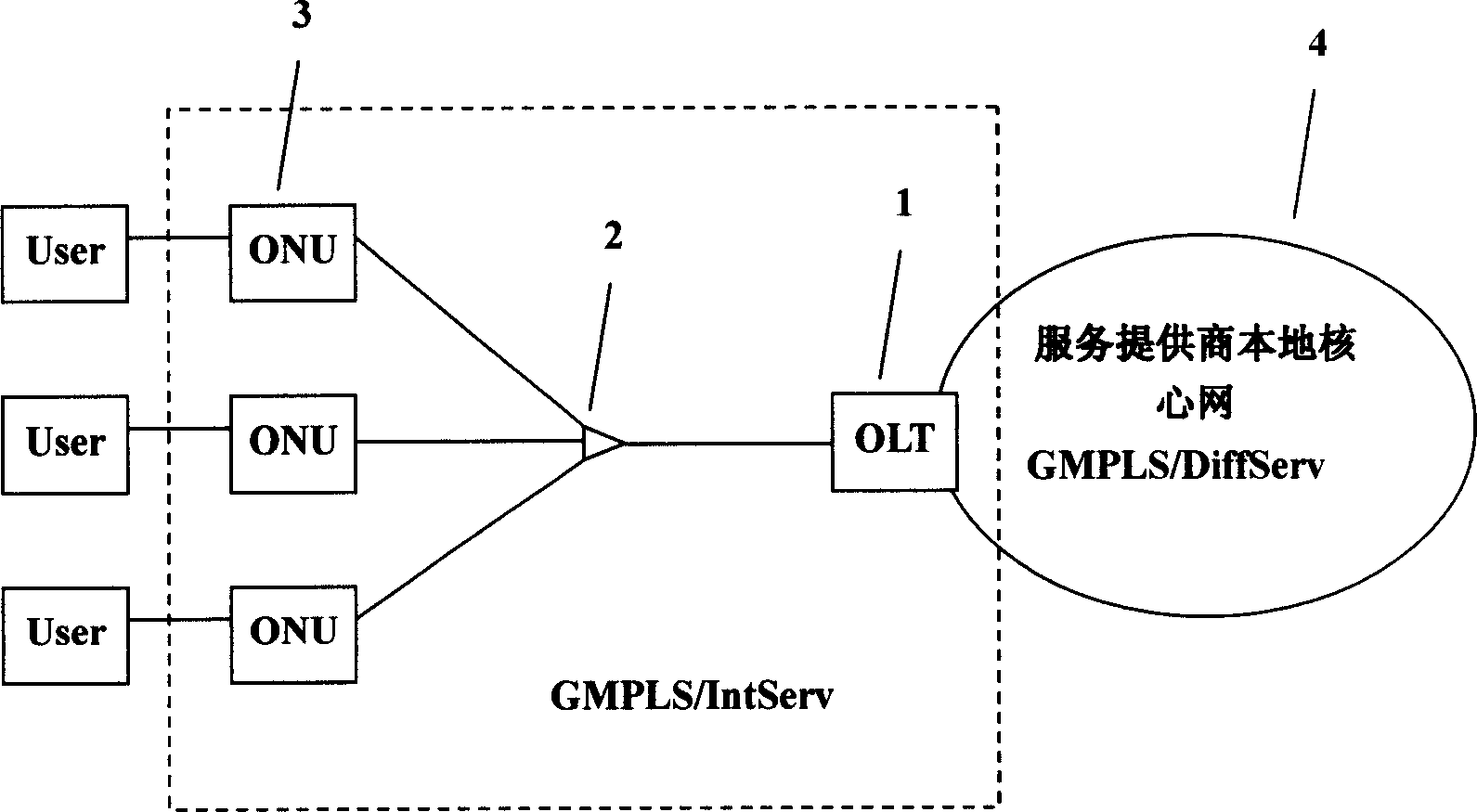

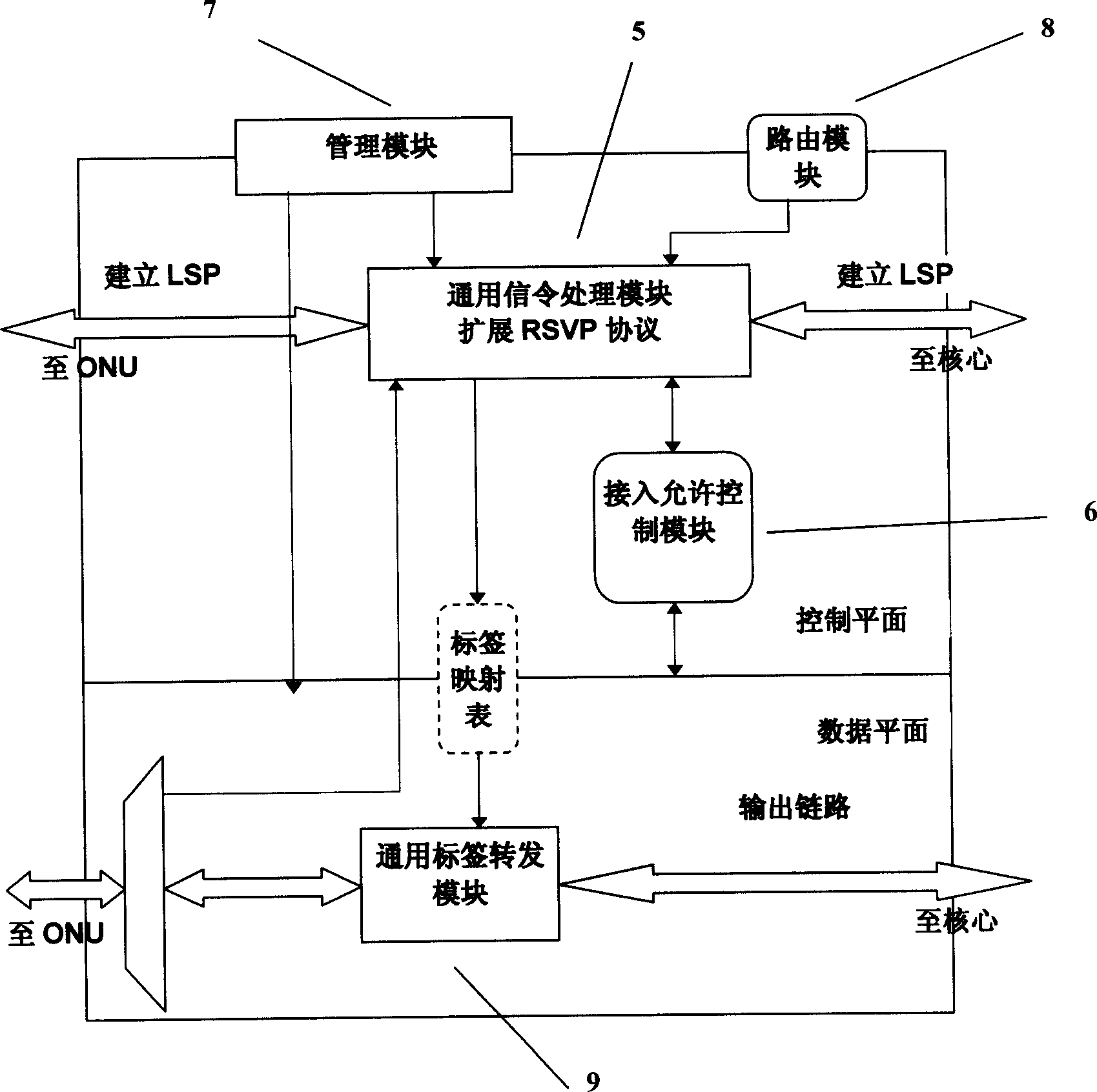

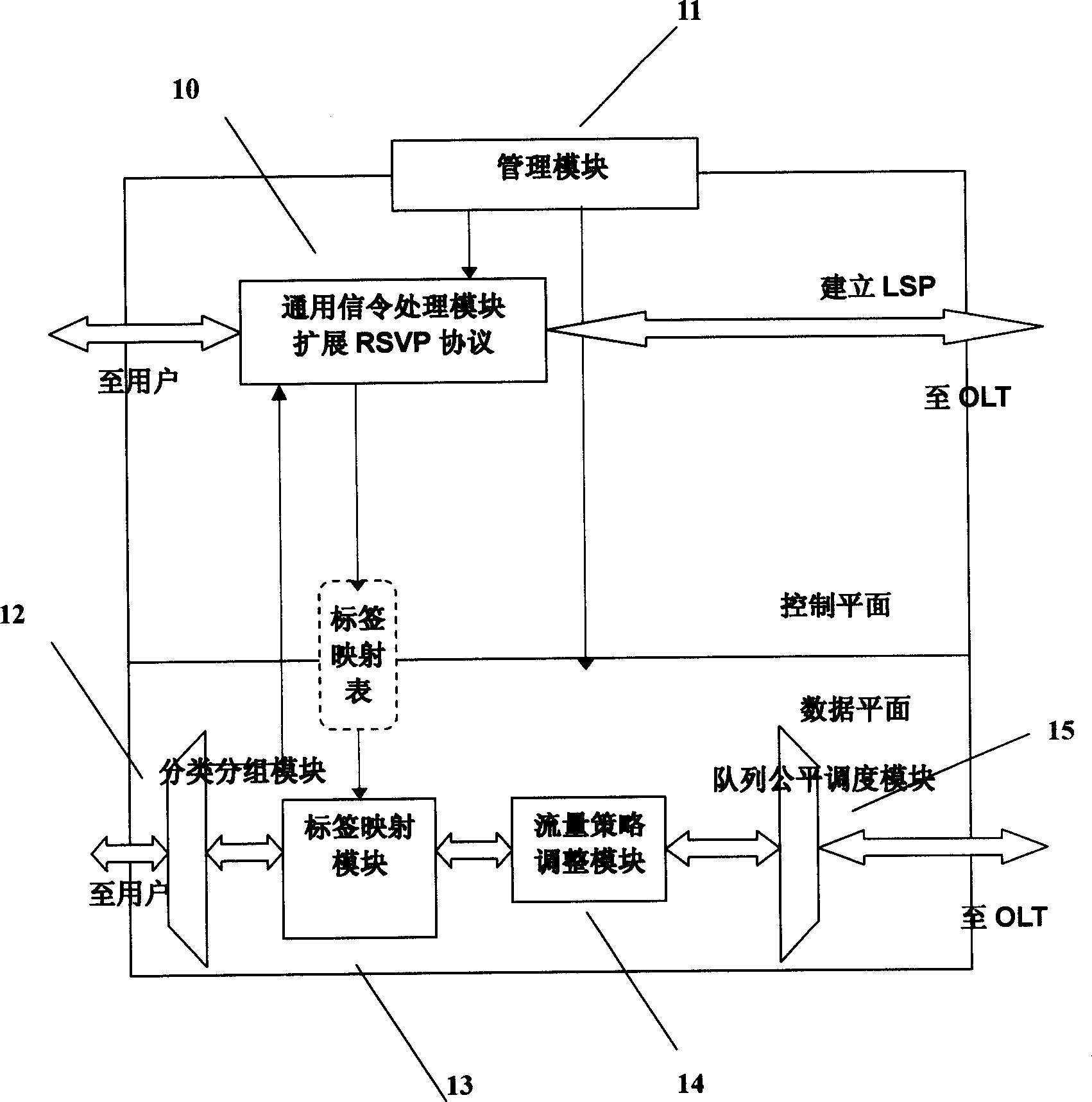

Passive optical network system based on generalized multiprotocol label switching (GMPLS) protocol

InactiveCN1725756ARealize intelligenceRealize intelligent controlTransmissionTelecommunications linkMultiprotocol Label Switching

A passive optical network system based on label exchanging protocol of universal multi-protocol is prepared as connecting optical line terminal OLT to multiple optical network unit ONU by wideband passive optical distribution network , using OLT and ONU as edge router and GMPLS domain of said exchanging protocol for being connected to the other GMPLS router in said multi-protocol by communication link , using OLT as intermediate router of integrated service in system individually for controlling all communication activities , using ONU as inlet router of integrated service in system for executing command of OLT .

Owner:SHANGHAI JIAO TONG UNIV

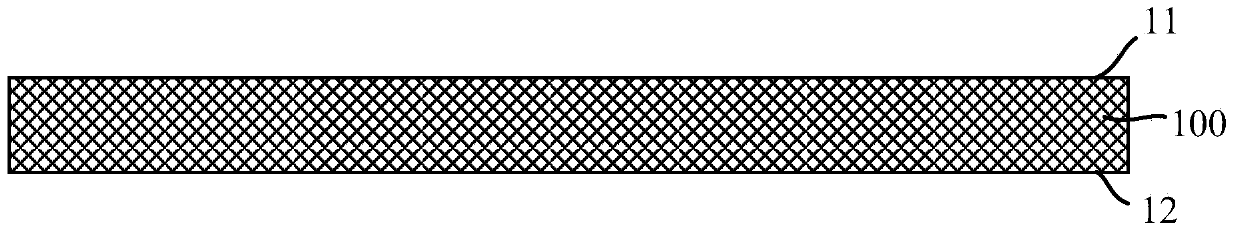

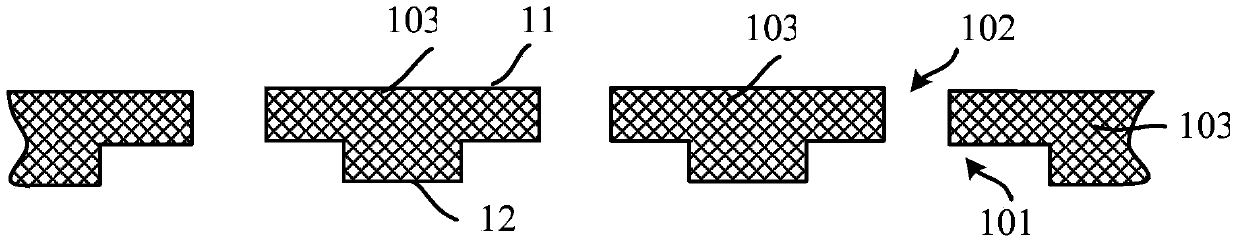

Packaging structure

ActiveCN103730429AHighly integratedImprove packaging efficiencySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A packaging structure comprises a lead frame, a pre-packaging face plate. The lead frame is provided with a plurality of bearing units distributed in a matrix mode and middle ribs used for fixing the bearing units, each bearing unit comprises a plurality of independent pins, and openings are formed between adjacent pins. The pre-packaging face plate comprises a first plastic-packaging layer, openings, and a second plastic-packaging layer, wherein a plurality of integration units distributed in a matrix mode are arranged in the first plastic-packaging layer, at least one semiconductor chip is arranged in each integration unit, a plurality of welding discs are arranged on the surface of the semiconductor chip, the welding discs are provided with metal protruding blocks, the pre-packaging face plate is inversely arranged on the first surface of the lead frame, the integration units correspond to the bearing units, the metal protruding blocks on the semiconductor pins are connected with the first surfaces of the pins in a welding mode. The openings are filled into the openings between the pins, the second plastic-packaging layer is filled into the space between the pre-packaging face plate and the first surface of the lead frame, and the second plastic-packaging layer is exposed of the second surfaces of the pins. The packaging structure is small in occupied space, and the integration level is improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

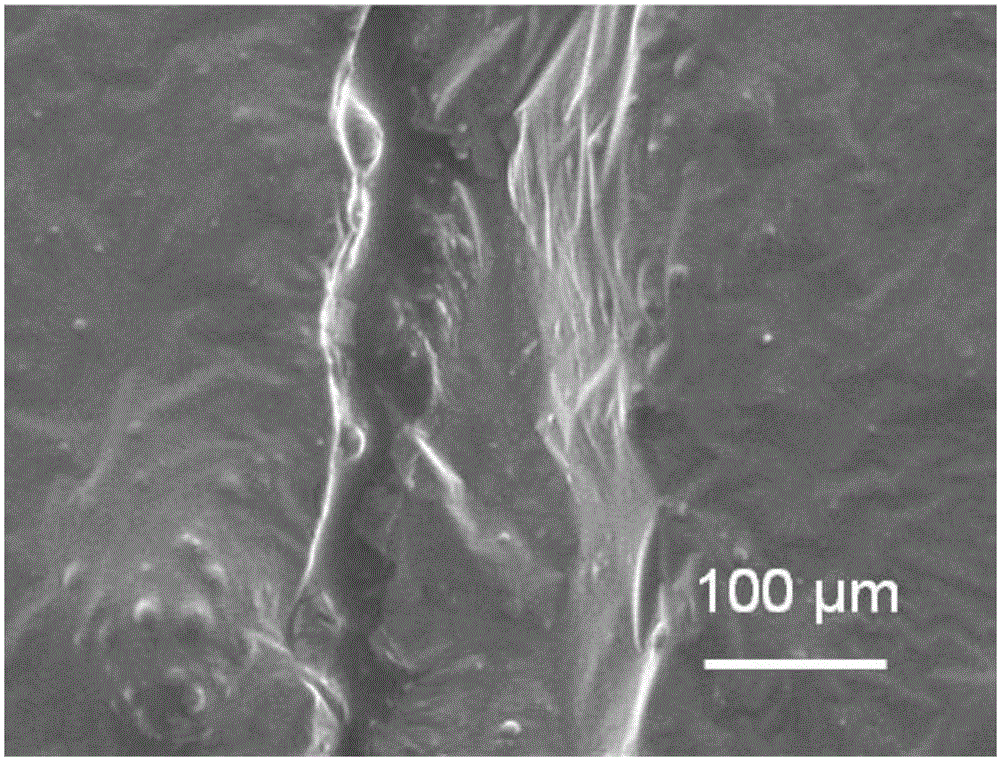

Double-capsule self-repairing epoxy coating and preparation method thereof

InactiveCN105833811ASimple preparation processIncrease productivityMicroballoon preparationMicrocapsule preparationChemistrySilicon dioxide

The invention discloses a double-capsule self-repairing epoxy coating and a preparation method thereof. The preparation method mainly uses Pickering emulsion droplet template method and conducts an interface polymerization of interface isophorone diisocyanate and tetraethylenepentamine in water-oil of epoxy interface to prepare epoxy microcapsule and tetraethylenepentamine microcapsule; and the two microcapsules are added to epoxy resin microcapsules for the formation of double-capsule self-repairing epoxy coating. The Pickering emulsion droplet template method ensures the stability of the emulsion, prevents emulsion droplet blending, improves package amount and efficiency of the microcapsule core material; Pickering emulsion improves the repair efficiency of the double-capsule self-repairing epoxy coating; the introduction of nano silica particles and nano clay in the capsule walls of the epoxy microcapsule and tetraethylenepentamine microcapsule improves the mechanical strength and thermal stability of the microcapsule wall, but also improves the brittleness of the microcapsule and the releasing efficiency of the microcapsule core material, so as to ensure the repair performance of the double-capsule self-repair coating.

Owner:SOUTH CHINA UNIV OF TECH

Straw crushing and packaging machine

InactiveCN105251583ATo achieve a completely crushed effectEasy to operateCuttersDirt cleaningEngineeringKnife holder

The invention discloses a straw crushing and packaging machine. The straw crushing and packaging machine comprises a base, wherein a controller is arranged in the base; a storage groove, a crushing box, a support seat and a packaging box are sequentially arranged on the upper surface of the base from the left to right; a conveying mechanism is arranged in the storage groove; a conveying belt on the conveying mechanism is connected with a charge port arranged in the left side of the top of the crushing box; a seat is arranged at the middle part of the right side of the crushing box; an oscillator is arranged in the seat, and a metal tube is arranged at one end of the oscillator; the left end of the metal tube sequentially penetrates through the seat and the crushing box, and extends into the crushing box; and the left end of the metal tube is connected with a filter screen plate which is arranged at the middle part of the inner cavity of the crushing box. The straw crushing and packaging machine is convenient to operate, achieves a uniform crushing effect, and increases the packaging efficiency; blades on knife holders are used for cutting and crushing straw, the crushed straw is filtered through the filter screen plate, and large straw continues to be crushed, thus a thorough crushing effect for straw is achieved.

Owner:吴绍莲

Semiconductor package having passive component disposed between semiconductor device and substrate

InactiveUS7166917B2Reduce thicknessImprove packaging efficiencySemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor packageSemiconductor device

A semiconductor package includes a semiconductor device and a passive component mounted and electrically coupled to a substrate. The passive component is disposed within a cavity portion formed on an upper surface of the substrate and the semiconductor device is disposed across the cavity portion of the substrate above the passive component.

Owner:ADVANCED SEMICON ENG INC

Stiffener reinforced foldable member

InactiveUS6910304B2Fold compactImprove packaging efficiencyCosmonautic vehiclesCosmonautic partsEngineeringElectrical and Electronics engineering

Owner:FOSTER-MILLER

Lipid vesicle compositions and methods of use

ActiveUS8747869B2Increase load capacityImprove the level ofOrganic active ingredientsFatty acid chemical modificationLipid formationDiagnostic agent

Owner:MASSACHUSETTS INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com