Patents

Literature

249results about How to "Improve encapsulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

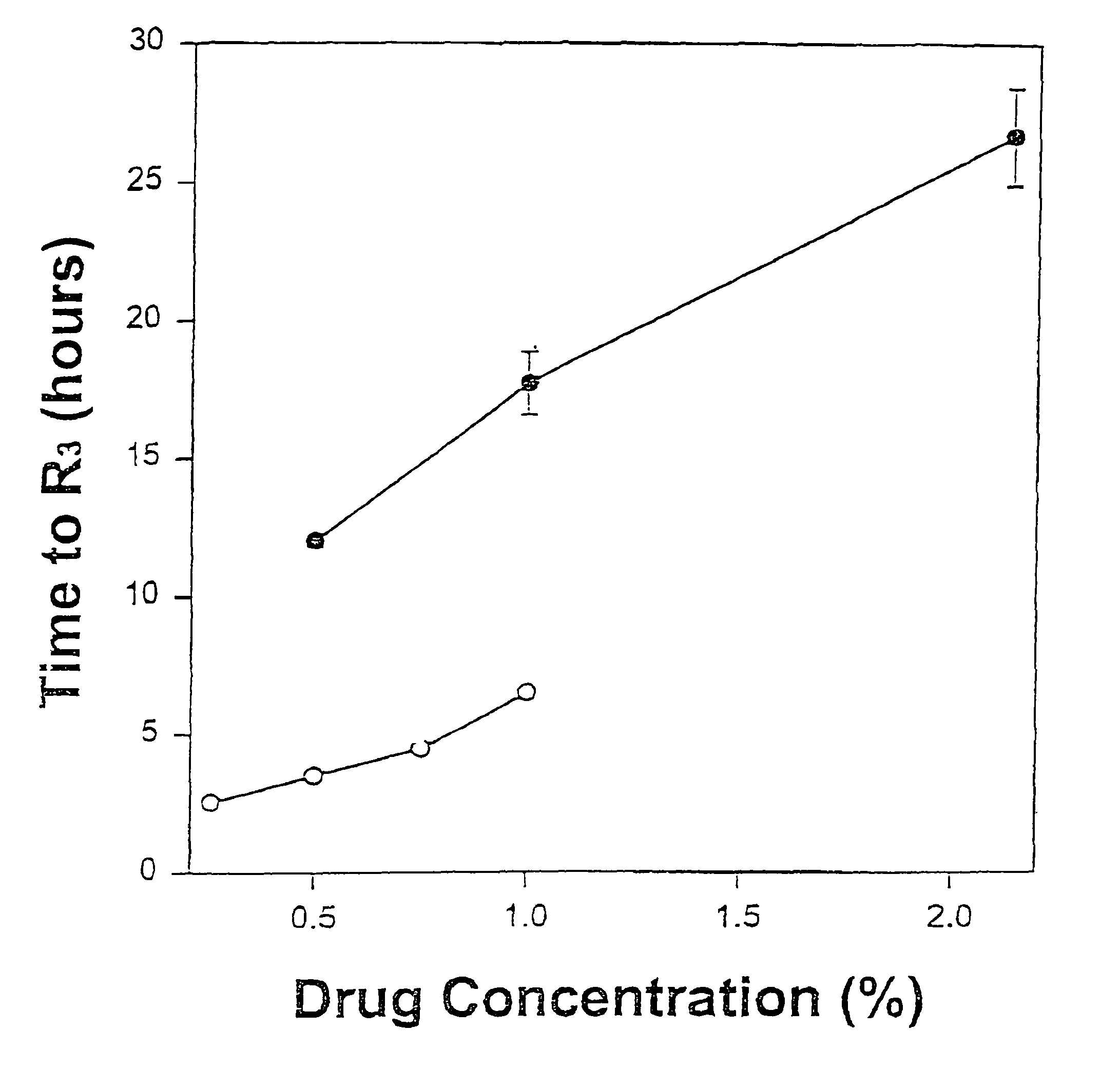

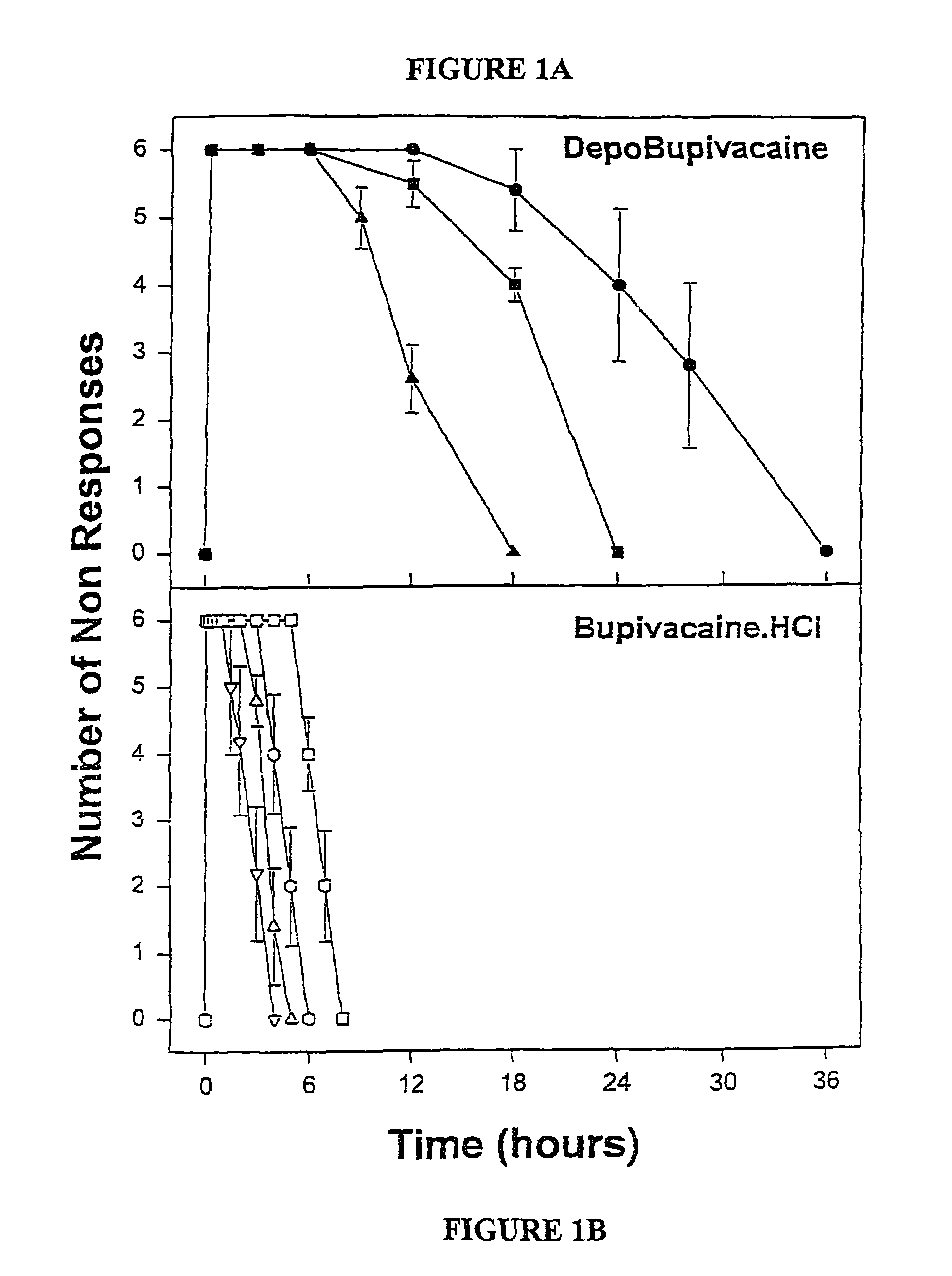

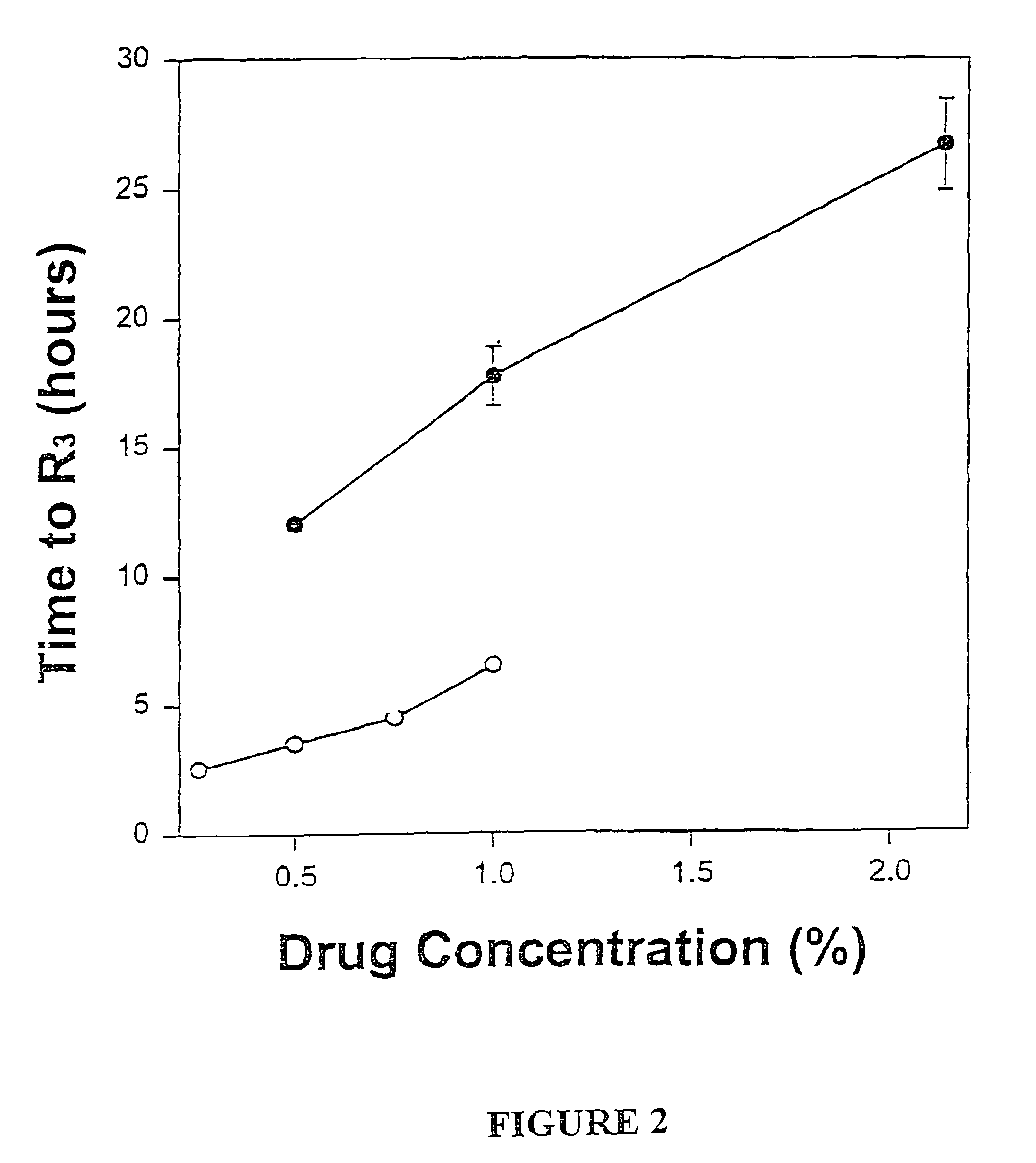

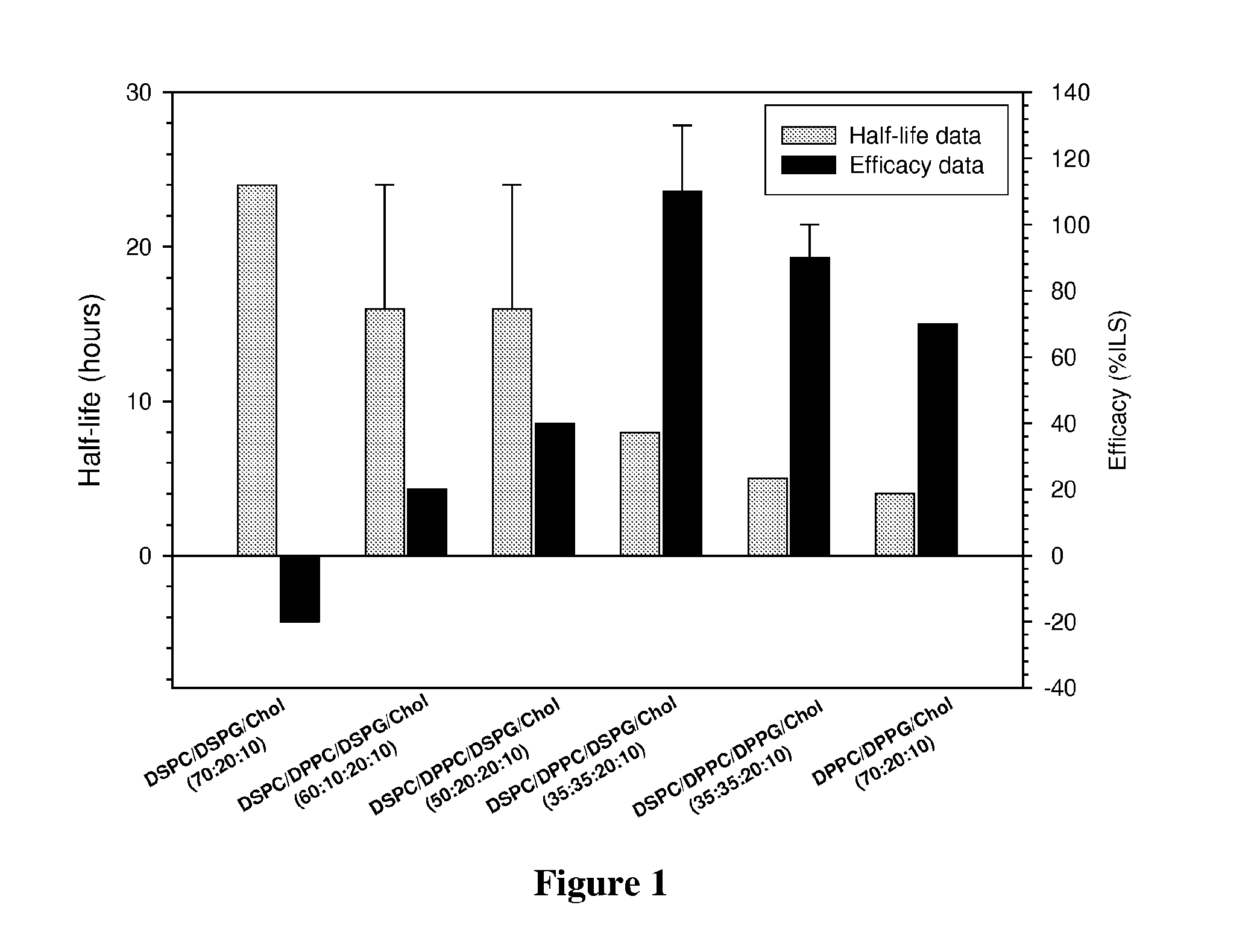

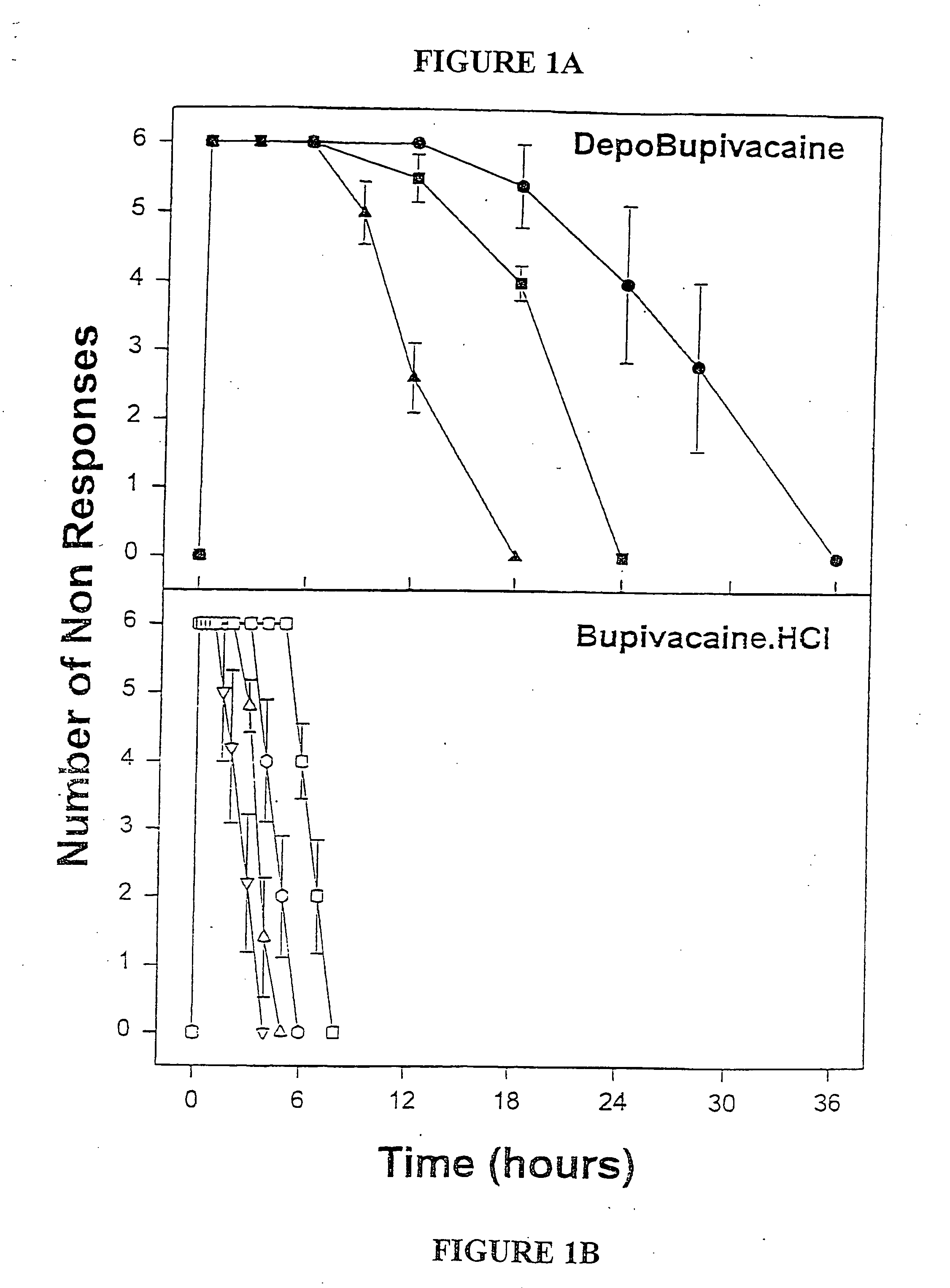

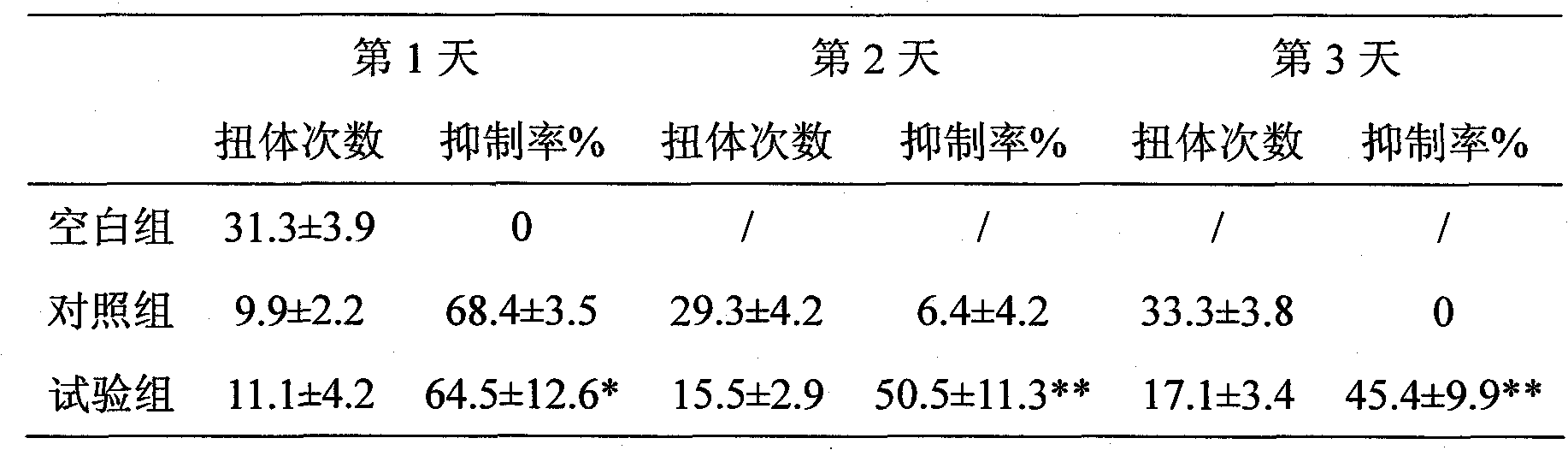

Sustained-release liposomal anesthetic compositions

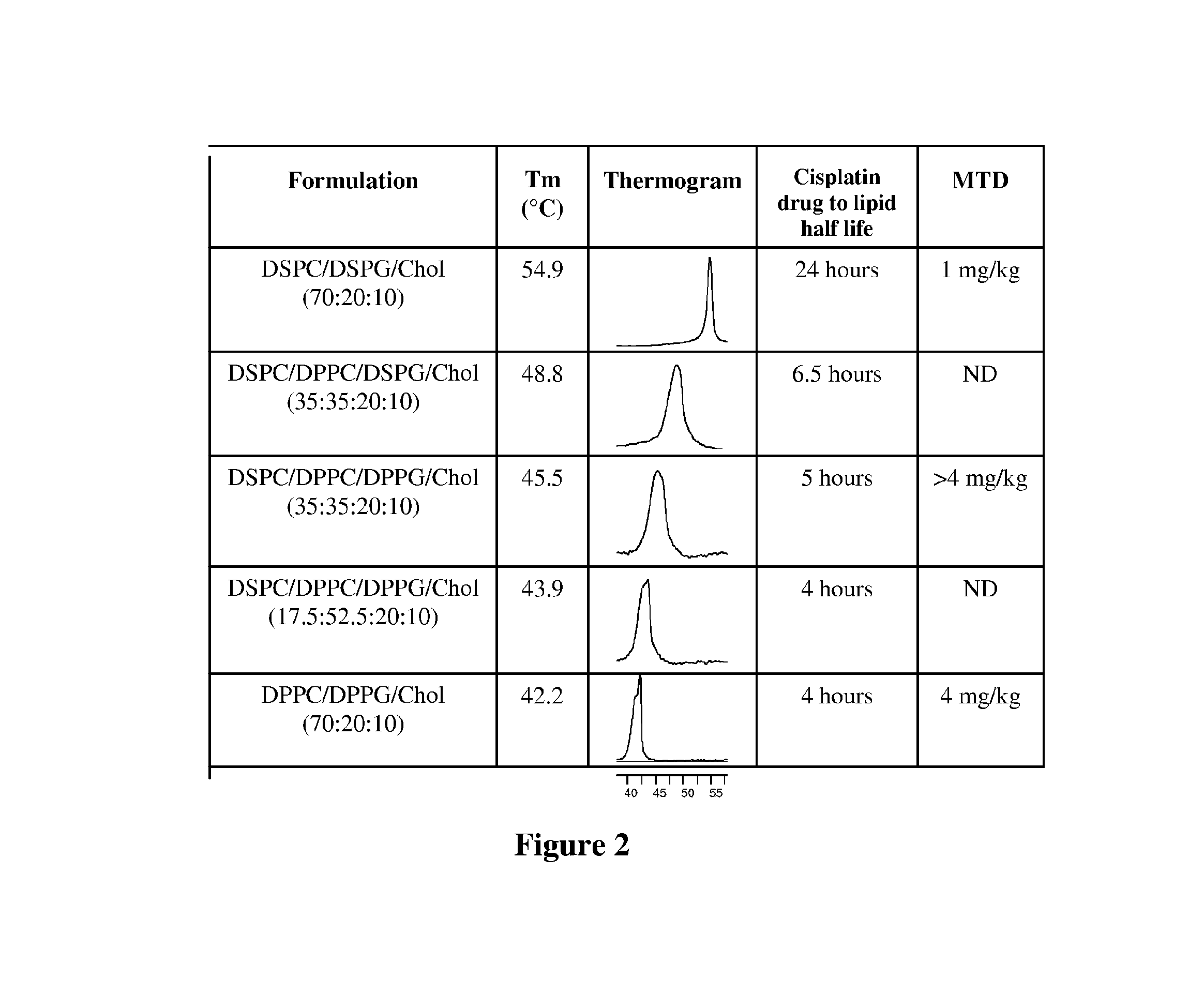

InactiveUS8182835B2High acceptabilityImprove encapsulationInorganic non-active ingredientsAnaestheticsHalf-lifeMaximum tolerated dose

Owner:PACIRA PHARMA INC

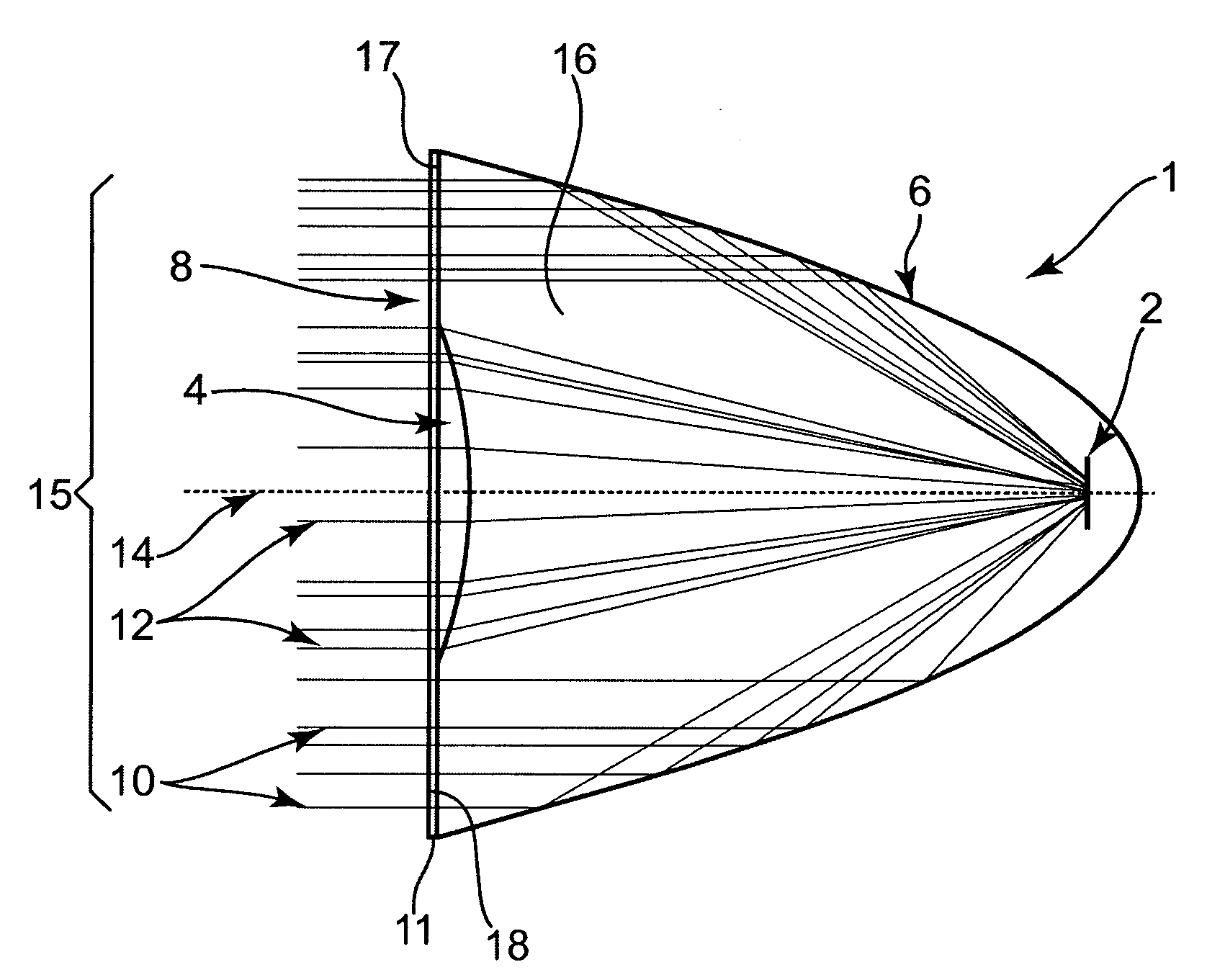

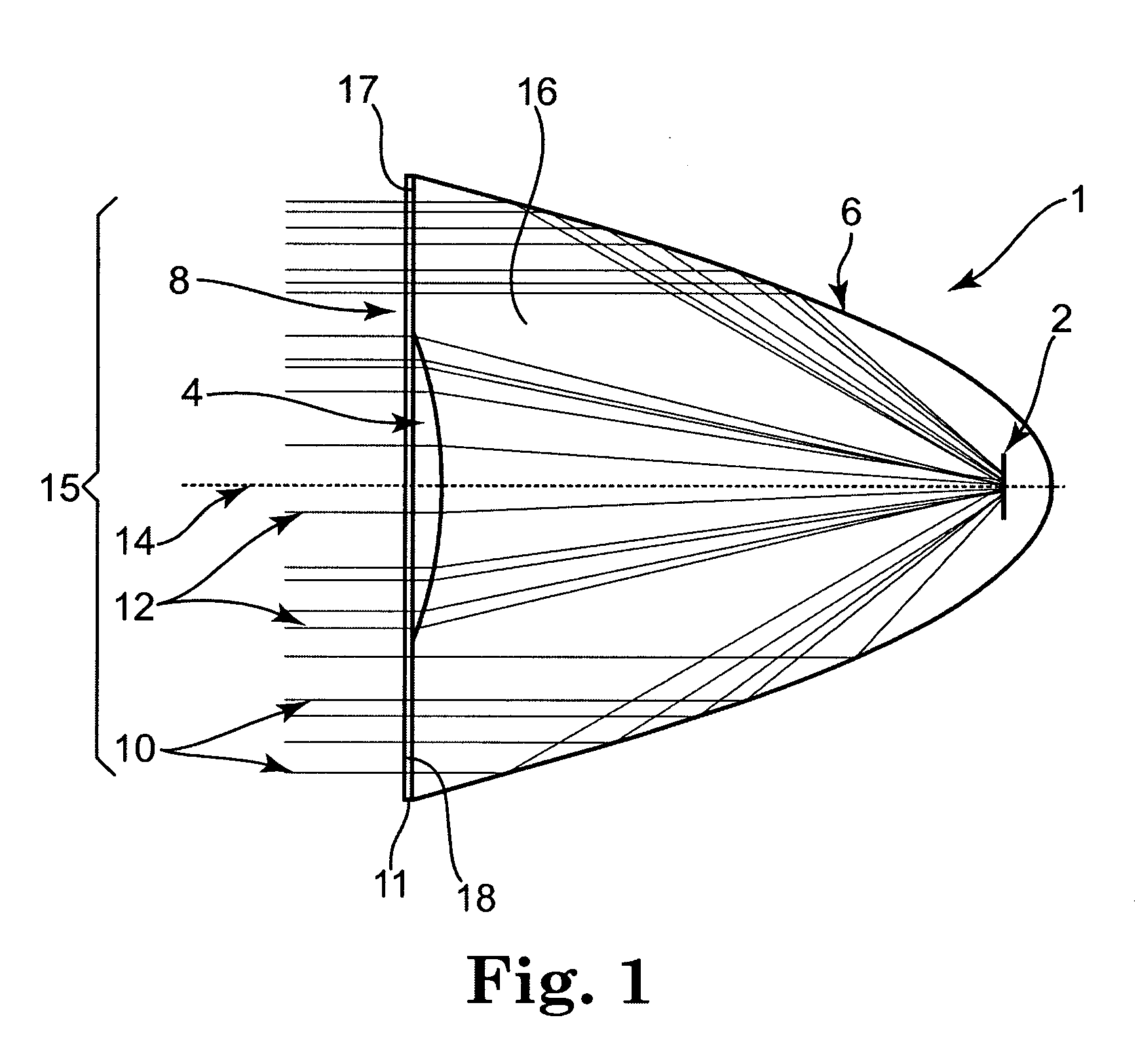

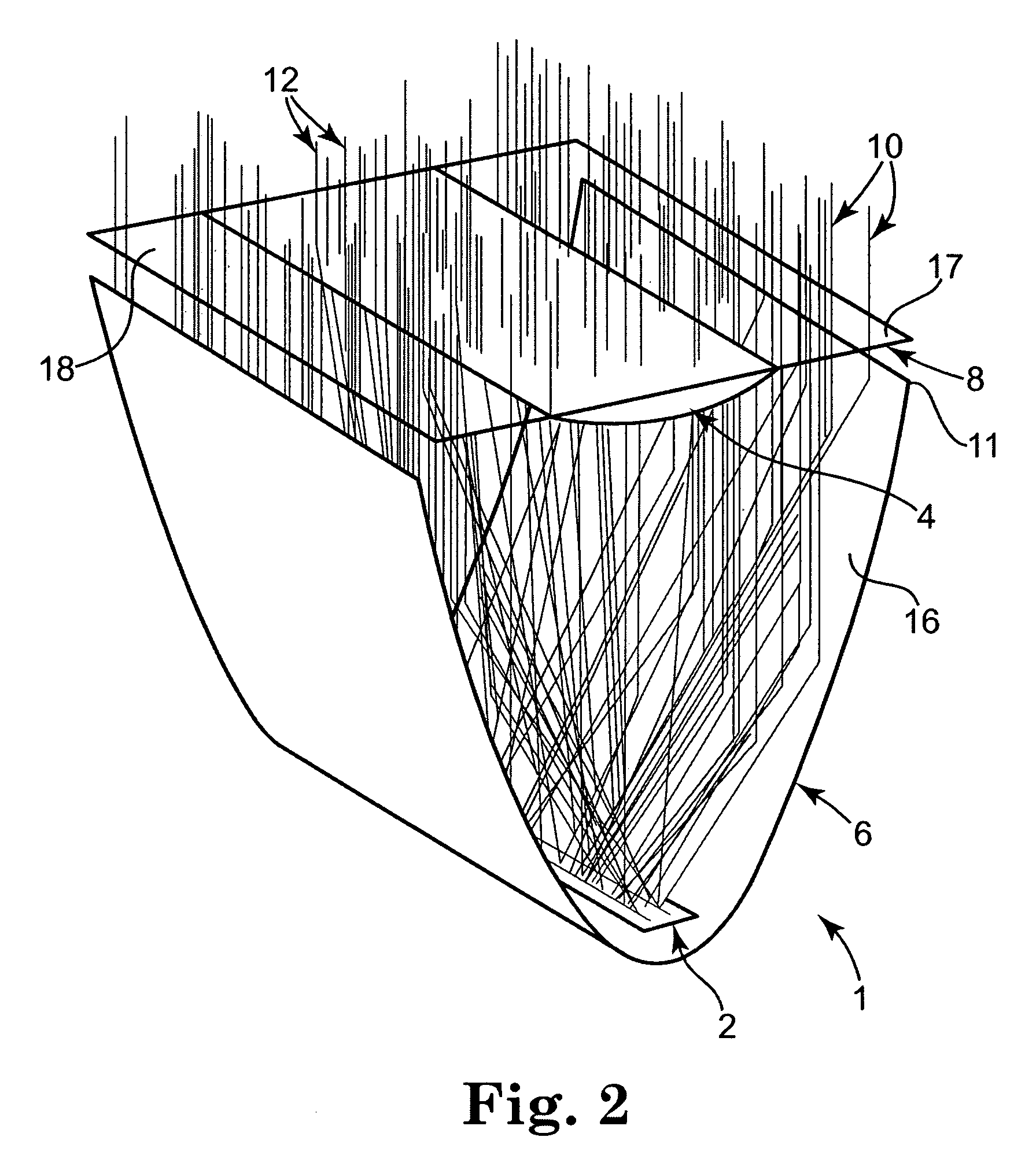

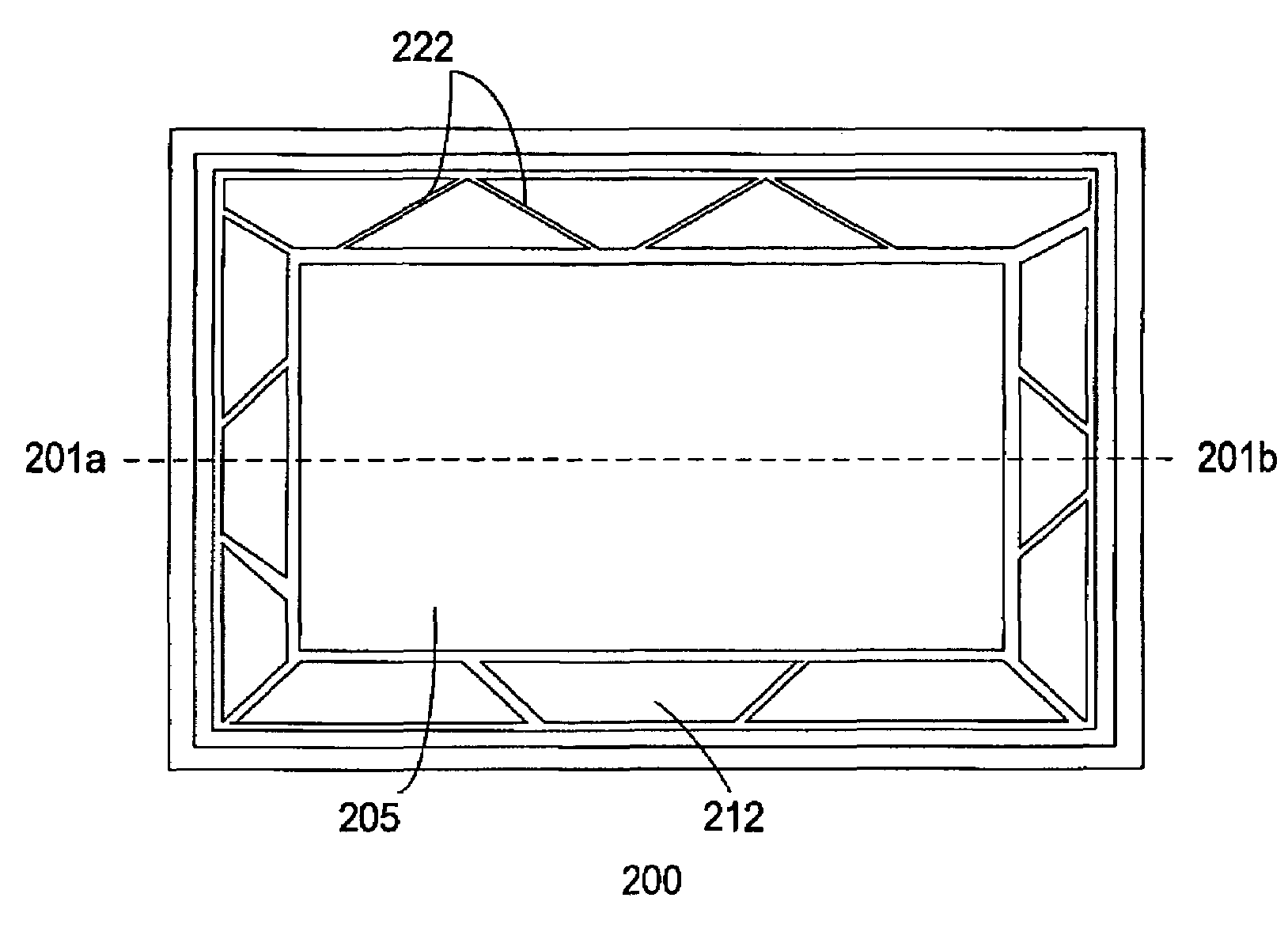

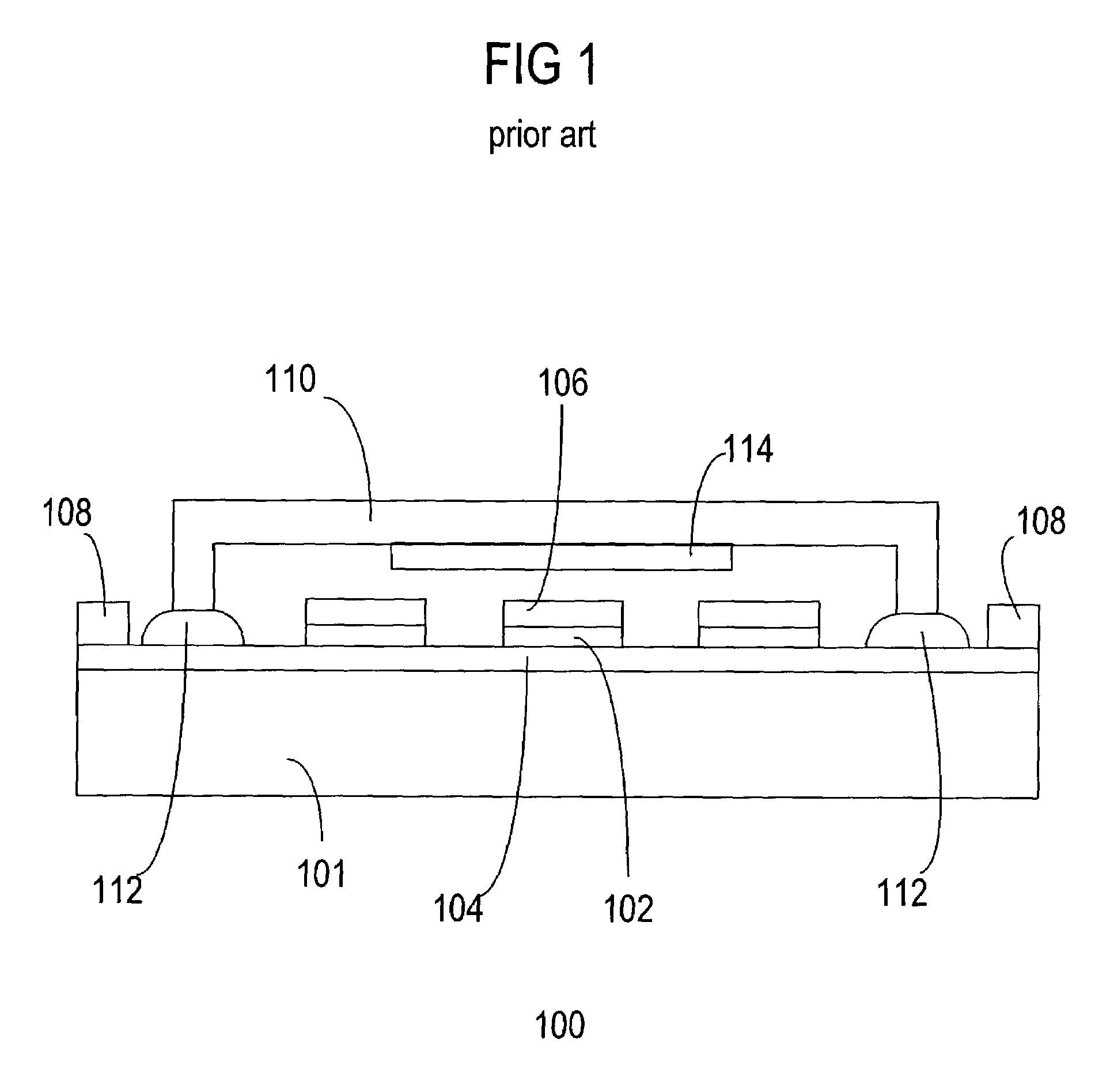

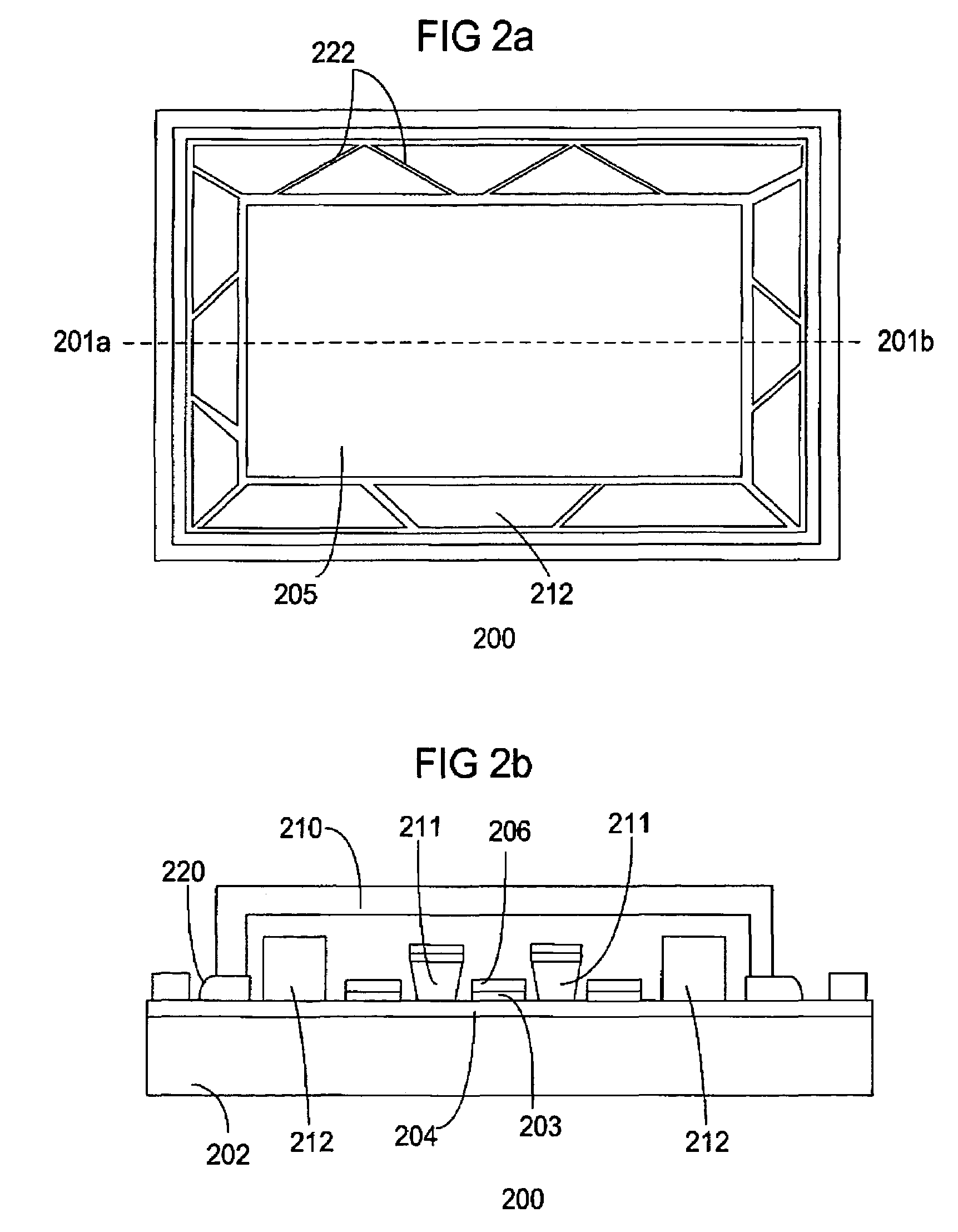

Photovoltaic receiver for solar concentrator applications

InactiveUS20090000662A1Impact performanceMaintaining dielectricFinal product manufactureLaminationDielectricThermal energy

The present invention provides solar concentrators incorporating photovoltaic receiver assemblies with improved thermal dissipation, dielectric, encapsulation, and cell / wiring protection characteristics. The concentrators are particularly useful for photovoltaic power systems such as rooftop mounted systems. The present invention teaches that the geometry of the substrate used to support receiver assemblies can have a dramatic impact upon thermal / dielectric performance. In particular, the present invention teaches how contours incorporated into such substrates can improve thermal performance (i.e., dissipation of thermal energy from photovoltaic cells through the substrate) while still maintaining dielectric and encapsulation objectives. In the past, dielectric and encapsulation objectives have been obtained at the expense of such thermal dissipation. Also, material choice and form also impacts thermal, dielectric, and encapsulation performance. In preferred embodiments, components of receiver assemblies are provided in sheet form and laminated together in the course of making the receiver assemblies.

Owner:SOLIANT ENERGY INC

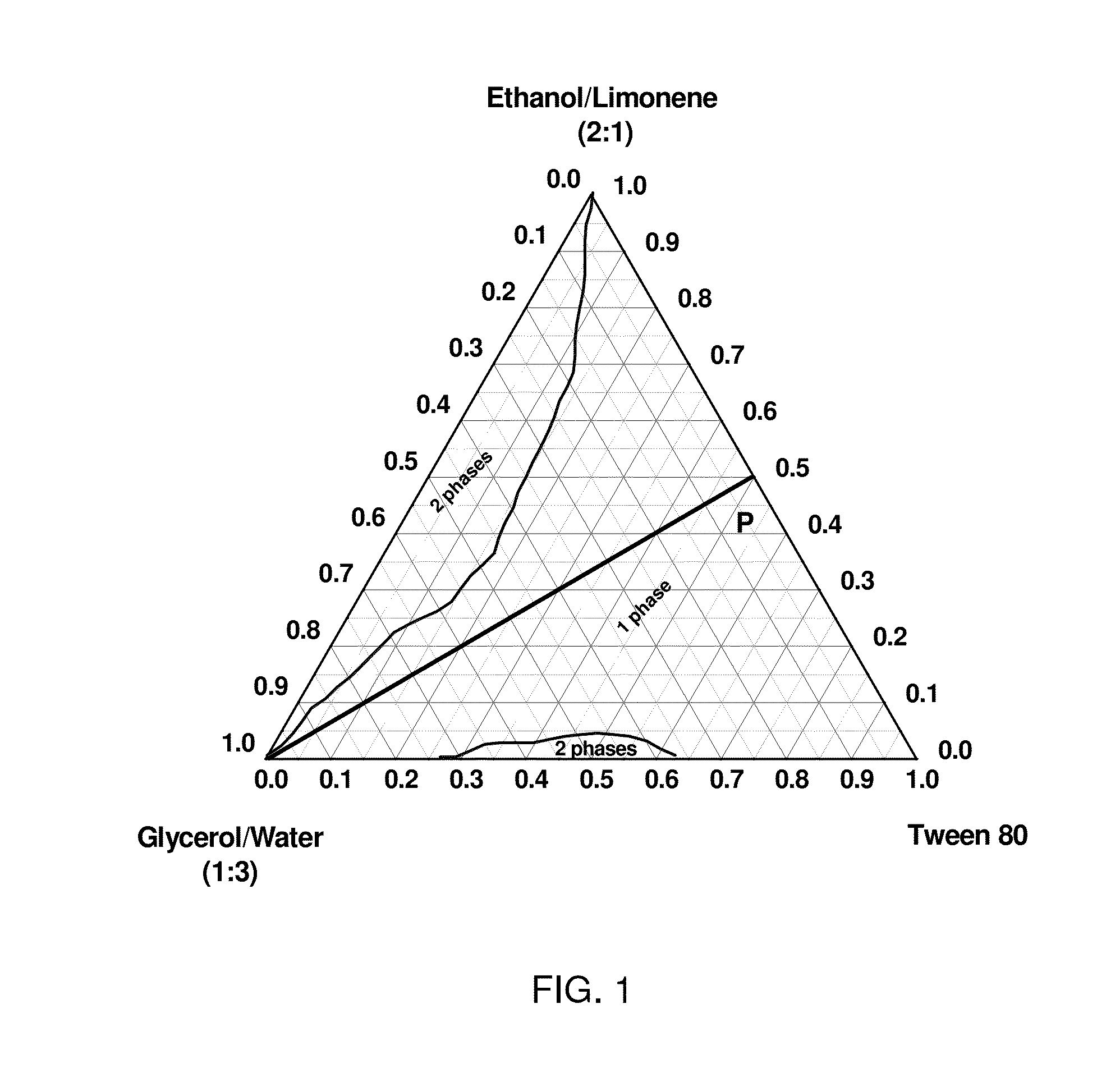

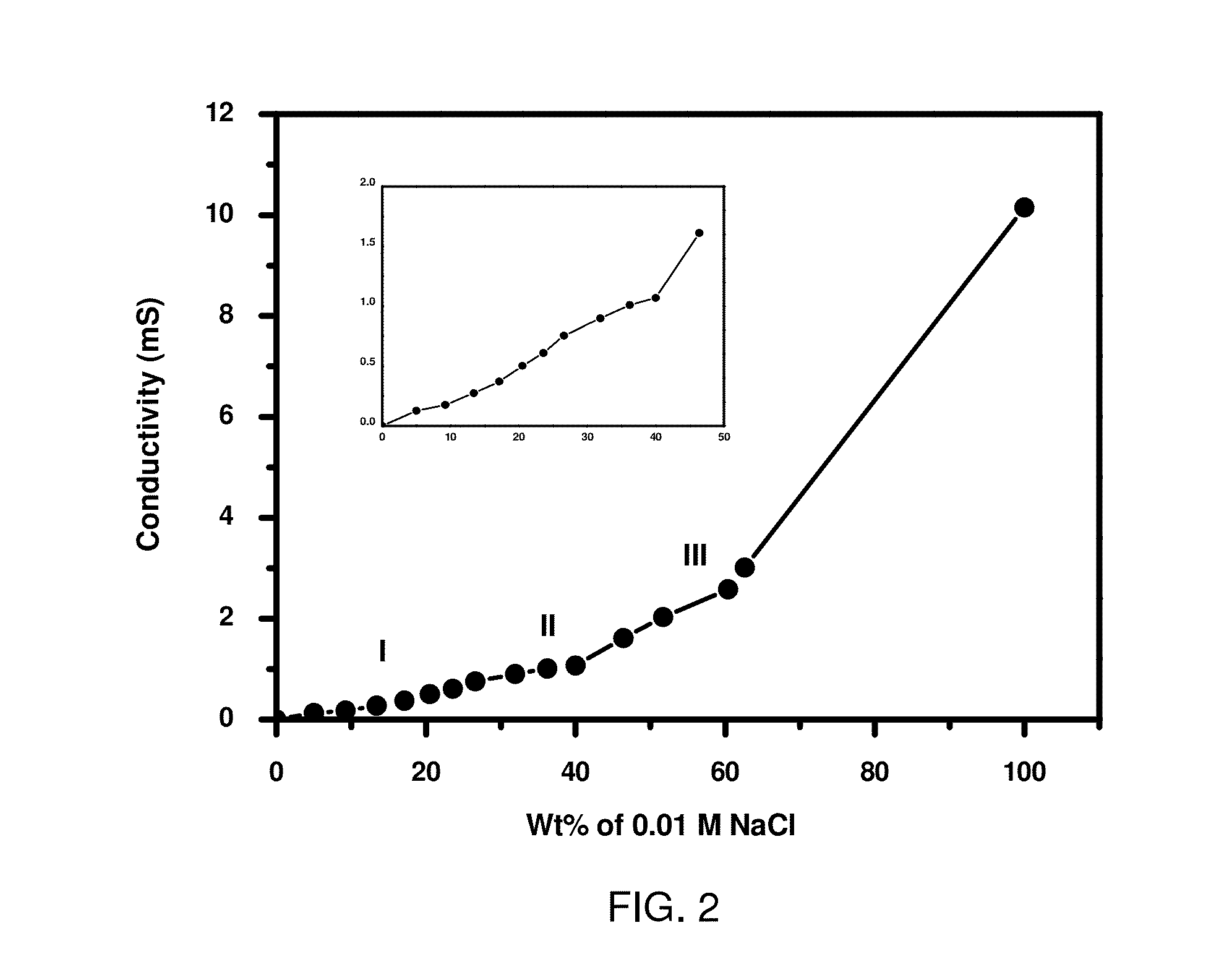

Method of Forming Encapsulated Compositions with Enhanced Solubility and Stability

InactiveUS20130004619A1Easy to makeEasy to operateEdible oils/fats ingredientsLiquid surface applicatorsSolubilityWater soluble

A method of forming an encapsulated composition with enhanced solubility and stability. A bicontinuous or Winsor Type III microemulsion is formed using an emulsifier, a solvent and a co-emulsifier. An active composition is added to the microemulsion resulting in a micellar network of the active composition within the microemulsion. The active composition can be either water-soluble or oil-soluble or both.

Owner:BANK OF AMERICA N A

Encapsulation for organic devices

InactiveUS7193364B2Improve encapsulationReduce likelihoodDischarge tube luminescnet screensElectroluminescent light sourcesGetterAtmospheric sciences

A method of encapsulating devices including providing a getter layer in the penetration path of atmospheric elements. The getter layer serves as a barrier to potentially deleterious atmospheric components, such as moisture and gases, that penetrate the device. In one embodiment, the getter layer surrounds an active region where active component or components are formed.

Owner:PICTIVA DISPLAY INT LTD

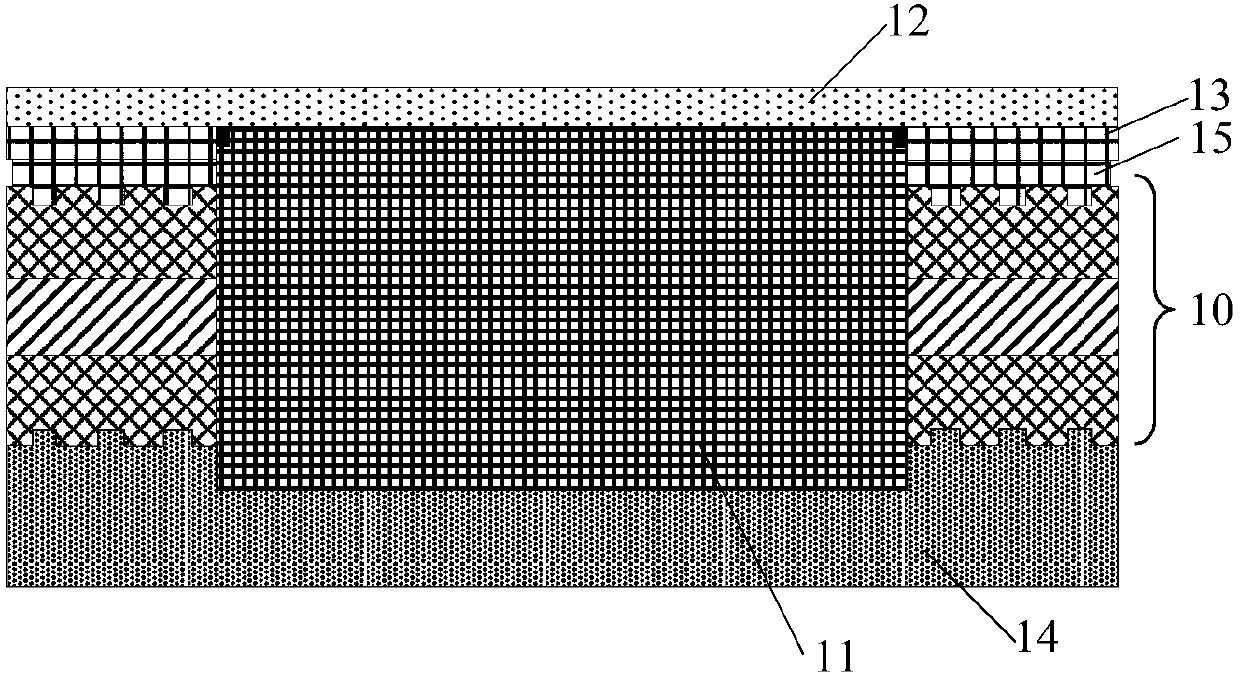

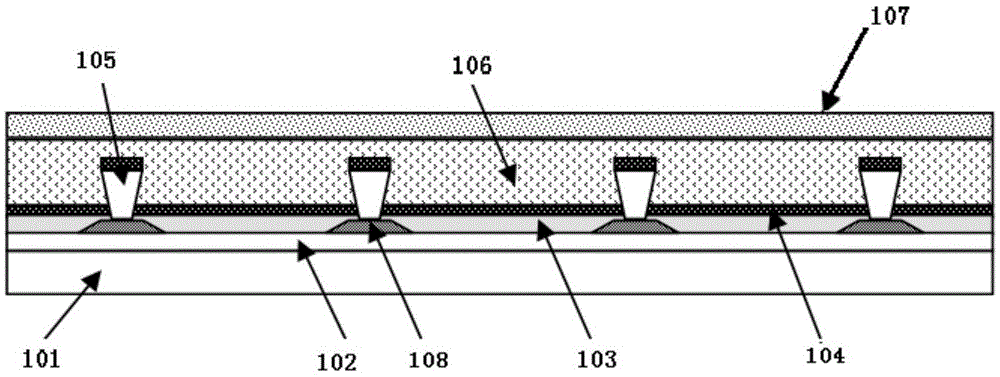

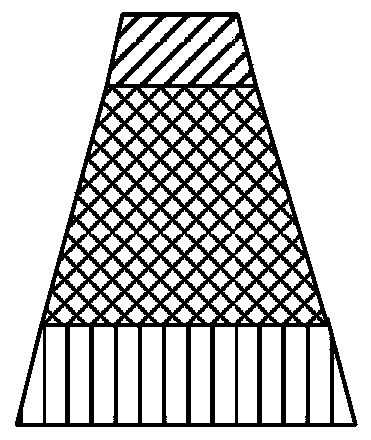

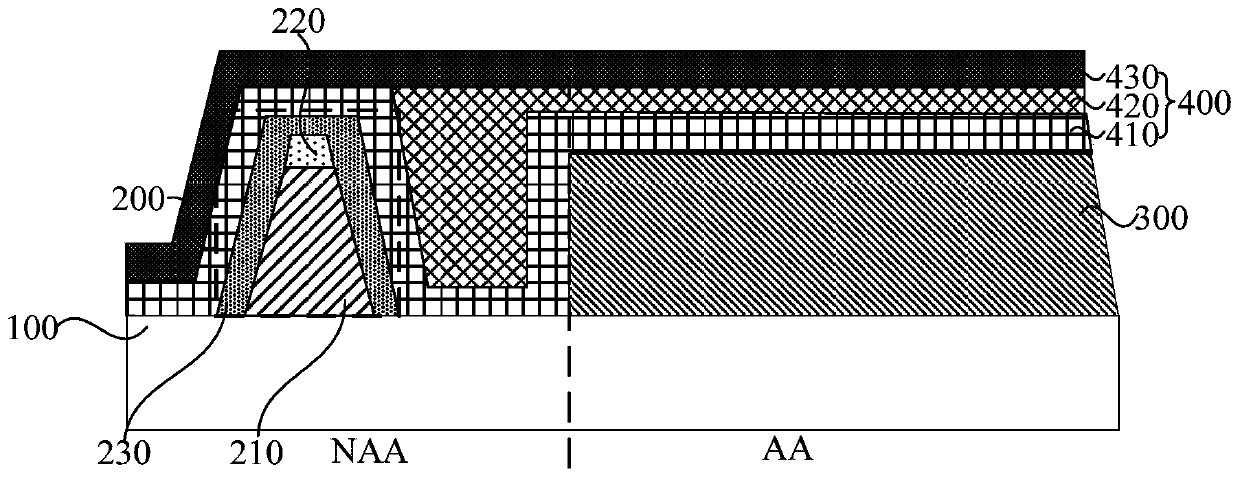

Display device, flexible display panel and manufacturing method thereof

ActiveCN105355645AAvoid contactGood encapsulation effectSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringBarrier effect

The invention discloses a display device, a flexible display panel and a manufacturing method thereof. The flexible display panel comprises a flexible substrate, a first barrier layer, display parts, a second barrier layer and a barrier effect indication layer, wherein the first barrier layer is arranged on the flexible substrate; the display parts are arranged on the first barrier layer; the second barrier layer is arranged on the first barrier layer, and covers the display parts; the barrier effect indication layer is arranged between the first barrier layer and the second barrier layer, and surrounds the display parts. The flexible display panel can indicate the packaging effect thereof, and ensures packaging effect thereof, thereby guaranteeing photoelectric characteristics of an organic light emitting diode device, and prolonging the service life of the organic light emitting diode device.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

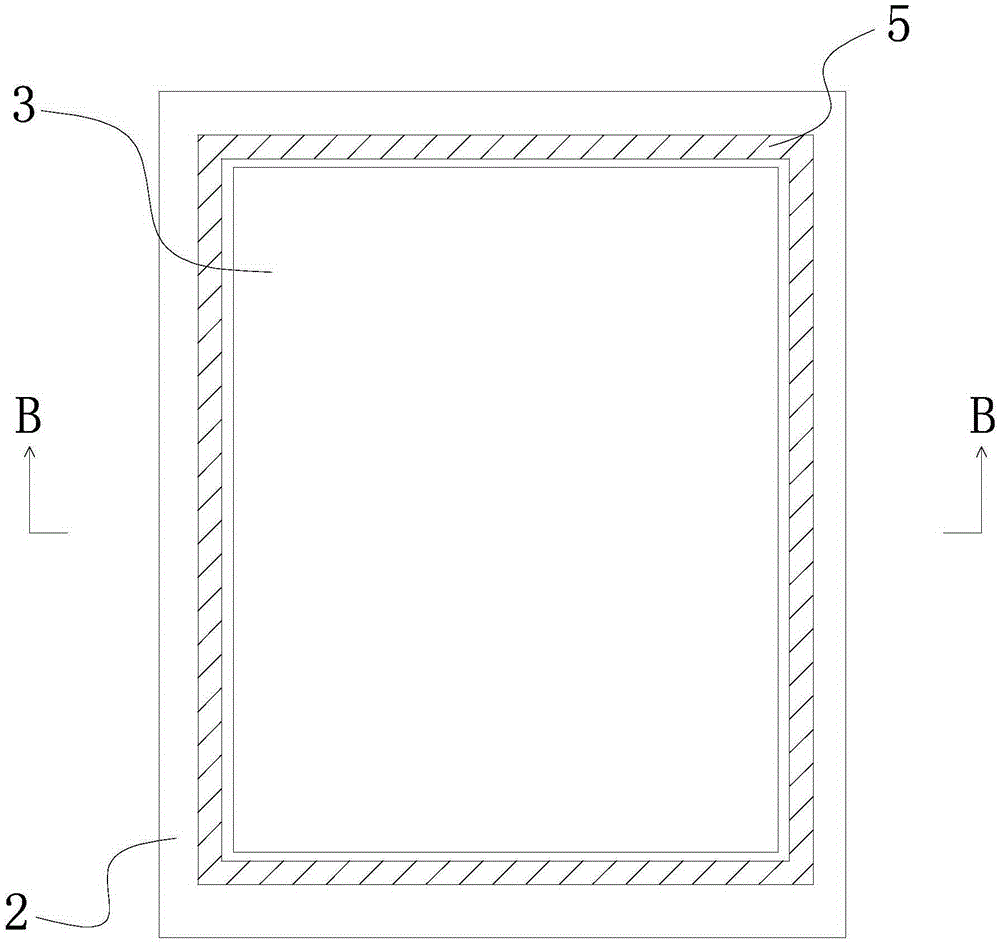

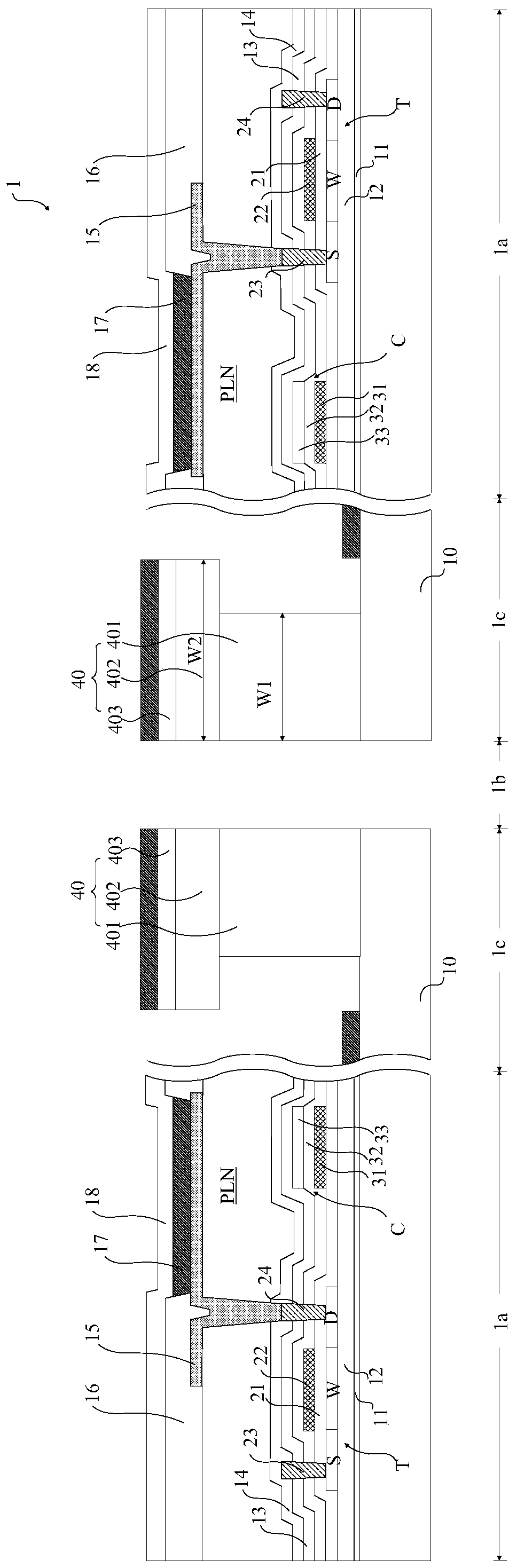

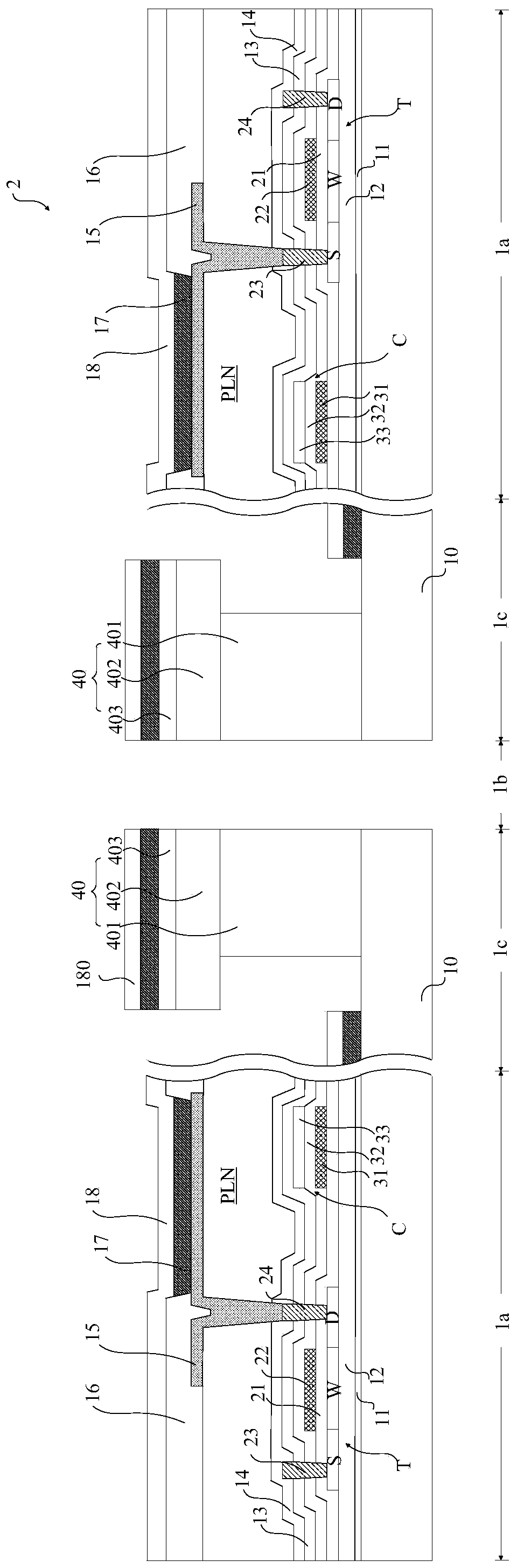

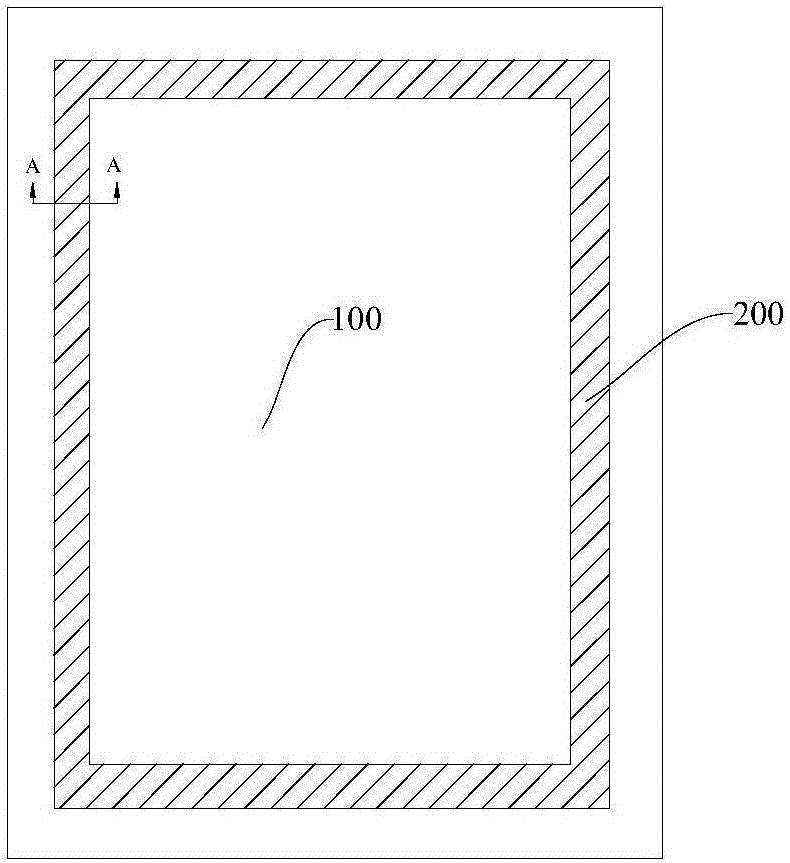

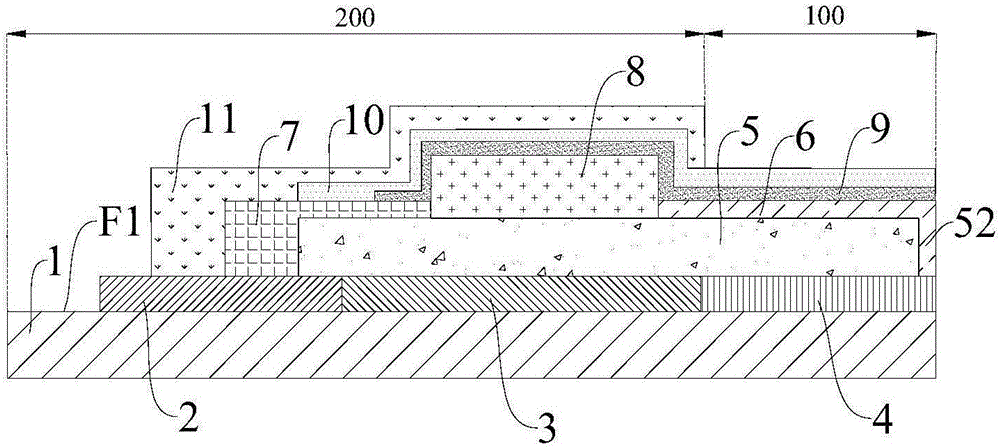

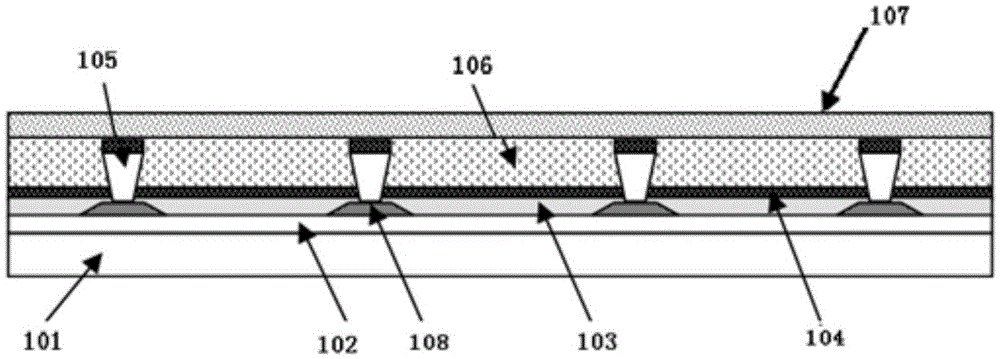

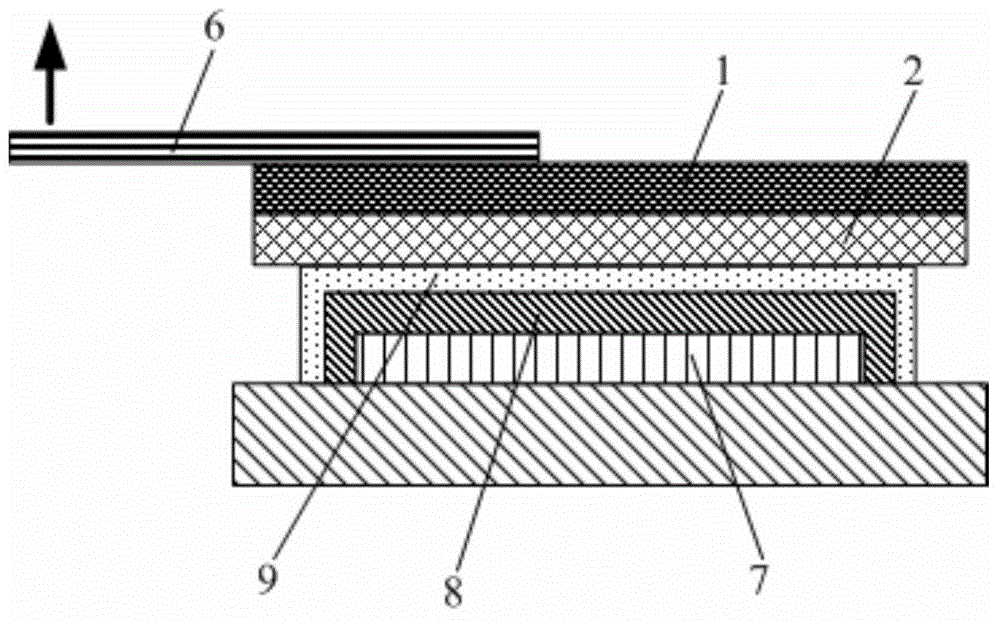

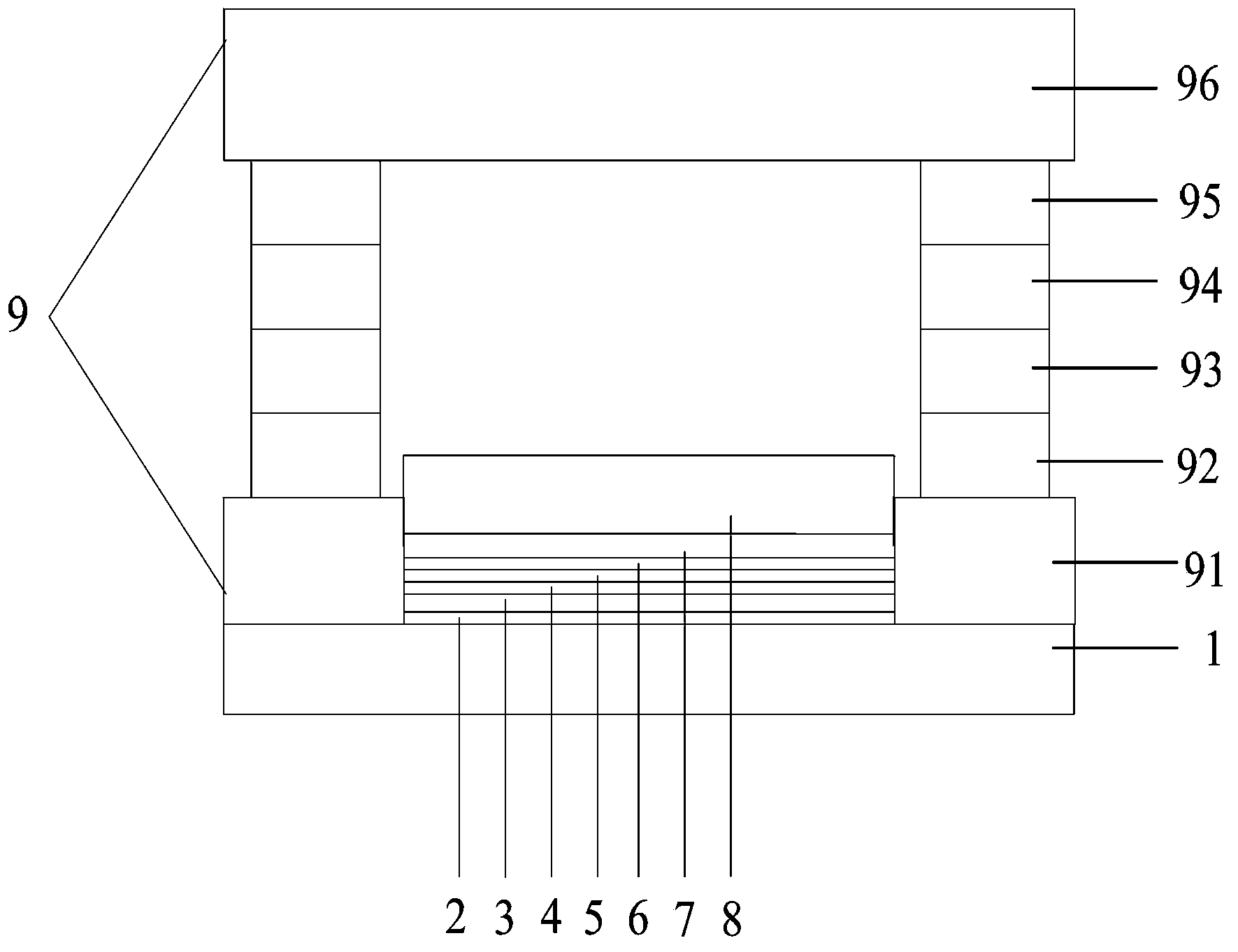

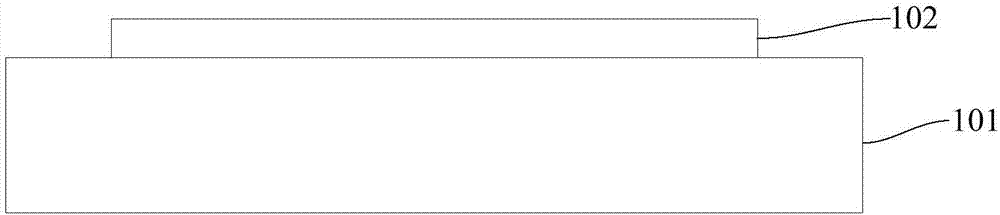

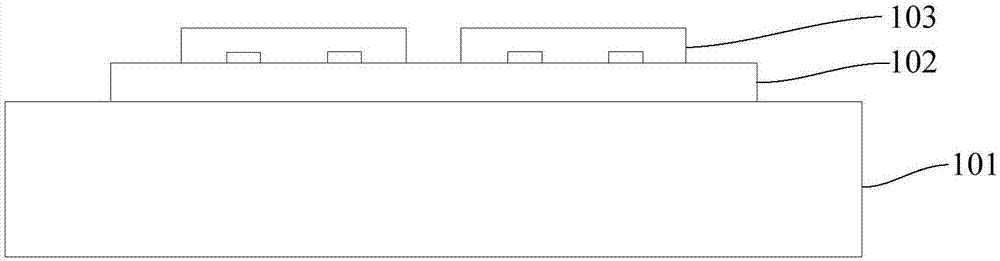

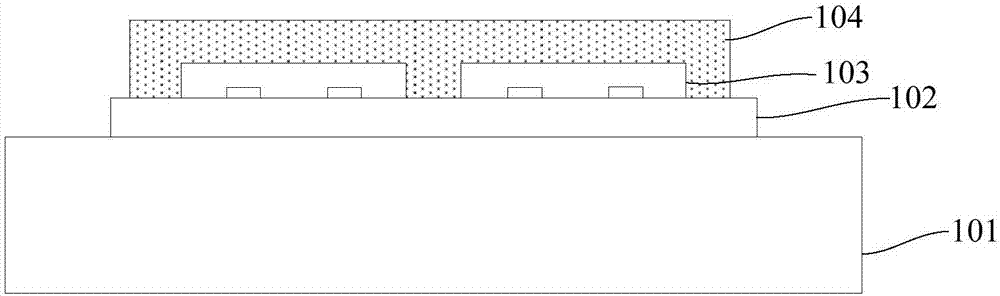

Packaging structure, packaging method for OLED display device, and display device

ActiveCN107104202AImprove encapsulationAvoid it happening againSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComputer science

The invention discloses a packaging structure, a packaging method for an OLED display device, and a display device, and relates to the field of display technologies, for solving the problem that when the OLED display device is packaged, residual particles are prone to generate at the edge of a mask plate, and thus service life of the OLED display device is influenced. The packaging method for the OLED display device comprises the steps of providing a substrate, wherein the substrate comprises a packaging area and a binding area positioned around the packaging area, and an electrode lead used for binding is arranged in the binding area; forming a sacrificial layer on the electrode lead; forming an OLED display device in the packaging area; forming packaging film covering all areas of the substrate; and removing the sacrificial layer to separate the sacrificial layer and the packaging film on the sacrificial layer from the substrate. The packaging method for the OLED display device provided the invention is used for packaging the OLED display device.

Owner:BOE TECH GRP CO LTD +1

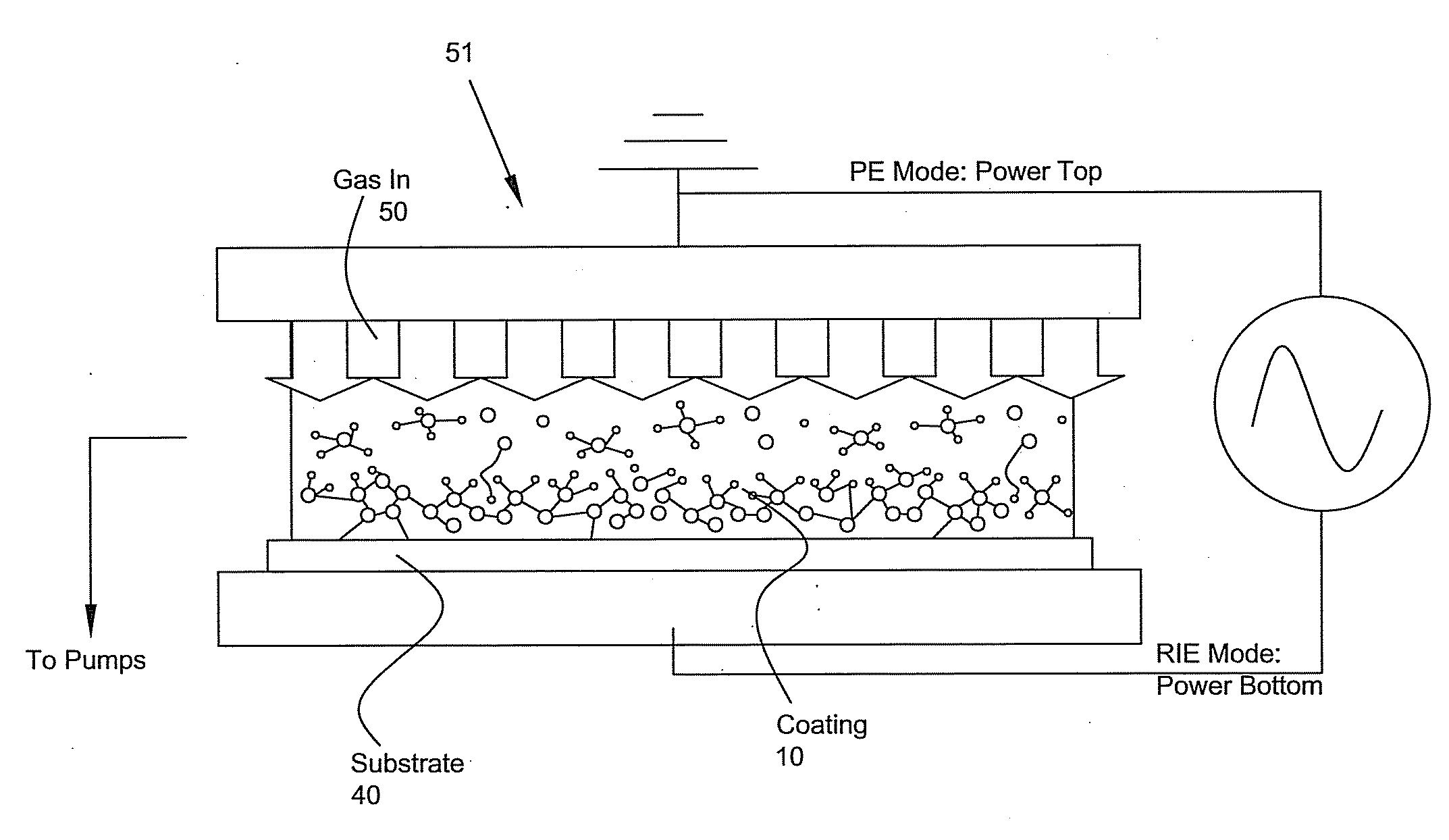

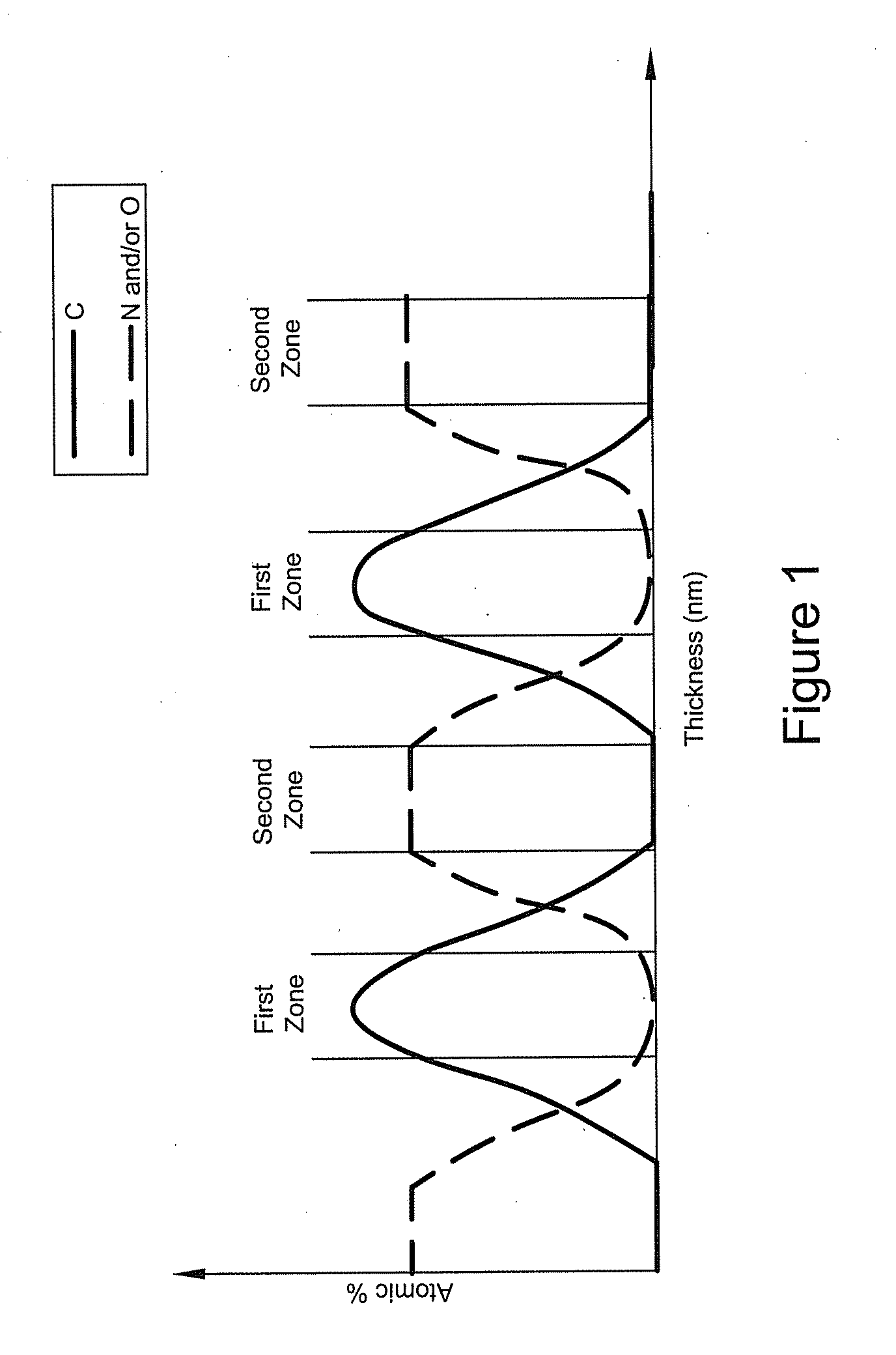

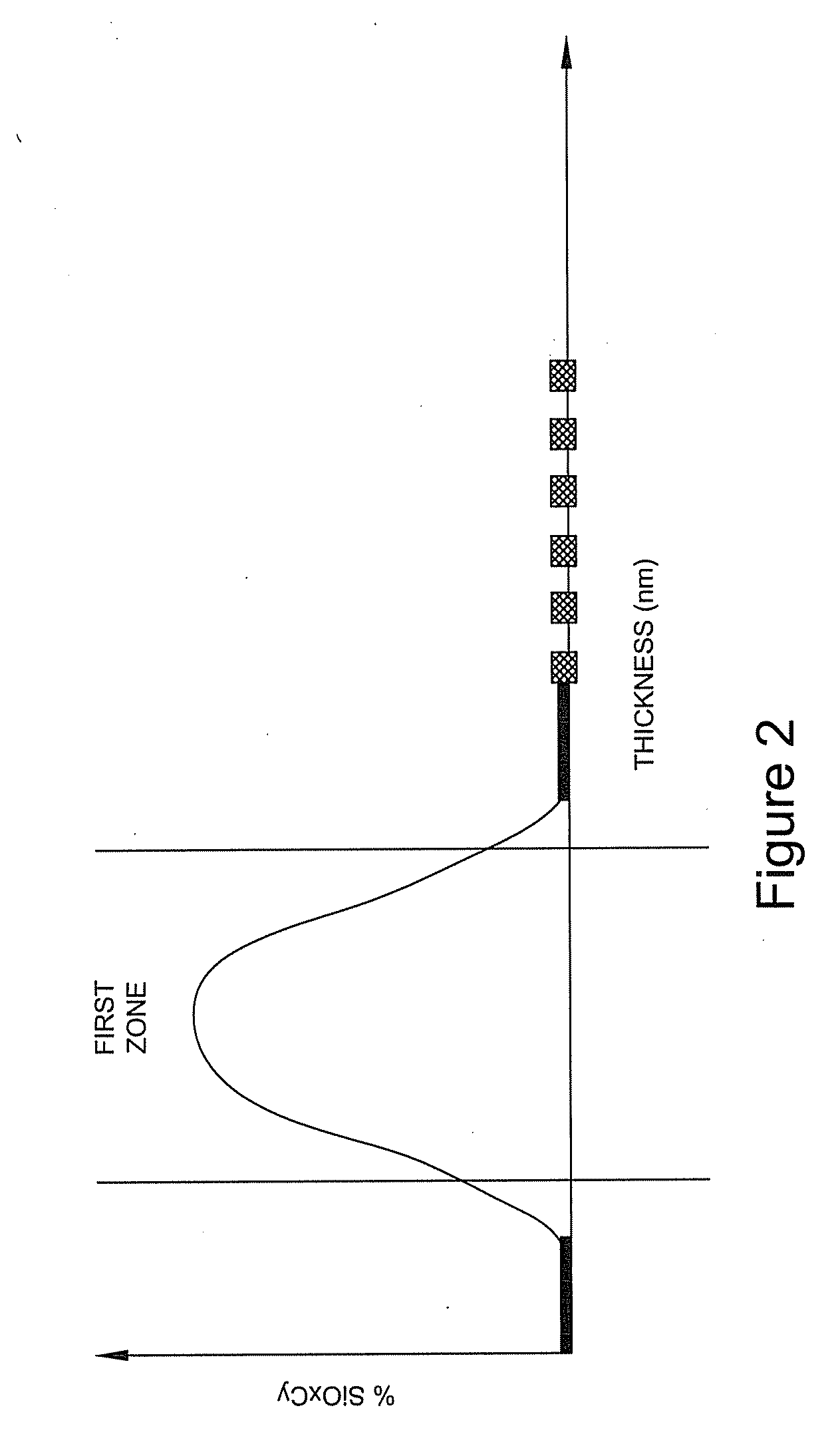

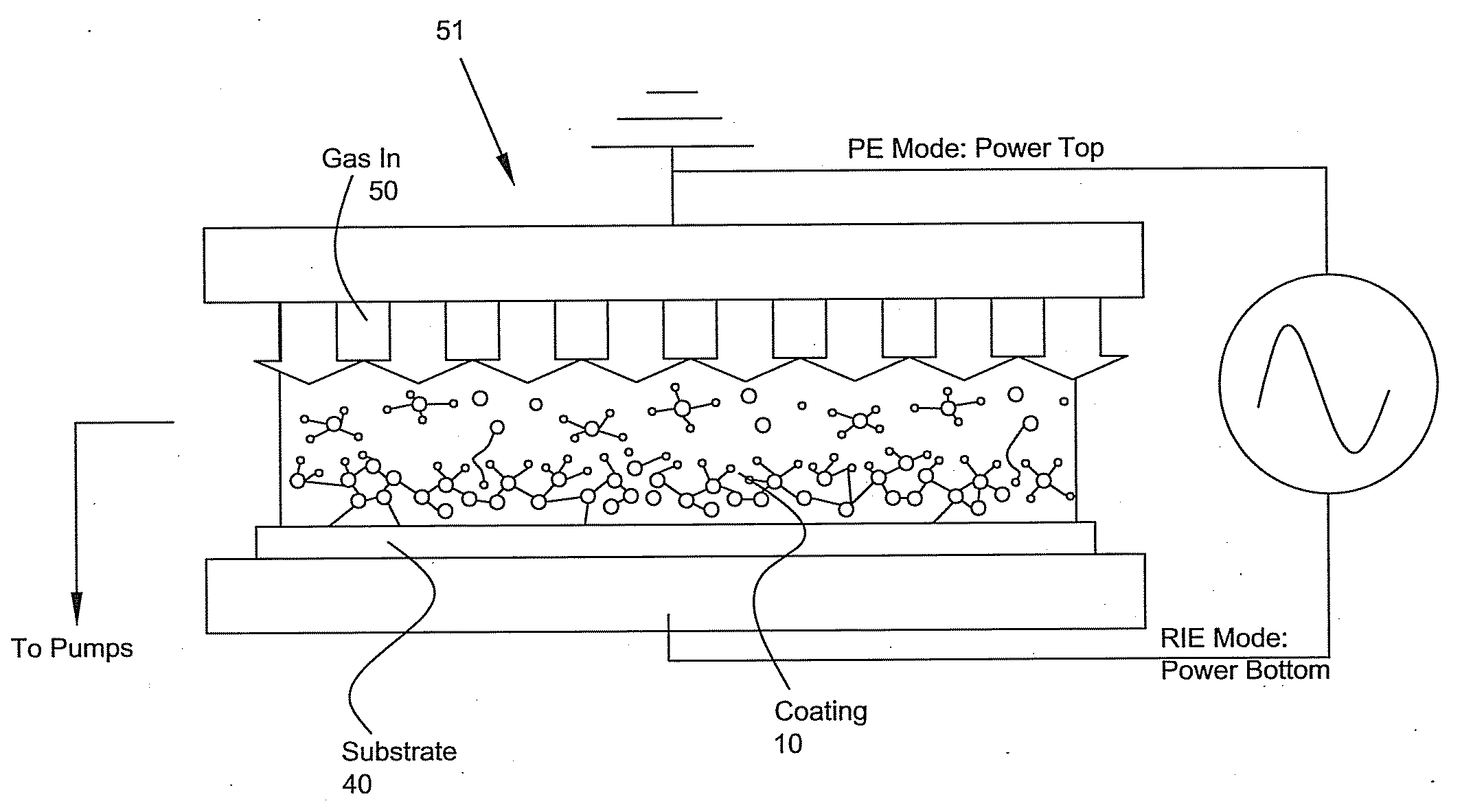

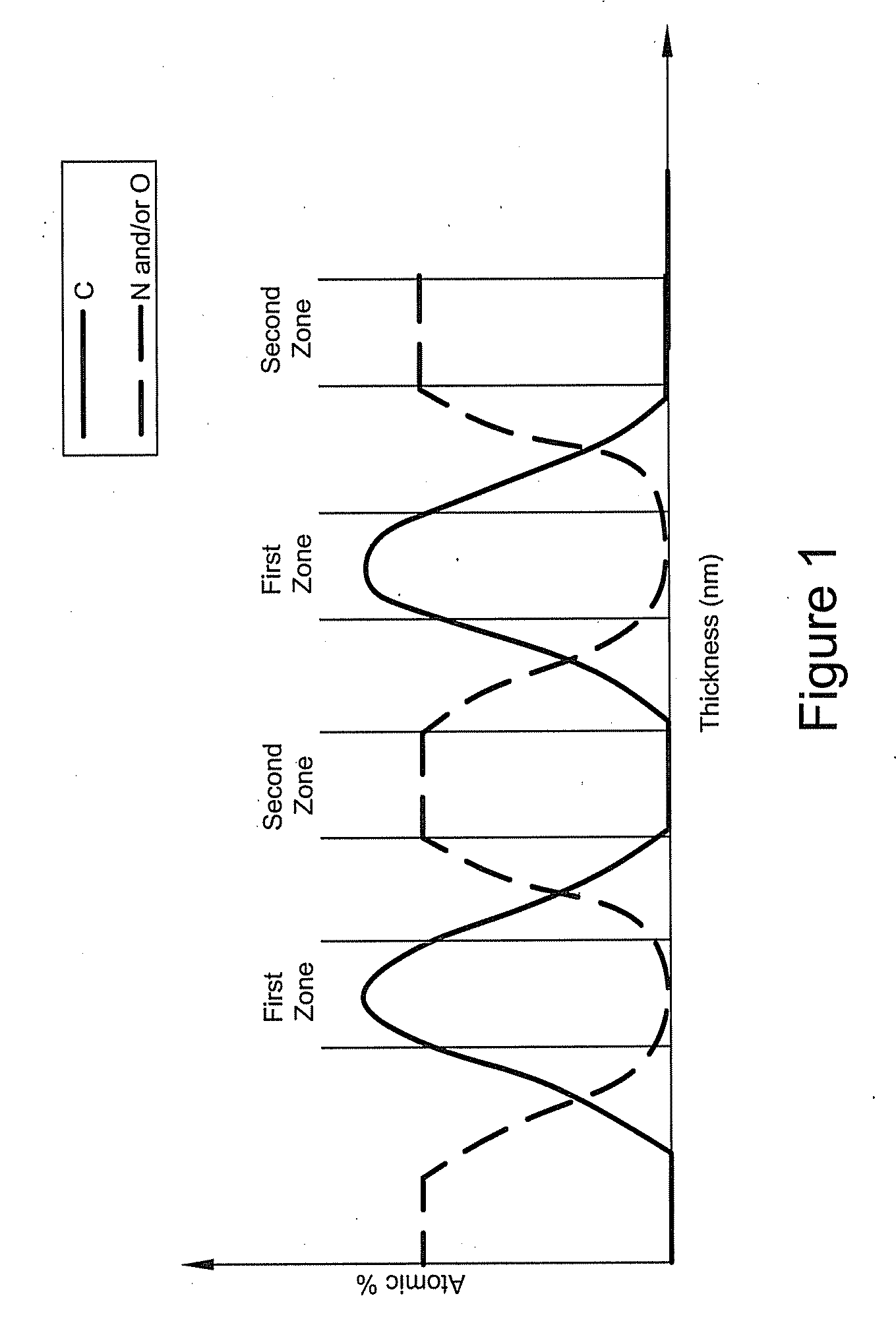

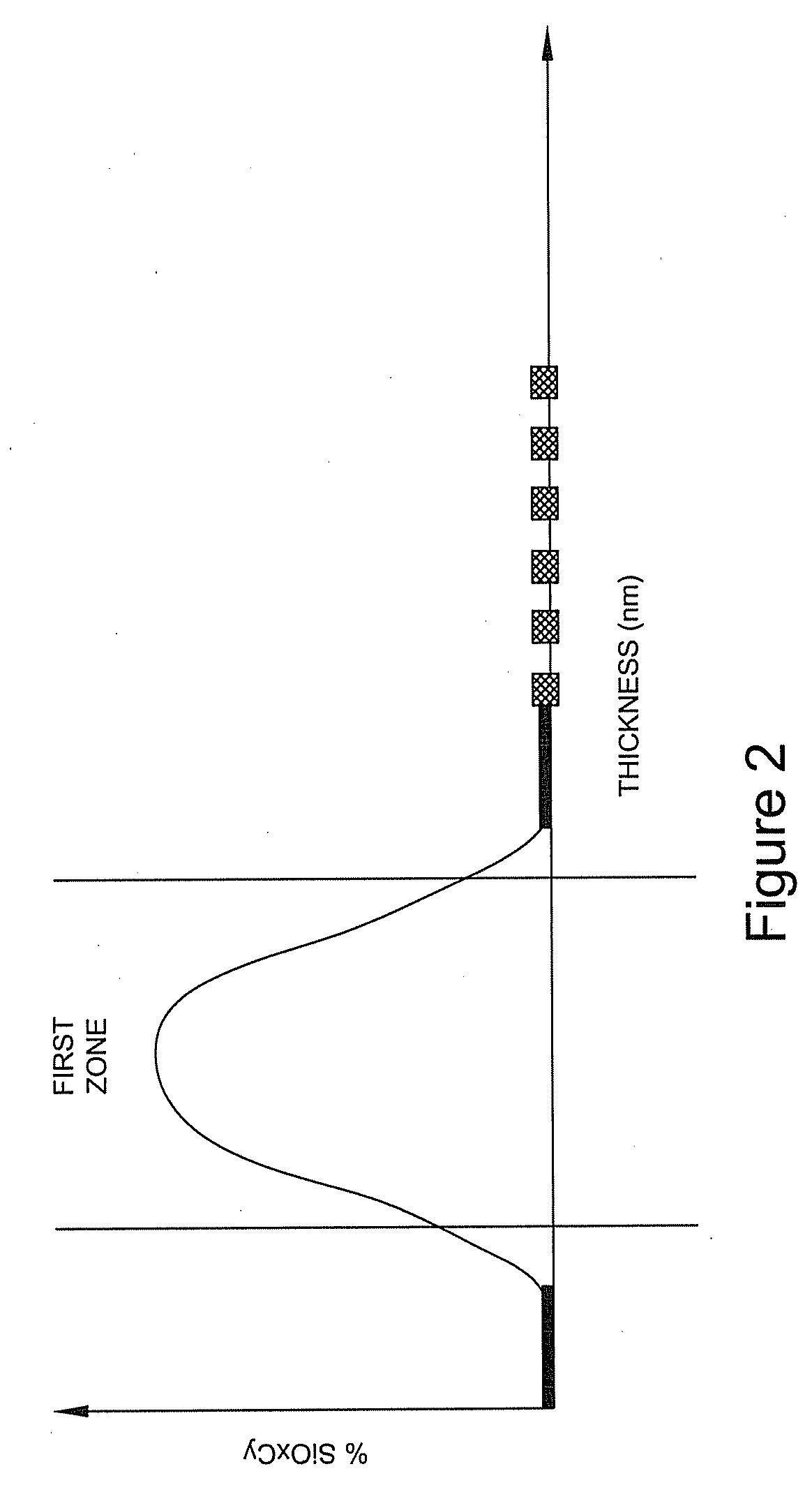

System and method for making a graded barrier coating

ActiveUS20090297813A1Better control of gradationGood coating performanceSynthetic resin layered productsSolid-state devicesOrganic electroluminescenceOLED

Methods and apparatus are disclosed relating to graded-composition barrier coatings comprising first and second materials in first and second zones. The compositions of one or both zones vary substantially continuously across a thickness of the zone in order to achieve improved properties such as barrier, flexibility, adhesion, optics, thickness and tact time. The graded-composition barrier coatings find utility in preventing exposure of devices such as organic electro-luminescent devices (OLEDs) to reactive species found in the environment.

Owner:BOE TECH GRP CO LTD

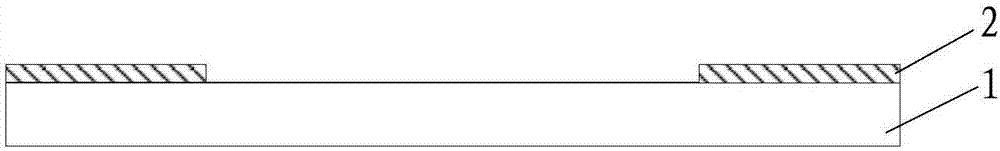

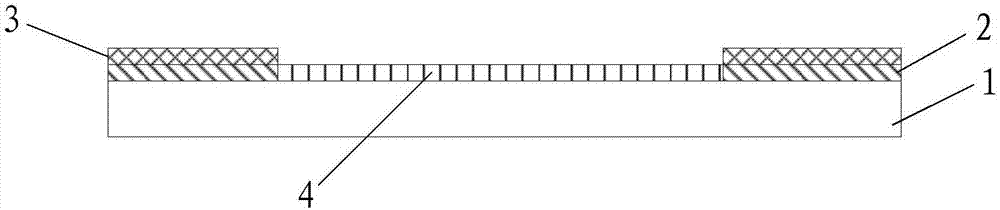

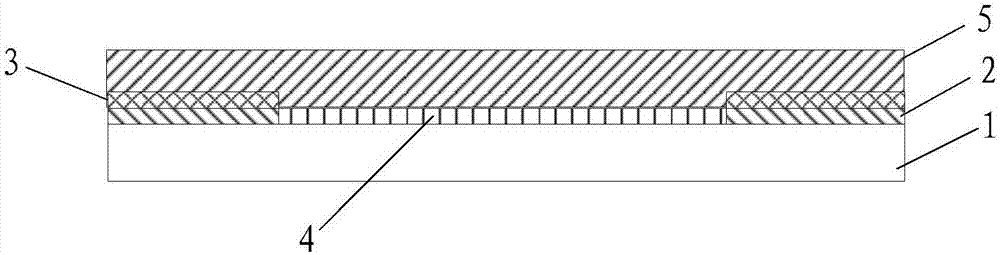

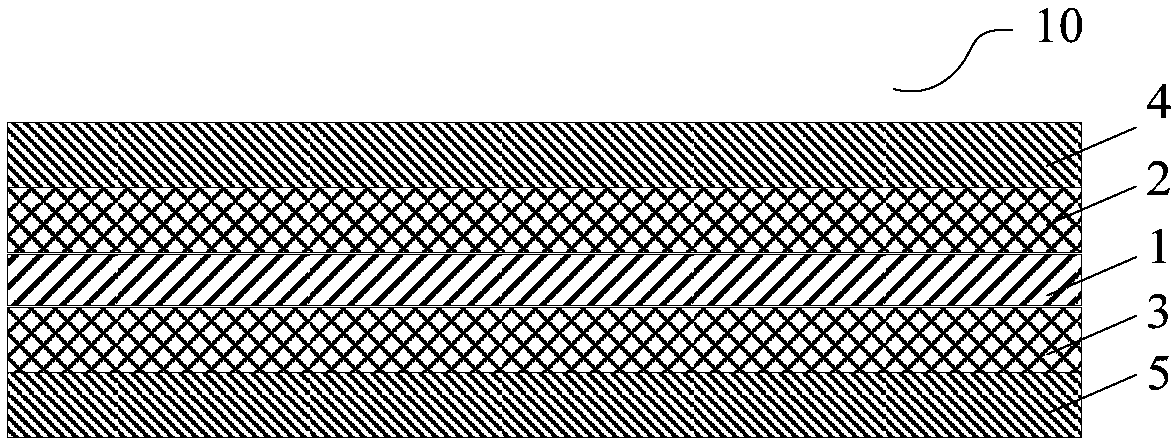

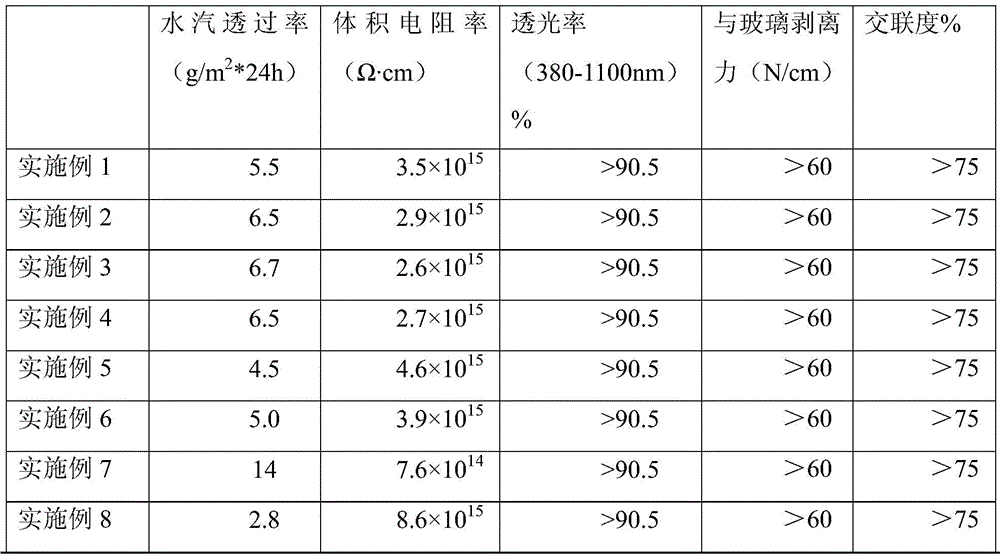

Laminated packaging film for solar batteries

InactiveCN102832280AImprove reflectivityImprove barrier propertiesPhotovoltaic energy generationSemiconductor devicesLight reflectionEngineering

The invention discloses a laminated packaging film for solar batteries. A solar battery rear panel using the packaging film and a solar battery module are used. The laminated packaging film for the solar batteries is characterized by comprising a transparent layer (1) and a functional layer (2) and has one or more of following functions: a light reflection function or / and a water-vapor blocking function or / and a radiating function. The laminated packaging film has good packaging function, enables the packaging material to have functions such as high reflectance, high barrier, high heat conduction and high insulating performance, and is capable of improving the photoelectric conversion efficiency of the solar battery.

Owner:CYBRID TECHNOLOGIES INC

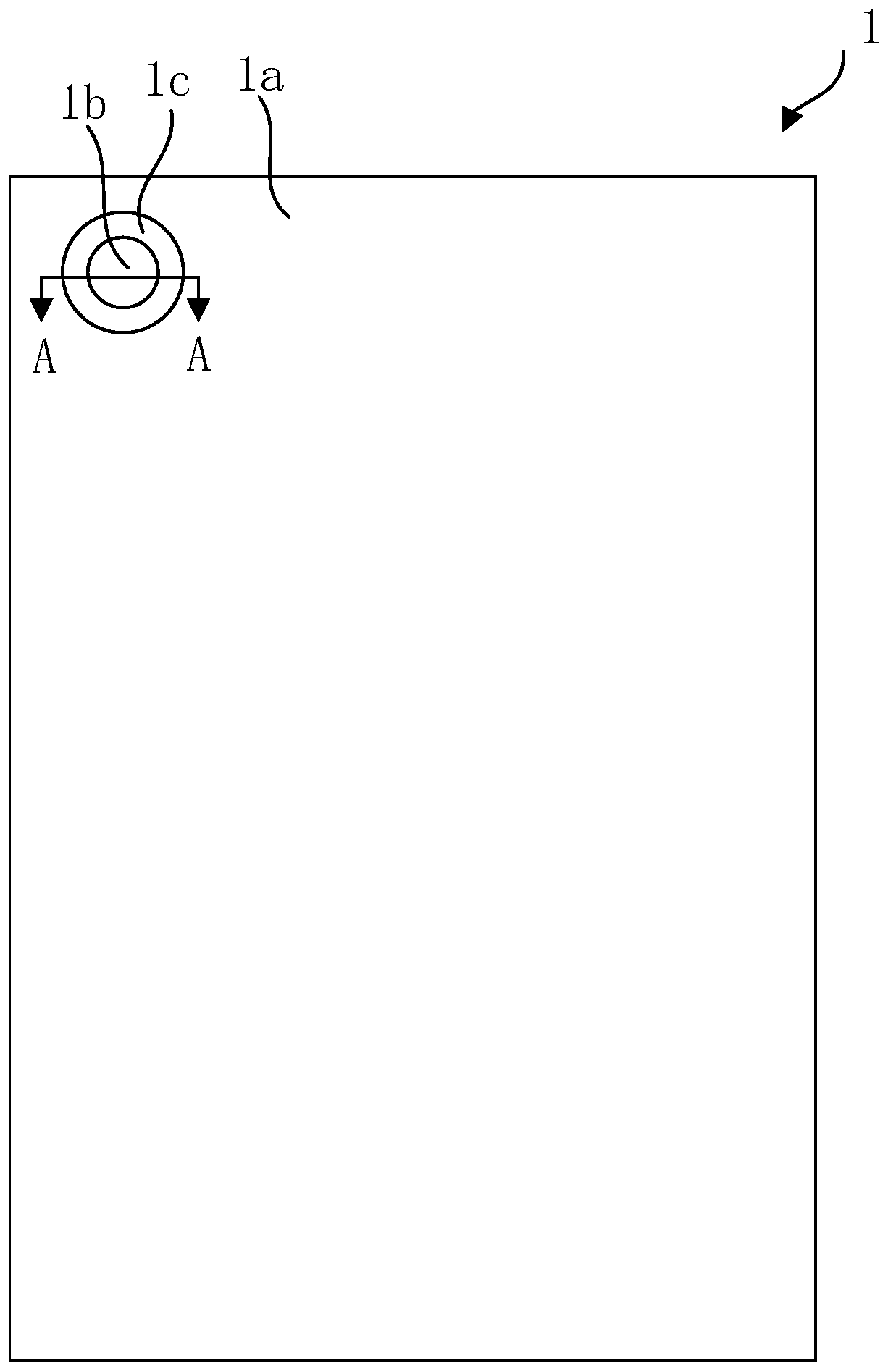

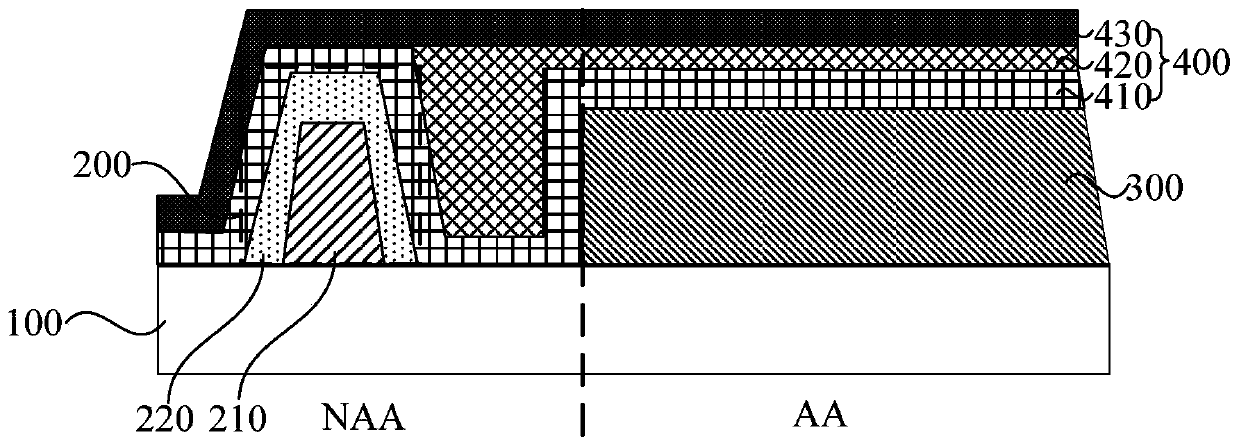

Display device and display substrate thereof

PendingCN110416282AGood partitionImprove pass rateSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOxygen

The invention provides a display device and a display substrate thereof. The display substrate comprises a display area, a porose area, and a partition area between the display area and the porose area. The partition area is provided with at least one partition ring surrounding the porose area, and is used for partitioning an organic light-emitting material layer. The partition ring comprises at least a support portion and a partition portion. The partition portion is provided with a tensile stress layer used for applying tensile stress to the partition portion. When the organic light-emittingmaterial layer is vapor-deposited, partial section of the partition portion in the partition ring is suspended. The partitioning effect on the organic light-emitting material layer is good, and external water and oxygen can be prevented from entering the display area from the opening. In addition, the partition portion can automatically block the organic light-emitting material layer. The use oflaser burning to remove the organic light-emitting material layer around the porose area is avoided. A hot process is omitted. The spacing between the porose area and the display area is shortened. The border of the porose area is reduced. Third, the tensile stress layer can apply tensile stress to the partition portion to prevent the suspended partition portion from collapsing and falling off. The partitioning performance of the partition portion is reliable.

Owner:YUNGU GUAN TECH CO LTD

Frame sealing adhesive, preparation method thereof, display panel and preparation method thereof

ActiveCN108034373AImprove bendabilityMake sure that the glue will not openFinal product manufactureFilm/foil adhesivesElastomerAdhesive

The invention belongs to the field of display technology, and particularly relates to a frame sealing adhesive, a preparation method thereof, a display panel and a preparation method thereof. The frame sealing adhesive comprises a substrate and an adhesive layer arranged on at least one side of the substrate, wherein the substrate is a first elastomer material; the adhesive layer comprises a second elastomer material and a crosslinking agent. Both the substrate and the adhesive layer of the frame sealing adhesive are made of elastomer materials, and the adhesive layer also contains the crosslinking agent to adjust the storage modulus of the adhesive layer, so that the frame sealing adhesive has high bending performance at the same time, can bear larger stress, and has higher viscosity to ensure that the frame sealing adhesive does not come apart when the display panel is folded. Thus, damage of the frame sealing adhesive during folding or bending of a flexible display panel can be avoided, and high packaging performance is ensured.

Owner:BOE TECH GRP CO LTD

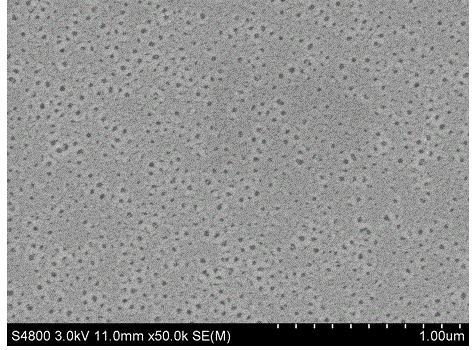

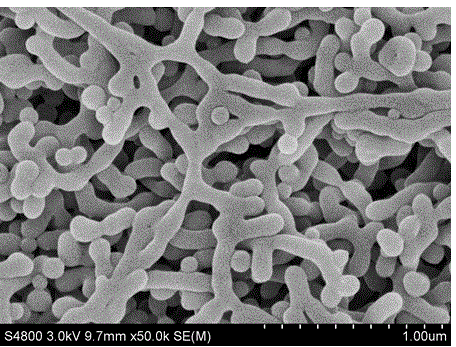

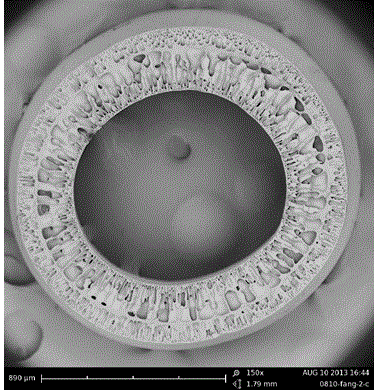

Preparation method of high-toughness equal-hole polymer hollow fiber separating membrane

ActiveCN104056558ANo update requiredNo need to remodelSemi-permeable membranesPolymer scienceSolvent

The invention discloses a preparation method of a high-toughness equal-hole polymer hollow fiber separating membrane. The preparation method comprises the following steps: dissolving a segmented copolymer and an additive or packing into a selective solvent which contains a segmented copolymer, so as to form a casting membrane solution, spinning the casting membrane solution to form hollow fibers, staying in air for appropriate time, and then immerging nascent fibers into a coagulating bath which contains a segmented copolymer, so as to solidify the nascent fibers to form the high-toughness equal-hole polymer hollow fiber separating membrane. According to the high-toughness equal-hole polymer hollow fiber membrane prepared by using the method, the ratio of the maximum hole diameter D to the minimum hole diameter d is less than 2.5, the breaking elongation is 5% to 1000%, and the tensile strength is 5MPa to 500MPa. The prepared high-toughness equal-hole polymer hollow fiber membrane has the relatively high separation accuracy and the relatively good processing and packaging performances.

Owner:ZHEJIANG UNIV

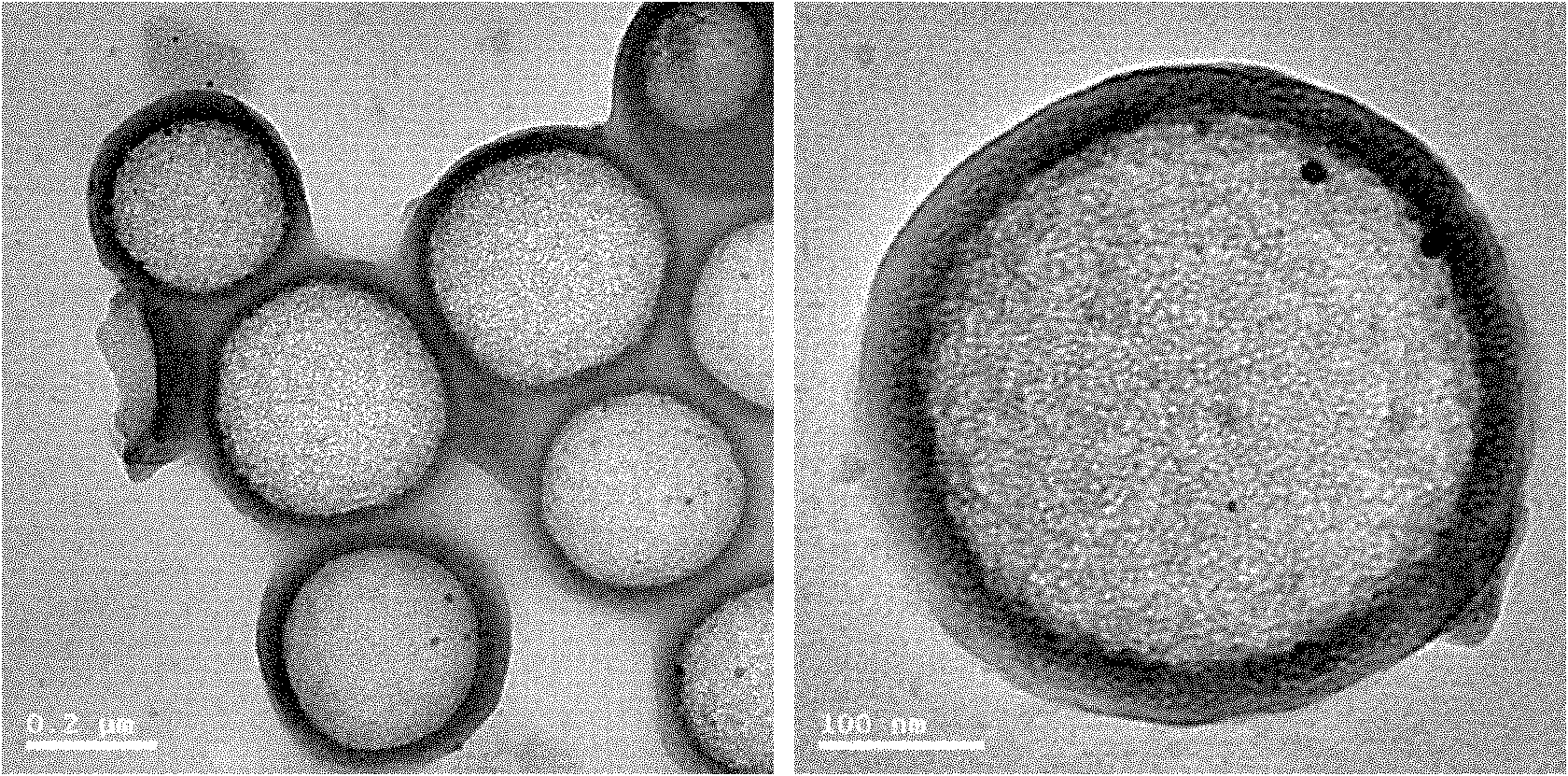

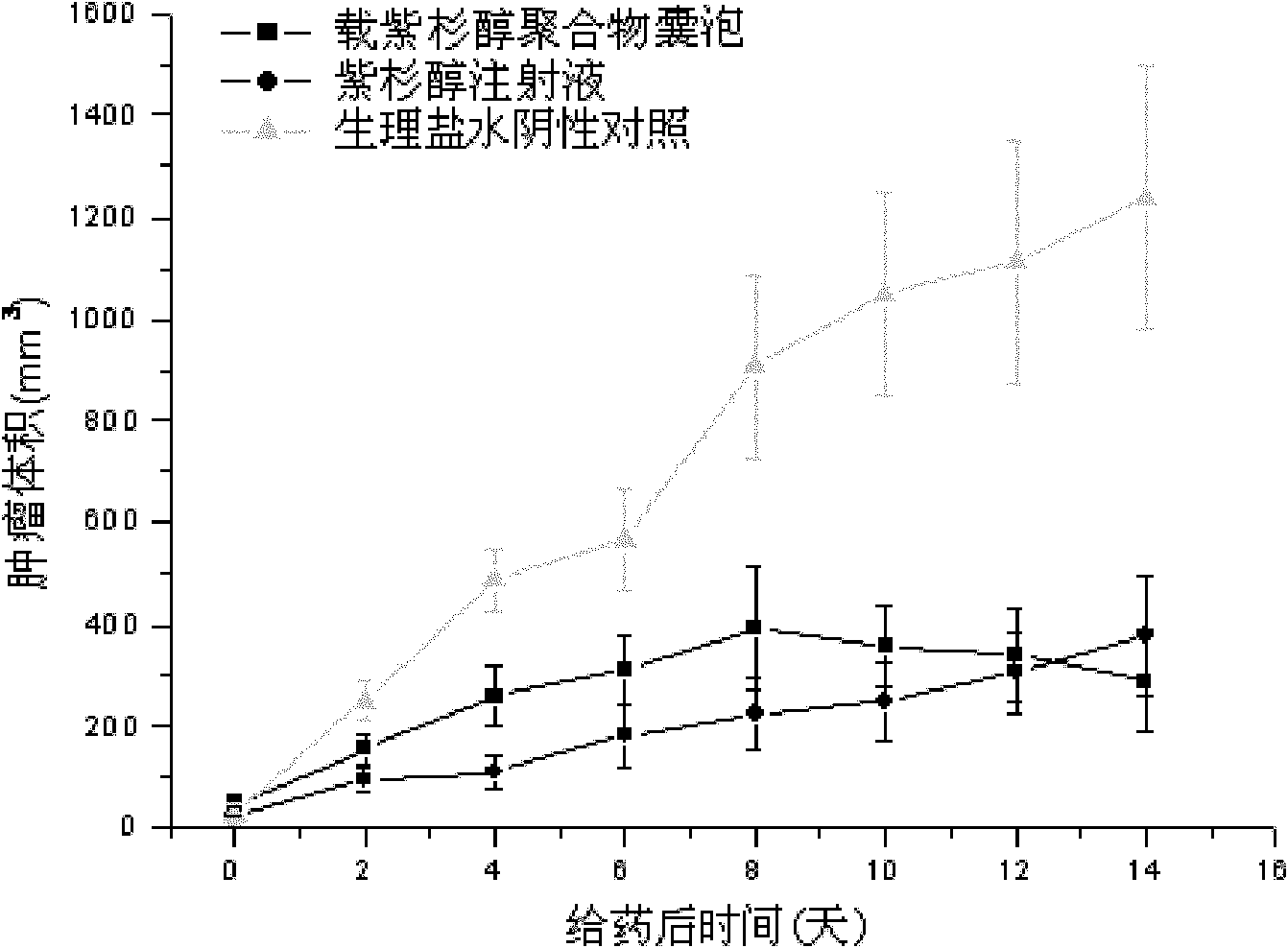

PCL-b-PEG-b-PCL carried hydrophobic medicine polymer vesica as well as preparation method and application thereof

InactiveCN101940792AFlexibleGood flexibilityEther/acetal active ingredientsPharmaceutical non-active ingredientsBiological bodySide effect

The invention discloses a PCL-b-PEG-b-PCL carried hydrophobic medicine polymer vesica as well as a preparation method and application thereof. The polymer vesica is manufactured by the following steps of: (1) dissolving amphipathy triblock copolymer and hydrophobic medicine in organic solvent, evaporating to remove the organic solvent to prepare film, blowing and drying; and (2) adding double distilled water and the product in the step (1) in a container, hydrating, evenly mixing through oscillation, performing ultrasonic to form stable emulsion, collecting filtrate and freezing after filtering the film. The vesica has the main advantages of particle medicine carrying systems such as liposome and nanometer; the stability inside and outside the polymer vesica is remarkably superior to the liposome; the film layer is thicker and is beneficial to packaging hydrophobicity medicine; in the preparation process, emulsifier or surface active agent is not needed, thereby overcoming the defect that the a great amount of emulsifier or surface active agent is needed for traditionally preparing a medicine release system and avoiding toxic side effect to the organism caused by using reagent.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

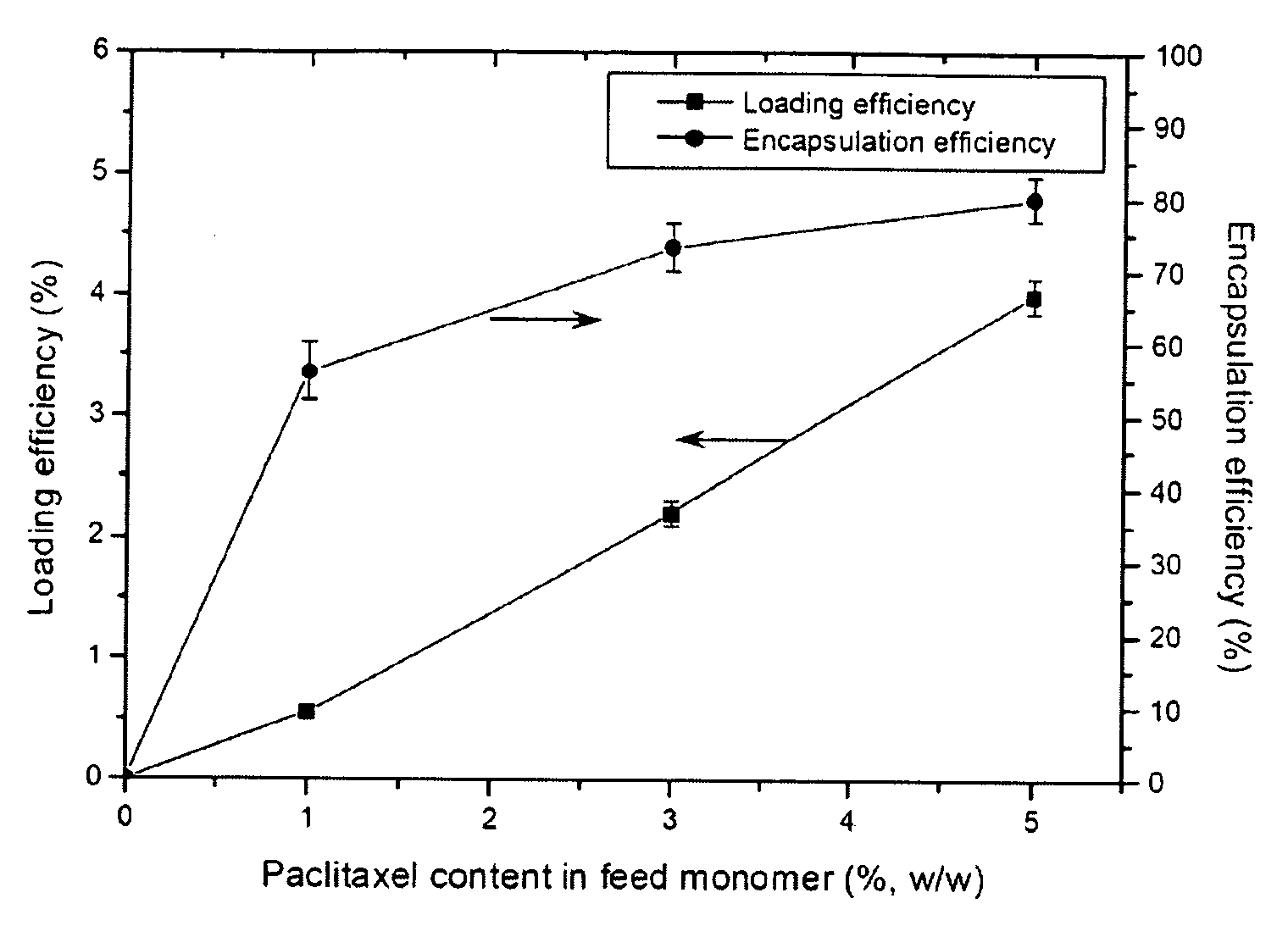

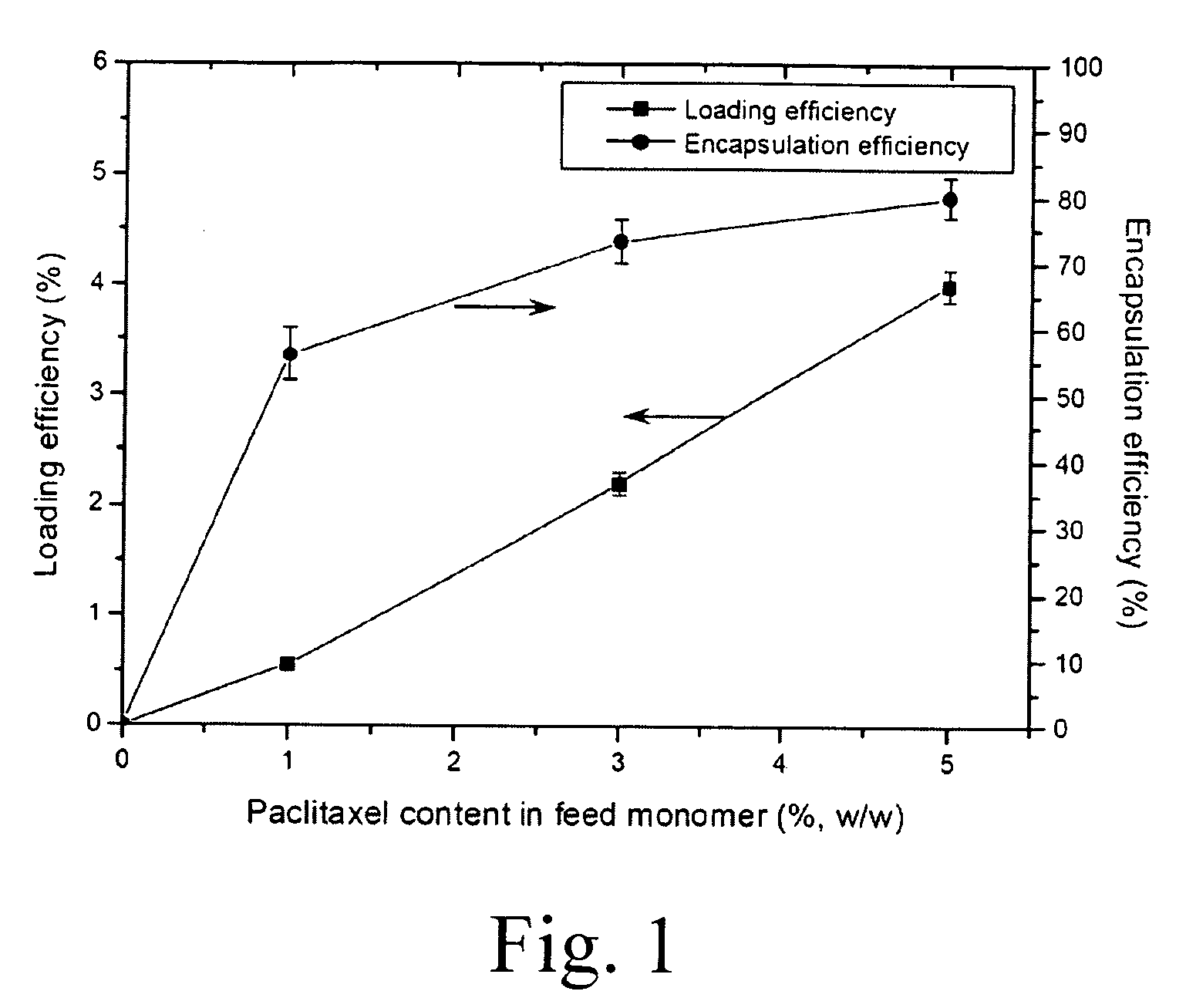

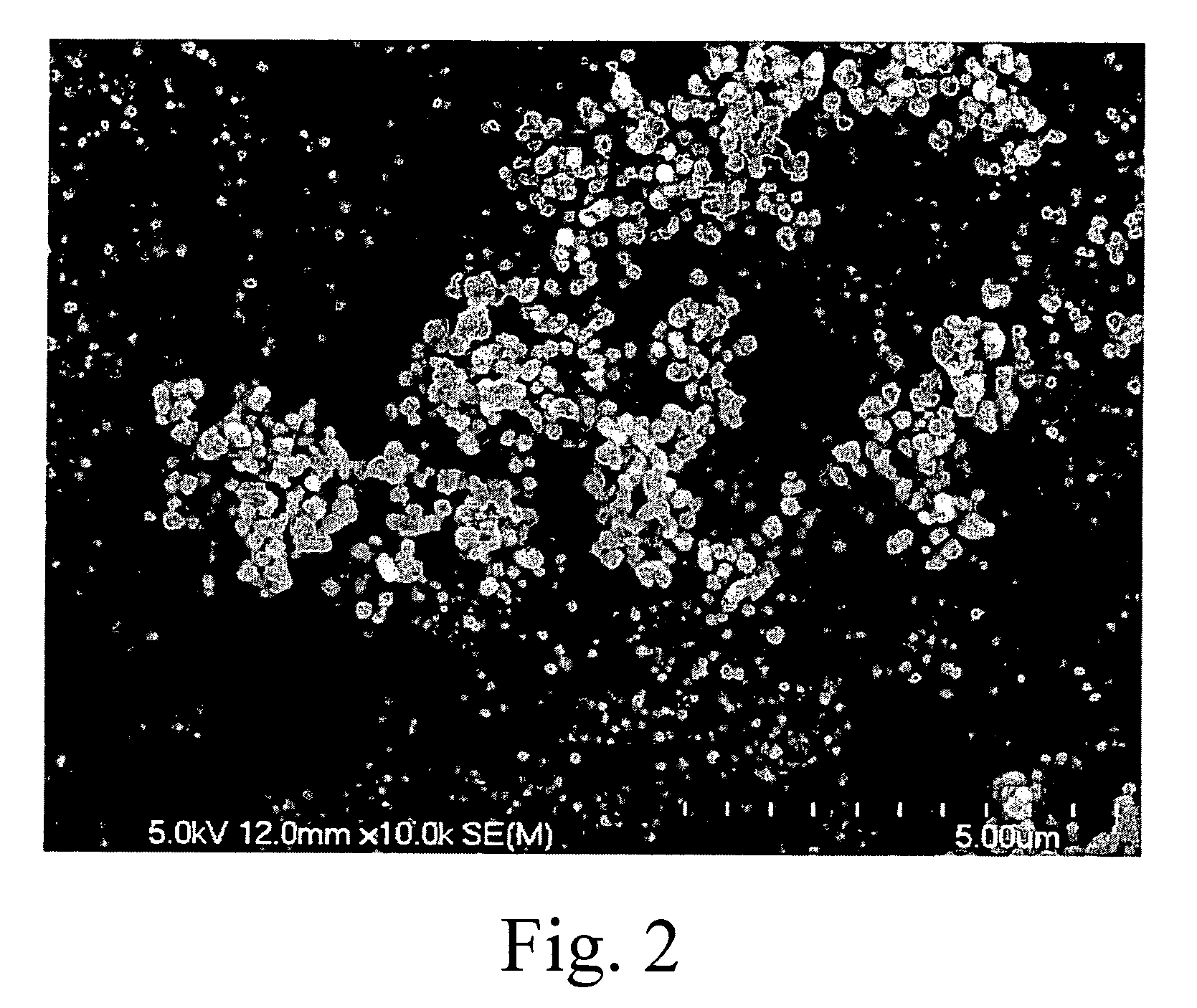

Drug-loaded poly (alkyl-cyanoacrylate) nanoparticles and process foe the preparation thereof

ActiveUS20080182776A1Increase loadImprove encapsulationAntibacterial agentsPowder deliveryCyanoacrylateActive agent

A process for preparing the drug-loaded cyanoacrylate nanoparticles is described. The cyanoacrylate nanoparticles which effectively deliver biological and therapeutic agents are synthesized by miniemulsion polymerization with surfactant, pluronic F127 or F68. Before initiation of polymerization, active agents with particularly highly hydrophobicity are dissolved in cyanoacrylate monomer. Compared with the drug-loaded polyalkylcyanoacrylate nanoparticles produced by emulsion polymerization, those produced by miniemulsion polymerization possess higher loading and encapsulation efficiencies. While the content of dissolved agents increases, furthermore, the loading and encapsulation efficiencies increase concurrently.

Owner:TONG SHEN ENTERPRISE

System and method for making a graded barrier coating

InactiveUS20090110892A1Better control of gradationGood coating performanceLayered productsSolid-state devicesOrganic electroluminescenceOLED

Methods and apparatus are disclosed relating to graded-composition barrier coatings comprising first and second materials in first and second zones. The compositions of one or both zones vary substantially continuously across a thickness of the zone in order to achieve improved properties such as barrier, flexibility, adhesion, optics, thickness and tact time. The graded-composition barrier coatings find utility in preventing exposure of devices such as organic electro-luminescent devices (OLEDs) to reactive species found in the environment.

Owner:GENERAL ELECTRIC CO

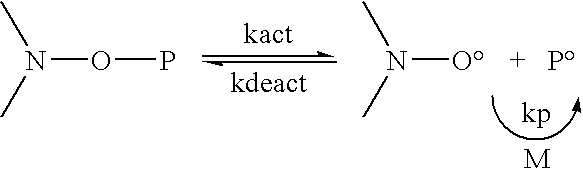

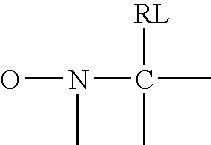

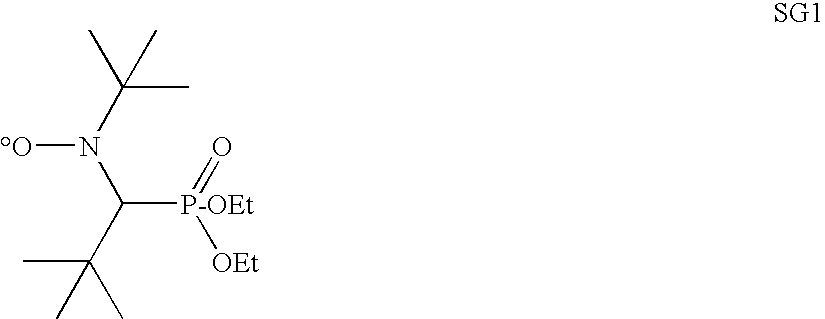

Polymer encapsulation and/or binding

ActiveUS20100010103A1Easy to controlImprove encapsulationCosmetic preparationsToilet preparationsPolymer chemistryBioactive molecules

Encapsulation of and binding to pegylated bioactive molecules via functionalized comb, block, branched type polymers formed by nitroxide mediated controlled radical polymerization is disclosed.

Owner:ARKEMA INC

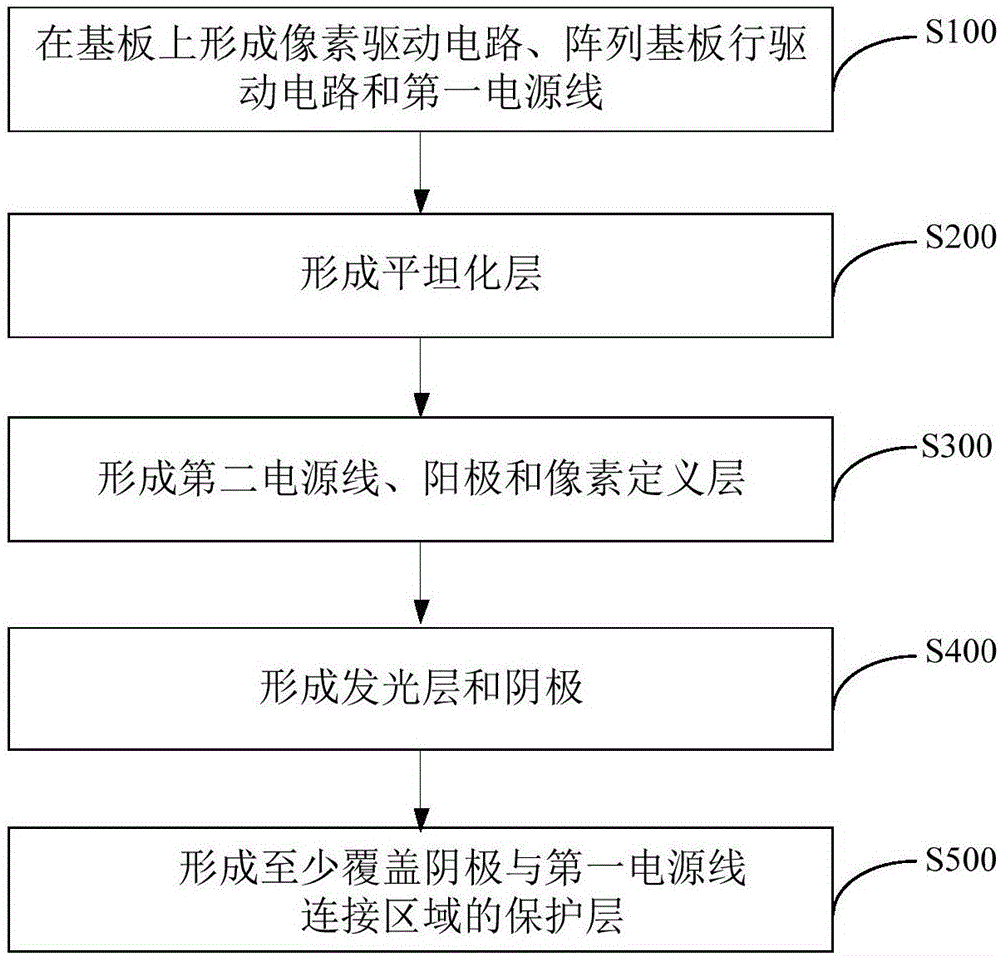

Organic electroluminescence display device, preparation method thereof and display device

ActiveCN106847867AReduce bonding resistanceReduce power consumptionSolid-state devicesSemiconductor devicesDisplay deviceOrganic electroluminescence

The invention provides an organic electroluminescence display device, a preparation method thereof and a display device. The organic electroluminescence display device comprises a light emitting area and a peripheral circuit area which surrounds the light emitting area. The light emitting area comprises a cathode, a light emitting layer, an anode and a pixel driving circuit. The peripheral circuit area comprises a first power supply line, a second power supply line and an array substrate line driving circuit. The cathode extends to the peripheral circuit area and is electrically connected with the first power supply line. The organic electroluminescence display device further comprises a protective layer which at least covers a connecting area between the cathode and the first power supply line. Through setting the protective layer, the organic electroluminescence display device, the preparation method thereof and the display device have advantages of effectively reducing cathode bonding resistance, reducing device power consumption, delaying cathode corrosion and improving packaging effect.

Owner:BOE TECH GRP CO LTD

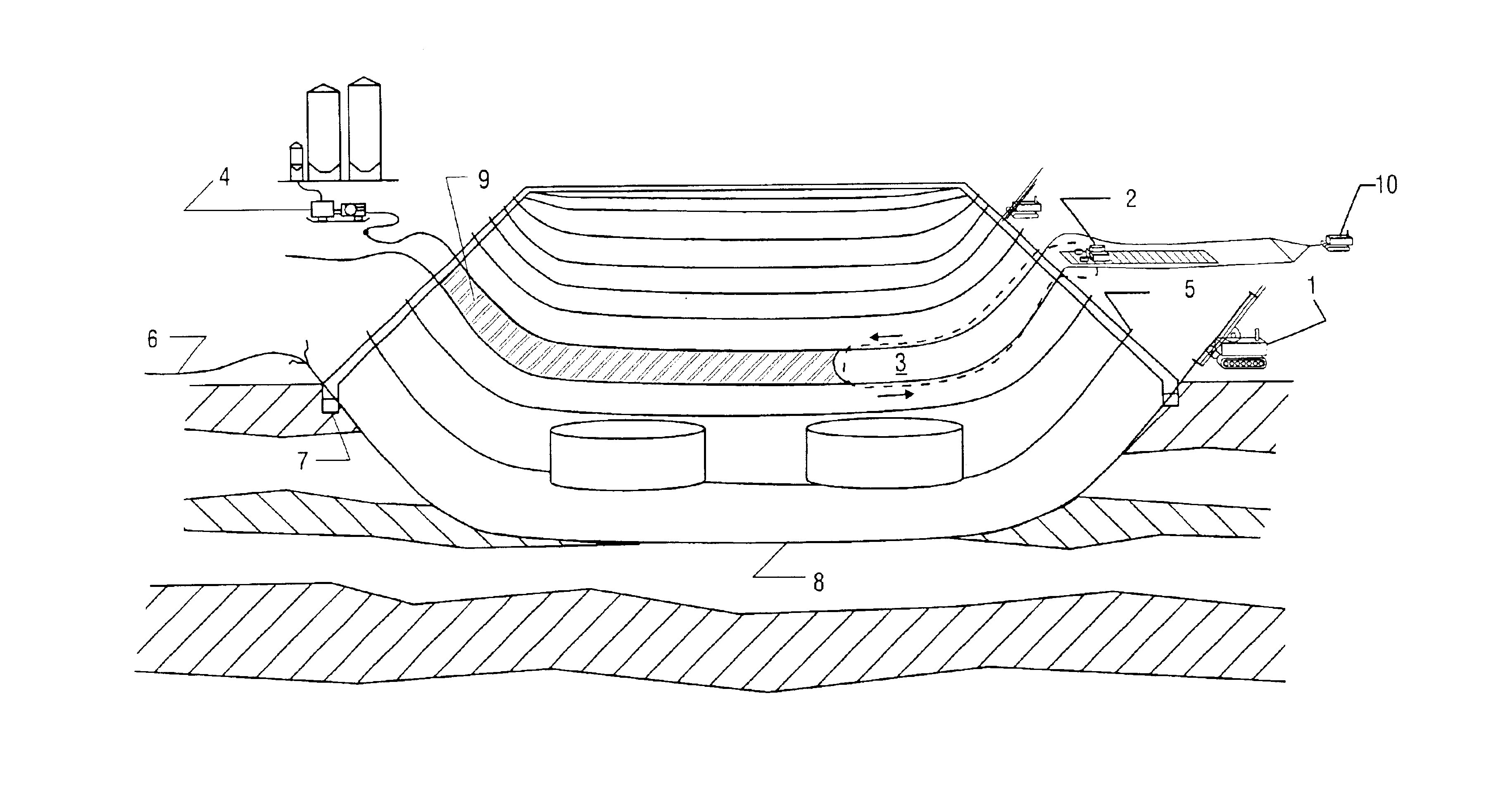

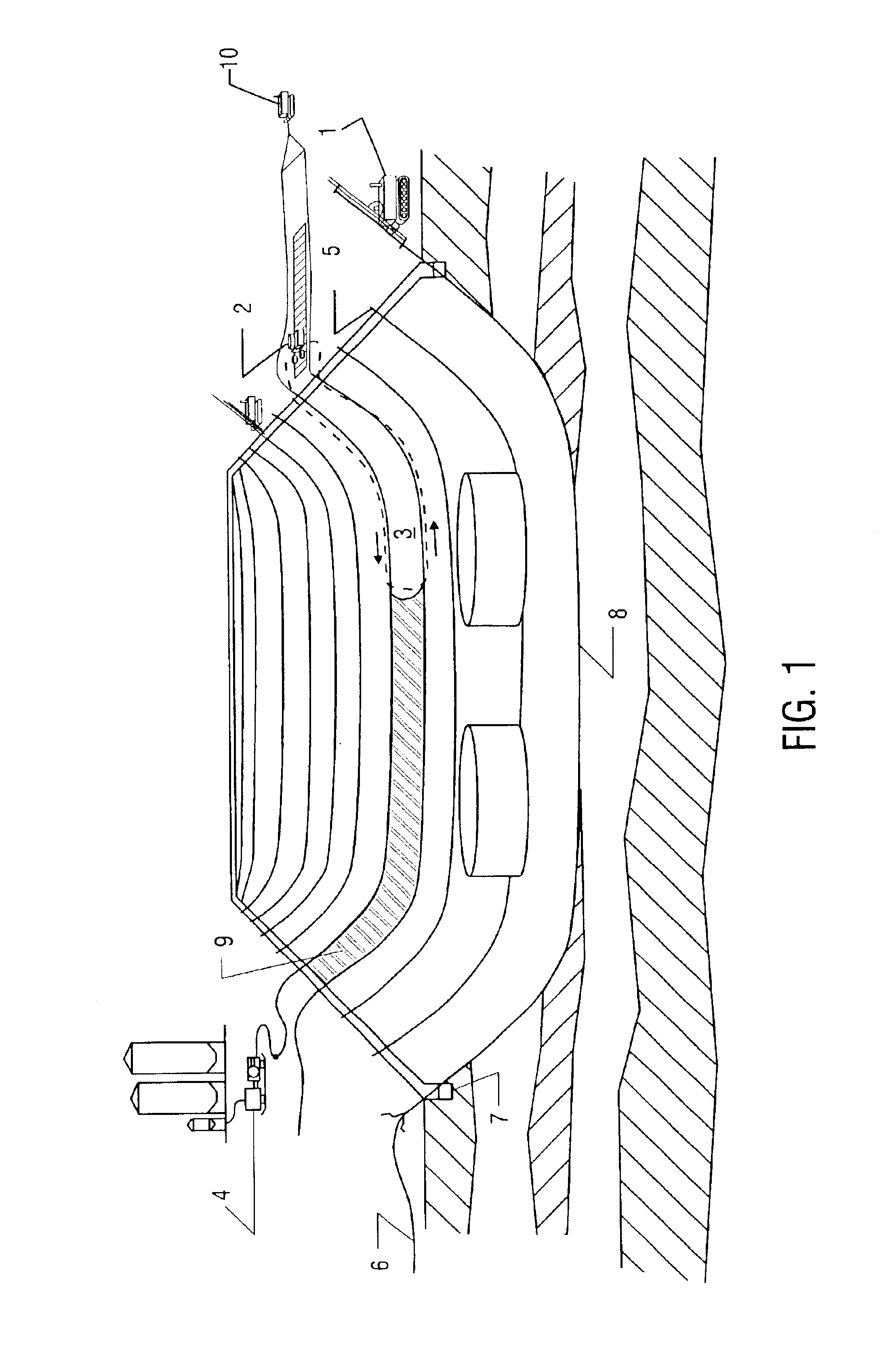

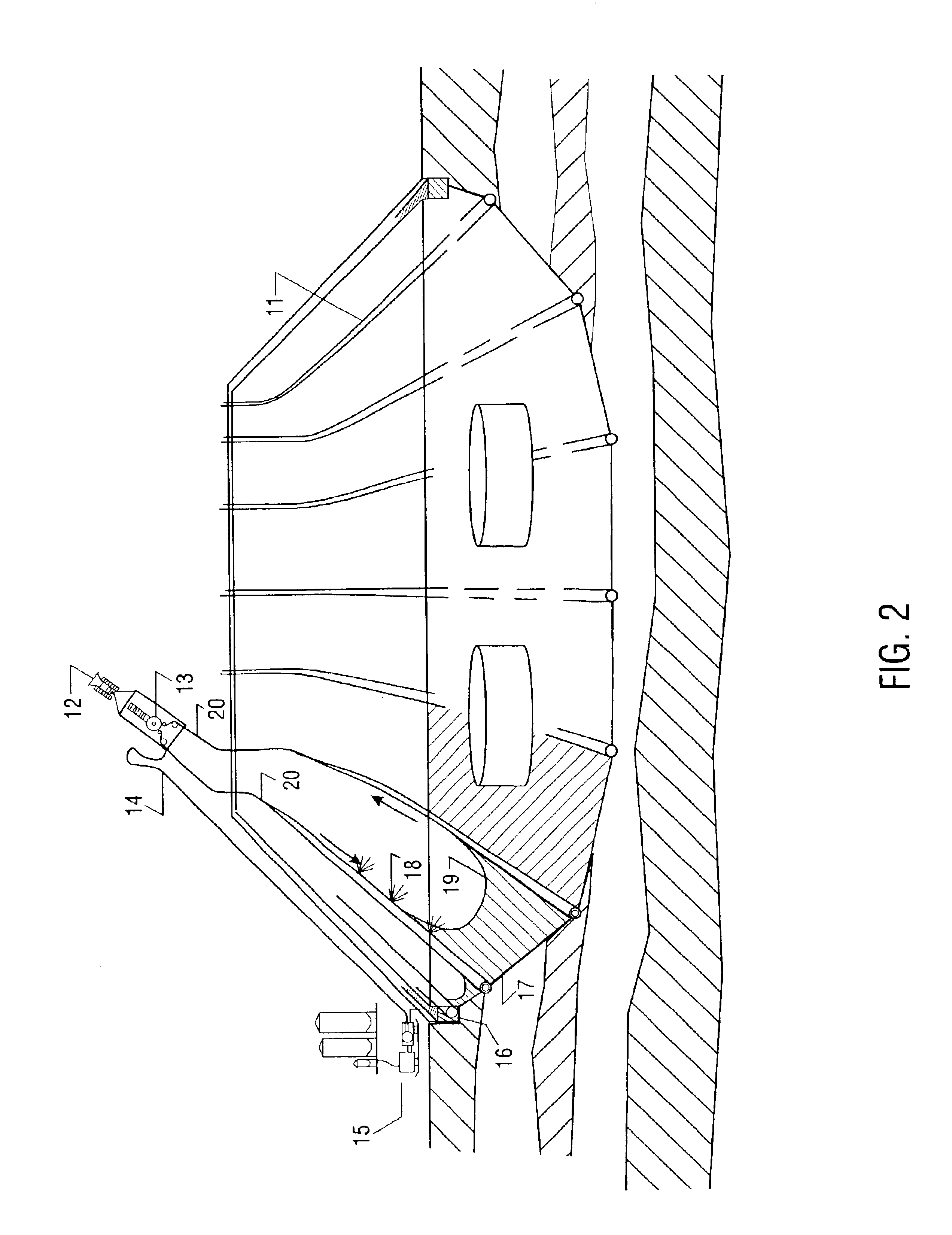

Grout compositions for construction of subterranean barriers

InactiveUS6860936B2Easy to adjustImprove permeabilitySolid waste disposalProtective foundationEngineeringSensor system

A method is disclosed for constructing, verifying, and maintaining underground vaults that isolate and contain radioactive burial sites. The method employs a buoyant lift technique to isolate a block of soil containing the contaminates from the surrounding soil. An impermeable synthetic liner is embedded in the vault to enhance the integrity of the system. The integrity of the vault is monitored by a system of sensors placed both inside and outside of the sealed vault. The method eliminates the need to excavate or drill in the contaminated areas.

Owner:CARTER JR ERNEST E

Reductively-responsive paclitaxel prodrug and preparation method for nano-micelle carrier

InactiveCN106083769AEasy to prepareHigh drug loadingOrganic active ingredientsOrganic chemistryHigh concentrationDspe peg

The invention discloses a reductively-responsive paclitaxel prodrug. The reductively-responsive paclitaxel prodrug is synthesized from paclitaxel (PTX) and dithiodicarboxylic acid in a mol ratio of 2: 1 through covalent combination via an ester bond, and the molecular structure of the synthesized paclitaxel prodrug is PTX-SS-PTX. A PTX prodrug nano-micelle carrier is mainly composed of PTX-SS-PTX and distearoyl-phosphatidylethanolamine-polyethylene glycol (DSPE-PEG). According to the PTX-SS-PTX prodrug in the invention, a disulfide bond can rotate freely; and on the condition that the paclitaxel prodrug and a paclitaxel prodrug nano-micelle drug delivery system provided by the invent are stimulated by a high-concentration glutathione reductive environment in tumor cells, the disulfide bond breaks, and a parent drug is released. The reductively-responsive paclitaxel prodrug can obviously improve the drug loading capacity and encapsulation efficiency of PTX and improves stability of a PTX nanometer drug delivery system.

Owner:NANJING MEDICAL UNIV

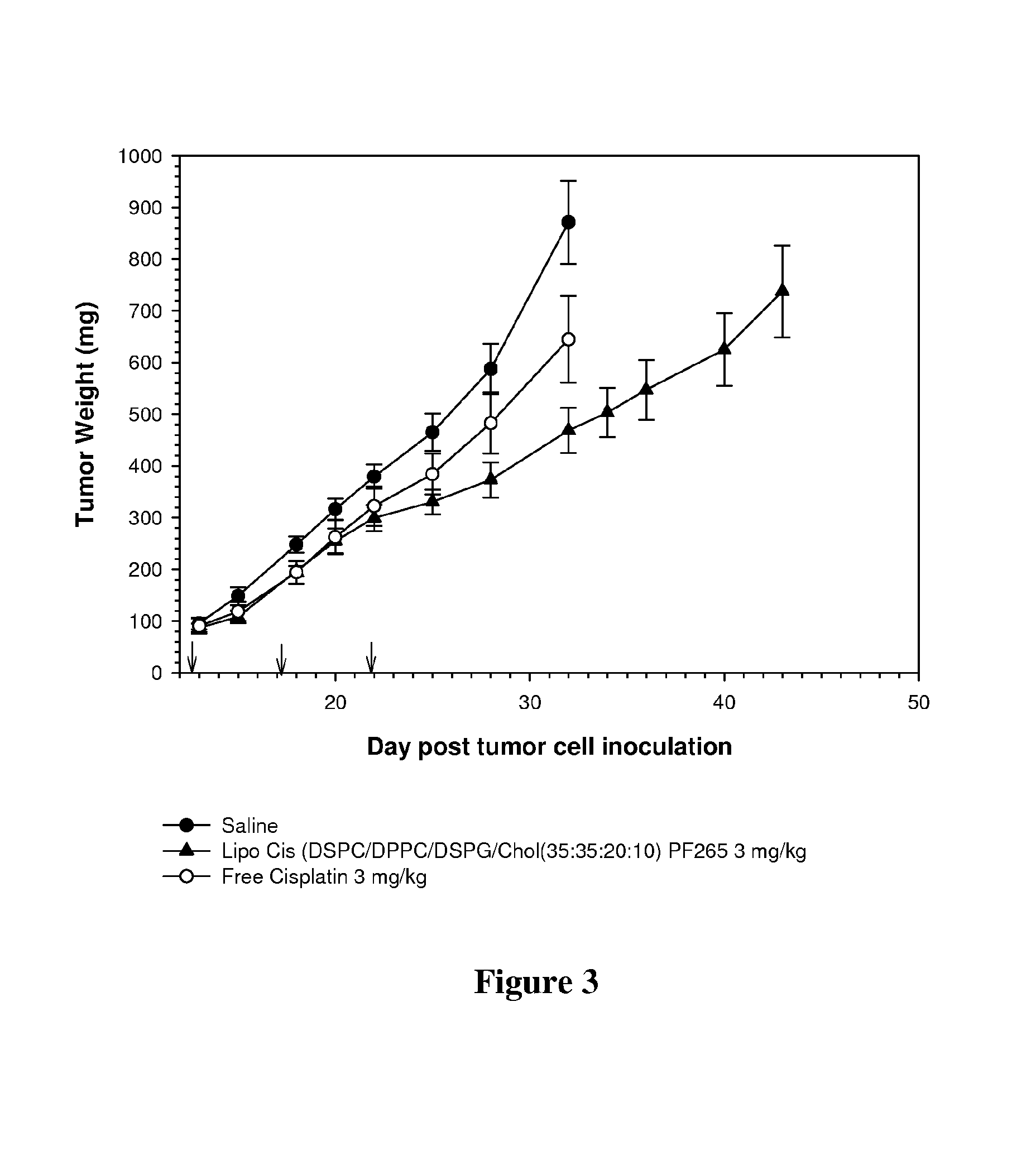

Platinum drug formulations

InactiveUS20160058704A1Improve therapeutic indexSufficient drug loadingBiocideHeavy metal active ingredientsPlatinumPlatinum Agents

Owner:CELATOR PHARMA INC

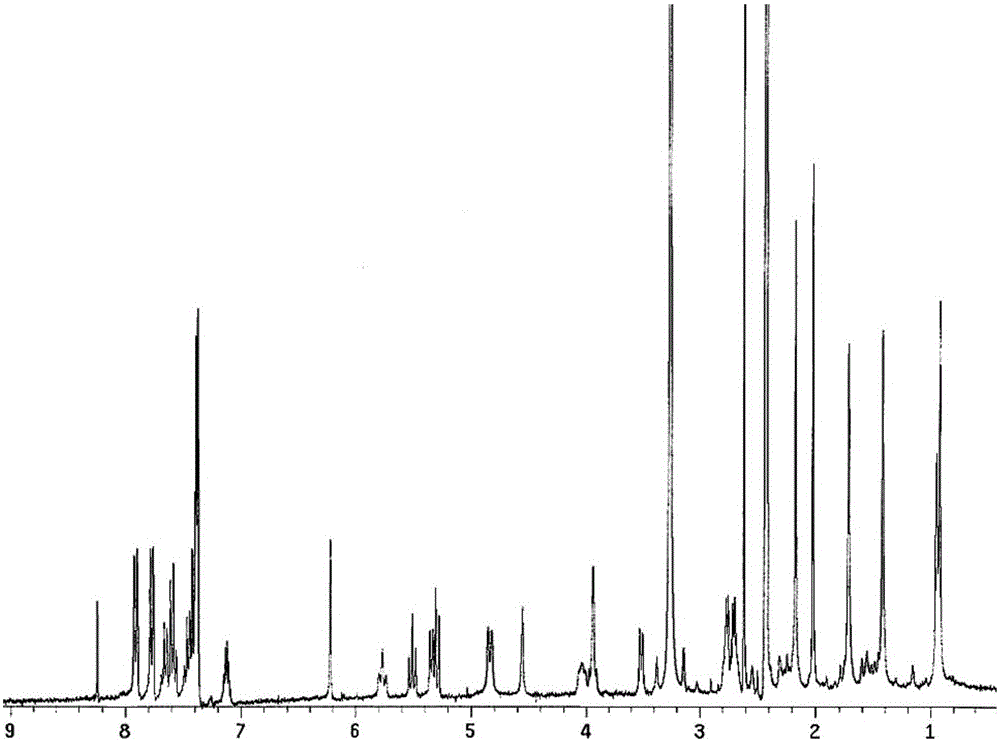

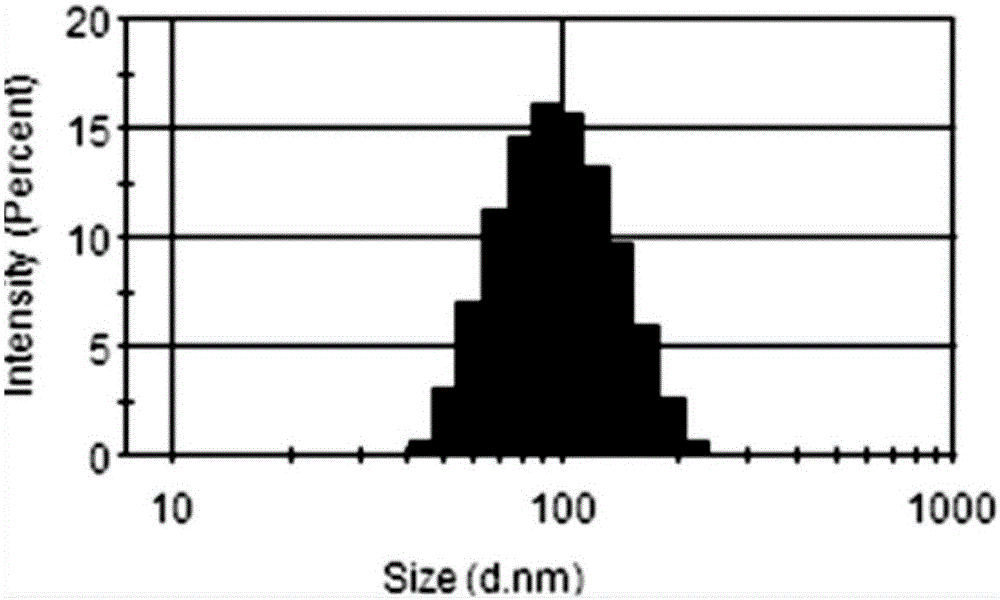

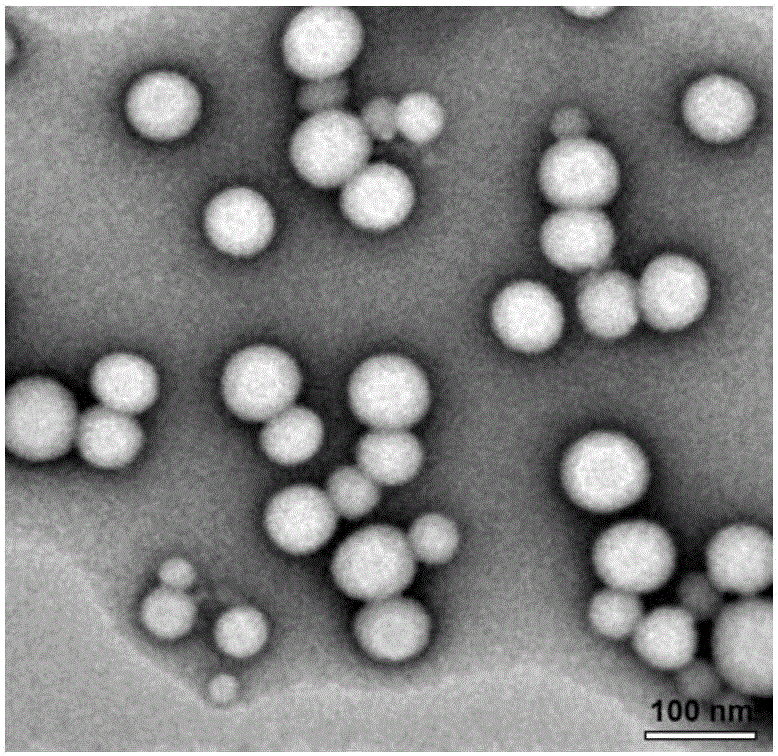

Sustained-release liposomal anesthetic compositions

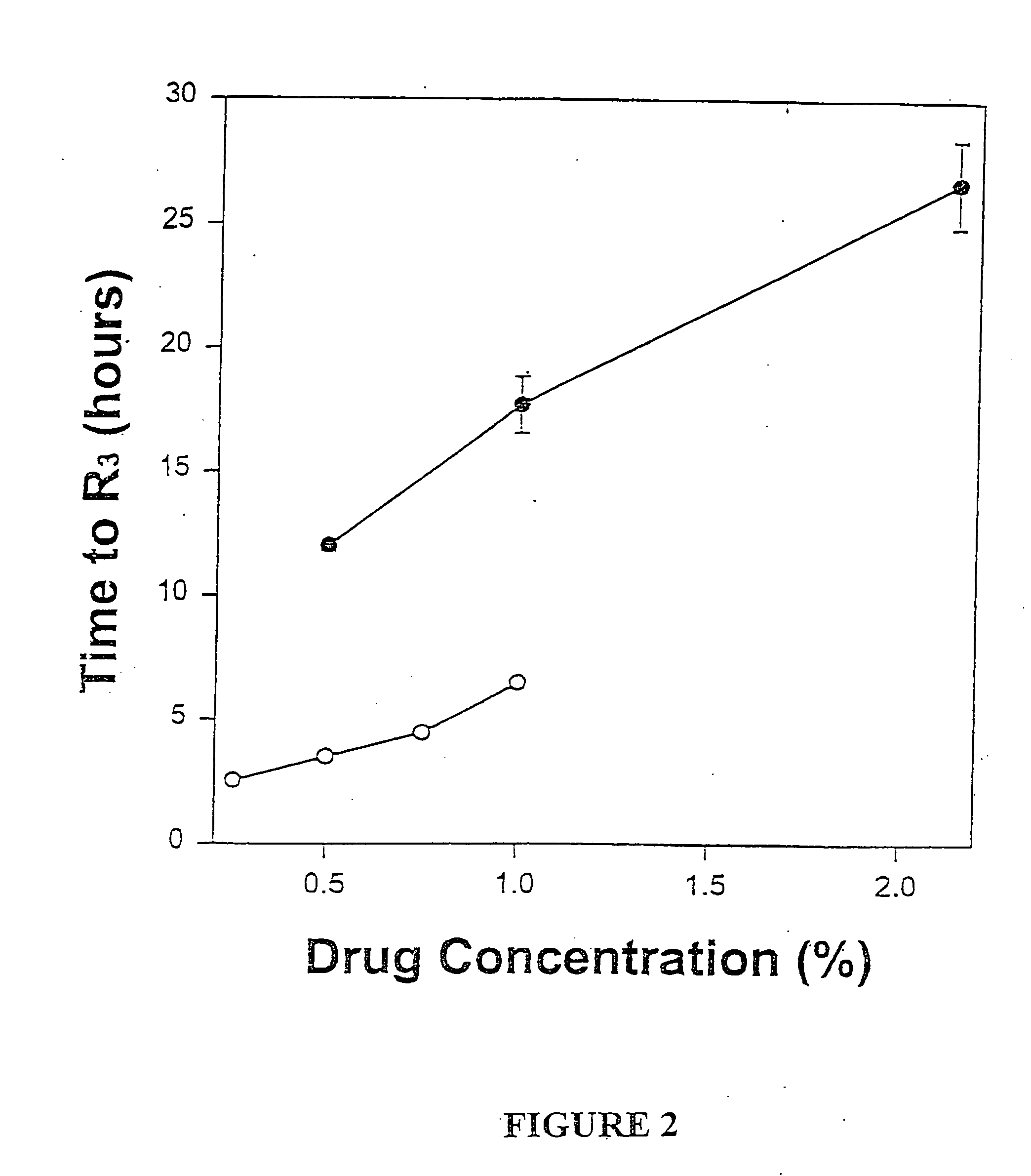

InactiveUS20060078606A1High acceptabilityImprove encapsulationInorganic non-active ingredientsRotary piston pumpsHalf-lifeMaximum tolerated dose

The invention provides a method for obtaining local anesthetics encapsulated in liposomes, such as multivesicular liposomes, with high encapsulation efficiency and slow release in vivo. When the encapsulated anesthetic is administered as a single intracutaneous dose, the duration of anesthesia and half-life of the drug at the local injection site is increased as compared to injection of unencapsulated anesthetic. The maximum tolerated dose of the encapsulated anesthetic is also markedly increased in the liposomal formulation over injection of unencapsulated anesthetic. These results show that the liposomal formulation of local anesthetic is useful for sustained local infiltration and nerve block anesthesia.

Owner:PACIRA PHARMA INC

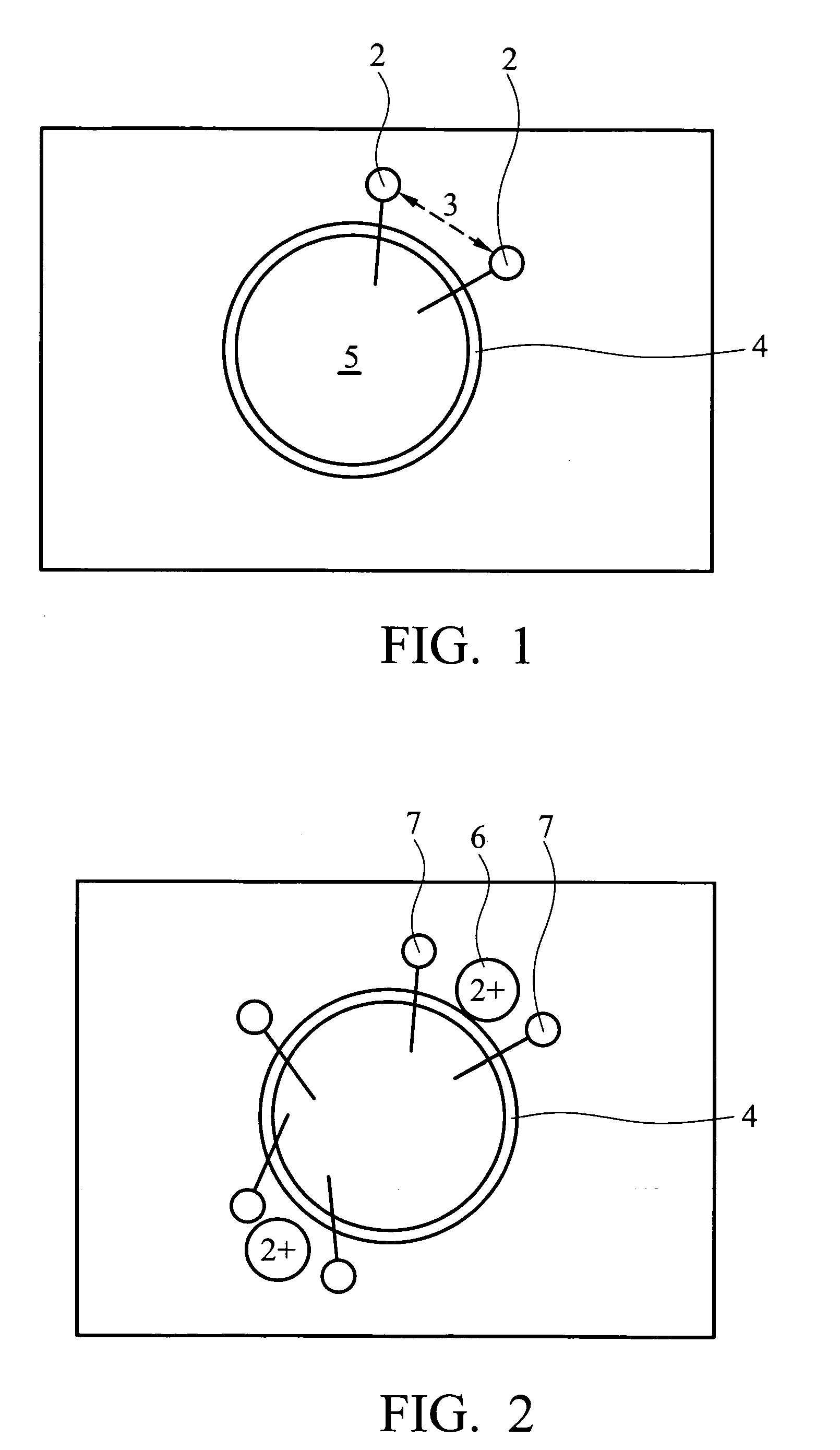

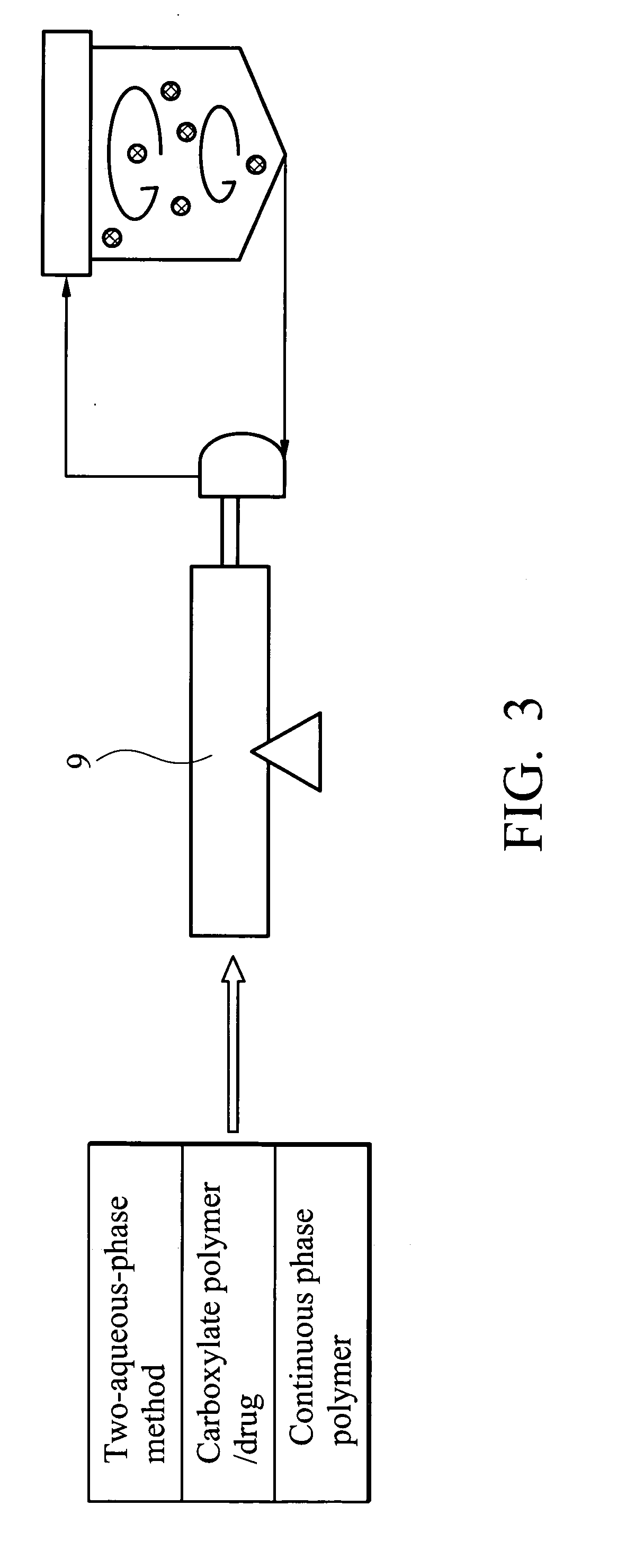

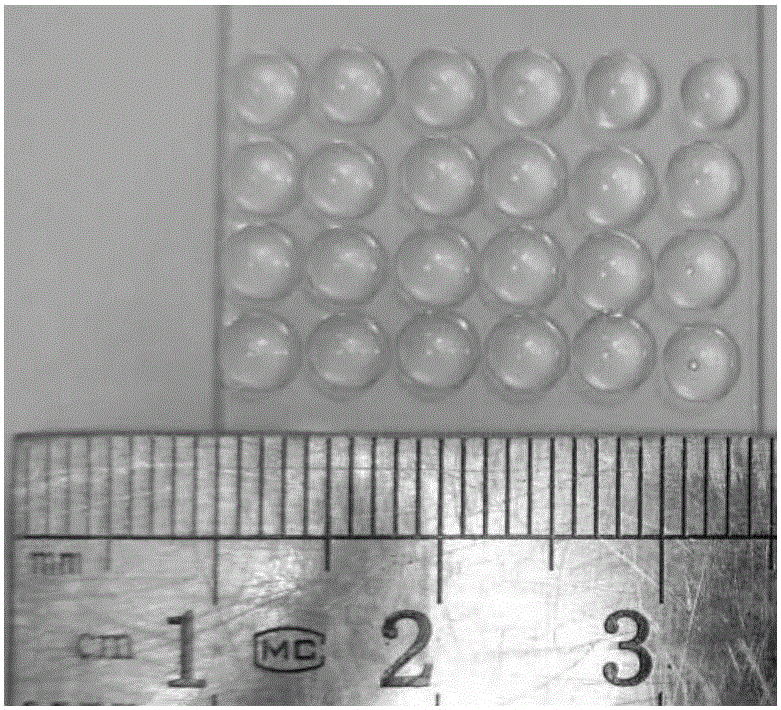

Method for preparing polymeric microsphere by aqueous two phase emulsion process

InactiveUS20050142207A1Improve encapsulationHigh yieldPowder deliveryGranular deliveryPolymer scienceEmulsion

A method for preparing polymeric microsphere by an aqueous two phase emulsion process. A first polymer aqueous solution is provided and the first polymer includes a functional group capable of forming cross-linking. A second polymer aqueous solution is provided, which is acidic and miscible with the first polymer aqueous solution. The first and second polymer aqueous solutions are mixed and stirred to form an emulsion, such that the first polymer solution forms a dispersed phase in a continuous phase of the second polymer solution. The dispersed phase includes a plurality of the first polymeric microsphere, and a solidification film formed by cross-linking of the functional group constitutes a microsphere surface. Finally, the first polymeric microsphere are separated out.

Owner:IND TECH RES INST

Thixotropic epoxy resin, preparation method and application thereof in LED chip packaging

ActiveCN105936815AEasy to prepareProcess parameters are easy to controlEpoxy resin adhesivesSemiconductor devicesPolymer scienceAntioxidant

The invention discloses thixotropic epoxy resin, a preparation method and application thereof in LED chip packaging. The preparation method consists of: (1) weighing bisphenol A epoxy resin, aliphatic epoxy resin, a thixotropic agent fumed silica, an adhesive force promoter, an antioxidant, an ultraviolet absorbent and a defoaming agent, and mixing them evenly to obtain a mixture 1; (2) weighing anhydride, diol, hydroxyl-terminated polybutadiene, and 2, 6-di-tert-butyl-4-methylphenol to carry out reaction to obtain a mixture 2; and (3) mixing the mixture 1 with the mixture 2, adding a phosphine-containing catalyst, and stirring the substances evenly at room temperature, thus obtaining the thixotropic epoxy resin. The method provided by the invention is simple, the technological parameters are easily controllable, and the preparation process does not involve solvent, and is green and environment-friendly. The obtained thixotropic epoxy resin has long storage life and good packaging effect. The thixotropic epoxy resin can be applied in chip packaging, and is especially suitable for chip packaging on a planar substrate, the glue mixing and dispensing process in original technology can be avoided, the production efficiency is high, the rate of finished products is high, and the cost is low.

Owner:TECORE SYNCHEM OPTOELECTRONIC TECH (TIANJIN) CO LTD

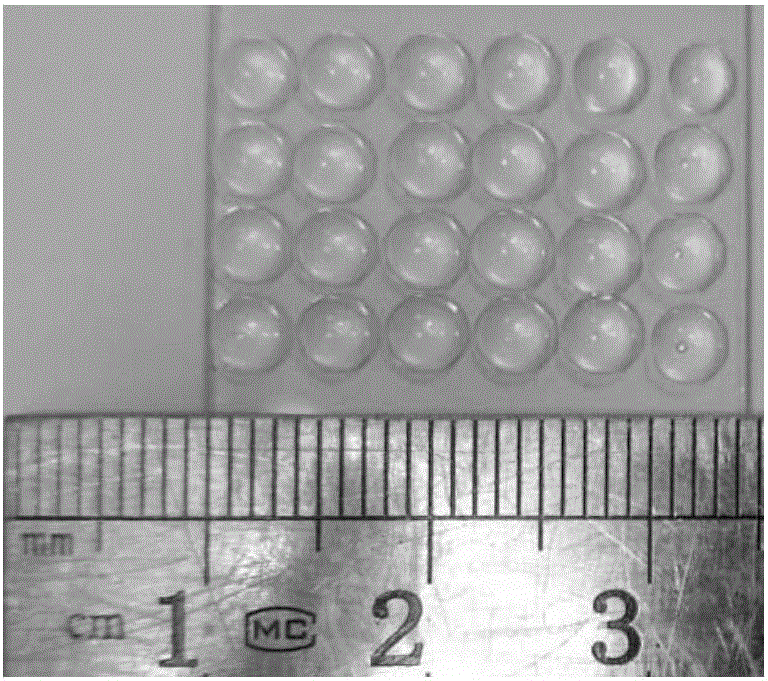

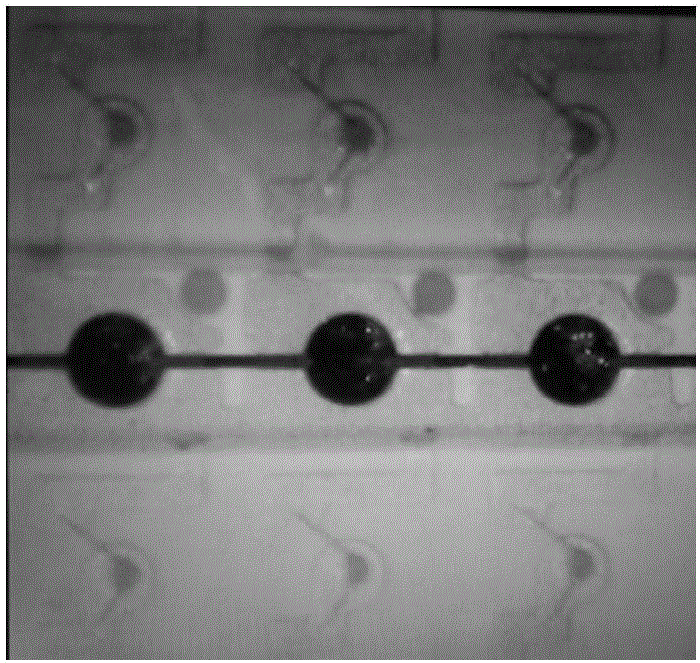

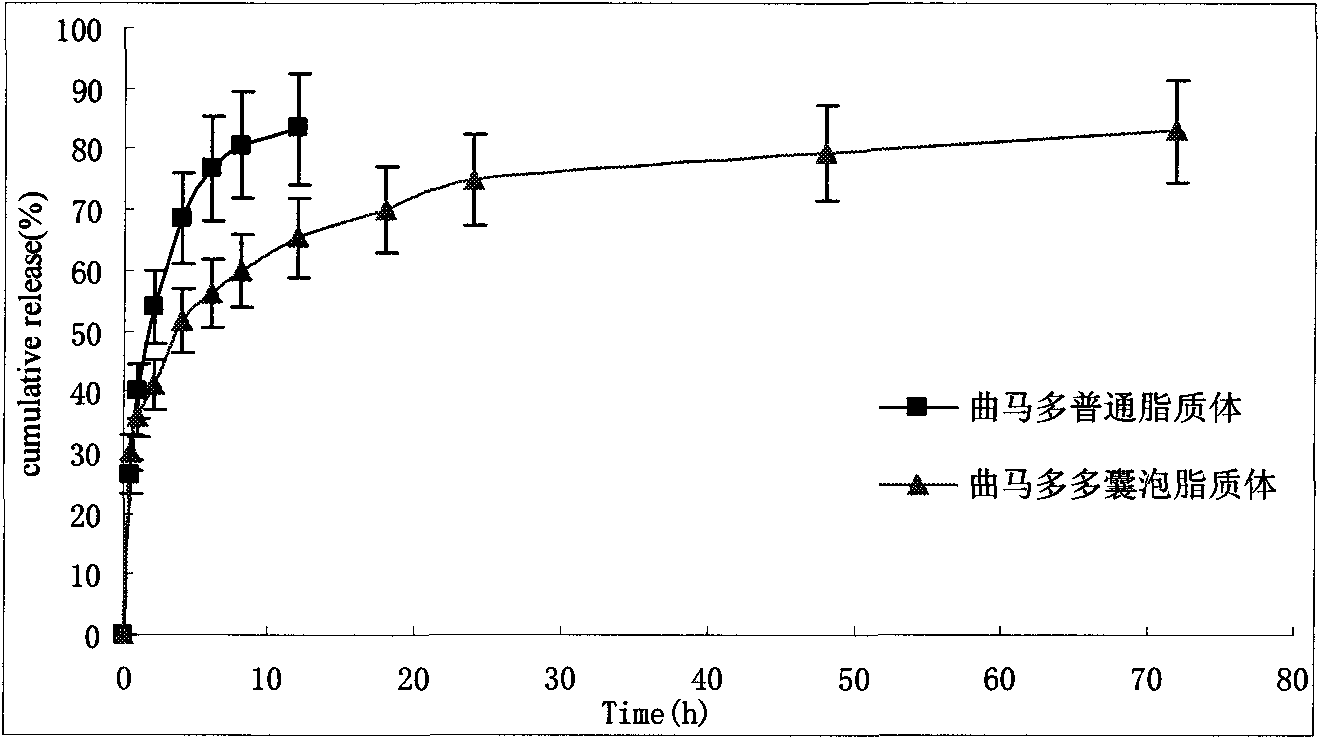

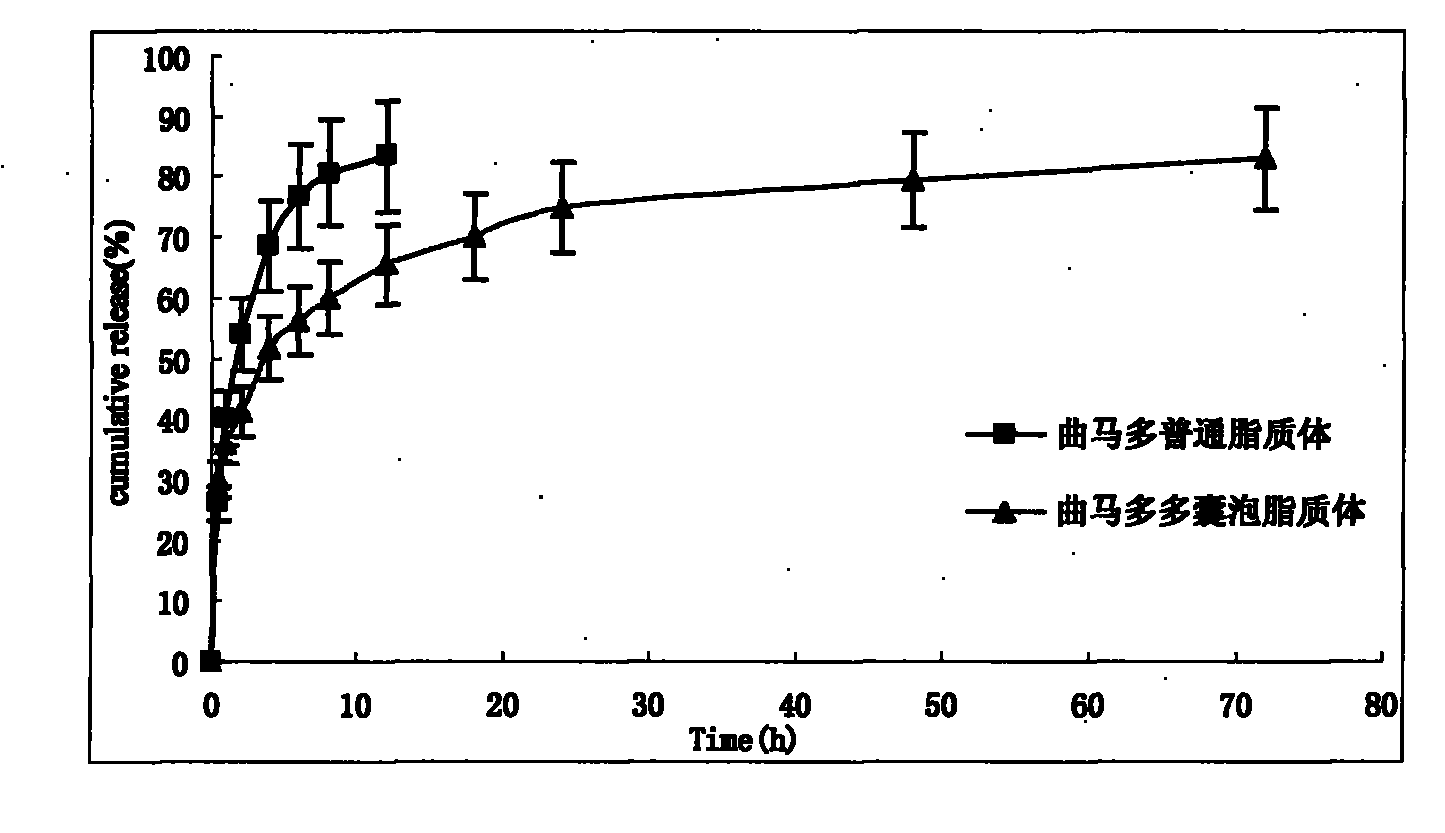

Tramadol multivesicular liposome and preparation method thereof

InactiveCN101780039AFirmly connectedHigh encapsulation efficiencyOrganic active ingredientsNervous disorderCholesterolNitrogen gas

The invention discloses a tramadol multivesicular liposome and a preparation method thereof. The preparation method comprises the following steps of: 1, dissolving phospholipids, cholesterol and neutral lipids into organic solvents to obtain a mixture which serves as an organic phase; 2, preparing 10 to 500mmol / L tramadol solution which serves as an internal water phase; 3, adding the internal water phase with the same volume as that of an organic phase into the organic phase, and mixing and emulsifying the mixture to obtain water-in-oil primary emulsion; 4, preparing an external water phase containing amino acid and osmotic modulators and / or surfactants, and adding the external water phase of which the volume is 2 to 10 times that of the water-in-oil primary emulsion into the water-in-oil primary emulsion, stirring the mixture to form oil-in-water type double emulsion; 5, adding the emulsion into the solution of the amino acid, introducing nitrogen or carbon dioxide into the mixed solution to remove the organic solvent from the emulsion to obtain suspension; 6, dissolving the suspension into the solution of amino acid, centrifuging and taking lower liposome suspension to obtain the tramadol multivesicular liposome. The prepared tramadol multivesicular liposome has the advantages of higher encapsulation efficiency, good slow release effect, and longer analgesic effect.

Owner:NANJING HAILING TRADITIONAL CHINESE MEDICINE RES CO LTD +2

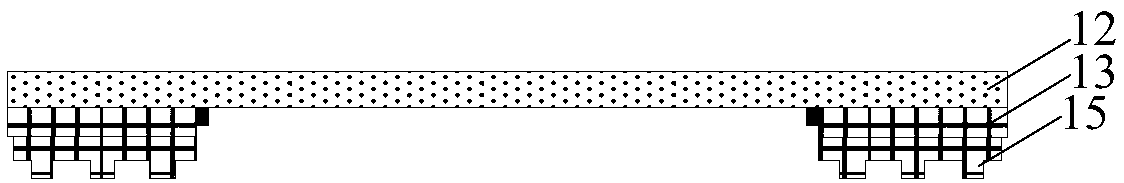

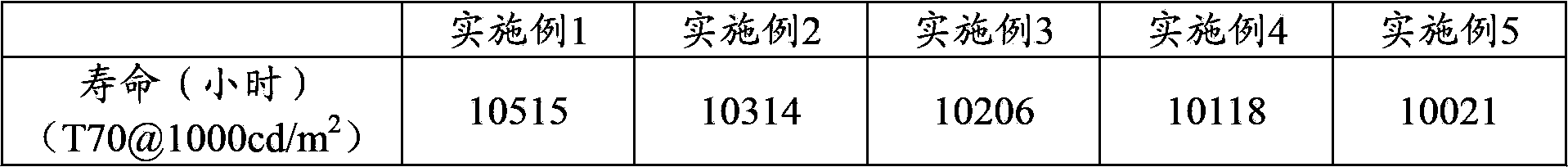

Thin film-packaged OLED screen body and preparation method thereof

ActiveCN105470284AAvoid breakingFit tightlySolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsPellicle membrane

The invention relates to a thin film-packaged OLED screen body and a preparation method thereof. The thin film-packaged OLED screen body comprises a conductive substrate and a thin film package layer, wherein an organic functional layer is arranged in an airtight space formed by the conductive substrate and the thin film package layer; second electrode layers are arranged at the upper part of the organic functional layer; the adjacent second electrode layers are insulated with each other; a flatten layer is arranged between the thin film package layer and the second electrode layer; a continuous plane structure is formed at one side, far away from the second electrode layers, of the flatten layer; and the thin film package layer is attached to the continuous plane structure. The thin film package layer is formed at one side, opposite to a continuous plane, of the flatten layer, so that the thin film package layer can be tightly attached to the flatten layer; the thickness uniformity is good; the packaging effect is good; and the thin film package layer cannot be easily damaged.

Owner:GUAN YEOLIGHT TECH CO LTD

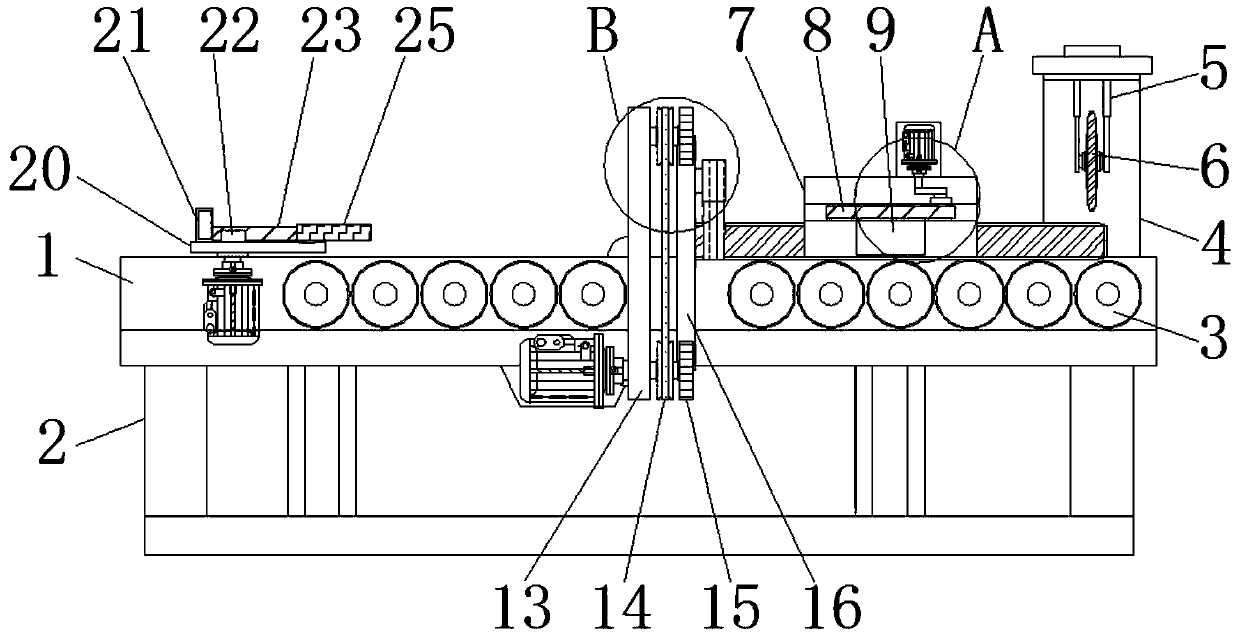

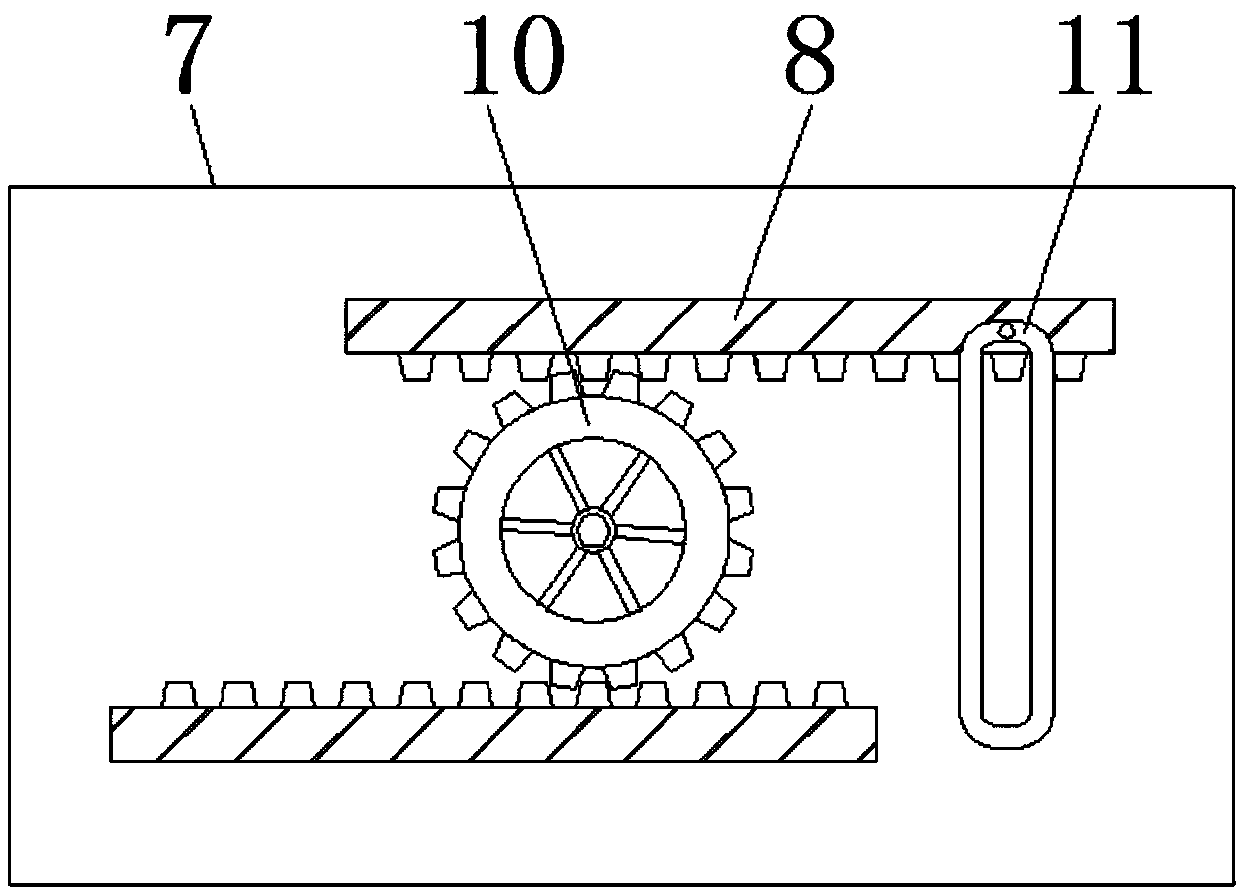

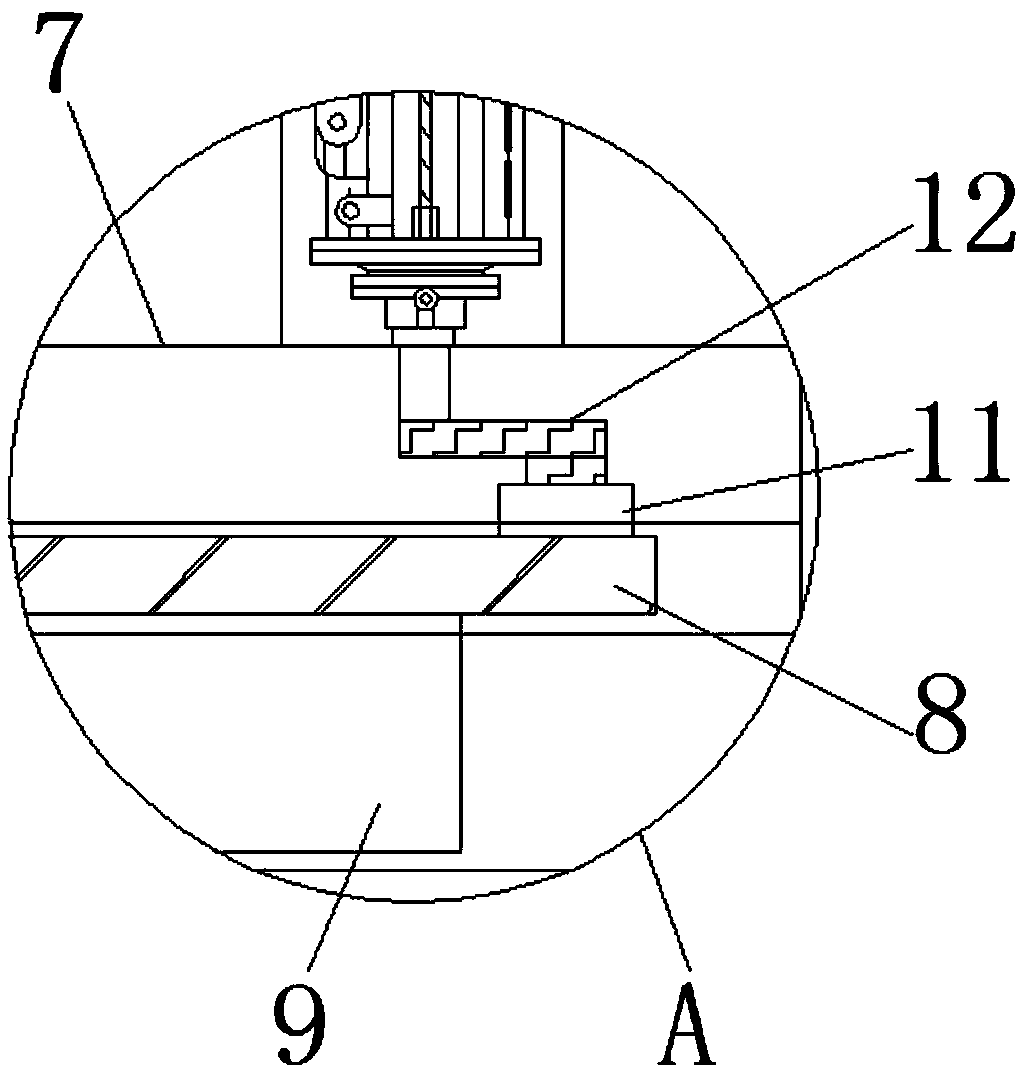

Machining and packing mechanism facilitating polishing

PendingCN109250173AHigh degree of automationImprove processing efficiencyWeb rotation wrappingShearing machinesEngineeringMachining

The invention discloses a machining and packing mechanism facilitating polishing. The machining and packing mechanism facilitating polishing comprises a working table, wherein a bottom rack is fixedlymounted at the lower end of the working table; the right side of the upper surface of the working table is fixedly connected with a first supporting rack in a welded manner; a cutting plate is movably connected between a telescopic rod and the inner side of the lower end of the telescopic rod; a second supporting rack is arranged on the left side of the first supporting rack; movable plates are separately movably connected to the front side and the rear side of the inside of the second supporting rack; a driving plate is connected between the movable plates in an engaged manner; the upper surface of each movable plate is fixedly connected with a limiting block; a fixed plate is fixedly mounted in the middle of the working table in a connected manner; the right side of a conveying roll iscoaxially connected with a first gear plate. According to the machining and packing mechanism facilitating polishing, a polishing device can polish several surfaces of a product simultaneously, manualsealing or packing is not required, the packing effect is good, and the machining and packing mechanism facilitating polishing is provided with a device which automatically transfers the product froma conveying device.

Owner:ZHEJIANG DONGXIN MASCH CO LTD

OLED device and packaging method and packaging device thereof

ActiveCN104538562AHigh light transmittanceHigh ultra-thin and flexibleSynthetic resin layered productsSolid-state devicesDevice formTransmittance

The invention provides an OLED device and a packaging method and a packaging device thereof. The OLED device formed on a substrate base plate is packaged by using the packaging method. The packaging method comprises the following steps that grapheme film formed on copper foil is separated from the copper foil, and the grapheme film is used for packaging the OLED device. The packaging method can give full play to the grapheme film characteristic of being high in light transmittance, thin and flexible, high in water and oxygen isolation degree, and prone to being transferred among substrates which means the grapheme film is easy to be separated from the copper foil and connected with the OLED device; through introducing the grapheme film into the OLED device packaging, not only is the packaging effect of the OLED device improved, but also the packaging technology of the OLED device is simplified, and the production efficiency is improved.

Owner:BOE TECH GRP CO LTD +1

Organic electroluminescent device and method for producing same

InactiveCN103811668AHigh bonding strengthStop erosionSolid-state devicesSemiconductor/solid-state device manufacturingFlat glassOrganic electroluminescence

The invention provides an organic electroluminescent device comprising an anode conductive substrate, a functional layer, a luminescent layer, a cathode layer, a protective layer, and an encapsulating layer. The encapsulating layer comprises an insulating layer, metallic layers, and plate glass. The insulating layer is arranged in a surrounding manner along the edge of the top surface of the anode conductive substrate. A groove is surrounded by the insulating layer surrounding structure. The functional layer, the luminescent layer, the cathode layer, and the protective layer are successively extended from the top surface of the anode conductive substrate to the groove. The metallic layers are disposed on the top surface of the insulating layer and a gap is arranged between the metallic layers and the functional layer, the luminescent layer, the cathode layer, and the protective layer. The sum of heights of the insulating layer and the metallic layers is more than that of the functional layer, the luminescent layer, the cathode layer, and the protective layer. The plate glass is disposed on the top surfaces of the metallic layers. The invention also provides a method for producing the organic electroluminescent device. The method effectively reduces erosion, caused by moisture and oxygen, on the device, and substantially prolongs the service life of the device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

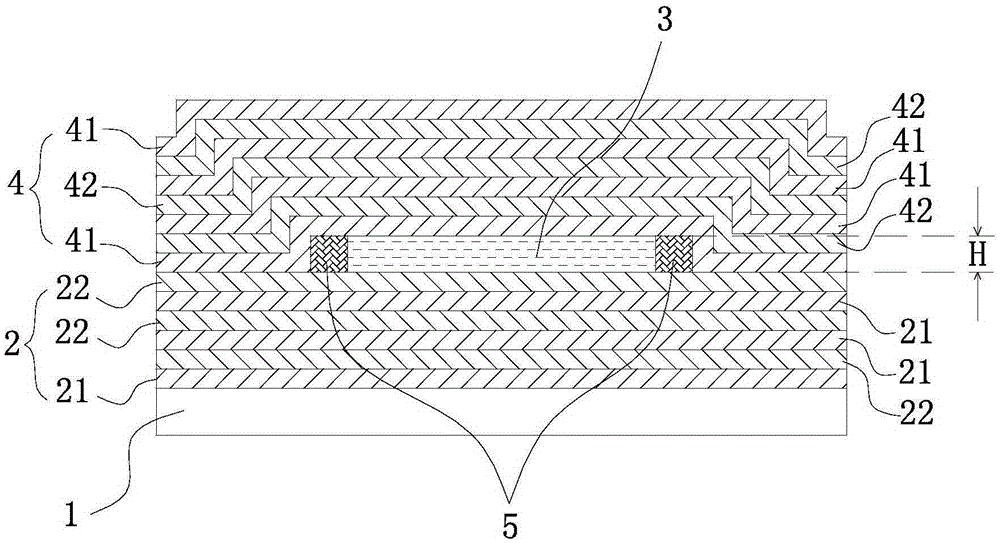

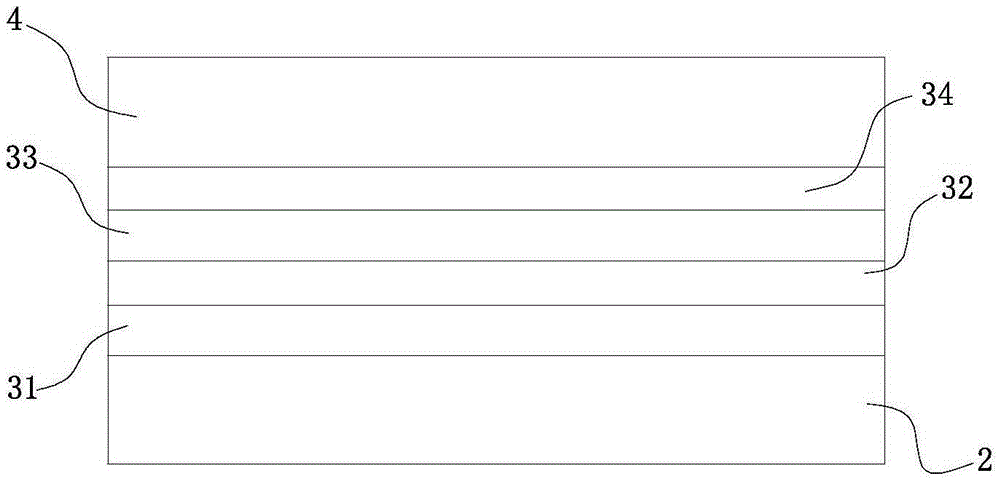

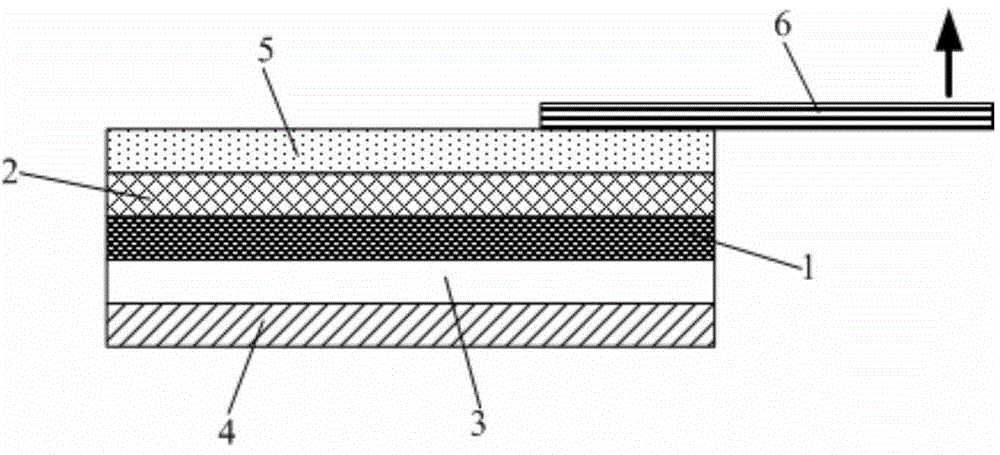

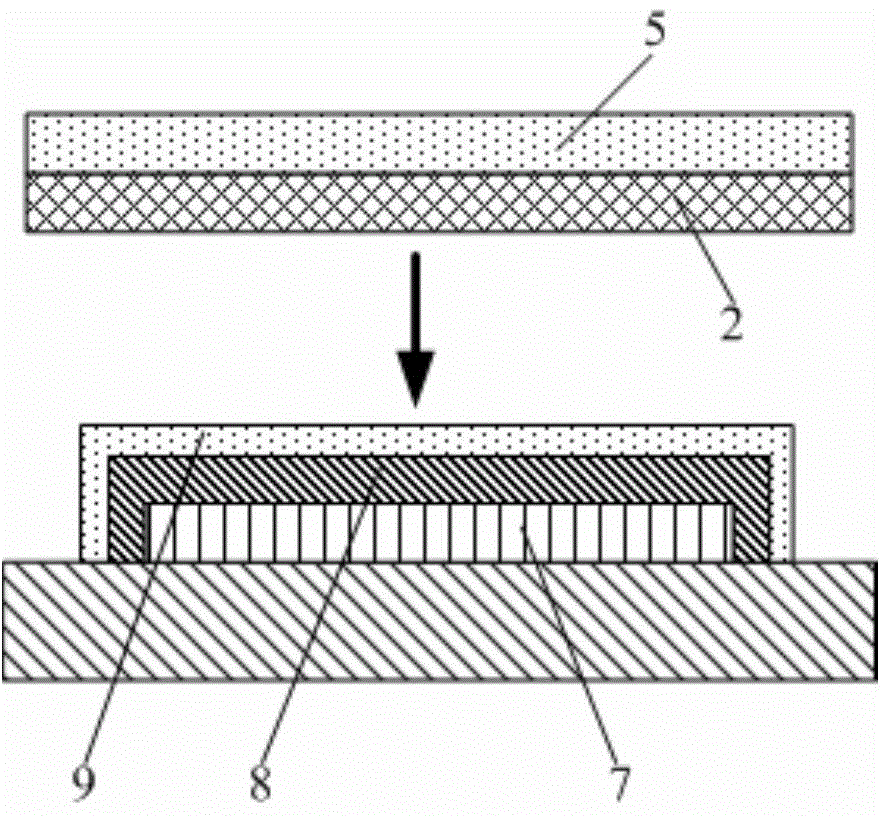

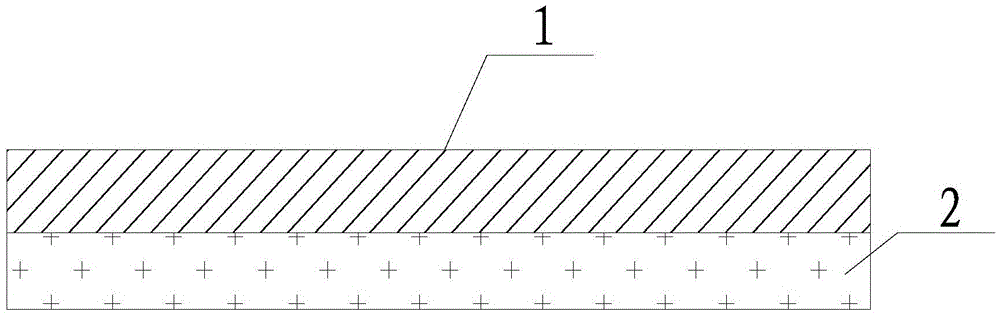

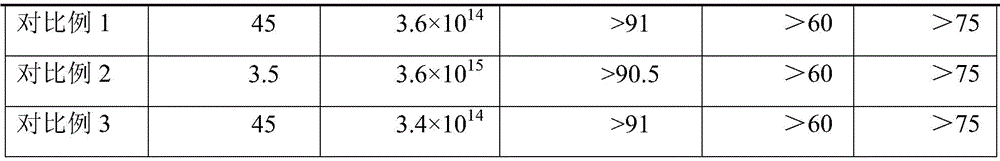

Laminated packaging film for solar cell and solar cell module with packaging film

ActiveCN105619986AImprove encapsulationImprove water vapor barrier performanceSynthetic resin layered productsPhotovoltaic energy generationPolyvinyl butyralElastomer

The invention relates to a laminated packaging film for a solar cell and a solar cell module with the packaging film. The laminated packaging film comprises a first resin layer and a second resin layer formed on any surface of the first resin layer, wherein the first resin layer is a poly(ethylene-vinyl acetate) layer or a polyvinyl butyral layer or an ionomer layer or a polyurethane layer, and the second resin layer is a polyolefin elastomer layer. As the first resin layer and the second resin layer are arranged in a stacked mode and made of different materials, and the second resin layer is a polyolefin elastomer layer, the packaging film has a good packaging function, and meanwhile the packaging film can be endowed with a high vapor barrier property, a low moisture ratio, high insulativity, PID resistance and other functions; in addition, the packaging film is low in cost and easy to popularize.

Owner:CYBRID TECHNOLOGIES INC

Display panel

ActiveCN109920937AExtended service lifePrevent intrusionSolid-state devicesSemiconductor/solid-state device manufacturingWater vaporEngineering

An embodiment of the invention discloses a display panel. The display panel comprises a substrate, at least one retaining wall, a light-emitting device and a packaging layer, wherein the substrate comprises a display area and a non-display area; the retaining wall is arranged on one side of the substrate, is positioned in the non-display area, and is arranged around the display area; the light-emitting device and the retaining wall are arranged on the same side of the substrate and are located in the display area; the packaging layer covers the retaining wall and the light-emitting device, wherein each retaining wall comprises at least two layers of blocking structures, wherein the blocking structure farthest from the packaging layer is coated by at least one of the other blocking structures, and then the invasion path of water oxygen between blocking structure film layers of the retaining wall is further prolonged, so that water vapor and oxygen are difficult to enter the display areaof the display panel between the barrier structure film layers of the retaining wall, the packaging effect of the display panel is improved, water vapor and oxygen are difficult to corrode the light-emitting device, and the service life of the display panel is prolonged.

Owner:YUNGU GUAN TECH CO LTD

EMI protection chip packaging structure and packaging method

PendingCN107248509AAvoid curlLow costSemiconductor/solid-state device detailsSolid-state devicesMetalSemiconductor chip

The invention provides an EMI protection chip packaging structure and an EMI protection chip packaging method. The structure comprises a rewiring layer comprising a first plane and a second plane opposite to each other; a metal lug formed on the first plane of the rewiring layer; a semiconductor chip electrically connected with the second plane of the rewiring layer; an electromagnetic shielding frame formed on the second plane of the rewiring layer and arranged around the semiconductor chip; packaging material covered on the semiconductor chip and the electromagnetic shielding frame, wherein he surface of the packaging material is exposed out of the electromagnetic shielding frame; and an electromagnetic shielding layer formed on the surface of the packaging material. According to the packaging structure provided by the invention, the fan-out type packaging structure is used for achieving electromagnetic shielded packaging, the used packaging material is the same as or similar to the material of the rewiring layer, so that CTE mismatch therebetween is lowered, and crack probability is reduced; the packaging structure has relatively high integration level, better packaging performance, and wide application prospects in the field of semiconductor packaging.

Owner:SJ SEMICON JIANGYIN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com