Thin film-packaged OLED screen body and preparation method thereof

A thin-film encapsulation and electrode layer technology, which is used in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

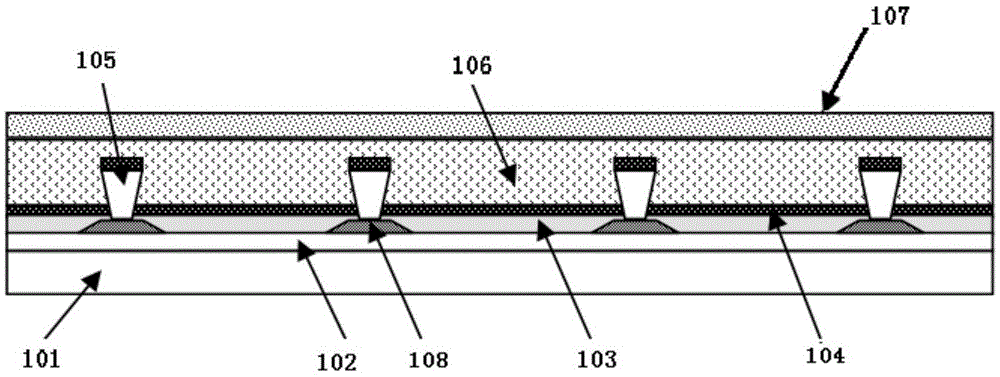

[0047] Such as figure 1 As shown, the thin-film-encapsulated OLED screen body of this embodiment includes a substrate 101 and a first electrode layer 102 (anode) disposed on the substrate 101, and several electrodes forming a continuous grid are arranged on the first electrode layer 102. The pixel definition layer 108 of the structure, the organic functional layer 103 is filled in the grid structure, the isolation column 105 is arranged above the pixel definition layer 108, and the second electrode on the adjacent organic function layer 103 is connected by the isolation column 105 Layers 104 (the cathodes) are insulated from each other. The shown organic functional layer 103 includes a stacked hole injection layer, a hole transport layer, a light emitting layer, an electron transport layer and an electron injection layer, wherein the hole injection layer, the hole transport layer, the electron transport layer and the electron injection layer One or more layers may be omitted....

Embodiment 2

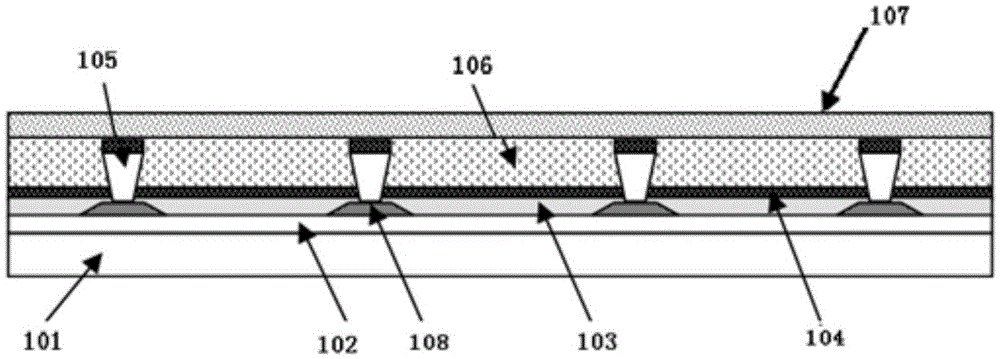

[0056] Such as figure 2 As shown, the structure of the film-encapsulated OLED screen of this embodiment is the same as that of Embodiment 1, wherein the planarization layer 106 is filled between the spacers 105, and its upper end and the top of the spacer 105 jointly form a continuous planar structure. The thin film encapsulation layer 107 is attached and disposed on the continuous planar structure.

[0057] Its preparation method is the same as that of the film-encapsulated OLED screen of Example 1, wherein step S3 is:

[0058] A planarization layer 106 is formed by evaporating an inorganic material above the second electrode layer 104, and the planarization layer 106 is filled between the isolation columns, and its upper end and the upper end of the isolation columns jointly form a continuous planar structure; or by printing The planarization layer 106 made of organic material is prepared by means of , silk printing, thermal deposition, etc., and its upper end and the uppe...

Embodiment 3

[0062] Such as figure 1 As shown, the structure of the thin-film-encapsulated OLED panel of this embodiment is the same as that of Embodiment 1, wherein the planarization layer 106 and the thin-film encapsulation layer 107 are an integrated structure made of polyhydrogensilazane materials. The molecular formula of silazane materials such as [SiH 2 NH], this type of material is prepared on the second electrode layer by wet coating or screen printing, and the polyhydrogensilazane type material reacts with moisture and oxygen in the air to form a cured film to form an integrated structure planarization layer 106 . After that, SiN or SiO is deposited by CVD as the thin film encapsulation layer 107 .

[0063] The mechanism of the reaction of silazane with water and oxygen is as follows, and the final buffer material is a silicon dioxide layer.

[0064] -[SiH 2 NH] n -+O 2 → SiO 2 +NH 3

[0065] and

[0066] -[SiH 2 NH] n -+H 2 O→SiO 2 +NH 3 +H 2

[0067] The prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com