Patents

Literature

98 results about "Thermal deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

One of the common methods of Physical Vapor Deposition (PVD) is Thermal Evaporation. This is a form of Thin Film Deposition, which is a vacuum technology for applying coatings of pure materials to the surface of various objects. The coatings, also called films,...

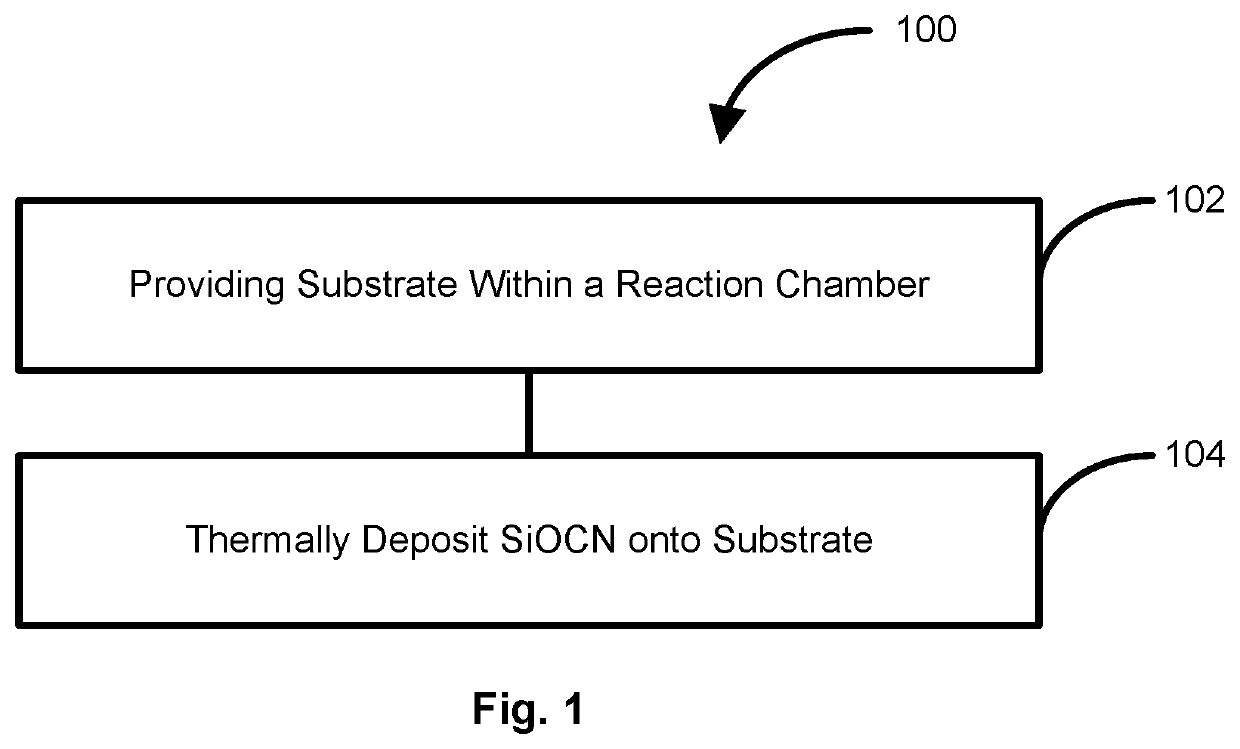

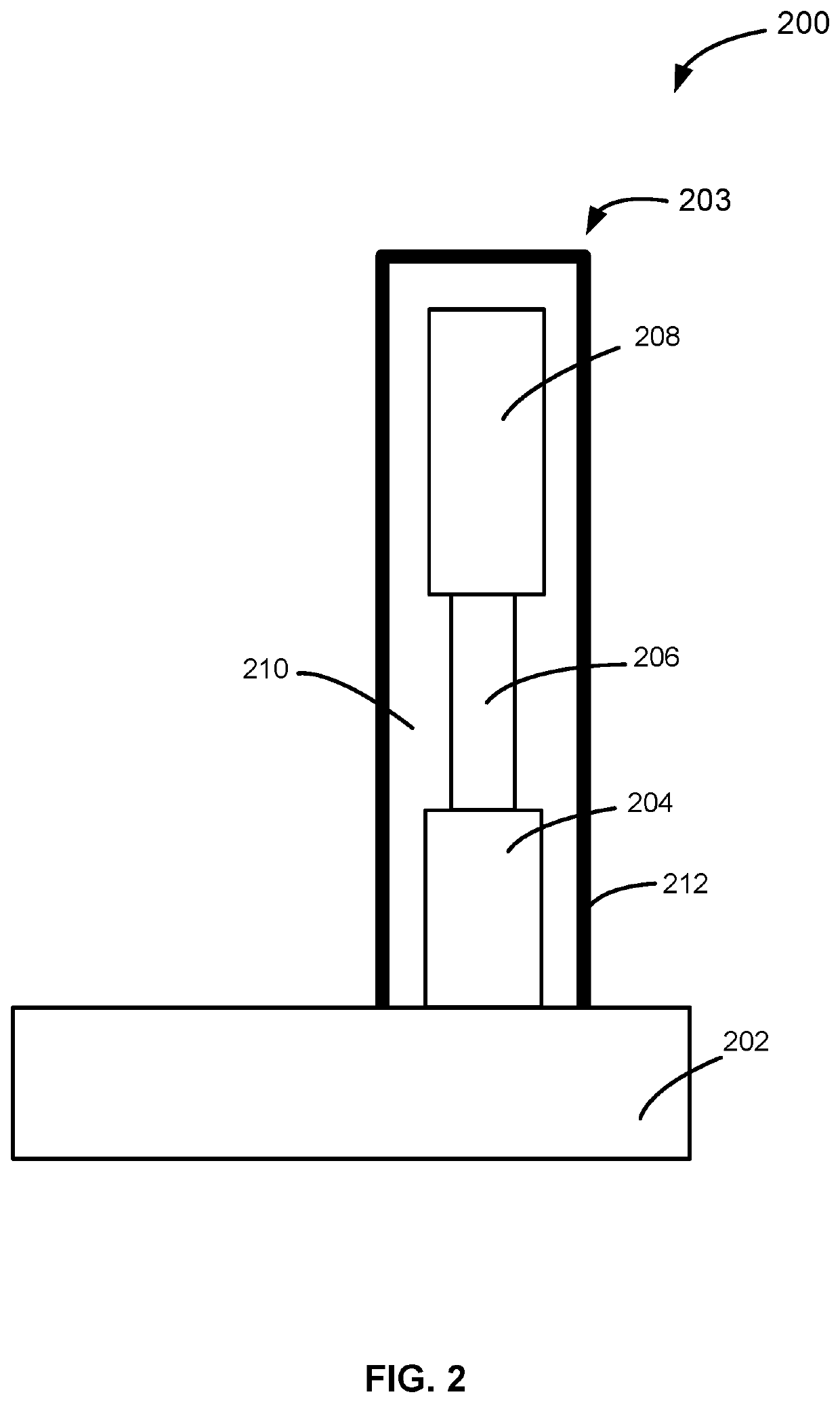

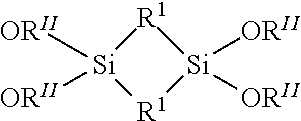

STRUCTURE INCLUDING SiOCN LAYER AND METHOD OF FORMING SAME

ActiveUS20200283893A1Manufactured usingDesired propertySemiconductor/solid-state device manufacturingChemical vapor deposition coatingThermal depositionEngineering

A method for forming a layer comprising SiOCN on a substrate is disclosed. An exemplary method includes thermally depositing the layer comprising SiOCN on a surface of the substrate. The layer comprising SiOCN can be used for various applications, including spacers, etch stop layers, and etch resistant layers.

Owner:ASM IP HLDG BV

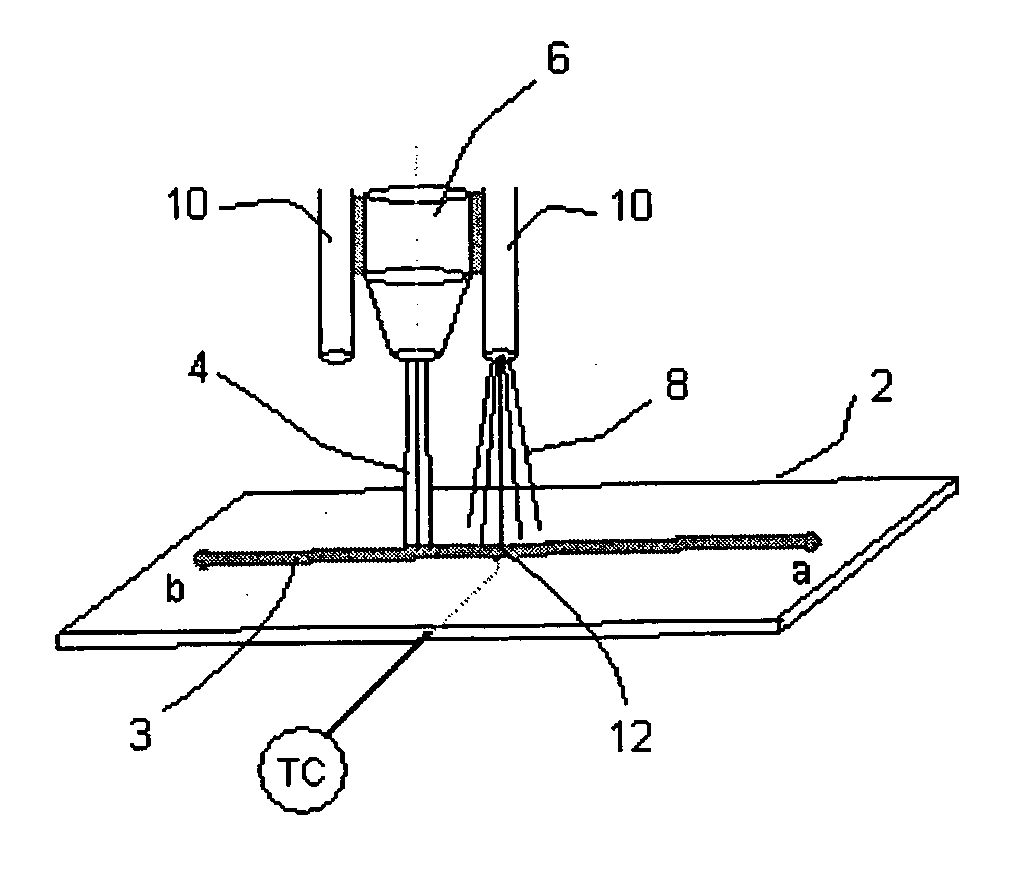

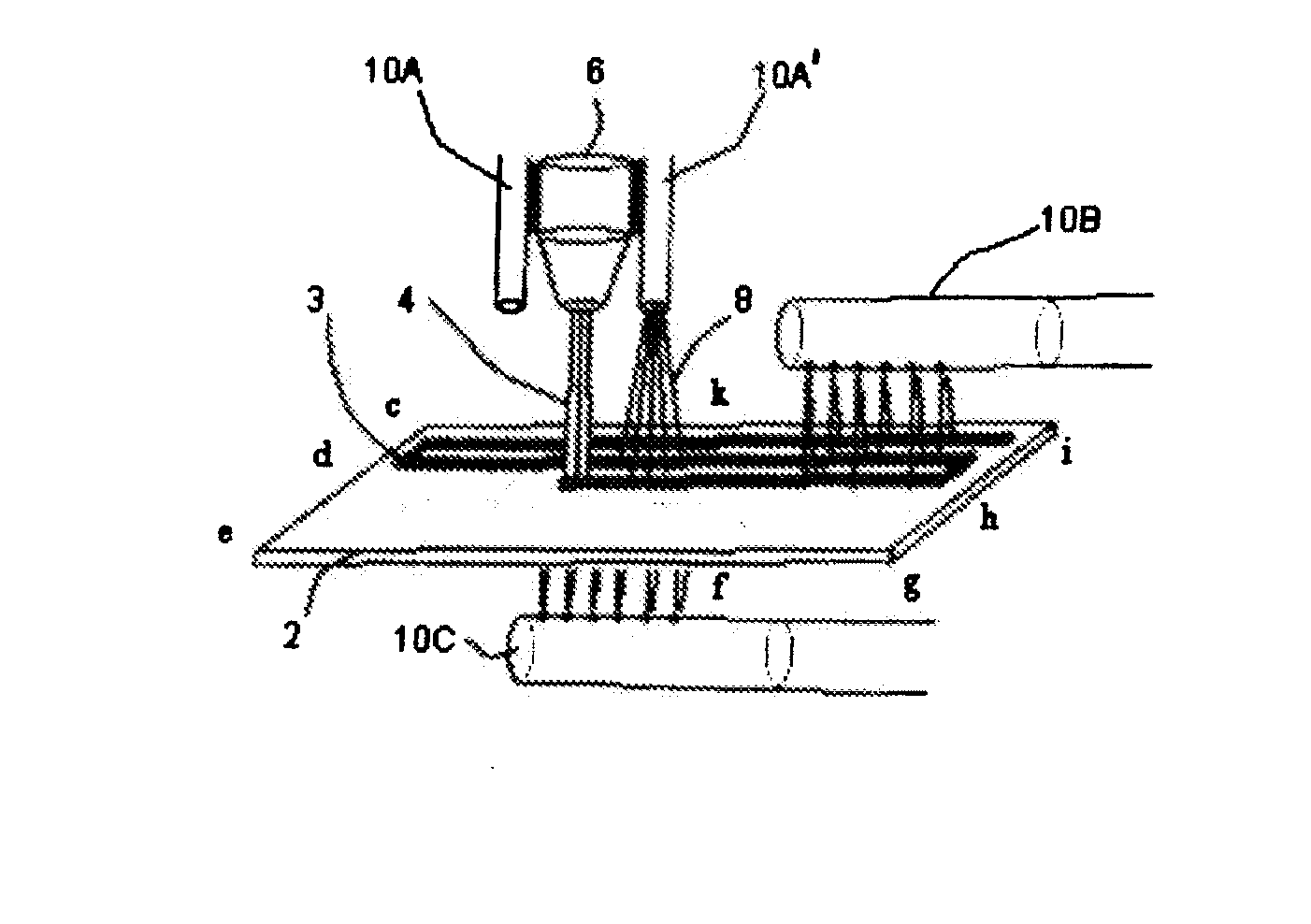

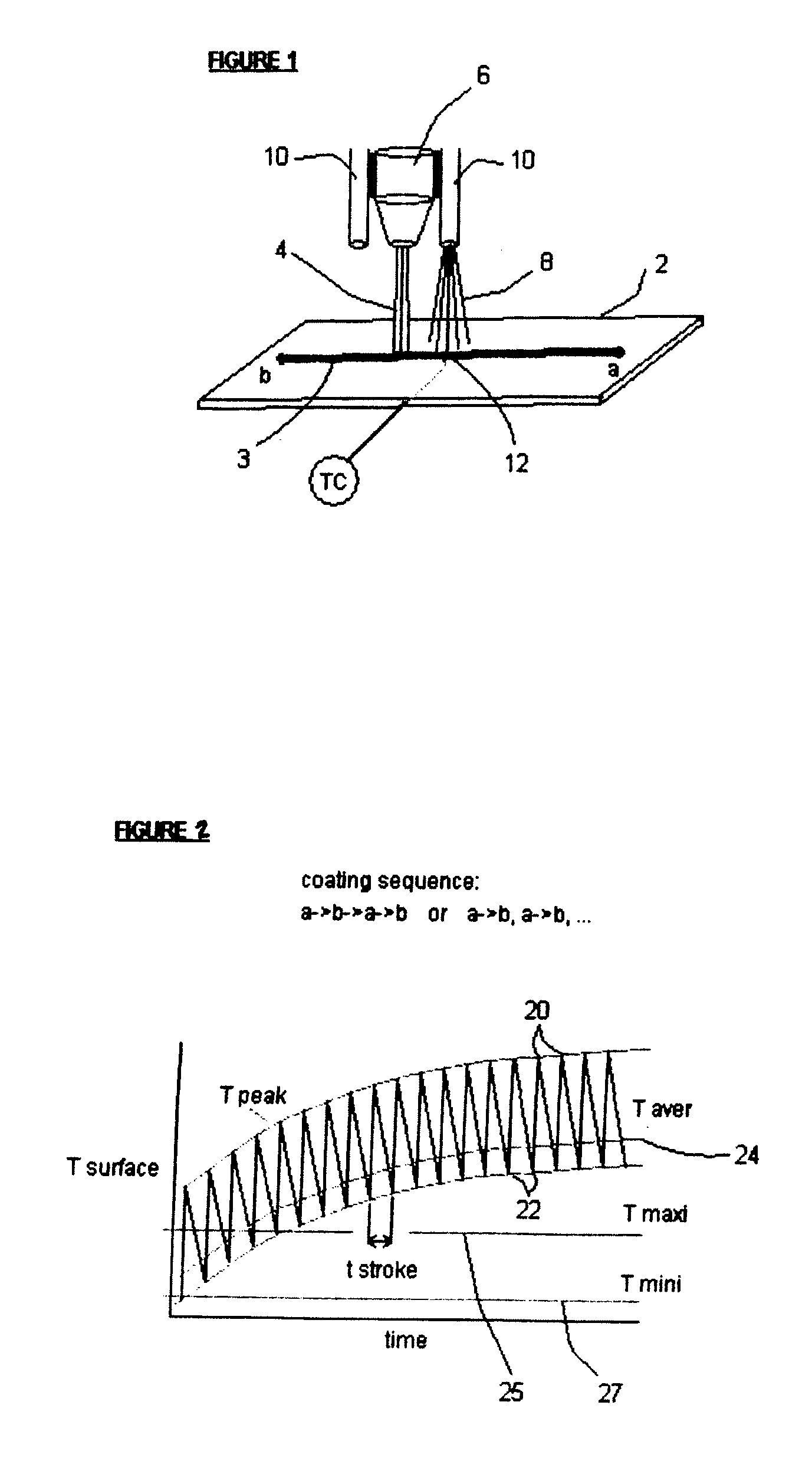

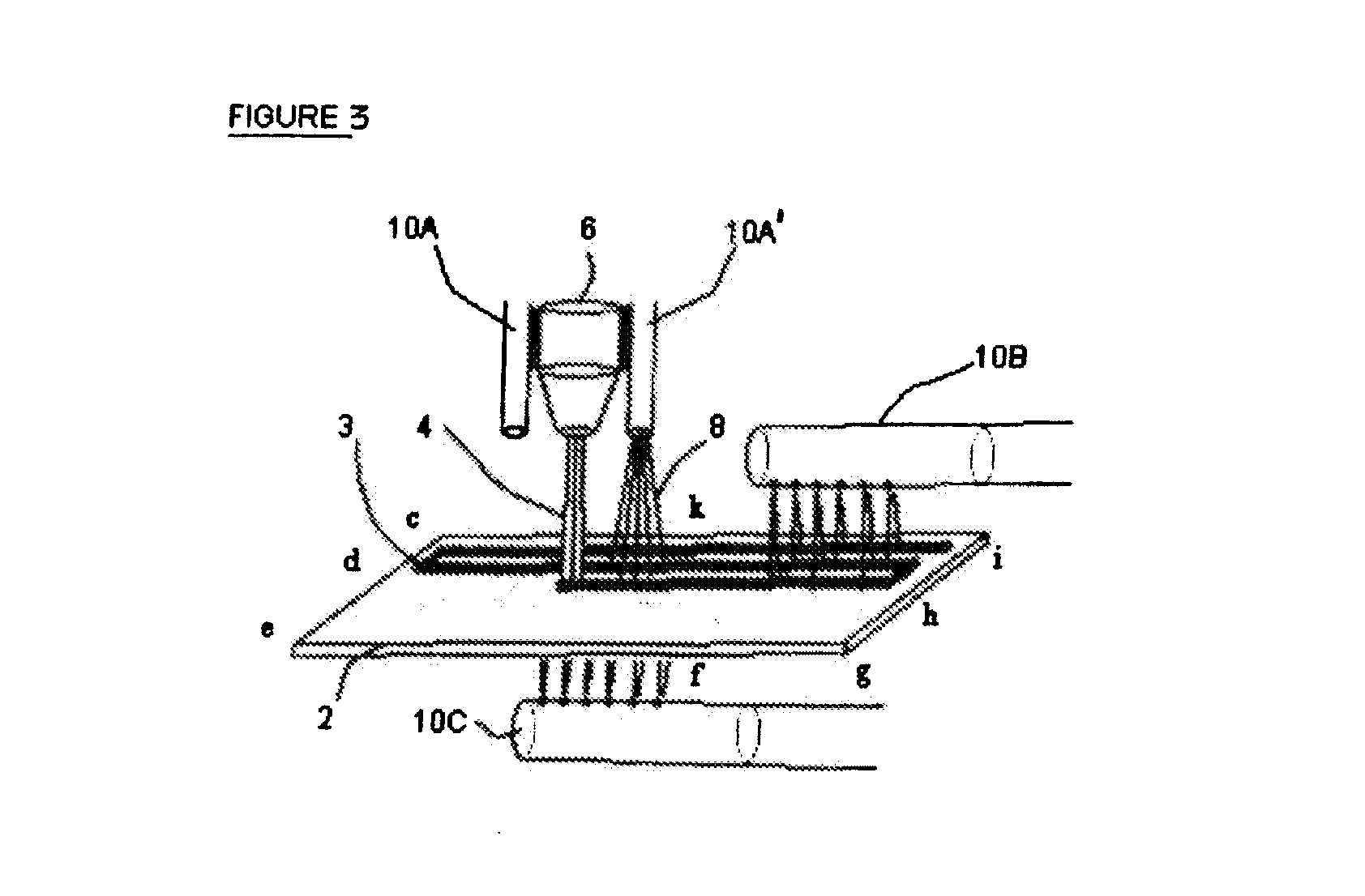

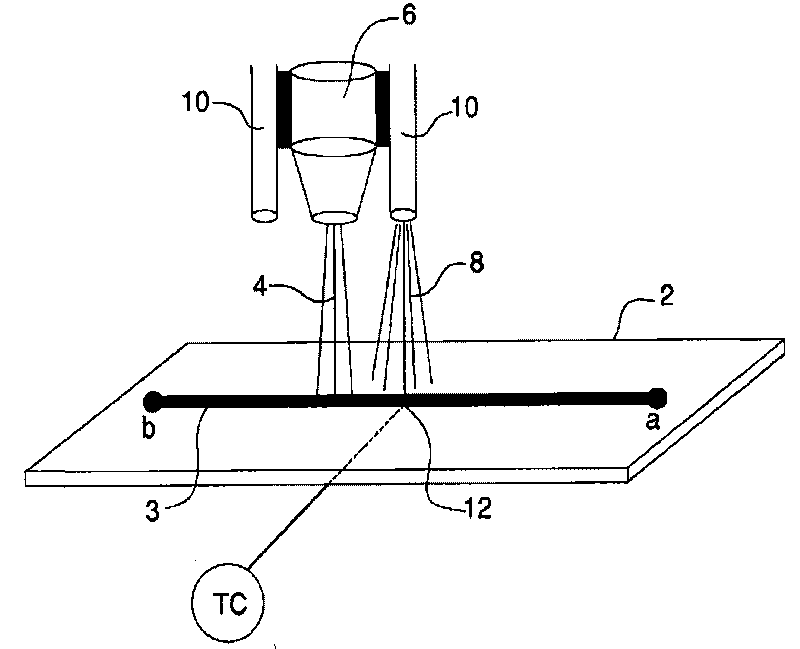

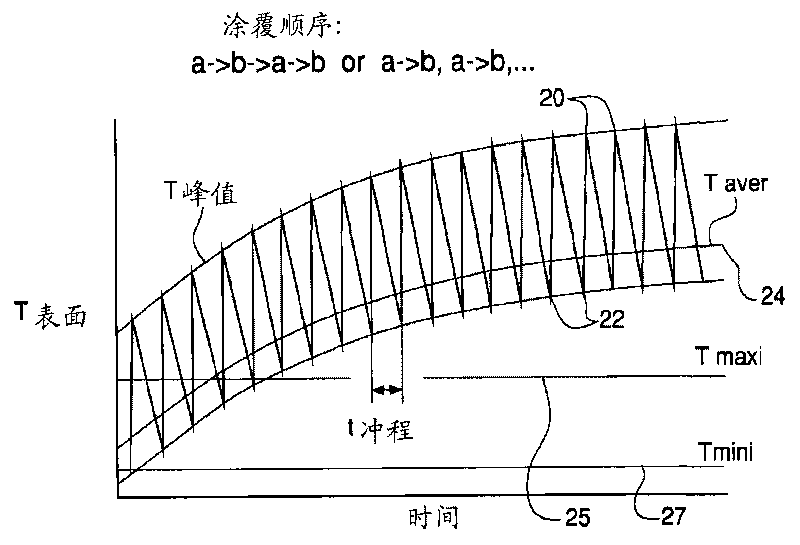

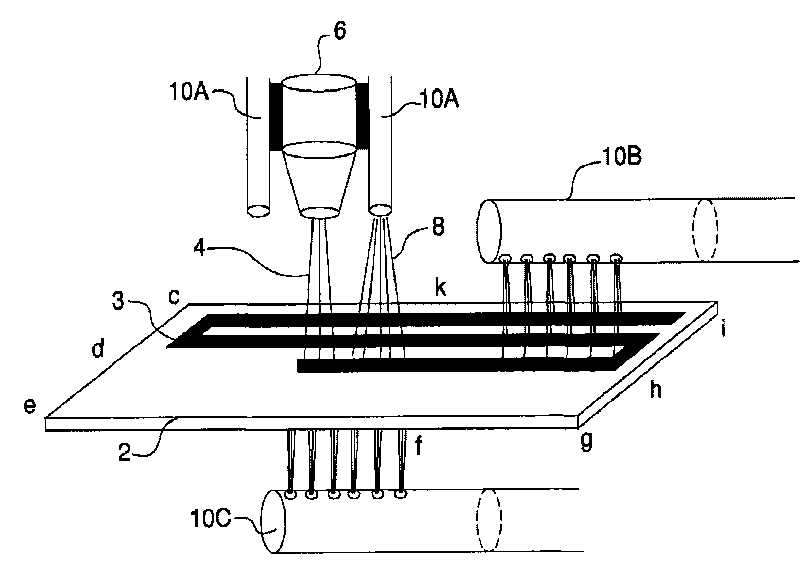

Thermal deposition coating method

ActiveUS20060228465A1Excellent coating production rateDamaging internal stressLiquid surface applicatorsMolten spray coatingThermal depositionRelative motion

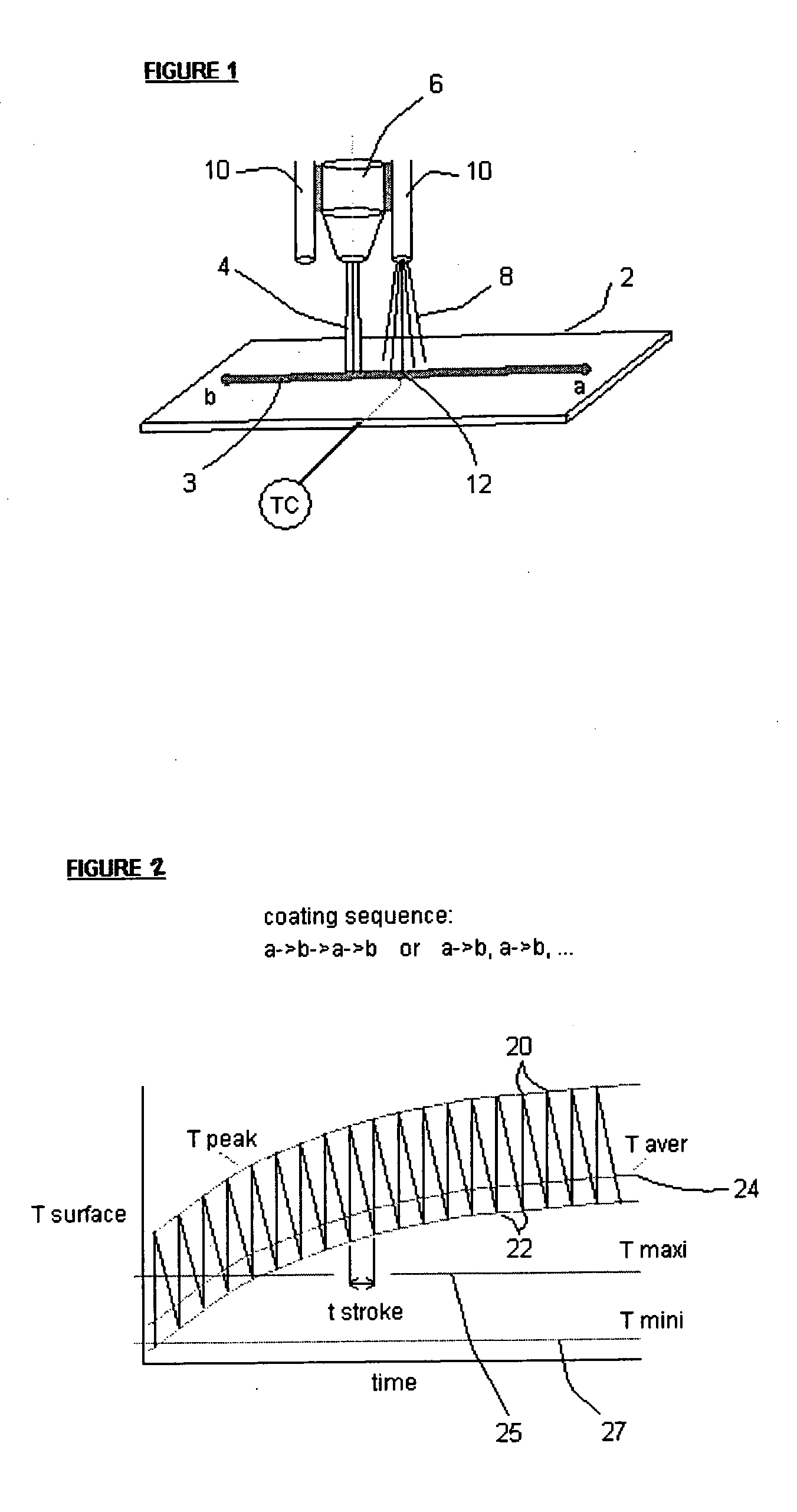

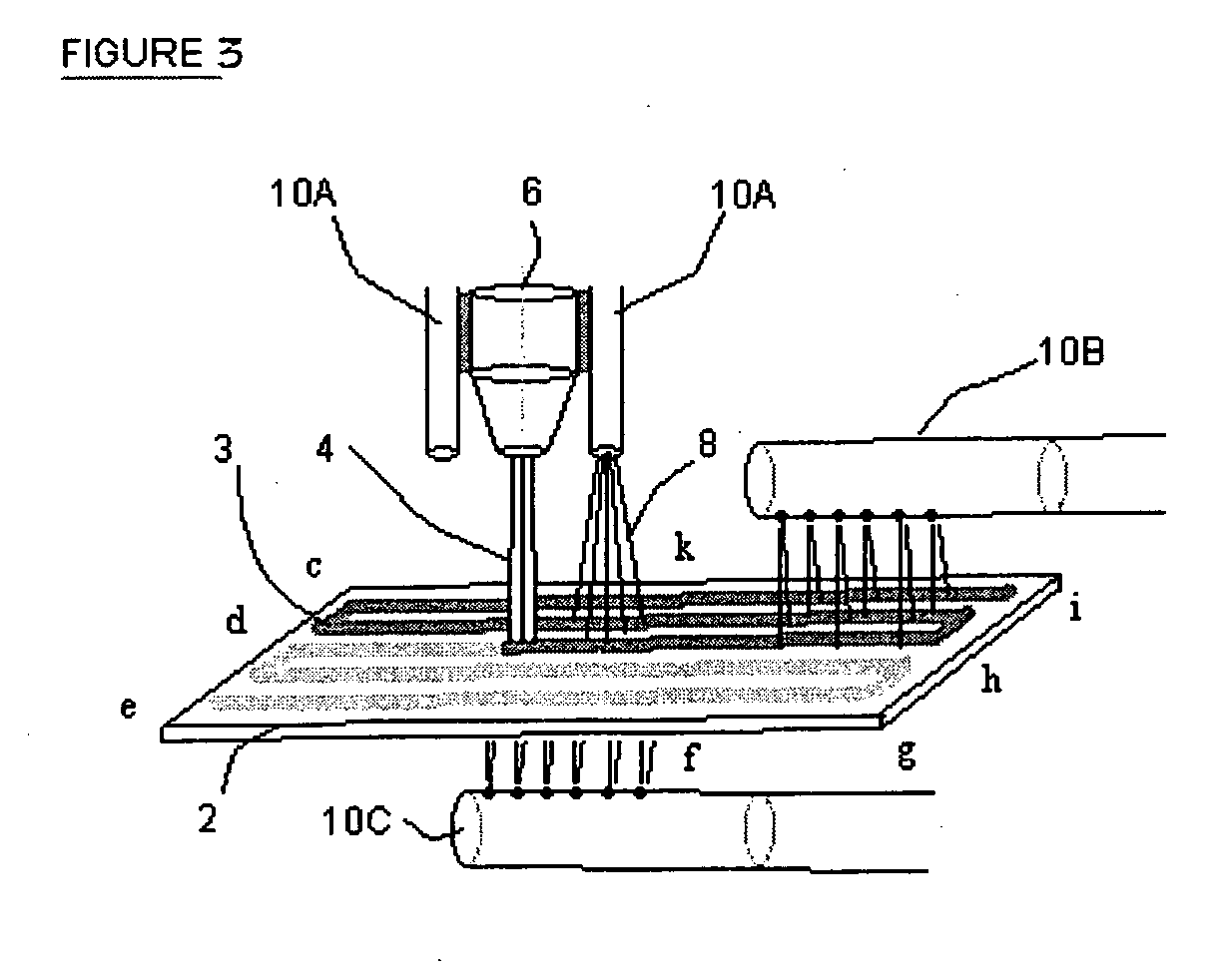

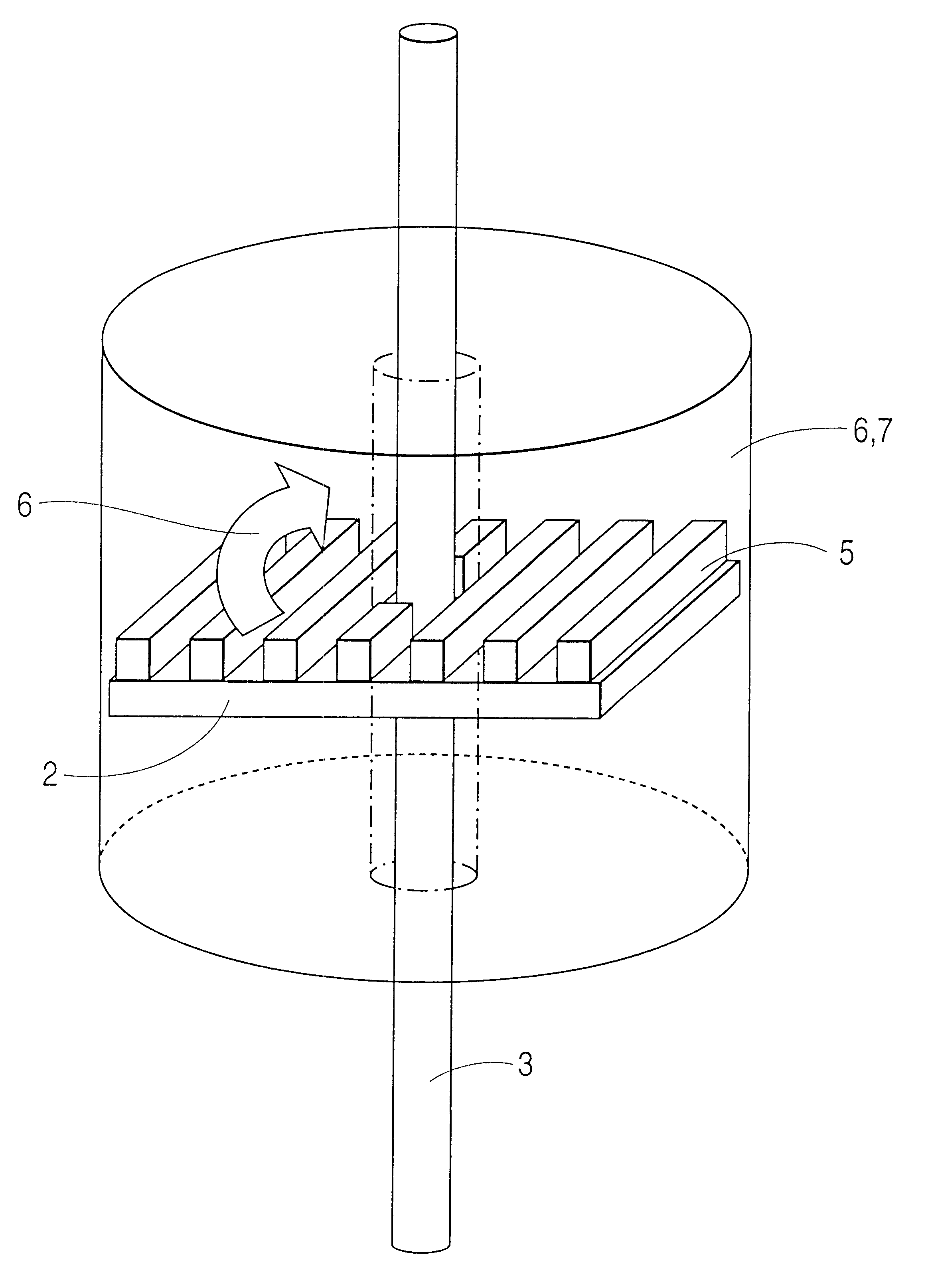

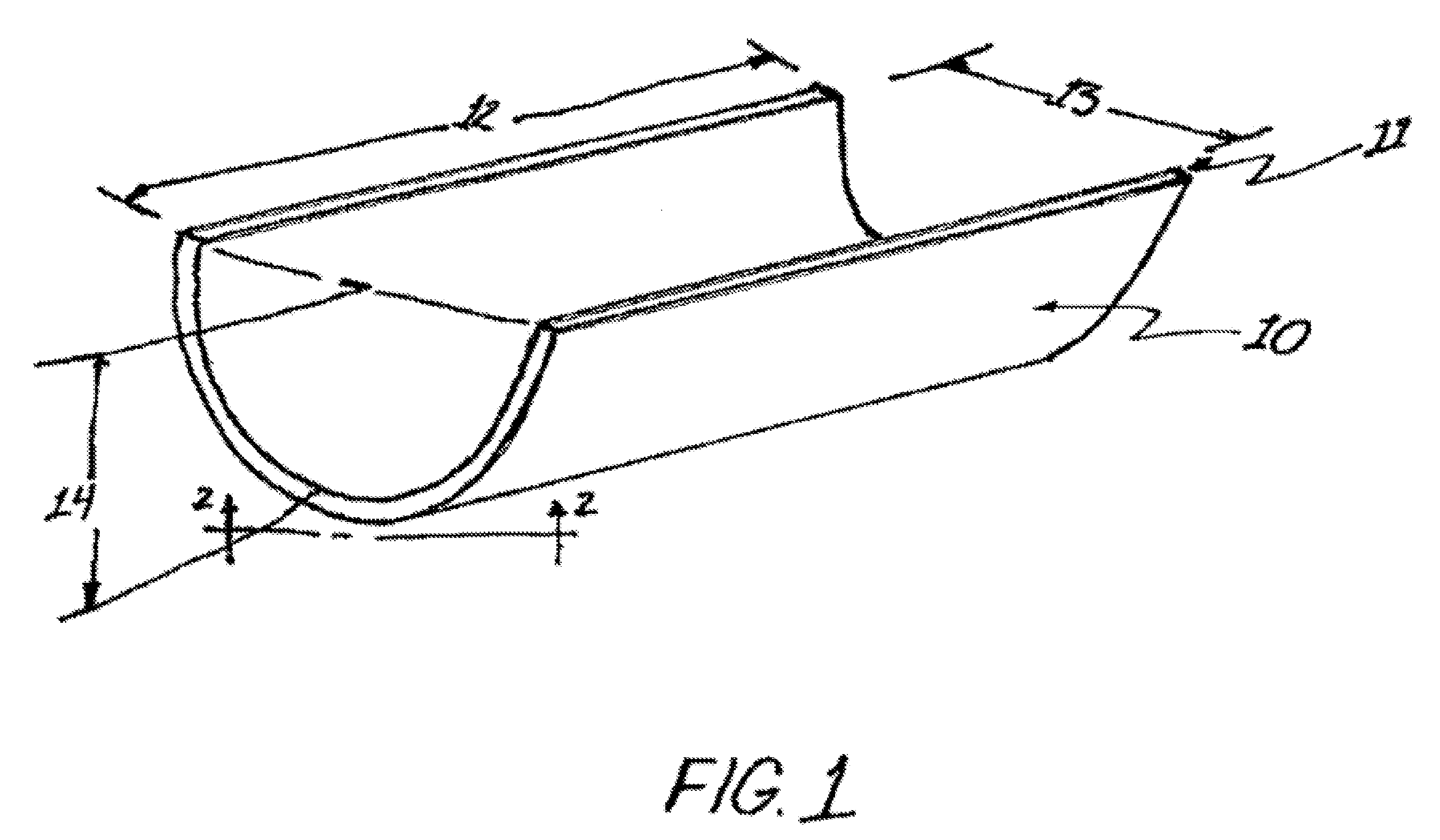

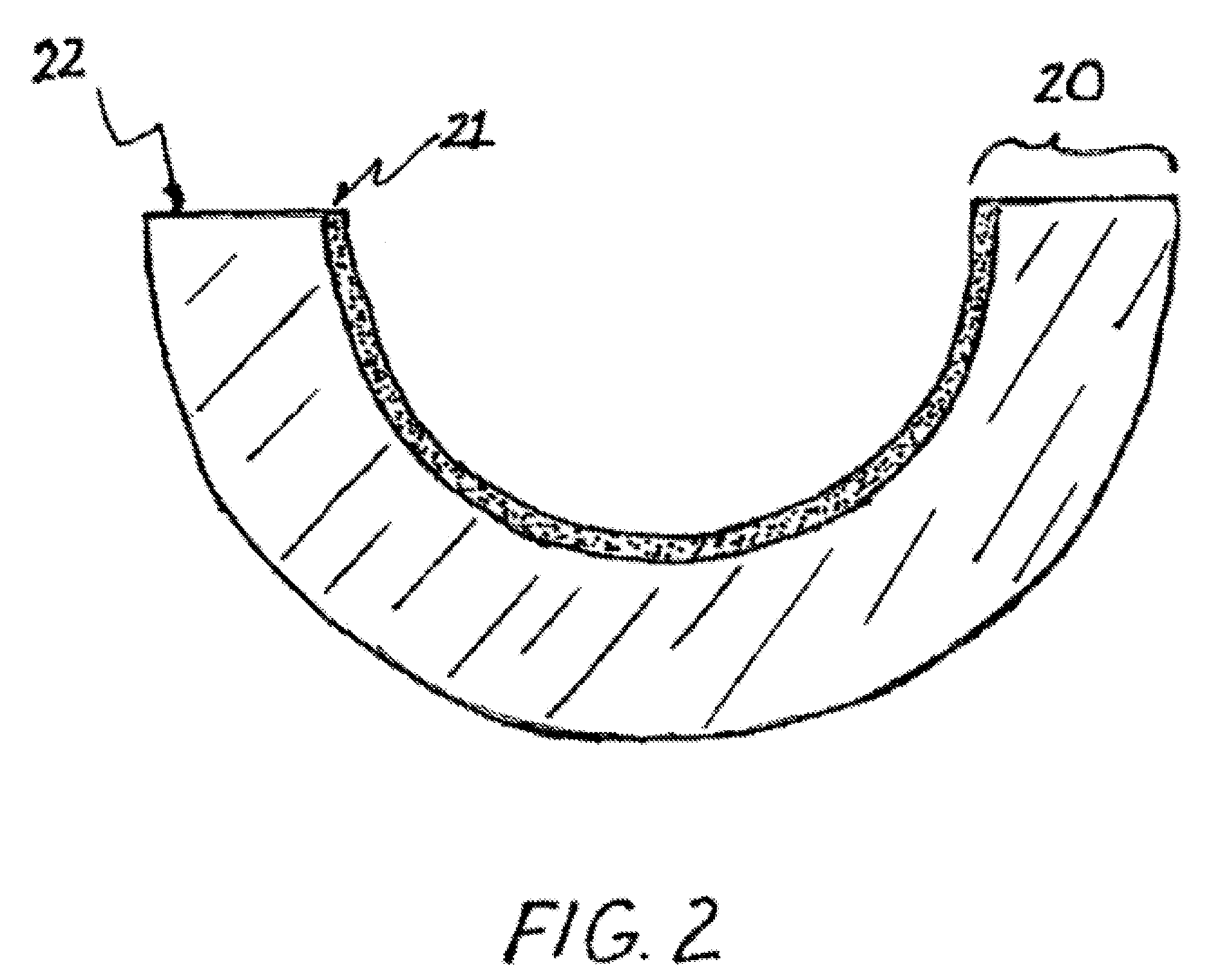

A process for the thermal deposition coating of a workpiece, said process comprising the steps of: (c) thermally depositing a coating on a metallic surface of a workpiece from a deposition head wherein at least one condition selected from the group of: coating deposition rate onto said surface, relative motion between the surface and said deposition head, and cryogenic coolant application rate onto said workpiece is controllable; (d) substantially simultaneously measuring temperatures at a plurality of locations over the metallic surface of the workpiece; (c) determining an average temperature of the temperatures measured in step (b); (d) comparing the average temperature to a preselected minimum temperature and a preselected maximum temperature for the workpiece; and (e) adjusting at least one of the controllable conditions if said average temperature is not between the preselected minimum temperature and the preselected maximum temperature for the workpiece. Standard deviations of all temperature readings and controlling the relative motion speed between the thermal coating deposition head and the workpiece provide another improvement for obtaining temperature uniformity over the workpiece surface.

Owner:AIR PROD & CHEM INC

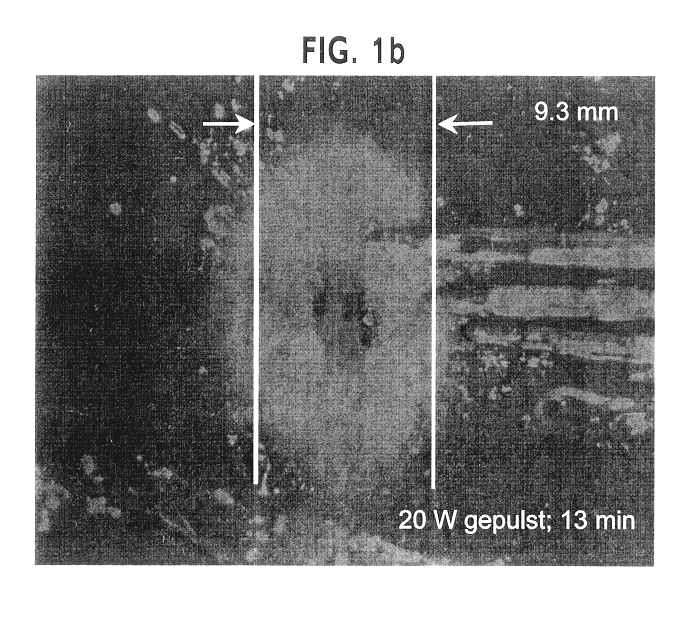

Method and device for controlling a targeted thermal deposition into a material

Disclosed is a process for controlling selective application of heat into a material, preferably into a biological material, having an ultrasonic-wave generating unit which couples the ultrasonic waves into the material, an ultrasonic-wave-detecting unit which detects the ultrasonic waves emerging from the material and an evaluation unit which generates information-providing parameters on the basis of the detected ultrasonic waves which provide information about the thermal and structural changes inside the material.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Thermal Deposition Surface Treatment Method, System and Product

ActiveUS20080087359A1Increase ratingsDamaging internal stressLiquid surface applicatorsMolten spray coatingThermal depositionCoolant flow

A process for treating a workpiece, said process comprising the steps of: (c) altering the temperature of a workpiece surface wherein at least one condition selected from the group of: thermal treatment rate, relative motion between the surface and said thermal treatment rate, coolant flow rate onto said surface, heating flow rate onto said surface and the relative speed between the heating means or the cooling means and the surface is controllable; (d) simultaneously measuring temperatures at a plurality of locations over the surface of the workpiece; (c) determining an average temperature of the temperatures measured in step (b); (d) comparing the average temperature to a preselected minimum temperature and a preselected maximum temperature for the workpiece; and (e) automatically adjusting at least one of the controllable conditions if said average temperature is not between the preselected minimum temperature and the preselected maximum temperature for the workpiece. A system for performing a thermal treatment process and the resulting product are also provided. Standard deviations of all temperature readings and controlling the relative motion speed between the thermal coating deposition head and the workpiece provide another improvement for obtaining temperature uniformity over the workpiece surface.

Owner:AIR PROD & CHEM INC

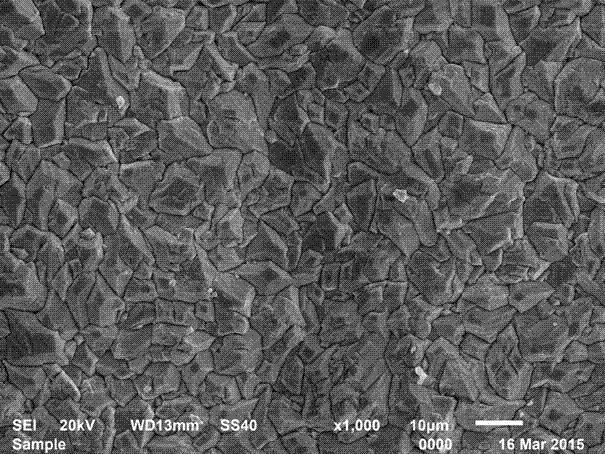

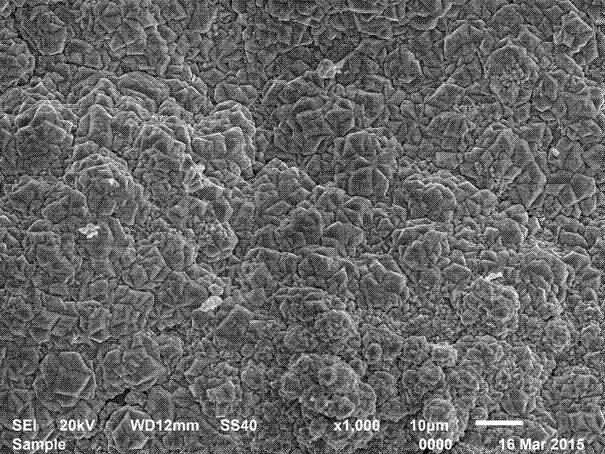

Graphene modified fluorine-contained lead dioxide electrode and preparation method thereof

ActiveCN106868509AImprove conductivityFast transferElectrolytic coatingsWater contaminantsLead dioxideMaterials science

The invention provides a graphene modified fluorine-contained lead dioxide electrode and a preparation method thereof. A tin antimony oxide bottom layer, an alpha-PbO2 middle layer and a beta-PbO2 active layer of the electrode all contain graphene. The preparation method comprises the steps of titanium plate pretreatment, thermal deposition of the tin antimony oxide bottom layer containing the graphene, acoustoelectric deposition of the alpha-PbO2 middle layer containing the graphene, and acoustoelectric deposition of the beta-PbO2 active layer containing the graphene. The graphene modified fluorine-contained lead dioxide electrode has the following advantages: the prepared graphene modified fluorine-contained lead dioxide electrode greatly is improved in electrocatalytic oxidation activity and largely prolonged in service life compared with a general fluorine-contained lead dioxide electrode, and is an anode material with development potential and suitable for electrocatalytic oxidation and degradation of organic pollutants in waste water.

Owner:JILIN NORMAL UNIV

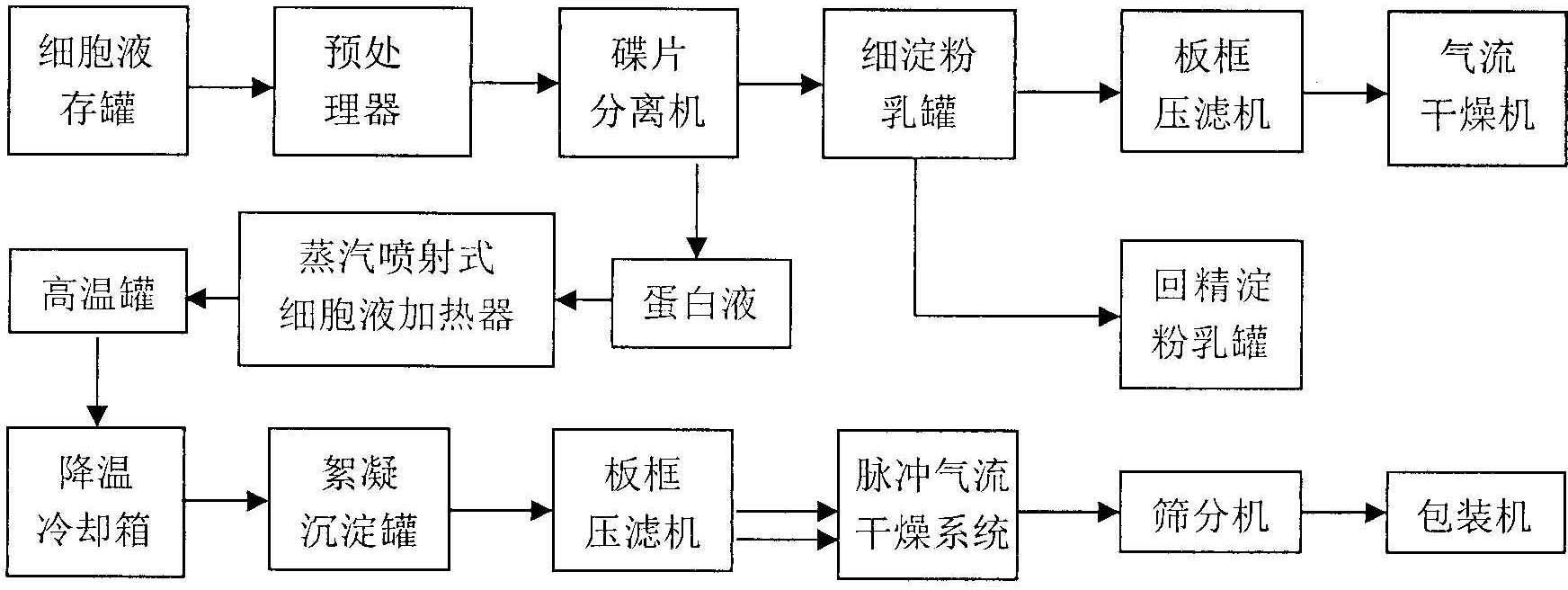

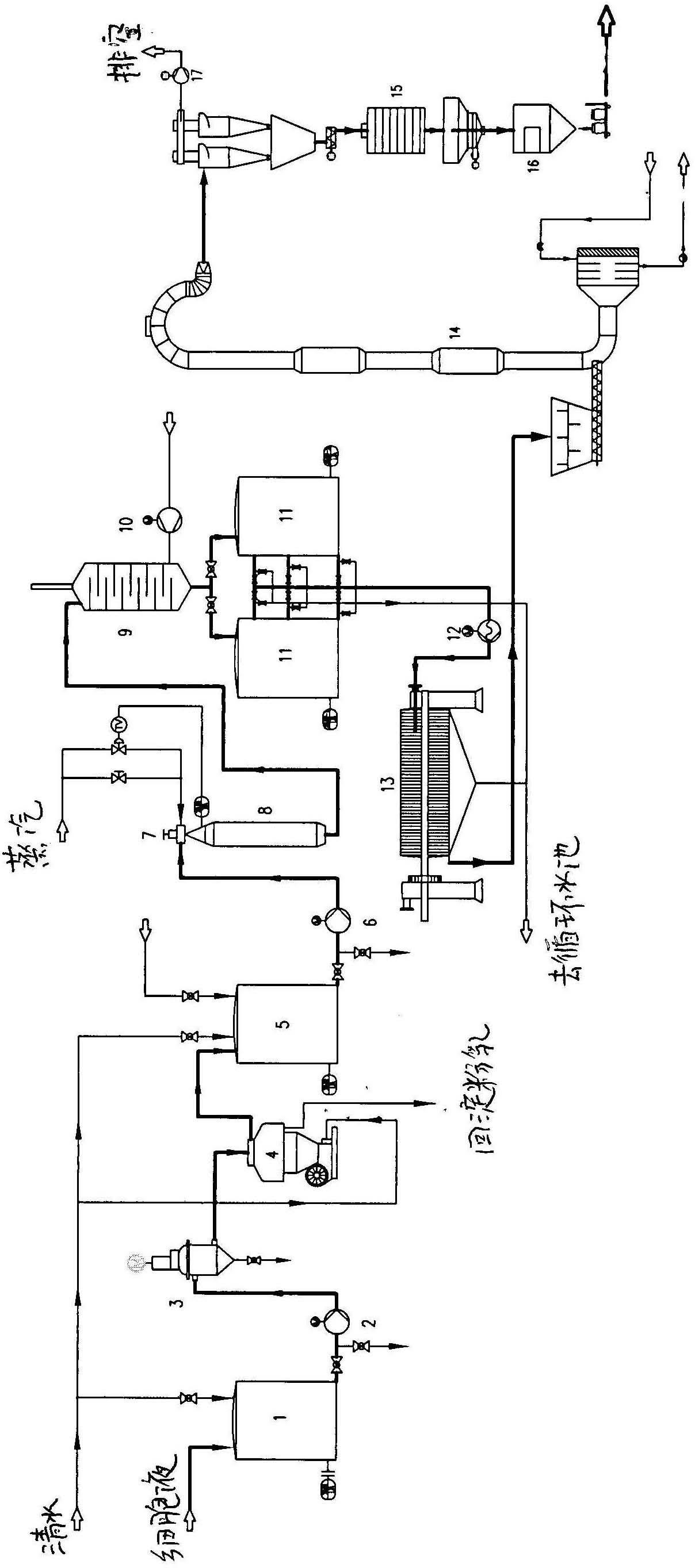

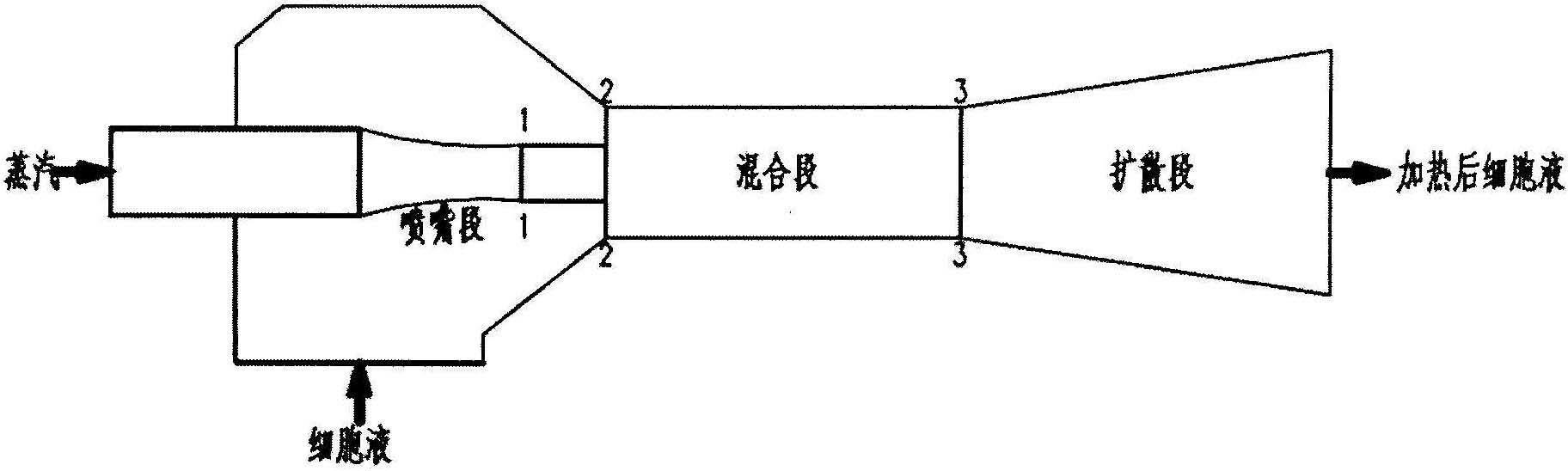

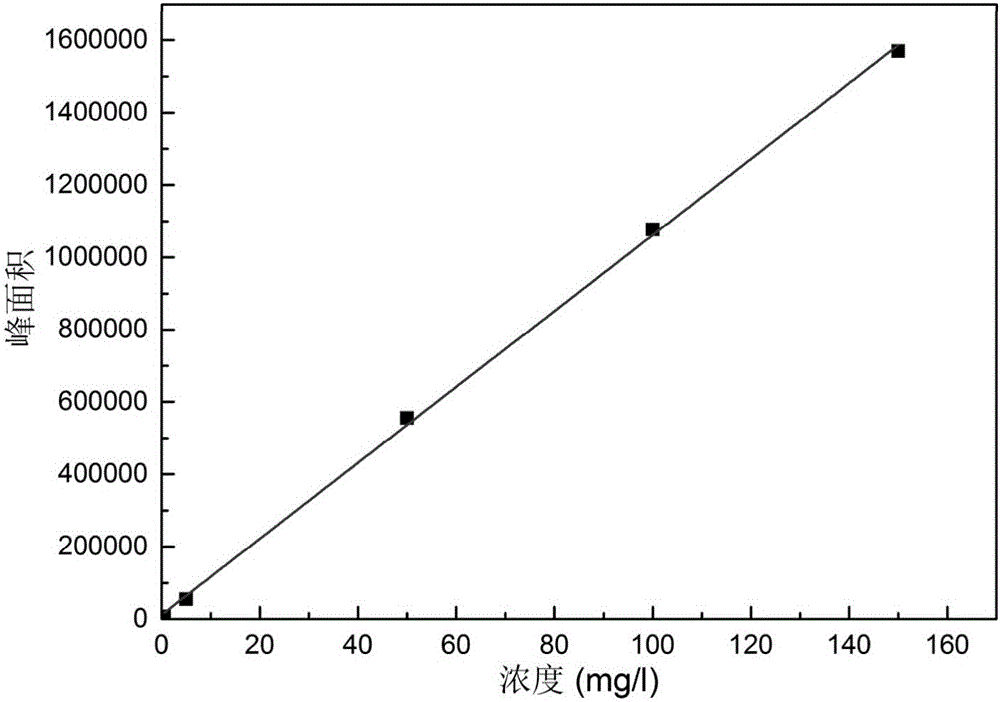

Process for extracting sweet potato protein by thermal deposition method

ActiveCN102558327ACompletely brokenEasy to separatePeptide preparation methodsPlant peptidesFiberSolubility

The invention relates to a process for extracting sweet potato protein by a thermal deposition method. The process is characterized by comprising the following steps of: treating cell sap to extract the sweet potato protein from the cell sap while producing sweet potato starch, separating and purifying by using a disc separator according to the difference of specific gravity of the protein and other substances such as starch and the like, removing fine fibers according to the solubility of the protein and the size of particles, and further purifying; purifying, concentrating, and degeneratingthe sweet potato protein to generate floccules according to the characteristic that the protein is degenerated at high temperature by a physical heating method; and concentrating, squeezing for dehydrating, drying, sieving, and performing aftertreatment to obtain a sweet potato protein commodity. The invention has the advantages that: (1) the sweet potato protein is degenerated by a steam jet cell sap heater, a moving part is not provided, and continuous production is ensured; (2) chemicals such as a flocculating agent and the like are not added, so that pollution is avoided, and subsequent treatment difficulty is reduced; and (3) the process is technically mature, and the industrial production capacity can be achieved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

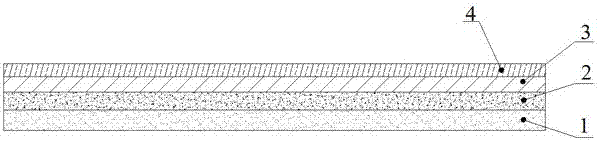

First wall part or low activation steel heat sink material coated with thick tungsten coating and making method thereof

InactiveCN1755840AInhibit growthImprove performanceNuclear energy generationVacuum evaporation coatingTemperature controlThermal deposition

The invention discloses first wall part with thick wolfram coating or low-activation steel thermal deposition material and opposite manufacture method. Wherein, selecting base plate as low-activation martensitic / ferritic steel to clear with transferred arc; using 70% stainless steel powder and 30% wolfram powder as interlayer of 0.5mm; spraying plasma arc has center temperature as 15000K speed as 500m / s, average particle size of wolfram powder is 10~15 microns, the coating has thickness as 2mm, density as 78~88% of body material and oxygen content is 0.06~0.15%; during whole spraying process, using active water cooling to control base plate temperature under 500Deg. As low-activation steel both as structure support material and thermal deposition material, this invention solves large area linkage key-problem and can bear stably long-time action of 1MW / m2 thermal load given active cooling condition.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

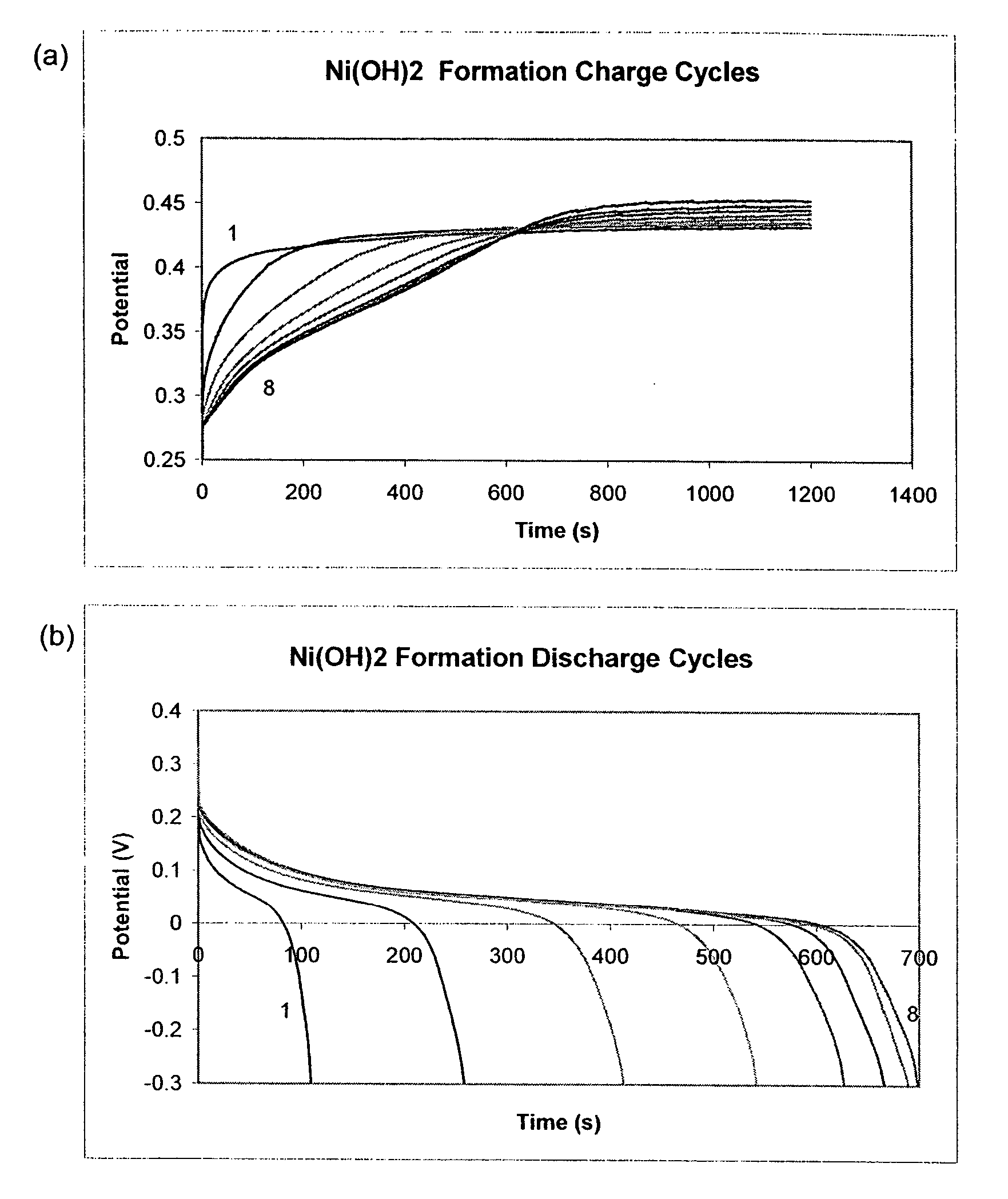

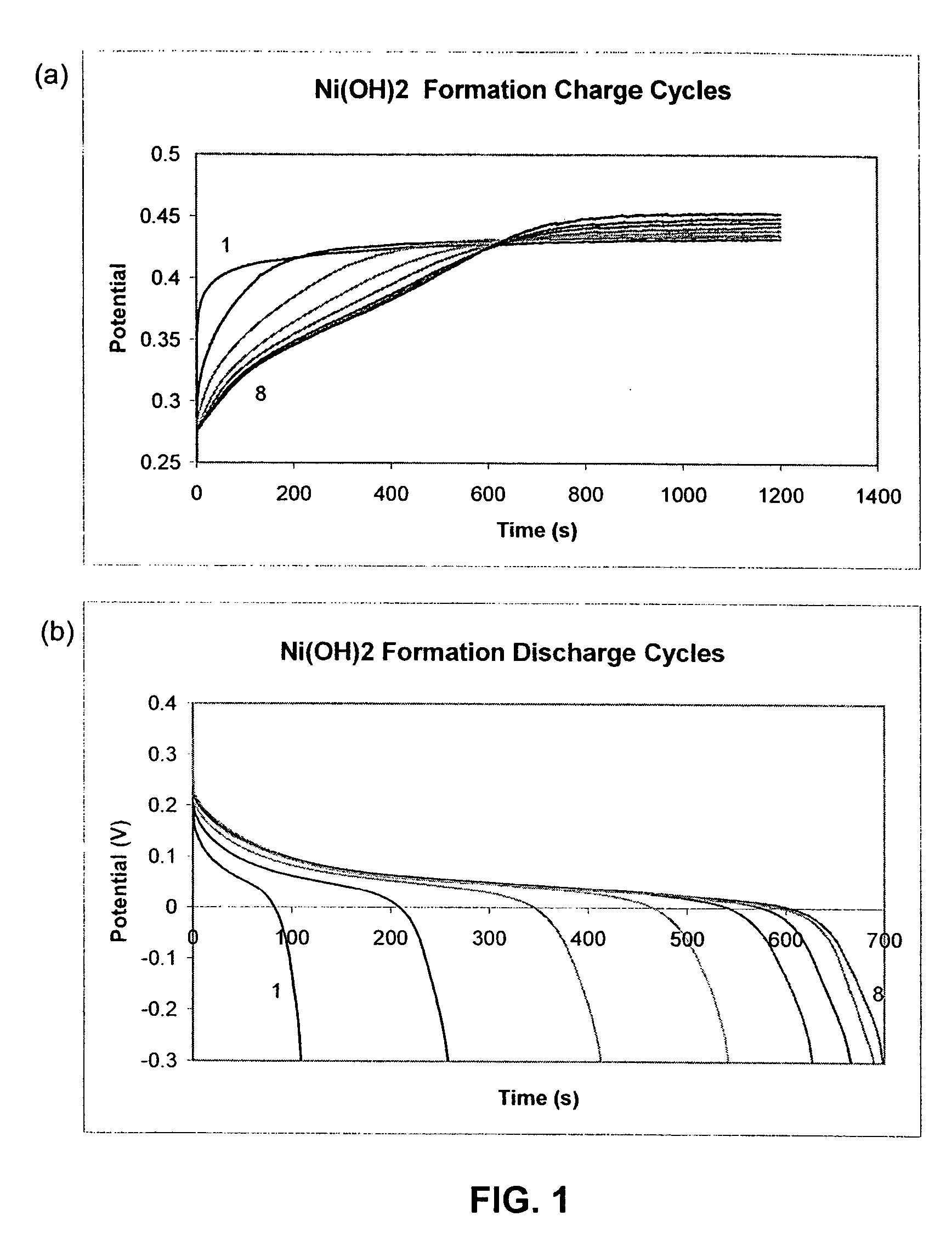

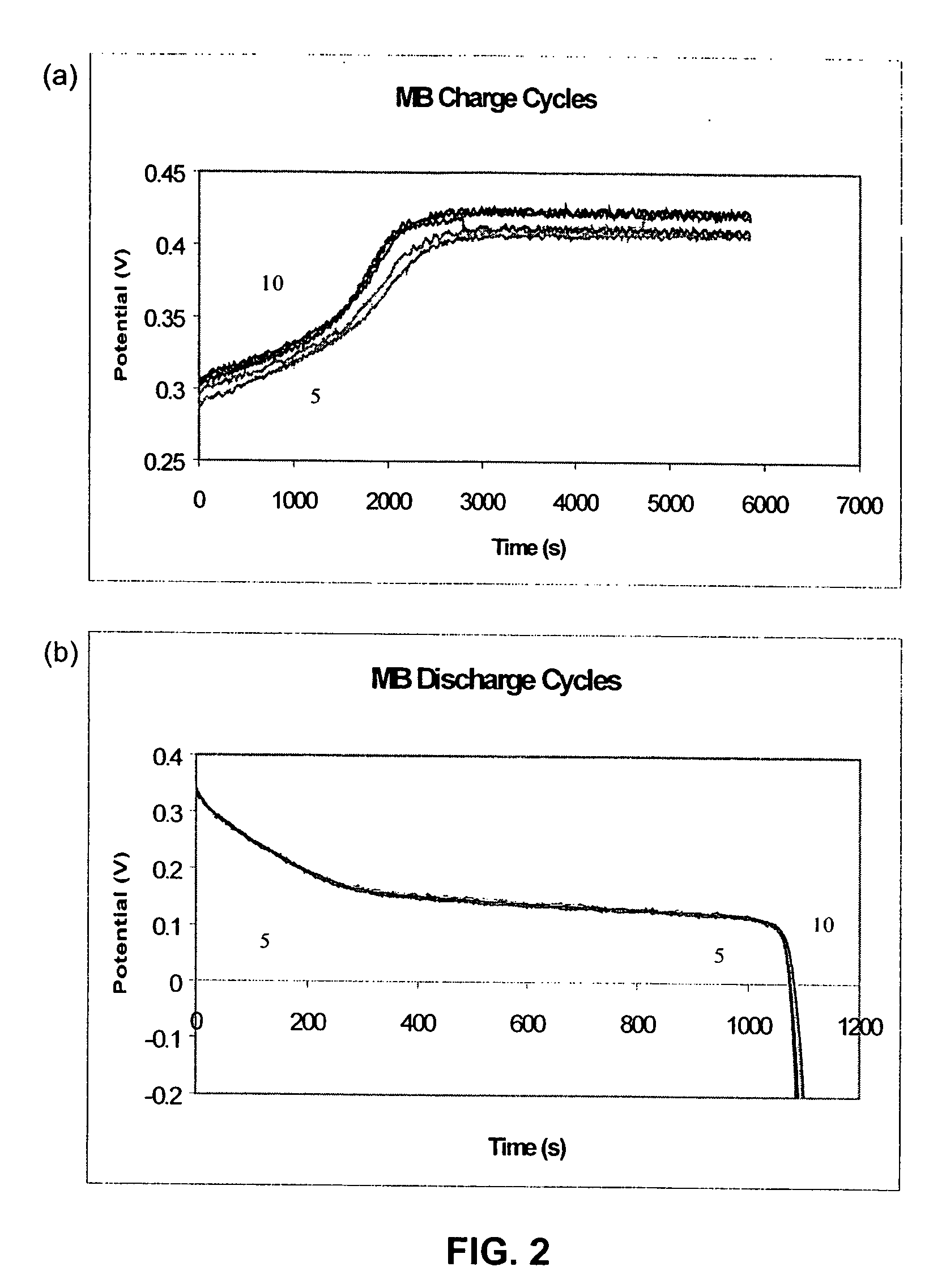

Nickel hydroxide impregnated carbon foam electrodes for rechargeable nickel batteries

InactiveUS20060024583A1Electrochemical processing of electrodesFinal product manufactureElectrical batteryCharge discharge

A novel nickel-carbon electrode, and methods for making the same, have been developed. The nickel-carbon electrode comprises an active mass (e.g., a nickel oxyhydroxide, hydroxide or oxide) deposited to a carbon foam using any one of chemical deposition, thermal deposition or electrochemical deposition. The nickel-carbon electrode is formed or “activated” through a series of charge-discharge cycles. The nickel-carbon electrode is comparable in volumetric capacities (mAh / cc) with commercial nickel electrodes but higher in gravimetric capacities (mAh / g). The nickel-carbon electrode may be used in rechargeable nickel-based batteries which have applications in cordless appliances, portable devices, standby power systems, the aerospace industry, and hybrid electric vehicles.

Owner:MICHIGAN TECHNOLOGICAL UNIVERSITY

Thermal deposition surface treatment method, system and product

A process for treating a workpiece, said process comprising the steps of: (c) altering the temperature of a workpiece surface wherein at least one condition selected from the group of: thermal treatment rate, relative motion between the surface and said thermal treatment rate, coolant flow rate onto said surface, heating flow rate onto said surface and the relative speed between the heating means or the cooling means and the surface is controllable; (d) simultaneously measuring temperatures at a plurality of locations over the surface of the workpiece; (c) determining an average temperature of the temperatures measured in step (b); (d) comparing the average temperature to a preselected minimum temperature and a preselected maximum temperature for the workpiece; and (e) automatically adjusting at least one of the controllable conditions if said average temperature is not between the preselected minimum temperature and the preselected maximum temperature for the workpiece. A system for performing a thermal treatment process and the resulting product are also provided. Standard deviations of all temperature readings and controlling the relative motion speed between the thermal coating deposition head and the workpiece provide another improvement for obtaining temperature uniformity over the workpiece surface.

Owner:AIR PROD & CHEM INC

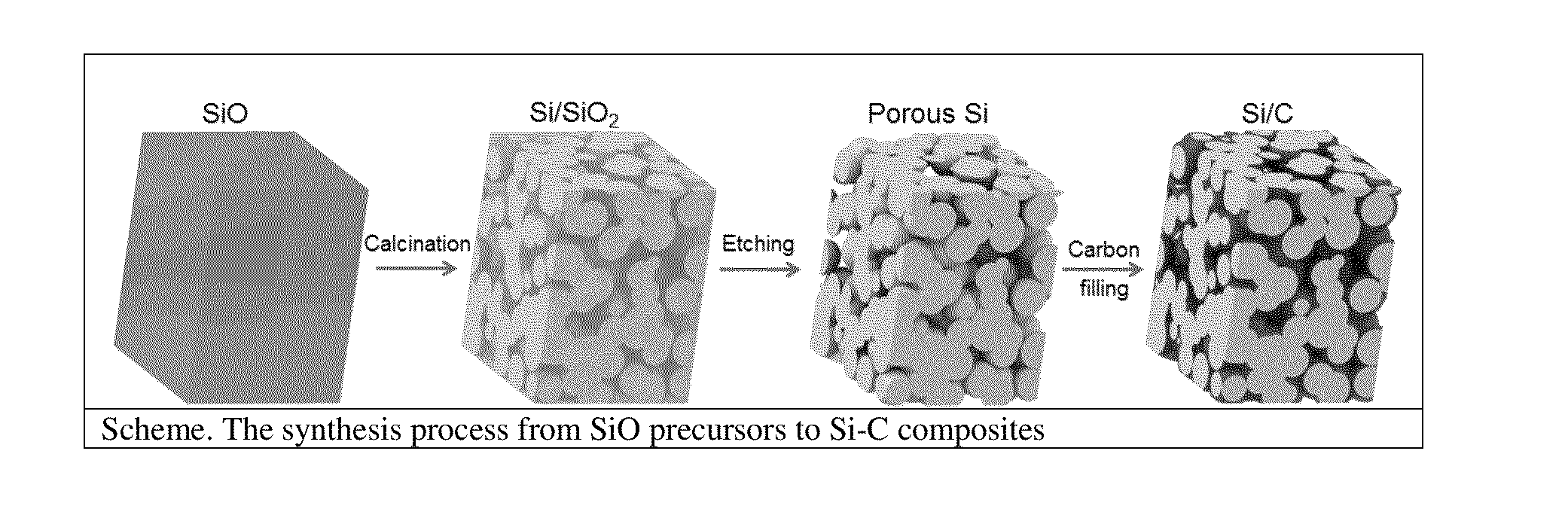

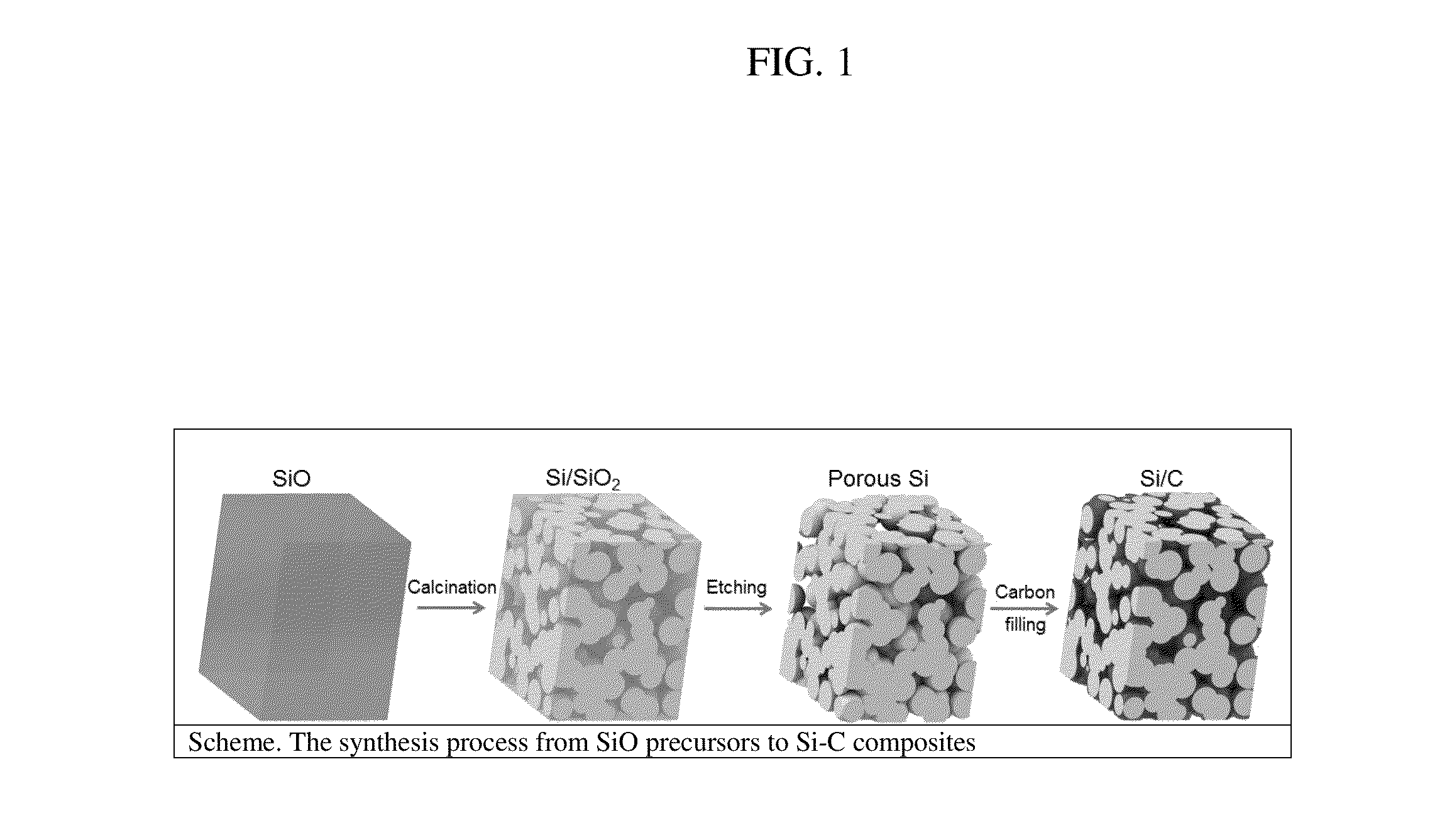

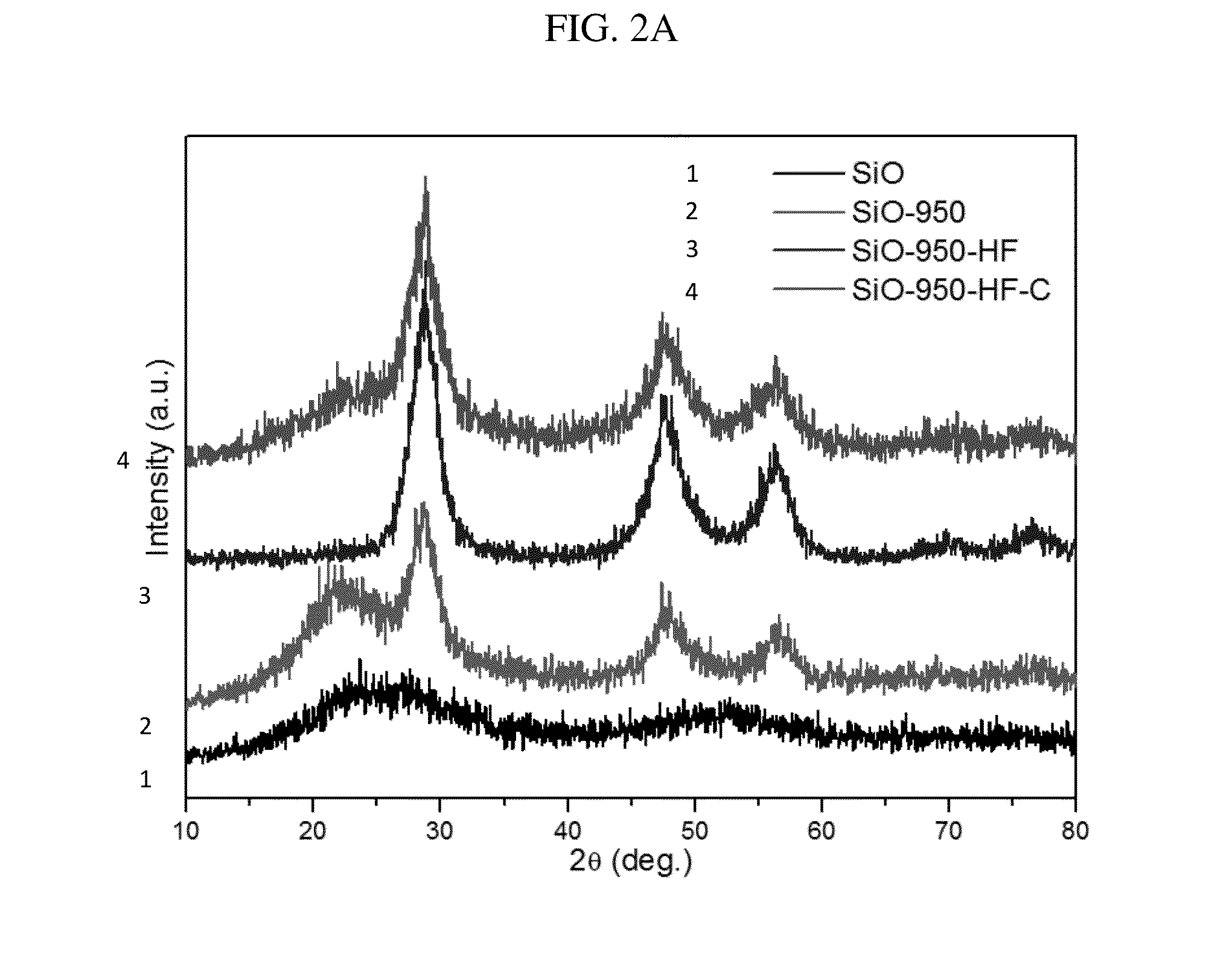

Synthesis of Micro-Sized Interconnected Si-C Composites

ActiveUS20140106219A1Improve electrochemical performanceImproved high-magnification performanceElectrode thermal treatmentPaper/cardboard articlesThermal depositionAlloy

Embodiments provide a method of producing micro-sized Si—C composites or doped Si—C and Si alloy-C with interconnected nanoscle Si and C building blocks through converting commercially available SiOx (0<x<2) to a silicon framework by calcination, followed by etching and then by carbon filling by thermal deposition of gas containing organic molecules that have carbon atoms.

Owner:PENN STATE RES FOUND

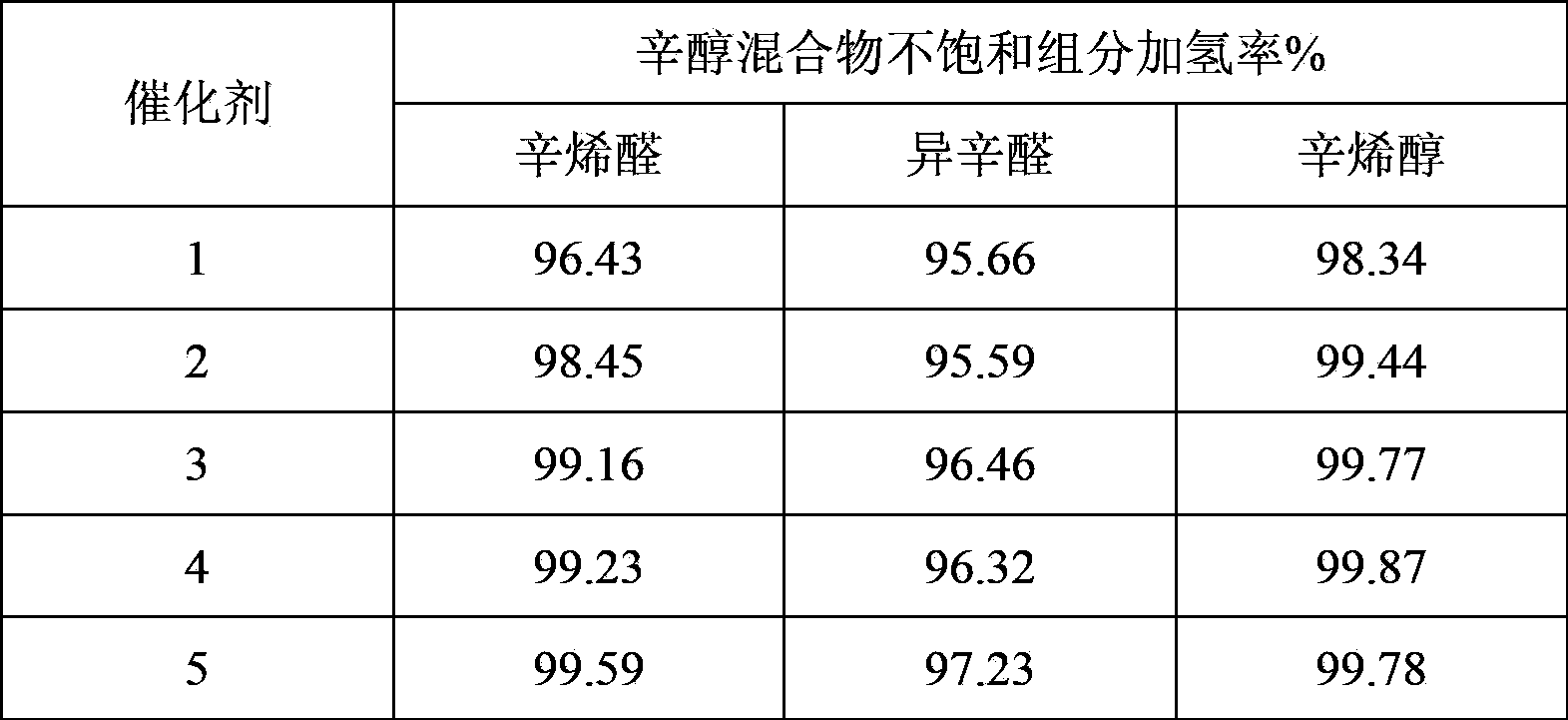

High-dispersion type catalyst for liquid phase hydrogenation of octanol mixture, and preparation and application thereof

ActiveCN103894207ASimple preparation conditionsEasy to makeOrganic compound preparationHydroxy compound preparationRare-earth elementDispersity

The invention relates to a high-dispersion type catalyst for liquid phase hydrogenation of an octanol mixture and preparation and application thereof. According to the invention, gamma-Al2O3 is used as a carrier, rare earth element lanthanum is used as a carrier modification auxiliary agent, nickel is used as a main active component, and copper and manganese are used as active auxiliary agents; in terms of mass (100%), the carrier accounts for 40 to 95% of the catalyst, the carrier modification auxiliary agent rare earth element lanthanum accounts for 0.1 to 12% in terms of La2O3, the content of the main active component nickel accounts for 1 to 30% in terms of NiO, the content of the active auxiliary agent Cu is 0.5 to 15% in terms of CuO, and content of the active auxiliary agent Mn is 0.5 to 10% in terms of MnO. According to the invention, through rare earth element surface modification and hydro-thermal deposition, the size and dispersity of active component particles can be effectively controlled, the content of surface active species is increased, and the catalyst has higher catalytic hydrogenation activity and stability on unsaturated components like octenal, isooctanol and isooctenal in the octanol mixture.

Owner:PETROCHINA CO LTD

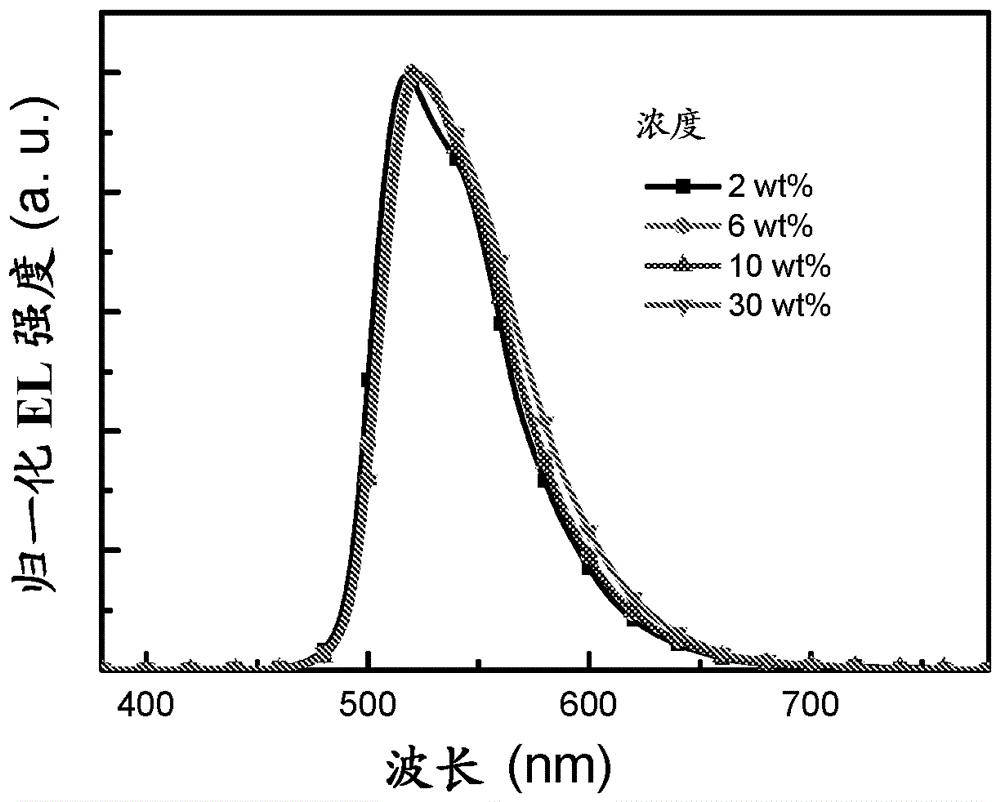

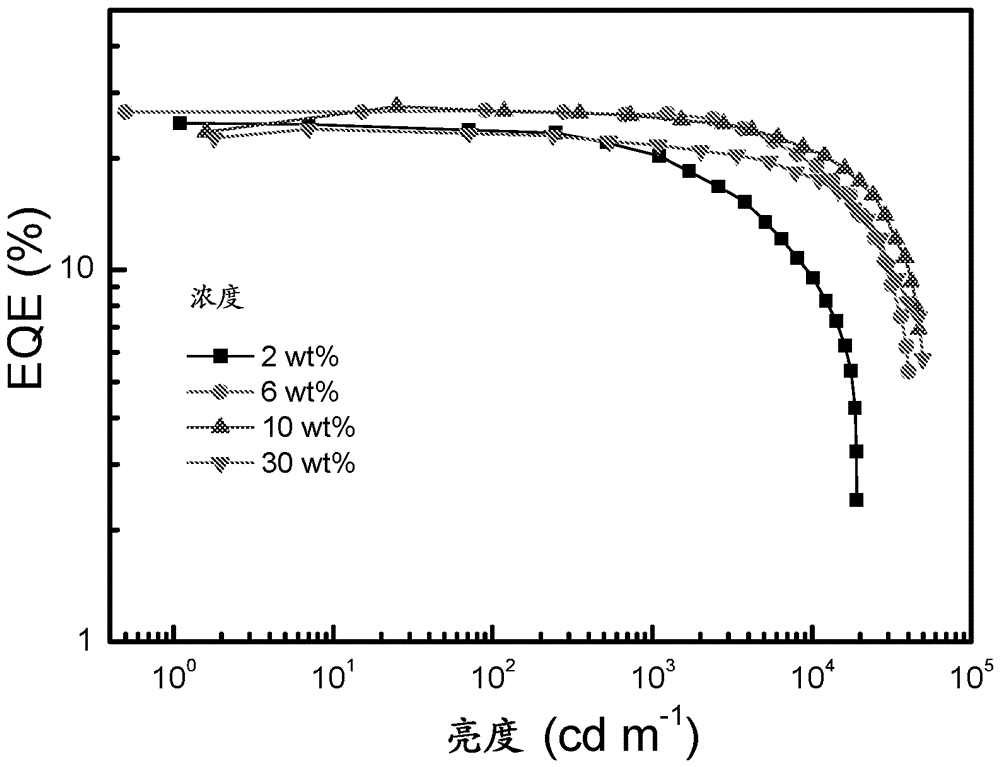

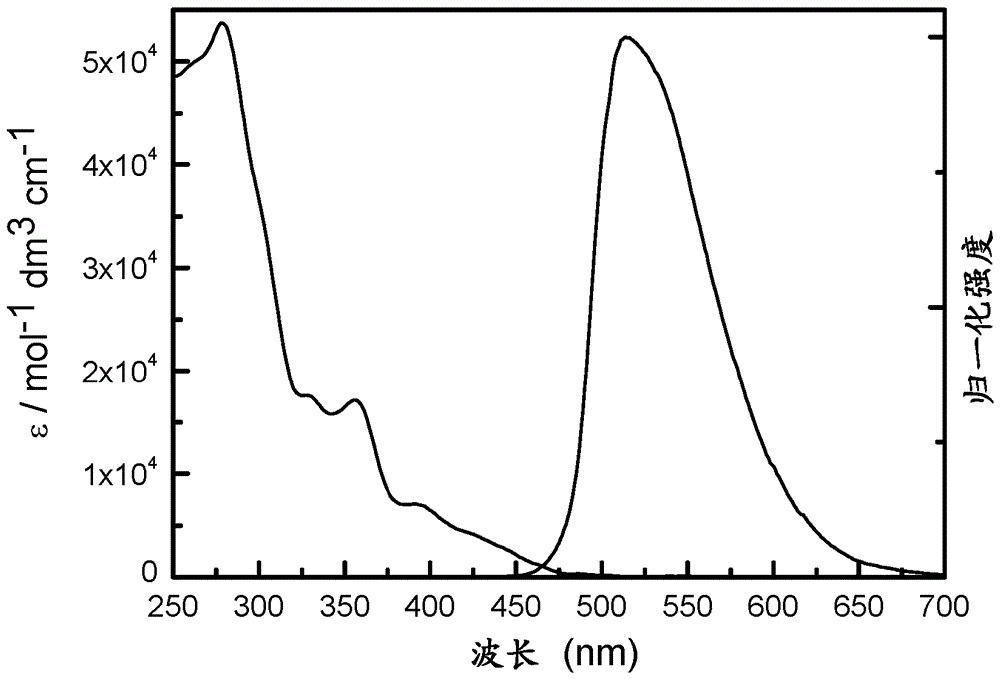

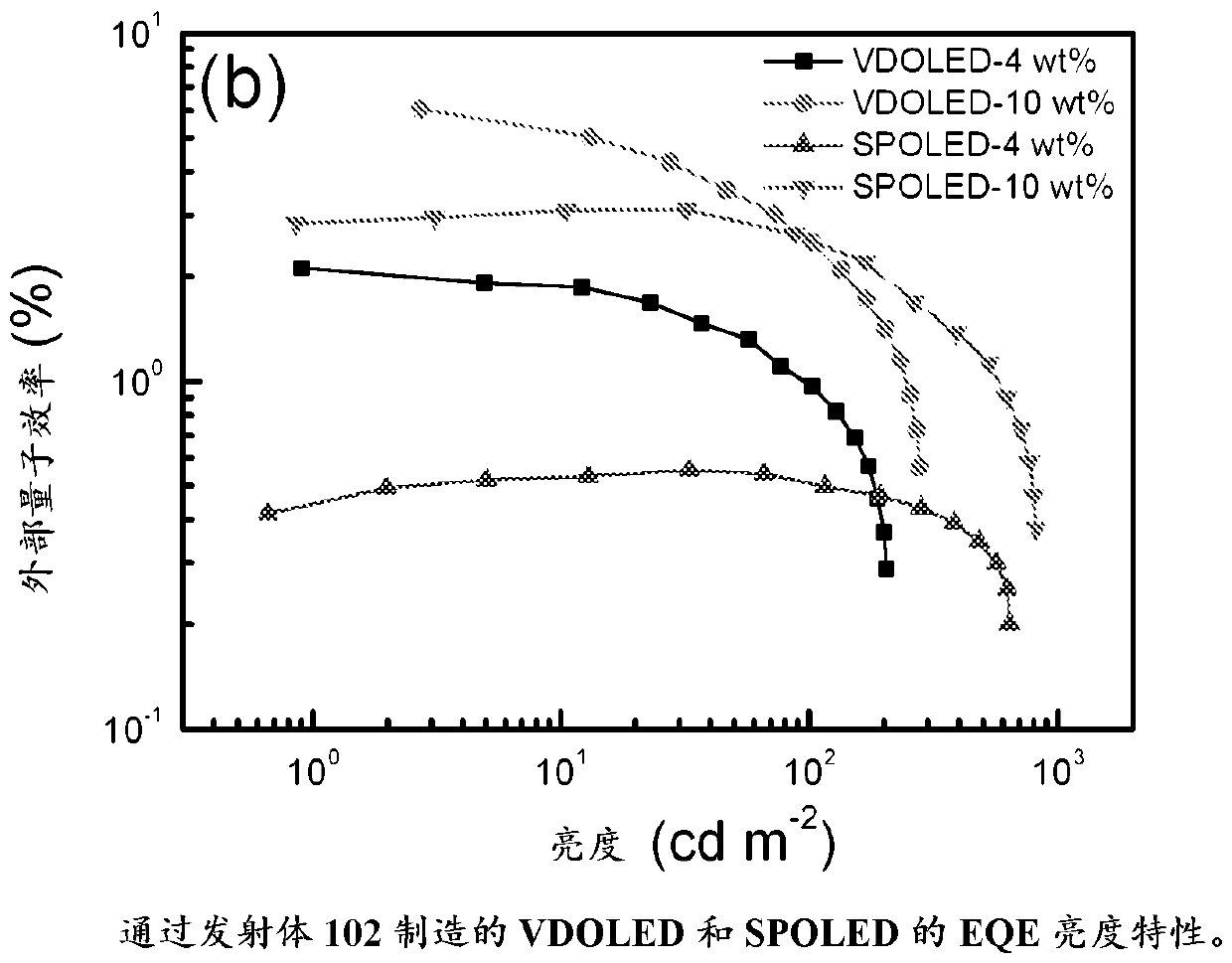

Platinum (II) emitters for OLED applications

ActiveCN106795428AImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingQuantum efficiencyPlatinum

Described herein are novel platinum (II) emitters. These material show high emission quantum efficiency, low self-quenching constant and stable in thermal deposition process. The OLED fabricated from these materials can have pure green emission, high efficiency and low efficiency roll-off.

Owner:VERSITECH LTD

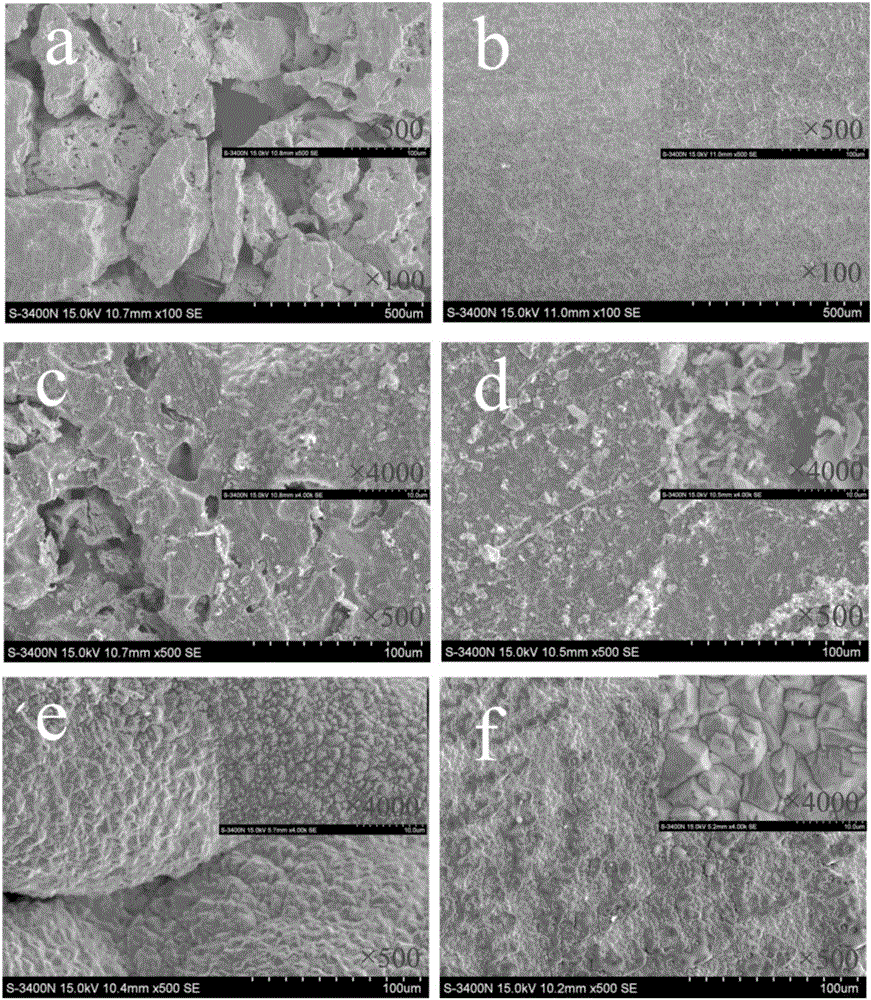

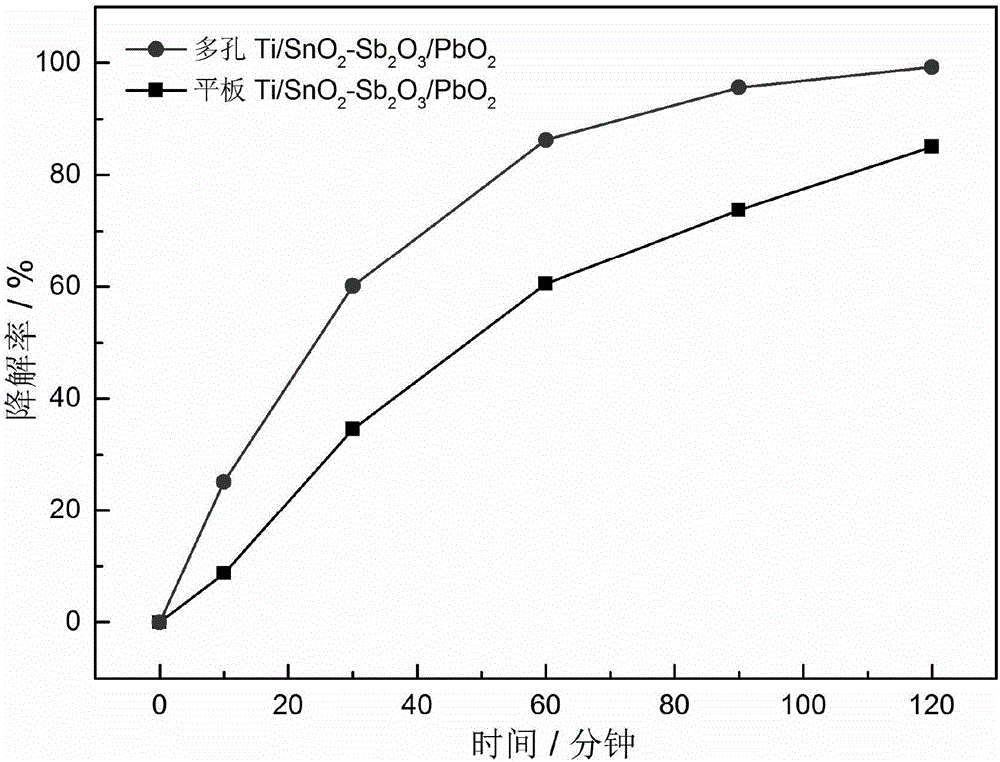

Three-dimensional porous titanium substrate lead dioxide electrode as well as preparation method and application thereof

InactiveCN105776441AHigh activityExtended service lifeWater contaminantsWater/sewage treatment using germicide/oligodynamic-processLead dioxideCopper foil

The invention discloses a three-dimensional porous titanium substrate lead dioxide electrode which comprises a porous titanium substrate, wherein interlayers are arranged on two side surfaces of the porous titanium substrate in a thermal deposition manner; the interlayers consists of a tin-antimony oxide; a lead dioxide surface active layer is arranged on the interlayer on one side surface of the porous titanium substrate in an electric deposition layer. The invention further provides a preparation method of the three-dimensional porous titanium substrate lead dioxide electrode, and further provides application of the three-dimensional porous titanium substrate lead dioxide electrode in musk ketone in degraded wastewater. In the musk ketone in the degraded wastewater, the three-dimensional porous titanium substrate lead dioxide electrode is taken as an anode, copper foil as a cathode and a sodium sulfate solution as an electrolyte, electrocatalytic oxidation is implemented for 1-2 hours, and then degradation treatment on the musk ketone in the wastewater can be completed. When the musk ketone is degraded by using the three-dimensional porous titanium substrate lead dioxide electrode under an electrifying condition, the degradation time is short, the degradation rate is high, and the operation is convenient.

Owner:SHANGHAI INST OF TECH

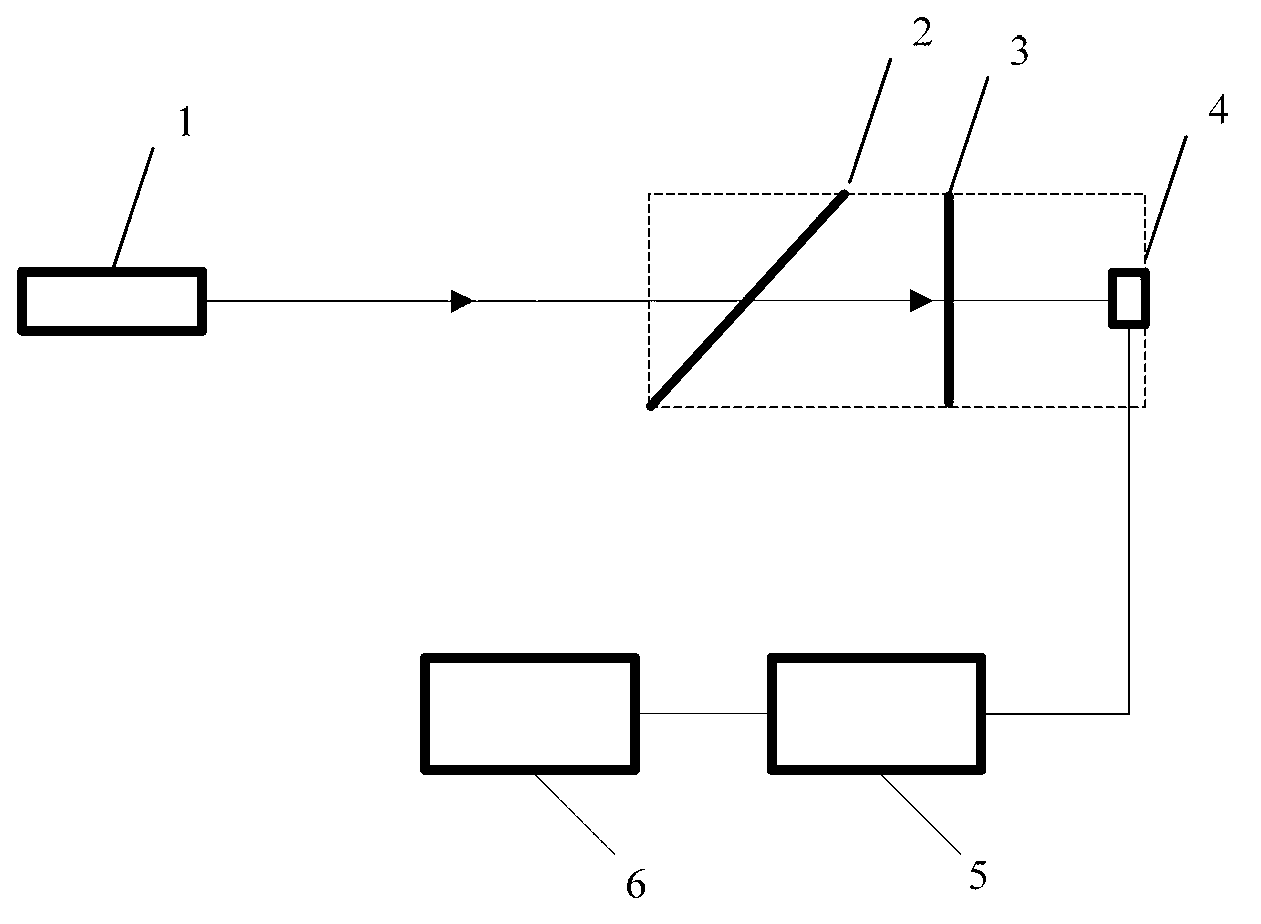

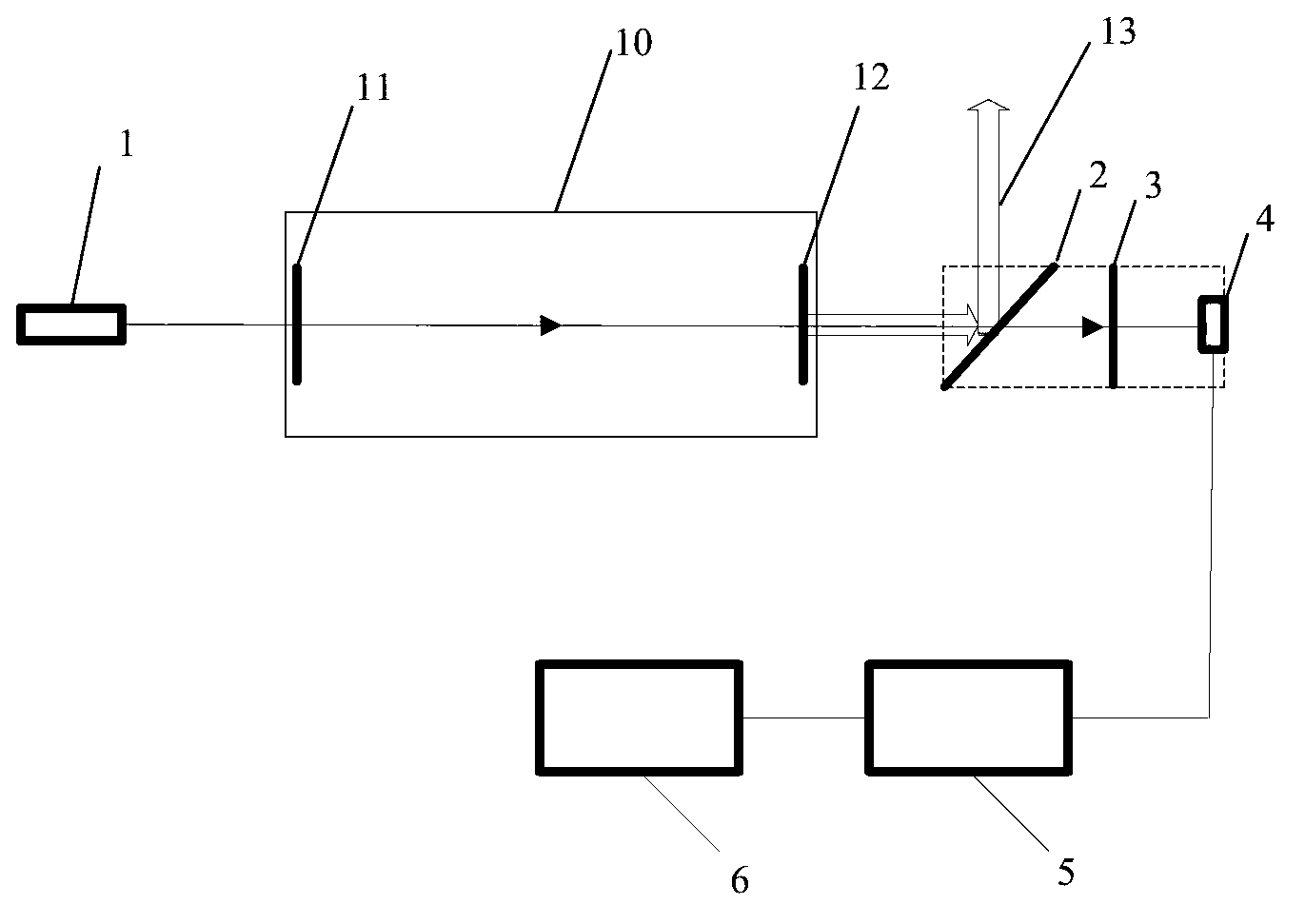

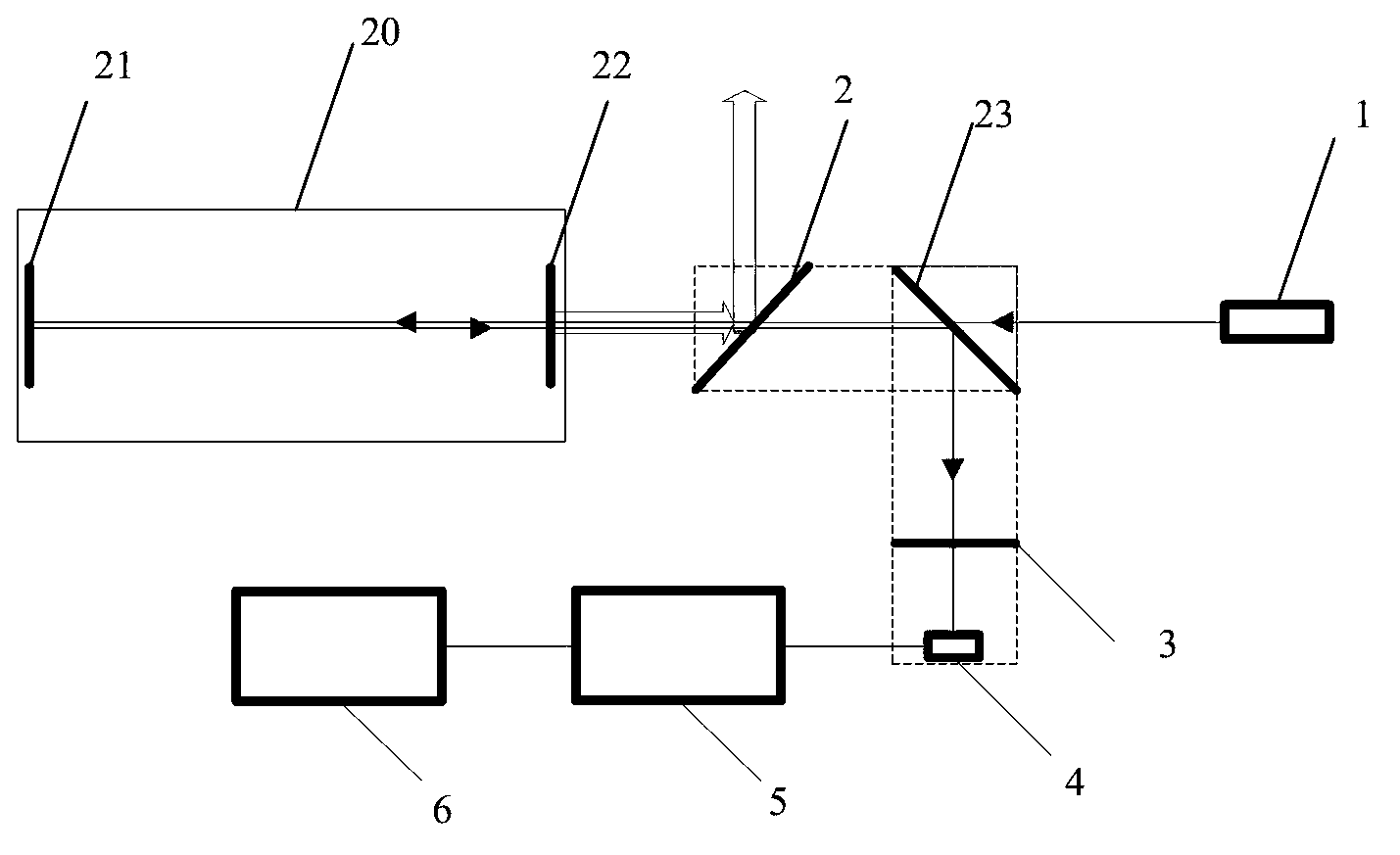

Pulse gas laser intracavity flow field measurement device based on four-quadrant detector

InactiveCN102980739AOvercoming complexityOvercome the disadvantages of expensive equipmentLaser detailsAerodynamic testingShock waveMeasurement device

The invention discloses a pulse gas laser intracavity flow field measurement device based on a four-quadrant detector. The pulse gas laser intracavity flow field measurement device comprises a detection light source, a detection light receiving system and a signal processing system. A light beam sent out by the detection light source is parallel to the optical axis direction of a pulse gas laser. The detection light receiving system comprises a four-quadrant photoelectric detector, a photosensitive face faces towards a detection area and is perpendicular to a detection light beam to be used for receiving the detection laser light beam, and signals of the four-quadrant photoelectric detector can be processed by a signal processing system to obtain laser wave transmission characteristic parameters. The pulse gas laser intracavity flow field measurement device is simple in structure and convenient to operate. The four-quadrant photosensitive sensor simplifies an experiment device. Laser wave disturbance and transmission direction of the laser wave can be judged according to movement of the center of a light spot of the four-quadrant photosensitive detector to improve detection flexibility. Simultaneously, a dichroic mirror is used to separate the detection light beam form laser of the pulse gas laser. The laser oscillation can simultaneously obtain real-time test results to overcome the defect that thermal deposition in non-laser resonant cavity test discharging area is high.

Owner:HUAZHONG UNIV OF SCI & TECH

Novel metallic film preparation technology on liquid phase substrate surface

InactiveCN1730716AEasy to operateUnique microstructureVacuum evaporation coatingSputtering coatingGrain structureVacuum evaporation

Disclosed is a novel metallic film preparation technology on liquid phase substrate surface, which comprises using liquid phase material whose saturated vapor tension is lower than the vacuum evaporation pressure as substrate, employing magnetron sputtering or thermal deposition method, evaporating the metal atoms with energy of argon ions in high speed movement or tungsten filament heated by electric current, then depositing the evaporated metal atoms onto liquid phase substrate surface, finally growing metallic film having polycrystalline grain structure through diffusion, core formation, rotation and agglomeration. The film has substantially no internal stress.

Owner:ZHEJIANG UNIV

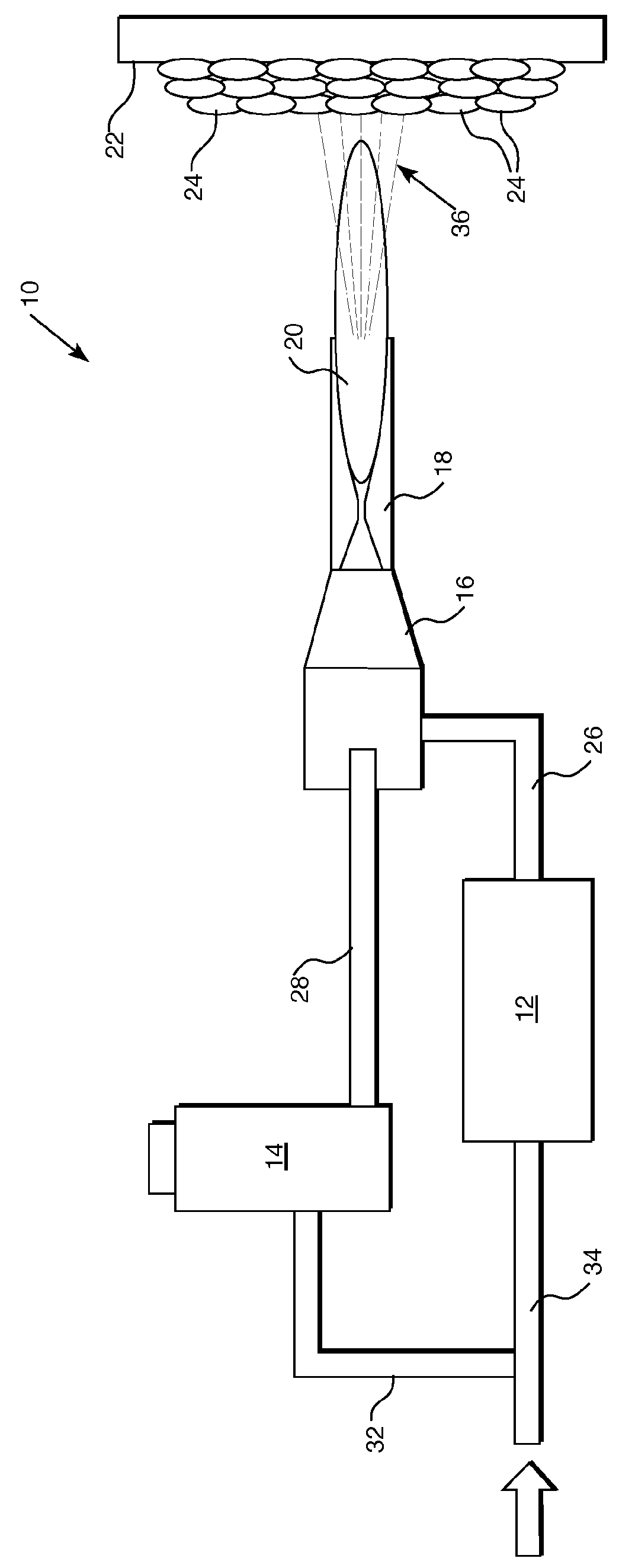

Duplex accident tolerant coating for nuclear fuel rods

ActiveUS20180096743A1Mitigate eutectic formationImproving accident toleranceOptical rangefindersFuel elementsNuclear reactor coreNuclear reactor

A method is described for forming duplex layers including an interlayer and a corrosion resistant boundary layer on a nuclear fuel rod cladding tube for use in a water cooled nuclear reactor. The method includes forming, by thermal deposition or physical vapor deposition, on the exterior of a substrate, an inner interlayer with Mo, Ta, W or Nb or other particles, and forming, by thermal deposition or physical vapor deposition, on the interlayer, an outer corrosion resistant layer with particles selected from the group consisting of Cr, a Cr alloy, and combinations thereof. The interlayer prevents eutectic formation between the corrosion resistant layer and the substrate.

Owner:WESTINGHOUSE ELECTRIC CORP +1

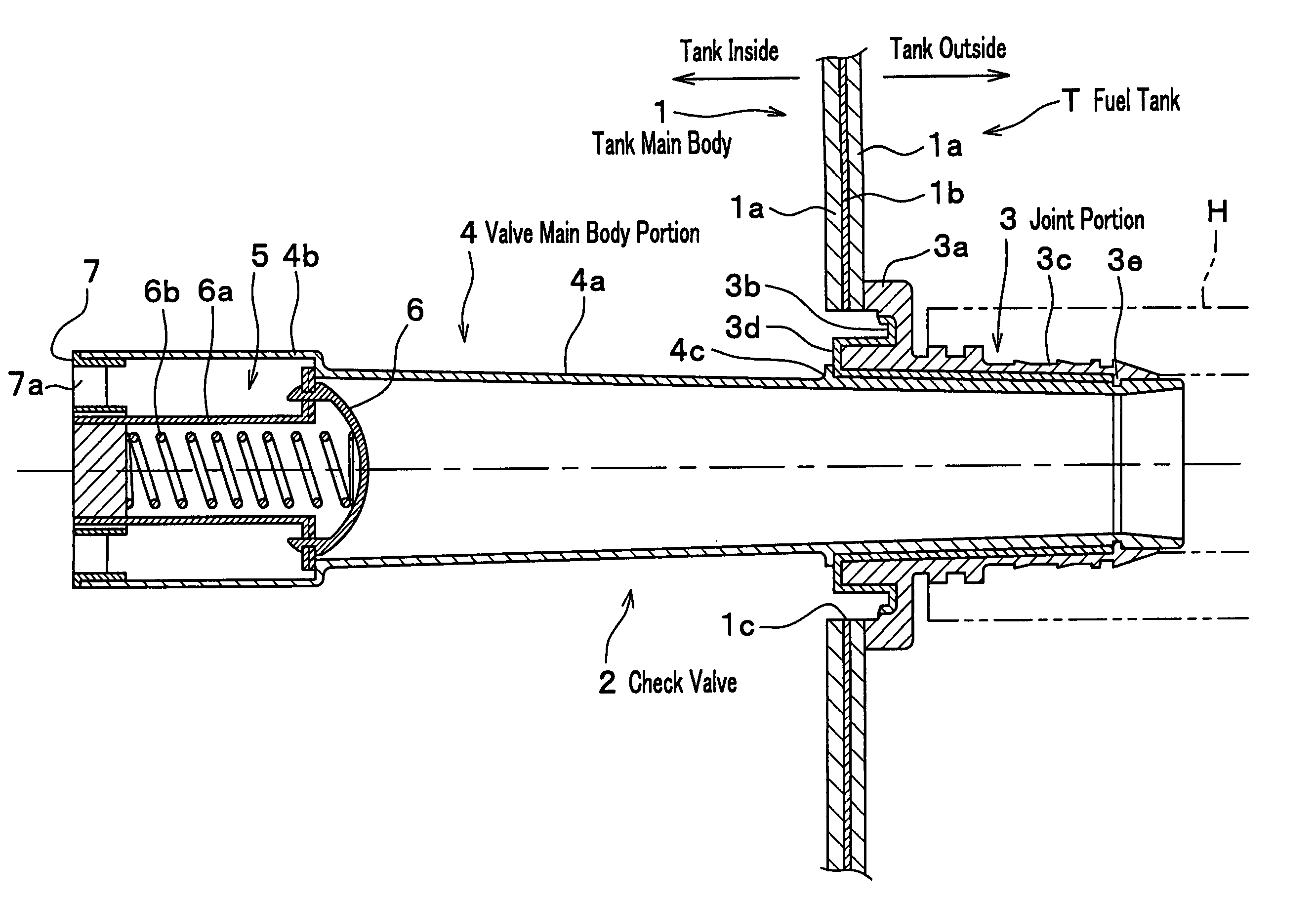

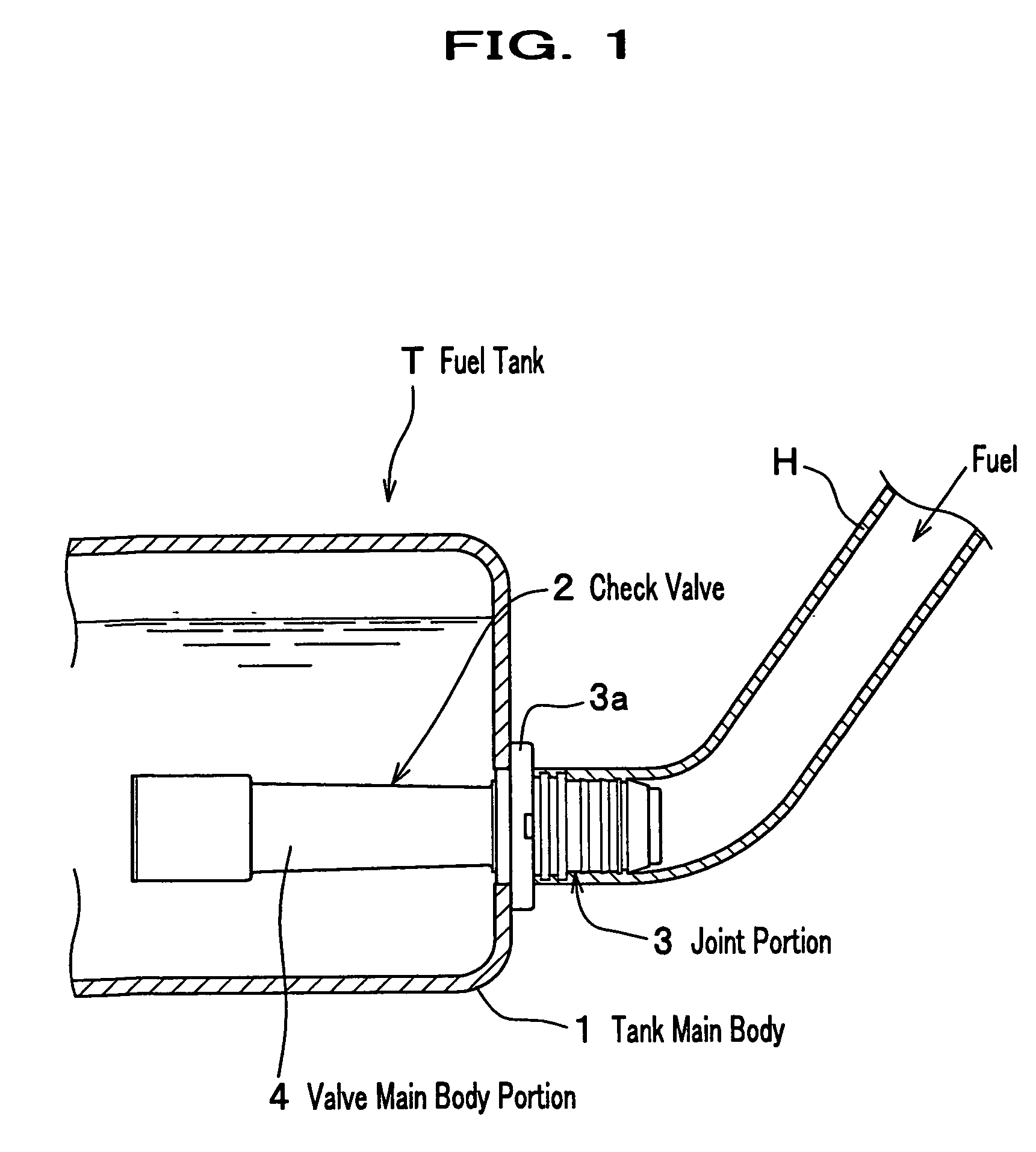

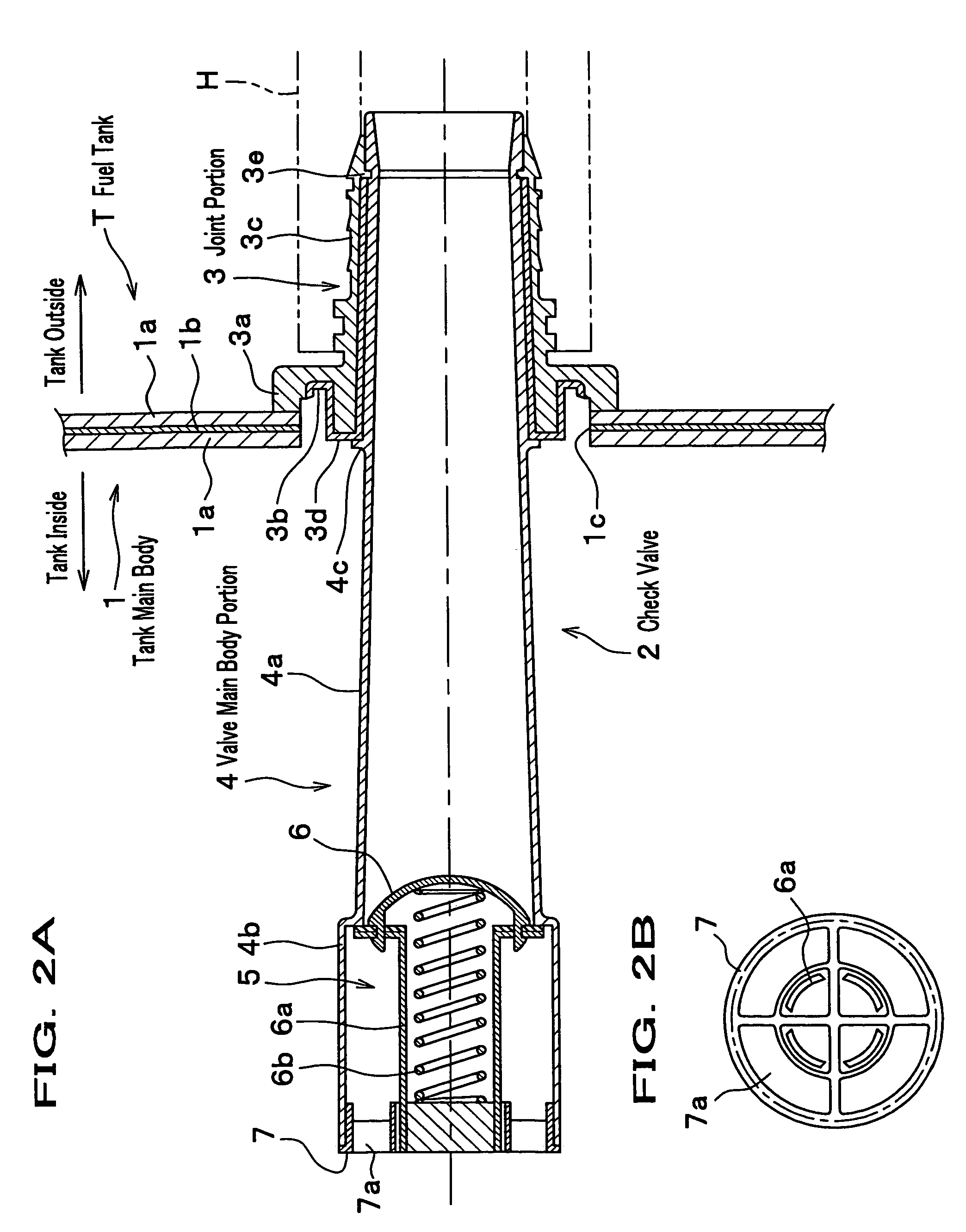

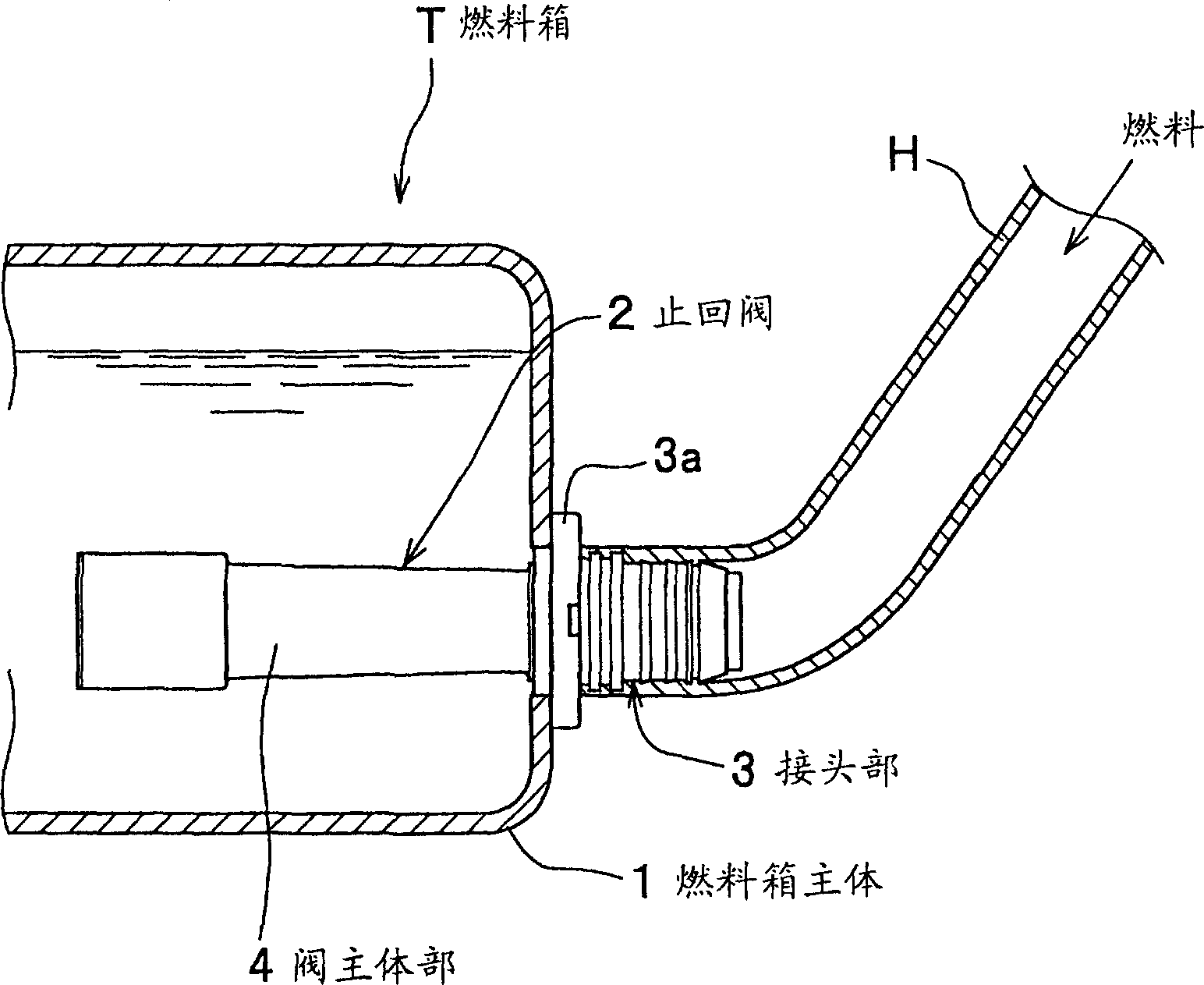

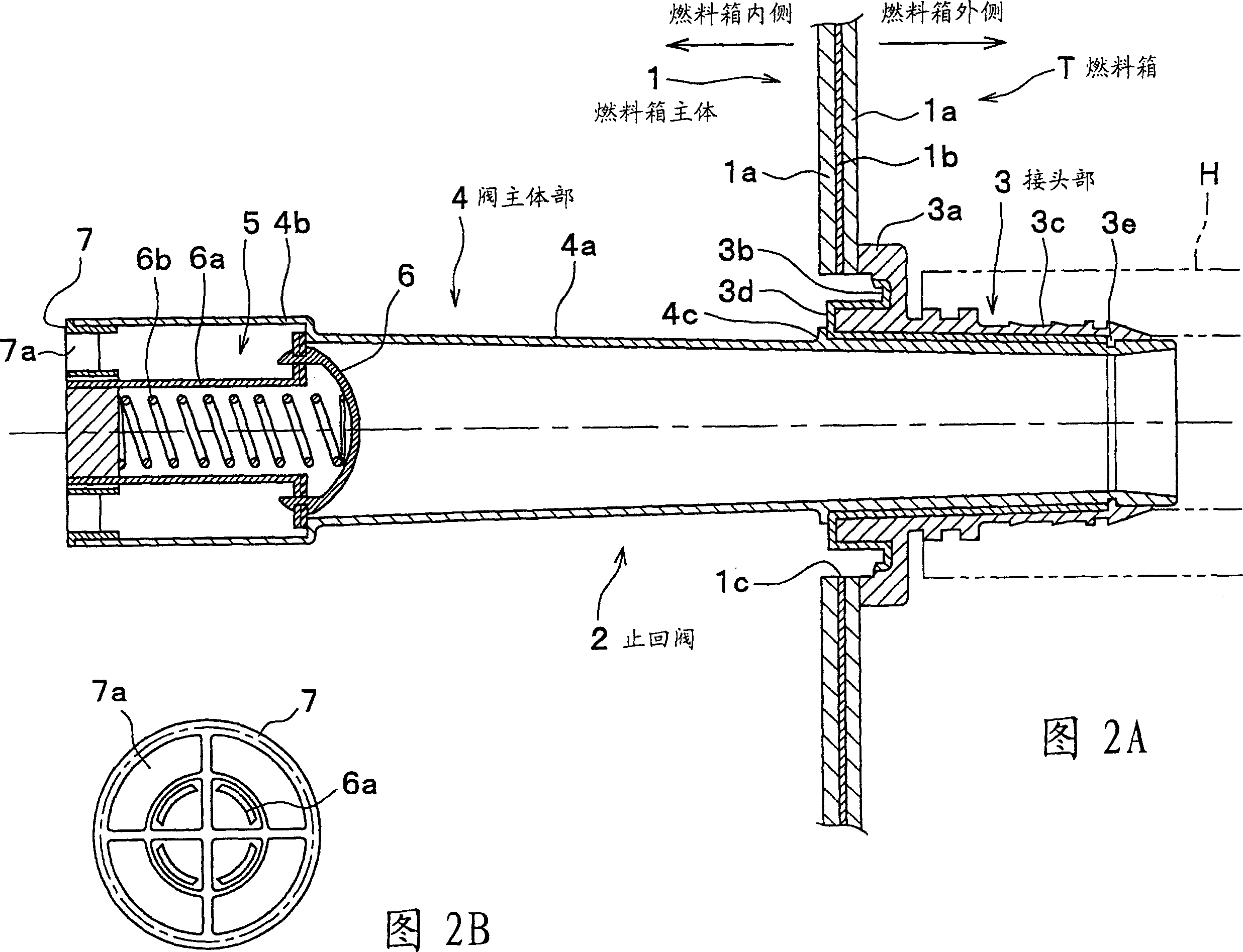

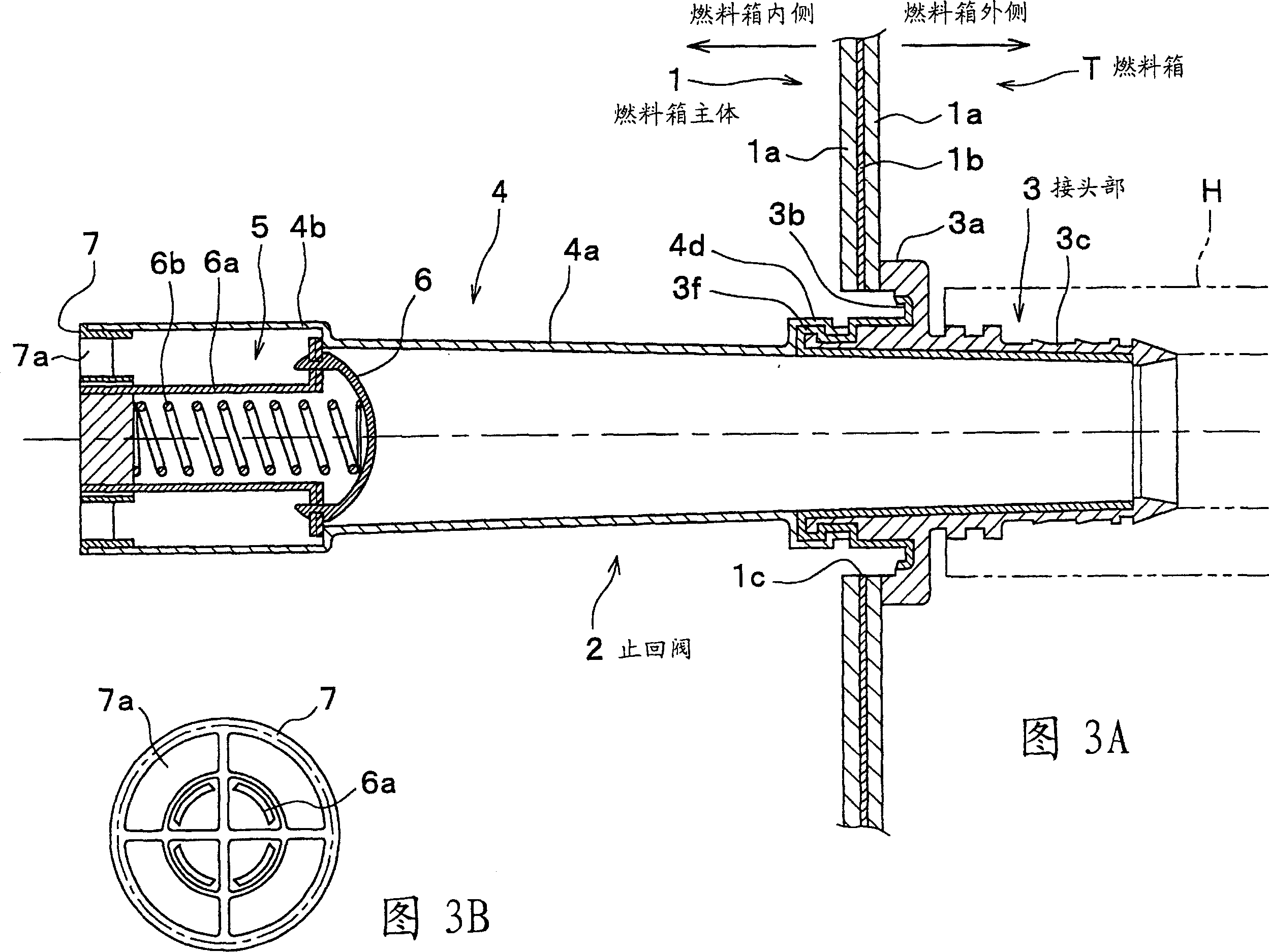

Attachment structure of a component in a fuel tank made of resin

InactiveUS7082964B1Sealing propertyImprove barrier propertiesCheck valvesEqualizing valvesThermal depositionFuel tank

In order to solve the problem of a conventional attachment structure of a fuel tank made of resin, the present invention is an attachment structure of a component of a fuel tank made of resin where a connection portion with a tank main body made of resin is formed of a thermally depositable material, and which tank comprises a joint portion connected with the tank main body by a thermal deposition and an inner tubular member supported by the joint portion and housed in the tank main body, wherein a movement regulation mechanism for regulating a movement in an axial direction of the inner tubular member for the joint portion is provided at least at one of the joint portion and the inner tubular member, and the joint portion and the inner tubular member are formed by an integral molding.

Owner:YACHIYO IND CO LTD +2

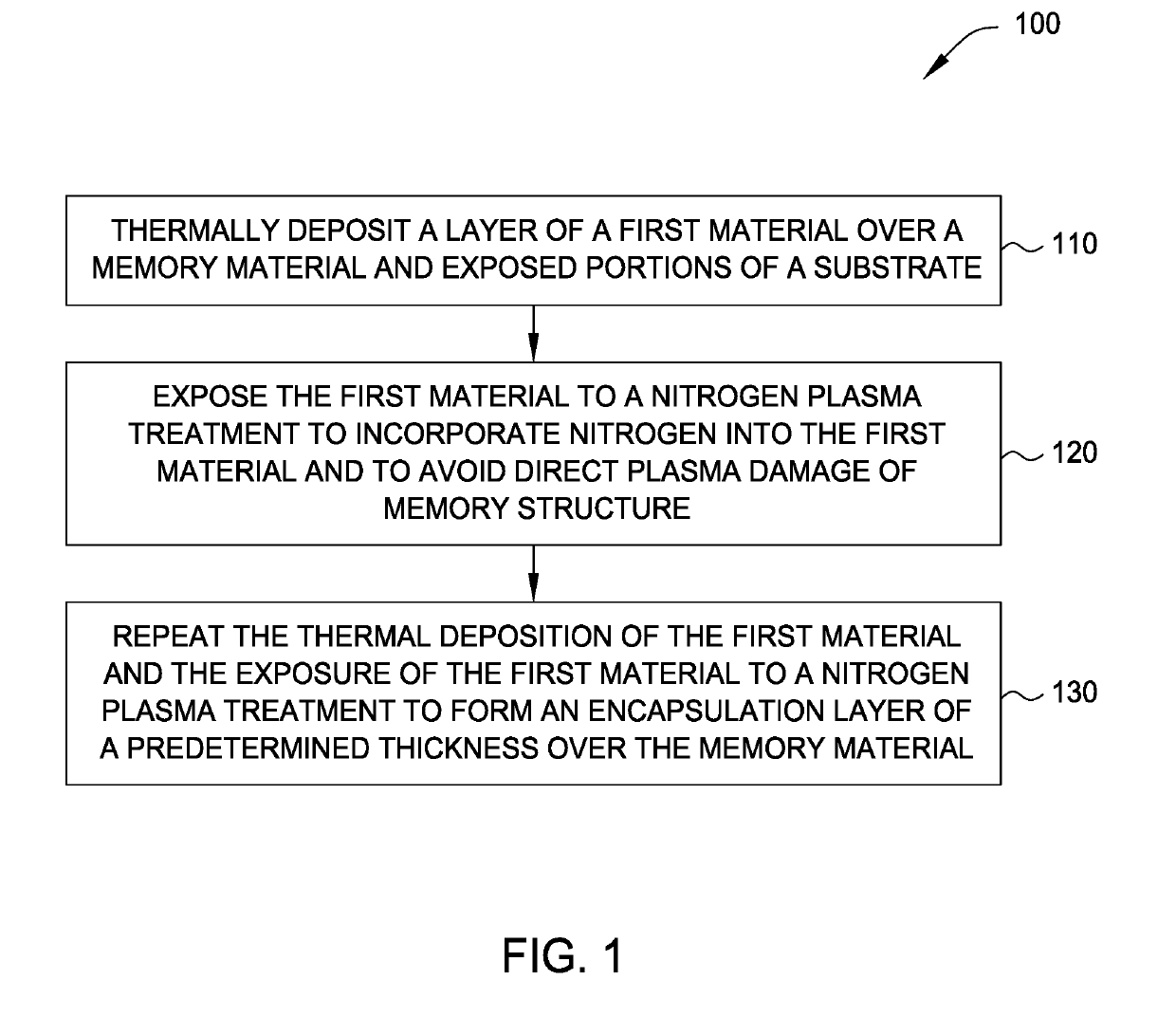

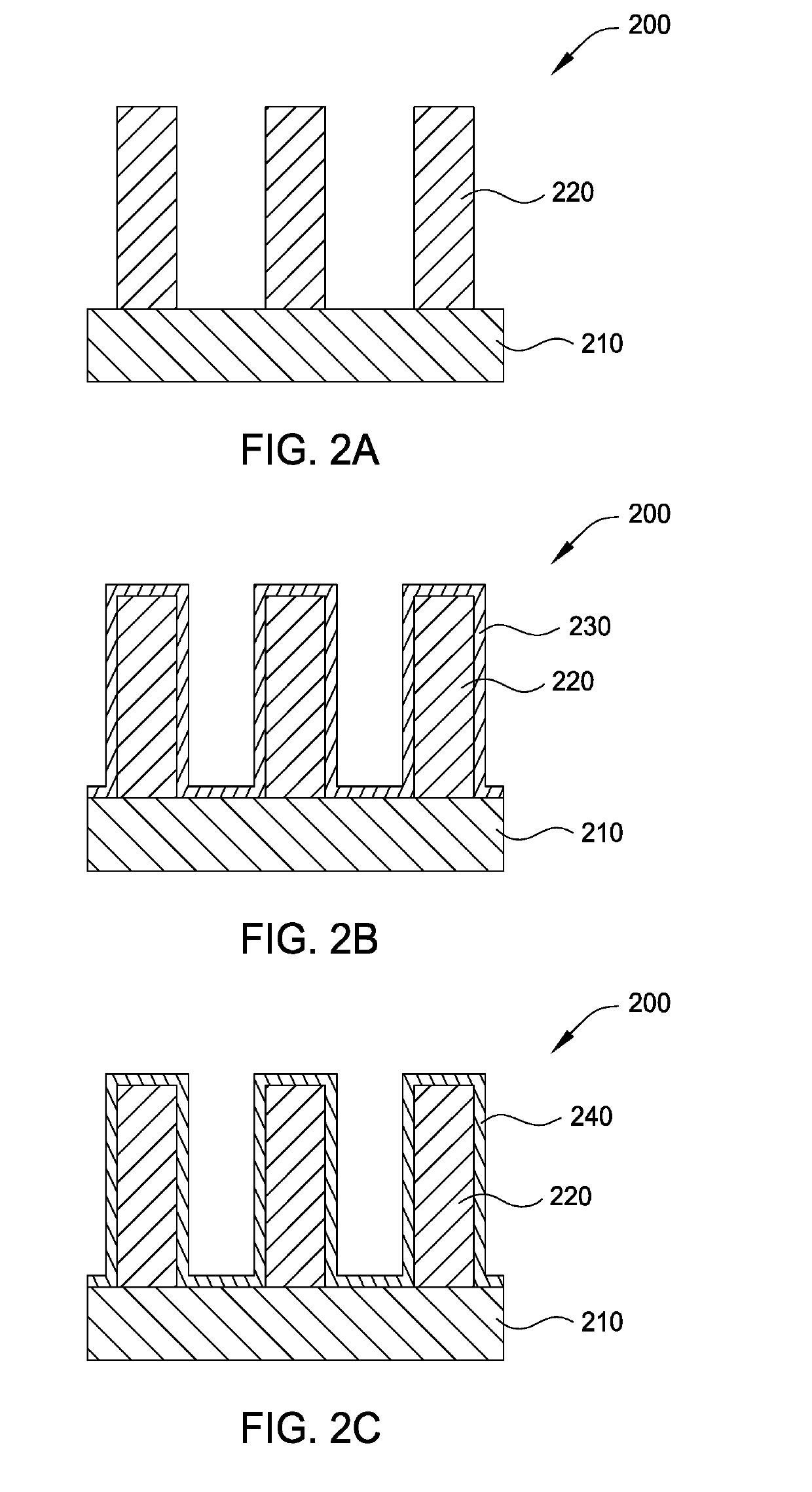

Sibn film for conformal hermetic dielectric encapsulation without direct RF exposure to underlying structure material

ActiveUS20190326110A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen plasmaThermal deposition

Embodiments disclosed herein relate to methods for forming memory devices, and more specifically to improved methods for forming a dielectric encapsulation layer over a memory material in a memory device. In one embodiment, the method includes thermally depositing a first material over a memory material at a temperature less than the temperature of the thermal budget of the memory material, exposing the first material to nitrogen plasma to incorporate nitrogen in the first material, and repeating the thermal deposition and nitrogen plasma operations to form a hermetic, conformal dielectric encapsulation layer over the memory material. Thus, a memory device having a hermetic, conformal dielectric encapsulation layer over the memory material is formed.

Owner:APPLIED MATERIALS INC

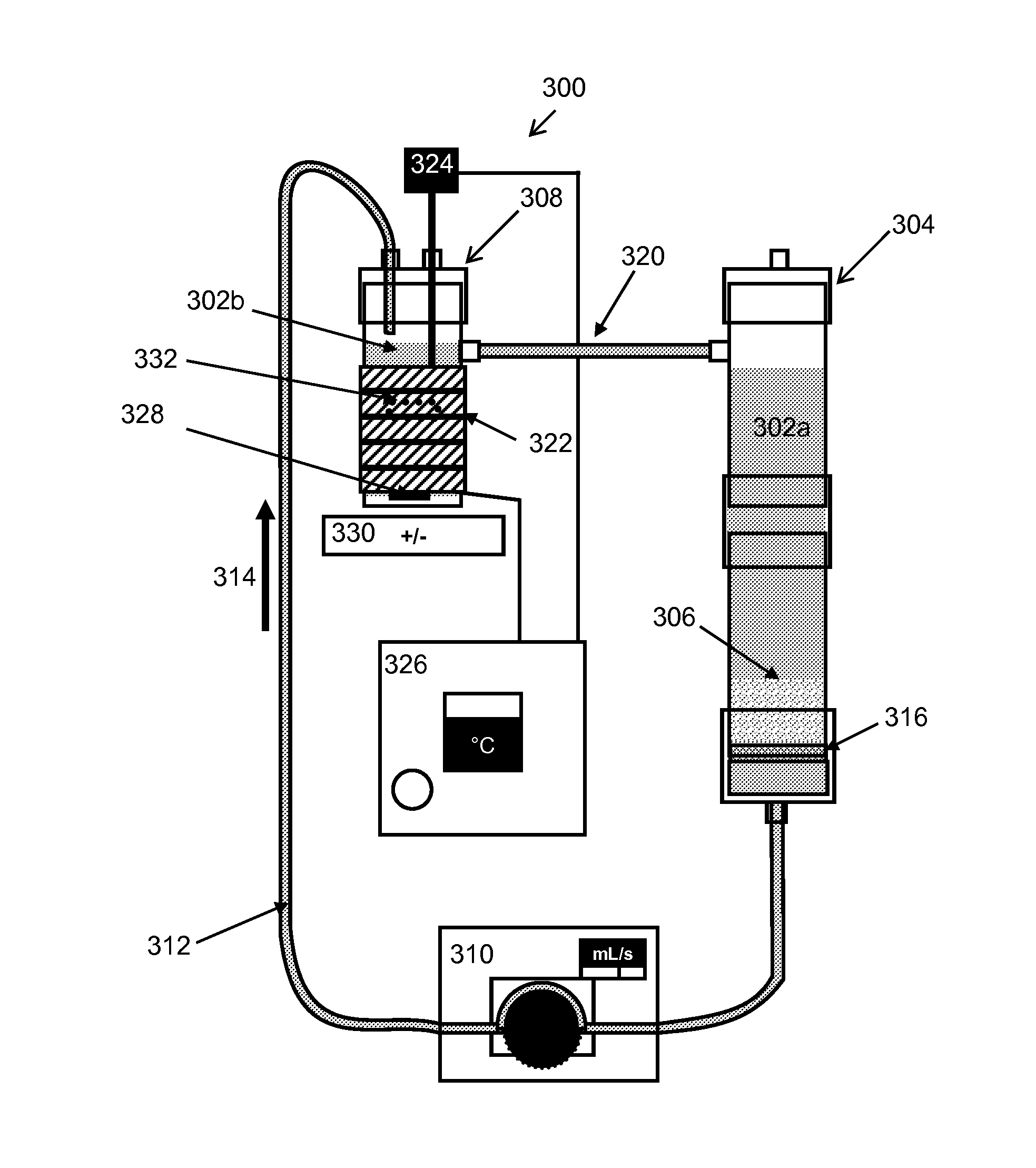

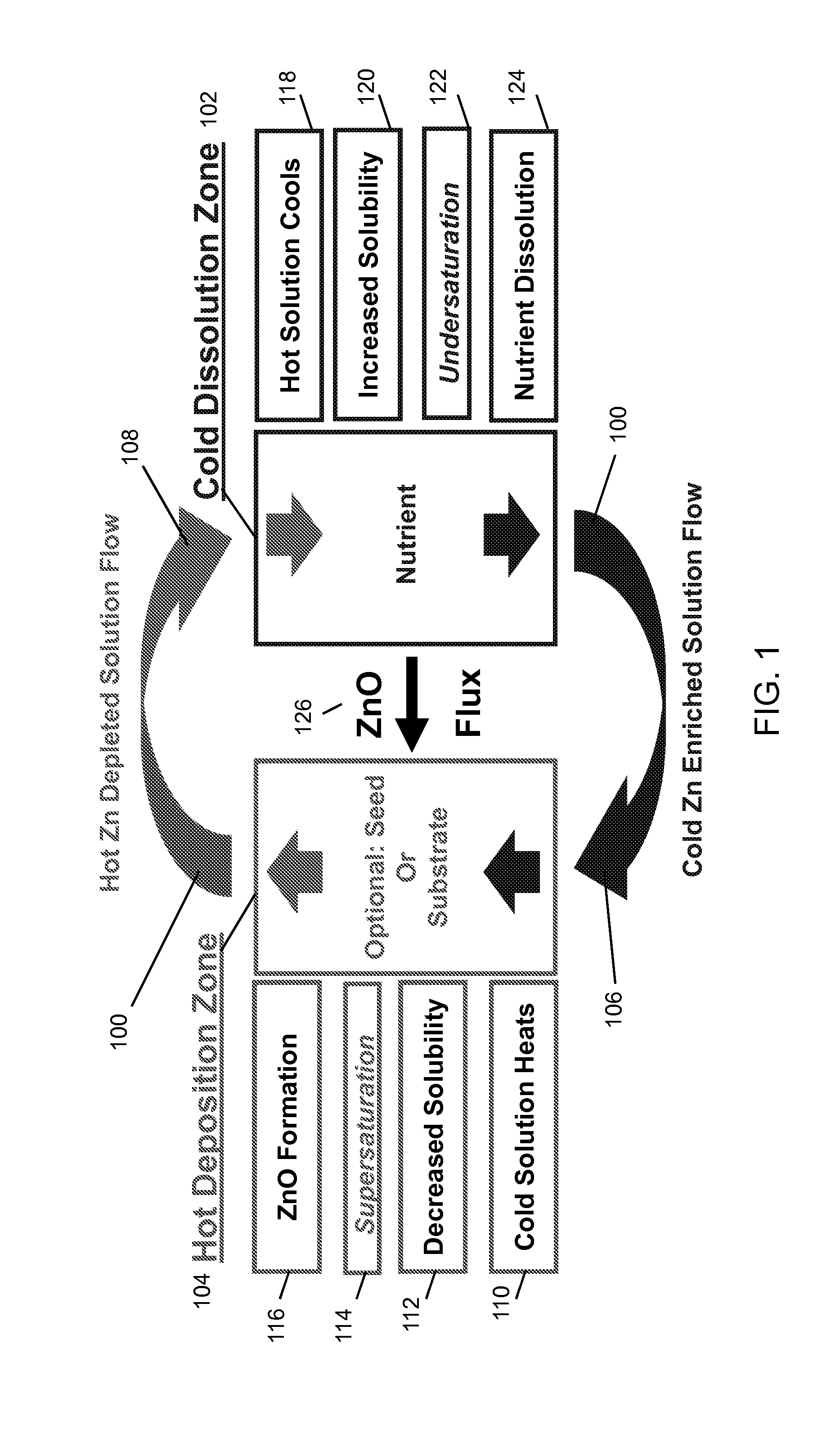

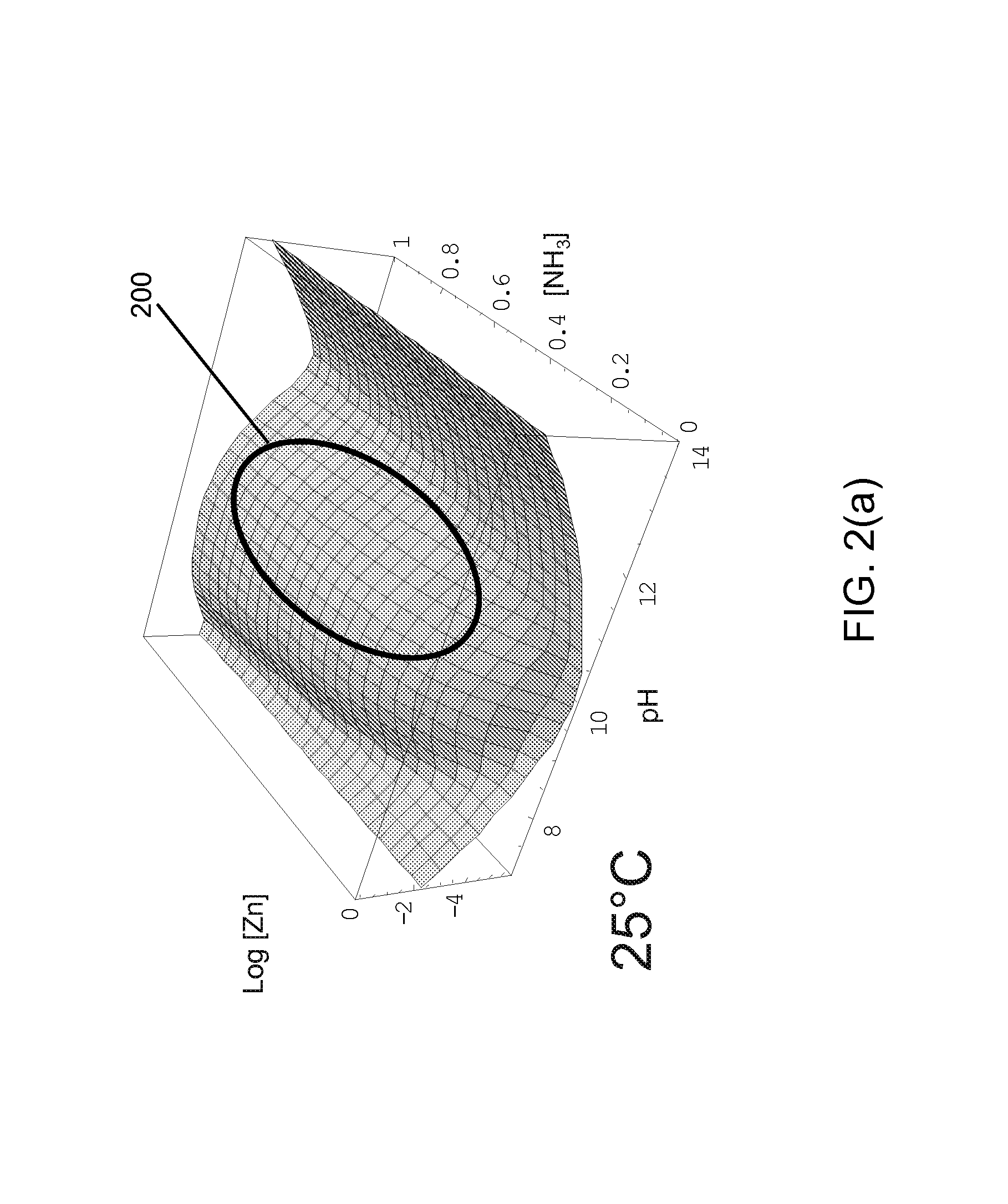

LOW TEMPERATURE CONTINUOUS CIRCULATION REACTOR FOR THE AQUEOUS SYNTHESIS OF ZnO FILMS, NANOSTRUCTURES, AND BULK SINGLE CRYSTALS

ActiveUS20140083352A1Improve compatibilityLowering environmental impact and costLiquid-phase epitaxial-layer growthZinc oxides/hydroxidesSource materialSingle crystal

A method for synthesizing ZnO, comprising continuously circulating a growth solution that is saturated with ZnO between a warmer deposition zone, which contains a substrate or seed, and a cooler dissolution zone, which is contains ZnO source material.

Owner:RGT UNIV OF CALIFORNIA

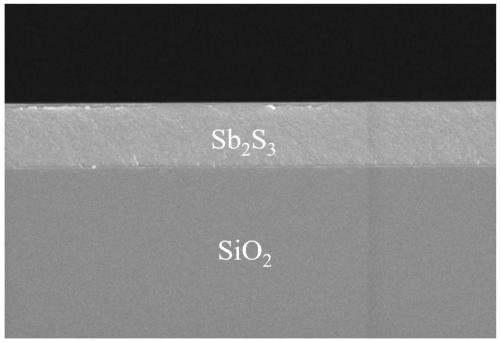

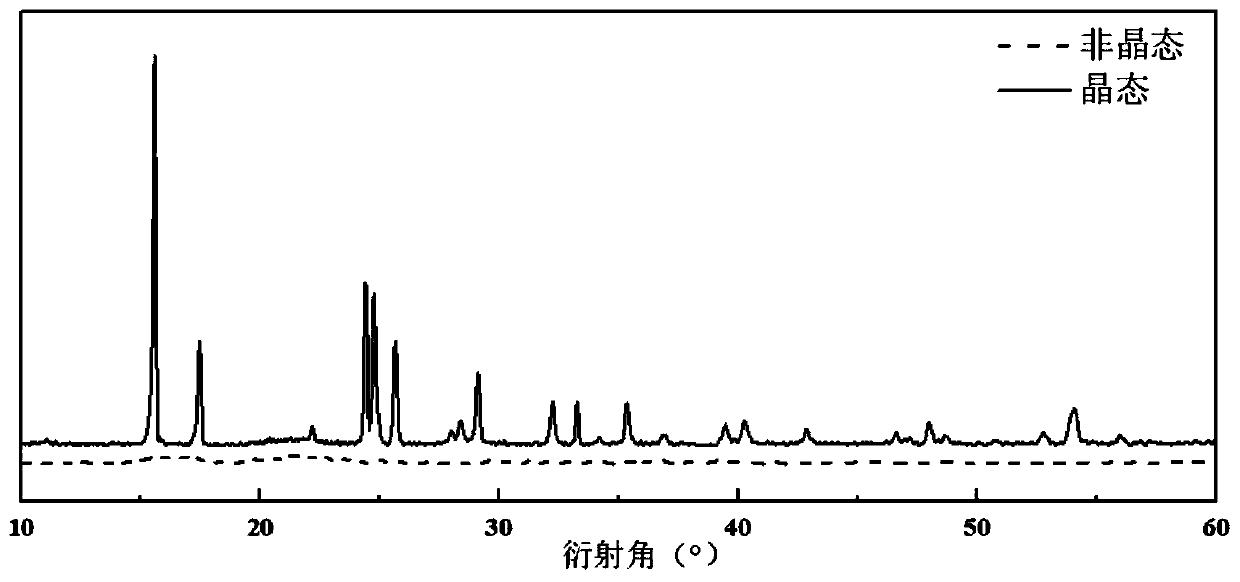

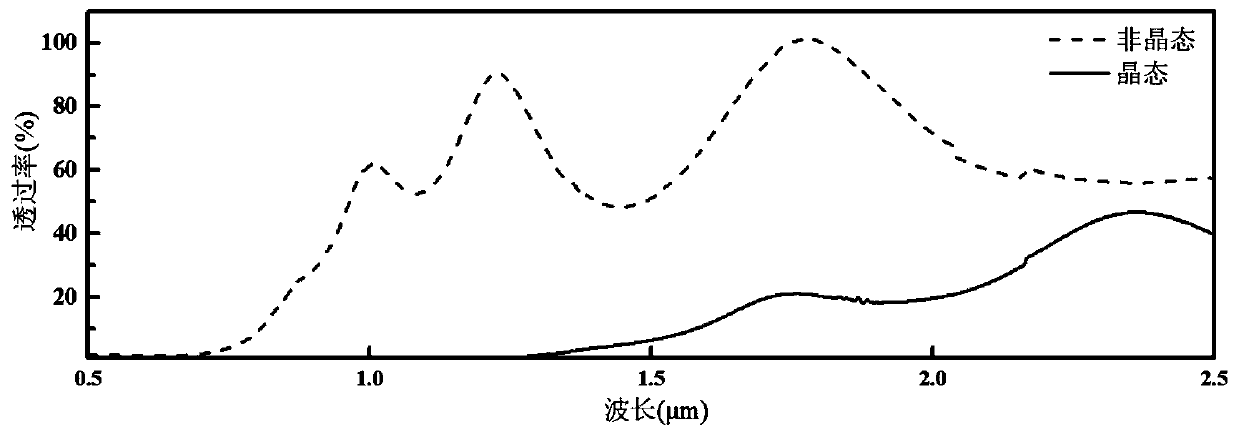

Chalcogenide phase-change film capable of being used for multispectral active optical regulation and preparation method thereof

InactiveCN111399255AMeet the integrationSatisfy functionVacuum evaporation coatingSputtering coatingThermal depositionRefractive index

The invention relates to a chalcogenide phase change film capable of being used for multispectral active optical regulation and a preparation method, and belongs to the field of optical films and optical phase change materials. The chemical formula of the phase change thin film is Sb<x>S<100-x>, wherein x is greater than 20 and less than 50. The amorphous high-quality optical thin film is preparedby adopting a high-vacuum rapid thermal deposition method. The film can be reversibly converted between a high refractive index (amorphous state) and a low refractive index (crystalline state) underthe thermal action of an external field. The crystalline state and the amorphous state of the material film can have obvious difference in refractive index within the range of 0.55-25 [mu]m, the lighttransmittance is good, the material film can be used for preparing a multispectral light field active regulation and control device, and the development requirements for integration, miniaturizationand multifunction of a traditional light field regulation and control device can be met.

Owner:SUN YAT SEN UNIV

Connecting structure for parts in fuel tank made of resin

The invention relates to a connection structure between the elements of resin fuel box. Wherein, the connection part is made from thermal deposition material, while said fuel box comprises a connecting head connecting the main body via thermal deposition, a inner tube supported by connecting head and contained inside the main body, and at least one motion adjuster at the connecting head and the inner tube to adjust the axial motion of inner tube along the connecting head. The connecting head and the inner tube are made by integrated molding.

Owner:YACHIYO IND CO LTD +2

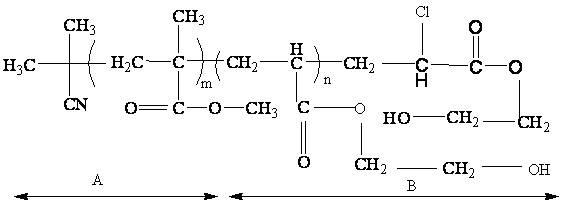

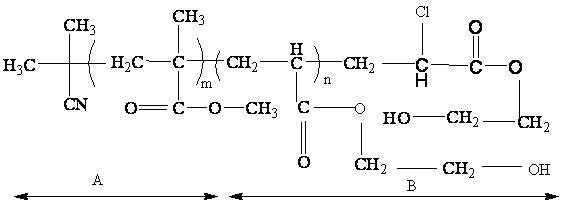

Block copolymer/nano-SiO2 composite material and preparation method thereof

The invention discloses a block copolymer / nano-SiO2 composite material and a preparation method thereof. The composite material comprises a block copolymer, namely polymethyl methacrylate-b-polyacrylic acid-2-hydroxyethyl ester, and nano-SiO2; and the preparation method of the composite material is as follows: synthesizing polymethyl methacrylate containing terminal group chlorine by adopting a reverse atom transfer free radical method, taking the prepared polymethyl methacrylate as a macromolecular initiator, and synthesizing the block copolymer, namely the polymethyl methacrylate-b-polyacrylic acid-2-hydroxyethyl ester, through a atom transfer free radical method; and adopting a silane coupling agent, namely gamma-methacryloxypropyltrimethoxy silane, to modify the nano-SiO2, and obtaining the activated nano-SiO2; performing surface grafting reaction on the activated nano-SiO2 and the block copolymer, namely the polymethyl methacrylate-b-polyacrylic acid-2-hydroxyethyl ester, and obtaining the block copolymer / nano-SiO2 composite material. Compared with the block copolymer, the composite material has higher thermal deposition temperature and better heat resistance.

Owner:GUANGDONG UNIV OF TECH

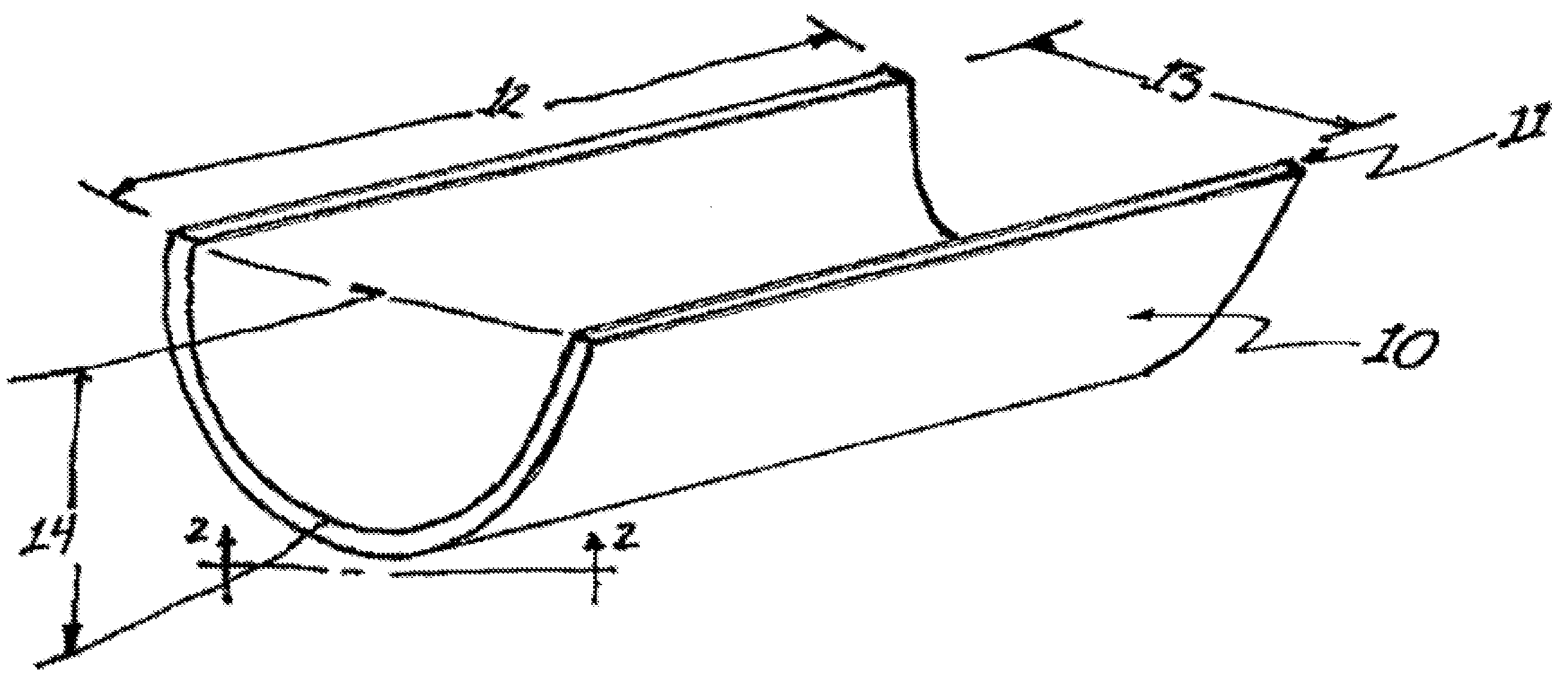

Protective coating for concrete delivery system components

The present invention relates to a component of a concrete delivery system comprising a substrate made of relatively thin gauge carbon steel or aluminum, and a protective coating of amorphous, nano or near-nanoscale steel, or mixtures thereof, overlying the substrate, wherein the coating may be formed by thermal deposition process from multi-component glass forming steel alloys. The protective coating may also be heat treated to increase wear life.

Owner:LINCOLN GLOBAL INC +1

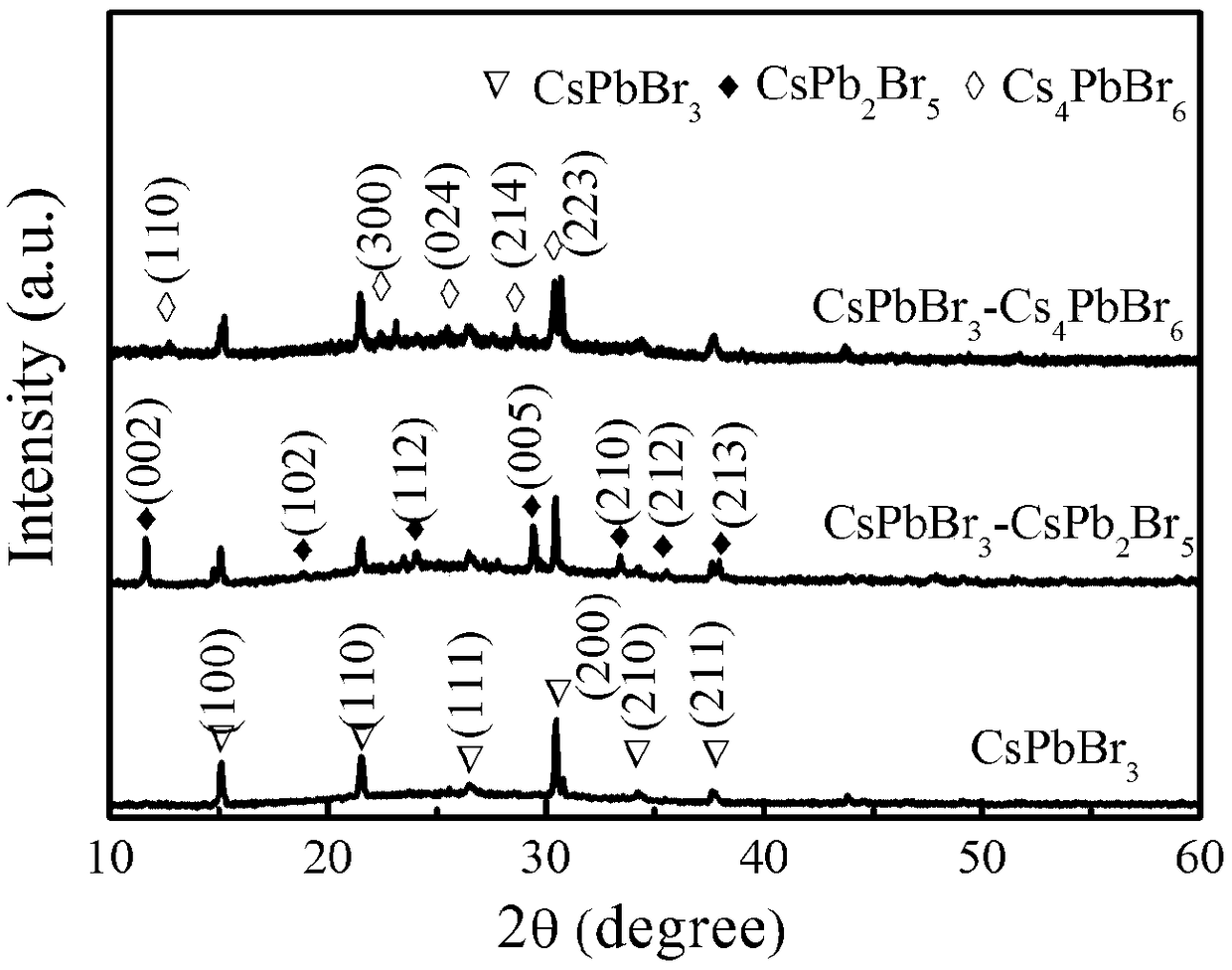

A preparation method of lithium ion using inorganic perovskite derivative phase as negative electrode material

ActiveCN109065834AEasy to getLow priceElectrode thermal treatmentSecondary cellsCooking & bakingCopper foil

The invention discloses a preparation method of an inorganic perovskite derivative phase used as a negative electrode material for lithium ions, which relates to the technical fields of preparation and research of the negative electrode material of lithium ion batteries and the like. The precursor of lead bromide and cesium bromide was evaporated by vacuum thermal deposition process and depositedon the copper foil of cathode current collector. The cathode material was homogeneous and dense by subsequent heating and baking. The invention utilizes the principle of chemical solid state reactionand thermal evaporation vapor deposition, Using inorganic lead bromide and cesium bromide as raw materials, the pure inorganic perovskite materials were prepared by vacuum heating and evaporation on current collector copper foil substrate. The evaporation rate of precursor material was adjusted and the thickness and thickness ratio of the precursor material were adjusted during the reaction. Applying it to the cathode material of lithium ion battery, it exhibits good thermodynamic stability and excellent physicochemical properties, and the process is simple.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

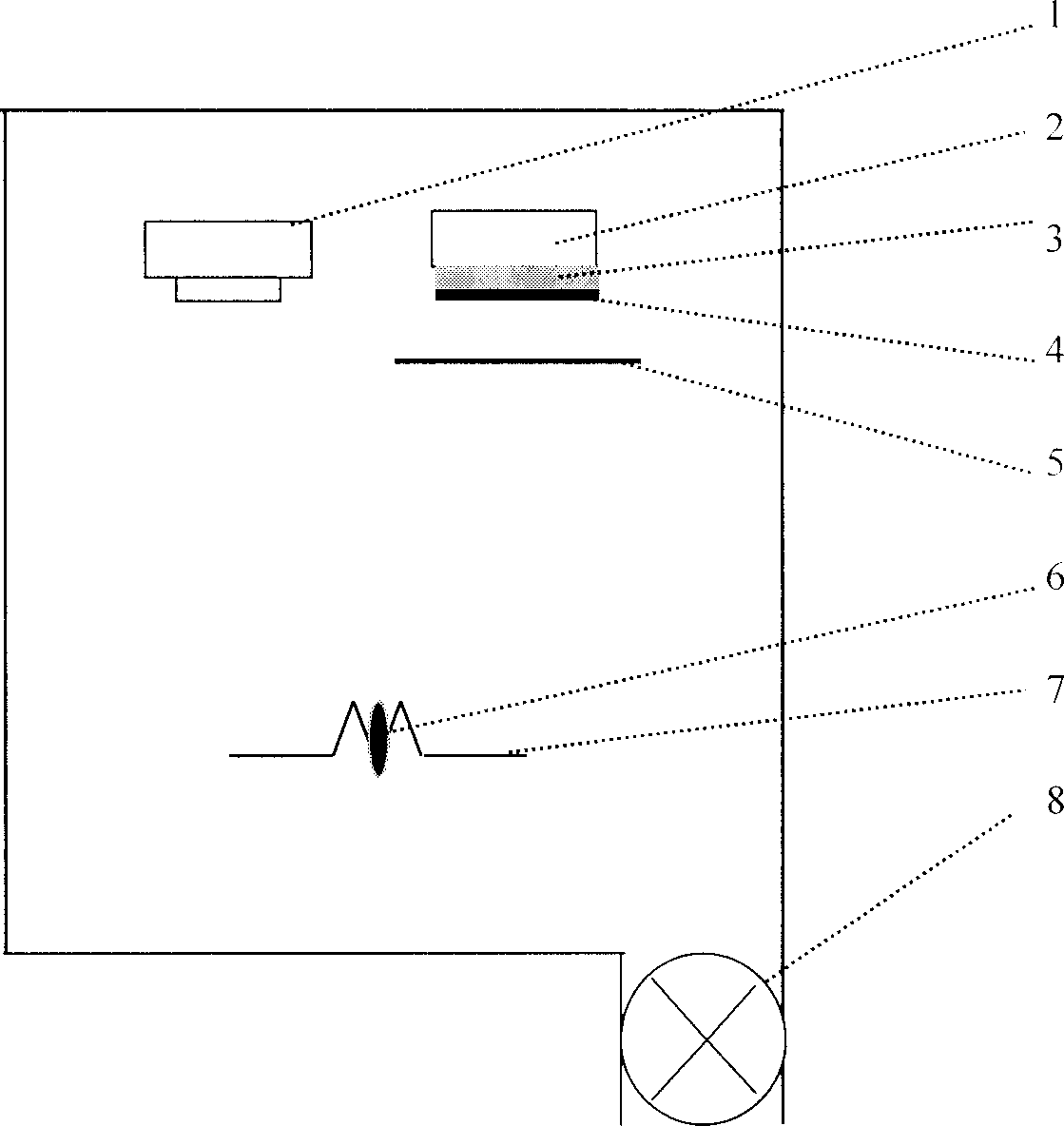

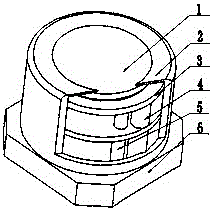

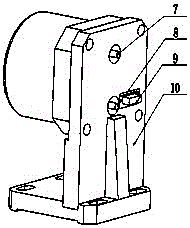

Wave-front defocus correction device

InactiveCN105700127AReduce the influence of thermal distortion on surface shapeAvoid aberrationsOptical elementsThermal depositionCooling chamber

The present invention provides a wave of correction devices, which include lens, cooling cavity, driver, water pipe, base, water inlet, outlet, and support;The other end is fixed with the base; one end of the water pipe is connected to the cooling cavity, and the other end is fixed with the base; the base is fixed on the support;The water pores on the seat correspond to one -to -one pores.This scheme can load different loads on the drive according to the application requirements. The mirror movement moves up and down under the action of the driver, so that the mirror surface deforms, thereby correcting the wave surface.The influence, avoid the introduction of unnecessary extra extension.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

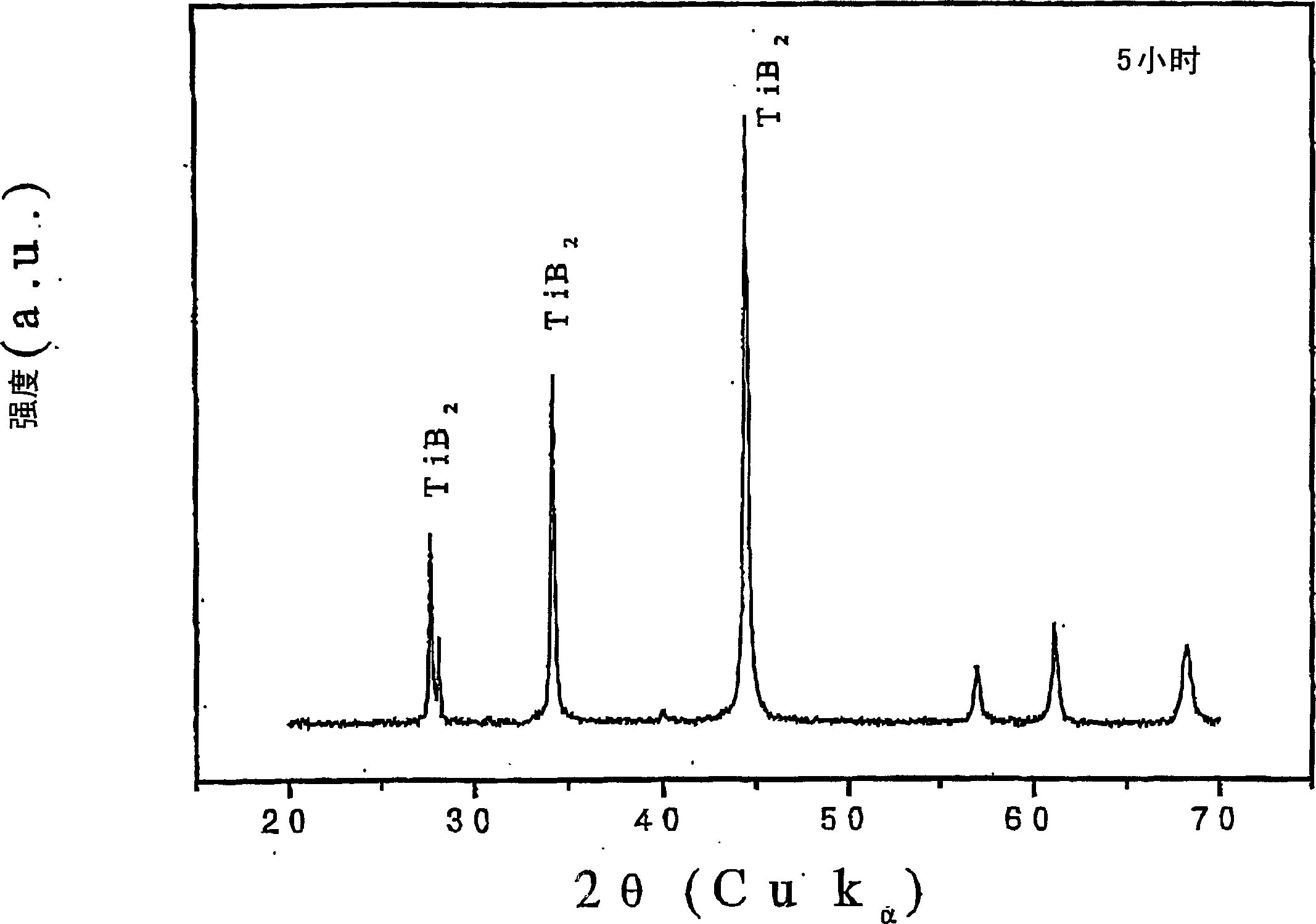

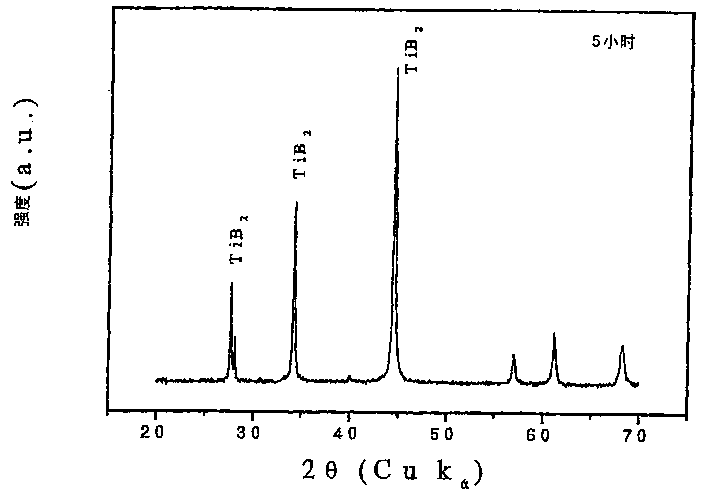

Refractory hard metals in powder form for use in the manufacture of electrodes

The invention relates to a refractory hard metal in powder form comprising particles having an average particle size of 0.1 to 30 mu m and each formed of an agglomerate of grains with each grain comprising a nanocrystal of a refractory hard metal of the formula (I): AxByXz wherein A is a transition metal, B is a metal selected from the group consisting of zirconium, hafnium, vanadium, niobium, tantalum, chromium, molybdenum, manganese, tungsten and cobalt, X is boron or carbon, x ranges from 0.1 to 3, y ranges from 0 to 3 and z ranges from 1 to 6. The refractory hard metal in powder form according to the invention is suitable for use in the manufacture of electrodes by thermal deposition or powder metallurgy.

Owner:密鲁塔拉集团公司

Vacuum insulation panel with improved rupturing and preparation method thereof

ActiveUS9523459B2Improve the immunityRaise the ratioLamination ancillary operationsThermal insulationThermal depositionMetal

Owner:ES GLOBAL CO LTD

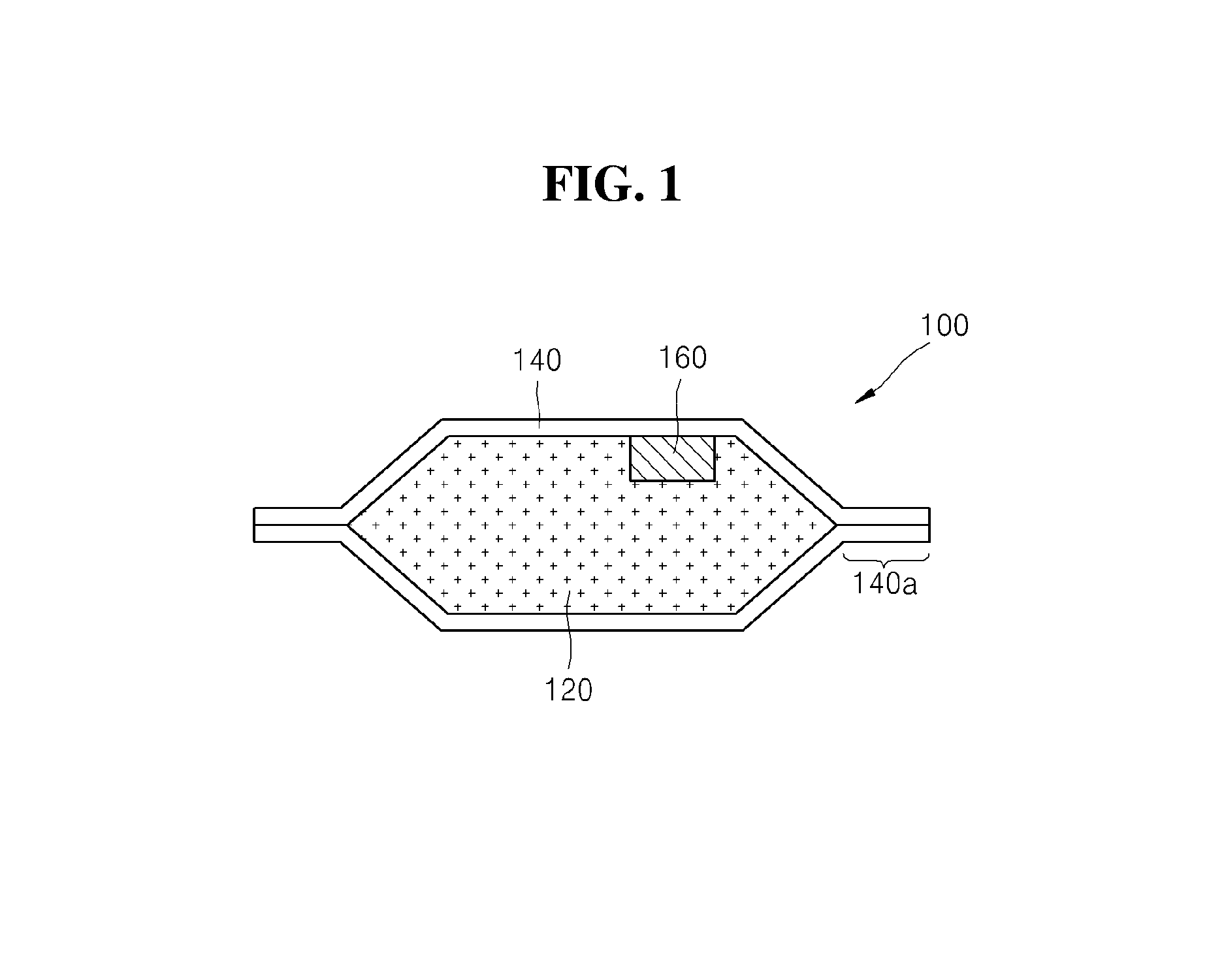

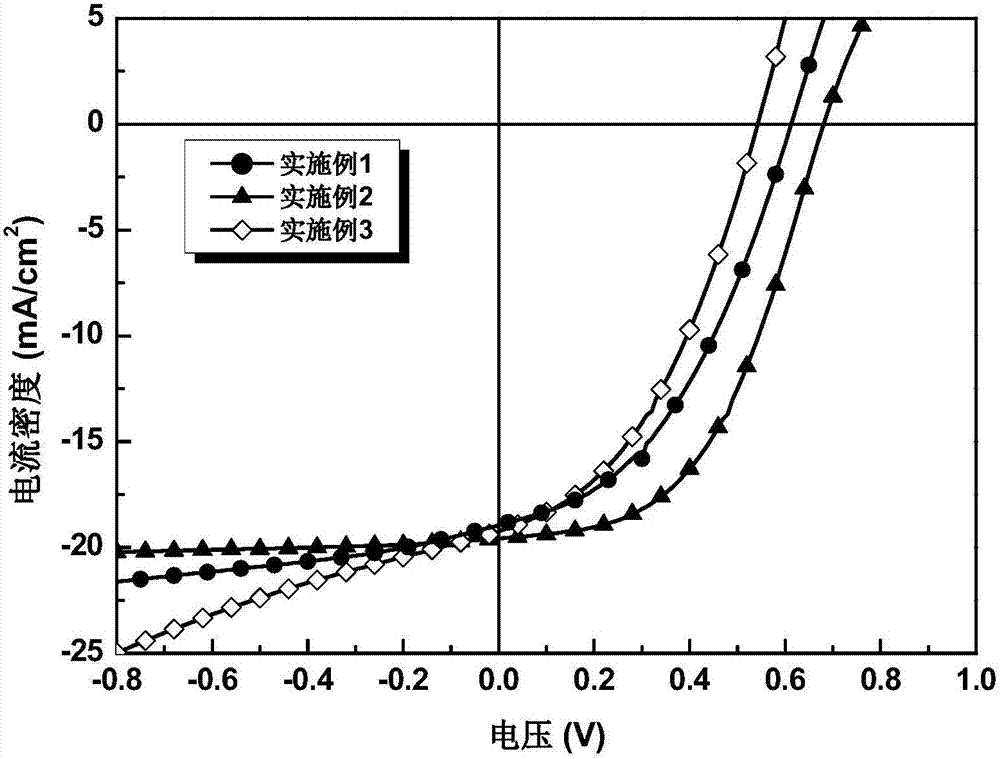

Perovskite film solar cell and preparation method thereof

ActiveCN107425121AMeet the requirements of photocurrent outputLow costSolid-state devicesSemiconductor/solid-state device manufacturingDopantPerovskite solar cell

The invention discloses a perovskite film solar cell comprising a first electrode; a perovskite light-absorbing layer which is arranged on the first electrode; a first electron transmission layer which is arranged on the perovskite light-absorbing layer; and a second electrode which is arranged on the first electron transmission layer, wherein the material of the first electron transmission layer is C60 doped with the organic micromolecule dopant. The preparation method of the solar cell comprises the steps that the organic micromolecule dopant and the C60 are deposited after evaporation by applying the double source vacuum thermal deposition technology, and the first electron transmission layer is prepared and formed on the perovskite light-absorbing layer. The C60 doped with the organic micromolecule dopant is used as the electron transmission layer so that the requirement of photocurrent output of the device can be met, the cost of the device can also be greatly reduced and thus industrial popularization and application of the perovskite film solar cell are facilitated.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

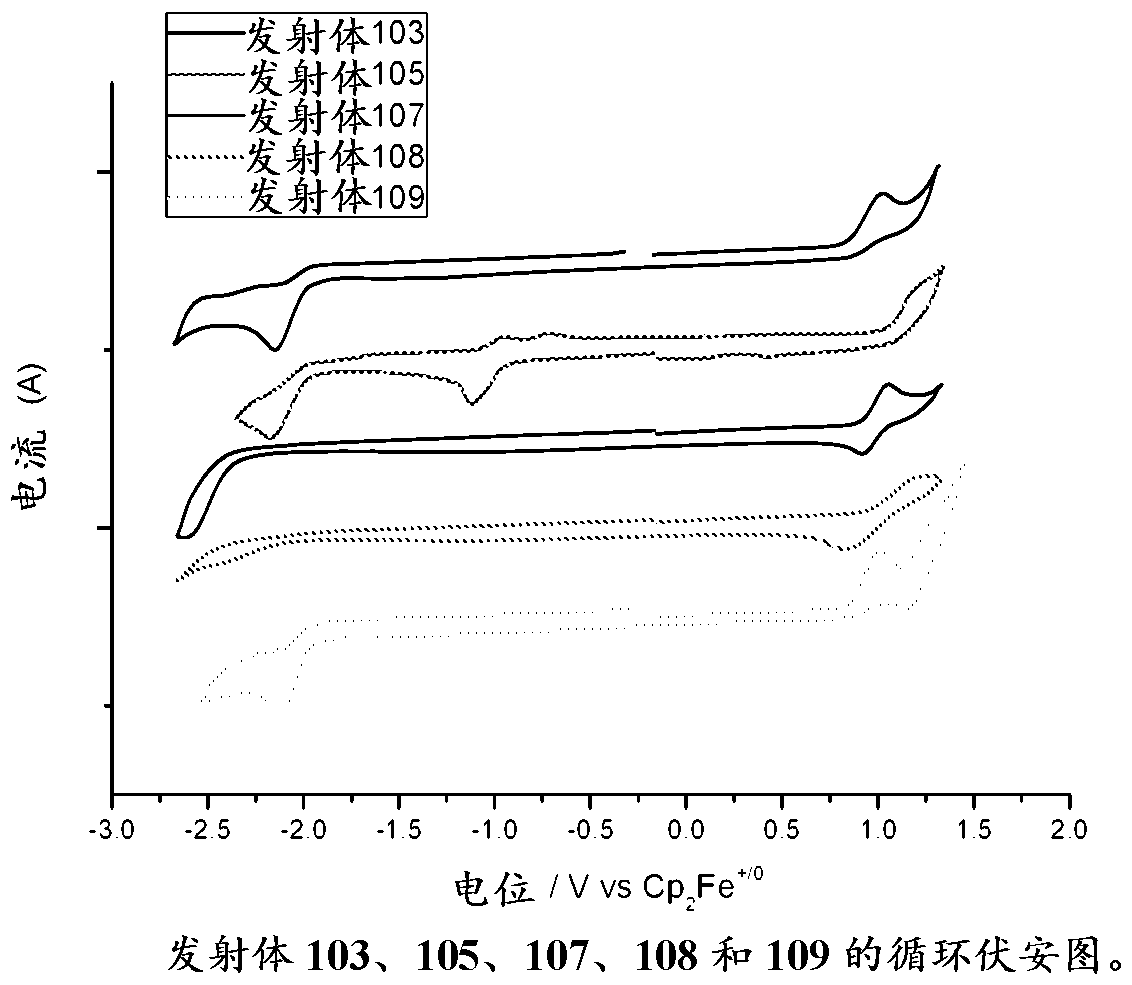

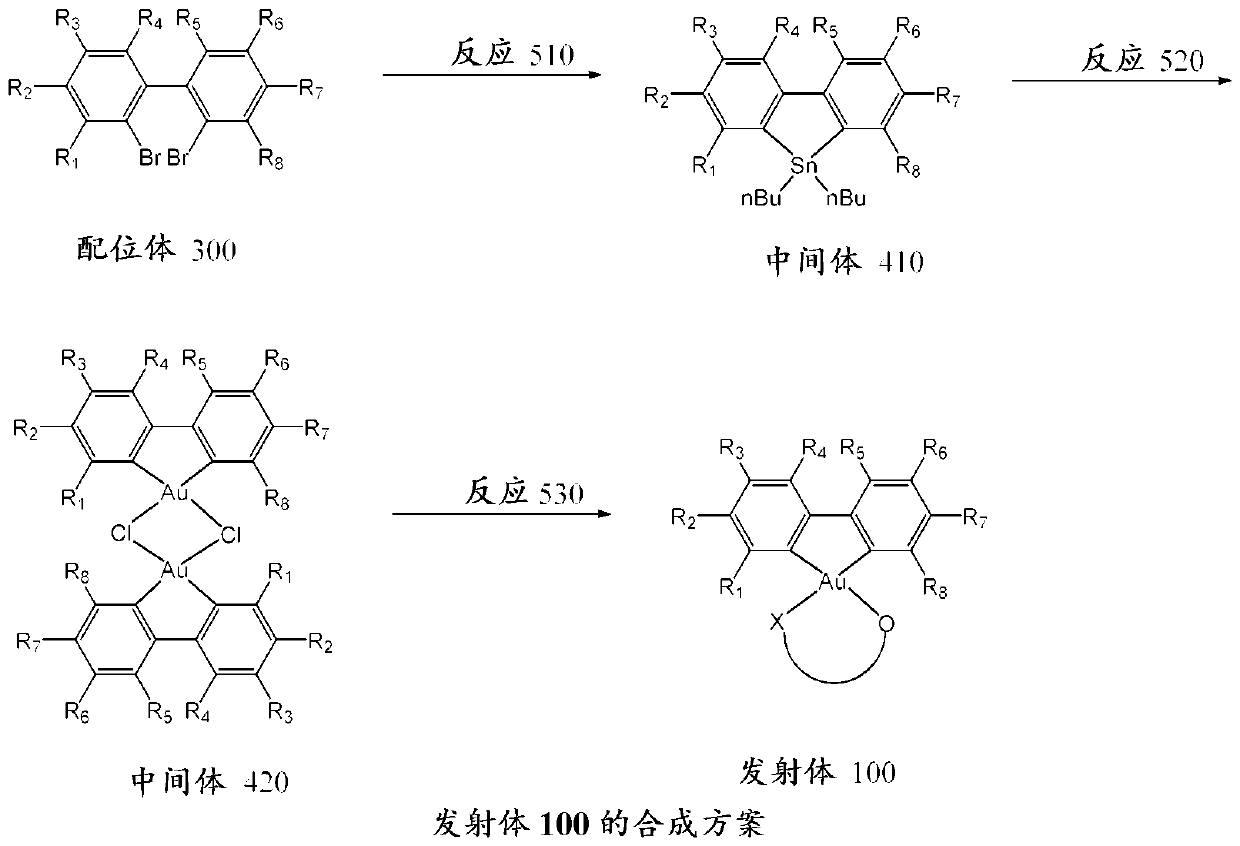

Gold complexes for OLED applications

ActiveCN107849062AGroup 5/15 element organic compoundsSolid-state devicesQuantum efficiencyThermal deposition

Gold (III) emitters showing high emission quantum efficiency and stable in thermal deposition process are described. High performance OLEDs can be fabricated from these emitters.

Owner:THE UNIVERSITY OF HONG KONG

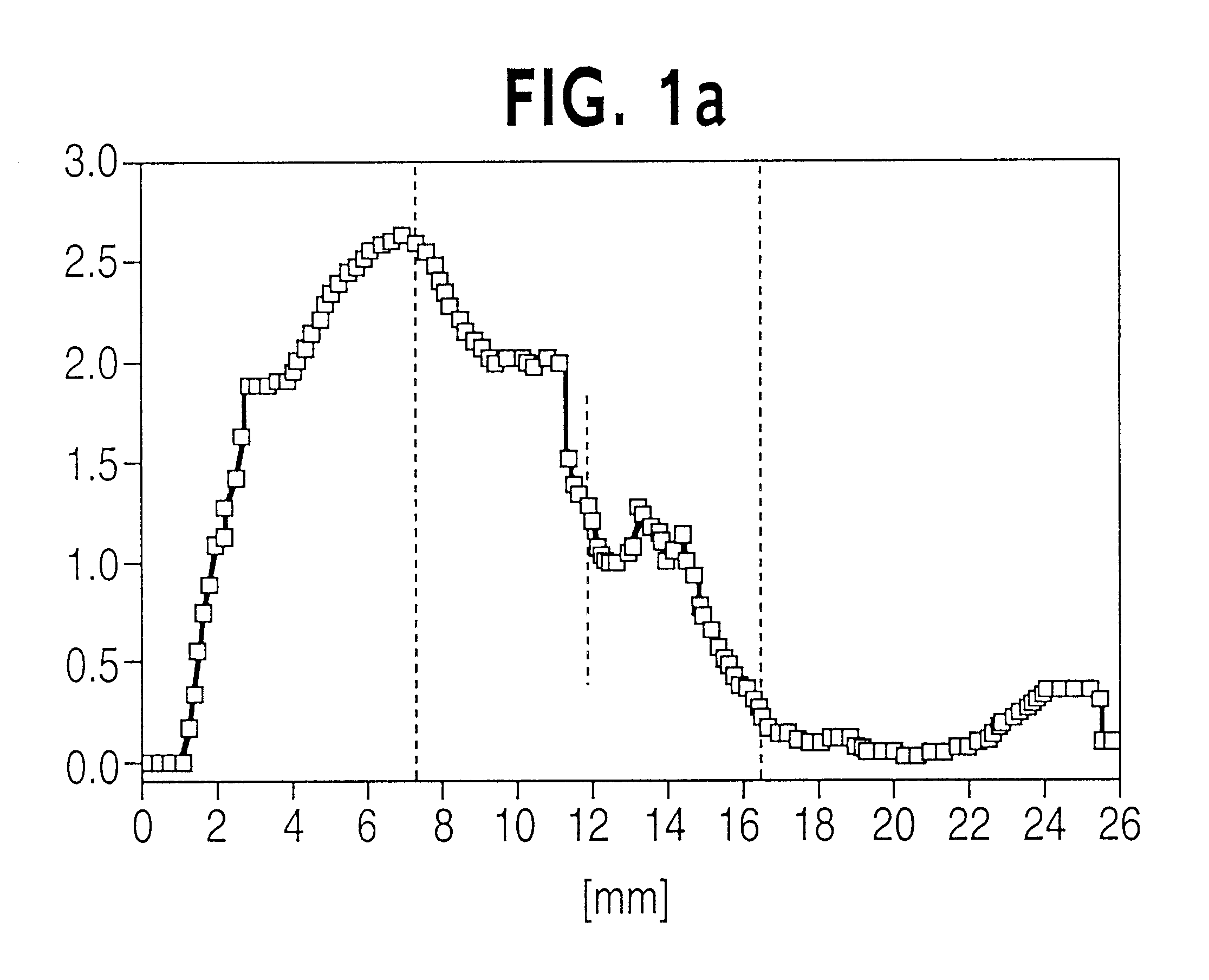

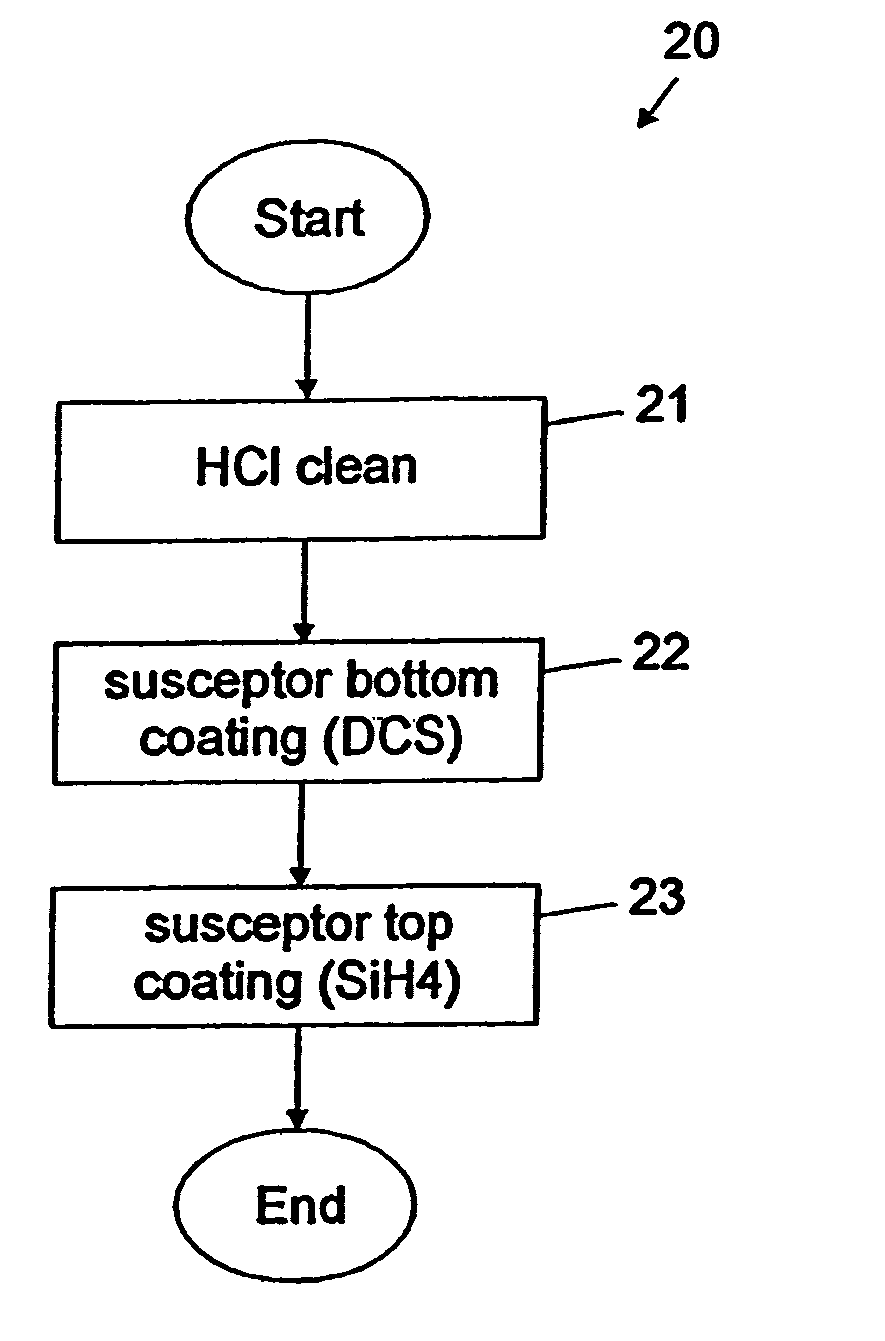

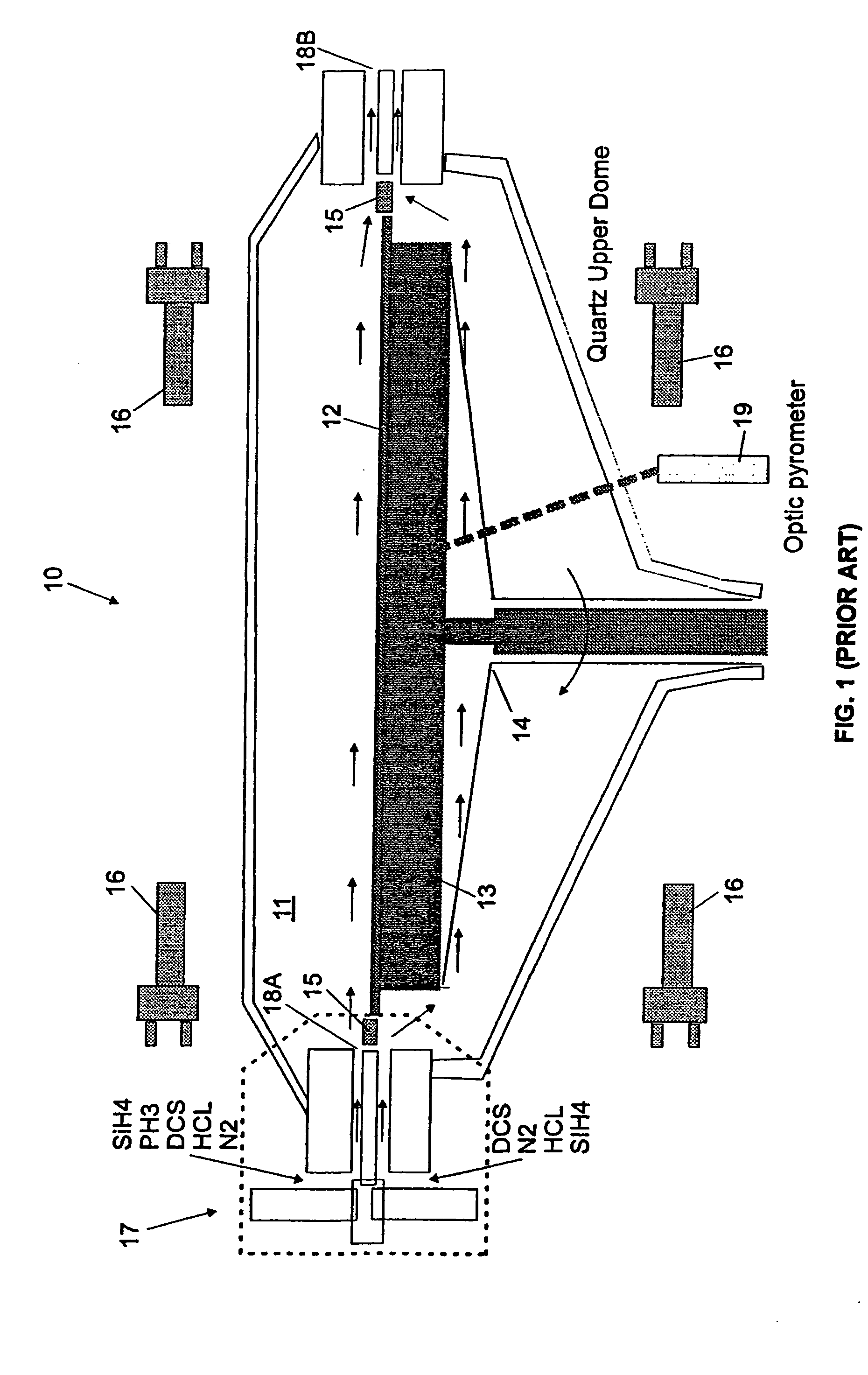

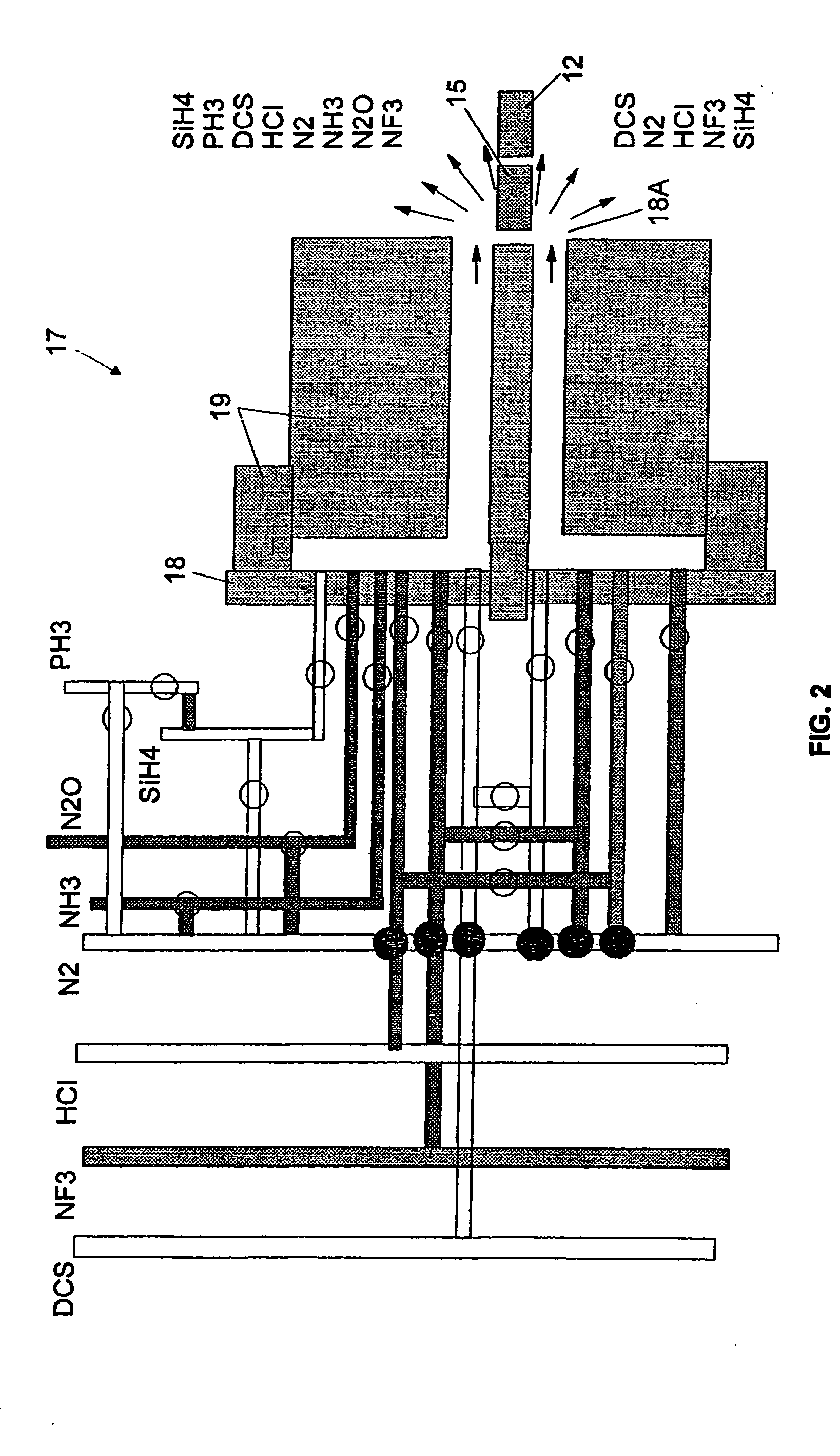

Multideposition SACVD reactor

InactiveUS20050229853A1Rapid thermal depositionFast depositionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingThermal depositionSusceptor

There is disclosed a high throughput multideposition SACVD reactor that enables the rapid thermal deposition of dielectric materials such as Si3N4, SiO2, and SiON and non-&electric materials such as polysilicon onto a semiconductor substrate in the same chamber according to the desired sequence. Such a reactor has a processing chamber which is well adapted to single semiconductor wafer processing. The processing chamber includes an improved susceptor to support the wafer and a specific gas distribution system adapted to supply the different gases used in the deposition process and for cleaning. The improved susceptor consists of a standard carbon plate coated with a polysilicon film to protect it against said cleaning gases when they are aggressive to carbon. The present invention also encompasses a method of fabricating said improved susceptor.

Owner:RAFFIN PATRICK +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com