Process for extracting sweet potato protein by thermal deposition method

A technology of sweet potato protein and extraction process, which is applied to the preparation method of peptides, chemical instruments and methods, and plant peptides. The effect of mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is further described below in conjunction with accompanying drawing:

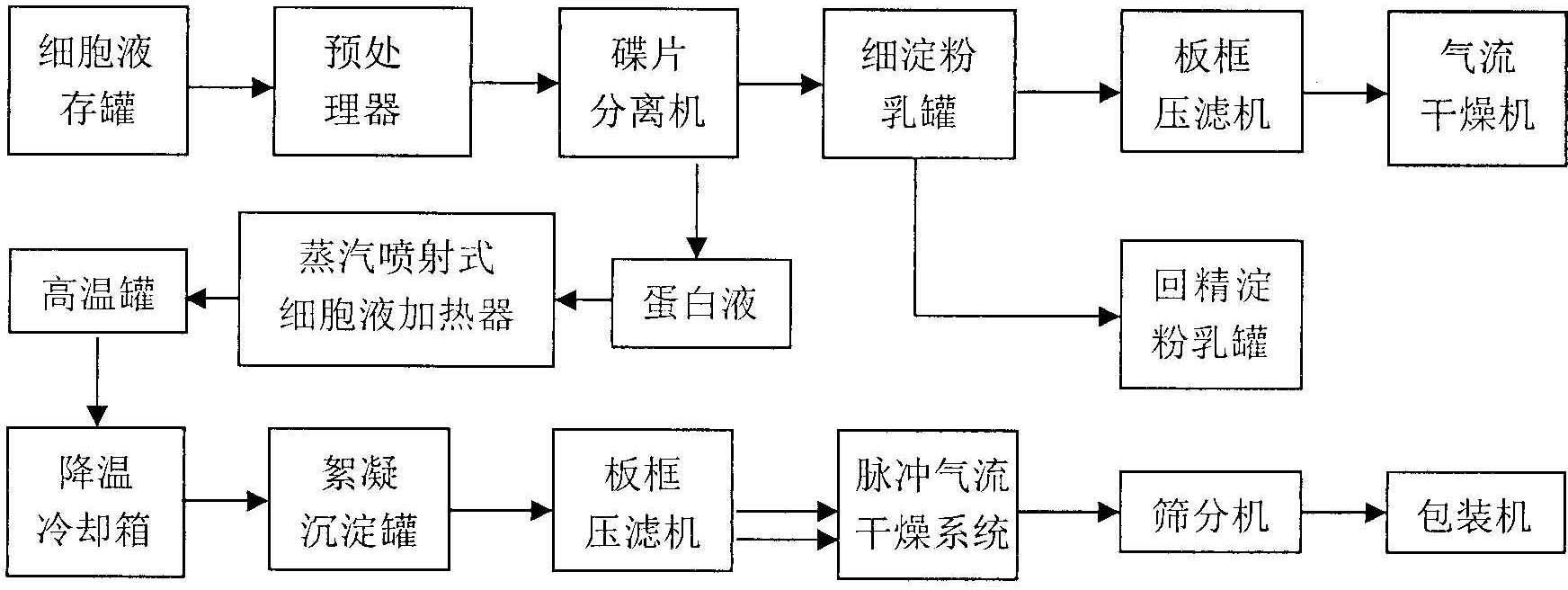

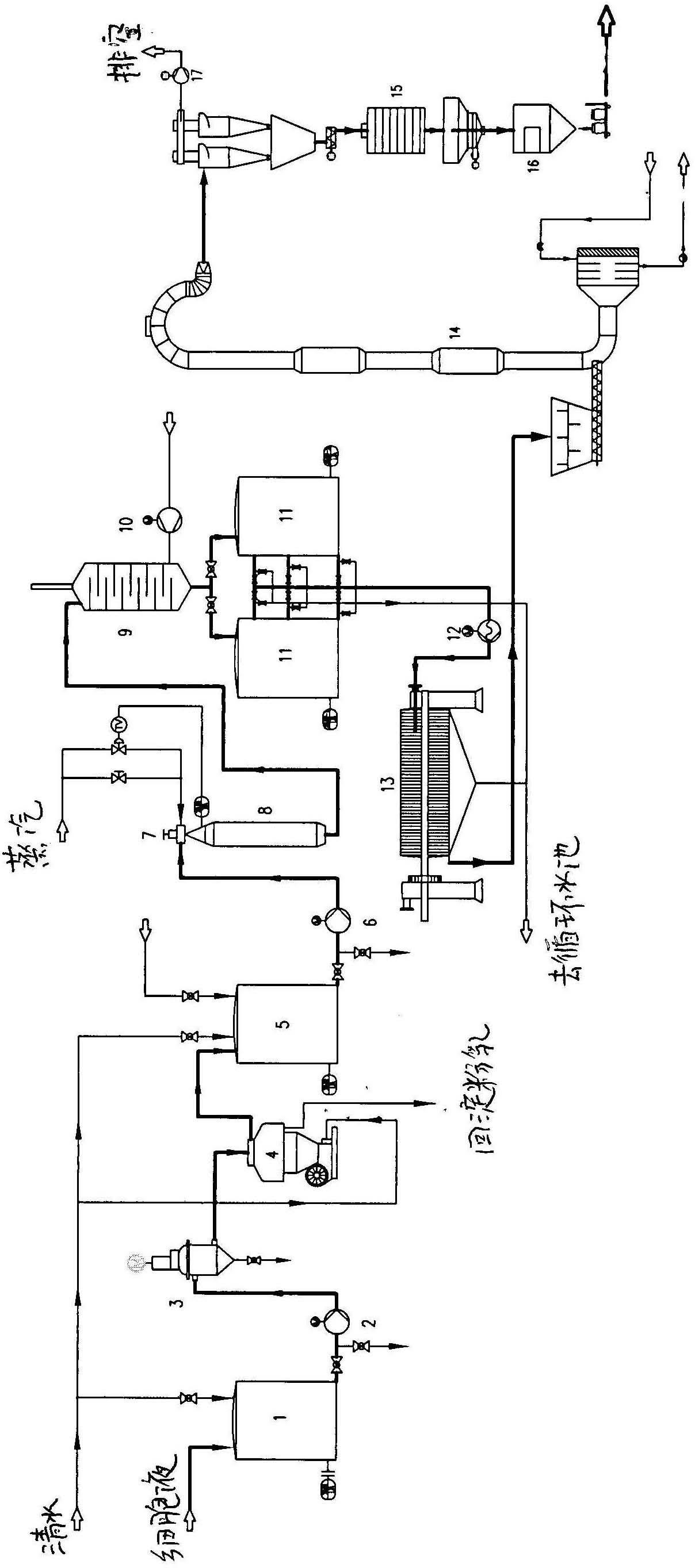

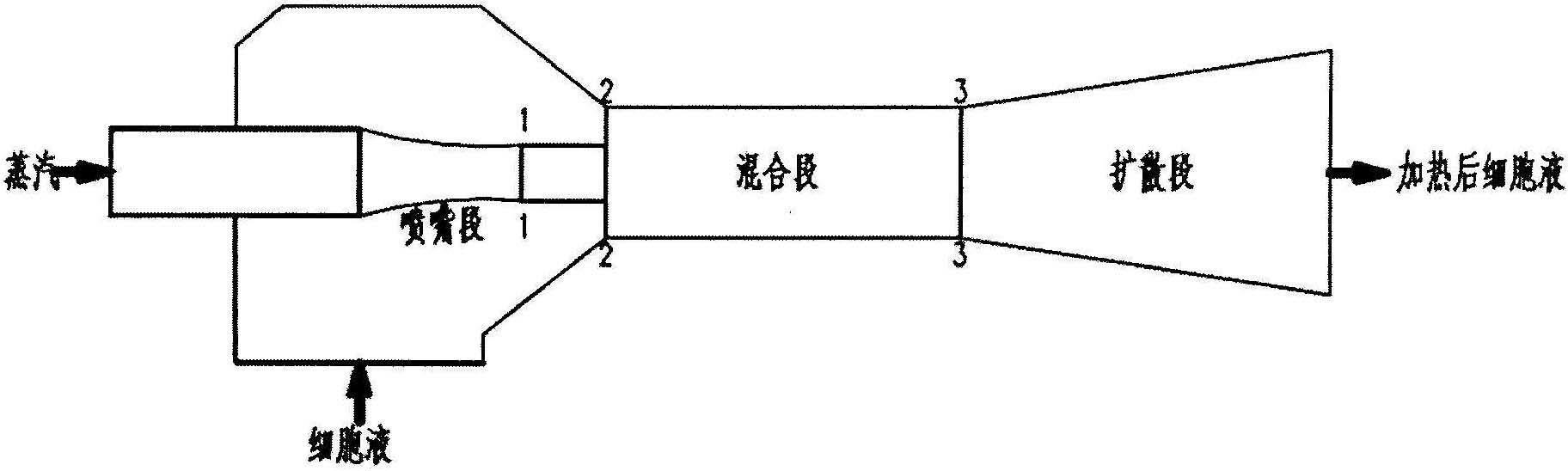

[0044] see Figure 1-5Shown: the cell liquid containing sweet potato protein is first pumped from the buffer tank (1) to the preprocessor (3) by the pump (2), and after most impurities are removed, it enters the disc separator (4) for separation. The function of the separator is to separate the light phase such as protein in the cell fluid from the heavy phase such as starch. Heavy phases such as starch are recovered, merged with refined starch milk and enter the downstream plate and frame filter press for dehydration, and then dried to become commercial starch. The cell fluid containing light phase such as protein separated by disc separator contains most of soluble protein and insoluble protein. The separated protein solution is sent to the steam jet type cell solution heater (7) through the pump (6) in the protein solution tank (5) for denaturation treatment. The principle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com