Patents

Literature

502results about How to "Guaranteed continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

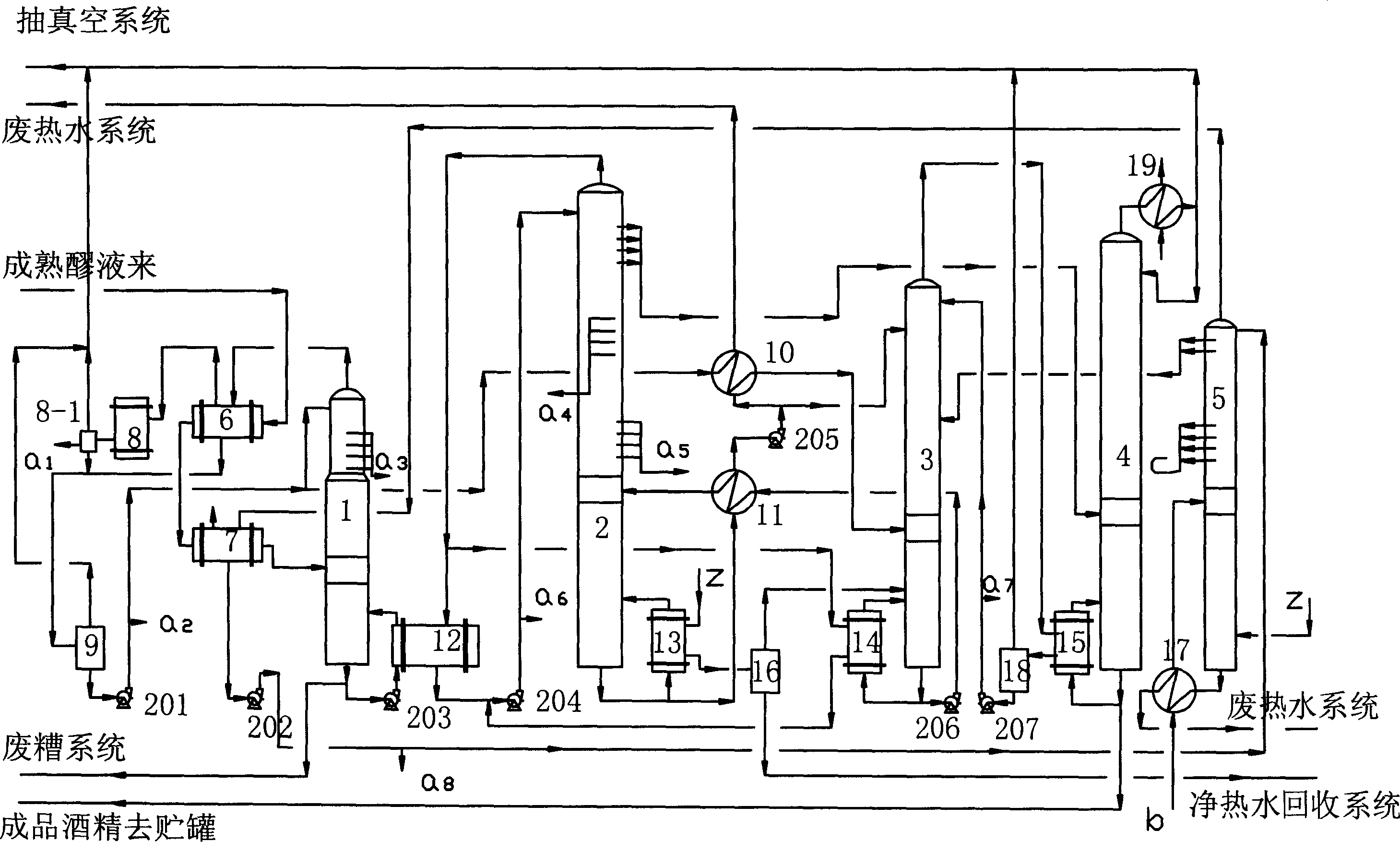

Alcohol quinque-towel differential pressure distilling arrangement and technique thereof

ActiveCN1736527APrevent scalingPrevent precipitationDistillation separationSteam condensationAqueous alcohol

The invention discloses a five-tower differential pressure distilling apparatus and the technique for alcohol: the fractionating tower operating with positive pressure, some alcohol vapor in the head tower flowing into the reboiler of crude distillation column, and the other into the reboiler of water scrubber; the leaving distilled water in the still of fractionating tower preheating the weak alcohol liquid from the bottom of water scrubber, then partly inpouring to crude alcohol preheater to preheat crude alcohol, and partly inpouring to water scrubber according to the requirement of flowmeter; by flash distillation the condensate water in the reboiler of fractionating tower generating indirect steam which enters directly into the still of water scrubber; the water scrubber operating with negative pressure, and the alcohol vapor in the head into the reboiler of the methanol heating tower. The significance effect is that: the energy saving effect is perfect when used to produce excellent edible alcohol and the vapor consuming index approaching the advanced lever of 2.3- 2.6 t / t.

Owner:广东省博罗中科天元高新技术工程有限公司

Method for producing specialized organic fertilizer for protected cultivation by silkworm excrement fermentation

InactiveCN102432356ASimple processShort fermentation cycleBio-organic fraction processingOrganic fertiliser preparationMicroorganismOrganic fertilizer

The invention discloses a method for producing a specialized organic fertilizer for protected cultivation by silkworm excrement fermentation, comprising the following steps of: inoculating active microorganisms to silkworm excrement, uniformly stirring, fermenting at high temperature, drying, granulating and sieving. According to the invention, silkworm excrement can be fully utilized to save resources and solve the pollution problem of waste silkworm excrement. The pH value of the silkworm excrement specialized organic fertilizer prepared in the invention ranges from 7.0 to 8.0, thus effectively solving the soil acidification problem frequently caused in protected cultivation. The organic fertilizer maintains original growth activating substances of silkworm excrement, contains a lot of beneficial microorganisms and more than 50% of organic matters, can be used to increase crop yield, improve crop quality and fertilize and improve soil, and is a good fertilizer for the production of nuisance free agricultural products.

Owner:ZHEJIANG UNIV

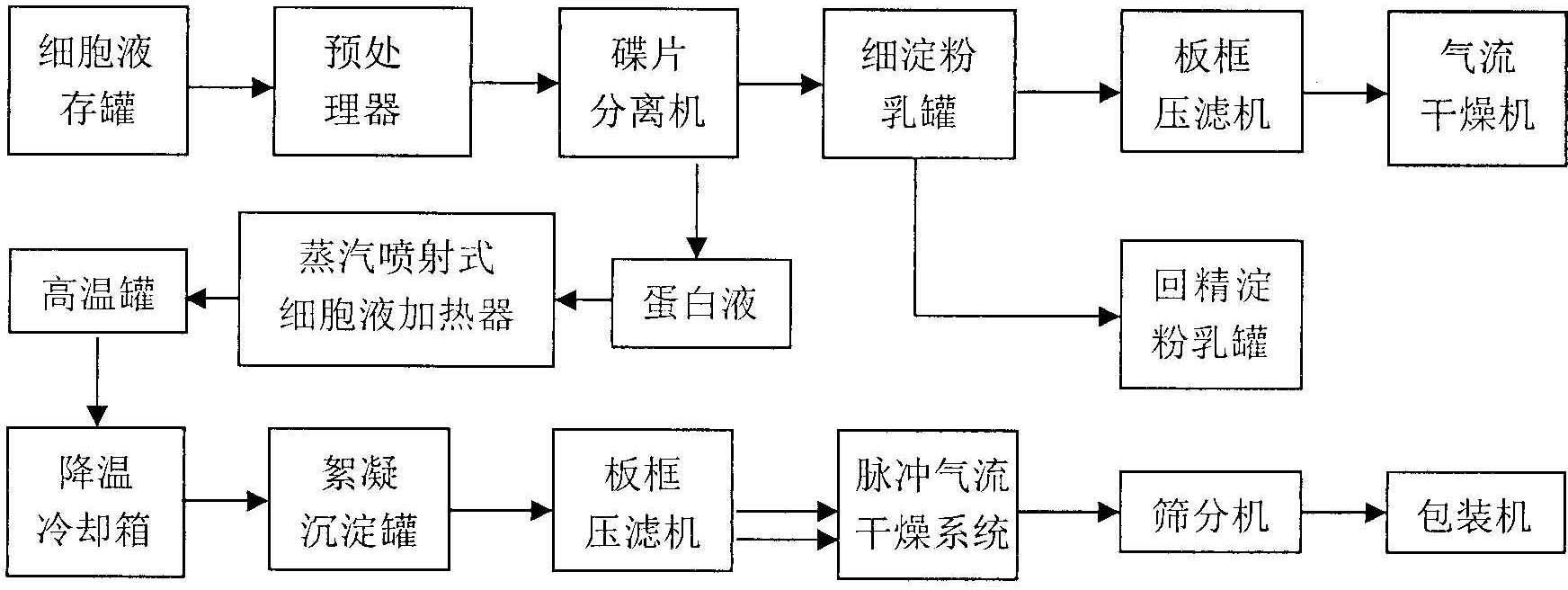

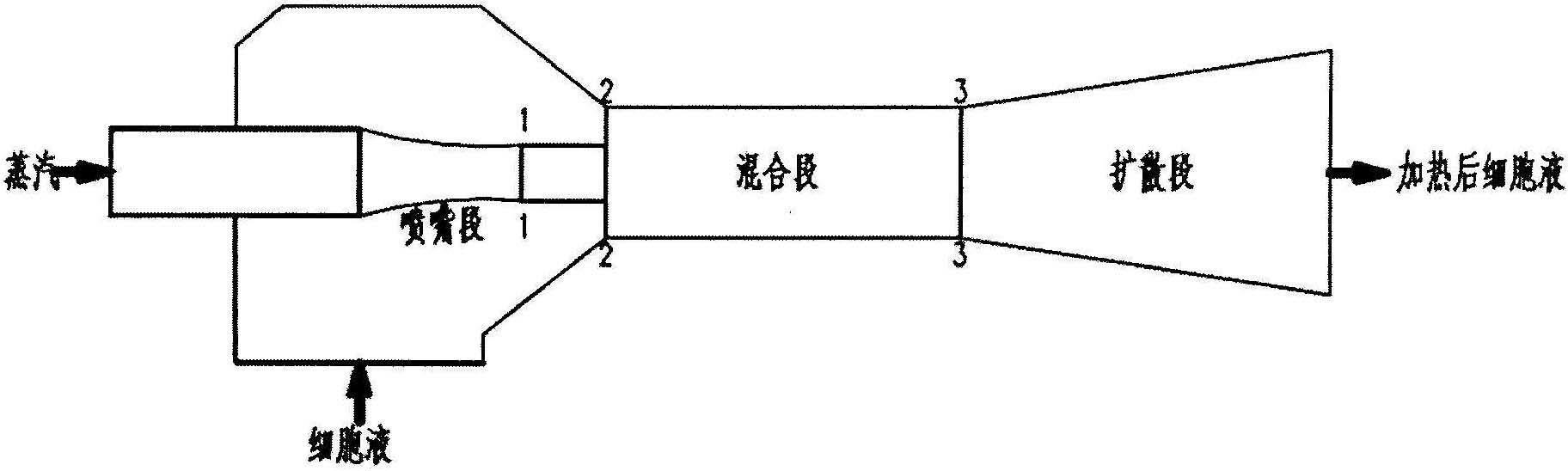

Process for extracting sweet potato protein by thermal deposition method

ActiveCN102558327ACompletely brokenEasy to separatePeptide preparation methodsPlant peptidesFiberSolubility

The invention relates to a process for extracting sweet potato protein by a thermal deposition method. The process is characterized by comprising the following steps of: treating cell sap to extract the sweet potato protein from the cell sap while producing sweet potato starch, separating and purifying by using a disc separator according to the difference of specific gravity of the protein and other substances such as starch and the like, removing fine fibers according to the solubility of the protein and the size of particles, and further purifying; purifying, concentrating, and degeneratingthe sweet potato protein to generate floccules according to the characteristic that the protein is degenerated at high temperature by a physical heating method; and concentrating, squeezing for dehydrating, drying, sieving, and performing aftertreatment to obtain a sweet potato protein commodity. The invention has the advantages that: (1) the sweet potato protein is degenerated by a steam jet cell sap heater, a moving part is not provided, and continuous production is ensured; (2) chemicals such as a flocculating agent and the like are not added, so that pollution is avoided, and subsequent treatment difficulty is reduced; and (3) the process is technically mature, and the industrial production capacity can be achieved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Ablation-resistant anti-aging cover for conveying belt and preparation method thereof

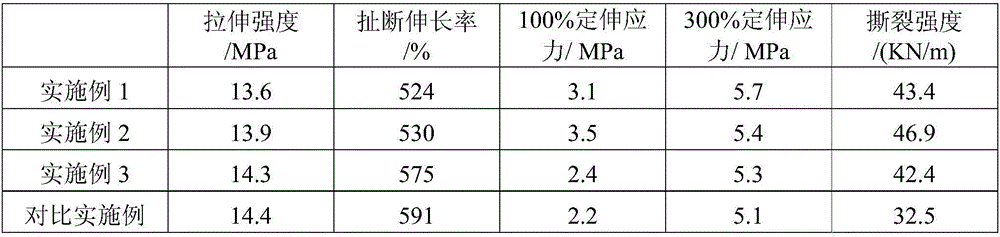

InactiveCN106336581AGood compatibilityGood physical and mechanical propertiesActive agentPlasticizer

The invention relates to an ablation-resistant anti-aging cover for conveying belt and preparation method thereof which belongs to the technological field of rubber conveying belt production. The preparation comprises the steps of: first mixing the EPDM, reinforcing filler, vulcanization active agent, plasticizer, antioxidant, ablative fiber, flame retardant, charcoal and compatibilizer together to acquire the mixed rubber, then adding the vulcanizing agent and co-crosslinking agent for the secondary mixing, and vulcanizing to obtain the product of ablation-resistant anti-aging cover for conveying belt. With the use of ablation-resistant anti-aging cover provided by the present invention the service life of the conveyor belt under high heat and open fire condition is dramatically prolonged, which guarantees the sustainable production of the enterprises and saves the costs and brings huge economic benefits.

Owner:WUXI BOTON TECH CO LTD +1

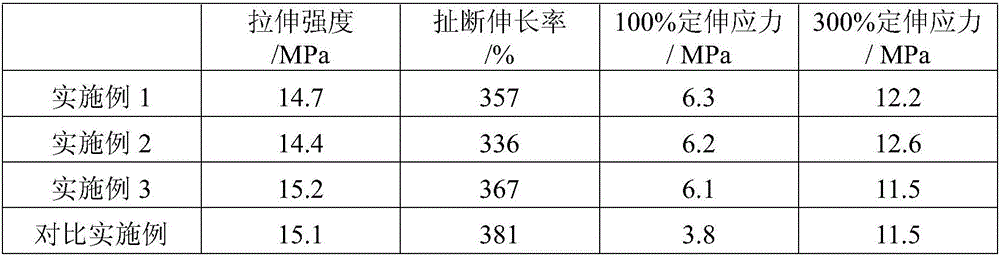

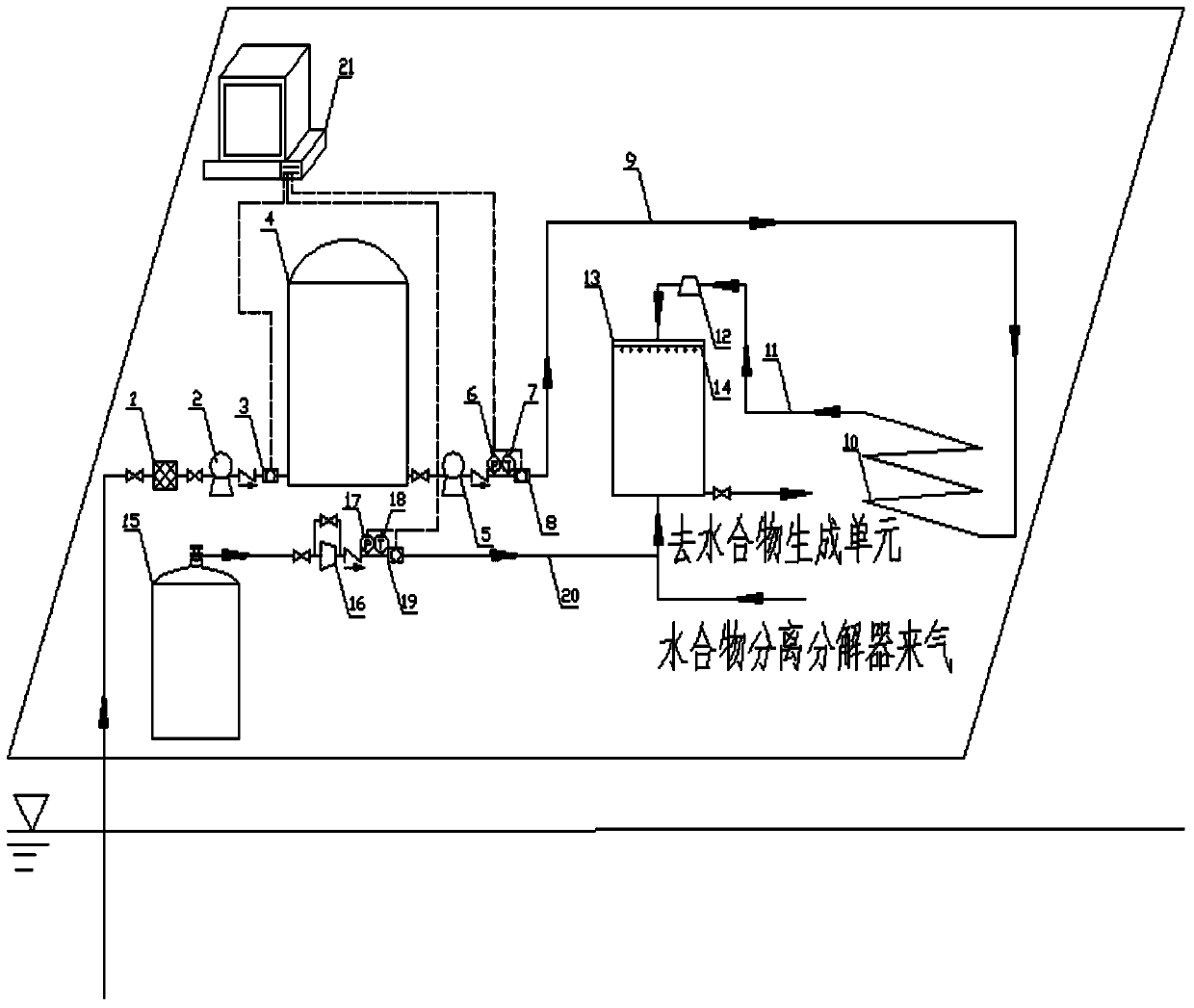

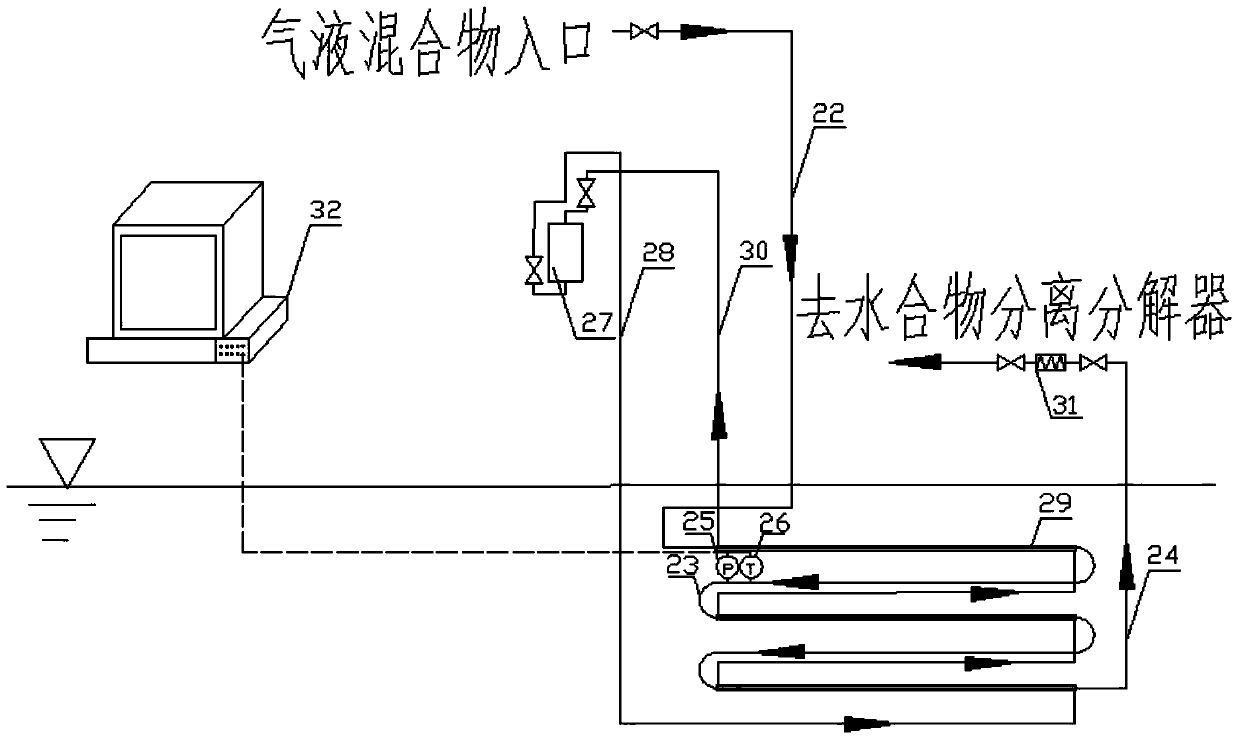

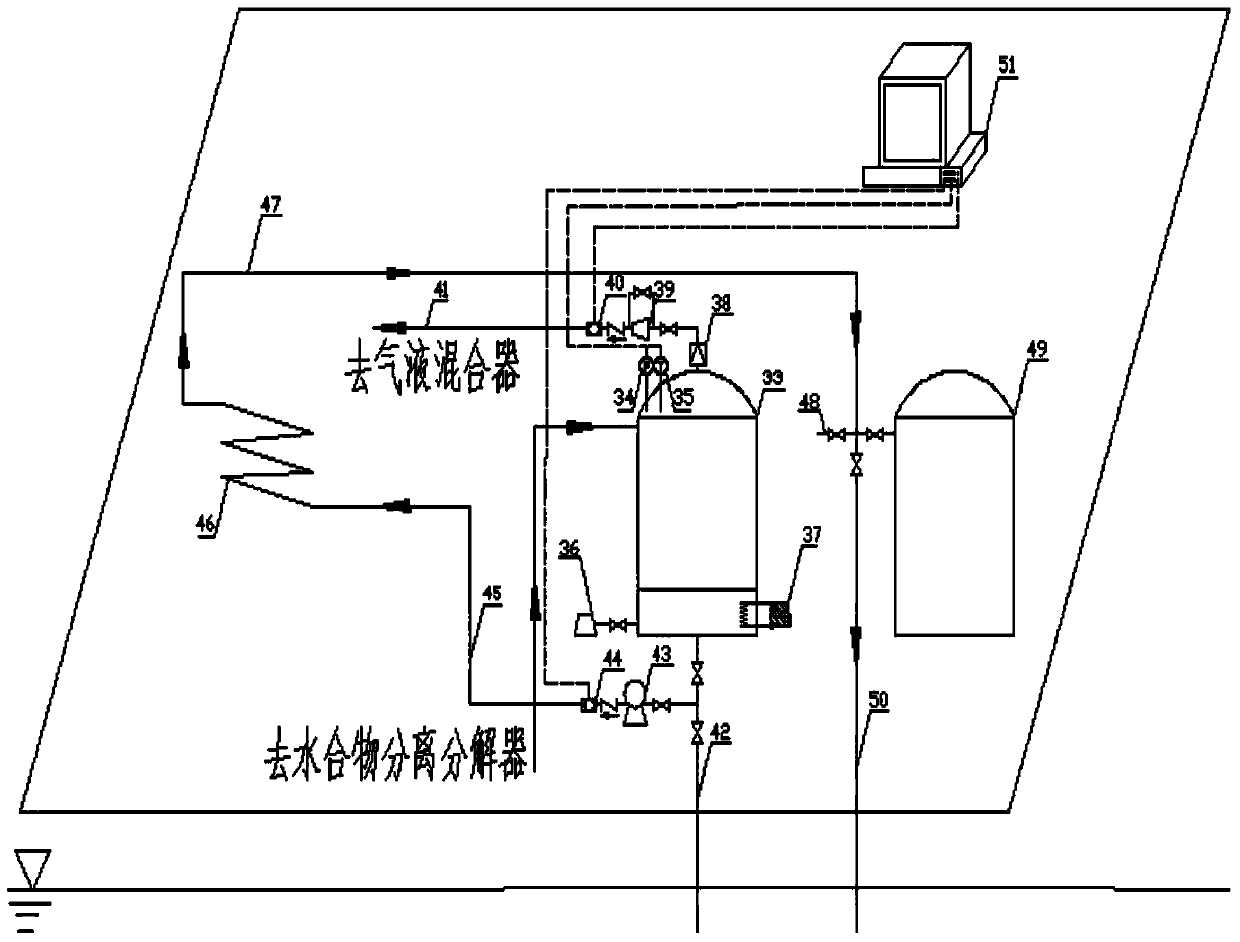

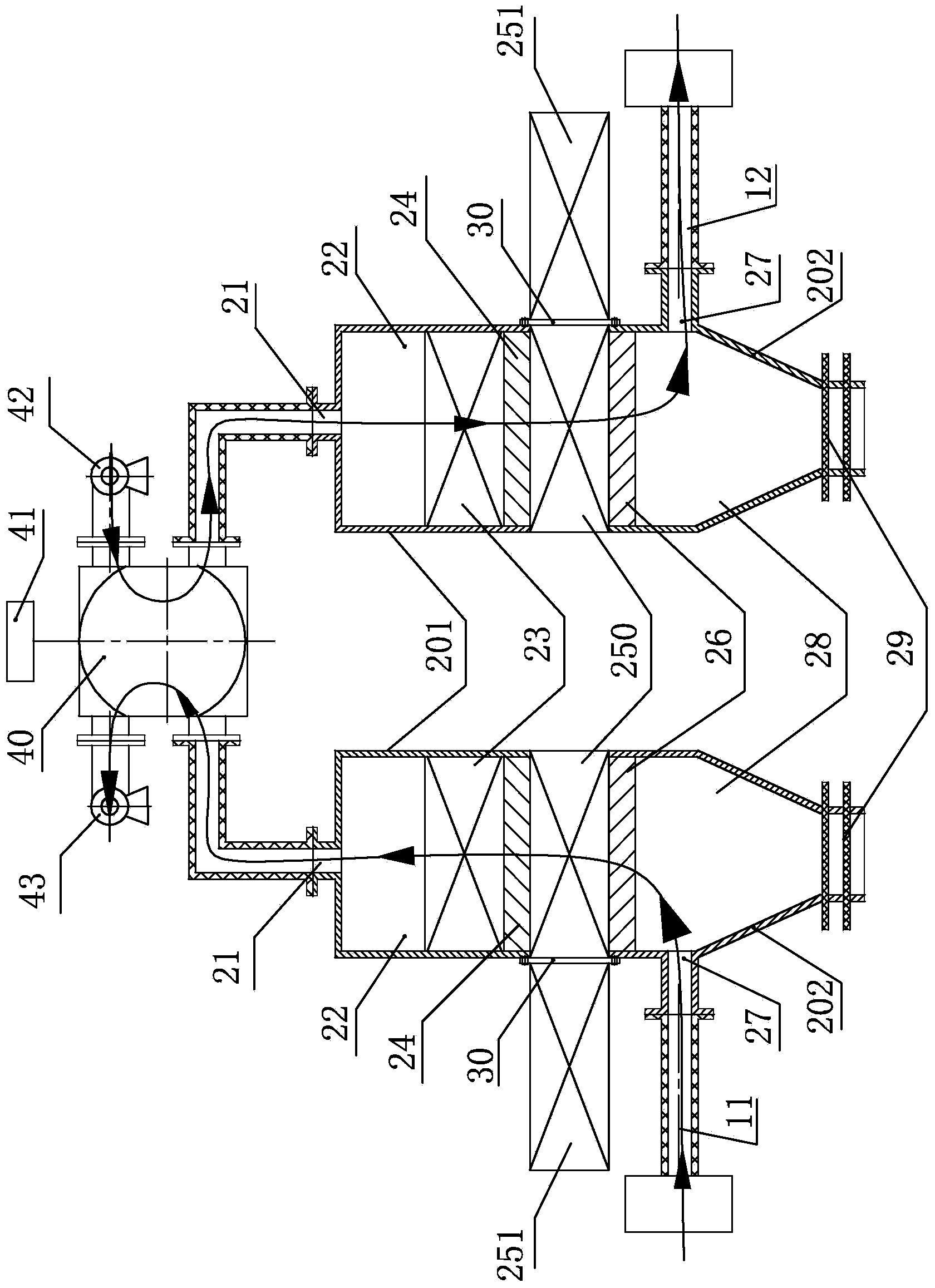

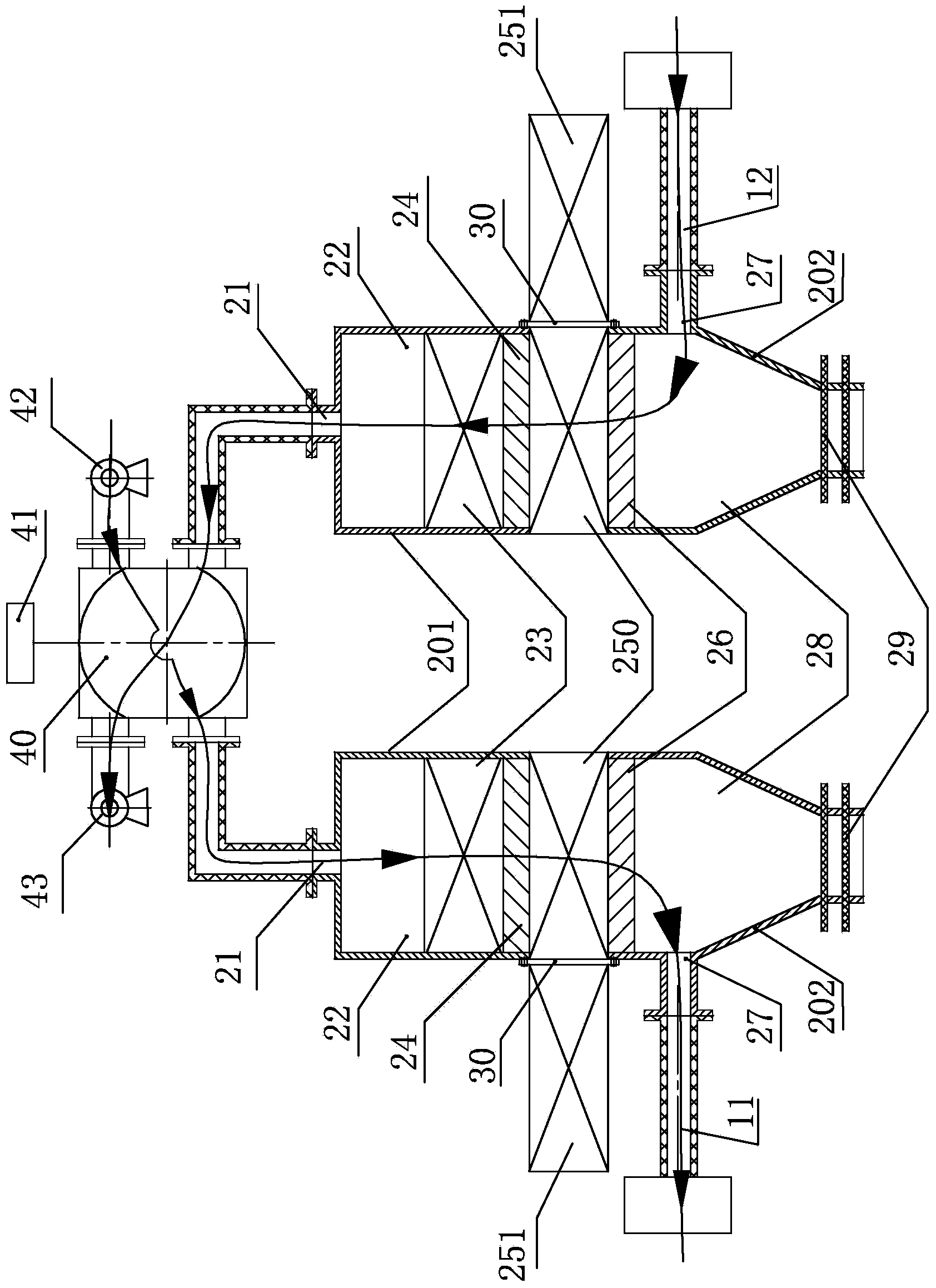

Two-stage sea water desalination method based on hydration and two-stage sea water desalination device based on hydration

ActiveCN103864243AWell mixedContinuous generation boostSeawater treatmentEnergy based wastewater treatmentWater desalinationDihydrogen oxide

The invention belongs to the field of gas hydrate technology application and particularly relates to a sea water desalination method and a two-stage sea water desalination device. The method comprises the following steps: generating a carbon dioxide hydrate from carbon dioxide and sea water by a first-stage sea water desalination system and then resolving the carbon dioxide hydrate so as to obtain fresh water; generating a propane hydrate from propane and sea water by a second-stage sea water desalination system and then resolving the propane hydrate so as to obtain fresh water. The Two-stage sea water desalination device comprises a first-stage sea water desalination device and a second-stage sea water desalination device which are connected in series; each stage of sea water desalination device comprises a gas-liquid supplying and mixing unit, a gas hydrate generating and conveying unit, and a gas hydrate dissociating and resolving unit. The device and the method are high in efficiency, low in energy consumption and easy to achieve.

Owner:江苏溢坤医疗科技有限公司

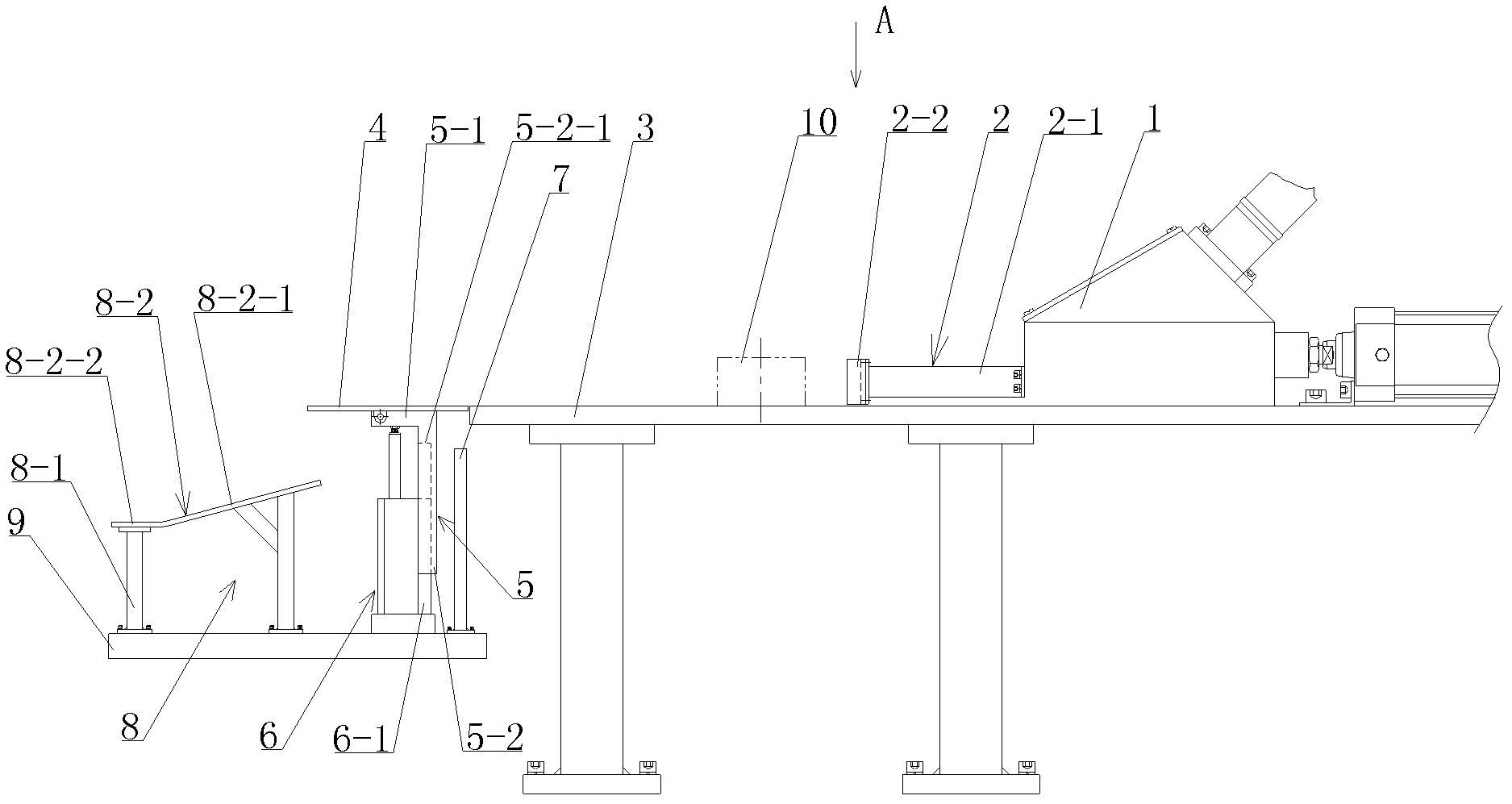

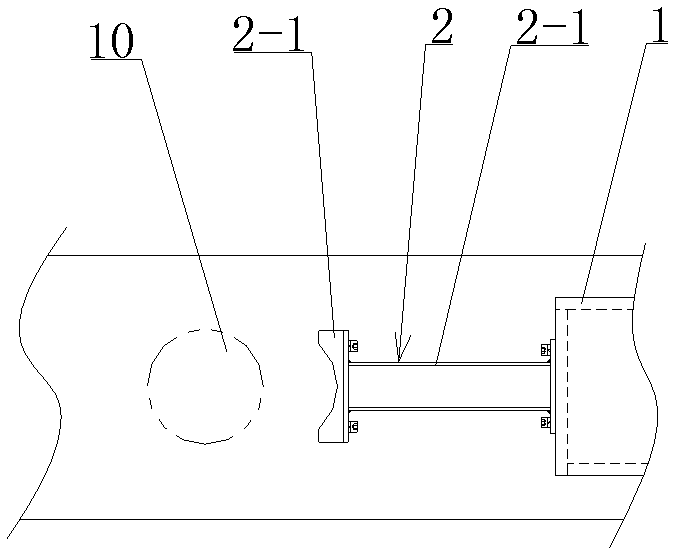

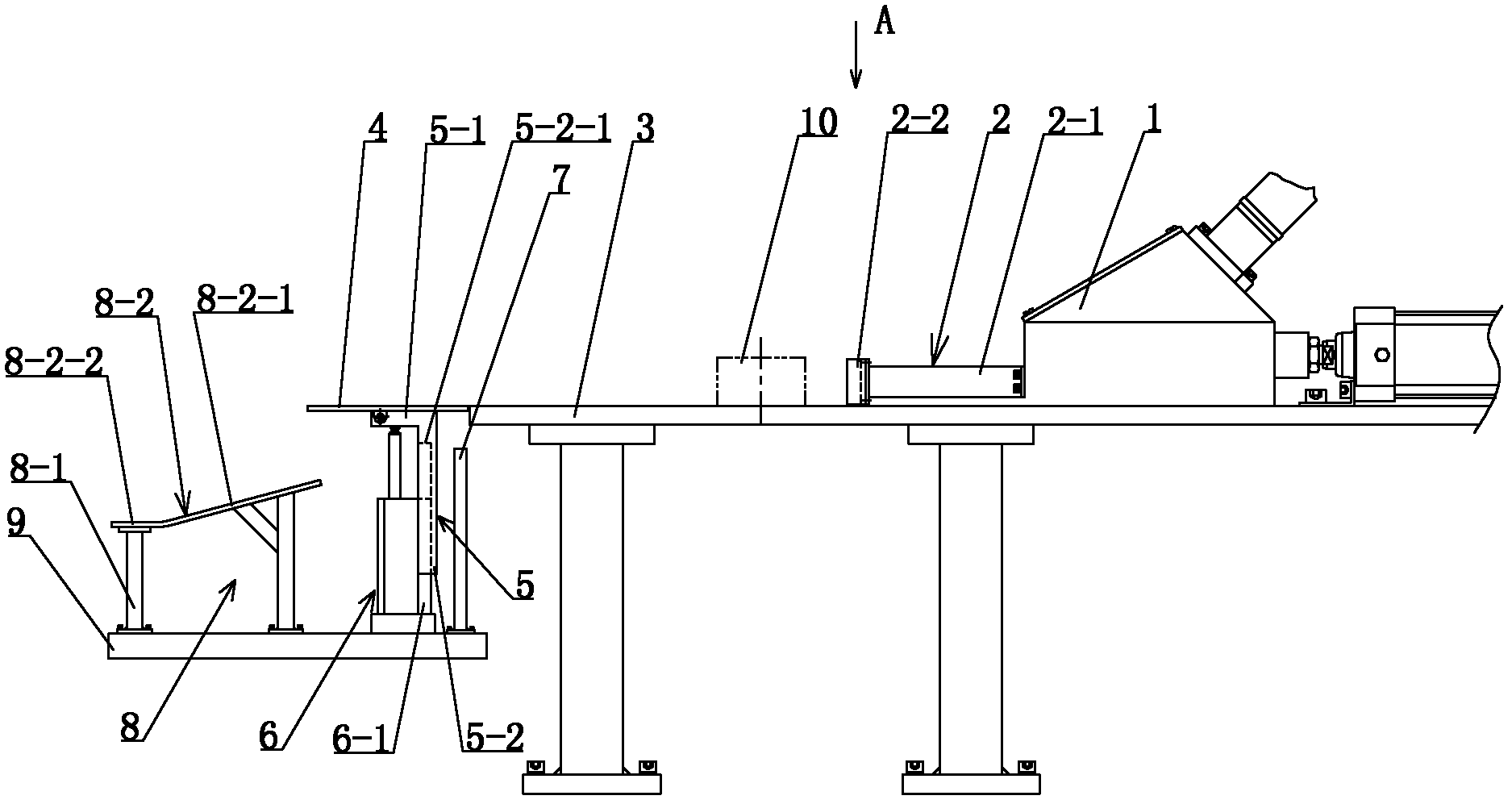

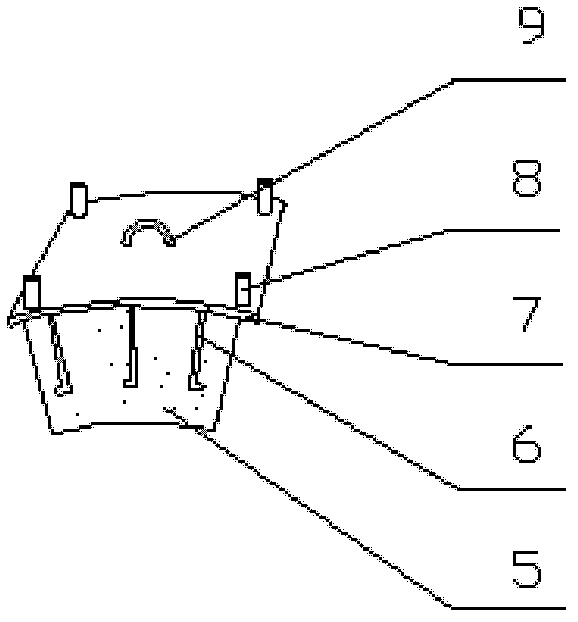

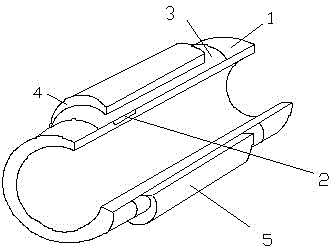

Automatic pushing and receiving device for powder hydraulic press

ActiveCN102274967ASimple structureReduce manufacturing costPressesHigh volume manufacturingManipulator

The invention relates to an automatic pushing and material receiving device for a powder hydraulic machine. The automatic blank pushing and material receiving device is characterized by comprising a push rod fixedly arranged at the front end of a material conveying box and a material receiving device arranged between a product support plate and conveying equipment, wherein the material receiving device comprises a material receiving flat plate, a bent plate which is arranged at the lower end of the material receiving flat plate and hinged with the material receiving flat plate, a driving cylinder arranged at the lower end of the bent plate, and a mandril and a material receiving bracket which are arranged at the lower end of the material receiving flat plate; the push rod end of the driving cylinder is fixedly connected with a horizontal part of the bent plate; a guide structure is arranged between a cylinder barrel of the driving cylinder and a vertical part of the bent plate; the material receiving bracket comprises ground jacks and a material receiving bent plate; and the material receiving bent plate comprises an upward inclined part and a horizontal part. By adopting the structure, a molded product is pushed onto a material conveying flat plate by the push rod during powder conveying; and under the action of the driving cylinder and the mandril, the molded product slides to a material pushing bent plate and finally to the conveying equipment through the bent plate. Compared with a special manipulator, the automatic blank pushing and material receiving device with the structure has a simple structure, is low in manufacturing cost and convenient to operate, guarantees continuous production due to one-to-one correspondence of conveying and pushing and meets the requirement of batch production.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Method for producing organic and inorganic compound fertilizer by utilizing duck dropping source

InactiveCN101628841AEnsure a virtuous circleShorten the fermentation cycleMagnesium fertilisersAlkali orthophosphate fertiliserInorganic compoundOxygen

The invention discloses a method for producing an organic and inorganic compound fertilizer by utilizing a duck dropping source, which comprises the following steps: regulating C / N ratio and water content of organic wastes; adding a CM fermenting agent to the organic wastes; carrying out aerobic fermentation and secondary fermentation on the organic wastes and then pulverizing the organic wastes; adding large and intermediate trace element chemical fertilizers and a fertilizer regulator or a plant growth regulator to the pulverized organic wastes; and granulating to prepare a commercial organic fertilizer. The invention has simple method, can process the duck dropping source at a time and has flexible nutrient proportioning and strong adaptability of the produced organic fertilizer and obvious fertilizer yield increasing effect.

Owner:JIANGSU YIHAI FERTILIZER

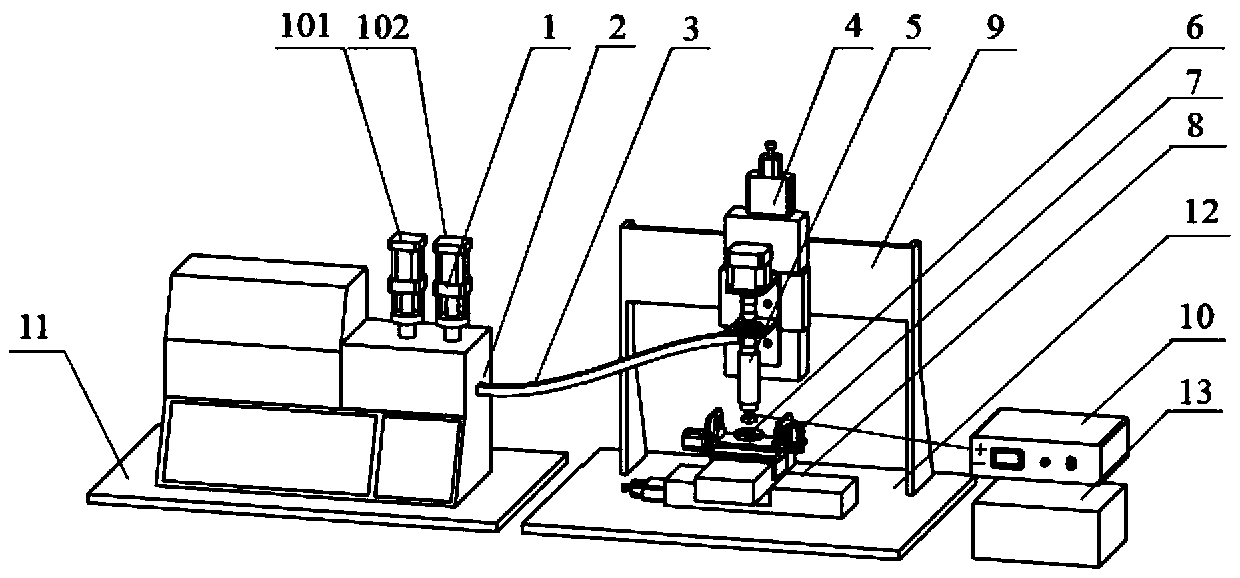

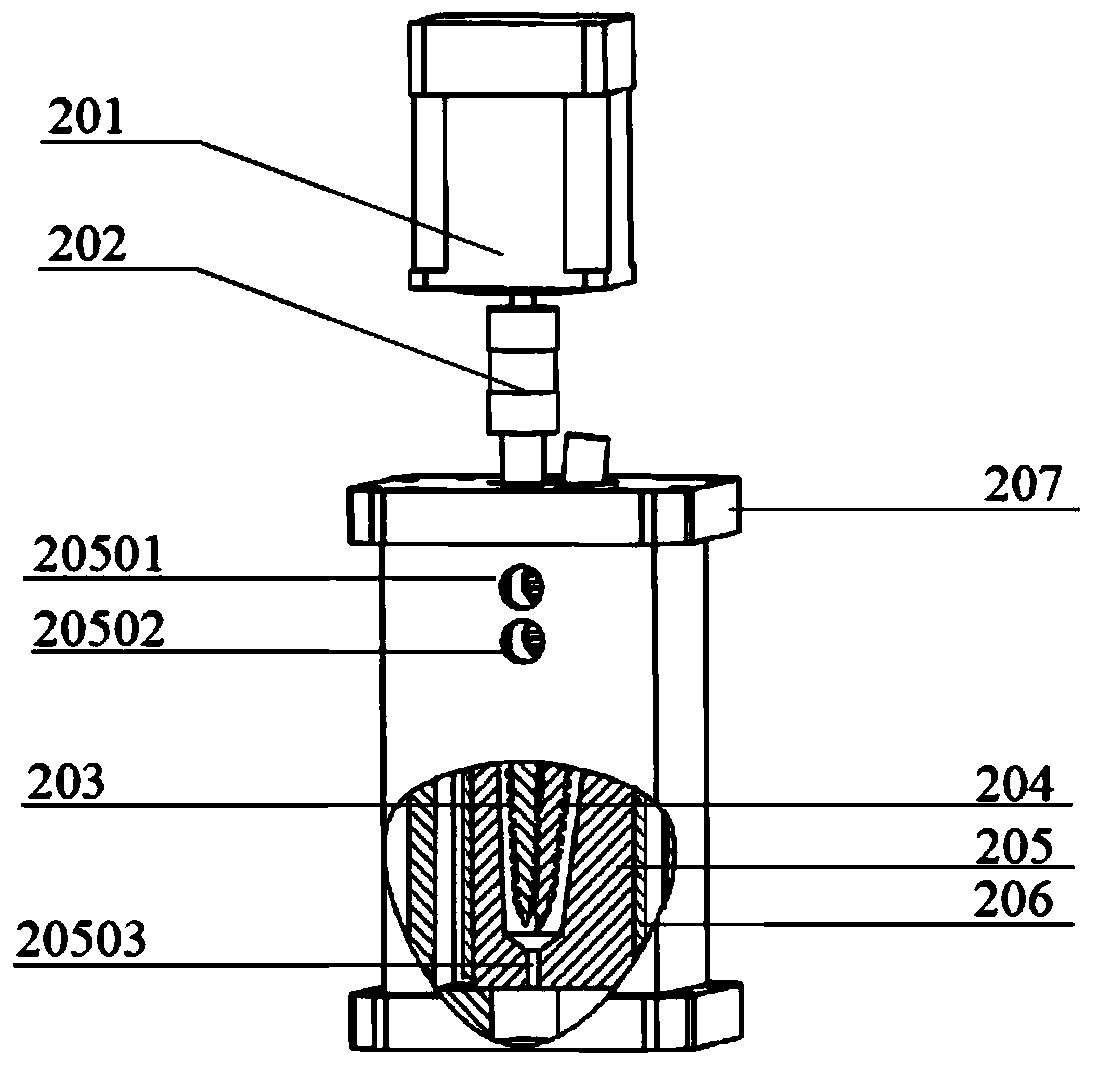

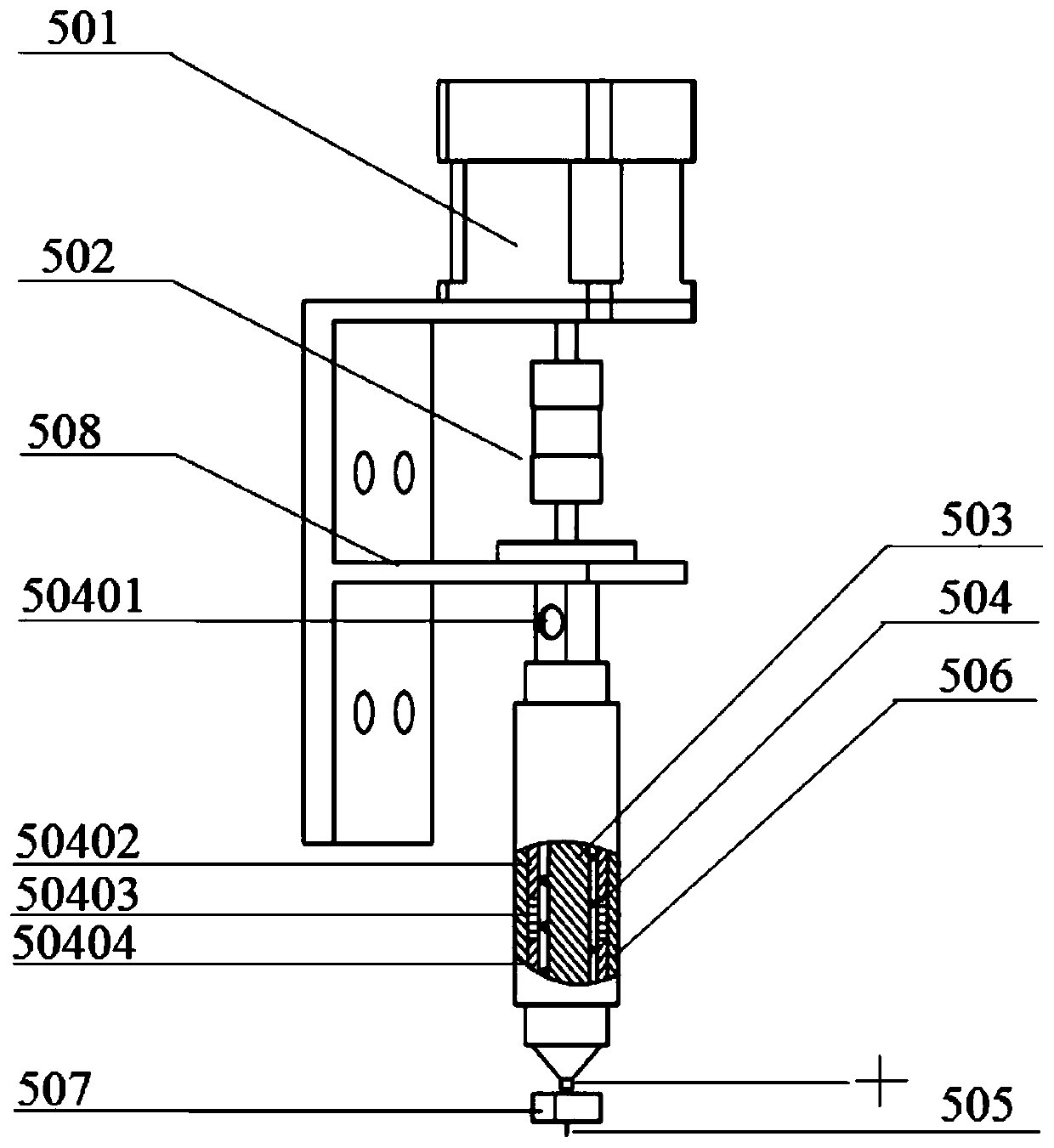

3D printer for integral manufacturing of functionally graded material and forming structure, and working method thereof

PendingCN109732905APrecise Controlled ExtrusionContinuous and stable printingAdditive manufacturing apparatus3D object support structuresImage resolutionEngineering

The invention provides a 3D printer for integral manufacturing of a functionally graded material and a forming structure, and a working method thereof. A feeding module, a mixing module and a printingsprayer are split; and through ingenious arrangement of the components, integral manufacturing of the continuous functionally graded material and the complex three-dimension structure can be achieved. The 3D printer has the characteristics and outstanding advantages of active, efficient and uniform mixing of various materials, high print resolution (due to micro-nano microscale characteristic structure printing), diverse applicable materials, high production efficiency, low cost and simple structure; and particularly, the 3D printer can achieve integral manufacturing of the continuous functionally graded material and the complex three-dimension structure based on material composition and microstructures.

Owner:QINGDAO 5D INTELLIGENT ADDITIVE MFG TECH CO LTD

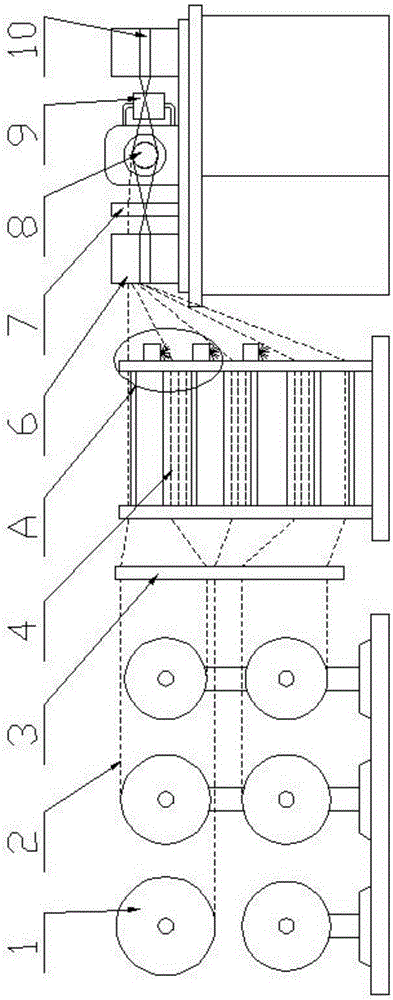

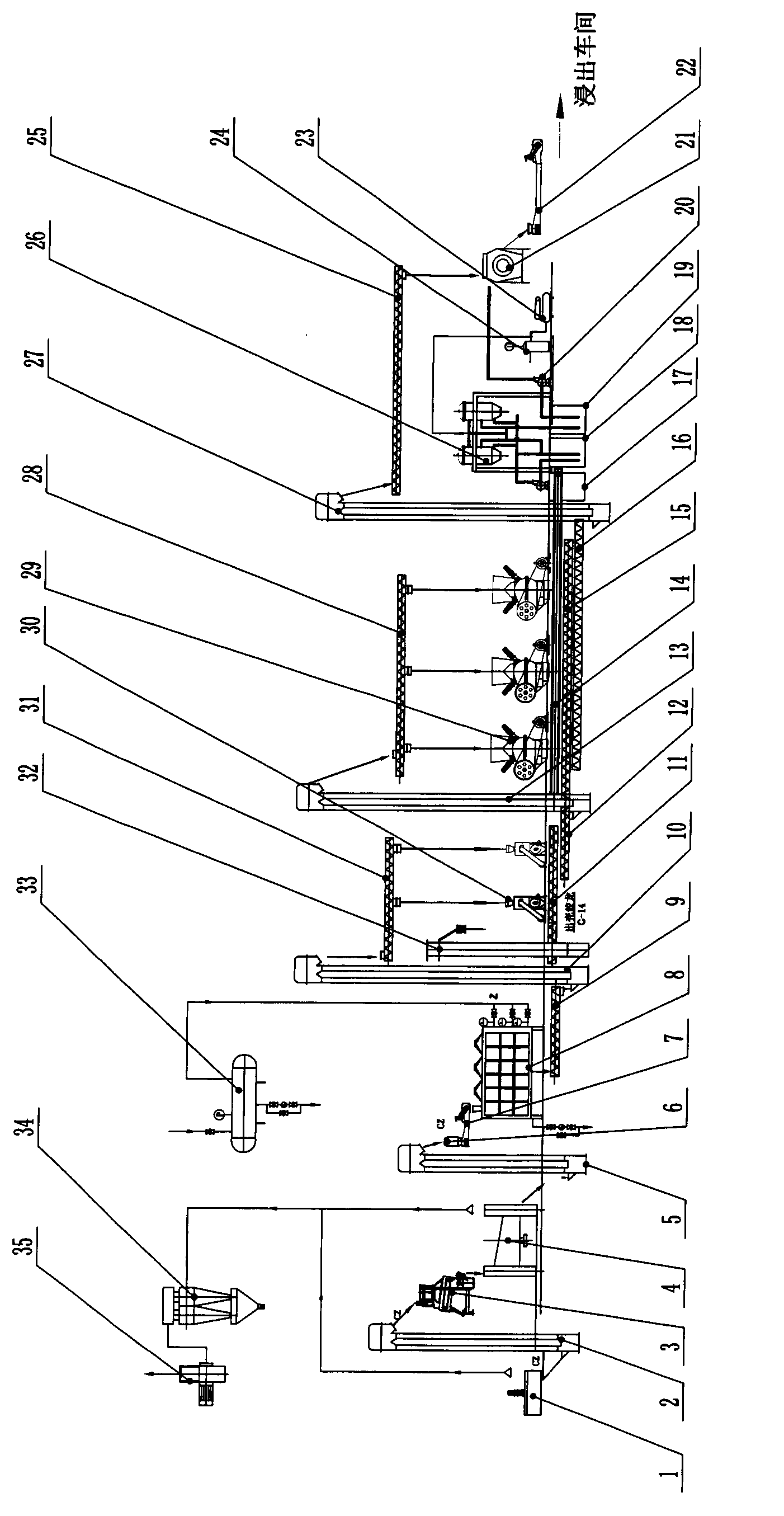

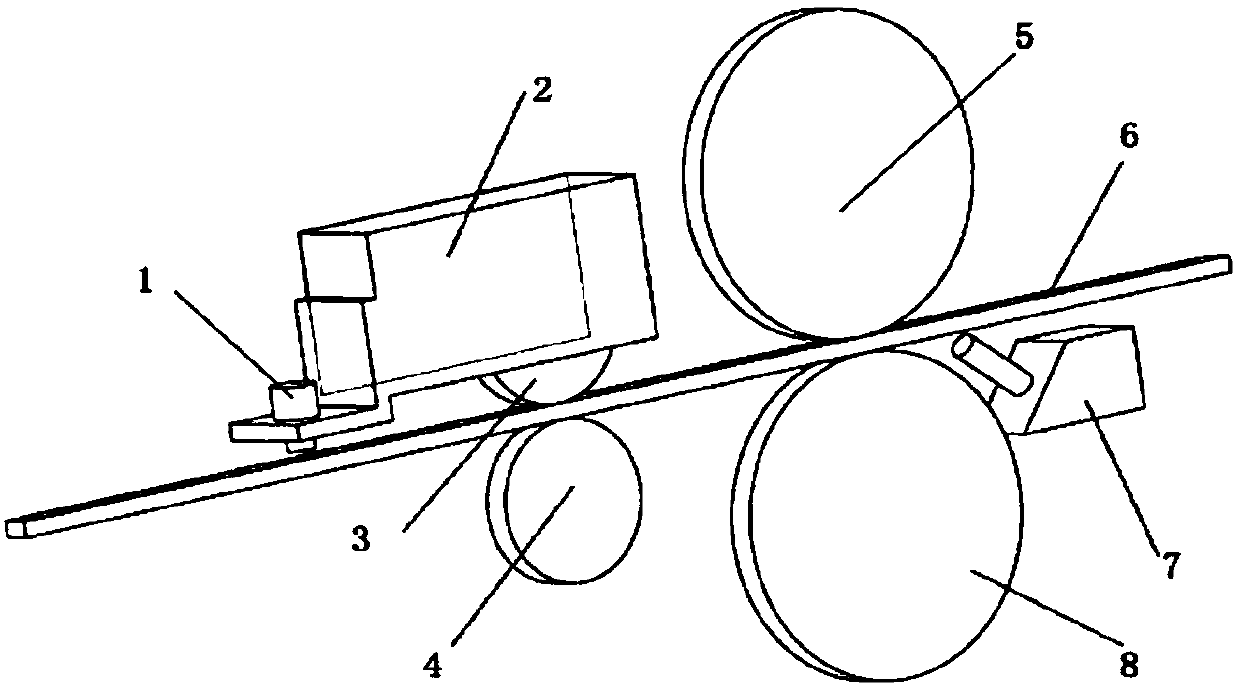

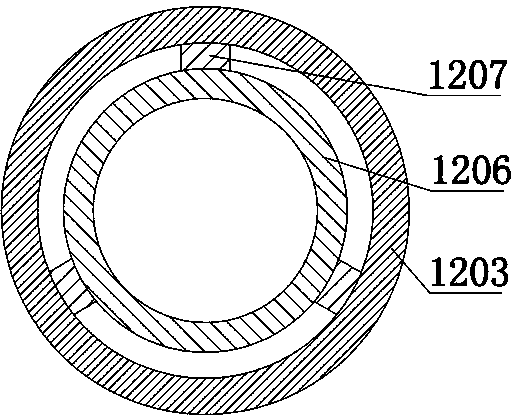

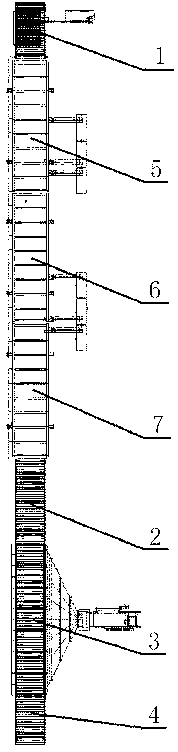

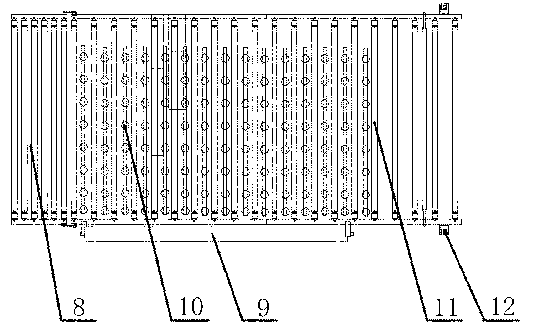

Continuous densification and efficient production line and technology of fiber-reinforced thermosetting plastic pipelines

ActiveCN105216340AEfficient productionContinuous compaction productivityTubular articlesProduction linePlastic pipework

The invention provides a continuous densification and efficient production line and technology of fiber-reinforced thermosetting plastic pipelines, and belongs to the field of fiber-reinforced thermosetting plastic pipeline manufacturing. After being innovatively improved, a paper tube machine production line is applied to the production field of the fiber-reinforced thermosetting plastic pipelines, the improved paper tube machine production line is sequentially provided with strip frames, a coating device, a curing agent applying device, hollow partition plates and a spiral paper tube machine refit device in the paper tube moving direction. Cylindrical dies transversely arranged above a rack are improved on the basis of an existing spiral paper tube machine, pressure perpendicular to the die direction and thrusting force parallel to the die direction are exerted on film strips wrapping the dies and impregnated and pre-cured fiber strips through a conveying belt, layer-by-layer densification and continuous efficient production are achieved, and the production efficiency is greatly improved. The produced pipelines have the beneficial effects of resisting pressure, being good in impact resistance and rigidity, resisting to corrosion and the like.

Owner:SHANDONG BOYUAN COMPOSITE MATERIALS TECH CO LTD

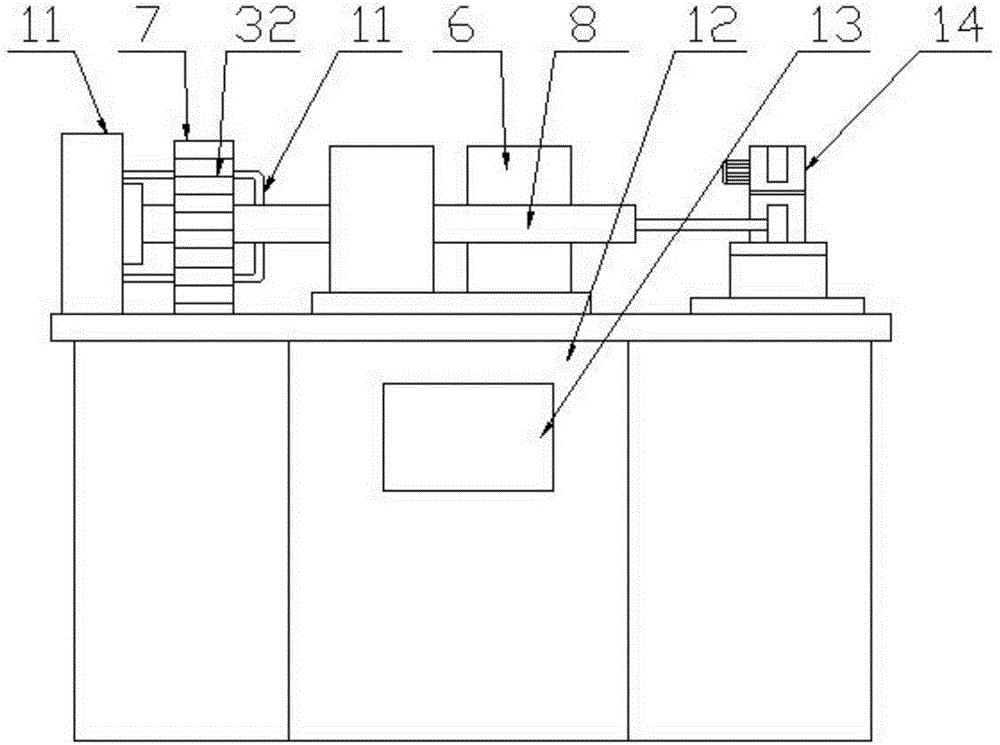

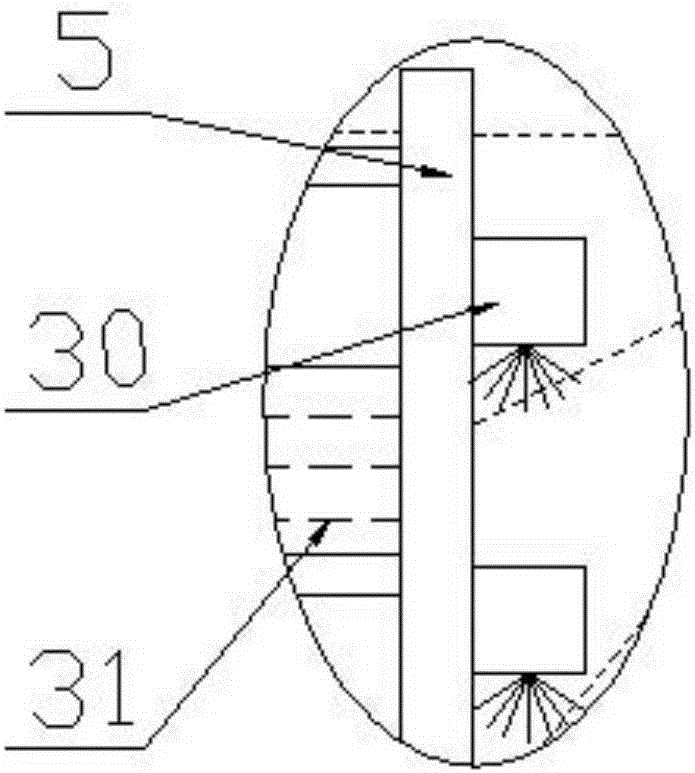

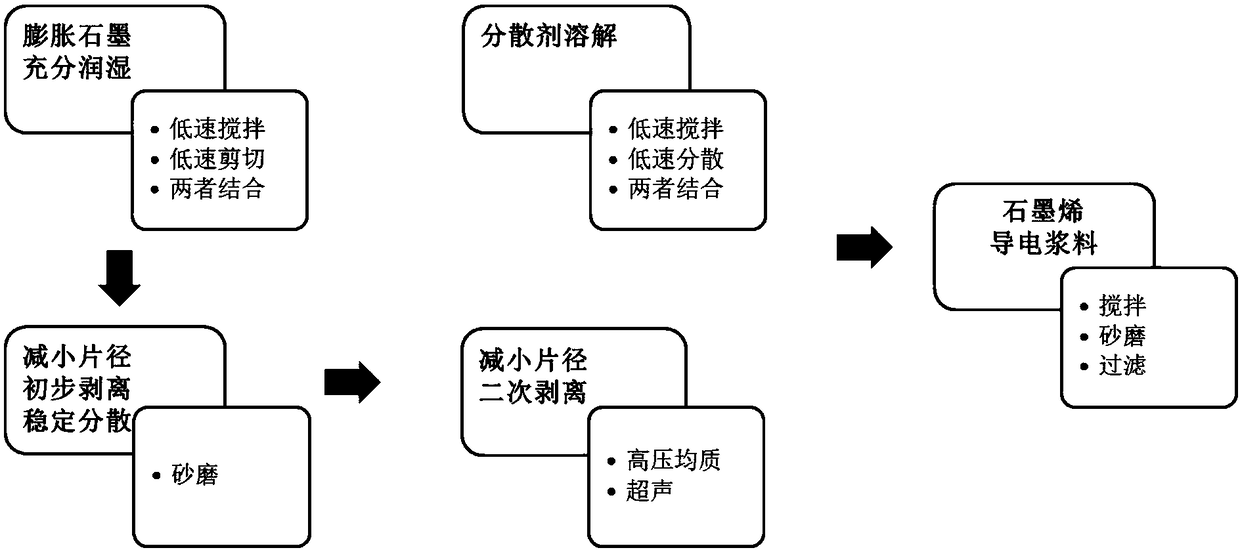

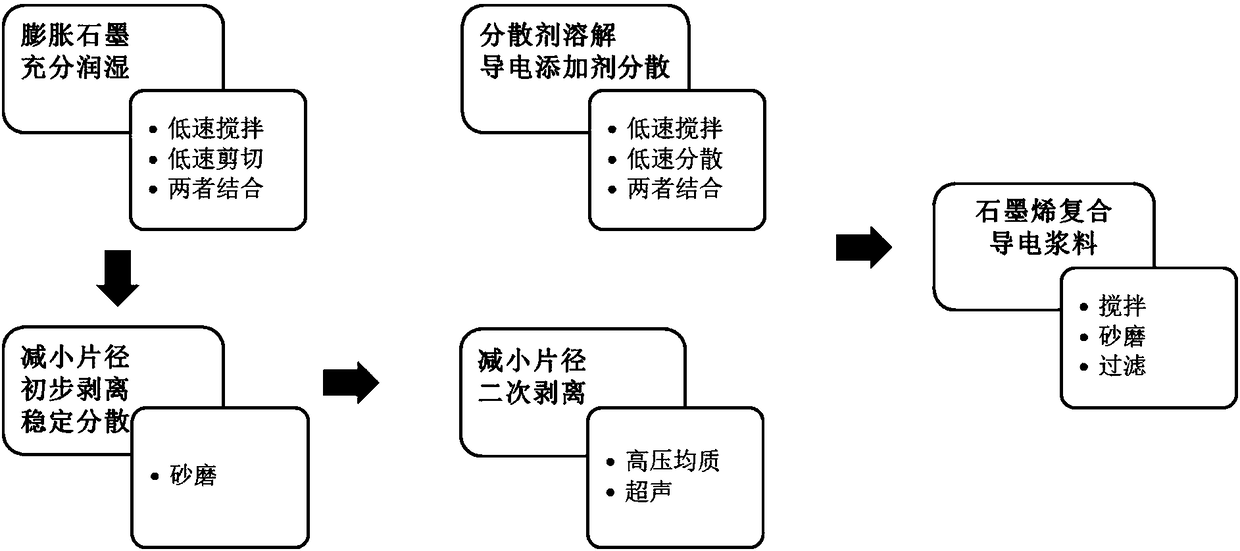

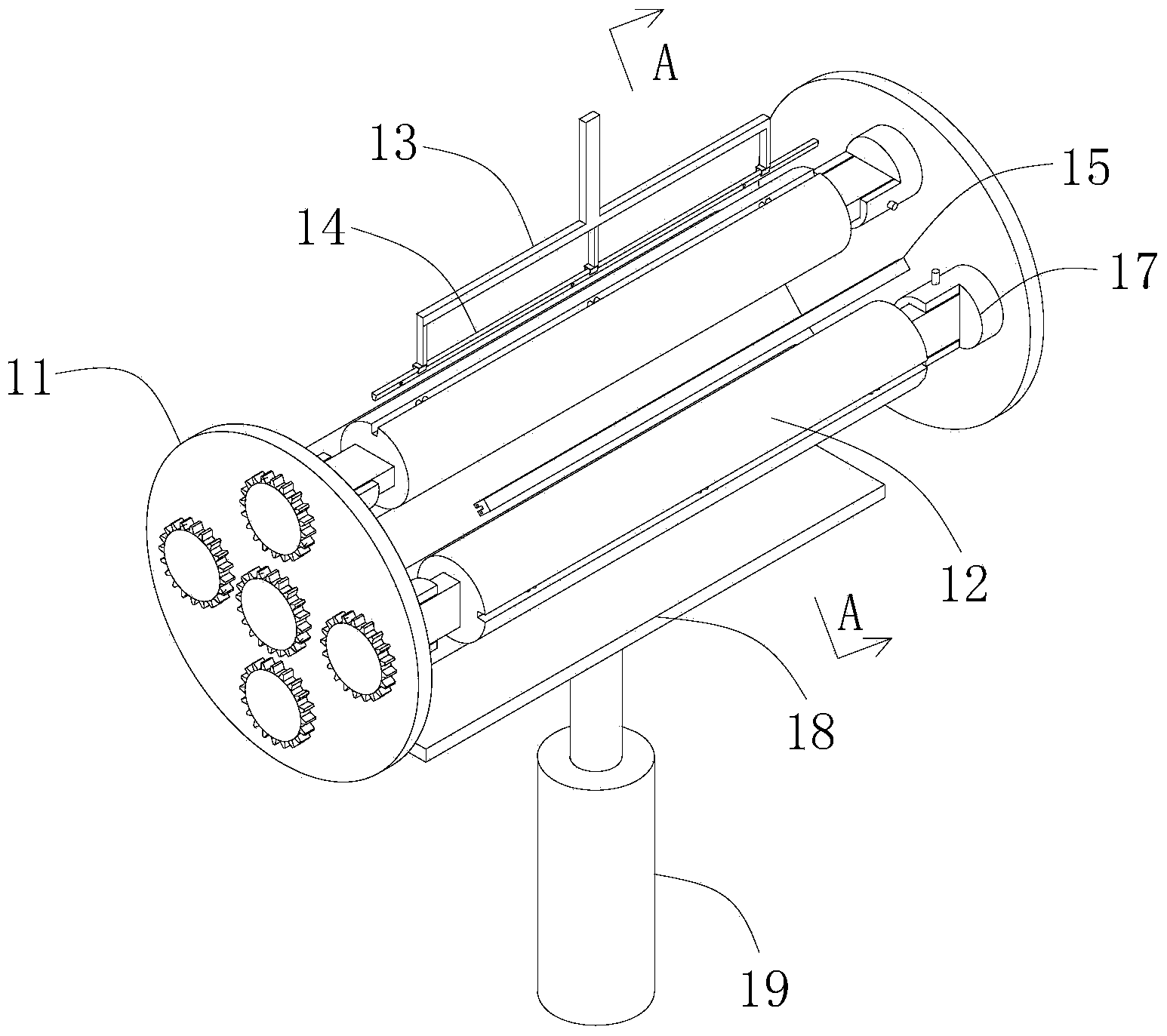

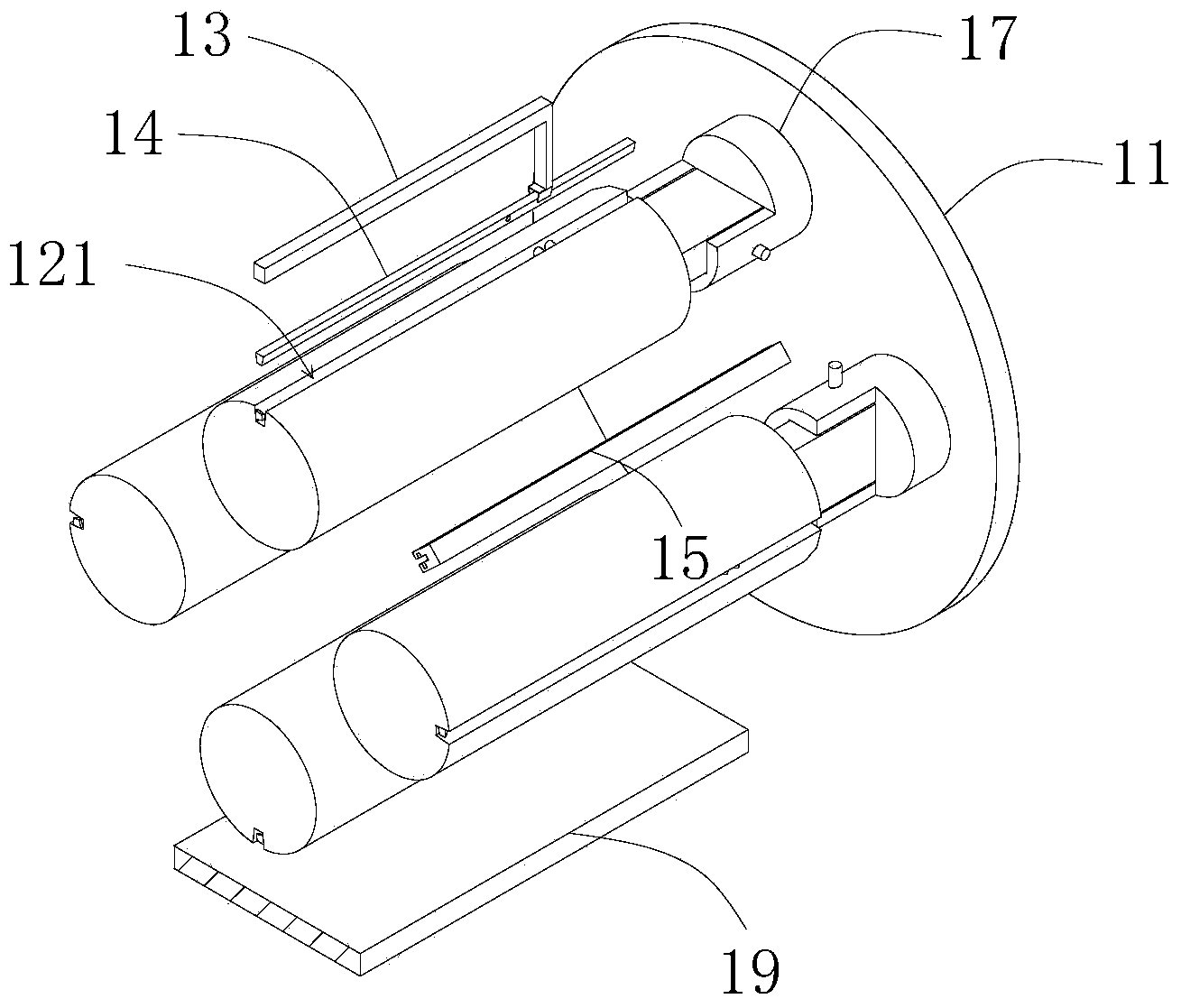

Method and device for massively producing graphene conductive slurry and prepared graphene conductive slurry

ActiveCN108630338AExcellent physical and chemical propertiesEvenly dispersedNon-conductive material with dispersed conductive materialCable/conductor manufactureHigh concentrationGraphite

The invention provides a method and a device for massively producing a graphene conductive slurry and a prepared graphene conductive slurry. The method comprises the following steps of a) mixing graphite and a solvent, carrying out at least one low-speed mixing processing or / and low-speed shearing processing and acquiring a graphite dispersion liquid; b) carrying out at least one sanding processing on the graphite dispersion liquid and acquiring a preliminary stripped graphene dispersion liquid; c) carrying out at least one high pressure homogenization processing or / and ultrasonic processing on the preliminary stripped graphene dispersion liquid, and acquiring a single layer or a small layer of graphene dispersion liquid; d) dissolving a dispersing agent in a solvent to obtain a dispersantsolution; and e) mixing the single layer or the small layer of graphene dispersion liquid and the dispersant solution, carrying out at least one sanding processing, and acquiring the graphene conductive slurry. By using the method, under the condition of environmental protection, the stable and uniformly-dispersed graphene conductive slurry with a high concentration is acquired. And the device issuitable for the continuous automatic production of the high-concentration and high-stability graphene conductive slurry.

Owner:北京地泽科技有限公司

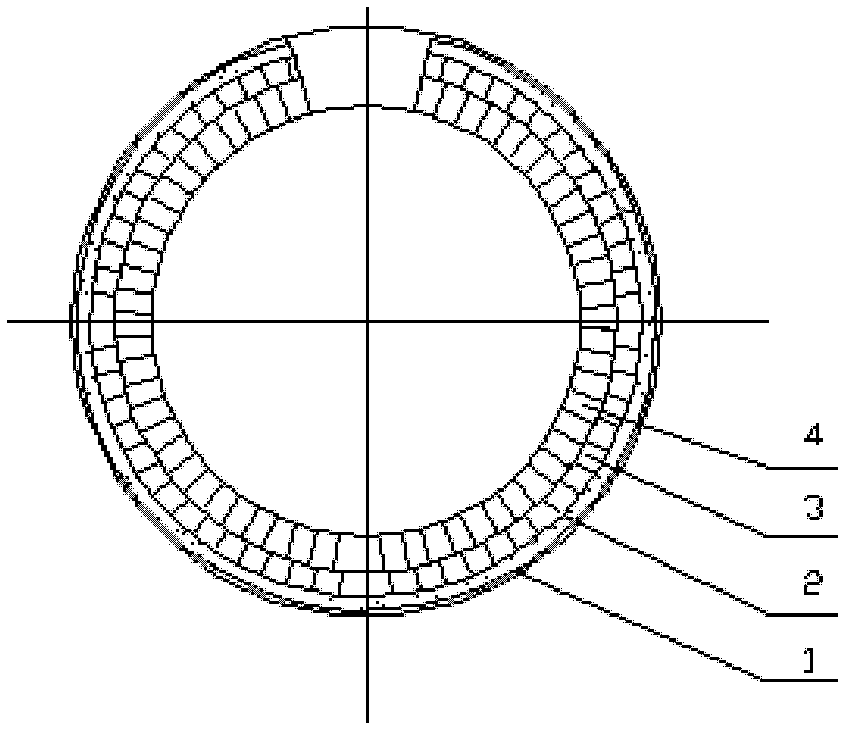

Method for patching damaged blast furnace hot air pipeline inner liner in hot state

InactiveCN102424872AGuaranteed continuous productionQuick fixBlast furnace detailsHeating stovesInsulation layerBrick

The invention discloses a method for patching a damaged blast furnace hot air pipeline inner liner in a hot state, which comprises the following steps that: A, a curved welding plate with the same thickness and the same diameter as a pipeline steel case is adopted according to the damage conditions of the inner liner; B, a plurality of fixed hooks are manufactured and are welded on the lower end surface of the curved welding plate, and a hanging lug and a pulp pressing hole are arranged on the upper end surface; C, holes are formed in the pipeline steel case, and regular shapes are formed; D, relevant dimensions are measured according to the inner liner shapes to be patched after being cleaned; E, mold erecting die casting is carried out by casting materials according to the measured shape, the casting materials are hung to a pipeline opening position by the hanging lug for installation, and the welding plate and the pipeline steel case are welded; and F, press slurry is pressed into gaps among heat insulation casting materials 5, a heat insulation layer, a light brick layer and a heavy brick layer through slurry pressing holes, and the construction pressure is maintained at 2kg / cm<2>. The hot air pipeline inner liner patching is carried out in the hot state, and only 15hours is needed, so the blast furnace hot air pipeline inner liner is quickly patched, the patching can be completed by the fixed maintenance time of a blast furnace, and the normal continuous production of the blast furnace is ensured.

Owner:TIANJIN IRON & STEEL GRP

Tea seed continuous cold pressing process

InactiveCN104046509AImprove oil yieldGuaranteed continuous productionFatty-oils/fats refiningFatty-oils/fats productionProduction lineSlag

The invention discloses a tea seed continuous cold pressing process. The process includes: cleaning camellia seeds, clearing iron from the camellia seeds by an iron remover; employing a flat dryer to conduct moisture drying regulation treatment; and conducting kernel-husk separation by a husking machine to ensure that the camellia seeds are not stuck in the pressing chamber of an oil press and improve the oil yield; adopting multi-row paralleling and automatic material distribution by the oil press, conducting regulation by a material distribution system when the oil press breaks down so as to ensure operation of the whole system; sending crude oil to a slag catching machine, and carrying out primary solid-liquid separation to the impurities contained by the crude oil; after separation, pumping the crude oil into two filters disposed in the filtering system to undergo separation again so as to guarantee continuous production of the production line; conveying the filtered crude oil into a refining workshop by an oil pump to undergo subsequent processes; sending the oil cake from the oil press into a crushing machine by a screw conveyor and a hoister to undergo crushing to undergo crushing; and conveying the crushed cake material into a leaching plant by conveying equipment to undergo oil extraction by leaching.

Owner:BEIJING ZHONGTIAN JINGU GRAIN OIL ENG TECH

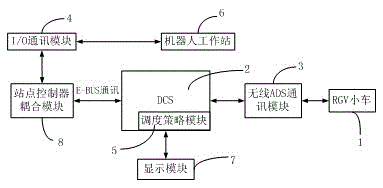

Intelligent rail guide vehicle (RGV) control device based on two vehicles on one rail

InactiveCN102722169AHigh degree of automationGuaranteed continuous productionTotal factory controlProgramme total factory controlDistributed control systemEngineering

The invention provides an intelligent rail guide vehicle (RGV) control device based on two vehicles on one rail. The device comprises two RGVs positioned on the same rail, a distributed control system (DCS), a wireless automation device specification (ADS) communication module, a robot working station, an input / output (I / O) communication module and a scheduling strategy module, wherein the RGVs wirelessly communicate with the DCS; the DCS dispatches tasks to the RGVs through the ADS communication module; the RGVs send real-time positions and states of the vehicles to the DCS through the ADS communication module; the robot working station controls a fixture to clamp and release a workpiece; the I / O communication module connects the DCS with the robot working station to finish information interaction between the DCS and the robot working station when the RGVs reach stations; and the scheduling strategy module makes the DCS schedule the RGVs according to different strategies. By adopting a two-vehicle mode, namely two RGVs respectively finish tasks of feeding and discharging materials, the automation degree is high, and continuous production can be guaranteed.

Owner:昆山华恒机器人有限公司

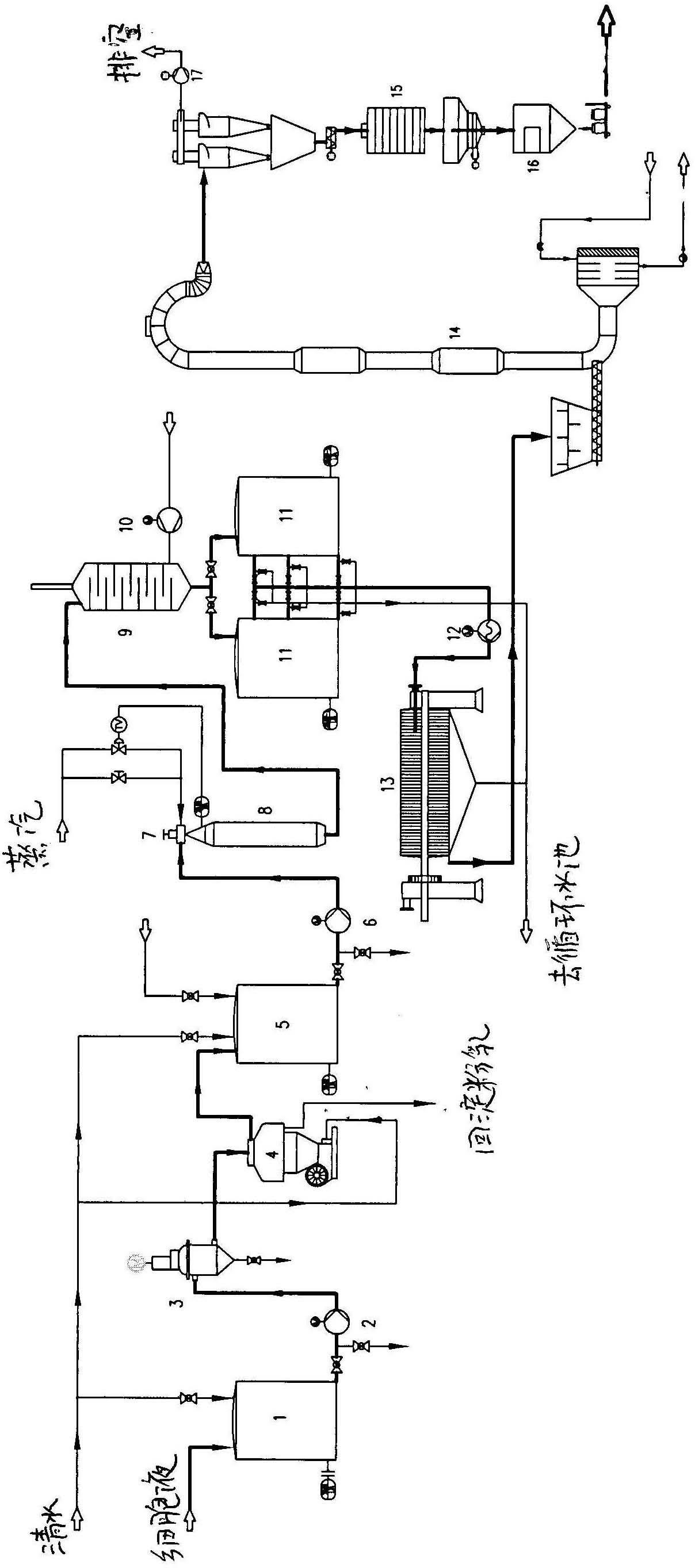

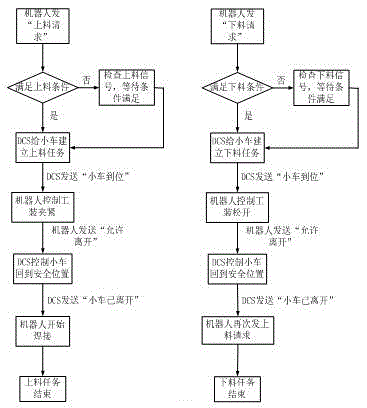

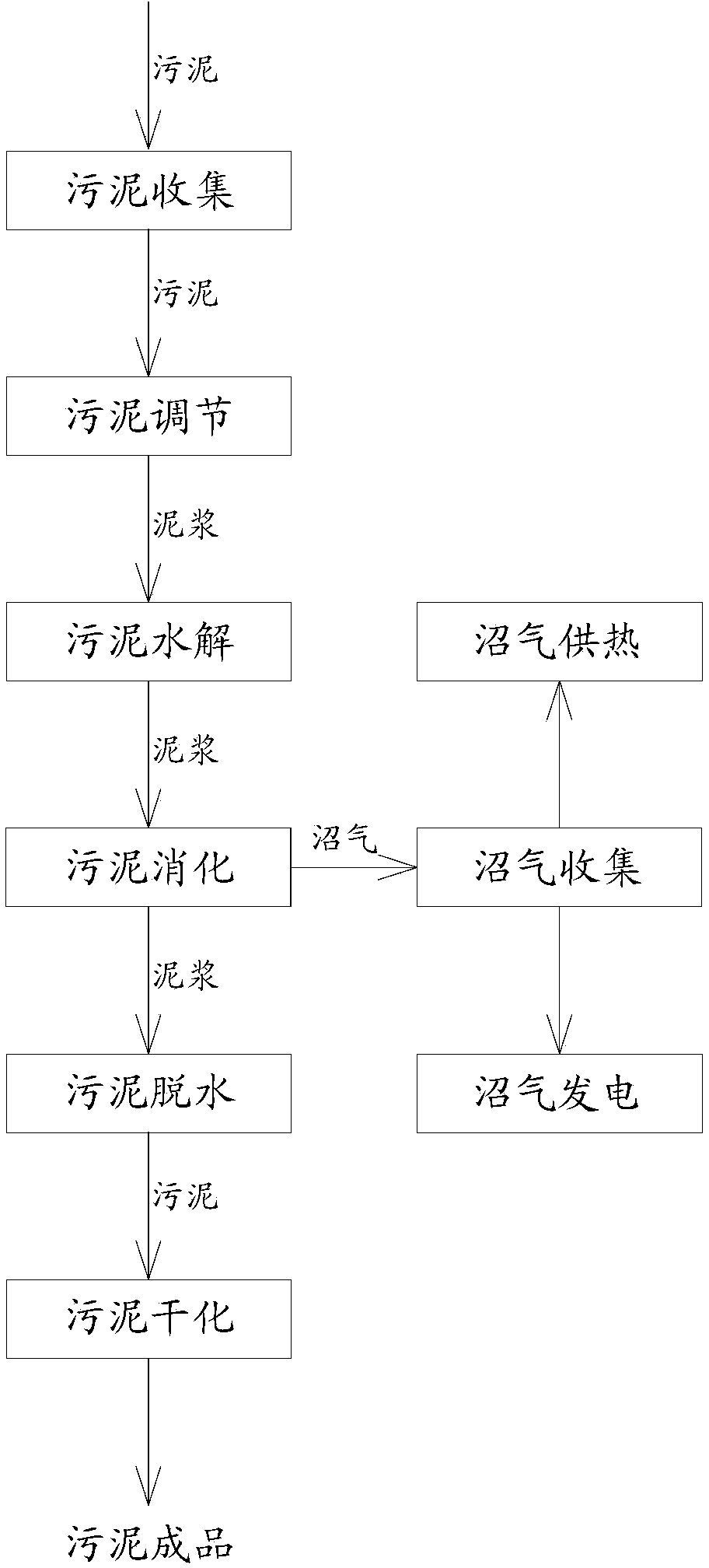

Sludge treatment system and sludge treatment method

InactiveCN104030537AIncrease in sizeSmall particlesSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisEngineeringThermal water

The invention discloses a sludge treatment system, comprising a sludge collecting tank, a sludge regulating pool, a sludge thermal hydrolysis device, a heat exchanger, an anaerobic reaction device, a sludge dewatering device and a sludge drying device, which are sequentially connected. The sludge treatment system also comprises a gas storage tank and a biogas boiler, wherein the input end of the gas storage tank is connected with the exhaust end of the anaerobic reaction device; the fuel input end of the biogas boiler is connected with the output end of the gas storage tank; the output end of the biogas boiler is connected with the sludge thermal hydrolysis device; the discharge end of the sludge dewatering device is connected with the input end of the sludge regulating pool. The invention also discloses a sludge treatment method. The sludge treatment method comprises the following steps: 1) collecting a sludge material and diluting by water; 2) hydrolyzing the diluted sludge material at high temperature; 3) carrying out anaerobic digestion on the sludge subjected to thermal hydrolysis to obtain biogas and digested sludge; 4) collecting the biogas; 5) dewatering and drying the digested sludge to obtain a sludge product. Reclamation, harmlessness, minimization and stabilization of sludge treatment are achieved by the steps and method.

Owner:王胜初

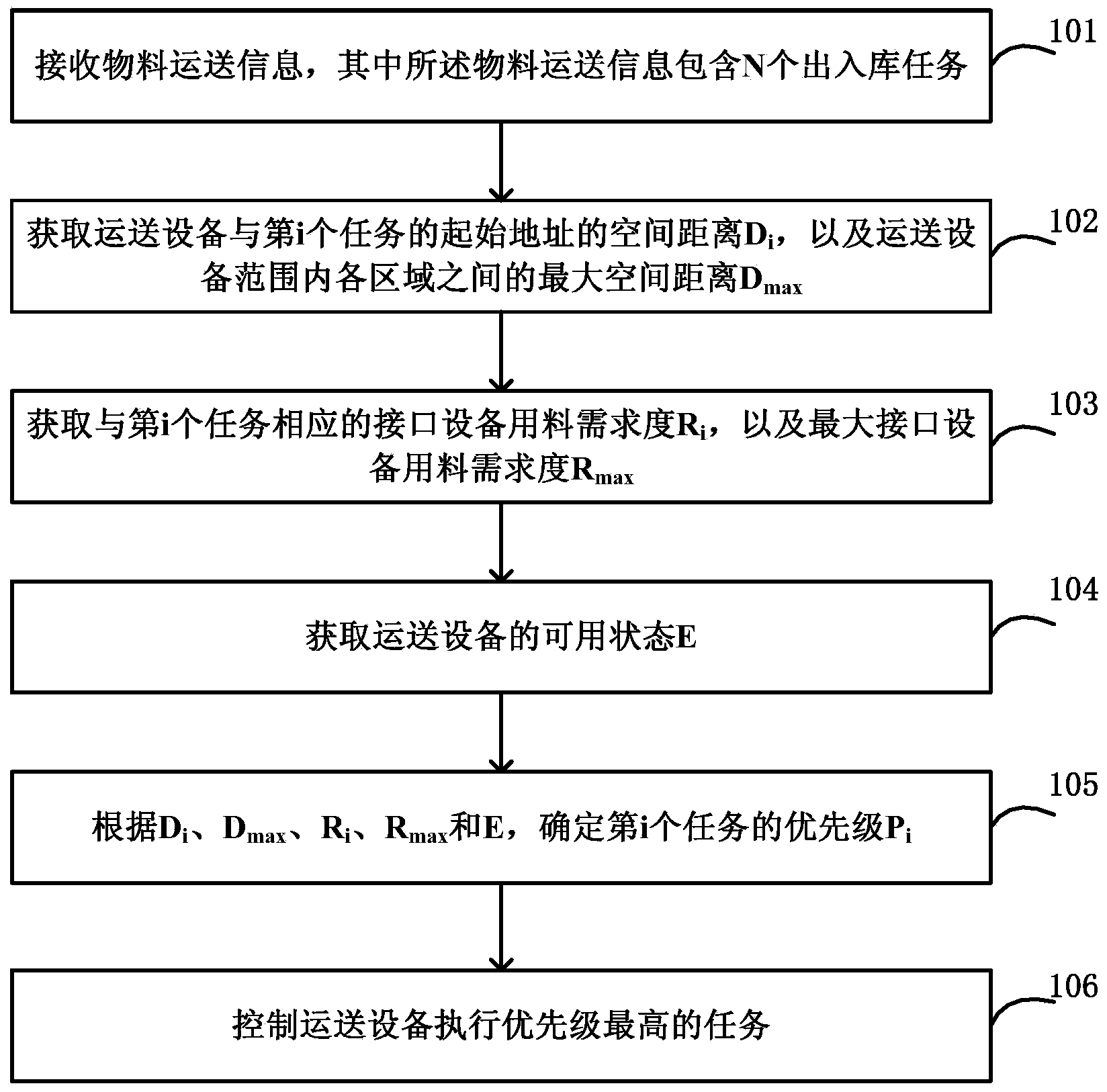

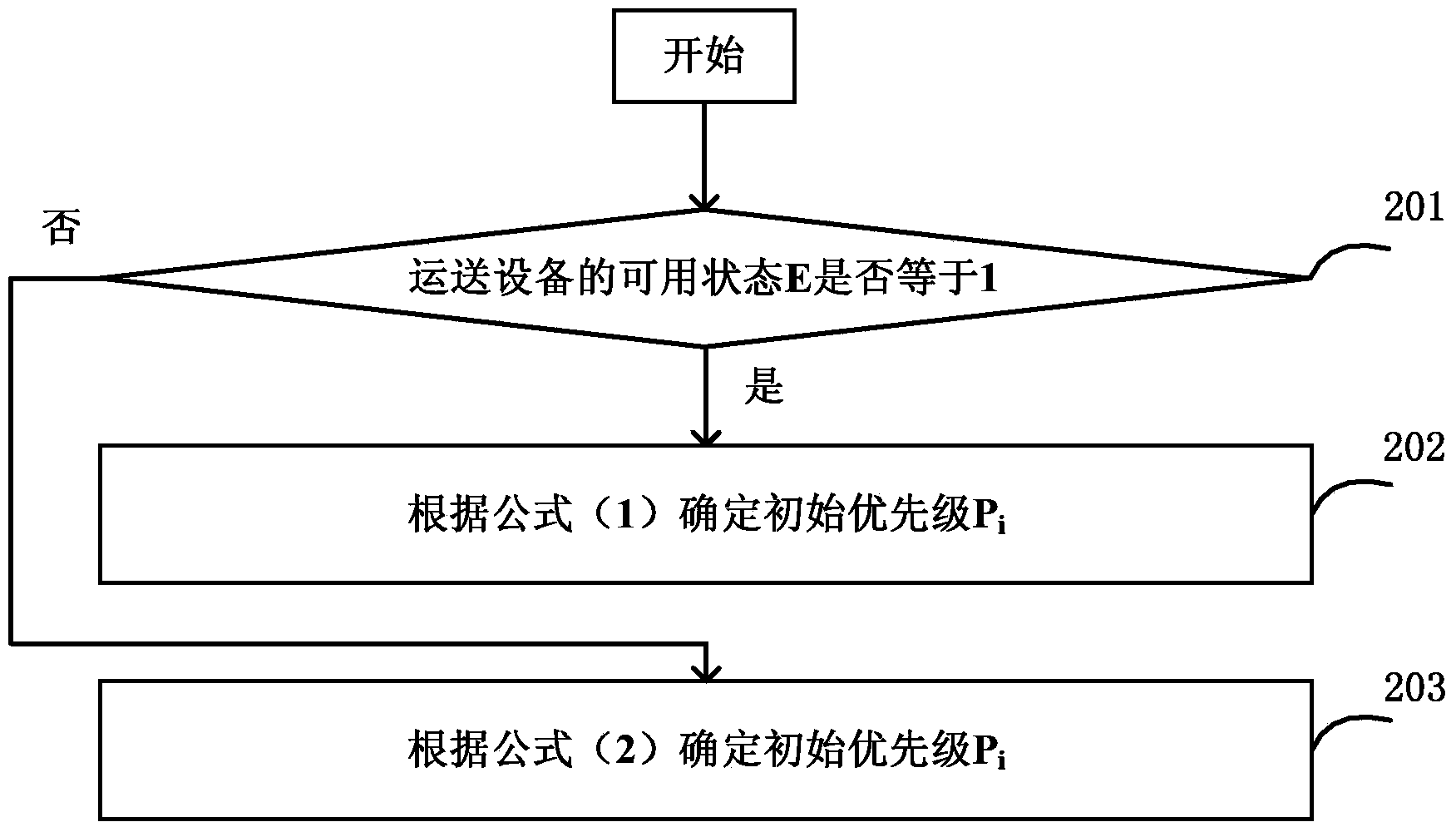

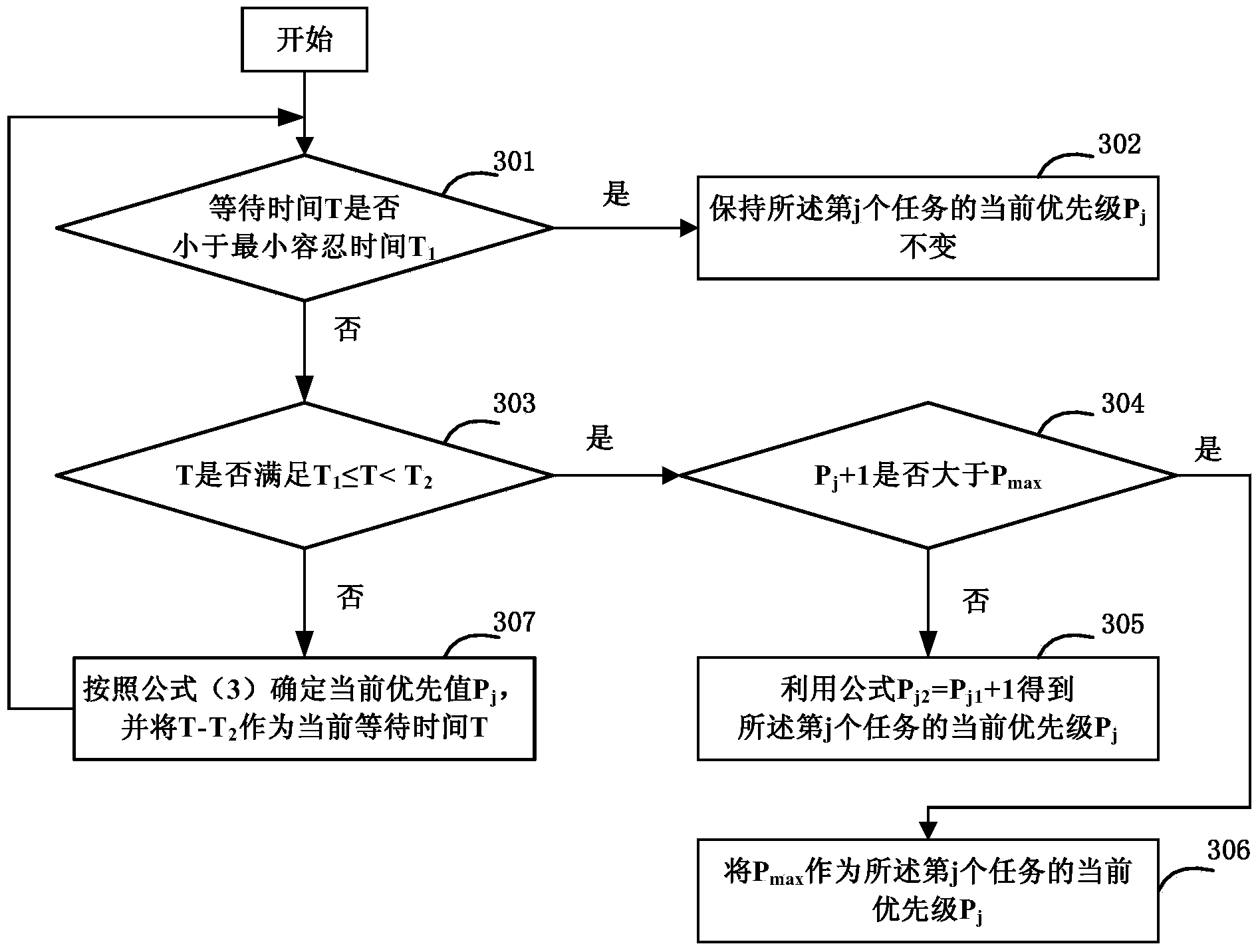

Dynamic priority scheduling method and device for logistics system, and logistics system

ActiveCN103870952AImprove scheduling efficiencyGuaranteed continuous productionLogisticsMaterial consumptionContinuous production

The invention discloses a dynamic priority scheduling method and device for a logistics system, and the logistics system. The method includes the steps of receiving material transport information including N warehouse output and input tasks, obtaining the spatial distance Di between a transport device and the start address of the ith task, obtaining the maximum spatial distance Dmax between all regions within the range of the transport device, obtaining the interface equipment material consumption demand degree Ri corresponding to the ith task, obtaining the maximum interface equipment material consumption demand degree Rmax, obtaining the available state E of the transport device, determining the priority Pi of the ith task according to Di, Dmax, Ri, Rmax and E, and controlling the transport device to execute the task with the maximum priority. According to the dynamic priority scheduling method and device and the logistics system, on the premise that the production process requirement is met, scheduling efficiency of the transport device can be improved, continuous production of interface equipment is ensured while logistics efficiency is ensured, the logistics resource, namely, the transport device, can not be wasted, and the unremittance of material transport can be ensured to a larger extent.

Owner:XIAMEN TOBACCO IND

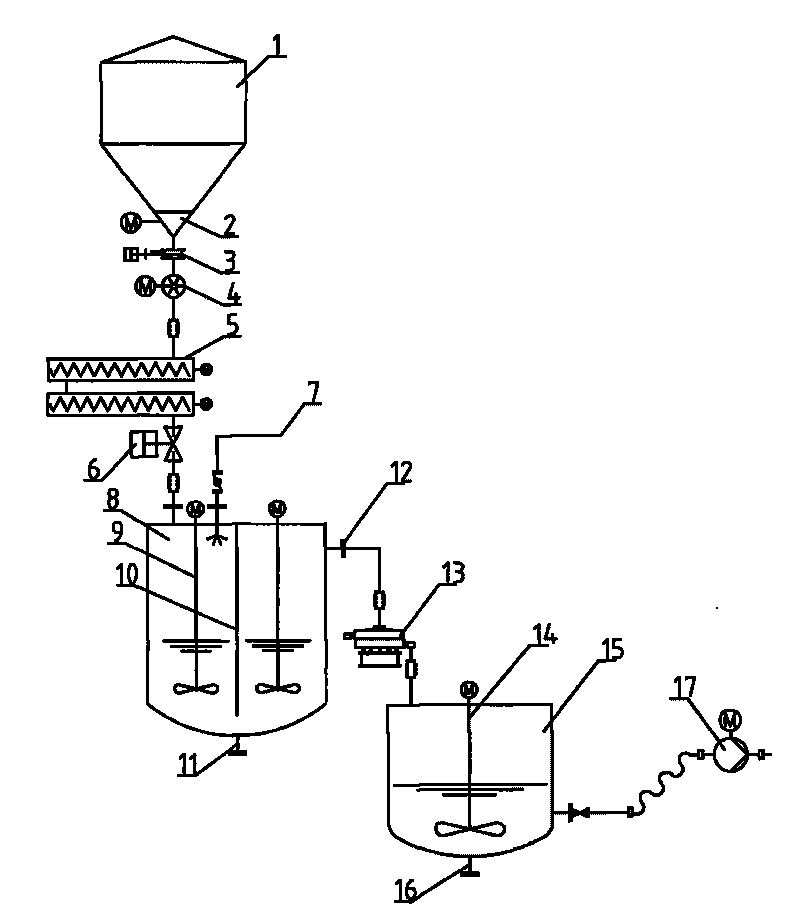

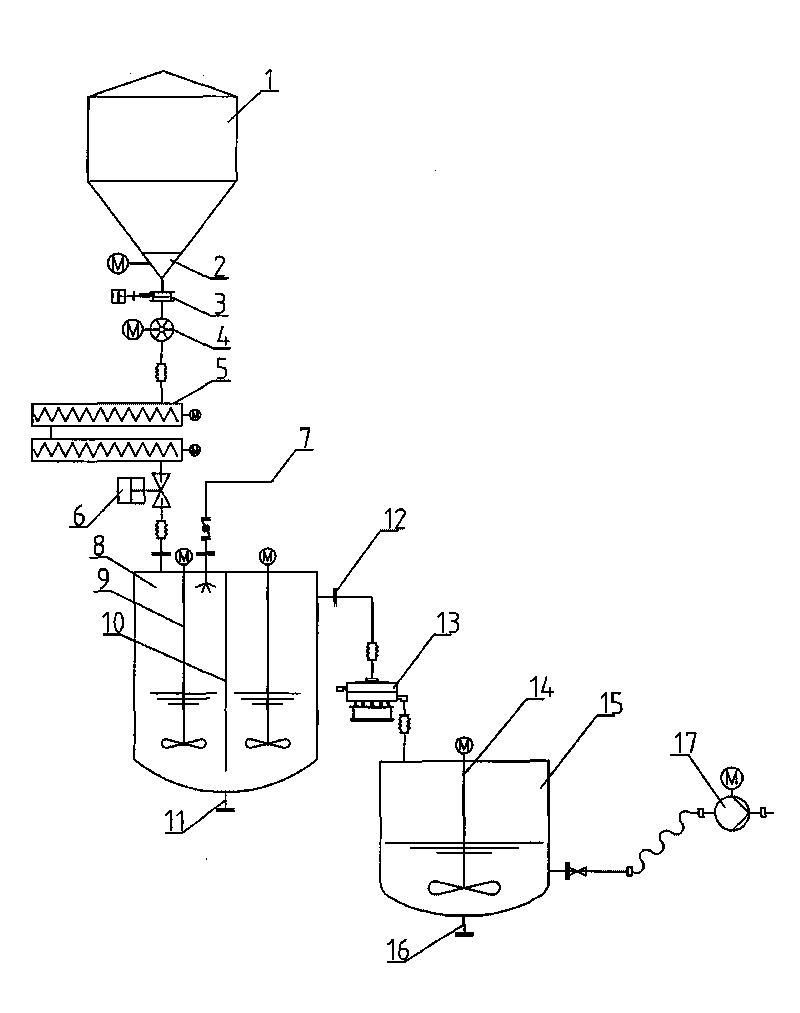

Continuous preparation system for lime slurry having fixed concentration

InactiveCN101723604AGuaranteed continuous productionAvoid enteringDispersed particle separationPulp and paper industryStorage tank

The invention relates to a continuous preparation system for lime slurry having a fixed concentration, and solves the problem that the prepared lime slurry is insufficient by using a large smoke semidry deacidifying process. The prepared lime slurry is delivered to a rotary atomizer through the system. The system comprises a lime cabin of which the lower part is provided with an activating hopper; the lime cabin is connected with a curing tank through a feeder; the curing tank is also connected with a tap water inlet tube; an outlet of the curing tank is connected with a storage tank through a vibrating filter; and the storage tank is connected with a lime slurry pump. The system is characterized in that: the curing tank is divided into two curing chambers through a chamber-dividing clapboard; and the two curing chambers are provided with a stirrer respectively.

Owner:无锡雪浪输送机械有限公司

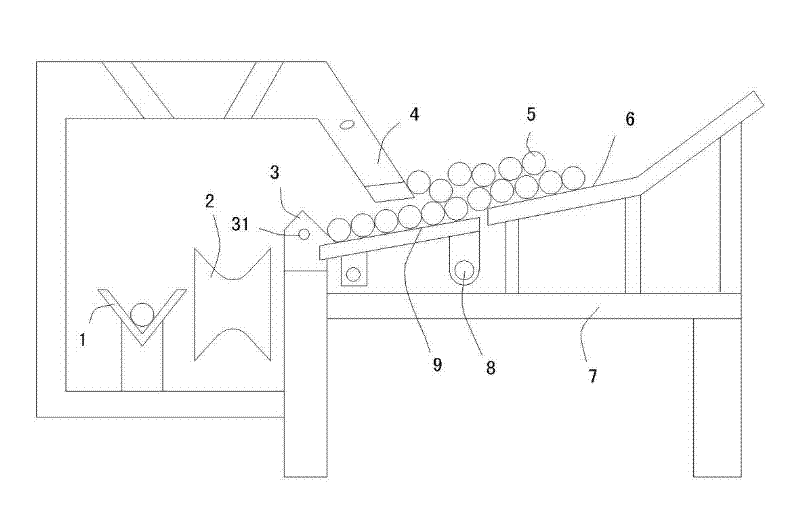

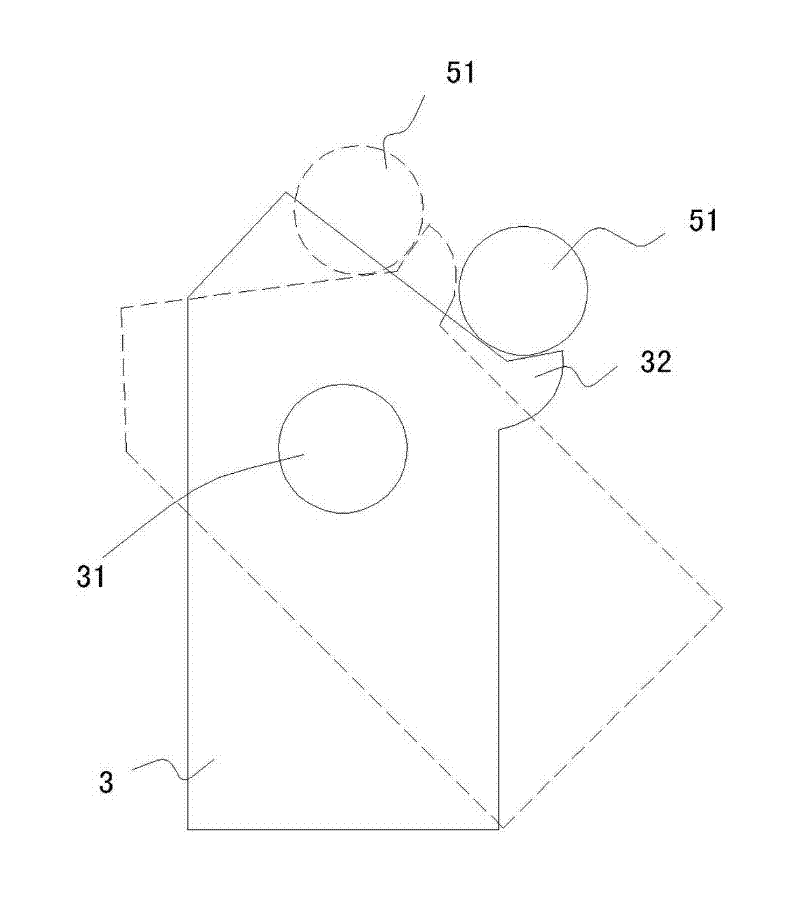

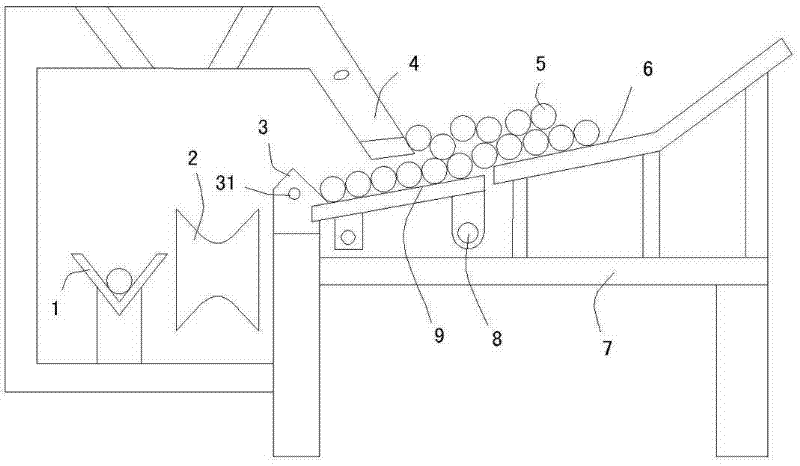

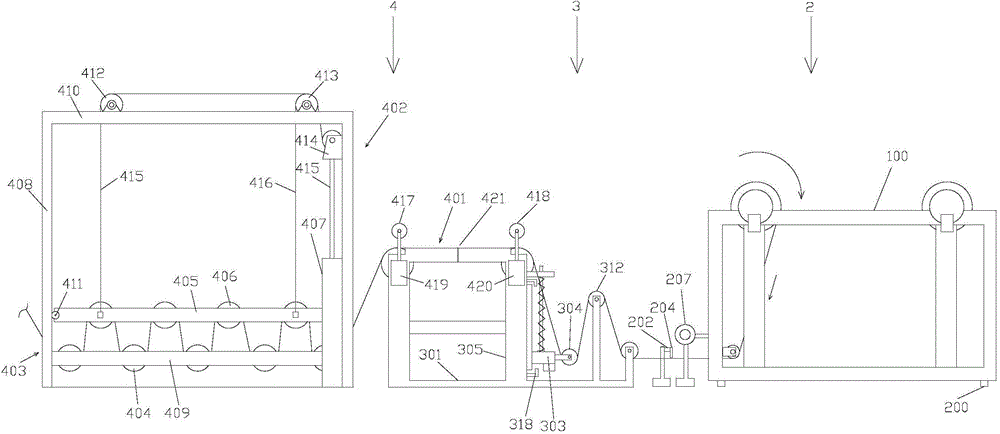

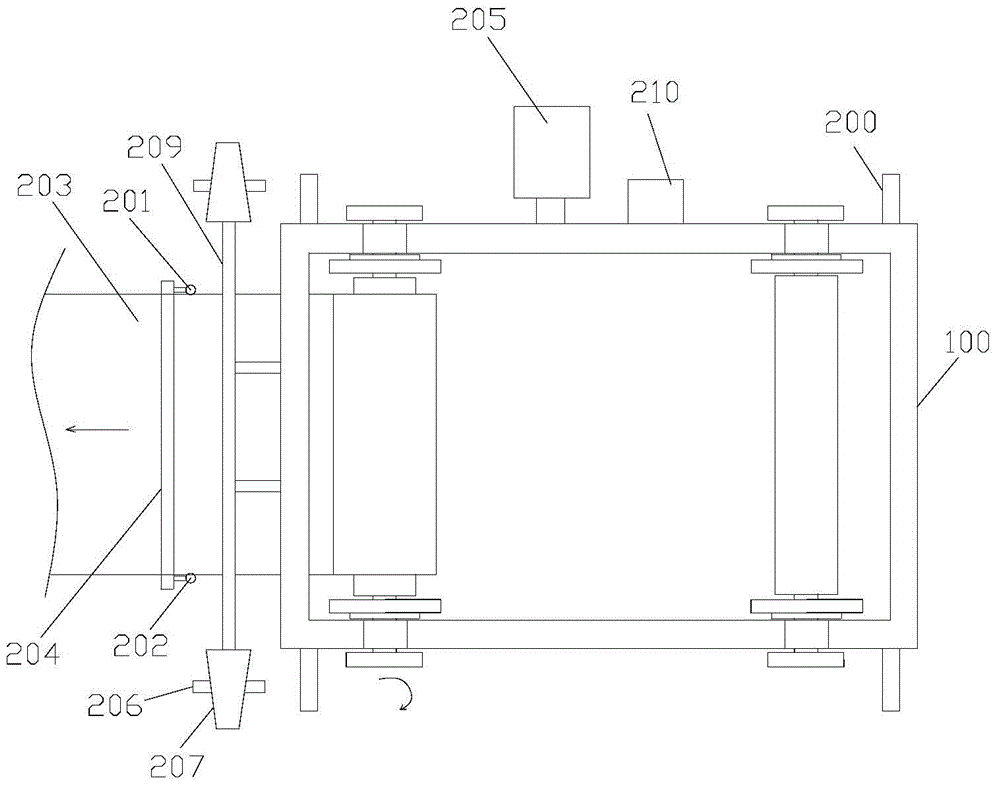

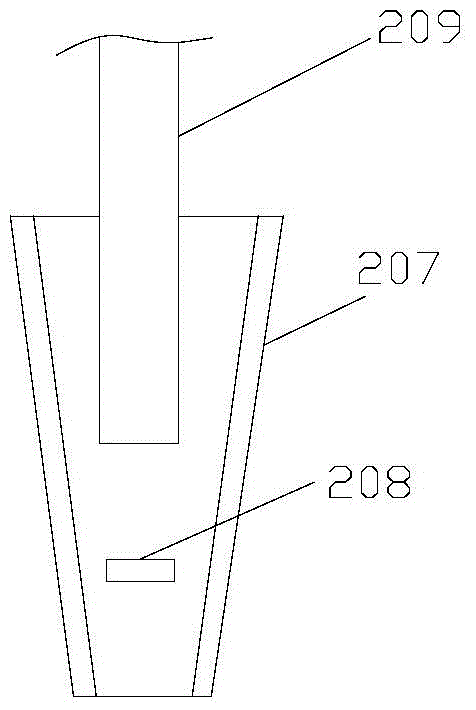

Automatic material distributing and conveying device of cold-drawn steel tubes

InactiveCN102527757AIncrease labor intensityHigh degree of automationEngineeringUltimate tensile strength

The invention relates to an automatic material distributing and conveying device of cold-drawn steel tubes. The automatic material distributing and conveying device comprises a frame, wherein the top surface of the frame is of a working face for stacking source steel tubes, and the automatic material distributing and conveying device is characterized in that the working face comprises two sections, namely a fixed inclined plane and a vibrating inclined plane, and the vibrating inclined plane is positioned at the downstream part of the fixed inclined plane; a flow limiting plate is arranged above an inlet of the vibrating inclined plane; a vertical turnover material stirring device and an axial feeding device are sequentially arranged on one side of the outlet end of the vibrating inclined plane; and the axial feeding device comprises a plurality of rolling wheels which are mounted axially relative to the source steel tubes and material turning rods arranged at the gaps between the rolling wheels. According to the automatic material distributing and conveying device, material distributing and conveying of the source steel tubes can be completed by utilizing the fixed inclined plane and the vibrating inclined plane, and the source steel tubes can be automatically conveyed to a V-shaped working groove under the action of the vertical turnover material stirring device and the axial feeding device, so that the automatic material distributing and conveying device has the advantages of low labor intensity, good operating environment, high degree of automation and continuous production, can realize the purpose of reliably ensuring quality and is further conductive to eliminating potential safety hazard.

Owner:浙江伦宝管业股份有限公司

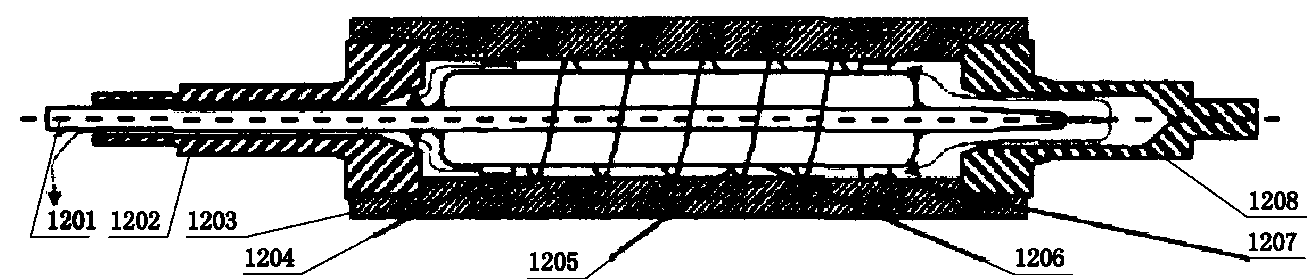

Medical fiber preparation method and uses thereof

InactiveCN101265609ASave raw materialsThe heating area of the upper beam is enlargedSuture equipmentsHeating/cooling textile fabricsFiberSingle stage

The invention discloses a method for preparing medical fiber and the application thereof, and includes the steps of drying, spinning, multilevel heat energy drafting, rolling, fiber placing, flow meshing and curling, and shrink-setting, wherein the multilevel heat energy drafting adopts single-stage process drafting of a plurality of double-rolls heating, and the flow meshing and curling step is carried out by a flow contact wheel for heating and curling. The method of the invention can reduce as much material for the trial run as possible, the double-rolls increase the upper bundle heating area, the interfacial residence time is increased, thereby ensuring the uniformity of the mechanical properties of the medical fiber, such as mightiness; having better crimpability and decentrality; and guaranteeing the continuous production of the medical fiber pipelining.

Owner:SHANGHAI JURUI BIOMATERIALS

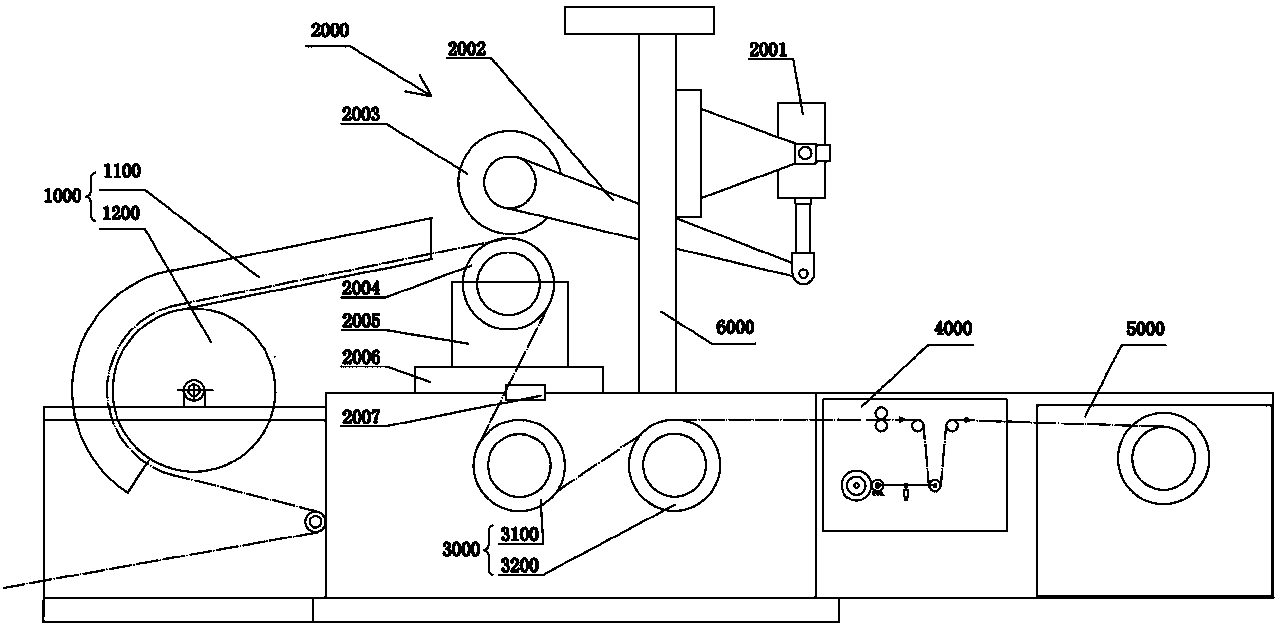

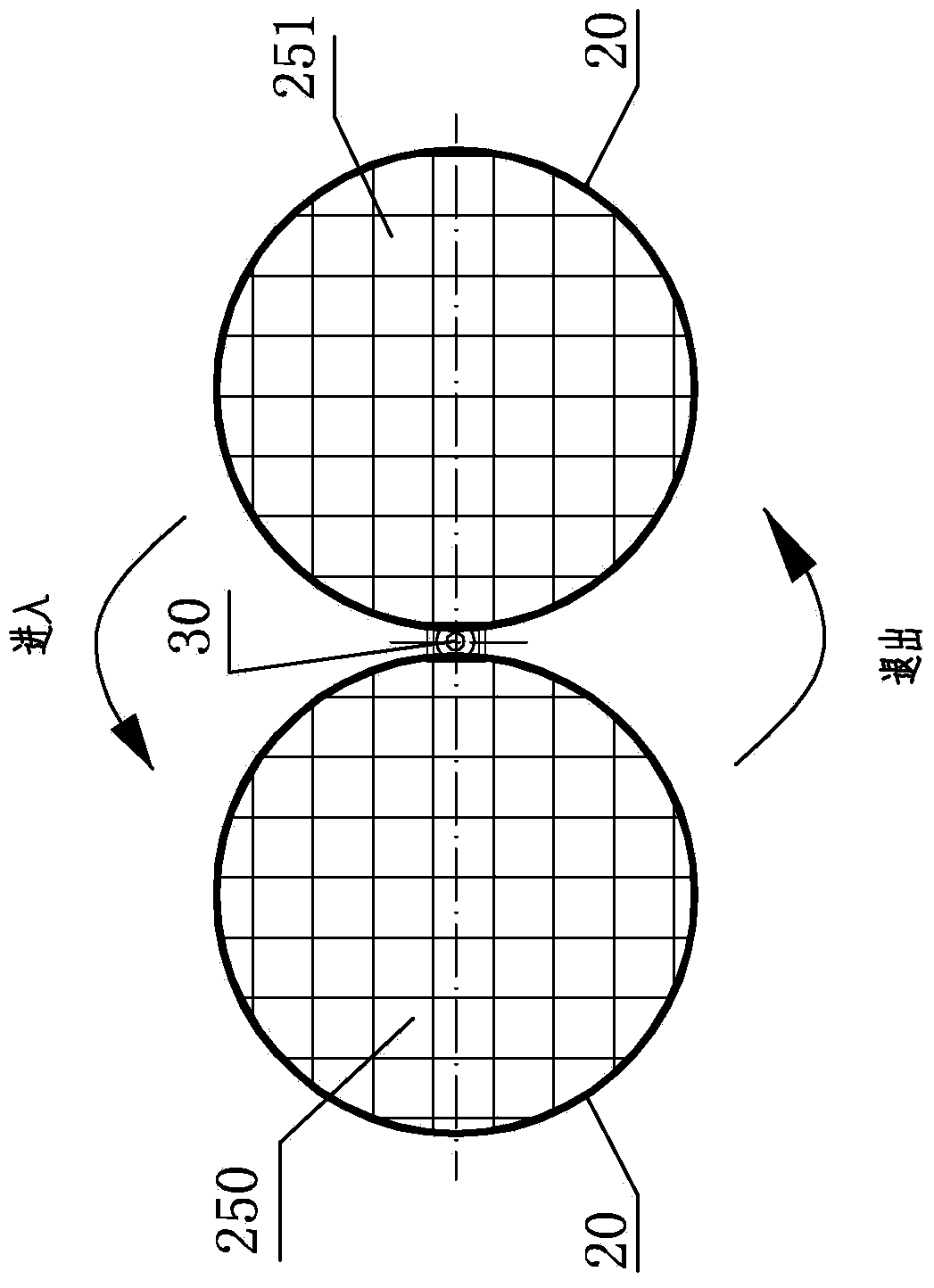

Supply device used for macromolecule roll goods production

ActiveCN104876045ACushion and adjust tensionAdjust tensionWebs handlingWaste managementWhole systems

The invention discloses a supply device used for macromolecule roll goods production. The supply device comprises a discharge mechanism, a discharge buffer mechanism and a collection mechanism arranged sequentially along the conveying direction of macromolecule substrates. The discharge mechanism can automatically correct the position of a discharge rack, and no deviation is ensured when the macromolecule substrates are conveyed to the subsequent procedure. The discharge buffer mechanism can automatically adjust tension degree of the macromolecule substrates, and an alarm can be triggered if the macromolecule substrates are too loose or too tight, so that operators can know relevant faults in time. The collection mechanism is provided with an operating platform used for collection, a pre-storage mechanism is arranged under the operating platform in advance, and the pre-storage mechanism can prestore a certain quantity of macromolecule substrates. In addition, the prestored macromolecule substrates can be distributed slowly for later use when spliced, the system is not halted during collection, continuous of the integral system is ensured and production efficiency is improved.

Owner:浙江港流高分子科技股份有限公司

Gas pipe corrosion defect under-pressure repair method

The invention discloses a gas pipe corrosion defect under-pressure repair method. The gas pipe corrosion defect under-pressure repair method comprises performing surface cleaning on the pipe repair position; filling the pipe perforation leakage position or the outer surface corrosion position with a repairing agent; brushing the epoxy resin primer at the pipe surface position which needs to be wrapped, wherein the thickness of the epoxy resin primer is not less than 0.2 mm; enabling a carbon fiber band to wind the epoxy resin primer brushed pipe surface in a spiral mode, wherein the carbon fiber band winds the first to third layer, a special adhesive is bonded between the layers, and the drum rolling is adopted in the process of winding of the carbon fiber band to avoid the interlayer bulge; brushing the anticorrosive paint at the carbon fiber band wrapping position of the pipe surface. According to the gas pipe corrosion defect under-pressure repair method, the defects of the traditional repair method are overcome; the pipe corrosion and perforation defects are repaired in the running state of a gas pipe, the stress state of the pipe is not changed, the flame operation is not required, and accordingly the potential safety hazard is avoided and the service life is long; the stop operation is not required and accordingly the continuous production is ensured.

Owner:SHANGHAI JINYI INSPECTION TECH

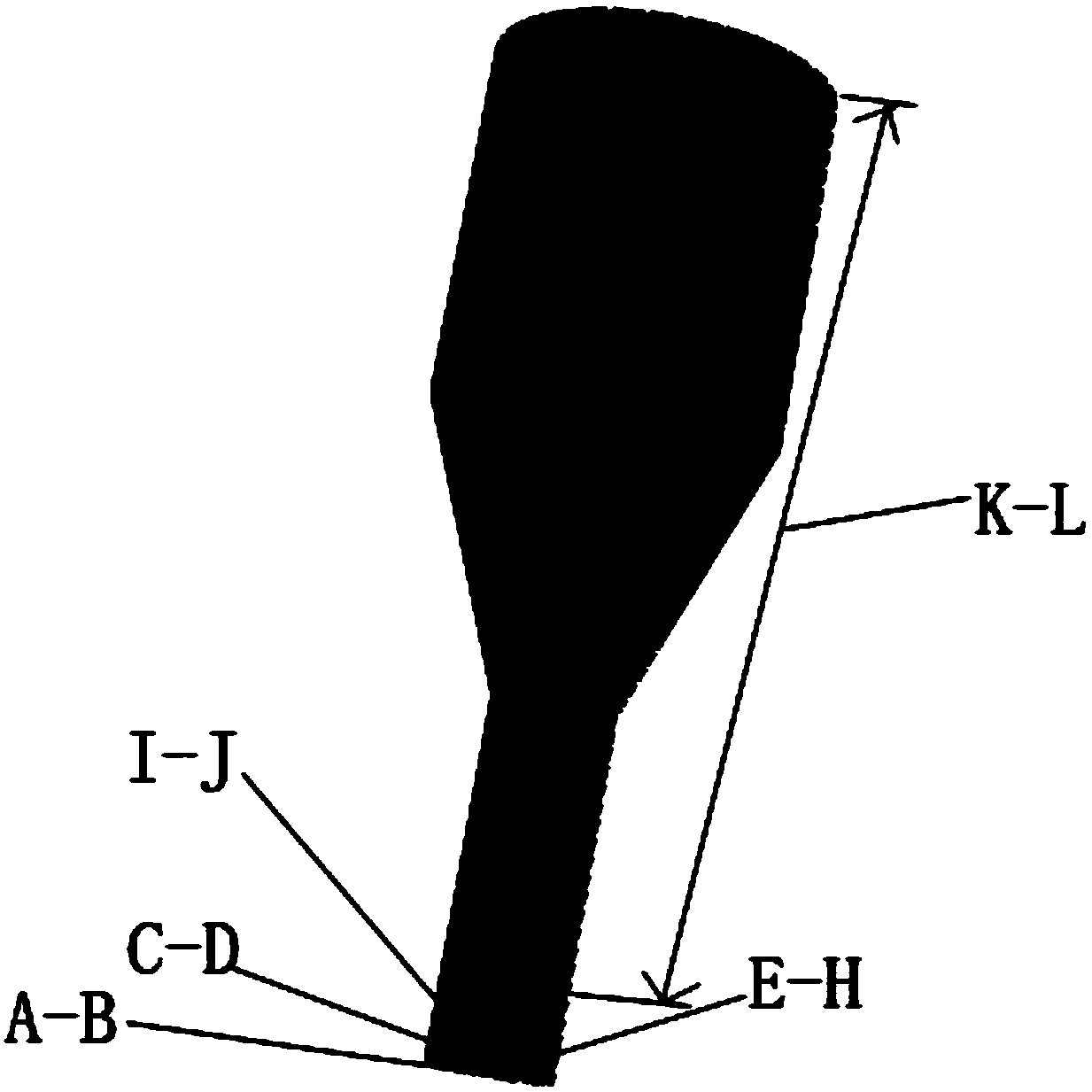

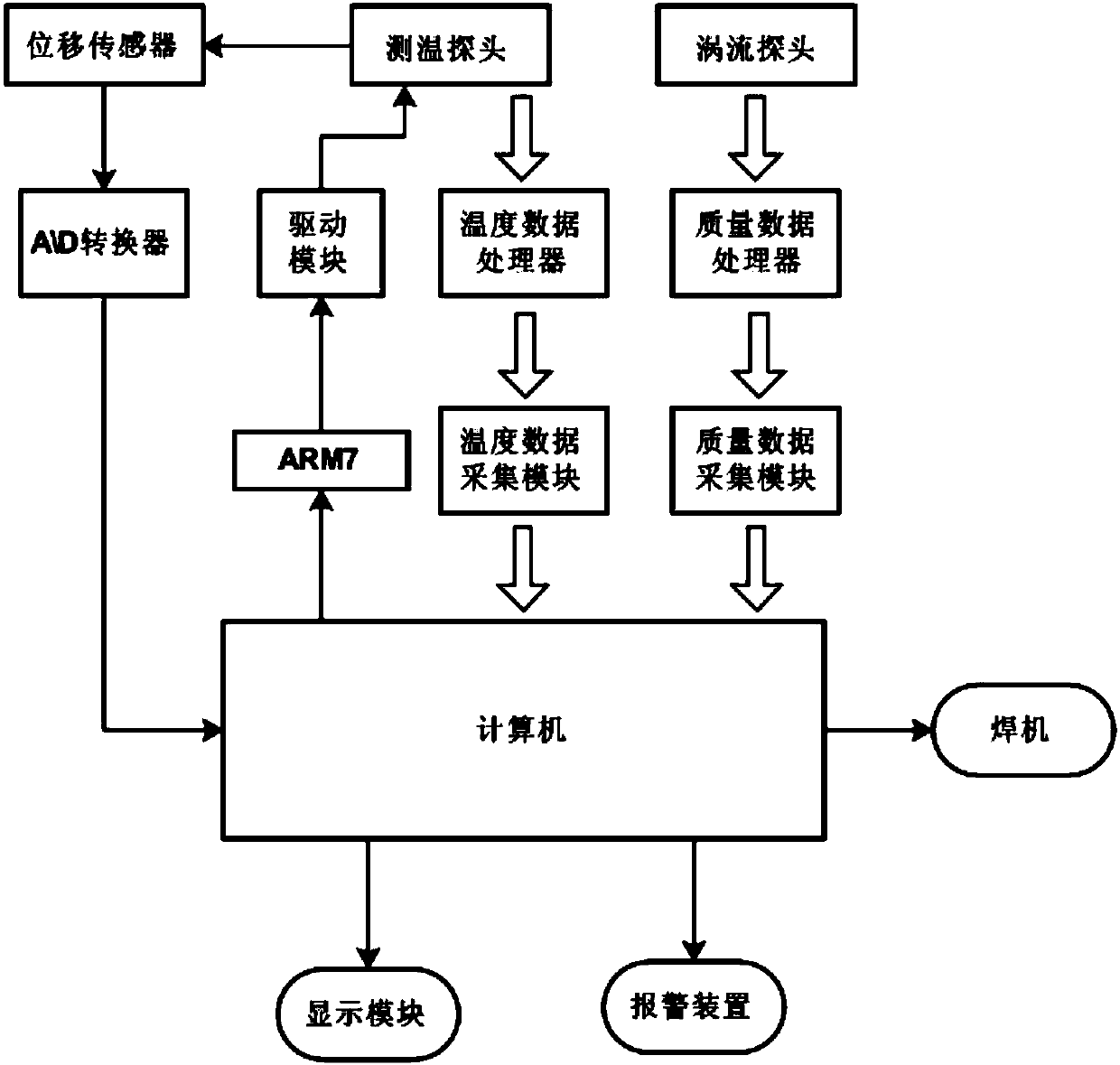

Method and device for improving quality of narrow lap welder weld joint

ActiveCN109570808AMeet needsSolve the problem that the temperature measurement point is relatively fixedWelding/cutting auxillary devicesAuxillary welding devicesComputer moduleBiomedical engineering

The invention discloses a method and device for improving the quality of a narrow lap welder weld joint. The method comprises the steps that (1), automatic tracking of a temperature probe on the weldjoint is controlled; (2), the temperature detected by the temperature measuring probe is kept constant; and (3), online detection and evaluation are conducted on the quality of the weld joint. Onlinedetection and evaluation on the quality of the weld joint comprise the steps that the optimum temperature detected by the temperature measuring probe when welding is conducted is determined; a weldingexperiment is conducted on a substrate plate, an optimum quality information curve and a maximum defect tolerance quality curve are determined, and a quality curve database is built; and the qualityinformation curve is matched with a weld joint quality information curve detected in real time, if the similarity of the quality information curve (the optimum curve similarity) in the database and the weld joint quality information curve detected in real time is 80% or above, a display module displays 'qualified', and if the similarity of the quality information curve (the optimum curve similarity) in the database and the weld joint quality information curve detected in real time is 80% or below, the display module displays 'unqualified', and an alarming device conducts alarming reminding.

Owner:BAOSHAN IRON & STEEL CO LTD

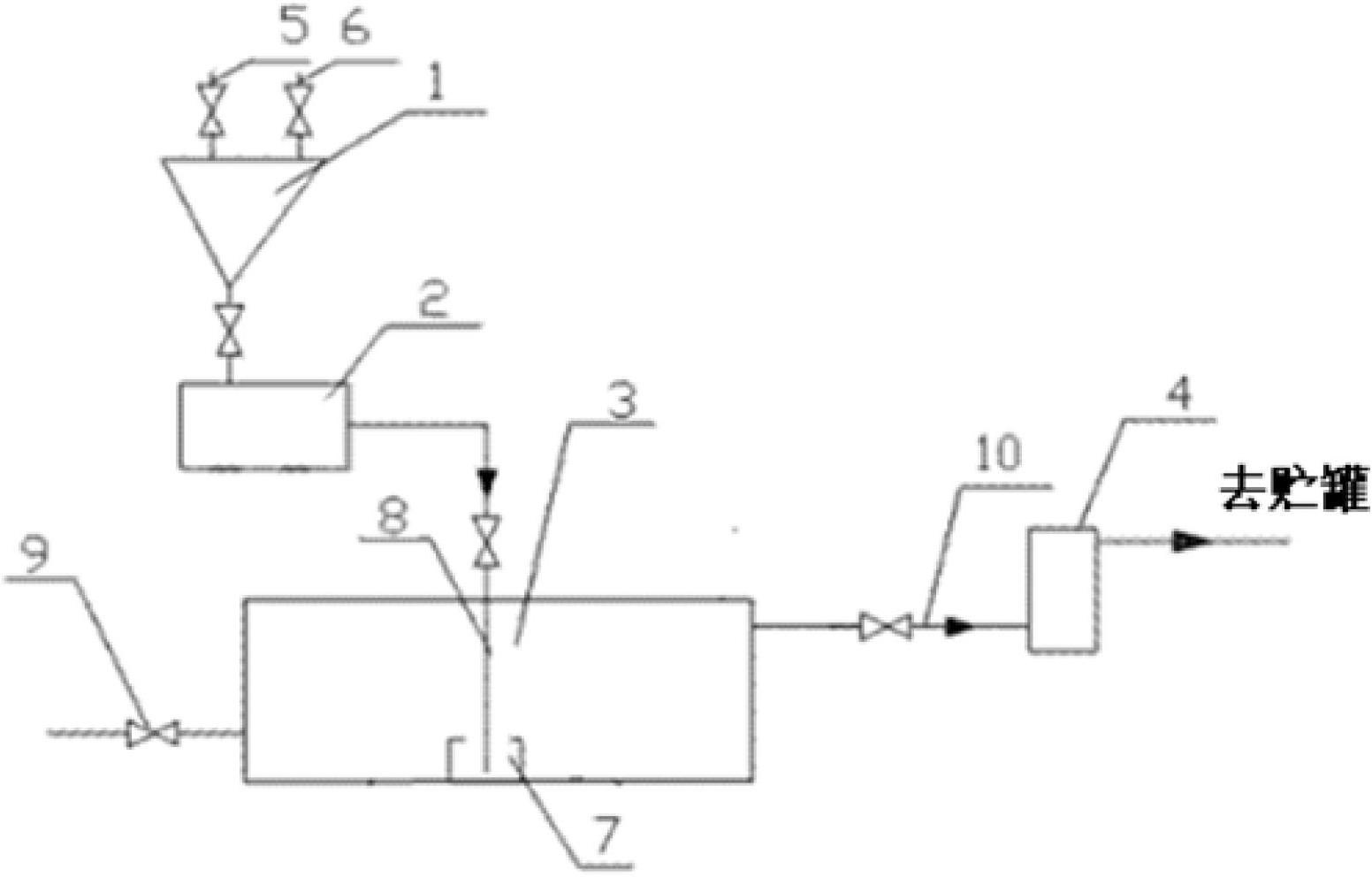

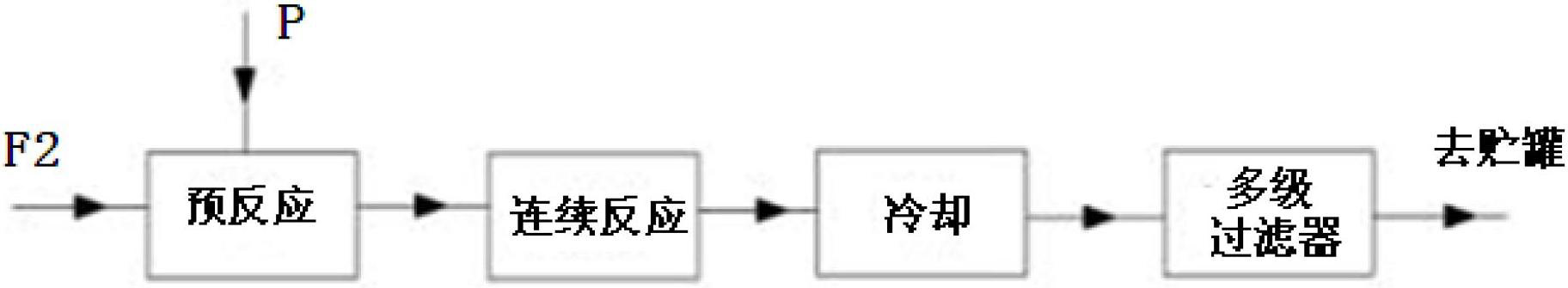

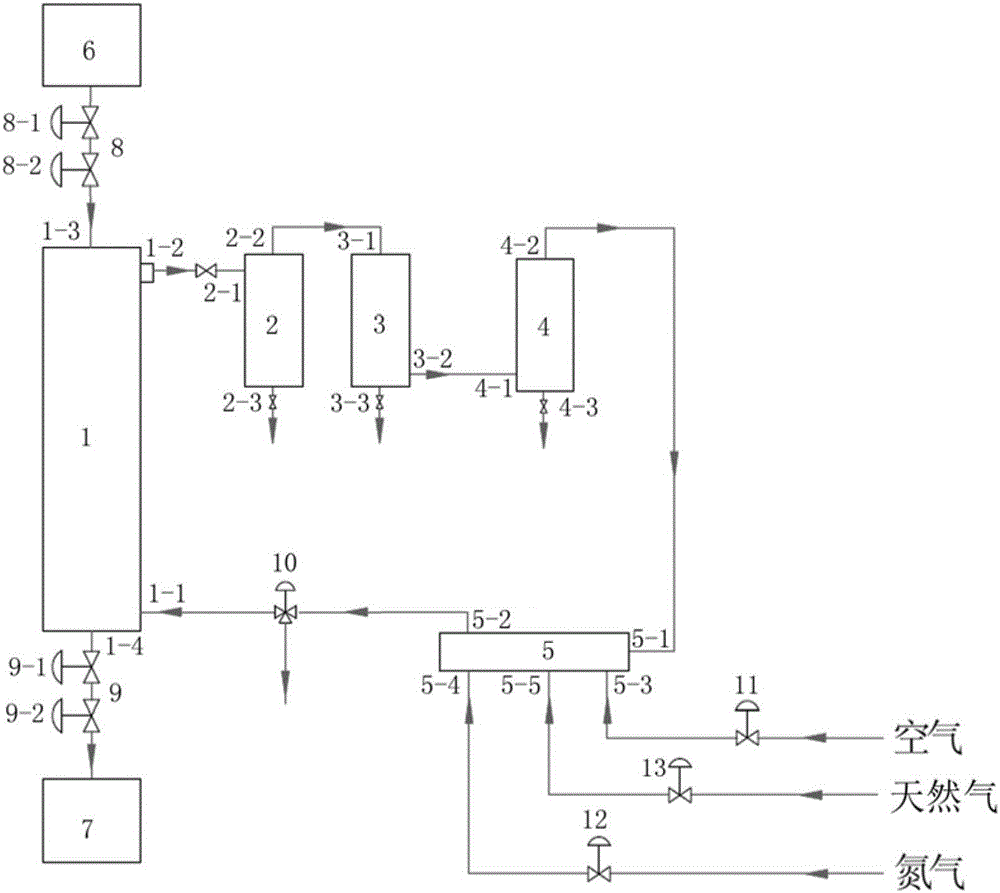

Continuous producing device and method of phosphorus pentafluoride

InactiveCN102674275AGuaranteed continuous productionThe production process is safe and controllablePhosphorus halides/oxyhalidesSingle substanceEngineering

The invention provides a continuous producing device of phosphorus pentafluoride, comprising a phosphorus single-substance closing silo, a spiral conveyer, a fluorine-phosphorus reactor, a cooling pipeline and a multi-grade filter. The continuous producing device of phosphorus pentafluoride is characterized in that the upper end of the spiral conveyer is connected to the lower end of the phosphorus single-substance closing silo, the tail end of the spiral conveyer is connected to the upper part of the fluorine-phosphorus reactor; one end of the fluorine-phosphorus reactor is connected with the cooling pipeline, and the other end of the cooling pipeline is connected with the multi-grade filter. The invention further provides a method for continuously producing phosphorus pentafluoride by using the device; the high-purity phosphorus pentafluoride gas is obtained by pre-reaction, continuous reaction, cooling and multi-grade filtering. According to the continuous producing device, the continuous production of phosphorus pentafluoride is realized; the continuous producing device has the advantages of being high in production efficiency, simple, safe and reliable in operation and good in product quality; the product purity can reach 99.8% above; therefore, the continuous producing device can be directly applied to the production of the lithium hexafluorophosphate.

Owner:ZHEJIANG KAISN FLUOROCHEM +1

Wallpaper printing system

ActiveCN104002507AReduce in quantityHigh thermal efficiencyMechanical working/deformationWebs handlingEngineeringHeating efficiency

The invention relates to a wallpaper printing system and belongs to the technical field of printing machines. The wallpaper printing system comprises a preheating mechanism, an embossing mechanism, a cooling mechanism, a tension mechanism, a winding mechanism and a machine frame. The preheating mechanism comprises a preheating cover and a heating roller, the preheating cover is arranged on a working surface of the heating roller, the embossing mechanism comprises a press roller and an embossing roller, and the press roller and the embossing roller are parallelly arranged and located on a discharging port of the preheating mechanism. Hot oil single-side inflow and outflow are adopted according to the preheating mechanism for the wallpaper printing system, the number of components in heat exchange with hot oil is reduced, and heat efficiency is improved; according to the preheating mechanism for the wallpaper printing system, an oil guide sleeve is adopted, the area of the hot oil in the heating roller is reduced, the circulation speed of the hot oil is accelerated, and the temperature of a roller can be kept constant to the largest extent.

Owner:陈换换

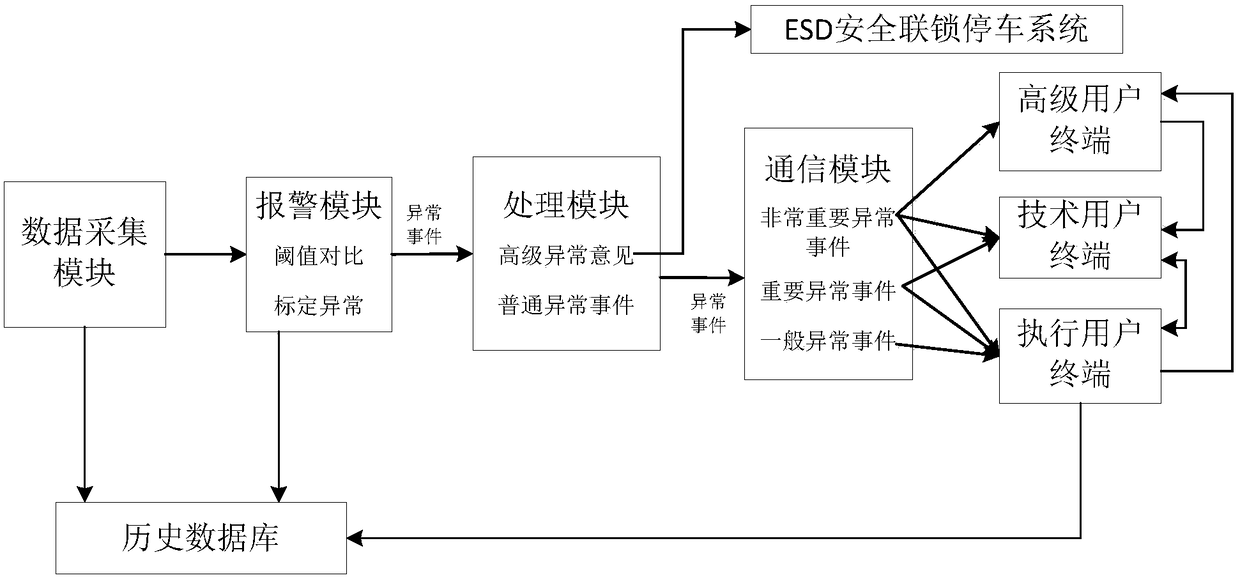

Abnormity warning and processing system of continuously-producing process

InactiveCN108319232AProcessing speedEnsure safetyTotal factory controlProgramme total factory controlComputer scienceSystem safety

The invention discloses an abnormity warning and processing system of a continuously-producing process, which can effectively conduct abnormity warning and processing timely without stopping producing, and is in favor of the continuous and stable operation of the producing process. Each process parameter during the producing process is monitored in a real-time manner, and the abnormity accidents and processing measures are stored in a historical database, and the situations of record failure, illegal processing and information withholding can be prevented. The abnormity accidents are classified, and for high-level abnormity accidents that the safety of the producing system will be affected if the vehicle is not stopped, the stopping instruction is immediately triggered, so that the producing safety can be ensured. As for general abnormity accidents which can be resolved by an executive agency, the executive agency can resolve the accidents by itself, and thereby the processing speed ofthe abnormity accidents can be accelerated, and continuous producing can be guaranteed. As for abnormity accidents which cannot be resolved by an executive agency, technical decision will be made bythe technical department so as to ensure production continuity.

Owner:甘肃银光聚银化工有限公司 +1

Toughening furnace for continuously producing half strengthened glass and production method of toughening furnace

InactiveCN103121793AAchieve continuous heatingImprove flatnessGlass tempering apparatusGlass productionSingle chamberToughened glass

The invention provides a toughening furnace for continuously producing half strengthened glass and a production method of the toughening furnace. The toughening furnace is characterized by comprising a feeding area, a heating area and the like arranged orderly, wherein the feeding area has a two-way feeding function; and the heating area comprises a first heating section, a second heating section and a third heating section. The production method of the toughening furnace comprises the following steps of heating treatment, cooling treatment and the like. The toughening furnace has the beneficial effects that the heating area is divided into three heating sections; the length of each heating section is 10m; the length of the heating area is greater than that of like product; the three heating sections adopt different temperature to heat; the glass can finish the heating requirement of the half strengthened glass after passing through the three heating sections; conveying for a plurality of times is not needed; and the rear glass does not need to wait in the feeding area, so that continuous heating of the glass is achieved; and the work efficiency is improved. The production efficiency of the toughening furnace is 3.5 times that of a common double-chamber toughening furnace, and is 5.5 times that of a common single-chamber furnace; and the energy consumption of each square meter of glass is reduced by about 39% in comparison with that of the common toughening furnace.

Owner:天津南玻节能玻璃有限公司 +2

Method for preparing biomass charcoal fuel from corn stalks through low-temperature carbonization

ActiveCN106318418AIncrease productionReduce consumptionDirect heating destructive distillationBiofuelsReaction temperatureCarbonization

The invention relates to a method for preparing biomass charcoal fuel from corn stalks through low-temperature carbonization, and belongs to the technical field of biomass pyrolysis. The method comprises the following steps that after nitrogen gas is introduced into a carbonization furnace, oxygen-free or low-oxygen environment is formed in the furnace; corn stalk raw material particles are fed from the top of the carbonization furnace; a hot air flow enters the carbonization furnace from the bottom of the carbonization furnace to form a reverse flow reaction region in the furnace; the reaction temperature at the bottom of the carbonization furnace is controlled to be 200 to 280 DEG C; the pressure inside the furnace is 1010 to 1200 mbar; the biomass charcoal fuel generated through reaction is output from the bottom of the carbonization furnace. The method for preparing biomass charcoal fuel from corn stalks through low-temperature carbonization has the advantages that the heat utilization efficiency is high; the carbonization temperature is low; the energy consumption is reduced; the mass yield of the biomass charcoal fuel obtained after the carbonization is 70 percent to 85 percent; the energy source yield is 85 percent to 95 percent; the energy source yield is high; the energy density of the obtained biomass charcoal is high; the biomass charcoal can be used as the fuel; the product purpose is expanded; a novel path is provided for the recovery and the utilization of the corn stalks.

Owner:河南博顿生物科技有限公司 +1

High-temperature flue gas waste heat recovery and dust extraction all-in-one device

ActiveCN103673643ALarge heat capacityModerate bulk densityDispersed particle filtrationCombustion processCombustionFiltration

The invention relates to a high-temperature flue gas waste heat recovery and dust extraction all-in-one device. The high-temperature flue gas waste heat recovery and dust extraction all-in-one device comprises furnace connectors, material filtering beds, a left wind passing unit, a right wind passing unit and a four-way reversing valve, wherein the furnace connectors and the material filtering beds are connected with air flues on the two sides of a high-temperature kiln. Each wind passing unit comprises an upper wind opening, the corresponding low-temperature area material filtering bed, a low-temperature area frame, the corresponding high-temperature area material filtering bed, a high-temperature area frame, the corresponding furnace connector, a dust collection box and an ash outlet with movable partition plates from top to bottom. Each material filtering bed comprises accumulated ceramic balls. The high-temperature flue gas waste heat recovery and dust extraction all-in-one device allows filtration and ash removing to be conducted in a mode that the leftward direction and the rightward direction are switched in a timed mode and filtration and ash removing are periodically and alternately conducted, and allows ash removing and heat absorption to be achieved in a mode that high-temperature flue gas from one side passes through the corresponding material filtering beds from bottom to top so that filtration and heat accumulation can be achieved, and air from the other side reversely blows the corresponding material filtering beds from top to bottom so that ash removing and heat absorption can be achieved. The ash-laden gas flue can be unceasingly filtered, waste heat in the high-temperature gas flue can be unceasingly recovered, meanwhile, function regeneration and fresh air preheating can be simultaneously conducted, cooling and dirt removing of the high-temperature flue gas are achieved, and combustion efficiency is improved.

Owner:宝武集团中南钢铁有限公司 +1

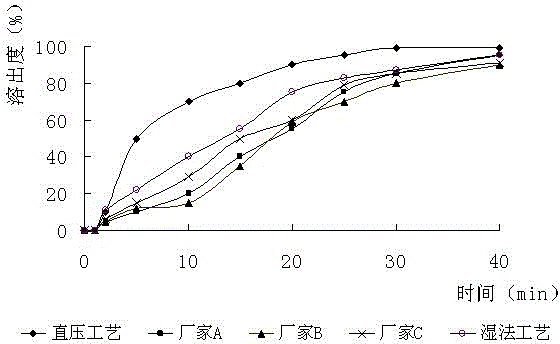

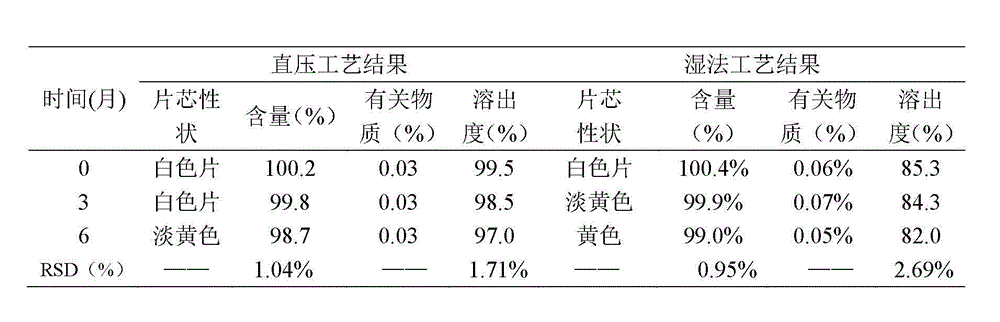

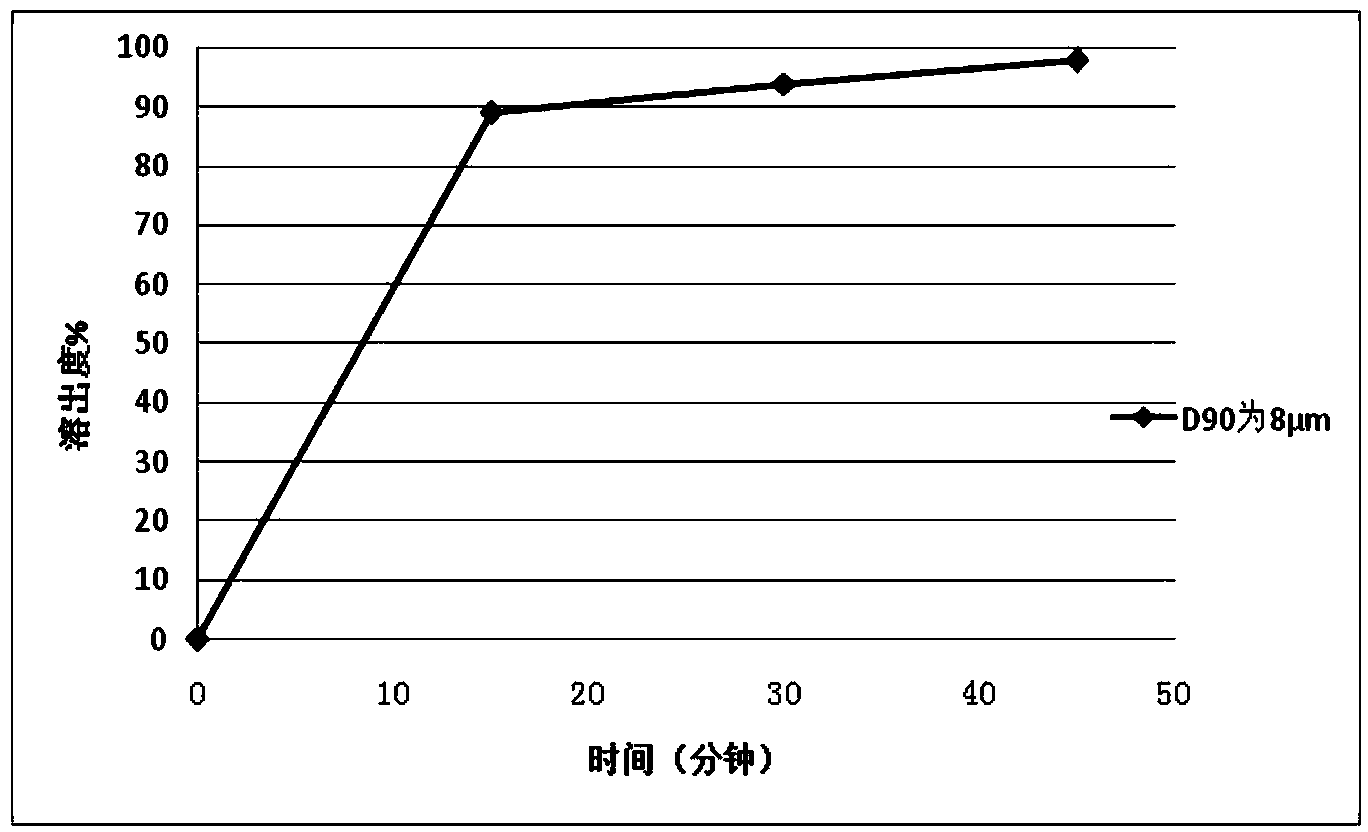

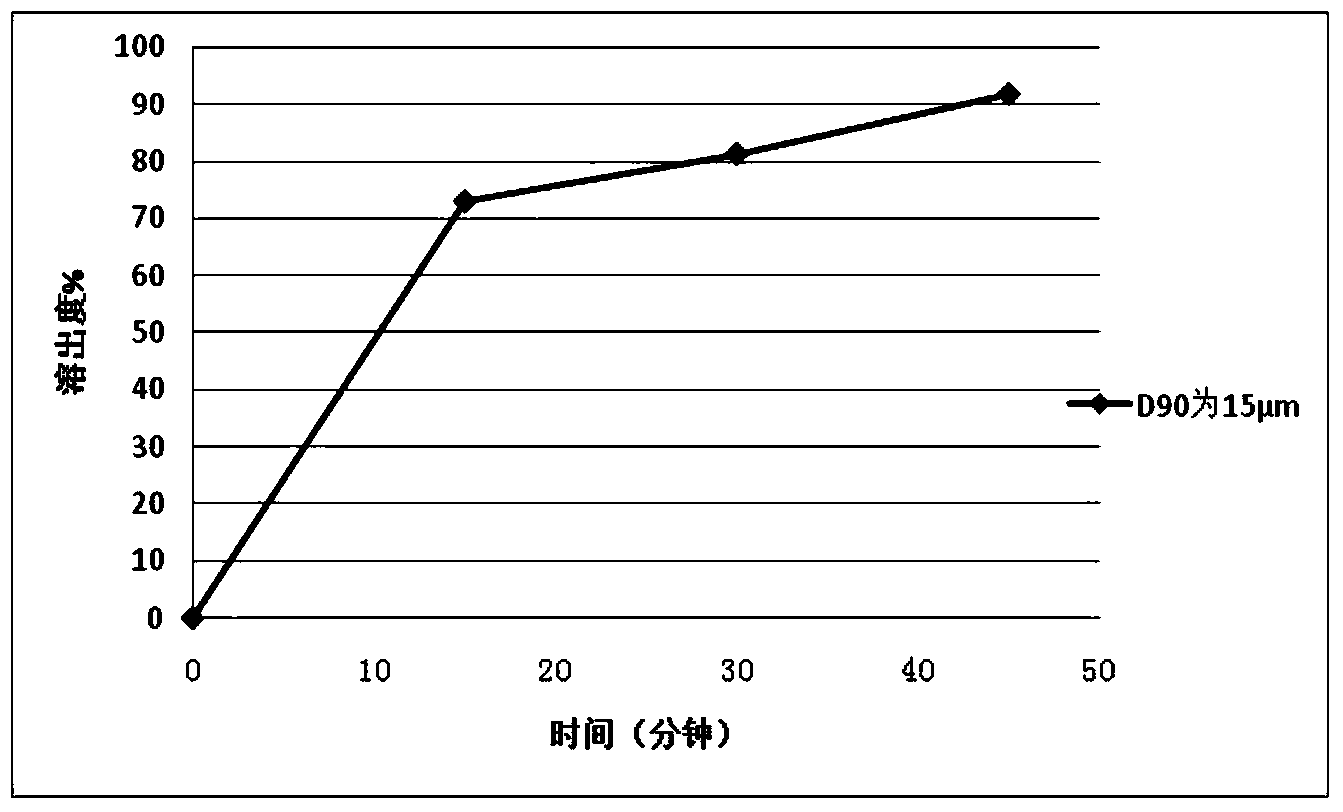

Method for preparing norfloxacin tablets

ActiveCN102940612AImprove liquidityEasy to compressAntibacterial agentsOrganic active ingredientsGranularityHeight difference

The invention discloses a method for preparing norfloxacin tablets. The method comprises the following steps of: sieving norfloxacin with a sieve of 40 to 100 meshes, sieving a disintegrating agent with a sieve of 60 to 100 meshes, sieving a lubricating agent and a flow aid with a sieve of 80 to 120 meshes, mixing the norfloxacin with a large part of disintegrating agent uniformly, mixing less than 2 percent of disintegrating agent, the lubricating agent and the flow aid uniformly, adding into the mixed powder, mixing uniformly, tabletting, and thus obtaining the norfloxacin tablets. The norfloxacin tablets comprise the following raw materials in percentage by weight: 20 to 80 percent of norfloxacin, 5 to 79 percent of disintegrating agent, and 1 to 8 percent of lubricating agent and flow aid. 5 to 70 percent of filling agent can also be added. The mixed materials obtain high flowability, excellent compression property and adhesive property, high attachment and low sensitivity to the lubricating agent through a large quantity of tests, advantage complementation of auxiliary materials, proper formula proportioning, reasonable granularity distribution and accurate powder mixing sequence. The method overcomes the defects of common material non-layering, non-uniform content, high tablet height difference, tablet powder fall, slow disintegration and the like in the direct tabletting production process, and solves the problems of color change of tablet cores, low dissolubility and the like of the wet granulation process.

Owner:YUNNAN PHYTOPHARML

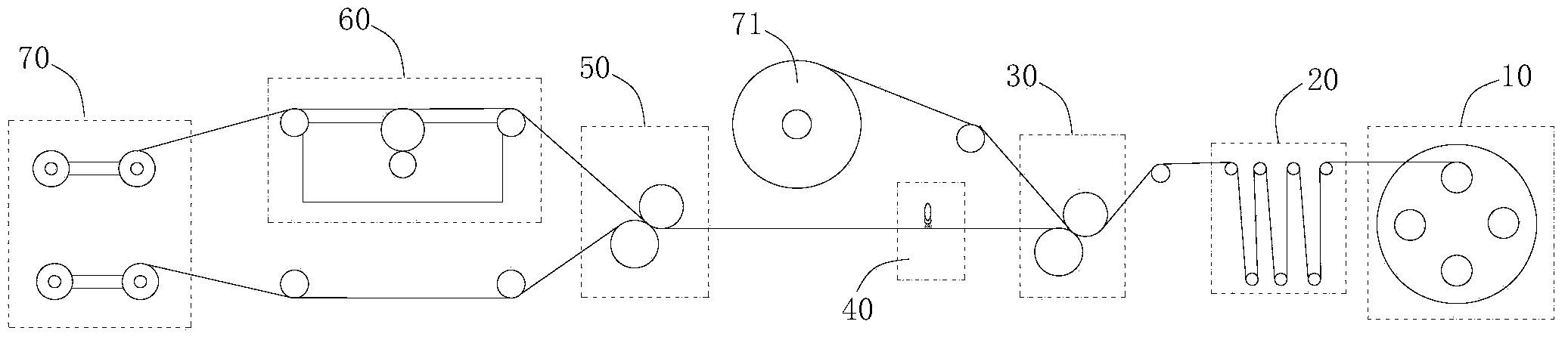

Composite packaging paper production equipment

ActiveCN103922172AAchieve fixationRealize continuous windingWebs handlingPaper productionPulp and paper industry

The invention discloses a set of composite packaging paper production equipment. The composite packaging paper production equipment comprises a discharging mechanism, a first coating mechanism, a second coating mechanism, a first combining mechanism, a second combining mechanism, a temporary material storage mechanism and a winding mechanism. The winding mechanism comprises a supporting plate and a material roller, a clamping groove is formed in the material roller, an insertion plate is arranged on the periphery of the supporting plate, a pushing assembly is arranged on a support, and a locking piece for locking the insertion plate is arranged in the clamping groove. Through the scheme, after winding is finished through the last material roller, the supporting plate is rotated so that another new material roller can be placed in the winding position. Because composite packaging paper is laid on the surface of the new material roller, when the insertion plate is inserted in the clamping groove of the new material roller, the insertion plate will press the composite packaging paper into the clamping groove at the same time so that the composite packaging paper can be fixed to the new material roller; then, the composite packaging paper between the two material rollers is cut off, a driving assembly drives the new material roller to rotate to winding the composite packaging paper, a finished paper roll is discharged after the winding, and thus the composite packaging paper can be wound continuously.

Owner:江苏研几包装科技有限公司

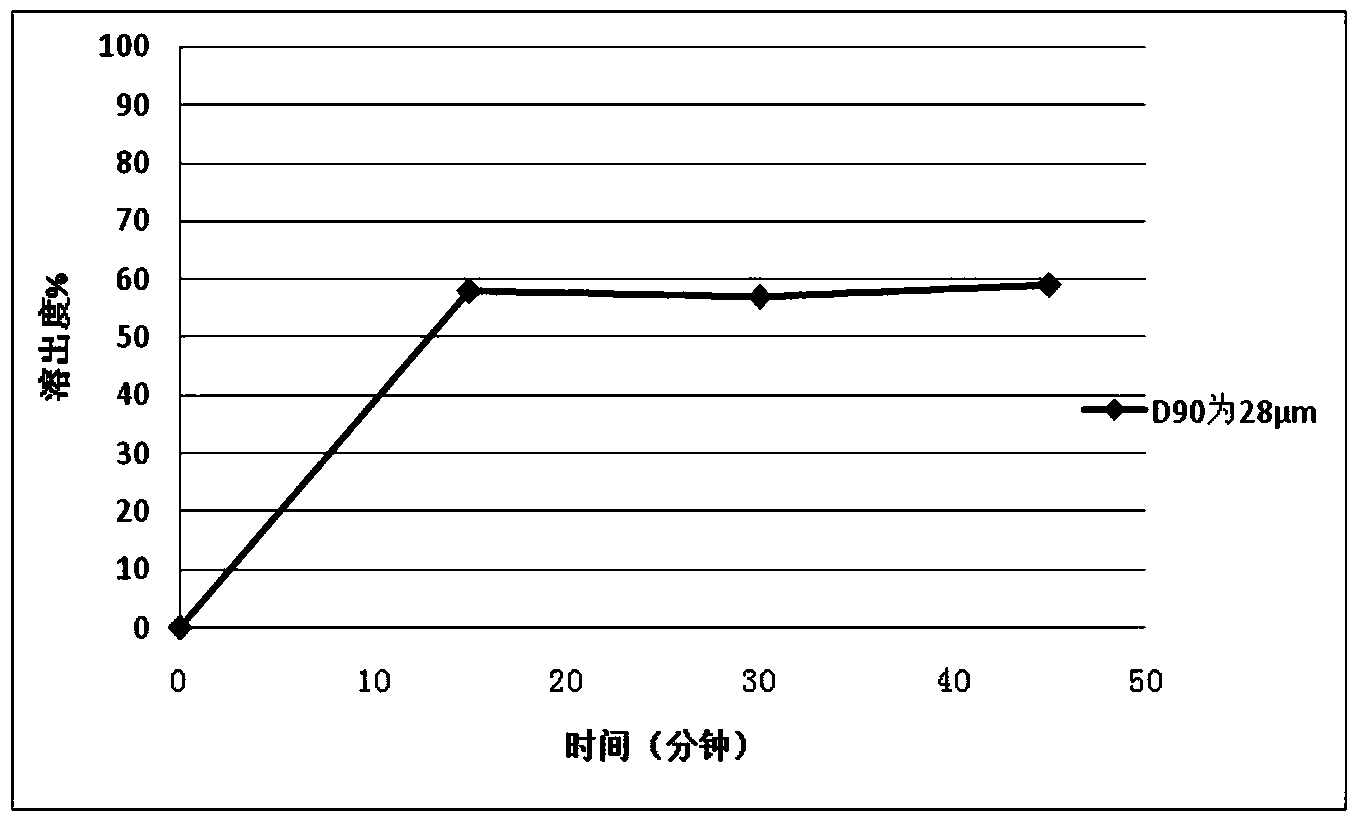

Repaglinide troche and preparation method thereof

ActiveCN103610677AAvoid stickingGood dispersionOrganic active ingredientsMetabolism disorderMedicineDissolution

The invention relates to an oral troche which contains repaglinide or pharmaceutically acceptable derivatives of repaglinide as well as a preparation method of the oral troche. According to the preparation method, powder of repaglinide or pharmaceutically acceptable derivatives of repaglinide is directly pressed into troche, so that the production cost is remarkably lowered, and the disintegration and the dissolution rate are greatly improved. The bioavailability and the stability of the medicine can be improved, and the problem of low content uniformity of existing small-dose medicines formed by the direct pressing method is overcome, so that the quality of the troche is better guaranteed.

Owner:华益泰康药业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com