Continuous preparation system for lime slurry having fixed concentration

A technology for preparation system and lime slurry, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of insufficient supply of lime slurry preparation, and achieve the effect of ensuring continuous preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

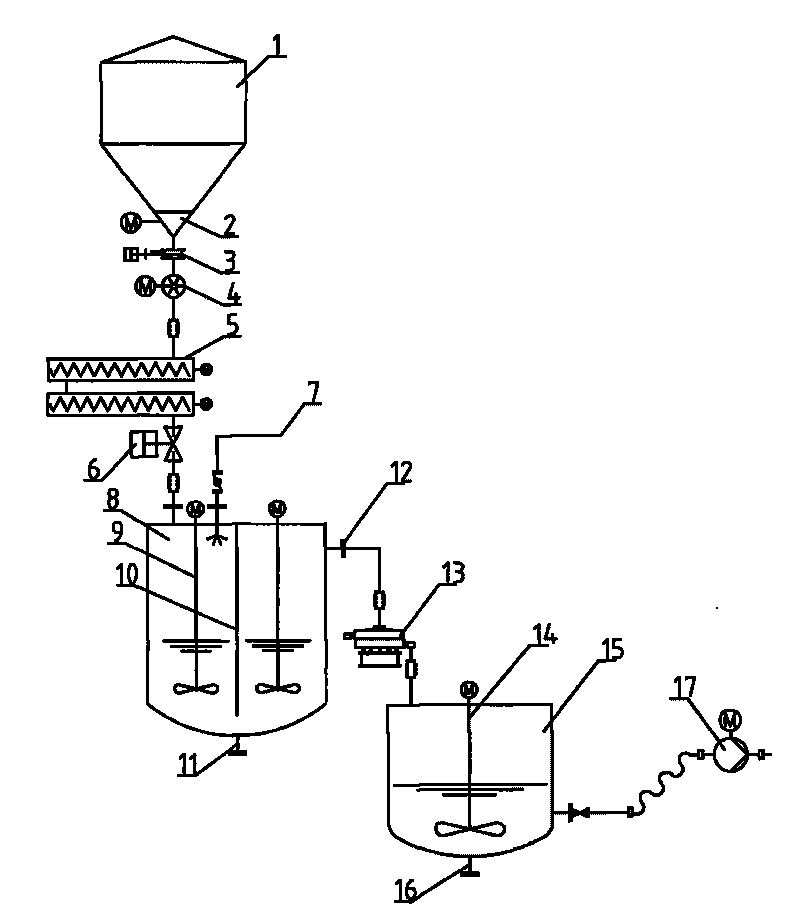

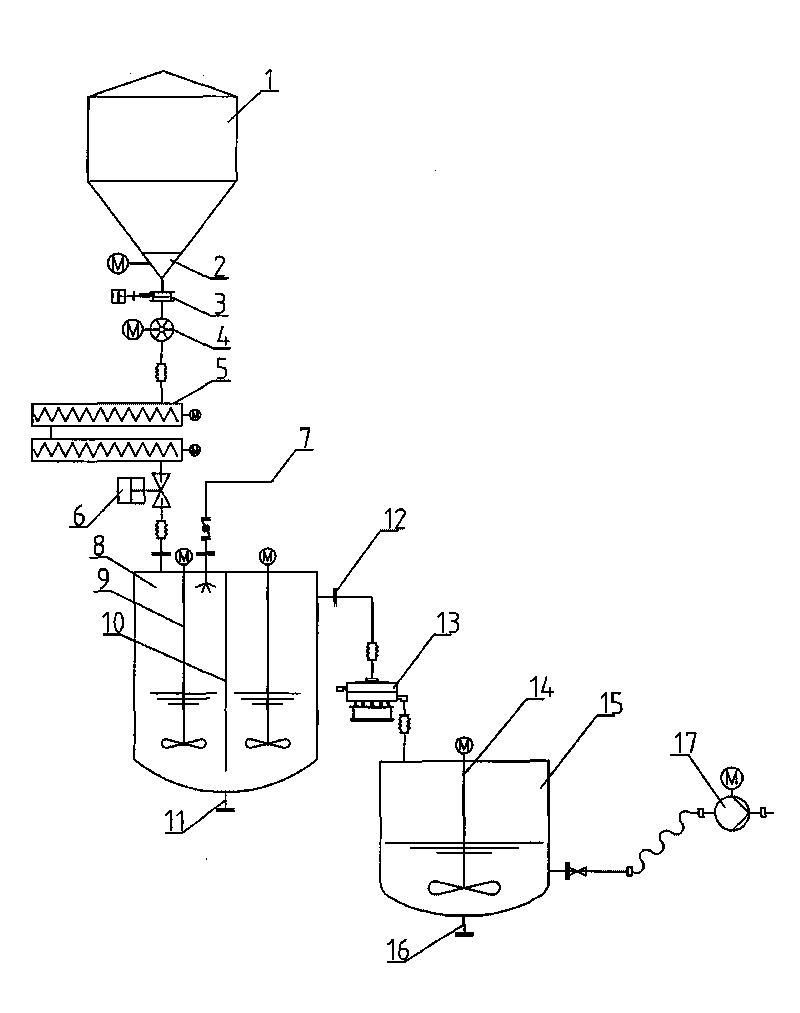

[0008] See figure 1 , a constant concentration lime slurry continuous preparation system of the present invention comprises a lime silo 1, an activation bucket 2 is installed at the lower part of the lime silo 1, the lime silo 1 is connected to a slaking tank 8 through a feeder 5, and the slaking tank 8 is also connected to a tap water inlet pipe 7. The discharge port of the curing tank 8 is connected to the storage tank 15 through the vibrating filter 13, and the storage tank 15 is connected to the lime slurry pump 17. The inside of the curing tank 8 is divided into two curing rooms by the compartment wall board 10, and the two curing rooms are respectively installed There are stirrers9. The aging tank 8 is provided with an upper overflow discharge port 12; the feeder 5 is a double-pipe spiral weighing feeder; the agitator 14 is installed in the storage tank 15; in the figure, 3 is an automatic switch valve, and 4 is a star discharge valve. Material valve, 6 is the feeder ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com