Method for preparing biomass charcoal fuel from corn stalks through low-temperature carbonization

A technology of corn stalks and biomass charcoal, which is applied in the fields of biofuel, special dry distillation, petroleum industry, etc., can solve the problems of not being able to be used as fuel, low energy density, high carbonization temperature, etc., so as to alleviate energy shortage and reduce production energy consumption , the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

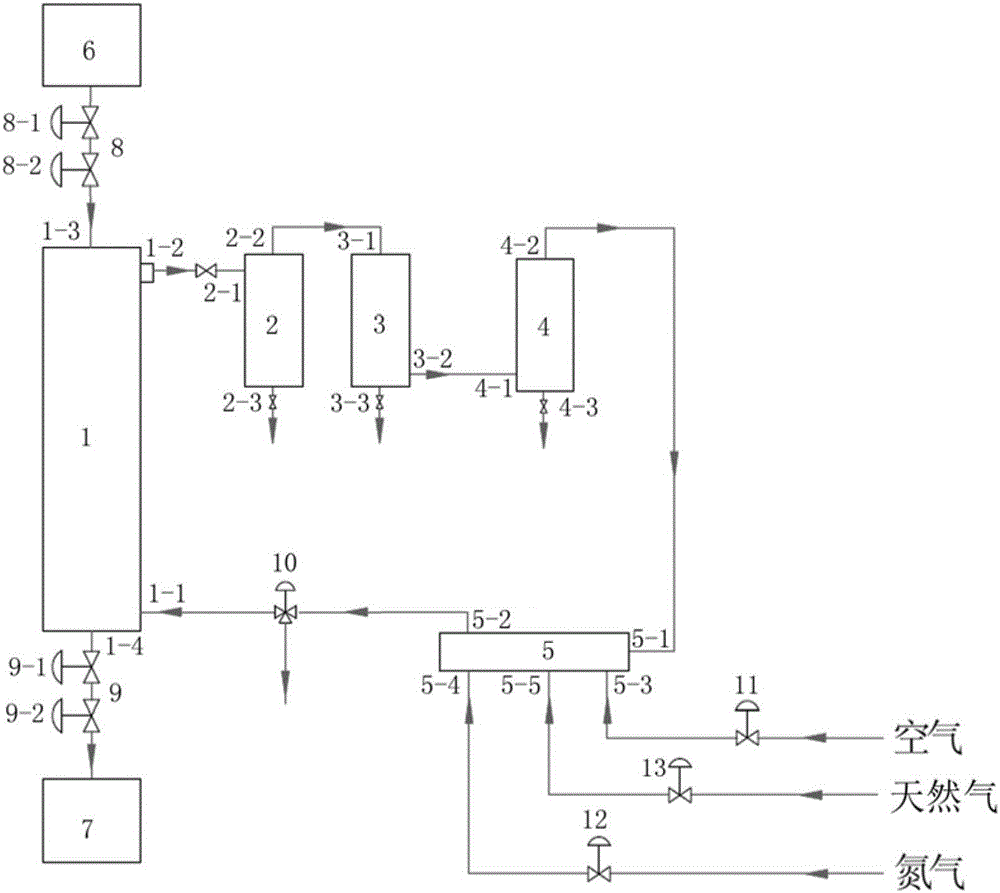

[0035] The method for preparing biomass charcoal fuel by low-temperature carbonization of corn stalks in this embodiment adopts the above-mentioned biomass continuous pyrolysis carbonization device, specifically:

[0036] Introduce nitrogen into the carbonization furnace to make the furnace an anaerobic or low oxygen environment (oxygen volume percentage is less than 10%), feed corn stalk raw material particles from the top of the carbonization furnace, and rely on its own gravity to flow downward; The air flow enters from the bottom of the carbonization furnace, rises from the bottom to the top, and forms a countercurrent reaction area in the furnace; the reaction temperature at the bottom of the carbonization furnace is controlled by hot air flow to 220°C, the pressure in the furnace is 1050mbar, and the residence time of the material in the furnace is 5h , The biochar fuel generated by the reaction is output from the bottom of the carbonization furnace, and the combustible g...

experiment example 1

[0044] In this experimental example, statistics and tests were carried out on the biomass charcoal fuel obtained by the method of preparing biochar fuel by the low-temperature carbonization of corn stalks in Examples 1-5.

[0045] The detection methods and instruments used are as follows:

[0046] Thermogravimetry and combustion characteristics analysis: STA449F3 synchronous thermal analyzer (Thermogravimetric Analyzer) from NETZSCH Instrument Company of Germany was used.

[0047] Determination of calorific value: using a calorimeter (Zhengzhou Hengya Instrument Co., Ltd., HY-A9) and an electronic balance (Shenzhen Infinity Weighing Instrument Co., Ltd., MAX-A6002).

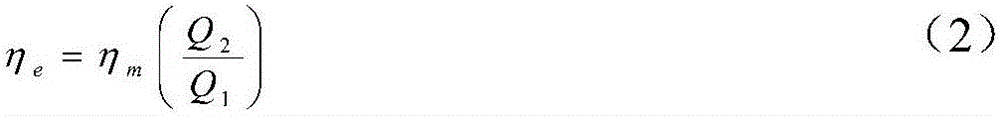

[0048] Mass yield and energy yield: mass yield η m and energy yield η e The calculation formula of is as follows,

[0049] η m = m 2 m 1 × 100 % - - - ...

experiment example 2

[0058] In this experimental example, the combustion performance of the biomass charcoal fuel obtained in the embodiment is tested.

[0059] The detection methods and instruments used are as follows:

[0060] Thermogravimetry and combustion characteristics analysis: STA449F3 synchronous thermal analyzer (Thermogravimetric Analyzer) from NETZSCH Instrument Company of Germany was used.

[0061] Industrial analysis: use a muffle furnace (Shanghai Kailang Instrument Equipment Factory, SX2-4-10) and a drying oven (Wujiang Minxin Oven Electric Furnace Manufacturing Co., Ltd., MX841-6).

[0062] Elemental analysis: vario EL III elemental analyzer from Elementar Company, Germany.

[0063] The results are shown in Table 3.

[0064] The combustion performance testing result of the obtained biomass charcoal fuel of the embodiment of table 3

[0065]

[0066]

[0067] It can be seen from Table 3 that the ignition temperature of the biomass charcoal fuel obtained in the embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com