Patents

Literature

174results about How to "Realize large-scale continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

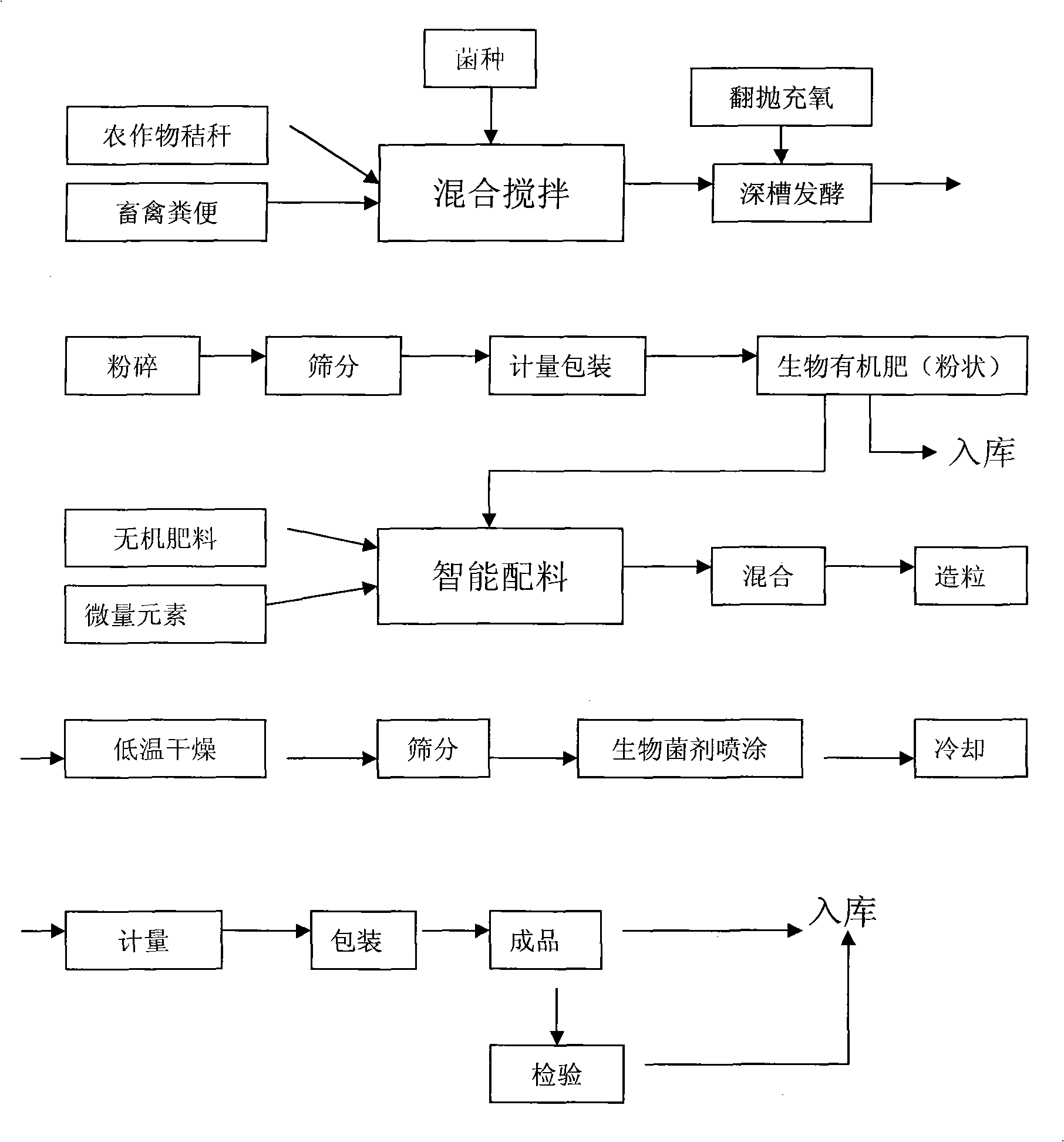

Production process of biological-organic-inorganic ternary compound fertilizer

InactiveCN101676243AShorten the decay cycleReduce nutrient lossBio-organic fraction processingOrganic fertiliser preparationChemistryOrganic component

The invention provides a production process of a biological-organic-inorganic ternary compound fertilizer which is prepared by the following steps: mixing crop stalks, such organic components as livestock manures and active biological agents, regulating the carbon nitrogen ratio from 26 to 35, PH from 5.5-8.2 and moisture from 40% to 65% according to the organic matter contents of the crop stalksand the livestock manures, fermenting the mixture at minus15-75 DEG C for 20-50 days and ensuring the living bacteria count to be 0.03-0.2 billion / g, carrying out turning and oxygenating, fermenting in deep tanks and grinding on the mixture to prepare the biological organic fertilizers, mixing the biological organic fertilizers with the inorganic fertilizers and trace elements and simultaneously adopting the low-temperature drying process after extruding granulation and the biological agent spraying and cooling technology. The method can greatly shorten the decay period, ensure little nutrientloss and little generating capacity of sour gases in the processes of fermentation and decay and complete decay and fermentation, can enhance the stress resistance of the crops, ensure obvious disease-resistant effects and high survival rates of specific functional bacteria and has wide application. Through field contrast tests, both the production and income are increased by 10-25% by applying the biological organic fertilizer.

Owner:辽宁元亨生物科技有限公司

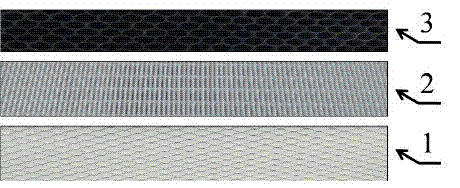

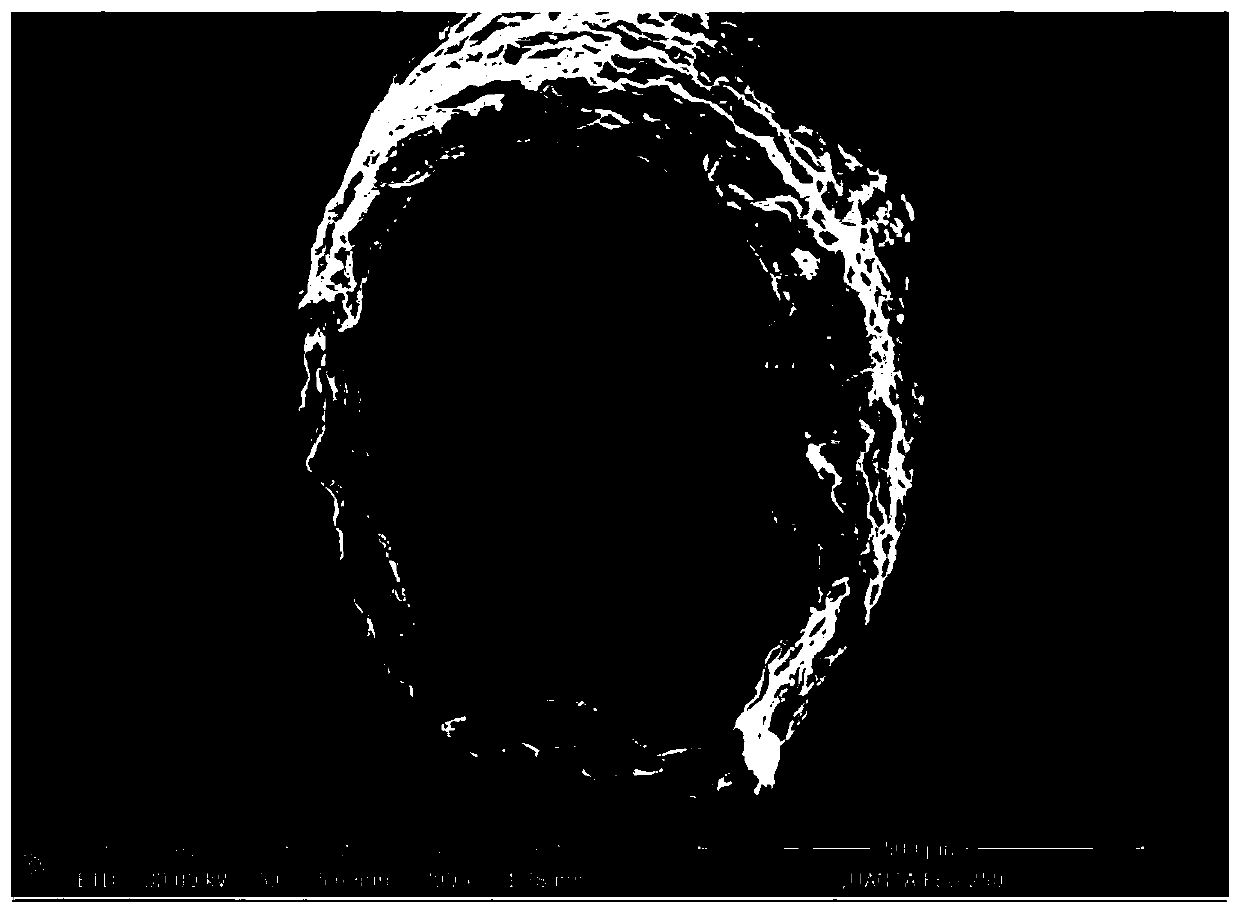

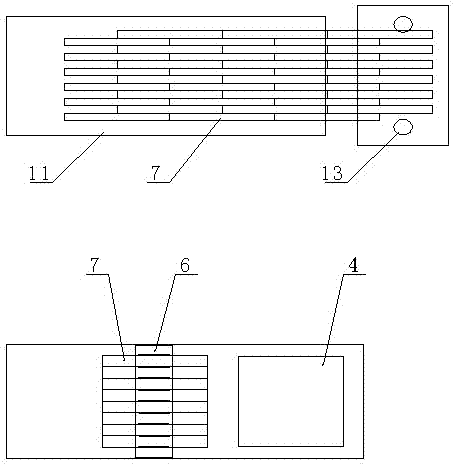

Multifunctional air purification filter screen

PendingCN107469614AEffective interceptionReduce wind resistanceGas treatmentDispersed particle filtrationAir filtrationHEPA

The invention discloses a multifunctional air purification filter screen, which comprises a primary filter module, an HEPA filter module, and a gas adsorption and catalytic degradation module. The multi-module structures are connected and fixed into an integral filter screen from the outside in, the filter screen can achieve effective interception of fine particulate matters (PM2.5), bacteria, viruses and other particulate pollutants and thorough decomposition and purification of formaldehyde, ozone, toluene and other gaseous pollutants, also has deodorization, bacteriostasis and sterilization effects, is a multifunctional air purification filter screen integrating air filtration, purification, antibacterial efficacy, etc. With the characteristics of small wind resistance, long service life and good stability, the multifunctional air purification filter screen provided by the invention has great application prospects in air purifiers, central ventilation systems and other air purification devices, also is low in cost, and can realize large-scale continuous production.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

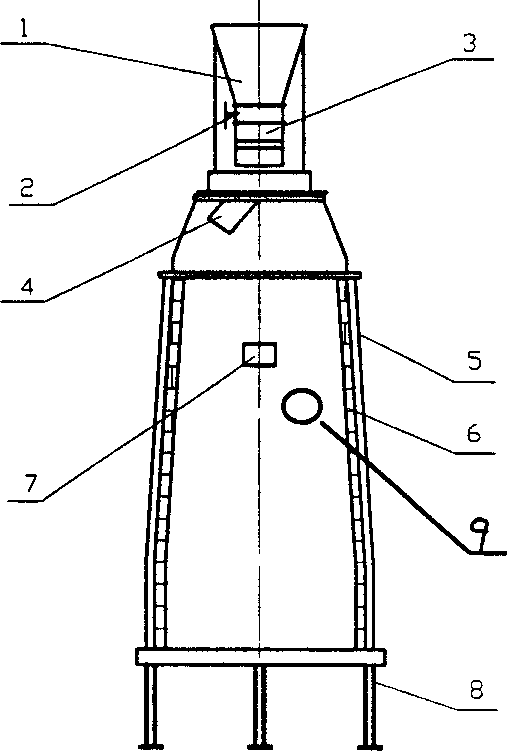

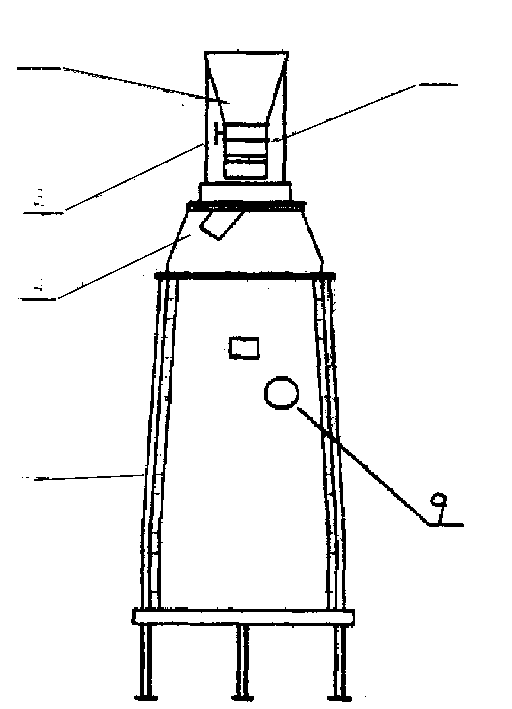

Method and apparatus for producing silicon nitride or ferro silicon nitride by low pressure combustion

InactiveCN1424249ARealize large-scale continuous productionSmooth feedingNitrogen-metal/silicon/boron binary compoundsSilica fumeFerrosilicon

A process for preparing silicon (or ferrosilicon) nitride from silicon powder (or ferrosilicon) powder and the fine powder of silicon (or ferrosilicon) nitride as diluent by low-voltage combustion includes such steps as continuous burning at 900-1850 deg.C in vertical reacting furnace, cooling, and grinding.

Owner:UNIV OF SCI & TECH BEIJING

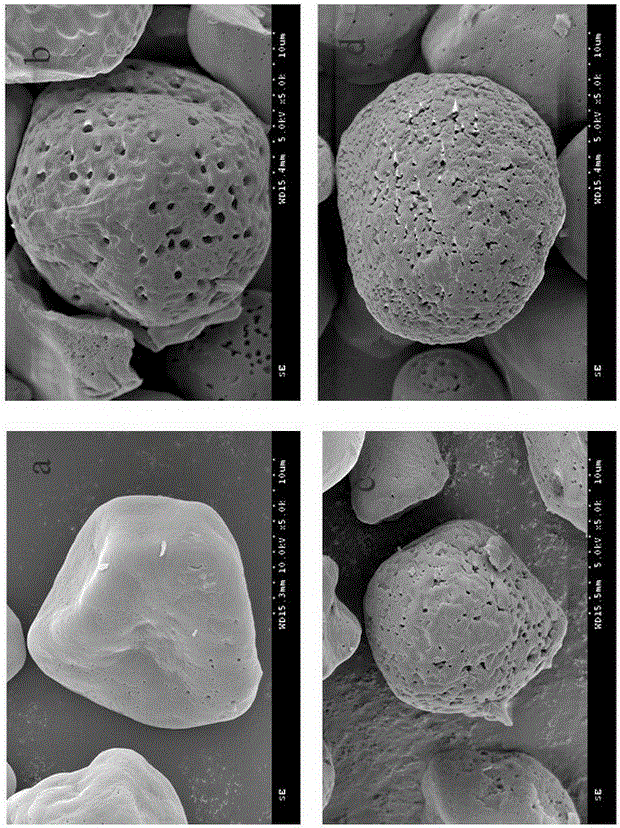

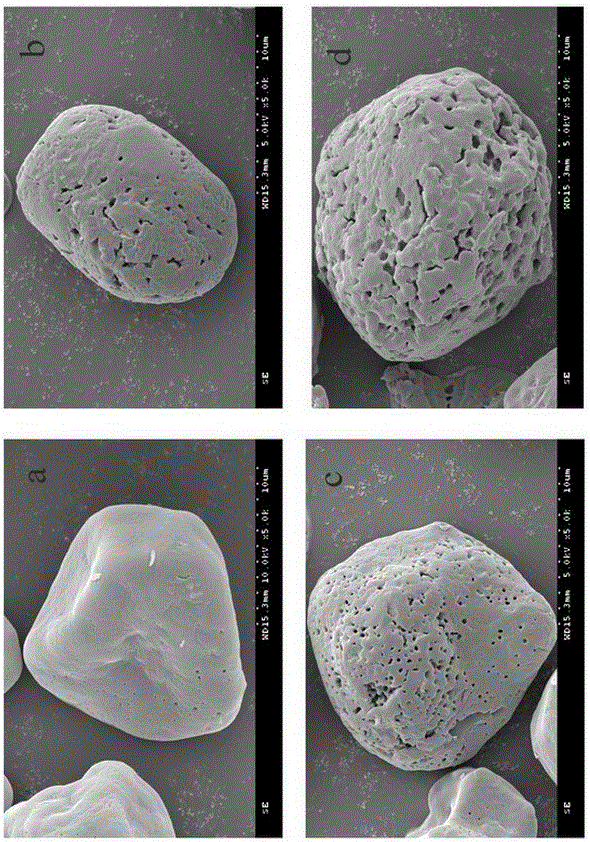

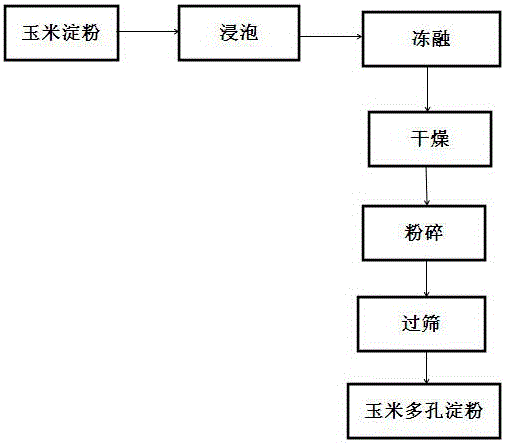

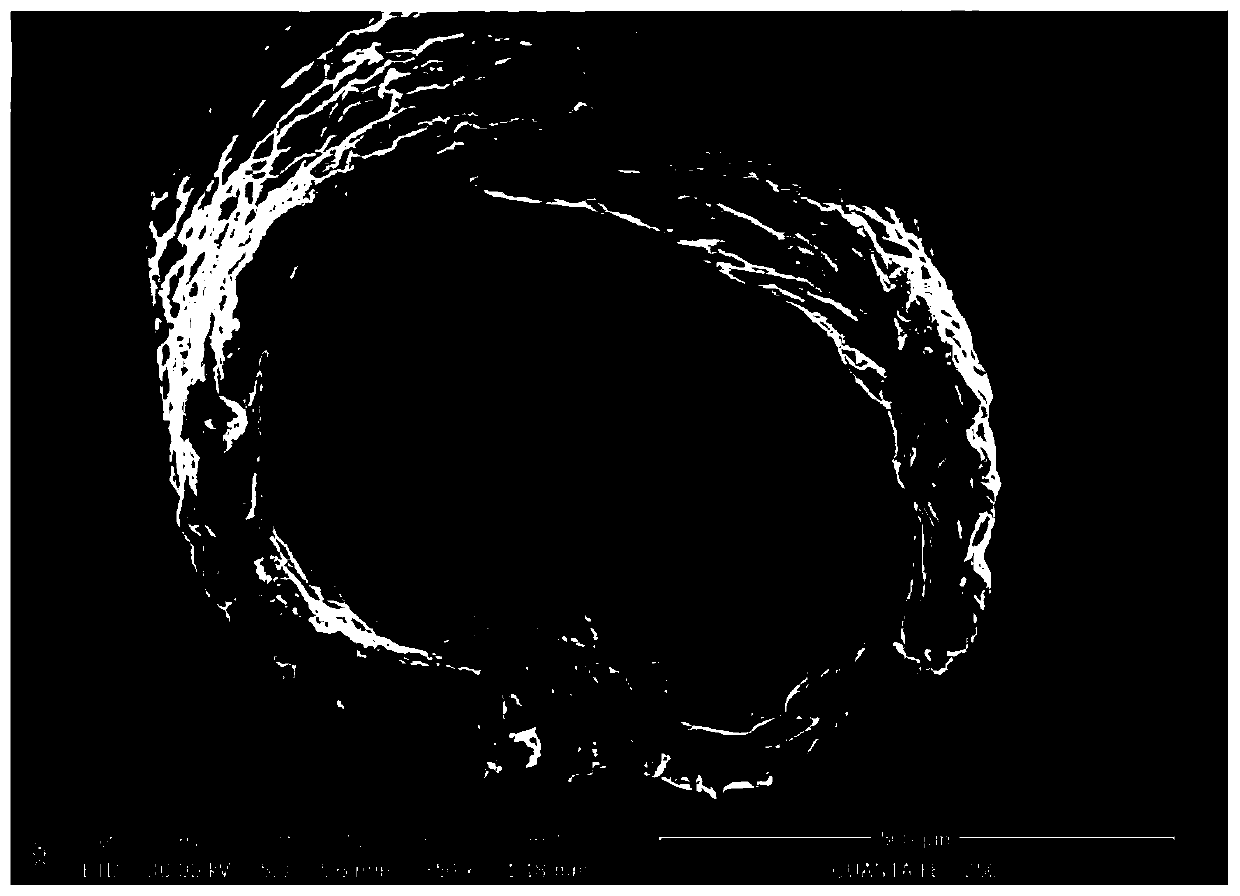

Method for producing corn porous starch by using low temperature freeze-thawing technology

A method for producing corn porous starch by using a low temperature freeze-thawing technology comprises the following steps: 1, immersing corn starch; 2, freeze-thawing: freezing the immersed corn starch at -10 ~ -196 DEG C for 0.5-12 h, unfreezing the frozen corn starch at 20-50 DEG C for 3-8 h, and repeatedly carrying out freezing and unfreezing treatment 1-50 times. The method has the advantages of simplicity in operation, high production efficiency, clean production technology, no pollution to environment, realization of large-scale continuous production, and low production cost due to adoption of reagents and materials having common specifications; and the corn porous starch produced in the invention has the advantages of high freeze-thawing stability, strong reaction activity, good adsorptivity and good embedding property.

Owner:QIQIHAR UNIVERSITY

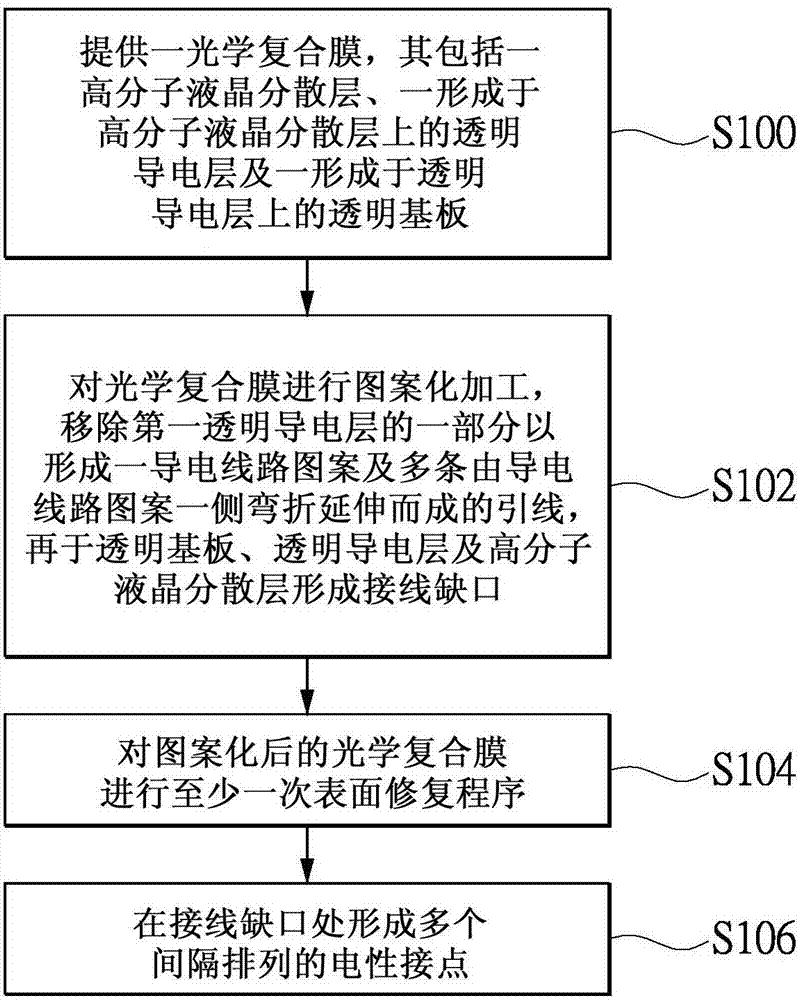

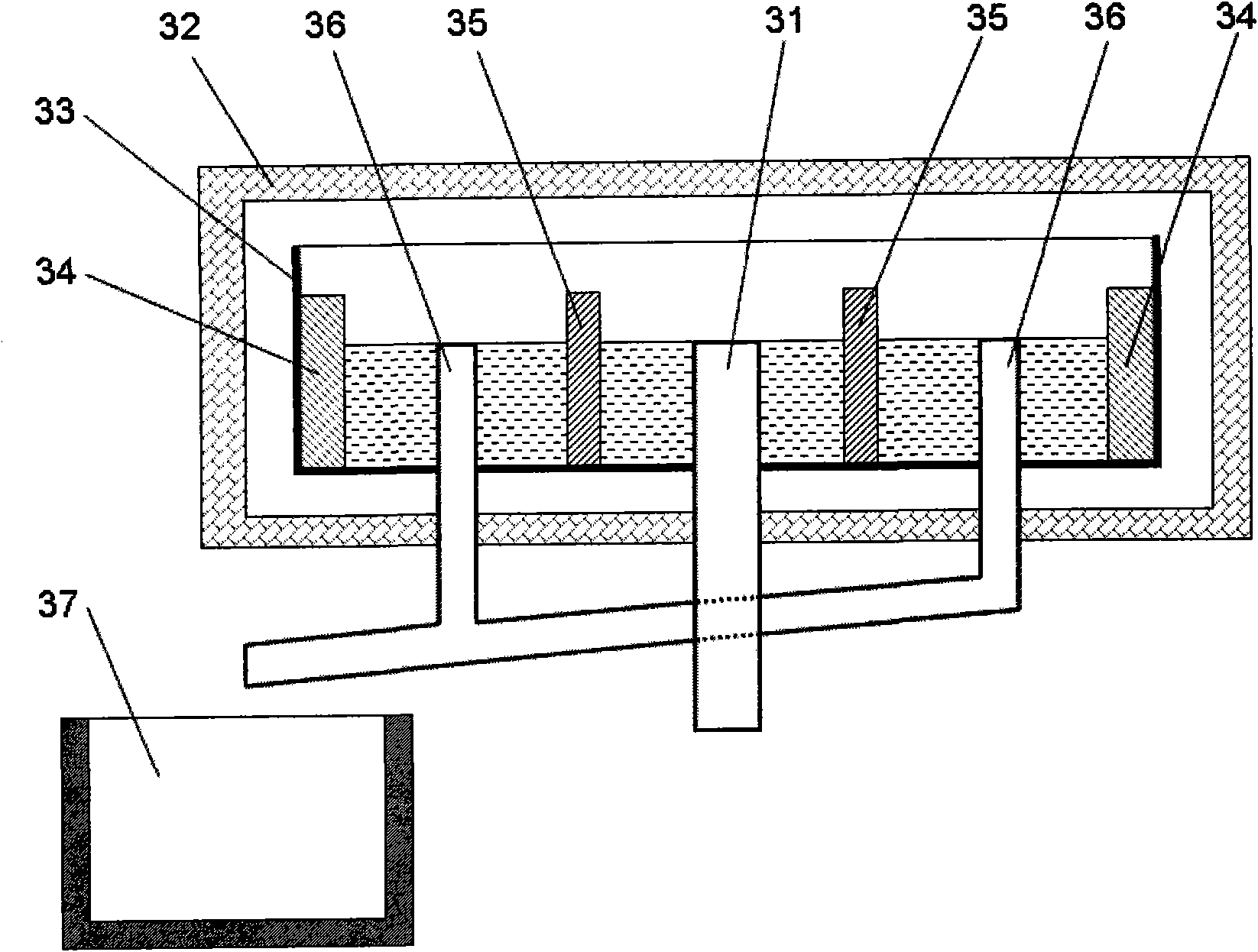

Method for manufacturing optical compound film structure with controllable transparency pattern changes

InactiveCN107045220ASimplify the process stepsRealize large-scale continuous productionNon-linear opticsComposite filmPolymer

The invention provides a method for manufacturing an optical composite membrane structure capable of controlling a change in light transmission pattern includes the steps of first providing an optical composite film comprising a polymer liquid crystal dispersion layer, a transparent conductive layer formed on the polymer liquid crystal dispersion layer, Transparent conductive layer; and then, the optical composite film is patterned to remove portions of the transparent conductive layer to form a conductive line pattern and a plurality of leads extending from the conductive line pattern side, and forming a transparent substrate A transparent substrate, a transparent conductive layer and a polymer liquid crystal dispersion layer; and then, at least a sub-surface repair program for the patterned optical composite film; and finally, an electrical contact is formed at the wiring gap.

Owner:NANOBIT TECH

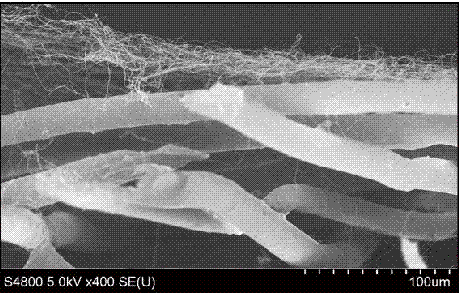

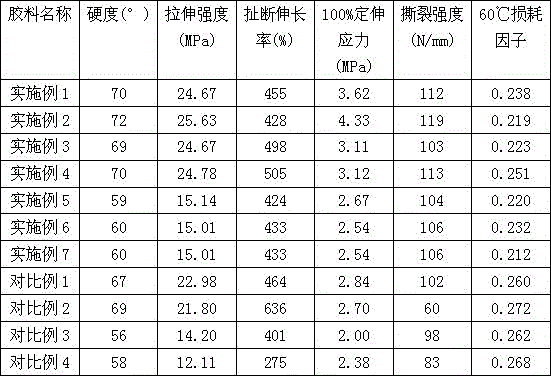

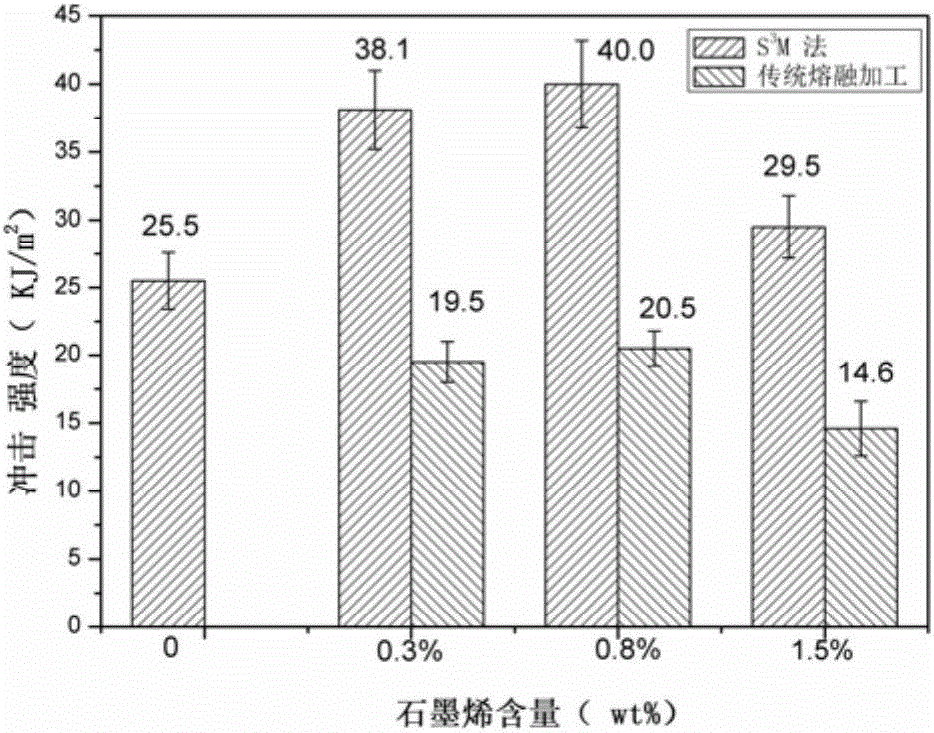

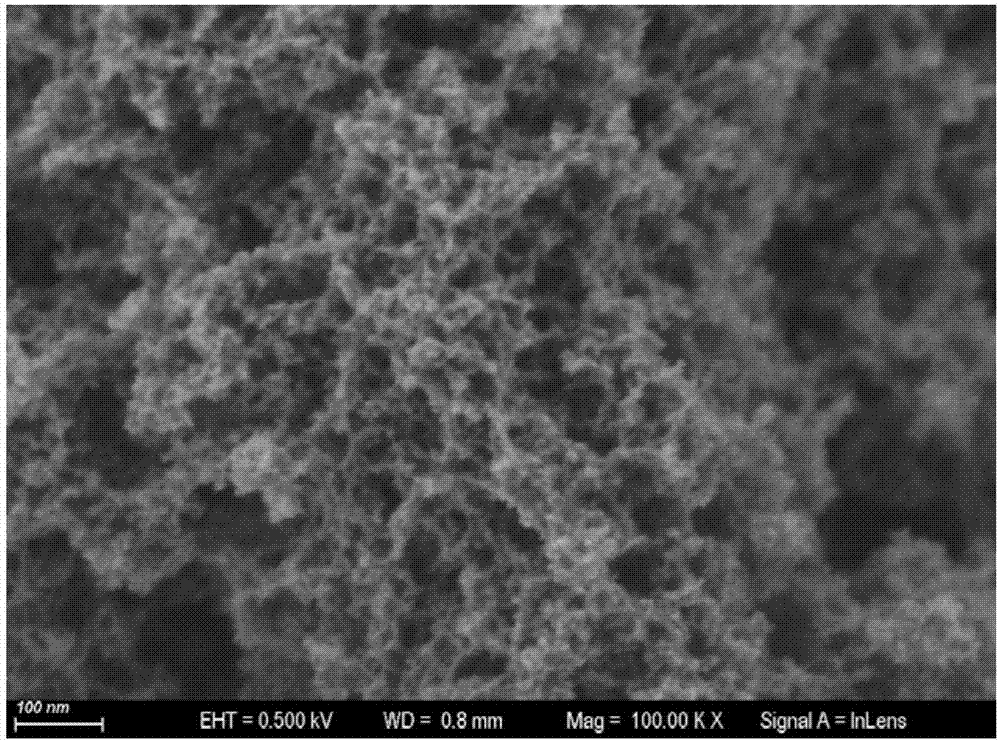

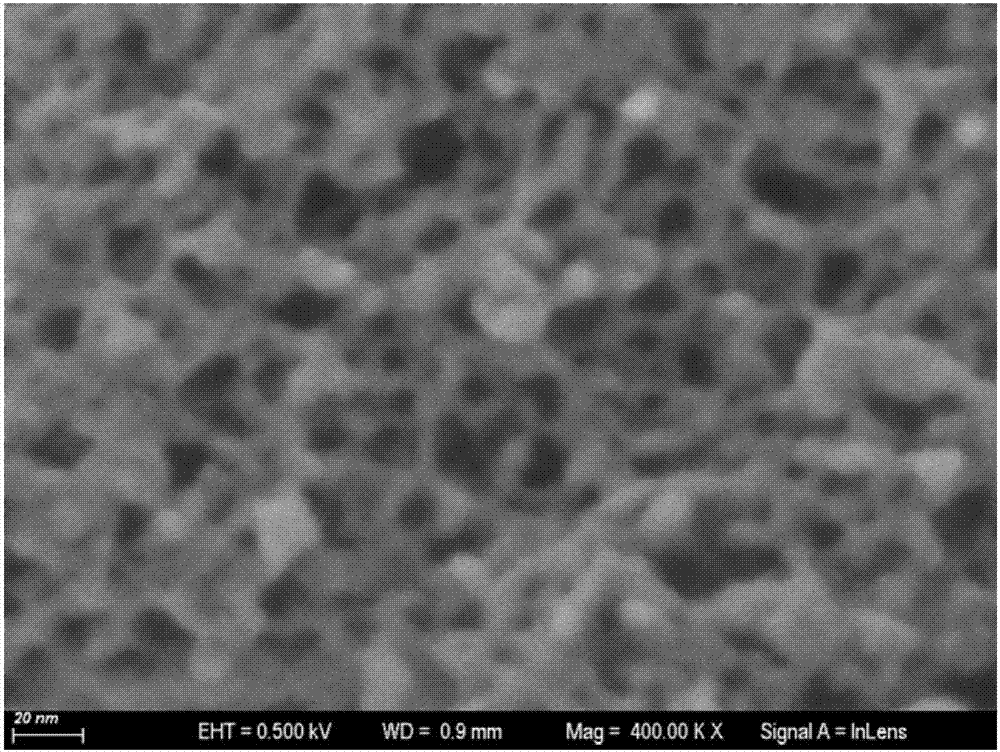

Method and production device for preparing graphene micro-plate pre-dispersion master batch

The invention relates to the technical field of technologies for processing rubber, in particular to a method and a production device for preparing graphene micro-plate pre-dispersion master batch. The method includes stirring and mixing graphene micro-plate dispersion liquid and latex with each other by the aid of a high-speed stirring machine to obtain mixed materials, adding flocculating agents into the mixed materials and coagulating the mixed materials to obtain pulp; dehydrating and drying the pulp to obtain the master batch. The method and the production device have the advantages that technologies are simple, the method and the production device are safe in operation, the graphene micro-plate pre-dispersion master batch can be continuously produced on a large scale, and the production efficiency can be improved as compared with original preparation technologies by the aid of batch processes; graphene micro-plates in the master batch prepared by the aid of the method can be highly dispersed as compared with melt processing methods; quick mixing and condensation can be implemented as compared with previous methods, drying and dehydrating phases are combined with squeezing drying and oven-drying modes, accordingly, the drying time can be shortened, rubber materials can be prevented from being aged, and the graphene micro-plate pre-dispersion master batch with excellent performance can be prepared by the aid of the method and the production device.

Owner:青岛蓝湾烯碳材料科技有限责任公司

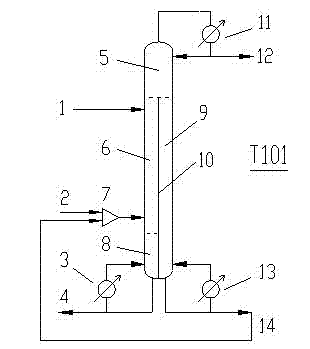

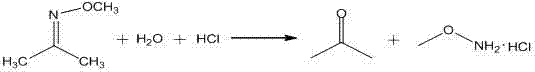

Continuous reactive distillation equipment for synthesising methoxylamine hydrochloride and process thereof

InactiveCN103113257AReduce production energy consumptionReduce material consumptionChemical industryCarbonyl compound preparation by hydrolysisGas phaseHydrolysis

The invention provides continuous reactive distillation equipment for synthesising methoxylamine hydrochloride by taking oxime methyl ether and hydrochloric acid as raw materials, and a process thereof, wherein a vertical clapboard is arranged in a reactive distillation dividing-wall column in the continuous reactive distillation equipment provided by the invention, and used for dividing the column into four areas, namely, a common distillation section, a reaction section, a stripping section and a lateral stripping section; and oxime methyl ether and hydrochloric acid solution enter from the upper part and the lower part of the reactive distillation section respectively, hydrolysis reaction for oxime methyl ether is performed in the reaction section, the generated methoxylamine hydrochloride is discharged from the bottom of the reactive distillation section, the generated by-product, namely, the mixture of acetone and oxime methyl ether, enters in the common distillation section in the form of a gaseous phase to be separated, more than 95% acetone is obtained on the top of the column, and the separated oxime methyl ether is recycled. According to the continuous reactive distillation equipment and the process provided by the invention, the dividing-wall column is combined with reactive distillation, and hydrolysis reaction and product separation are intensively performed in one column, thus effectively reducing energy consumption and equipment investment cost.

Owner:FUZHOU UNIV

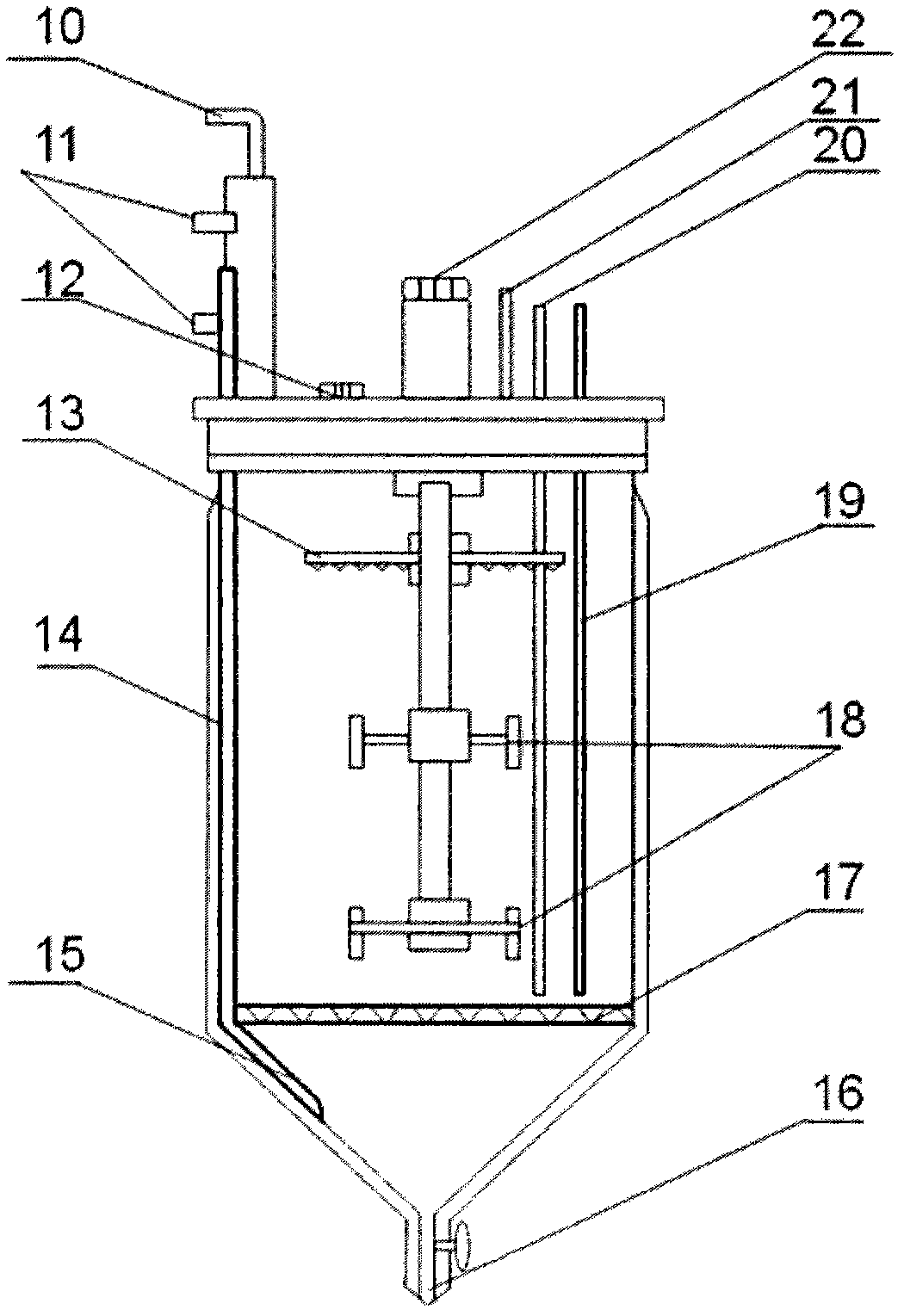

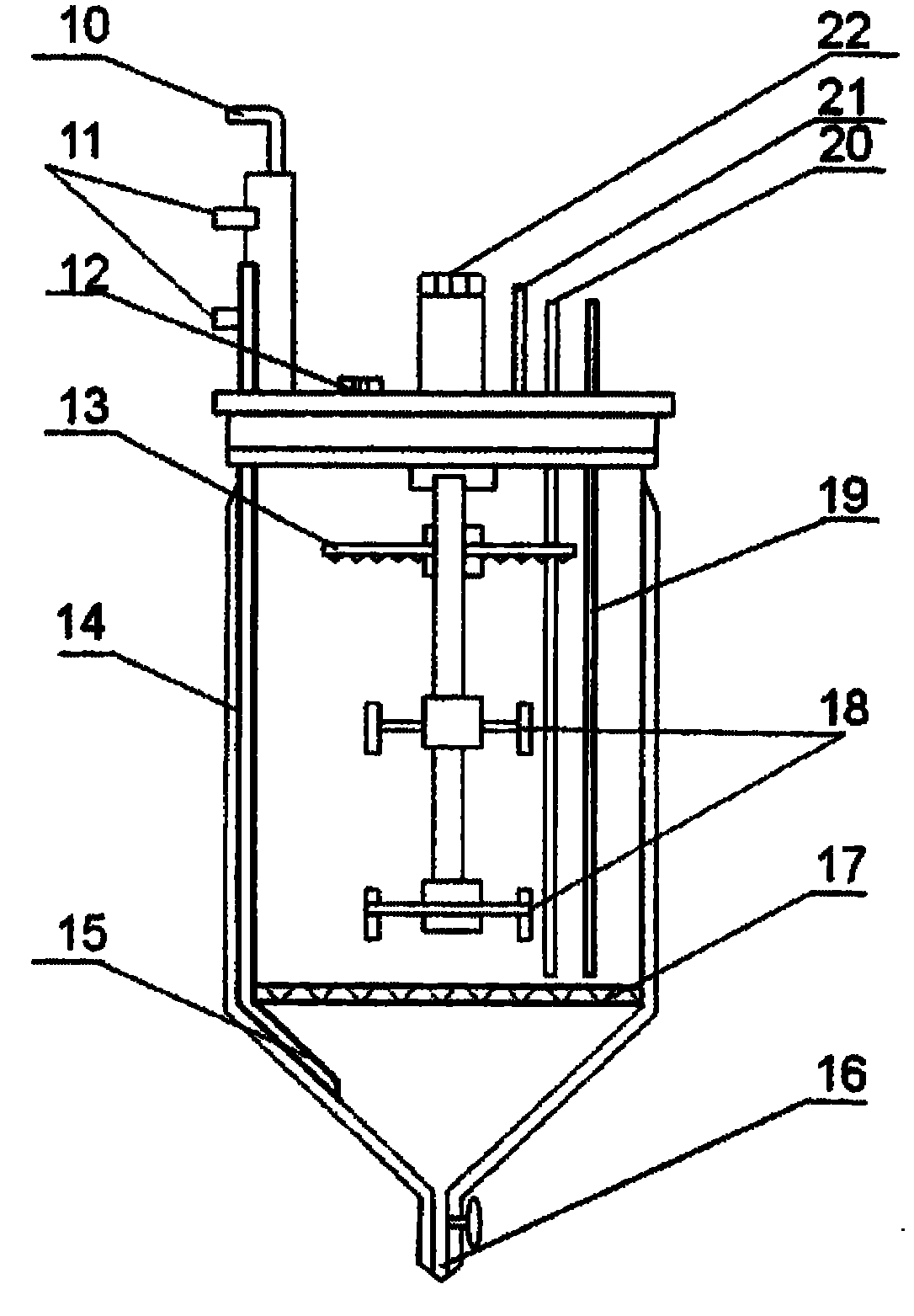

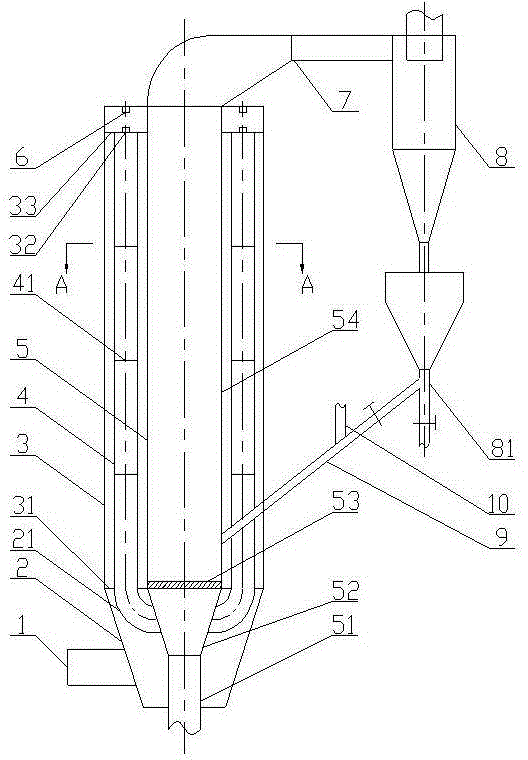

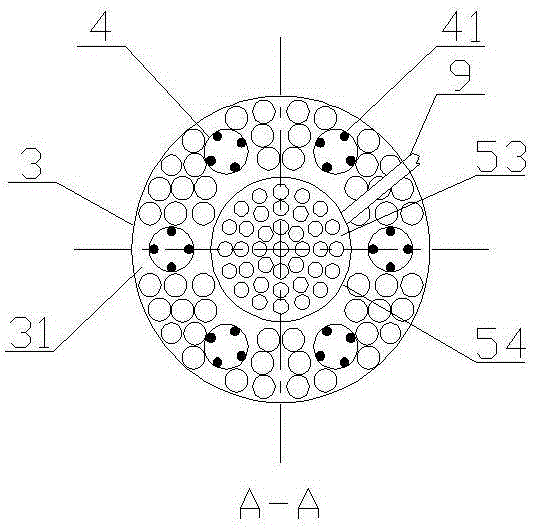

Bioreactor and sophorolipid continuous production method by using the same

InactiveCN102492605ARealize continuous productionEfficient continuous productionBioreactor/fermenter combinationsBiological substance pretreatmentsTowerFermentation broth

According to a bioreactor and a sophorolipid continuous production method by using the same provided by the invention, as fed-batch of a fermentation broth, a product is recovered at a liquid outlet through intravenous drip. A technology mainly comprises the following steps: centrifuging a fermentation waste liquid by a centrifuge and recovering precipitated yeast byproduct at a lower layer; mixing a centrifuged supernatant and a crude product from intravenous drip and recovering a lower layer product to a secondary purified product gathering tank 2-5 h after settlement layering; disinfecting the secondary purified product by an autoclave and storing directly, or drying at 55-75 DEG C in a drying tower to gain a constant weight and storing.

Owner:中海石油环保服务(天津)有限公司 +1

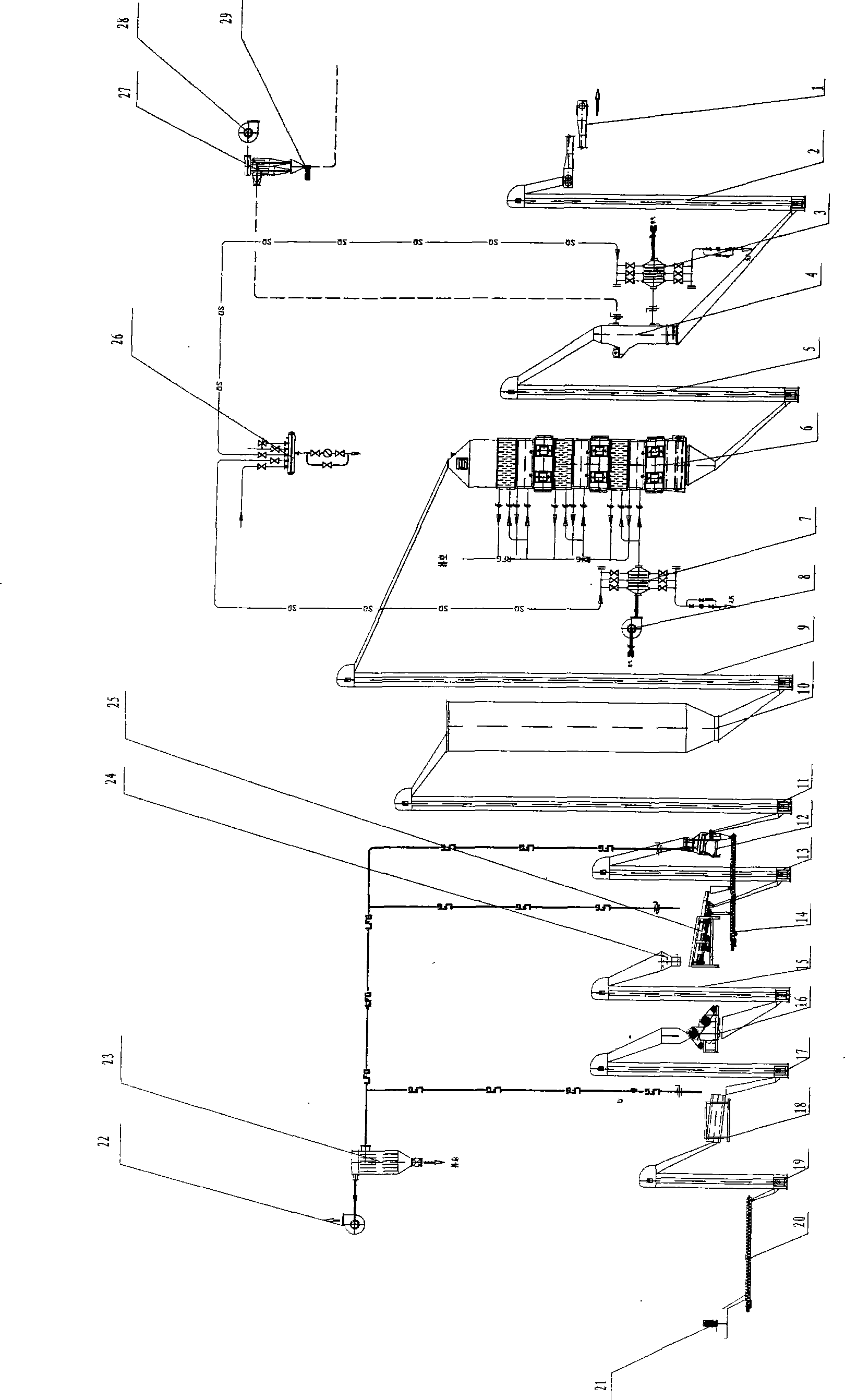

Special husking and drying technology for oil tea fruits

InactiveCN103789078AEasy to storeSimple processFatty-oils/fats productionCamellia oleiferaDried fruit

The invention discloses a special husking and drying technology for oil tea fruits. The technology comprises the following steps: carrying out coarse impurity separation of green oil tea fruits picked in the later mature period, carrying out two-stage husking to remove green peels; carrying out two-stage drying, conveying the obtained dried fruits to an efficient refinement separating system, and sorting; and conveying the sorted fruits through a conveying apparatus to a seed storehouse to preserve the sorted fruits for squeezing technology oil extraction. The technology improves the work efficiency, so the technology has the advantages of large scale production, simple process, good crude oil quality, energy saving, low running cost, less apparatus investment, high oil yield, easy storage of processed oil tea seeds, and the like, and can realize the large scale continuous production.

Owner:BEIJING ZHONGTIAN JINGU GRAIN OIL ENG TECH

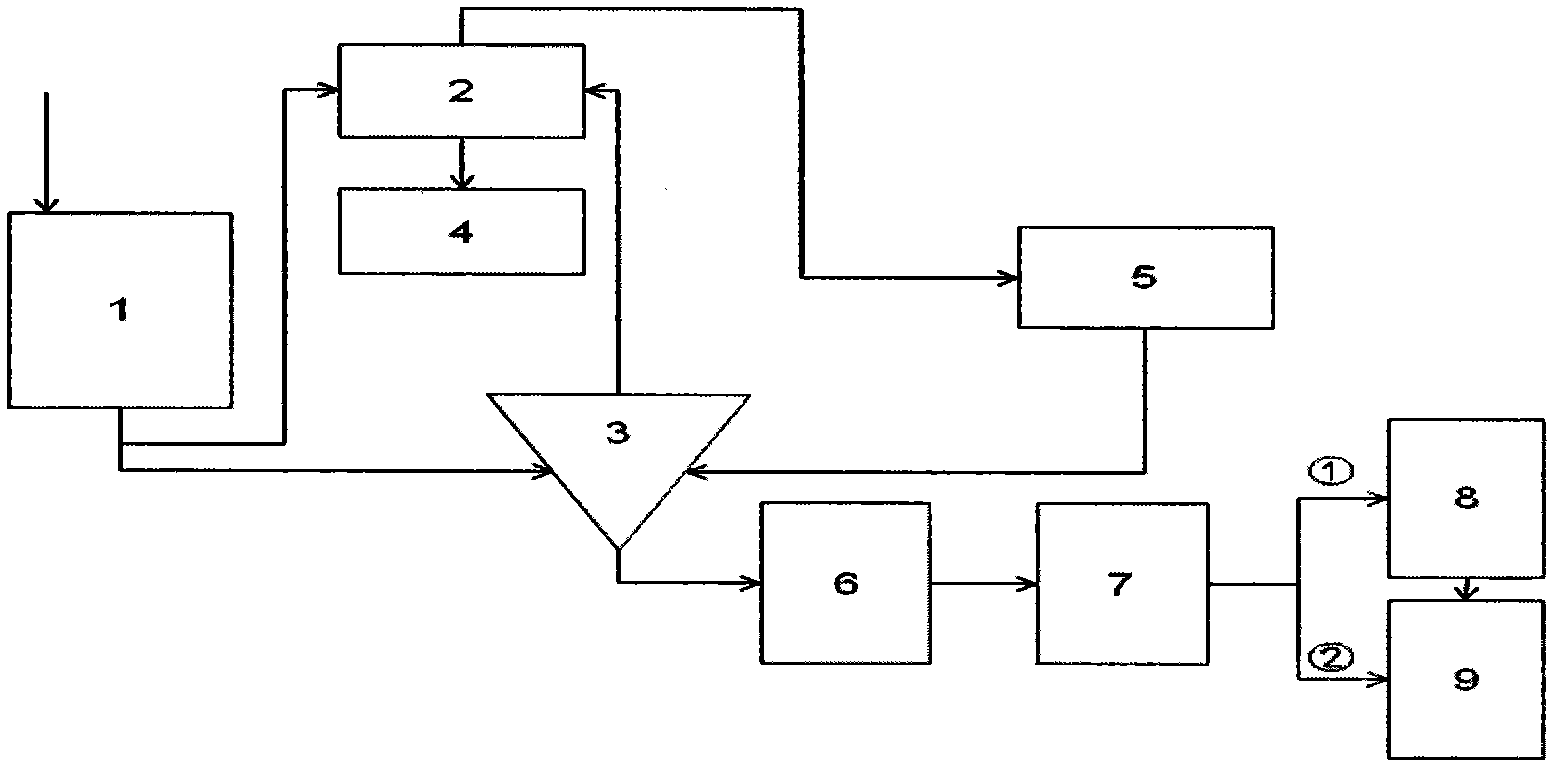

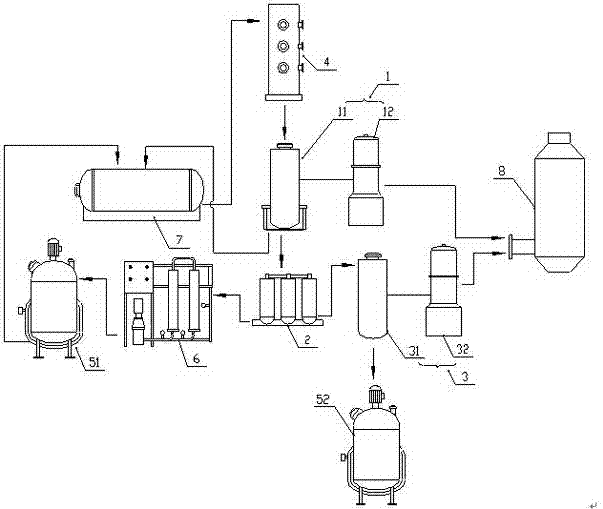

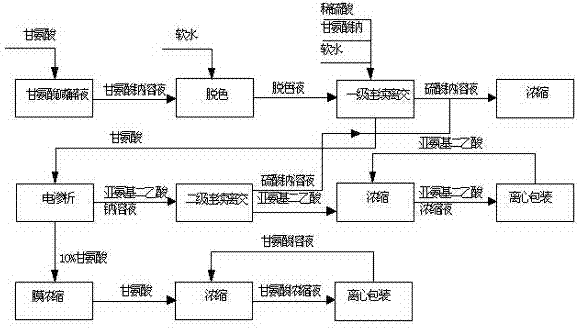

System for continuously separating and purifying amino acid from water solution of amino acid containing alkaline metal salt

ActiveCN103964989AAchieve separationImprove qualityOrganic compounds purification/separation/stabilisationOrganic compound preparationIon exchangeAqueous solution

The invention discloses a system for continuously separating and purifying amino acid from a water solution of amino acid containing alkaline metal salt. The system at least comprises the following sequentially-connected devices: a first-stage continuous ion exchange device for enabling the water solution of the amino acid containing alkaline metal salt to be subjected to continuous ion exchange reaction, an electrodialysis device for desalting a water solution of crude amino acid and a second-stage continuous ion exchange device for enabling a water solution of an iminodicarboxylate alkaline metal acidic salt to be subjected to continuous ion exchange reaction. The system is easy to operate and capable of avoiding generating a peritectic phenomenon, favorably realizing the separation of amino acid and iminodicarboxylate as a byproduct and improving the quality of an amino acid product.

Owner:CHONGQING UNISPLENDOUR CHEM

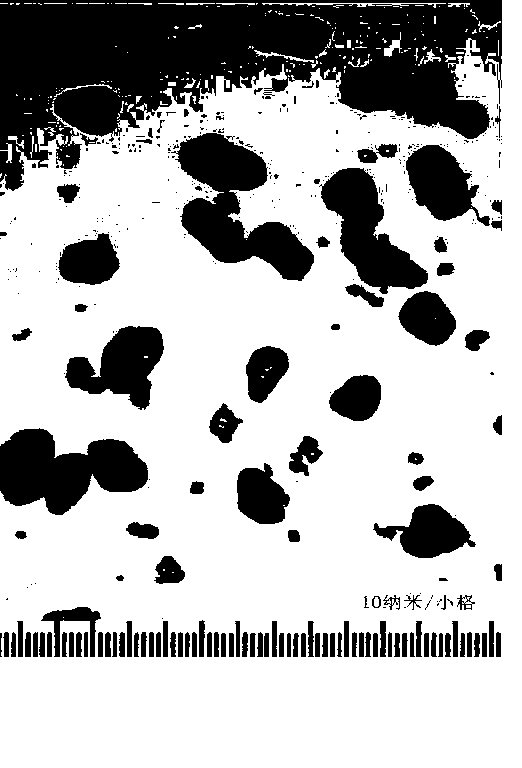

Polyolefin graphene nanocomposite material, and preparation method thereof

The invention belongs to the field of polymer / graphene composite materials, and more specifically relates to a polyolefin graphene nanocomposite material, and a preparation method thereof. The preparation method comprises following steps: polyolefin is smashed using a solid phase mechanical reactor, graphene is added, and an obtained mixture is mixed to be uniform; the mixture is grinded using the solid phase mechanical reactor so as to obtain a polyolefin graphene composite powder; the polyolefin graphene composite powder is subjected to extrusion, injection molding or hot press molding so as to obtain the polyolefin graphene nanocomposite material. The preparation method is capable of dispersing graphene preferably, is low in cost, and is friendly to the environment; and the obtained polyolefin graphene nanocomposite material is high in yield strength and impact strength.

Owner:SICHUAN UNIV

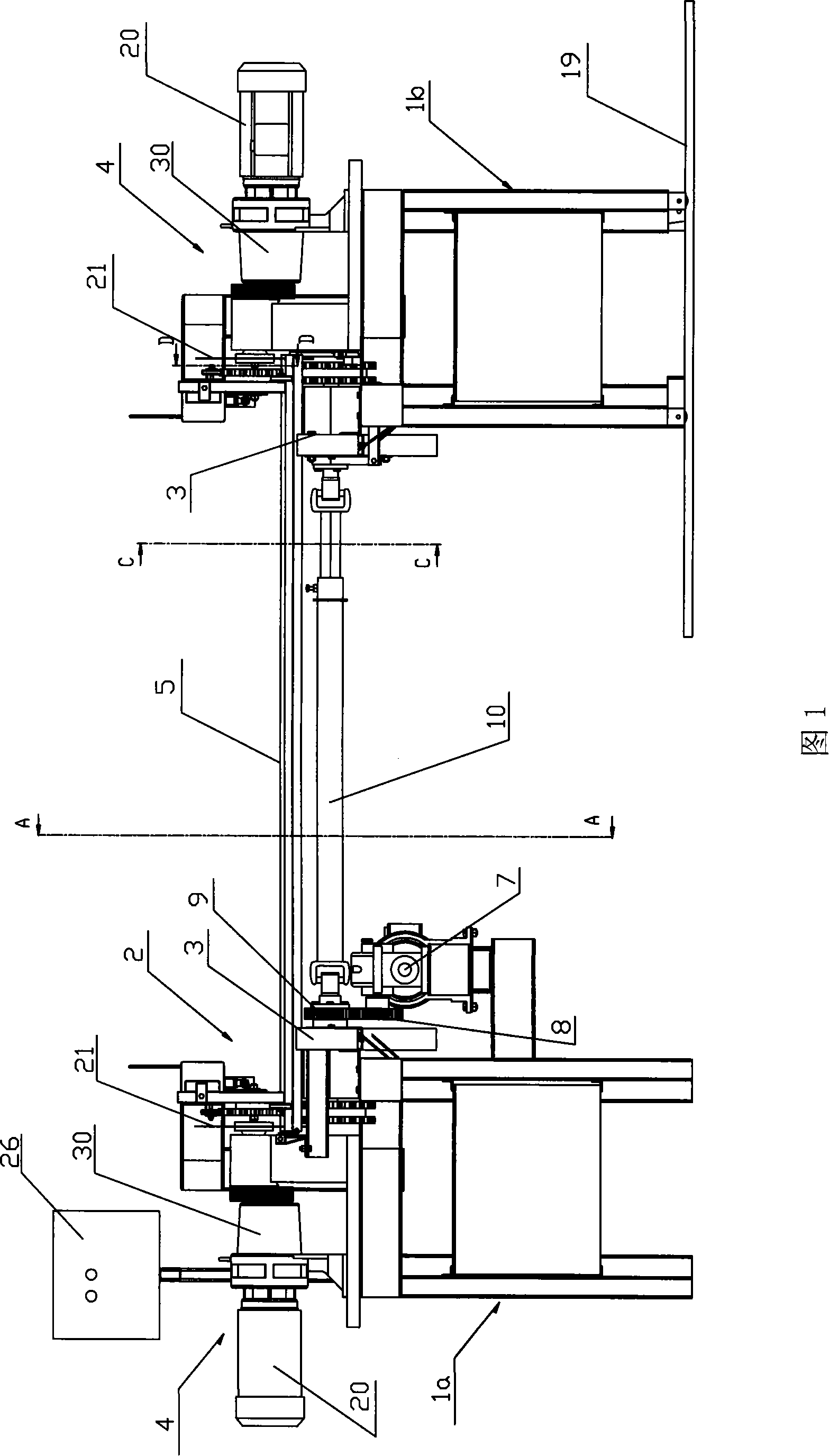

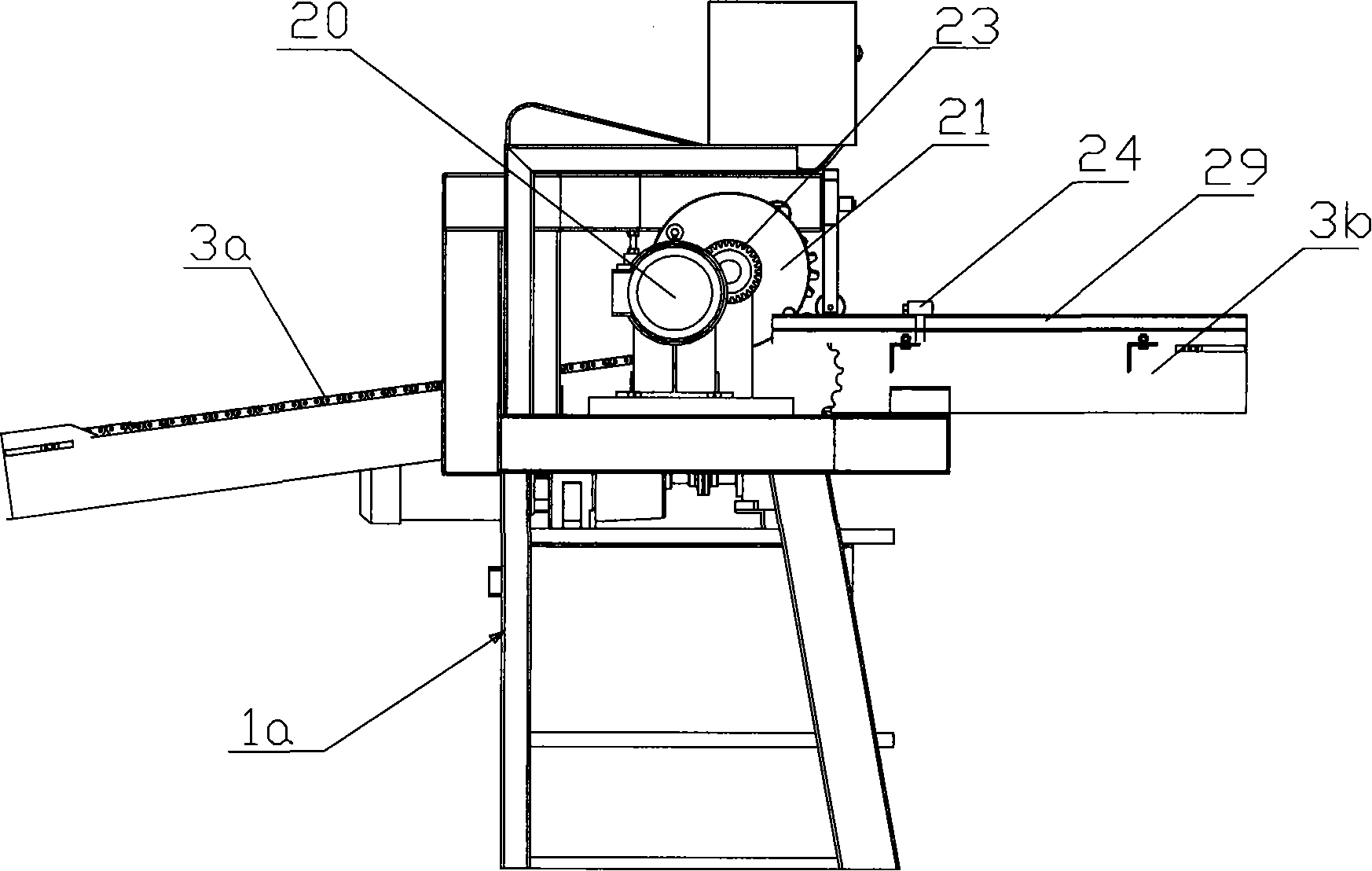

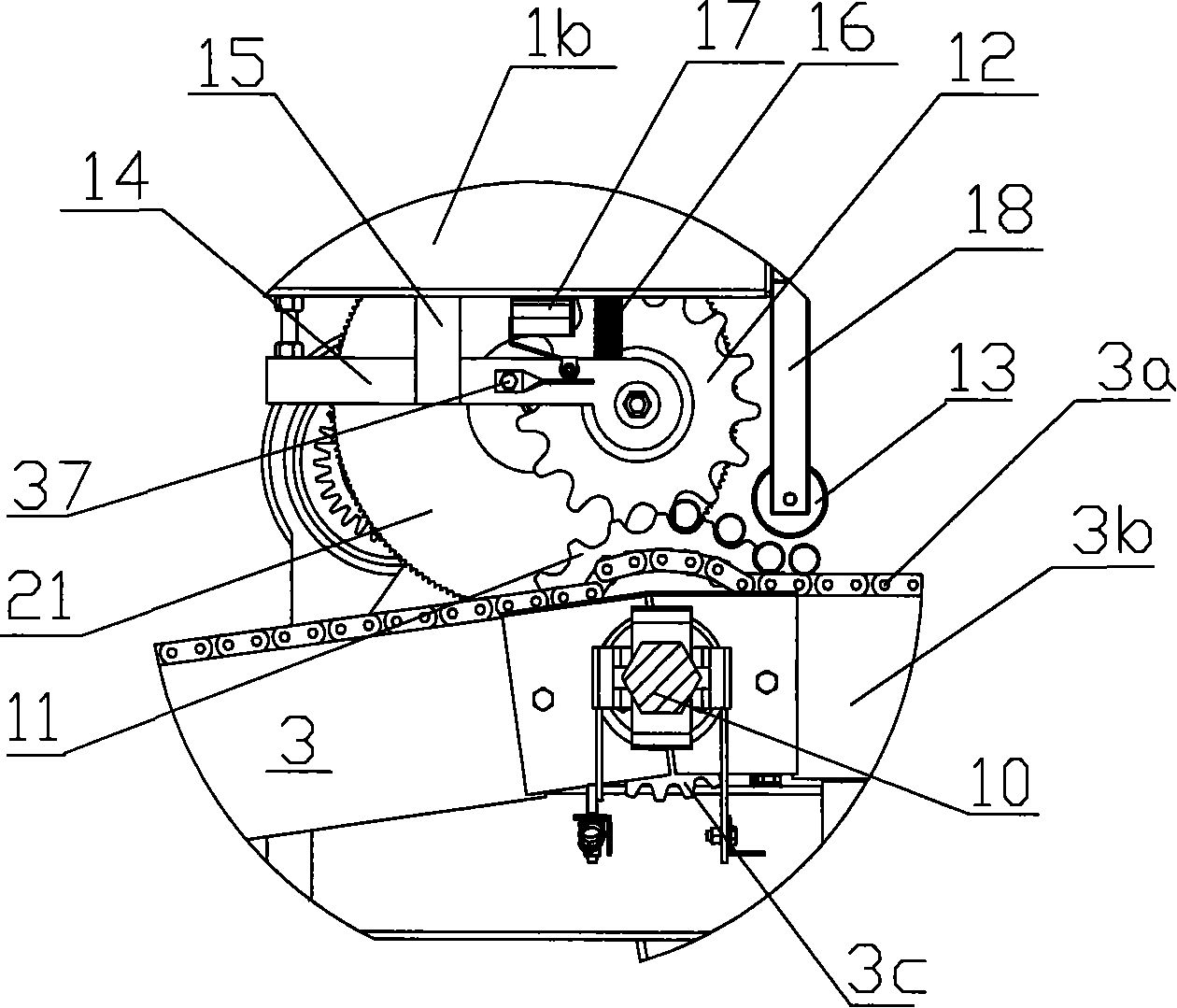

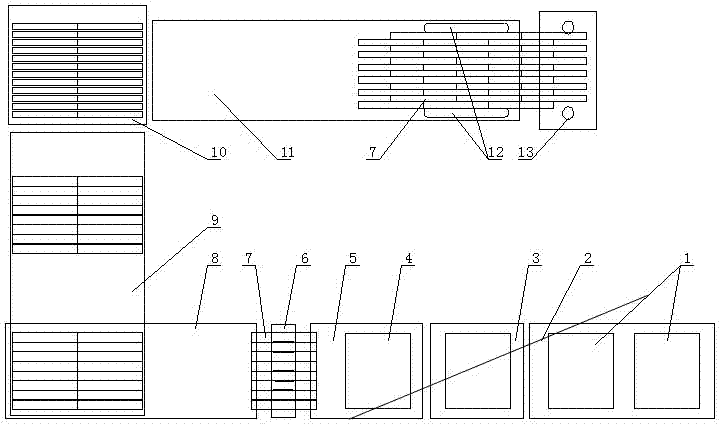

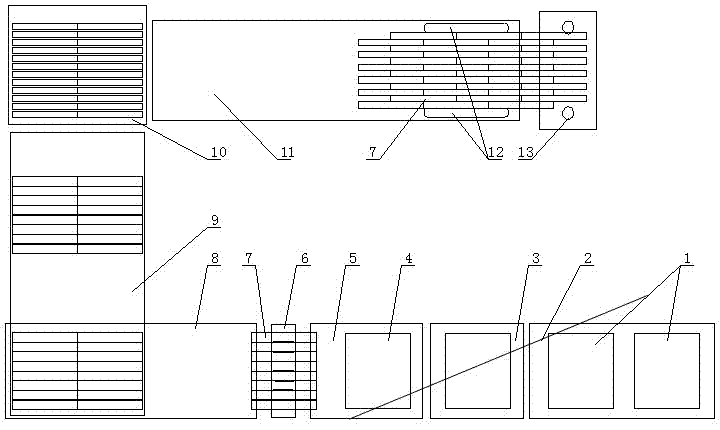

Straight pipe double-ended automatic non-bur cutter device

InactiveCN101249574AImprove work efficiencyRealize large-scale continuous productionMetal sawing devicesDeformation ProblemThin walled

A double-end automatic burr-free cutting device for straight pipes comprises a first and a second supports correspondingly arranged on both sides, pipe clamping structures positioned on the supports on both sides for fixing both ends of a pipe to be cut, and pipe transport rails respectively linked with the pipe clamping structures on both sides for supporting and transporting the pipe to be cut, wherein pipe cutting structures are correspondingly arranged on the supports on both sides and outside the pipe clamping structures and the pipe transport rails. The pipe clamping structure comprises a drive motor, a gear box, a pipe clamping drive gear and a transmission shaft fixed on the axis of the pipe clamping drive gear, which are sequentially connected with each other, wherein lower pipe clamping gears are respectively connected with both ends of the transmission shaft, and upper pipe clamping gears engaged with the lower pipe clamping gears are arranged thereon. The cutting device can achieve automatic double-end clamping, automatic feeding and simultaneous cutting, thus greatly improving the work efficiency and achieving large-scale continuous production. The cutting device can overcome the deformation problem of thin-wall pipes during clamping and cutting, and can be operated by users away from saw blades, thus obviating the occurrence of industrial accident.

Owner:鲍洪文

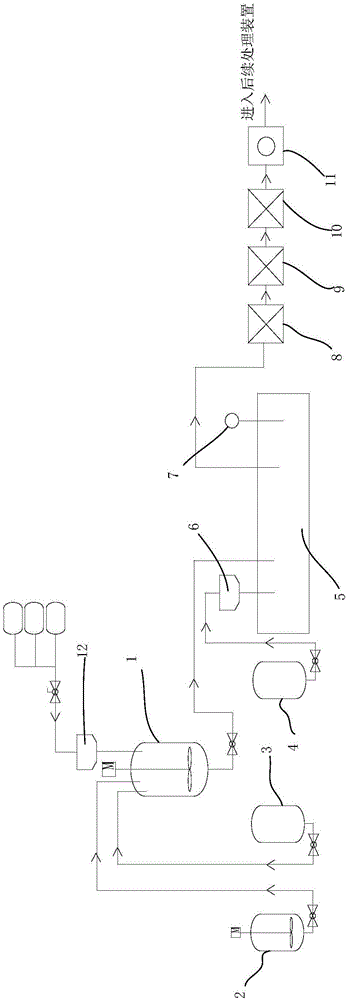

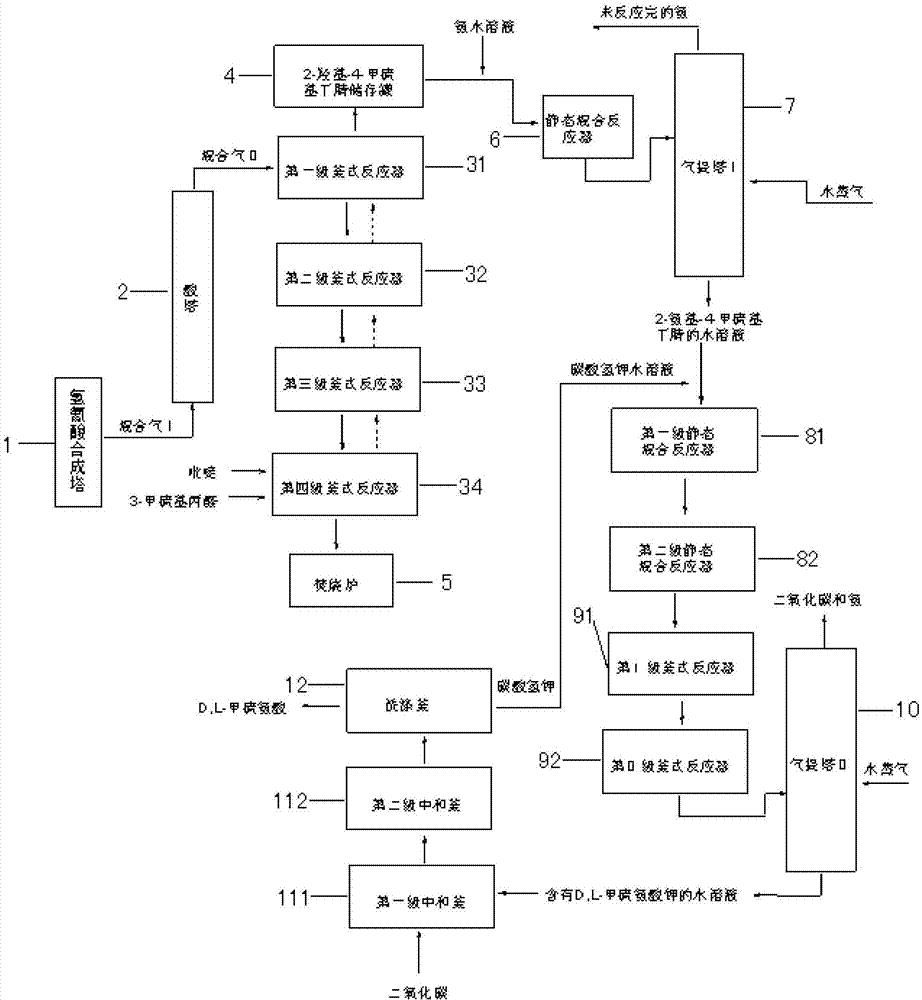

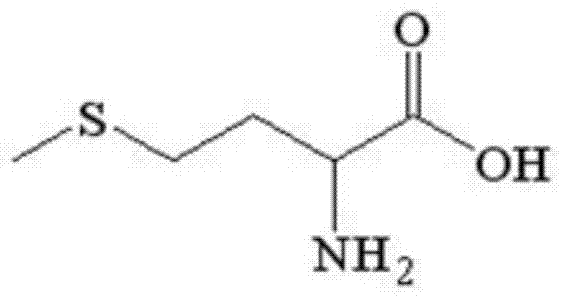

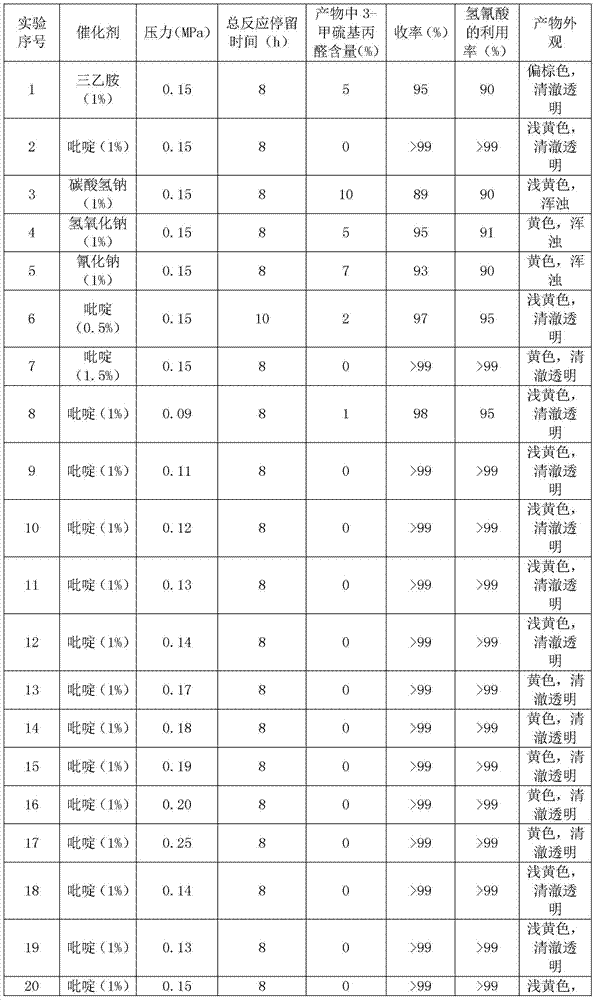

Method and device for using crude hydrocyanic acid to continuously produce D, L-methionine

ActiveCN103664719AReasonable configurationAvoid emissionsSulfide preparationPotassiumMethionine biosynthesis

The invention relates to a method and device for using crude hydrocyanic acid to continuously produce D, L-methionine. The device comprises a hydrocyanic acid synthetic tower, an acid tower, a multi-level series tank reactor, a static mixing reactor I, a stripping tower I, a static mixing reactor II, a tank reactor, a stripping tower II and a neutralizing kettle. The method for continuously producing the D, L-methionine comprises the steps of the preparation of cyanic acid mixed gas II, the preparation of 2-hydroxy-4-methylthio-butyronitrile in the multi-level series tank reactor, the preparation of 2-amino-4-methylthio-butyronitrile in the static mixing reactor I, the preparation of D, L-methionine potassium in the static mixing reactor II and the tank reactor, the preparation of the D, L-methionine through the neutralization in the neutralizing kettle, and the treatment on products or reaction residues by using a low-temperature storage tank, an incinerator, a stripping tower, a washing kettle and the like. According to the device and method, provided by the invention, crude hydrocyanic acid and crude methylthiopropanal are used for continuously producing the D, L-methionine, the production cost is low, the side reactions are few, the yield is high, and industrial large-scale continuous production can be realized.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Method for preparing low-polymerization-degree water-soluble ammonium polyphosphate from ammonium phosphate

InactiveCN104724688AReduce energy consumptionEasy to controlPhosphorus compoundsSolubilityWater insoluble

The invention belongs to the technical field of the production of phosphate in inorganic chemical industry, in particular to a production technology for preparing low-polymerization-degree water-soluble ammonium polyphosphate from ammonium phosphate. The method is used for preparing a solid low-polymerization-degree ammonium polyphosphate product which is good in water solubility by innovatively mixing and heating ammonium phosphate, ammonium phosphate, urea and water which are taken as main raw materials. The method is low in production energy consumption, easy in production control, relatively easy in operation, easy in product package convenient in use and capable of reducing production and transportation costs, and the produced solid low-polymerization-degree ammonium polyphosphate product contains less than 0.15wt% of water-insoluble matters; the solid ammonium polyphosphate product is suitable for preparing a high-quality liquid fertilizer, applicable to airplane spraying forest fire fighting, liquid fertilizer airplane spraying, preparation of other liquid fertilizer and other purposes, and the solid ammonium polyphosphate product can be used for greatly promoting the rapid development of Chinese modern agriculture.

Owner:BLACK P2 USA INC

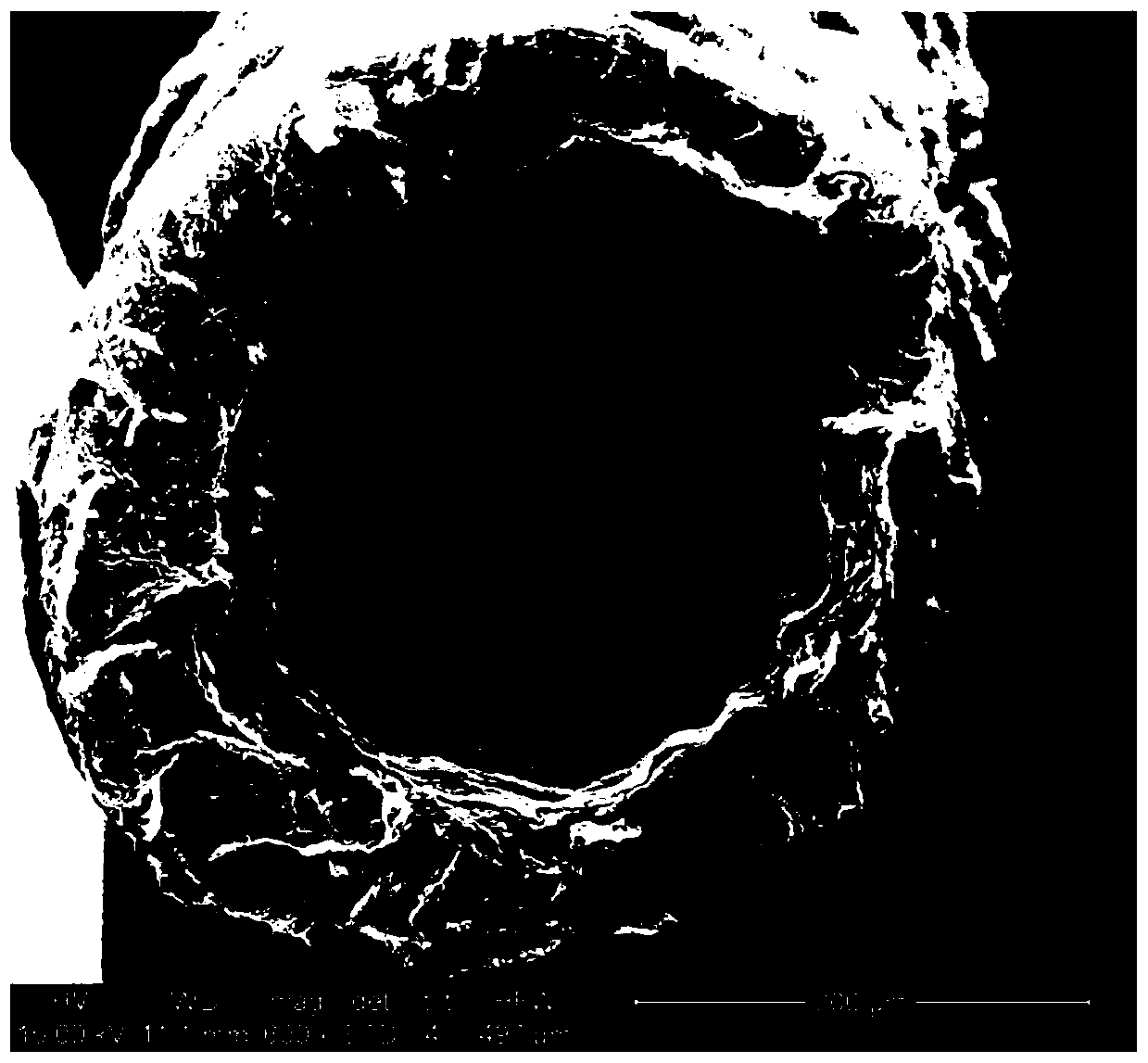

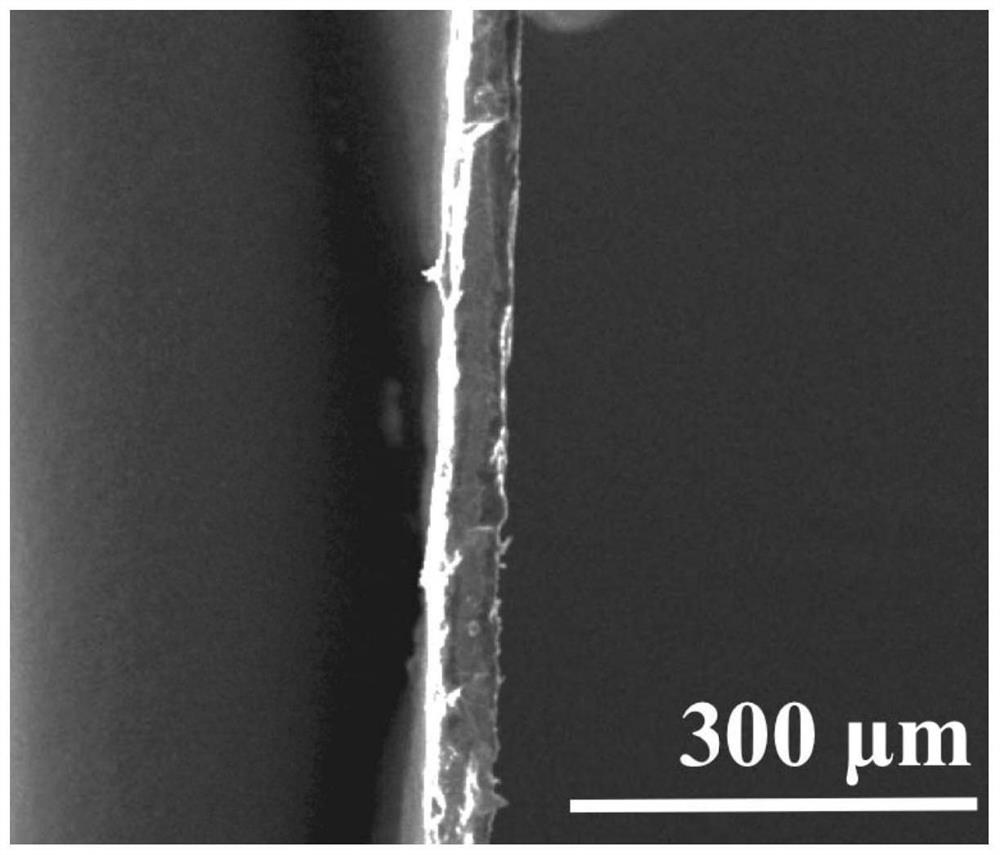

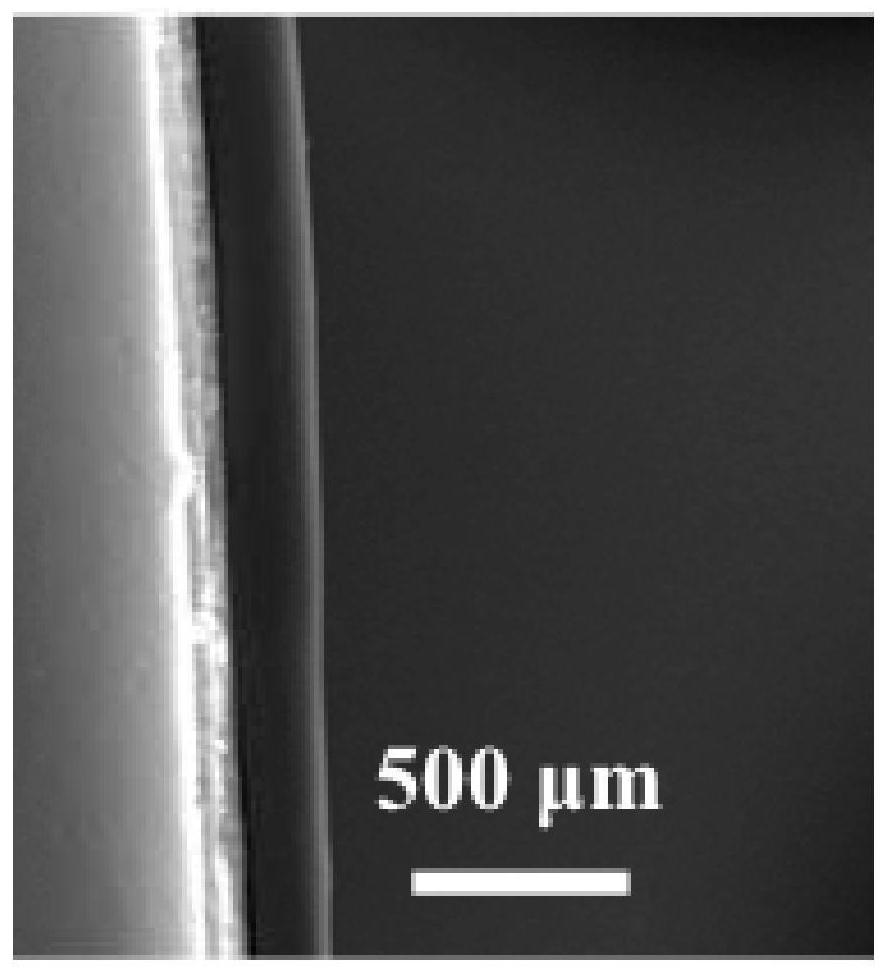

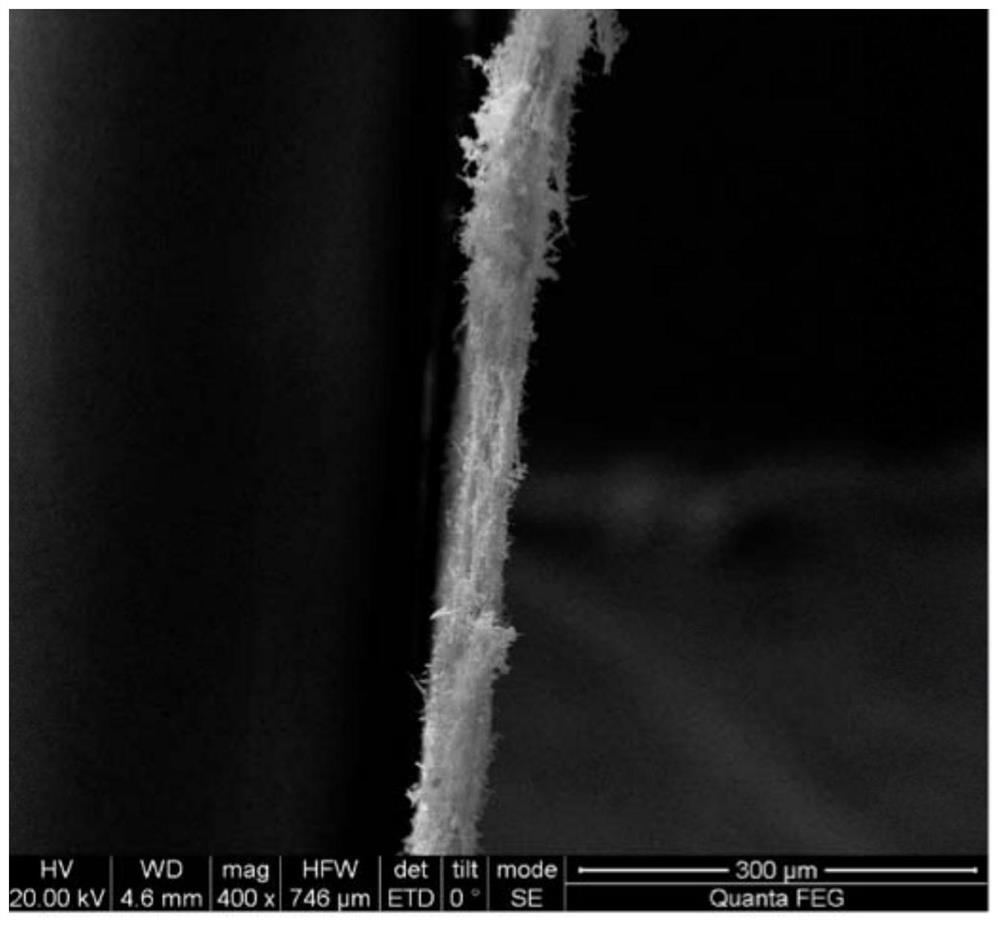

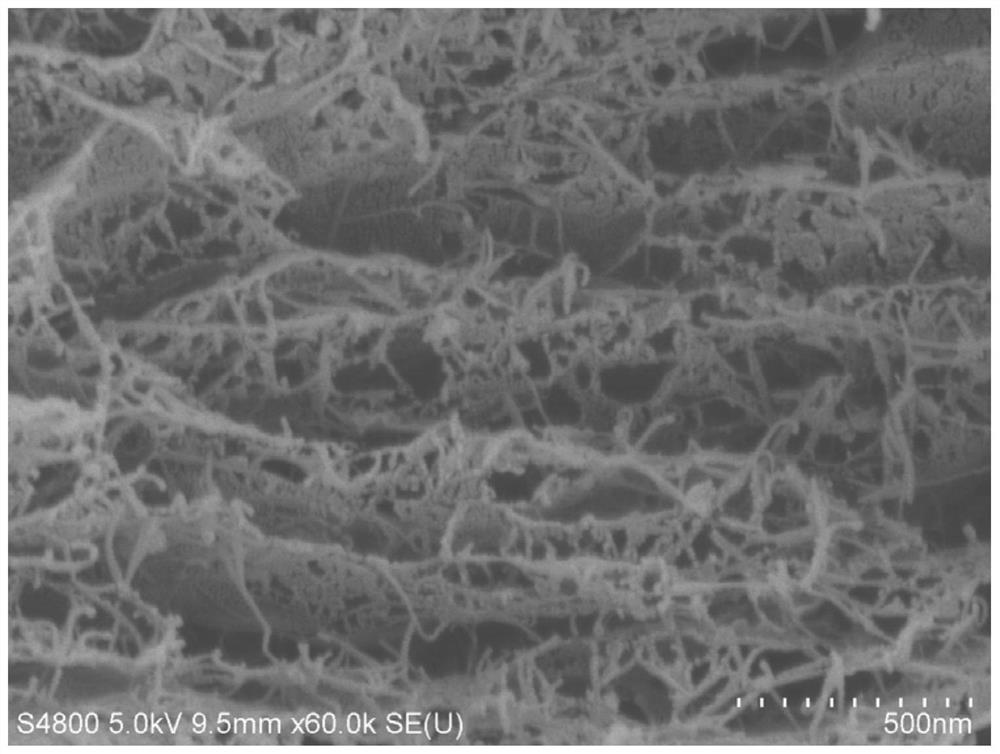

Graphene aerogel hollow fiber, and preparation method and application thereof

ActiveCN110607577AExcellent Mechanical FlexibilityExcellent fluid transport performanceGeneral water supply conservationSeawater treatmentFiberFreeze-drying

The invention discloses a graphene aerogel hollow fiber, and preparation method and application thereof. The graphene aerogel hollow fiber is provided with an annular closed graphene aerogel wall anda duct cavity penetrating the axial direction of the fiber, the graphene aerogel wall is provided with a continuous three-dimensional porous network formed by three-dimensional overlapping of graphenesheets, and the duct cavity is formed by enclosing the graphene aerogel wall. The preparation method comprises the steps: preparing a graphene hydrogel hollow fiber by a coaxial needle-assisted sol-gel technology, and then subjecting the graphene hydrogel hollow fiber to supercritical fluid drying and / or freeze drying treatment to obtain the graphene aerogel hollow fiber. The graphene aerogel hollow fiber has excellent mechanical flexibility, water transmission performance and photothermal conversion performance and has important applications in the fields of photothermal conversion, fluid transmission, seawater desalination and the like, the preparation process is simple, the reaction conditions are mild, and the graphene aerogel hollow fiber is suitable for continuous production.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

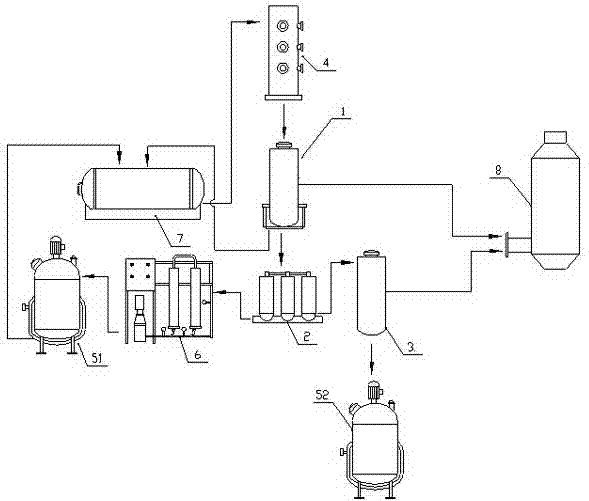

Purifying system of high purity polysilicon and purifying method

ActiveCN101824650AGood purification effectSimple equipmentPolycrystalline material growthSingle crystal growth detailsElectric fieldElectromigration

The invention discloses a purifying system of high purity polysilicon and a method for preparing the high purity polysilicon by using the system. The system comprises a silicon material melting device arranged in a closed cavity, an electromigration device and an orientation solidification device, wherein the silicon material melting device and the electromigration device are connected through a first overflow pipe, and the electromigration device and the orientation solidification device are connected through a second overflow pipe. The method is characterized in that a horizontal direct current electric field which is vertical to the flowing direction of silicon liquid is forced on melted silicon liquid, cation impurities and anion impurities in the silicon liquid respectively migrate towards the direction of a cathode and the direction of an anode under the function of an electric field and gather in electrode regions at both sides, high impurity concentration silicon liquid and high purity silicon liquid are separated by a division baffle, the high purity silicon liquid is treated by orientation solidification ingot casting, and finally, a high purity polysilicon ingot is obtained. The invention can realize large scale continuous purifying production of high purity silicon and has the advantages of favorable purifying effect, simple equipment, little investment and low production cost.

Owner:上海太阳能电池研究与发展中心

Integrated bag-type dust removal and fluidized adsorption device

InactiveCN102716622AFull gas-solid contactPromote regenerationHuman health protectionDispersed particle filtrationSorbentAdsorption effect

The invention relates to an integrated bag-type dust removal and fluidized adsorption device. The integrated bag-type dust removal and fluidized adsorption device comprises a dust bin, a box body and a dust cleaning device, wherein the box body is divided into one or more chambers; a plurality of bag filters for removing dust are arranged in each chamber; a fluidized bed is arranged in the dust bin and the box body; the fluidized bed is provided with a discharge pipe, a flue gas collection box, a gas distribution plate and a lift pipe in sequence from the bottom up; the equivalent diameter of the lift pipe is 1 to 15 percent that of the box body; one side at the lower part of the lift pipe is connected with a feed pipe; the upper part of the fluidized bed is connected with a gas-liquid separator through a smoke exhaust pipe; and flue gas, in which the dust is removed by the bag filters, enters the flue gas collection box through a flue gas pipeline and fluidizes absorbent in the lift pipe through the gas distribution plate, and the absorbent is used for adsorbing gaseous pollutants. The integrated bag-type dust removal and fluidized adsorption device has the advantages of simple structure, convenience and reliability in operation, no secondary pollution and no water consumption. Meanwhile, the integrated bag-type dust removal and fluidized adsorption device can effectively remove the gaseous pollutants such as particles, SO2, NOx and Hg as well as various poisonous and adverse organic industrial emissions and has good dust removal and adsorption effects.

Owner:HARBIN INST OF TECH AT WEIHAI

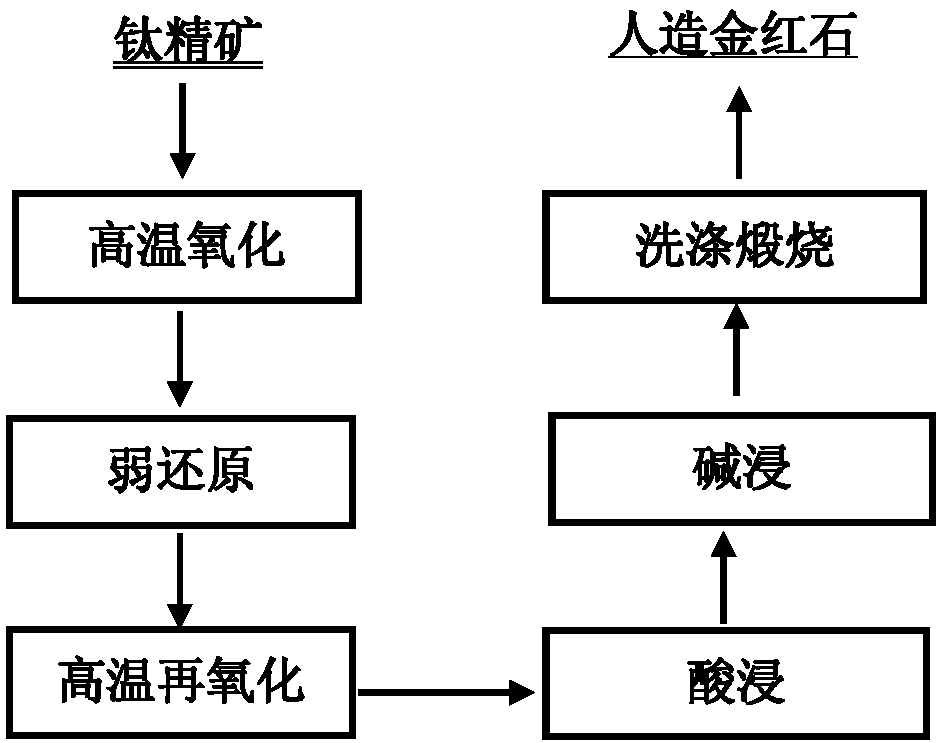

Method of producing high-strength artificial rutile from ilmenite

The invention discloses a method of producing high-strength artificial rutile from ilmenite and belongs to the technical field of metallurgy. In order to solve the problem that artificial rutile has low strength and powdering proneness, the invention provides a method of producing high-strength artificial rutile from ilmenite; the artificial rutile is produced by subjecting ilmenite to high-temperature oxidation before weak reduction, high-temperature secondary oxidation, acid leaching, alkali leaching, and calcining. The method has the advantages that microscopic composition and morphology ofilmenite are changed through the pretreatment of high-temperature oxidation, weak reduction and high-temperature secondary oxidation for ilmenite, ilmenite is imparted good reaction activity and mechanical force resistance in the subsequent acid leaching and alkali leaching cleaning process, titanium recycle rate is increased to 98% and above, the product quality is high, the content of TiO2 is higher, particle size is kept better, and fine power ratio is lower.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

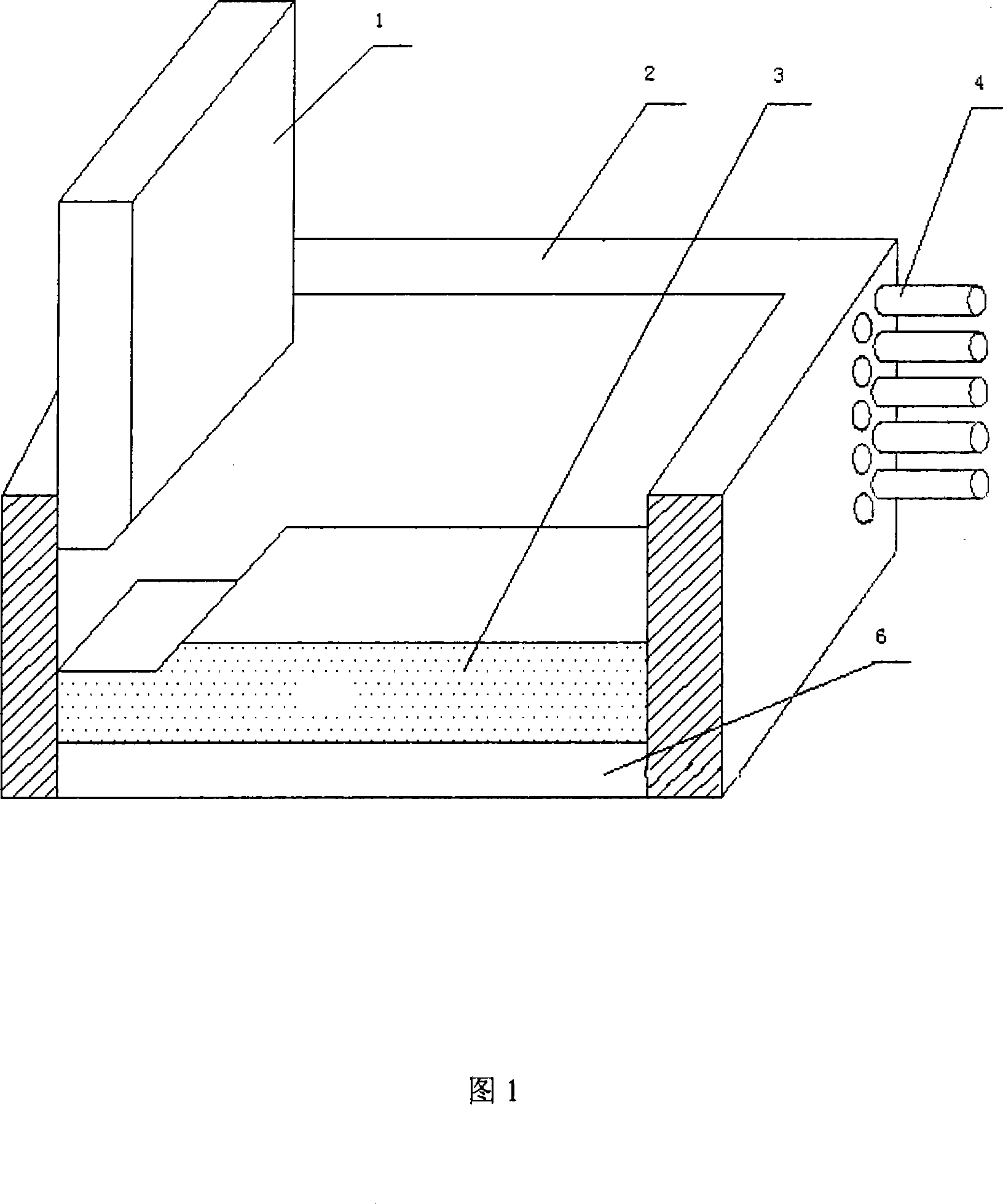

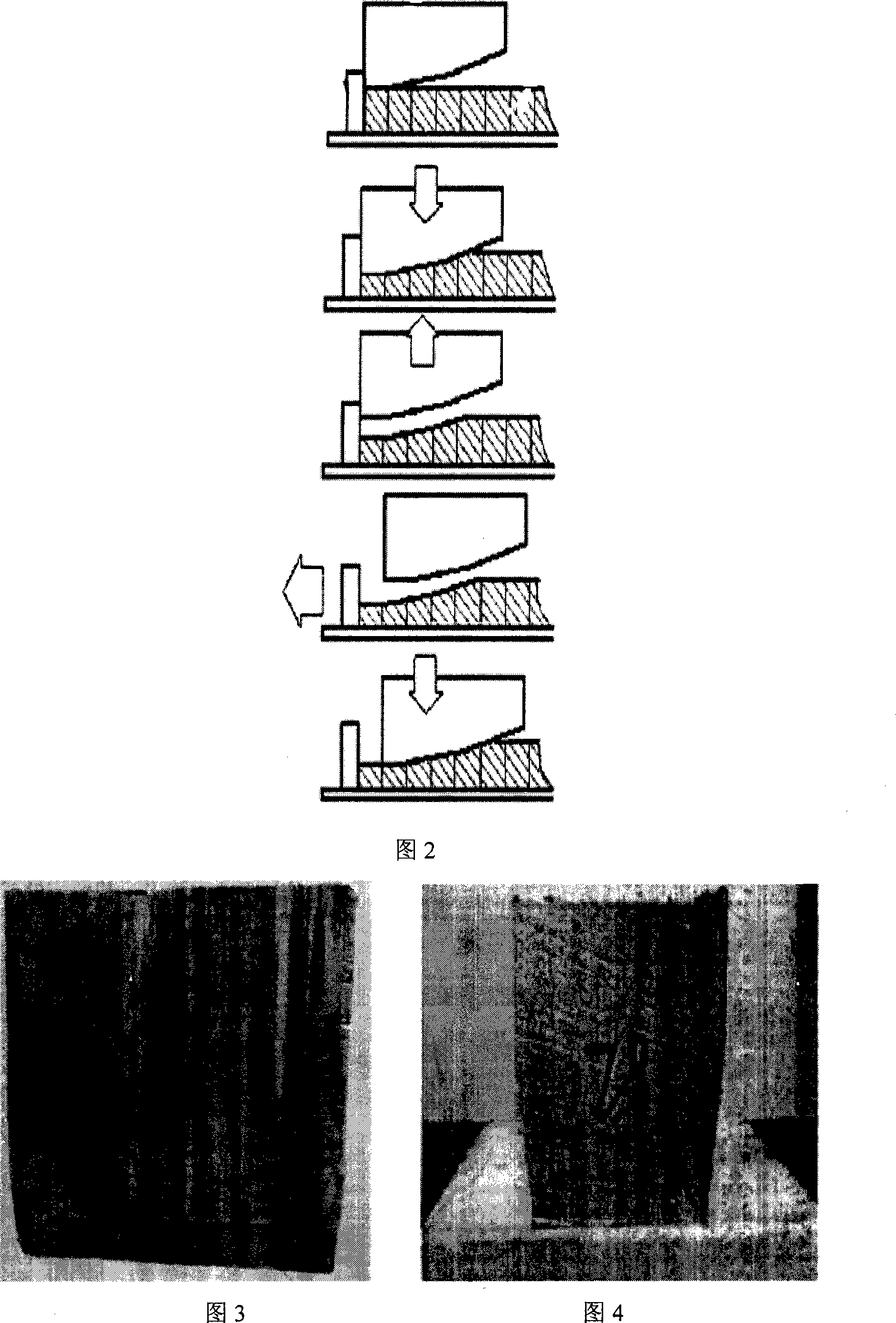

Deformation method and device for gradient temperature wedge pressure for injecting and depositing porous material

Disclosed is a ladder temperature band-pressing deforming method and device, which is made of spraying settling cellular materials. The utility model puts blanks into a ladder temperature mold of which the temperature increases step-by-step from the top to the bottom, the lower surface of the blanks contacts the heating bottom board, when the blanks which are ready to be used also has temperature gradient from the top to the bottom, using wedge indenters to compress partially, and the blanks are accumulated from local deformation to integral large deformation step by step. The utility model comprises a mold with a heating and cool-off device, a bottom board with a heating tube and a wedge indenter. The utility model has the advantages of reasonable structure, simple art work. After bringing in ladder temperature, weakening resistance of deformation of the blanks from the top to the bottom, overcoming the phenomenon of compact ill effect of the bottom of the blanks which is caused by frictional force of the mold wall produced in the process of molding and compacting of the large blanks, thereby weakening the briquetting pressure. The utility model is especially applicable to the compacting manufacturing procedure of large spraying settling cellular materials, and expanding application foreground of large units of spraying settling cellular materials.

Owner:HUNAN UNIV

Method for separating high purity theaflavin from black tea pigment solution

ActiveCN102229591APacking is cheapImprove adsorption capacityOrganic chemistryTheaflavinAqueous solution

The invention discloses a method for separating high purity theaflavin from a black tea pigment solution. The method uses the black tea pigment solution obtained by extraction of black tea or oxidation of tea polyphenol as a raw material, uses AB-8 or NKA-9 or Mitsubishisp-207 or other macroporous resins as a separating medium, uses ethanol water as an elution solution, and carries out separationto obtain the high purity theaflavin. The method disclosed in the invention has the advantages of simple technology, low energy consumption, simple operation and safe, in favor of realizing large-scale continuous production.

Owner:杭州英仕利生物科技有限公司

Preparation method of positive electrode material of lithium iron phosphate battery

ActiveCN103943855ASolve the coarse grainUneven solutionCell electrodesLi-accumulatorsContinuous reactorAlkaline earth metal

The invention discloses a preparation method of a positive electrode material of a lithium iron phosphate battery. A reciprocating single screw extruder is used as a disposable continuous reactor, and a screw rod does an axial reciprocating movement in a radial rotation process, so that a material is sheared, dispersed, and stretched under the melt condition to reach a homogenizing reaction; through induction of a grain growth inducer, a grain rapidly grows and is completely coated and isolated by a high-molecular polymer, and thus a lithium iron phosphate grain is uniform and fine, and the size of the lithium iron phosphate grain is less than 50nm. Furthermore, according to the preparation method, divalent stable metal ions of an alkaline earth metal periodic system IIA-family element are uniformly doped in the lithium iron phosphate grain, a completely plasticized and dispersed polymer is carbonized through high temperature and high pressure, and thus the conductivity of the lithium iron phosphate grain is improved.

Owner:江西省金锂科技股份有限公司

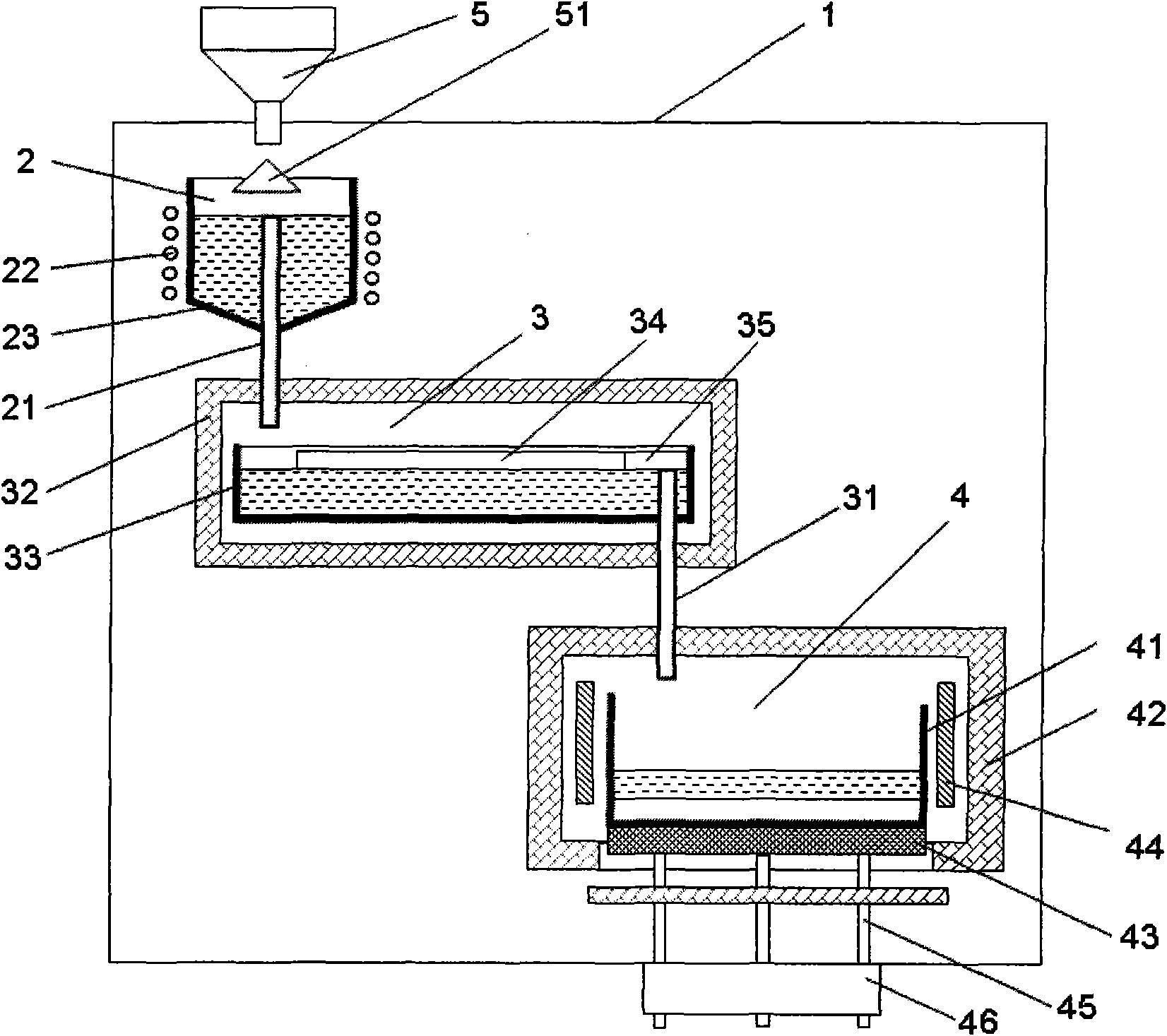

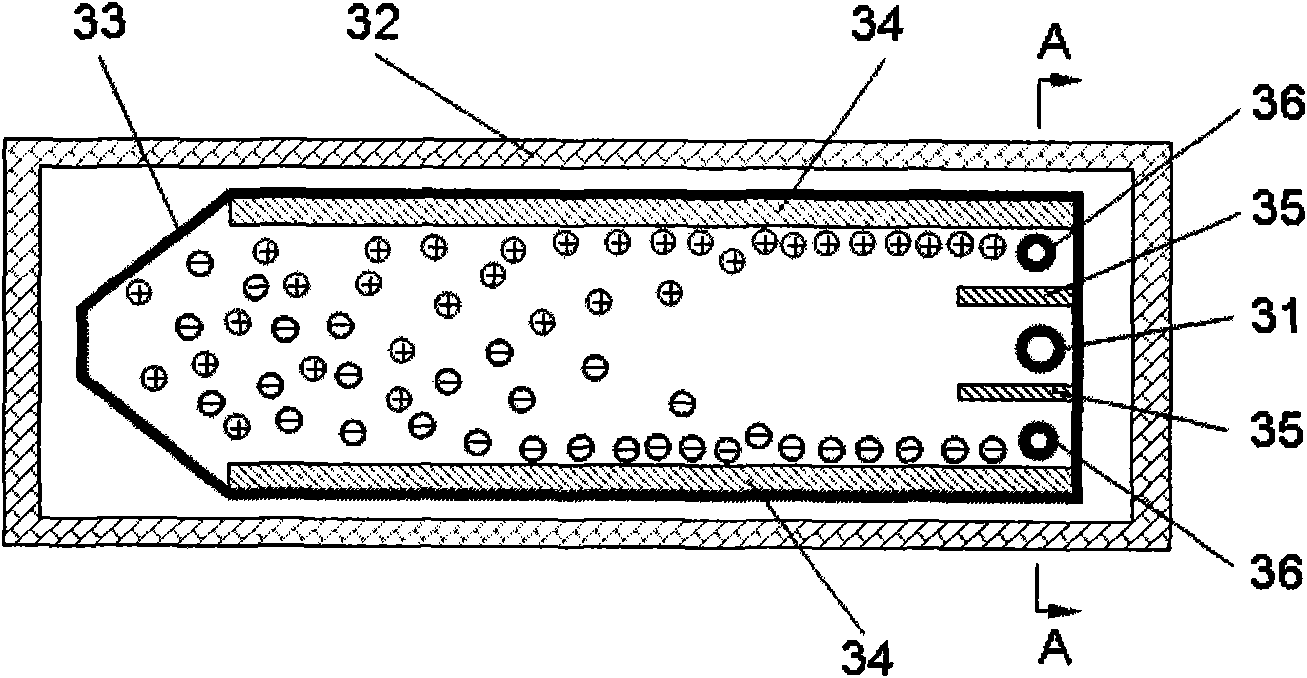

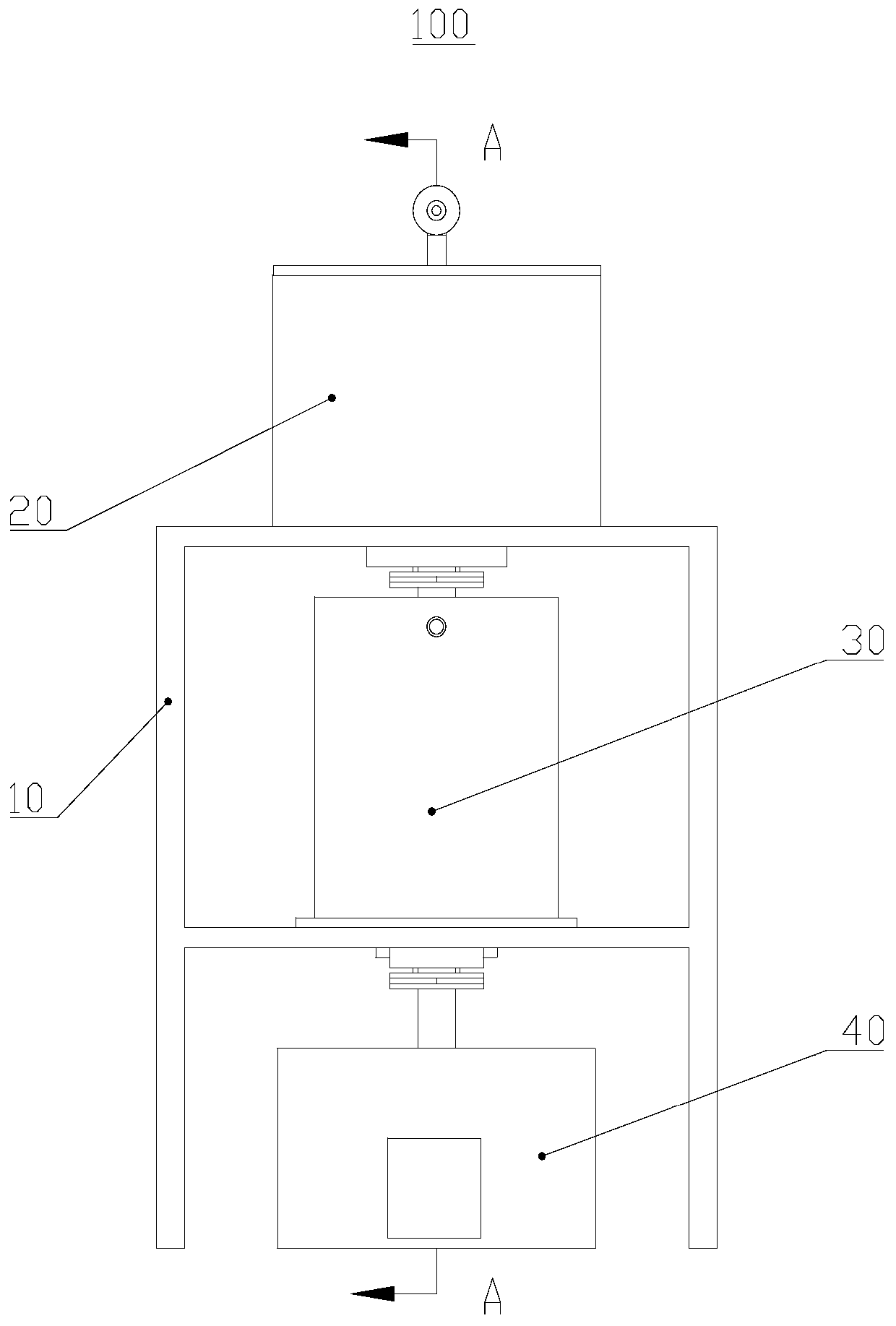

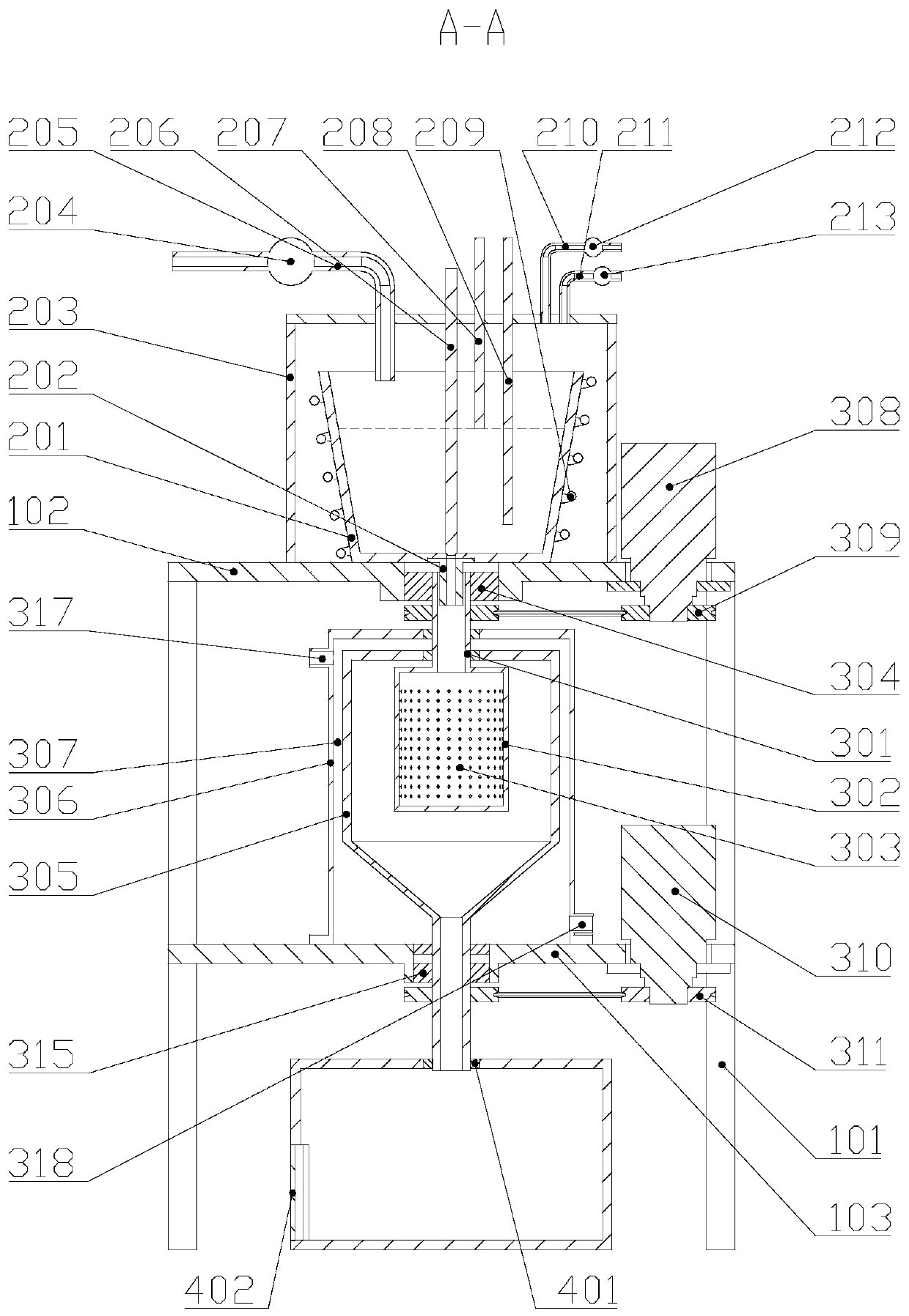

Production plant and production method of rapid setting metal powder

PendingCN111230133ARealize large-scale continuous productionEasy to makeIncreasing energy efficiencyMg alloysMetallurgy

The invention discloses a production plant and production method of rapid setting metal powder and belongs to the field of metal powder preparation. Molten metal enters a centrifugal atomizer rotatingat a high speed and is flung out through rotation liquid spray atomization holes in the centrifugal atomizer under the effect of centrifugal force, and small molten metal drops are flung to a quenching wall of a quenching chamber rotating at a high speed similarly to set rapidly. The obtained rapid setting metal powder is collected in a powder collection device at the bottom of the quenching chamber. The high-performance rapid setting metal powder is obtained in the mode of combination of high-speed centrifugal atomization and water cooling rotation metal barrel quenching, mass production canbe achieved, and the production plant and production method are suitable for preparing the high-strength metal powder of aluminum alloy, magnesium alloy and the like.

Owner:四川科匠轻金属材料科技有限公司

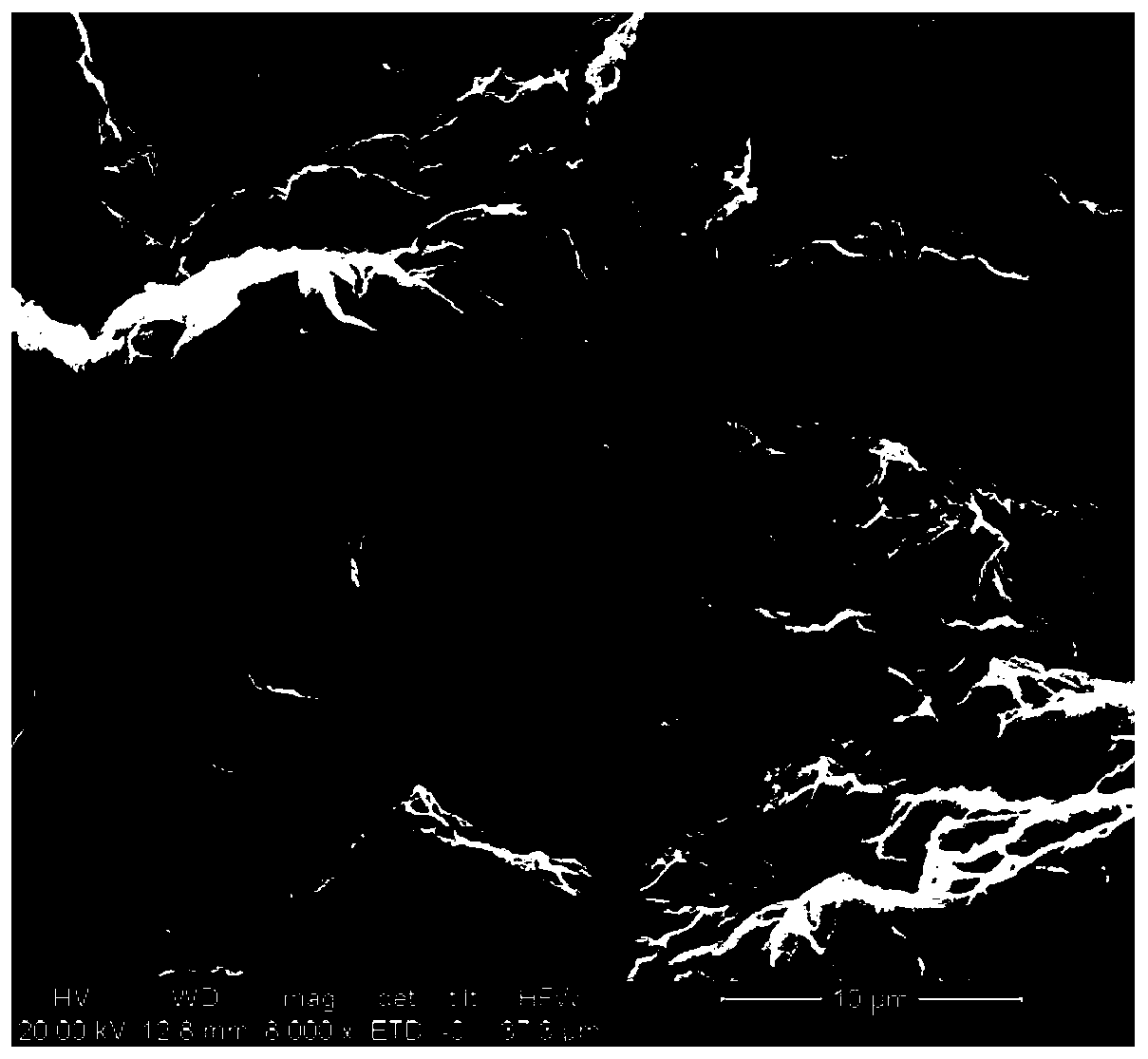

Boron nitride aerogel phase-change film, and preparation method and application thereof

ActiveCN111793472AAdjustable thicknessShape adjustableHeat-exchange elementsAerogel preparationBoron nitrideMaterials science

The invention discloses a boron nitride aerogel phase-change film, and a preparation method and application thereof. The boron nitride aerogel phase-change thin film is composed of a boron nitride aerogel thin film and a phase-change material, wherein the boron nitride aerogel thin film is provided with a three-dimensional porous network formed by mutually winding and overlapping boron nitride nanoribbons, and the porous network of the boron nitride aerogel thin film is filled with the phase-change material. The preparation method comprises the following steps: carrying out cutting, pressure-induced assembling, high-temperature pyrolysis and phase-change material fusion filling on a melamine borate-based material in a block form so as to successively realize lightening and thinning, densification, pyrolysis purification and composite filling of the material, thereby obtaining the boron nitride aerogel phase-change film. The boron nitride aerogel phase-change film obtained by the invention has the function of reversibly absorbing and releasing heat energy, can be used for heat management of portable electronic equipment and wearable electronic equipment under the condition of future5G technology, creates a comfortable use environment and a comfortable work environment for human bodies and electronic elements, and is simple in preparation process.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

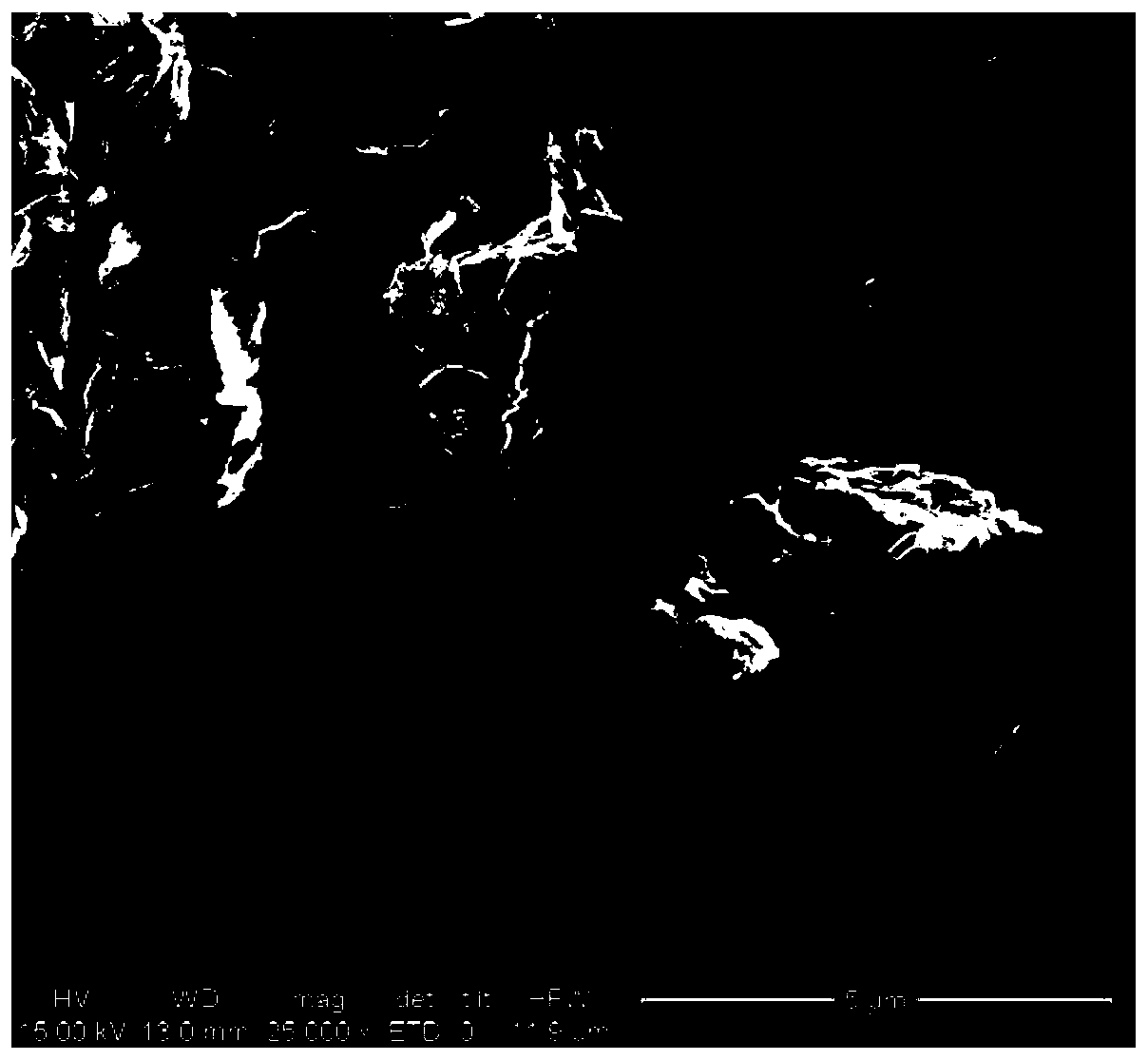

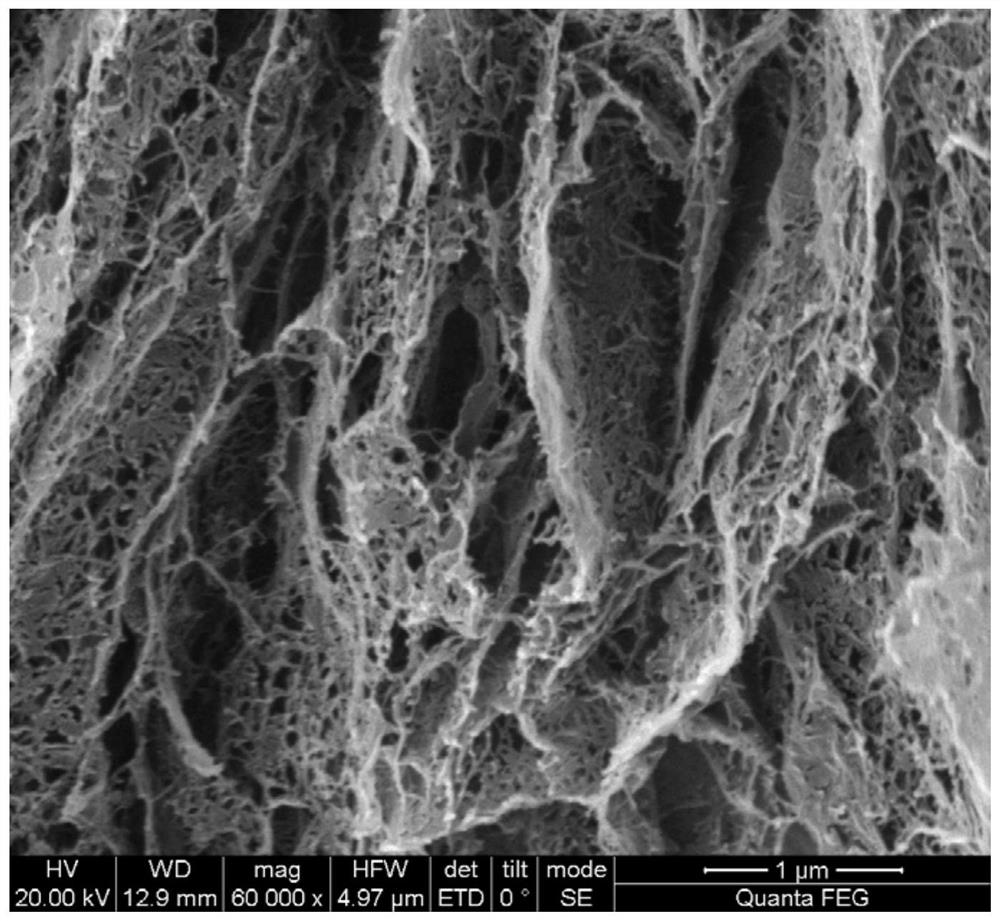

Bifunctional graphene aerogel as well as preparation method and application thereof

ActiveCN110980705AImprove mechanical propertiesImprove hydrophilicityGeneral water supply conservationSeawater treatmentBifunctionalGraphene flake

The invention discloses a difunctional graphene aerogel as well as a preparation method and application thereof. The difunctional graphene aerogel has a continuous three-dimensional porous network structure, the three-dimensional porous network structure is formed by overlapping graphene sheet layers modified by vegetable tannin, and the vegetable tannin is uniformly attached to the graphene sheetlayers. The preparation method comprises the following steps: dispersing graphene oxide and the vegetable tannin in a solvent to obtain a uniform precursor dispersion liquid, heating and standing toobtain a graphene wet gel, and drying to obtain the difunctional graphene aerogel. The difunctional graphene aerogel has good mechanical strength, excellent hydrophilicity and water absorbability, excellent photo-thermal water evaporation performance and uranium adsorption performance, photo-thermal water evaporation and uranium extraction can be achieved at the same time, the preparation processis simple, reaction conditions are mild, operation is easy, the cost is low, environmental friendliness and no pollution are achieved, and continuous production can be achieved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

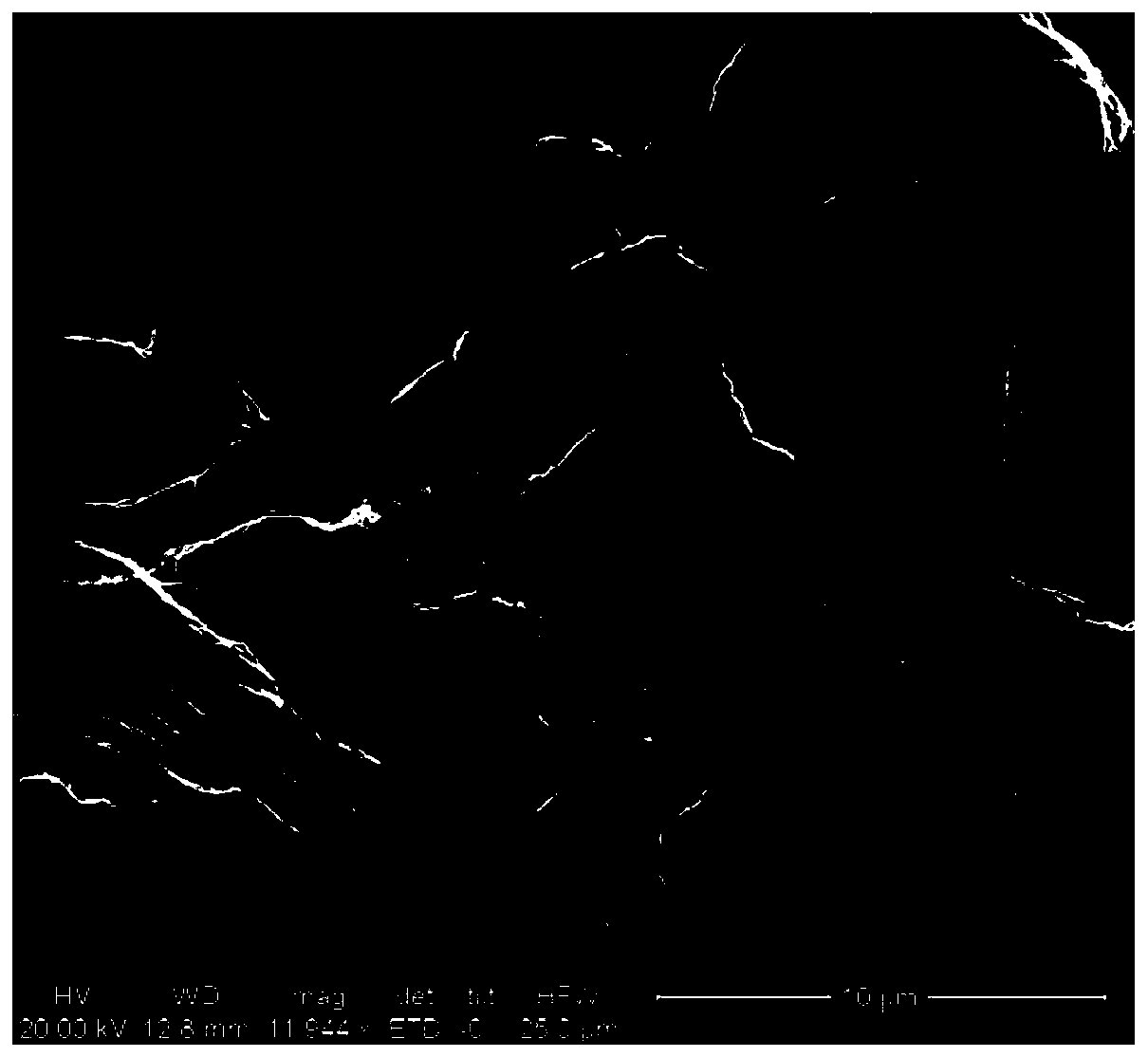

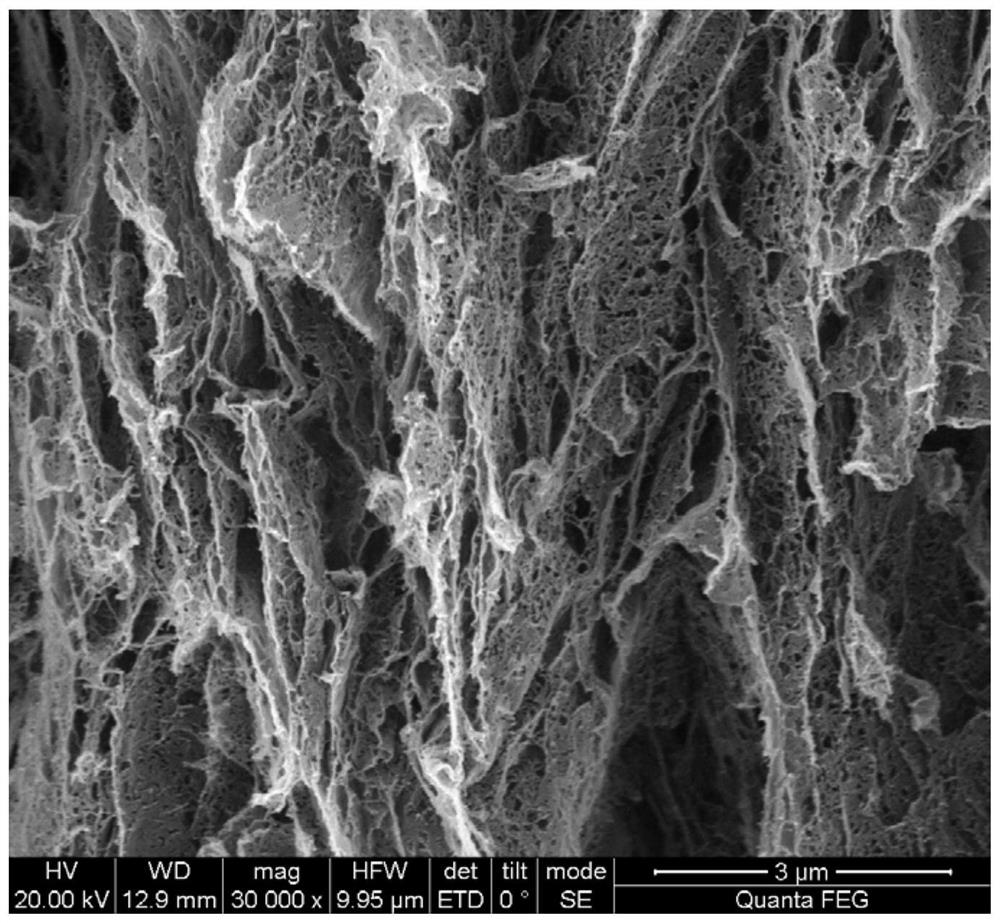

Graphene composite aerogel film with rivet structure as well as preparation method and application of graphene composite aerogel film

ActiveCN111977644AEfficient brine power generation performanceEfficient power generation performanceGrapheneSpinningGraphene flake

The invention discloses a graphene composite aerogel film with a rivet structure as well as a preparation method and an application of the graphene composite aerogel film. The rivet-structured graphene composite aerogel film has a continuous, regular and ordered graphene three-dimensional porous network structure and a rivet structure, wherein the three-dimensional porous network structure is formed by overlapping graphene sheet layers; and the rivet structure is formed by compounding hydroxyl iron oxide nanofibers and the graphene sheet layers in a manner that the hydroxyl iron oxide nanofibers bridge and penetrate through the graphene sheet layers. The preparation method comprises the following steps: preparing a graphene composite hydrogel film with a rivet structure by utilizing a sol-gel preparation technology assisted by wet spinning, and then carrying out solvent replacement and drying treatment to obtain the graphene composite aerogel film with the rivet structure. The graphenecomposite aerogel film with the rivet structure has relatively high mechanical strength and excellent hydrophilicity, and can be assembled into a photovoltaic device to realize high-efficiency brinepower generation, and in addition, the preparation process is concise, the reaction conditions are mild, the operation is easy, the cost is low, the film is green and pollution-free, and realize continuous production can be realized.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Rock wool or glass wool preprocessing device and method in the sandwich panel production process

InactiveCN102173130AIncrease productivityIncrease productionMetal layered productsSocial benefitsConveyor belt

The invention relates to a rock wool or glass wool preprocessing device and a rock wool or glass wool preprocessing method in the sandwich panel production process. The device comprises a cutting machine, a before-compounding conveyor belt, and a side milling mechanism, and is characterized in that: rock wool or glass wool is piled on a caterpillar conveyer; the outlet of the caterpillar conveyer is provided with an hoister provided with a propulsion unit; the outlet of the propulsion unit is provided with a before-cutting conveyor which is arranged at the inlet of the cutting machine; the outlet of the cutting machine is provided with an after-cutting conveyor which is connected with a conveying steering gear; the outlet of the conveying steering gear is provided with a tilter; and the outlet of the tilter is formed at the inlet of the before-compounding conveyor belt. The invention has the advantages that: the production efficiency of rock wool or glass wool color steel sandwich panels is improved, unmanned operation can be realized, large-scale continuous production is realized, the yield and quality of the rock wool or glass wool color steel sandwich panels can be improved, and the economic and social benefits are obviously increased.

Owner:SHANGHAI YONGMING MACHINERY MFG

Polyvinylidene fluoride composite membrane prepared through multilayer coextrusion tape casting method

InactiveCN102649309AGood weather resistanceImproves UV resistanceFlat articlesPolyvinylidene difluoridePolyvinylidene fluoride

The invention relates to a process for preparing a polyvinylidene fluoride composite membrane through a multilayer coextrusion tape casting method. The method comprises the following steps: resin modification is performed on PVDF (Polyvinylidene Fluoride) resin by using TiO2 and PMMA, and then different modified resins are respectively added into a corresponding machine of multilayer coextrusion equipment, and finally, the composite membrane is formed through extrusion tape casting of the multilayer coextrusion equipment. The polyvinylidene fluoride composite membrane prepared through the multilayer coextrusion tape casting method is characterized is that the polyvinylidene fluoride composite membrane prepared through the multilayer coextrusion tape casting method adopts a multilayered structure, the outer layer of the multilayered structure is a PVDF protecting layer, the middle layer is a modified layer, and the inner layer is an EVA glue layer. The composite membrane not only has the excellent weather resisting property, the uvioresistant property and the excellent mechanical property of the PVDF, meanwhile has an excellent adhesive property, and can be well bonded together with a solar energy rear panel base material. In addition, the product cost performance is high, the degree of automation of the production technology is high, and the polyvinylidene fluoride composite membrane is suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH

Fast preparation method of silicon dioxide aerogel

The invention provides a fast preparation method of silicon dioxide aerogel. According to the method, tetraethyl orthosilicate is used as a silicon source; low-concentration organic weak acid is added for catalyzed hydrolysis reaction; then, the condensation polymerization reaction and the hydrophobic modification of the gel are completed in one step through reasonably controlling the addition quantity of the nitrogen-containing silane, the dripping speed and the reaction time; the addition of basic catalysts is not needed; the consumption of a great number of replacement solvents in the general post hydrophobic modification method is avoided; waste liquid is not generated; the preparation period is greatly shortened; the process cost is reduced; the industrial production is easy; meanwhile, the prepared silicon dioxide aerogel product has excellent performance.

Owner:TIANJIN BUILDING MATERIALS SCI RES INST +1

High-barrier composite plastic allowing direct blow molding and preparation method

The invention belongs to the technical field of preparation of high-barrier composite plastic and provides high-barrier composite plastic allowing direct blow molding and a preparation method. According to the method, surface-modified graphene oxide is firstly prepared and mixed with an ethylene-vinyl alcohol copolymer, an ethylene-vinyl acetate copolymer and silicon dioxide aerogel in a certain ratio, high-density polyethylene grafted maleic anhydride is added, and low-temperature grinding and homogenization are performed; a product, high-density polyethylene and an antioxidant are subjected to extrusion palletization, and the high-barrier composite plastic allowing direct blow molding is obtained. Silicon dioxide aerogel has a porous network structure and is interwoven and compounded with a polymer and graphene, an interweaving body structure capable of obstructing oil, gas and water is formed in the whole system, a directly blow-molded film has high barrier property, and defects of complicated conventional barrier film multi-layer composite process and high cost are overcome.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

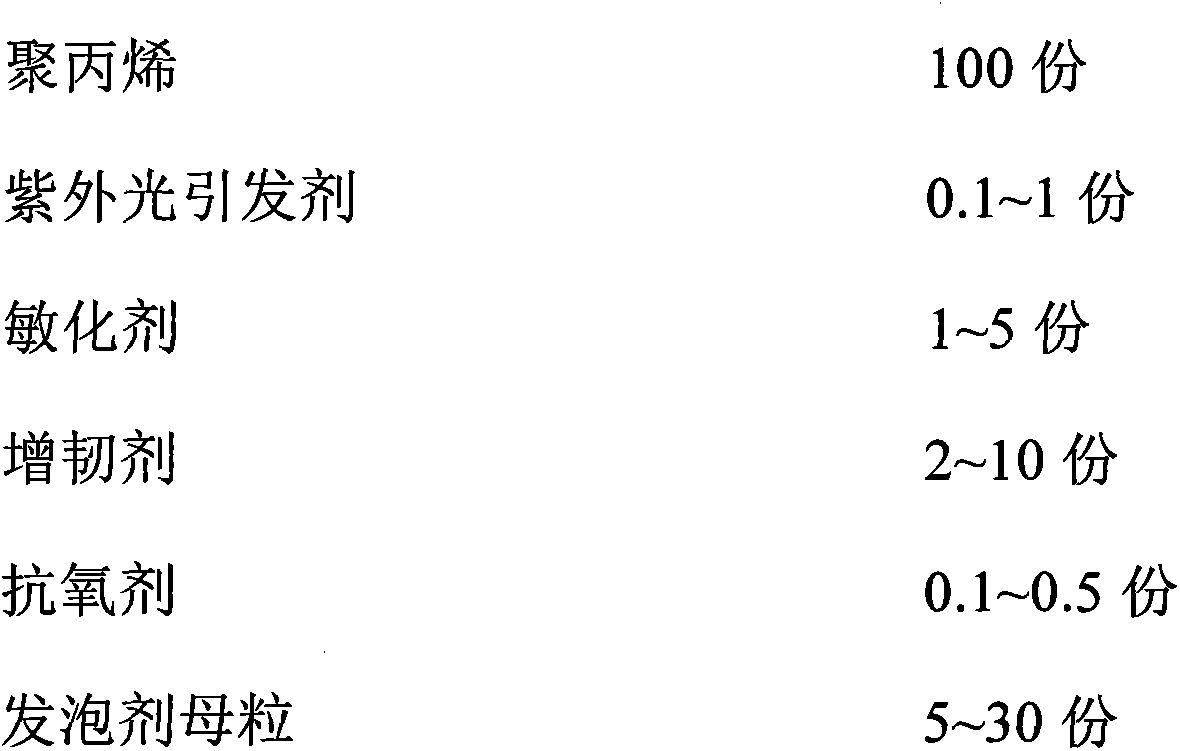

Preparation method of polypropylene foaming sheet material through ultraviolet light radiation crosslinking

The invention relates to a polypropylene foaming sheet material preparation method utilizing an ultraviolet light radiation crosslinking technology. The method adopts ultraviolet light radiation to trigger polypropylene grafting and crosslinking so as to improve the melt strength of polypropylene, and can be applied to the development and production of a polypropylene sheet material with a high foaming ratio. The preparation method is characterized in that a special polypropylene foaming sheet material can be produced through an excellent blending technology and an energy-saving, controllable, and continuous ultraviolet light radiation technology, the obtained foaming material after a conventional chemical foaming technology has a uniform pore size, and the foaming ratio can reach 10 to 30 times. Furthermore, the energy consumption is low, the emission is zero, and the operation is simple during the production process; large-scale continuous production can be achieved, the technology controllability is high, and the product quality is stable.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com