Special husking and drying technology for oil tea fruits

A technology of camellia oleifera fruit and process, applied in the project field, can solve the problems of unsuitable large-scale production, long operation time, low processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

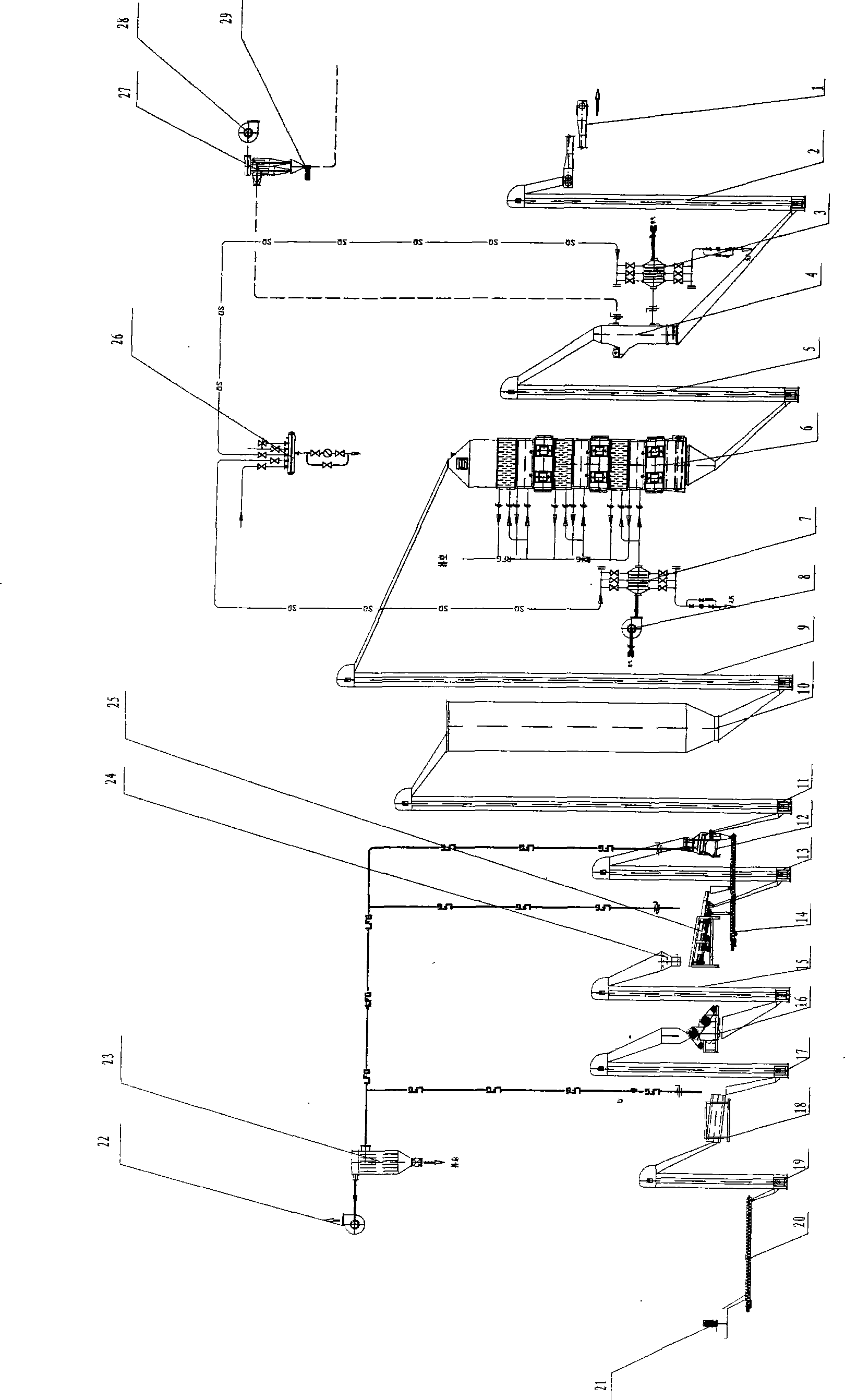

[0007] The specific technological process involved in this project: Camellia oleifera fruit enters the feeder 21, and is transported to the No. 2 screw conveyor 20 at a constant flow rate; quantitatively transported to the No. 8 hoist 19; and is transported to the cylinder cleaning screen through the No. 8 hoist 19 18 for primary cleaning of coarse sundries. The green camellia oleifera after one-time cleaning is transported to the two-stage tea fruit peeling machine 16 through the No. 7 hoist 17 to peel off the camellia oleifera skin; Hopper 24. Camellia oleifera seed and tea husk mixture are evenly dispersed from the sub-hopper 24, and are transported to the multi-stage separation sieve 25 for multi-stage separation; the tea seed mixture with a small amount of tea husk is transported to the shell seed separator 12 through the No. 5 elevator 13 Carry out shell seed and separate again. The tea husks separated from the multi-stage separating sieve 25 and the fine particles and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com