Patents

Literature

51 results about "Seed separator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A seed separator is a structure found in the follicles of some Proteaceae. These follicles typically contain two seeds, with a seed separator between them. The seed separator is nothing but a little chip of wood, but in some cases it serves an important function: in serotinous species, the follicles open only in response to fire, but the seed separator remains in position, thus preventing the seeds from falling out immediately, onto burnt or burning ground. Some separators loosen and fall out once they have cooled, thus ensuring that the seeds are released only after the fire has passed; others loosen and fall only after they have been moistened, thus ensuring that the seeds are released at the first rain after fire. Still others function as levers, recurving when moist and straightening when dry, and thus gradually levering the seeds out of the follicle in the course of a wet-dry cycle. This last case also occurs in non-serotinous species: follicles may open spontaneously, but seed release is delayed until the next rain.

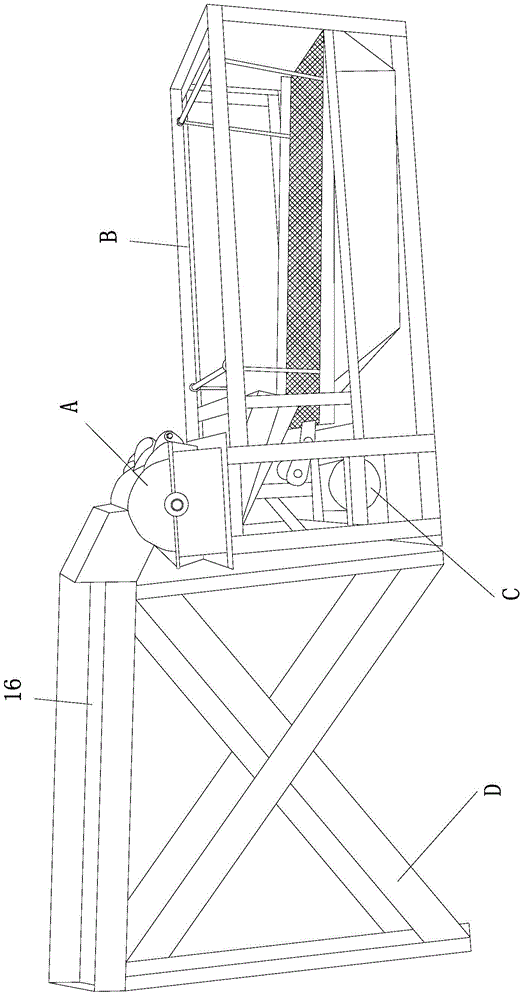

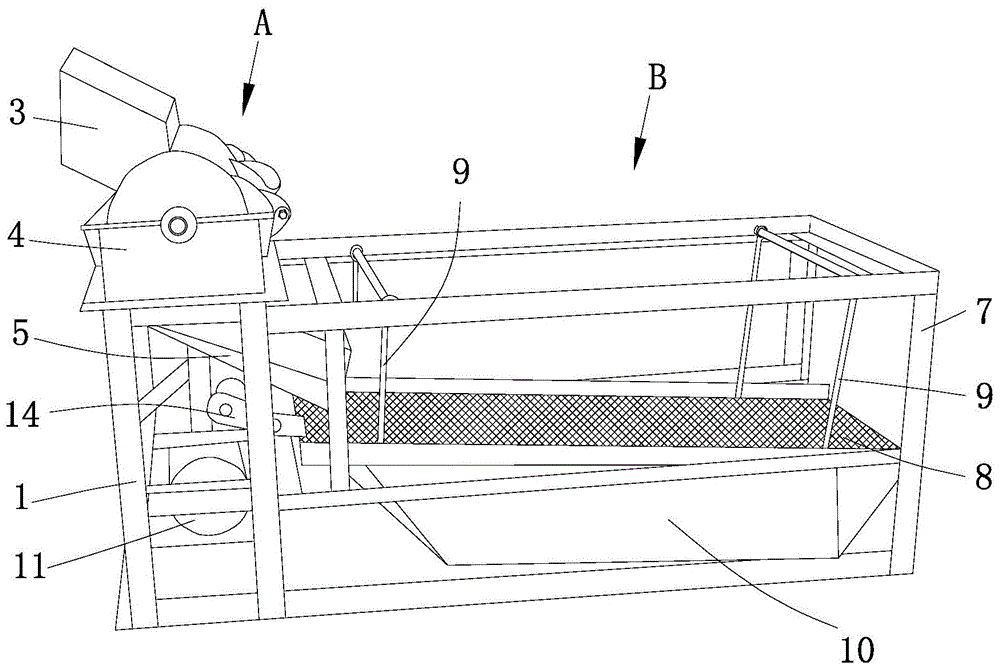

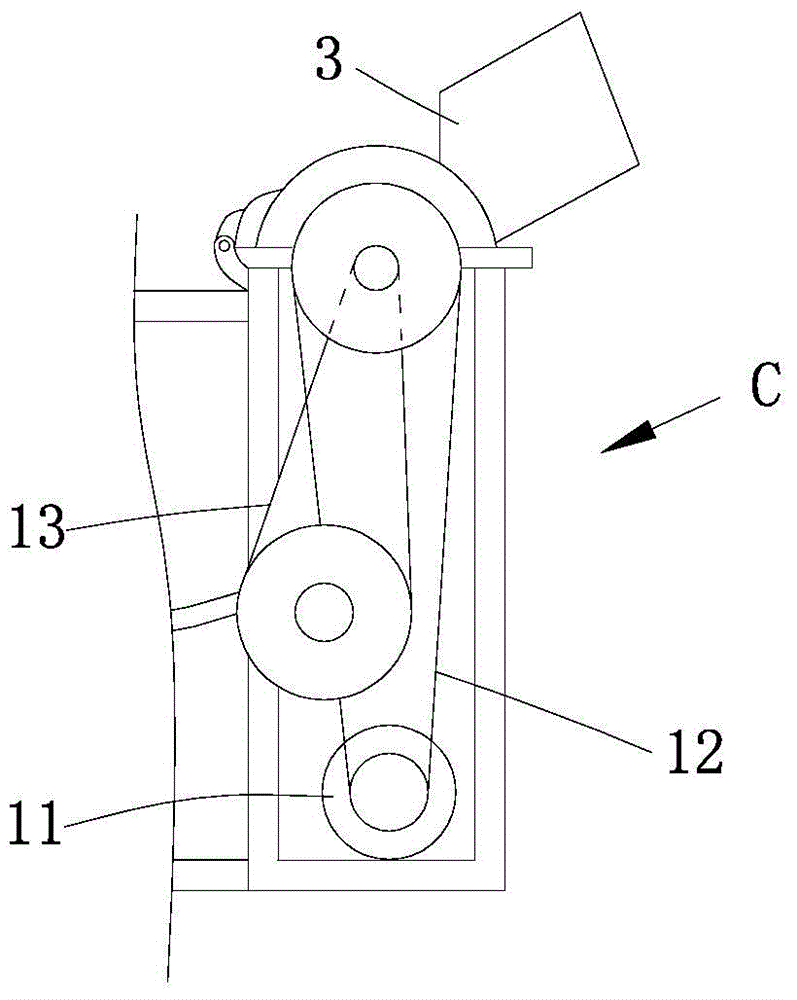

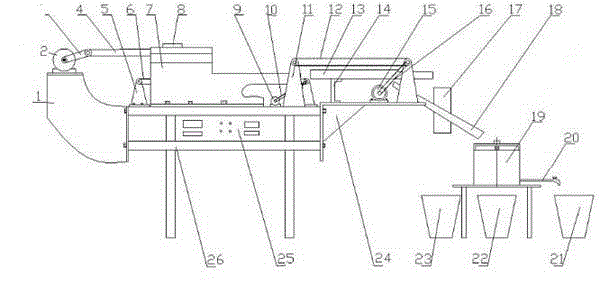

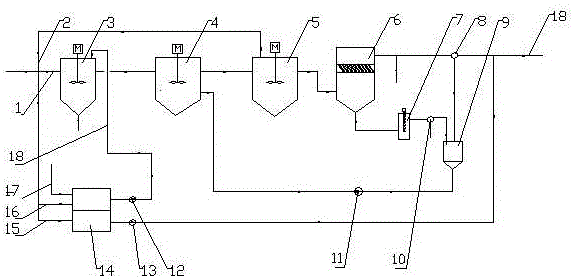

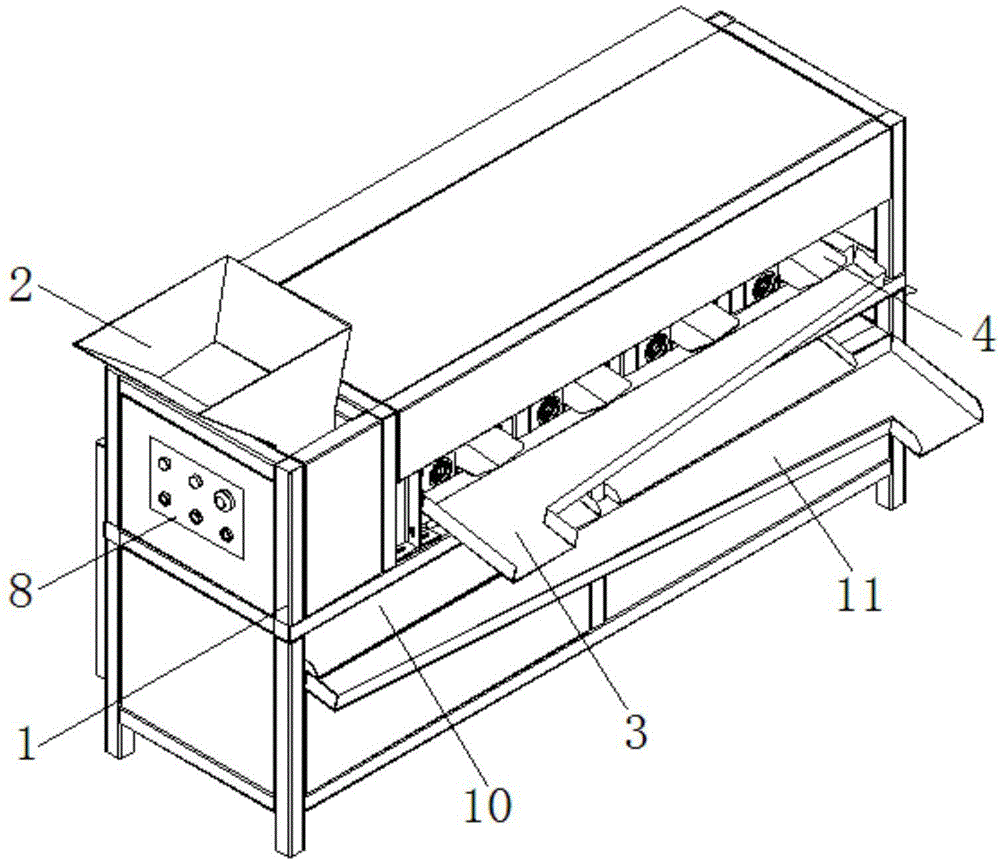

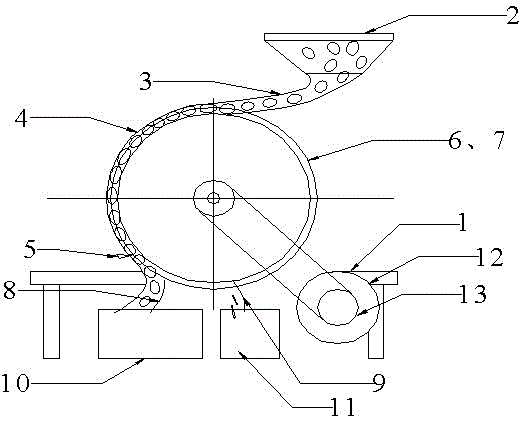

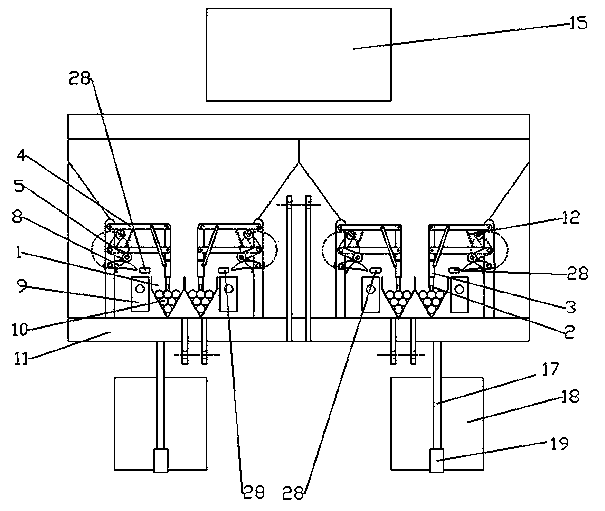

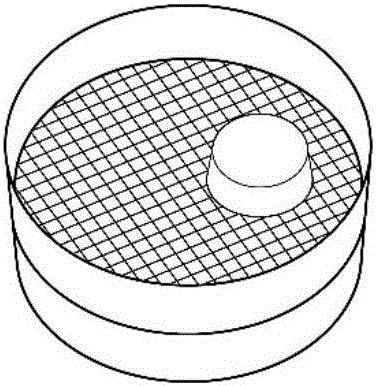

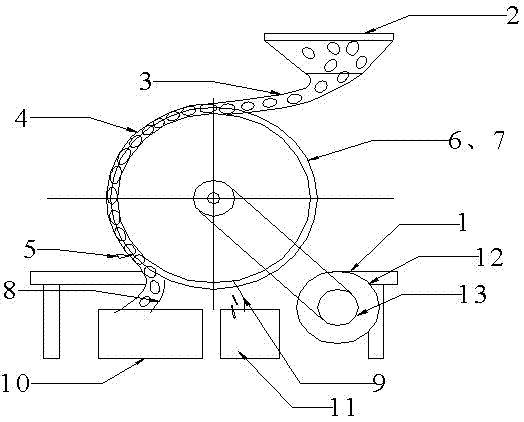

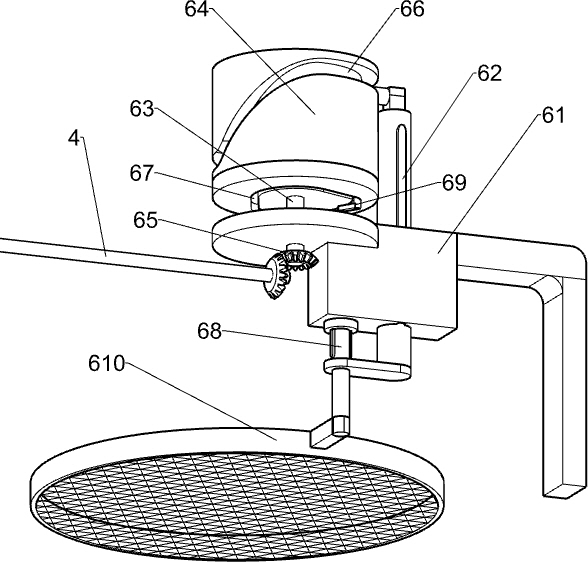

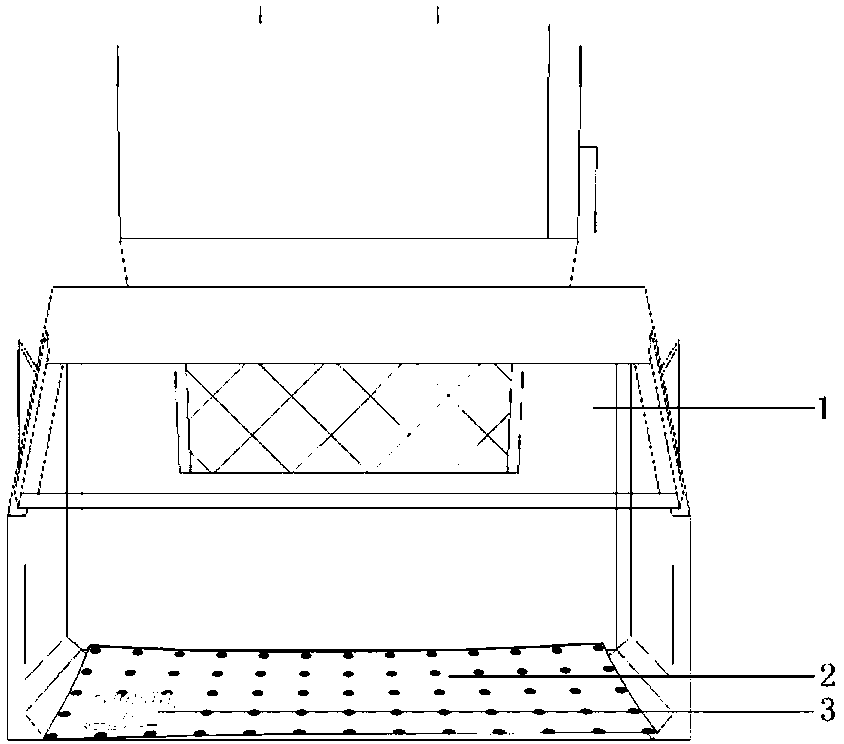

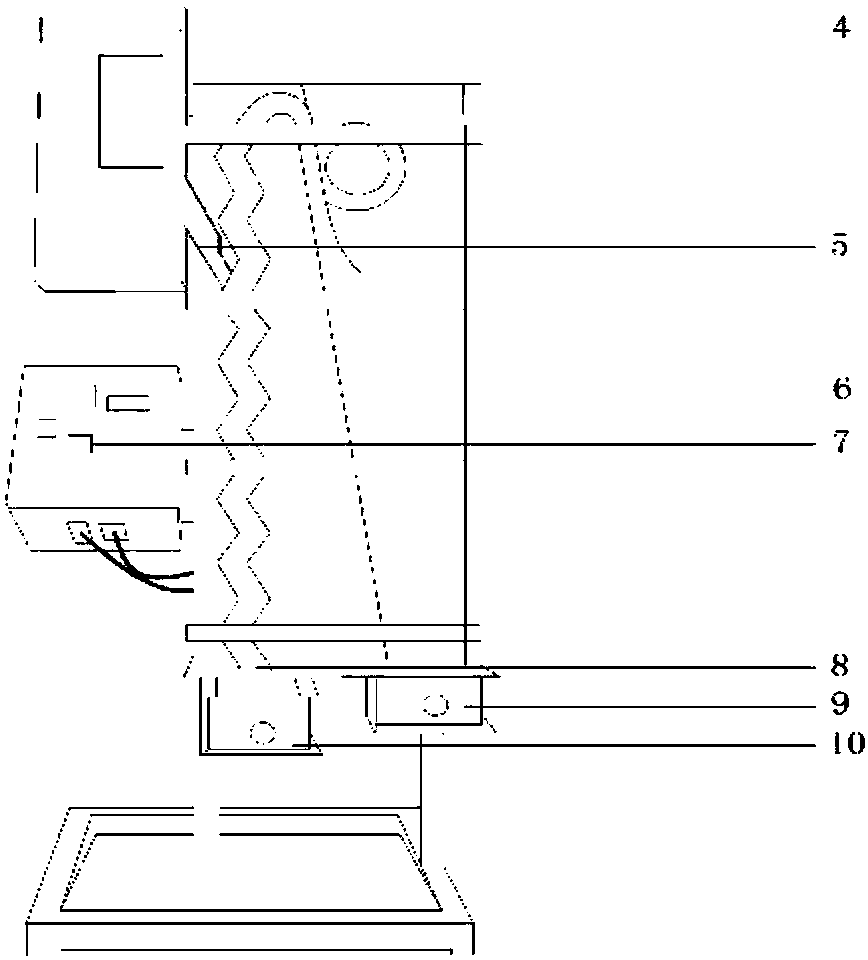

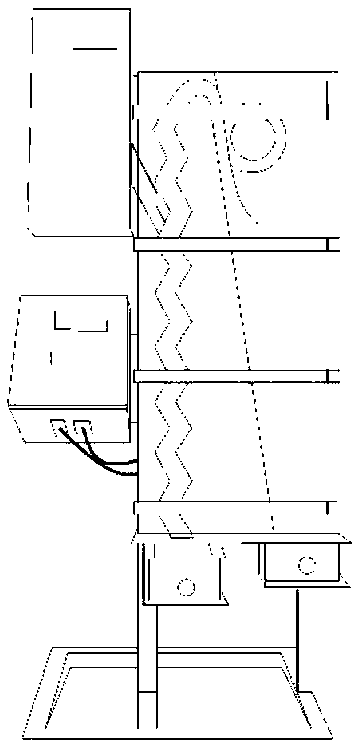

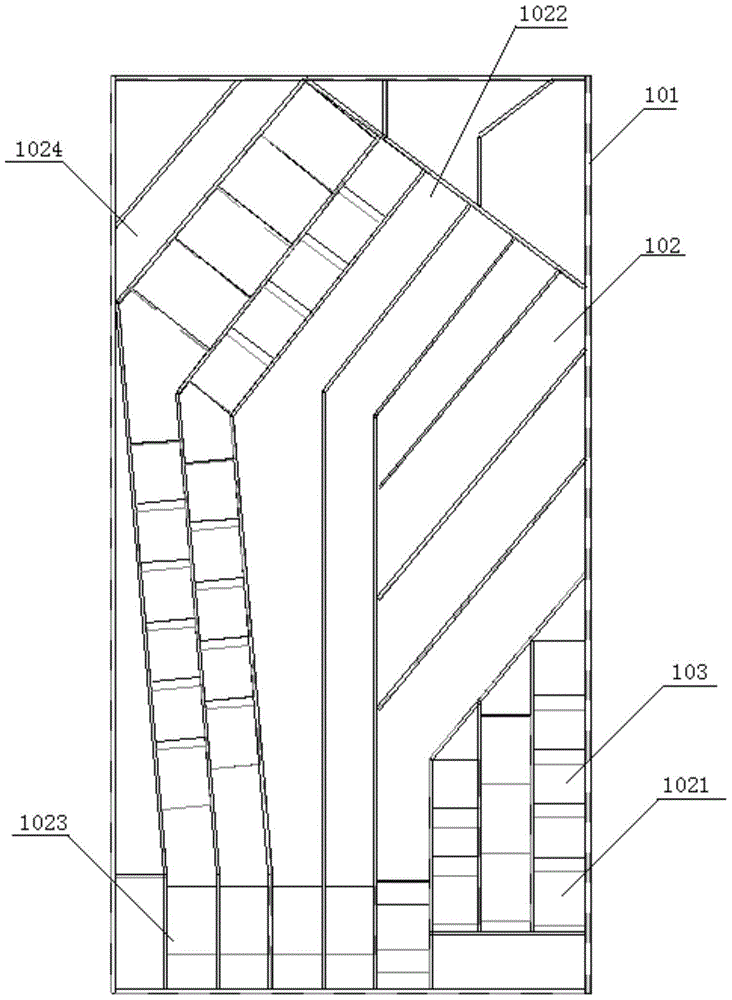

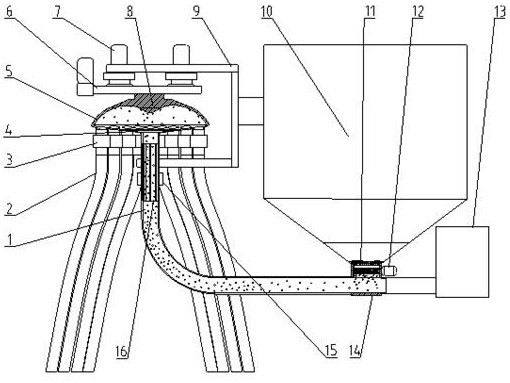

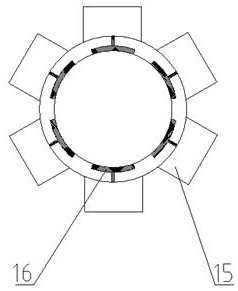

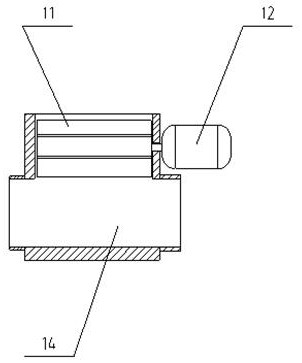

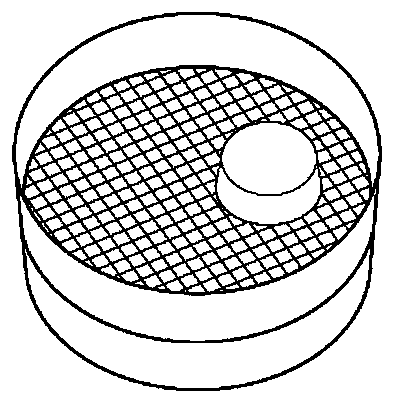

Chilli hull and seed separator

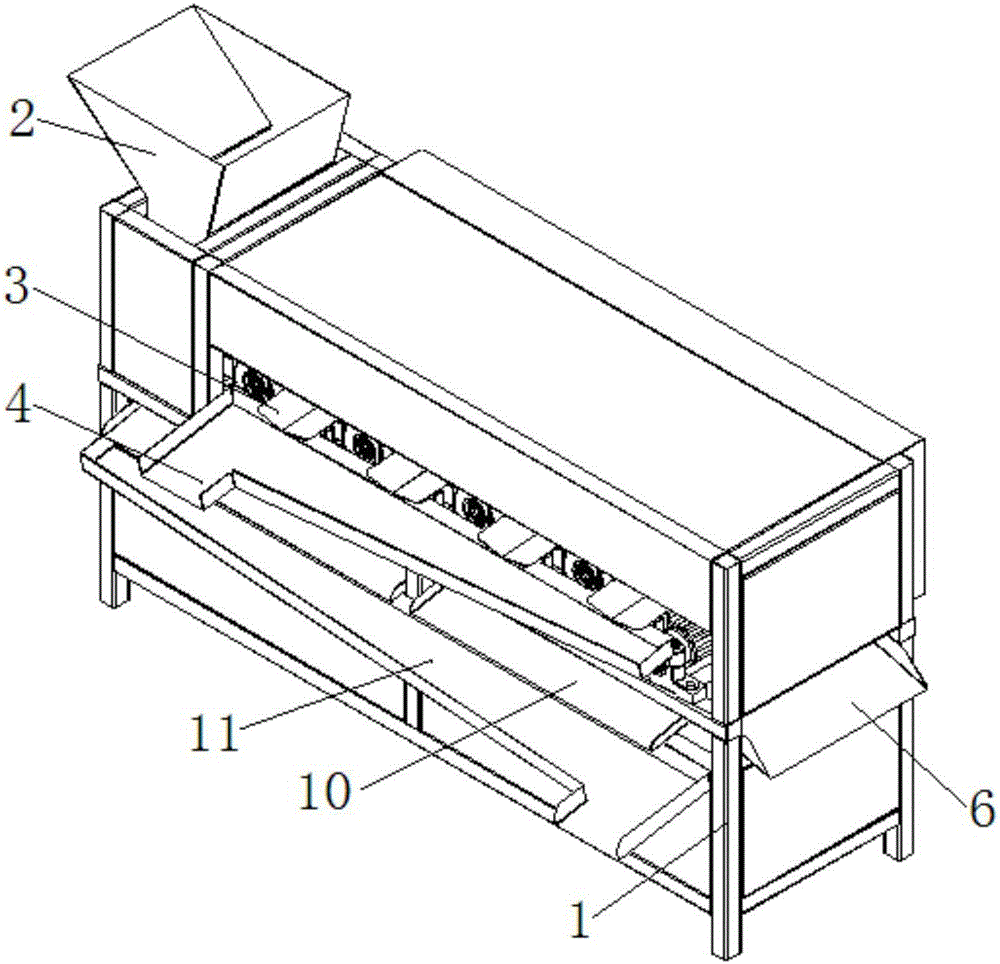

The invention discloses a chilli hull and seed separator which comprises a feeding mechanism, a crushing mechanism, a distributing mechanism and a drive mechanism, wherein the crushing mechanism comprises a first support frame, a mixing and crushing wheel, a feeding hopper, a crushing bin, a discharging hopper and crushing gratings, the mixing and crushing wheel comprises a rotating shaft and a crushing member, the crushing gratings are laid along the arc shape of the bottom of the crushing bin at equal intervals; the distributing mechanism comprises a second support frame, a screen, a screen suspending rod and a guide dustpan; the drive mechanism comprises a drive motor, a first belt wheel, a second belt wheel and a crankshaft connecting rod system; the drive motor drives the mixing and crushing wheel by means of the first belt wheel to rotate, and a rotating shaft of the mixing and crushing wheel drives a crankshaft of the crankshaft connecting rod system by means of the second belt wheel to rotate so as to drive the screen to swing forwards and backwards swing and simultaneously vibrate slightly up and down. The chilli hull and seed separator is simple in structure, novel in design, skilled in design, and high in automation degree, and has two functions of crushing and separating; the production efficiency and the chilli seed quality are remarkably improved.

Owner:石柱土家族自治县辣椒研究中心

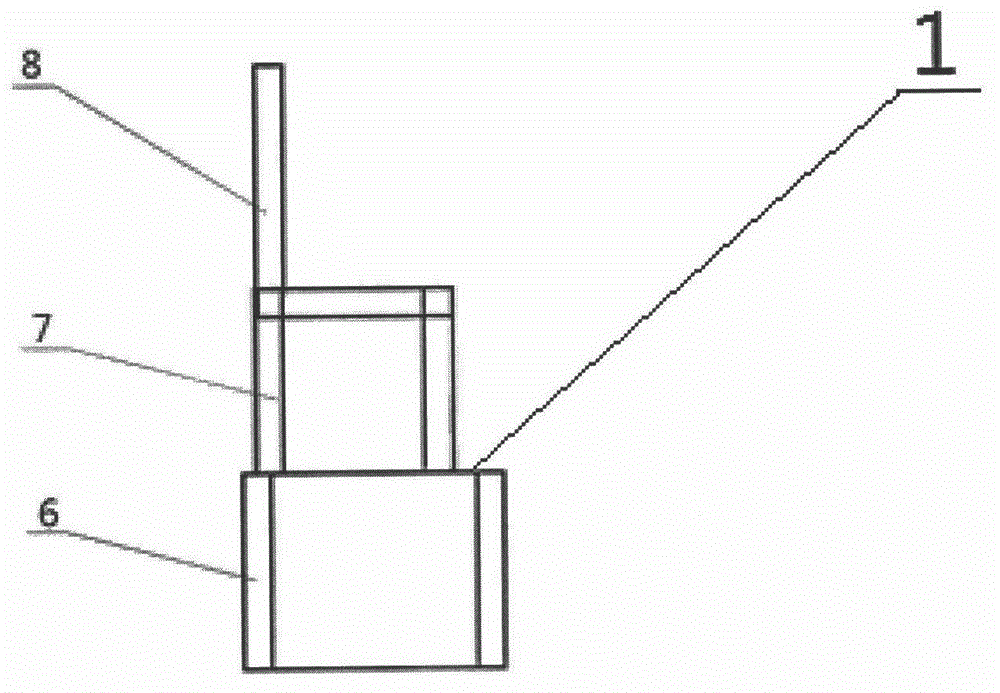

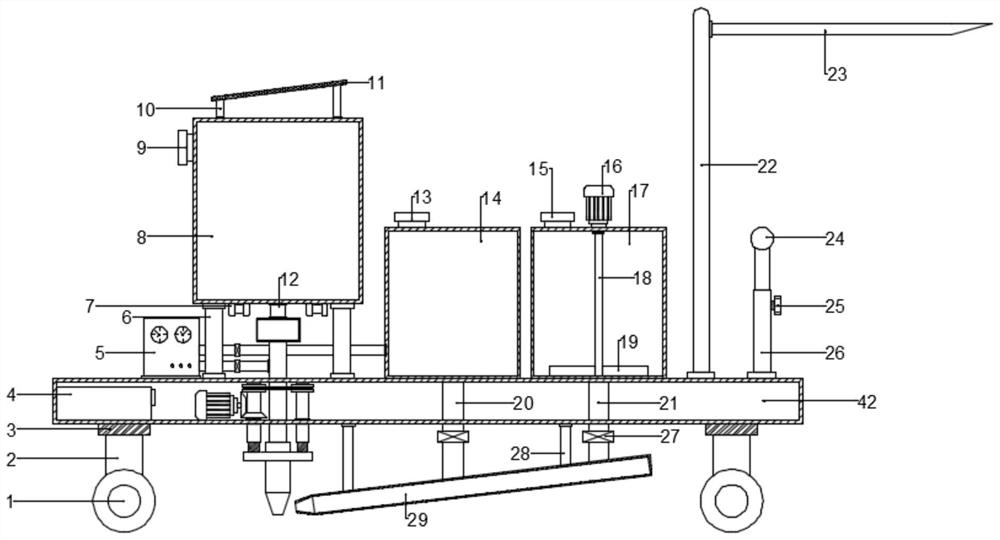

Hand push type seeder

InactiveCN105340423AImprove seeding efficiencyAvoid wastingPlantingFurrow making/coveringSeederEngineering

The invention provides a hand push type seeder. The seeder comprises a body and a supporting wheel, the supporting wheel is arranged at the lower end of the body, the front end of the body is provided with a drilling head, the drilling head is driven by a drilling cylinder arranged at the upper end of the drilling head to drill, a seeding tube is arranged beside the drilling head, the body is provided with a seed storage barrel, and the seeding tube is connected with the seed storage barrel. The drilling cylinder drives the drilling head to drill, and seeds are sowed in holes through the seeding tube, so artificial drilling and seeding are avoided, and the seeding efficiency of small fields is improved; a seed separator is arranged to control the quantity of seeds in every pit, so seed distribution non-uniformity caused by a plurality of seeds in one pit is prevented; and an extension cylinder is arranged, and drives the seeding tube to stretch into holes drilled by the drilling head in order to realize seeding, so wastes, caused by no entrance of the seeds to the pits, are prevented.

Owner:WUHU BOKE ELECTROMECHANICAL

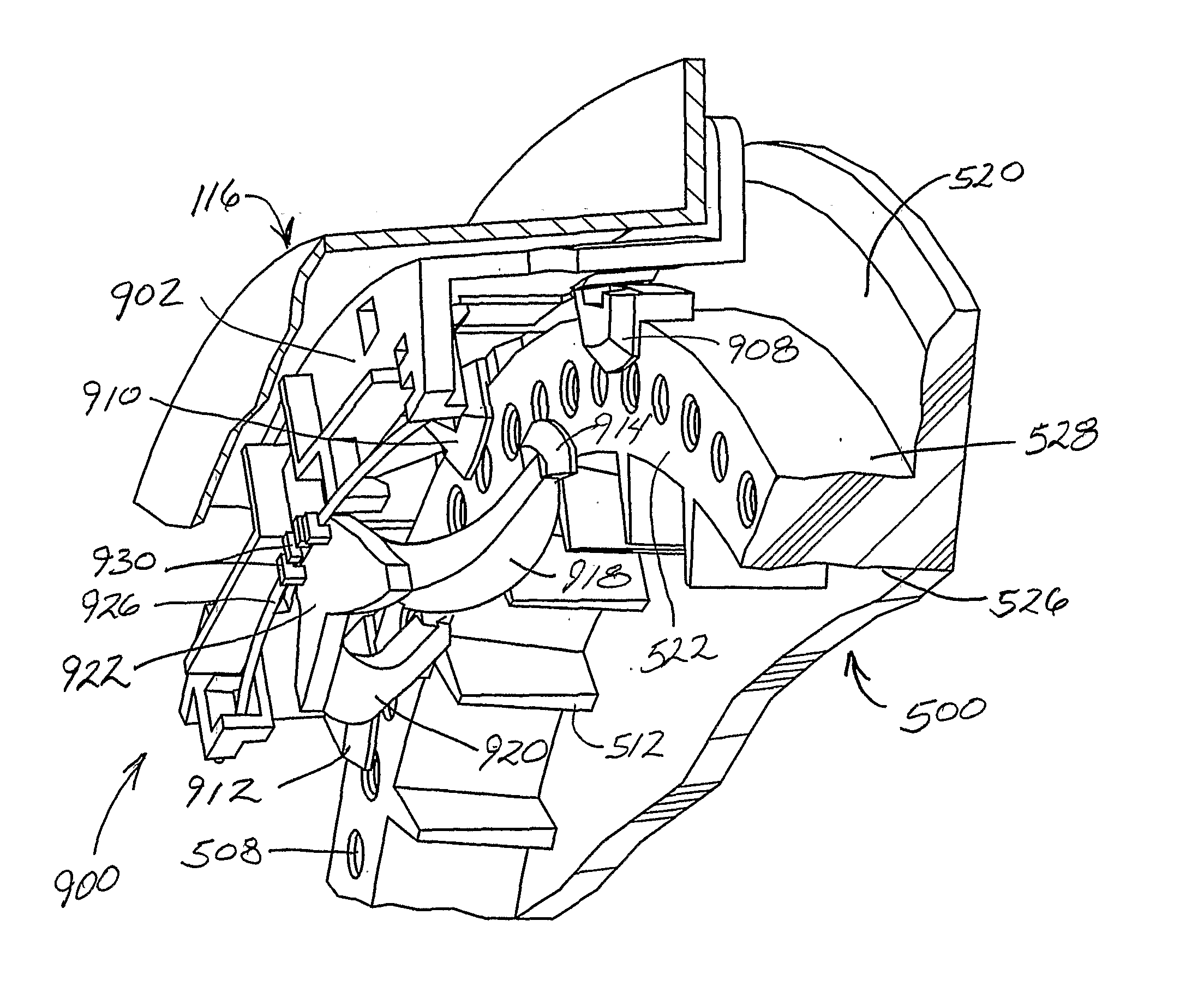

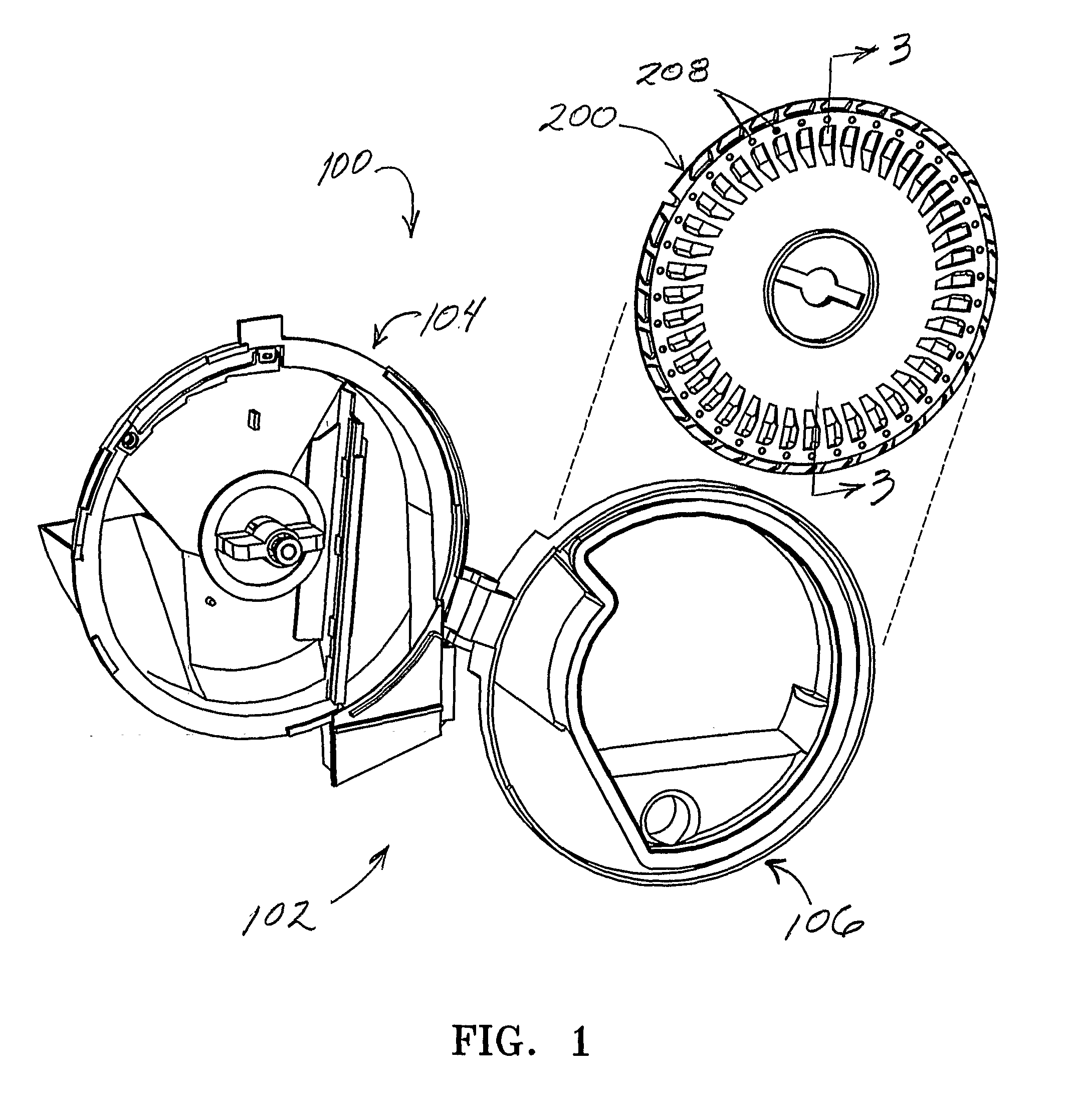

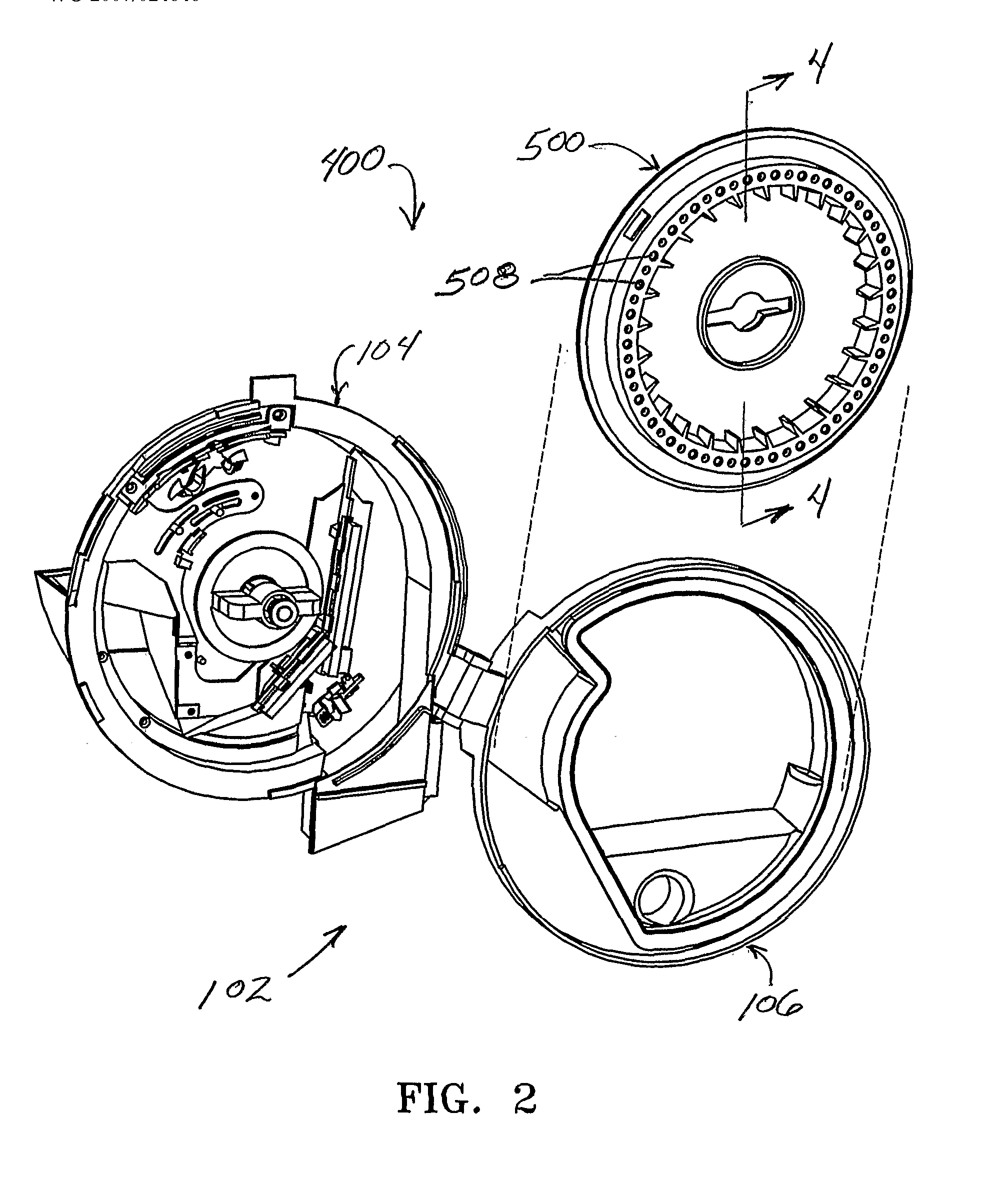

Seed Singulator

Owner:PRECISION PLANTING LLC

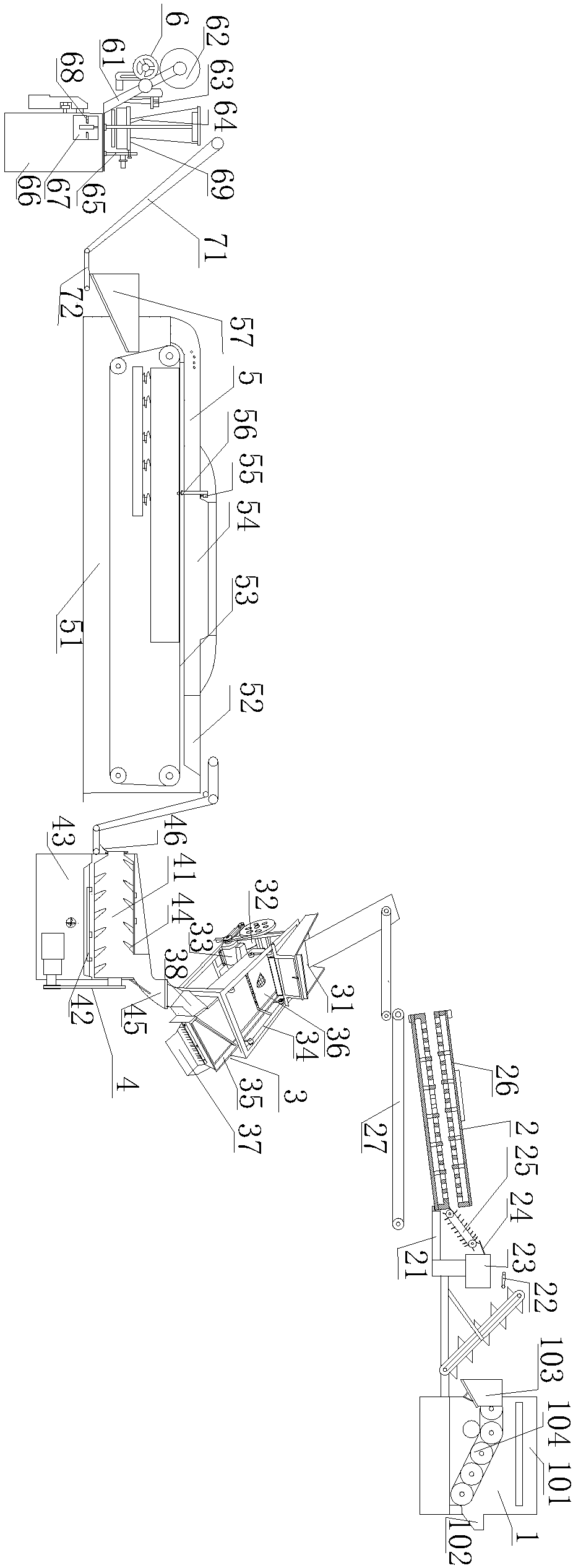

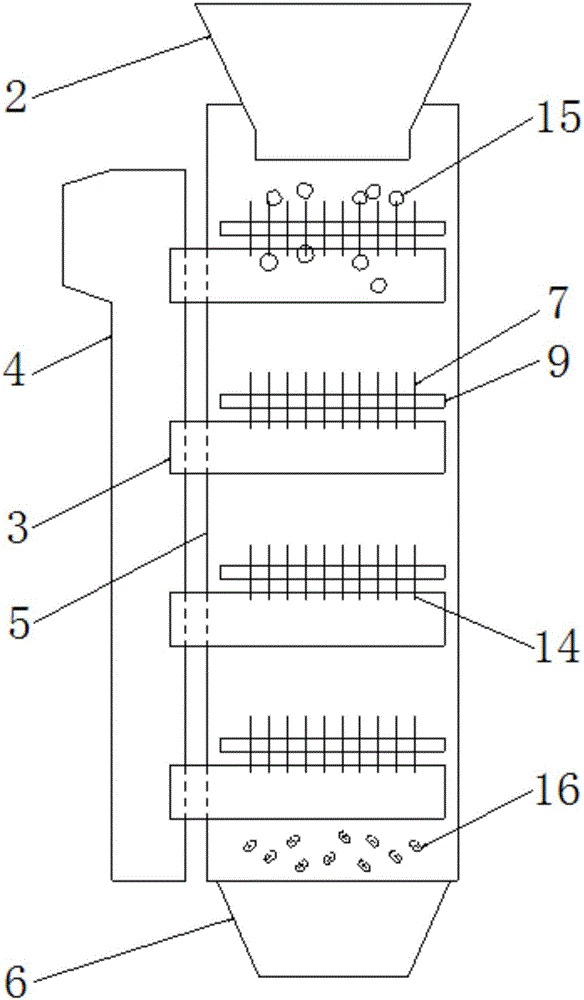

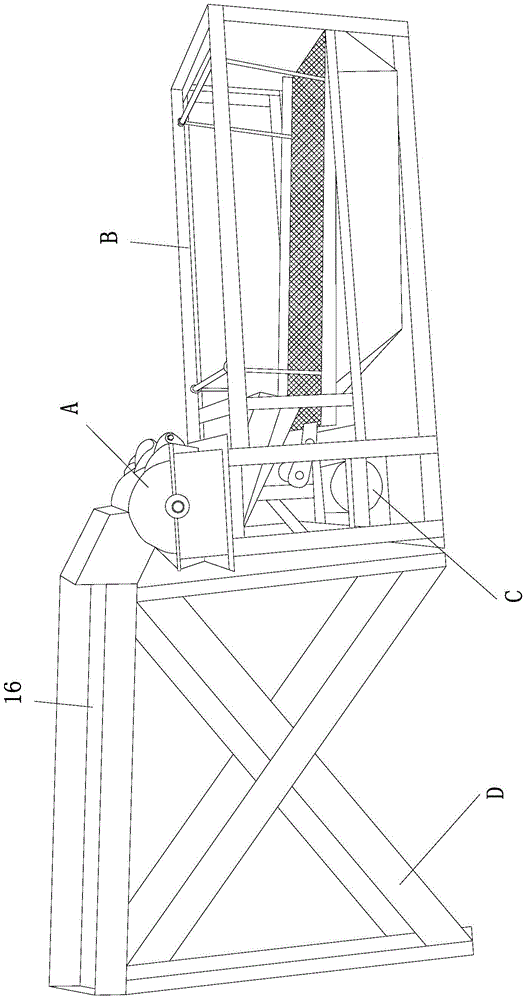

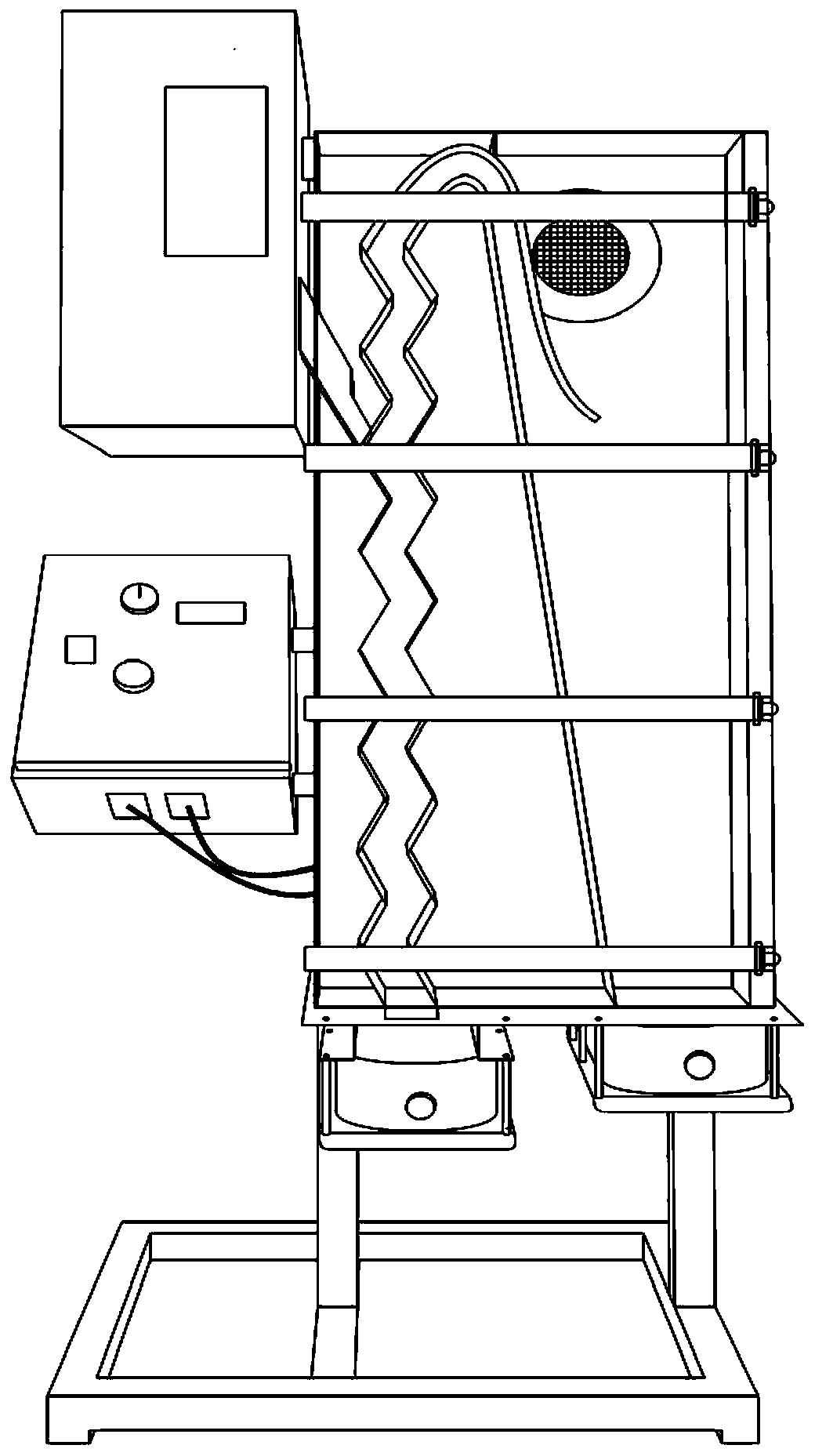

Processing production line for snake gourd fruit shells

InactiveCN107758018ARealize continuous processingLabor savingSievingGas current separationProduction lineSnake gourd

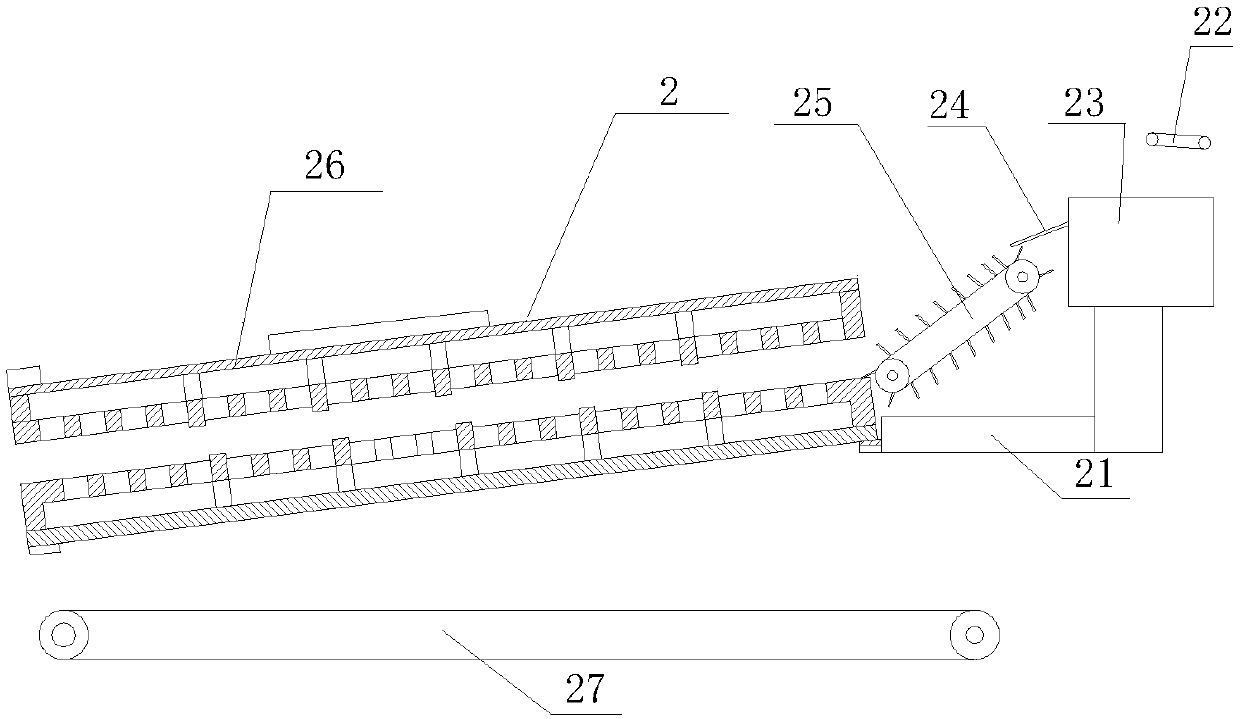

The invention provides a processing production line for snake gourd fruit shells. The processing production line comprises a snake gourd fruit cleaning machine, a snake gourd fruit shell and seed separator, a snake gourd fruit shell and seed picking machine, a food dryer, a snake gourd fruit shell shredder and a food vacuum packaging machine which are sequentially arranged and further comprises conveying mechanisms arranged between every two adjacent machines of the snake gourd fruit cleaning machine, the snake gourd fruit shell and seed separator, the snake gourd fruit shell and seed pickingmachine, the food dryer, the snake gourd fruit shell shredder and the food vacuum packaging machine. The conveying mechanisms comprise lifting devices and horizontal conveying devices, the lifting devices are obliquely-arranged conveyor belts, and the horizontal conveying devices are horizontal conveyor belts. All the machines are electrically connected with a control cabinet. Picked snake gourd fruits can be continuously processed so as to obtain the completely-packaged snake gourd fruit shells, a great deal of labor force is saved, and automatic operation is facilitated.

Owner:QIANSHAN YOUYU TRICHOSANTHES KIRILOWII MAXIM DEV CO LTD

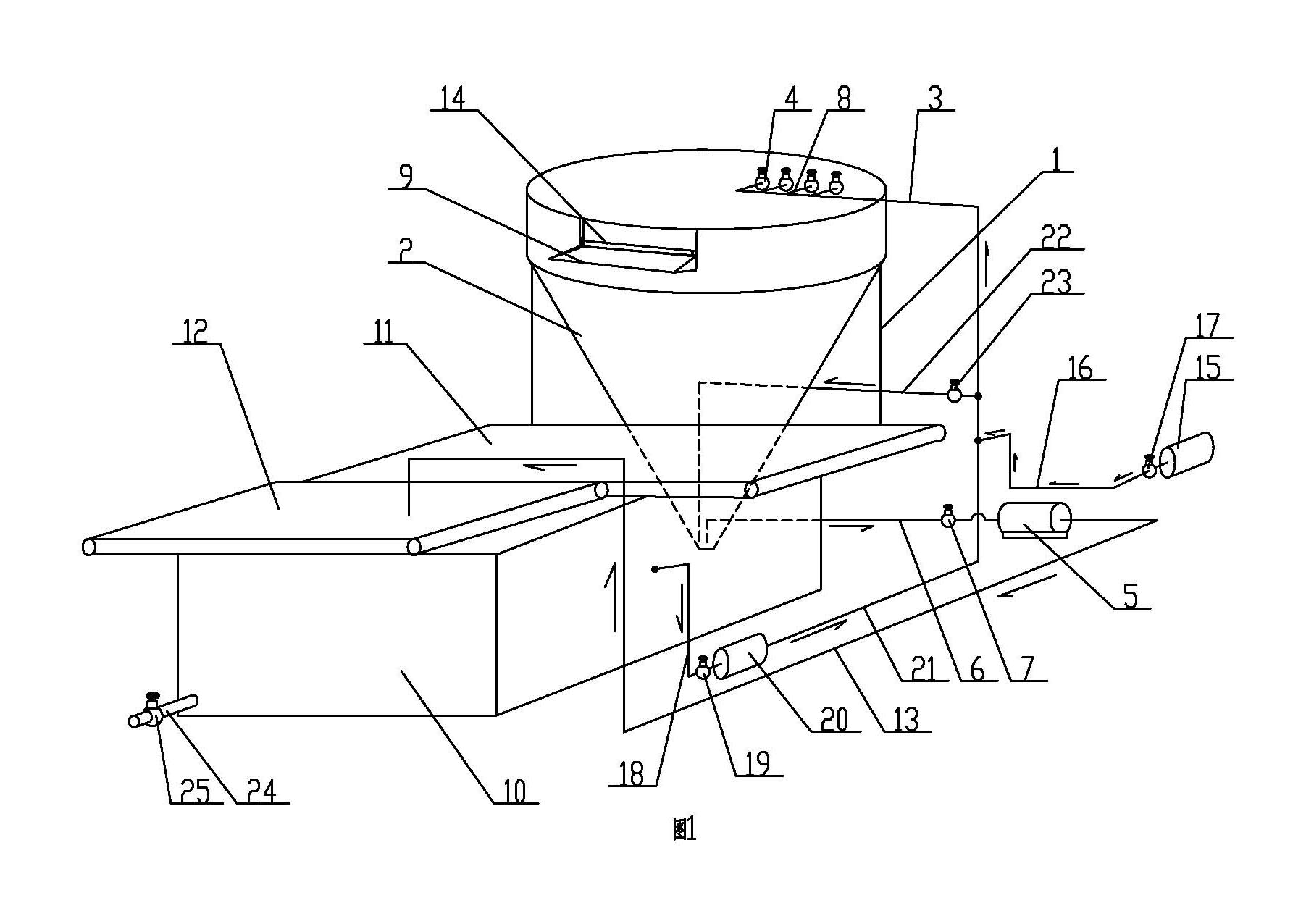

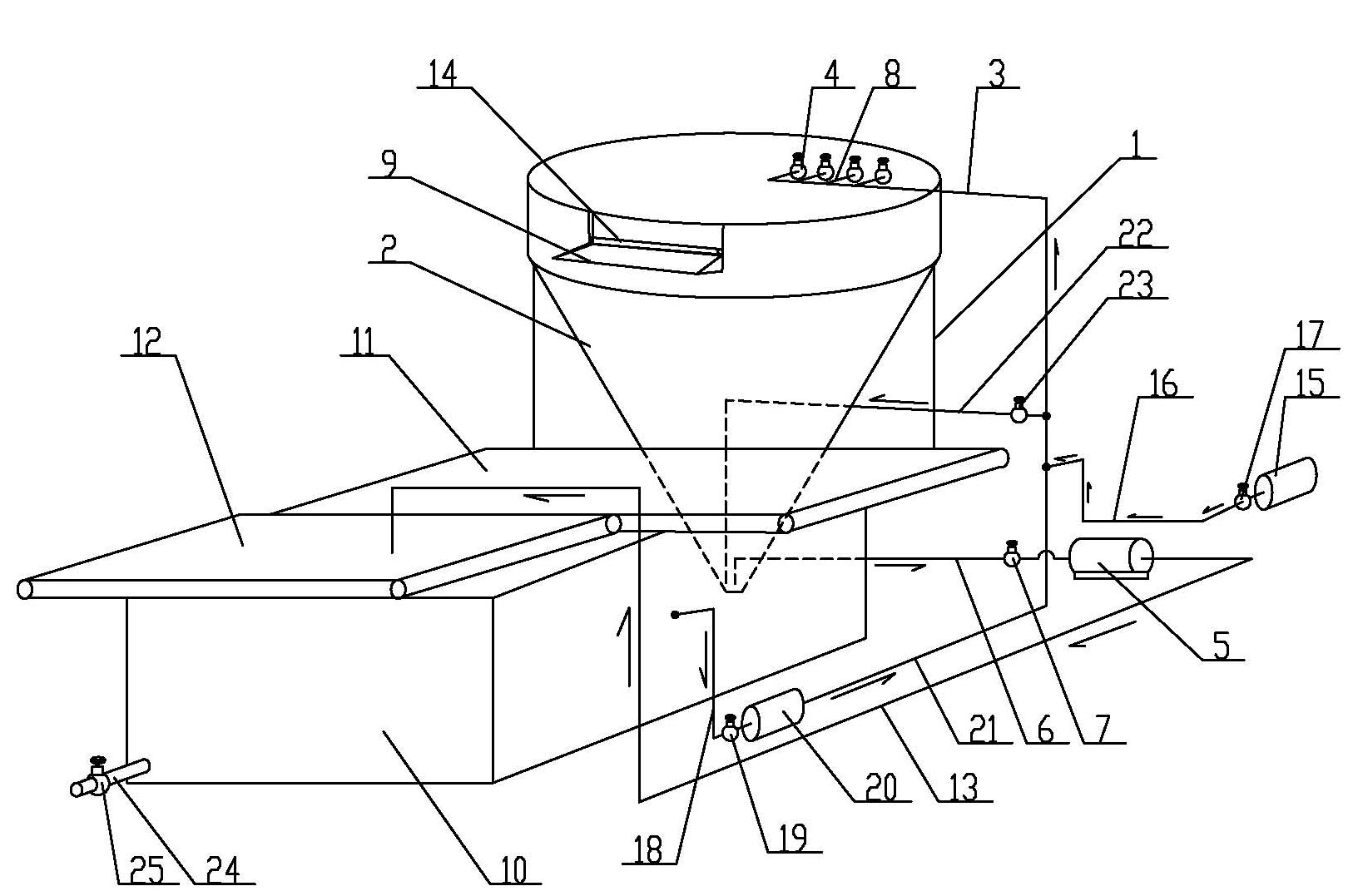

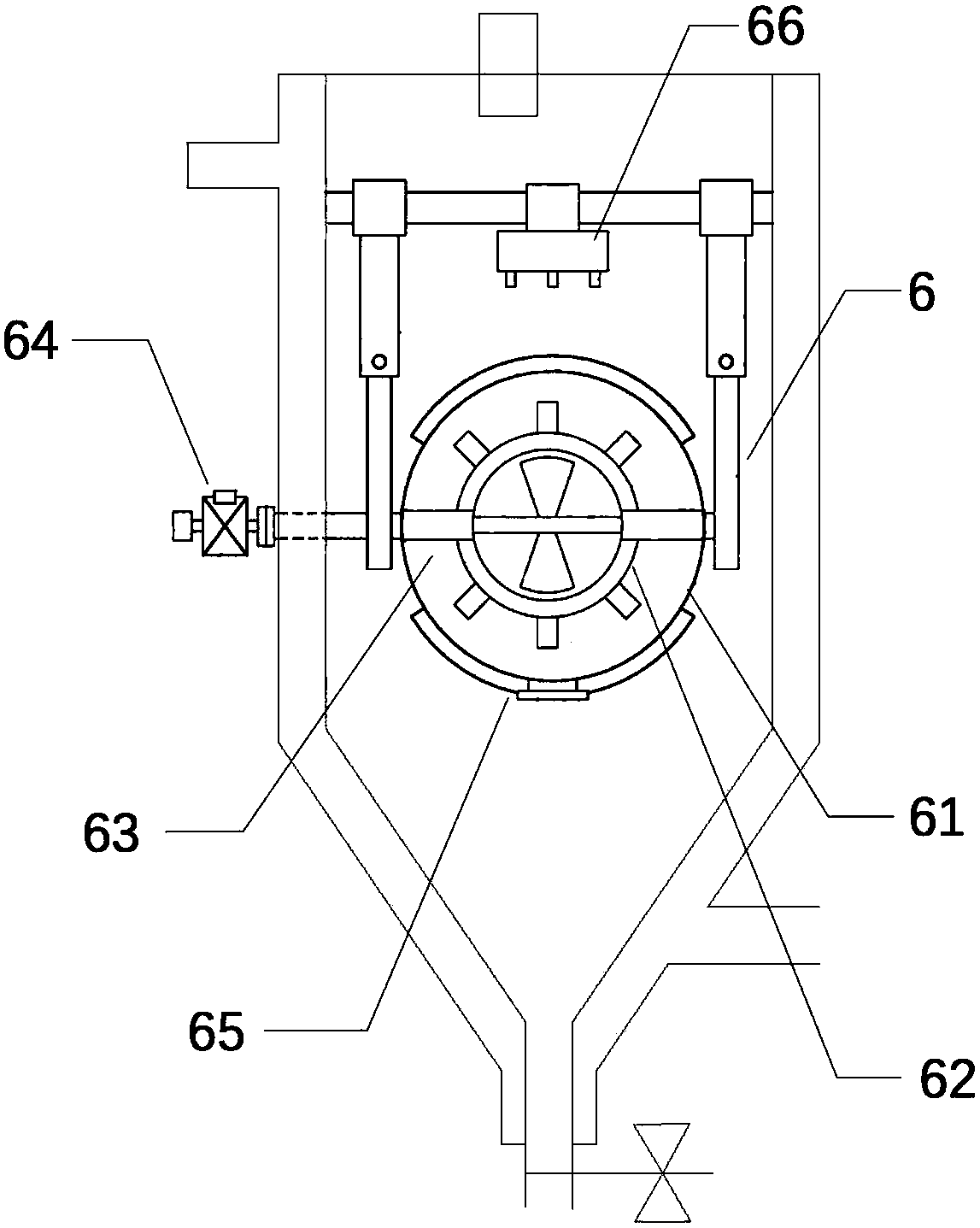

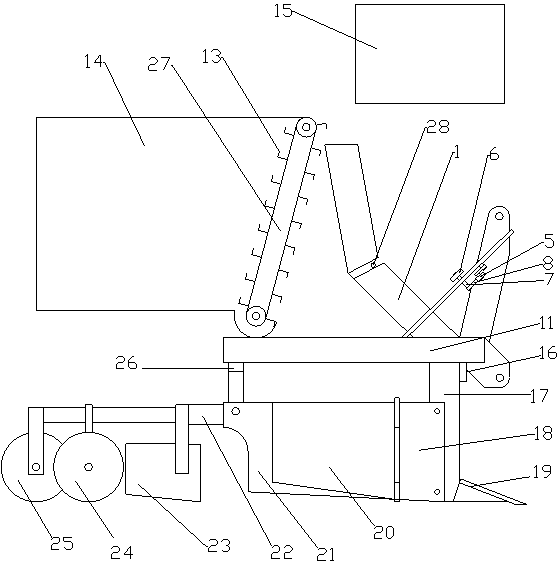

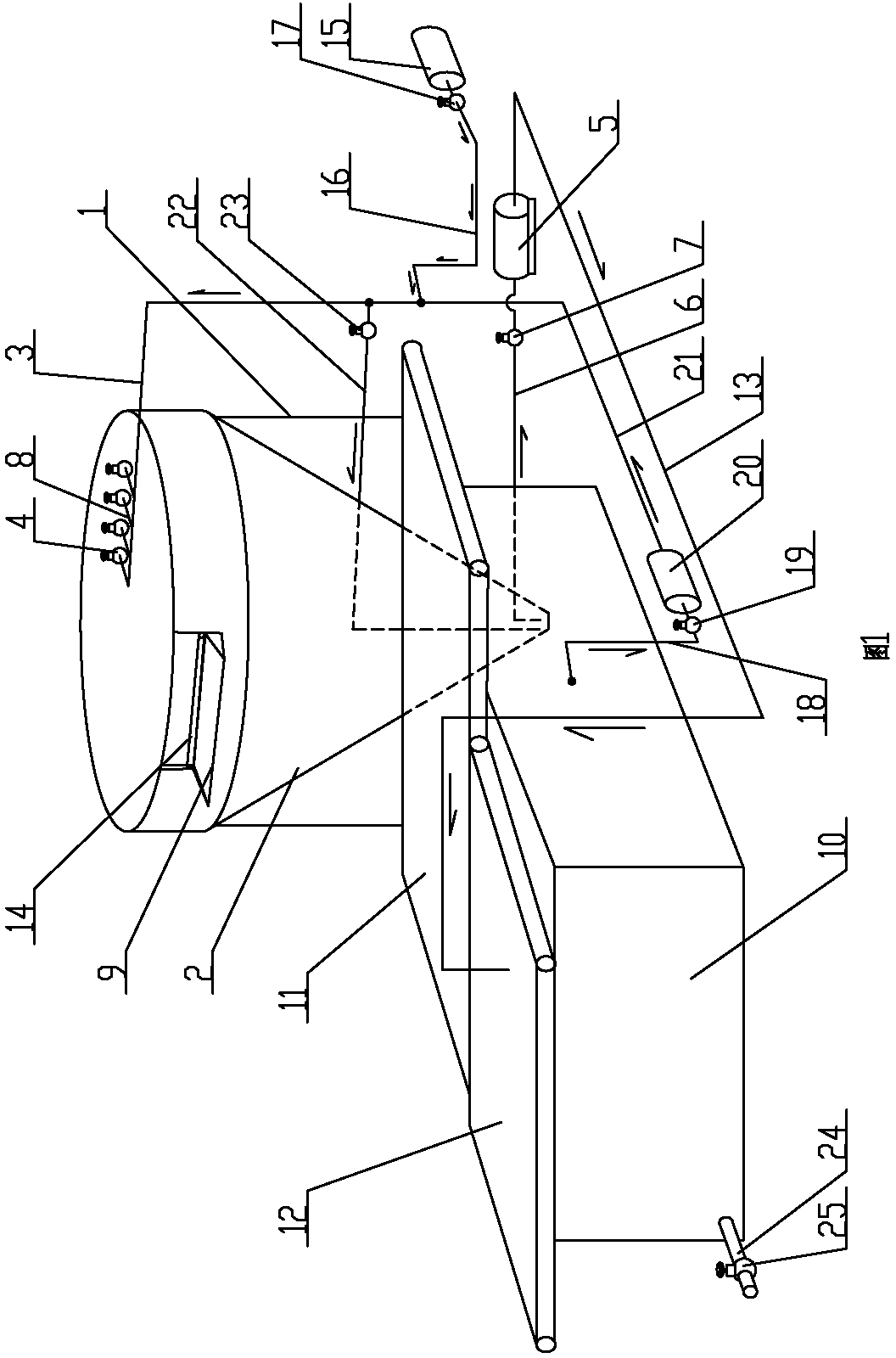

Automatic rind, pulp and seed separator for stauntonia latifolia

The invention provides an automatic rind, pulp and seed separator for stauntonia latifolia. The separator is characterized by comprising a crank sliding block type vibration screening mechanism, a feeding conveying mechanism, a pushing belt, a driving mechanism of the pushing belt, a cutter device, a rind and pulp separating mechanism, a pulp and seed separating mechanism and a control device; the stauntonia latifolia which is screened by vibrating is fed to a cutter through a directional sliding groove, the rind is cut off and expanded under the effect of the pushing belt as well as the extruding effect of the cutter which is of a special structural form; the pulp adhered to the rind is separated from the rind under the effect of the rind and pulp separating mechanism; water is added to the pulp and seed separator, the pulp and the seeds are processed into pulp size and seeds through an agitating crushing rotating mechanism, the pulp size flows into a size collecting barrel, and the seeds and little pulp size remained at the bottom part of an inner barrel flow into a seed collecting barrel, so as to achieve the pulp and seed separation. Compared with the traditional manual separating mode, the automatic rind, pulp and seed separator for stauntonia latifolia has the characteristics of being complete to separate, free of damage on seeds, high in efficiency, simple and convenient to operate, and high in automation degree.

Owner:JIUJIANG UNIVERSITY

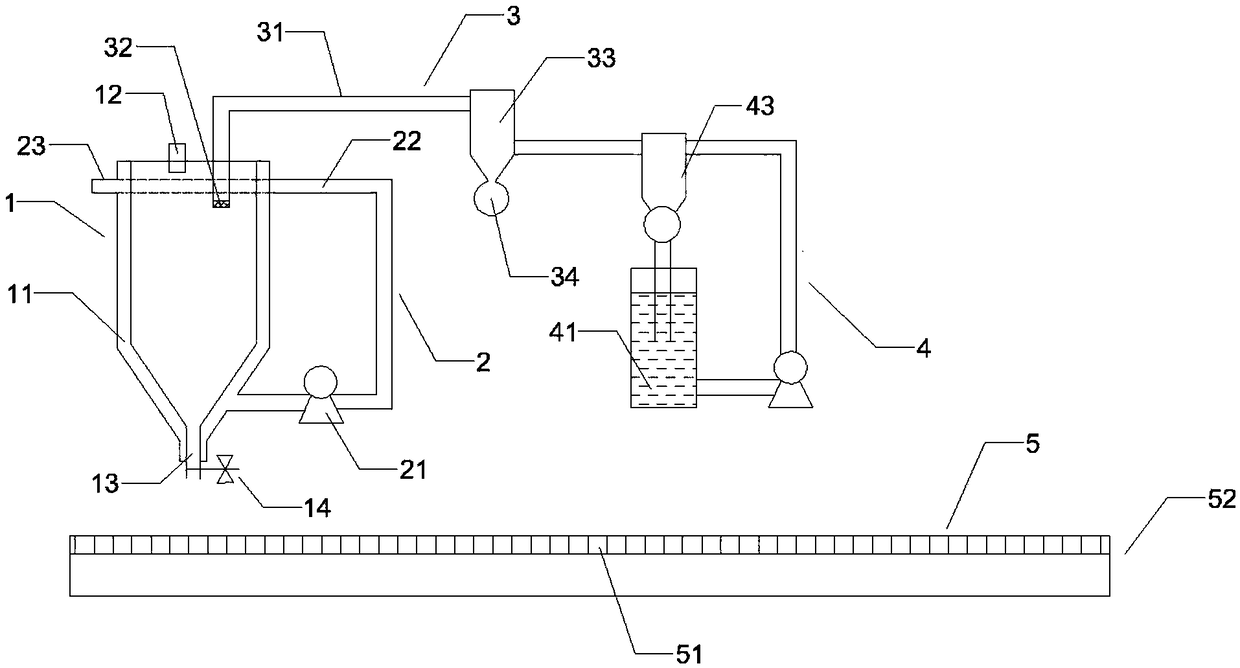

System and method for treating industrial water by induced crystallization process

InactiveCN106746061AReduce sewageAvoid breedingSpecific water treatment objectivesWater/sewage treatment with mechanical oscillationsDolomiteSeed crystal

The invention provides a system and method for treating industrial water by an induced crystallization process. Principally, the PH value of raw water is increased such that CaCO3 and MgCO3 in the water are saturated, and the saturated CaCO3 and MgCO3 particles are mixed with other fouling in a seed crystal crystallizer, wherein the seed crystal is a material capable of inducing crystallization of CaCO3 and MgCO3, such as iron powder, aluminum oxide, magnesium oxide, dolomite, calcium carbonate, or the like. Then, the CaCO3, MgCO3 and other fouling can crystallize on the crystal seed and grow gradually. The crystal seed that adsorbs the CaCO3, MgCO3 and other fouling settles in an inclined tube or inclined plate sedimentation tank, and the crystal seed is separated from the CaCO3, MgCO3 and other fouling carried by the crystal seed settling at the bottom of the inclined tube or inclined plate sedimentation tank by a crystal seed separator, and then recycled to the crystallizer.

Owner:山东深信节能环保科技有限公司

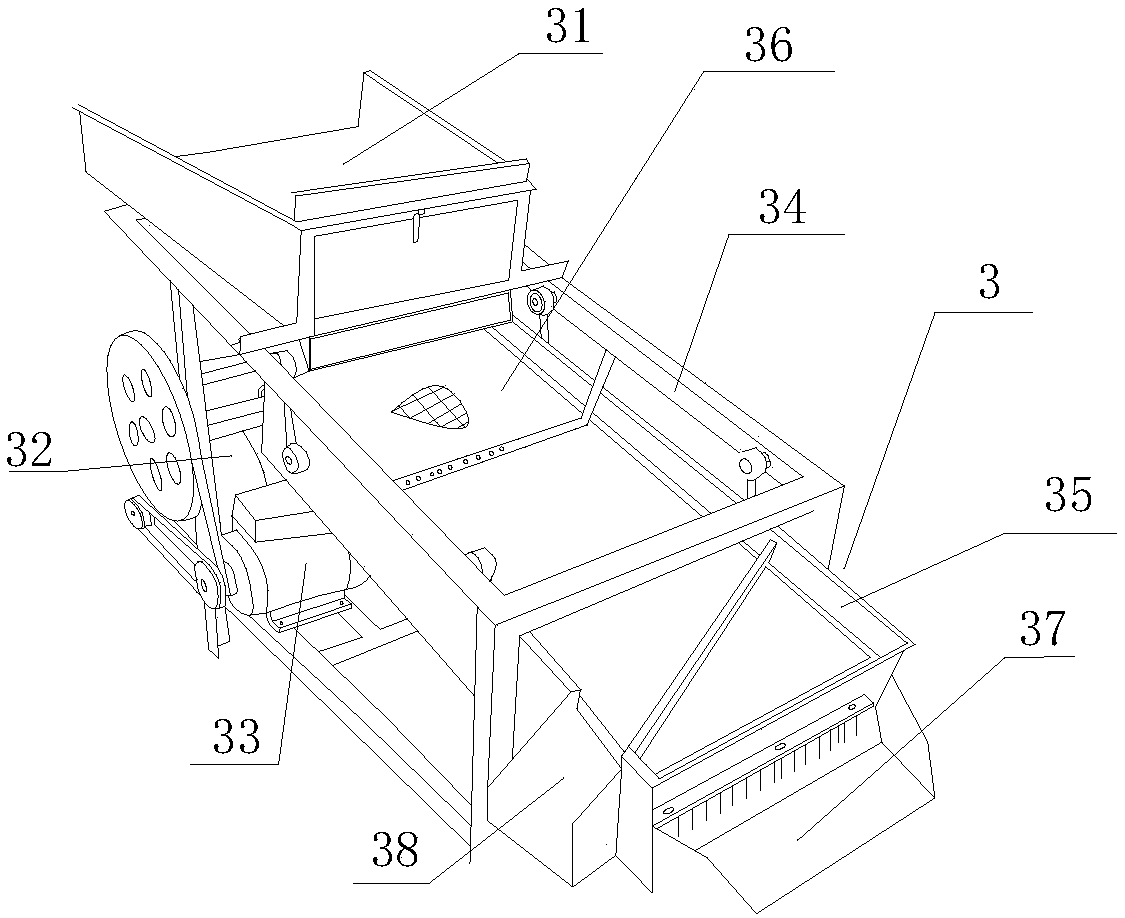

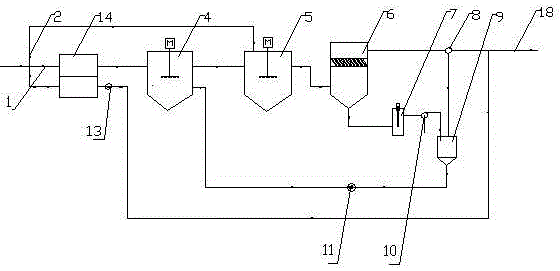

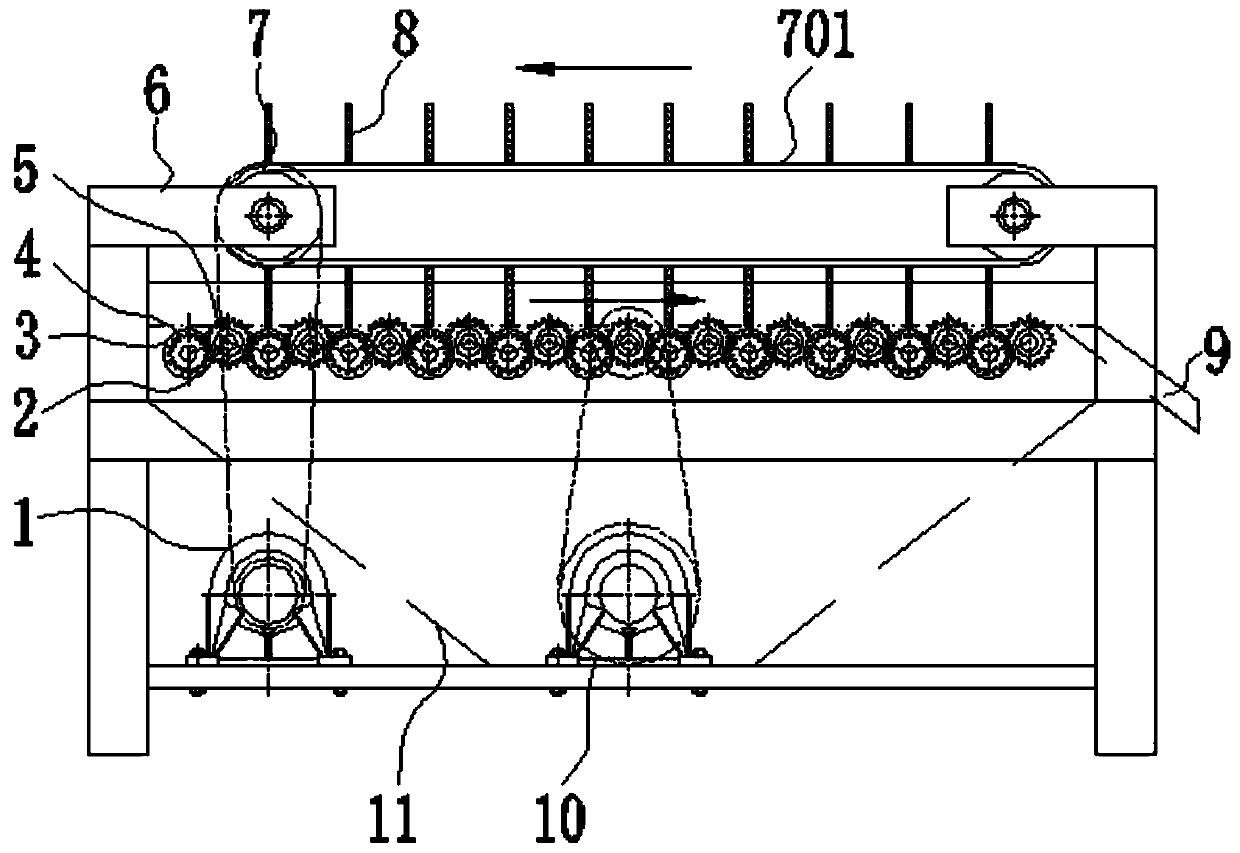

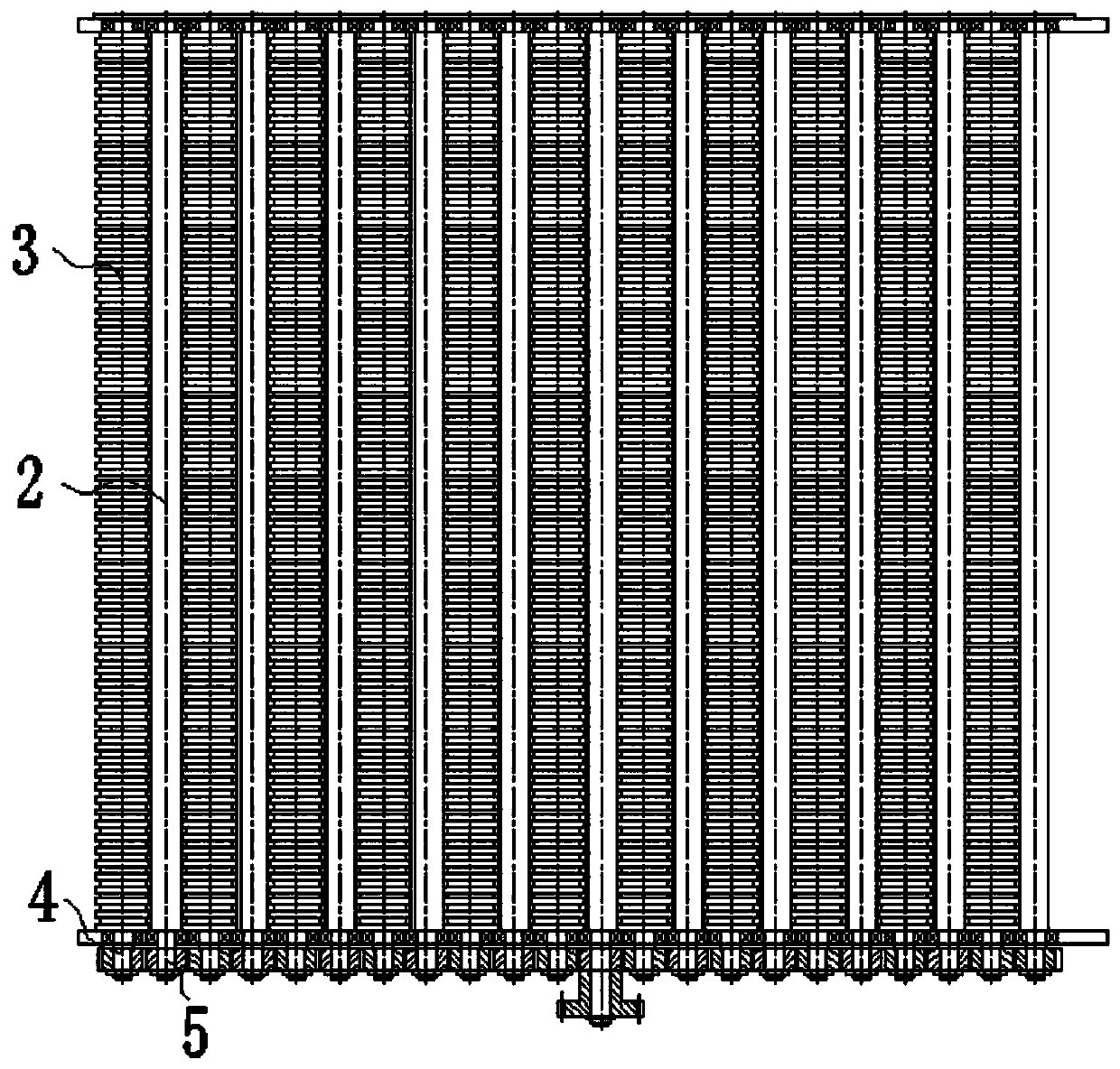

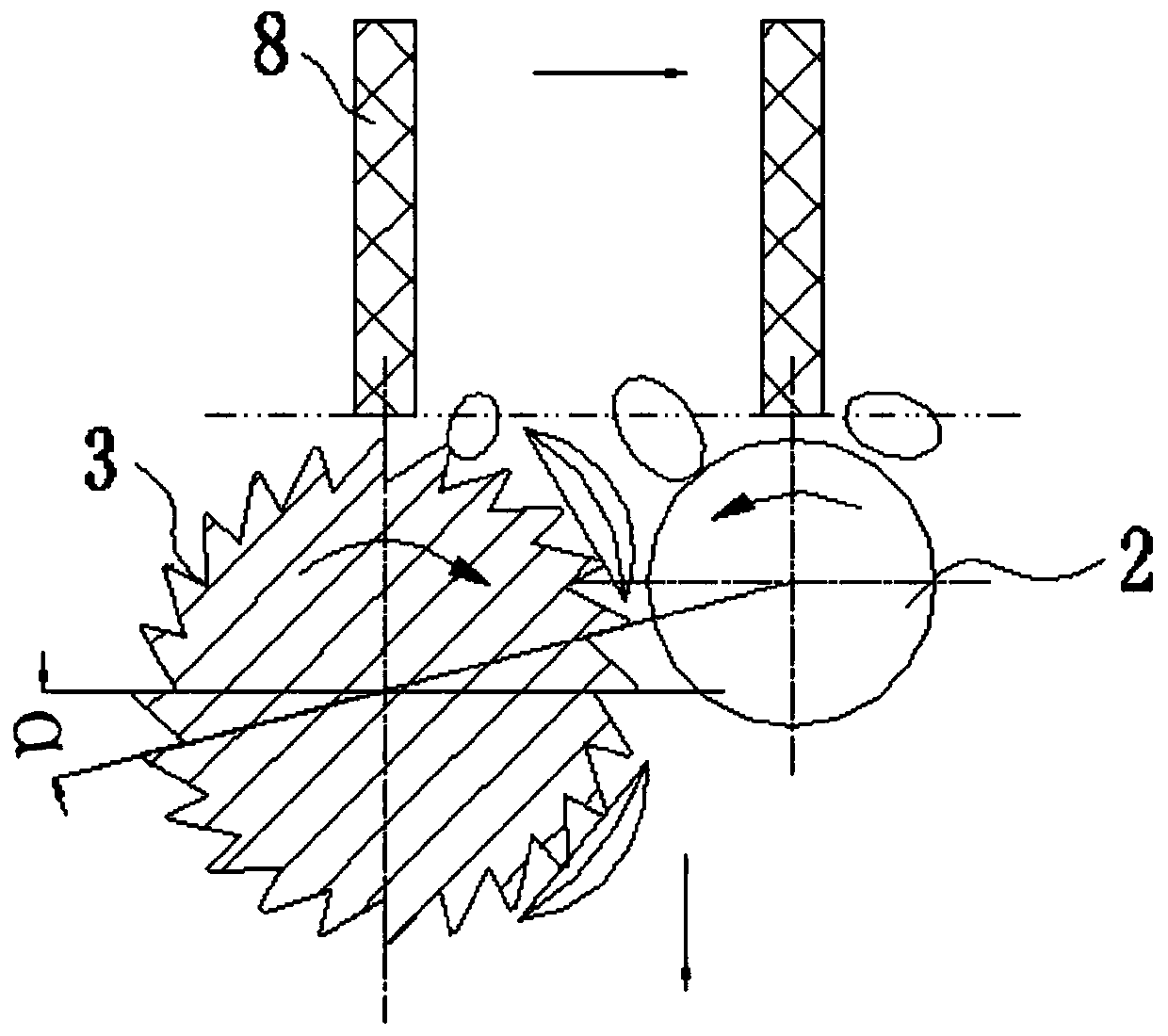

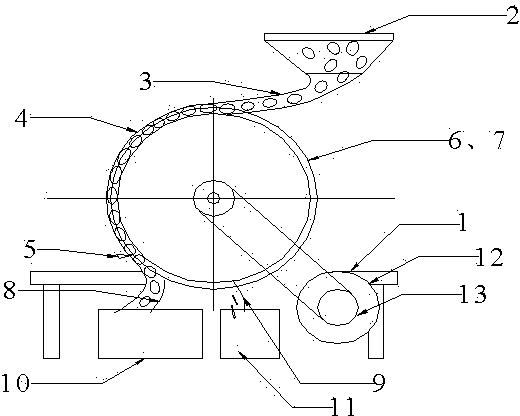

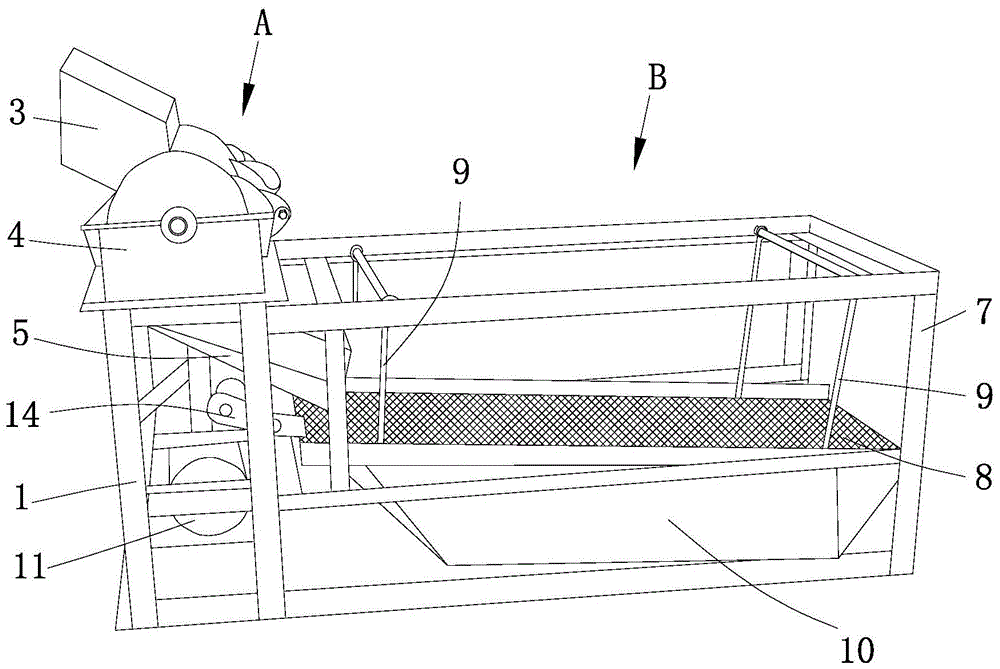

Separation process of camellia hull and seed and camellia hull and seed separator

ActiveCN106753760AEasy to separateImprove shelling efficiencyFatty-oils/fats productionGradingEngineeringSeed separator

The invention provides a separation process of camellia hull and seed and a camellia hull and seed separator. A sorting bush-hook is used to sort camellia hulls among camellia mixed hull and seed on a transporter, the camellia hulls are hooked by the rotating sorting bush-hook, and the camellia hulls are separated from the sorting bush-hook by using a hulling board and then fall on the hulling board; the transporter with gaps on a delivery element is adopted to transport the camellia mixed hull and seed, and the tiny camellia hulls, lesion and withered camellia seeds and other impurities drop out through the gaps. The separation process of camellia hull and seed can be carried out simultaneously during transportation of camellia mixed hull and seed, and has the advantages that the separating efficiency is high; the hull and seed separating result is good; the rate of hull in camellia seeds is lower than 3%, the rate of seed (normal camellia seed) in hulls is lower than 2%; the obtained camellia seed particles are uniform; the scale industrial production is suitable; the structure of camellia hull and seed separator is simple; the setting of controller and complex circuit structures and the like is not required; the equipment cost is low; the operation is safe and convenient; the work is stable.

Owner:湖北四季春茶油股份有限公司 +1

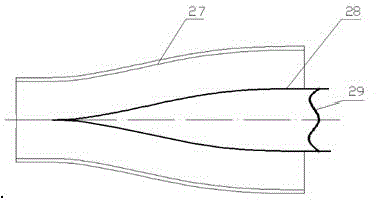

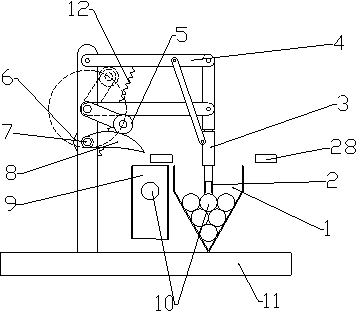

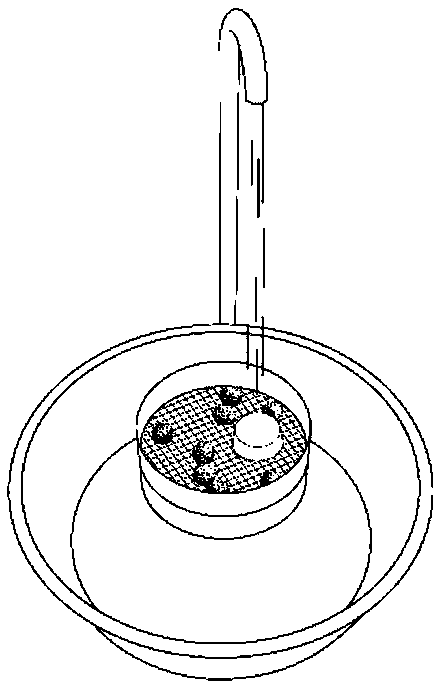

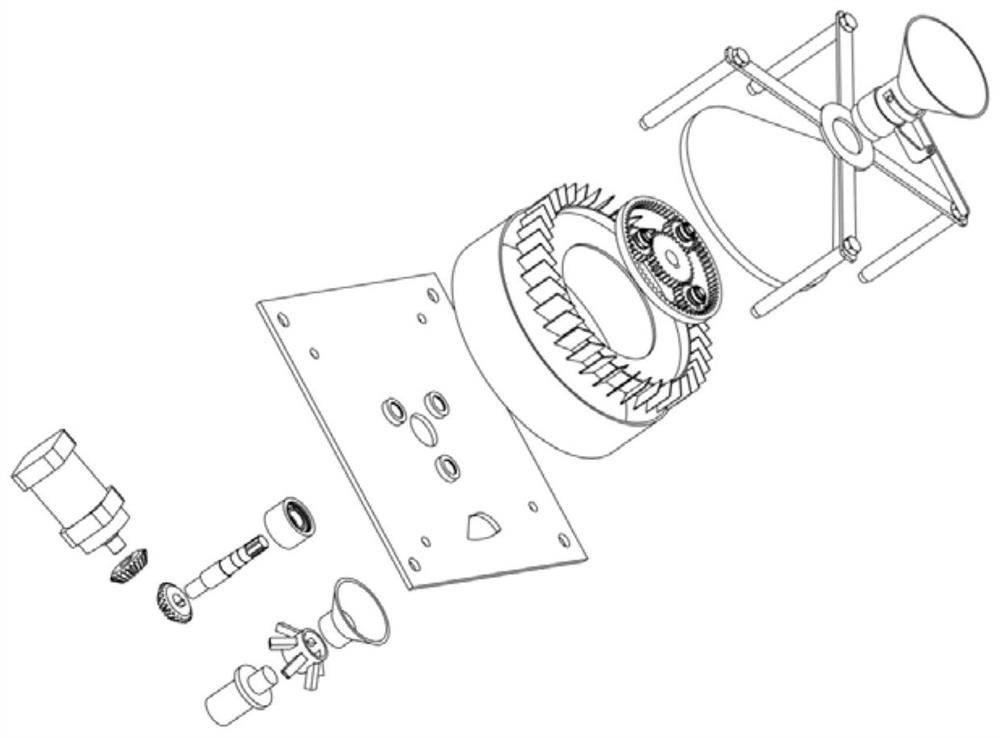

Eddy suspension-type seedcase-seed separator

InactiveCN101972033ACompact and reasonable structureEasy to useFood treatmentSeed separatorPetroleum engineering

The invention relates to the technical field of a seedcase-seed separating device of tomatoes or grapes, and the application thereof. The invention discloses an eddy suspension-type seedcase-seed separator and a using method thereof. The eddy suspension-type seedcase-seed separator comprises a support, a tapered tank, a water supply pipe and a seed adsorption pipe. The tapered tank is fixedly arranged on the support, and a tapered cavity with big top and small bottom is arranged in the tapered tank. The upper end of the tapered tank is provided with a feed port, the upper cavity of the tapered tank is internally provided with at least one nozzle in the tangential direction of the rounded surface of the tapered tank, and each nozzle is with the water supply pipe. The upper part of the tapered tank is provided with a water outlet capable of discharging the floated seedcase, the inner end of the seed adsorption pipe is communicated with the lower part of the cavity of the tapered tank, and the outer end of the seed adsorption pipe is communicated to the exterior of the tapered tank. The separator provided by the invention has reasonable and compact structure, and convenient use. The separator realizes the separation of the seedcase and the seed through the eddy suspension effect of the tapered tank, has the characteristics of simple structure, easy operation, good separation effect and convenience, and is labor-saving, economic, and high efficient.

Owner:巴州友邦生物科技有限公司

Fruit shelling device and shell and seed separator comprising the shelling device

The present invention discloses a fruit shelling device and a shell and seed separator comprising the shelling device, and belongs to the field of agricultural machinery. The fruit shelling device comprises a closed and internally accommodating shelling cavity body; the shelling cavity body conducts air bath heating for contents under a certain pressure difference condition for shelling; heat source for heating is arranged outside the shelling cavity body; and the heat source is thermally conducted to the interior of the cavity body through the outer wall of the shelling cavity body. The fruitshelling device and the shell and seed separator comprising the shelling device use a drying principle to conduct the fruit shelling, can avoid carbonization of fruit peels, fruit pulp, etc. in the shelling processes, ensure the homogeneous degree of the shelling effects, are suitable for fruits with the relatively high water content fruit peels and high-temperature easy carbonized fruit pulps oftea-seed oil Chinese olives, etc., further ensure the quality of the raw materials in the processes of subsequent fruit pulp extraction, oil extraction, etc., improve the extraction rate of the beneficial substances in the fruit pulp, the oil yield of the fruit pulp, etc., and improve the separation efficiency and effects of the shelling.

Owner:海南侯臣生物科技有限公司

Oil tea fruit seed separator provided with tooth smooth roller on plane

PendingCN110238022AGuaranteed cleanlinessEfficient separationSievingScreeningCamellia oleiferaAgricultural engineering

The invention discloses an oil tea fruit seed separator provided with a tooth smooth roller on a plane, and belongs to the technical field of oil tea production. The oil tea fruit seed separator comprises a frame; and a belt roller motor and a chain transmission, and a fruit seed separation motor and a chain transmission are fixed at the bottom of the frame through bolts. A tooth smooth roller fruit seed separator with a seed cleaning plate and arranged on the plane can effectively separate fruits from tea seeds for fruit seed mixtures with different humidity and different sizes after oil tea fruit removal, and can guarantee cleaning of the tea seeds, so that the fruit seed separation capacity is high, the effect is good, and the tea seeds are low in damage and loss; through a mode of combining multiple identical tooth pieces on a tooth roller shaft as a tooth roller, each tooth piece is singly machined and manufactured, and is combined on one tooth roller shaft; and compared with a whole-machined tooth roller, the tooth roller in the new form greatly shortens the machining time, reduces the machining cost, and is simple in structure, convenient to install and disassemble and easy to maintain.

Owner:JIANGXI AGRI MACHINERY RES INST

Rotary broad bean peeling machine

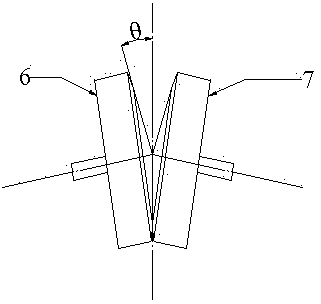

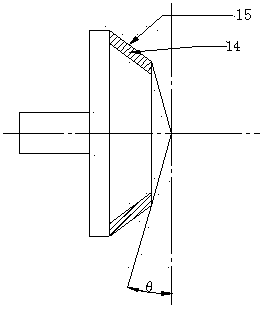

InactiveCN102823928BAchieving step-by-step extrusionAchieve continuous peelingFood treatmentTransmitted powerSeed separator

The invention relates to a rotary broad bean peeling machine. A motor is connected with a pair of extrusion wheels through a power transmission part and transmits power to the extrusion wheels; a processing slot is formed in one sides of the extrusion wheels; the upper end of the processing slot is connected with a material feeding device through a material guide slot; the processing slot and the pair of extrusion wheel forms a closed space; a processing tool bit is arranged in the processing slot; a bean seed separator and a bean skin separator are respectively arranged on the left side and the right side below the pair of extrusion wheels; and a bean material slot and a bean skin material slot are respectively formed below the bean separator and the bean skin separator. The rotary broad bean peeling machine can gradually extrude broad beans by rotatably driving the broad beans to pass through different spaces according to the difference of the sizes of the spaces formed by the pair of extrusion wheels arranged in an included angle manner, so that the broad beans are peeled. The machine can continuously peel the broad beans, so that the production efficiency is greatly improved. The extrusion process is continuous, so that the processing quality is relatively high. Simultaneously, the machine is simple in structure, relatively few in number of parts, relatively low in manufacturing cost, and convenient to maintain.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

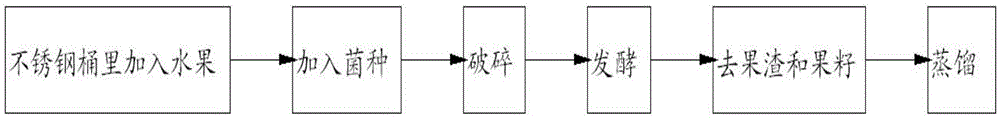

Production line of fruit distilled liquor and producing method thereof

InactiveCN105462764ALow costImprove efficiencyAlcoholic beverage preparationAlcohol contentProduction line

The invention relates to a production line of fruit distilled liquor and a method thereof. The production line comprises a plurality of stainless steel buckets, fruit fermenting, fruit smashing, removing of fruit peels and fruit seeds in smashed fruits and fermented fruit distilling for methyl alcohol and fusel liquor separating are sequentially carried out in the same stainless steel buckets, delivering is carried out between adjacent stations by pushing the stainless steel buckets, and the semi-continuous production line of the fruit distilled liquor is formed. The production line and the method have the advantages that the converted universal sliding stainless steel buckets serve as bases in cooperation with a special fruit smashing stirrer, a fruit-seed separator and a distiller, and the production line low in cost, high in efficiency and capable of producing slap-up fruit distilled liquor with low methyl alcohol and low fusel is composed. According to the capacity of the stainless steel buckets, the daily yield of the fruit distilled liquor with the alcohol content of 50% is 9-72 L.

Owner:GUILIN ACADEMY OF AGRI SCI

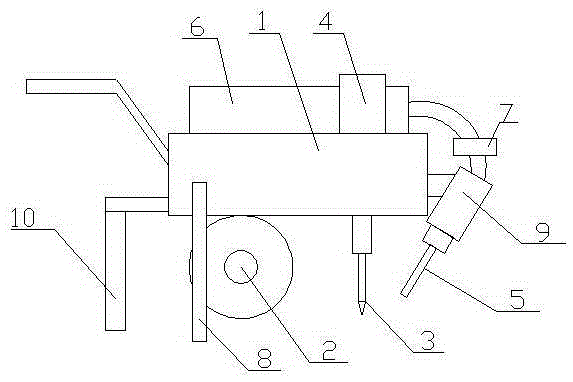

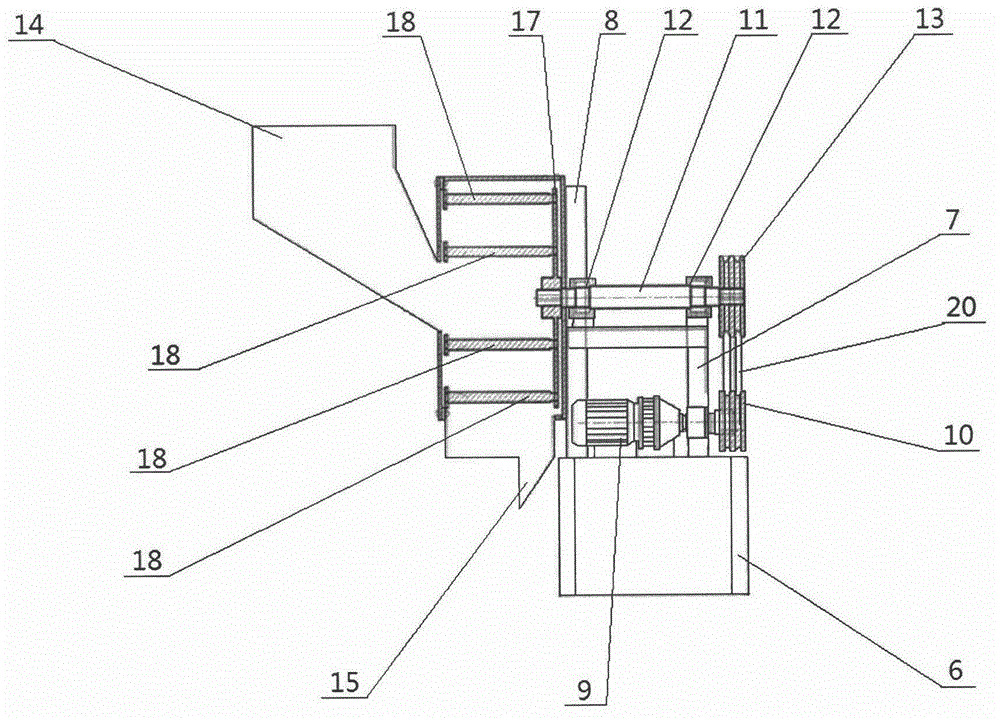

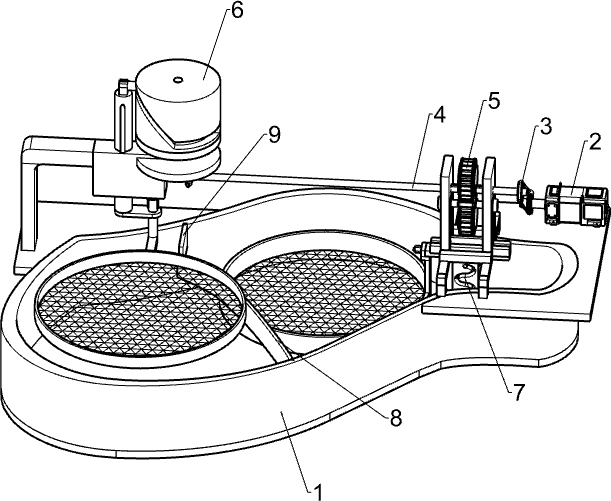

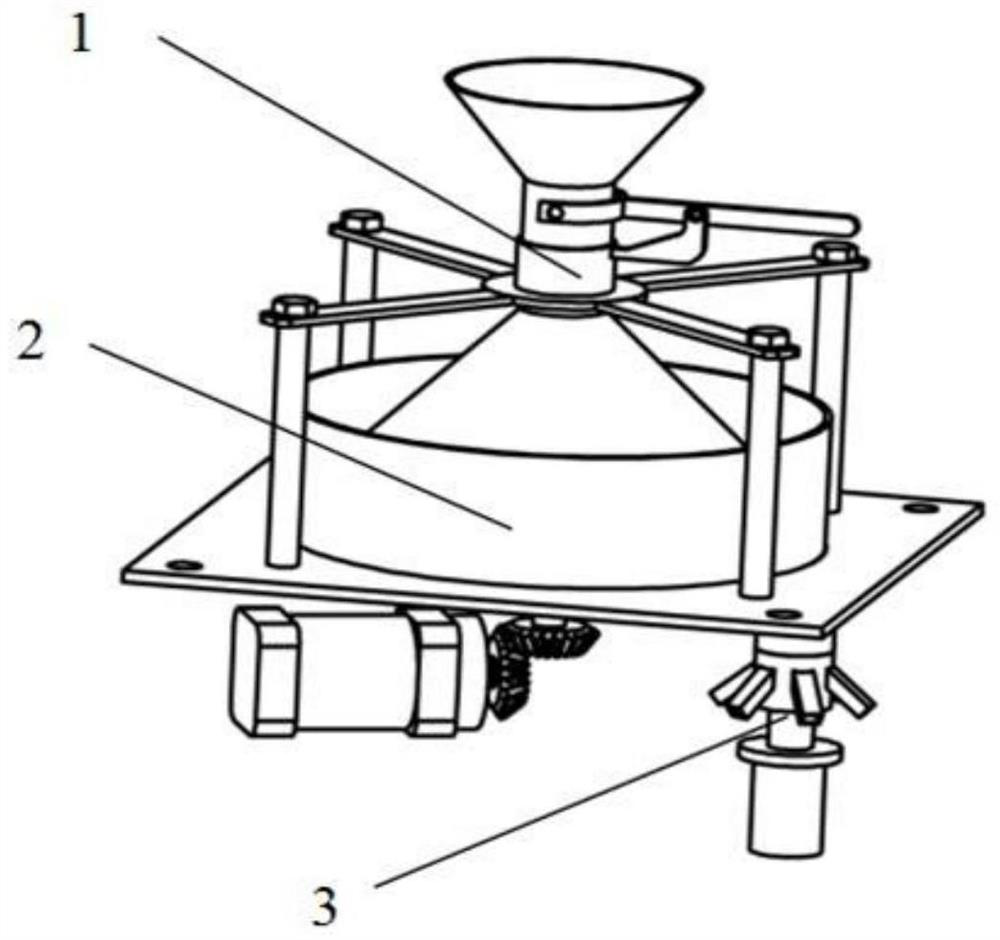

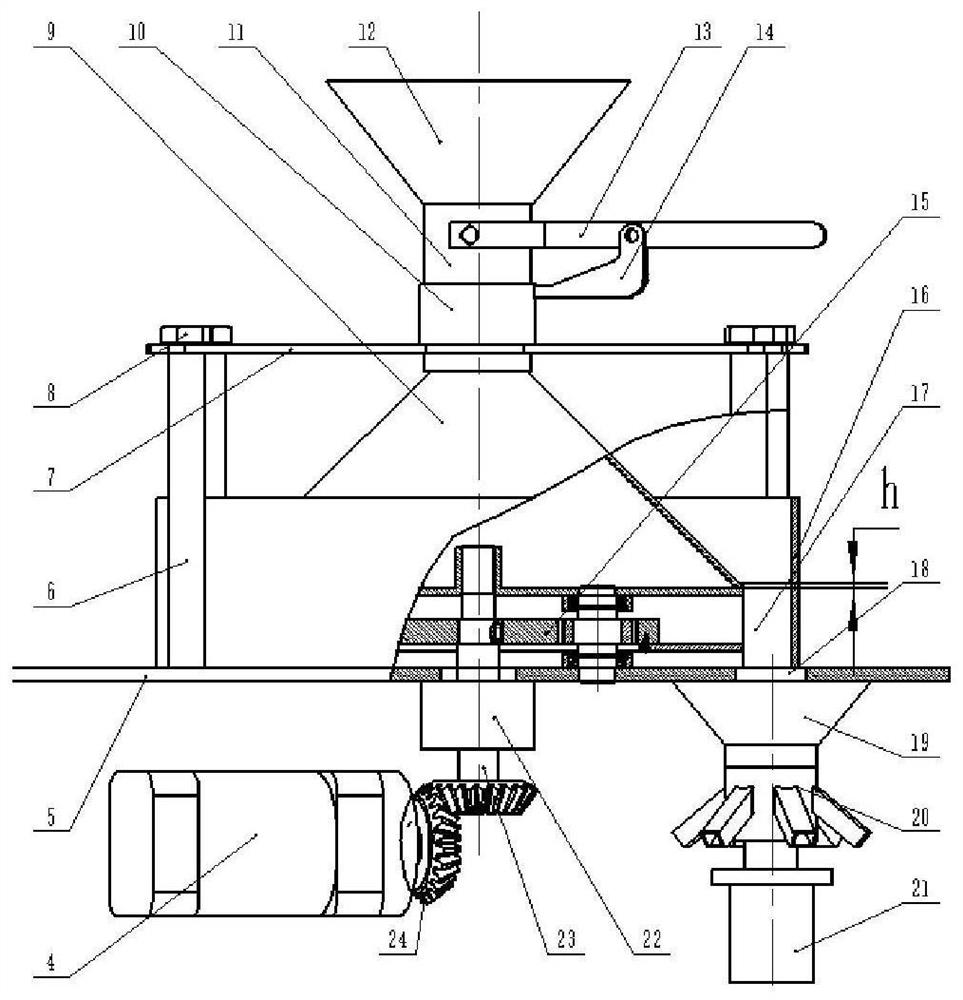

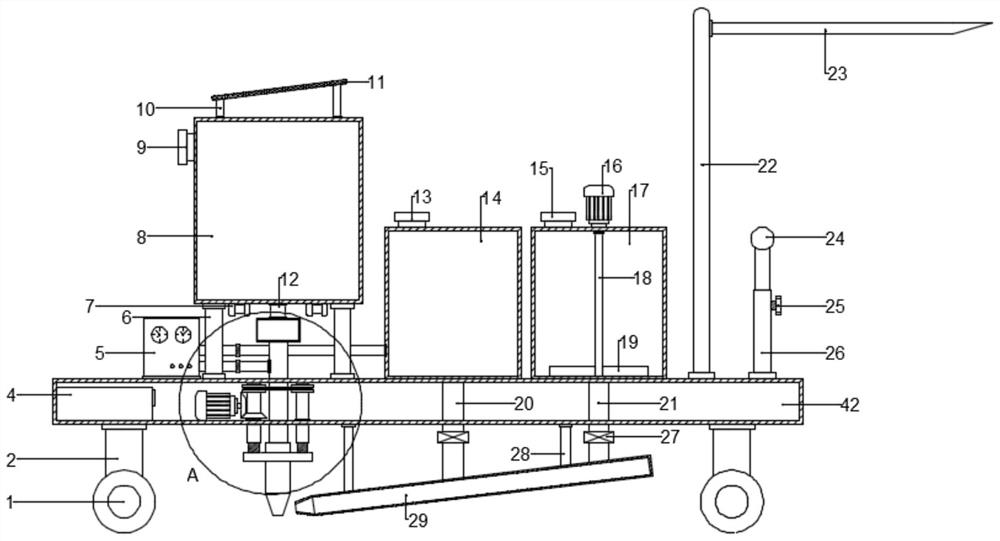

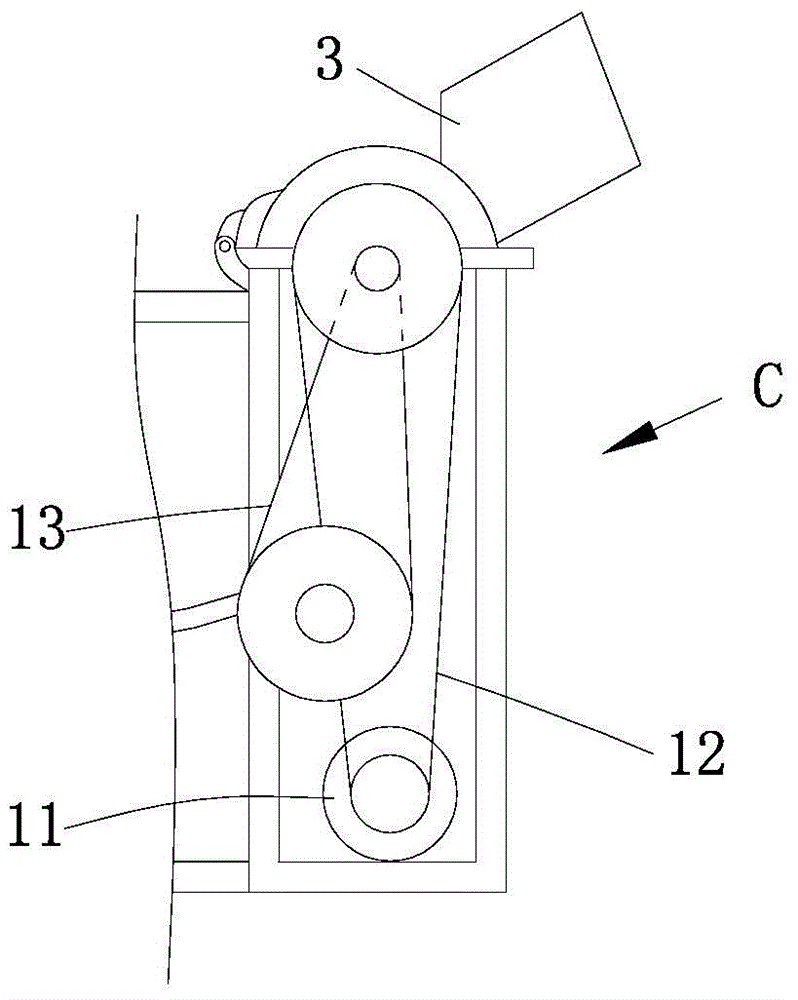

Mango pulp and seed separator

InactiveCN105077522ANovel ideaApplication process measures uniqueJuice extractionFruit stoningSeed separatorEnergy consumption

The invention discloses a mango pulp and seed separator, which specially comprises a body frame, a power driven system, a rotating system, a case, a breaking system, wherein the power driven system, the rotating system and the case are arranged on the body frame, the breaking system is arranged in the case and is sleeved on the rotating system, the power driven system and the rotating system are connected together through a belt to form a whole mango pulp and seed separator. The mango pulp and seed separator is extremely simple in mechanism during the appliance process, places mangoes into the case, breaks seeds of the mangoes in the case by beating through a breaking bar of the breaking system, does not damage mango seeds, and separates mango pulps and seeds. The shape and the layout of the breaking bar enable mango seeds not to be damaged during the breaking process of mangoes, and enable mango pulps to be complete. Simultaneously, the mango pulp and seed separator is simple in structure, low in making cost, low in energy consumption during the use process and high in application effect. Simultaneously, the mango pulp and seed separator can be widely applied in pulp and seed separating and pulping of other fruits.

Owner:GUANGXI TIANDONG XINGXIN KILN ENG

Gorgon fruit shelling device

ActiveCN109673270ARealize separate seedingImprove shelling efficiencyThreshersDrive shaftEngineering

The invention discloses a novel gorgon fruit shelling device which comprises a worktable, wherein a feeding mechanism and a shelling mechanism are arranged on the worktable; the feeding mechanism comprises a hopper and a seed separator; the shelling mechanism comprises multiple shelling components; each shelling component comprises a squeezer and a sheller; each sheller comprises a mounting sleeveand a shelling knife; and the squeezer comprises a base and a squeezing rod. The top end of the squeezing rod is intermittently squeezed by squeezing guide rails so as to pop up gorgon fruit seeds positioned in the shelling cavity and rotate by virtue of the shelling knife, so that the gorgon fruit seeds are rotated and squeezed to shell; and the transmission shaft is driven to rotate by the driving mechanism, and the seed driver and the seed separator are driven to rotate, so that the seed separation holes in the seed separation disc and feeding holes in a feeding bottom plate are intermittently conducted, the gorgon fruit seeds in the guide tube are intermittently stopped by limiting pieces on the limiting disc, and individual gorgon fruit seeds are separately taken. The novel gorgon fruit shelling device disclosed by the invention has the advantages that the shelling efficiency of the gorgon fruit seeds is improved.

Owner:合肥九州龙腾科技成果转化有限公司

Sugarcane seeder unit

The invention provides a sugarcane seeder unit, which comprises a seed guide box for storing sugarcane seeds, a seed guide groove for enabling the sugarcane seeds to fall into earth and a needle type seed taking part, wherein the needle type seed taking part comprises a linkage mechanism, a seed taking needle and a seed separator; the seed taking needle is used for taking the sugarcane seeds from the seed guide box; the linkage mechanism is used for enabling the seed taking needle to move to and fro between the upper part of the seed guide box and the upper part of the seed guide groove; the seed separator is used for separating the sugarcane seeds from the seed taking needle, and enabling the sugarcane seeds to enter the seed guide groove. According to the sugarcane seeder unit, the seeds can be highly automatically taken and sown, and the planting efficiency can be improved; moreover, the sugarcane seeds are cut before being sown, so that a user can conveniently perform bud selection, sterilization and germination acceleration on the sugarcane seeds.

Owner:黄小文

Cleaning method of saussurea obvallata fruits

The invention discloses a cleaning method of saussurea obvallata fruits. The cleaning method includes steps: drying the saussurea obvallata infructescence; using a rubber plug to slightly rub the infructescence on a stainless steel screen net of 1.4-2.36mm in mesh size to enable fruits to shed out from involucre and to be separated from pappus; putting fruits and a small part of pappus mixture in an underframe into a seed separator, selecting to use wind power when rotating speed of a fan is 12-25.46Hz to enable full fruits to be separated from empty fruits, fruits damaged by insects and pappus; manually picking out remaining residue and mixed fruits; using paper bags to pack fruits after being cleaned. The cleaning method is simple and easy to implement and short in needed cleaning time; each of fullness ratio and purity of the fruits after being cleaned can reach 100%, storage space of the fruits in a refrigeratory can be reduced effectively, and convenience is brought to subsequent fetching and using of the fruits. The cleaning method is suitable for cleaning other fruits of the Saussurea DC. and can be used for cleaning other seeds of asteraceae on the condition of changing mesh size of the stainless steel screen net and the rotating speed of the seed separator.

Owner:KUNMING INST OF BOTANY - CHINESE ACAD OF SCI

Rotary broad bean peeling machine

InactiveCN102823928AAchieving step-by-step extrusionAchieve continuous peelingFood treatmentTool bitTransmitted power

The invention relates to a rotary broad bean peeling machine. A motor is connected with a pair of extrusion wheels through a power transmission part and transmits power to the extrusion wheels; a processing slot is formed in one sides of the extrusion wheels; the upper end of the processing slot is connected with a material feeding device through a material guide slot; the processing slot and the pair of extrusion wheel forms a closed space; a processing tool bit is arranged in the processing slot; a bean seed separator and a bean skin separator are respectively arranged on the left side and the right side below the pair of extrusion wheels; and a bean material slot and a bean skin material slot are respectively formed below the bean separator and the bean skin separator. The rotary broad bean peeling machine can gradually extrude broad beans by rotatably driving the broad beans to pass through different spaces according to the difference of the sizes of the spaces formed by the pair of extrusion wheels arranged in an included angle manner, so that the broad beans are peeled. The machine can continuously peel the broad beans, so that the production efficiency is greatly improved. The extrusion process is continuous, so that the processing quality is relatively high. Simultaneously, the machine is simple in structure, relatively few in number of parts, relatively low in manufacturing cost, and convenient to maintain.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

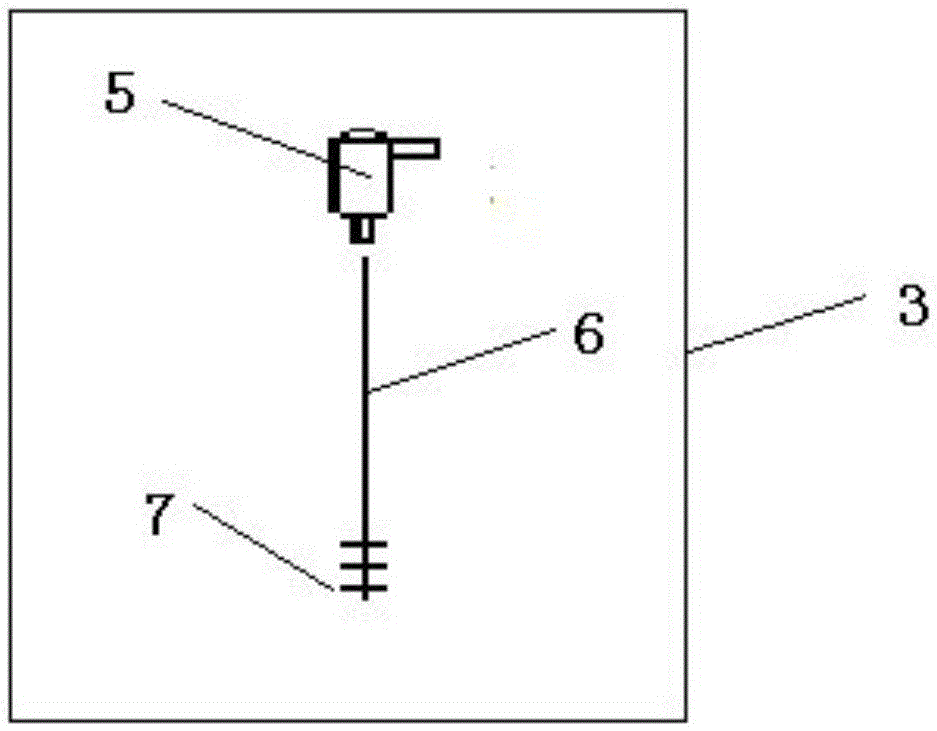

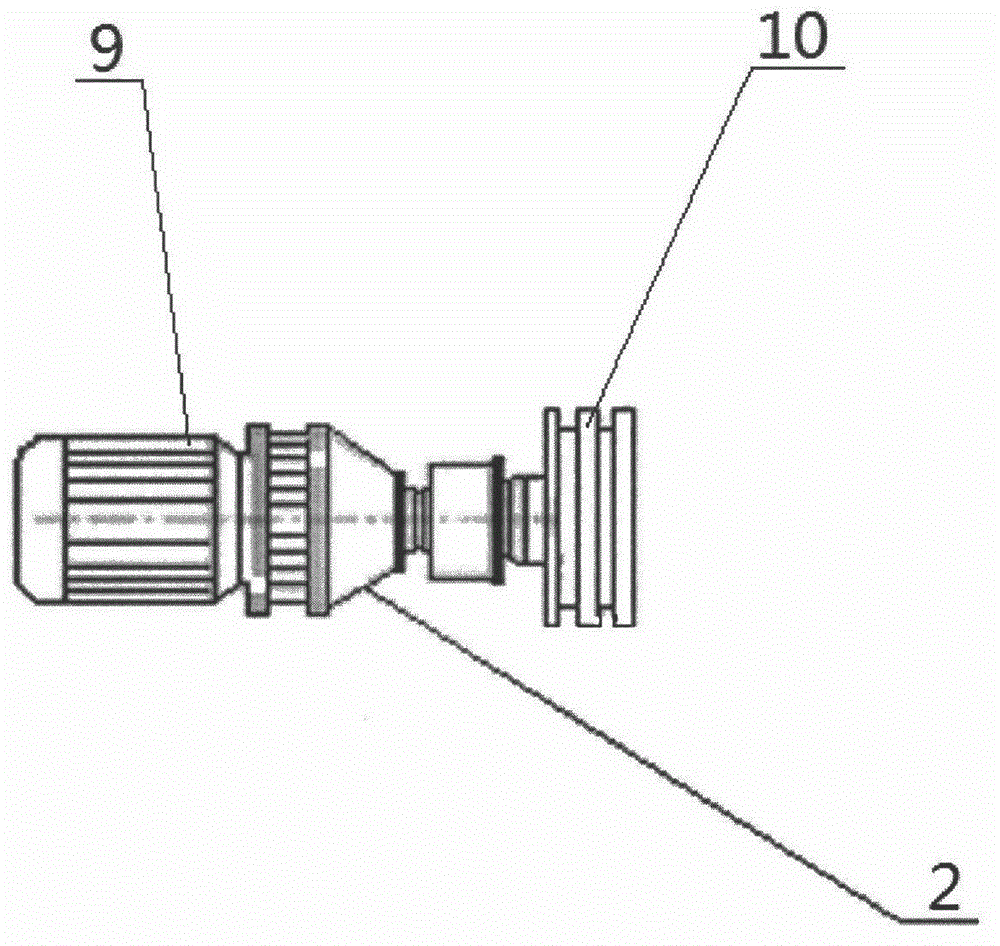

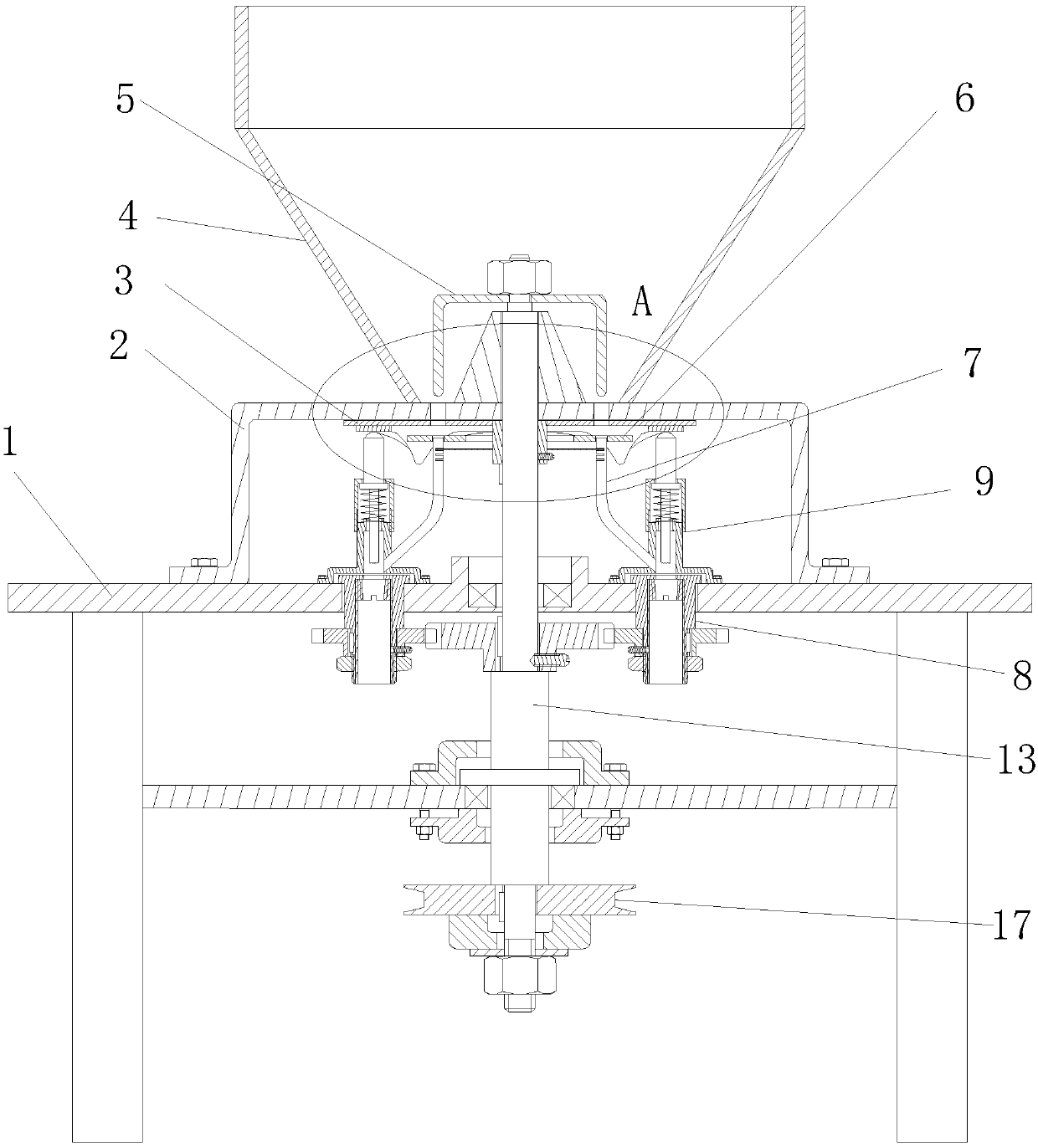

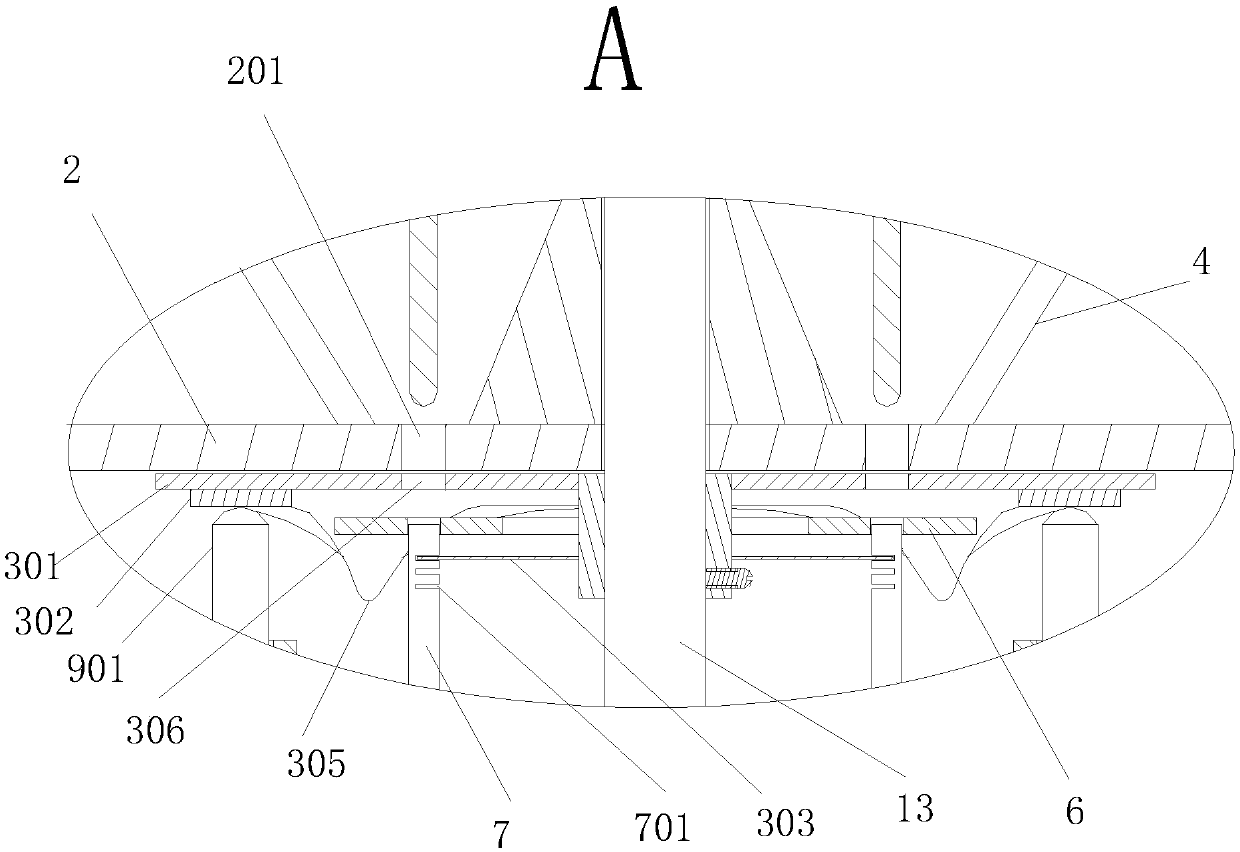

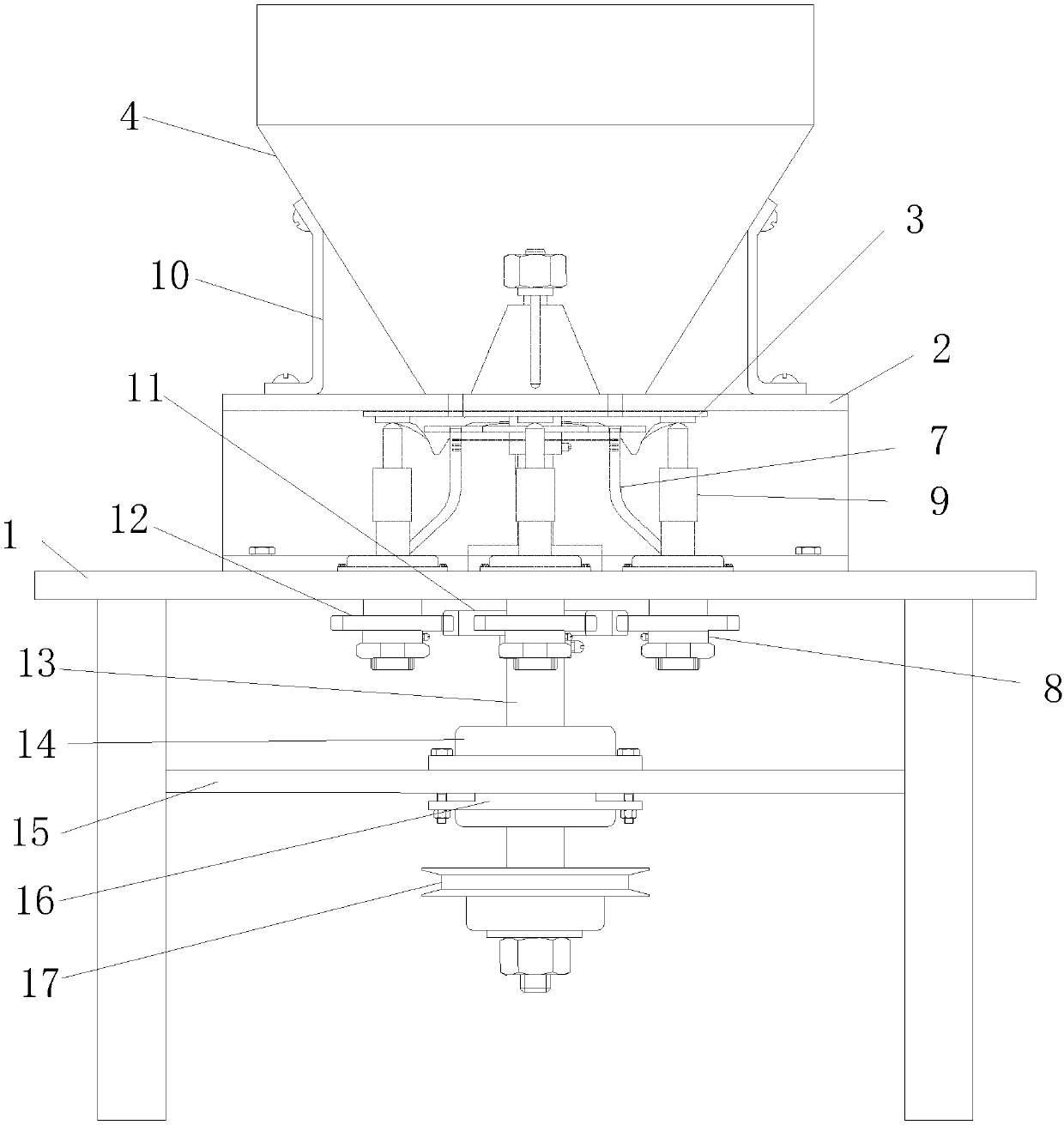

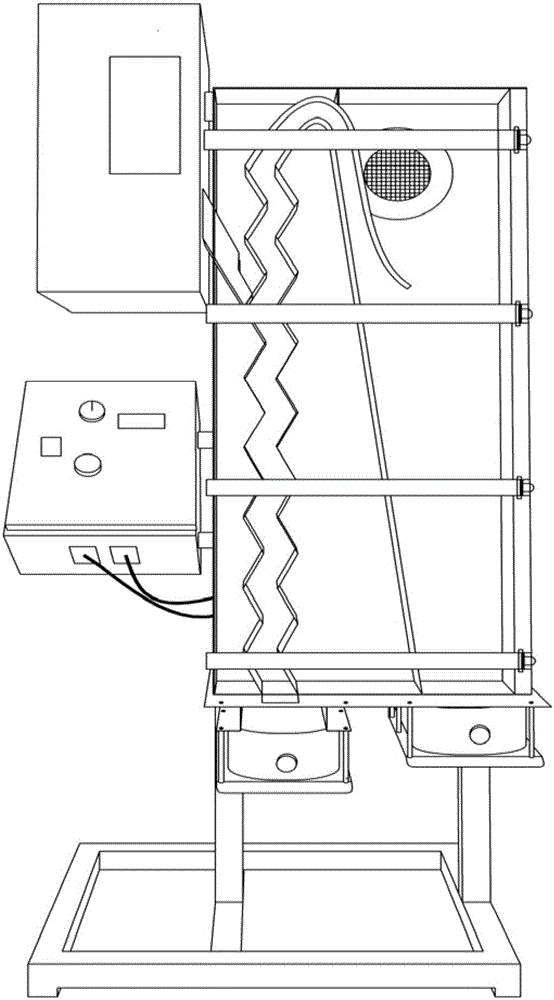

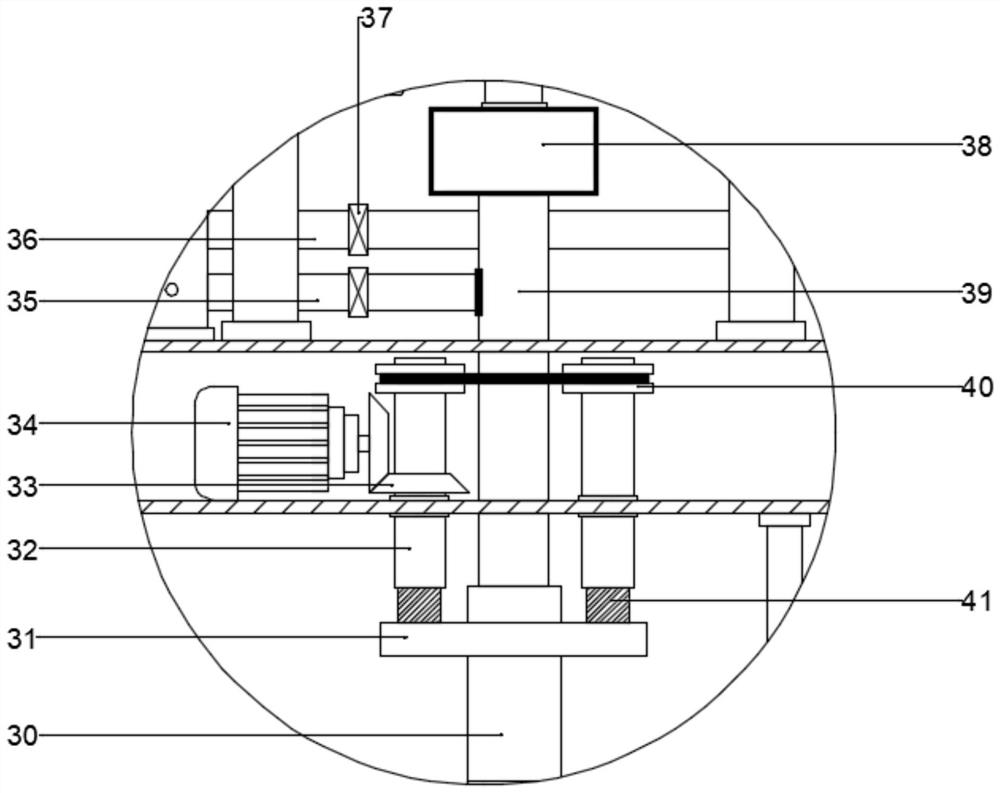

Portable seed separator

ActiveCN111715391AEasy to float outAvoid mixingSeed and root treatmentWet separationDrive shaftElectric machinery

The invention relates to a separator, in particular to a portable seed separator. The separator aims to provide the portable seed separator which can automatically separate and collect seeds, improvethe seed separation efficiency and reduce the manual operation. According to the technical scheme, the portable seed separator comprises a base and a transmission shaft; a motor is arranged on one side of the top of the base, and an up-down reciprocating mechanism is arranged on the side, close to one side of the motor, of the base; and the transmission shaft is rotationally connected to a component in the up-down reciprocating mechanism, and a belt assembly is connected between the side, close to one side of the motor, of the transmission shaft and an output shaft of the motor. According to the separator, through the up-down reciprocating mechanism, a placing basket can be automatically placed in water and lifted out of the water surface, and the placing basket is not needed to be manually and repeatedly lifted; and through a swing mechanism, the placing basket can swing left and right in the up-down moving process to screen the seeds in the placing basket so that the damaged seeds can conveniently emerge out of the water surface.

Owner:酉阳县敏兴农林有限责任公司

Method for processing flour with low aluminum content

The invention relates to a flour processing method, and in particular to a method for processing flour with low aluminum content. The method comprises the following steps: removing big impurities from crude wheat by using a grain cleaning machine; removing relatively big sands and stones by using a specific gravity stone remover; removing iron impurities by using a permanent magnetic roller; removing grass seeds by using a seed separator; threshing the wheat by using a horizontal wheat threshing machine; screening out impurities by using a vibrating screen; removing relatively small sands and stones by using the specific gravity stone remover; threshing the wheat by using the horizontal wheat threshing machine; screening out the impurities by using the vibrating screen; washing the wheat by using a strong wheat washer; watering for the first time (moistening the wheat); watering for the second time; rubbing the wheat by using a strong wheat rubbing machine; removing fine impurities by using a planar rotary screen to obtain pure wheat; and milling the wheat by using a milling machine to obtain the flour. The process of washing the wheat by using the strong wheat washer is added before the process of watering for the first time (moistening the wheat), and the process of threshing the wheat by using the horizontal wheat threshing machine after the process of watering for the second time is changed into the process of rubbing the wheat by using the strong wheat rubbing machine, so that the husk of the wheat can be removed relatively completely, the aluminum content of the flour can be effectively controlled, and relevant export standards can be met completely.

Owner:厦门市兴集成面粉有限公司

Rotary lotus seed peeling machine

InactiveCN111053254AAchieving step-by-step extrusionAchieve continuous peelingHuskingHullingAgricultural engineeringSeed separator

The invention relates to a rotary lotus seed peeling machine, which is characterized in that a motor is connected with an extrusion pair wheel through a power transmission member to transmit power tothe extrusion pair wheel, a processing groove is formed in one side of the extrusion pair wheel, the upper end of the processing groove is connected with a feeding device through a guide groove, a closed space is formed by the processing groove and the extrusion pair wheel, a processing cutter head is arranged in the processing groove, a lotus seed separator and a lotus peel separator are respectively mounted on the left side and the right side below the extrusion pair wheel, and a lotus seed groove and a lotus peel groove are respectively arranged below the lotus seed separator and the lotuspeel separator. According to the invention, the size difference of the space formed by the extrusion pair wheel placed at the included angle is utilized, and lotus seeds are driven to pass through different spaces through rotation to achieve the step-by-step extrusion of the lotus seeds, so that the peeling action of the lotus seeds is completed; the machine can achieve the continuous peeling of lotus seeds so as to substantially improve the production efficiency, and the extrusion process is continuous, so that the processing quality is high; and the rotary lotus seed peeling machine is simple in structure, less in parts, low in manufacturing cost and convenient to maintain.

Owner:湘潭博奥生态科技有限公司

Cleaning method of oriental clematis fruit

ActiveCN106068962BSolve cleaning difficultiesEasy access laterAgriculture tools and machinesSeed and root treatmentInfructescenceClematis pitcheri

The invention discloses a cleaning method of clematis orientalis fruits. The cleaning method comprises the following steps: drying clematis orientalis infructescences; wearing rubber gloves and slightly rubbing the infructescences on rubber cushions with hands, so as to separate the fruits, infructescence axles and styluses; putting the mixture of the fruits, the styluses and the infructescences into a seed separator and selecting proper wind power to separate completely filled fruits from empty fruits, fruits damaged by worms, a large part of the styluses and the infructescence axles; further screening to remove residues of the styluses and the infructescences with a screen; manually picking and removing the remained residues of the styluses and the infructescences; and packaging the cleaned fruits with paper bags. The method is simple and feasible and a lot of cleaning time can be saved; the cleaned fruits have a high full rate and are loose and separable so that the fruits are very convenient to take at a later period; and a storage space of the fruits in a cold storage can be effectively reduced. The cleaning method is also applicable to cleaning of other fruits of clematis.

Owner:KUNMING INST OF BOTANY - CHINESE ACAD OF SCI

A kind of cleaning method of sorghum bubble fruit, gray cocoa berry and raspberry fruit

ActiveCN106617206BImprove storage qualityAvoid wastingSeed and root treatmentFood treatmentEngineeringSorghum

The invention provides an effective cleaning method of rubus lambertianus fruits. The cleaning method comprises the following steps of removing fruit stems and sepals of rubus lambertianus aggregate fruits; then putting the rubus lambertianus aggregate fruits without the fruit stems and the sepals on a stainless steel screen stencil of which the hole diameter is 0.71-1.4mm in a plastic box, and under the rinsing of running water, performing grinding with a rubber stopper so that fruit kernels are separated from fruit pulp to fall onto the surface of the screen stencil and the fruit pulp and most of fruit peel are washed away along with the water; spreading cleaned fruit kernels and a few fruit peel residues on a stainless steel filter net, performing drying in shade for 5-7 days, and then putting the dried fruit kernels and the dried fruit peel residues in a drying room for drying for a week; putting the dried fruit kernels and a few dried fruit peel residues into a seed separator, and under the wind power of a fan of which the rotating speed is 24.74-35.26Hz, enabling full fruit kernels to be separated from empty, shrivelled and worm-eaten fruit kernels and fruit peel residues; and finally packaging cleaned full fruit kernels with paper bags. The method is simple and effective, and under the situation that the fruit kernels are not damaged, the purity, the cleanliness and the full rate of the fruit kernels of the cleaned rubus lambertianus can reach 100%. In addition, the method is also suitable for cleaning other rubus fruits, other drupes and berries.

Owner:KUNMING INST OF BOTANY - CHINESE ACAD OF SCI

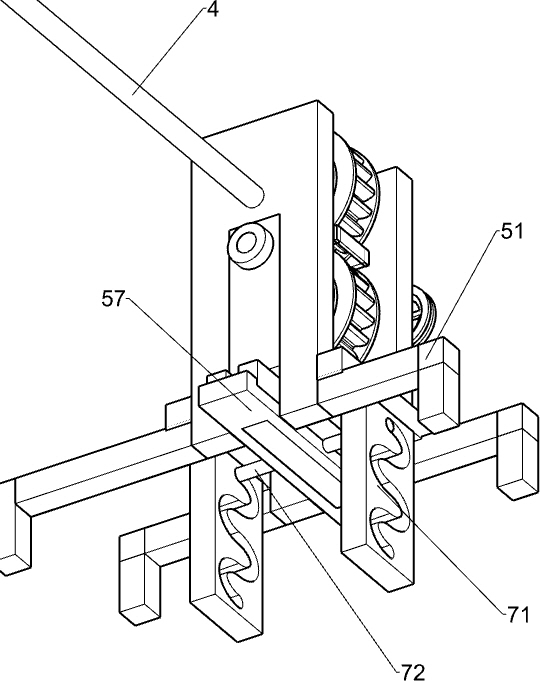

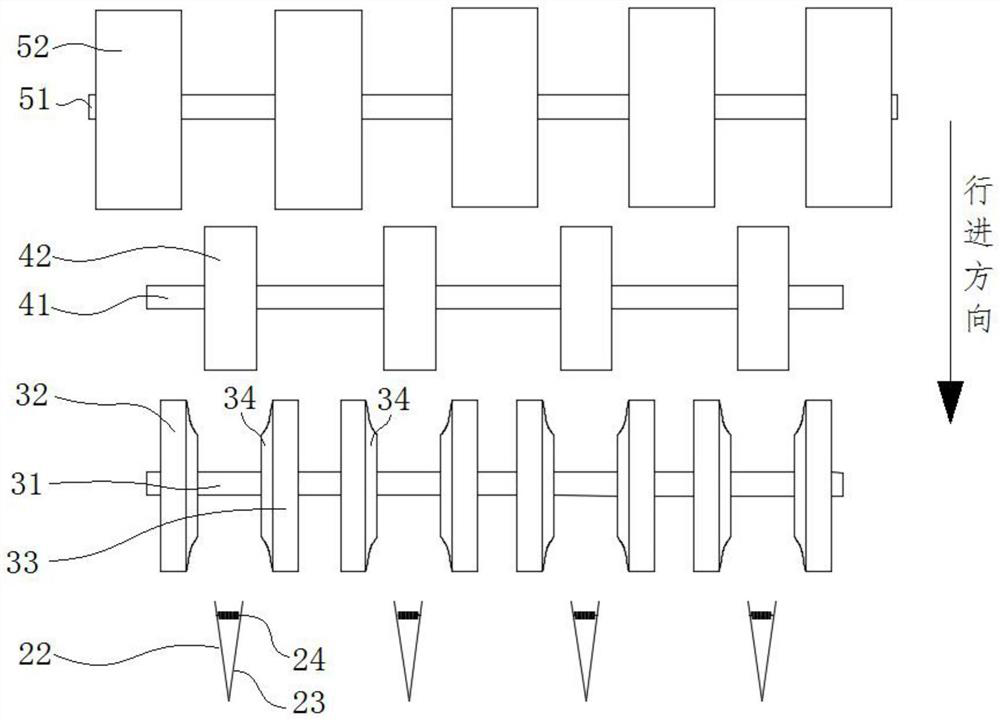

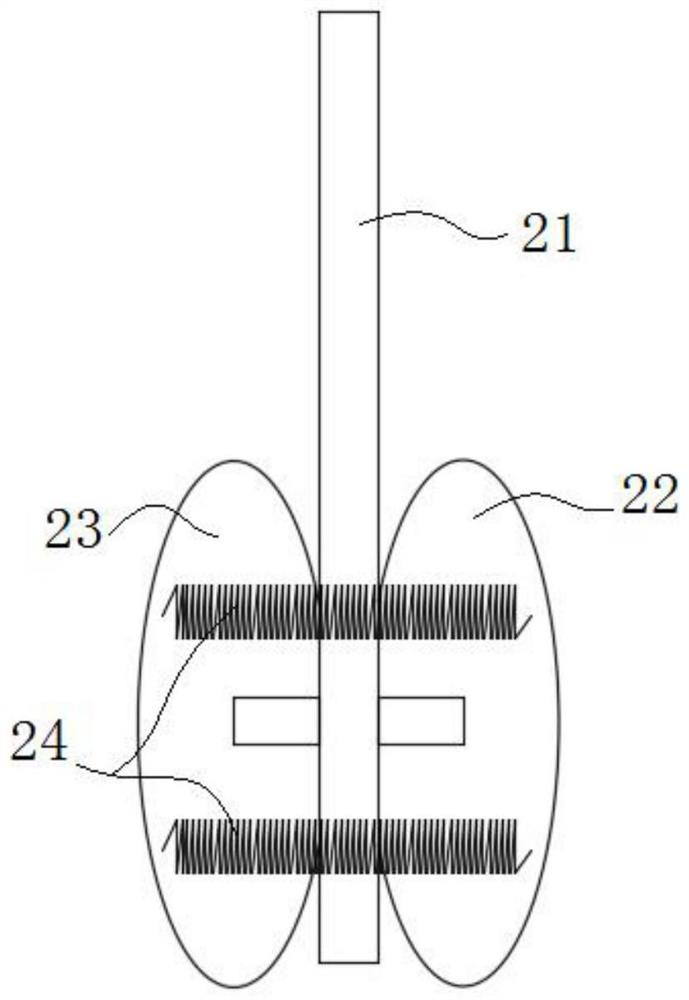

A differential speed plot seeding device

ActiveCN109121601BSolve the problem of disconnectionSeed depositing seeder partsSeederElectric machine

A differential-speed plot seeding device, including a seed storage mechanism, a seed metering mechanism, and a sorting mechanism. The seed storage mechanism includes a seed pouring funnel, a seed storage tube, a lifting lever and a lever base, which are used to put and store seeds, and the lifting lever It is used to drive the seed storage cylinder to lift upwards, and the seeds are filled; the seed metering mechanism includes a cone, a parallel inclined plate type seed transport grid, a differential transmission device and a stepping motor, and the stepping motor provides power, through the differential transmission The device realizes the differential rotation of the cone and the parallel inclined plate type seed grid, and the parallel inclined plate type seed grid is divided into multiple spaces by multiple parallel partitions; the sorting mechanism includes a seed collection funnel, a seed divider and a DC motor , the DC motor rotates at a high speed to evenly distribute the seeds falling from the seed opening into each row. The differential speed seeding method solves the problems of unevenness between rows and low precision; the use of parallel slanting plate seed transport grids to divide the space solves the problem of seed interruption caused by the presence of partitions in the seeding machinery.

Owner:CHINA AGRI UNIV

Eddy suspension-type seedcase-seed separator

InactiveCN101972033BCompact and reasonable structureEasy to useFood treatmentAgricultural scienceAgricultural engineering

The invention relates to the technical field of a seedcase-seed separating device of tomatoes or grapes, and the application thereof. The invention discloses an eddy suspension-type seedcase-seed separator and a using method thereof. The eddy suspension-type seedcase-seed separator comprises a support, a tapered tank, a water supply pipe and a seed adsorption pipe. The tapered tank is fixedly arranged on the support, and a tapered cavity with big top and small bottom is arranged in the tapered tank. The upper end of the tapered tank is provided with a feed port, the upper cavity of the tapered tank is internally provided with at least one nozzle in the tangential direction of the rounded surface of the tapered tank, and each nozzle is with the water supply pipe. The upper part of the tapered tank is provided with a water outlet capable of discharging the floated seedcase, the inner end of the seed adsorption pipe is communicated with the lower part of the cavity of the tapered tank, and the outer end of the seed adsorption pipe is communicated to the exterior of the tapered tank. The separator provided by the invention has reasonable and compact structure, and convenient use. The separator realizes the separation of the seedcase and the seed through the eddy suspension effect of the tapered tank, has the characteristics of simple structure, easy operation, good separation effect and convenience, and is labor-saving, economic, and high efficient.

Owner:巴州友邦生物科技有限公司

An agricultural seeding device

ActiveCN111512746BEasy to operateImprove farming efficiencyPlantingTransportation and packagingAgricultural scienceAgricultural engineering

The invention discloses an agricultural seeding device, which comprises a seed box and a base. The bottom of the base is symmetrically provided with a plurality of load-bearing columns, and the lower ends of the load-bearing columns are fixed with moving wheels. Above the base, there is a seed divider below the seed box, and a seed pipe at the bottom of the seed box. The lower end of the seed pipe is connected to the input end of the seed divider, and the output end of the seed divider is connected to a seed conduit. The end of the seed conduit away from the seed divider extends to the bottom of the base. The seed conduit slides on the pipe section below the base and the sealing sleeve is provided with a ground pipe. The base is fixed with an air pump, and the output end of the air pump is connected to the first air guide tube. The base is fixed with a water tank and a fertilizer tank. The device adopts a combination of push type and ground type sowing operation mode. After sowing, irrigation and fertilization operations can be completed synchronously. It saves time and effort, is easy to operate, and greatly improves the cultivation efficiency. practical.

Owner:江苏润扬种业股份有限公司

Pepper Seed Shell Separator

The invention discloses a chilli hull and seed separator which comprises a feeding mechanism, a crushing mechanism, a distributing mechanism and a drive mechanism, wherein the crushing mechanism comprises a first support frame, a mixing and crushing wheel, a feeding hopper, a crushing bin, a discharging hopper and crushing gratings, the mixing and crushing wheel comprises a rotating shaft and a crushing member, the crushing gratings are laid along the arc shape of the bottom of the crushing bin at equal intervals; the distributing mechanism comprises a second support frame, a screen, a screen suspending rod and a guide dustpan; the drive mechanism comprises a drive motor, a first belt wheel, a second belt wheel and a crankshaft connecting rod system; the drive motor drives the mixing and crushing wheel by means of the first belt wheel to rotate, and a rotating shaft of the mixing and crushing wheel drives a crankshaft of the crankshaft connecting rod system by means of the second belt wheel to rotate so as to drive the screen to swing forwards and backwards swing and simultaneously vibrate slightly up and down. The chilli hull and seed separator is simple in structure, novel in design, skilled in design, and high in automation degree, and has two functions of crushing and separating; the production efficiency and the chilli seed quality are remarkably improved.

Owner:石柱土家族自治县辣椒研究中心

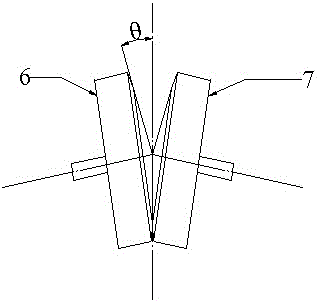

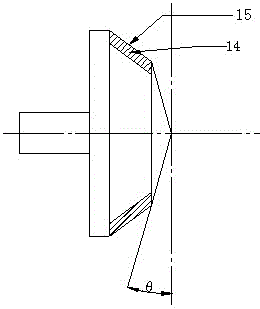

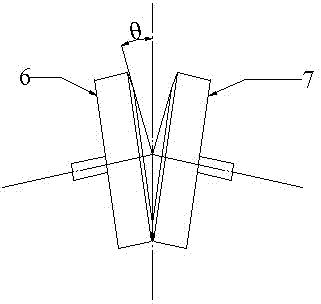

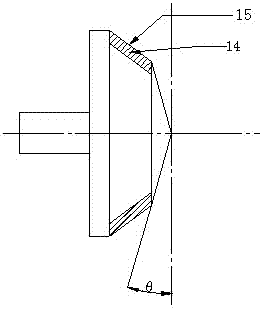

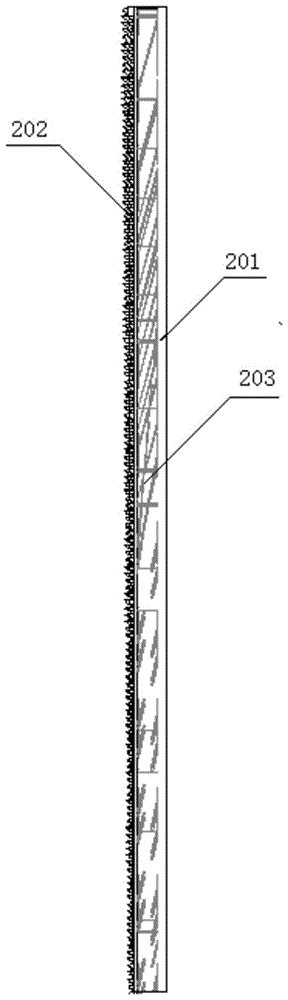

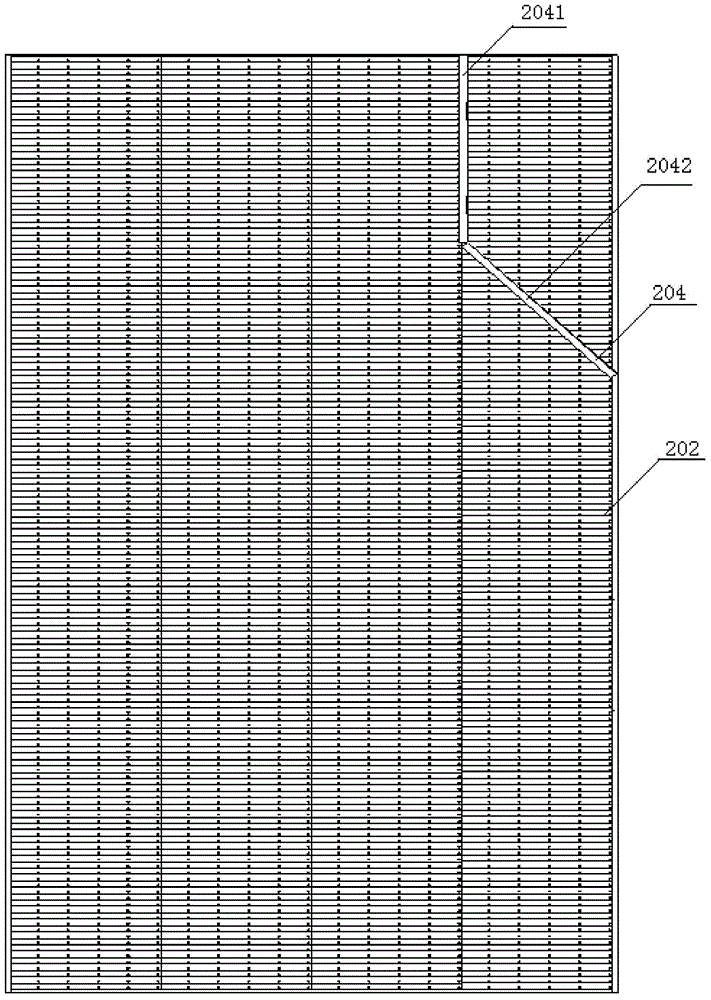

Air guides, sieve panels with air guides and cleaners

ActiveCN104259103BEven by forceObvious stratificationGas current separationAgricultural engineeringSeed separator

Owner:SHIHEZI DEV ZONE TIANZUO SEED MACHINERY

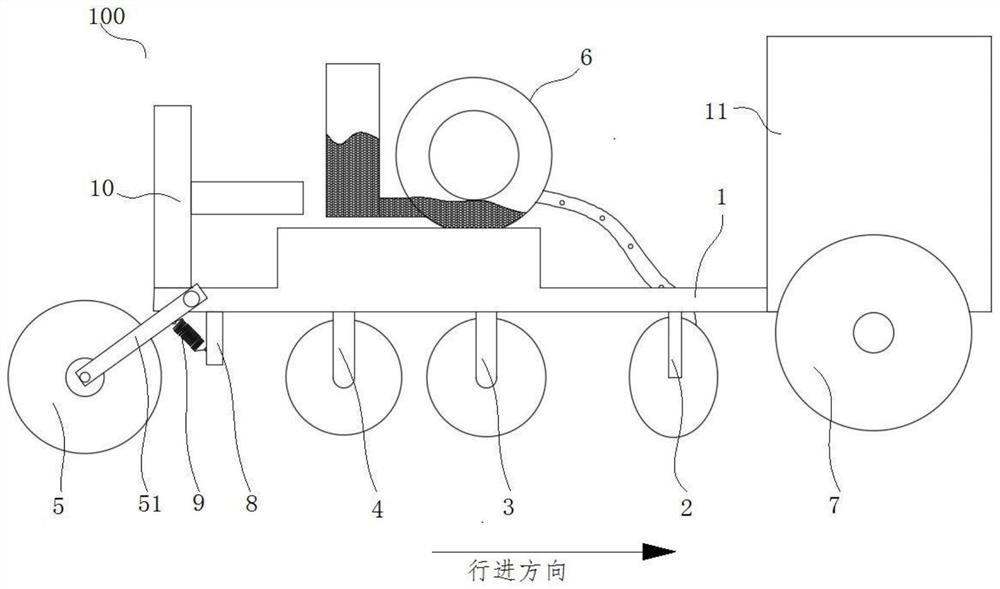

Agricultural seeding machine

PendingCN114375649AImprove quality and efficiencyImprove seeding efficiencyPlantingFurrow making/coveringSeederAgricultural science

The invention discloses an agricultural seeder which comprises a rack, a furrow opener, a ridging covering device, a compacting machine, a ridge separator and a seed separator, and walking wheels are arranged on the rack. The agricultural seeder provided by the invention can realize single seeding by controlling the seed dividing wheel to rotate at a constant speed and the walking wheel to advance at a constant speed, seeding is uniformly performed at intervals, the control precision of the seeding density is improved, and meanwhile, the ridging and covering device, the compacting machine and the ridge dividing device sequentially roll the land, so that seed soil covering, compacting and accurate ridge dividing are realized, and the working efficiency is improved. The seeding quality and the seeding efficiency of the seeding machine are favorably improved, and the seeding machine is suitable for seeding soybeans, corns, Chinese yams, garlic and the like and high in practicability.

Owner:黑龙江省农业科学院大豆研究所

Pneumatic centralized conveying type seed distribution system based on electrostatic attraction and seed separation operation method

ActiveCN113692813AImprove seeding consistencyImprove sowing qualityAgriculture gas emission reductionSeed depositing seeder partsElectric machineAgricultural engineering

The invention provides a pneumatic centralized conveying type seed distribution system based on electrostatic attraction and a seed separation operation method. The seed separation operation method comprises the steps that the seeding rate and the seed feeding force of each row are detected in real time; the seed distribution system is adjusted in real time; the seeding consistency of each row is improved; the seeding rate is accurately controlled; and then the seeding quality is improved. The pneumatic centralized conveying type seed distribution system based on the electrostatic attraction comprises a rack, a seed box, a seed separation device, a seed metering device and a pneumatic centralized conveying device, the seed metering device comprises a seed metering wheel, a seed metering motor and a seed metering box, the seed metering box is located below a seed falling opening, the seed metering wheel is located in the seed metering box, and the seed metering wheel is driven by the seed metering motor; the pneumatic centralized conveying device comprises a fan and a conveying pipe; the seed separation device comprises a seed separator, a bulge is arranged at the top end of an inner cavity of the seed separator, and a plurality of seed guide pipes are connected below the seed separator; a seed separation quantity adjusting device comprises electrostatic generators and gravitation plates, the gravitation plates are positioned in the conveying pipe close to the upper end, and the electrostatic generators are arranged outside the gravitation plates.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI +1

The cleaning method of bract snow lotus fruit

ActiveCN106385867BSolve cleaning difficultiesReduce chances of getting germsSeed and root treatmentInfructescenceAsteraceae

The invention discloses a cleaning method of saussurea obvallata fruits. The cleaning method includes steps: drying the saussurea obvallata infructescence; using a rubber plug to slightly rub the infructescence on a stainless steel screen net of 1.4-2.36mm in mesh size to enable fruits to shed out from involucre and to be separated from pappus; putting fruits and a small part of pappus mixture in an underframe into a seed separator, selecting to use wind power when rotating speed of a fan is 12-25.46Hz to enable full fruits to be separated from empty fruits, fruits damaged by insects and pappus; manually picking out remaining residue and mixed fruits; using paper bags to pack fruits after being cleaned. The cleaning method is simple and easy to implement and short in needed cleaning time; each of fullness ratio and purity of the fruits after being cleaned can reach 100%, storage space of the fruits in a refrigeratory can be reduced effectively, and convenience is brought to subsequent fetching and using of the fruits. The cleaning method is suitable for cleaning other fruits of the Saussurea DC. and can be used for cleaning other seeds of asteraceae on the condition of changing mesh size of the stainless steel screen net and the rotating speed of the seed separator.

Owner:KUNMING INST OF BOTANY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com