Patents

Literature

181results about How to "Improve shelling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double vibration shucking and separation method and device for oil camellia fruits

InactiveCN104998816AImprove shelling efficiencyReduce the broken seed rateSievingScreeningCamellia oleiferaAgronomy

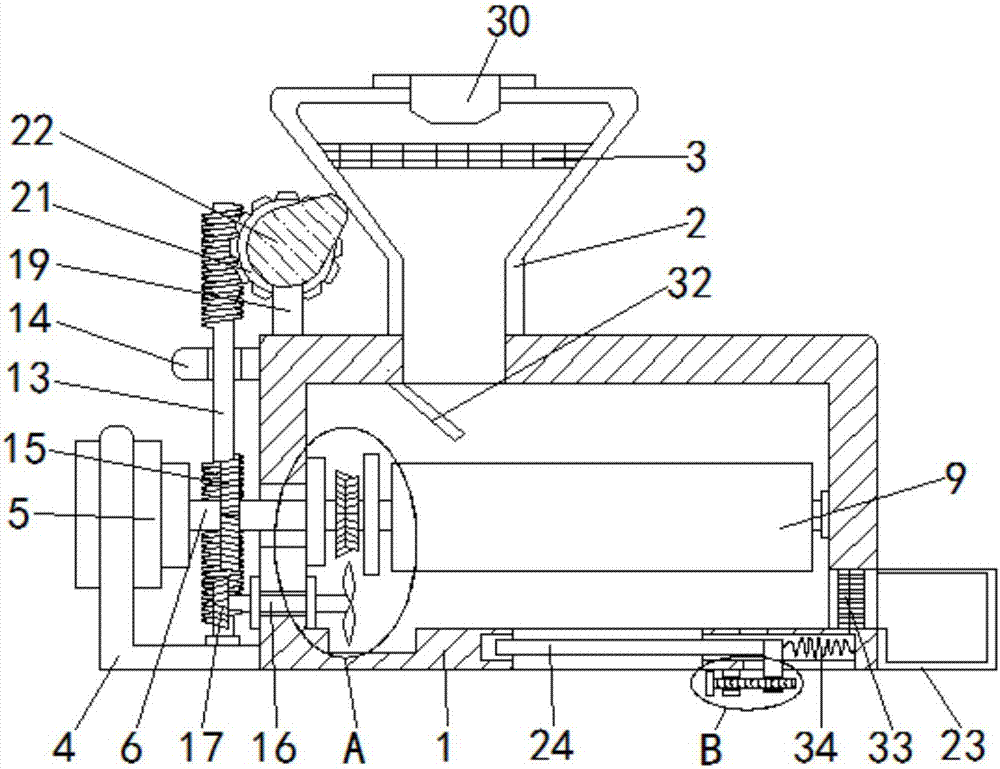

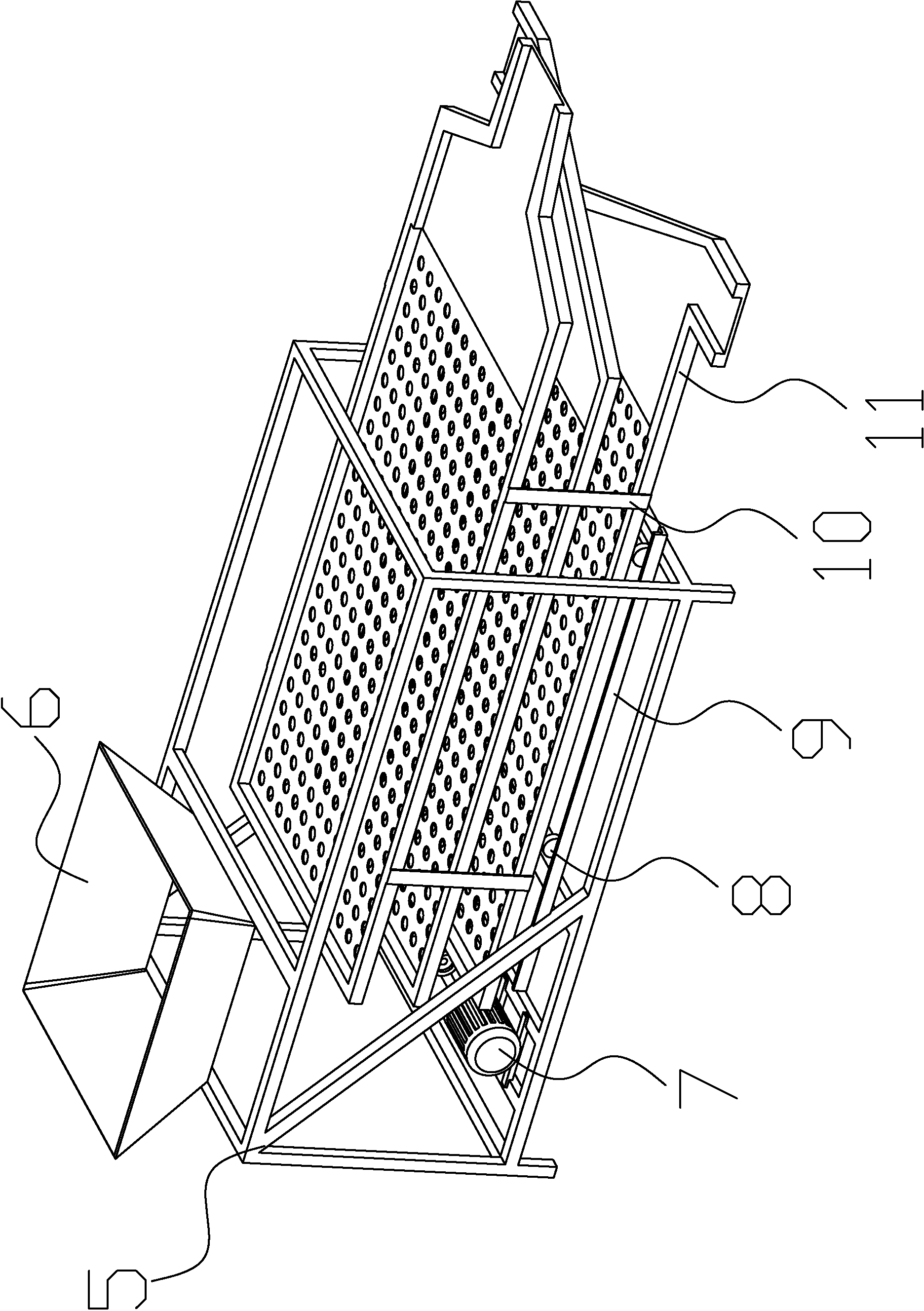

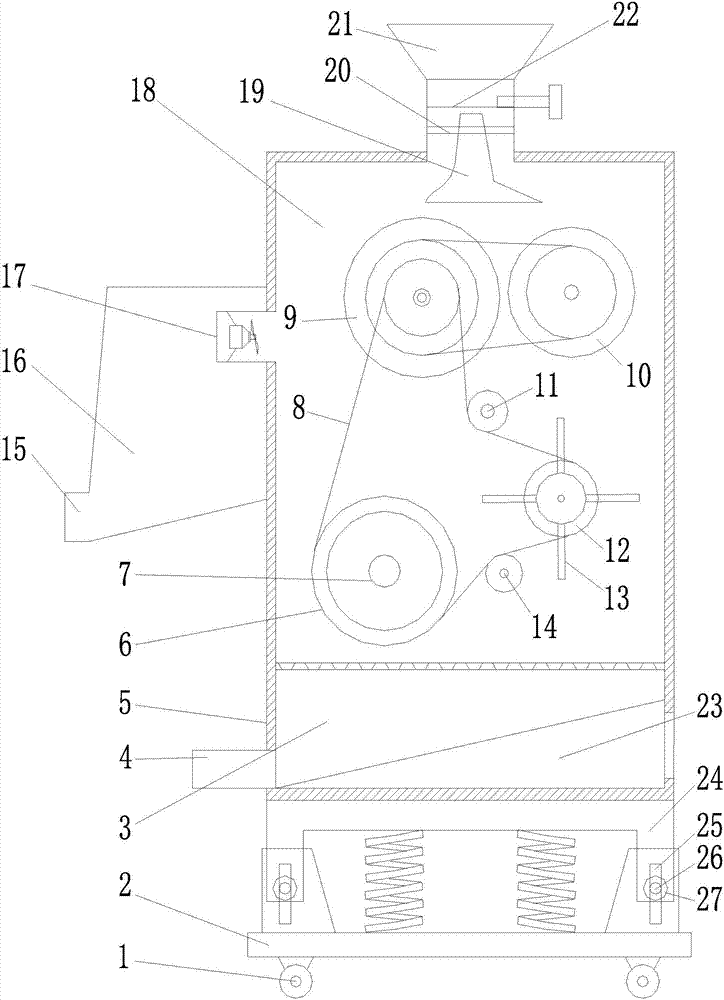

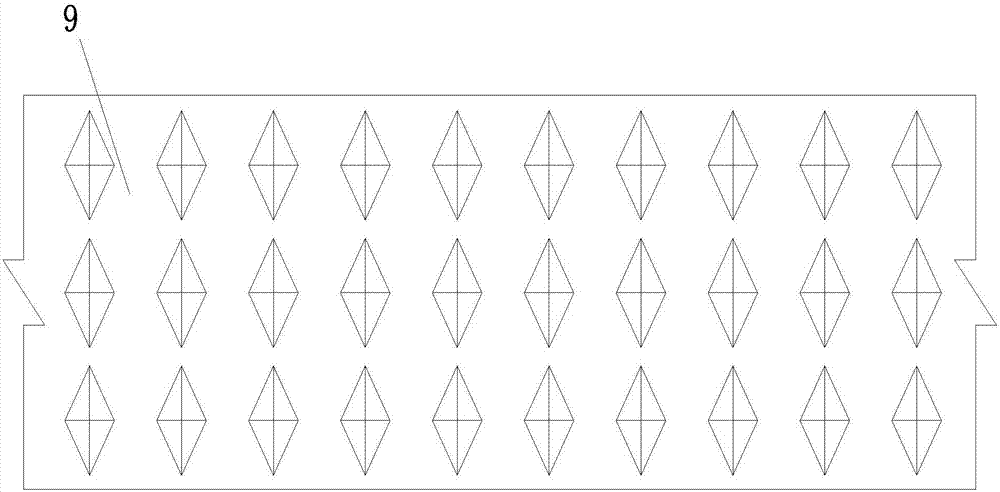

The invention discloses a double vibration shucking and separation method and a device for oil camellia fruits. The method is characterized in that shucking and separation of the oil camellia fruits are carried out by adopting a multistage vibration mode; the oil camellia fruits are subjected to classification separation by a classification vibration system, which allows the oil camellia fruits to be subjected to size classification through vibration; the oil camellia fruits after the classification are put in an oil camellia fruit shucking and separation device or discharged; and the oil camellia fruits entering the oil camellia fruit shucking and separation device are shucked, and then subjected to vibration separation by a separation vibration system, thereby realizing cleaning separation of an oil camellia shell and seed mixture. According to the method and the device, the classification separation of the oil camellia fruits is realized by two stages of vibration; the method is suitable for the shucking and the separation of the picked fresh oil camellia fruits or the oil camellia fruits subjected to stack retting treatment; the cleaning separation effect is good; and the efficiency is high.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

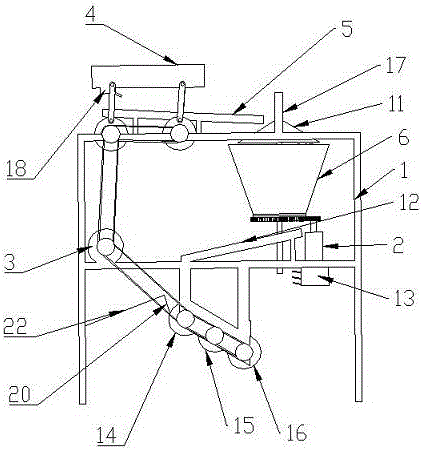

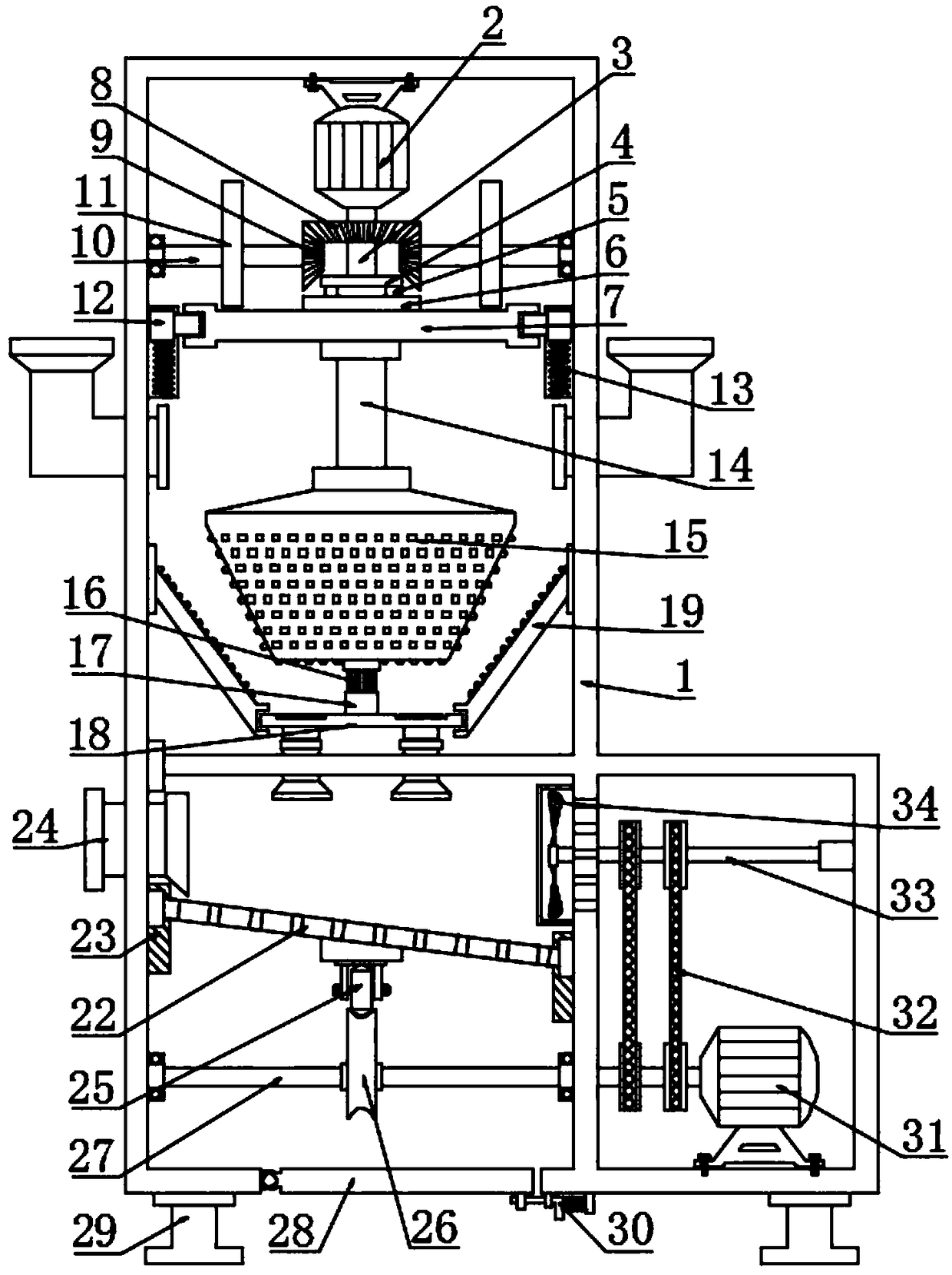

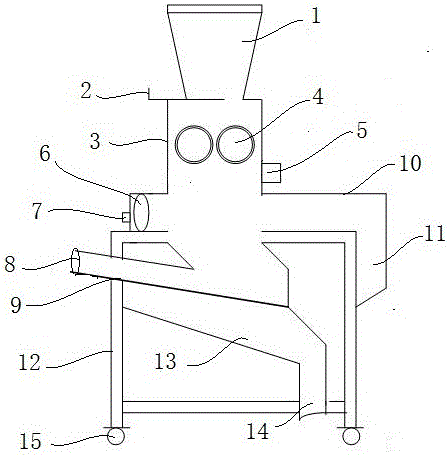

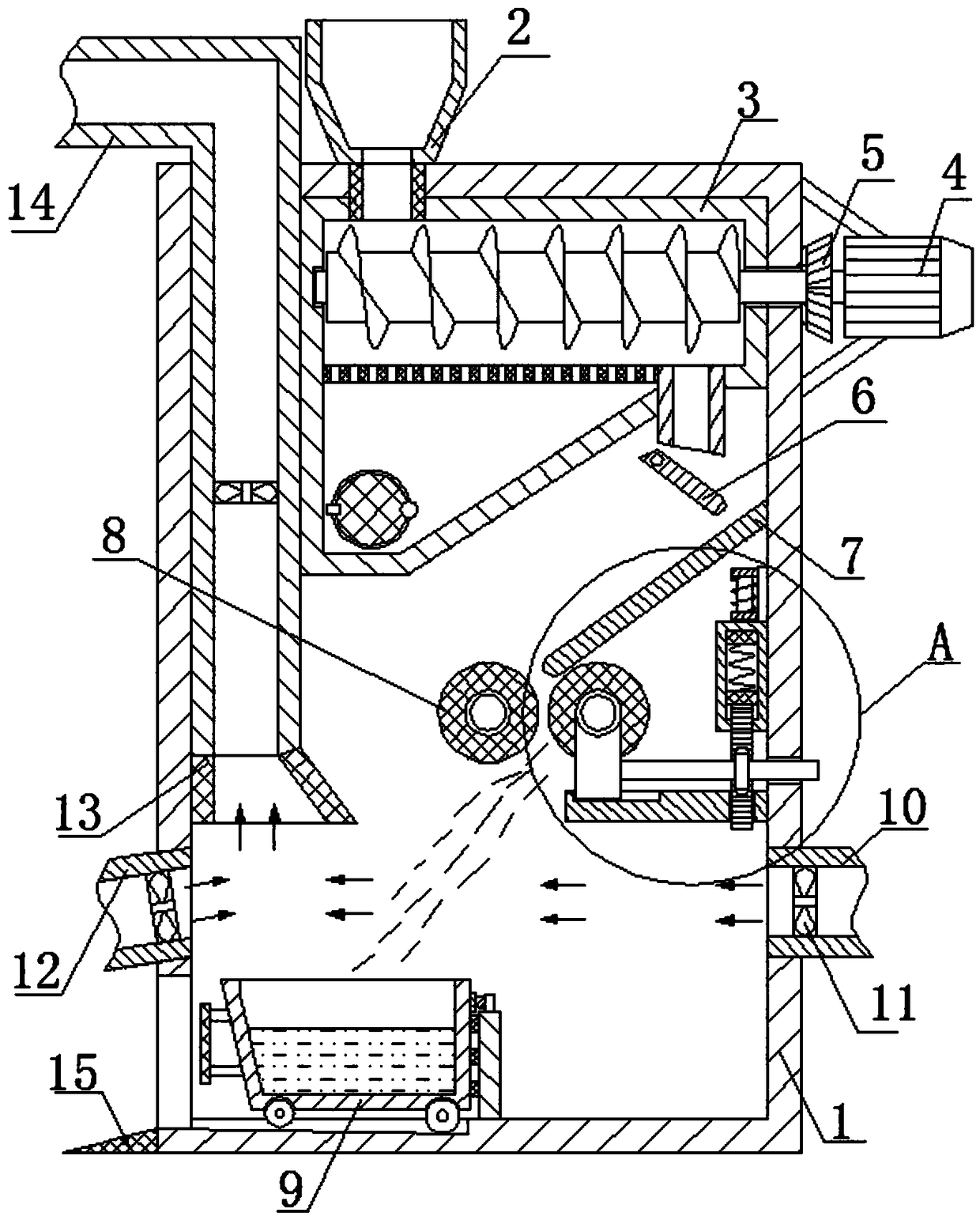

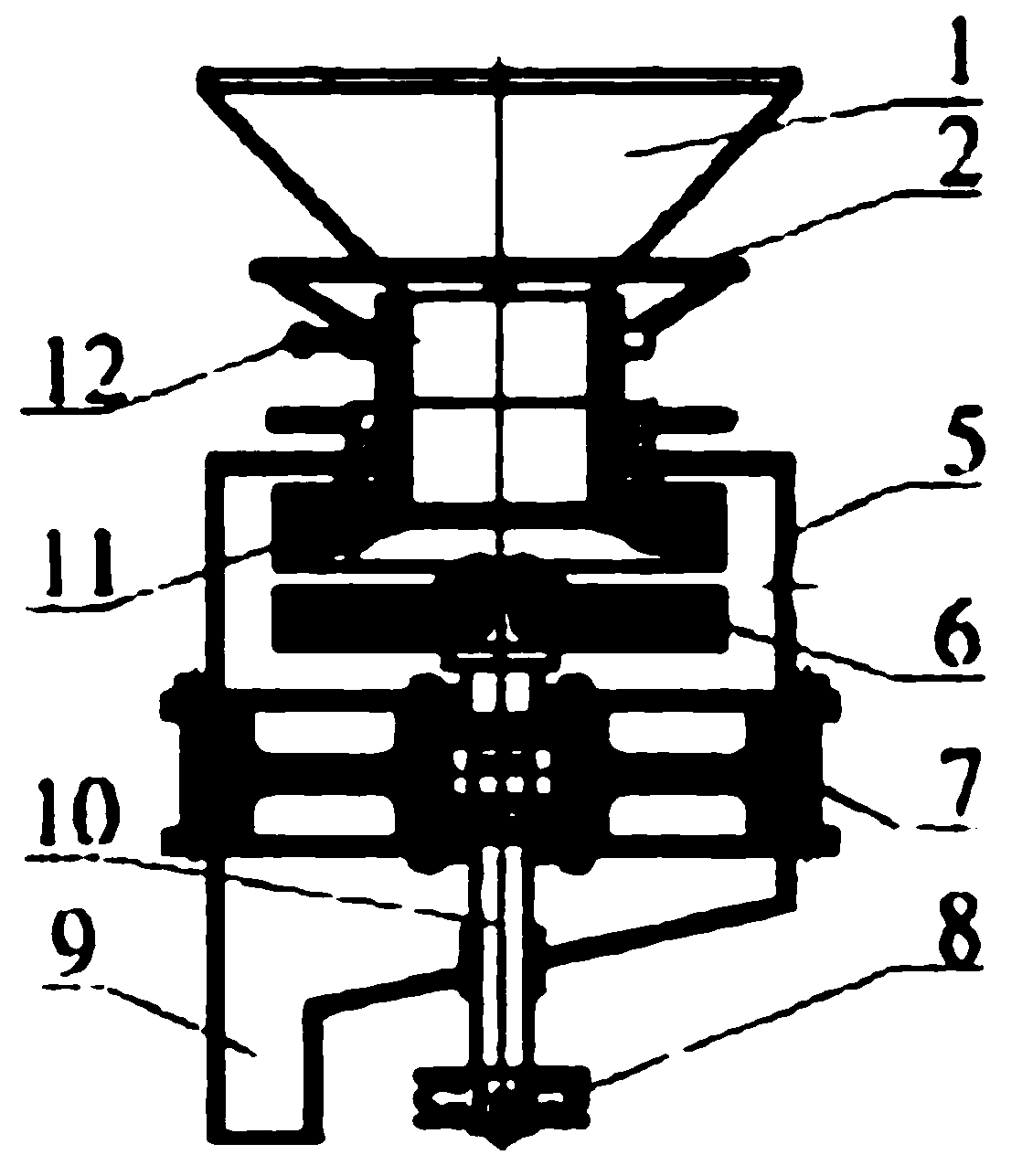

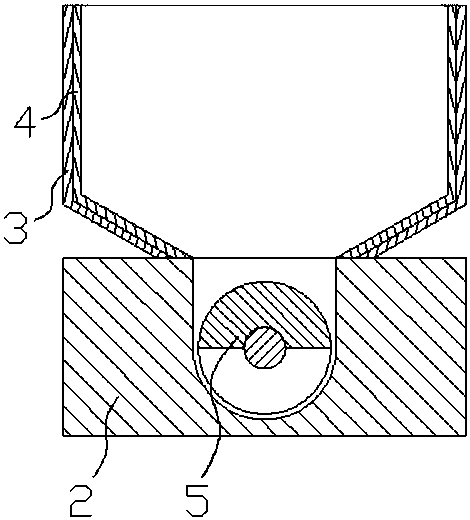

Peanut huller

InactiveCN102028299AEasy to separateAvoid stayingHuskingHullingAgricultural engineeringStructural engineering

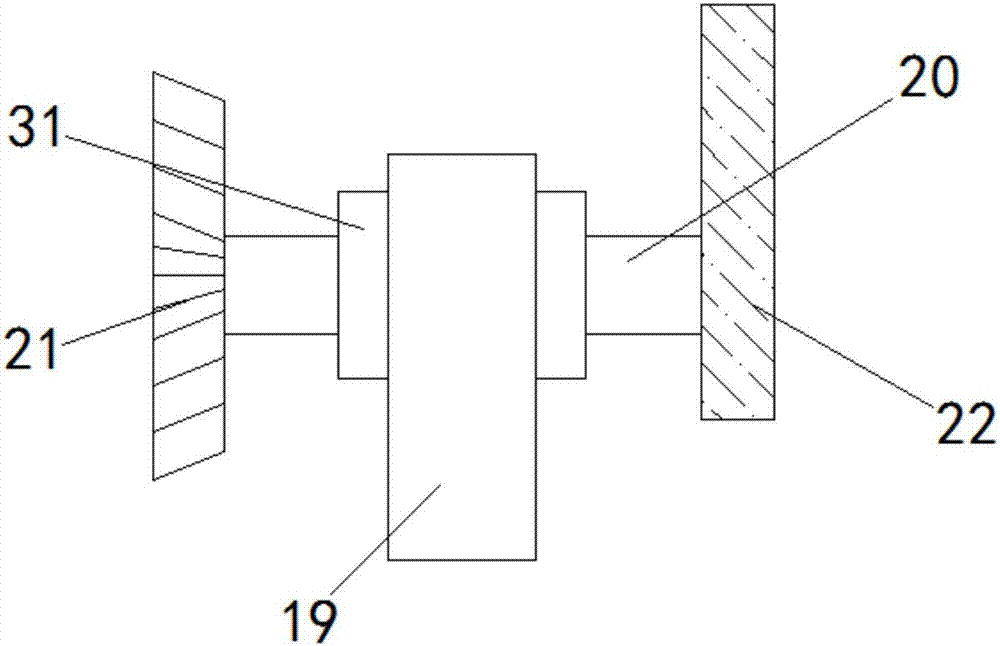

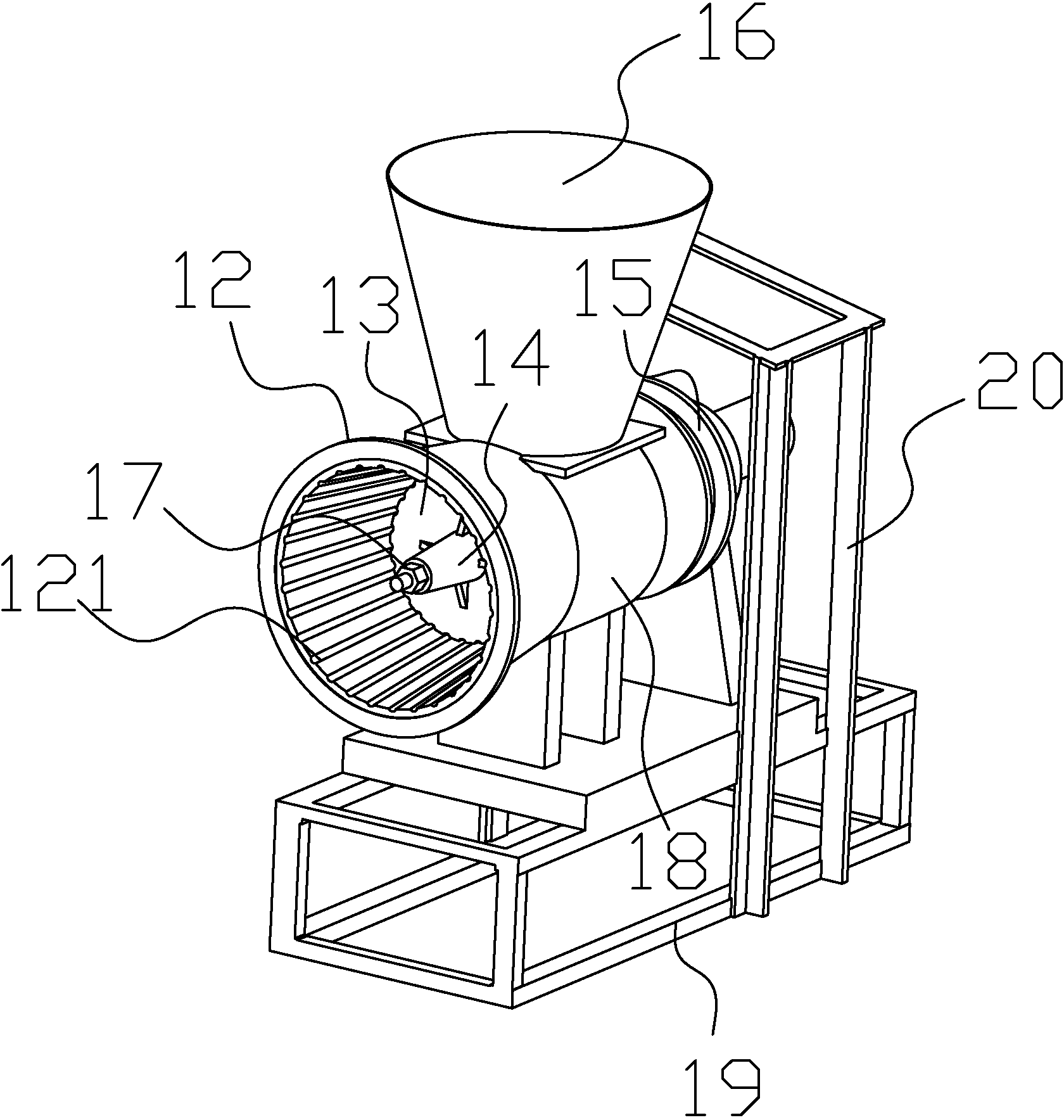

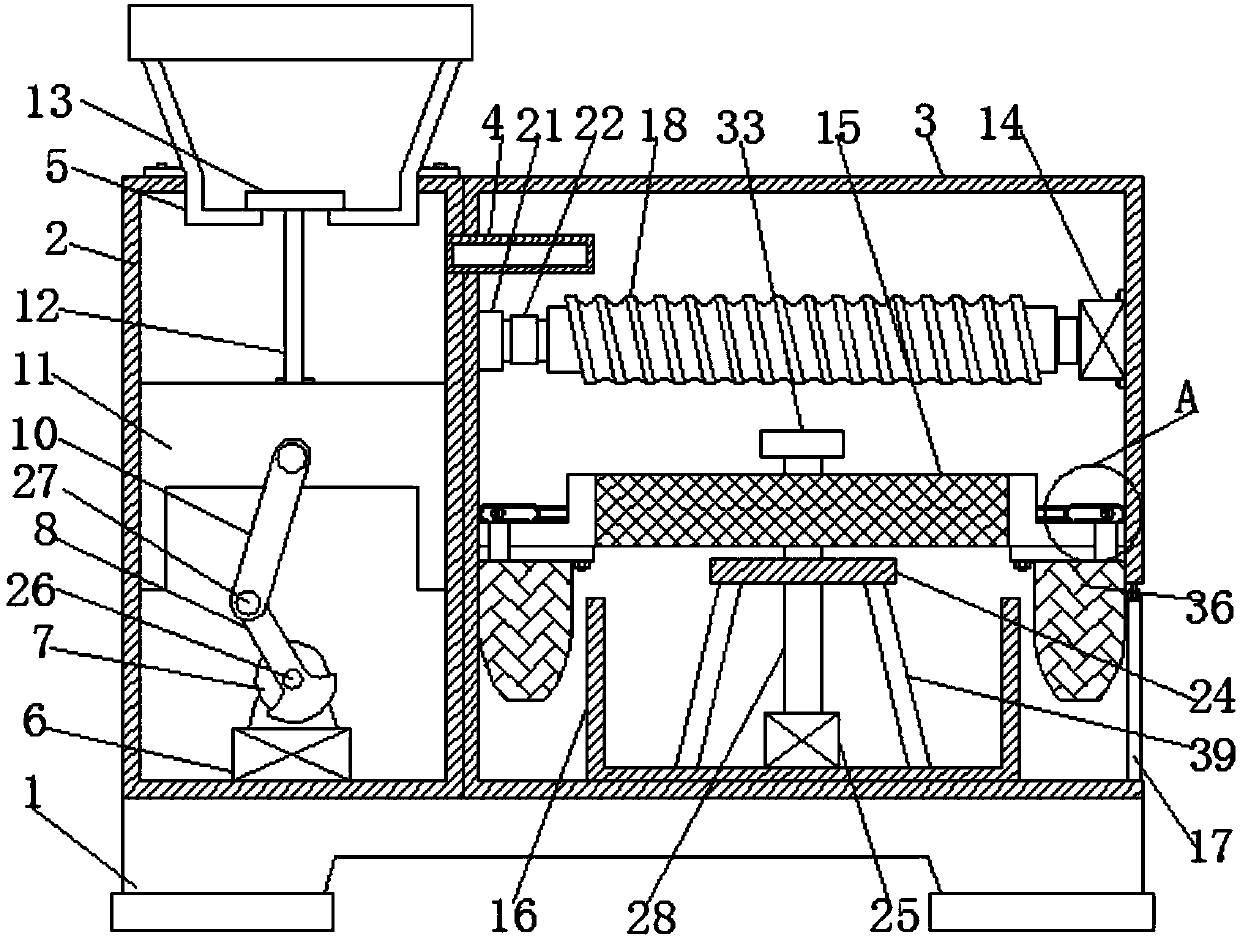

The invention relates to a peanut huller which is characterized by comprising a feeding hopper, a rotary drum, a rotary drum shaft, a notch board sieve, a material collecting drum, a material receiving board, a motor and a rack; the exterior of the rotary drum is fixed with an inverted cone-shaped vertical type hollow drum with spiral bulged ribs; the notch board sieve is also in an inverted cone shape; the annular hulling region between the rotary drum and the notch board sieve is gradually contracted from top to bottom; and the upper end of the rotary drum is provided with a cone-shaped uniform distributor with a spiral rib board. The peanut huller has the advantages that a vertical type hulling mode is adopted; the large area of the notch board sieve is effectively utilized and the hulling speed is enhanced so as to enhance the hulling efficiency; the rapid separation of peanuts from the hulling region is realized so as to avoid the peanuts from remaining in the hulling gap; the damage is decreased so as to reduce the damage rate of the peanuts; thus, the peanut huller can automatically adapt to the actual condition of different shape sizes of the peanuts; the hulling damage is lightened, and the completely hulling rate and the hulling efficiency are enhanced; and the hulling gap can be adjustable to adapt to the hulling of the peanuts with different varieties and shape sizes.

Owner:SHENYANG AGRI UNIV

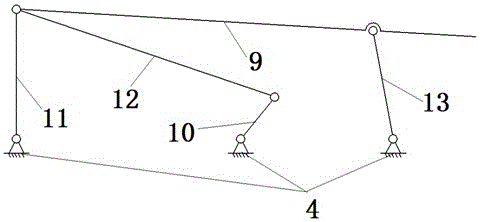

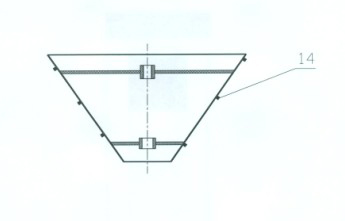

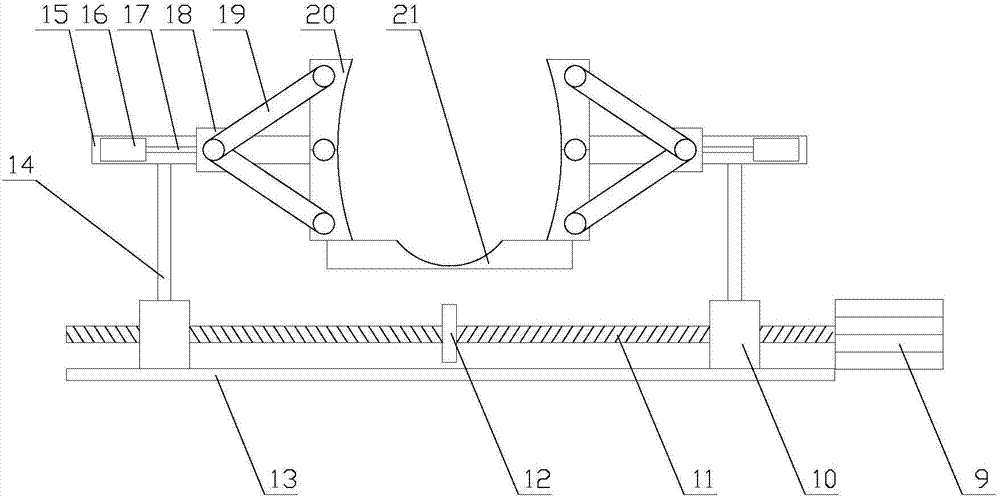

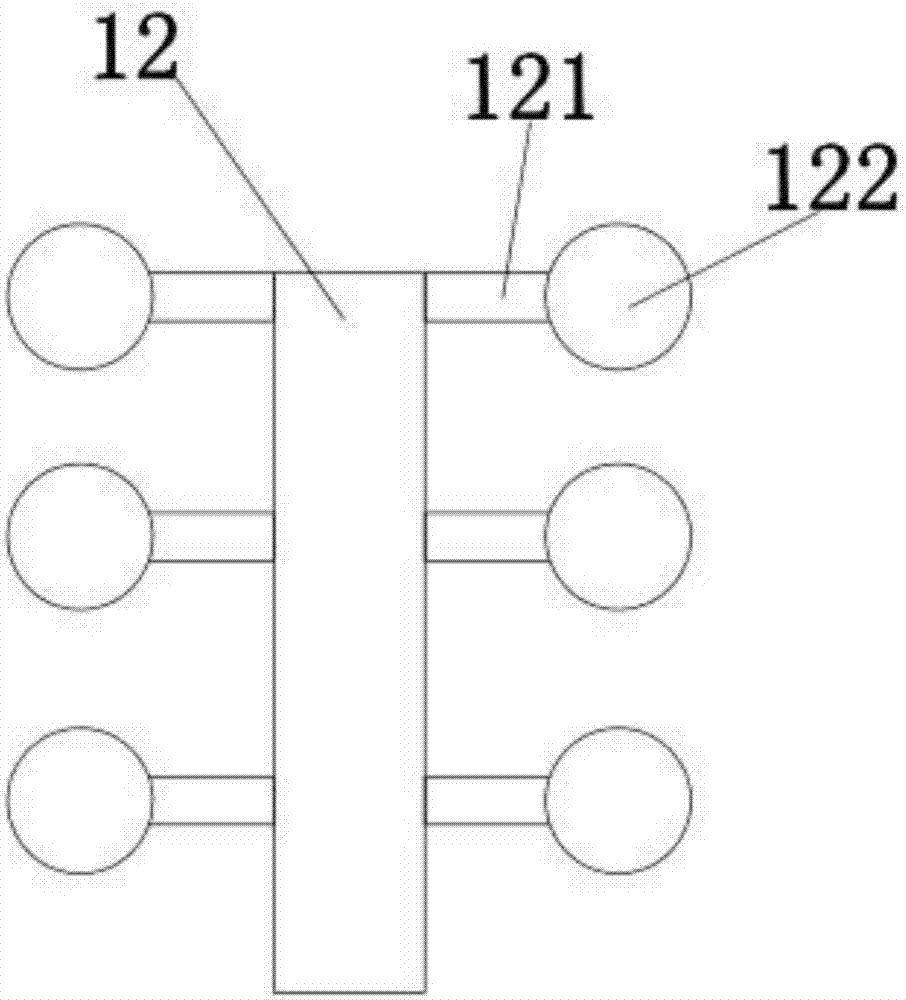

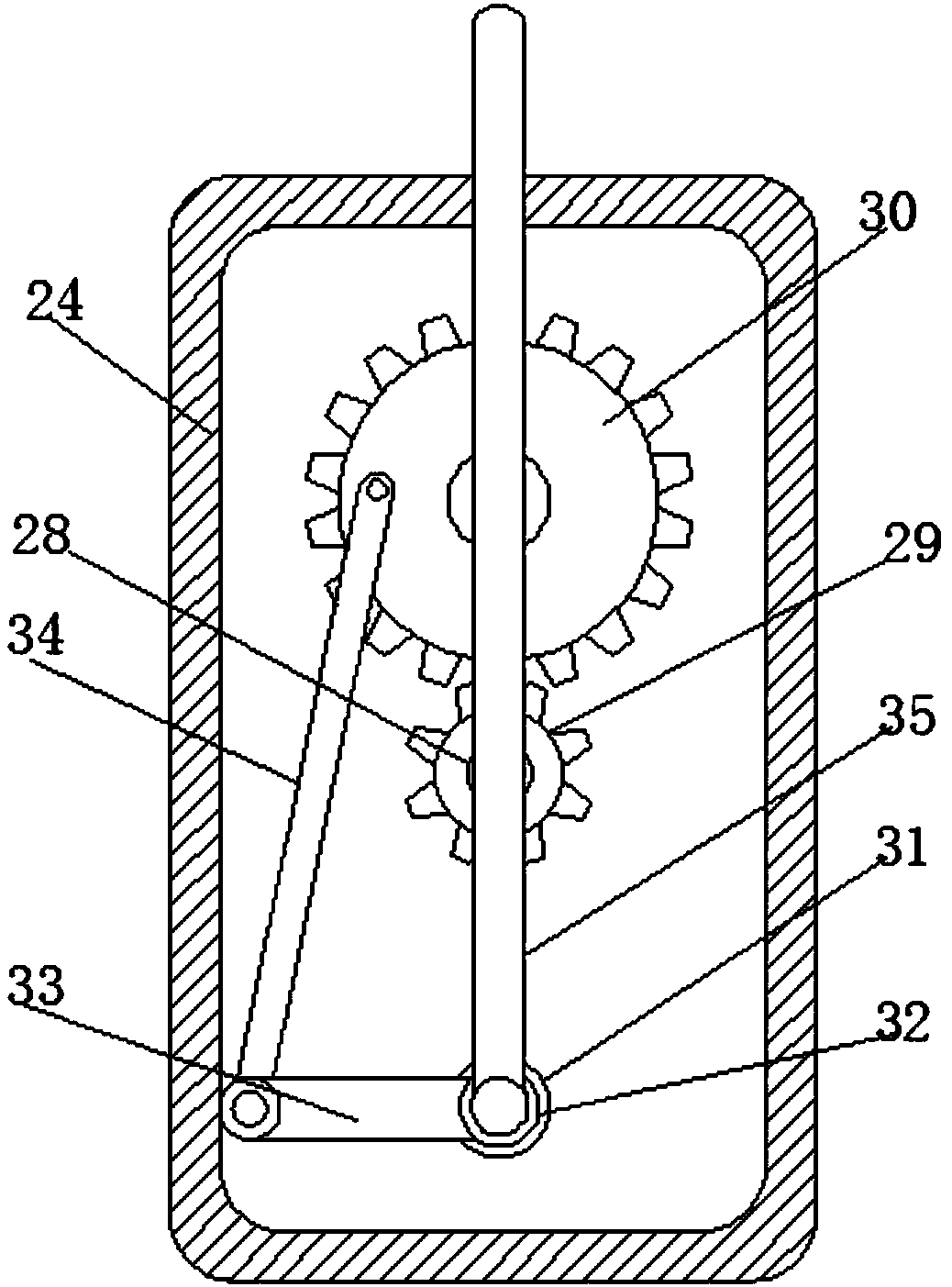

Graded peanut huller

InactiveCN105852155AReduce breakage rateEasy to separateSievingGas current separationEconomic benefitsEngineering

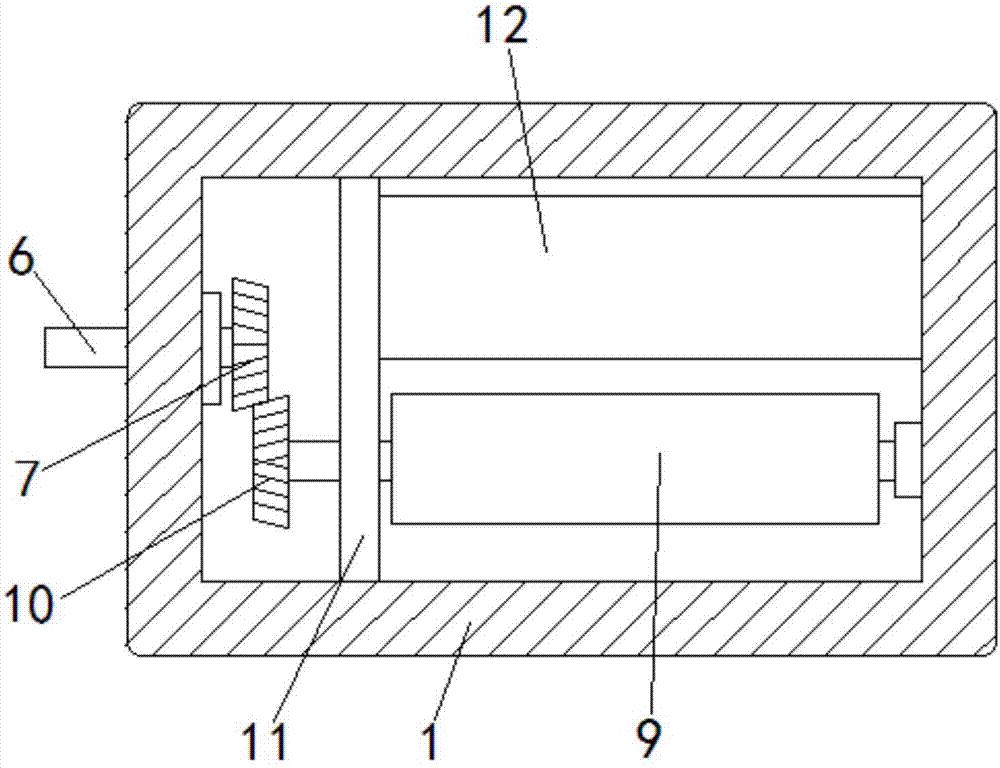

The invention provides a graded peanut huller. A power device of the graded peanut huller is respectively connected with a screening device, a hulling device and a collection device; the collection device is arranged under an outlet of the hulling device and comprises three rollers and a belt and is capable of collecting and distinguishing peanuts of different sizes; the hulling device comprises a feeding hopper and a hulling drum; the hulling drum comprises an inner part and an outer part, the inner side of the hulling drum is provided with an umbrella-shaped structure connected to a shaft, the umbrella-shaped structure is of a four-link mechanism, and the outer side of the hulling drum is provided with a roller, and rubber is adhered to the inner wall of the roller; a power device is of a dual-direction rotating motor and a single-direction rotating motor; the bottom of the vibrating screen is provided with three valves; a single chip microcomputer is adopted for control; in combination with the umbrella-shaped structure, and by aiming at different species, peanuts of different sizes are fed and hulled; the control device consists of a K51 single chip microcomputer and a stepping motor. The graded peanut huller is of an adjustable umbrella-shaped structure, and is capable of not only hulling peanuts of different sizes, but also reducing phenomena of peanut breakage caused by overhigh rigidity of the roller and improving the economic benefits.

Owner:NANCHANG UNIV

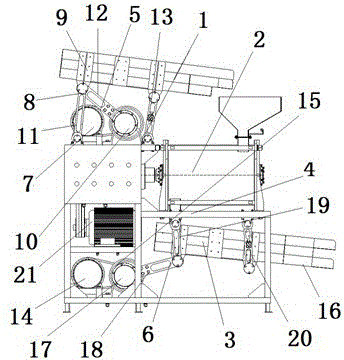

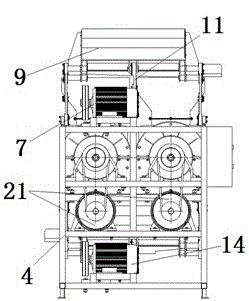

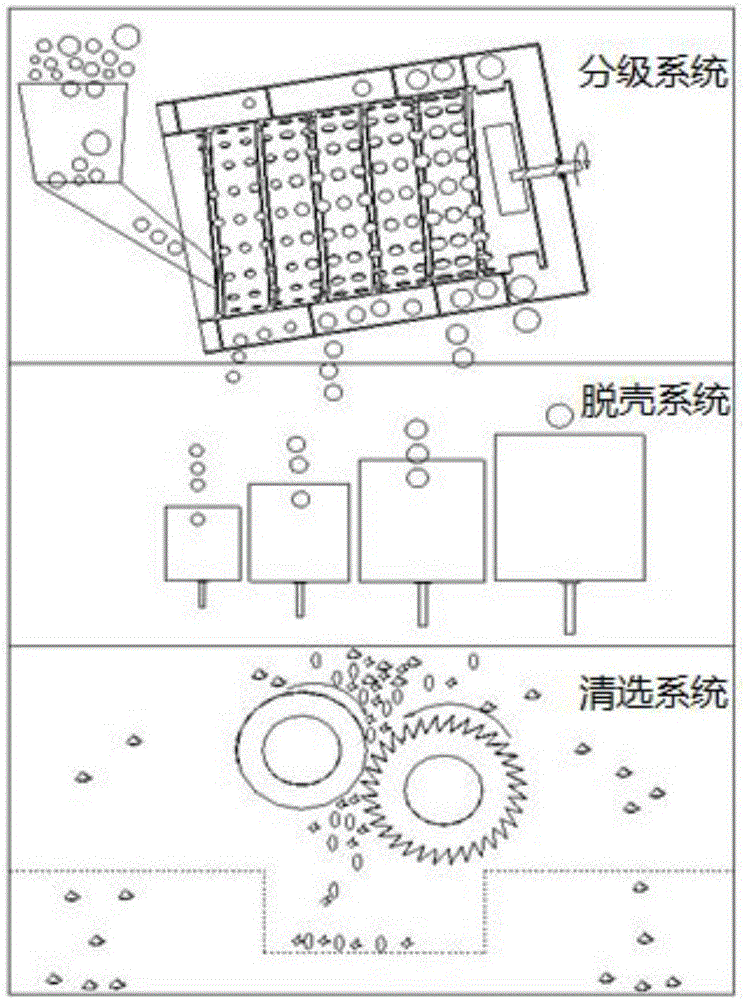

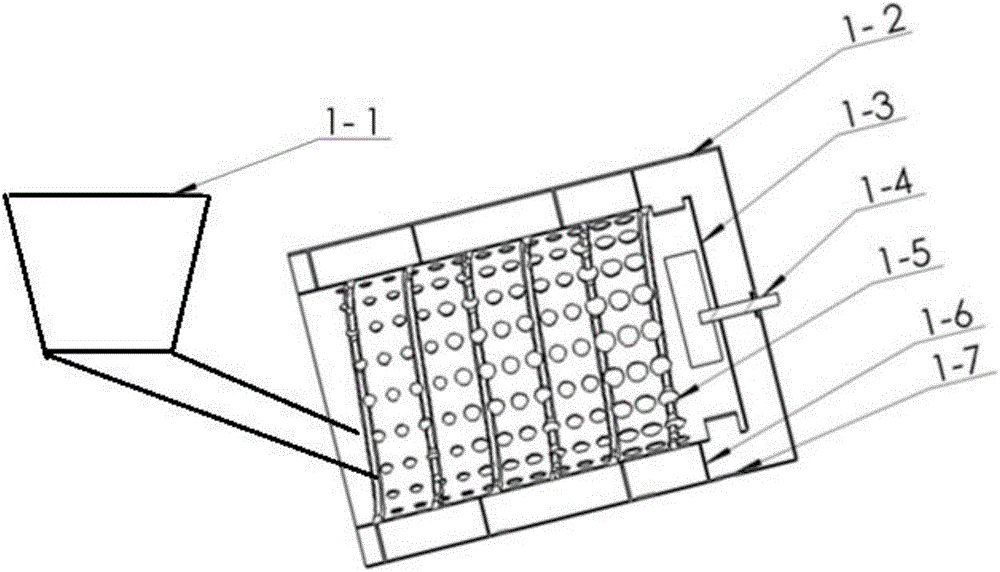

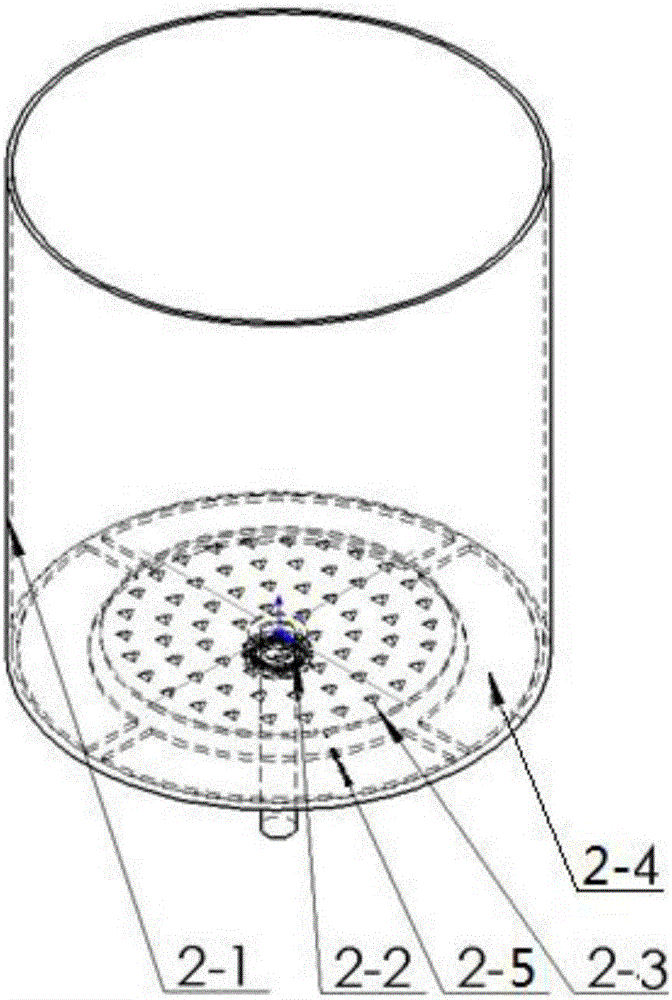

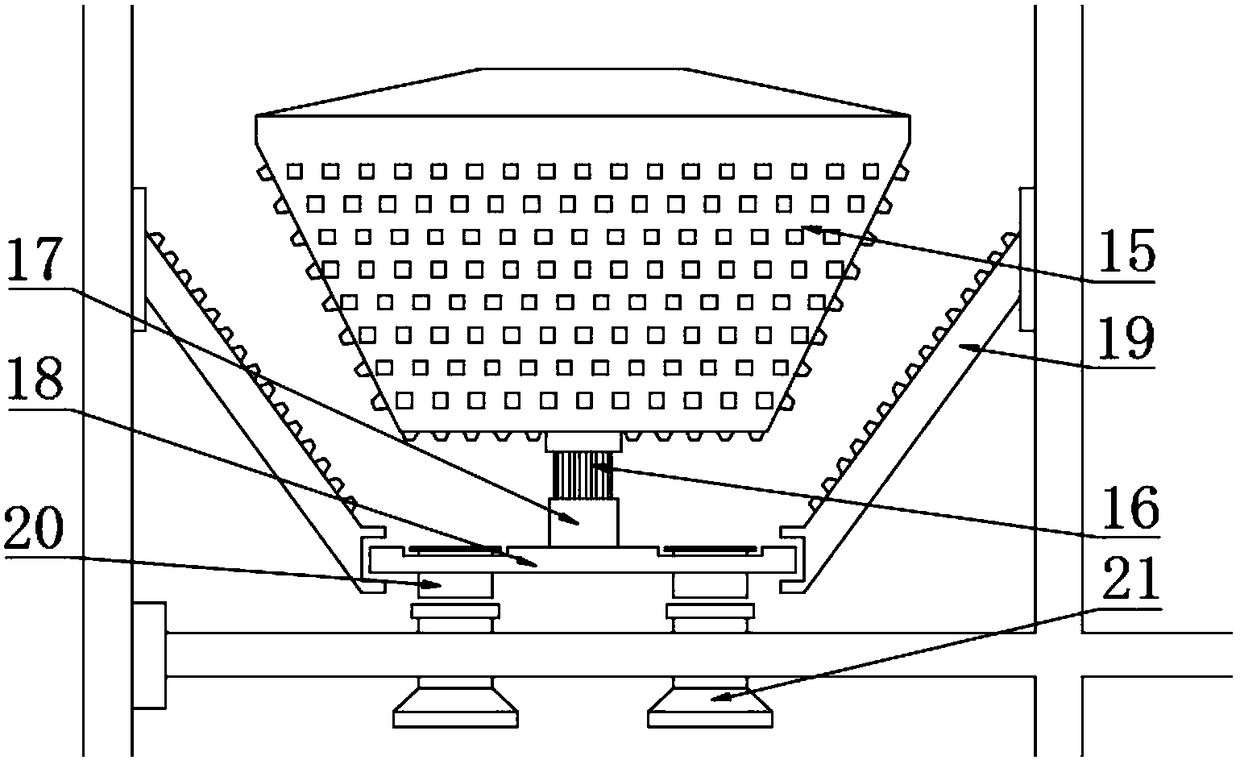

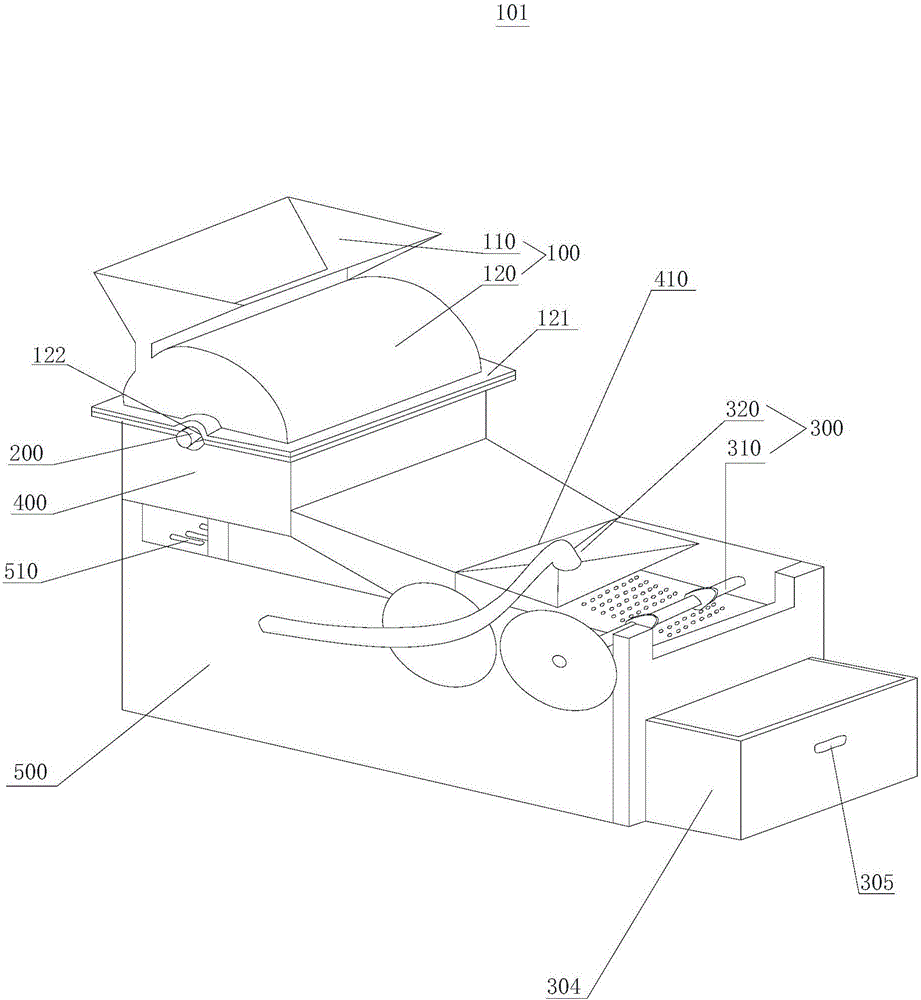

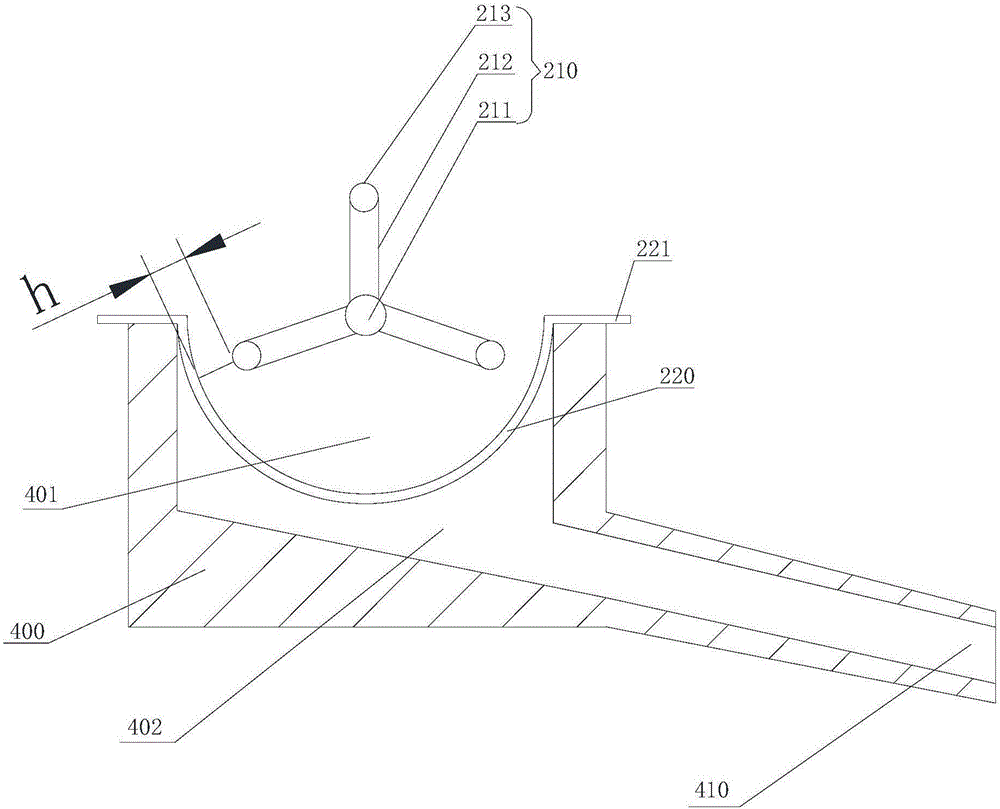

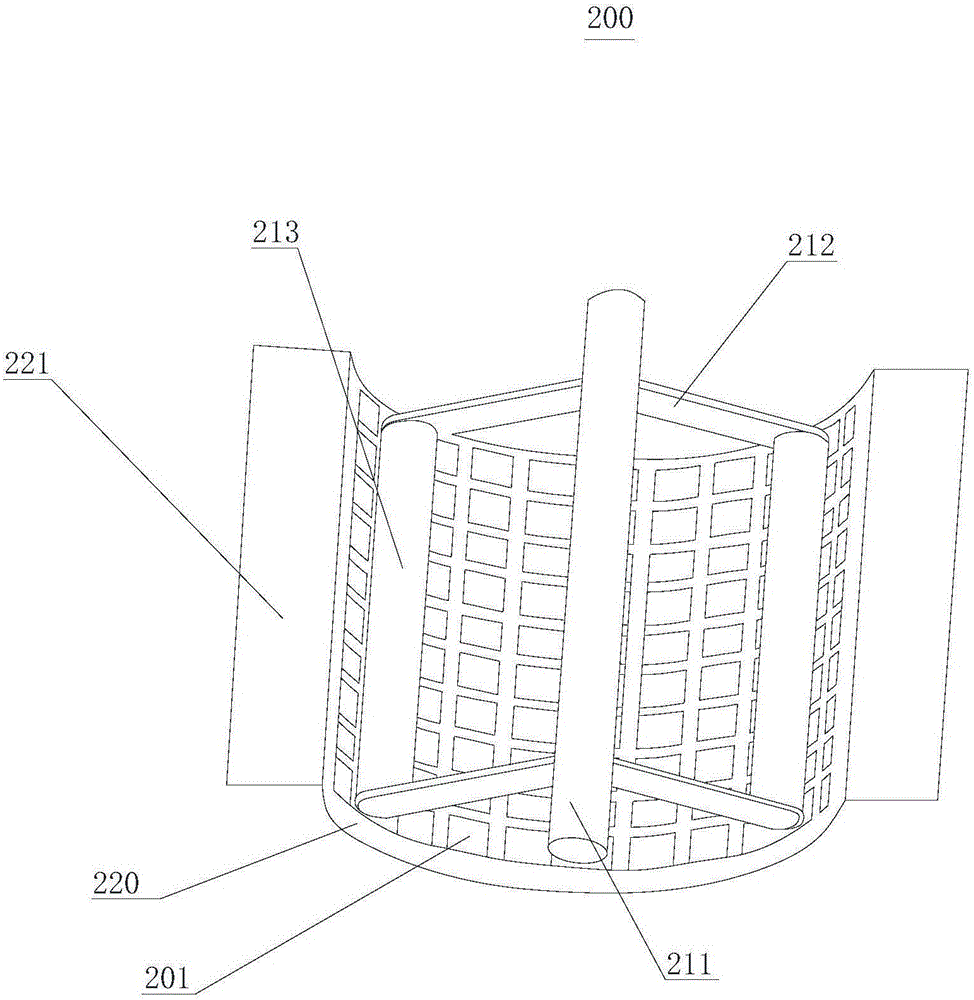

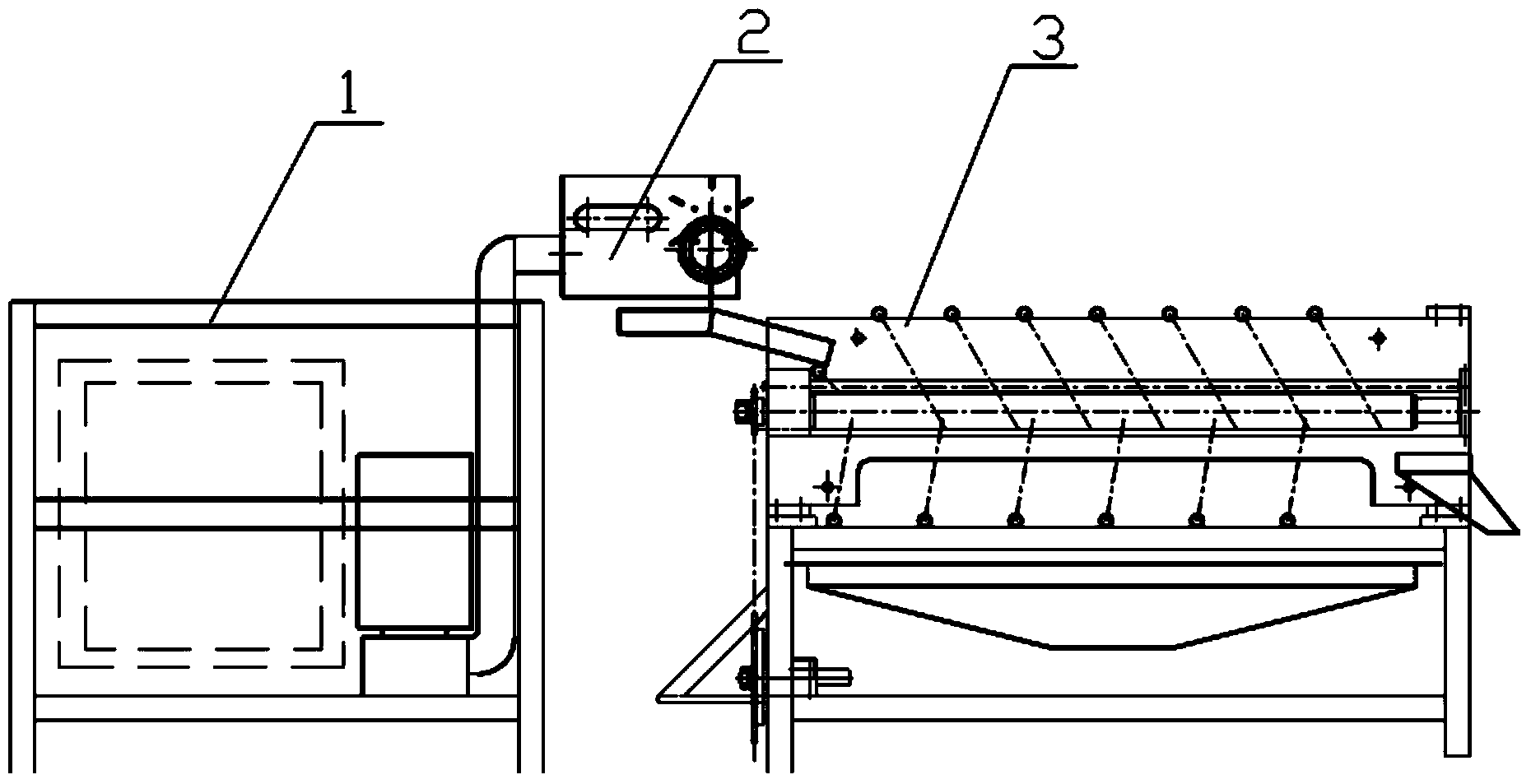

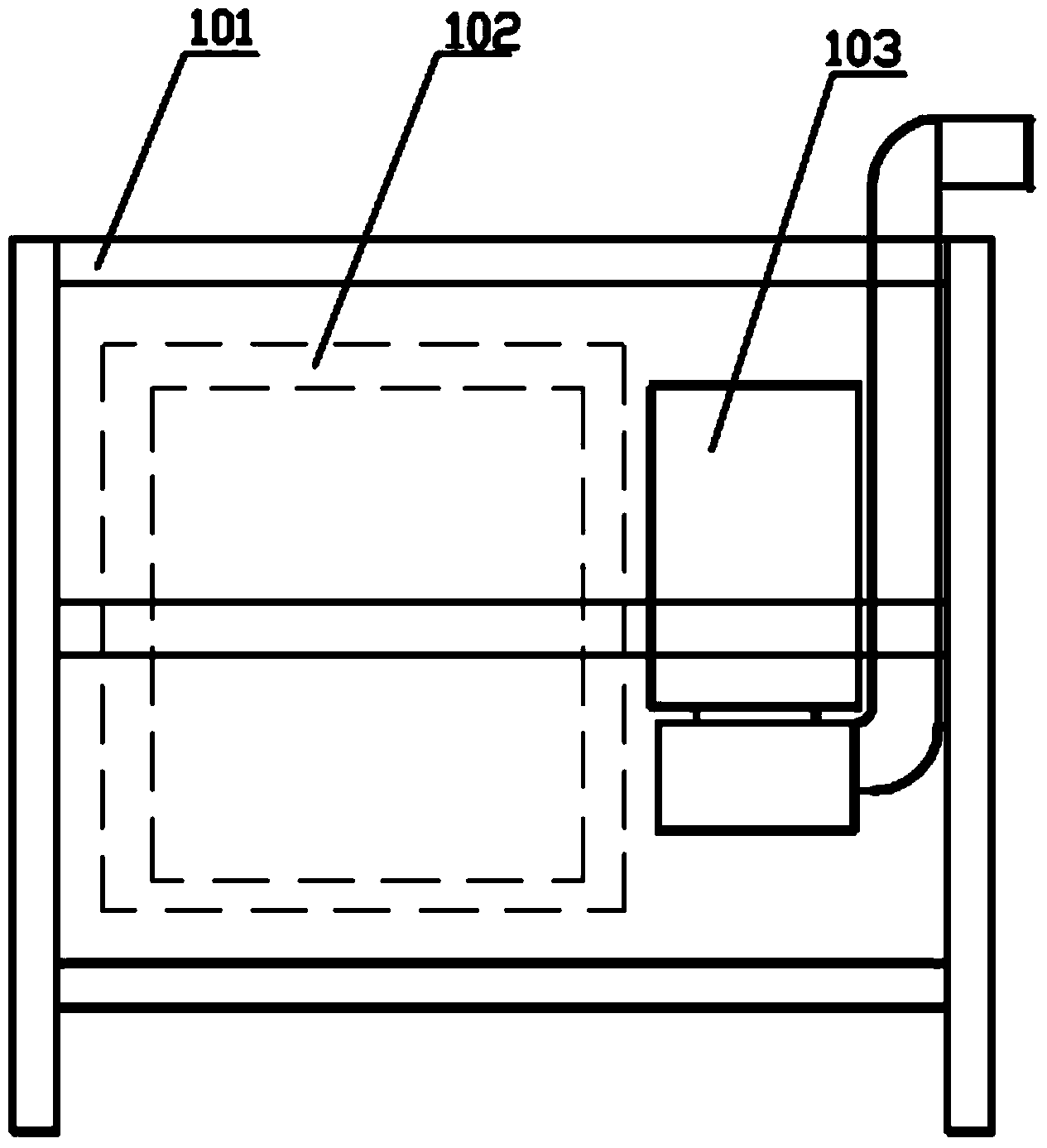

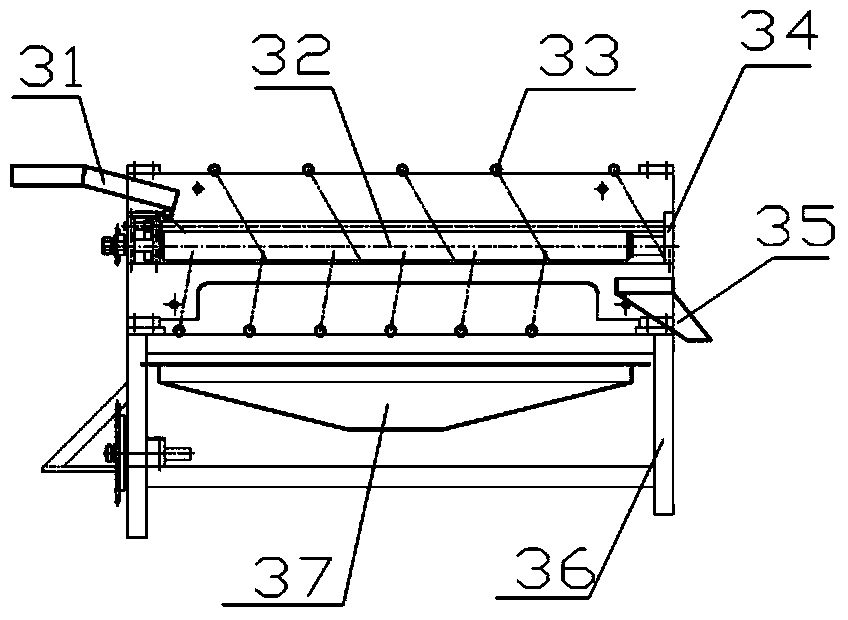

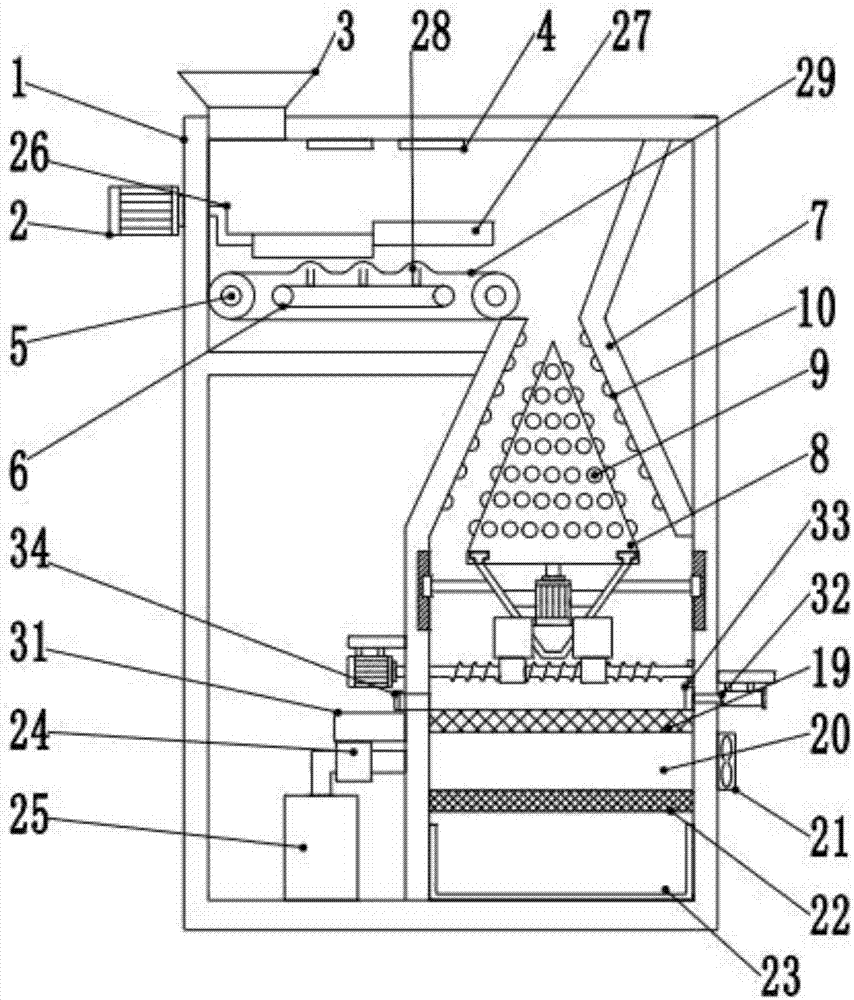

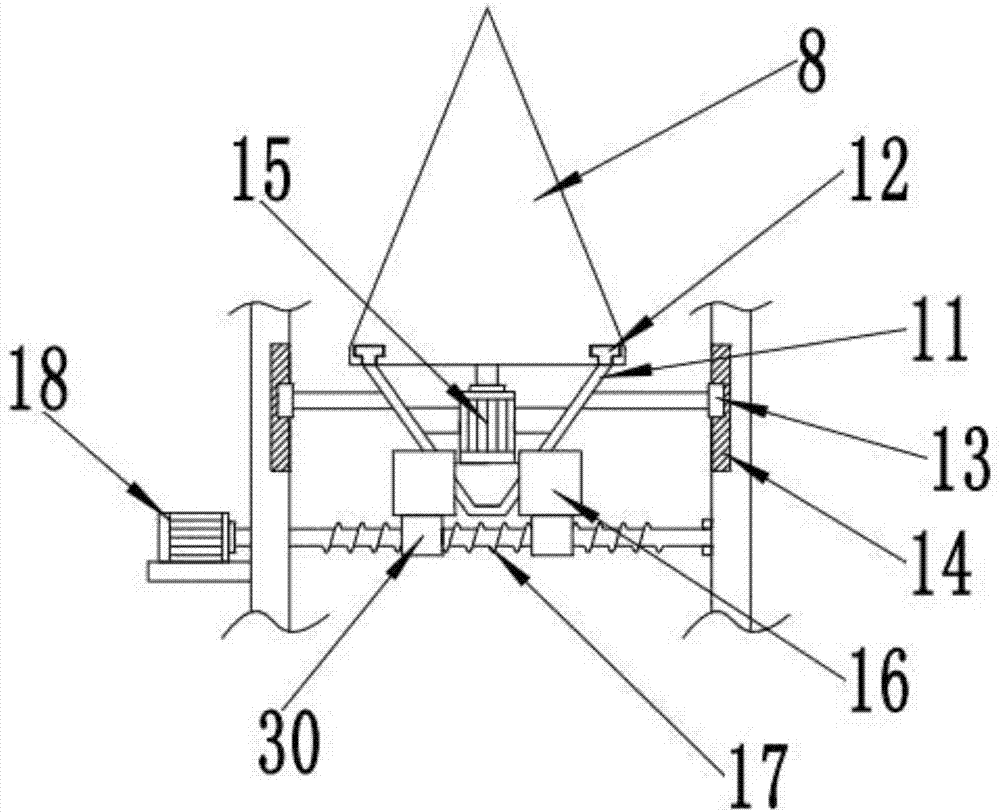

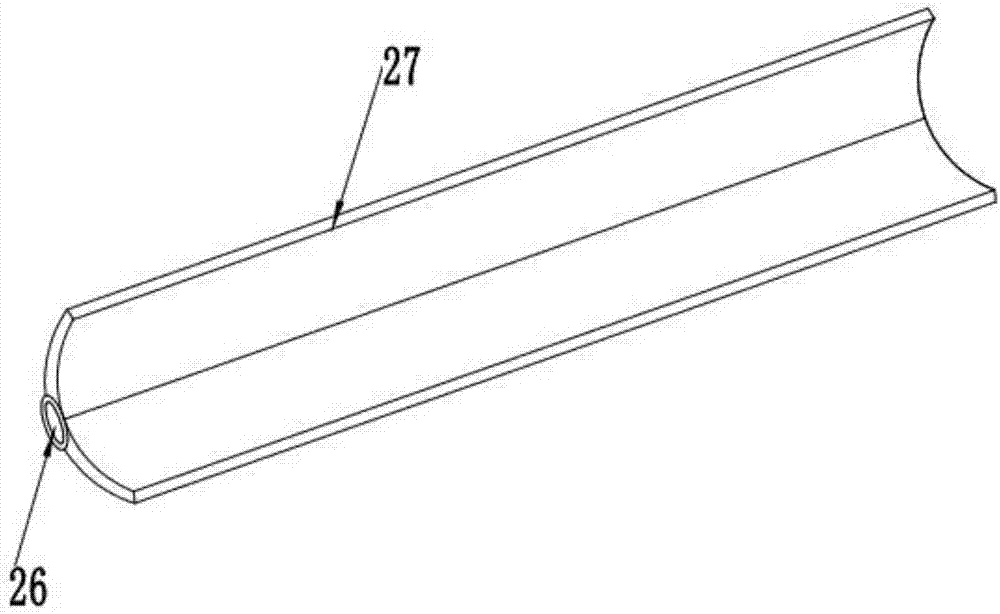

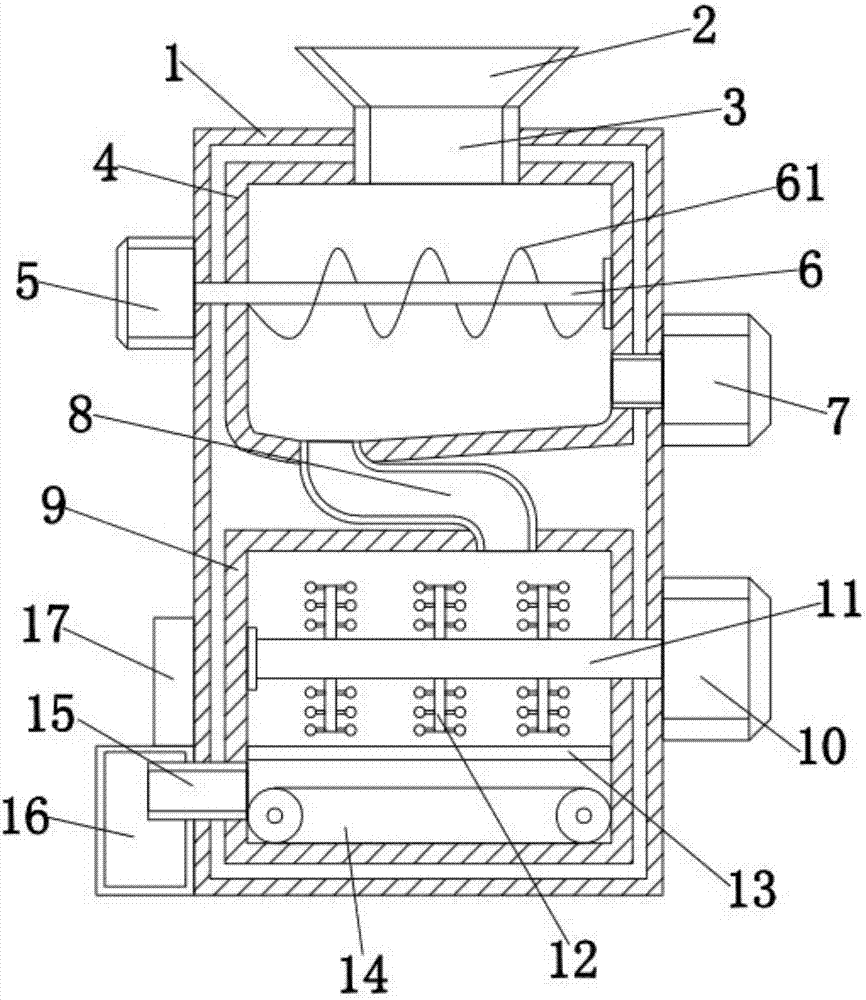

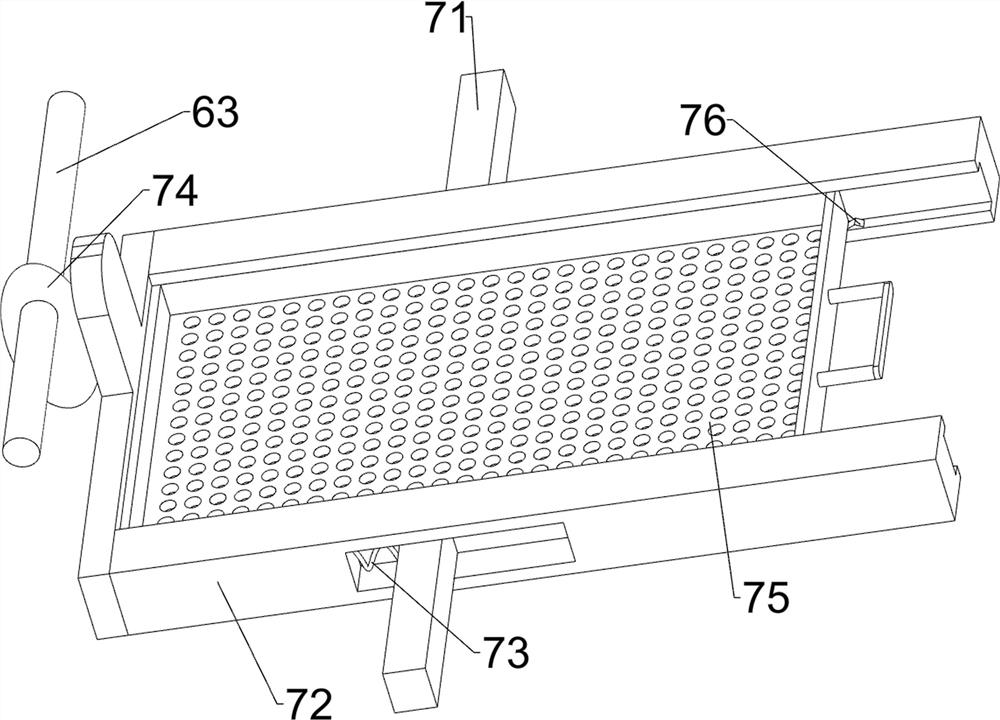

Fresh oil tea fruit grading and shelling cleaner and method

InactiveCN106475301AEfficient shelling and screeningImprove shelling efficiencySievingScreeningEngineeringGrade system

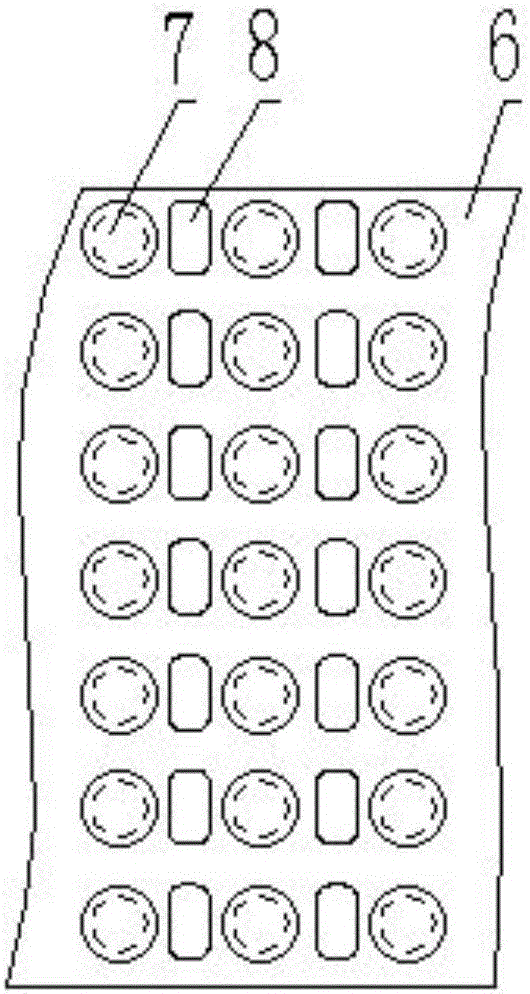

The invention discloses a fresh oil tea fruit grading and shelling cleaner and method. The fresh oil tea fruit grading and shelling cleaner comprises a grading system, a shelling system and a cleaning system, wherein the grading system is a of nested structure including a fixed outer cylinder and a movable inner cylinder, the inner wall of the inner cylinder is provided with a guiding helix, round array holes are distributed in the cylindrical wall, the diameters of the array holes are increased in the motion direction of the helix, partition plates corresponding to diameter partition zones of the array holes are arranged in the outer cylinder, and low points in the areas among the partition plates are provided with corresponding-sized round holes. The shelling system is of a combined structure including a fixed cylinder and a disc-shaped knife board, the cylinder is free of an upper end cover to facilitate feeding, blades or a protruding structures are distributed on the knife board, and gaps distributed in an array mode are formed in a base plate of the cylinder facilitate discharging. The cleaning system is designed to be of a toothed smooth roll structure, the toothed smooth roll is arranged at a certain angle and rotate reversely, and the shell-seed separating purpose is achieved by combining a screen. The fresh oil tea fruit grading and shelling cleaner is mainly used for fresh oil tea fruit grading, shelling and cleaning.

Owner:TSINGHUA UNIV

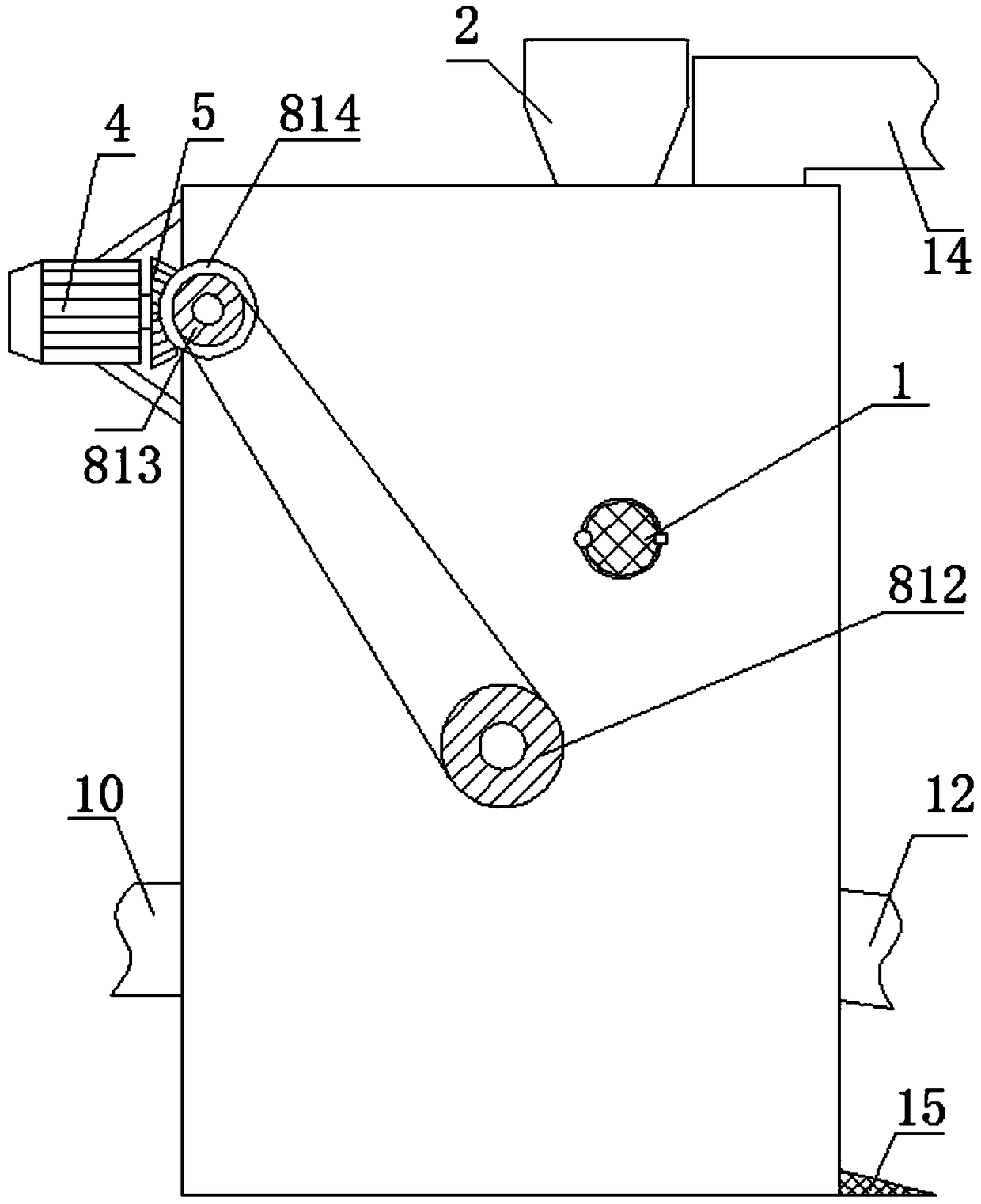

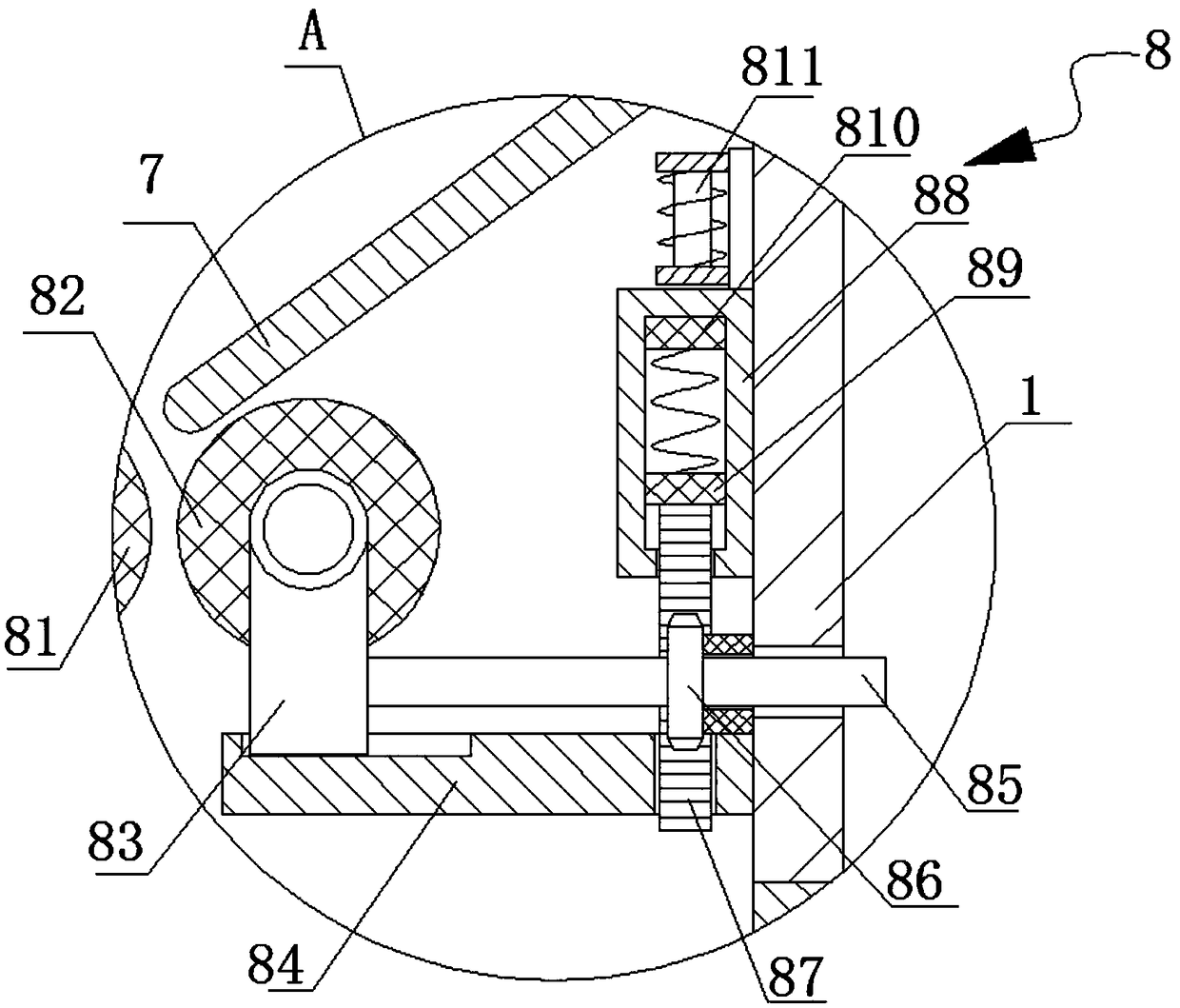

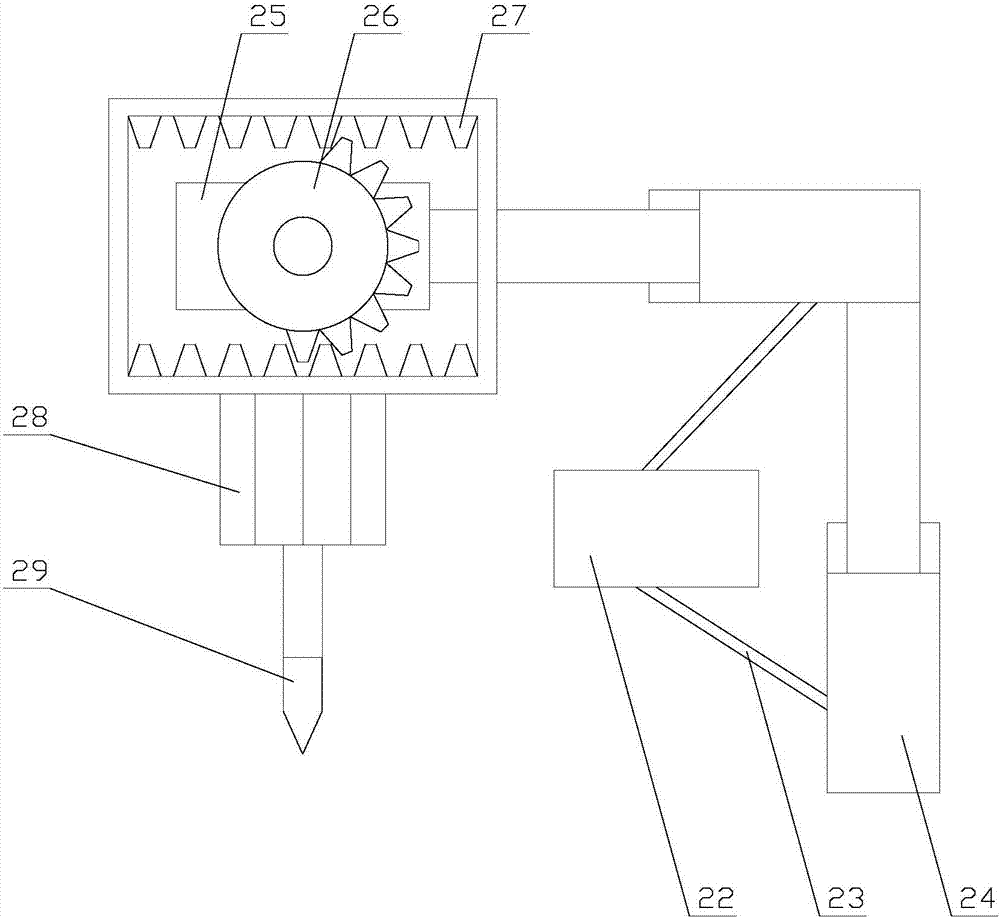

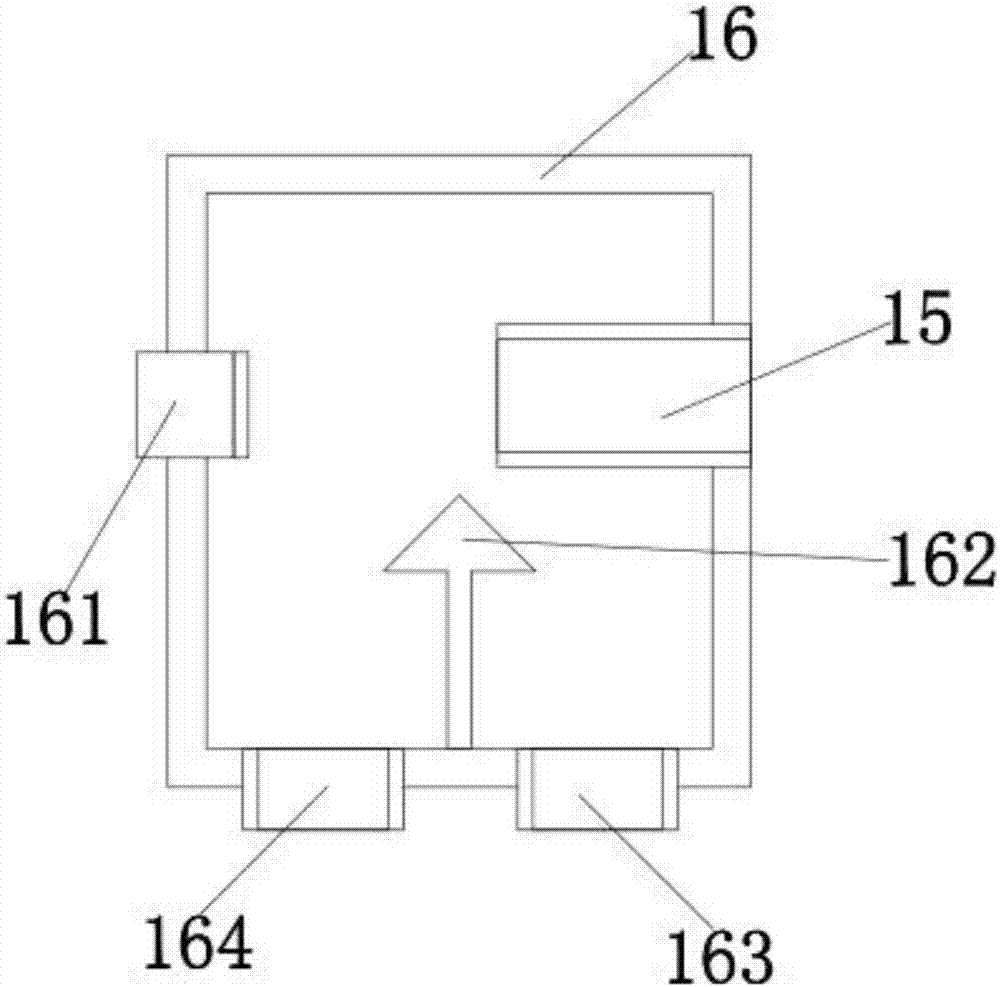

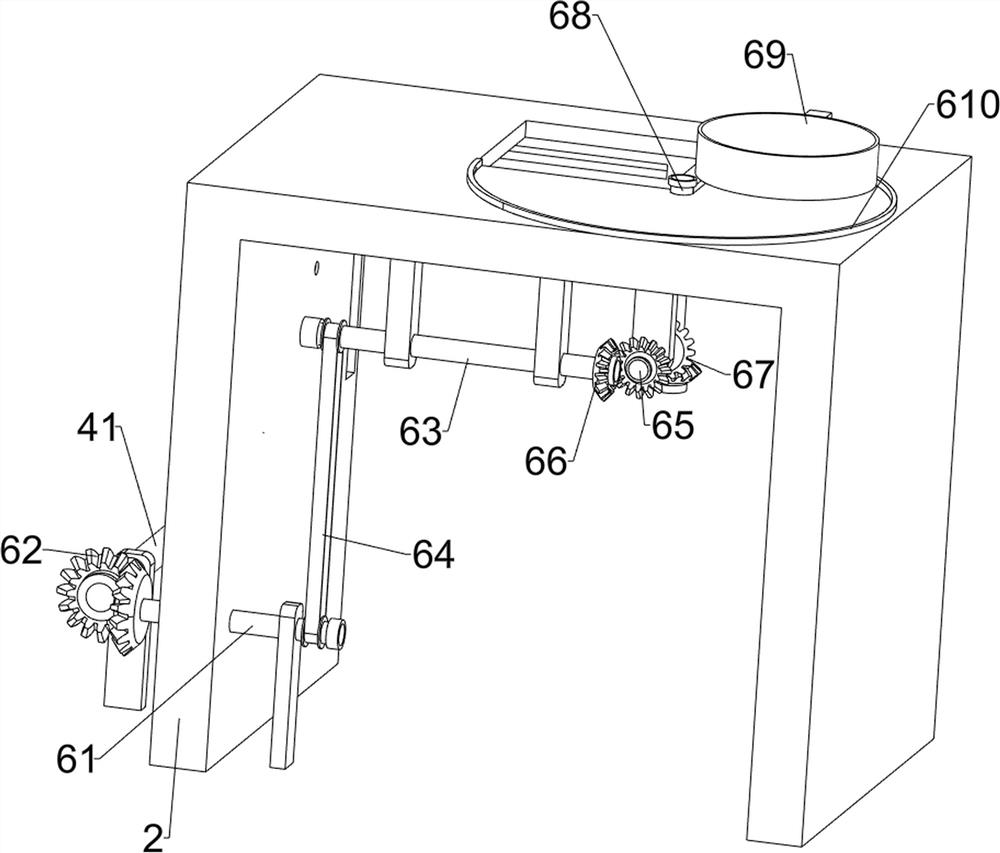

Agricultural peanut shell-removing device

InactiveCN108185452AReasonable and applicable structural designImprove shelling efficiencyGas current separationHuskingAgricultural engineeringWheel drive

The invention discloses an agricultural peanut shell-removing device. The circumferential direction of the lower end of a rotating disk is fixedly connected with clamping columns; the middle of a drive shaft is fixedly connected with a first bevel gear; a second bevel gear is fixedly connected with the ends of driven shafts; the middle of the driven shafts is fixedly connected with first eccentricwheels; the lower ends of the first eccentric wheels are connected with the upper surface of the rotating disk in an abutting manner; the bottom of a sliding groove is fixedly connected with the lower ends of pressure springs; a plurality of bayonets are uniformly formed in the circumferential direction of the surface of a sheave; the lower end of the middle of the rotating disk is fixedly connected with the upper end of a vertical support rod; and the lower end of the vertical support rod is fixedly connected with a shell-breaking roller. According to the agricultural peanut shell-removing device, the rotating disk reciprocates up and down while intermittently rotating to drive the shell-breaking roller to synchronously move, skewed tooth plates rotate and crush peanut shells while pressing the peanuts downward, the second eccentric wheel drives an inclined filter plate to oscillate to enable peanut kernels to be separated from peanut shells, and a rotating fan blows the peanut shells to move up and discharge from a shell discharge opening; and the device is reasonable and applicable in structural design, the peanut shell removing efficiency is greatly improved, the labor is saved, and the shell removing effect is excellent.

Owner:沈德旭

Peanut shell removing and peanut seed peeling integrated device enabling peeled peanut seed and peanut seed coat to be separated

InactiveCN105410953AImprove shelling efficiencyEfficient collectionHuskingHullingTransmission beltEngineering

The present invention discloses a peanut shell removing and peanut seed peeling integrated device enabling peeled peanut seeds and peanut seed coat to be separated. The device includes a motor, a machine base, a machine frame arranged on the machine base and a shell removing mechanism, wherein the shell removing mechanism comprises a receiving cavity and a shell removing plate installed inside the receiving cavity, convex teeth are arranged on the inner wall of the receiving cavity, the distance between the shell removing plate and the convex teeth is 1-2 cm, a material charging hopper is arranged on the top of the machine frame, a material separating trough and a material storing barrel are arranged inside the machine frame, the other end of the receiving cavity communicates with the material separating trough, a material collecting pipe is connected with a first fan through an air duct, the first fan is arranged at the other side of the material storing barrel on the machine frame, the shell removing plate is connected with the motor through a transmission belt, a cavity communicating with the material storing barrel is arranged inside the machine base, a spray chamber is arranged above the cavity, a plurality of nozzles communicating with water pipes are arranged inside the spray chamber, and a plurality of rotatable rollers are arranged below the spray chamber. The device aims to solve the problems that the existing peanut shell removing process is low in efficiency, high in shell breakage rate and difficult in collection and utilization of peanut seed coat.

Owner:重庆乐嚼食品有限公司

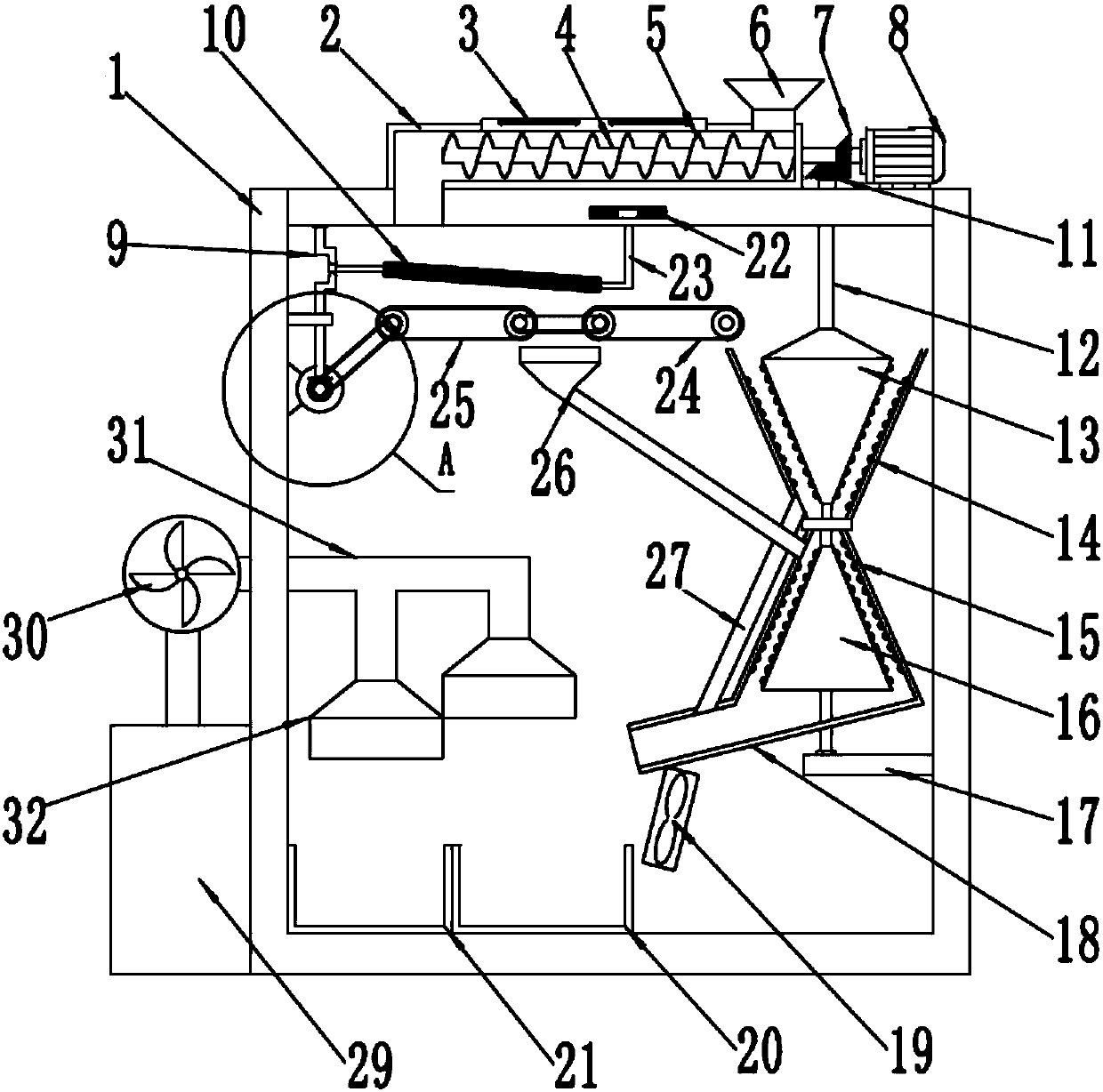

Peanut sheller

The invention relates to a sheller, in particular to a peanut sheller. The peanut sheller comprises a feed hopper, a shelling mechanism, a shell and kernel separation mechanism and a first box body with an open upper end, wherein the feed hopper is connected to the top of the first box body and the bottom of the feed hopper and the first box body jointly form a shelling cavity for accommodating the shelling mechanism; the shelling mechanism comprises a rotating barrel assembly and a downwards concave screen; the rotating barrel assembly is connected to the first box body; the screen is located below the rotating barrel assembly and the clearance between the rotating barrel assembly and the screen is larger than 20 mm; the shell and kernel separation mechanism comprises a peanut kernel collecting mechanism and a crushed shell sucking mechanism; a discharge hole is formed in the inner wall of the bottom of the first box body, and arranged above one side of the peanut kernel collecting mechanism; and the crushed shell sucking mechanism is arranged on a position corresponding to the discharge hole. The peanut sheller has a simple mechanical structure to rapidly and efficiently shell peanut, separation of peanut kernel and crushed shell is effectively completed, and cleanliness after shelling is kept.

Owner:YANCHENG INST OF TECH

Peanut classifying and shelling device

InactiveCN107736624AEasy to shellShelling is effectiveSievingScreeningAgricultural engineeringEngineering

The invention discloses a peanut sorting and shelling device, comprising a shell, a feeding hopper, a feeding structure, a sorting mechanism, a shelling mechanism, a blower and a suction fan; the upper end of the shell is provided with a first motor, and the output end of the first motor is fixed A first rotating shaft is connected; a feeding mechanism is arranged on the left side of the first motor; a classification mechanism is arranged inside the casing, and the classification mechanism includes a crankshaft, a sieve plate, a chute, an L-shaped sliding rod, a second conveyor belt, a first A conveyor belt, a bevel gear C, a second motor, a bevel gear D and a runner; the right side of the sorting mechanism is provided with a dehulling mechanism, and the dehulling mechanism includes a second rotating shaft, a tapered roller A, a dehulling groove A, and a dehulling mechanism. Shell groove B, tapered roller B, support plate and discharge port. The invention has novel design and simple structure. The drying device dries the peanuts, and then sorts them through a classification mechanism and then removes the hulls, thereby improving the hulling efficiency, greatly reducing the crushing rate of peanut grains, and having good hulling effect and practicability. powerful.

Owner:冯辉升

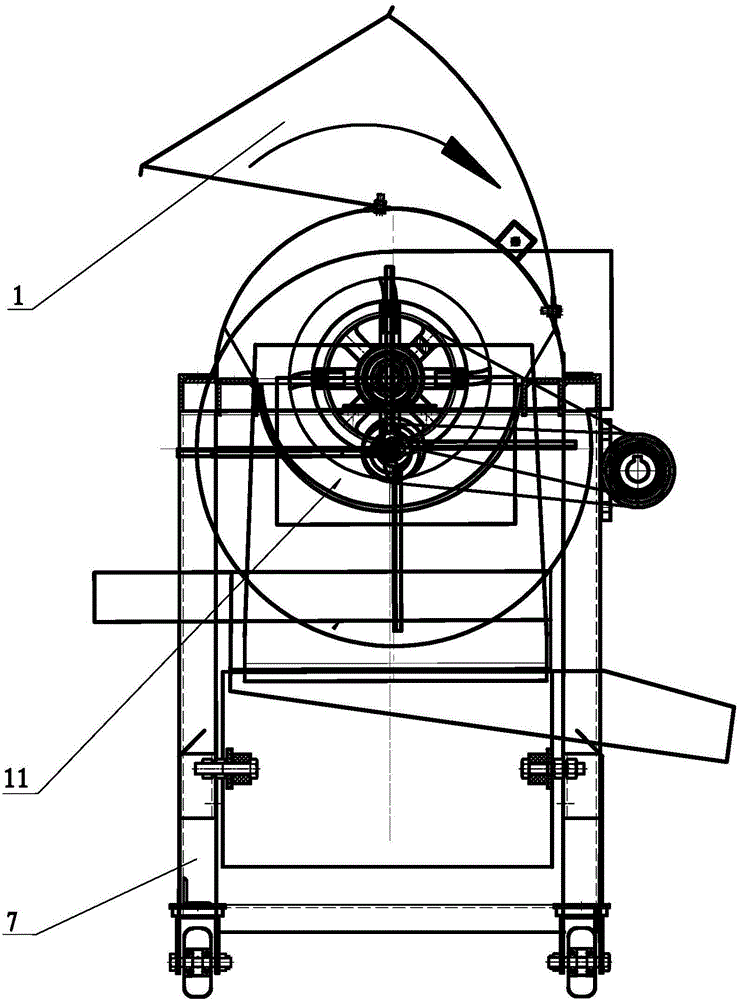

Euphausia superba shelling device

ActiveCN104322646AEasy to useImprove shelling efficiencyShrimp/lobster processingBiomedical engineeringEuphausia

The invention relates to the technical field of fishery machinery and in particular relates to a euphausia superba shelling device. The euphausia superba shelling device comprises a discharging device, a homogenizing device arranged at one end of the discharging device and a shelling device arranged at the other end of the discharging device. The euphausia superba shelling device is convenient to use and has a high shelling effect when used for shelling euphausia superb.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

High-efficiency peanut shelling device

InactiveCN107692250AImprove shelling effectImprove shelling efficiencyHuskingHullingAgricultural engineeringThreaded rod

The invention discloses a high-efficiency peanut shelling device, which comprises a shell, a feeding hopper, a drying mechanism, a shelling mechanism, a screening mechanism and a collecting tank; a feeding hopper is arranged at the upper end of the shell, and a drying mechanism is arranged under the feeding hopper The lower end of the drying mechanism is provided with a shelling mechanism, and the shelling mechanism includes a shelling chamber, a tapered roller, a raised block A, a raised block B, a tapered groove, an extrusion block, a forward and reverse motor, a slider, Threaded rod and fixed block. A screening mechanism is arranged below the shelling mechanism, and the screening mechanism includes a first filter screen, a filter cavity, a blower, a second filter screen, a suction fan, a waste shell box, an electric telescopic rod, a push plate and a recovery chamber, and the lower end of the shelling mechanism A first filter is provided. The invention has simple mechanism and convenient operation, improves the peanut shelling efficiency, realizes the separation of peanut grains and peanut shells, and greatly reduces labor force.

Owner:郑州味觉信息技术有限公司

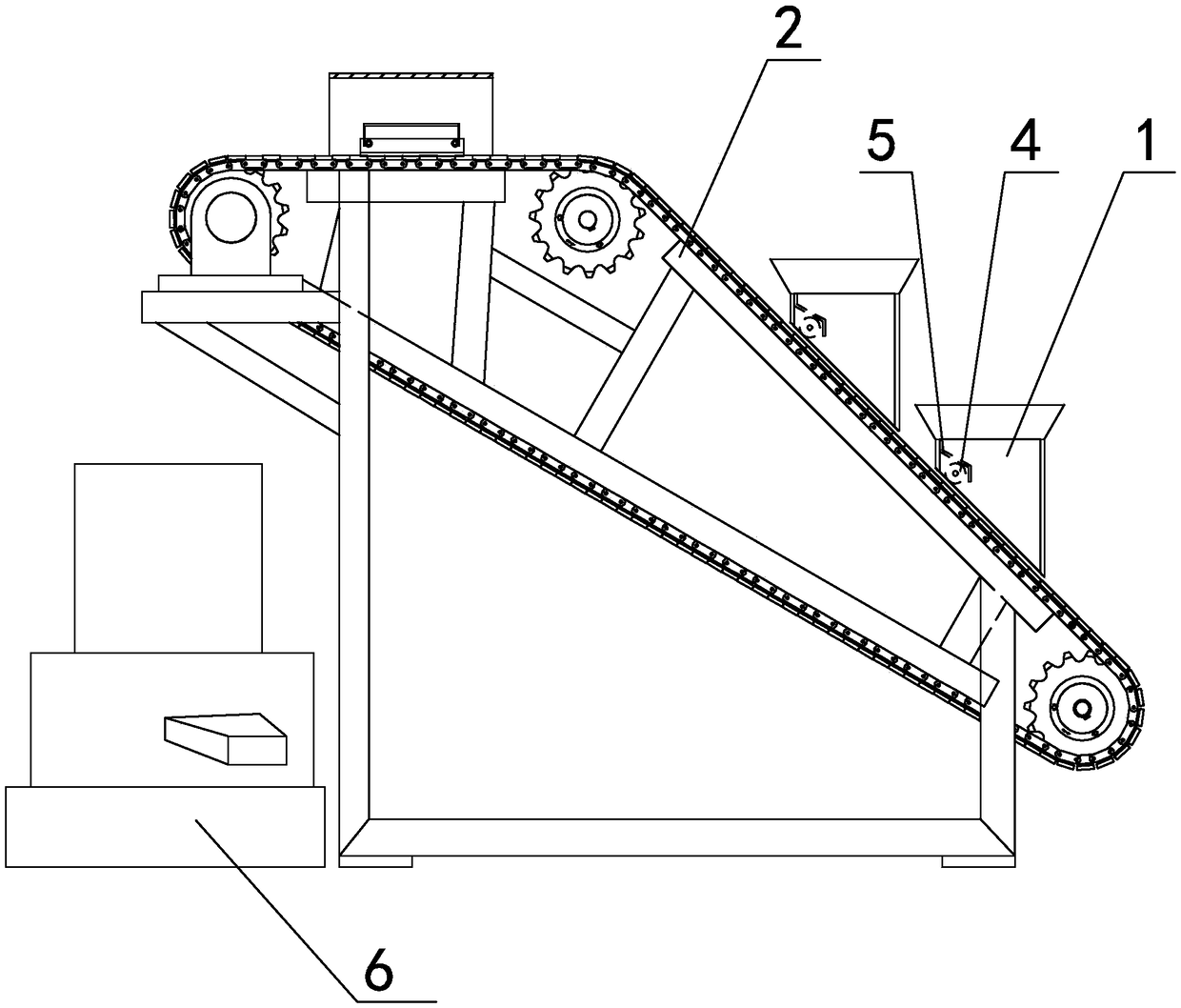

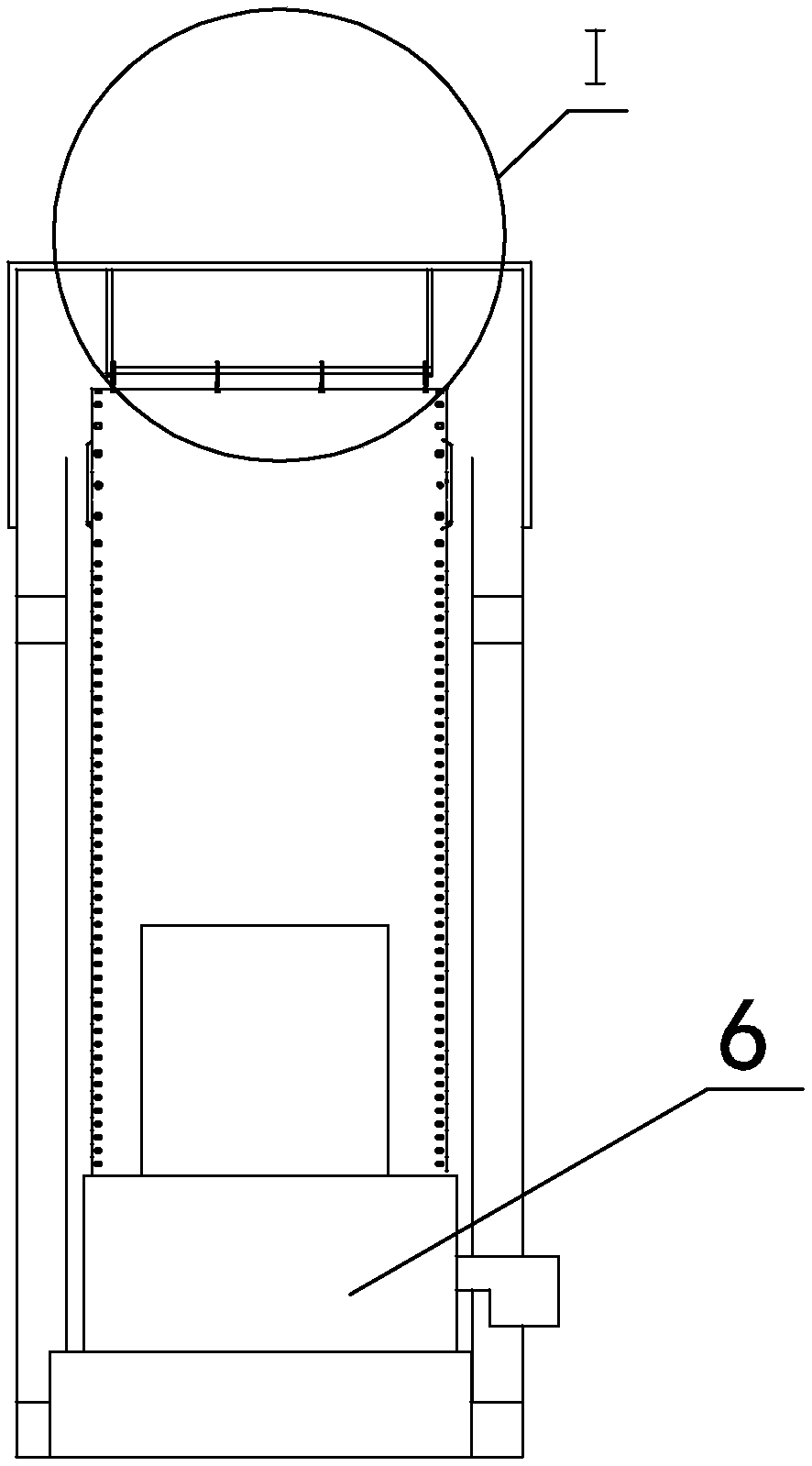

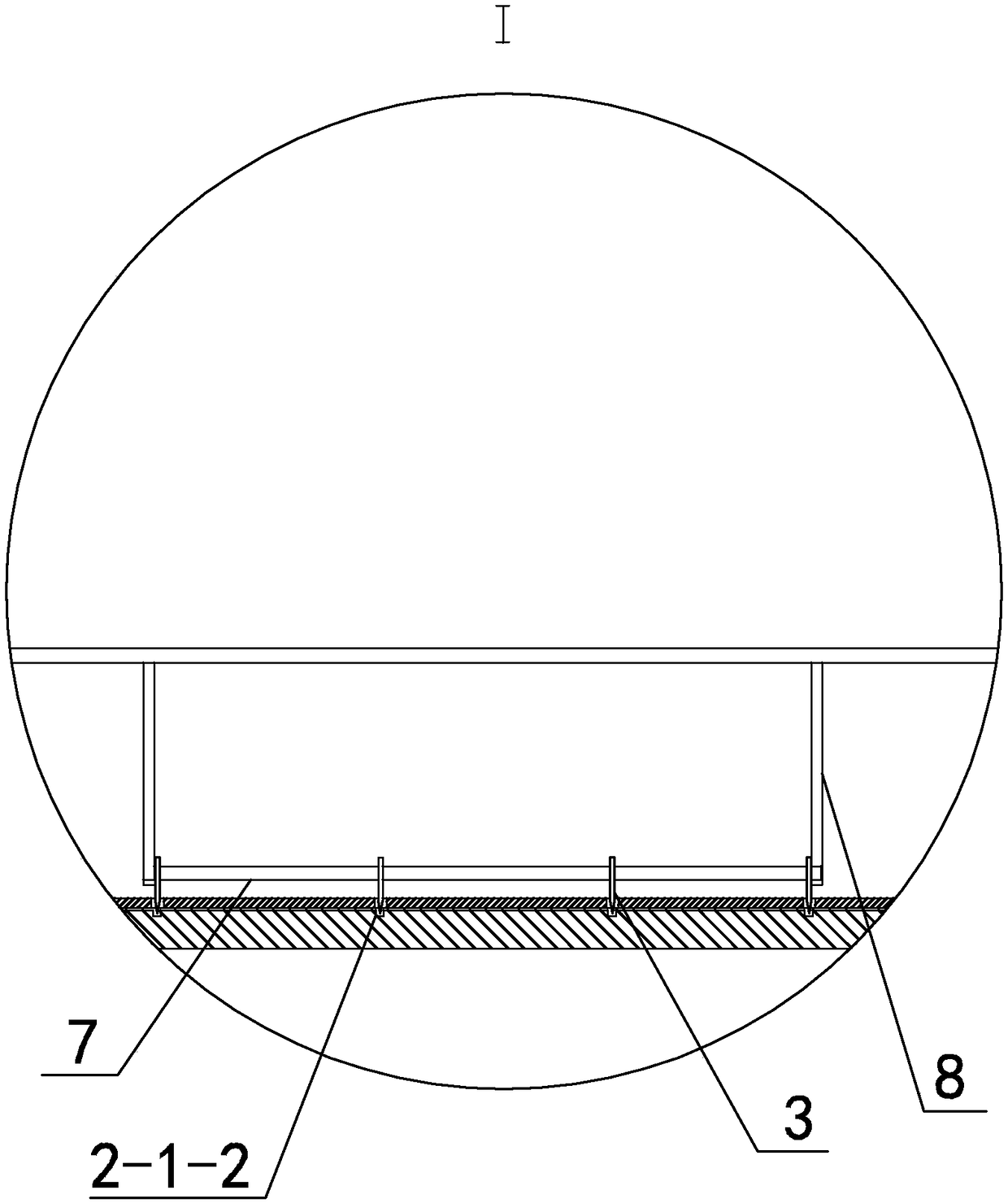

Husking device for processing and remaining rice germs

InactiveCN108970675AAvoid the problem of machining being worn offAvoid wear-off problemsGrain huskingGrain polishingFilling rateKnife blades

The invention provides a husking device for processing and remaining rice germs, and relates to the husking device. According to the husking device, the problems that germs are ground off by an existing rice husking device in the machining process, the filling rate of rice is low, and consumers are liable to purchase fake rice on the market are solved. The husking device comprises a plurality of blades, a conveyor, electric brushes and a plurality of hoppers; the conveyor is a chain plate conveyor of which the input end is obliquely arranged downwards, and the output end of the chain plate conveyor is arranged horizontally; each chain plate of the chain plate conveyor is provided with a plurality of rows of rice slots in multiple columns, and each rice groove is able to hold only one ricegrain; the center of the rice grooves in each column in the width direction is provided with a cutter groove, and each hopper is internally provided with the electric brushes and baffles; and each hopper is arranged on one side of the input end of the chain plate conveyor, and a certain clearance is provided between a port of each hopper and the corresponding chain plate. The husking device is applicable for husking germ-remaining rice.

Owner:HARBIN QUANQING TECH SERVICE CO LTD

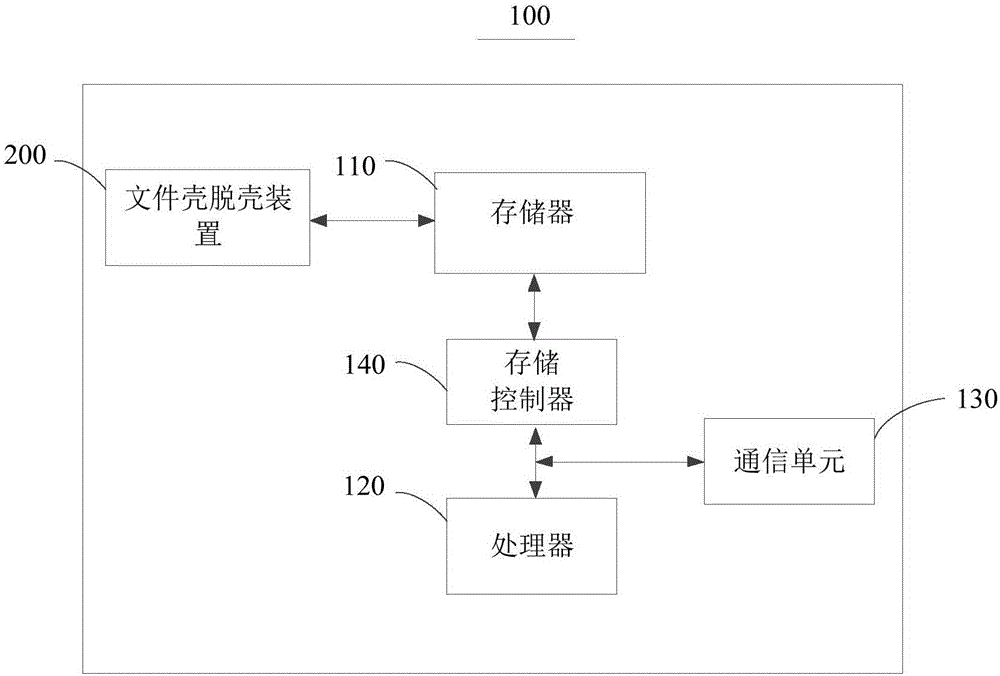

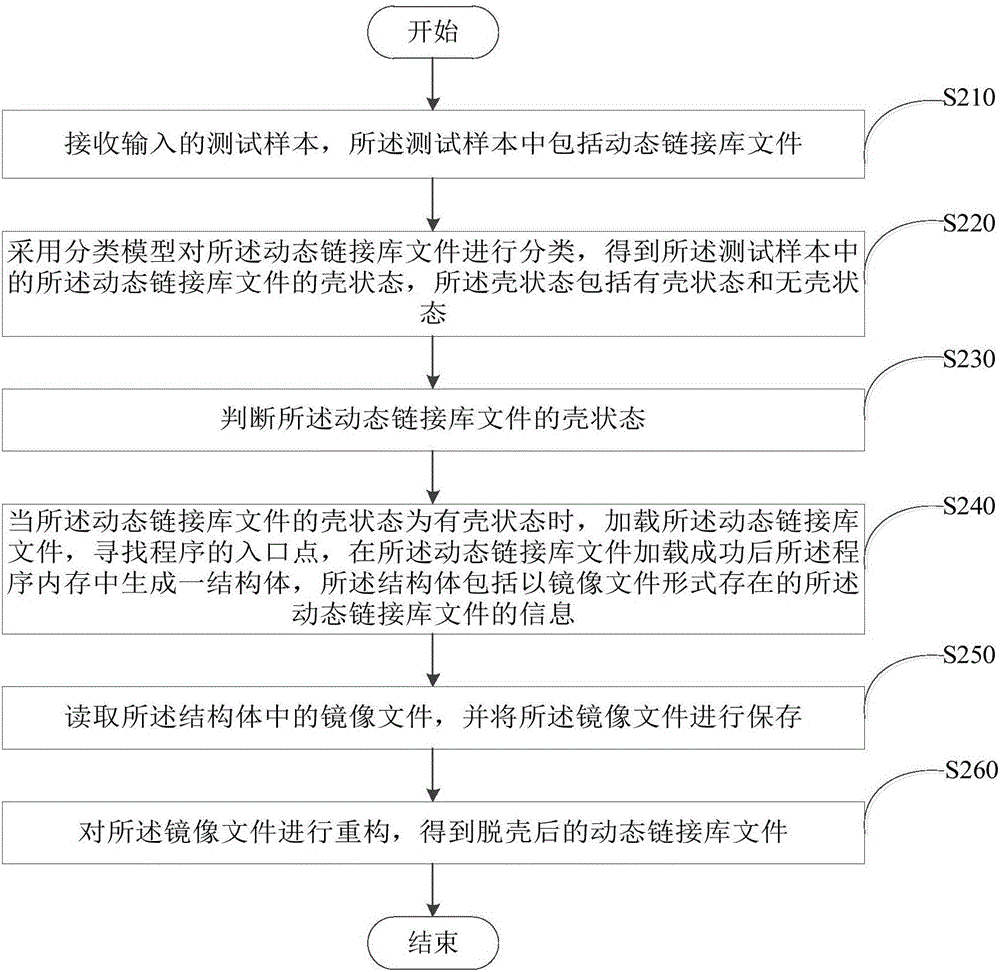

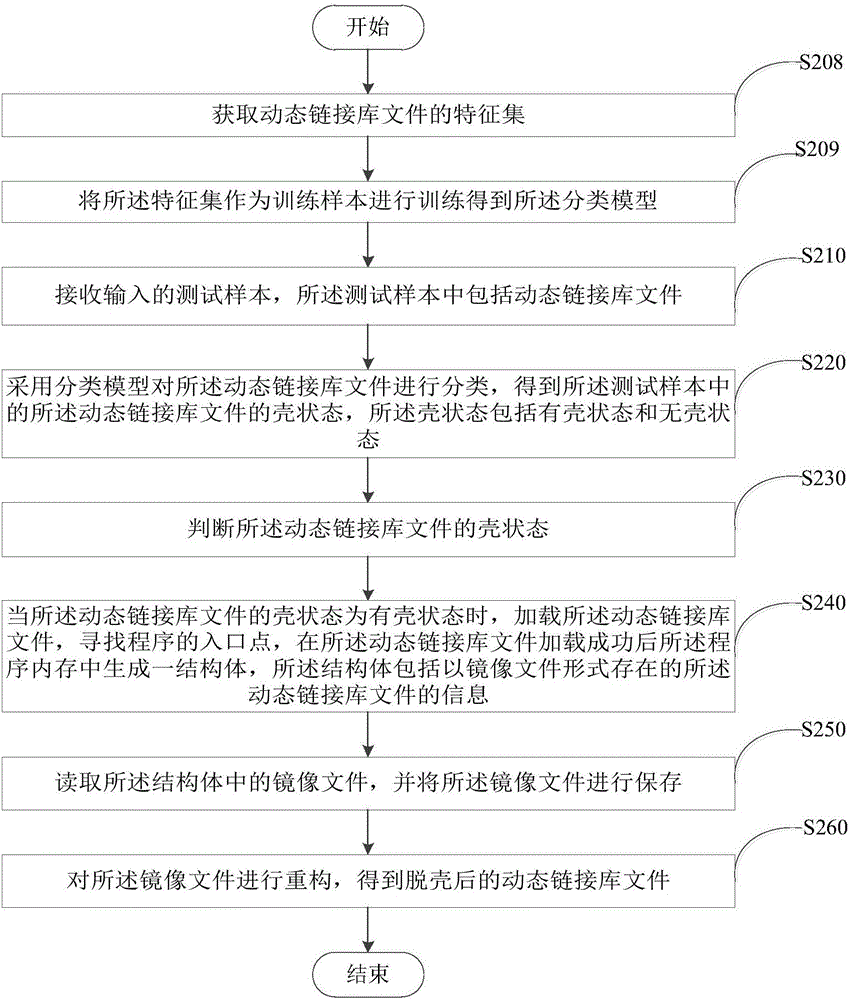

Document packer unpacking method and device

The invention provides a document packer unpacking method and device. The method comprises steps as follows: an input test sample is received, and the test sample comprises dynamic-link library documents; the dynamic-link library documents are classified according to a classification model, packer states of the dynamic-link library documents in the test sample are obtained and comprise a state with packers and a no-packer state; the packer states of the dynamic-link library documents in the test sample are judged; when the dynamic-link library documents in the test sample are in the state with packers, the dynamic-link library documents are loaded, an entry point of a program is searched, and a structural body is generated in a program memory after the dynamic-link library documents are successfully loaded and comprises information of dynamic-link library documents in a form of a mirror image document; mirror image documents in the structural body are read and are saved; the mirror image documents are reconstructed, and the unpacked dynamic-link library documents are obtained. The unpacking efficiency of the dynamic-link library documents can be effectively improved.

Owner:四川无声信息技术有限公司

Peanut shelling device

InactiveCN107173825ARealize automatic shellingReduce damage rateHuskingHullingAgricultural engineeringPeanut kernel

The invention discloses a peanut shelling device, which comprises a shelling box, a frame, a blower A, a blower B and a motor. The shelling box is arranged on the top of the frame, wheels are arranged below the frame, a feed hopper is provided at the top of the shelling box, and a switch valve is arranged between the feed hopper and the shelling box. The lower side of the feed hopper and the shelling box are provided with two side-by-side shell crushing rollers, and the shell crushing rollers are started by connecting with a motor. The left side of the shelling box is provided with a blower fan A, and the blower fan A is provided with a speed regulating switch, and the air outlet of the blower blower A is facing the inlet of the air duct. The right side of the shelling box is provided with an air duct, the lower end of the air duct is provided with a peanut shell outlet, the bottom of the shelling box is provided with a sieve plate, the left side of the sieve plate is provided with a fan B, and the lower end of the sieve plate is provided with a A collection tank, a peanut kernel outlet is provided below the collection tank. The invention can realize automatic shelling of peanuts, has high shelling efficiency and low damage rate of peanut kernels.

Owner:泰州佰超机械有限公司

Automatic purification husking device for rice processing

InactiveCN108855305AImprove the rice yieldEffective tearing and peelingGrain huskingGrain polishingEngineeringUltimate tensile strength

The invention provides an automatic purification husking device for rice processing. The automatic purification husking device comprises a device shell and a feeding hopper. The feeding hopper is connected to the upper end of the device shell in an inserted and penetrating mode, and the lower end of the feeding hopper reaches an inner cavity of the device shell and is connected to the upper end ofa cleaning device in a penetrating mode. The upper end of the cleaning device is fixedly connected to the inner top wall of the device shell, and a motor is welded to the upper end of the outer sidewall of one side of the device shell through a first bracket. The automatic purification husking device overcomes the deficiencies of the prior art, has reasonable design and a compact structure, effectively purifies dried-up seed and grass seed in rice, improves the milled rice rate of the rice and can timely and effectively transport the processed brown rice; and the labor intensity of rice processing personnel is reduced, and the quality of the brown rice is improved.

Owner:怀宁县谷丰米业有限公司

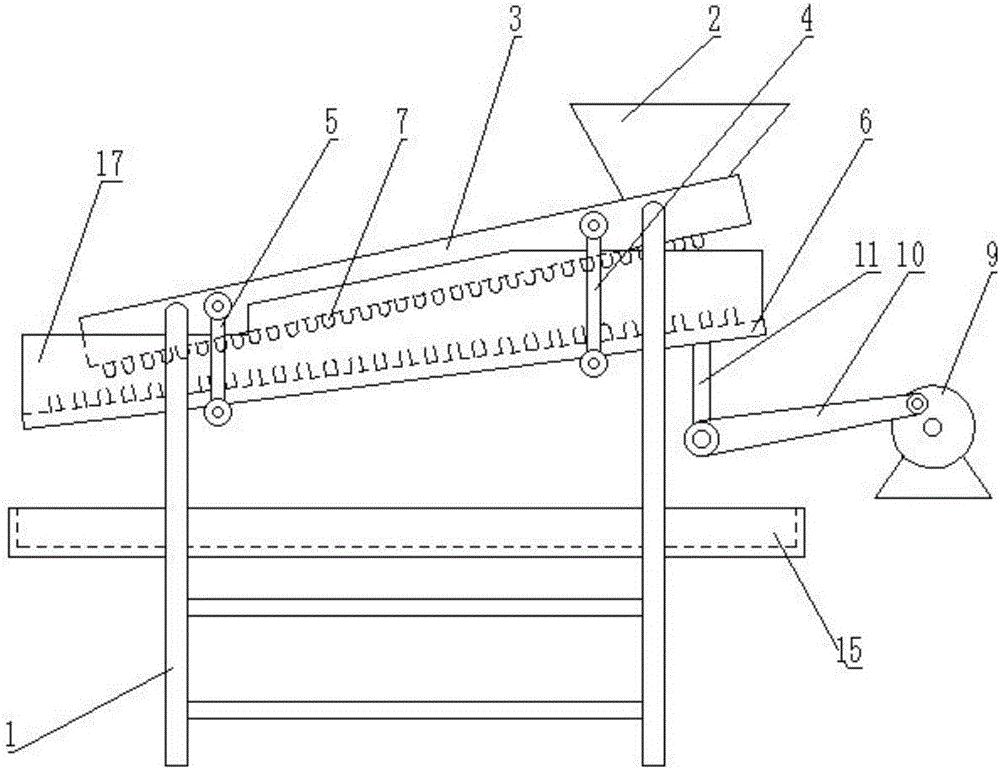

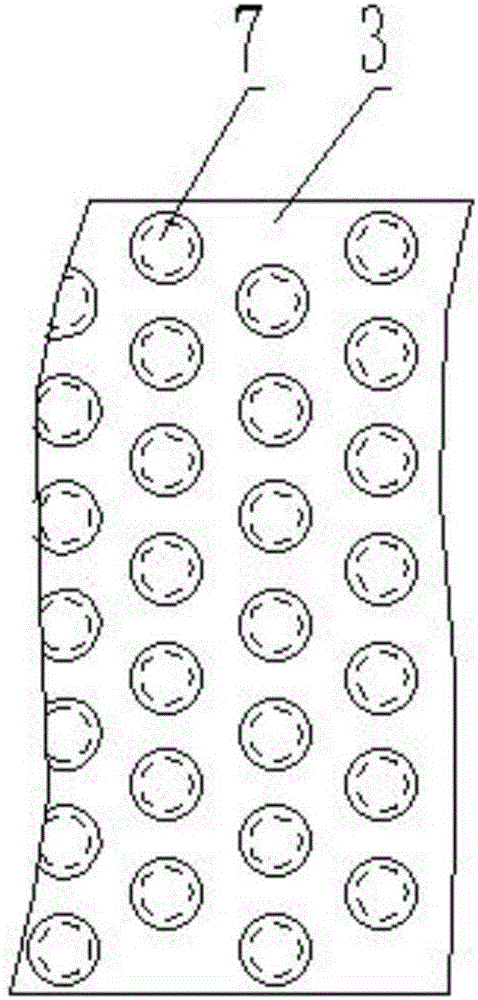

Peanut sheller

The invention belongs to the field of agricultural mechanical equipment and particularly provides a peanut sheller. The peanut sheller comprises a rack, a feeding hopper, a shelling mechanism and a driving mechanism, wherein the shelling mechanism comprises an upper jaw plate fixedly installed on the rack and a lower jaw plate with two ends hinged to the lower portion of the upper jaw plate respectively through a long hinge rod and a short hinge rod, an included angle formed by the upper jaw plate and a horizontal line is 6-10 degrees, an included angle formed by the lower jaw plate and a horizontal line is 2-4 degrees, and multiple protruding shelling units are evenly arranged on the lower surface of the lower jaw plate and the upper surface of the lower jaw plate at intervals. The driving mechanism drives the lower jaw plate to perform back and forth swing around the upper jaw plate with the long hinge rod and the short hinge rod as swing arms. The peanut sheller is novel in concept and simple in structure, the upper jaw plate and the lower jaw plate are adopted to form a wedge-shaped dynamic shelling space, the protruding shelling units can inwards extrude, drag and crush peanuts from an inlet of the wedge-shaped space stage by stage, and the peanut threshing rate is greatly improved.

Owner:广西壮族自治区农业科学院经济作物研究所

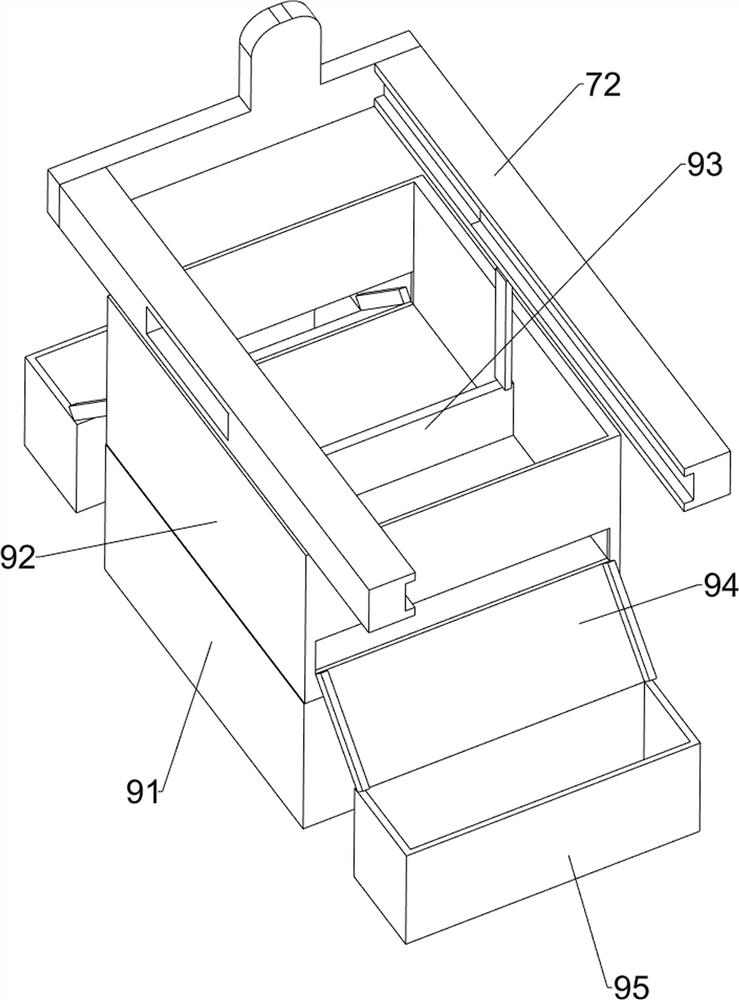

Automatic myotonin shelling and storing device

InactiveCN107362848AEfficient removalImprove shelling efficiencyGrain huskingGrain polishingEngineeringDrive motor

The invention discloses an automatic peeling and storing device for coix seed and rice, which comprises a main box body, the top of the main box body is fixedly connected with a material guide box, and the inner bottom of the material guide box is provided with a The inner top of the material guide box is provided with a feed port, the top of the inner wall of the material guide box is fixedly connected with a screen, and the end of the main box close to the material guide box is fixedly connected with a drive motor through a support rod The output end of the driving motor is fixedly connected with a transmission rod, and the end of the transmission rod away from the driving motor penetrates the outer wall of the main box and is fixedly sleeved with the first gear. roll. In the present invention, through the arrangement of multiple transmission mechanisms and rubber rollers, the device can effectively remove the outer wall of the barley when shelling the barley, and at the same time, the device has a shell storage box that can automatically collect the barley shells, thereby improving the quality of the barley. shelling efficiency.

Owner:GUIZHOU RENXIN AGRI DEV CO LTD

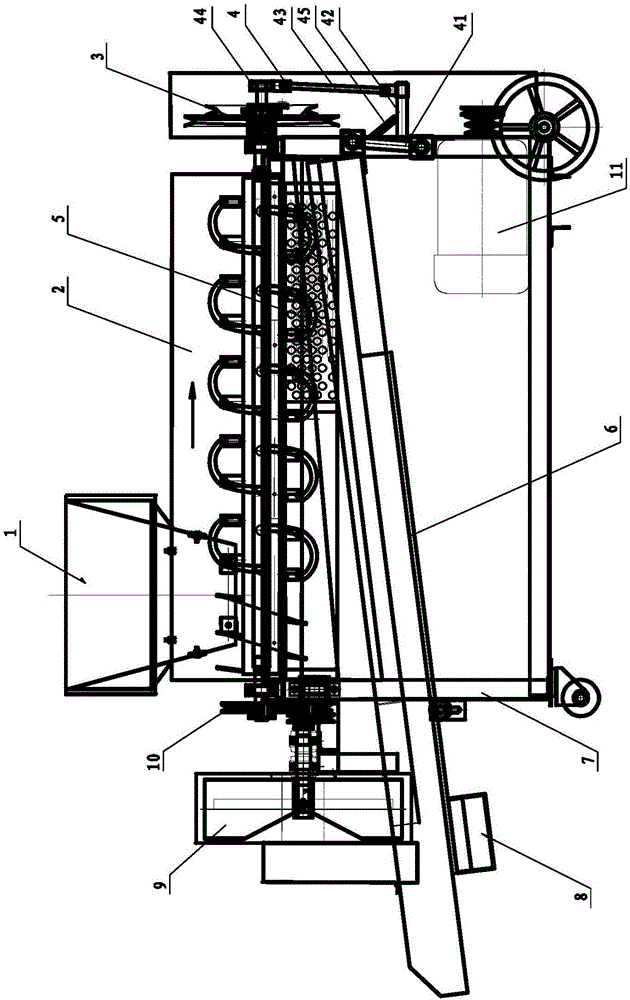

Oil tea fruit shelling and screening processing method and equipment

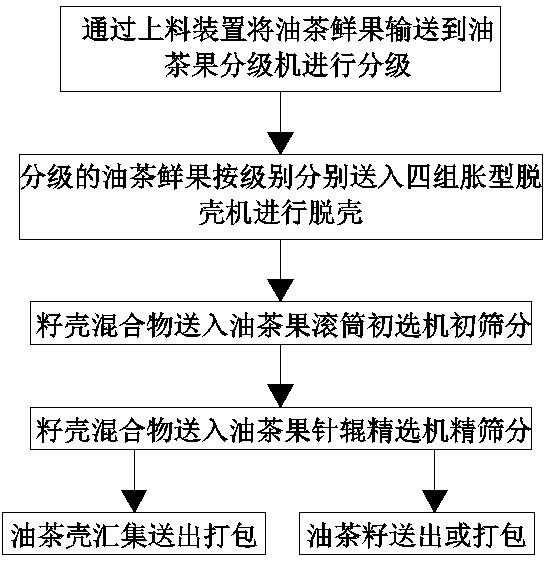

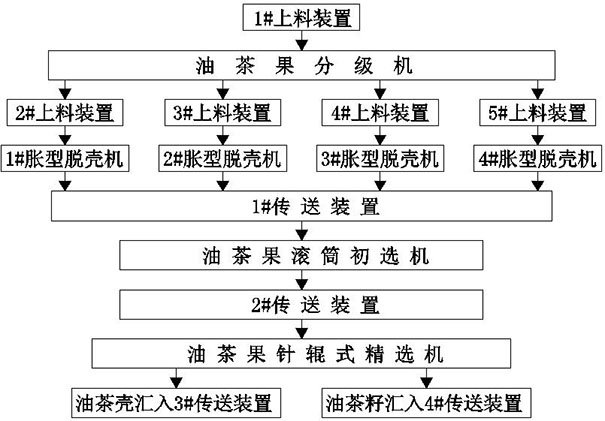

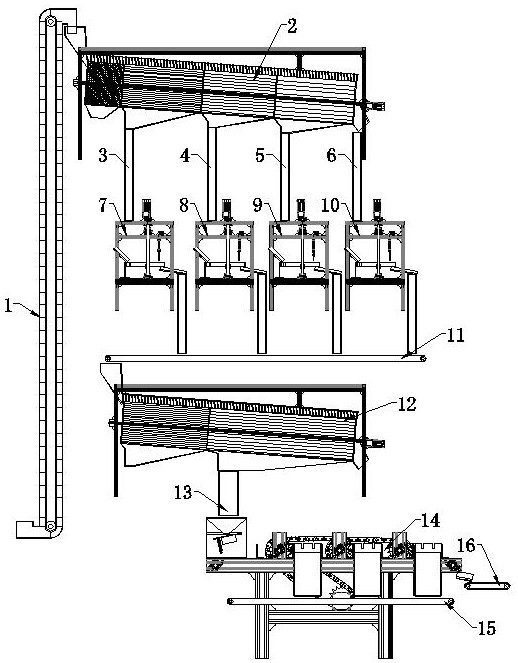

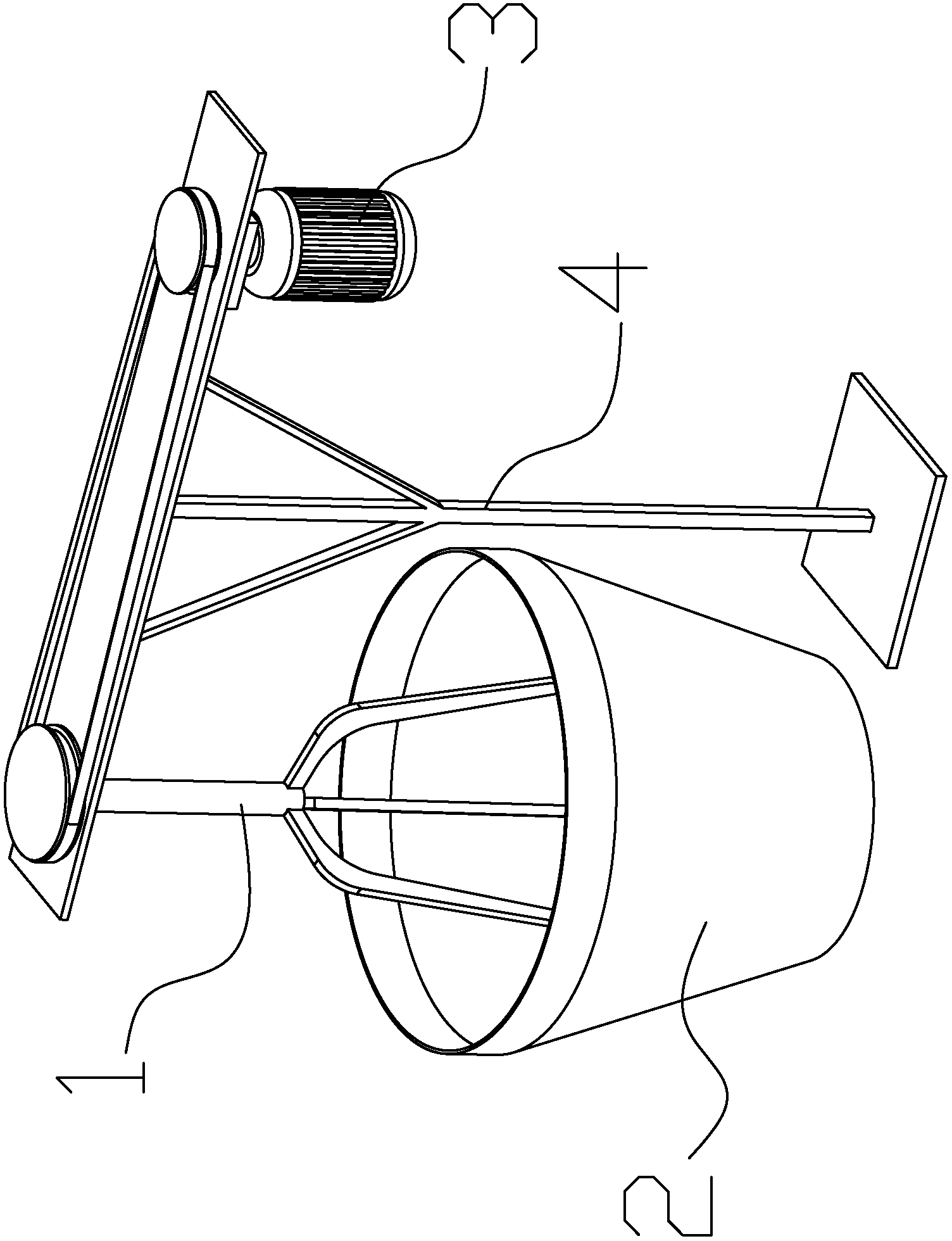

InactiveCN111642757AImprove cleaning efficiencyImprove versatilitySievingGas current separationCamellia oleiferaPrimary screening

The invention discloses an oil tea fruit shelling and screening processing method and equipment. The processing method and equipment are mainly used for fresh oil tea fruit shelling and oil tea seed shell screening. The processing method includes the following steps: (1) conveying fresh oil tea fruits to an oil tea fruit grading machine to grade; (2) respectively sending the fresh oil tea fruits to four sets of expanding shellers to perform shelling according to grades; (3) sending a seed shell mixture to a roller primary selection machine to perform primary screening; (4) performing fine screening through a needle roller fine selection machine; and (5) collecting and packaging the oil tea shells, and collecting and sending the oil tea seeds out. The equipment includes a feeding device, the grading machine, a transmission device, the expanding shellers, the roller primary selection machine and the needle roller fine selection machine. The processing method can overcome the technical disadvantages of complex processes, many processing equipment, low processing efficiency and low seed shell screening efficiency of existing oil tea fruit processing technologies; and the processing method is simple and reasonable in technology process, scientific in equipment structure, time-saving, energy-saving, high in production efficiency, good in cleaning effect and low in production cost, and can process the fresh oil tea fruits in batch.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

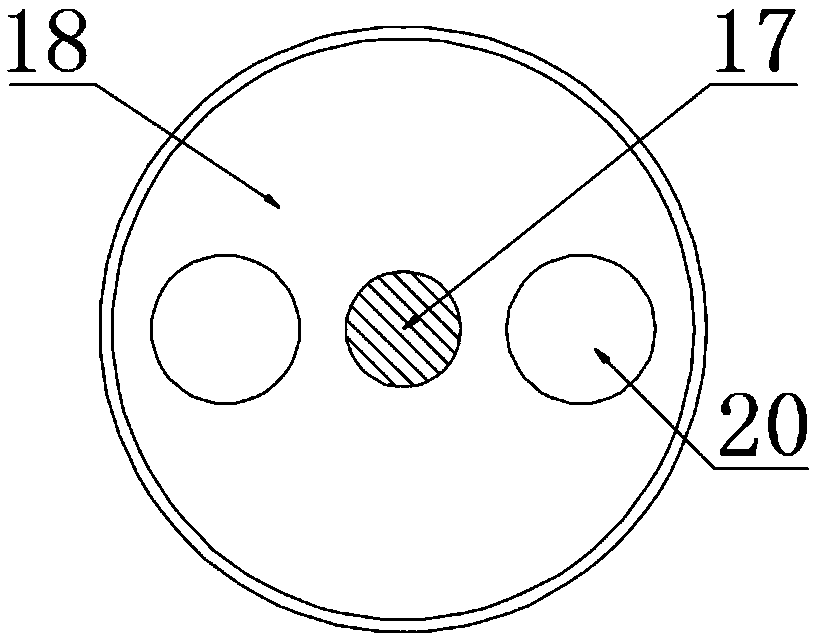

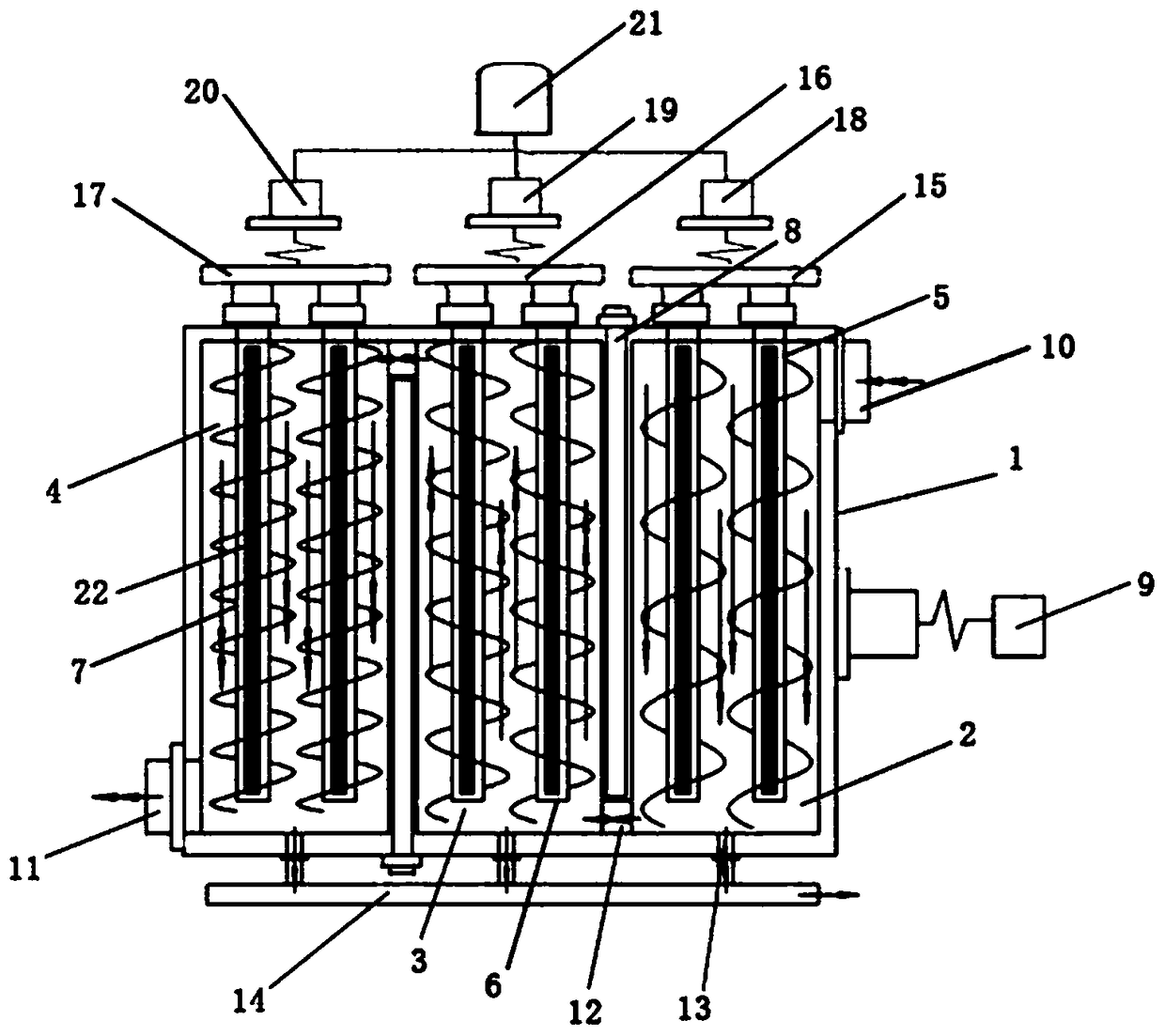

Gorgon fruit husking method and automatic gorgon fruit husking production device

ActiveCN103005620ARealize mechanized productionImprove shelling efficiencyHuskingHullingHorticultureExtrusion

The invention discloses a gorgon fruit husking method, which is characterized in that firstly, gorgon fruit seeds and capsule coats covered outside the gorgon fruit seeds are separated, then, the separated gorgon fruit seeds are separated according to the particle size, next, the gorgon fruit seeds with the same particle size are poured into a casing with grooves on the inner wall, and the husking is carried out through the extrusion on the gorgon fruit seeds by a rotating fluted disc arranged in the casing. The invention simultaneously provides an automatic gorgon fruit husking production device, which comprises a capsule coat separating device, an automatic screening device and a husking device, the husking requirement of the gorgon fruit seeds through a mechanical device can be met, the husking efficiency of the gorgon fruit seeds is improved, and the mechanical production of the gorgon fruit husking is realized.

Owner:淮南湖鑫水产养殖有限公司

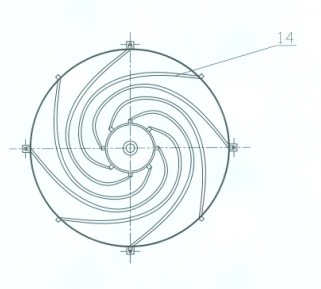

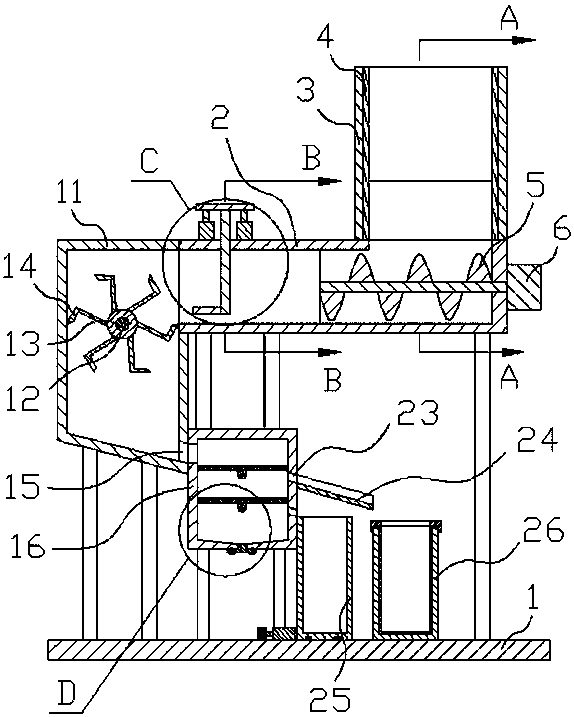

Sheller for barley or buckwheat

ActiveCN103816958ASeparate as soon as possibleAvoid damageGrain huskingGrain polishingPolygonum fagopyrumEngineering

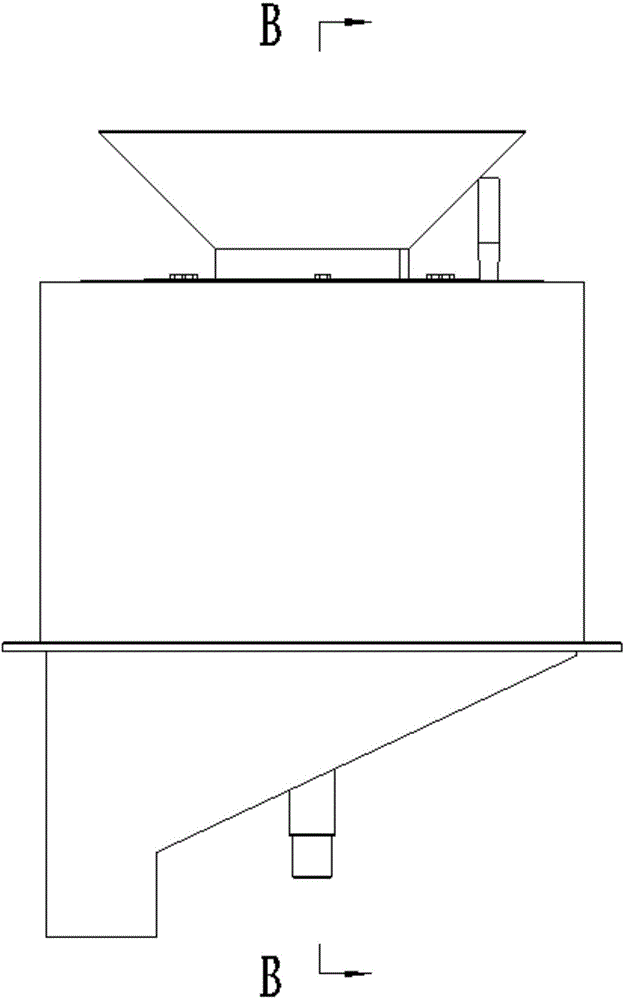

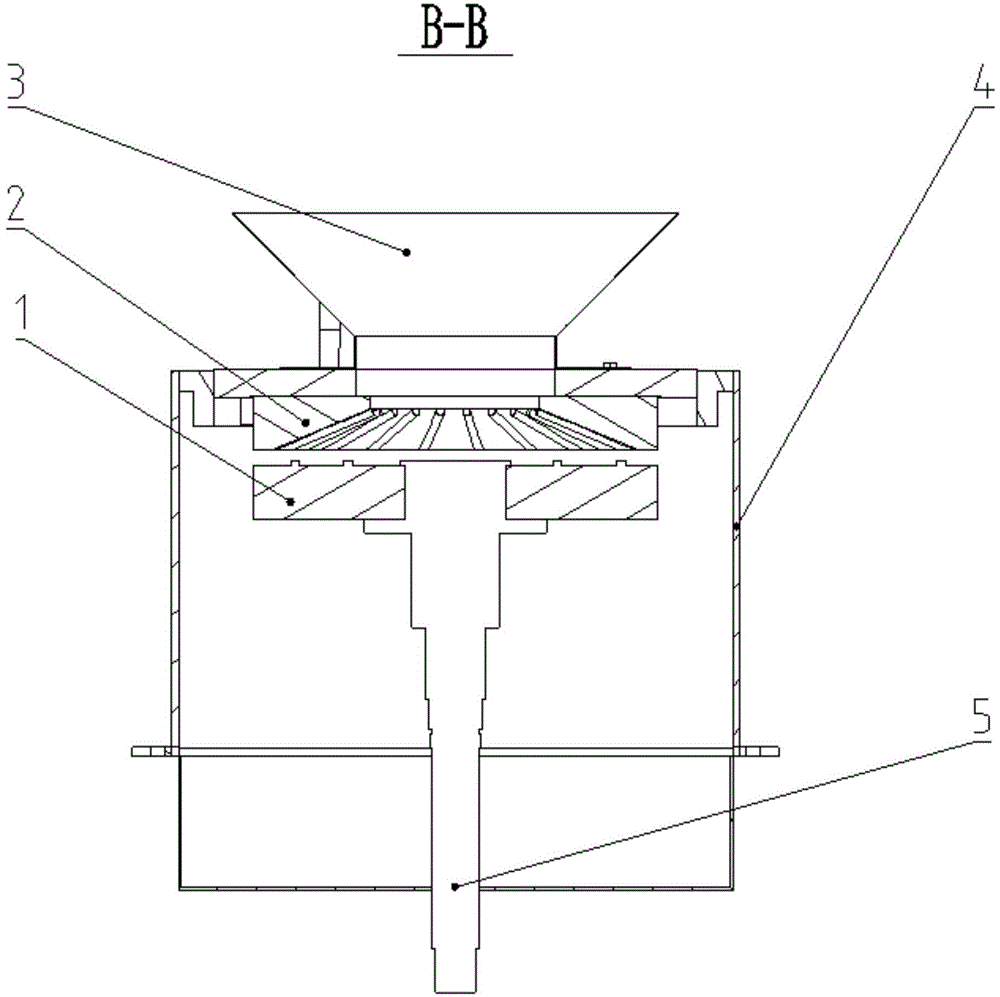

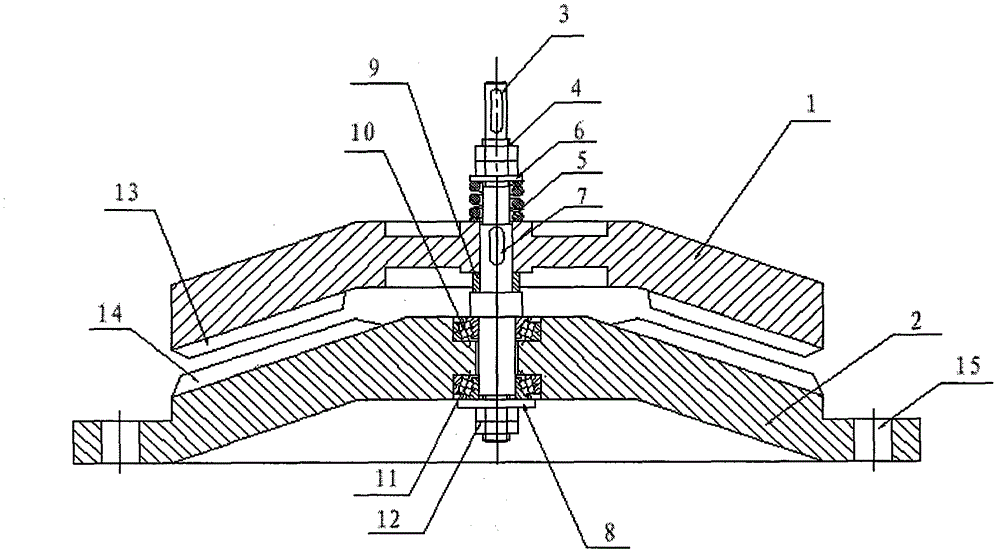

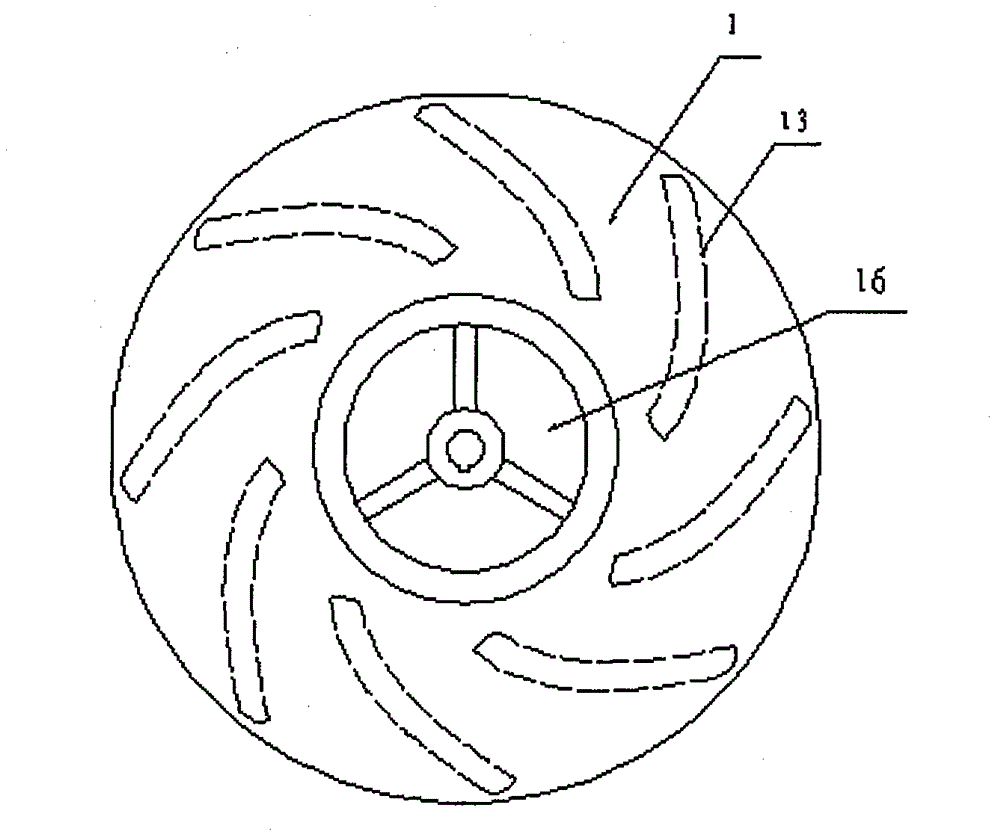

The invention relates to corn sheller equipment, in particular to a sheller for barley or buckwheat, and belongs to the technical field of agricultural machinery and equipment. The sheller for barley or buckwheat comprising a hopper (3) and a material bin (4) is characterized in that a static disc (2) is arranged below the hopper (3), a feeding hole is formed at the center of the static disc (2) and coaxially corresponds to the hopper (3), a plurality of groove holes are formed on the static disc from the center to the outer diameter in a diverged manner, soft rubber rods are fixed in the groove holes, and the bottoms of the soft rubber rods and the bottom of the static disc (2) are located in a same height or almost in the same height; a movable disc (1) is arranged below the static disc (2); curved bars are arranged on the upper plane of the movable disc (1) and adopt the center of the movable disc as arc cores.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

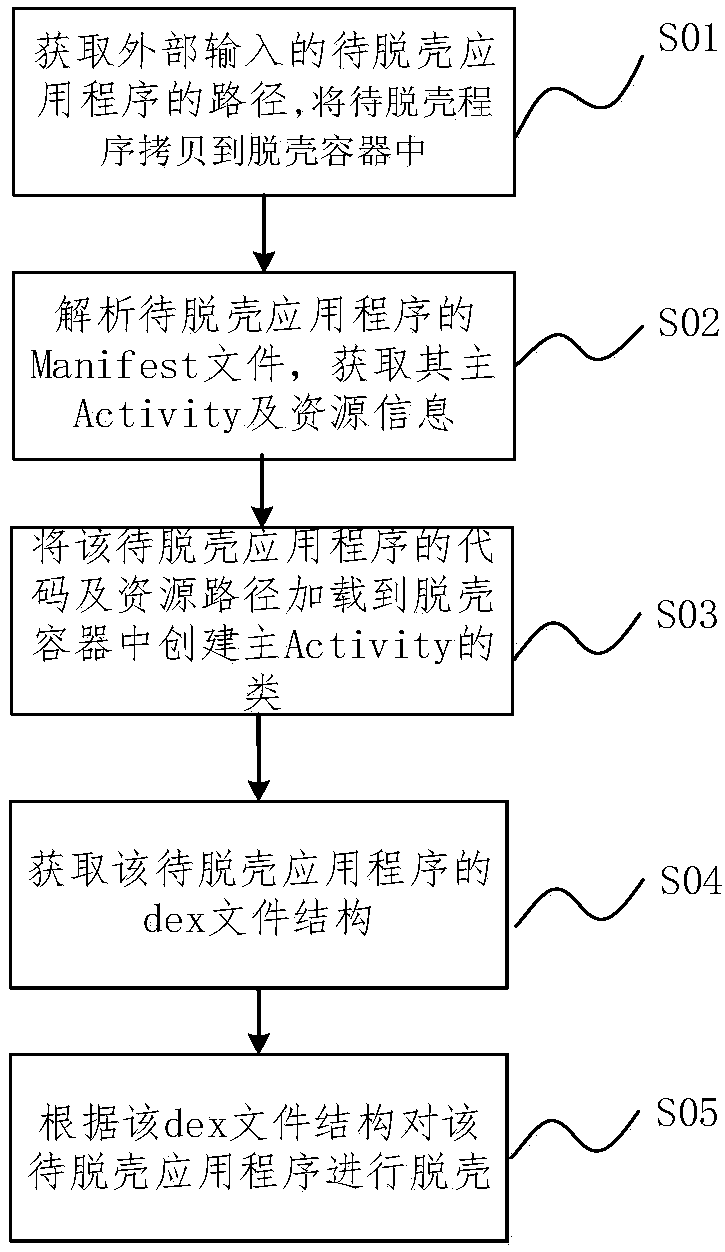

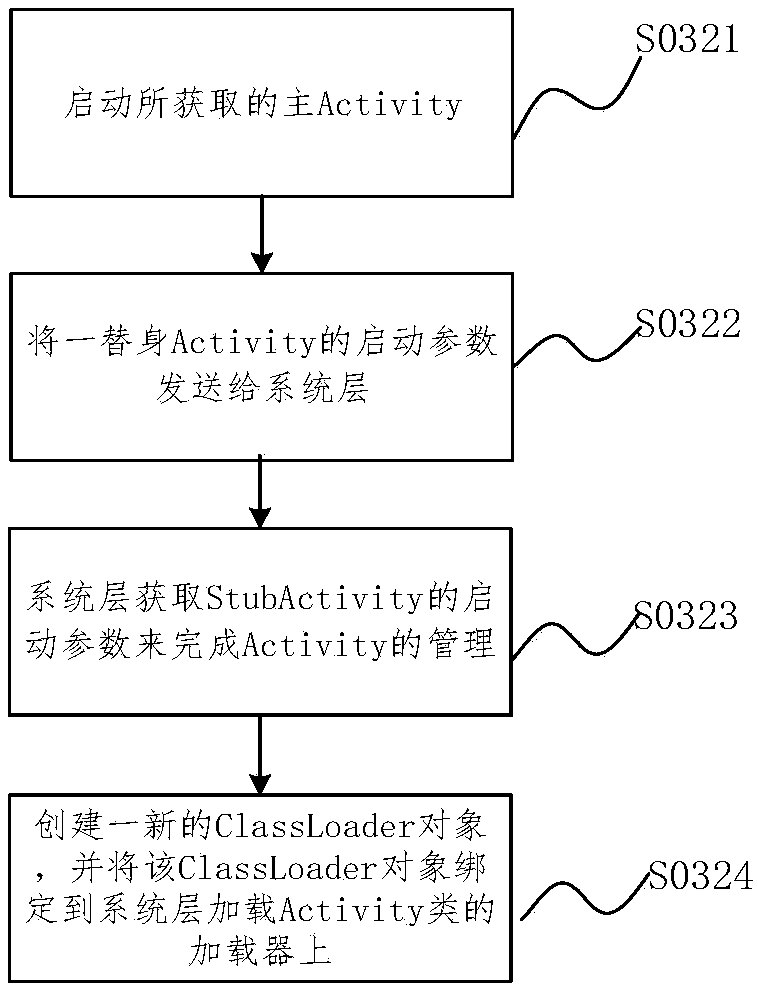

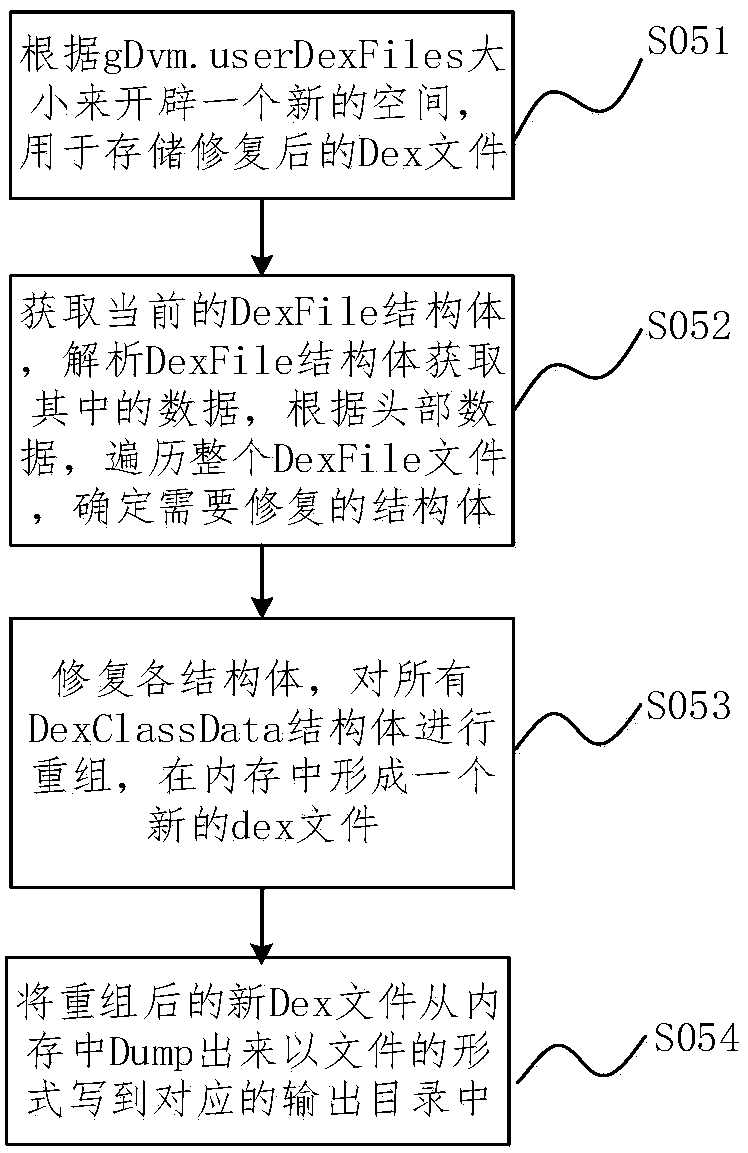

Shelling method of Android platform application program and container

ActiveCN108229107AEasy to shellEasy to implementProgram/content distribution protectionManifest fileResource information

The invention discloses a shelling method of an Android platform application program. The shelling method is applied to a preset shelling container located on an application layer. The shelling methodcomprises the steps of obtaining a path of an application program to be shelled input by the outside and copying the application program to be shelled into a file catalogue of the shelling container;analyzing a Manifest file of the application program to be shelled and obtaining main Activity and resource information of the Manifest file, wherein the resource information at least comprises a resource path; according to the path of the application program to be shelled, loading the resource path of the application program to be shelled and a code into a progress space of the shelling container; obtaining a dex file structure of the application program to be shelled; according to the dex file structure, shelling the application program to be shelled. The invention further discloses the shelling container, and the shelling container comprises an analyzing module, a dynamic loading module and a core shelling module. Root rights are not needed, a system source code does not need to be modified either, and the shelling method is convenient to implement and high in shelling efficiency.

Owner:WUHAN ANTIY MOBILE SECURITY

Coix seed huller

InactiveCN107737622ASimple structureImprove shelling efficiencyGrain huskingGrain polishingEngineeringProduct processing

The barley shelling machine of the present invention relates to the field of agricultural product processing equipment, in particular to a barley shelling machine, comprising a feeding hopper and a fixed grinding disc, characterized in that the feeding hopper is connected to an upper casing through a base, and the fixed grinding disc is There is a feeding channel in the center, which communicates with the feeding hopper; a main shaft is connected to the upper casing through a bearing seat, and the bearing seat is fixedly connected with the upper casing. One end of the main shaft is fixedly connected with a rotating grinding disc, and the other end is There is a belt pulley connected to it, the central axes of the rotating grinding disc and the fixed grinding disc are on the same straight line, and the rotating grinding disc and the fixed grinding disc are arranged parallel to each other; the invention has the advantages of simple structure, high husking efficiency, low broken rice rate, and low energy consumption. The relative speed between the fixed grinding disc and the rotating grinding disc is used to rub the coix seed grain, and the mutual rubbing and friction between the barley grain and the sand grains of the mill disc makes the cortex of the barley grain be torn under different forces, so as to achieve the purpose of shelling.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

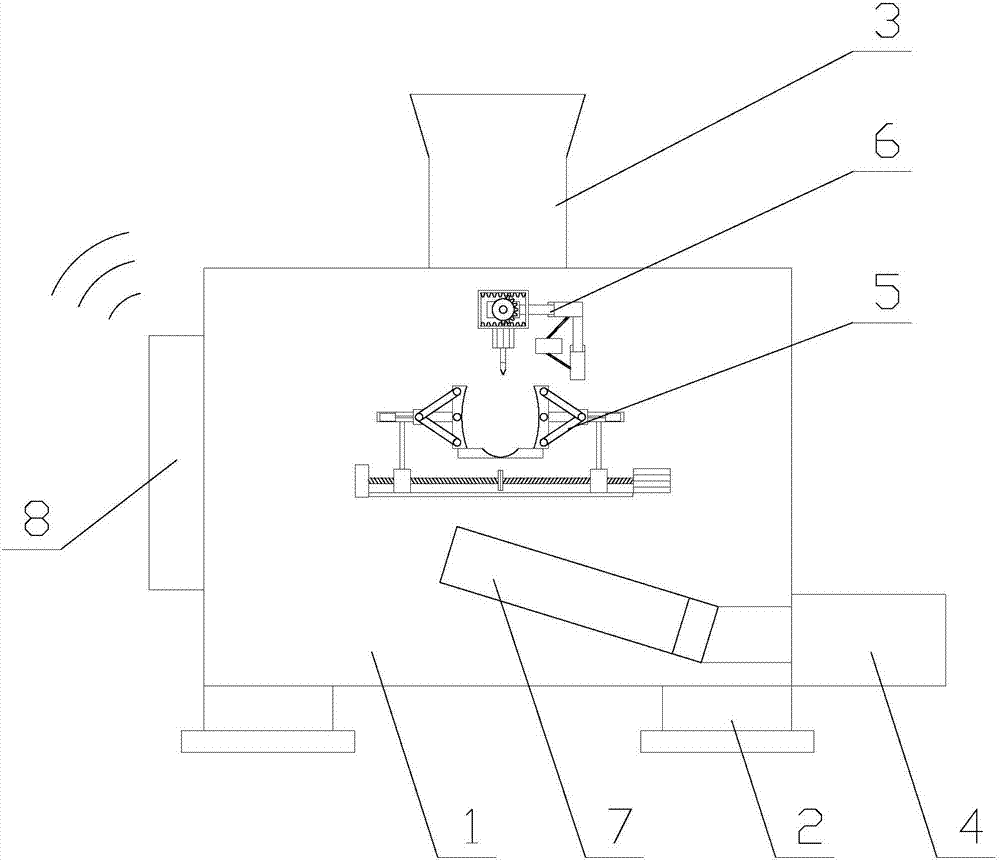

Domestic robot with various-nut-shell opening function based on internet of things

ActiveCN107212777AImprove eating effectShelling saves effortKitchen equipmentManipulatorThe InternetEngineering

The invention relates to a domestic robot with a various-nut-shell opening function based on the internet of things. The domestic robot comprises a body, a base, a feeding inlet, a discharging outlet, a clamping mechanism, a shell opening mechanism, a rolling mechanism and a center control mechanism. The clamping mechanism comprises a placement plate, a driving assembly and two movable assemblies. The driving assembly comprises a first motor, a first driving shaft and a movable block. Each movable assembly comprises a movable unit and a clamping unit. The shell opening mechanism comprises a stretchable assembly and a shell opening assembly. The stretchable assembly comprises an air pump, a connecting pipe and a stretchable rod, and the shell opening assembly comprises a reciprocating unit and a rotating unit. According to the domestic robot with the various-nut-shell opening function based on the internet of things, nuts of different kinds and sizes can be fastened through the clamping mechanism, each nut shell can be divided into two parts through the shell opening mechanism, nut pulp and nut shells can be separated, people can eat nuts conveniently through the mechanisms, the nut shell removal efficiency is improved, and the practicability of the robot is greatly enhanced.

Owner:乐聚(深圳)机器人技术有限公司

Automatic dehulling machine

The invention discloses an automatic shelling machine in the technical field of product processing, which includes a case, a dryer is arranged on the right side of the case, a feeding pipe is arranged at the bottom of the drying case, and the feeding pipe is The bottom is provided with a shelling box, and the outer wall of the shelling transmission shaft is evenly provided with shelling brushes, and the bottom left side of the cabinet is provided with a separate discharge box. Through the setting of the drying box and the dryer, the product is Dry and dehumidify before shelling to increase the brittleness of the shell and make the shelling efficiency better. Through the setting of the S-shaped feeding pipe, the product can not easily rebound out of the feeding port during the shelling process, ensuring the shelling process The smooth progress of the shell, through the setting of the beating rod and the beating ball with the elastic rubber layer on the outer wall, can fully contact the product during the shelling process, increase the shelling efficiency, and reduce the contact with the product through the protection of the elastic rubber layer. The impact force has the effect of protecting the integrity of the nuts.

Owner:青岛恒新辉瑞工业技术有限公司

Production method of linseed oil as well as vacuum low-temperature pressing device of linseed oil

ActiveCN109504529AImprove shelling efficiencyLow costFatty-oils/fats productionPressesHigh pressure pulsePre treatment

The invention discloses a production method of linseed oil as well as a vacuum low-temperature pressing device of the linseed oil. The production method comprises the following steps: A, unshelling linseeds by ultrahigh-pressure equipment and performing separation by using a high-speed rotating fan; B, performing pretreatment curing on linseed kernels by a high-pressure electric field; C, puttingthe linseed kernels into a crushing machine and crushing to obtain coarse-grained linseed kernels; D, performing ultrasonic treatment on the coarse-grained linseed kernels by using an ultrasonic chamber to obtain to-be-pressed raw materials; E, performing vacuum low-temperature pressing on the to-be-pressed raw materials into oil to obtain refined clean linseed oil; F, protecting and storing the linseed oil by using inert gas high-purity nitrogen. Through treatment by physical processes such as ultrahigh-pressure technology unshelling, high-pressure pulse electric field pretreatment, crushing,ultrasonic retreatment and vacuum low-temperature pressing, the oil pressing time is shortened, the oil yield is increased, and the obtained linseed oil retains the specific active substances such aslinolenic acid and vitamin E of the linseeds, is free of pollution and has high safety and high oil product quality.

Owner:北京同仁堂安徽中药材有限公司

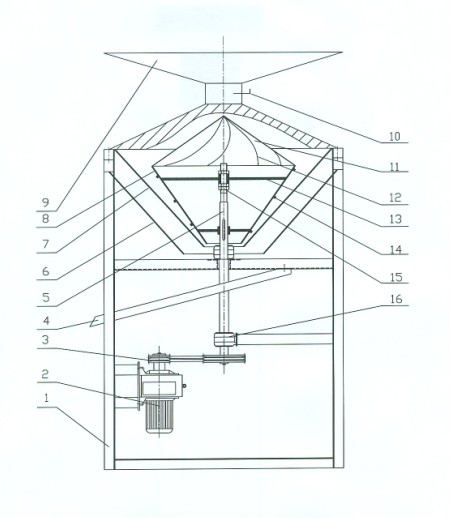

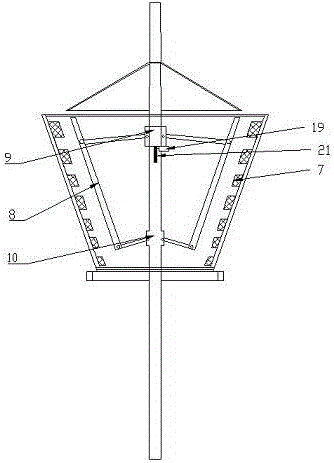

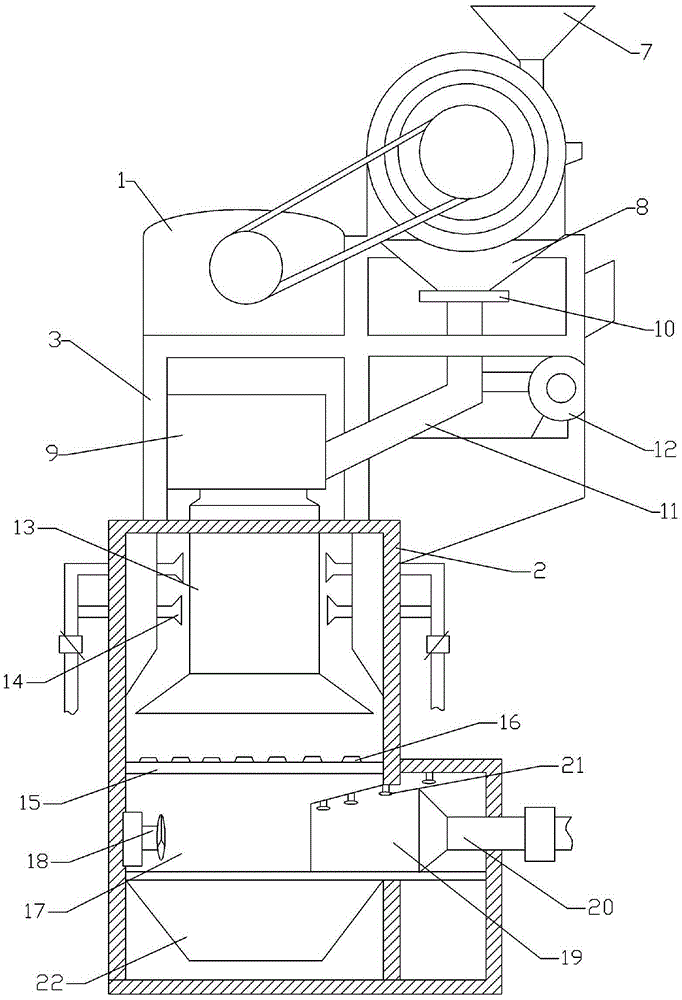

Chinese chestnut and hazelnut dual-purpose huller

ActiveCN105029650AImprove peeling efficiencyImprove shelling efficiencyHuskingHullingSieveDual purpose

The invention discloses a Chinese chestnut and hazelnut dual-purpose huller, and belongs to the technical field of peeling machinery. The huller comprises a rack, a motor, transmission mechanisms, a main shaft roller, a semicircle sieve, a vibrating screen and a blower fan. The main shaft roller is arranged at the top end of the rack; a feeding port is arranged on one side of the main shaft roller; the two ends of a main shaft of the main shaft roller are mounted on the rack; the main shaft inside the main shaft roller is sleeved with a driving roller; the semicircle sieve is arranged below the driving roller of the main shaft roller and close to the material pushing end; the vibrating screen is obliquely arranged below the semicircle sieve; one end of the main shaft is connected to an output shaft of the motor through the transmission mechanism I, and the other end of the main shaft is connected to the blower fan through the transmission mechanism II; a discharging port is arranged at the bottom of the vibrating screen and close to the tail end of the vibrating screen; and an air outlet of the blower fan is arranged at the discharging port at the lower end of the vibrating screen. The huller can peel hazelnuts or Chinese chestnuts, and the peeling efficiency is high. With the cooperation of the driving roller, the semicircle sieve and the vibrating screen, peeling demands can be met, the peeling efficiency is high, and good peeling effects are achieved.

Owner:丹东先科液压设备有限公司

Nut shelling equipment for food processing

ActiveCN112189854AAchieve automatic flappingAchieve the effect of automatic feedingSievingGas current separationProcess engineeringWaste material

The invention relates to a shelling equipment, in particular to a nut shelling equipment for food processing. The invention provides a nut shelling equipment for food processing, which has high shelling efficiency and capable of collecting waste materials in time. The nut shelling equipment for food processing comprises a base and a workbench, the workbench is arranged on the top of the base, a servo motor which is mounted on the base, a beating mechanism which is arranged on an output shaft of the servo motor and the workbench, and a discharging mechanism which is arranged on the the base, the beating mechanism and the workbench. Through ingenious cooperation of the beating mechanism and the discharging mechanism, the effects of automatic beating and automatic discharging are achieved, and the purpose of automatic shelling is realized; and through cooperation of a poking mechanism, the beating mechanism and the discharging mechanism, the nuts are intermittently poked to the baffle forbeating and shelling.

Owner:阿克苏浙疆果业有限公司

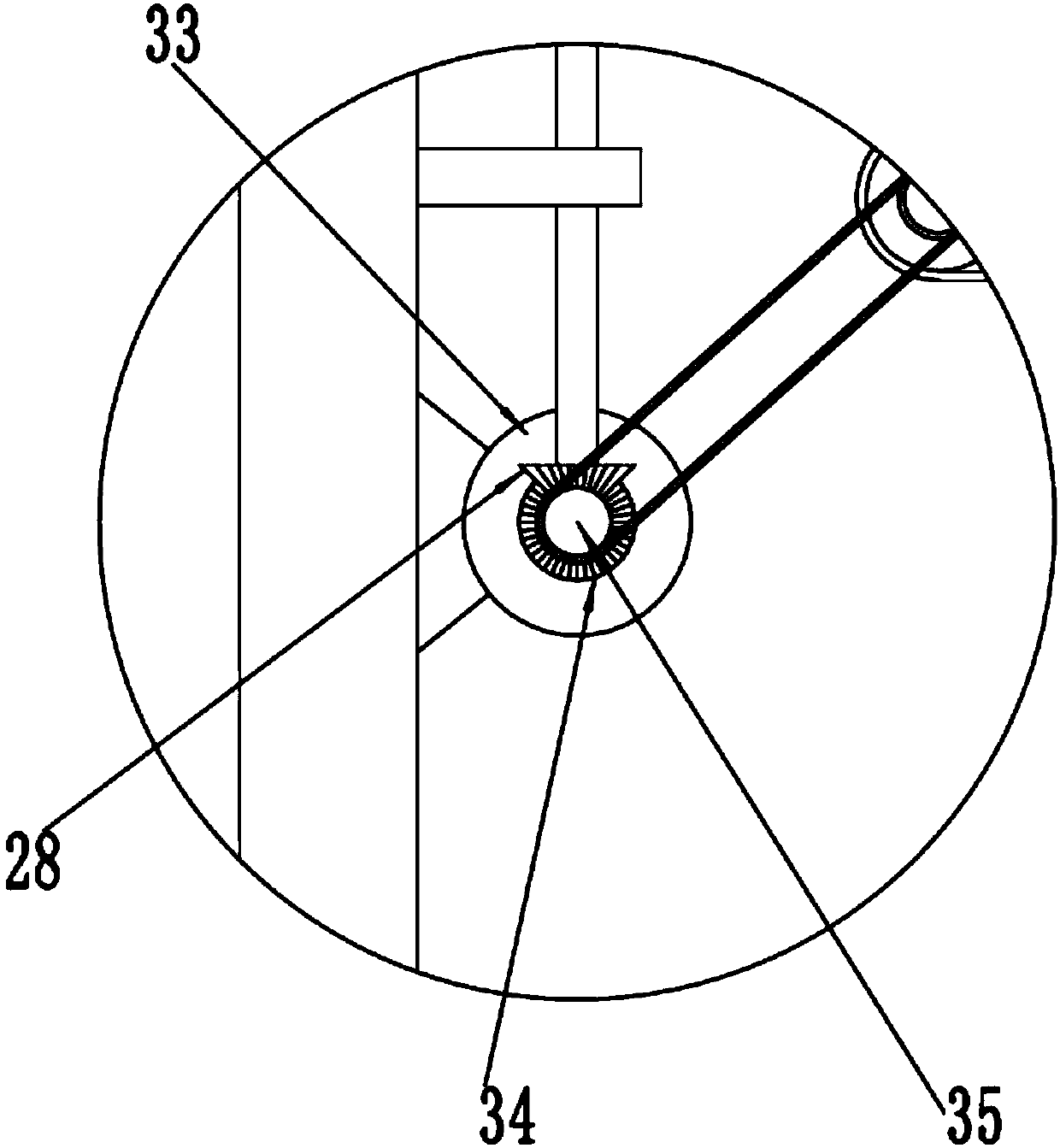

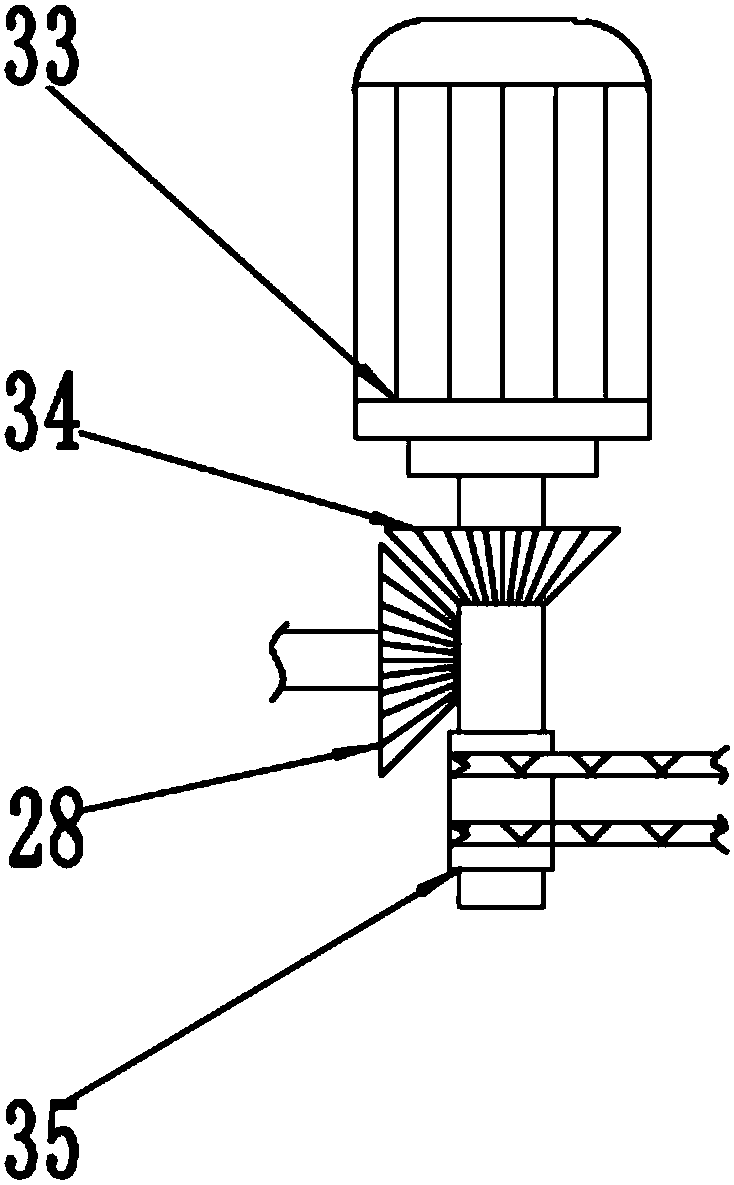

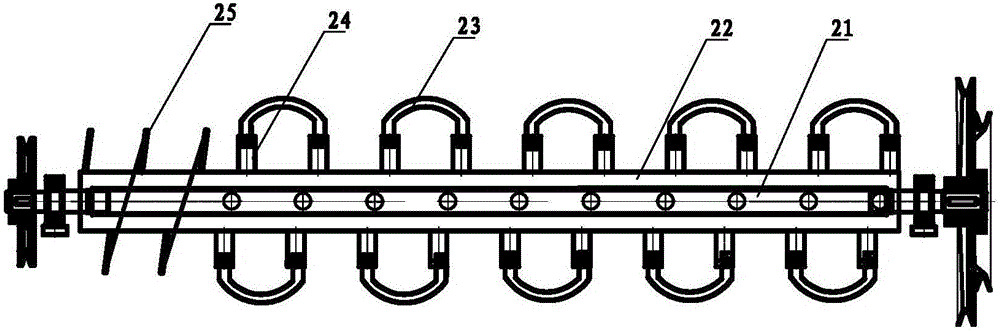

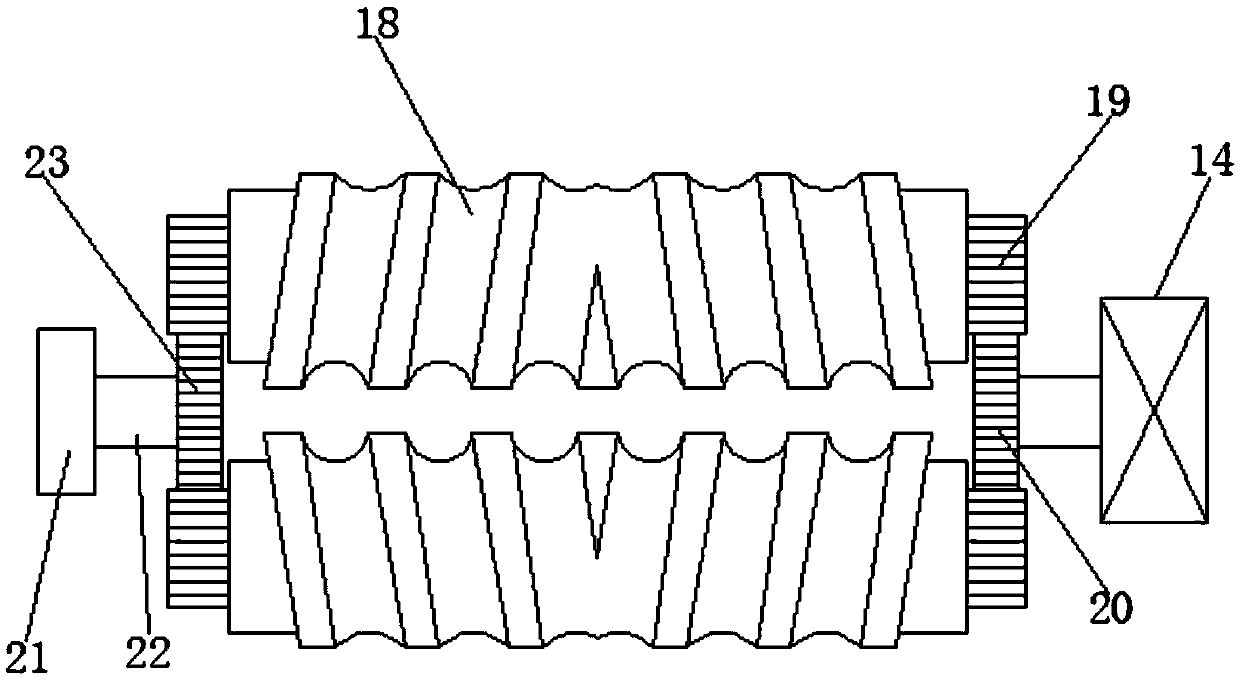

Shelling mechanism for camellia oleifera fruits

InactiveCN108552540AAvoid damageImprove shelling efficiencySievingScreeningCamellia oleiferaMechanical engineering

The invention relates to a shelling mechanism for camellia oleifera fruits. The shelling mechanism for camellia oleifera fruits comprises a machine frame; a shelling conveyor groove and a shelling barrel, which are in mutual cooperation, are arranged on the machine frame; an shelling conveyor auger is arranged in the shelling conveyor groove, and is connected with an auger motor; a shelling rotating shaft, which rotates forwards and backwards, is arranged in the shelling barrel, and is connected with a shelling rotating motor; a shelling rotating sleeve sleeves on the shelling rotating shaft;shelling material-receiving grooves, which are in cooperation with the shelling conveyor groove, uniformly sleeve on the shelling rotating sleeve; a lower part of the shelling rotating sleeve is a slope; and a shelling material outlet is formed at the lowest point of the slope. The purpose of the invention is to provide a shelling mechanism for camellia oleifera fruits in which the rotatable shelling material-receiving grooves and the shelling conveyor groove are adopted in cooperation so as to realize shelling of cracked camellia oleifera fruits by performing downward dropping and collision,and thus, the shelling mechanism for camellia oleifera fruits has improved shelling efficiency compared with manual shelling; moreover, damages on camellia oleifera seeds are also avoided so as to improve shelling effects.

Owner:DONGGUAN UNIV OF TECH

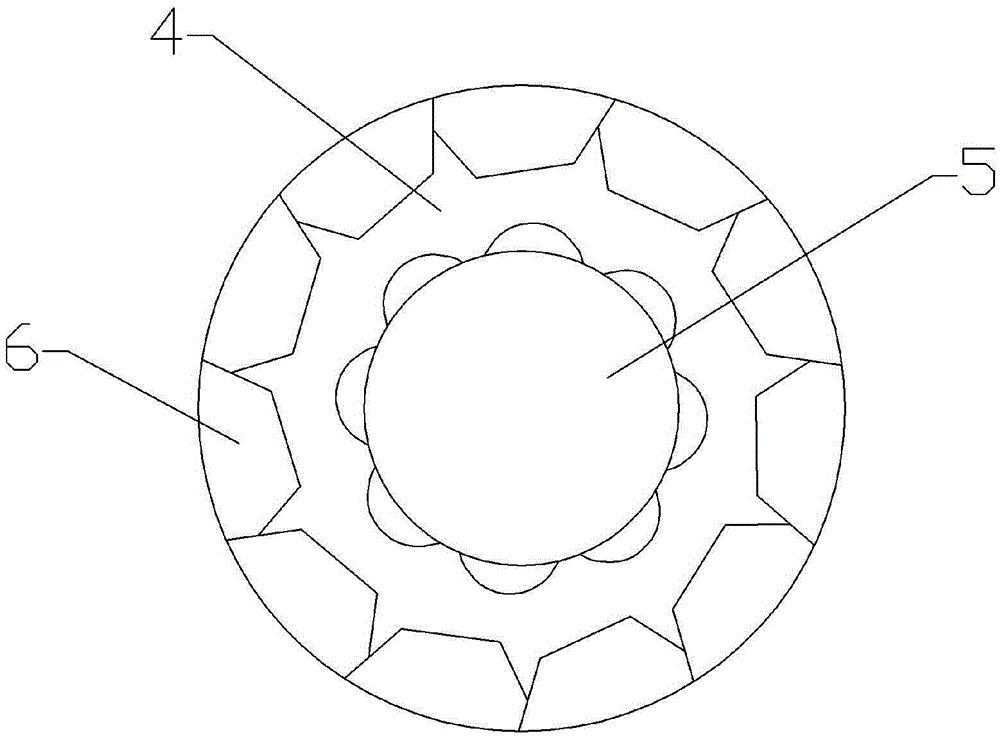

Nut shelling device with tapered millstone

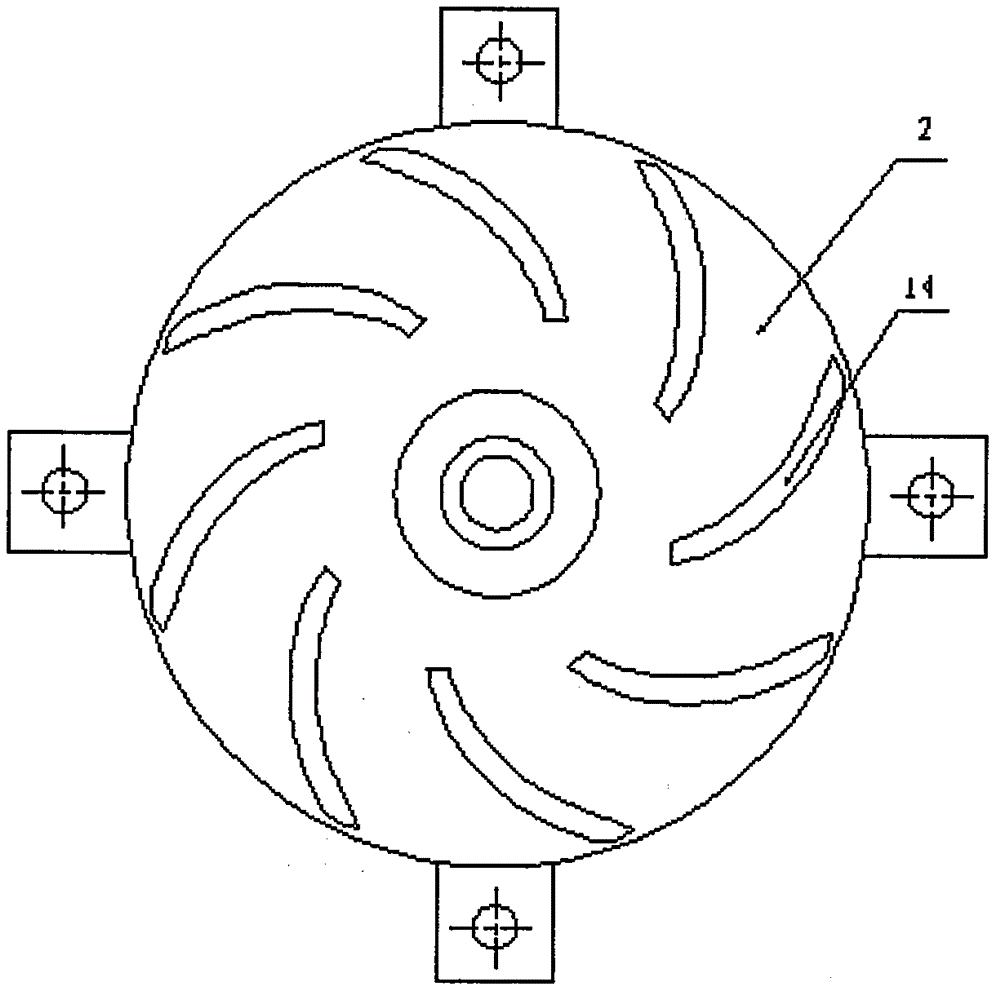

A device for shelling dried fruit with conical grinding discs, including a rotating grinding disc and a fixed grinding disc, the fixed grinding disc is fixed on the frame, and the rotating grinding disc is installed on the fixed grinding disc through a vertically arranged transmission shaft, so that the rotating grinding disc is driven by the transmission shaft, thereby relatively It rotates on the fixed grinding disc, and there is a gap (and adjustable) larger than the outer diameter of the dried fruit between the rotating grinding disc and the fixed grinding disc to form a shelling space. The opposite surface is a downward-sloping conical surface so that a downward passage is formed around the shelling space. There are multiple ribs protruding outward on the opposite surface of the rotating grinding disc and the fixed grinding disc. The ribs are arranged around the transmission shaft and Each rib extends radially along the rotating grinding disc and the fixed grinding disc to cover the glide path of the entire shelling space, and the gap between the rib on the rotating grinding disc and the opposite surface of the fixed grinding disc is smaller than the outer diameter of the dried fruit and larger than the outer diameter of the dried nut. The device has high shelling efficiency, good shelling quality, low damage rate of dried nut kernels and stable discharge.

Owner:HUNAN AGRICULTURAL UNIV

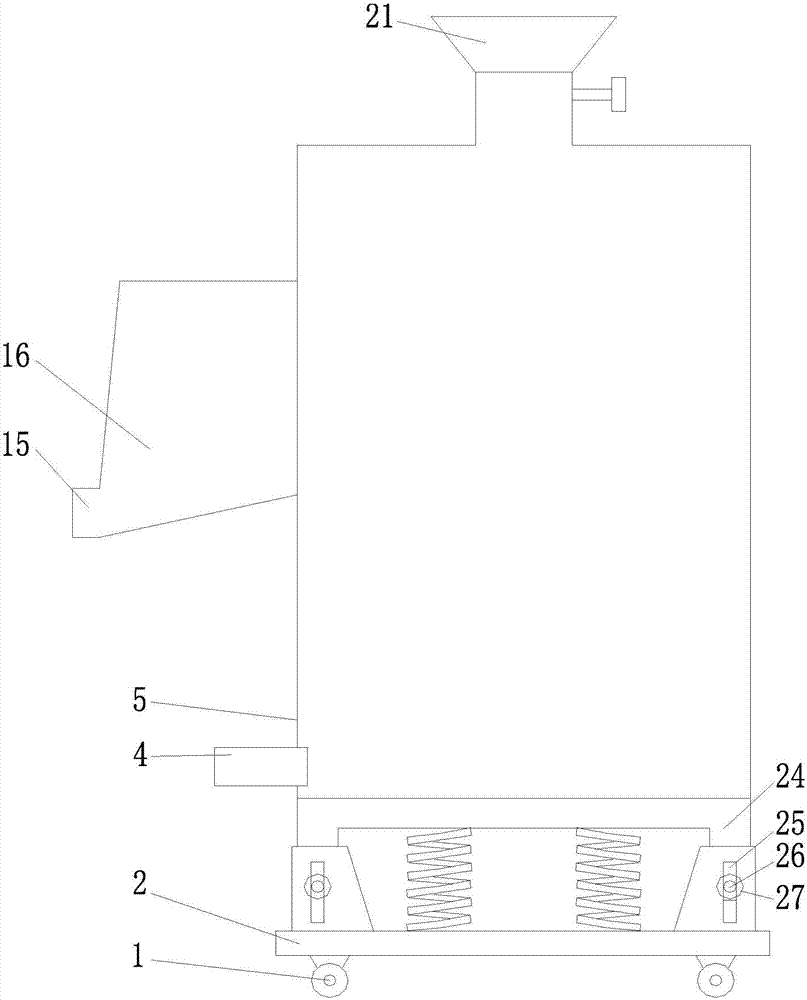

Rice mill with damping function

InactiveCN107126999AImprove shelling qualityImprove the efficiency of shellingGrain huskingGrain polishingReduction functionNoise pollution

The invention discloses a rice milling machine with a shock absorbing function, which is composed of a universal wheel, a support plate, a collecting box, a rice outlet, a casing, a driving wheel, a motor, a belt, a driving and driving rubber roller, and a driving and driving roller. Rubber roller, pressing wheel A, toggle wheel, toggle plate, pressing wheel B, bran outlet, bran collecting bucket, negative pressure fan, rice milling box, splitter bucket, splitter bracket, rice inlet, gate, It consists of a tool box, an upper platen, an adjustment hole, an adjustment stud, and an adjustment nut; the invention adopts a combination of a toggle wheel and a toggle plate, which can blow up grains and counterattack them to the roller surface again for secondary removal, improving the The quality of grain husking also improves the efficiency of husking, and the double shock-absorbing bottom can ensure the stability of the equipment during operation and improve the service life. The outer shell is wrapped with sound-proof cotton, which can reduce noise pollution. , improve user experience.

Owner:赵志坚

Integrated processing device for husking and screening paddy

ActiveCN107597237AImprove shelling efficiencyMobile status is stableGrain huskingSievingElectric machineryEngineering

The invention discloses an integrated processing device for husking and screening paddy. The integrated processing device for husking and screening the paddy comprises a base, wherein a feeding tank and a processing tank arranged side by side are arranged on the base and communicate through a feed pipe; a storage tank is arranged at the upper side of the feeding tank, and penetrates through an upper side wall of the feeding tank so as to communicate with the feeding tank; a first drive motor is arranged at a bottom wall of the feeding tank; a rotary plate is connected to an output end of the first drive motor, and is rotatably connected with a first rotary rod through a first rotary shaft; a second rotary rod is rotatably connected to one end, far away from the rotary plate, of the first rotary rod through a second rotary shaft; a moving table is connected to one end, far away from the first rotary rod, of the second rotary rod, and is slidably connected with inner walls of two sides of the feeding tank; and a fixing rod is connected to an upper side wall of the moving table, and penetrates through the storage tank. The integrated processing device for husking and screening the paddy provided by the invention can be high-efficiently husking and screening the paddy, and the paddy cannot be broken easily during a processing process.

Owner:广东巧康电器股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com